Indigenous microorganism activation and exogenous microorganism intensified oil production method in offshore oilfield

A technology of endogenous microorganisms and enhanced oil recovery, applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve problems such as the reduction of oil displacement efficiency of endogenous microorganisms, the explosion of flammable mixtures, and the destruction of abandoned gas injection pipelines. Achieve the effect of enhancing oil washing and oil displacement, improving fluidity and increasing interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

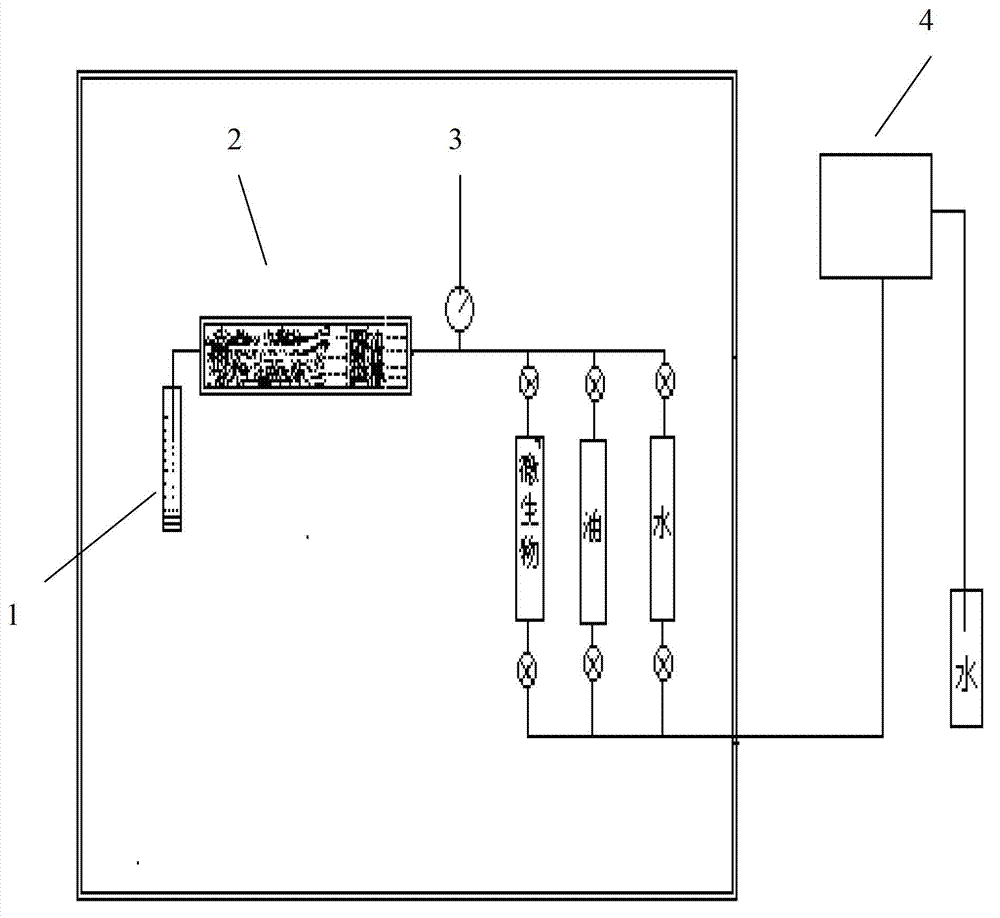

[0039] See attached figure 1 . A method for enhancing oil recovery of endogenous microorganisms and exogenous microorganisms in offshore oilfields, which is applied to the process of enhancing oil recovery in offshore oilfields: injecting exogenous microorganisms and activators into oil reservoirs for oil displacement.

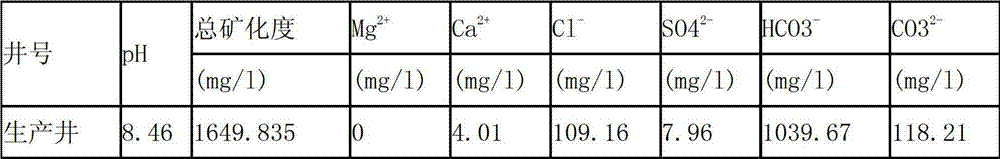

[0040] 1. Oil well selection:

[0041] To select a block in the oilfield as a block suitable for microbial flooding, the basic conditions are as follows:

[0042] parameters

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com