Patents

Literature

408results about How to "Smooth disengagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

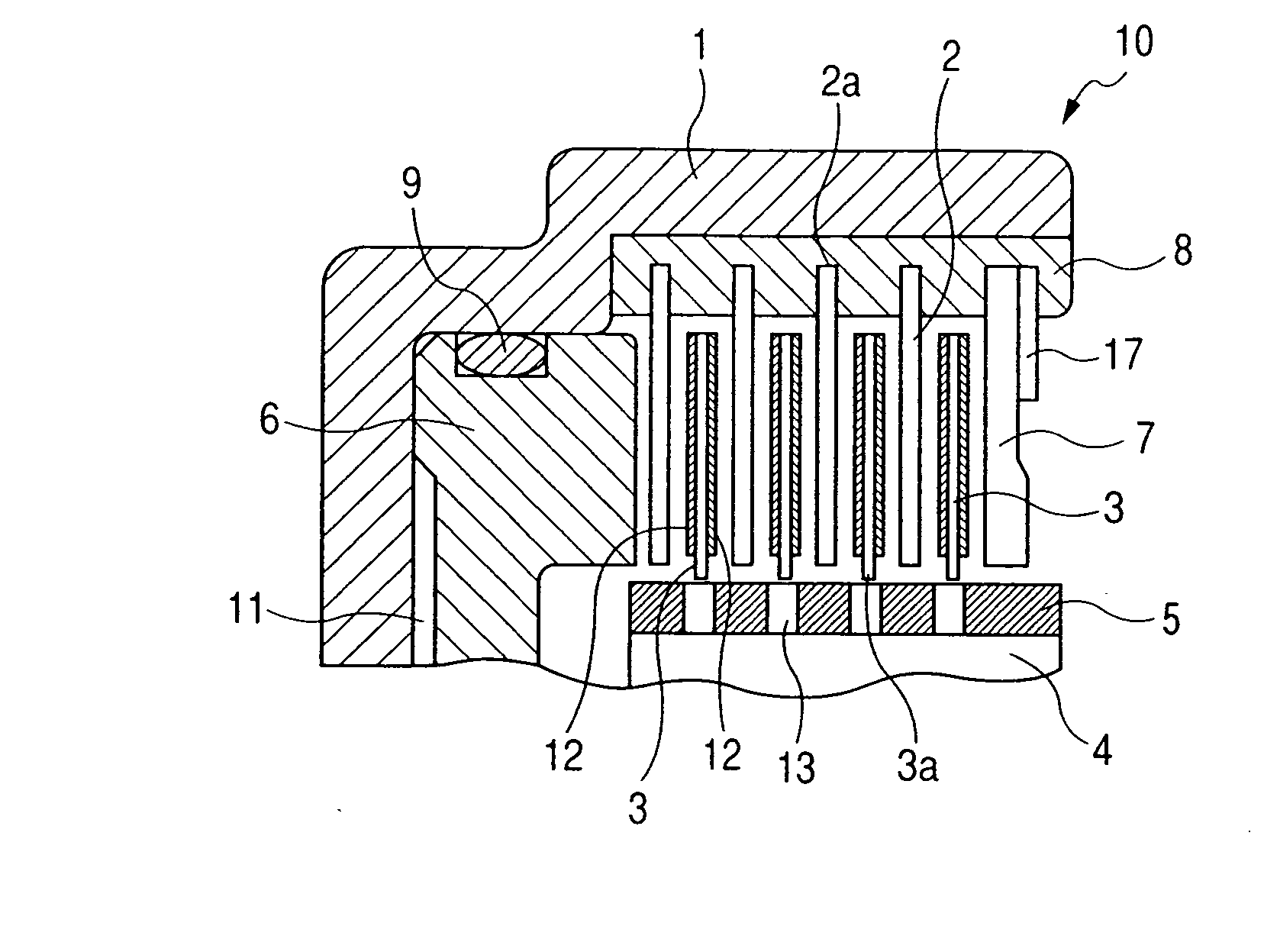

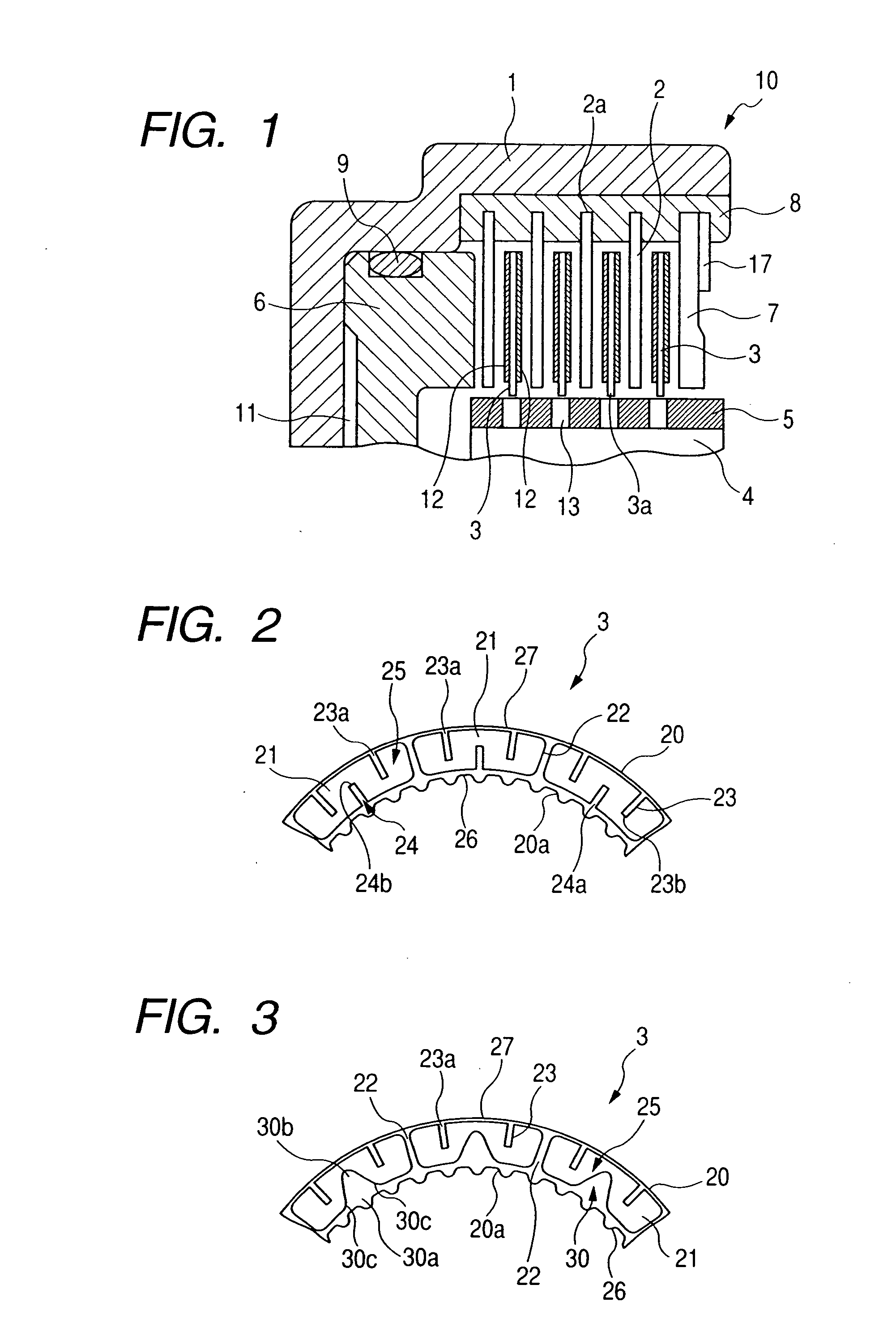

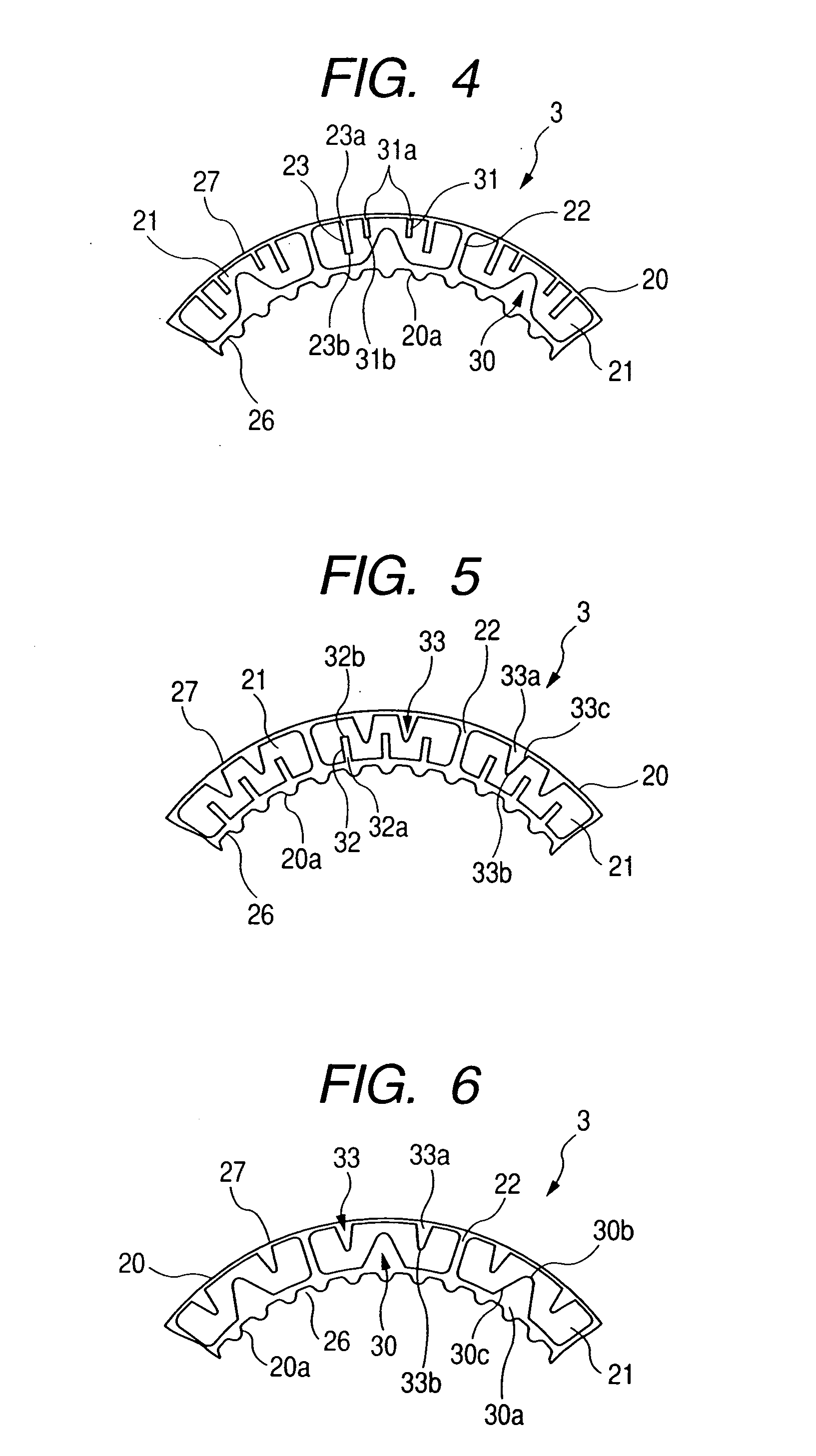

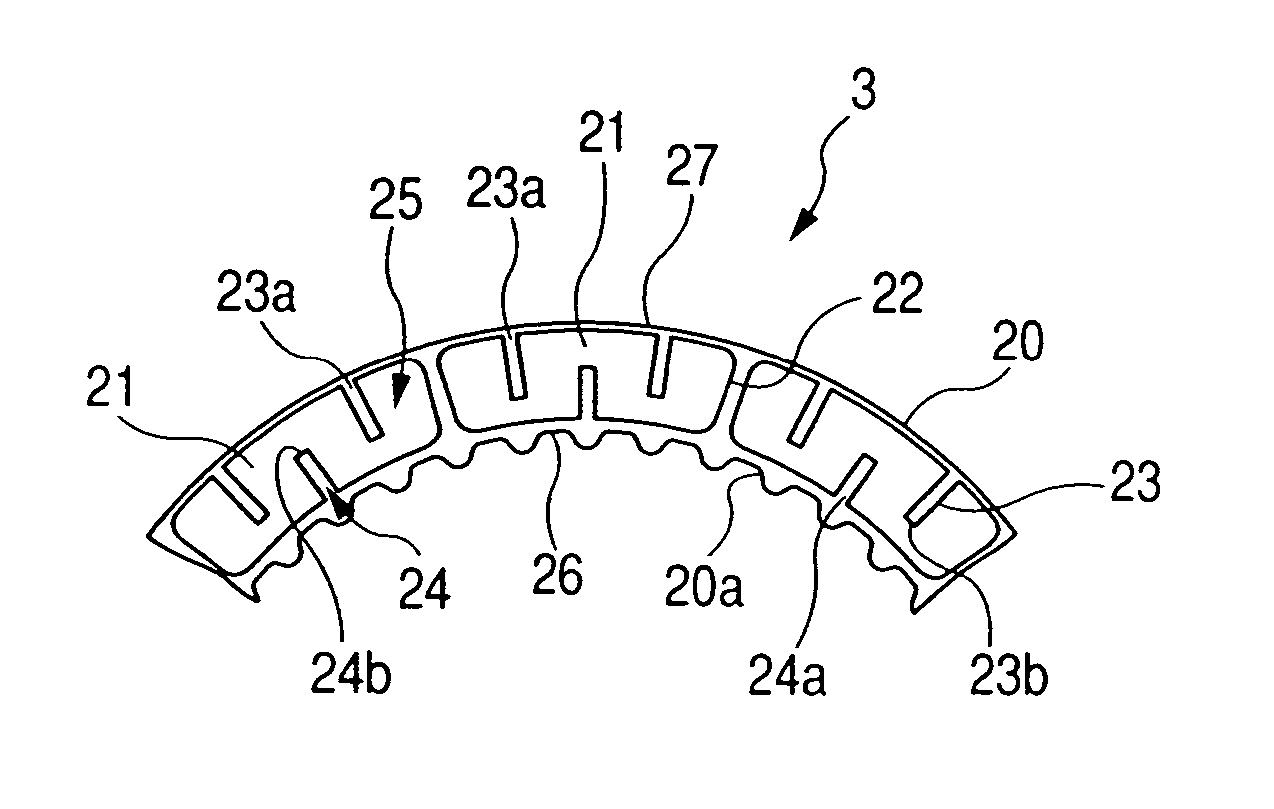

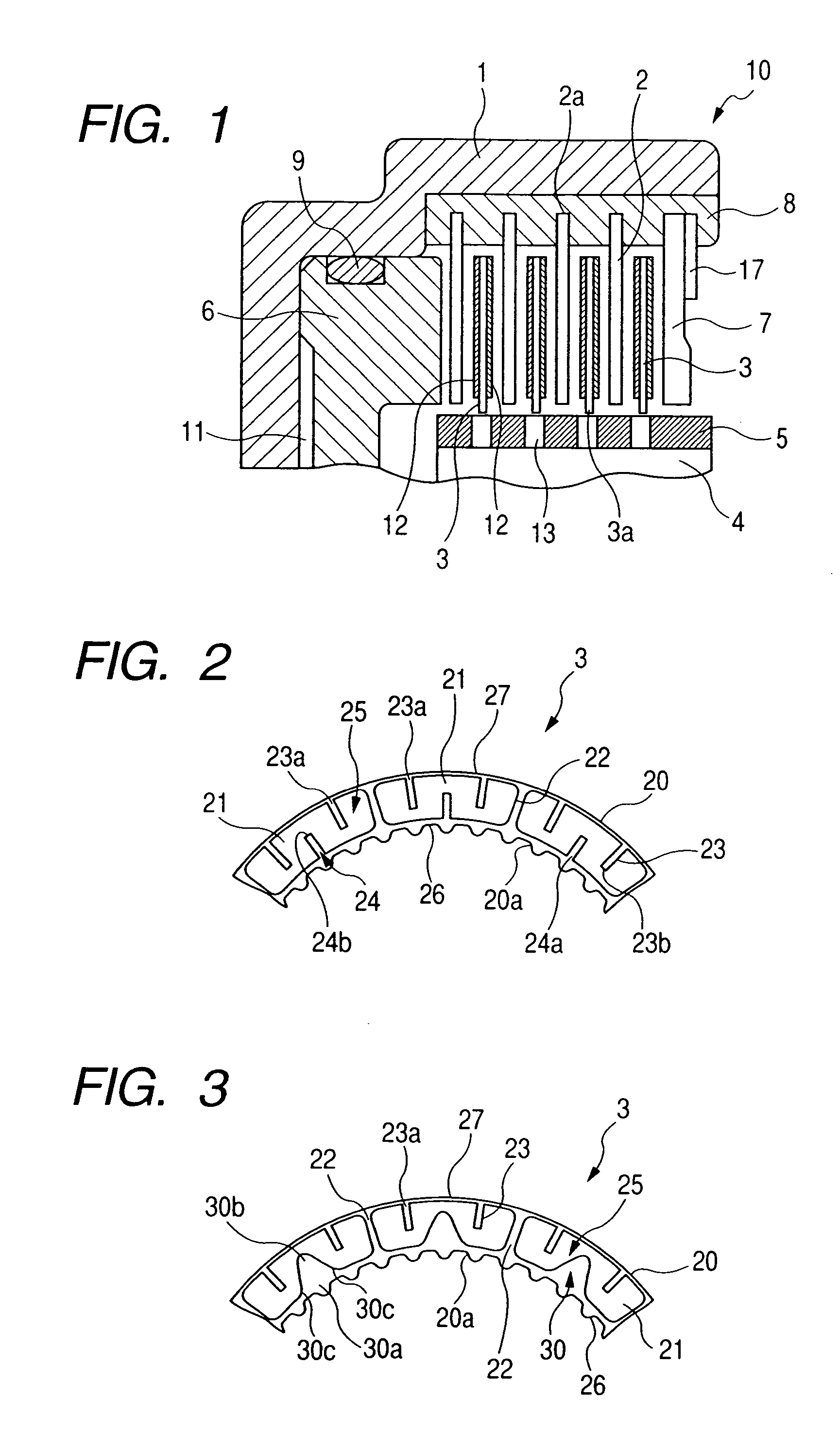

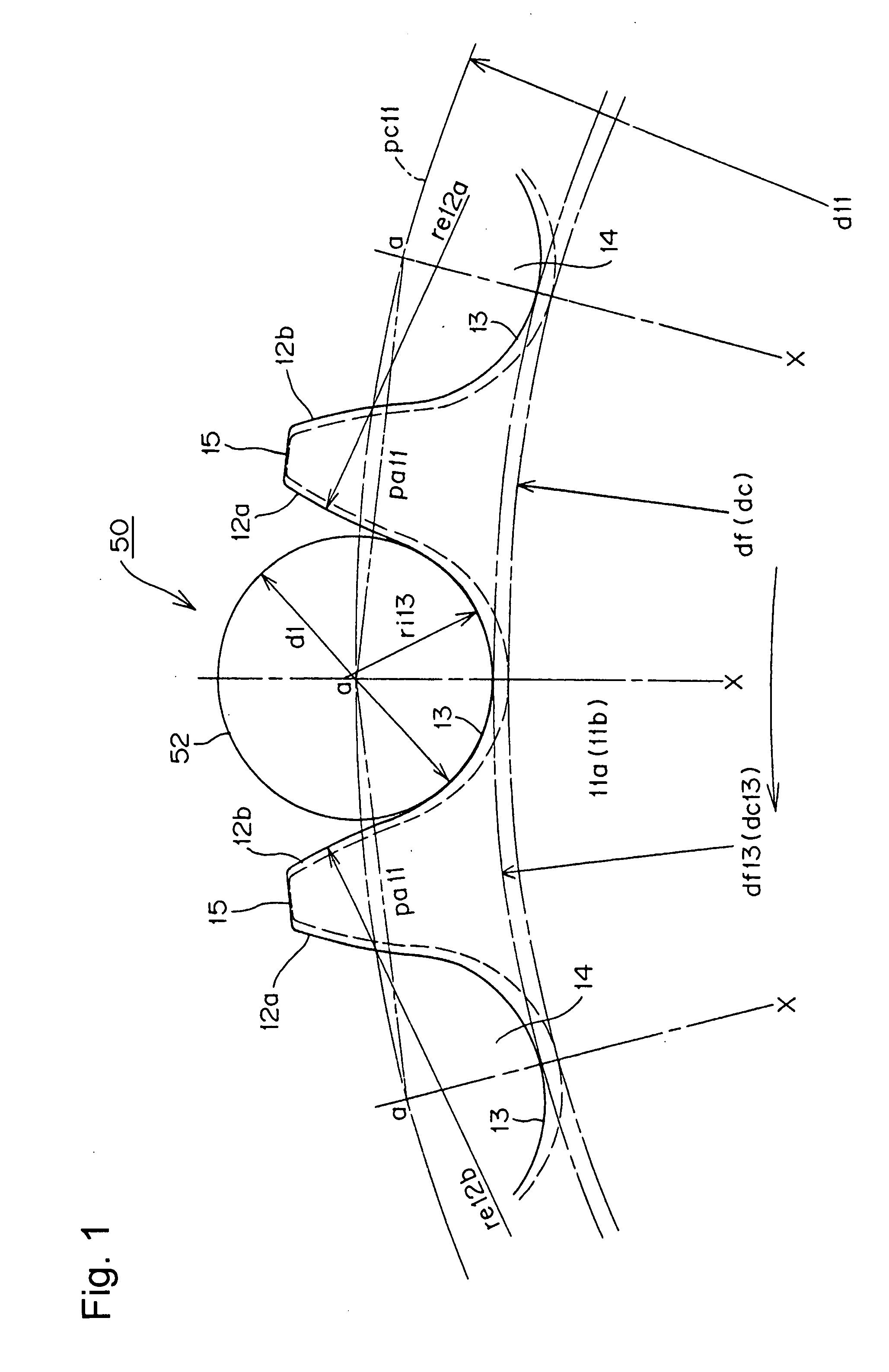

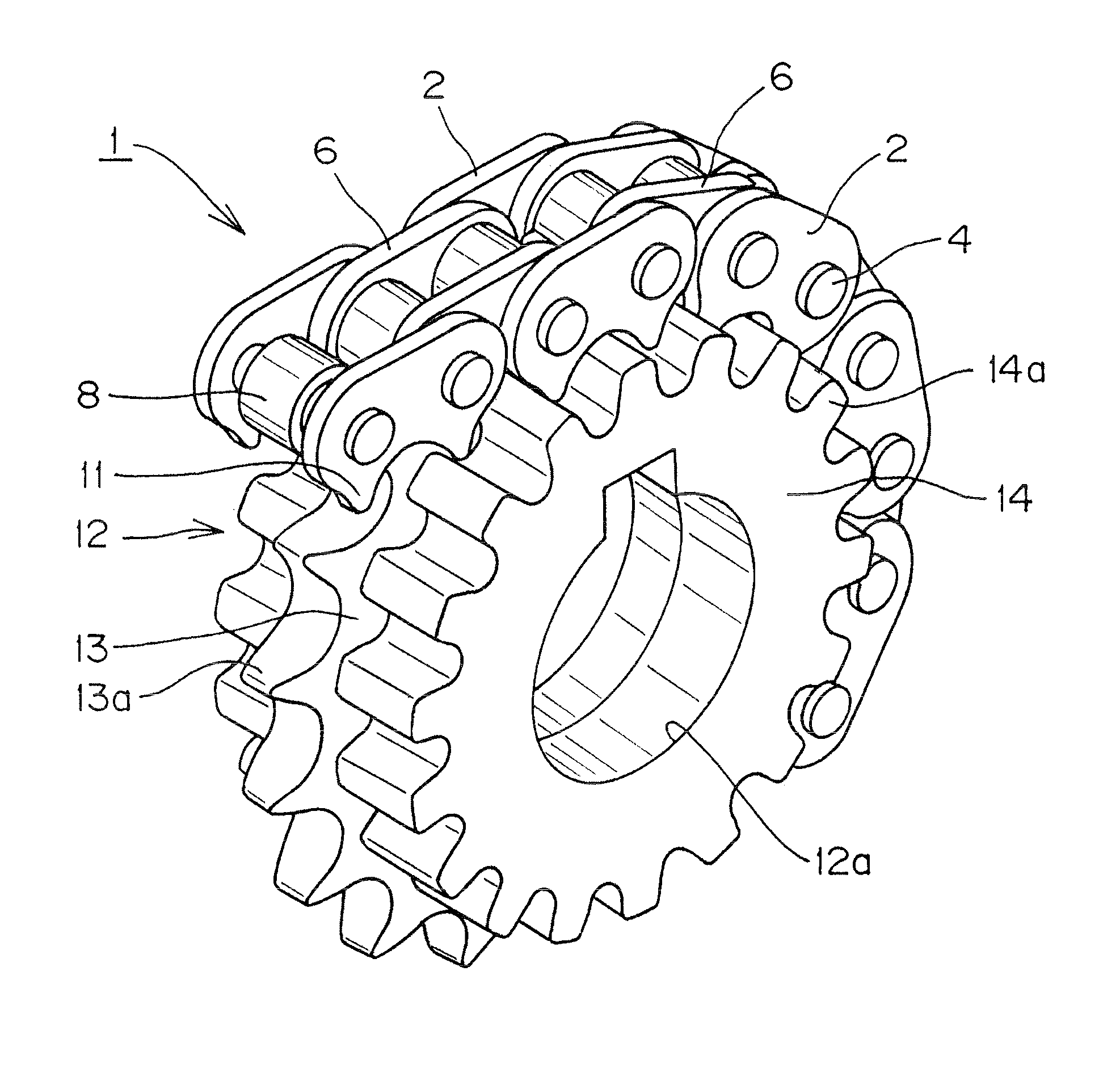

Friction plate and wet-type multi-plate clutch

InactiveUS20070102258A1Improve heat resistanceReduce participationFluid actuated clutchesFriction clutchesEngineeringClutch

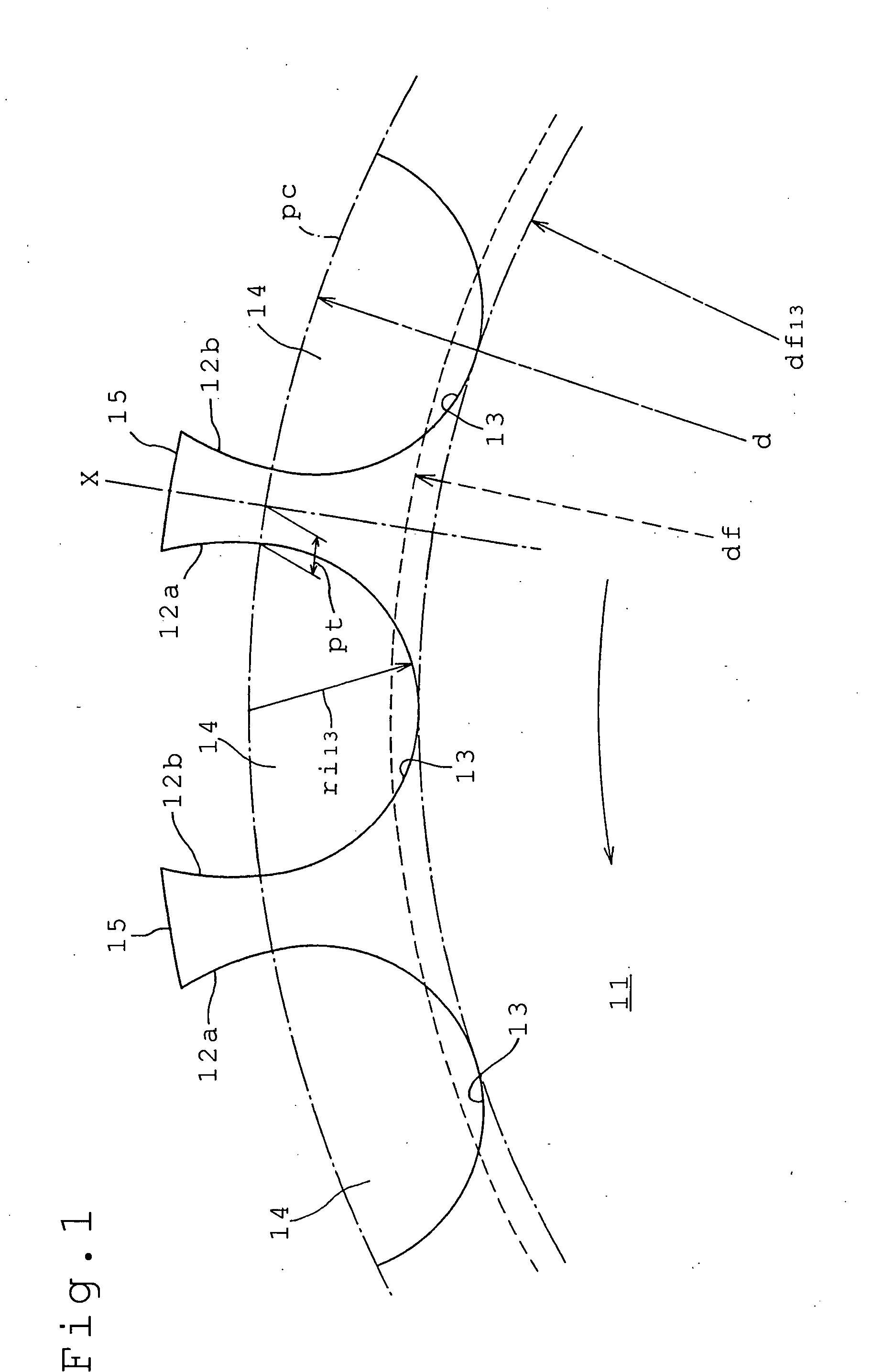

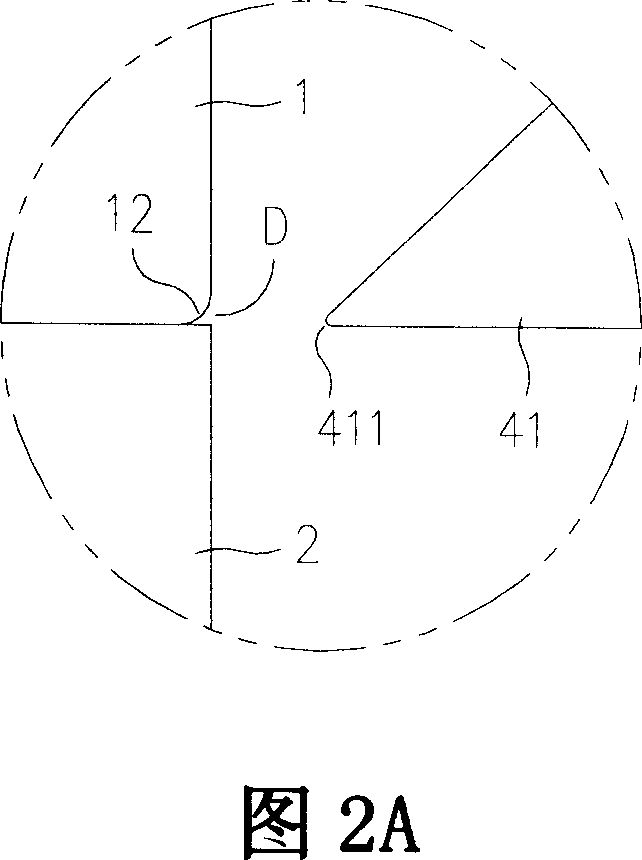

The present invention provides a friction plate having a friction surface formed by adhering a friction material to a substantially annular core plate and wherein the friction surface is provided with an oil passage communicated with inner and outer peripheral edges of the friction plate, a first oil groove having an opening portion opened to the inner peripheral edge of the friction plate and an end portion terminating at a position between the inner and outer peripheral edges, and a second first oil groove having an opening portion opened to the outer peripheral edge of the friction plate and an end portion terminating at a position between the inner and outer peripheral edges.

Owner:NSK WARNER

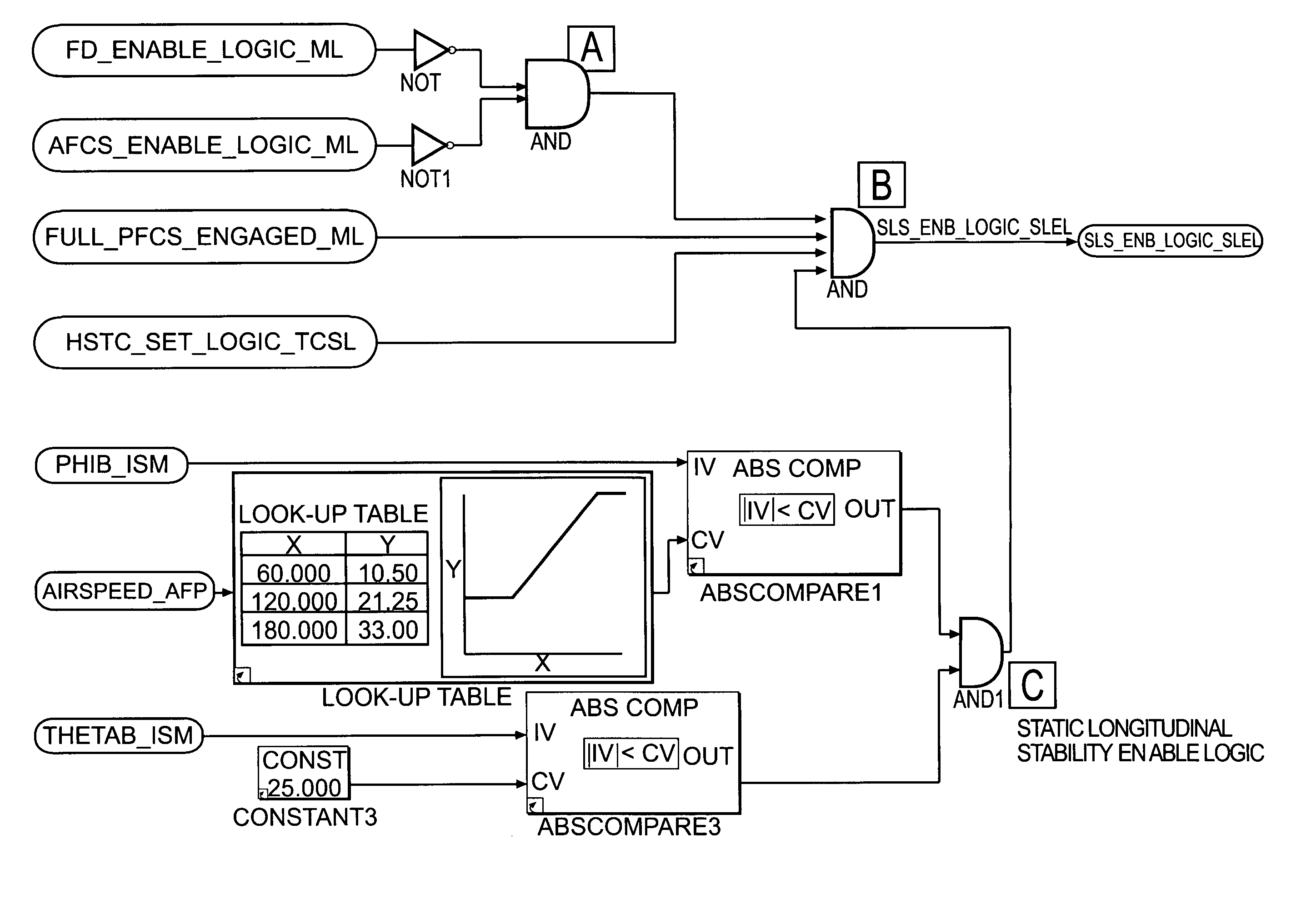

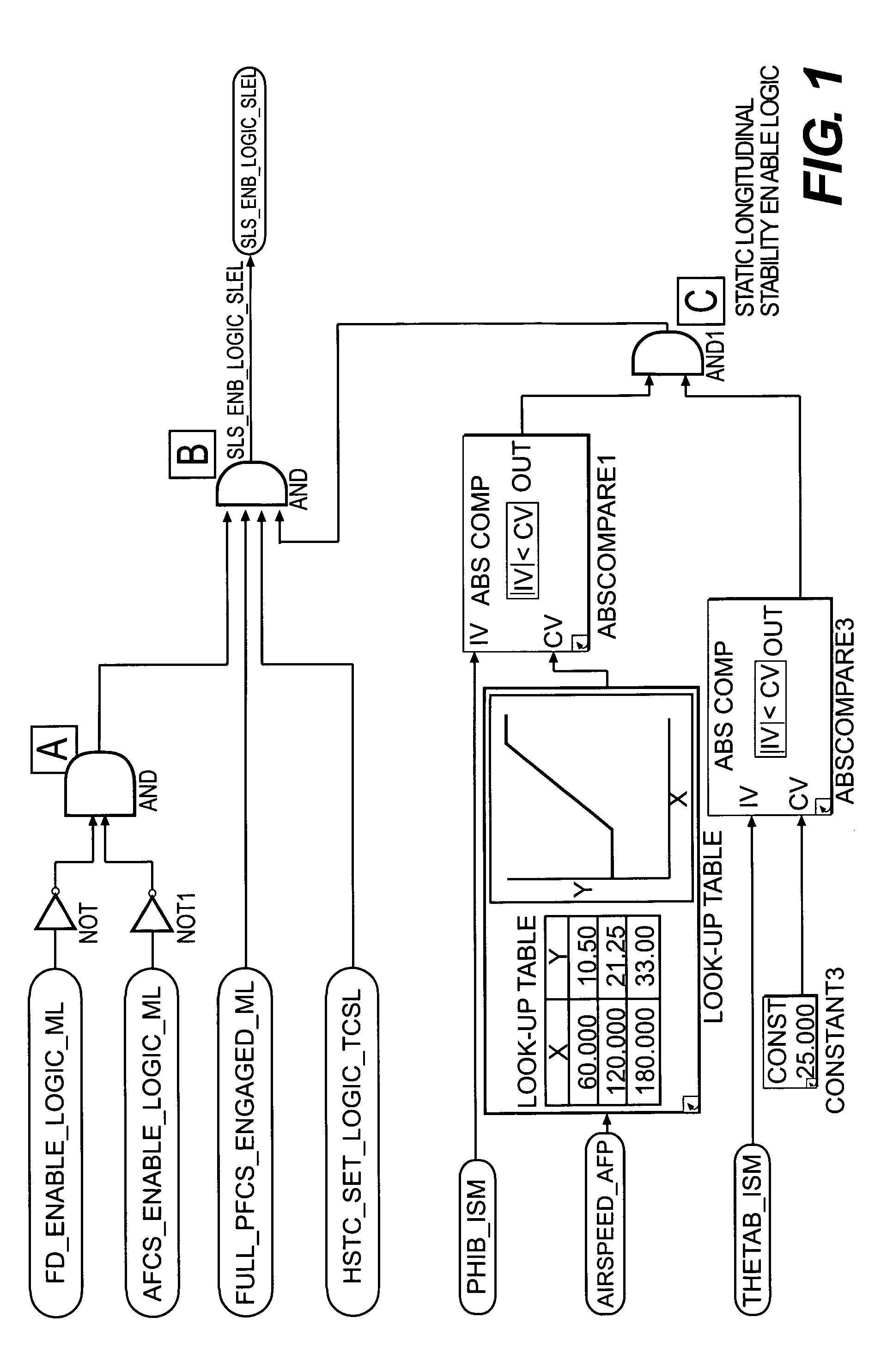

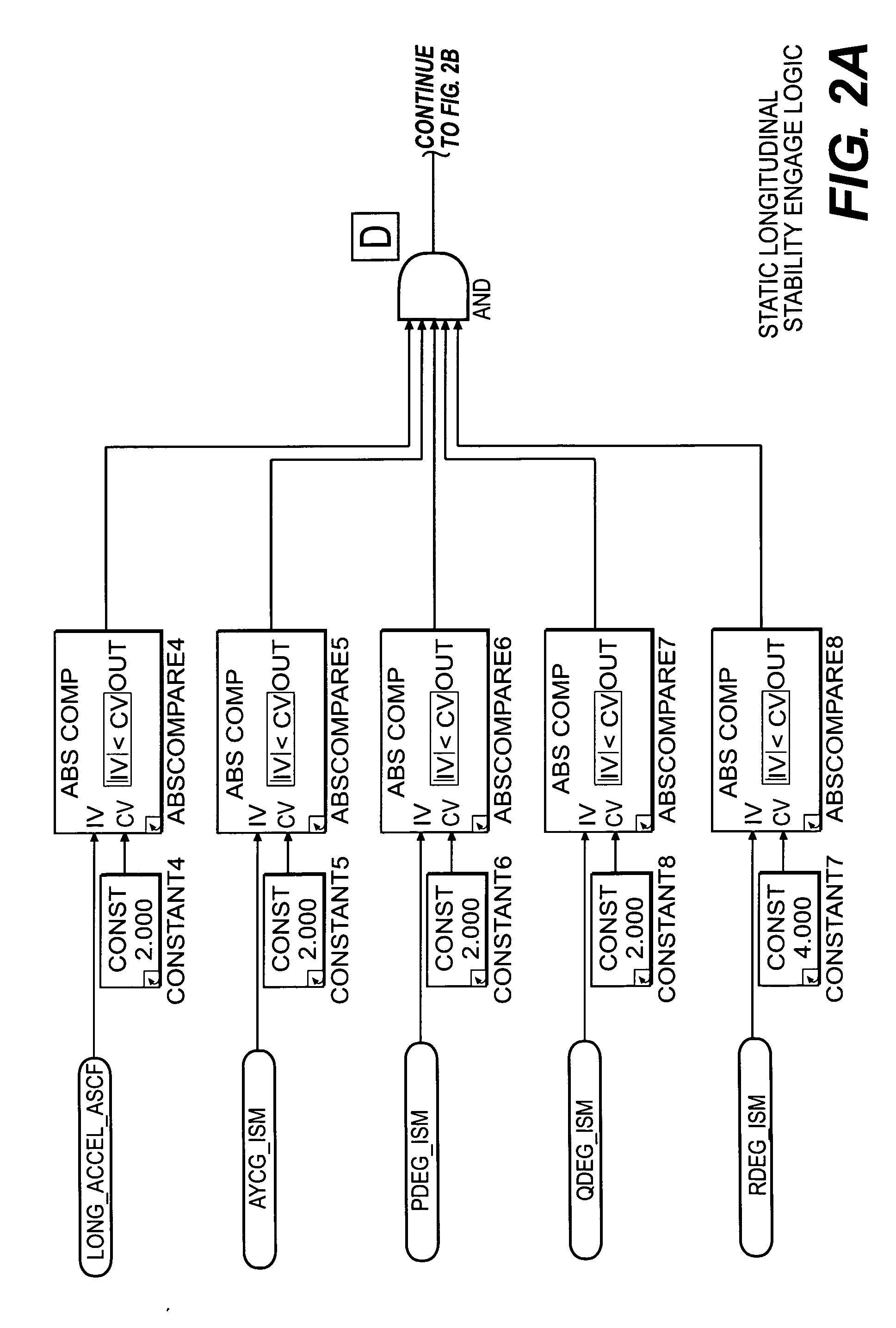

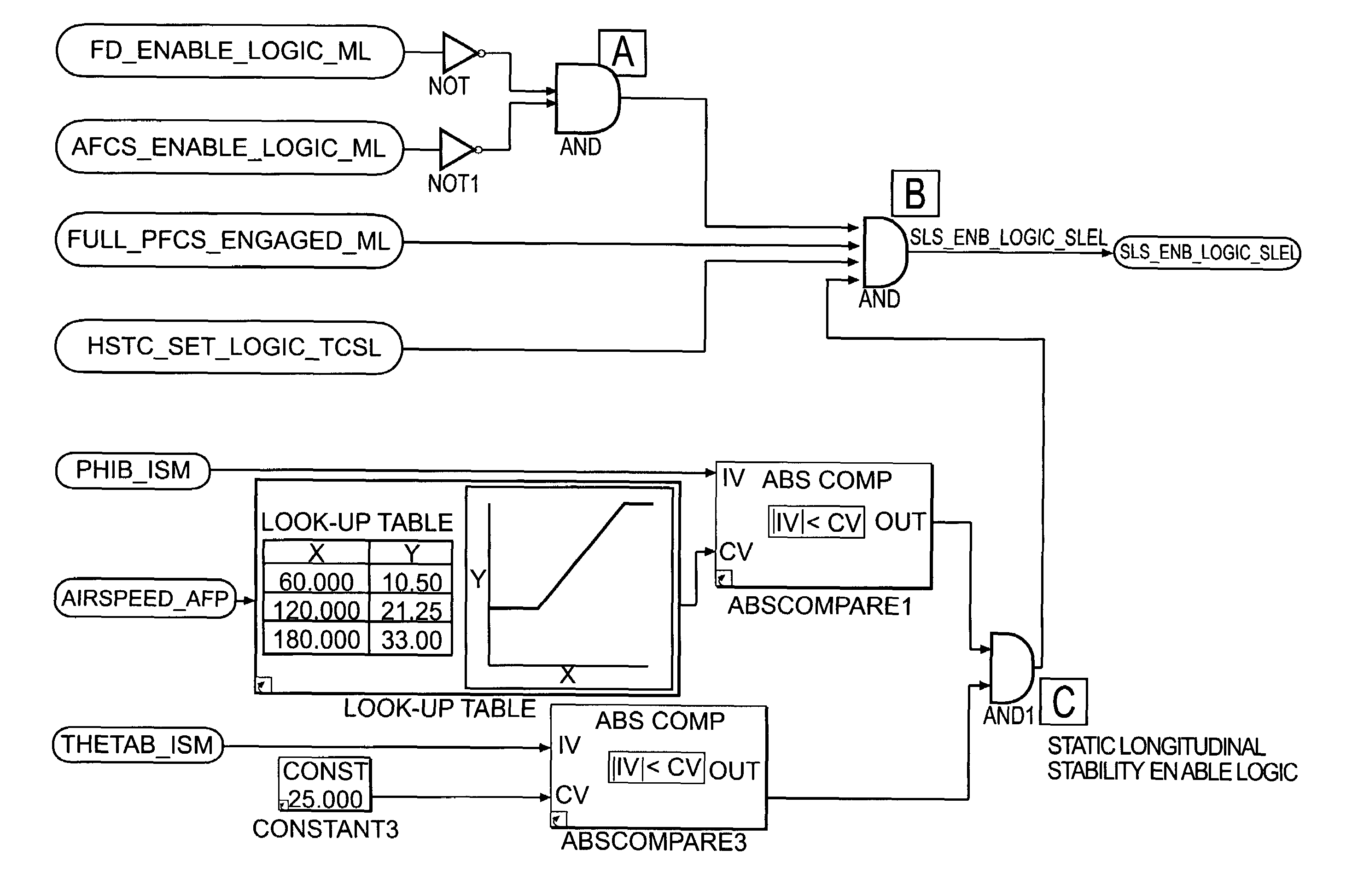

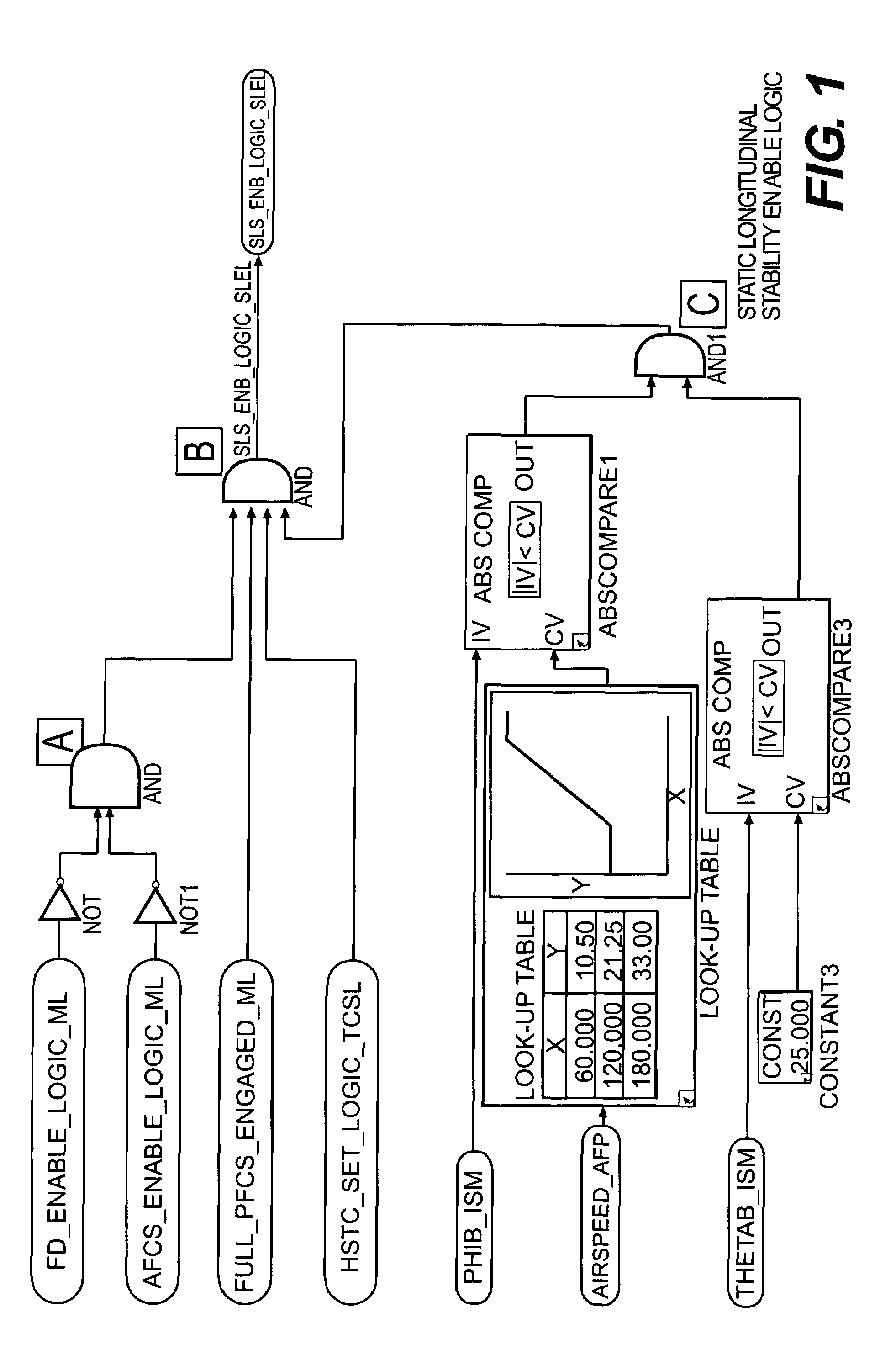

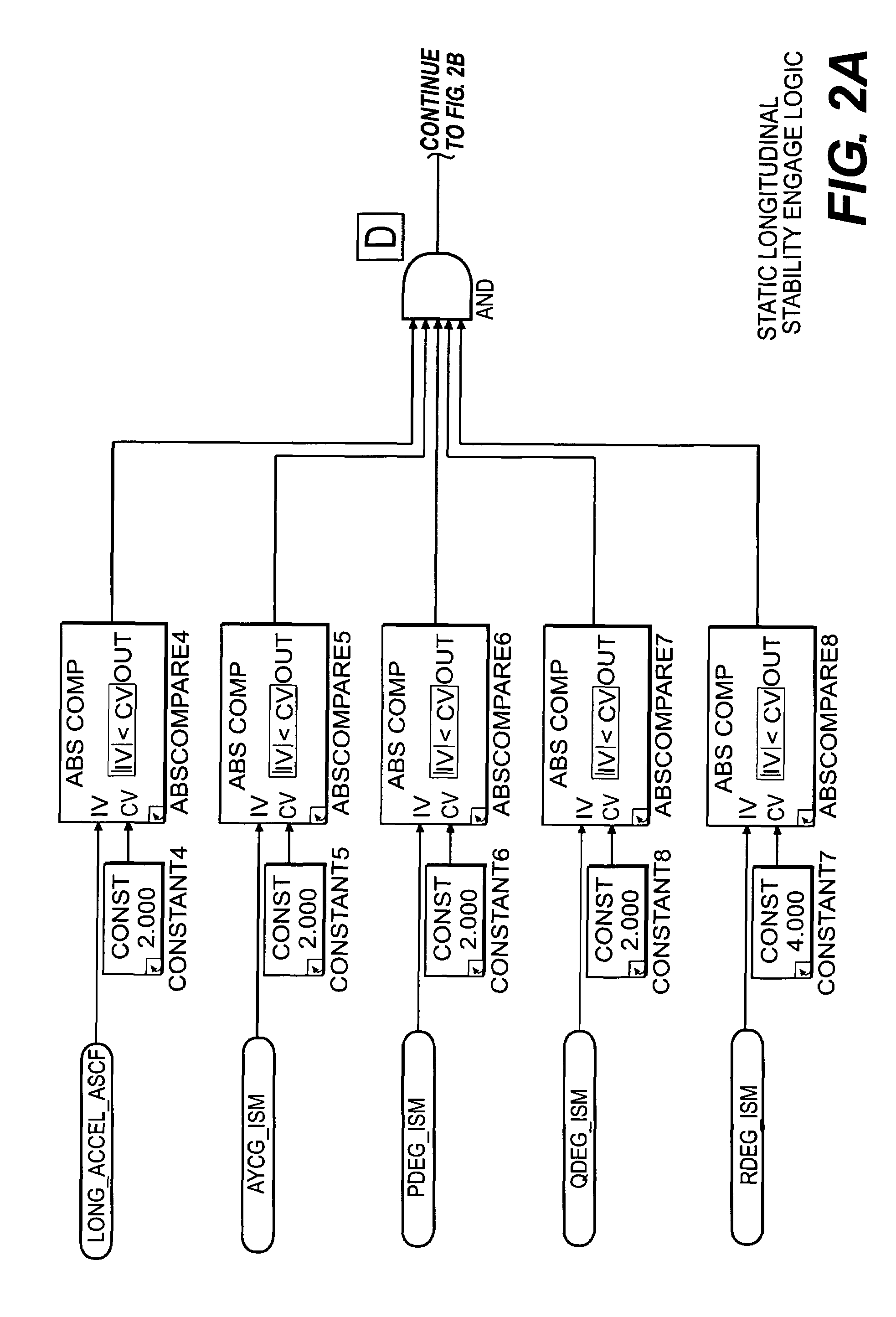

Fly by wire static longitudinal stability compensator system

InactiveUS20060253230A1Smooth disengagementDigital data processing detailsNavigation instrumentsFly-by-wireMode selection

A static longitudinal stability (SLS) system provides an unobtrusive airspeed hold function that reacts to the pilot control inputs into the flight control system and the measured states of the aircraft to engage and disengage smoothly without any explicit mode selection by the pilot. The SLS engages airspeed hold when the aircraft is close to trimmed, non-accelerating state. This logic allows the pilot to either fly close to a desired airspeed and let SLS engage, or trim the aircraft in an accelerating / decelerating maneuver and just wait for the SLS to capture a speed when longitudinal acceleration is small. The SLS is not dependant on the pilot specifically selecting this mode, but rather engages and disengages in response to flight control system status and how the aircraft is being maneuvered.

Owner:SIKORSKY AIRCRAFT CORP

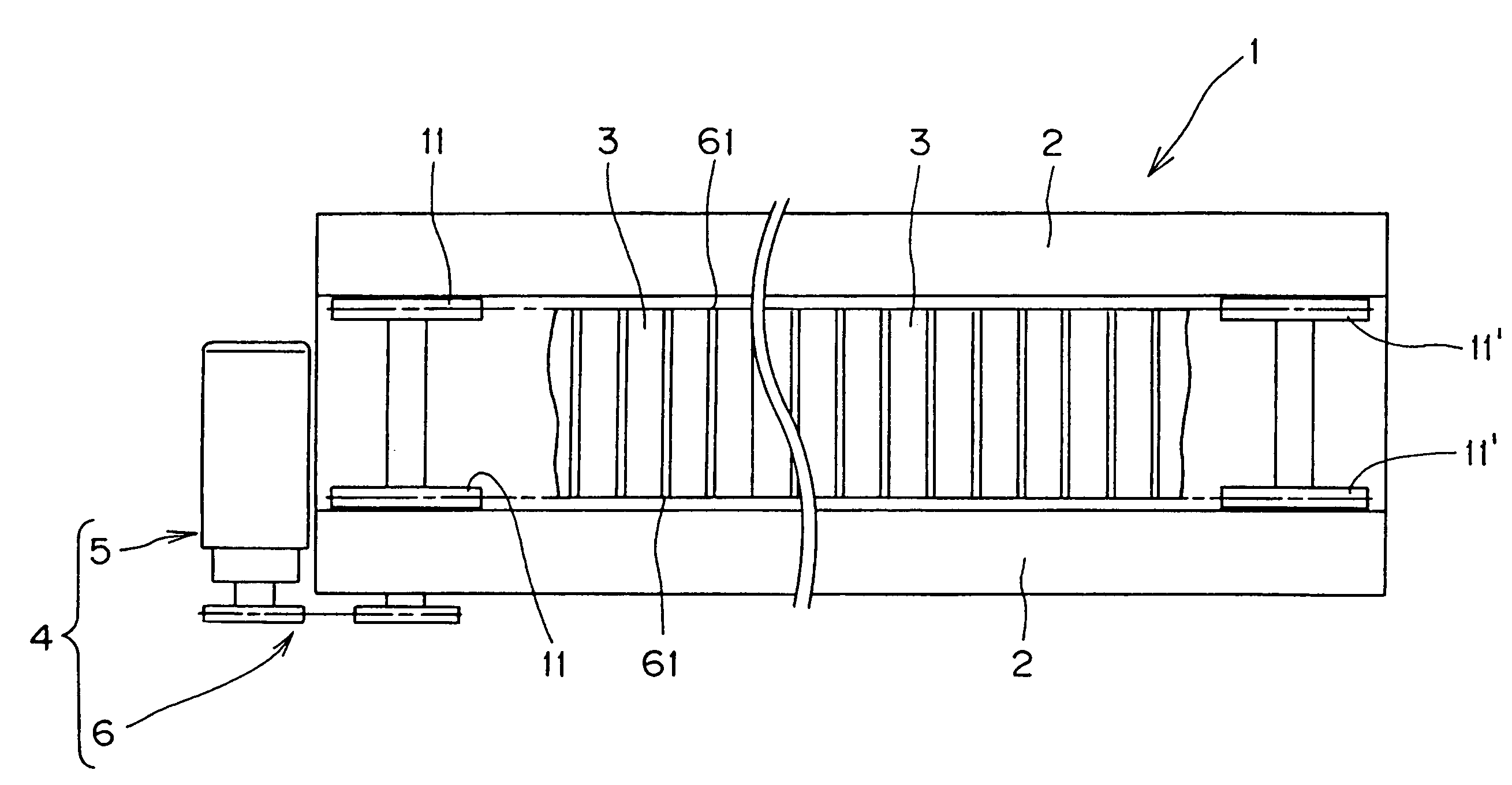

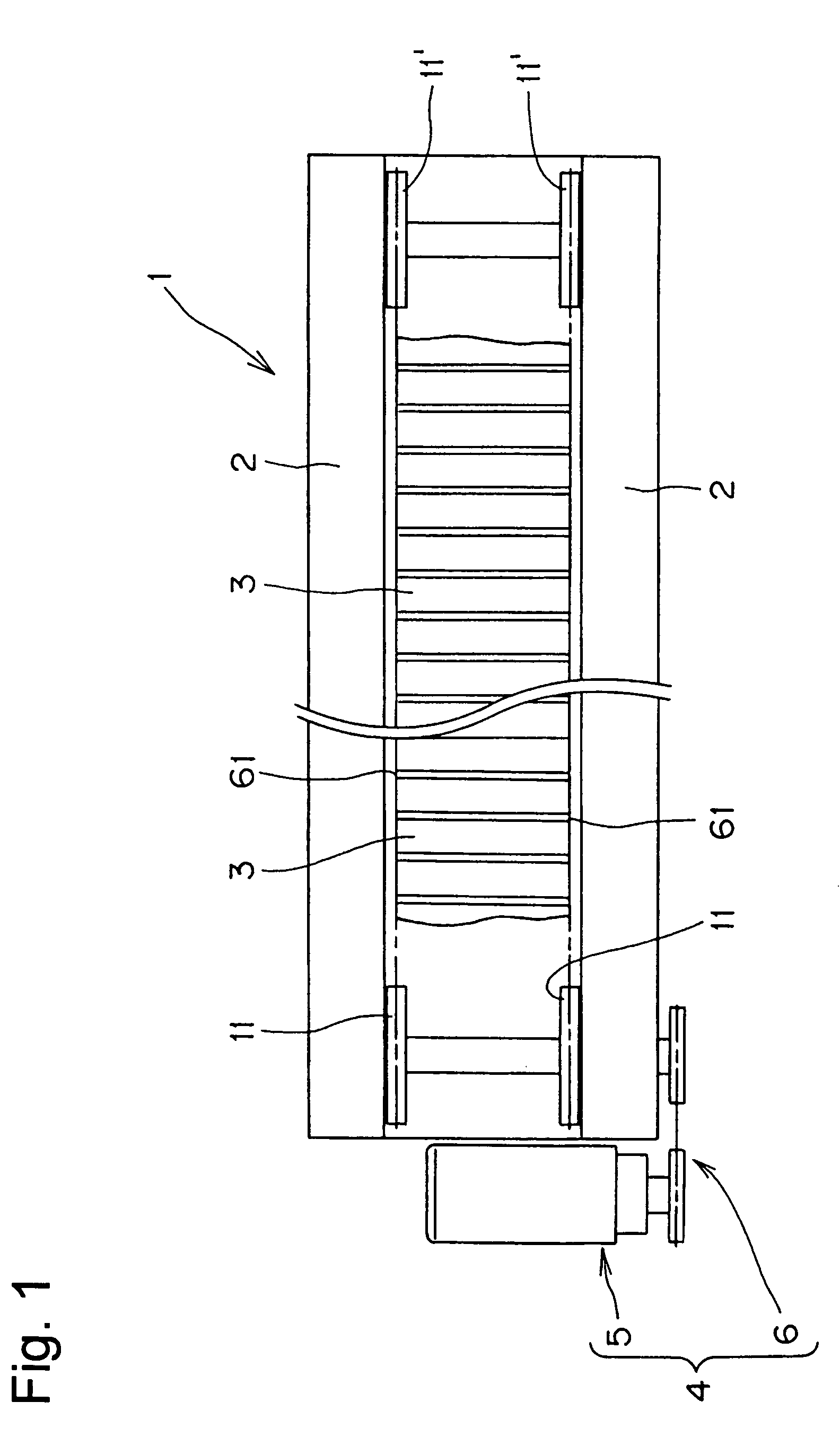

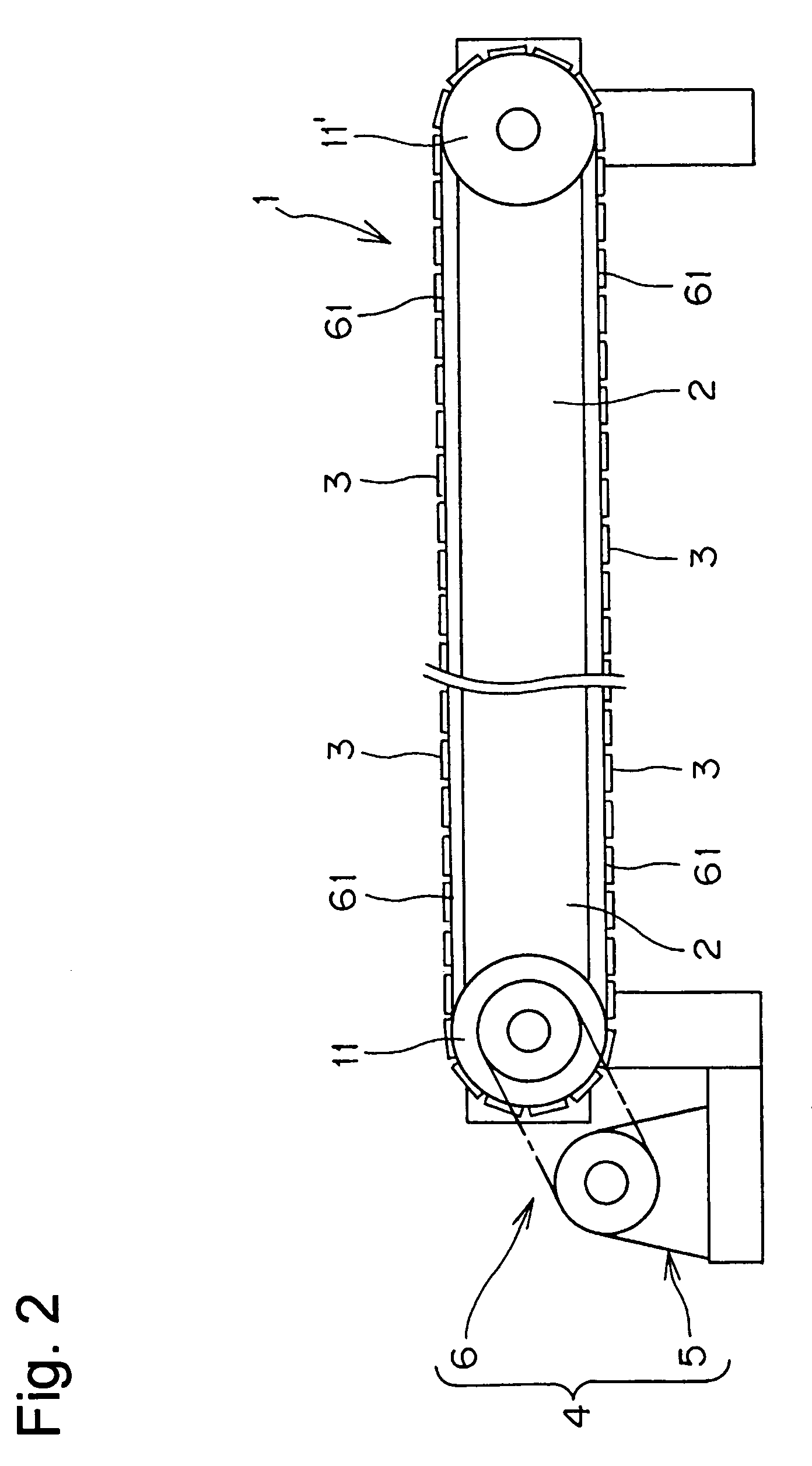

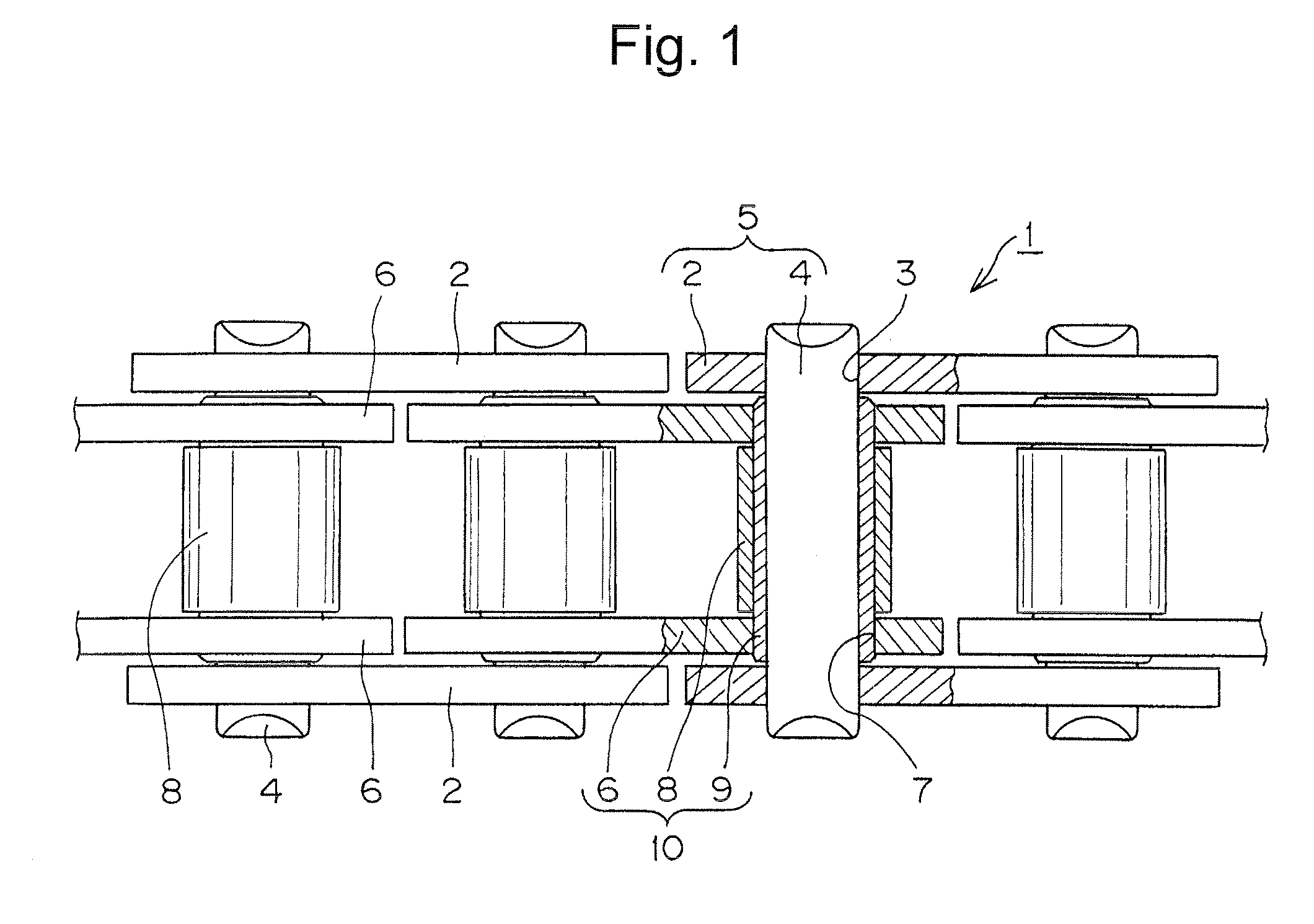

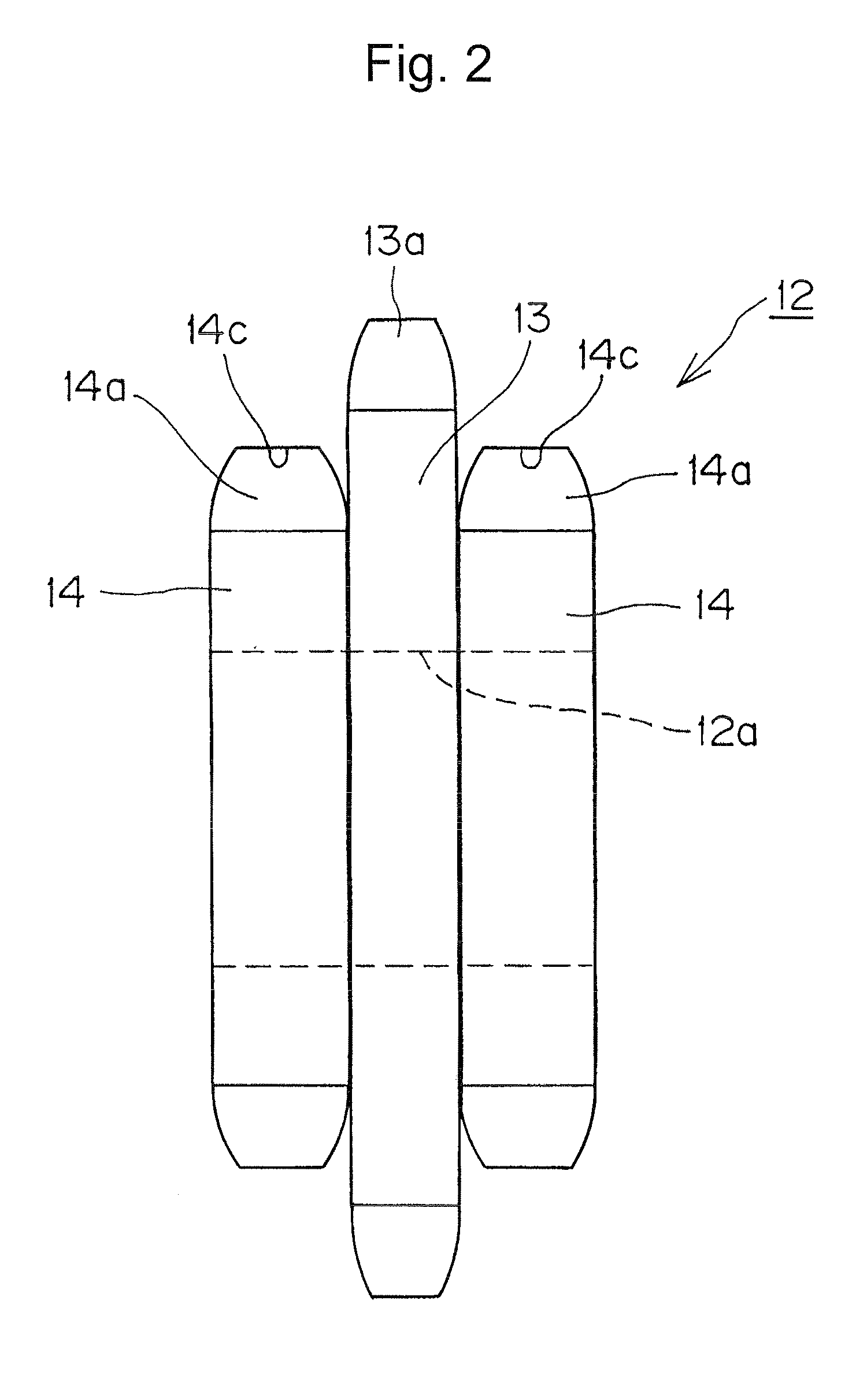

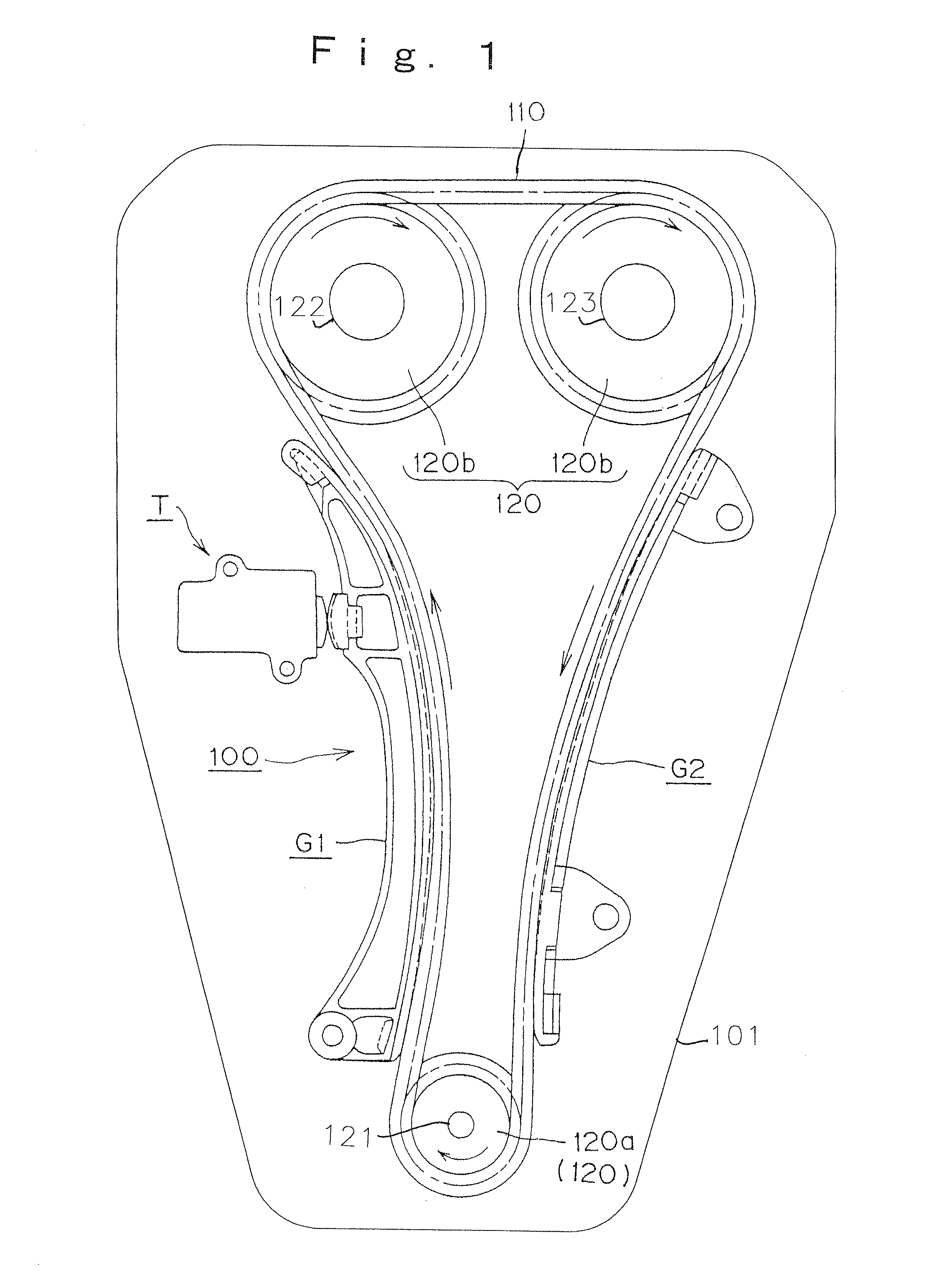

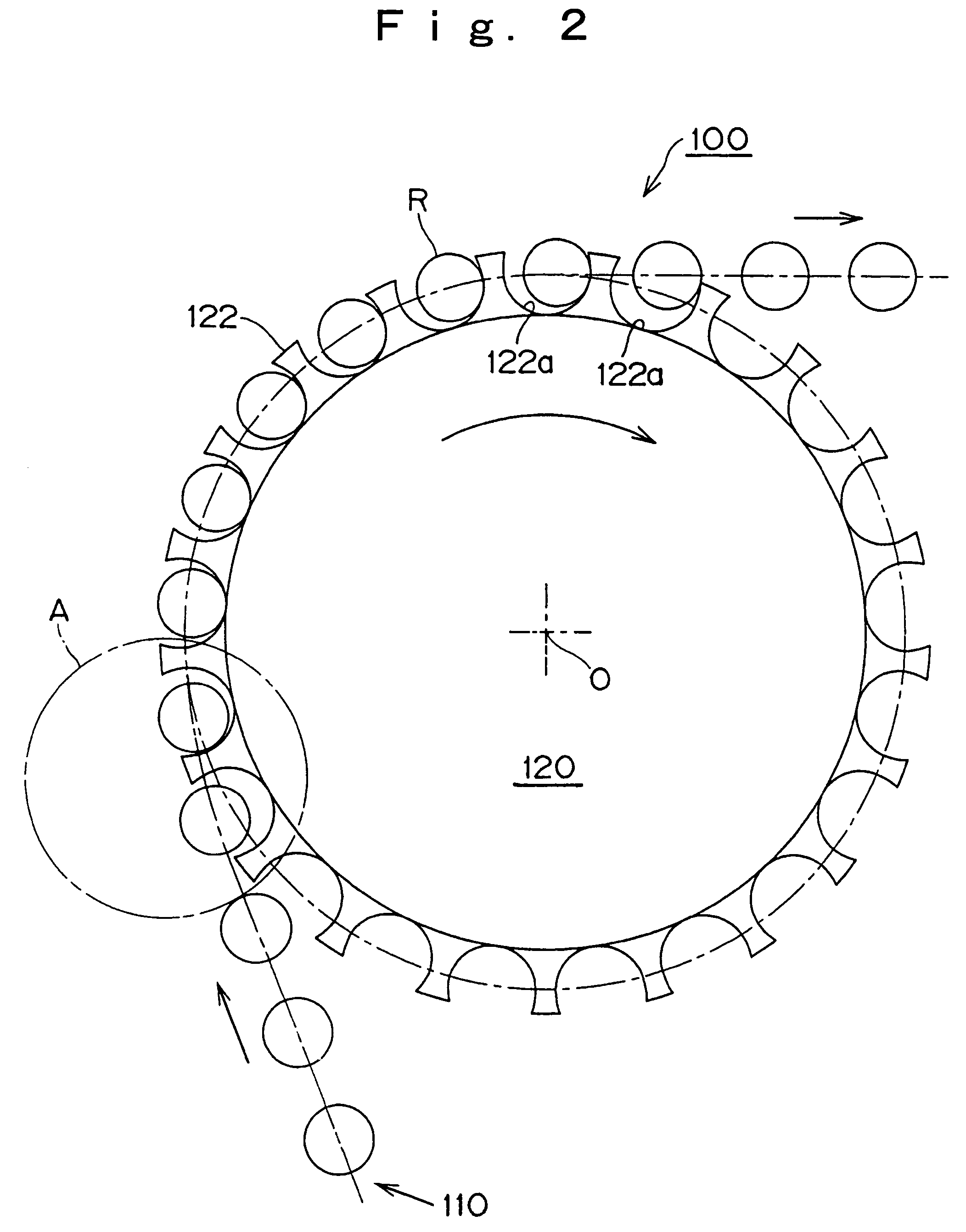

Conveyance system

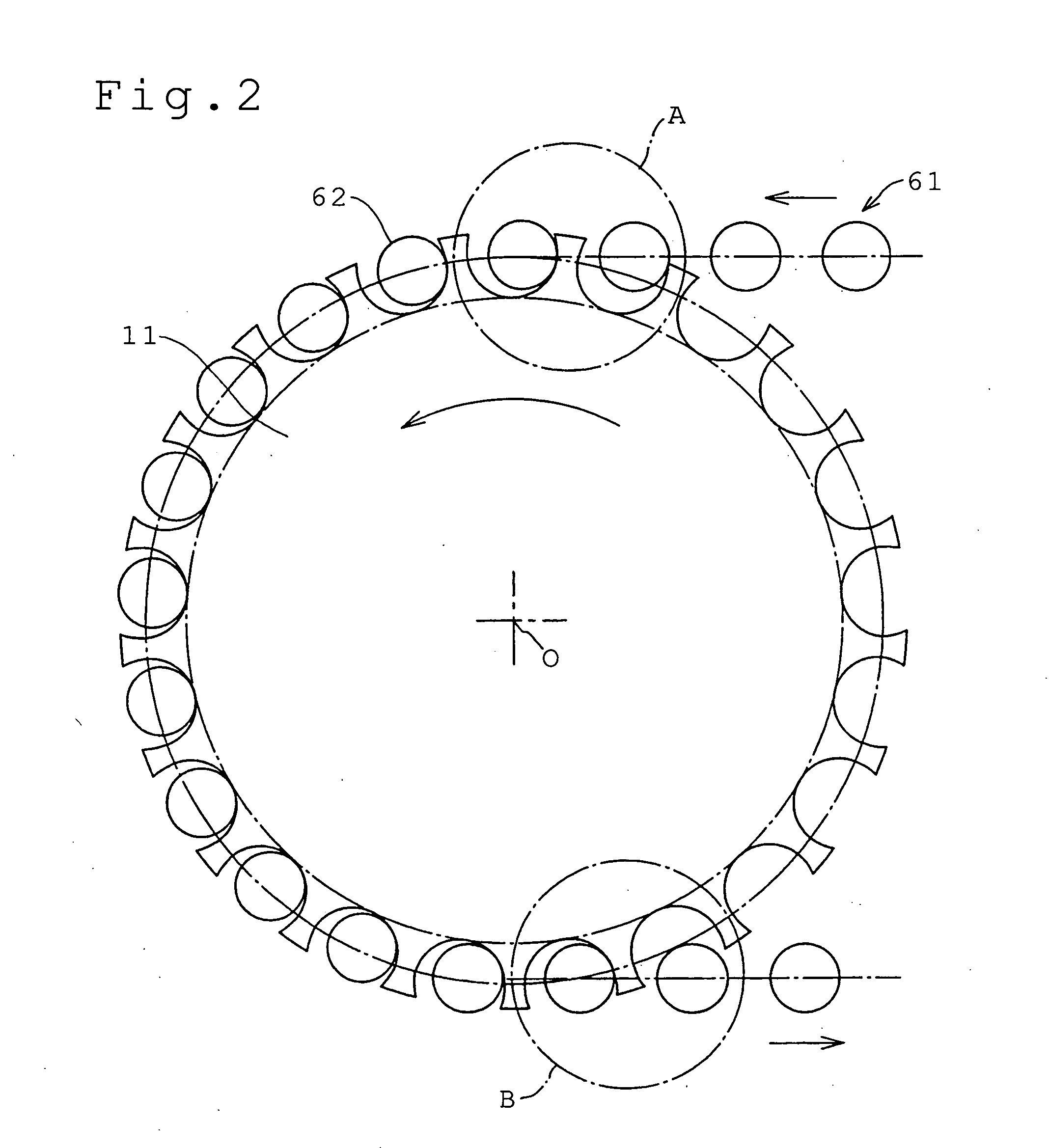

InactiveUS7442139B2Efficient executionReduce vertical movementConveyorsV-beltsRoller chainEngineering

In a slat conveyor, slats for supporting conveyed articles and personnel extend between two side-by-side, spaced, endless roller chains engaged with driving sprockets at one end of the conveying path and driven sprockets at the other end. At a location radially outward from the pitch circle, the distance between the front surface of the sprocket teeth to the tooth center line is at least as great as the distance from the centerline to the front surface at the pitch circle. The tooth faces merge smoothly with the tooth gap bottom, and the root diameter is smaller than the root diameter according to ISO standards.

Owner:TSUBAKIMOTO CHAIN CO

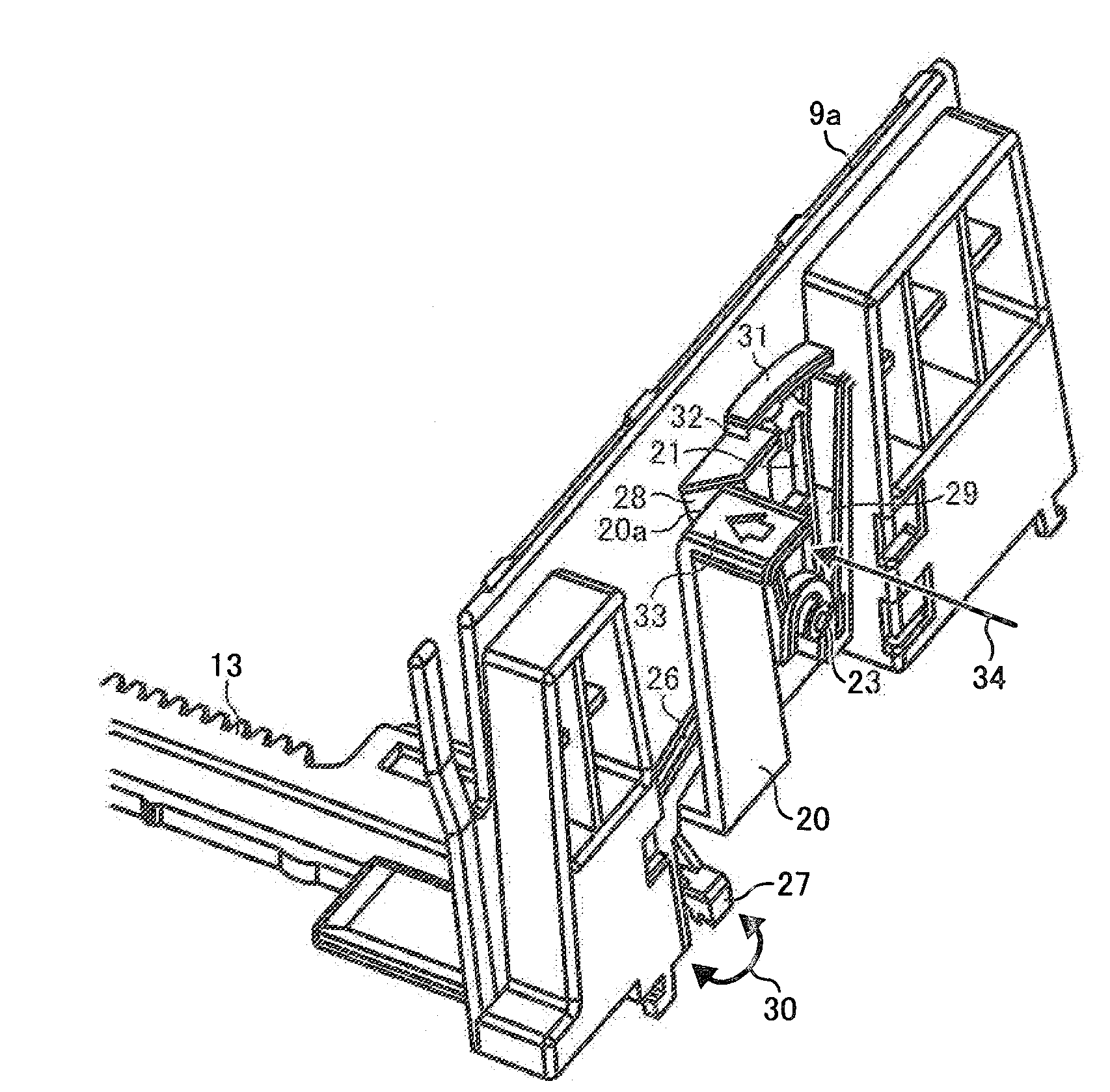

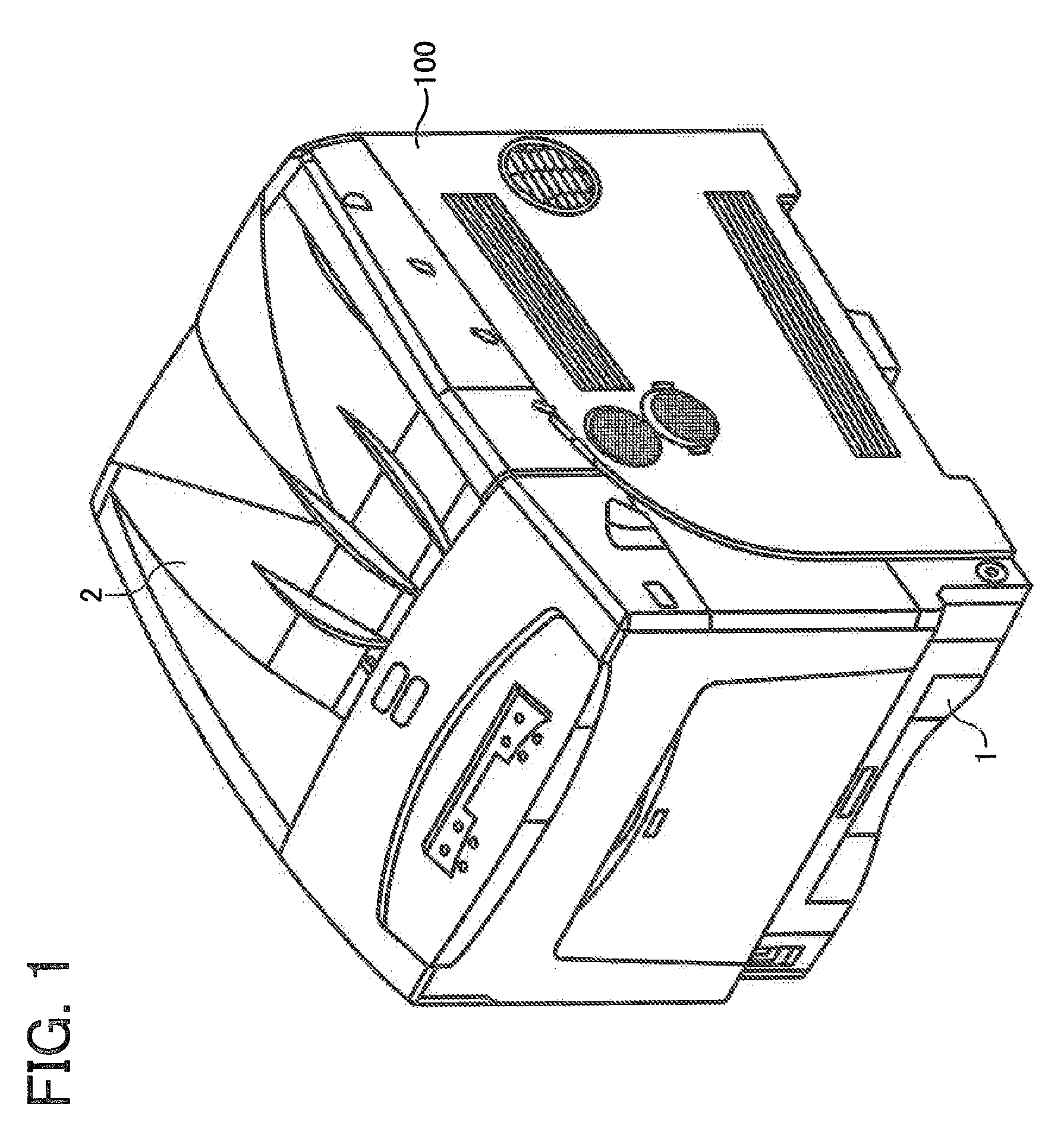

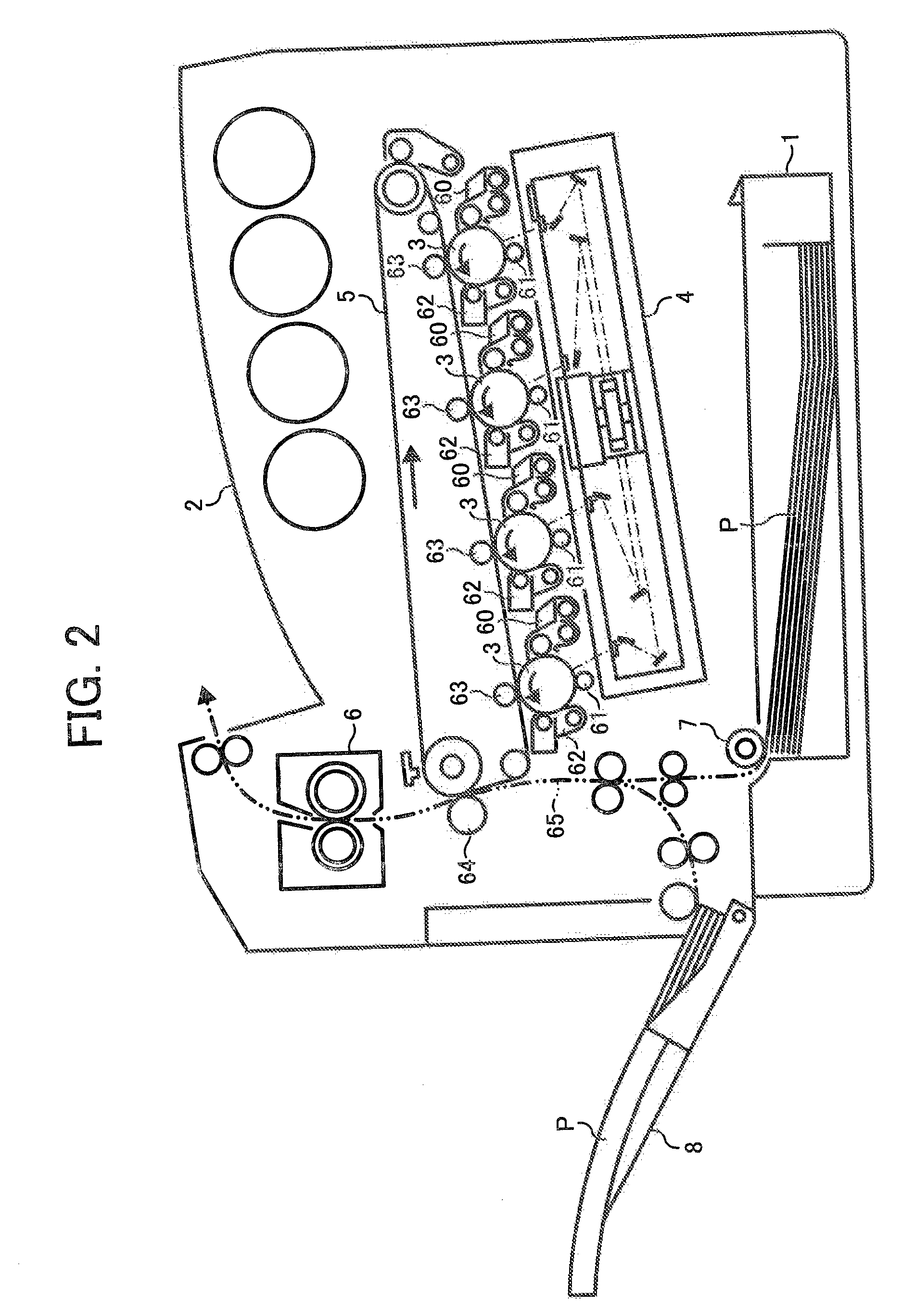

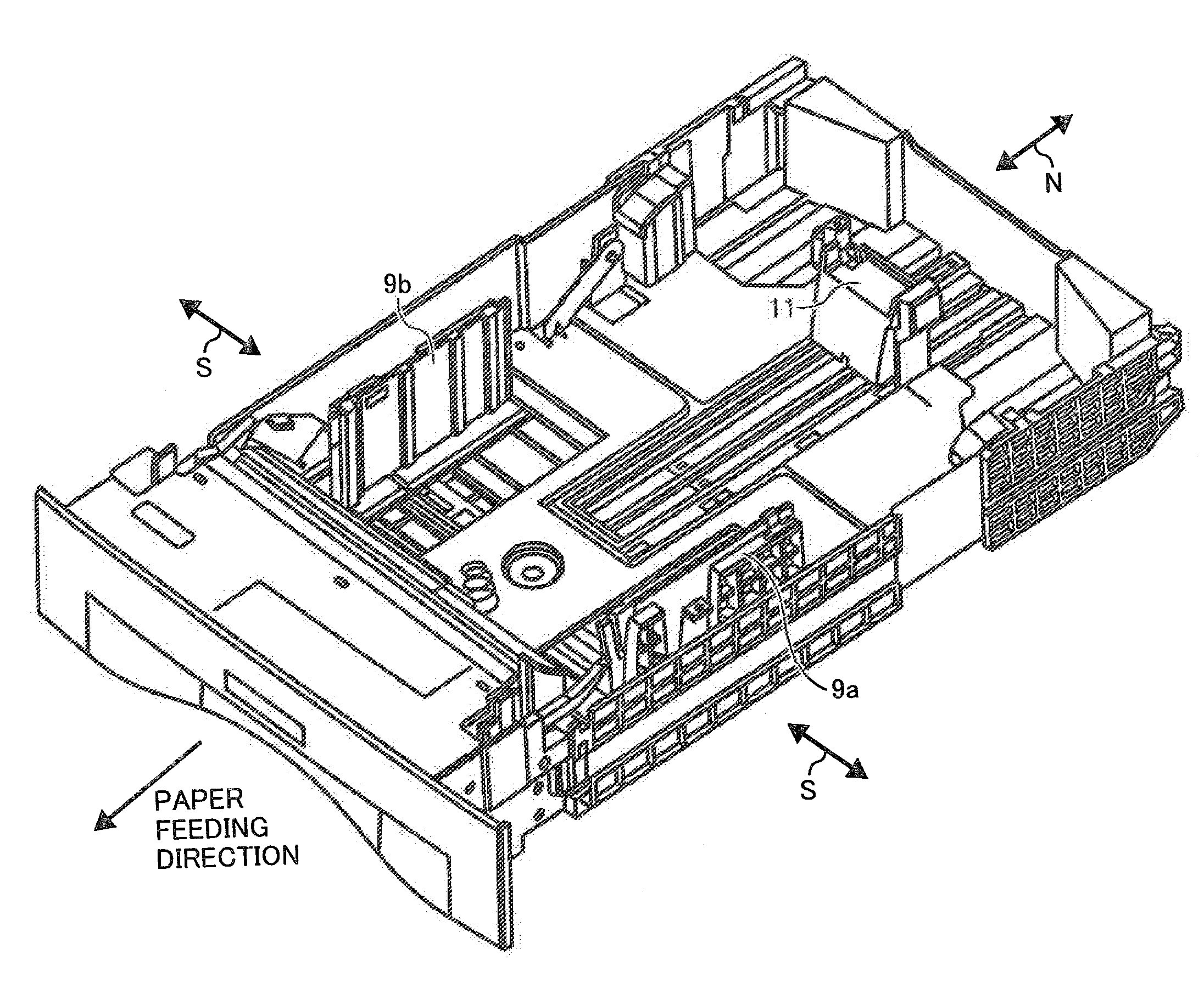

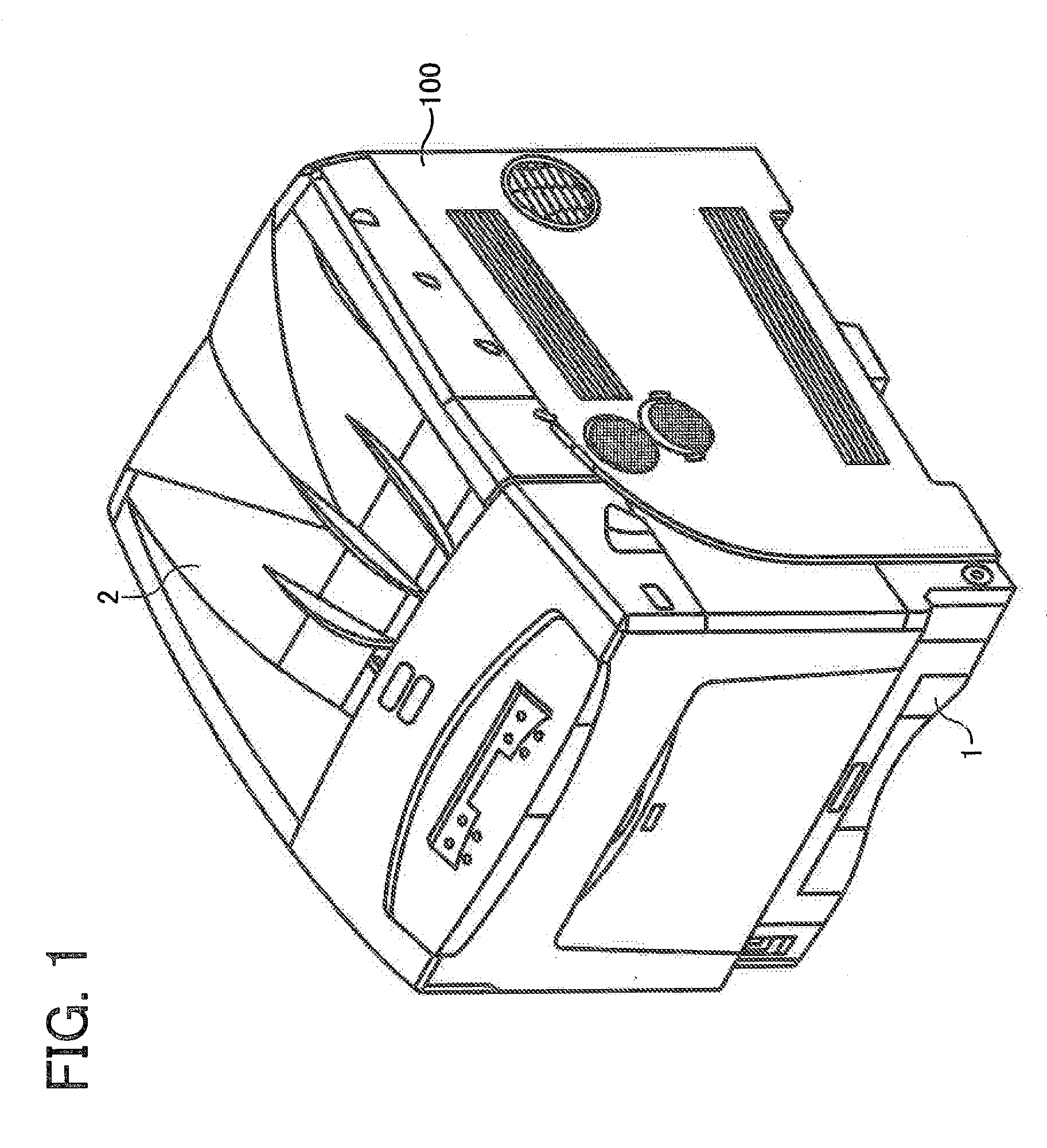

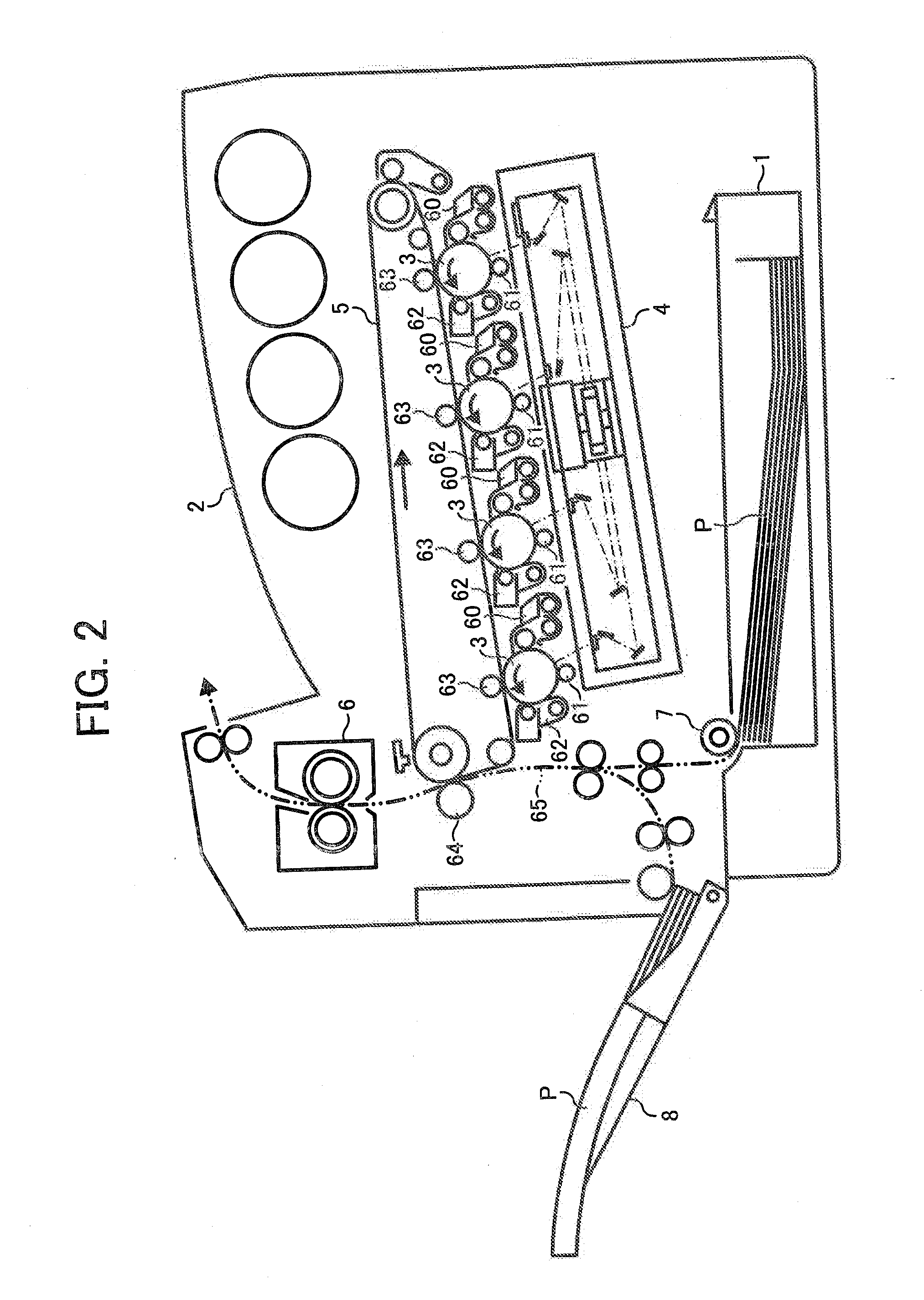

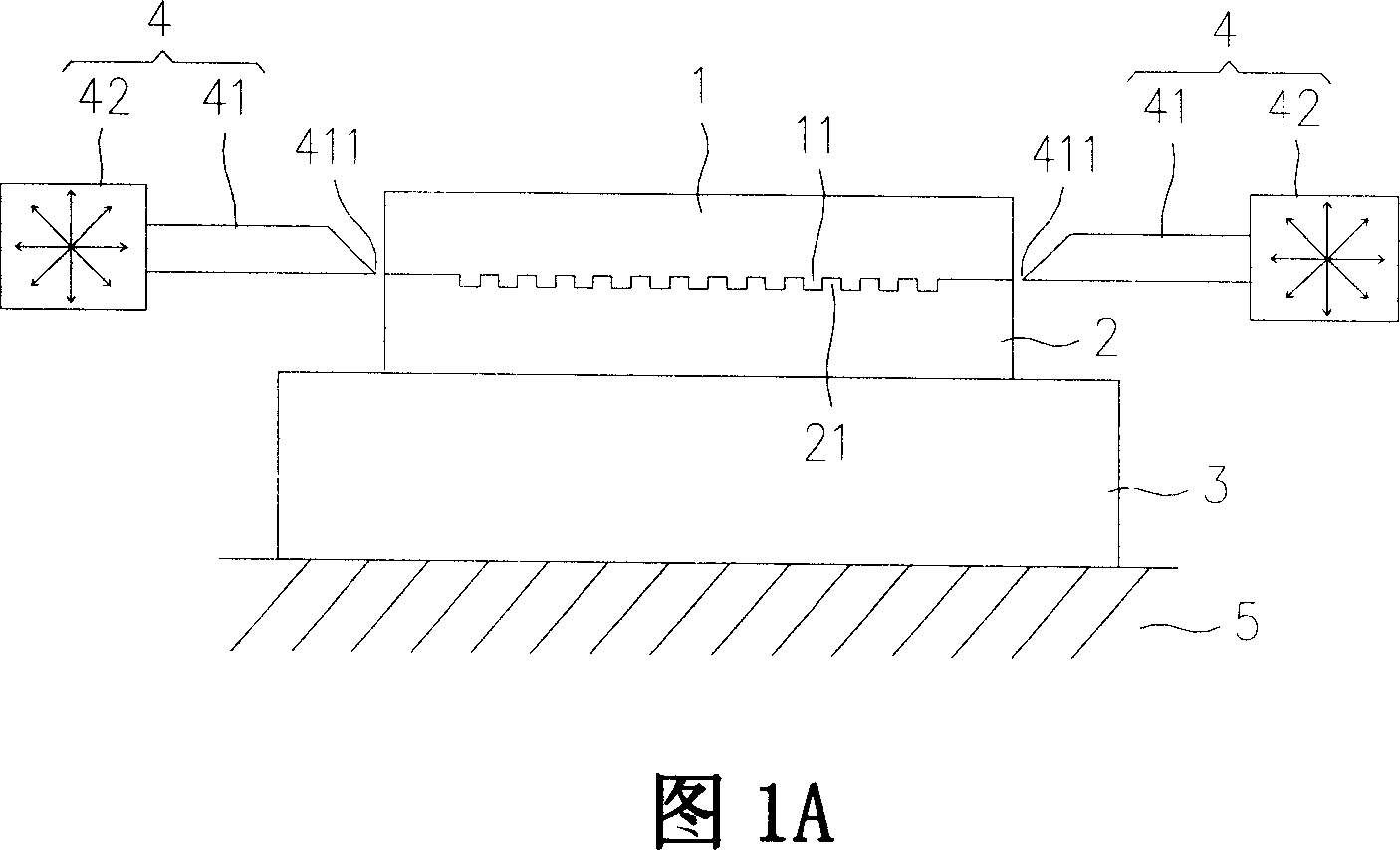

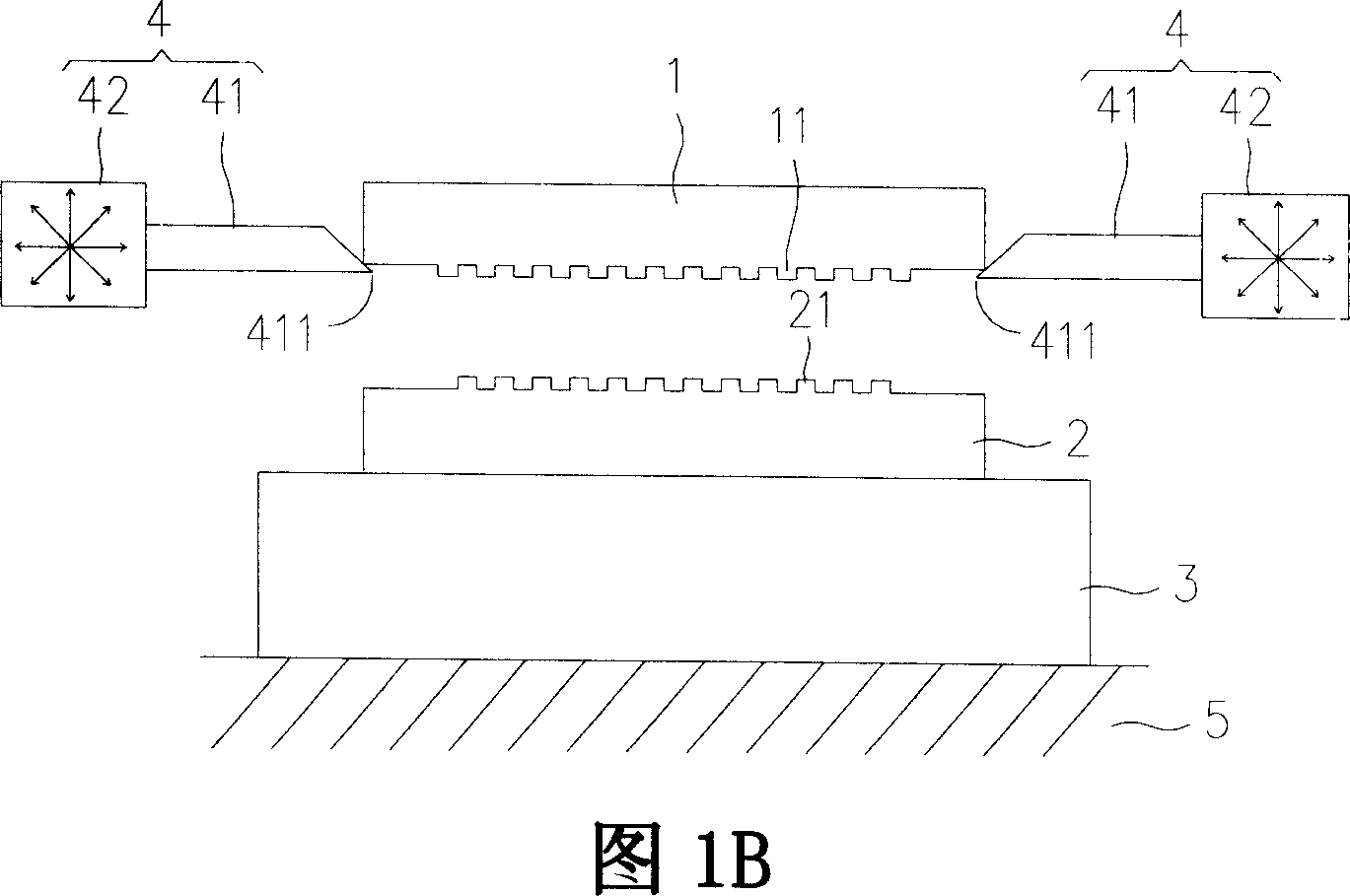

Sheet feeding cassette and image forming apparatus

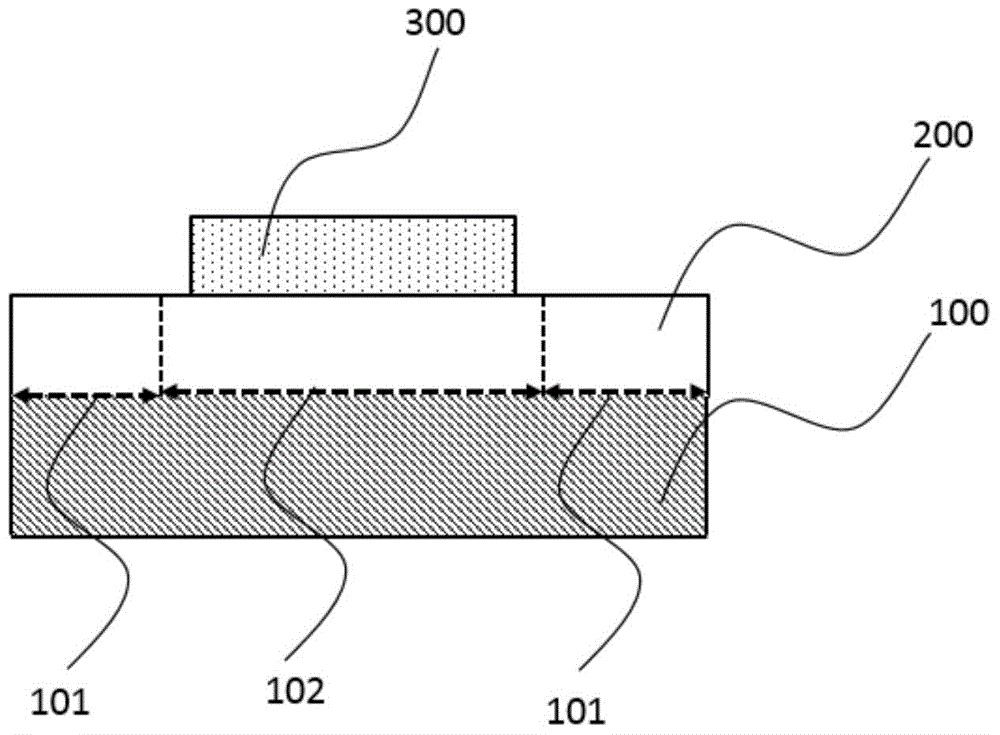

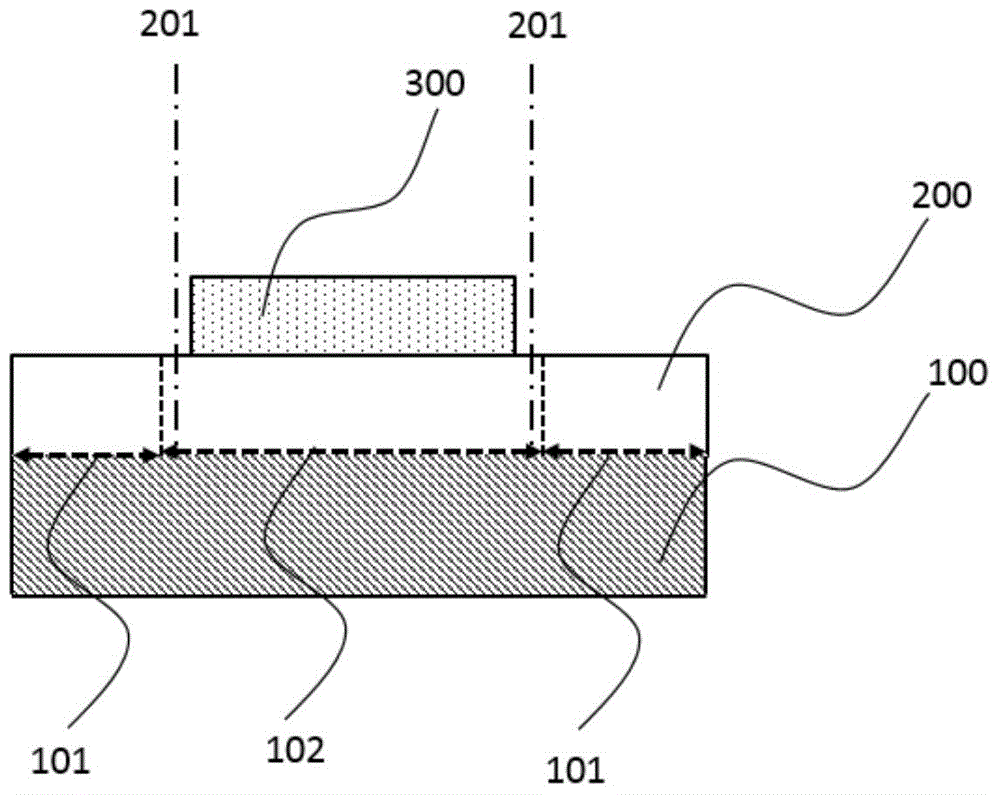

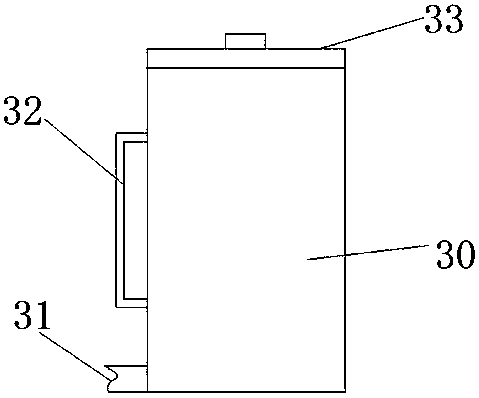

ActiveUS7694958B2Guaranteed uptimeLess forceElectrographic process apparatusArticle separationEngineeringPerpendicular direction

A sheet feeding cassette, including a main body of the sheet feeding cassette accommodating sheets having a trench; a fence movably attached to the main body configured to define a setting position of the sheets; a fixing portion included in the fence that includes a tooth portion engaging with the trench and turns to substantially perpendicular direction of the moving direction of the fence; a lever portion included in the fence that is possible to move corresponding to the moving direction of the fence and the lever portion configured to rotate the fixing portion by moving of the lever portion.

Owner:RICOH KK

Sheet Feeding Cassette and Image Forming Apparatus

ActiveUS20070189822A1Improve aspectReduce in quantityElectrographic process apparatusArticle separationPerpendicular directionVia fence

A sheet feeding cassette, including a main body of the sheet feeding cassette accommodating sheets having a trench; a fence movably attached to the main body configured to define a setting position of the sheets; a fixing portion included in the fence that includes a tooth portion engaging with the trench and turns to substantially perpendicular direction of the moving direction of the fence; a lever portion included in the fence that is possible to move corresponding to the moving direction of the fence and the lever portion configured to rotate the fixing portion by moving of the lever portion.

Owner:RICOH KK

Friction plate and wet-type multi-plate clutch

InactiveUS7789209B2Improve heat resistanceReduce participationFluid actuated clutchesFriction clutchesEngineeringClutch

The present invention provides a friction plate having a friction surface formed by adhering a friction material to a substantially annular core plate and wherein the friction surface is provided with an oil passage communicated with inner and outer peripheral edges of the friction plate, a first oil groove having an opening portion opened to the inner peripheral edge of the friction plate and an end portion terminating at a position between the inner and outer peripheral edges, and a second first oil groove having an opening portion opened to the outer peripheral edge of the friction plate and an end portion terminating at a position between the inner and outer peripheral edges.

Owner:NSK WARNER

Medium-length hole mixed wedge cut blasting method capable of realizing directed fracture using cutting cartridge bag for solid rock roadway

InactiveCN103983146AReduce unit consumptionControl disturbance damageBlastingEngineeringUltimate tensile strength

The invention discloses a medium-length hole mixed wedge cut blasting method capable of realizing directed fracture using a cutting cartridge bag for a solid rock roadway. According to the method disclosed by the invention, 3-4 pairs of vertical wedge cutting holes are arranged at lower half places of an excavating working face; the vertical wedge cutting holes comprise mirror-arranged primary cutting holes and secondary cutting holes that are arranged at the two sides of the primary cutting holes; the primary cutting holes comprise three blast holes that are arranged side by side; the secondary cutting holes comprise four blast holes that are arranged side by side; 1-2 straight holes are formed in the middle portion of each primary cutting hole; a distance between every two adjacent blast holes in the primary cutting holes is 800-1000mm. According to the method disclosed by the invention, the advantage of directed fracture blasting of the cutting cartridge bag is fully utilized, so that an orifice distance and a row distance of the primary cutting holes are increased, the number of blasting holes is reduced, explosive unit consumption is decreased, disturbance damage to the roadway surrounding rocks by cut blasting is effectively controlled, the original strength and stability of the roadway surrounding rocks are guaranteed, and favourable conditions are provided for repairing and maintenance works during later roadway support and operation progresses.

Owner:HENAN POLYTECHNIC UNIV

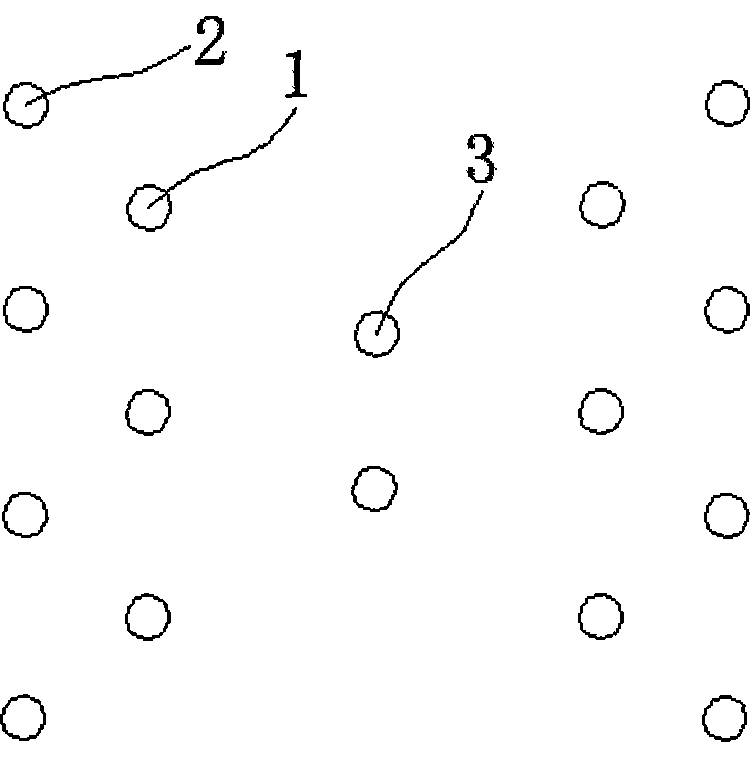

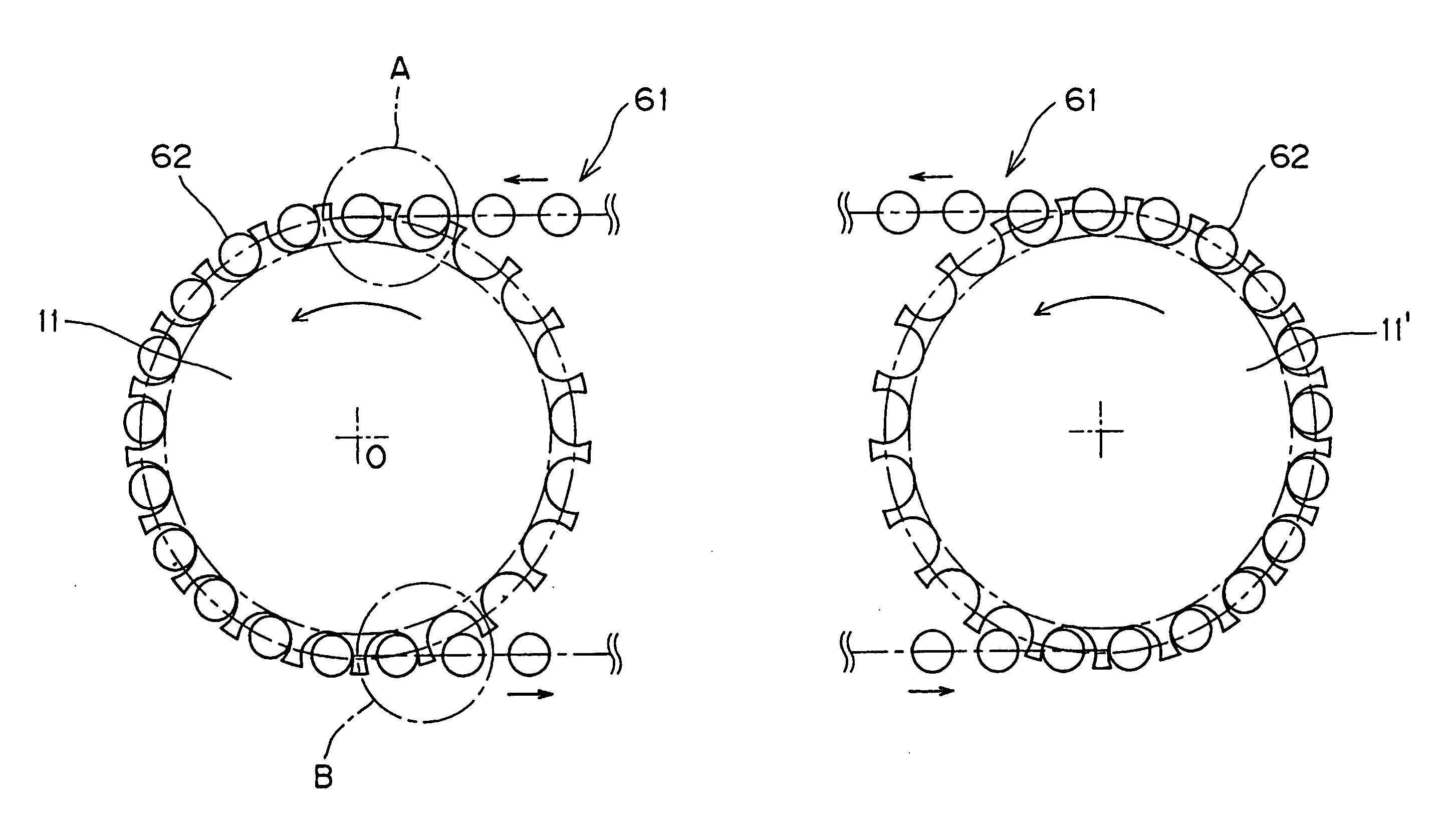

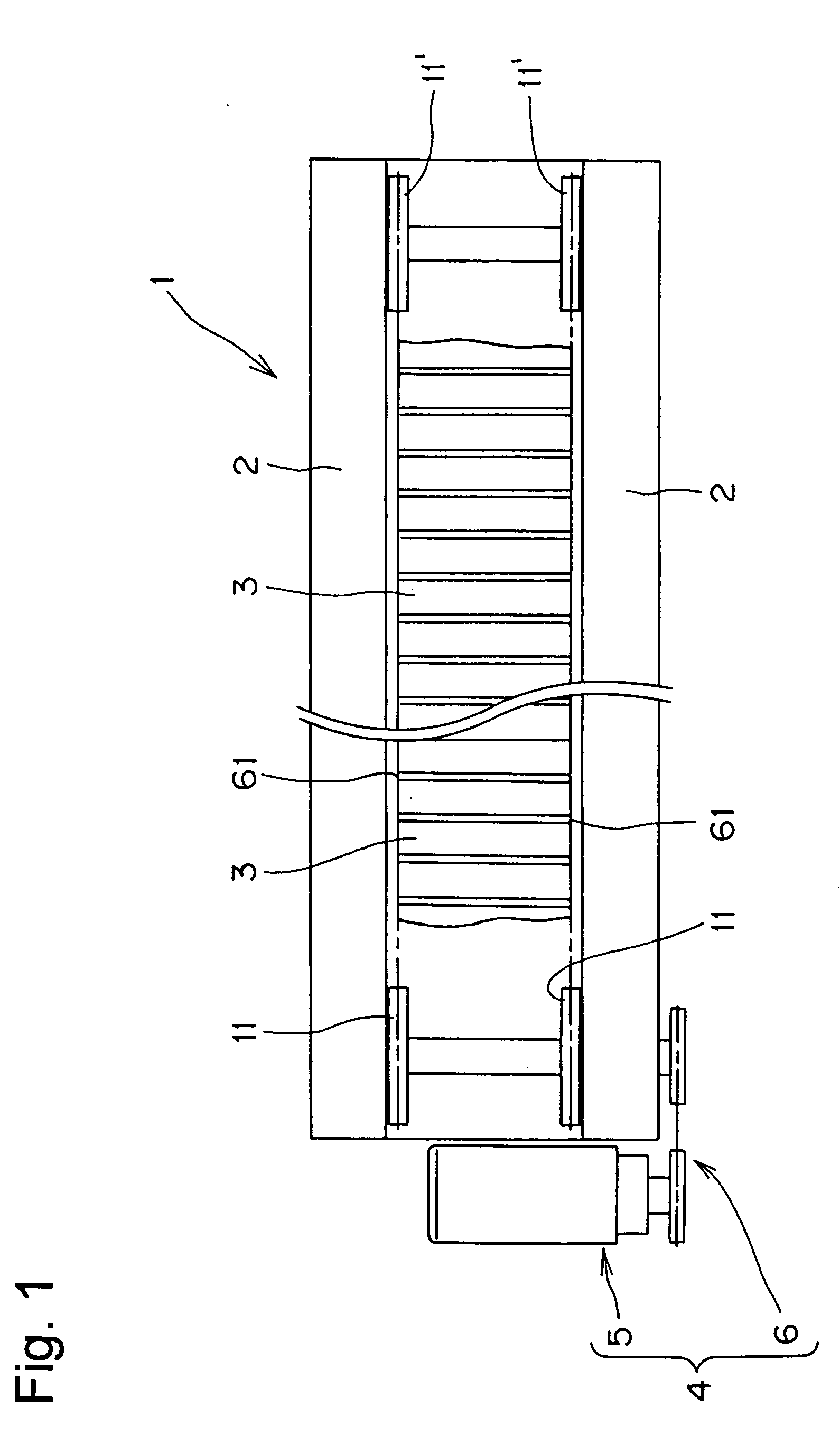

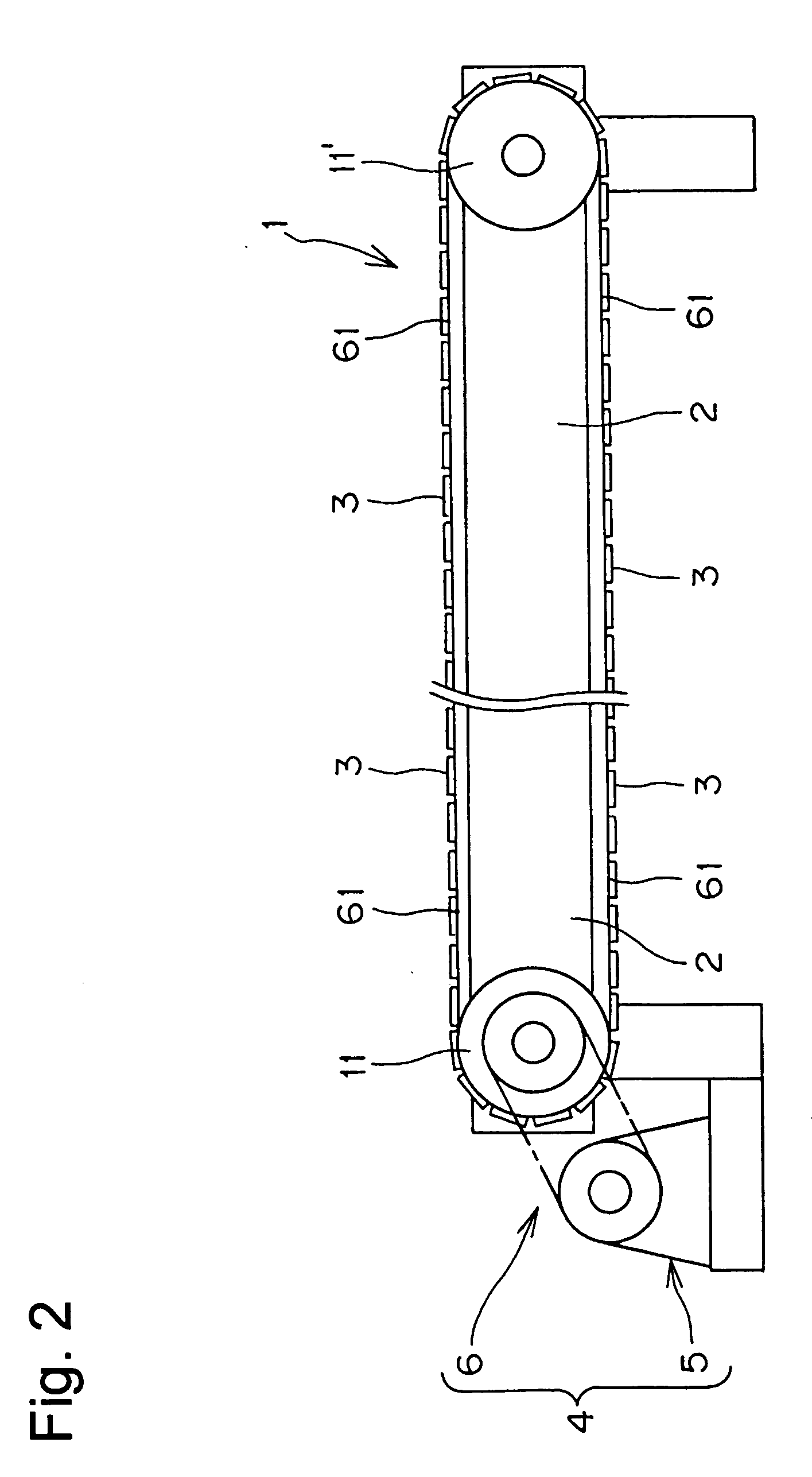

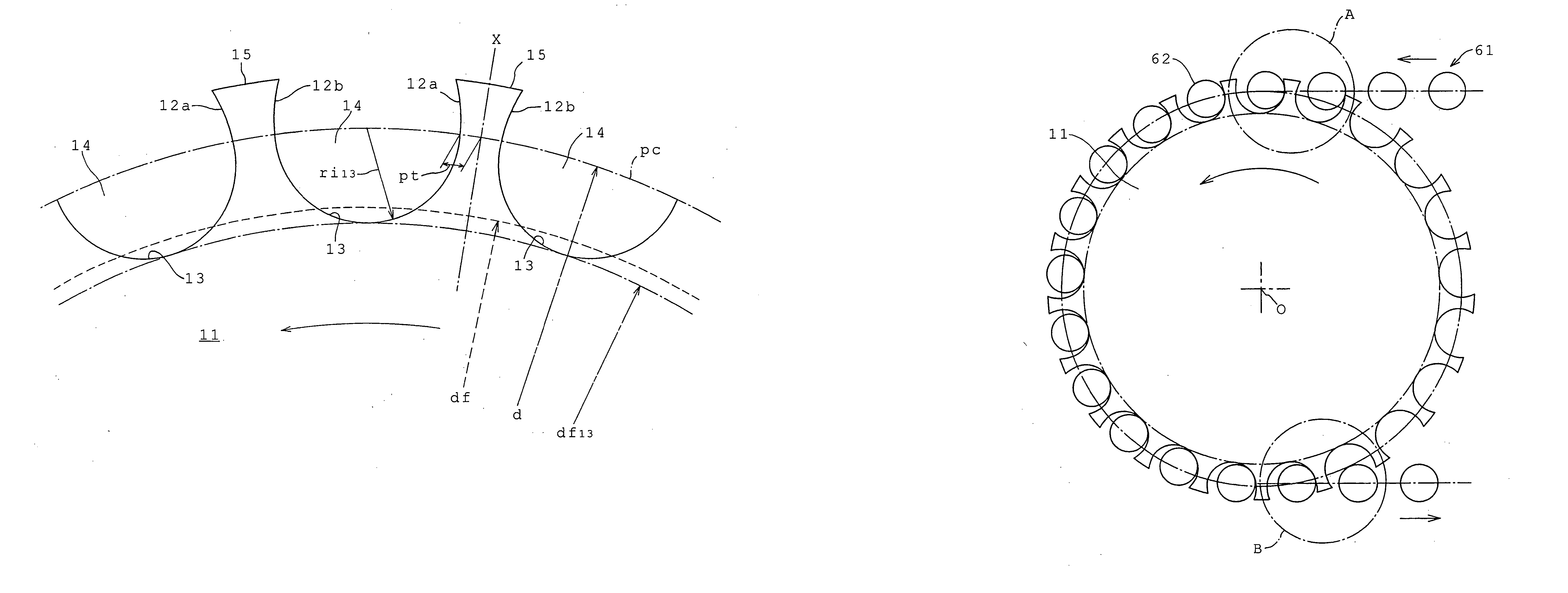

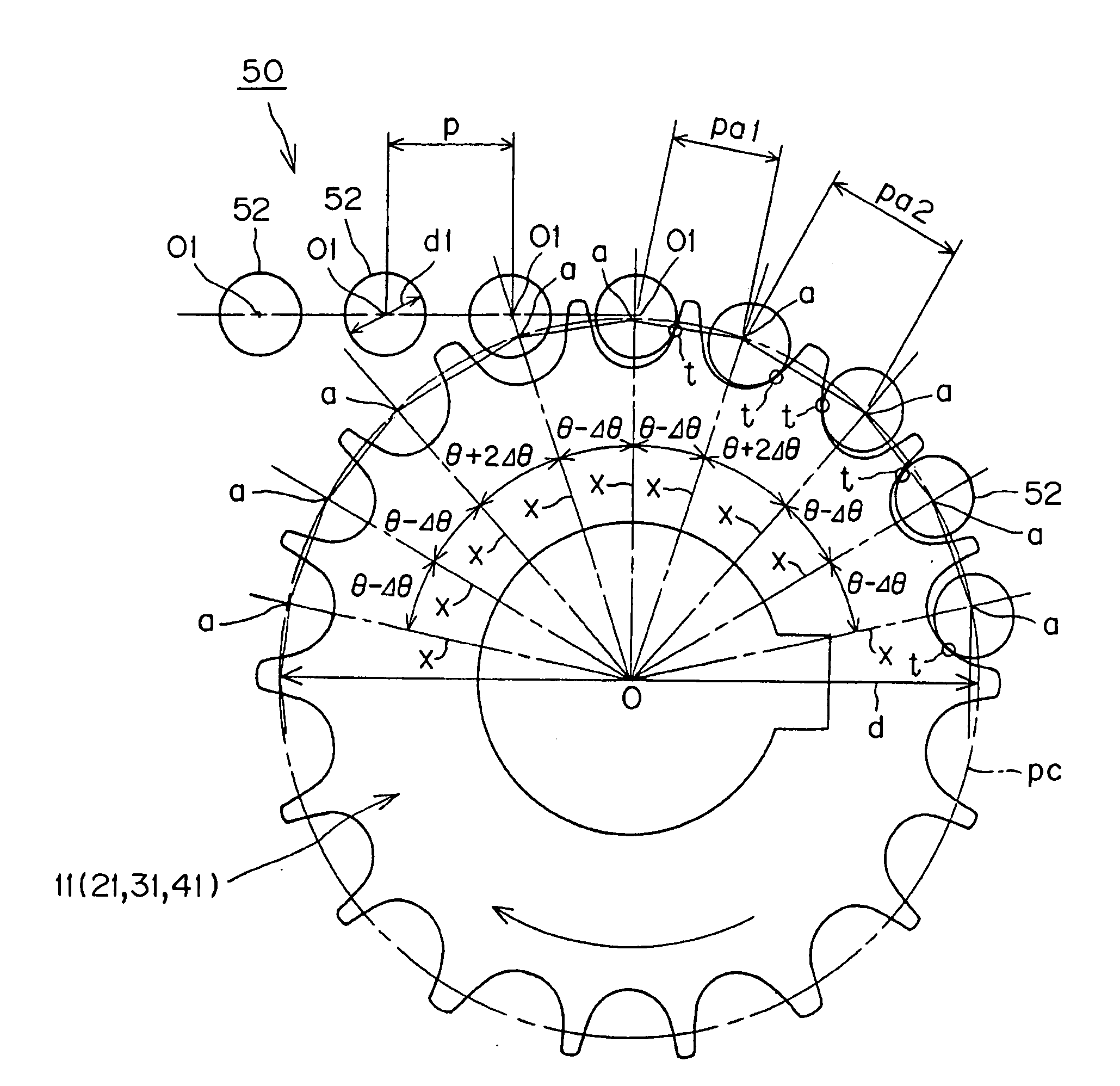

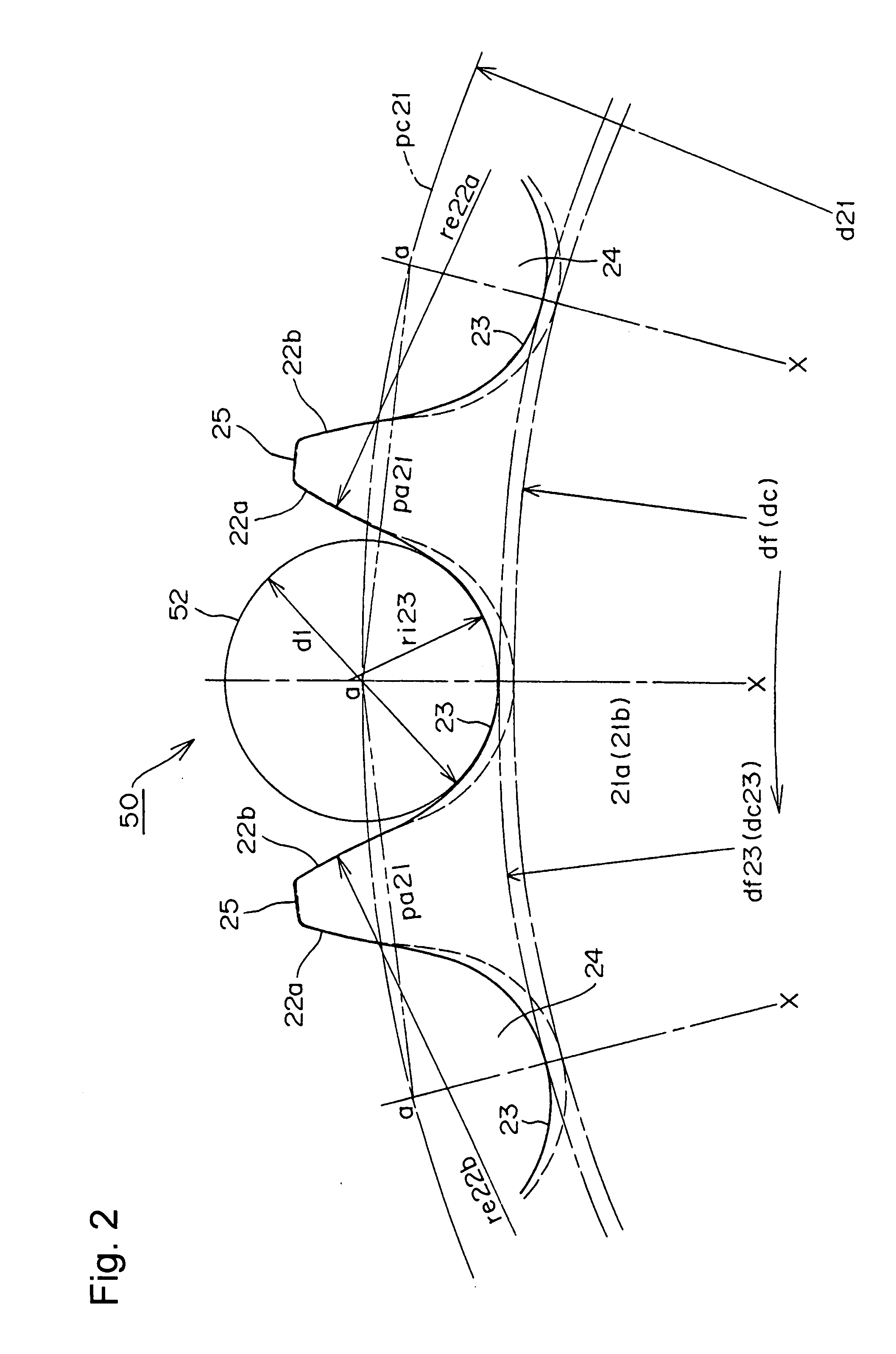

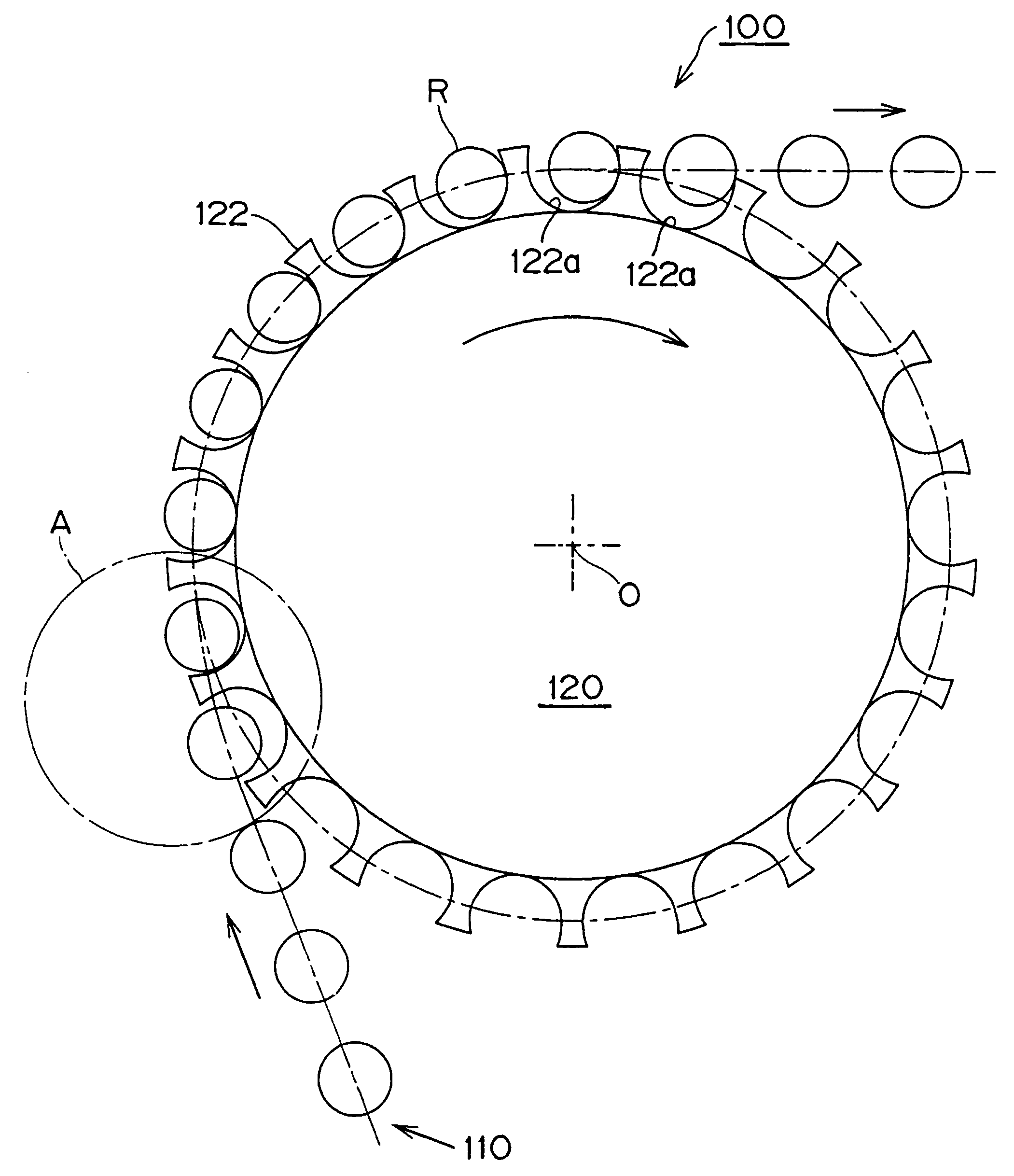

Conveyance system

InactiveUS20060084542A1Efficient executionReduce vertical movementConveyorsV-beltsEngineeringRoller chain

In a slat conveyor, slats for supporting conveyed articles and personnel extend between two side-by-side, spaced, endless roller chains engaged with driving sprockets at one end of the conveying path and driven sprockets at the other end. At a location radially outward from the pitch circle, the distance between the front surface of the sprocket teeth to the tooth center line is at least as great as the distance from the centerline to the front surface at the pitch circle. The tooth faces merge smoothly with the tooth gap bottom, and the root diameter is smaller than the root diameter according to ISO standards.

Owner:TSUBAKIMOTO CHAIN CO

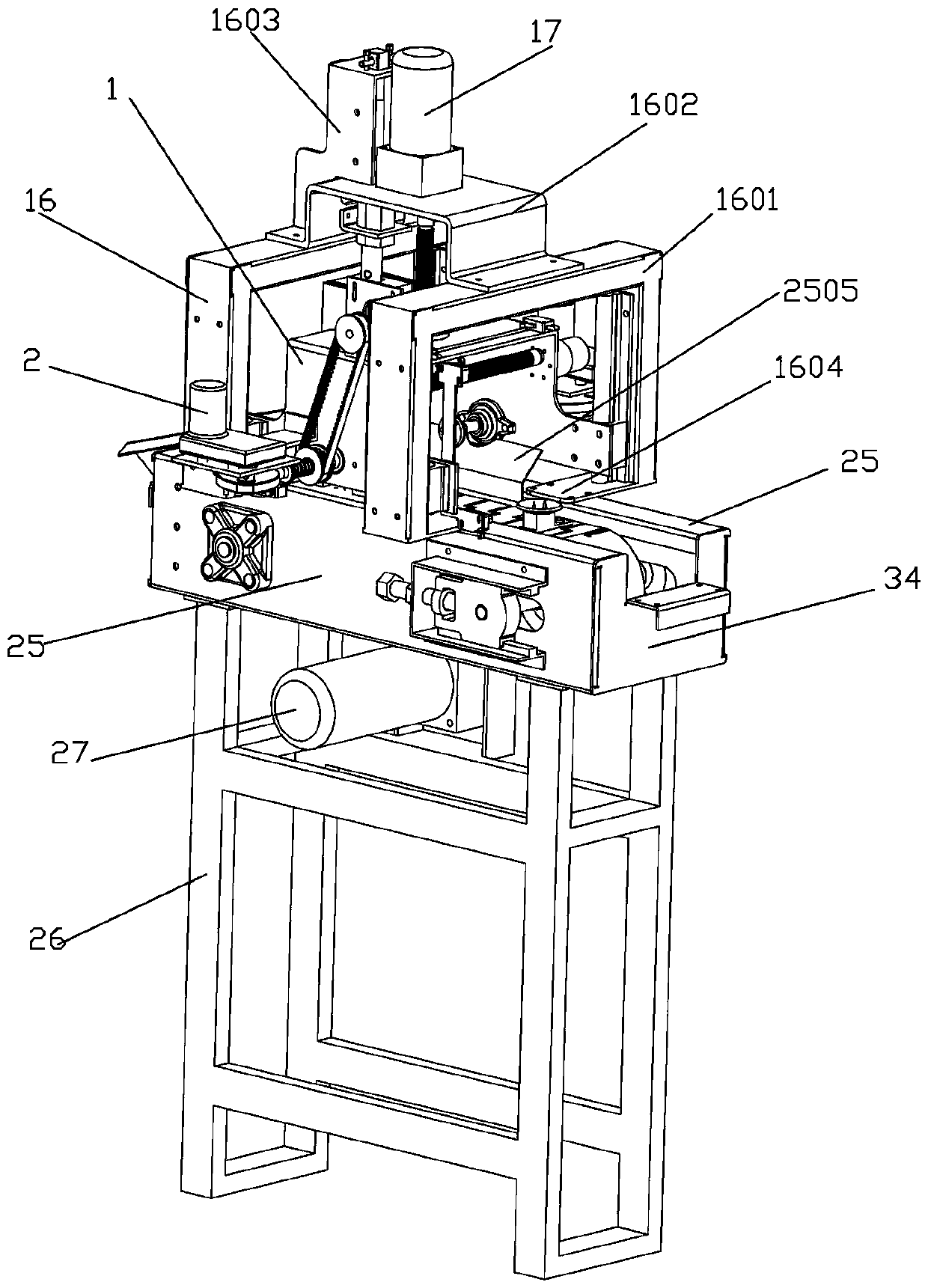

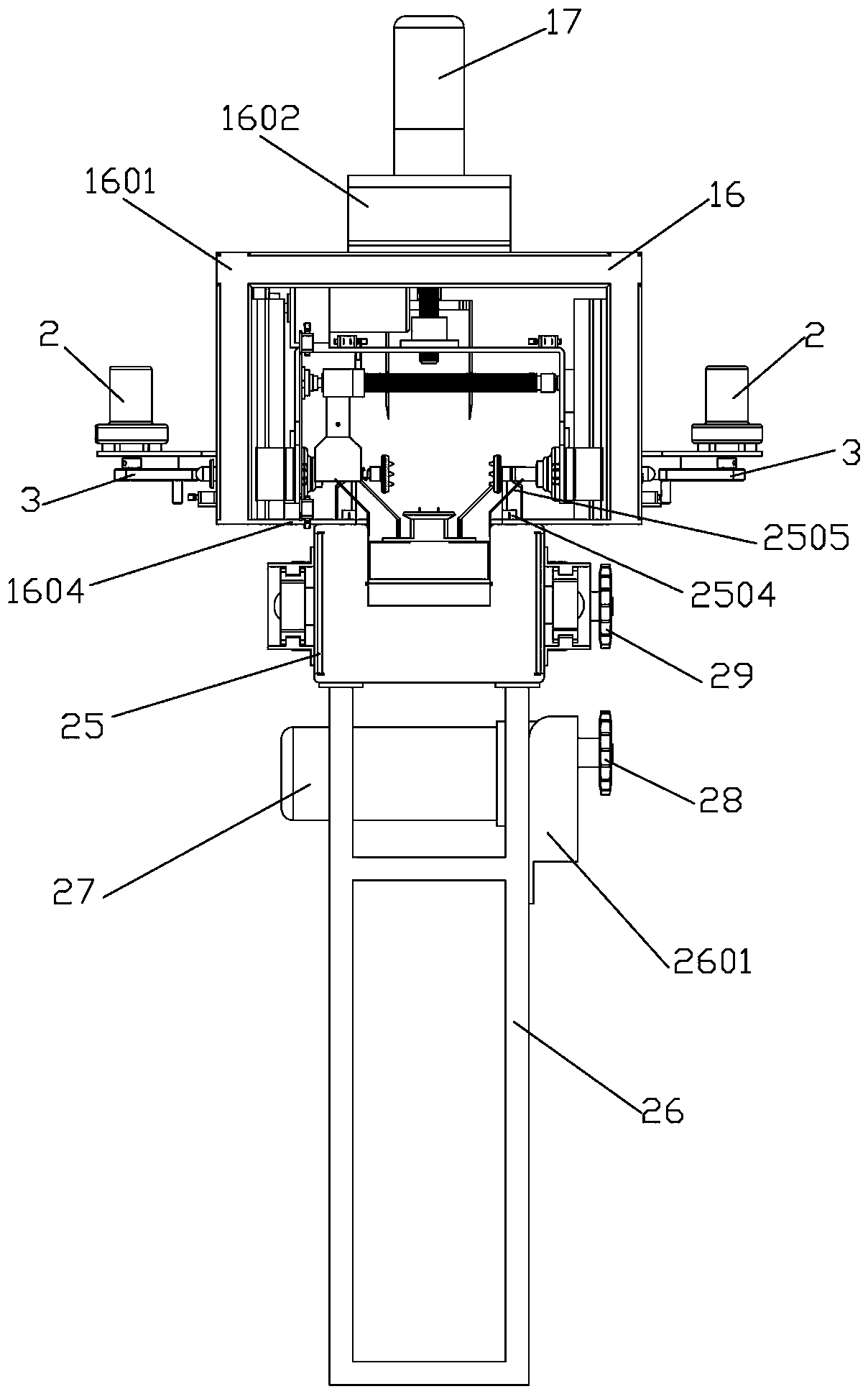

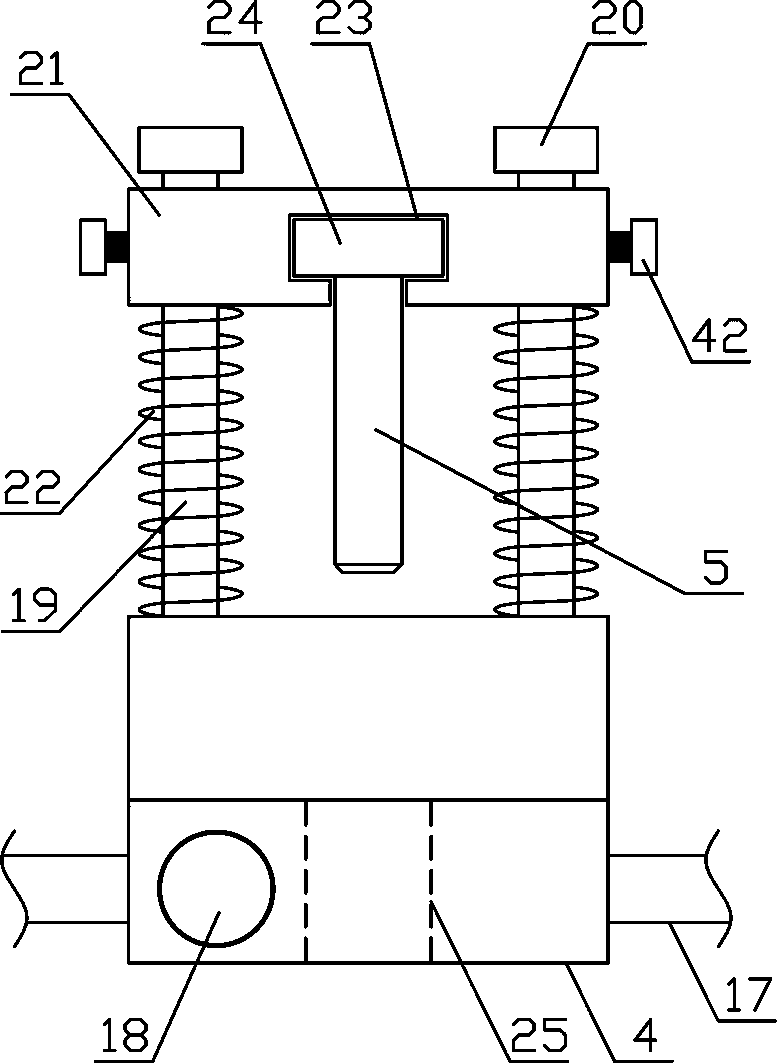

Peeling device for juicer

A peeling device for a juicer comprises a lifting frame, an upper support, a transmission frame and a lower landing leg. A tip sleeve is provided with an annular baffle and a compression spring, and the tip sleeve can go back to the starting position by its self. The tip sleeve is provided with a tip sliding groove, a tip can firmly clamp a fruit through the tip, a sliding rod, a pin on the sliding rod and a buffer spring on the tip, and when clamping is finished, stable disengaging can be carried out. Fruits are constantly conveyed to procedure positions through a transmission motor, a driving transmission wheel, a driven transmission wheel, a transmission belt and a plurality of fruit fixing trays. The fruit fixing trays are provided with conical protruding concave faces, and the fruits can be stably placed. A lifting threaded rod drives the lifting frame to move up and down so that the fruits can disengage from the fruit fixing trays or can be placed into the fruit fixing trays. By means of two pairs of sensors, the fruits can be accurately stopped at the corresponding working positions. The peeling device is high in automation degree and high in efficiency, and the working demands of the juicer are met.

Owner:袁华冰

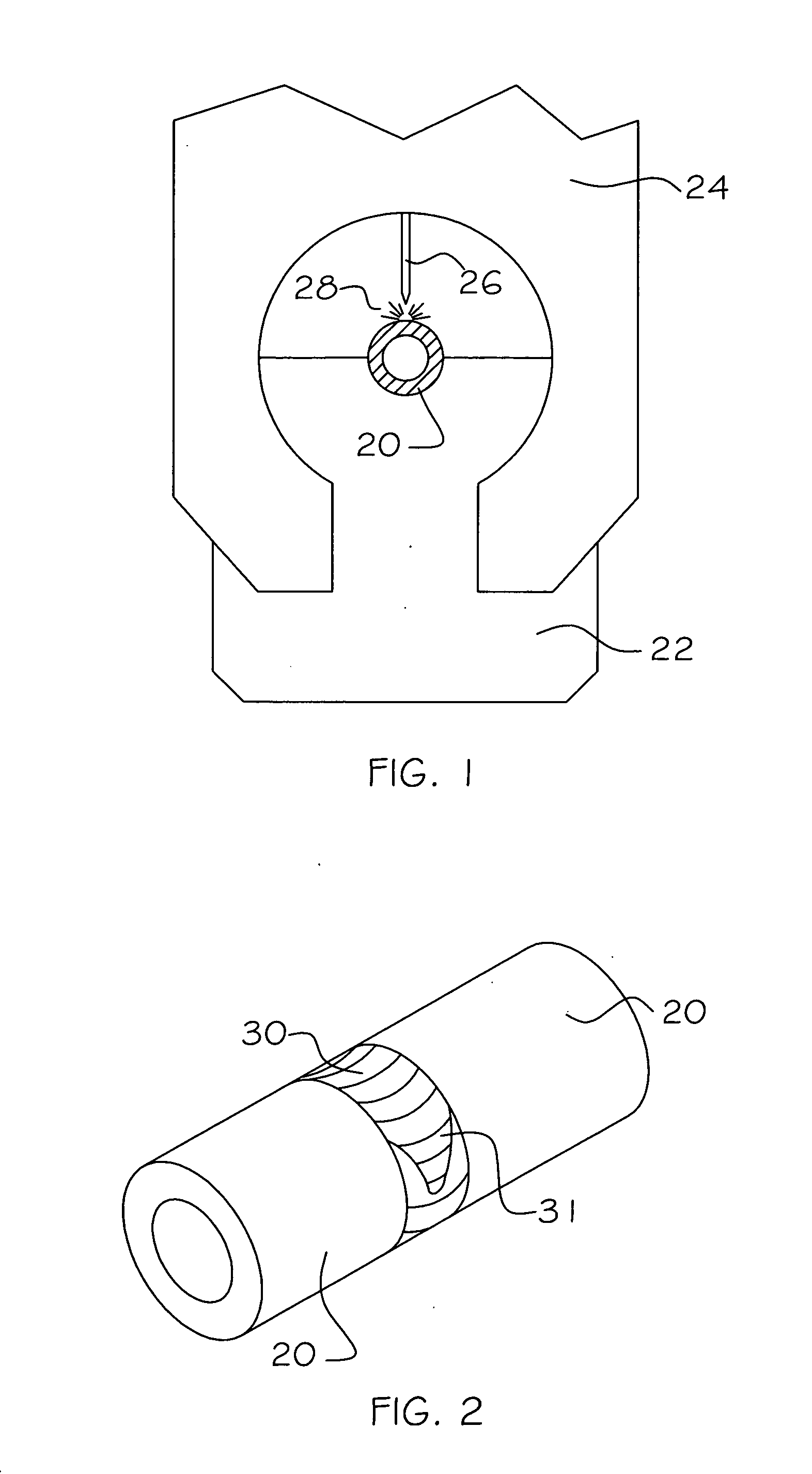

Sprocket for chain

In a sprocket for a roller chain, the tooth form is such that the distance between the tooth center line and a part of the front tooth surface, at a location on the tooth head side of the pitch line, is greater than the distance between the tooth center line and the front surface of the tooth along the pitch line. The diameter of the tooth gap bottom circle is smaller than the diameter of a tooth gap bottom circle in a sprocket having an ISO tooth form for the same chain.

Owner:TSUBAKIMOTO CHAIN CO

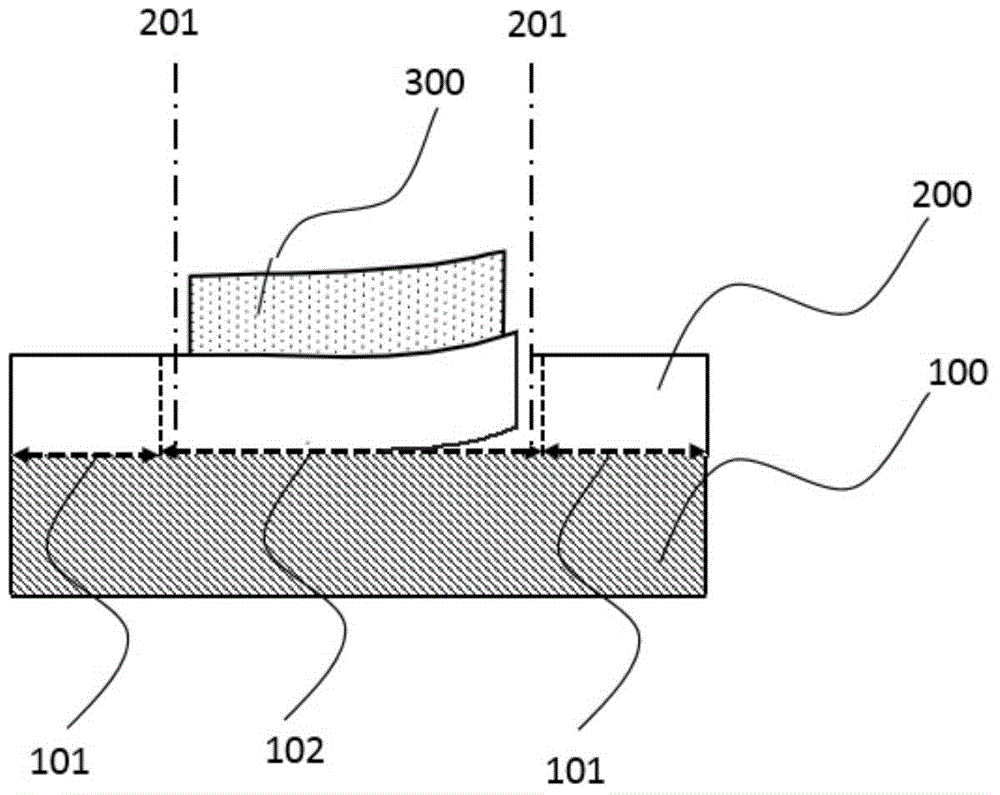

Flexible membrane liner and substrate separation process for producing flexible display device

InactiveCN104362263AEnhanced adhesionSimple separation processFinal product manufactureSolid-state devicesSeparation processBiomedical engineering

The invention discloses a flexible membrane liner and substrate separation process for producing a flexible display device. The process includes the steps: (1) producing a flexible membrane liner on a carrier substrate, and treating the juncture of the flexible membrane liner and the carrier substrate to enable some regions to become high-adhesion regions and the rest region to become a low-adhesion region; (2) producing an electronic component on the flexible membrane liner over the low-adhesion region; (3) cutting vertically and downwardly from the flexible membrane liner along the periphery of the electronic component to form a cutting line, wherein the low-adhesion region is located under the cutting line; (4) separating the flexible membrane liner from the carrier substrate. The flexible membrane liner is stably attached to the carrier substrate in the subsequent device production process, and the process is simple in liner and substrate separation, low in cost and rapid and causes no damage to the device.

Owner:SOUTH CHINA UNIV OF TECH

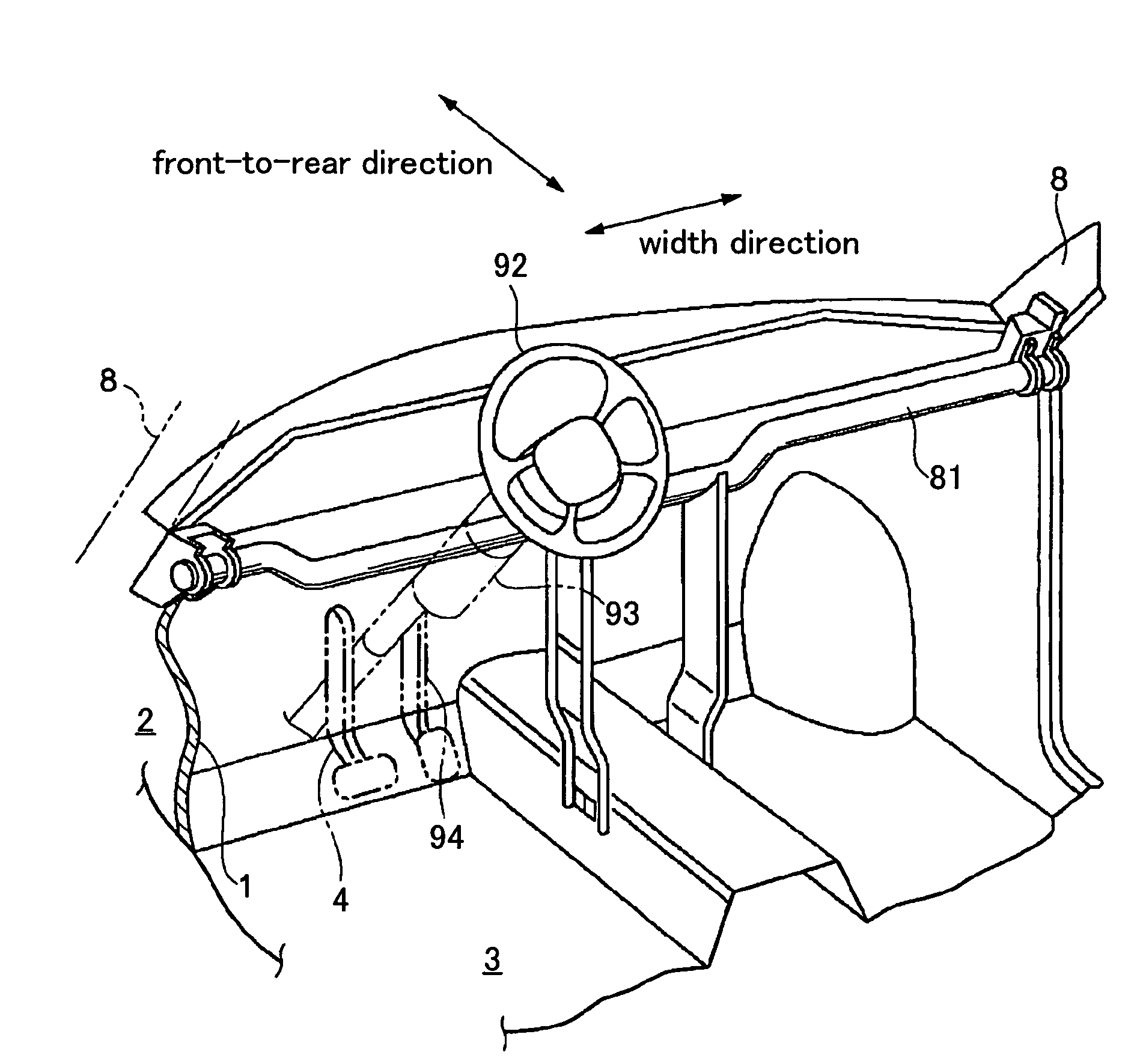

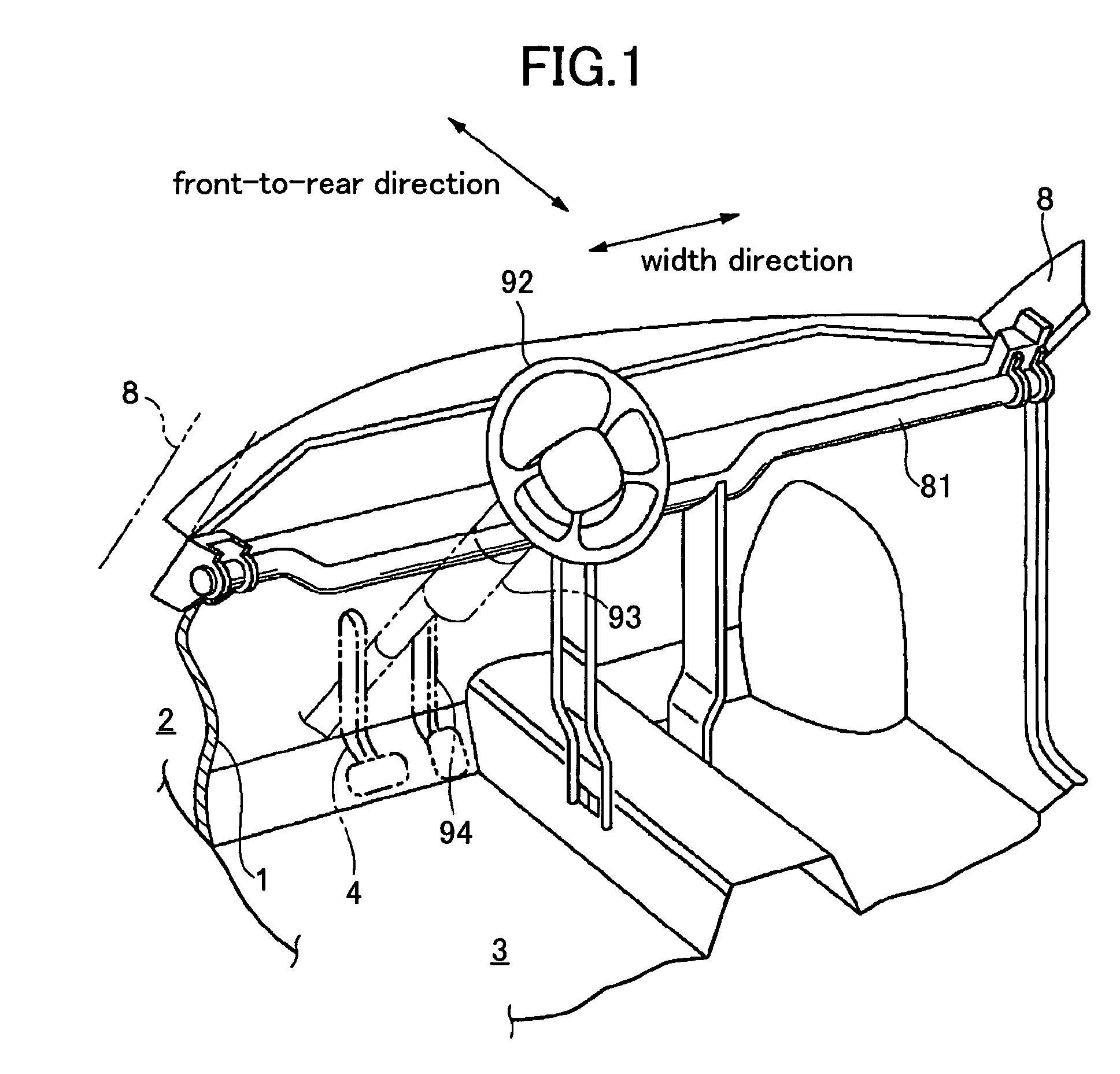

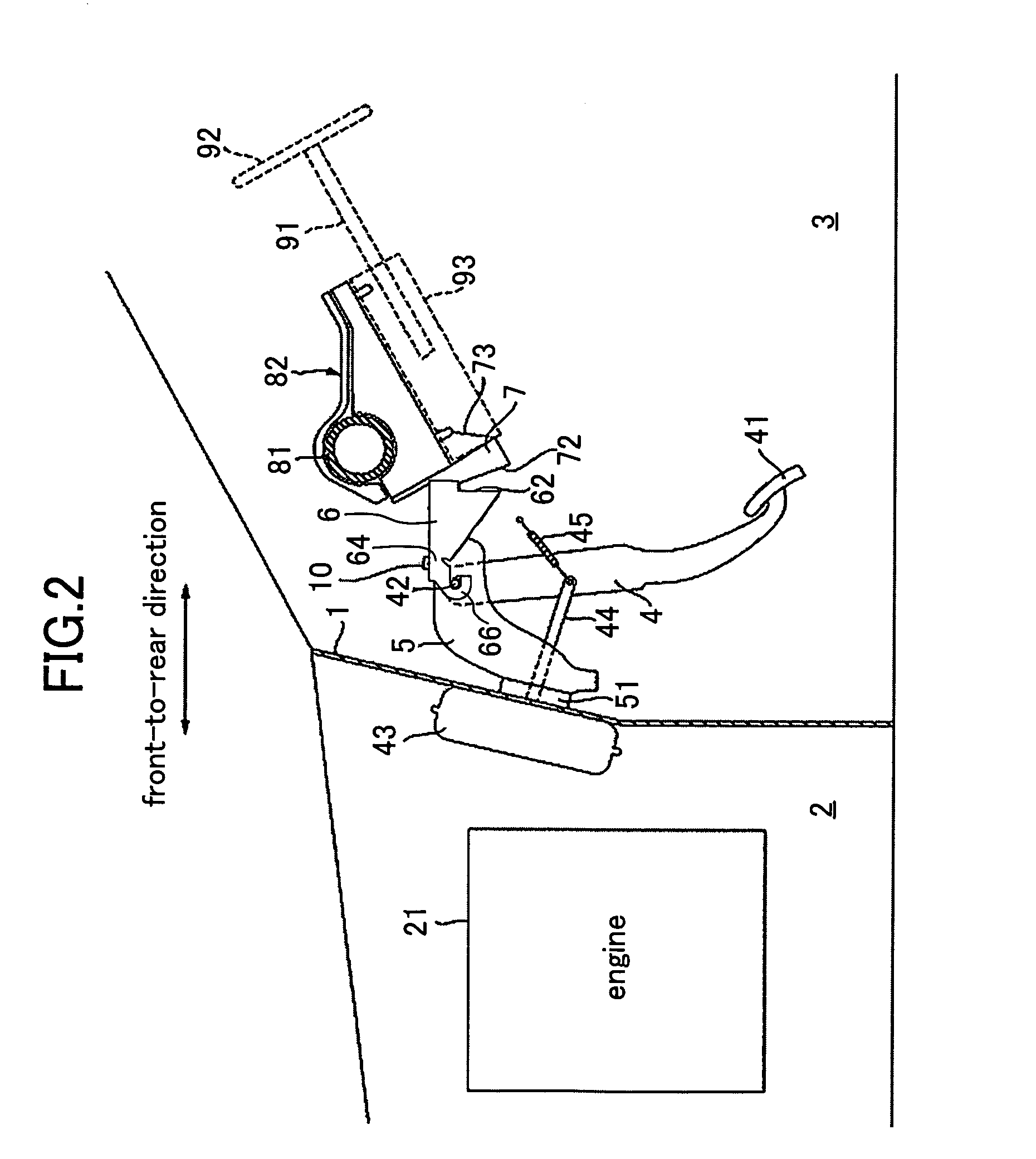

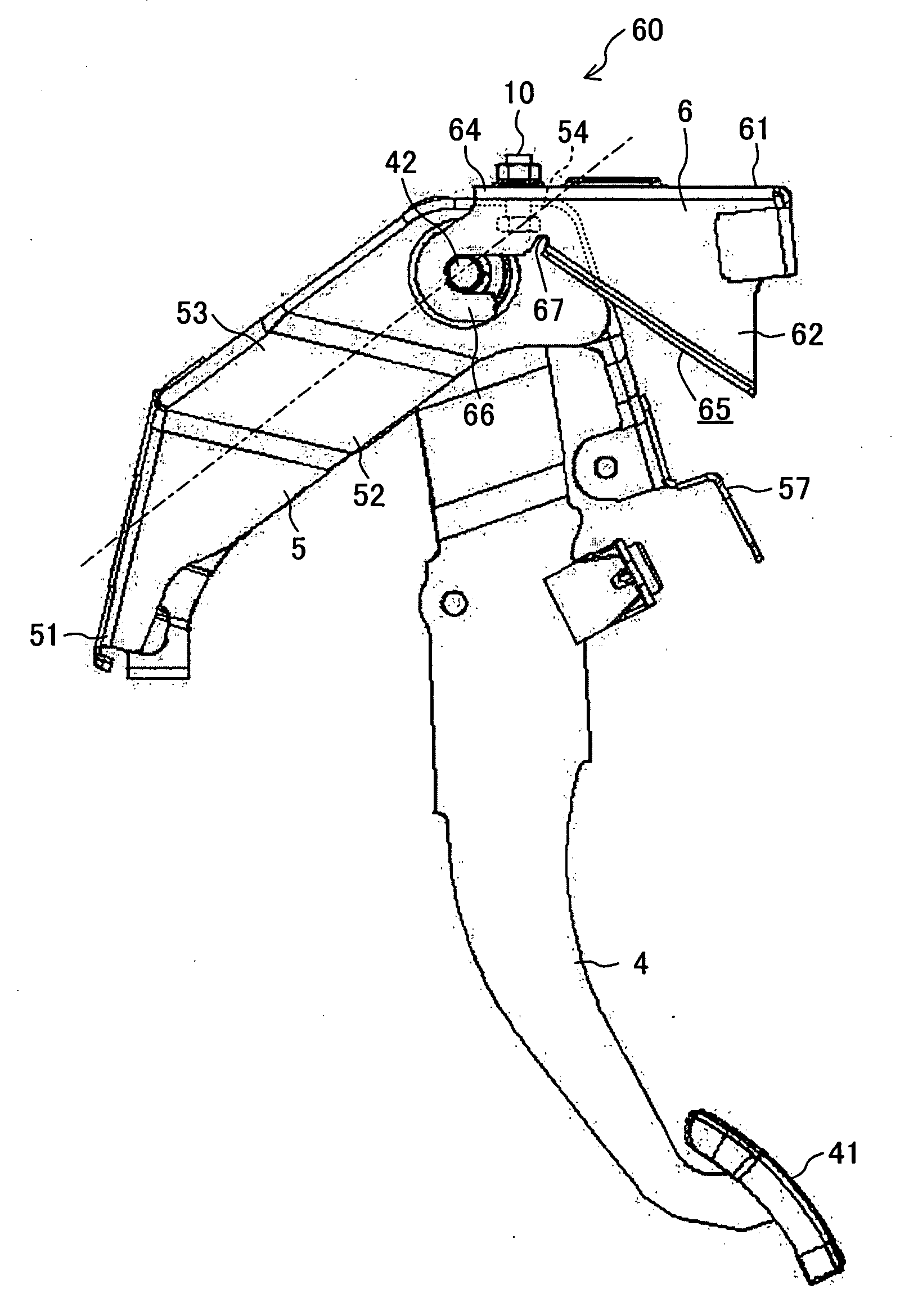

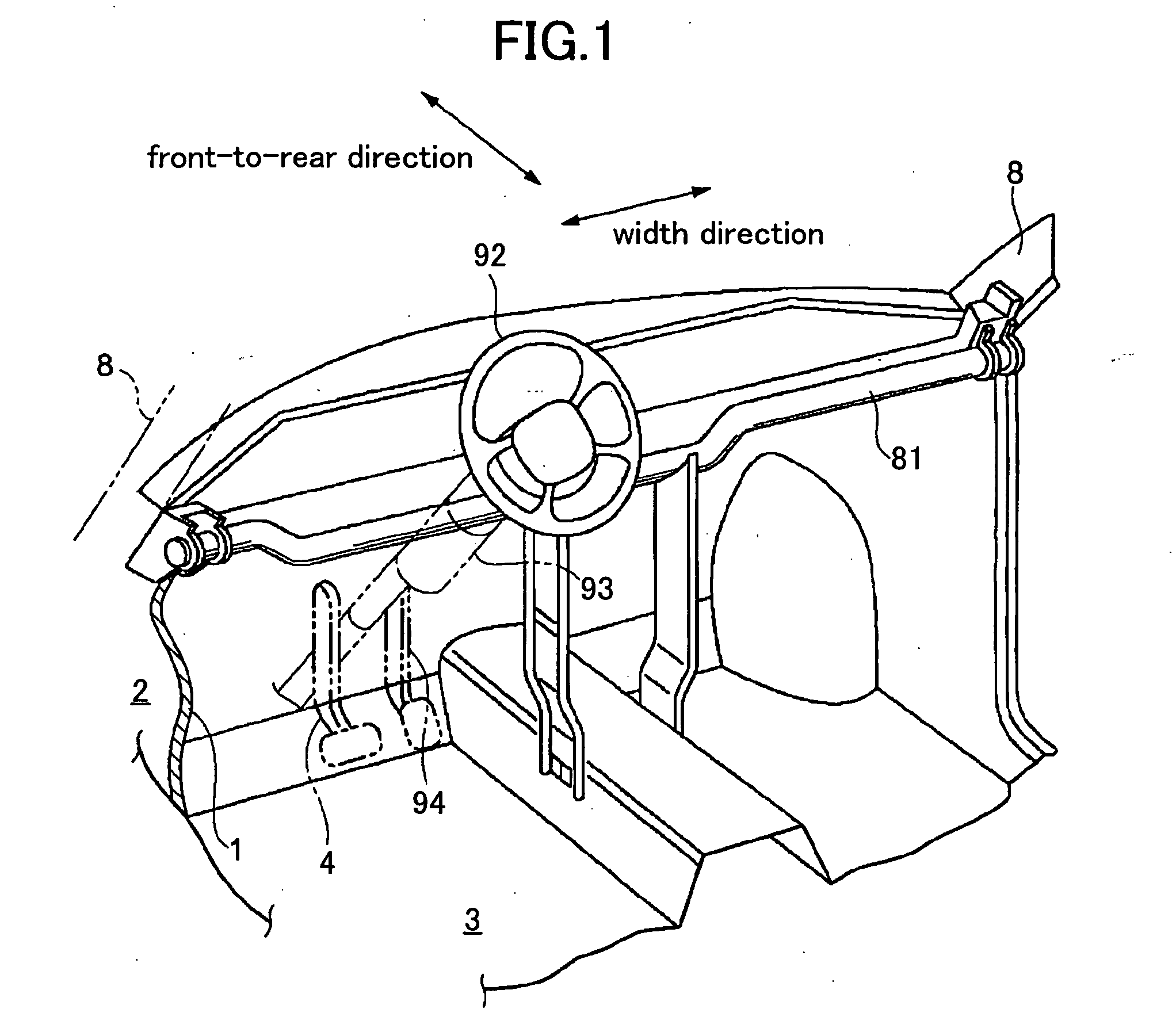

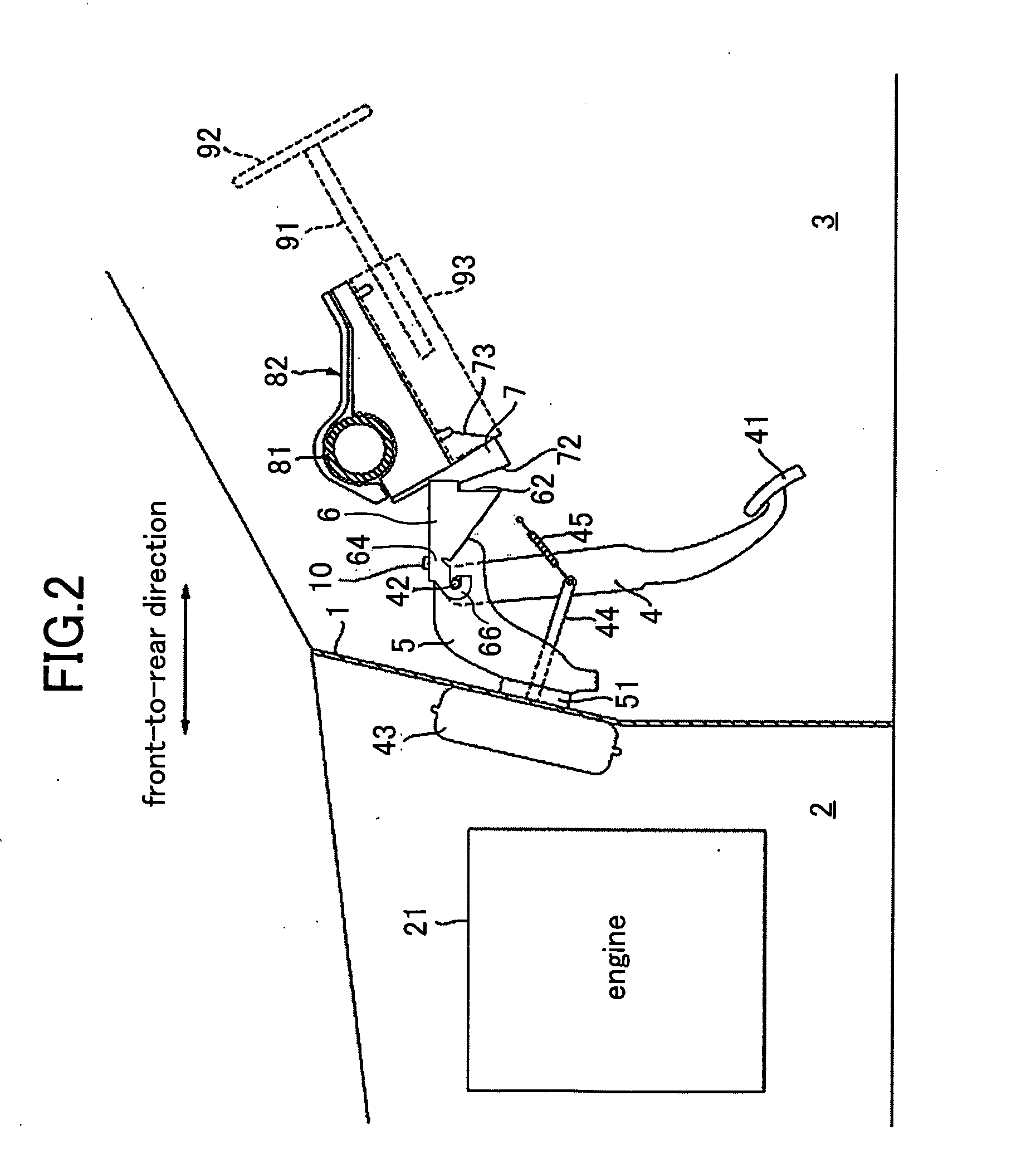

Pedal assembly support structure for vehicle

InactiveUS7434648B2Prevent movementSmall frictional resistanceControlling membersMechanical apparatusRelative shiftFootplate

A vehicle pedal assembly support structure comprises: a bracket to which a pivot shaft for a pedal lever is mounted; a guide member fixed to a vehicle body member other than a dash panel; a fixing mechanism for normally fixing a rear end portion of the bracket to a front end portion of the guide member but disengaging the bracket from the guide member in a vehicle collision; and a relative shift restricting member for restraining the rear end portion of the bracket from relatively shifting in directions other than the rearward direction of the vehicle to the front end portion of the guide member. The guide member is provided with a guide surface for downwardly guiding the bracket moving backward in the vehicle collision to change the posture of the bracket.

Owner:MAZDA MOTOR CORP

Pedal assembly support structure for vehicle

InactiveUS20060070487A1Small frictional resistanceSmooth disengagementControlling membersMechanical apparatusRelative shiftMechanical engineering

A vehicle pedal assembly support structure comprises: a bracket to which a pivot shaft for a pedal lever is mounted; a guide member fixed to a vehicle body member other than a dash panel; a fixing mechanism for normally fixing a rear end portion of the bracket to a front end portion of the guide member but disengaging the bracket from the guide member in a vehicle collision; and a relative shift restricting member for restraining the rear end portion of the bracket from relatively shifting in directions other than the rearward direction of the vehicle to the front end portion of the guide member. The guide member is provided with a guide surface for downwardly guiding the bracket moving backward in the vehicle collision to change the posture of the bracket.

Owner:MAZDA MOTOR CORP

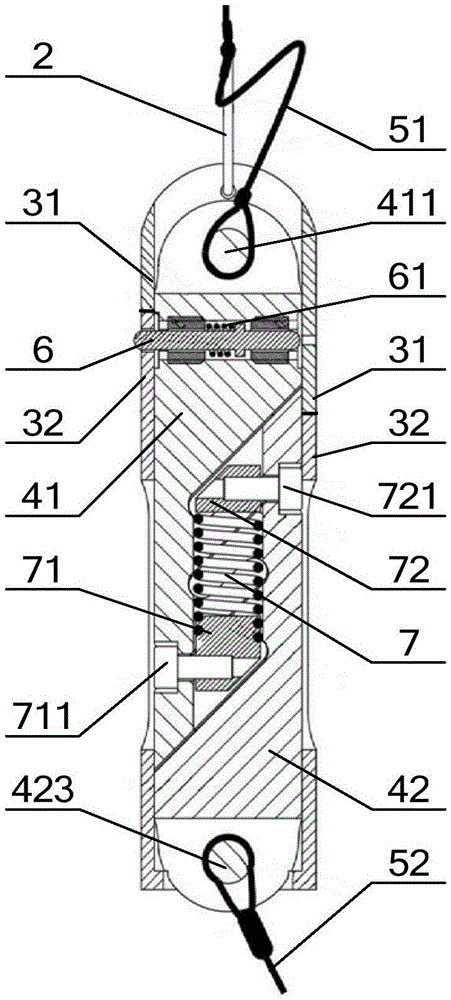

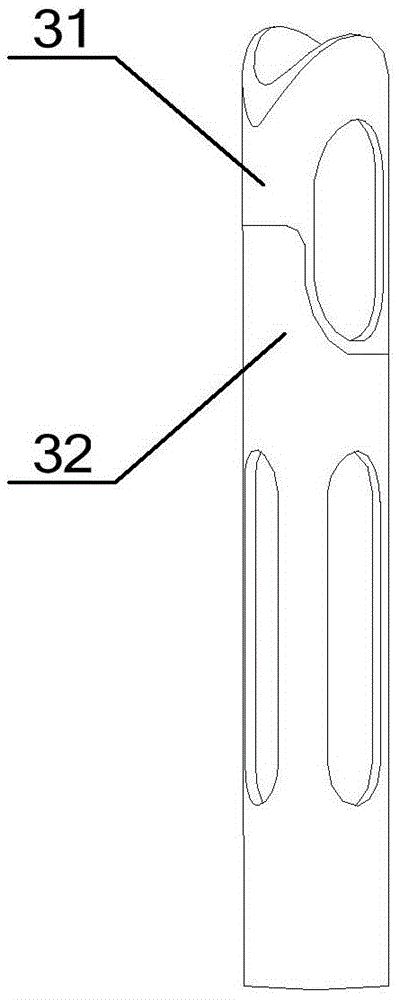

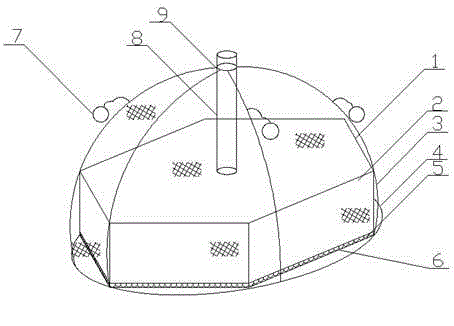

Automatic release device of unmanned aerial vehicle parachute

The invention discloses an automatic release device of an unmanned aerial vehicle parachute and relates to the technical field of separation and release devices. The automatic release device aims at solving the problem that the automatic release device of the unmanned aerial vehicle parachute in the prior art causes damage to unmanned aerial vehicle equipment easily. The automatic release device comprises a hook, an upper housing, a lower housing, an upper lock cylinder and a telescopic needle. The top end of the hook is connected with the parachute, the bottom end of the hook is connected with the top end of the upper housing, the lower housing is in butt joint with the upper housing, the upper lock cylinder is arranged in the upper housing and the lower housing, an upper shaft is arranged in the top region of the upper lock cylinder, and the position between the upper shaft and the top end of the hook is connected and sleeved with a parachute rope. The telescopic needle is arranged in the upper lock cylinder and located under the upper shaft. One end of the telescopic needle is in clamped connection with the lower housing, the other end of the telescopic needle abuts against the inner wall of the upper housing, and the outer side of the telescopic needle is sleeved with a telescopic needle spring. The automatic release device is mainly applied to manufacturing of unmanned aerial vehicles.

Owner:中天智控科技控股股份有限公司

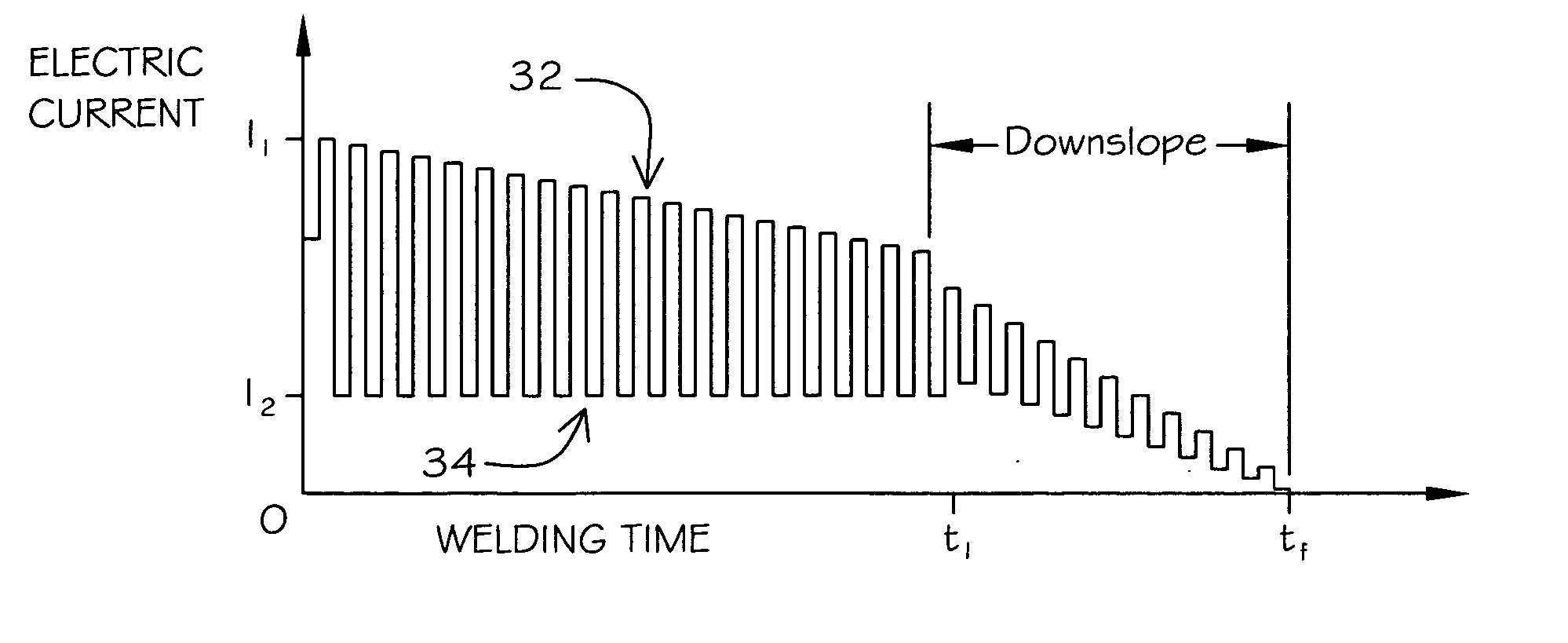

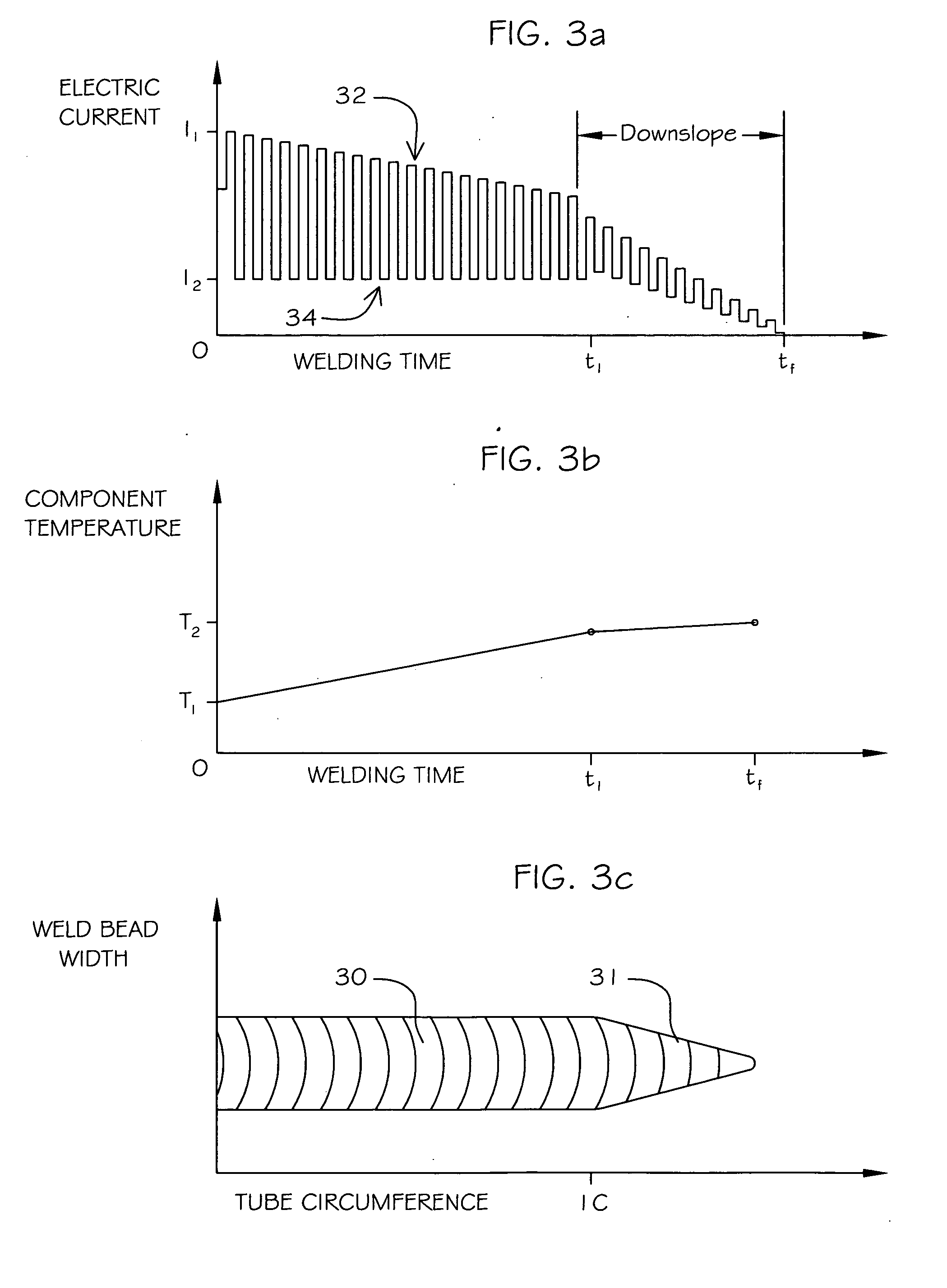

Method for orbital welding using a pulsed current

InactiveUS20060213893A1Reduce widthSmooth disengagementWelding/cutting auxillary devicesAuxillary welding devicesAverage currentEngineering

A method for the orbital welding of tubular elements held in abutment comprising the steps of striking an arc at a strike point with an orbital welder between an electrode and a seam formed by a first tubular element and a second tubular element, held in abutment within a fixture; initiating an orbit of said electrode around an abutment of said first tubular element and said second tubular element; adjusting the current of said arc in a pulsed manner from a maximum current to a minimum current at a set frequency, combination of said maximum current and said minimum current forming an average current; decreasing said average current in a generally continuous manner as said orbit of said electrode progresses from said strike point, the rate of decrease of said maximum current having a generally inverse relationship to the rate of increase in temperature experienced by said tubular elements.

Owner:ORBITAL ACQUISITION

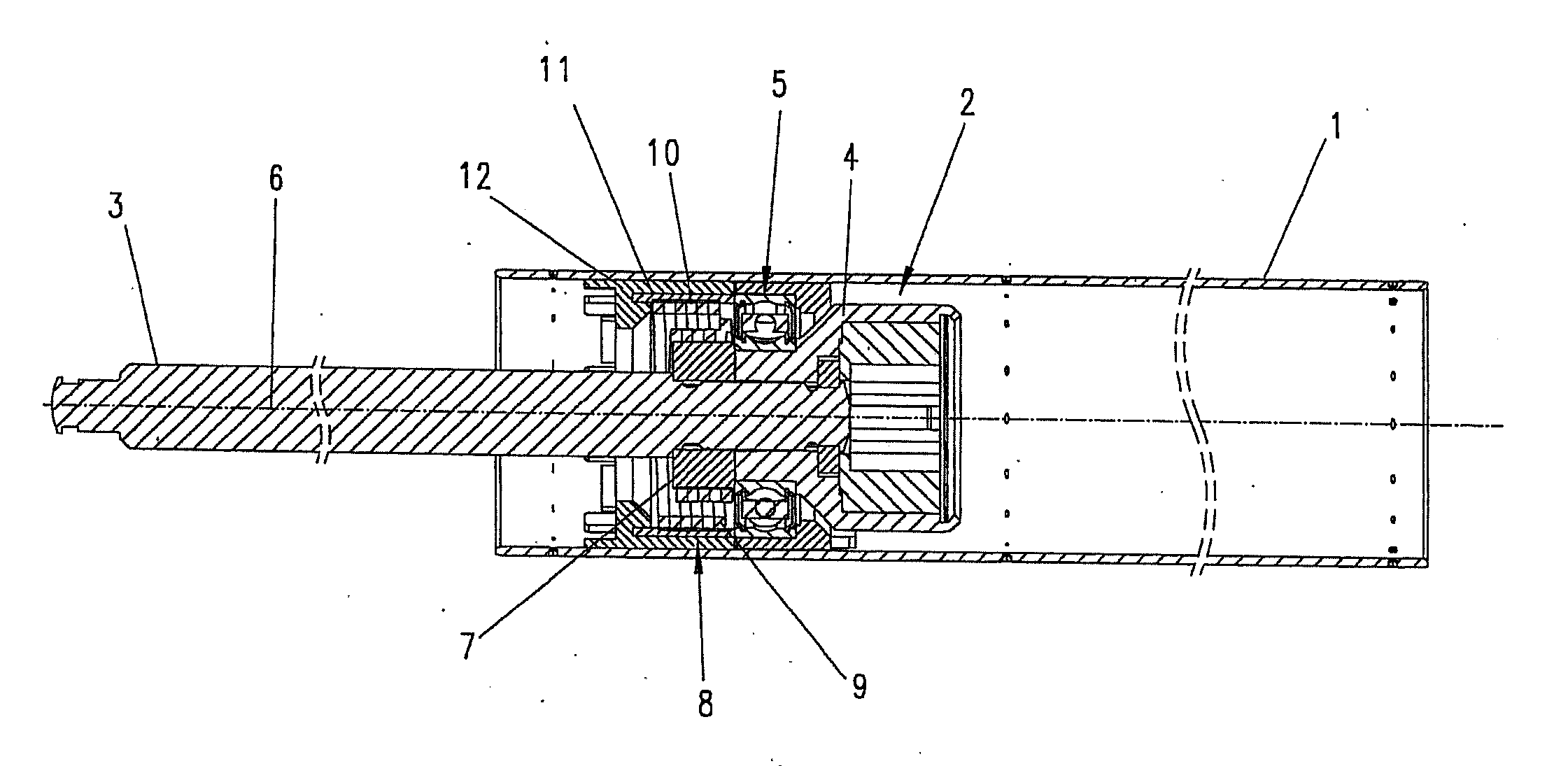

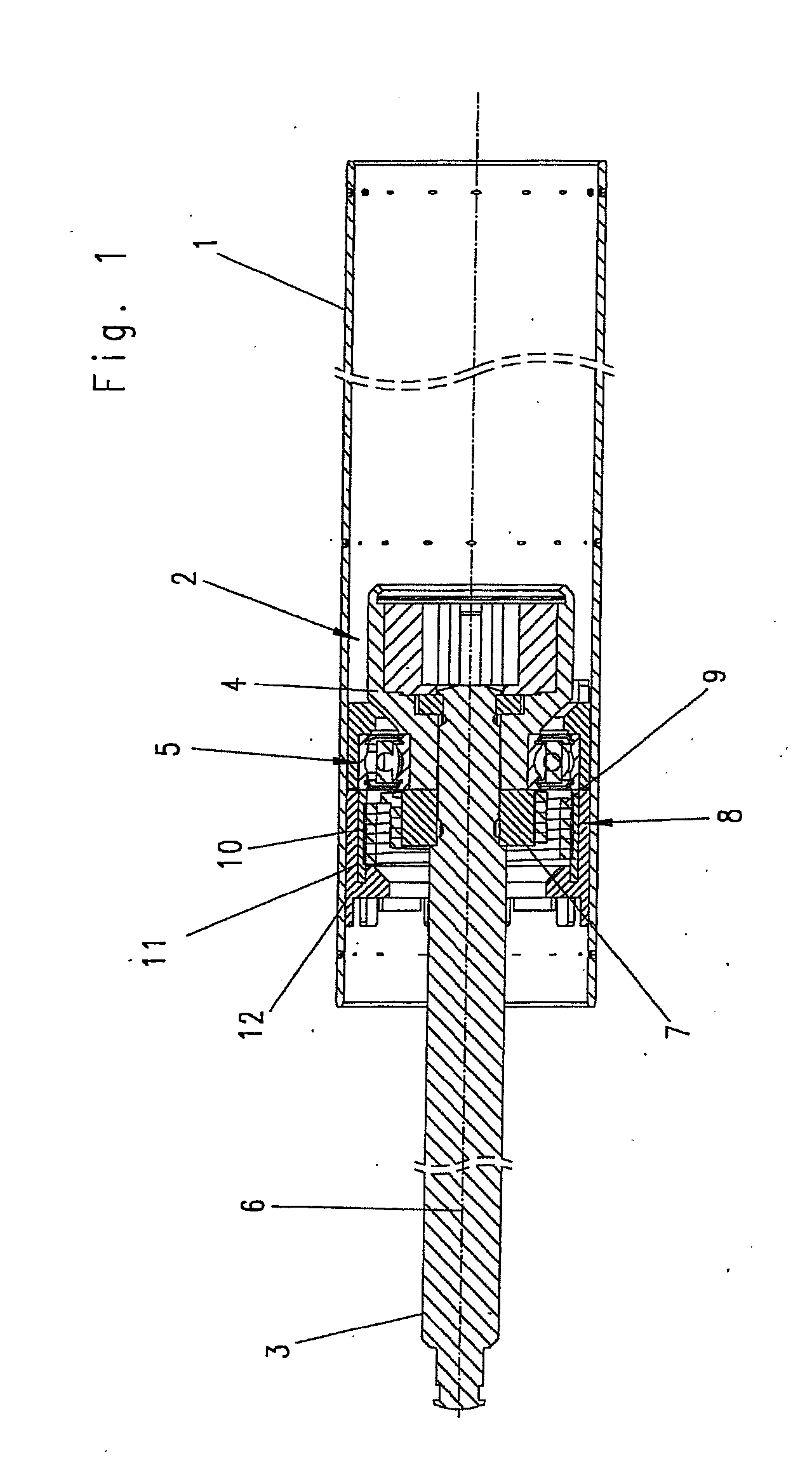

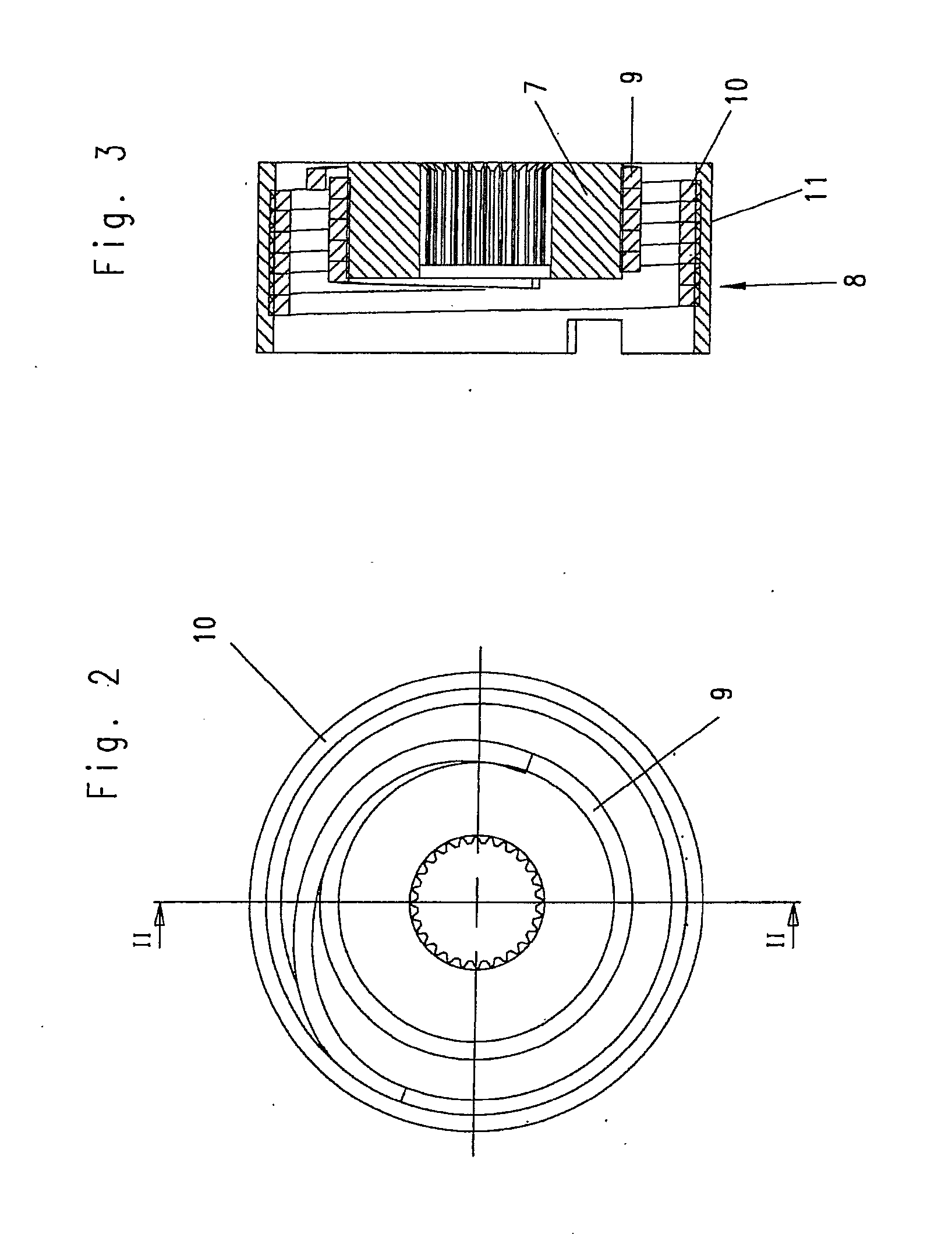

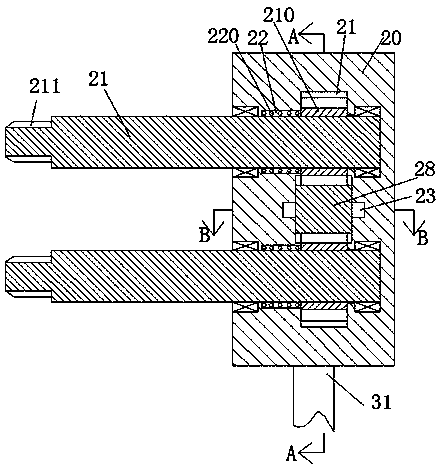

Drive device

ActiveUS20150300468A1Reduce quantityReduces assembly effortToothed gearingsPower-operated mechanismEngineeringMechanical engineering

A drive device has a spindle drive having a threaded spindle and a spindle nut arranged on the threaded spindle. The spindle drive is configured to drive a first component element and a second component element so as to be axially movable relative to one another. The spindle drive is reversibly rotatably drivable around an axis of rotation extending coaxial to the threaded spindle by a rotatably driven driveshaft arranged in a housing so as to be fixed with respect to rotation. A brake device prevents axially relative movement of the first component element and second component element relative to one another through axial application of force to the first component element and / or second component element.

Owner:STABILUS

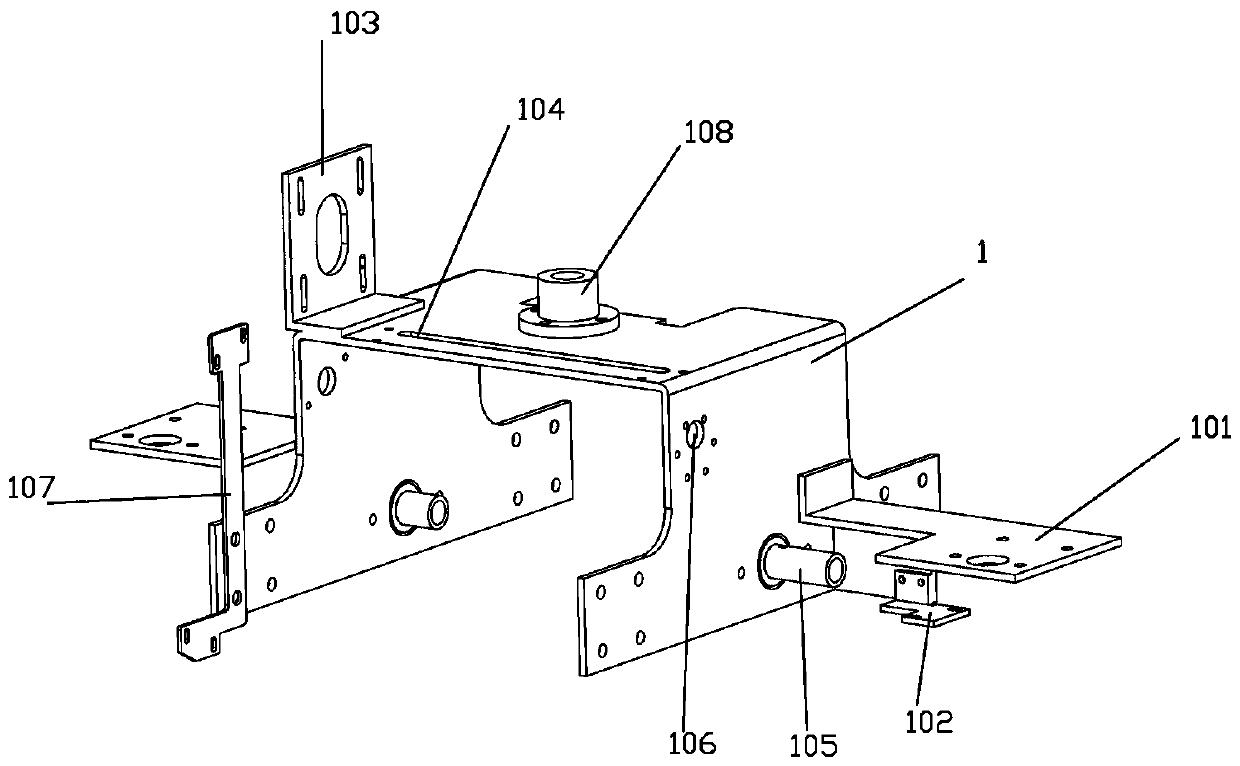

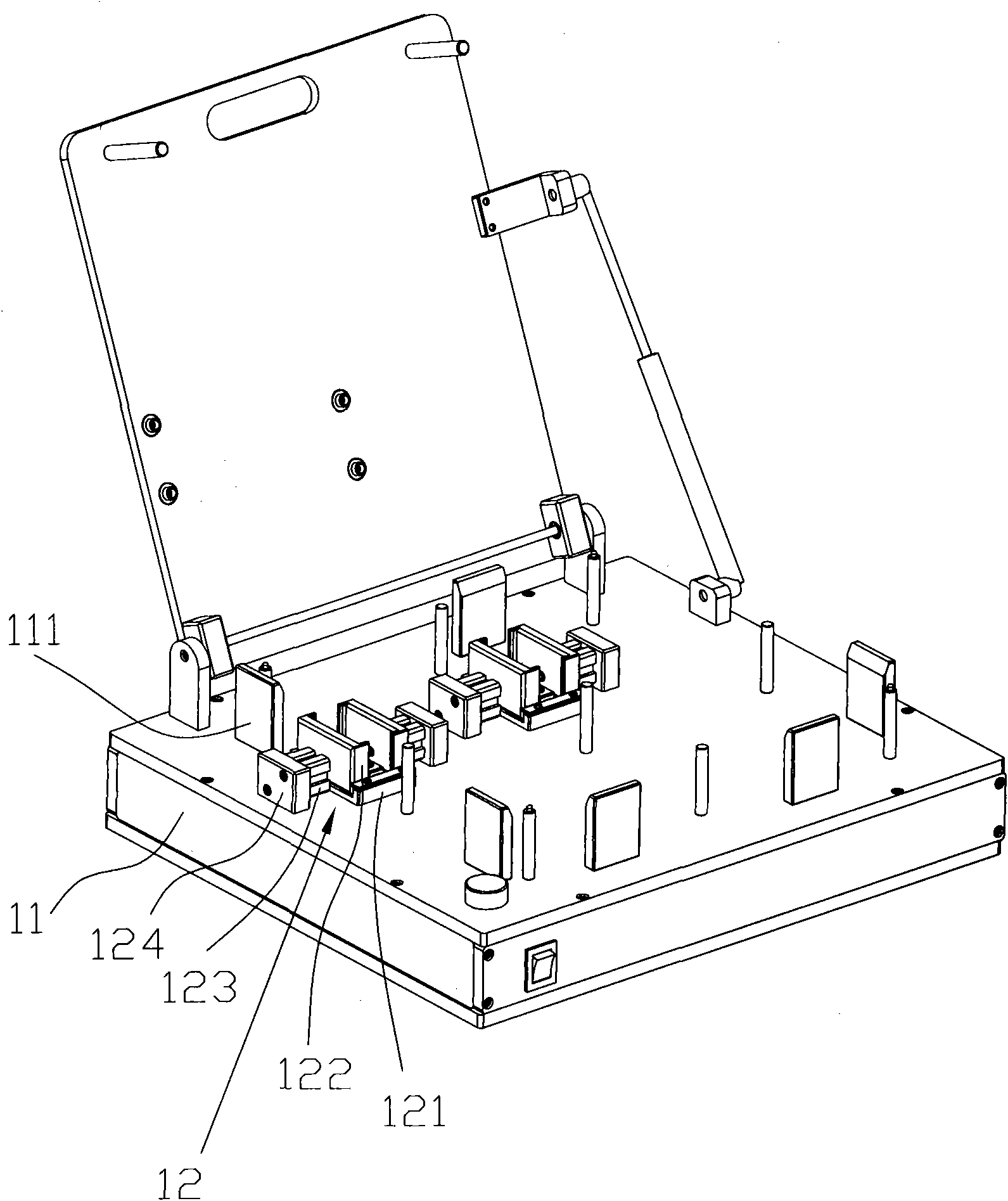

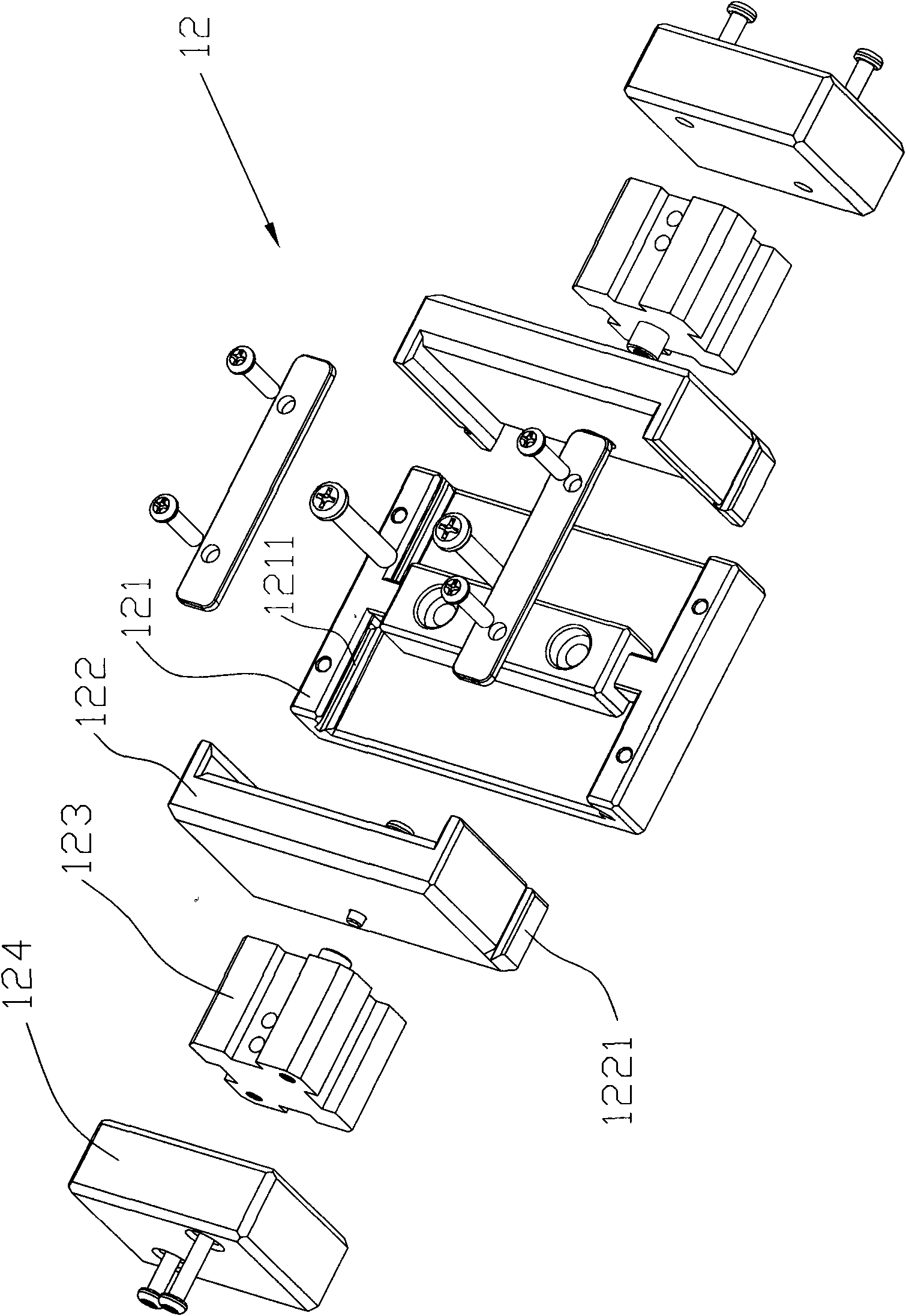

Jig

InactiveCN101596671ASave assembly timeImprove production and assembly efficiencyDigital data processing detailsAssembly machinesMotherboardHeat spreader

The invention relates to a jig for positioning a radiating fin so as to assemble the radiating fin, in particular to a jig for positioning a radiator assembly so as to assemble the radiator assembly. The jig comprises a main box body provided with a circuit control device and at least one positioning device for clamping a radiator. The positioning device comprises a concave guide positioning piece, two clamping blocks and two cylinders, wherein the concave guide positioning piece is fixedly locked on the main box body by a screw assembly, and both relative sides of both side walls of the concave guide positioning piece are provided with guide grooves; both corresponding positions of both side surfaces of each clamping block are provided with tenons; the two cylinders are fixedly locked to the relative side surfaces of the guide positioning piece of the clamping blocks respectively and connected to the circuit control device by a wire. The two clamping blocks are pushed by the two cylinders to move face to face or in the opposite direction so that a clamped, positioned or assembled main plate of the radiating fin is smoothly taken out; the jig can be also provided with a plurality of positioning devices for simultaneously positioning and assembling a plurality of radiating fins, thereby saving the assembly time and improving the assembly and manufacture efficiency.

Owner:MITAC COMP (SHUN DE) LTD

Fly by wire static longitudinal stability compensator system

InactiveUS7433765B2Smooth disengagementConvertible aircraftsDigital data processing detailsFly-by-wireMode selection

A static longitudinal stability (SLS) system provides an unobtrusive airspeed hold function that reacts to the pilot control inputs into the flight control system and the measured states of the aircraft to engage and disengage smoothly without any explicit mode selection by the pilot. The SLS engages airspeed hold when the aircraft is close to trimmed, non-accelerating state. This logic allows the pilot to either fly close to a desired airspeed and let SLS engage, or trim the aircraft in an accelerating / decelerating maneuver and just wait for the SLS to capture a speed when longitudinal acceleration is small. The SLS is not dependant on the pilot specifically selecting this mode, but rather engages and disengages in response to flight control system status and how the aircraft is being maneuvered.

Owner:SIKORSKY AIRCRAFT CORP

Chain transmission device

InactiveUS20080161144A1Reduce kinetic energyReduce participationGearingPortable liftingRoller chainEngineering

In a chain transmission a standard ISO roller chain meshes with a modified sprocket having a root diameter larger than the root diameter of a standard sprocket designed for use with the standard chain. The angular tooth pitches can be either of two kinds. In a first version, the sprocket has two irregularly distributed tooth pitches, θ−Δθ and θ+2Δθ, there being two tooth pitches θ−Δθ for each tooth pitch θ+2Δθ. In a second version, the sprocket has three angular tooth pitches, θ−Δθ, θ, and θ+Δθ, in equal numbers, also distributed irregularly.

Owner:TSUBAKIMOTO CHAIN CO

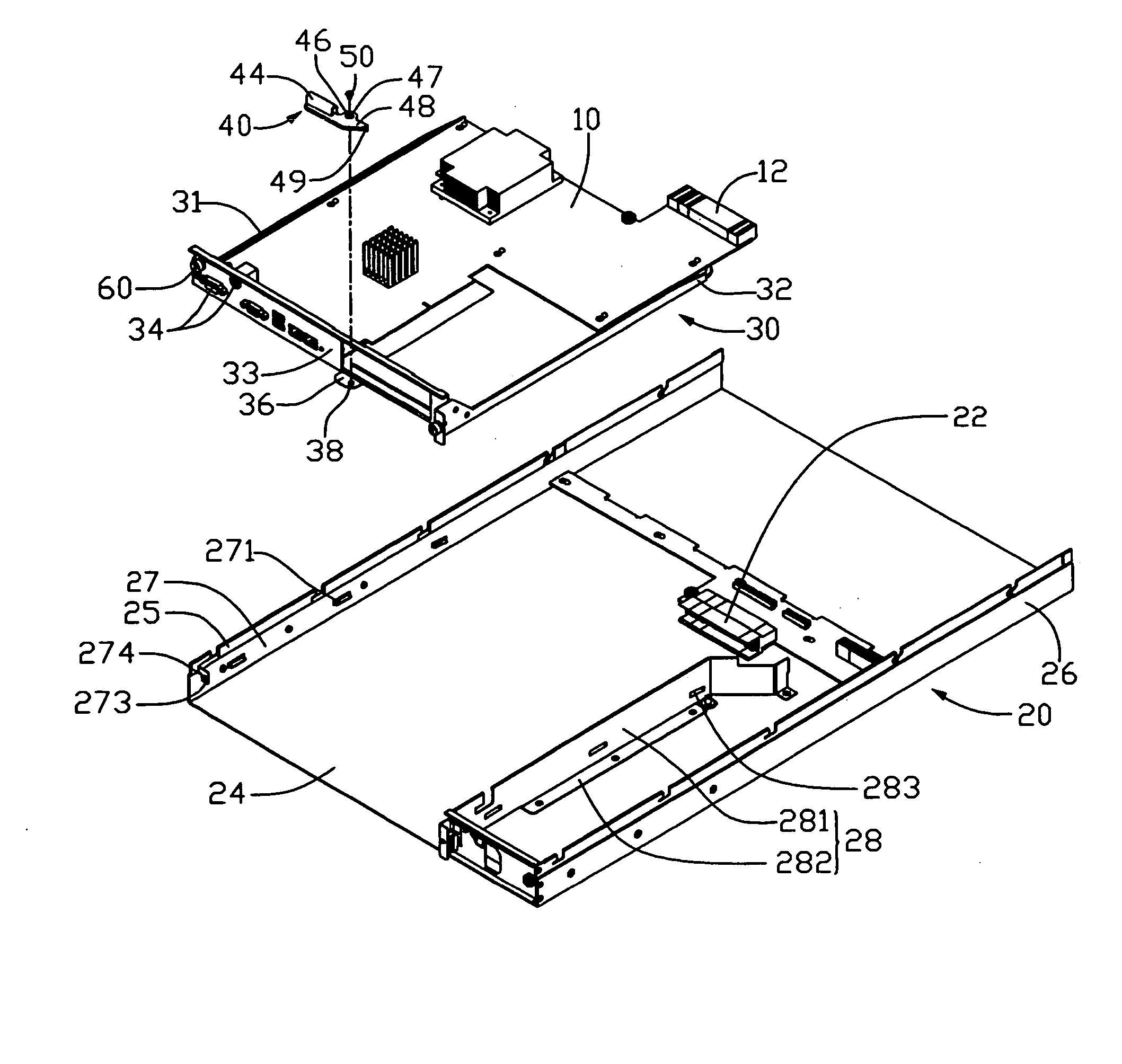

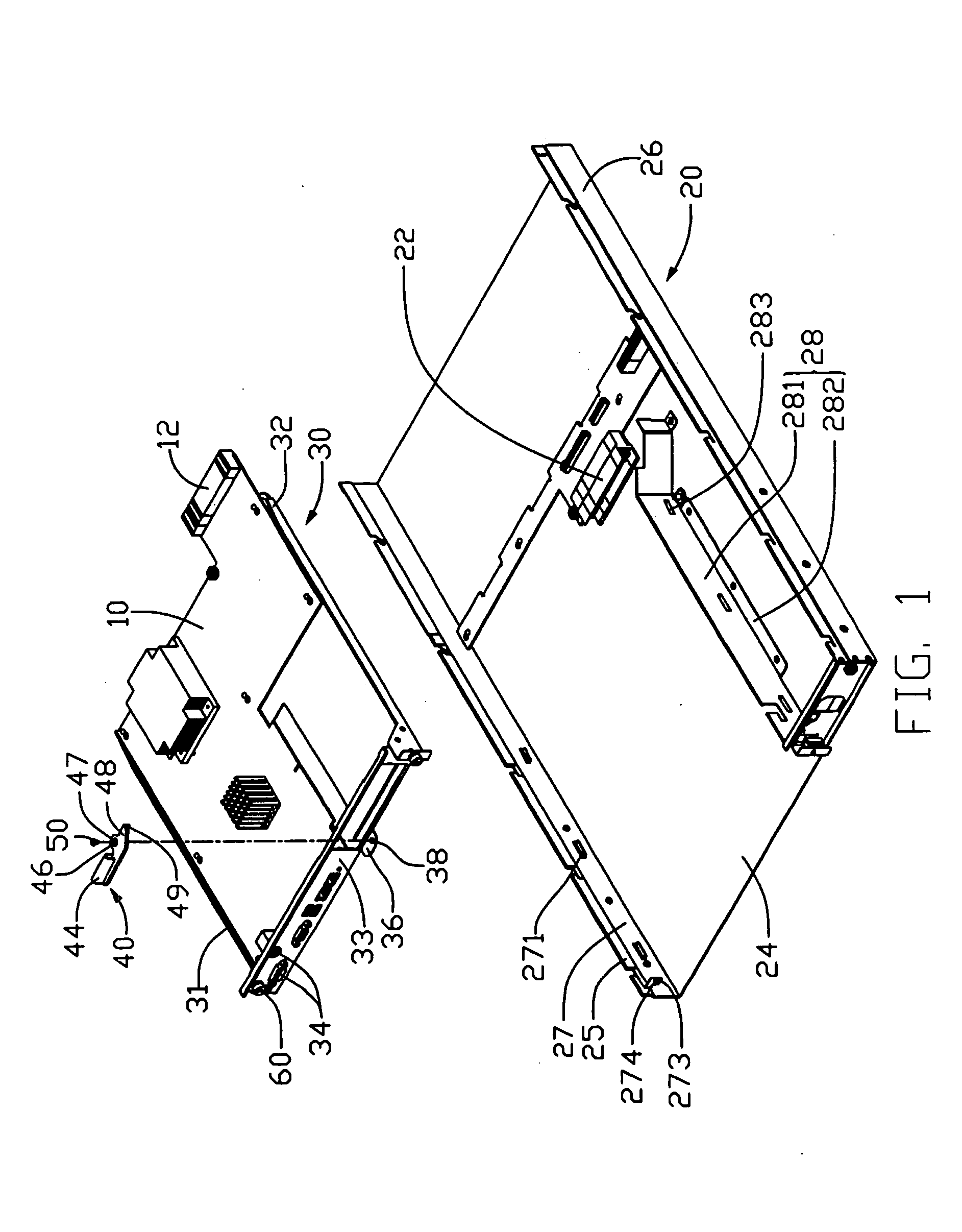

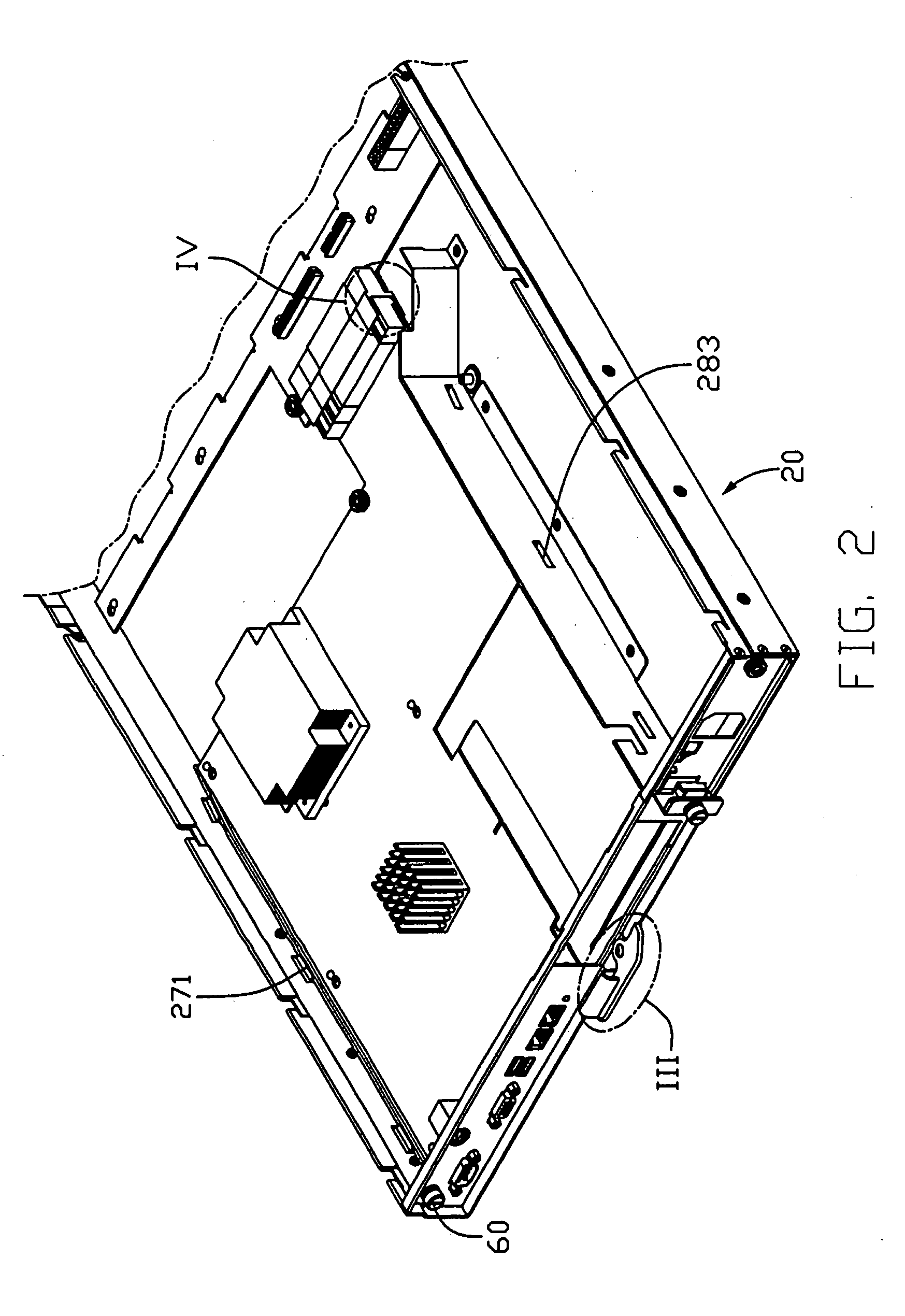

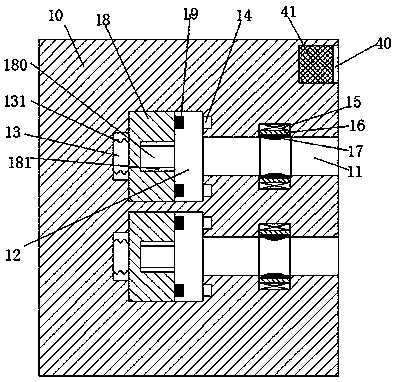

Ejector for motherboard

InactiveUS20050231923A1For quick ejectionSmooth disengagementCasings/cabinets/drawers detailsClamping/extracting meansFront edgeMotherboard

An ejection assembly as shown is used for rapidly ejecting a motherboard (10) from a server chassis (20). The ejection assembly includes a tray (30) for supporting the motherboard, and an ejector (40). A connector (22) is disposed in the chassis. The ejector is pivotally mounted to the tray, and includes an ejecting portion (48) to abut against a front edge of a bottom plate (24) of the chassis when the motherboard is electronically connected to the connector of the chassis. The ejector is pivoted outwardly so that the ejecting portion presses the front edge of the bottom plate to draw the tray outwardly, the motherboard is thereby horizontally and rapidly ejected from the connector of the chassis.

Owner:HON HAI PRECISION IND CO LTD

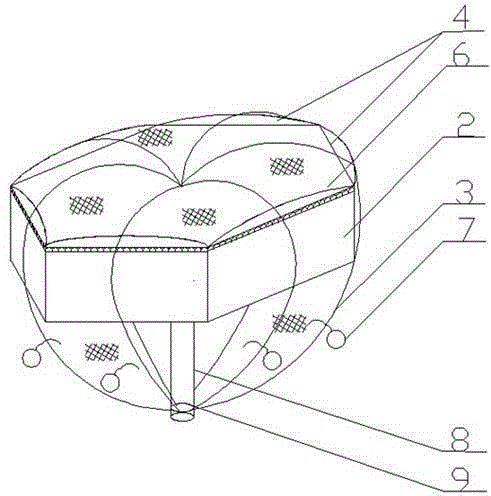

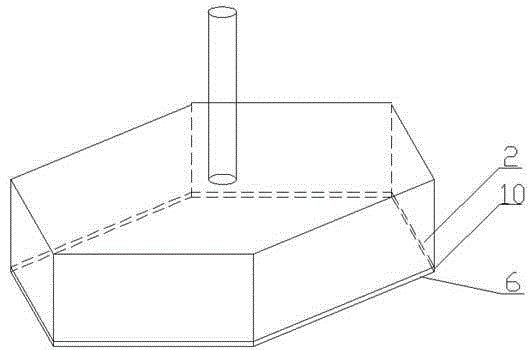

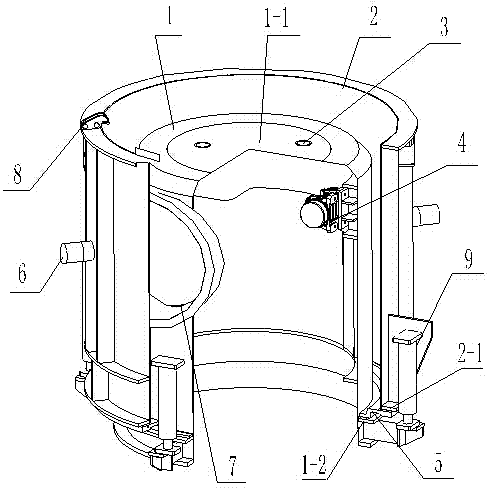

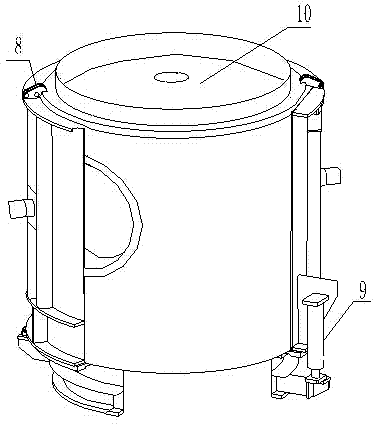

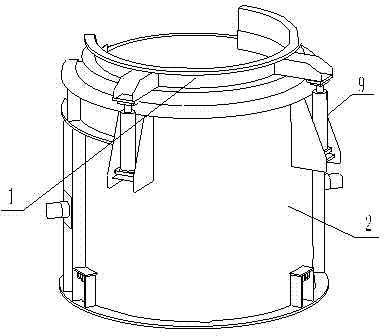

Vulgaris half-isolated mariculture cages and farming method

ActiveCN103598123AReduce the chance of cannibalismMeet like darkClimate change adaptationPisciculture and aquariaMaricultureAquatic animal

The invention puts forward a vulgaris half-isolated mariculture cages and farming method. The vulgaris half-isolated mariculture cages and farming method achieves vulgaris mode in half-isolated and the phenomenon that the vulgaris is easy to cause cannibalism in traditional culture cages is overcame, and the survival rate of the vulgaris is seriously influenced. The invention completes the cultivation of the vulgaris, by going through selection of breading area, setting of cages, capture of vulgaris offspring seed, development of management, release of bait and acquirement of harvest the processes, among which the container body has semi-closed structure making use of the constructure of the cages and is composed of a mesh enclosure and a attachment plaque. Net layer that is composed of different mesh size is equipped on the external rim and artificial vulgaris in a honeycomb structure configuration is equipped on the surface of the attachment plaque and a isolated panel is equipped on the external rim. The invention has the advantages that vulgaris half-isolated mariculture mode is achieved, the rate of cannibalism is lowered and the survival rate of the vulgaris is improved.

Owner:ZHEJIANG OCEAN UNIV

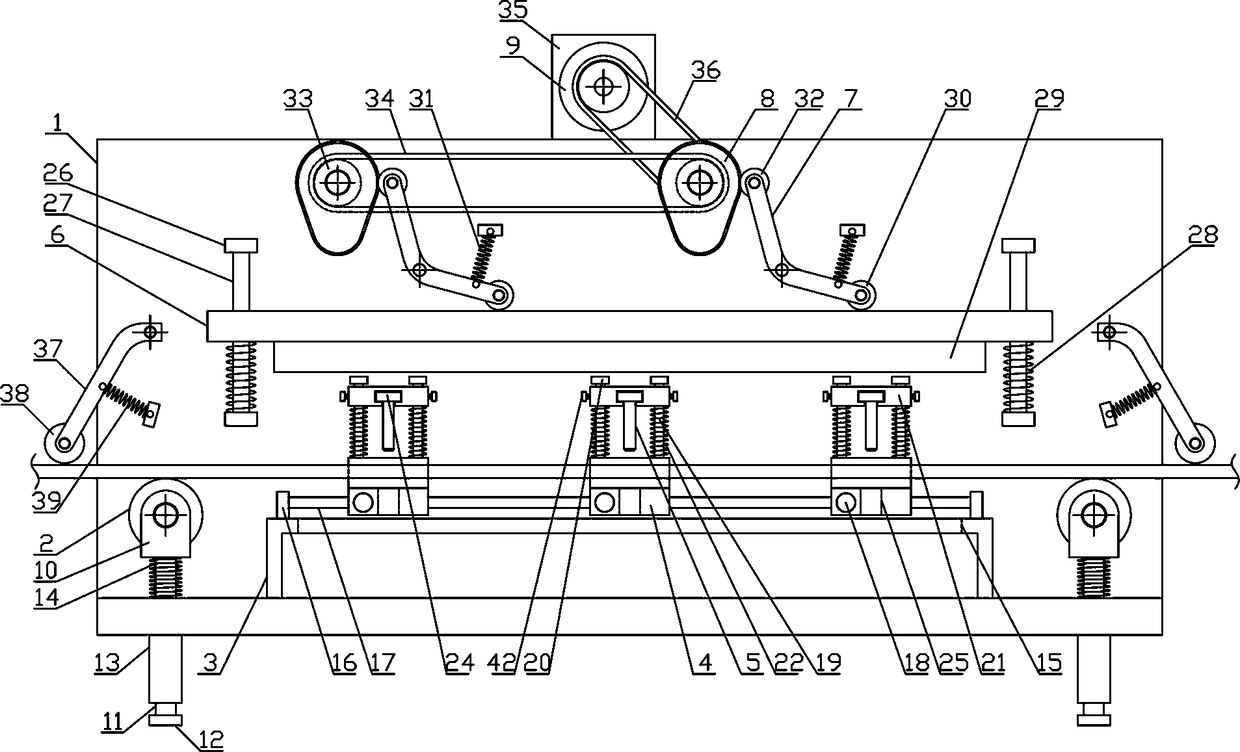

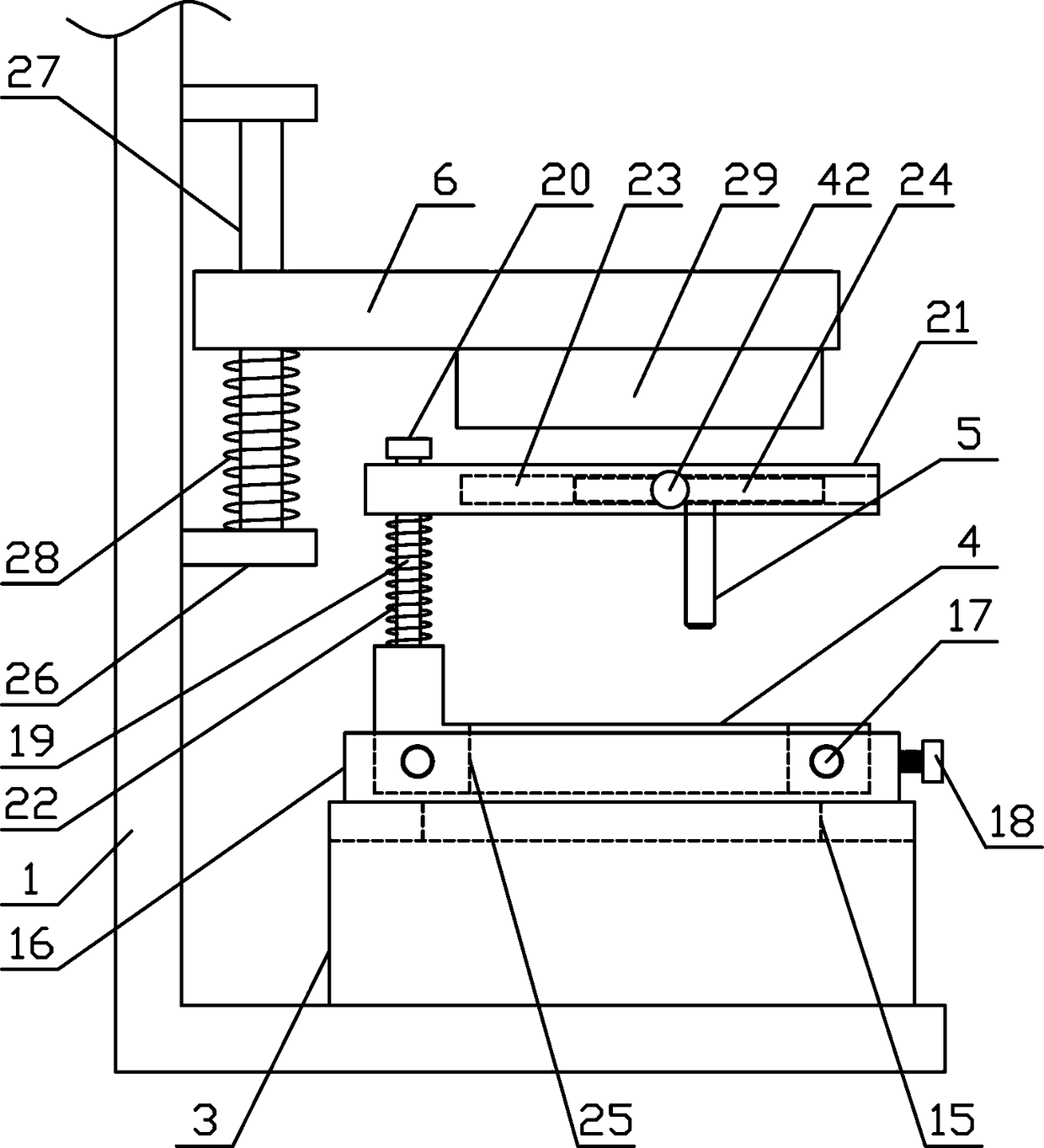

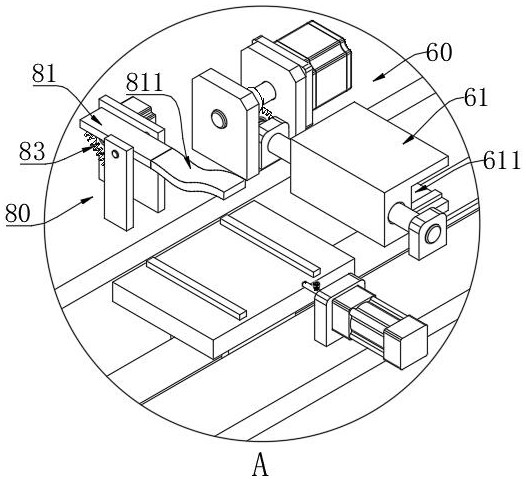

Aluminum product continuous punching mechanism

InactiveCN108787856AEasy to assemble and disassembleReasonable structural designMetal-working feeding devicesStripping-off devicesPunchingEngineering

The invention discloses an aluminum product continuous punching mechanism and belongs to the field of sectional material machining equipment. Rotating roller brackets on the two sides of a space belowa material conveying bracket are rotationally connected with material guide rotating rollers; a plurality of punching brackets are arranged on a horizontal movement guide rod in a sliding manner in the horizontal direction; punching pressure rods are vertically and fixedly arranged at the middle parts of the lower sides of adjusting guide plates; a punching pressure plate is horizontally and fixedly arranged on the lower side of a lifting pressure plate; rotating pressure rods are correspondingly and vertically arranged at the parts, on the two sides of a space above the lifting pressure plate, on the material conveying bracket; pushing rod cams are arranged at the parts, on one sides of the rotating pressure rods, on the material conveying bracket; and the output end of a rotary electromagnet is in transmission connection with the pushing rod cam on one side of the material conveying bracket by a punching belt. The structural design is reasonable, aluminum products can be subjected to punching machining conveniently, rapidly, stably and efficiently in the conveying process according to the requirement, scratched marks on the surfaces of the aluminum products in the machining process can be avoided, the punching machining efficiency and the punching machining quality of the aluminum products are improved, and the machining and using requirements are met.

Owner:蔡燕

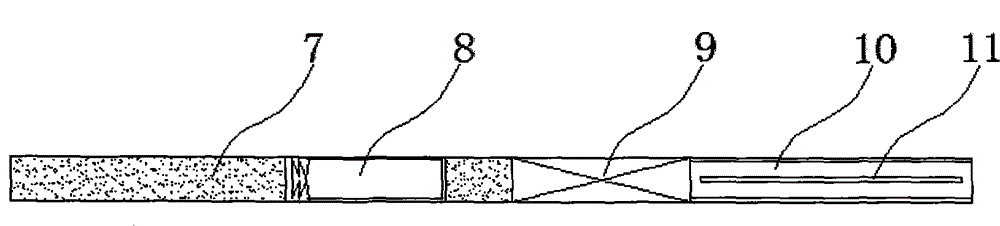

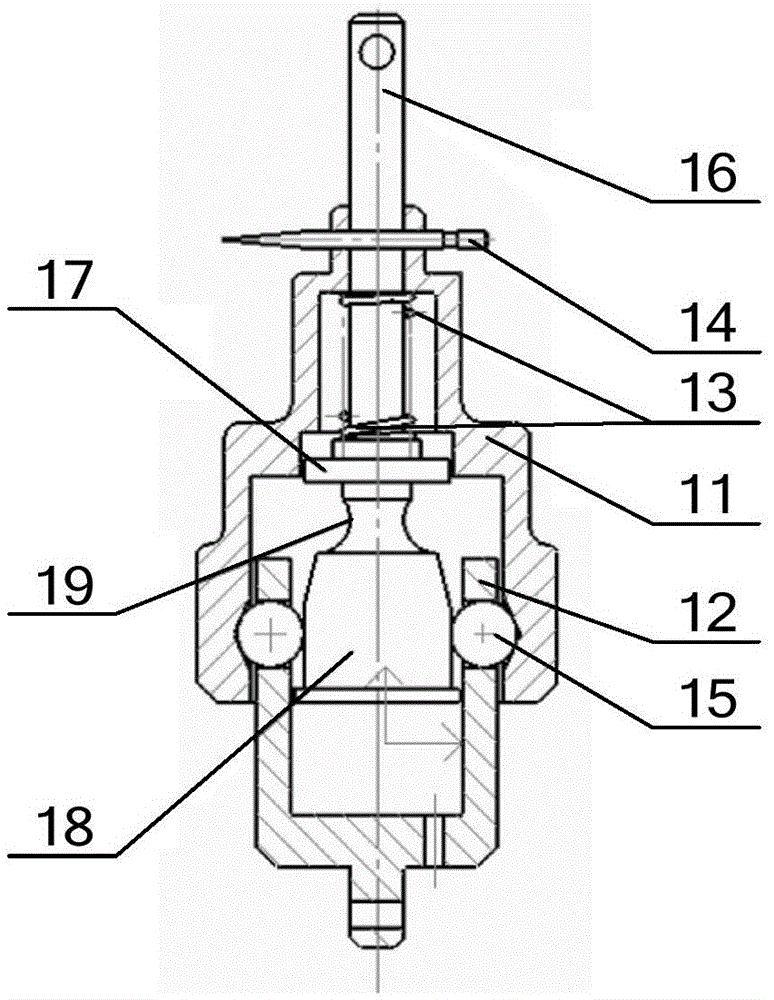

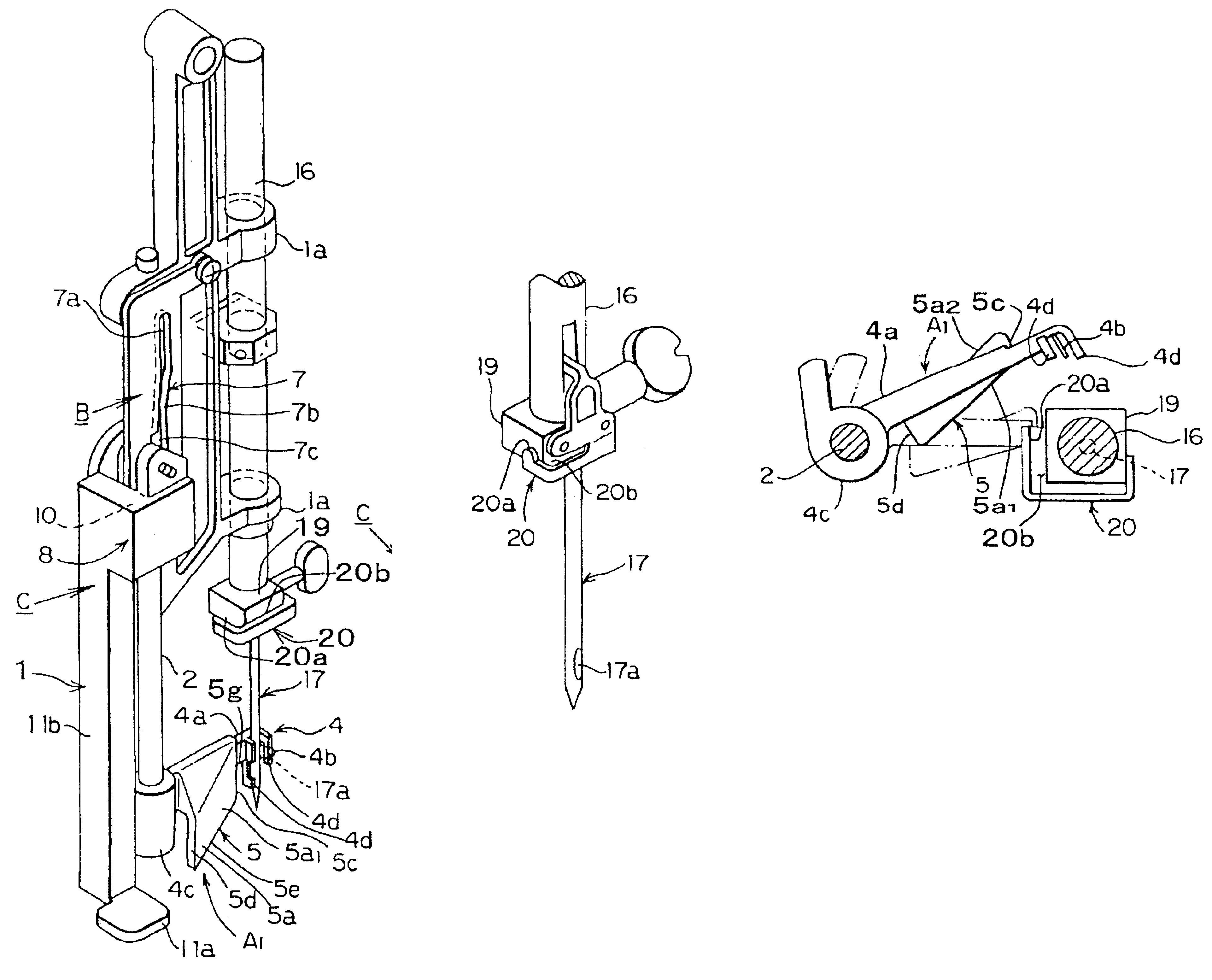

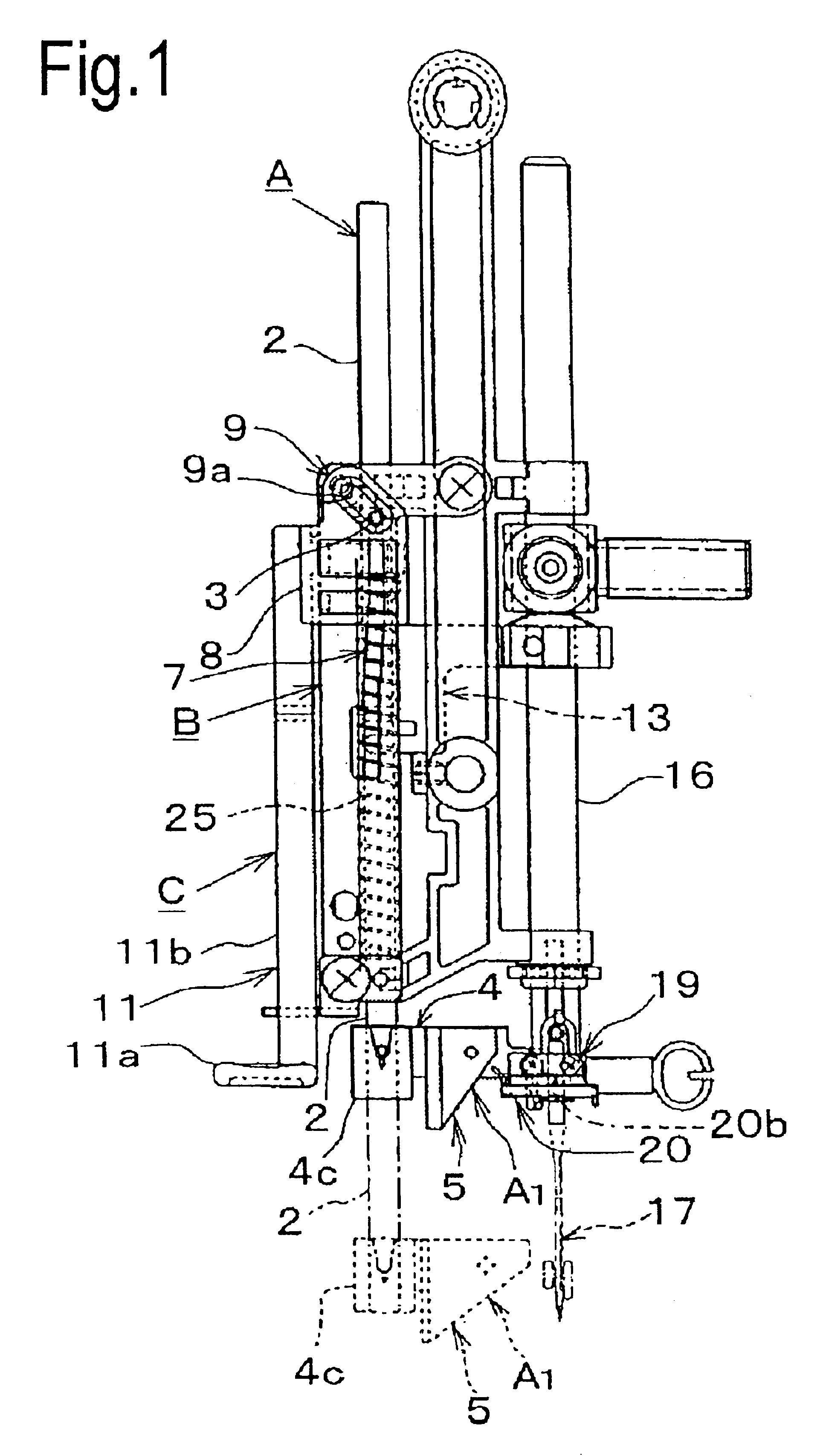

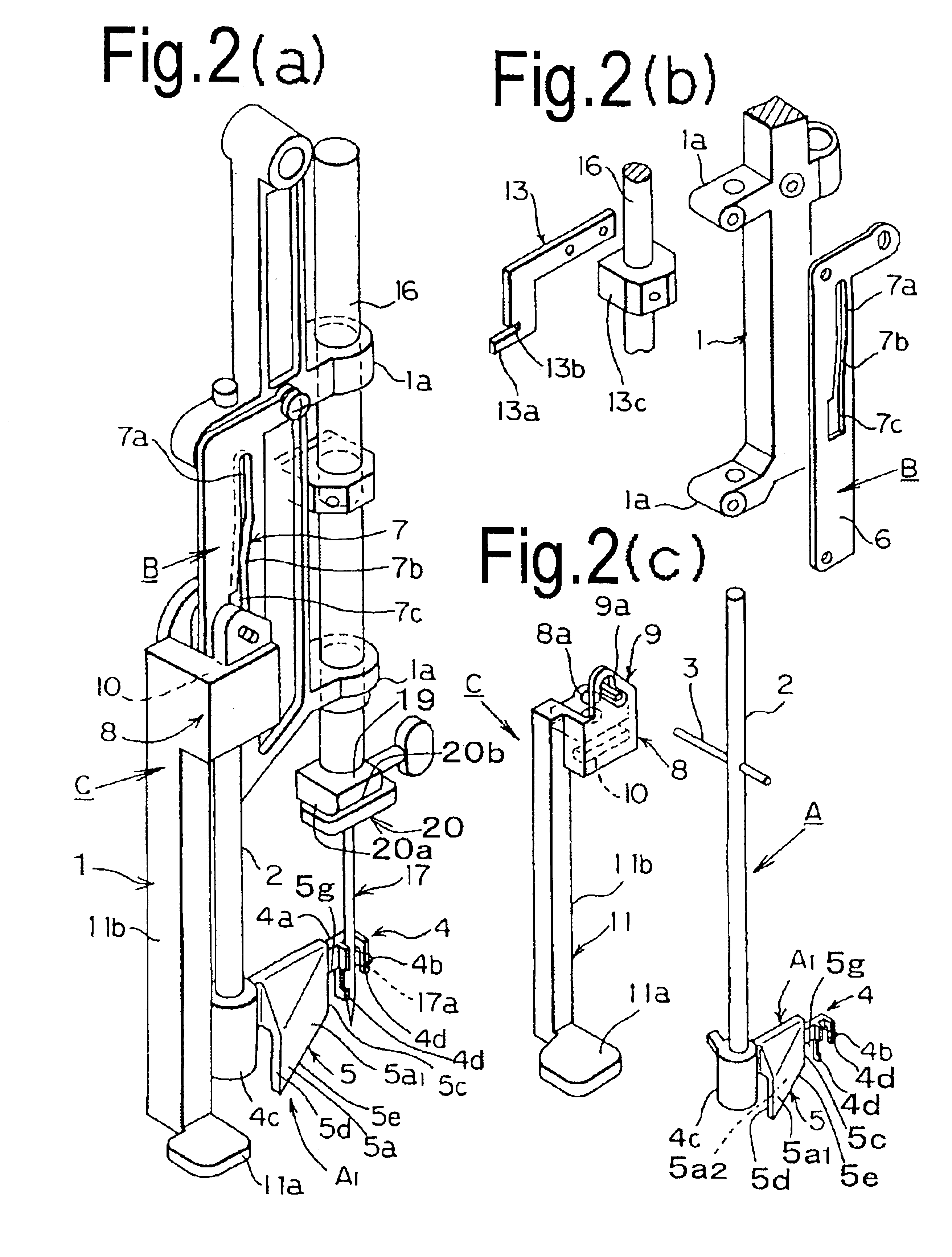

Threading device of sewing machine

ActiveUS6918344B2Easy to operateSimple structureThread-laying mechanismsNeedle-threading devicesBiomedical engineeringSewing machine

A threading device of sewing machine is disclosed, wherein the upper thread extended from a thread supply mounted on a sewing machine body may be easily and smoothly guided into engagement with a thread holder simultaneously when the threading device is operated to pass the upper thread through the eye of needle attached to the lower end of needle bar, the thread holder being arranged between the thread supply and the needle. The threading device comprises a vertically movable needle bar 16 having a needle attached to the lower end thereof, the needle having a needle eye, a needle bar support 1 for supporting the needle bar 16 such that the same may be vertically movable, a thread holder 20 mounted to the lower end of the needle bar 16, a threading member A1 having a thread engaging portion 5 and a threading hook 4b, a threading shaft 2 for having the threading member A1 secured to the lower end thereof, an operating section C for vertically moving and axially rotating the threading shaft 2 to pass the upper thread n through the needle eye 17a, the threading member A1 being so formed as to provide the thread engaging portion 5 for guiding the upper thread to the needle eye 17a, the needle holder 20 being formed with a groove 20b for holding the upper thread n, the groove 20b having an opening 20a at which the upper thread n is guided into the groove 20b from the rear side of the thread holder 20 while the thread engaging portion 5 is moved down with the upper thread n which is to be passed through the needle eye 17a.

Owner:JANOME CORP

Chain transmission

InactiveUS20090105024A1Light weightWear elongation is suppressedGearingDriving chainsSprocketEngineering

A hybrid chain comprises outer links composed of link plates connected in side-by-side relationship by two connecting pins fitted to holes in the outer plates, and inner links composed of link plates in spaced, side-by-side relationship and connected by two bushings on which rollers are mounted, the bushings being fitted to holes in the inner plates. The inner and outer links are connected in alternating, overlapping, relationship, with each pin of an outer link extending through a bushing of an adjacent overlapping inner link. The chain meshes with a sprocket composed of a central sprocket engaged by the rollers, and two side sprockets. The inner link plates, the outer link plates, or both, have two teeth, with outer flanks in the form of arcs each centered on the more remote pin or bushing hole. The inner link plates, outer link plates, or both, can be double-sided link plates.

Owner:TSUBAKIMOTO CHAIN CO

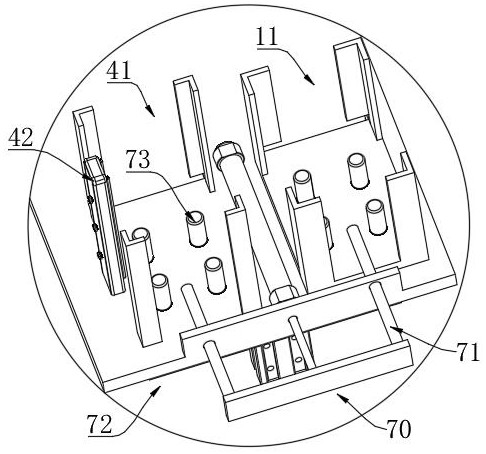

Lead frame jumper wire combination device

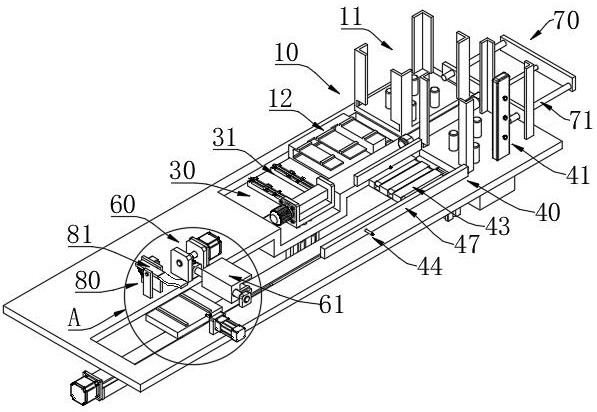

ActiveCN113421842AHigh degree of automationIncrease productivitySemiconductor/solid-state device manufacturingConveyor partsStructural engineeringVacuum tube

The invention provides a lead frame jumper wire combination device. The lead frame jumper wire combination device comprises a first conveying mechanism, a first turnover mechanism, a second conveying mechanism and a second turnover mechanism. The first conveying mechanism comprises a first storage mechanism and a conveying plate. The first turnover mechanism is arranged at the tail end of the moving direction of the conveying plate; the first turnover mechanism comprises a pair of rotating rods and is used for overturning the frame suckers on the conveying plate by 180 degrees; vent holes are formed in the bottoms of the frame suckers; vent pipes corresponding to the vent holes are arranged on the top surface of the rotating rod; the second conveying mechanism comprises a second storage mechanism and a vacuum pipe, and a pipe valve is arranged on one side of the jumper wire sucker; the vacuum pipe is provided with air suction holes corresponding to each layer of jumper wire suckers of the stack; a transfer plate is movably arranged at the outlet end of the second storage mechanism in the output direction, and the first turnover mechanism is located on one side of the middle section of the moving track of the transfer plate; and the second turnover mechanism is arranged at the tail end of the transfer plate in the moving direction and comprises a rotating block. The automation degree is high, and the production efficiency is greatly improved.

Owner:四川旭茂微科技有限公司

Forming stripper, and method

Owner:IND TECH RES INST

Improved water cup

InactiveCN108113389AEasy to pull outSmooth disengagementDrinking vesselsEngineeringMechanical engineering

The invention discloses an improved water cup. The improved water cup comprises a water cup body, a plug-in head connected to the water cup body through a wire and a plug-in socket cooperatively connected with the plug-in head; the left side face of the water cup body is fixedly provided with a handle, and the top of the water cup body is provided with a cup cover; the plug-in head is internally provided with a sliding connection groove with an opening facing forwards, a sliding connection strip is slidably installed in the sliding connection groove, the upper and lower end faces of the sliding connection strip are both provided with racks, the upper and lower end walls of the sliding connection groove are internally and symmetrically provided with switching grooves communicated with the sliding connection groove, mounting holes which are communicated with the switching grooves and provided with openings facing leftwards are also up and down symmetrically formed in the plug-in head, aplug shaft is rotatably installed in each mounting hole, gears fixedly connected with the plug shafts are installed in the switching grooves, and an outer ring of each gear extends into the sliding connection groove and is in matched connection with the corresponding rack.

Owner:广州大正机械科技开发有限公司

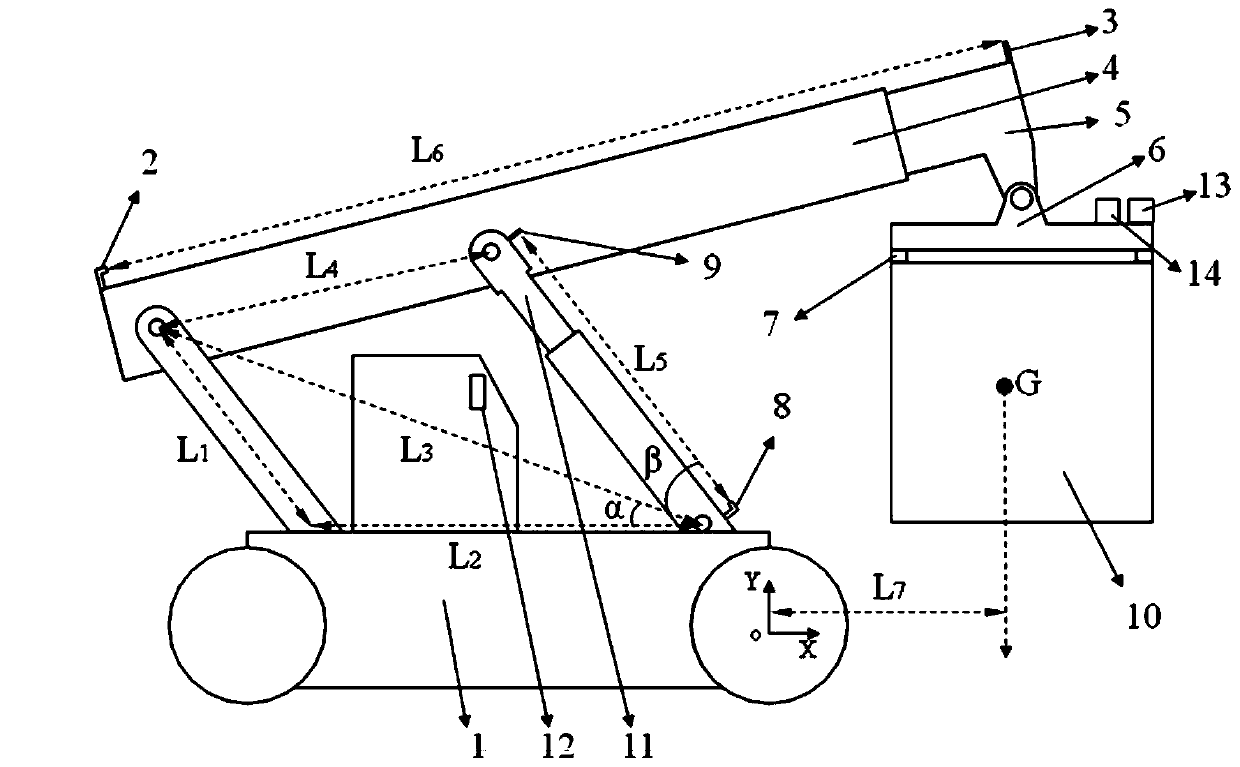

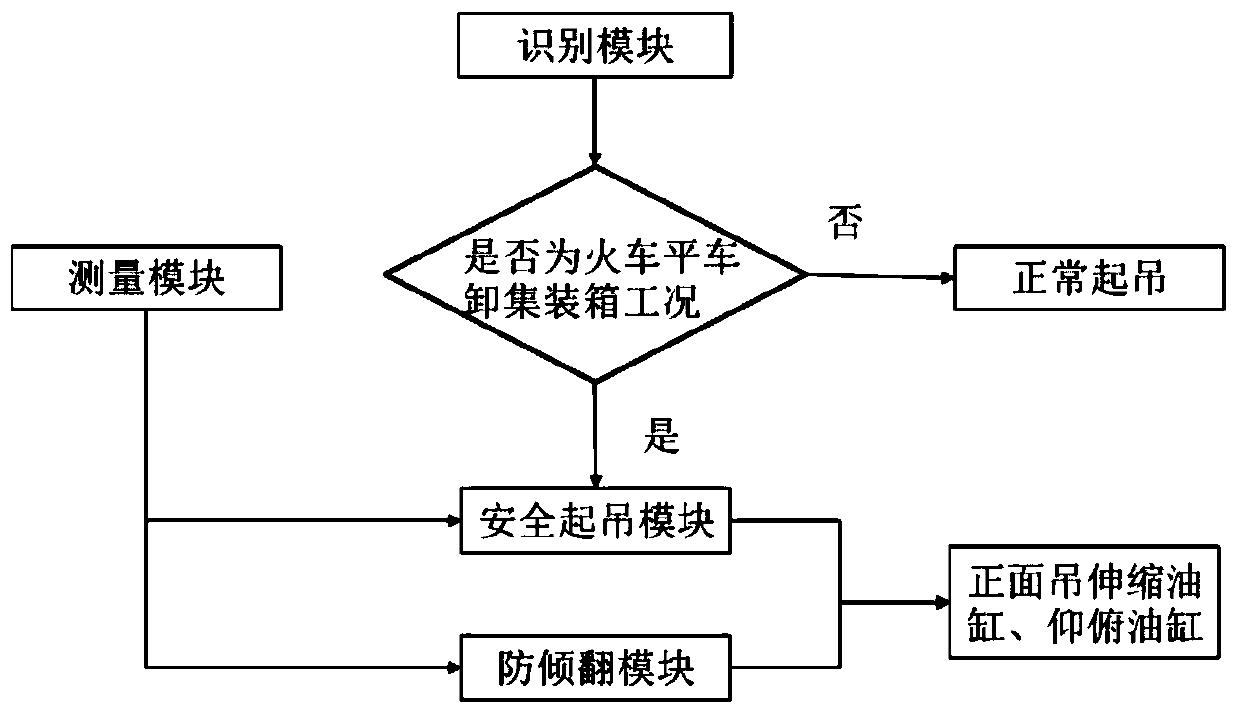

Control system and control method of safe hoisting of front hoist

The invention discloses a control system and a control method of safe hoisting of a front hoist. The system comprises an identification module, a measurement module, a safe hoisting module and an anti-tipping module, wherein the identification module is used for collecting images through a camera, identifying the images and judging whether the condition is a condition in which a container is unloaded from a train flatcar or not; the measurement module is used for measuring the length of a telescopic cylinder and the length of a pitching oil cylinder in real time through laser distance measurement sensors; four rotary locking type tension and pressure sensors on a hoisting appliance are used for measuring hoisting force of the container in real time; the safe hoisting module is used for judging a relative position between the container and a flatcar floor in the hoisting process according to collected data of the rotary locking type tension and pressure sensors; a hoisting speed and a hoisting direction of the hoisting appliance are controlled on the basis of data collected by the measurement module, so that a bottom corner part of the container can smoothly disengage from an F-TR lock on the flatcar, and the damage and the derailment of the flatcar are avoided; the anti-tipping module is used for considering the actual gravity center position of the container; compared with theexisting anti-tipping system of the front hoist, the anti-tipping module is more accurate and reliable.

Owner:TRANSPORTATION & ECONOMICS RES INST CHINA ACAD OF RAILWAY SCI CORP LTD

Concrete inspection well molding mould with base

ActiveCN104742250AOvercome mobilityOvercome the problem that it is not easy to inject into the inner cavity of the moldMouldsCeramic shaping coresLocking mechanismMaterials science

The invention provides a concrete inspection well molding mould with a base. The concrete inspection well molding mould comprises a cylindrical inner die and an outer die; one end of the inner die is provided with a bottom part, and an inspection well molding space forms between the inner die and the outer die; a faucet disk used for supporting concrete material filled in the molding space is arranged between one end of the inner die without the bottom part and corresponding end of the outer die; the faucet disk is fixedly connected with the inner die or the outer die, and one end of the inner die without the bottom part is connected with the outer die through a jacking mechanism. The concrete inspection well molding mould further comprises a bottom tray for pressing the concrete material filled in the molding space and a locking mechanism used for locking the bottom tray on the mould. By adopting the concrete inspection well molding mould, the molding efficiency and production quality of the inspection well are obviously improved.

Owner:苏州科星混凝土水泥制品装备有限公司

Chain transmission

In a chain transmission in which a roller chain transmits power from a driving sprocket to one or more driven sprockets, the sprocket teeth are shaped so that at a location radially outward from the sprocket pitch circle, the distance between the front surface of each sprocket tooth to a radial reference line from the sprocket center through the center of the tooth root, is at least as great as the distance from the centerline to the front tooth surface at the pitch circle. The tooth faces merge smoothly with the tooth gap bottom, the sprocket root diameter is smaller than the root diameter according to ISO standards, and the radius of the arcuate tooth gap bottom is greater than the radius of the chain roller.

Owner:TSUBAKIMOTO CHAIN CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com