Patents

Literature

223results about How to "Anti-fouling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultraviolet light cured transfer printing film and preparation method and application thereof

InactiveCN101941339AHigh material strengthGood weather resistanceDecorative surface effectsOrnamental structuresLacquerPrinting ink

The invention belongs to the field of decorative materials, and particularly relates to an ultraviolet light cured transfer printing film and a preparation method and application thereof. The preparation method comprises the following steps of: uniformly coating or printing a mold release agent on a base load film, and performing infrared curing; uniformly coating or printing an ultraviolet light cured printing ink with a patterning function on a mold release agent layer, and performing curing through ultraviolet irradiation; or uniformly coating or printing an ultraviolet cured protective layer coating with anti-scratching and wear-resistant functions on the mold release agent layer first, then uniformly coating or printing the ultraviolet light cured printing ink with the patterning function on the mold release agent layer after the curing through the ultraviolet irradiation, and performing the curing through the ultraviolet irradiation; and uniformly coating or printing an ultraviolet light cured bottom color coating on an ultraviolet light cured printing ink decorative pattern layer, and performing the curing through the ultraviolet irradiation to obtain the ultraviolet light cured transfer printing film which can be used for producing an ultraviolet light cured transfer printing film decorative board. The ultraviolet light cured transfer printing film has high material strength, and has the advantages of high weathering resistance, high environmental protection, rich colors and patterns, full lacquer film, high hardness, scratch resistance, easy cleaning, noninflammability and the like.

Owner:ZHUHAI DONGCHENG UV MATERIALS

Nanocomposite road marking coating material

InactiveCN104263198AWith sterilizationWear-resistantAntifouling/underwater paintsLuminescent paintsEpoxyNano structuring

The invention discloses a nanocomposite road marking coating material. The nanocomposite road marking coating material comprises the following ingredients in parts by weight: 20-30 parts of glass powder, 6-10 parts of aluminum oxide powder, 50-80 parts of filler, 30-40 parts of epoxy resin, 15-20 parts of aqueous epoxy modified acrylate, 15-20 parts of glass micro-beads, 10-20 parts of chitin, 15-20 parts of chitosan, 20-40 parts of nano titanium white, 15-20 parts of nano zinc oxide, 10-15 parts of nano-silica, 2-4 parts of 25wt% ammonia water, 30-40 parts of acrylic emulsion and 15-20 parts of nano rare-earth self-luminous material. The invention further discloses a preparation method of the nano coating material. The nanocomposite road marking coating material disclosed by the invention is high in drying speed and long in service life, is wear-resistant and anti-fouling and has a bacterium resisting effect, and nano-materials or nano-structured ingredients are introduced into an organic coating material, so that organic and inorganic matched compositing or hybridization is realized. The advantages of organic polymers and inorganic-structured ingredients are integrated, so that the properties of the coating material are obviously improved.

Owner:句容亿格纳米材料厂

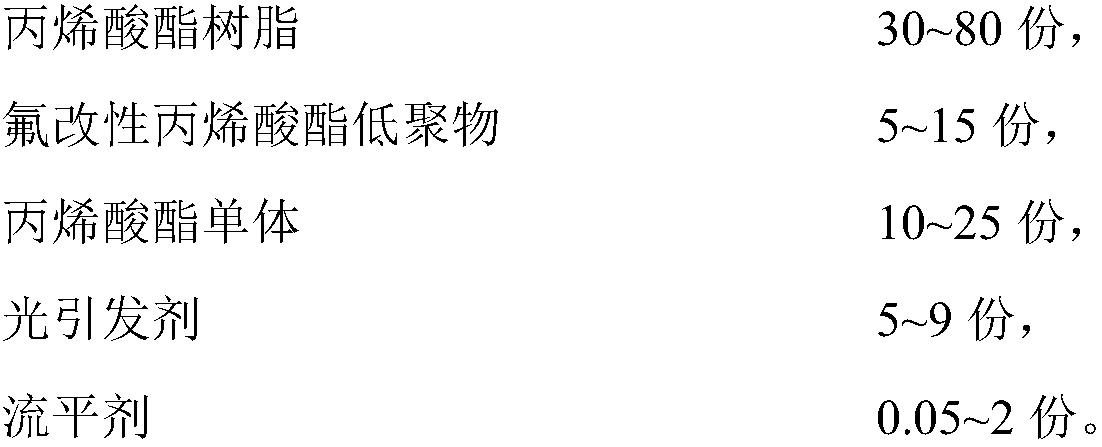

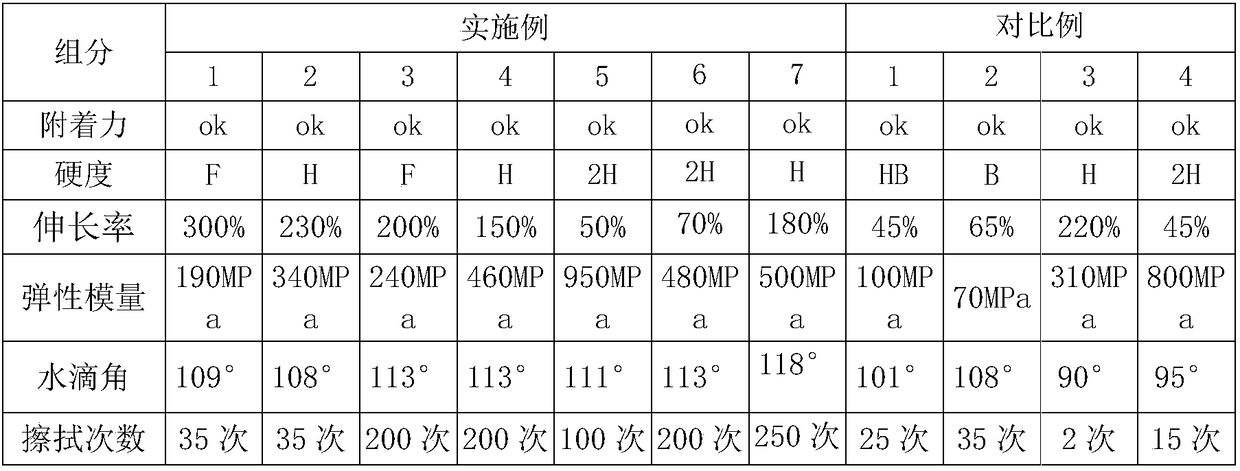

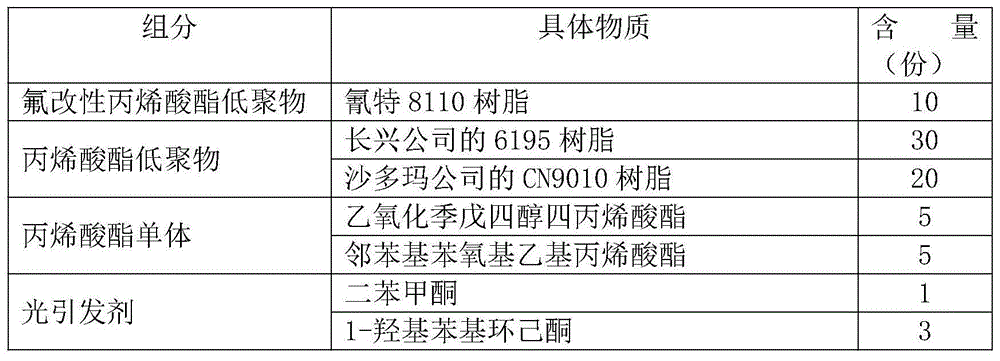

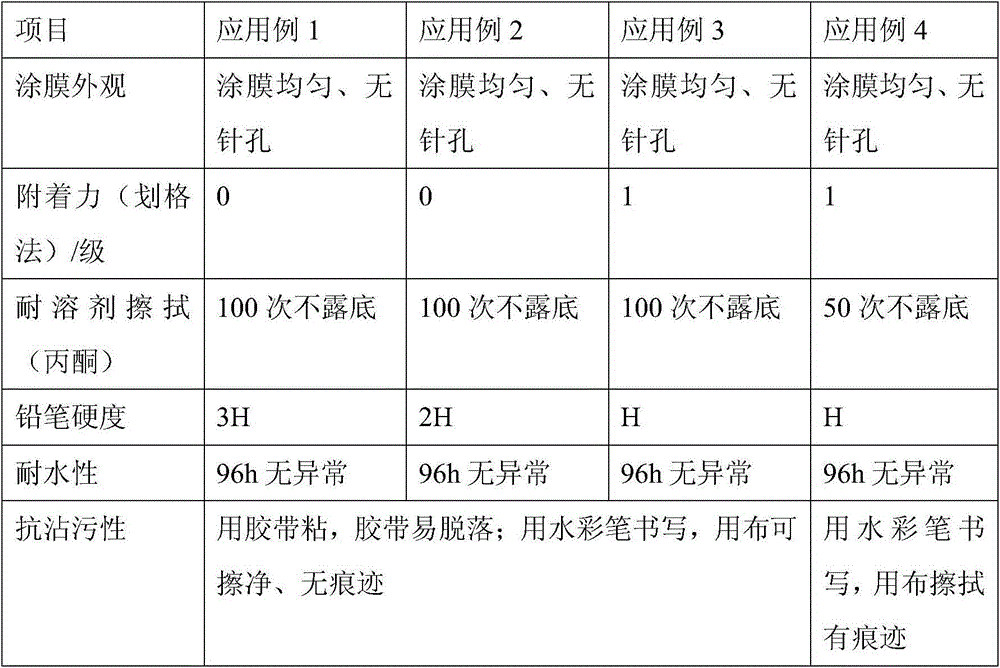

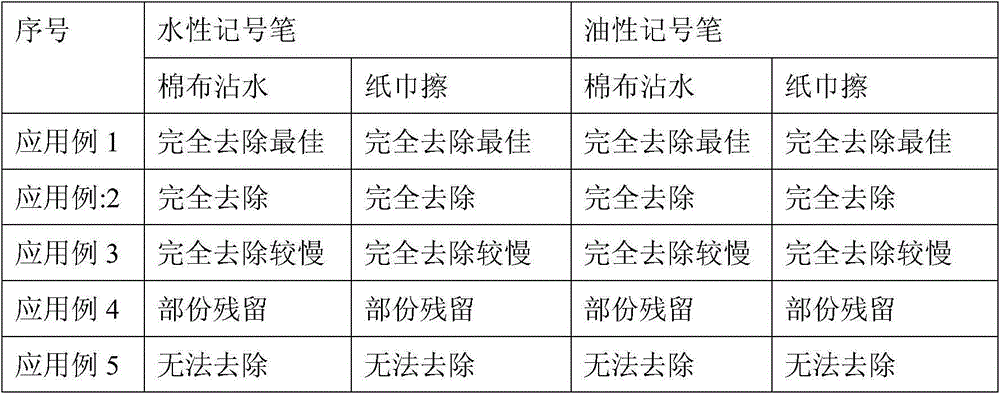

Flexible and stain-resistant ultraviolet curable coating composition and preparation method thereof

InactiveCN108264838AHas hardnessWith highlightsAntifouling/underwater paintsPaints with biocidesOligomerHardness

The invention provides a flexible and stain-resistant ultraviolet curable coating composition. The composition comprises, by weight, 30-80 parts of acrylate resin, 5-15 parts of a fluorine-modified acrylate oligomer, 10-25 parts of an acrylate monomer, 5-9 parts of a photoinitiator and 0.05-2 parts of a leveling agent. Compared with coatings in the prior art, the coating composition in the invention has a higher flexibility, and has the advantages of certain hardness, wear resistance, stain resistance, suitableness for bendable and crimped substrates, excellent comprehensive performances and wide applicability .

Owner:SHANGHAI CHENGYING NEW MATERIALS +1

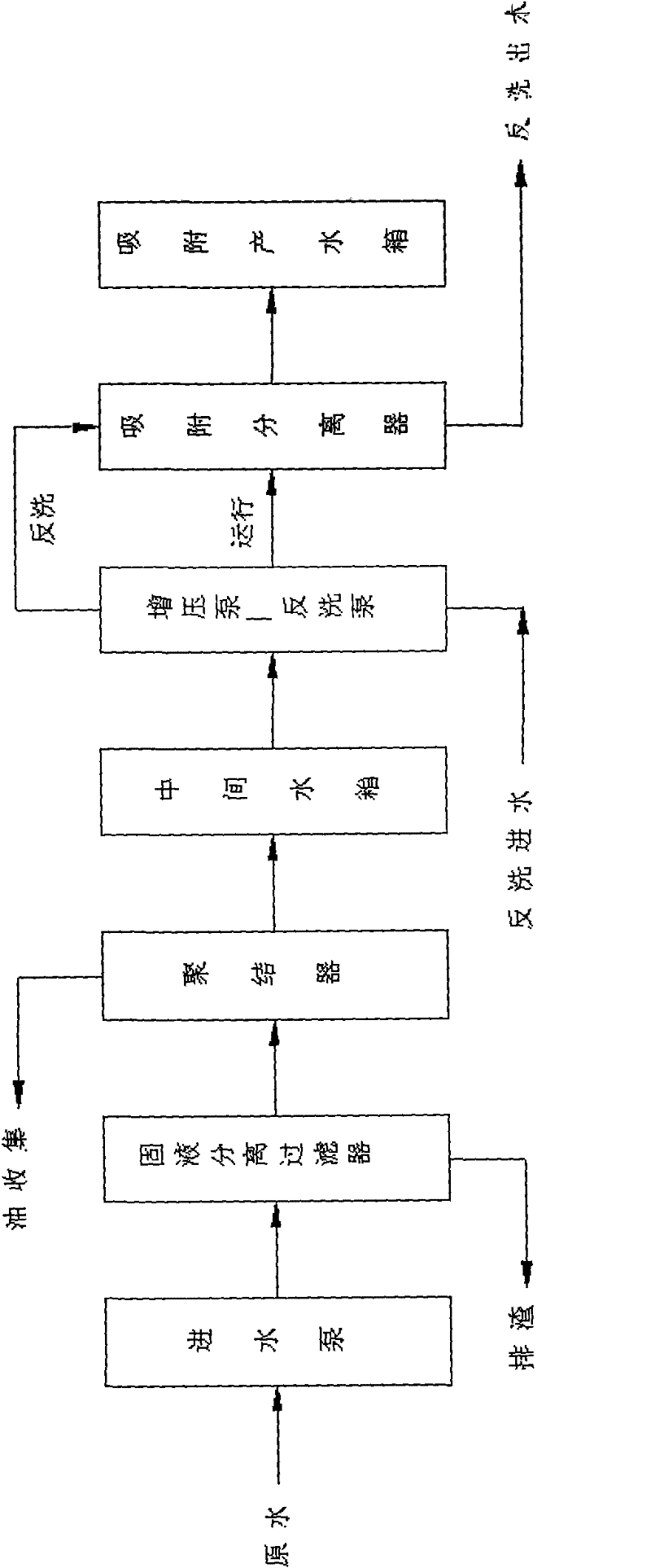

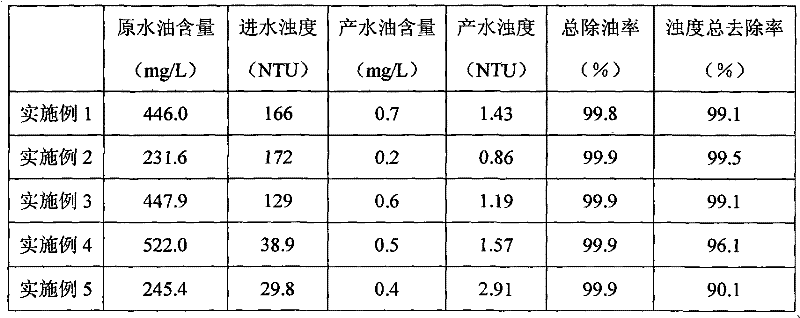

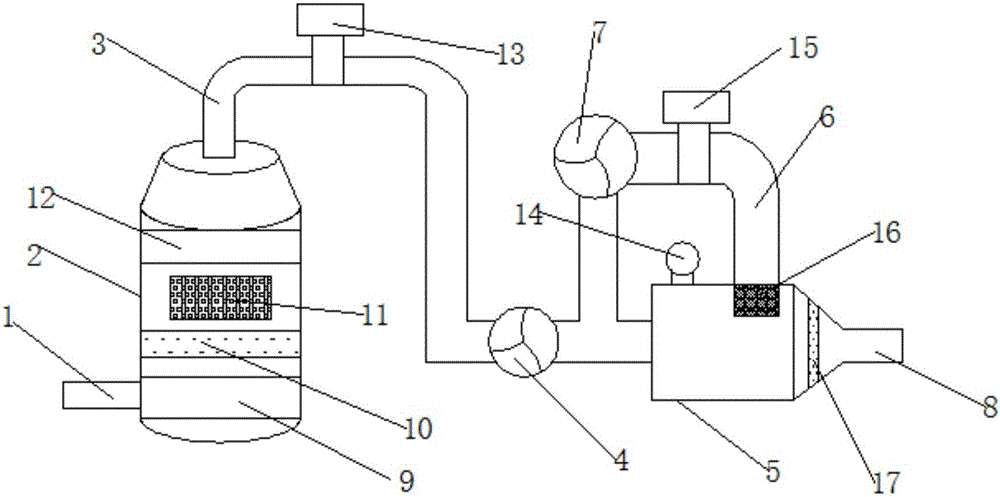

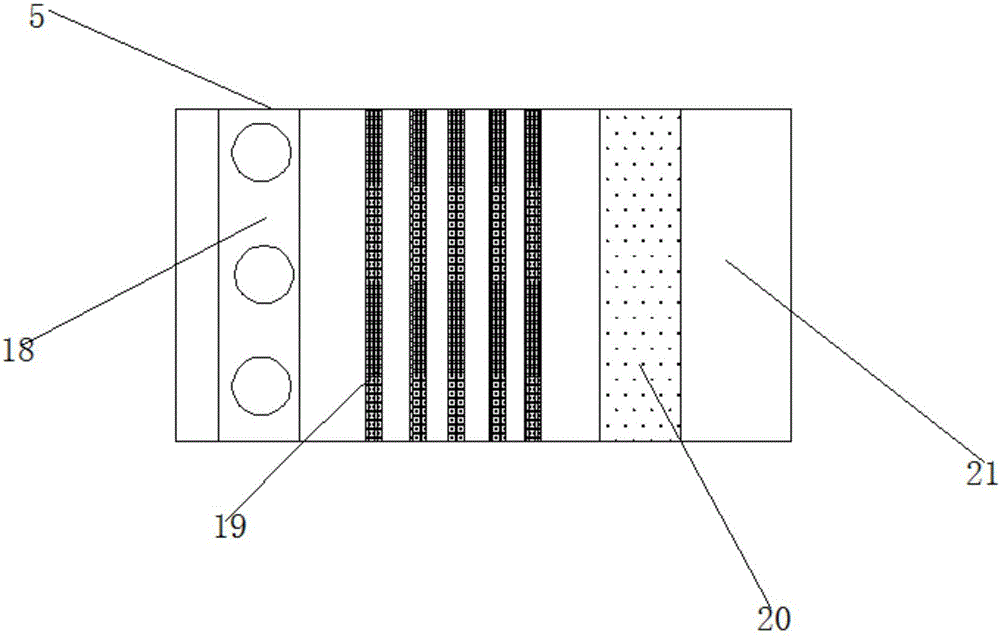

Process for treating oil-containing waste water for ship

InactiveCN102464413AHigh adsorption capacityReduce volumeMultistage water/sewage treatmentWater/sewage treatment by sorptionChemistryOil content

The invention relates to a process for treating oil-containing waste water for a ship. The process comprises the following technical steps of: performing solid and liquid separation, coalescing separation treatment, adsorbing separation treatment and the like on pretreated ship oil-containing waste water sequentially. When the oil content in supplied water is less than or equal to 500 mg / L and the turbidity of the supplied water is less than or equal to 200 NTU, the oil content in discharged water quality is less than or equal to 1 mg / L and the turbidity of the discharged water quality is less than or equal to 5 NTU; and the national standard of the Integrated Pollutant Discharge Standard GB8978-1996 can be met. The method is high in treatment capacity of purifying the oil-containing waste water, namely the waste water treatment amount is up to 10 to 100 m<3> / hr, and is high in purifying efficiency, namely the oil removal rate is more than 99 percent and the turbidity removal rate is more than 90 percent. The process for treating the oil-containing waste water for the ship can be also applied to various types of oil-containing waste water, such as oil-field reinjected water, oil-base oil-containing waste water, metallurgical oil-containing waste water, steel factory oil-containing waste water, machined oil-containing waste water and the like, so that the treated oil-containing waste water can be treated until reaching the standard, and waste oil resources can be recycled.

Owner:浙江瑞普环境技术有限公司

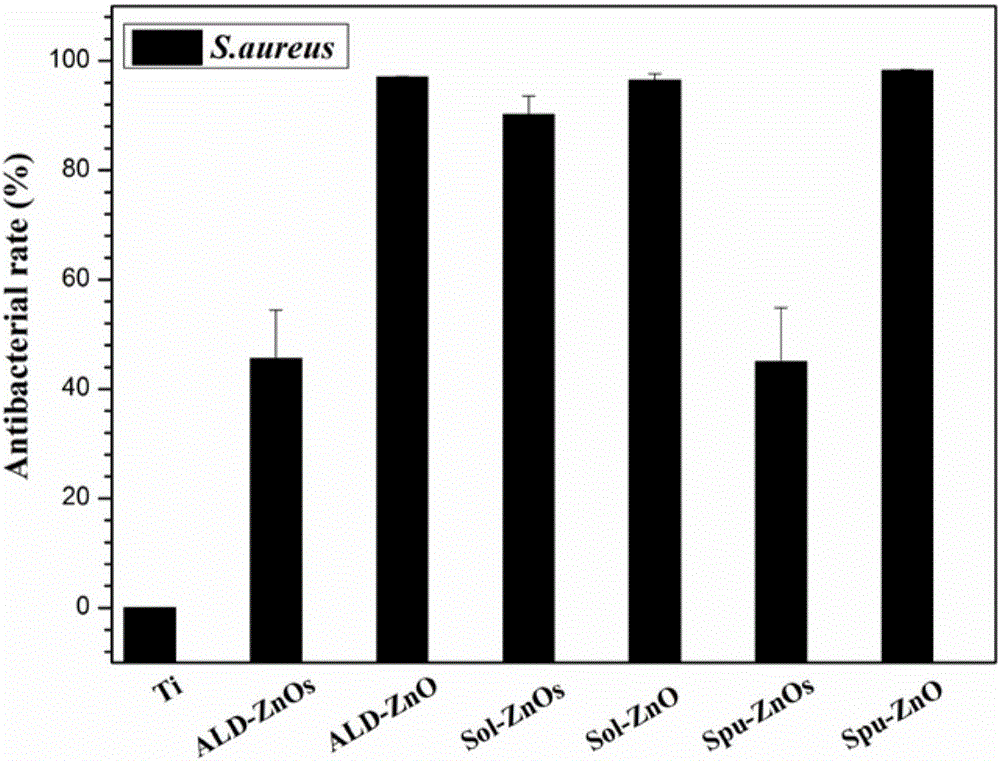

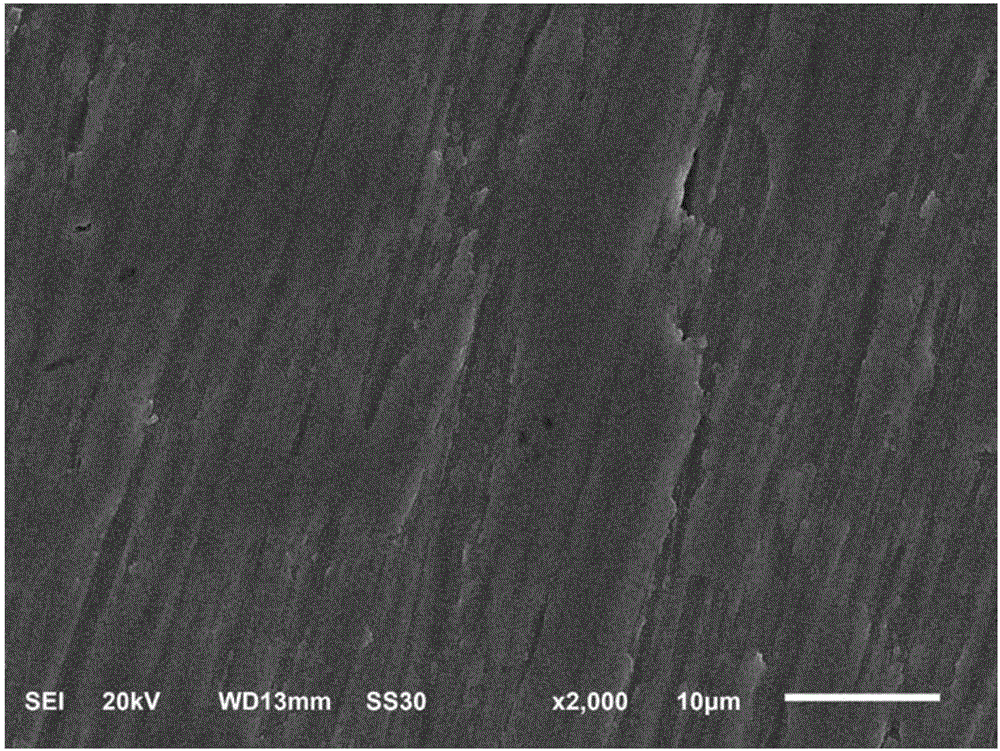

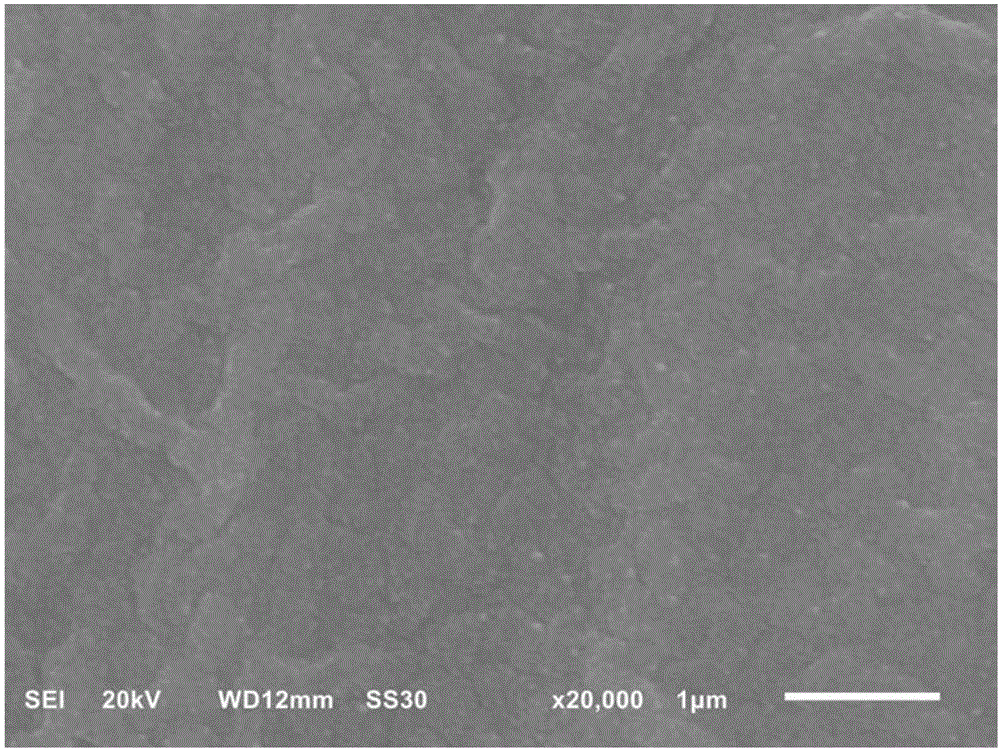

Preparation method of antibacterial hydrophobic ZnO nanorod

ActiveCN106756898ANothing producedImprove antibacterial propertiesMaterial nanotechnologySurgeryHexamethylenetetramineHigh heat

The invention discloses a preparation method of an antibacterial hydrophobic ZnO nanorod. The preparation method comprises the following steps: (1) mechanical polishing of titanium pieces: the titanium pieces are polished in sequence to obtain smooth surfaces; and the polished titanium pieces are positioned in acetone, anhydrous ethanol and de-ionized water in sequence for respective ultrasonic cleaning by 15 minutes, and are naturally dried at room temperature for future use; (2) preparation of a ZnO seed layer: the polished titanium pieces obtained in the step (1) are used as a substrate to plate the uniform ZnO seed layer; and (3) preparation of a ZnO nanorod: the substrate coated with the ZnO seed layer in the step (2) is reversely suspended in water solution of zinc nitrate hexahydrate and hexamethylenetetramine for hydrothermal reaction and natural cooling; and after the substrate is taken out for cleaning by the de-ionized water, the substrate is dried to form the ZnO nanorod. The ZnO nanorod has the advantages of: better antibacterial efects, no need of high-temperature heating, no harmful gas, economy, environmental protection, broad spectrum, high efficiency, long bacteria resistance and a certain biological compatibility.

Owner:HUBEI UNIV

Method for preparing functional vinyl polysiloxane nanofiber membrane through electrostatic spinning

ActiveCN104805599ANo pollution in the processGuaranteed uniformitySucessive textile treatmentsLiquid/gas/vapor removalAir filtrationChemical industry

The invention relates to a method or preparing a functional vinyl polysiloxane nanofiber membrane, belonging to the technical field of processing of textile materials. The method comprises the following steps: mixing vinyl polysiloxane, functional nanoparticles and an organic solvent according to proportions to prepare a spinning solution; carrying out electrostatic spinning by using an electrostatic spinning machine; collecting; and finally drying to obtain the functional vinyl polysiloxane nanofiber membrane. The functional vinyl polysiloxane nanofiber membrane prepared by the preparation method disclosed by the invention can realize a synergistic effect of multiple functions, can be widely used for biomedicine, energy and chemical industry, water purification, air filtration, lithium ion battery separators and carrier materials and also can be used for preparing self-cleaning, waterproof and windproof, windproof and heat preservation, moisture-permeable and air-permeable textile materials. The preparation method disclosed by the invention is simple, high in production efficiency, low in energy consumption, free of pollution to the ecological environment and suitable for industrial production.

Owner:WUHAN TEXTILE UNIV

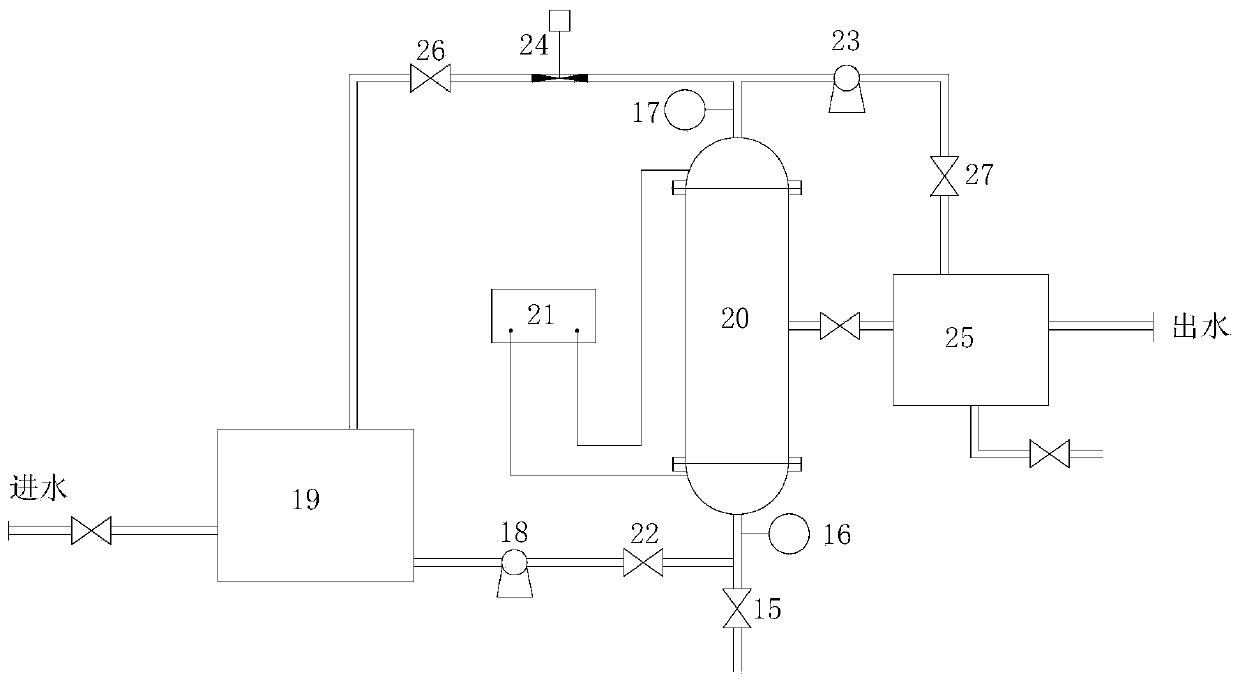

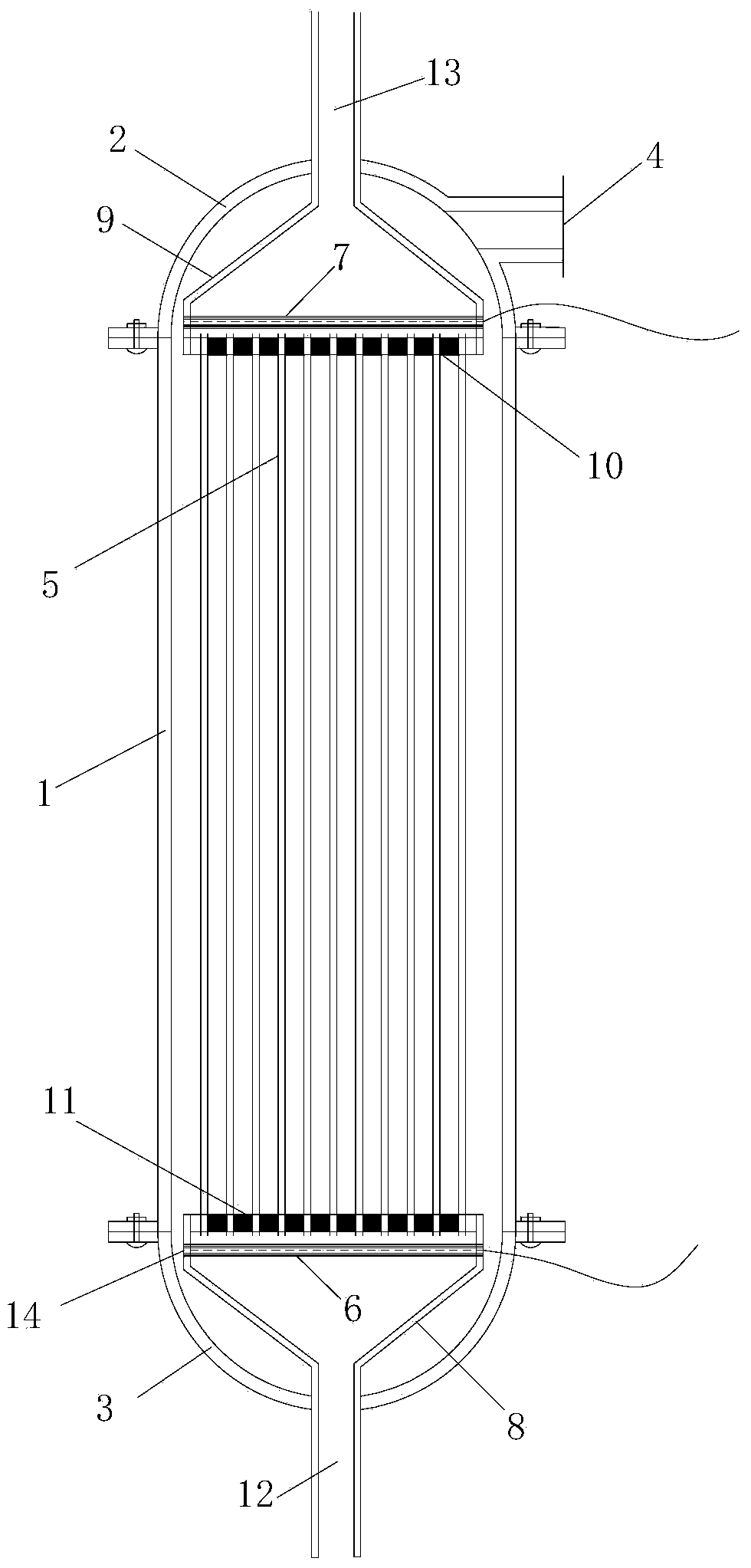

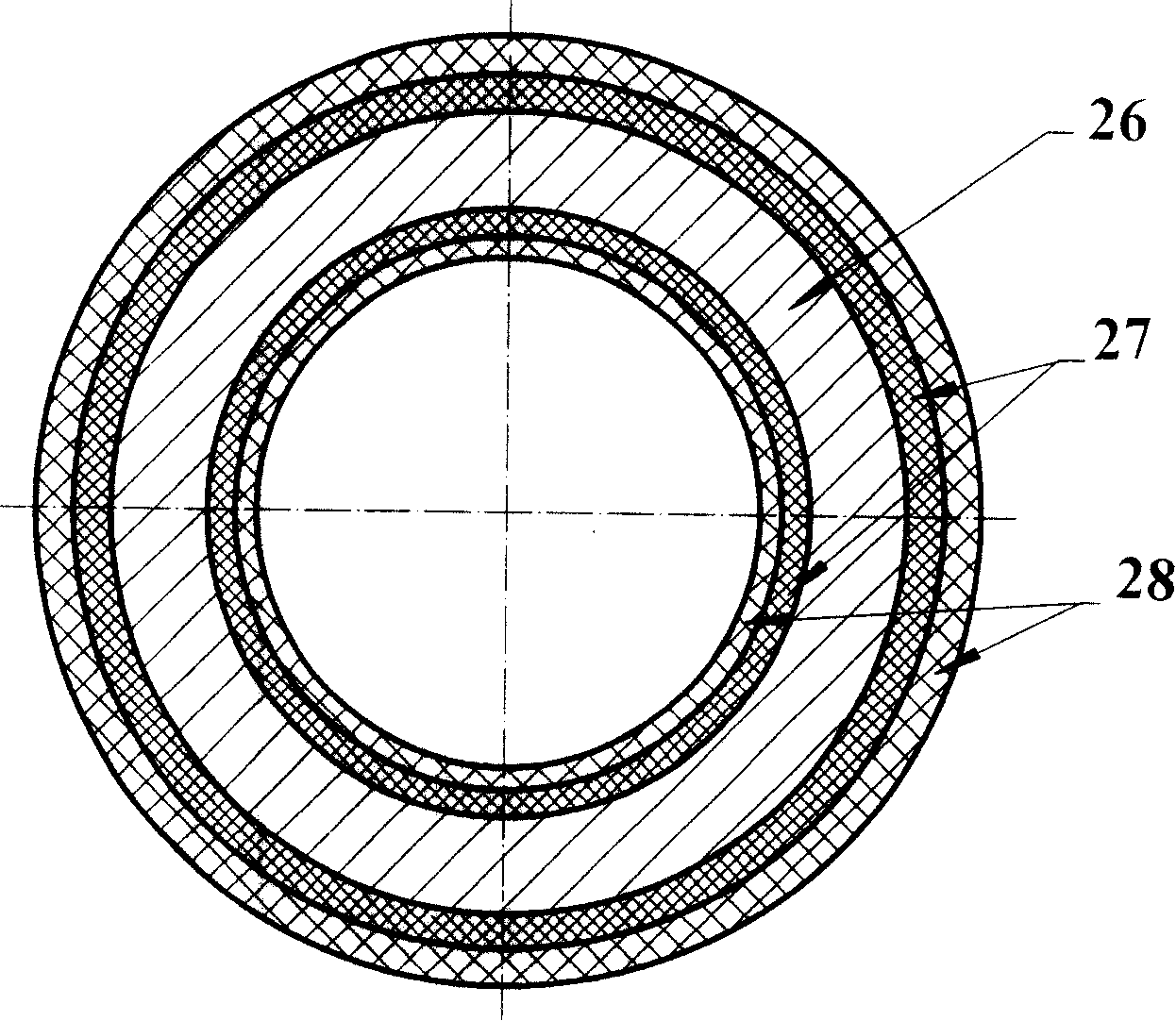

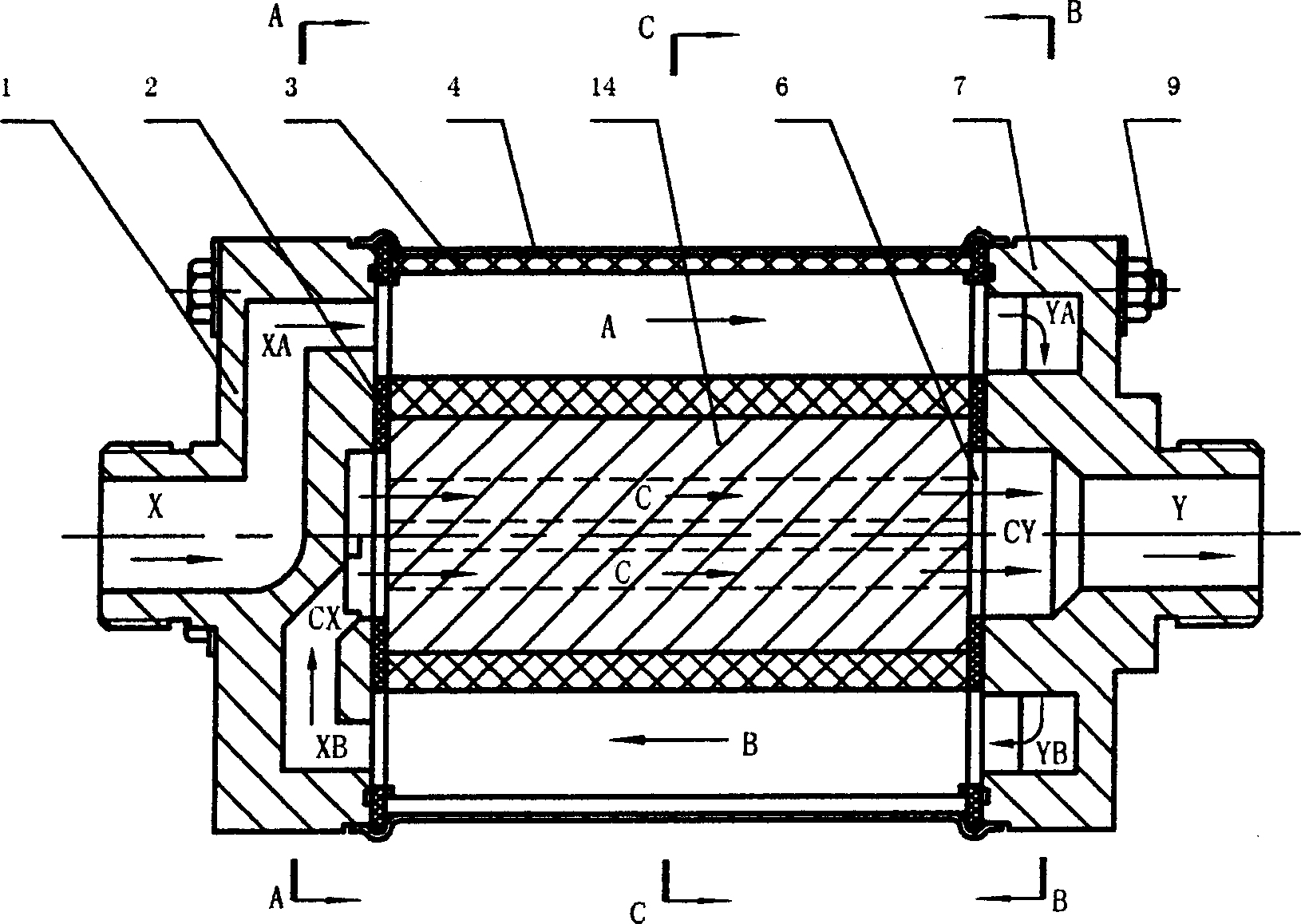

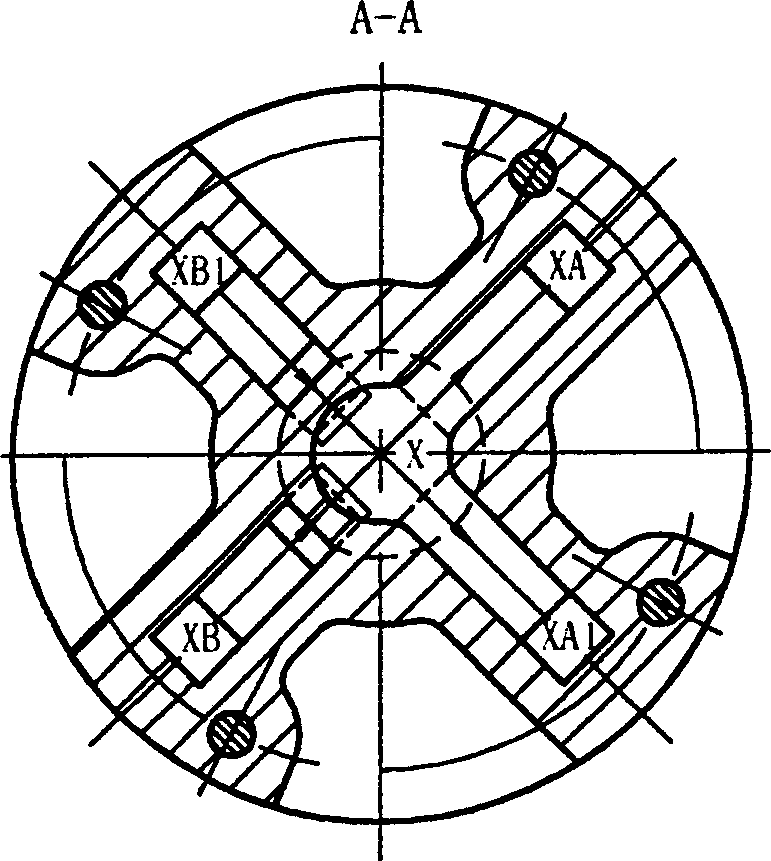

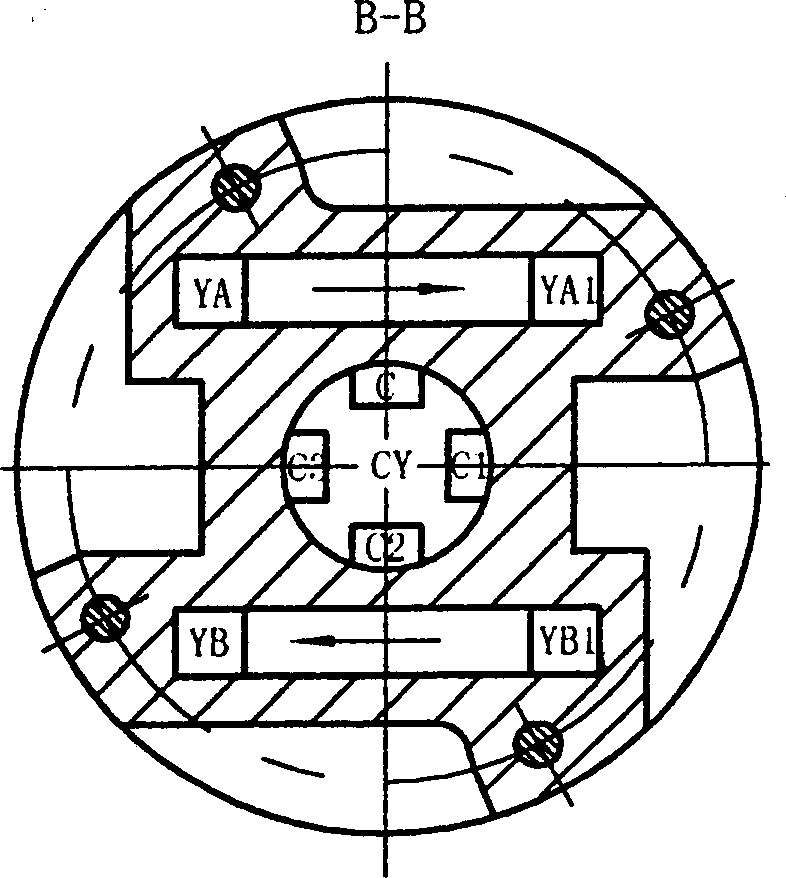

Device and method for strengthening filtering of internal-pressure membrane by using pulsed electric field

ActiveCN103623705AReduce accumulationReduce pollutionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisHollow fibreInternal pressure

The invention discloses a device and a method for strengthening filtering of an internal-pressure membrane by using a pulsed electric field. The device comprises a shell, a membrane assembly and a pulse power supply, wherein the shell is provided with a penetrating fluid outlet; the shell is composed of a barrel and end sockets at the two ends; the membrane assembly comprises a membrane bundle, a negative electrode, a positive electrode, a water inlet cover and a water outlet cover; the membrane bundle is composed of a plurality of membranes which are arranged at intervals in parallel; the membrane bundle is arranged in the barrel and the two ends of the membrane bundle are fixed by membrane heads; the water inlet cover is arranged between one membrane head and the end socket at the end; the water outlet cover is arranged at the other membrane head and the end socket at the other end; water inlets and water outlets of the water inlet cover and the water outlet cover respectively stretch out of the two end sockets; the negative electrode and the positive electrode which are vertical to the membranes are arranged in the water inlet cover and the water outlet cover respectively; a gap is formed between the negative electrode and one membrane head and a gap is formed between the positive electrode and one membrane head; the negative electrode and the positive electrode are connected with the pulse power supply; the membranes are hollow fiber internal-pressure membranes. According to the device and the method, different pulse electric fields are respectively applied in the filtering and washing processes; the filtering condition can be improved, the washing effect is strengthened and the service life of the membrane is prolonged.

Owner:SOUTH CHINA UNIV OF TECH

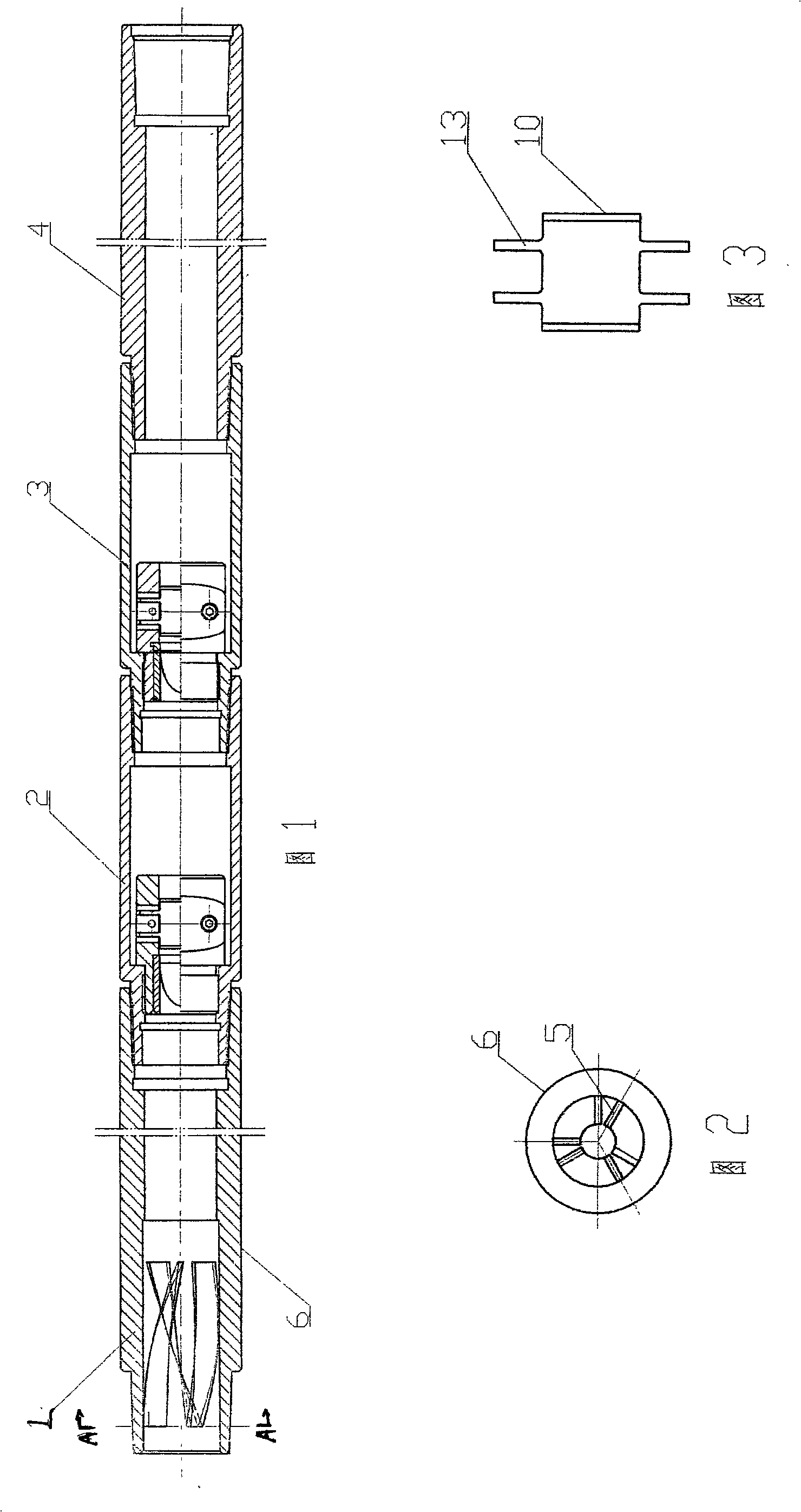

Environment protection type wax-proof anti-scaling viscosity reduction machine

ActiveCN101328796AIncrease productionScientific and reasonable adjustmentCleaning apparatusFluid removalCycloneEnvironmental resistance

The invention relates to oil production equipment, in particular to an environment-friendly paraffin-scale preventive viscosity reducer for underground oil pumping, comprising a jet flow ultrasonator, an ultrasonic cavitation cavity and a cyclone. The viscosity reducer is characterized in that: the cyclone is an inlet end; the back end of the cyclone is butted against a jet flow ultrasonic signal emitter and then is butted orderly against the jet flow ultrasonator and the ultrasonic cavitation cavity; and the outer end of the ultrasonic cavitation cavity is an outlet. The viscosity reducer solves the problem that the prior similar products are not ideal in the effects of preventing paraffin and reducing viscosity, really has ultrastrong functions of preventing paraffin, reducing viscosity and preventing scale, greatly increases the liquidity of crude oil, raises pump efficiency, increases oil well yield, needs no additional power, is safe and environment-friendly, accords with oil production wells with different types, and is suitable for the oil wells with different paraffin content and water content as well.

Owner:SHANDONG QUNFENG PETROLEUM TECH DEV CO LTD

Production process of anti-staining automobile interior leather

ActiveCN103602764AAnti-aging leather bodyFeel comfortableTanning treatmentPre-tanning chemical treatmentDyeingEngineering

The invention relates to the field of the manufacturing of industrial leather, and in particular relates to a production process of anti-staining automobile interior leather. The production process comprises the steps of soaking, fleshing, liming, fleshing splitting, deliming, softening, pickling, tanning, aging, shaving, conditioning, retanning, neutralizing, dyeing, electrostatic conditioning, wringing stretching, wet vibrating, vacuum drying, vibrating, milling, bottom layer coating, electrostatic treatment, knurling, intermediate painting, anti-staining top layer preparing, anti-staining reinforced layer preparing, measuring and warehousing, wherein anti-staining top layer paint and anti-staining reinforced layer paint are respectively proportioned according to the appropriate components and then are sprayed onto the leather surface according to the appropriate coating amount, and then the leather is dried. Through the combined action of different functions, not only is the anti-staining performance strong, but also the anti-staining effect is remarkable, stains which are not repelled are easy to scrub and clean due to the difficulty in combination and permeation, and the automobile interior leather which is anti-staining and easy to clean can be achieved.

Owner:HAINING SENDE LEATHER

Surface self-cleaning coating and preparation method thereof

InactiveCN104356826AIncreased durabilityWill not harmAntifouling/underwater paintsPaints with biocidesPlasticizerActive agent

The invention discloses a surface self-cleaning coating and a preparation method thereof. The surface self-cleaning coating comprises such components as 4-15% of deionized water / ester compound, 0.3-2% of flatting agent, 0.3-0.6% of defoamer, 0.4-0.6% of dispersant, 5-10% of nano mineral filler, 30-40% of binder, 1-3% of plasticizer, 10-15% of pigment paste, 1-3% of surface active additive, 1-2% of anti-staining seal-cleaning non-sticking agent, 2-4% of antifungal and moss / sludge / alga growing preventing inhibitor, and 18-28% of curing agent. The surface self-cleaning coating is capable of effectively preventing graffiti and resisting scaling, and self-cleaning; heavy metals or other toxic substances such as organic tin are not contained in the formula, and no chemical surfactant and alkaline products are adopted, and therefore, the film formed after the coating is cured has better durability and the surface of the film cannot be damaged by effective cleaning.

Owner:珠海市澜诺新材料科技有限公司

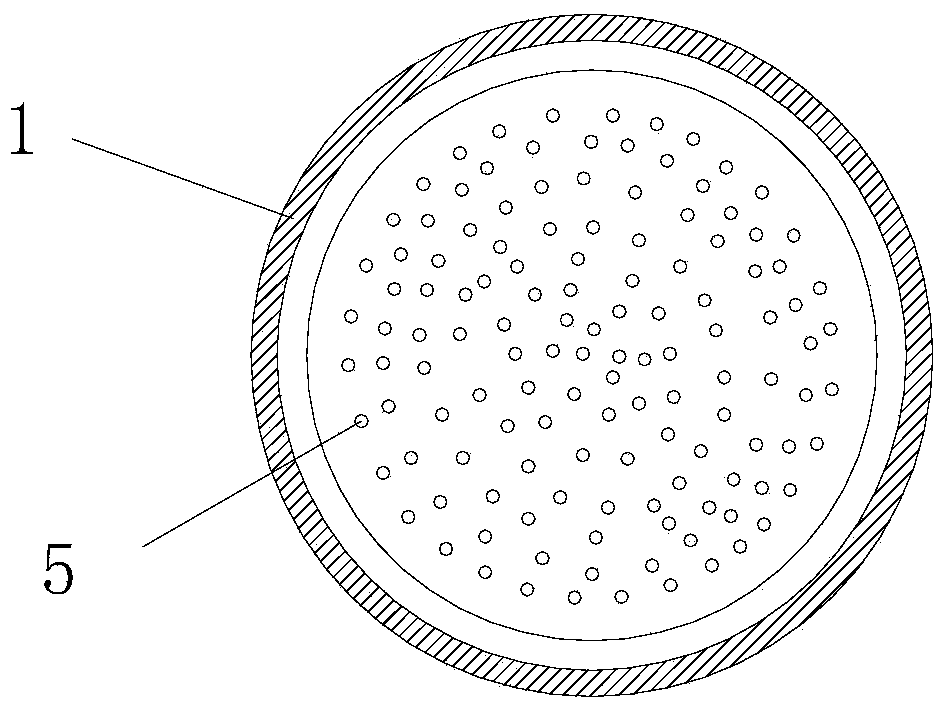

Nano coating protective pipe and its coating manufacture process

InactiveCN101169215ASmall volume shrinkageSmooth rotationCorrosion preventionPipe protection against corrosion/incrustationSteel tubeParaffin oils

The invention discloses a nanometer coating protective pipe prepared by nanometer squama coating and production technique of coating, wherein, the nanometer coating protective pipe consists of three parts of a pipe body, a basal layer and a function layer. The basal layer is the substrate of the nanometer coating and coated on the surface of the pipe body when contacts with a metal base body. The function layer is the facial layer of the nanometer coating and coated on the surface of the basal layer when the function layer contacts with corrosive medium. The nanometer coating the protective pipe disclosed in the invention changes the surface characteristic of the steel pipe products, and acquires a novel characteristic completely different from the original steel pipe products and enables the products to satisfy the need of people towards hi-tech development. The nanometer coating can provide oil pipe products with good performance in resisting corrosion, paraffin, scale and abrasion, so as to greatly prolong the maintenance period of the pipeline products in oil extracting wells, water injecting wells and conveying pipelines of oil fields.

Owner:白日忠

Terylene leisure sport fabric with elastic weft and warp

The invention discloses terylene sports fabric with elastic warp yarns and weft yarns. The fabric is characterized in that: at least one of the warp yarn and weft yarn is high-elasticity yarn prepared by the combination of polyethylene terephthalate(PET) and polypropylene terephthalate(PTT), the denier of the warp yarn and weft yarn is between 50 and 300D, and the denier per filament is between 0.5 and 3.2D. The fabric has the characteristics of loose texture, soft touch, good elasticity and drapability, good size stability, easy washing, no need of ironing, water resistance, stain resistant and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

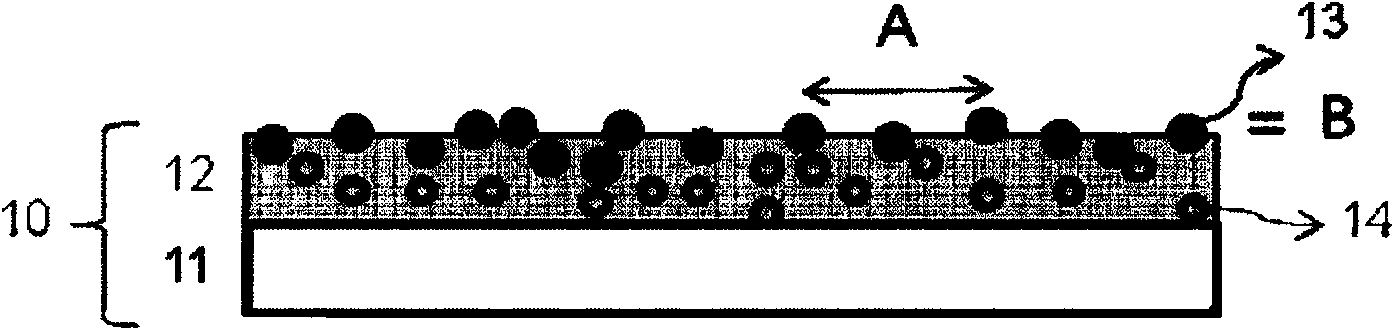

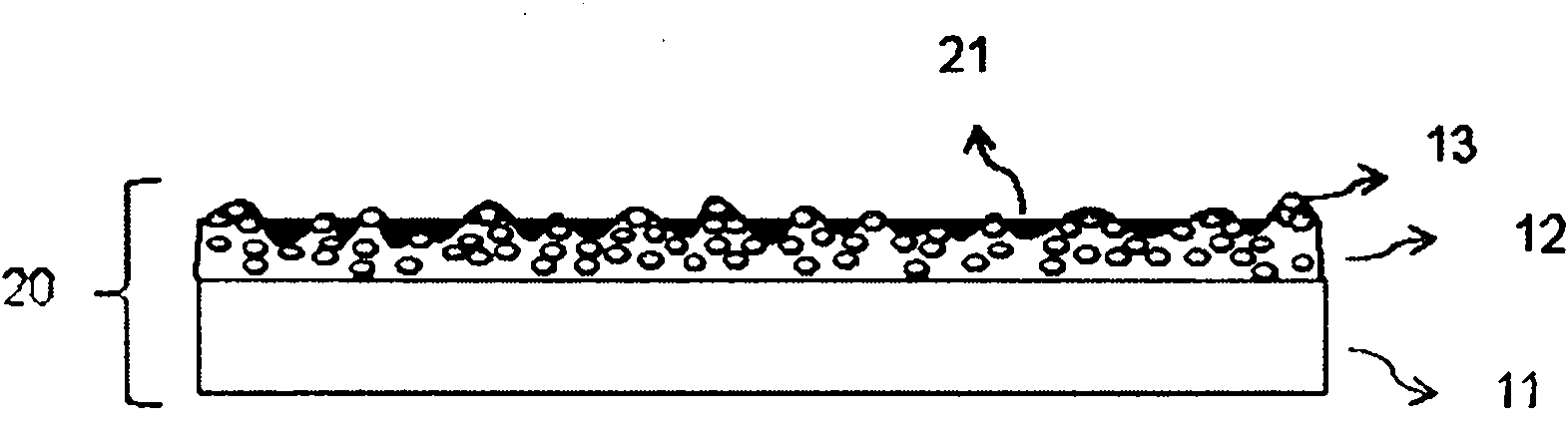

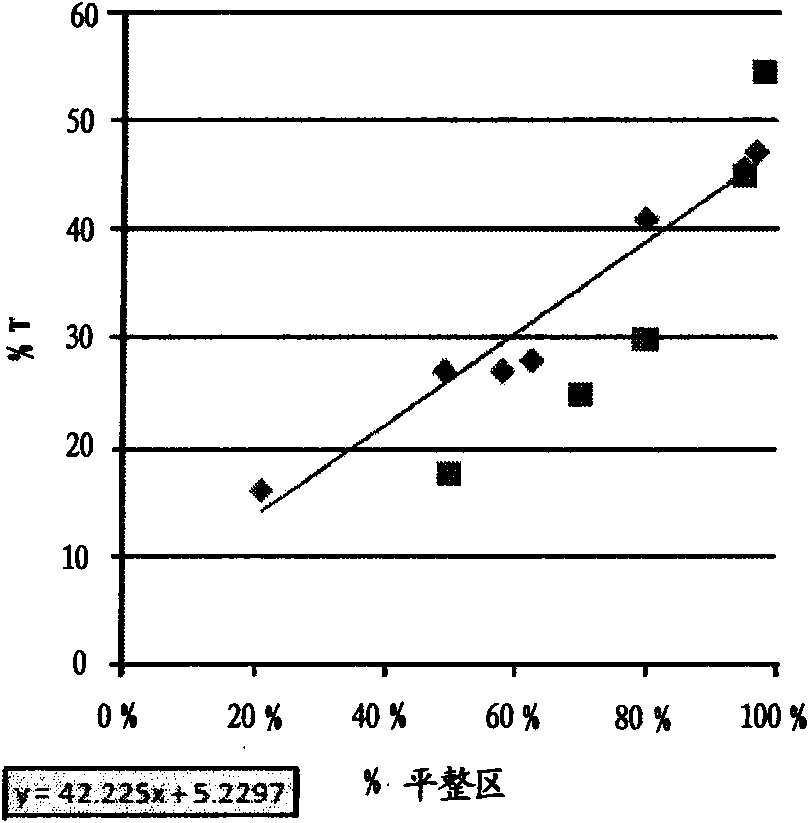

High-transmittance flexible touch material and making method thereof

InactiveCN101817249AHigh light transmittanceSoft touch enhancement of light transmissionSynthetic resin layered productsLuminosityEngineering

The invention relates to a high-light transmittance flexible touch material and a making method thereof. The high-light transmittance flexible touch material comprises a plastic substrate and a semi-transparent resin layer with a hemispherical surface, wherein the light transmittance of the plastic substrate is greater than 60%; the semi-transparent resin layer with the hemispherical surface is fully or partially arranged on the plastic substrate, the ratio of the exposed diameter dp of the protruded hemisphere to the average space Sm of protruded points is 0.1-0.8, and the integral light transmittance of the material is 10%-50%. The making method comprises the following steps of: selecting a high-light transmittance substrate and fully coating or partially printing one semi-transparent resin layer, wherein the surface of the semi-transparent resin layer is provided with hemispherical elastic granules; controlling the hemispherical elastic granules to ensure that the ratio of the exposed diameter dp of the protruded hemisphere to the average space Sm of the protruded points is 0.1-0.8 and the integral light transmittance of the material is 10%-50%. The method can improve the light transmittance of the flexible touch material, and back patterns of the flexible touch material are clear and visible, and the method can obtain the effect of simultaneously improving touch, decoration and information identification.

Owner:E SAN PRECISION COATING

Nano function material for treating water and its application

InactiveCN1381405AImprove permeabilityIncreased "energy"Magnetic bodiesWater/sewage treatment by magnetic/electric fieldsRare earthWater quality

A nanometre function material for treating water or used to preparing scale-removing energy-saving unit of boiler is prepared from pig iron HT No.200, powdered containing trace nuclear element (U, Th, etc.), zinc powder containing Ti or its oxide, and nanometre RF rare-earth material. Its advantage is high effect on removing scale and saving energy.

Owner:SUN YAT SEN UNIV +1

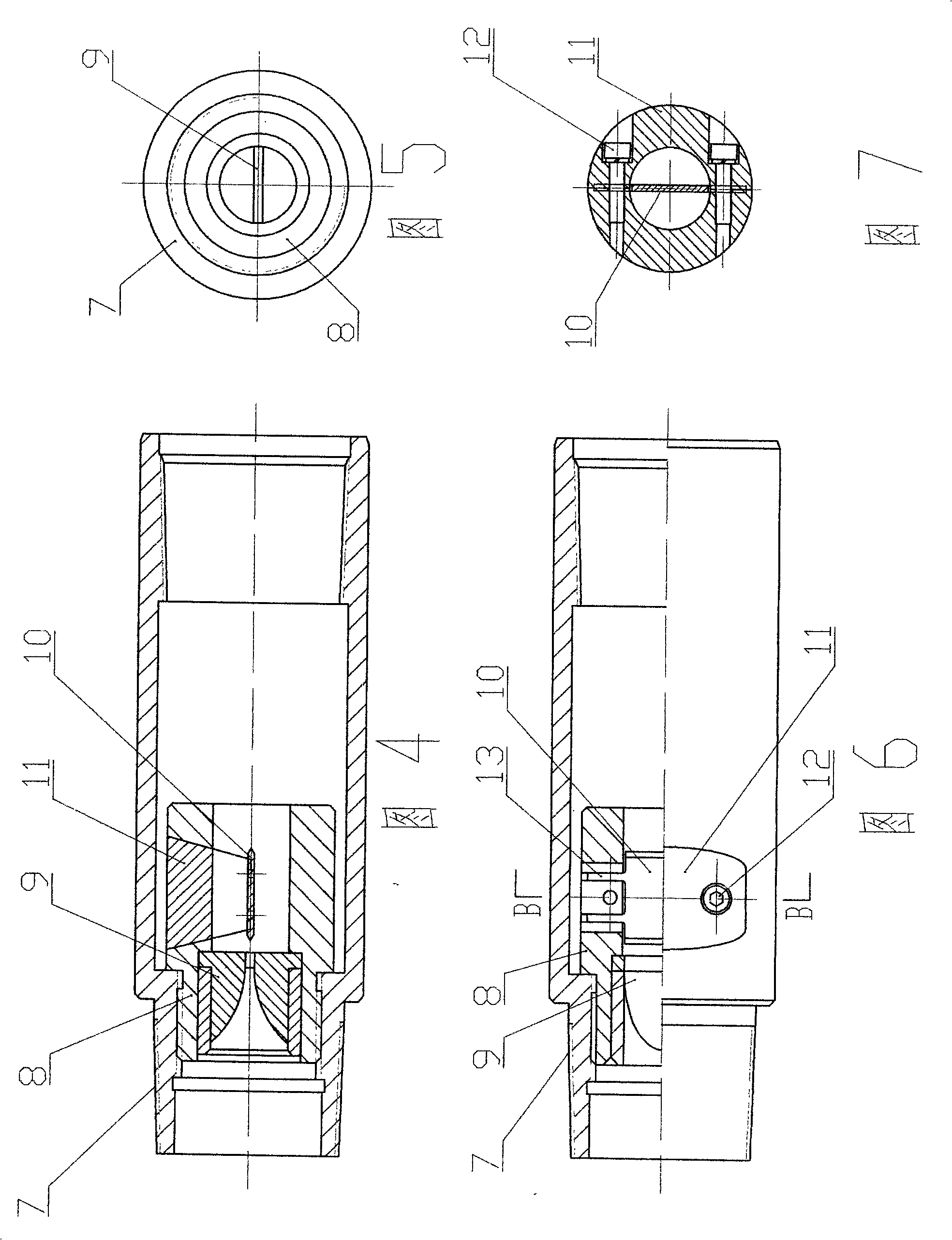

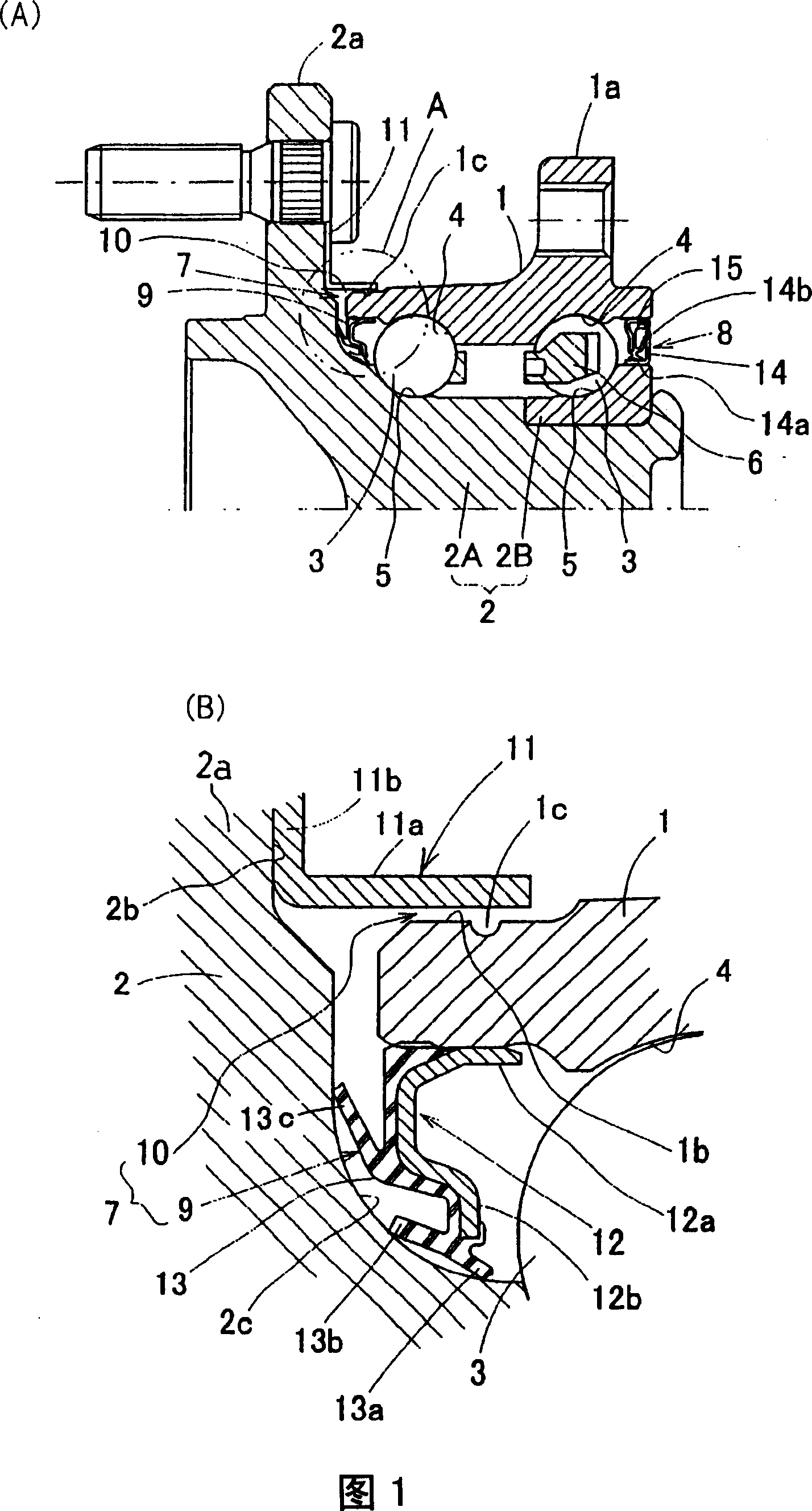

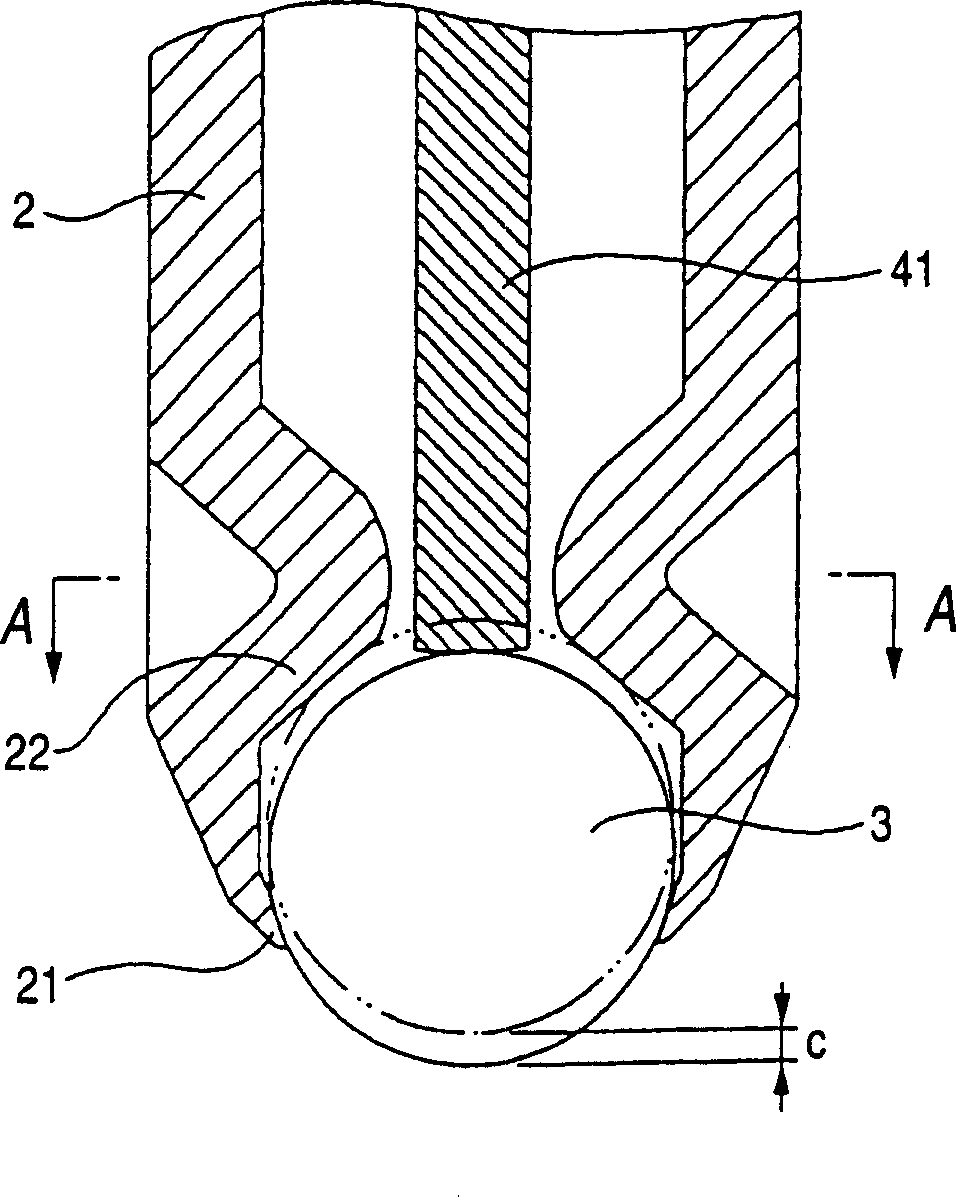

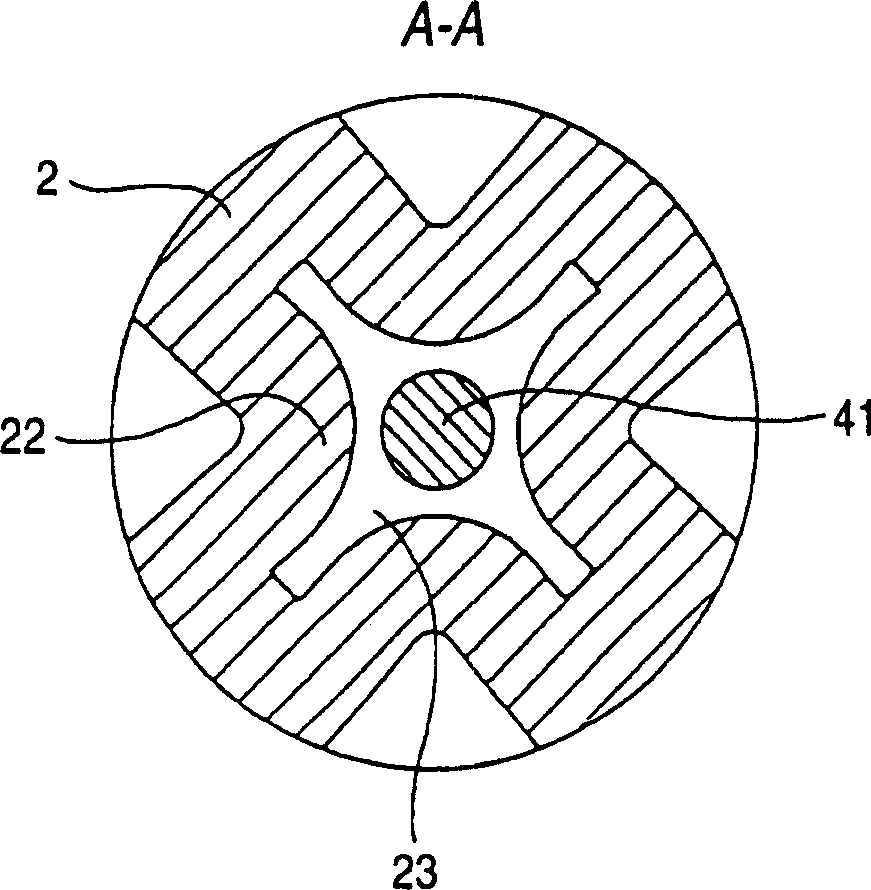

Vehicle bearing device

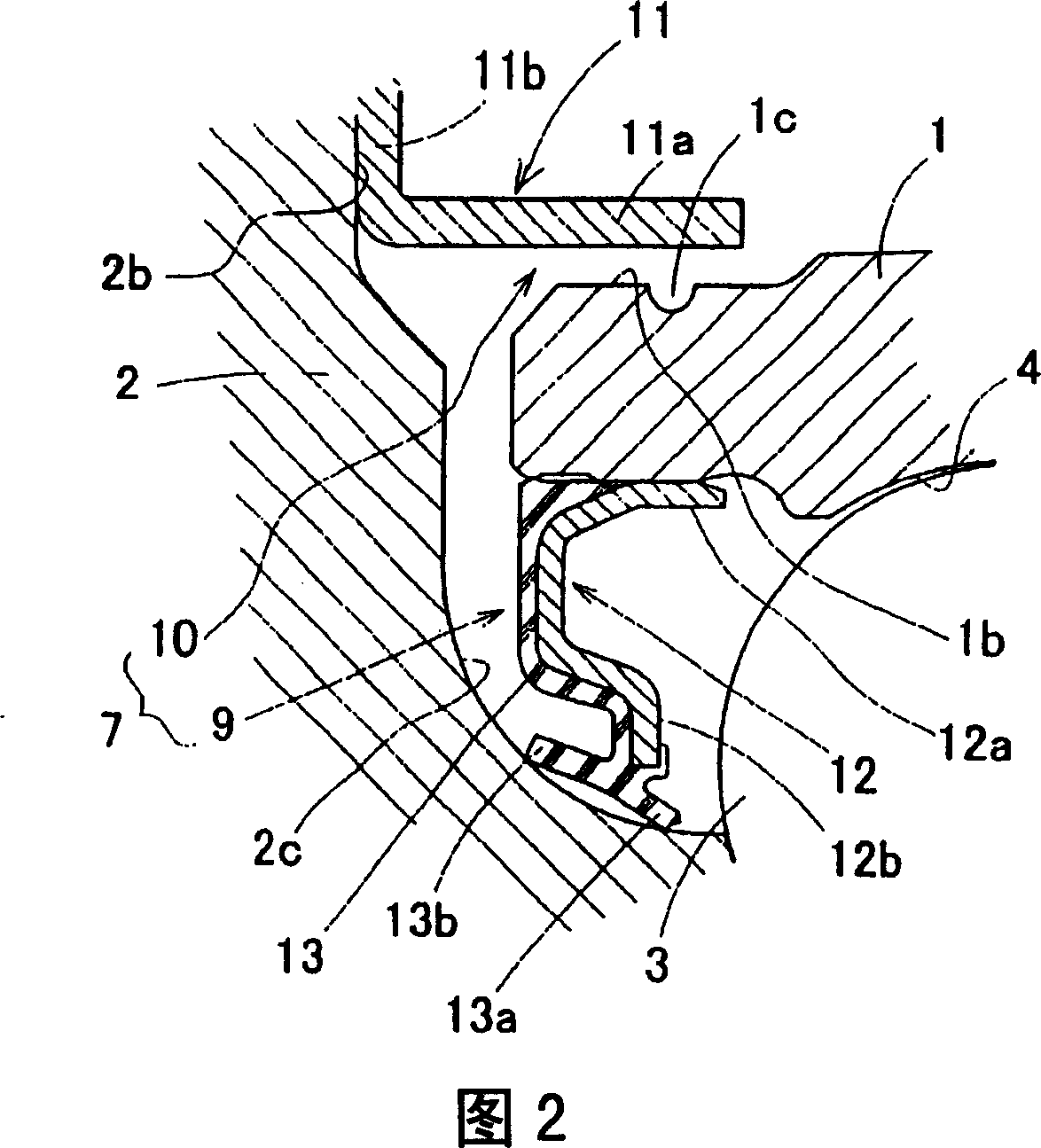

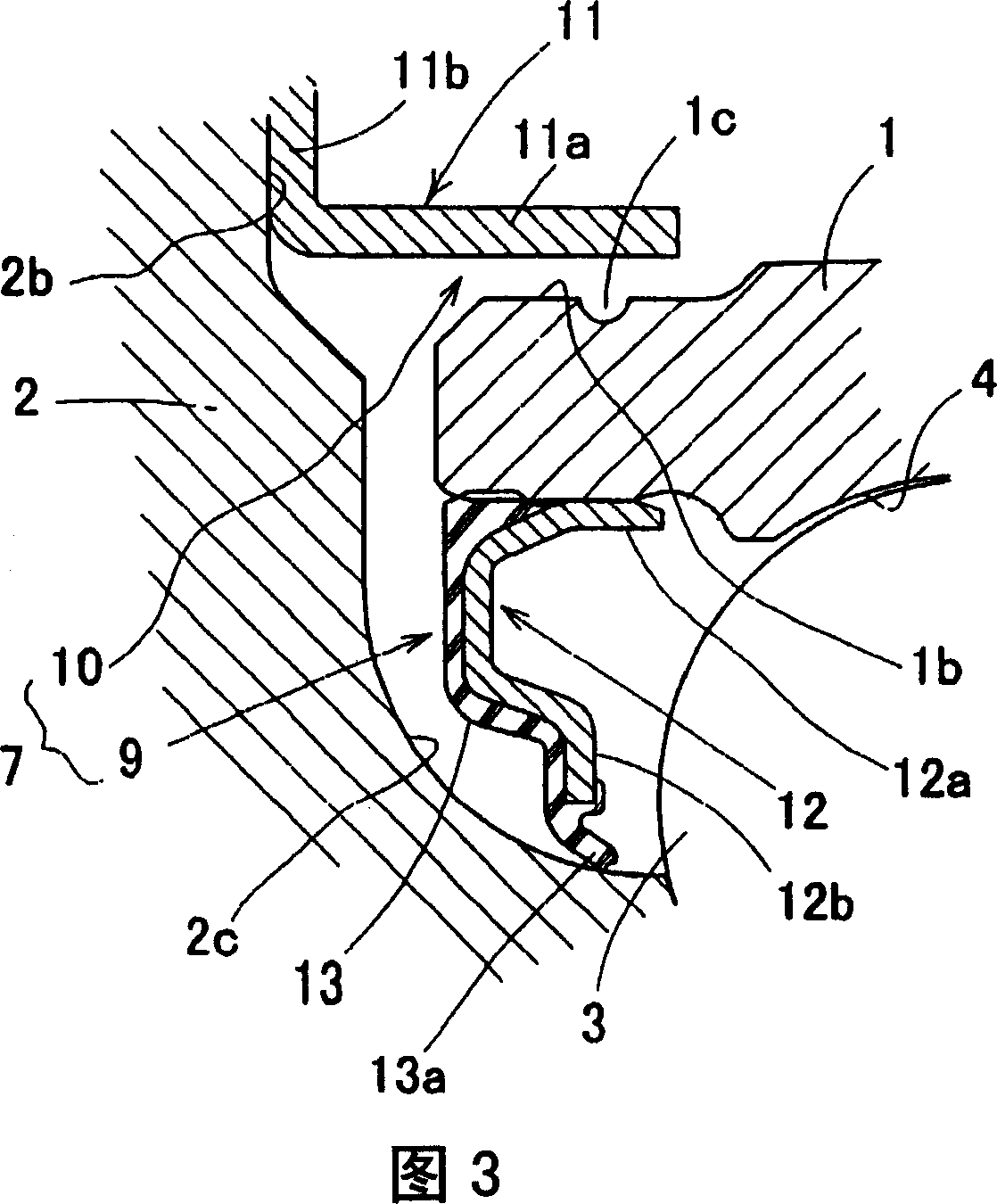

InactiveCN1957187AAnti-foulingAvoid loss of tightnessRolling contact bearingsCastorsWater flowFlange

Sealing structures (7, 8) are installed to seal opposite open ends of an annular bearing space between an outer member (1) and an inner member (2). A wheel mounting flange (2a) of the inner member (2) is provided with a shielding plate (11). The shielding plate (11) has a tubular wall (11a) forming a labyrinth seal (10) in the vicinity of an outer peripheral surface (1b) of an outboard end of the outer member (1). The outer peripheral surface (1b) is provided with a guide structure (1c) for guiding downwardly water, flowing in between the shielding plate (11) and the outer member (1) along the flange (2a) and the shielding plate (11), and water flowing in between the shielding plate (11) and the outer member (1) along the outer peripheral surface of the outer member (1). The guide structure (1c) is constituted by an annular groove or projection.

Owner:NTN CORP

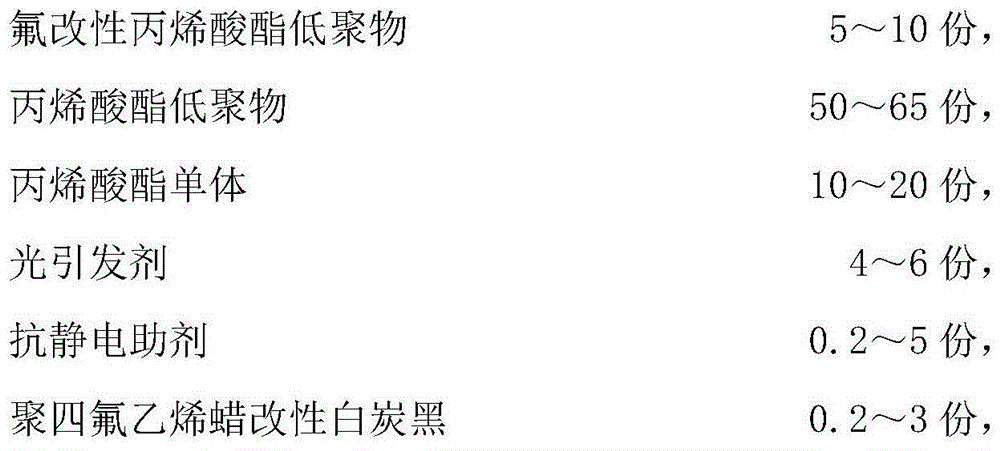

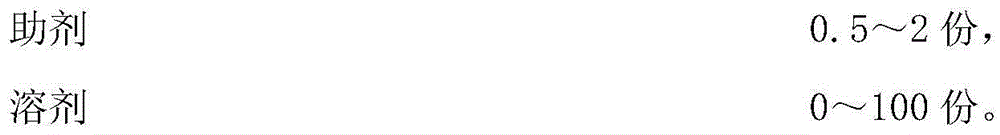

Anti-glare and anti-static light radiation curing coating composition

InactiveCN104312232AEasy to operateWide range of coating methodsAntifouling/underwater paintsPaints with biocidesWaxOligomer

The invention discloses an anti-glare and anti-static light radiation curing coating composition. The coating composition comprises the following components in parts by weight: 5-10 parts of a fluorine-modified acrylate oligomer, 50-65 parts of an acrylate oligomer, 10-20 parts of an acrylate monomer, 4-6 parts of a photoinitiator, 0.2-5 parts of an anti-static additive, 0.2-3 parts of polytetrafluoroethylene wax-modified white carbon black and 0.5-2 parts of additives. The coating composition disclosed by the invention adopts the radiation curable anti-static additive matched with fluorine-modified anti-glare particles, and is directly used in an existing PMMA (polymethylmethacrylate) plate hardened coating system; and after curing, a coating has anti-glare, anti-fouling and anti-static effects, and the effects are further obvious and lasting.

Owner:SHANGHAI WEIKAI CHEM

Biodegradable modified lignin particles and production method thereof

The invention relates to biodegradable modified lignin particles. The biodegradable modified lignin particles comprise the following raw components: 35 to 45 weight parts of lignin, 40 to 55 weight parts of poly(butylene adipate / terephthalate), 4 to 6 weight parts of auxiliary agents and 0.5 to 1 weight part of an organic anti-blocking agent; the auxiliary agents comprise stearic acid and polyethylene wax. A production method for the biodegradable modified lignin particles comprises the following steps: mixing the raw components according to the above parts by weight; heating and obtaining a coarse material after the raw components are mixed uniformly; taking the coarse material and granulating the coarse material to obtain the biodegradable modified lignin particles. The biodegradable modified lignin particles can be completely biodegraded after use, have high mechanical and processing performance, and have important significance to protect ecological environment and reduce white pollution. The biodegradable modified lignin particles are simple in production process and low in cost, and are suitable for batch production.

Owner:高陈堰

Multifunctional car water tank antifreeze fluid

The invention provides a multifunctional car water tank antifreeze fluid. The antifreeze fluid comprises the following components, by weight, 50-65 parts of alcohols, 30-45 parts of deionized water and 1-5 parts of an additive. The freezing point of the antifreeze fluid can reach -40DEG C or lower, so north cold weather demands can be satisfied; and the boiling point of the antifreeze fluid can reach 140DEG C or more, so an overheat case does not appear even in hot summer, thereby the car driving safety and the normal operation of a cooling system are guaranteed. The two used alcohols are nontoxic and harmless, so the damages of harmful substances to human bodies are eliminated, and environmental protection and safety are realized. The antifreeze fluid has the anticorrosion, antirust and antiscale effects, and can effectively protect the car cooling system, so the service life of the cooling system is prolonged.

Owner:马文俊

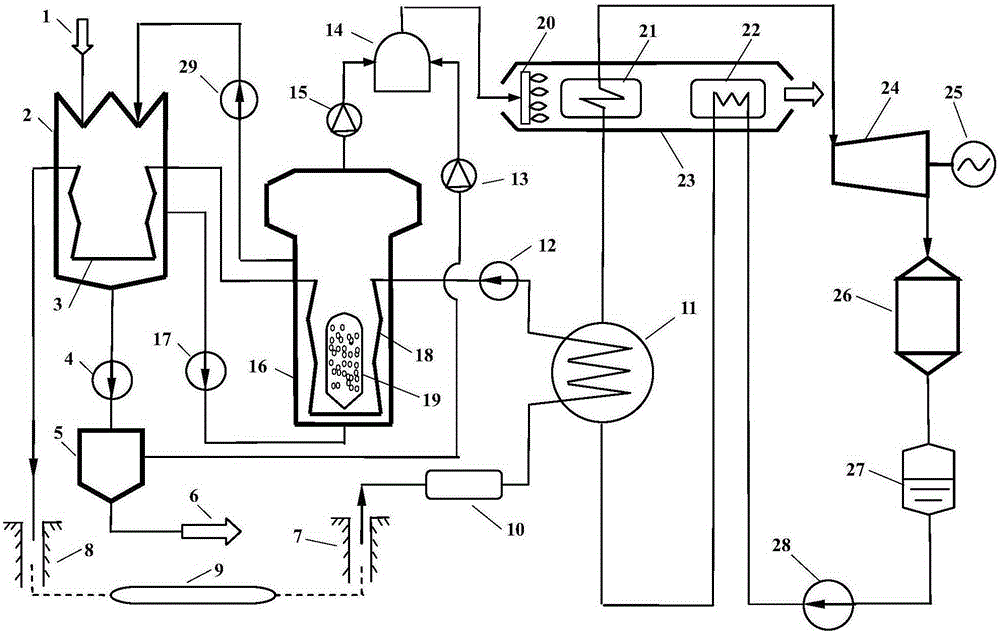

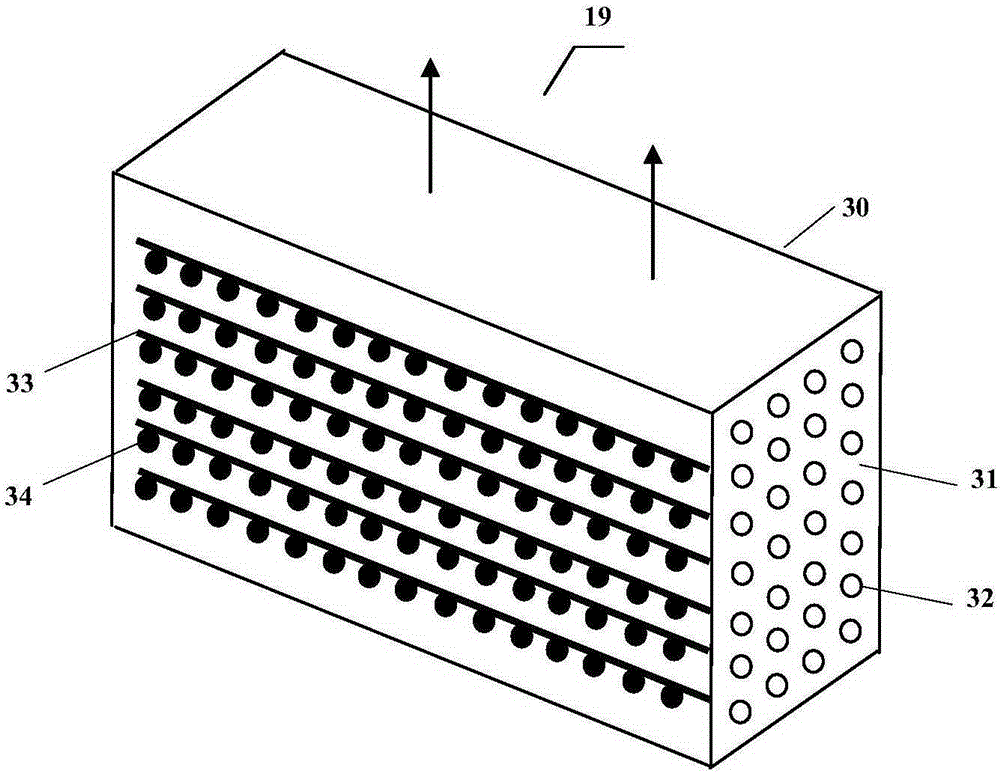

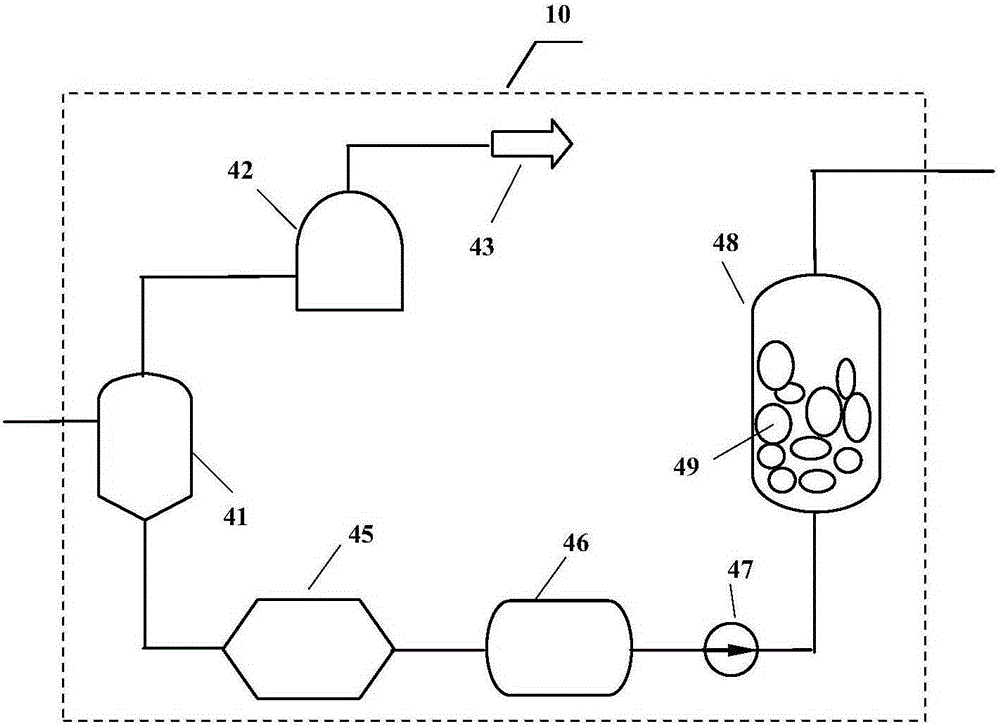

Medium-and-low temperature ground heat and biomass gas combined power generation system and power generation cost calculating method

ActiveCN105221363APrevent freezingStable and clean power generationGeothermal energy generationGeothermal systemsSuperheaterWater processing

A medium-and-low temperature ground heat and biomass gas combined power generation system is characterized in that a working medium evaporator is connected with a working medium superheater, a prime motor and a power generator of a gas boiler, the prime motor is communicated with a working medium condenser and a working medium storage tank, and the working medium storage tank is communicated with a working medium preheater of the gas boiler through a working medium booster pump; a production well is communicated with a ground heat water processing device and the working medium evaporator, and the working medium evaporator is communicated with a second inner heating pipe and a first inner heating pipe; the first inner heating pipe is communicated with an inverted well, an underground heat storage part and the production well; biomass is communicated with an acidification hydrolysis tank and communicated with a biogas residue fermentation tank and biogas fertilizer through a biogas residue circulation pump, and the biogas residue fermentation tank is communicated with a gas storage tank through a first gas booster pump; the acidification hydrolysis tank is communicated with an anaerobic digestor through an organic acid circulation pump; the anaerobic digestor is communicated with the gas storage tank and a combustor in the gas boiler through a second gas booster pump; and an anaerobic digester filling module is arranged in the anaerobic digestor. A power generation cost calculating method for the medium-and-low temperature ground heat and biomass gas combined power generation system is provided.

Owner:NORTHEAST DIANLI UNIVERSITY

Degradable hyperbranched resin and preparation method and application thereof

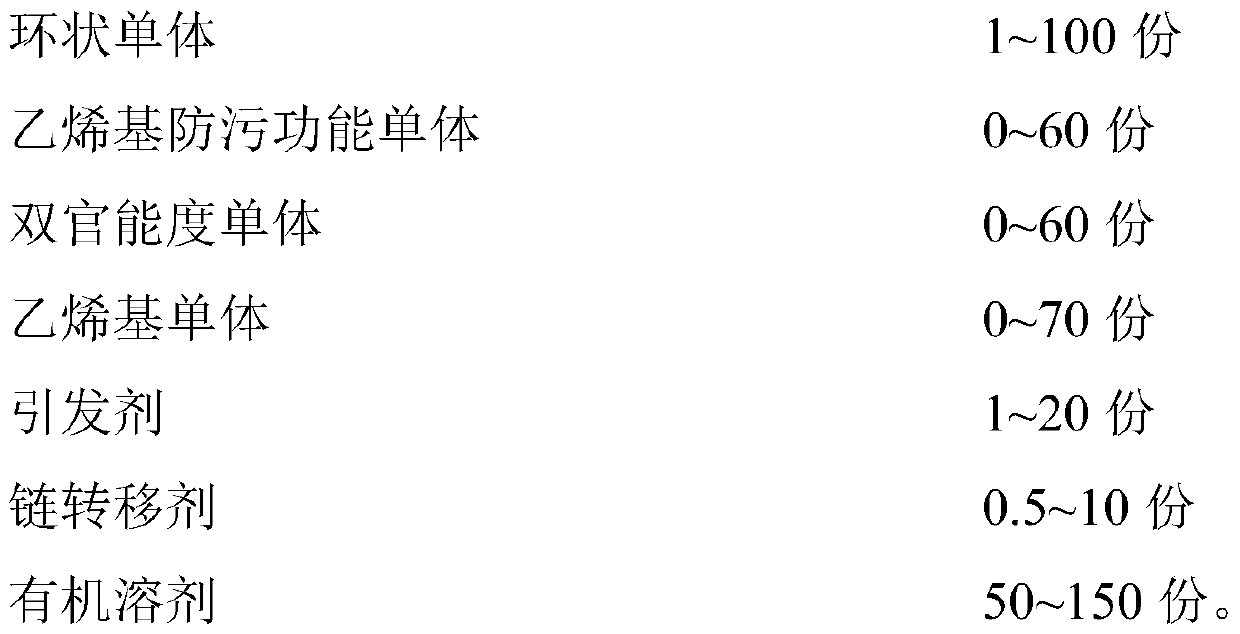

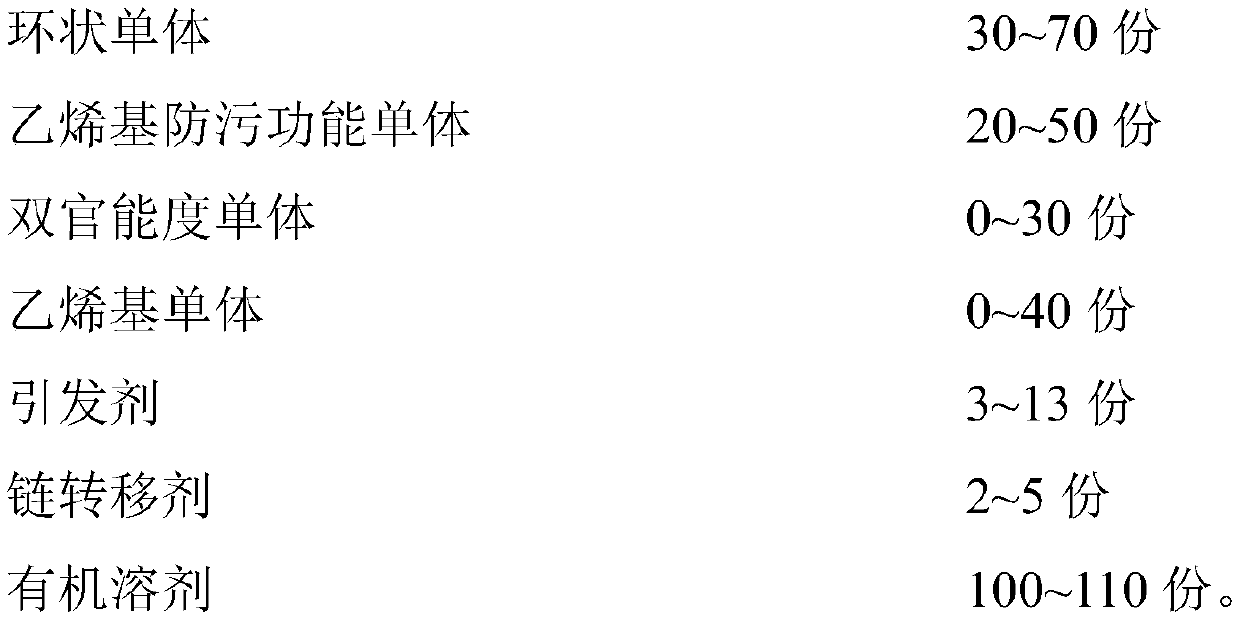

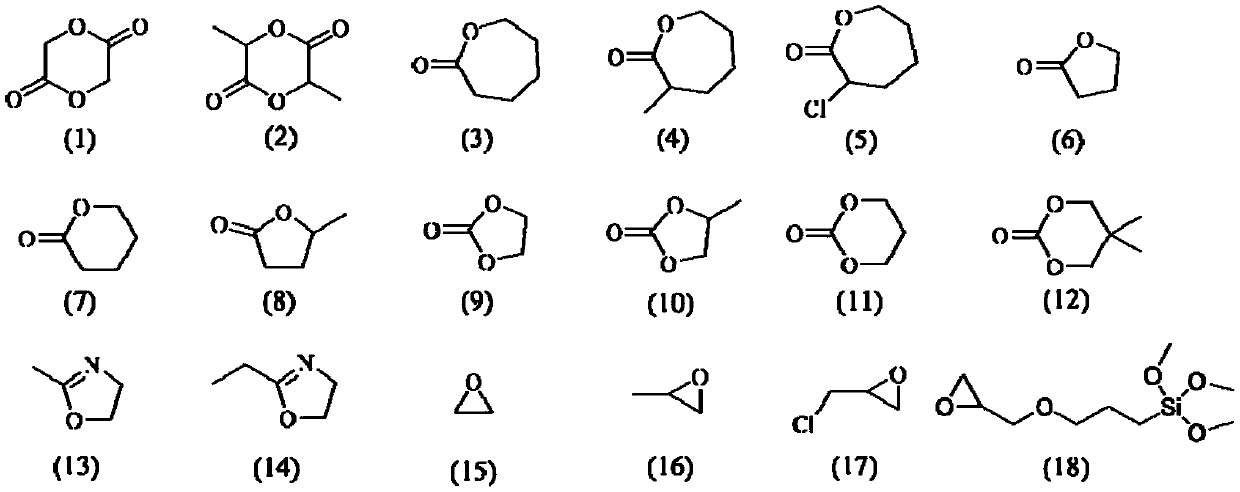

ActiveCN110540652ASmall molecular weightAvoid pollutionAntifouling/underwater paintsPaints with biocidesPolymer scienceFunctional monomer

The invention belongs to the technical field of marine antifouling materials, and discloses degradable hyperbranched resin and a preparation method and application thereof. The degradable hyperbranched resin is prepared from the following components in parts by weight: 1-100 parts of a cyclic monomer, 0-60 parts of a vinyl antifouling functional monomer, 0-60 parts of a bifunctional monomer, 0-70parts of a vinyl monomer, 1-20 parts of an initiator, 0.5-10 parts of a chain transfer agent and 50-150 parts of an organic solvent. According to the invention, the bifunctional monomer and the chaintransfer agent are introduced in the process of polymerization, and a hyperbranched structure is prepared from traditional straight-chain polymer antifouling resin and is applied to the field of marine antifouling for the first time. Besides, the resin also has the same advantages of high solid content and low viscosity as a hyperbranched polymer; and the preparation method is simple and feasiblein process, low in cost and suitable for industrial production, and has good development prospects in the field of marine antifouling coatings.

Owner:广东海巍新材料科技有限公司

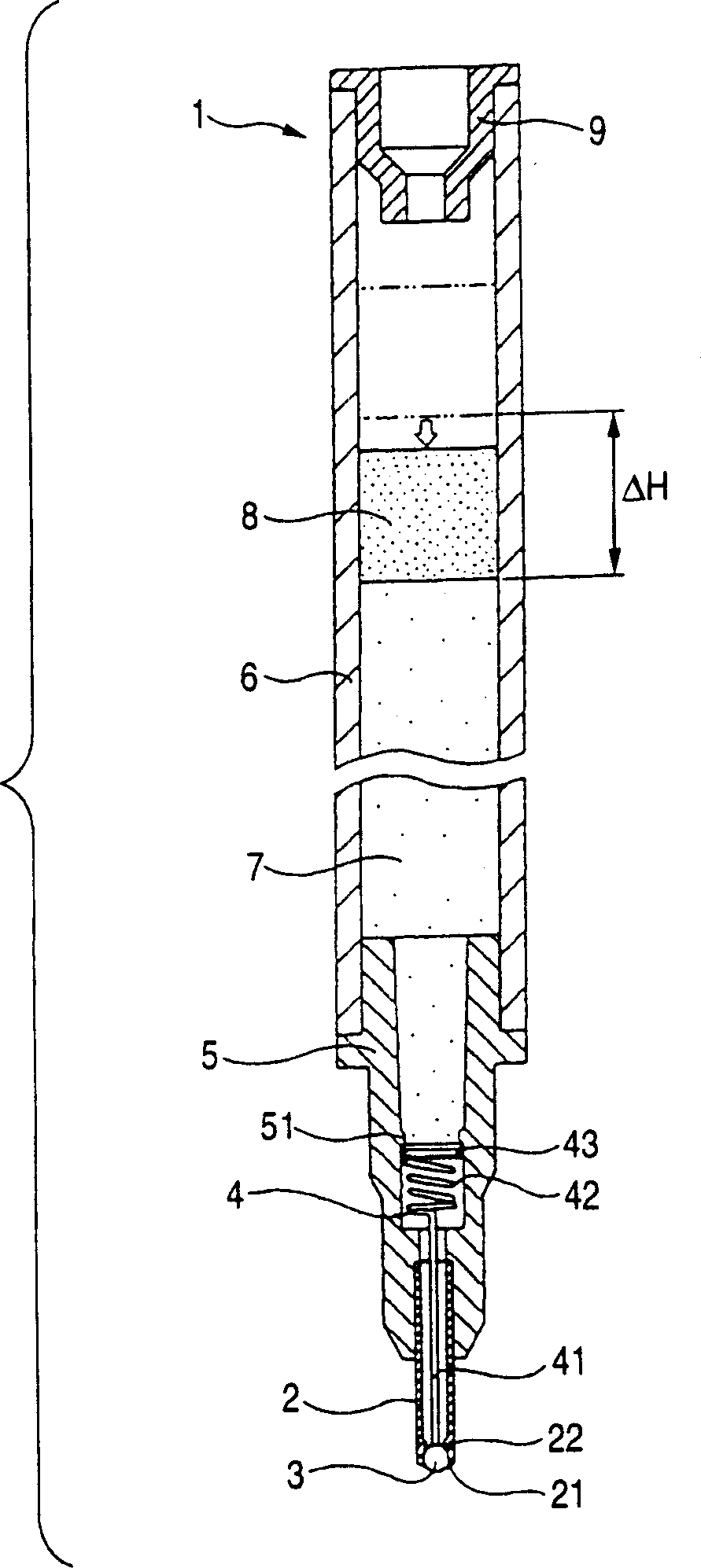

Ball-point pen

Owner:THE PILOT INK CO LTD

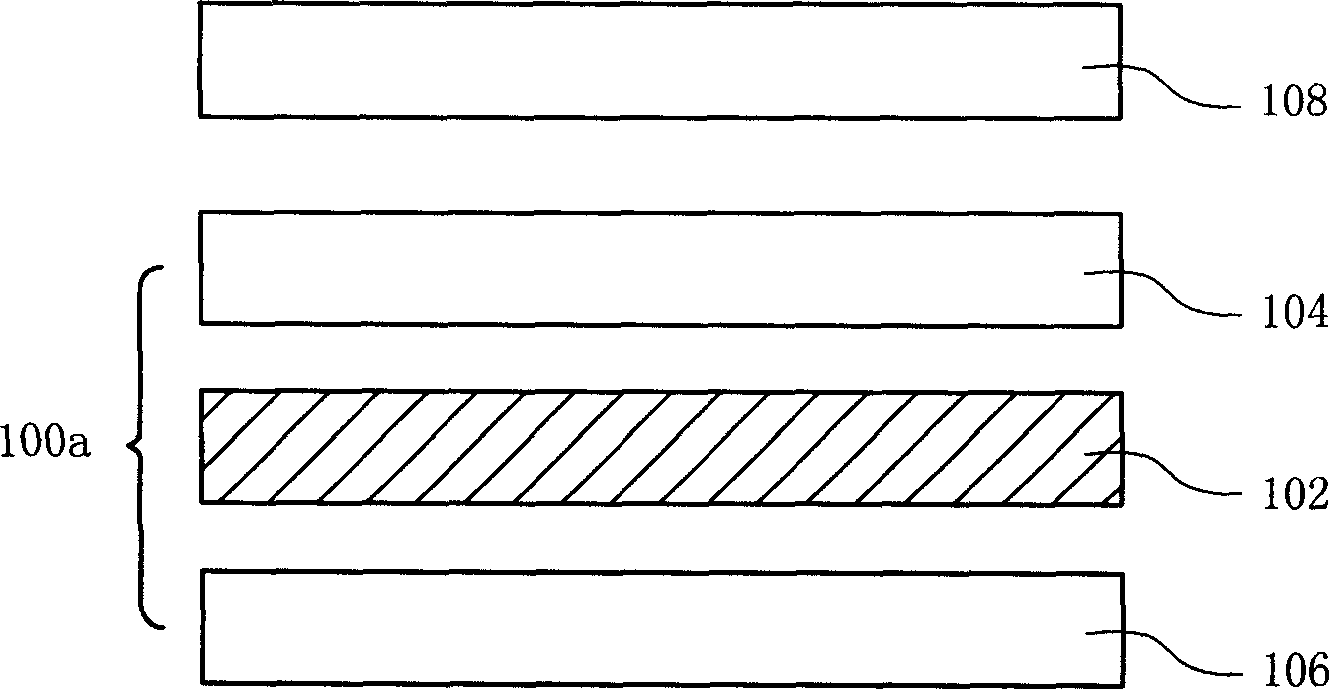

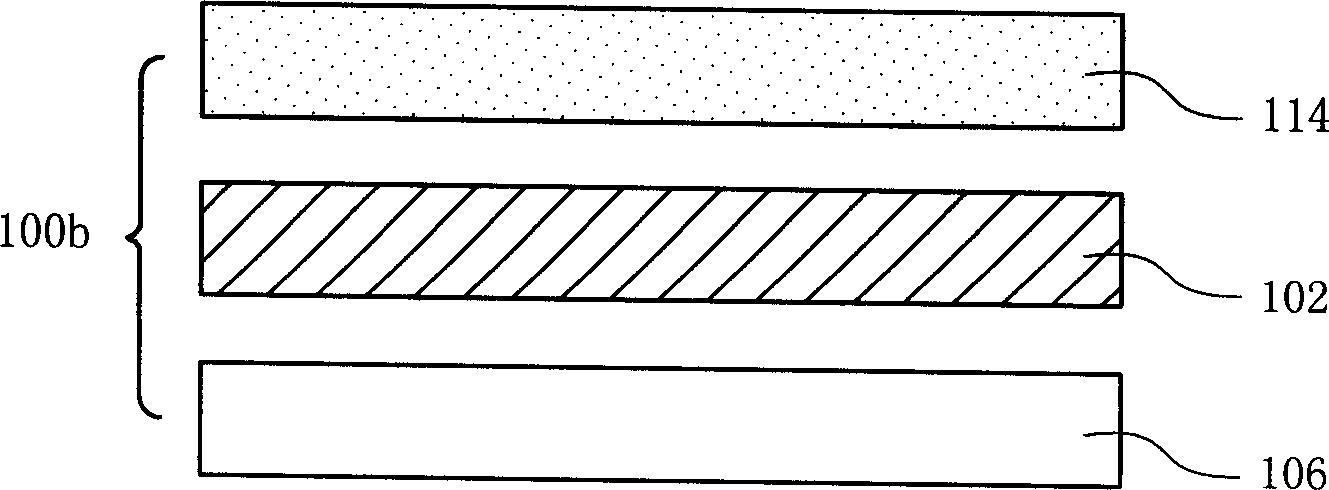

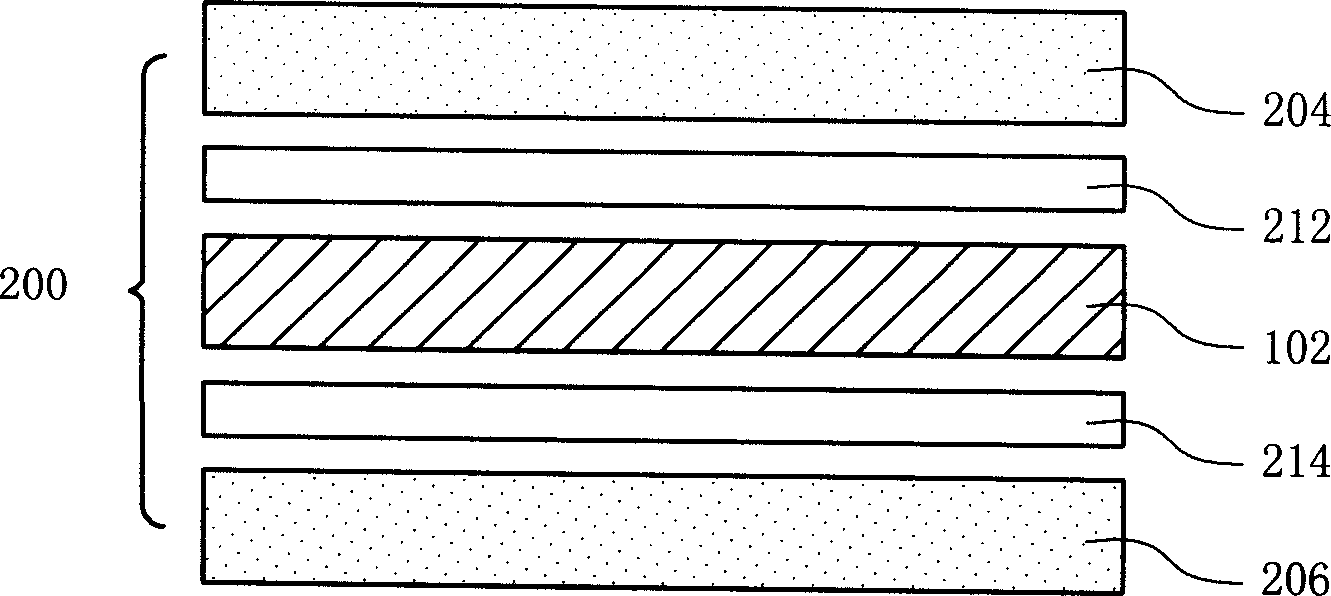

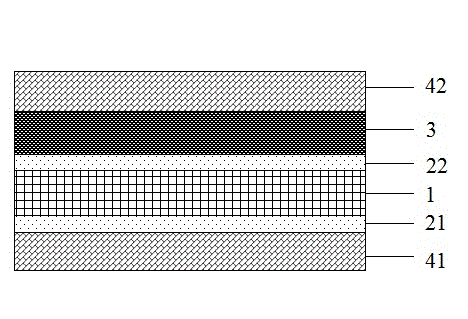

Polarized light plate and preparation method

InactiveCN1727954ASmall sizeGood weather resistancePolarising elementsNon-linear opticsCyclo olefin polymerProtection layer

A polarized light plate consists of the first protection layer, linear polarized light layer and the second protection layer. Its preparing method includes providing the first protection layer prepared by material of group formed from cycloolefine multipolymer and cycloolefine polymer, sticking a linear polarized light layer on the first protection layer by the first adhesive layer and sticking the second protection layer made by the same material as the first one on linear polarized light layer by the second adhesive layer.

Owner:OPTIMAX TECHNOLOGY CORPORATION

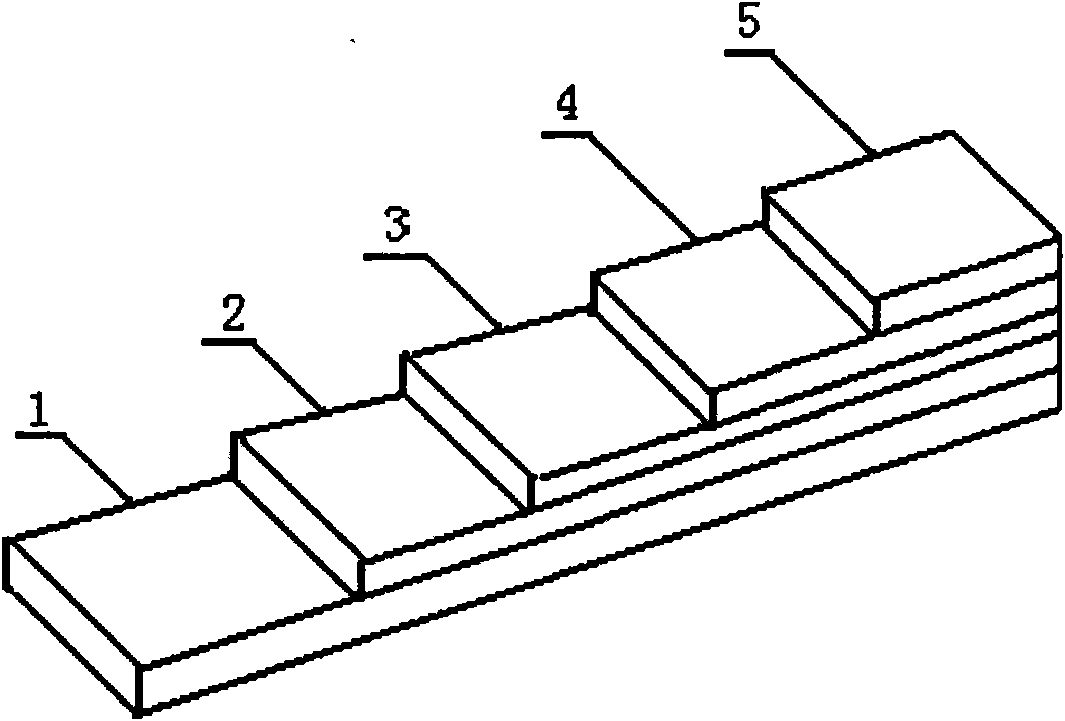

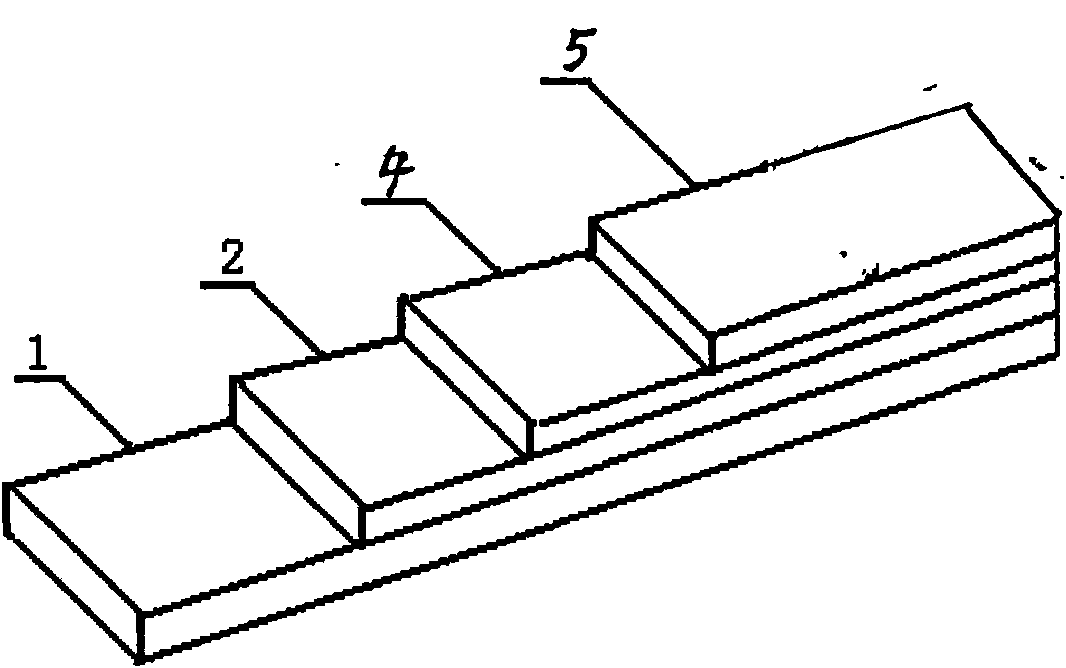

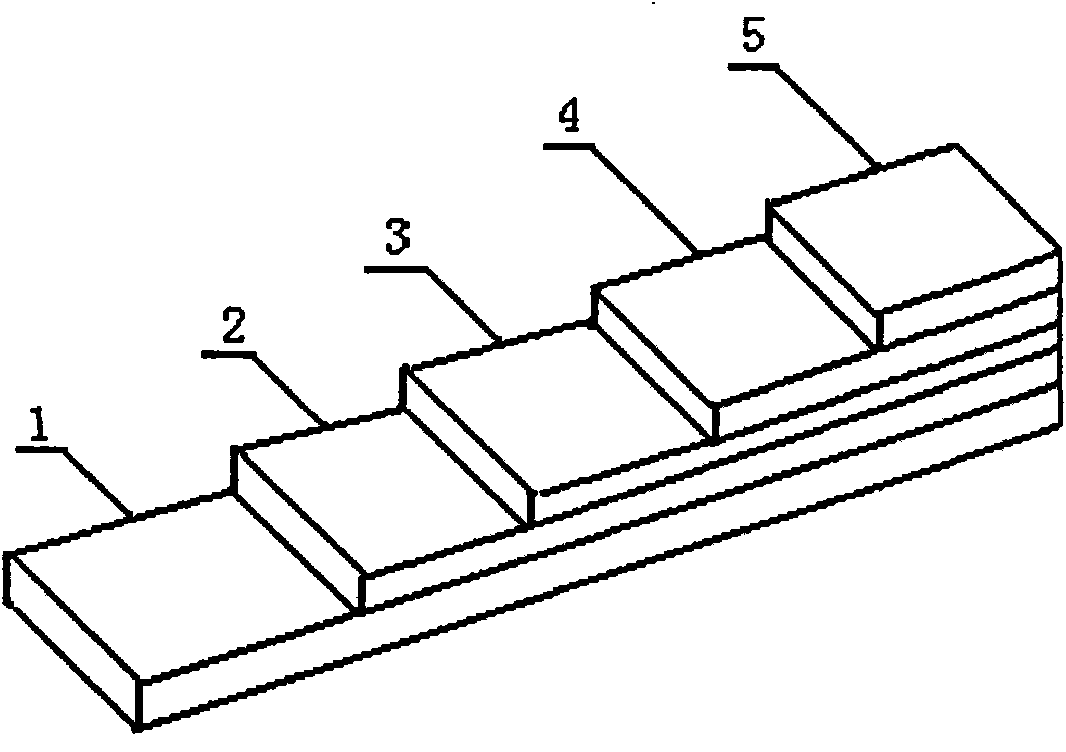

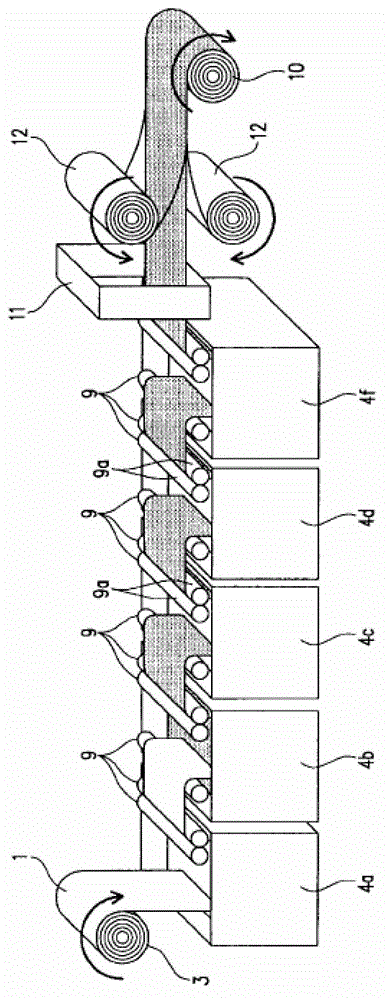

Method for manufacturing curve compact grade laminate

InactiveCN102756533AHigh strengthImprove impact resistanceLaminationLamination apparatusAntioxidantPlasticizer

The invention relates to a method for manufacturing a curve compact grade laminate. The method includes that firstly, a plasticizer, a light stabilizer, an ultraviolet absorber, an antioxidant and an antiaging agent are added in a first adhesive agent, and facial tissues are put into the first adhesive agent to be subjected to steeping and drying; secondly, a diluent agent, the antioxidant, the antiaging agent, the plastizer, dyes and a fire retardant are added in a second adhesive agent, and pieces of kraft paper are put into the second adhesive agent to be subjected to the steeping and the drying; thirdly, a plurality of pieces of dried kraft paper are overlaid, and pieces of dried facial tissues are placed on the upper and lower end surfaces of the overlaid kraft paper respectively; and fourthly, a finished product is formed by compressing the kraft paper and the facial tissues through a press, and the press comprises matched molds which are suitable for compressing U-shaped or arc-shaped compact grade laminates. According to the method, the manufactured curve compact grade laminate has the advantages of being colorful, high in intensity, impact resisting, uvioresistant, water-proofing, weather-proofing, anti-static, anti-fouling and easy to manufacture, so that the manufactured curve compact grade laminate can be widely applied to building outer walls, furniture, facilities, signs and the like, and the problem of splicing of the compact grade laminate at corners can be prevented.

Owner:江苏天润盛凯新材料股份有限公司

Photo-oxygen catalysis waste gas treatment device

InactiveCN106390714AEfficient degradationEfficient killingGas treatmentDispersed particle separationOzone generatorExhaust fumes

The invention discloses a photo-oxygen catalysis waste gas treatment device. The photo-oxygen catalysis waste gas treatment device comprises an air inlet, a waste gas treatment furnace, an air pipe and a secondary waste gas treatment furnace, wherein the waste gas treatment furnace is arranged on one side of the air inlet; the upper part of the waste gas treatment furnace is connected with the air pipe, and the other end of the air pipe is connected with the secondary waste gas treatment furnace; a filter screen is arranged at the bottom end inside the waste gas treatment furnace; a molecule pulverizator is arranged above the filter screen; an ozone generator is arranged above the molecule pulverizator; a photolysis oxygenizer is arranged above the ozone generator; the air pipe is connected with the secondary waste gas treatment furnace through a blower; and a photocatalyst layer is arranged inside the secondary waste gas treatment furnace. The photo-oxygen catalysis waste gas treatment device is simple in structure and novel in design, poisonous and harmful gas in air can be effectively degraded, and the device also has the functions of formaldehyde removal, deodorization, pollution prevention, air purification and the like, the purification efficiency is high, the purification can be circulated, present requirements can be met, and the safety performance is high.

Owner:永康市信政恒涂装设备有限公司

Method for bonding polymer film and method for producing polarizing film

InactiveCN102947074AProhibition of useImprove qualityOptical articlesPolarising elementsPolyvinyl alcoholLaser beams

The purpose is to achieve excellent bonding of a polymer film, such as a polyvinyl alcohol-based resin film, while controlling the use of a light absorbing agent. Provided are a method for bonding a polymer film which comprises face-contacting the surface of the polymer film with the surface of an adherend and laser welding the interface, characterized in that the laser beam is irradiated to the polymer film, which is in the water-absorbed state at least in the interface side thereof, and the thus absorbed water is allowed to absorb the laser beam to thereby achieve the laser welding, and so on.

Owner:NITTO DENKO CORP

Energy storage type self-luminous nano coating material

ActiveCN104263153AWear-resistantAnti-foulingAntifouling/underwater paintsLuminescent paintsNano structuringWear resistant

The invention discloses an energy storage type self-luminous nano coating material. The energy storage type self-luminous nano coating material comprises the following ingredients in parts by weight: 30-40 parts of perforated expanded perlite, 50-80 parts of filler, 30-40 parts of resin, 15-20 parts of glass micro-beads, 10-20 parts of chitin, 15-20 parts of chitosan, 20-40 parts of nano titanium white, 15-20 parts of nano zinc oxide, 10-15 parts of nano-silica, 30-40 parts of acrylic emulsion and 15-20 parts of nano rare-earth self-luminous material. The invention further discloses a preparation method of the nano coating material. Through the compounding of the raw materials of the energy storage type self-luminous nano coating material, the energy storage type self-luminous nano coating material disclosed by the invention is wear-resistant, is long in service life and has a bacterium resisting effect, and nano-materials or nano-structured ingredients are introduced into an organic coating material, so that organic and inorganic matched compositing or hybridization is realized. The advantages of organic polymers and inorganic-structured ingredients are integrated, so that the properties of the coating material are obviously improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Preparation method and applications of hydroxyalkyl silicone oil

InactiveCN105017535ASimple processWater resistantAntifouling/underwater paintsPaints with biocidesHydrosilylationNitrogen gas

The present invention relates to the technical field of coating material additives. In order to solve the problem of not significant effect of the anti-doodle and anti-fouling coating material, the present invention provides a hydroxyalkyl silicone oil preparation method, wherein mixed siloxane is adopted as a raw material and is balanced under the acid catalysis effect to obtain hydrogen-terminated silicone oil, nitrogen introducing and solvent adding are performed under the platinum catalyst effect, and the hydrogen-terminated silicone oil and olefin alcohol are subjected to a hydrosilylation reaction to obtain the hydroxyalkyl silicone oil. According to the present invention, the process is simple, the hydroxyalkyl silicone oil is applied in the anti-doodle and anti-fouling coating material, and the effect is significant.

Owner:JIANDE JUHE NEW MATERIALS

Superstrong hydrophobic self-cleaning material, production method thereof and composite insulator produced from superstrong hydrophobic self-cleaning material

InactiveCN107325563ACorrosion resistanceAnti-salt sprayInsulatorsTetraethyl orthosilicateSilicone resin

The invention relates to a superstrong hydrophobic self-cleaning material, a production method thereof and a composite insulator produced from the superstrong hydrophobic self-cleaning material. The superstrong hydrophobic self-cleaning material contains the following components in parts by weight: fluoroalkyl vinyl silicone rubber, pentyl silicone resin, phenyl polysiloxane, fluoroether polysiloxane, diphenyl silicon glycol, dimethyldiethoxysilane, alpha,omega-dialkoxy siloxane, amino siloxane, epoxy alkylsiloxane, a vinyl silane coupling agent, tetraethyl orthosilicate, high-reinforced white carbon black, titanium dioxide, aluminum hydroxide, manganese carbonate, zinc carbonate, antimony trioxide, mica powder, cadmium oxide, molybdenum disulfide, barium oxide, iron oxide, pigments and a peroxide curing agent. The production method of the superstrong hydrophobic self-cleaning material comprises the following steps: (1) carrying out closed refining; (2) carrying out secondary refining; (3) mixing until the materials are uniform; (4) preparing a rubber blank; (5) preparing mixed rubber; and (6) preparing a mixed rubber sheet. The mixed rubber sheet can be used for preparing the composite insulator.

Owner:河北硅谷化工有限公司

Anti-pollution flashover coating for electrical device and preparation method thereof

InactiveCN107652885ABoth hydrophobicHydrophobicAntifouling/underwater paintsPaints with biocidesSilanesSolvent

The invention relates to the field of coatings, and specifically relates to an anti-pollution flashover coating for an electrical device and a preparation method thereof. The coating is hydrophobic, insulated and self-cleaning coating developed based on pollution flashover occurring principle and is applicable to the surface treatment of an outdoor electrical device, in particular an insulator. The anti-pollution flashover coating comprises 5-20 parts of organic silicon resin, 2-12 parts of fluoridized titanium dioxide powder, 1-10 parts of fumed silica powder, 0.1-0.5 part of silane couplingagent, 0.2-3 parts of auxiliary, 0.3-2 parts of carbon black, 50-80 parts of mixed solvent, and 8-15 parts of a curing agent. The anti-pollution flashover coating has the beneficial effects of being hydrophobic, anti-pollution, self-cleaning, and insulated, and is applicable to an outer coating layer of the outdoor electrical device; nano silica and the silane coupling agent are compounded, so that the superficiality of the coating layer is greatly reduced, and the hydrophobic and oleophobic performances of the coating layer are improved; nano fluoridized titanium dioxide is added, so that thecoating is capable of self-cleaning; the coating has a good adhering performance relative to a base material, and is high in weather resistance, resistant to high- and low-temperature, resistance toillumination, and resistance to radiativity.

Owner:湖南创研工业技术研究院有限公司

Spray-painting advertisement cloth and production process thereof

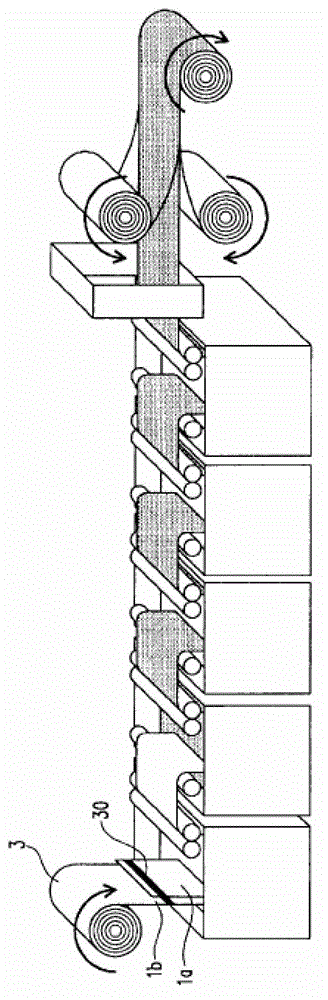

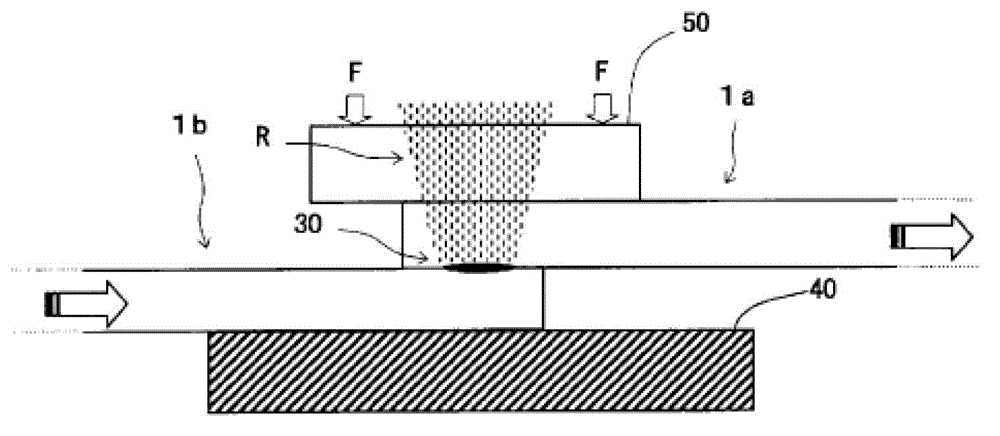

InactiveCN104057684ASimple production processComplete processLaminationLamination apparatusEngineeringPolymer coating

The invention relates to an advertisement-displaying and decorative material carrier, and especially relates to spray-painting advertisement cloth and a production process thereof. The spray-painting advertisement cloth comprises base cloth, coatings at the two sides, and PVC films at two sides of the coatings; the production process comprises the following steps: 1) unreeling a PVC light-color film, coating the PVC light-color film with a polymer coating by an anilox roller; 2) attaching the PVC light-color film to base cloth; 3) treating a PVC dark-color film according to the step 1), coating the polymer coating, attaching the PVC dark color film to the other side of the base cloth; 4) preheating another PVC light-color film, and attaching to the PVC dark-color film; 5) reeling and packaging. The production process is concise, and the process flow is complete; the coating is thin and light in mass, which greatly improves the production efficiency and raw material utilization rate, and saves cost; the coating is flat and uniform; the product has good spray-painting performance, excellent ink absorption performance, high color rendition degree, and wide applications.

Owner:SHANGHAI NAR INDAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com