Patents

Literature

92results about How to "Avoid loss of tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

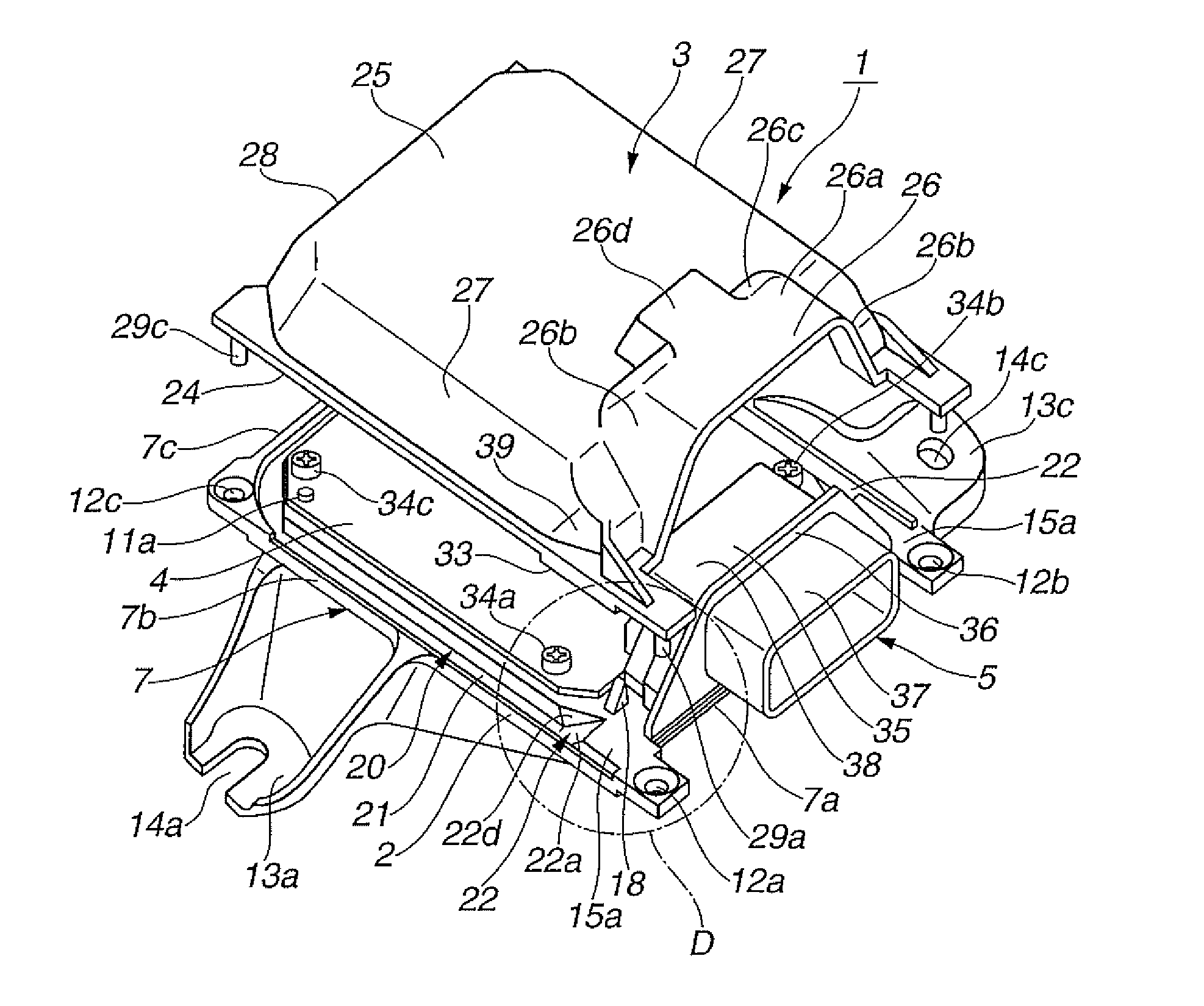

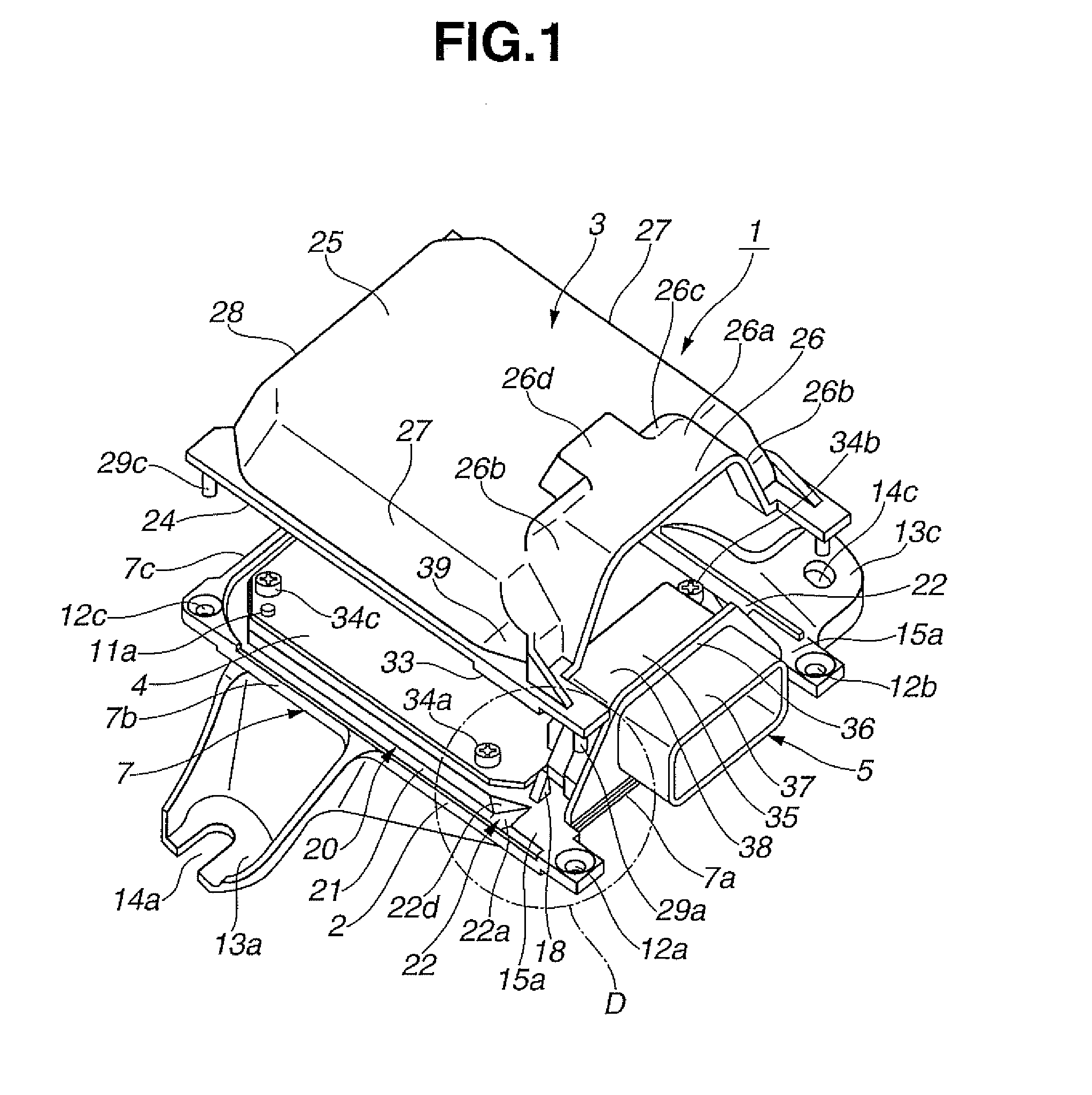

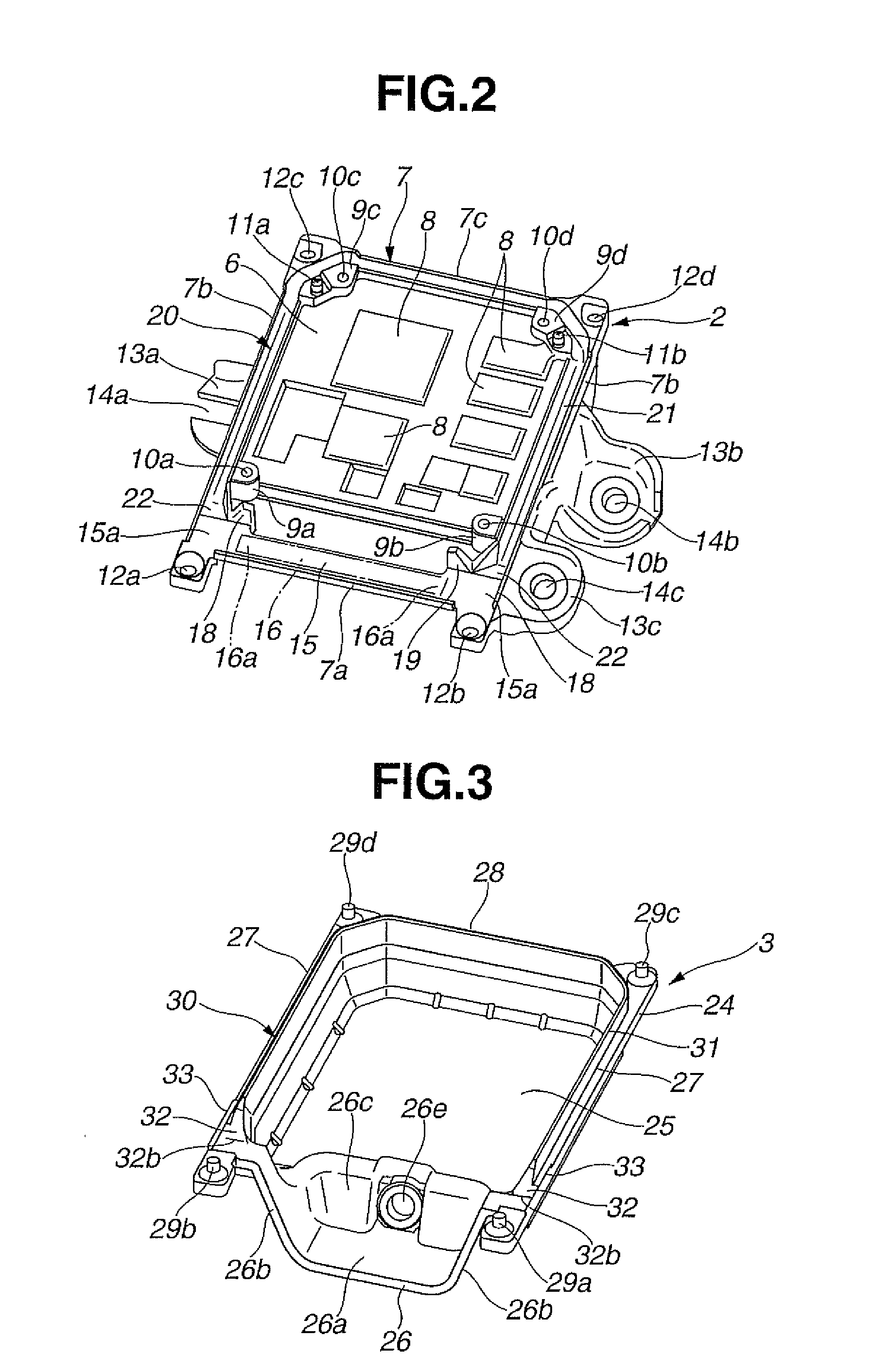

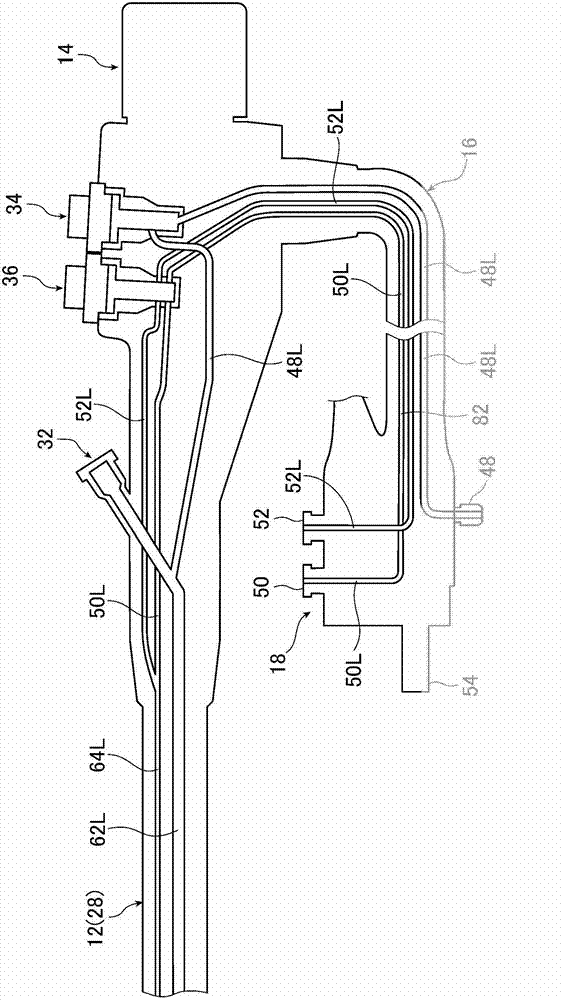

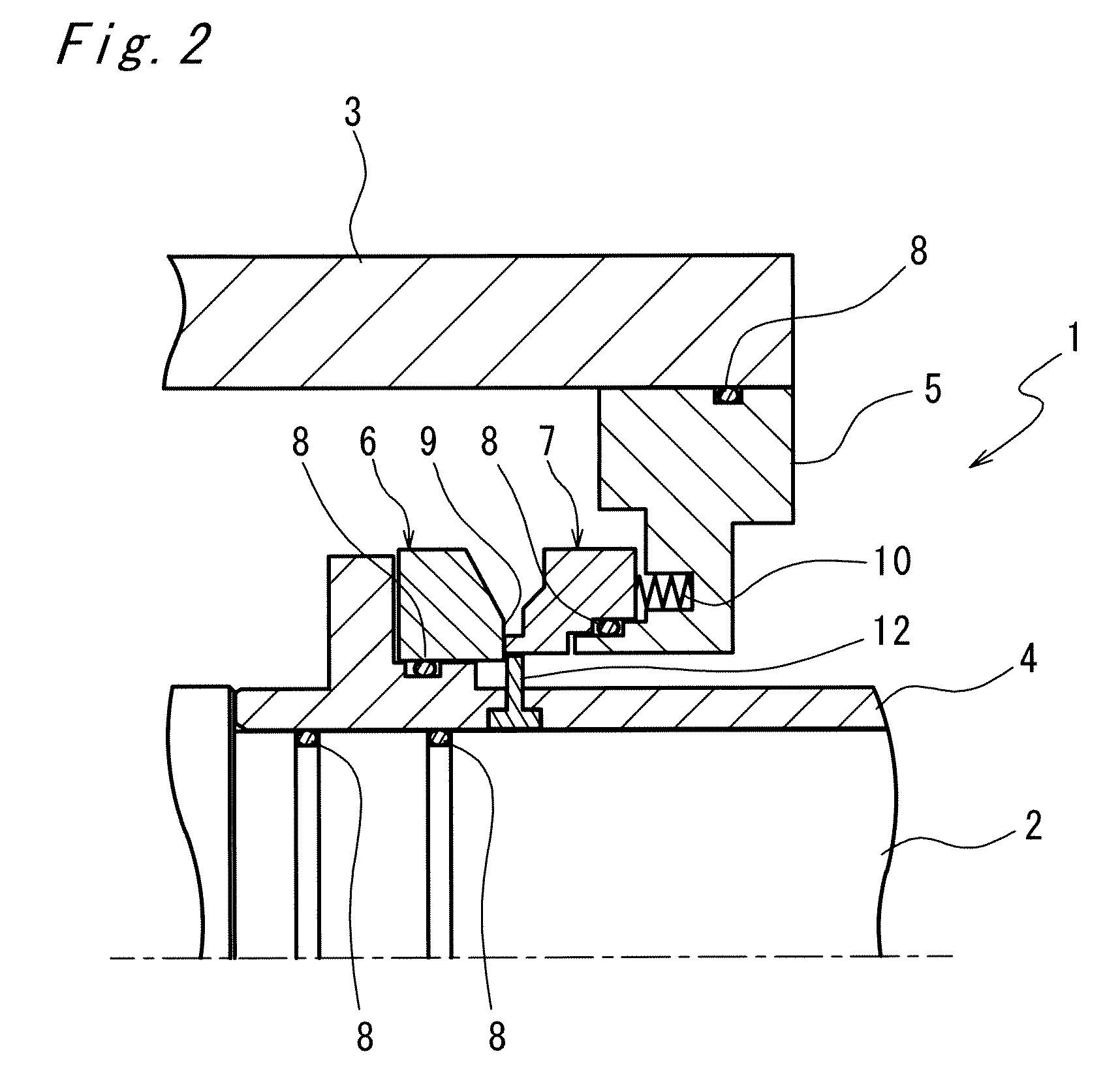

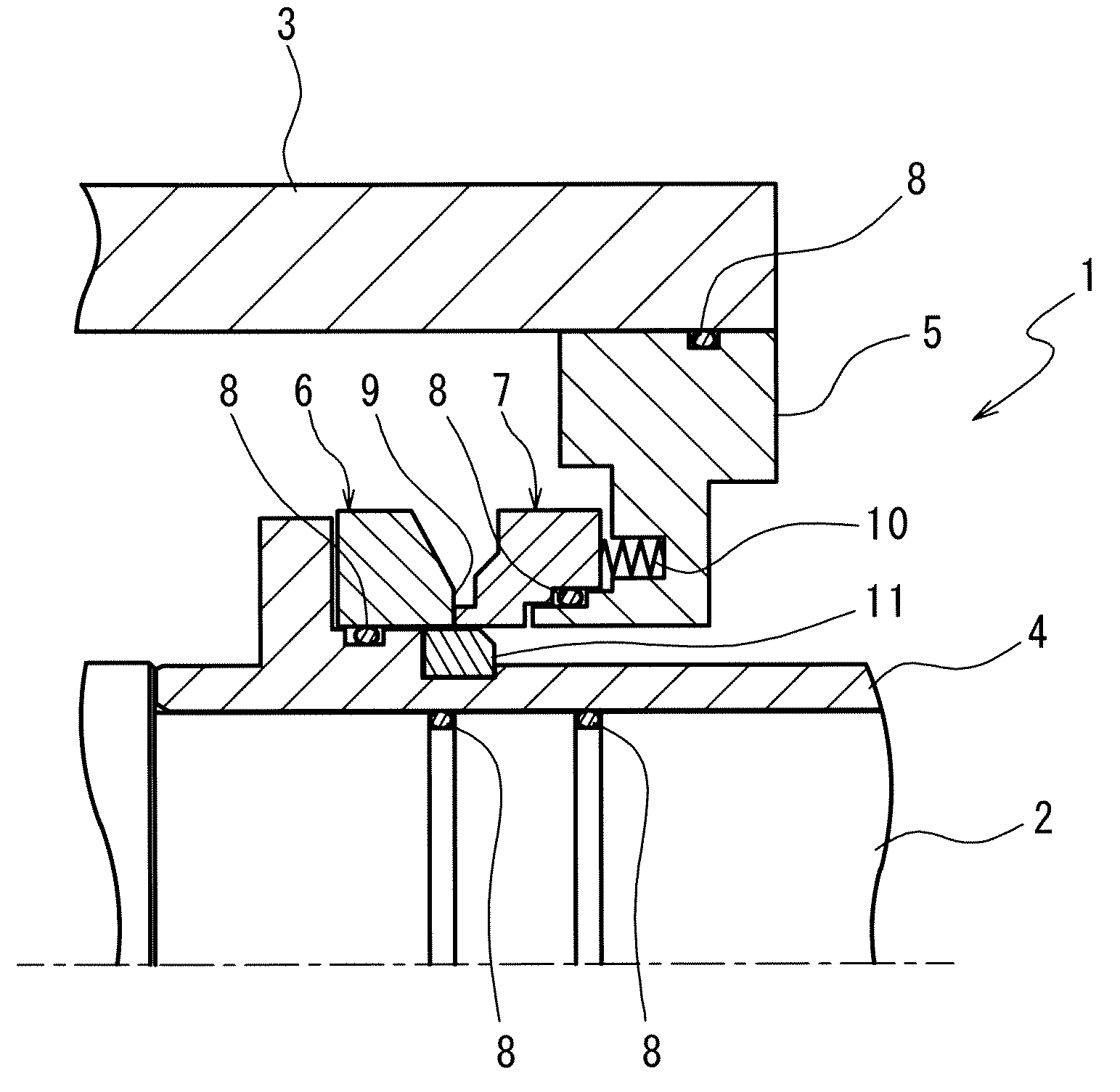

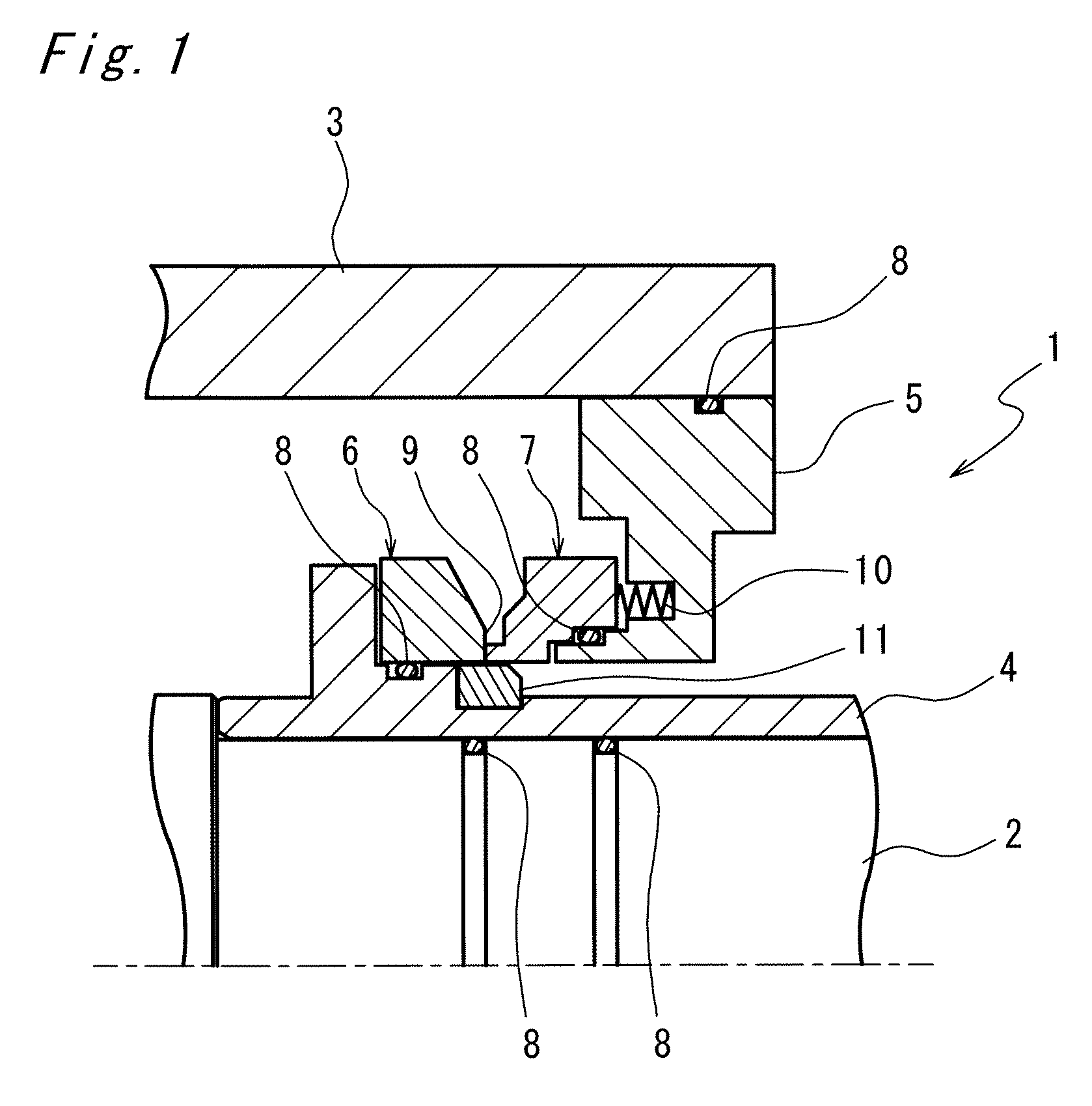

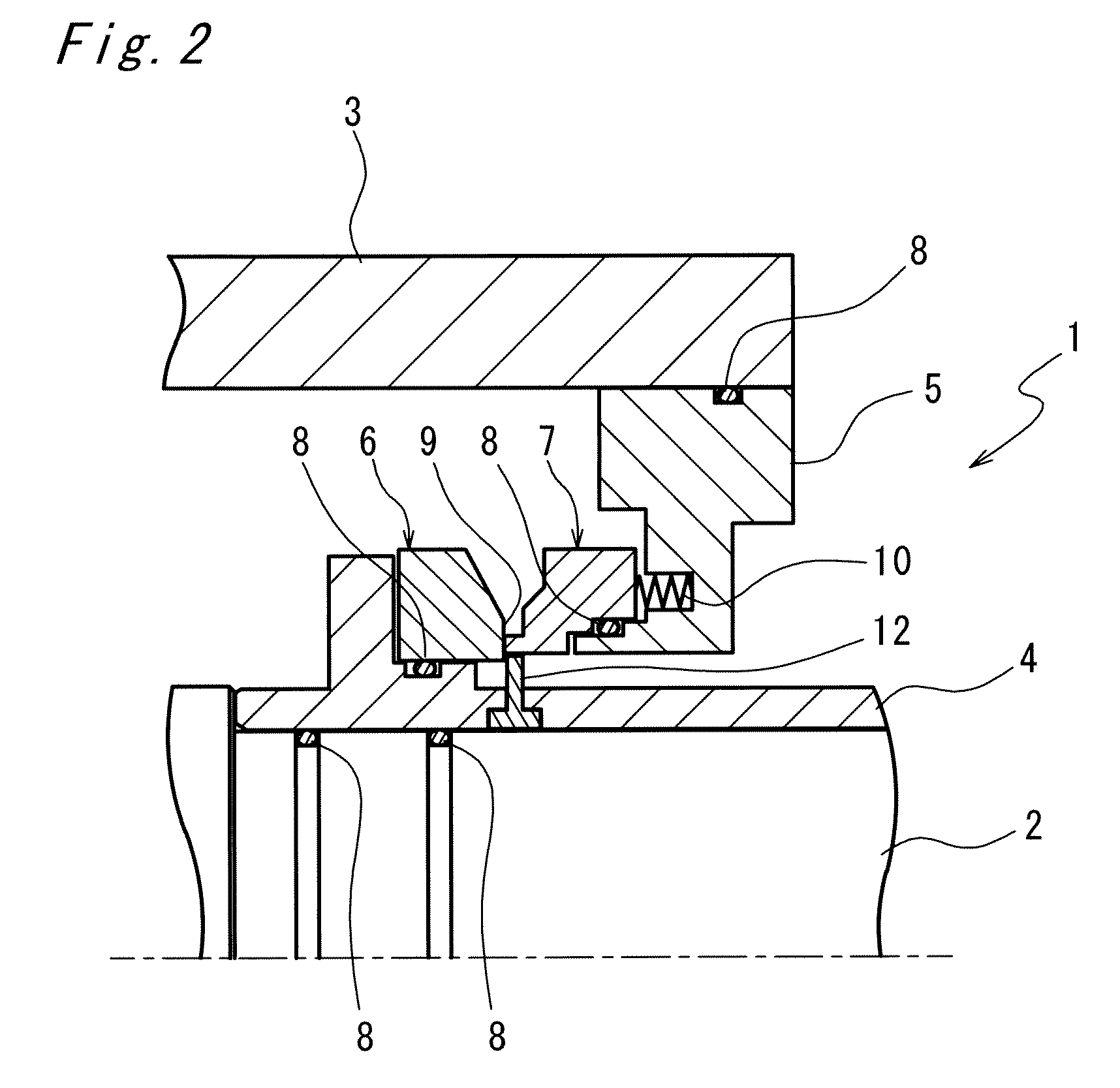

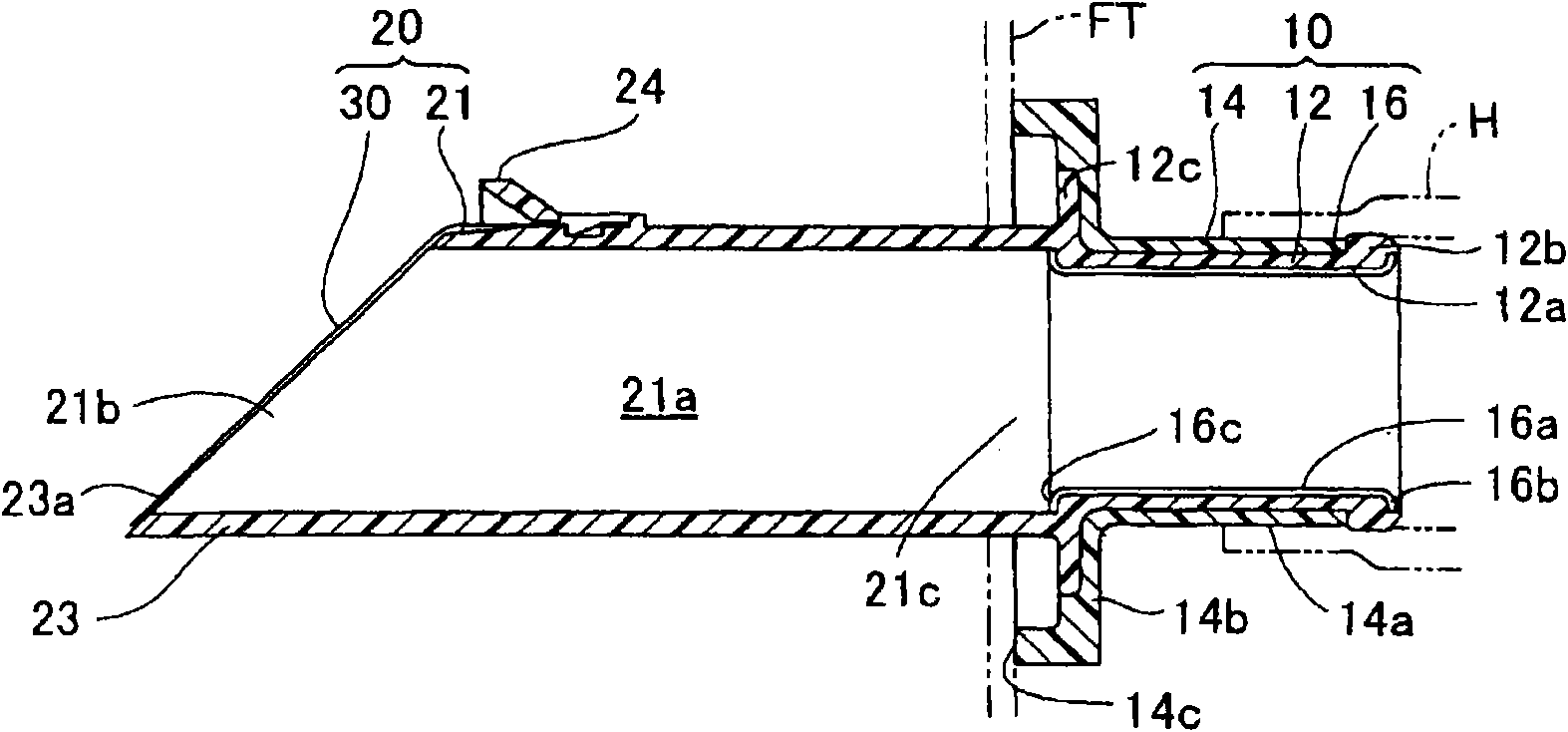

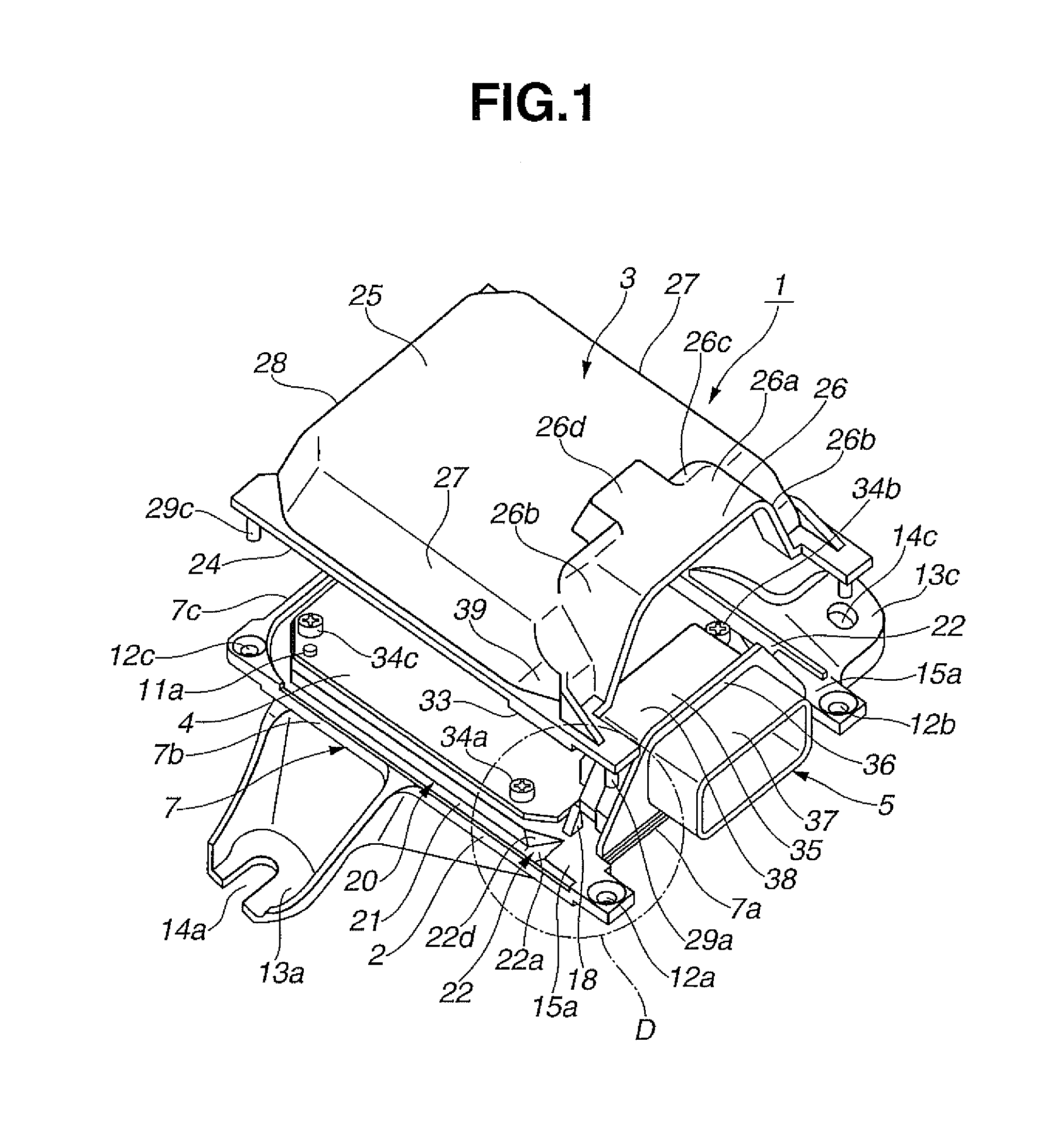

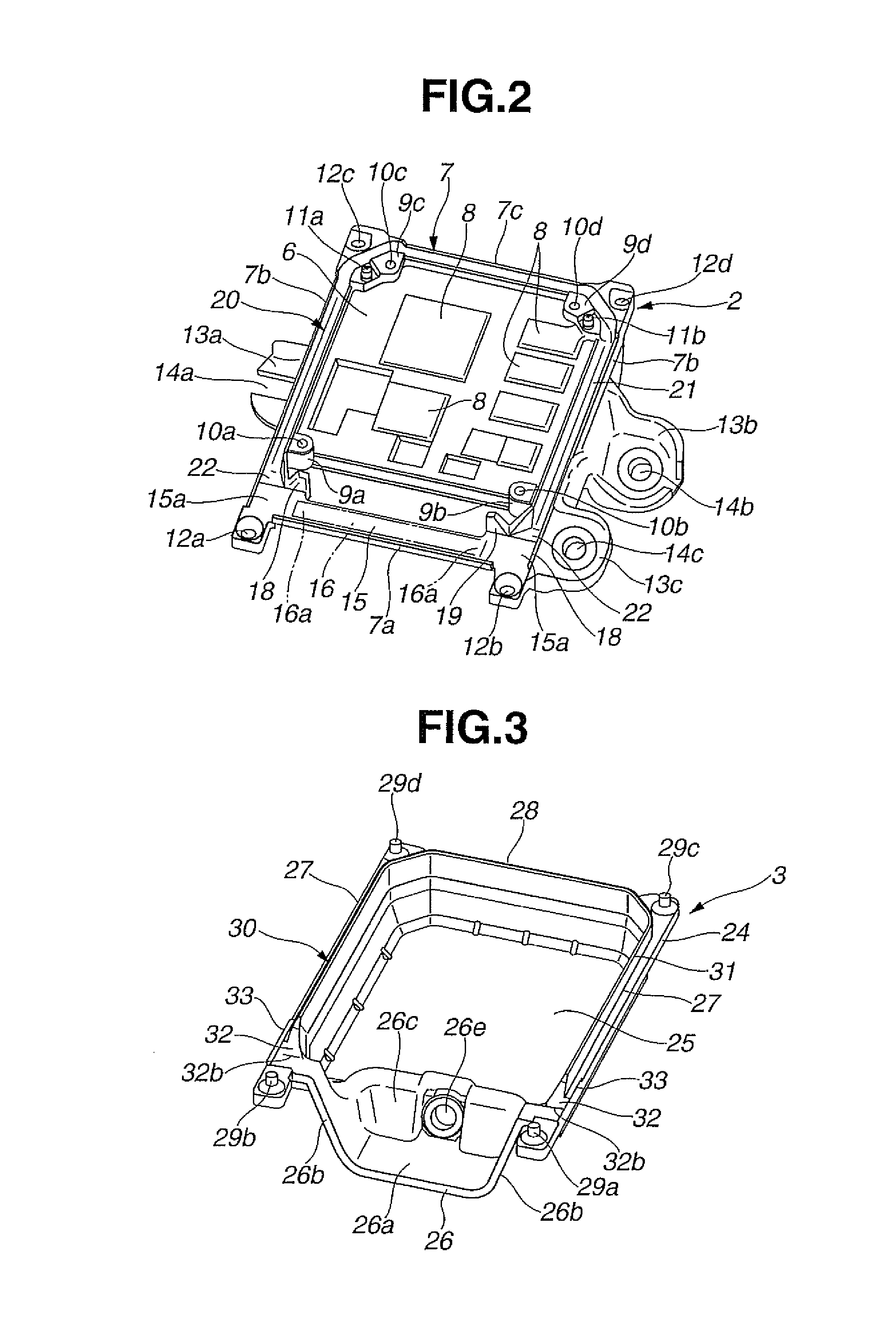

Seal Structure for Electronic Control Device

ActiveUS20150250072A1Preventing deterioration in seal performanceReduce controlSecuring/insulating coupling contact membersTwo-part coupling devicesEngineeringSealant

Disclosed is a seal structure for an electronic control device where a circuit board is accommodated in a housing with a connector attached to the circuit board and held between base and cover members of the housing. The seal structure includes a connector seal surface formed on a front end portion of the base member, a seal material arranged between the connector seal surface and the connector, a seal groove formed in an outer peripheral portion other than the front end portion of the base member, a seal protrusion formed on the cover member and engaged in the seal groove, and a sealant filled between the seal groove and the seal protrusion. Longitudinal end regions of the connector seal surface are extended in a width direction of the connector. Longitudinal end regions of the seal groove are connected perpendicular to the respective end regions of the connector seal surface.

Owner:HITACHI ASTEMO LTD

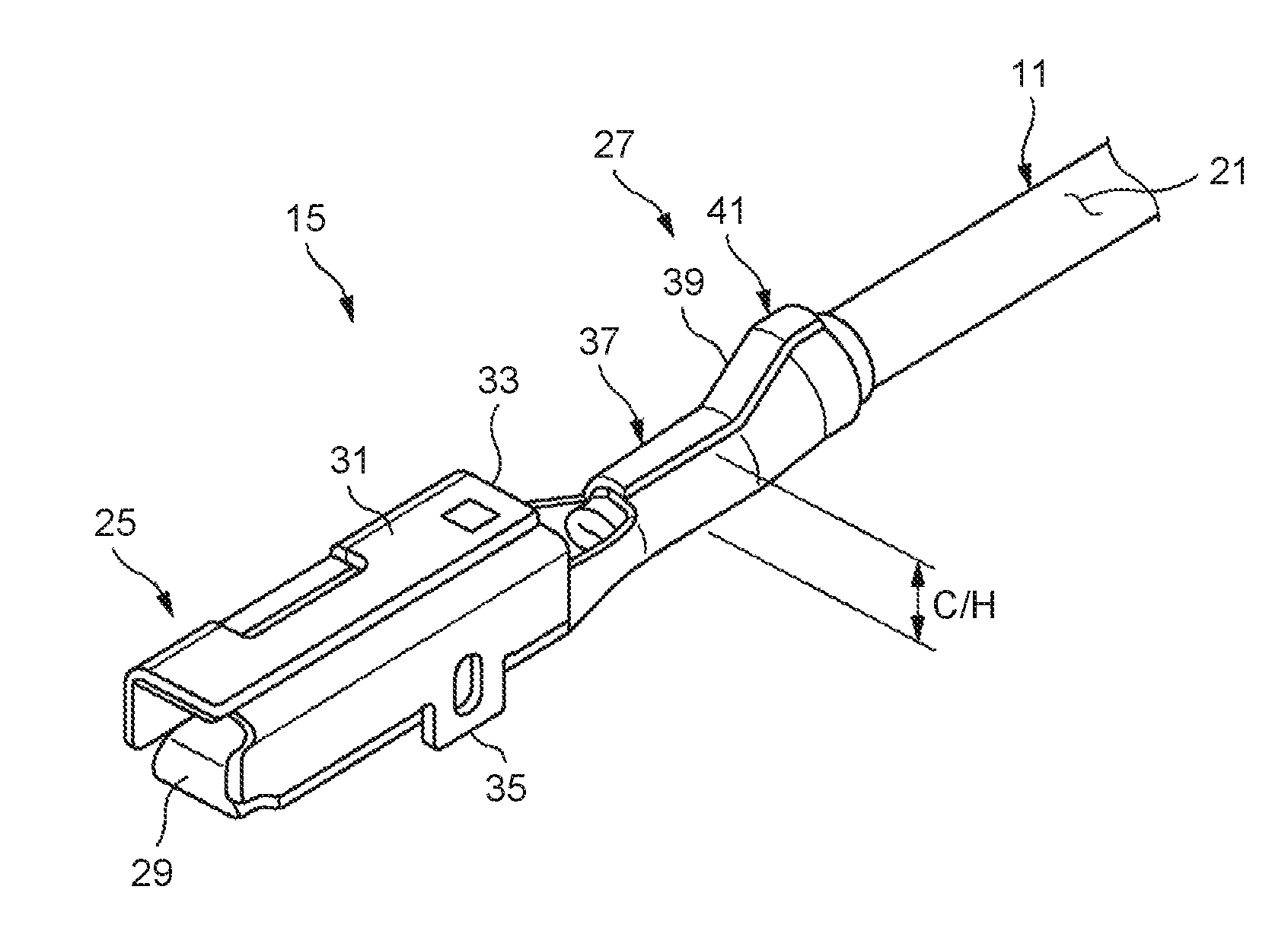

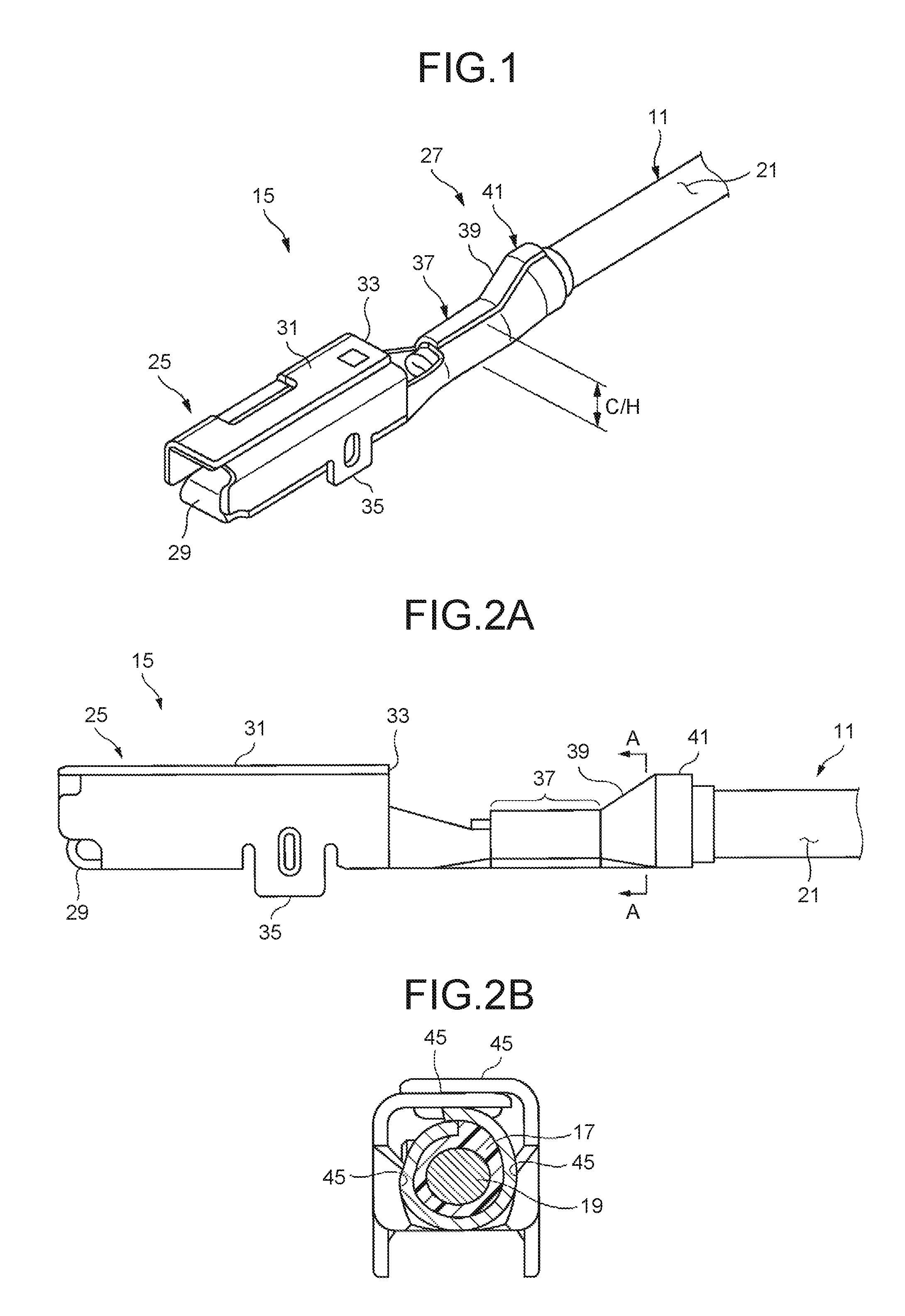

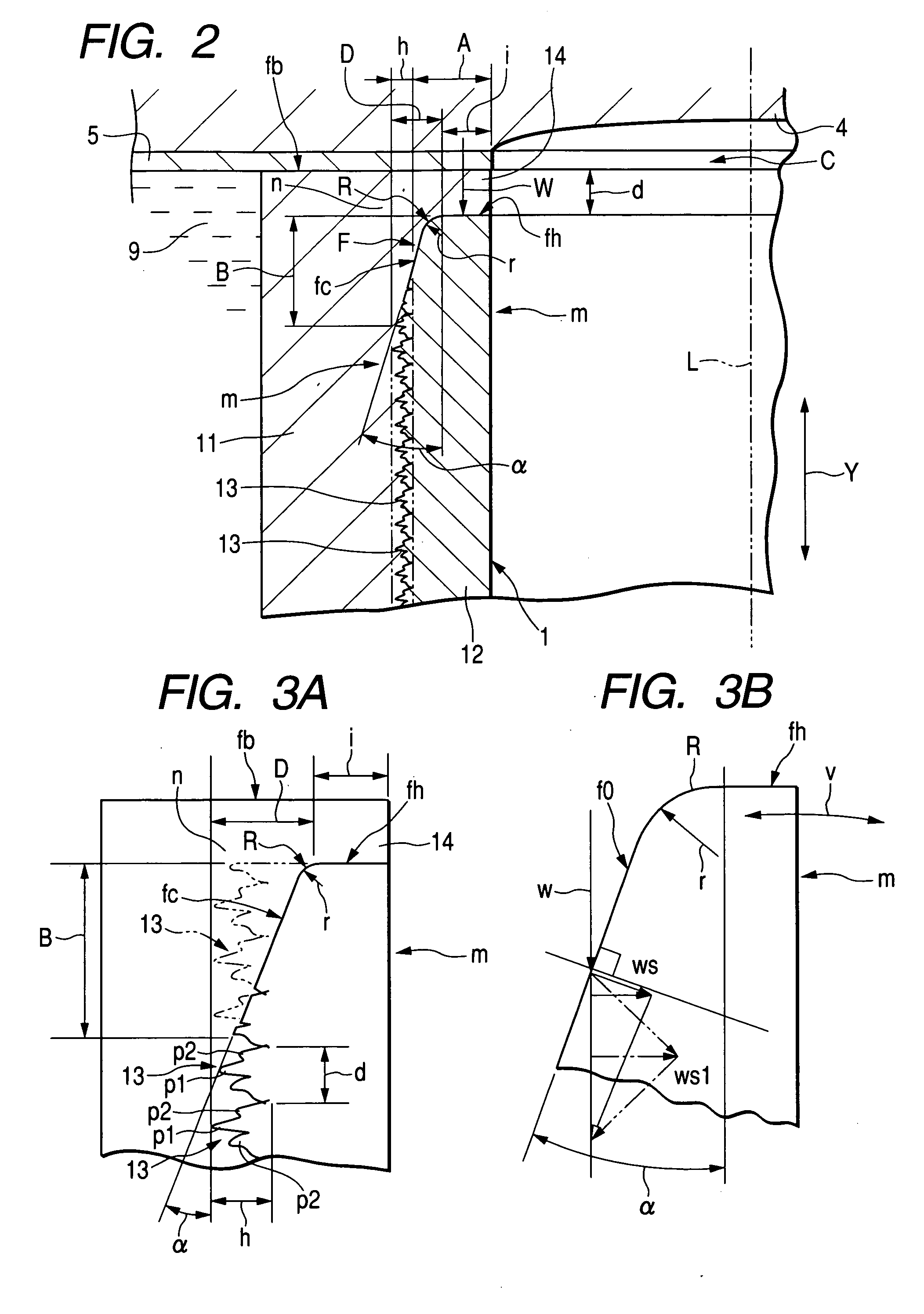

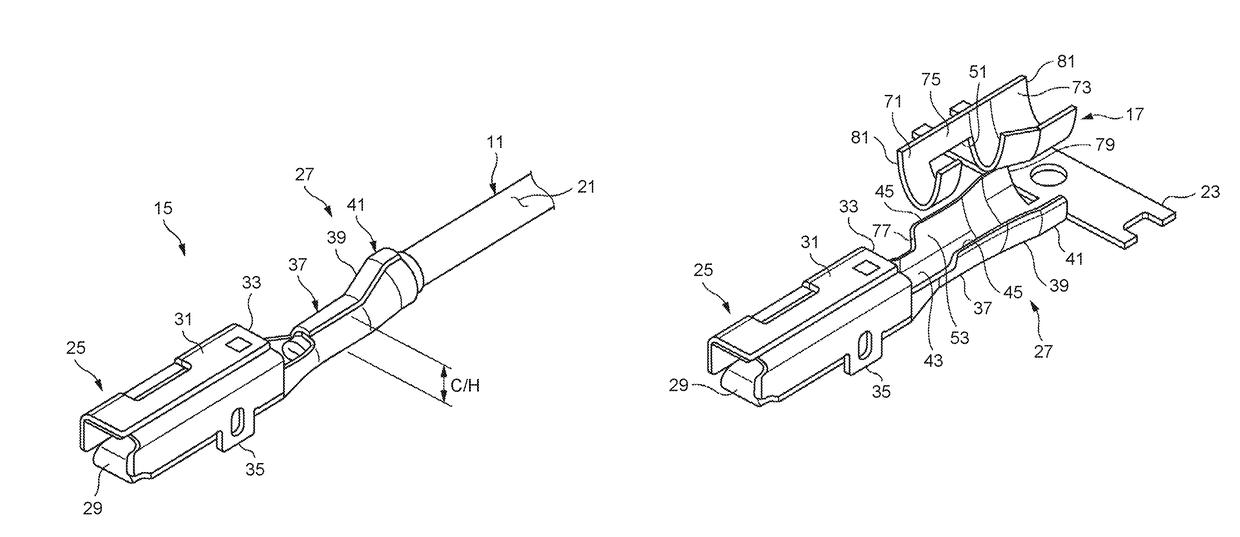

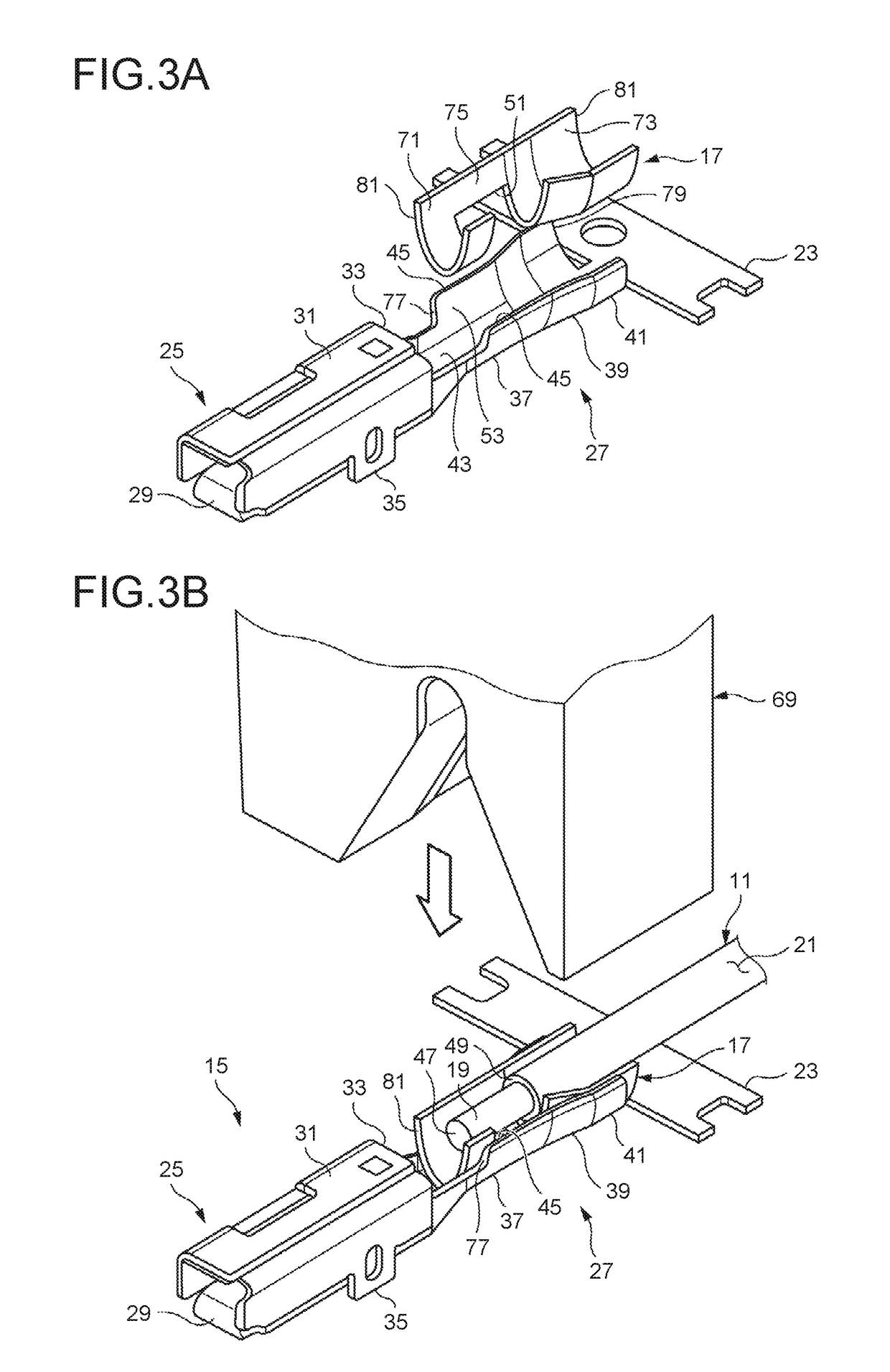

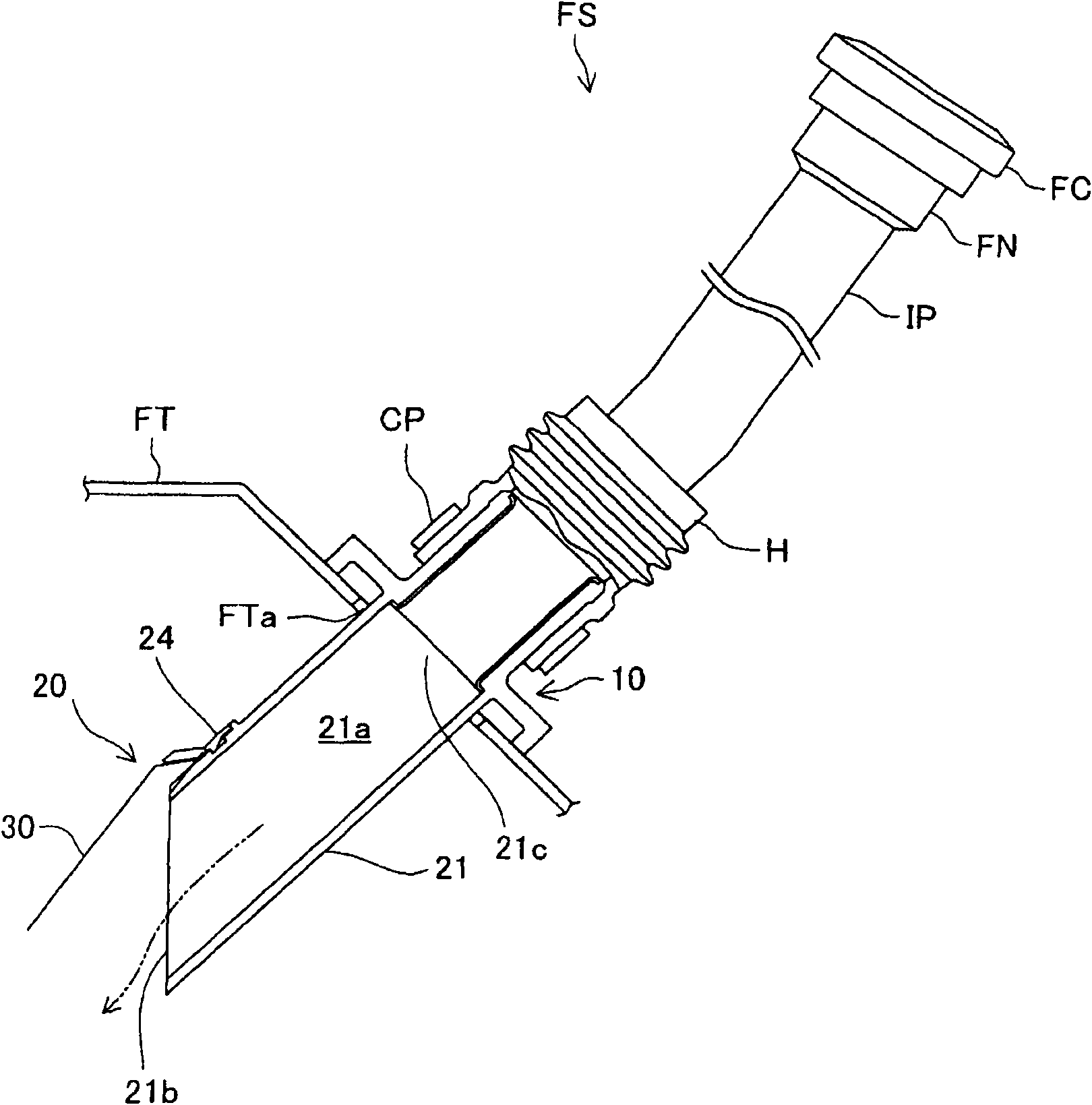

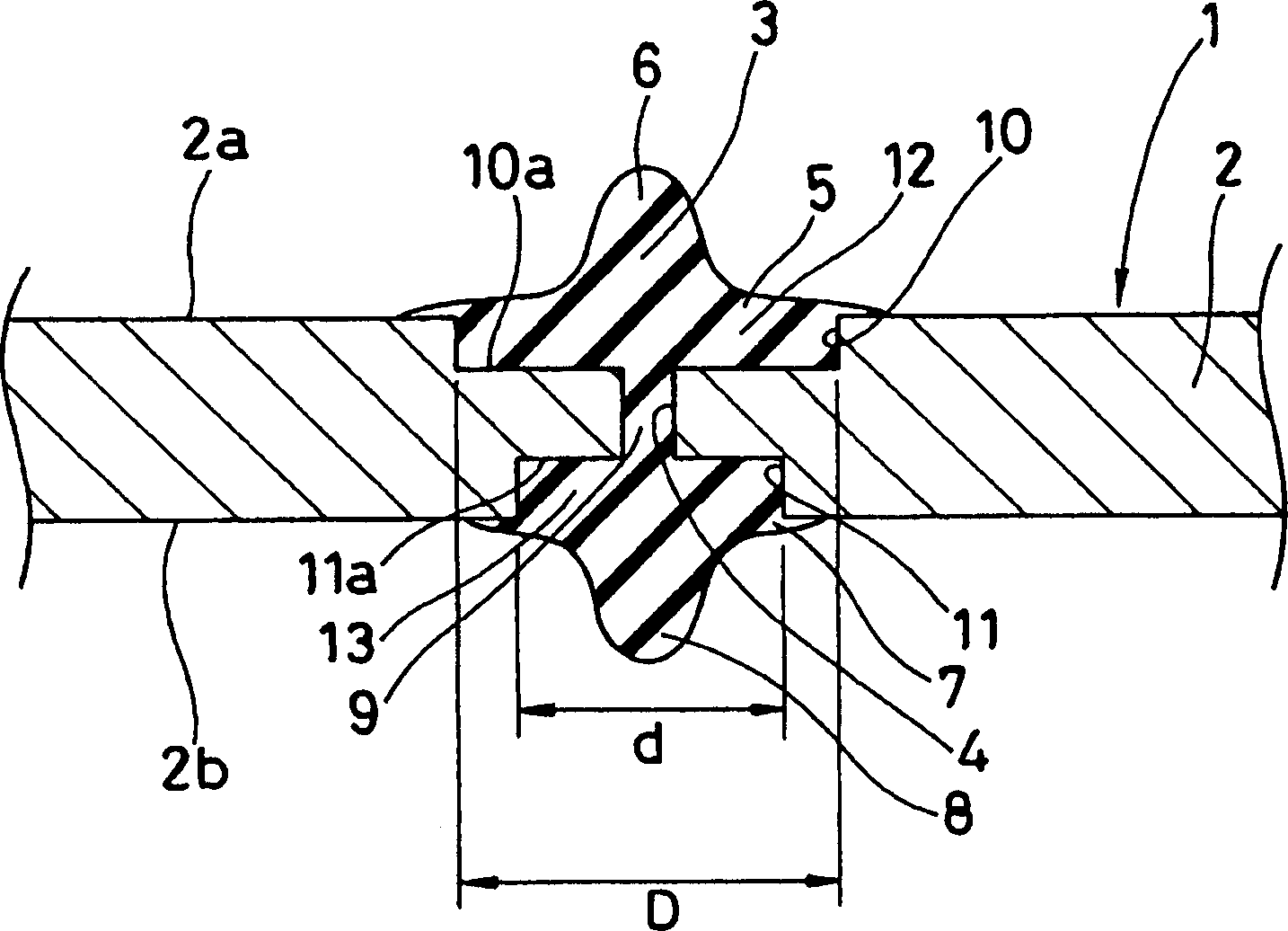

Connecting structure of crimp terminal and electric wire

ActiveUS20160359245A1Less squeezeAvoid loss of tightnessCouplings bases/casesConnections effected by permanent deformationElectrical conductorEngineering

A structure for connecting a crimp terminal and an electric wire includes: a crimp terminal that includes a conductor crimping portion and a coating crimping portion serially and includes an electric wire connector that is to be crimped to the electric wire; and a water stop sheet having an opening for bringing a conductor into contact with the conductor crimping portion, and laid between the electric wire connector and the electric wire. When a joint is swaged and crimped, the swaged and crimped joint has a second included angle θ2 between the bottom plate and a second line that is larger than a first included angle θ1 between the bottom plate and a first line in a cross section that is perpendicular to a bottom plate of the electric wire connector and that includes an electric wire axial line.

Owner:YAZAKI CORP

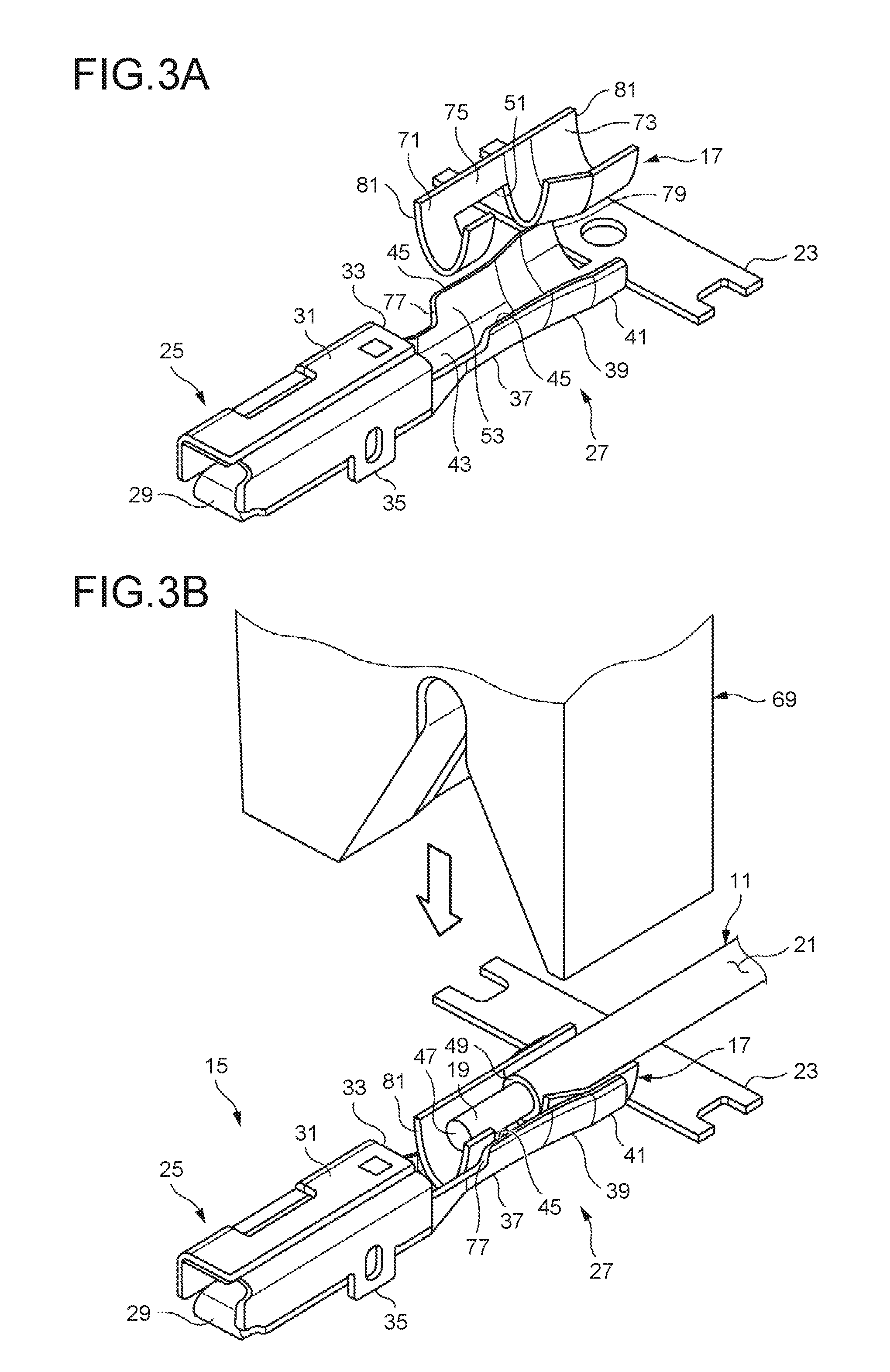

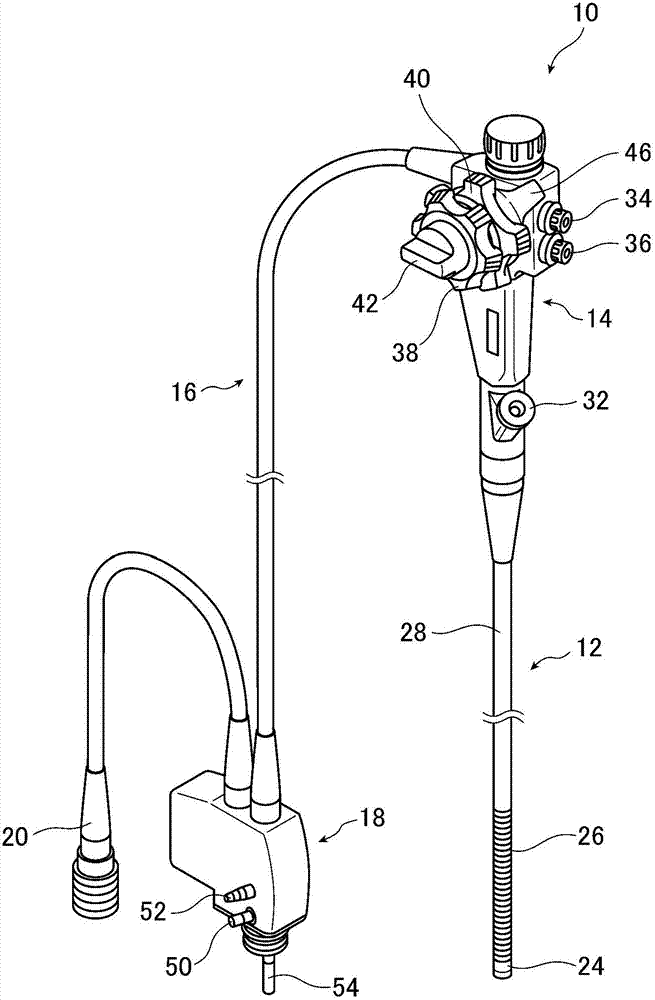

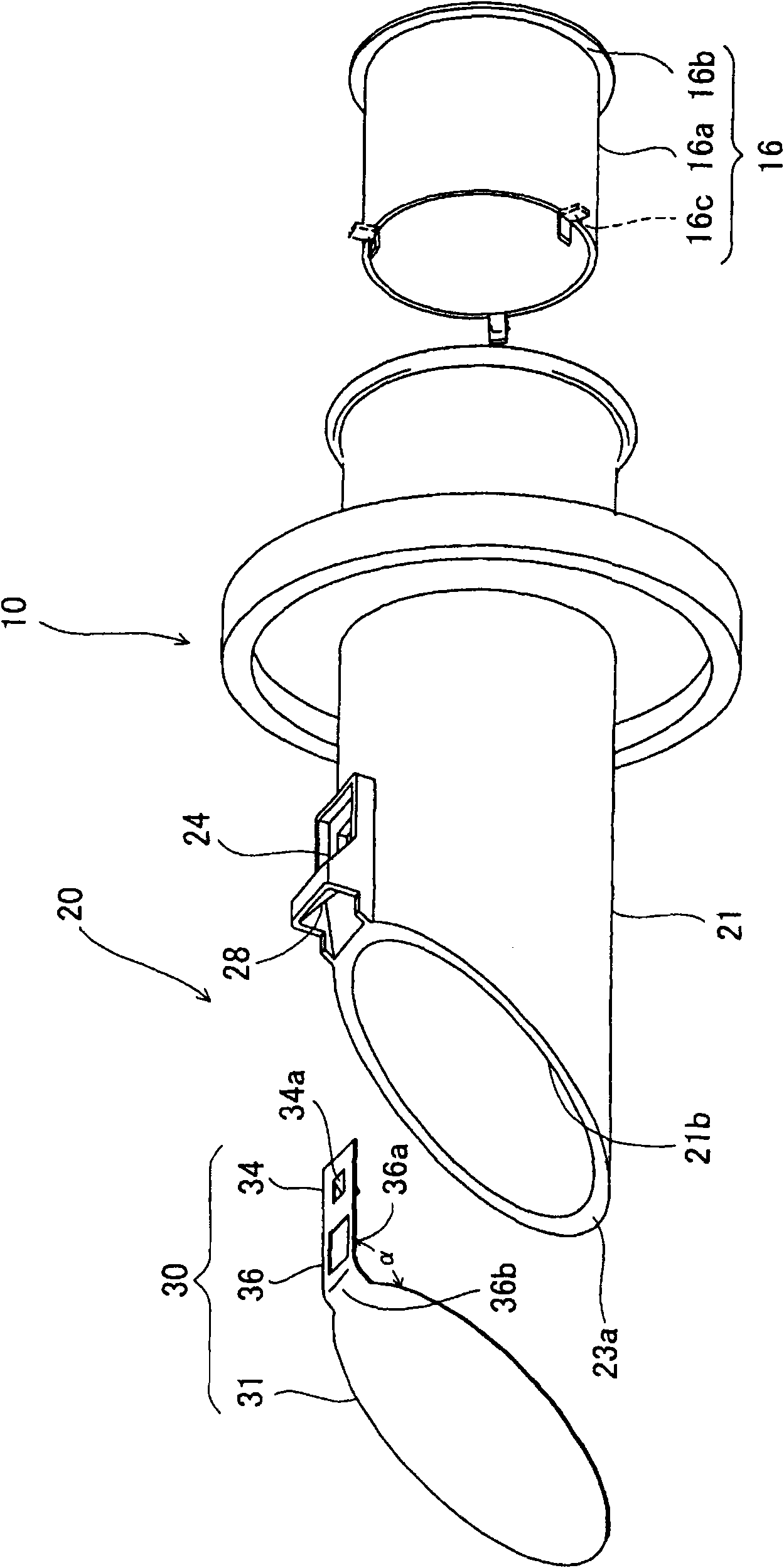

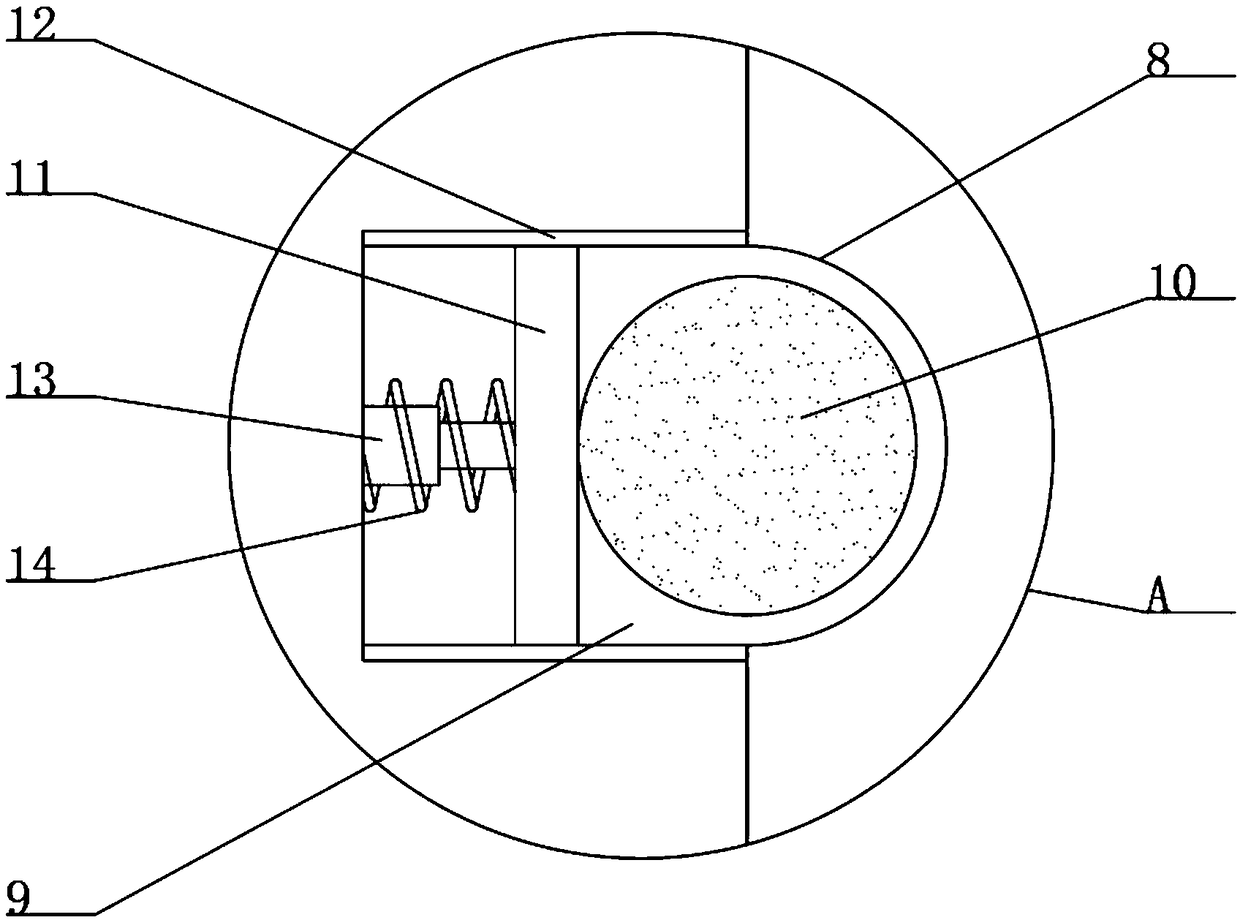

Fluid pipeline switching device and endoscope

The present invention provides a fluid pipeline switching device. In the fluid pipeline switching device for an endoscope, when a piston is detached, contact between the filter and connecting holes formed on an operating cylinder can be prevented, thereby preventing filler damage. The fluid pipeline switching device is provided with the following components: a press button which is provided with a piston and a plurality of sealing components; the operating cylinder which gradually necks in an insertion direction of the piston and is provided with the connecting holes connected with the fluid pipeline; and a limiting member which is used for limiting the lower position of the piston. The plurality of sealing components gradually thins to the front end and separates the space in the operating cylinder along the axis direction. The diameter of the sealing component is smaller than the inner diameter of the upper segment of the segment of the piston, which is in slidable contact with the sealing component. Furthermore the positions of the connecting holes for connecting each fluid pipeline with the operating cylinder are closer to the front end than the lower-end position of the sealing components which slidably contact with corresponding components, thereby settling the task of the invention.

Owner:FUJIFILM CORP

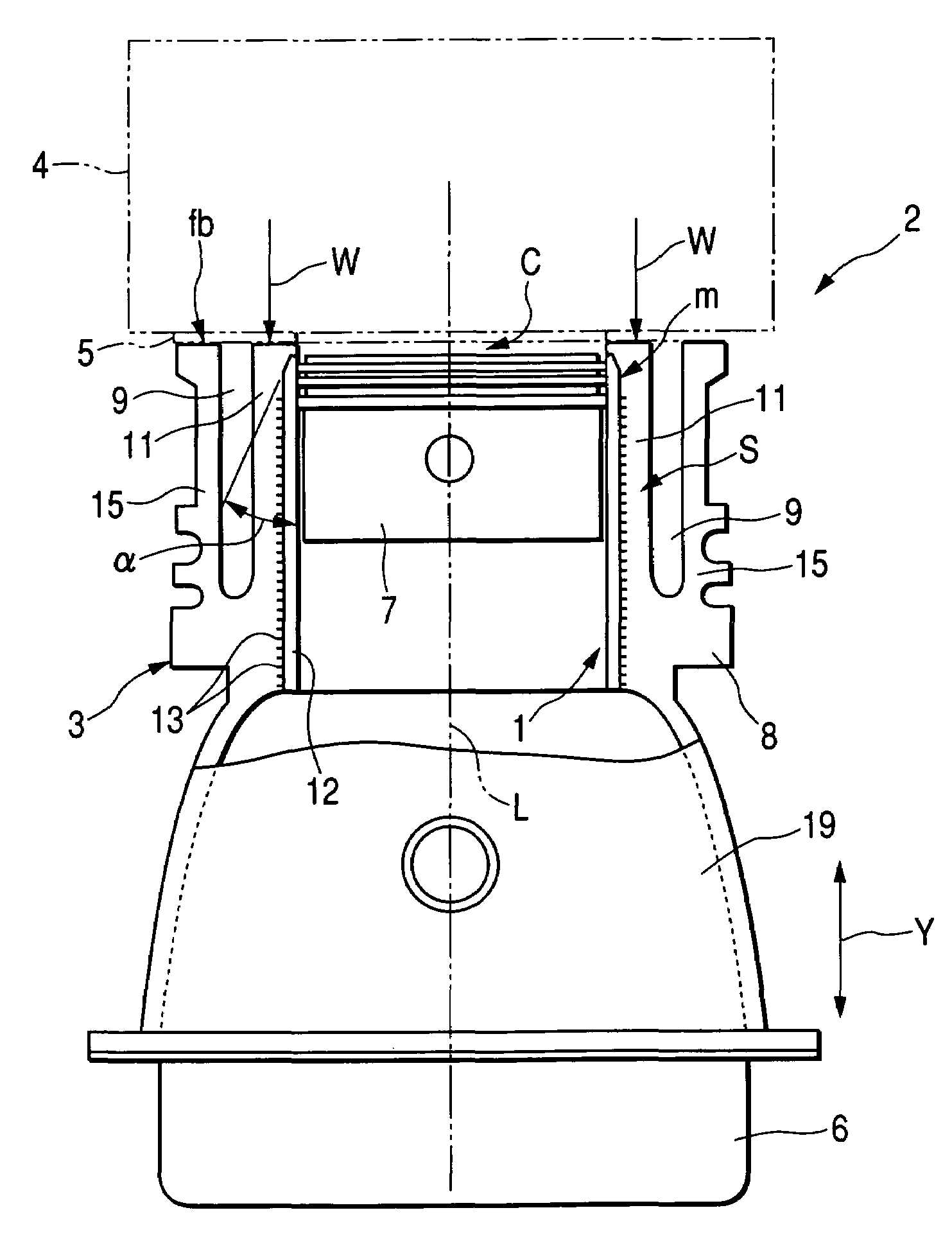

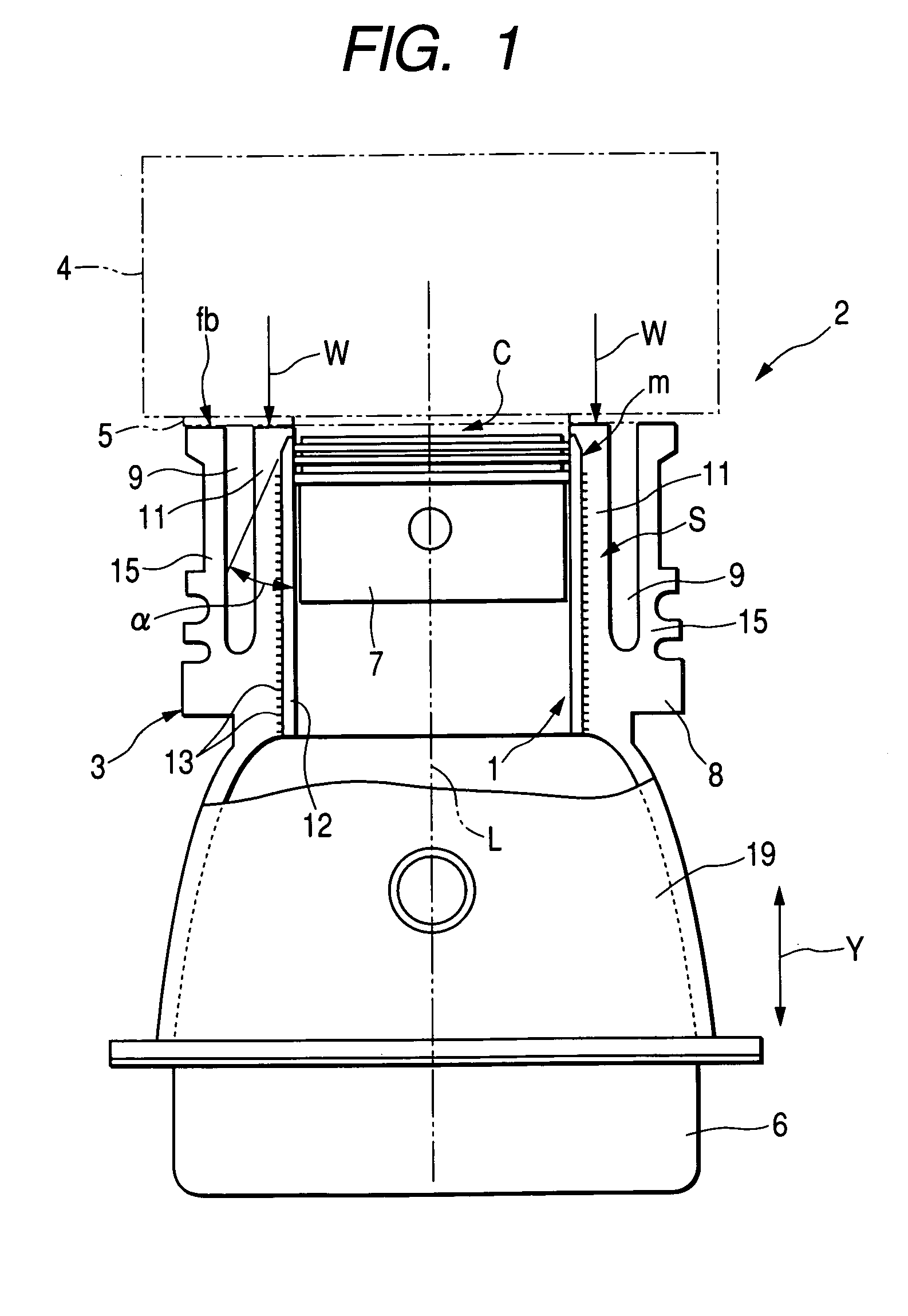

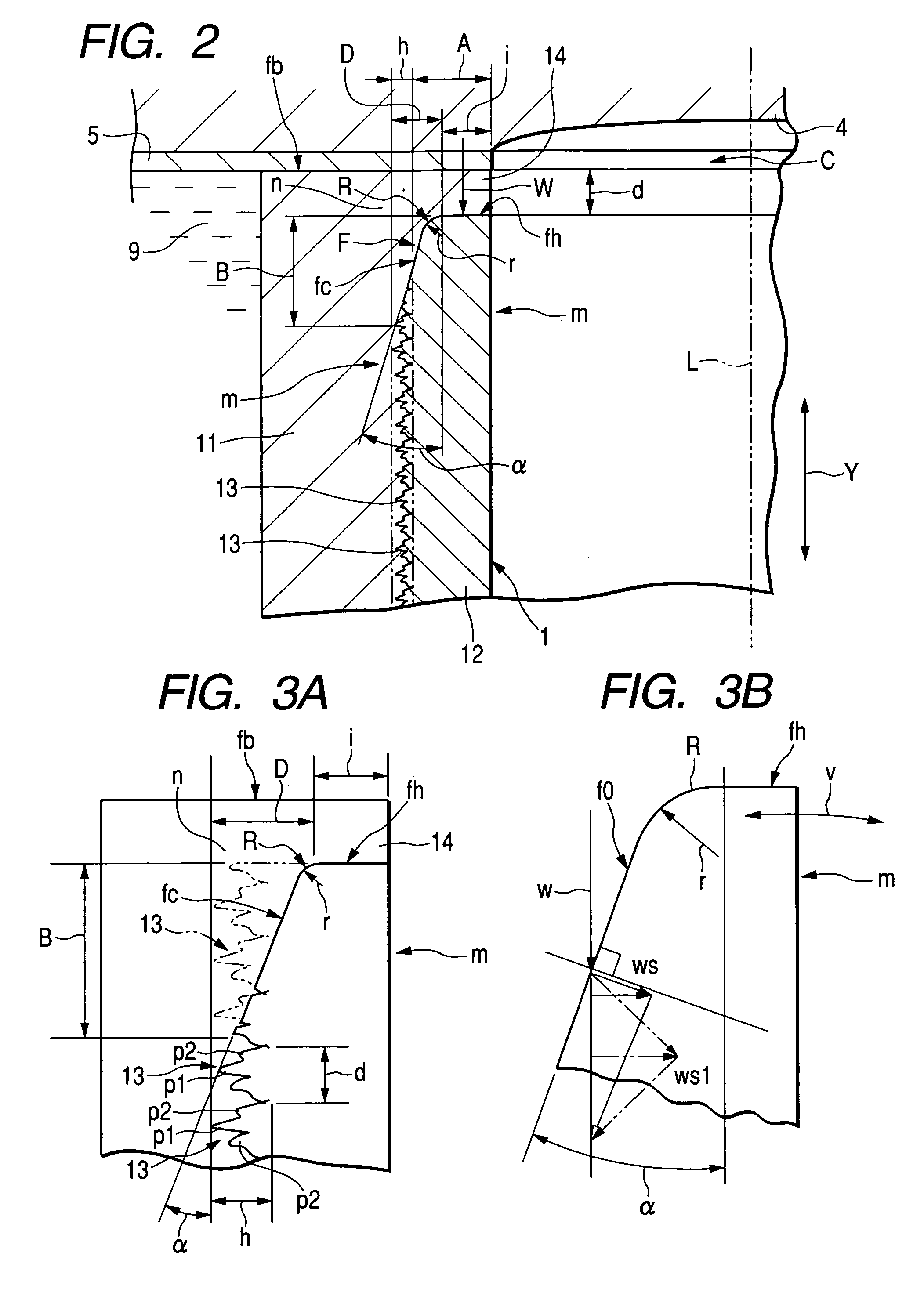

Engine cylinder liner construction

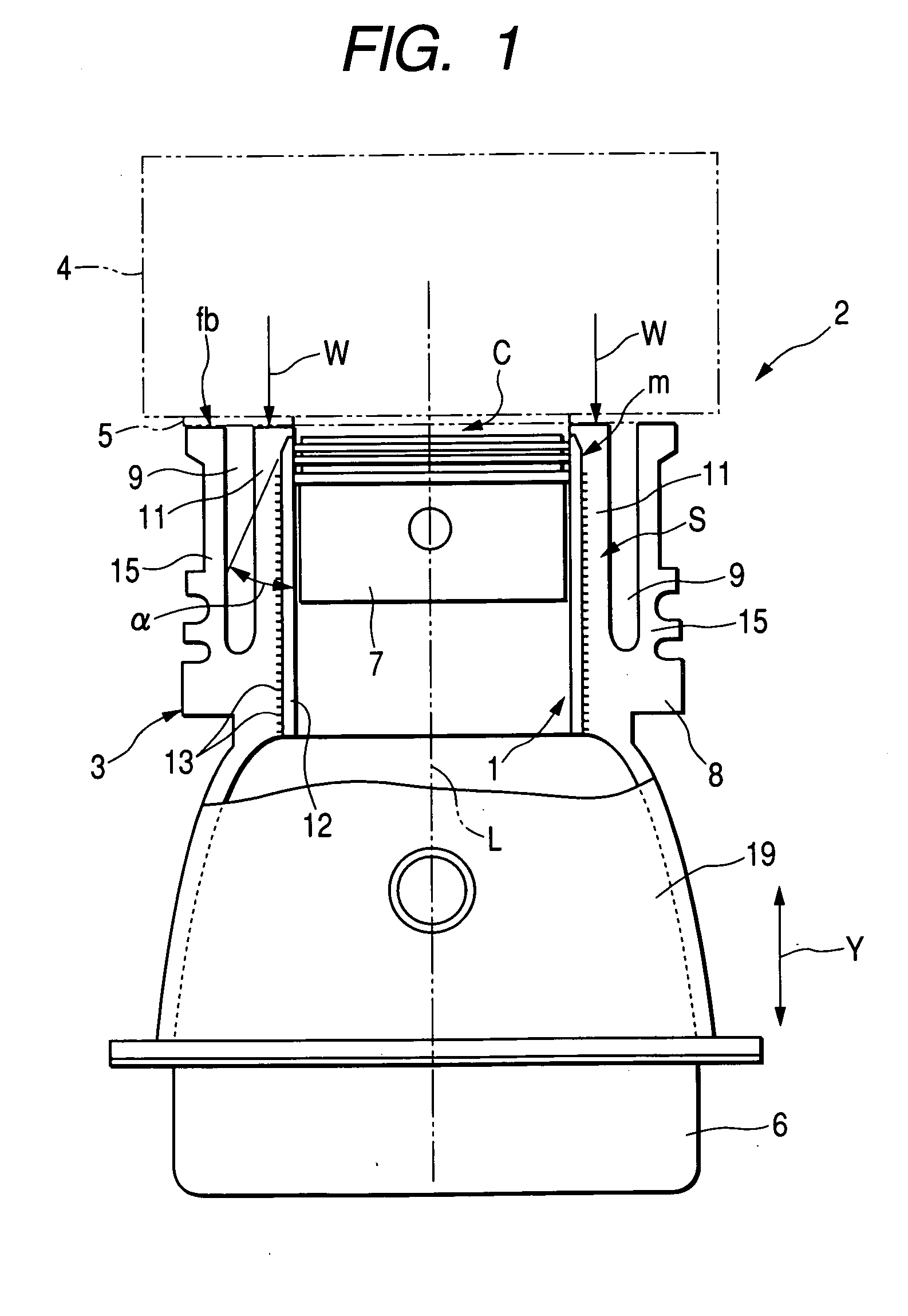

ActiveUS7171935B2Inhibit the generation of cracksAvoid loss of tightnessCylinder headsCylindersCylinder headCylinder block

Owner:MITSUBISHI MOTORS CORP

Wheel Support Bearing Assembly

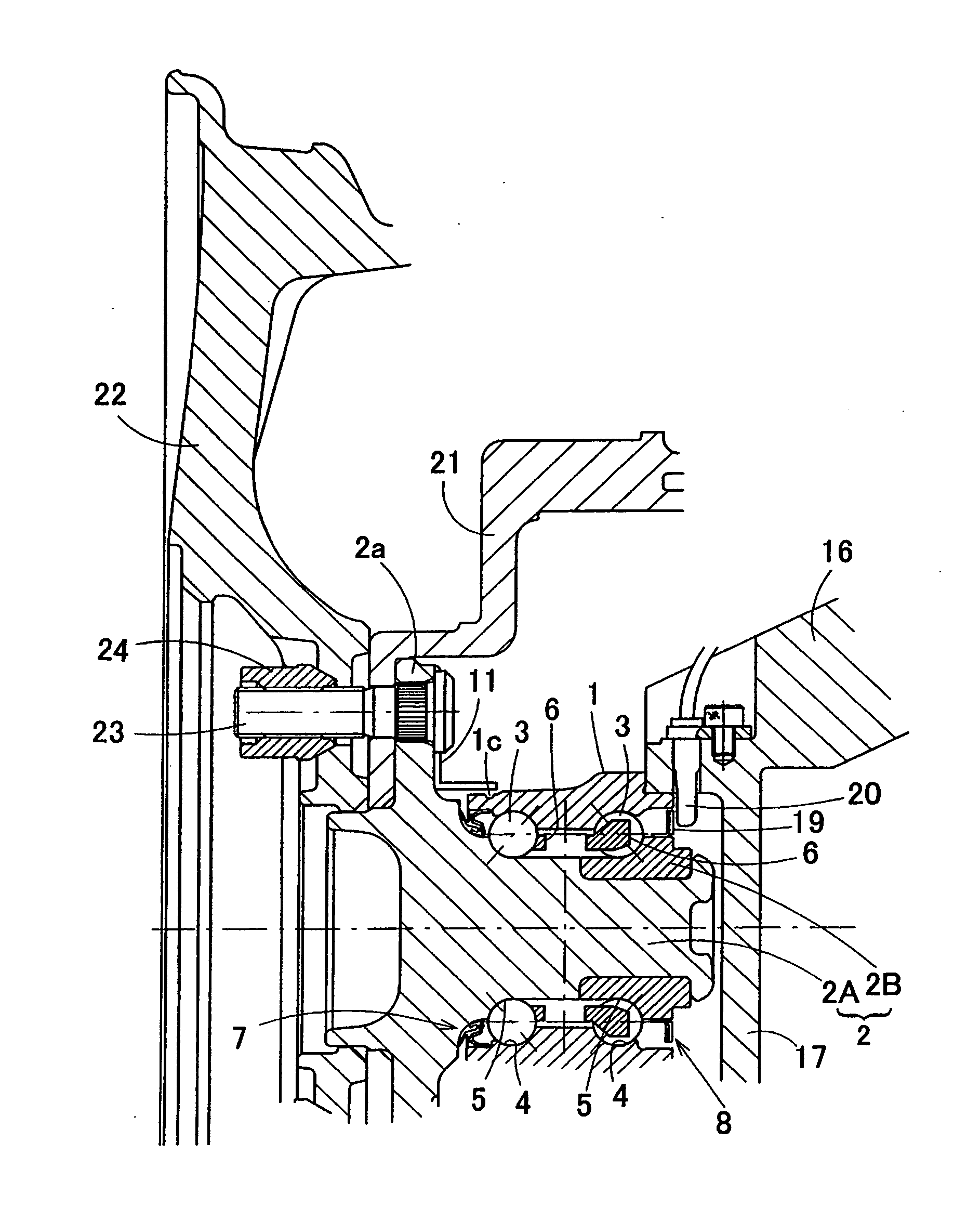

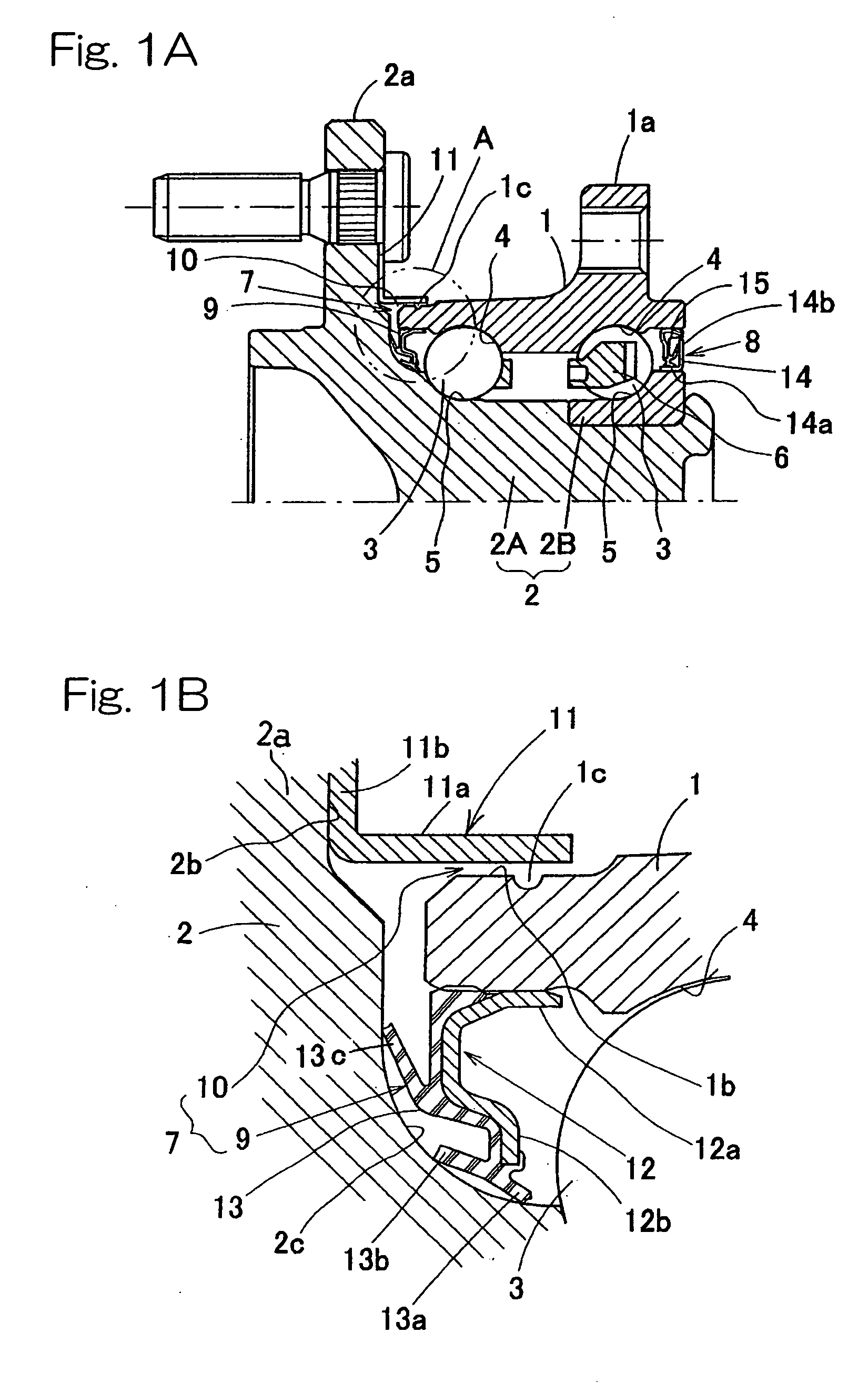

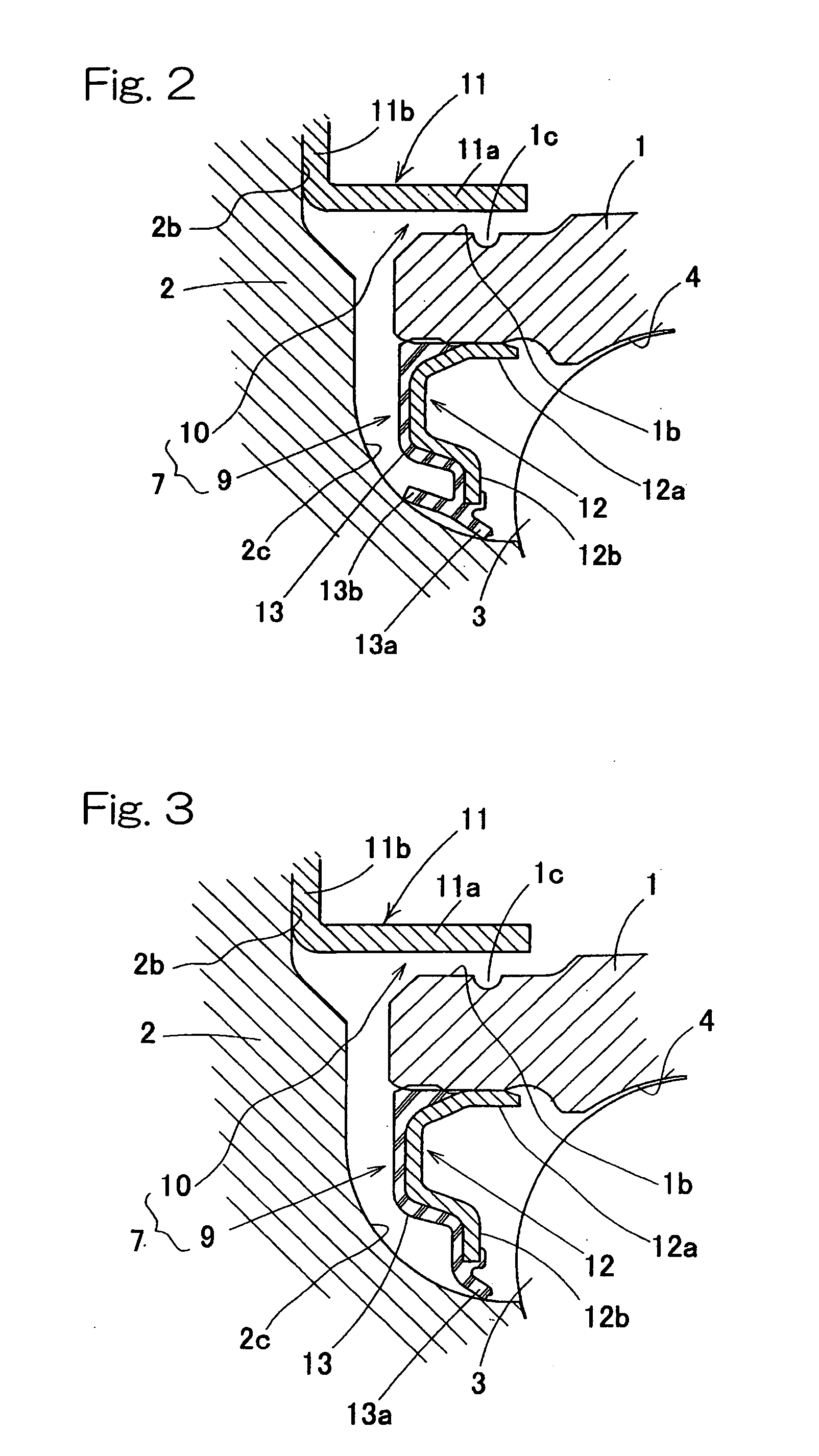

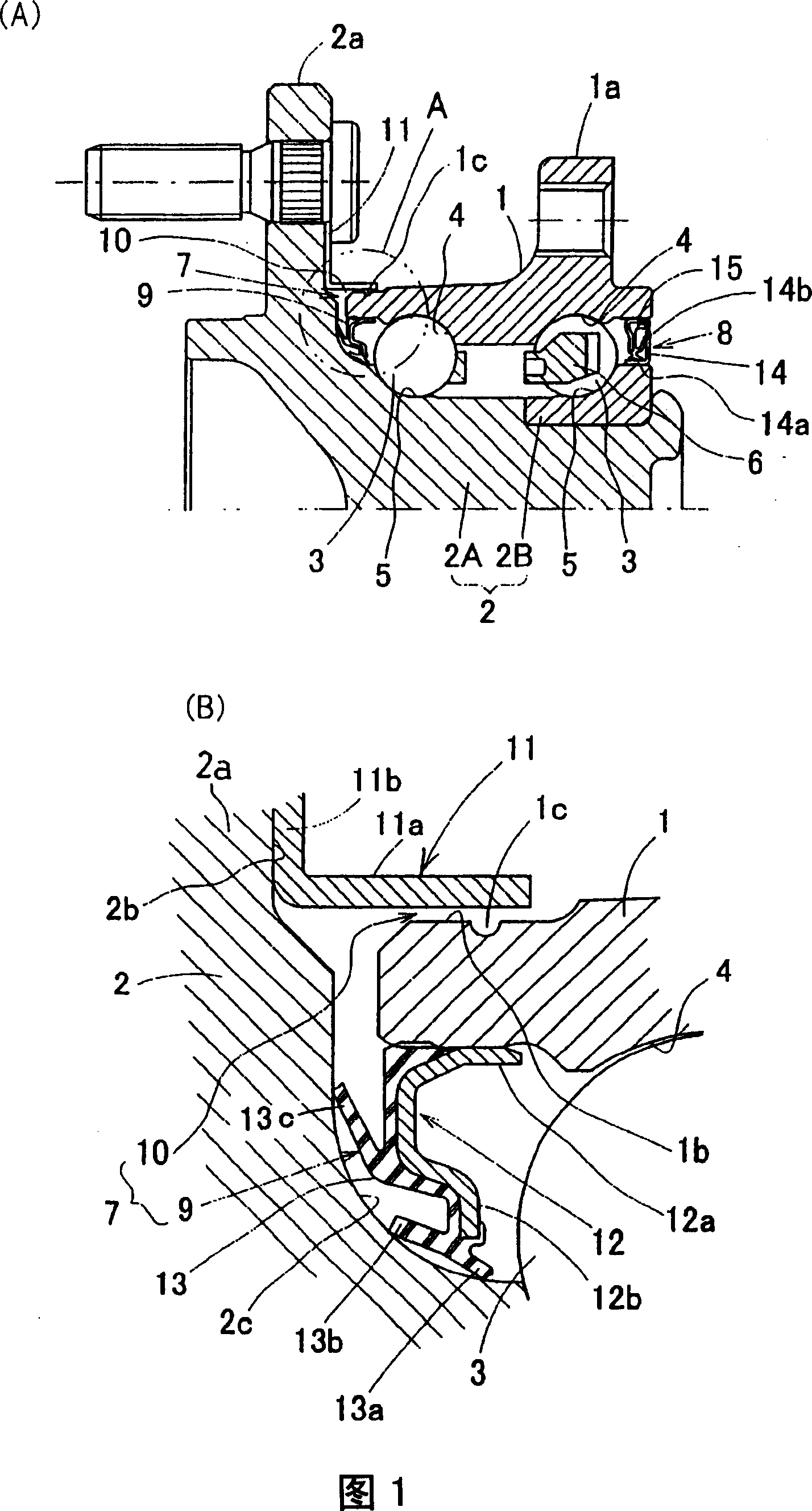

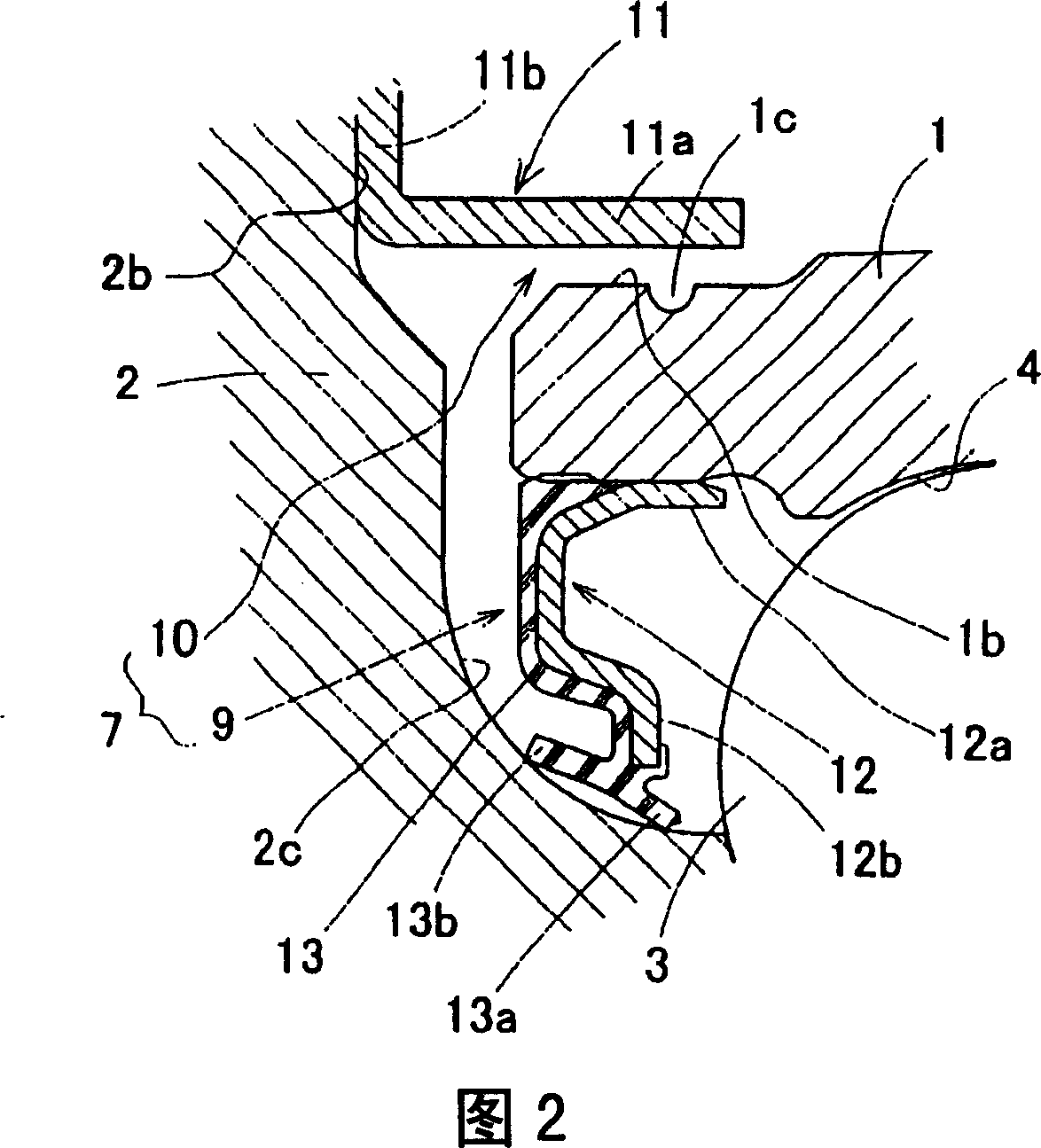

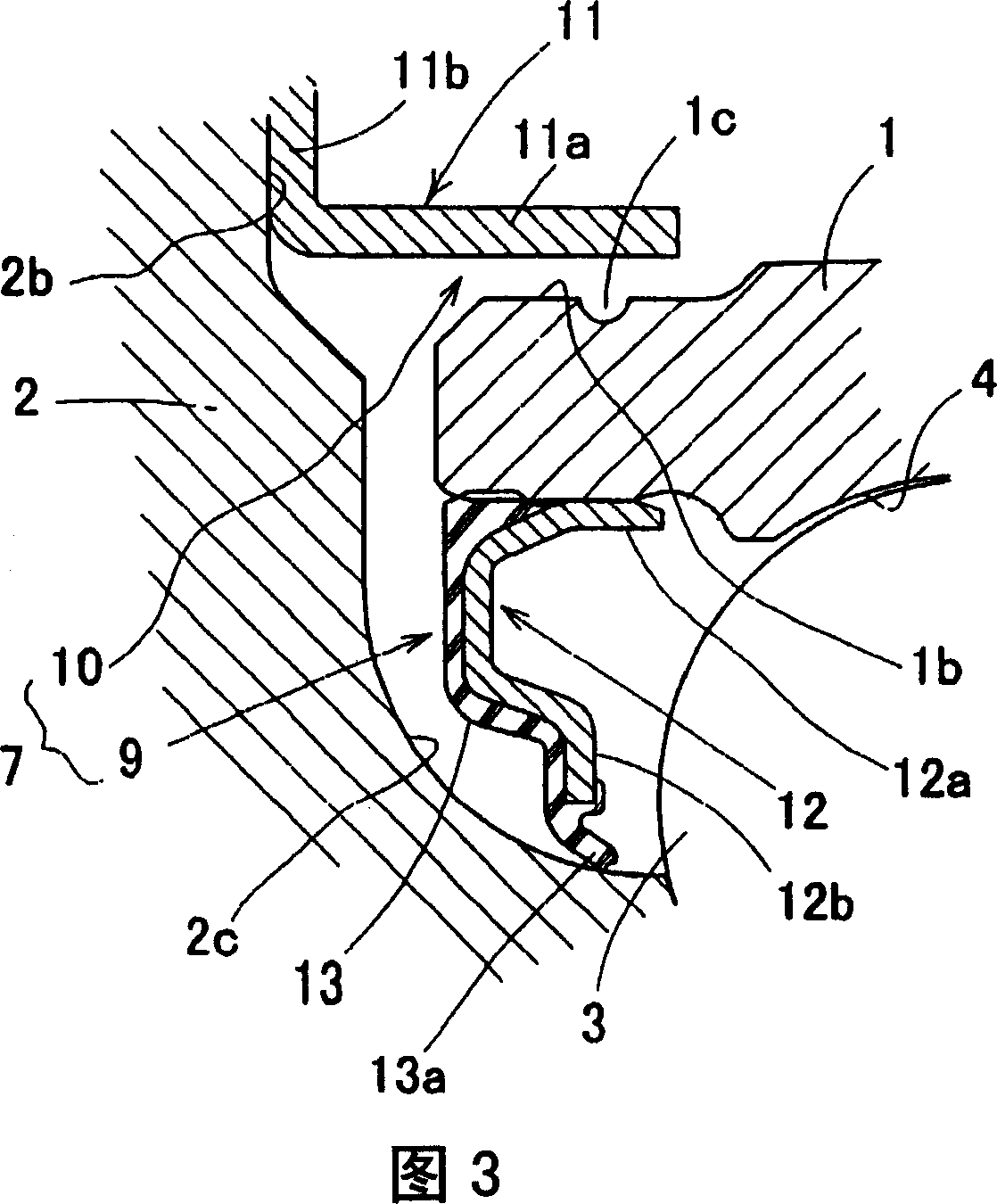

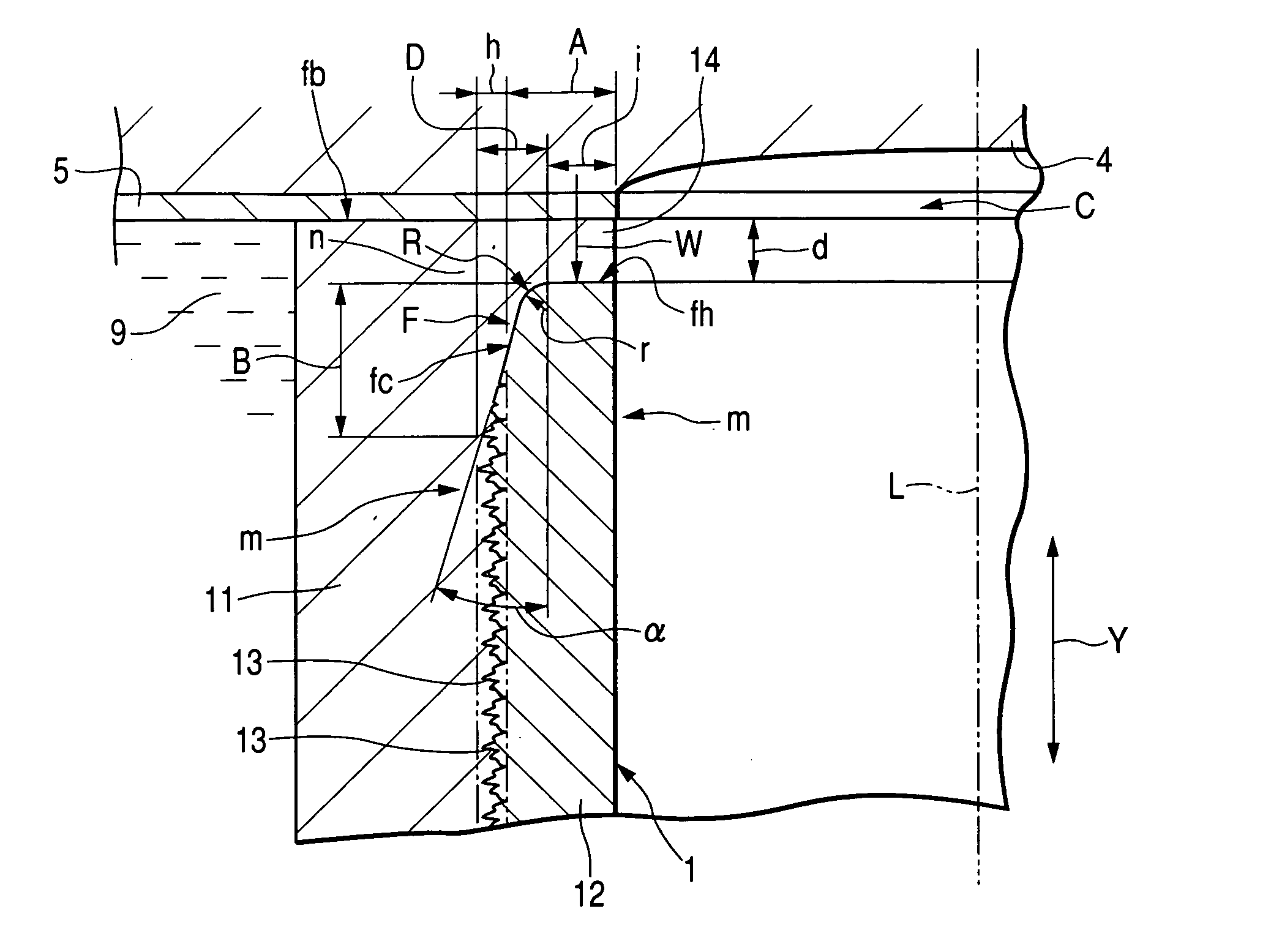

InactiveUS20080199120A1Reduction in sealabilityAvoid loss of tightnessRolling contact bearingsCastorsEngineeringFlange

Sealing structures (7, 8) are installed to seal opposite open ends of an annular bearing space between an outer member (1) and an inner member (2). A wheel mounting flange (2a) of the inner member (2) is provided with a shielding plate (11). The shielding plate (11) has a tubular wall (11a) forming a labyrinth seal (10) in the vicinity of an outer peripheral surface (1b) of an outboard end of the outer member (1). The outer peripheral surface (1b) is provided with a guide structure (1c) for guiding downwardly water, flowing in between the shielding plate (11) and the outer member (1) along the flange (2a) and the shielding plate (11), and water flowing in between the shielding plate (11) and the outer member (1) along the outer peripheral surface of the outer member (1). The guide structure (1c) is constituted by an annular groove or projection.

Owner:NTN CORP

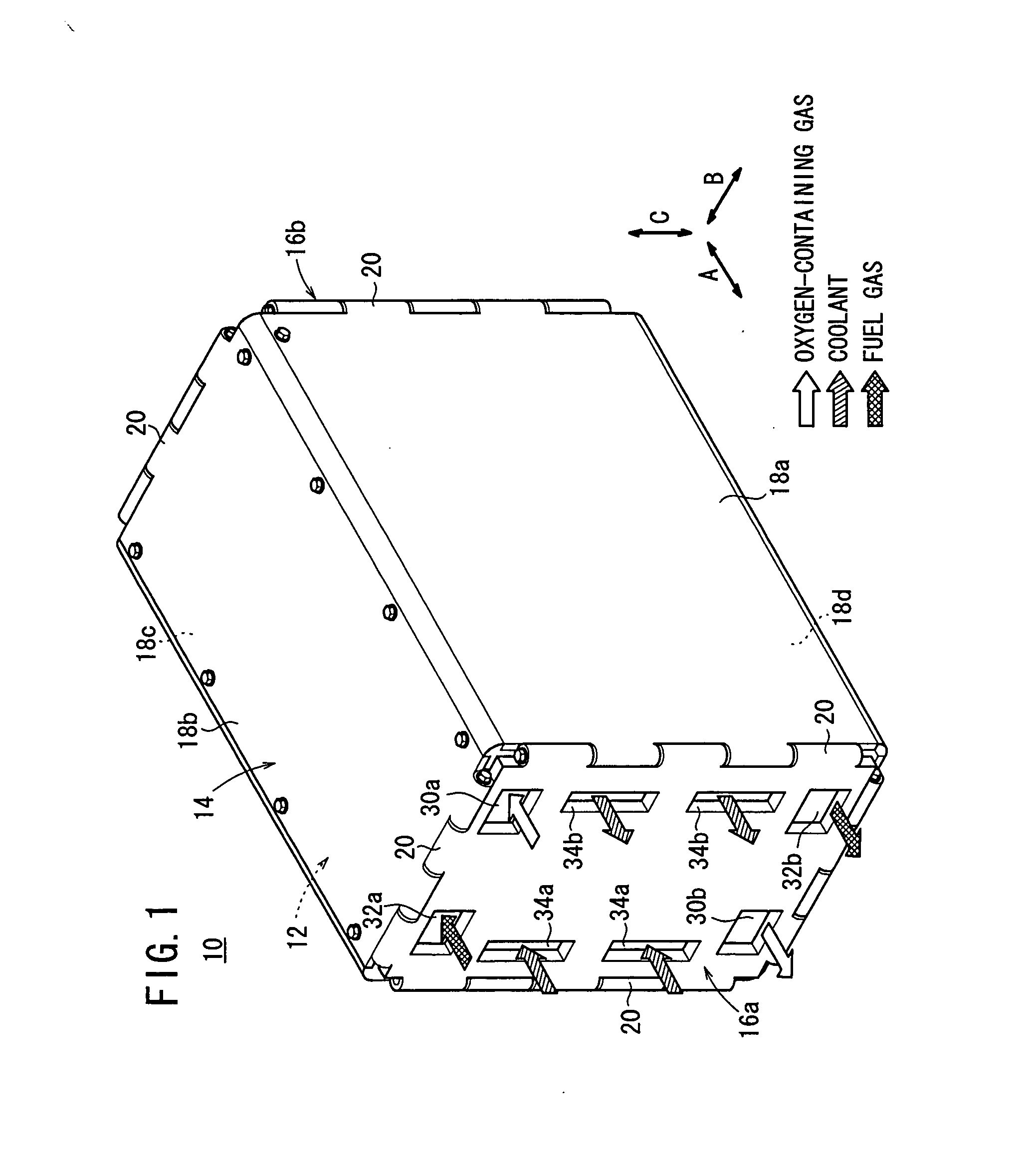

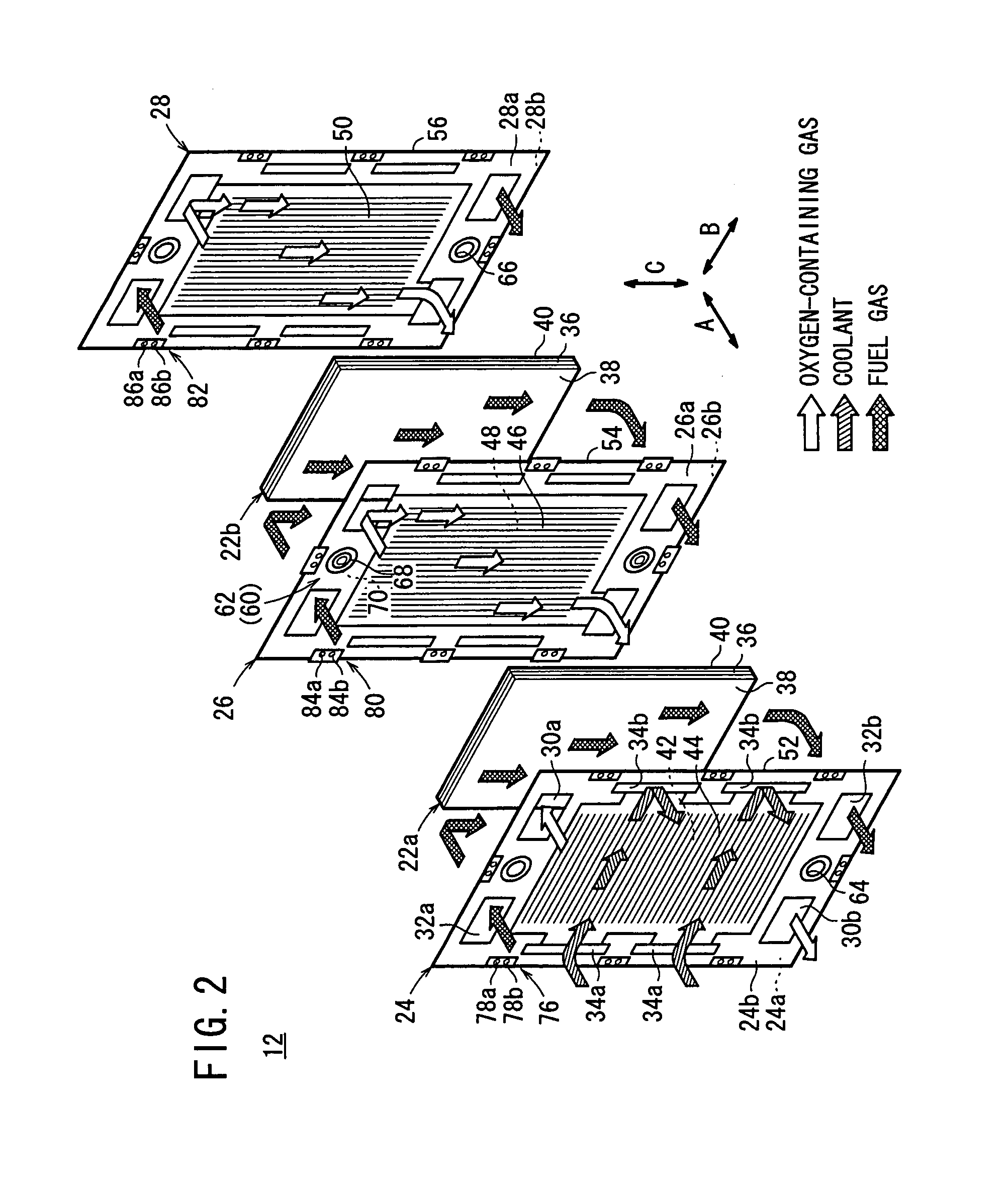

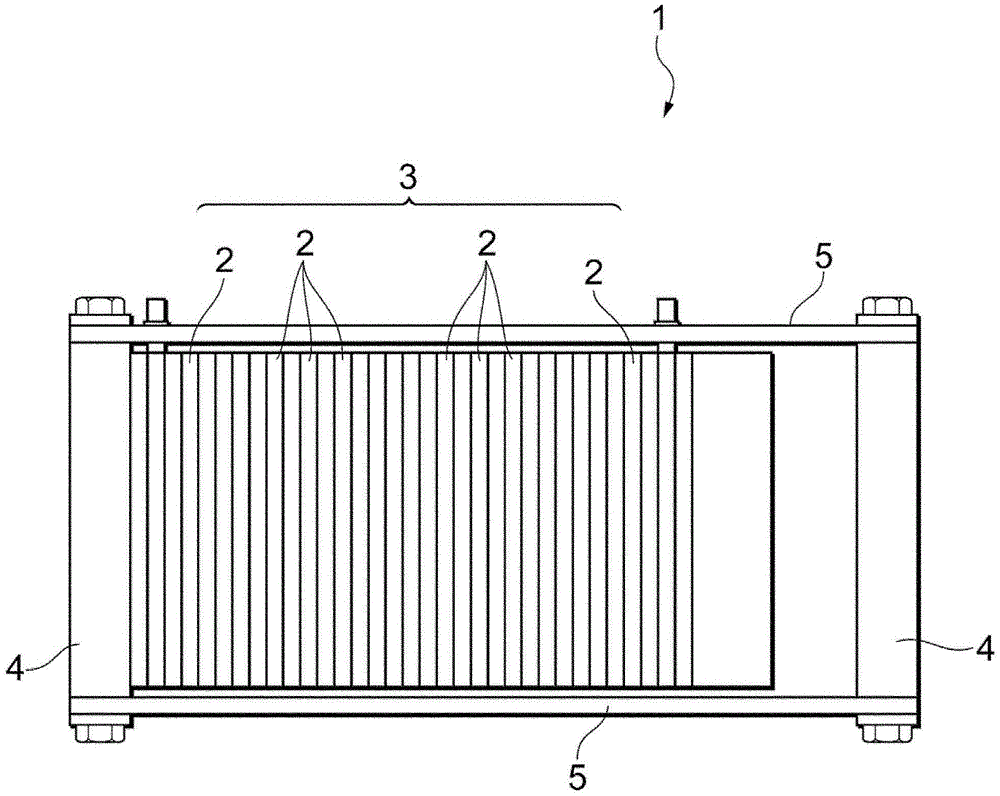

Fuel cell stack

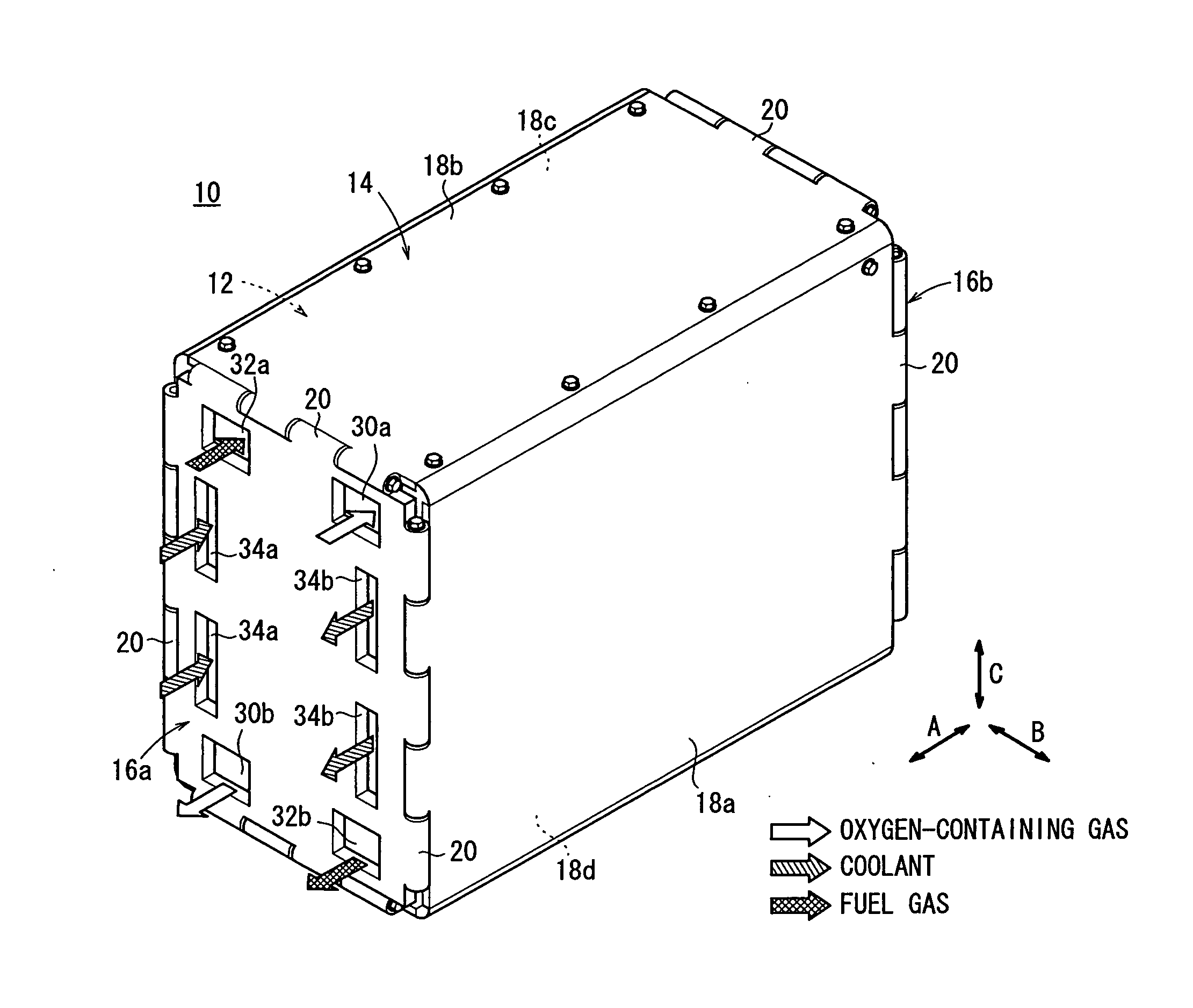

ActiveUS20080268319A1Simple structureAvoid loss of tightnessFuel cells groupingCell component detailsFuel cellsElectrical and Electronics engineering

Each of the fuel cell units making up a fuel cell stack includes a first separator, a second separator, and a third separator. A predetermined number of load receivers are provided integrally on outer ends of the first separator, the second separator, and the third separator. The load receivers of the second separator protrude toward the casing beyond the other load receivers. Resin clips are inserted into the load receivers, such that the first separator, the second separator, and the third separator are fixed together by the resin clips.

Owner:HONDA MOTOR CO LTD

Mechanical seal

Owner:KOBE STEEL LTD +1

Mechanical seal

A mechanical seal that prevents deposition of a degradation material generated on a sliding interface is to be provided. In a mechanical seal including a sleeve that rotates with a rotating shaft, a seal cover fixed to a housing, a rotating ring attached to the sleeve and a fixed ring attached to the seal cover and disposed in sliding-contact with the rotating ring via a sliding interface perpendicular to the rotating shaft, a scraping member is provided on the sleeve at a position close to an inner edge of the sliding interface so as to remove a degradation material from the inner edge of the sliding interface. Alternatively a discharging structure is formed on the sleeve so as to discharge the fluid stuck to the sleeve 4 to outside of the seal cover by the rotation of the sleeve. Otherwise, a solvent or an inert gas may be filled in a space defined by the sleeve 4, the rotating ring 6, the fixed ring 7 and the seal cover 5.

Owner:KOBE STEEL LTD +1

Vehicle bearing device

InactiveCN1957187AAnti-foulingAvoid loss of tightnessRolling contact bearingsCastorsWater flowFlange

Sealing structures (7, 8) are installed to seal opposite open ends of an annular bearing space between an outer member (1) and an inner member (2). A wheel mounting flange (2a) of the inner member (2) is provided with a shielding plate (11). The shielding plate (11) has a tubular wall (11a) forming a labyrinth seal (10) in the vicinity of an outer peripheral surface (1b) of an outboard end of the outer member (1). The outer peripheral surface (1b) is provided with a guide structure (1c) for guiding downwardly water, flowing in between the shielding plate (11) and the outer member (1) along the flange (2a) and the shielding plate (11), and water flowing in between the shielding plate (11) and the outer member (1) along the outer peripheral surface of the outer member (1). The guide structure (1c) is constituted by an annular groove or projection.

Owner:NTN CORP

Engine cylinder liner construction

ActiveUS20050161014A1Inhibit the generation of cracksAvoid loss of tightnessCylinder headsCylindersCylinder headEngineering

An engine cylinder liner construction in which a cylinder liner that is cast into a cylinder block has a tubular portion and a number of spines integrally formed on an outer surface of the tubular portion, the engine cylinder liner construction being characterized in that a chamfered portion is formed at an end portion m of the tubular portion which faces a cylinder head by chamfering the end portion together with the spines located thereat in a tapered fashion.

Owner:MITSUBISHI MOTORS CORP

Connecting structure of crimp terminal and electric wire

ActiveUS9755327B2Less squeezeAvoid loss of tightnessCoupling contact membersCouplings bases/casesElectrical conductorElectric wire

A structure for connecting a crimp terminal and an electric wire includes: a crimp terminal that includes a conductor crimping portion and a coating crimping portion serially and includes an electric wire connector that is to be crimped to the electric wire; and a water stop sheet having an opening for bringing a conductor into contact with the conductor crimping portion, and laid between the electric wire connector and the electric wire. When a joint is swaged and crimped, the swaged and crimped joint has a second included angle θ2 between the bottom plate and a second line that is larger than a first included angle θ1 between the bottom plate and a first line in a cross section that is perpendicular to a bottom plate of the electric wire connector and that includes an electric wire axial line.

Owner:YAZAKI CORP

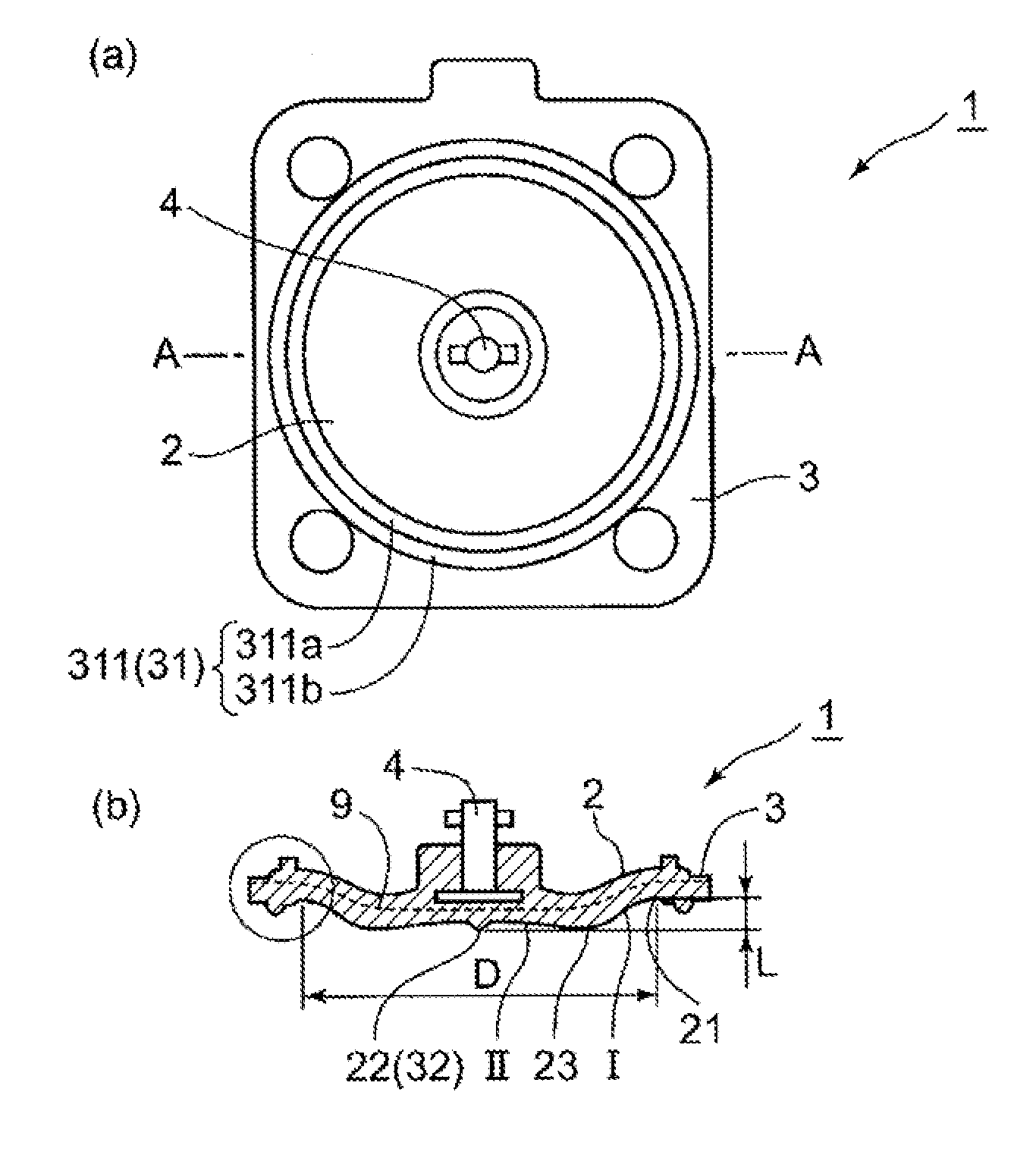

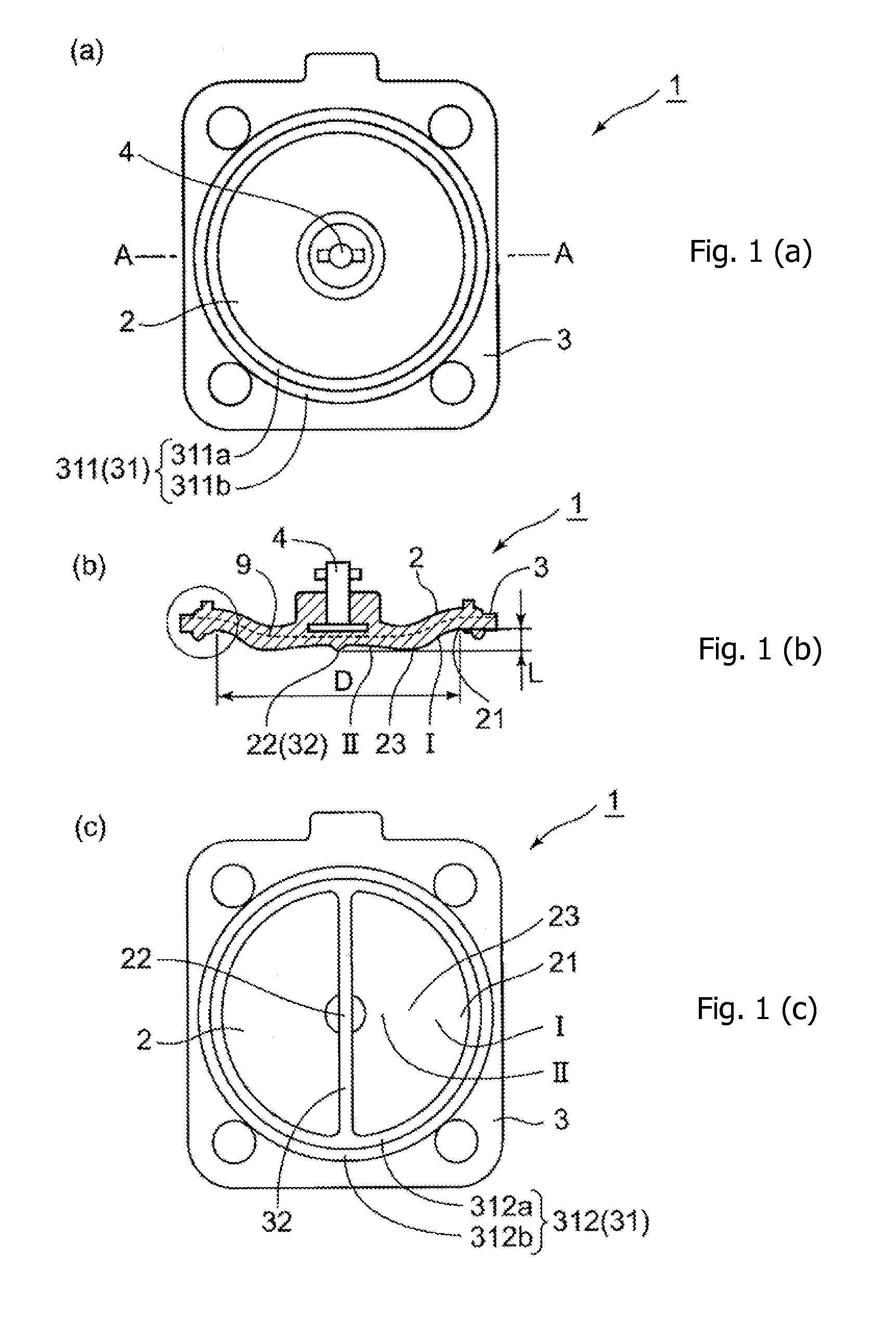

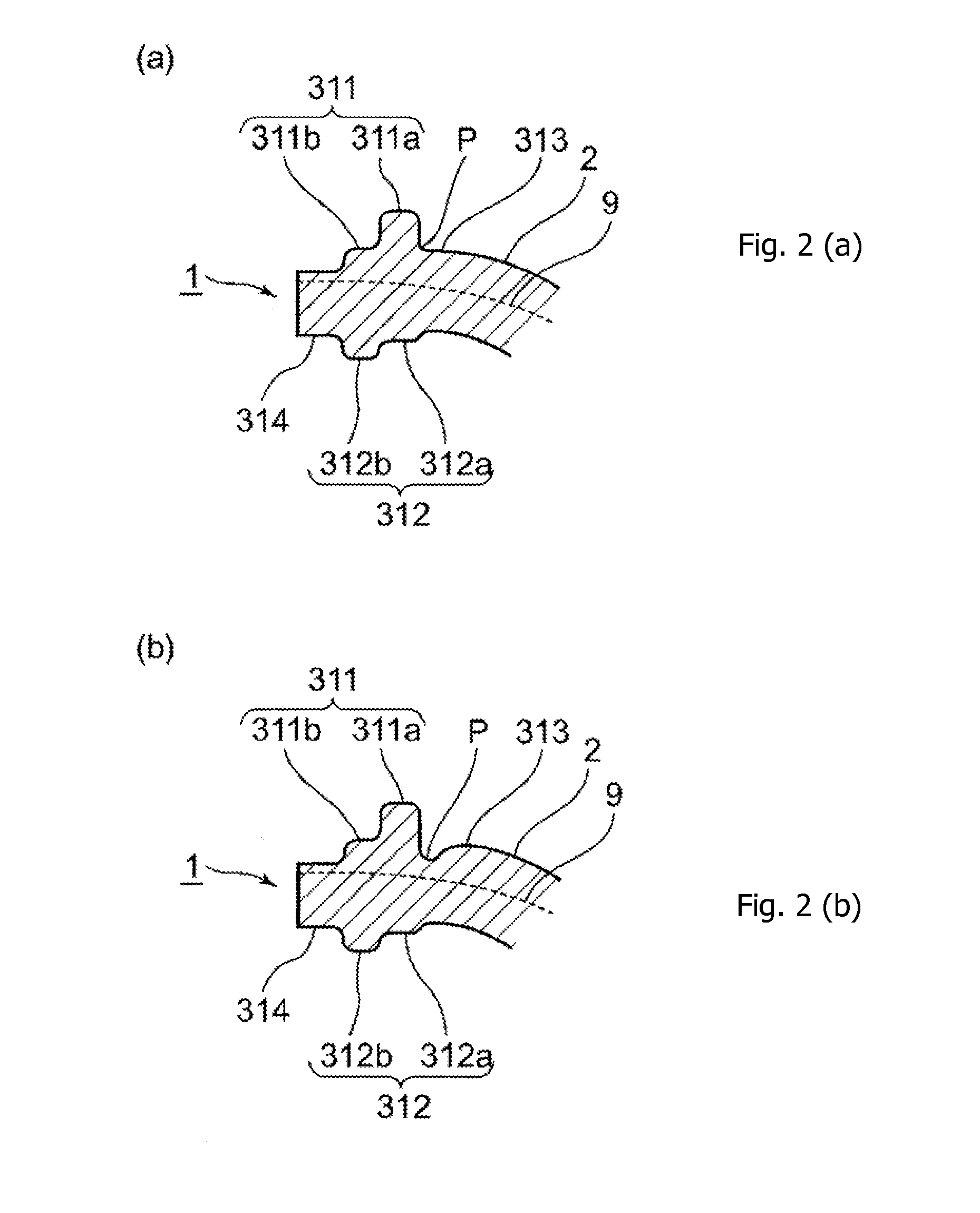

Diaphragm and Diaphragm Valve

ActiveUS20150167853A1Avoid deformationAvoid loss of tightnessDiaphragm valvesOperating means/releasing devices for valvesRubber materialDiaphragm valve

A durable diaphragm valve has a single-layer structure consisting of rubber materials. The single-layer structure has a membrane part deforming and moving up and down with opening and closing of a flow channel and a flange part which is provided around said membrane part and sandwiched between a valve body and a bonnet. The flange part has an annular ridge consisting of an upper ridge protruding upward and a lower ridge protruding downward from a position corresponding to said upper ridge. The upper ridge has an inner upper ridge and an outer upper ridge with its protruding height being lower than the inner upper ridge, which are consecutively formed in a staircase pattern.

Owner:FUJIKIN INC

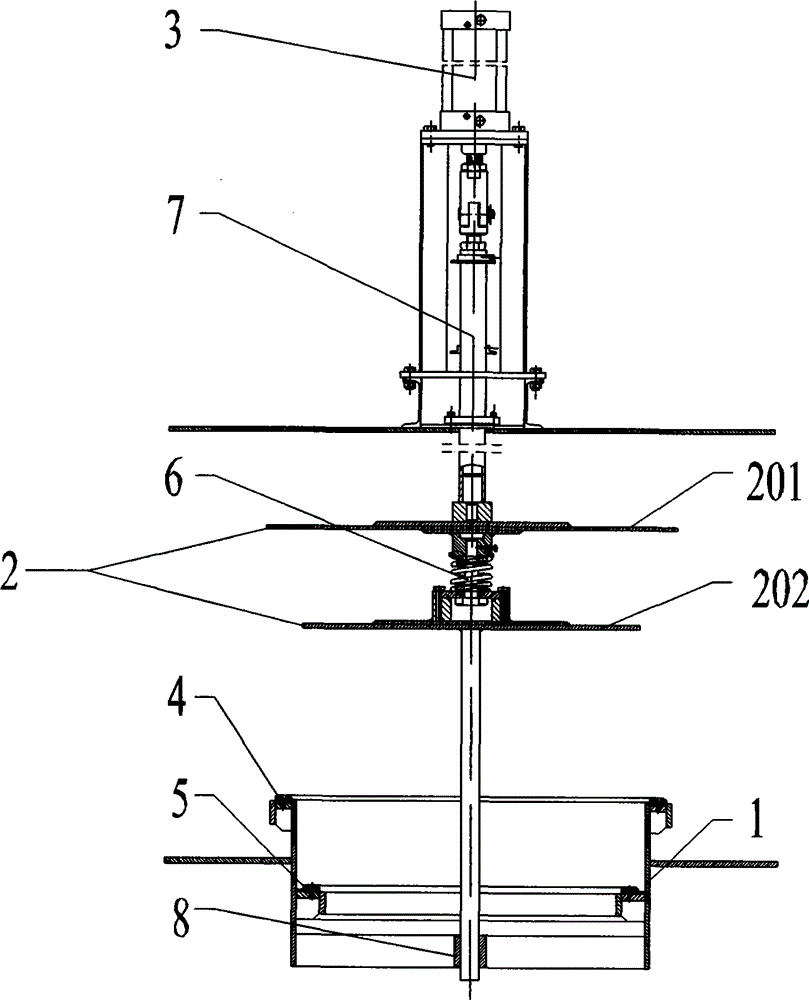

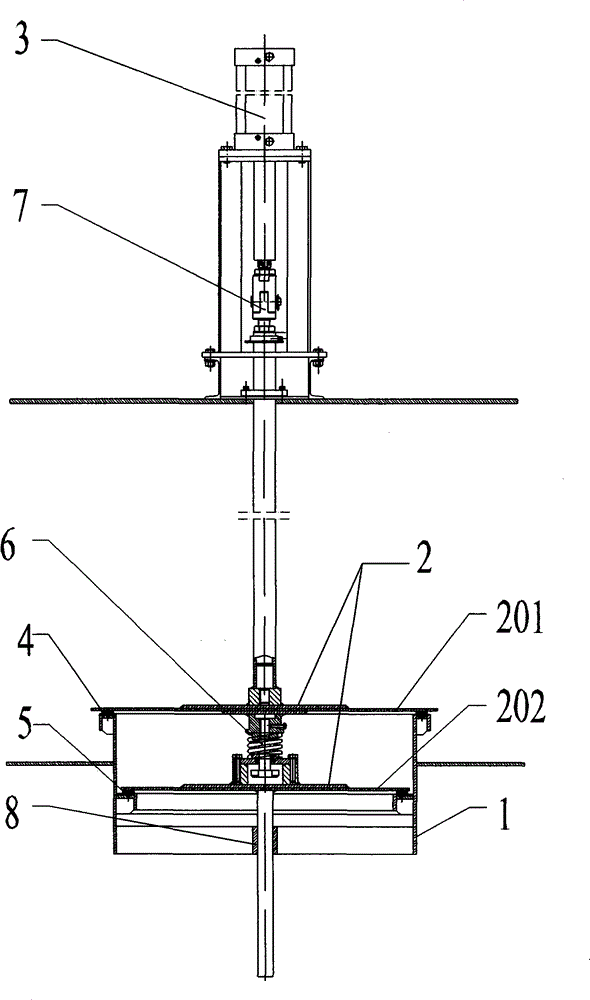

Double-layer sealing type lift valve

The invention discloses a double-layer sealing type lift valve which comprises a valve body, a valve plate assembly and a lifting driving device connected with the valve plate assembly, wherein an upper-layer valve seat and a lower-layer valve seat are arranged inside the valve body, sealing strips are arranged on the upper-layer valve seat and the lower-layer valve seat respectively, the valve plate assembly comprises an upper-layer valve plate matched with the upper-layer valve seat and a lower-layer valve plate matched with the lower-layer valve seat, and a compression spring is arranged between the upper-layer valve plate and the lower-layer valve plate. According to the double-layer sealing type lift valve, the double layers of valve seats are arranged in the valve body, the corresponding double layers of valve plates are arranged, the compression spring is arranged between the two layers of valve plates, repulsive force is provided for the double layers of valve plates through the compression spring, and in this way, the sealing performance of the lift valve is effectively guaranteed, the situation that the sealing performance is reduced due to deformation of the valve seats or ash is avoided, and then the safety performance of a dedusting system is effectively improved and normal work of a boiler system can be effectively guaranteed.

Owner:北京赫宸智慧能源科技股份有限公司

Check valve

The invention provides a check valve, which has a simple structure and can prevent a stop closure part (31) of a valve plate (30) opened or closed on a convection outlet (21b) from being excessively opened and reduce the flow path resistance during a valve opening process. The check valve comprises a path forming part (21) and a valve plate formed by cutting and bending a flexible thin plate. The path forming part comprises an installing part (24) for installing the valve plate. The valve plate comprises a stop closure part, an installed part (34) and a flexible deforming part (36). The installing part has an opening-degree limit part (28) provided with a limiting plane (28a). The limiting plane is provided with a following space which substantially keeps an angle bending state and meanwhile performs flexible deformation with a part connecting the flexible deforming part and the installed part as a pivot when the stop closure part is pushed by the fluids flowing through a path (21a). By the abutting against the flexible deforming part of the limiting plane, the opening angle of the stop closure part relative to the fluid outlet is limited.

Owner:TOYODA GOSEI CO LTD

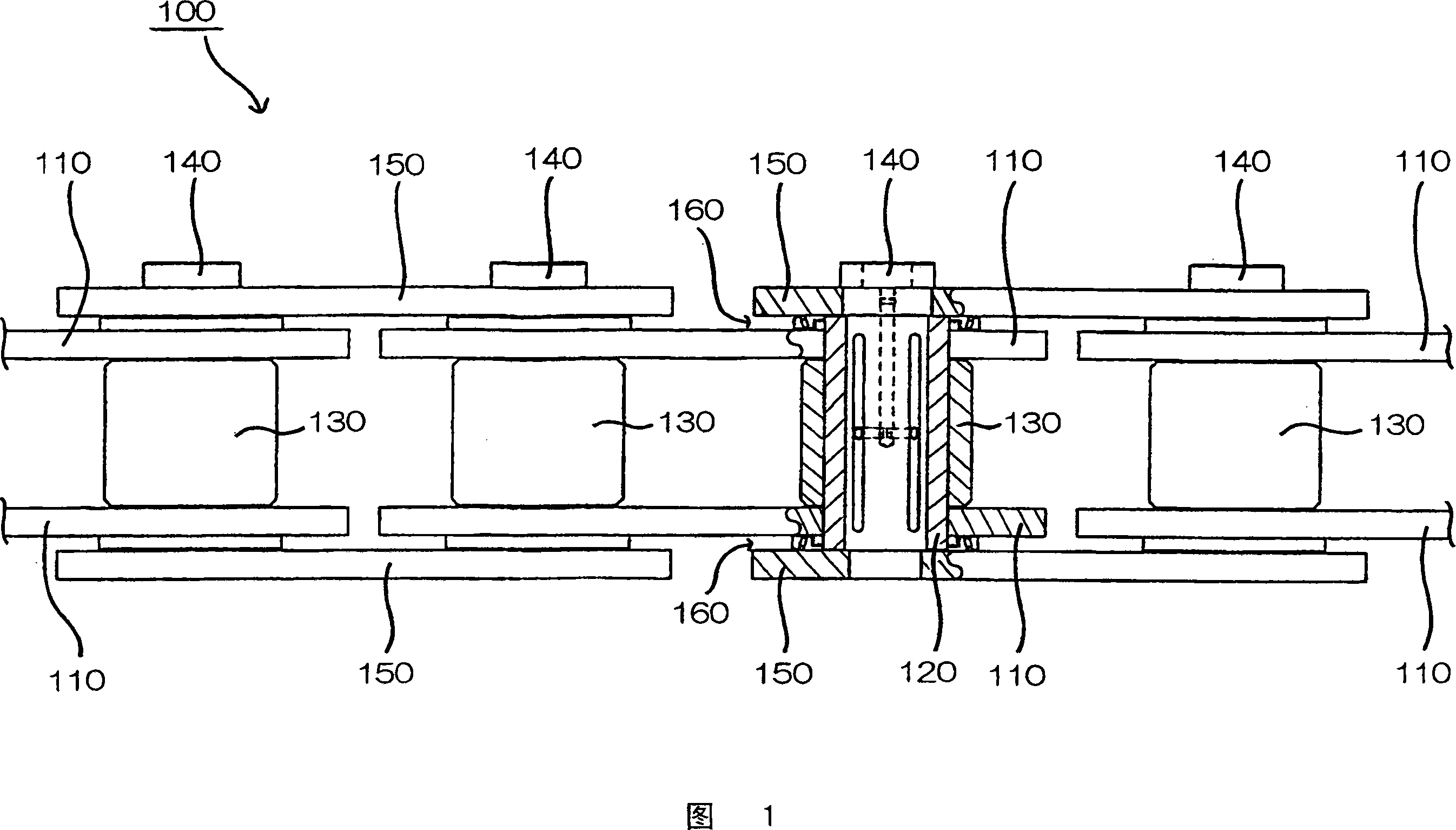

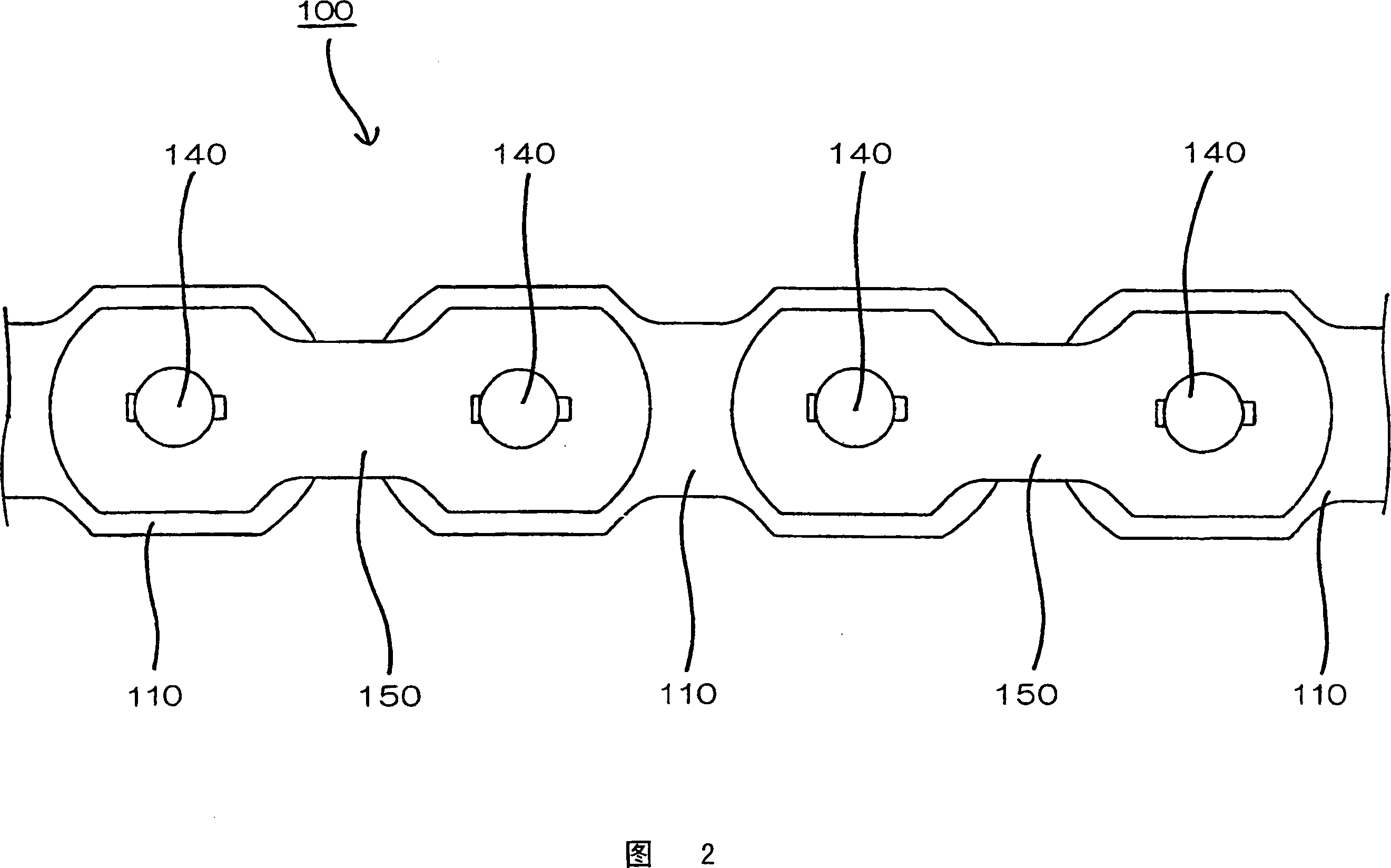

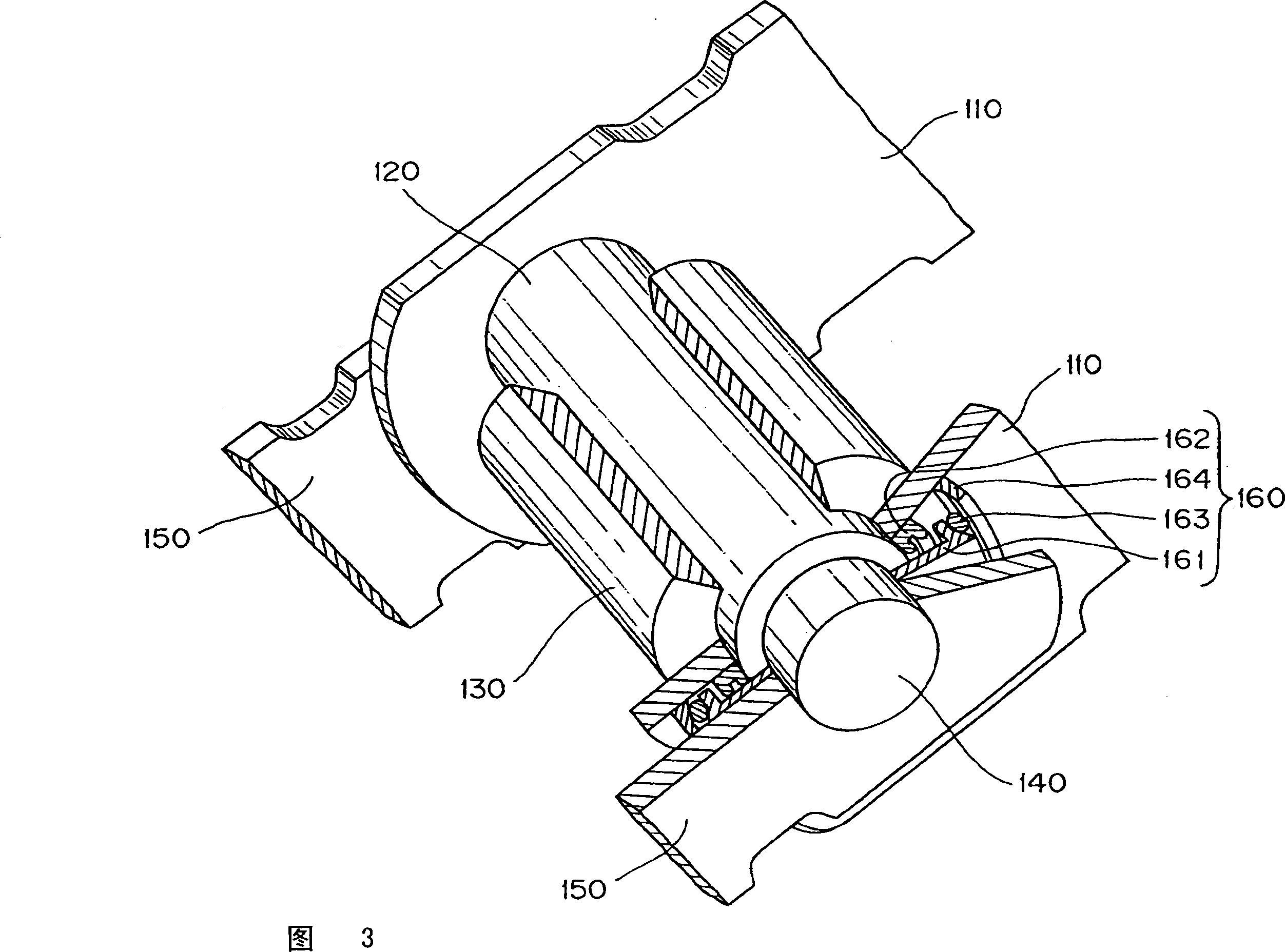

Sealing chain

InactiveCN101210603AContainment leakSeepage momentum weakensEngine sealsConveyorsEngineeringSliding contact

The present invention provides a sealing chain, capable of preventing lubricant between a connecting pin and a sleeve from leaking as well as preventing dust from enterring, avoiding the sleeve and an outer link plate to sliding contact with each other directly, so to play excellent sealing performance for a long time and have long sealing lifetime without implementing surface thin processing to the outer link plate. The sealing mechanism (160) of the sealing chain (100) setting between the outer link plate (150) and an inner link plate (110) includes: a ring sealing piece supporting component (161), a first elastic sealing piece (162), a second elastic sealing ring (163) and a steeliness sealing ring (164).

Owner:TSUBAKIMOTO CHAIN CO

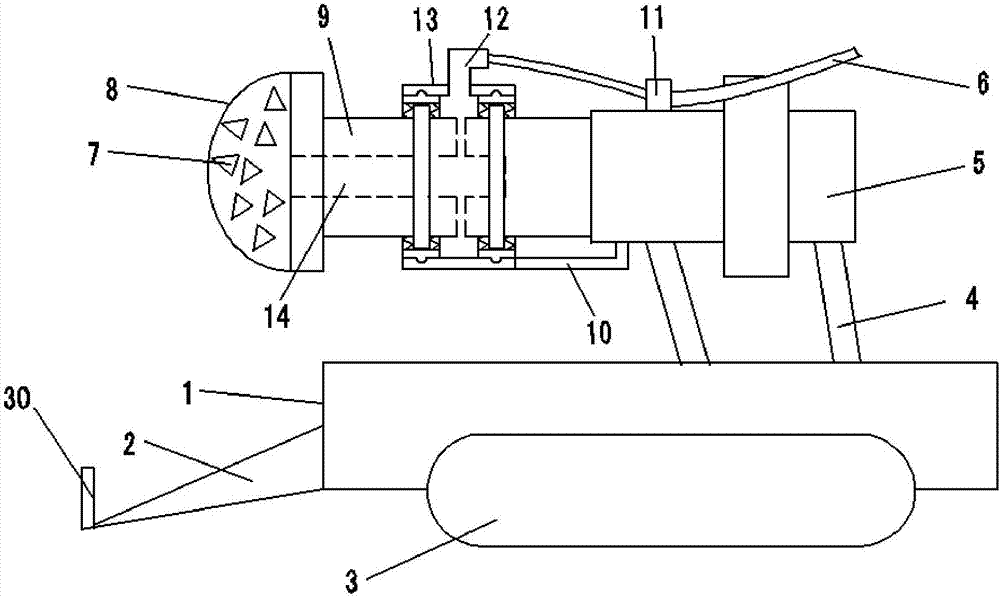

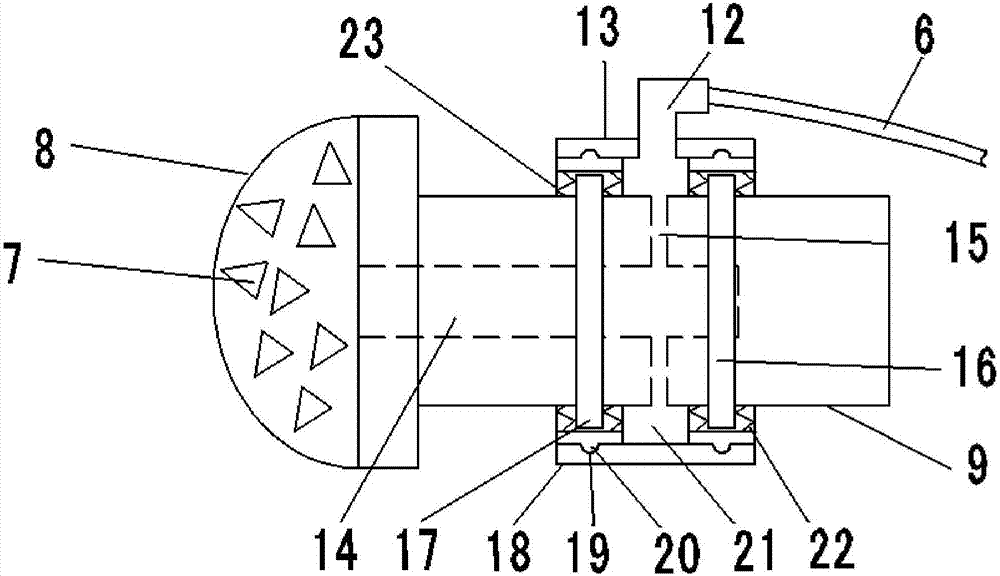

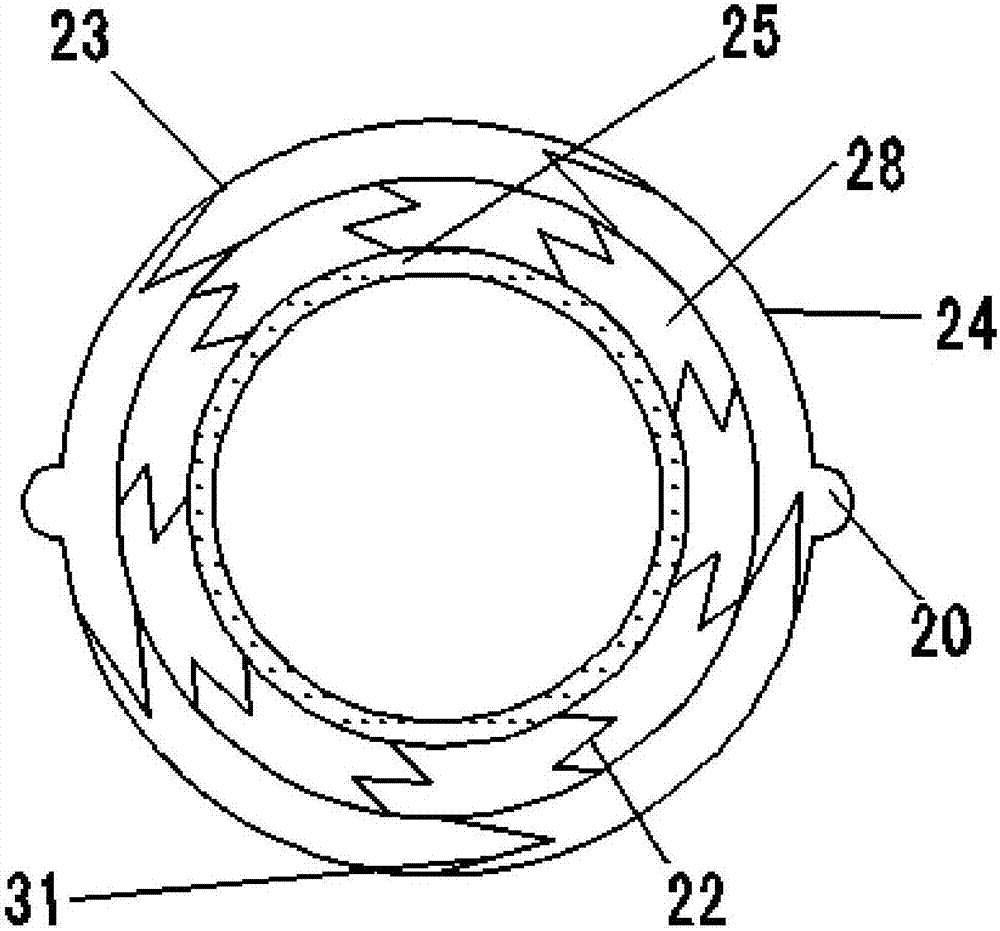

Improved roadway boring machine

ActiveCN106907150AAvoid explosion riskImprove efficiencySlitting machinesTunnelsHydraulic motorRubber ring

The invention discloses an improved roadway boring machine. The upper portion of a rack is connected with a hydraulic motor and a cantilever, the outer side of the cantilever is connected with a cutting head, a nozzle is arranged on the outside of the cutting head, and a water injection pipe is further arranged inside the cantilever; a first through hole is formed between the cantilever and the water injection pipe, the hydraulic motor is connected with a water injection ring through a support frame, and the water injection ring is connected with a water inlet pipe through a water pipe joint; and the outside of the bearings are sleeved with sealing rings, each sealing ring comprises a first rubber ring and two second rubber rings, and the two second rubber rings are respectively located on both sides of each bearing, first springs are arranged between the second rubber rings and the first rubber rings, the two sides of the second rubber rings and the first rubber rings are connected through connection rigs, annular cavities are further formed inside the first rubber rings, two second through holes are formed inside the annular cavities, and the outside of two first rubber rings are sleeved with sleeve tubes. The improved roadway boring machine can improve the deficiencies of the prior art, and a spray structure of the improved roadway boring machine has a better sealing and a cooling effect.

Owner:JIANGXI UNIV OF SCI & TECH

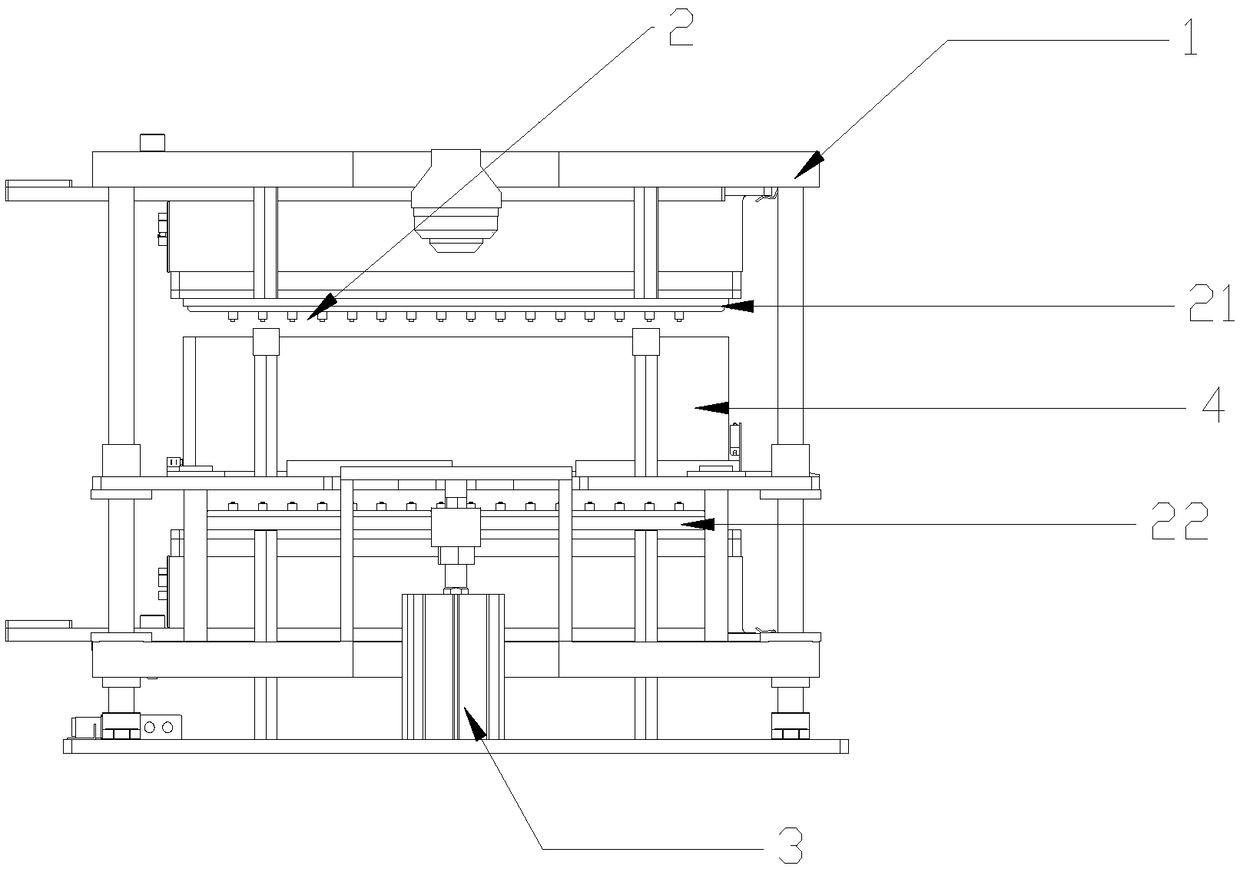

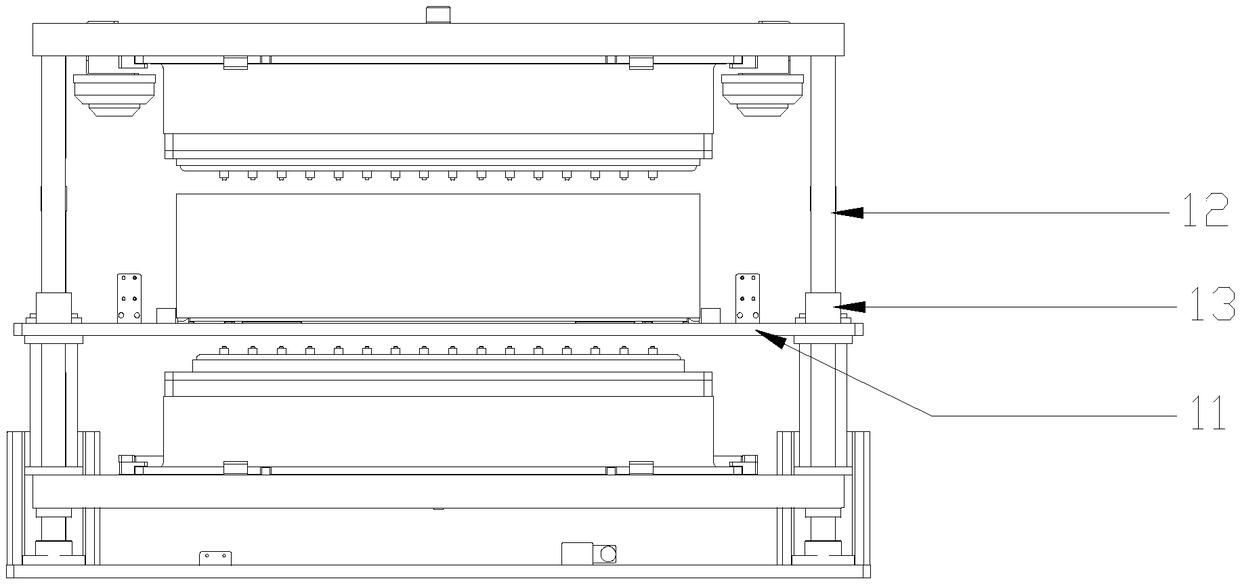

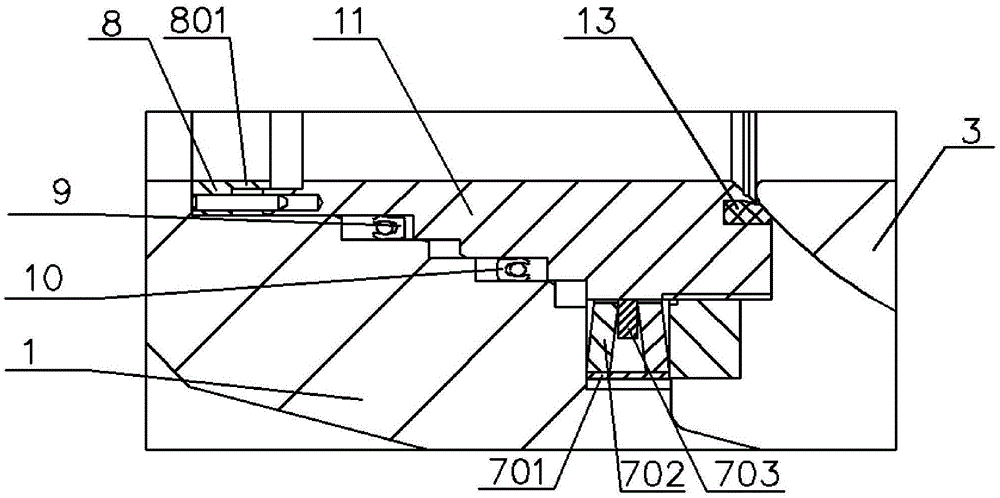

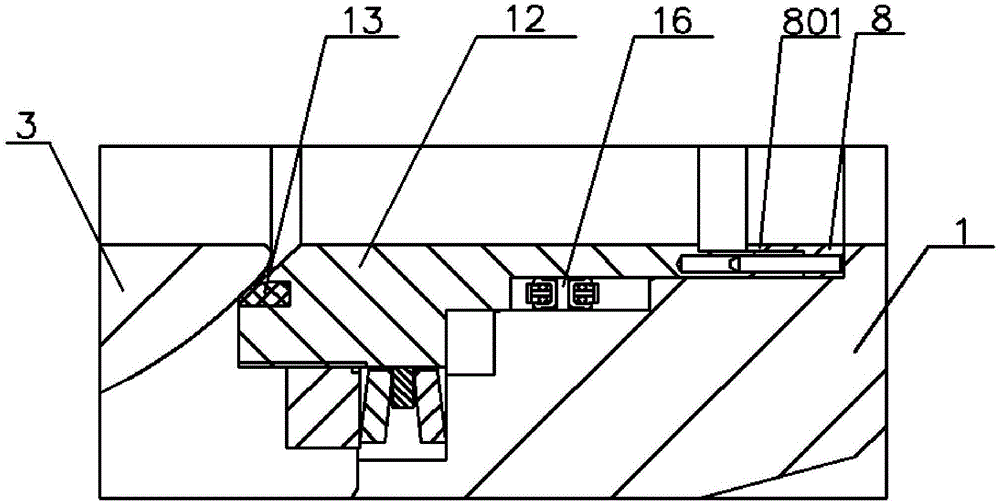

Lithium battery cavity negative pressure formation method and apparatus

PendingCN109449495AReduce turn-on timeAvoid loss of tightnessFinal product manufactureSecondary cells charging/dischargingEngineeringWork time

The invention discloses a lithium battery cavity negative pressure formation method and an apparatus. The method comprises the following steps: 1) placing a battery core, for which liquid injection iscompleted, into a charging and discharging formation device; 2) turning on a vacuum valve, starting to vacuumize; 3) performing formation charging; 4) after completing formation charging, turning offthe vacuum valve, and breaking a vacuum state through inert gas; 5) taking out the battery from the charging and discharging device, namely, obtaining the needed lithium battery which is subjected tonegative pressure formation. The apparatus comprises a support apparatus, a needle plate component, a driving air cylinder, a tray and a control apparatus. The method and the apparatus provided by the invention have the following beneficial effects: negative pressure requirements of the lithium batteries of various forms can be guaranteed, alignment of battery liquid injection holes is not needed, moreover, a negative pressure pipeline is not directly contacted with the battery, and pollution to the battery caused by electrolyte of the previous batch is avoided. The cavity is sealed through aspecial seal groove design, tightness is better, negative pressure effect can be better, work time of a negative pressure pump is reduced, and an effect of saving energy and reducing emission is realized.

Owner:ZHEJIANG HANGKE TECH

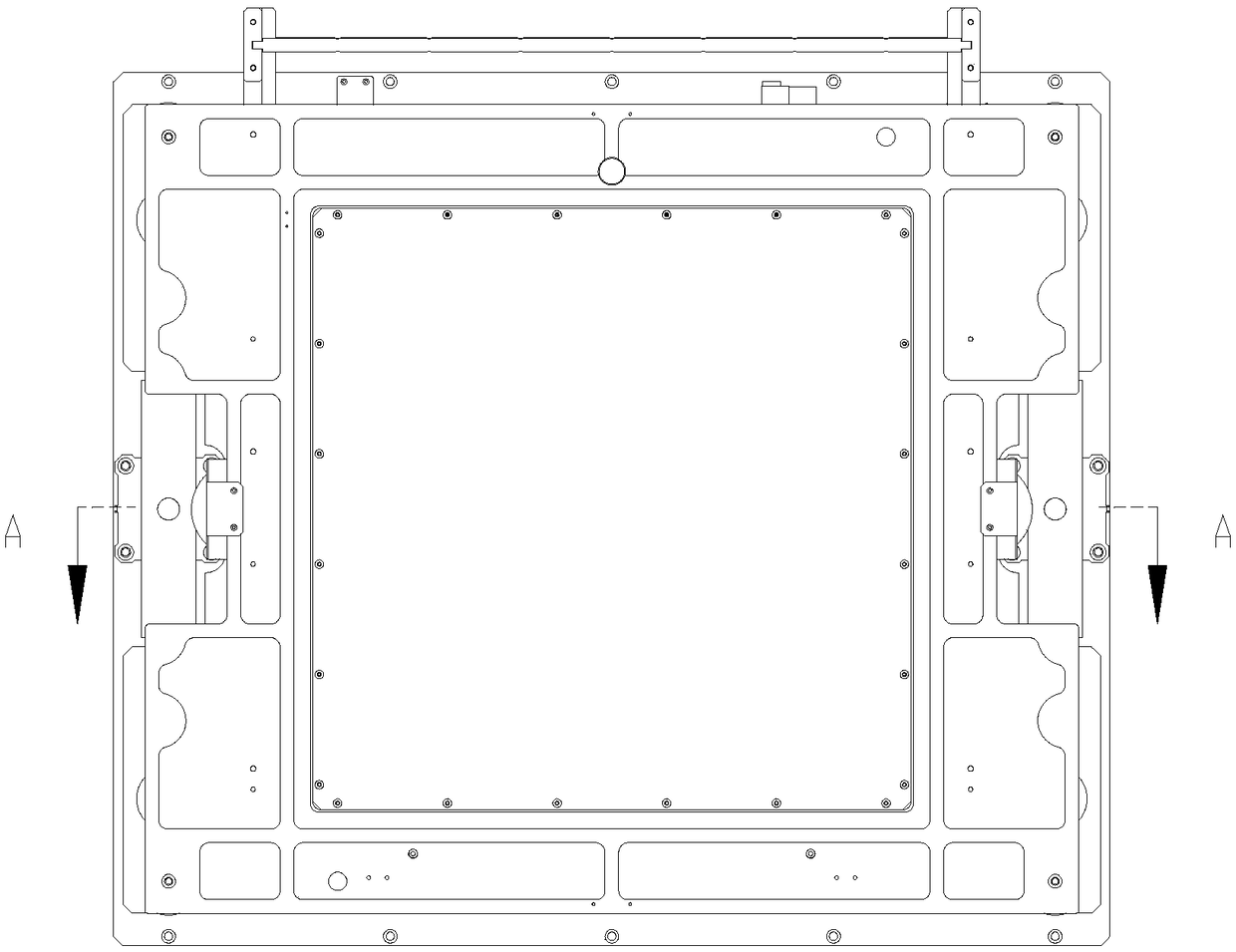

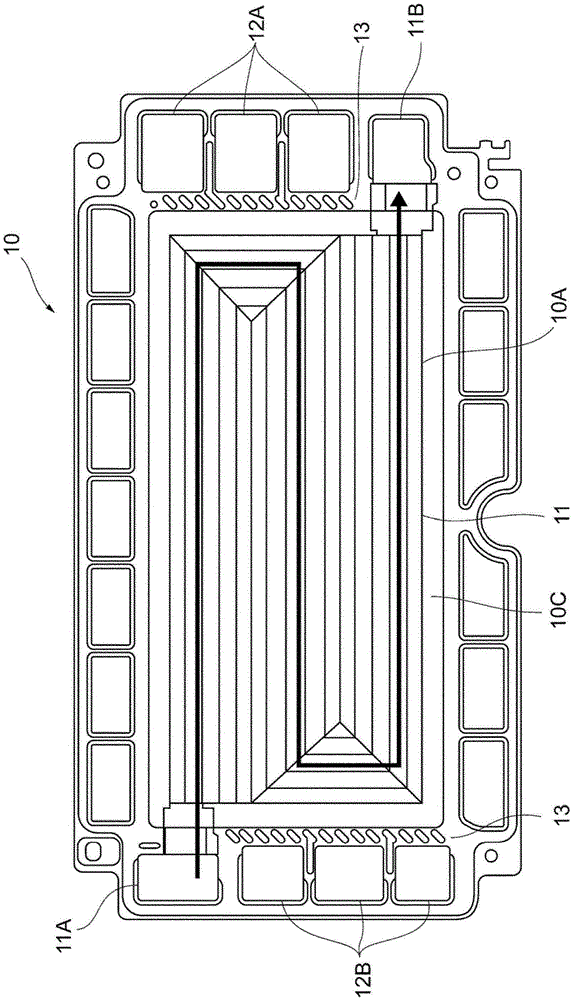

Fuel cell separator, fuel cell and fuel cell battery

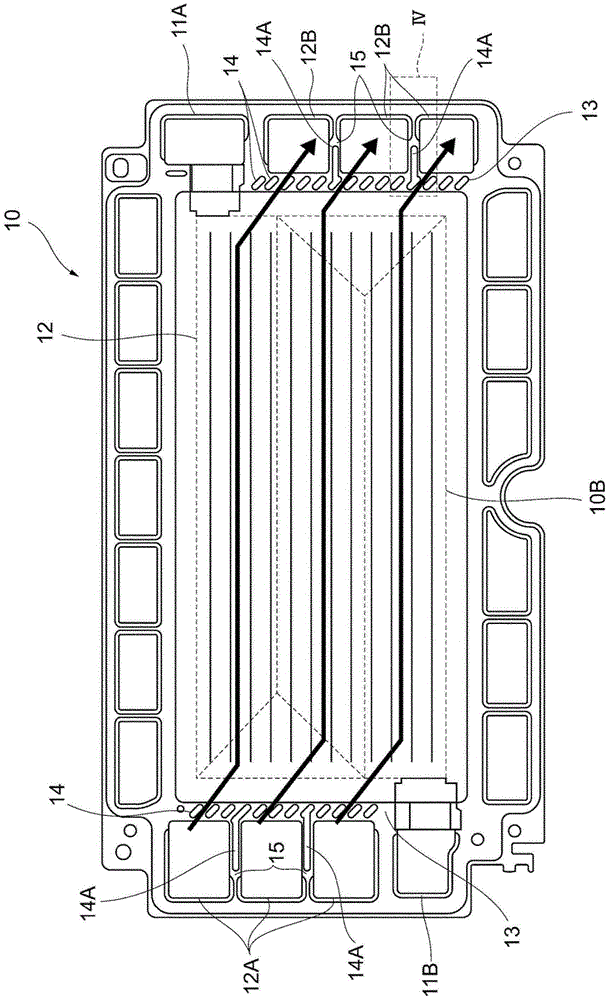

ActiveCN105591121AAvoid deformationAvoid loss of tightnessFuel cellsFuel cellsElectrical and Electronics engineering

The invention relates to a fuel cell separator, a fuel cell and a fuel cell battery. It is an object of the present invention to prevent deterioration in sealing performance by suppressing the deformation of manifold portions of a fuel cell separator. A fuel cell separator 10 includes a power generation section 10B provided in a central region on a surface of the separator formed into a plate, a plurality of manifolds 11A, 11B, 12A, and 12B provided in a region closer to the outer periphery than the power generation section 10B, and a reinforcing portion 14A provided so as to extend from a manifold beam portion 15 formed between the plurality of manifolds 11A, 11B, 12A, and 12B to a gap region 13 formed between the power generation section 10B and the manifolds 11A, 11B, 12A, and 12B.

Owner:TOYOTA JIDOSHA KK

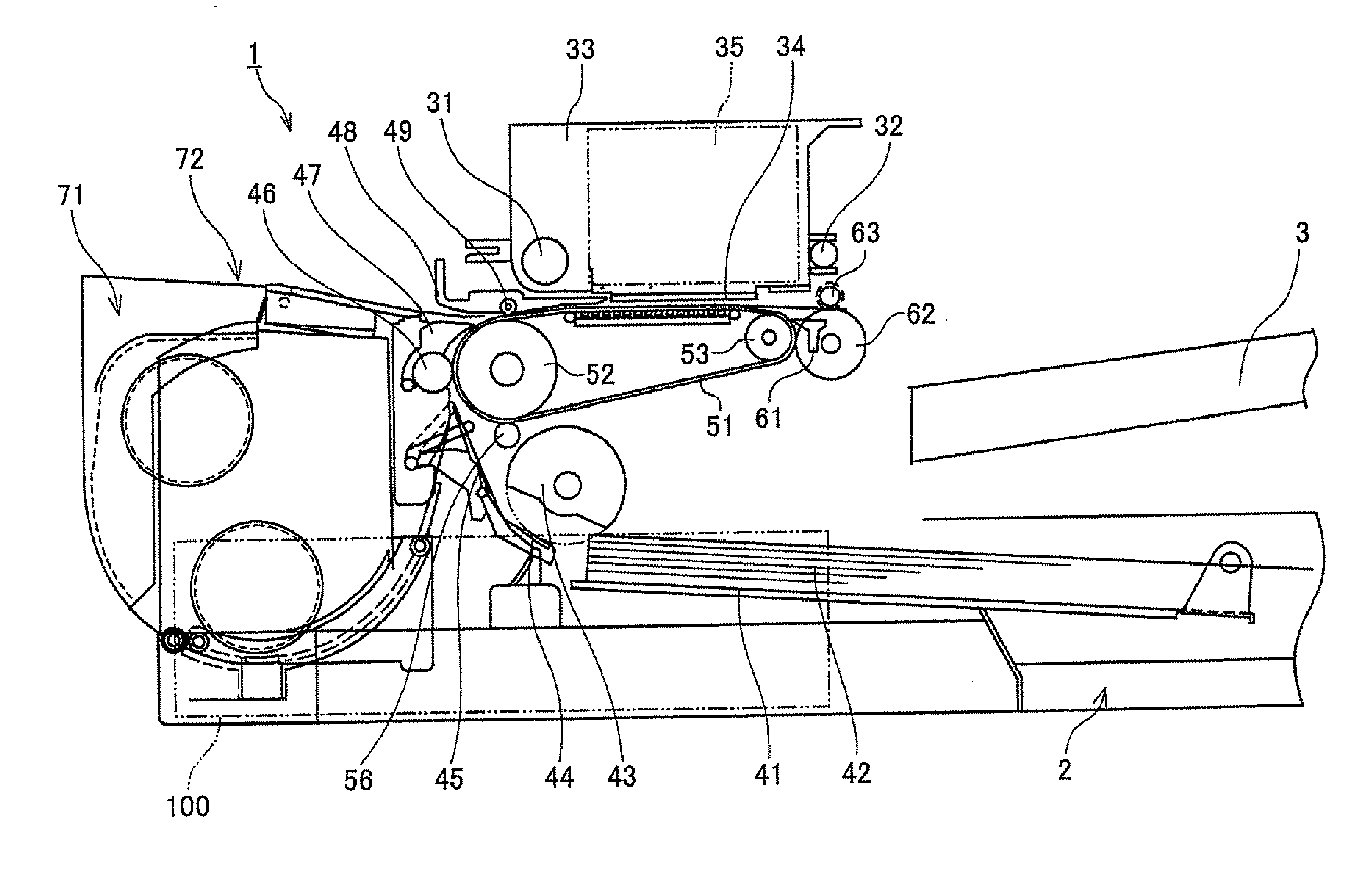

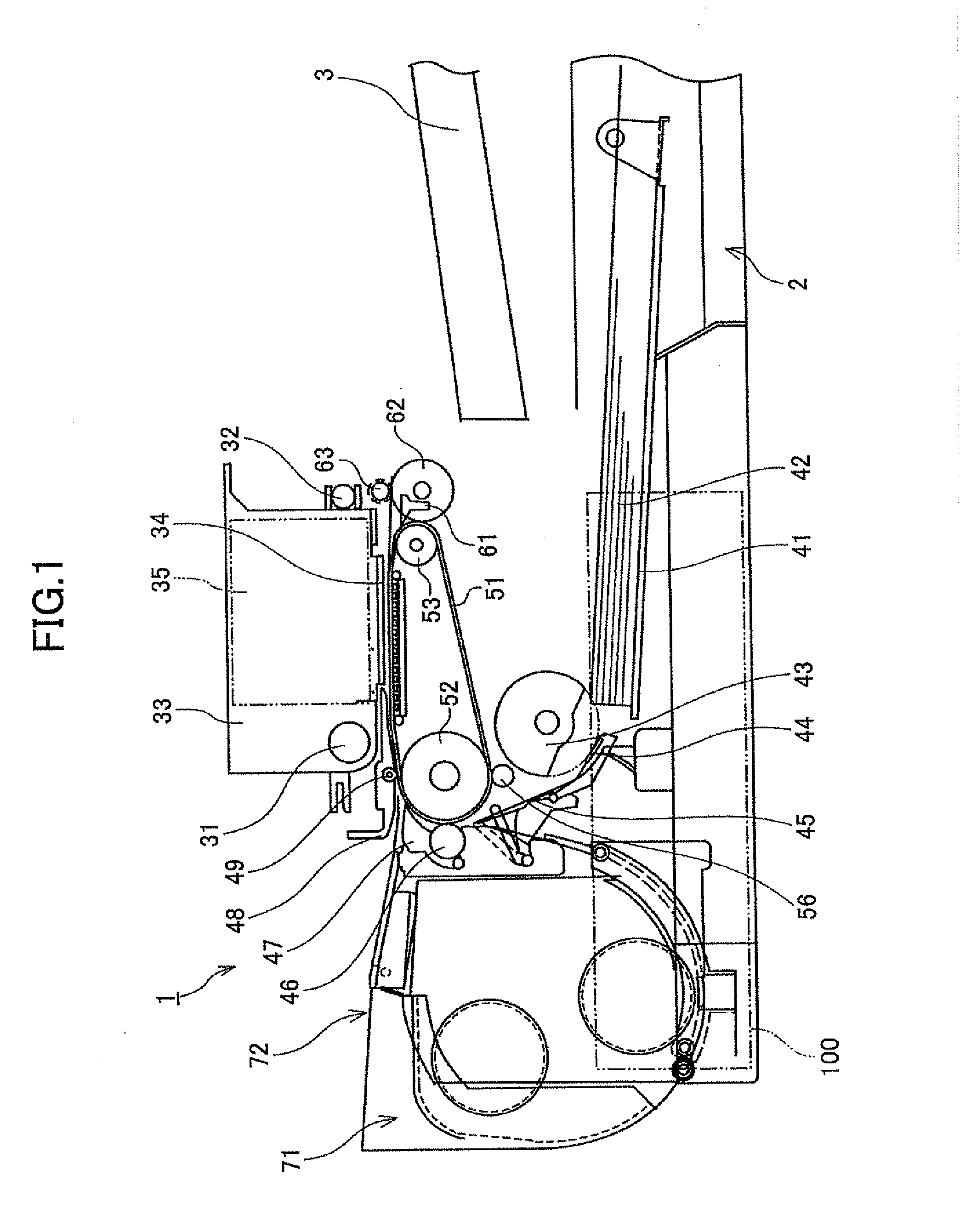

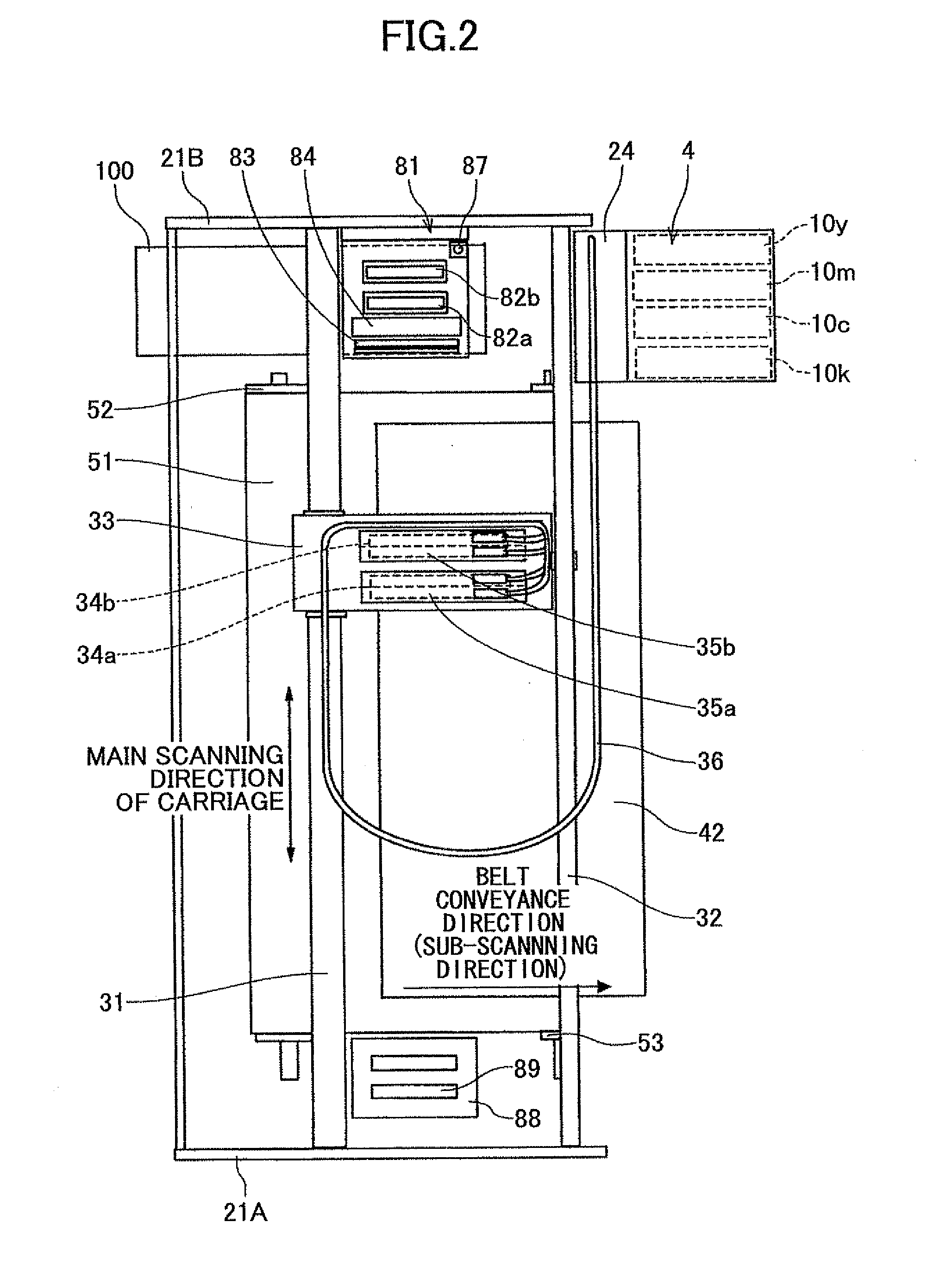

Image forming apparatus

An image forming apparatus, includes a liquid jet head; a container main body; an air opening mechanism configured to open and close an air opening path in the container main body. The air opening mechanism includes a holding part, and an opening member movably provided at the holding part. The opening member includes an air communicating path, a filter member, and an air room. An opening cross-sectional area of the air room in a direction perpendicular to an air flow-in direction is greater than an opening cross-sectional area of the air communicating path in a direction perpendicular to an air flow-in direction.

Owner:RICOH KK

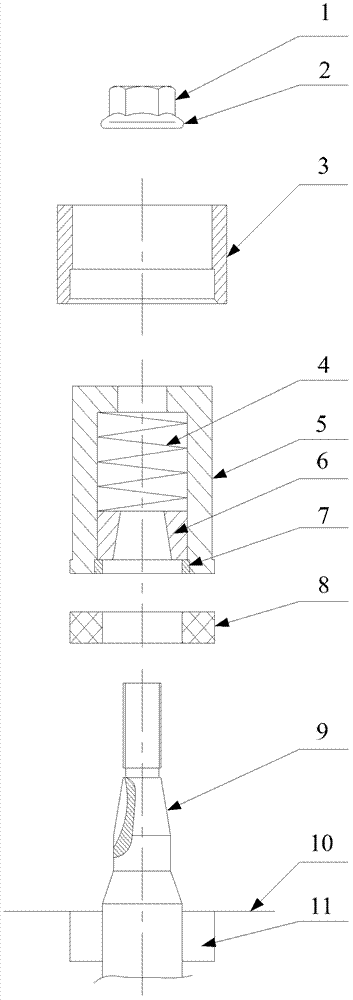

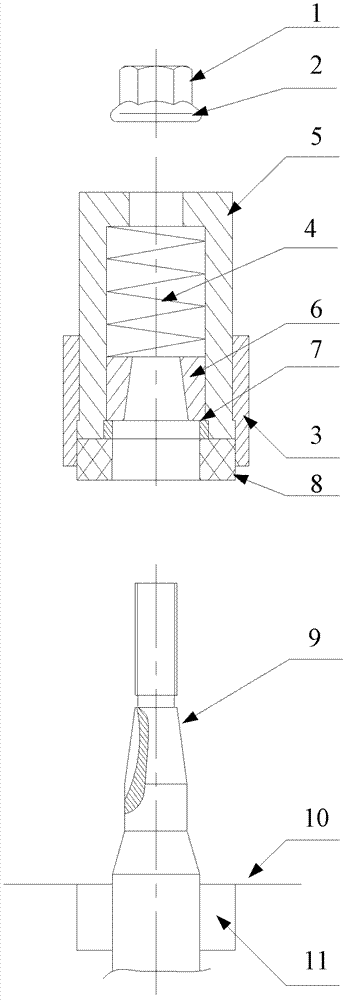

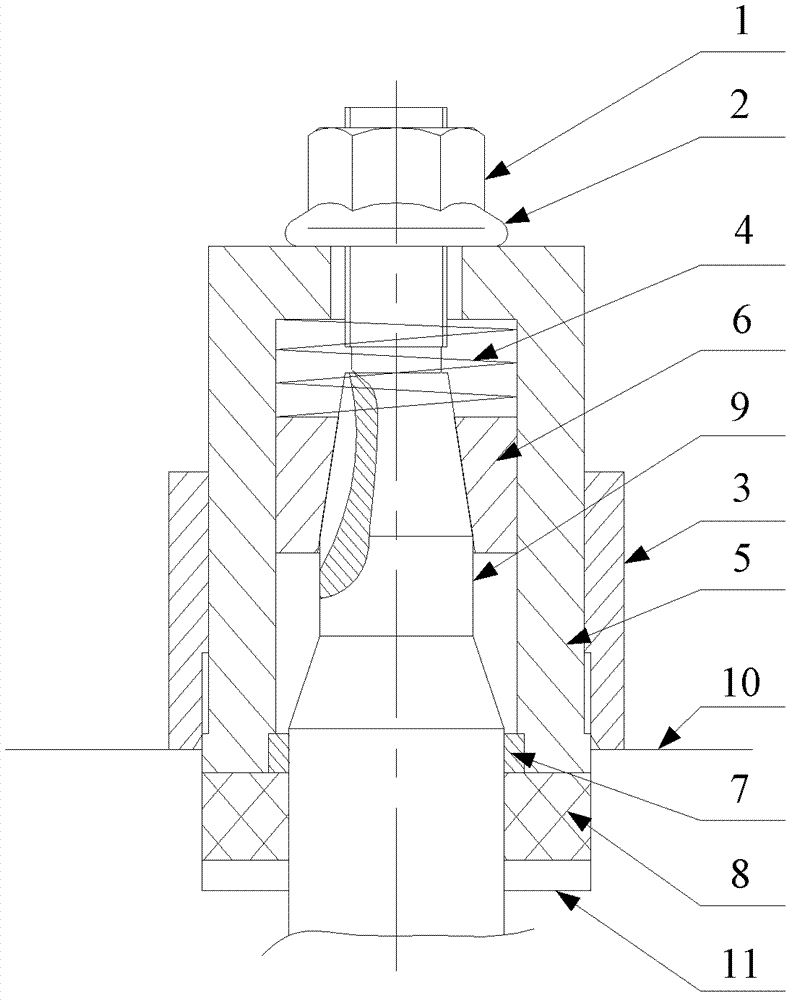

Positioning assembly device

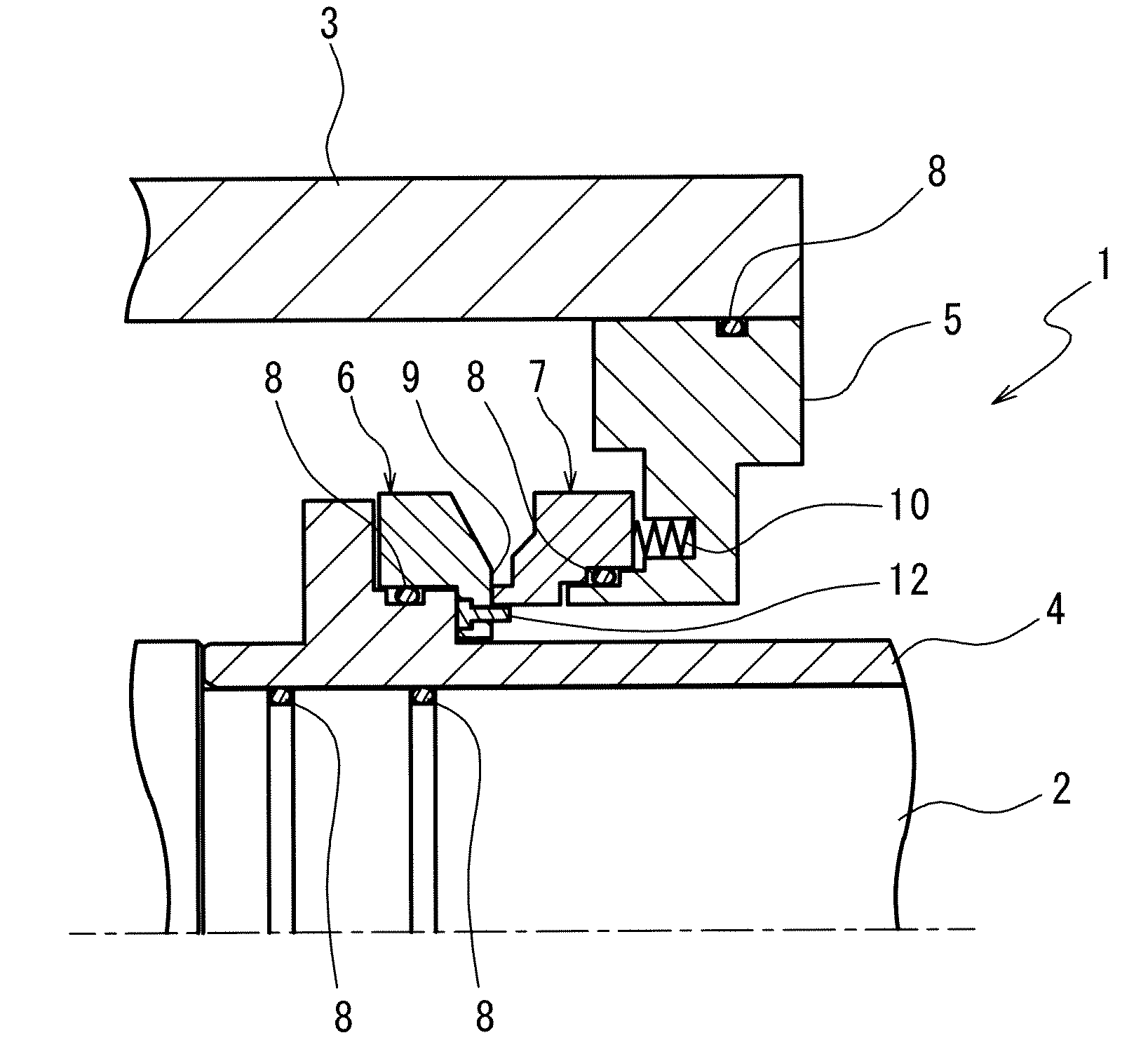

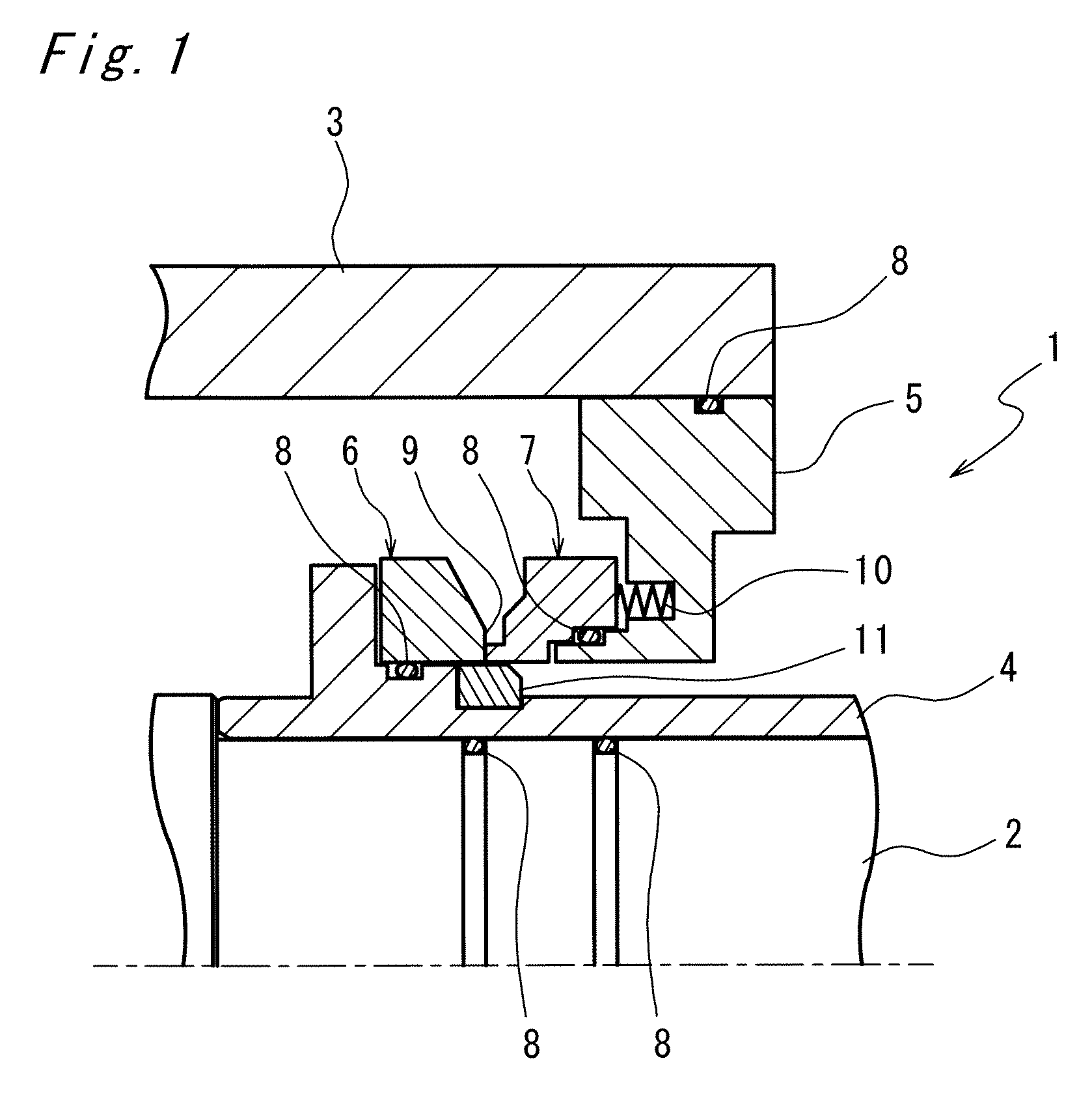

ActiveCN102950572AAvoid loss of tightnessExtended service lifeMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a positioning assembly device which is used for mounting of an on-shaft seal ring (8) of a countershaft (9). The positioning assembly device comprises a sleeve (5), a taper ring (6), a spring (4), a retainer ring (7) and a positioning ferrule (3). The top end of the sleeve (5) is provided with a hole with the diameter smaller than that of a cavity of the sleeve (5); the outer wall of the taper ring (6) is closely attached to the inner wall of the sleeve (5), taper ring (6) is capable of moving axially along the sleeve (5), and the center of the taper ring (6) is provided with a taper hole with the diameter smaller than that of the bottom end; the spring (4) is arranged in the sleeve (5) and positioned between the taper ring (6) and the top end of the sleeve (5); the retainer ring (7) is arranged in the sleeve (5) and positioned in a cylindrical opening at the bottom end of the taper ring (6); and the positioning ferrule (3) is sleeved on the sleeve (5), and the inner wall of the positioning ferrule (3) is attached to the outer side wall of the on-shaft seal ring (8). Using the positioning assembly device for mounting the on-shaft seal ring, scratch damage between the on-shaft seal ring and a shell can be prevented, and weakening of tightness caused by scratch of the on-shaft seal ring by the shell due to improper mounting can be avoided.

Owner:ZHEJIANG PIONEER MACHINERY & ELECTRON

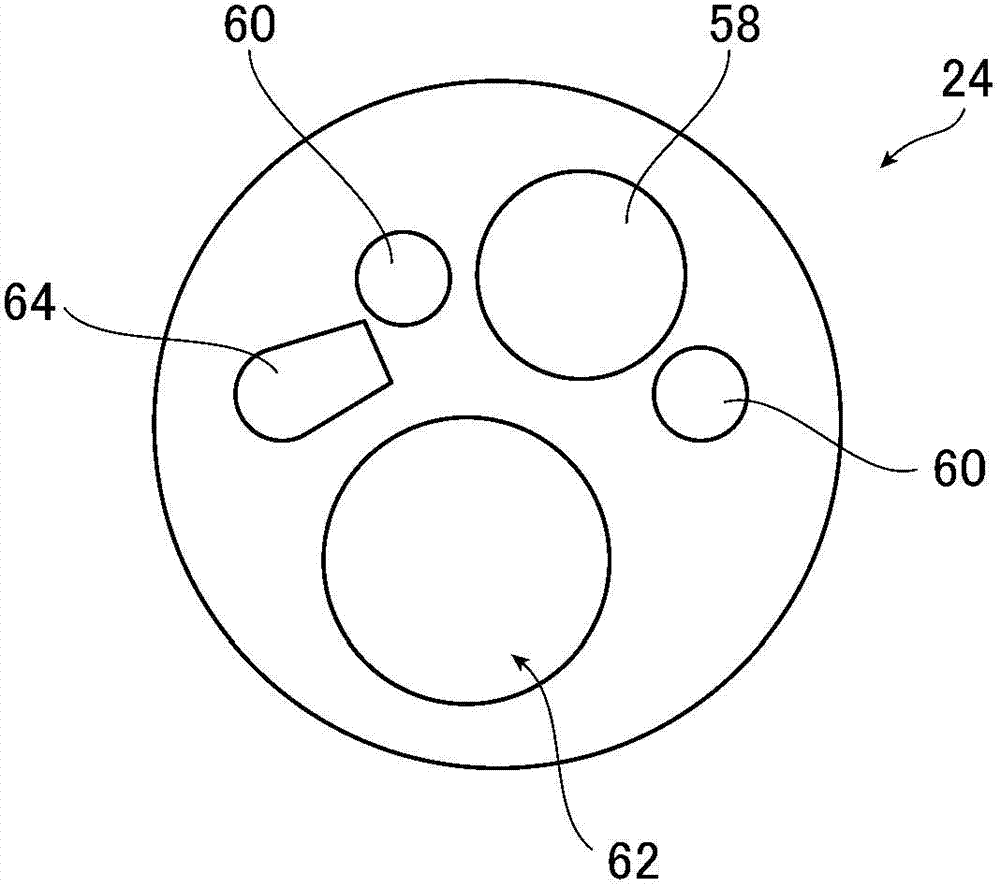

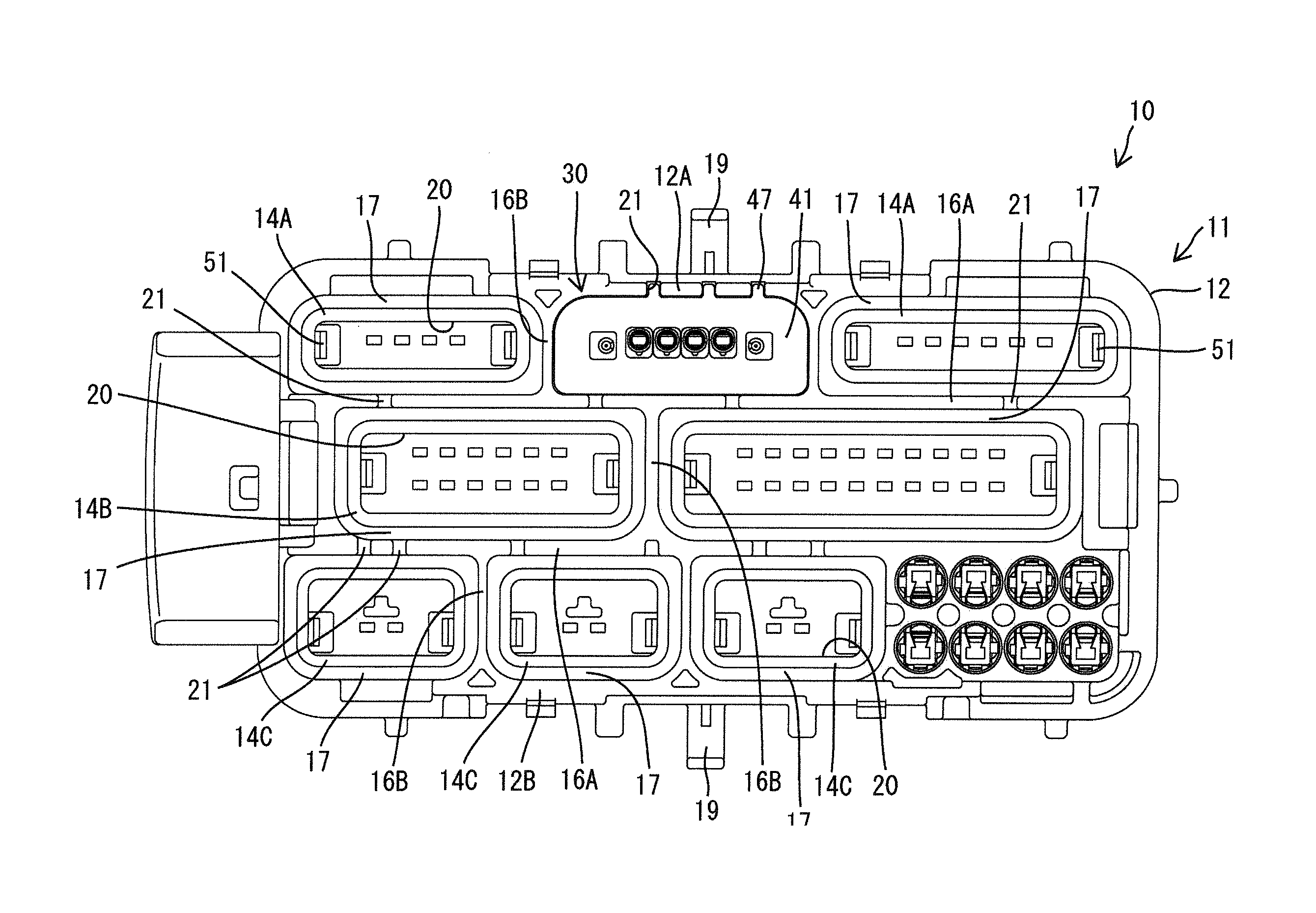

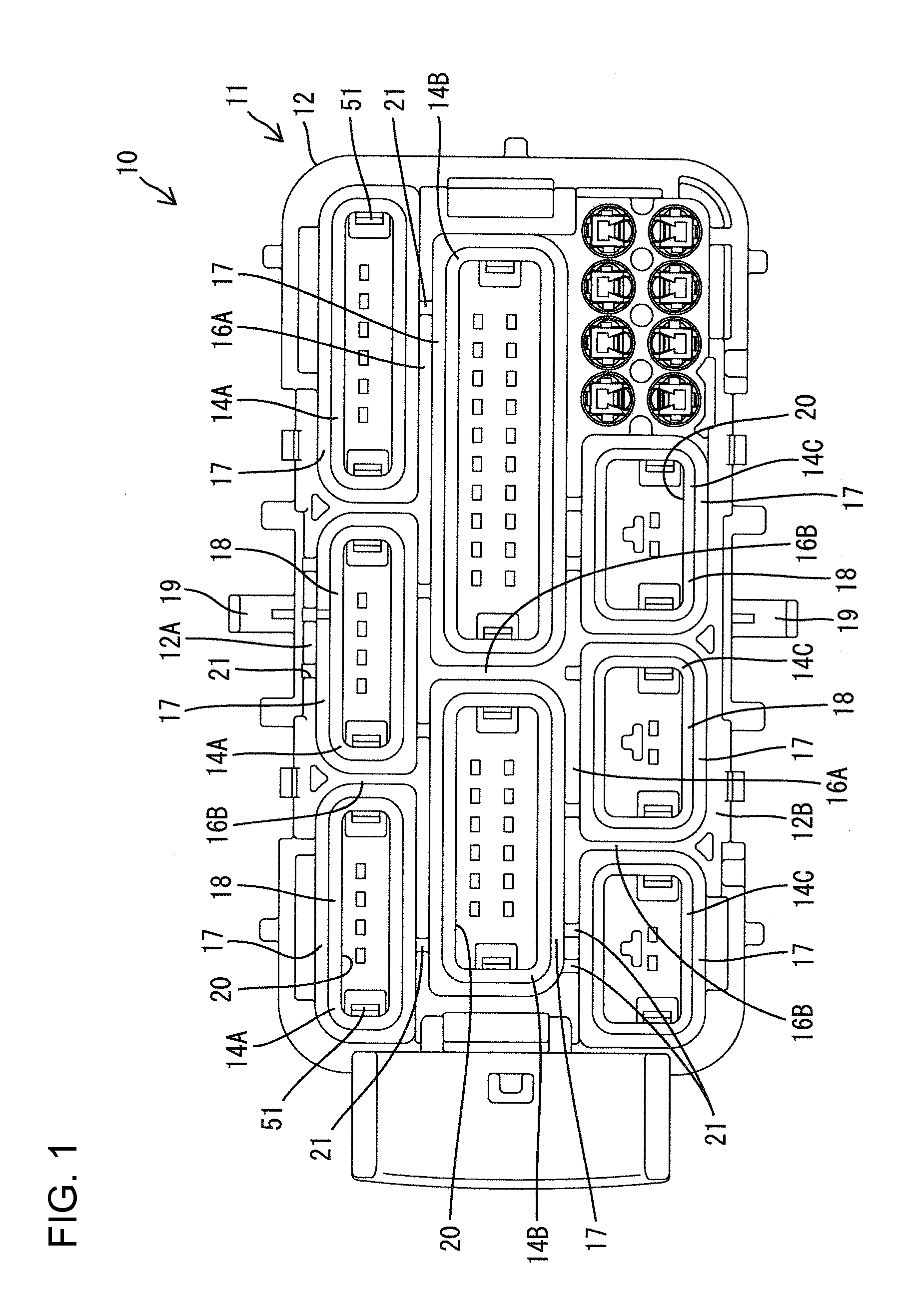

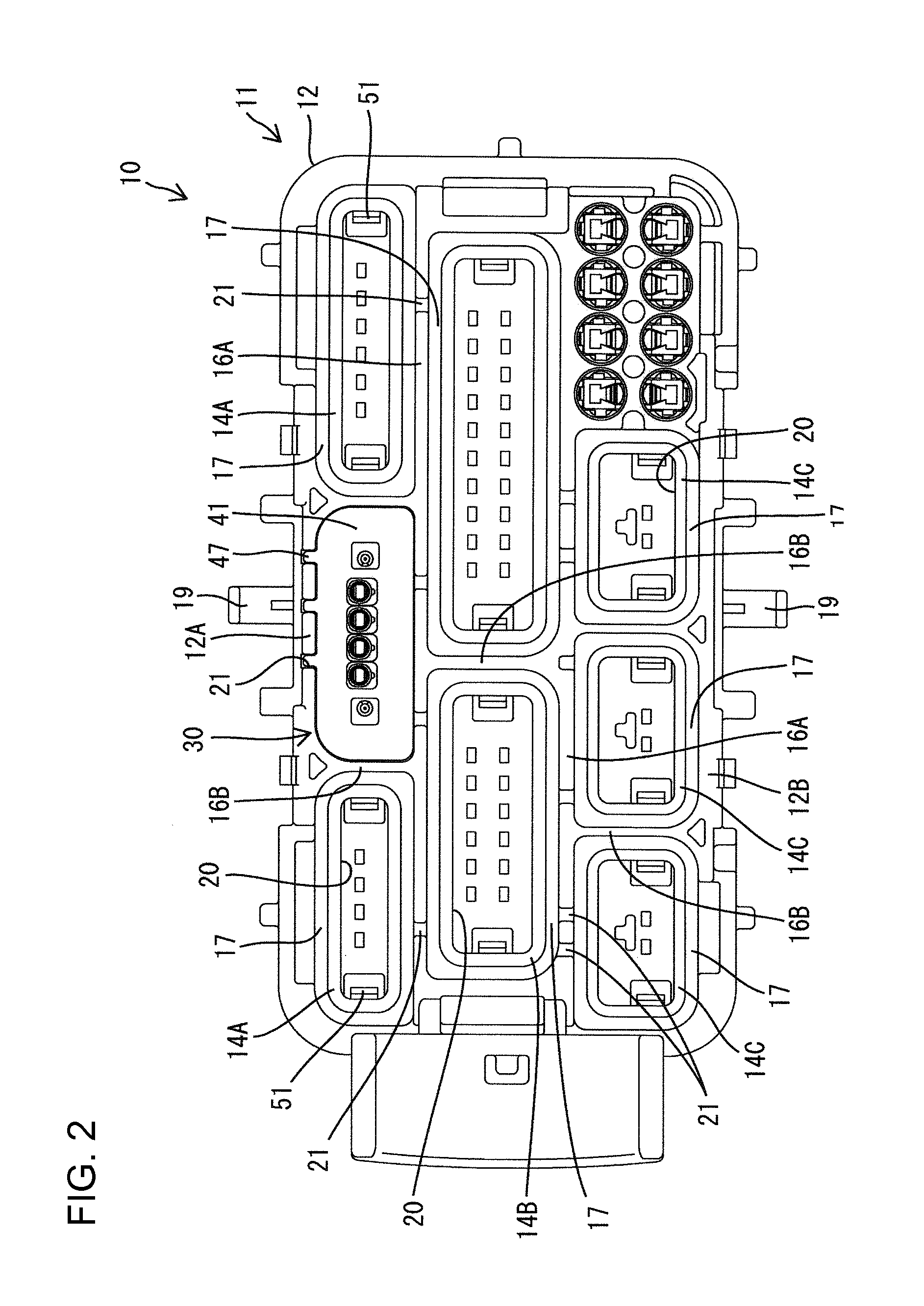

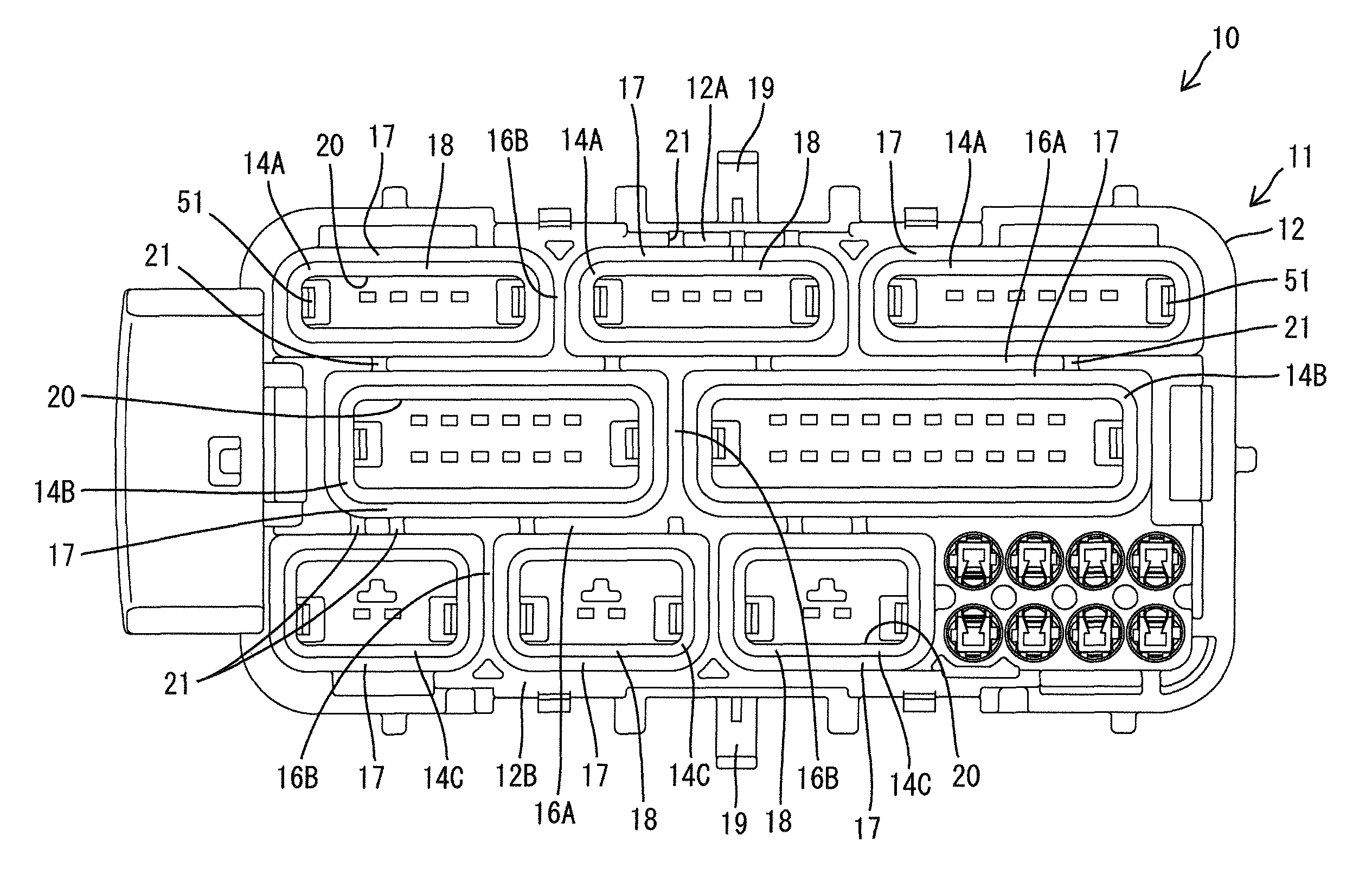

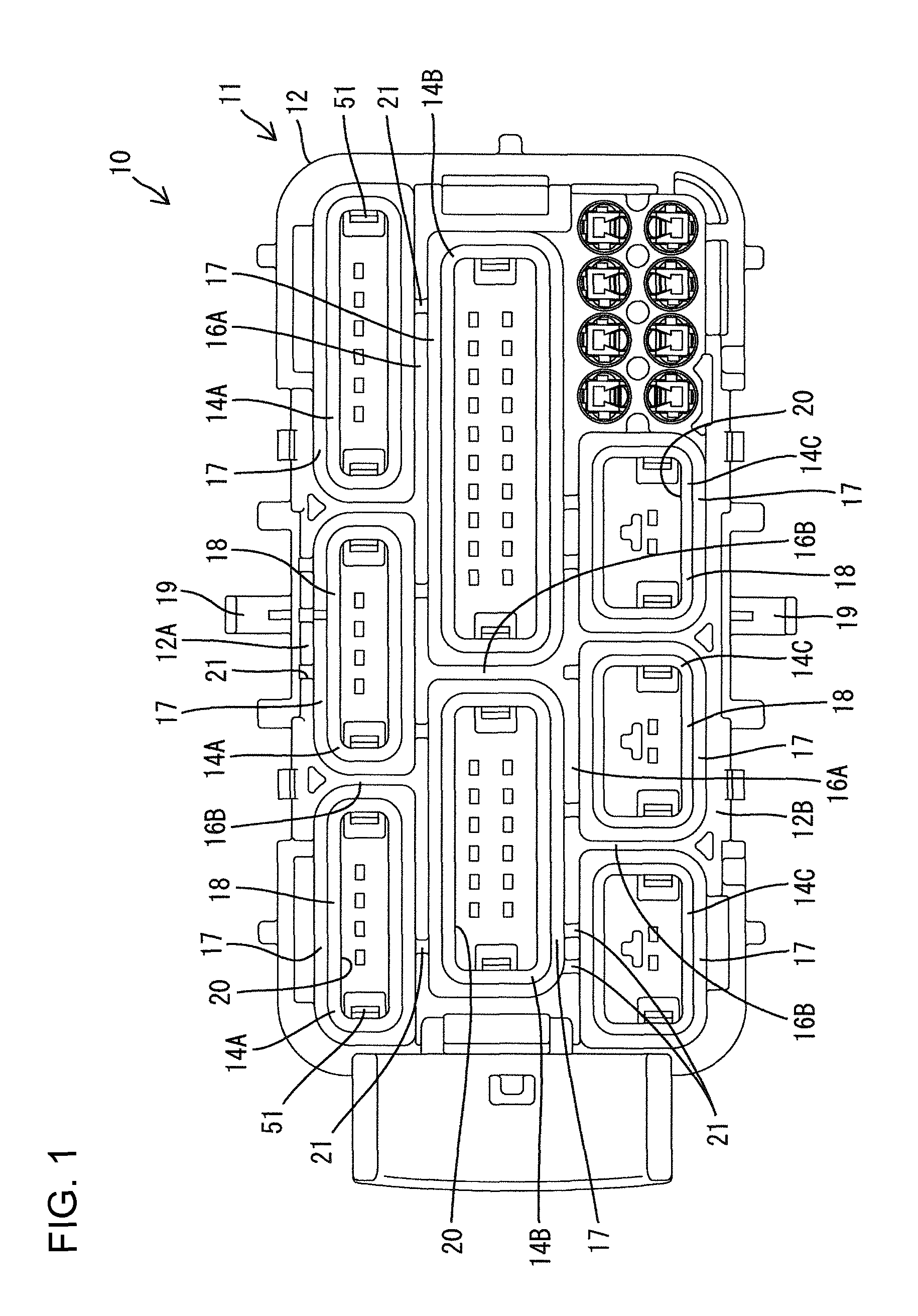

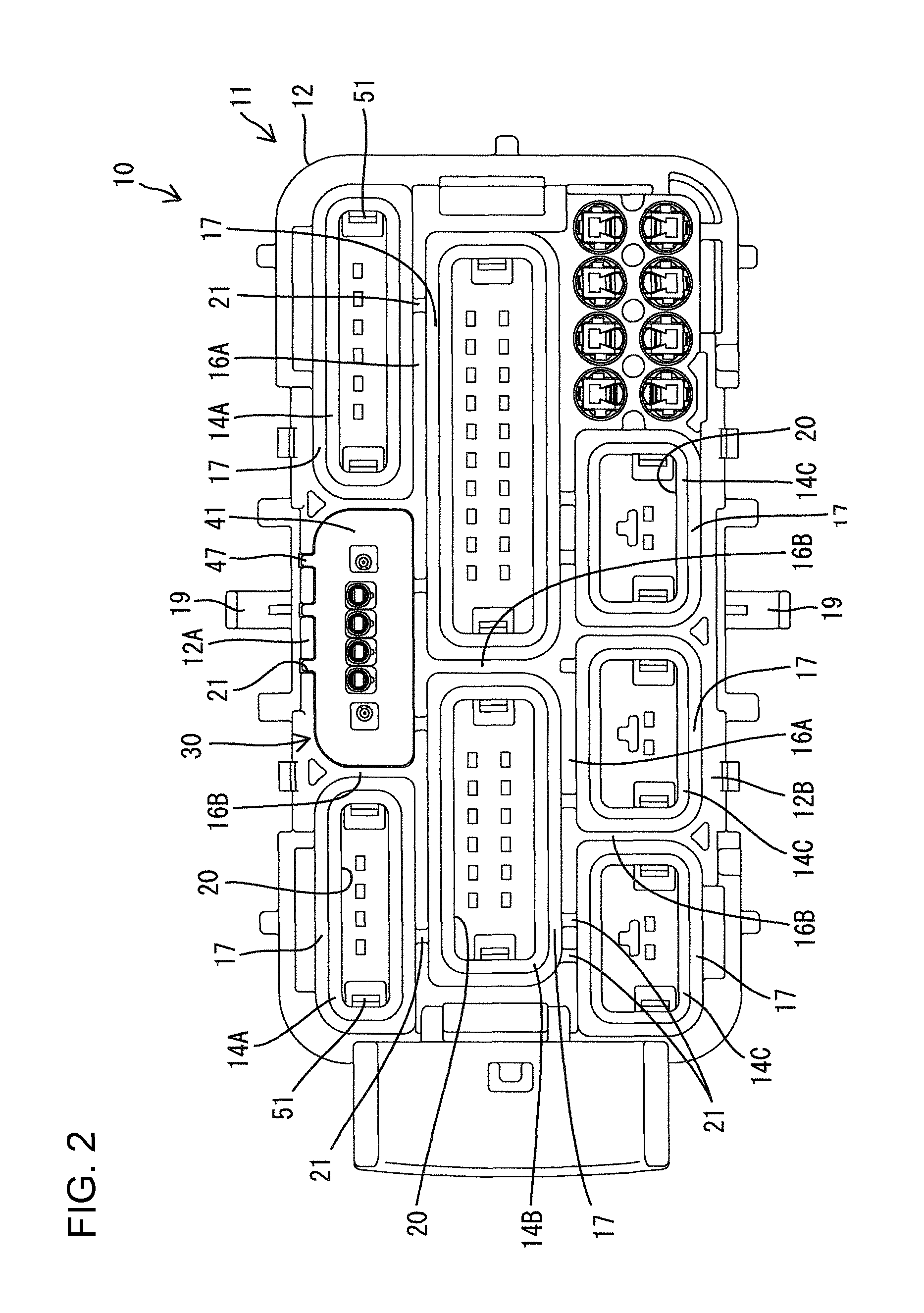

Connector

ActiveUS20120009809A1Avoid loss of tightnessEfficient use ofCouplings bases/casesEngineeringCam follower

A first housing (10) has a frame (11) with concave accommodation portions (20). A sub-connector (31) with female terminal fittings (33) is accommodated in the concave accommodation portions (20). A collective rubber stopper (36) is accommodated inside the concave accommodation portions (20) to seal a gap between a peripheral surface of an electric wire (34) pulled out of the sub-connector (31) and an inner peripheral surface of each concave accommodation portion (20). A first cam follower (19) is formed on an outer surface of the frame (11) and can engage an operation member (80). The frame (11) has an outer wall (12) defining an outer surface thereof where the first cam follower (19) is formed and an inner wall (18) separated from the outer wall part (12) via separated spaces (17) and constructing the inner peripheral surface of each concave accommodation portions (20).

Owner:SUMITOMO WIRING SYST LTD

Lever-type connector with collective rubber stopper

A first housing (10) has a frame (11) with concave accommodation portions (20). A sub-connector (31) with female terminal fittings (33) is accommodated in the concave accommodation portions (20). A collective rubber stopper (36) is accommodated inside the concave accommodation portions (20) to seal a gap between a peripheral surface of an electric wire (34) pulled out of the sub-connector (31) and an inner peripheral surface of each concave accommodation portion (20). A first cam follower (19) is formed on an outer surface of the frame (11) and can engage an operation member (80). The frame (11) has an outer wall (12) defining an outer surface thereof where the first cam follower (19) is formed and an inner wall (18) separated from the outer wall part (12) via separated spaces (17) and constructing the inner peripheral surface of each concave accommodation portions (20).

Owner:SUMITOMO WIRING SYST LTD

Separator for fuel battery

ActiveCN1802763AAvoid damageAvoid loss of tightnessEngine sealsCollectors/separatorsFuel cellsEngineering

A separator for a fuel battery, where gasket is formed integrally with a separator body by forming rubber in gasket forming grooves provided in the separator body. When rubber is formed in the grooves, damage to the grooves can be constrained, and this prevents lowering of sealing ability caused by damage to the separator. The width of a gasket forming groove formed in one surface of the separator body is greater than a gasket forming groove formed in the other surface. Groove side-surfaces in a gasket forming groove has an inclined shape or a curvature is provided on square corners of groove bottom surfaces.

Owner:NOK CORP

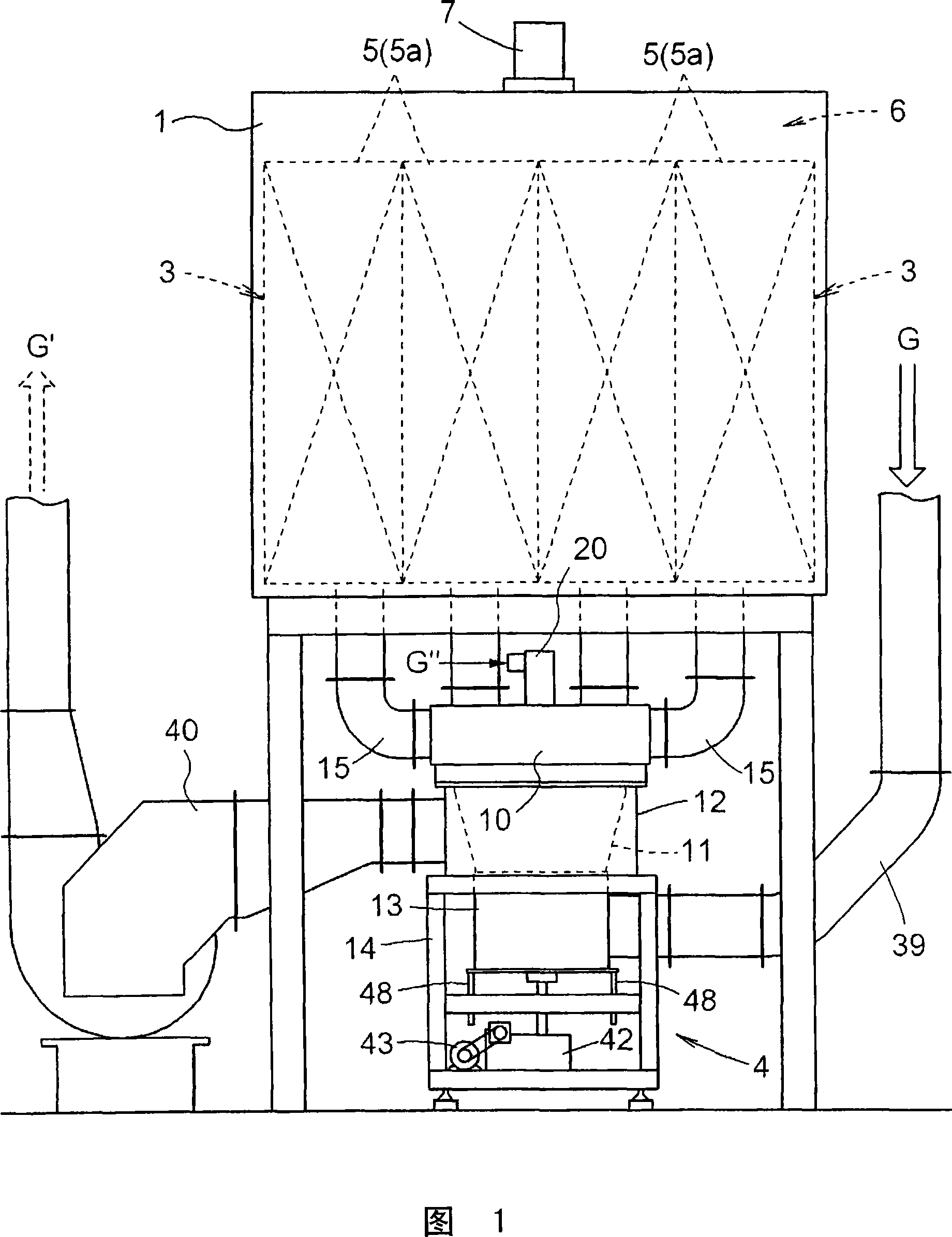

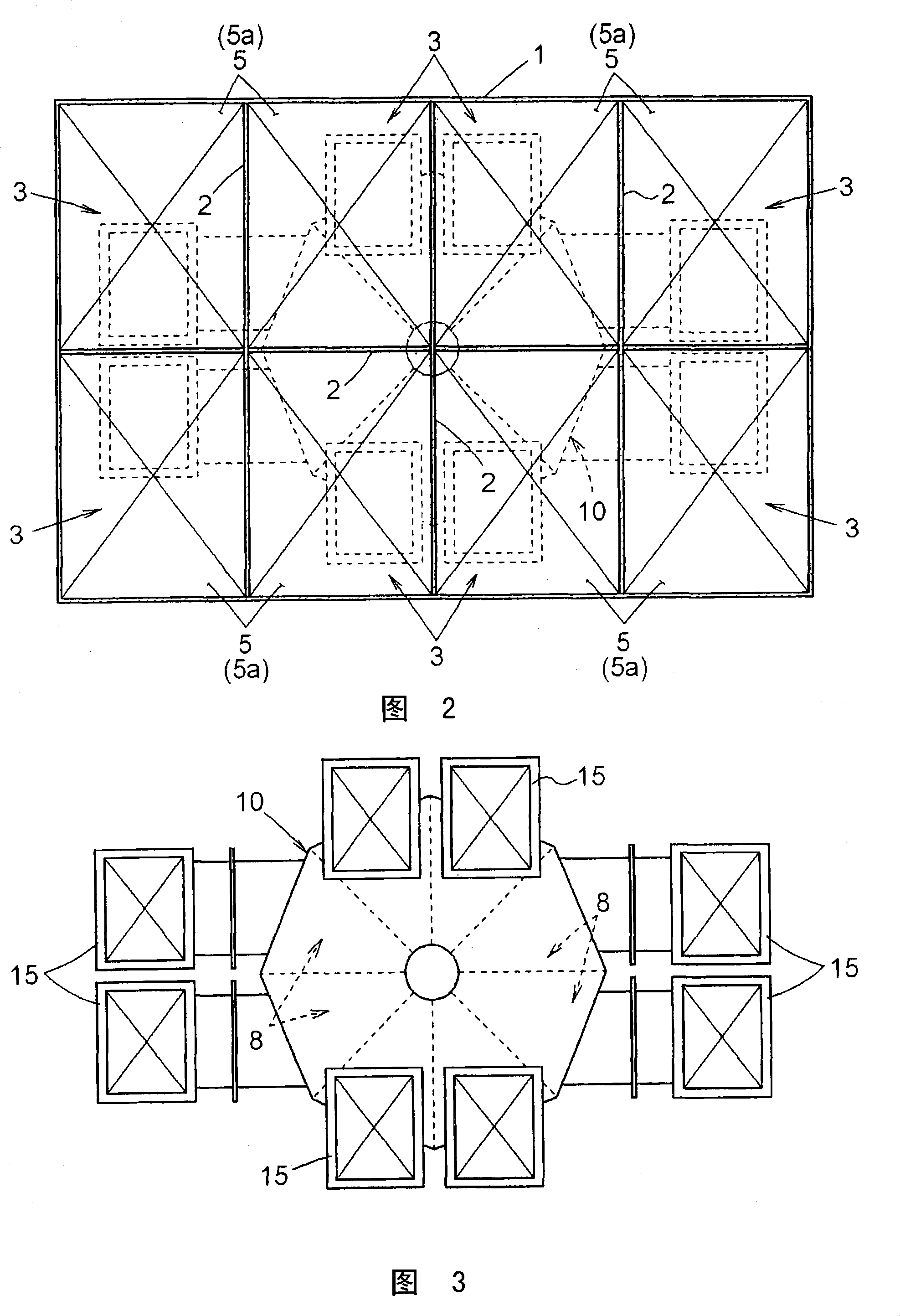

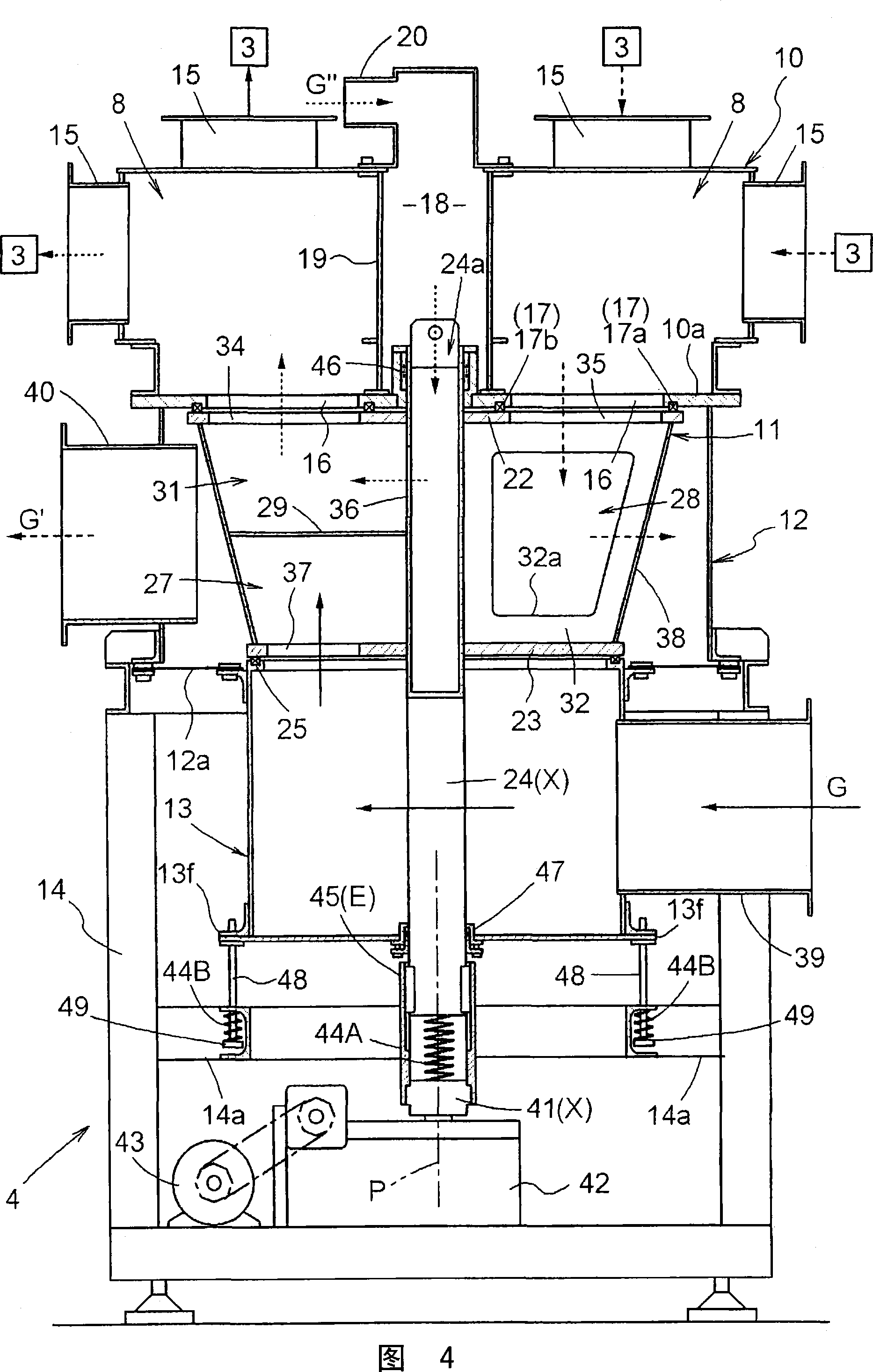

Heat accumulating gas processing system

InactiveCN101014804AAvoid loss of tightnessSimple structureMultiple way valvesDamper arrangementCombustion chamberProcess engineering

A heat storage type gas processing apparatus capable of providing a high sealing function by a simple structure. A gas to be treated (G) and a treated gas (G') are passed, in this order, through a plurality of heat storage chambers (3) having one ends allowed to communicate with a combustion chamber (6) by oppositely communicating a supply port (33) for the gas to be treated formed on the valve element (11) side and an exhaust port (35) for the treated gas, in this order, with supply and exhaust ports (16) formed on the distributor (10) side according to the rotation of the valve element (11). The apparatus also comprises an energizing means (44A) for the valve element supporting the valve element (11) in the state of being displaceable in the longitudinal direction to the distributor (10), and pressing the valve element (11) to the distributor (10) side in the non-acting state on an atmospheric chamber (13).

Owner:TAIKISHA LTD

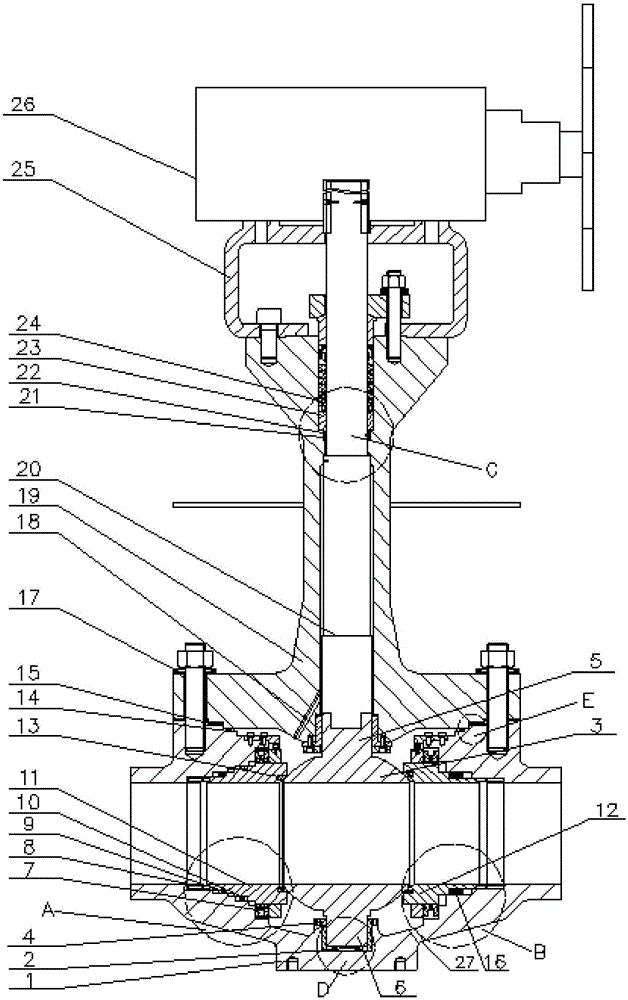

Low-temperature top-assembling type fixed ball valve

The invention discloses a low-temperature top-assembling type fixed ball valve and belongs to the technical field of ball valves of liquefied natural gas pipelines. The low-temperature top-assembling type fixed ball valve comprises a valve body, a ball body, an upstream valve seat, a downstream valve seat, a valve cover, a valve rod, a connecting support and an actuator; an upper short shaft and a lower short shaft are arranged at the upper end and the lower end of the ball body correspondingly, the upper short shaft, the lower short shaft and the ball body are of an integrated structure, and the valve rod is connected with the upper short shaft; first elastic compensating components and spring seal rings are arranged between the upstream valve seat and the valve body and between the downstream valve seat and the valve body; the upstream valve seat is of a step-type structure and can move in the horizontal direction; and the downstream valve seat is of a step-type structure and can move in the horizontal direction. The low-temperature top-assembling type fixed ball valve is high in size accuracy, good in the sealing property, long in service life and capable of meeting the demand that the ball valve is used at the temperature of minus 162 DEG C. Even if a caliber reaches six inches or above, all properties of the low-temperature top-assembling type fixed ball valve can still meet the demand.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

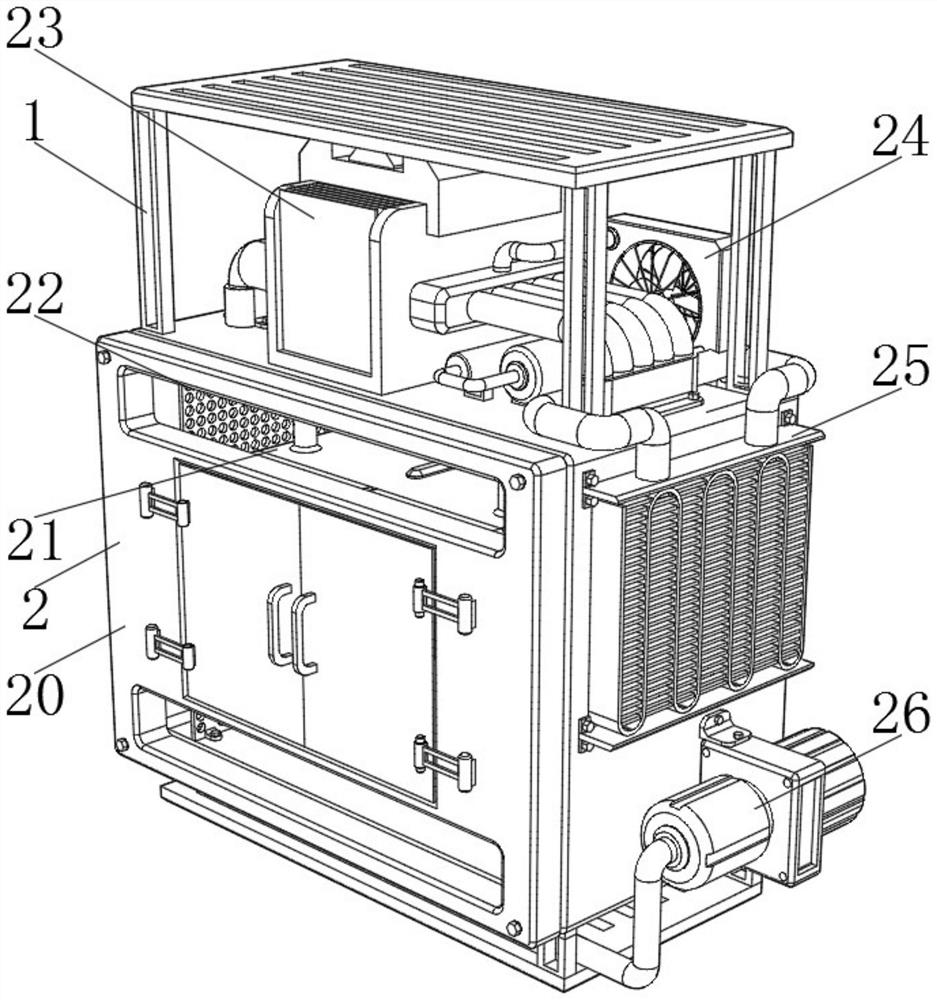

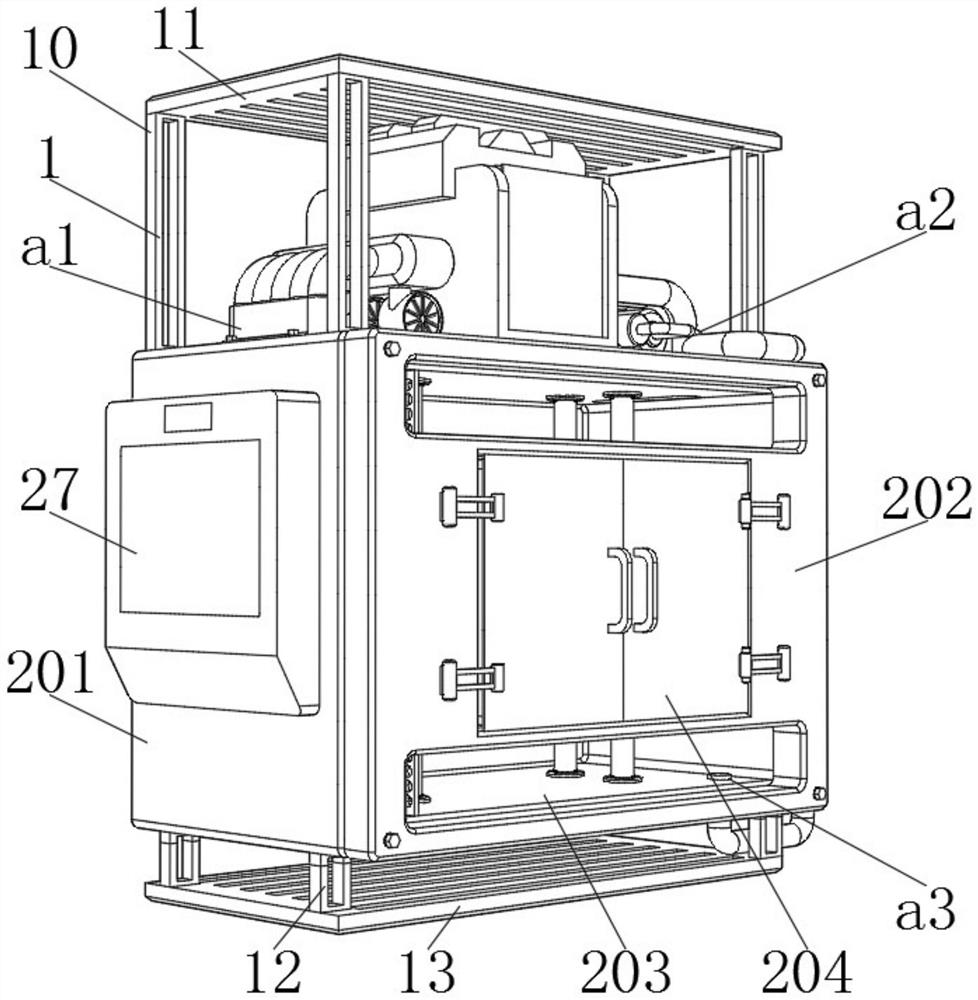

Radiation low-pressure environment simulation cabin

InactiveCN113413931AEasy to cleanAdjust the clamping forceHeating or cooling apparatusAir-pressure/air-lock chambersTemperature conditioningEngineering

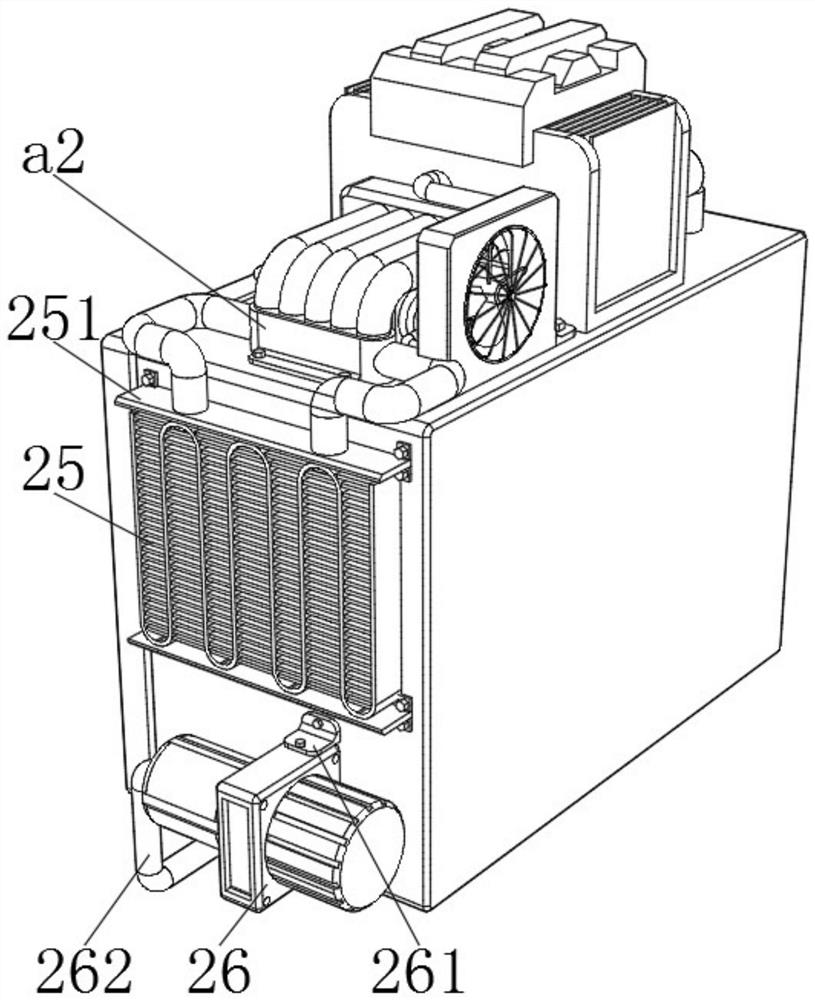

The invention discloses a radiation low-pressure environment simulation cabin, which comprises a protection frame and a simulation cabin. The inner side of the protection frame and the outer side of the simulation cabin are fixedly installed, and the simulation cabin comprises a heat preservation cabin body, a low-pressure cabin body, a ventilation hole plate, a circulating fan, a heating unit, a refrigerating unit, an evaporator, a vacuum unit and a temperature sensor. According to the radiation low-pressure environment simulation cabin, the refrigerating unit, the heating unit and the circulating fan are started to send the adjusted temperature to the position above the ventilation hole plate in the heat preservation cabin body through the air pipe, then the adjusted temperature is evenly sent into the heat preservation cabin body through the ventilation hole plate, and the adjusted air evenly radiates the six wall faces of the low-pressure cabin body under the flowing condition; the purpose of controlling and adjusting the temperature in the low-pressure cabin body is achieved, air in the heat preservation cabin body returns to the temperature adjusting section through the air pipe, circulation in the heat preservation cabin body is formed, meanwhile, the circularly flowing air can be dehumidified and dried at the position where the air passes through the evaporator, and dew condensation on the wall face of the low-pressure cabin body is further avoided.

Owner:云沛科技集团有限公司

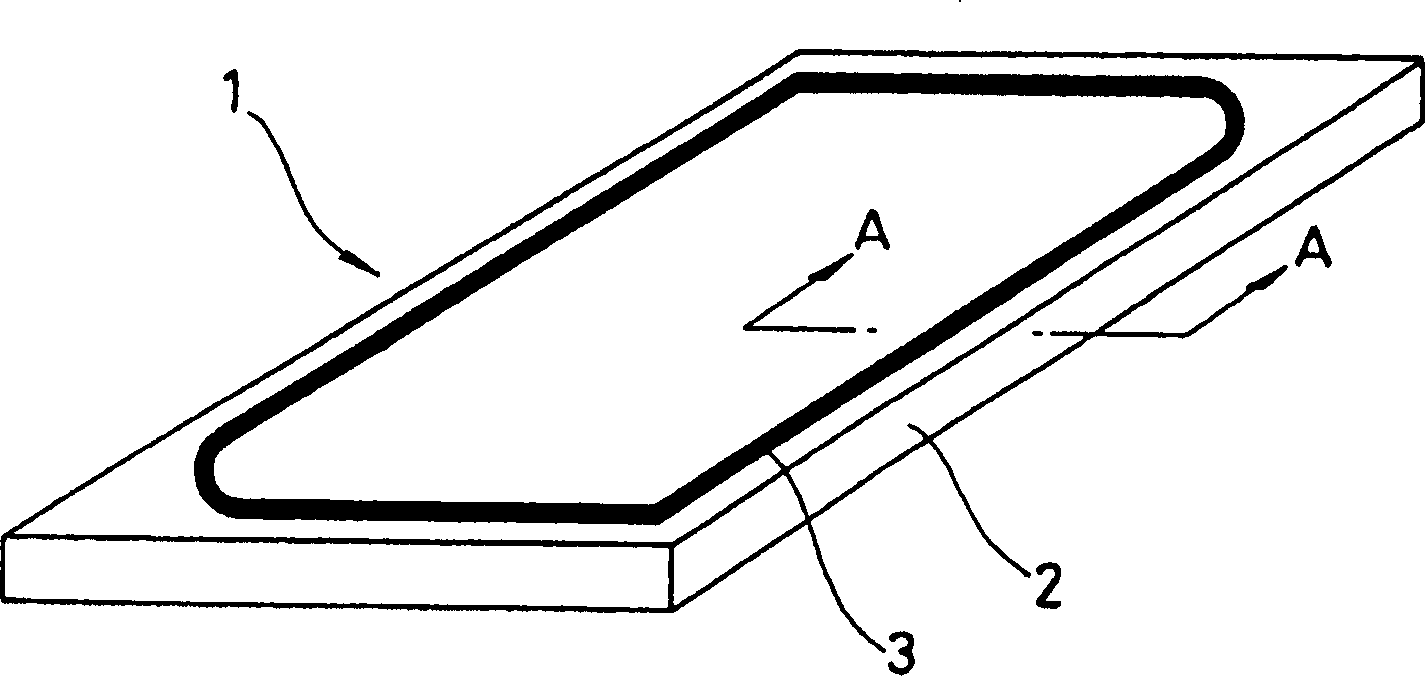

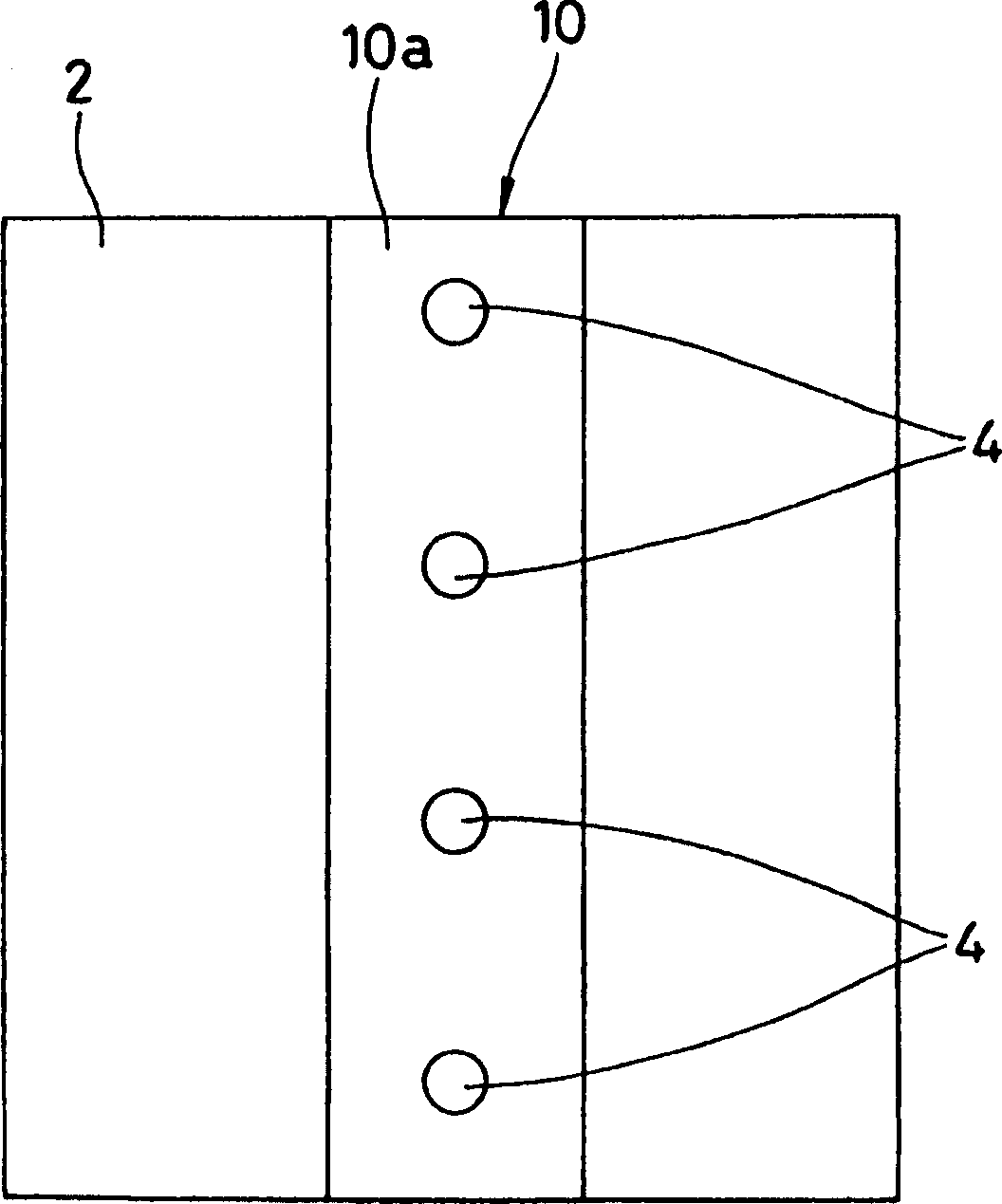

Yarn and gland packing

ActiveCN101300381ANo bad situationAvoid loss of tightnessEngine sealsWeft knittingAspect ratioPartial loss

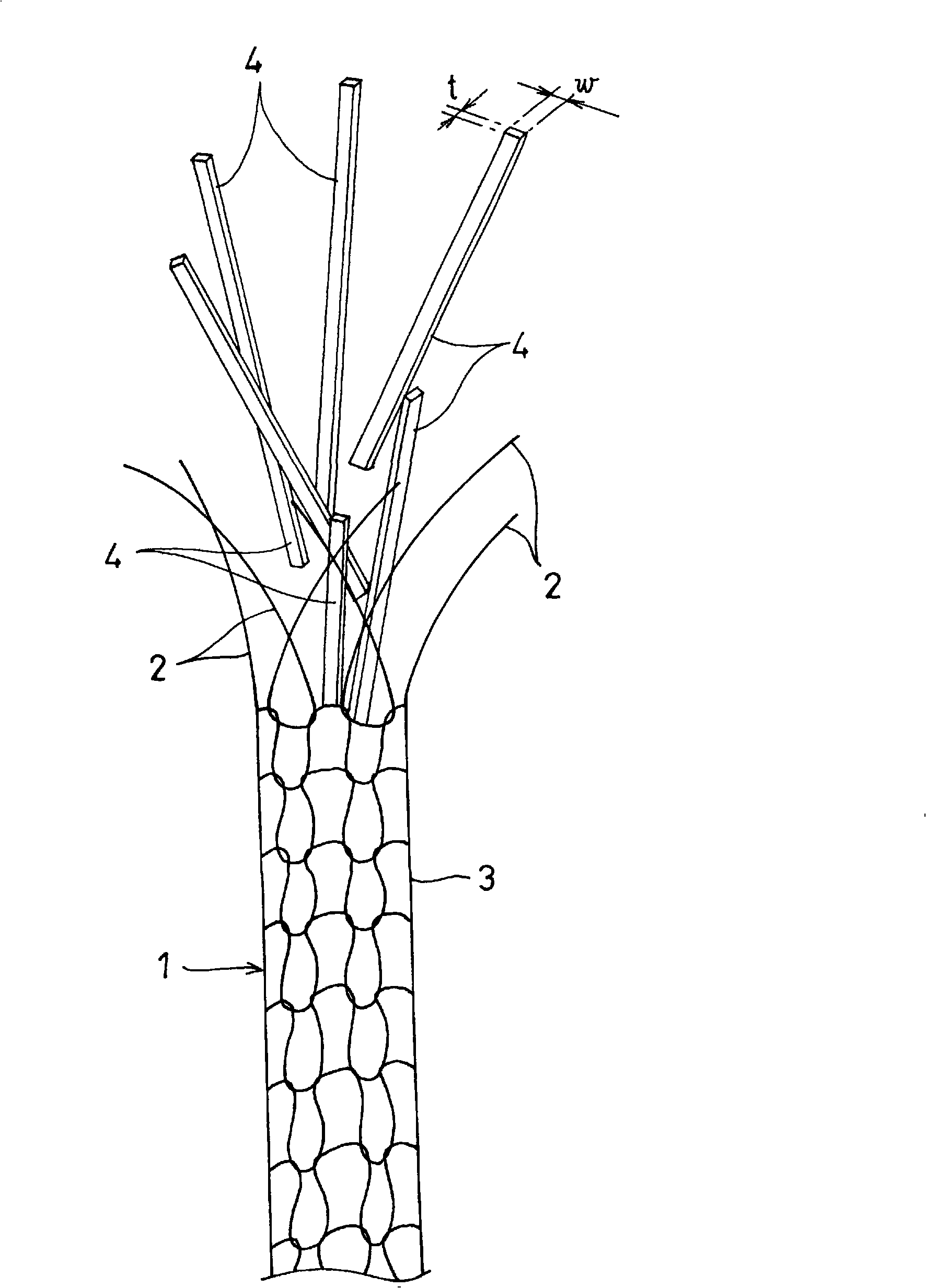

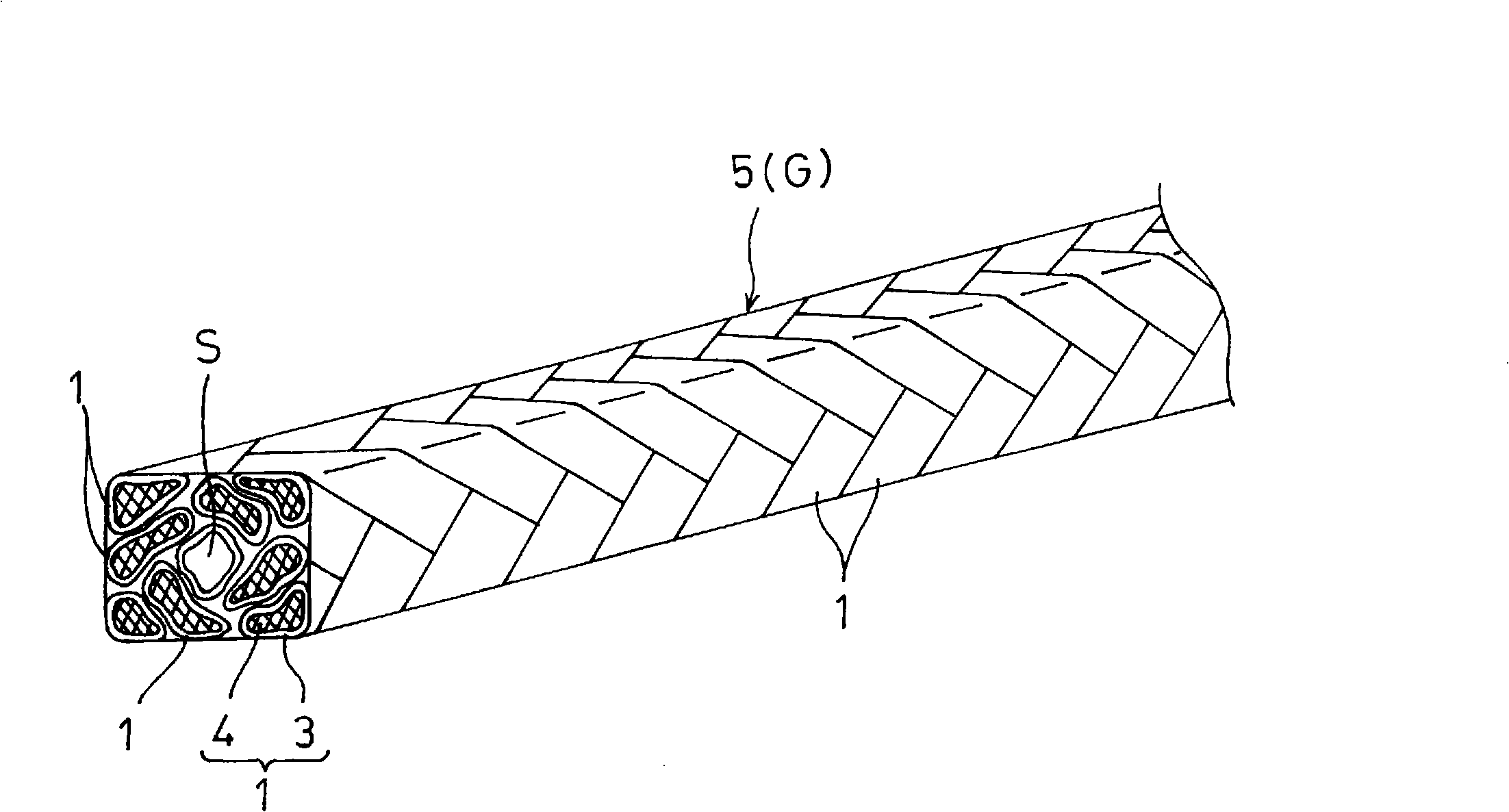

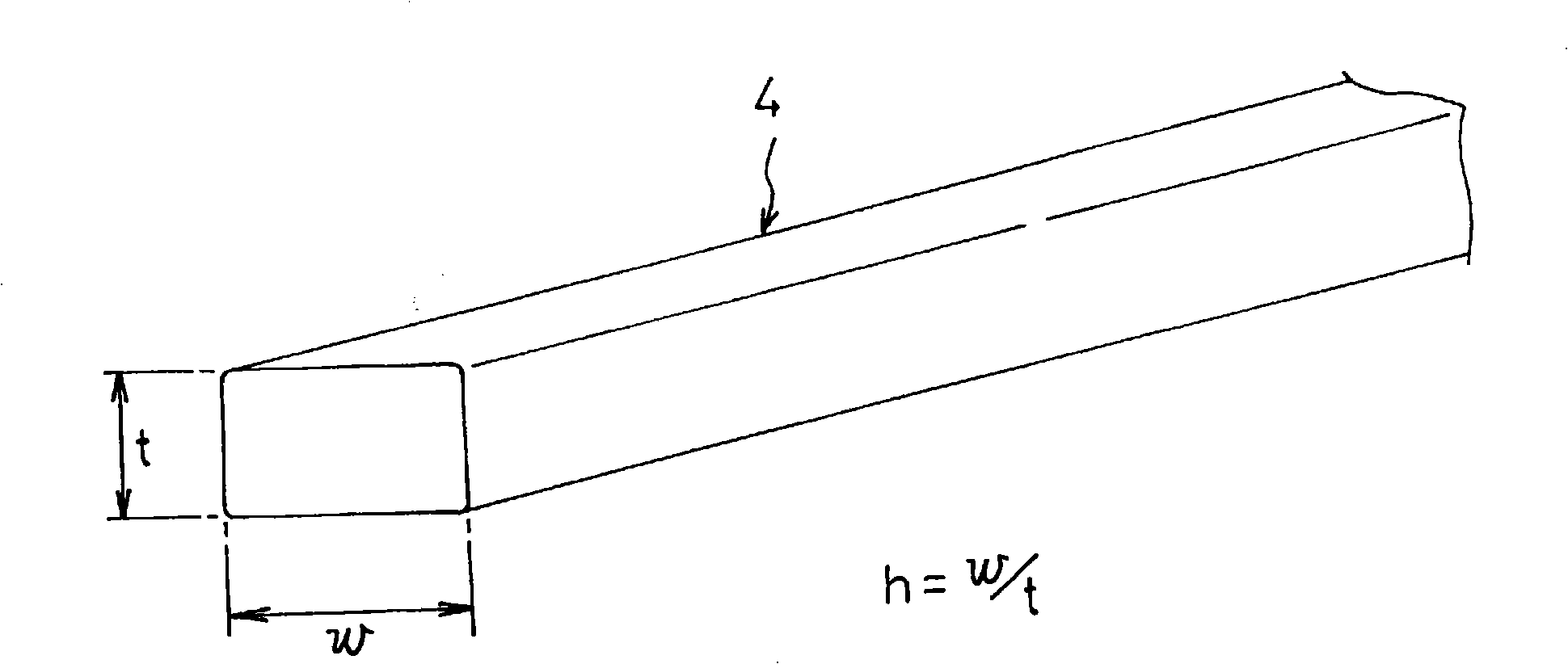

A yarn of exfoliated graphite as a base material that is improved so as to have enriched flexibility free from any stick-out of exfoliated graphite at ordinary bending processing, thereby avoiding any partial loss of exfoliated graphite at twisting or braiding operation for preparing of a gland packing. Yarn (1) for gland packing is produced by filling the interior of tubular member (3) obtained by knitting or folding Inconel wire (2) of 0.1 mm diameter with fibrous exfoliated graphite (4) in the form of a fiber with a cross section set so as to exhibit an aspect ratio, being a quotient of width (h=w / t) divided by thickness (t), of 1 to 5.

Owner:NIPPON PILLAR PACKING CO LTD

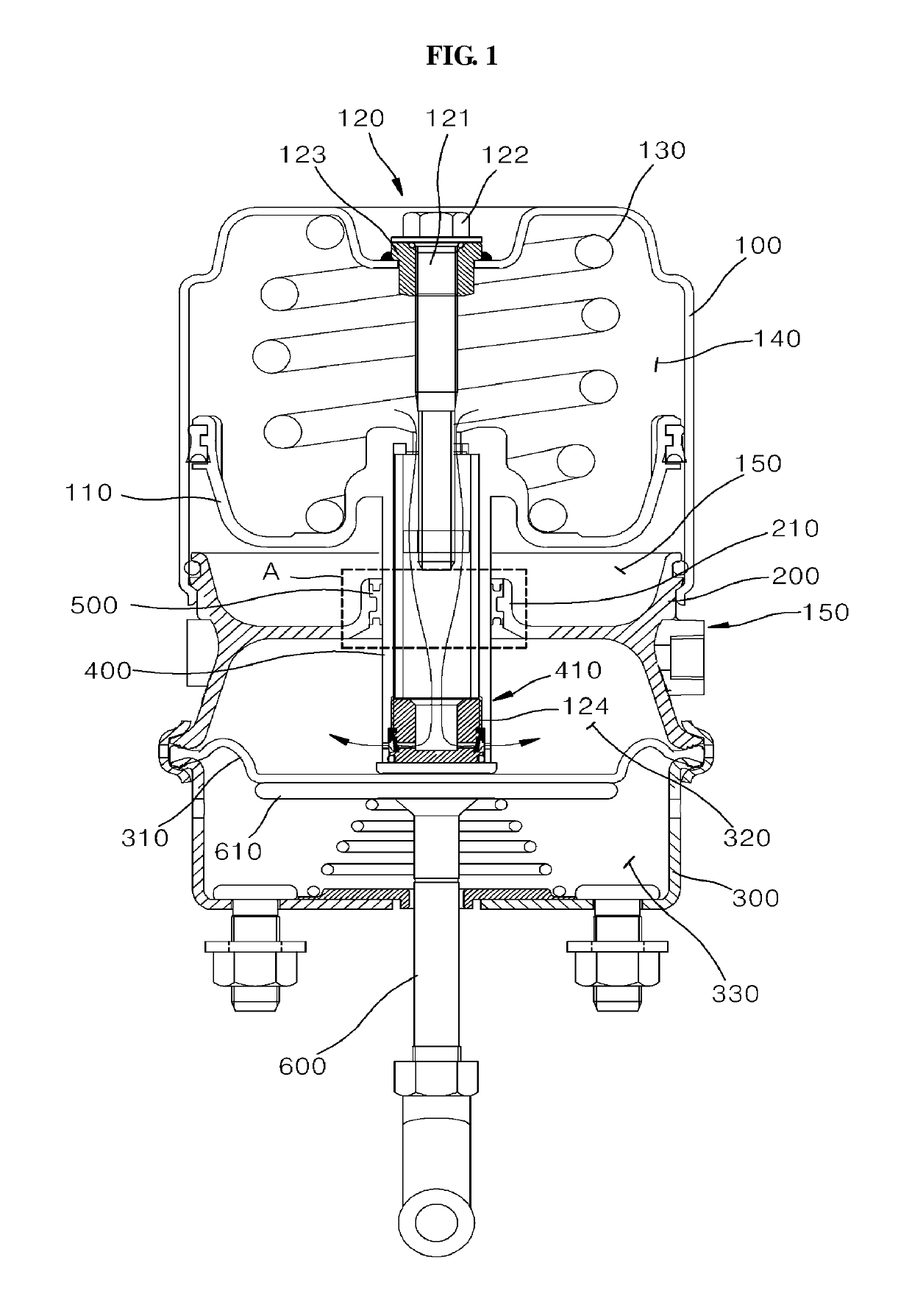

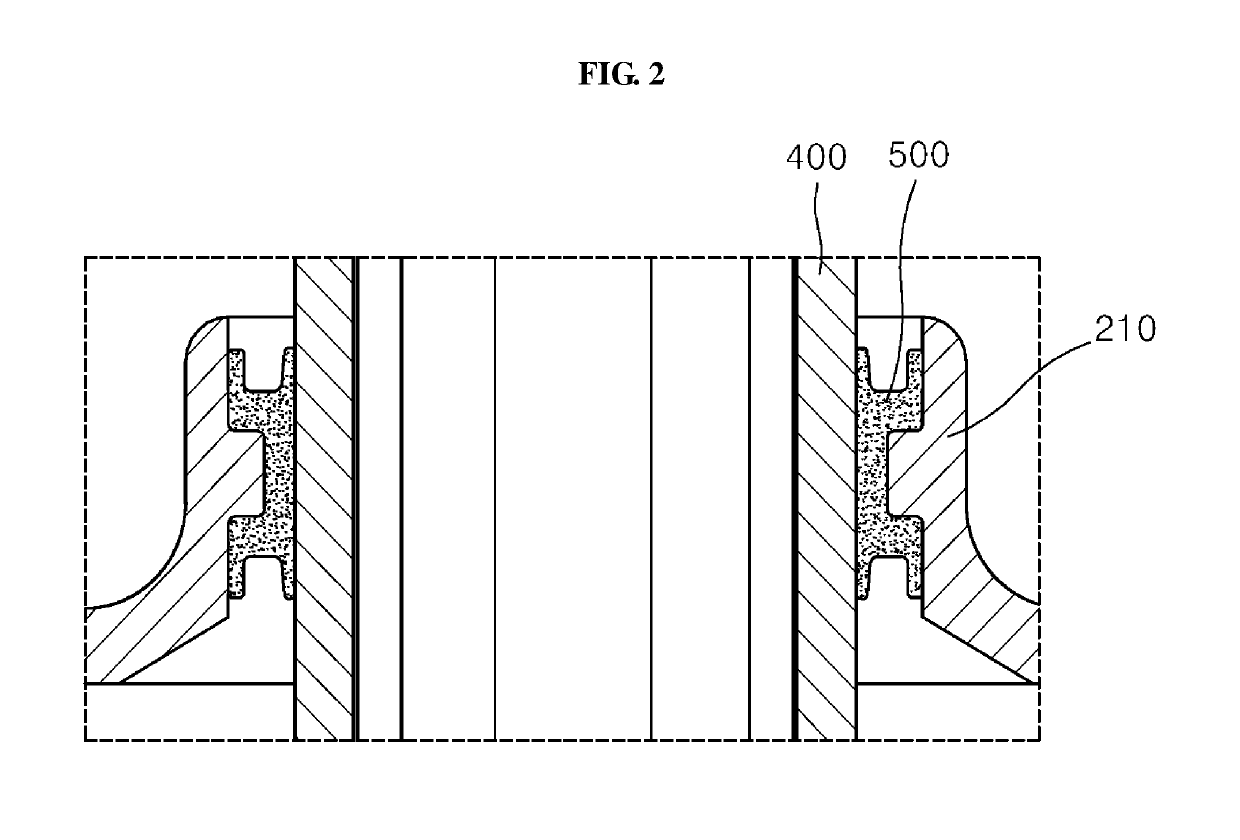

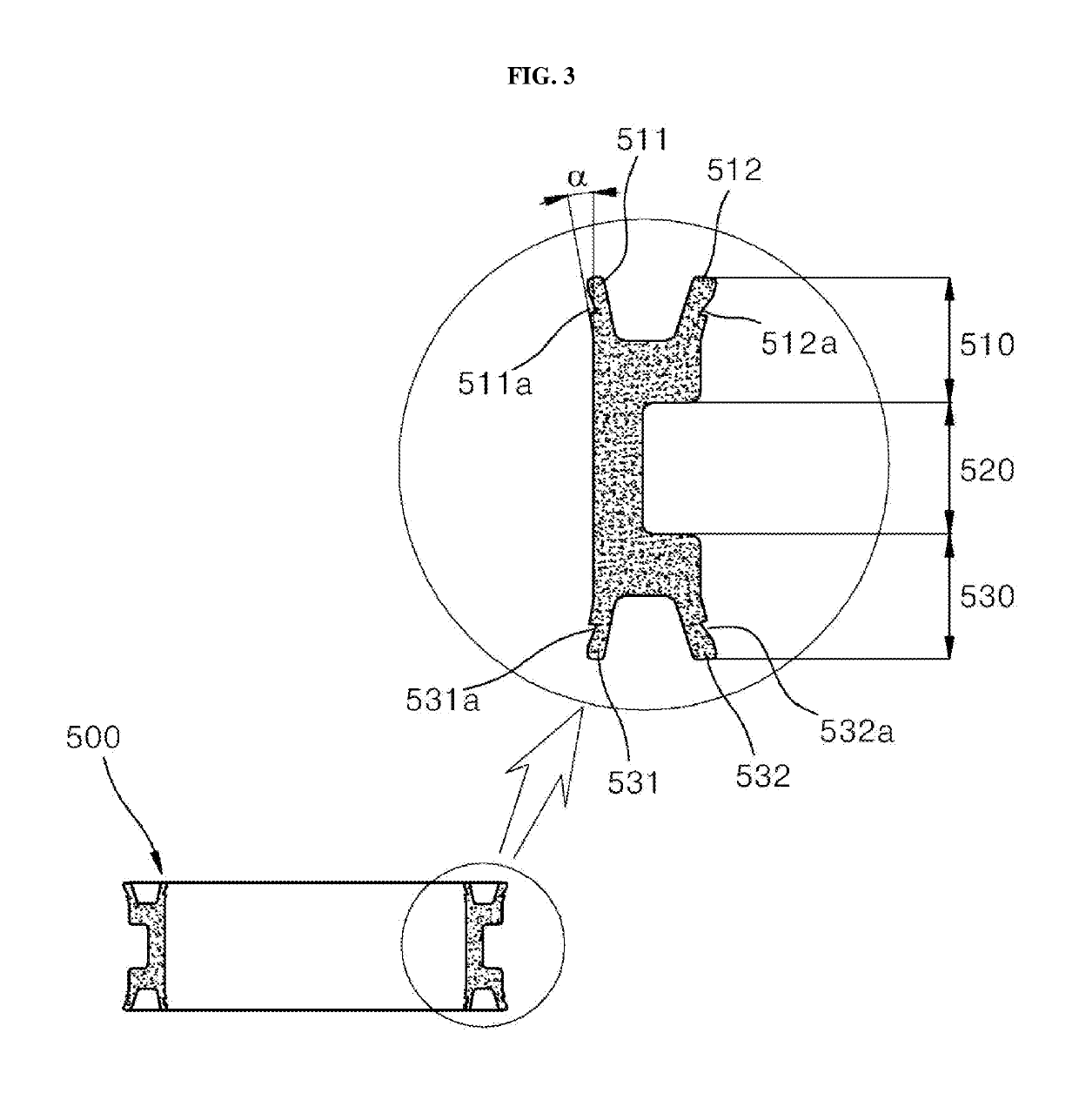

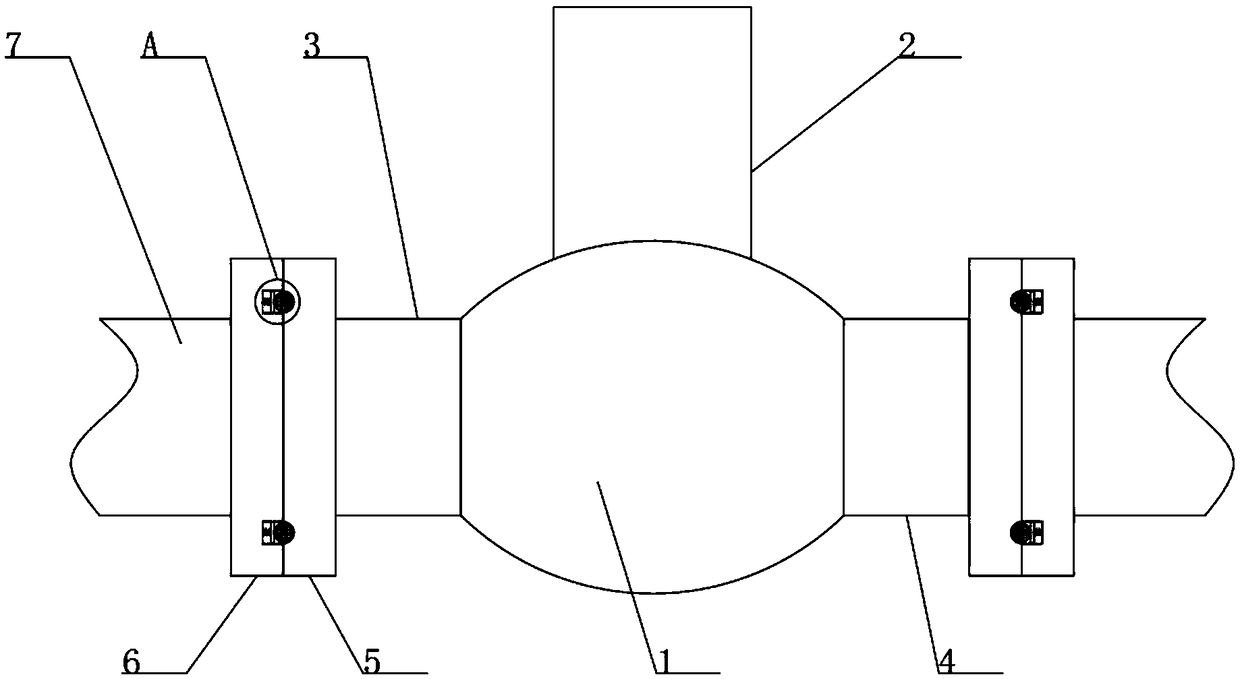

Double-lip seal of pneumatic spring brake chamber for vehicle

ActiveUS10286889B2Avoid performanceAvoid loss of tightnessBrake actuating mechanismsActuatorsActuatorLip seal

The present disclosure relates to a double-lip seal of a pneumatic spring brake chamber for a vehicle, the double-lip seal has sealing performance between an inner circumferential surface of a through-hole of an adaptor housing and an outer circumferential surface of an actuator rod to prevent degradation in sealing performance of the lip seal, thereby maintaining constant sealing performance and preventing fluid leakage.

Owner:MIRAEVC

Water pump having good sealing effect

InactiveCN108916027AAvoid offsetAvoid loss of tightnessPositive displacement pump componentsLiquid fuel engine componentsSlide plateEngineering

The invention discloses a water pump having a good sealing effect. The water pump includes a pump body, a motor is arranged at the top of the pump body, a water inlet is arranged on one side of the pump body, and a water outlet is arranged on the other side of the pump body. First flanges are disposed on one side of the water inlet and one side of the water outlet, one side of each first flange isprovided with a second flange, one side of the second flange is provided with an external water pipe, the surface of one side of the first flange is provided with a sealing groove, the surface of oneside of the second flange is provided with a seal ring groove, a seal ring is disposed in the seal ring groove, and one side of the seal ring is provided with a sliding push plate. The top and the bottom of the inner wall of the seal ring groove are provided with sliding plates, and one side of the sliding push plate is provided with a telescopic rod. The sliding push plate is disposed on one side of the seal ring, a spring is disposed on one side of the sliding push plate, and through the tension action of the spring, the seal ring always presses the sealing groove to avoid loosening the seal ring.

Owner:合肥信仁液压机械有限公司

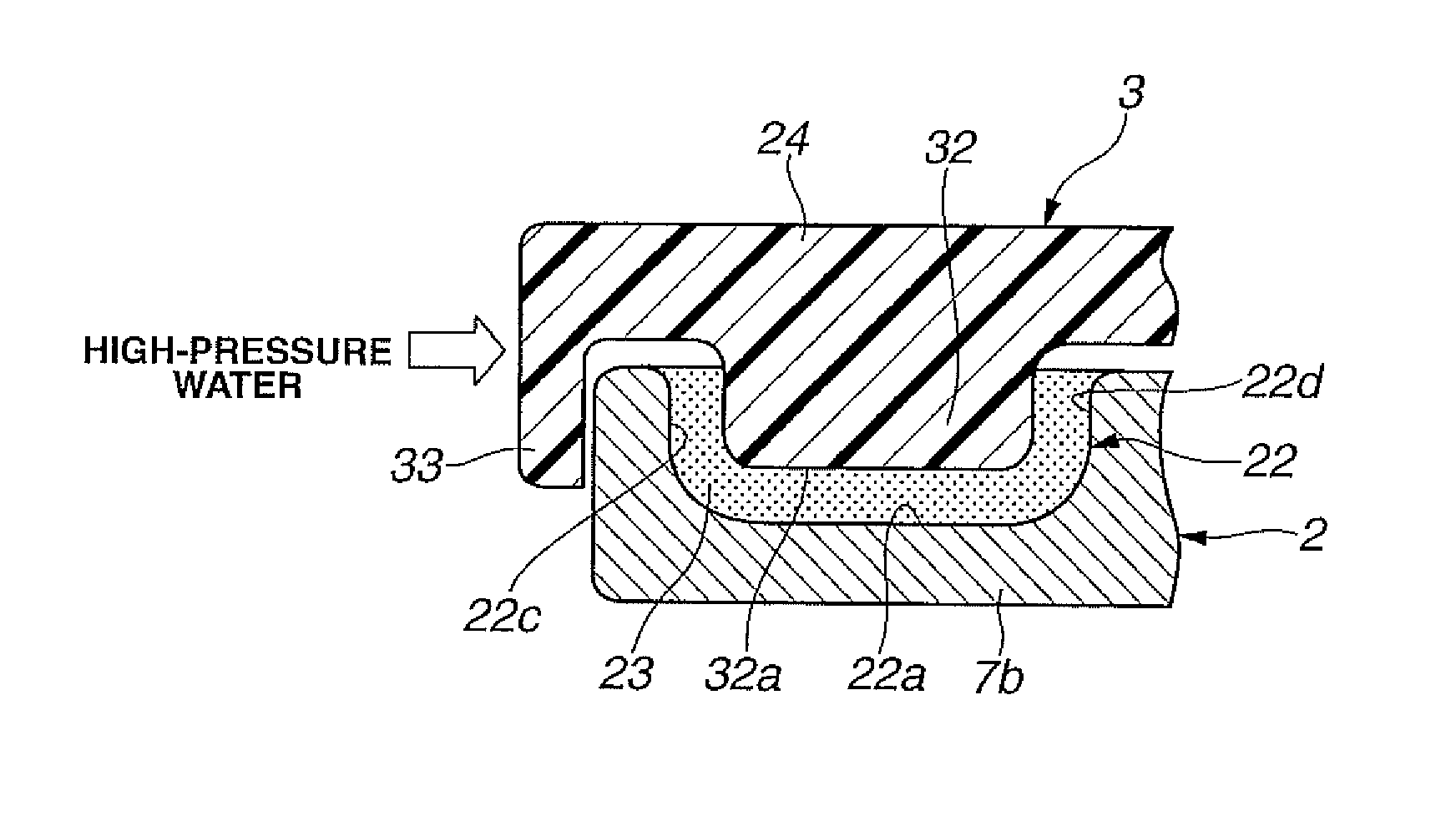

Seal structure for electronic control device

ActiveUS9295175B2Preventing deterioration in seal performanceReduce controlCouplings bases/casesTwo-part coupling devicesEngineeringSealant

Disclosed is a seal structure for an electronic control device where a circuit board is accommodated in a housing with a connector attached to the circuit board and held between base and cover members of the housing. The seal structure includes a connector seal surface formed on a front end portion of the base member, a seal material arranged between the connector seal surface and the connector, a seal groove formed in an outer peripheral portion other than the front end portion of the base member, a seal protrusion formed on the cover member and engaged in the seal groove, and a sealant filled between the seal groove and the seal protrusion. Longitudinal end regions of the connector seal surface are extended in a width direction of the connector. Longitudinal end regions of the seal groove are connected perpendicular to the respective end regions of the connector seal surface.

Owner:HITACHI ASTEMO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com