Compression refuse collection vehicle

A garbage truck, compression technology, applied in the direction of garbage receptacle, transportation and packaging, to prevent the phenomenon of garbage trapping, easy maintenance, and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

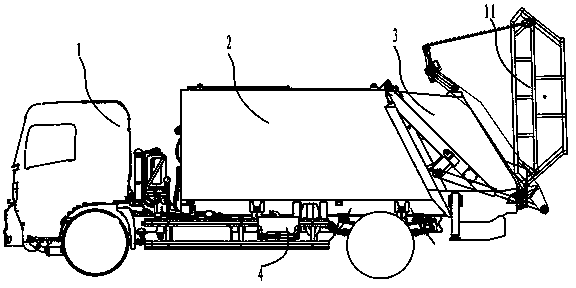

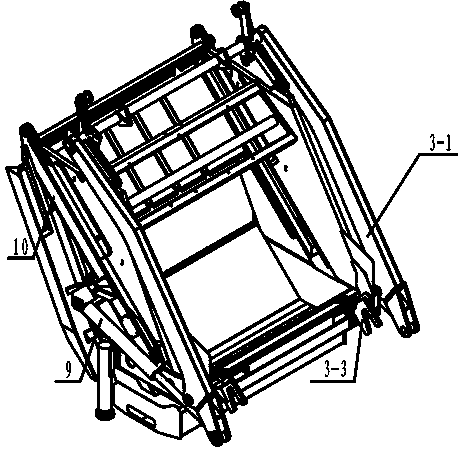

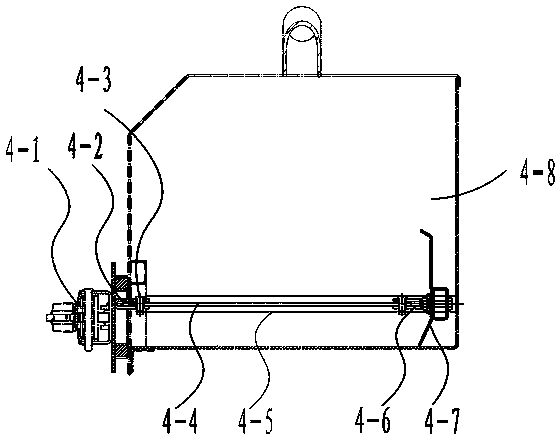

[0044] Describe structure of the present invention below in conjunction with accompanying drawing and working process thereof.

[0045] as attached Figure 1~4 As shown, it includes chassis 1, carriage 2, filling mechanism with hoisting mechanism 3, sewage tank with dredging device 4, garbage anti-clamping device 5, filling device housing 6, slide plate 7, crushing plate 8, and driving mechanism 9. Filling device 10, hoisting bucket 11 and chain 12. The carriage 2 is installed on the chassis 1, the filling device 10 is hinged at the rear of the carriage 2, and the slide plate 7 and the crushing plate 8 are installed on the filling device 10. Inside the loading device housing 6, the filling mechanism 3 is fixed at the rear end of the filling device housing 6, one end on the left and right sides of the driving mechanism 9 is respectively fixed on both sides of the garbage truck filling device 10, and the other end of the driving mechanism 9 is fixed on the filling device. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com