Automatic assembling method of light emitting diode (LED) lamp tube

A technology for automatic assembly of LED lamp tubes, applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of low assembly efficiency, high cost, and large labor consumption, and achieve high efficiency, low cost, and improved The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

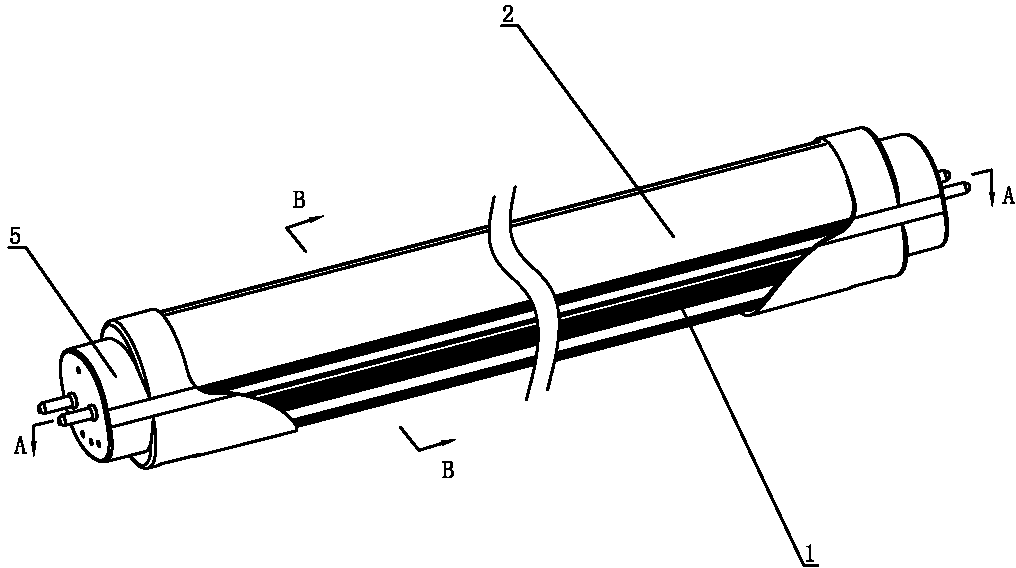

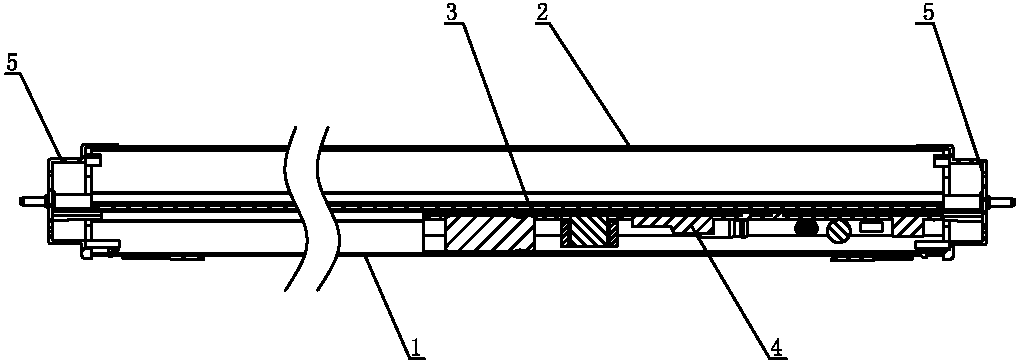

[0032] Such as Figure 1 to Figure 4 As shown, the LED lamp tube includes a housing 1 , a lampshade 2 , an LED light source 3 , a power supply 4 and a lamp holder 5 .

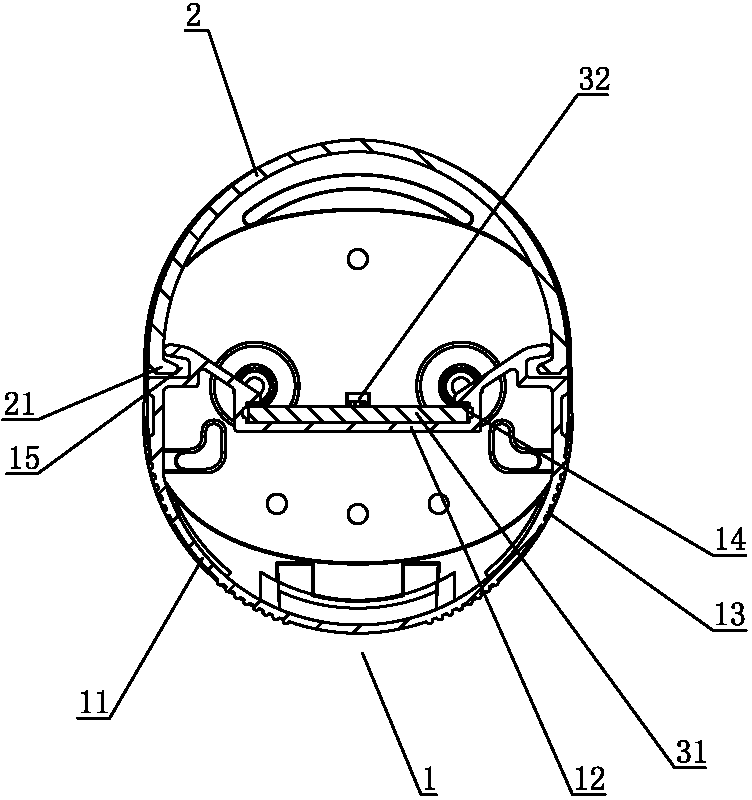

[0033] Such as Figure 4 As shown, the housing 1 includes a housing 11 and a bearing plate 12. The cross section of the housing 11 is U-shaped. The bearing plate 12 is arranged at the opening of the housing 11. The housing 11 and the bearing plate 12 are integrally formed. An accommodating chamber is formed between them, a bayonet (not shown) is provided on the shell, and a cooling rib 13 is provided on the outer wall of the shell 11 to improve the heat dissipation speed. The first card slot 14 and the second card slot 15 are formed on the outer end of the housing 11 .

[0034] A clip bar 21 is formed on the lampshade 2 , and the clip bar 21 is clipped in the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com