Patents

Literature

153results about How to "Adjustable clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

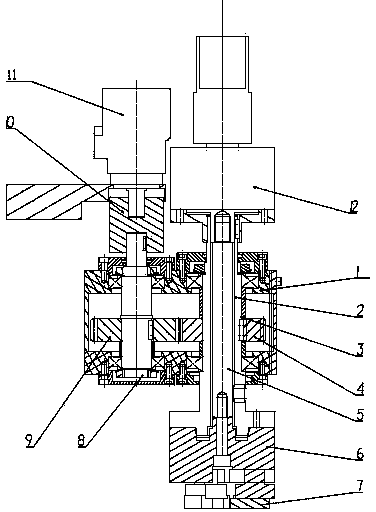

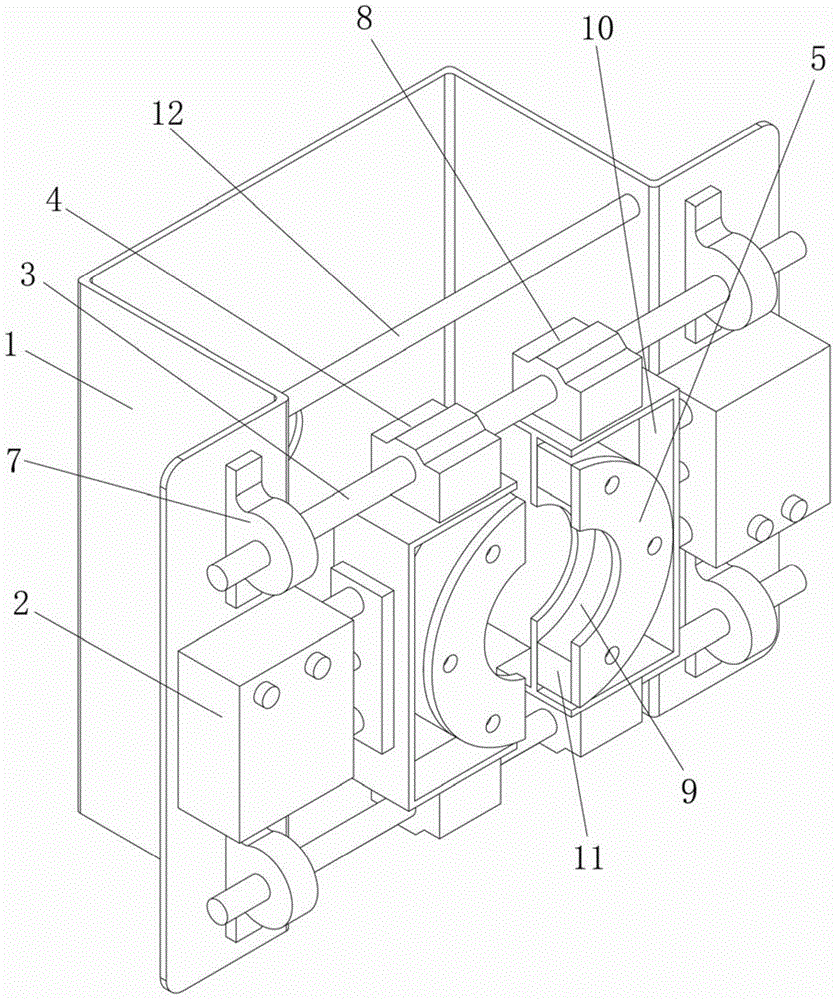

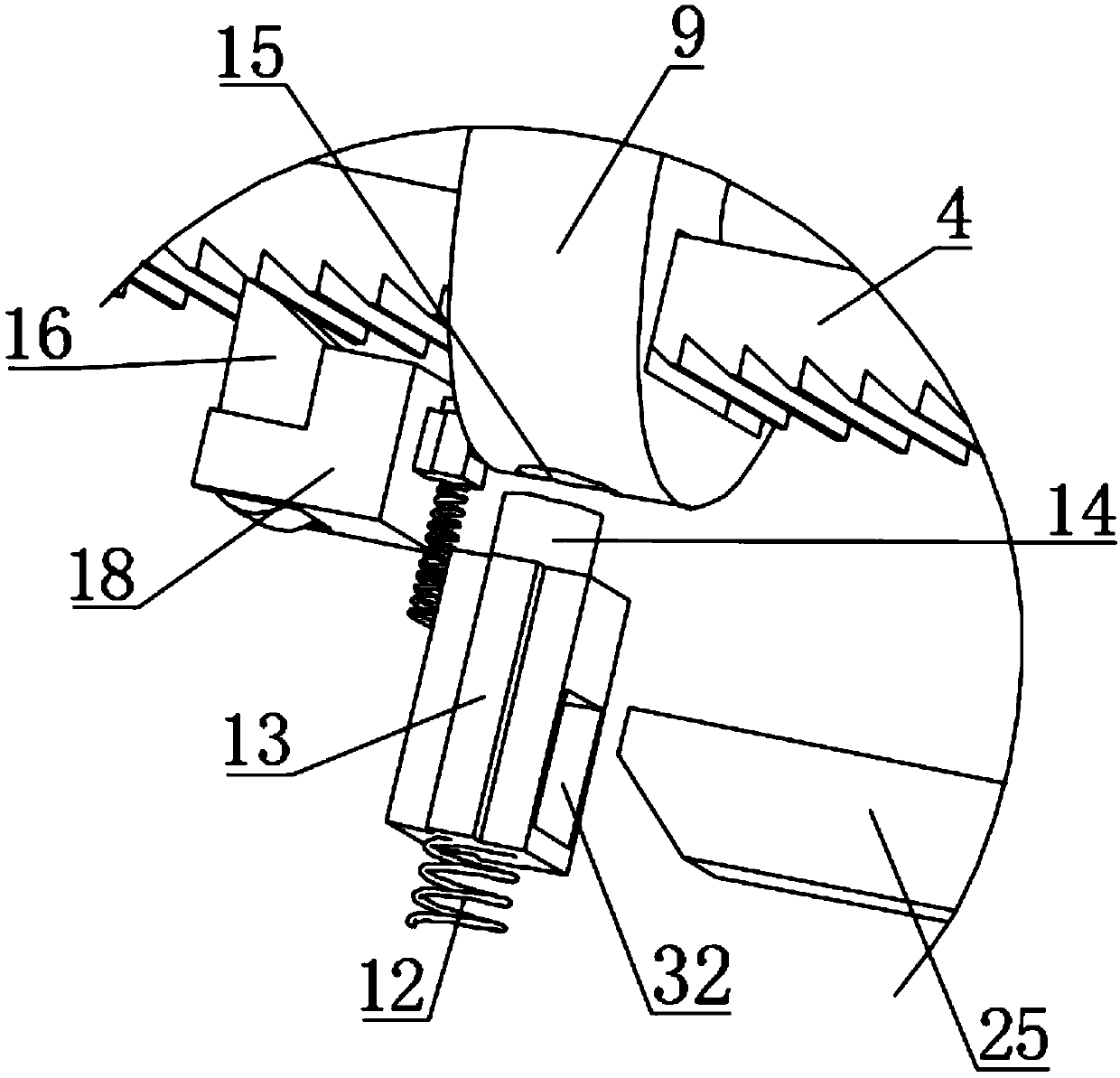

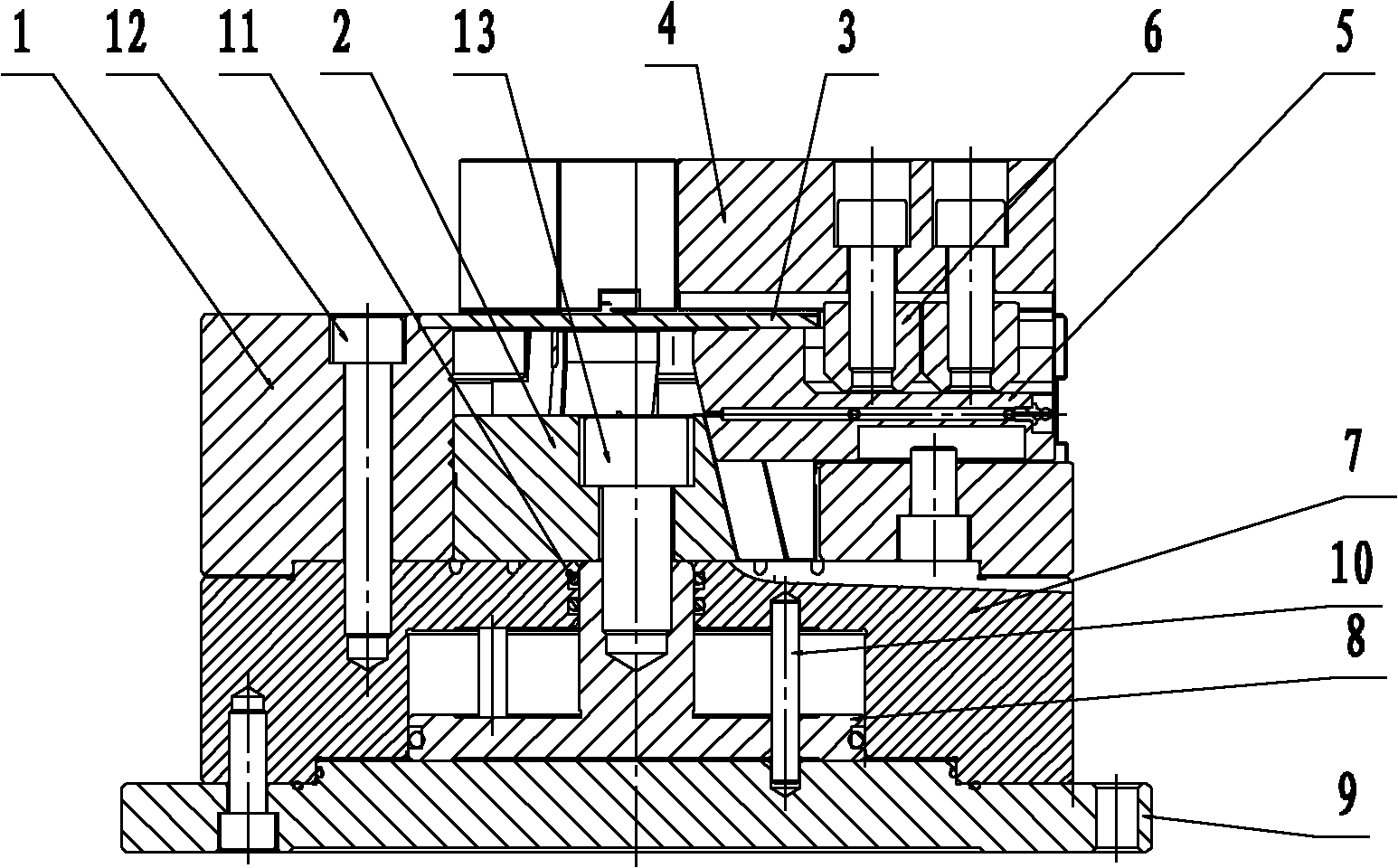

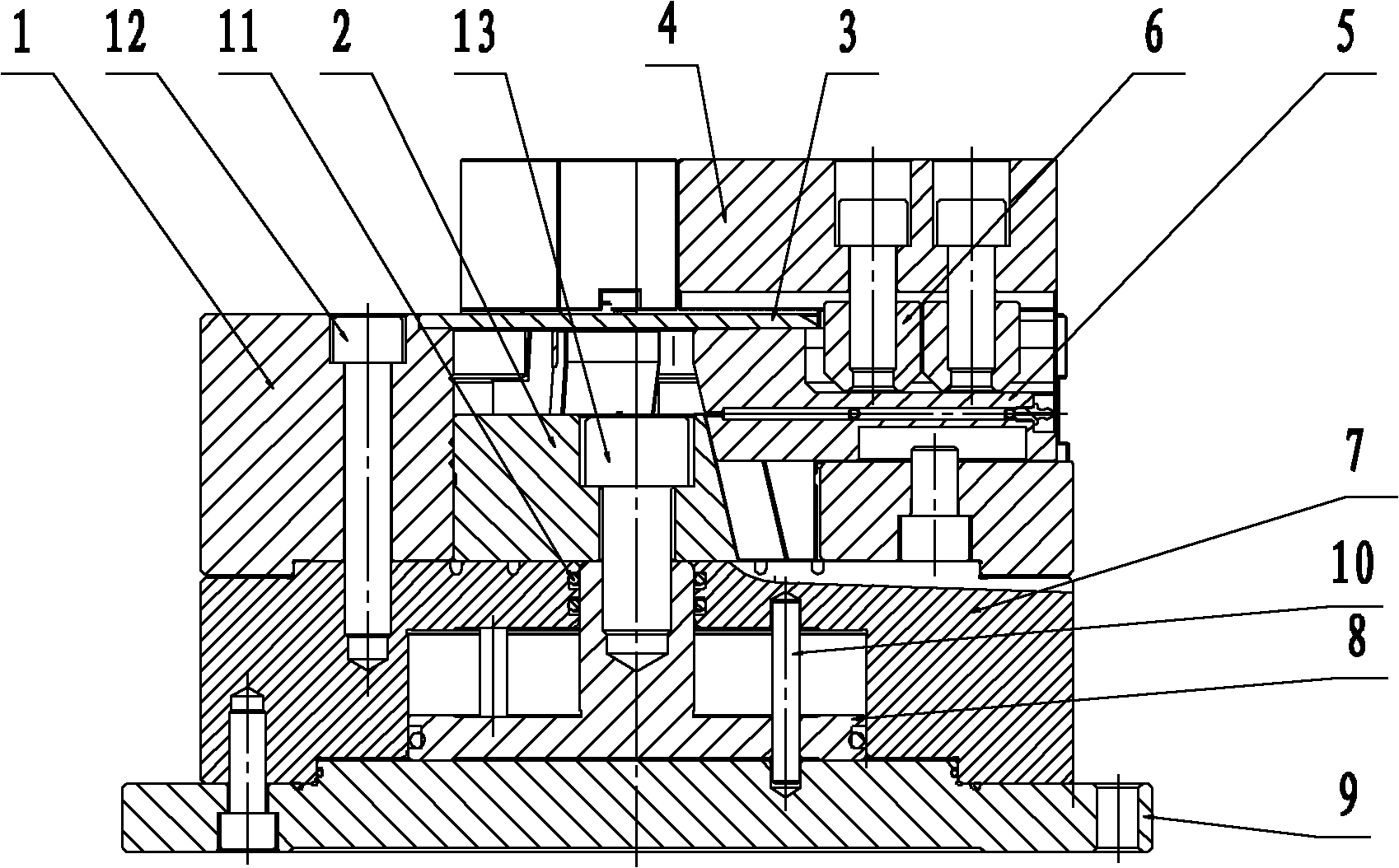

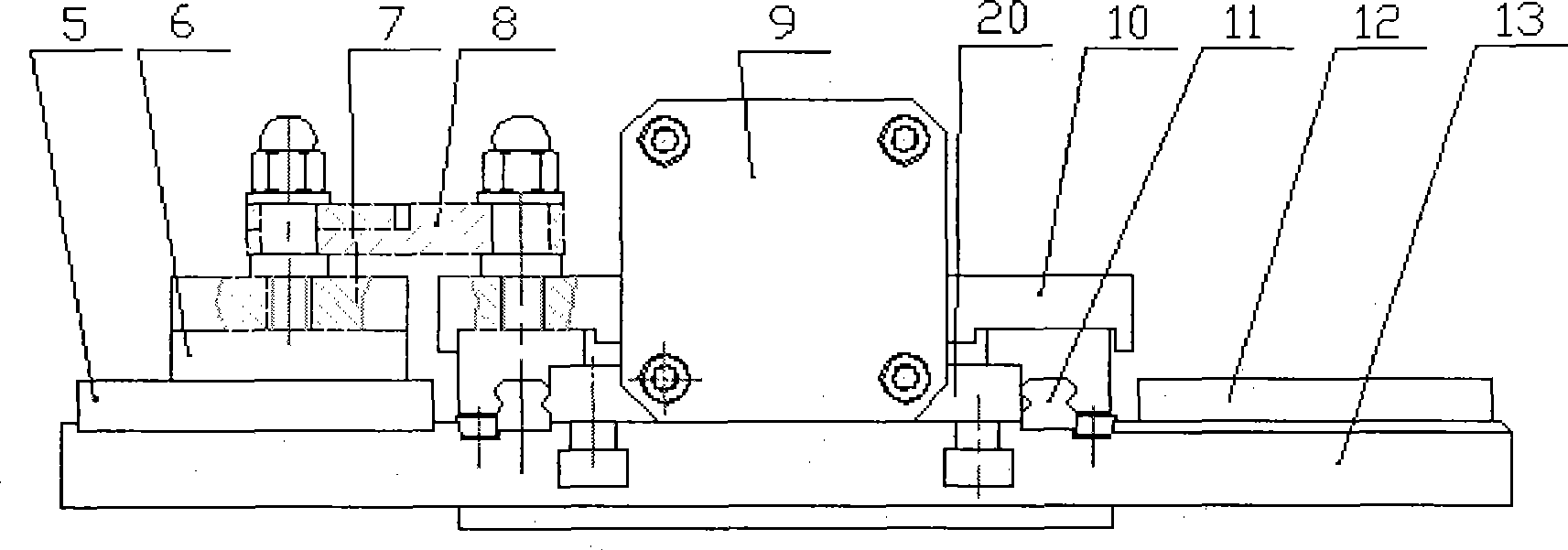

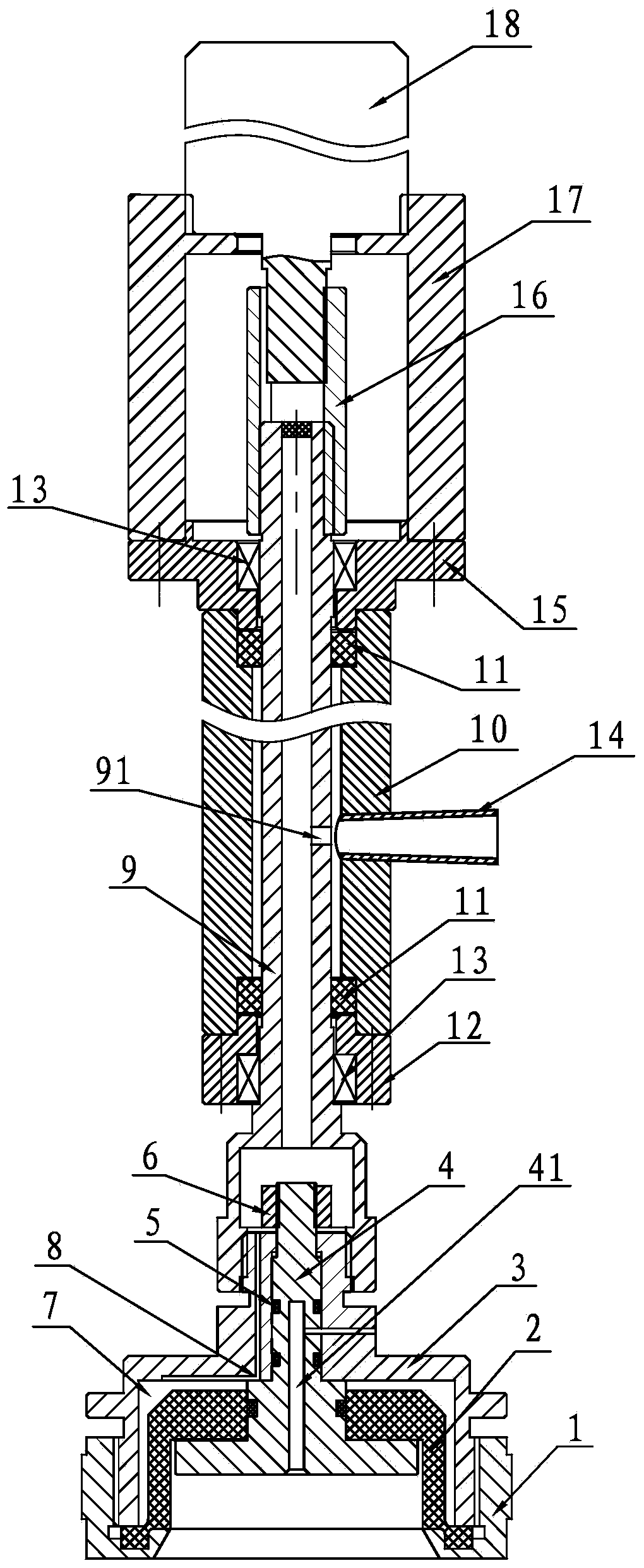

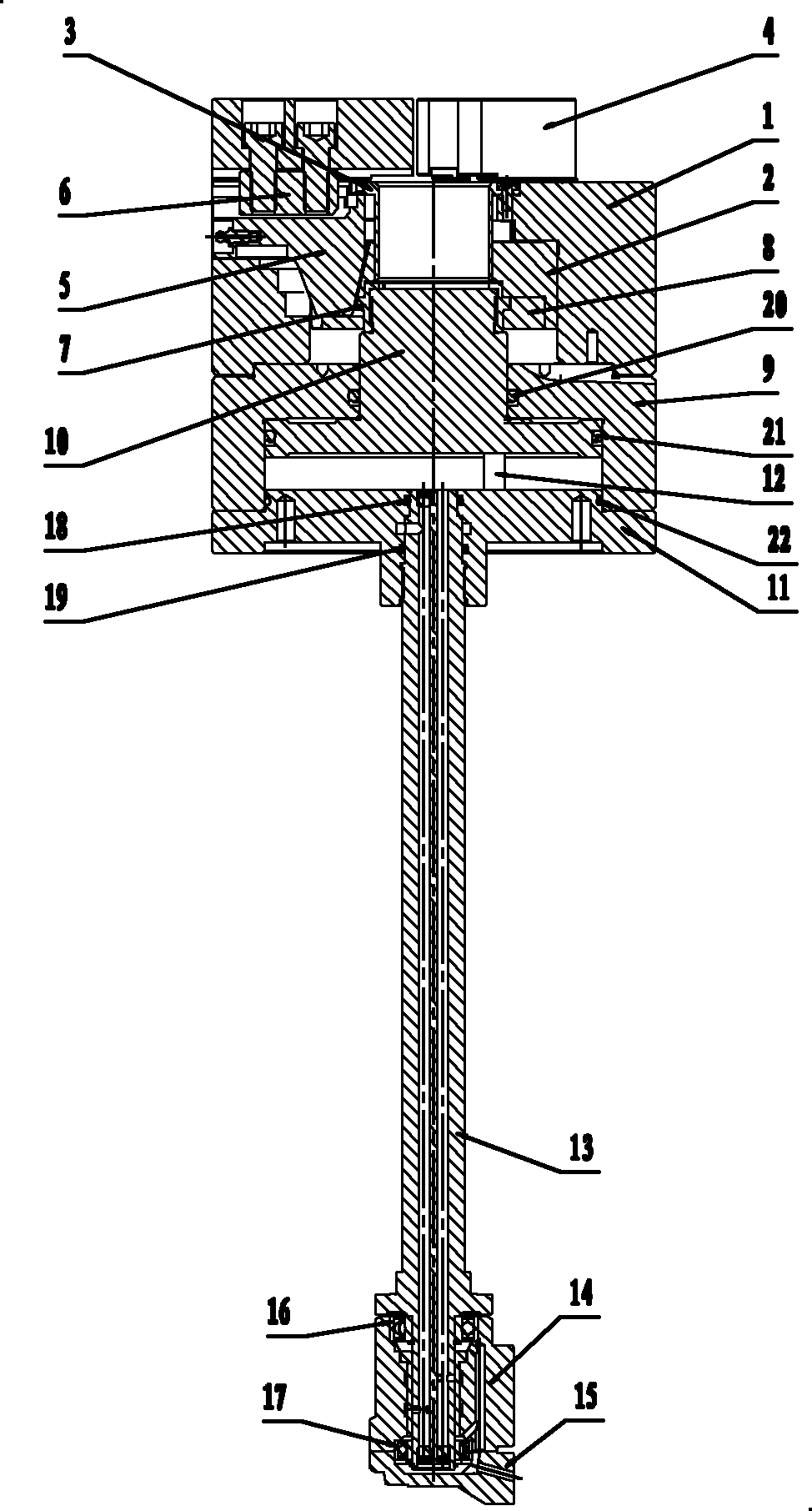

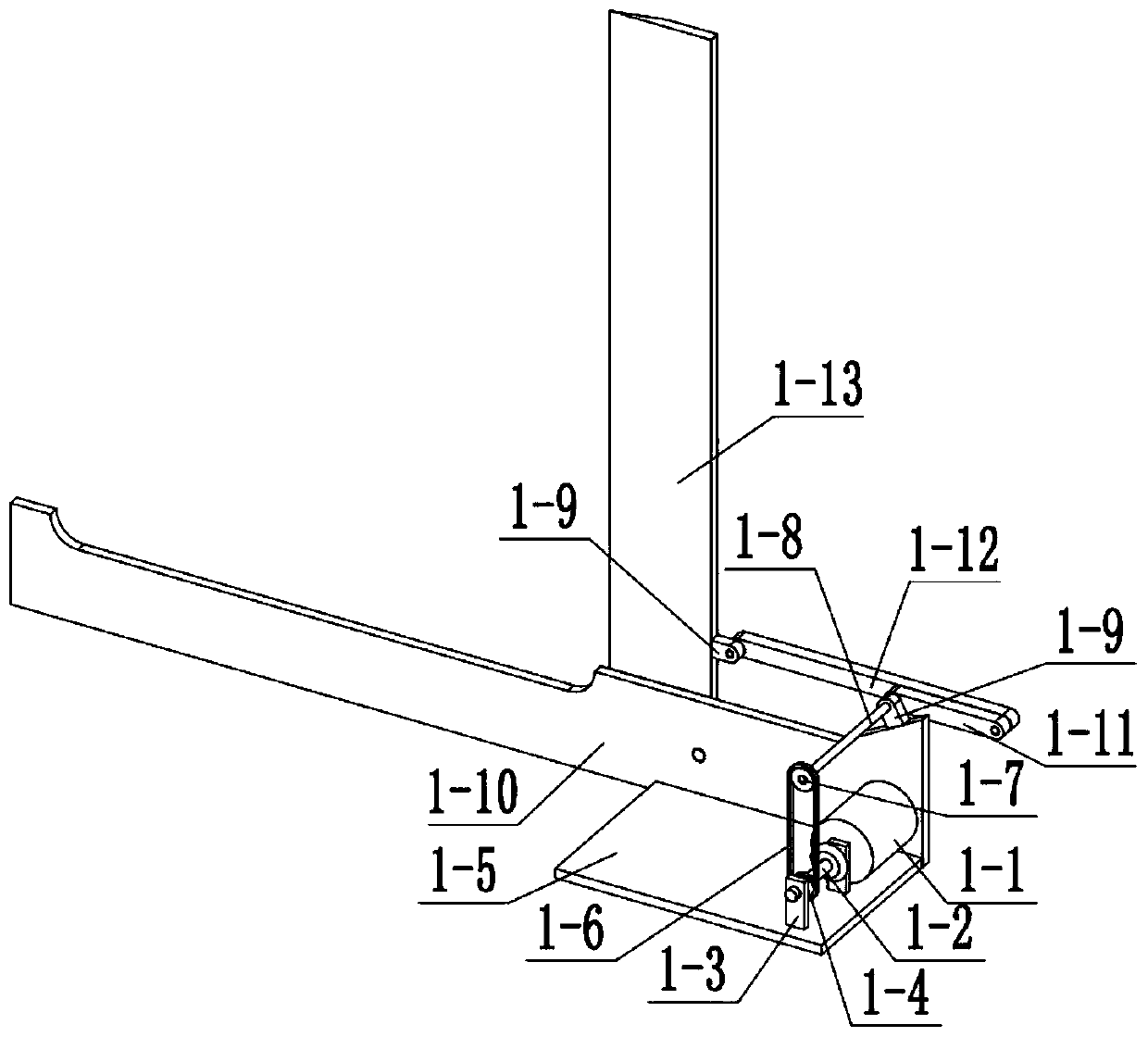

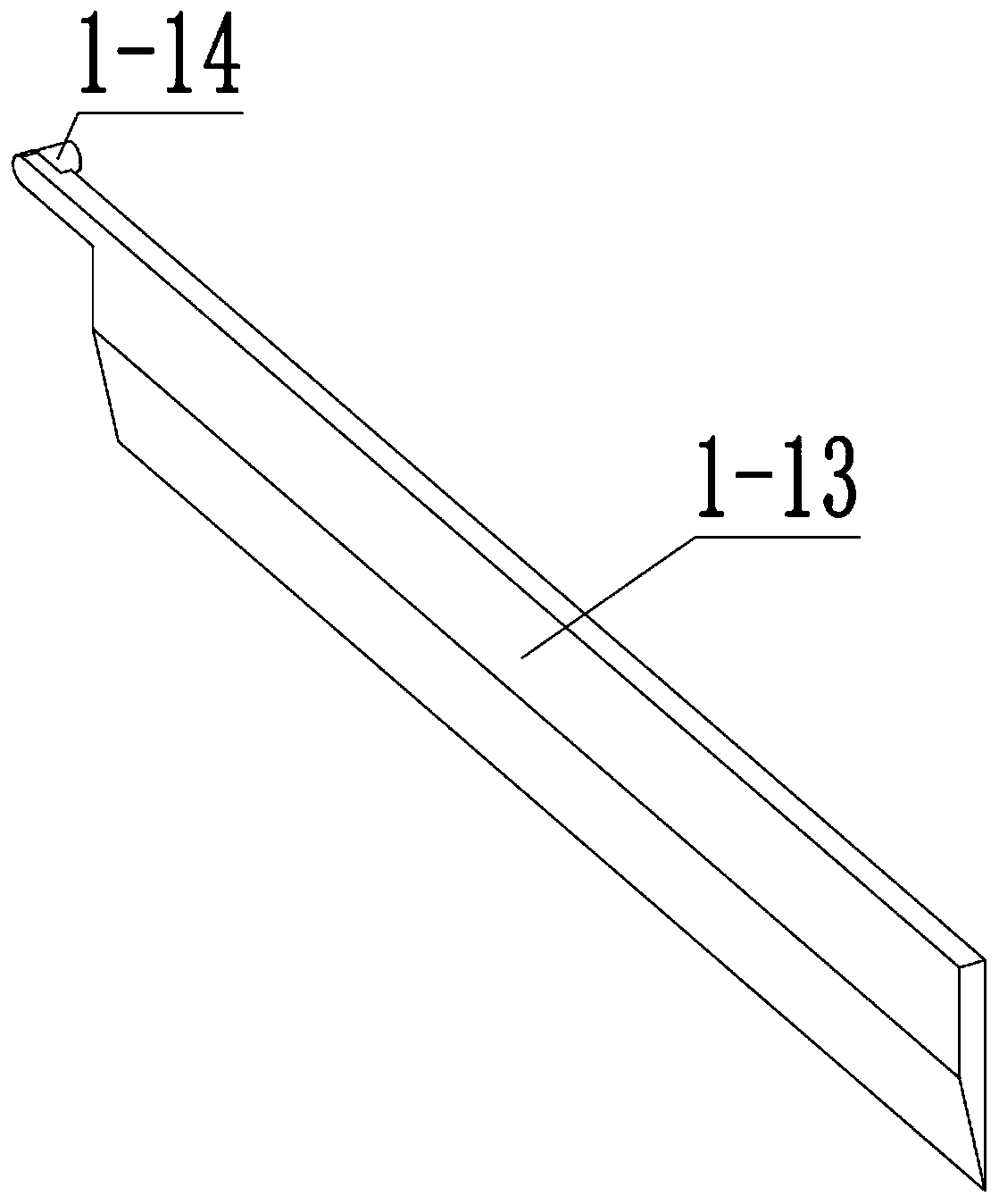

Fuze rotary demounting device for small-caliber aircraft projectiles

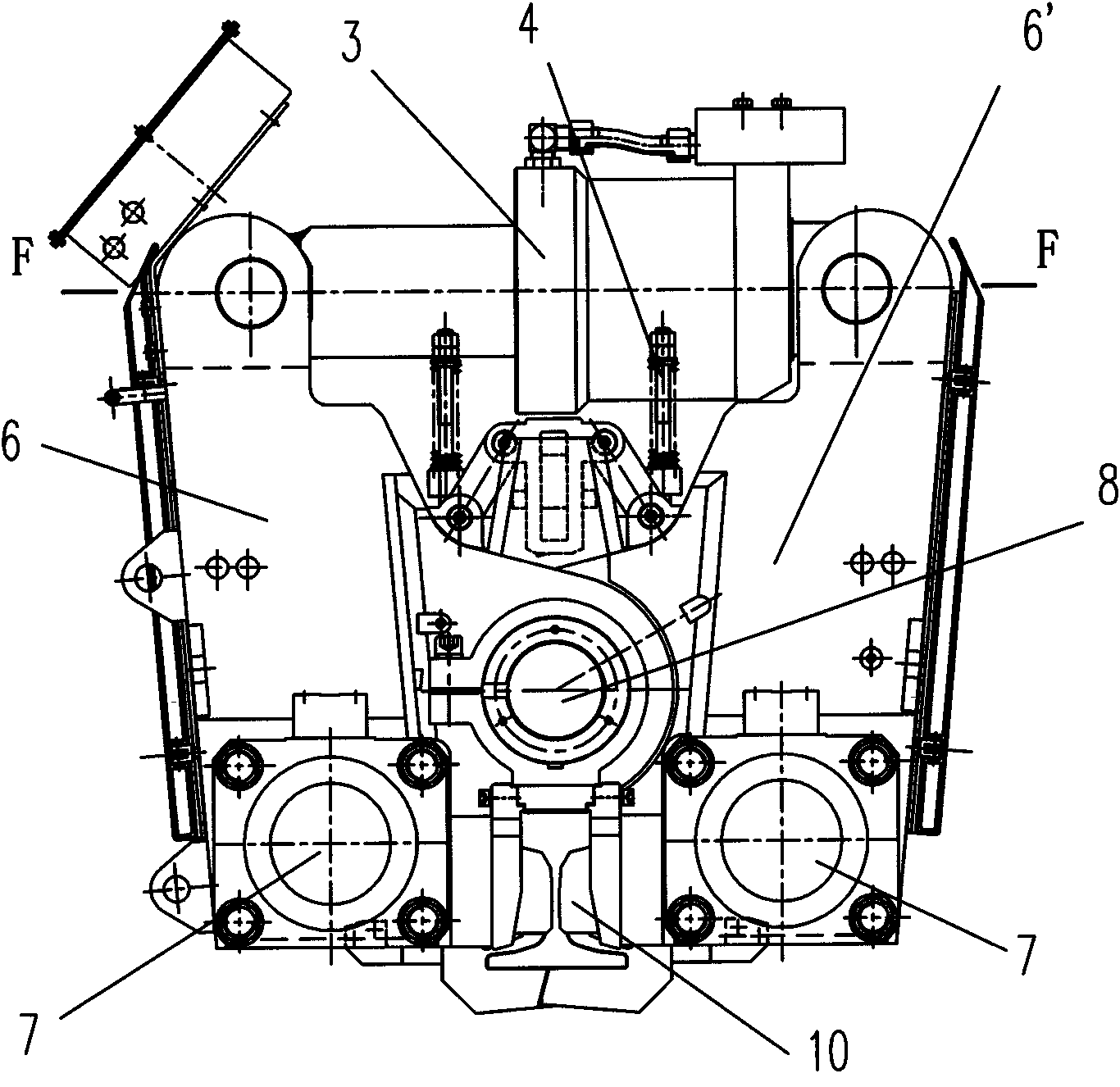

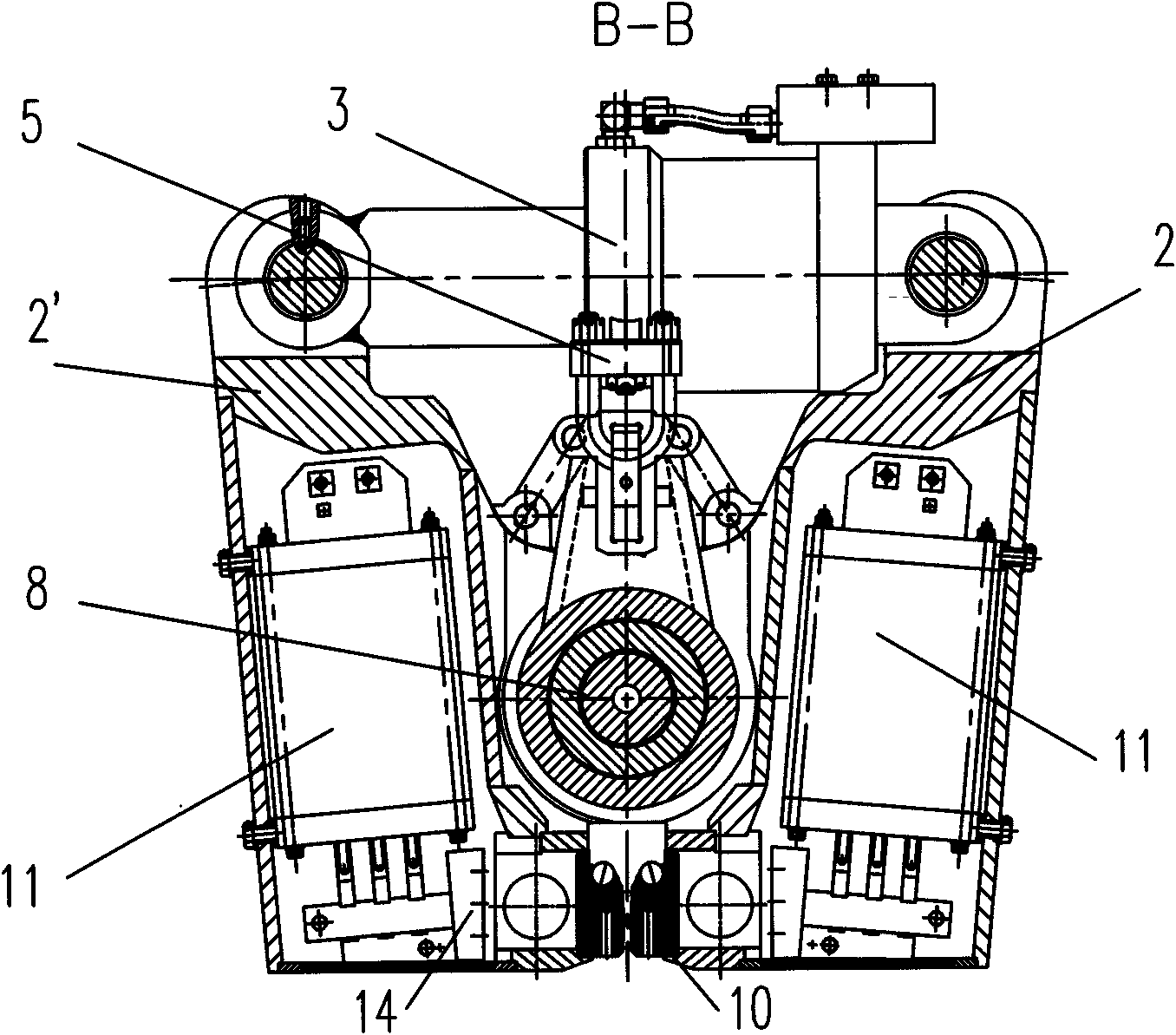

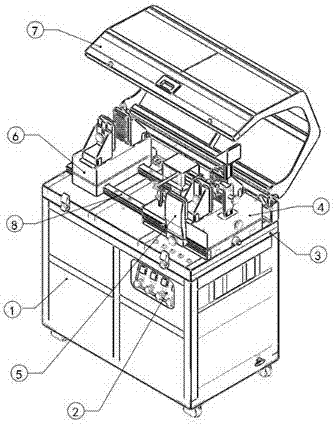

The invention relates to a fuze rotary demounting device for small-caliber aircraft projectiles and belongs to an automatic demounting line for the small-caliber aircraft projectiles. The fuze rotary demounting device comprises a rotary demounting power head, a projectile positioning clamping mechanism, a positioning lifting slide table, a fuze-moving-out mechanical arm, a counter weight mechanism and a rack. A hydraulic floating jaw and a spring seat are used for solve the key technical problem of fuze streamline conical surface clamping, reliable projectile positioning is guaranteed by the shape-following design of the cartridge jaw, and safe and reliable operation of the device is guaranteed by the clamping force for hydraulic clamping a fuze and a battle part. A rotary demounting separating end falls by the aid of the axial force and self weight, rotary demounting is performed according to screw pitch, and disordered fastening is avoided. By the fuze rotary demounting device, safe, fast and automatic fuze rotary demounting is achieved through electric, gas and liquid linkage control, automatic demounting of the small-caliber aircraft projectiles is achieved, and good technical support is provided for retired ammunition demounting.

Owner:CHANGCHUN EQUIP TECH RES INST

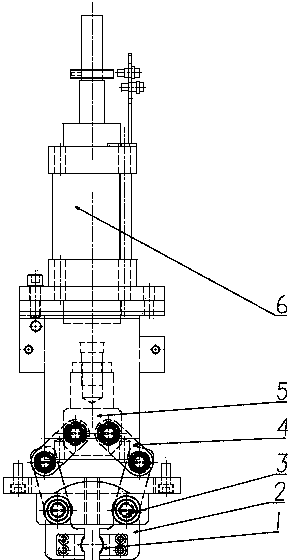

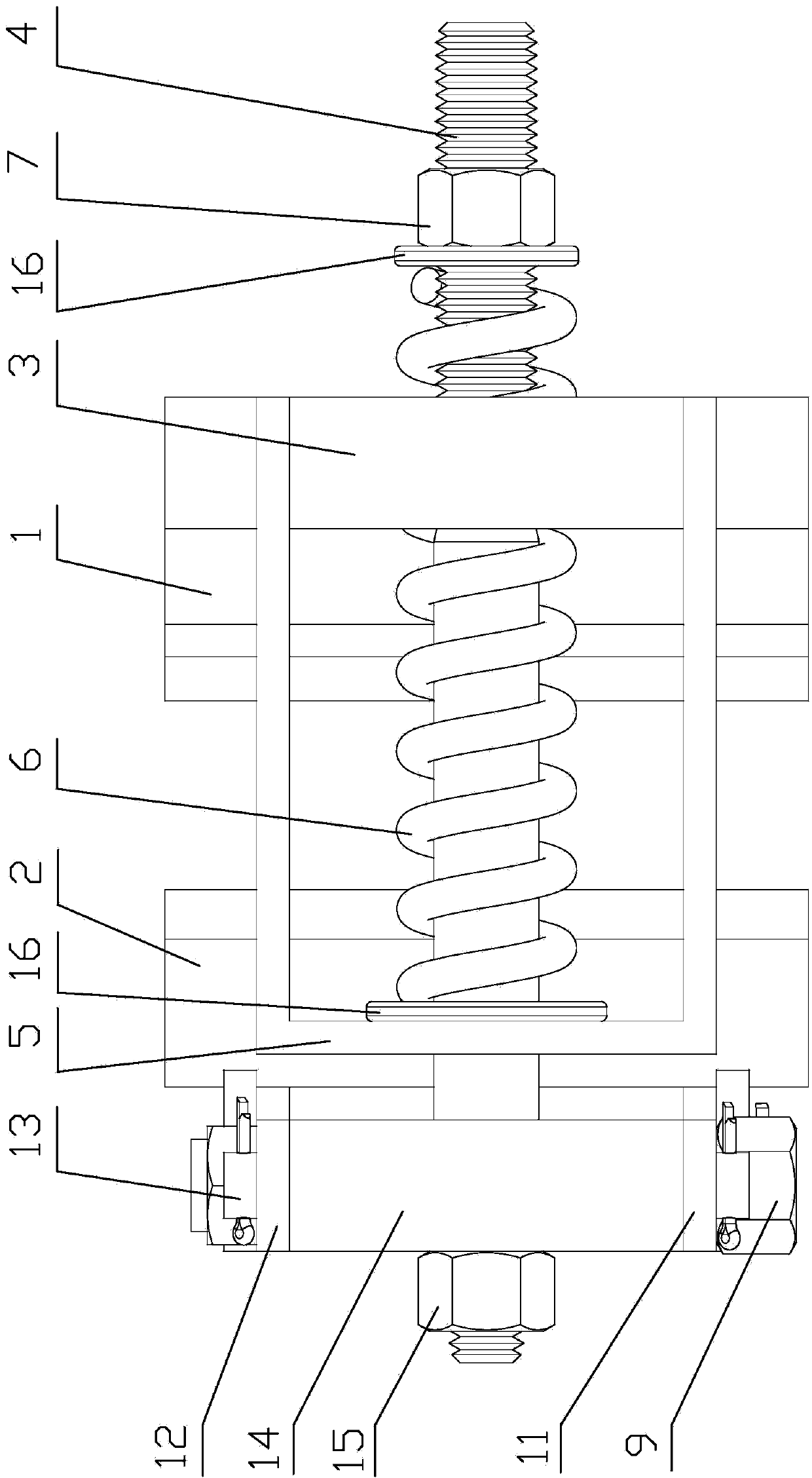

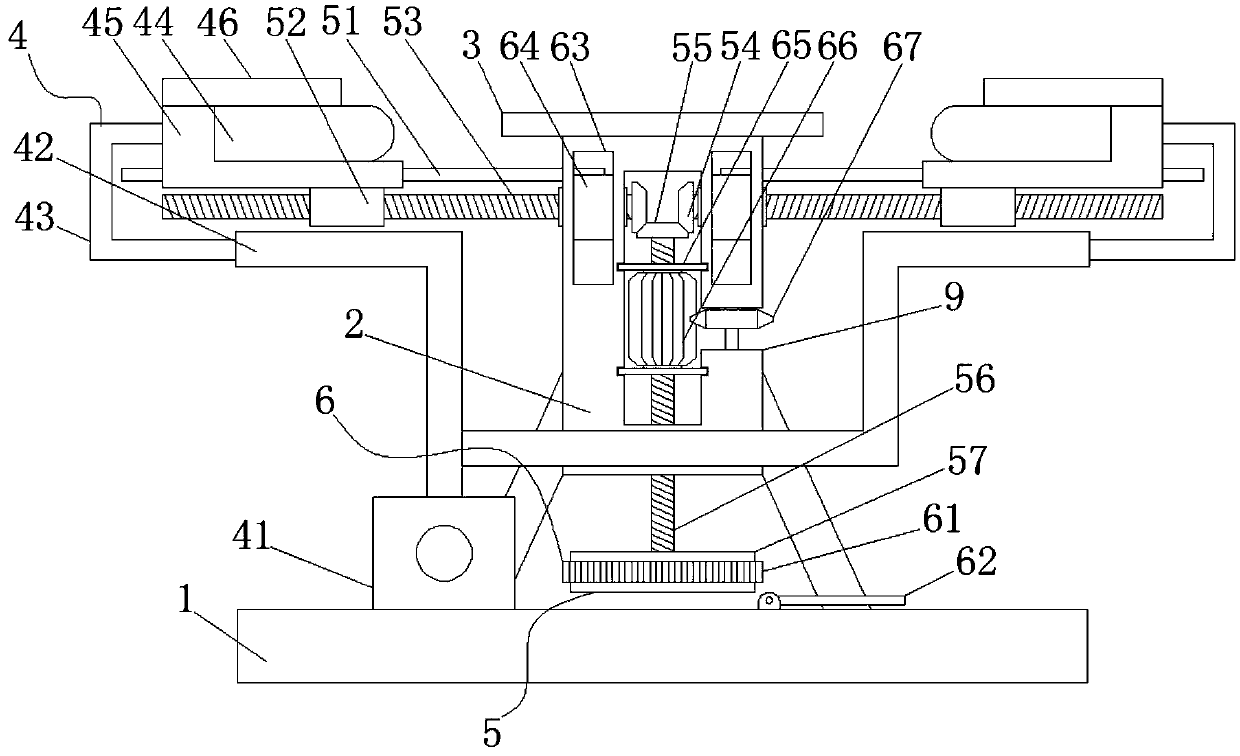

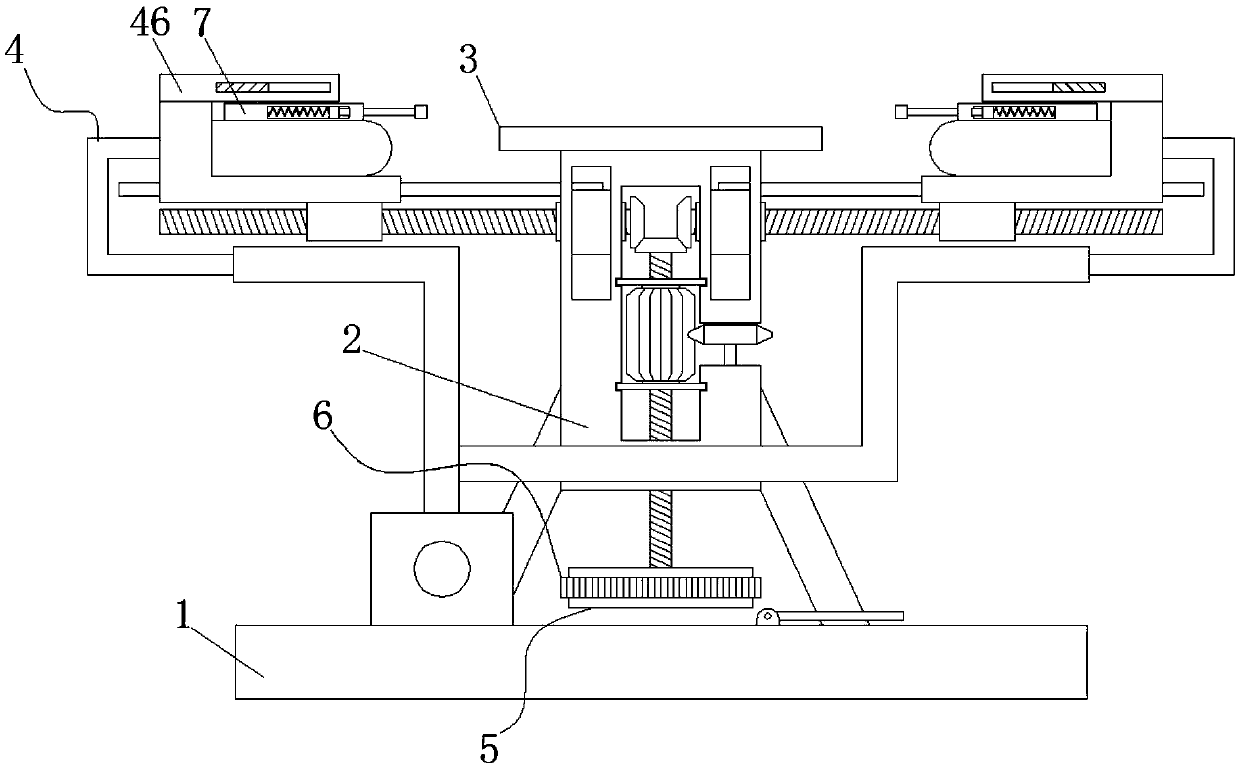

Clamping mechanism of cylindrical workpieces

InactiveCN104493569AAdjustable clamping forcePositioning apparatusMetal-working holdersIndustrial engineering

The invention discloses a clamping mechanism of cylindrical workpieces. The clamping mechanism comprises a base, an upper clamping plate and a lower clamping plate. The lower clamping plate is fixed on the base. The upper clamping plate comprises a top pressure device, a left clamping plate and a right clamping plate, and the left clamping plate and the right clamping plate are provided with arc grooves respectively. The top pressure device comprises a left clamping jaw, a right clamping jaw, a sliding rod, a conical sliding block and a top pressure block. An arc groove is formed in the lower end of the top pressure block, a support is arranged on the base and connected with the sliding rod, and the lower end of the sliding rod penetrates through the conical sliding block to be vertically connected with the upper end of the top pressure block. The small-diameter end of the conical sliding block is close to the top pressure block, and the big-diameter end of the conical sliding block is far away from the top pressure block. A pull rod is arranged at the upper end of the conical sliding block, and the lower portion of the left clamping jaw butts against the outer wall of the left clamping plate. The lower portion of the right clamping jaw butts against the outer wall of the right clamping plate. The clamping mechanism of cylindrical workpieces overcomes defects of the existing expanding sleeve type clamping device of the cylindrical workpieces of incapability in clamping force control and poor applicability; can adjust the clamping strength according to the diameters of the workpieces, and is strong in applicability.

Owner:CHONGQING ANTAI SPRING IND

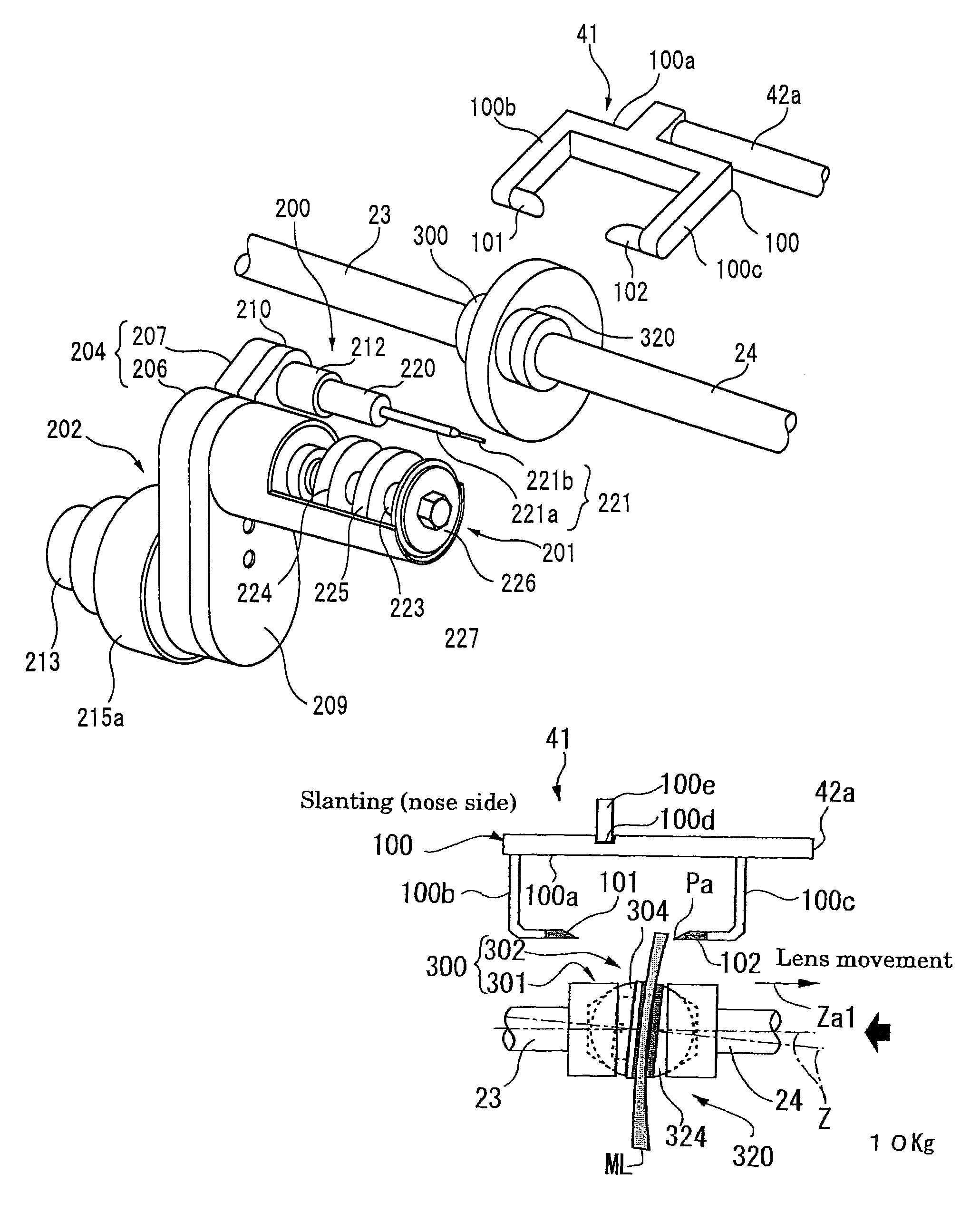

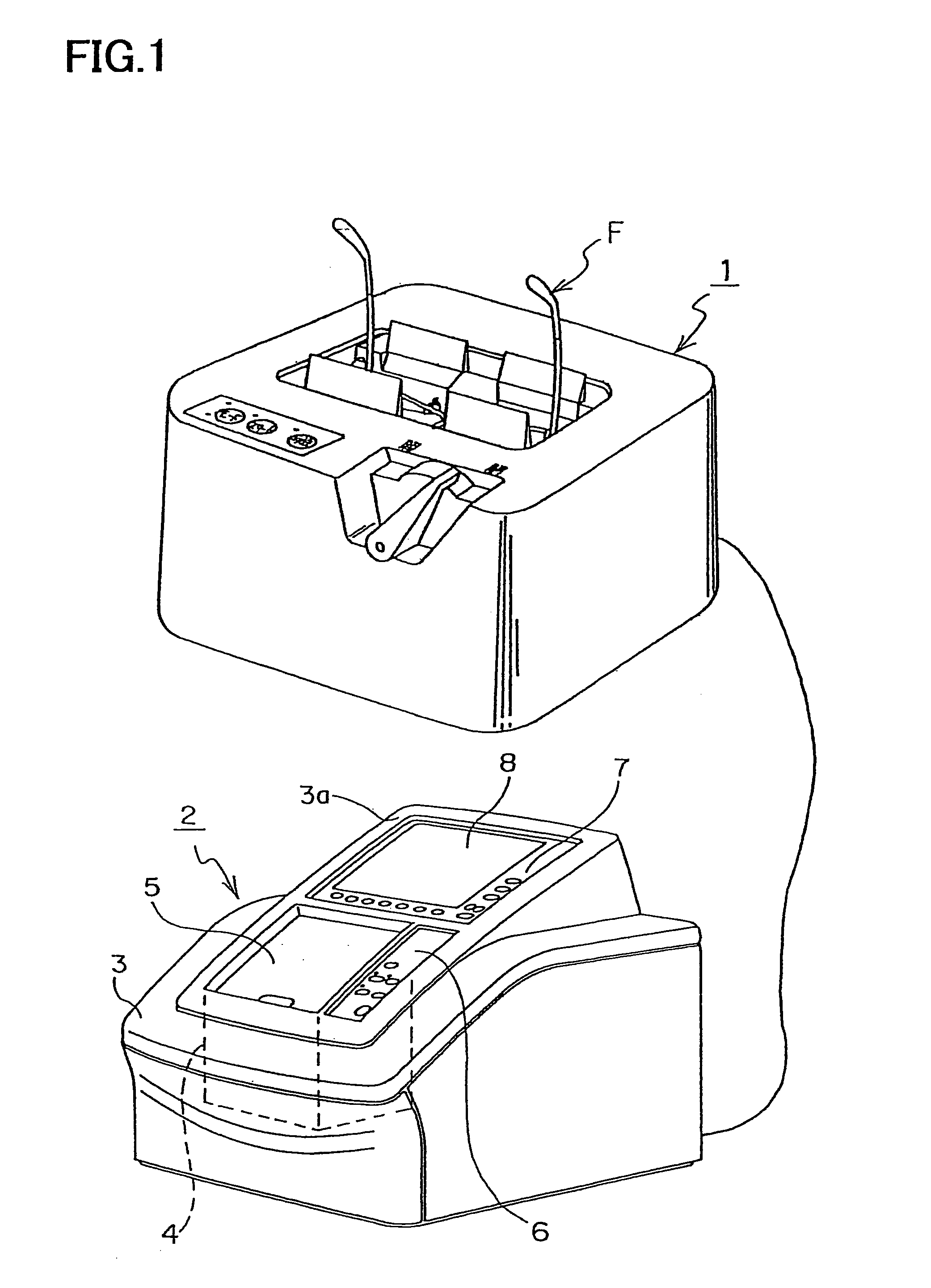

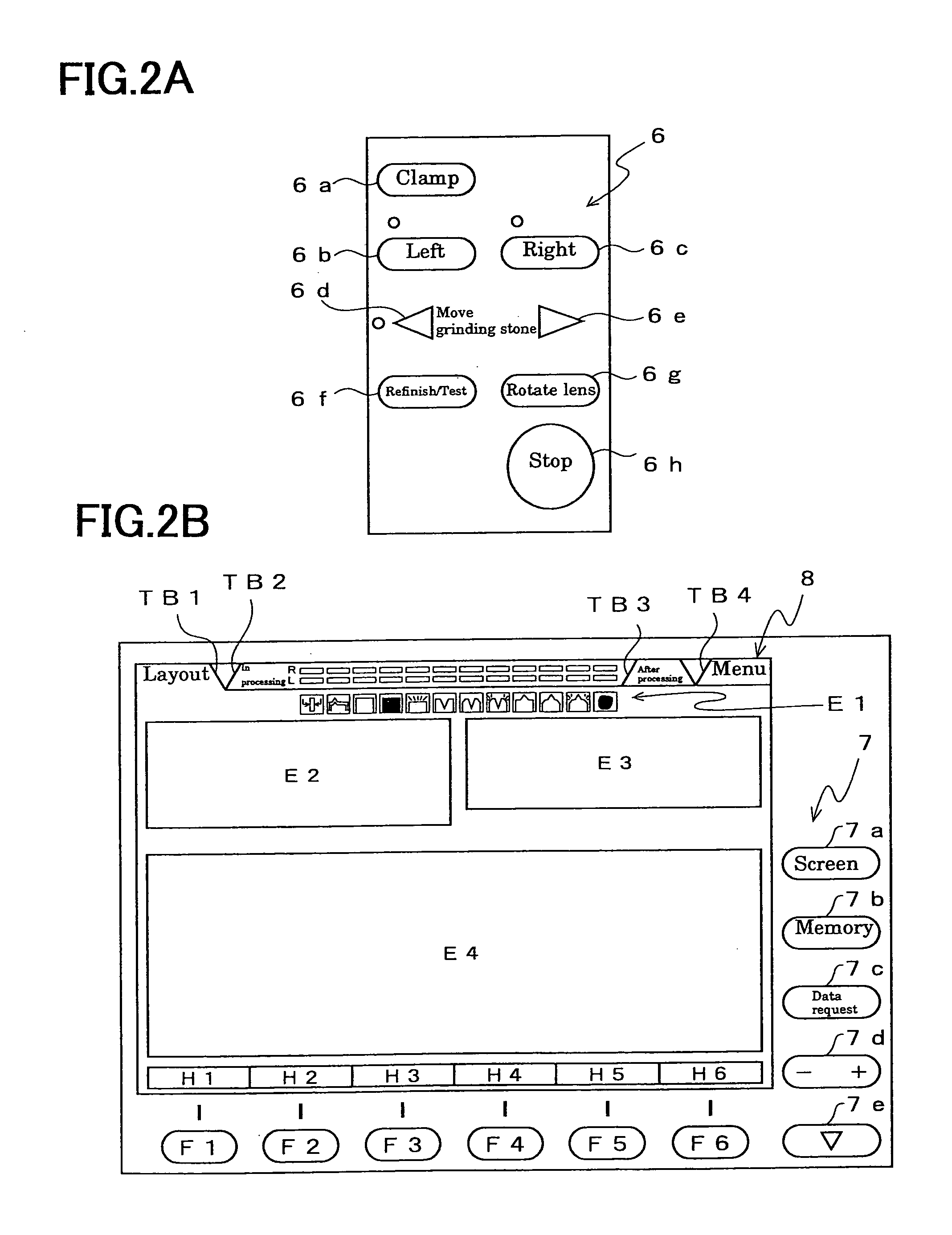

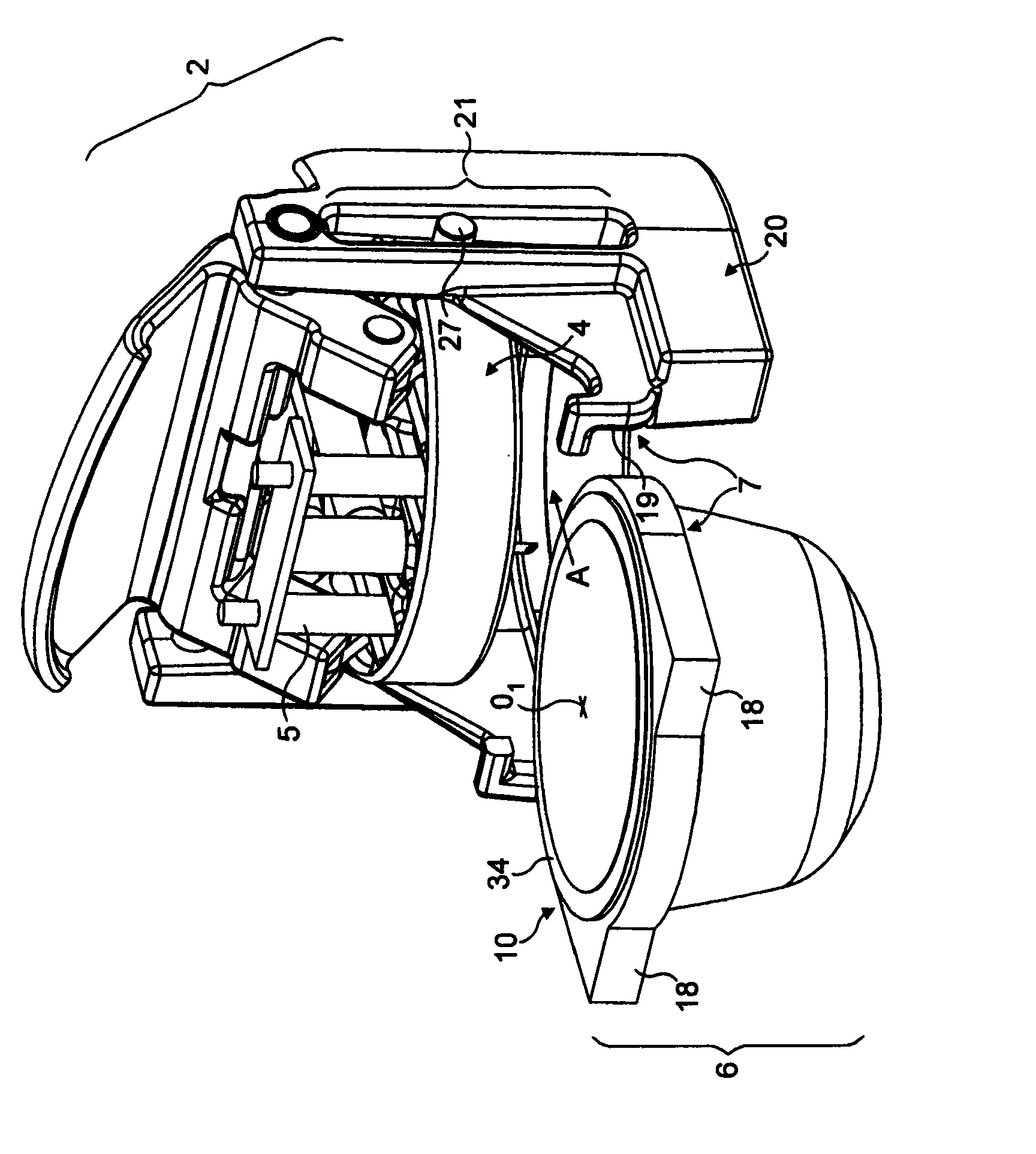

Lens grinding processing apparatus

InactiveUS6984161B2Simple structureAdjustable clamping forceSpectales/gogglesEdge grinding machinesCamera lensEngineering

A lens grinding processing apparatus of the present invention has lens rotating shafts 23 and 24 for holding an eyeglass lens ML, a lens retaining members (300, 320) fixed respectively to opposed end sections of the lens rotating shafts 23 and 24 capable of slanting adjustably, a drilling device (drilling processing device 200) for drilling a hole for a point frame into the slanted eyeglass lens ML, and a grinding stone (grinding stone 35, chamfering stones 224, 225) for grinding and processing a circumferential part of the eyeglass lens ML.

Owner:KK TOPCON

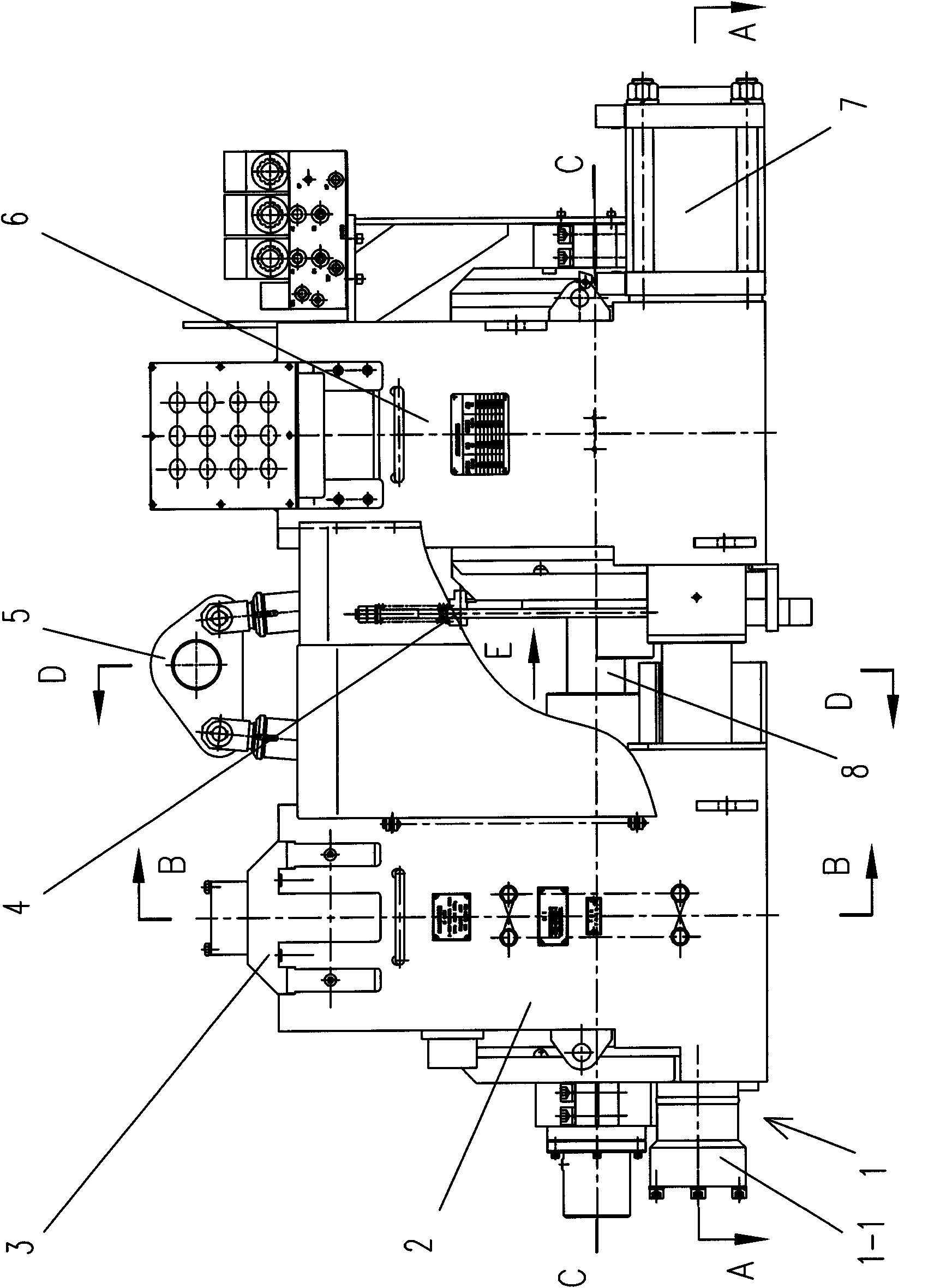

Steel rail flash welding machine

The invention discloses a steel rail flash welding machine, which comprises a first pair of box body, a second pair of box body, a central shaft, a clamping oil cylinder, an upsetting oil cylinder, a knob removing device and a welding transformer, wherein the clamping oil cylinder comprises a cylinder body, a piston, a piston rod, a piston rod end connecting piece and an end cover; the cylinder body is divided into a first cavity and a second cavity; the inside of the piston rod is provided with a supercharged piston; the inner cavity of the piston rod is divided into a third cavity and a fourth cavity; the end part of the cylinder body is provided with a first oil line and a second oil line and is connected with a hydraulic integrated block provided with an electromagnetic reversing valve, a pilot reducing valve and a hydraulic control one-way valve; and the periphery of an oil conduit at least forms a segment of sliding fit with the through hole of the supercharged piston. The steel rail flash welding machine is large in clamping force, simple and reasonable in structure, facilitates the control of the output clamping force and is suitable for welding steel rails with different lengths and weights.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

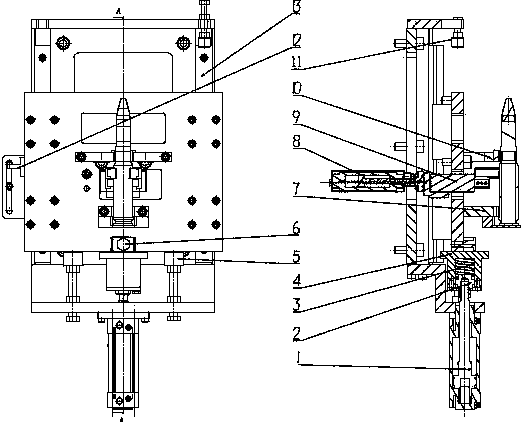

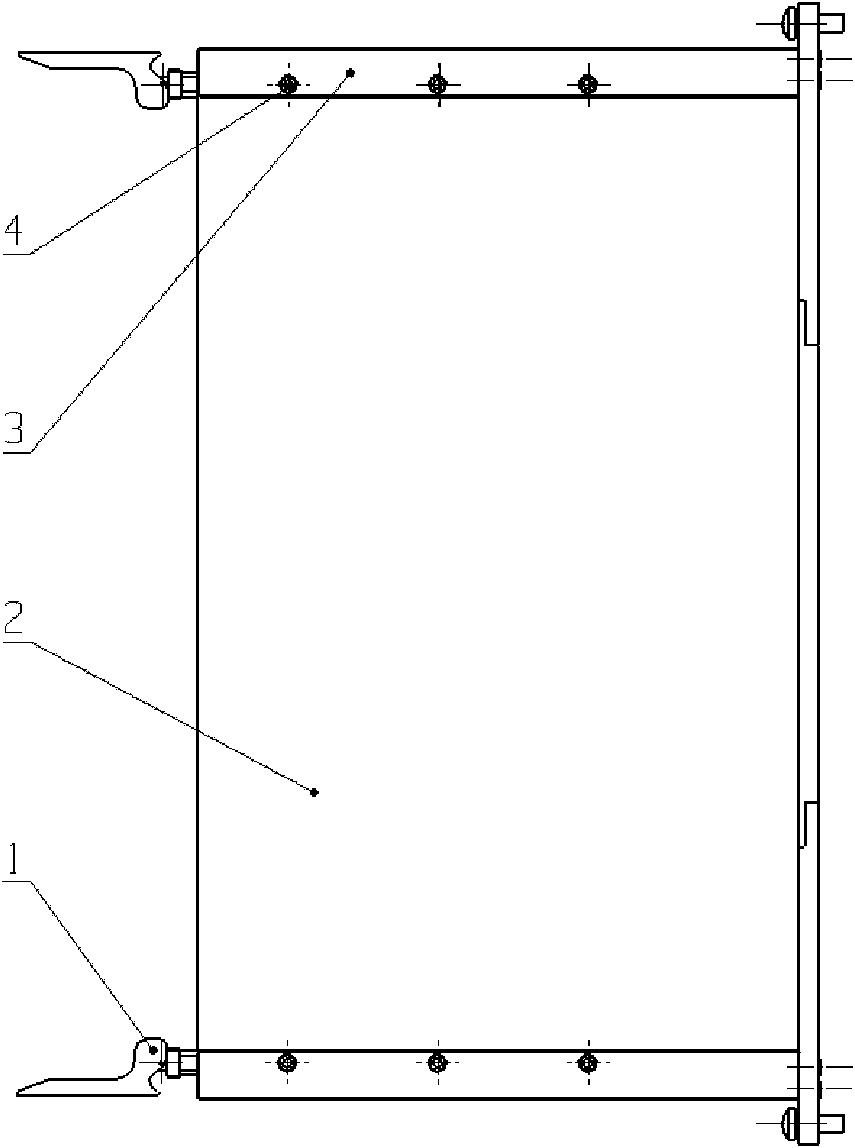

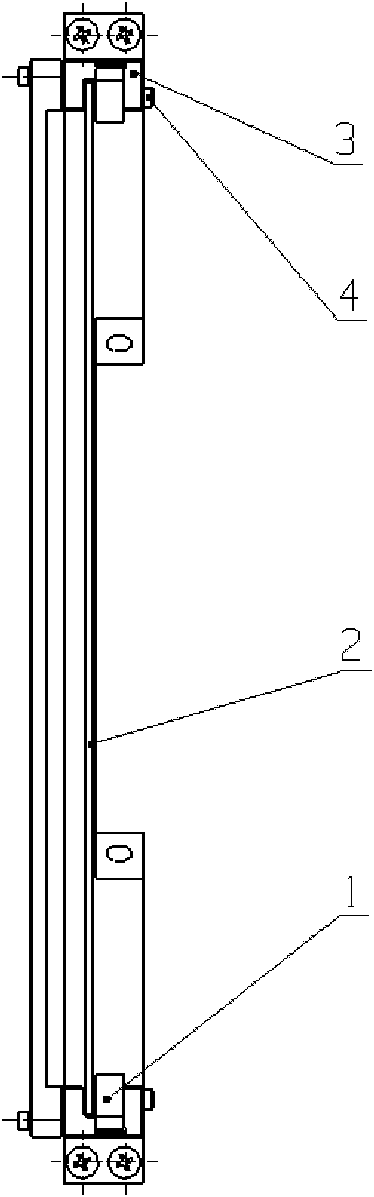

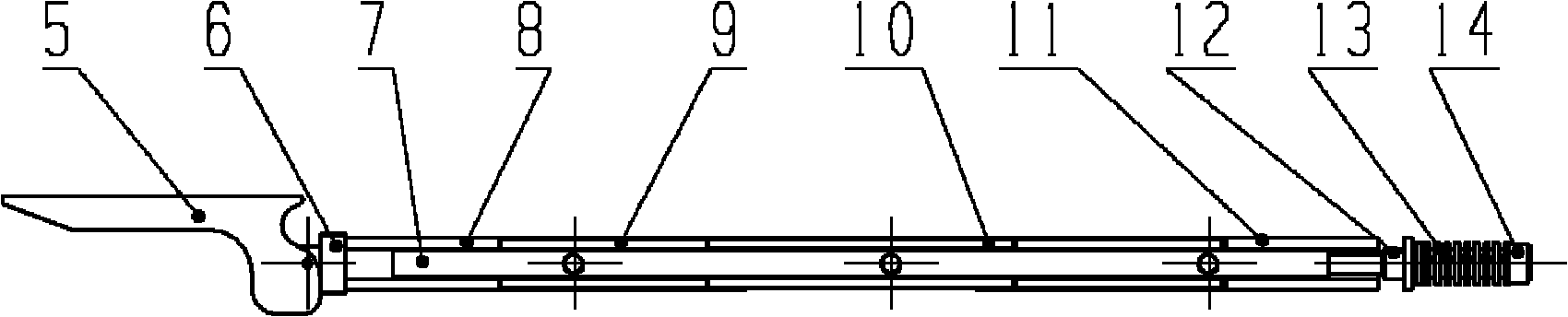

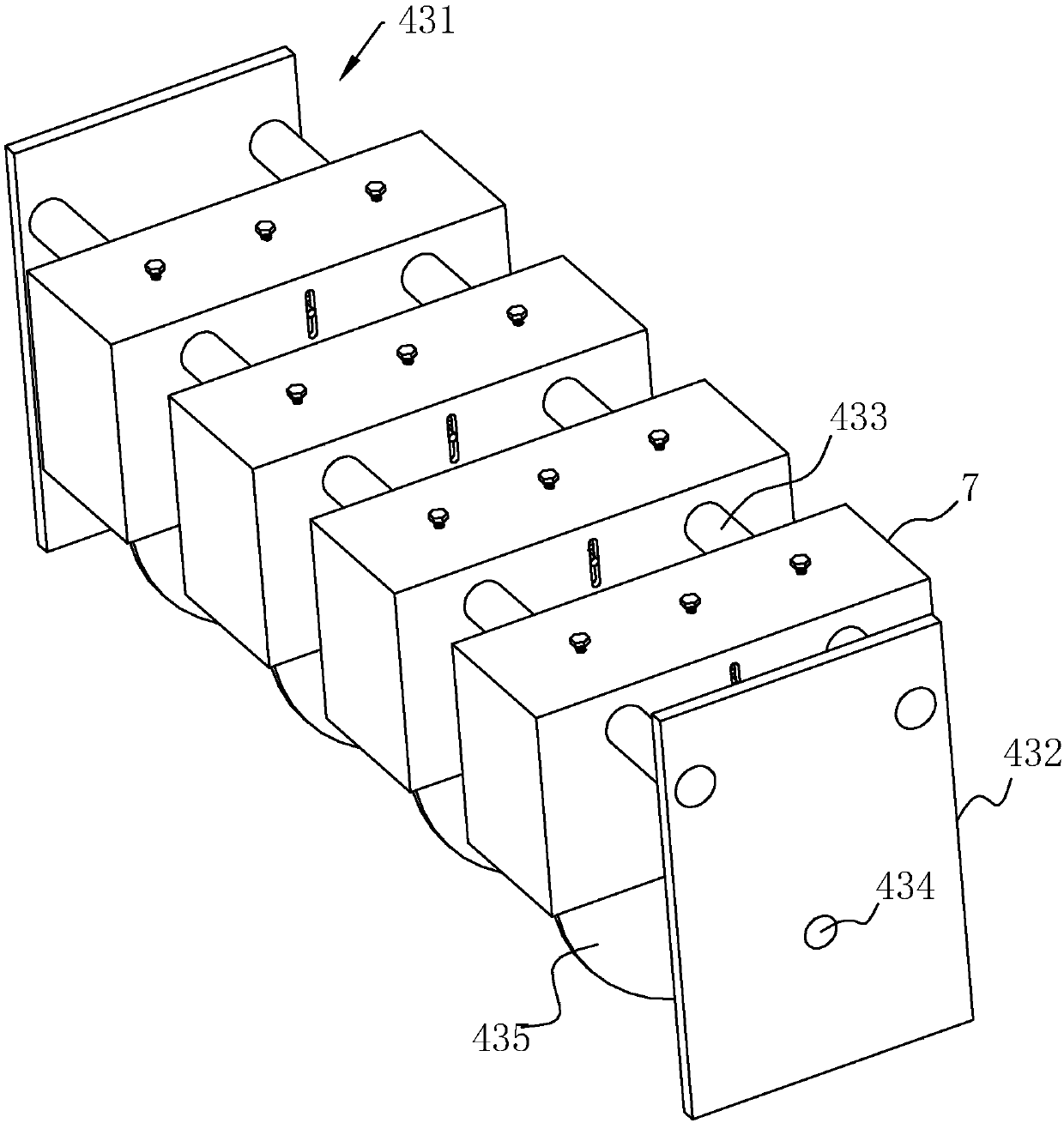

Locking and fixing device for quickly replacing printed board

InactiveCN102497761AQuick changeAdjustable clamping forceSupport structure mountingMaintainabilityEngineering

The invention discloses a locking and fixing device for quickly replacing a printed board, and relates to the technical field of precision machineries. The locking and fixing device comprises a pressing mechanism, a supporting frame and screws, wherein the pressing mechanism comprises a locking handle, an upper sliding limit block, a sliding rail, an end part sliding block, a pressing sliding block, a transition sliding block, a tail end sliding block, a locking and adjusting nut, an elastic pressing piece and an adjusting screw, the sliding rail is fixedly arranged in a groove of the supporting frame, the upper sliding limit block, the end part sliding block, the transition sliding block and the tail end sliding block are positioned in a sliding groove of the sliding rail and can move on the sliding rail, the elastic pressing piece is sleeved on the adjusting screw and is tightly pressed by the locking and adjusting nut, the adjusting screw is arranged in a screw hole at one end of the sliding rail, and the locking handle is hinged at the other end of the sliding rail. The locking and fixing device for quickly replacing the printed board disclosed by the invention has the beneficial effects that the quick replacing for the printed board and the adjustability of a fixed pressing force are realized, the reliability and the maintainability of the printed board are increased, and the service life of the printed board is further prolonged.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

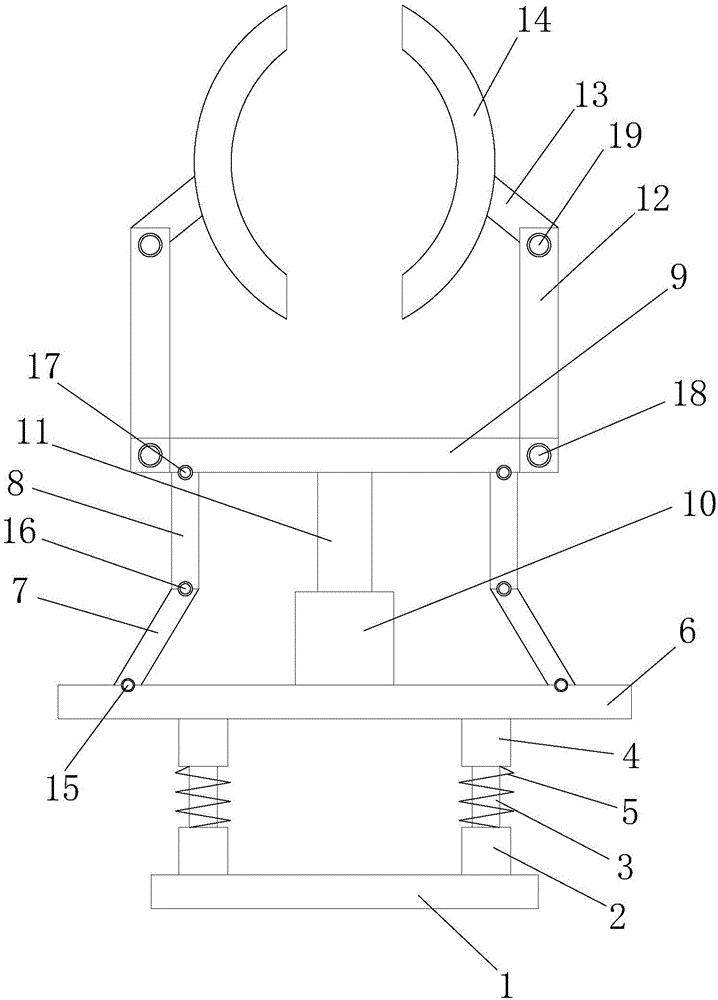

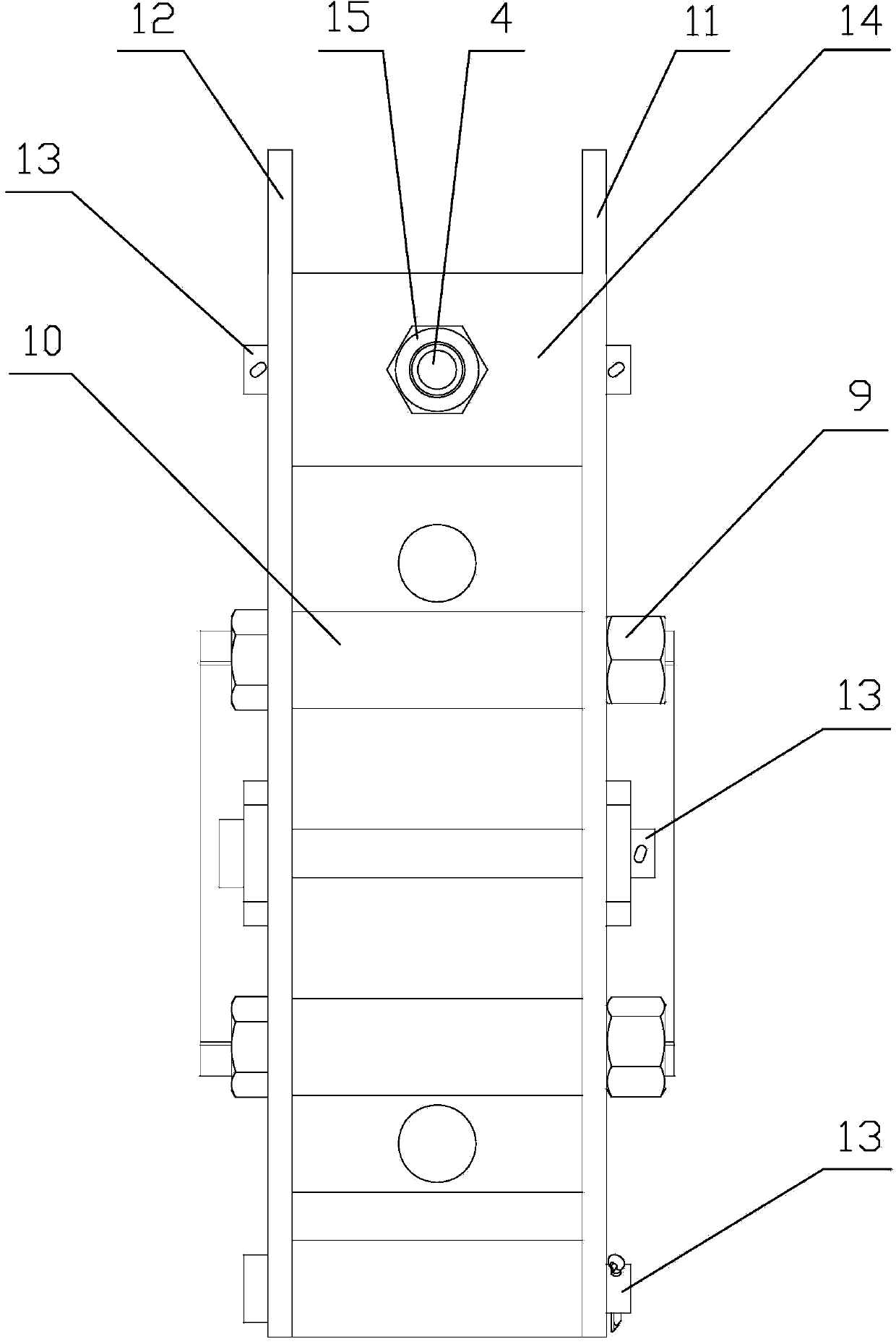

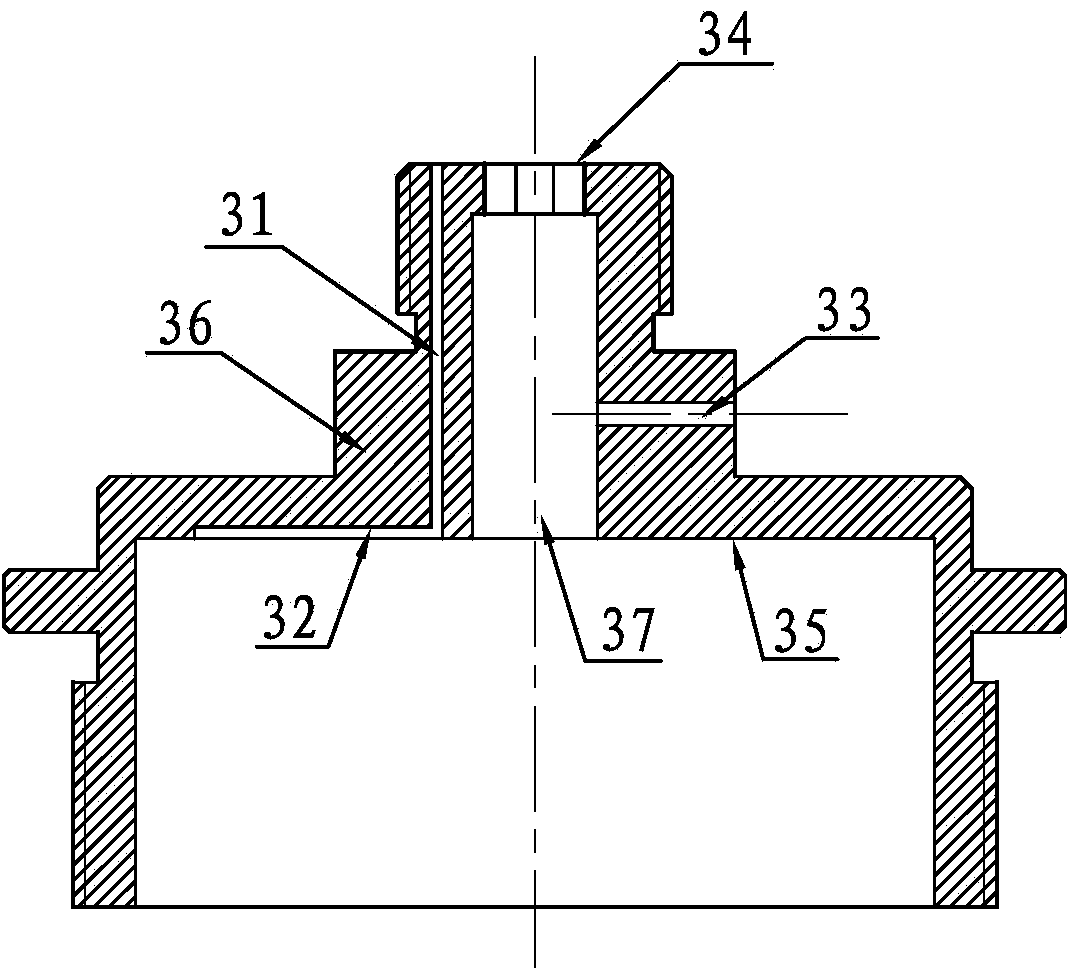

Pipe fitting clamping device

InactiveCN106346283AAdjustable clamping forceImprove shock absorptionPositioning apparatusMetal-working holdersPipe fittingEngineering

The invention discloses a pipe fitting clamping device which comprises a base. Lower supporting sleeves are vertically mounted on the base; telescopic rods are mounted on the lower supporting sleeves; upper supporting sleeves are mounted above the telescopic rods, and damping springs are arranged outside the telescopic rods; a supporting plate is mounted on the upper supporting sleeves; connecting rods A are respectively mounted at both sides of the supporting plate; connecting rods B are movably mounted on the connecting rods A ; the top ends of the connecting rods B are mounted below a pushing rod, and a driver is mounted at the middle position at the upper end of the supporting plate; a drive rod is mounted on the driver; the top end of the drive rod drives the pushing rod to move, and movable rods are movably mounted at both sides of the pushing rod; inclined rods are movably mounted at the upper ends of the movable rods; clamping blocks are mounted at one ends of the inclined rods. In the using process of the pipe fitting clamping device, a pipe fitting is arranged between the clamping blocks, and driving is carried out by the driver to drive the clamping blocks to carry out a clamping operation on the pipe fitting; by arranging the damping springs, a damping effect of the integral device can be improved.

Owner:周末

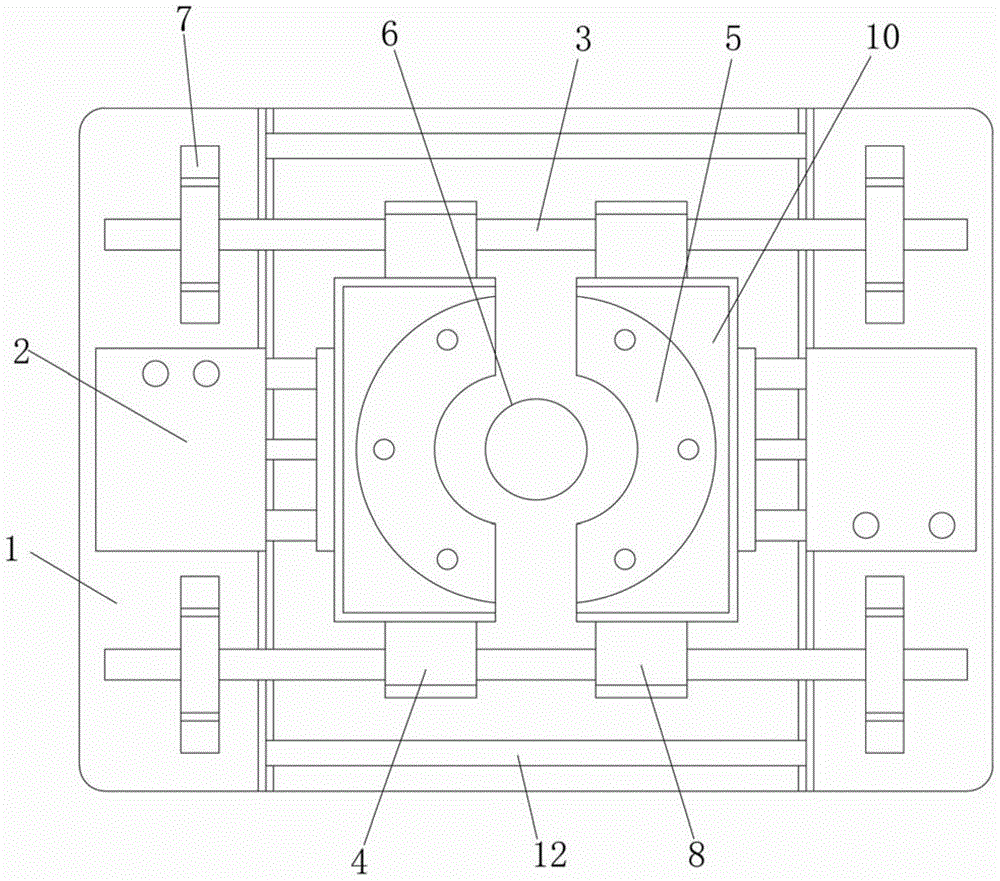

Mechanical clamping device for rotary workbench

The invention discloses a mechanical clamping device for a rotary workbench. The device comprises a sliding seat body on the lower part and a workbench on the upper part, and a sliding guide rail surface is positioned between the sliding seat body and the workbench; a piston shaft passes between the sliding seat body and the workbench, the lower part of the piston shaft is connected with a piston, an oily cylinder is matched with the piston, the bottom end face of the piston and the bottom of the oil cylinder form a lower cavity are connected with a hydraulic oil port, and the upper end of the piston shaft is connected with a clamping nut by screw thread; and a disc spring sleeved on the piston shaft is arranged in an upper cavity formed between the upper part of the piston and the upper part of the oil cylinder. By using the mechanical clamping mode of the disc spring, the device has large clamping force, is safe and reliable, and can adjust the amplitude of the clamping force; and the clamping force is directly acted on the sliding guide rail surface, so the device has simple structure and flexible action, does not cause additional deformation of the workbench surface, and can ensure reliable clamping and cannot cause related accidents even if hydraulic faults occur.

Owner:DALIAN HUAGEN MACHINERY

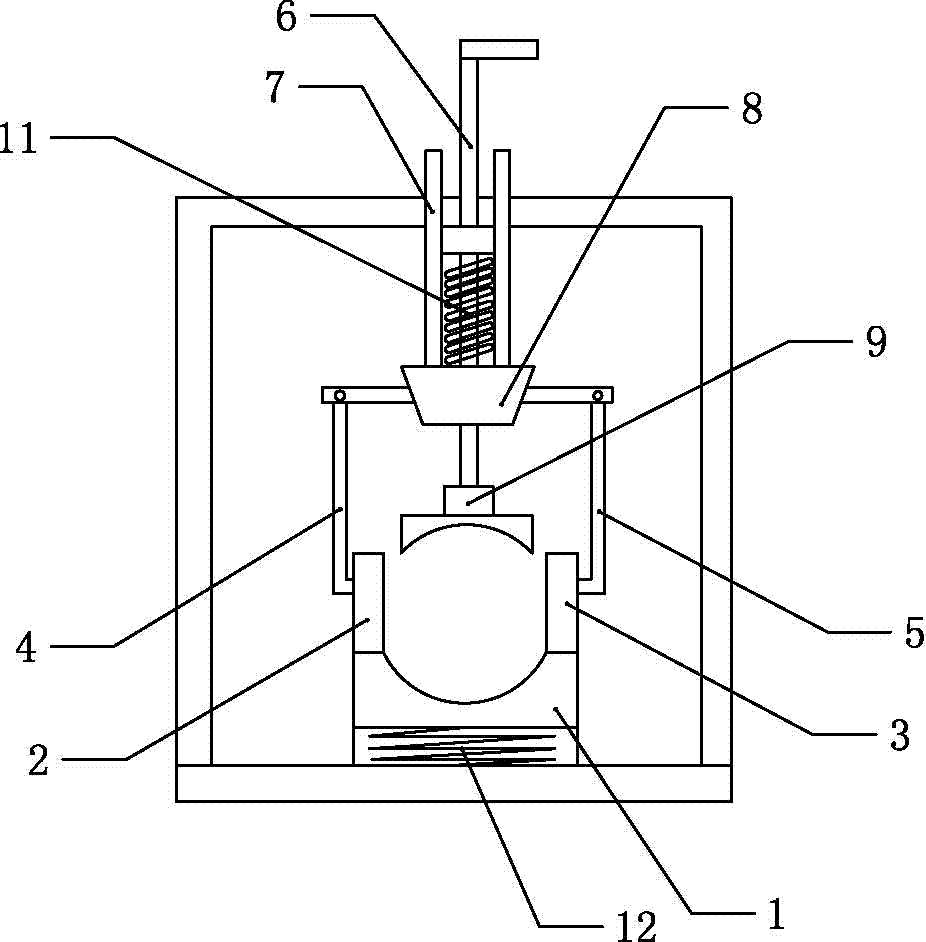

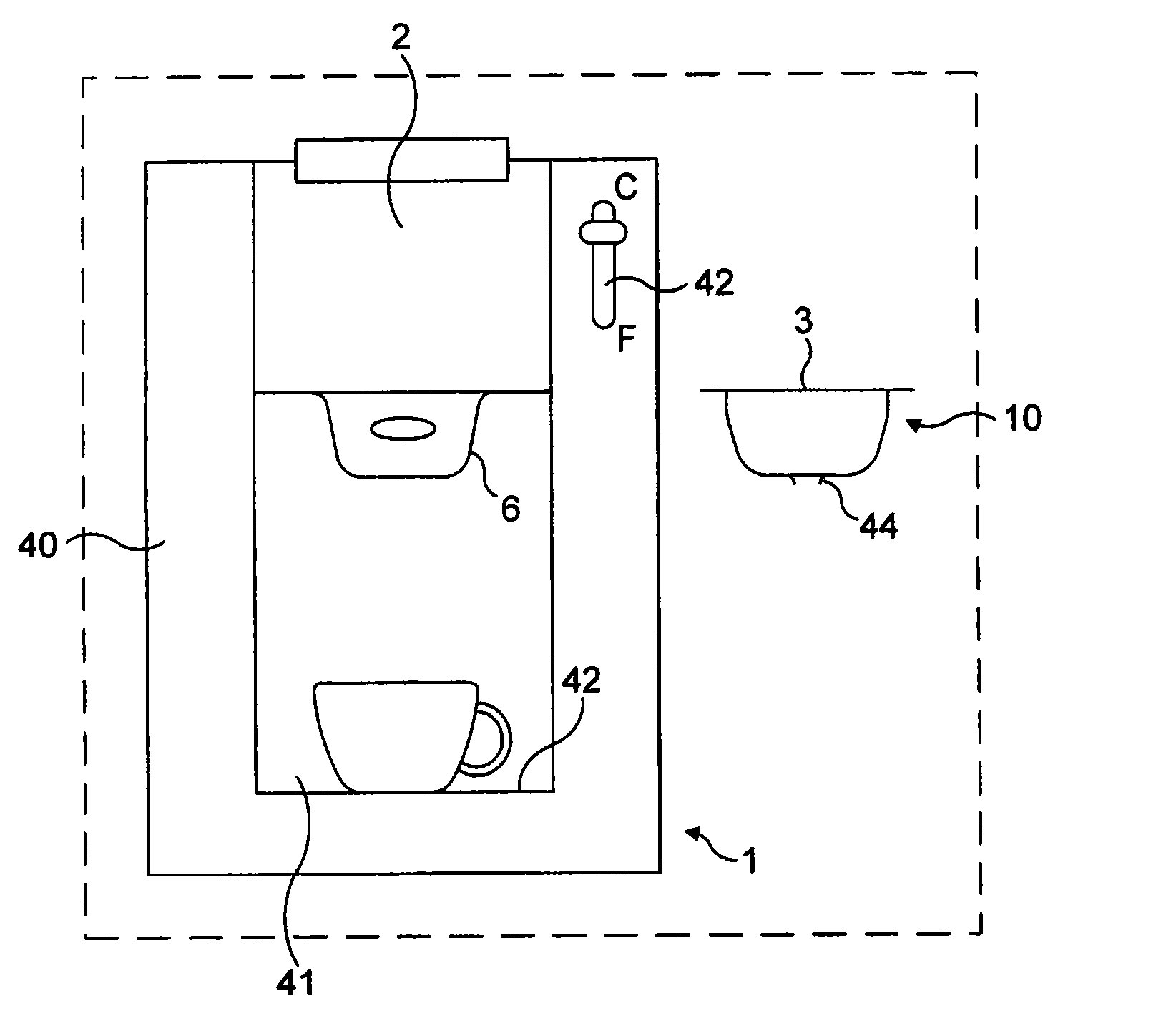

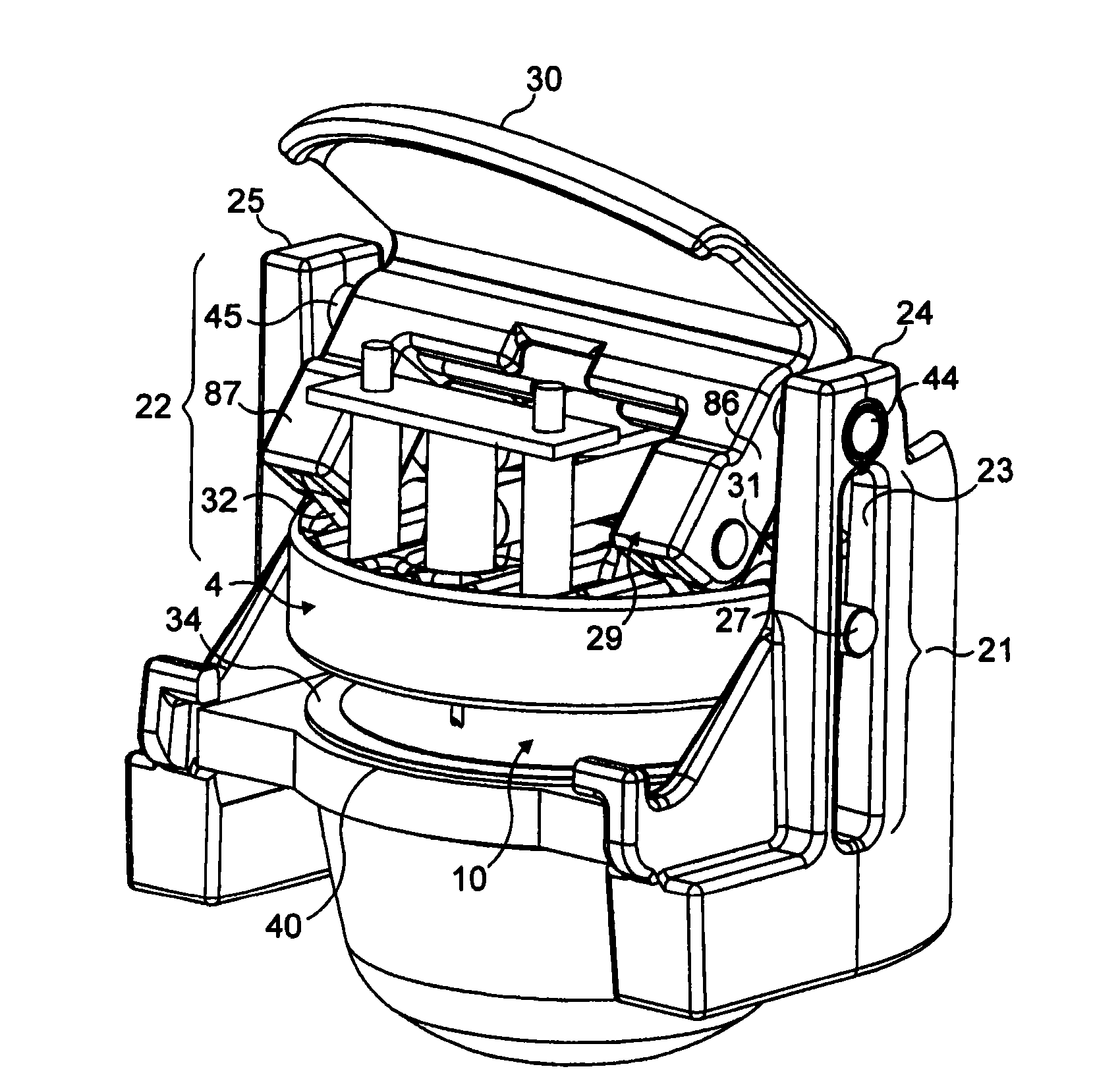

Device for preparing a liquid beverage from a cartridge

ActiveCN101668461AImprove sealingImprove solubilityBeverage vesselsThin material handlingBiomedical engineeringFluid supply

The device has a capsule holder receiving and supporting a capsule and detachable from a pressurized fluid supply unit. An injection unit (5) is provided through an injection support i.e. disc, of thesupply unit, and movable in engagement to the capsule. An elastic ring (16) is associated with the injection unit for carrying out local and direct sealing between the injection unit and an injectionwall of the capsule. An activation system applies a locking effort of the supply unit against a support side (40) of the capsule holder and an edge (34) of the capsule. An independent claim is also included for a method for reducing liquid resurgence or gas-liquid mixture through an injection point of a capsule.

Owner:NESTEC SA

Pneumatic banana spike stem clamping device

InactiveCN104647231ACompact structureLight in massMachine part testingWork holdersEngineeringMechanical engineering

Owner:SOUTH CHINA AGRI UNIV

Novel mechanical gripper with pressure buffer structure

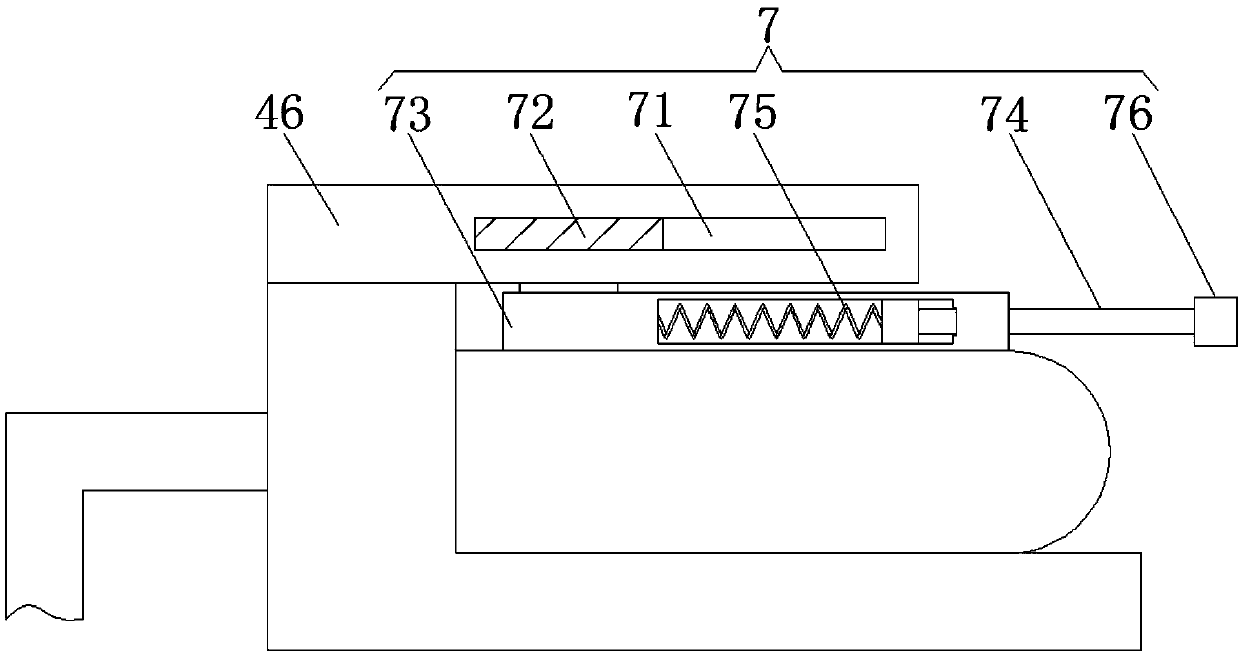

PendingCN109623859APlay the role of clamping bufferAdjustable clamping forceGripping headsEngineeringSlide plate

The invention discloses a novel mechanical gripper with a pressure buffer structure. The novel mechanical gripper with the pressure buffer structure comprises a support connected with an external mechanical arm; the two ends of the support are connected with bases, a first guide rod and a second guide rod are arranged between the bases, the first guide rod is sleeved with a regulating block, and the second guide rod is slidably sleeved with a first slide plate and a second slide plate; the lower sides of the first slide plate and the second slide plate are fixedly connected with claws; the right side wall of the first slide plate is fixedly connected with a plurality of guide pillars; the portion, between the regulating block and the first slide plate, of the outer side wall of each guidepillar is sleeved with a third spring; and the second slide plate is provided with ejector rods. The novel mechanical gripper with pressure buffer structure can make the regulating block slide to theright through the screw rod rotation, so that the regulating block pushes the first slide plate to slide through the third spring, and the two claws approach slowly and then clamp objects; and the third spring acts as a clamping buffer and makes the device more stable when the device grasps the objects.

Owner:周博文

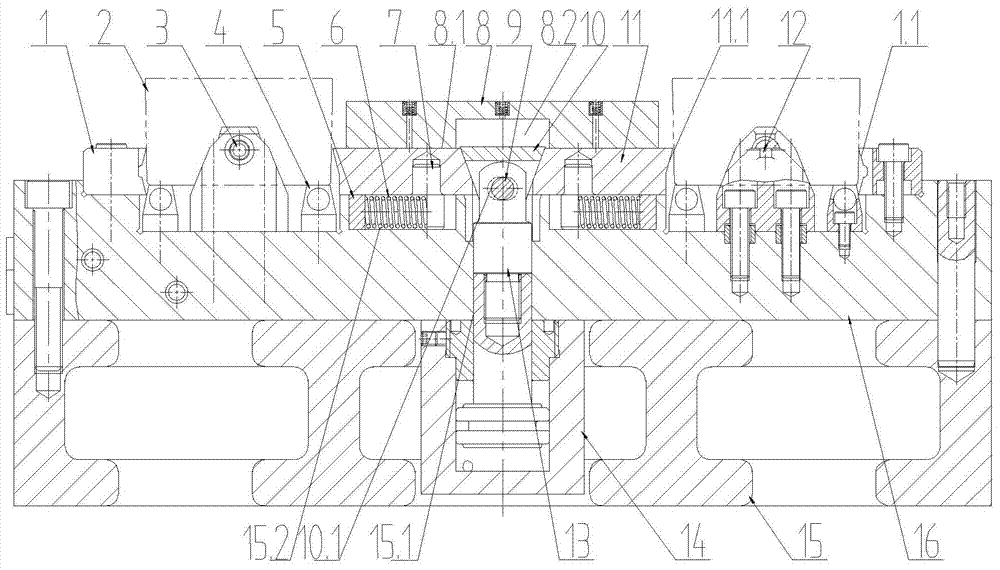

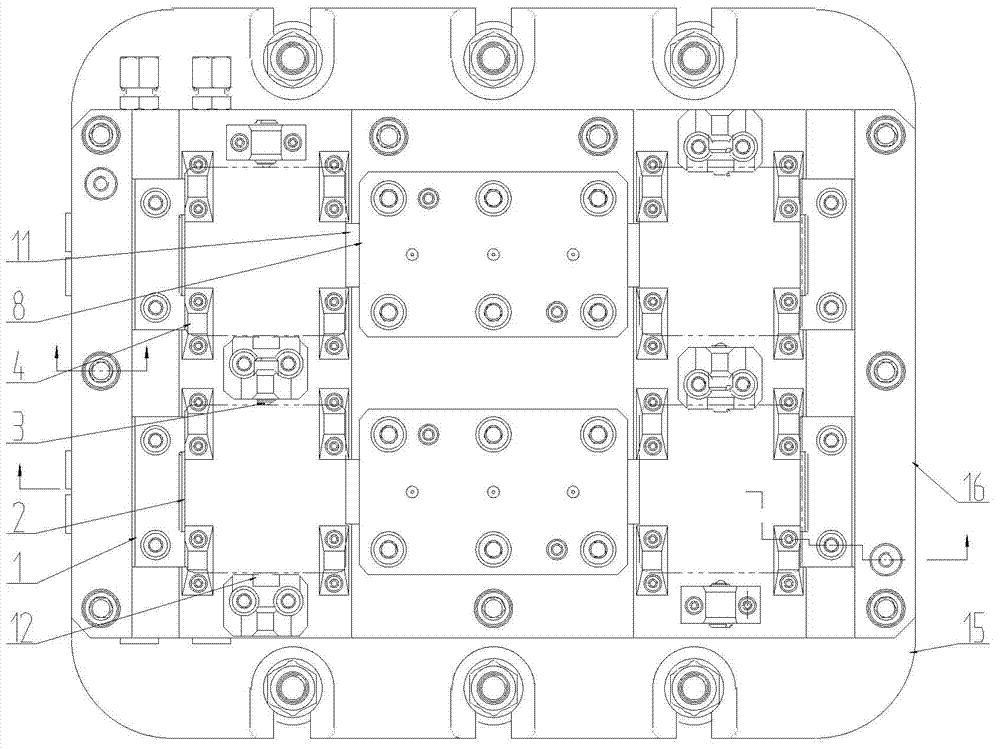

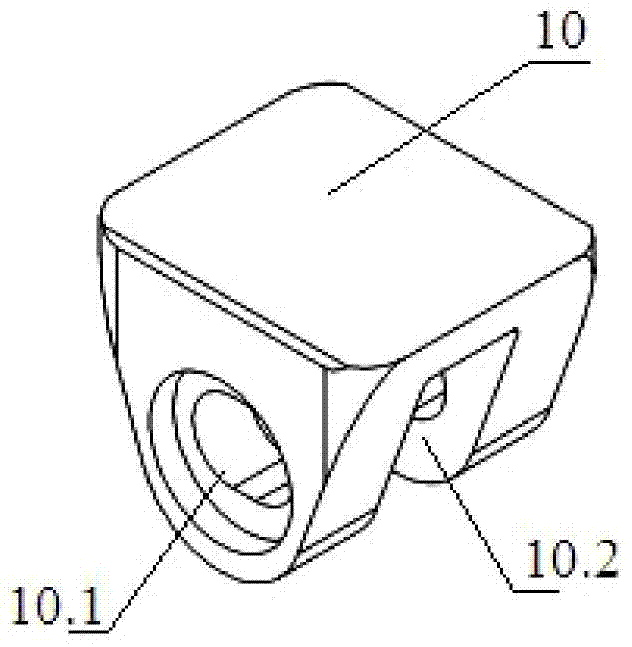

Double-oblique-face double-way floating pairing workpiece automatic clamping jig

ActiveCN104741954AAvoid upturningSimple structurePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention relates to a double-oblique-face double-way floating pairing workpiece automatic clamping jig and relates to a workpiece jig for cutting the upper end face of a workpiece with the appearance contour similar to a rectangle. The jig comprises a base, a bottom plate arranged on the base, an oil pressure cylinder arranged in the base, a double-oblique-face pulling block hinged to a piston rod which extends out of the upper portion of the bottom plate from the oil pressure cylinder, moving oblique face jaws in sliding connection to the bottom plate and a fixed oblique face locating jaw which is fixed on the bottom plate and is used for being matched with the moving oblique face jaws. The number of the moving oblique face jaws is two. The two moving oblique face jaws are arranged on the two sides of the double-oblique-face pulling block symmetrically and respectively and are in contact connection with the two side oblique faces of the double-oblique-face pulling block. The jig can clamp the workpiece in a pairing mode, when the workpiece is clamped, downward component force is applied on the workpiece, and the phenomenon of upwarping of the workpiece with pattern draft during a clamping process is avoided.

Owner:DONGFENG MOTOR CORP HUBEI

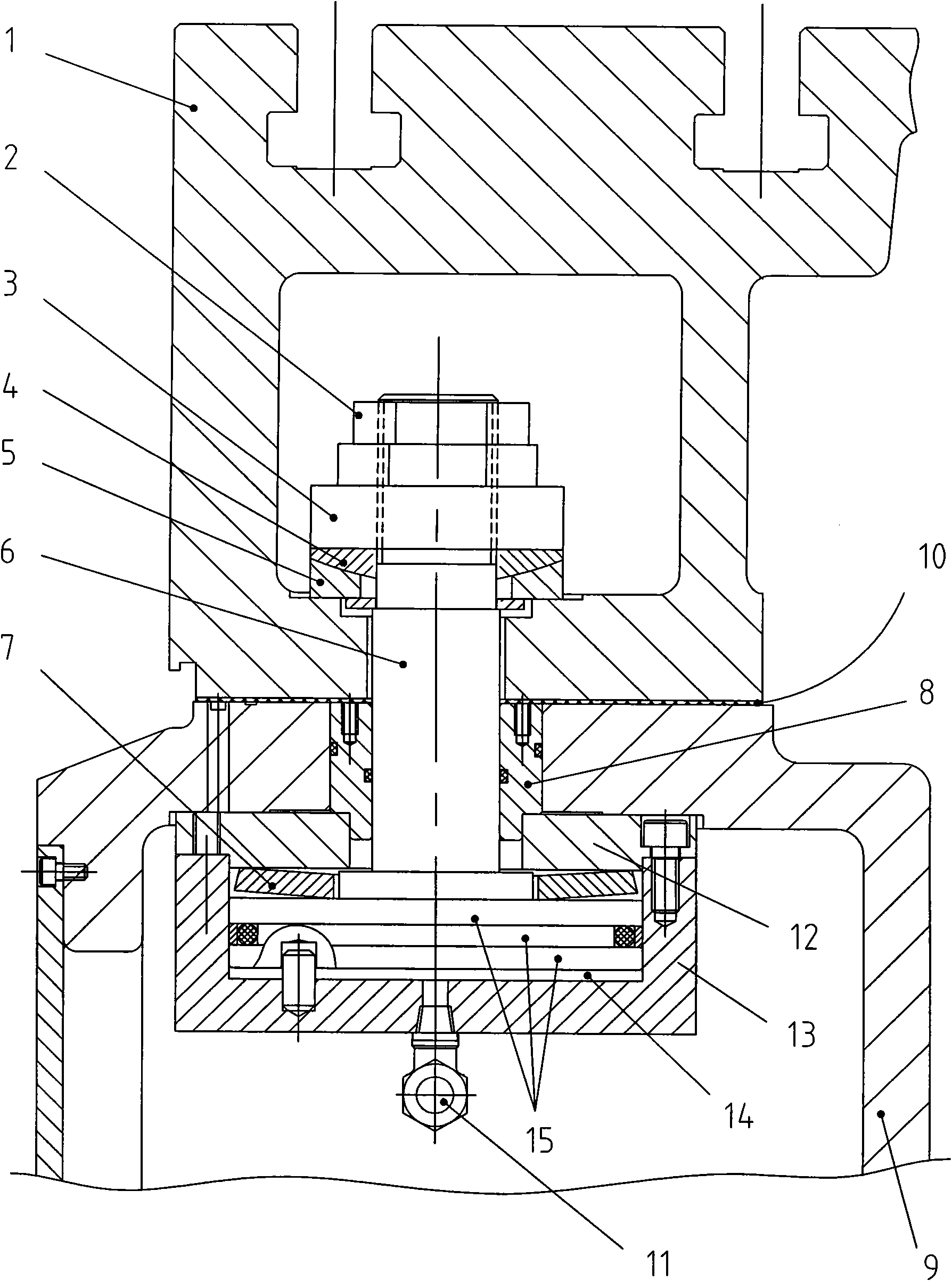

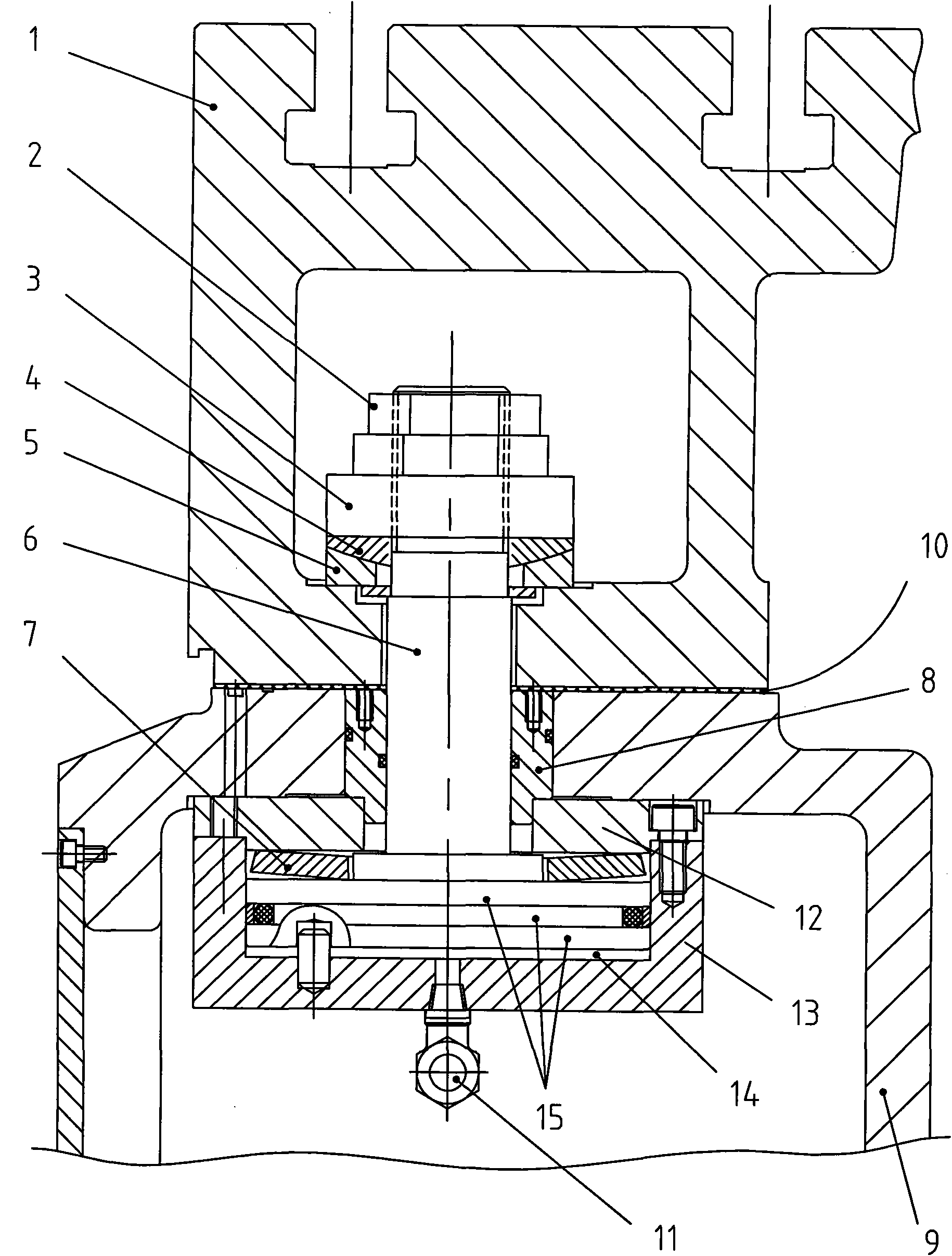

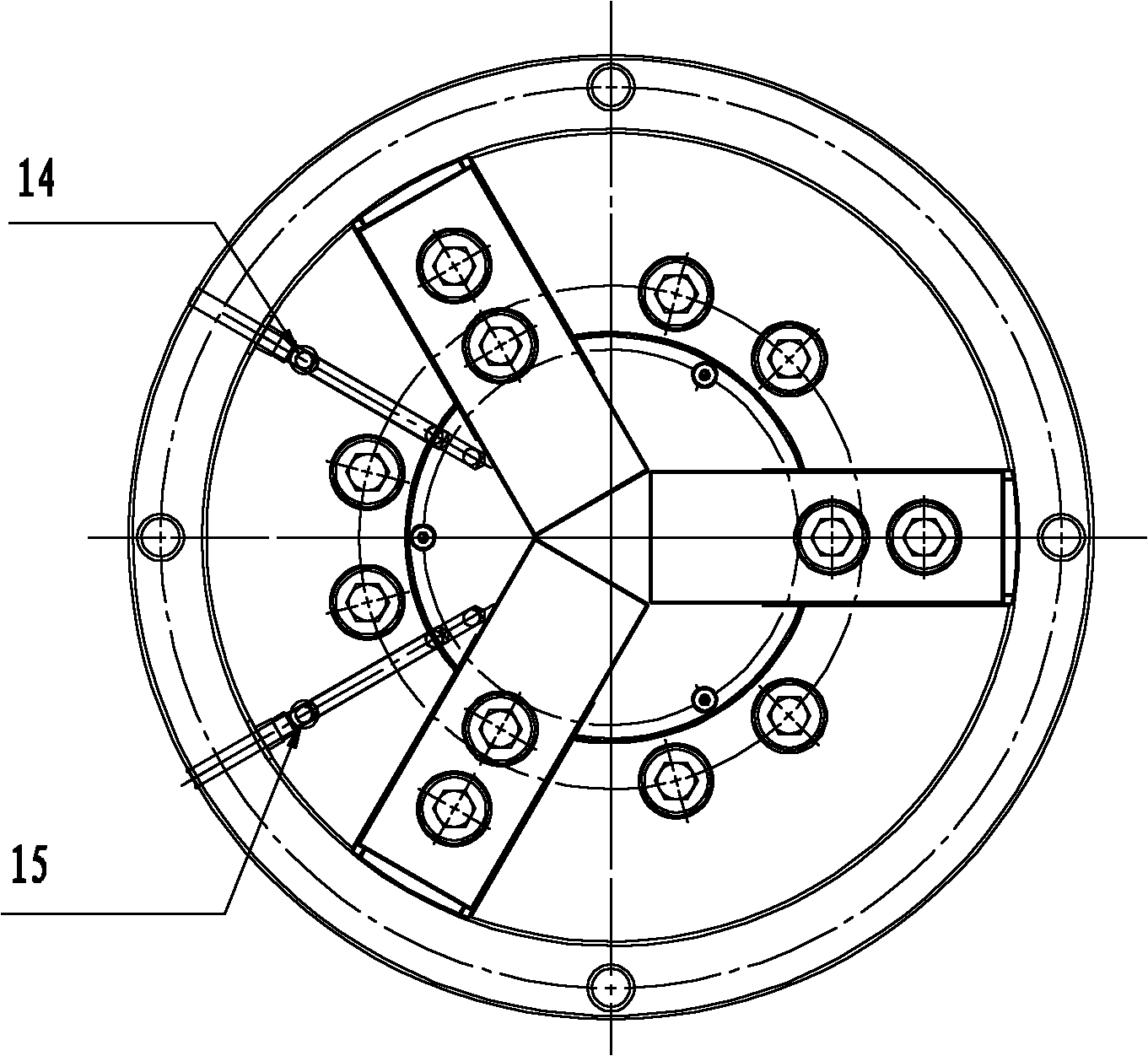

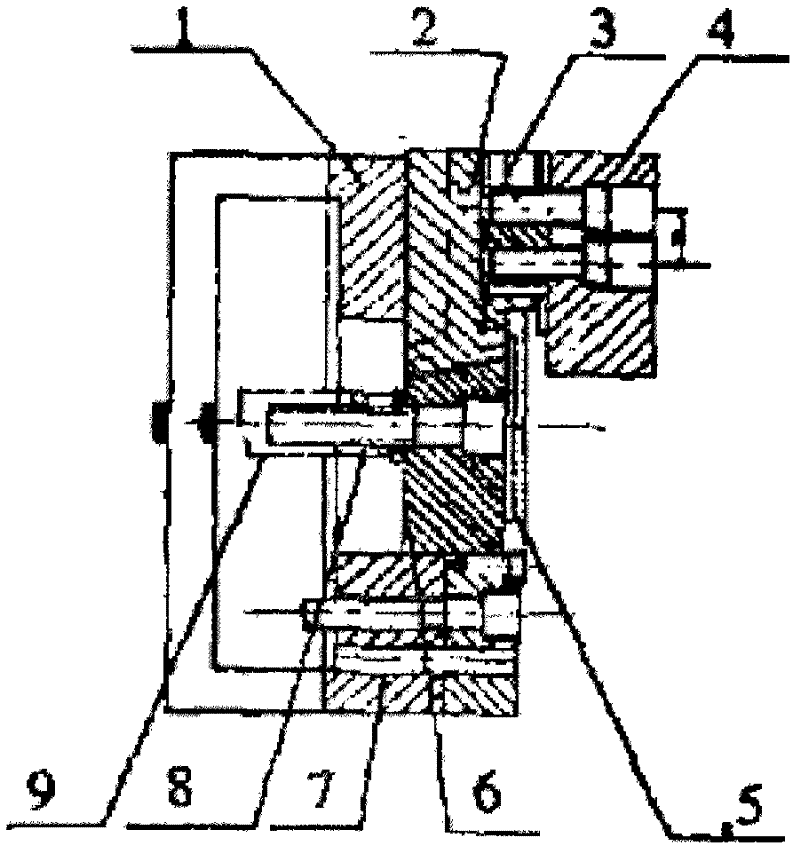

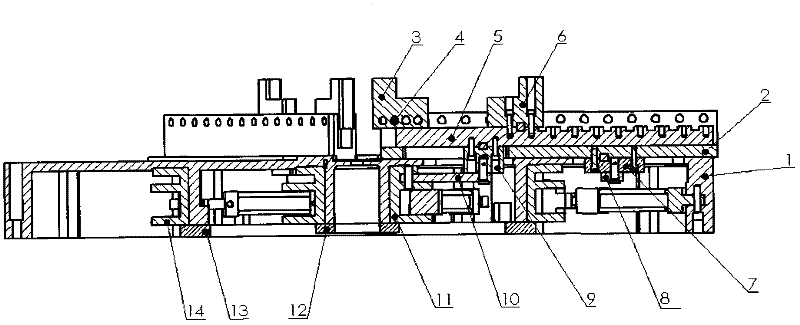

Vertical type fixed hydraulic power chuck

The invention relates to a vertical type fixed hydraulic power chuck which comprises a chuck body, a wedge catch system, a blocking cover, three claws, three slide carriages and six T-shaped blocks, and is characterized in that an oil cylinder body and a base form an oil cylinder main body; a piston is installed in the oil cylinder body and slides in the oil cylinder body along the direction of a guiding shaft; an upper oil chamber and a lower oil chamber are formed above and below the piston; the control hydraulic oil of the upper oil chamber and the lower oil chamber is controlled by a left oil inlet and outlet hole or a right oil inlet and outlet hole; the piston is connected with the wedge catch system by a driving connecting screw; under the driving of the piston, the wedge catch system slides up and down in the chuck body; and the chuck body is connected seamlessly and fixedly with the oil cylinder body by a connecting bolt. The structure of the invention is simple, compact and reasonable, the vertical type fixed hydraulic power chuck connects the cylinder body and the chuck integrally and is loaded on a work bench, a workpiece can be loaded and clamped conveniently, and quick die changing can be realized, thereby greatly lightening the labor intensity, shortening the clamping time, improving the productivity, having adjustable clamping force, and being suitable for matching with a numerical control machining center.

Owner:江苏无锡建华机床附件集团有限公司

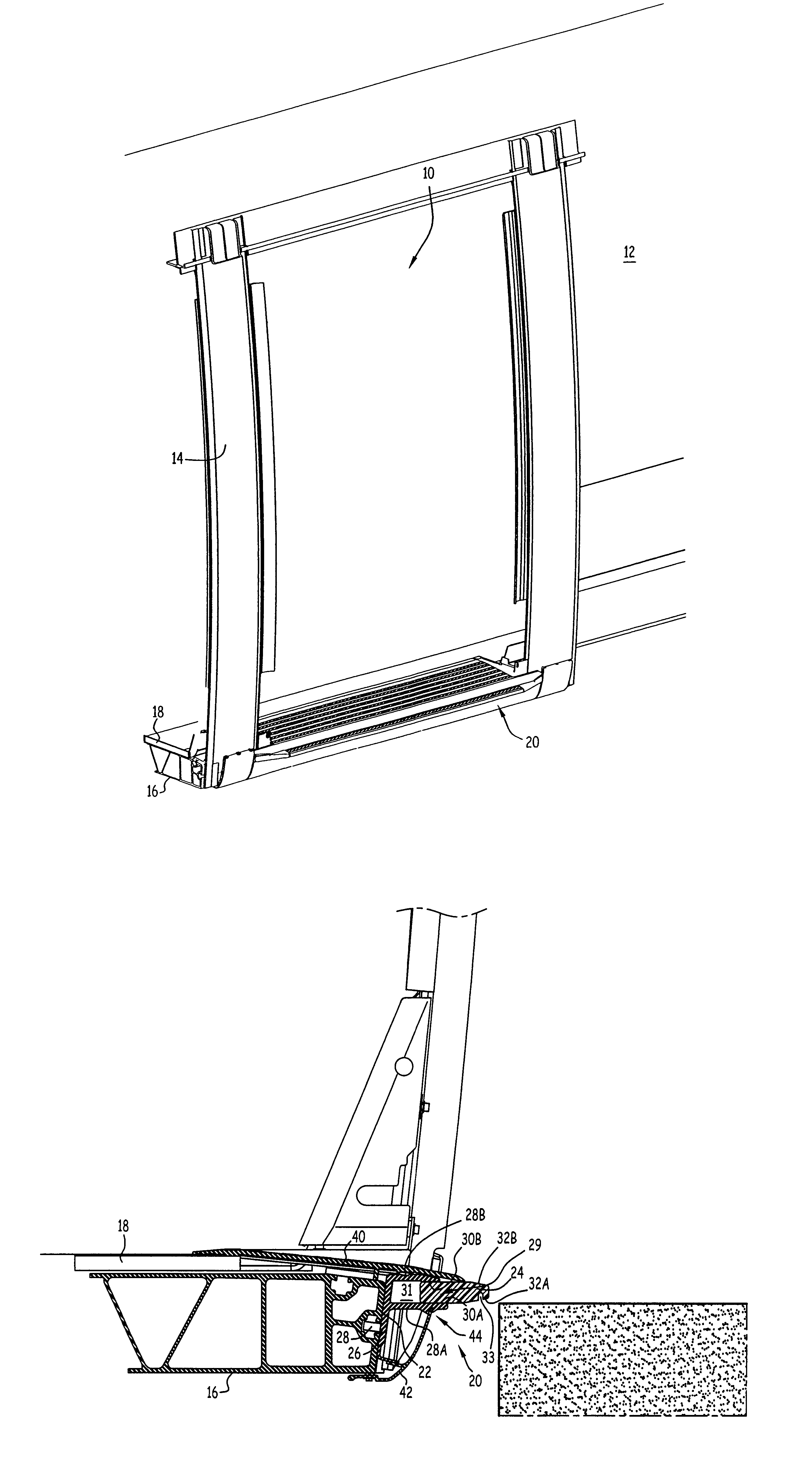

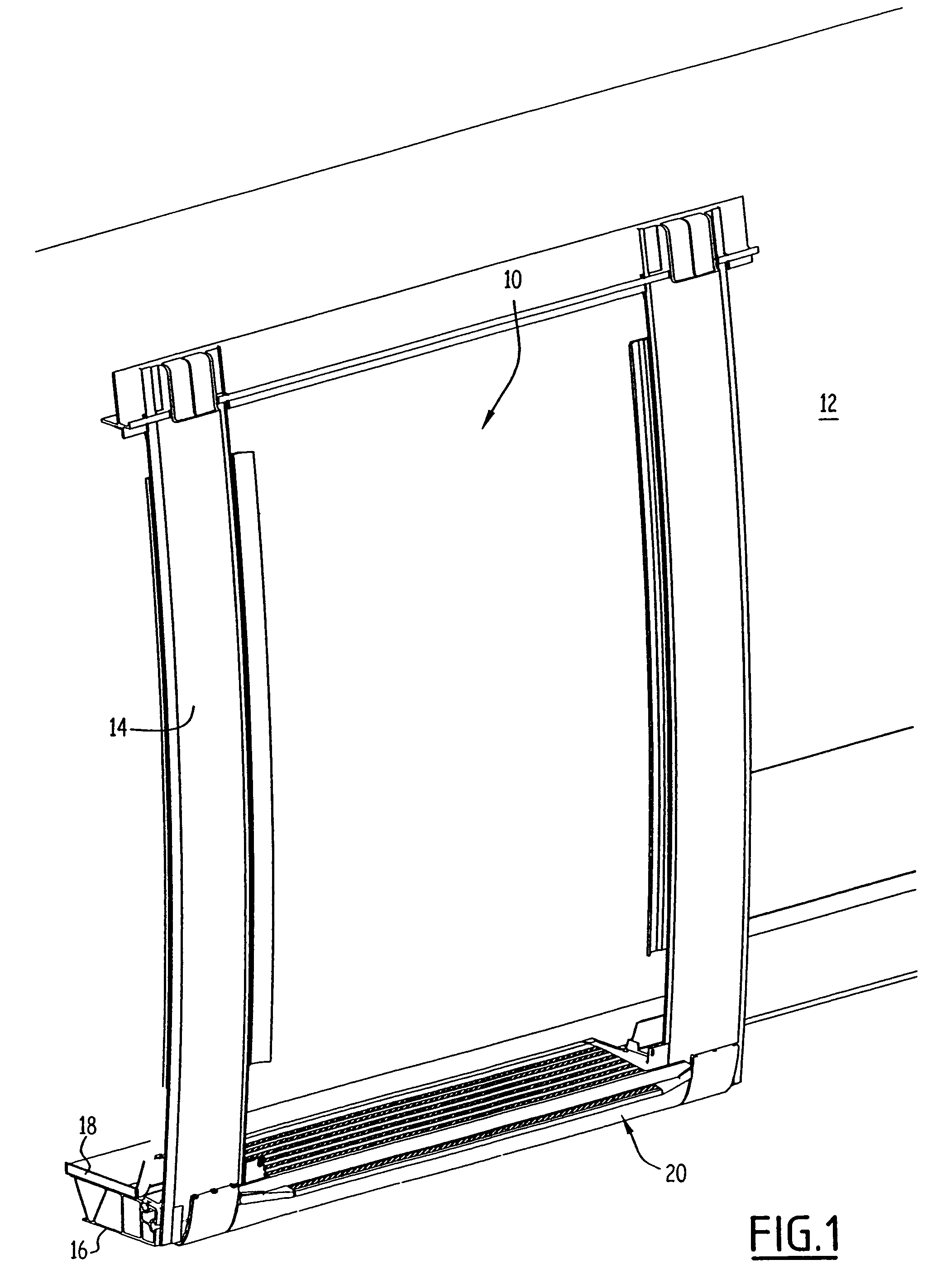

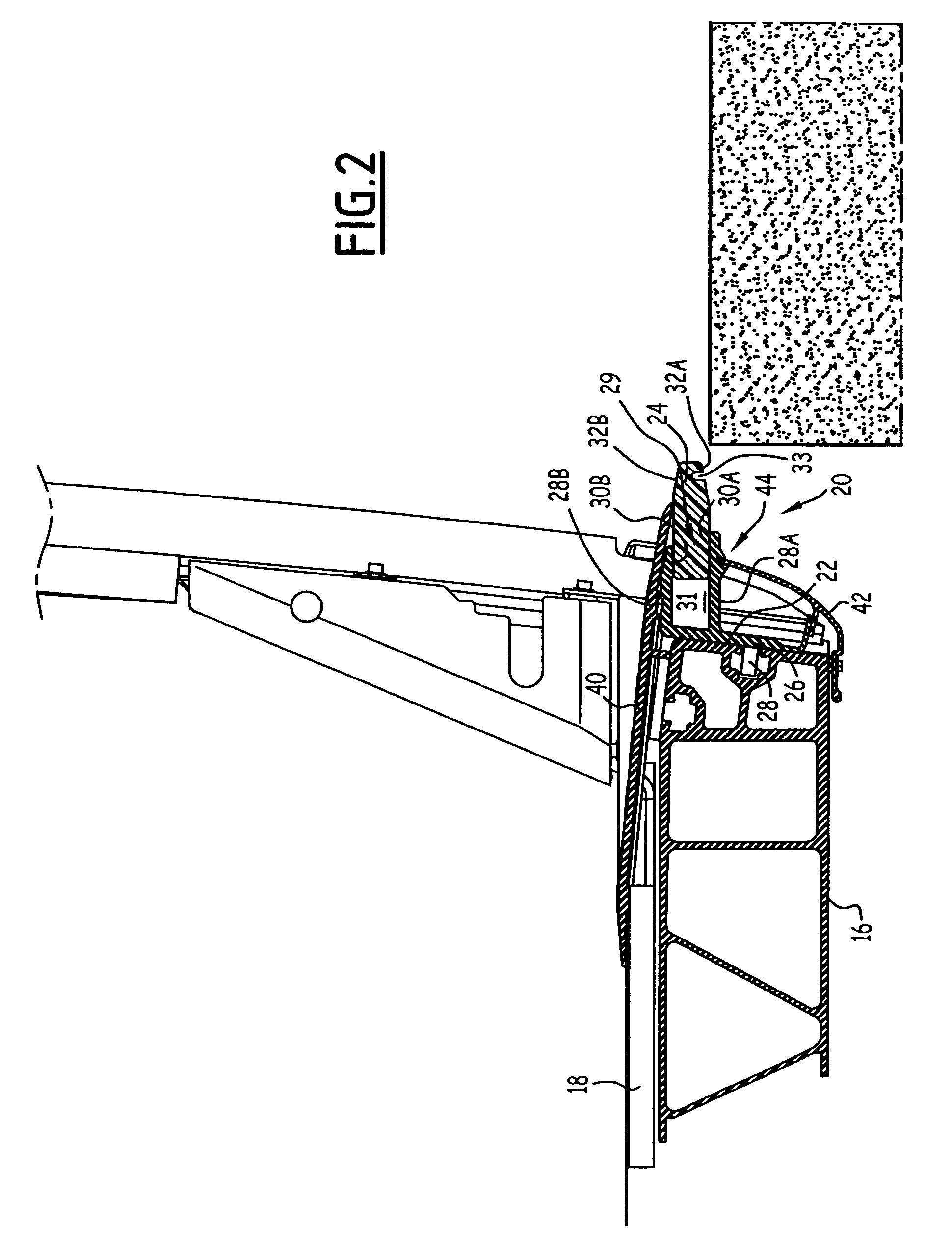

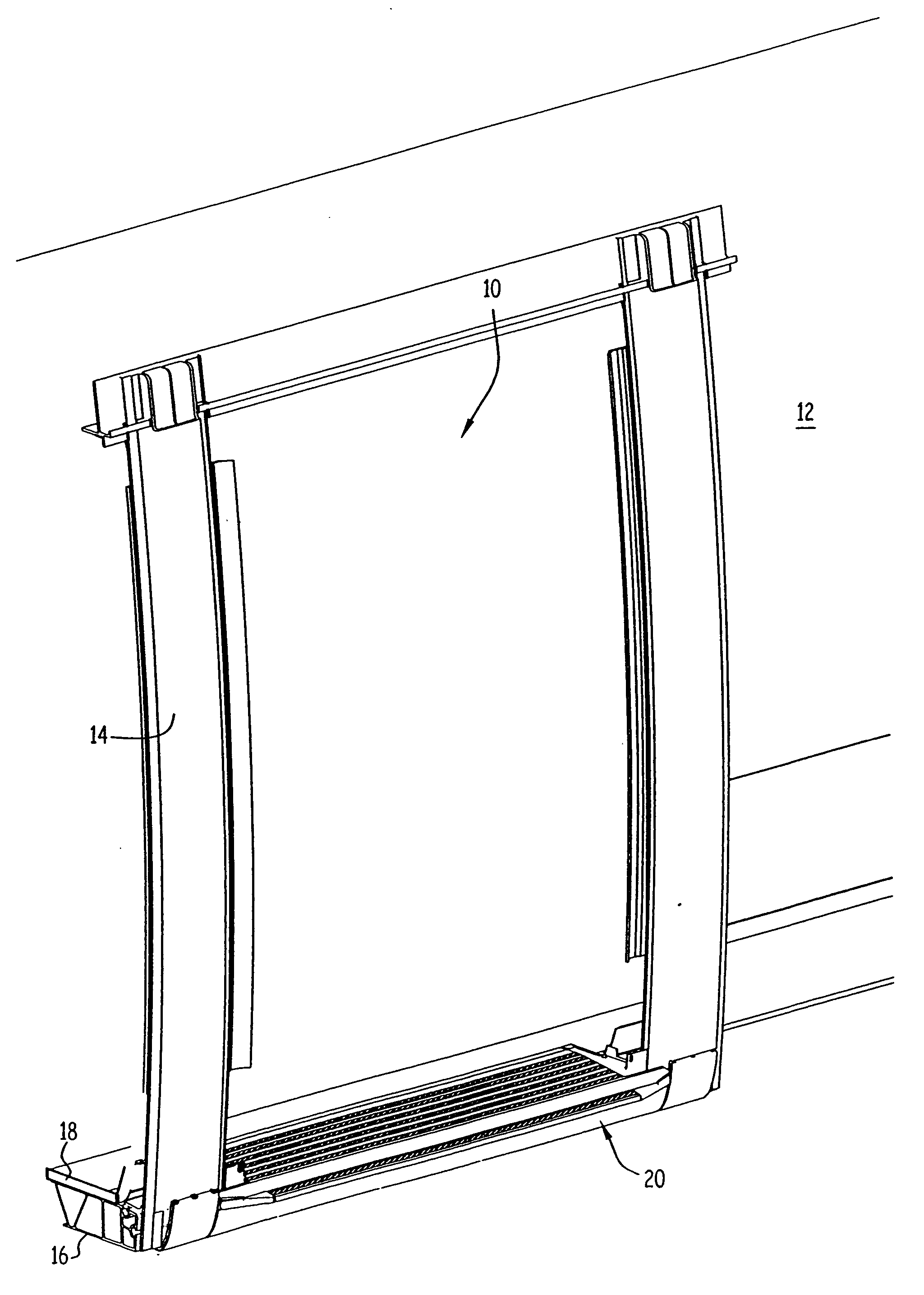

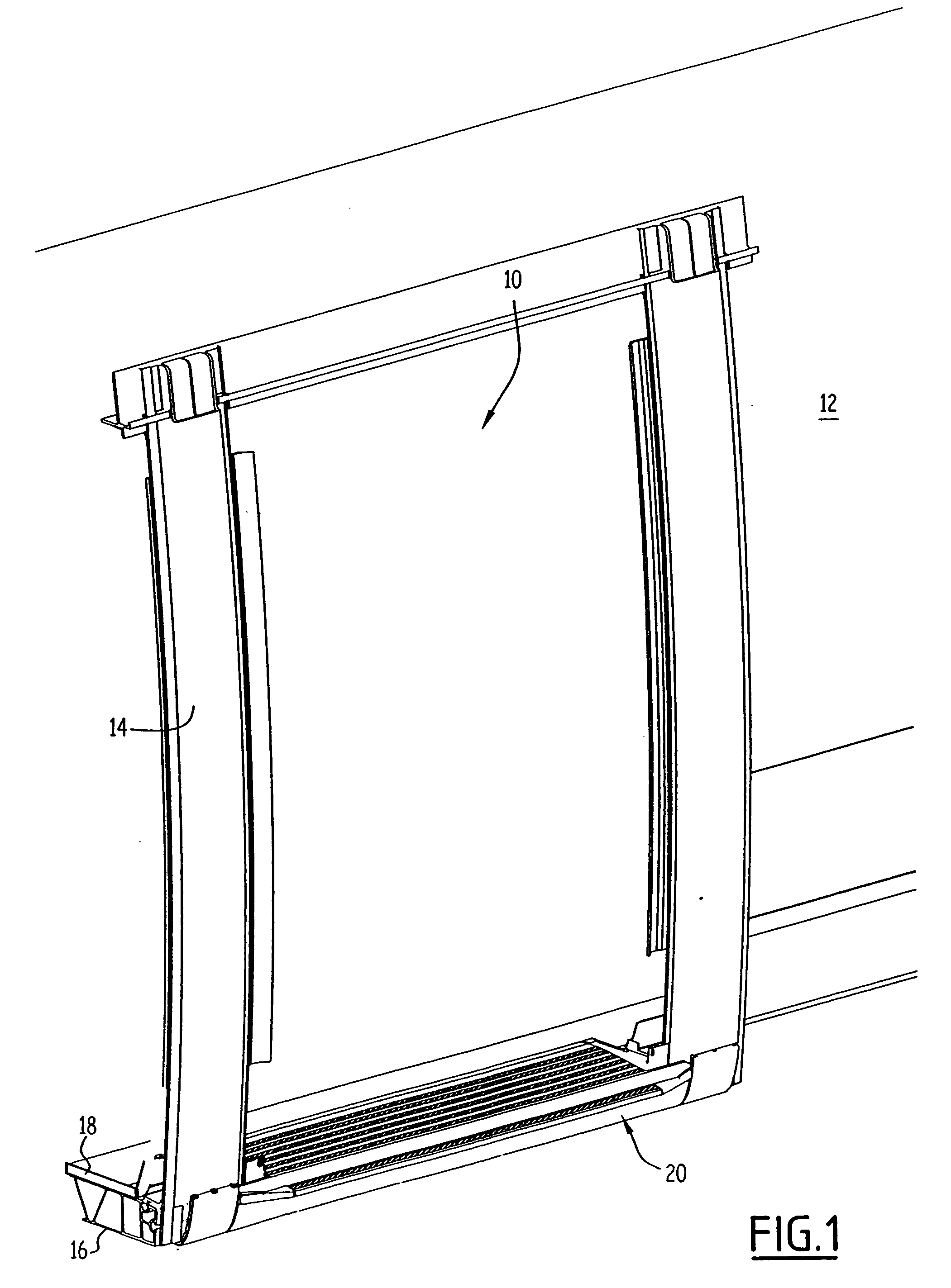

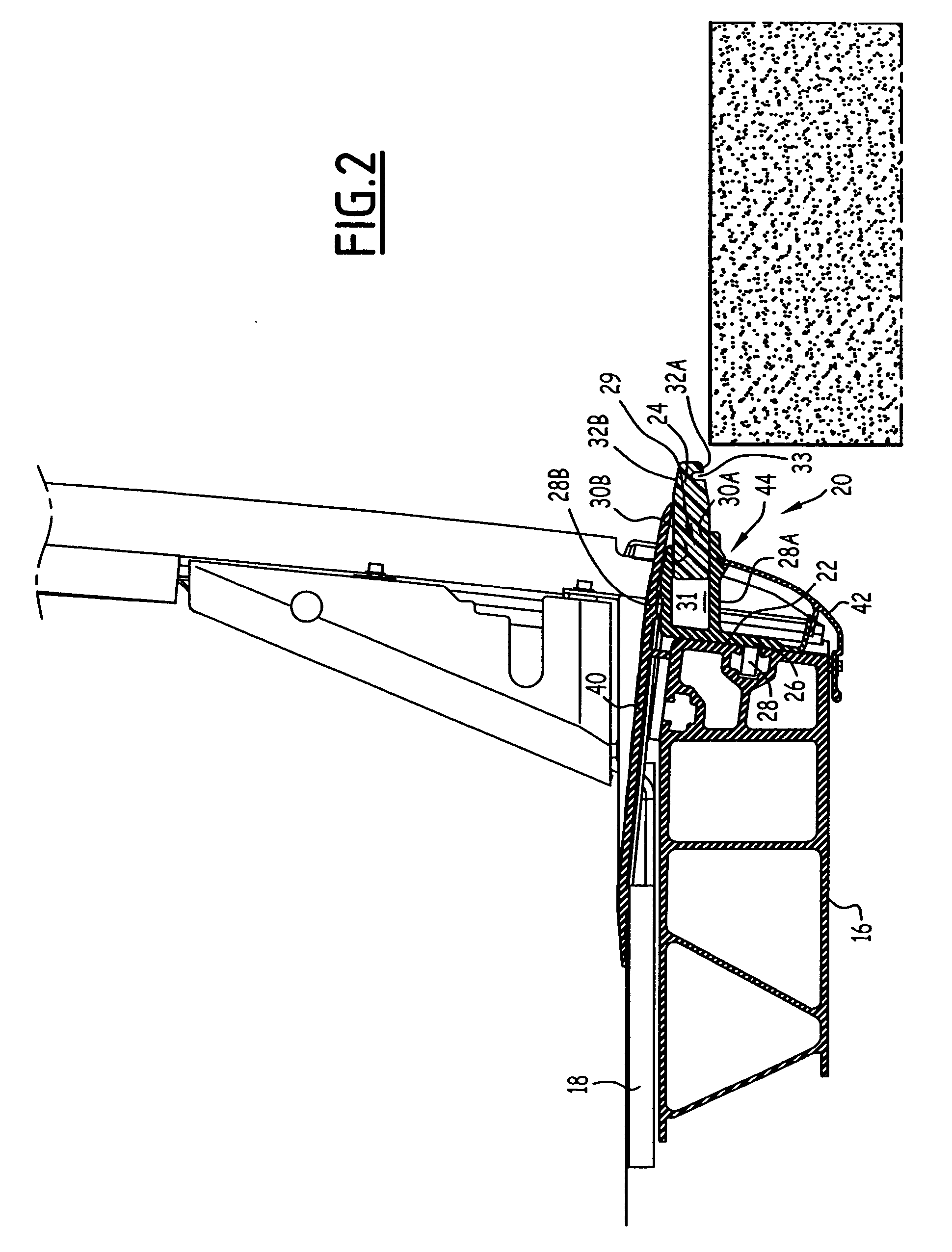

Door threshold for access to the interior of a railway vehicle

ActiveUS7178467B2High operating costsEfficient fillingRailway stationLocomotivesEngineeringMechanical engineering

The door threshold for a railway vehicle is intended to partially fill the gap between the vehicle and a platform. It comprises a support (22) which can be connected to the structure (16) of the railway vehicle and a strip (24) which is retained by the support (22). The strip (24) can be displaced between a normal position, in which it projects relative to the support (22), and a position retracted in the support (22). It comprises means (30A, 30B) for clamping the strip against at least a clamping surface (30A, 30B) of the support in order to produce friction of a specific value between the strip (24) and the support (22) counter to the displacement of the strip (24) relative to the support (22) in the plane of the or each clamping surface (30A, 30B).

Owner:ALSTOM TRANSPORT TECH SAS

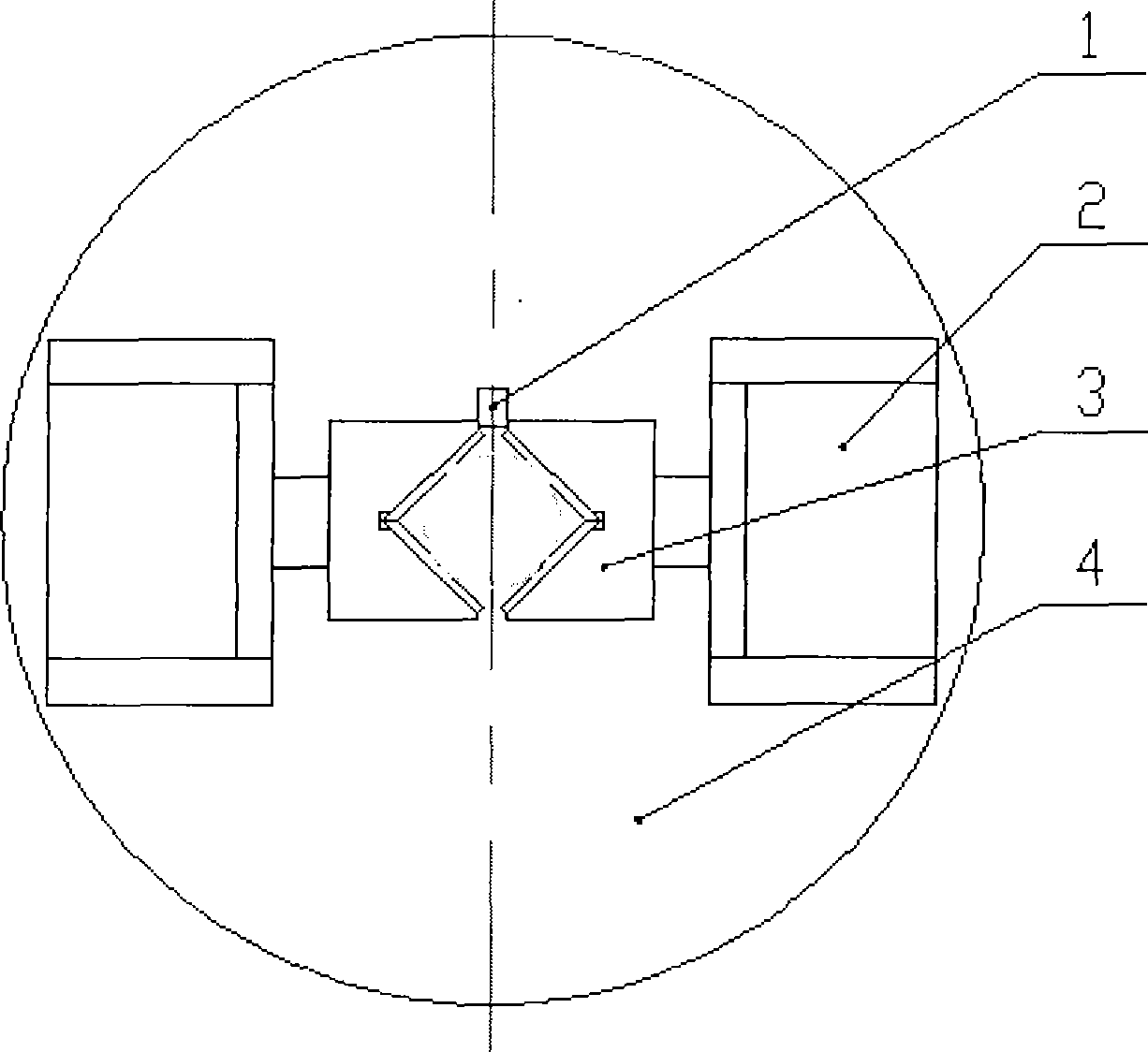

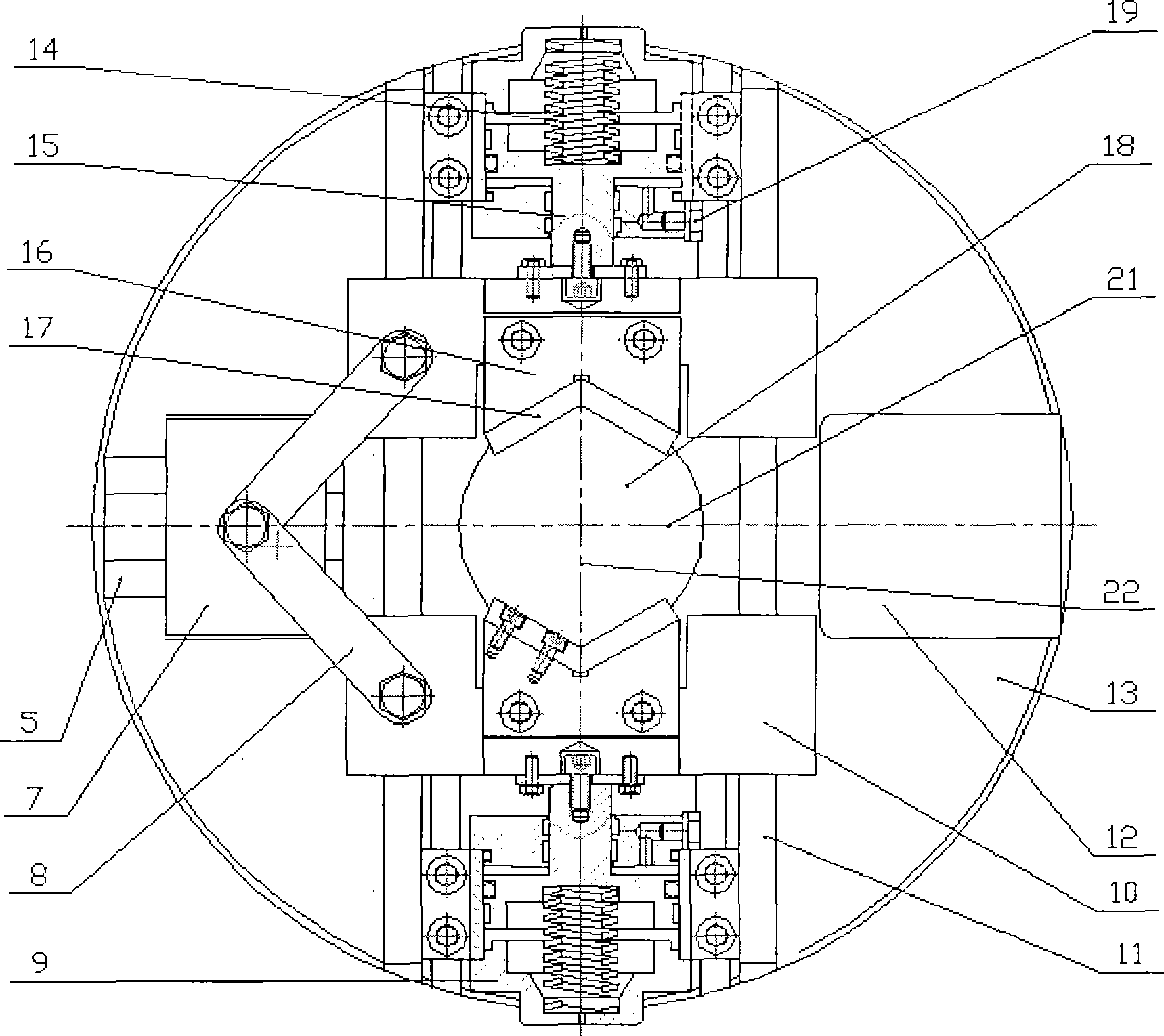

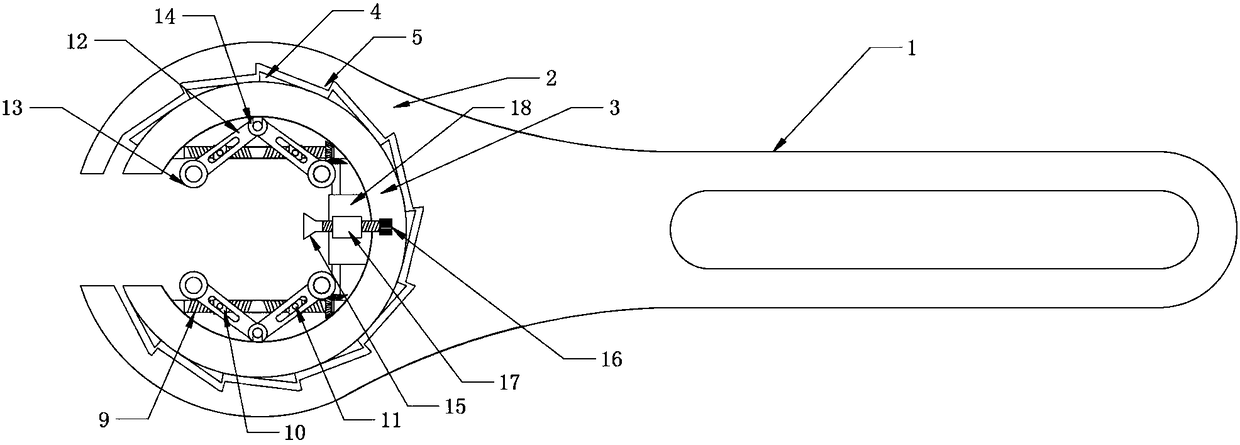

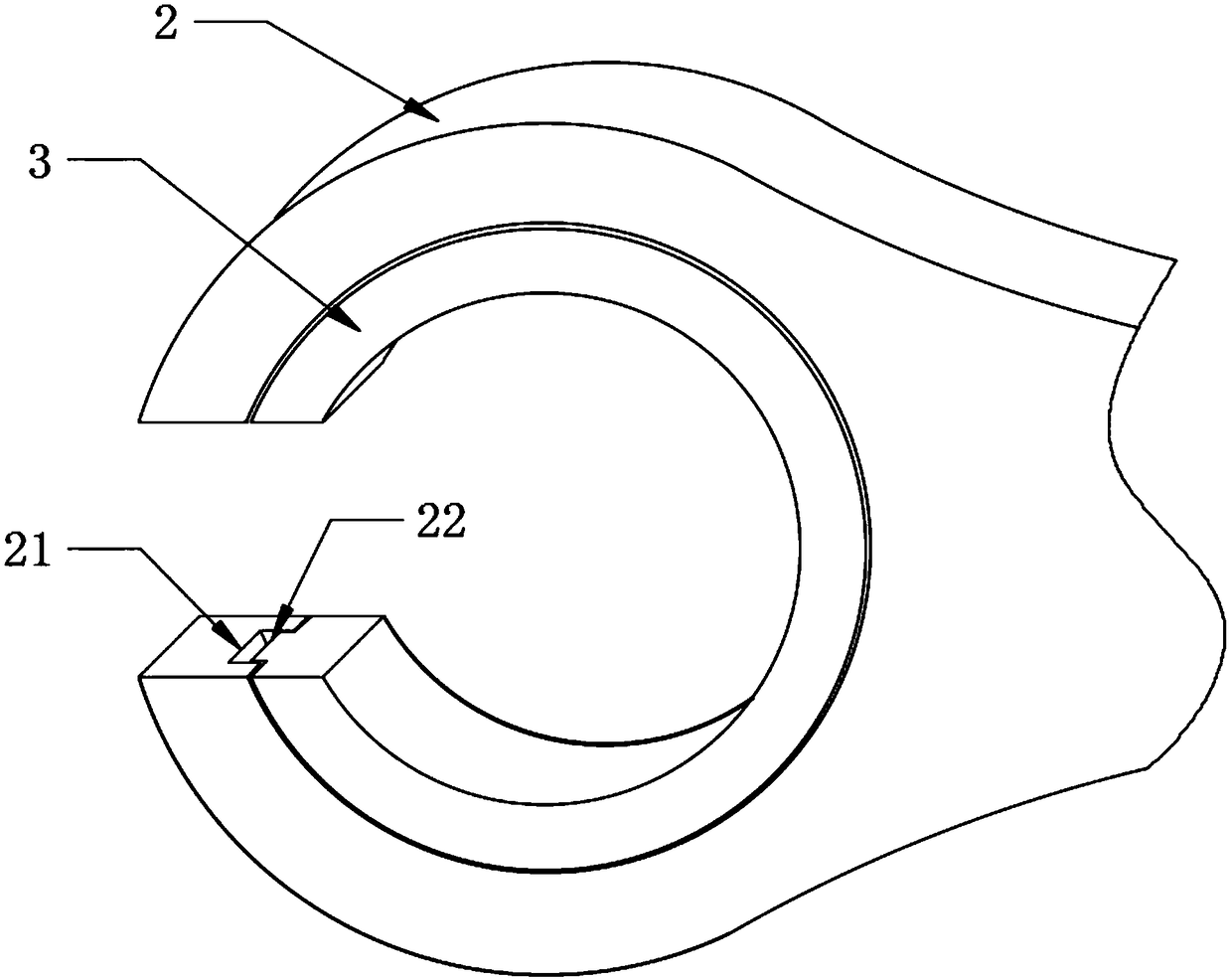

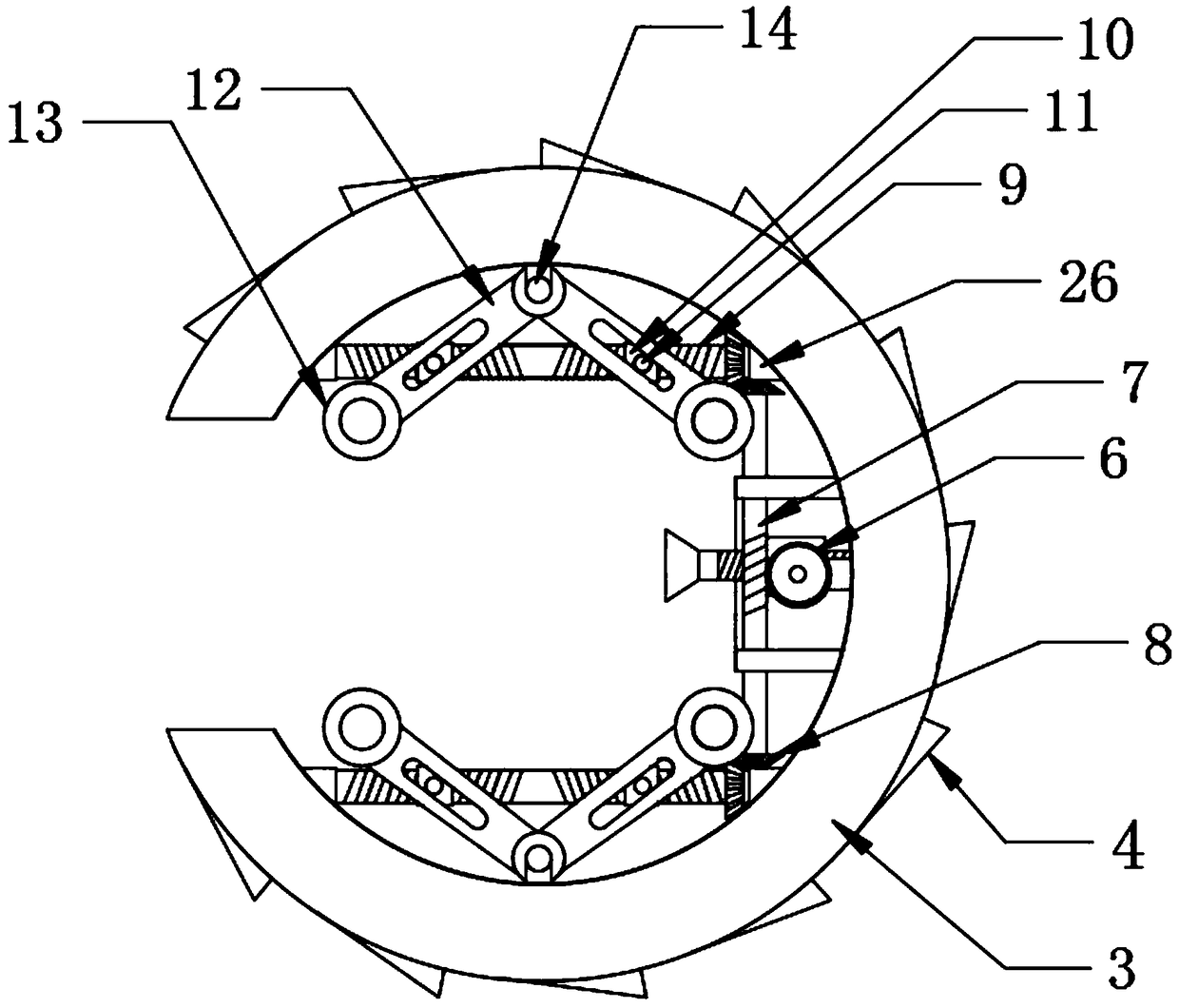

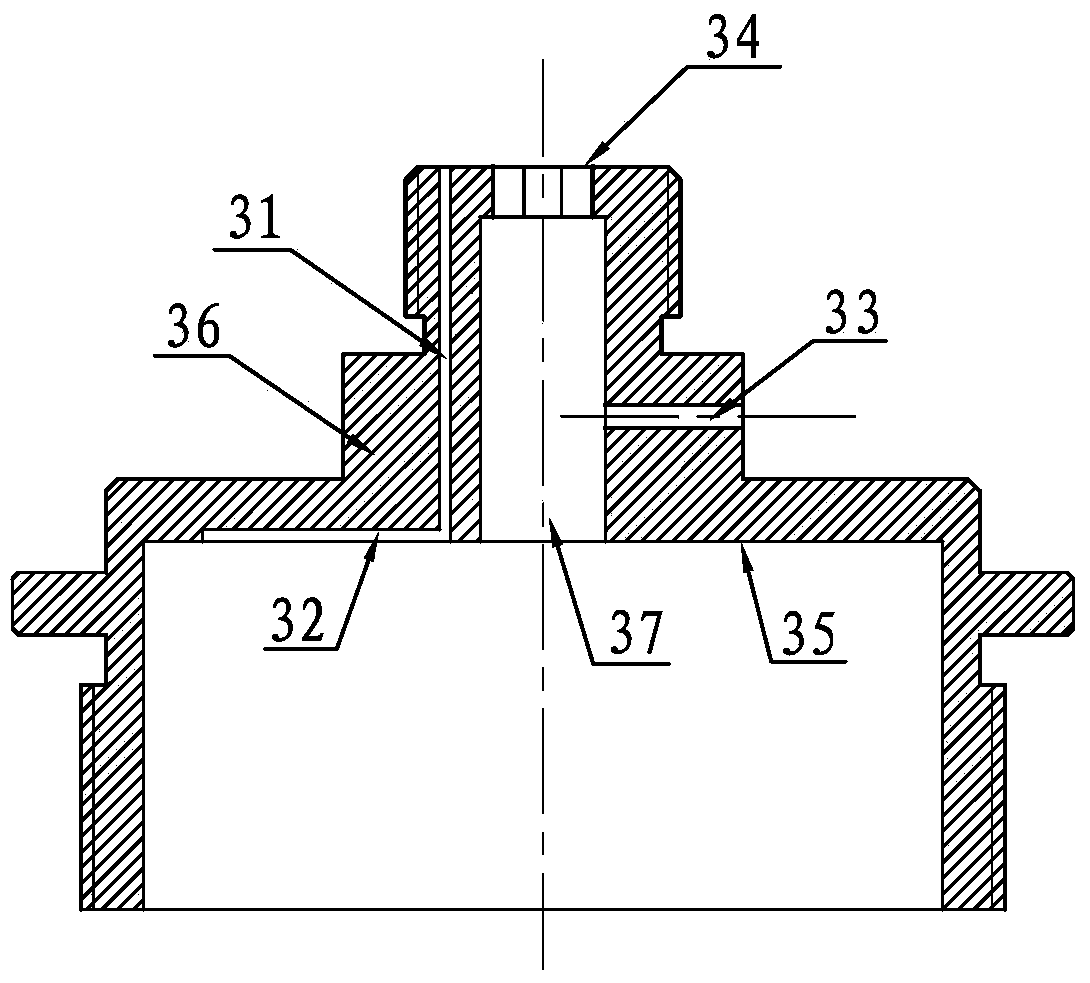

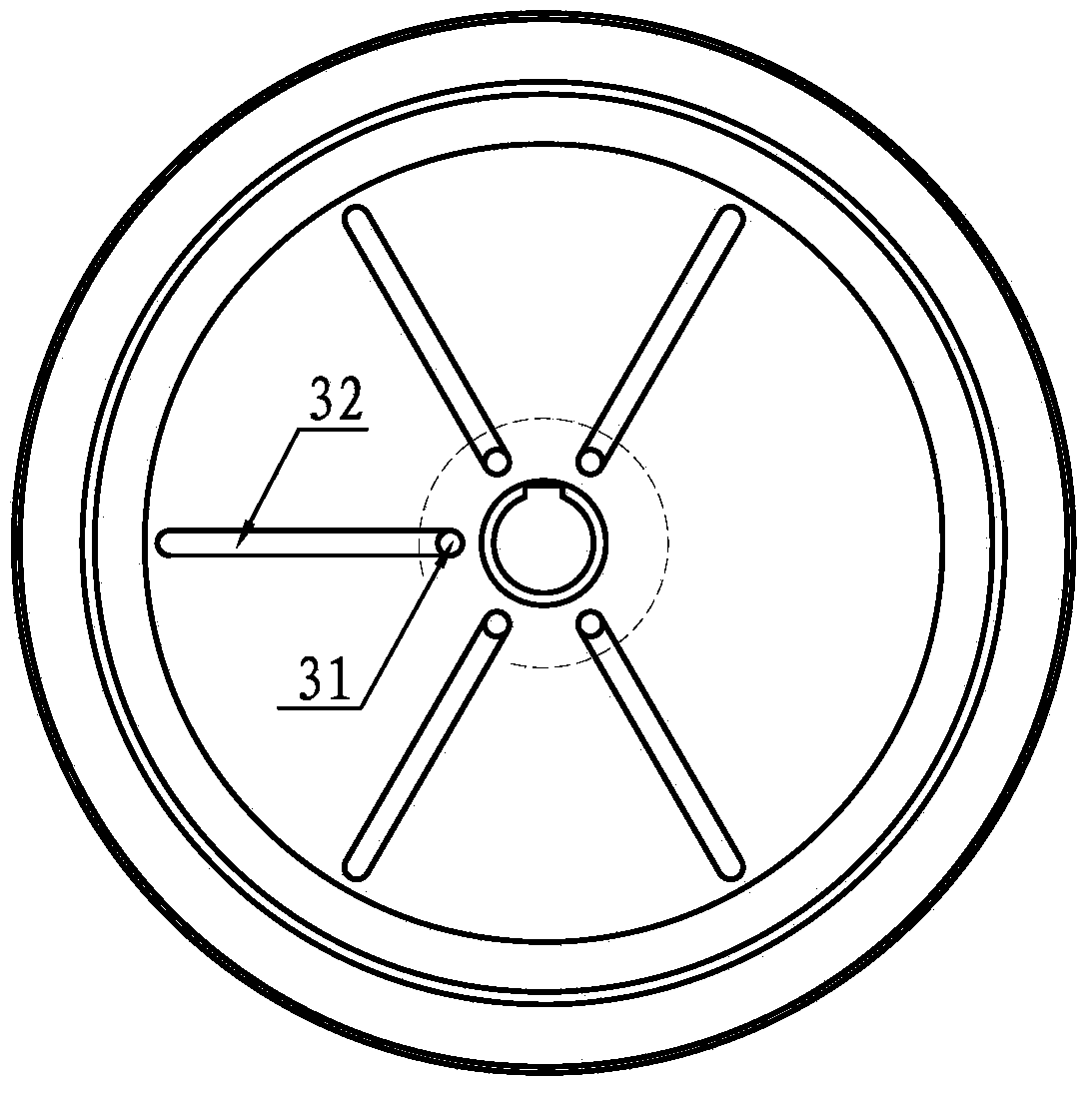

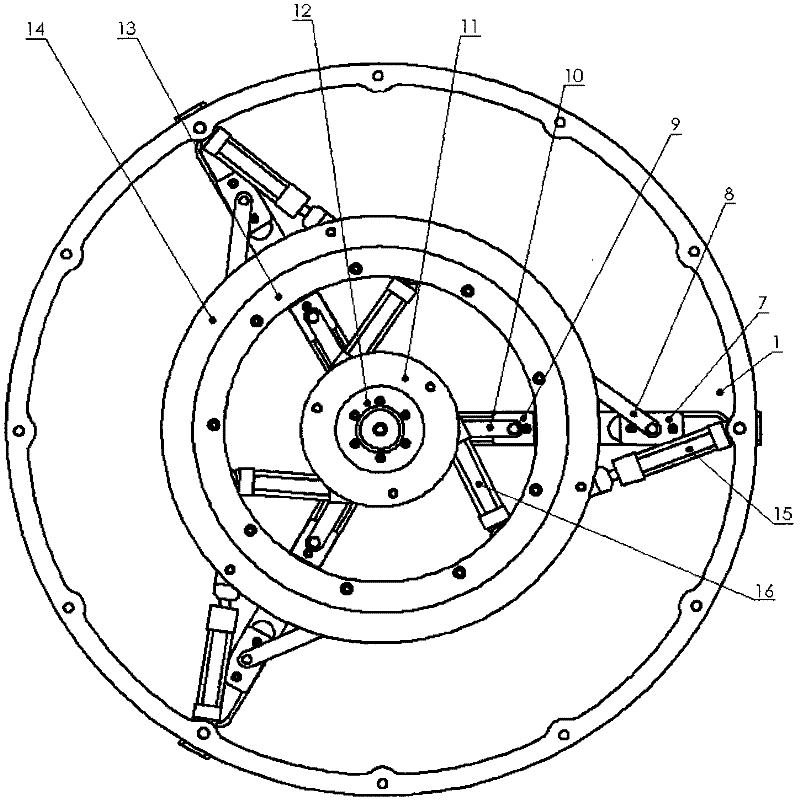

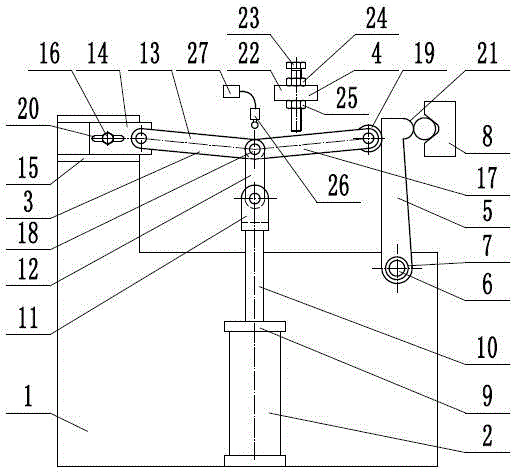

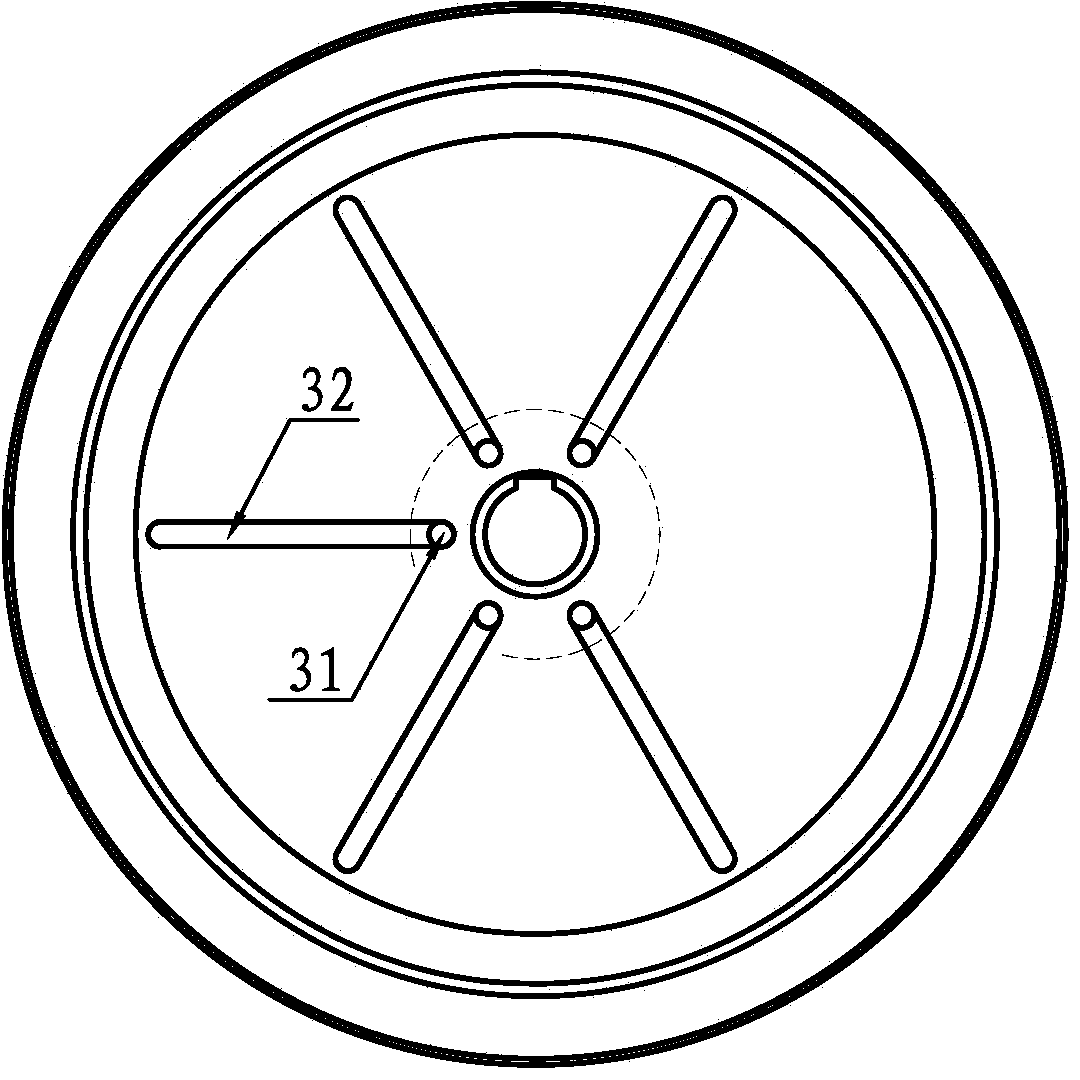

Linkage rod type air chuck for laser pipe cutter

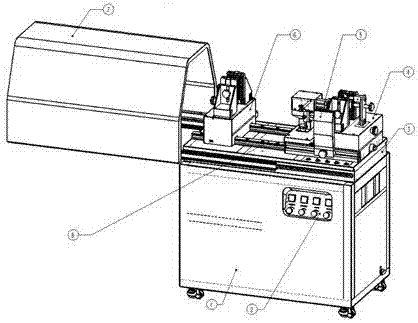

InactiveCN101439454AAdjustable clamping forceRealize Songka automatic controlWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlLinkage concept

The invention provides a connecting rod typed gas static-pressing chuck used for a laser pipe cutting machine, belonging to a chuck in the field of mechanical equipment technique. The technical problem to be solved is that the connecting rod typed gas static-pressing chuck used for the laser pipe cutting machine is provided; the technical proposal comprises a horizontal transverse sliding connecting rod mechanism, a horizontal longitudinal clamping mechanism and a chuck seat; the whole chuck takes the longitudinal symmetry axis as a center; the horizontal longitudinal clamping mechanism is symmetrically arranged in longitudinal direction of the chuck; the transverse symmetry axis is taken as a center, the left side of the chuck is provided with the horizontal transverse connecting rod mechanism and the right side thereof is provided with a counterweight. The chuck controls the clamping force by inflating and deflating the cylindrical and by extending and contracting the spring so as to complete a working period of loosening and clamping of the pipes, and is provided with a through hole which allows the pipes to pass by; the clamping block can be adjusted upwards and downwards and the sliding block can be adjusted to the left and the right; the concentricity in a large range can be adjusted without the requirement of replacing the clamping block; the connecting rod typed gas static-pressing chuck is applicable to the clamping requirement of various pipe diameters and can automatically control the loosening and clamping of the chuck.

Owner:CHANGCHUN BEIXING LASER EQUIP

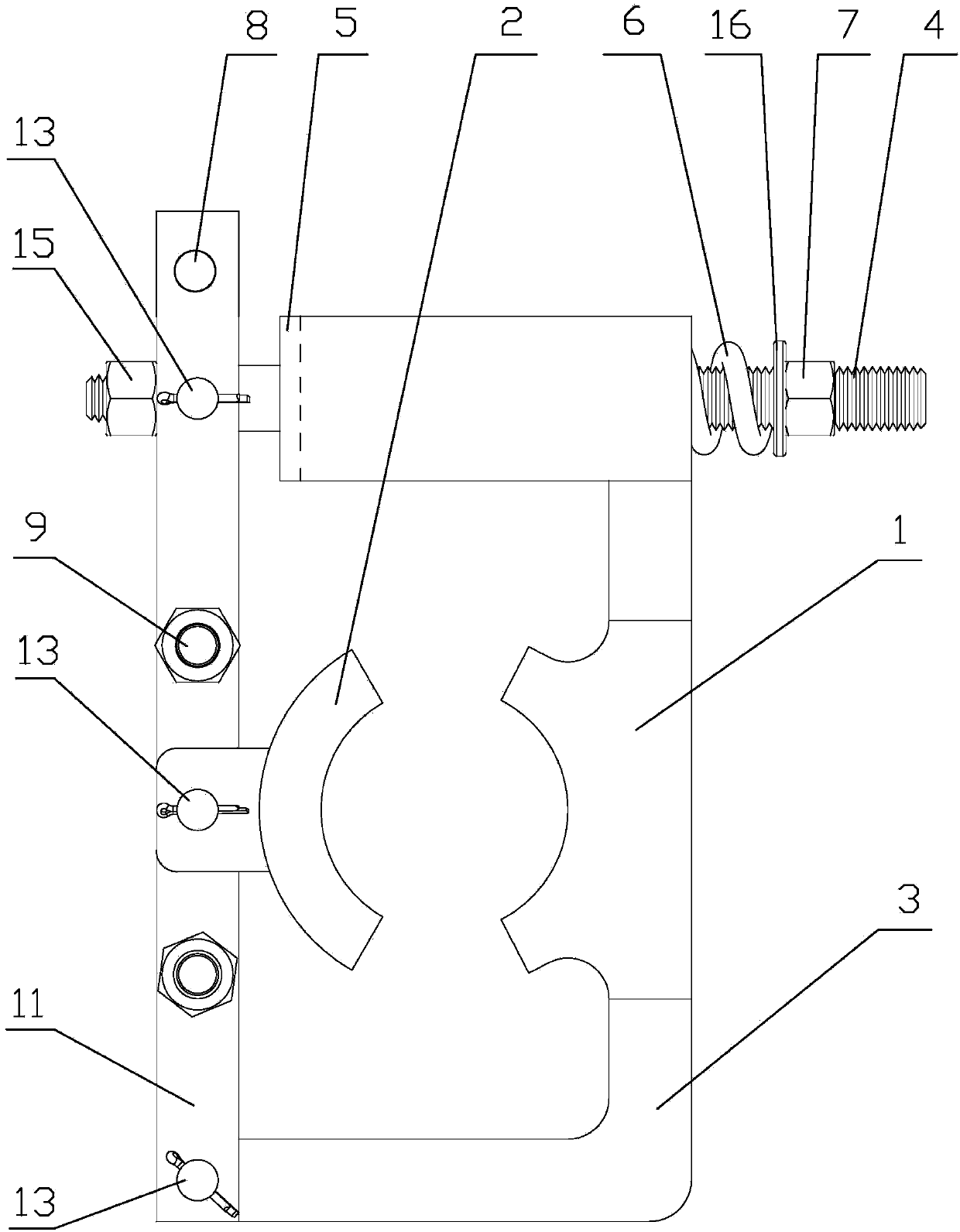

Pipe clamping device

InactiveCN103419152ACompact structureEasy to installPipe supportsWork holdersEngineeringMechanical engineering

The invention discloses a pipe clamping device. The pipe clamping device comprises a fixed clamping block, a movable clamping block, a swinging arm and a folding fixed arm, wherein the fixed clamping block and the movable clamping block are used for clamping a pipe; one end of the swinging arm is hinged to one end of the fixed arm; the other swinging end of the swinging arm is connected with the other end of the fixed arm through a clamping mechanism in a locking way; the fixed clamping block is fixedly connected to the fixed arm; the movable clamping block is hinged to the swinging arm; the clamping mechanism comprises a screw, a spring baffle and a spring; the spring baffle is fixedly connected to the fixed arm; one end of the screw is positioned on the swinging arm; a body of the screw penetrates through the spring baffle and is sleeved with the spring; an adjusting nut is screwed at the other end of the screw and is used for extruding the spring on the spring baffle so as to tightly pull the swinging arm toward the fixed arm; pin holes are formed in one swinging end of the swinging arm and are reserved installation holes of an unlocking mechanism which is used for pushing the swinging arm away from the fixed arm. The pipe clamping device has the integrated advantages of a screw clamping mechanism and a lever mechanism, and is simple and compact in structure and convenient to install and operate.

Owner:QINZHOU UNIV +2

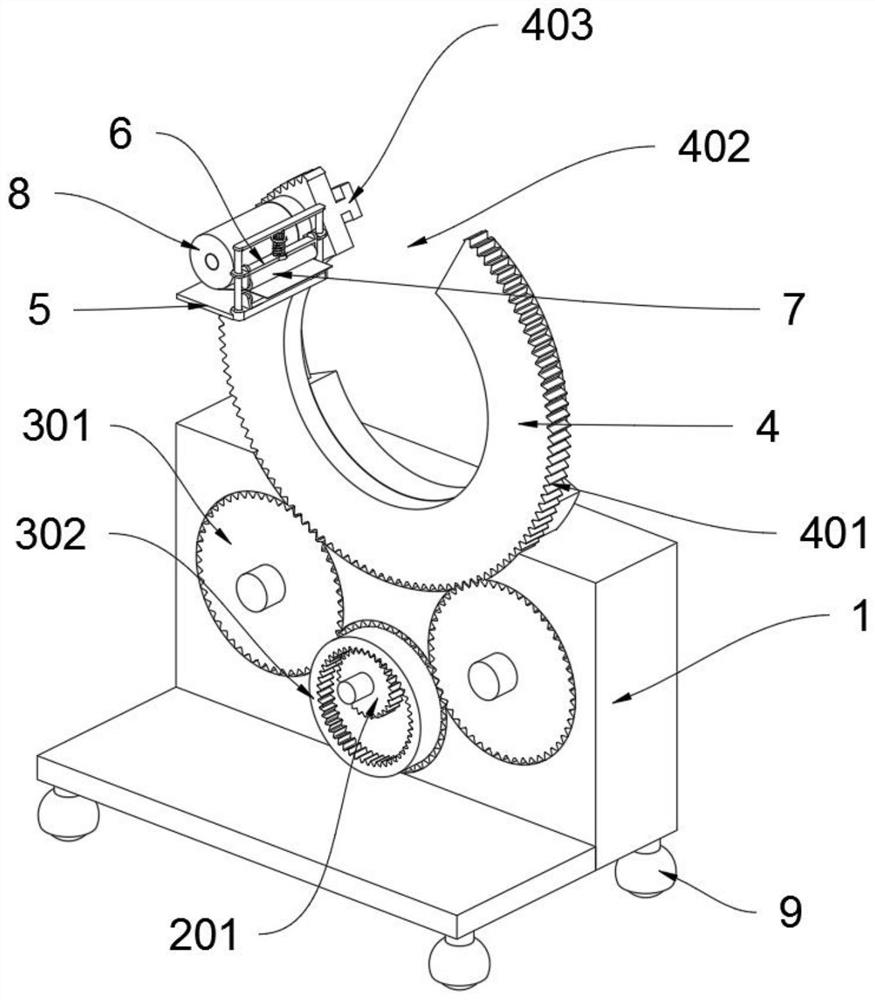

Ratchet cable stripper

PendingCN108512142AImplement peelingImprove efficiencyApparatus for removing/armouring cablesIntermittent motionEngineering

The invention provides a ratchet cable stripper, which comprises a handle, a ratchet and pawl mechanism arranged at one end of the handle, a clamp assembly which is arranged in the ratchet and pawl mechanism and is used for clamping a cable, and a tool bit assembly for scraping the cable skin, wherein the ratchet and pawl mechanism comprises a circular columnar handle head part, a circular columnar ratchet arranged on the inner wall of the handle head part in a sleeving manner, multiple straight triangular teeth arranged on the outer wall of the ratchet in a uniform spacing manner along the circumferential direction of the ratchet, and a pawl part which is arranged on the inner wall of the handle head part and is matched with the straight triangular teeth. The ratchet cable stripper provided by the invention has the beneficial effects that: the tool bit assembly and the clamp assembly are driven to rotate around a cable by use of the unidirectional intermittent motion characteristic ofthe ratchet and pawl mechanism, so as to scrap the cable skin; and furthermore, the handle can swing back and forth within a certain angle range on one side of the cable instead of rotating around the cable, so that the labor is saved, and the efficiency is high.

Owner:WUHAN JIANGXIA DISTRICT POWER SUPPLY CO STATE GRID HUBEI ELECTRIC POWER CO +2

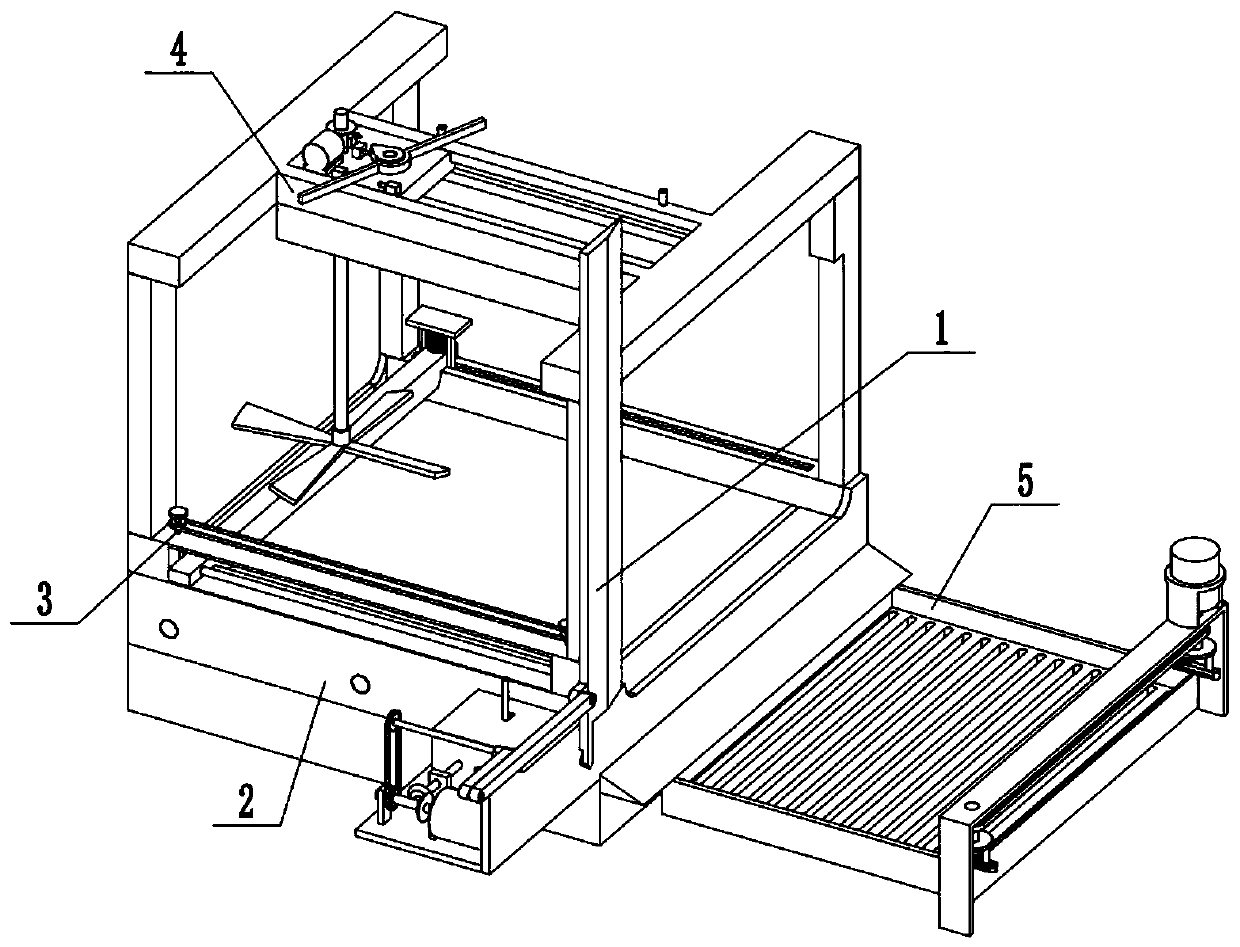

Bread production line and cutting mechanism thereof

ActiveCN107751275AImprove fitImprove guidanceDough dividingDough shaping and cutting apparatusProduction lineEngineering

The invention discloses a bread production line and a cutting mechanism thereof. According to the technical scheme, the bread production line is characterized by comprising a matching device, a stirring device, a fermentation tank, a forming device, a resting box and a baking oven which are sequentially arranged, wherein the cutting mechanism in the forming device comprises a mounting frame and cutters arranged on the mounting frame at intervals, the mounting frame comprises a cross rod, boxes corresponding to the cutters are arranged on the cross rod, slots allowing the cutters to penetrate out are formed in the bottoms of the boxes, and scraping plates abutting against side walls and cutting surfaces of the cutters are arranged in the boxes. By the aid of the scraping plates, the cutterscontinuously rotate in the flour cutting process, so that flour stick to the cutters can be scraped by the scraping plates continuously and left in the boxes, the flour cannot stick to the side wallsand the cutting surfaces of the cutters for a long time, and the following flour cutting process can be conducted well in order.

Owner:北京义利面包食品有限公司

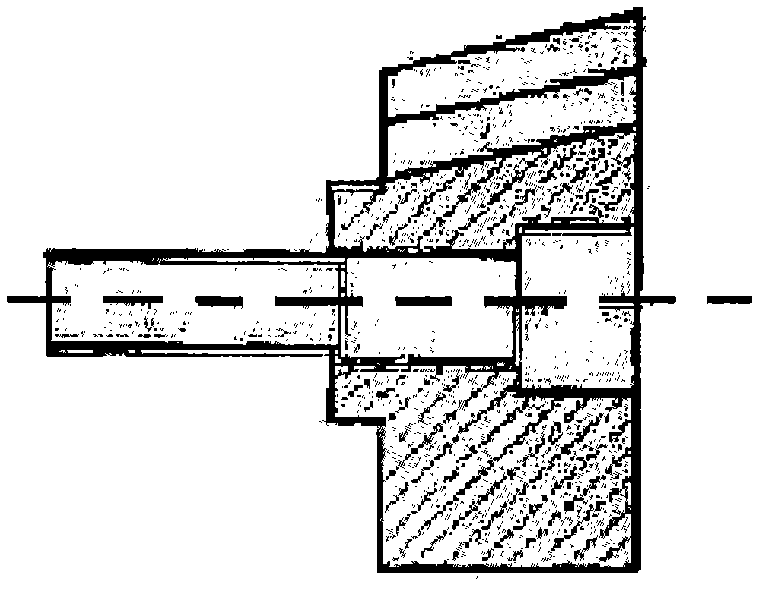

Split type inverted wedge type power chuck for machine

The invention discloses a split type inverted wedge type power chuck for a machine, which mainly comprises a chuck body, a sliding seat, a T-shaped key, a clamping jaw, a dustproof cover, a sliding shaft, a location key, a regulating pad and a pull rod, wherein an integral semi-closed structure of a guide groove is changed into an open surface, thus groove width precision and smooth finish of a guide surface are improved, and movement precision and service life of the chuck are improved; and by adopting an inverted cone chuck, the split type inverted wedge type power chuck has replaceability. By adopting round corner transition, the diameter range of clamping a workpiece is increased. A packing and a guide block of the chuck are separately manufactured, and then assembled into a whole, thus the split type inverted wedge type power chuck has the advantages of compact structure, convenience for maintenance, large clamping range, convenience for regulation, adjustable clamping force, higher automatic centering precision and the like.

Owner:唐淑娟

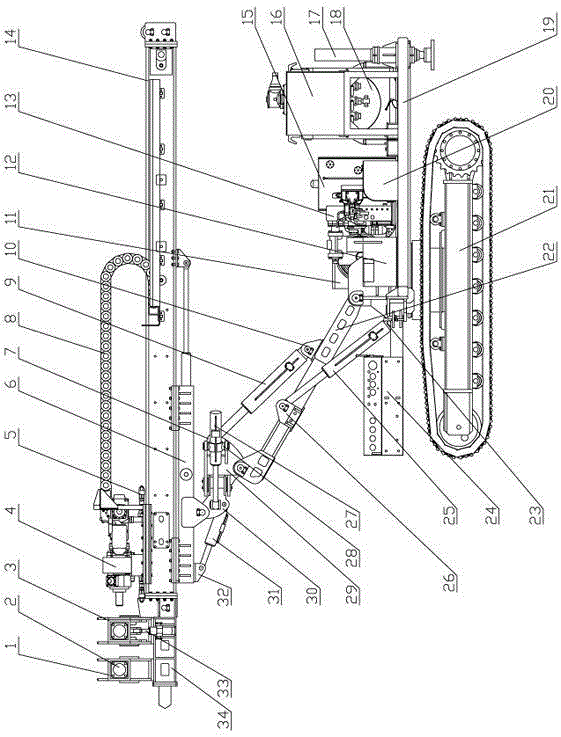

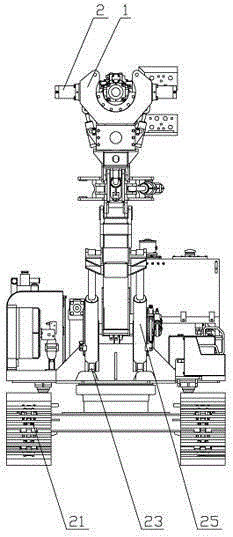

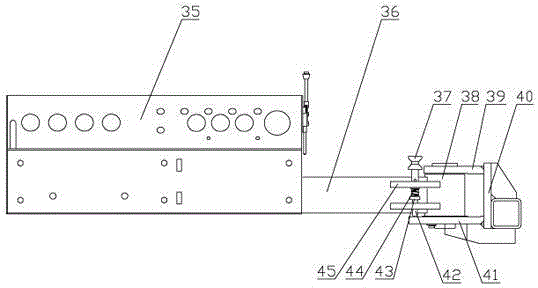

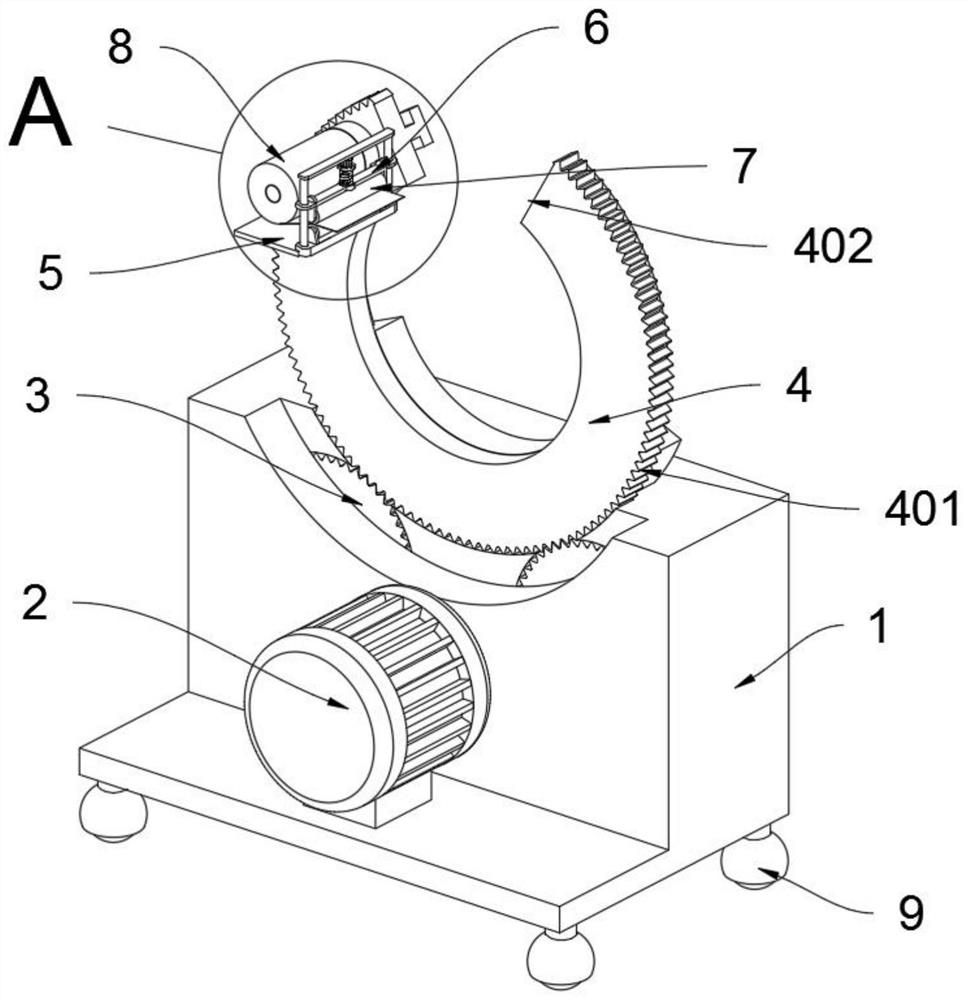

Anchor drill

ActiveCN105350910AFlexible rotationEasy to change positionDrilling rodsDirectional drillingPropellerDiesel engine

The invention provides an anchor drill which is provided with a movable chassis, wherein an upper turntable is arranged at the upper part of the chassis; a support leg, a support leg cylinder, a hydraulic oil tank assembly, a diesel engine power assembly, a diesel tank assembly, a tool kit, an oil return filtering assembly, an auxiliary control console, an oil cooler assembly, a main control console, an amplitude-changeable support arm device, a bracket and a propeller assembly are arranged on the upper turntable; and the propeller assembly comprises a guide rail, a power head assembly, a hose support chain and a rod disassembling device assembly. The anchor drill is compact and novel in structure and flexible and convenient in operation and can simultaneously adapt to multiple different working conditions; and compared with a common anchor drill, the anchor drill provided by the invention has the advantages of low use cost and good popularization and application values.

Owner:HUBEI SHOUKAI MACHINERY

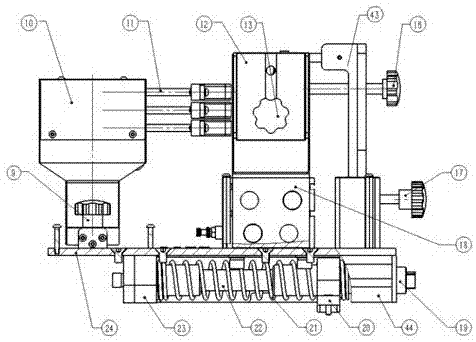

Pneumatic torque-adjustable cap screwing device capable of flexibly clamping

InactiveCN103449343ANo damageStable and uniform torqueThreaded caps applicationScrew threadBottle cap

The invention discloses a pneumatic torque-adjustable cap screwing device capable of flexibly clamping, which comprises a cap screwing thread bushing, an elastic clamp ring, a rotary cover base, a gland core, a central spindle seal ring, a tightening nut, an air cavity, air inlet passages, a hollow rotating shaft, a protecting bush, an axial seal ring, a lower bearing pedestal, a bearing, an air inlet pipe, an upper bearing pedestal, an adapter sleeve, a connecting seat and a pneumatic motor, wherein the cap screwing thread bushing, the elastic clamp ring, the rotary cover base, the gland core, the central spindle seal ring, the tightening nut, the air cavity and the air inlet passages form a bottle cap pneumatic chuck; the hollow rotating shaft, the protecting bush, the axial seal ring, the lower bearing pedestal, the bearing, the air inlet pipe, the upper bearing pedestal, the adapter sleeve, the connecting seat and the pneumatic motor form a pneumatic cap screwing drive part; the bottle cap pneumatic chuck is utilized to flexibly clamp a bottle cap, the clamping force can be adjusted, the bottle cap cannot be damaged, and clamp marks cannot be preserved on the bottle cap. The pneumatic cap screwing drive part can stably screw the bottle cap in a fixed torque manner according to the predetermined requirements, and the torque of cap screwing can be adjusted and controlled. A pressure relief air passage communicated with the outside is arranged on the lower end surface of the gland core, so that a bottle cap can be conveyed to a certain position. The device has the advantages that the structure is simple, the pneumatic flexible clamp is realized, the pneumatic cap screwing is performed in a torque-adjustable manner, the cap screwing operation is stable and reliable, the cap screwing speed is high and steady, the running cost is low, and the maintenance is facilitated.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

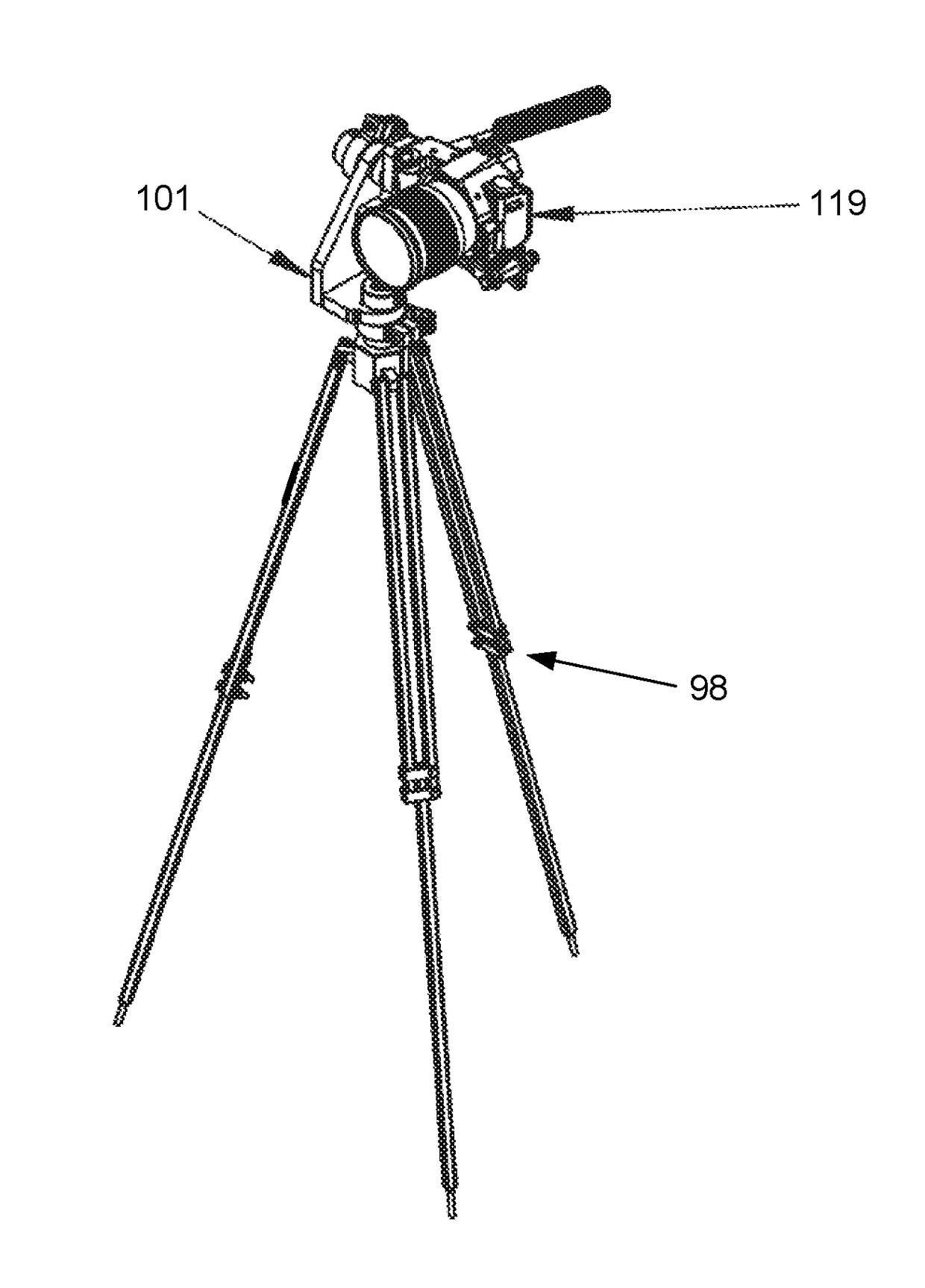

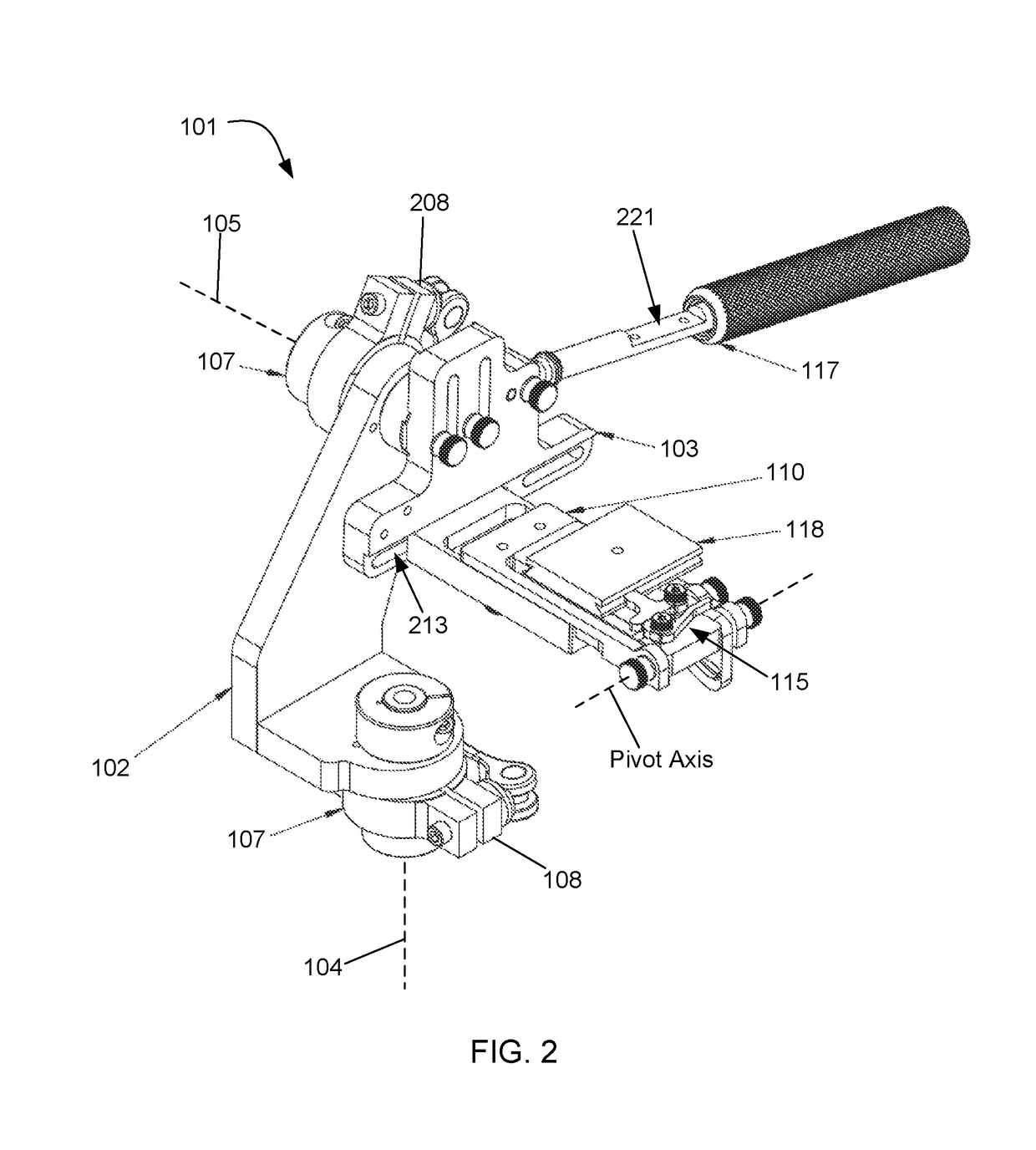

Optical mounting device

InactiveUS9989836B1Precise adjustable clamping forceEasy to controlStands/trestlesCamera body detailsOptical mountEngineering

An optical mounting device is disclosed that enables an optical device to be pointed in the desired orientation with minimal effort between a horizontal and a vertical position. The device includes a yoke, a saddle, and a payload platform assembly. The device can lock the position of the optical device into a desired orientation. The payload platform assembly has a lower base that is coupled to the saddle and an extendable upper section attached to a rotation pivot guide that allows the upper section to rotate up to 90 degrees from horizontal landscape orientation to a vertical portrait orientation.

Owner:RIDDEL CHARLES STEPHEN +1

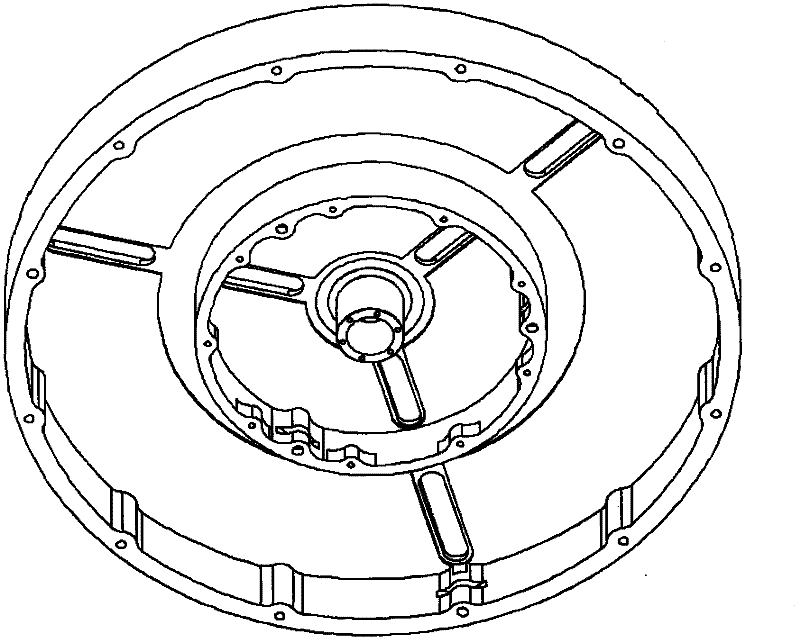

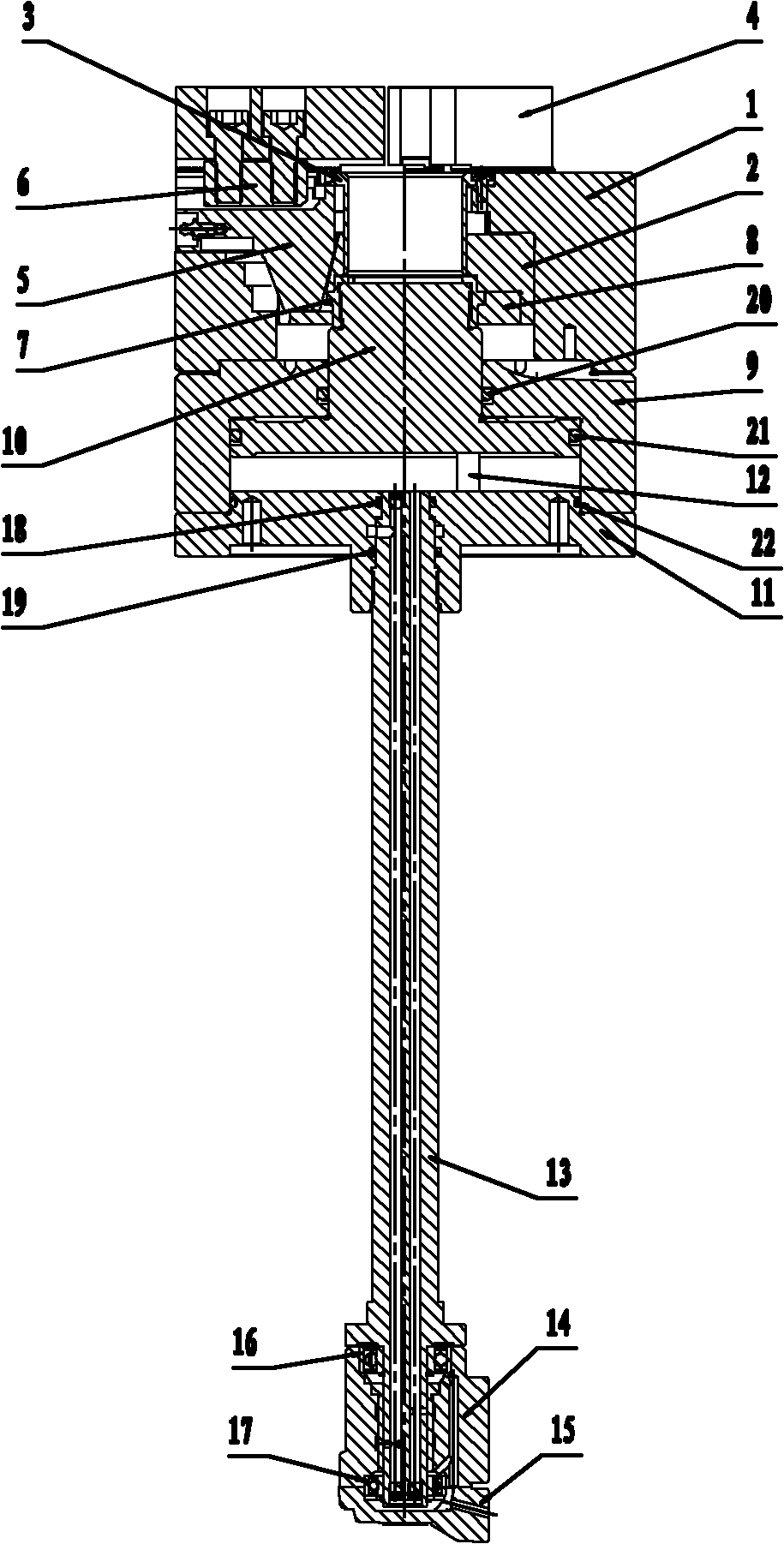

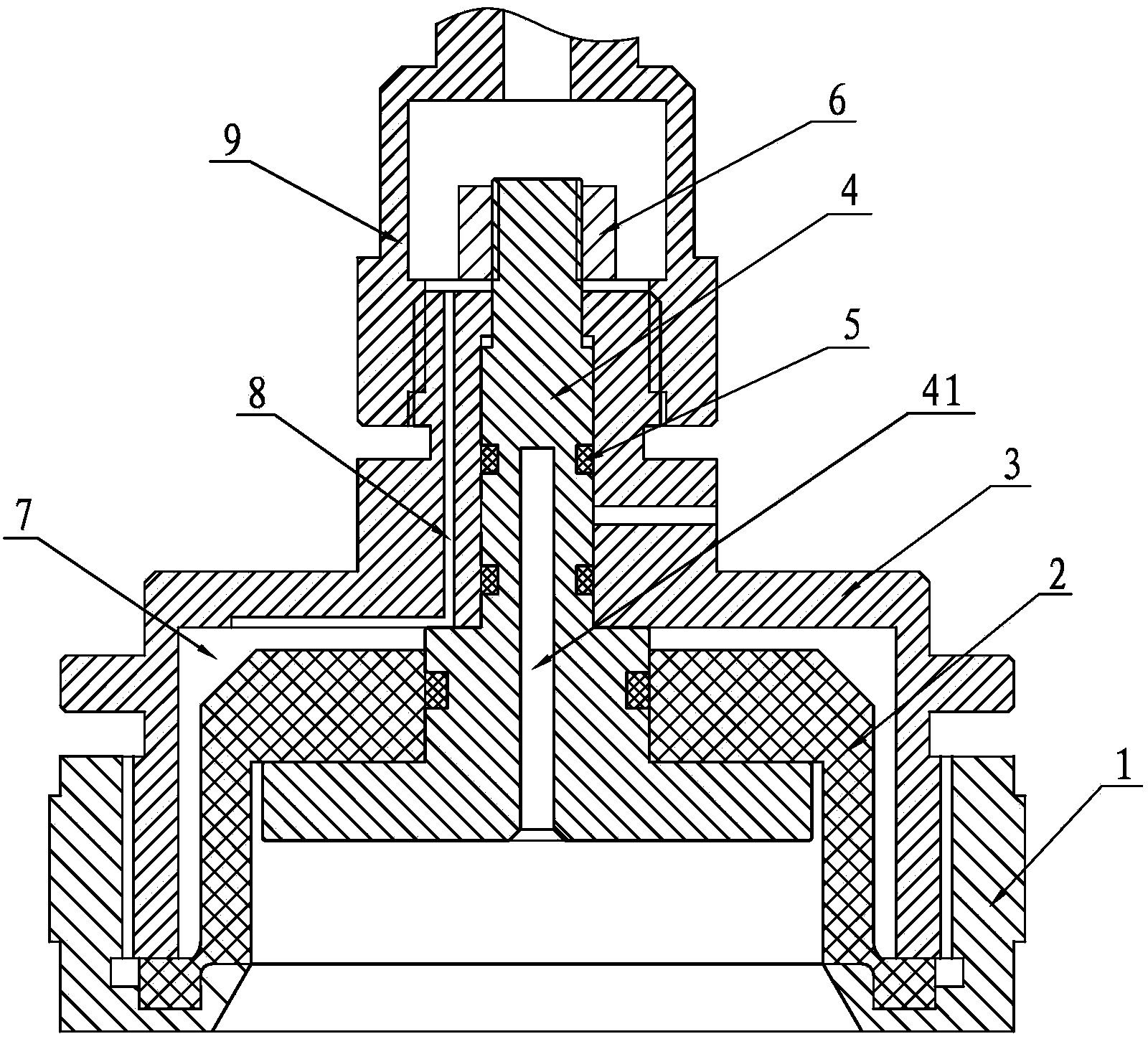

Bidirectional self-centering power chuck

InactiveCN102672226AImprove machining accuracyAdjustable clamping forceChucksPush and pullEngineering

The invention relates to a bidirectional self-centering power chuck, which comprises a chuck body, an inner clamping claw base, an inner clamping claw, an inner clamping claw pin, an outer clamping claw base, an outer clamping claw, an outer slide block, outer connecting rods, an inner slide block, inner connecting rods, an inner rotating tower, an outer rotating tower, an outer oil cylinder and an inner oil cylinder. According to the power chuck, the straight line motions of inner and outer oil cylinder rods are converted into opposite circular motions of the inner and the outer rotating towers respectively; and through n groups of inner and outer connecting rods, the inner and the outer slide blocks and the inner and the outer clamping claws, the inner and the outer rotating towers drive the inner and the outer clamping claws in match to be in opposite self-centering clamping motion, and thereby a workpiece is pushed and pulled to the center of a circle to be clamped bidirectionally at one same clamping point. Compared with the prior art, the invention has the advantages that the power chuck is high in machining precision, wide in application range and multiple in function.

Owner:贺自清

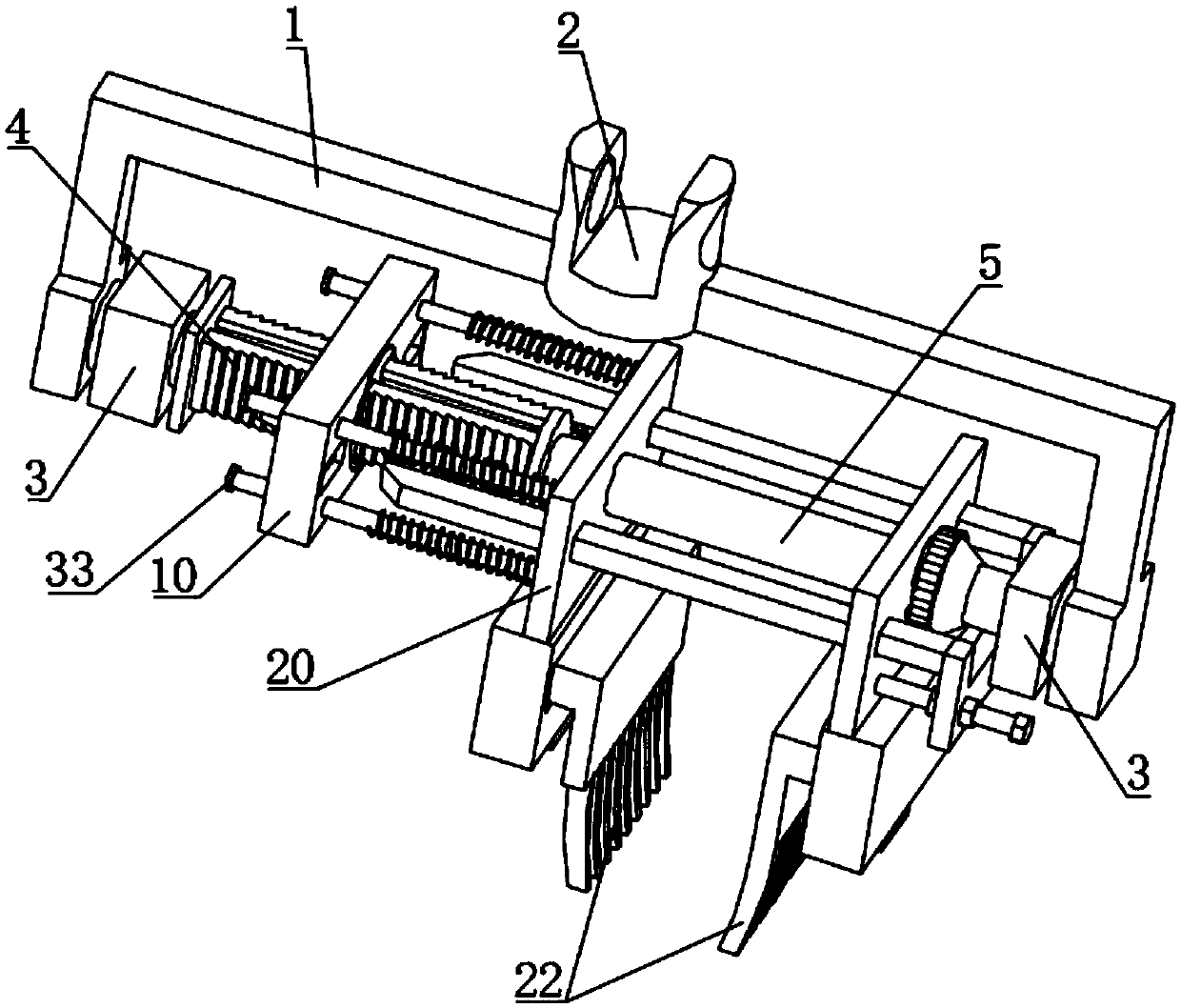

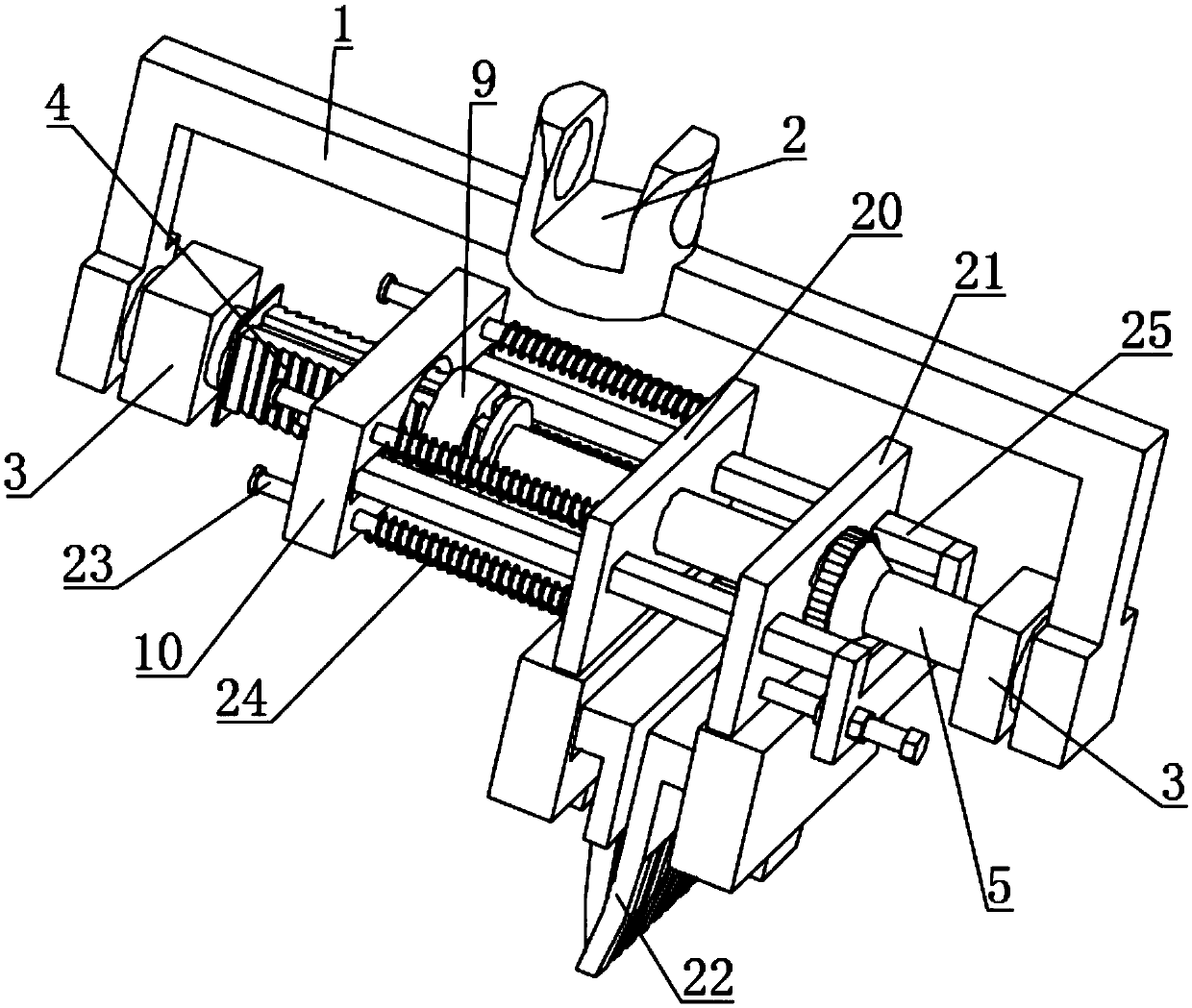

Universal shooting frame for long guns and short guns

The invention relates to a universal shooting frame for long guns and short guns, and belongs to the technical field of detection and identification of firearms. The universal shooting frame for long guns and short guns comprises a base, a muzzle height adjusting platform, a rear clamping unit, a percussion unit, a front clamping unit and a linear sliding guide track, wherein the muzzle height adjusting platform is arranged on the top of the base; the linear sliding guide track is arranged on the muzzle height adjusting platform; the rear clamping unit is arranged on the linear sliding guide track; and the percussion unit is arranged on the rear clamping unit. By the universal shooting frame for long guns and short guns, a detected gun can be reliably clamped effectively, the magnitude of a clamping force is adjustable and is accurately displayed on a display original part, and therefore, the problems that percussion is unreliable and even a gun is damaged due to over-large clamping force caused by blind adjustment, the gun cannot be clamped stably due to too small clamping force, and potential safety hazards exist are avoided.

Owner:卡目索纳智能科技研发(江苏)有限公司

Back distribution type front pneumatic chuck

The invention relates to a back distribution type front pneumatic chuck which comprises a chuck body, a wedge core sleeve, a retaining cap, three jaws, three sliding bases and three T shaped blocks. The back distribution type front pneumatic chuck is characterized in that an air cylinder body is connected with a base to forma an air cylinder main body, a piston is installed in the air cylinder body and connected with the wedge core sleeve through a push-pull sleeve and a push-pull ring, the wedge core sleeve slides up and down in the chuck body under the driving of the piston, an upper air chamber and a lower air chamber are formed above and below the piston, the base is fixedly connected with an extended valve rod in a thread screwing way, the valve rod and a valve body are connected through a bearing and can rotate relatively at a high speed, and a valve cap is connected with the valve body through a screw. The back distribution type front pneumatic chuck has simple, compact and reasonable structure; since the air cylinder body and the chuck body are connected into a whole and a distributing valve is arranged at the rear part independently, the back distribution type front pneumatic chuck can be successfully installed in a narrow space at the tail part of a machine tool, thereby greatly reducing the labor intensity, shortening clamping time and improving productivity; and in addition, since the clamping force is adjustable, the back distribution type front pneumatic chuck can be matched with numerical control equipment which needs air distribution at the tail part of the machine tool and has limited space at the tail part.

Owner:江苏无锡建华机床附件集团有限公司

Rebar feed reinforcement clamping device

InactiveCN106239205AGood reliabilityExtended service lifePositioning apparatusMetal-working holdersRebarEngineering

The invention provides a rebar feed reinforcement clamping device and belongs to the technical field of machining. The rebar feed reinforcement clamping device comprises a connection rod mechanism and a limiting mechanism. A rocker support plate of the connection rod mechanism is provided with a U-shaped groove and is installed on a rack through a fastening screw. The left end of a rocker is hinged to the rocker support plate. The lower end of a bearing connection rod is hinged to a connection support lug. The upper end of the bearing connection rod, the right end of the rocker and the left end of a first connection rod are hinged through hinge pins. A pressing wheel is rotationally arranged at the right end of the first connection rod. The lower end of a pressing rod is hinged to the rack through a pressing rod hinge pin and is further provided with a return torsional spring. The upper end of the pressing rod is attached to the pressing wheel tightly. The limiting mechanism is arranged above the first connection rod. According to the rebar feed reinforcement clamping device, the reinforcement characteristic of the connection rod mechanism near a dead center position is utilized, very large clamping force is generated to a rebar through small cylinder thrust, the rebar feed reinforcement clamping device can be suitable for clamping of various models of rebars, and thus the applicability is high.

Owner:ZHEJIANG WILLING TECH

High-accuracy intelligent feeding tool

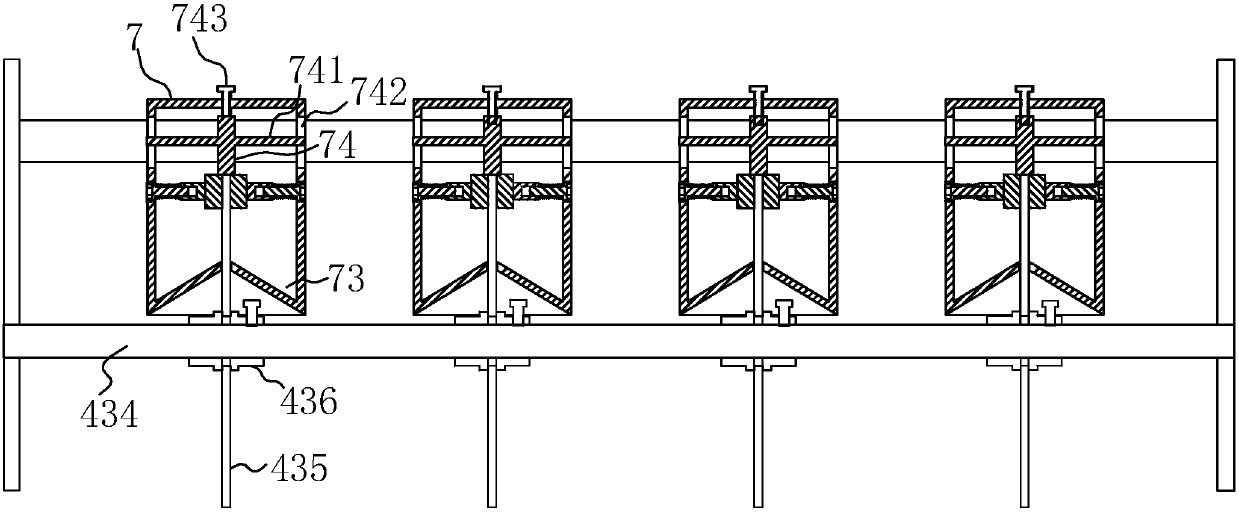

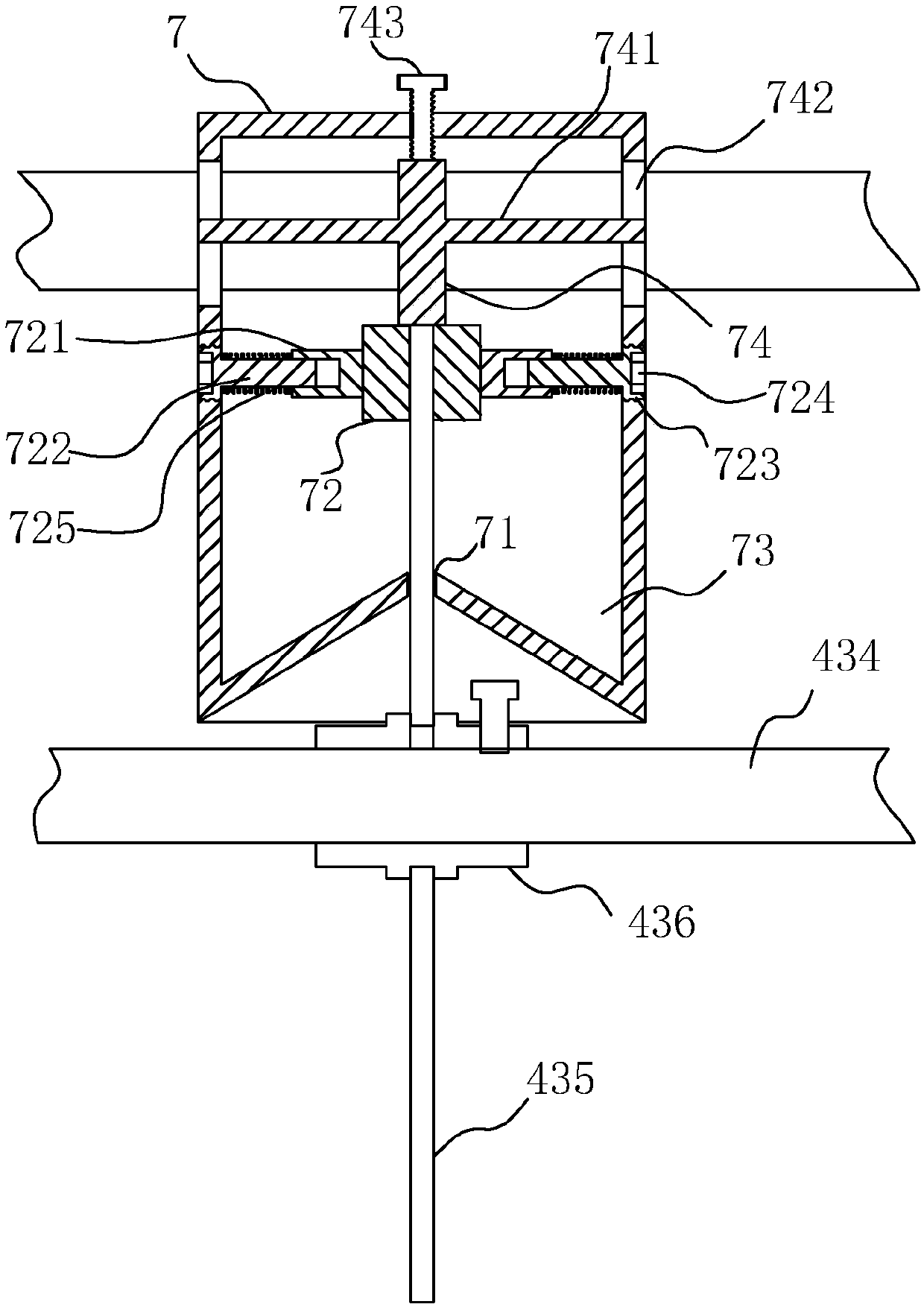

InactiveCN109607197ANo distractionGuaranteed clamping accuracyCharge manipulationConveyor partsEngineeringCentral symmetry

The invention relates to the technical field of optical lens polishing tool equipment, and discloses a high-accuracy intelligent feeding tool. The high-accuracy intelligent feeding tool comprises a base plate and a supporting column, wherein the supporting column is fixedly installed on the upper end face of the base plate. A supporting platform is fixedly installed on the upper end face of the supporting column, and a window is formed in the right side face of the supporting platform. The high-accuracy intelligent feeding tool further comprises four clamping mechanisms, a horizontal movementmechanism and a vertical movement mechanism. The four clamping mechanisms are arranged on the periphery of the supporting column in a central symmetry distribution mode and used for clamping materialsin the four directions. The horizontal movement mechanism is arranged on the lower end faces of the clamping mechanisms, installed on the supporting column, and used for moving the clamping mechanisms in the horizontal direction and adjusting the clamping force. The vertical movement mechanism is arranged inside the supporting column, and used for adjusting the clamping mechanisms in the verticaldirection and adjusting the clamping height. By the adoption of the high-accuracy intelligent feeding tool, the clamping position can be adjusted according to the size and the thickness of an opticallens, and the clamping accuracy is improved. In addition, flexible clamping operation can be utilized to replace rigid clamping operation, and the lens is better protected.

Owner:武汉安比克科技有限公司

Traditional Chinese medicine sectioning and screening device

The invention relates to the field of the pharmacy department, in particular to a traditional Chinese medicine sectioning and screening device. The traditional Chinese medicine sectioning and screening device comprises a sectioning assembly, a conveying assembly, a clamping assembly, a clearing assembly and a screening assembly. During storage, traditional Chinese medicines usually need to be cutto specified length for storage, and cannot be automatically sectioned in the prior art, cut-off length cannot be changed, and residues can not be separated from medicine sections. In order to solve the problems, medicines can be placed on a conveyor belt by opening a pressure rod, and clamping force of the medicines can be adjusted by putting down the pressure rod and rotating a rotary handle, sothat the pressure rod presses the medicines, and can slide forwards along with the conveyor belt for continuously clamping; every time a cut-off tool laterally cuts, the conveyor belt is not moved; after the cut-off tool laterally cuts every time, the conveyor belt continuously conveys, and travelling distance before the conveyor belt stops every time is adjustable; and sectioning length can be adjusted by adjusting the distance, a fan automatically travels back and forth above the conveyor belt to blow medicine residues into a drawer for storage, and the cut-off traditional Chinese medicinesare shaken left and right, as well as up and down through a sieve plate for separating the medicine sections from the medicine residues.

Owner:岳炳勇 +1

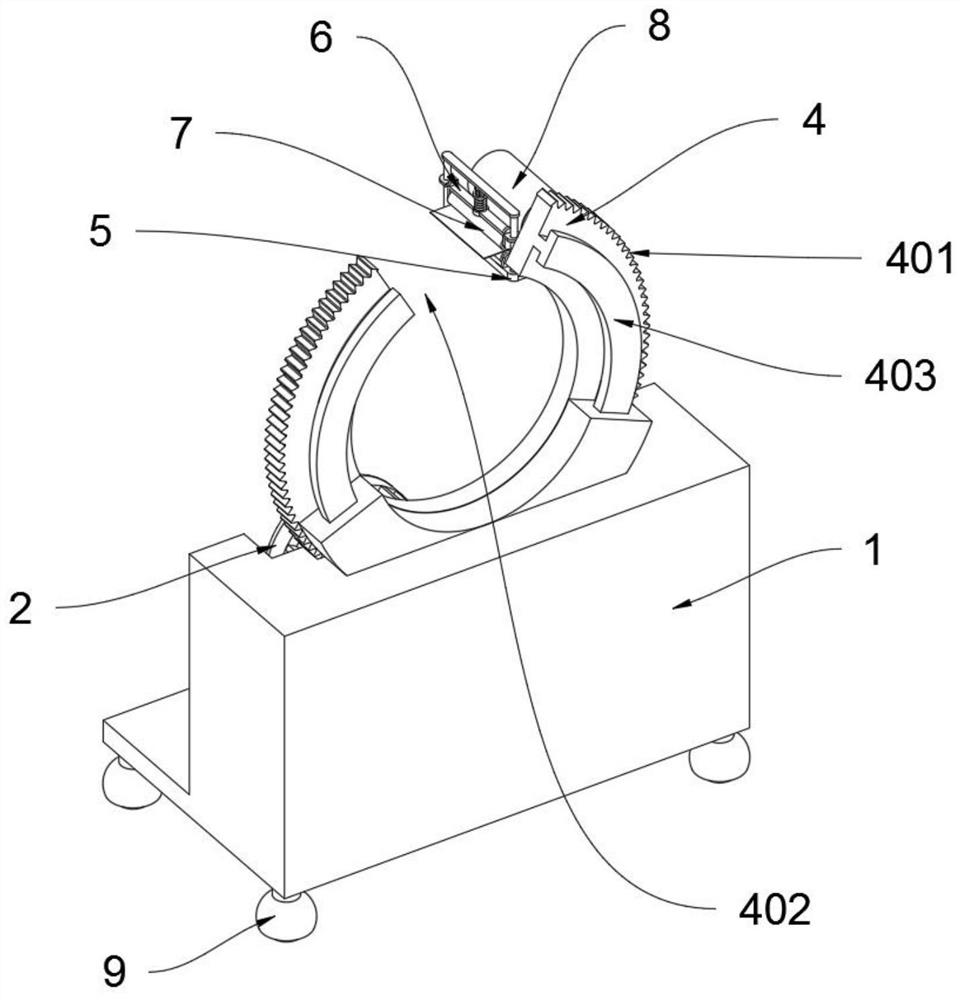

Orthopedic splint mounting and fastening device for orthopedics department

InactiveCN113397832AReduce workloadAdjustable clamping forceBandagesOrthopedic departmentMechanical engineering

The invention discloses an orthopedic splint mounting and fastening device for the orthopedics department, relates to the technical field of orthopedic treatment, and solves the problems that according to an existing orthopedic splint, a bandage is manually wound around an affected part to be fixed, so that the labor amount is large, and it cannot be guaranteed that the fastening force is kept consistent. The orthopedic splint mounting and fastening device for the orthopedics department comprises a mounting and fastening ring; and the mounting and fastening ring is rotationally connected to the interior of the top surface of a fixed mounting seat. When the device is used, a motor can be driven to drive the mounting and fastening ring to rotate around the affected part, so that the bandage is uniformly wound outside the orthopedic splint at the affected part, manual winding is not needed, and the workload of treatment personnel is reduced; the device is convenient to use, and the clamping force between two damping rollers is adjustable, so that the fastening force during bandage winding can be adjusted; the fastening force is uniform, so that the follow-up treatment effect is better; and the automation degree is high, and the use is convenient and flexible.

Owner:宿州市易鑫信息科技有限公司

Door threshold for access to the interior of a railway vehicle

ActiveUS20050217533A1High operating costsEfficient fillingVehicle arrangementsSupplementary fittingsEngineeringFriction force

The door threshold for a railway vehicle is intended to partially fill the gap between the vehicle and a platform. It comprises a support (22) which can be connected to the structure (16) of the railway vehicle and a strip (24) which is retained by the support (22). The strip (24) can be displaced between a normal position, in which it projects relative to the support (22), and a position retracted in the support (22). It comprises means (30A, 30B) for clamping the strip against at least a clamping surface (30A, 30B) of the support in order to produce friction of a specific value between the strip (24) and the support (22) counter to the displacement of the strip (24) relative to the support (22) in the plane of the or each clamping surface (30A, 30B).

Owner:ALSTOM TRANSPORT TECH SAS

Flexible pneumatic bottle cap clamping part

InactiveCN103466522AWon't hurtGuaranteed uptimeThreaded caps applicationEngineeringAtmospheric pressure

A flexible pneumatic bottle cap clamping part comprises a capping threaded sleeve, an elastic clamp ring, a rotating seat cover, a gland core, a mandrel seal ring, a tightening nut, an air chamber and an air inlet. The flexible pneumatic bottle cap clamping part is characterized in that pressure air enters the air chamber from the air inlet to force an inner side of the elastic clamp ring to pressure the bottle cap for clamping; due to the fact pressure of the pressure air is adjustable, the size of the clamping force to the bottle cap can be changed; with the bottle cap to be flexibly clamped through the inner side of the elastic clamp ring, the elastic clamp ring does no damage to the bottle cap and leaves no clamp marks during the clamping and capping; when the bottle cap is tightened, the air chamber is made to be communicated with outside, and after the loss of the pressure, the bottle cap is automatically loosened. The flexible pneumatic bottle cap clamping part has the advantages that cover taking without resistance, flexible pneumatic clamping and loosening are achieved, operation is stable and reliable, and clamping force is adjustable. Furthermore, the flexible pneumatic bottle cap clamping part can support the use of a pneumatic motor or a servo motor to be served as a cover taking and capping part of a capper.

Owner:JIANGSU JINWANG PACKING SCI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com