Patents

Literature

61results about How to "Adjust the clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

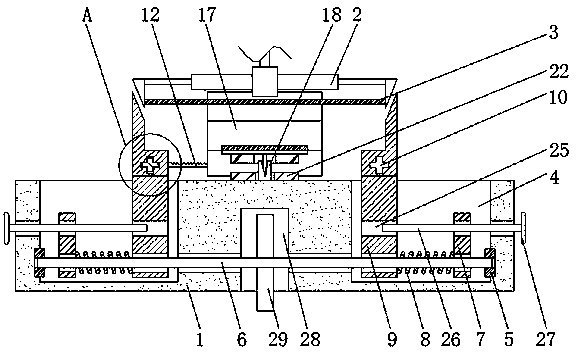

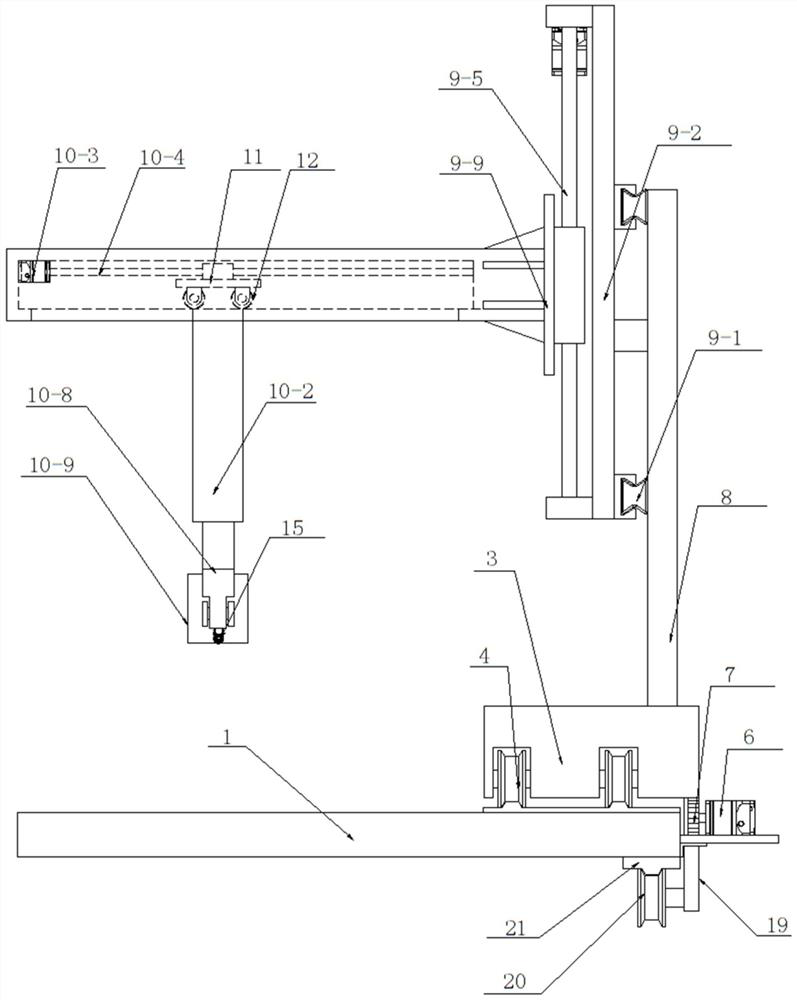

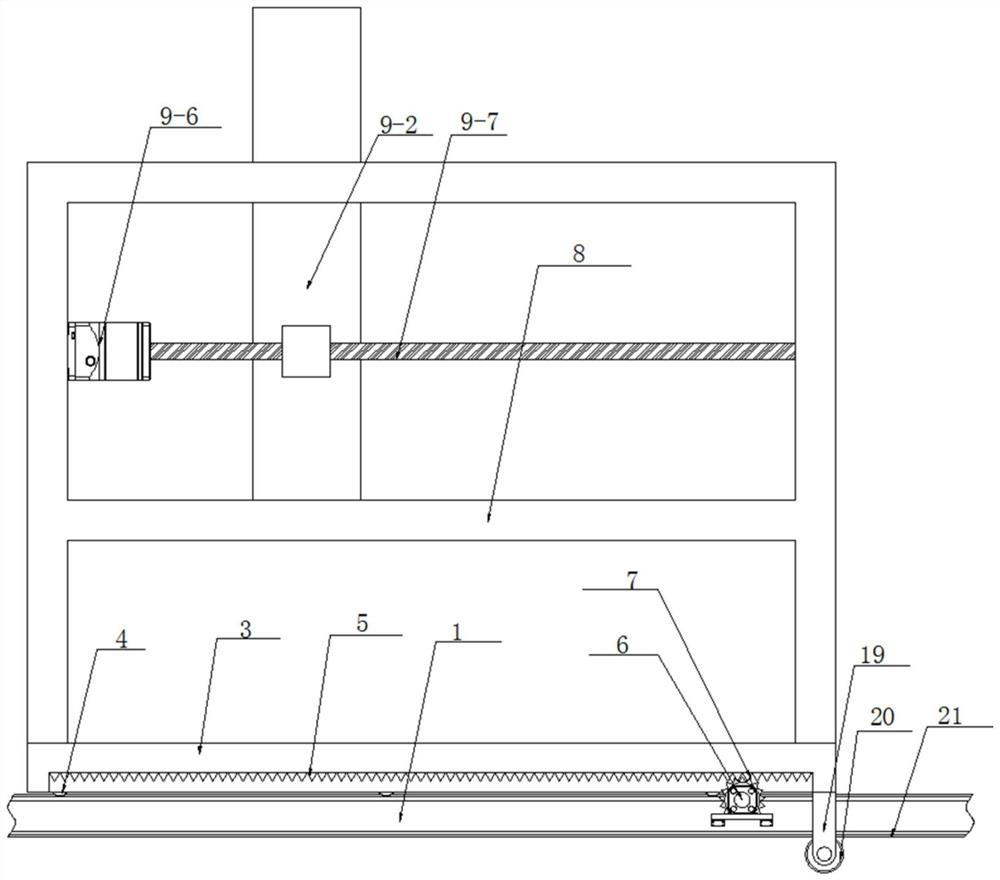

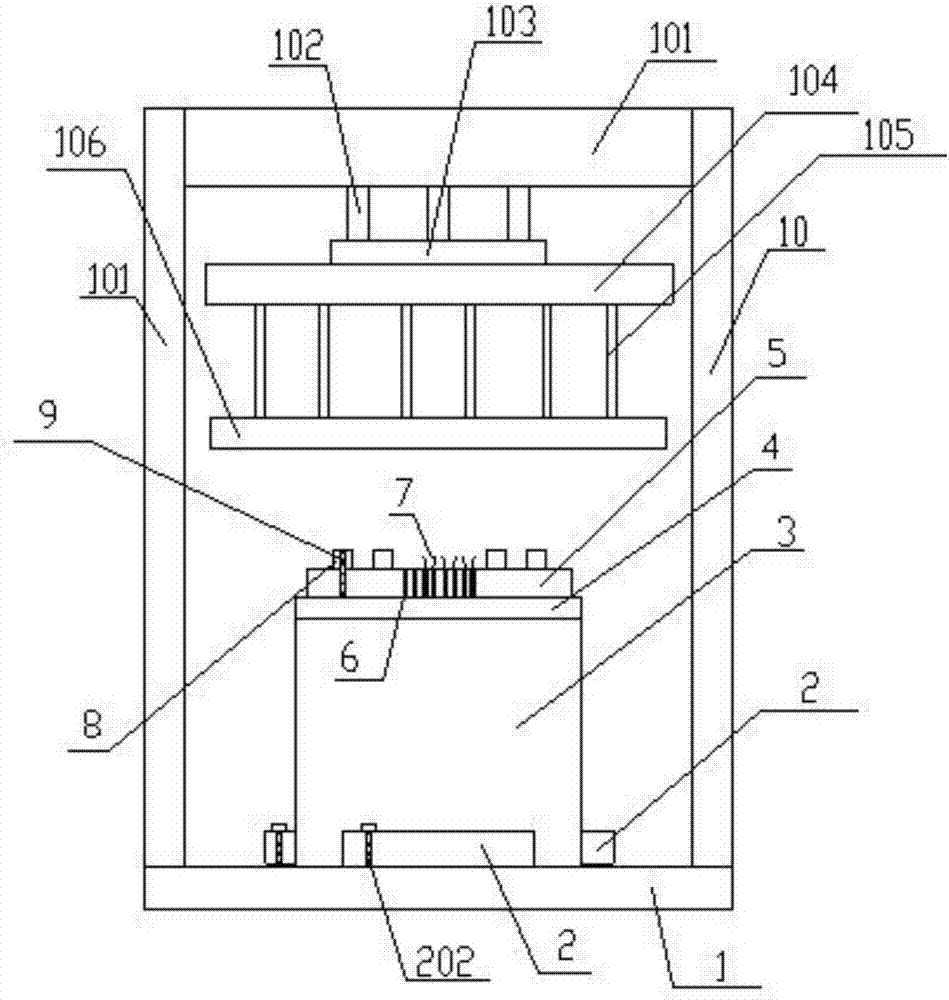

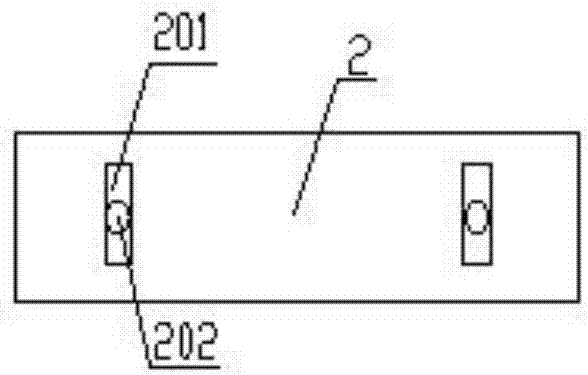

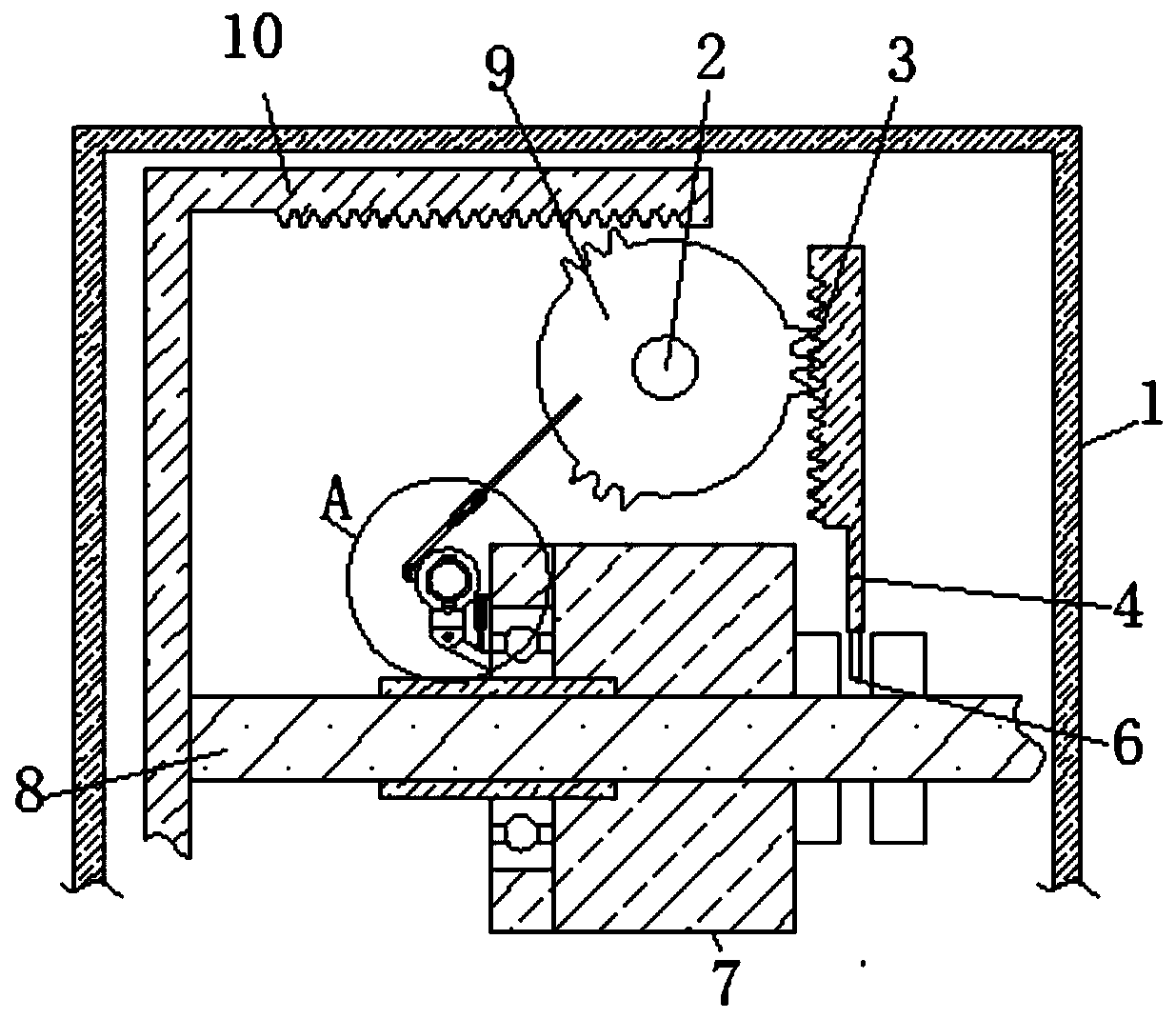

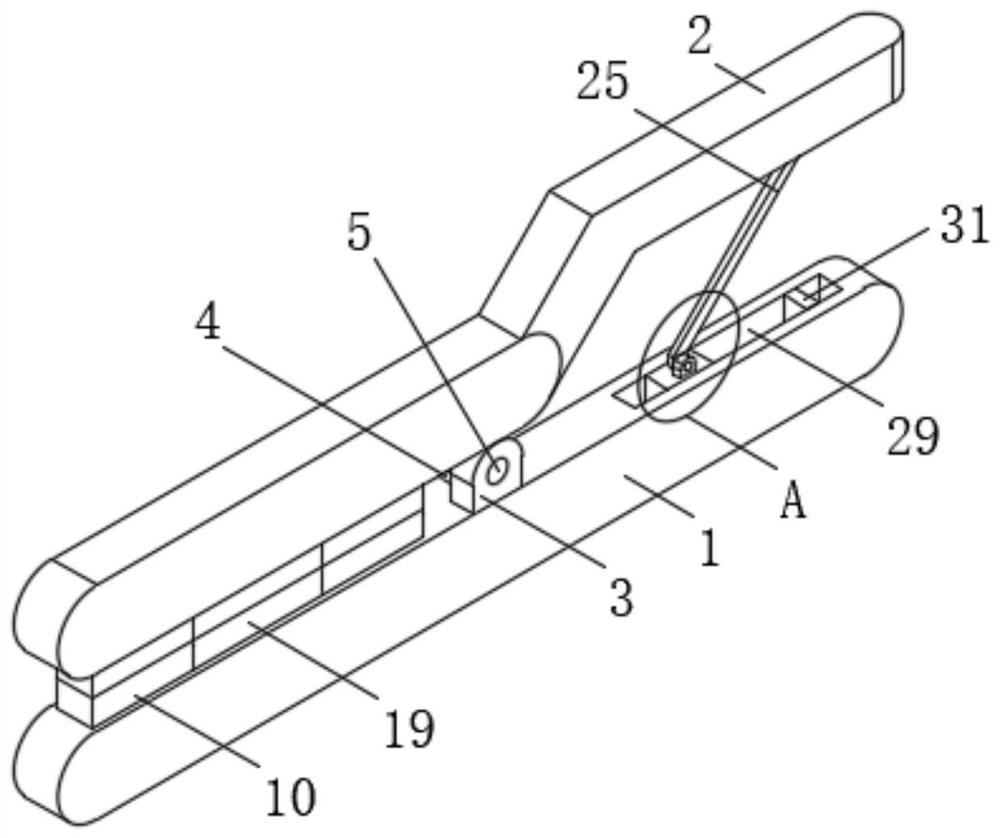

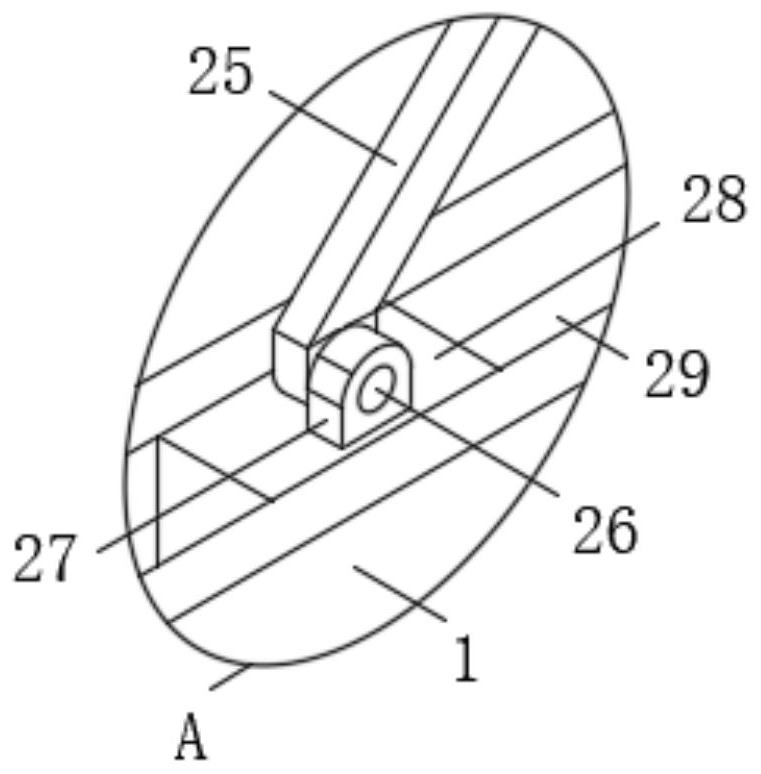

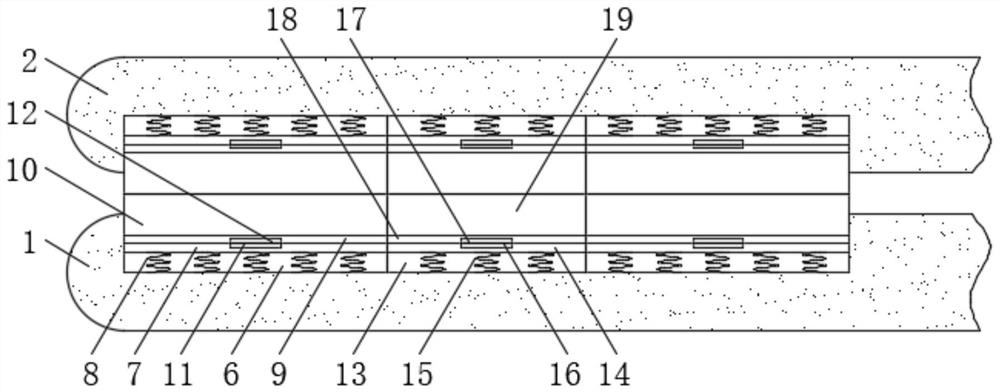

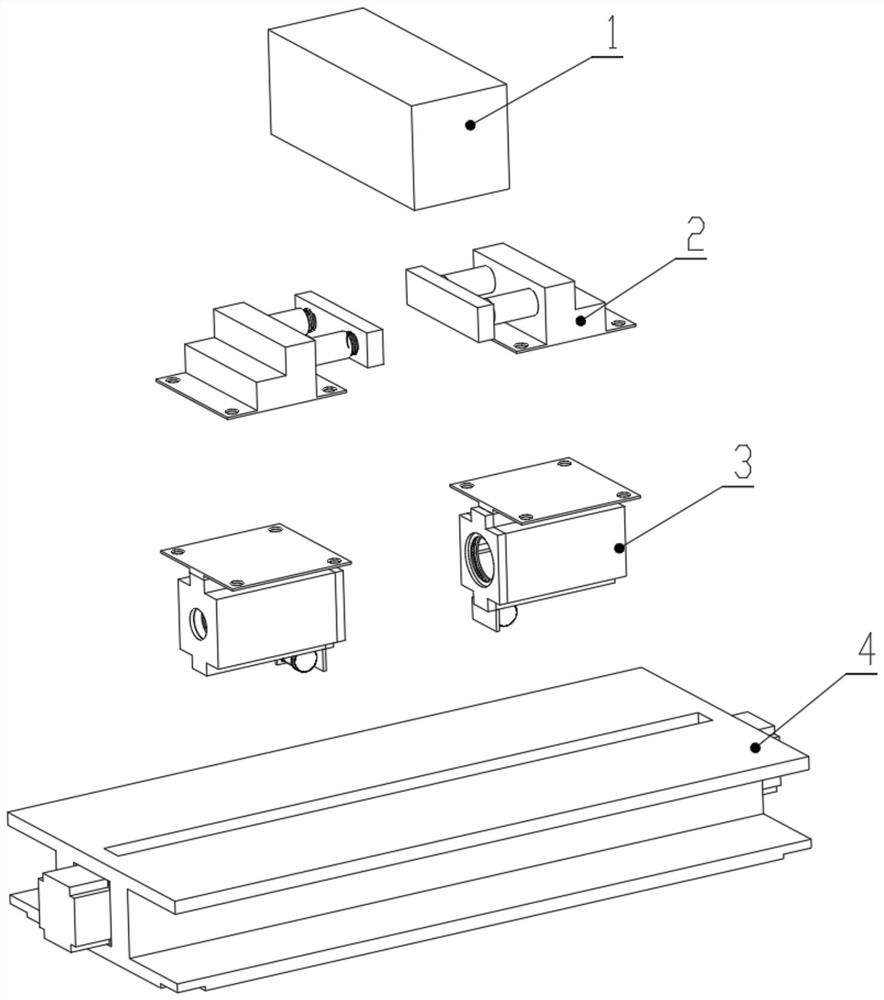

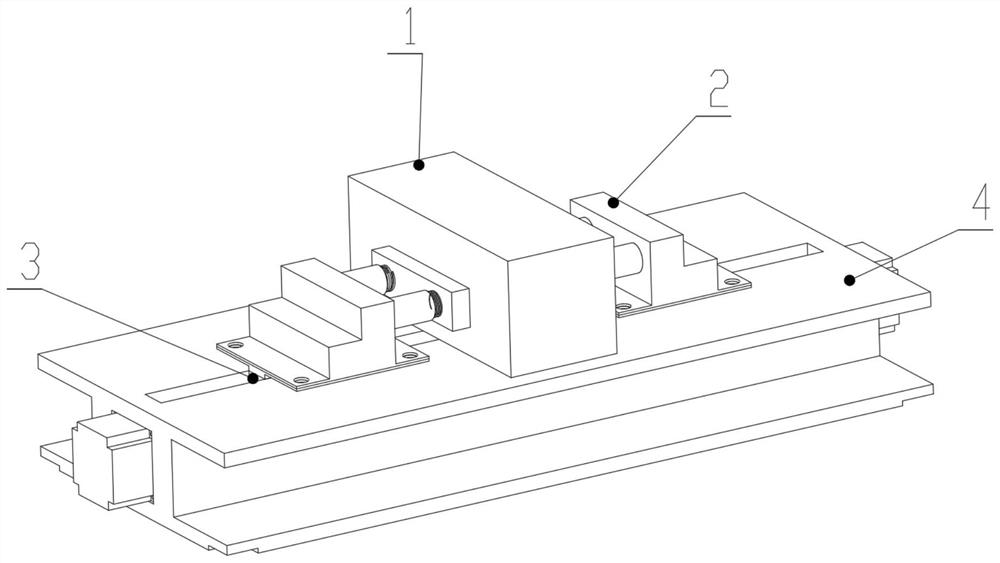

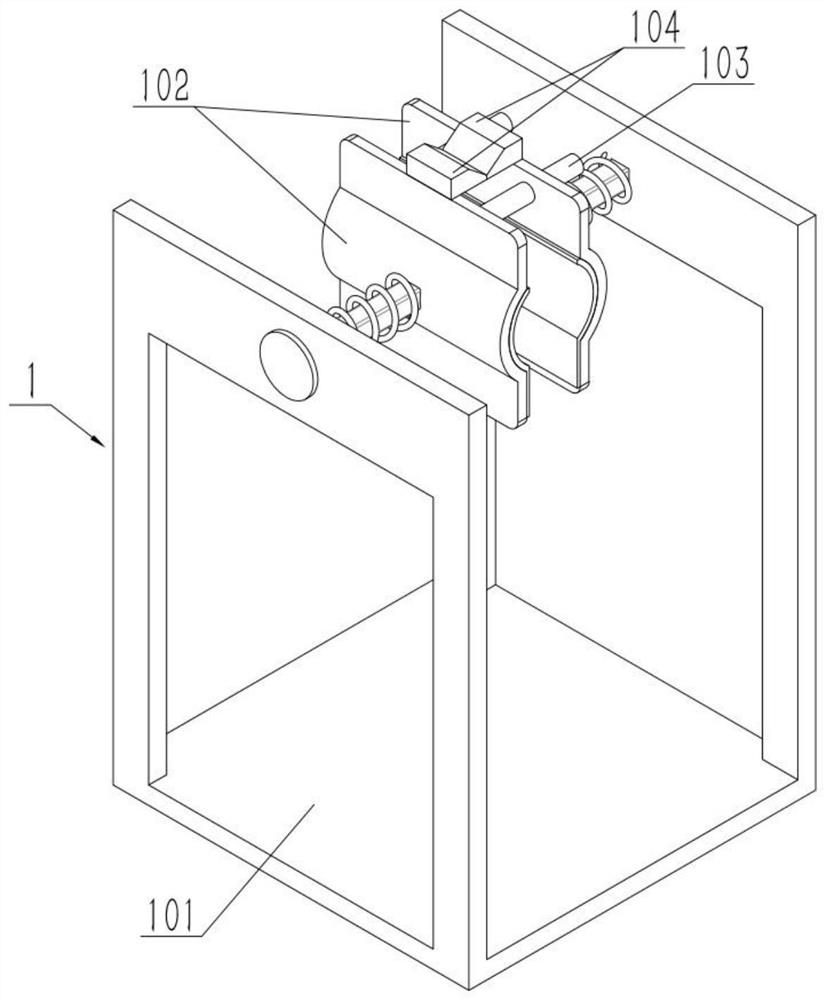

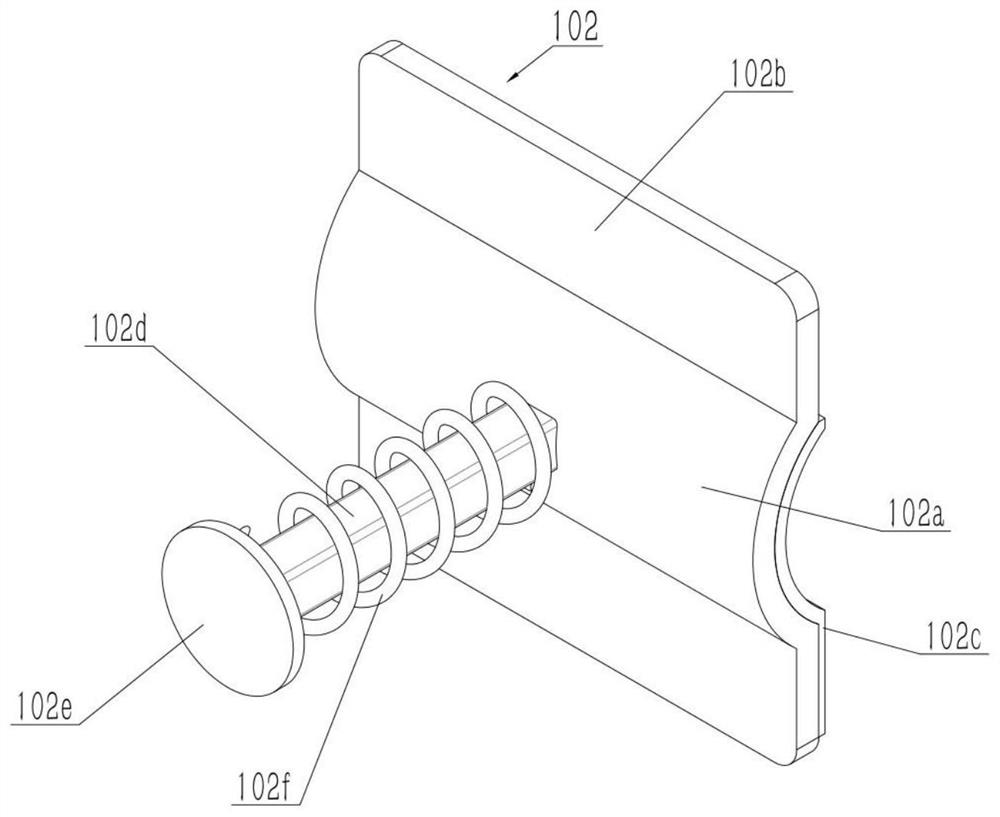

Numerical control machine tool having clamping function and used for PCB production

InactiveCN107671570AWith clamping functionReduce mistakesCircuit board tools positioningPositioning apparatusNumerical controlEngineering

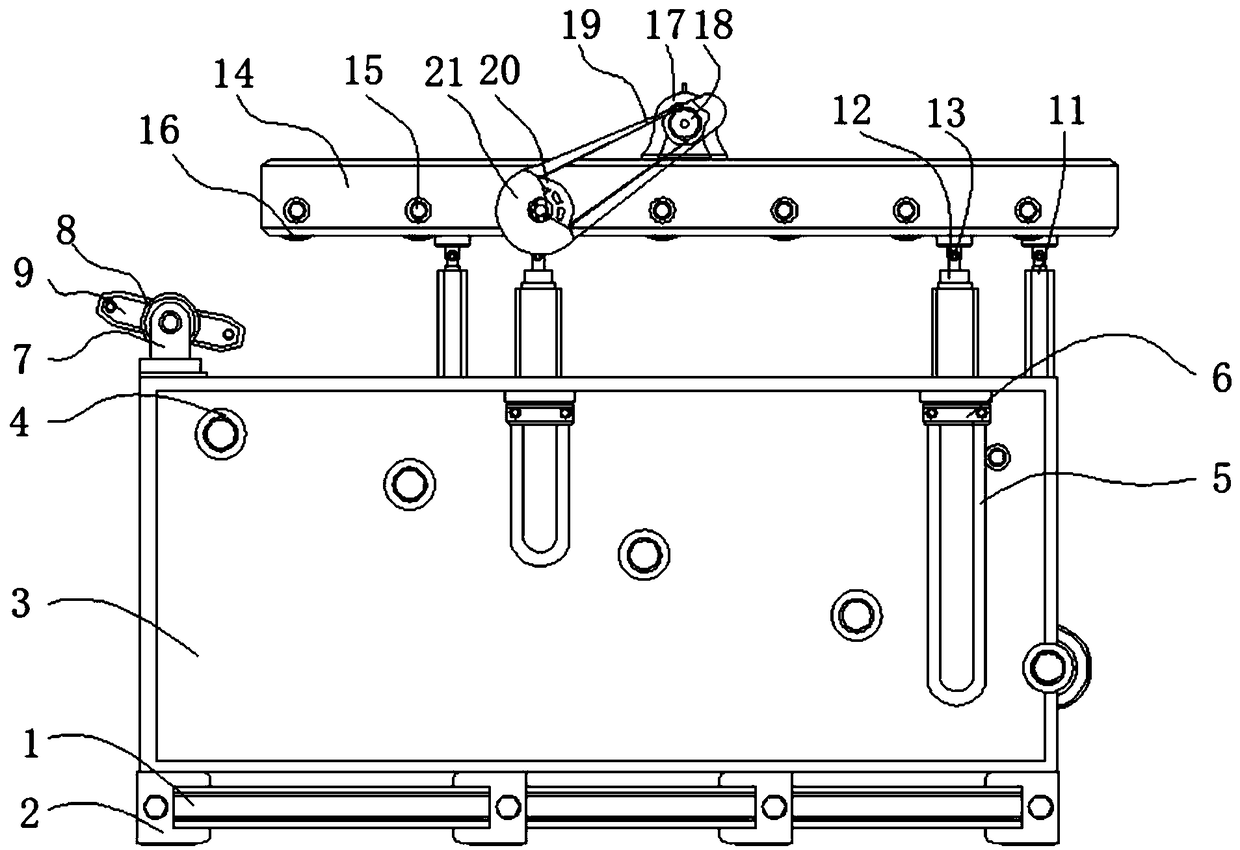

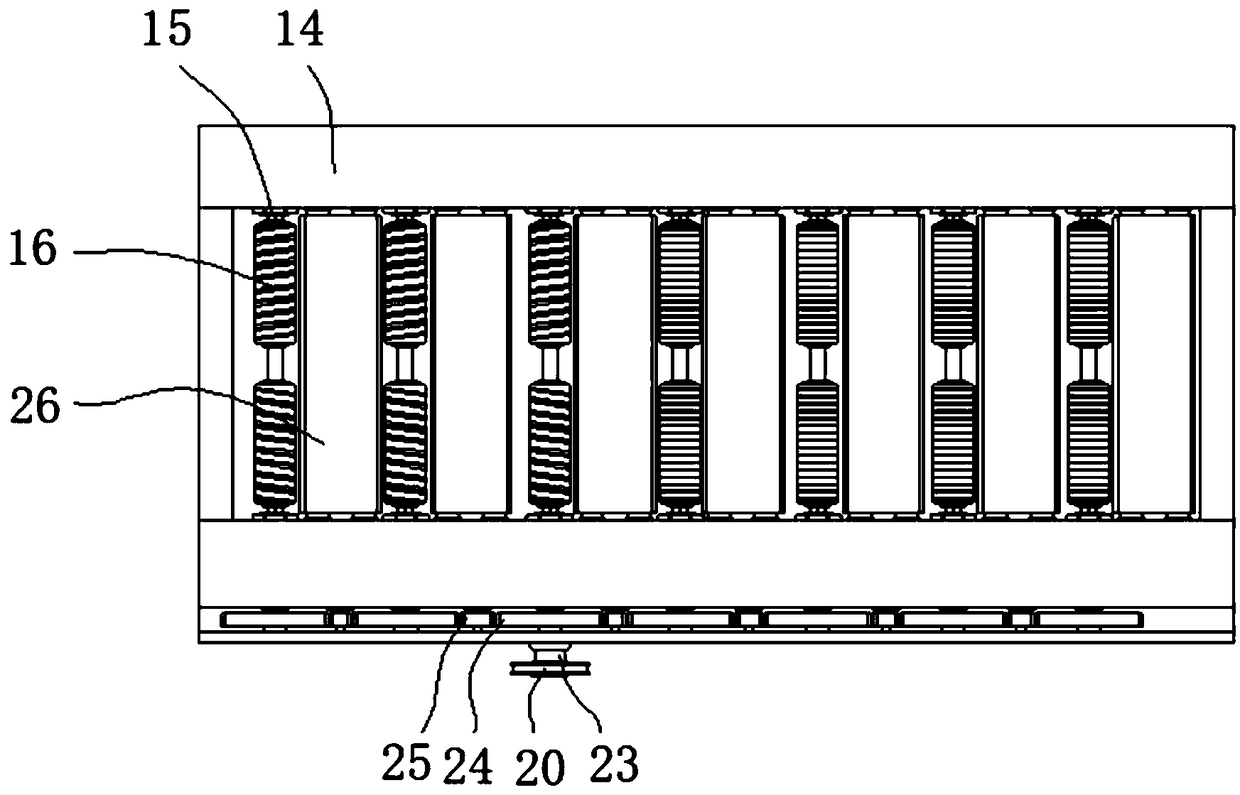

The invention discloses a numerical control machine tool having a clamping function and used for PCB production. The numerical control machine tool comprises a workbench and a manipulator, the manipulator is located over the workbench, and the two opposite faces of the manipulator are movably connected with the two sides of a PCB respectively. Sliding grooves are formed in the upper surface of theworkbench, first bearings are embedded in the inner walls of the sliding grooves, the inner walls of the first bearings are fixedly connected with the surface of a guide rod, and the guide rod is movably sleeved with moving blocks, springs and first clamping plates. Each moving block is located on the side, away from the center of the workbench, of the corresponding first clamping plate. The front faces and the back faces of the moving blocks and the first clamping plates are in sliding connection with the inner walls of the sliding grooves. By arranging the guide rod, the moving blocks, thesprings, the first clamping plates, a rack, a gear and a second clamping plate, the problems that PCB components and wiring precision are affected due to the facts that the position of the PCB on thesurface of the numerical control machine tool is not fixed and the stop position has errors are solved.

Owner:周言鑫

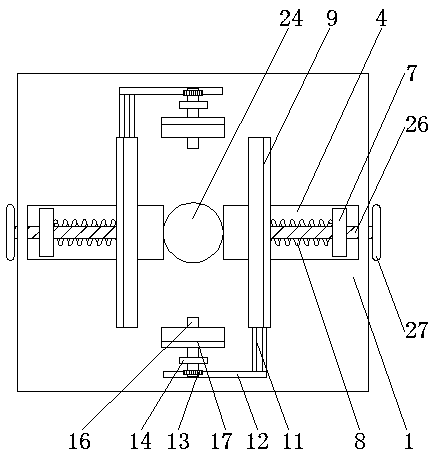

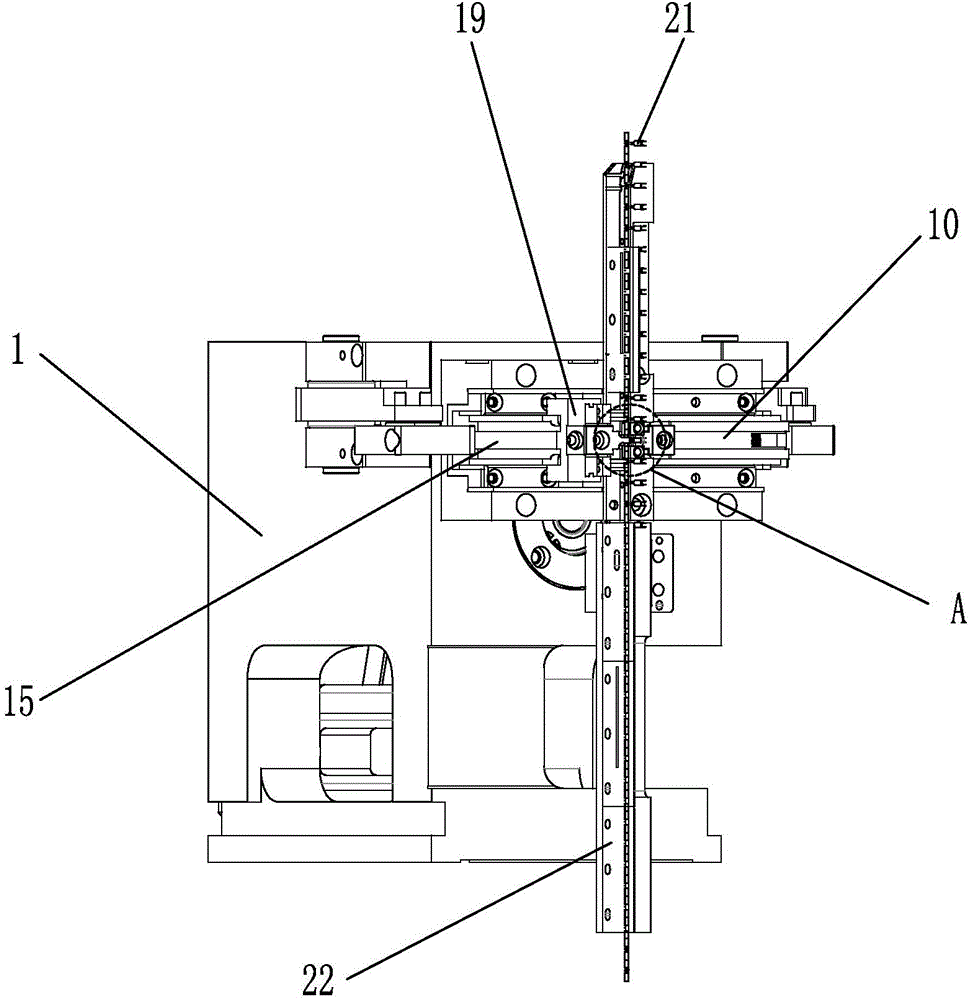

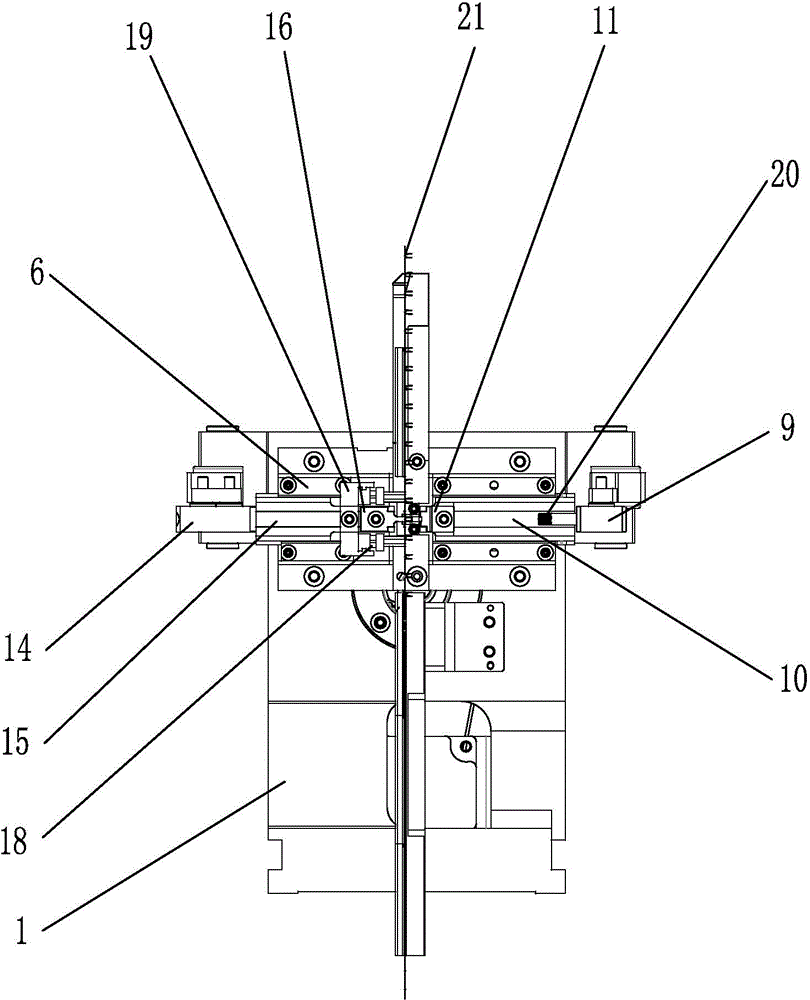

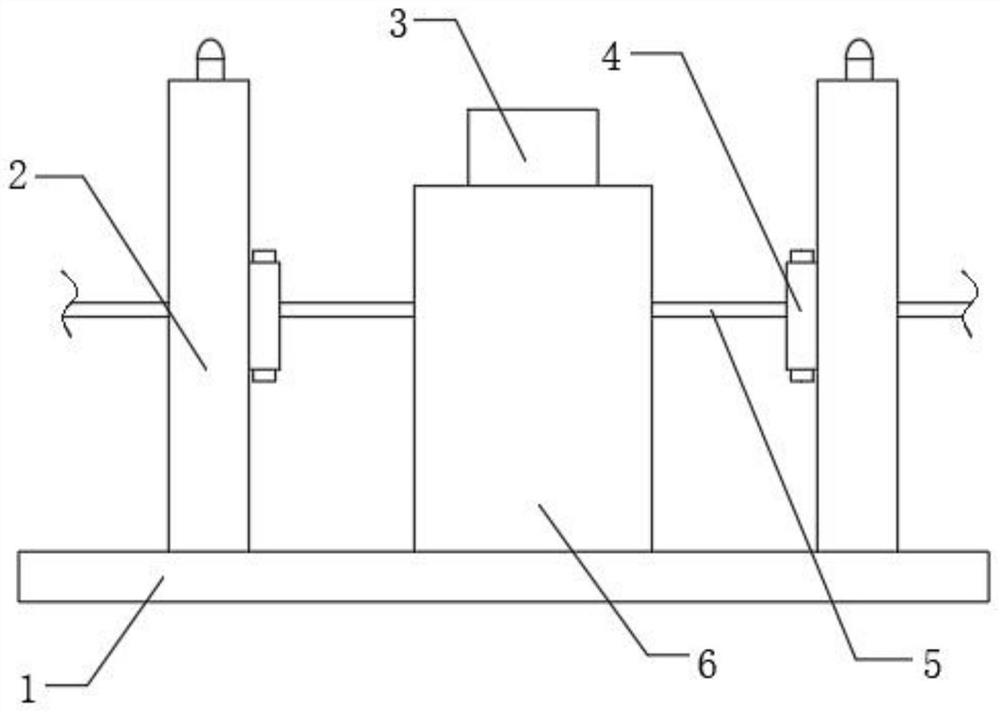

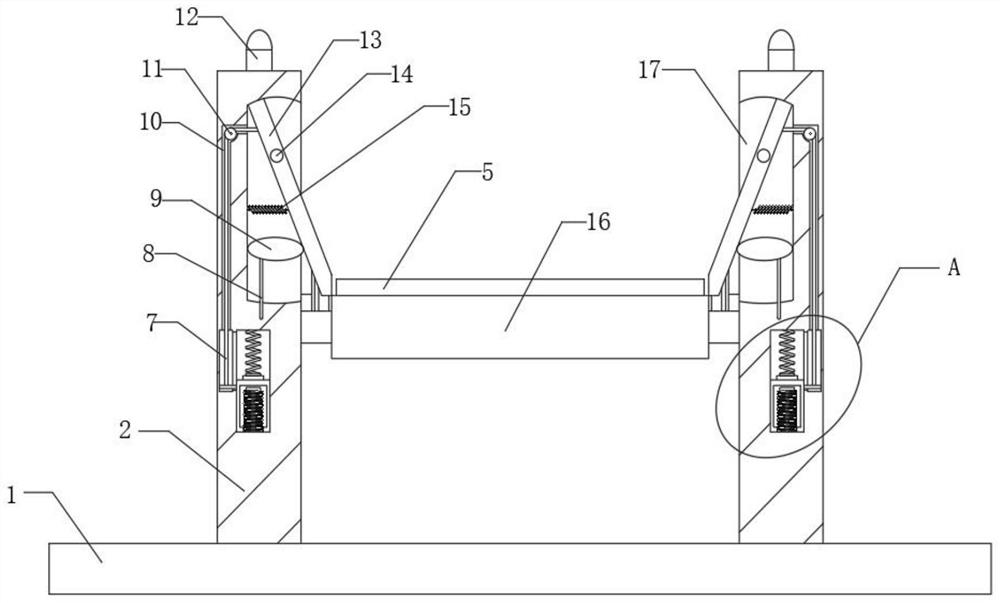

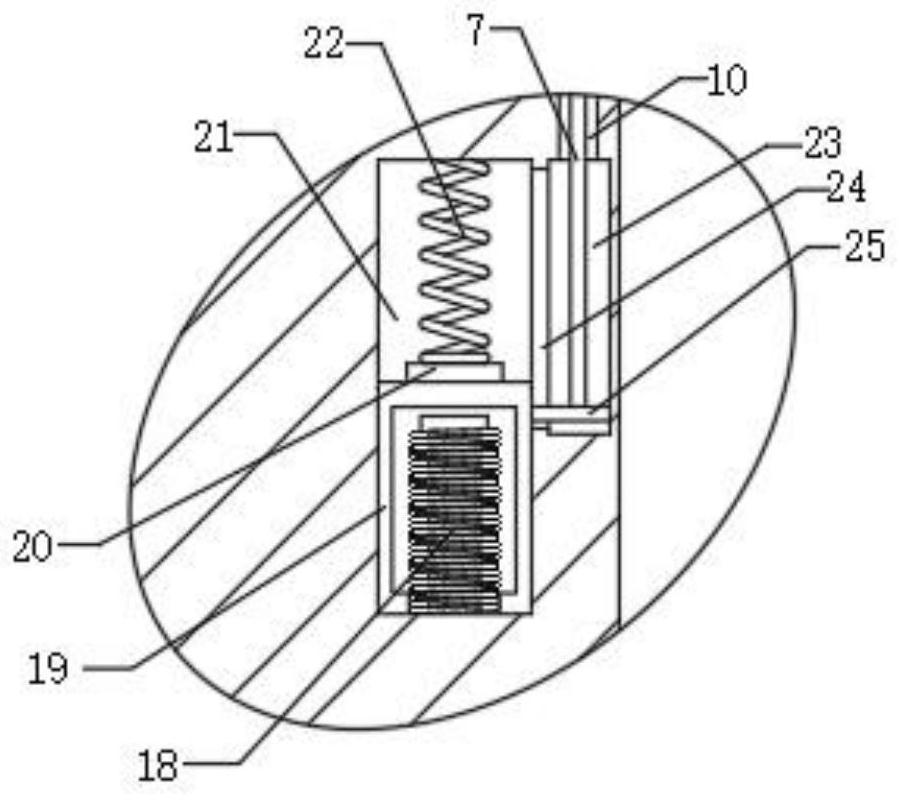

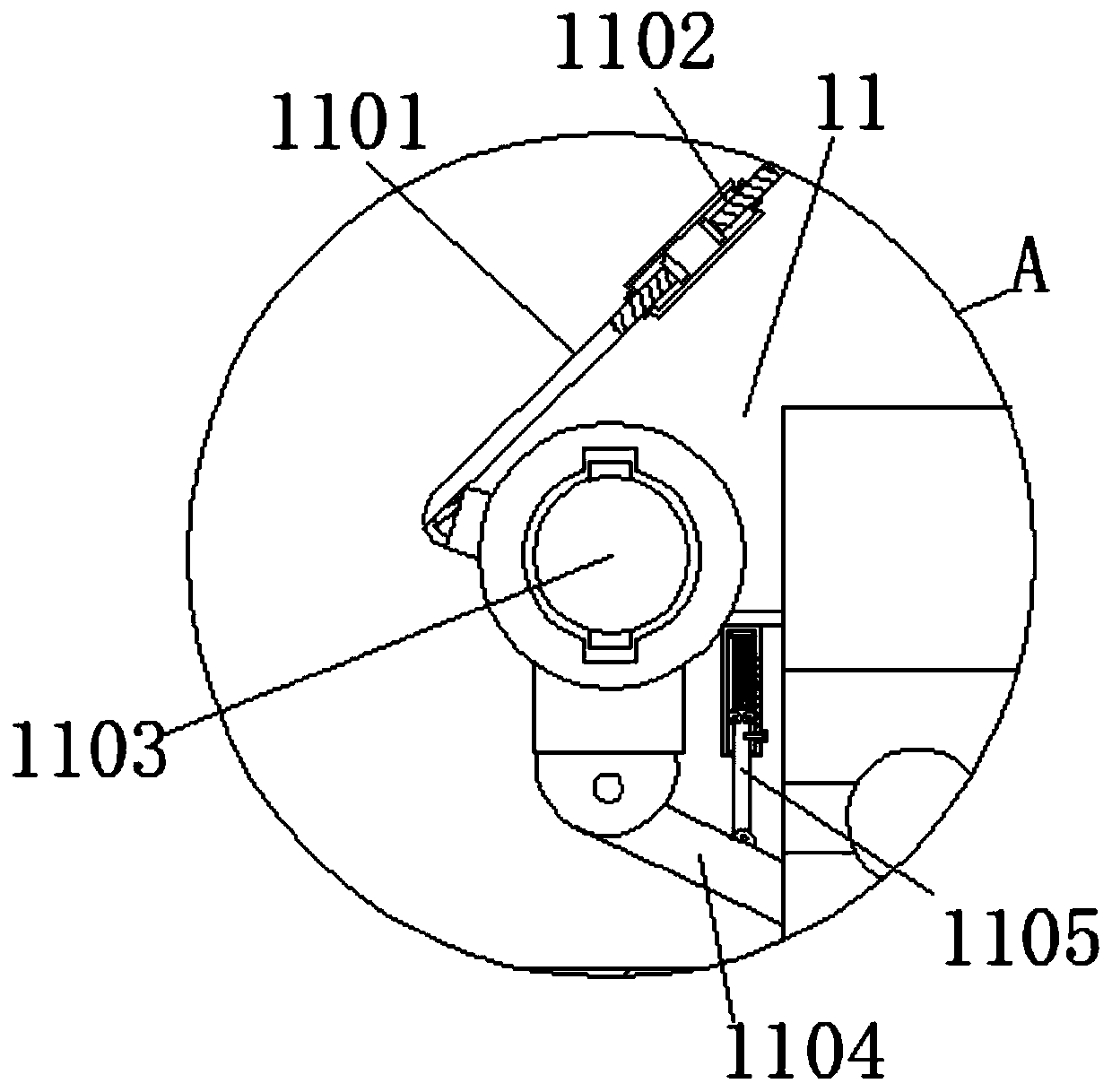

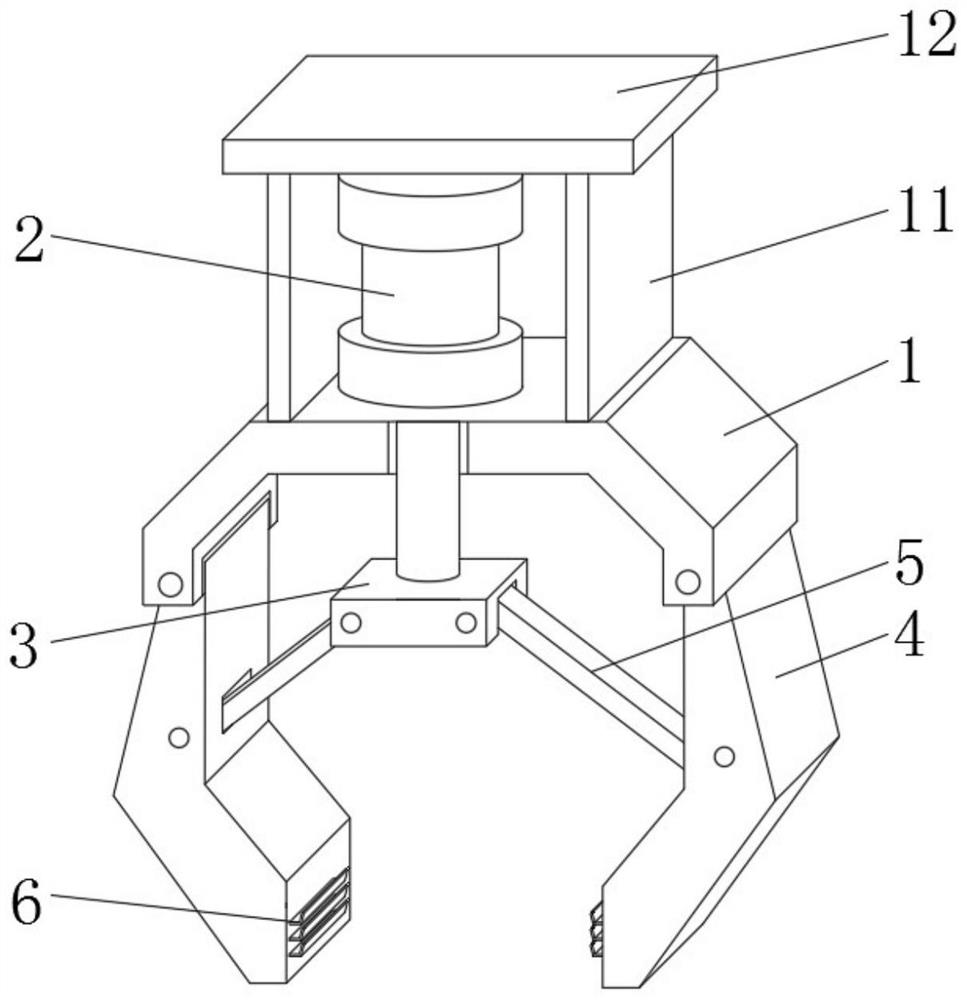

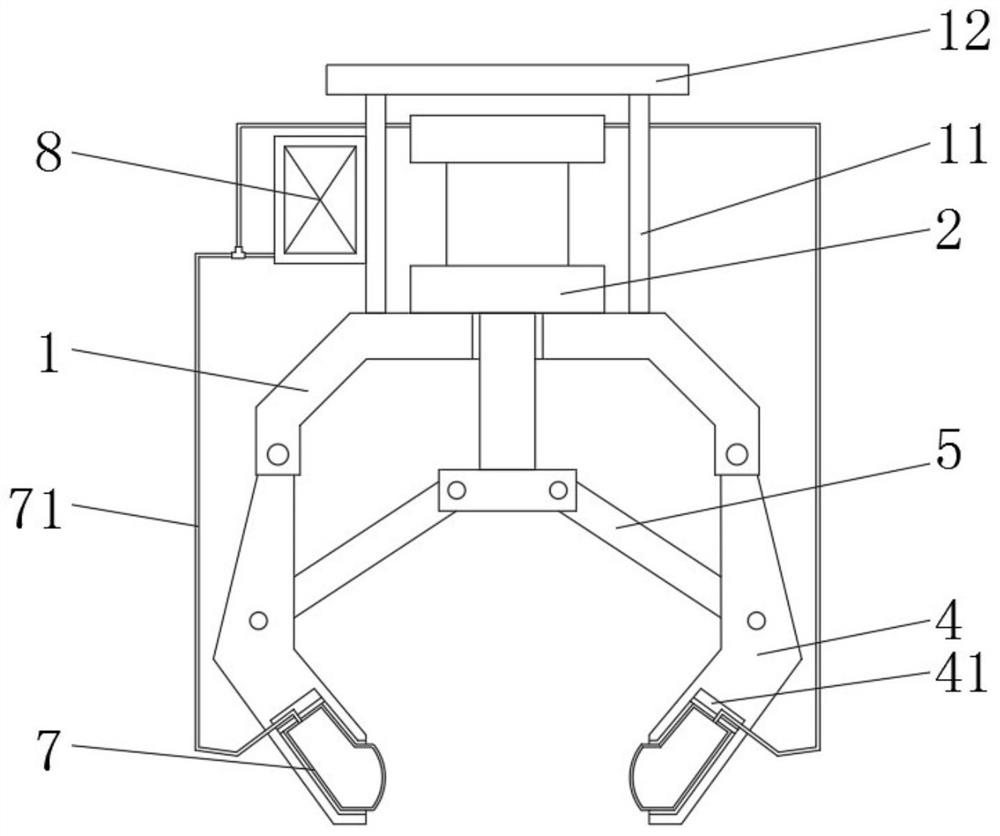

Manipulator based on automatic control

ActiveCN111844001AReduce consumptionReduce manufacturing costProgramme-controlled manipulatorGripping headsAutomatic controlRobotic arm

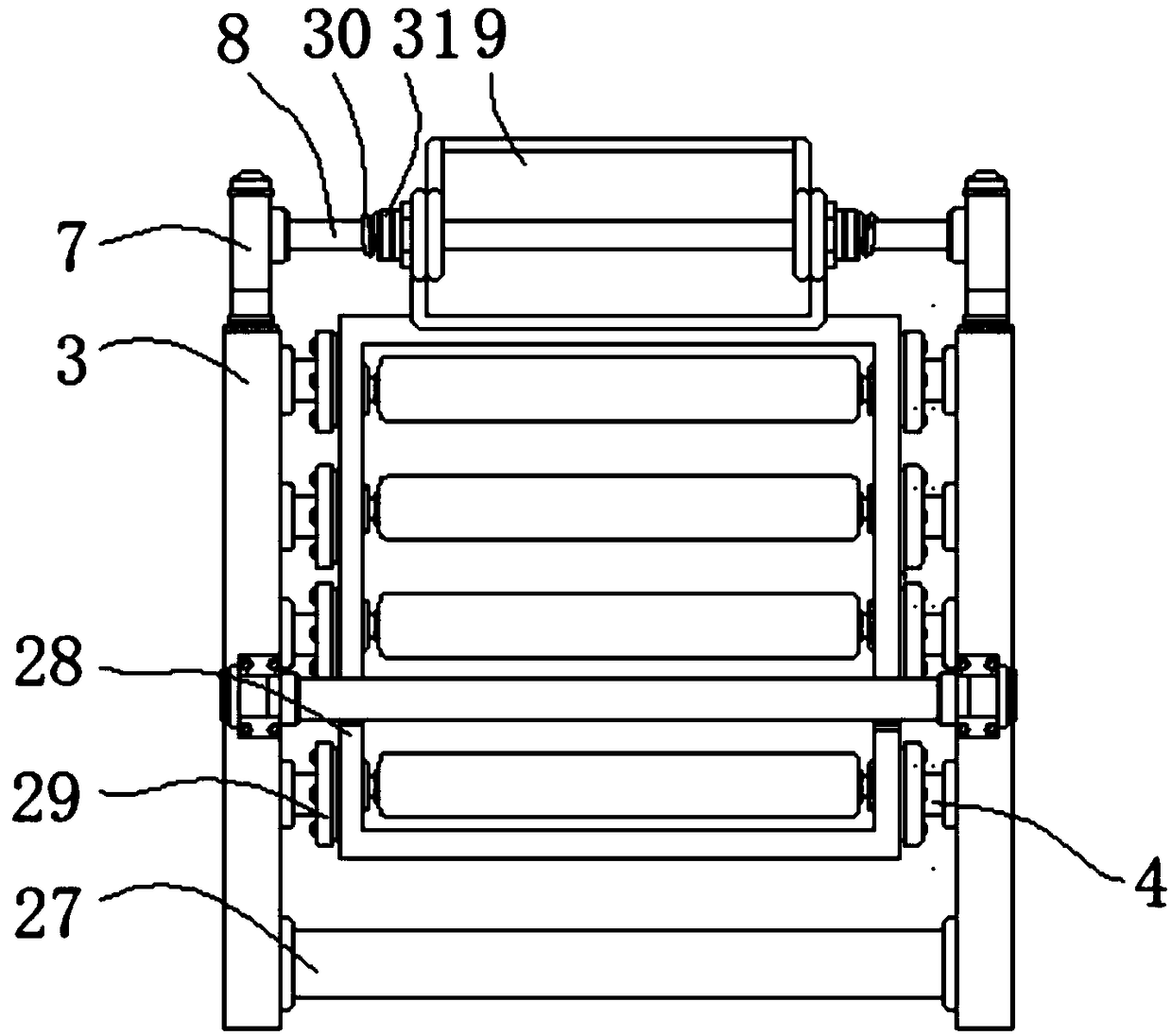

The invention relates to the technical field of mechanical equipment, in particular to a manipulator based on automatic control. A vertical plate is arranged on the front side of a sliding rail, and the rear side of the vertical plate is slidably arranged on the sliding rail through a sliding block; the rear side wall of the vertical plate is fixedly connected with a nut which is in threaded connection with a first lead screw; an adjusting plate is movably arranged on the front side of the vertical plate, and the rear side wall of the adjusting plate is fixedly connected with a nut in threadedconnection with a second lead screw; a cross beam is vertically and fixedly arranged on the front side wall of the adjusting plate, and a clamping mechanism is arranged on the lower side of the crossbeam; clamping arms are symmetrically and rotationally arranged on the left and right sides of the lower end of an internal thread pipe through rotating shafts and bearings; and clamping plates are movably connected to the lower ends of the clamping arms on the left side and the right side through hinge pieces, the manipulator is driven by a motor to move, no structures such as an air throttle needs to be adopted for cooperative work, the manufacturing cost and energy consumption are reduced, the whole device is convenient to repair and maintain through motor driving, and the cargo clamping force can be effectively controlled in the cargo clamping process.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

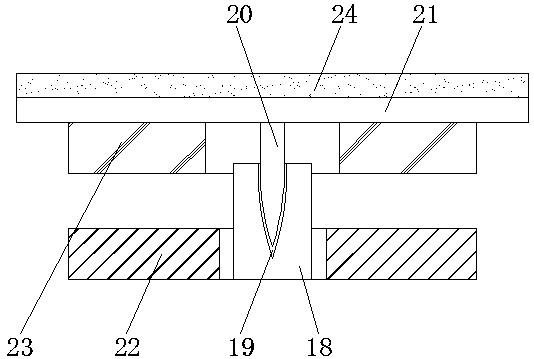

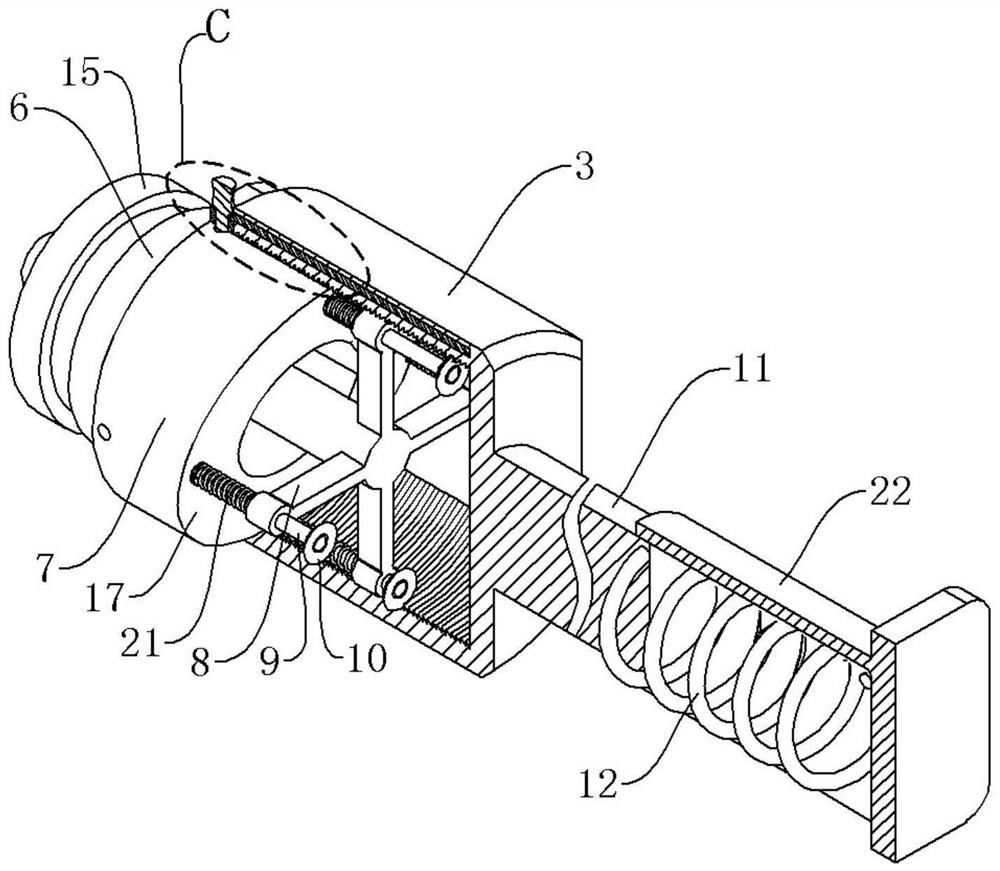

Terminal pin-inserting device

InactiveCN104979736AStable clampingAdjust the clamping forceContact member assembly/disassemblyDrive shaftEngineering

The invention provides a terminal pin-inserting device which comprises a cam box body, a cam connecting shaft, a pin-inserting cam, a connecting block, a driving shaft, a pin-inserting push block, a clamping cam, a clamping swing rod, a first U-shaped block, a chuck sliding block, a clamping cutter, a cutting cam, a cutting swing rod, a second U-shaped block, a cutting sliding block, a cutting tool and a static cutter block. The terminal pin-inserting device provided in the invention can integrally complete terminal clamping, terminal cutting and terminal pin inserting actions, and has the advantages of high machining precision, fast speed and high production efficiency.

Owner:SUZHOU HANCHUAN CO LTD AKA HARMONTRONICS

Terminal pin plugging device

InactiveCN104901123AAdjust the clamping forceStable clampingContact member manufacturingContact member assembly/disassemblyEngineeringCam

The invention provides a terminal pin plugging device comprising a cam box body, a cam connecting shaft, a cutting cam, a pin plugging cam, a material clamping cam, a cutting transmission shaft, a pin plugging transmission shaft, a material clamping transmission shaft, a cutting connecting block, a pin plugging connecting block, a material clamping connecting block, an upper knife track block, a lower knife track block, a first slide block supporting base, an upper knife slide block, a lower knife slide block, an upper cutting knife, a lower cutting knife, an upper clamping head slide rod, a lower clamping head slide rod, an upper clamping head, a lower clamping head, an upper clamping head track block, a lower clamping head track block, an upper clamping head slide block, a lower clamping head slide block and a second slide block supporting base. A cutting mechanism, a material clamping mechanism and a pin plugging mechanism are driven to actuate orderly by the cam connecting shaft so that motions of terminal material clamping, terminal cutting and terminal pin plugging can be completed by the terminal pin plugging device in an integrated way, and the terminal pin plugging device is high in processing precision, high in speed and high in production efficiency.

Owner:SUZHOU HANCHUAN CO LTD AKA HARMONTRONICS

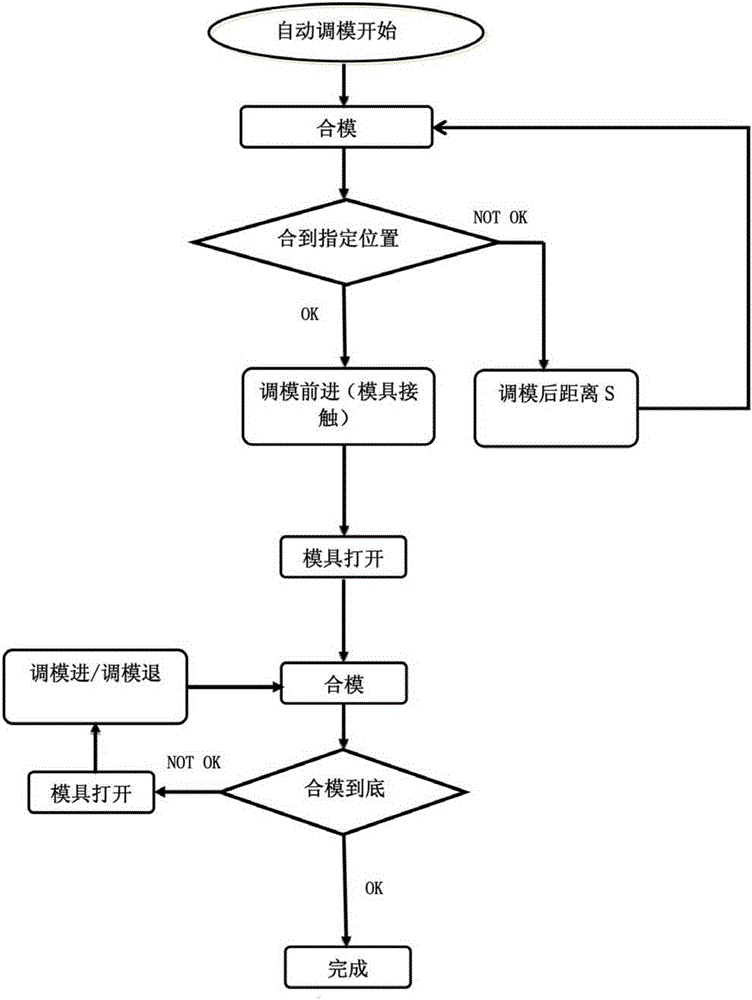

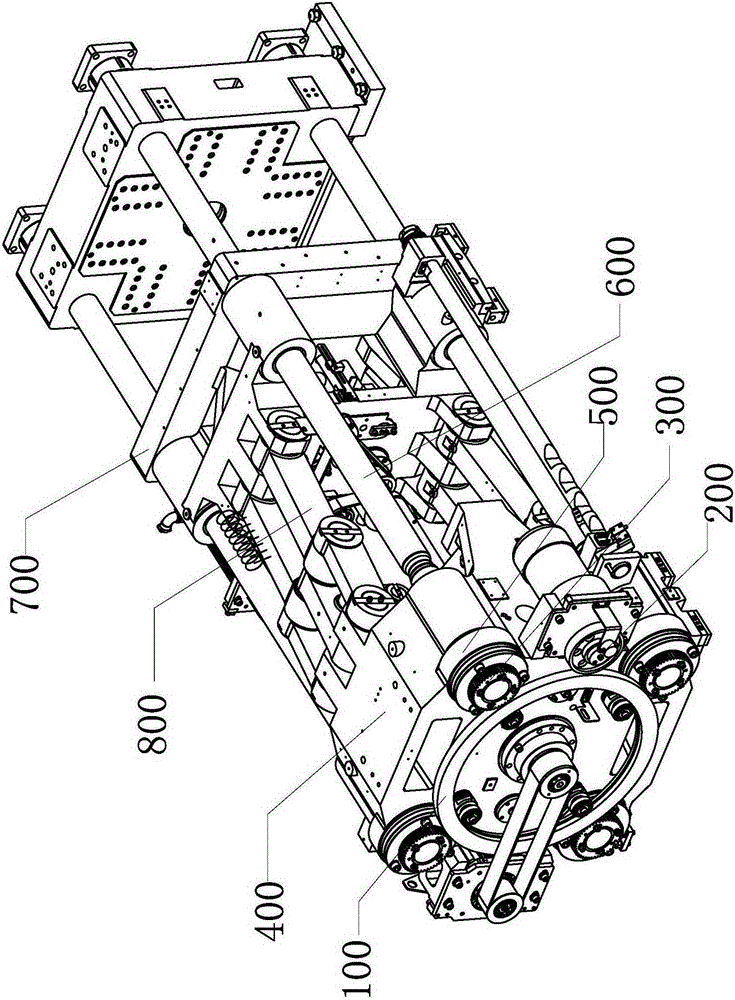

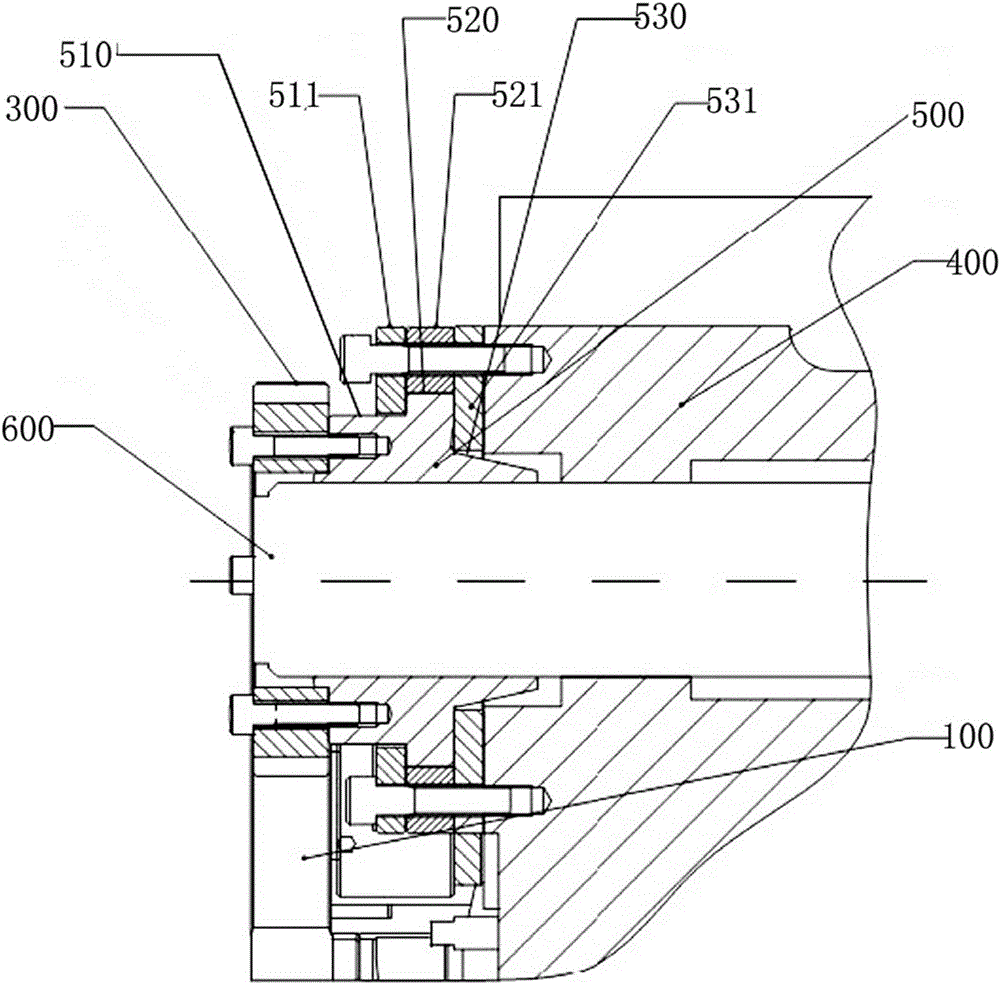

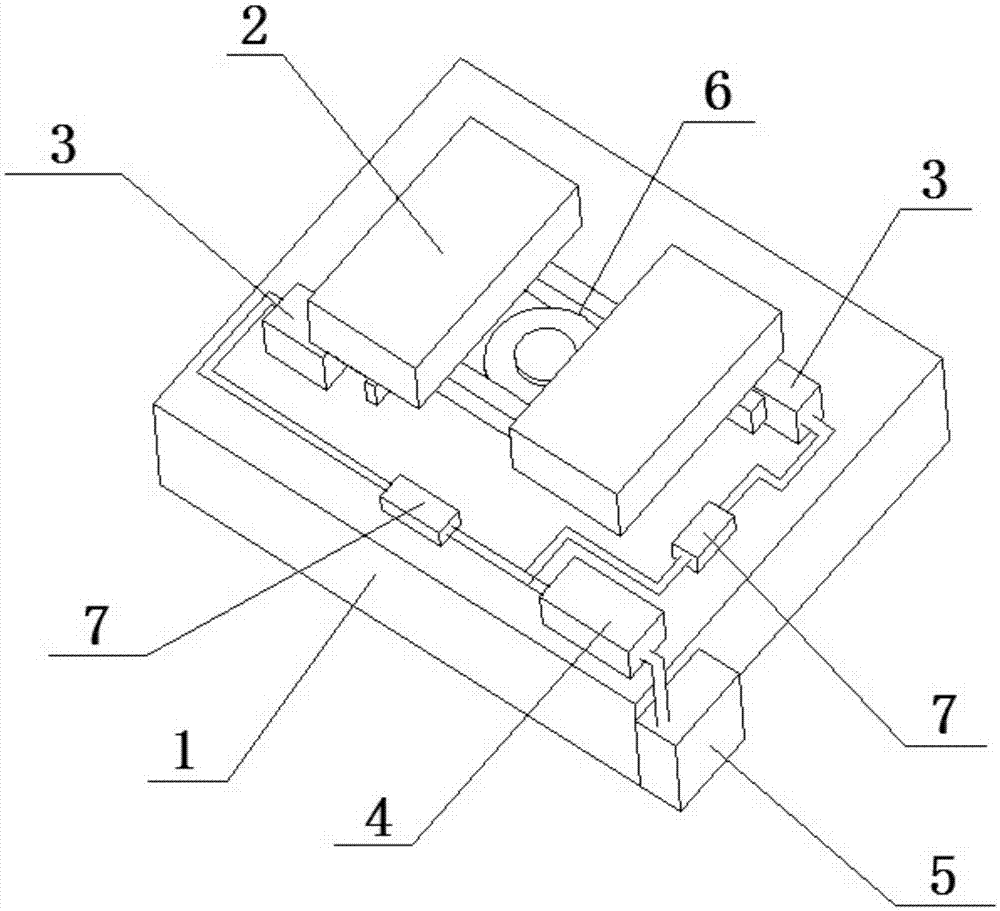

Rapid mold adjusting method and mold adjusting device for injection molding machine

The invention relates to a rapid mold adjusting method for an injection molding machine. The method includes the following steps that S1, a moving mold plate is controlled to move to a predetermined position; whether the moving mold plate makes contact with a mold or not is judged, and if yes, the next step is performed; otherwise, the moving mold plate is continued to move to the predetermined position; S2, the mold is opened, a mold adjusting gear wheel rotates, and a pulling rod is adjusted to move forwards or backwards, so that the fine adjustment of the distance between the moving mold plate and the mold is achieved; S3, the moving mold plate is finely adjusted to reach the preset mold locking force, and the mold adjusting is successful; and if the mold locking force does not reach or exceeds the preset value, the step S2 is continued. The invention further relates to a rapid mold adjusting device for the injection molding machine. By means of the rapid mold adjusting method and the mold adjusting device for the injection molding machine, the time of the whole mold adjusting process is greatly shortened, and the working efficiency of the injection molding machining is improved.

Owner:NINGBO ZHAFIR PLASTICS MACHINERY

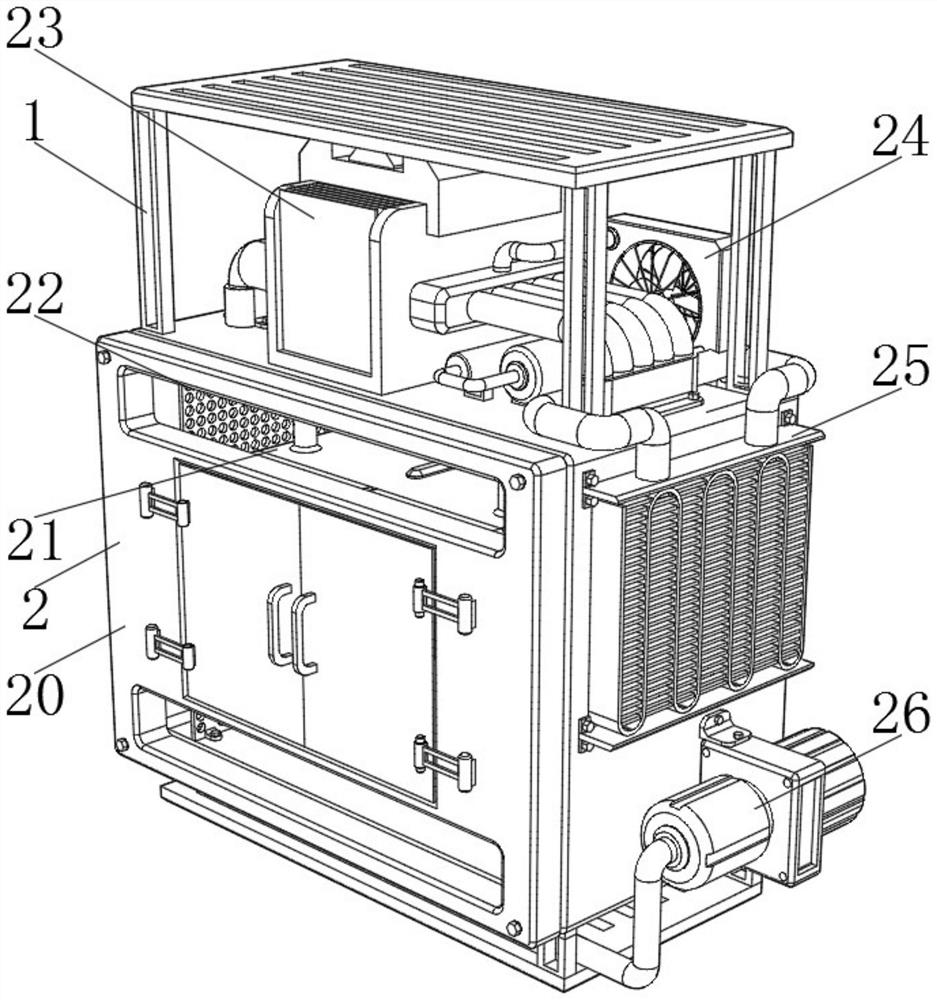

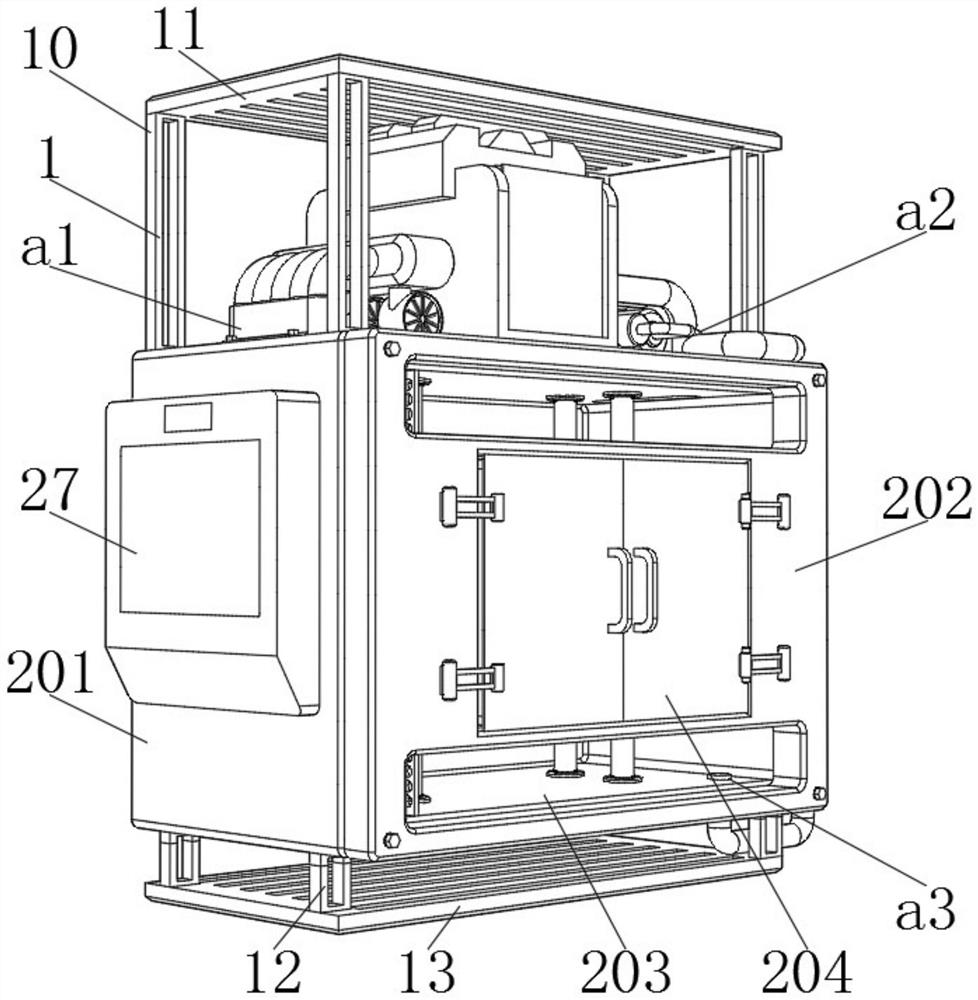

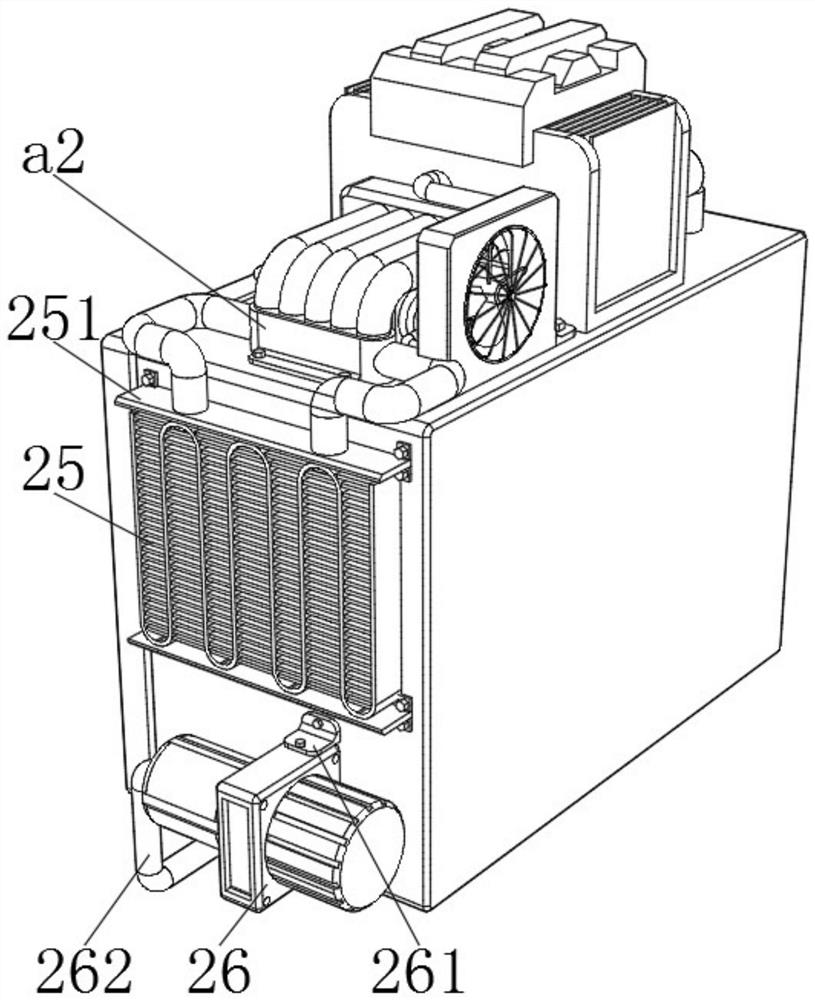

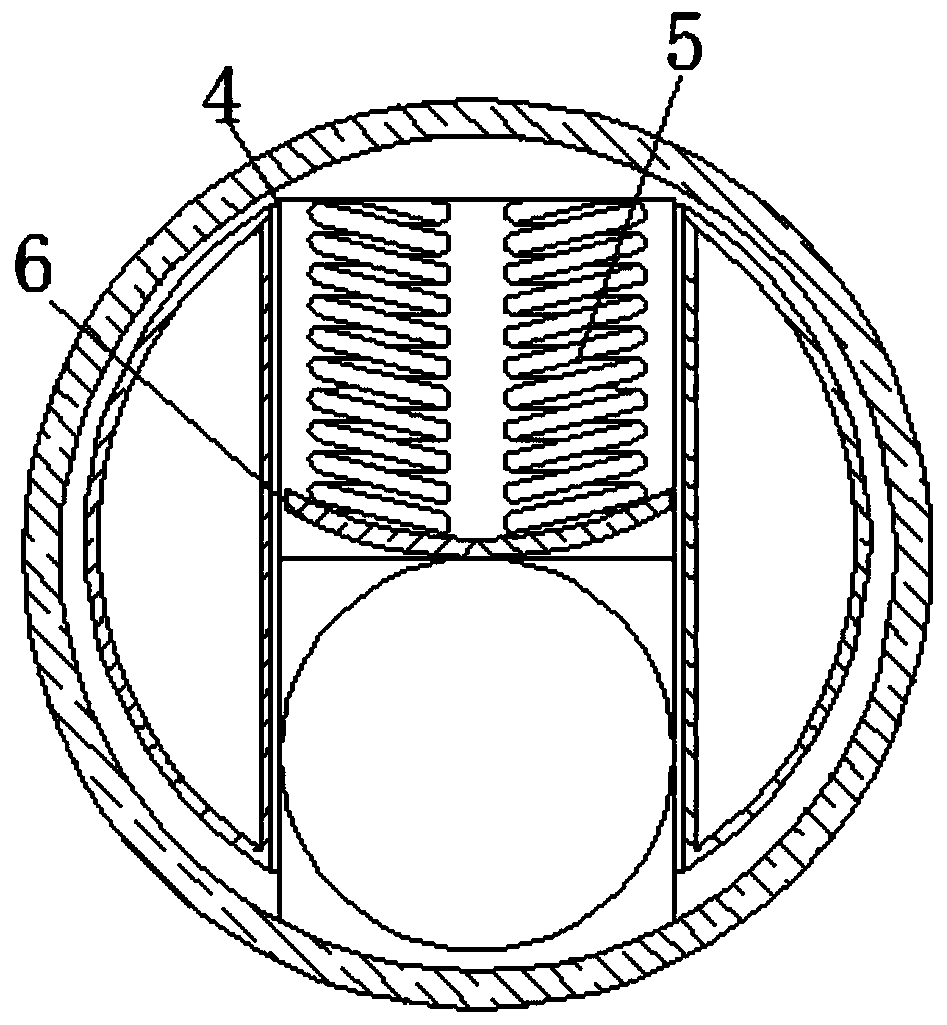

Radiation low-pressure environment simulation cabin

InactiveCN113413931AEasy to cleanAdjust the clamping forceHeating or cooling apparatusAir-pressure/air-lock chambersTemperature conditioningEngineering

The invention discloses a radiation low-pressure environment simulation cabin, which comprises a protection frame and a simulation cabin. The inner side of the protection frame and the outer side of the simulation cabin are fixedly installed, and the simulation cabin comprises a heat preservation cabin body, a low-pressure cabin body, a ventilation hole plate, a circulating fan, a heating unit, a refrigerating unit, an evaporator, a vacuum unit and a temperature sensor. According to the radiation low-pressure environment simulation cabin, the refrigerating unit, the heating unit and the circulating fan are started to send the adjusted temperature to the position above the ventilation hole plate in the heat preservation cabin body through the air pipe, then the adjusted temperature is evenly sent into the heat preservation cabin body through the ventilation hole plate, and the adjusted air evenly radiates the six wall faces of the low-pressure cabin body under the flowing condition; the purpose of controlling and adjusting the temperature in the low-pressure cabin body is achieved, air in the heat preservation cabin body returns to the temperature adjusting section through the air pipe, circulation in the heat preservation cabin body is formed, meanwhile, the circularly flowing air can be dehumidified and dried at the position where the air passes through the evaporator, and dew condensation on the wall face of the low-pressure cabin body is further avoided.

Owner:云沛科技集团有限公司

Machining fixing and limiting mechanism capable of adjusting limiting strength conveniently

ActiveCN111531382ASufficient powerFast clamping limitPositioning apparatusMetal-working holdersElectric machineGear wheel

The invention discloses a machining fixing and limiting mechanism capable of adjusting limiting strength conveniently. The machining fixing and limiting mechanism comprises a fixed workpiece, clampingmechanisms, adjusting and control mechanisms and a transmission mechanism. The adjusting and control mechanisms are in symmetric threaded rotary sliding connection to the inner end face of the transmission mechanism. If users need to adjust the strength of clamping the fixed workpiece, the users can start fixed motors through the outer adjusting and control mechanisms, the fixed motors can drivegear grooves to shift towards the front portion, then connecting baffles and elastic switches are driven to shift towards the front portion, the shift stroke of limiting clamp blocks is indirectly prolonged at this moment, then shifting generated when the limiting clamp blocks pull spring clamp rings is longer, and the strength that the clamping mechanisms clamp and locate the fixed workpiece is improved; and the users can adjust the distance between the connecting baffles and limiting sliding plates, then the clamping strength to the fixed workpiece is adjusted, the users can adjust the strength of clamping the fixed workpiece rapidly and conveniently, and safety performance of clamping the fixed workpiece is improved.

Owner:贵阳一舟航科机械设备制造有限公司

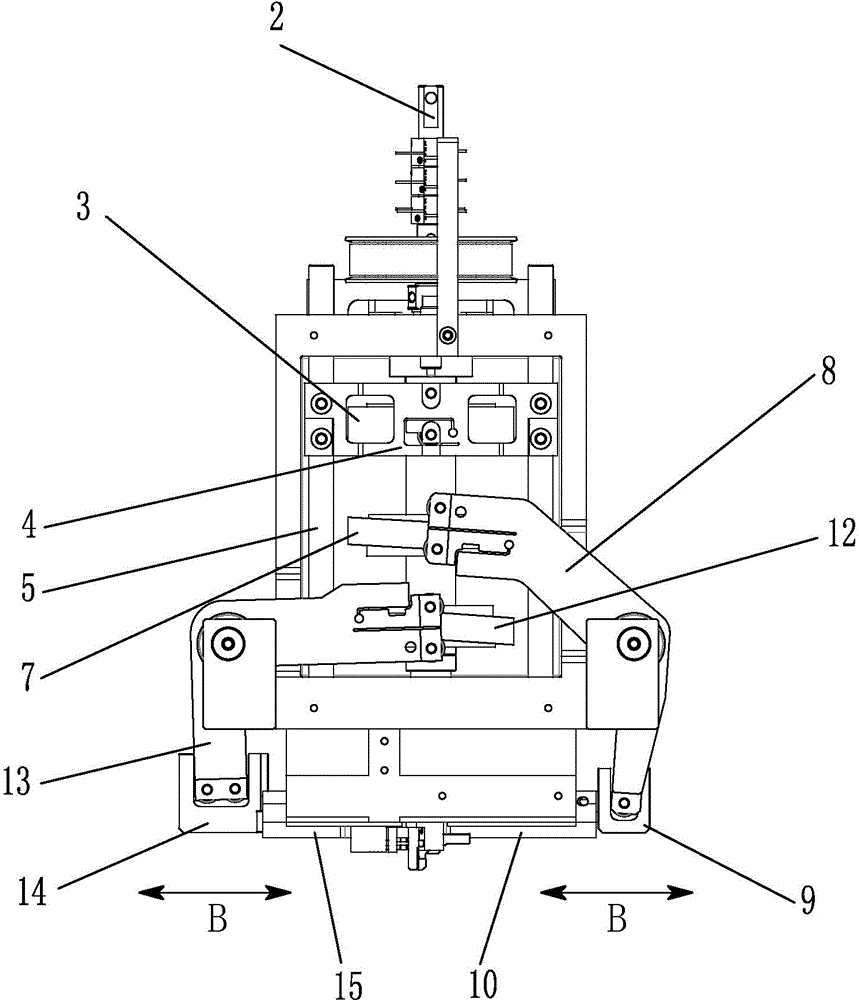

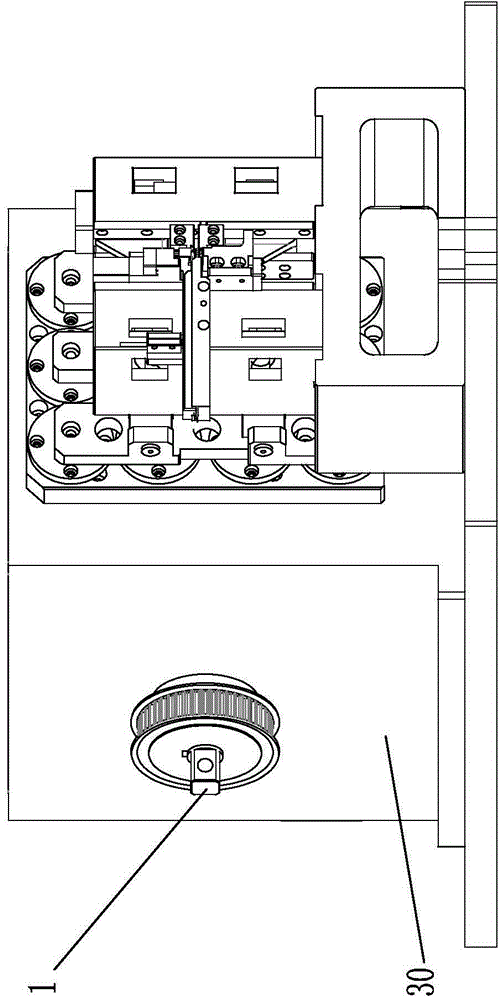

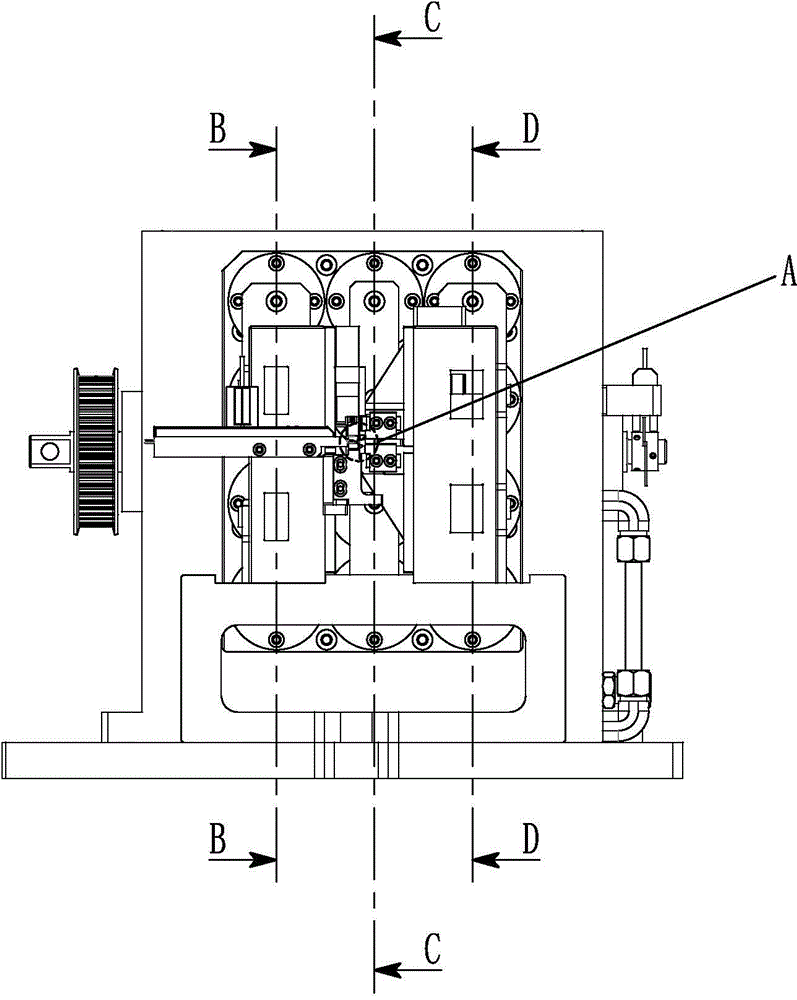

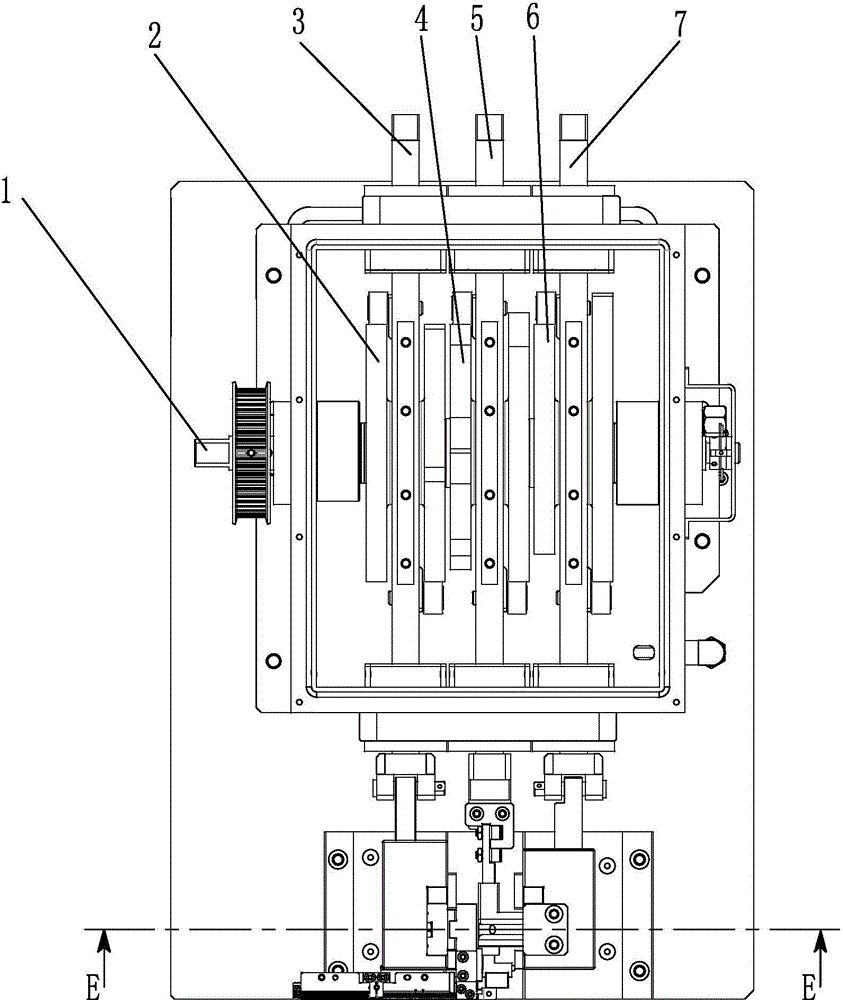

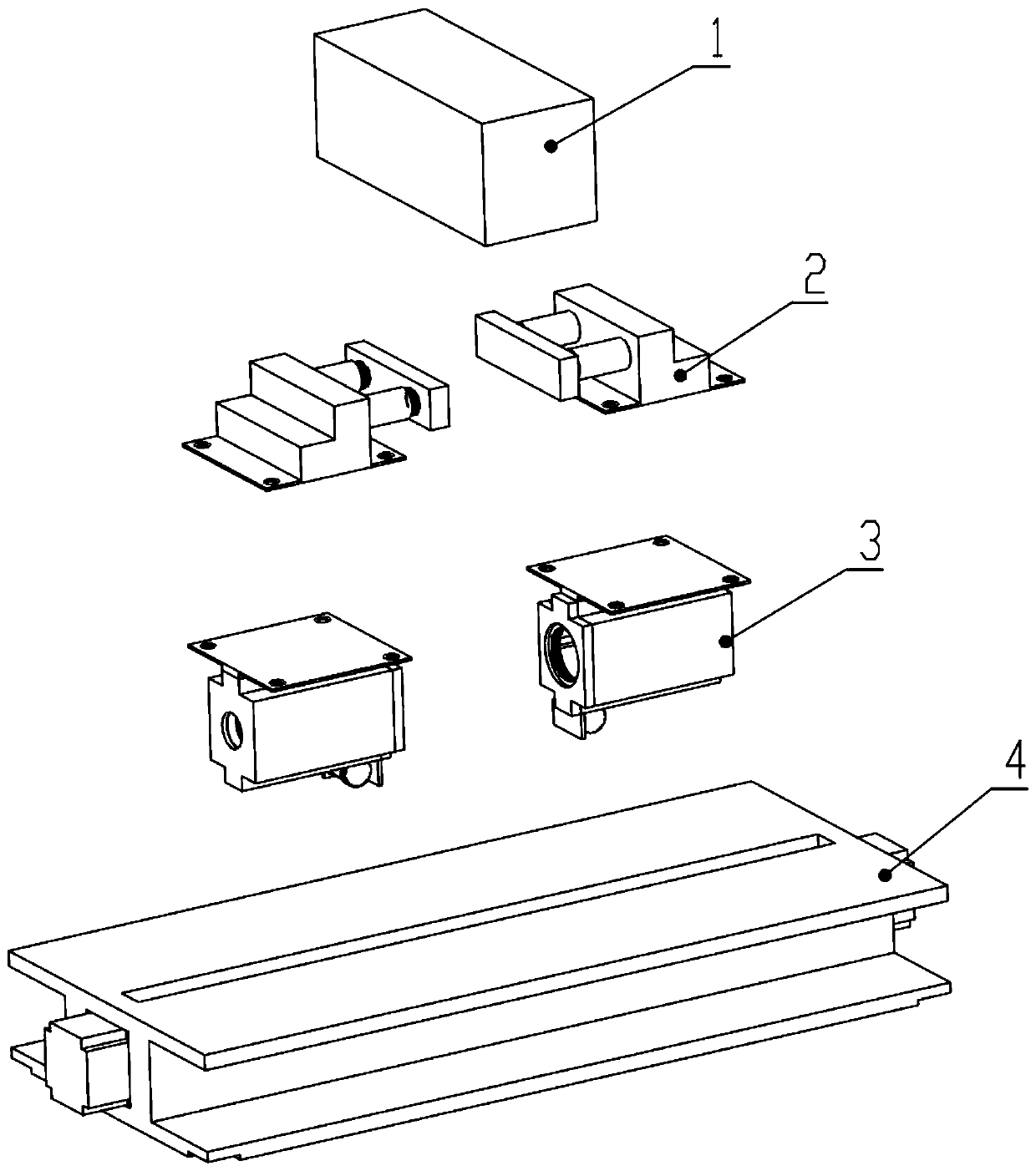

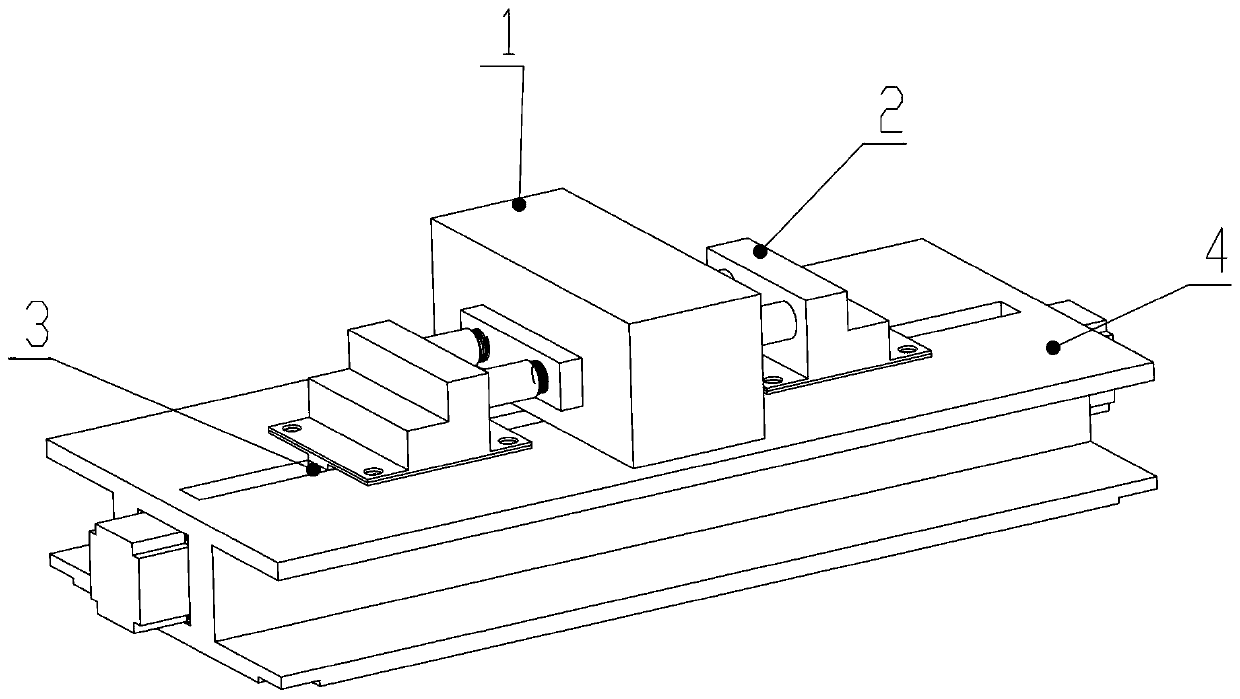

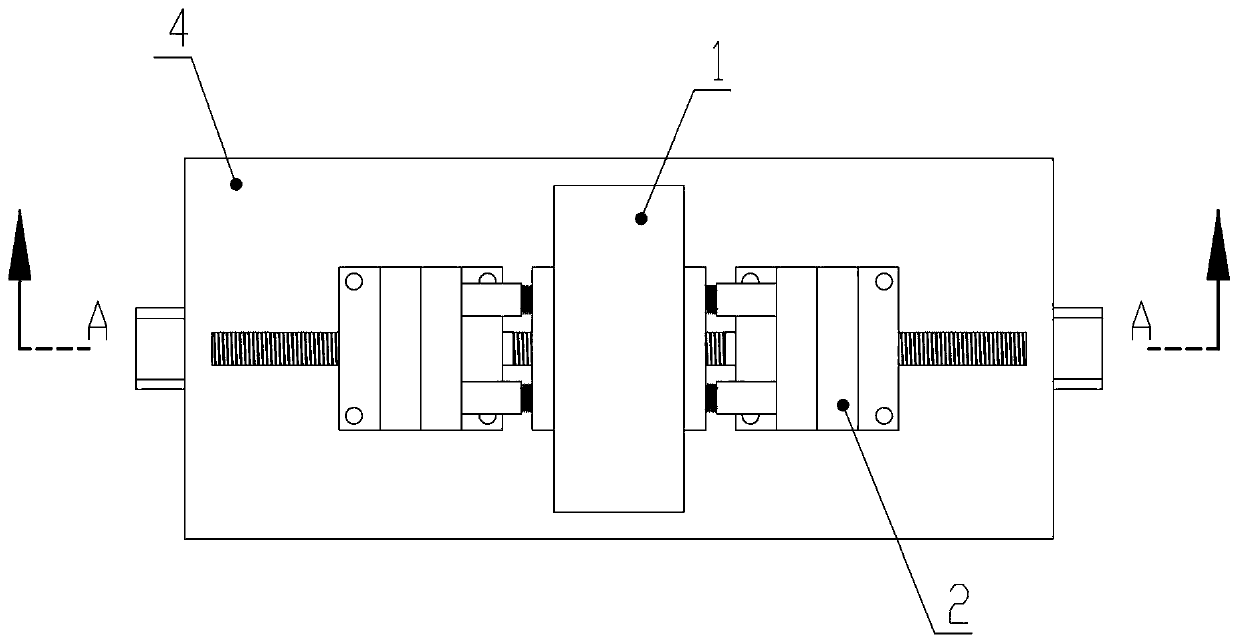

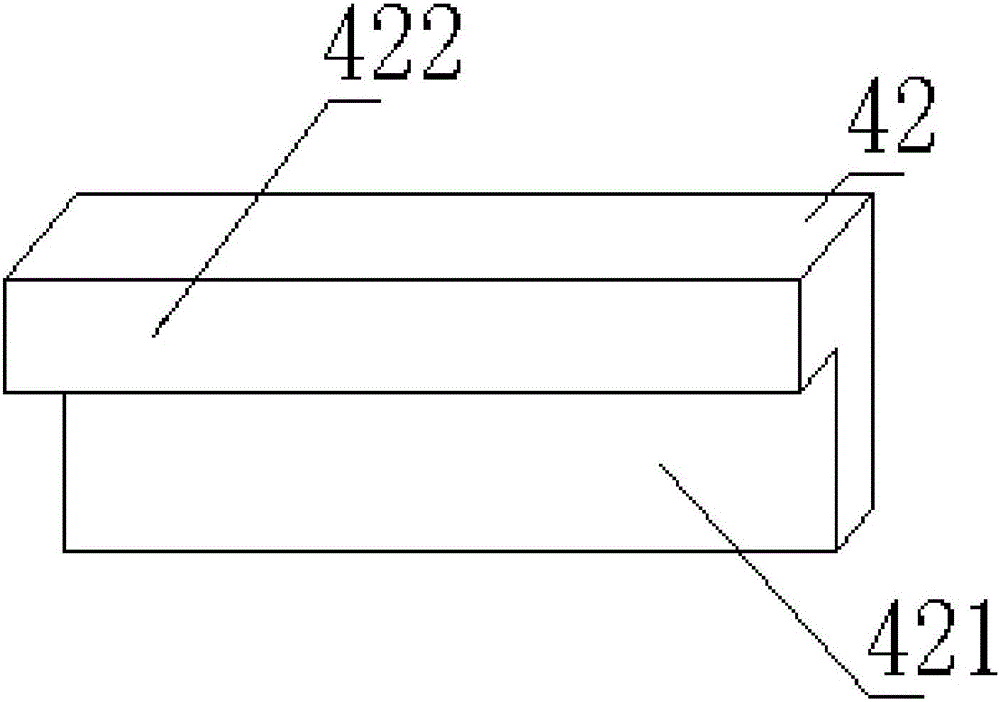

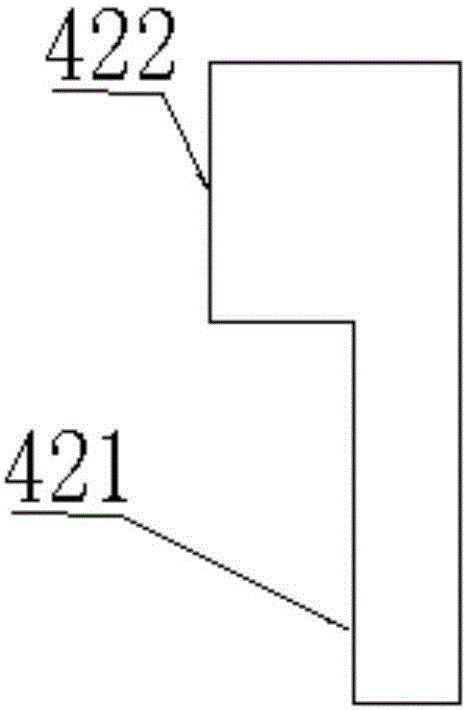

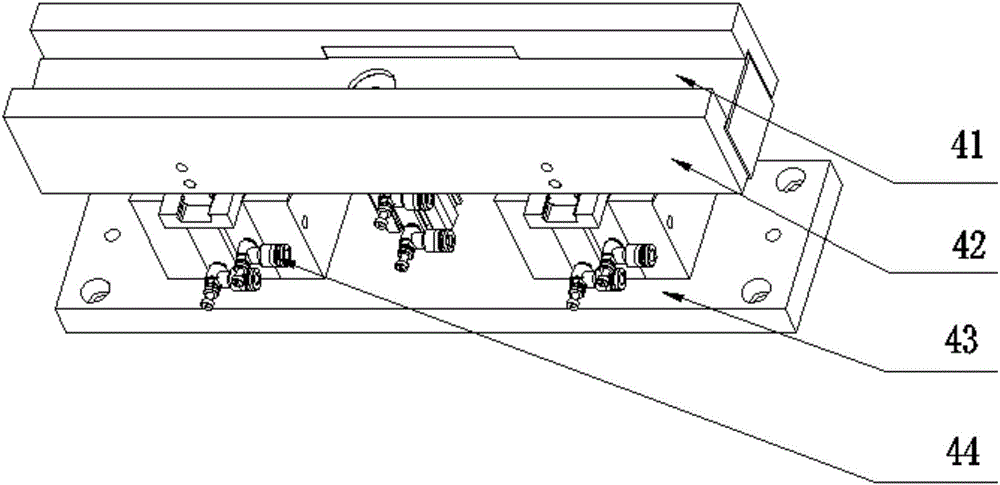

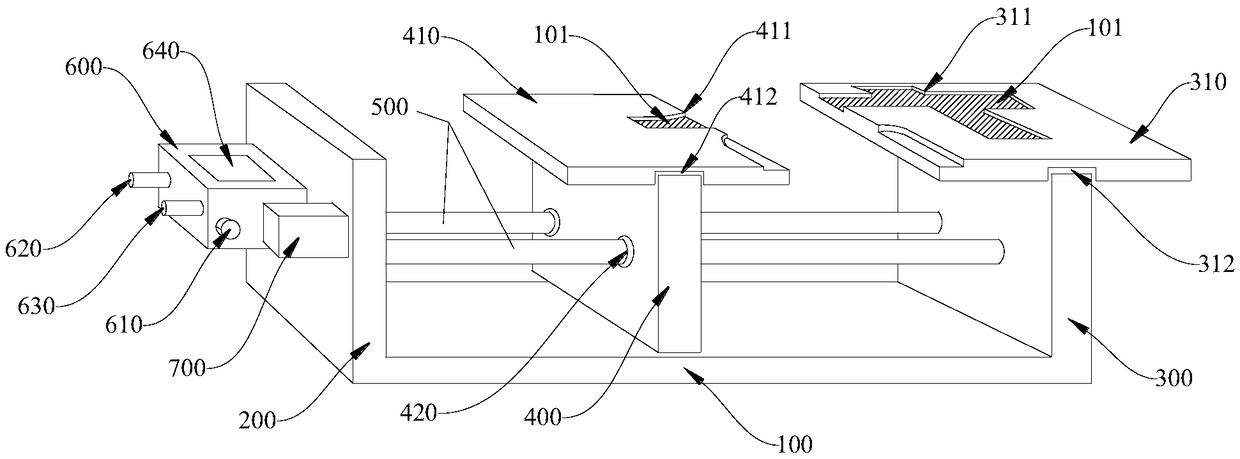

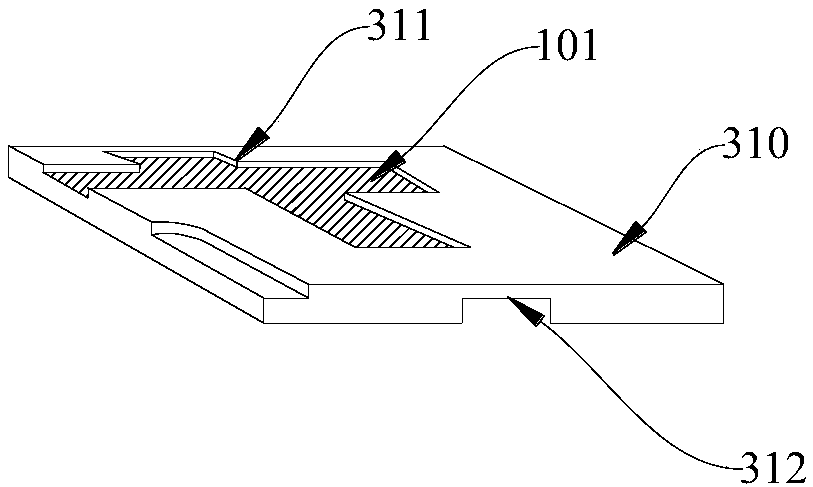

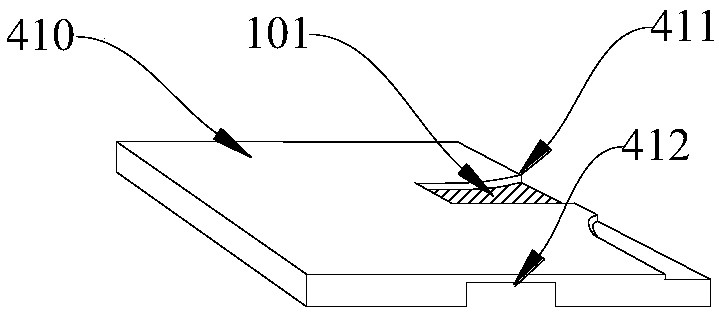

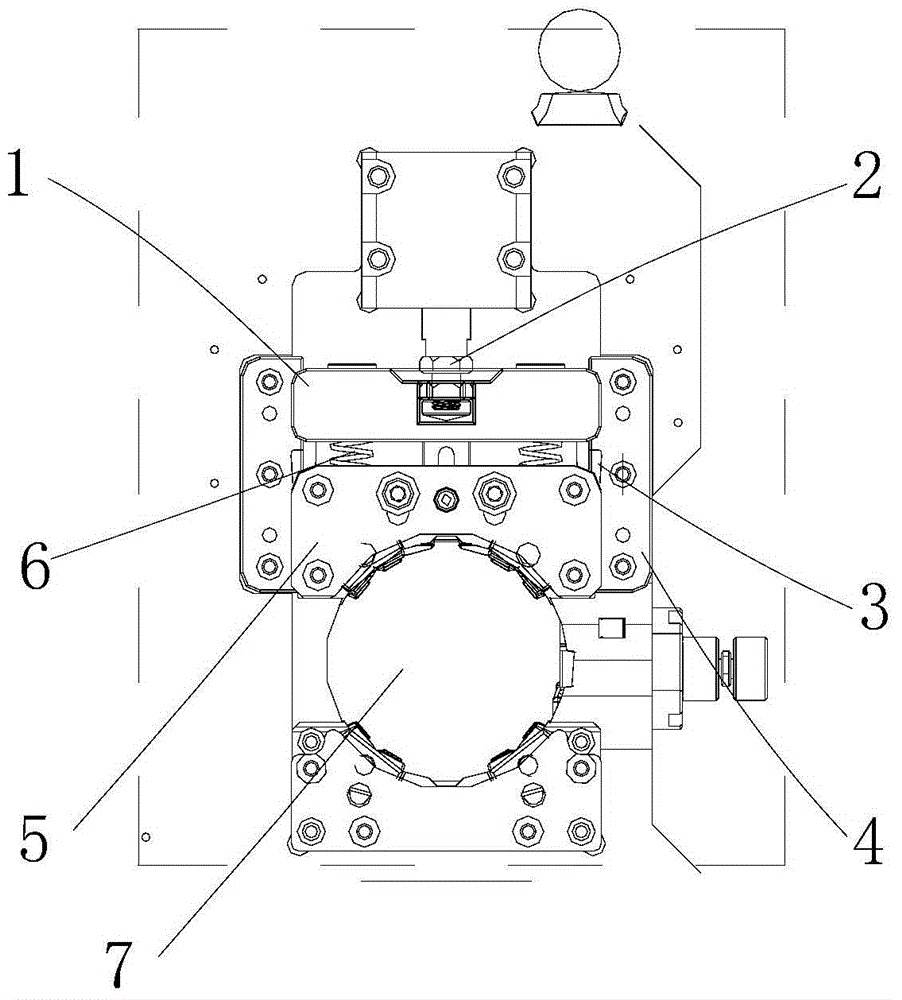

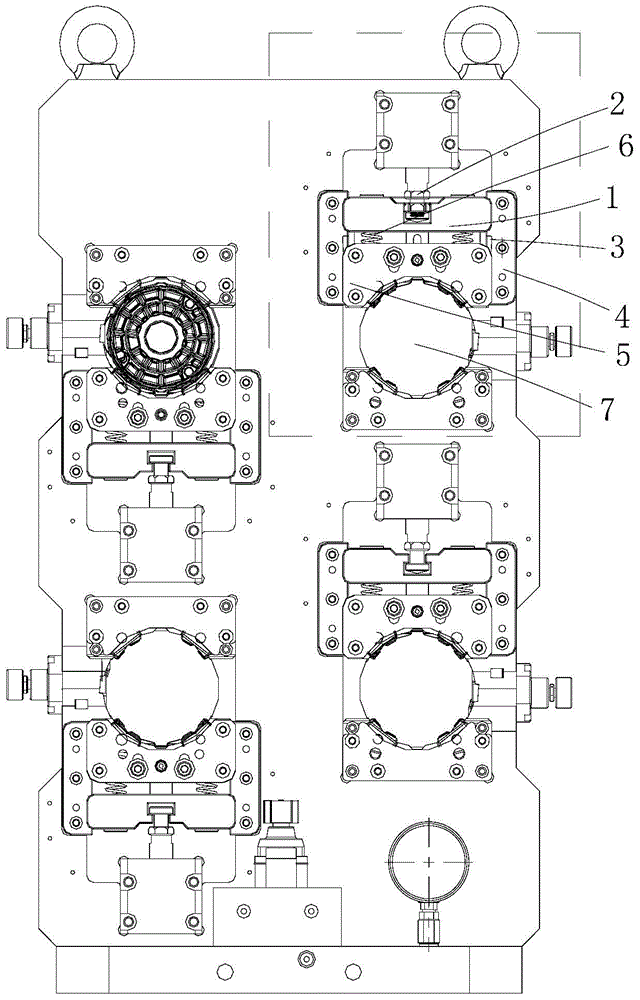

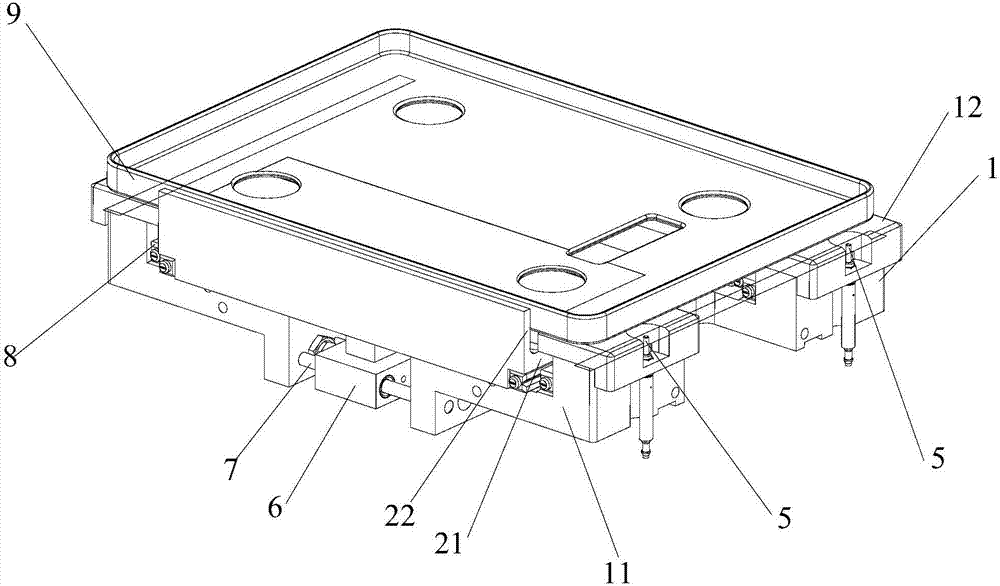

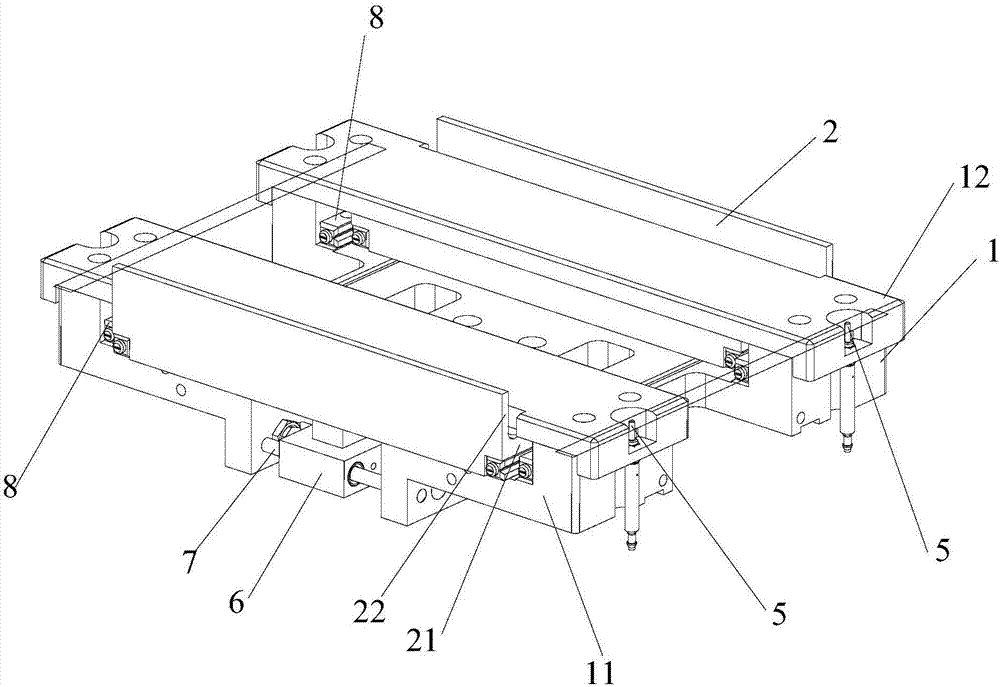

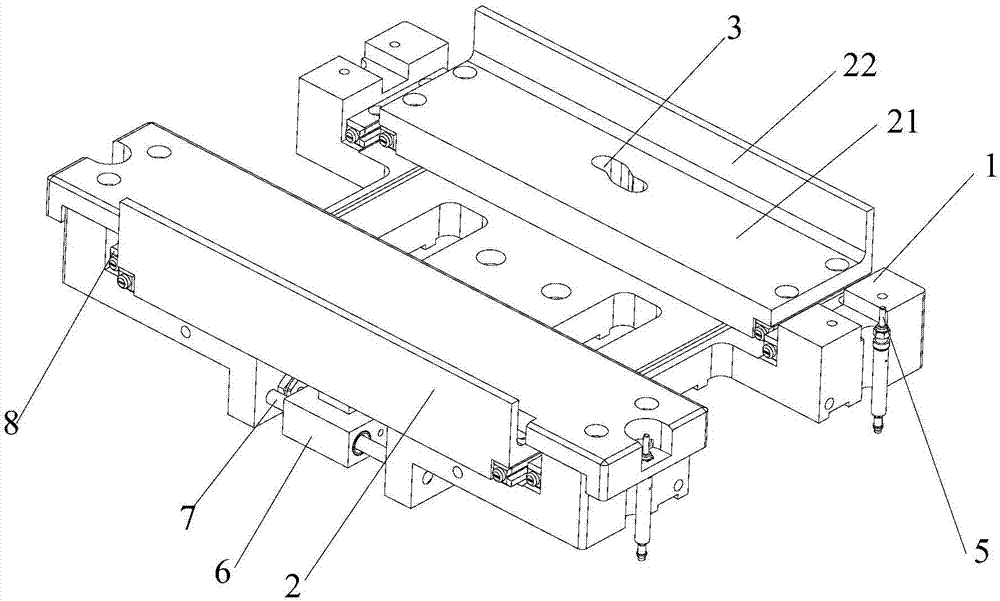

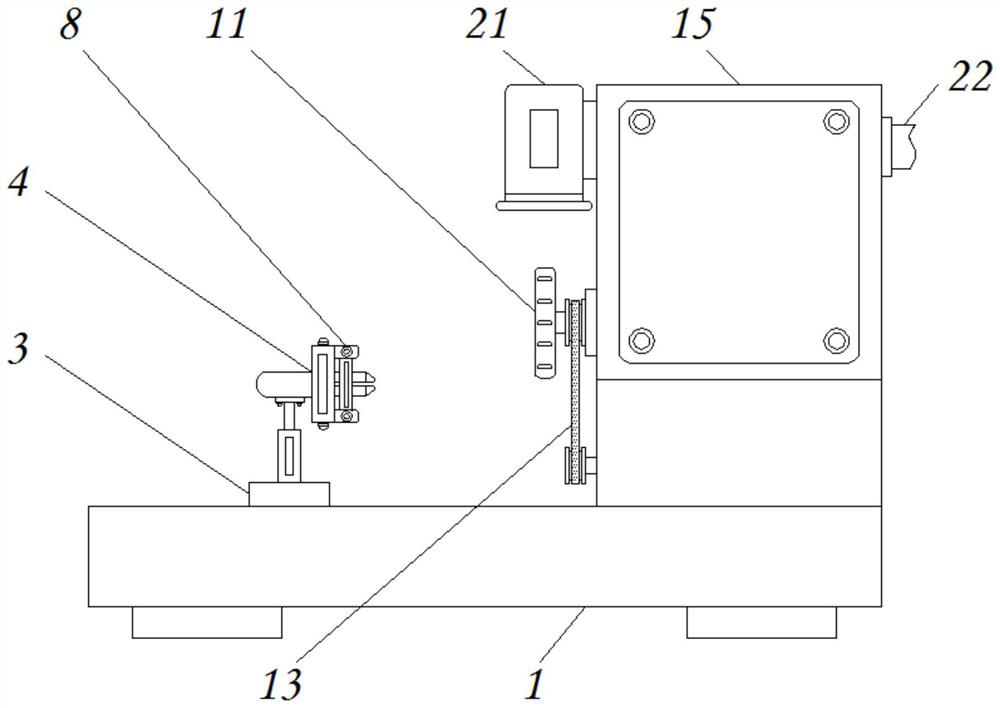

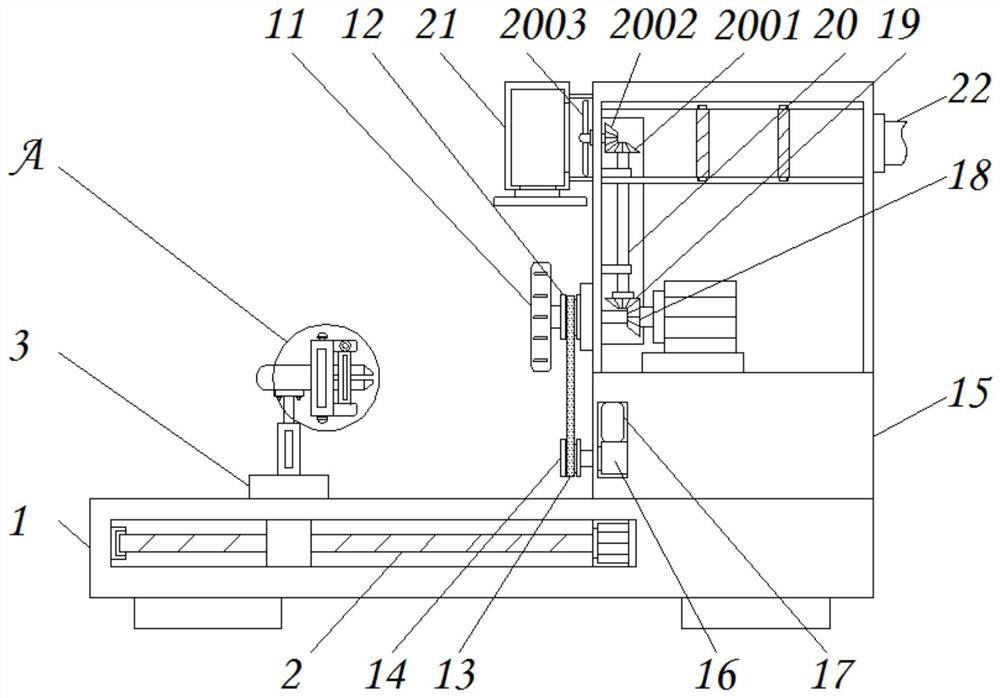

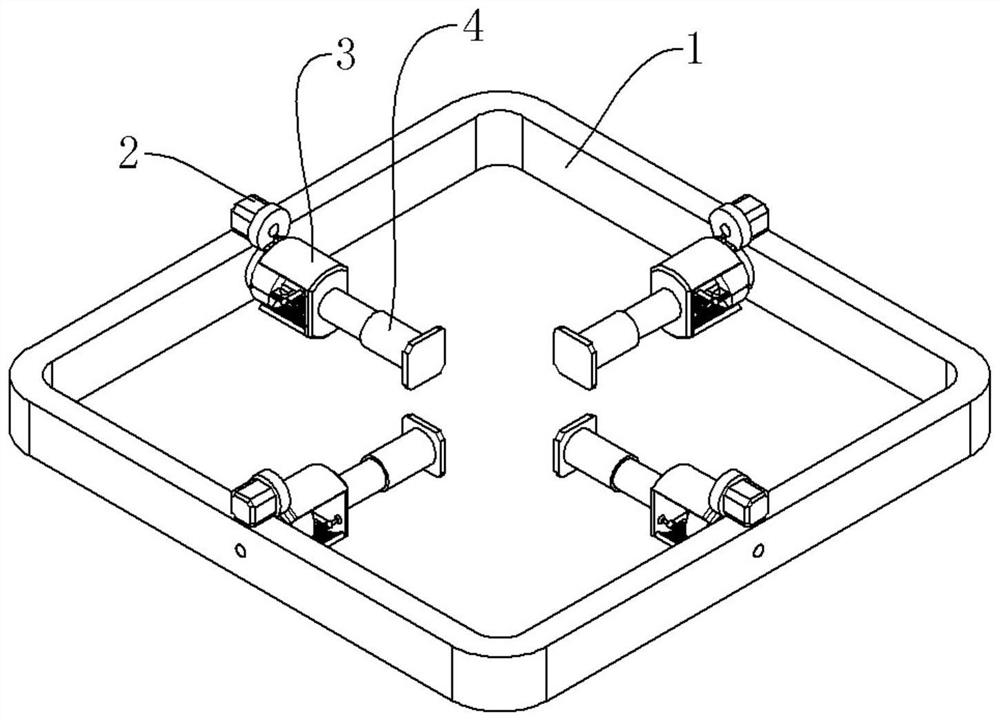

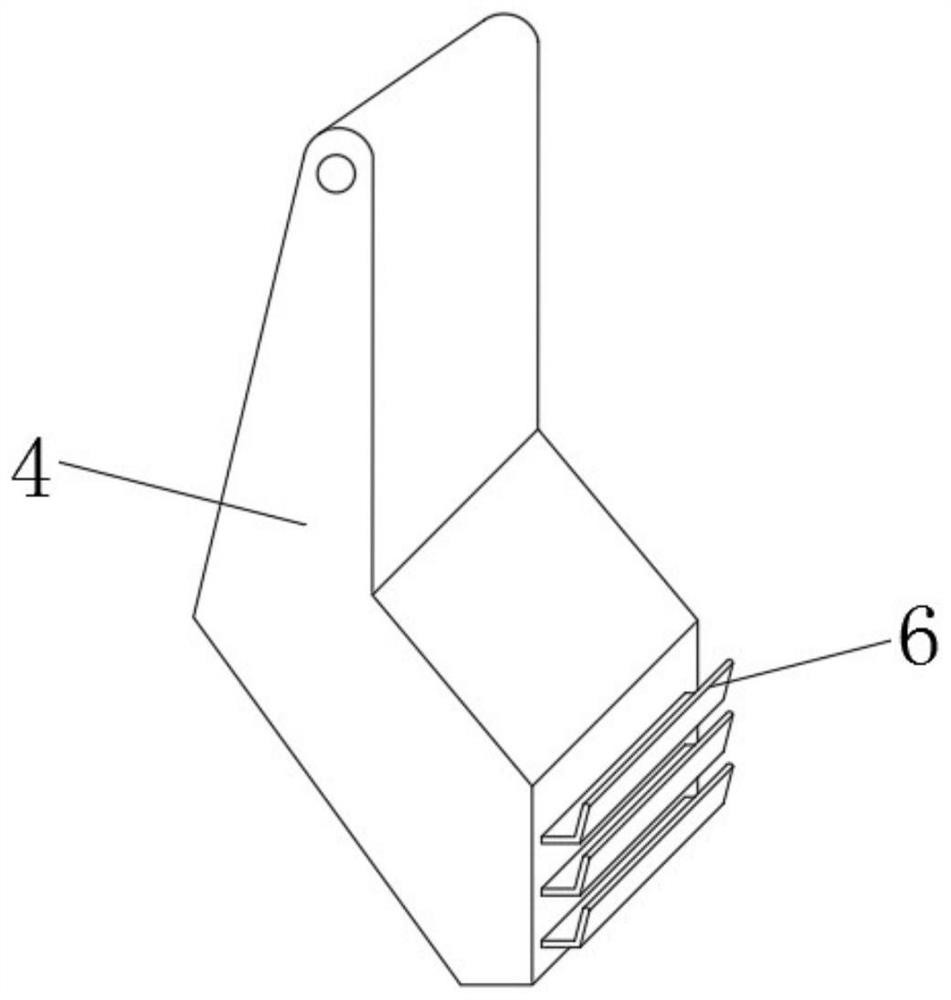

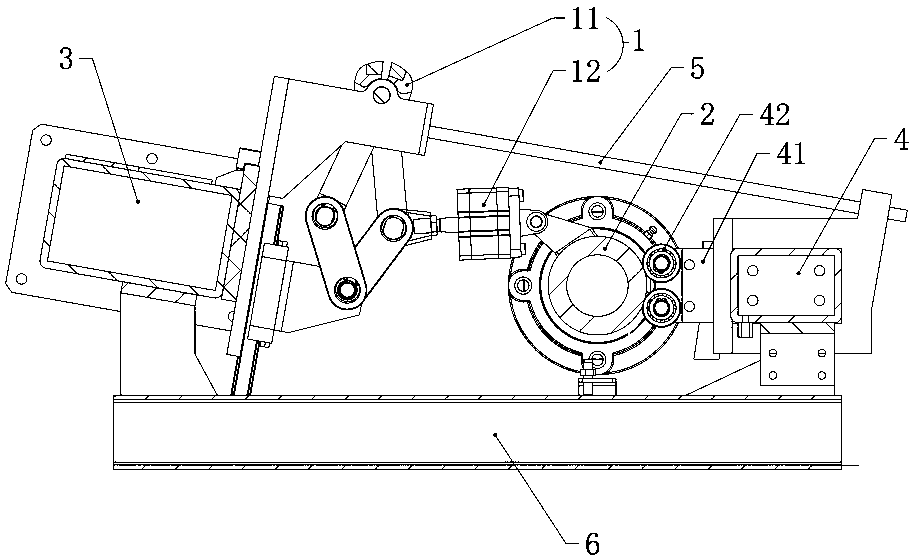

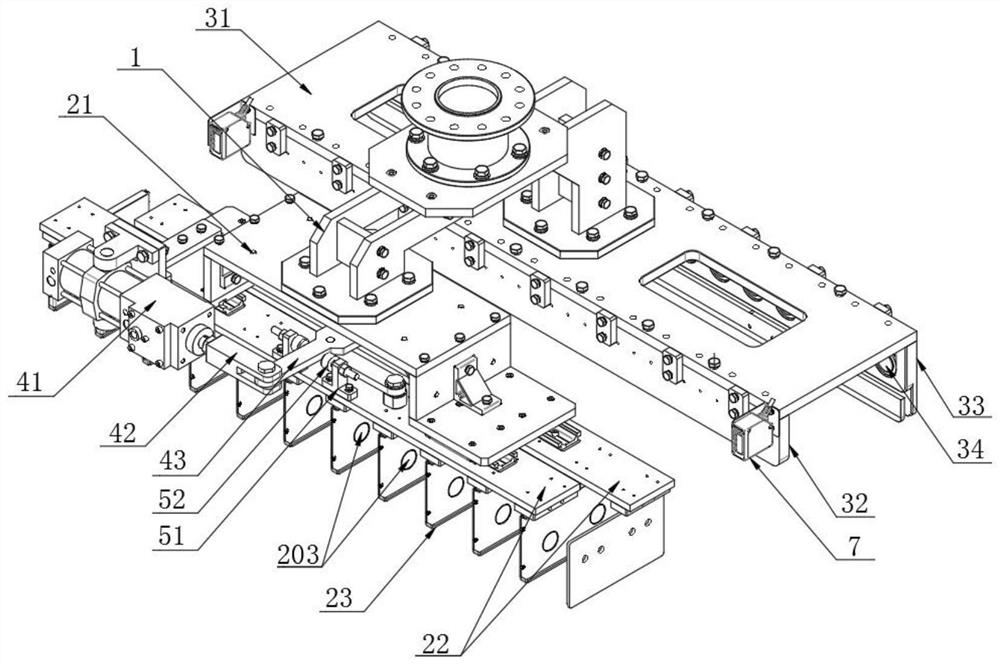

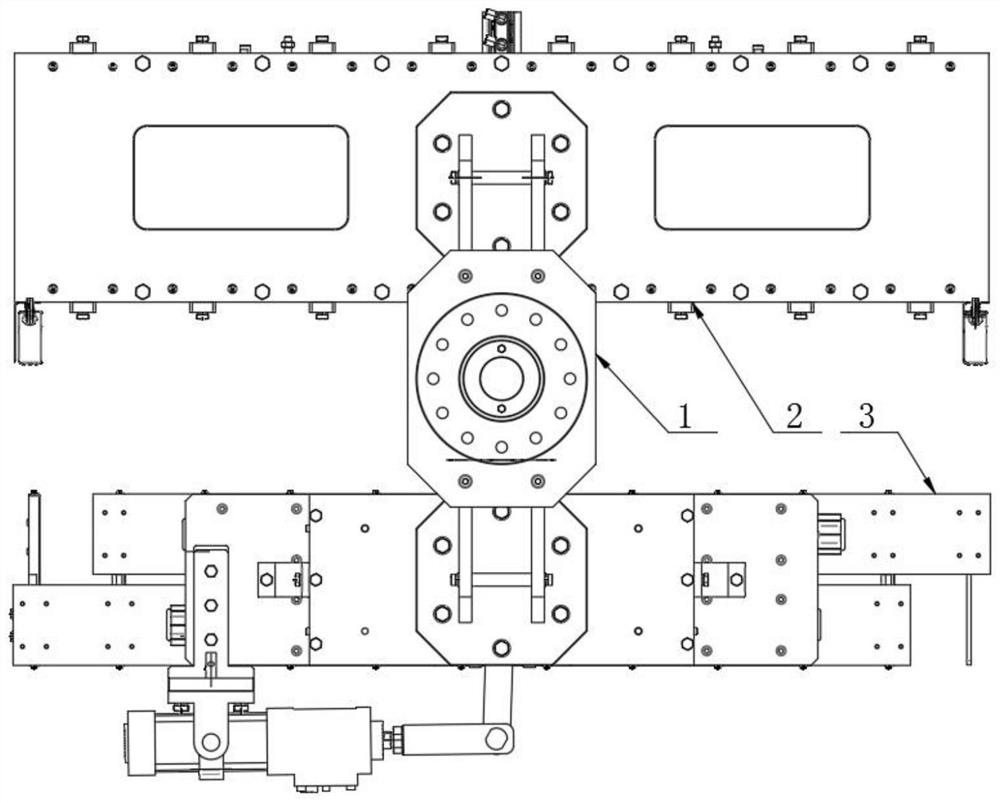

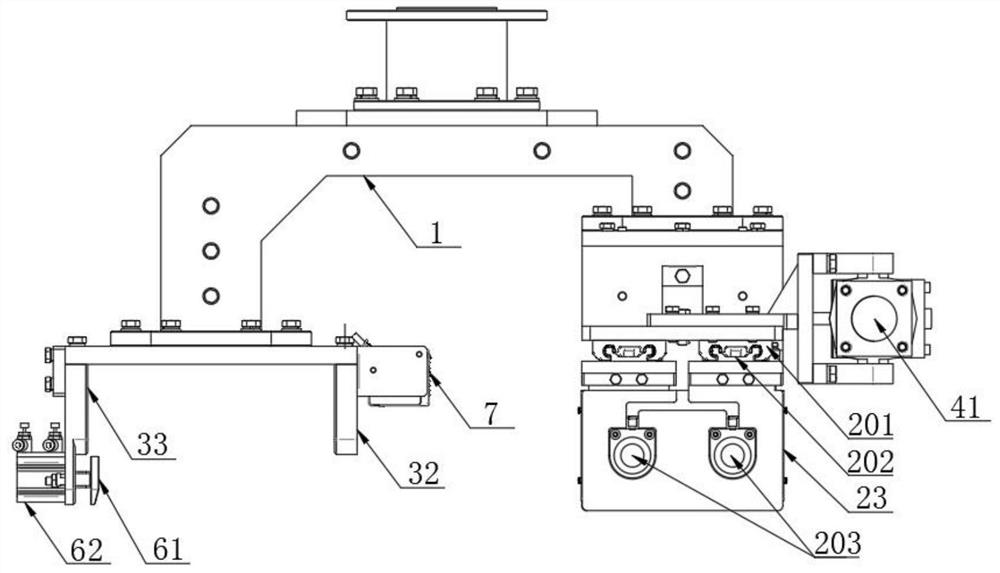

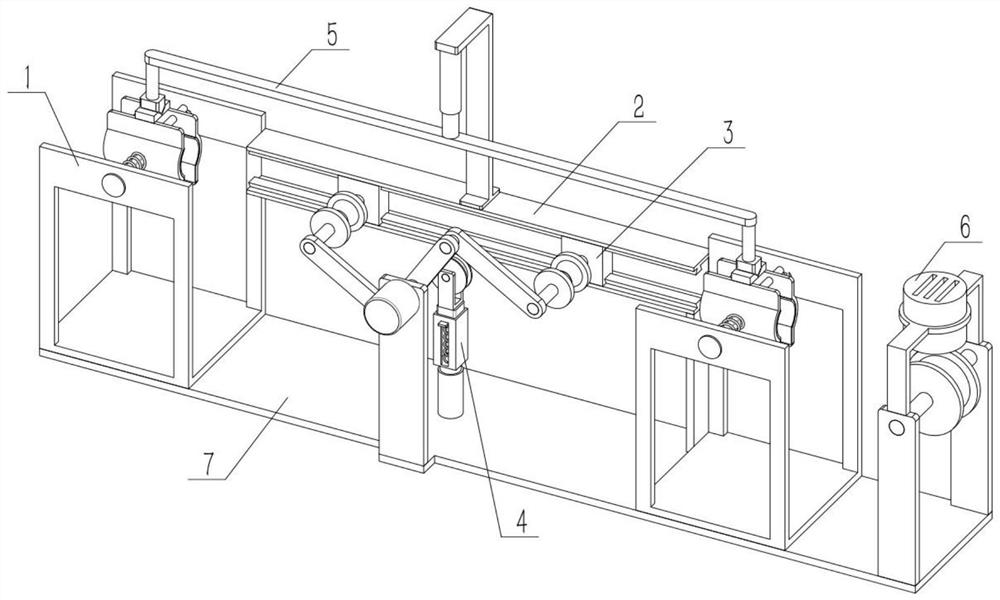

Automobile seat sliding track assembling machine, clamping mechanism thereof and adjusting method

ActiveCN106112874ALarge clamping forceGuaranteed assembly qualityAssembly machinesWork holdersMechanical engineering

The invention relates to the field of manufacturing of automobiles, in particular to an automobile seat sliding track assembling machine, a clamping mechanism thereof and an adjusting method. The automobile seat sliding track assembling machine comprises a clamping supporting seat, movable clamping plates, a fixed bottom plate and clamping finger cylinders, wherein the two movable clamping plates are respectively arranged on two sides of the clamping supporting seat; the two clamping finger cylinders are respectively fixed on the fixed bottom plate and are respectively connected with the two movable clamping plates; each movable clamping plate has a 7-shaped structure and comprises a lower adjusting surface and an upper adjusting surface; each upper adjusting surface is arranged on a projection; and each lower adjusting surface is arranged on a recess. The automobile seat sliding track assembling machine has the advantages that after clamping, the distance between the two movable clamping plates is constant, and the clamping force is convenient to adjust.

Owner:襄阳寒桦精机有限公司

Precision pneumatic clamp for machining

InactiveCN108907826AAdjust the clamping forceEasy to usePositioning apparatusMetal-working holdersEngineeringSlide plate

The invention is suitable for the technical field of machines, and provides a precision pneumatic clamp for machining. The precision pneumatic clamp comprises a base, a first fixed side plate, a second fixed side plate, a sliding plate, a fixed clamping block, a sliding cover plate, two guide rails, an air cylinder, a manual valve and an airflow adjusting valve; the first fixed side plate and thesecond fixed side plate are installed on the left and right ends of the base, the air cylinder and the airflow adjusting valve are installed on the outer side wall of the first fixed side plate, the fixed clamping plate is installed at the upper end of the second fixed side plate, one ends of the two guide rails are inserted into the first fixed side plate to be connected with the air cylinder ina penetrating manner, and the other ends of the two guide rails are inserted into the second fixed side plate; and the sliding plate is installed on the two guide rails and are located between the first fixed side plate and the second fixed side plate, the sliding cover plate is installed at the upper end of the sliding plate, the fixed clamping plate is flush with the sliding cover plate, the manual valve is installed on the air cylinder, and the air cylinder is connected with the airflow adjusting valve and the manual valve. The clamp is convenient to use and high in clamping efficiency, theclamping force can be evenly adjusted, and the product cannot deform and is stable in size.

Owner:深圳市晶铸科技有限公司

Polyvinyl chloride (PVC) waterproof coiled material

InactiveCN114162652ALower resistanceEasy to handleVisible signalling systemsWebs handlingPolyvinyl chlorideEngineering

The invention discloses a polyvinyl chloride (PVC) waterproof coiled material which comprises a base, two pairs of mounting plates are arranged on the outer wall of the top of the base, a cooling box is arranged between the mounting plates, cooling equipment is arranged on the outer wall of the top of the cooling box, a first rotating roller is arranged between each pair of mounting plates, and the same coiled material body is arranged in the first rotating rollers and the cooling box. A warning lamp is arranged on the outer wall of the top of the mounting plate, swing grooves are formed in the outer wall of one side of the mounting plate, fixing columns are fixedly connected into the swing grooves, swing plates are rotatably connected to the outer walls of the fixing columns, first connecting springs are arranged between the lower ends of the swing plates and the inner walls of the swing grooves, and guide grooves are formed in the upper portions of the inner walls of one sides of the swing grooves. And a guide pulley is arranged in the guide groove. When the deviation distance of the coiled material body on the first rotating roller is gradually increased, the resistance value of the resistor is smaller and smaller, so that the warning lamp is brighter and brighter, an early warning can be given, a worker can be reminded of the deviation degree of the coiled material body, and the worker can deal with the deviation degree conveniently.

Owner:王鑫

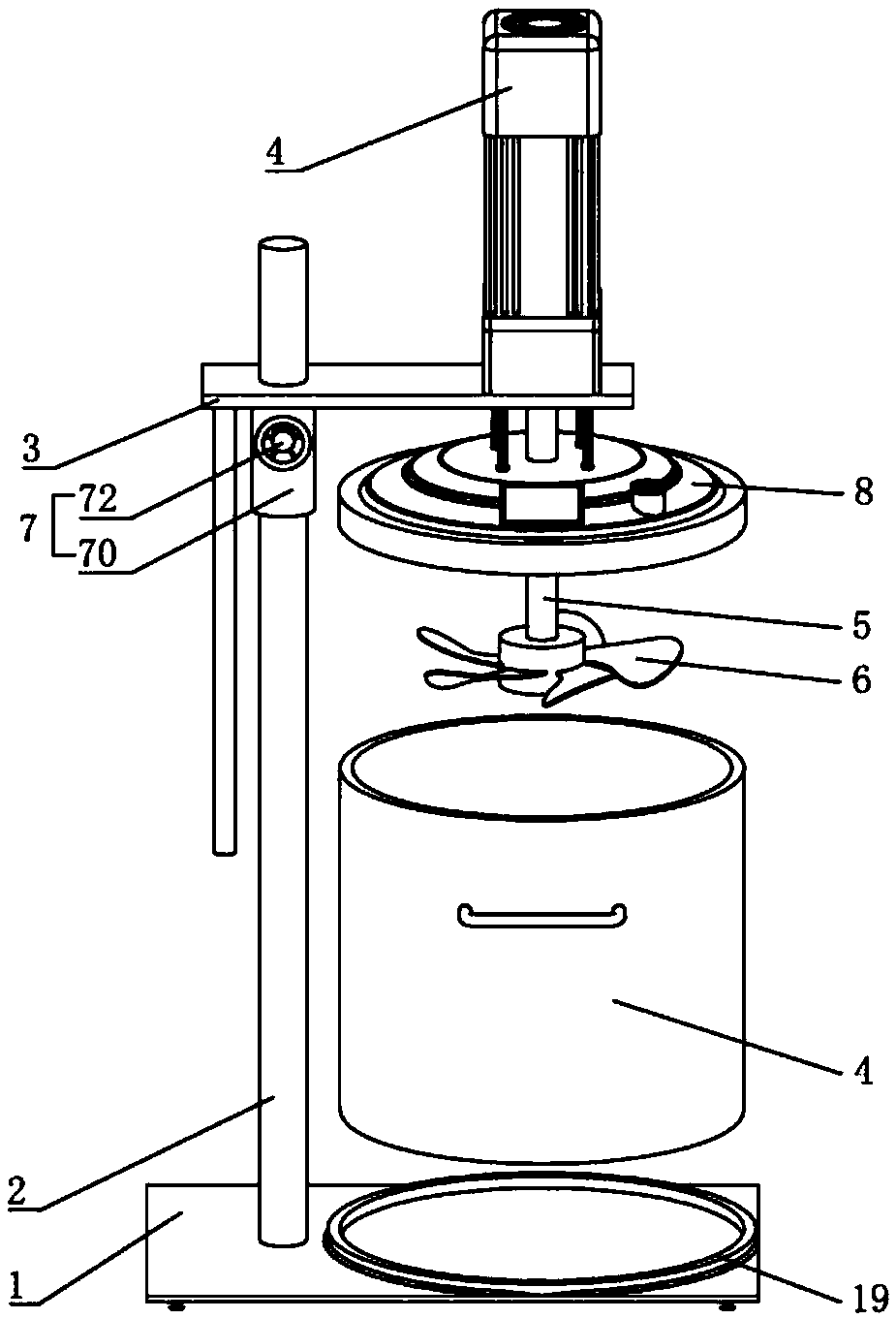

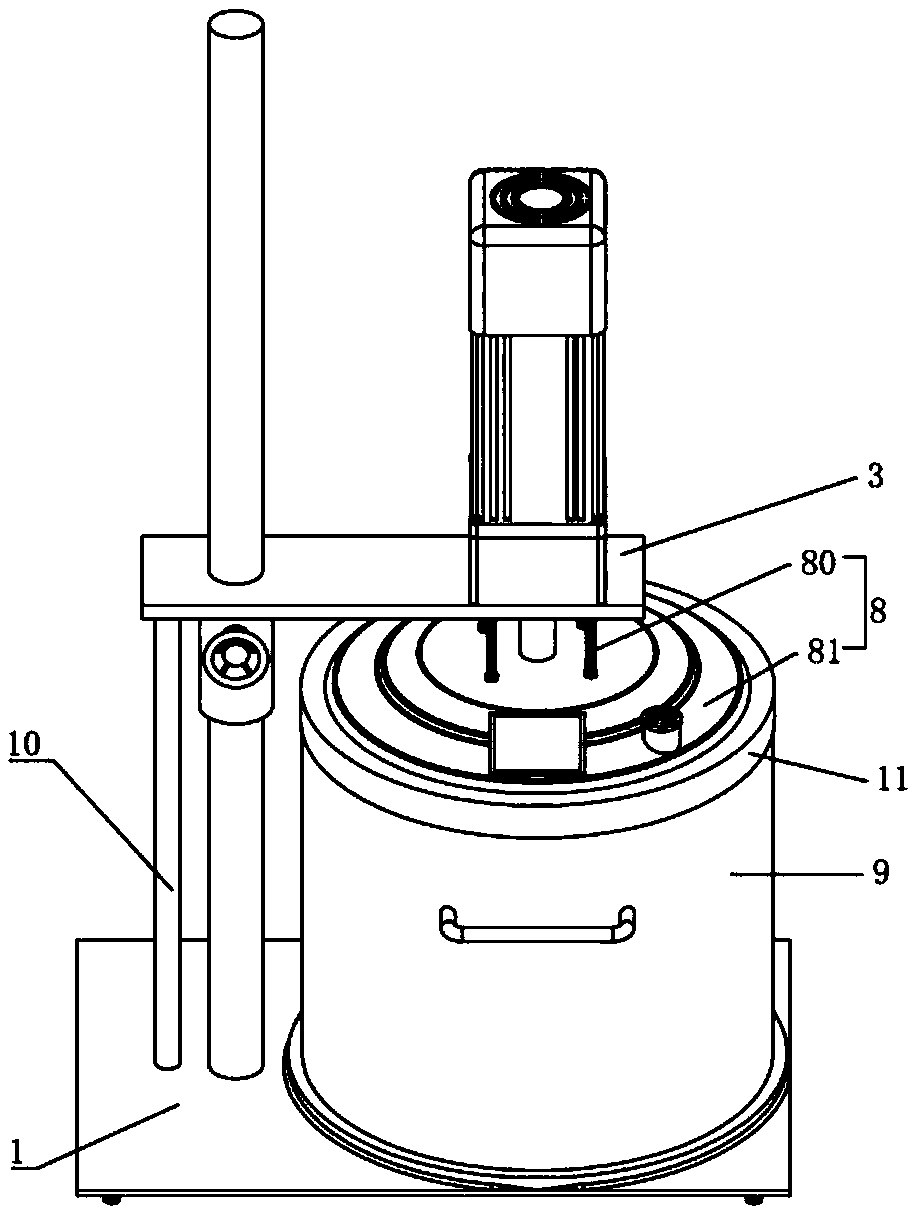

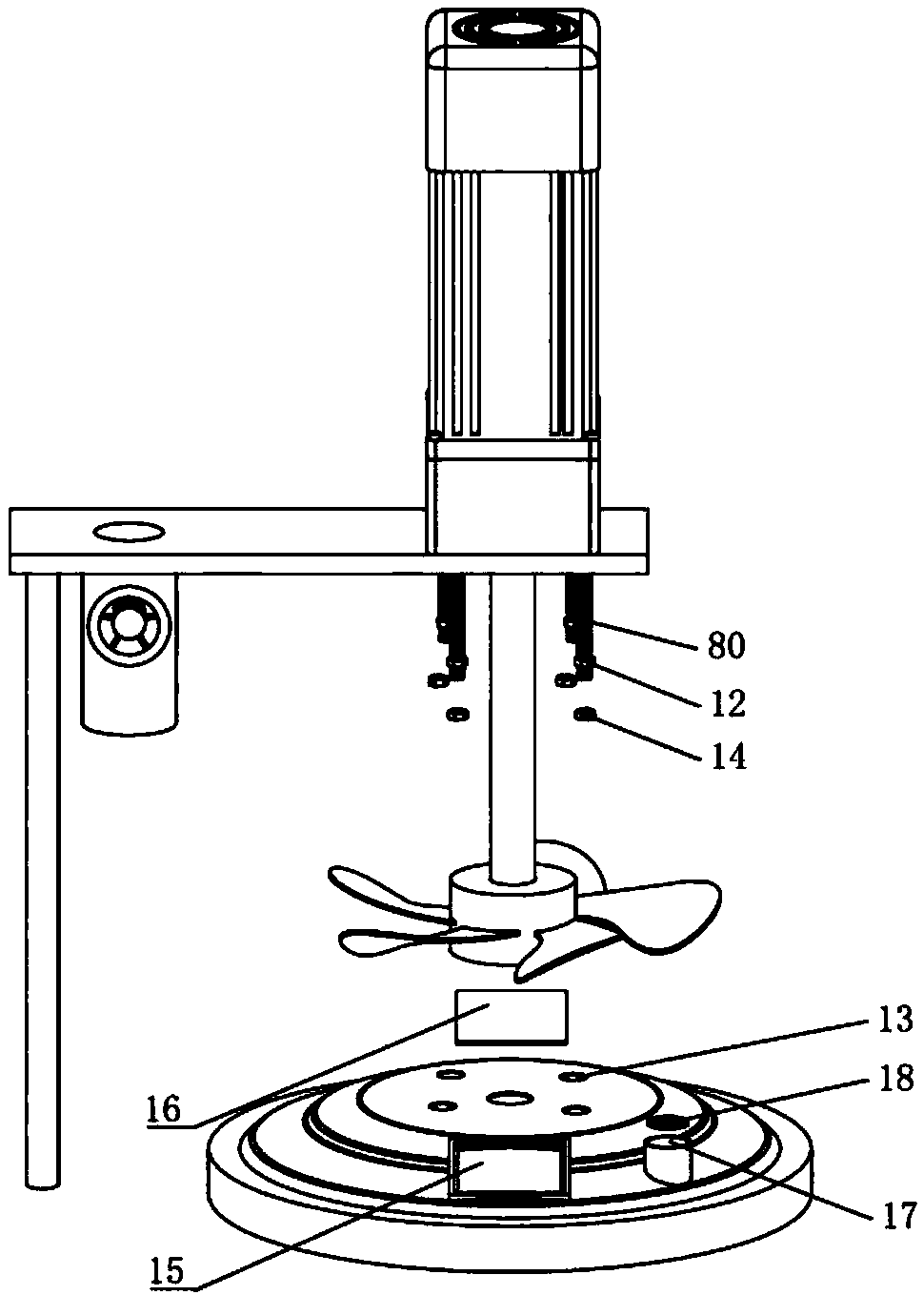

Novel dustproof dispersion machine

InactiveCN111097311APrecise positioningAdjust the clamping forceRotary stirring mixersTransportation and packagingElectric machineStructural engineering

The invention discloses a novel dustproof dispersion machine. According to the technical scheme, the novel dustproof dispersion machine comprises a base, a supporting column which is vertically fixedon the base, a mounting seat which is slidingly arranged on the supporting column, a stirring motor which is connected with the mounting seat, a rotating shaft which is connected with one side, closeto the base, of the stirring motor, blades which are connected to the end, deviating from the stirring motor, of the rotating shaft, a limiting piece which is used for limiting the sliding position ofthe mounting seat on the supporting column, and a stirring barrel unit which is used for being filled with paint; the novel dustproof dispersion machine further comprises a dustproof assembly arranged on the mounting seat; the dustproof assembly comprises a dustproof plate and a connecting piece used for connecting the dustproof plate to the mounting seat a communicating hole allowing the rotating shaft to penetrate through is formed in the dustproof plate, and when the blades are located at the proper stirring position in the stirring barrel, the dustproof plate can cover an opening in the stirring barrel unit. According to the novel dustproof dispersion machine, the amount of substances diffused from the stirring barrel unit during stirring of the novel dustproof dispersion machine canbe reduced.

Owner:成都市阡陌汇商贸有限公司

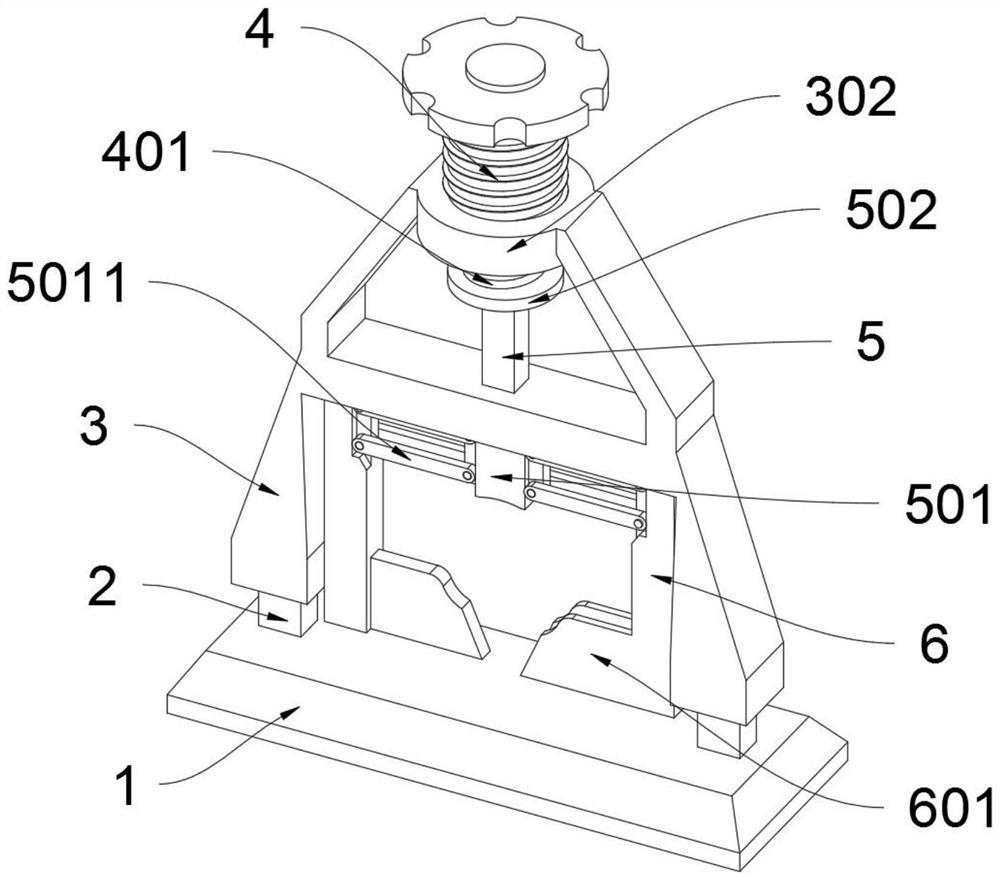

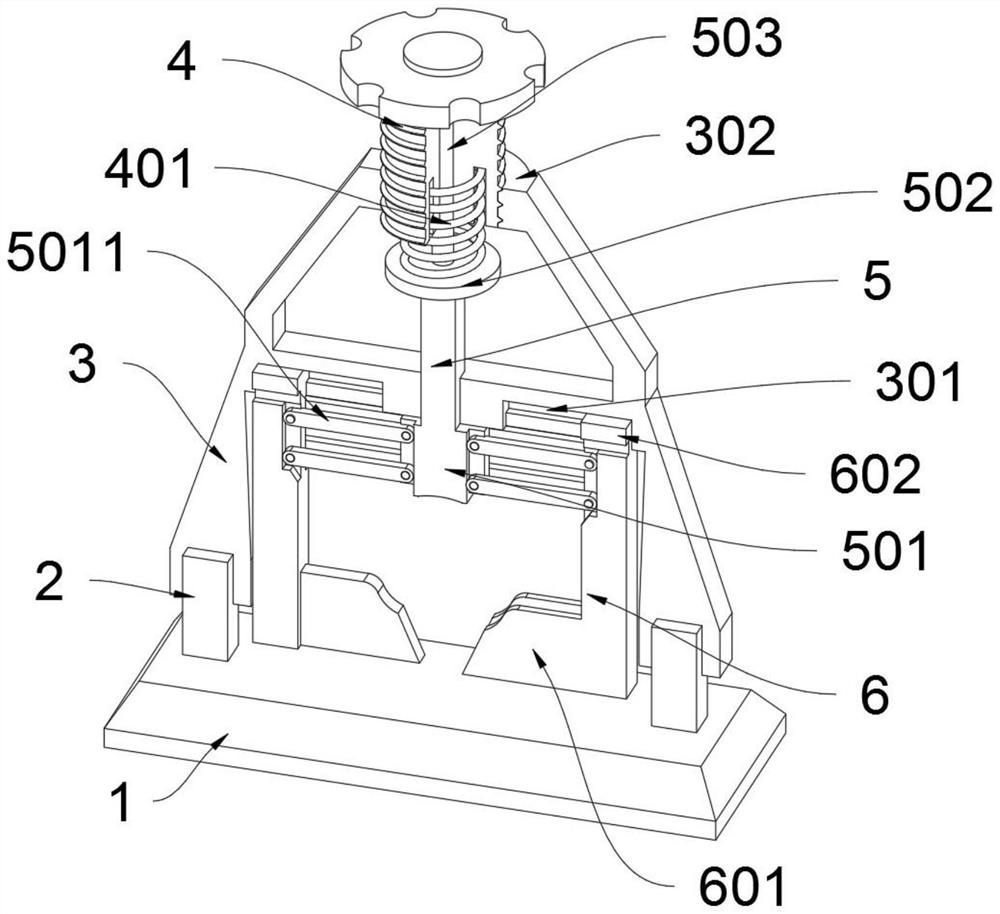

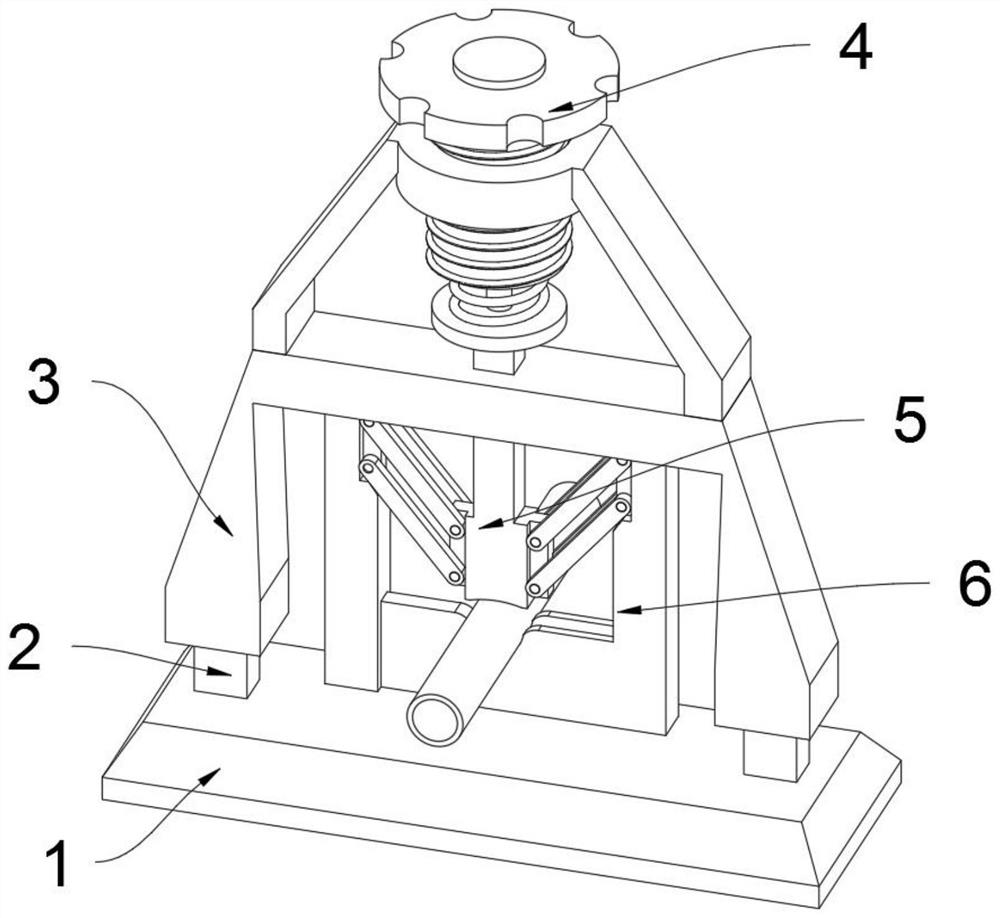

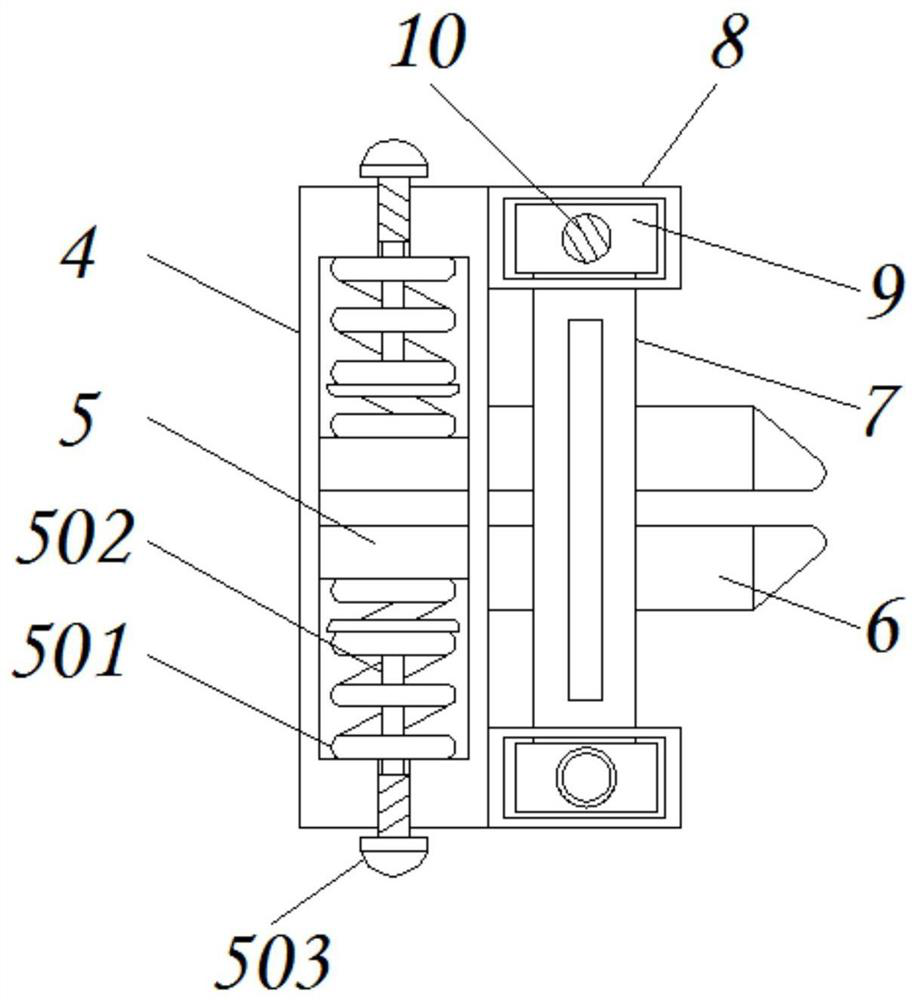

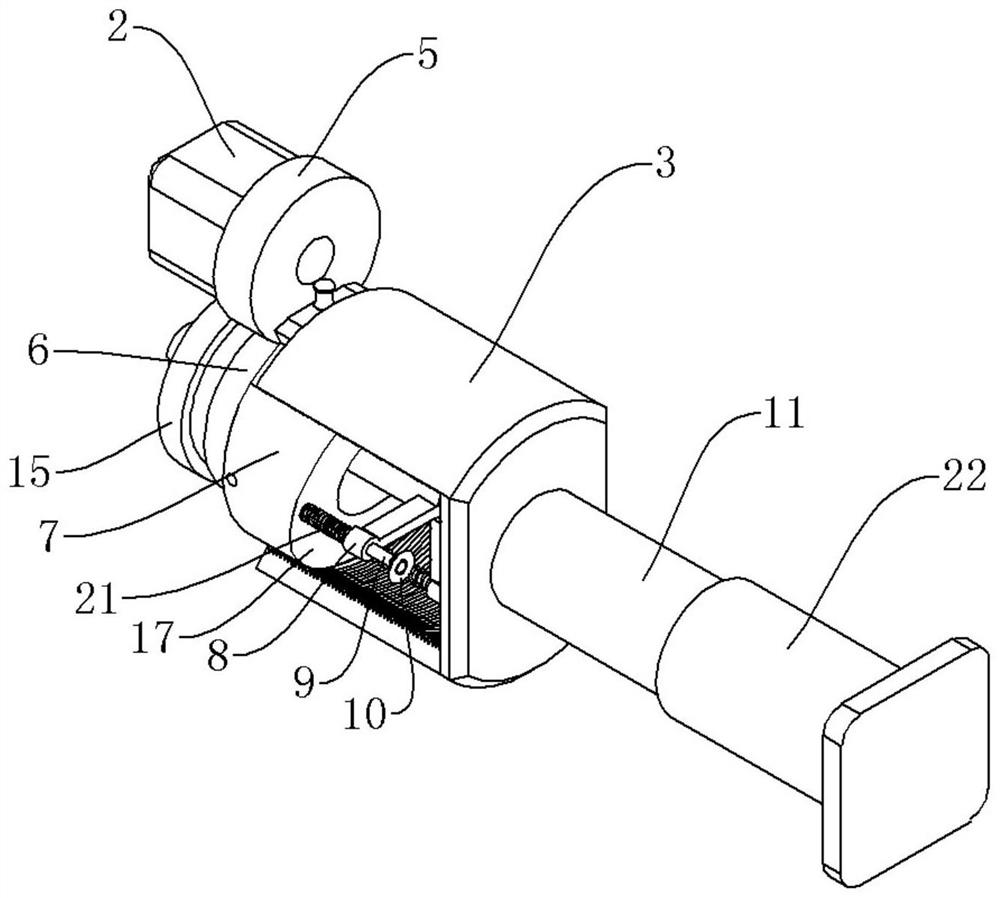

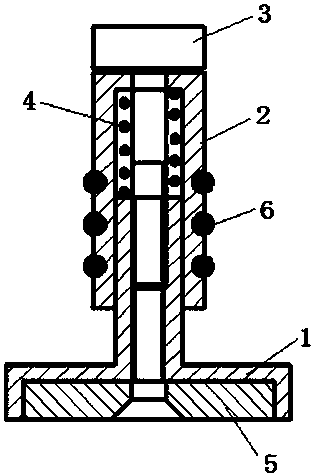

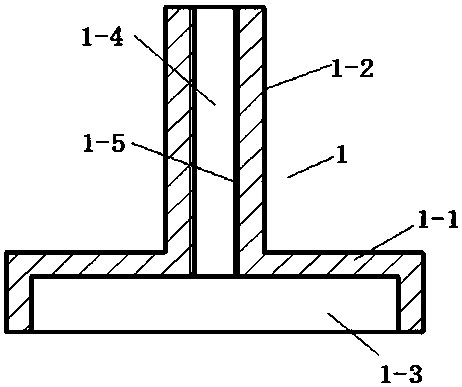

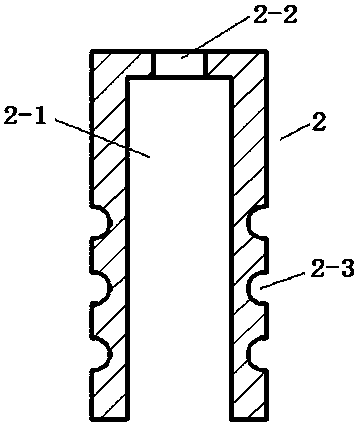

Thin-wall piece mechanical fixed force clamping self-locking device and method

ActiveCN105108518AEasy to operateAdjust the clamping forceWork clamping meansPositioning apparatusSelf lockingMachining process

The invention discloses a thin-wall piece mechanical fixed force clamping self-locking device and a method. The device comprises an oil cylinder push rod, an adjusting bolt, an inclined wedge, guide blocks, a pressing block, a spring and a clamping ring, wherein the adjusting bolt is mounted in an inner cavity at the top of the oil cylinder push rod; the pressing block is mounted at the bottom of the spring; the guide blocks are mounted at the left and right sides of the back surface of the pressing block; and the clamping ring is mounted at the bottom of the pressing block. The adjusting bolt, the inclined wedge and the spring mounted on the thin-wall piece mechanical fixed force clamping self-locking device effectively enhance the adjusting amplitude of tool clamping force of the clamping self-locking device; meanwhile, the thin-wall piece mechanical fixed force clamping self-locking device adopts a mechanical fixed force clamping self-locking device, so that the tool design difficulty and cost are reduced, and the capacity in the product size machining process is improved; and the clamping self-locking device is simple in operation, and greatly reduces the ability requirements of operators.

Owner:菲斯达精密工业部件(苏州)有限公司

Automatic clamping device for 5G oscillator

InactiveCN112847197AStable and fixed processingAdjust the clamping forceWork holdersEngineeringMachining

The invention discloses an automatic clamping device for a 5G oscillator, and relates to the technical field of clamping devices. the problems that when an existing clamp fixes an oscillator arm, clamping force is not easy to adjust, the oscillator arm is easy to clamp and shrink and materials are wasted are solved. The automatic clamping device for the 5G oscillator comprises a clamping linkage rod, wherein the clamping linkage rod is inserted into the bottom of a transverse rod in the middle of a clamping supporting shell. The automatic clamping device can perform three-point clamping on the oscillator arm under matching action of two clamping positioning pieces and a linkage block when clamping the oscillator arm, and stable and fixed machining of the oscillator arm is ensured; the automatic clamping device can slowly clamp the oscillator arm under the action of a adaptive top spring when clamping the oscillator arm, so that an adjusting stroke side length of the clamping force is increased, the clamping force of the oscillator arm can be conveniently adjusted during machining, convenience and rapidness are achieved, the phenomenon that the oscillator arm is damaged due to the fact that the clamping force is too large is avoided, and the production and machining yield of the oscillator arm is increased.

Owner:白过海

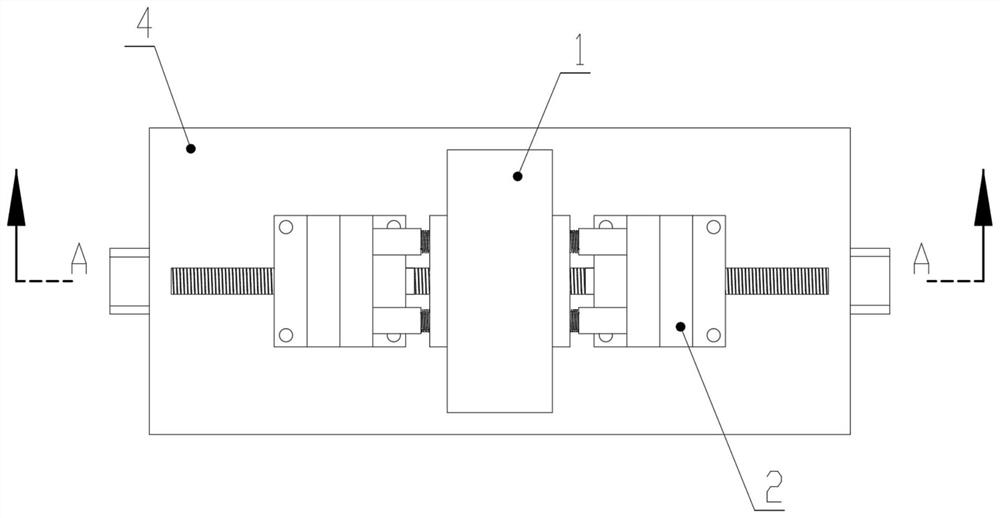

Parallel clamping mechanism

ActiveCN106903630AAdjust the clamping forceSimple structureWork holdersEngineeringMechanical engineering

The invention discloses a parallel clamping mechanism and belongs to the technical field of clamping equipment. The parallel clamping mechanism is designed for solving the problems that existing devices are poor in clamping effect, large in size and the like. The parallel clamping mechanism comprises a base. The base comprises a first side edge and a second side edge which are arranged oppositely. A clamping assembly is arranged on the first side edge and an auxiliary clamping structure is arranged on the second side edge. The clamping assembly comprises a power device and a clamping part arranged on the base in a sliding mode. An arc-shaped sliding groove is formed in the clamping part, and a driving sliding block in sliding fit with the interior of the arc-shaped sliding groove is arranged on the power device. The power device can drive the driving sliding block to conduct linear movement in the length direction of the base, so that the clamping part is driven to slide on the base in the width direction of the base. According to the parallel clamping mechanism, the position of the clamping part can be determined by controlling the position of the driving sliding block in the arc-shaped sliding groove, and thus clamping force is adjusted, control precision is high, and the clamping effect is good.

Owner:SUZHOU SECOTE PRECISION ELECTRONICS CO LTD

Mechanical automatic polishing device capable of adjusting clamping force

ActiveCN113103112AAdjustable clamping forceAdjust the clamping forceEdge grinding machinesDispersed particle filtrationGear wheelPolishing

The invention discloses a mechanical automatic polishing device capable of adjusting the clamping force. The mechanical automatic polishing device capable of adjusting the clamping force comprises a fixed base, a limiting plate, a grinding disc and a rotating gear. A transmission rod is movably installed in the fixed base, the top of the transmission rod is connected with a connecting base, and the top of the connecting base is fixedly connected with a hollow block. A movable block is installed in the hollow block, a clamping plate is fixedly connected to one side of the movable block, the limiting plate is fixed to the outer side of the clamping plate, first connecting blocks are fixedly installed at the two ends of the limiting plate, sliding blocks are installed in the first connecting blocks, rotating rods are connected to the middles of the sliding blocks, and the grinding disc is installed on the right side of the limiting plate. The mechanical automatic polishing device capable of adjusting the clamping force has the secondary polishing effect, raised dust generated by polishing can be sucked away, meanwhile, the appropriate clamping force can be adjusted according to requirements, and a user can conveniently adjust and use the mechanical automatic polishing device.

Owner:CHANGDE CITY ZHONGKAI MACHINERY IND

LED circuit board detection device

The invention relates to an LED circuit board detection device, which comprises a workbench, and is characterized in that a bracket is arranged on the workbench, a set of baffle plates are fixed at the surface of the workbench, the middle of baffle plates is provided with a work box, the work box is provided with a cover, the cover is provided with a carrier plate, the carrier plate is provided with multiple groups of holes, each hole is internally provided with a probe, a group of bosses are arranged around the multiple groups of holes, and each boss is internally provided with a threaded hole. The LED circuit board detection device is novel in structure design convenient to use and has the advantages of abilities of protecting the workbench surface, keeping the workbench surface to be clean and tidy, preventing static electricity, improving the overall aesthetics and being simple in process and structure.

Owner:佛山杰致信息科技有限公司

Automatic clamping equipment for metal product machining

ActiveCN114227314AAdjust the clamping forcePositioning apparatusMetal-working holdersGear wheelElectric machinery

The invention relates to the field of metal product machining, in particular to automatic clamping equipment for metal product machining. A mounting hole is formed in the middle of each edge of the fixing frame. The driven gear is rotatably installed on the inner wall of the fixing frame, and the motor drives the driven gear to rotate through the transmission mechanism. The propelling column is fixedly connected with the driven gear, and the inner end face of the propelling column is an inclined face. The transmission arc plates are slidably mounted on the propelling column in the axial direction, a plurality of mounting positions of the transmission arc plates are arranged on the propelling column, and the two transmission arc plates are symmetrically arranged on the propelling column. The inner and outer ends of the fixing rod extend out of the inner end of the pushing column. Each pushing rod is installed on one rod of the fixing frame in a sliding mode in the axial direction of the pushing column, and the inner end of each pushing rod makes contact with the inclined face of the pushing column so that the transmission arc plates can be pushed to move inwards when the pushing rods move inwards. And the pushing spring is sleeved on the pushing rod and is positioned between the shaft shoulder and the fixing frame. And the position of the transmission arc plate on the pushing column is adjusted, so that the effect of adjusting the clamping force is achieved.

Owner:沭阳天勤工具有限公司

Rhizomatic traditional Chinese medicine slicing device based on clamping slicing technology

InactiveCN110480705AAdjust the clamping forceUniform thicknessMetal working apparatusPediatricsKnife holder

The invention relates to the technical field of rhizomatic traditional Chinese medicine slicing, and discloses a rhizomatic traditional Chinese medicine slicing device based on clamping slicing technology. The device comprises a rack, wherein the inside of the rack is movably connected with a feeding mechanism; the right side of the feeding mechanism is meshed with a straight tooth, and the lowerpart of the straight tooth is fixedly connected with a knife holder; the knife holder comprises a return spring, and one end of the return spring away from the knife holder is elastically connected with a blade; the lower part of the feeding mechanism is fixedly connected with a clamping mechanism, and a placing slot is formed in the center of the clamping mechanism; the feeding mechanism comprises an incomplete gear, and the upper portion of the incomplete gear is meshed with a transverse rack, the lower portion of which is fixedly connected to the placing slot; and the surface of the incomplete gear is hinged with a supporting mechanism, and one end of the supporting mechanism away from the incomplete gear is movably connected with the clamping mechanism, so that a warped rod in the supporting mechanism presses a wedge block, a slide bar moves in a chute, and the effect of adjusting the clamping force of a clamping ring is achieved.

Owner:夏德亮

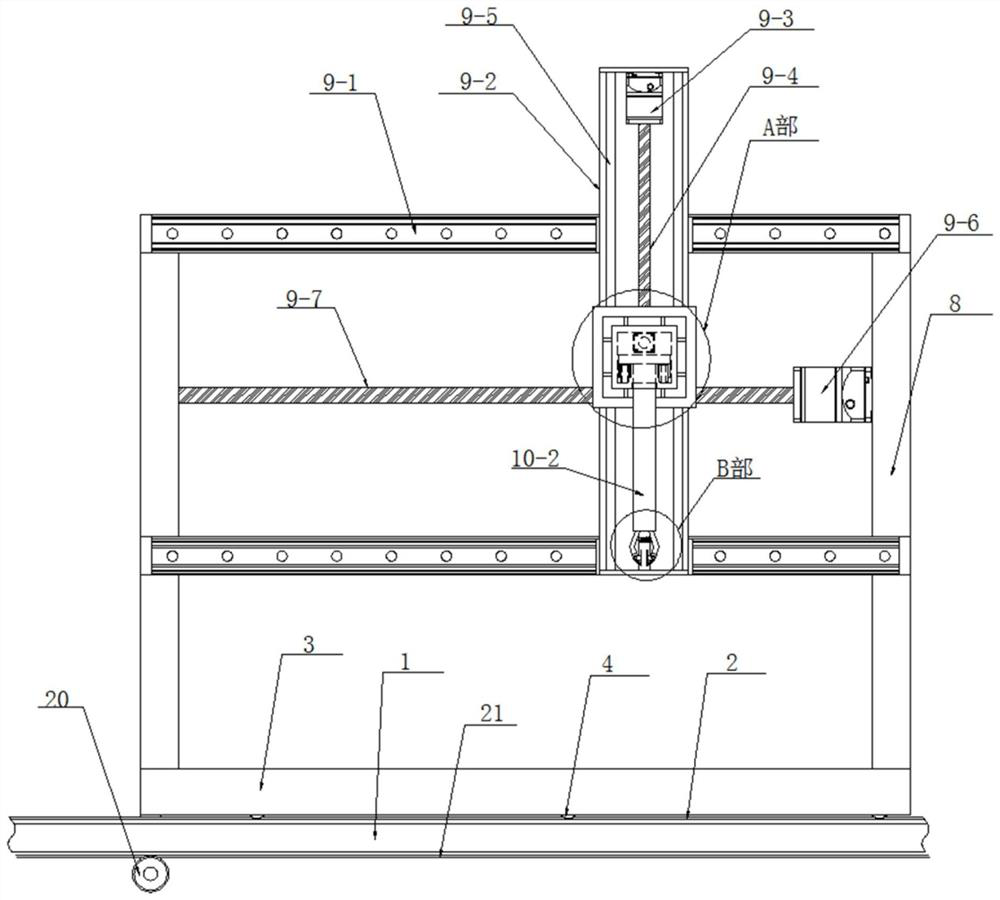

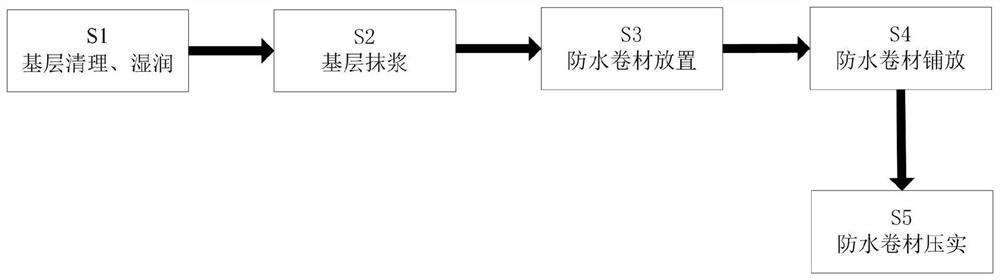

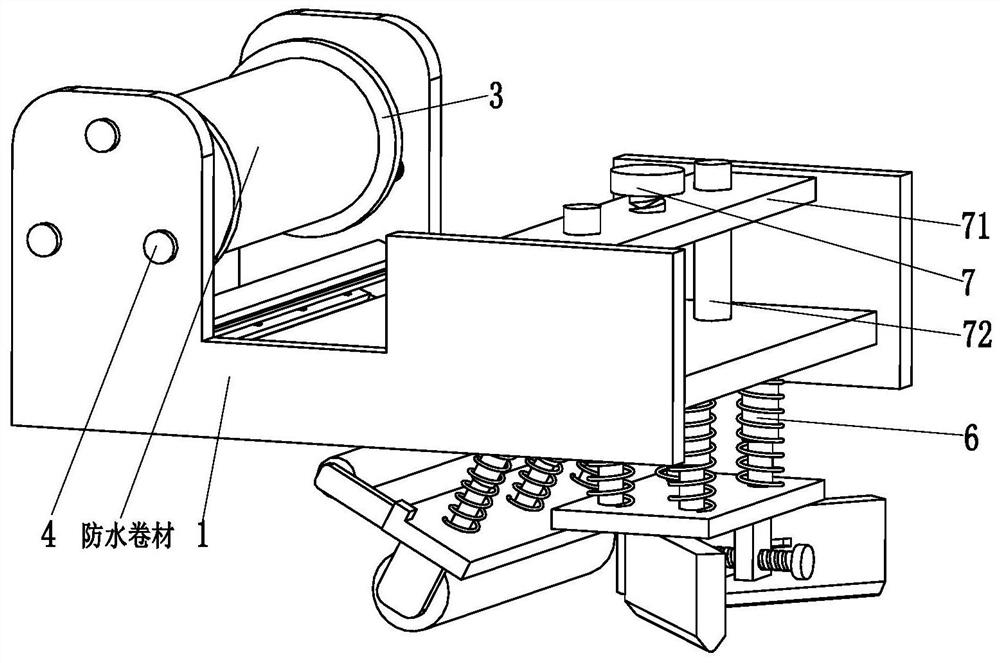

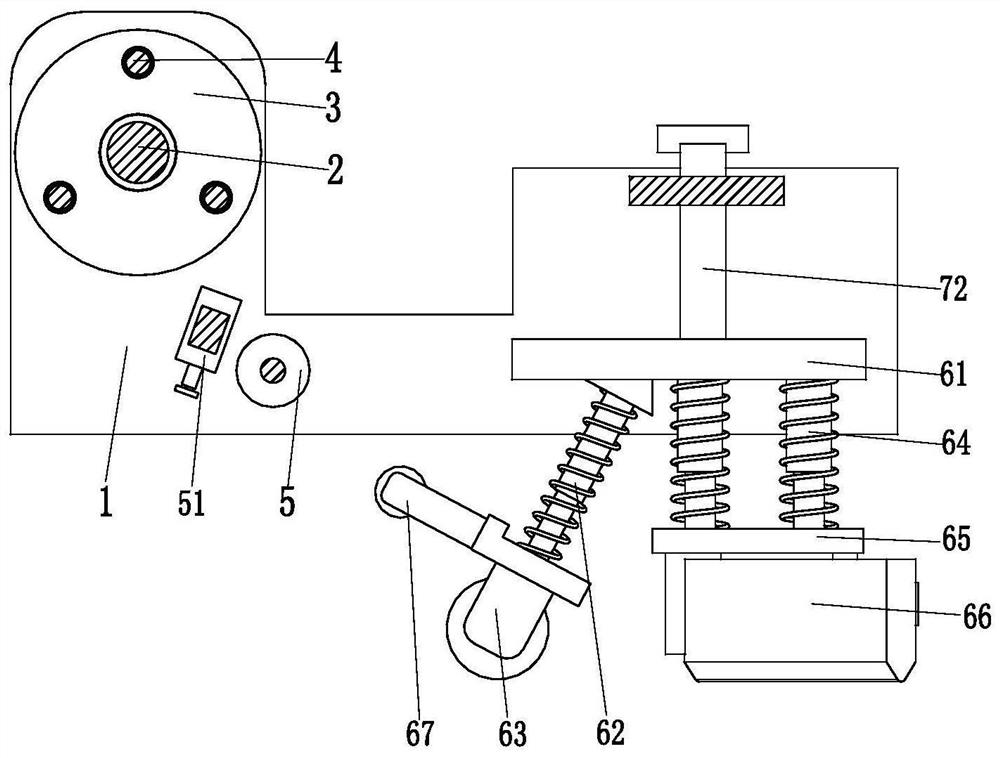

A construction method for laying polymer waterproof membrane

ActiveCN111997286BImprove laying effectImprove compactnessRoof toolsMechanical engineeringMacromolecule

The invention relates to a construction method for laying a polymer waterproofing membrane. The construction method for laying a polymer waterproofing membrane adopts the following waterproofing membrane laying device. The waterproofing membrane laying device comprises a side support plate, a locking rod, a positioning disc and a positioning spring column , a guide roller and a paving mechanism; a construction method for laying a polymer waterproofing membrane using the above-mentioned waterproofing membrane laying device includes the following steps: S1, cleaning and moistening the base layer; S2, plastering the base layer; S3, placing the waterproof membrane; S4, the waterproofing membrane is laid; S5, the waterproofing membrane is compacted. The present invention can solve the existing problem when laying the waterproof coiled material manually: when the waterproof coiled material is laid, its front and rear ends are infinite, so that the position of the waterproofing coiled material is skewed during laying, thereby affecting the laying effect of the waterproofing coiled material and waterproofing. When the membrane is laid, it cannot be tightened, which makes it easy to twist the waterproof membrane when it is laid.

Owner:山东红花防水建材有限公司

Industrial robot capable of adjusting grabbing force and using method of industrial robot

InactiveCN113977614AWith strength adjustment abilityAvoid damageProgramme-controlled manipulatorGripping headsRobot handAlgorithm

The invention discloses an industrial robot capable of adjusting grabbing force and a using method of the industrial robot, and relates to the field of robotics. The industrial robot comprises a mounting base and an air cylinder fixedly mounted on the mounting base, clamping jaws are rotationally mounted at the two ends of the mounting base correspondingly, the output end of the air cylinder penetrates through the mounting base and is fixedly connected with a connecting plate, supporting rods are rotationally installed at the two ends of the connecting plate, the tail ends of the supporting rods are rotationally connected to clamping jaws, force adjusting pads are fixedly connected to the clamping positions of the lower ends of the clamping jaws, vertical plates are fixedly connected to the positions, located on the two sides of the air cylinder, of the upper side of the mounting base, and a mounting top plate is jointly and fixedly connected to the upper ends of the two vertical plates. The force adjusting pads are arranged on the clamping jaws of a manipulator, so that when the manipulator clamps an object, the friction force between the object and the manipulator is increased, the object is prevented from being damaged due to the fact that the object is separated from the manipulator, and the force adjusting pads can adjust deformation of themselves according to the weight of the object, and therefore, the manipulator has certain force adjusting capability.

Owner:南京付联微网络科技有限公司

Novel glue-free roll tail sealing device

ActiveCN107720366AAdjust the opening and closing rangeAdjust the clamping forceWebs handlingEngineeringMechanical engineering

Owner:FOSHAN NANHAI DECHANGYU PAPER MASCH MFG CO LTD

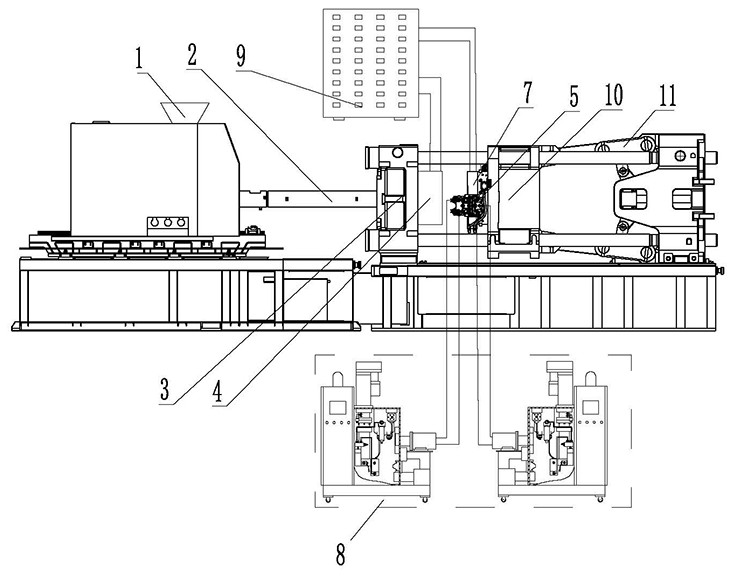

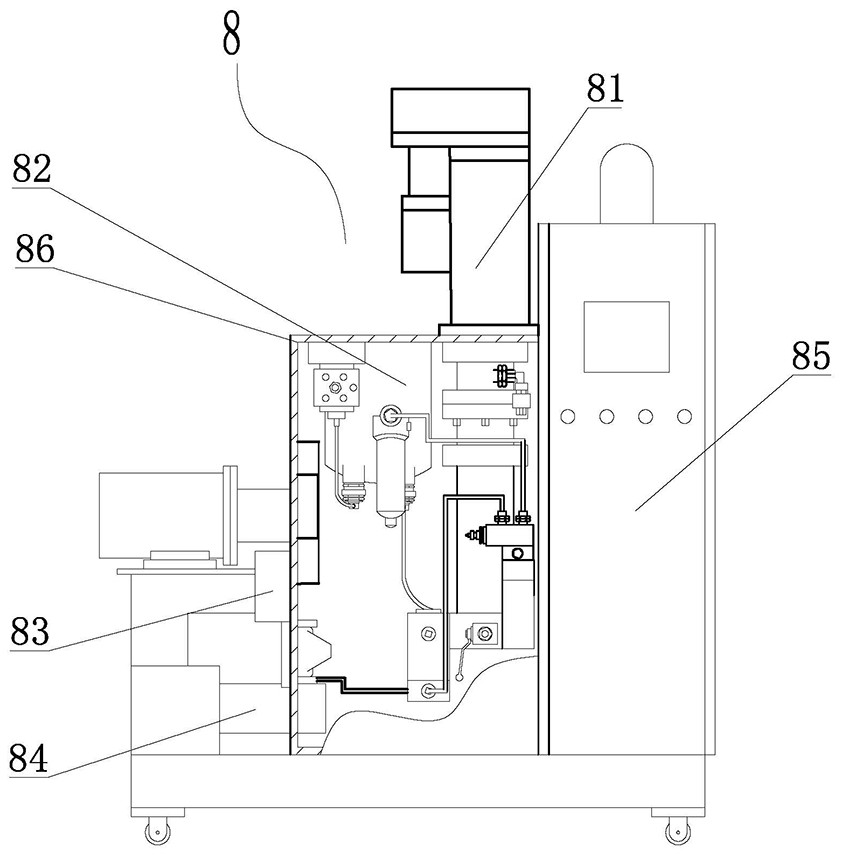

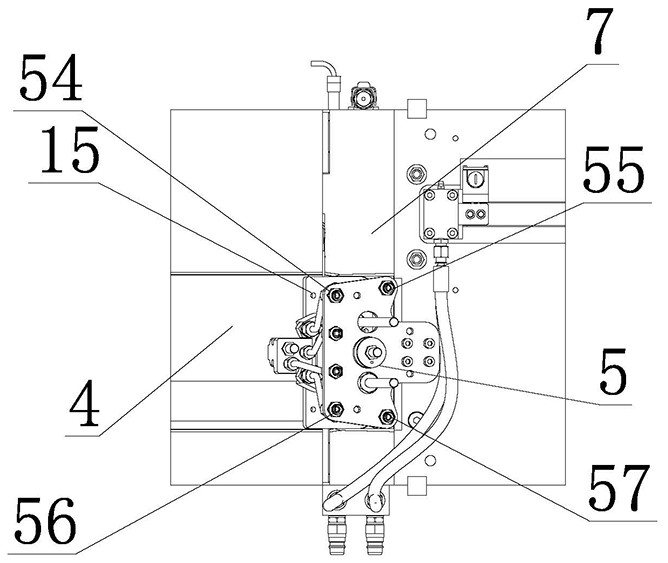

In-mold spraying system and process method thereof

ActiveCN114147915AIncrease productivityReduce equipment costsDomestic articlesEngineeringTemperature control

The invention discloses an in-mold spraying system which comprises an injection machine, a PU injection device and a mold temperature control unit, the injection machine comprises a hopper, an injection part, a front mold plate, a movable mold plate and a mold closing mechanism, a first half mold is arranged on the front mold plate, a second half mold and a third half mold are arranged on the movable mold plate, and the mold temperature control unit is arranged on the second half mold. The second half mold and the third half mold are respectively assembled with the first half mold to form a base material injection mold cavity and a PU injection mold cavity, and the side surface of the third half mold is provided with a double-inclined mixing nozzle connected with a PU injection device; the outer part of the double-inclined type mixing spray head is in inclined sealing connection with the side surface of the third half mold and is in inclined sealing butt joint with the side surface of the first half mold in the mold closing process; and the internal spraying axis of the double-inclined type mixing spray head is inclined to the axis of an injection runner in the PU injection mold cavity. The invention further discloses a technological method for conducting spraying through the in-mold spraying system. And a pair of inclined mixing nozzles is obliquely mounted on the side surface of the third half mold, so that the quality stability and continuity are improved.

Owner:TEDERIC MACHINERY +1

Hemostatic clip stable in clamping and not prone to fall off

ActiveCN112617953AGuaranteed stabilityEasy to clamp and fixWound clampsPhysical medicine and rehabilitationApparatus instruments

The invention discloses a hemostatic clip stable in clamping and not prone to fall off, and belongs to the technical field of medical instruments. The hemostatic clip comprises a lower plate clamp; an upper plate clamp is arranged above the lower plate clamp; a first connecting groove is formed in each of opposite surfaces of the upper plate clamp and the lower plate clamp; and a first lifting seat is connected in each first connecting groove in a sliding manner. According to the hemostatic clip, with the mutual cooperation of designed structures including first moisture absorption sponges, second moisture absorption sponges, first anti-skid plates, second anti-skid plates, first supporting springs, second supporting springs, third supporting springs, a threaded cylinder, a bearing, a threaded rod and the like, the stability of the first anti-skid plates and the second anti-skid plates when pipeline tissue is clamped can be guaranteed, thus avoiding the bad phenomenon of falling off and the like, and the hemostatic clip has a certain lifting buffer effect on the basis of guaranteeing stability, can conveniently clamp and fix pipeline tissues different in thickness, can further provide different clamping force according to different clamping requirements, and has high adaptive capacity and a good practical effect.

Owner:苏州优脉瑞医疗科技有限公司

Hydraulic fastening device

InactiveCN106862967AImprove clamping effectImprove stabilityPositioning apparatusMetal-working holdersHydraulic cylinderFuel tank

The invention provides a hydraulic fastening device, comprising a support platform, a clamping block symmetrically arranged on the support platform, a hydraulic cylinder driving the clamping block, a hydraulic pump connected to the hydraulic cylinder, and the hydraulic pump is connected to an oil tank. The beneficial effects of the present invention are: adopting the above technical scheme, the clamping block is pushed by the hydraulic cylinder to clamp the workpiece, which can reduce the application of manpower, and at the same time, the clamping effect is good and the stability is high; and the clamping can be gradually adjusted as required intensity.

Owner:TIANJIN HAOFENGYUAN TOOL & DIE TECH DEV CO LTD

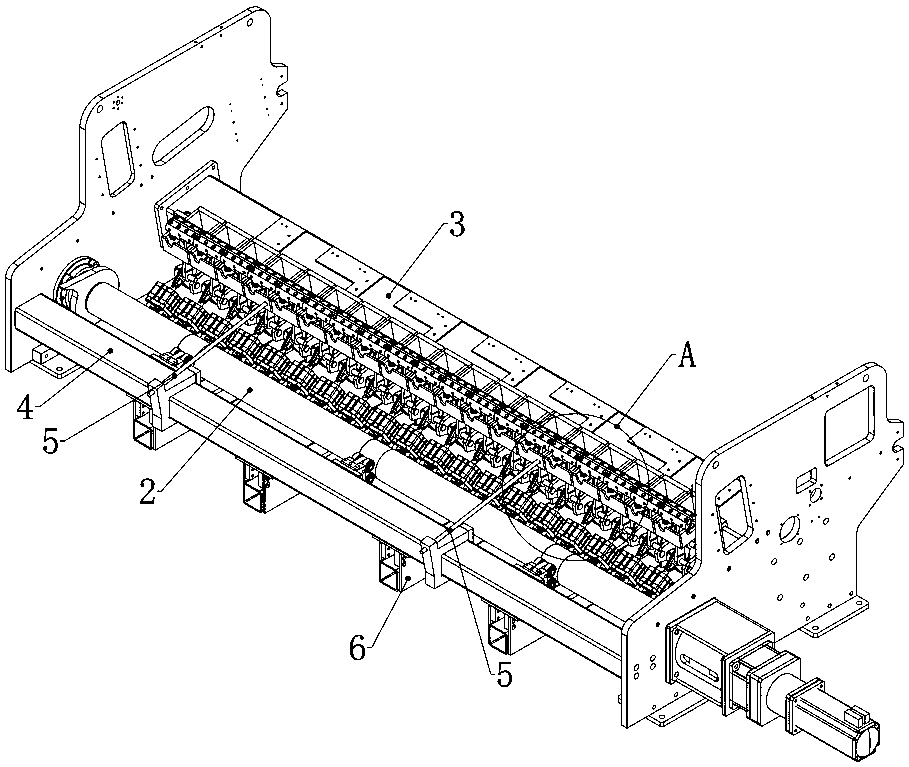

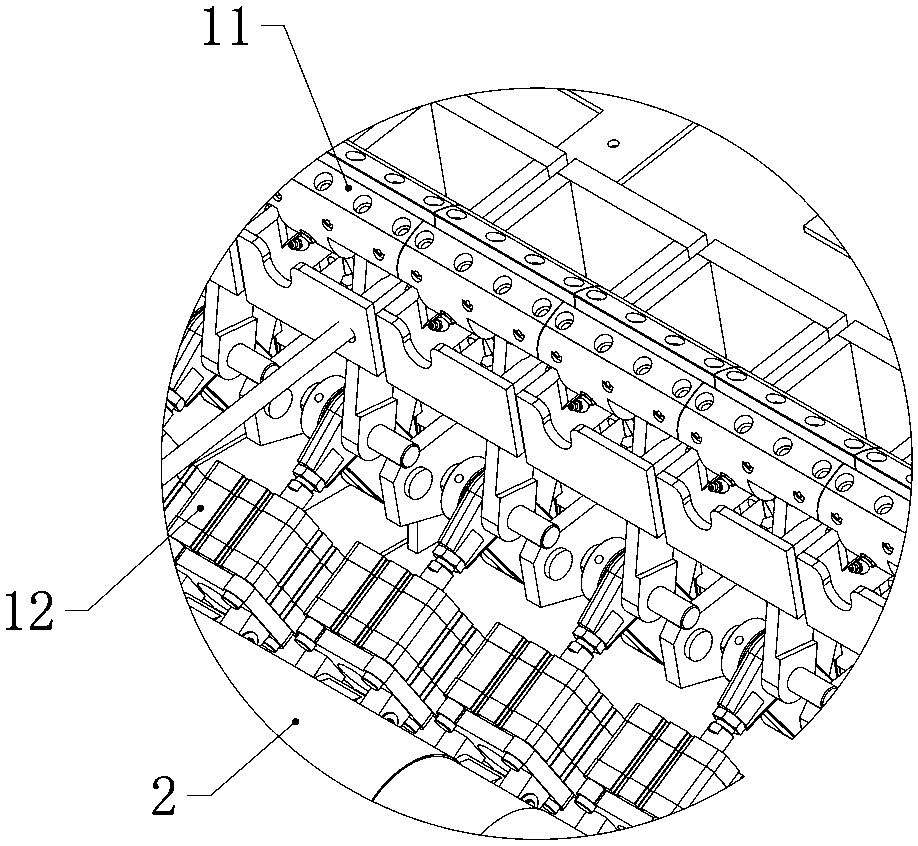

High-speed numerical control knitting machine with self-lubricating structure and controllable discharging position

ActiveCN109082766AImprove rigidityLess likely to break and collapseWeft knittingWarp knittingNumerical controlPulp and paper industry

The invention relates to a high-speed numerical control knitting machine with a self-lubricating structure and a controllable discharging position. The machine comprises a base, supporting rods and asecond rotating shaft; supporting tables are distributed at the two ends of the outer side of the base; a machine body is installed at the tops of the supporting tables, the supporting tables and themachine body are welded, a fixing column is installed at the inner wall of the lower end of the machine body, the supporting rods are arranged at the two sides of the upper end of the machine body, the supporting rods and the machine body are welded, the second rotating shaft runs through the middles of the inner sides of the supporting rods, and a lead screw is connected to the inner side of thesecond rotating shaft. By arranging the base, the supporting tables and the machine body, the base, the supporting tables and the machine body are of a welded integrated structure, the base and the supporting tables are horizontally placed, the base, the supporting tables and the machine body are all made from stainless steel materials, the good rigidity is achieved, when the machine is in use, nocracking or collapse condition happens, meanwhile, the whole device is horizontally placed when in use, and it is ensured that the whole device is operated in the normal state during working.

Owner:威海市长荣网具有限公司

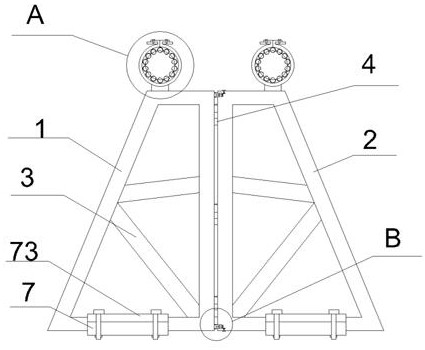

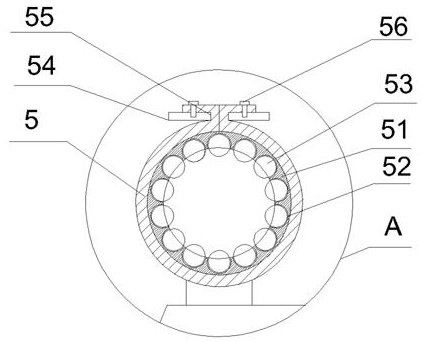

Special tool for replacing overhead lightning conductor of power transmission line

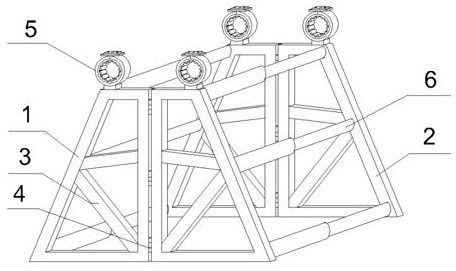

ActiveCN112582942AEasy to moveAvoid the Hassle of Difficult ShippingApparatus for overhead lines/cablesEngineeringStructural engineering

The invention relates to the technical field of line replacement equipment, and discloses a special tool for replacing an overhead lightning conductor of a power transmission line, which comprises a bracket main body and an iron tower frame, an auxiliary bracket is arranged on one side of the bracket main body, fixing frames are arranged in the bracket main body and the auxiliary bracket, and hinges are arranged between the bracket main body and the auxiliary bracket; and fixing hoops are arranged at the top ends of the bracket main body and the auxiliary bracket, telescopic rods are arrangedbetween the bracket main body, and bases are arranged at the lower ends of the bracket main body and the auxiliary bracket. According to the special tool for replacing the overhead lightning conductorof the power transmission line, the bracket main body and the telescopic rod are assembled for use, so that the bracket main body is convenient to carry and transport and quick and convenient to assemble; and the base is matched with the top seat to stably fix the bracket main body on an iron tower, so that the influence of bolt loosening on the stability of the bracket main body can be effectively reduced, and the friction force borne by the lightning conductor in the traction process is reduced by utilizing the rolling of the ball in the arc-shaped groove.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

A fixed limit mechanism for mechanical processing that is convenient for adjusting the limit force

ActiveCN111531382BSufficient powerFast clamping limitPositioning apparatusMetal-working holdersElectric machineGear wheel

The invention discloses a fixed limit mechanism for mechanical processing which is convenient for adjusting the limit force, which includes a fixed workpiece, a clamping mechanism, a control mechanism and a transmission mechanism. If the present invention needs the user to adjust the strength of clamping and fixing the workpiece, the user can start the fixed motor through the external control mechanism, and the fixed motor can drive the gear groove to move forward, and then drive the connecting baffle and the elastic switch to move forward. The time directly lengthens the displacement stroke of the limit block, which in turn makes the displacement of the limit block pull the spring snap ring longer, and improves the strength of the clamping mechanism for clamping and positioning the fixed workpiece. The user can connect the baffle according to the adjustment The distance from the limit slide plate further adjusts the clamping strength of the fixed workpiece, which is convenient for the user to quickly and conveniently adjust the clamping strength of the fixed workpiece, and improves the safety performance of clamping the fixed workpiece.

Owner:贵阳一舟航科机械设备制造有限公司

Quick-clamping jig for printed boards and method of use

ActiveCN105430919BClamping speed blockEasy and flexible operationPrinted circuit manufactureEngineeringMagnet

The invention relates to a printed-board rapid clamping tooling clamp and a usage method thereof. The clamp comprises a pedestal, an outer sleeve, a guide bar, a spring, a magnet and O-shaped rings. The tooling clamp is placed on an iron plate plane. A whole tooling clamp is firmly adsorbed on an iron plate. Portions of the three O-shaped rings on the outer sleeve are held and are pressed downwardly. The outer sleeve moves downwardly on a circular pipe of the pedestal. At this time, an upper end surface of the outer sleeve and a small round surface of the guide bar generate a segment of spacing gap. A printed board is put into the gap. The outer sleeve is not pressed by the hand right now. Through an effect of the spring, the outer sleeve moves upwardly on the circular pipe of the pedestal. The printed board is clamped in the gap between the upper end surface of the outer sleeve and the small round surface of the guide bar. By using the clamp and the method, an installation and clamping speed is fast; operation is flexible and convenient; the tooling is small, which is convenient for moving and carrying.

Owner:TIANJIN 712 COMM & BROADCASTING CO LTD

Automatic stacking fixture

PendingCN112249726AAdjust the swingSwing range can be adjustedStacking articlesDe-stacking articlesEngineeringSlide plate

The invention discloses an automatic stacking fixture. The automatic stacking fixture comprises a robot and a connecting plate. One end of the connecting plate is provided with a koji stacking mechanism, and the other end is provided with a koji unloading mechanism. The koji stacking mechanism comprises a base and two parallel sliding plates connected to the bottom of the base slidably, wherein parallel clamping plates are evenly arranged at the bottoms of the sliding plates, the distance between every two adjacent clamping plates is matched with the width of koji blocks, and a power mechanismfor driving the sliding plates to move is arranged on the base. The koji unloading mechanism comprises a bottom plate and side plates arranged on the two sides of the bottom plate, wherein the distance between the two side plates is matched with the length of the koji blocks, and a first floating clamping mechanism used for clamping the koji blocks is arranged on any side plate. According to theautomatic stacking fixture, the traditional process of manually transferring the koji blocks is replaced, the automation degree is high, the labor intensity is reduced, the production cost is reduced,and the production efficiency is improved; and moreover, the automatic stacking fixture is a composite fixture, can finish the transfer of koji blocks in two procedures on the same device at the sametime, and is high in universality.

Owner:北京京城智通机器人科技有限公司

A kind of carbon fiber composite material and its preparation system and preparation method

The invention relates to the preparation of composite materials, more specifically a carbon fiber composite material and its preparation system and preparation method. The method comprises the following steps: step 1, carrying out a tension test on the carbon fiber composite material by using the off-stop mechanism, a supporting mechanism and a tester; step two, dehydrating the carbon fiber composite material after the tension test by using the off-stop mechanism and the tail sequence mechanism; Step 3, impregnating the dehydrated carbon fiber composite material with glue. The carbon fiber composite material is used to prepare a plug-in core.

Owner:云晟(安徽)能源装备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com