Patents

Literature

348results about How to "Simple separation process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method for waste of positive electrode material of lithium battery

InactiveCN106505272AHigh recovery rateGuaranteed purityWaste accumulators reclaimingProcess efficiency improvementPhysical chemistryManganese

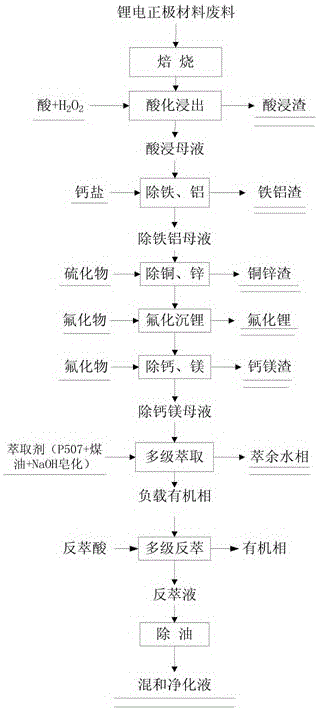

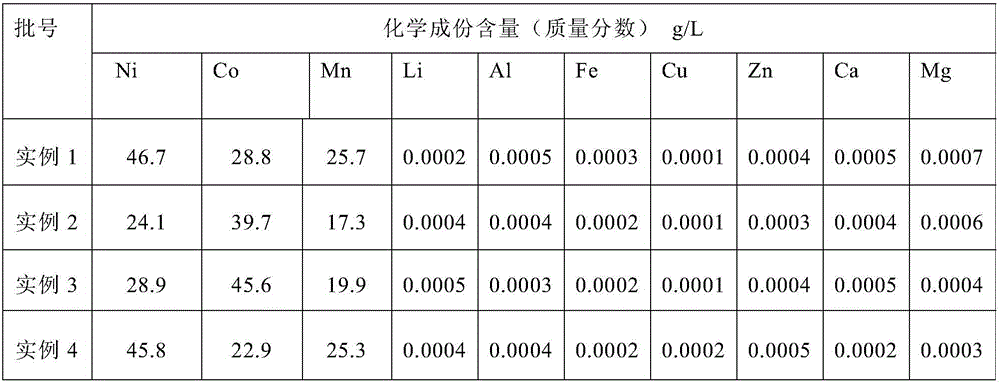

The invention discloses a treatment method for waste of a positive electrode material of a lithium battery. The method comprises the steps of (A) roasting; (B) acidifying and leaching; (C) iron and aluminum removal; (D) copper and zinc removal; (E) fluorinating lithium deposition; (F) calcium and magnesium removal; (G) multi-stage extraction; and (H) oil removal. According to the treatment method for the waste of the positive electrode material of the lithium battery, multiple valuable metals of lithium, cobalt, manganese, nickel and the like contained in the positive electrode material of the lithium battery can be comprehensively recovered; the treatment method has the advantages that the metal recovery rate is high, the obtained lithium product is good in quality and the treatment method is friendly to environment, low in production cost and suitable for industrial production.

Owner:GANFENG LITHIUM CO LTD

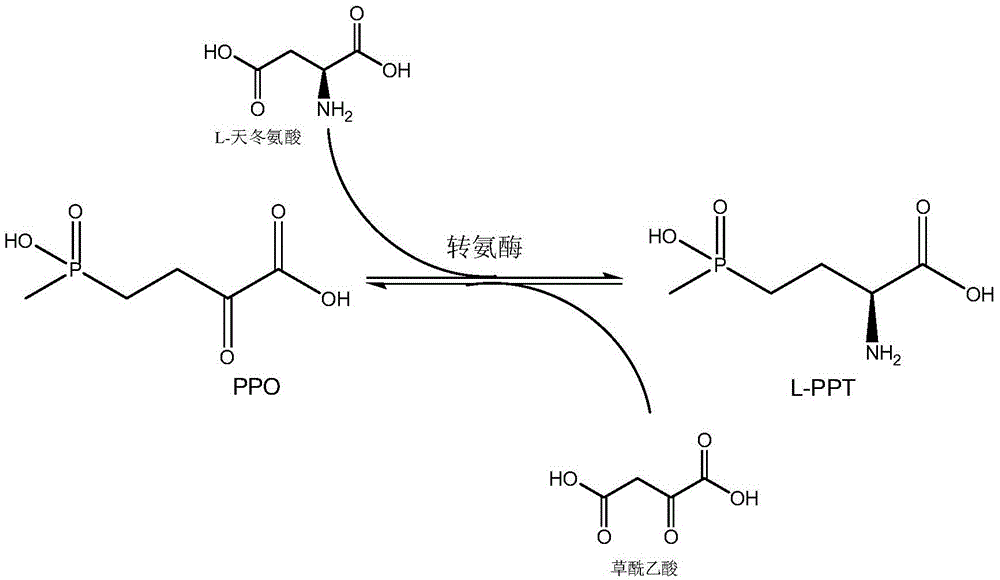

Production method of L-glufosinate

ActiveCN105603015AImprove conversion rateSimple separation processTransferasesMicroorganism based processesButyric acidHydroxy compound

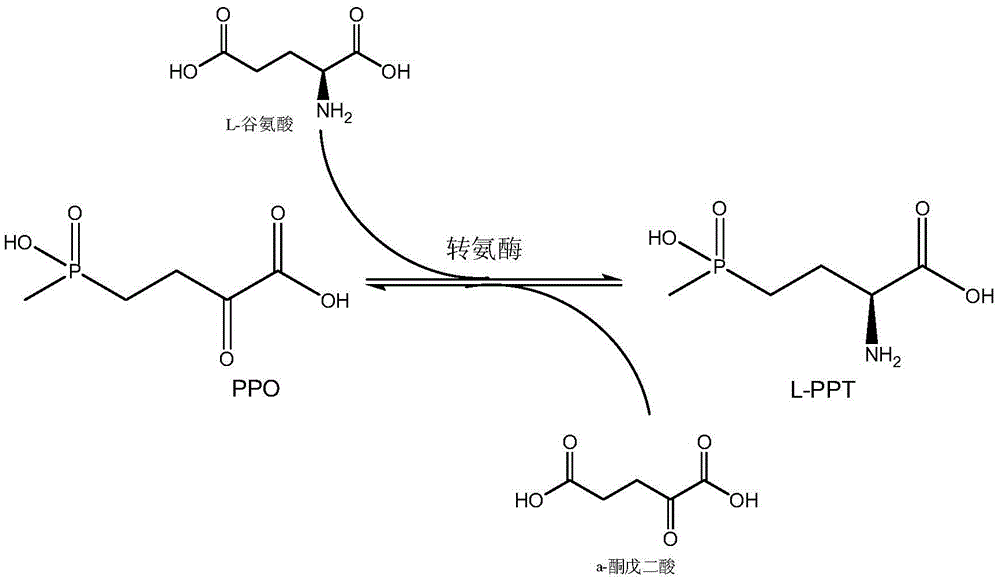

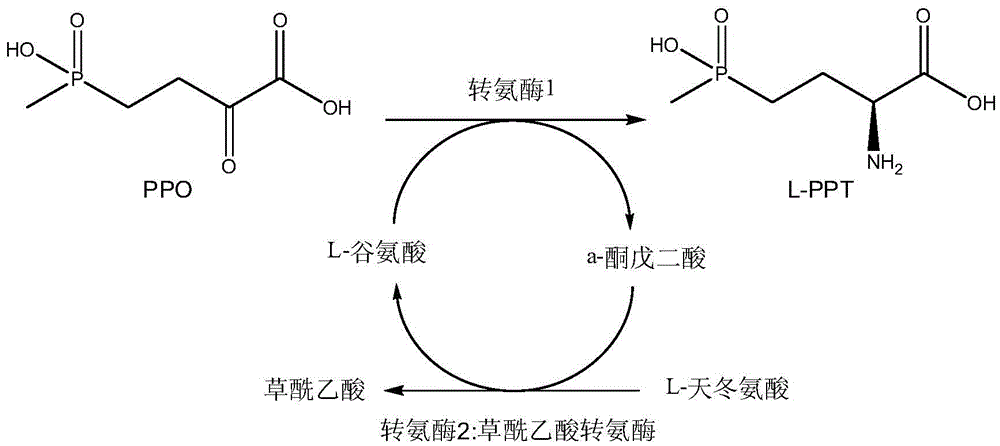

The invention discloses a production method of L-glufosinate. The method includes the steps that with 2-carbonyl-4-(hydroxyl methyl phosphoryl) butyric acid and salt thereof being a substrate, isolated transaminase or a cell catalysis substrate of in-vitro expression transaminase reacts with an amino donor under the condition that the amino donor exists, so that L-glufosinate is obtained, wherein the amino donor is alanine, and the amino acid sequence of transaminase is shown in SEQ ID NO.1-3. With 2-carbonyl-4-(hydroxyl methyl phosphoryl) butyric acid and salt thereof being the substrate and alanine being the amino donor, the transamination reaction occurs through the specific transaminase catalysis substrate, the substrate can be completely converted into L-glufosinate, and the conversion rate of raw materials is high and can reach 100%.

Owner:ZHEJIANG UNIV

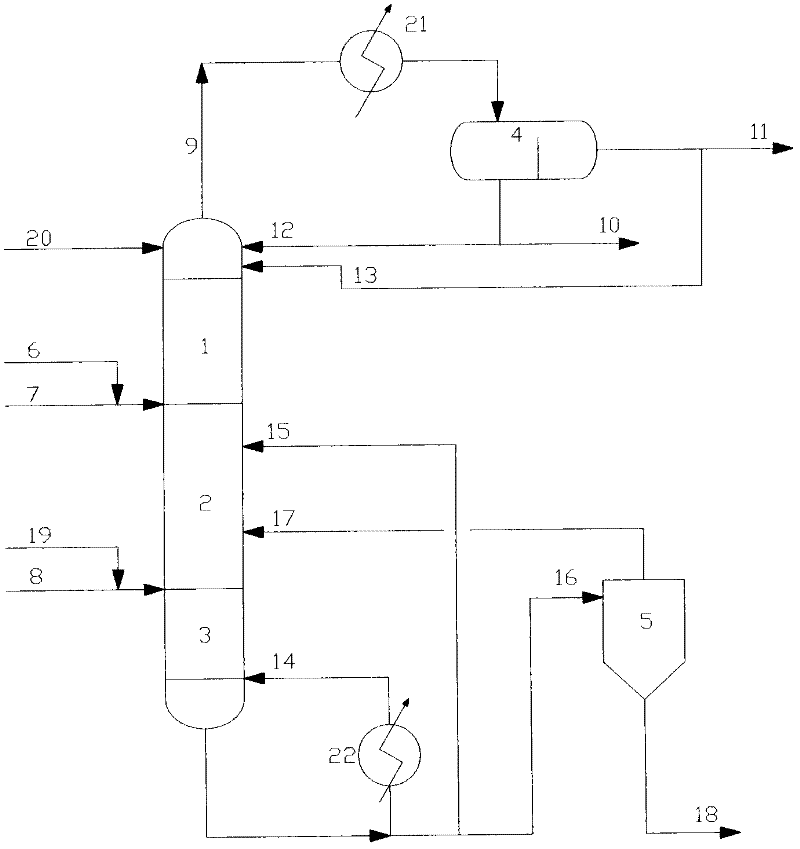

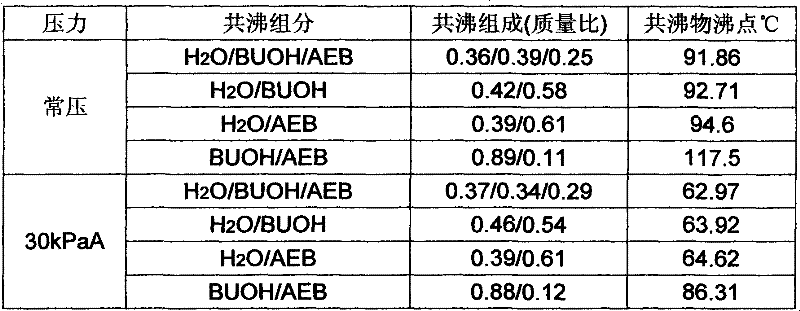

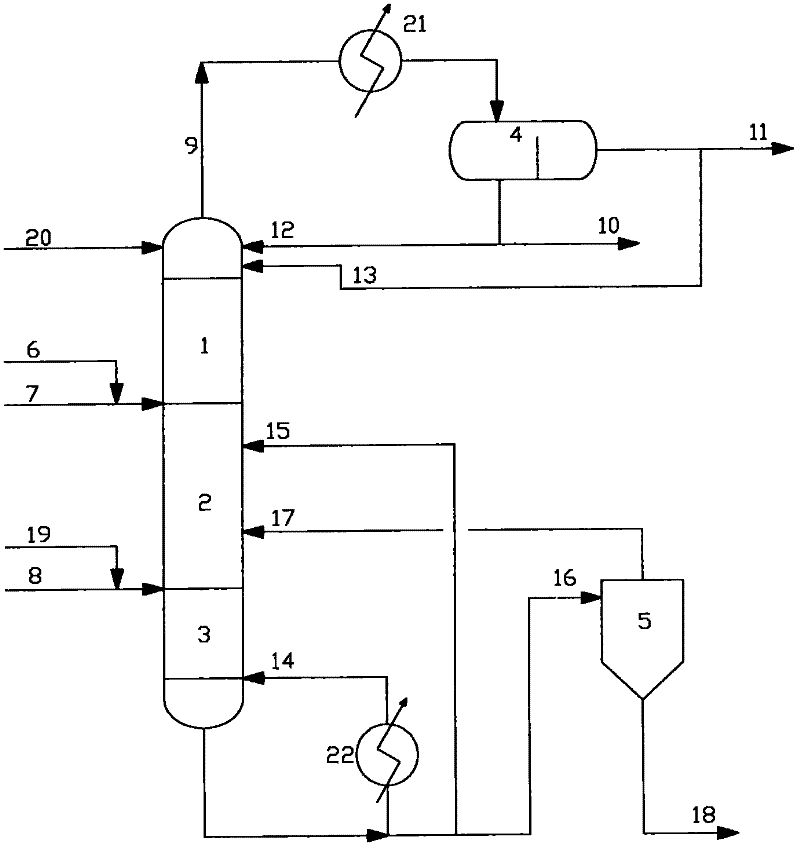

Preparation method of butyl acrylate

ActiveCN102249913AReduce concentrationQuick responseOrganic compound preparationCarboxylic acid esters preparationOrganic chemistryRaw material

The invention relates to a preparation method of butyl acrylate, which is characterized in that the synthesis of butyl acrylate is completed in a reaction rectifying tower, the separation of products and raw materials is completed through azeotropic rectification, and heavy components generated by the reaction in a stripping section and the tower are resolved into the raw materials and the products so as to finally obtain a butyl-acrylate-enriched organic phase having an acrylic acid content of 4ppm at the tower top.

Owner:SHANGHAI HUAYI NEW MATERIAL

Separation process of free monomer for polyurethane curing agent

A method of separation of the dissociative monomer in the polyamido ester solidifying agent, incldues the following steps: (1) get rid of the solvent in the solidifying agent; (2) add the extracting agent and the extractive smuggling agent to the solidifying agent, then make the molecular distillation and the distilled leaving is the solidifying agent; (3) dilute the solidifying agnet; compared with the chemical-reaction method and the vacuum-distilling method, this method can reduce the content of the dissociative monomer in the polyamido ester, at the same time it can't augment the relative molecular weight and the distribution of the relative molecular weight, and reduce the compatibility of the solidifying agent with the hydroxy ester; and the gained solid content can be optionally adjusted and even reach the weight of 80-100 % of the high solid content.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing sec-butyl acetate

ActiveCN101143819ASimplified product separation processReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationChemistryCatalytic distillation

A preparation method of secondary butyl acetate applies the method of catalytic distillation to enable acetic acid and mixed C4 (or butylene) to respectively enter into a catalytic distillation column from the upper rectifying section and the lower stripping section of the tower, a catalyzer is loaded in a reaction section, the acetic acid is countercurrent contacted with the mixed C4 (or butylene) on the surface of the catalyzer, the unreacted mixed C4 (or butylene) is evaporated from the top of the column, and a product mixture flows out from the bottom of the column. By applying the method to prepare the secondary butyl acetate, in the follow-up working procedure of separation, a flash column which is used to remove the unreacted mixed C4 (or butylene) is not needed, as a result, the separation technique of products is simplified, and energy consumption is reduced.

Owner:HUNAN ZHONGCHUANG CHEM

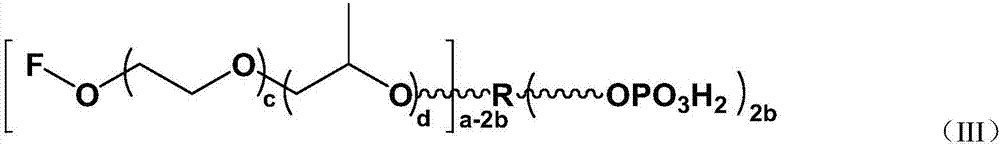

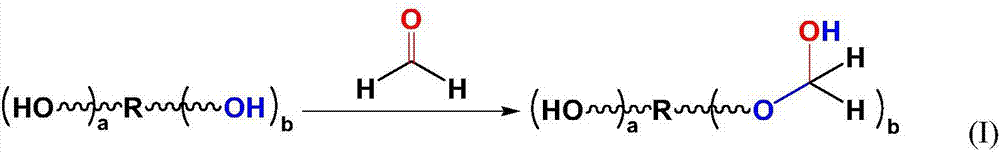

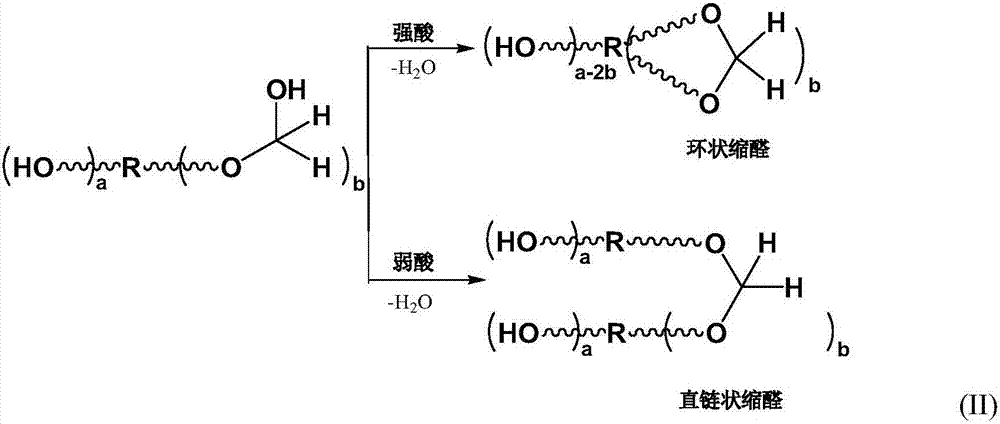

Synthesis and application of terminal-hyperbranched polyether phosphate water reducing agent

ActiveCN107337790AImprove adsorption capacityGood water reduction effectSide chainPhosphate adsorption

The invention provides a terminal-hyperbranched polyether phosphate water reducing agent which has one or more polyether long side chains. All phosphate adsorption groups are centrally arranged on one end of each polyether long side chain. The terminal-hyperbranched polyether phosphate water reducing agent has the advantages of excellent slump retaining properties, excellent setting retardancy, excellent clay tolerance and simple preparation technique.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

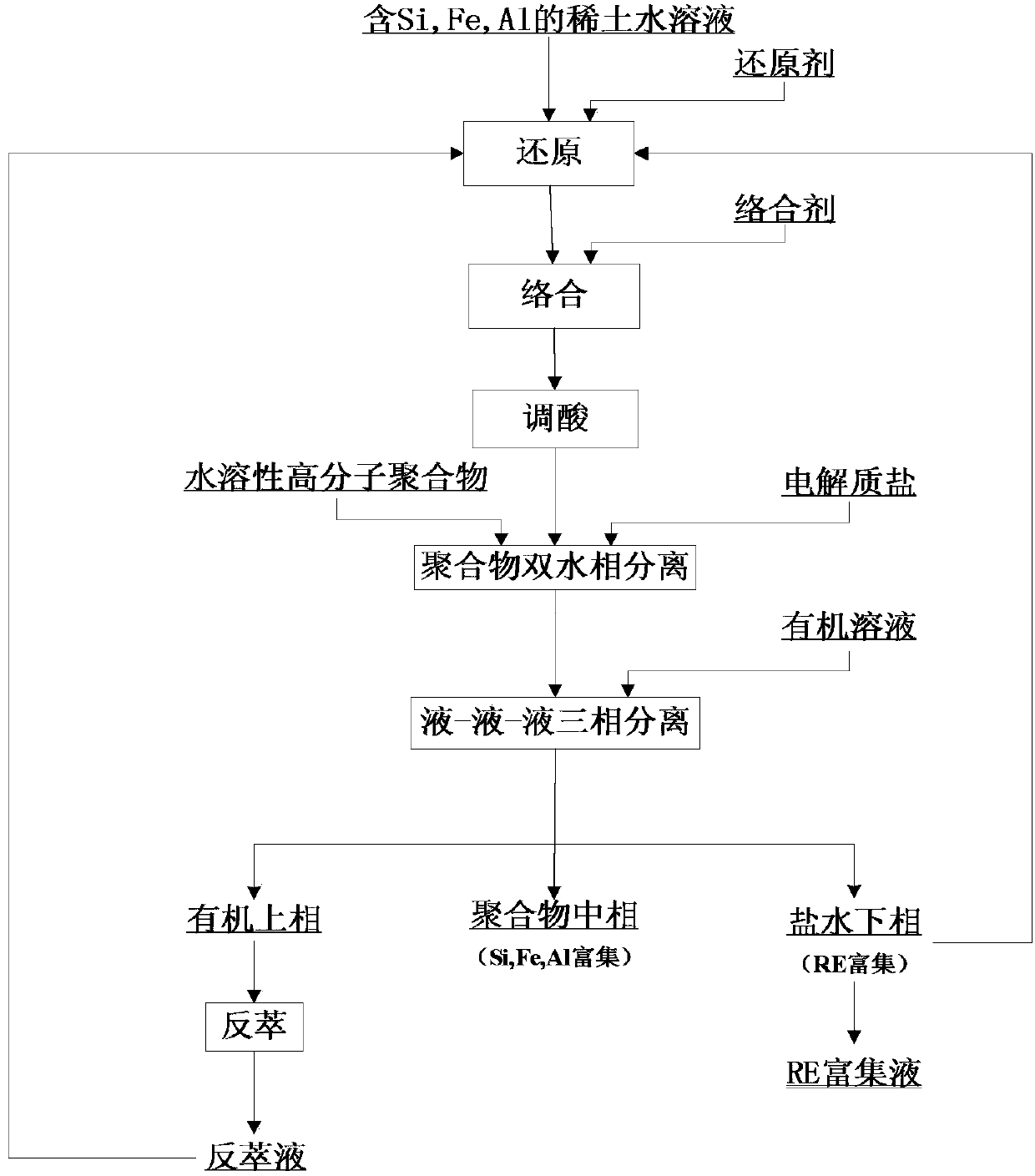

Method for removing metal ion purity of rare earth aqueous solution extraction

ActiveCN103468950AImprove separation efficiencySimple separation processProcess efficiency improvementHydroxylamine HydrochlorideInorganic electrolyte

The invention relates to a method for removing metal ion purity of rare earth solution aqueous solution aqueous solution extraction, and belongs to the metallurgy filed of rare earth extraction. The method comprises the following steps: hydroxylamine hydrochloride or ascorbic acid taken as a deoxidizer and a hydrosoluble chemical complexing agent are added to an aqueous solution containing various kinds of rare earth ions and purity metal ions of aluminum, iron and / or silicon; the pH value of the aqueous solution is regulated; a hydrosoluble high polymer and an inorganic electrolyte salt are sequentially added into the aqueous solution, and are vibrated and mixed at the room temperature, so that a polymer dual-phase aqueous system is obtained; an organic solution not dissolving in water is added, and a liquid-liquid-liquid three-layer liquid phase coexistence system is obtained. Purity metal ions of aluminum, iron and silicon can gather in a three-phase system polymer while rare earth ion selectively gather in the organic upper phase and / or brine lower phase of a three-phase system. The method can extract and separate rare earth ions, and extract and remove purity metal ions of the aluminum, silicon, iron and the like, and is simple in process flow and high in separation efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

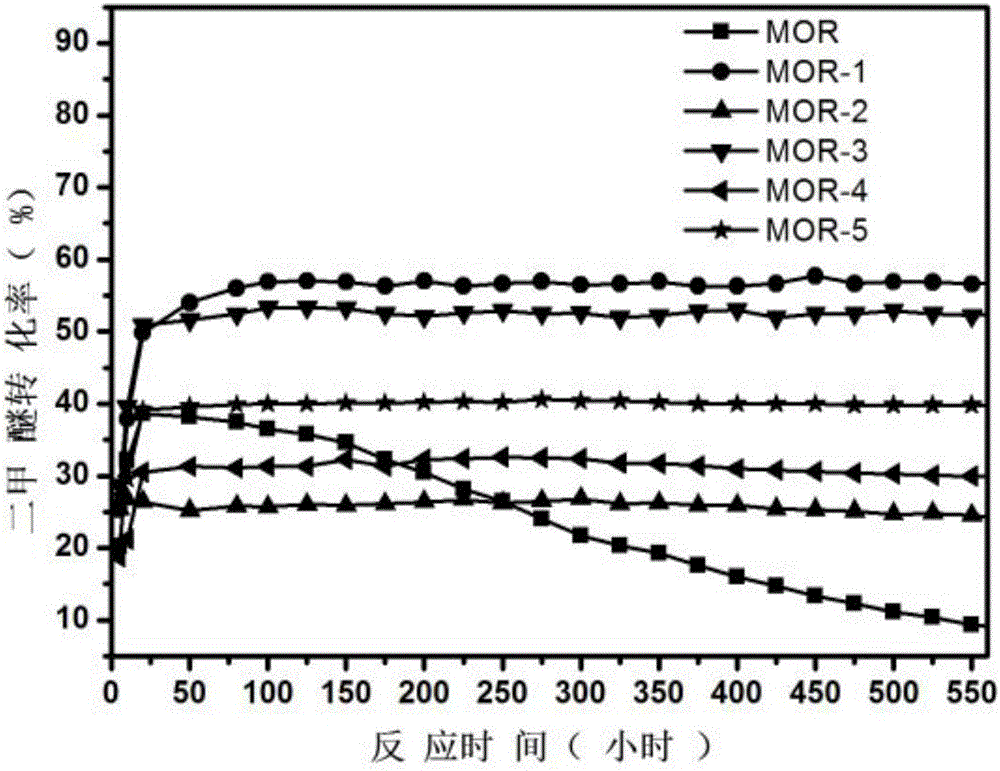

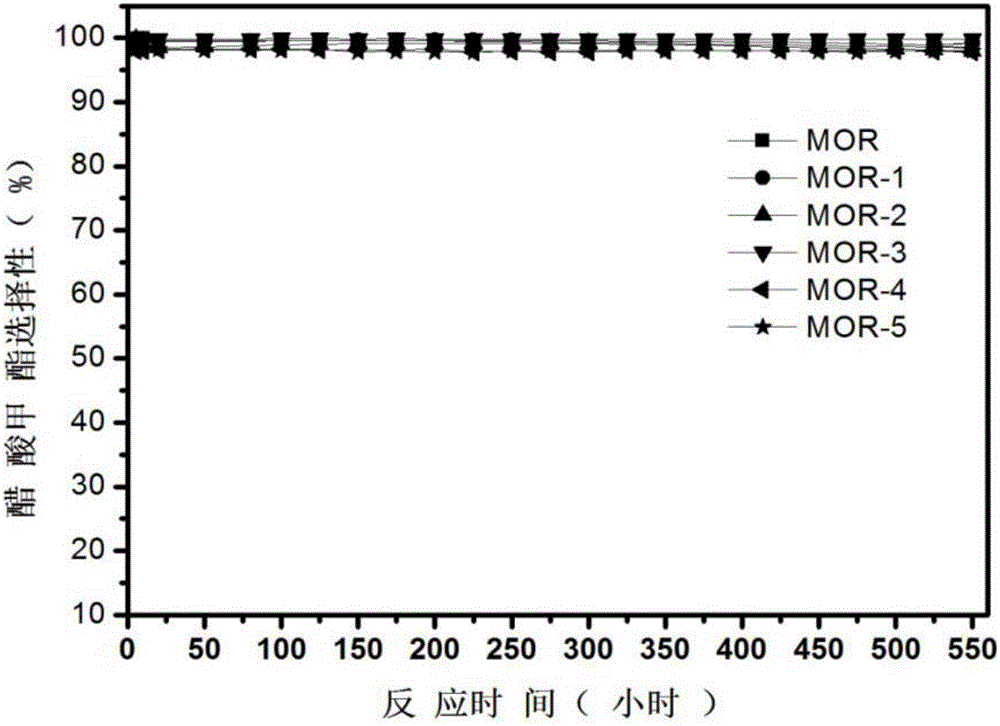

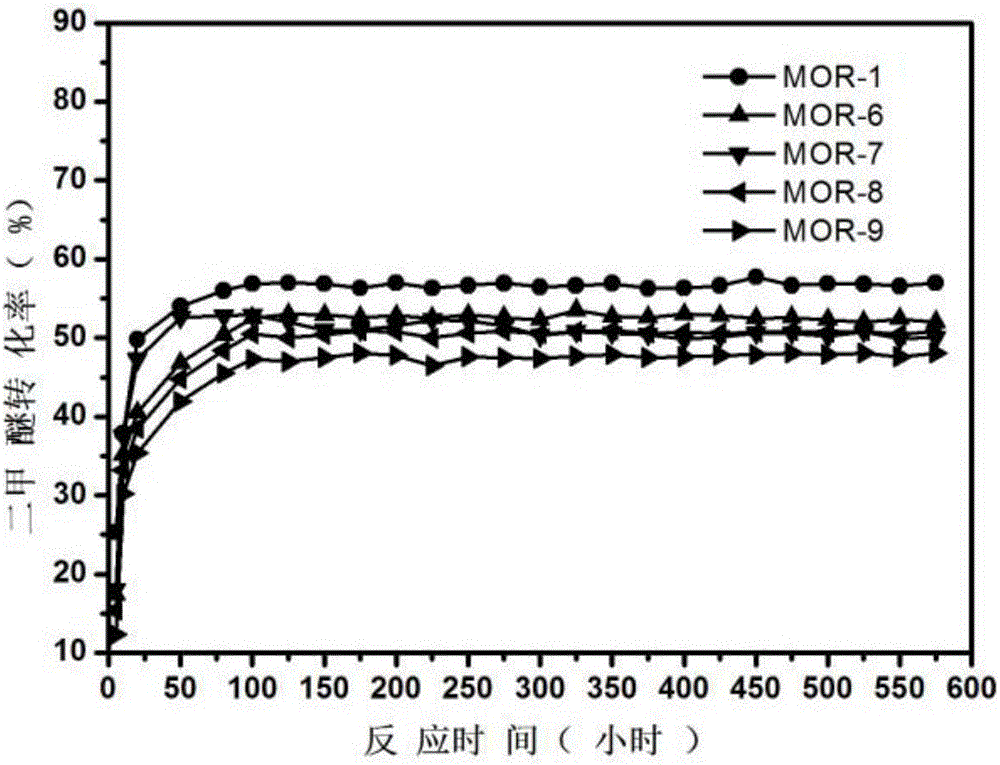

Method for making methyl acetate through carbonylation of dimethyl ether and the modified molecular sieve catalyst and modification method thereof

ActiveCN106311336AExtend your lifeImprove conversion rateCatalyst protectionMolecular sieve catalystsMolecular sieveHydrogen

The invention discloses a method for making methyl acetate through carbonylation of dimethyl ether and the modified molecular sieve catalyst and modification method thereof. The modification method is to pass the modified substance that is diluted by the diluent gas through the reactor filled with hydrogen type zeolite molecular sieve catalyst at an adsorbent temperature of 100-400 oC under normal pressure condition, so that the modified substance can have chemisorption on the hydrogen type zeolite molecular sieve catalyst to obtain modified molecular sieve catalyst; the modified substance can be liquid modified substance and / or gaseous modified substance. The modified molecular sieve catalyst can be obtained by using the modification method in which the modified molecular sieve catalyst for making methyl acetate through carbonylation of dimethyl ether can be obtained. The method for making methyl acetate through carbonylation of dimethyl ether is to pass the raw gas consisting of dimethyl ether, carbon monoxide and hydrogen through the reactor filled with the modified molecular sieve catalyst for reaction to obtain the methyl acetate. Through the modification of hydrogen type zeolite molecular sieve catalyst by the modified substance, the method can effectively inhibit the side-reaction of carbon deposit and greatly prolong the service life.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Process for separating and purifying gamma-aminobutyric acid

ActiveCN101928736AGood decolorizationHigh purityOrganic compound preparationAmino-carboxyl compound preparationGamma-Aminobutyric acidImpurity

The invention discloses a process for separating and purifying a gamma-aminobutyric acid, which aims to effectively solve the problems of complex separation and purification steps and high industrial cost which are caused by complex components of fermentation liquor in the biological preparation of the gamma-aminobutyric acid. In the process, impurities in conversion liquor are reduced by adopting a bioconversion method to simplify a separation process, and the conversion liquor is simply decolored to obtain the gamma-aminobutyric acid with high purity and recovery rate. The process has the advantages of simple method and high recovery rate of products, and is suitable for large-scale industrial production.

Owner:JIANGNAN UNIV

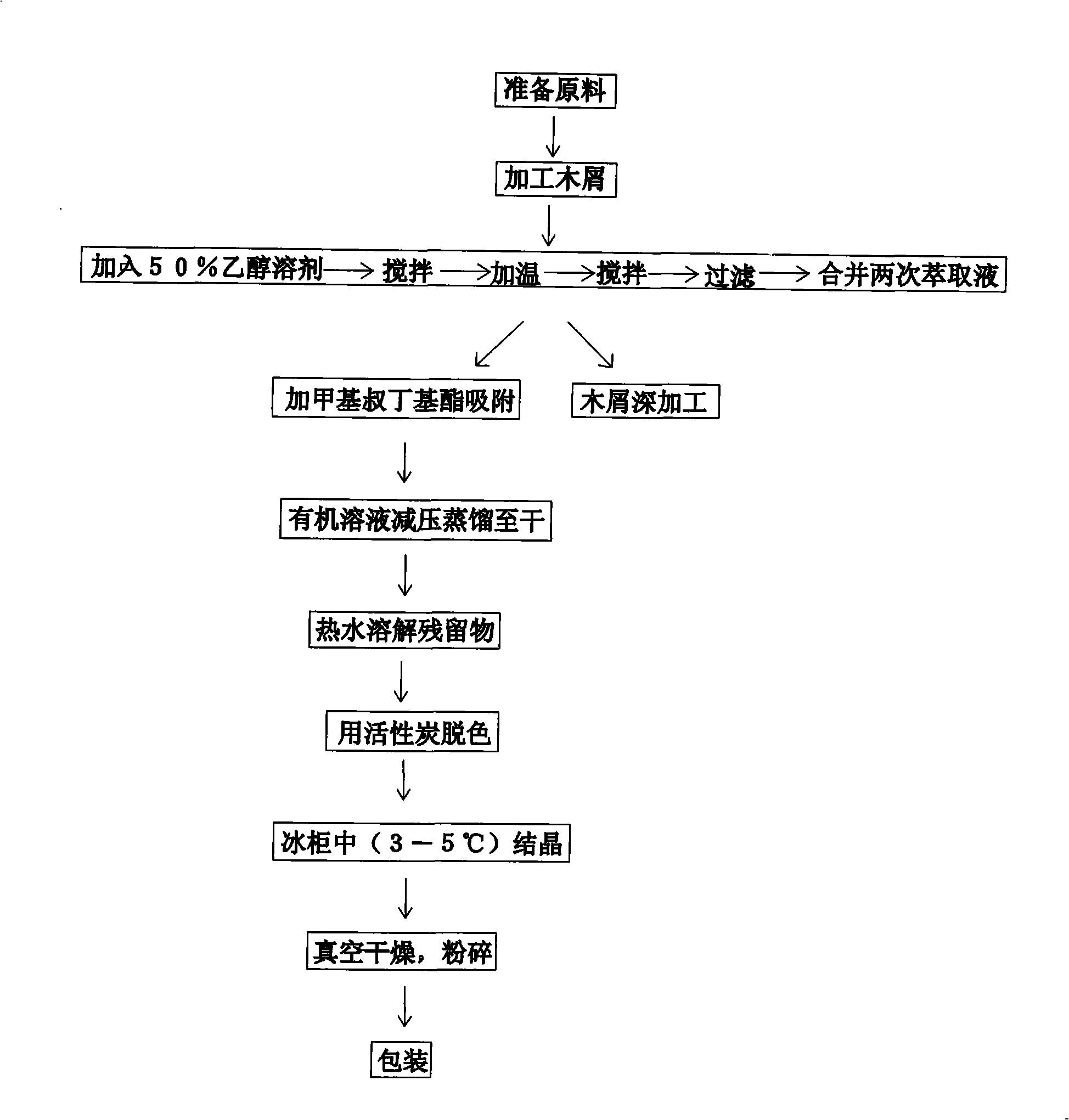

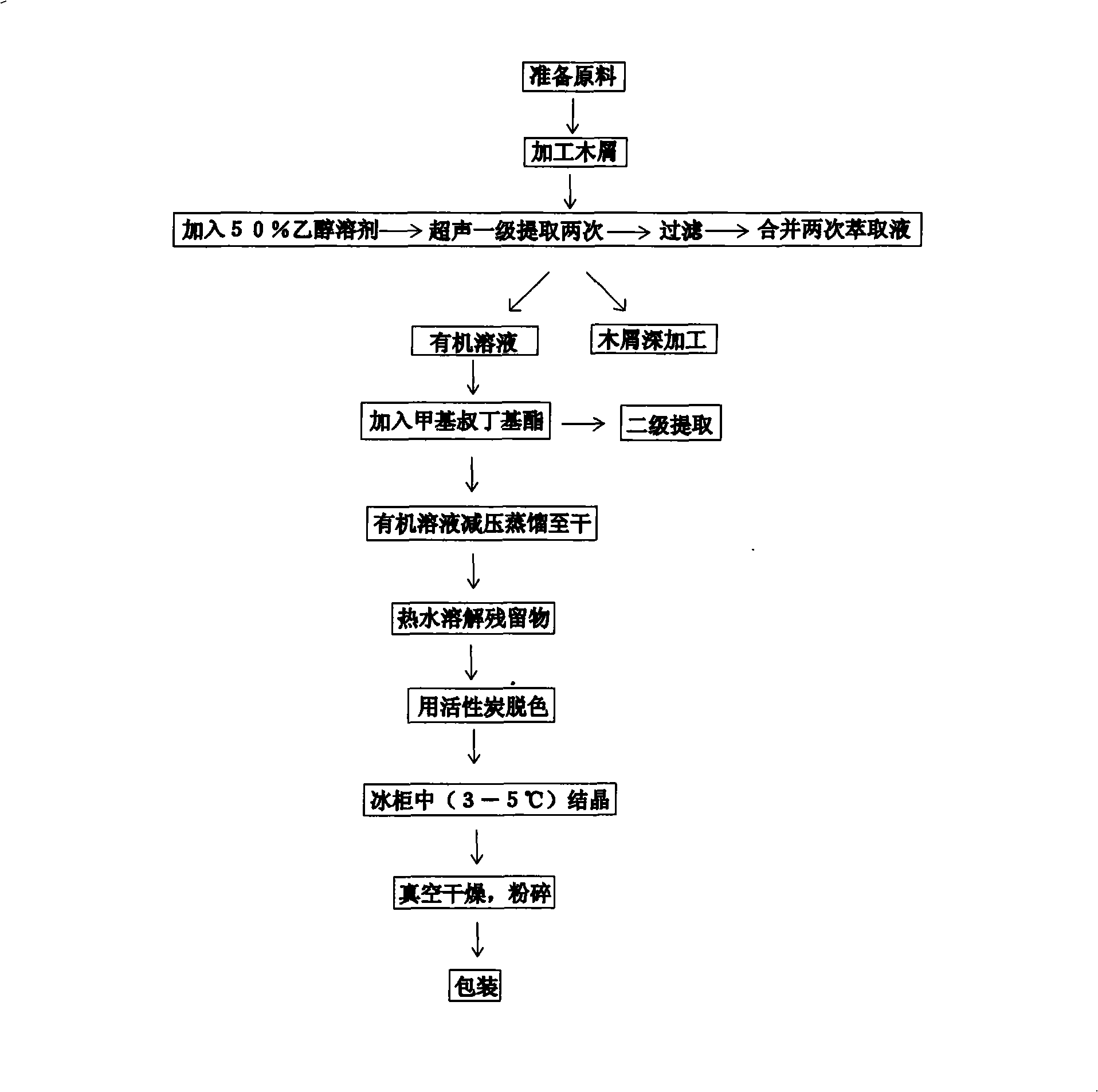

Method for extracting dihydroquercetin form larch

InactiveCN101333203AFree radical scavengingLesion hindranceOrganic chemistryConiferophyta medical ingredientsLarchUnit/Kilogram

Disclosed is a method for extracting dihydro quercetin from larch. The invention is an improved production method. Due to different production materials and extraction processes, the dihydro quercetin products in U.S. and European markets are very expensive, at a price of 200-1000 euros per gram. Such a high market price economically limits the wide range of practicability of dihydro quercetin products. During the pretreatment of raw materials, 50 kilograms of larch wood chips and 500-800 liters of 50% ethanol solution are added into a reactor to get fully stirred and mixed; then the mixture is extracted and filtered for the second extraction; the filtrates are combined and adsorbed; the organic solvents are collected and dried by a vacuum evaporator through organic phase vacuum distillation; according to a weight proportion of 10:1, the residues are dissolved with hot water, decolorized with activated carbon and then crystallized at a temperature of 3-5 DEG C to precipitate the dihydro quercetin product which is then crushed after vacuum drying to finished product. The invention is used to extract dihydro quercetin from larch.

Owner:黑龙江花旗科技发展有限公司 +2

Method for catalyzing phosphotungstic acid ionic liquid to prepare biodiesel

ActiveCN104194948AHigh activityReduce dosageFatty acid esterificationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystReaction temperature

The invention belongs to the technical filed of ionic liquid catalysis preparation of biodiesel and particularly relates to a method for catalyzing phosphotungstic acid ionic liquid to prepare biodiesel. The method comprises the following steps: by taking biolipid and methanol as raw materials, taking a phosphotungstic acid ionic fluid as a catalyst to prepare the biodiesel by virtue of ether exchange reaction, wherein a molar ratio of the biolipid to the methanol is (1:20) to (1:50), the ionic liquid accounts for 1-10% of the mass of the biolipid, the reaction temperature is 45-64 DEG C and the reaction time is 3-11 hours. The method has the following advantages that firstly, the ionic liquid is simple in preparation process and relatively low in cost; secondly, the catalyst is high in activity, less in dosage, gentle in reaction condition and short in reaction time; and thirdly, the ionic liquid is stable in performance, capable of being repeatedly used, simple in separating process, low in after-treatment cost, free of pollution, free of corrosion on equipment, environmentally friendly, and capable of being expected to become a clean process route with competitive force.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

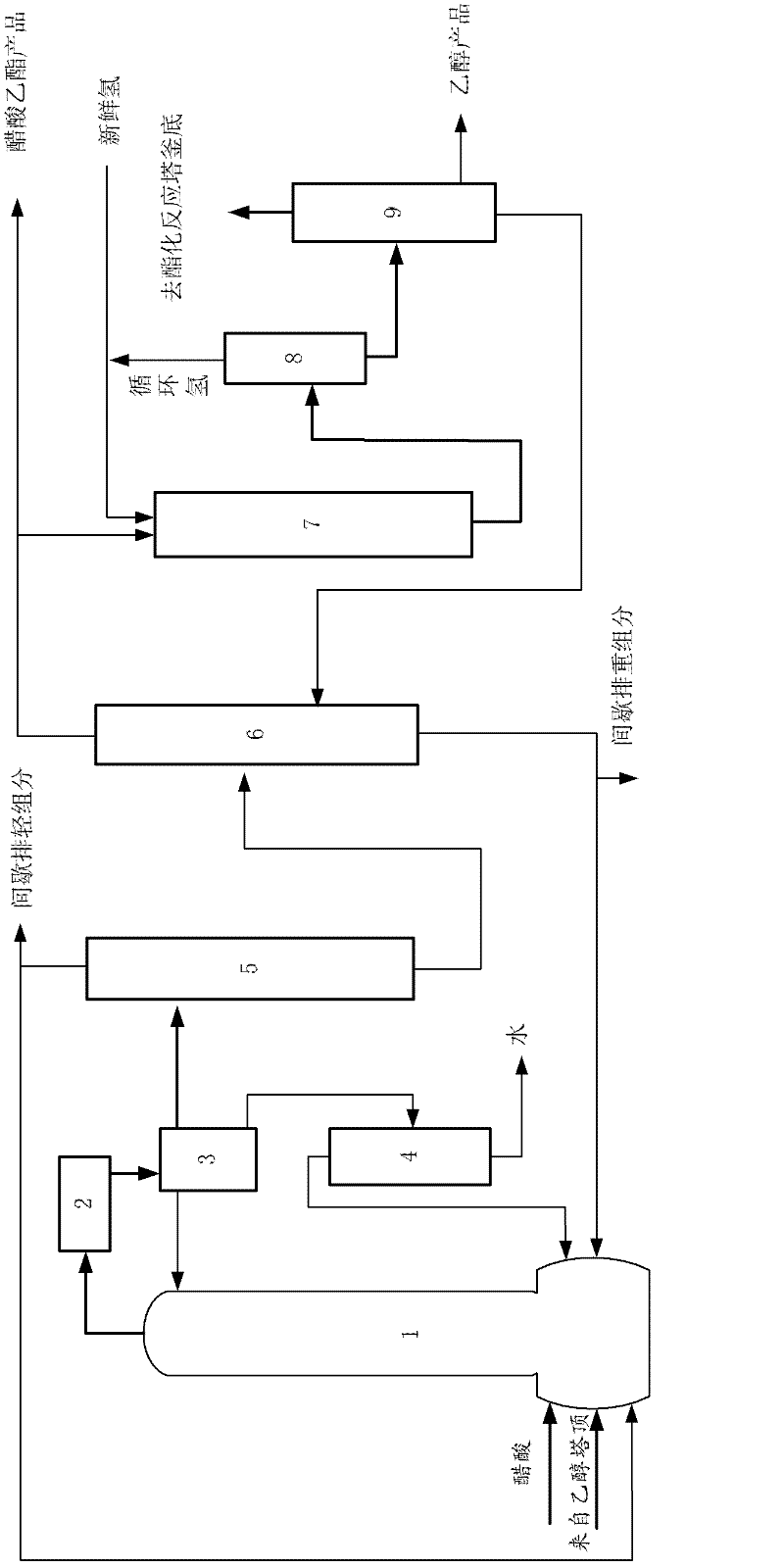

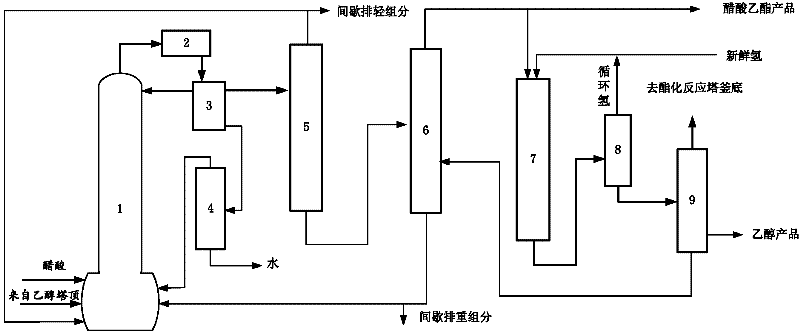

Process for separate production or joint production of ethanol and acetic ether through acetic acid indirect hydrogenation

ActiveCN102557931AReduce consumptionIncrease conversion rate per passOrganic compound preparationCarboxylic acid esters preparationAcetic acidReactive distillation

The invention relates to a process for separate production or joint production of ethanol and acetic ether through acetic acid indirect hydrogenation. Acetic acid and ethanol are placed in an esterification tower, the acetic acid and the ethanol are subjected to reactive distillation in the presence of acid catalysts, the acetic ether and water are obtained, the mixture is distilled off from the top of the tower and enters a water segregator, a rectification light removal tower and a rectification heavy removal tower after being condensed, so that impurities are removed and conforming products of the acetic ether are obtained. Part of the products are sold, and others are regarded as raw materials for producing the ethanol in a hydrogenolysis reaction, led to a hydrogenolysis tower and subjected to catalytic hydrogenolysis so as to selectively obtain the ethanol. Part of or all the ethanol obtained by hydrogenolysis of the acetic ether is regarded as a raw material for an esterification reaction and reacts with the acetic acid in the esterification tower. Compared with the existing technologies, the process is simple in flow and low in production cost; and either the ethanol or the acetic ether can be produced selectively, or both the ethanol and the acetic ether can be produced in a certain proportion through adjustment of the production capacity of a hydrogenolysis and hydrogen production device.

Owner:ZHONGRONG TECH CORP LTD +1

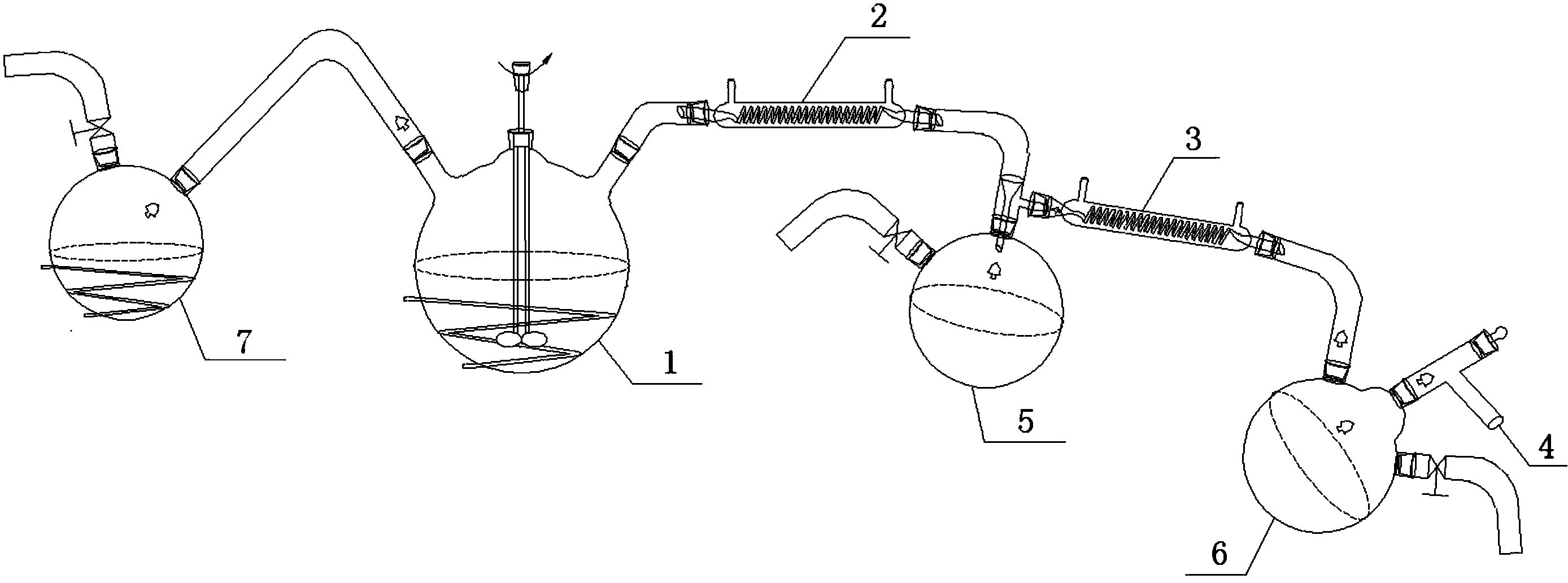

Method and device for continuously producing isosorbide

ActiveCN103980286APromotes selective dehydration reactionSimple separation processOrganic chemistryIsosorbideDistillation

The invention relates to a method for continuously producing isosorbide, which comprises the following steps: (1) feeding: mixing sorbitol and a catalyst in a reactor; (2) reaction: under reduced pressure, controlling the temperature in the reactor to sequentially initiate first dehydration reaction and second dehydration reaction of the sorbitol so as to generate the isosorbide, and meanwhile, enabling the isosorbide and water to form a gaseous mixture; and (3) condensation separation: controlling the condensation temperature of the condenser to sequentially condense the isosorbide and water in the gaseous mixture from the reactor, thereby obtaining the isosorbide. The invention also relates to a device for the method.In the sorbitol dehydration reaction process, the isosorbide and water are separated in time by distillation, thereby promoting the selective dehydration reaction, simplifying the separation technique and implementing purification of the isosorbide.

Owner:长春鸿成生物化工材料技术开发有限公司

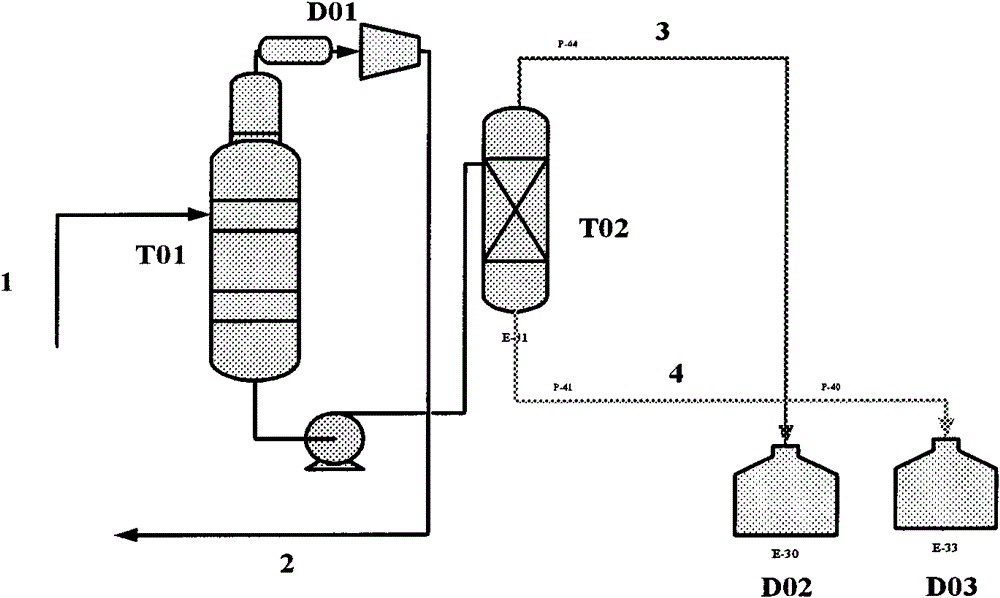

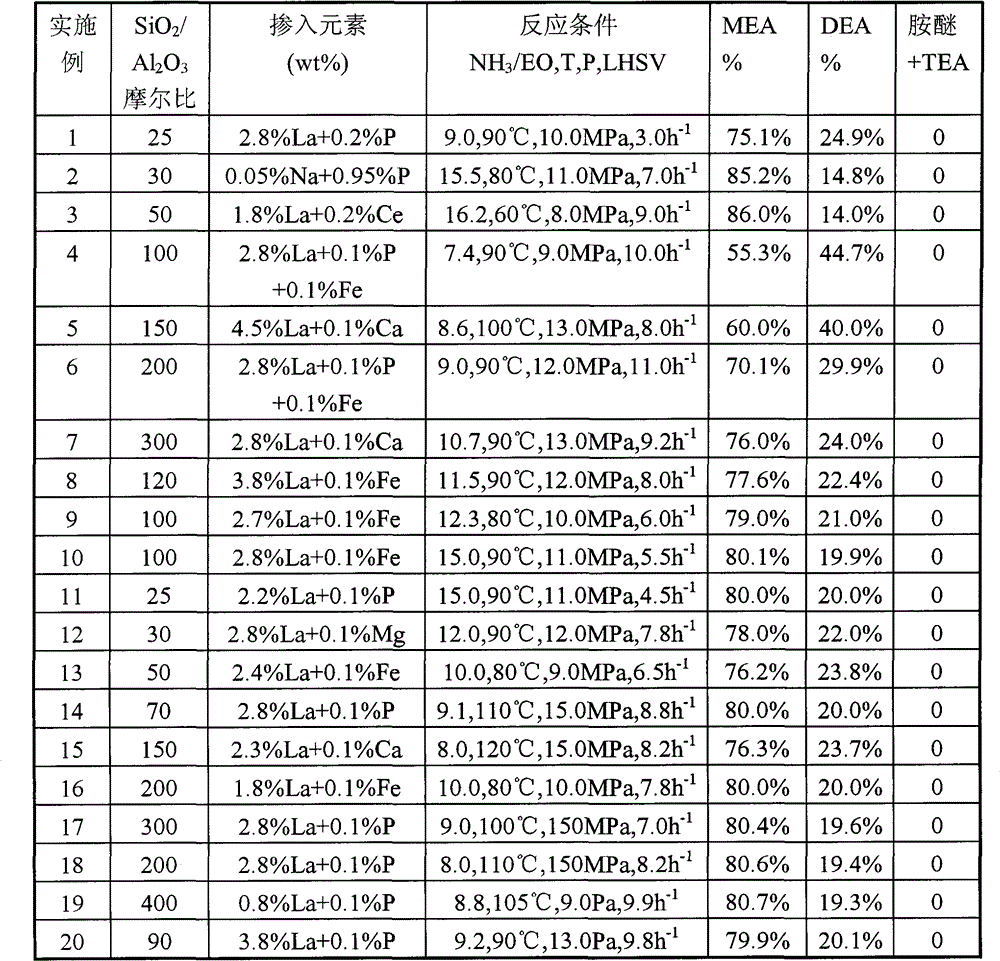

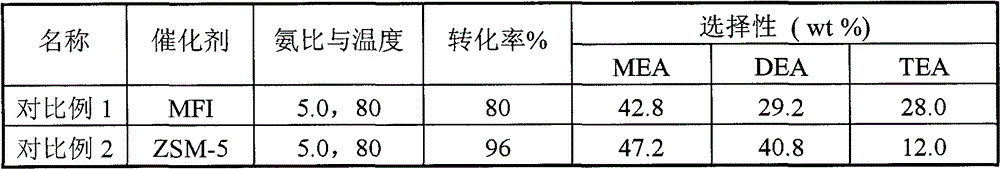

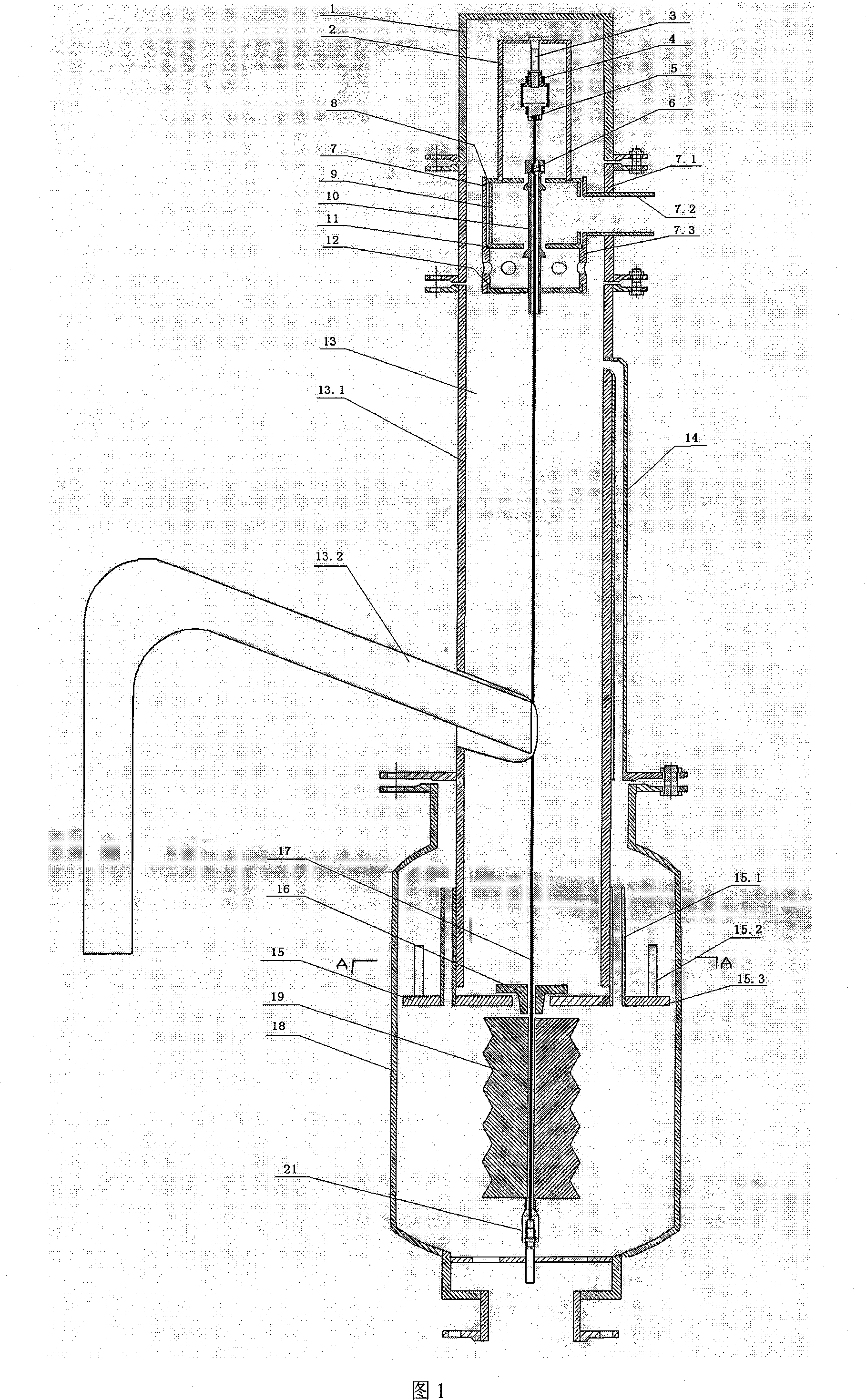

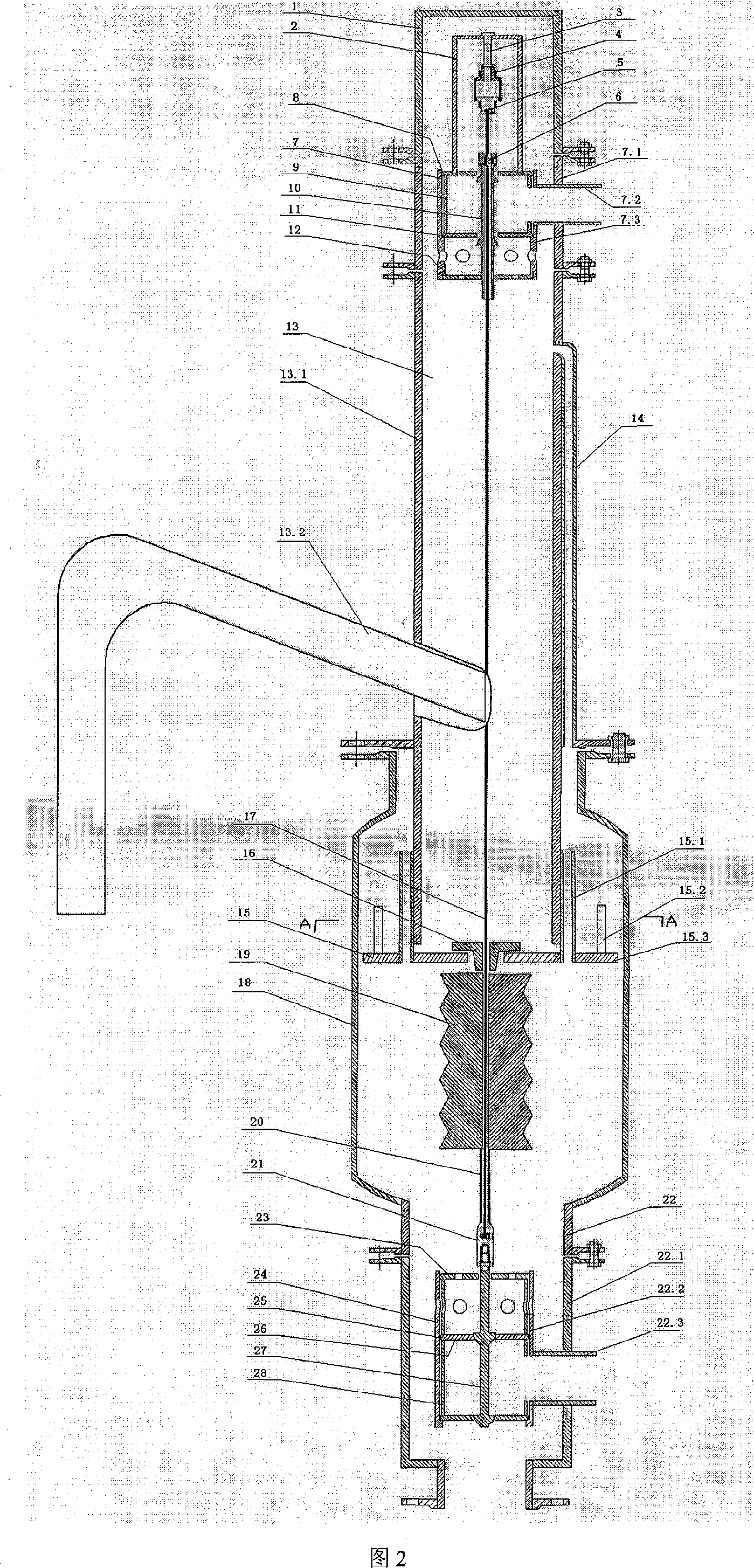

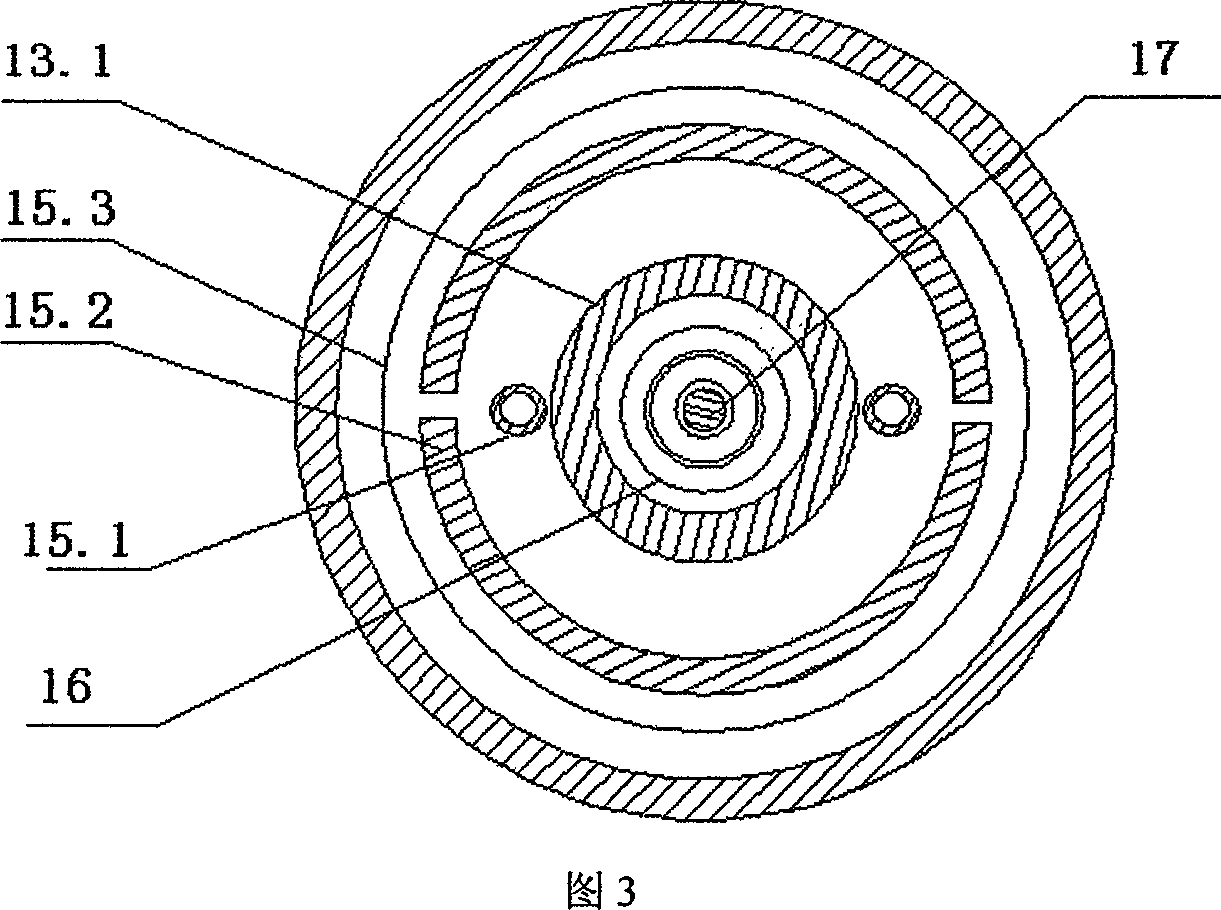

Production method of ethanolamine

ActiveCN102746165ASimple separation processLow costMolecular sieve catalystsOrganic compound preparationMolecular sieveEthanolamines

The invention relates to a production method of ethanolamine, and aims to mainly solve the problem that products need separation by multiple towers in the existing production technologies. According to the invention, EO and NH3 are adopted as raw materials, which contact a binder-free zeolite molecular sieve catalyst having an MFI structure for reaction to generate effluent I. The effluent I is subjected to deamination by a deamination tower to generate effluent II, which enters an MEA tower so as to realize product separation. The technical scheme adopted in the invention well solves the problem, and can be applied to industrial production of ethanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self controlled high efficient gas and liquid separator

InactiveCN101053723AEfficient separationSeparators work efficientlyReversed direction vortexDispersed particle separationVapor–liquid separatorProduct gas

The invention relates to a self-control gas-liquid separator, especially to a control and separation integral self-control high efficiency gas-liquid separator. The embodiment is to connect to the gas valve (7) of said gas conditioning unit through the lower end of the spring (1) in which a bracket (2) is mounted. The bracket (2) vertically hangs a liquid level transmitting control unit, and basipetally impenetrates the said gas conditioning unit and gas-liquid separating unit in turn. The beneficial effect is that: control-separate one-piece design of the self-control gas-liquid separator, whose control unit uses self-operated control principle and whose separating unit gives priority to hydrocyclone Separation process and assists with gravity separation, the efficiency for gas-liquid separating is high, and the effect of separation is excellent; the reasonable structure makes it easily to manufacturing activity and have a low manufacturing and using cost without maintenance and have a long longevity; compared with conventional gravity separator matching to the self-control system, the gas-liquid separating technological process is largely simplified and the cost can save larger than 70 percent at the same time.

Owner:房师礼

Method for preparing bio diesel oil by idesia polycarpa maxim. var. vestita diels oil catalysis using solid base as catalyst

InactiveCN101358141AExtended service lifeReduce manufacturing costBiofuelsLiquid hydrocarbon mixture productionIndustrial waste waterBiodiesel

The present invention discloses a technique which uses solid alkali to catalyze idesia polycarpa var.vestita bites to prepare biodiesel. After the extracted idesia polycarpa var.vestita bites is treated by the processes of degumming, alkali refining and deacidification and decolorization, solid alkali Mg-Al composite oxide is utilized to catalyze low-carbon alcohol, so that ester exchange reaction occurs between the low-carbon alcohol and the idesia polycarpa var.vestita bites to prepare crude biodiesel, and after depressurization and distilling, the light-colored refined biodiesel is produced. The yield of the biodiesel prepared by the technique is high, the product reaches the national standards, meanwhile, the production cost of the biodiesel can be reduced, the service life of equipment can be prolonged, the subsequent separation process can be simplified, and the drainage of industrial waste water can be reduced.

Owner:四川省毛叶山桐子科技股份有限公司 +1

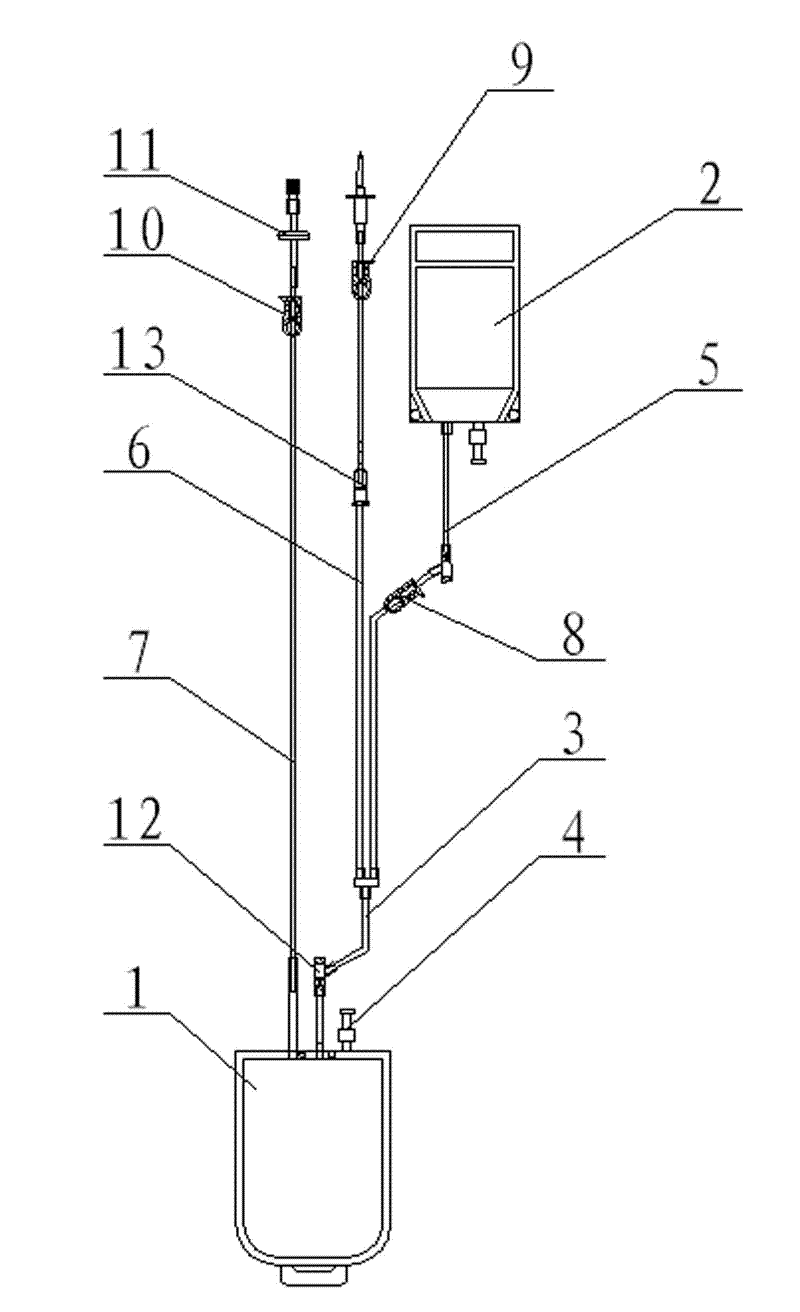

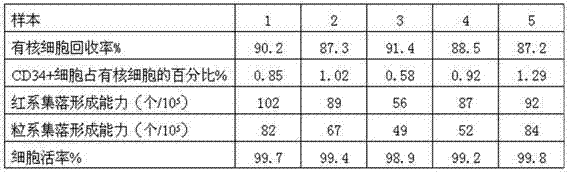

Method for separating hemopoietic stem cells through cord blood separation double bag

ActiveCN102337245AAffect storageAffect usabilityBlood/immune system cellsCord blood stem cellBlood plasma

The invention relates to a method for separating hemopoietic stem cells through a cord blood separation double bag. According to the method provided by the invention, red blood cells and blood plasma are separated and transferred to a transfer bag step by step by adopting a main bag and the transfer bag, and a freezing protection liquid is added, the cells are transferred to a cell freezing bag and are finally frozen and stored. The method realizes the separation of the hemopoietic stem cells by adopting a centrifugal method, the structure of the adopted transfer bag for separation is simple and practical, the overall separation process is simple and convenient, the separation is totally enclosed, the pollution is reduced, the storage volume of the hemopoietic stem cells can be safely and effectively concentrated, and the recovery rate of the hemopoietic stem cells can be improved as much as possible.

Owner:江苏省北科生物科技有限公司

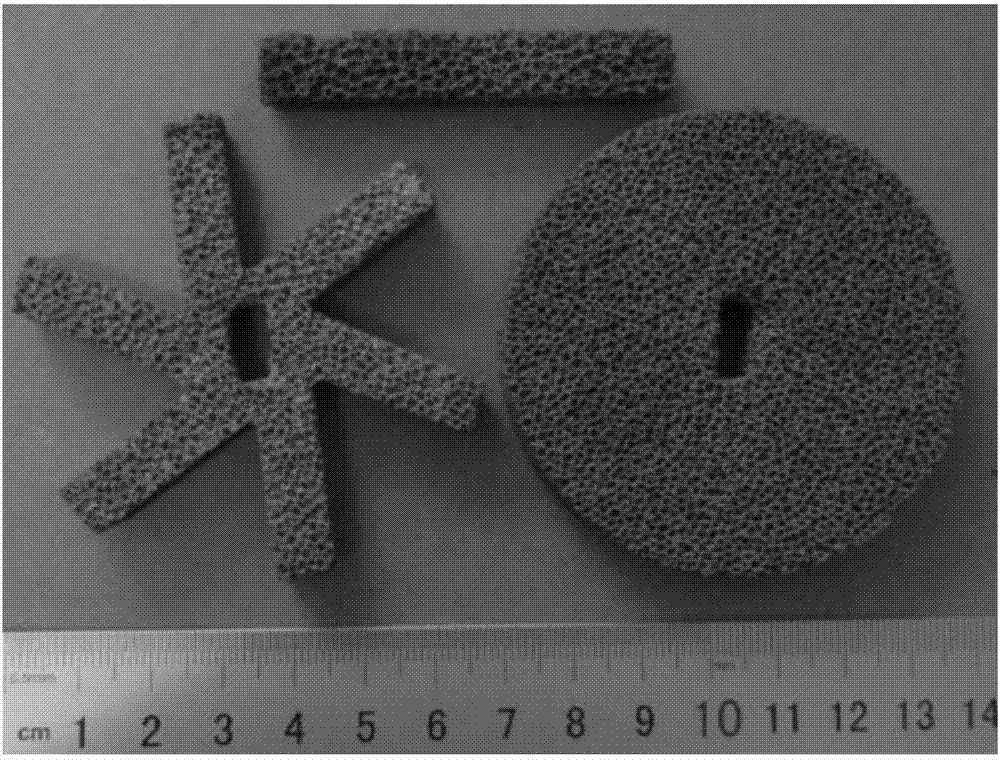

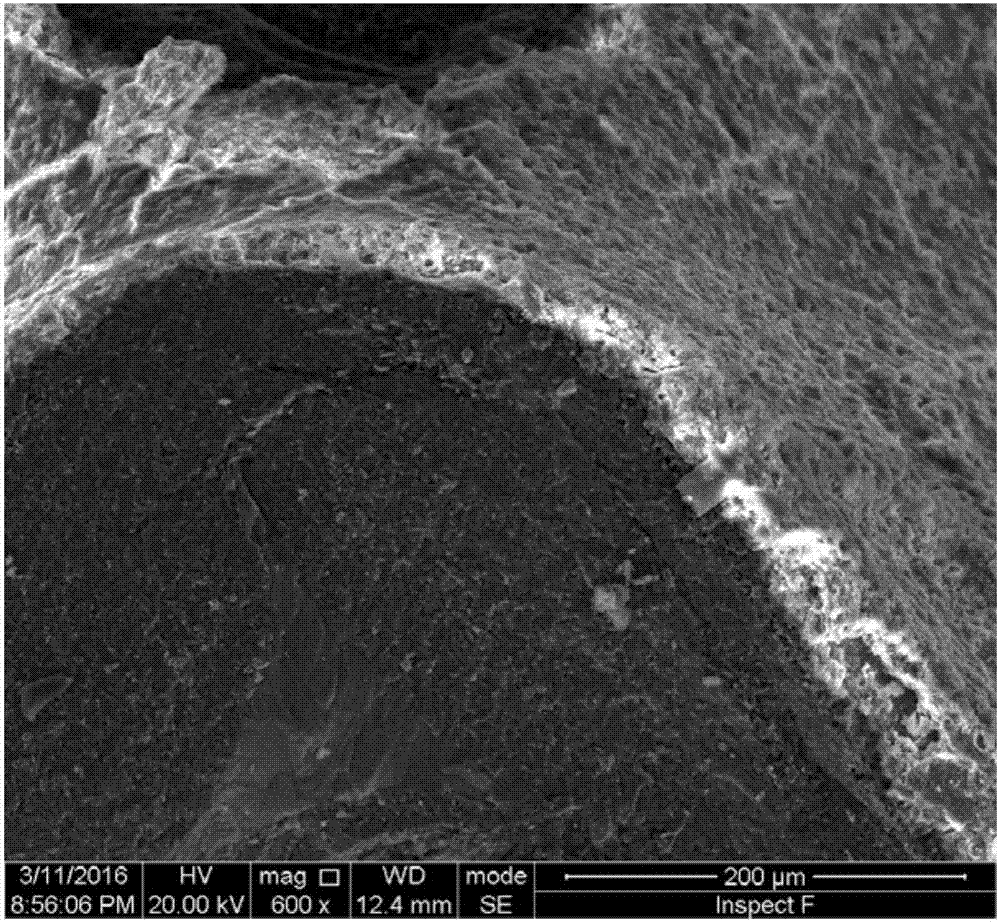

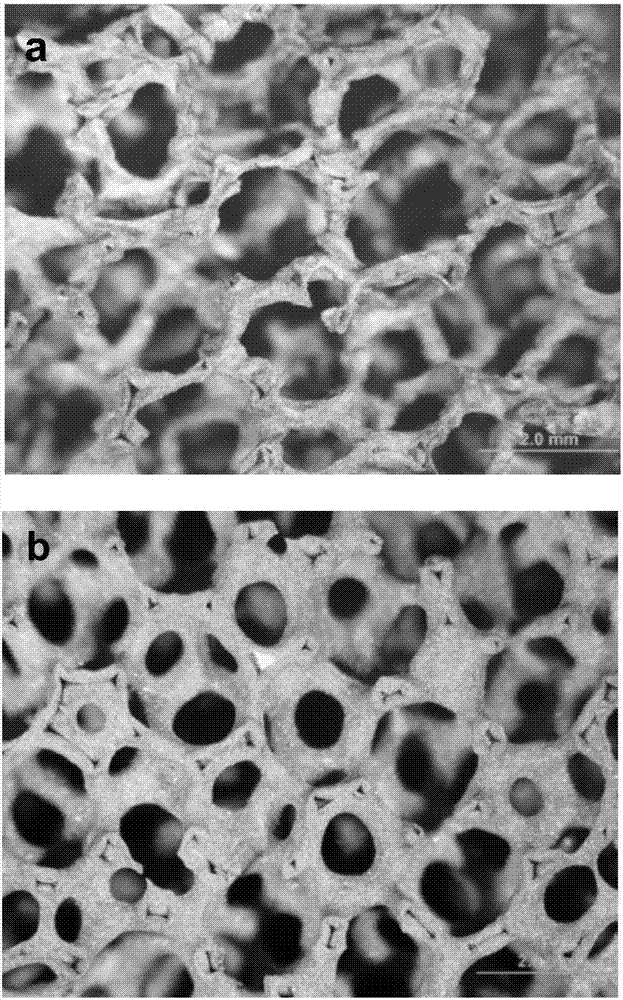

Foam-structure catalyst used in reaction for preparing benzyl alcohol from benzaldehyde through hydrogenation and preparation thereof

InactiveCN107442149AHigh catalytic activityAvoid wear and tearOrganic compound preparationHydroxy compound preparationPtru catalystBenzaldehyde

The present invention relates to the field of structured catalytic materials, in particular to a foam-structure catalyst used in a reaction for preparing benzyl alcohol from benzaldehyde through hydrogenation and a preparation method thereof. The objective of the invention is to overcome the problems that conventional granular catalysts are prone to wearing; the catalysts are difficult to separate from reaction products; recovery processes are complex; etc. The foam-structure catalyst in the invention is of a three-dimensional interconnected network foam structure; the main structure of the catalyst is composed of a foam ceramic material used as a first carrier, a coating (used as a second carrier), a catalytically active component and the like, wherein the second carrier uniformly coats the surfaces of foam ribs of the first carrier, and the catalytically active component is uniformly supported in the second carrier with a high specific surface area. The foam-structure catalyst of the invention is used for a reaction for preparing benzyl alcohol from benzaldehyde through liquid-phase hydrogenation; technology is simplified; and complicated equipment is not needed. The foam-structure catalyst can enhance the mass transfer process of a chemical reaction while avoiding catalyst wearing and simplifying a separation process, and has the advantages of high mass transfer efficiency, good catalytic activity, high benzyl alcohol selectivity and good stability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Culture medium for separating enterococcus and streptococcus from milk sample and preparation method of culture medium

InactiveCN104789502ASimple separation processSimplify the process of analytical qualificationBacteriaMicroorganism based processesPolymyxin BSodium acid carbonate

The invention discloses a culture medium for separating enterococcus and streptococcus from a milk sample and a preparation method of the culture medium. The culture medium is used for separating enterococcus and streptococcus simultaneously and comprises components as follows: 15-25 g of bacterial peptone, 2-5 g of yeast, 2-5 g of beef heart extract or beef extract, 1-3 g of glucose, 1.8-2.5 g of sodium chloride, 0.3-0.5 g of disodium hydrogen phosphate, 2.0-3 g of sodium carbonate, 12-20 mg of nalidixic acid, 1.2-2 mg of polymyxin B, 0.1-0.3 mg of crystal violet, 2-5 g of aesculin, 0.3-0.8 g of ferric citrate and 10-18 g of agar, and the strain culture temperature is in a range from 35 DEG C to 37 DEG C. The culture medium has the advantages that the overall separation process is simple, visual and fast, the culture medium can separate enterococcus and streptococcus from the milk sample simultaneously, pathogen species are directly positioned to specific species or genuses, and the downstream analysis and identification process is simplified greatly. Besides, the invention further provides a culture medium component for independently separating streptococcus from the milk sample.

Owner:GANSU AGRI UNIV

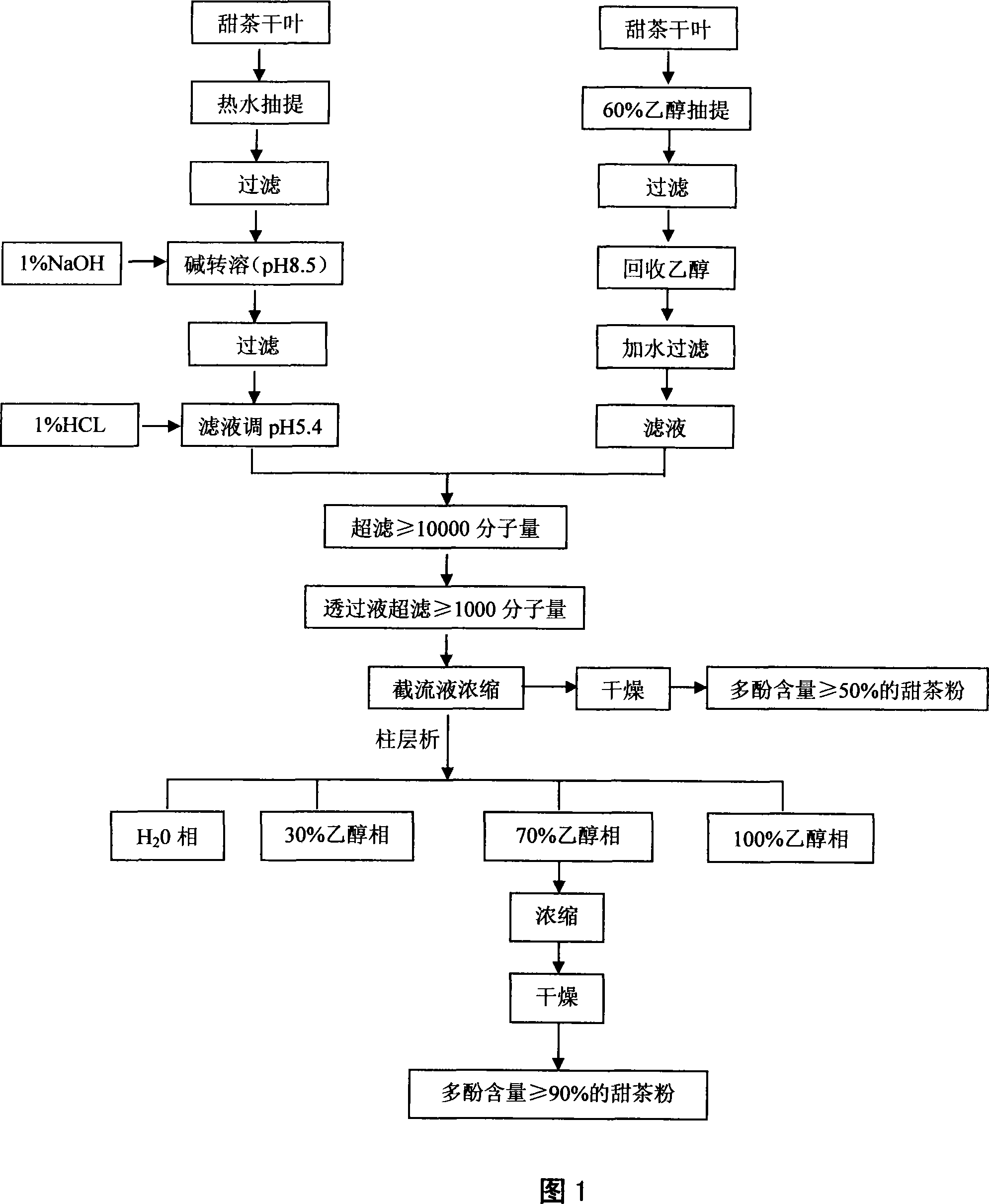

Method for separating and extracting sweet tea tannins

InactiveCN101190276ASimple separation processEasy to operateSugar derivativesMetabolism disorderChlorobenzeneUltrafiltration

The invention relates to the separation and extraction methods of a sweet tea polyphenols. The invention uses integration of ultrafiltration with resin adsorption separation technique. Only ethanol is used as organic solvent during producing process and the separation technique of sweet tea polyphenols is optimized; the simple operation helps realize industrialized production; besides, the production process accords with environment protection requirement and the products accord with food and drug raw material requirements. The invention uses Guangxi sweet tea as raw materials to produce sweet tea polyphenols containing over 50% and 90%. Hyaluronidase inhibition in vitro experiment, in vivo experiments of mice passive dermato-allergic reaction and the delayed cutaneous hypersensitivity caused by dinitro-chlorobenzene confirm the invention has significant anti-anaphylaxis activity.

Owner:GUANGXI UNIV

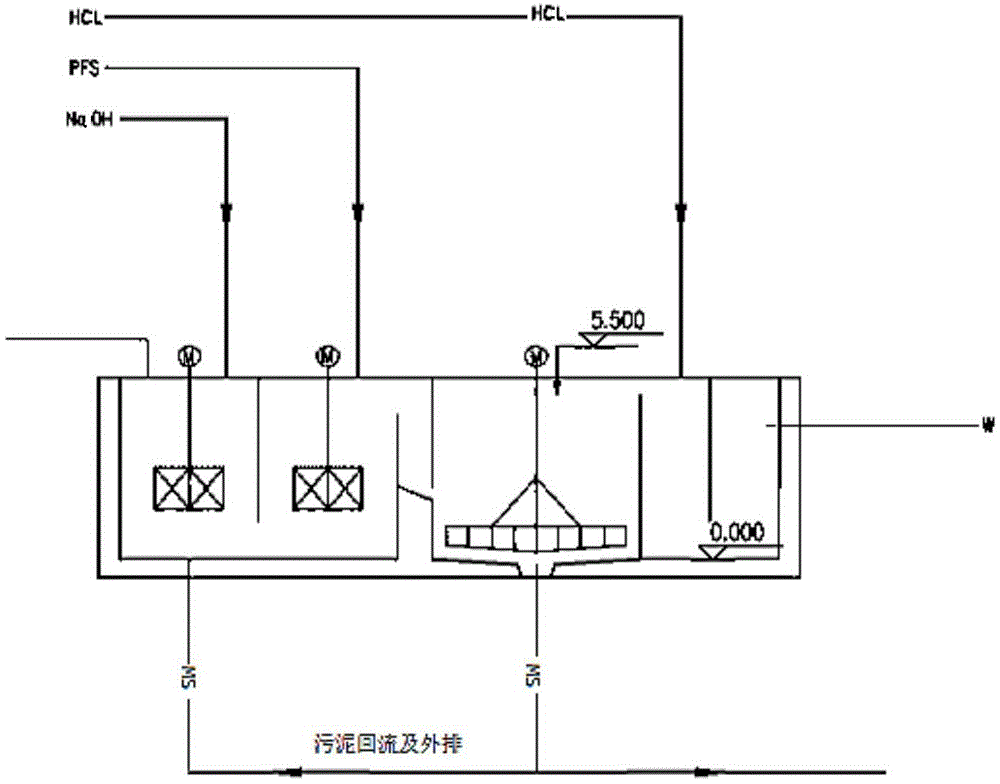

Industrial park heavy metal wastewater advanced treatment device and method

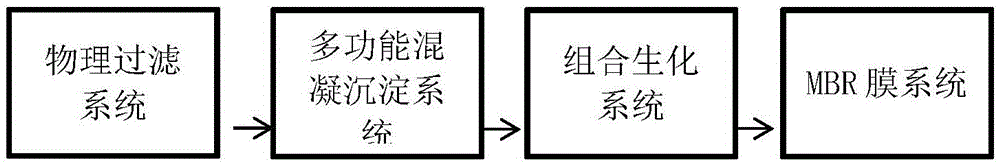

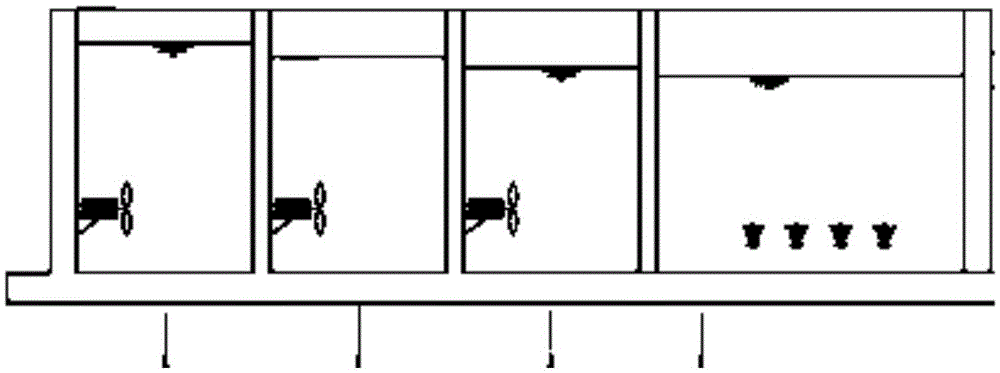

InactiveCN105645678AGuaranteed uptimeUniform water qualityWater contaminantsTreatment involving filtrationHeavy metalsSewage

The invention relates to an industrial park heavy metal wastewater advanced treatment device which comprises a physical filter system (1), a multifunctional coagulative precipitation system (2), a combined biochemical system (3) and an MBR (membrane bioreactor) membrane system (4) which are sequentially connected, wherein the physical filter system is a 2mm fine grid, and is used for removing smaller floating materials and solid matters with the diameter of greater than 2mm in sewage, thereby ensuring the effect of the subsequent biological treatment system and the stable operation of maintenance equipment. The combined biochemical tank is composed of a hydrolysis+A2O tank, the MBR membrane system and a matched sludge concentration tank. The water treatment technique is carried out by sequentially using the units above. The physical filter system is a 2mm fine grid, and a stirrer is respectively arranged in an anaerobic section and an anoxic section. The anaerobic region, anoxic region and aerobic region are strictly separated, thereby being beneficial to the reproduction and growth of different microbial florae, and having favorable denitrification and dephosphorization effects.

Owner:NANJING CEC ENVIRONMENTAL ENGINEERING CO LTD

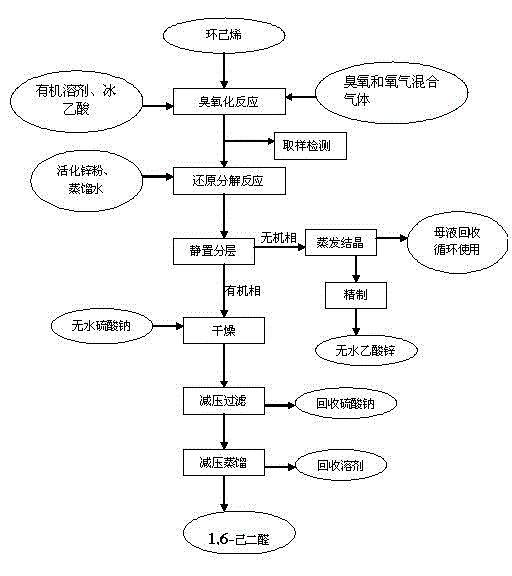

Method for preparing 1,6-adipaldehyde

InactiveCN102746127AHigh activityGood choicePreparation by ozonolysisCarboxylic acid salt preparationCyclohexeneReaction temperature

The invention belongs to the field of synthesis of fine chemicals, and discloses a method for preparing 1,6-adipaldehyde. The method comprises the following steps of: performing an ozonization reaction on cyclohexene serving as a raw material by taking ozone as an oxidant and taking an organic solvent and glacial acetic acid as mixed solvents at the reaction temperature of between 20 DEG C below zero and 10 DEG C to obtain an ozonized reaction liquid, and directly performing a reducing reaction on an ozonide without separating; and reducing and decomposing by adopting zinc powder, and reacting under the protection of nitrogen gas at the room temperature for 0.5-1.5 hours to obtain 1,6-adipaldehyde. Compared with the conventional method, the method has the advantages: ozone is taken as an oxidant, so that high oxidizing capacity and high selectivity are realized, the environmental pollution is low, the requirement of ozonization reaction temperature is low, energy is saved, and consumption is lowered. After reacting, a product is easy and convenient to separate; and zinc acetate is recovered from a water phase by concentrating and crystalizing, so that production cost is lowered, and industrial production is facilitated.

Owner:中国平煤神马控股集团有限公司 +1

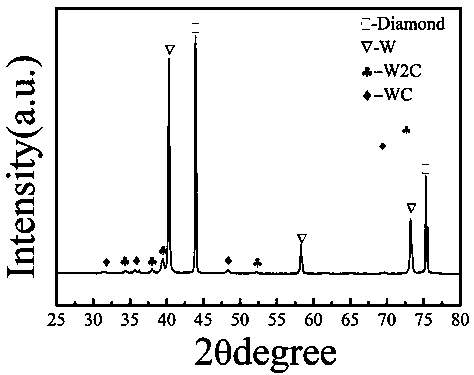

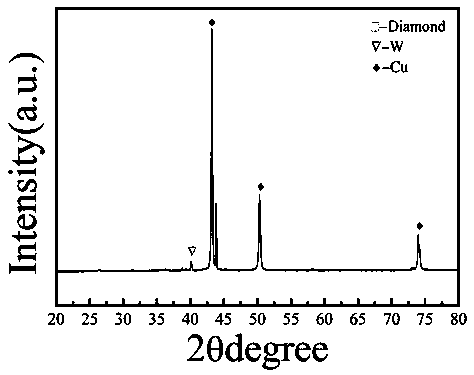

Preparation method of diamond/copper composite high in heat conduction performance

ActiveCN107916356AImprove protectionSimple separation processTransportation and packagingMetal-working apparatusPowder mixtureRoom temperature

The invention discloses a preparation method of a diamond / copper composite high in heat conduction performance. The preparation method comprises the following steps of 1, uniformly mixing diamond obtained after surface of the diamond is subjected to degreasing and roughening treatment with tungsten powder according to the mass ratio of 1: 4.5, heating a powder mixture under the vacuum condition, conducting heat preservation for 2-8 hours at the temperature of 1030 DEG C, and finally, separating out modified tungsten-plated diamond, wherein the vacuum degree is 10<-2>-10<-4> Pa, and the temperature rising rate is 5 DEG C / min; and 2, uniformly mixing the tungsten-plated diamond, with the mean particle size being 125 microns, obtained after surface modification with copper powder with the mean particle size being 45 microns with the total volume content of the tungsten-plated diamond accounting for 55%, sintering an obtained powder mixture, and then cooling the obtained power mixture to the room temperature, so that the diamond / copper composite is obtained, wherein the sintering parameters are that the pressing pressure is 40 MPa, the temperature is 1000 DEG C, the temperature risingrate is 100 DEG C / min, the sintering time is 10 minutes, and the atmosphere is vacuum.

Owner:ZHENGZHOU UNIV

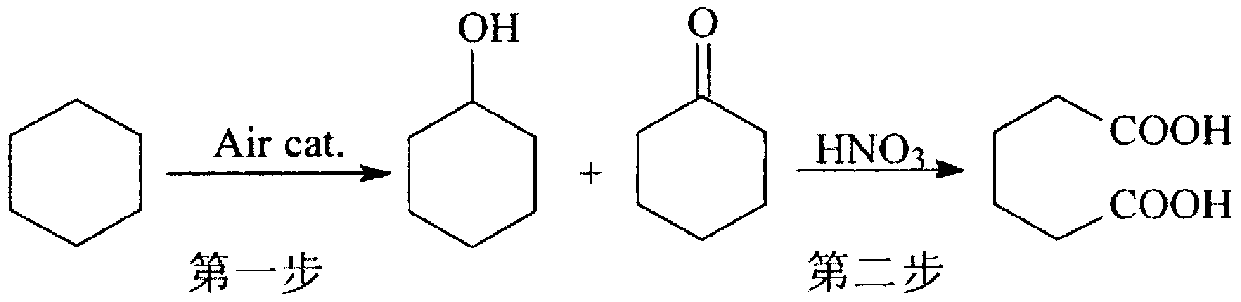

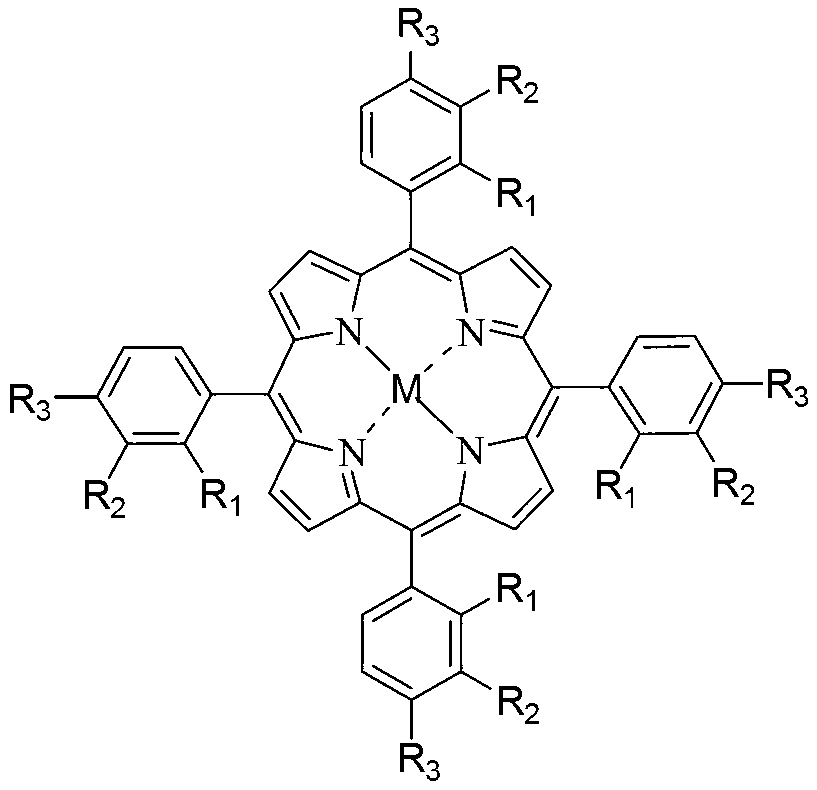

Method for preparing adipic acid through co-catalytic oxidation of six-carbon oxygenated compound and cyclohexane

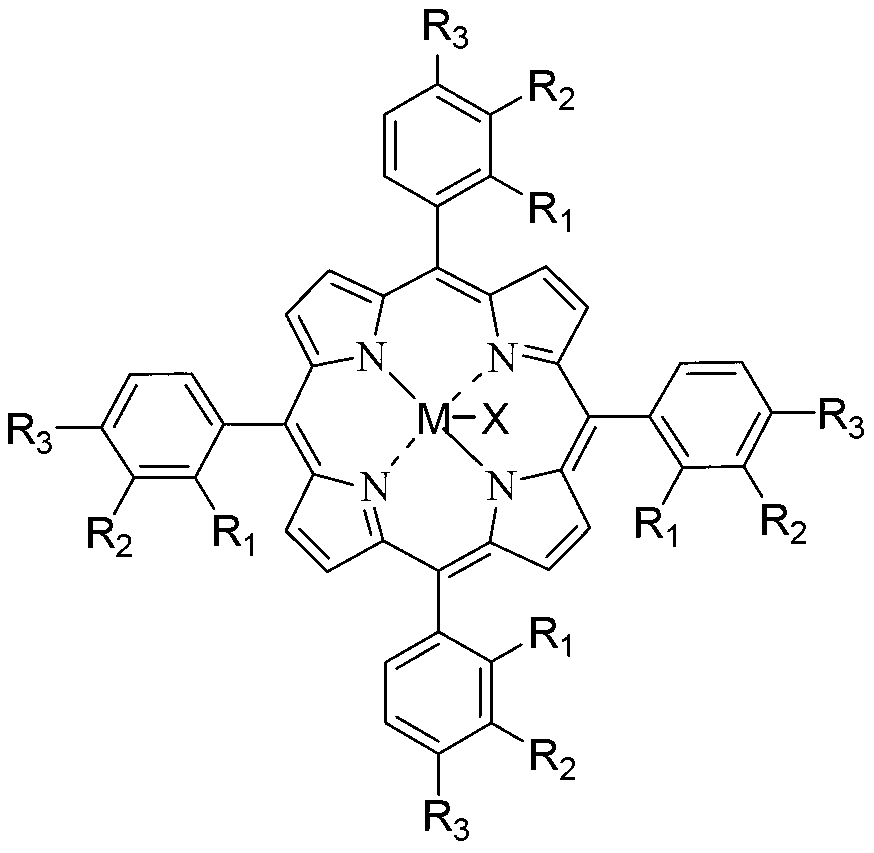

ActiveCN103254060AHigh selectivityLow priceOrganic compound preparationCarboxylic compound preparationSolventChemistry

The invention discloses a method for preparing adipic acid through co-catalytic oxidation of a six-carbon oxygenated compound and cyclohexane. According to the method, cyclohexane is used as a raw material, a six-carbon oxygenated compound is used as a co-oxidant, and one of transitional metal salt or oxide, N-hydroxyphthalimide and analogues, metal phthalocyanine and metalloporphyrin, or a mixture of several ones thereof is used as a catalyst, the mass ratio of the six-carbon oxygenated compound to the cyclohexane is (0.003-9):1, and the dosage of the catalyst is 1-100,000ppm of the total weight of the cyclohexane; and under the conditions that an oxygen-containing gas is continuously introduced, the reaction temperature is 80-155 DEG C, the reaction pressure is 0.1-1.2MPa and the reaction time is 0.4-4 hours, the cyclohexane is oxidized into adipic acid in a solvent in one step. The method disclosed by the invention has the advantages of mild reaction conditions, high once through yield of product, good selectivity and environmental protection.

Owner:上海立科化学科技有限公司

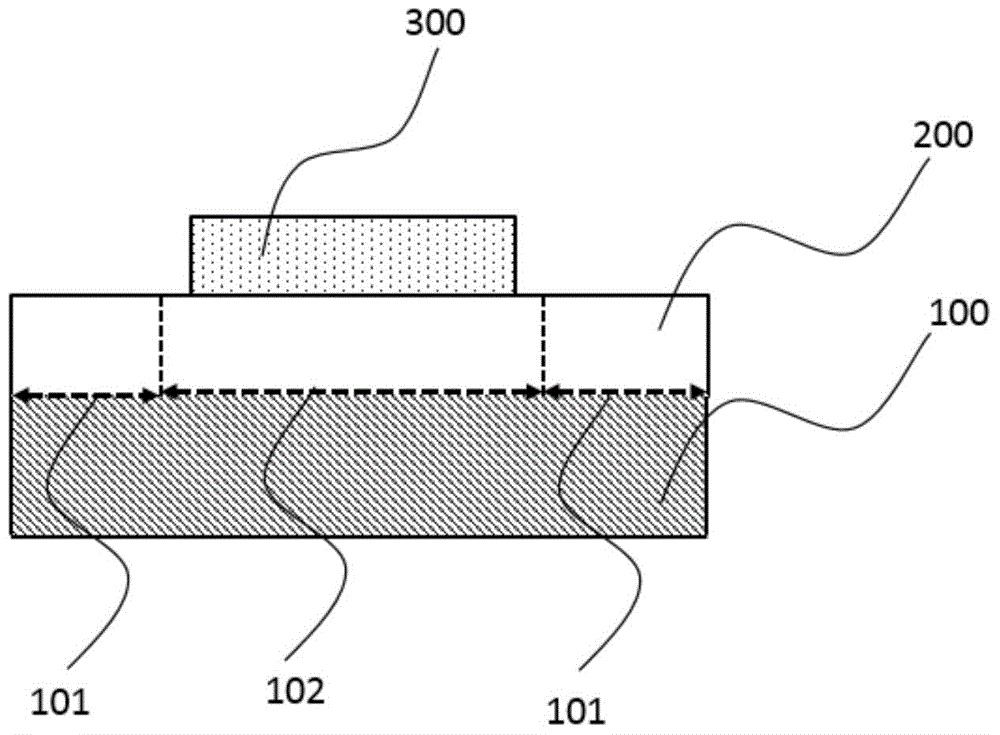

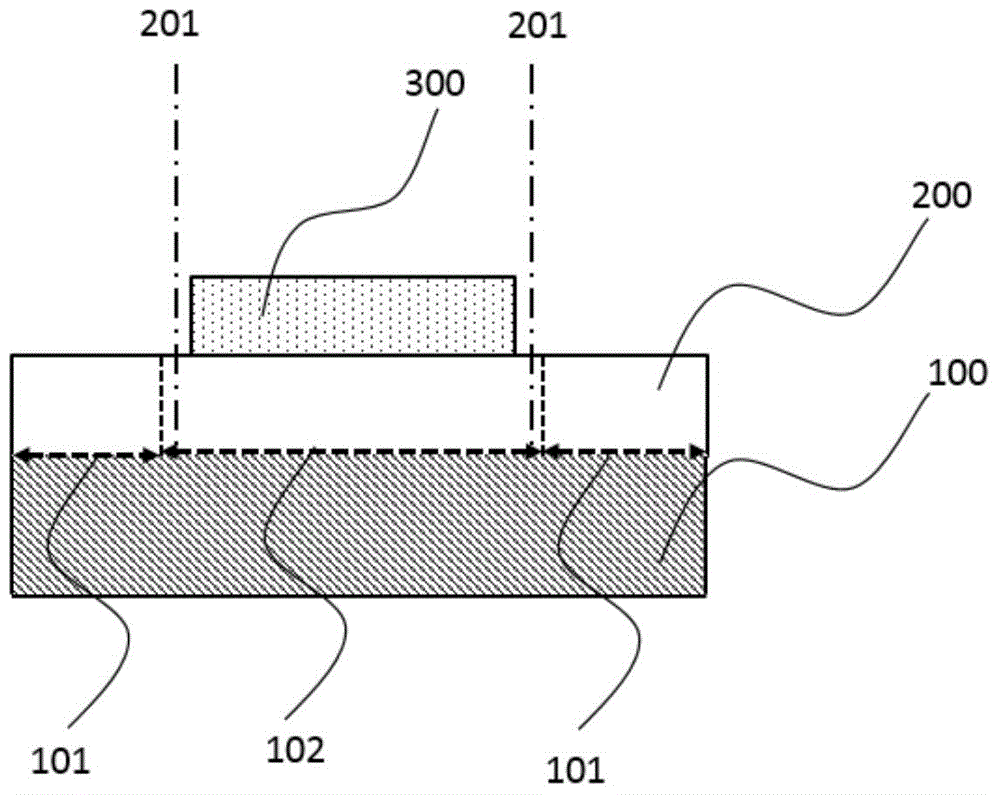

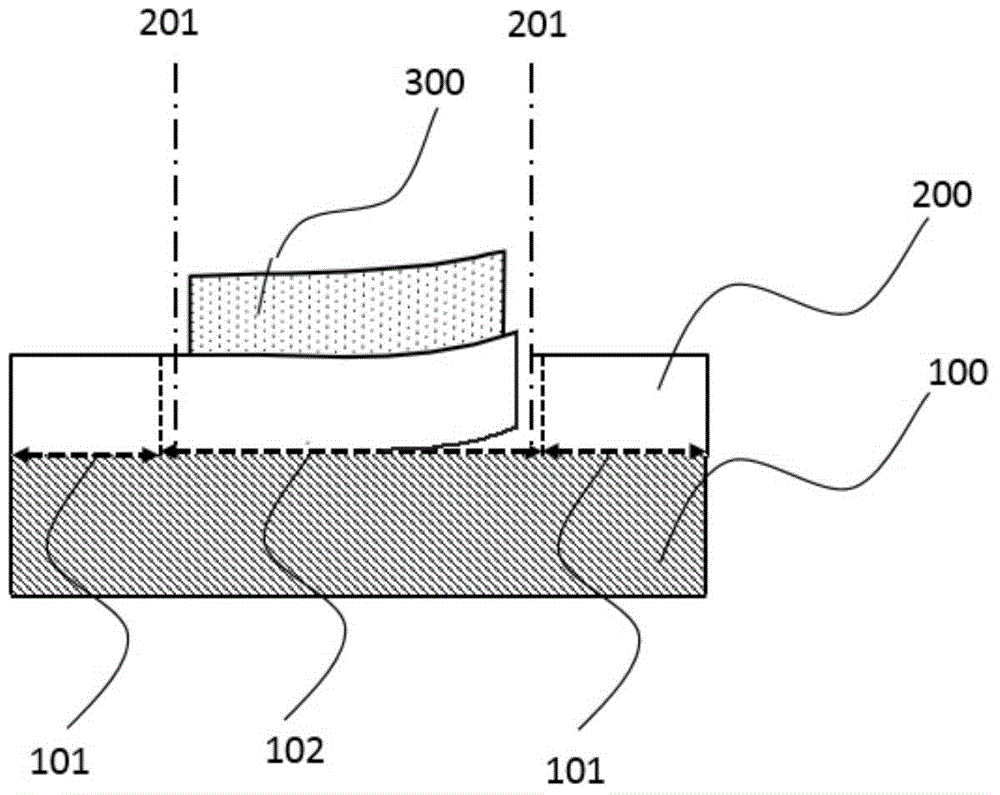

Flexible membrane liner and substrate separation process for producing flexible display device

InactiveCN104362263AEnhanced adhesionSimple separation processFinal product manufactureSolid-state devicesSeparation processBiomedical engineering

The invention discloses a flexible membrane liner and substrate separation process for producing a flexible display device. The process includes the steps: (1) producing a flexible membrane liner on a carrier substrate, and treating the juncture of the flexible membrane liner and the carrier substrate to enable some regions to become high-adhesion regions and the rest region to become a low-adhesion region; (2) producing an electronic component on the flexible membrane liner over the low-adhesion region; (3) cutting vertically and downwardly from the flexible membrane liner along the periphery of the electronic component to form a cutting line, wherein the low-adhesion region is located under the cutting line; (4) separating the flexible membrane liner from the carrier substrate. The flexible membrane liner is stably attached to the carrier substrate in the subsequent device production process, and the process is simple in liner and substrate separation, low in cost and rapid and causes no damage to the device.

Owner:SOUTH CHINA UNIV OF TECH

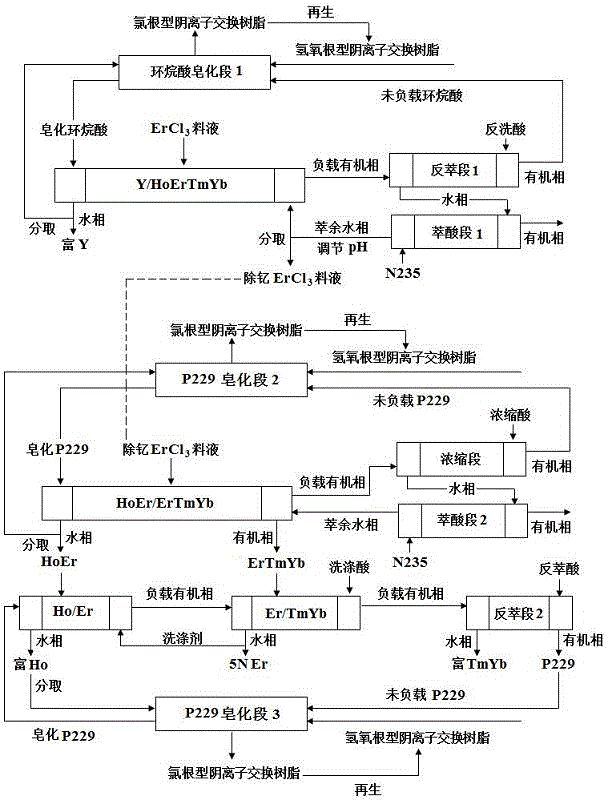

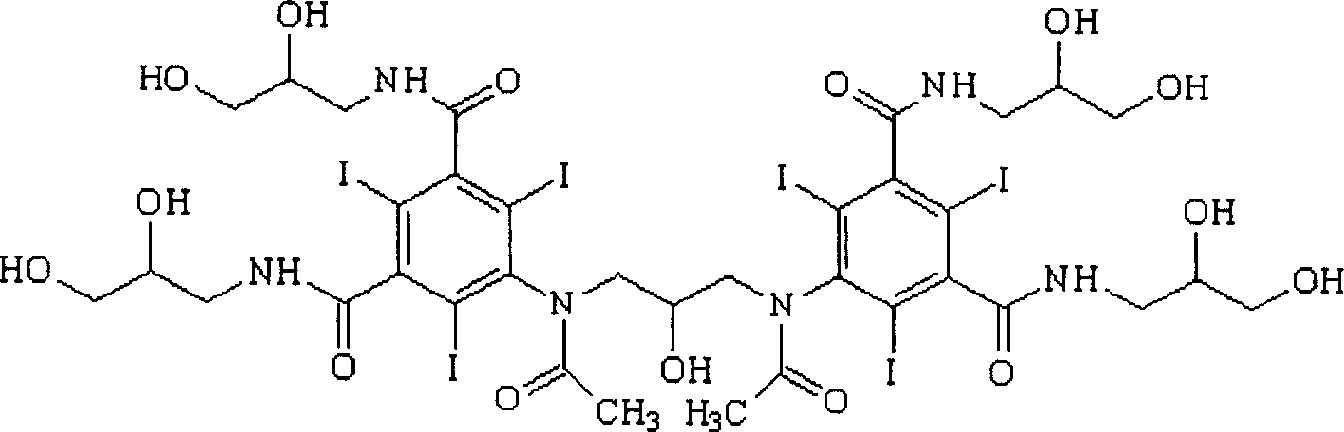

Process for preparing 5N erbium by extracting and separating

InactiveCN105779762AReduce consumptionSimple separation processProcess efficiency improvementThuliumRare earth

The invention discloses a process for preparing 5N erbium by extracting and separating. Erbium chloride of 2N to 3N grades is taken as feed liquid, naphthenic acid is taken as an extracting agent for separating yttrium, and an acidic phosphine reagent P229 is taken as an extracting agent for separating erbium, thulium and ytterbium. The process comprises twelve steps including four separating steps and eight auxiliary steps, wherein the four separating steps separately comprise a Y / HoErTmYb separating work section, an HoEr / ErTmYb separating work section, an Ho / Er separating work section and an Er / TmYb separating work section; the eight auxiliary steps separately comprise a reverse extraction work section for extracting the naphthenic acid, an acid extraction work section, a rare earth saponification work section of the naphthenic acid, a concentration work section, an acid extraction work section, a P229 rare earth saponification work section, a reverse extraction work section for extracting the P229 and a P229 rare earth saponification work section. Ho / Er separation and Er / TmYb separation are connected in series. According to the process disclosed by the invention, a 5N grade erbium product with relative purity of 99.9990 percent to 99.9996 percent can be obtained, and the yield of the product is as high as 94.88 to 97.34 percent. The process disclosed by the invention has the advantages of high purity and high yield of erbium products, large production scale, low consumption of chemical reagents, simplicity and convenience in operation, low production cost and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

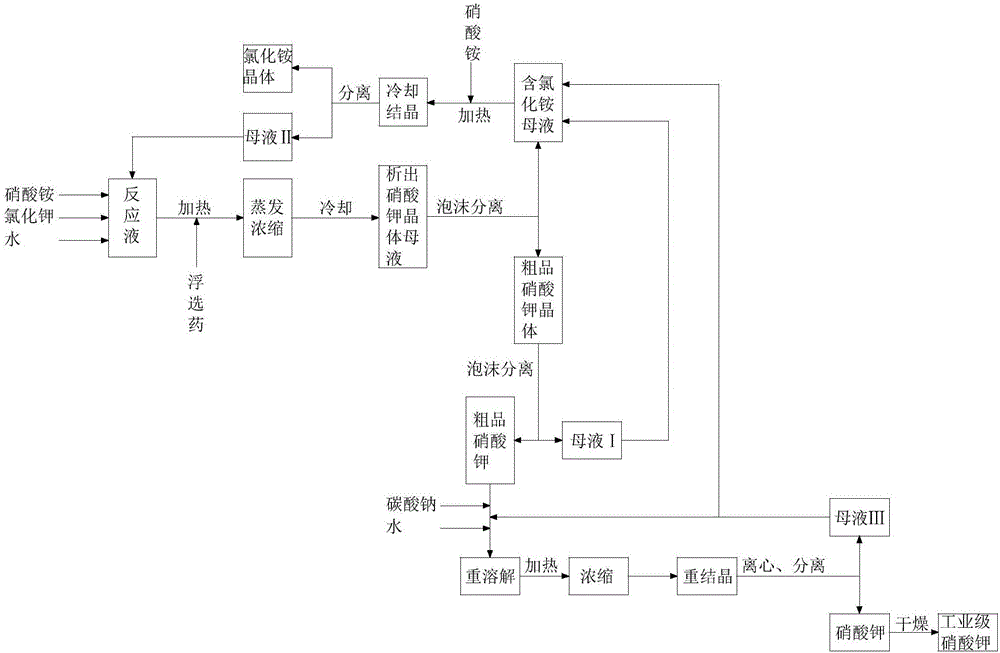

Potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate

ActiveCN105060317AHigh quality contentSimple separation processAlkali metal nitrate preparationWater useSeparation technology

The invention discloses a potassium chloride and ammonium nitrate double decomposition and circulation method for producing high quality potassium nitrate. According to the method, potassium chloride and ammonium nitrate are taken as the raw materials, and the method comprises steps of raw material preparation, potassium nitrate crystallization, foam floatation and separation, potassium nitrate refinement, and ammonium chloride crystallization. The method is developed on the basis of conventional potassium nitrate production technology by improving part of the technology; wherein in the foam flotation and separation technology, in the presence of a floatation reagent (C12-C20 higher straight-chain aliphatic amine) and in a certain pH value range, the ammonium chloride and coarse potassium nitrate can be separated through foam entrainment; in the potassium nitrate refinement, the refined potassium mother liquid in the previous circulation is used to wash the coarse potassium nitrate, and then potassium nitrate is purified by sodium carbonate. In one aspect, the conventional potassium nitrate production technology is optimized, the potassium nitrate quality is improved, and the impurity content of the potassium nitrate product is greatly reduced. In the other aspect, the water using amount is reduced, the labor intensity is also reduced, and the production cost is saved. The industrial grade KNO3 mass content is not less than 99.7%, the content of Cl<-> is not more than 0.01%, and the content of NH4<+> is not more than 0.03%. the method has a wide application value and can generate prominent social benefit and economic benefit.

Owner:湖南丹化农资有限公司

Lymphocyte separation liquid and method of separating spleen lymphocyte

The invention discloses a separating liquid of lymphocyte with Iodixanol density at 14.0-17.5%, which comprises the following steps: grinding the separated liquid of spleen; making single-cell suspension; centrifuging.

Owner:SHENZHEN DAKEWE BIOENG

Method for extracting dihydroquercetin form larch

InactiveCN101333204AFree radical scavengingInhibition of lesionsOrganic chemistryConiferophyta medical ingredientsLarchUnit/Kilogram

Disclosed is a preparation method for extracting dihydro quercetin from larch. The invention is an improved production method. Due to different production materials and extraction processes, the dihydro quercetin products in U.S. and European markets are very expensive, at a price of 200-1000 euros per gram. Such a high market price economically limits the wide range of practicability of dihydro quercetin products. During the pretreatment of raw materials, 50 kilograms of larch wood chips and 500-800 liters of 50% ethanol solution are added into an extractor to get fully stirred and mixed; then the mixture is extracted and filtered for the second extraction; the filtrates are combined and adsorbed; the organic solvents are collected and dried by a vacuum evaporator through organic phase vacuum distillation; according to a weight proportion of 10:1, the residues are dissolved with hot water, decolorized with activated carbon and then crystallized at a temperature of 3-5 DEG C to precipitate the dihydro quercetin product which is then crushed after vacuum drying to finished product. The invention is used to extract dihydro quercetin from larch.

Owner:黑龙江花旗科技发展有限公司 +2

Intelligent molecular blotting affinity membrane for chiral resolution and its preparation method

InactiveCN1788832ASimple separation processIncrease throughputSemi-permeable membranesChiral resolutionSeparation process

The present invention is chiral resolving affinity membrane for resolving, concentrating and separating chiral molecules and its preparation process. The present invention prepares temperature sensitive intelligent chiral resolving affinity membrane with porous inorganic or organic membrane as base membrane, and through heating polymerization or UV initiated polymerization of acrylate, acrylic acid, acrylamine, diacrylamine, isopropyl acrylamine, initiator and template molecule solution inside the pores and on the surface of the base membrane, and subsequent washing off the template molecule via altering the temperature. The preparation process includes the steps of: base membrane treatment, compounding monomer solution, polymerization and eliminating template. The intelligent chiral resolving affinity membrane has simple separation process, high chiral resolving capacity, high treating amount and no selectivity.

Owner:李连超

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com