Vehicle bearing device

A technology for bearing devices and wheels, which is applied in the direction of bearings, axles, wheels, etc., can solve the problems of increased bearing torque, increased contact resistance, and increased wear of sealing lips, and achieve the effect of avoiding the number of components and avoiding complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

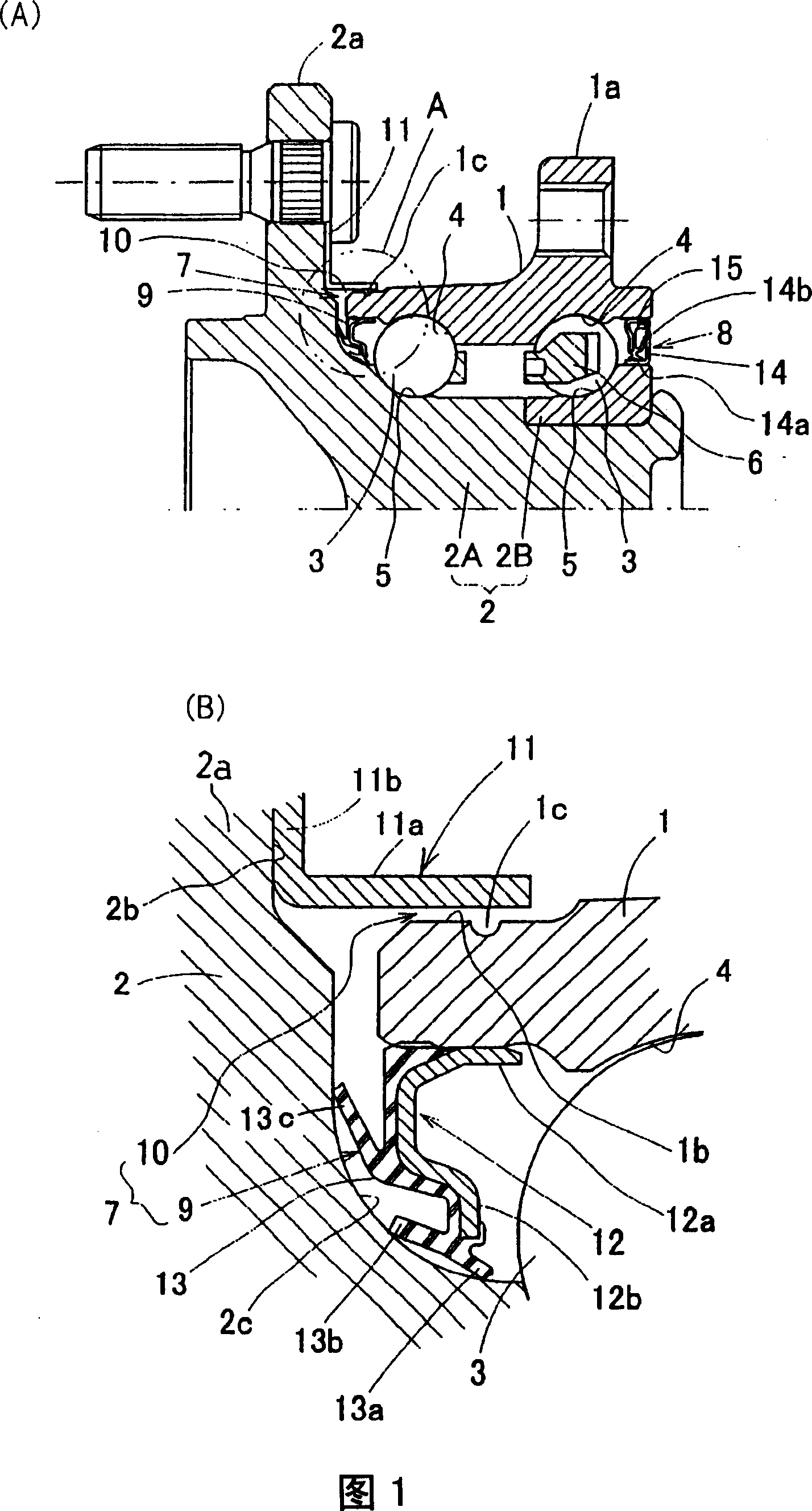

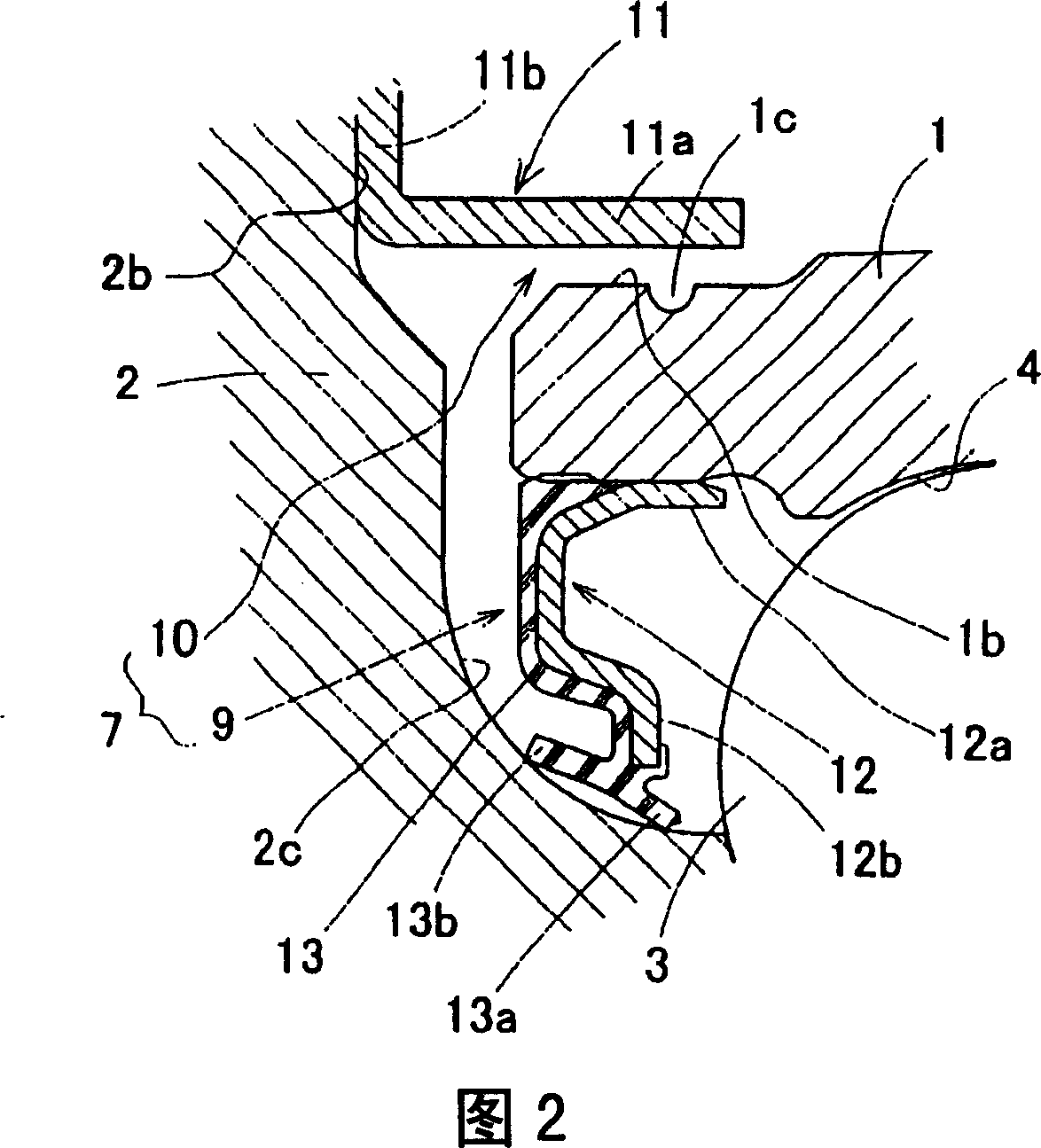

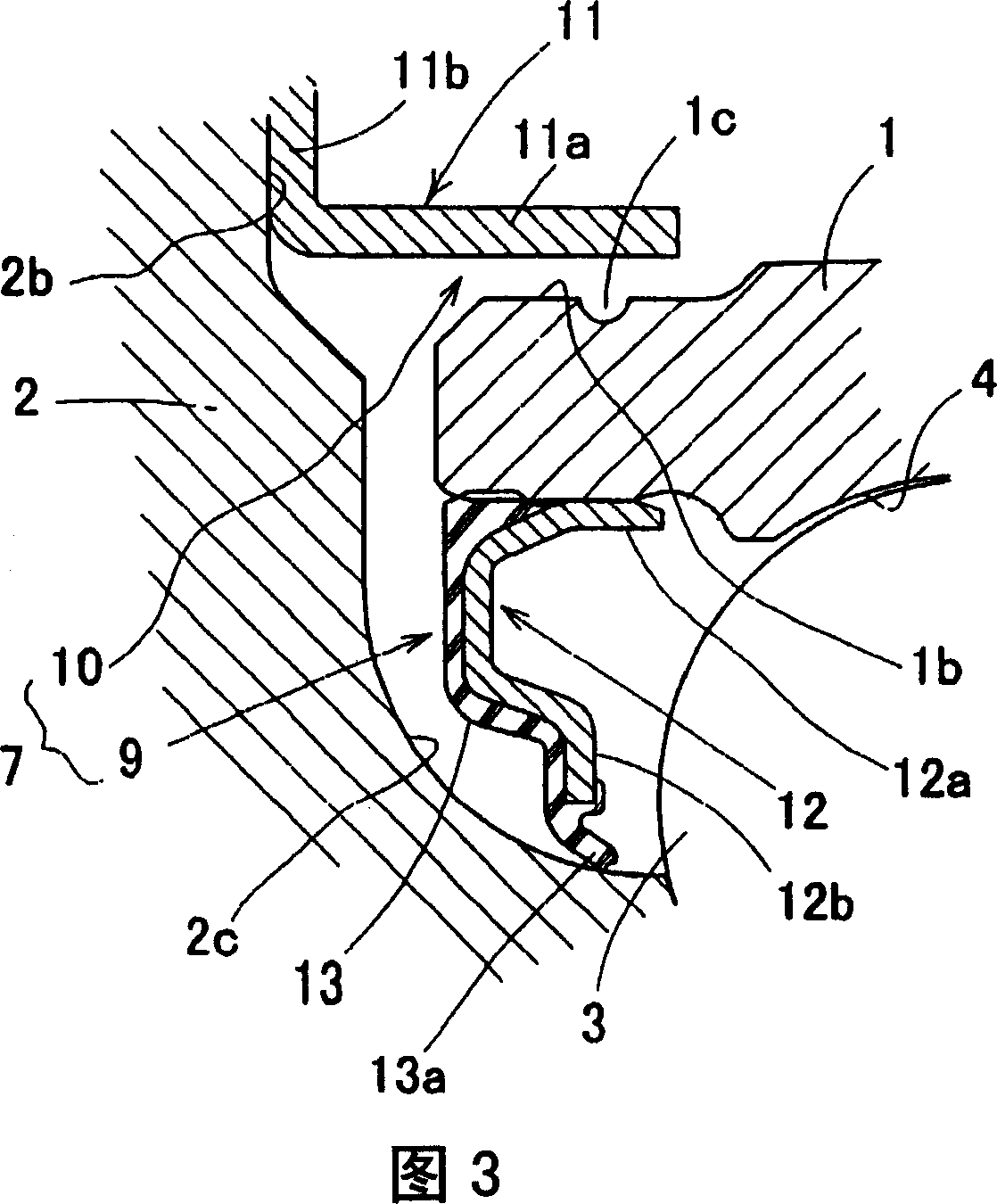

[0023] A first embodiment of the present invention will be described with reference to FIG. 1 . This embodiment is an inner wheel rotation type, a wheel bearing device for supporting a driven wheel, and is classified as a third-generation type. In addition, in this specification, in the assembled state of the vehicle, the side closer to the outer side in the vehicle width direction is called the outer side, and the side closer to the center in the vehicle width direction is called the inner side. In Fig. 1, the left side is the outer side, and the right side is the inner side.

[0024] This wheel bearing device includes: an outer member 1 having a plurality of rows of raceway surfaces 4 on the inner periphery; an inner member 2 having raceway surfaces 5 respectively facing these raceway surfaces 4; The multi-row rotating body 3. The rotors 3 are made of balls and are held by cages 6 for each row. This bearing device for a wheel is a multi-row angular contact ball bearing, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com