Peeling device for juicer

A juice machine and fruit technology, applied in peeling utensils, applications, household utensils, etc., can solve the problems of low efficiency and lack of peeling devices in the juice machine, and achieve the effect of high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

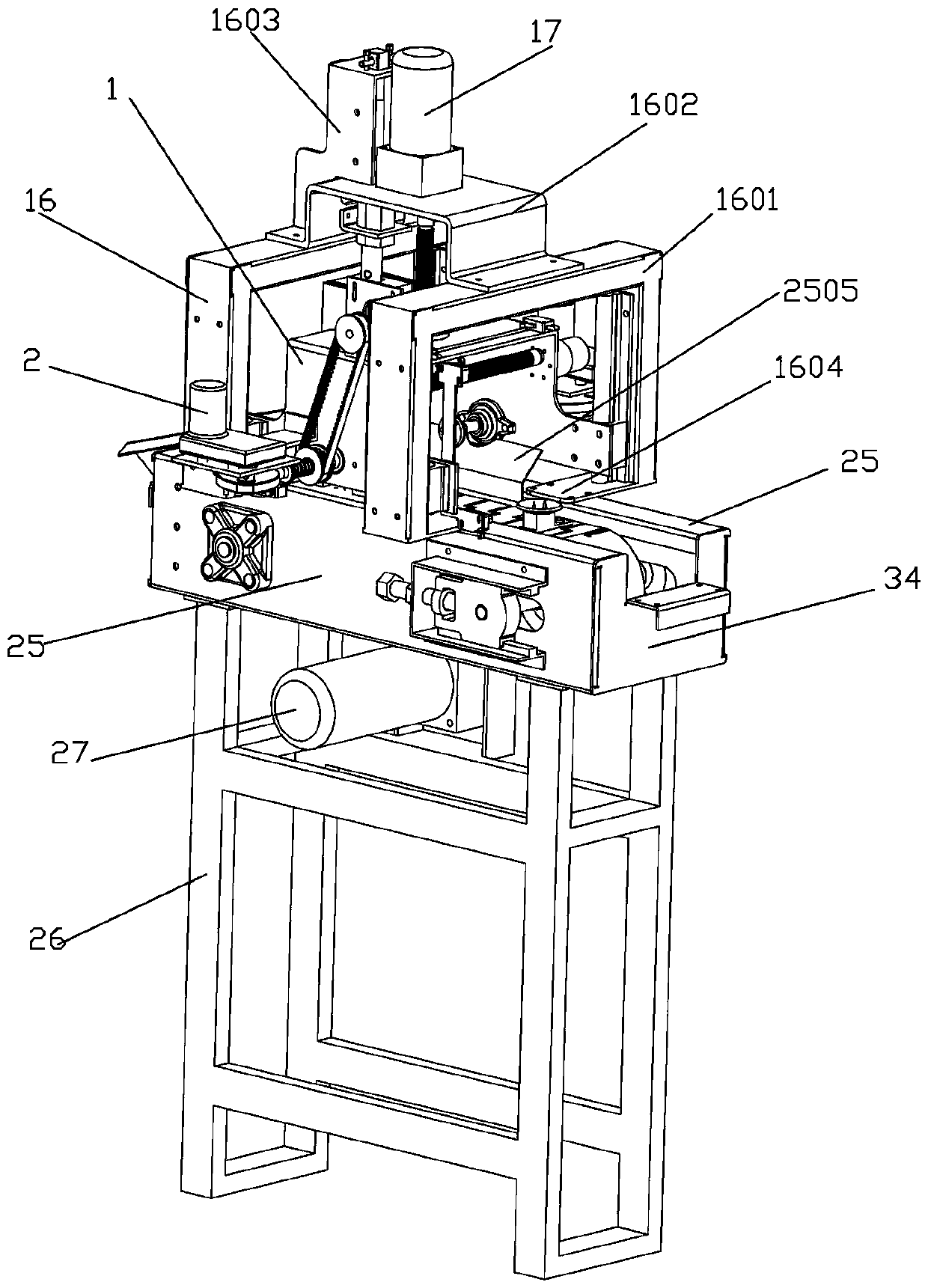

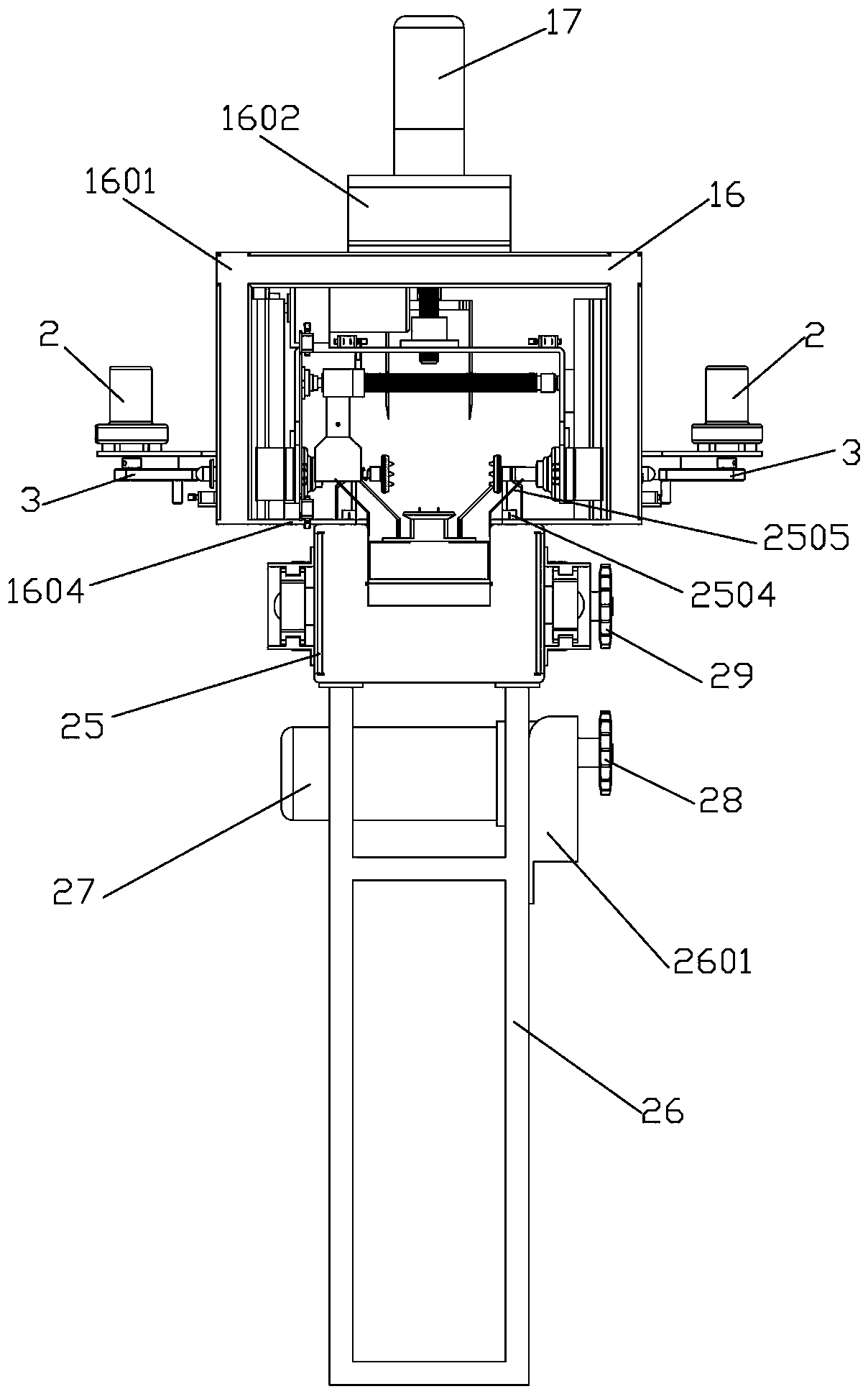

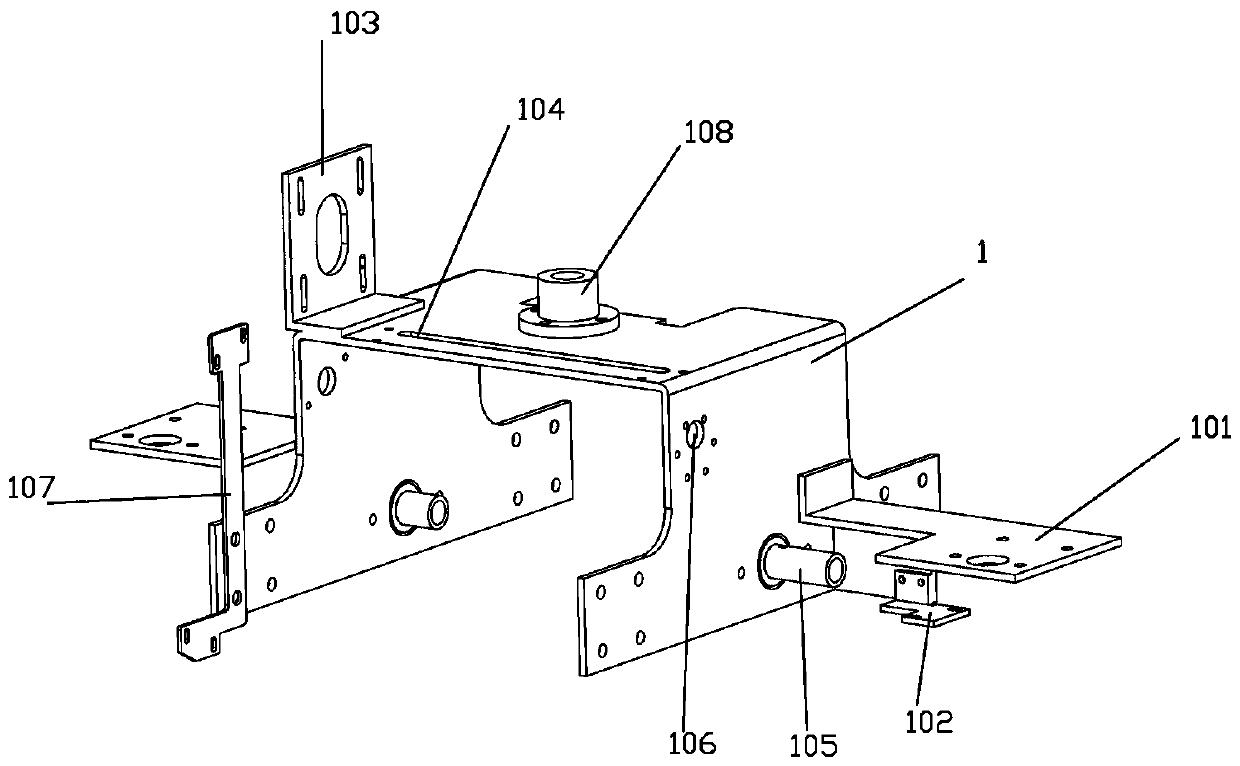

[0031] Reference for specific embodiments of the present invention Figure 1-15 , A peeling device for a juice machine, comprising a lifting frame 1, an upper frame 16, a transmission frame 25 and a lower leg 26, characterized in that:

[0032] The lifting frame 1 includes a top plate, a left side plate, and a right side plate. A cam motor 2 mounted on the cam motor mounting plate 101 is symmetrically provided on the outer side of the left and right side plates of the lifting frame 1 and mounted on the limit switch. The limit switch 4 on the plate 102, the top hollow shaft 105 that passes through the middle through hole and is matched with the top bearing seat 7 fixed on the inner side of the left and right side plates of the lifting frame 1, and the cam motor 2 is connected with a cam limit The cam 3 of the rod 301, the center hollow shaft 105 is equipped with a center sleeve 8, the inner end of the center sleeve 8 has a center 9 with a disc-shaped end surface, and the outer end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com