Environment protection type wax-proof anti-scaling viscosity reduction machine

An environment-friendly, wax-proof technology, which is applied in the direction of cleaning equipment, mining fluid, wellbore/well parts, etc., can solve problems such as unreasonable structure, unsatisfactory wax-proof and viscosity-reducing effect, and weak ultrasonic sound field strength, so as to improve pump efficiency , increase the liquidity of crude oil, and save energy on the output of crude oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

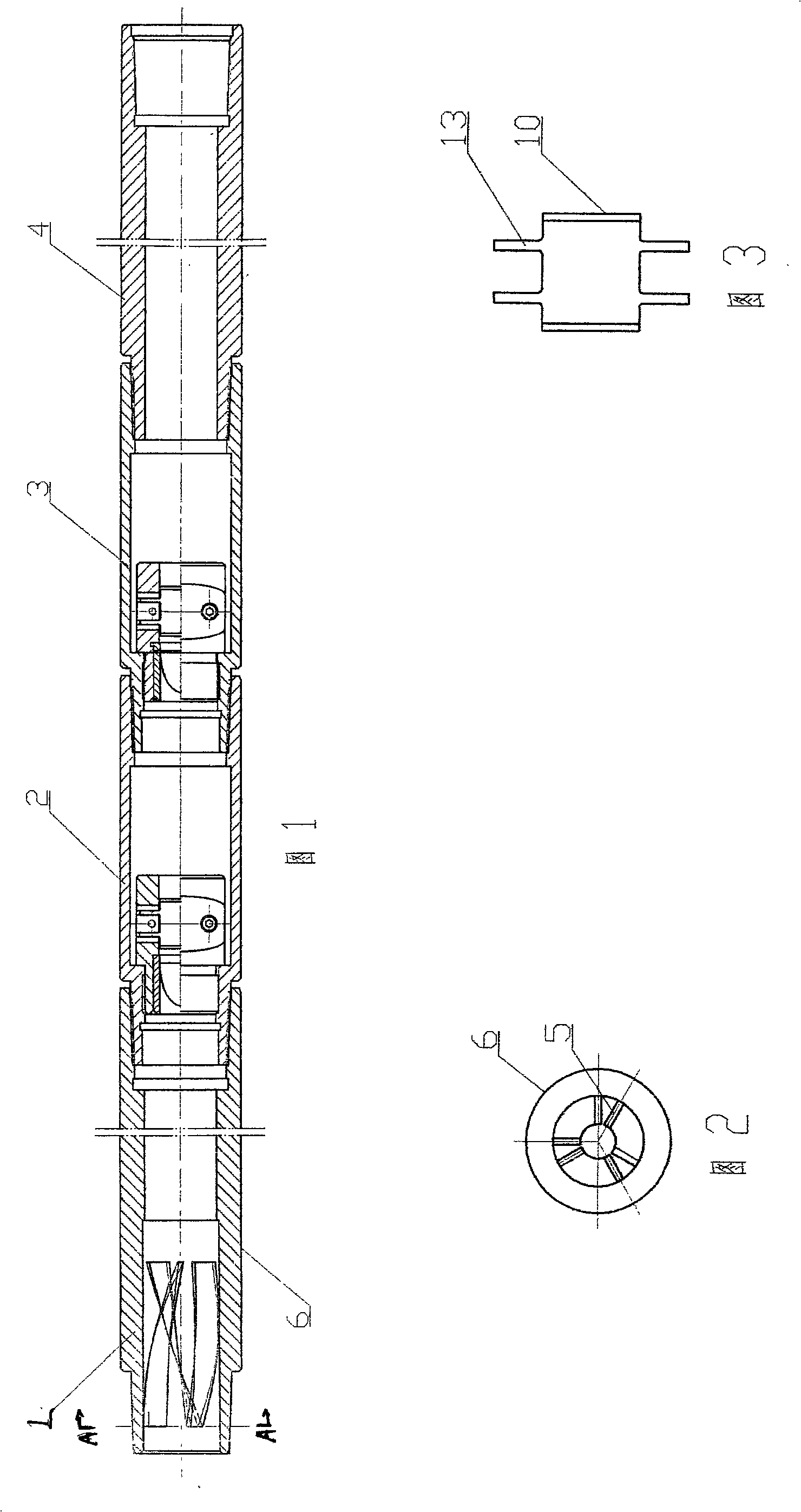

[0024] Referring to Fig. 1, the present invention is formed by sequentially docking a hydrocyclone 1, a jet ultrasonic transmitter 2, a jet ultrasonic oscillator 3, and an ultrasonic cavitation chamber 4; The right end of the chamber 4 is the outlet.

[0025] Wherein, the specific structure of the cyclone 1 in the present invention can be seen in Fig. 1 and Fig. 2 . It has a tube tube 6, and the two ends of the tube tube 6 are made into a butt joint structure; three swirl fins 5 (or one or more pieces) are installed inside the front section of the tube tube 6 .

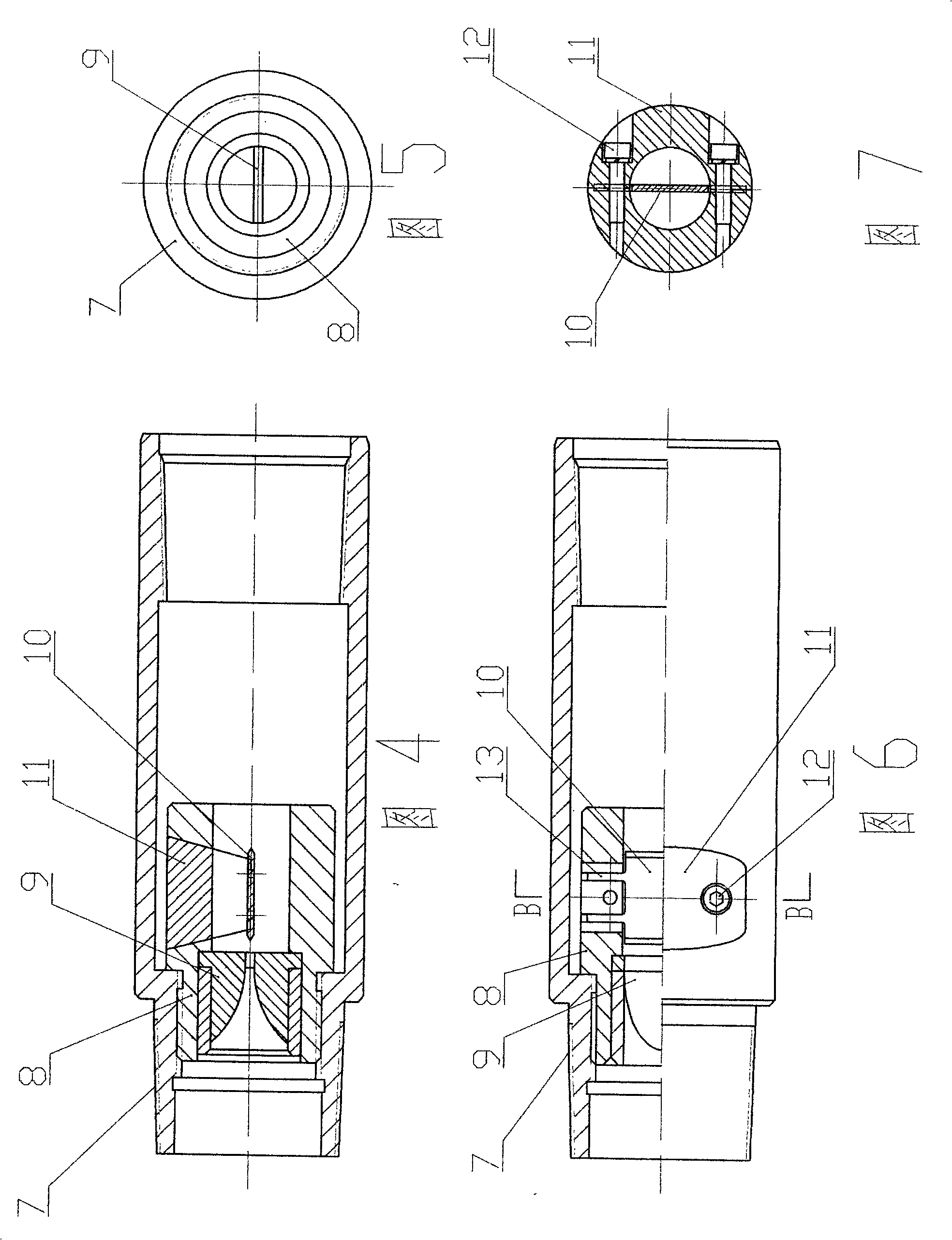

[0026] The specific structure of jet ultrasonic signal transmitter 2 among the present invention is referring to Fig. 4,5,6,7, and it has tube barrel 7, and the two ends of tube barrel 7 are made docking structure; Seat 8, a jet nozzle 9 is embedded in the front section of the jet device base 8, the inner cavity of the jet nozzle 9 is a trumpet cavity, the cross section is approximately trapezoidal, and the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com