Double-oblique-face double-way floating pairing workpiece automatic clamping jig

An automatic clamping and double-slope technology, which is applied in the direction of manufacturing tools, metal processing machinery parts, clamping, etc., can solve the problems of reducing workpiece processing accuracy, dimensional deterioration, and positioning accuracy reduction, and achieves adjustable clamping force , Simple structure, reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

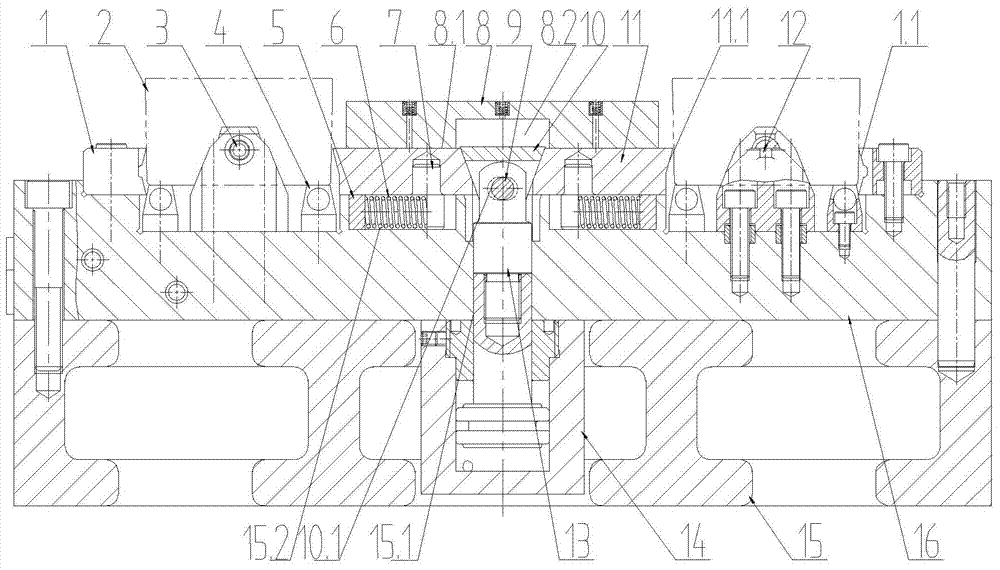

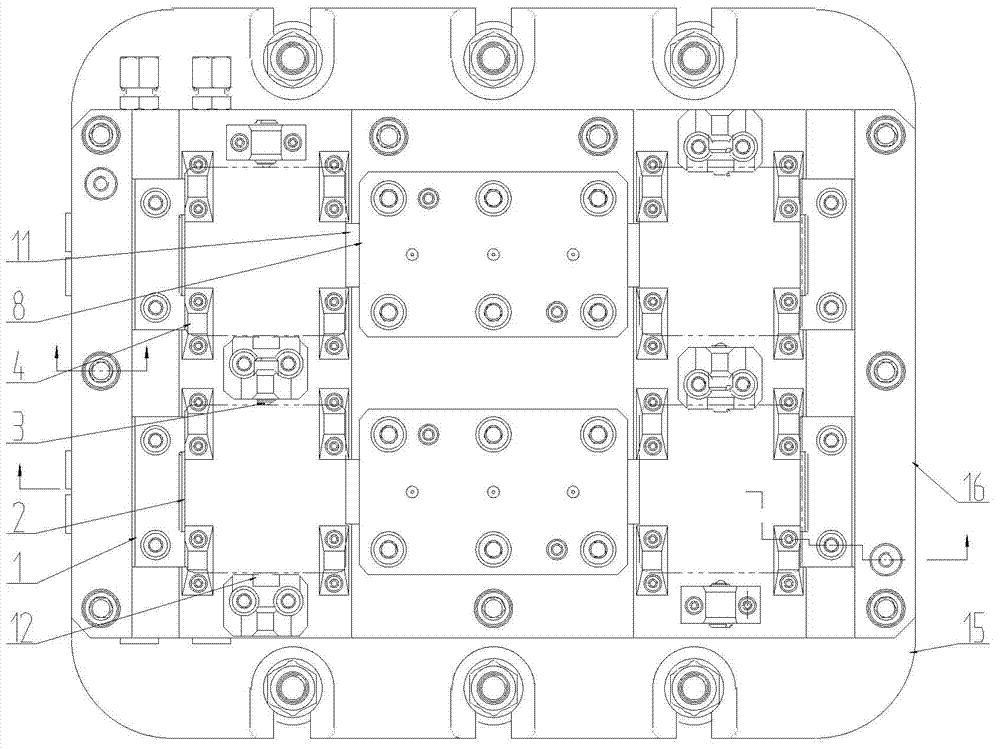

[0021] Such as figure 1 As shown, the present invention includes a cast iron base 15, on which a bottom plate 16 with an oil circuit is installed through an inner hexagon screw and a cylindrical pin, and an oil circuit board type hydraulic cylinder 14 is installed on the bottom plate 16 through an inner hexagon screw, and the oil of the bottom plate 16 The road communicates with the oil circuit of the hydraulic cylinder 14, leading to the rod chamber and the rodless chamber of the hydraulic cylinder 14 respectively.

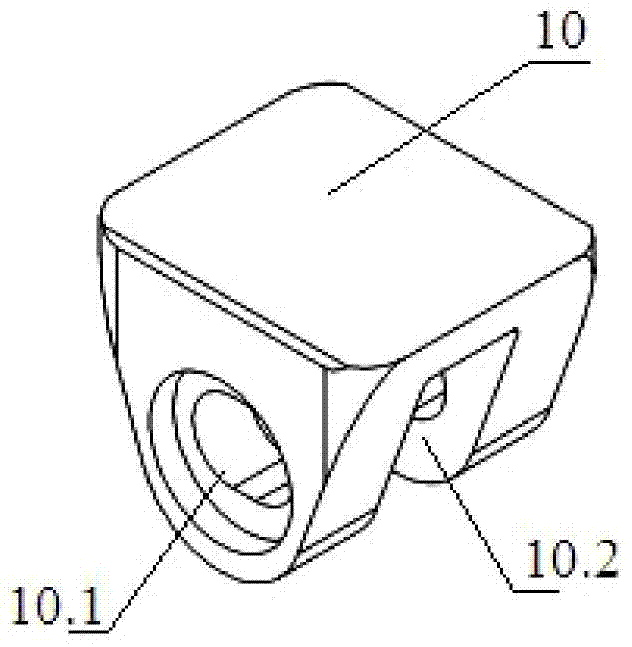

[0022] combine image 3 , Figure 4 As shown, the piston rod of the hydraulic cylinder 14 passes through the through hole 15.1 opened in the bottom plate 16 and is fixedly connected with the bottom of the connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com