Patents

Literature

487results about How to "Avoid hard contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

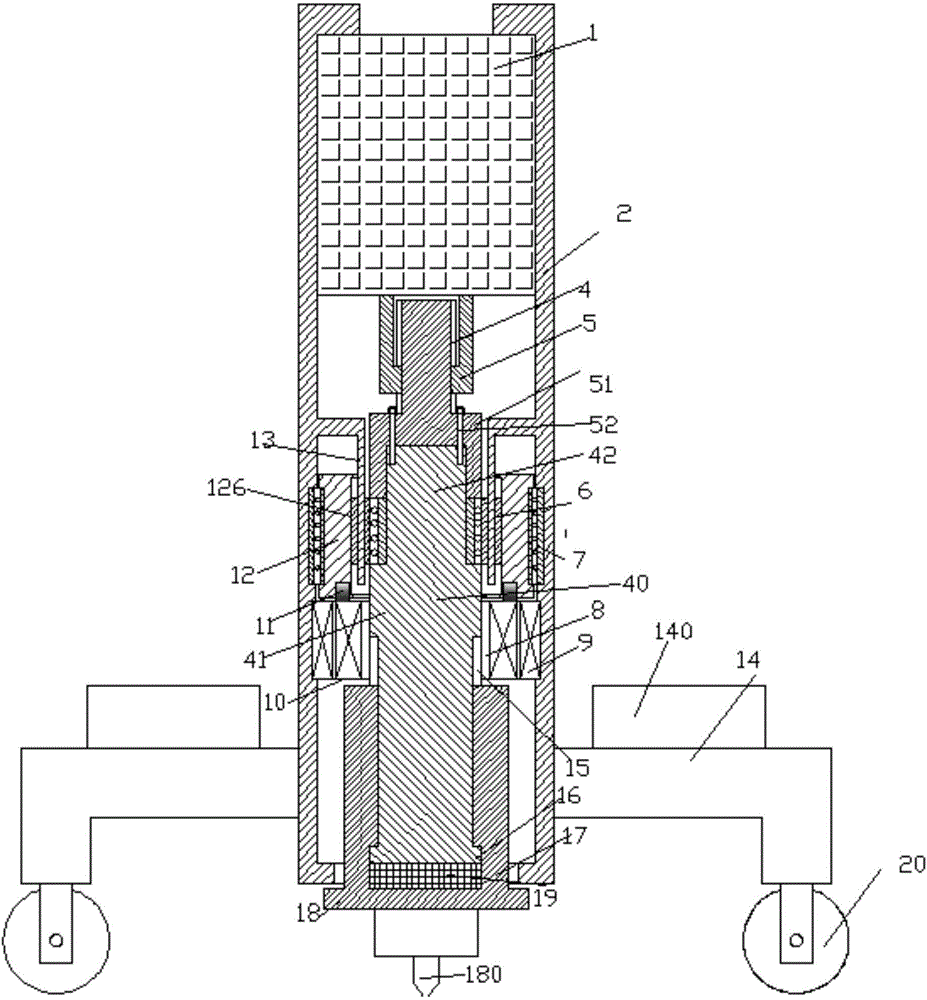

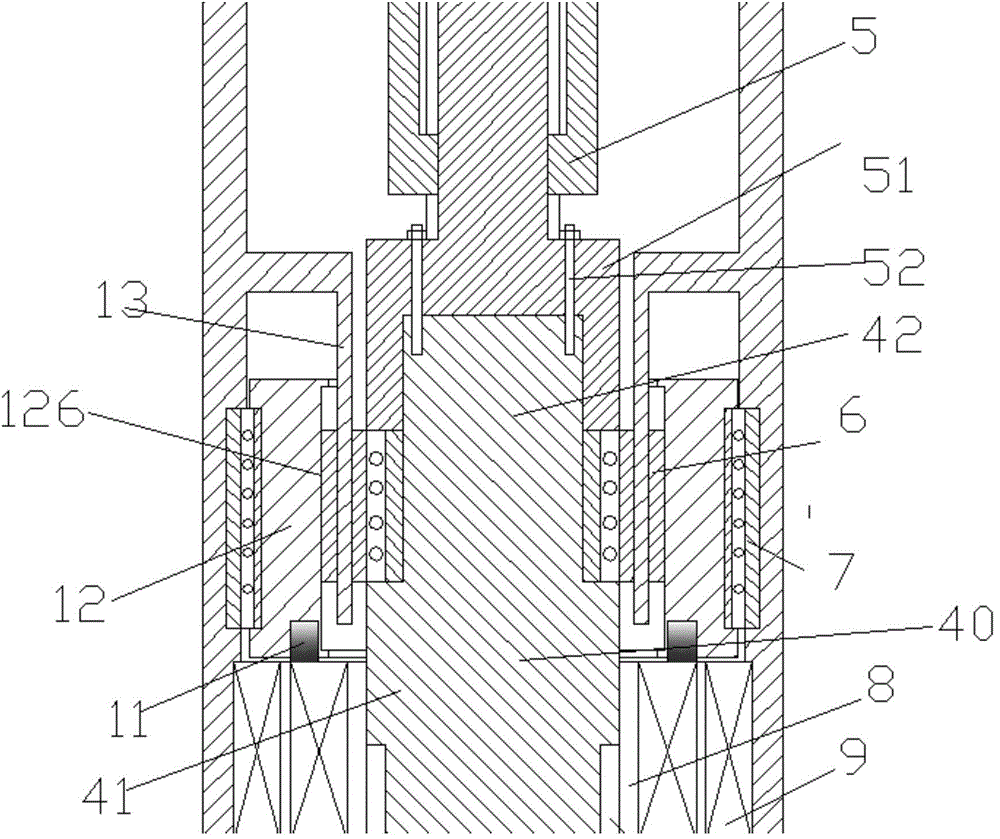

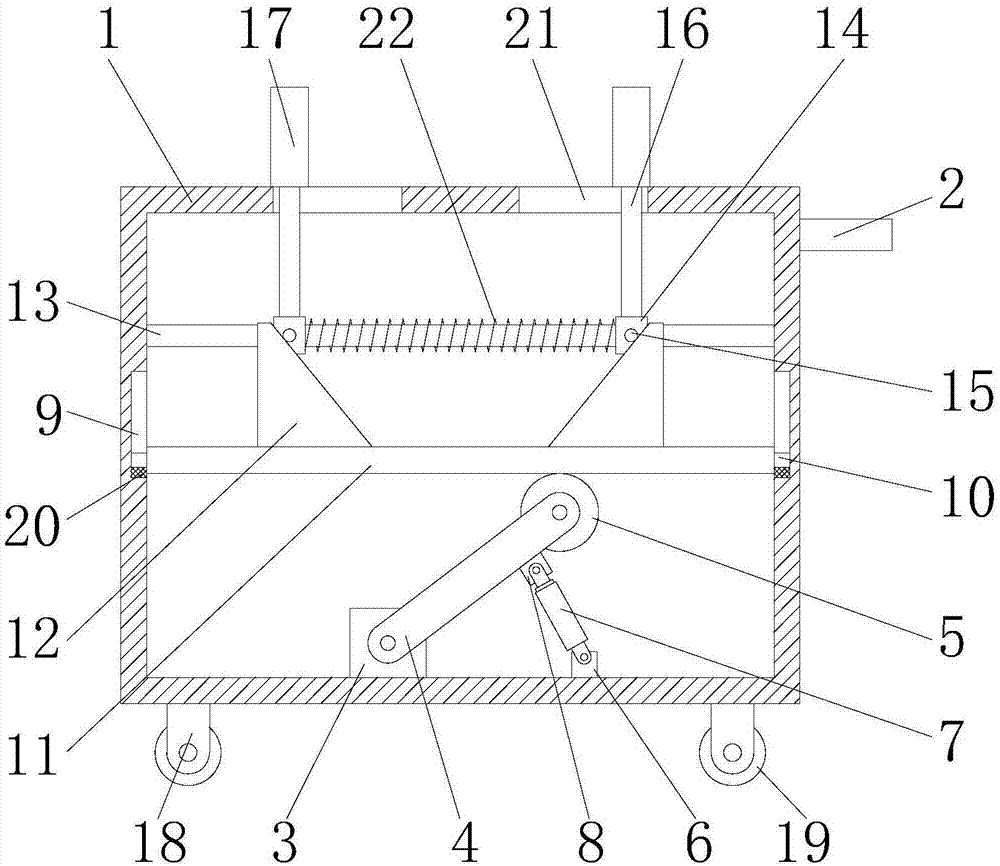

Movable type hole drilling device

InactiveCN104526004AAvoid hard contactEasy to assembleBoring/drilling componentsBoring/drilling machinesCouplingPipe fitting

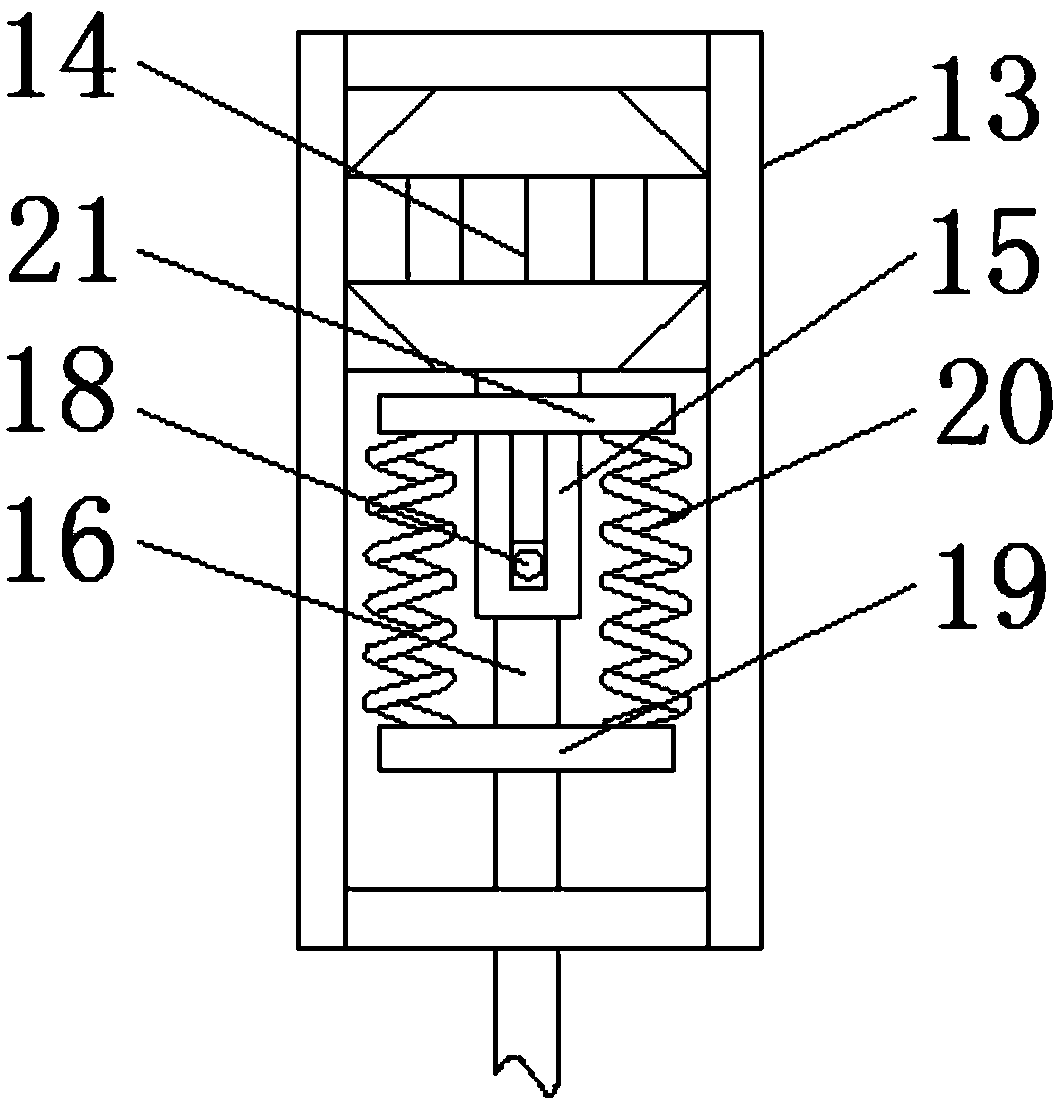

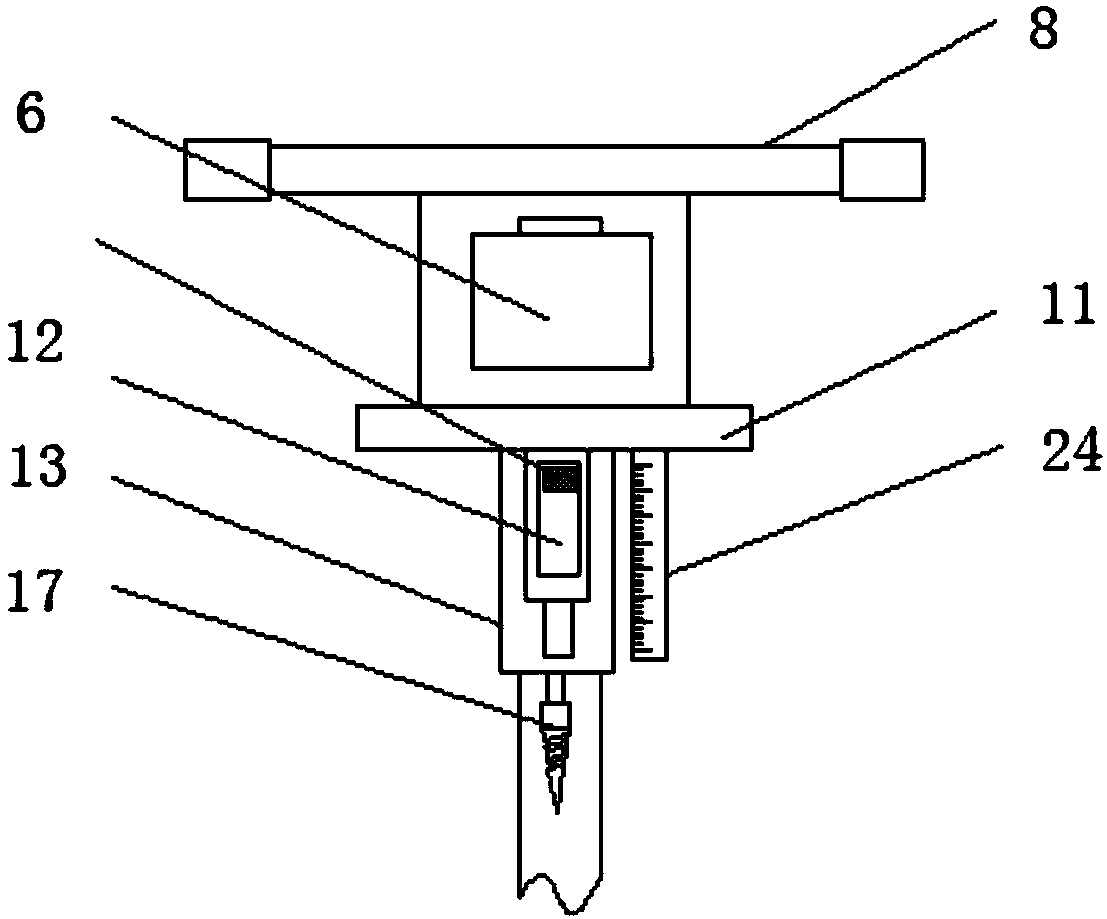

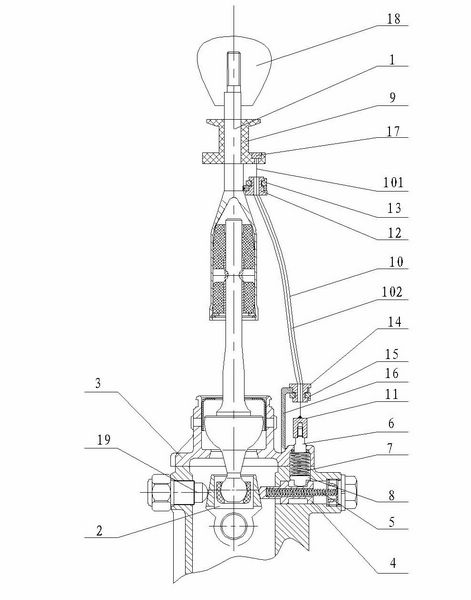

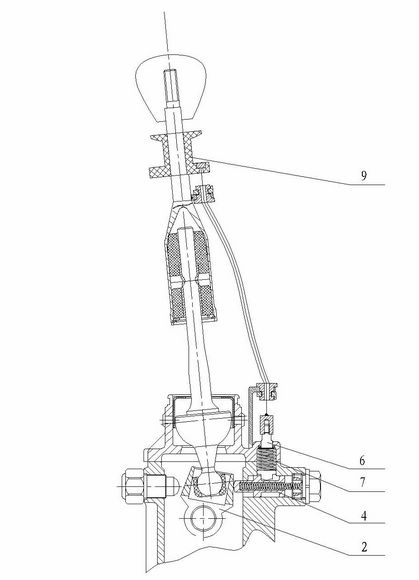

Provided is a movable type hole drilling device. The movable type hole drilling device comprises a shell (2). The lower portion of the shell (2) is fixedly connected with an idler wheel installation part (14). The lower portion of the idler wheel installation part (14) is provided with idler wheels (20) used for moving the hole drilling device. The upper portion of the idler wheel installation part (14) is capable of removably placing weight blocks (140) used for providing downward pressure during the hole drilling process. The upper portion of the shell (120) is provided with a hole drilling driving motor (2). The hole drilling driving motor (2) is in power connection with spline housing pipe fittings (5). The spline housing pipe fittings (5) are matched with spline shafts arranged on the upper portions of spline shaft connecting pieces (4). The lower portions of the spline shaft connecting pieces (4) are provided with a coupling sleeve. A concave portion of the coupling sleeve is used for containing a minor diameter part (42) on the upper portion of a drill driving shaft (40), and the coupling sleeve is fixedly connected with the drill driving shaft (40) through longitudinal extending fastening bolts (52).

Owner:王达

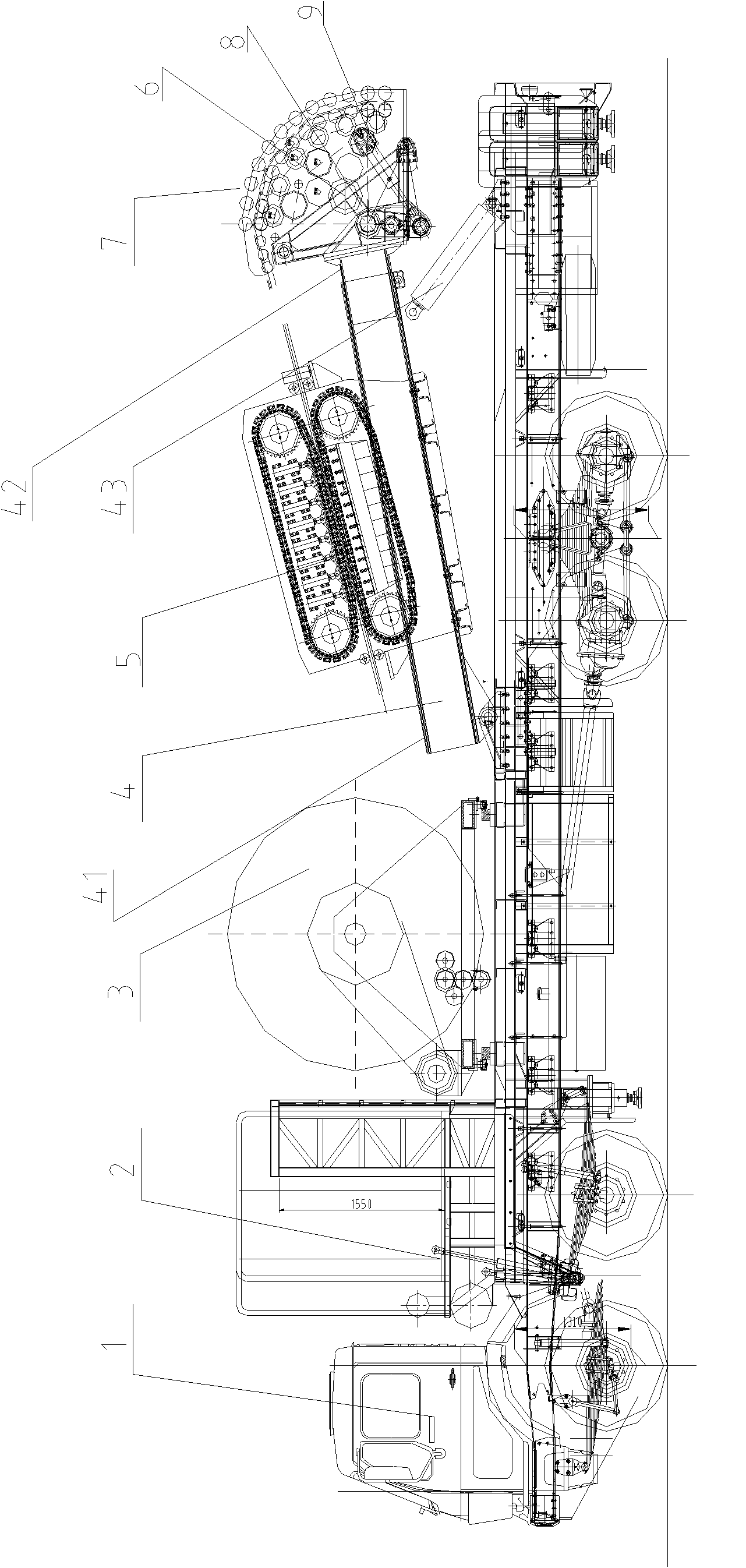

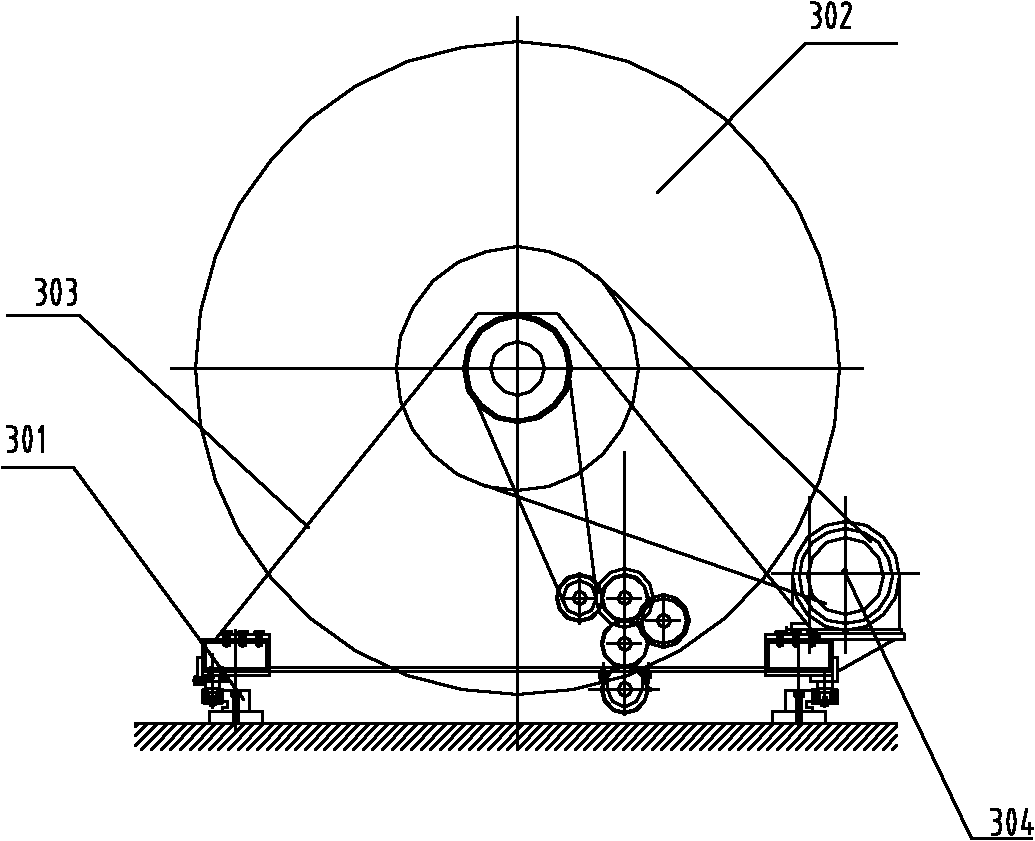

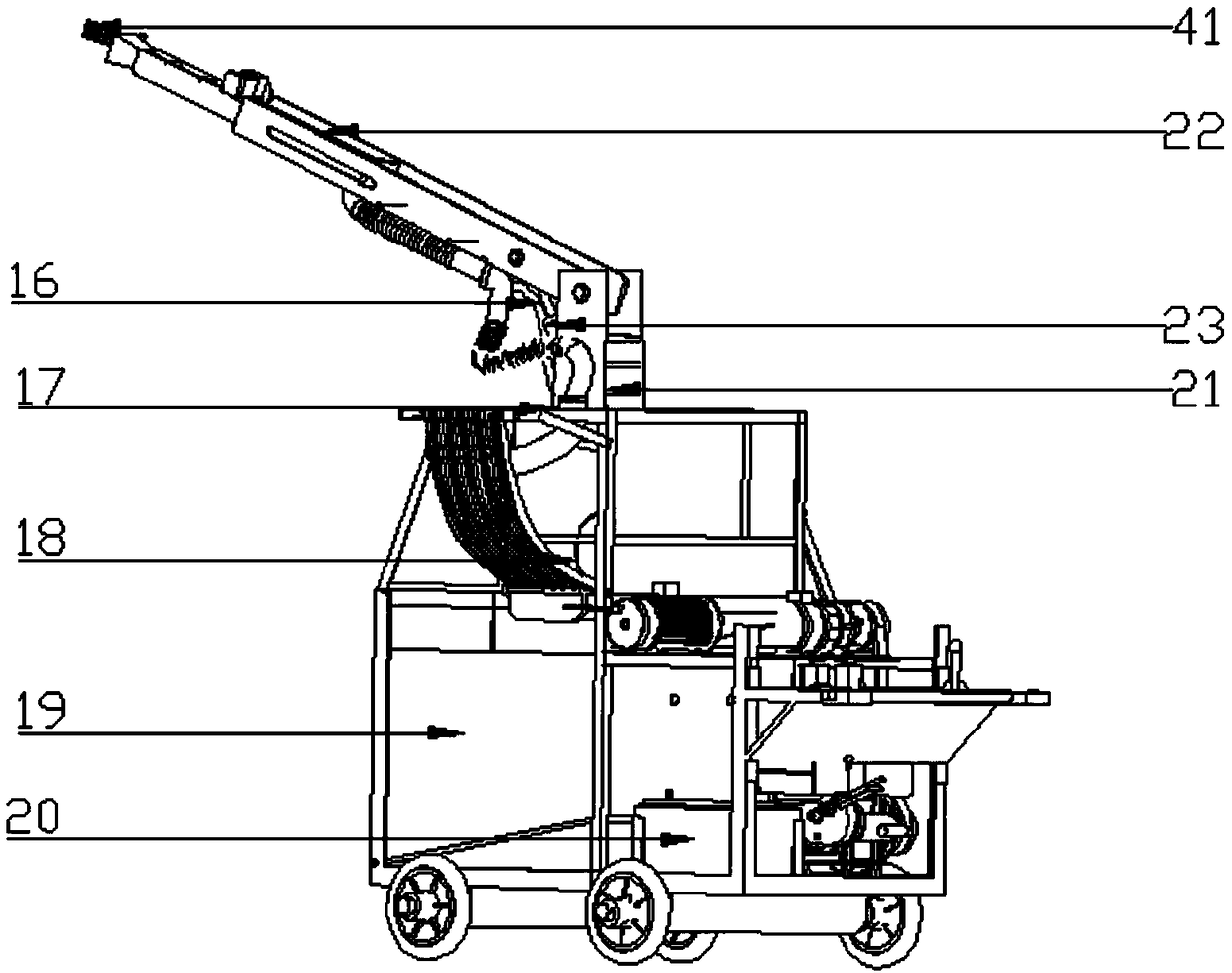

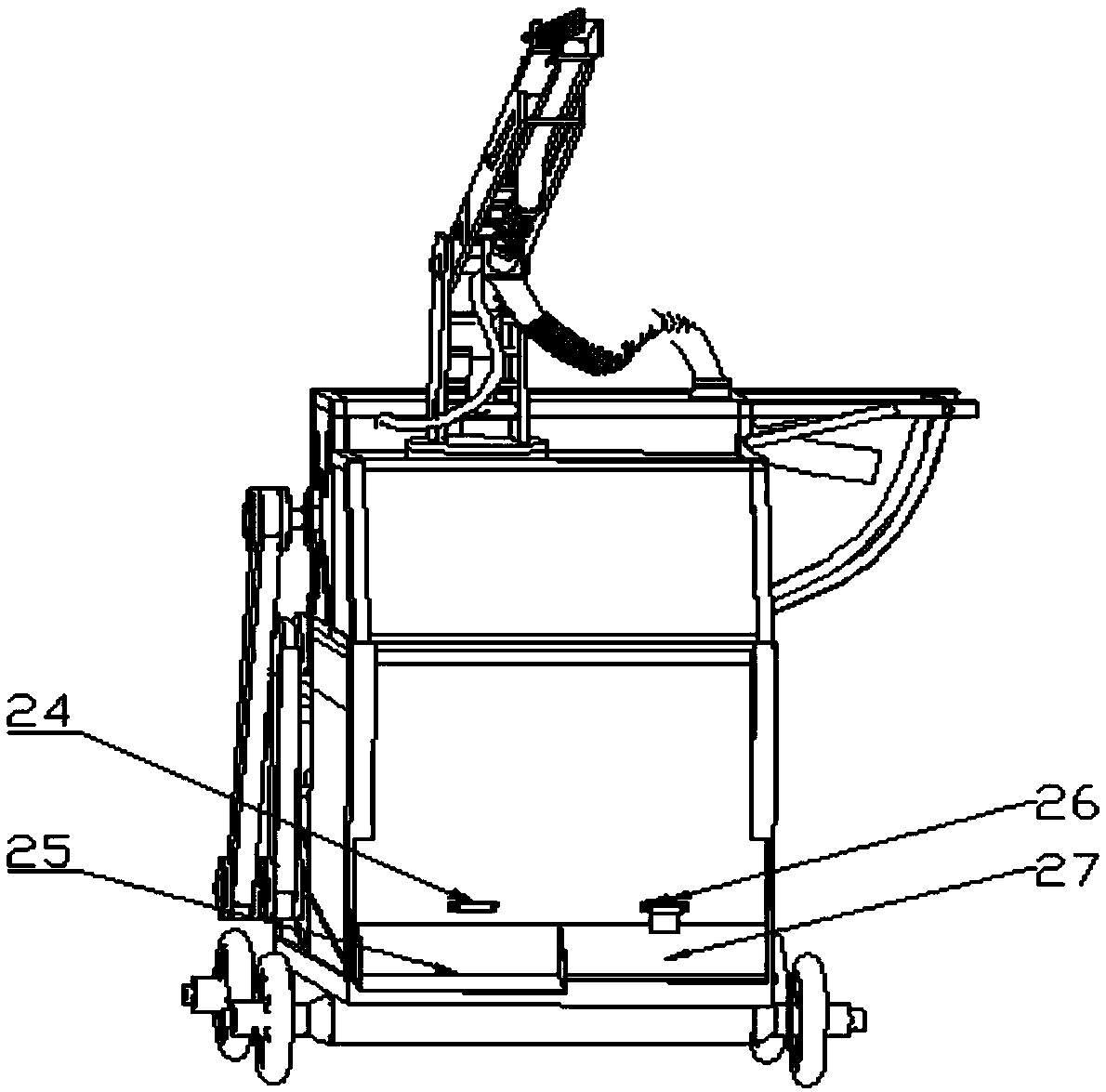

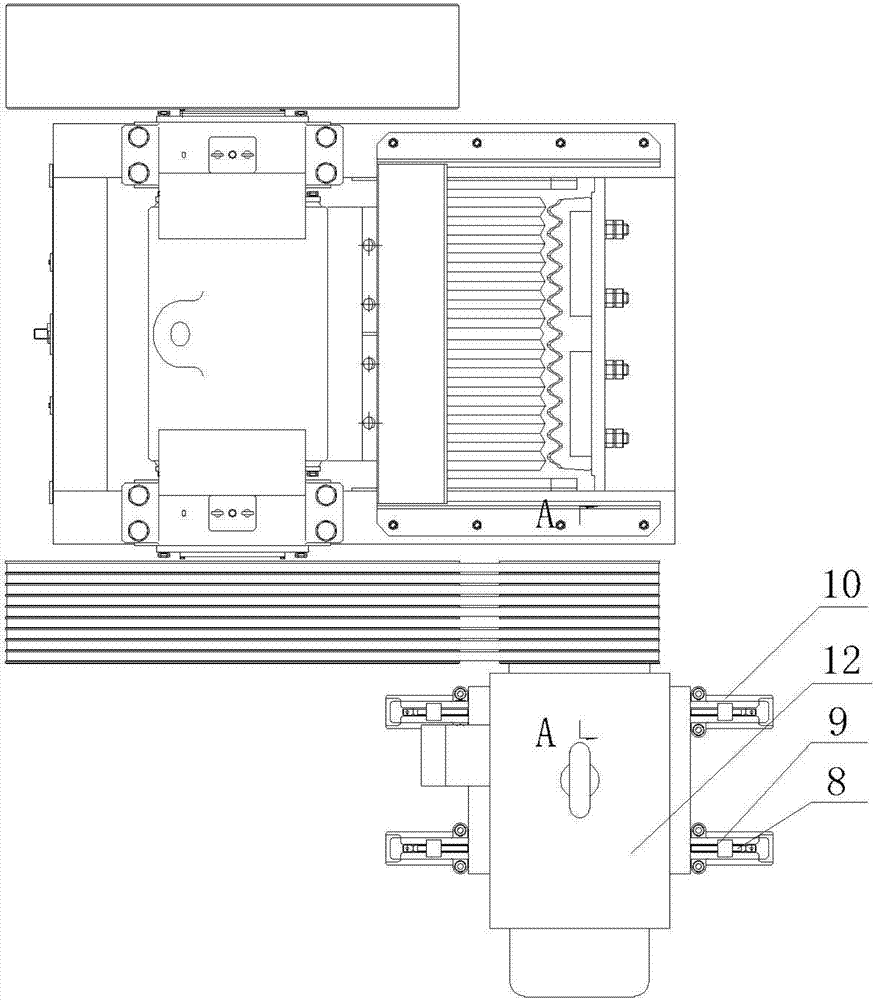

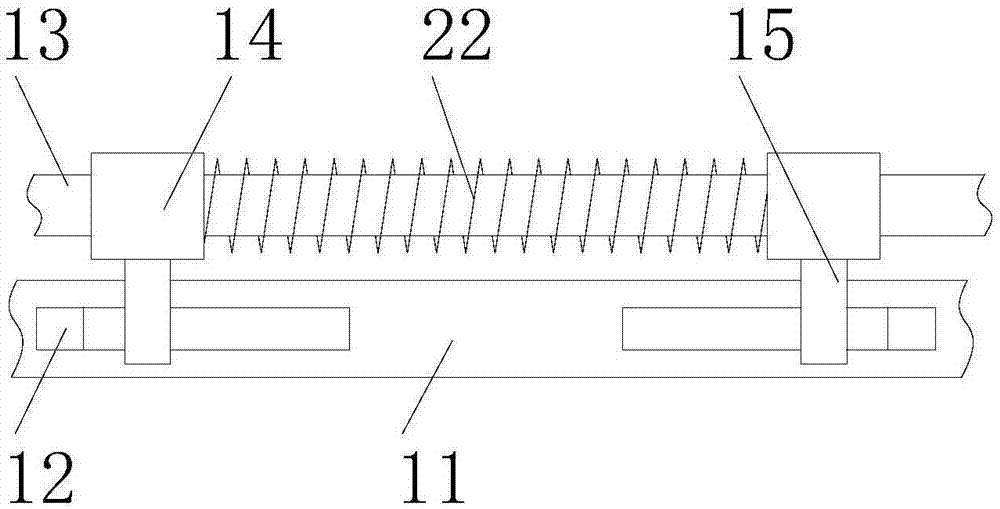

Continuous pipeline tripping device

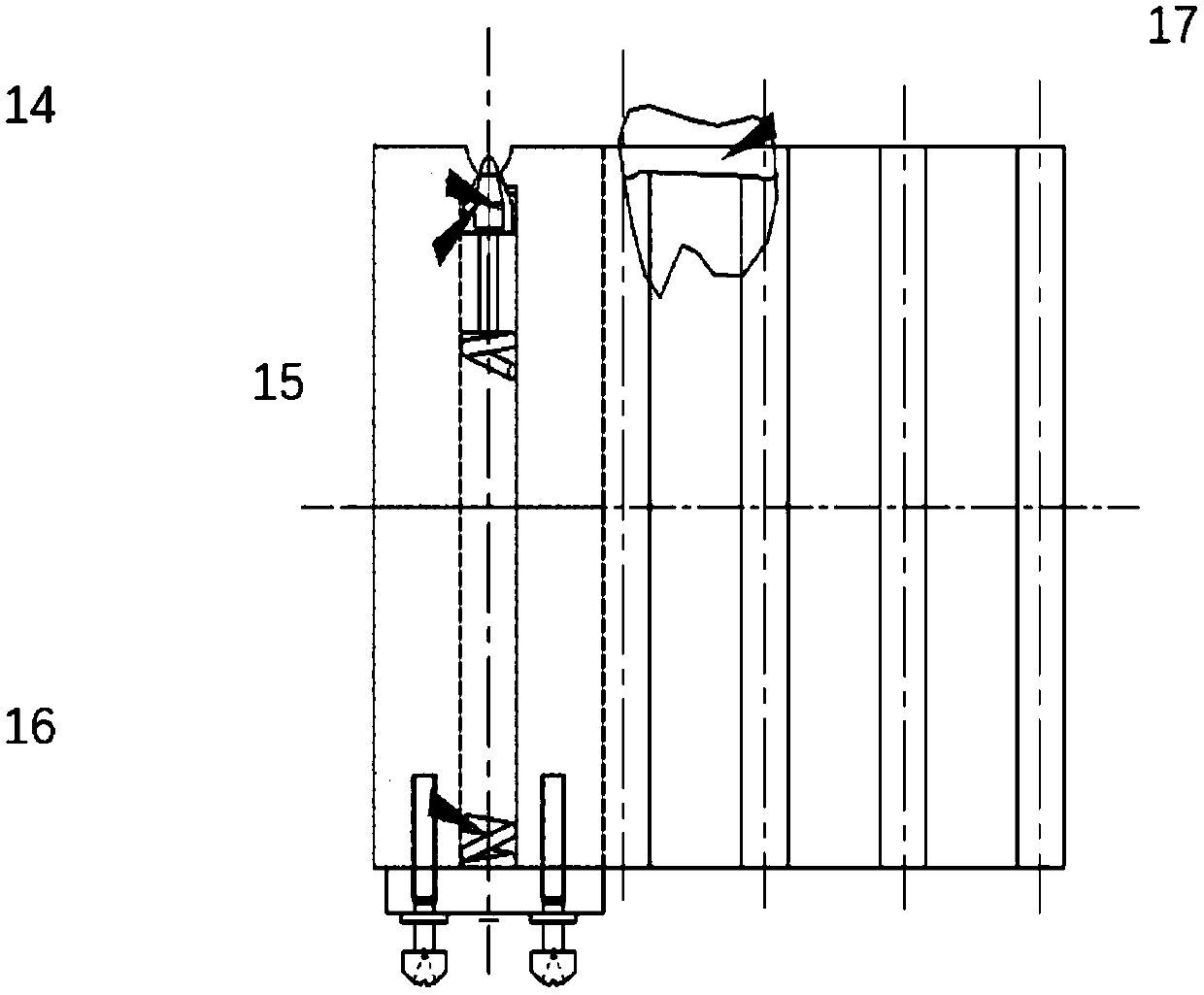

ActiveCN102733768AQuick connectionEasy to operateDrilling rodsDrilling casingsTraction systemRotating drum

The invention discloses a continuous pipeline tripping device, comprising a rotating drum retracting, laying and releasing system, a guided injection system, a traction system, and a hydraulic power system used for supplying power for the above systems. The rotating drum retracting, laying and releasing system comprises a rotating drum, a cable laying device and a guide rail, wherein the guide rail is fixed on an underpan of a vehicle system, the rotating drum is in a sliding connection with the guide rail through a rotating drum supporting seat, the cable laying device is fixed on one side of the rotating drum, the rotating drum is driven to move along the guide rail by the cable laying device, thereby realizing the arrangement of an oil pipeline on the rotating drum. The traction system comprises a double-arm crane and a flat track frictional transmission device. When the rotating drum rotates, the oil pipeline on the rotating drum passes through the flat track frictional transmission device and a guided injection head in sequence to enter into an oil well. According to the invention, a fast connection with the mouth of the well is guaranteed, the operational process of site construction is simplified, the damage of pipelines is prevented, and the success rate of construction is increased.

Owner:PETROCHINA CO LTD

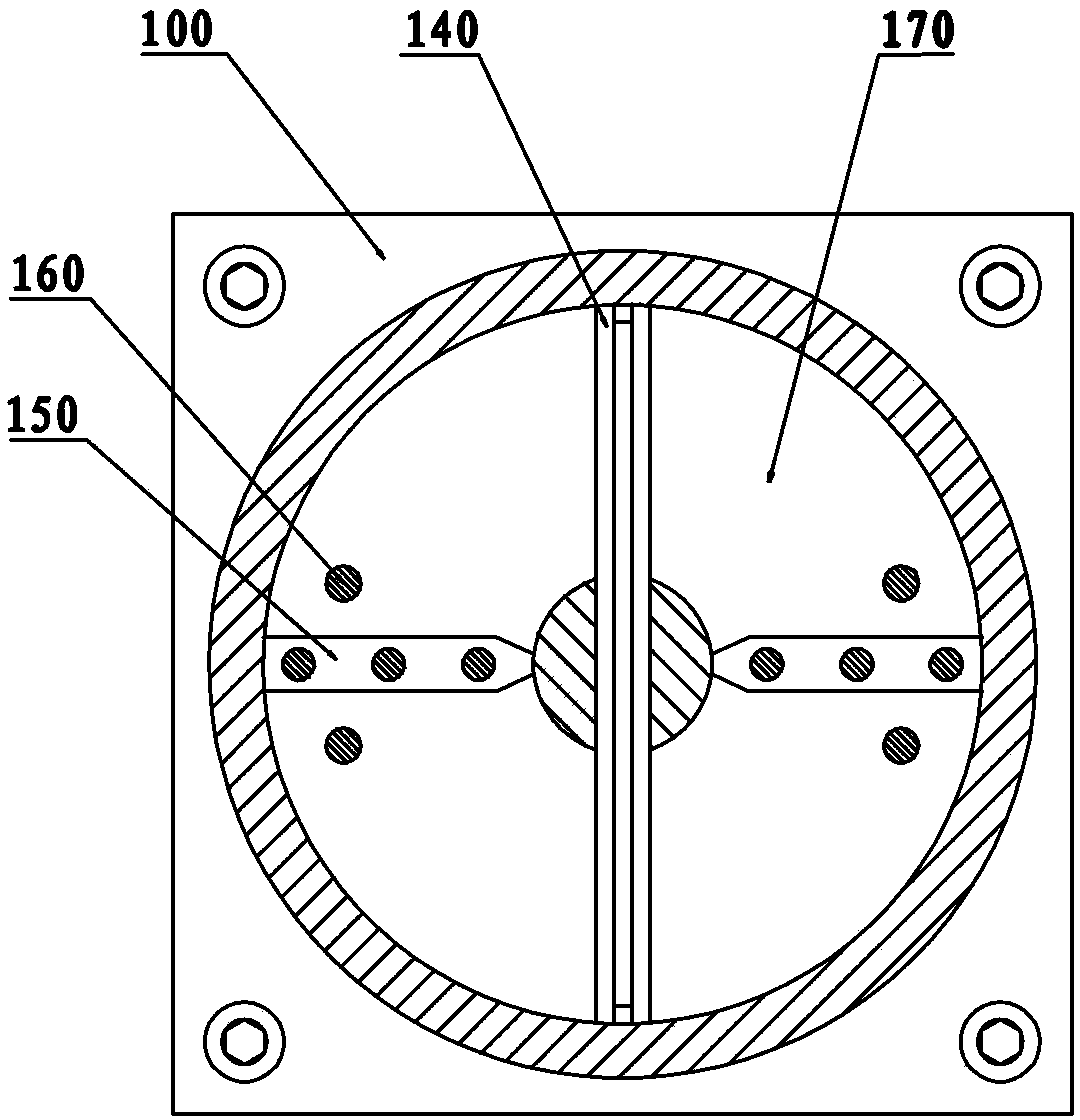

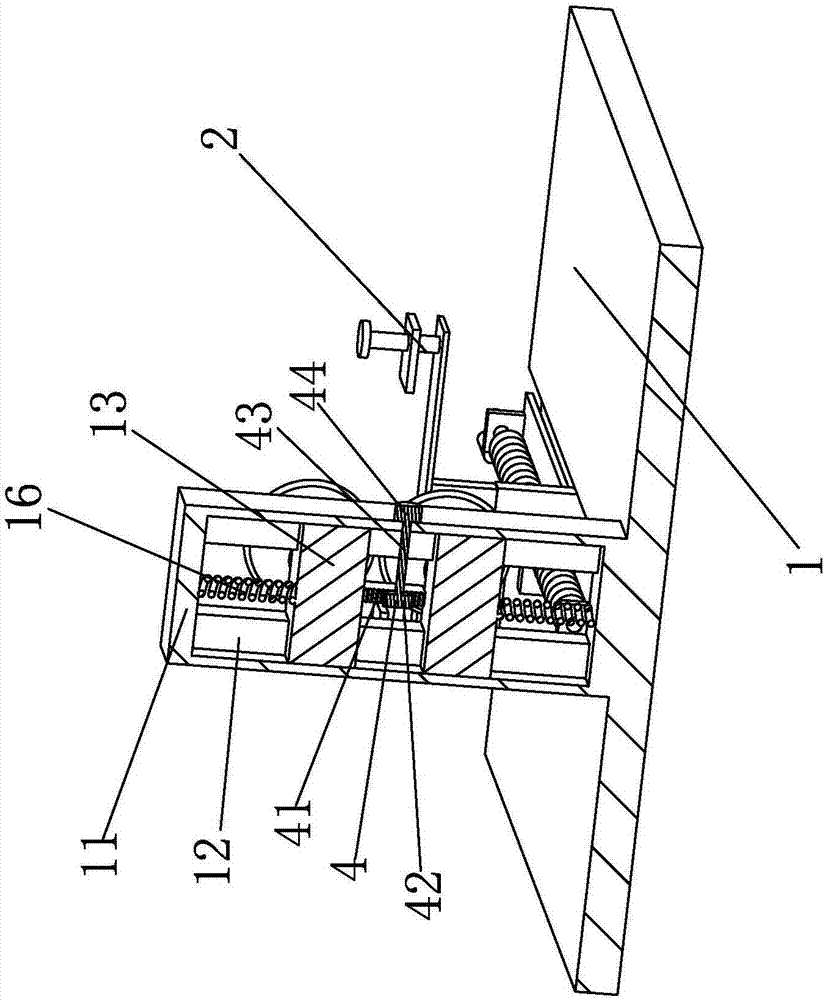

Rotary type viscous fluid damper

InactiveCN103388360AGood resistance to torsional vibrationMeet construction requirementsShock proofingEngineeringFront and back ends

The invention relates to the design field of dampers, in particular to a rotary type viscous fluid damper, which comprises a cylinder body, a front guide sleeve, a rear guide sleeve, a cavity dividing block, a rotary blade and a rotary shaft, wherein the front guide sleeve and the rear guide sleeve are respectively arranged on front and back ends of the cylinder body so as to form a closed space; the rotary blade, the rotary shaft and the cavity dividing block are simultaneously arranged in the closed space; one end of the rotary shaft penetrates through a central point of the front guide sleeve; the other end of the rotary shaft is movably connected with a central point of the rear guide sleeve; the rotary blade is arranged on the side face of the rotary shaft; the cavity dividing block is simultaneously connected with the front guide sleeve and the rear guide sleeve, and divides the closed space into spaces with equal volume; damping holes are arranged on the rotary blade; and damping medium are filled in the closed space. Through applying the technical scheme, the damping effect is better, and the size is smaller.

Owner:刘康安

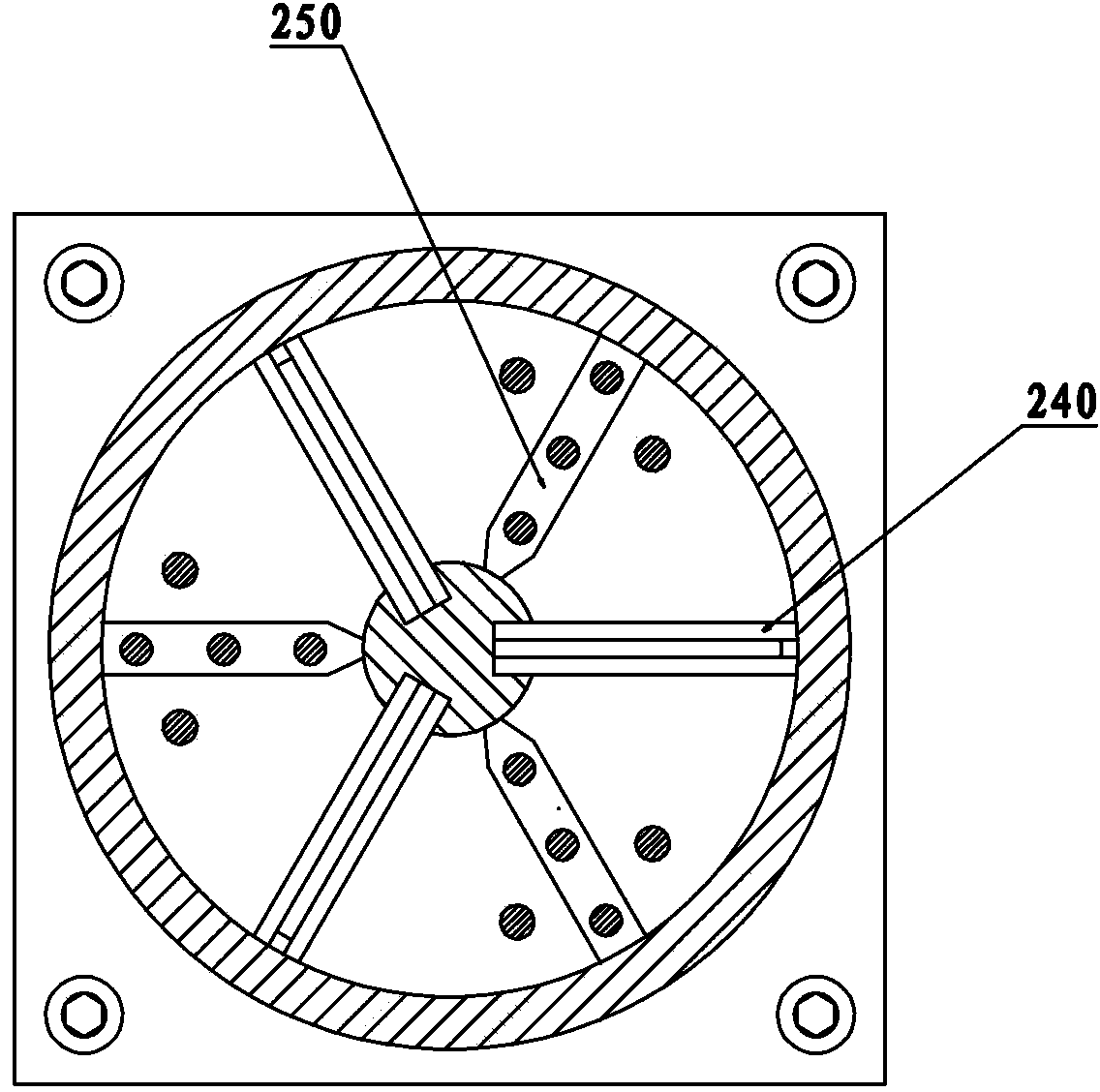

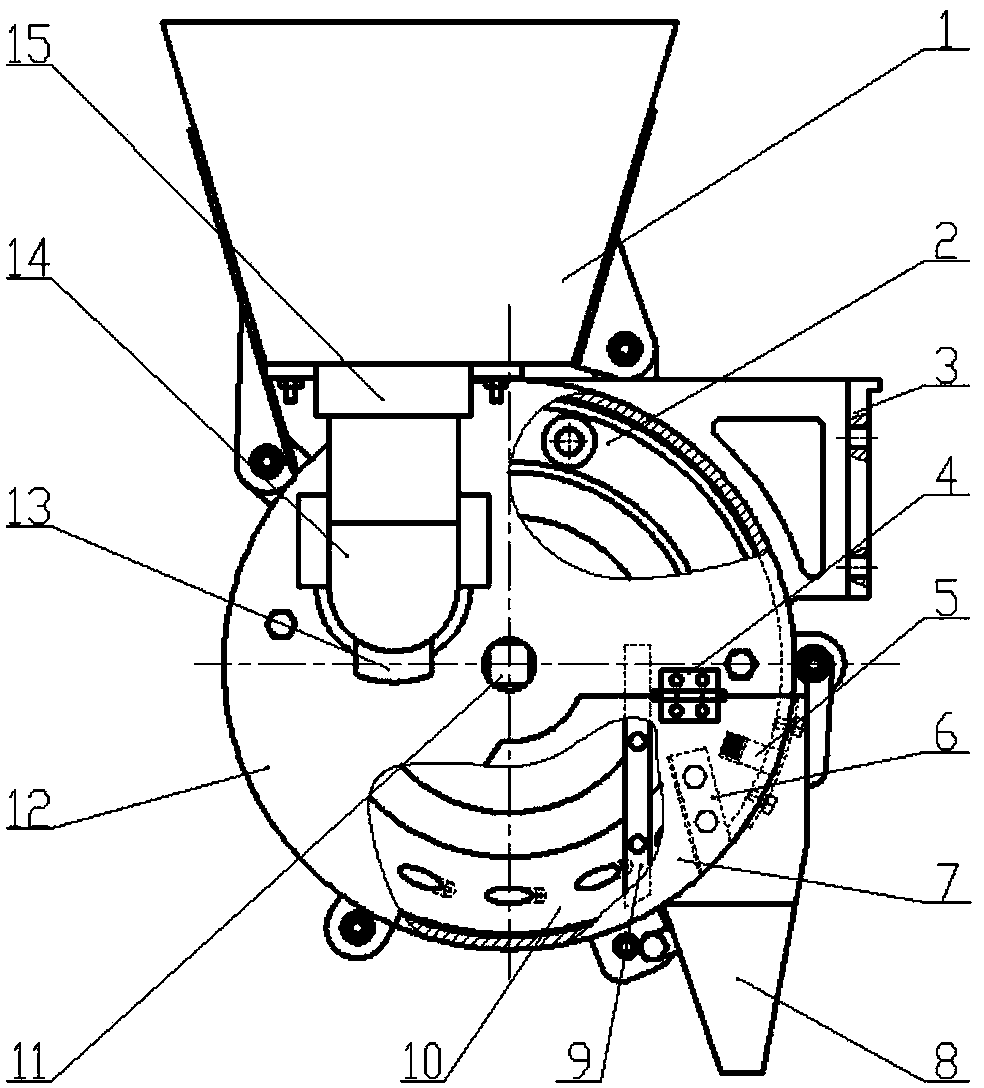

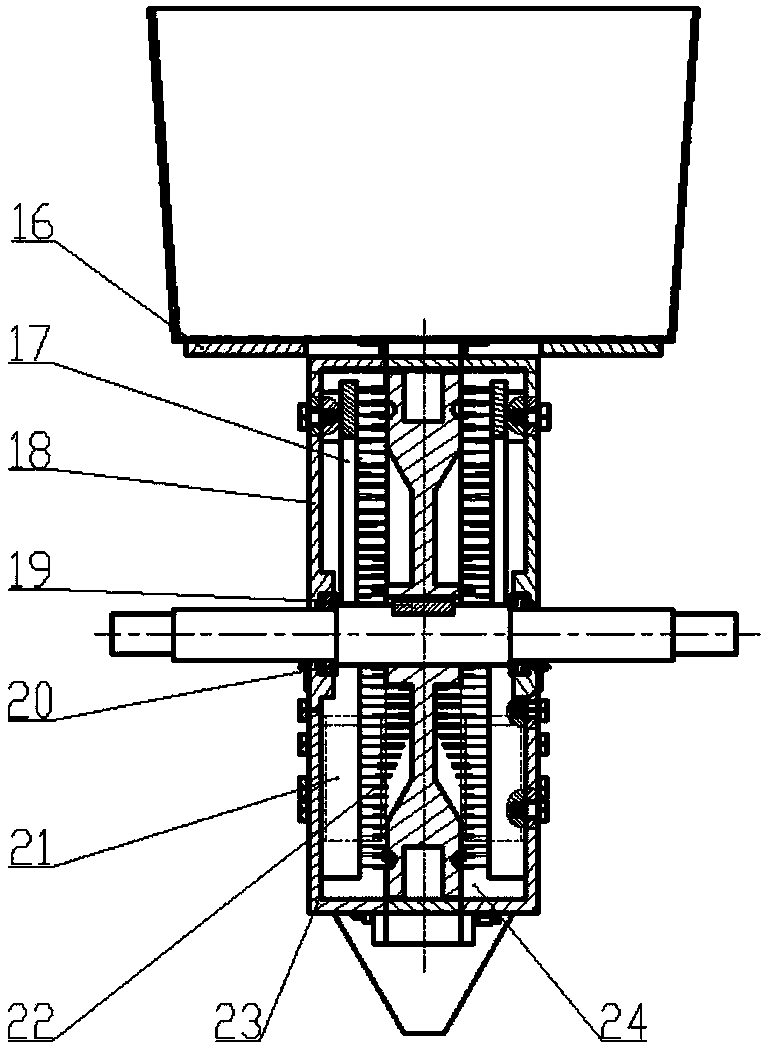

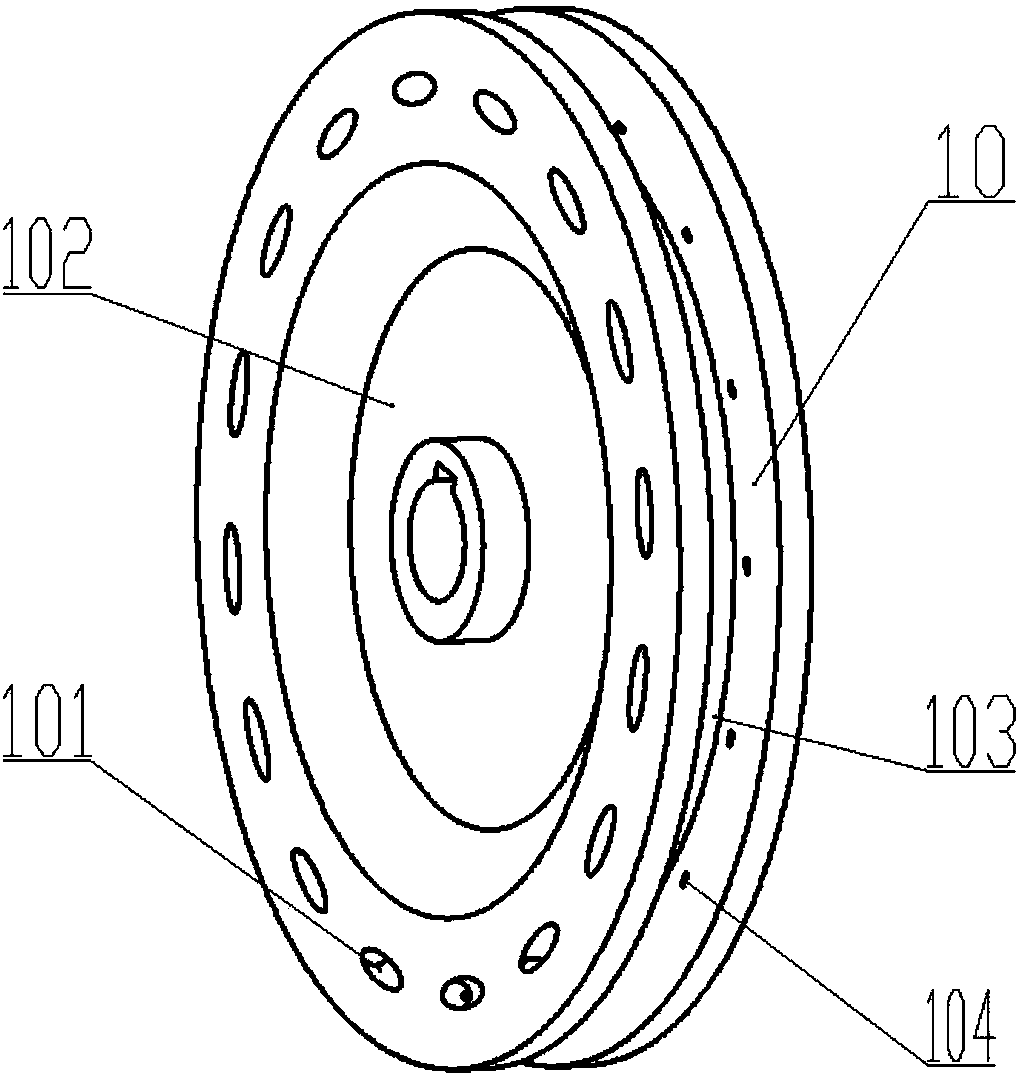

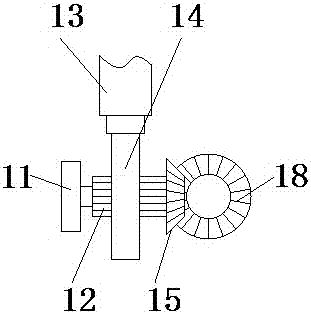

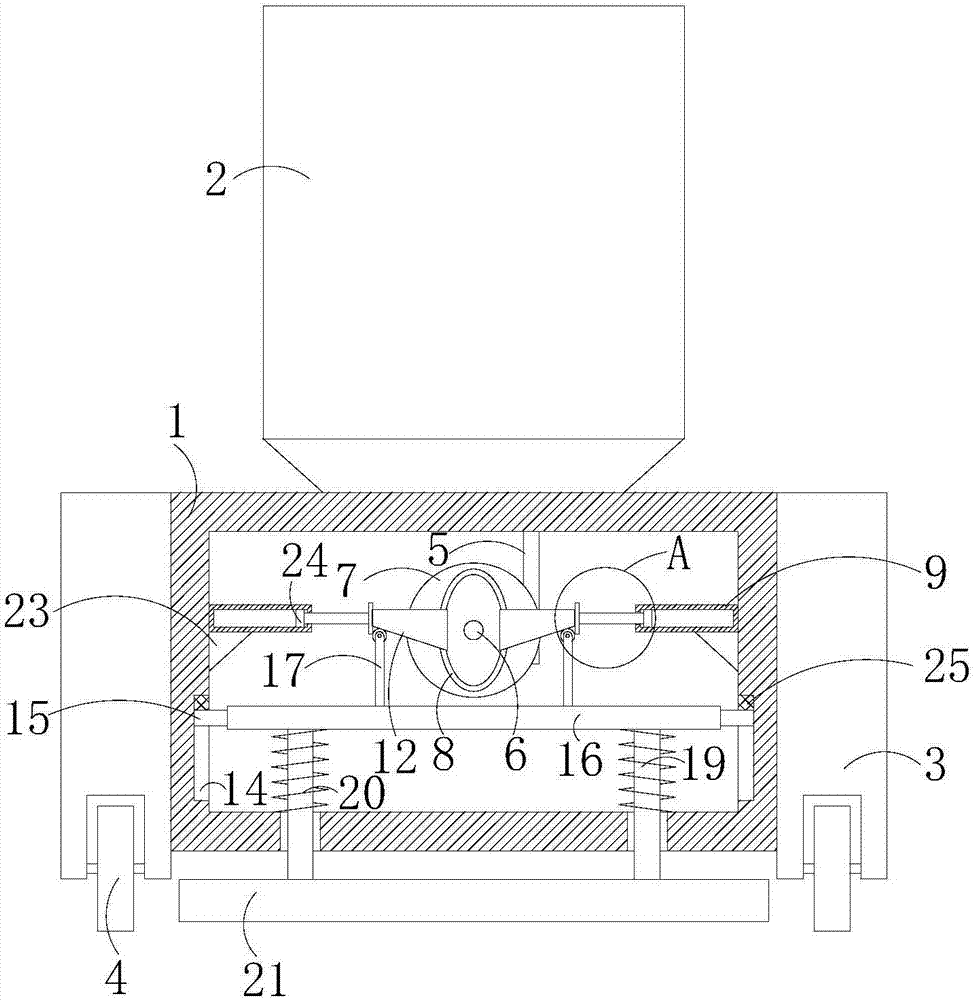

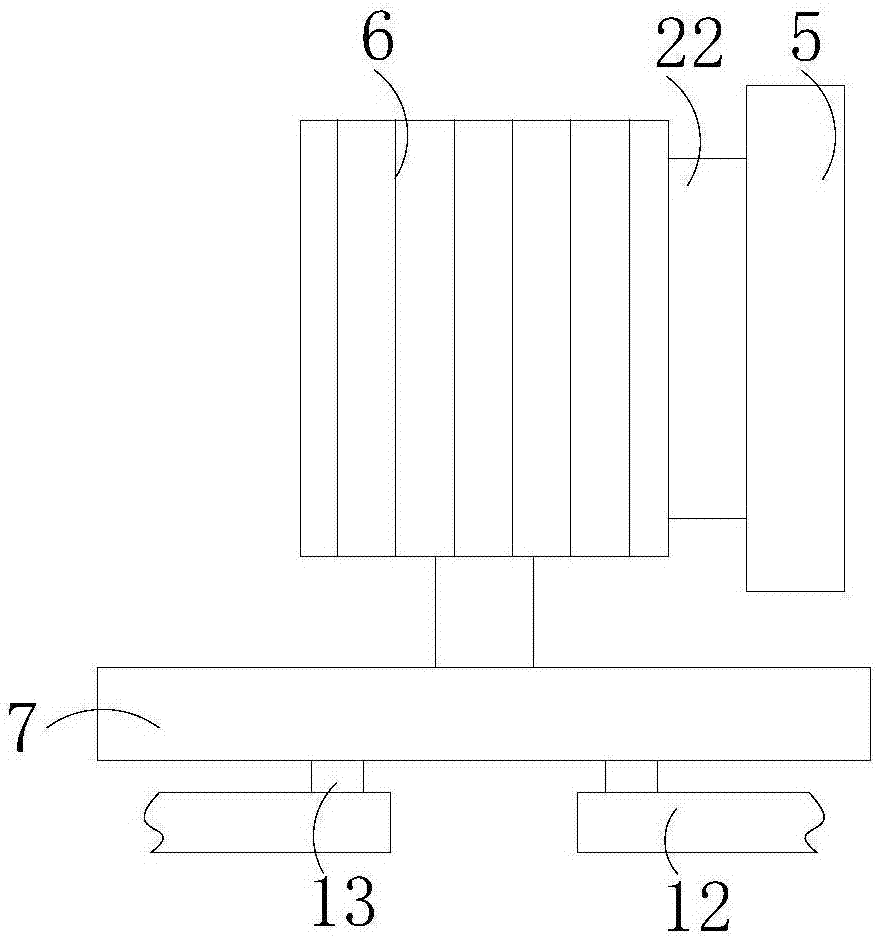

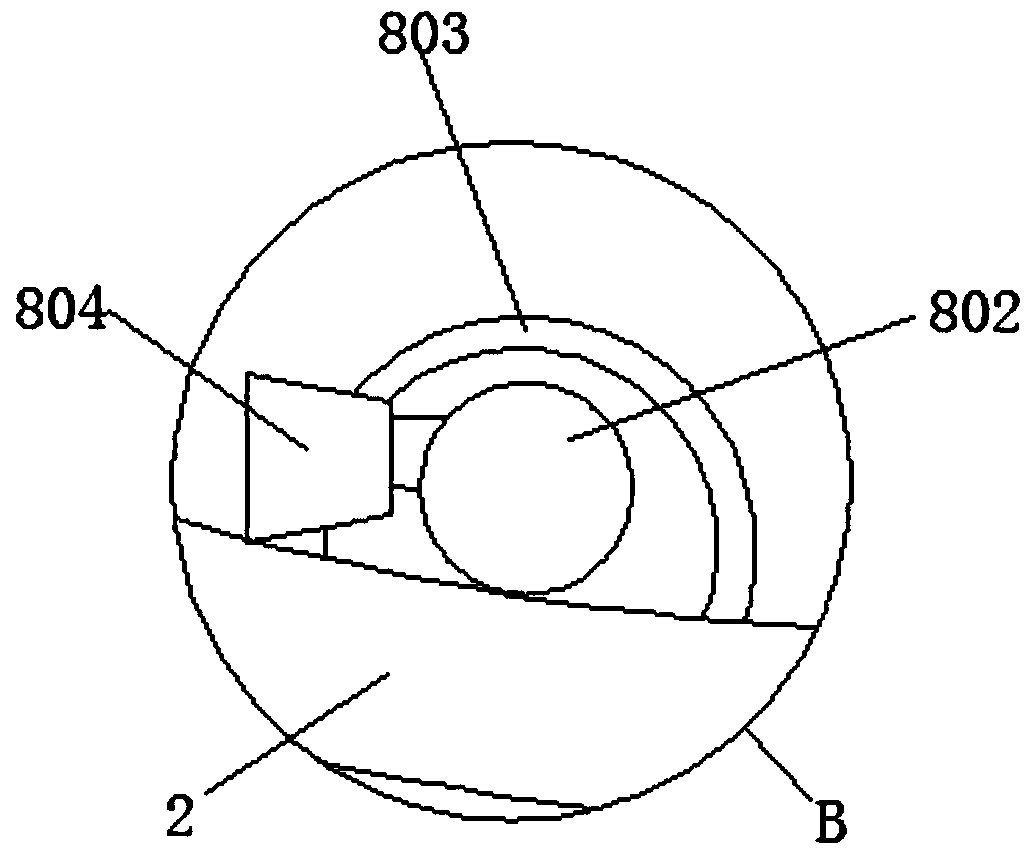

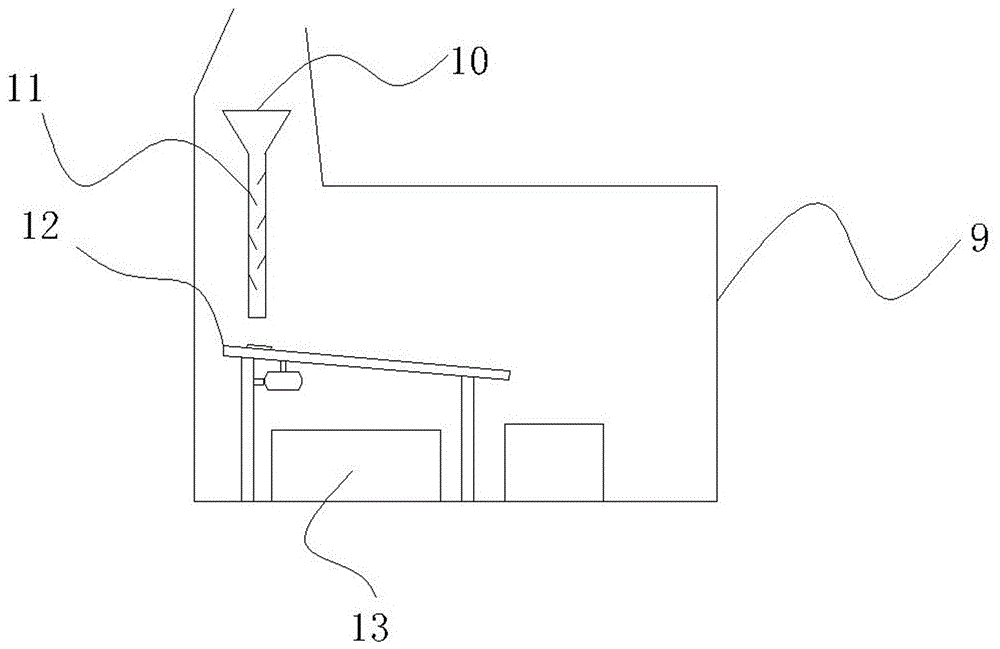

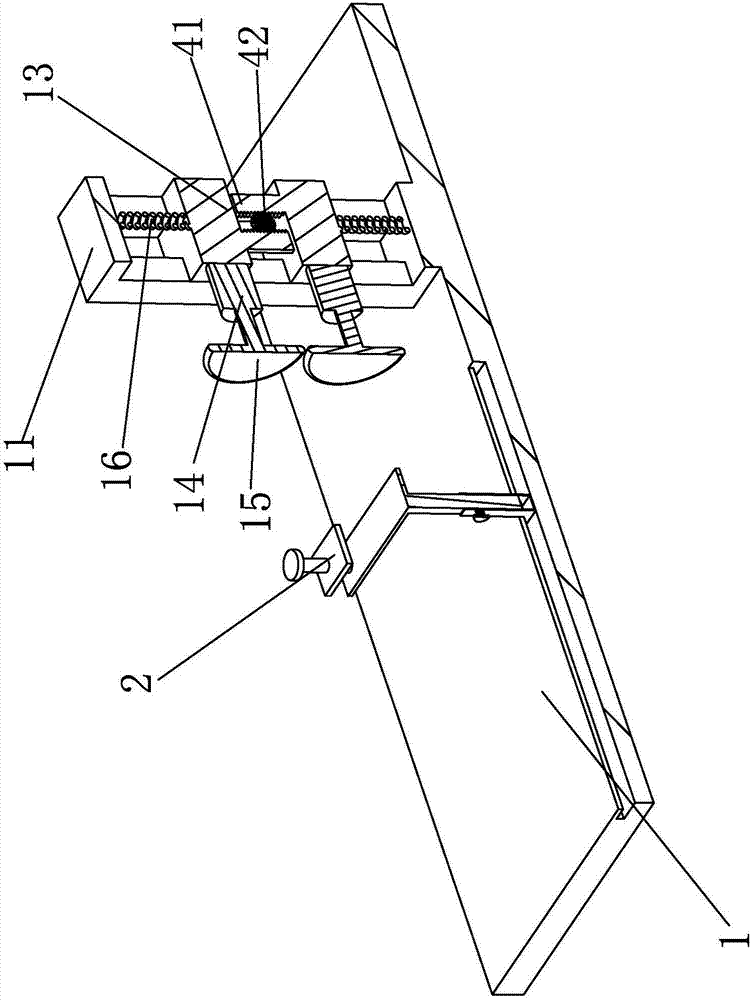

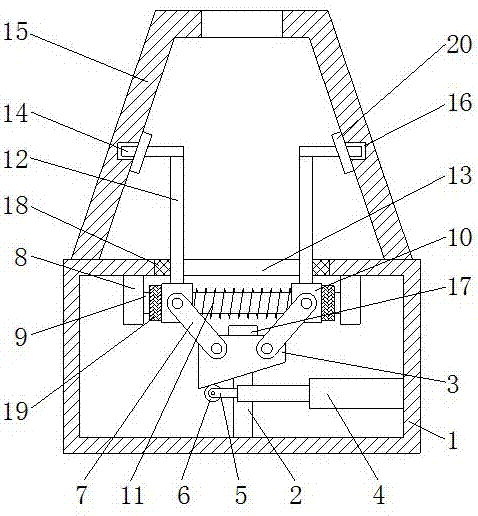

Mechanical type dual-cavity seeding apparatus

The invention discloses a mechanical type dual-cavity seeding apparatus. Two cavities are bilaterally symmetric. The mechanical type dual-cavity seeding apparatus comprises a seed box, shells, a seed feeding pipe, a seed charging nozzle, a left overturning type seed discharging cover, a right overturning type seed discharging cover, a left seed separating hairbrush, a right seed separating hairbrush, a seed discharging disc and a seed discharging shaft. A groove of the seed discharging disc, wall surfaces of the left shell and the right shell, the left seed separating hairbrush and the right seed separating hairbrush form a left seed filling cavity and a right seed filling cavity which are communicated with the seed feeding pipe, holes are formed in disc surfaces of two sides of the seed discharging disc, a left arc-shaped seed removing and protecting plate and a right arc-shaped seed removing and protecting plate as well as the left seed separating hairbrush and the right seed separating hairbrush are arranged on the inner sides of the left shell and the right shell, the left seed separating hairbrush and the right seed separating hairbrush prevent seeds from directly entering the seed charging nozzle from the left seed filling cavity and the right seed filling cavity, an upper end opening of the seed charging nozzle is aligned to the holes in the seed discharging disc, and seeds are filled in the holes along with the rotation of the seed discharging disc in a seed filling region, and then enter a seed removing region and a seed protecting region to complete seed removing and seed protecting, and finally enter a seed charging region to complete seed filling. The mechanical type dual-cavity seeding apparatus is novel in structure; by adopting a manner of filling the seeds, protecting the seeds and discharging seeds on the side edge of a dual-cavity vertical disc, the mechanical type dual-cavity seeding apparatus is compact in structure, capable of achieving precise and less hole sowing, and adjustable in row spacing.

Owner:HUAZHONG AGRI UNIV

Metal plate drilling device

InactiveCN108284239AReduce processing efficiencyAvoid wastingPositioning apparatusMetal working apparatusPunchingEngineering

The invention relates to the field of drilling equipment, and discloses a metal plate drilling device. The metal plate drilling device comprises a base. An end face bearing is fixedly arranged on oneside of the top of the base. A supporting column is fixedly sleeved with the middle portion of the end face bearing. The top end of the supporting column is fixedly sleeved with a rotation block. A sliding rod is fixedly connected to the side face of the rotation block. The end, away from the rotation block, of the sliding rod is fixedly connected with a limiting baffle. According to the metal plate drilling device, a positioning nut rotates on a threaded rod, and the deepest punching position is determined in cooperation with the positions of a right side marker post and a dividing ruler. During punching, only a moving pipe needs to be downwards moved, a drill bit is driven to move downwards to conduct drilling till a left side marker post makes contact with the positioning nut, then drilling is conducted to the deepest position, accordingly, the situation that the metal plate depth cannot be accurately controlled, the metal plate drilling quality cannot meet the project requirement,consequently, raw materials are wasted, and the metal plate machining efficiency is reduced is avoided.

Owner:陈灵燕

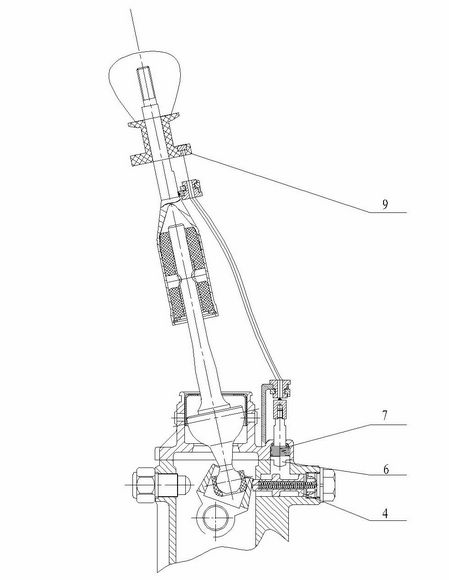

Six-gear directly selecting structure for automobile speed changer

InactiveCN102072313AAvoid hard contactExtended service lifeGearing controlEngineeringElectrical and Electronics engineering

Owner:GREAT WALL MOTOR CO LTD

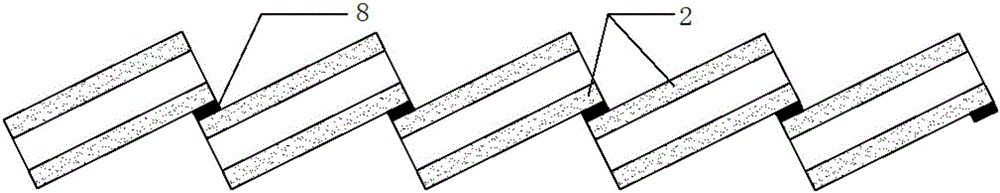

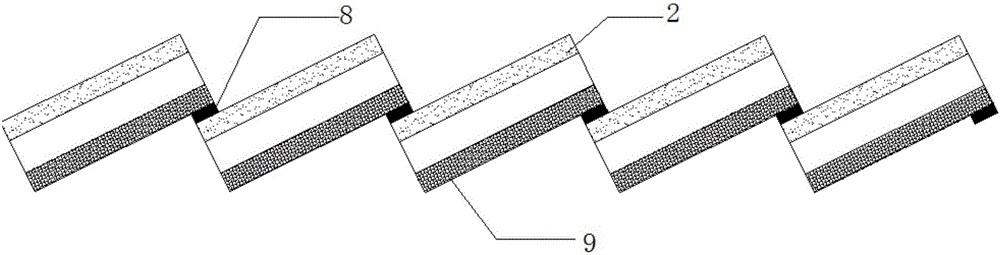

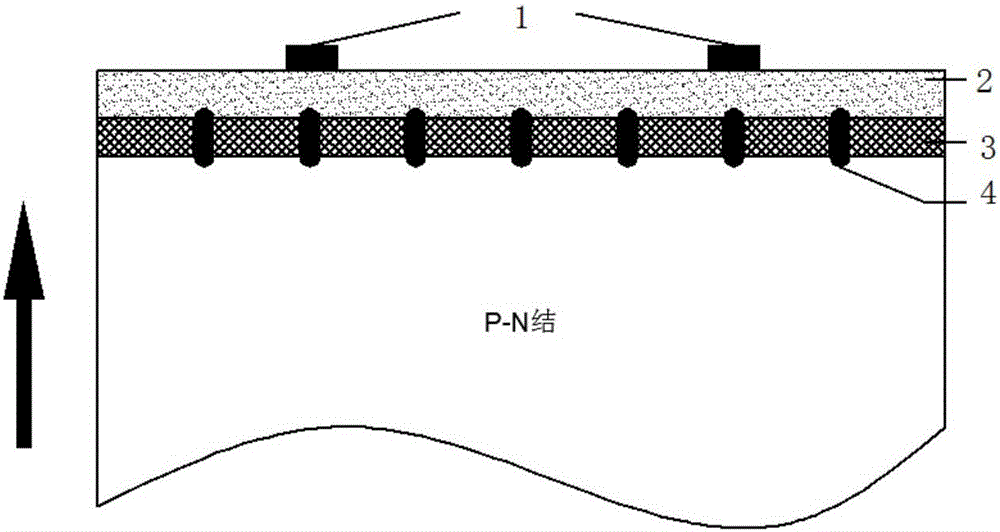

Connecting structure of crystalline silicon photovoltaic cell with transparent electrodes

ActiveCN105870216AIncrease the area that can generate electricityHigh power outputPhotovoltaic energy generationSemiconductor devicesComposite electrodeTransparent conducting film

The invention discloses a connecting structure of a crystalline silicon photovoltaic cell with transparent electrodes. Front electrodes of cell pieces forming a cell pack string are transparent conductive film-metal composite electrodes, and back electrodes are transparent conductive film-metal composite electrodes or back metal electrodes. The adjacent crystalline silicon photovoltaic cells are connected in series in the mode that the front electrodes and the back electrodes are overlapped, and joints are filled with a conductive binding agent so as to make a cell pack string circuit closed. The transparent conductive film-metal composite electrodes are adopted for the front and / back electrodes of the cells forming a photovoltaic assembly, so that the using amount of metal for making solar cell electrodes is greatly reduced, metal can even be not used at all, the light shielding area is reduced, and the production cost is reduced. The power generating area of the assembly is further increased through overlapped connection of the cells, and thus the power output of the assembly is increased.

Owner:LONGI SOLAR TECH CO LTD

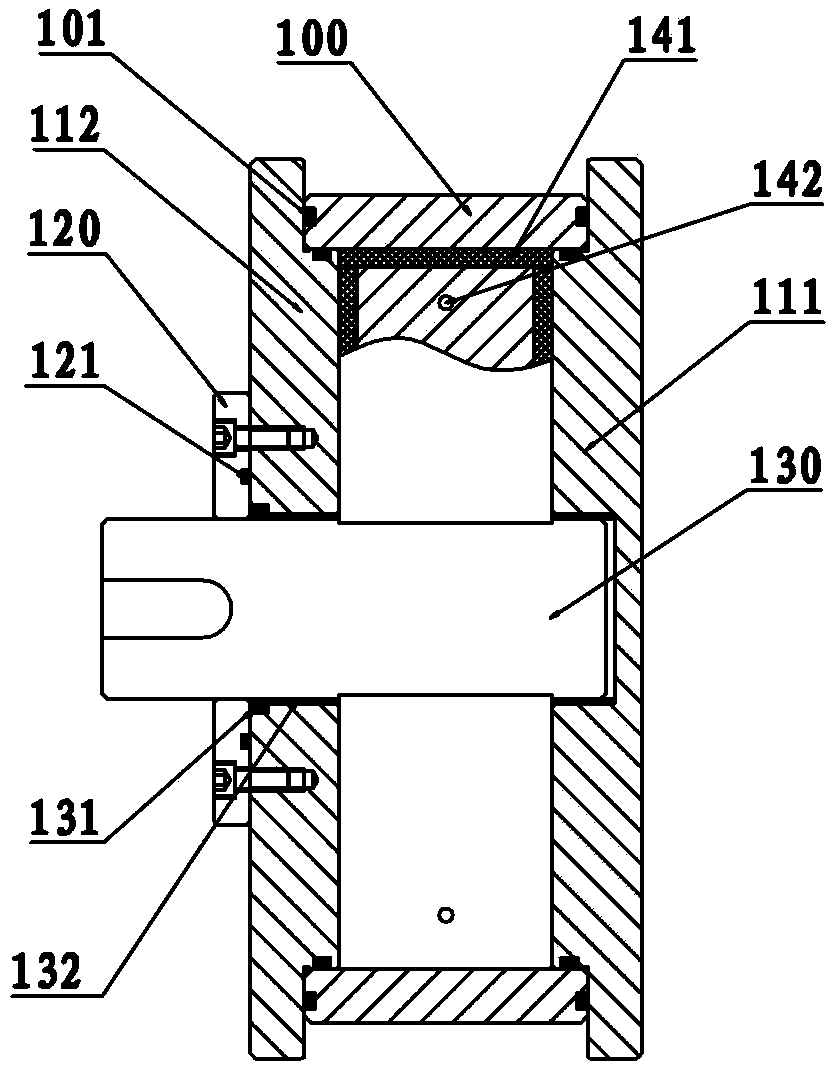

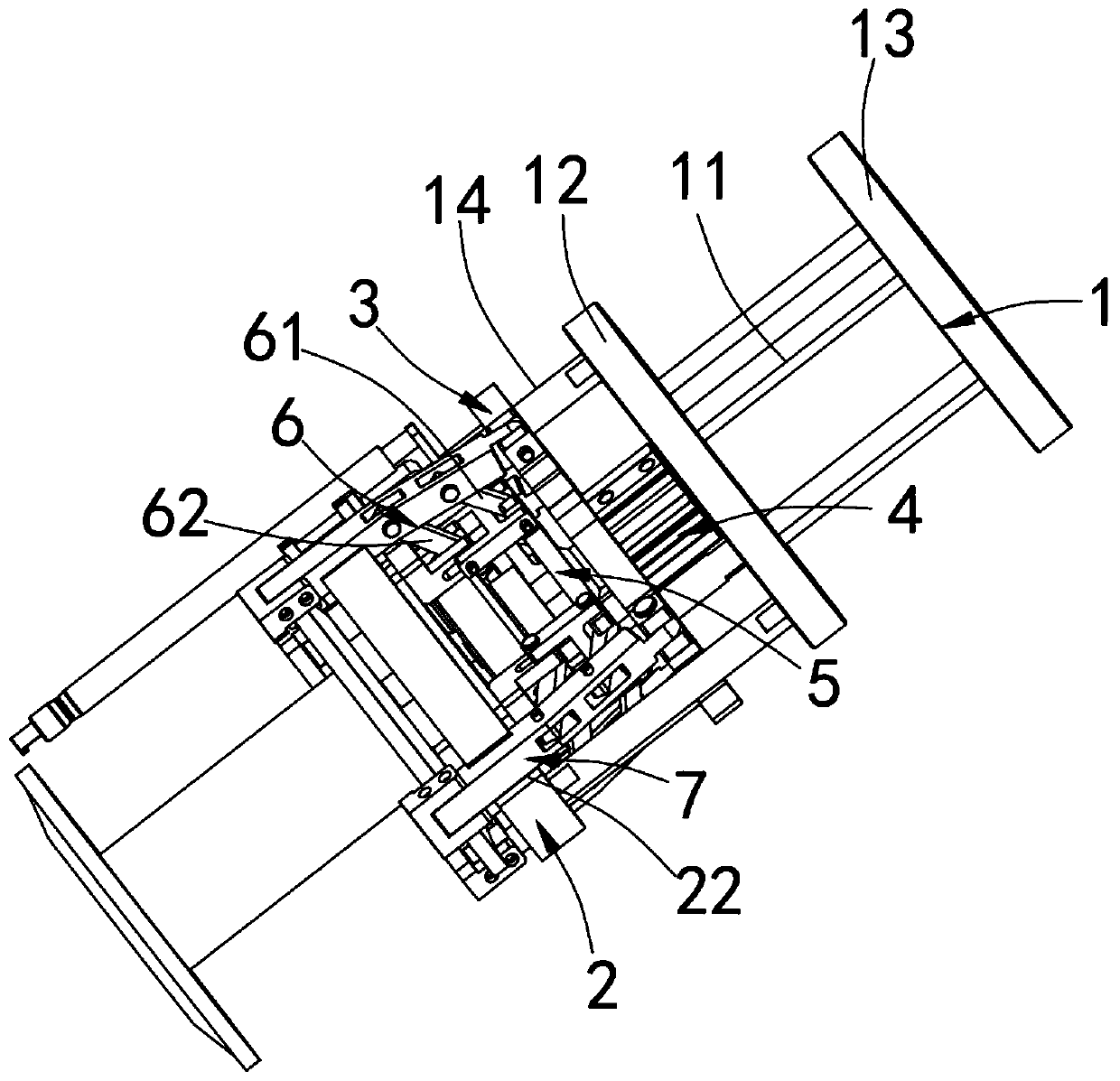

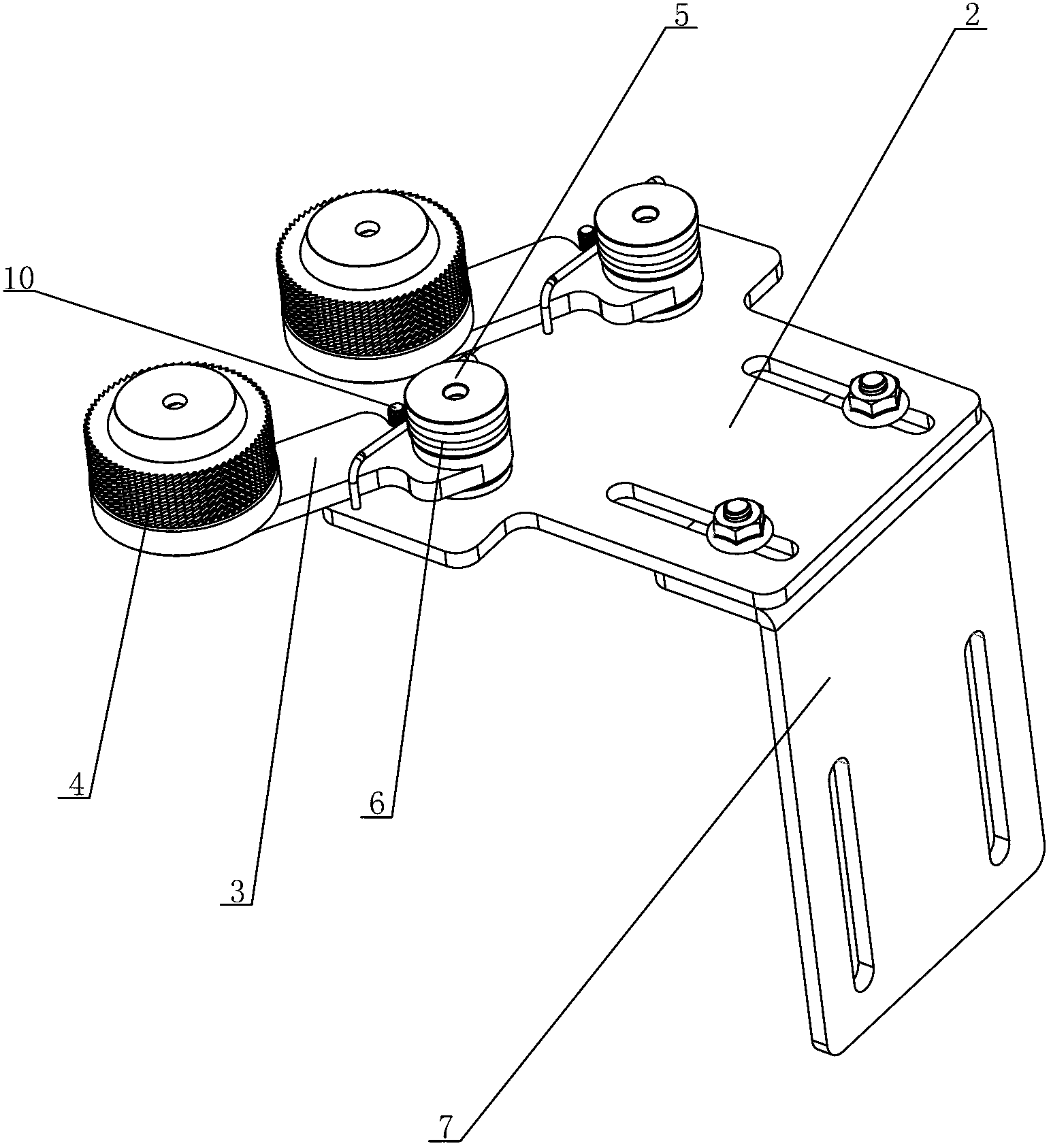

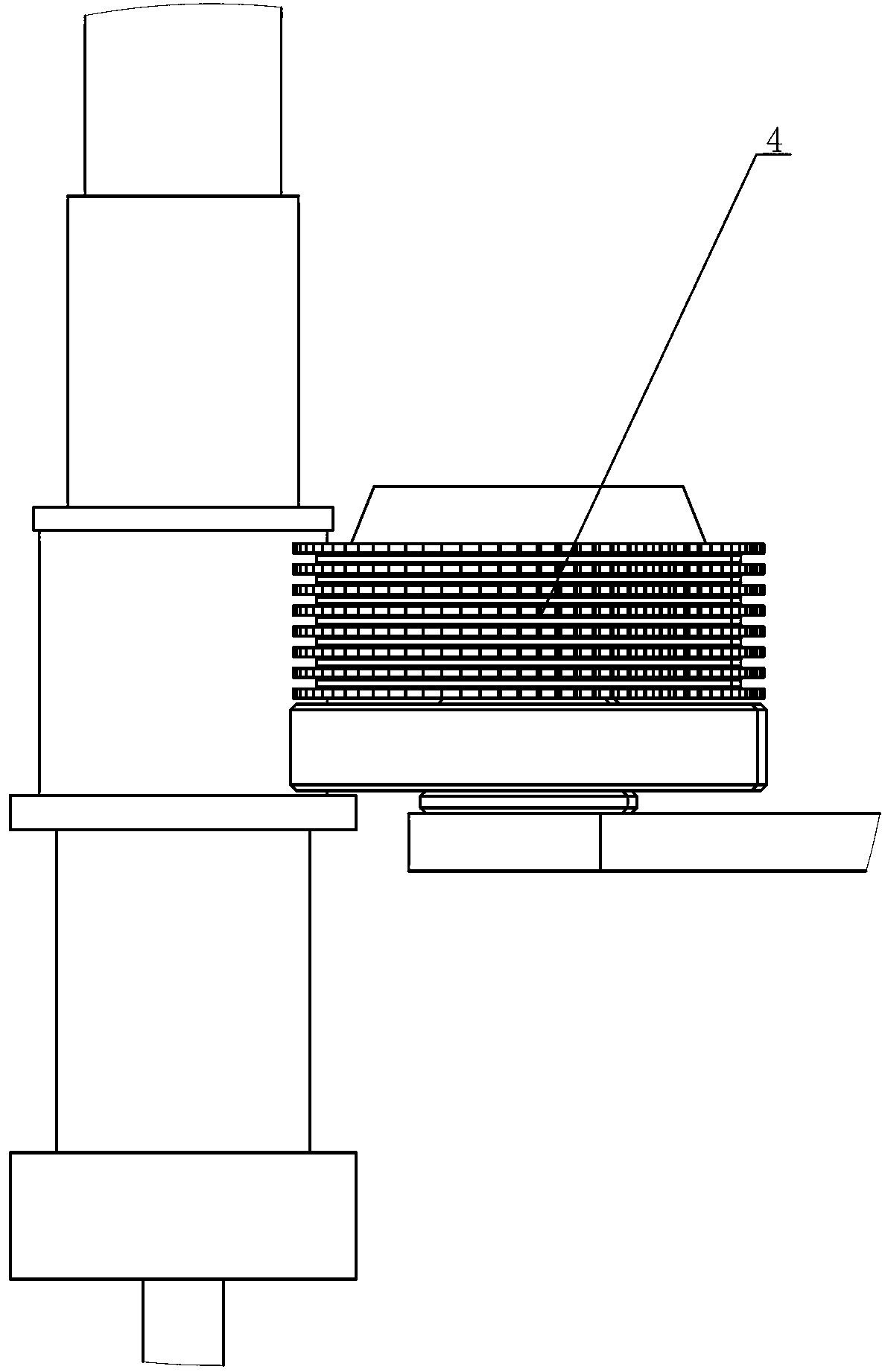

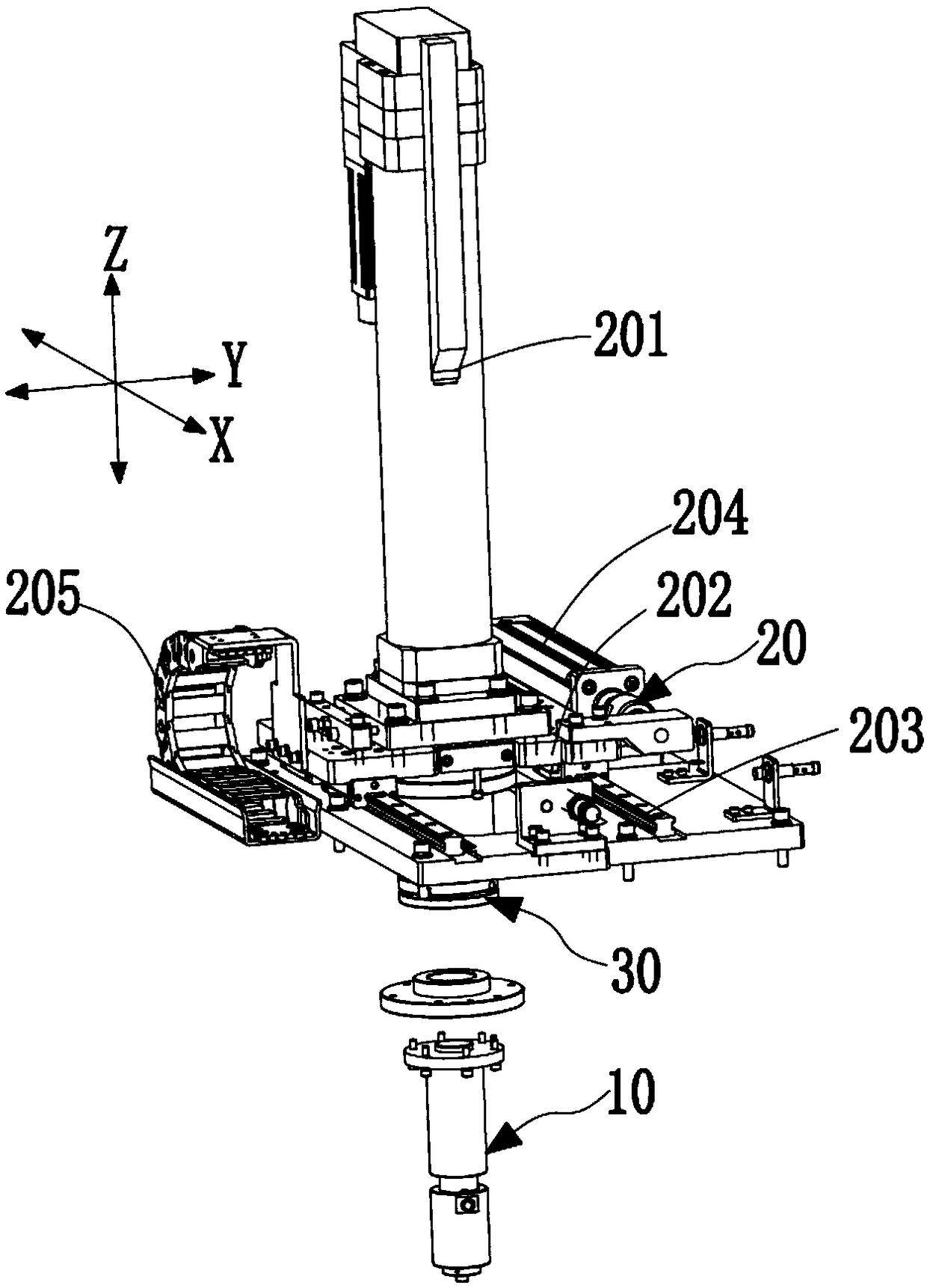

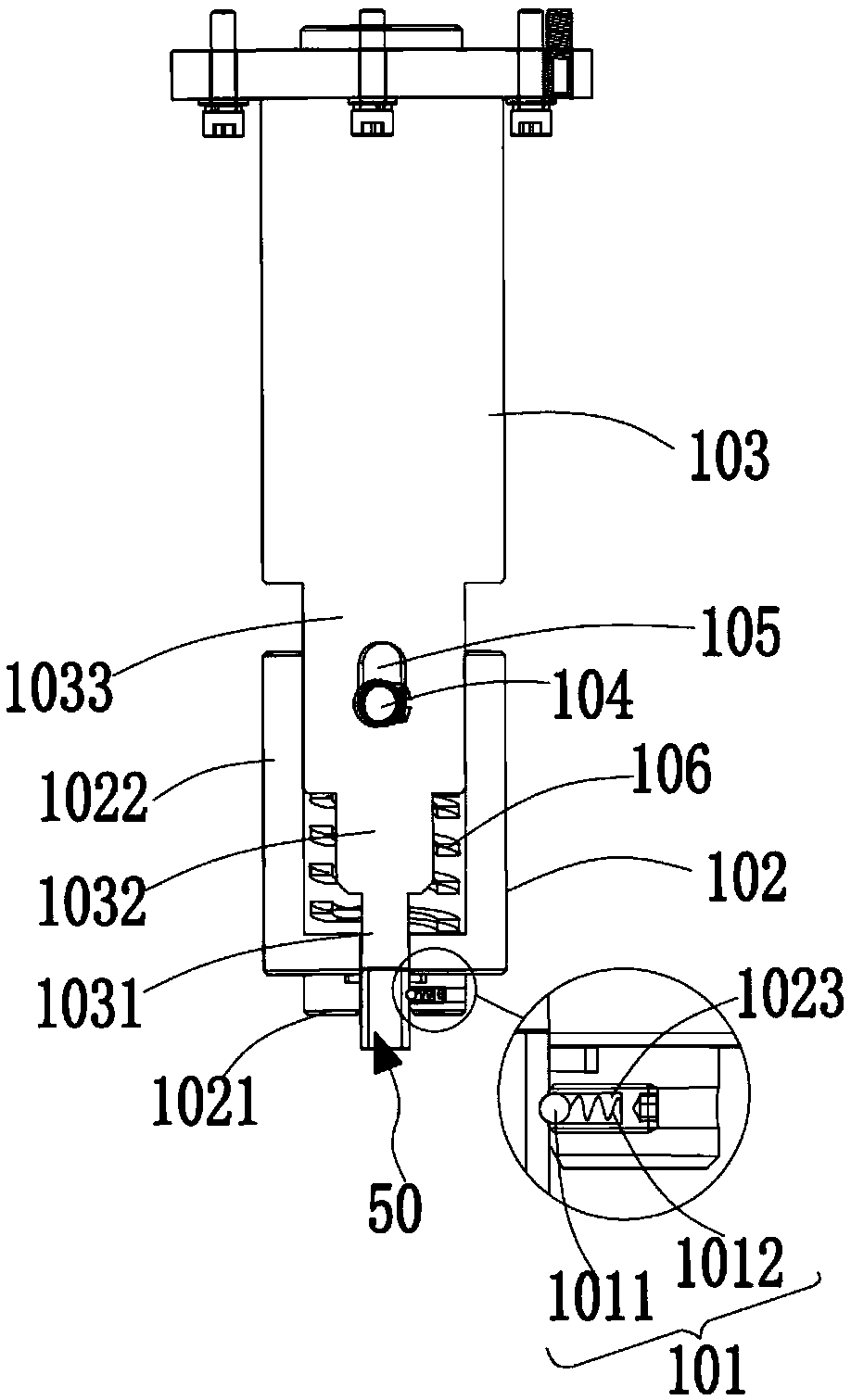

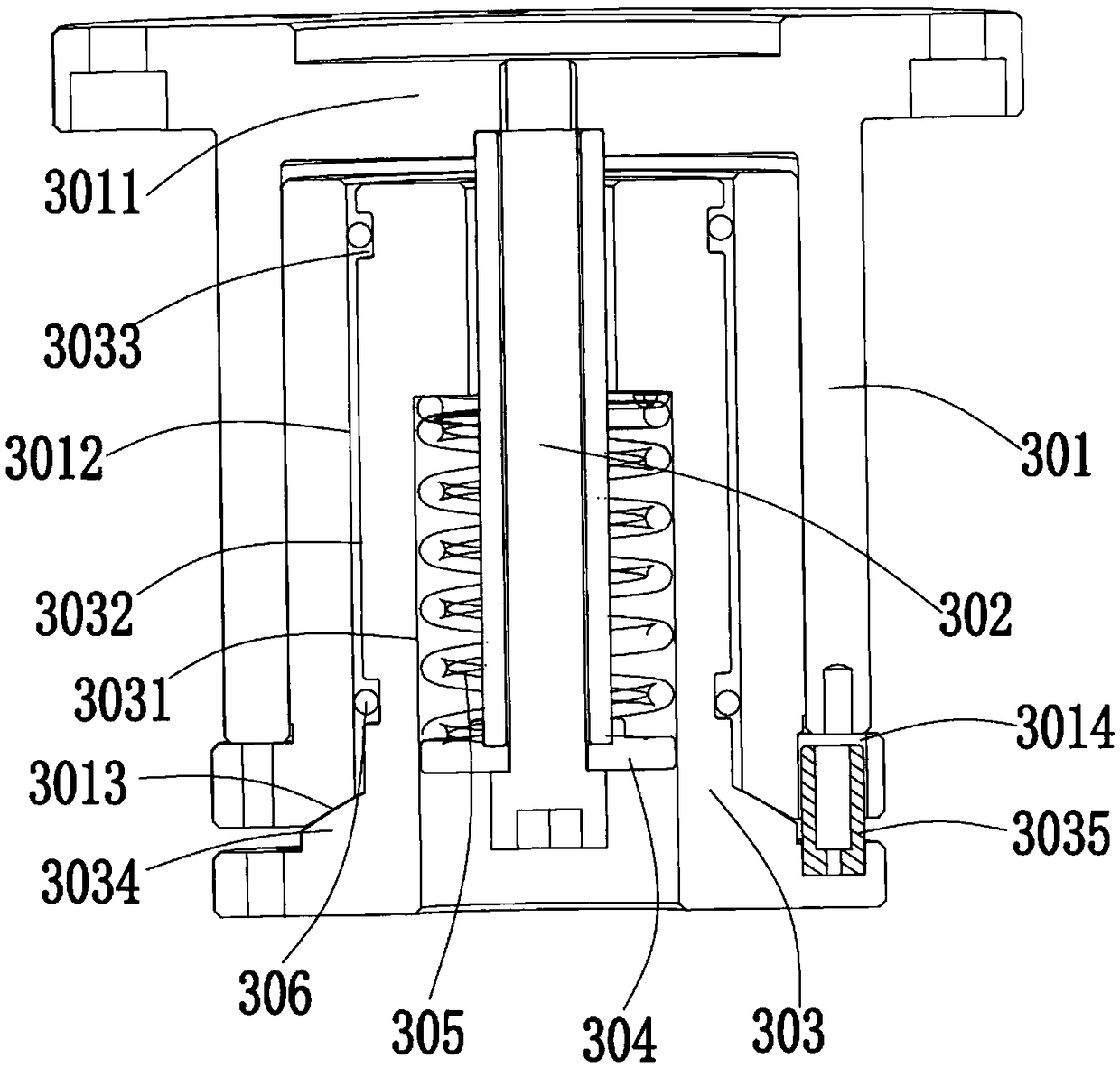

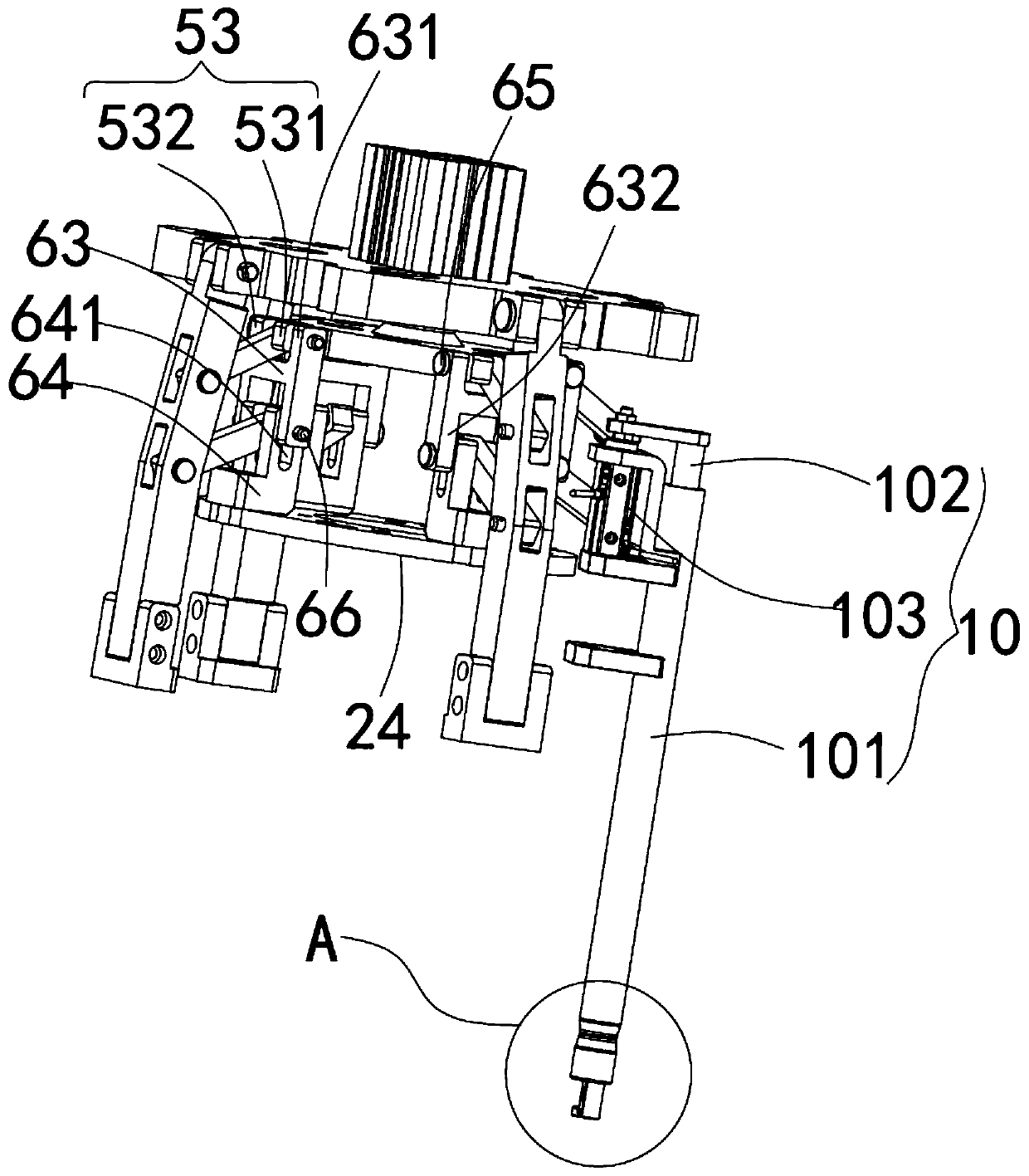

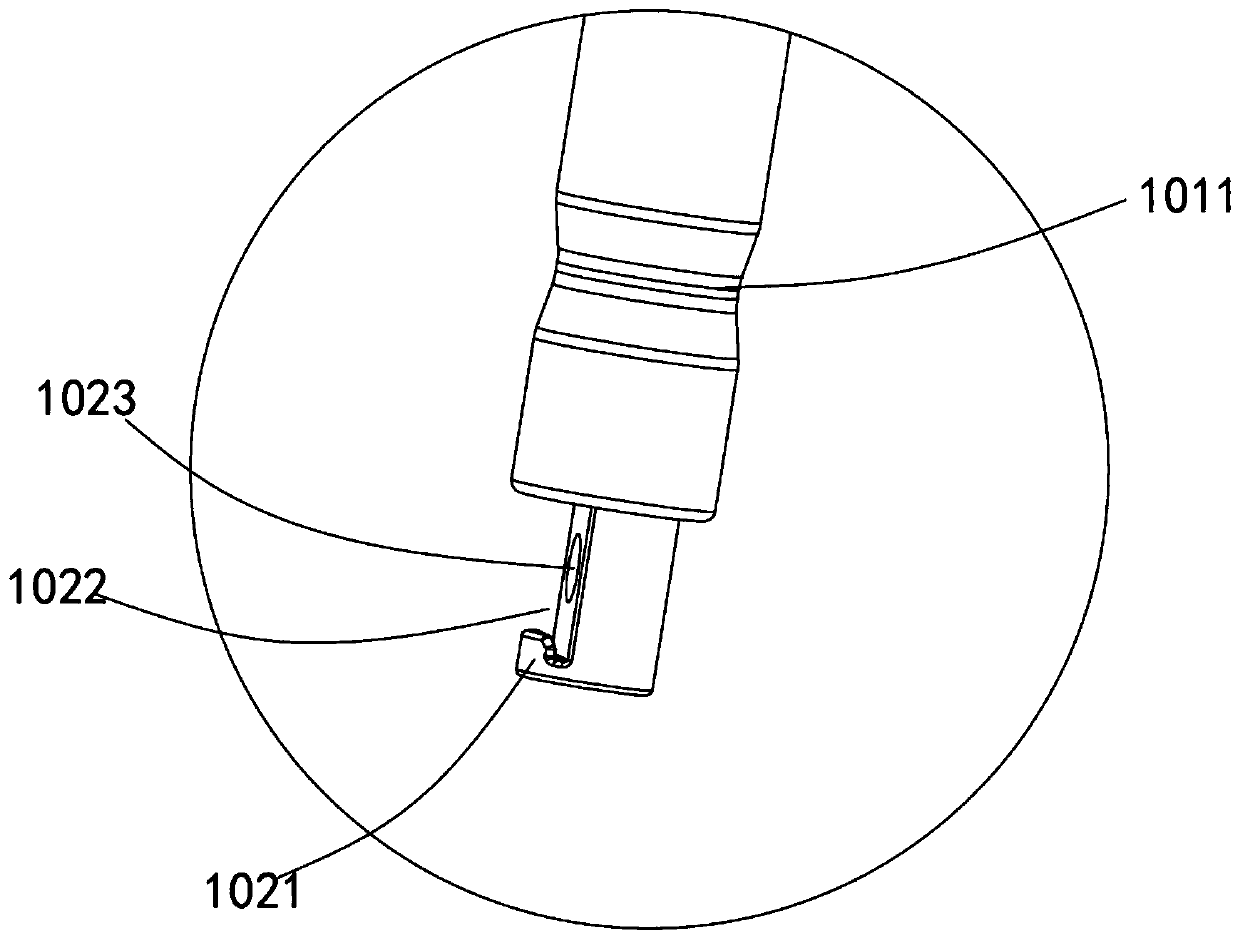

Wire reel clamping jaw and using method thereof

The invention discloses a wire reel clamping jaw and a using method thereof. The wire reel clamping jaw comprises a connection base, the front end face of the connection base is provided with a bearing plate, a base plate and an air cylinder, the air cylinder is fixed to the base plate, and an air cylinder shaft is connected with a transmission plate. The transmission plate is connected with at least three jaw bodies through a linkage type transmission mechanism fixed to the bearing plate, one ends of the jaw bodies are in pivoted connection with the base plate, the other ends of the jaw bodies extend to the front end of the bearing plate, and each jaw body is in pivoted connection with the codirectional ends of a first driving rod and a second driving rod of the linkage type transmissionmechanism, and is driven by the air cylinder to rotate around a pivot shaft connected with the base plate. According to the scheme, a baffle at one end of a wire reel is clamped with the jaw bodies which can synchronously shrink and expand, and the problem is effectively prevented that in the prior art, when baffles at the two ends are clamped, a clamping jaw interferes with a wire reel placementtable top. By using the linkage type transmission structure, double linkages are adopted to be connected with the jaw bodies, the rigidity of the jaw bodies is effectively improved, the bearing capacity is improved, and a guarantee is provided for transverse placement of the wire reel.

Owner:SUZHOU JIANGJIN AUTOMATION TECH

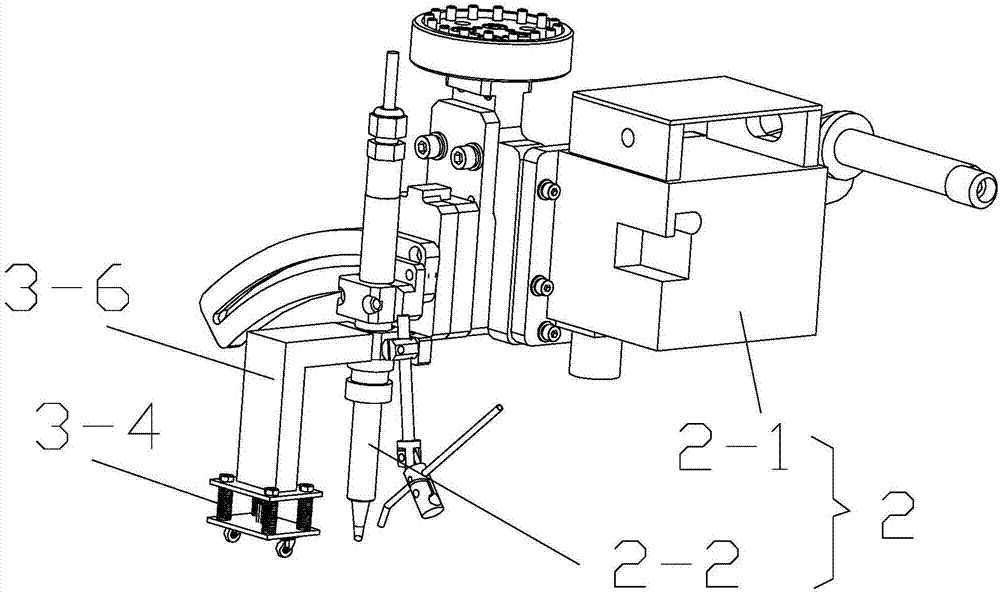

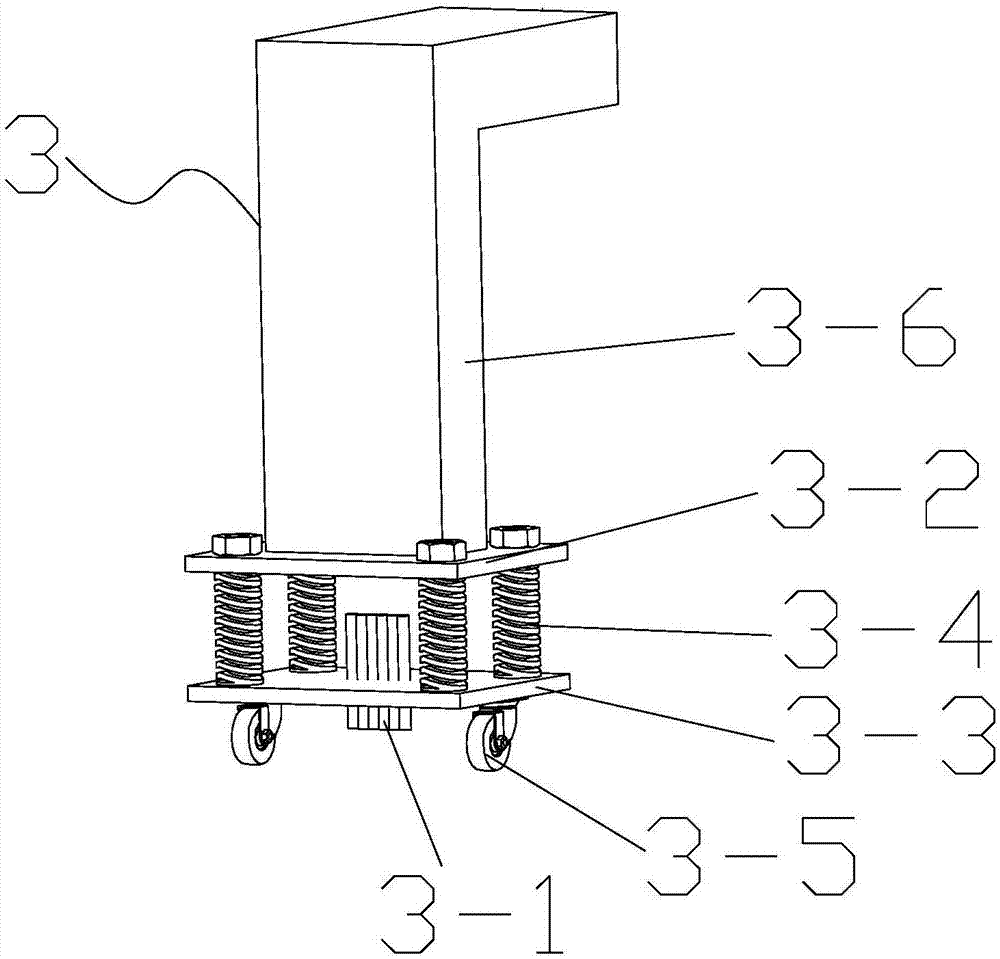

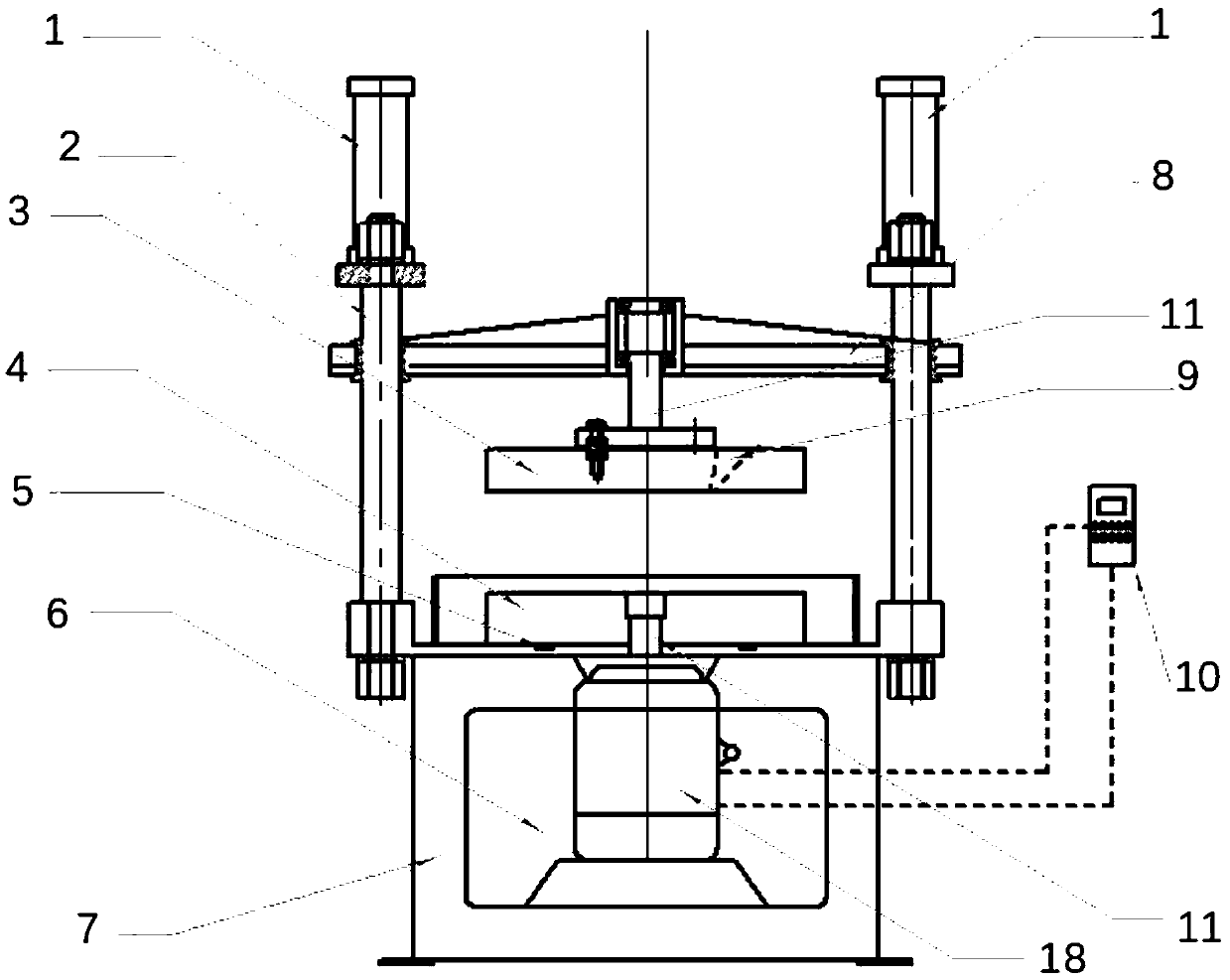

Weld seam tracking device

ActiveCN107511564ARealize online real-time trackingHigh precisionArc welding apparatusElectricityControl system

The invention belongs to the technical field of welding and particularly relates to a weld seam tracking device. The weld seam tracking device comprises a weld seam tracking device body and further comprises a control system, a servo motion system, a welding system and a weld seam tracking system, wherein the servo motion system, the welding system and the weld seam tracking system are electrically connected with the control system. The welding system and the weld seam tracking system are arranged side by side. The weld seam tracking system comprises a diffuse reflection optical fiber and an optical fiber amplifier arranged on the diffuse reflection optical fiber. The diffuse reflection optical fiber is composed of multiple optical fiber heads. Each optical fiber head independently emit light and the light is transmitted to the control system through the optical fiber amplifier. The control system acquires the positions and depths of weld seams of workpieces to be welded. By the adoption of the weld seam tracking device, the weld seam width and the depth information can be identified accurately, and meanwhile the measurement numerical values are fed back to the servo motion system for tracking the directions of the weld seams, so that the welding quality is improved.

Owner:JIANGSU UNIV OF TECH +1

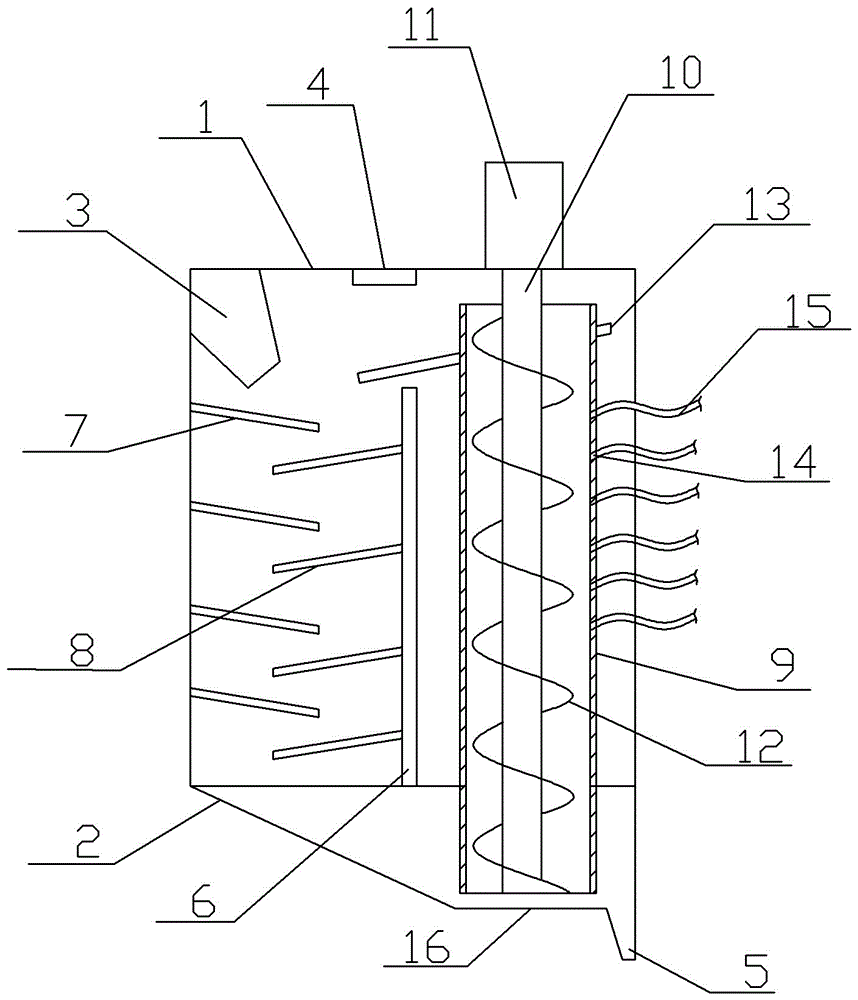

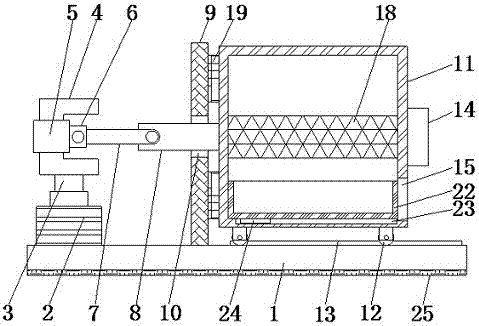

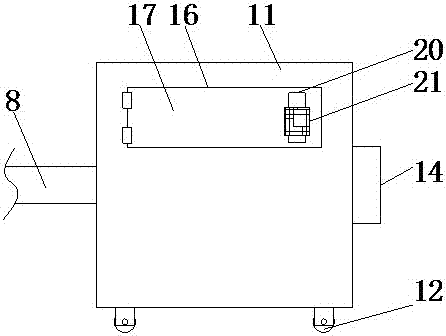

Dryer for broadleaf holly leaves

ActiveCN105910413AImprove drying effectReduce impact forcePre-extraction tea treatmentTea dryingSpiral bladeEngineering

The invention belongs to the technical field of broadleaf holly leaf processing, and particularly relates to a dryer for broadleaf holly leaves. The dryer comprises a casing and an air heater, wherein a casing cover is fixed at the top of the casing; a feeding hopper is arranged at the upper end of the casing; a main hot air inlet connected with the air heater is formed in the casing cover; the dryer also comprises a conical barrel which is fixedly connected with the lower end of the casing; a discharge opening is formed in the lower end of the conical barrel; a separating board is arranged inside the casing; an inner cavity of the casing is divided into a left chamber and a right chamber by the separating board; the feeding hopper is positioned above the left chamber; first folded plates and second folded plates which are mutually staggered are arranged in the left chamber; free ends of the first folded plates and the second folded plates are separately downwards inclined; a vertical cylinder is arranged in the right chamber; a rotating shaft extending into the cylinder is rotationally connected onto the top cover; the lower end of the rotating shaft extends into the conical barrel; and a spiral blade is welded on the rotating shaft. The dryer disclosed by the invention is simple in structure; and compared with a traditional dryer, the dryer disclosed by the invention has the advantages that tea can be sufficiently contacted with hot air, and the influence on final modeling of the tea is avoided.

Owner:桐城市建设投资发展有限责任公司

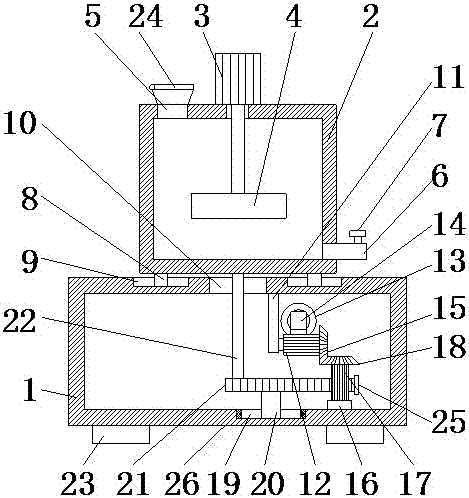

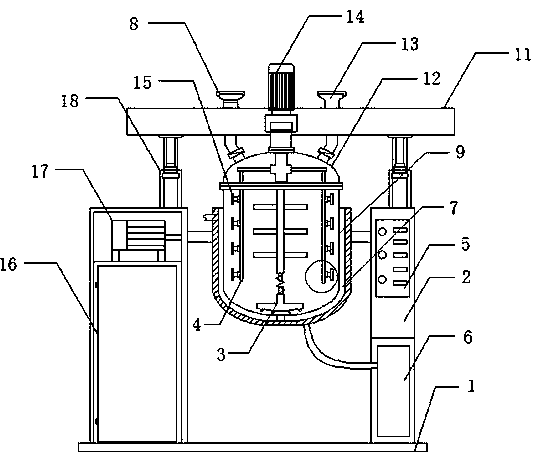

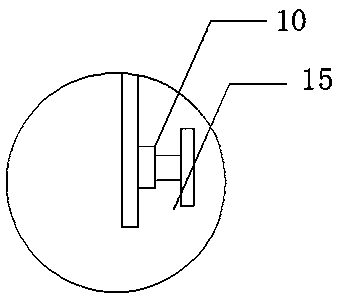

Stirring machine used for chemical machinery

InactiveCN107321245AEfficient mixingIncrease frictionShaking/oscillating/vibrating mixersTransportation and packagingElectric machineryChemical products

The invention discloses a stirring machine used for chemical machinery. The stirring machine comprises a bottom box, wherein a stirring tank is arranged on the top of the bottom box; the top of the stirring tank is fixedly connected with a motor; the output end of the motor passes through the stirring tank, extends to the interior of the stirring tank, and is fixedly connected with a stirring blade; the left side of the top of the stirring tank is communicated with a feed hopper; and the bottom of the right side of the stirring tank is communicated with a discharging pipe. By setting cooperative use of the stirring tank, the motor, the stirring blade, a first sliding rod, a first sliding chute, a through hole, the supporting plate, a first gear, an electric telescopic rod, a first tooth plate, a first bevel gear, a bearing, a second gear, a second bevel gear, a second sliding chute, a second sliding rod, a second tooth plate and a connecting rod, the effect of efficiently stirring chemical products is reached, and the problems that an existing stirring machine used for chemical machinery is free of the function of efficiently stirring the chemical products, the stirring efficiency of the chemical products is reduced and the machining cost of the chemical product is increased are solved.

Owner:刘占超

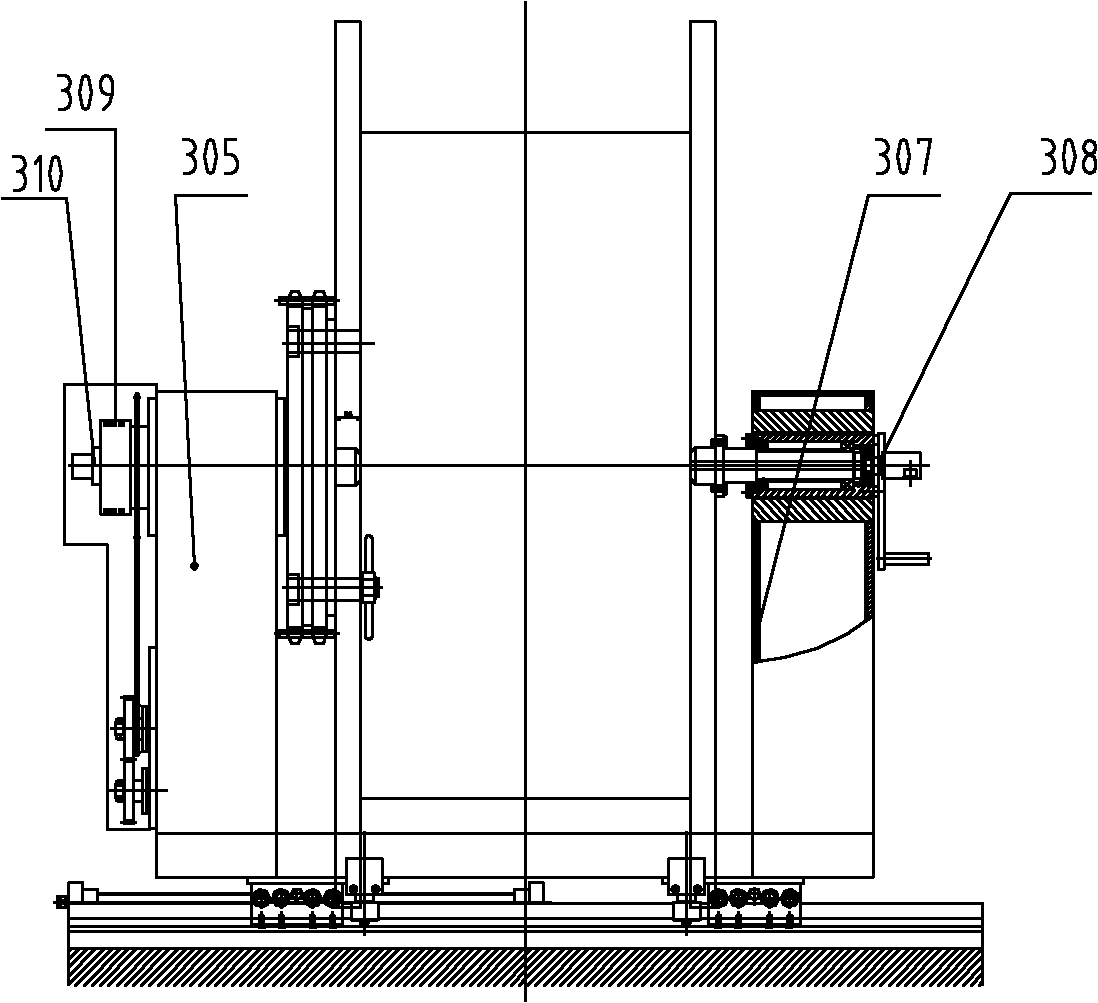

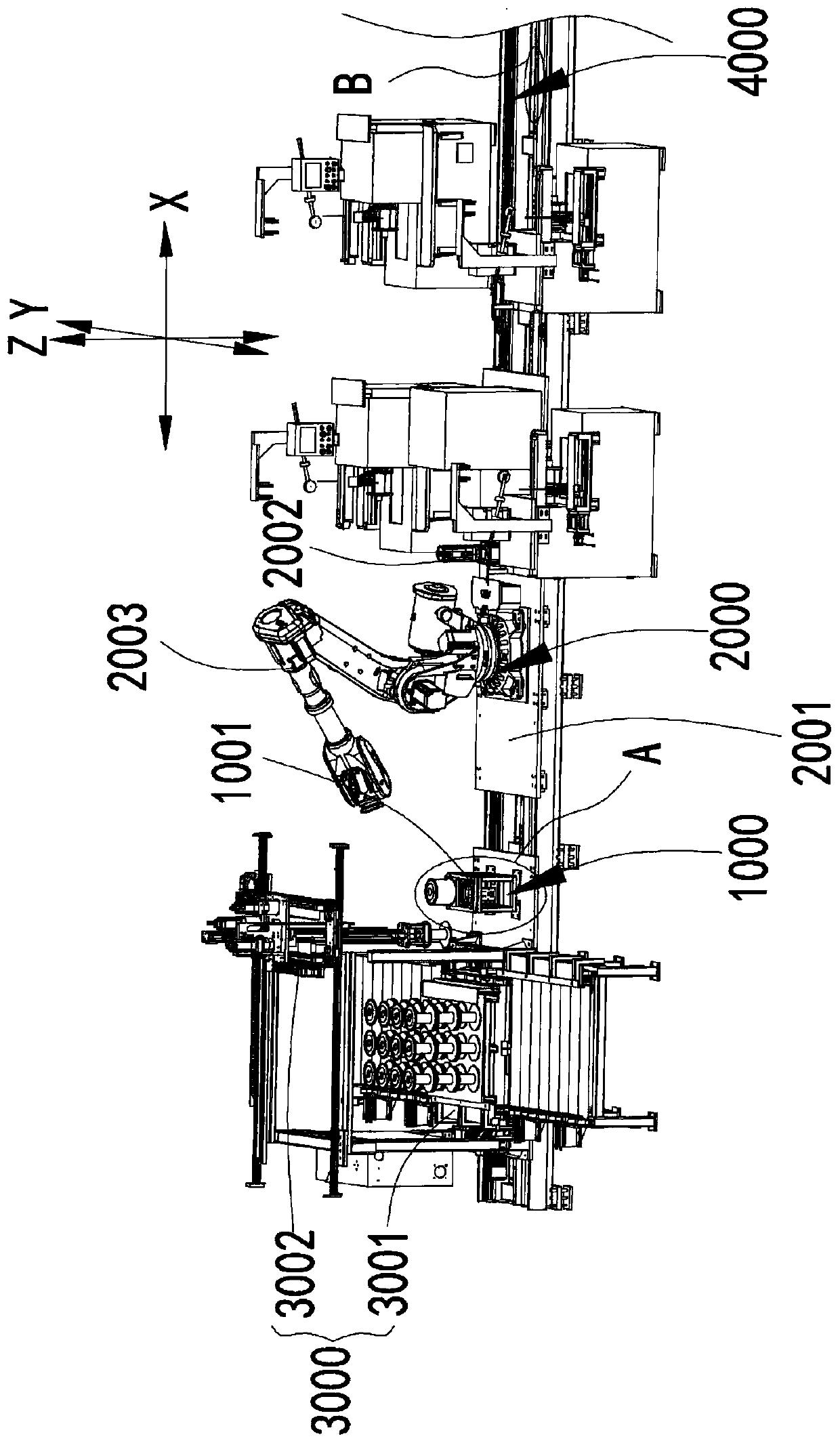

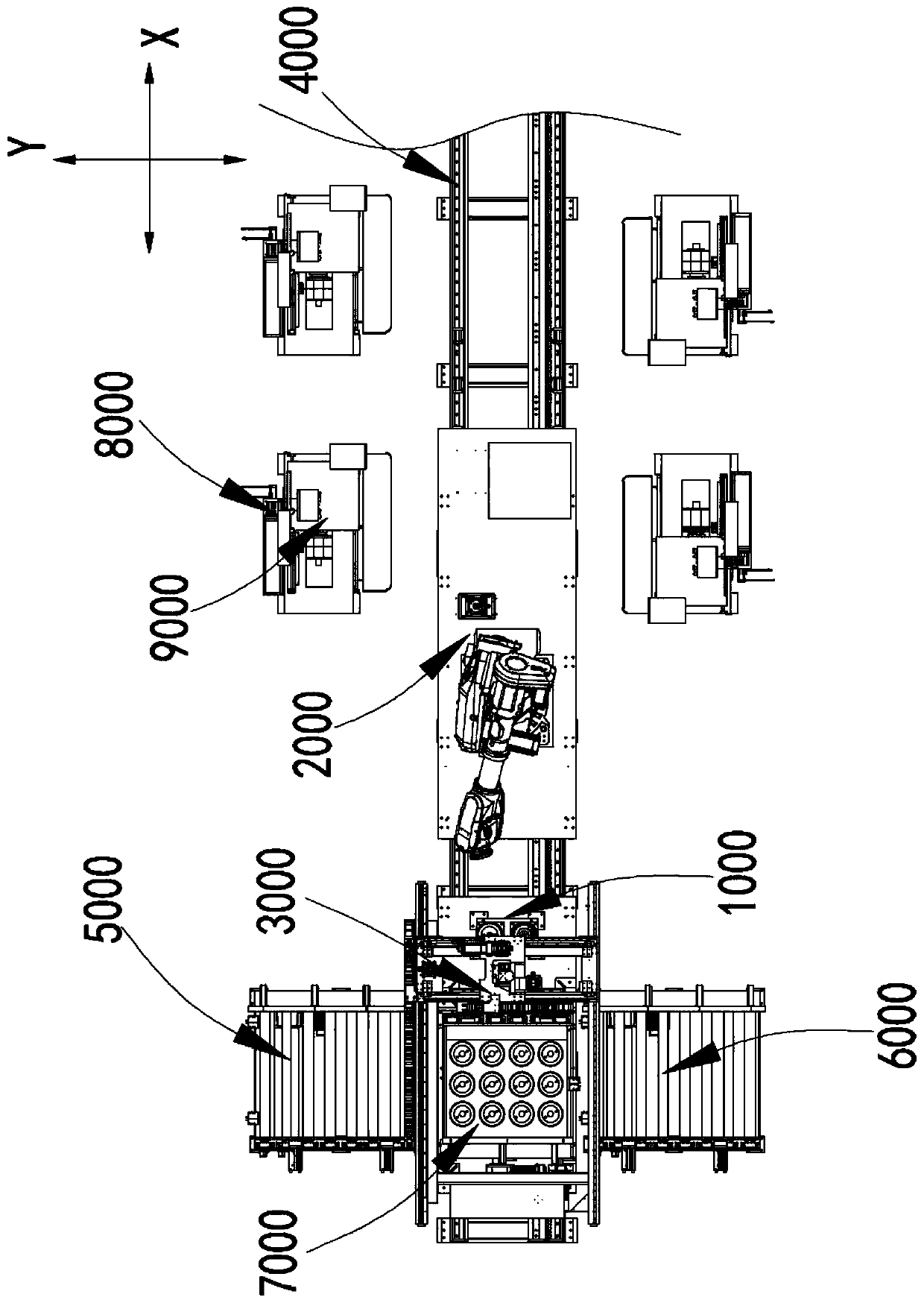

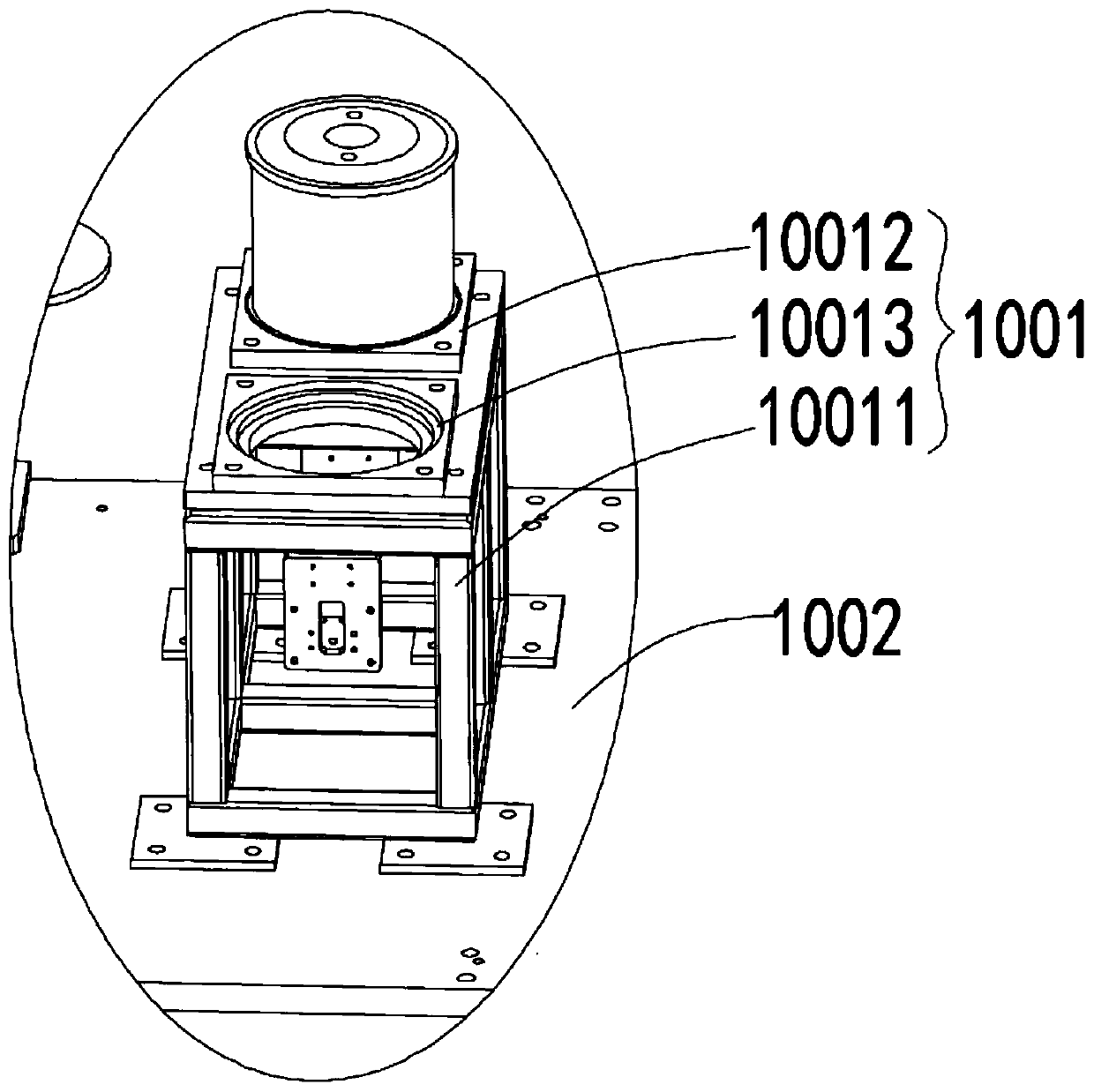

Automatic wire reel feeding and discharging system and feeding and discharging method thereof, and wire winding production line

The invention discloses an automatic wire reel feeding and discharging system and a feeding and discharging method thereof, and a wire winding production line. The feeding and discharging system involves a wire reel transportation trolley, a wire reel feeding and discharging trolley and a wire reel feeding and discharging station; the wire reel transportation trolley is provided with a platform for placing at least two wire reels, and can be moved to at least one processing device; the wire reel feeding and discharging trolley is provided with a structure for transferring the wire reels between the wire reel transportation trolley and the processing device and can be moved between the processing device and the wire reel feeding and discharging station; and the wire reel feeding and discharging station is fixed in position and is provided with a wire reel placement table and a transferring mechanism for transferring the wire reels between the wire reel transportation trolley and the wire reel placement table. According to the scheme, the dead weight of each trolley can be effectively reduced, so that the power requirement is reduced, the problem that the trolley feeding and discharging and the wire winding machine feeding and discharging can not be simultaneously carried out in an existing structure is effectively avoided, the time loss caused by the trolley stopping for feedingand discharging is saved, the processing beat is improved, and the processing efficiency is improved.

Owner:SUZHOU JIANGJIN AUTOMATION TECH

Engineering machine transferring device with good stability

Owner:长兴能工机械有限公司

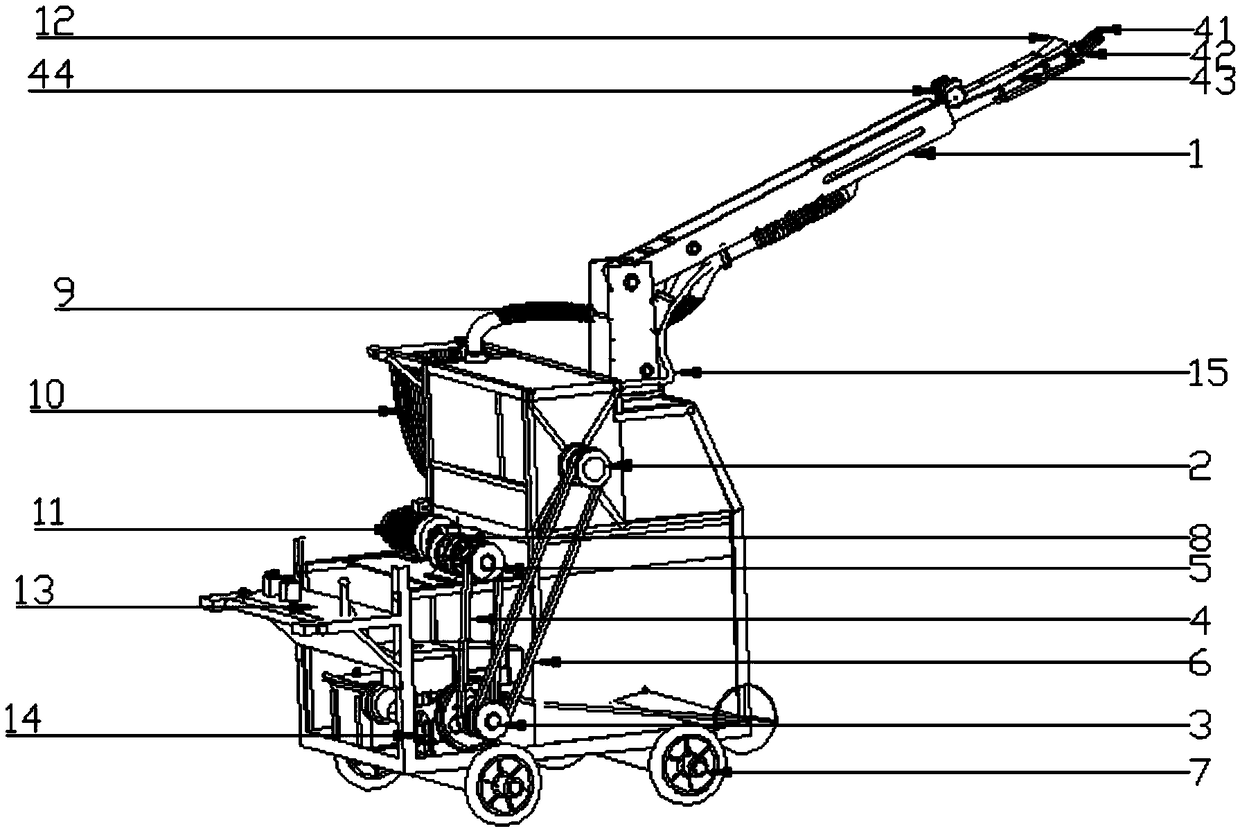

Mechanical auxiliary negative pressure collecting jujube leaf separation automatic jujube-picking machine

InactiveCN108617253AImprove qualityAvoid damageSievingGas current separationZiziphus jujubaChinese Jujube

The invention discloses a mechanical auxiliary negative pressure collecting jujube leaf separation automatic jujube-picking machine. The machine comprises a mechanical arm, wherein the mechanical armis attached with a jujube-conveying pipe; the front part and the rear part of the jujube-conveying pipe are respectively connected with an air-suction negative-pressure pipe; the air-suction negative-pressure pipe is connected with the fan; one end of the jujube conveying pipe is communicated with the jujube suction opening on the mechanical arm, the other end is communicated with the jujube leafseparation device, the front part of the jujube suction opening is provided with a jujube claw, and the jujube leaf separation device is used for separating the jujube and the jujube leaf, and a red jujube grading device is arranged at the next station of the jujube leaf separation device, the red jujube grading device is used for grading the red jujube; and the tail end of the red jujube gradingdevice is provided with a red jujube collecting device. The machie adopts a negative-pressure air-suction type jujube-absorbing and a jujube claw auxiliary picking mode, so that the working efficiencyis improved, the hard contact of the picking device and the red jujube is avoided, the peel of the jujube is protected, and the jujube picking is more thorough.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

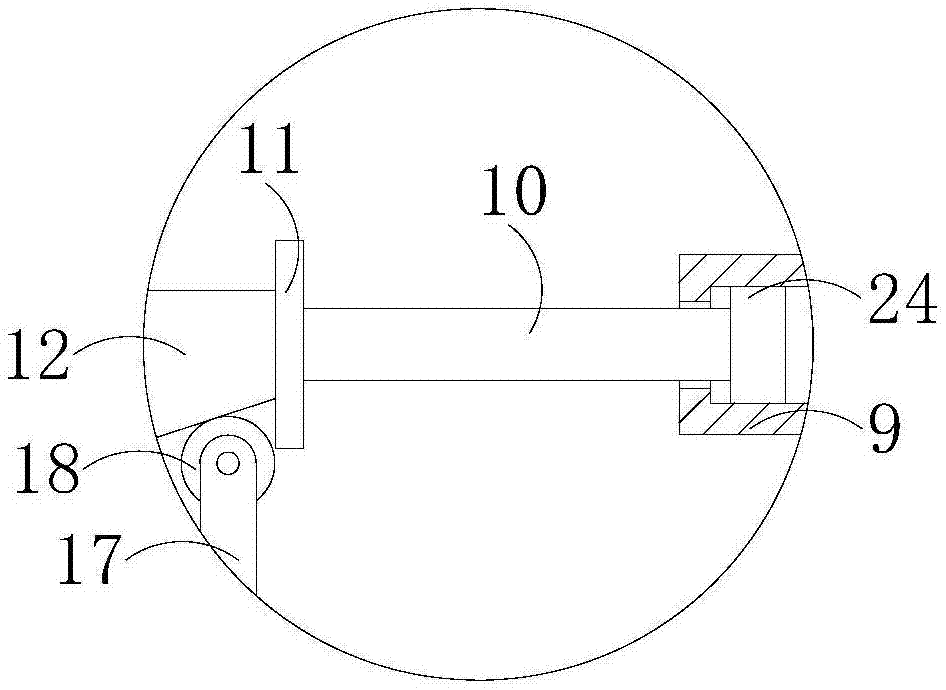

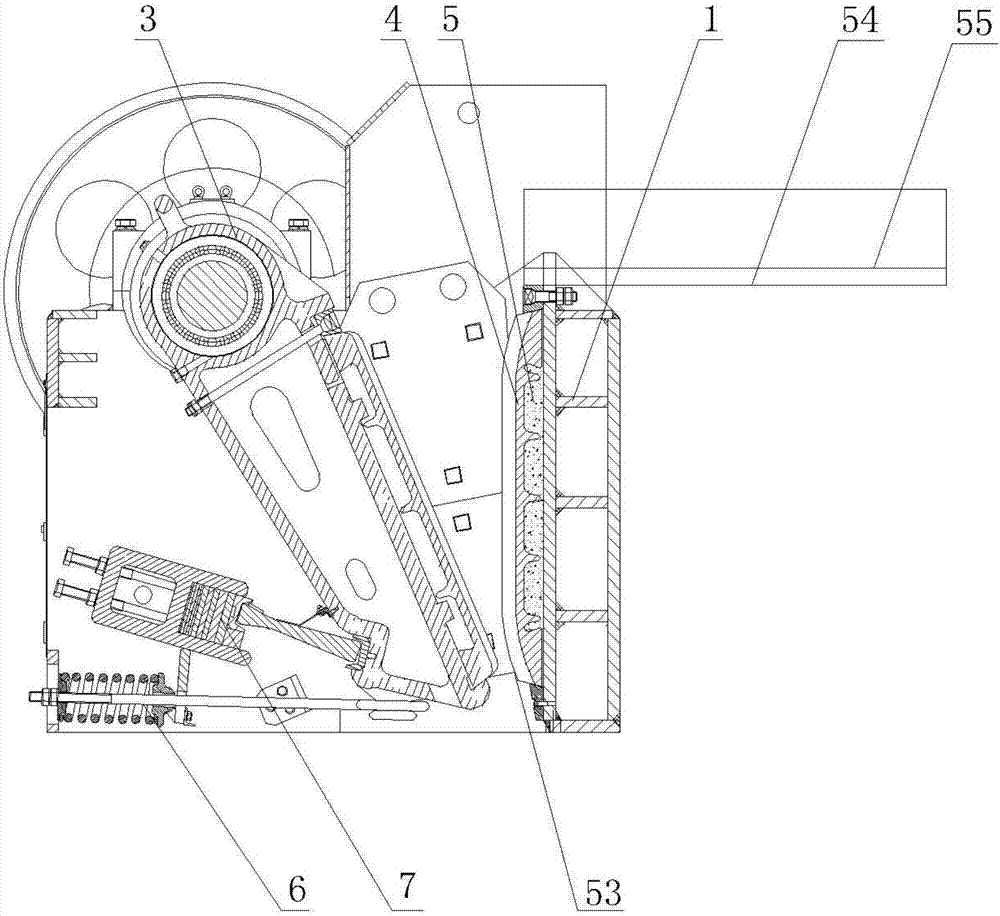

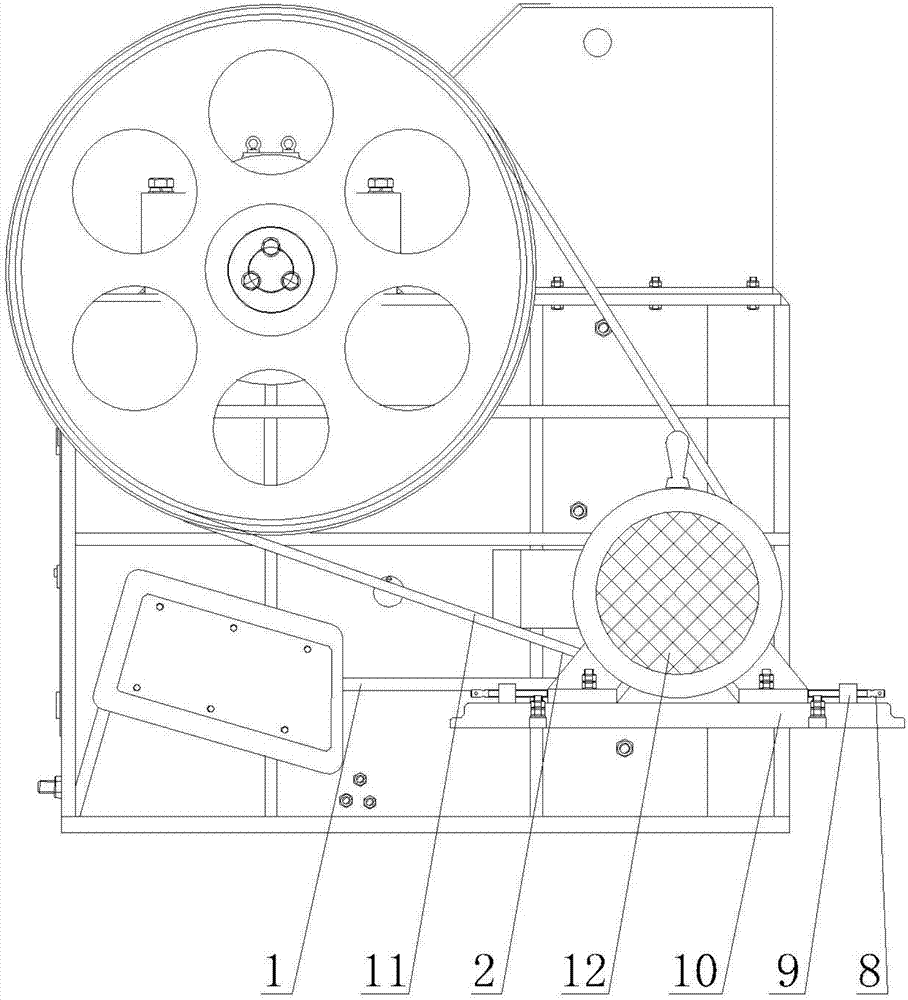

Jaw crusher for rare earth minerals and crushing method of jaw crusher

The invention relates to a jaw crusher for rare earth minerals and a crushing method of the jaw crusher. The jaw crusher for the rare earth minerals and the crushing method of the jaw crusher mainly solve the problems that an existing crusher is low in efficiency and poor in smashing effect and a lining plate is abraded easily. The jaw crusher for the rare earth minerals comprises a rack, a transmission mechanism, a movable jaw mechanism, a movable jaw pull rod mechanism and an adjusting mechanism, wherein the transmission mechanism, the movable jaw mechanism, the movable jaw pull rod mechanism and the adjusting mechanism are arranged on the rack, a tooth-shaped lining plate is perpendicularly arranged on the front wall inside the rack, a cement pouring layer is arranged between the tooth-shaped lining plate and the rack, the bottom of the movable jaw mechanism is connected with the movable jaw pull rod mechanism and the adjusting mechanism, the top of the movable jaw mechanism is connected with the transmission mechanism, and a crushing cavity is formed between the tooth-shaped lining plate and the movable jaw mechanism. The technical scheme solves the problems well and can be used for crushing of the rare earth minerals.

Owner:XINFENG BAOGANG XINLI RARE EARTH

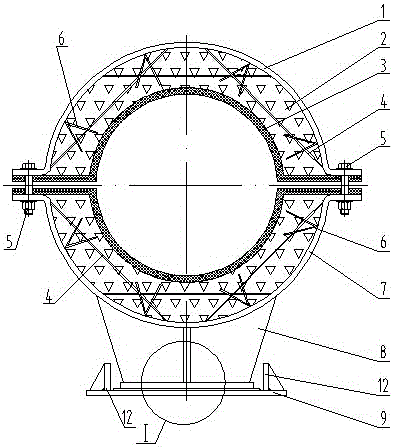

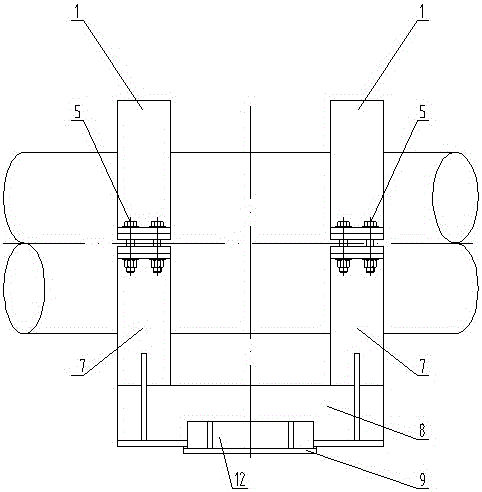

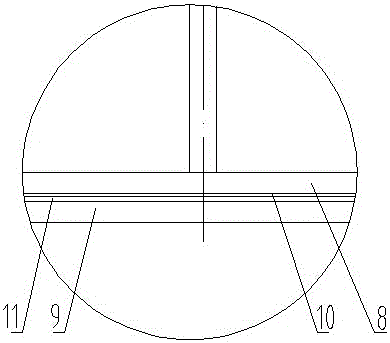

Efficient heat insulation guide pipe bracket

InactiveCN105889636AIncrease stiffnessImprove fusion effectPipe supportsThermal insulationEngineeringSlide plate

The invention discloses an efficient heat insulation guide pipe bracket which comprises an upper hoop, heat insulation tile blocks, high-temperature-resistant soft heat preservation materials, bolt fasteners, a lower hoop, a base and a foundation bed. The upper hoop and the lower hoop are each of a semi-ring structure, and the two sides of the upper hoop and the two sides of the lower hoop extend to form fixing ends. The heat insulation tile blocks are poured on both the inner wall of the upper hoop and the inner wall of the lower hoop. The high-temperature-resistant soft heat preservation materials adhere to the inner walls of the heat insulation tile blocks. The upper hoop and the lower hoop are connected through the bolt fasteners arranged at the fixing ends. The lower hoop is connected to the base in a welded mode. The bottom of the base is provided with an upper sliding plate which is arranged on a lower sliding plate above the foundation bed. Accordingly, the efficient heat insulation guide pipe bracket is formed. Anchor nails and pull rods are additionally arranged between the upper hoop and the heat insulation tile blocks and additionally arranged between the lower hoop and the heat insulation tile blocks. According to the efficient heat insulation guide pipe bracket, by the adoption of the structural form that the anchor nails and the pull rods are additionally arranged between the upper hoop and the heat insulation tile blocks and additionally arranged between the lower hoop and the heat insulation tile blocks, the load bearing capacity of the pipe bracket is ensured, the loading capacity is high, and the heat transfer insulating effect is good.

Owner:JIANGSU BAOHENG PIPE FITTINGS CO LTD

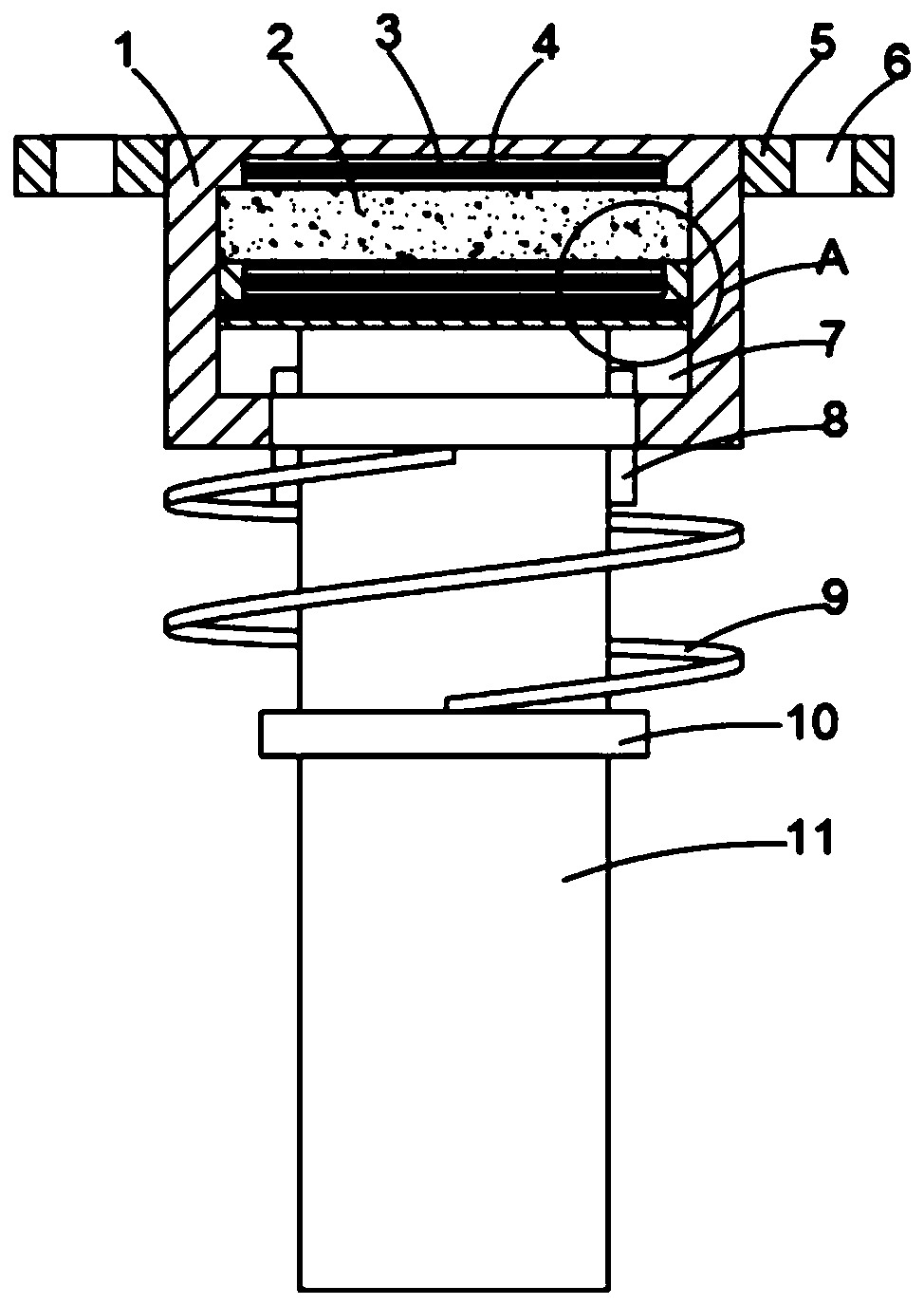

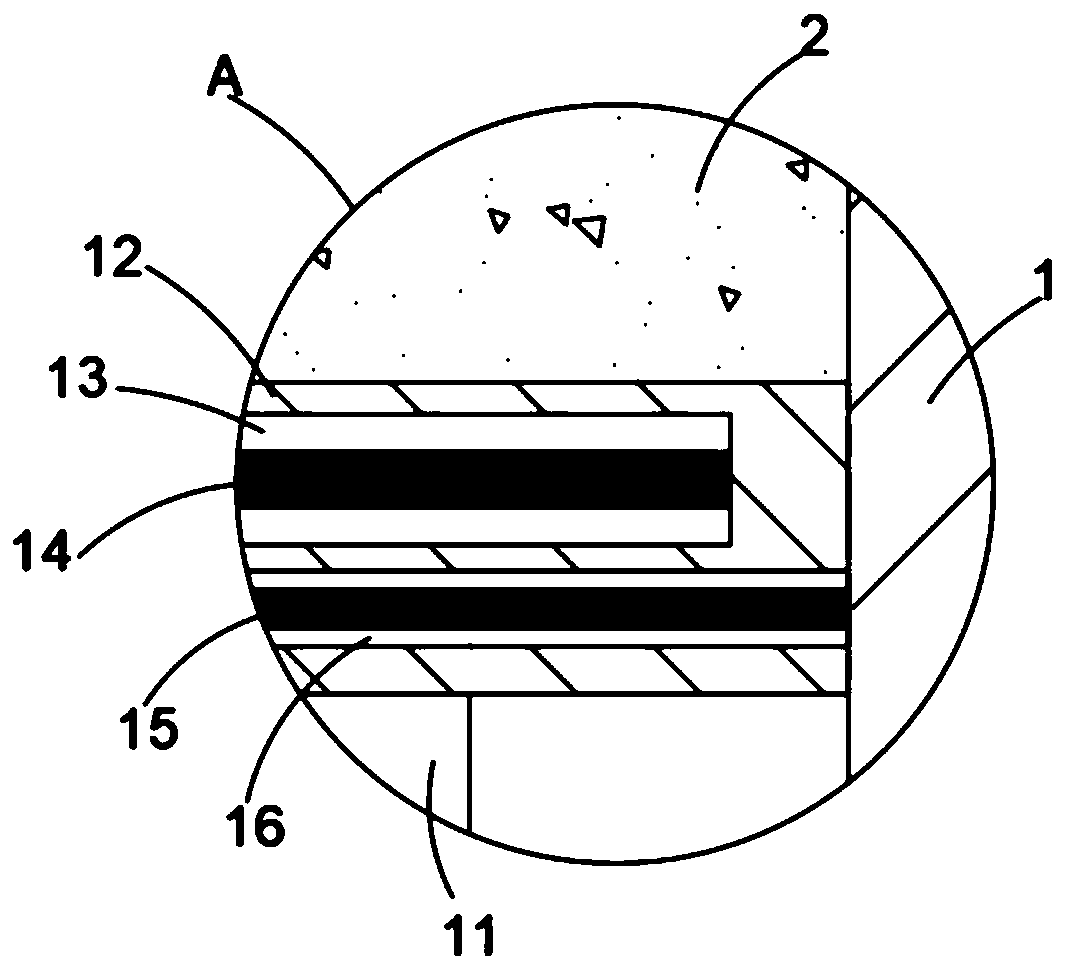

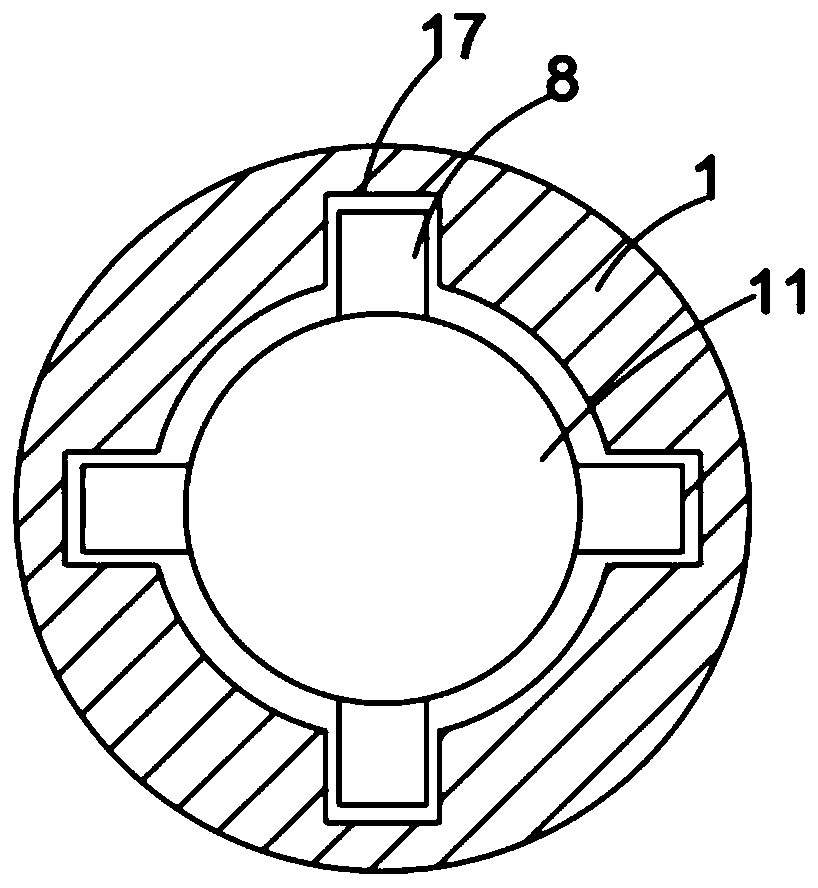

Buffering punch for punching die and punching method

The invention discloses a buffering punch for a punching die and a punching method. The buffering punch comprises a mounting block, a mounting cavity is formed in the mounting block, a slide block isslidably connected to the interior of the mounting cavity, a vertical punch body is arranged on the side wall of the lower side of the slide block, and the side, away from the slide block, of the punch body penetrates through the side wall of the mounting block and is slidably connected with the side wall of the mounting block; a transverse first cavity is formed in the inner wall of the upper side of the mounting block, an upper capacitance plate is arranged in the first cavity, a transverse second cavity is formed in the slide block, and a lower capacitance plate parallel to the upper capacitance plate is arranged in the second cavity; a power port is formed in the side wall of one side of the mounting block, and electrically connected with the upper capacitance plate and the lower capacitance plate through a guide wire, and the portion between the inner wall of the upper side of the mounting block and the slide block is filled with electrorheological fluid. By means of the bufferingpunch for the punching die, the punch body can be sufficiently buffered, so that the punch body is prevented from being severely abraded, and thus the service life of the punch body is prolonged.

Owner:RIZHAO CHAOJIE MASCH MFG CO LTD

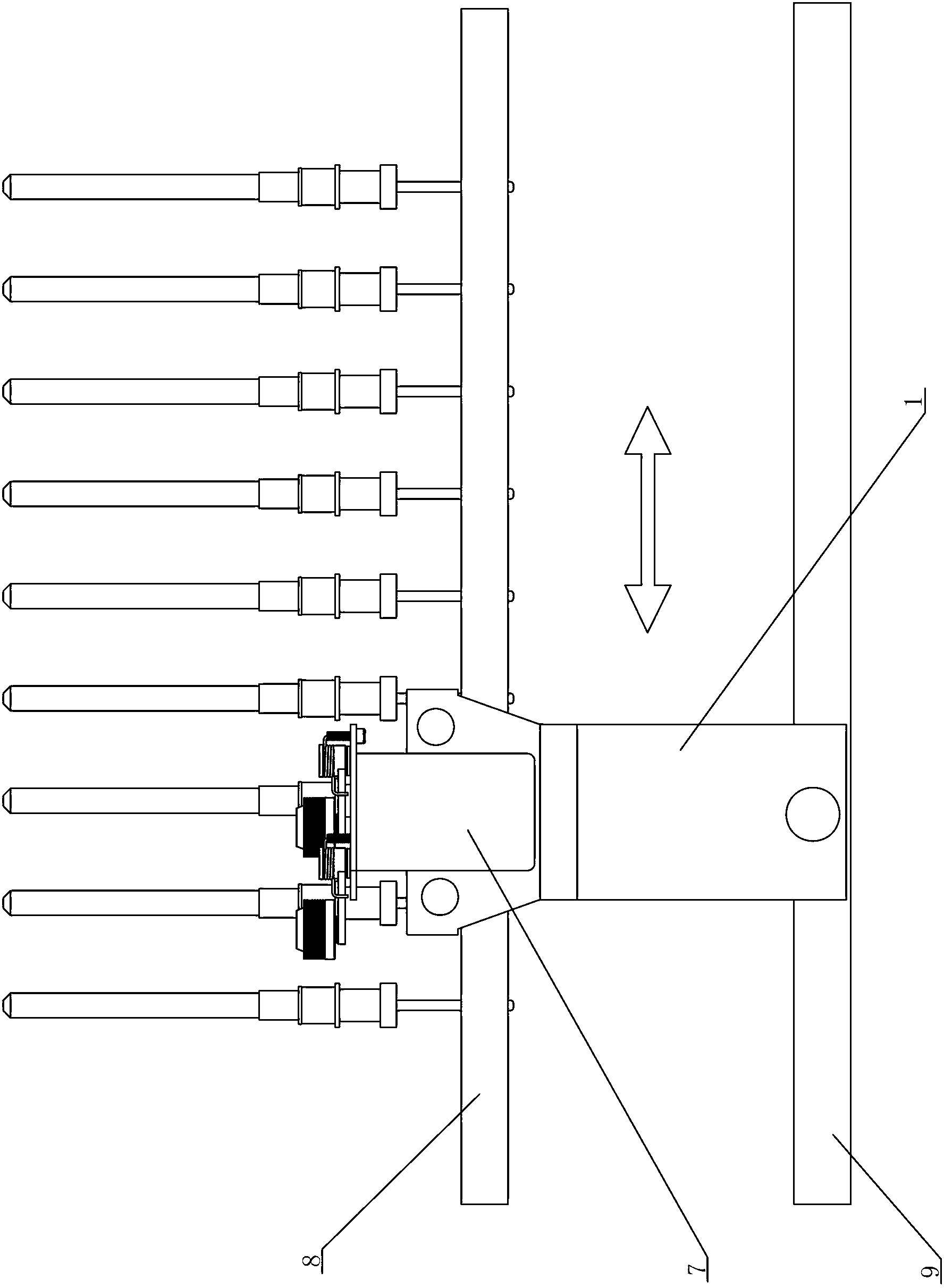

Device for automatically cleaning tail yarn

InactiveCN103231943AAutomatic cleaning up toShorten the timeFilament handlingYarnReciprocating motion

The invention relates to an automatic device used for cleaning a tail yarn on a spindle blade of a spinning frame. The automatic device replaces manual cleaning, saves time and improves production efficiency. The device for automatically cleaning the tail yarn comprises a guide rail and a support frame, wherein the guide rail is horizontally and suitably arranged at one side of the spindle blade of the spinning frame; the support frame can do reciprocating motion along the guide rail; a horizontal panel is arranged on the support frame; and the horizontal panel is provided with at least a connecting arm; a rotary knife flywheel is arranged at the free end of the connecting arm; the central shaft of the knife flywheel is arranged vertically; and the knife flywheel is formed by laminating multiple layers of zigzag blades.

Owner:TONGLING SOBONE INTELLIGENT EQUIP

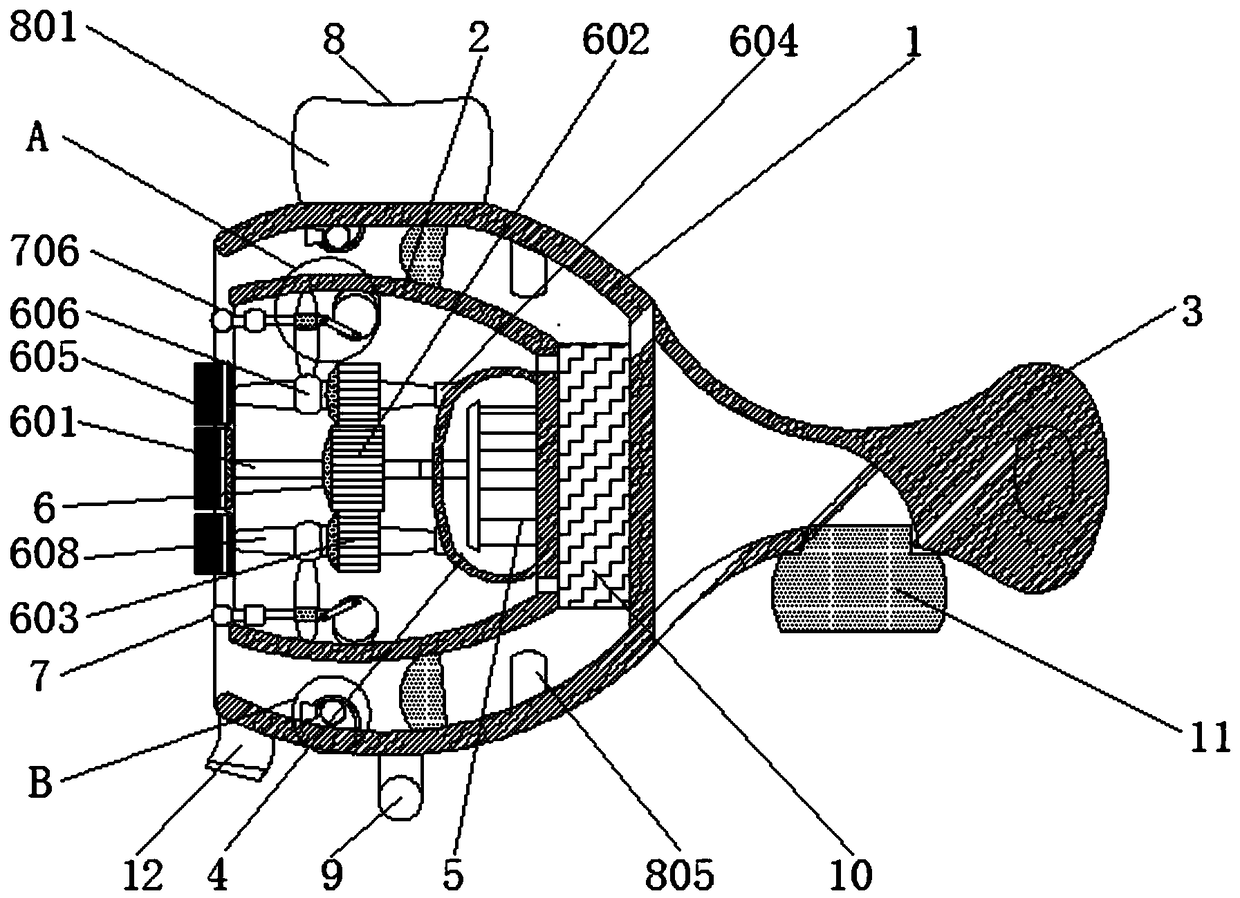

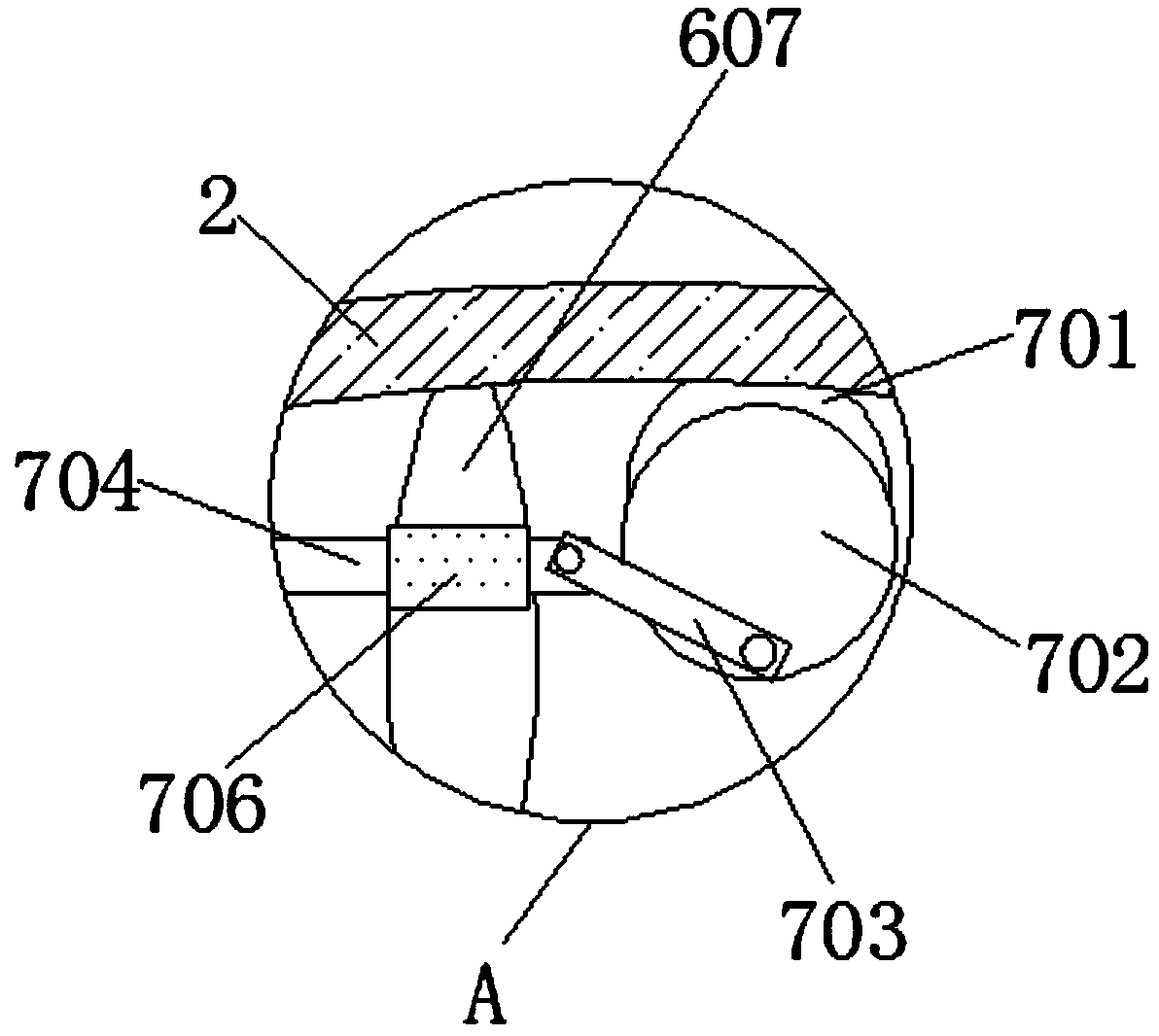

Household screen window decontaminating device combining clockwise and anticlockwise circumferential brushing and negative pressure suction

The invention provides a household screen window decontaminating device combining clockwise and anticlockwise circumferential brushing and negative pressure suction, relates to the mechanical field and solves the problem that an arranged screen window is hardly cleaned. The household screen window decontaminating device combining clockwise and anticlockwise circumferential brushing and negative pressure suction comprises a fixed outer housing. A mounting inner shell is adhered to the fixed outer housing through a connecting block, a humidifying and deoiling mechanism is arranged between the fixed outer housing and the mounting inner shell, an opening is formed in the left end of the fixed outer housing, and a tail connecting protecting barrel is adhered to the right end of the fixed outerhousing. According to the household screen window decontaminating device combining clockwise and anticlockwise circumferential brushing and negative pressure suction, a control motor controls cleaninghairbrushes on the end parts of a driving rotating rod and a driven rotating rod to rotate to clean dust on the surface of the screen window, so that the condition that the local part of the screen window is not cleaned as a result of unidirectional rotation is avoided. The motor controls a telescopic protecting part to beat the screen window continuously to simulate the action of flickering thewindow with a finger, so that dust is scattered effectively.

Owner:NANJING JONQUIL CONSTR TECH CO LTD

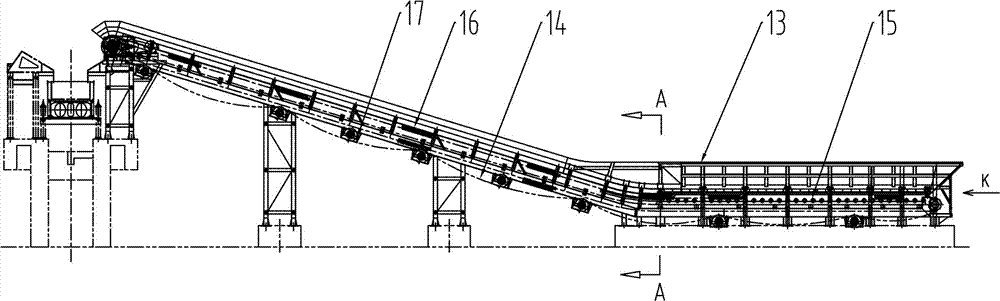

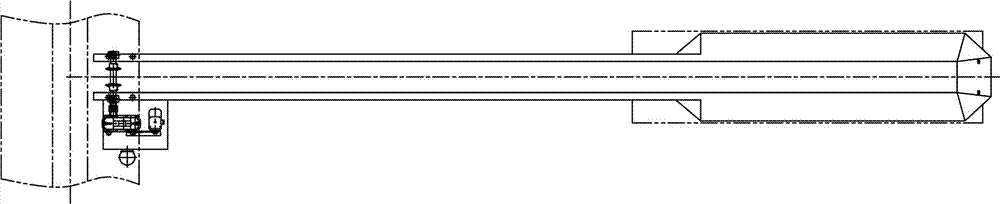

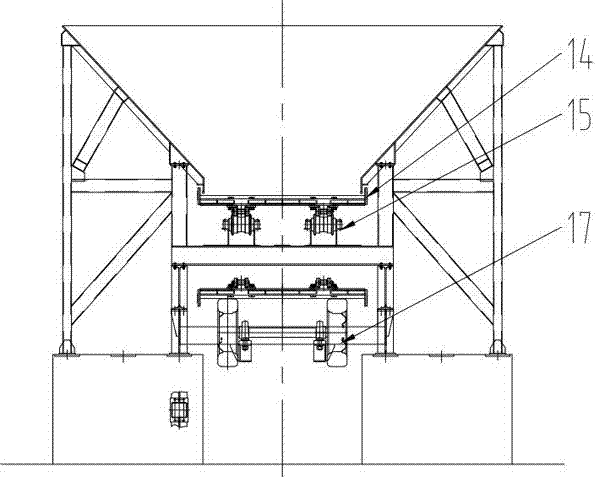

Waste steel apron conveyor, conveying method and application

PendingCN108001948AImprove impact resistanceStrong impact resistanceConveyorsMechanical engineeringSingle section

The invention provides a waste steel apron conveyor, a conveying method and application. The waste steel apron conveyor comprises a rack, an apron set for conveying of waste steel is arranged on the rack, circularly moves along a horizontal supporting mechanism, an oblique supporting mechanism and a return stroke supporting mechanism and comprises aprons and a conveying chain. The aprons comprisesquare tubes, upper channel plates and lower channel plates, the multiple square tubes are distributed on the upper channel plates, and the upper channel plates and the lower channel plates are mutually bent and buckled to form hollow stress frames. The conveying chain comprises two side plates, connecting circular tubes are welded to the front end of the position between the two side plates, pinshafts are mounted at the rear end of the position between the two side plates, and adjacent single-section chain bodies are connected into a whole by means of the method that the pin shafts are sleeved with the connecting circular pipes. Anchorage plates are mounted on the two side plates in a left-right symmetry mode, and the conveying chain is connected with the lower channel plates through theanchorage plates. According to the waste steel apron conveyor, through arrangement of the reinforced apron set, the overall conveying performance of the waste steel apron conveyor is improved.

Owner:YIDU ZHONGQI HEAVY IND MASCH CO LTD

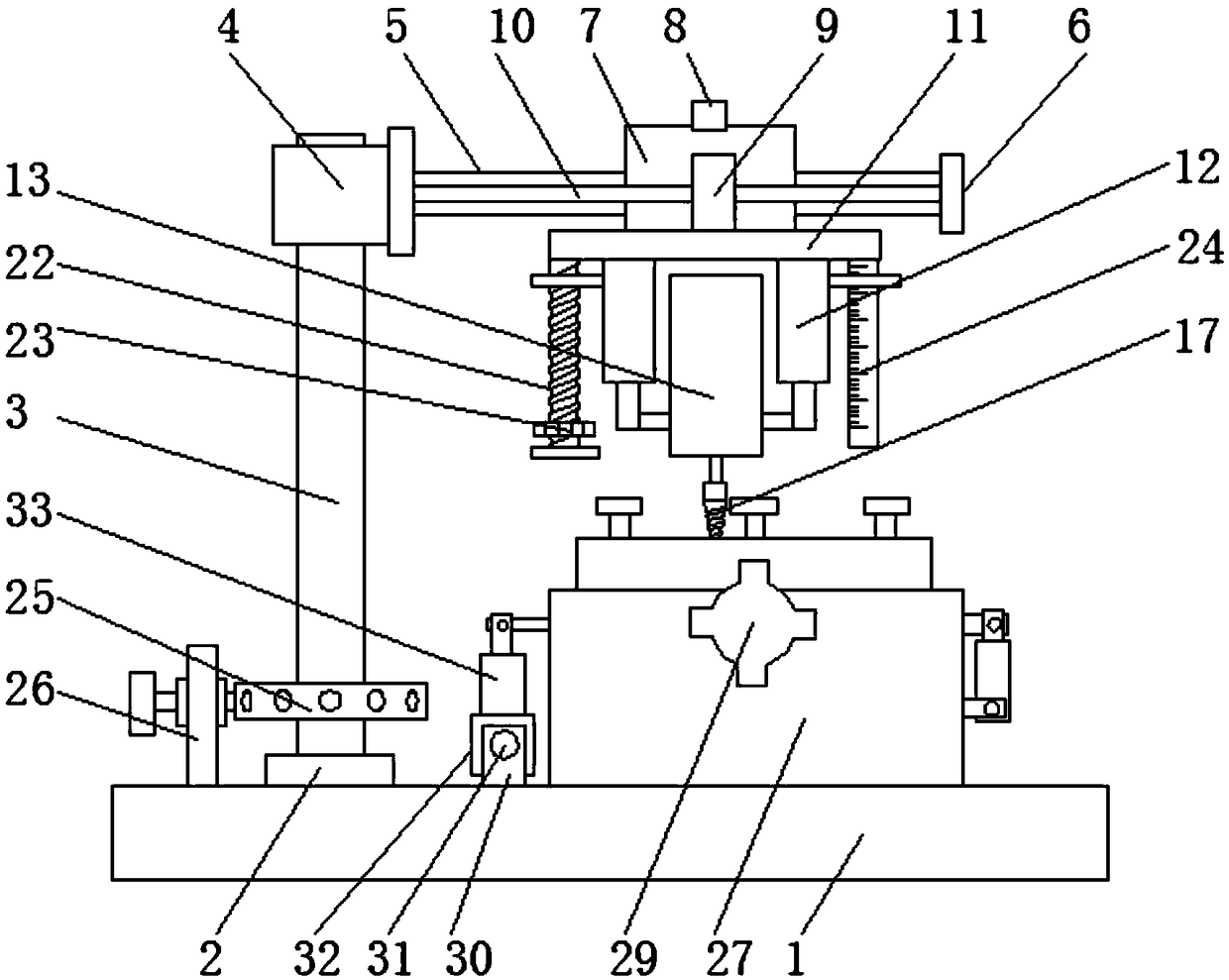

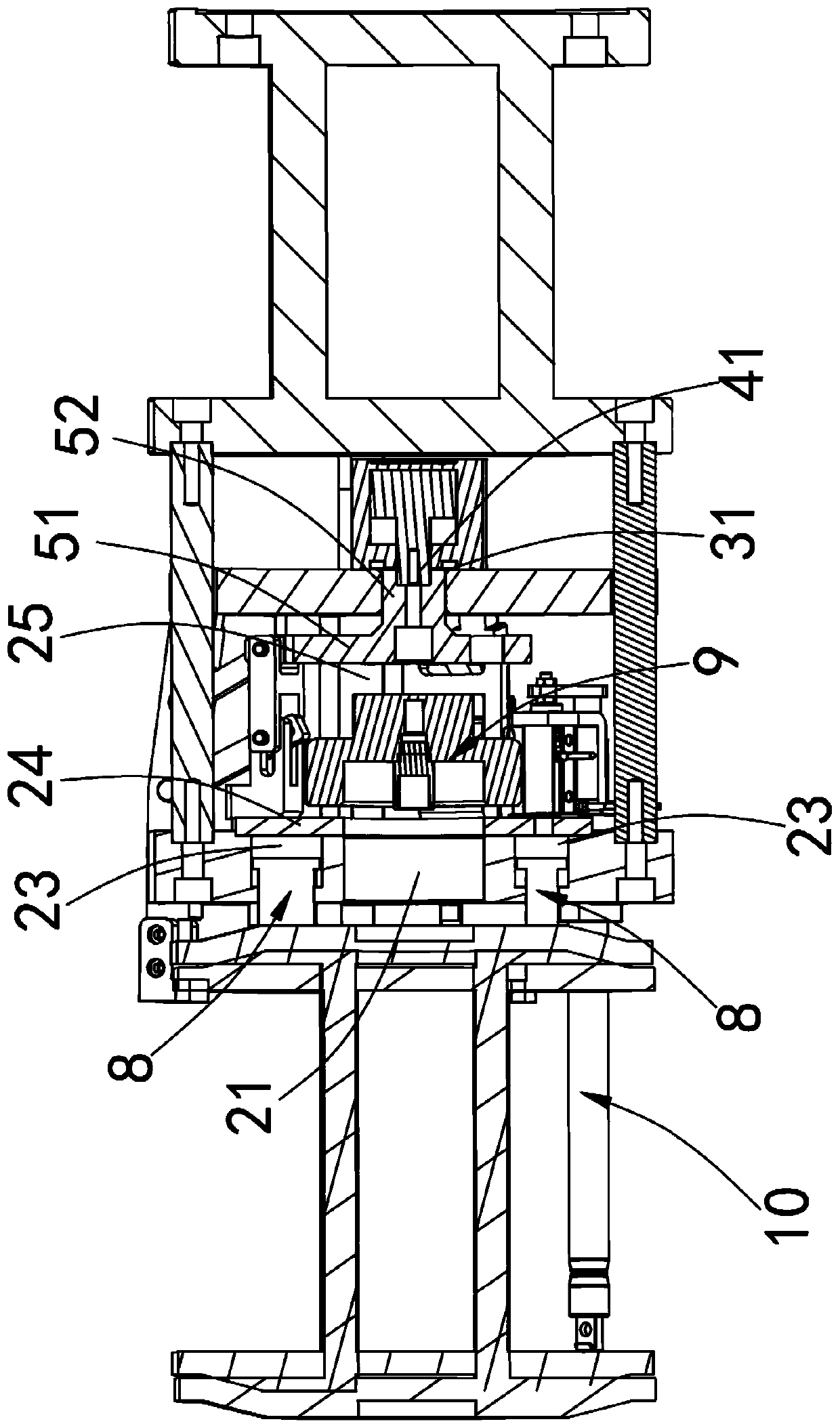

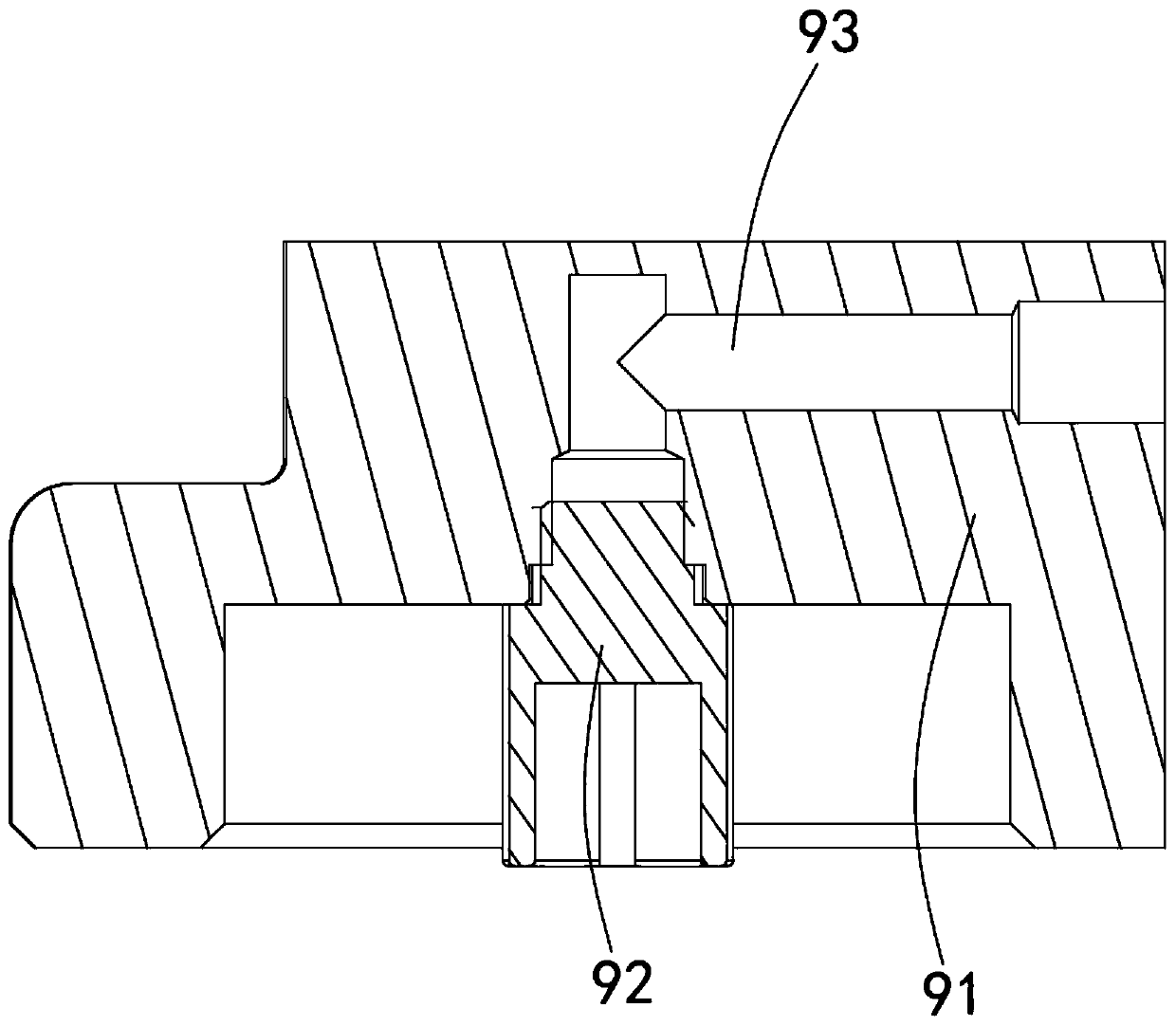

Self-adaptive press-fitting machine, automatic press-fitting system and press-fitting method thereof

The invention discloses a self-adaptive press-fitting machine, an automatic press-fitting system and a press-fitting method thereof. The self-adaptive press-fitting machine comprises a pressure head and a driving device for driving the pressure head to move in a first direction and a second direction in a reciprocating mode, the pressure head is connected with the driving device through a coaxiality fine adjustment device. According to the scheme, the design is ingenious, the structure is simple, and the coaxiality fine adjustment device is arranged between the pressure head and the driving device, so that the pressure head can swing slightly with respect to the driving device; when press fitting is carried out, if a column-shaped body and a hole or a groove are not in a co-axial state, the column-shaped body clamped by the pressure head can be coaxial with the hole or the groove through slight swinging of the pressure head, so that the coaxiality is improved, and smooth press fittingis facilitated; and meanwhile, the damage of the column-shaped body or a workpiece easily caused by direct rigid pressing can be avoided, and the safety of press fitting is guaranteed.

Owner:KUNSHAN JIEYUN INTELLIGENT EQUIP CO LTD

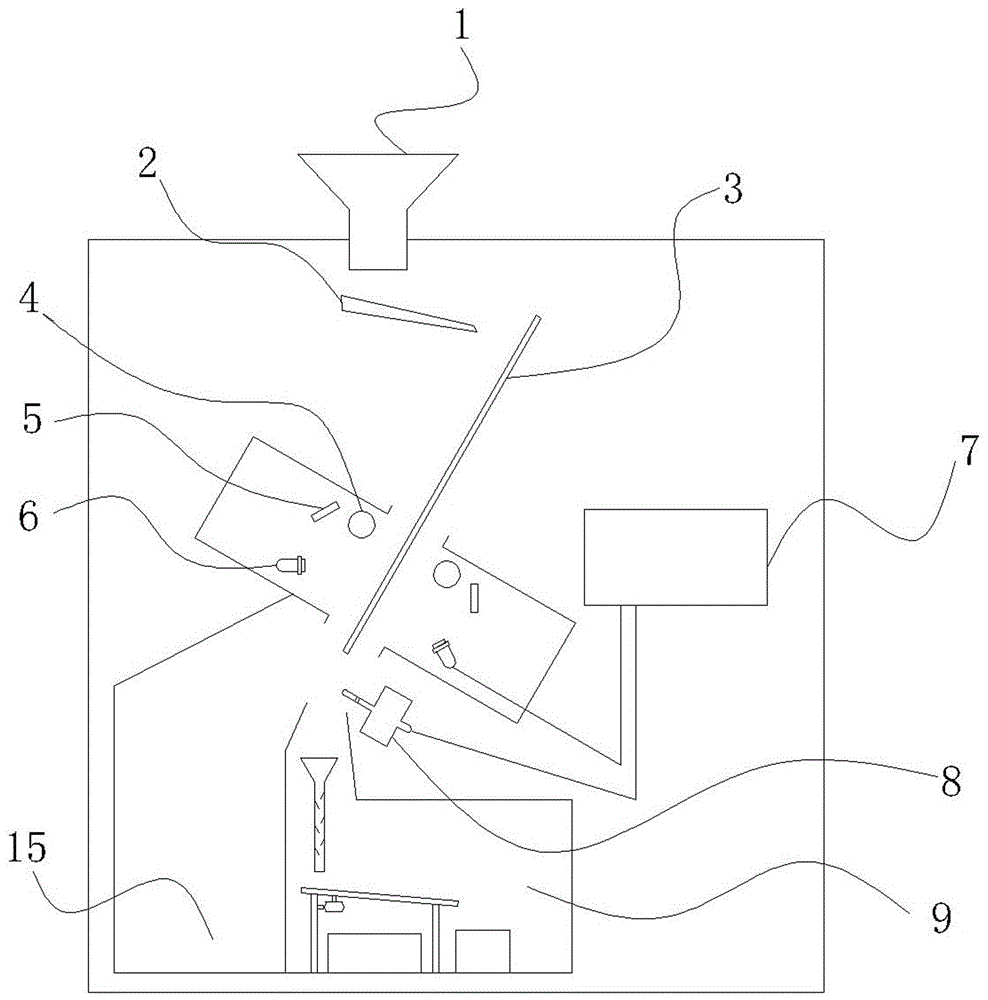

Color sorter for rice

The invention discloses a color sorter for rice. The color sorter comprises a machine body, a feed hopper, a vibrating feeder, a rice sliding channel, a light source, a background plate, a CCD lens, an electronic optical analysis meter, an electronic airflow ejector and a discharge bin are installed in the machine body, the discharge bin comprises a first-grade bin collecting high-quality rice and a second-grade bin collecting poor-quality rice, a speed reducing mechanism and a vibrating screen are arranged inside the first-grade bin, the speed reducing mechanism comprises a receiving hopper and a speed reducing channel, the receiving hopper communicates with the speed reducing channel and is located below the rice sliding channel to receive the high-quality rice, speed reducing plates are arranged inside the speed reducing channel, and the speed reducing channel is located right above the vibrating screen and is used for conveying the high-quality rice to the vibrating screen. According to the color sorter, a screening machine adopted before color sorting is eliminated innovatively, a screening mechanism is designed inside the color sorter, the rice undergoes color sorting firstly to screen out the poor-quality rice and the high-quality rice, then the high-quality rice is screened by size, and therefore color sorting and screening are combined, and the working pressure of the screening step is lowered.

Owner:湄潭县宫廷香米业有限责任公司

Seed sieving device

InactiveCN107321604AReduce labor intensityImprove screening efficiencySievingScreeningElectric machineryEngineering

Owner:吴保霞

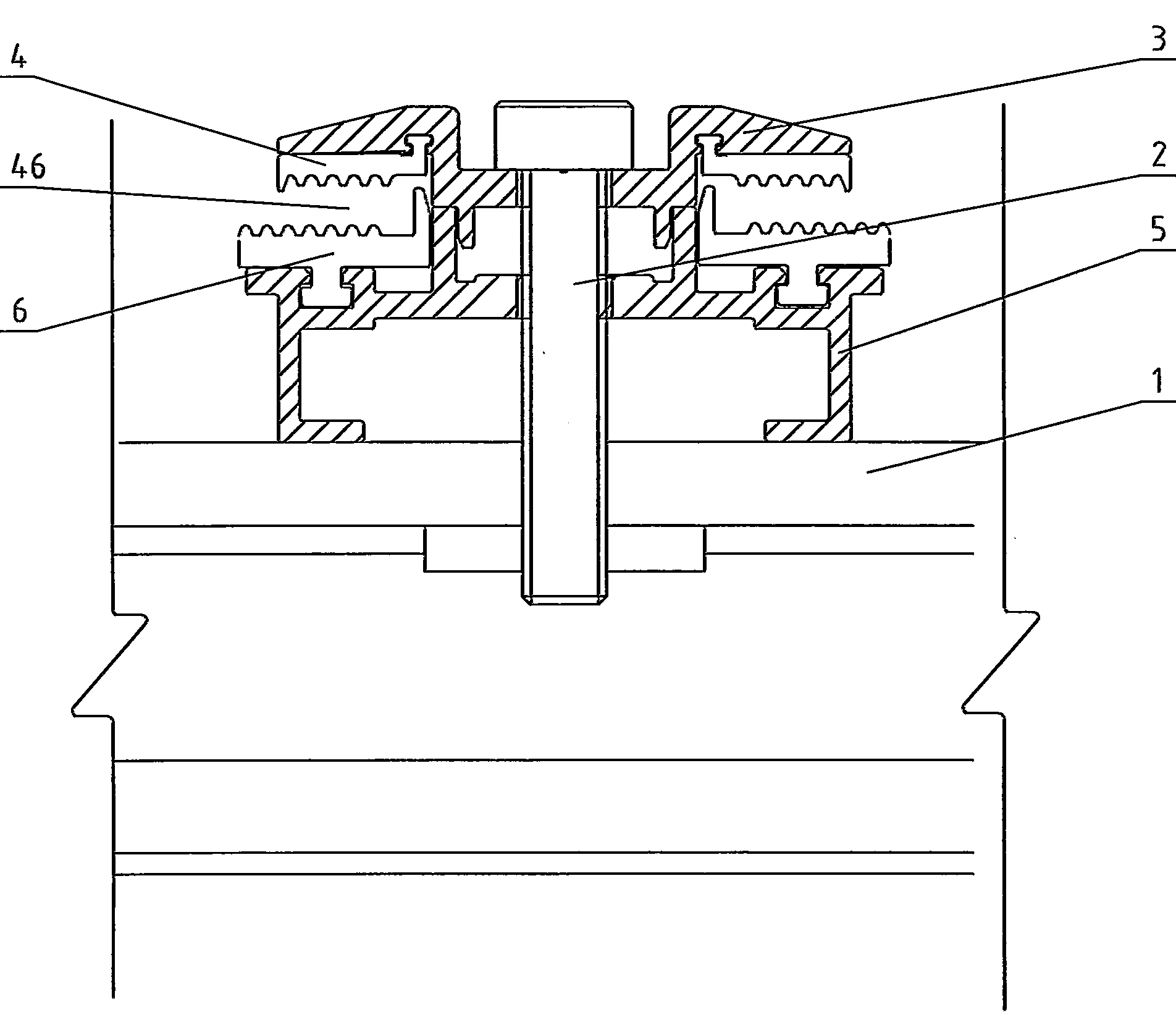

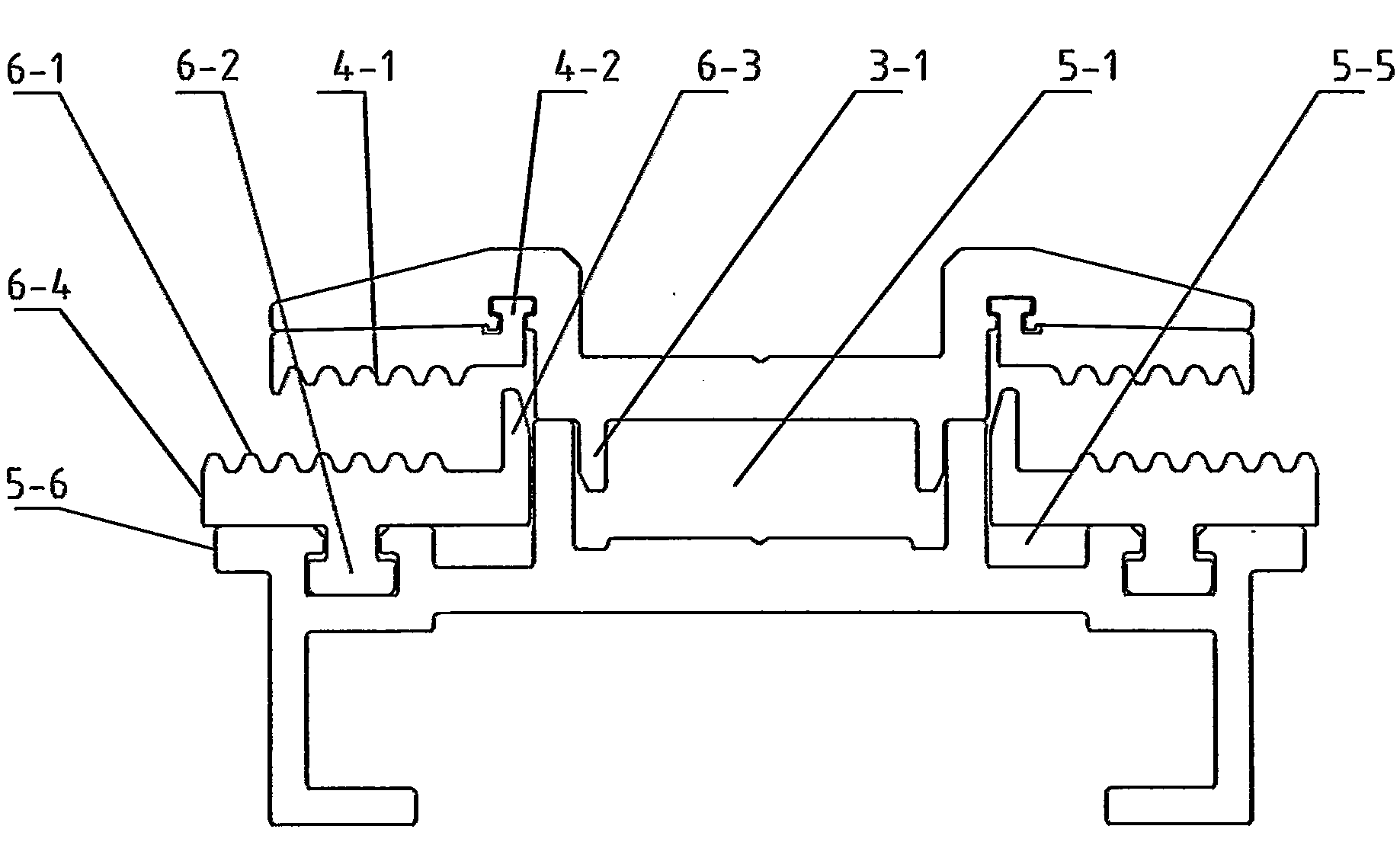

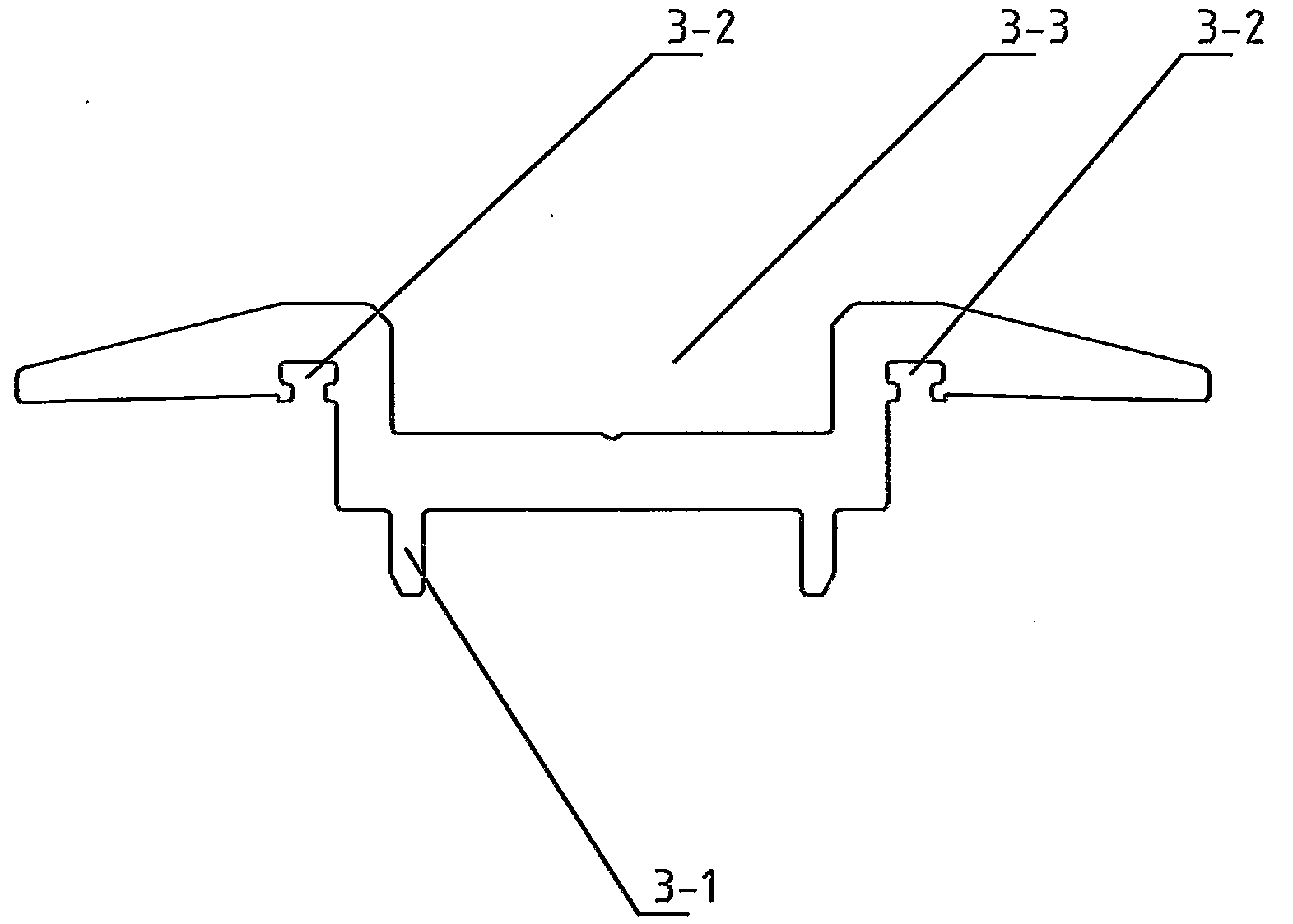

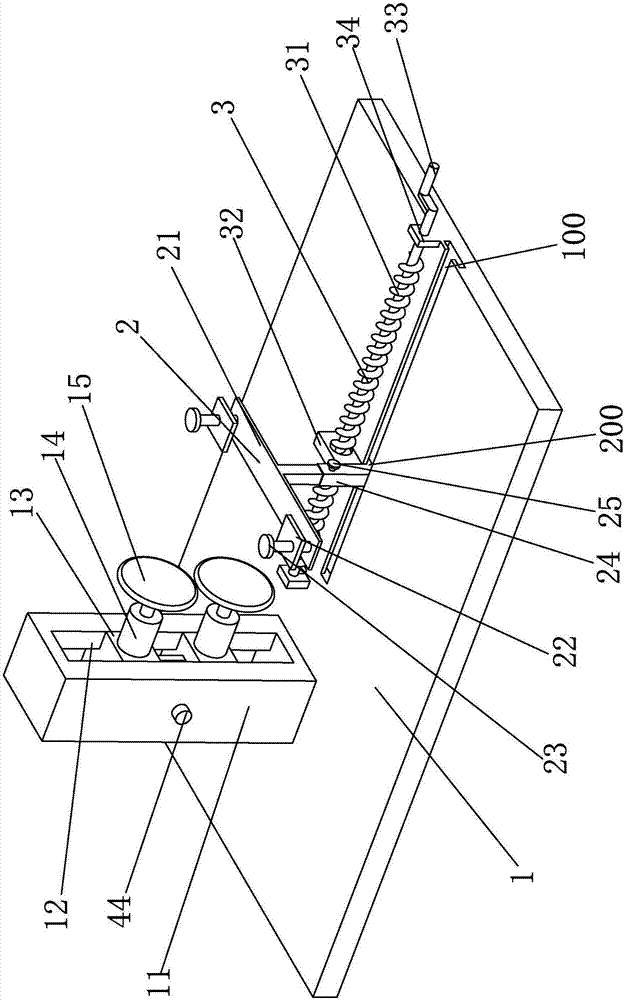

Solar module mounting clamping device

ActiveCN103258882AStrong load bearing capacityAvoid hard contactPhotovoltaic supportsPhotovoltaic energy generationEngineeringLarge size

The invention discloses a solar module mounting clamping device which comprises a support, a connecting screw rod, an upper pressing block, an upper rubber pad, a pressing block seat and a lower rubber pad. The connecting screw rod penetrates through the upper pressing block and the pressing block seat and then is fixedly connected with the support, the upper rubber pad is mounted on the upper pressing block in a clamping mode, the lower rubber pad is mounted on the pressing block seat in a clamping mode, the upper rubber pad is provided with a clamping face, the lower rubber pad is provided with a bearing face, and a clamping groove used for clamping a solar module is formed between the clamping face and the bearing face. A positioning groove is formed in the pressing block seat, a positioning rib set is arranged at the bottom end of the upper pressing block, and the positioning rib set is inserted in the positioning groove and matched with the positioning groove to achieve guiding and positioning. By means of the solar module mounting clamping device, the load bearing ability for mounting the solar module can be improved, and the solar module mounting clamping device is suitable for large-size solar modules.

Owner:TRINA SOLAR CO LTD

Textile transport device facilitating clamping

The invention discloses a convenient clamping textile transportation device, which comprises a box body, a handle is fixedly connected to the top of the right side of the box body, a fixed block is fixedly connected to the left side of the bottom of the inner wall of the box body, and the fixed The front of the block is movably connected with the first support, the top of the first support is movably connected with the first roller, the right side at the bottom of the inner wall of the box is fixedly connected with the first connecting block, and the front of the first connecting block is movably connected with an electric telescopic rod. The present invention sets fixed block, first bracket, first roller, first connecting block, electric telescopic rod, second connecting block, chute, sliding rod, partition plate, trapezoidal plate, polished rod, slip ring, transmission rod, connecting The combined use of the rod and the clamping plate solves the problem that the existing textile transportation device is inconvenient to use and cannot clamp the textile. Perform clamping.

Owner:HUZHOU LINGHU ZHONGZHAO JINHUI SILK WEAVING FACTORY

Cutter polishing equipment with good polishing effect

InactiveCN107350904AAvoid hard contactSimple structureGrinding carriagesOther manufacturing equipments/toolsEngineeringMotor shaft

The invention discloses cutter polishing equipment with a good polishing effect. The cutter polishing equipment comprises a fixed base, a fixed rod is arranged on the fixed base, a movable groove is formed in the fixed rod, movable blocks are symmetrically arranged in the movable groove, motors are arranged at the front ends of the movable blocks, polishing wheels are arranged on motor shafts of the motors, and pushing springs capable of pushing the movable blocks to the middle of the movable groove are arranged between the movable blocks and the fixed rod; and an adjusting device capable of adjusting the distance between the two movable blocks is arranged between the two movable blocks, a fixing device capable of fixing a cutter is arranged at the position, at the front end of a polishing wheel, of the fixed base, and a movement mechanism capable of driving the fixing device to move front and back is arranged at the position, on one side of the fixing device, of the fixing base. The cutter polishing equipment is simple in structure and convenient to use.

Owner:陈秋菊

Textile bobbin convenient to replace

The invention discloses a textile bobbin convenient to replace. The textile bobbin comprises a bearing table. A polished rod is fixedly connected to the bottom of the inner wall of the bearing table. A trapezoidal block is slidably connected to the surface of the polished rod. An electric telescopic rod is fixedly connected to the bottom of the right side of the inner wall of the bearing table. A support is fixedly connected to the left end of the electric telescopic rod. A rolling wheel is movably connected to the left side of the support. The surface of the rolling wheel makes contact with the left side of the bottom of the trapezoidal block. Connecting plates are movably connected to both the two sides of the front face of the trapezoidal block. According to the textile bobbin, through matched use of the bearing table, the polished rod, the trapezoidal block, the electric telescopic rod, the support, the rolling wheel, the connecting plates, a support plate, a sliding rod, a sliding ring, a spring, a fixed rod, a through hole, a clamping rod, a bobbin body and a clamping groove, the effect of convenient bobbin replacing is achieved, and the problems that an existing bobbin is inconvenient to replace by a worker, textile production efficiency is influenced, and economic benefits of a factory are lowered are solved.

Owner:SUZHOU BONUQI TEXTILE CO LTD

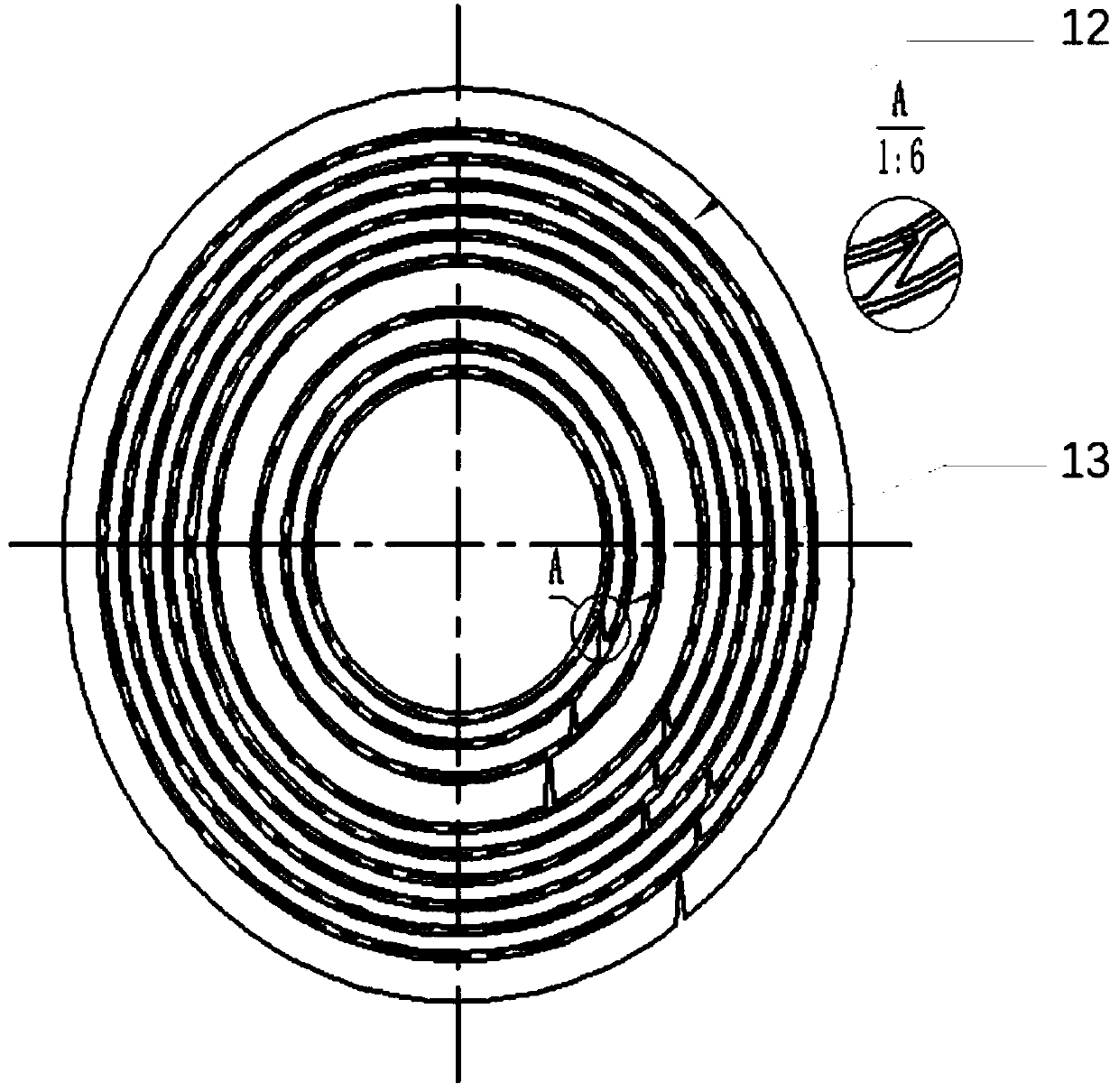

Variable-ball-diameter automatic screening and ball grinding machine

PendingCN109648427AAvoid Stack FragmentationPrecision grindingGrinding drivesSpherical surface grinding machinesEngineeringHardness

The invention provides a variable-ball-diameter automatic screening and ball grinding machine, aiming at solving the problems that bearing steel balls and hard alloy balls with high hardness and highbrittleness will have larger ring belt phenomenon after machining and are not prone to rolling behaviors in the grinding process, and the balls are easy to be cracked when being squeezed mutually, thus affecting the product quality. According to the variable-ball-diameter automatic screening and ball grinding machine, multiple concentric raceways and valve ports are arranged on the surface of a lower grinding disc, so that the effects that a core raceway grinds off ring belts of balls at a lower linear speed to prevent the balls from being stacked and crushed, the outer raceway accurately grinds at a higher linear speed, and the sizes of the balls are automatically screened by utilizing centrifugal force of the variable-ball-diameter automatic screening and ball grinding machine are achieved; and the variable-ball-diameter automatic screening and ball grinding machine can improve the production efficiency and the product quality.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

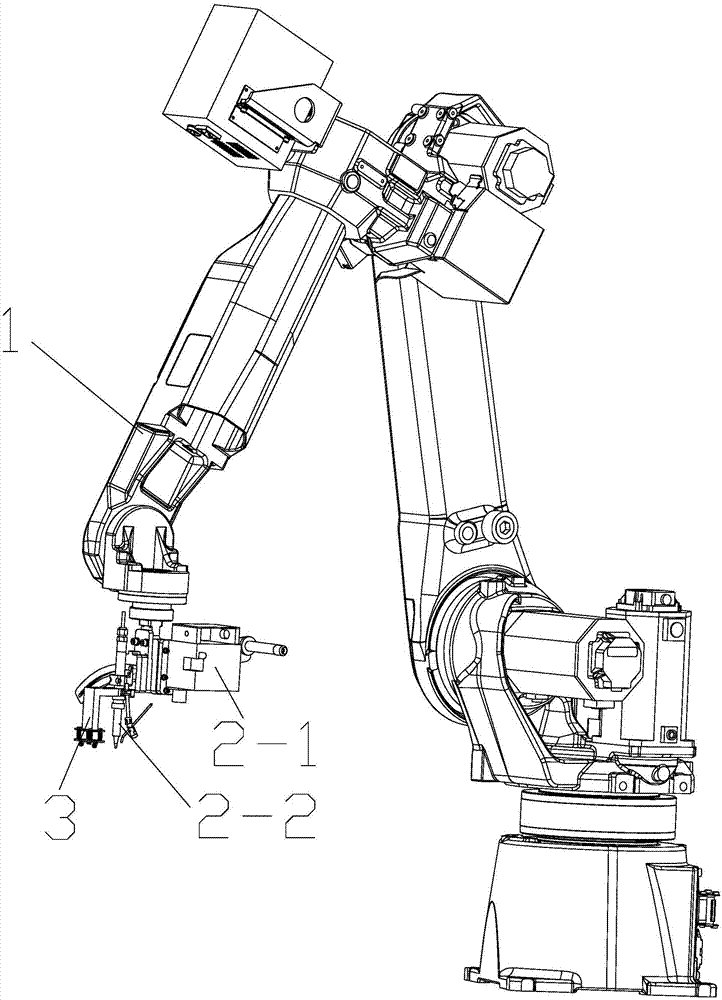

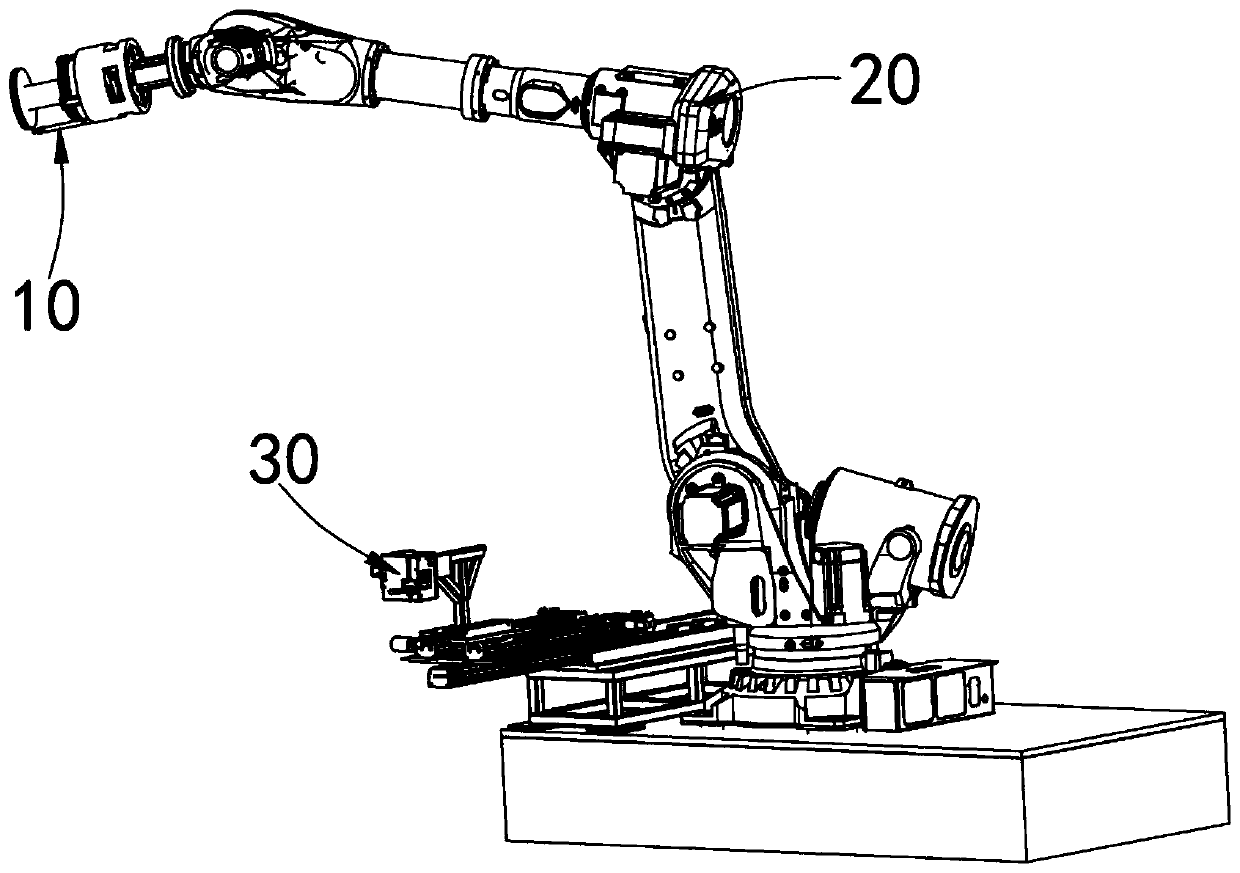

Wire end tightening humanoid robot and using method thereof

ActiveCN110625624AGuaranteed reliabilityMeet cutting requirementsGripping headsHeight differenceEngineering

The invention discloses a wire end tightening humanoid robot and a using method thereof. The humanoid robot comprises a wire end gripping device, a moving device for driving the wire end gripping device and a guide fusing device, wherein the guide fusing device comprises an upper partition column, a lower partition column and a fusing device body, and a height difference is generated between the upper partition column and the lower partition column. In a first state, the upper partition column and the lower partition column can cooperate with at least one side plate to limit a wire from movingoutwards from the inside of the guide fusing device; in a second state, notches at same positions are formed in the upper partition column and the lower partition column so as to allow the wire to pass through; and the fusing device body can fuse the wire between the upper partition column and the lower partition column when the upper partition column and the lower partition column are in the first state. According to the scheme, manual work can be simulated to tighten wire ends, therefore, the wire end fixing firmness can be ensured, packaging tape is not required in use, and the cost is low. The wire is cut off by combining with a hot fusing way, the cutting requirements of various materials, such as metal, can be effectively met, the cutting stability is high, and the application rangeis wide.

Owner:SUZHOU JIANGJIN AUTOMATION TECH

Mixing device for preparing amino acid organic fertilizer

InactiveCN111266037AAvoid hard contactWell mixedTransportation and packagingRotary stirring mixersHydraulic cylinderAgricultural engineering

The invention discloses a mixing device for preparing an amino acid organic fertilizer. The device includes a bottom plate, wherein output shafts of two electric hydraulic cylinders are fixedly connected with the two sides of the bottom end of a top plate correspondingly. An output shaft of a stirring motor penetrates through the top plate and is fixedly connected with a stirring shaft in a tank cover; a scraping plate is mounted on one side of each of a plurality of buffer devices; the inner wall of a heating shell is fixedly sleeved with the outer wall of the tank body. According to the disclosed mixing device, the plurality of scraping plates connected with the buffer devices are arranged on the two sides of the stirring shaft; the scraping plates can be in contact with the inner wall of the tank body to clean raw materials adhered to the inner wall surface of the tank body and guarantee uniform mixing, meanwhile, when the tank body is placed obliquely, the buffer devices provide buffer force for the scraping plates, hard contact between scrapers and the inner wall of the tank body is avoided, the scrapers and the tank body are effectively protected, and meanwhile, a stirring bottom block is arranged to mix the raw materials at the bottom of the tank body.

Owner:JIANGSU HANLING FERTILIZER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com