Synthesis and application of terminal-hyperbranched polyether phosphate water reducing agent

The technology of polyether phosphate and hyperbranched polyether is applied in the synthesis and application field of polyether phosphate water-reducing agent, and can solve the problem of low adsorption point density, few adsorption sites of water-reducing agent, and poor performance of water-reducing agent and other problems to achieve the effect of improving the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

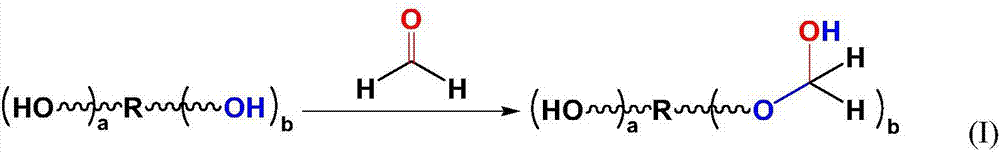

[0078] Preparation of starter intermediate in which 2 hydroxyl groups of glycerol are acetalized.

[0079] The molar ratio of hydroxyl and aldehyde groups in glycerin and paraformaldehyde is 3:1, the amount of water used is 25% of the mass of glycerin, and the amount of catalyst NKC-9 is 3.5% of the mass of glycerin. Weigh 100 parts of glycerin, 15 parts of water, 3 parts of NKC-9, and 32.6 parts of paraformaldehyde, and add the above materials into the reaction kettle. Under the condition of 0.1MPa and room temperature, react for 1.5h.

[0080] Then the reaction kettle is heated to 85°C, and nitrogen is preheated to 85°C at the same time, and then passed into the reaction kettle from the bottom of the reaction kettle, and the moisture in the reaction system is continuously taken out through the volatilization of the gas. The pressure in the reaction kettle is the reaction system itself Pressure, continue to react for 5h. After the reaction, the heterogeneous catalyst NKC-9 ...

Embodiment 2

[0098] The polyether preparation and capping of end hyperbranched of embodiment 2

[0099] Q1 is the synthesis and end-capping of initiator, methyl-terminated end hyperbranched polyether with a molecular weight of 2980.

[0100] Polyether Synthesis:

[0101] The basic catalyst for polymerization synthesis is NaOH, and the catalyst consumption is 3% of the quality of the initiator intermediate Q1. Weigh 100 parts of initiator Q1 and 3 parts of NaOH, add the above materials into the reaction kettle, vacuumize to -0.1MPa at room temperature, then raise the temperature to 50°C and continue vacuuming for 20min. Continue to raise the temperature of the reactor to 80°C, and feed 30 parts of ethylene oxide into the reaction system. After the pressure in the reactor drops and the temperature rises, it means that the polymerization reaction starts, and continue to feed 3100 parts of ethylene oxide into the reactor. During the feeding process, the temperature of the reactor is maintain...

Embodiment 3

[0113] Preparation and end-capping of block polyether with terminal hyperbranching of embodiment 3

[0114] Q2 is the synthesis and end capping of initiator, methyl-terminated end hyperbranched block polyether with a molecular weight of 4025.

[0115] Polyether Synthesis:

[0116] The amount of catalyst sodium hydride (60%) is 5% of the quality of the starter intermediate Q2. Weigh 100 parts of Q2 and 8.3 parts of sodium hydride, put the above materials into the reactor, and vacuumize the reactor to -0.1MPa at room temperature. Then the temperature was raised to 50°C and the vacuum was continued for 20 min. Put 30 parts of propylene oxide into the reaction kettle, wait until the pressure in the reaction kettle drops and the temperature rises, indicating that the polymerization reaction starts, keep the reaction at 120-140°C, and the pressure between 0.2MPa-0.4MPa, continue to feed 310 parts of propylene oxide, continue insulation reaction after feeding finishes, until press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com