Rotary type viscous fluid damper

A viscous fluid, rotary technology, applied in the direction of building components, shockproof, etc., can solve the problems of poor anti-torsional vibration performance, increase construction cost, large length and other problems, achieve good vibration performance and reduce construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

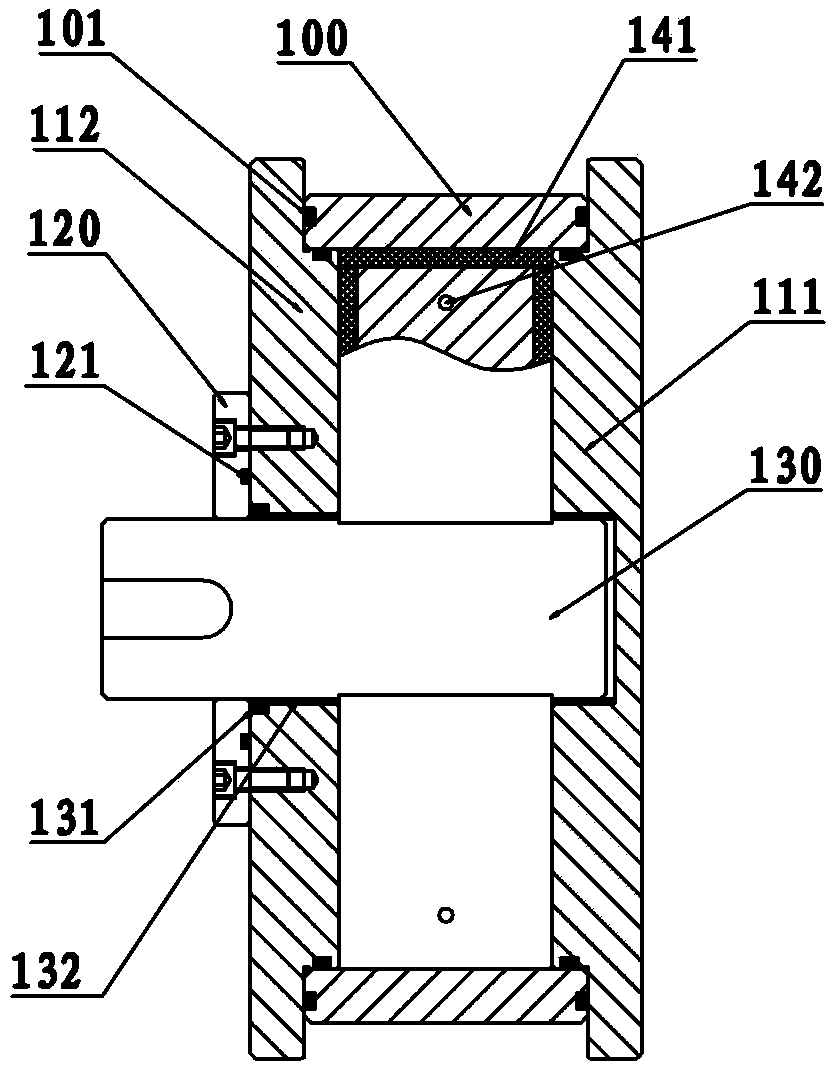

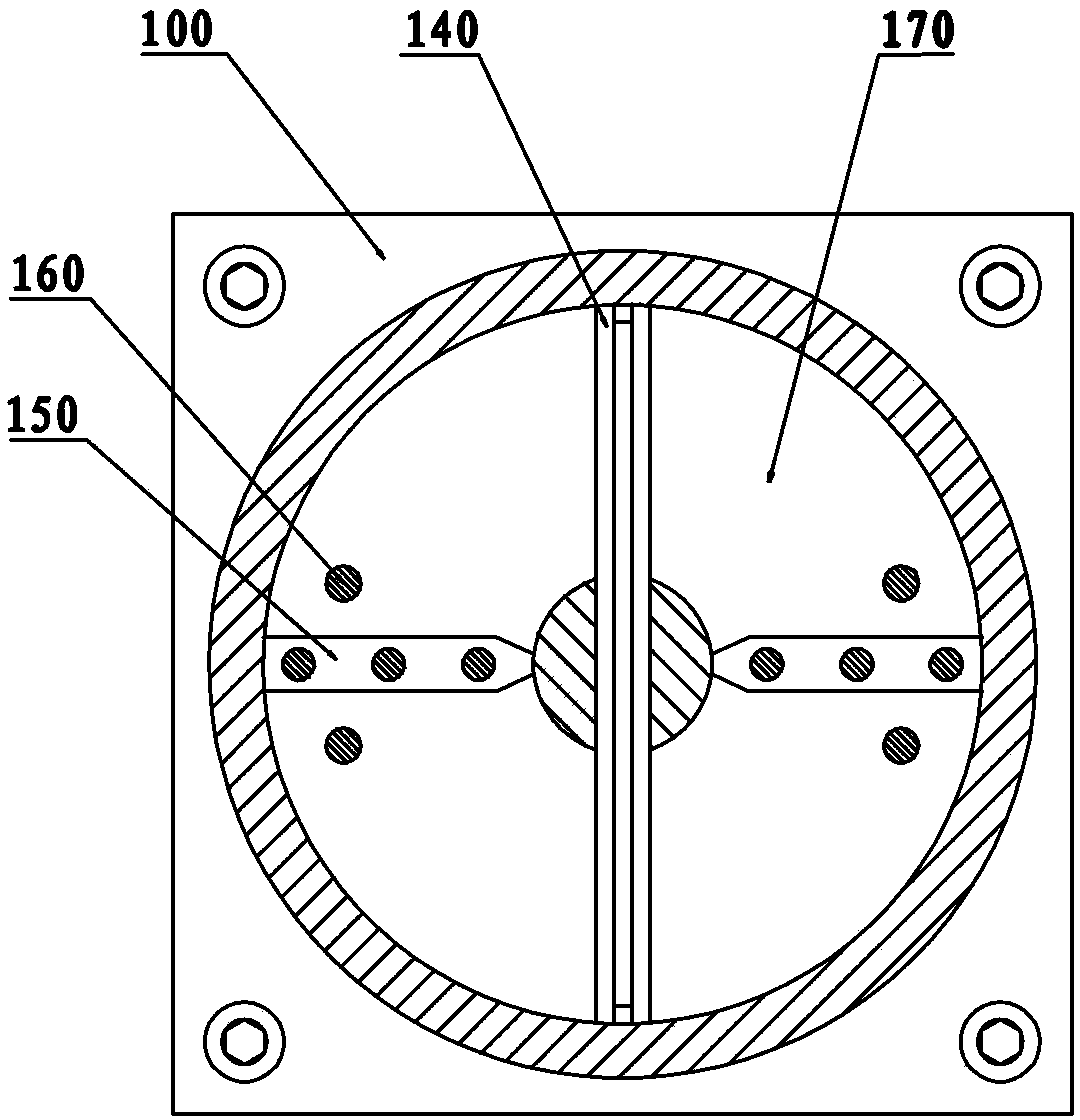

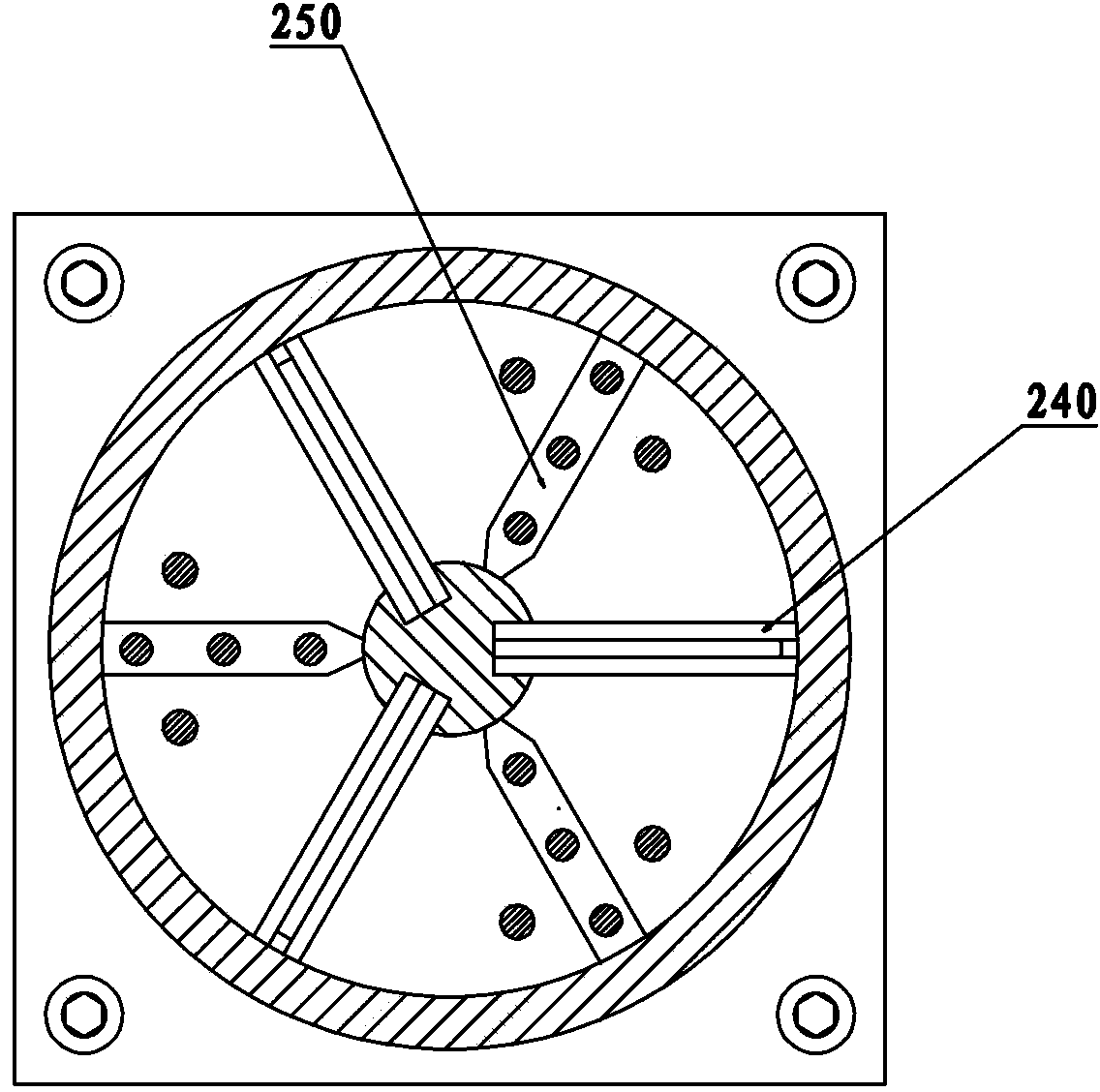

[0018] Such as figure 1 , figure 2 As shown, this embodiment discloses a rotary viscous fluid damper, including a cylinder 100, a front guide sleeve 112, a rear guide sleeve 111, a sub-chamber block 150, a rotating blade 140, and a rotating shaft 130; the front guide sleeve 112, Rear guide sleeves 111 are respectively mounted on the front and rear corresponding ends of the cylinder body 100 to form a closed space; rotating blades 140, rotating shafts 130, and sub-cavity blocks 150 are simultaneously arranged in the enclosed space; one end of the rotating shaft 130 passes through the front guide sleeve 112, the other end is movably connected with the center point of the rear guide sleeve 111; the rotating blade 140 is installed on the side of the rotating shaft 130; A space of equal volume; a damping hole 142 is opened on the rotating blade 140; the damping medium 170 is filled in the sealed space.

[0019] This embodiment is uniquely designed with a rotary viscous fluid dam...

Embodiment 2

[0021] Such as figure 1 , figure 2 As shown, this embodiment discloses a rotary viscous fluid damper with better sealing effect. , which includes a cylinder block 100, a front guide sleeve 112, a rear guide sleeve 111, a sub-cavity block 150, a rotating blade 140, and a rotating shaft 130; , and a sealing ring 101 is installed at each contact position to form a closed space; the rotating blade 140, the rotating shaft 130, and the sub-cavity block 150 are simultaneously arranged in the closed space; one end of the rotating shaft 130 passes through the center point of the front guide sleeve 112, The other end is movably connected with the central point of the rear guide sleeve 111, and a sliding bearing 132 and an oil seal 131 are installed at the contact position between the rotating shaft 130 and the front guide sleeve 112; 120 is fixed on the left side of the front guide sleeve 112 by screws, and a sealing ring 121 is arranged on the contact surface between the two; A sea...

Embodiment 3

[0024] Such as figure 1 , figure 2 As shown, this embodiment discloses a rotary viscous fluid damper with longer service life, which includes a cylinder body 100, a front guide sleeve 112, a rear guide sleeve 111, a sub-chamber block 150, a rotating blade 140, and a rotating shaft 130; The guide sleeve 112 and the rear guide sleeve 111 are respectively mounted on the front and rear corresponding ends of the cylinder body 100 to form a closed space; the rotating blade 140, the rotating shaft 130 and the sub-chamber block 150 are simultaneously arranged in the closed space; one end of the rotating shaft 130 is passed through The center point of the front guide sleeve 112 is passed, and the other end is movably connected with the center point of the rear guide sleeve 111; the rotating blade 140 is installed on the side of the rotating shaft 130; The enclosed space is divided into spaces of equal volume; a damping hole 142 is opened on the rotating blade 140; a damping medium 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com