Real vehicle collision test system of rail vehicles

A test system and technology for rail vehicles, applied in the field of rail vehicle collision test systems, can solve the problems of high energy level, large collision area and large volume during collision, and achieve the effect of simple and easy operation, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

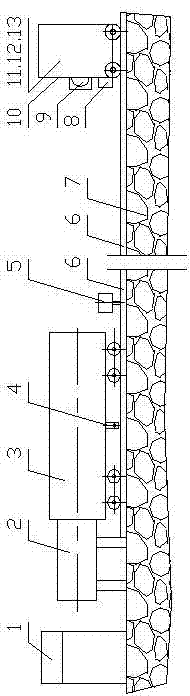

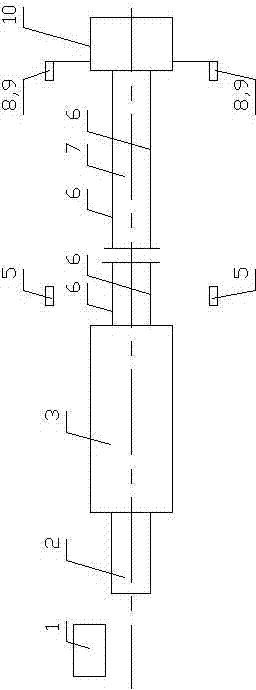

[0052] The real car 3 and the simulated car 10 are placed on the same rail 6 installed on the foundation 7; the transmitter 2 is installed at the end of the real car 3 facing away from the simulated car 10; the quality of the simulated car 10 can be adjusted as required; the simulated car 10 The end facing the actual vehicle 3 is sequentially installed with a uniform force plate 11 and a load cell array 12 from the outside to the inside; the simulation vehicle 10 is installed on one side or both sides of the end facing the actual vehicle 3, and the impact speed measuring device 8 and the high-speed photography device 9 are installed on the cantilever , the vertical line of the impact speed measuring device 8 and the high-speed photography device 9 is located in the plane formed by the end face of the simulated vehicle 10 facing the real vehicle 3; the electronic control part of the central console 1 and the transmitter 2, the impact speed measuring device 8, the The force-measu...

Embodiment 2

[0054] On the basis of Embodiment 1, another transmitter 2 connected to the central console 1 is configured for the simulated vehicle 10; during the impact test, the two transmitters 2 work simultaneously, respectively pushing the real vehicle 3 and the simulated vehicle 10 towards each other or Glide in the same direction until they collide. Able to conduct collision or rear-end collision tests.

Embodiment 3、4

[0056] On the basis of Embodiments 1 and 2 respectively, both the real vehicle 3 and the simulated vehicle 10 are equipped with a speed-regulating braking device connector 4 used in the commissioning condition, and the braking device connector 4 can be connected to the braking device; Two sets of debugging speed measuring devices 5 are installed on one side or both sides. The vertical lines of one set of debugging speed measuring devices 5 are located at the position where the actual vehicle 3 starts to slide freely, and the other set of debugging speed measuring devices 5 are located at the same position. The position where the simulated car 10 starts to slide freely; but the real car 3 and the simulated car 10 cannot be connected to the braking device at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com