Flexible membrane liner and substrate separation process for producing flexible display device

A flexible film and flexible display technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as difficult separation process, detachment of flexible film substrate, difficulty in controlling the balance of adhesion, etc. Achieve the effect of simple separation process, enhanced adhesion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

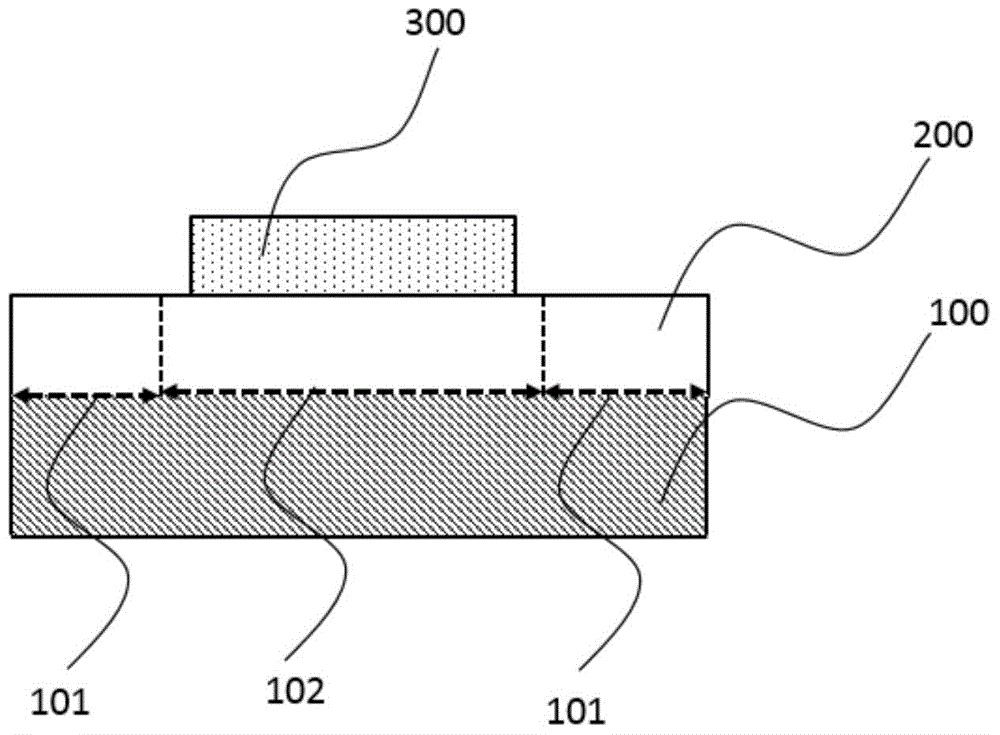

[0033] The flexible film substrate and substrate separation process for the preparation of flexible display devices in this embodiment includes the following steps:

[0034] (1) if figure 1 As shown, the flexible film substrate 200 is prepared on the carrier substrate 100, and differential treatment is performed on the joint between the flexible film substrate 200 and the carrier substrate 100, so that there is a gap between the flexible film substrate 200 and the carrier substrate 100 in some areas. The adhesion force between the flexible film substrate and the carrier substrate in other areas is 0 dB or 1 dB, forming a low adhesion area 102 . dB is the unit of action for expressing adhesion in the industry. The standard is formulated by ASTM, and an integer from 0 to 5 is used to represent the magnitude of adhesion, of which 5 represents the highest adhesion, and 0 corresponds to no adhesion.

[0035] In this embodiment, differential treatment is performed on the joint betw...

Embodiment 2

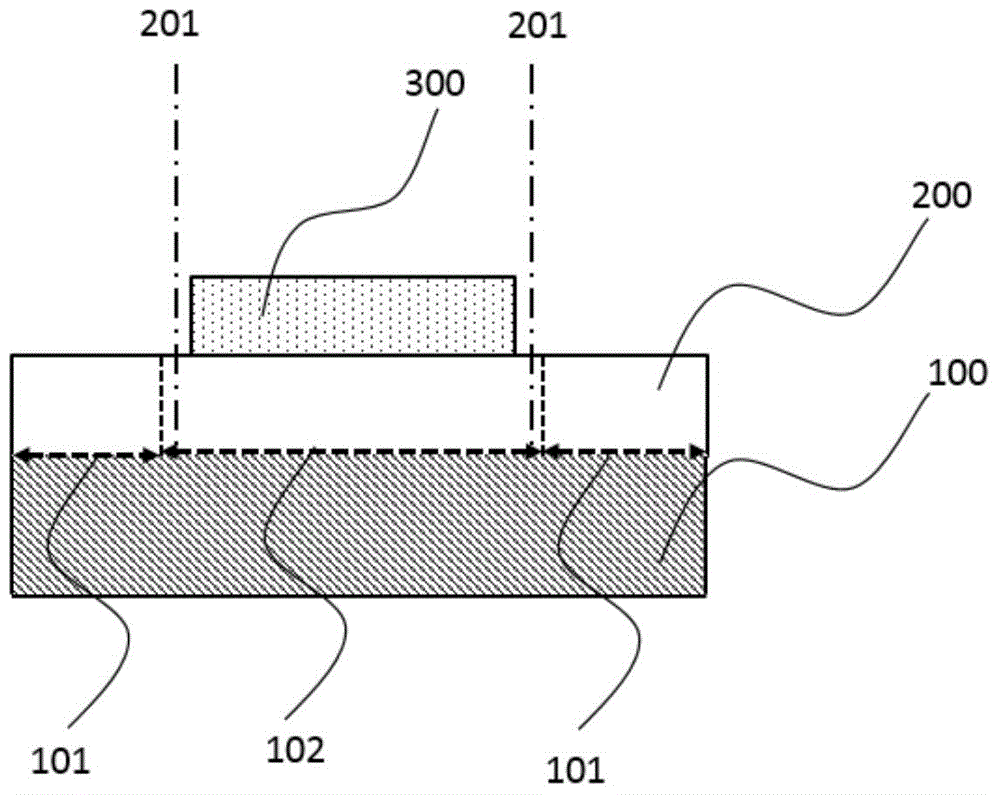

[0046] The flexible thin film substrate and substrate separation process for the preparation of flexible display devices in this embodiment, other features are the same as in embodiment 1, the difference lies in the joint between the flexible thin film substrate and the carrier substrate in step (1) Differentiated processing is carried out in the following ways:

[0047] After the flexible film substrate 200 is prepared on the carrier substrate 100, on the flexible film substrate 200 above the high-adhesion region 101 to be formed, a high-temperature, high-pressure heat treatment is performed with a thermal probe, such as Figure 5 shown.

[0048] In this embodiment, after the flexible film substrate is heat-treated, the molecular chains of the polymer flexible film substrate begin to move in the vicinity of the glass transition temperature (350°C-500°C), and the side reaction phenomenon is intensified, such as the hydroxyl group on the polyimide Forms covalent bonds with the...

Embodiment 3

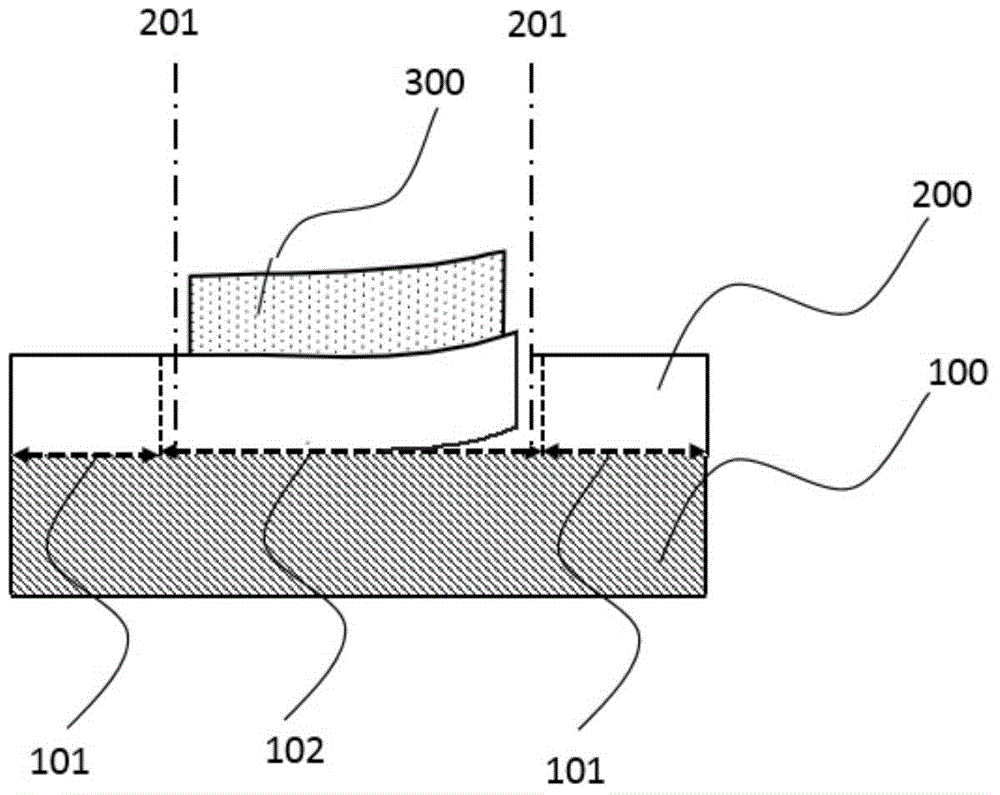

[0051] The flexible thin film substrate and substrate separation process for the preparation of flexible display devices in this embodiment, other features are the same as in embodiment 1, the difference lies in the joint between the flexible thin film substrate and the carrier substrate in step (1) Differentiated processing is carried out in the following ways:

[0052] Before preparing the flexible thin film substrate 200, the bonding layer 400 is sputtered on some regions of the surface of the carrier substrate 100, so that these regions become high adhesion regions 101 after the flexible thin film substrate is prepared, such as Figure 6 shown.

[0053] The thickness of the bonding layer is between 1 and 300 microns, and the specific material is a metal film, which can be aluminum, titanium or molybdenum metal film; the bonding layer can also be a metal oxide film, which can be aluminum oxide, indium zinc oxide or copper oxide film. The bonding layer can be deposited as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com