Full-turn paddle rudder

A full-turn and paddle rudder technology, which is applied in the direction of steering and steering with propulsion components, ship propulsion, ship parts, etc., can solve the problems of high manufacturing and maintenance costs, low transmission efficiency, and high precision of parts installation, achieving low maintenance costs, Large transmission power and good rotary vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

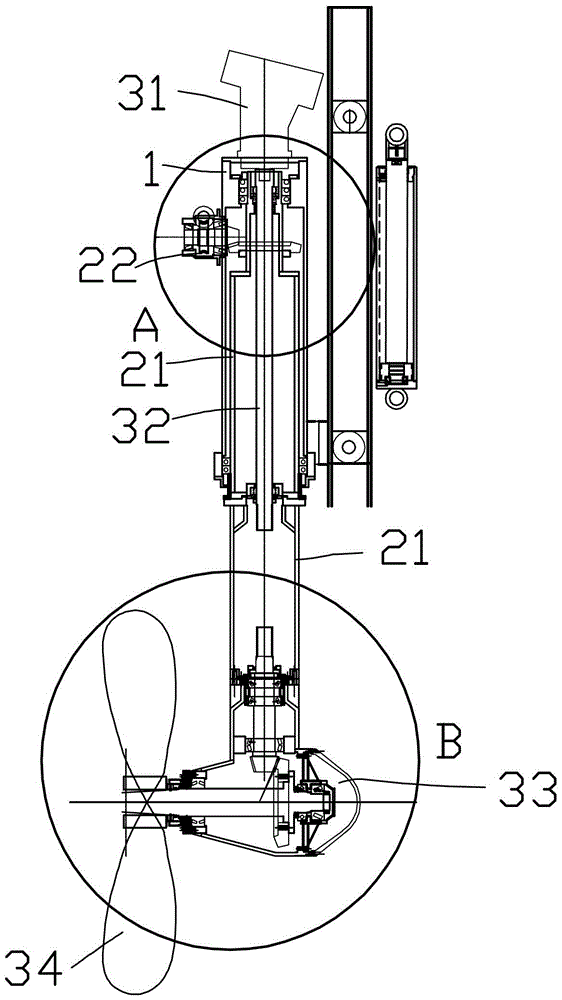

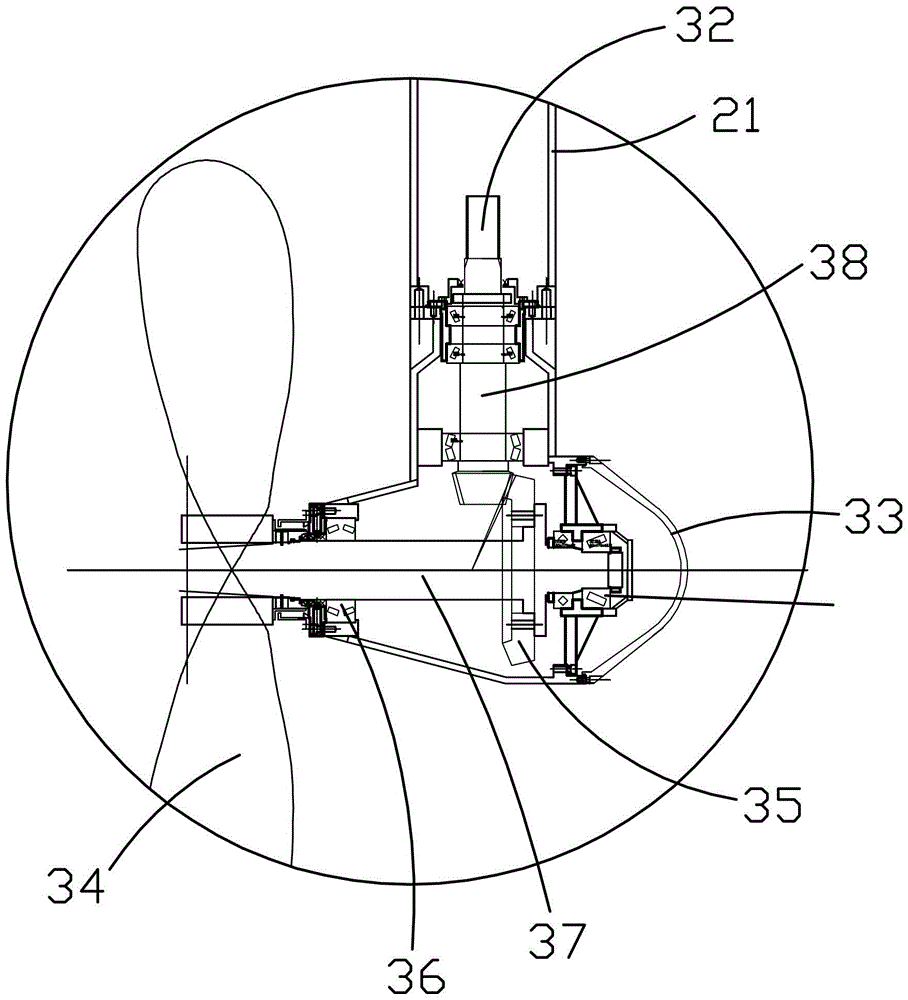

[0021] The following is attached figure 1 , 2 3. To further describe the present invention in detail. A full-rotation propeller rudder, the device includes a support sleeve 1, a slewing system 2, a power propulsion system 3;

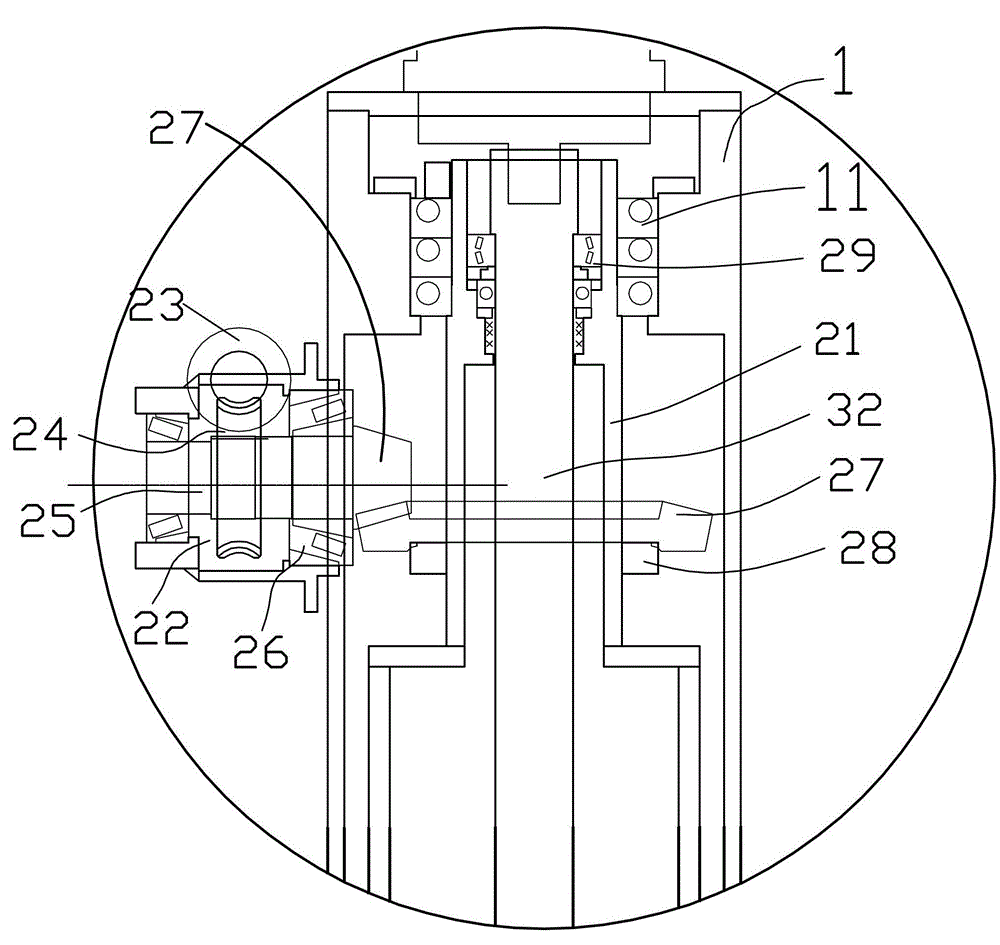

[0022] The support sleeve 1 is hollow, the support sleeve 1 is fixedly installed on the hull, the top of the support sleeve 1 is provided with a power platform, the upper part is provided with a worm gear box 22 installation platform, and the inner or end can be provided with a bearing seat; motor 31 Installed on the power platform;

[0023] The slewing system 2 includes a slewing sleeve 21, a worm and worm gear box 22, and a set of bevel gears 27. The slewing sleeve 21 is hollow, and the slewing sleeve 21 is movably installed in the supporting sleeve 1, and the slewing sleeve 21 is supporting The sleeve 1 can rotate around the axis; the worm and worm gear transmission box 22 is fixedly installed on the support sleeve 1; a bevel gear 27 is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com