Patents

Literature

245results about How to "Reduce the chance of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

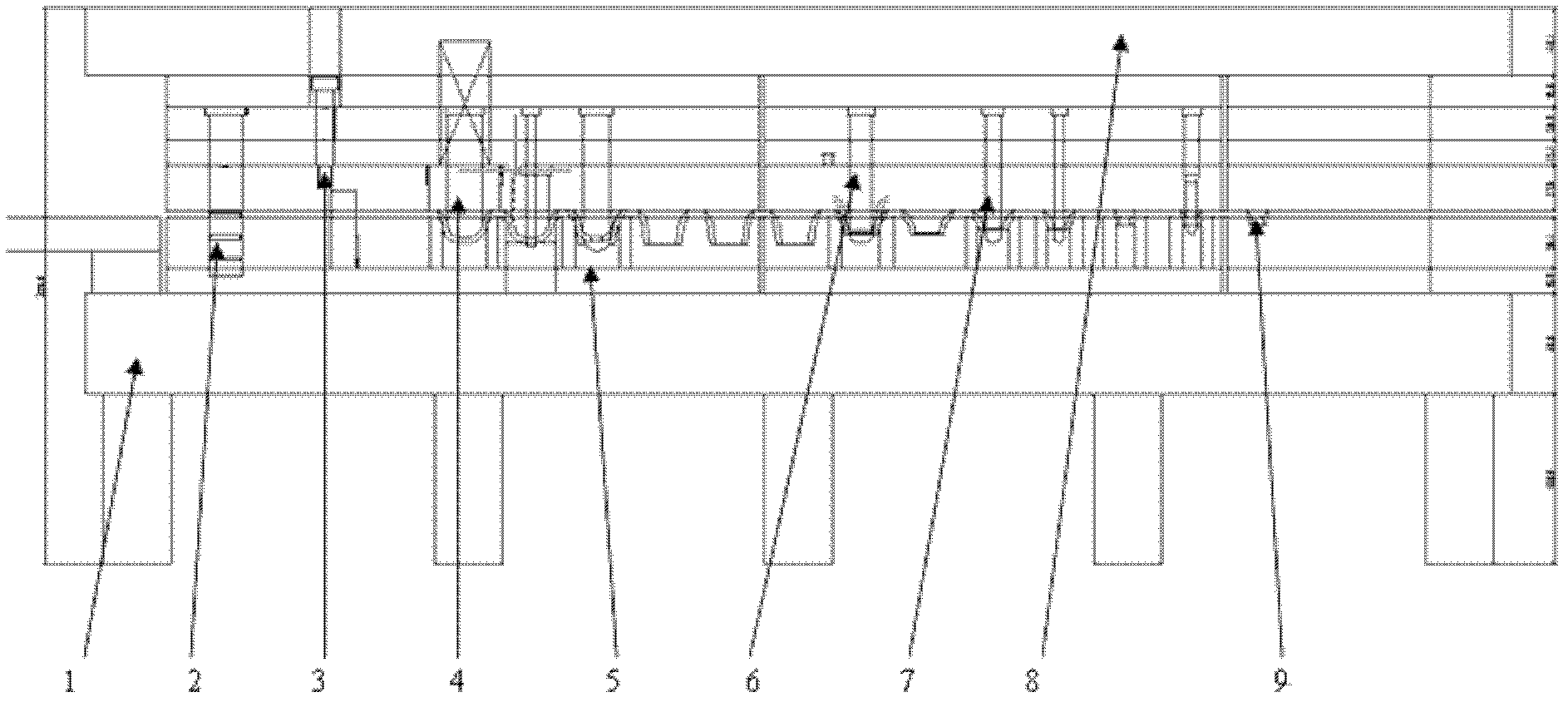

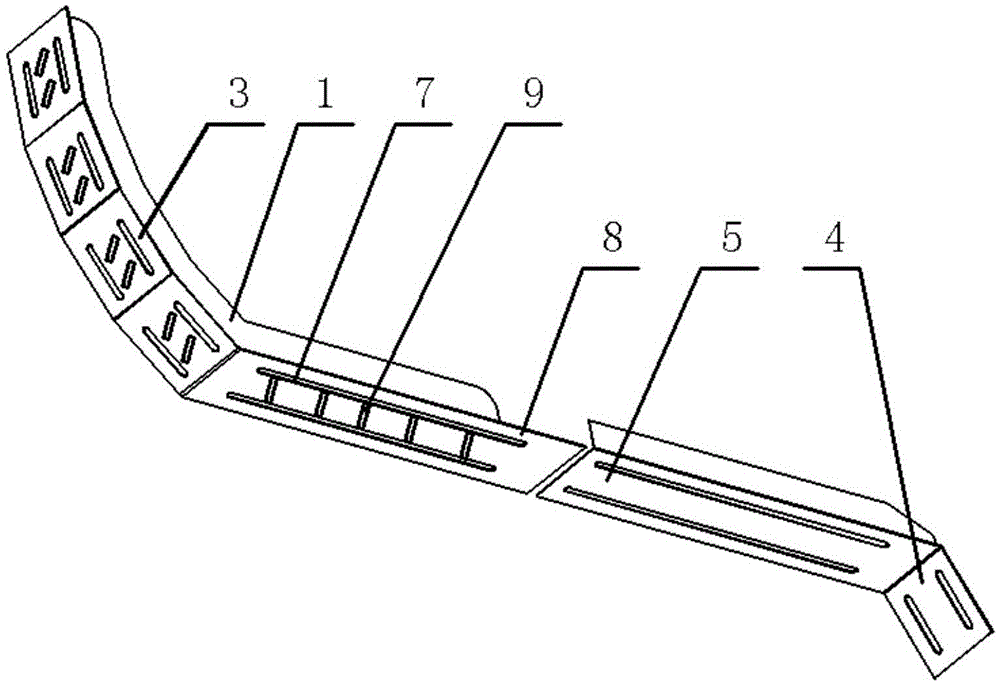

Apparatus for producing reflective membrane with microprism array structure

ActiveCN101672939AImprove work efficiencyImprove performanceOptical elementsUV curingHeat resistance

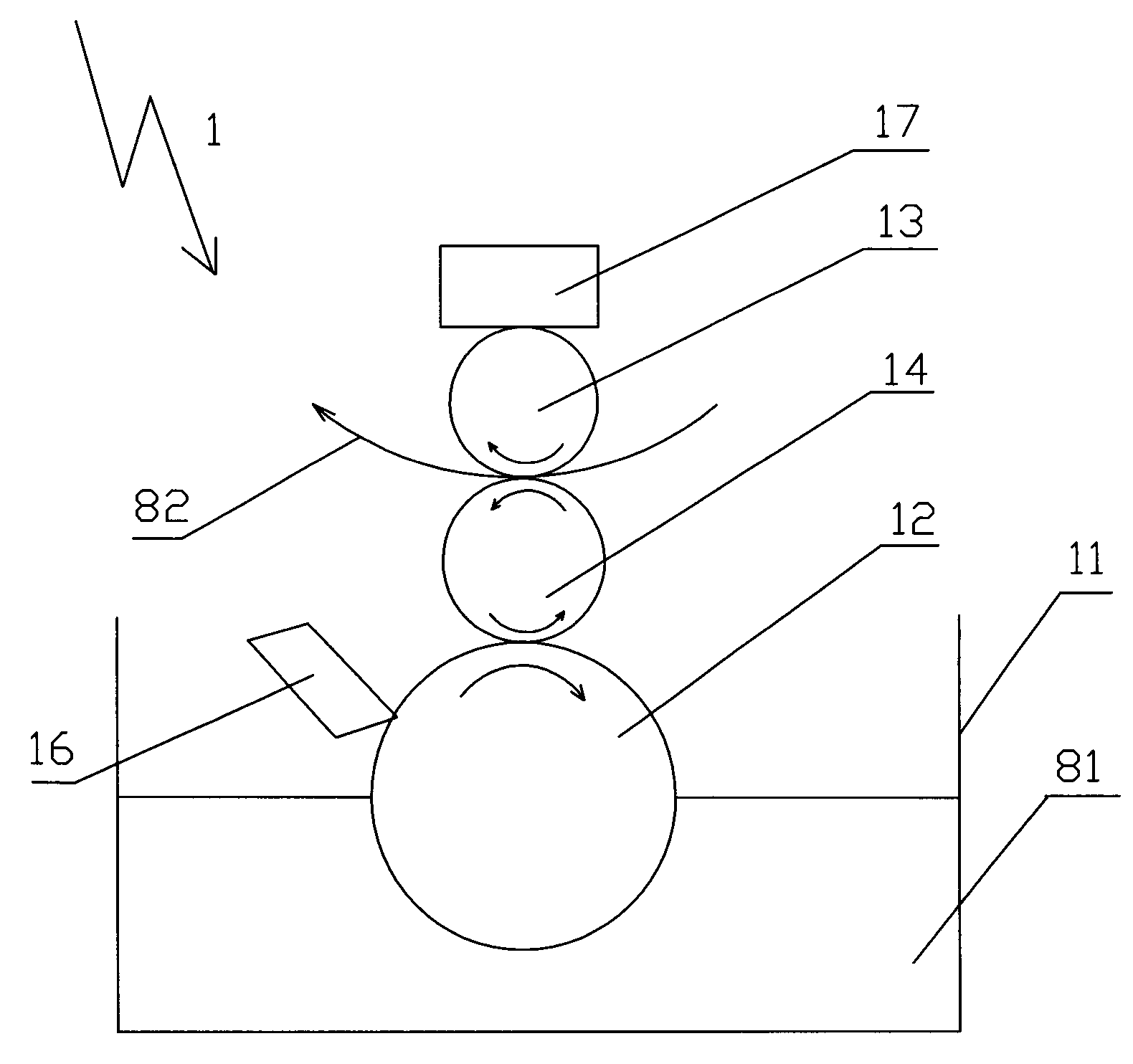

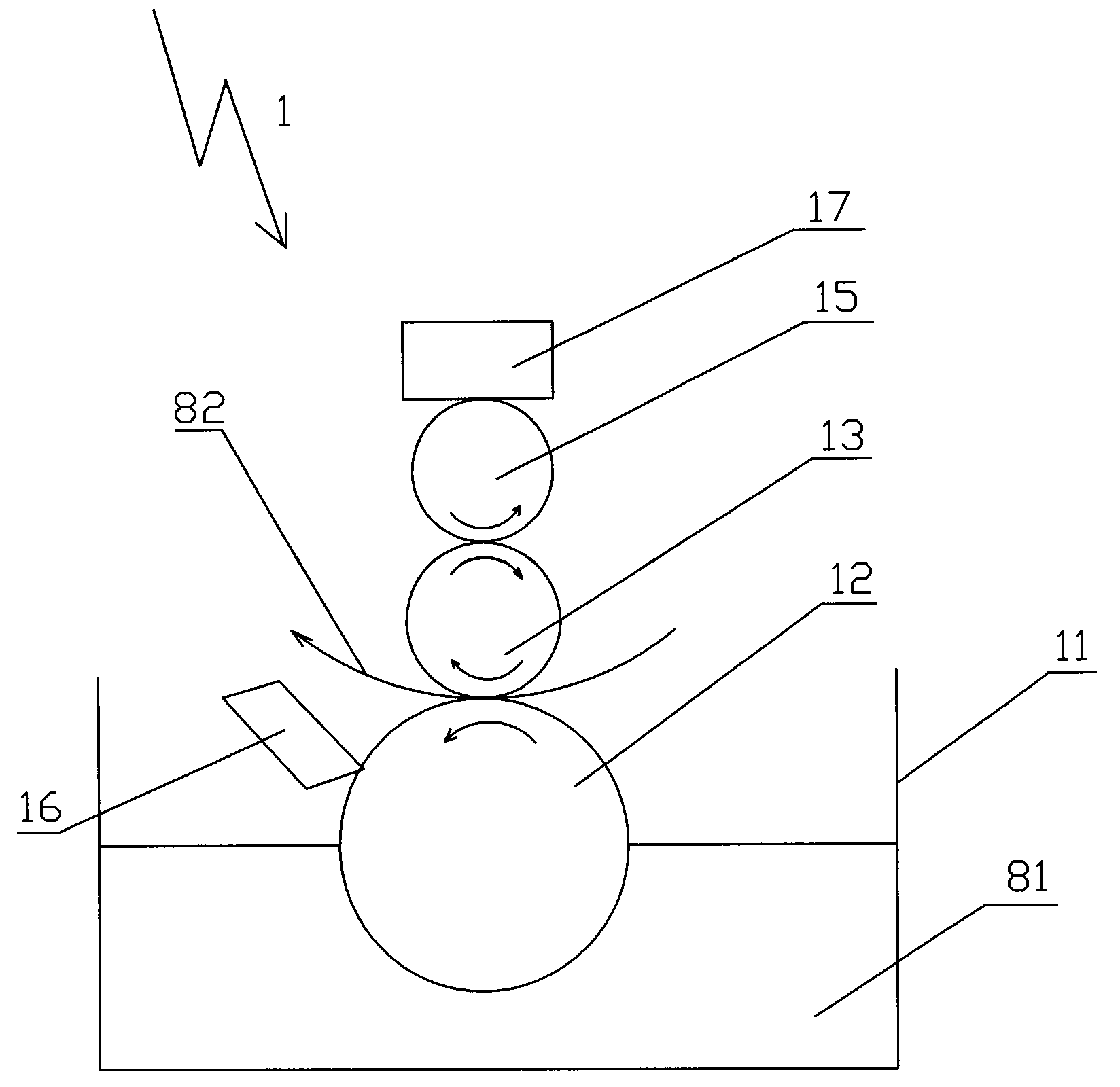

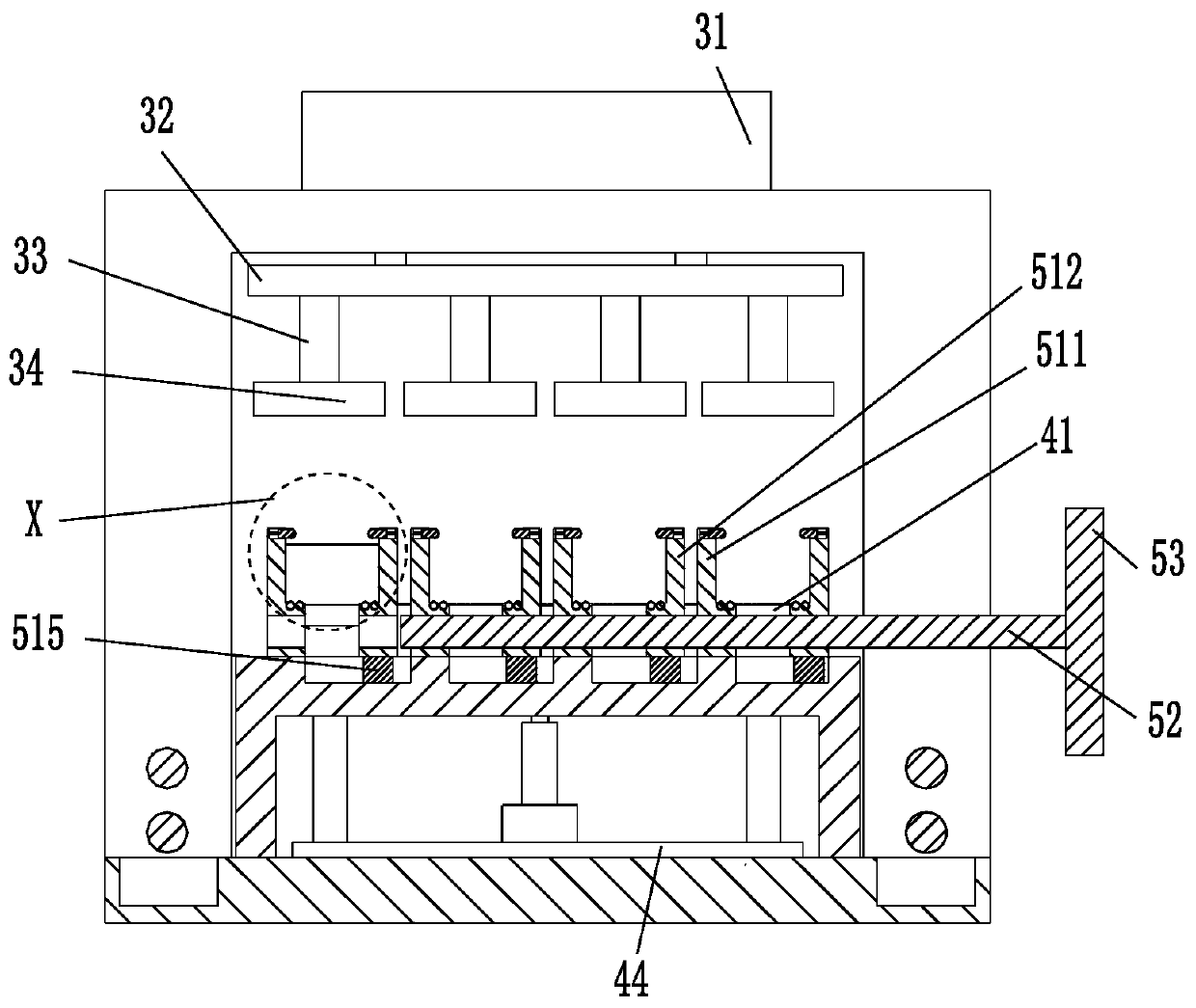

The invention relates to an apparatus for producing a reflective membrane with a microprism array structure and solves the defects in the prior art that the hardness, scratch resistance, heat resistance and solvent resistance of microprisms are disappointing, the product consistency is poorer, the production speed is lower, the work efficiency is not high, and the like. The apparatus comprises anannular strip-shaped mould, a heating membrane pressing device and a cooling device, wherein the annular strip-shaped mould is provided with an inner surface and an outer surface which is provided with a convex continuous precise microprism array structure. The apparatus also comprises a coating device, a drying device and a UV curing device. By adding the coating device, the drying device and theUV curing device, the microprism structure is formed after the UV curing of photosensitive resin, the hardness, scratch resistance, heat resistance and solvent resistance of microprism of the microprism structure are greatly improved, and the product consistency is fine. In addition, the apparatus can also obviously improve the production speed and the work efficiency.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

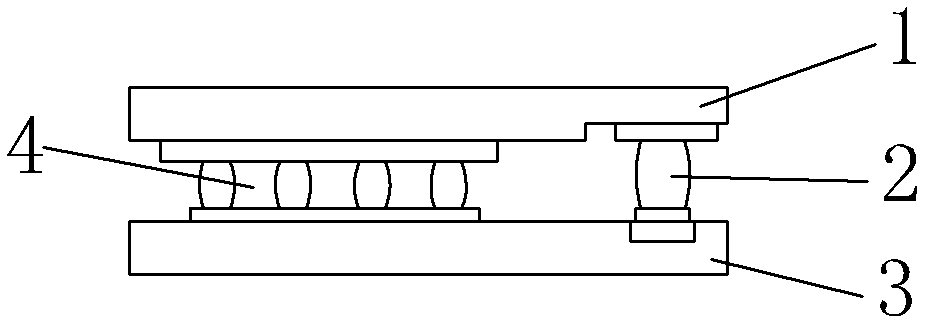

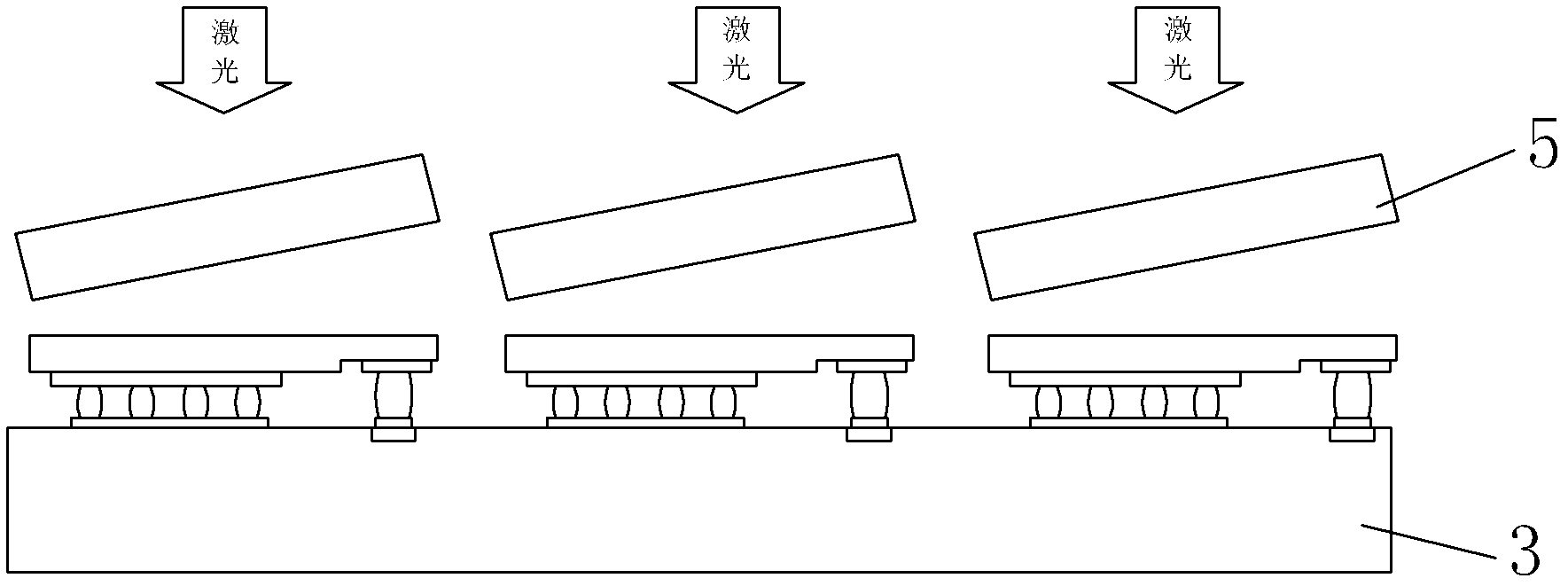

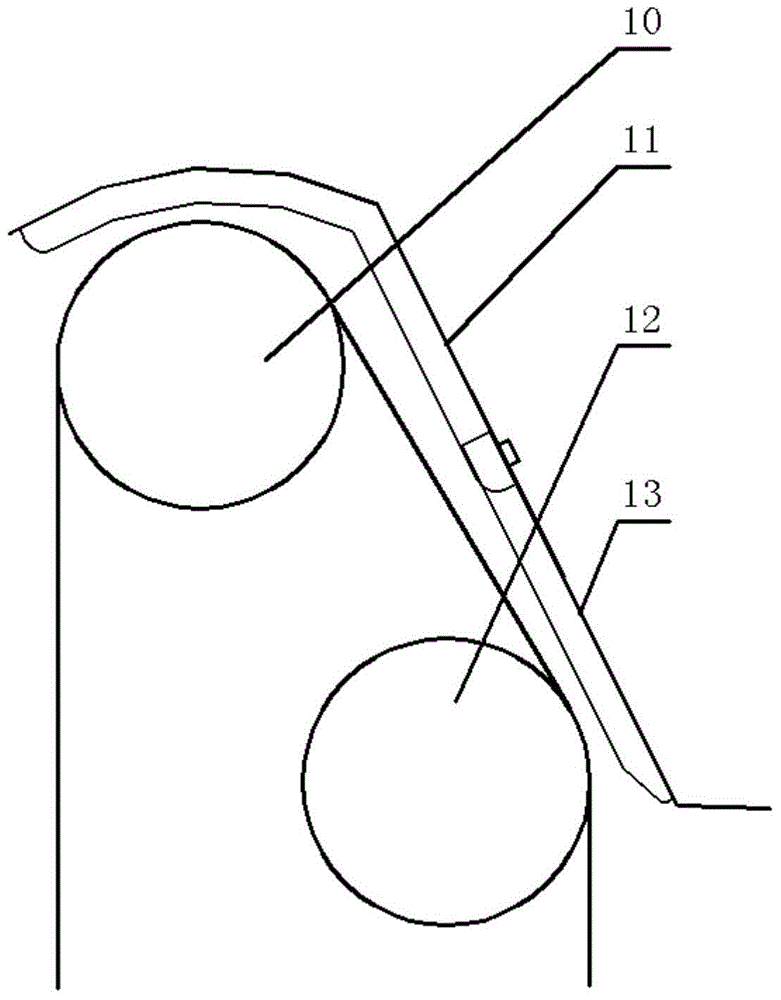

Method for producing reflective film with microprism array structure

ActiveCN101561523AHigh hardnessImprove scratch resistancePhotomechanical apparatusOptical elementsLight irradiationBand shape

The invention relates to a method for producing a reflective film with a microprism array structure. The invention overcomes the defects of poor hardness, scratch resistance, thermal resistance and solvent resistance of a microprism, poor product consistency, low production speed, low working efficiency and the like existing in the prior art. The invention adopts an endless belt-shaped mould of which a protruded continuous precise microprism array structure is arranged on the outer surface and comprises the following production steps that: a resin film is coated with photosensitive resin and then subjected to drying, heated film pressure and quickly solidification by UV light irradiation, so that the resin film coated with the photosensitive resin and the microprism structure on the photosensitive resin layer jointly form a laminated film, and the laminated film is cooled to obtain the reflective film with the microprism array structure. The method has the advantages of simple and convenient operation, high production speed and high working efficiency; and the formed microprism has the advantages of better hardness, scratch resistance, thermal resistance and solvent resistance, and good product consistency.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

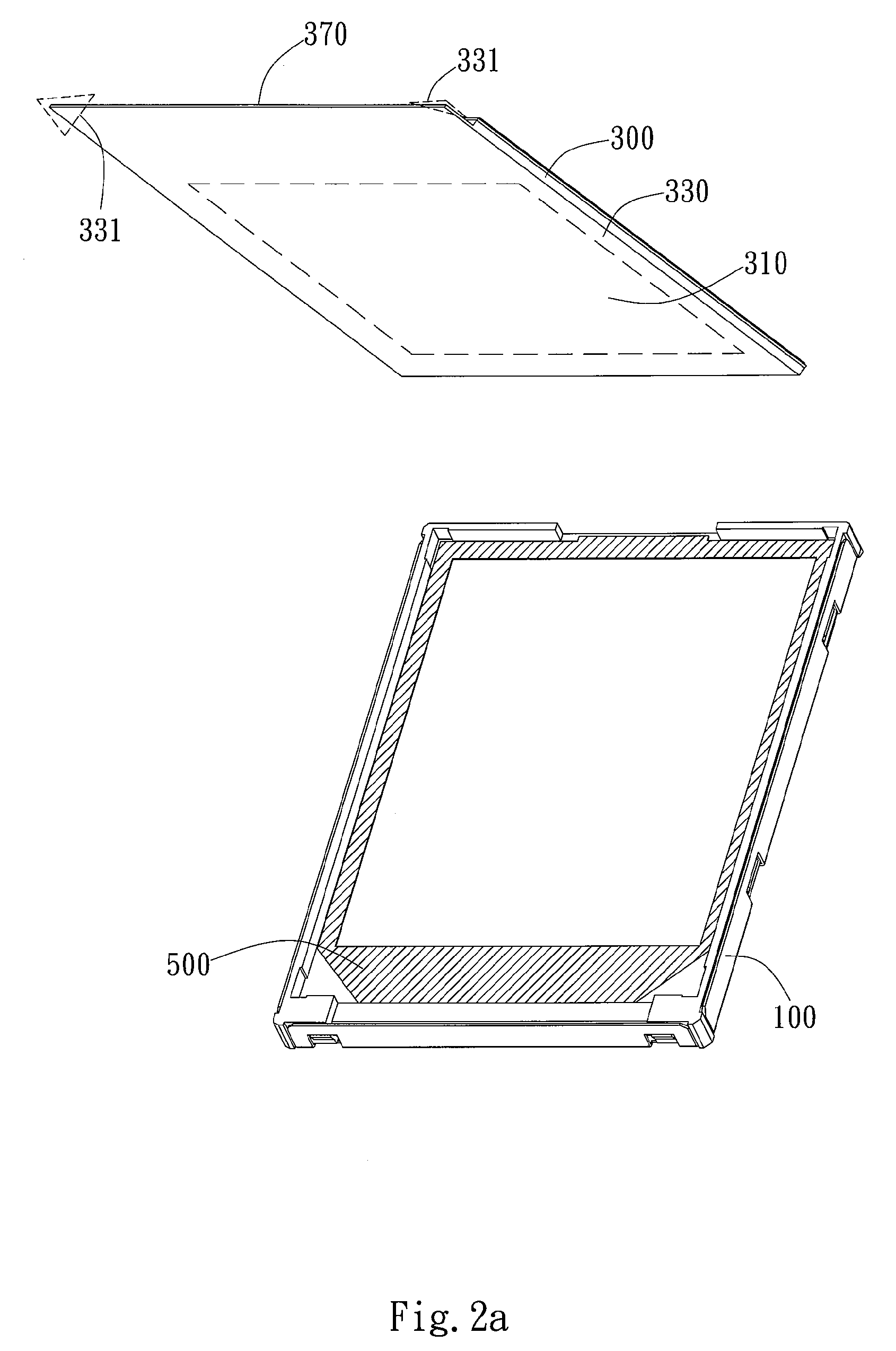

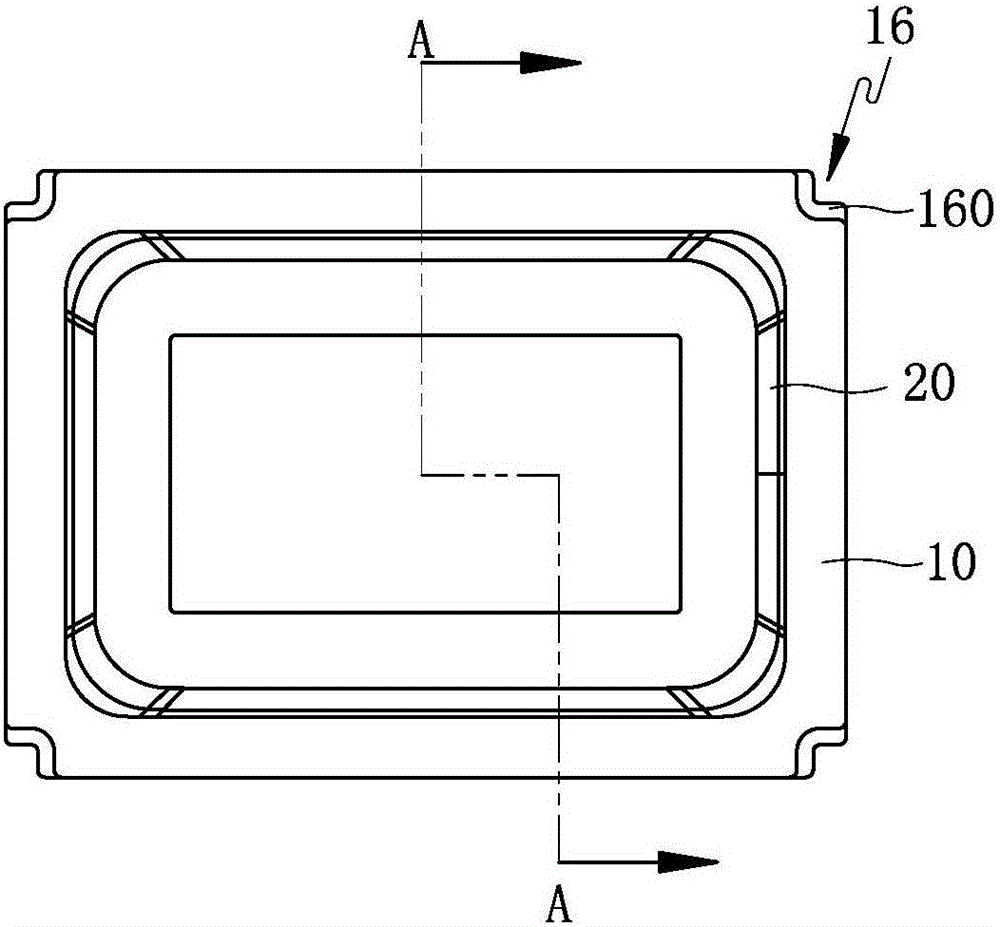

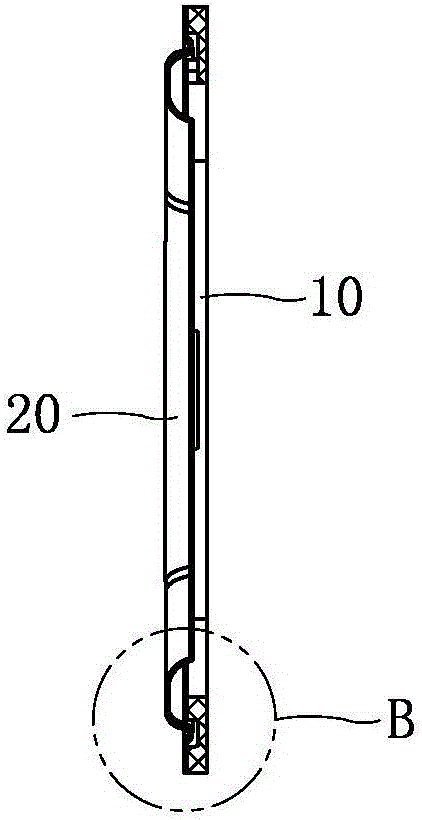

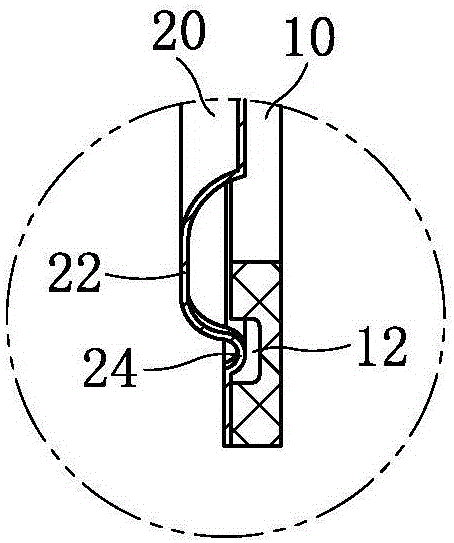

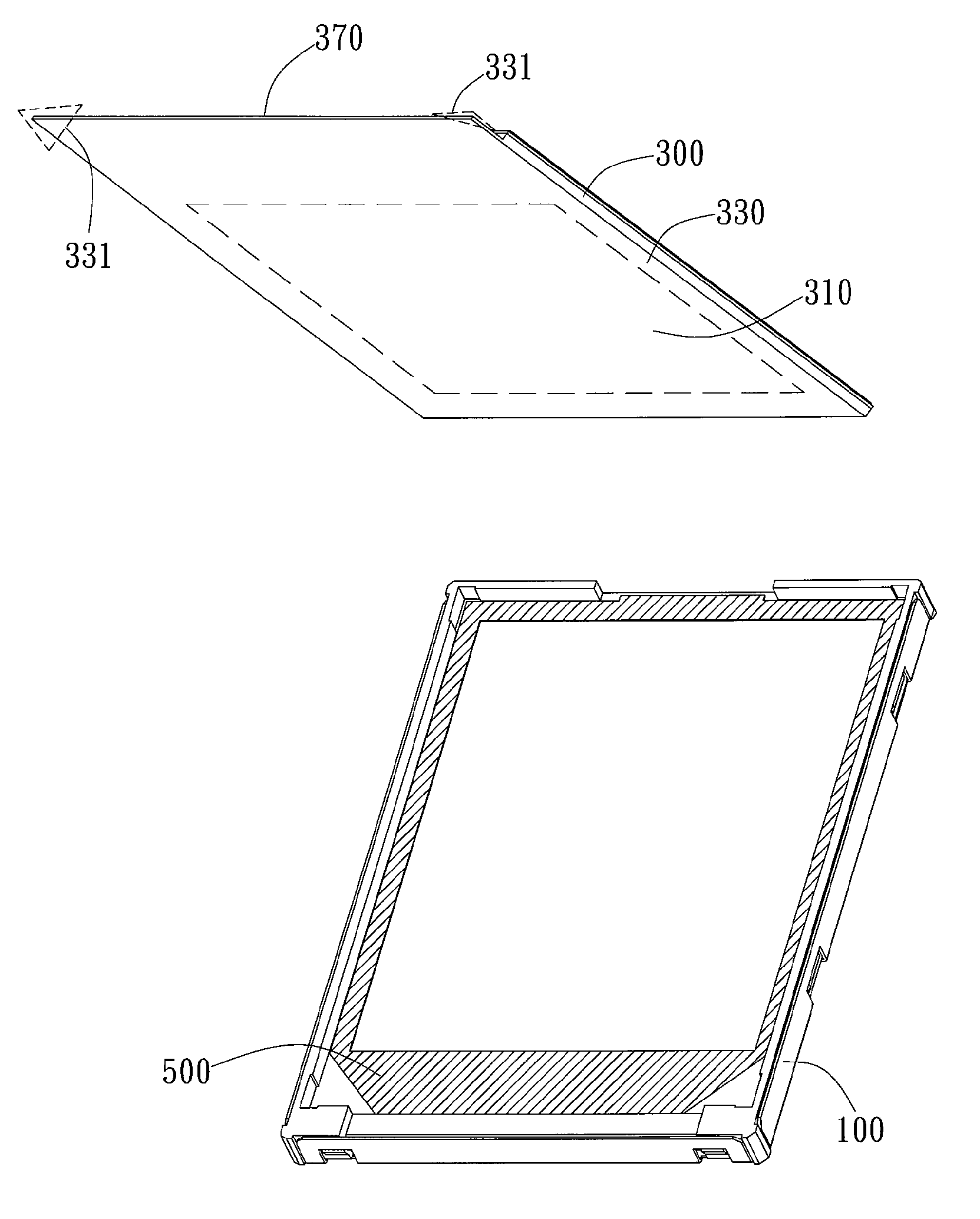

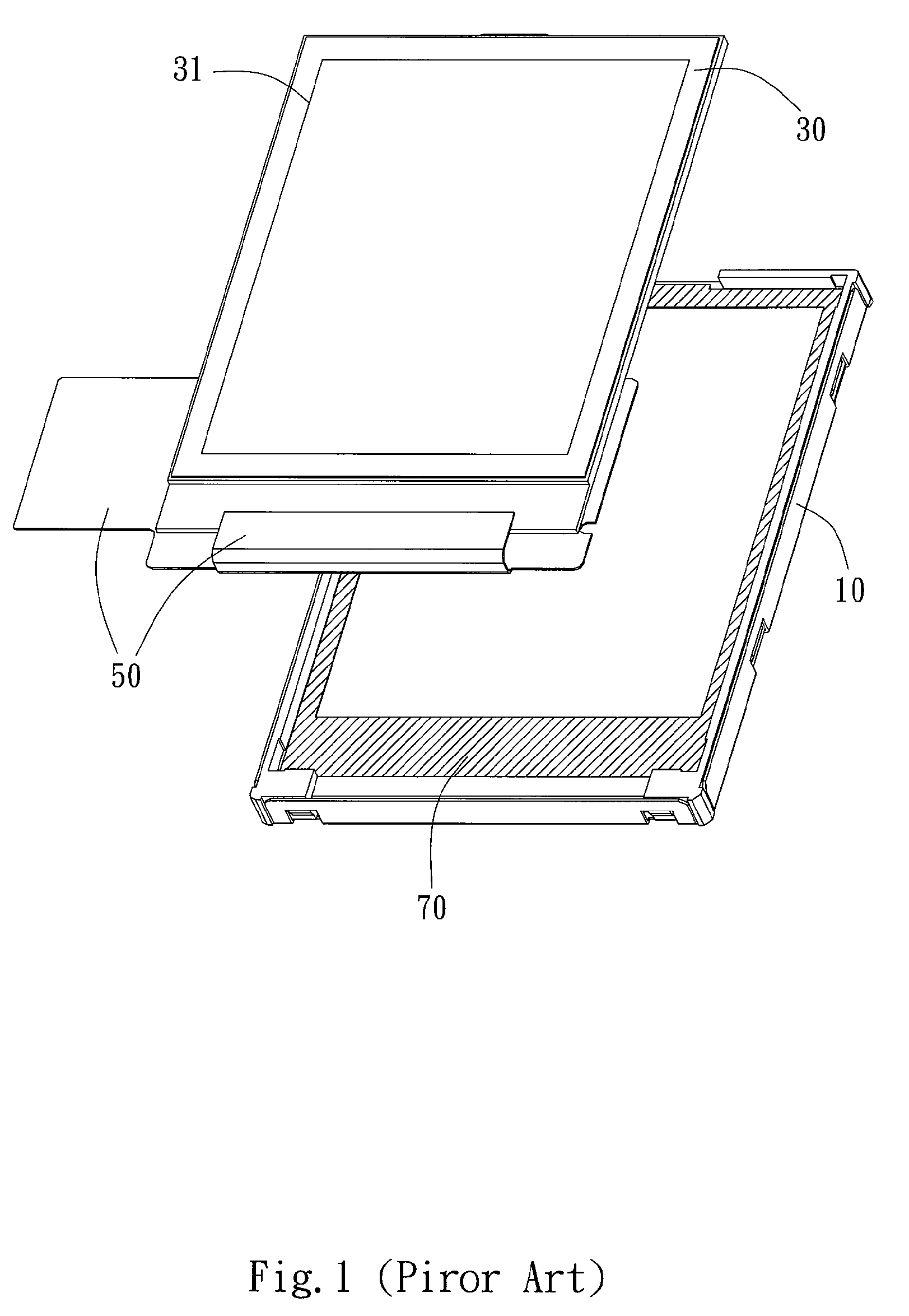

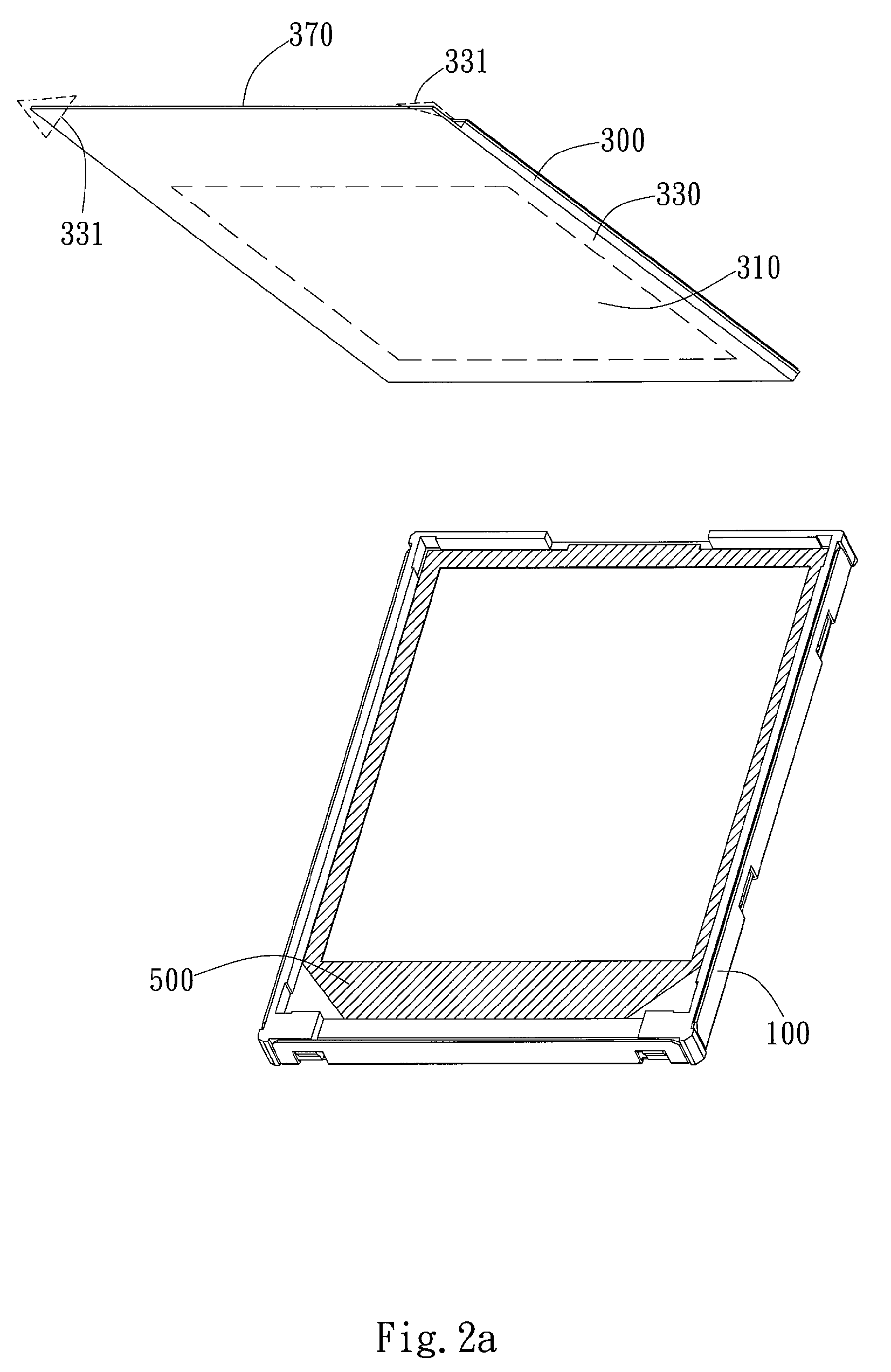

Display Device with Shielding Adhesive Layer and a Method for Manufacturing Thereof

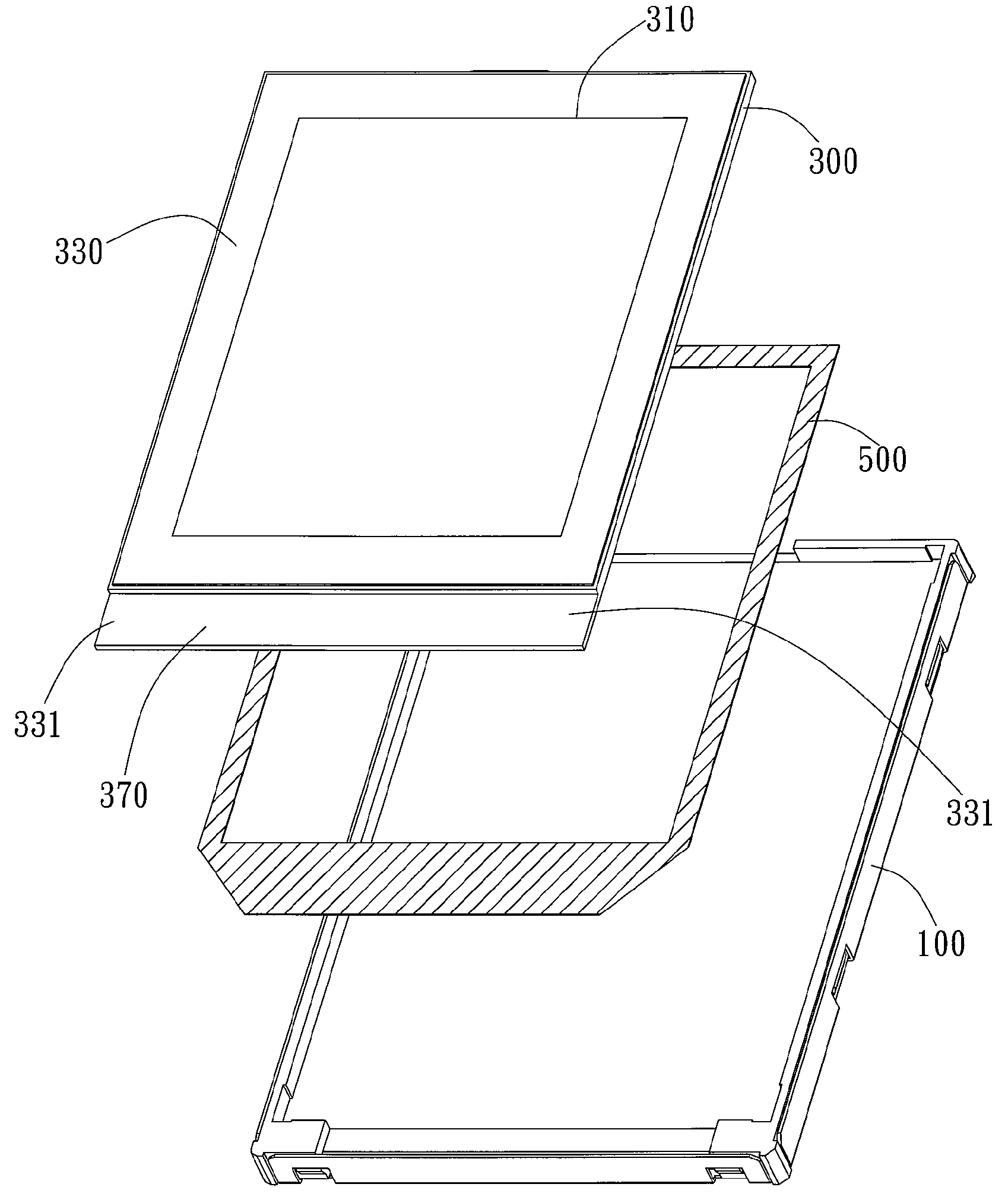

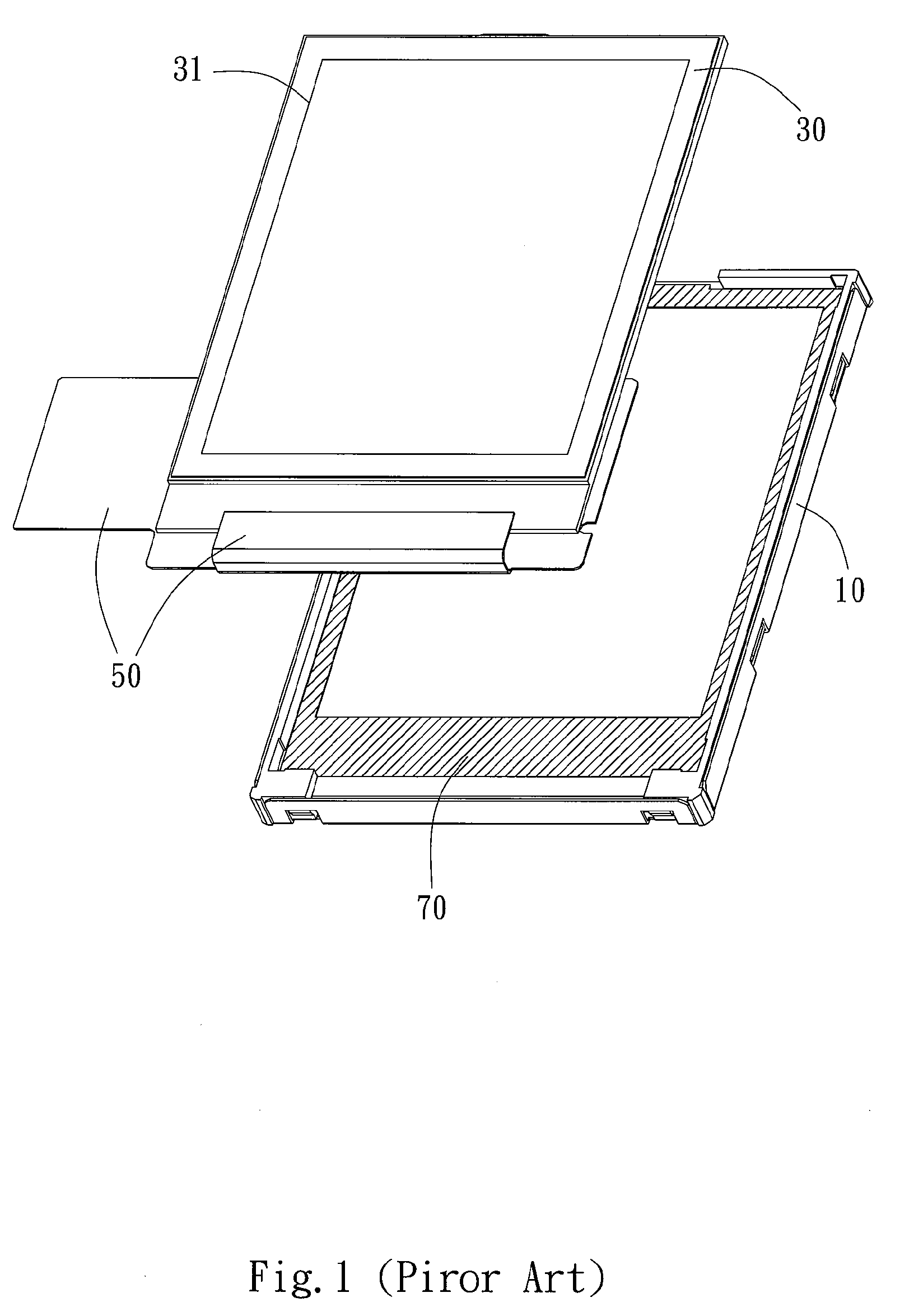

ActiveUS20090021679A1Reduce chance of deformationReduce the chance of deformationNon-linear opticsEngineeringDisplay device

A display device and a manufacture method thereof are provided. The display device includes a base, a display panel, and a shielding adhesive layer. The display panel is disposed on the base. The display panel includes an active area and a border area encolosing the active area, wherein the border area has a corner portion. The shielding adhesive layer is disposed between the base and the display panel and distributed on the border area. The shielding adhesive layer does not extend to the corner portion and therefore directly exposes the corner portion to the base.

Owner:AU OPTRONICS CORP

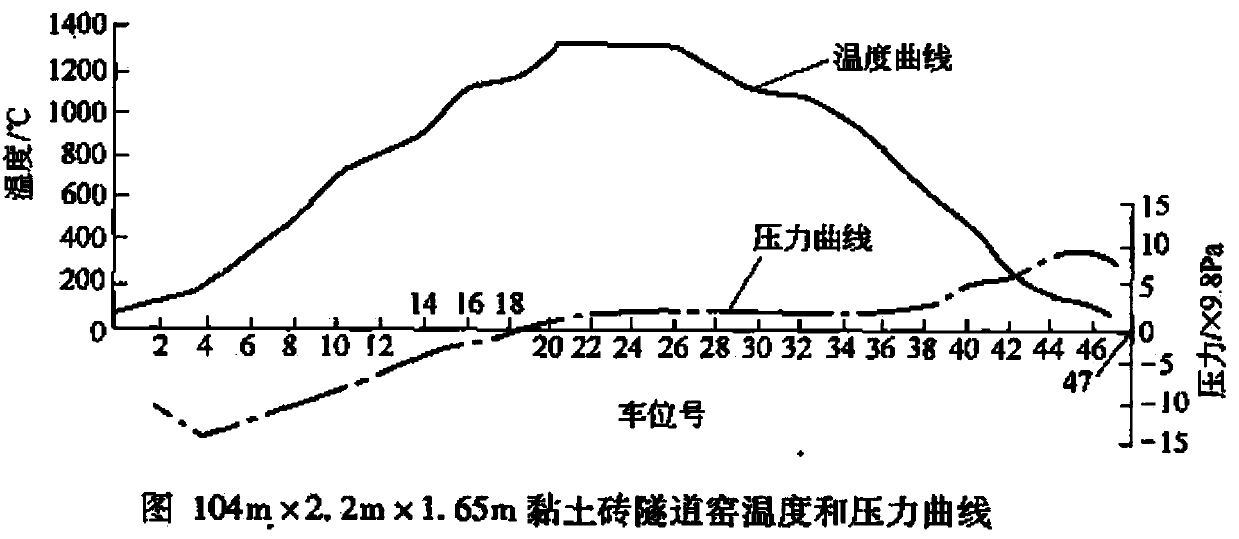

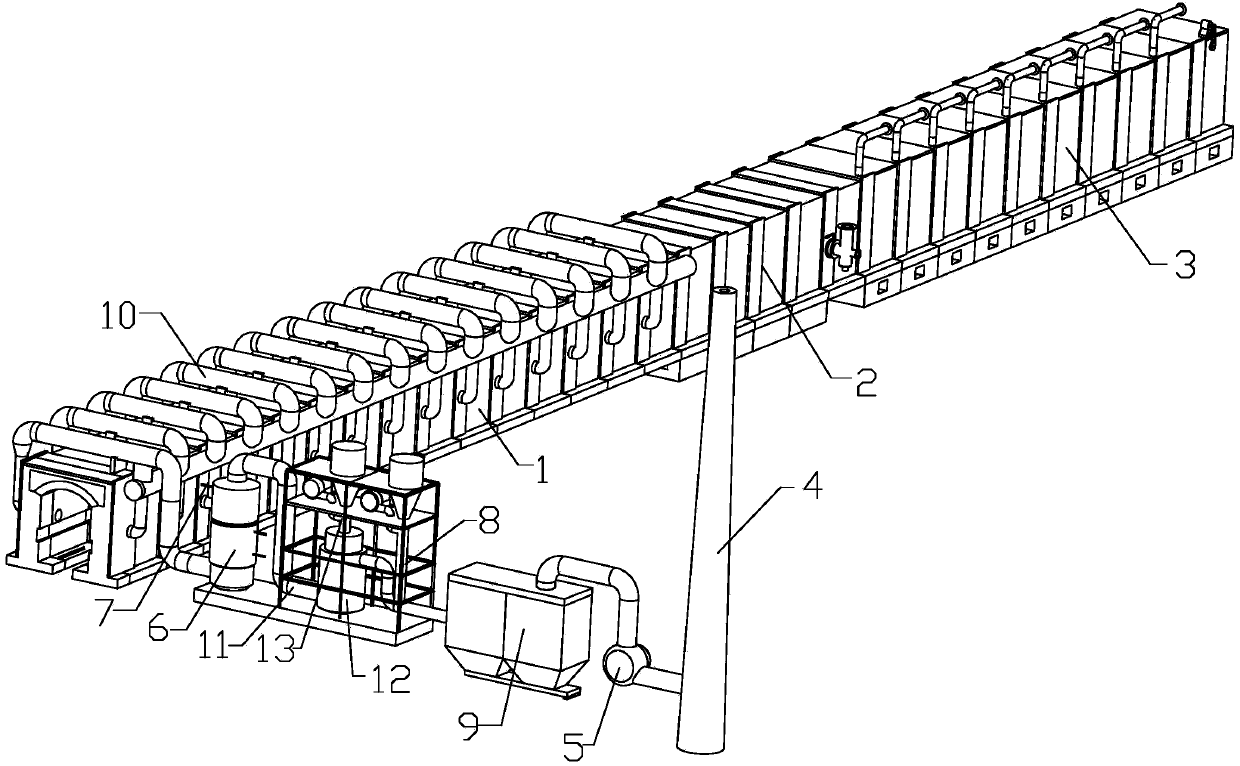

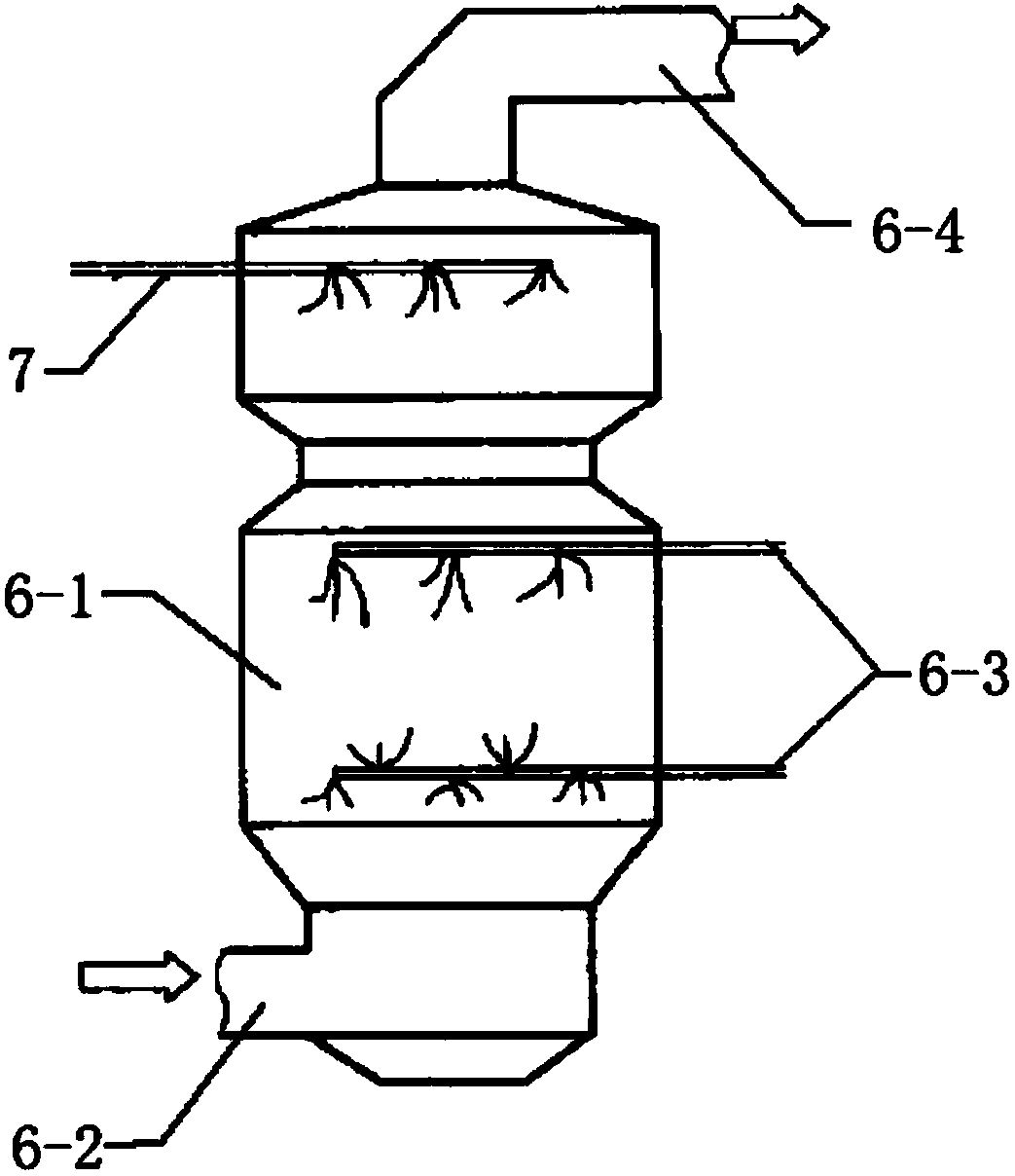

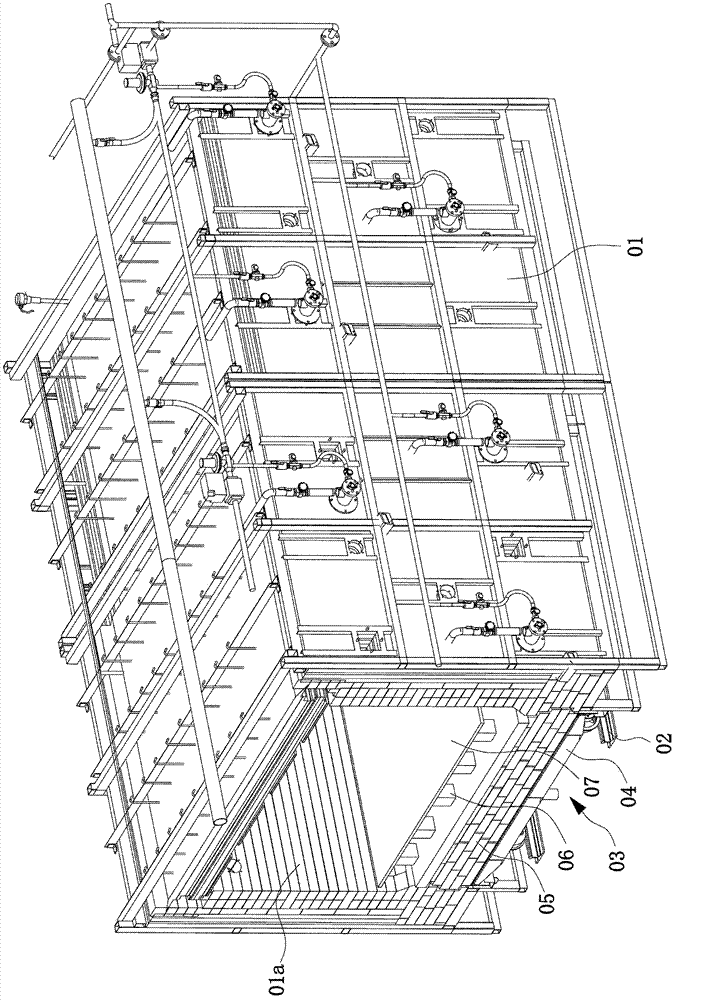

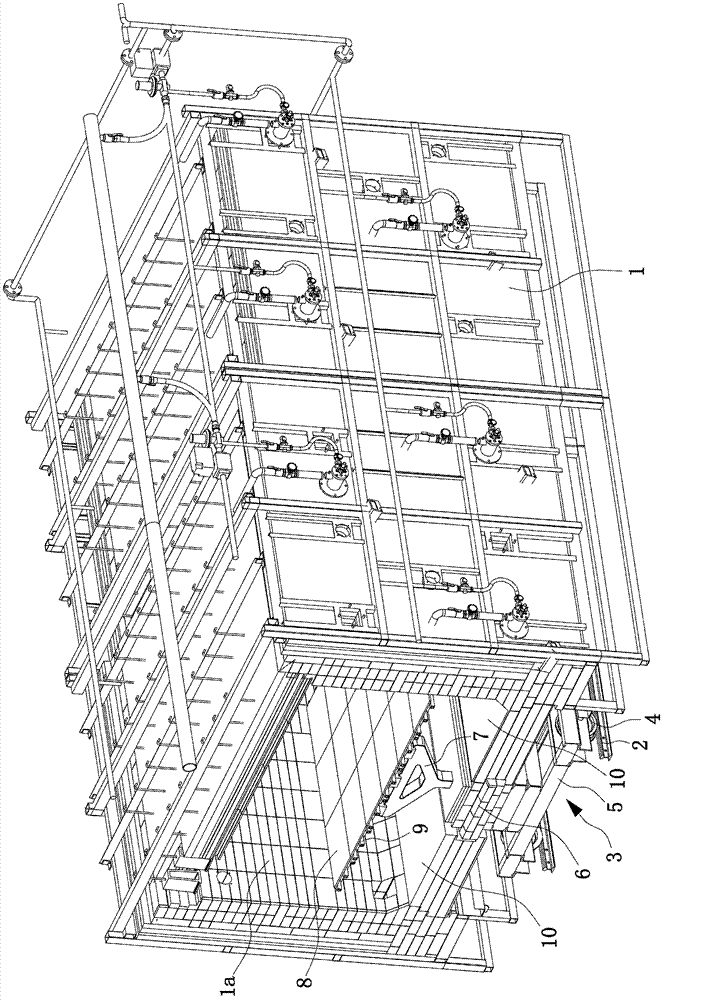

Novel tunnel kiln structure and method for tunnel kiln to process organic polluted soil

ActiveCN104197702ASpeed up temperature riseImprove smoke exhaust effectFurnace typesCeramic materials productionTunnel kilnBrick

The invention provides a novel tunnel kiln structure and a method for processing organic polluted soil. The method comprises the steps of detecting types and contents of mineral substances in the organic polluted soil, then adding required materials according to the tile firing requirements or the firing requirements, adding internal fuel, adding water to mix the materials to obtain raw pug materials, sequentially pugging, pelletizing, extruding and forming the raw pug materials, decaying or curing the raw pug materials for 5-10 days, drying the raw pug materials, sending the raw pug material into the tunnel kiln to be fired, sequentially keeping green bricks or green tiles in a preheating zone kiln body at the temperature of 150-750 DEG C for 30 minutes to 1 hour and in a firing zone kiln body at the temperature of 750-1350 DEG C for 2-3 hours, then sending the green bricks or the green tiles into a cooling zone kiln body to be naturally cooled to the normal temperature and outputting the green bricks or the green tiles. The method can completely remove toxic substances like various pesticide residues in the soil through high temperature and is high in processing efficiency, low in cost, free of secondary pollution and obvious in environmental-friendly benefit.

Owner:WUHAN HUIZHONG DACHUAN AUTOMATIC CONTROL EQUIP CO LTD

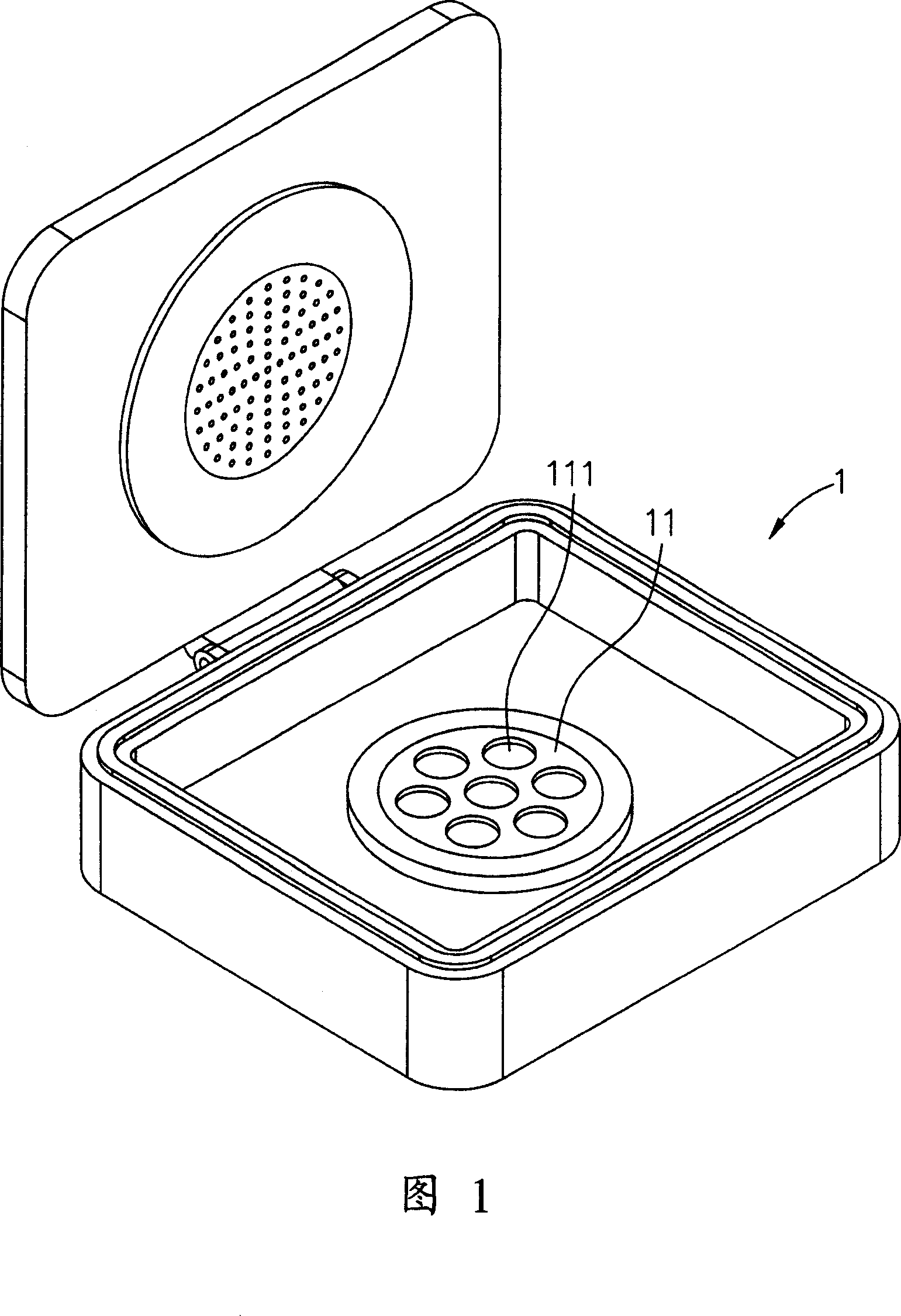

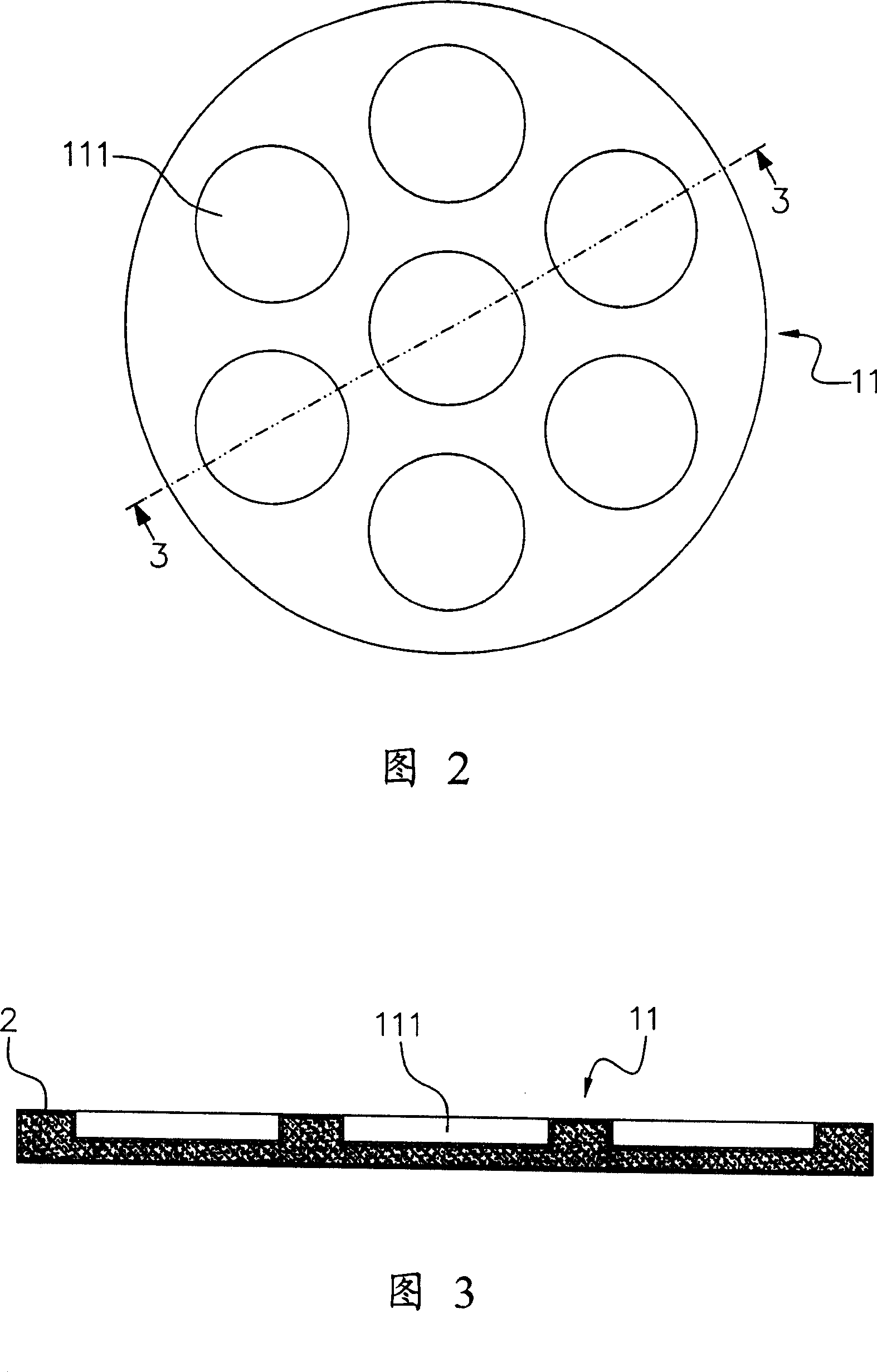

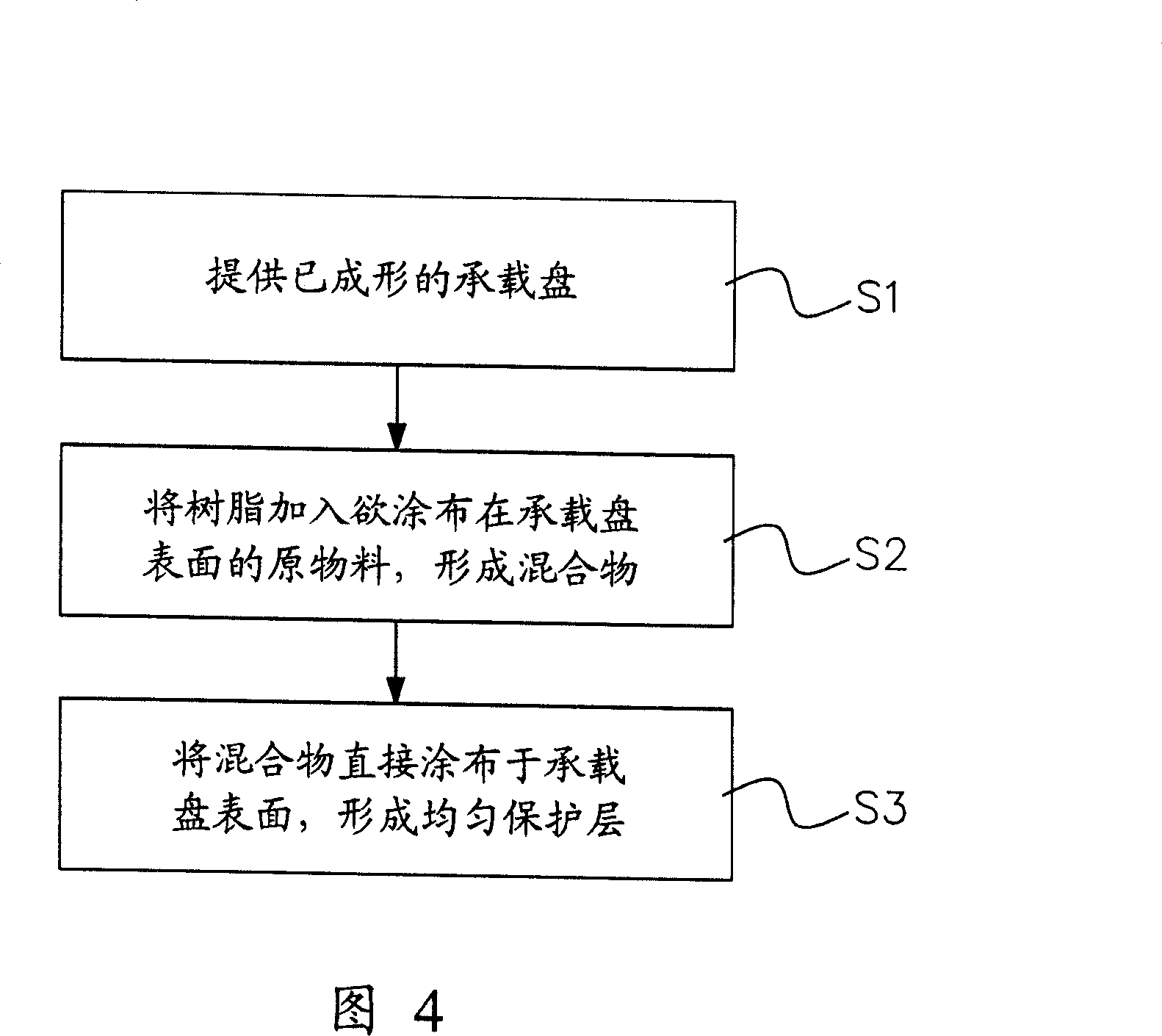

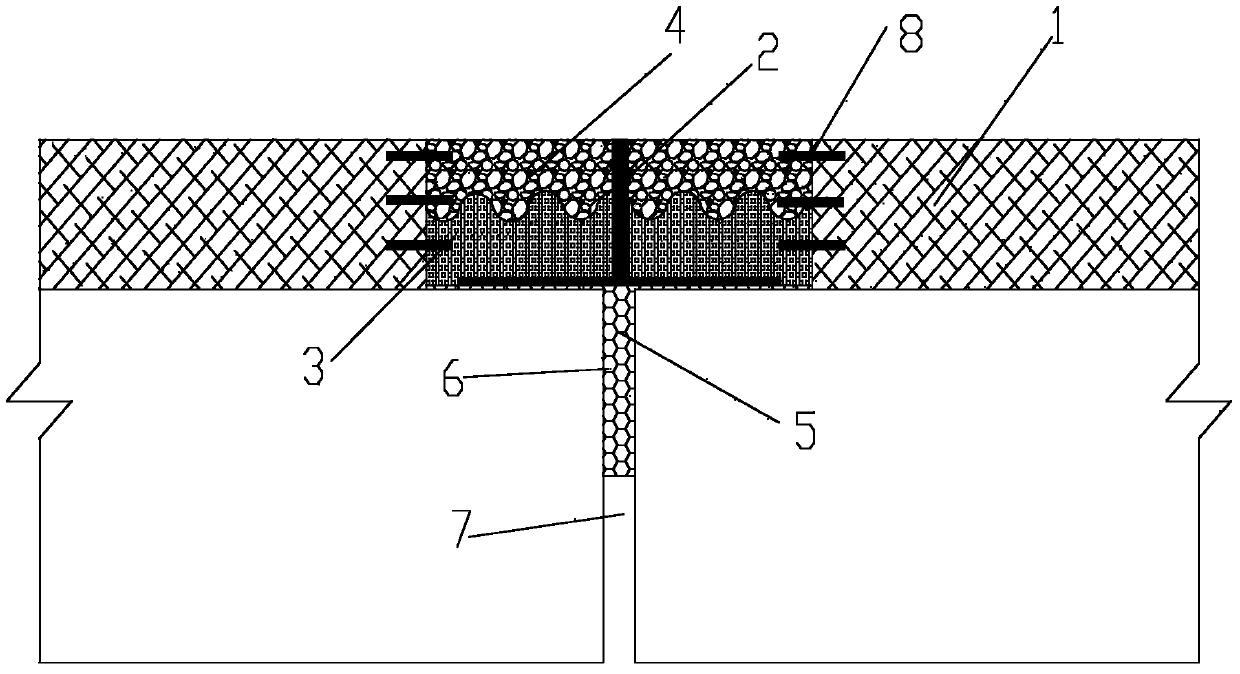

Method for producing chip-bearing disc protective layer

InactiveCN101024213AReduce flakingReduce the chance of deformationSemiconductor/solid-state device manufacturingPretreated surfacesEpoxySoaking Procedure

The invention relates to a wafer loading disk protective layer manufacturing method. The loading wafers go along wafer manufacturing and washing process in the plant response room, improve the corrosion resistance of the loading disk, of which mainly supplies a wafer loading disk with the main material, the capacity space for containing the loading wafer installed on the front face of the loading disk, and then adding a heat resistant epoxy resin into SiC of the loading surface into a mixture, through soaking procedures to cover the mixture directly on the disk outer surface, the formation of uniform procedures baking protective layer to reduce the load disk surface spalling or deformation opportunities.

Owner:陈国栋

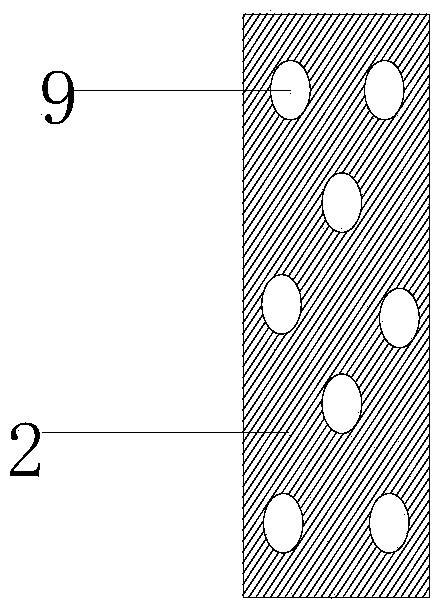

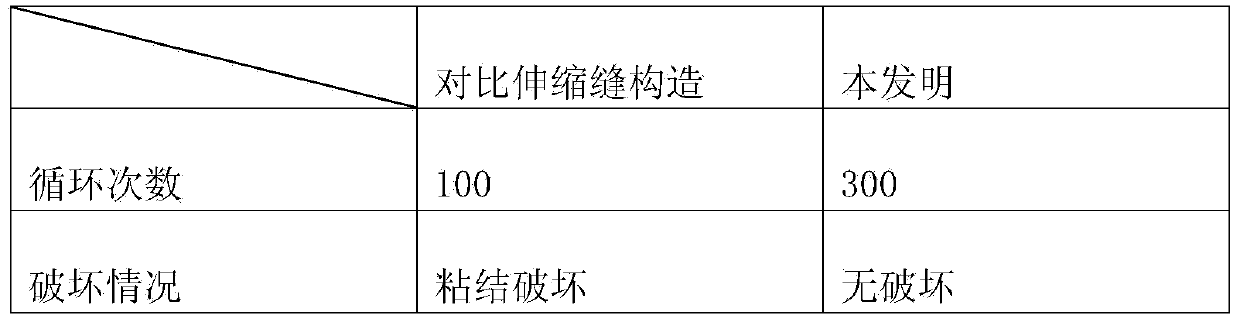

Road and bridge expansion joint structure

InactiveCN103669202AEasy constructionReasonable designBridge structural detailsStress conditionsIn vehicle

The invention discloses a road and bridge expansion joint structure. The road and bridge expansion joint structure comprises an inverted-T-shaped plate component with the bridge longitudinal cross section being in an inverted T shape. Two wing plates of the inverted-T-shaped plate component transversely extend into a base body of a bridge pavement layer. A web extends upwards to be flush with the upper surface of the bridge pavement layer. Each wing plate is sequentially provided with a cushion layer and a protection wear-resisting layer from bottom to top in a laying mode and is longitudinally connected with the bridge pavement layer. An expansion joint notch and the two sides of the expansion joint notch are filled with elastic layers to be sealed. The road and bridge expansion joint structure has the advantages of being convenient to construct, reasonable in design, high in efficiency, good in vehicle load bearing performance, good in elasticity, smooth and attractive in surface, and good in waterproofing, anti-aging, anti-fatigue, shock resistance and corrosion resistance. In accordance with the characteristics of an expansion joint, three materials of different components and matching ratios are adopted, layered pavement is conducted according to different stress conditions and states, good durability is achieved, construction is rapid and simple, and the expansion joint performance requirement can be well met.

Owner:孟献春

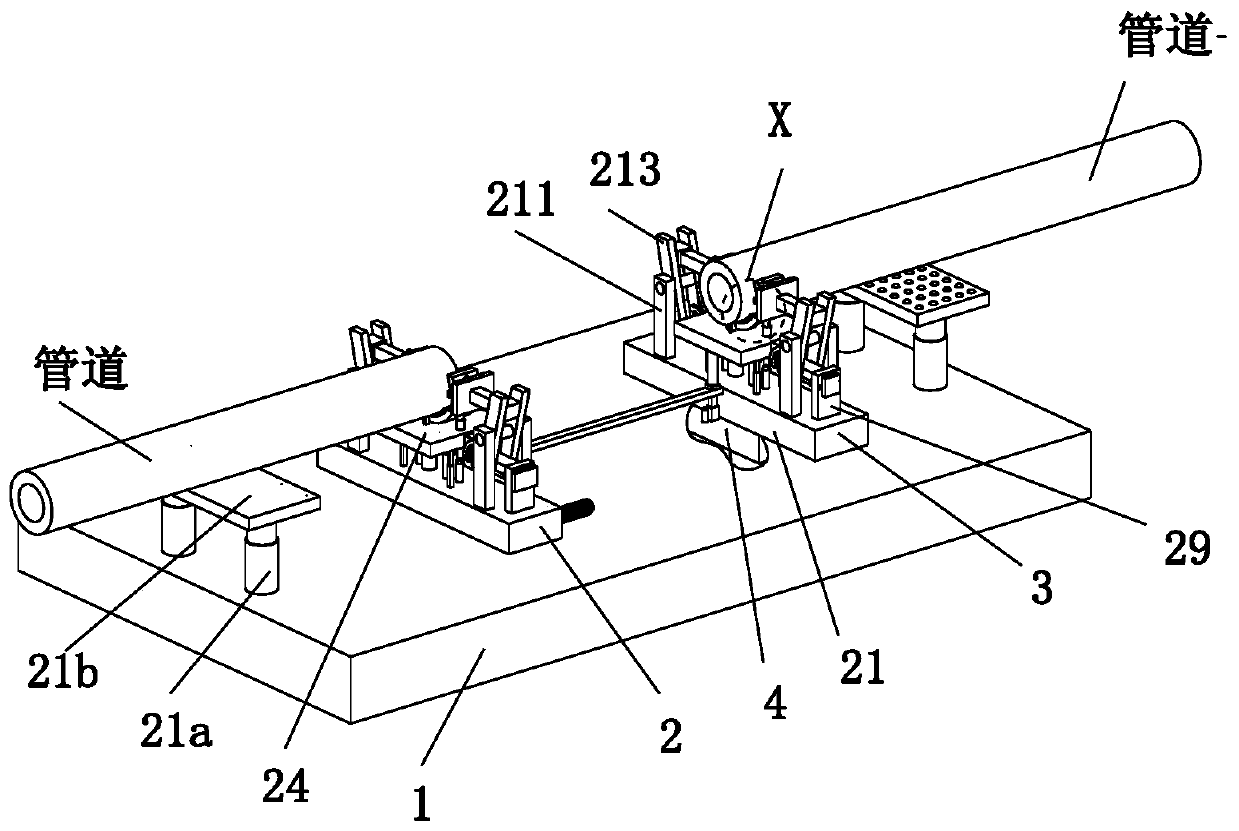

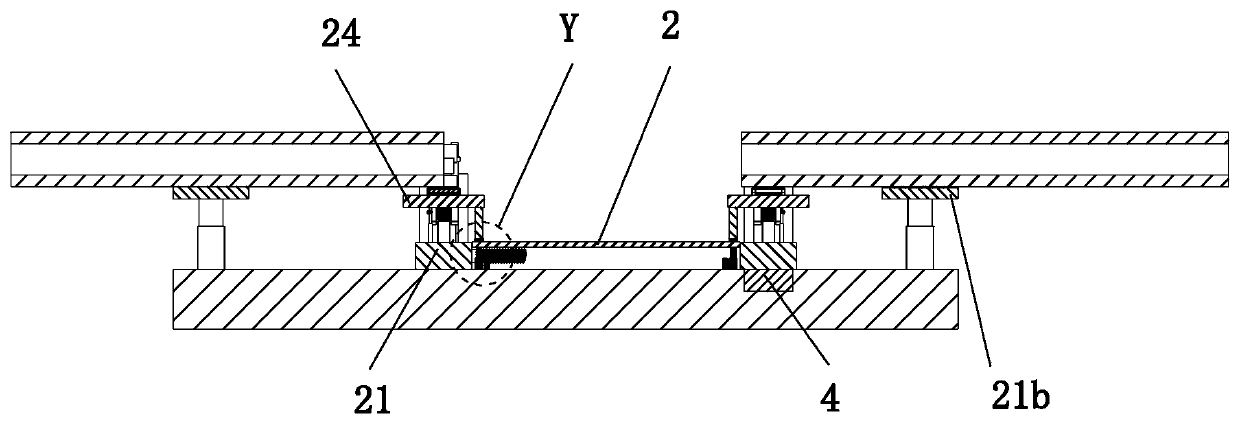

Oil and natural gas pipeline erection construction method

ActiveCN111336317AImprove the stabilityHigh precisionPipe laying and repairStructural engineeringOil and natural gas

The invention relates to an oil and natural gas pipeline erection construction method, and uses an oil and natural gas pipeline erection construction device. The oil and natural gas pipeline erectionconstruction device comprises a work truck, a first clamping mechanism, a second clamping mechanism and an electric sliding block, the first clamping mechanism is installed at the left end of the upper end surface of the working truck, the second clamping mechanism is arranged on the right side of the first clamping mechanism, and the electric sliding block is installed at the lower end of the second clamping mechanism and installed at the upper end of the working truck through a sliding matching manner. According to the oil and natural gas pipeline erection construction device, the design concept of an adjustable clamping structure is adopted to carry out the erection construction of oil and natural gas pipelines, the oil and natural gas pipeline erection construction device can conduct installation of a single pipeline and docking of two pipelines simultaneously, a plurality of horizontal test control structures are arranged to conduct horizontal calibration in the process of singlepipeline installation and two pipeline docking, and the overall stability of the pipeline and the accuracy of two pipeline docking are improved accordingly.

Owner:金华馨菲科技有限公司

Automobile nut plate part die

InactiveCN103182440AReduce equipmentReduce in quantityShaping toolsEngineeringMechanical engineering

Owner:SHANGHAI ZHONGDA AUTO PARTS

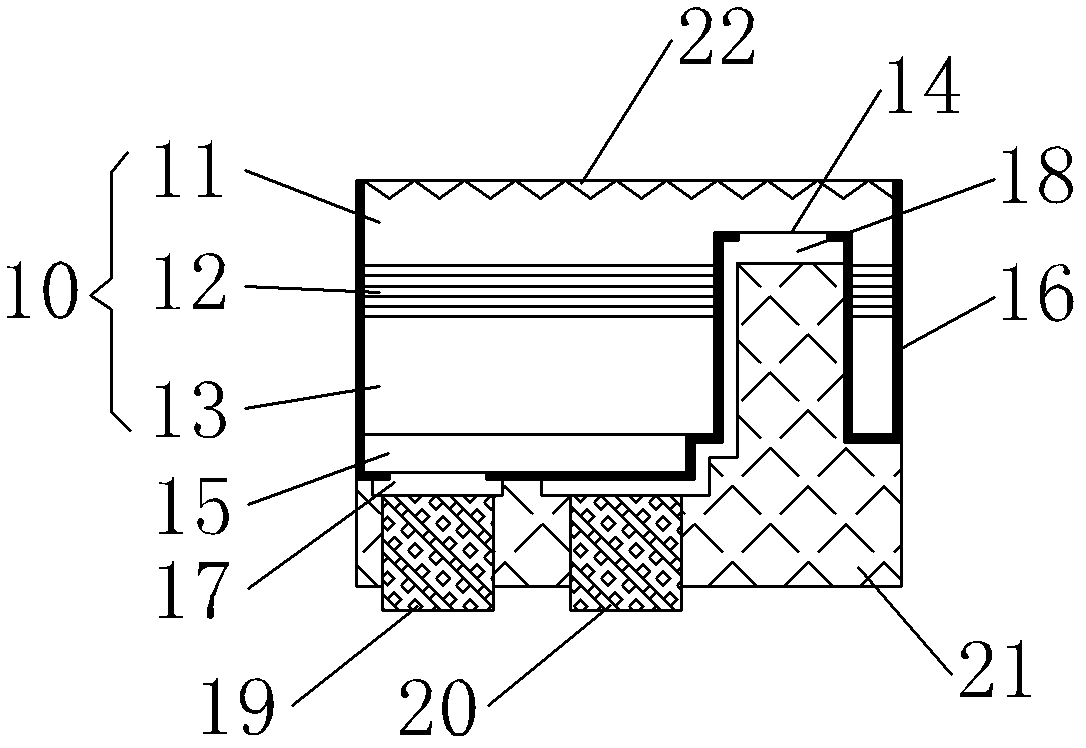

Film LED (light-emitting diode) chip device as well as manufacturing method and application thereof

ActiveCN102683517AReduce the probability of ruptureReduce the chance of deformationSemiconductor devicesFilm baseReflective layer

The invention provides a film LED (light-emitting diode) chip device, comprising a GaN-based epitaxial film base which is provided with an etching groove, and a fixed film which is coated on a GaN-based epitaxial film, wherein a metal reflection layer is attached to the surface of the P-shaped semiconductor layer of the GaN-based epitaxial film base, passive films are deposited on the metal reflection layer and the GaN-based epitaxial film base to form the GaN-based epitaxial film, the passive film on the surface of the metal reflection layer and the passive film on the bottom surface of the etching groove are respectively provided with a hollowed-out area, a P pole multilayer metal bonding layer and a N pole multilayer metal bonding layer are respectively arranged on the corresponding hollowed-out area, and a P pole conductive support thick metal layer and an N pole conductive support thick metal layer are respectively arranged on the P pole multilayer metal bonding layer and the N pole multilayer metal bonding layer. The invention also provides a manufacturing method and application of the film LED chip device. According to the invention, the occurrence rate of wafer fracture and the probability of wafer deformation in the subsequent laser stripping process are reduced, and the yield of products is improved.

Owner:ELEC TECH PHOTOELECTRIC TECH DALIAN

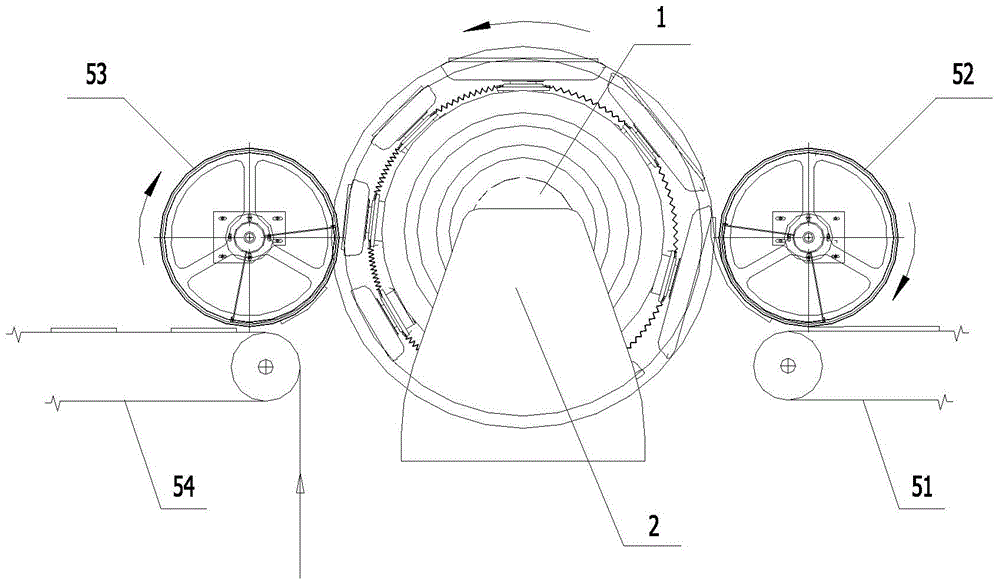

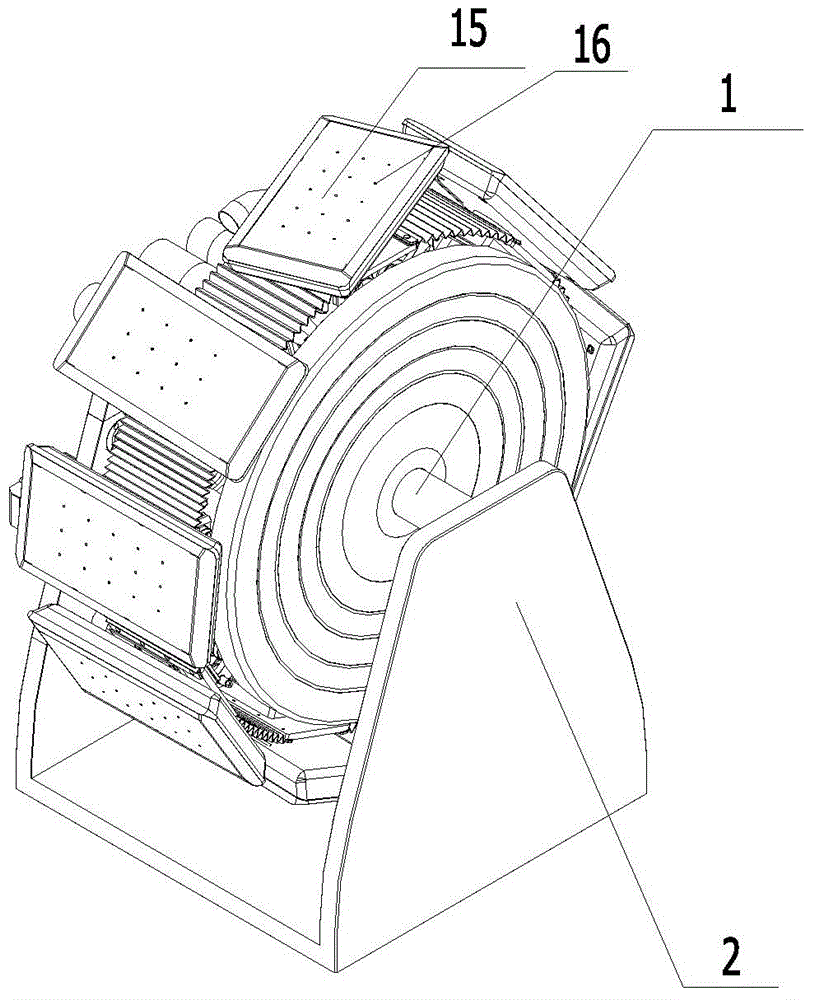

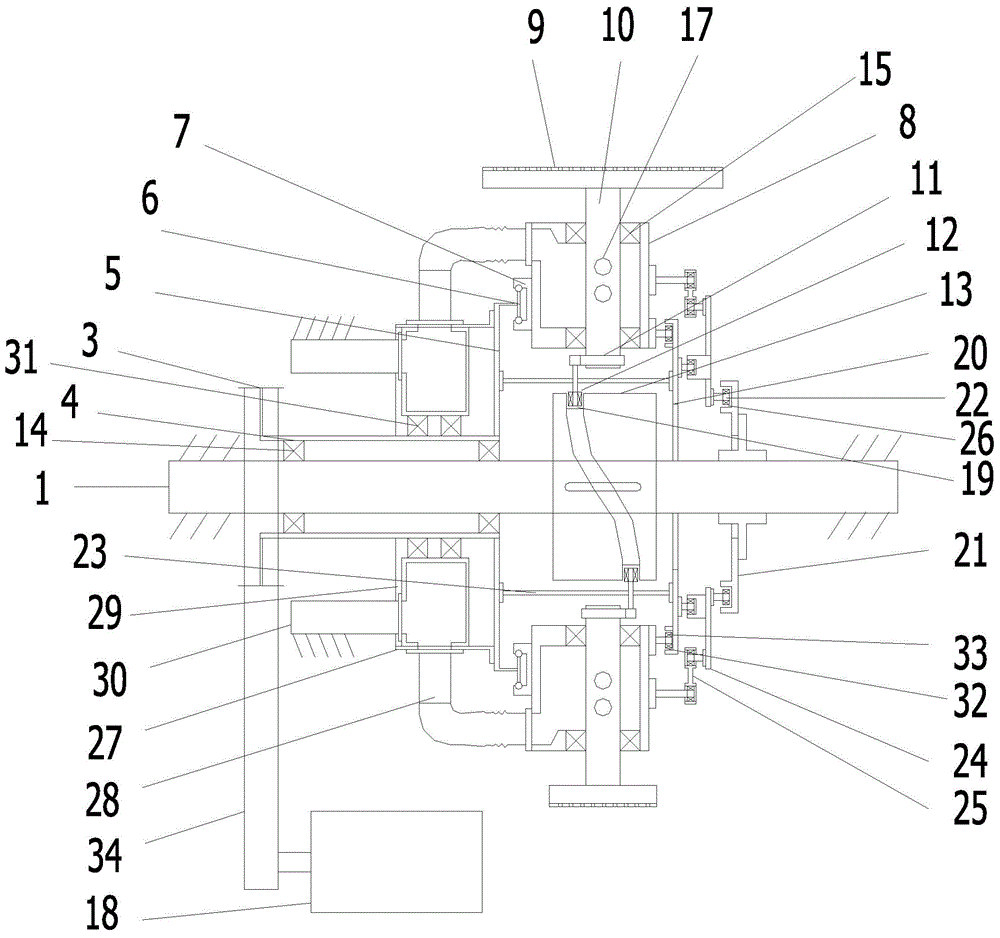

Reversing and pitch control assembly for hygienic products

ActiveCN105213110ATakes up little host spacePowerfulAbsorbent padsBaby linensCamDistribution function

The invention relates to a reversing and pitch control assembly for hygienic products, comprising a reversing mechanism, a pitch control mechanism and a gas distribution mechanism sleeving a spindle in order. The spindle is fixedly connected with a frame. The reversing mechanism comprises a power input wheel, a connecting shaft, a drive disc, an arc guide rail, a slider, a sucker seat, a sucker, a sucker shaft, a rocker, a first guide wheel and a cam disc fixed in the middle of the spindle. The pitch control mechanism comprises a rotating disc, an eccentric disc, a second guide wheel, a support rod, a rocker and a link. The gas distribution mechanism comprises a distribution disc, a distribution port, a negative pressure chamber and an intake port. The reversing, variable speed and gas distribution functions are integrated to a single device, thus the device uses little space of a main unit and has powerful functions and compact structure. By integrating the reversing mechanism and the pitch control mechanism, products are transferred among the suckers of different mechanisms fewer times and have a slimmer chance of deformation.

Owner:ANQING HENG CHANG MACHINERY

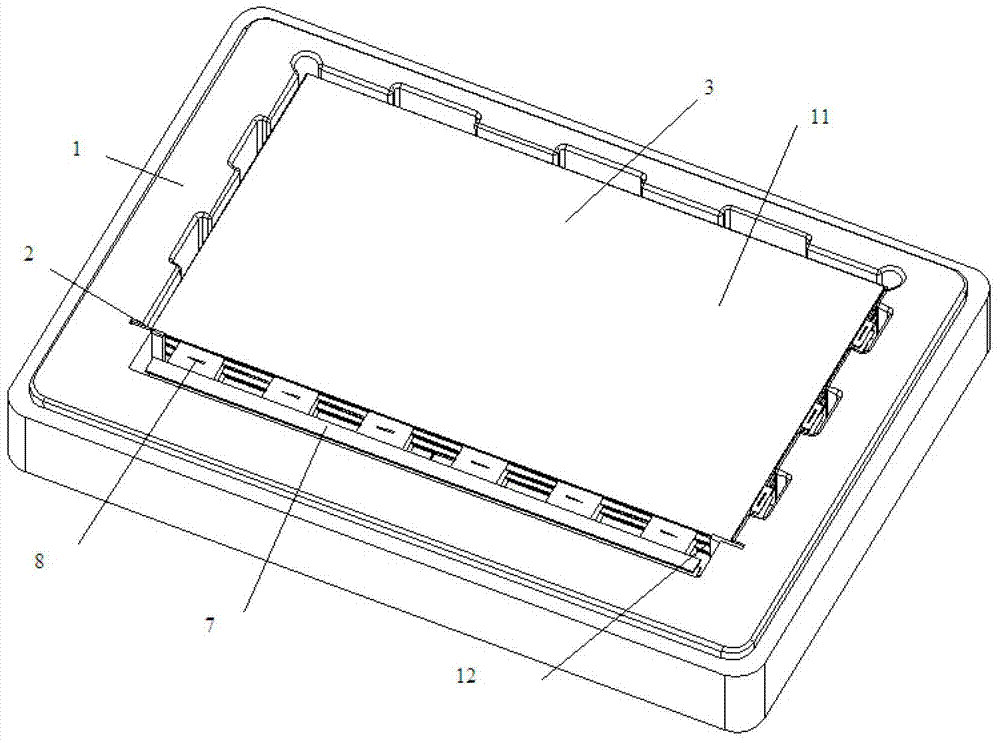

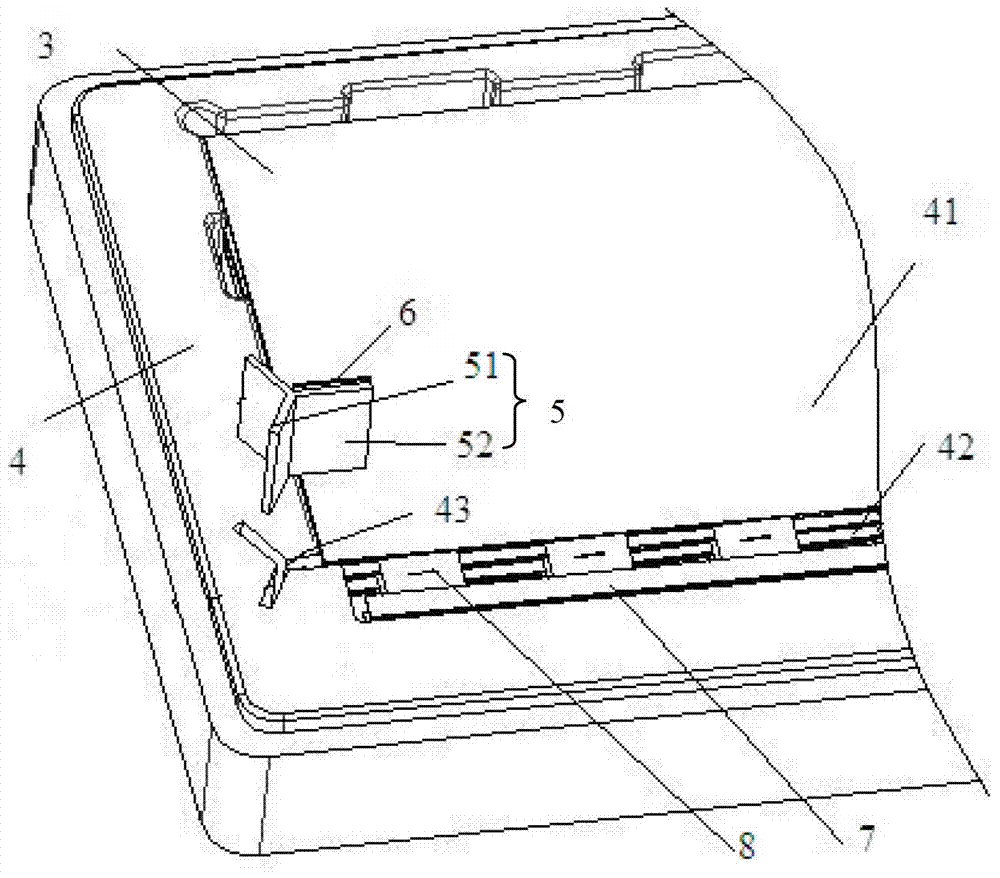

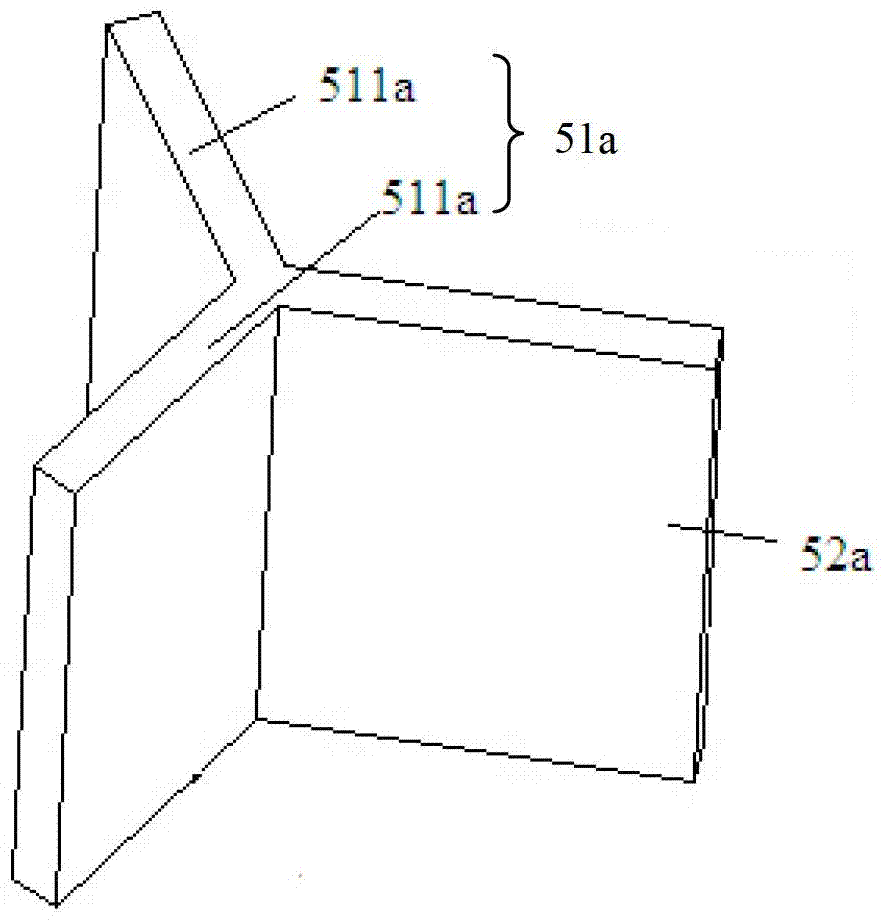

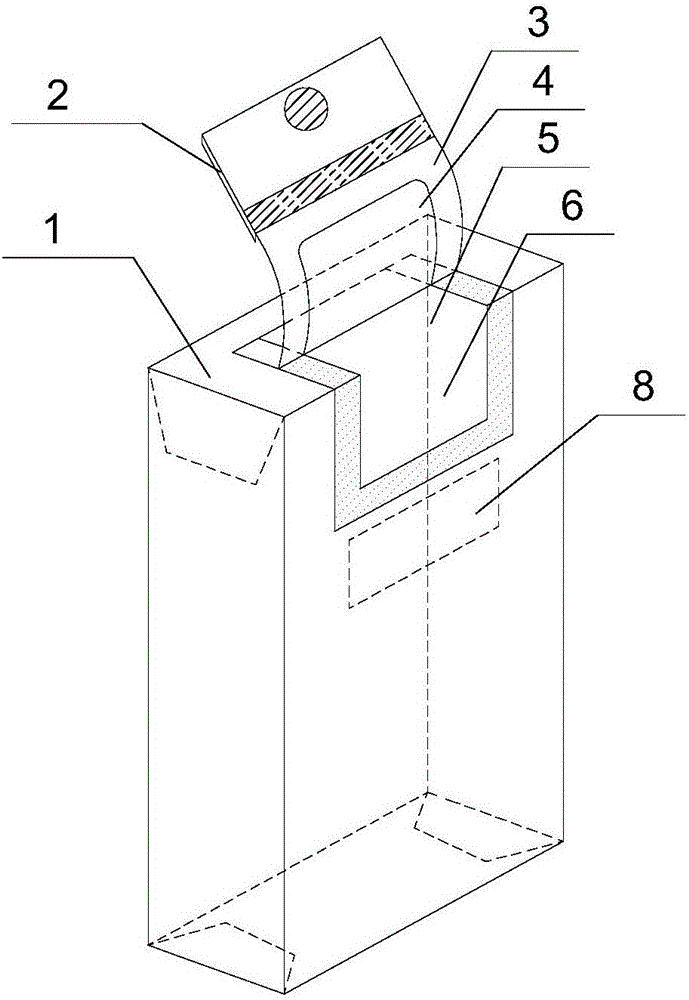

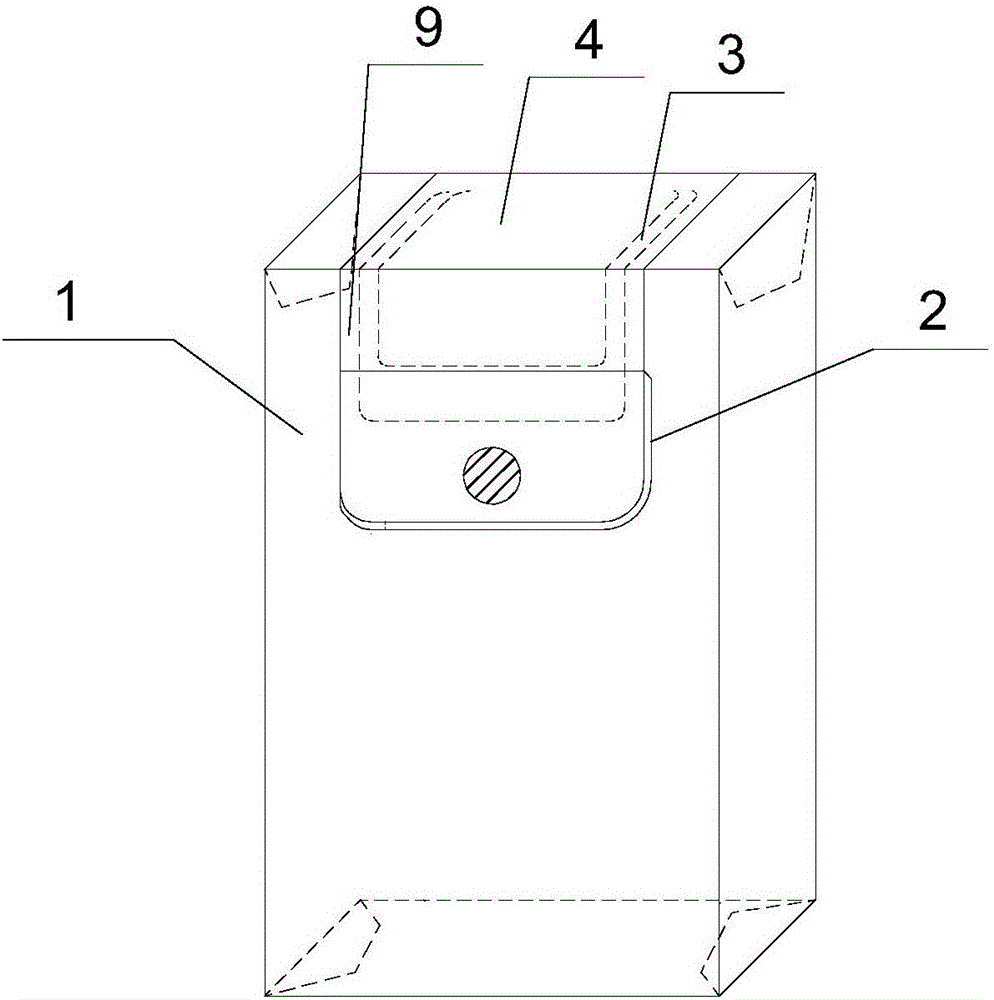

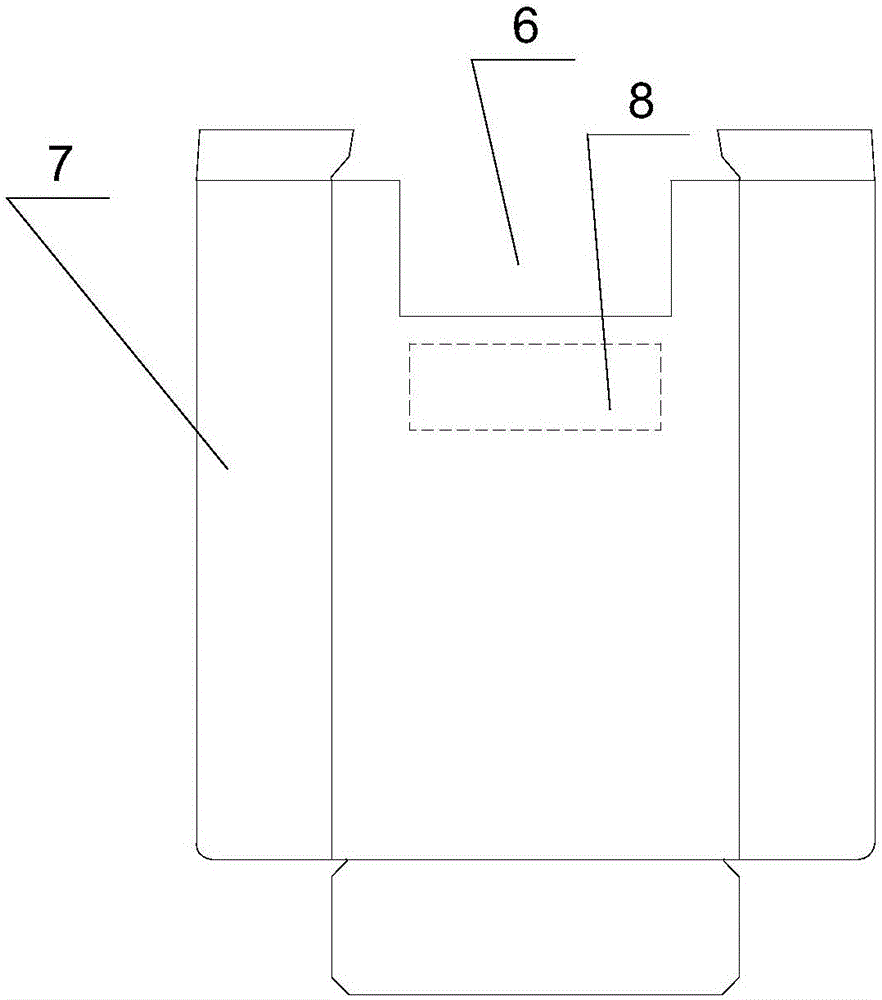

Packaging device

ActiveCN103204291AReduce the chance of deformationPrevent slipping outDamagable goods packagingInternal fittingsVertical planeEngineering

The invention discloses a packaging device. The packaging device comprises a box used for containing packaged products and limit parts arranged on two sides of the inner wall of the box. Each limit part comprises a fixing portion and a limit portion, the limit portion is connected to one side of the fixing portion and extends away from the fixing portion, and the length of projection of the fixing portion perpendicular to a vertical plane of the limit portion is larger than the thickness of the limit portion. The fixing portion is fixedly fastened in the box, and the limit portion extends into the box and is used for clamping the packaged products. The limit parts can be prevented from slipping and protect the packaged products from damaging.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Packaging box with gluing and absorbing combined sealing function

InactiveCN106240987ASolve the problem of open edge warpingRealize the closed functionRigid containersLocking devicesEngineeringSheet material

The invention discloses a packaging box with a gluing and absorbing combined sealing function. The packaging box is formed by a supporting frame and a wrapping sheet. The supporting frame is of a box-shaped support structure and is provided with a frame opening used for enabling packaged articles in the supporting frame to be taken out. The wrapping sheet wraps the supporting frame, and the wrapping sheet and the supporting frame form the packaging box together. An article taking opening is formed in the wrapping sheet and provided with a sealing sheet, the position of the sealing sheet corresponds to that of the article taking opening, and the size of the sealing sheet is identical to that of the article taking opening. The sealing sheet is covered with a sticky cover sheet. The packaging box is simple in structural design, and machine packaging can be achieved simply by modifying existing packaging machine equipment to a certain degree. Meanwhile, due to the fact that a start label is adopted in the packaging box, the problems that a sealed package is covered with an adhesive sticker cover sheet at present, the appearance is simple and crude, and use is inconvenient are solved, and meanwhile the package sense of beauty is improved.

Owner:SHANTOU DONGFENG PRINTING CO LTD

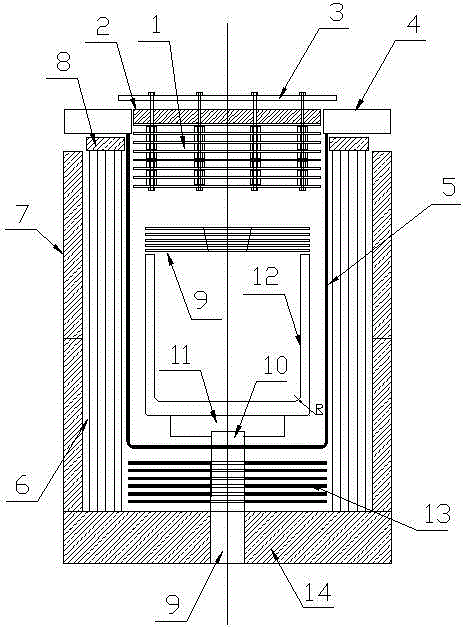

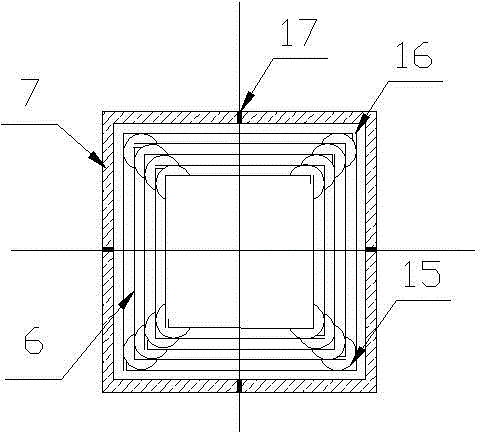

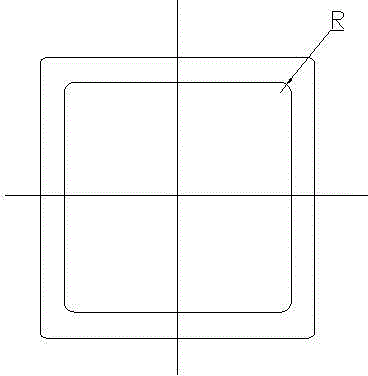

Square sapphire monocrystal furnace heat field structure

ActiveCN104805501AReduce internal defectsImprove insulation effectPolycrystalline material growthUsing seed in meltCrucibleCopper

The invention provides a square sapphire monocrystal furnace heat field structure. The square sapphire monocrystal furnace thermal field structure comprises an upper heat shield, a side heat shield, a lower heat shield, a crucible cover, a square crucible made of metallic tungsten, a square pallet, a circular pillar, and a square heating body structure formed by connecting a right-angled copper current conducting plate with a tungsten rod. The square sapphire monocrystal furnace heat field structure has the advantages of good heat insulation effect, stable temperature field, reasonable temperature gradient, few defects in grown sapphire crystals, and small heat stress.

Owner:HARBIN AURORA OPTOELECTRONICS TECH

Sheet metal part machining device

The invention relates to the technical field of sheet metal part machining and discloses a sheet metal part machining device comprising an upper die and a lower die. The two sides of the lower die areboth provided with pressing and fixing mechanisms which are used for pressing a sheet metal part flat and fixing the sheet metal part. Each pressing and fixing mechanism comprises a column body, wherein a rotating rod is rotationally connected to the column body. One end of each rotating rod is located on the movement path of the lower die. The other end of each rotating rod is hinged to a connection rod. The side portion of the lower die is connected with sliding plates in a sliding manner. The end, far away from a concave portion, of each sliding plate is hinged to a connection rod. One sliding plate is provided with a pulling mechanism. A rotary grinding mechanism used for deburring of a punched hole is arranged in the lower die. When the sliding plate slides away from the sheet metalpart, the rotary grinding mechanism can be driven by the pulling mechanism to conduct deburring treatment on the punched hole. According to the sheet metal part machining device, the fixing work and pressing flattening work are welled conducted on the sheet metal part before punching, so that it is avoided that the sheet metal part deforms in the punching process; and the rotary grinding mechanismis adopted after punching of the sheet metal part, so that burrs generated after punching are removed, and therefore the punching quality of the sheet metal part is improved.

Owner:象山维治模具有限公司

High fire-resistant high heat-resistant automobile explosion-proof tire

The invention discloses a high fire-resistant high heat-resistant automobile explosion-proof tire. The tire is integrally formed by a high fire-resistant high heat-resistant synthetic rubber material, the synthetic rubber material comprises the following raw materials in parts by weight: 80-100 parts of raw rubber of butadiene styrene rubber, 20-50 parts of natural rubber, 20-50 parts of gas-phase white carbon black, 1-2 parts of an anti-aging agent aw, 3-7 parts of zinc oxide, 1-1.2 parts of sulphur, 1-2 parts of a promoter NS, 2-4 parts of palm wax, 2-4 parts of aluminum silicate fibers, 4-6 parts of thermally-stabilized resin, 1-2 parts of hollow glass micro-beads, 3-4 parts of dibutyl phthalate, 1-2 parts of aluminum dihydrogen phosphate, 5-10 parts of 2,4'-dihydroxy diphenyl sulfone and 1-8 parts of bisphenol A. The high fire-resistant high heat-resistant automobile explosion-proof tire enhances reaction activity and thermal stability, enhances heat resistance of resin blends, binding property and mechanical property, increases thermal stability of the material of the finished product tire, reduces tire burst risk, solves defect problem of the common butadiene styrene rubbers at an early stage of production period, reduces cost for post-production of the tire, and can reach high heat -esistance and high flame retardation performances.

Owner:张启义

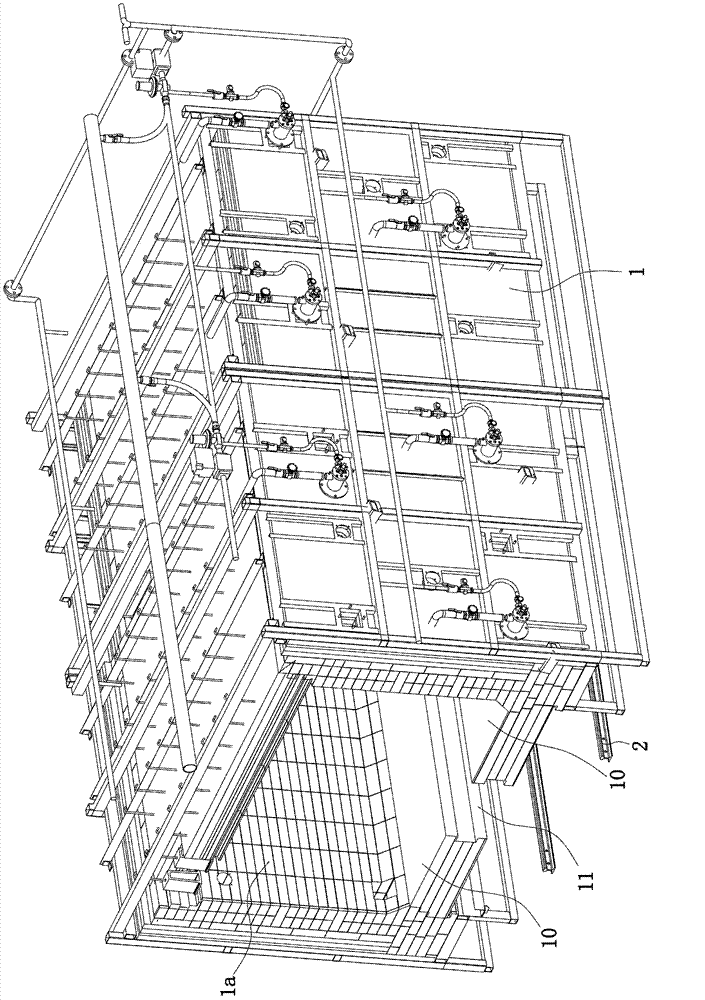

Novel energy-saving tunnel kiln firing system

InactiveCN102735049AReduce widthReduce the chance of deformationFurnace typesTunnel kilnInsulation layer

The invention discloses a novel energy-saving tunnel kiln firing system which can reduce heat loss, save energy and reduce volume and weight of a kiln car. The novel energy-saving tunnel kiln firing system comprises a kiln body, tracks and a kiln car, wherein the tracks penetrate through along a kiln body channel, the kiln car is arranged on the tracks and slides on the tracks and comprises a frame with wheels, a heat-insulation layer, a high temperature-resistant strut, the heat-insulation layer is laid on the frame, a horizontally arranged high temperature-resistant beam frame for bearing products is supported at the top of the high temperature-resistant strut, the bottom of the high temperature-resistant strut is fixedly connected together with the frame after penetrating through the heat-insulation layer, the width of the heat-insulation layer and the width of the frame are smaller than that of the high temperature-resistant beam frame, a fixed kiln bottom with a heat-insulation function is arranged in the kiln body channel, the tracks are positioned below the kiln bottom, an open slot is arranged at the kiln bottom along the whole length of the kiln body, the height and width of the open slot are consistent with those of the heat-insulation layer, and the heat-insulation layer slides in the open slot.

Owner:MODENA TECH LTD

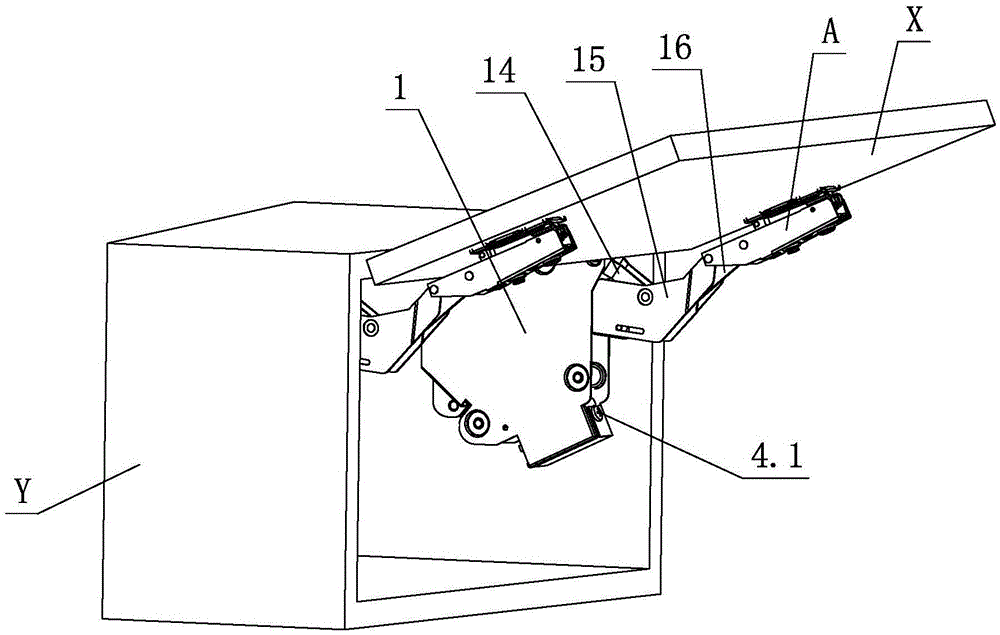

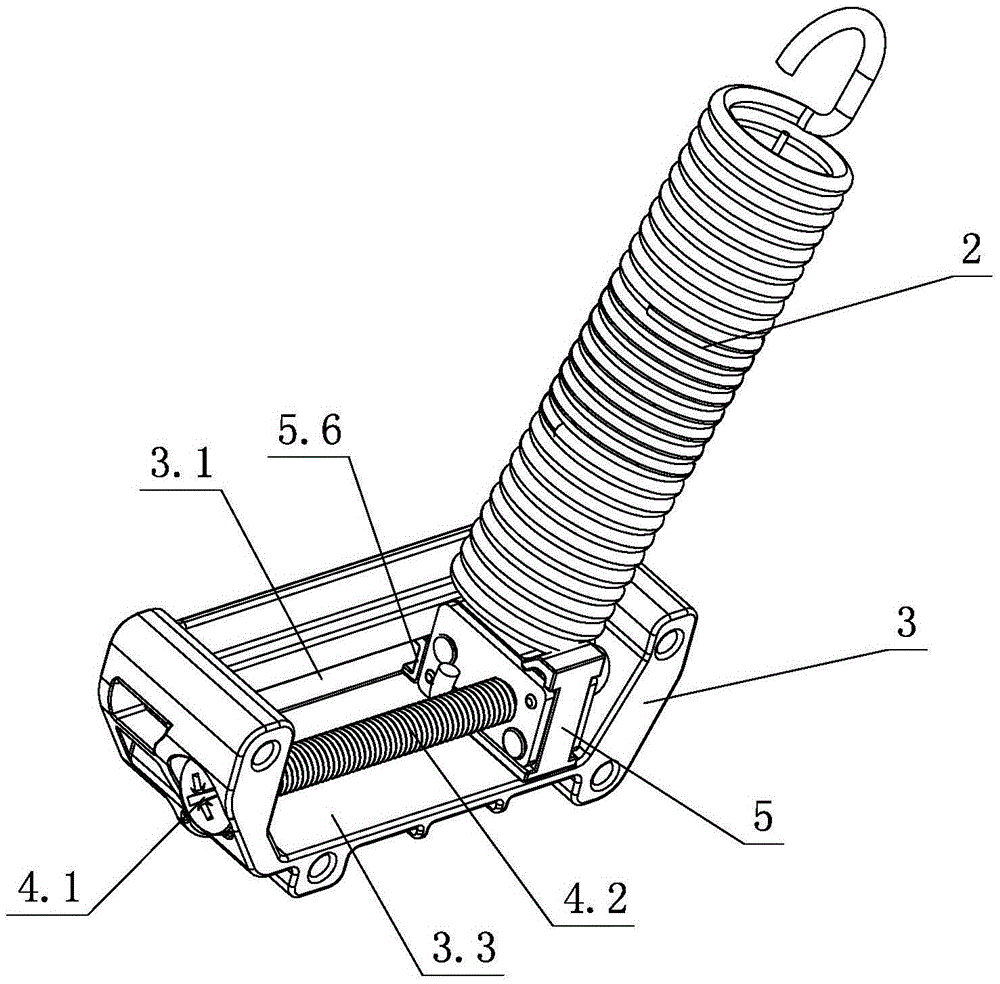

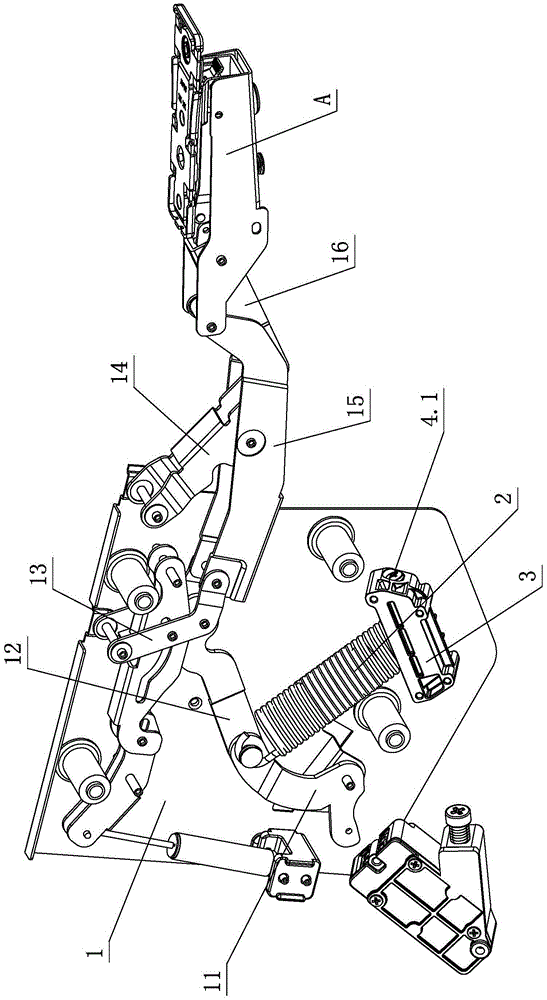

Furniture tilt-up door opening-closing force adjusting mechanism

InactiveCN105587196APrecise positioningIncrease elasticityBuilding braking devicesPin hingesEngineeringTilt up

Disclosed is a furniture tilt-up door opening-closing force adjusting mechanism. The furniture tilt-up door opening-closing force adjusting mechanism comprises a locking and unlocking device arranged on a furniture tilt-up door and a tilt-up device disposed on a furniture cabinet body. The furniture tilt-up door is turned over and opened or closed on the tilt-up device of the furniture cabinet body through the locking and unlocking device. The tilt-up device comprises a positioning element, a spring and a connecting arm assembly. One end of the connecting arm assembly is connected with the locking and unlocking device, and the other end of the connecting arm assembly is connected with the positioning element. A support is disposed on the positioning element. An adjusting screw rod is mounted on the support. A pushing element is arranged between the positioning element and the support. The pushing element is in threaded connection with the adjusting screw rod. One end of the spring is connected with the pushing element, and the other end of the spring is connected with the connecting arm assembly. A tool acts on an acting part of the adjusting screw rod, the adjusting screw rod is positioned and rotated on the support, and one end of the spring and the pushing element are driven to perform displacement relative to the support, so that the elastic force, exerted on the connecting arm assembly, of the other end of the spring is increased or decreased, accordingly the opening and closing force adjustment of the tilt-up device is achieved finally, and the practicability is high.

Owner:伍志勇

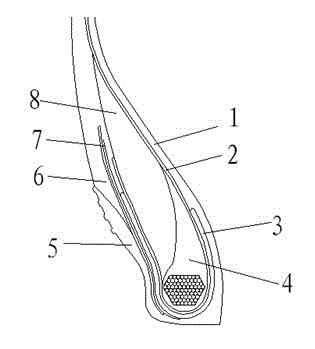

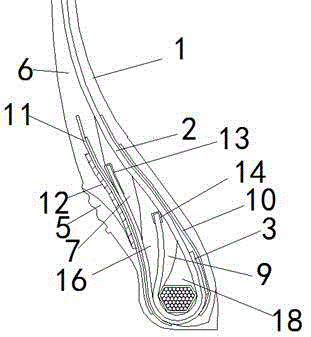

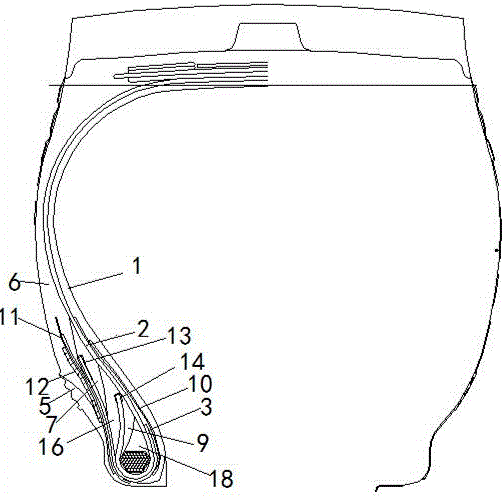

All-steel radial heavy-duty tire

InactiveCN104669952AReduce the chance of deformationExtended service lifeTyre beadsStress concentrationHeavy duty

The invention provides an all-steel radial heavy-duty tire and relates to the field of tires. The tire comprises a carcass ply layer, wherein the carcass ply layer comprises a main body part and a return part, the main body part passes through a tire sidewall part from a tread part to reach a bead core of a bead part, and the return part is connected with the main body part and returns from the axial inner side of the all-steel radial heavy-duty tire to the axial outer side around the bead core. The tire further comprises lower composite apex rubber and upper composite apex rubber, wherein the lower composite apex rubber comprises lower hard apex rubber and lower soft apex rubber, the lower hard apex rubber is closely attached to one side, far away from the tire axis, of the main body part and the bead core respectively, and the lower soft apex rubber is closely attached to the lower hard apex rubber and the return part respectively; the upper composite apex rubber comprises upper hard apex rubber and upper soft apex rubber which are closely attached to each other, and the upper soft apex rubber and the lower soft apex rubber clamp at least one part of the return part which extends from a turn-up end of the return part. According to the tire, abrasion to the turn-up end of the carcass ply layer due to stress concentration can be effectively avoided, and the probability of deformation of the tire is decreased.

Owner:SHANDONG LINGLONG TIRE

Investment casting technology for transmission housing

InactiveCN107486543ALow shrinkageGood toughnessFoundry mouldsFoundry coresTemperature resistanceInvestment casting

The invention discloses an investment casting technology for a transmission housing. The investment casting technology comprises the following steps that (1) wax pouring is conducted, specifically, a mixed wax material is homogenized and then processed at the temperature of 75-80 DEG C and the temperature of 50-54 DEG C; (2) a mold housing is manufactured, specifically, four inner mold material layers and two outer mold material layers are smeared on the surface of a wax mold and subjected to drying treatment; (3) dewaxing is conducted, specifically, the dried mold housing is subjected to dewaxing at the temperature of 76-80 DEG C and washed with gasoline; (4) roasting is conducted, specifically, the dried mold housing is roasted at the temperature of 450-500 DEG C and the temperature of 800-850 DEG C; (5) pouring is conducted, specifically, molten iron is subjected to still standing treatment at the temperature of 900-930 DEG C after pouring and subjected to vacuum cooling; and (6) polishing and inspection are conducted, specifically, the transmission housing subjected to precision casting is polished, and the inspection precision and internal damage are inspected. The transmission housing produced through the investment casting technology has the characteristics of being high in percent of pass, tensile strength and percentage reduction of area, and is good in abrasion resistance and high temperature resistance.

Owner:HEFEI CITY TENVER PRECISION CASTING

Mini loudspeaker

InactiveCN105721994AImprove reliabilityExtended service lifeElectrical transducersLoudspeakersEngineeringLoudspeaker

The invention discloses a micro-speaker, which relates to the technical field of electroacoustic products, and comprises a combined front cover and a casing, and a vibration system and a magnetic circuit system are accommodated in a space enclosed by the front cover and the casing. The vibration system includes a vibrating membrane, and the surrounding ring part of the vibrating membrane is composed of an inner surrounding ring and an outer surrounding ring connected together and protruding in opposite directions, the outer surrounding ring protrudes toward the direction of the front cover, the An annular avoidance groove is provided on the inner side of the front cover corresponding to the position of the outer ring, and the outer surface of the front cover is a planar structure. The micro-speaker of the present invention solves technical problems such as poor strength and easy deformation of the front cover of the micro-speaker in the prior art.

Owner:GOERTEK INC

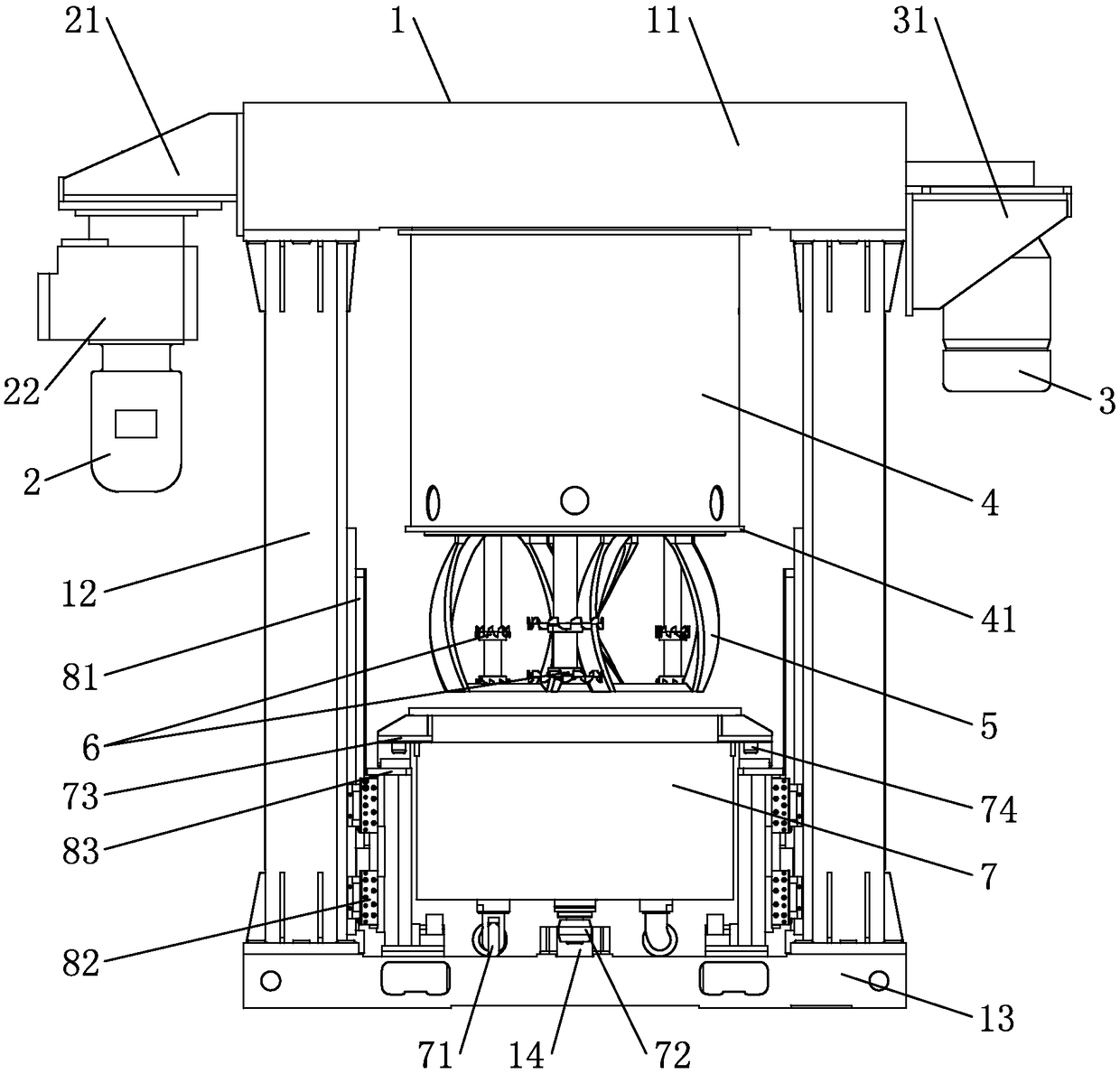

Industrial stirring equipment

InactiveCN108079870AReduce loadImprove the mixing effectTransportation and packagingRotary stirring mixersPulp and paper industryMixing effect

The invention relates to industrial stirring equipment mainly used for mixing lithium-battery materials. The industrial stirring equipment comprises a rack, a stirring mechanism, a dispersing mechanism, a supporting component, a stirring driving device and a dispersion driving device, wherein the supporting component is rotatably matched with the rack; the stirring mechanism and the dispersing mechanism are respectively and rotatably arranged on the supporting component; the supporting component is provided with synchronous gears; the rack is provided with fixed gears; the synchronous gears are meshed with the fixed gears and rotate around the fixed gears. The industrial stirring equipment has the beneficial effects that stirring paddles of the stirring mechanism and dispersing shafts of the dispersing mechanism can realize autorotation and revolution simultaneously and can pass more areas, so that the mixing effect is improved; in addition, the stirring paddles and the dispersing shafts are respectively and independently driven by a stirring motor and a dispersing motor, so that the load of the motors is reduced and the working is more reliable.

Owner:FOSHAN HONGRUIDE NEW ENERGY PRECISION EQUIP CO LTD

Method for producing reflective film with microprism array structure

ActiveCN101561523BObvious production speed advantageImprove work efficiencyPhotomechanical apparatusOptical elementsLight irradiationBand shape

The invention relates to a method for producing a reflective film with a microprism array structure. The invention overcomes the defects of poor hardness, scratch resistance, thermal resistance and solvent resistance of a microprism, poor product consistency, low production speed, low working efficiency and the like existing in the prior art. The invention adopts an endless belt-shaped mould of which a protruded continuous precise microprism array structure is arranged on the outer surface and comprises the following production steps that: a resin film is coated with photosensitive resin and then subjected to drying, heated film pressure and quickly solidification by UV light irradiation, so that the resin film coated with the photosensitive resin and the microprism structure on the photosensitive resin layer jointly form a laminated film, and the laminated film is cooled to obtain the reflective film with the microprism array structure. The method has the advantages of simple and convenient operation, high production speed and high working efficiency; and the formed microprism has the advantages of better hardness, scratch resistance, thermal resistance and solvent resistance, and good product consistency.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

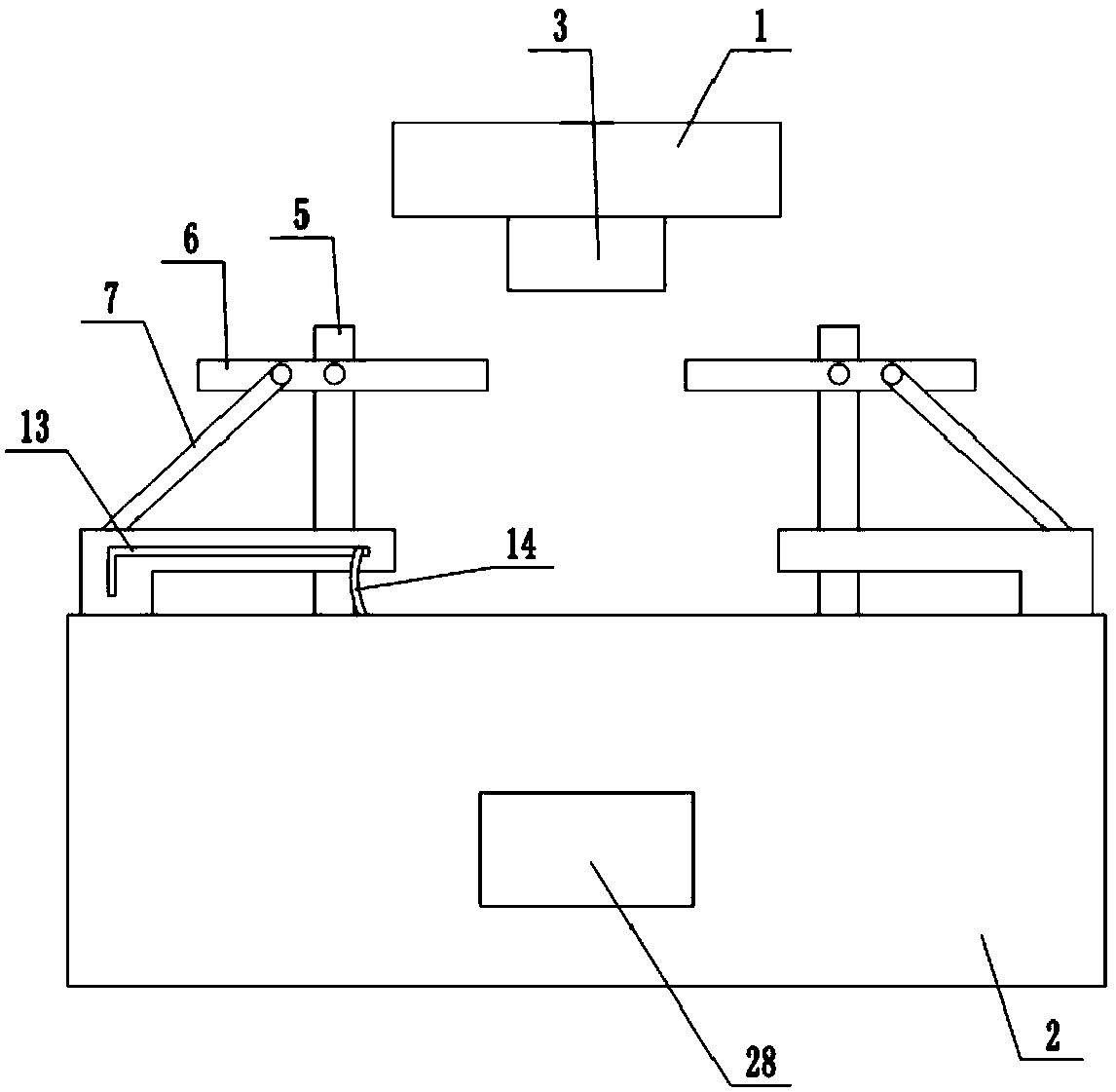

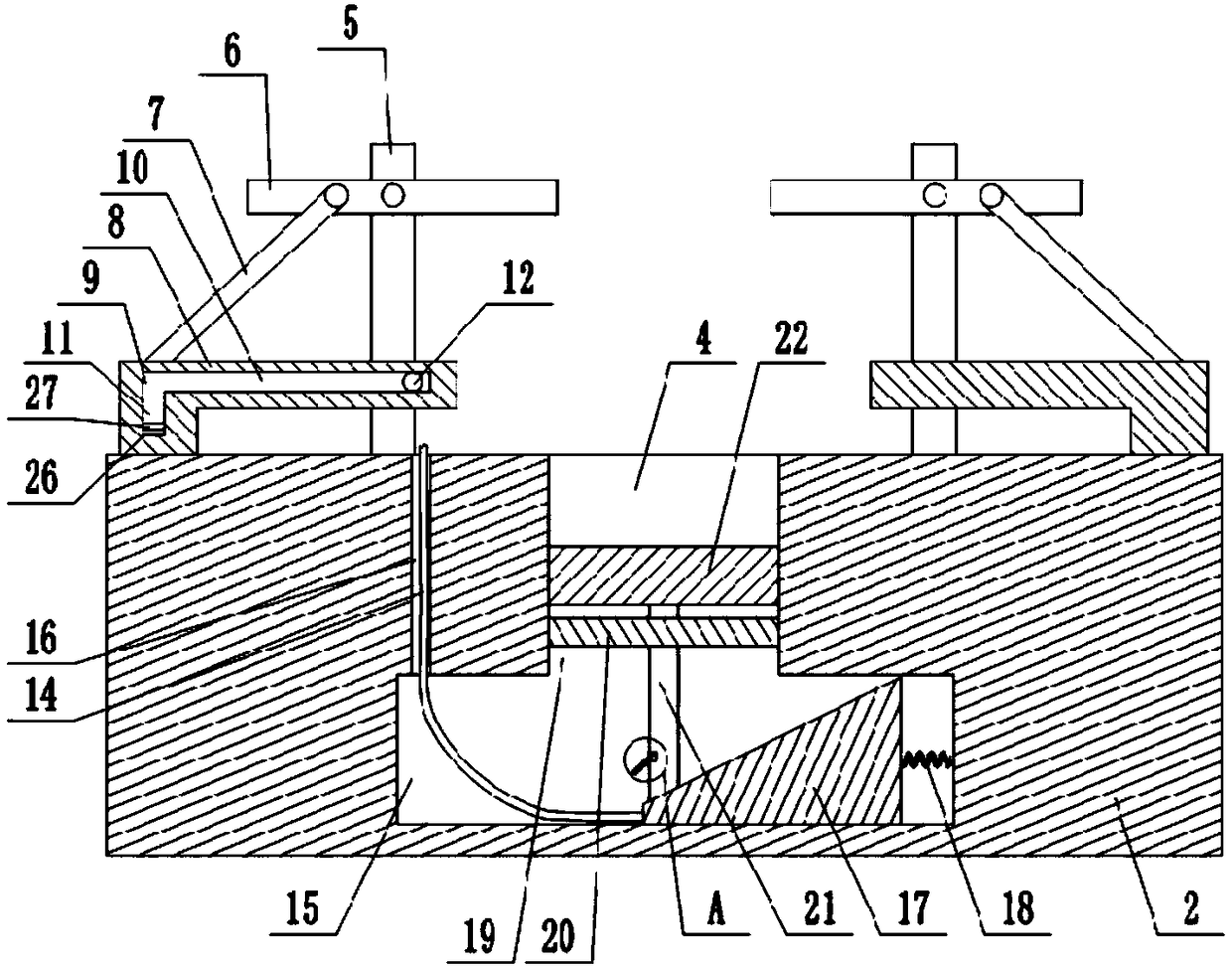

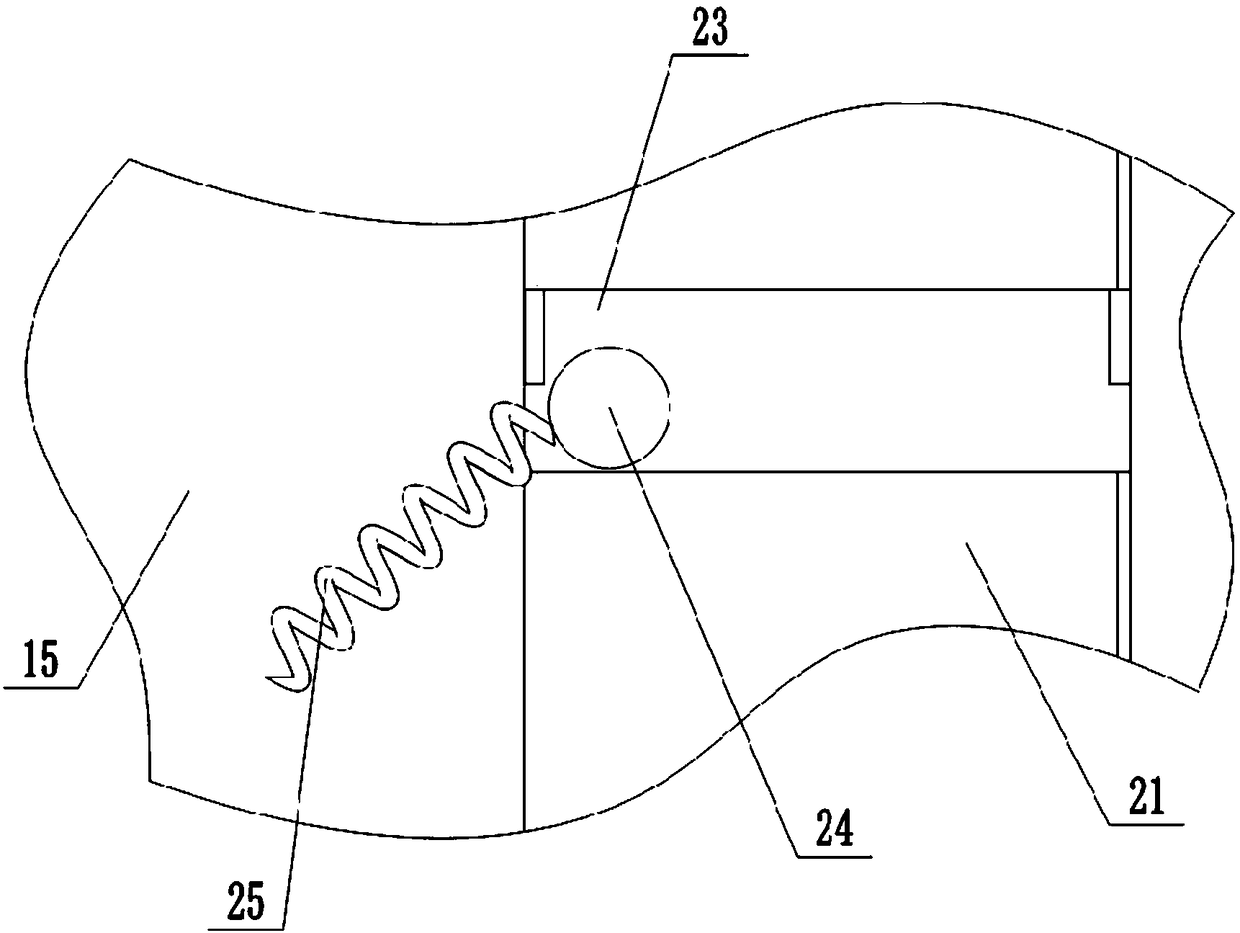

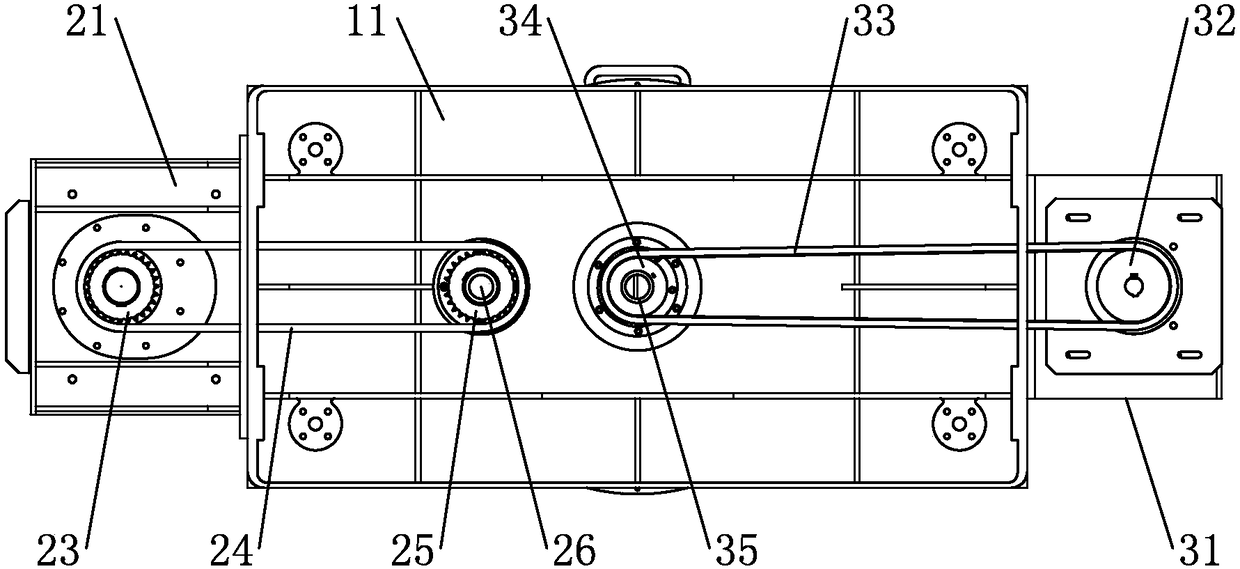

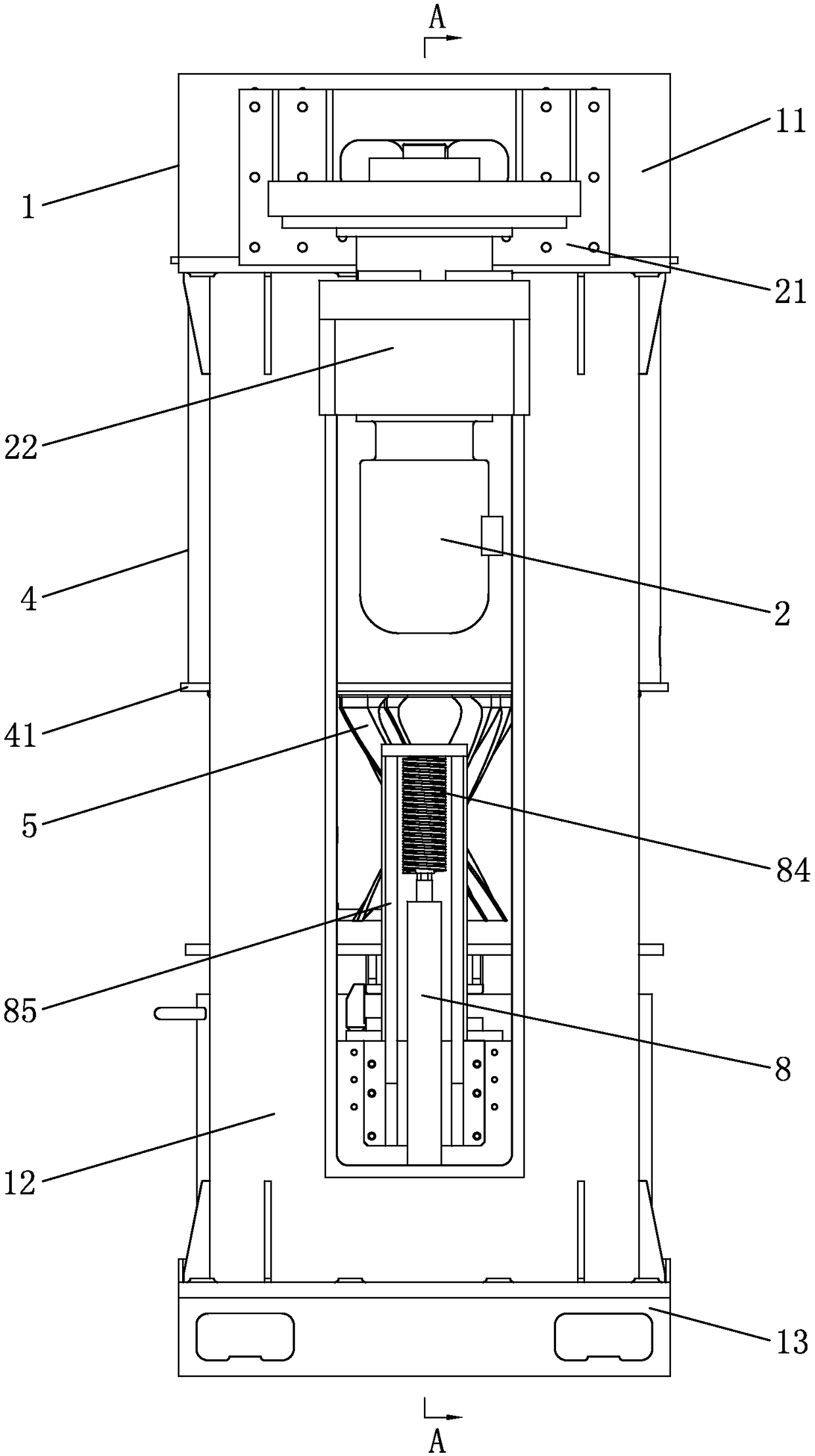

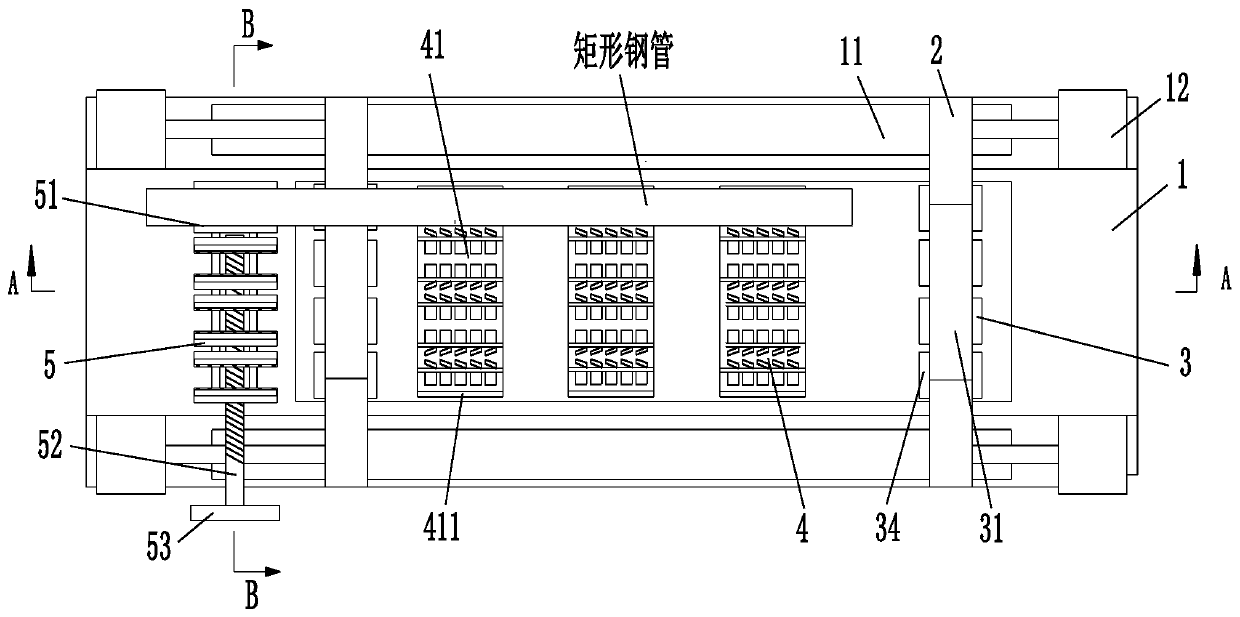

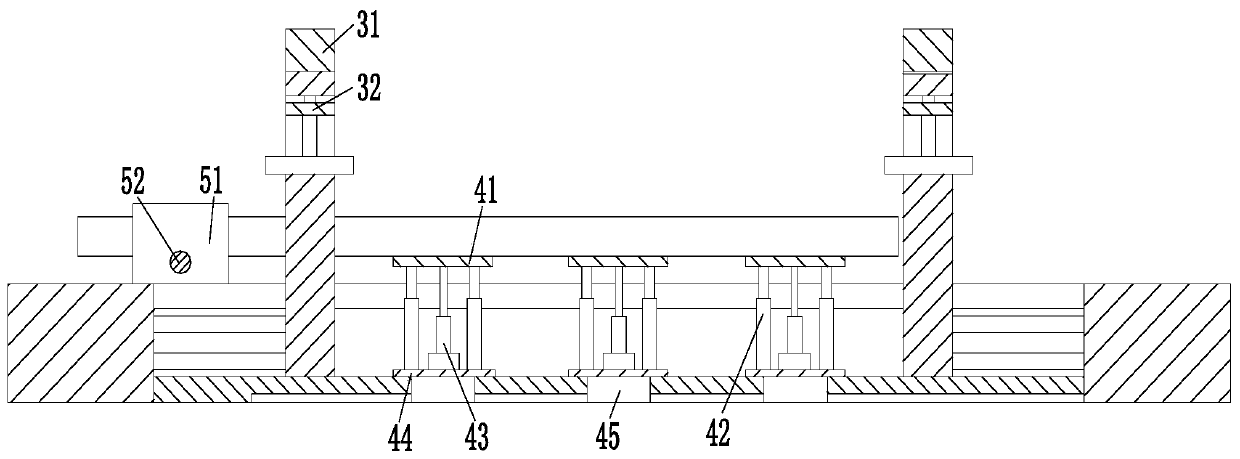

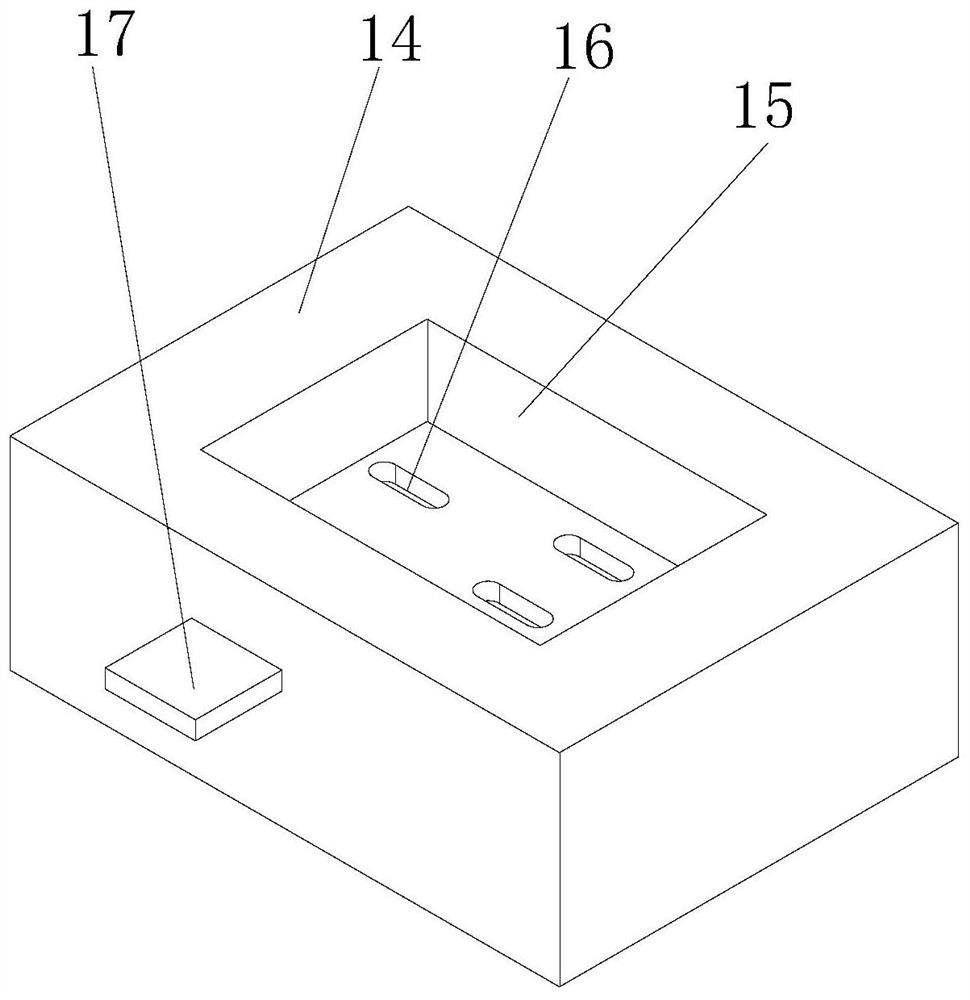

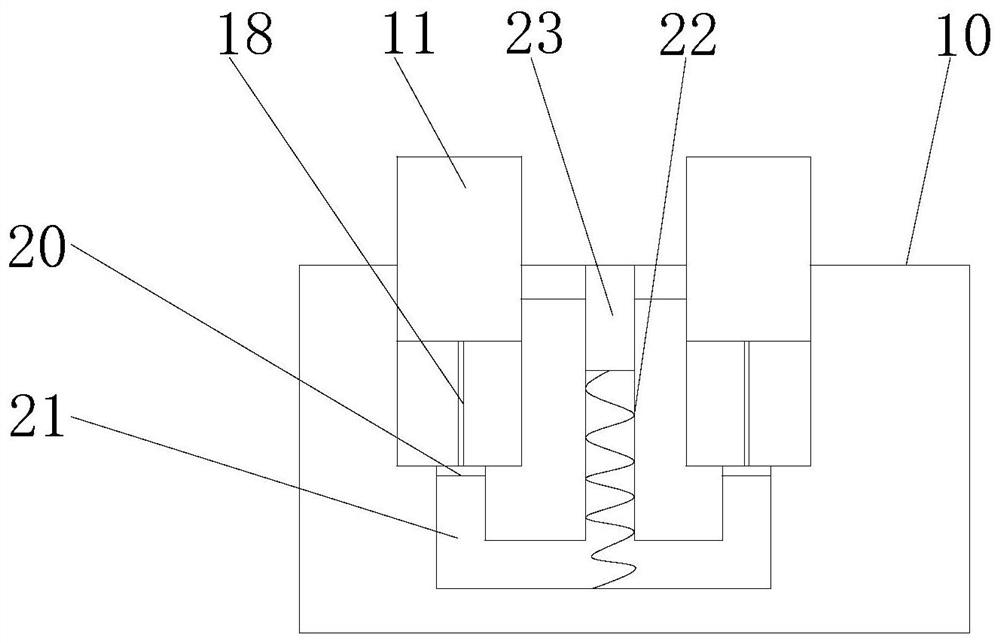

Fixing fixture for synchronous cutting of multiple rectangular steel pipes

ActiveCN110605598AReduce the chance of deformationReduce the amount of horizontal movementWork clamping meansPositioning apparatusEngineeringPortal frame

The invention relates to a fixing fixture for synchronous cutting of multiple rectangular steel pipes. The fixing fixture comprises a worktable, portal frames, pressing devices, supporting devices anda clamping device; the portal frames are symmetrically arranged on the left and right sides of the worktable through a sliding mode; the pressing devices are arranged on the portal frames through a sliding mode; a rectangular through groove is formed in the middle part of the worktable; the supporting devices are arranged in the rectangular through groove in sequence from left to right; and the clamping device is arranged on the left side of the upper end surface of the worktable, and is positioned on the left side of the portal frame on the left side of the worktable. The fixing fixture cansolve such difficulties as easy deformation of cutting places of the rectangular steel pipes or even bending deformation of the whole rectangular steel pipes due to cantilever beam type cutting formedby fixation of one ends of the rectangular steel pipes by using a fixture without needing other fixing tools, easy blockage of cutters and different cutting sections in a traditional fixing fixture for rectangular steel pipe cutting.

Owner:福建泉州业德弗科技有限公司

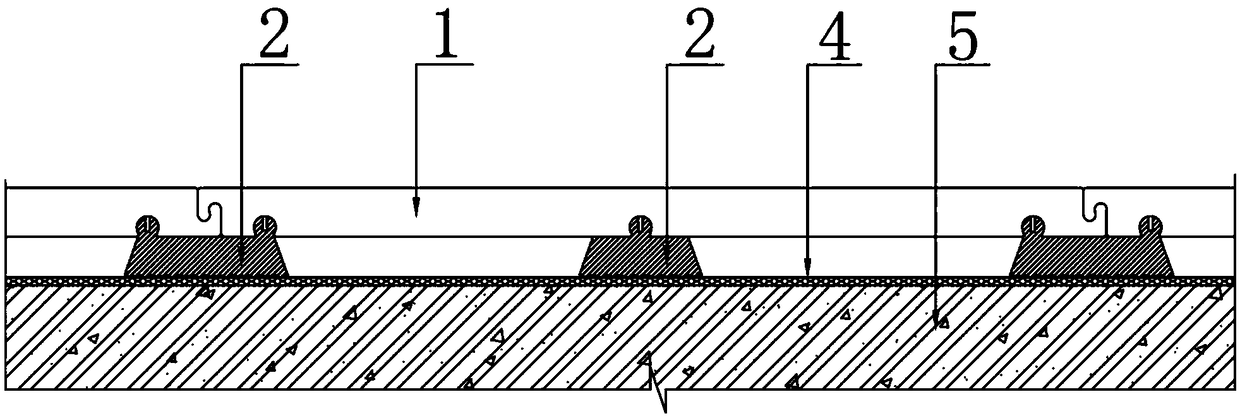

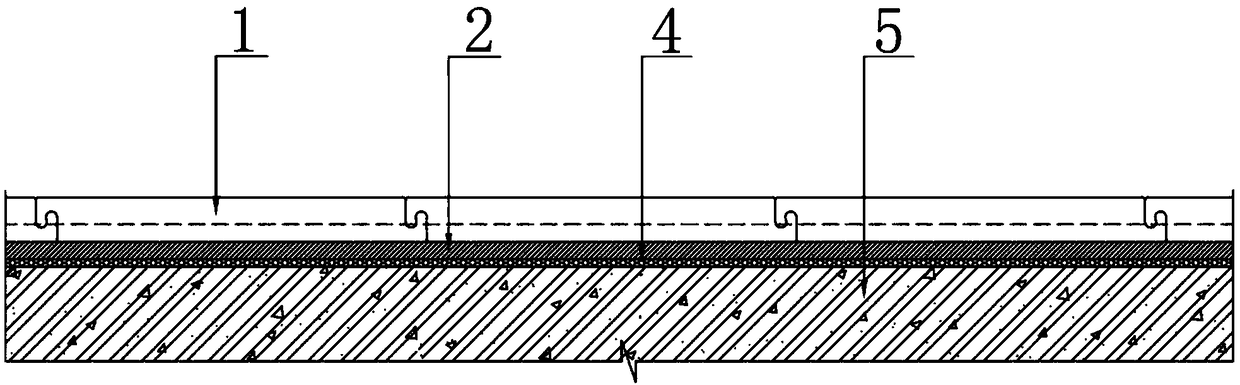

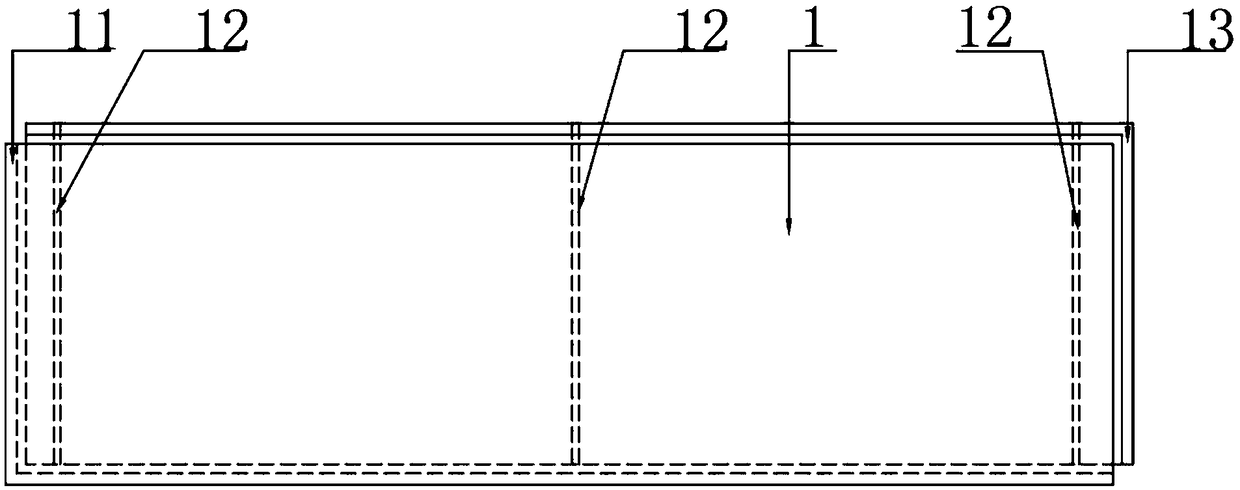

Assembled floor installation structure and installation method thereof

PendingCN109162424AWith sound insulationImprove construction efficiencyCovering/liningsFlooring insulationsSolid woodKeel

The invention discloses an assembled floor installation structure and an installation method thereof. The installation structure comprises an elastic keel and a splicing floor. The elastic keel and the splicing floor are provided with a connection male member and a connection female member which are matched with each other. The elastic keel is arranged on the ground, and the connection male memberis matched with and connected to the connection female member, and the splicing floor is arranged above the elastic keel to achieve floor installation. According to the scheme, a wooden keel is substituted with the elastic keel, the material stability is improved, and the probability of deformation is reduced. The assembly-type construction technology is employed, the construction efficiency andthe comfort of use can be improved, the stability of a solid wood floor is improved, and common quality problems are avoided. At the same time, the assembled floor installation structure has a certainsound insulation function, and the noise interference between floors is reduced. The elastic keel has a standard design and can be produced on a large scale in a factory, the assembled floor installation structure has a wide application range, and various specifications of solid wood floors can be installed.

Owner:SHENZHEN RUIHE CONSTR DECORATION

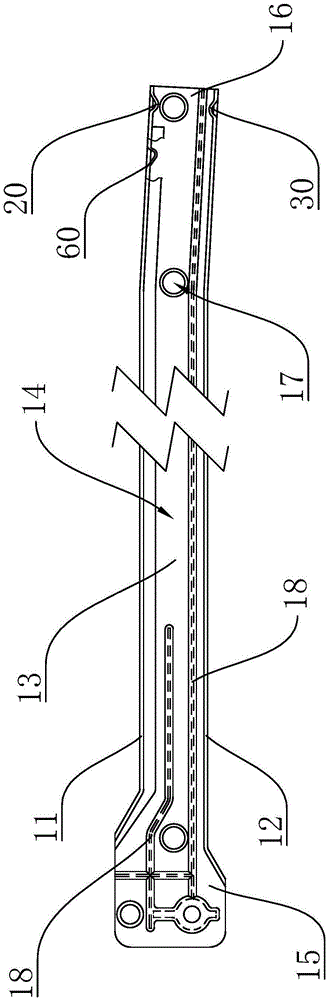

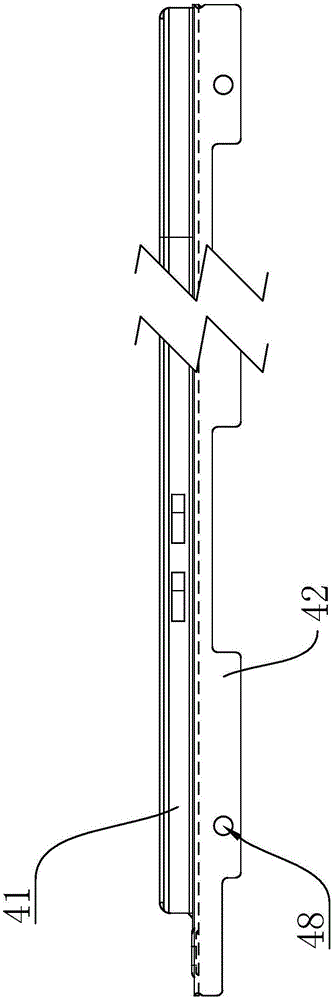

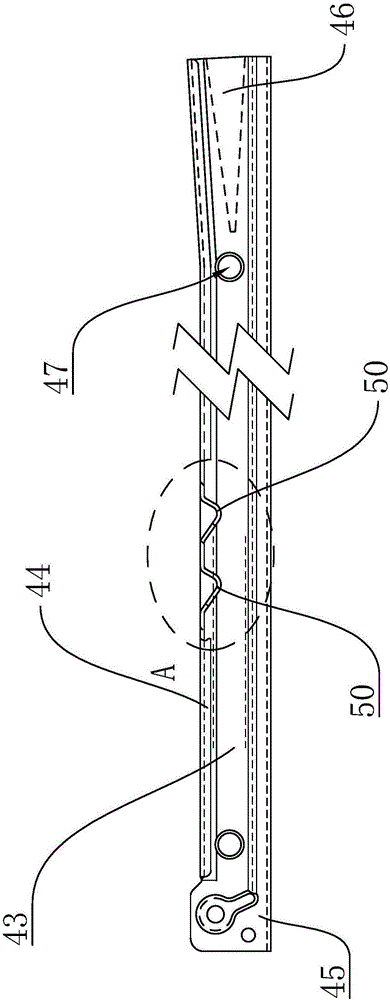

Impact-resistant and anti-rebound sliding rail

The invention provides an impact-resistant and anti-rebound sliding rail which comprises a static rail and a movable rail. The static rail comprises a top plate I, a base plate I and side plates I forming a sliding groove and is provided with a static rail first end and a static rail second end, and the static rail first end is used for installing a first pulley. The movable rail comprises a top plate II, a base plate II and side plates II, the top plate II downward extends to form an upturned edge. The movable rail is provided with a movable rail first end and a movable rail second end, the movable rail first end is used for installing a second pulley, at least two protrusions playing an impact-resistant buffering effect are formed on the inner wall of the top plate II and are of asymmetric structures, and the separation distance between the two adjacent protrusions is preset. A downward protruding stop portion I is formed on the inner wall of the top plate I, an upward protruding stop portion II is formed on the inner wall of the base plate II, the stop portion I and the stop portion II are located at the second end of the static rail, and a limiting portion for preventing the movable rail from rebounding and regressing is arranged on the inner wall of the top plate I in a protruding mode and is an elastomer of an asymmetric structure.

Owner:HAINING JINMAO HARDWARE

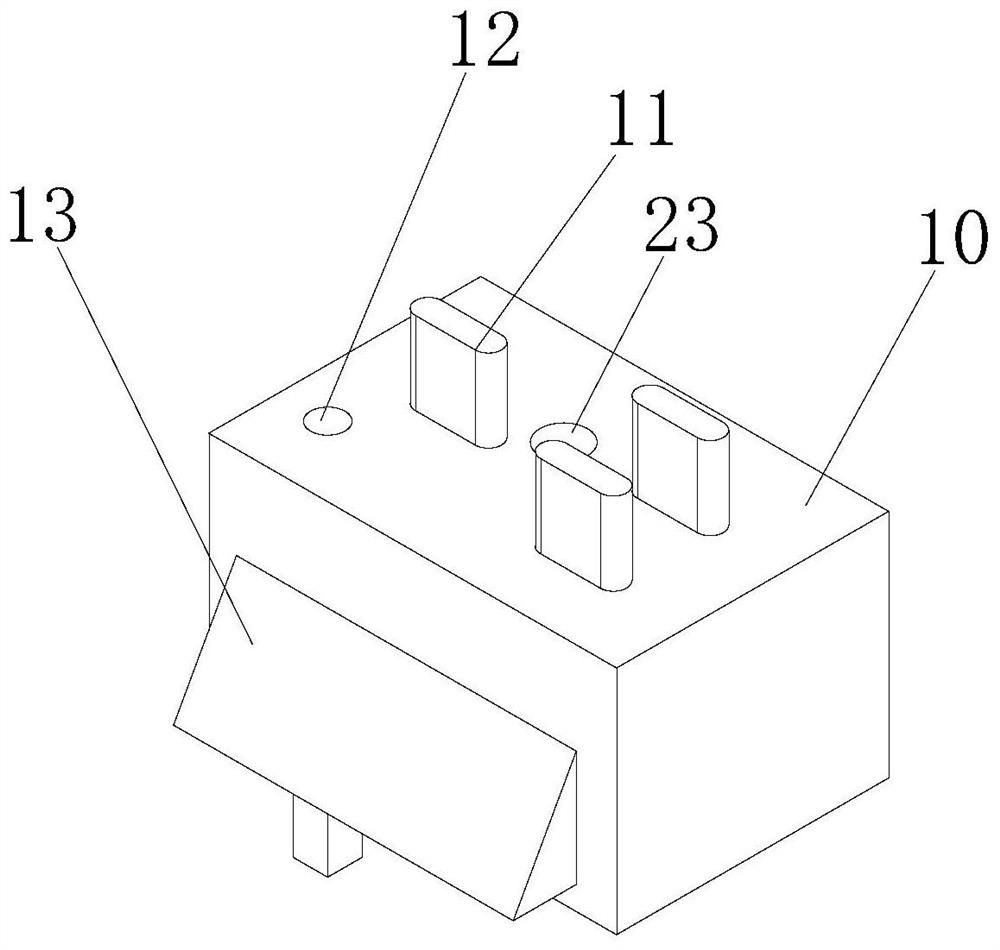

Three-phase charging plug pulled out by single hand

ActiveCN112736540ALow costImprove reliabilityTwo-part coupling devicesLive contact access preventionEngineeringSlide plate

The invention relates to the technical field of charging equipment, and discloses a three-phase charging plug pulled out by a single hand, and the three-phase charging plug comprises an insertion block and a base, a copper sheet is movably connected to the insertion block, the insertion block and the base are both cuboids, and a lifting mechanism is arranged on the insertion block, a sliding mechanism and an inserting guide mechanism are arranged on a clamp block turnover mechanism, a clamp block fixing mechanism a clamp block release mechanism and the base, the lifting mechanism comprises a sliding plate, a first sliding groove, a first spring and a first jacking column, the first sliding groove is formed in the insertion block, the first jacking column is slidably connected with the first sliding groove, one end of the first spring is fixedly connected with the bottom surface of the first jacking column, the other end of the first springis fixedly connected with an insertion block, a sliding plate is slidably connected with the first sliding groove, one end of a second connecting rod is fixedly connected with the top face of the sliding plate, the first jacking column abuts against the bottom face of the groove, so that the first jacking column retracts into the insertion block, the first jacking column pushes hydraulic oil in the first sliding groove to drive the sliding plate to push the second connecting rod, and the second connecting rod drives a copper sheet to slide out of the insertion block, so that a simple mechanical mechanism is low in cost and high in reliability.

Owner:国网浙江省电力有限公司龙游县供电公司

Display device with shielding adhesive layer and a method for manufacturing thereof

ActiveUS7880827B2Reduce the chance of deformationReduce chanceNon-linear opticsDisplay deviceEngineering

Owner:AU OPTRONICS CORP

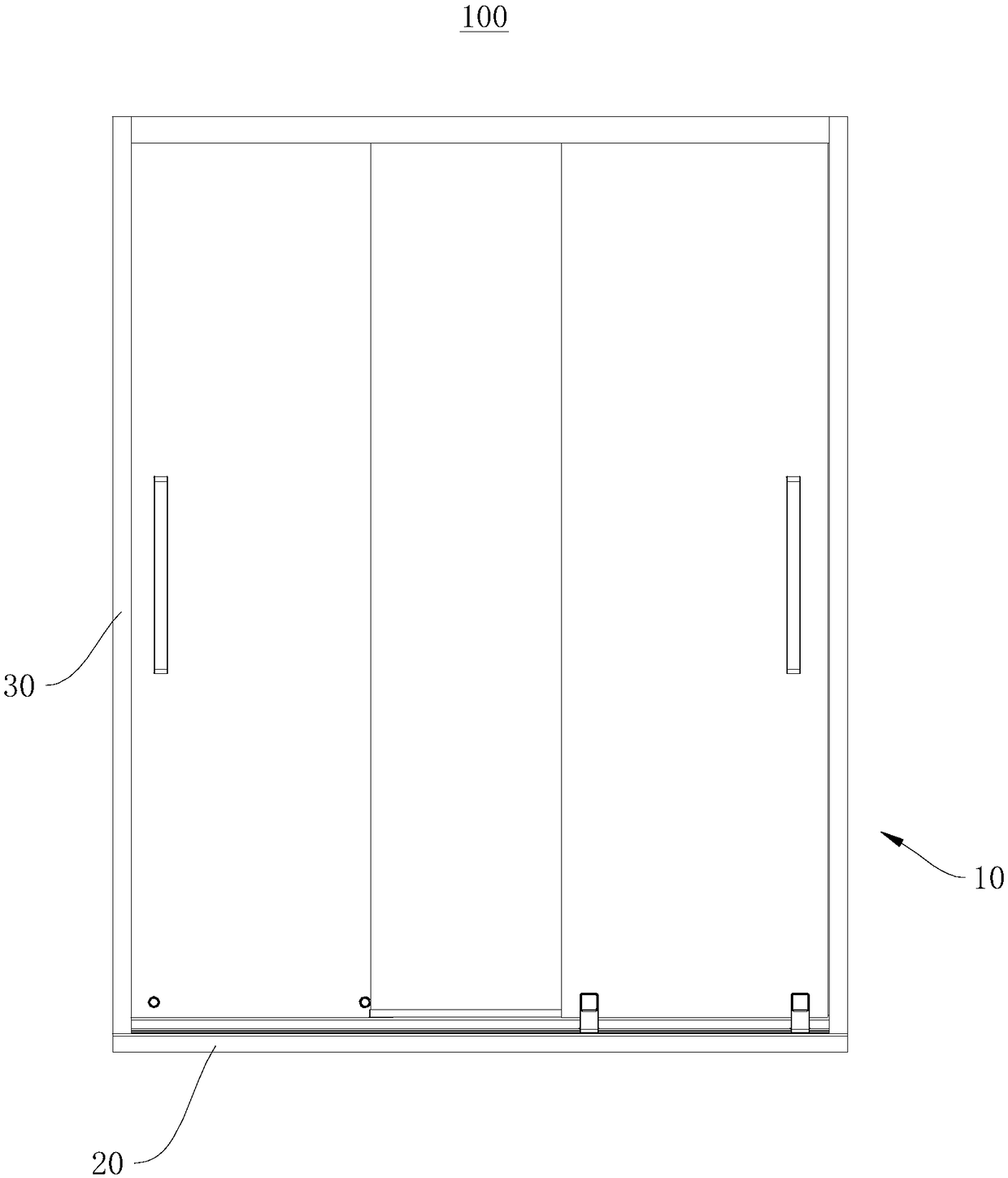

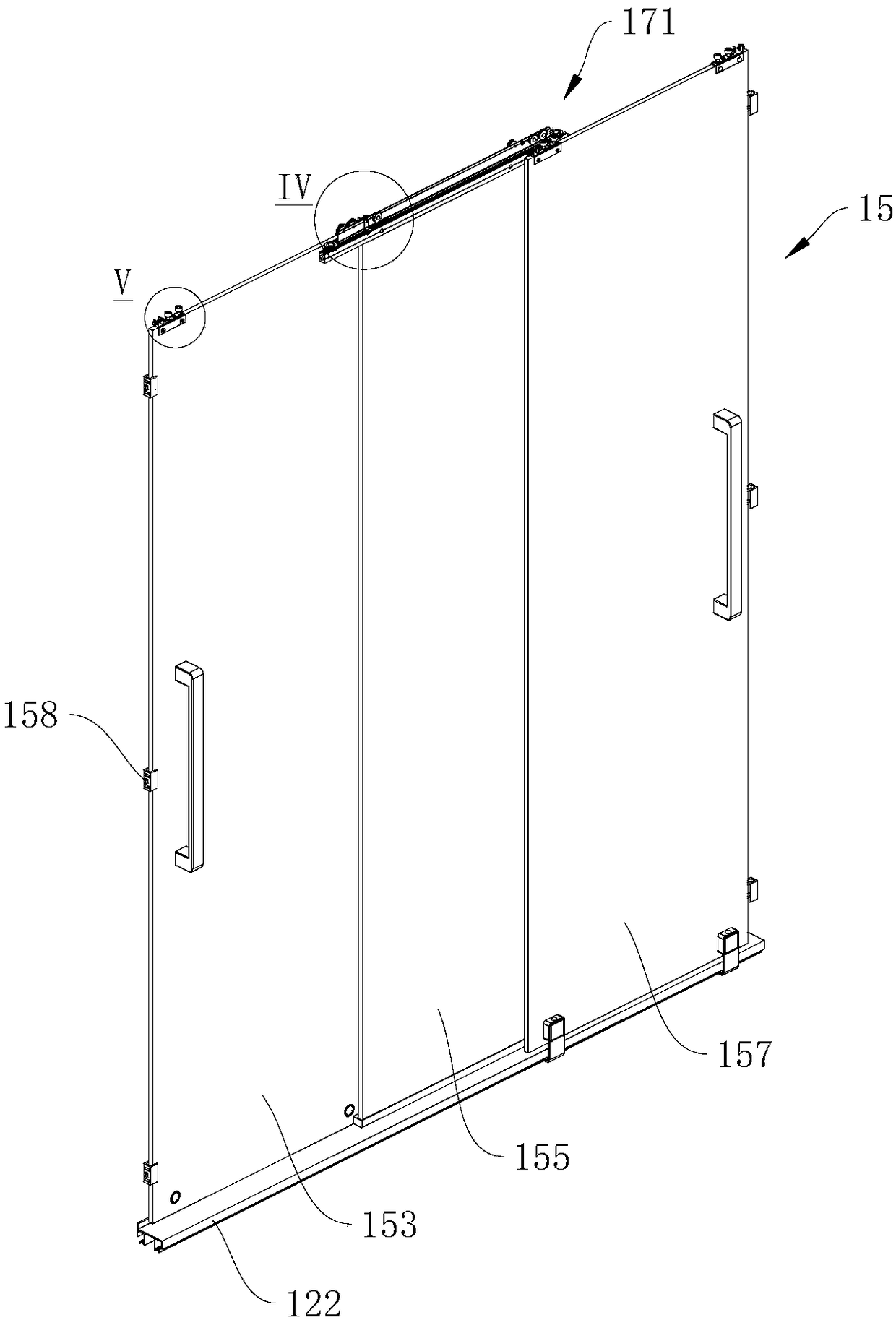

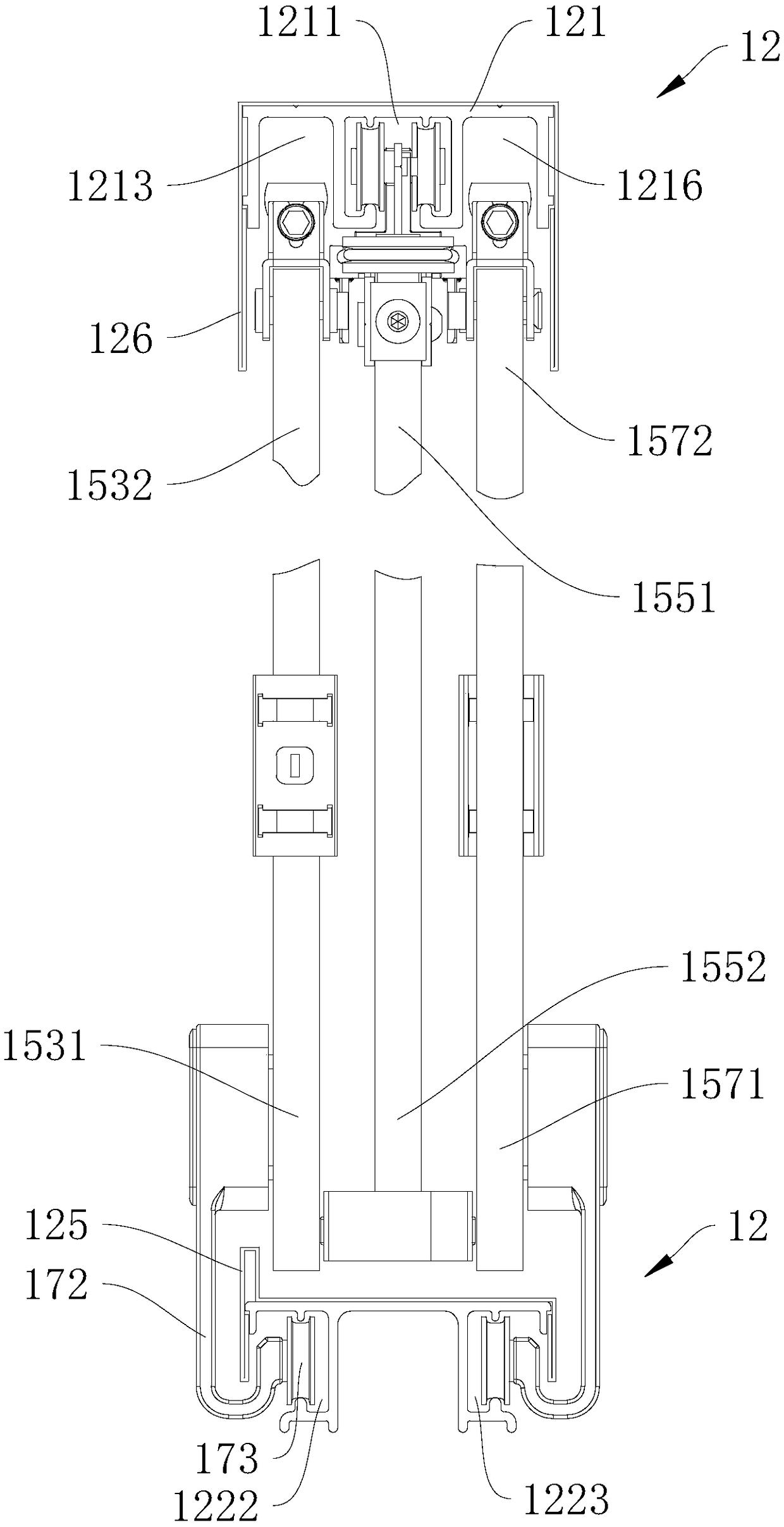

Triple linkage door and shower room door

PendingCN109505486AReduce the carrying weightReduce the chance of deformationWing operation mechanismsWing arrangementsWeight distributionLow volume

The invention discloses a triple linkage door and a shower room door, and relates to the technical field of linkage doors. A track assembly of the triple linkage door includes a first guide rail and asecond guide rail, the first guide rail is provided with a first track, and the second guide rail is provided with a second track and a third track. A door assembly includes a first door body, a second door body and a third door body. Two ends of the first door body are respectively a first sliding end and a first guiding end, one end of the second door body is a second sliding end, and two endsof the third door body are respectively a third sliding end and a third guiding end. The second sliding end is in sliding connection to the first track, the first sliding end is in sliding connectionto the second track, and the third sliding end is in sliding connection to the third track. A sliding assembly includes a linkage mechanism, and the linkage mechanism is adjacent to the first guide rail and is respectively connected to the second sliding end, the first guiding end and the third guiding end. The triple linkage door and the shower room door have the advantages of being uniform in weight distribution, uniform in upper and lower volume and convenient to install due to the fact that the guide rails are not easily deformed.

Owner:GUANGZHOU OUPAI SHOWER EQUIP

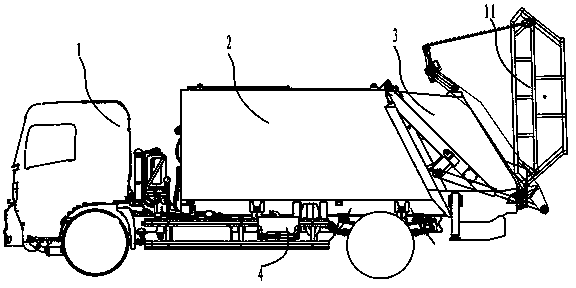

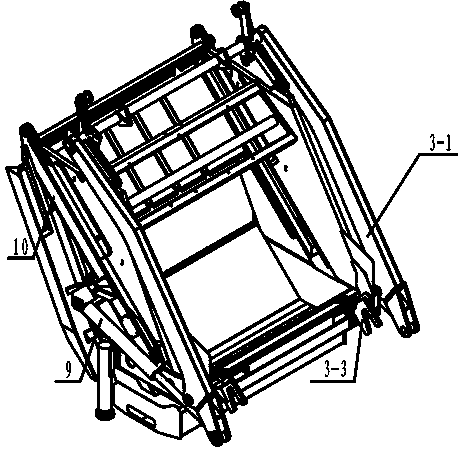

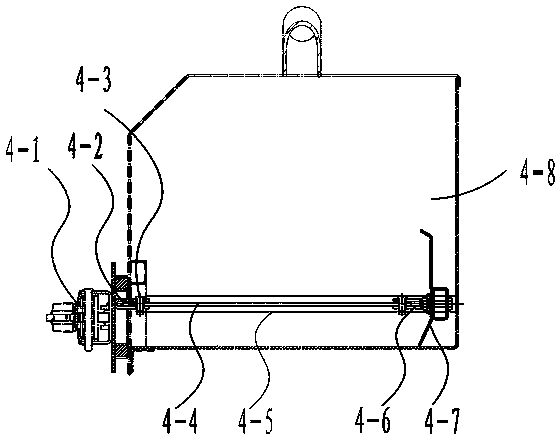

Compression refuse collection vehicle

ActiveCN103708153APrevent Trash TrappingReduce the chance of being caughtRefuse vehiclesAutomotive engineeringSewage

The invention relates to a compression refuse collection vehicle, in particular to a compression refuse collection vehicle which is capable of lifting different lifted hoppers, meanwhile solves the problem that refuse is clamped by a filling device and achieves the aims of collecting sewage and eliminating sediments of a sewage tank. The compression refuse collection vehicle comprises a chassis, a carriage, a filling mechanism with a lifting mechanism, the sewage tank with a dredging device and a refuse clamping-preventing device, wherein the carriage is installed on the chassis, the filling mechanism is fixed to the rear portion of the carriage, and the sewage tank is installed in the middle of the chassis. The compression refuse collection vehicle is easy to operate, the pouring angle of a lifted hopper is large, refuse can be completely poured, the different lifted hoppers can be lifted, the refuse-clamped phenomena can be effectively prevented, maintenance is easily achieved, the phenomena that the sewage tank is blocked by the sediments, and removal can not be achieved are avoided, and secondary pollution is effectively prevented.

Owner:广西玉柴专用汽车有限公司

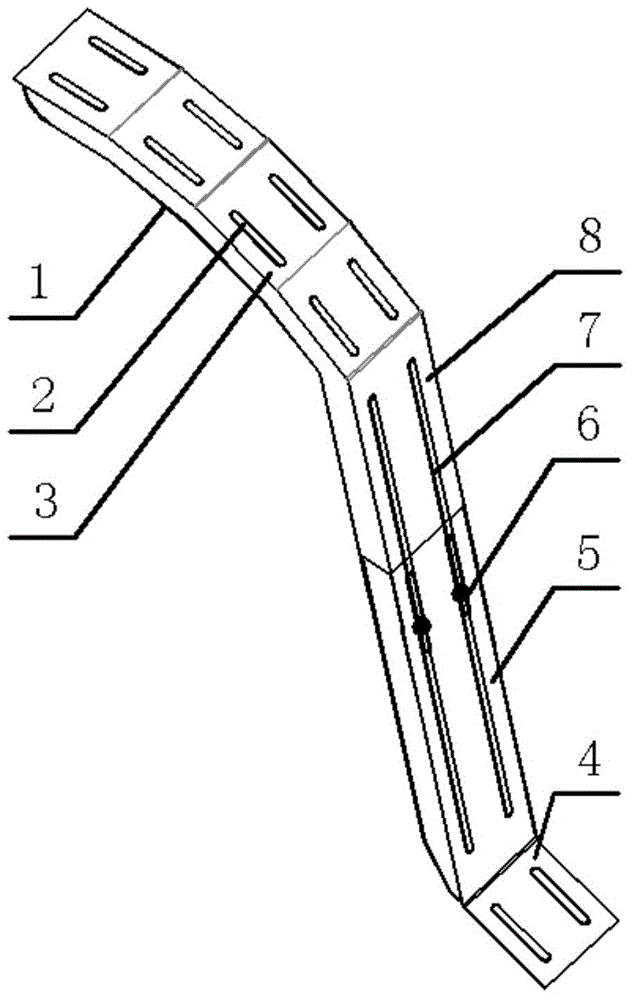

Protective cover of elevator traction machine

InactiveCN106276518AEnhance the ability of anti-shock and anti-knockReduce the chance of deformationBuilding liftsBatch productionAgricultural engineering

The invention relates to a protective cover of an elevator traction machine. The protective cover comprises an upper end movable cover body and a lower end fixed cover body. The upper end movable cover body is composed of an arc-shaped upper mounting part and an upper adjustment connecting part which is obliquely arranged below the upper mounting part. The lower end fixed cover body is composed of a lower adjustment connecting part and a lower mounting part which is obliquely arranged at the tail end of the lower adjustment connecting part. Both the upper mounting part and the lower mounting part are provided with long mounting hole sets. Both the upper adjustment connecting part and the lower adjustment connecting part are correspondingly provided with long adjustment hole sets. The upper end movable cover body can achieve adjustment and fixation with the lower end fixed cover body through the matching of screws and the two long adjustment hole sets. The protective cover further comprises reinforcing ribs. The reinforcing ribs are evenly arranged on the inner side face of the upper end movable cover body and the inner side face of the lower end fixed cover body. The protective cover of the elevator traction machine is scientific and reasonable in structural design and has the advantages of being wide in applied range, convenient to adjust, capable of achieving batch production, safe and stable, and capable of reducing installation cost.

Owner:SIGNOR ELEVATOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com