Patents

Literature

102 results about "Orbital welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Orbital welding is a specialized area of welding whereby the arc is rotated mechanically through 360° (180 degrees in double up welding) around a static workpiece, an object such as a pipe, in a continuous process. The process was developed to addresses the issue of operator error in gas tungsten arc welding processes (GTAW). In orbital welding, computer-controlled process runs with little intervention from the operator. The process is used specifically for high quality repeatable welding.

Orbital welding device for pipeline construction

InactiveUS20070119829A1Increase production speedArc welding apparatusLaser beam welding apparatusLight guideBeam source

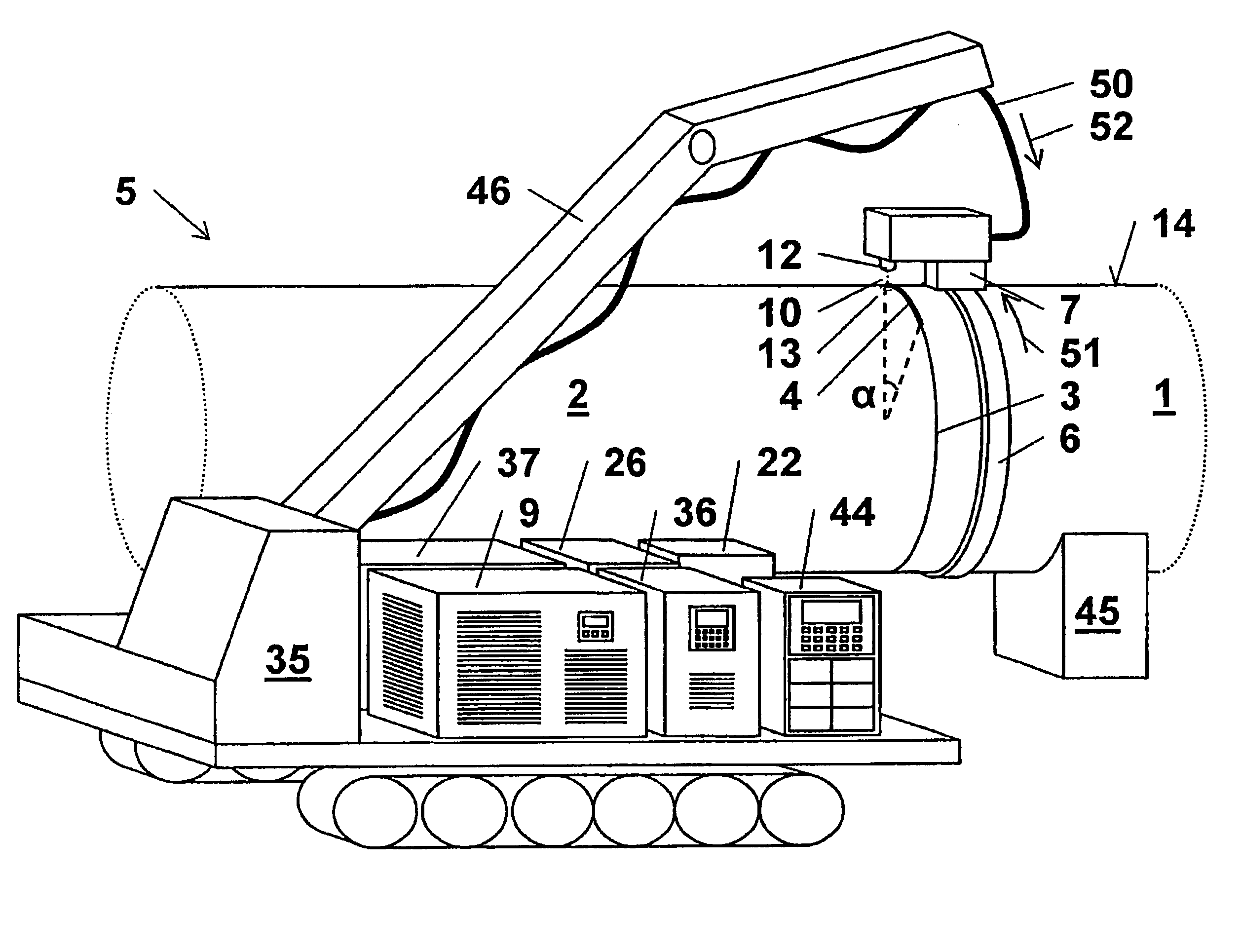

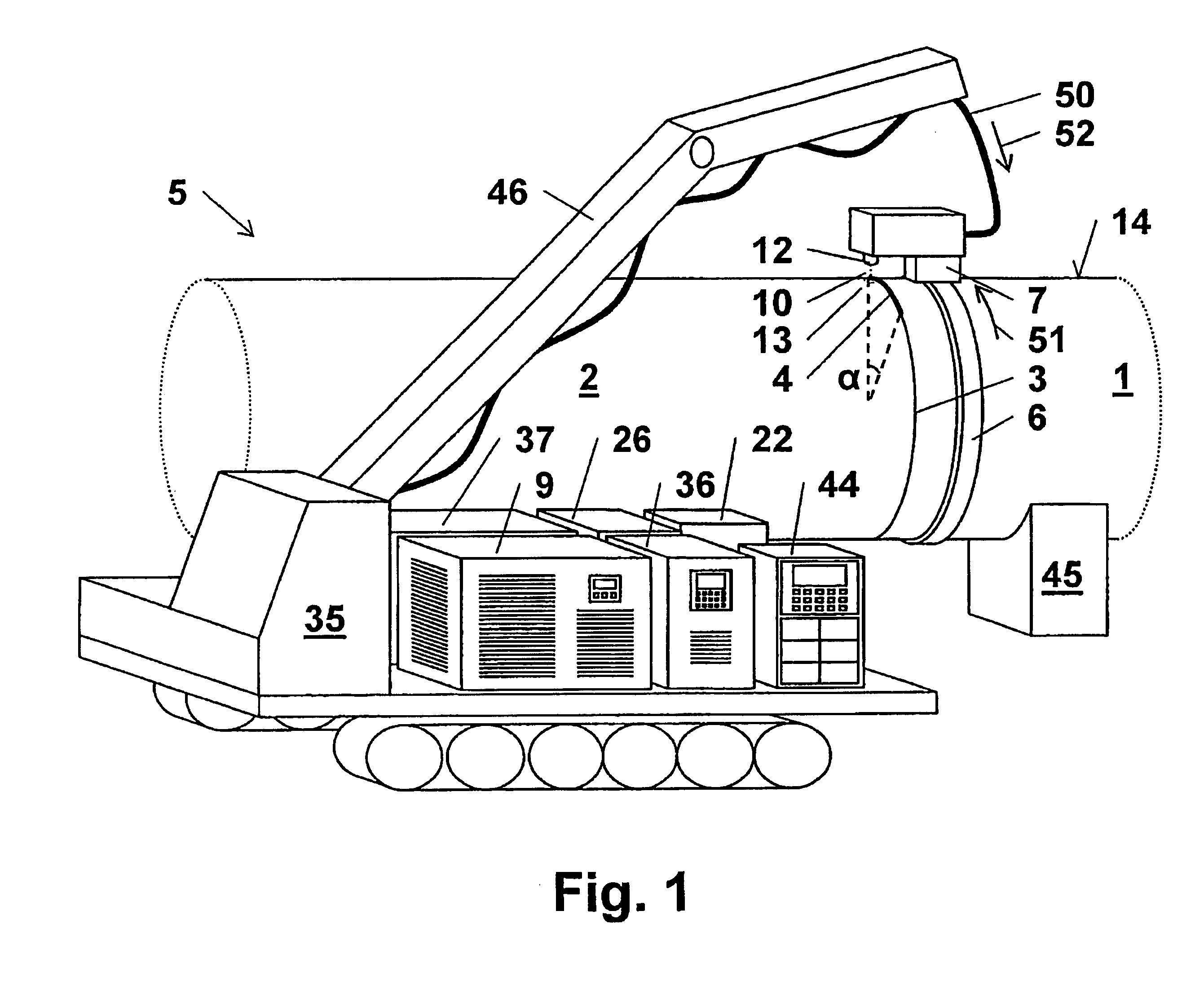

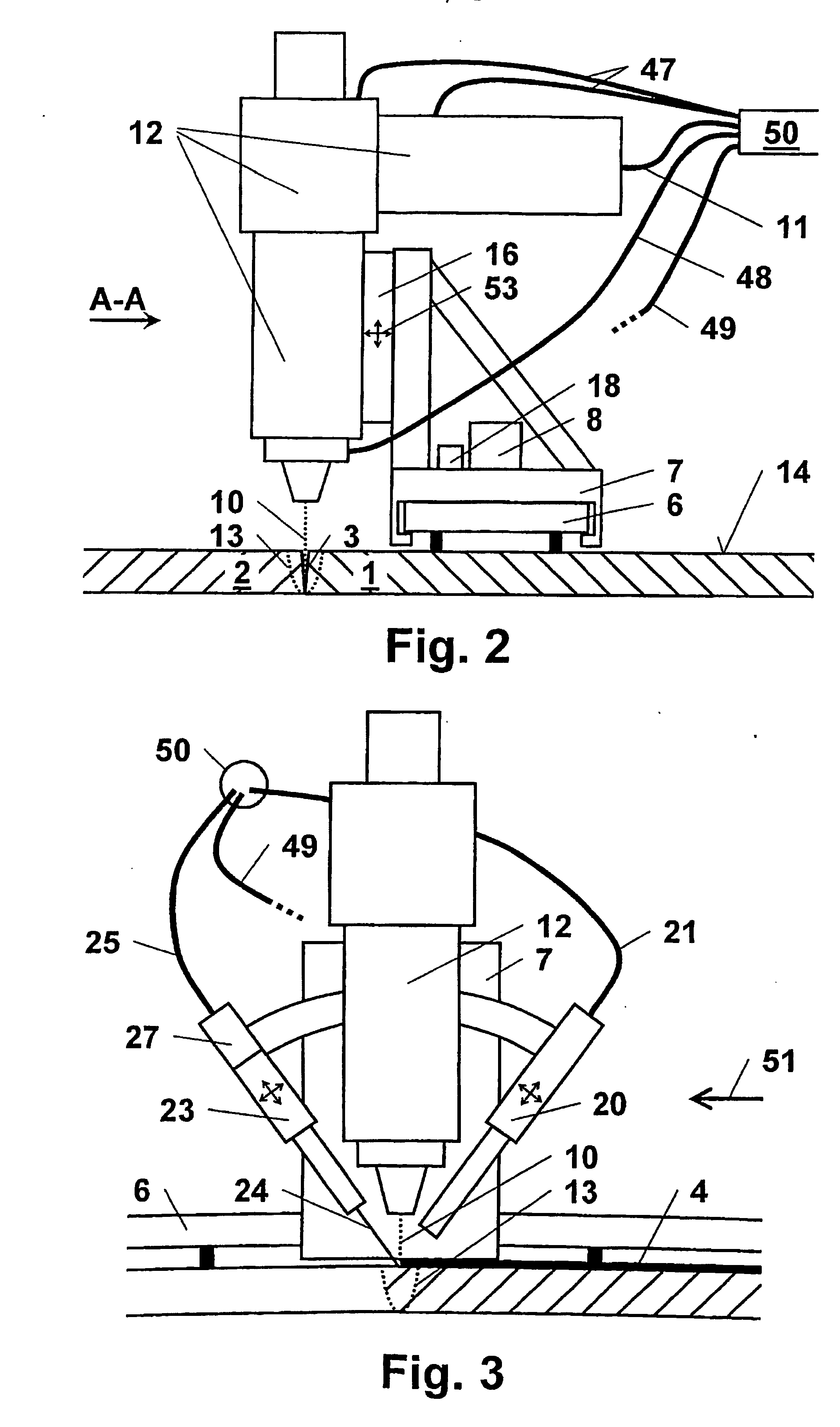

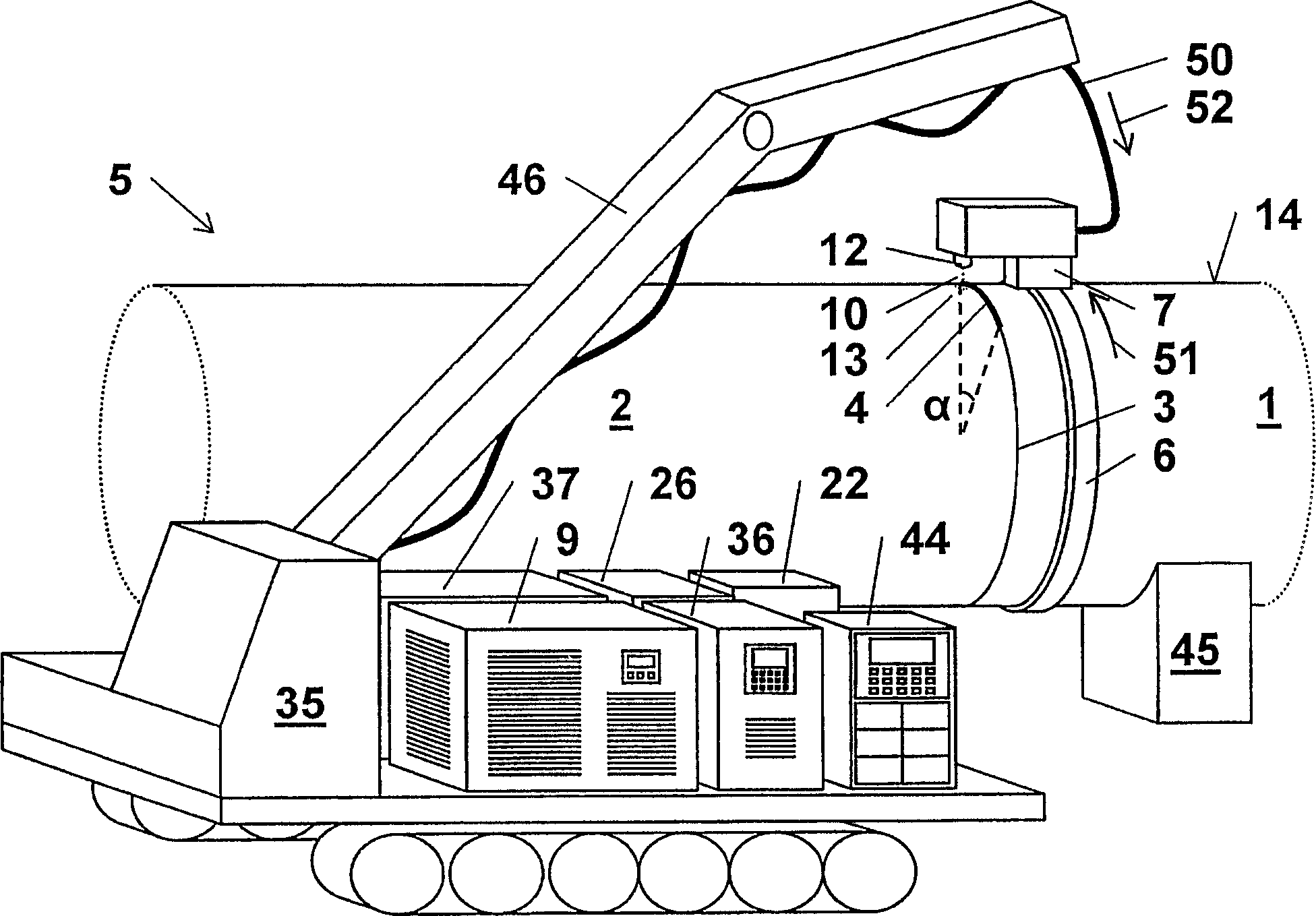

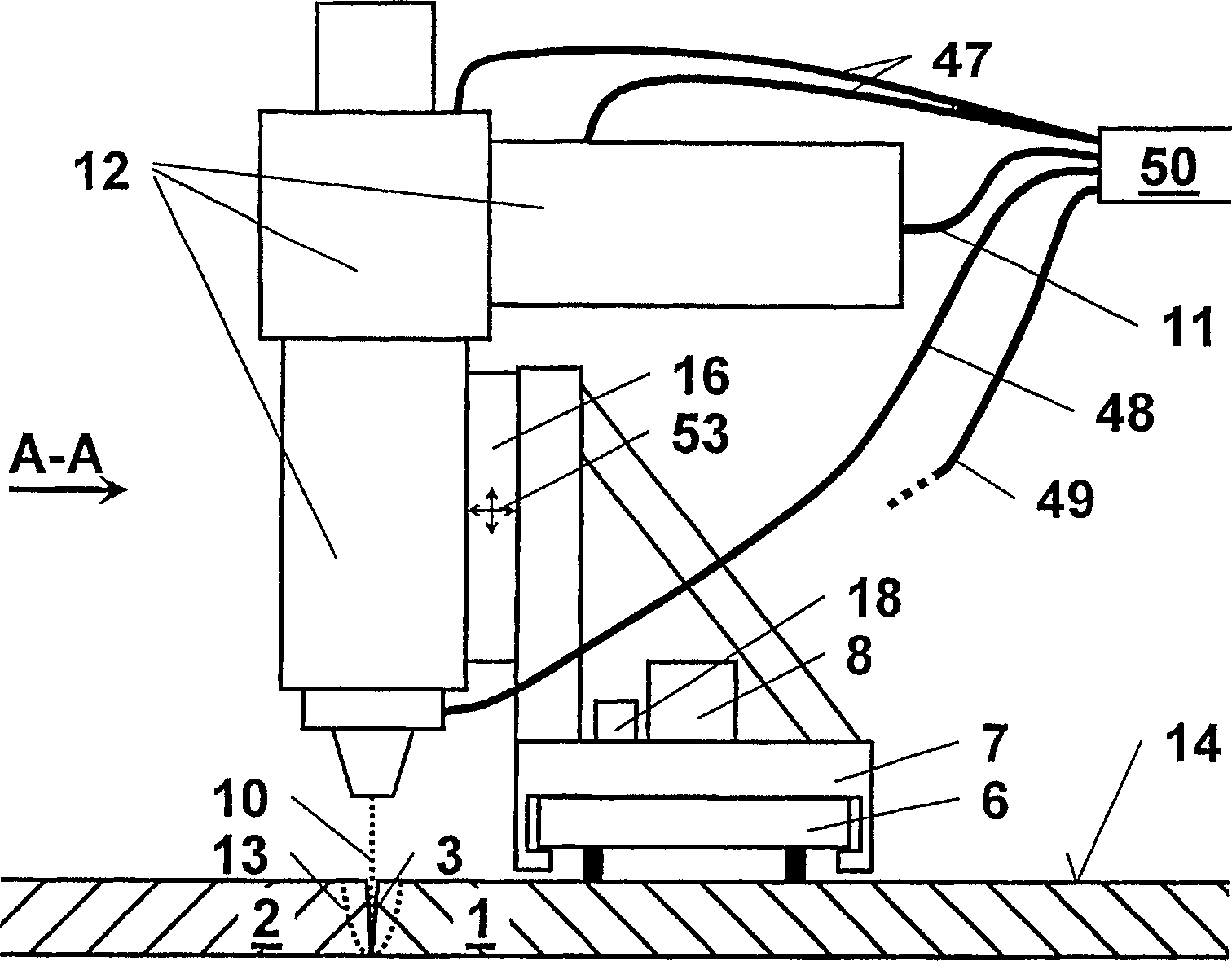

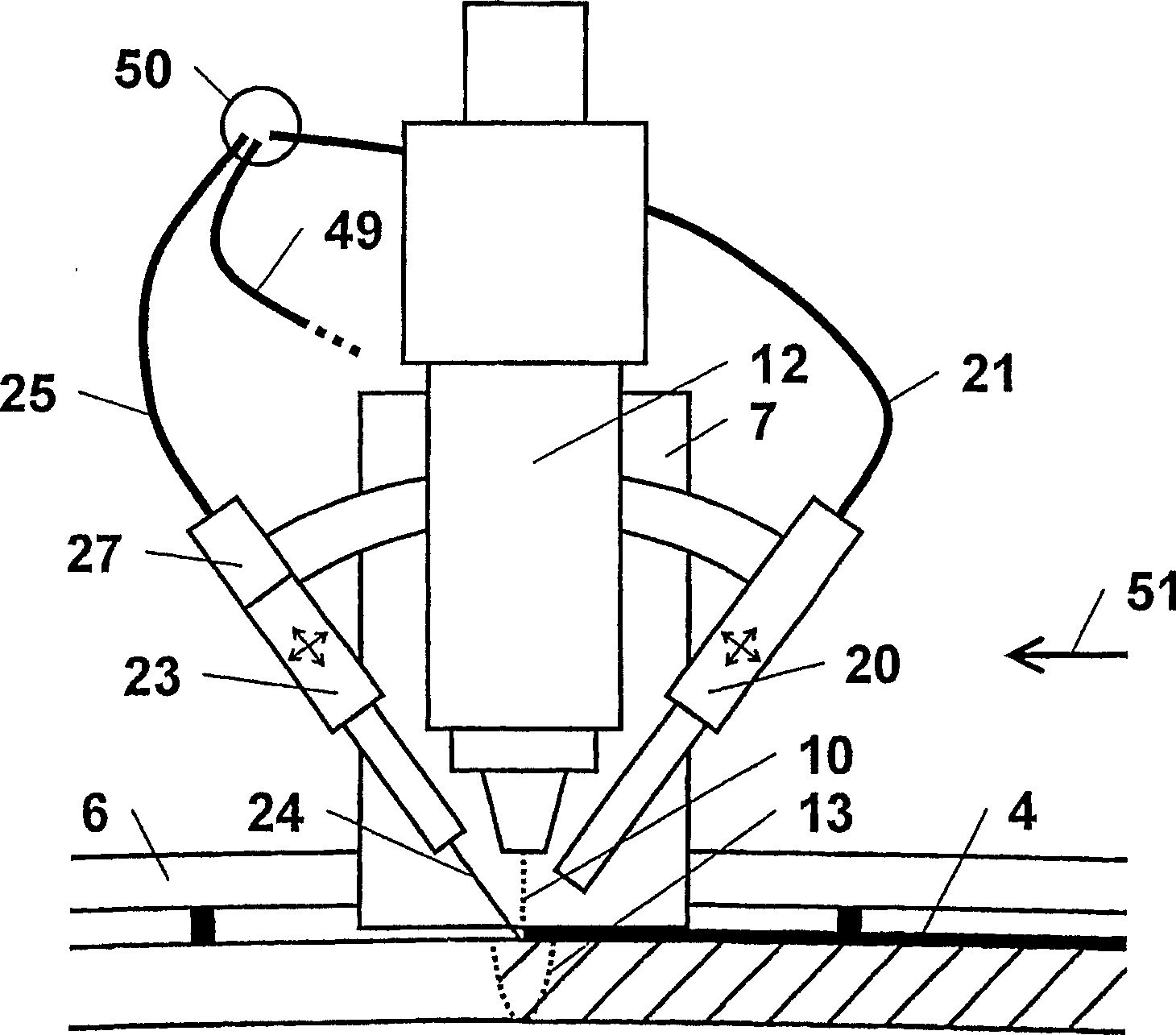

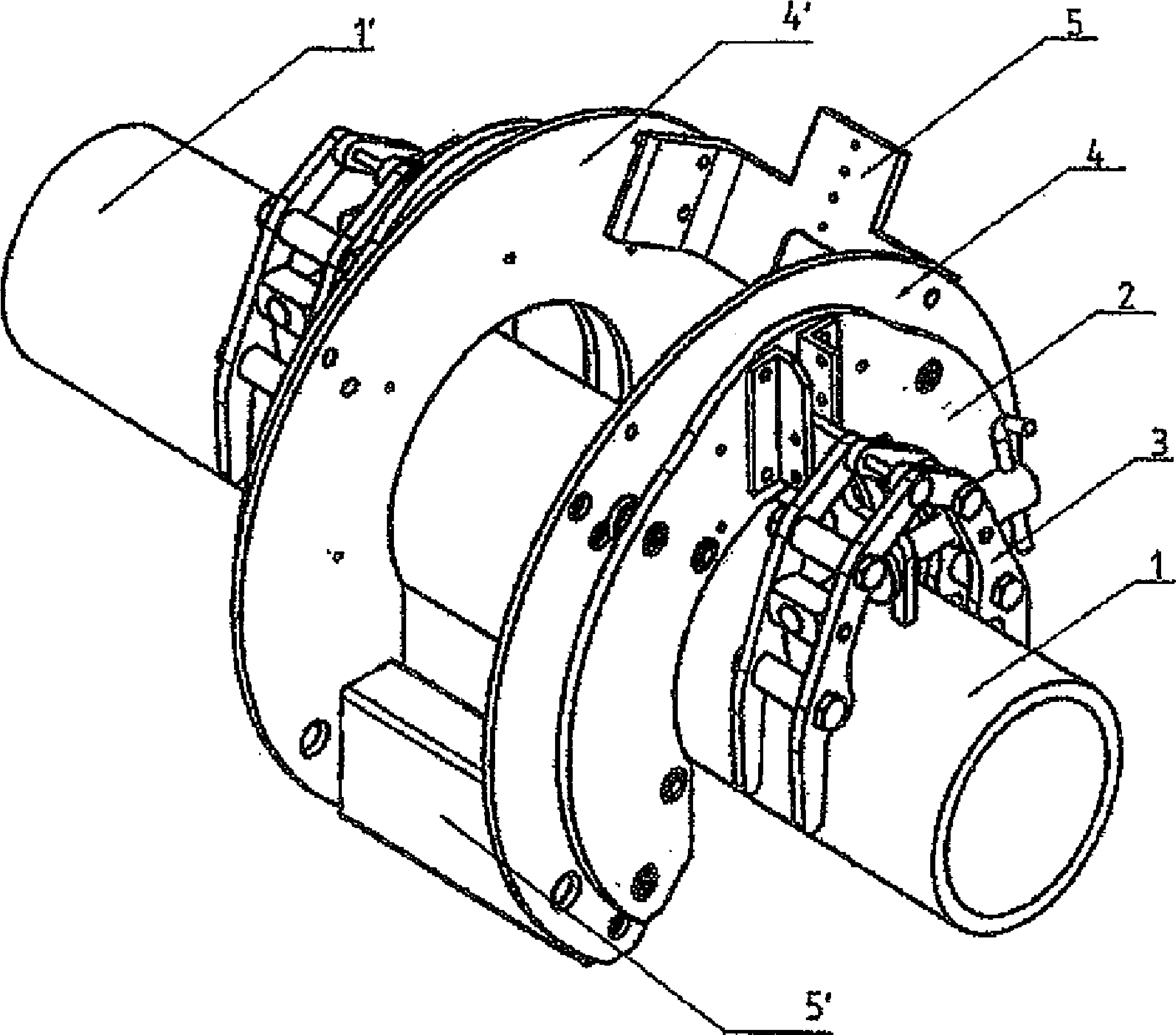

The invention relates to an orbital welding device for mobile use in order to join a first pipe (1) and a second pipe end (2) along a circumferential joint (3) by at least one weld seam (4), particularly for producing a pipeline (5) to be placed on land. The inventive device includes a guide ring (6), which can be oriented toward the first pipe end (1) and the circumferential joint (3), and an orbital carriage (7) that can be motor-displaced along the guide ring (6) via an advancing device (8). On the orbital carriage (7), a laser welding head (12) for directing a laser beam (10) into a laser welding zone (13) is mounted in a manner that enables it to be oriented toward the circumferential joint (3) whereby enabling the production of the weld seam (4) along the circumferential joint (3) by displacing the orbital carriage (7). The laser beam (10) is produced by a high-power fiber laser beam source (9) located, in particular, on a mobile transport vehicle (35) while being situated at a distance from the orbital carriage (7), is guided by light guide (11) passing through a tube bundle (50) to the orbital carriage (7) and then supplied to the welding head (12). A significant advantage of the invention resides in the fact that the joining of two pipe ends by only one single welding process during a short period of time is made possible in the field with autonomous operation.

Owner:VIETZ

Rail welderhead shear apparatus

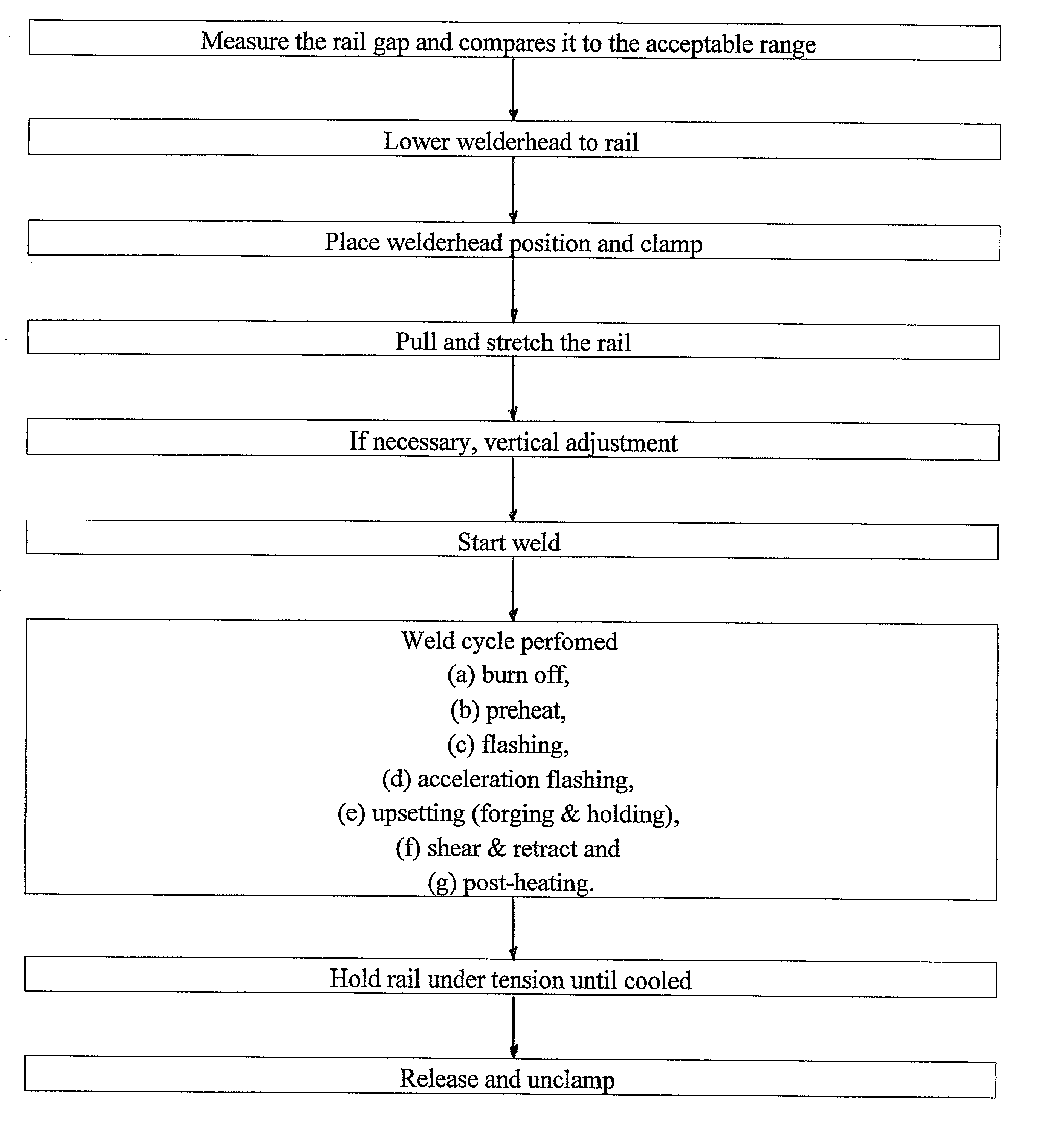

A flash butt rail welding welderhead combines in a single unit, the ability for the three functions of rail pulling, flash butt forging and maintaining the "after forged" displacement without any change in platen position such that shearing may be accomplished in three stages, a single stage, multiple stages or a progressive stage, all while maintaining clamping and stretching force on the rails.

Owner:HOLLAND CO

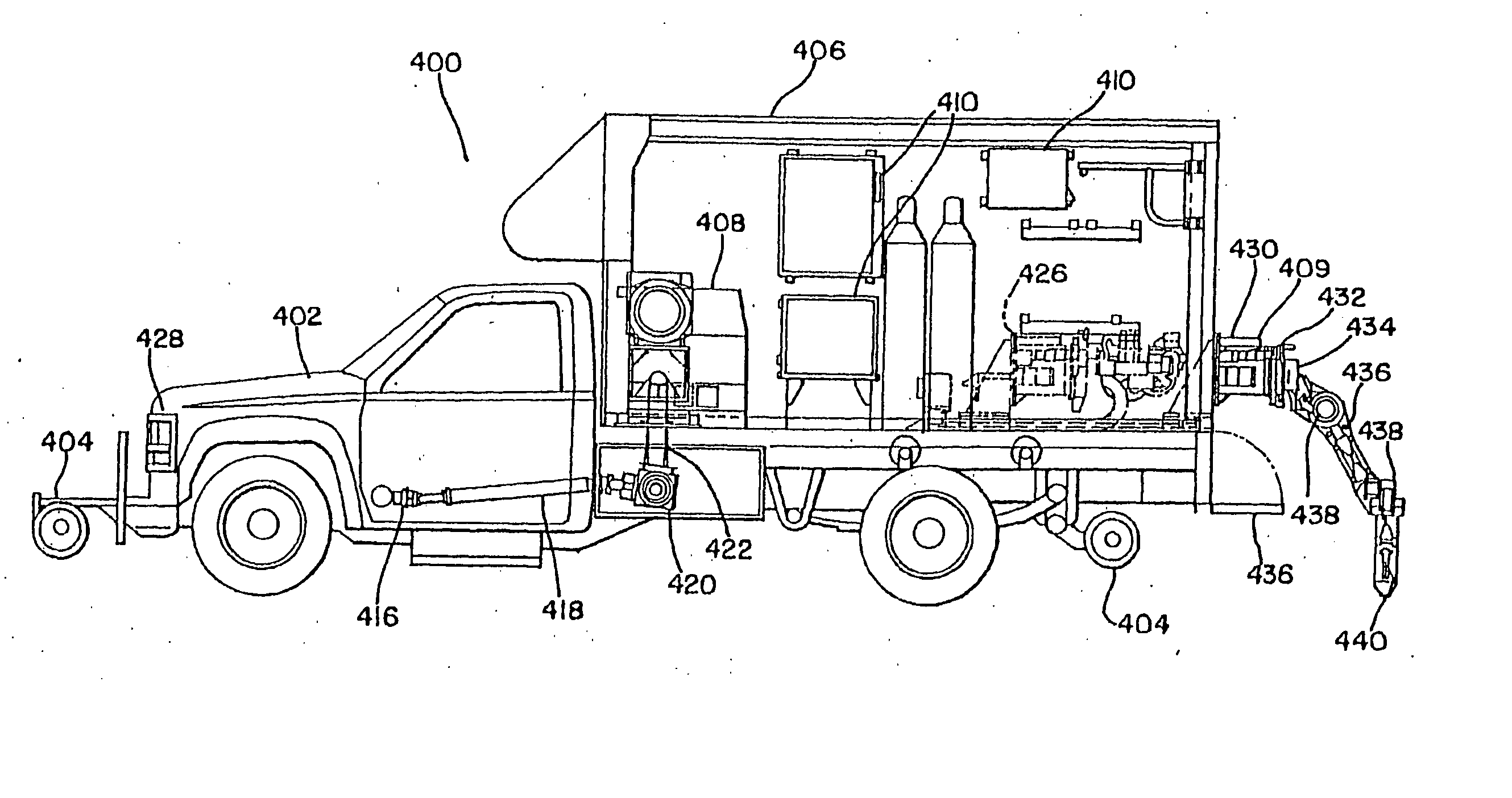

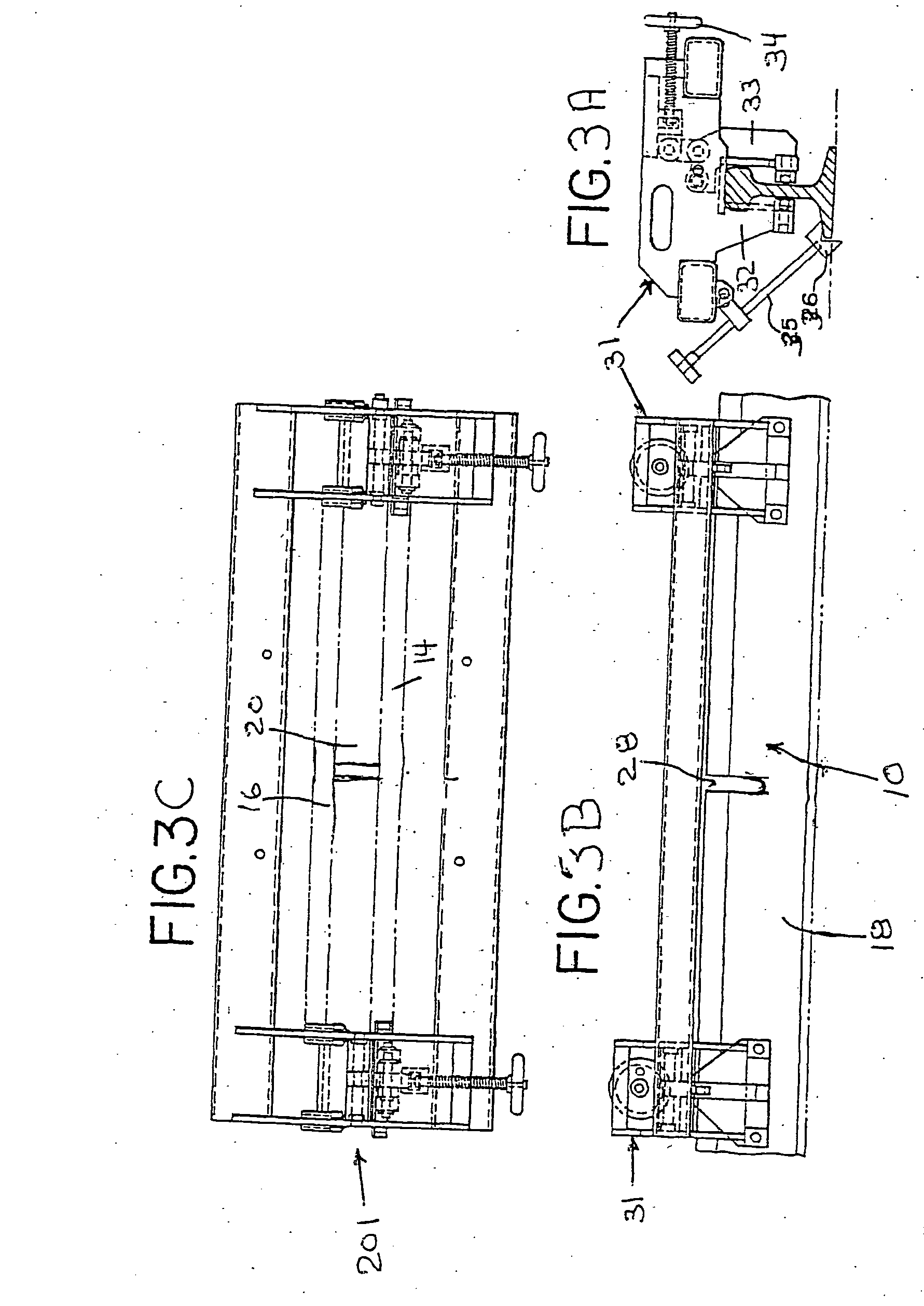

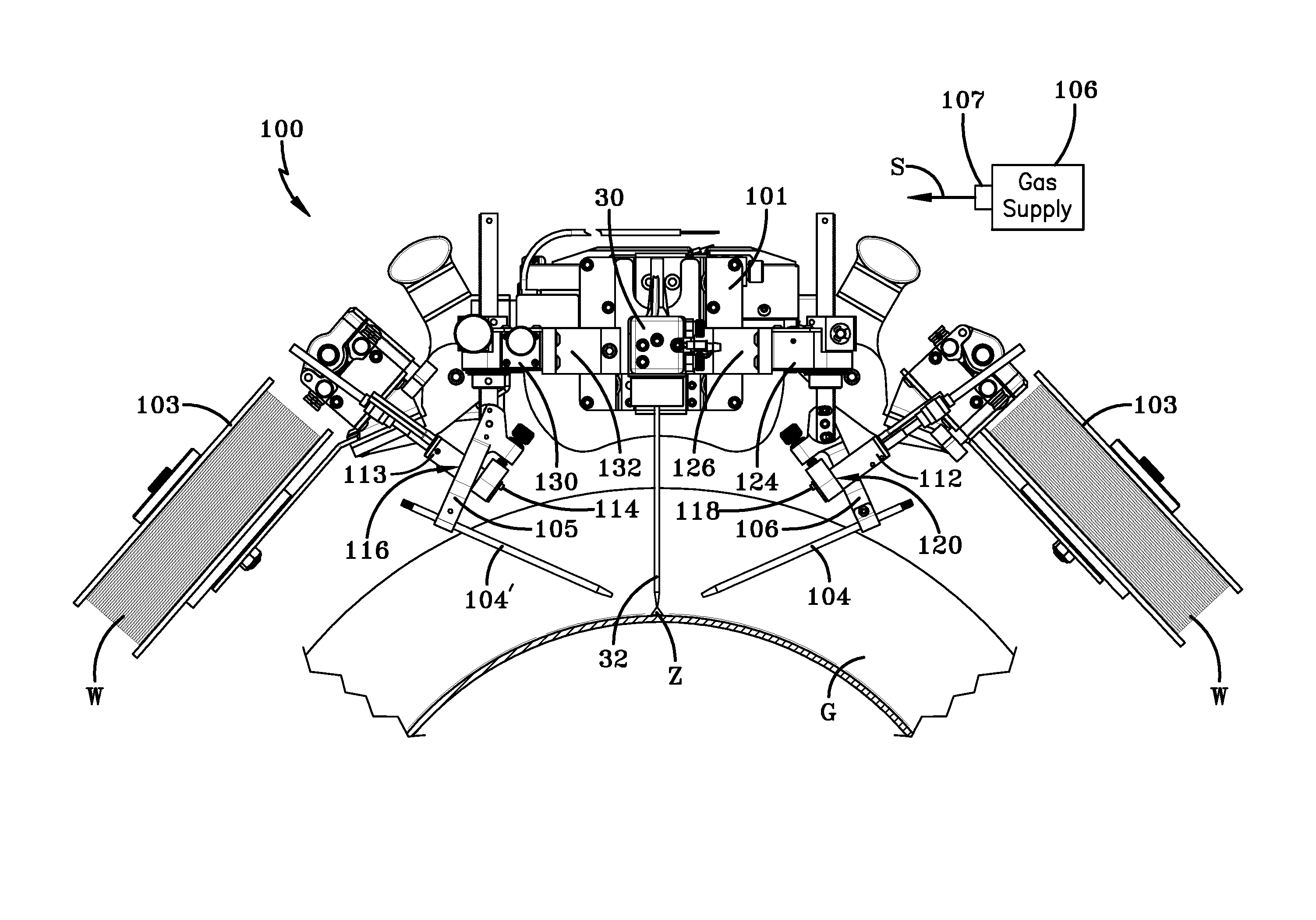

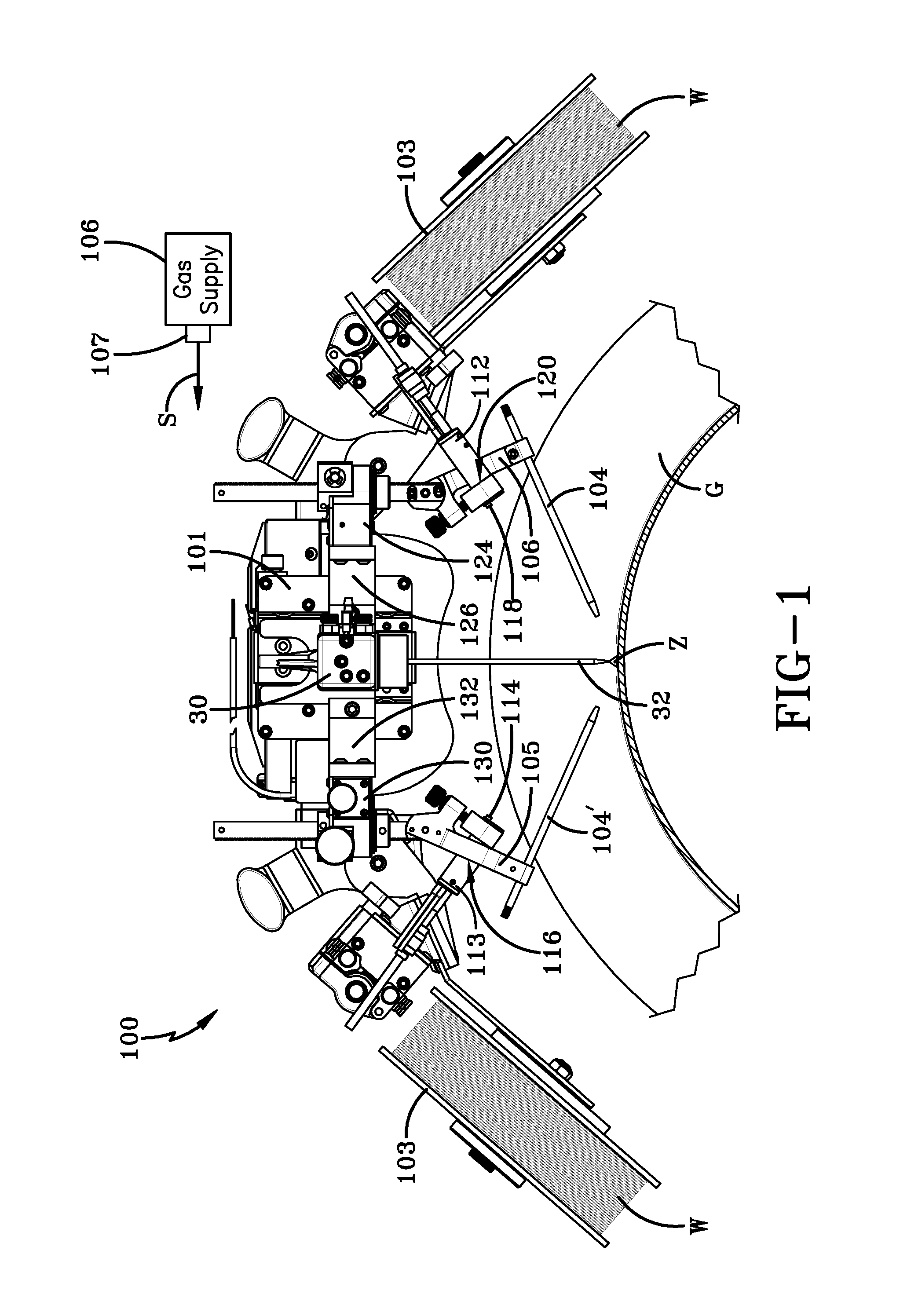

On-site rail welding apparatus

An on site railroad rail welding repair apparatus wherein a railroad rail is an operating railroad track and a defect in the rail has been removed to provide a void and a rail-void interface while maintaining continuity of the rail having pair of cooling blocks which have an internal configuration to complement the rail, and an arc welder that fills the void with appropriate molten metal and causes the molten metal and the rail at the rail-void interface to bond. Also, a robotic welding apparatus and a weld containment apparatus engageable with the rail-void interface by movement having a pivotal and longitudinal component. Further, a mobile weld delivery unit delivering materials through an umbilical to a robotic welding apparatus having a welding device proximate the rail-void interface so that a weld can be made joining the rail-void interface.

Owner:HOLLAND CO

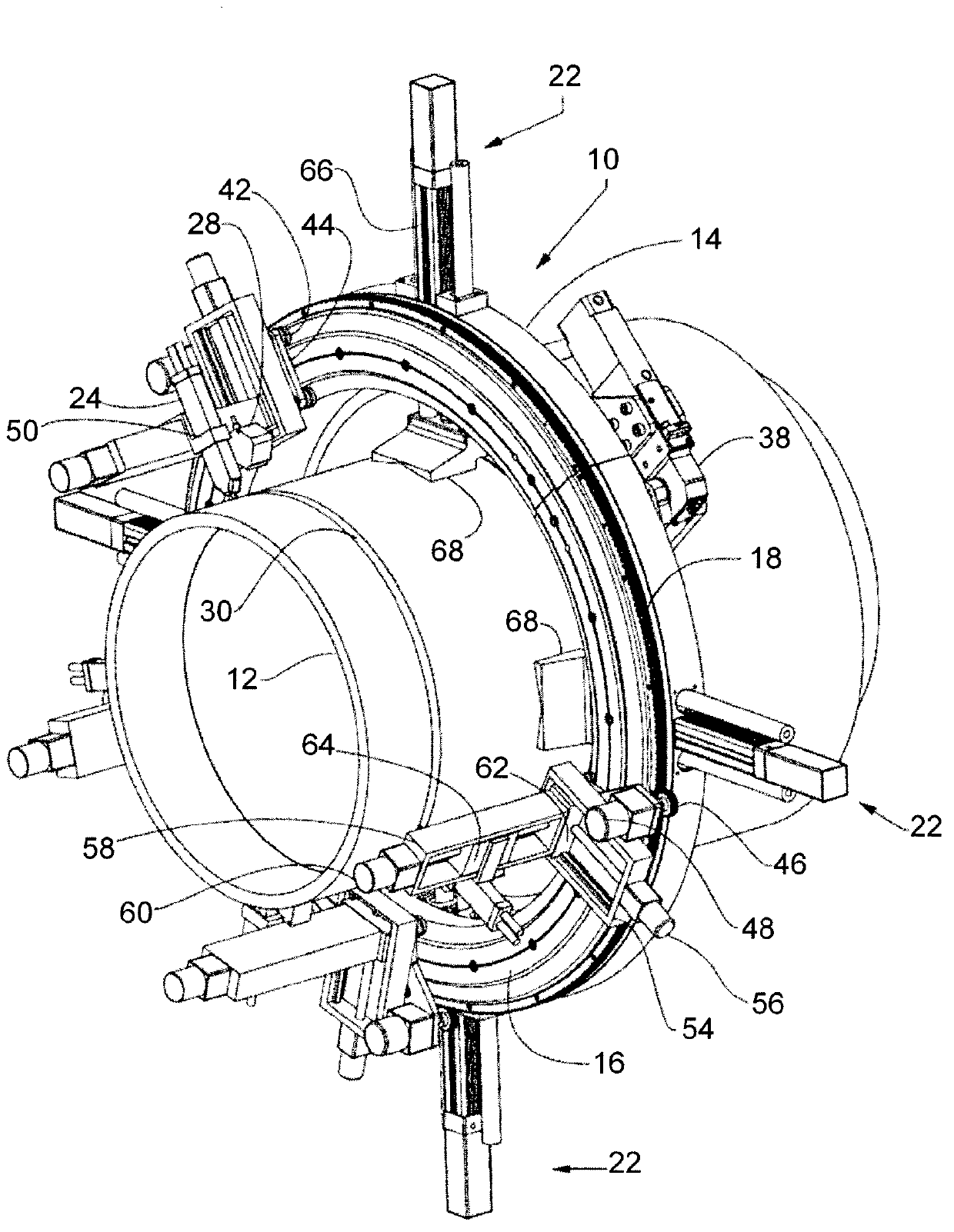

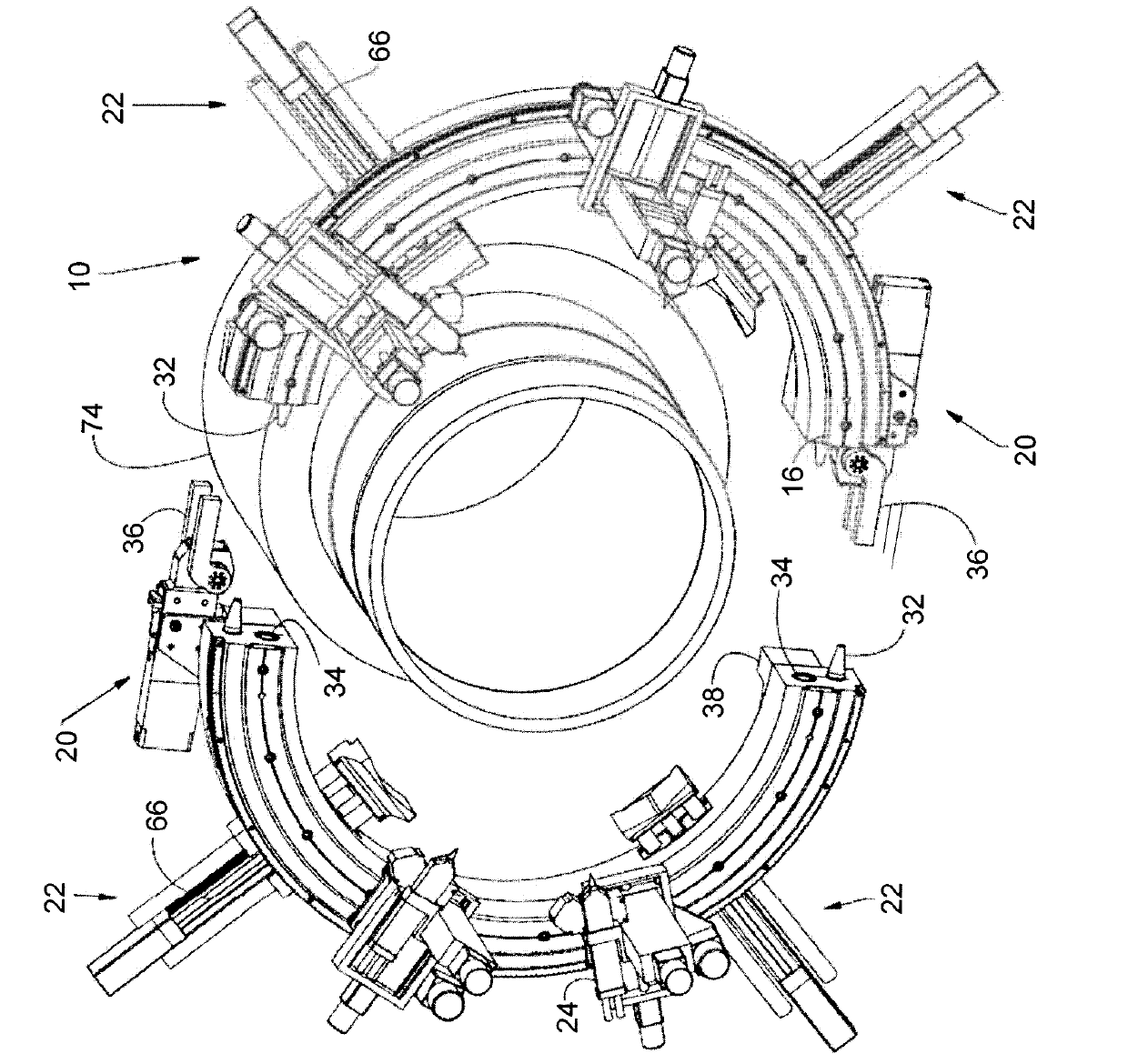

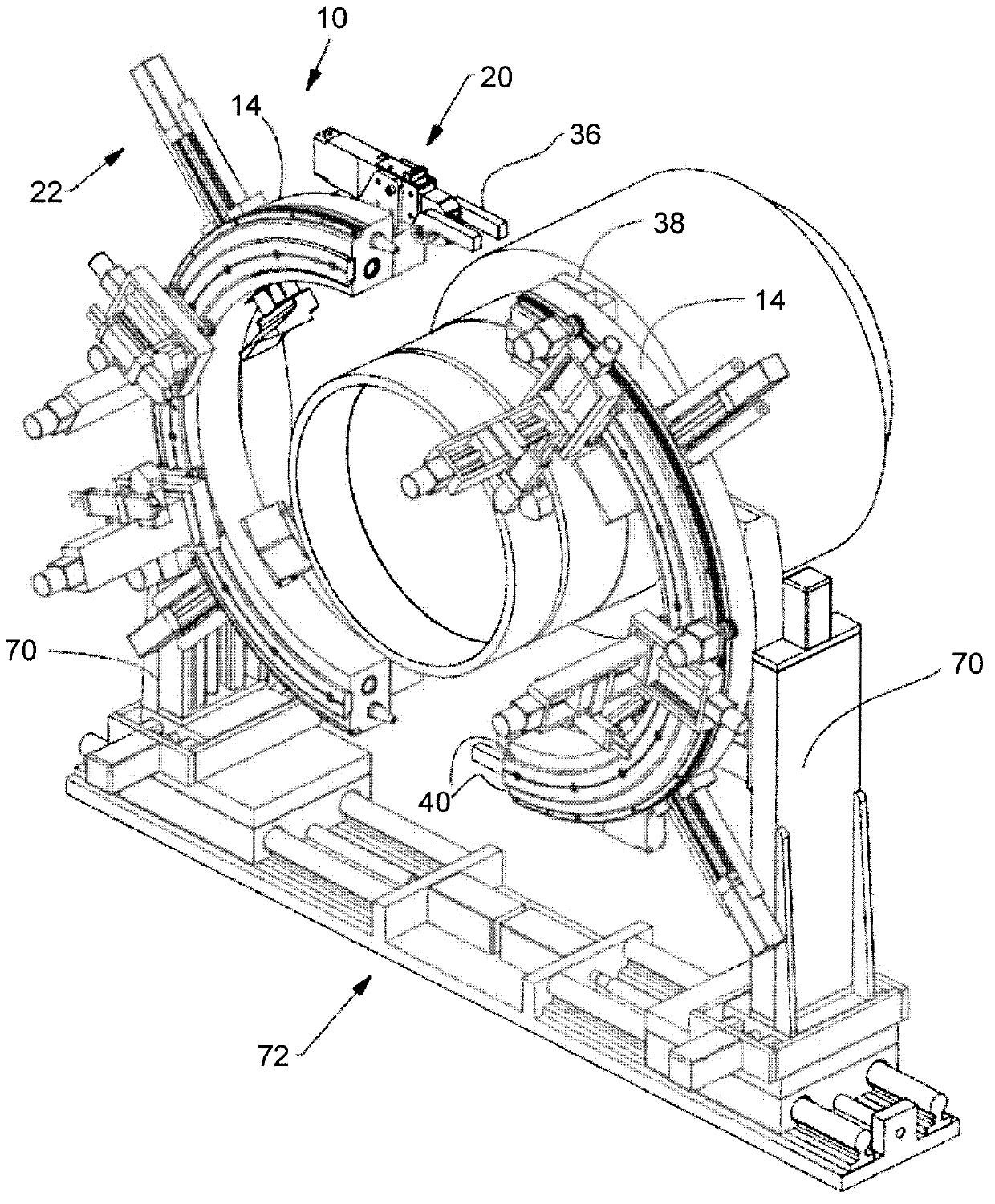

Orbital welding apparatus

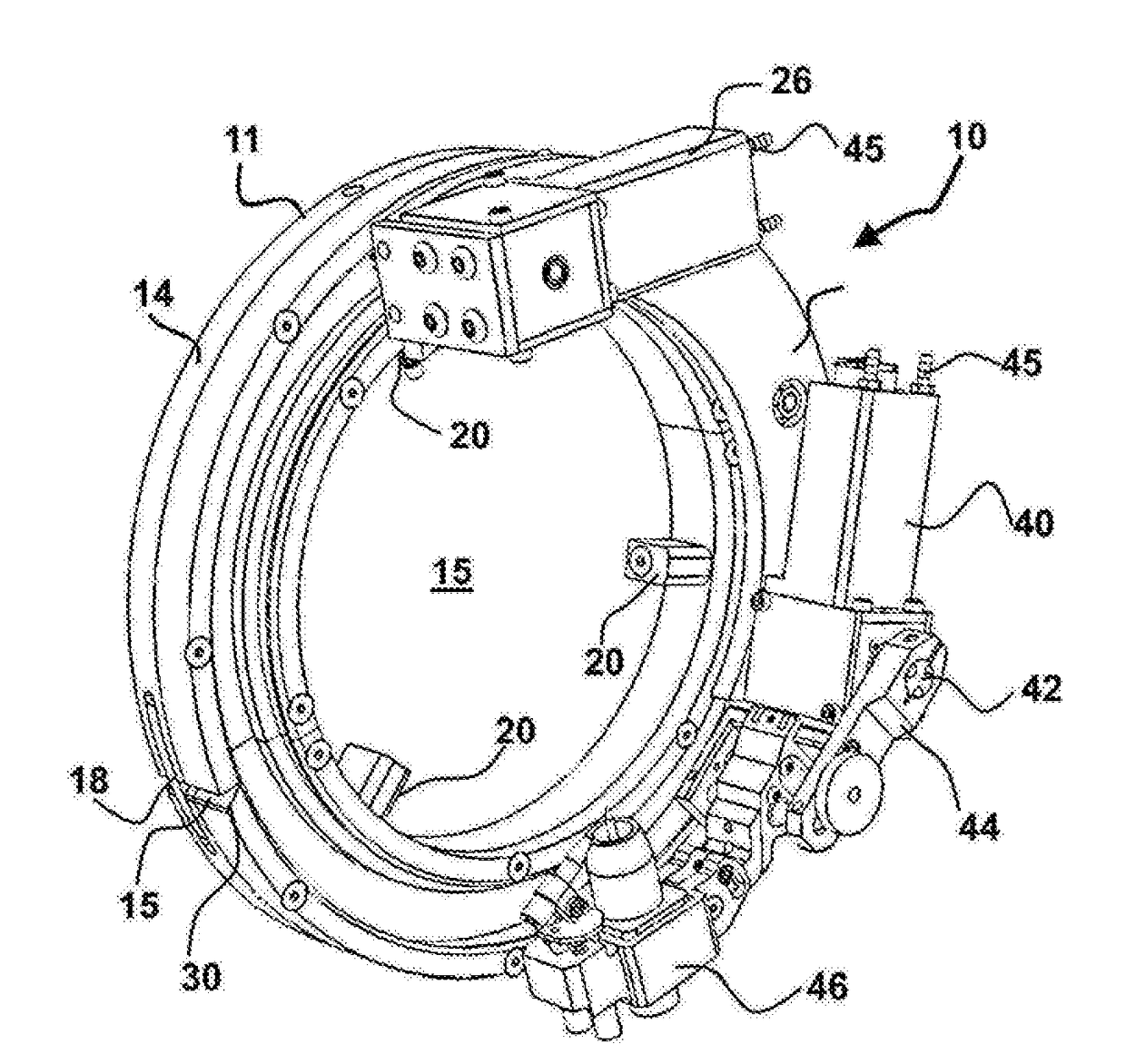

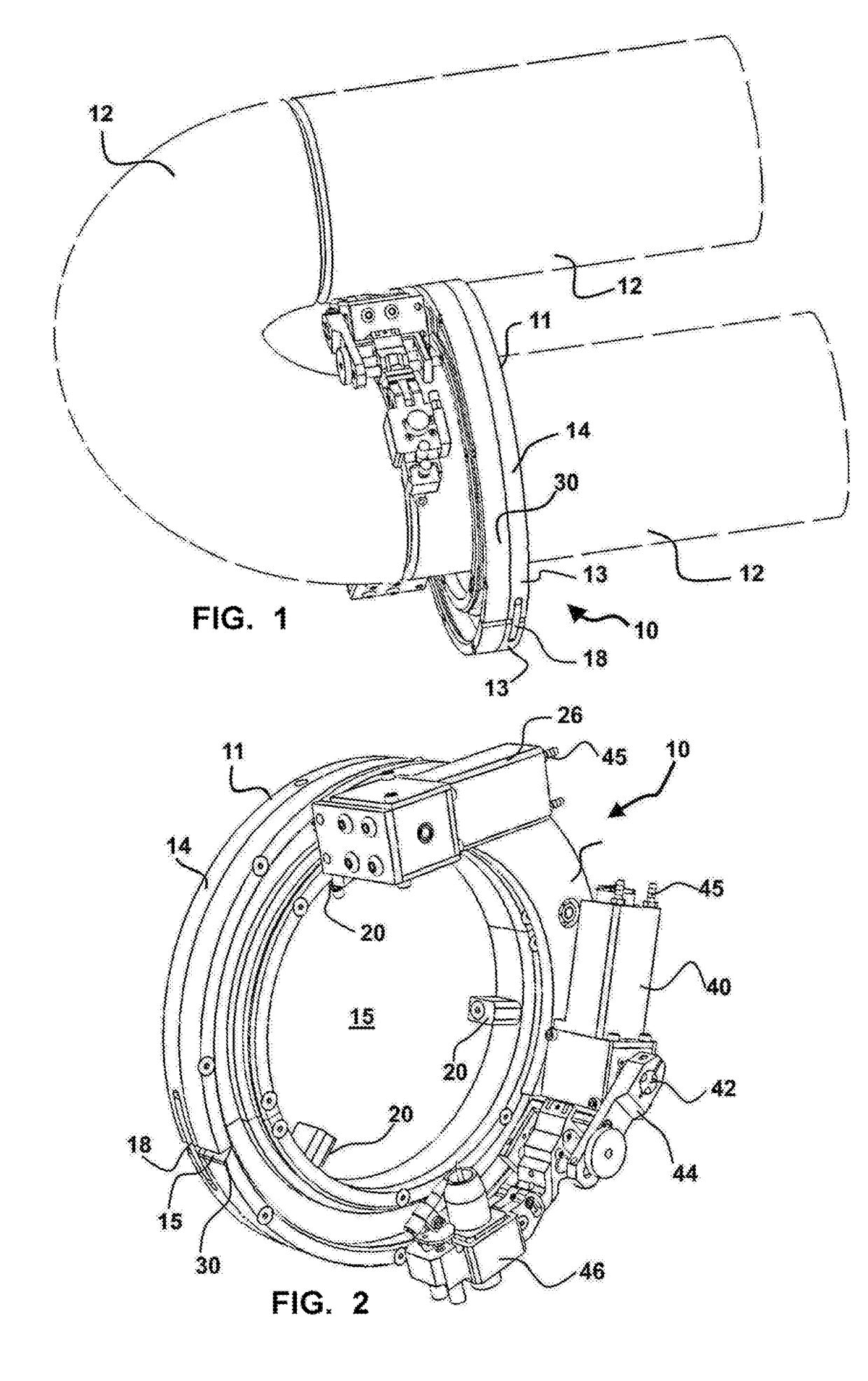

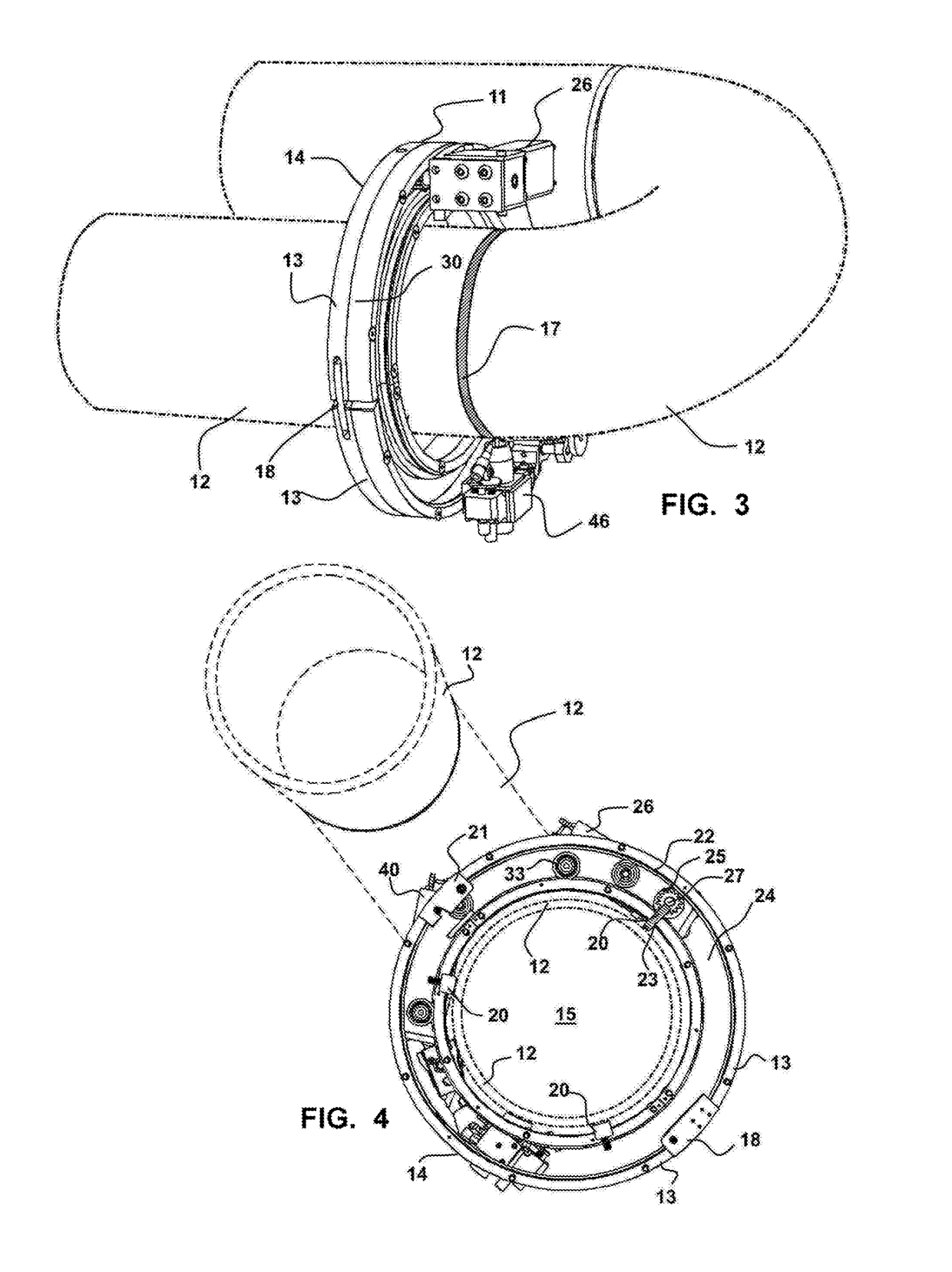

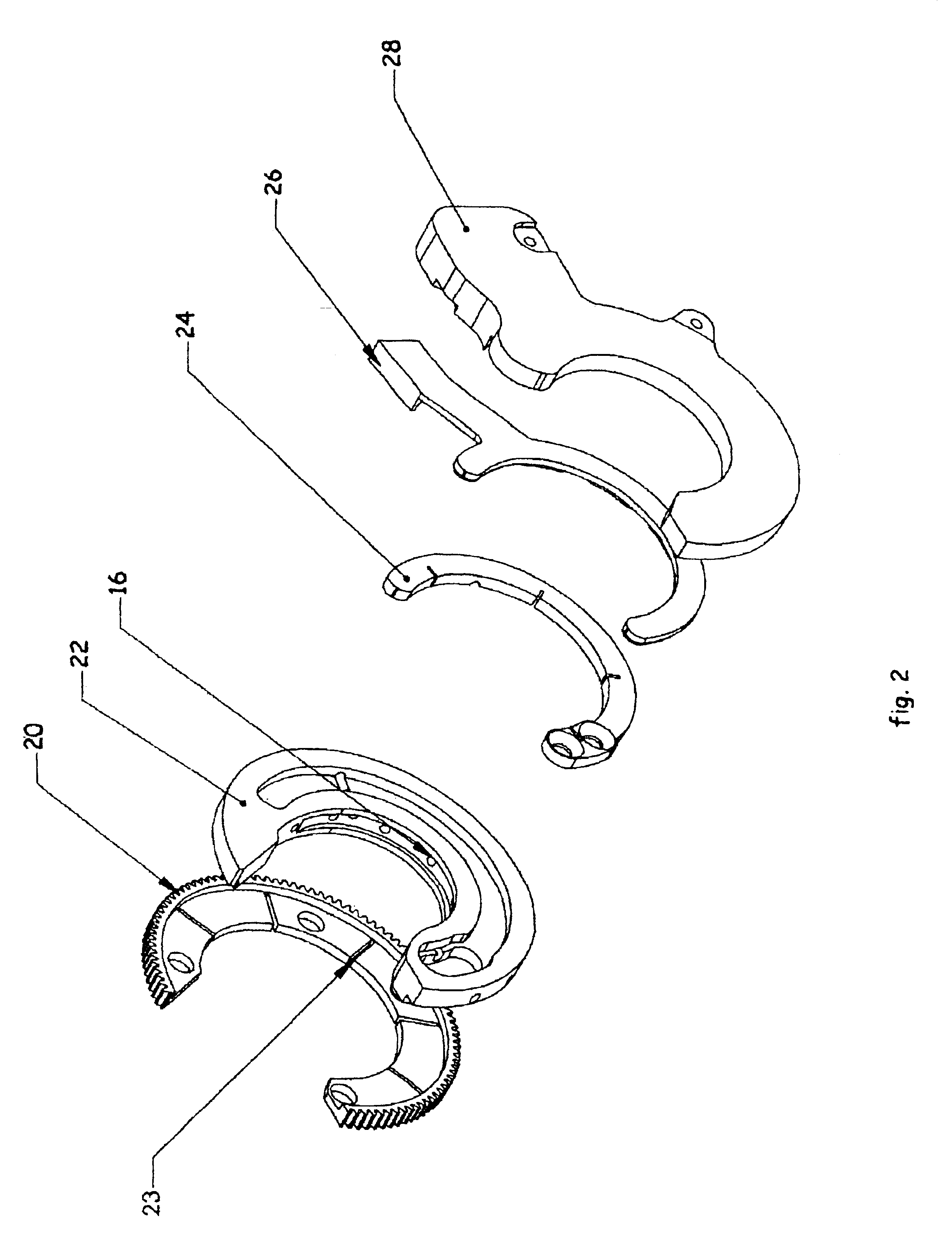

A pipe welding arrangement that allows for real-time independent control of all carriages, torches, and ancillary components by design is provided. The approach uses a split-ring race that is mounted on a backing ring of similar design. Numerous welding heads are mounted on carriages that are distributed at set intervals along the circumference of the race. The left and right side race and backing ring assemblies are split at the twelve o'clock and six o'clock positions. They can be decoupled and spread apart horizontally to facilitate installation and for clearing obstacles. Alignment tools (tapered pins) acilitate assembly. Locking devices located near each split interface, coupled with the alignment pins, assure that the race acts as a continuous unit during the welding operation. Linear actuators mounted on the backing rings maintain concentricity between the race and the welded tube and act as a positive clamping system.

Owner:J RAY MCCDERMOTT SA

Orbital welding device for pipeline construction

Owner:FITS GMBKH

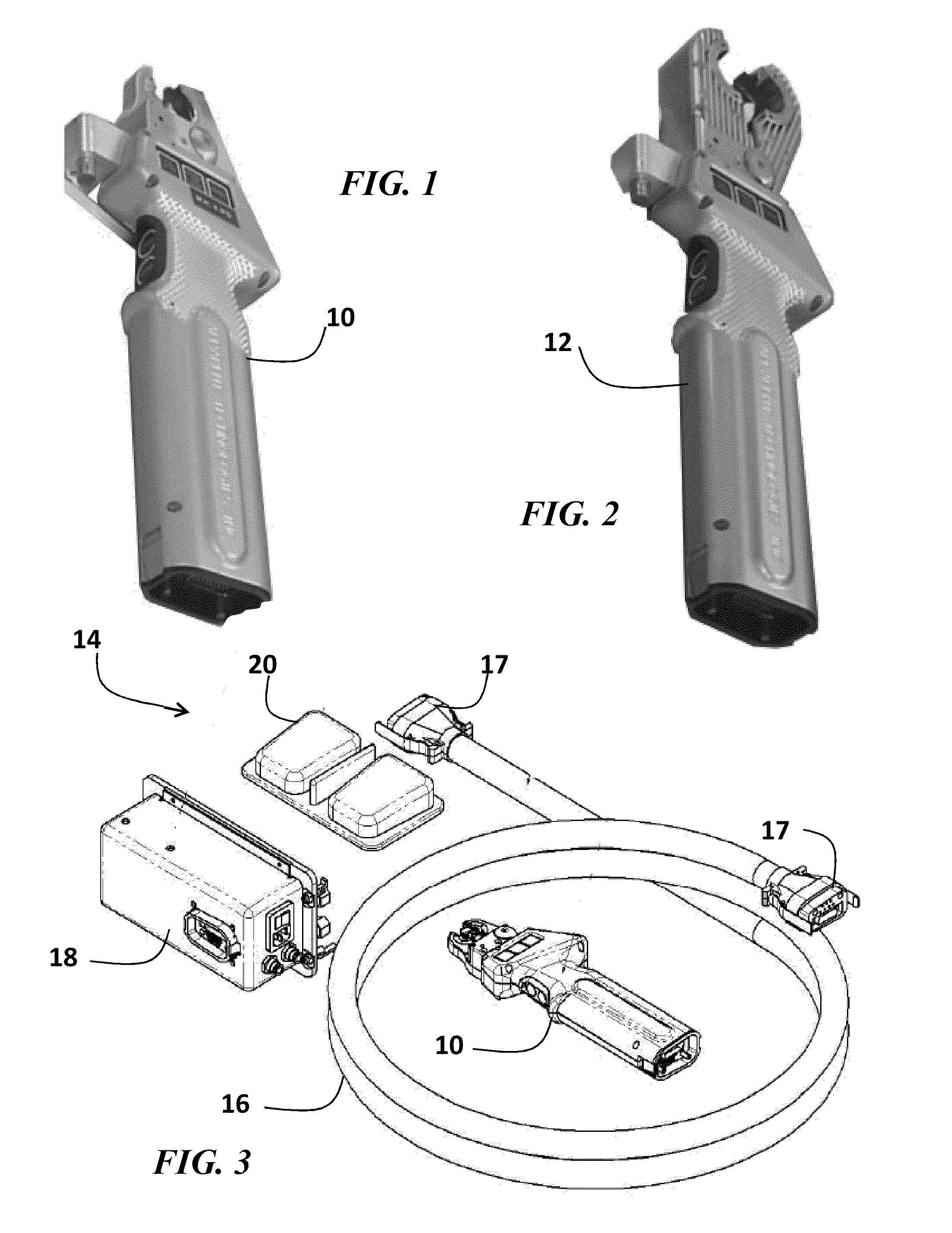

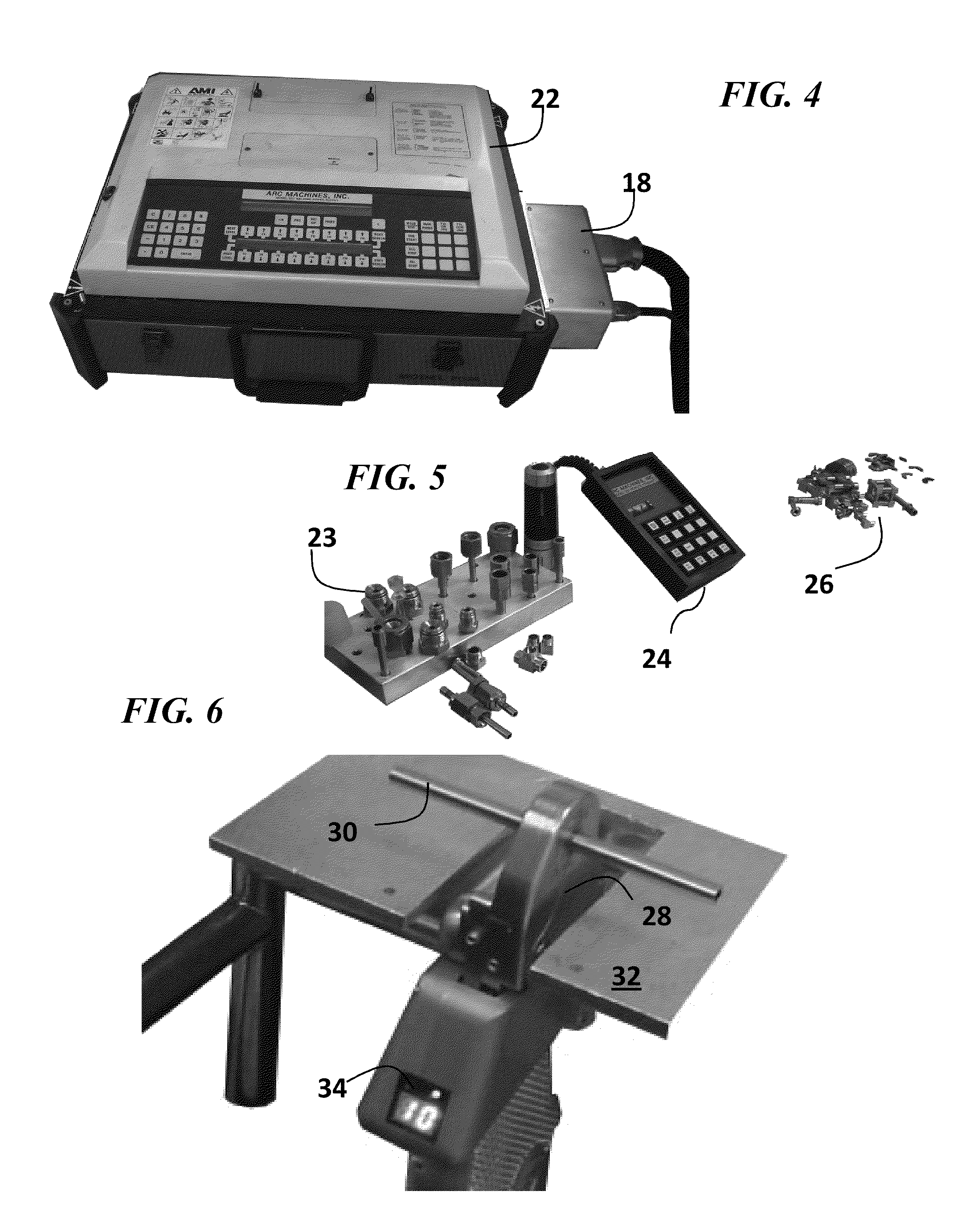

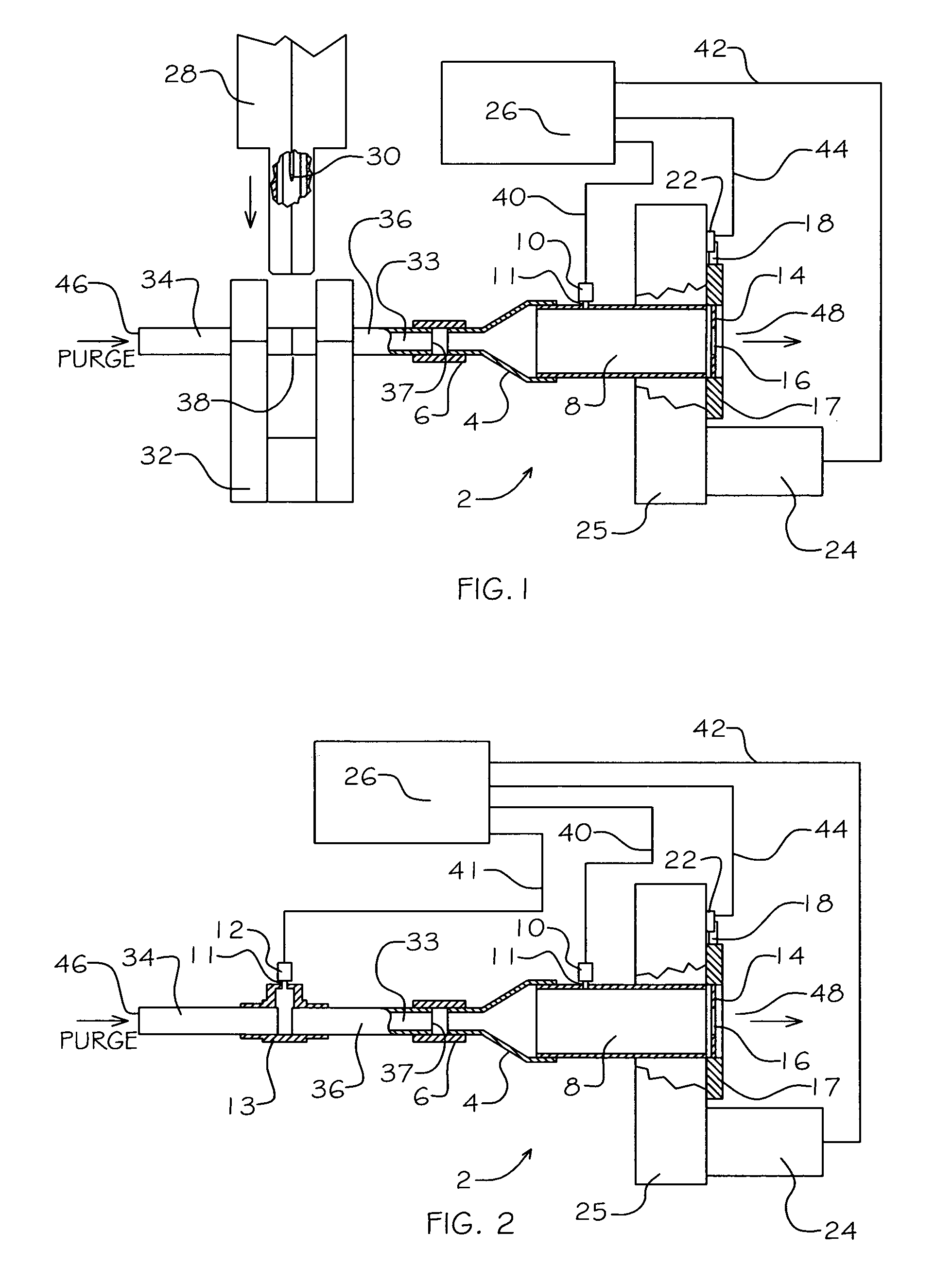

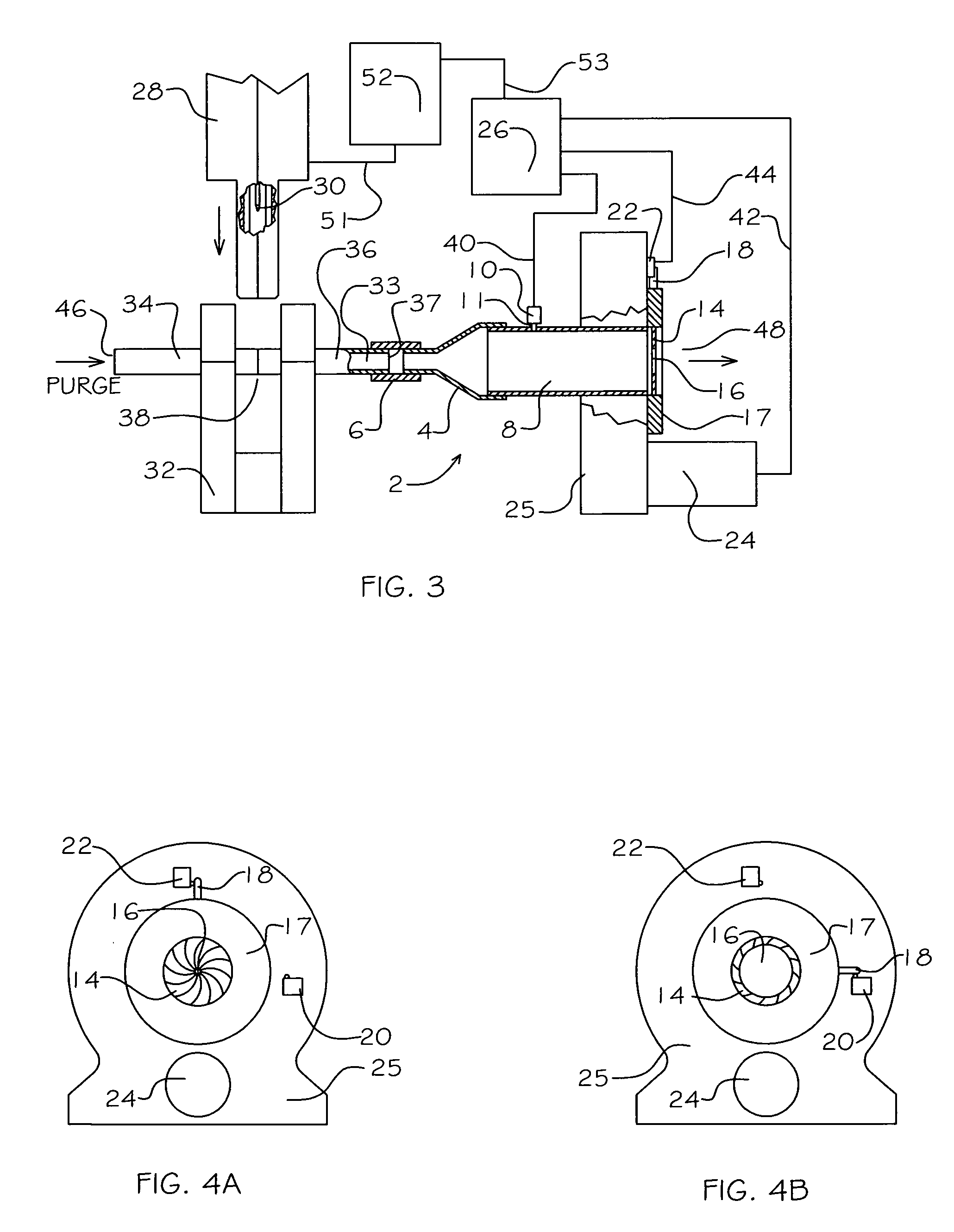

Orbital welding system and methods of operations

InactiveUS20100051586A1Arc welding apparatusResistance welding apparatusMechanical engineeringControl parameters

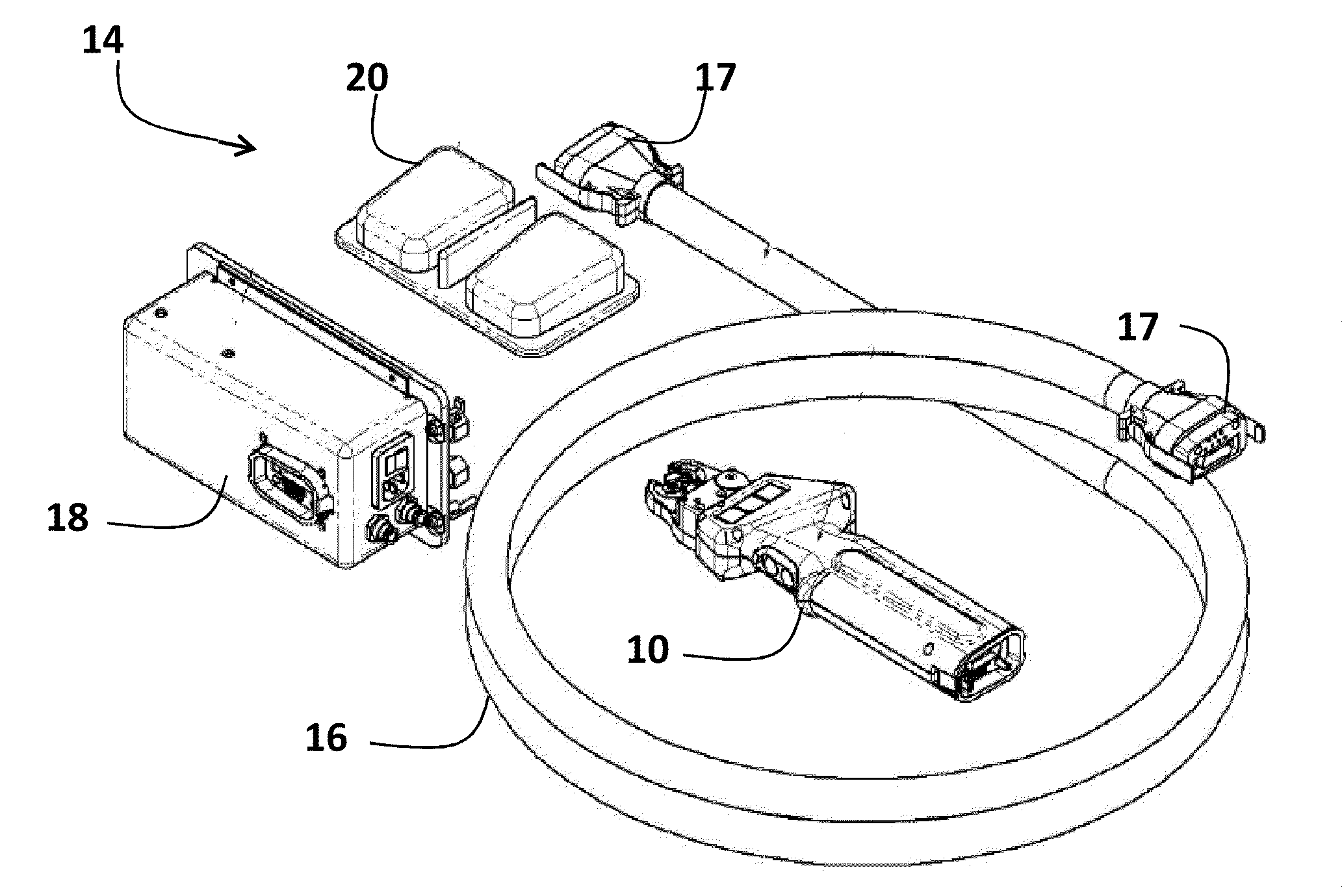

An orbital welding system and methods of operation controllably and safely weld a first metal tubing to a second metal tubing. A weld head includes interlocking clamping jaws for clamping the tubing. An alignment mechanism aligns the second tubing with the first tubing. The interlocking clamping jaws clamp the second tubing following the aligning of the second tubing with the first tubing. An alignment measurement mechanism measures relative alignment between the first tubing and the second tubing. A weld environment mechanism establishes a gaseous environment for orbitally welding the first tubing to the second tubing. The weld environment mechanism includes a weld environment sealing mechanism for sealing the gaseous environment and an electrode for gas arc welding. The weld environment mechanism orbits the first tubing and second tubing during the orbitally welding. Interface circuitry interfaces a power supply with the weld head and controls parameters associated with said weld head.

Owner:ARC MACHINES

Full-automatic welding machine for steel gas pipeline

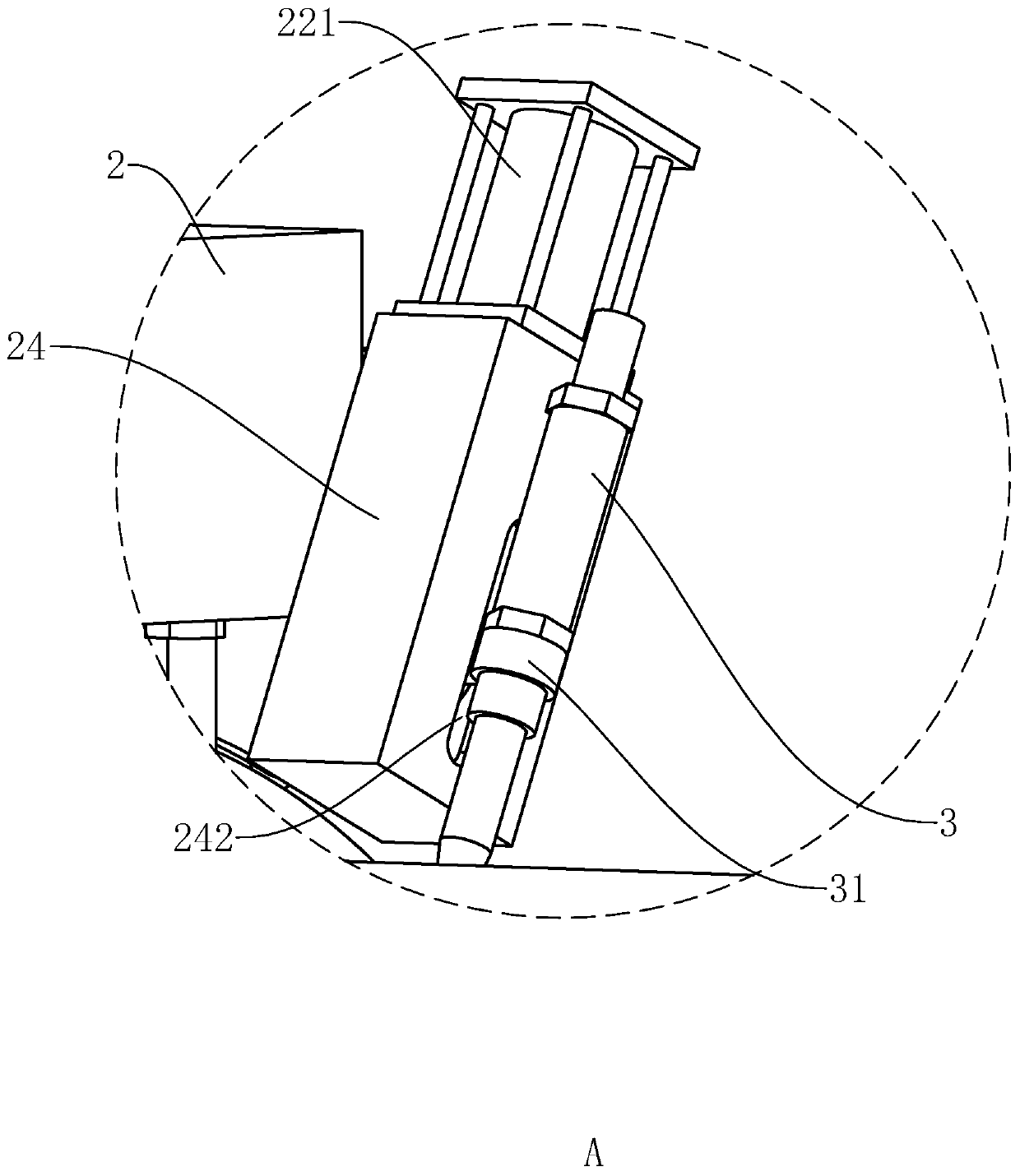

InactiveCN111136411AEasy to installAdjust spacing in real timeWelding/cutting auxillary devicesAuxillary welding devicesWeld seamDistance sensors

The invention relates to the technical field of pipeline welding, in particular to a full-automatic welding machine for a steel gas pipeline. The full-automatic welding machine comprises a track, a welding trolley and a welding gun. A driving mechanism is arranged on the welding trolley. An adjusting mechanism is fixedly arranged on the welding trolley. A welding gun bracket is arranged between the welding gun and the welding trolley. The welding gun is fixedly connected with the welding gun bracket. The adjusting mechanism can adjust the distance between the welding gun bracket and the welding trolley. The welding trolley is fixedly provided with a range sensor and a controller. The range sensor is used for measuring the distance from the range sensor to the connecting seam between a first pipeline and a second pipeline. The range sensor is used for transmitting an electric signal to the controller. When the numerical value measured by the range sensor exceeds the threshold value of the controller, the controller controls the adjusting mechanism to move so as to drive the welding gun bracket to get close to or far away from the weld seam. The full-automatic welding machine has theadvantages that the position of the welding gun can be adjusted in real time, the welding quality can be improved, and the mounting precision of the track can be reduced.

Owner:上海安宏建设工程有限公司

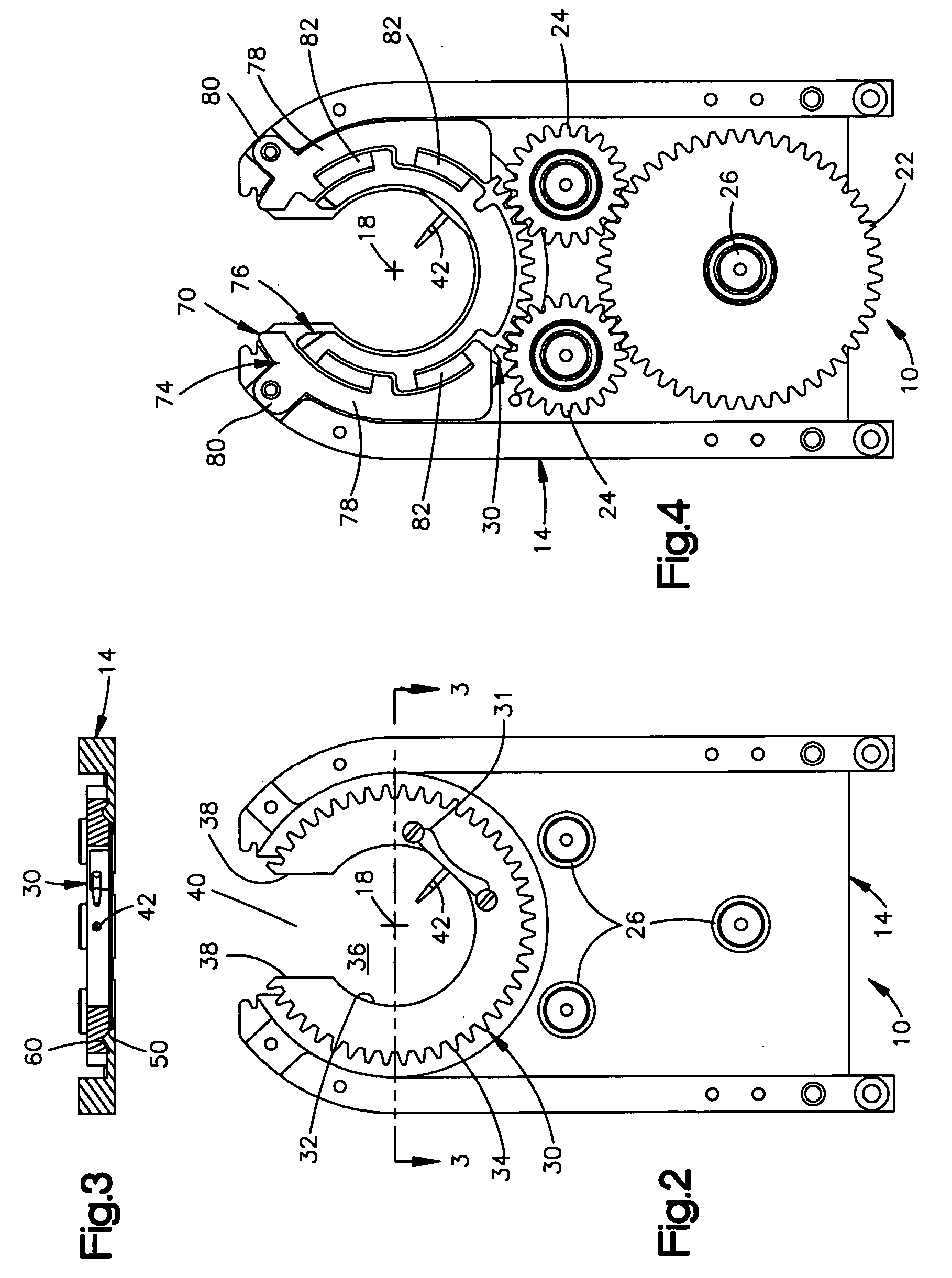

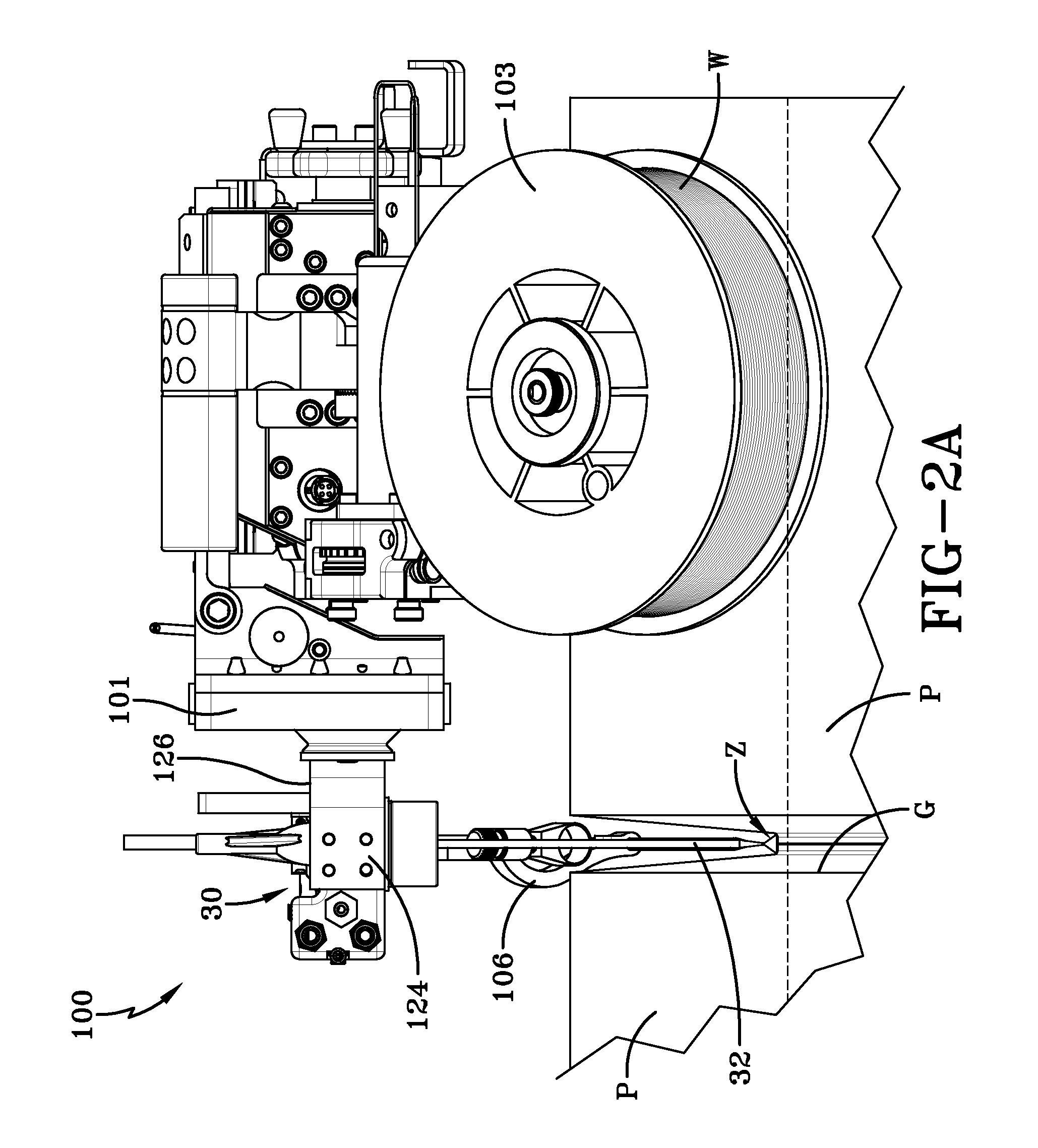

Orbital Welder With Integrated Track And Gear Drive

ActiveUS20170252845A1Easily removably positionableEasy to engageWelding/cutting auxillary devicesArc welding apparatusGear driveEngineering

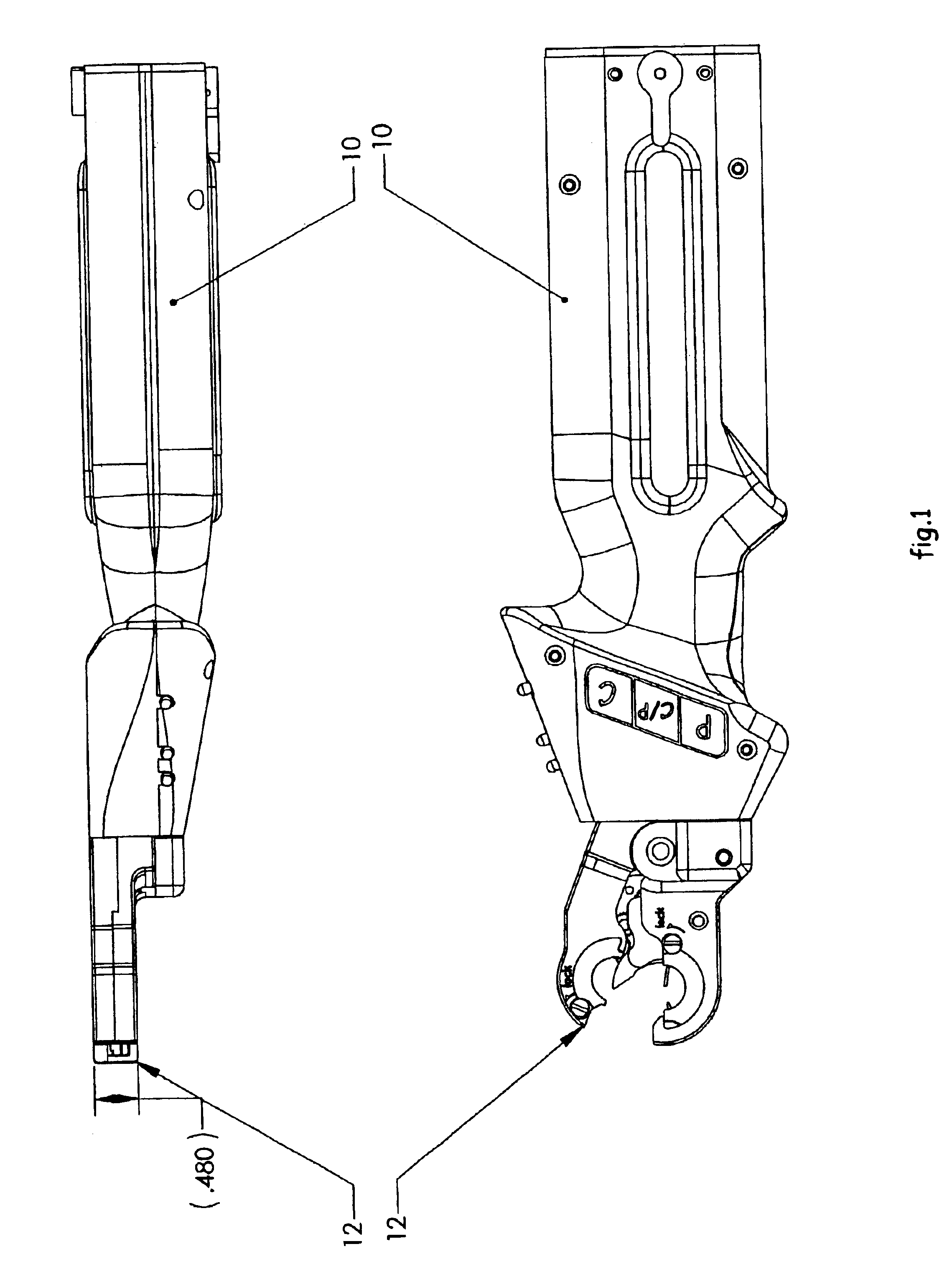

An orbital welding device for forming a circumferential weld bead to engage adjoining segments of pipe is provided. The device features an annular track ring having an opening for engagement around the pipe. A travel carriage rotationally engaged with the annular track ring has a first motor for rotating the travel carriage and an engaged welding head around the pipe for forming a weld thereon. A second motor is provided to adjust a distance of the welding head from the pipe.

Owner:BHI ENERGY I SPECIALTY SERVICES LLC

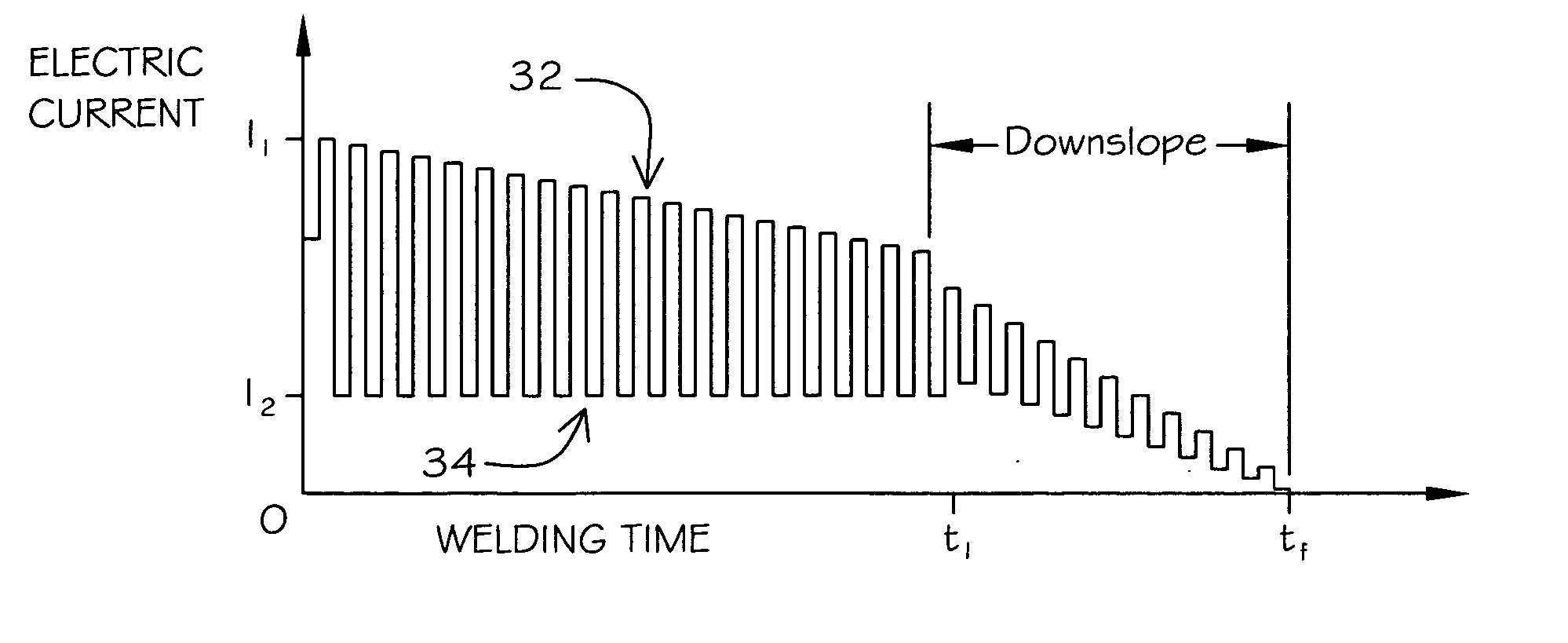

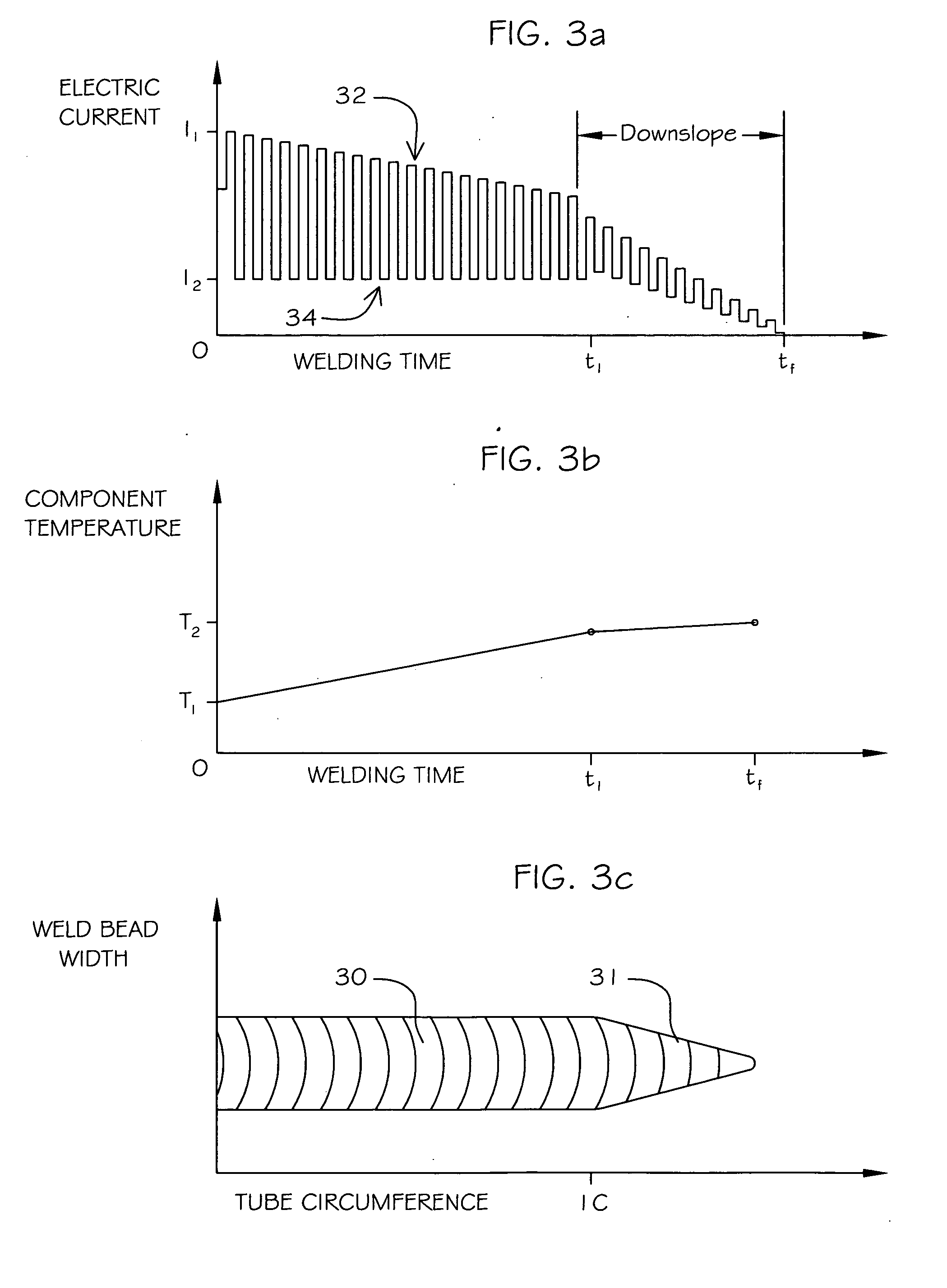

Method for orbital welding using a pulsed current

InactiveUS20060213893A1Reduce widthSmooth disengagementWelding/cutting auxillary devicesAuxillary welding devicesAverage currentEngineering

A method for the orbital welding of tubular elements held in abutment comprising the steps of striking an arc at a strike point with an orbital welder between an electrode and a seam formed by a first tubular element and a second tubular element, held in abutment within a fixture; initiating an orbit of said electrode around an abutment of said first tubular element and said second tubular element; adjusting the current of said arc in a pulsed manner from a maximum current to a minimum current at a set frequency, combination of said maximum current and said minimum current forming an average current; decreasing said average current in a generally continuous manner as said orbit of said electrode progresses from said strike point, the rate of decrease of said maximum current having a generally inverse relationship to the rate of increase in temperature experienced by said tubular elements.

Owner:ORBITAL ACQUISITION

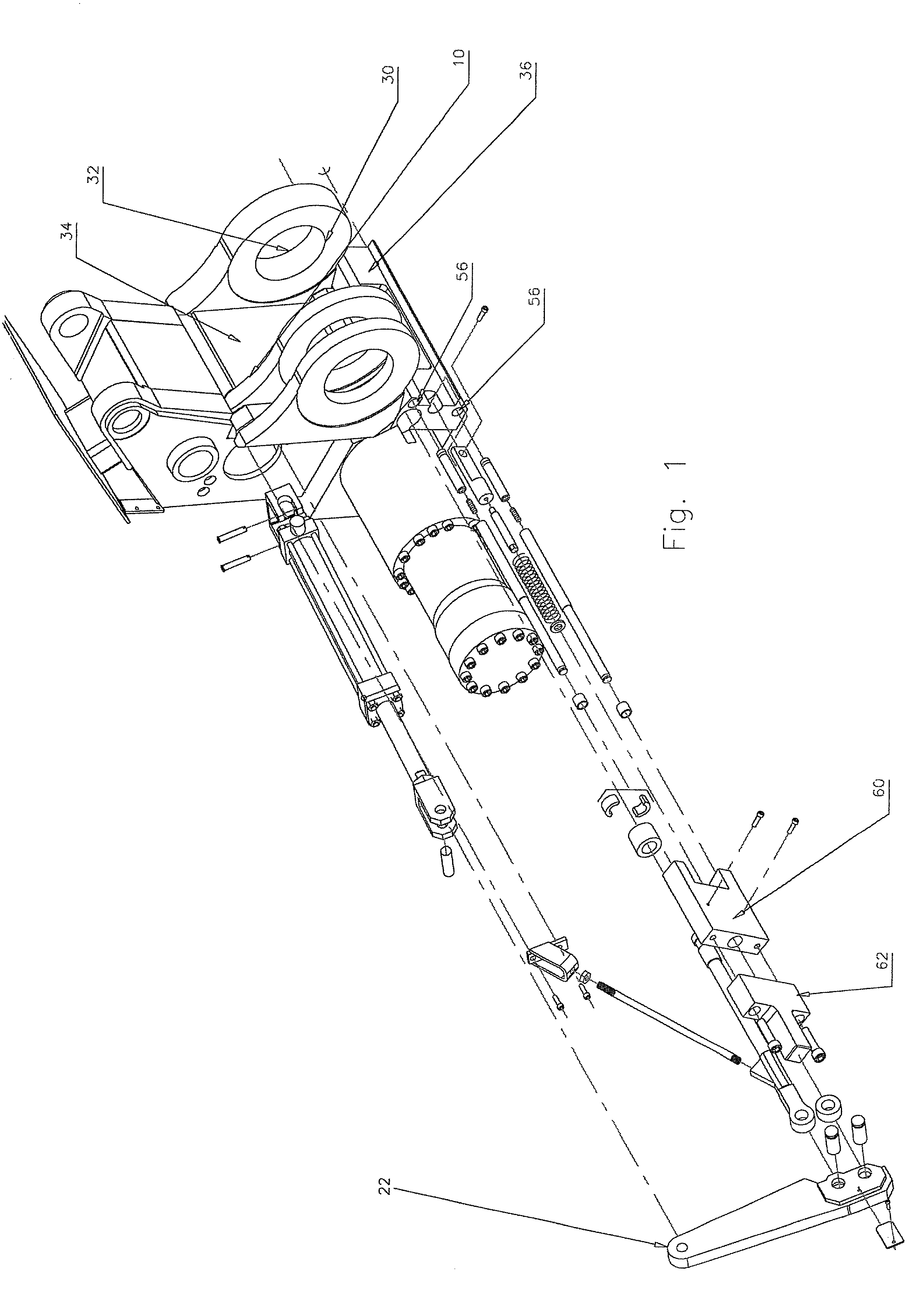

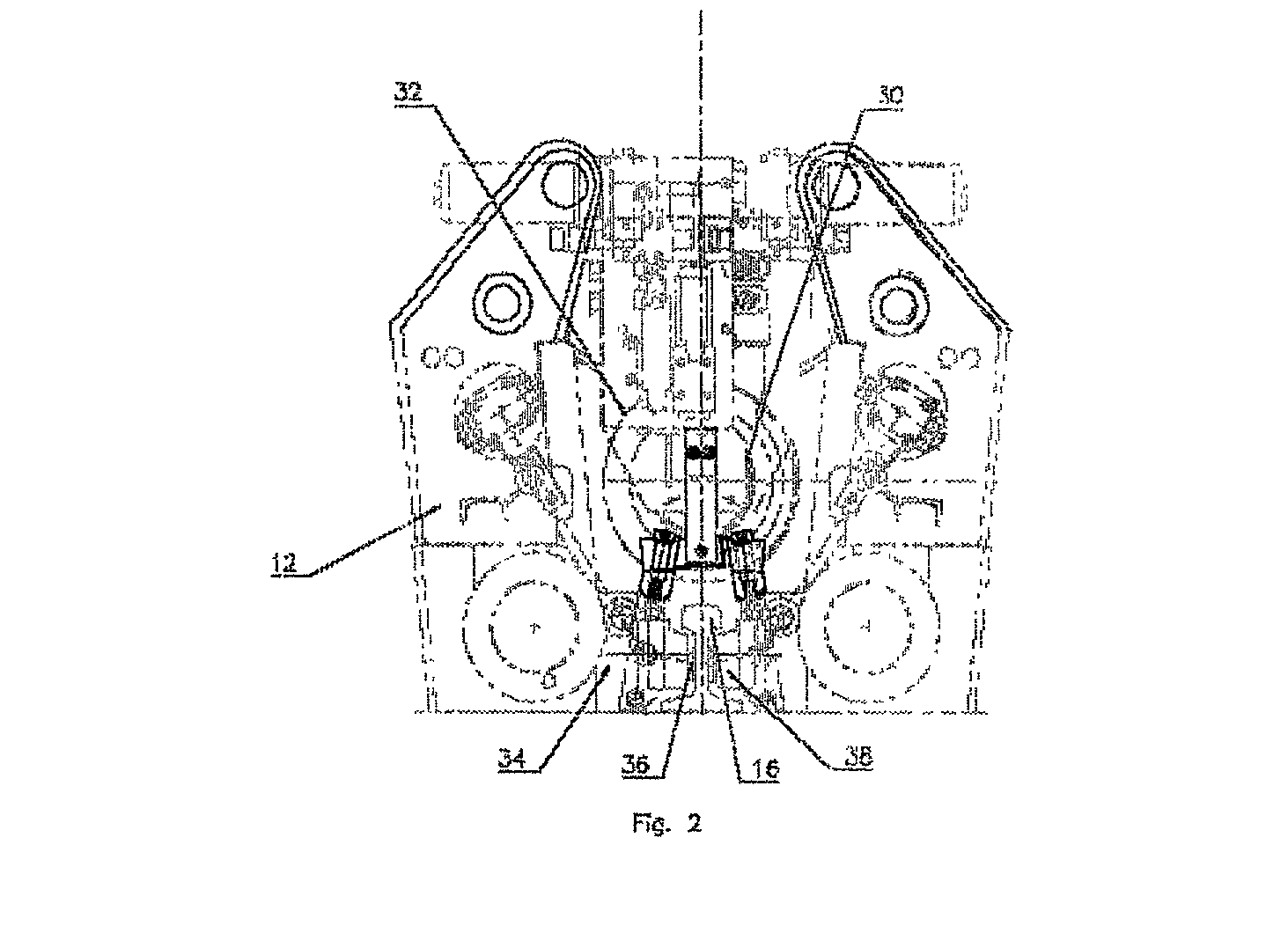

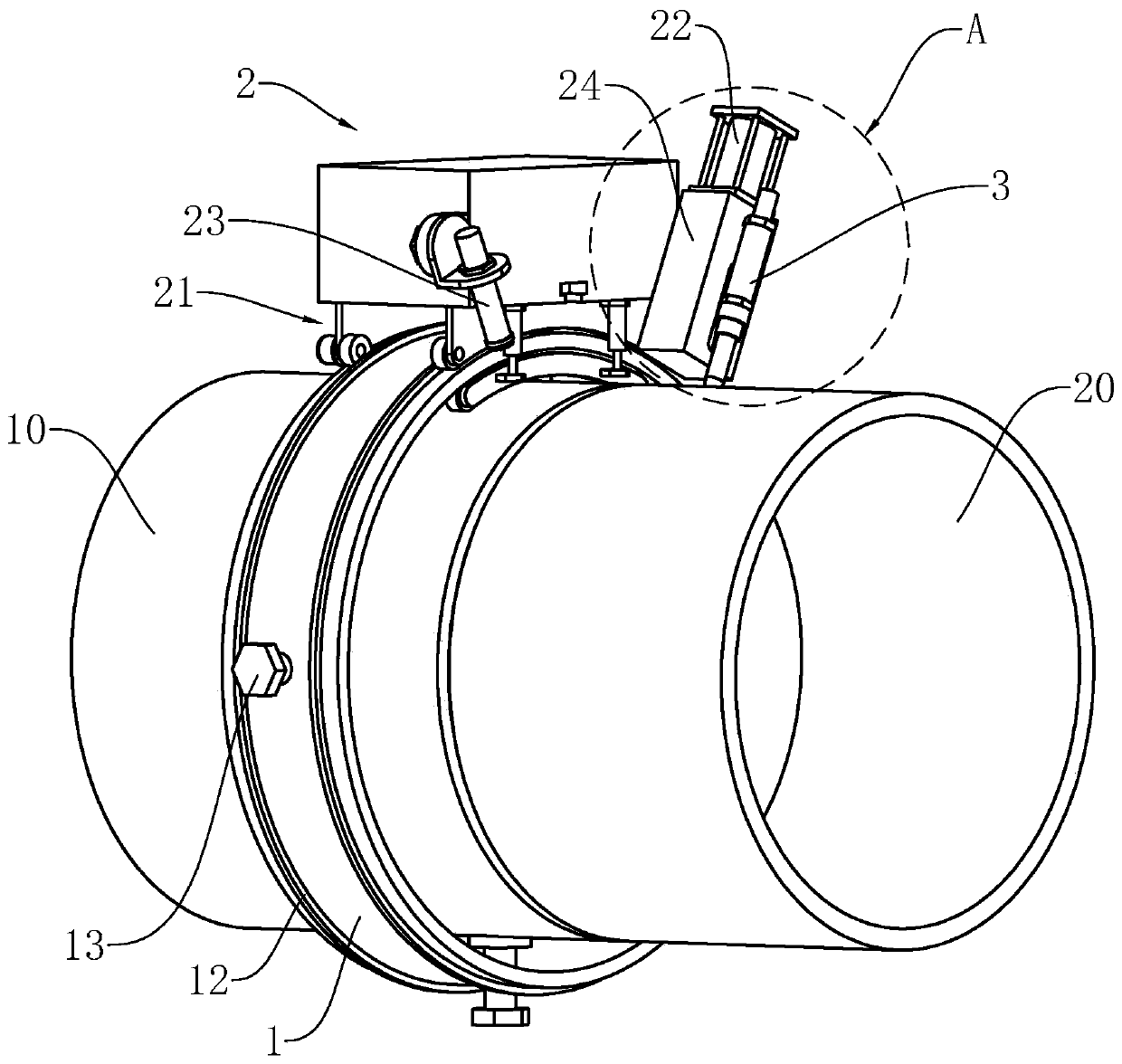

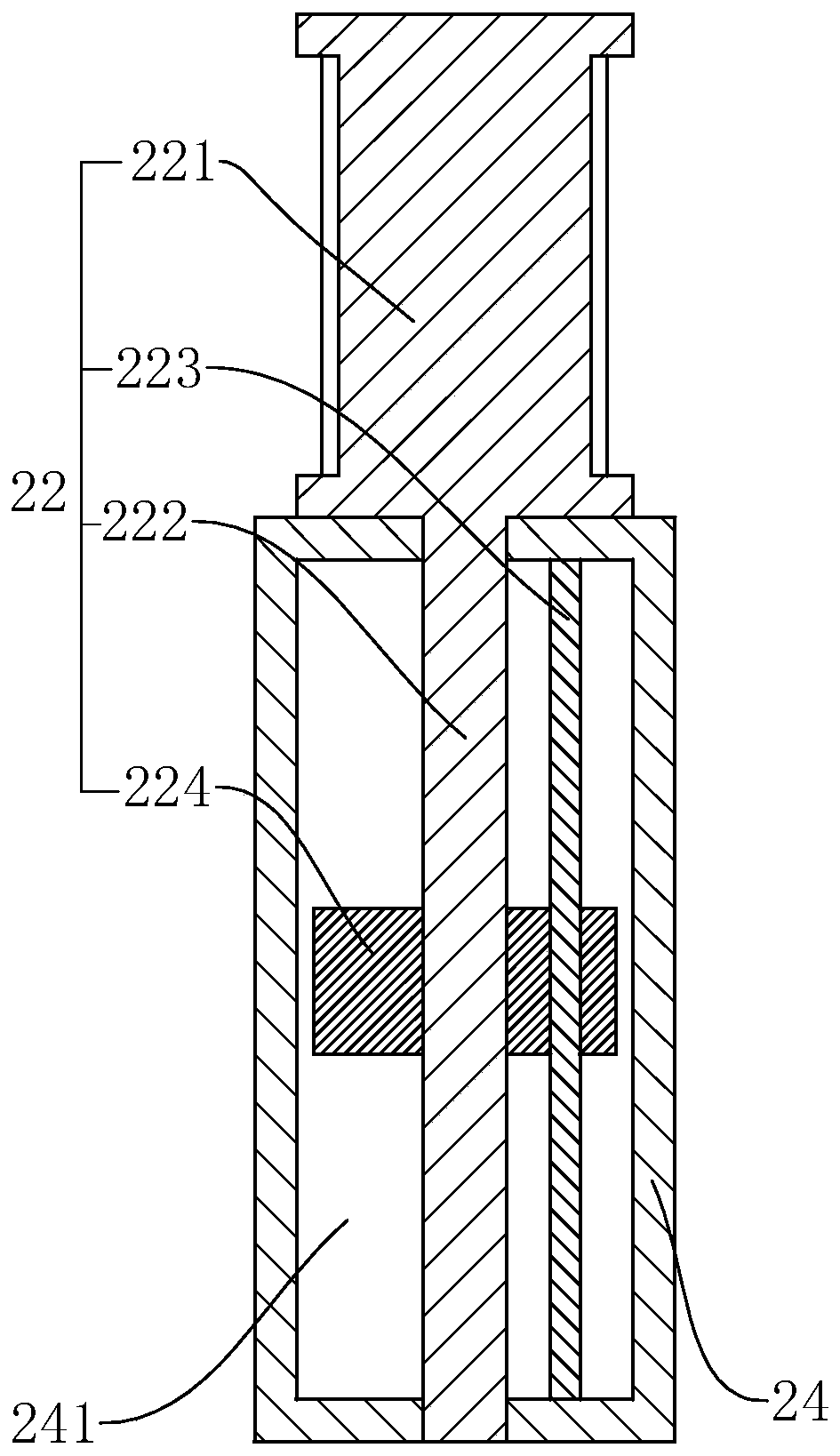

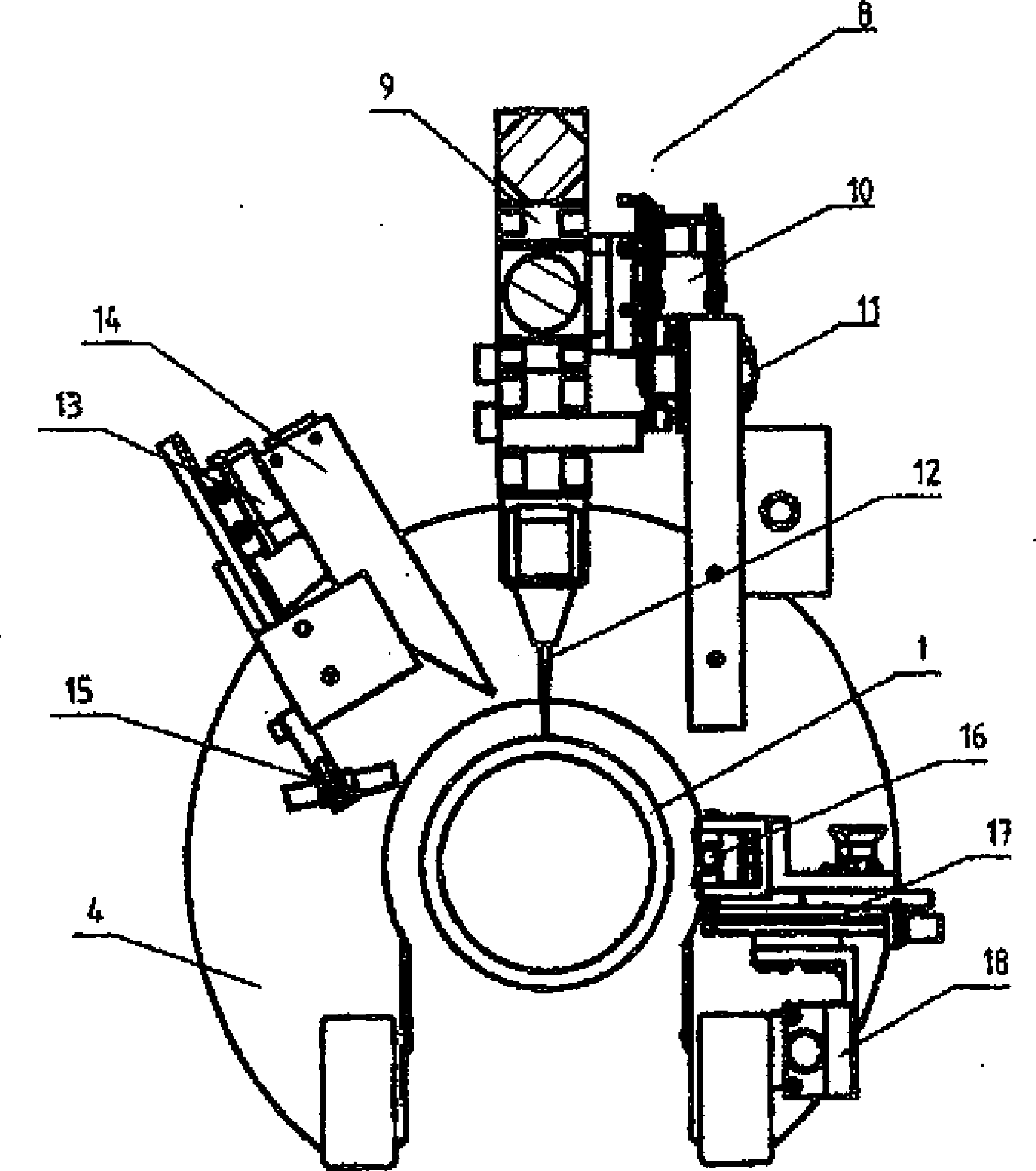

Device for connecting the ends of pipes made of steel by means of an orbital welding process

ActiveCN104364047AMaterial analysis using sonic/ultrasonic/infrasonic wavesWelding/cutting auxillary devicesEngineeringOrbital welding

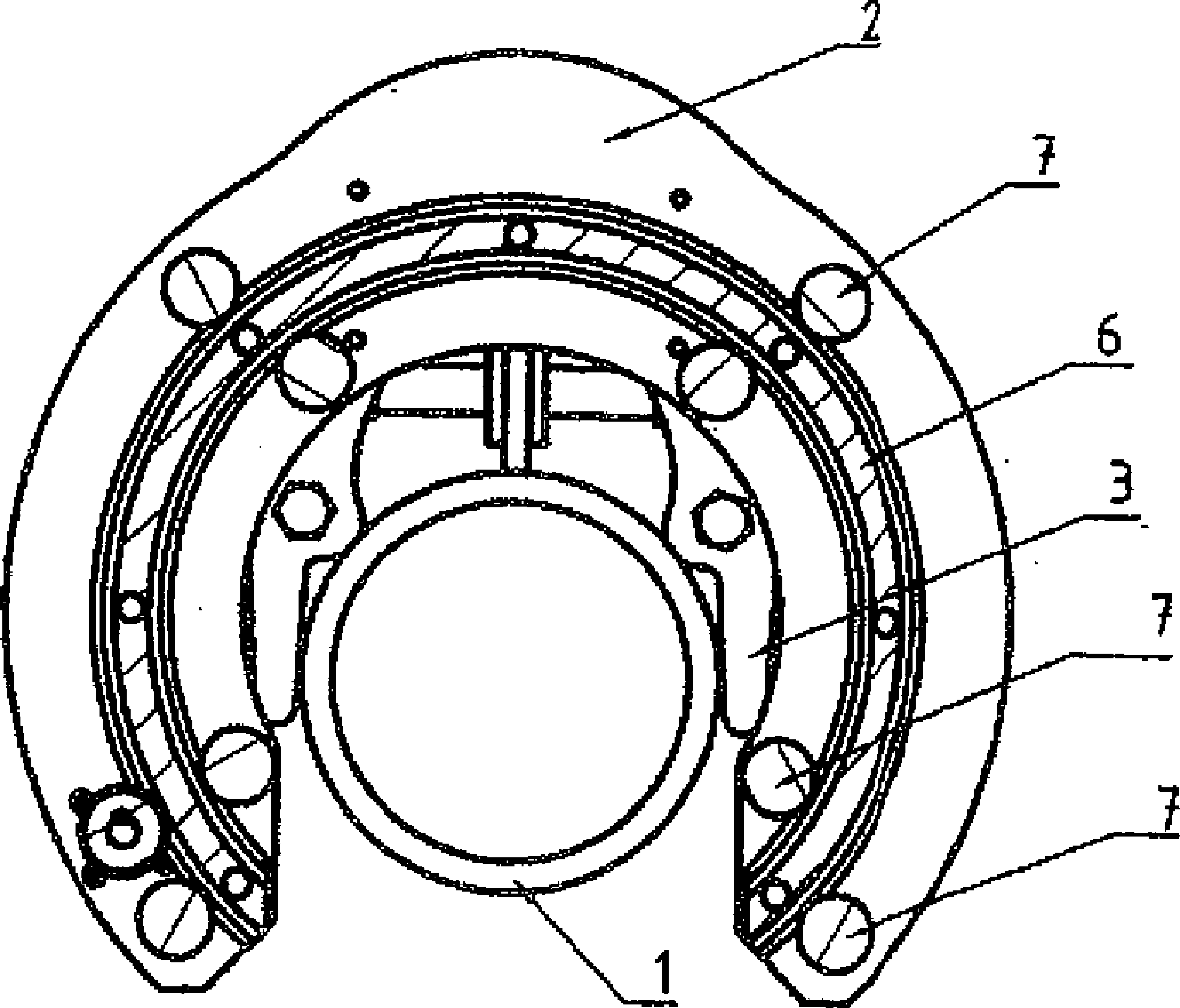

The invention relates to a device for connecting the ends of pipes, which are already aligned and tack-welded and which are made of steel in particular, by means of an orbital welding process using a welding joint which is formed by the pipe ends and using tools which can be moved about the welding joint in an orbital manner for welding and checking the welding seam. The device consists of guide base plates which can be placed on both sides at each pipe end in the region of the welding point and which can be rigidly clamped to said pipe ends. The guide base plates centrally have a circular recess with a radial opening for the feed-through of the pipes to be welded and for centrally receiving said pipes in the recess. The guide base plates comprise clamping elements for clamping the guide base plates to the pipe ends, said clamping elements being rigidly connected to each guide base plate face facing away from the welding joint, and a frame for receiving the welding and checking tools, said frame being rotatably mounted between the guide base plates on the inner faces facing the welding joint and being centrally pivotal about the pipe ends by at least 360°.

Owner:SALZGITTER MANNESMANN LINE PIPE

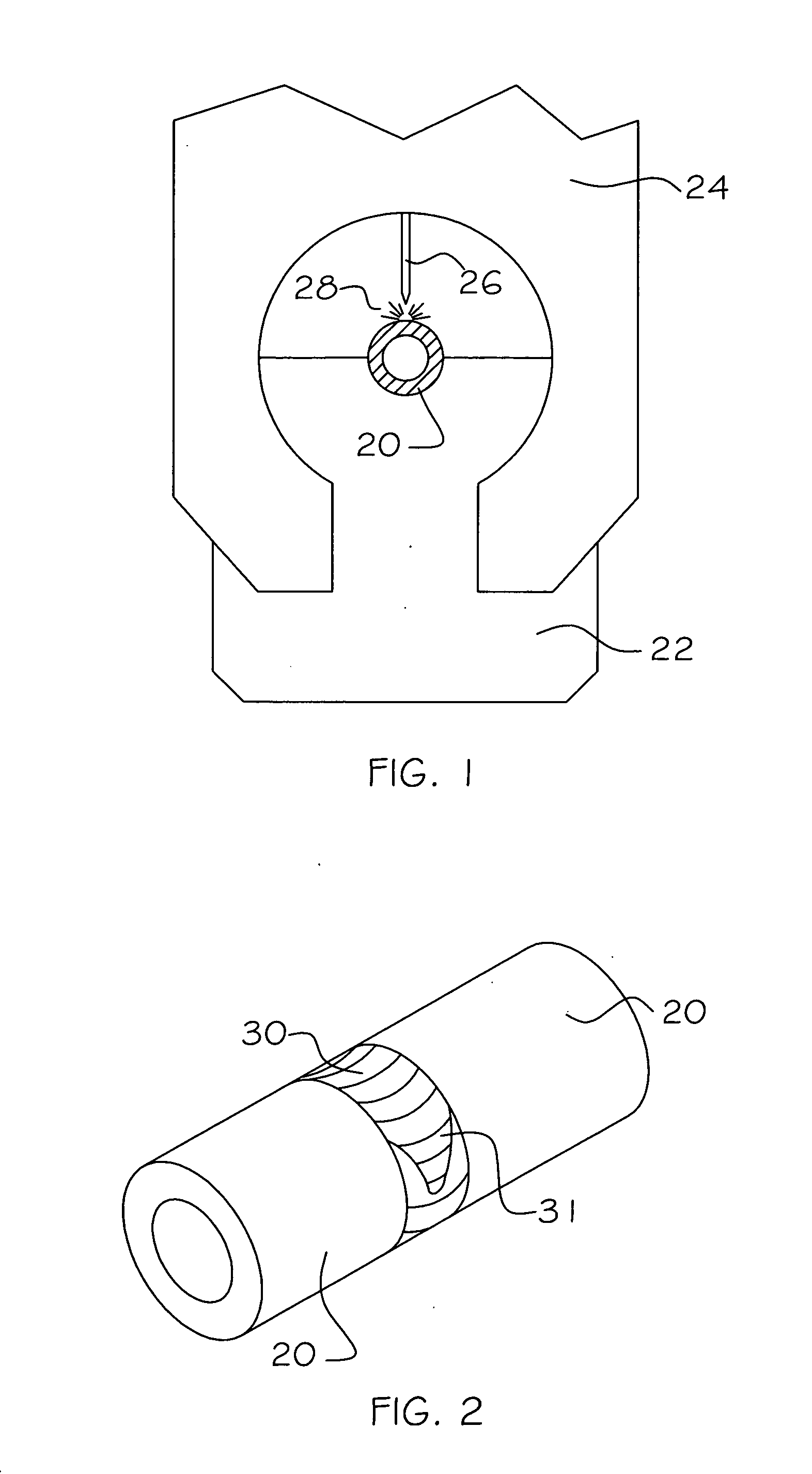

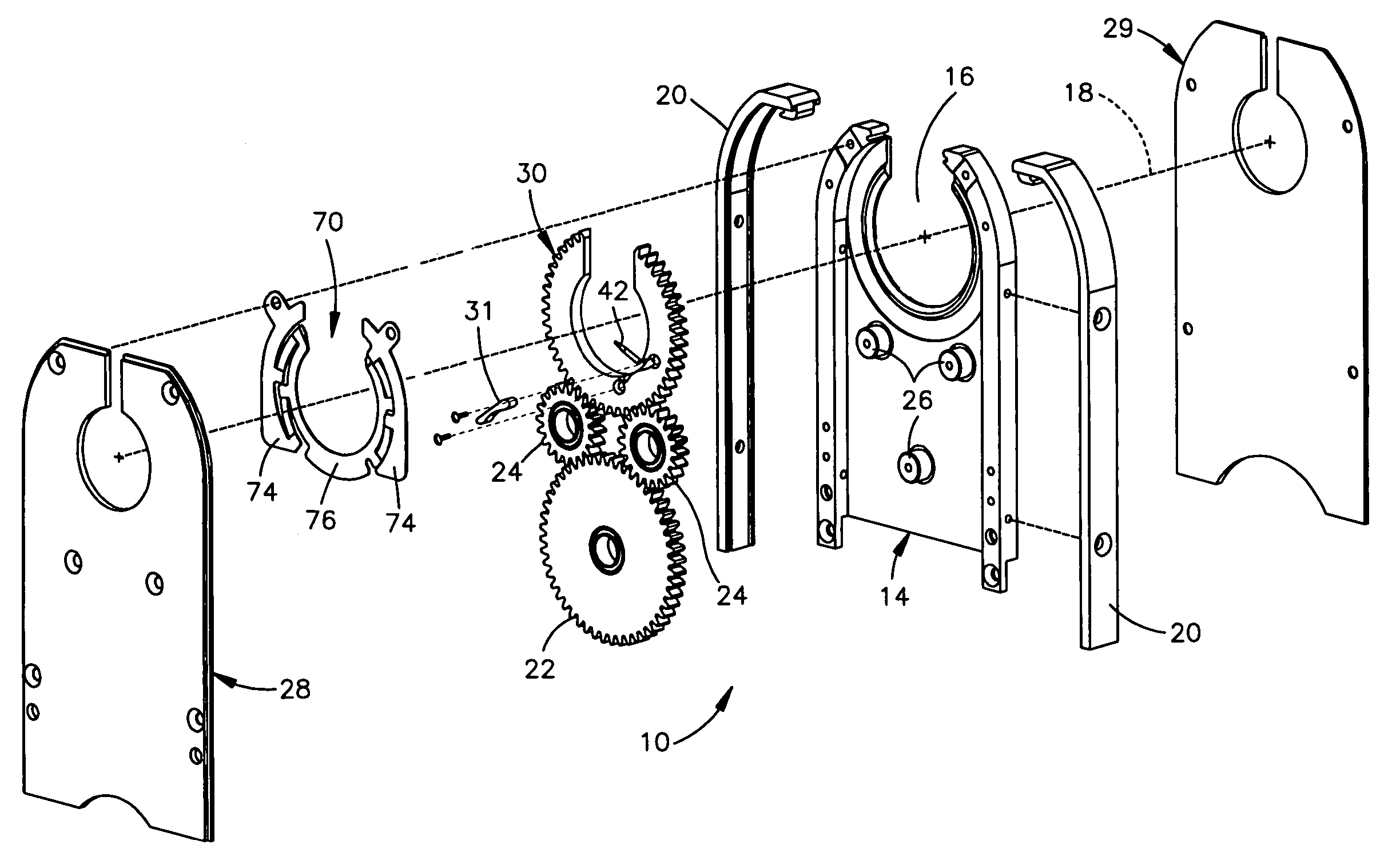

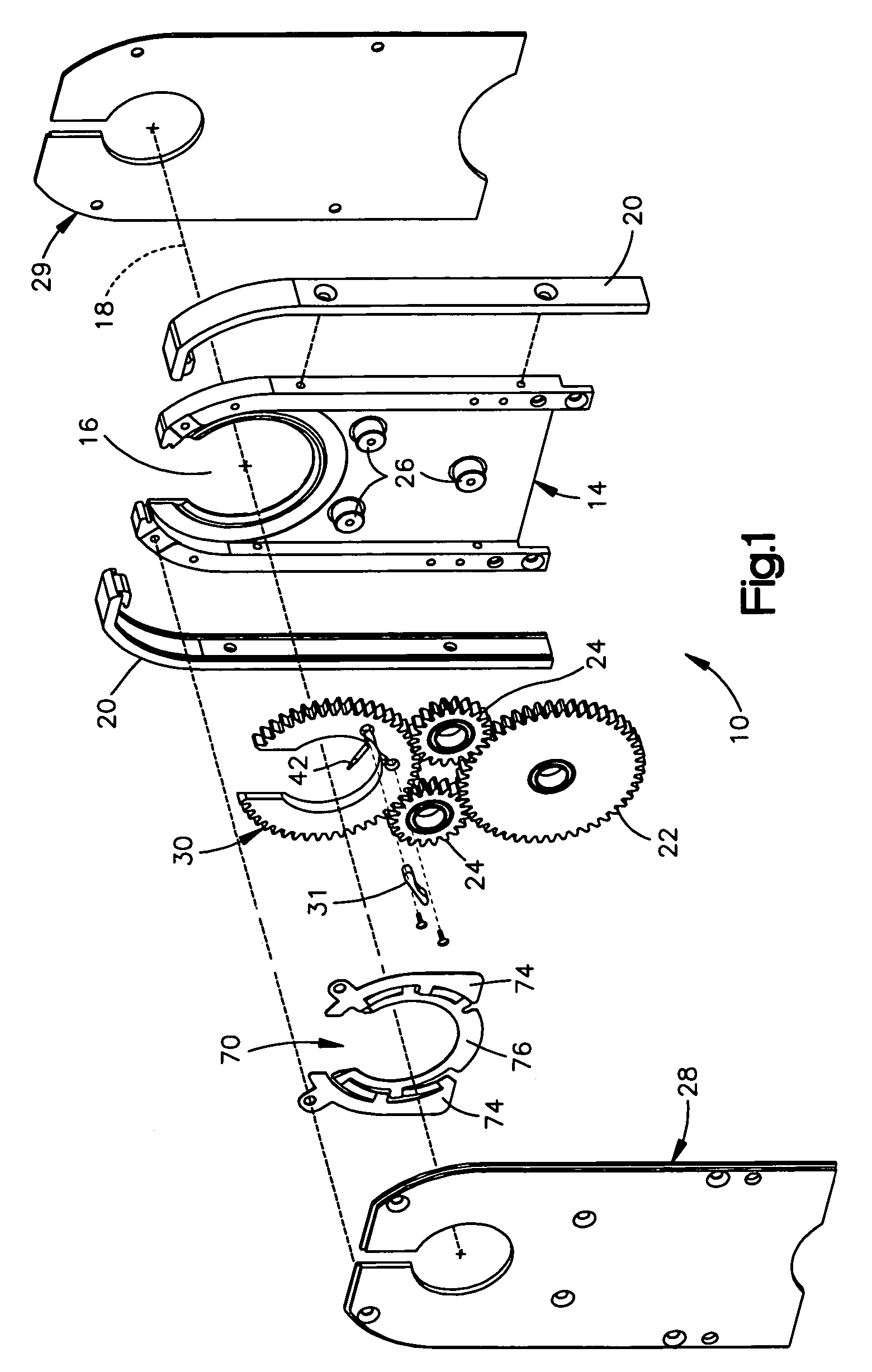

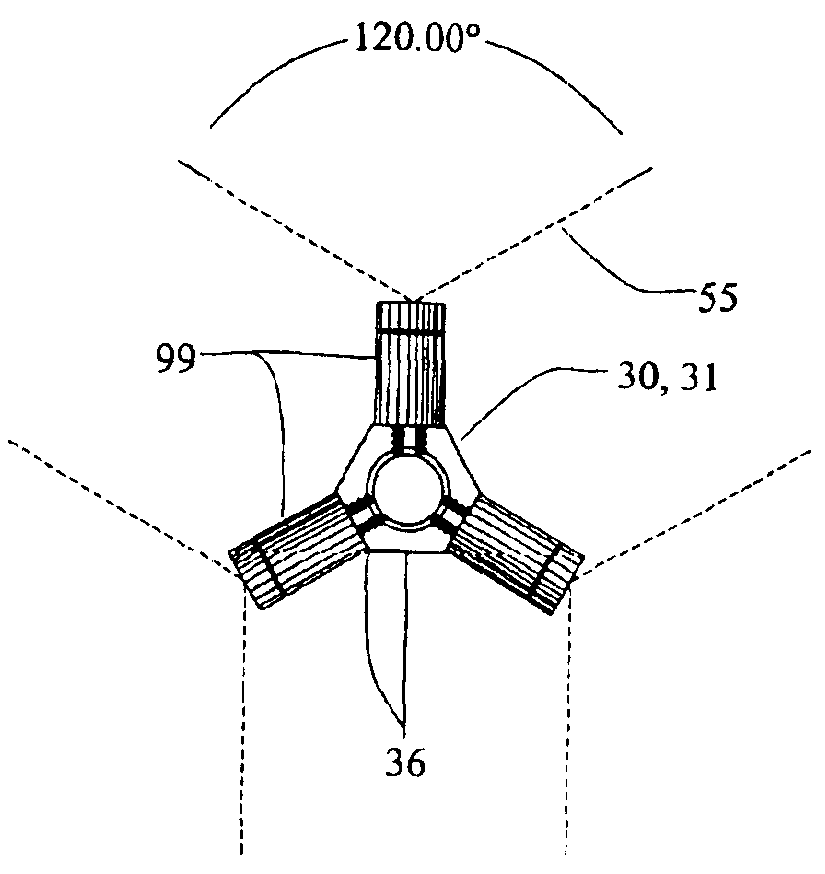

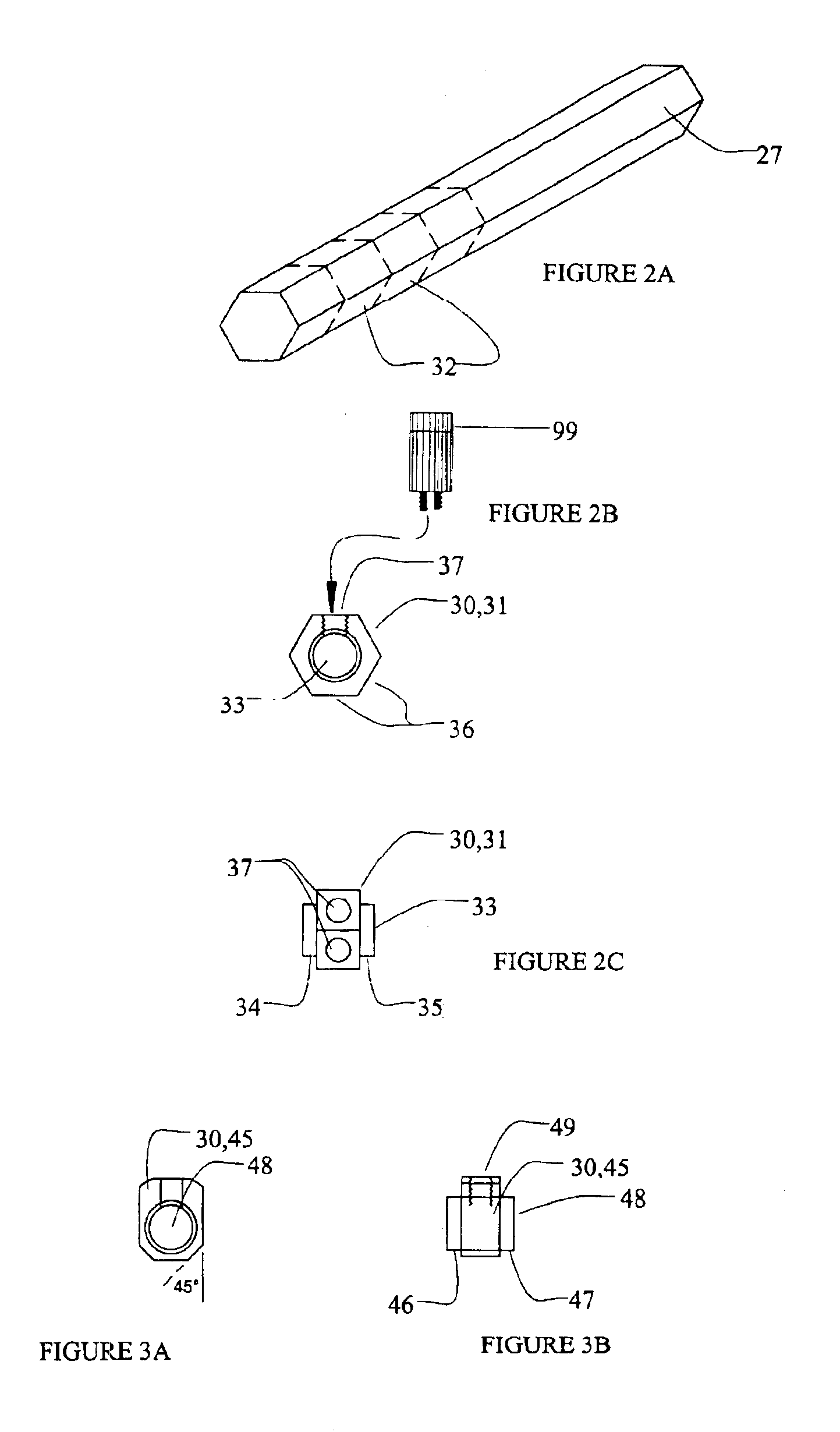

Ceramic weld insulator and metal weld gear combination for an improved micro weld head component of an orbital tube welding apparatus

InactiveUS7026568B2Reduce conductionApparent advantageWelding/cutting auxillary devicesAuxillary welding devicesButt jointEngineering

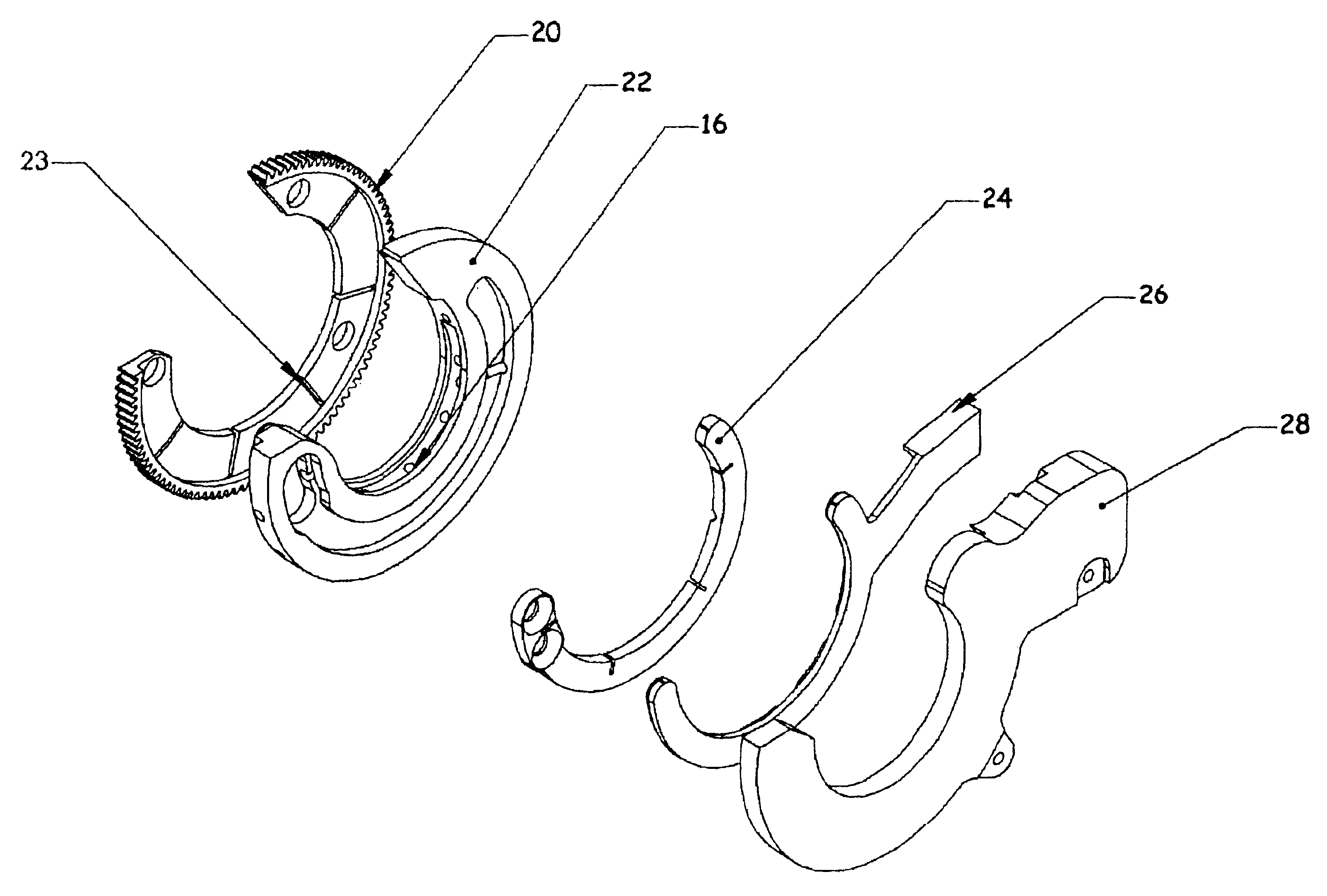

The invention is of an improvement to orbital welding heads and welding systems for welding pipe and tubing butt joints, consisting of a novel combination of materials, including a ceramic weld insulator and a metal weld gear. Such a combination, which has a greater dielectric strength than a plastic housing design, results in a more concentric tungsten travel path, increases the duty cycles of the weld head, minimizes erratic and wandering arcing, creates an electrical insulation yielding minimal expansion, allows for increased clamping surface for improved tube alignment, and provides a compact and very robust weld head.

Owner:ARC MACHINES

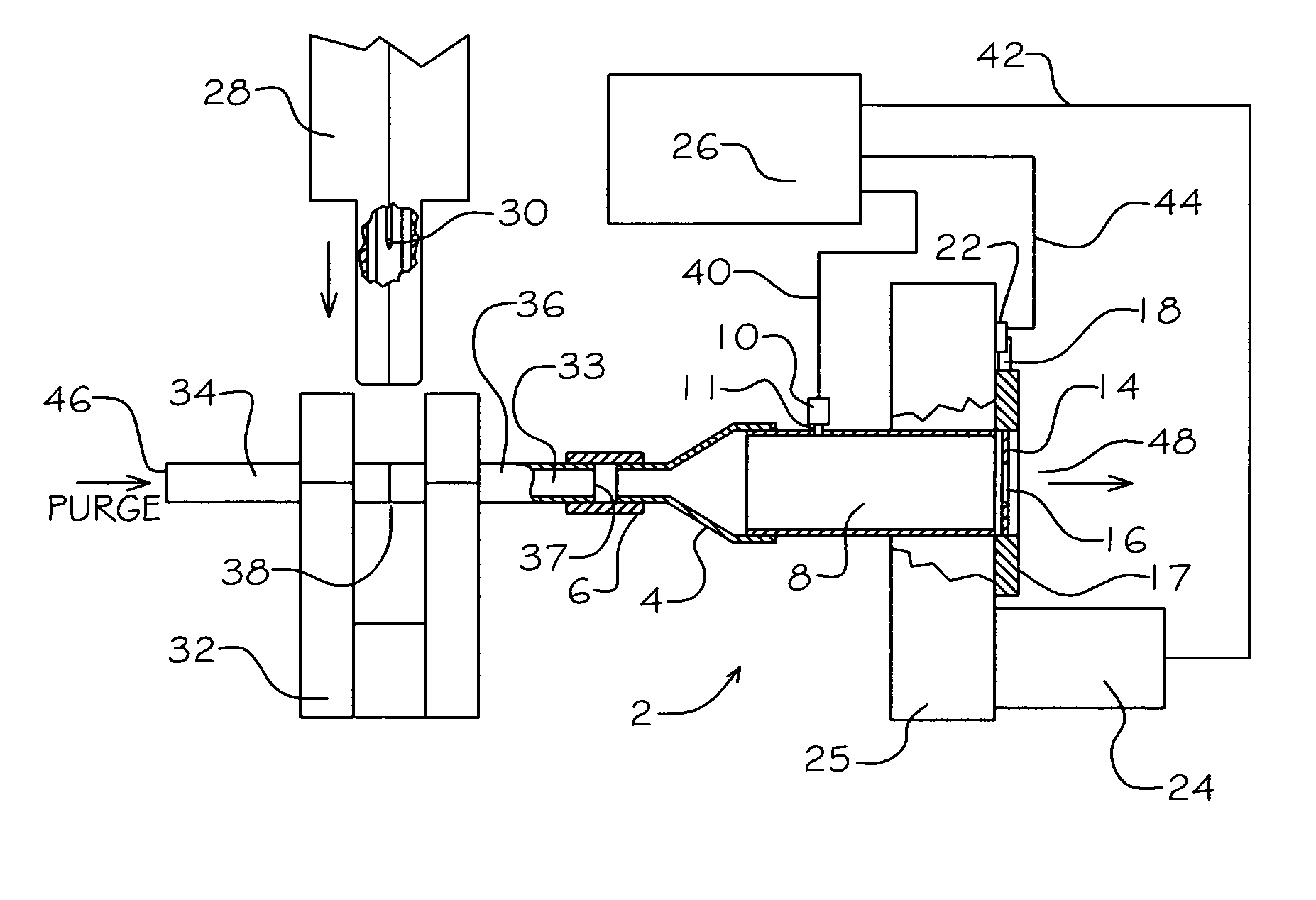

Orbital welding internal pressure control

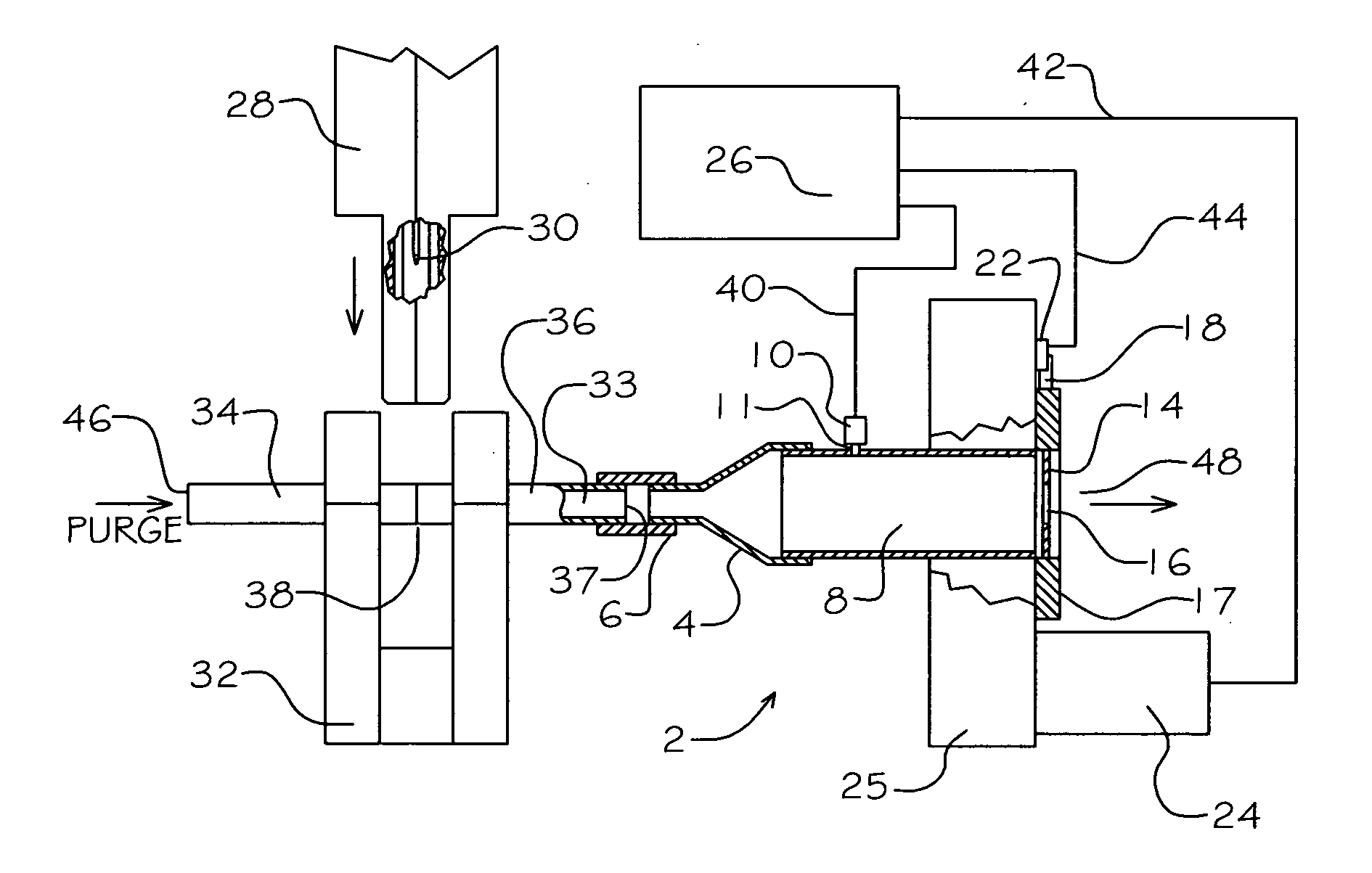

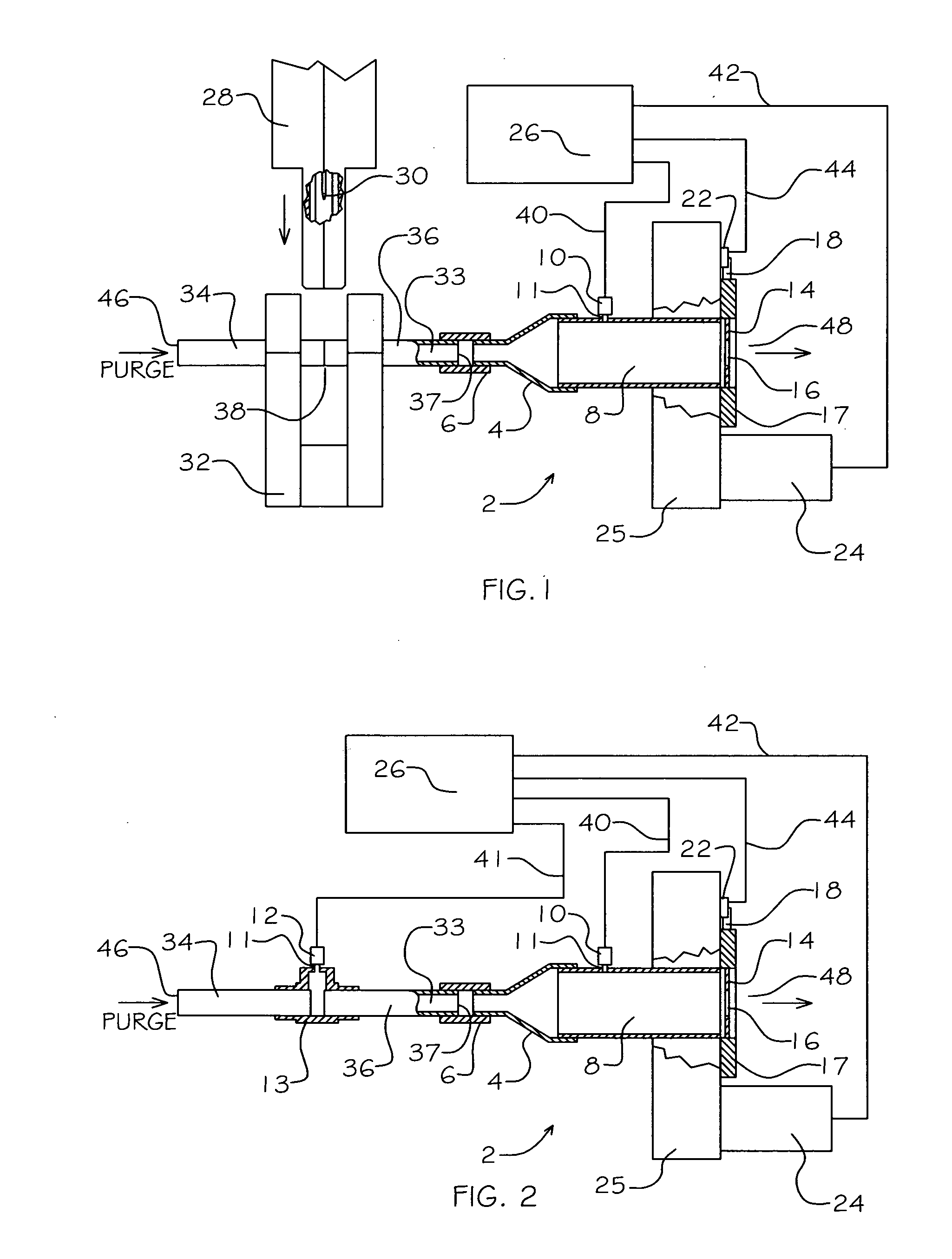

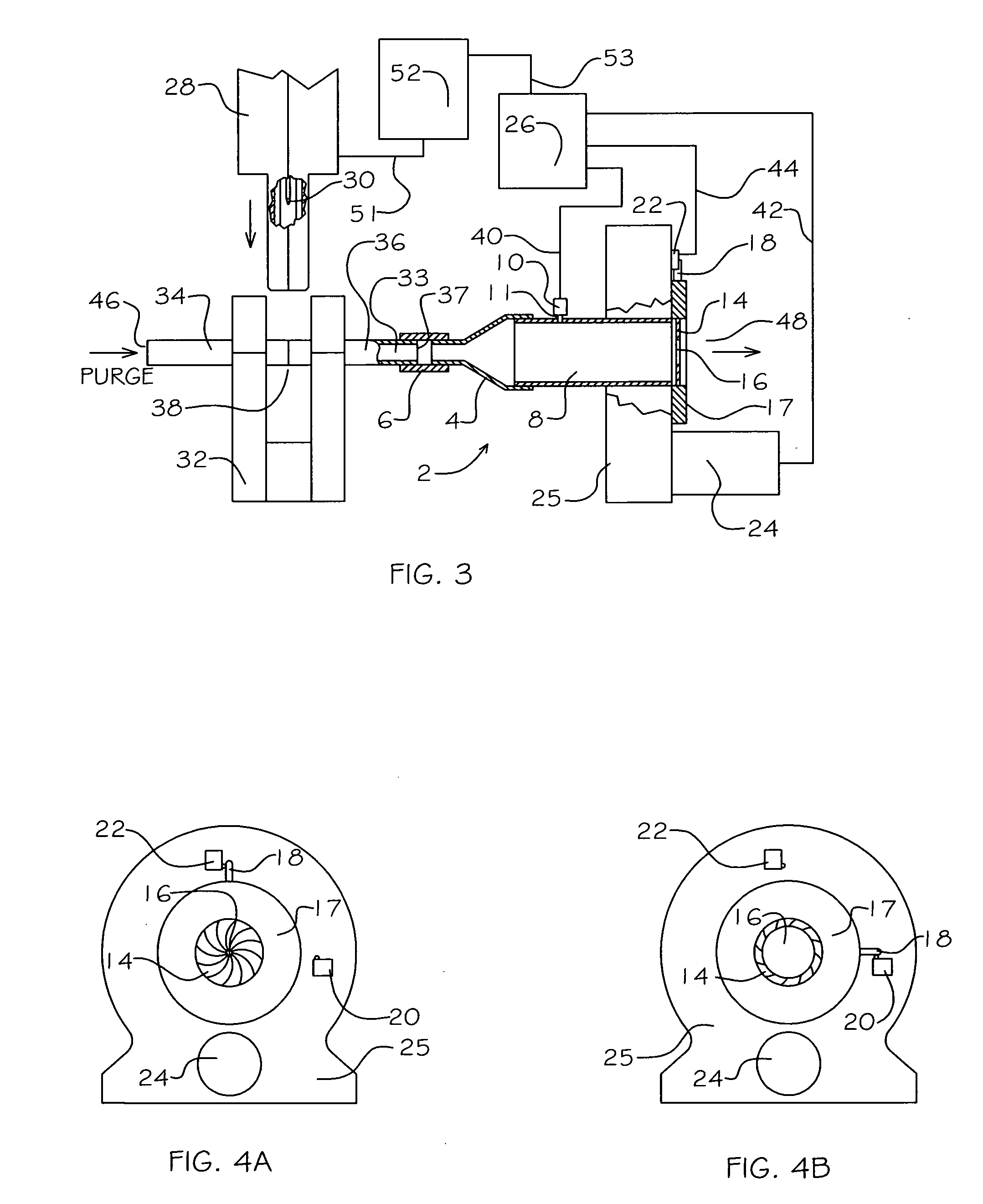

InactiveUS20060118526A1Overcome deficienciesShielding gas supply/evacuation devicesWelding/cutting auxillary devicesInternal pressurePull force

A weld bead geometry control system is provided for use in welding in abutment tubes or tubular components. The present invention can accurately and quickly correct for changes in purge gas pressure due to flow losses in real-time, to prevent any undesired protrusion or concavity of a molten weld bead, while allowing complete penetration of the weld. The present invention can additionally dynamically adjust the internal purge pressure to counteract the effects of gravitational pull on the molten weld bead. The weld bead geometry control system can in act in concert with existing orbital welding systems to consistently produce high quality and fully penetrated weld beads that meet or exceed industry standards.

Owner:ORBITAL ACQUISITION

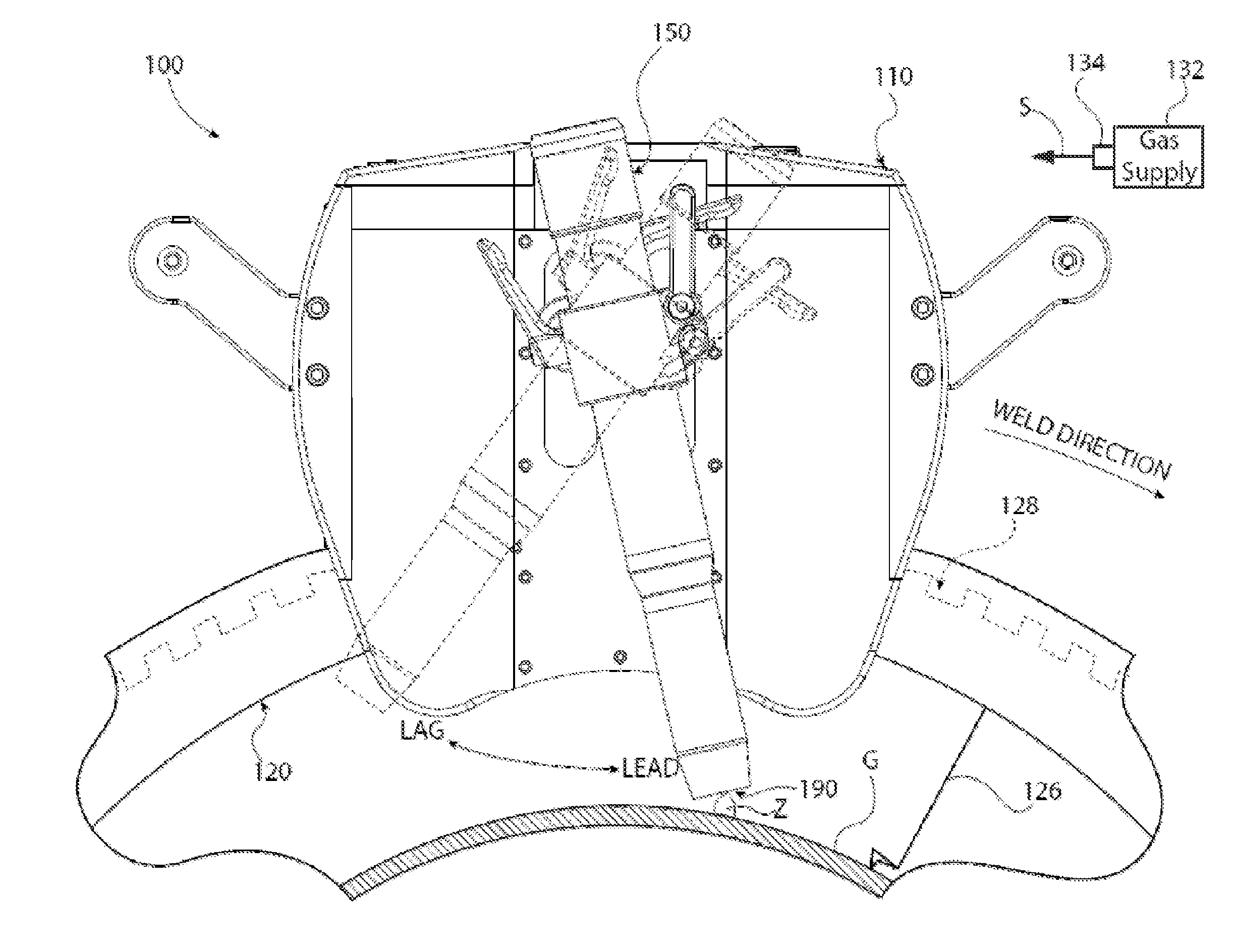

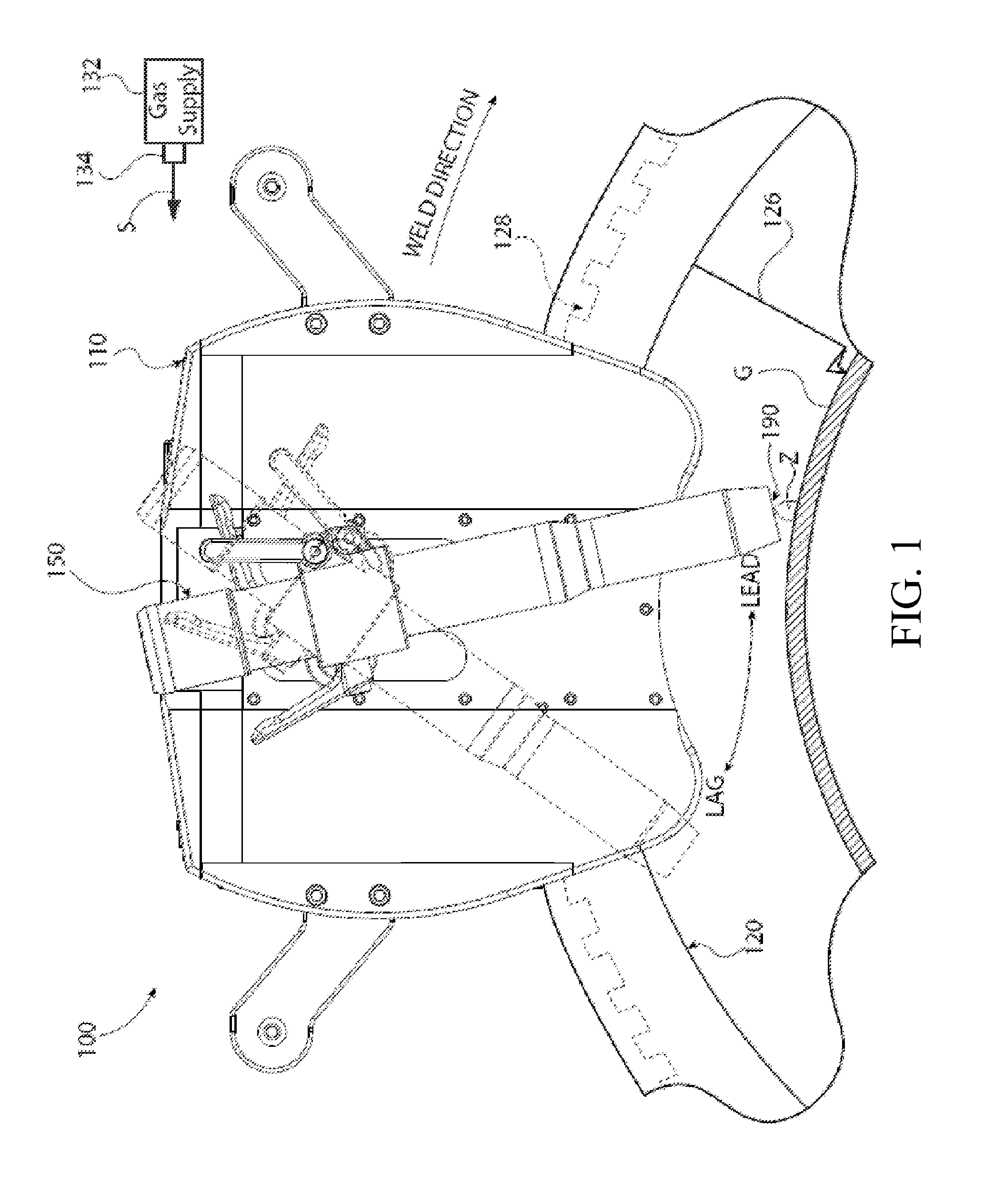

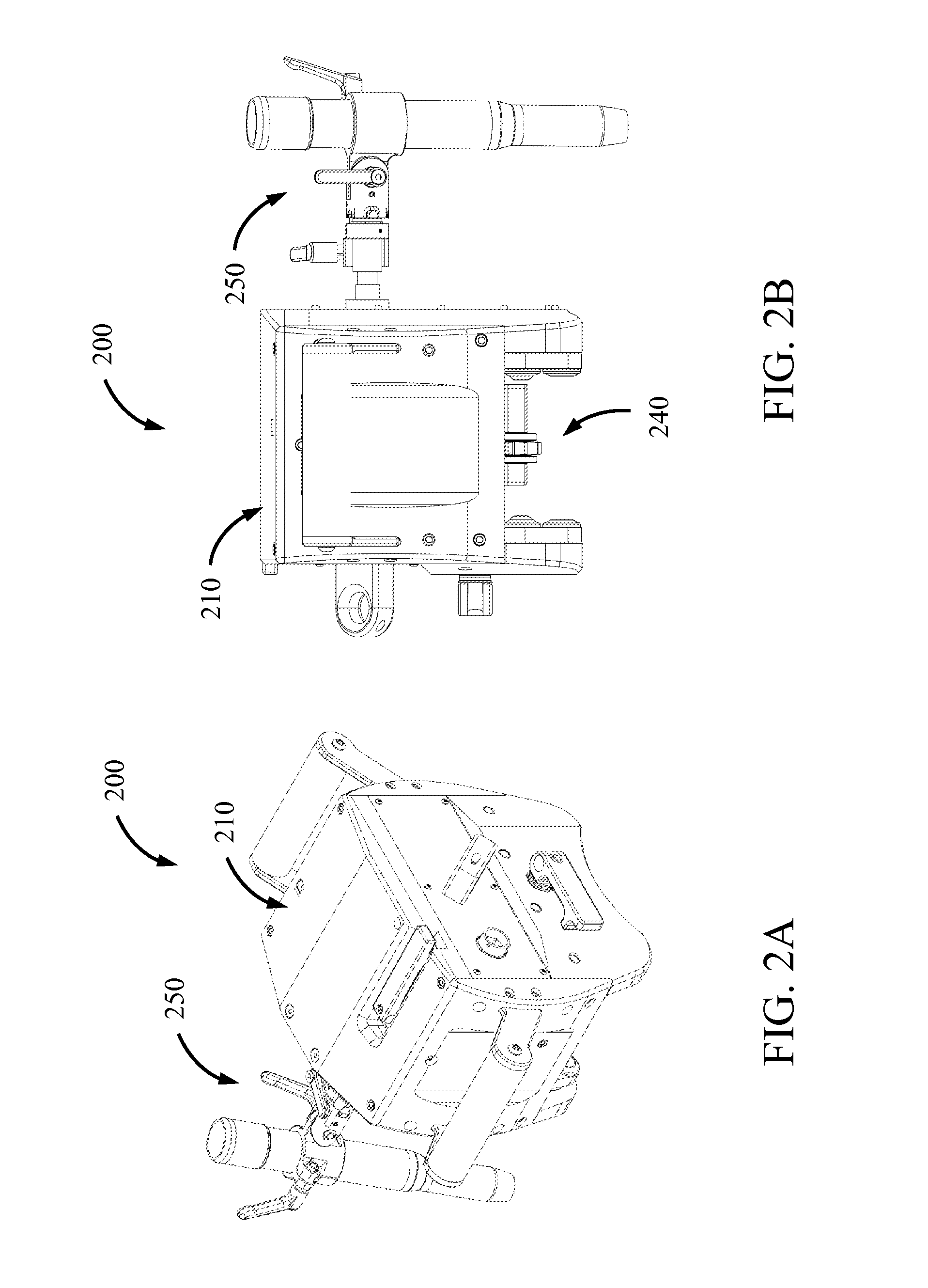

Orbital welding torch systems and methods with lead/lag angle stop

The invention described herein generally pertains to systems and methods related to repeatable and accurate setting of welding torch lead and lag positions, particularly with orbital welding systems. Specifically, a torch is coupled with a lead-lag coupler having a stop lug. A stop set with a stop pin is rotated to a desired position of lead or lag and secured. The lead-lag coupler, and torch which rotates therewith, are then unsecured and rotated until the stop lug contacts the stop pin. In this position, the torch is maintained at the desired angle. The stop pin remains in place throughout operation(s) to permit quick, accurate return to the desired angle if the torch is temporarily moved out of position.

Owner:LINCOLN GLOBAL INC

Orbital welding internal pressure control

InactiveUS7057137B1Overcome deficienciesShielding gas supply/evacuation devicesWelding/cutting media/materialsInternal pressureEngineering

The present invention is generally comprised of a tube adaptor, a chamber, a chamber pressure sensor, a calibration pressure sensor, an iris valve, an iris valve drive means, and a control and data processing means. In a calibration mode, the calibration pressure sensor measures the purge pressure at the abutment of two flow elements, while concurrently measuring the corresponding pressure at the chamber pressure sensor. In the welding mode, the calibration pressure sensor is removed, and the corresponding pressure within the chamber is maintained throughout the welding process to affect the geometry of the molten weld bead.

Owner:ORBITAL ACQUISITION

Orbital weld head

ActiveUS20050045596A1Accurate and consistent weldConsistent gapWelding/cutting auxillary devicesAuxillary welding devicesEngineeringOrbit

An orbital weld head includes a metal insert and rotor. The covers are made from mica laminate. A metal spring / brush that is preferably one piece side loads the rotor against the insert. The rotor and insert have interengaging portions, preferably trapezoidal, that cause the rotor to move axially when it expands from heat, thus minimizing binding.

Owner:SWAGELOK CO

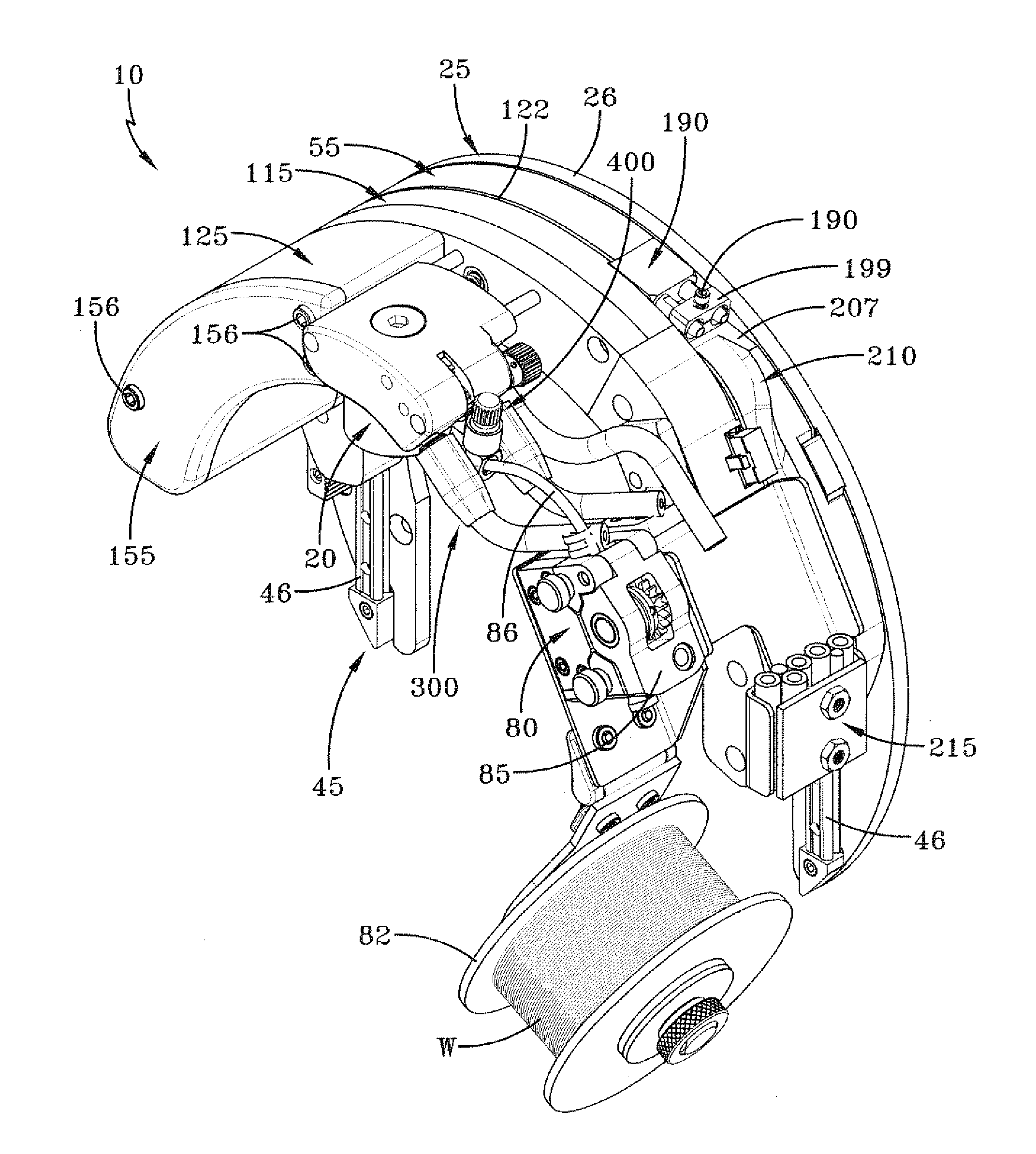

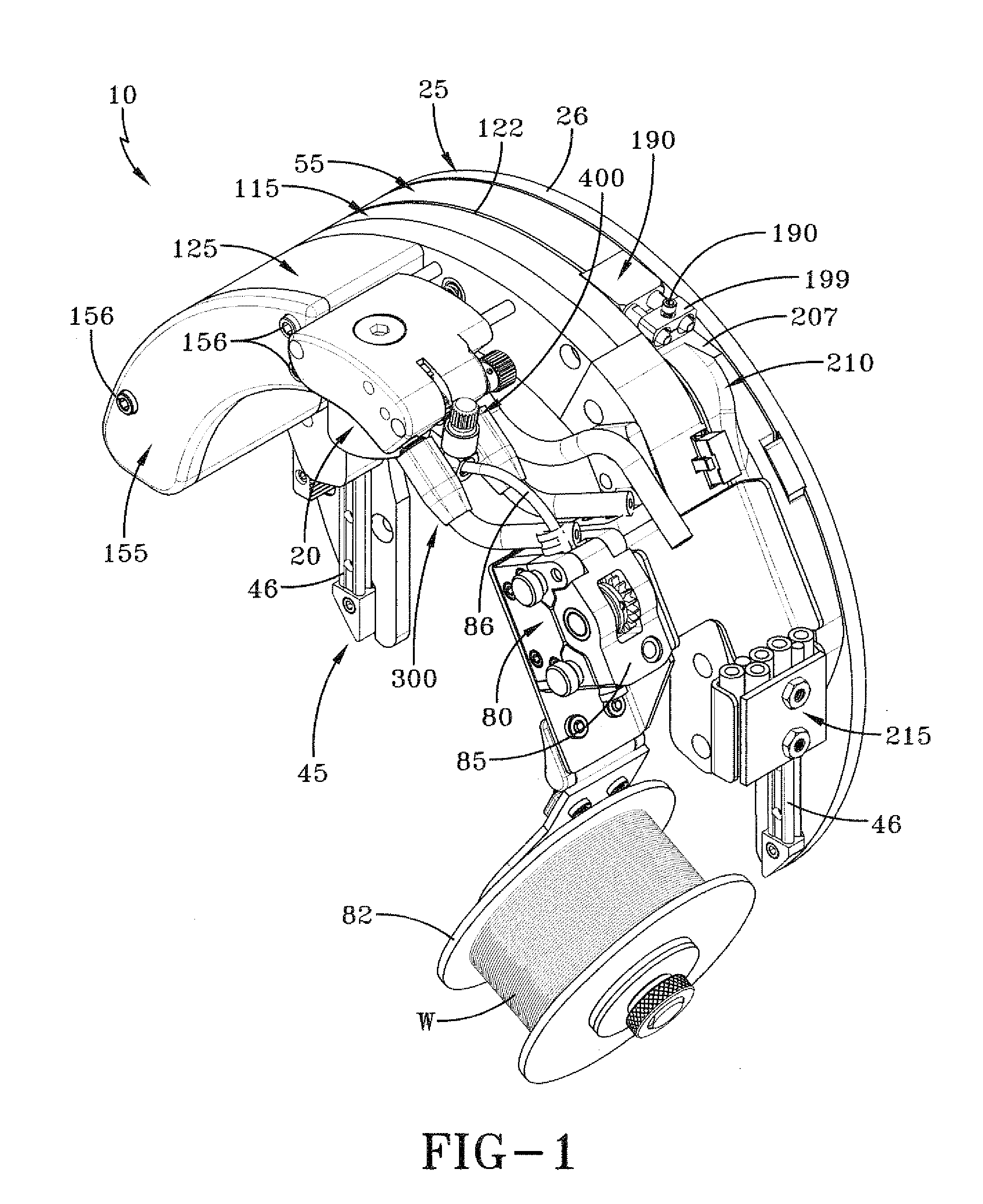

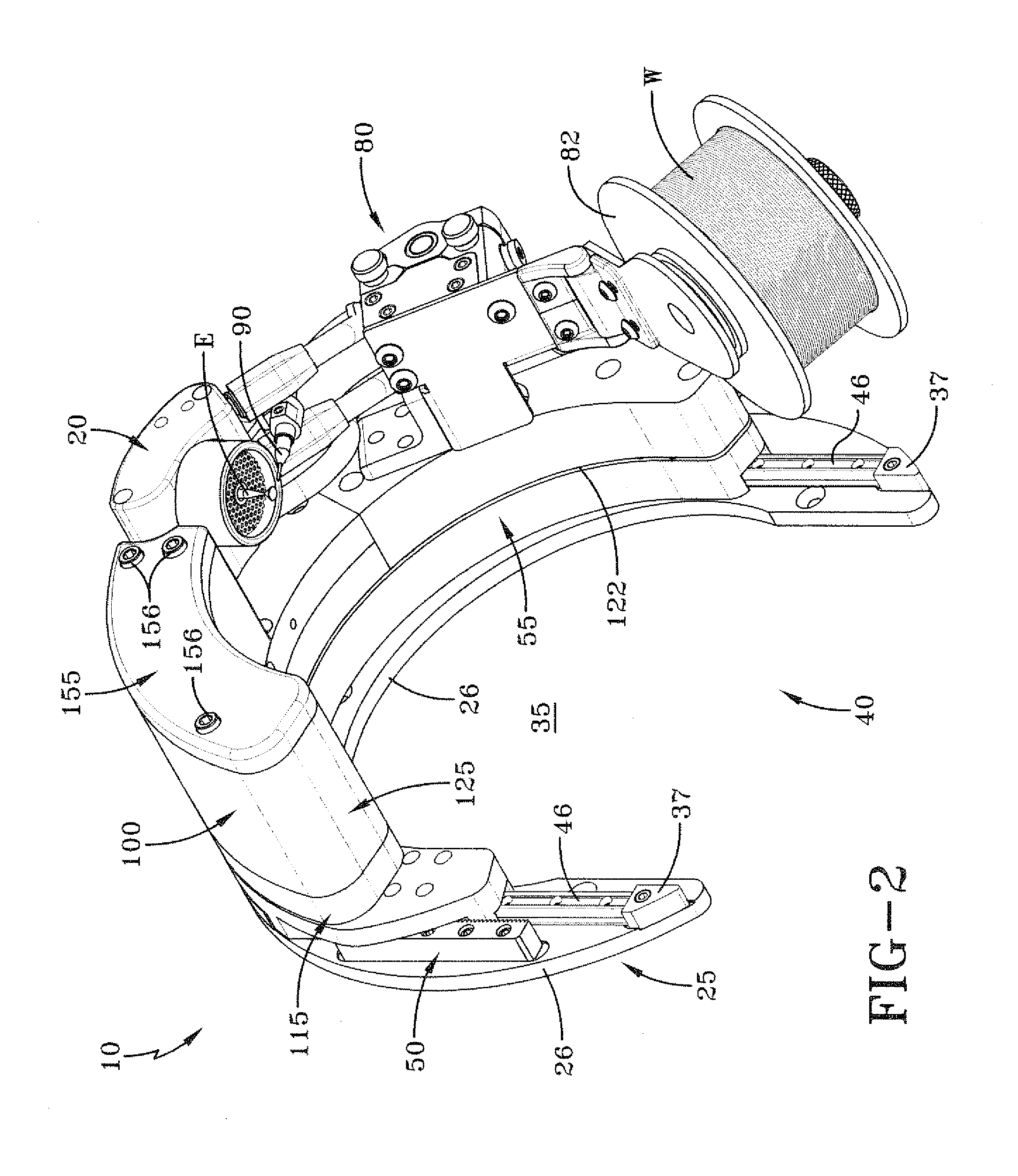

Multi-fuction orbital welding system

InactiveUS20140263257A1Electric discharge heatingNon-shielding electrode holdersEngineeringMechanical engineering

A torch head in a welding system for applying a weld to a workpiece, the torch head including a torch head body having a first side, a second side, an inward side and a outer side, the torch head body further including a lower surface and a top surface forming a solid; the torch body defining a slot extending from the lower surface to the top surface on the first side; an electrode assembly including an electrode mounted on the torch body, the electrode extending downward relative to the lower surface of the torch body; a wire adjustment assembly including a bracket supporting a wire guide that receives a wire from a wire supply; the bracket being attached to a rack and pinion supported within the slot, the rack being located inward of the pinion and slideable within the slot, the pinion being rotatable within the slot, and engaged with the rack to move the bracket vertically upon rotation of the pinion to adjust the vertical position of the wire.

Owner:LINCOLN GLOBAL INC

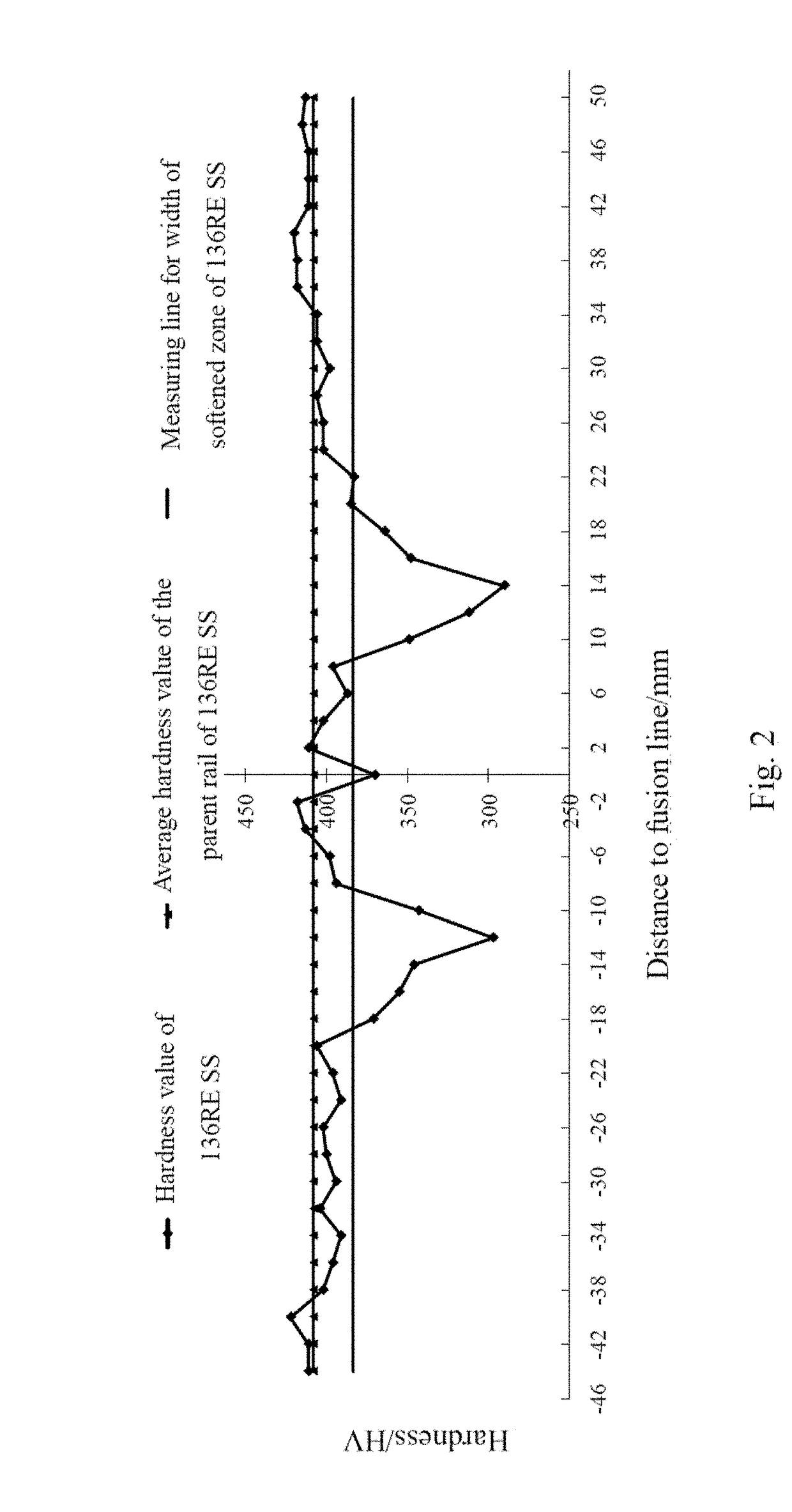

Mobile flash butt welding method for 136re+ss heat-treated rail

ActiveUS20190061041A1Improve welding qualityLess internal defectRailsFurnace typesDrop weightButt welding

The invention discloses a mobile flash butt welding method for 136RE+SS heat-treated rail, and particularly a mobile flash butt welding method for 136RE+SS heat-treated rail in the technical field of rail welding. The mobile flash butt welding method for 136RE+SS heat-treated rail in the invention includes a pre-flash stage, a flash stage, a boost stage, an upset stage and a forge stage, with a total heat input of 7.1 MJ-10.0 MJ, a total duration of 110 s-135 s and an upsetting distance of 12.8 mm-16.7 mm during the welding process. By adopting the method of the invention, mobile flash butt welding can be conducted for 136RE+SS heat-treated rail successfully, and the rail joint has less internal defects but stable welding quality, and can pass fatigue test, tensile test and slow bend test to meet the requirements. Besides, the rail joint can pass the drop weight test for 15 welds continuously, demonstrating better stability.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

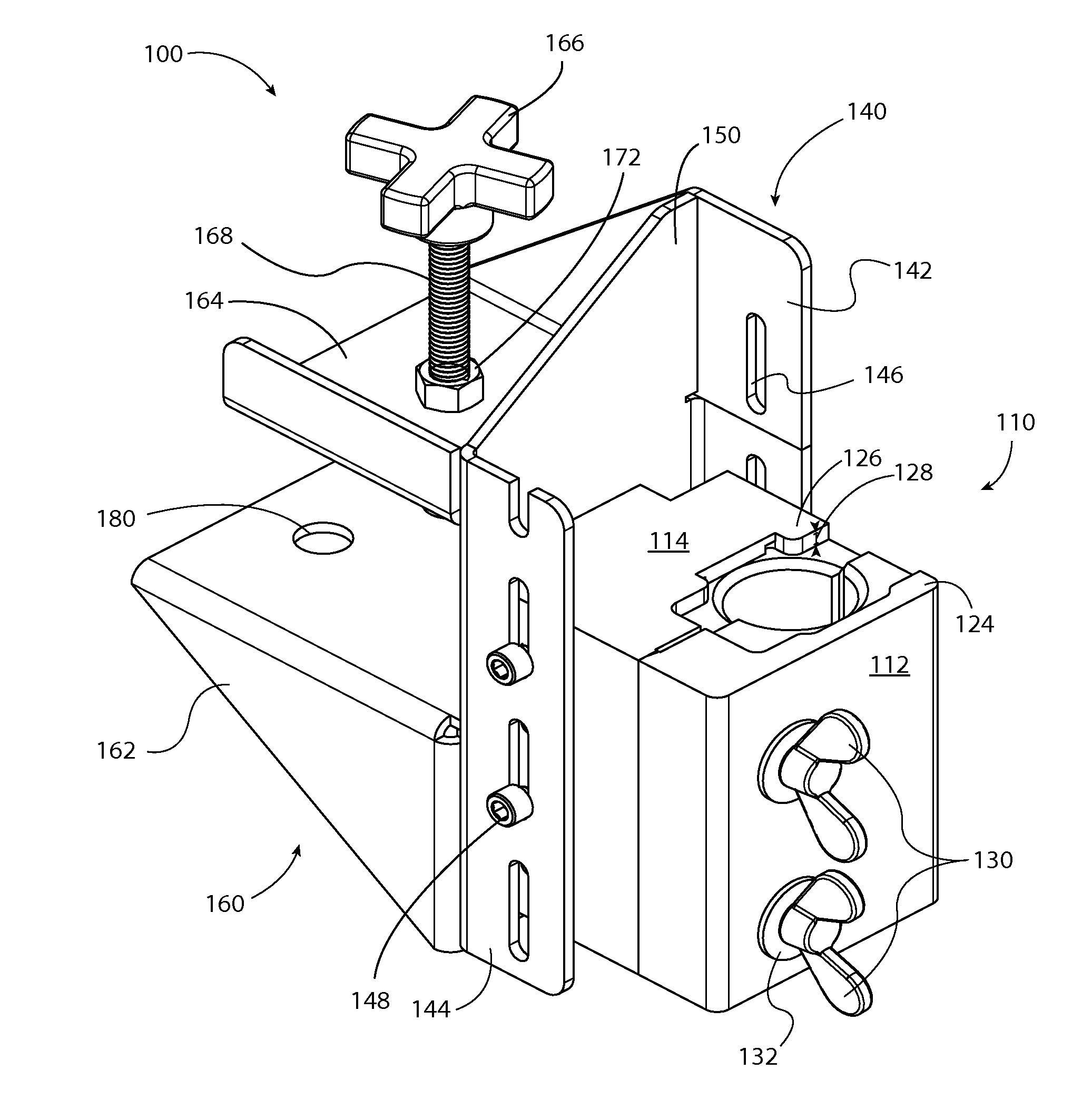

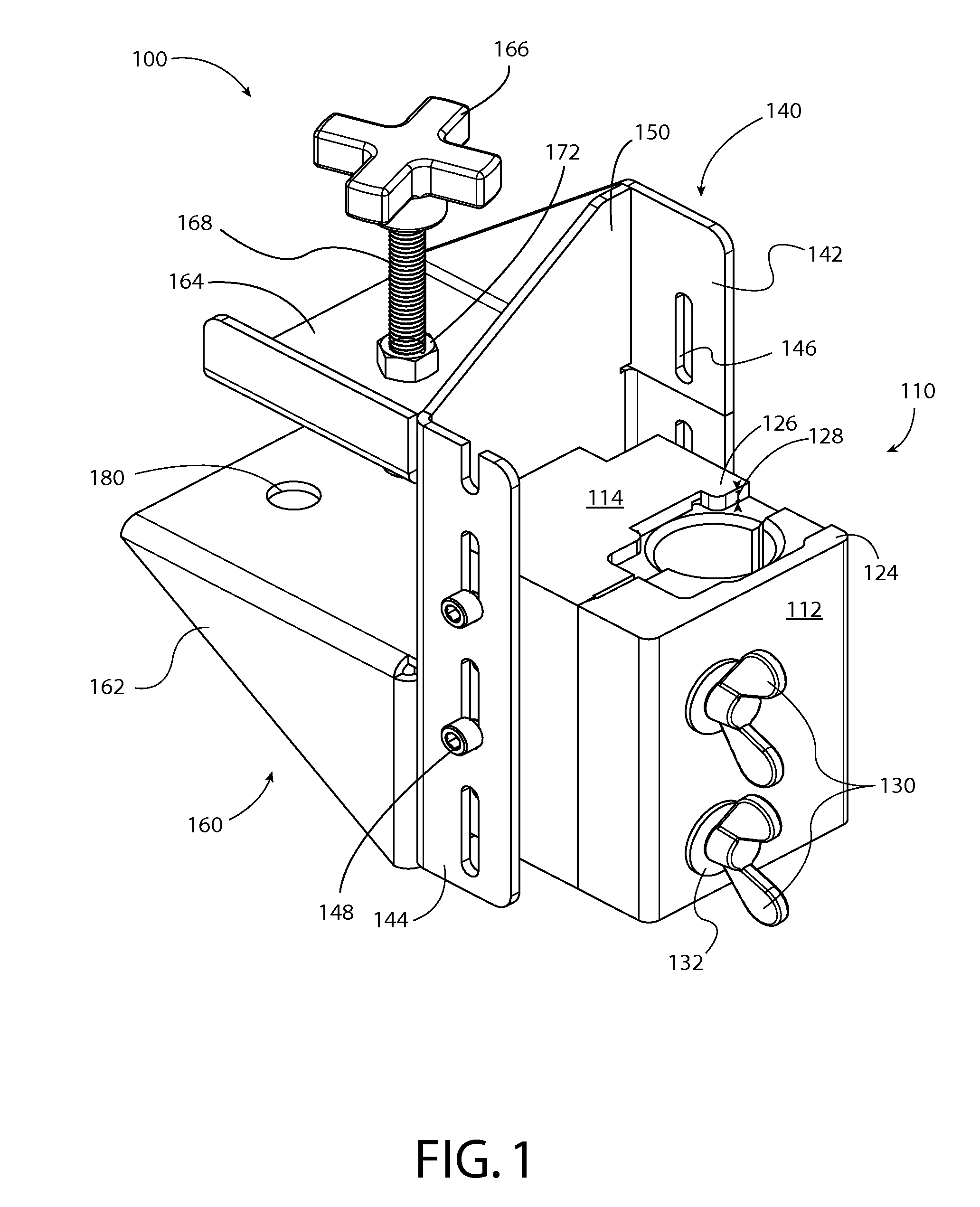

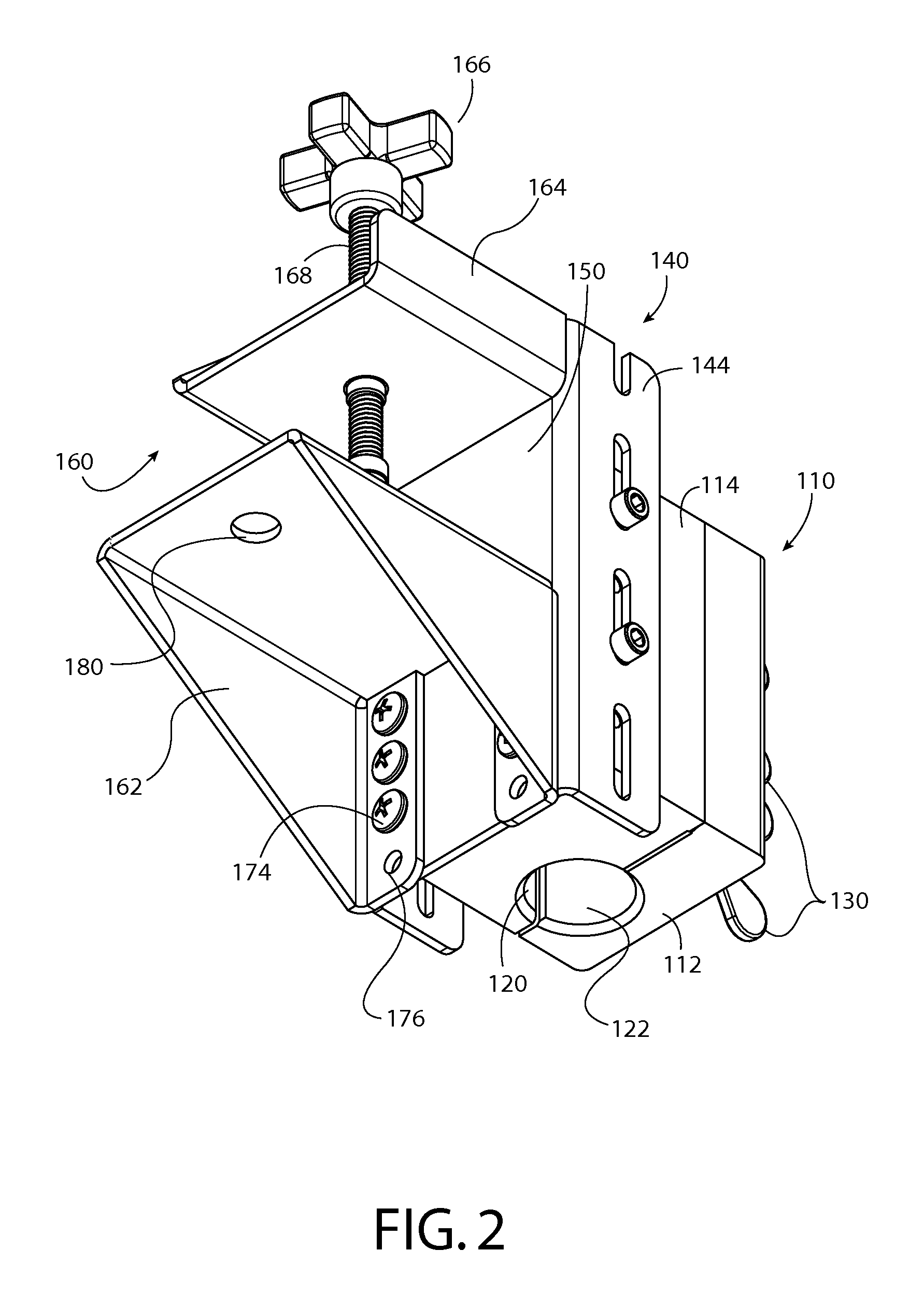

Systems and methods for keyed welding clamp

The invention described herein generally pertains to systems and methods for accurately and precisely mounting an orbital welder for static use. Clamp systems as described herein can include a keyed welding clamp assembly for retaining the orbital welder having an orbital welder clamp, a clamp adapter, and a clamp mount. Similarly, methods herein can include disposing a welder extension in a first extension recess of a first clamp portion and a second extension recess of a second clamp portion, aligning an alignment key with a first key recess of the first clamp portion and a second key recess of the second clamp portion, and closing the first clamp portion toward the second clamp portion using a clamp mechanism. An operational welding system including clamps herein can further include the orbital welder and / or components thereof.

Owner:LINCOLN GLOBAL INC

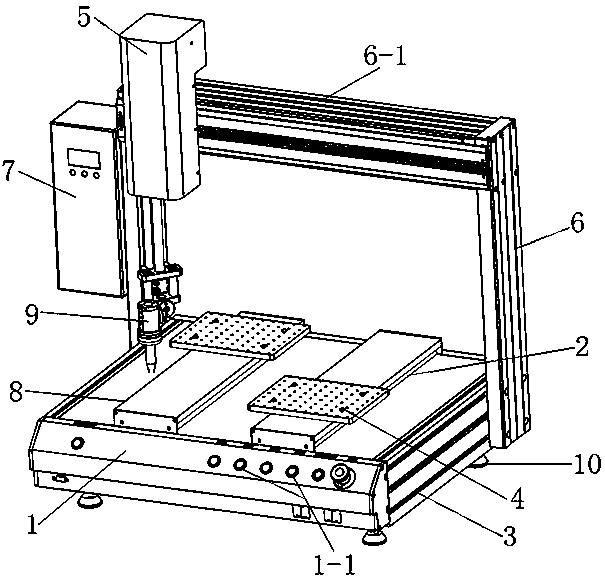

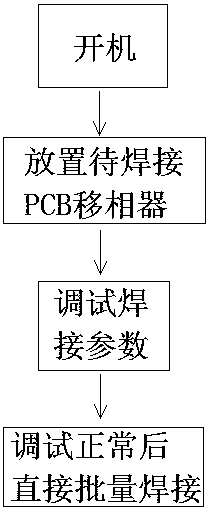

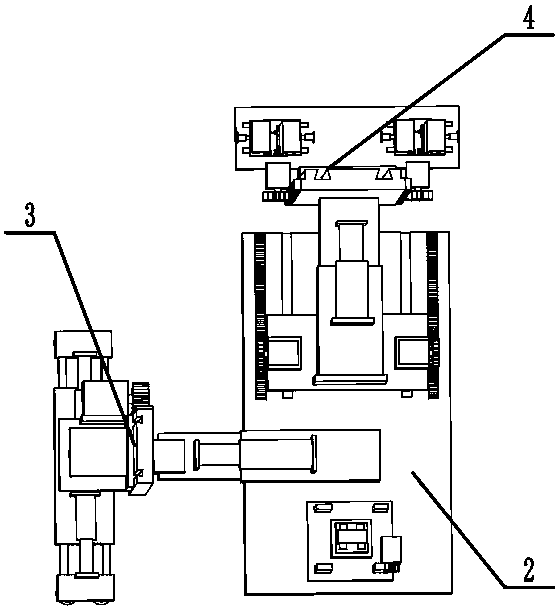

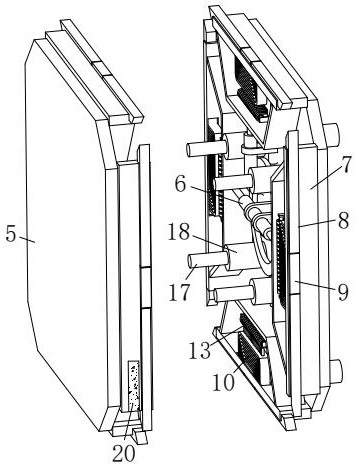

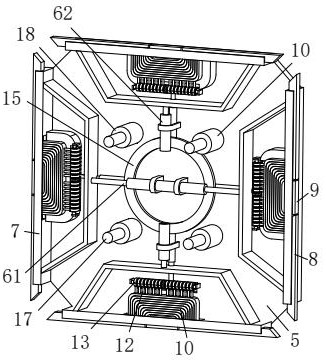

Automatic welding machine for welding of phase shifter

PendingCN108436213AIngenious ideaEasy to useSoldering bitsSoldering ironEngineeringMechanical engineering

The invention relates to welding equipment, in particular to an automatic welding machine for welding of a phase shifter. The automatic welding machine for welding of the phase shifter comprises a base, base upper tracks, base side tracks, welding tools, a welding arm, a welding arm support and a control box. The base is shaped like a cube. The upper surface of the base is provided with two equal-size tool locating bosses parallel to the side edges. The base upper tracks are arranged on the two sides of the tool locating bosses. One welding tool is arranged on each tool locating boss. The welding tools are fixed to the corresponding tool locating bosses through screws or buckled onto the base upper tracks through buckles to be movably mounted on the tool locating bosses. The automatic welding machine can be used for welding different sizes of products by replacing the welding tools.

Owner:ZHONGTIAN BROADBAND TECH +1

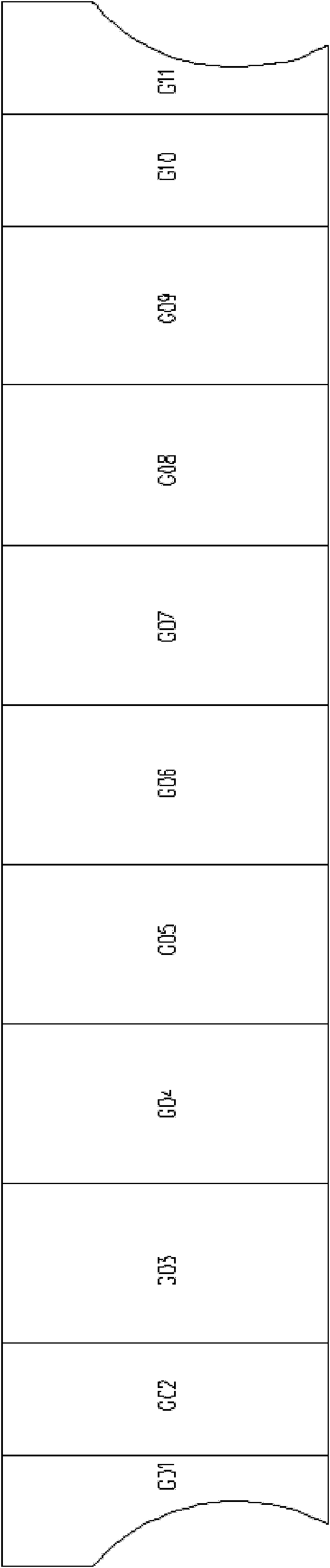

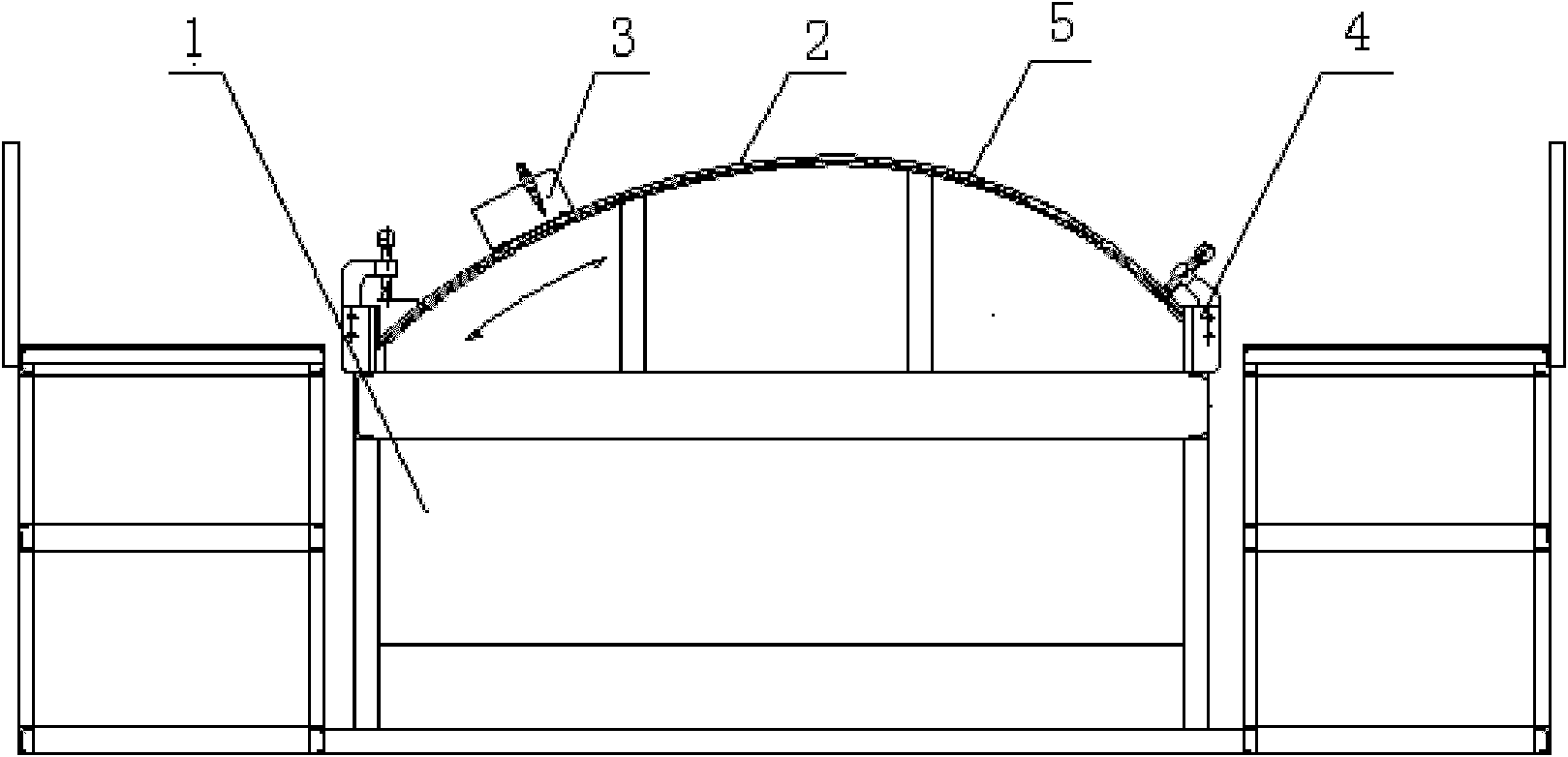

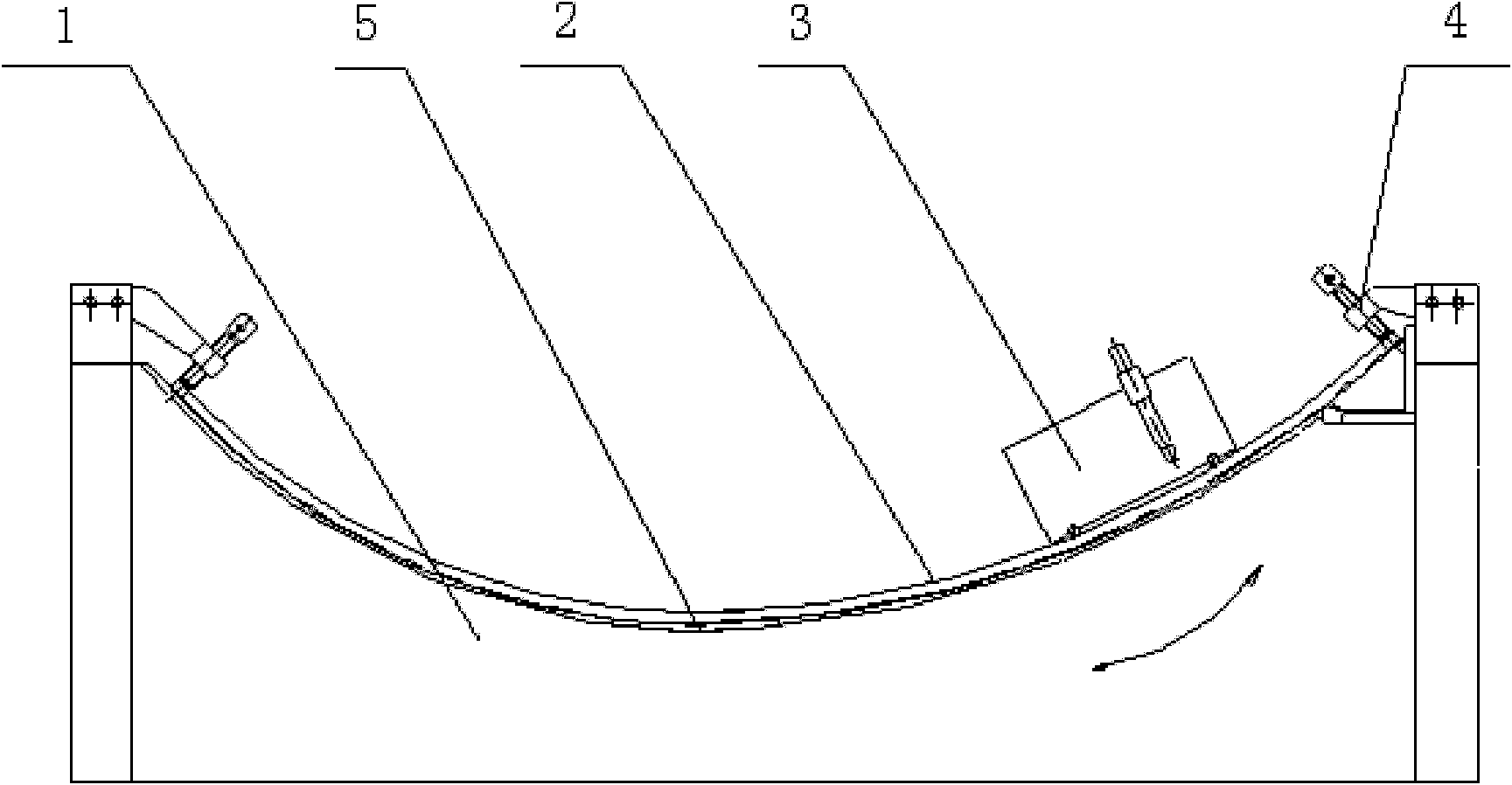

Manufacturing method of wrapper plate type side wall structure of wagon

InactiveCN102069309ASimple manufacturing processImprove the quality of manufactured productsWelding apparatusSingle plateOrbital welding

The invention provides a manufacturing method of a wrapper plate type side wall structure of a wagon. The manufacturing method comprises the following steps: (1) decoiling and pre-treating a plate; (2) blanking and leveling the plate; (3) cutting a side wallboard and then laminating, i.e., according to the length and shape requirement of a side wallboard product, cutting out N equi-length single plates G01, G02...G0N, dividing the N equi-length single plates G01, G02...G0N into M groups in sequence, wherein each group comprises 2-4 single plates, and then carrying out double-face welding on each group of single plates so as to splice M large plates; (4) respectively rounding the M large plates into M arc-shaped side wallboards according to the required radian; and (5) assembling and welding side walls: successively hanging the M arc-shaped side wallboards on a side wall assembling base seat tire, assembling various arc-shaped side wallboards, carrying out positioning welding after clamping and fixing, carrying out assembling gap welding by using a welding tractor matched with a flexible track, after the side wallboards are turned over, clamping and positioning the inner side faces of the side wallboards, and carrying out continuous full-length welding on the inner side faces of the side wallboards by using the welding tractor matched with the flexible track.

Owner:CRRC YANGTZE CO LTD

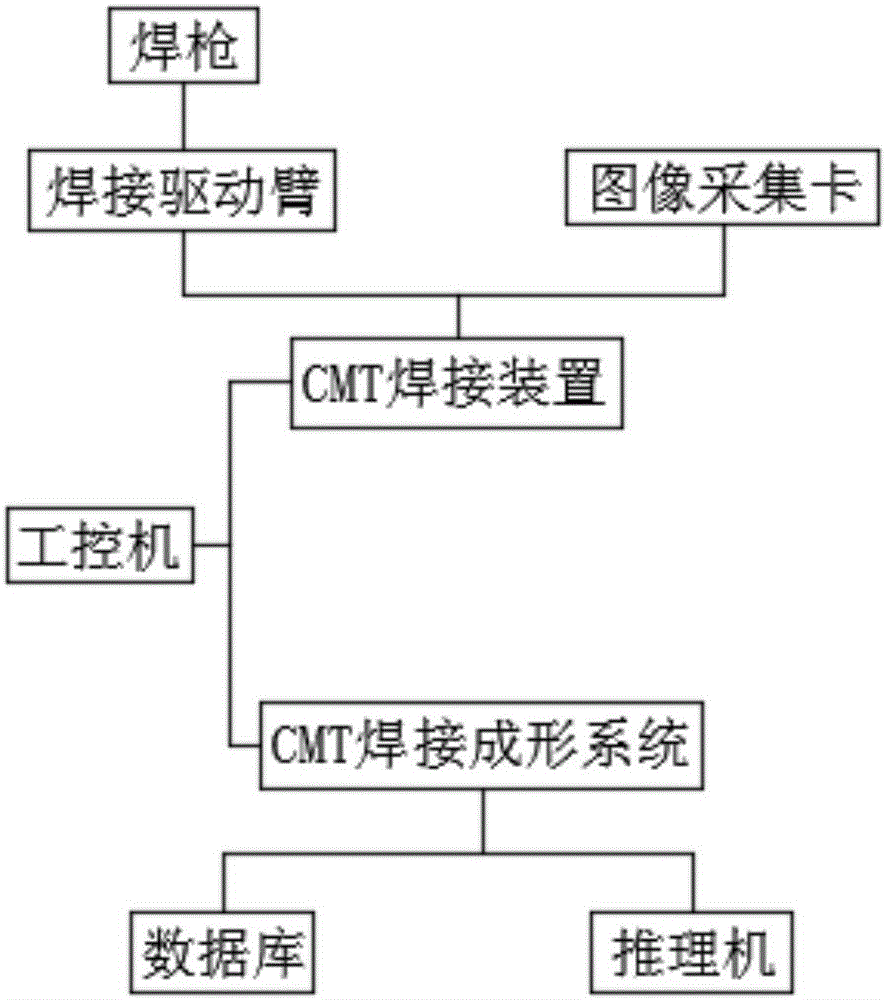

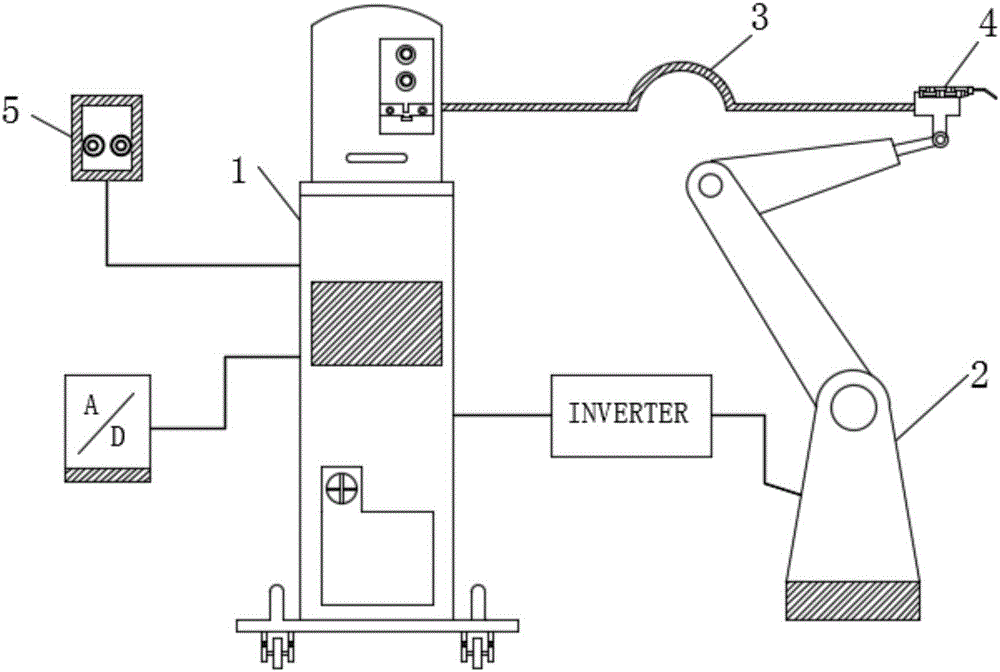

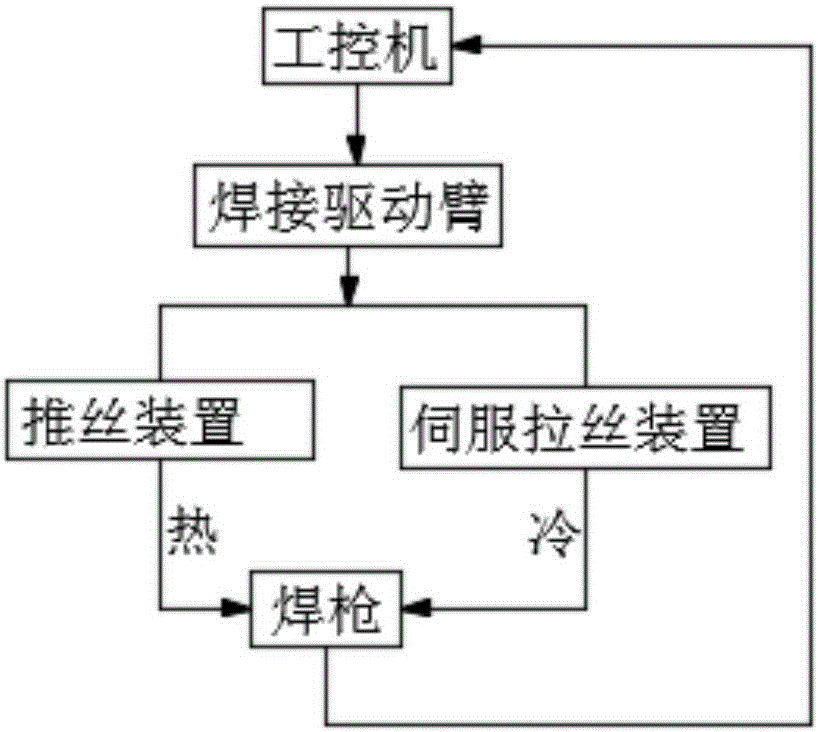

Metal welding forming system and metal welding forming method based on CMT (cold metal transition)

InactiveCN106363323AShape matchingAchieve closed-loop heating and cooling controlWelding/cutting auxillary devicesAuxillary welding devicesClosed loopEngineering

The invention discloses a metal welding forming system based on CMT (cold metal transition). The metal welding forming system comprises a welding industrial personal computer, wherein the welding industrial personal computer is connected with an operation panel. The invention also discloses a metal welding forming method based on the CMT. The metal welding forming method comprises the following steps of putting a processed part, analyzing the shape of the processed metal by the CMT welding system, encoding by an inference engine to set a working track, welding by a welding mechanism along the track, and comparing and straightening in the welding process. The metal welding forming system and the metal welding forming method have the advantages that an image collection card and an optical visual sensor are used for inputting the to-be-welded shape of the metal into the industrial personal computer, database analysis is performed by the CMT welding forming system in the industrial personal computer, a track forming analysis code is encoded through the inference engine, and the welding of the welding mechanism is controlled, so that the shape of the welding metal meets the actual requirements; the forward delivery and back-drawing of a welding wire are controlled by a wire pushing device and a servo wire drawing device in the welding mechanism, so that the closed-loop cold and heat control function is realized.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

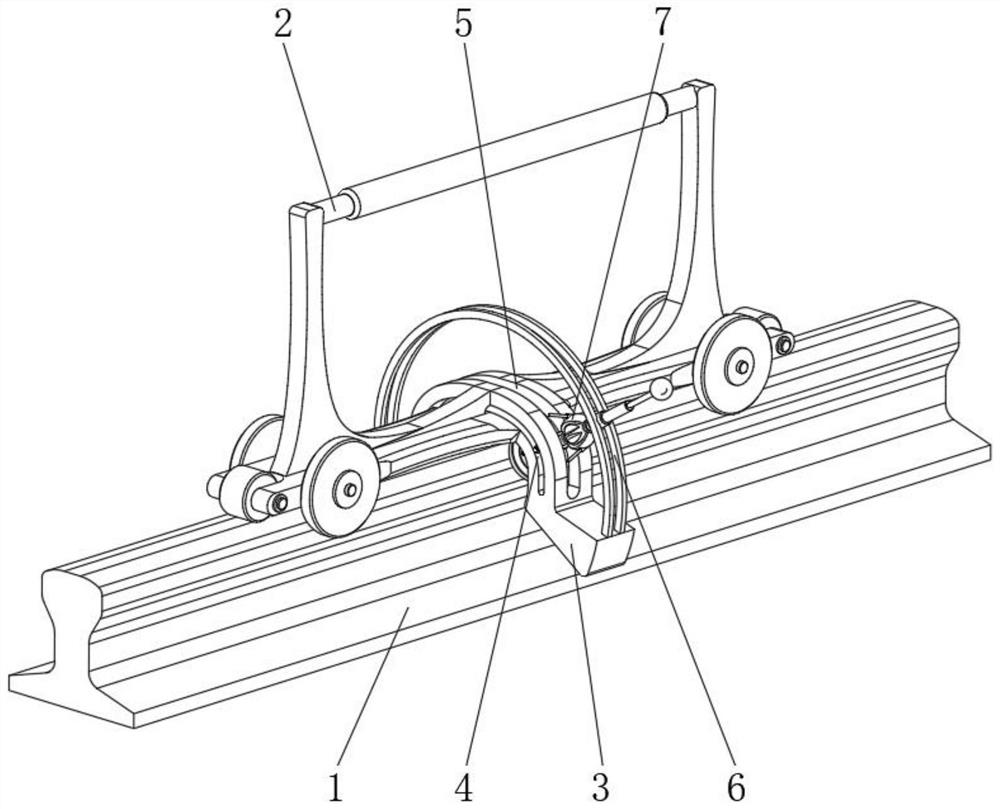

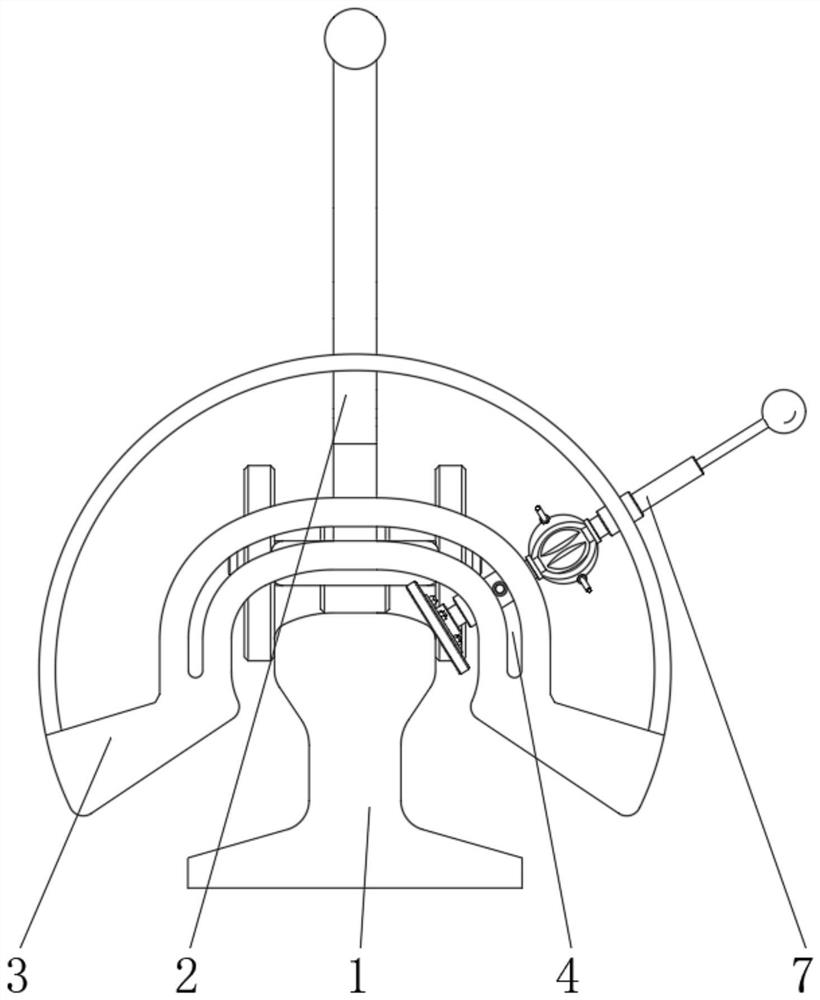

Grinding mechanism for track welding spots

InactiveCN112917297AEasy to operateSave time and effortEdge grinding machinesGrinding drivesSlide plateOrbital welding

The invention relates to the technical field of track welding and grinding equipment, and discloses a grinding mechanism for track welding spots. The grinding mechanism comprises a steel rail, wherein a walking bracket is clamped on the surface of the steel rail, a track sliding plate is arranged at the bottom end of an inner cavity of the walking bracket, a track sliding groove which is through left and right is formed in the track sliding plate, a vertically-through fixed sliding groove is formed in the track sliding plate, and a grinding mechanism body is movably connected into the track sliding plate in a sleeved mode. According to the grinding mechanism for the track welding spots, the track sliding plate, the track sliding groove and the fixed sliding groove are arranged, so that the grinding mechanism can drive a grinding disc on the grinding mechanism to conduct movable grinding operation on the surface of the steel rail along the track of the track sliding groove; and compared with an existing track grinding mechanism, the whole grinding mechanism does not need to be moved when the welding spots on the steel rail are ground, operation of the grinding mechanism is greatly simplified, time and labor are saved when the grinding mechanism is used, and controllability and stability are relatively high.

Owner:叶洪娟

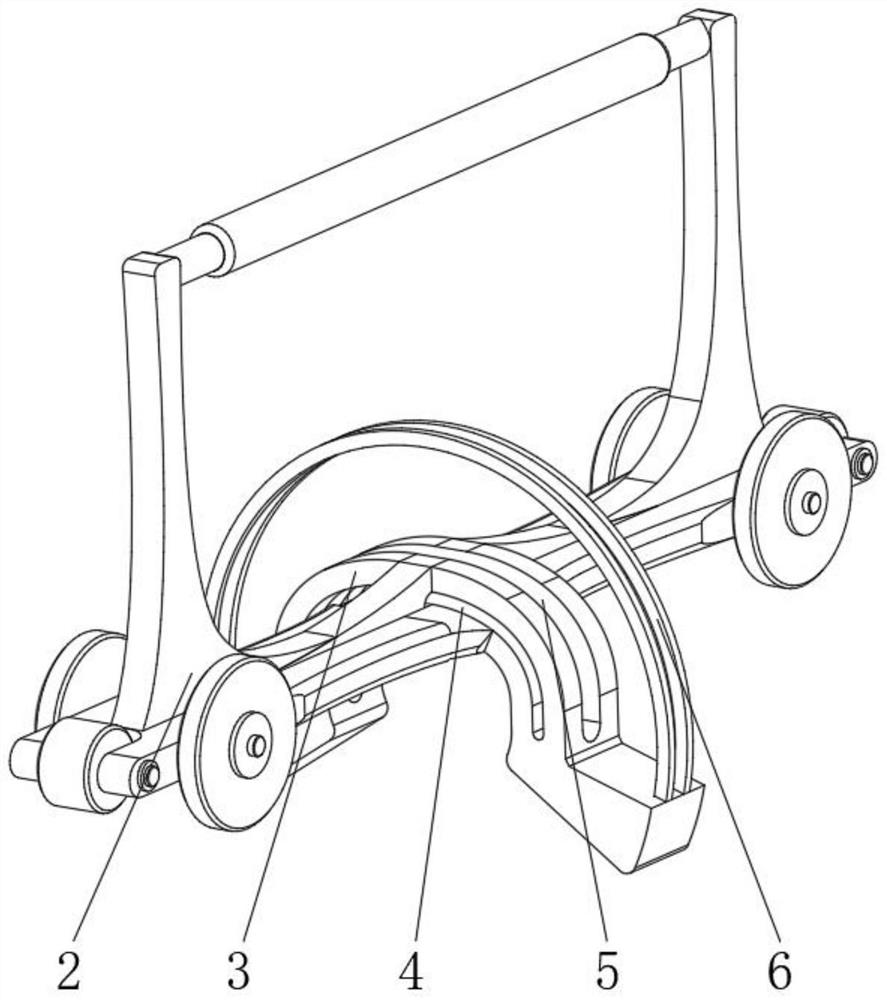

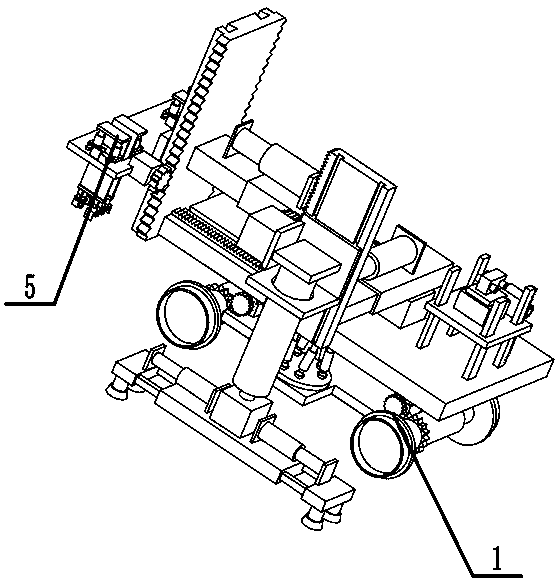

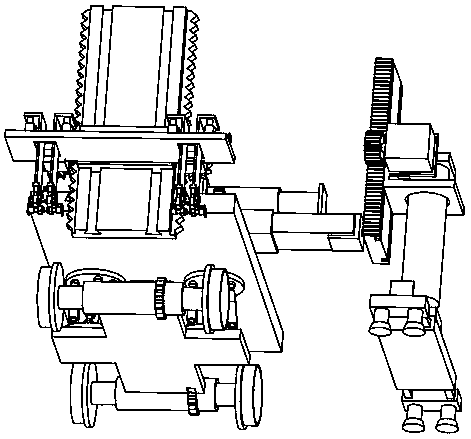

Train track welding equipment

InactiveCN108655600AIncrease job securityImprove the quality of workWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderMotor drive

The invention discloses train track welding equipment. The equipment comprises a walking part, a base, a support part, a welding part pushing frame and four welding parts; the lower surface of a bottom plate of the base is fixedly connected with the upper surfaces of bottom plates of two second parallel mechanisms of the walking part; a motor shaft of a first steering engine of the base is fixedlyconnected with the lower surface of a first extension sleeve of the support part; eight fourth dovetail grooves of the four welding parts are glidingly mounted on eight second positioning strips of the welding part pushing frame, respectively; two third hydraulic cylinders passing through the support part extend to drive four suckers to move toward the two sides; a third step motor drives a thirdrack so as to drive the four suckers of a support column to be sucked to the ground; through 180-degree rotation of a third steering machine, the whole machine is driven to leave the railway, so thatthe machine can avoid the trains at any time, thereby improving the working safety, realizing the large-range application and improving the working quality..

Owner:羊月生

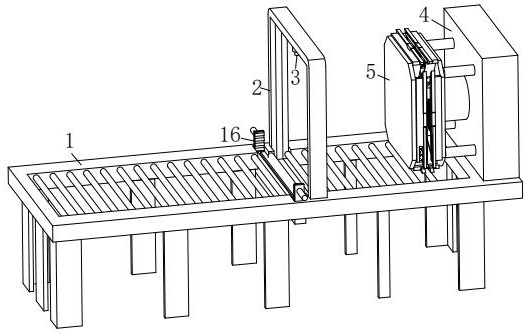

Stainless steel air pipe machining and welding equipment

ActiveCN114346585AEasy to fixImprove the anti-deformation effectWelding/cutting auxillary devicesAuxillary welding devicesMachiningOrbital welding

The invention provides stainless steel air duct machining and welding equipment, and belongs to the technical field of air duct welding, the stainless steel air duct machining and welding equipment comprises a welding machining table, a rectangular welding track is arranged on the welding machining table, a telescopic mounting seat is fixedly arranged on the welding machining table, and an inner supporting anti-deformation part is connected to the telescopic mounting seat; the telescopic mounting base is used for controlling the inner supporting anti-deformation part to do telescopic motion towards the rectangular welding track, the inner supporting anti-deformation part comprises main bearing plates which are symmetrically arranged, inner edge supporting units are symmetrically arranged on the opposite faces of the main bearing plates in a sliding mode, the number of the inner edge supporting units is four, and the inner edge supporting units are distributed on the corresponding faces in a rectangular shape. The stainless steel air duct machining and welding equipment is used for attaching, tightly supporting and fixing a stainless steel air duct from the inside, has the advantages of being good in fixing effect, high in stress uniformity, good in deformation prevention effect and high in welding efficiency, effectively improves the welding convenience and welding quality, can be suitable for stainless steel air ducts of different sizes, and is suitable for popularization and application. And the application range of the invention is correspondingly improved.

Owner:江苏美劳智能家居有限公司

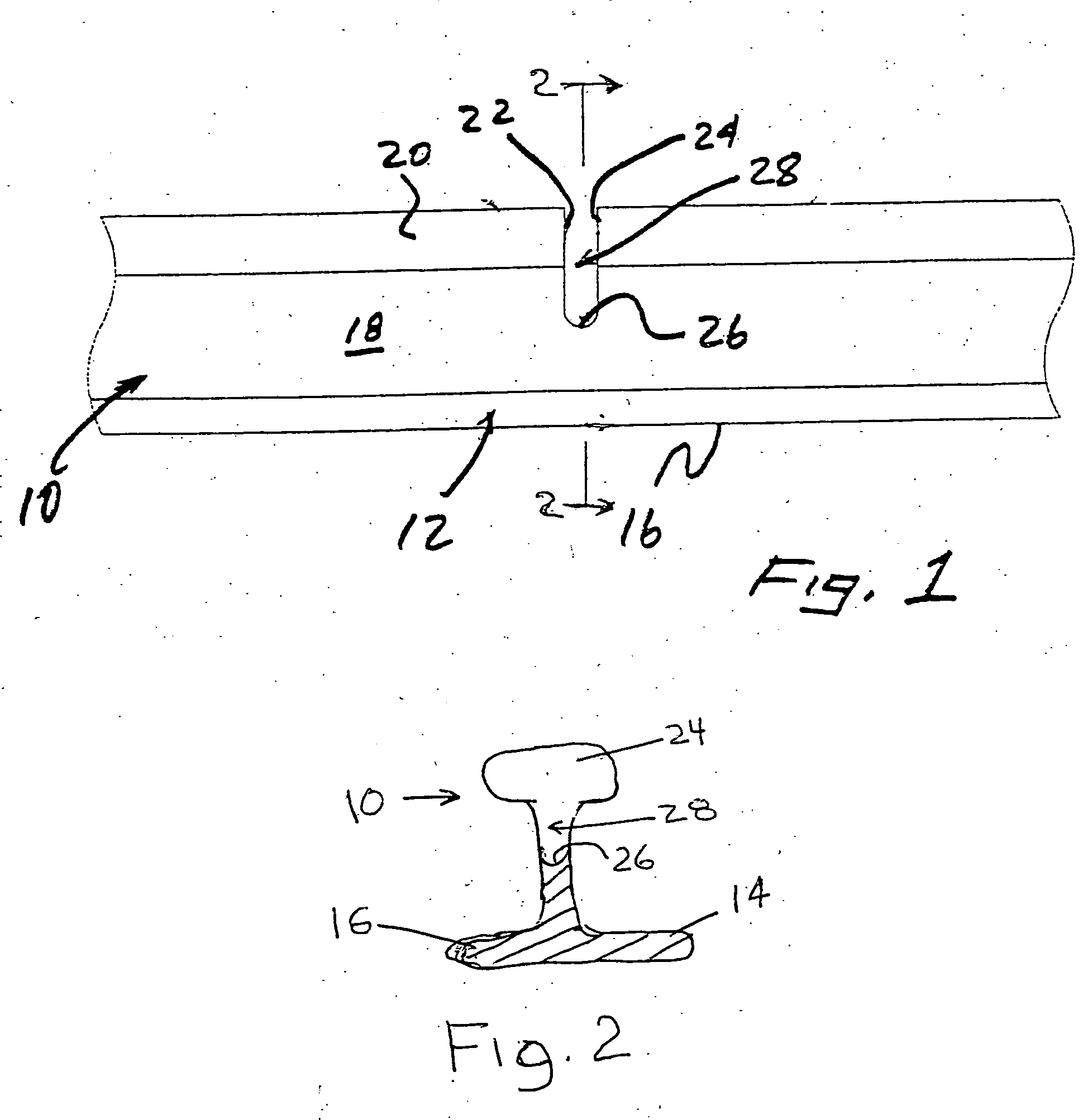

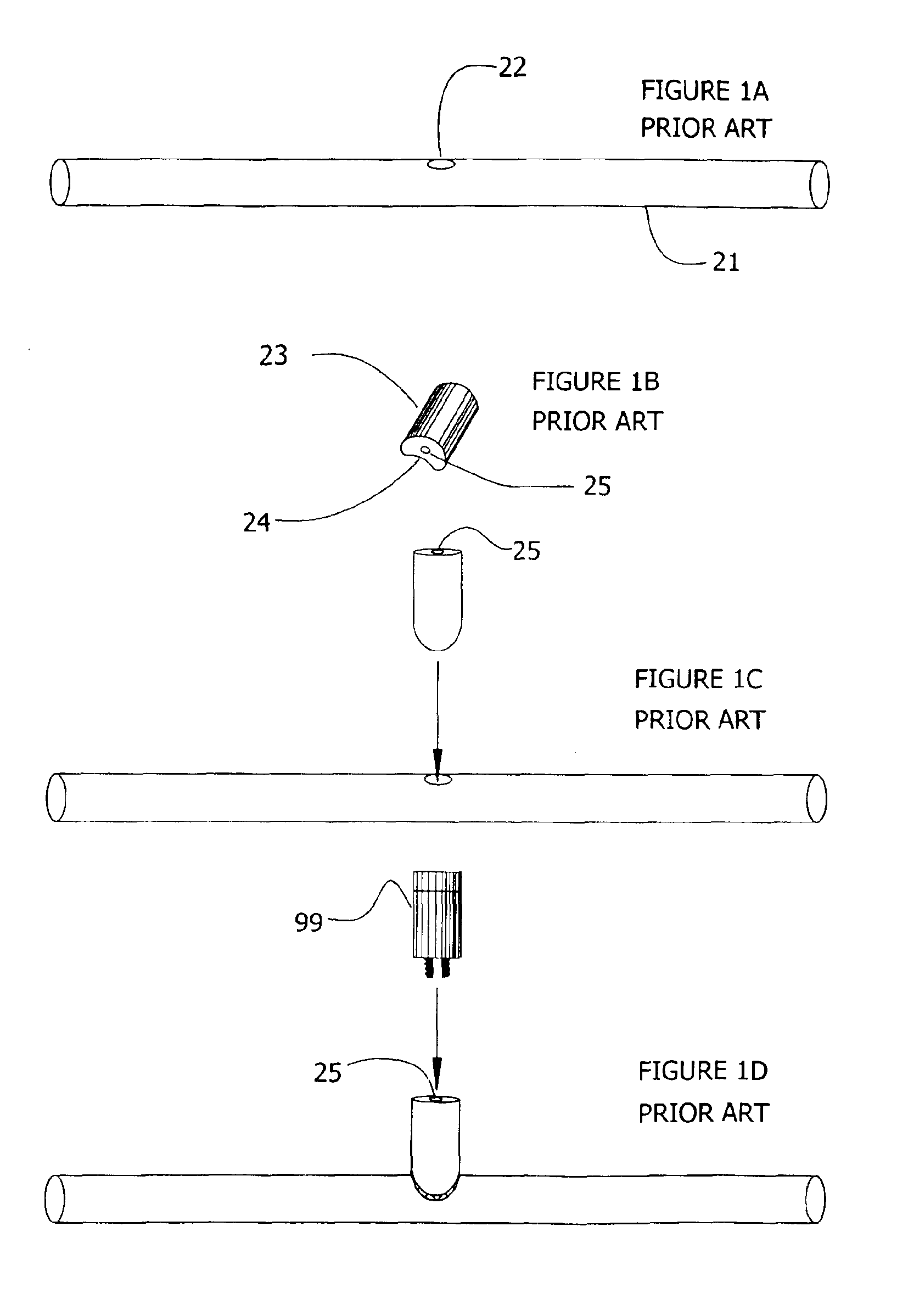

Misting manifold apparatus and method of manufacture

InactiveUS6948648B2Precise constructionPrecise positioningCooking-vessel materialsElectrically conductive connectionsMechanical engineeringOrbital welding

A method and apparatus for a constructing misting manifold is disclosed that uses a standardized intermediate member joined to tubing. The method allows mass production, particularly with use of orbital welding, easy alignment of the component part and high quality welds.

Owner:ARMSTRONG NEAL N

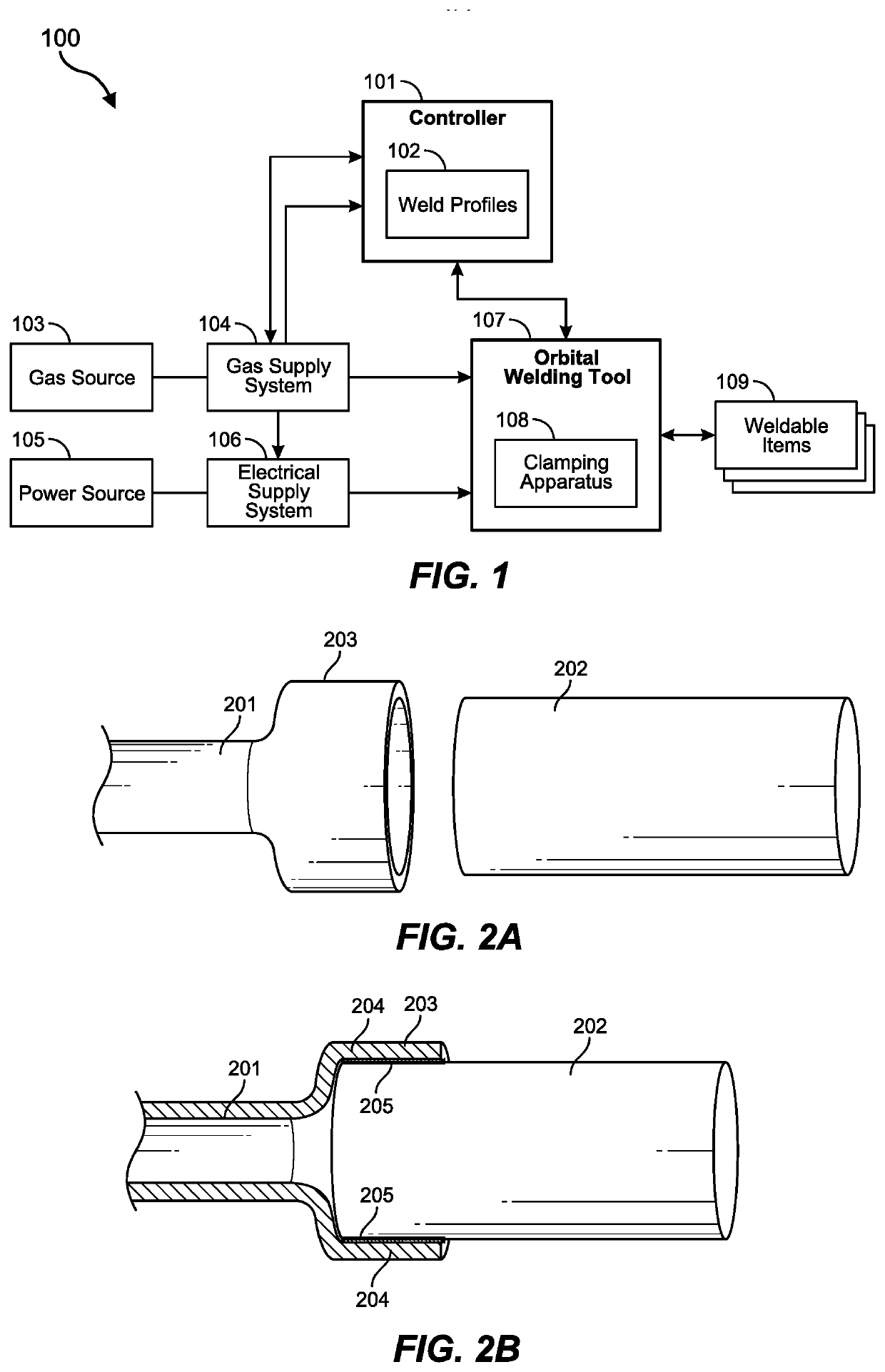

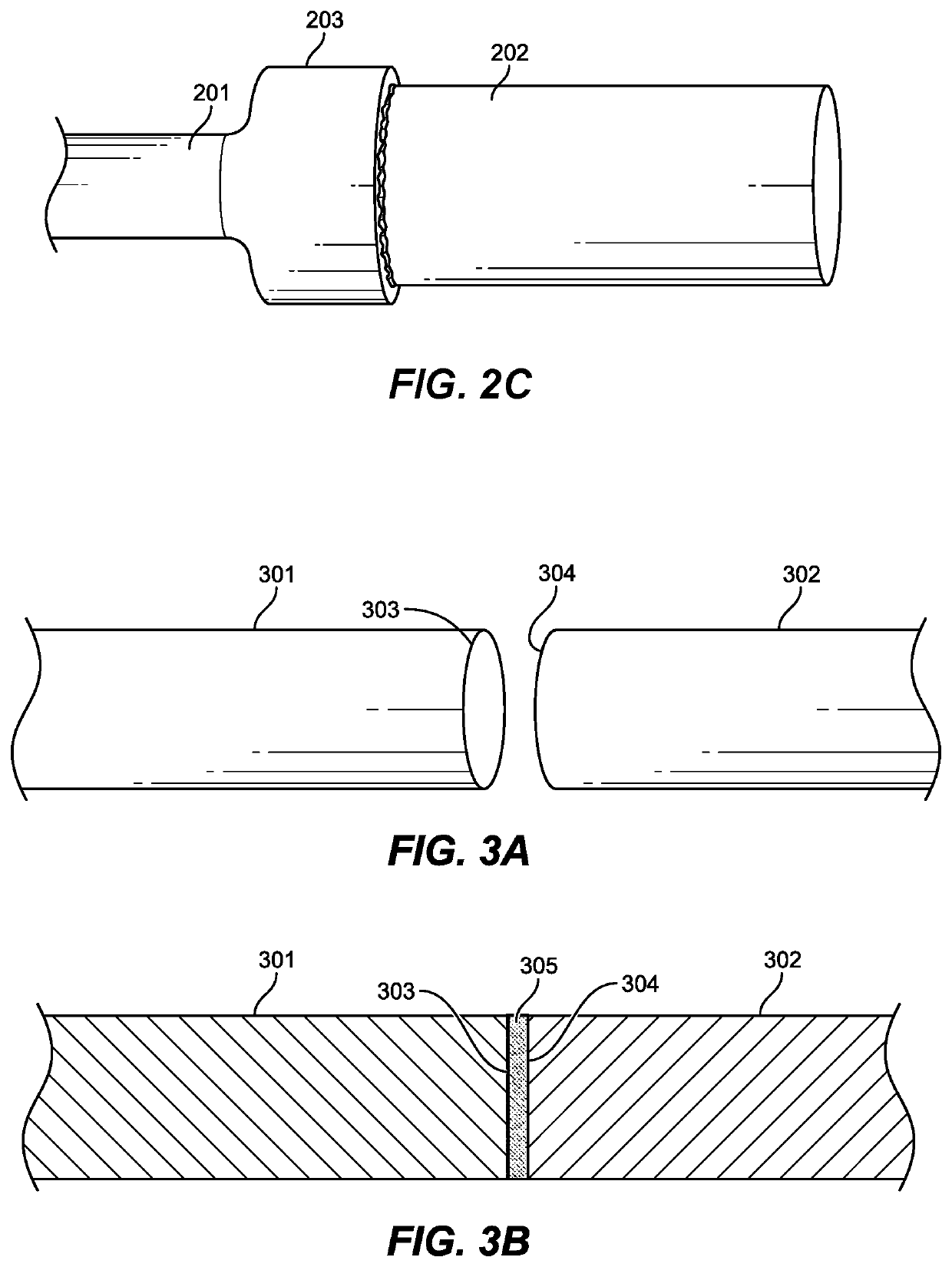

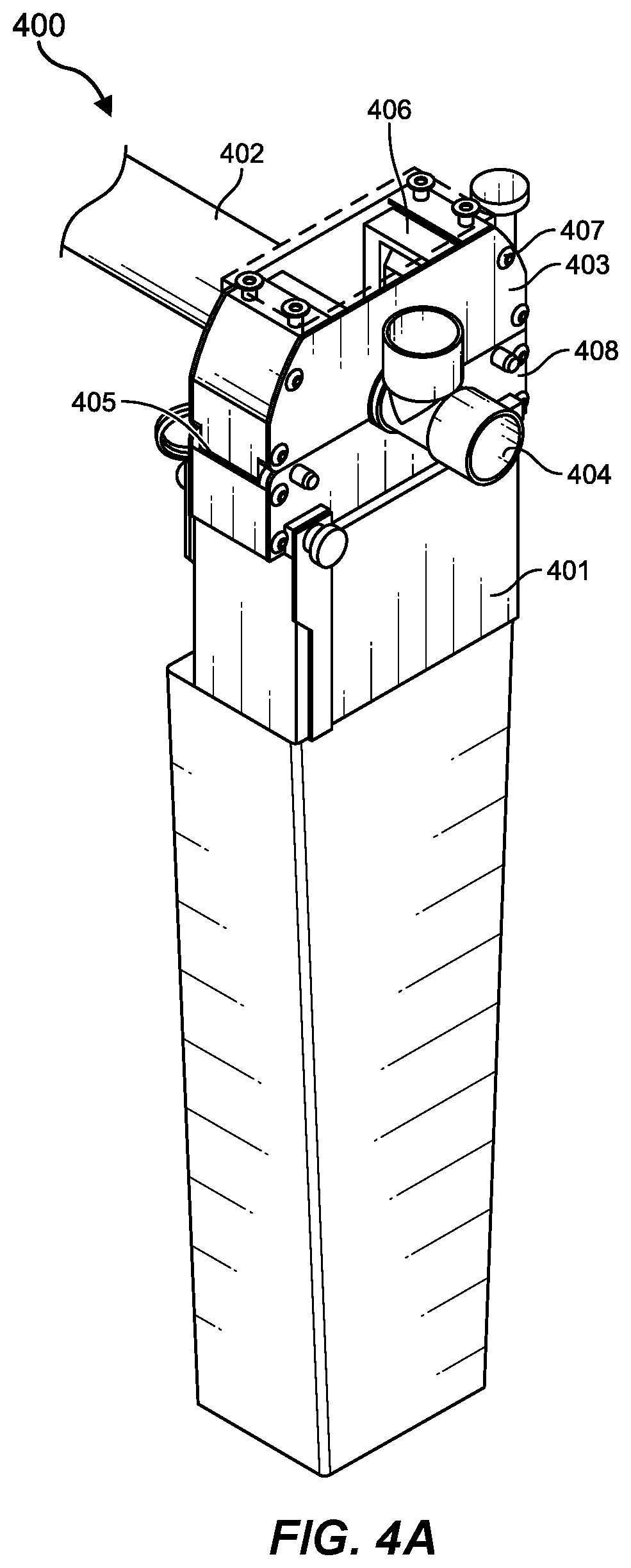

Orbital welding system and method

InactiveUS20210053135A1Reliable and reliableAddressing slow performanceWelding/cutting auxillary devicesArc welding apparatusControl signalShielding gas

Embodiments are directed to an orbital welding system, including customized orbital weld head fixtures, and computer-controlled programs for performing homogeneous orbital welds. In one scenario, an orbital welding system includes a controller, a shield gas supply system that supplies gases to an orbital welding tool, an electrical supply system that supplies an electrical current to the orbital welding tool, and the orbital welding tool, which includes a welding electrode that is configured to weld two or more items together using the supplied electrical current and the gases supplied by the gas supply system. The controller generates control signals that direct the orbital welding tool, the electrical supply system, and the gas supply system to homogeneously orbital weld the at least two items together, so that the at least two items are homogeneously welded together without using a filler material. Various other methods, systems, and apparatuses are also described.

Owner:CRITICAL SYST

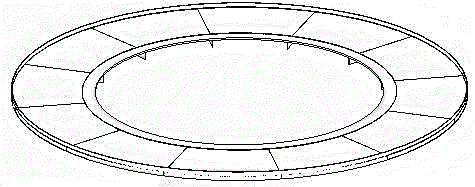

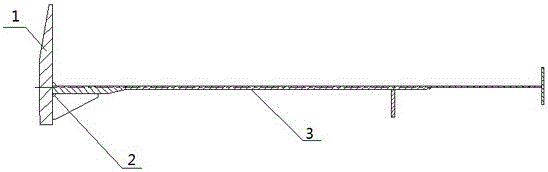

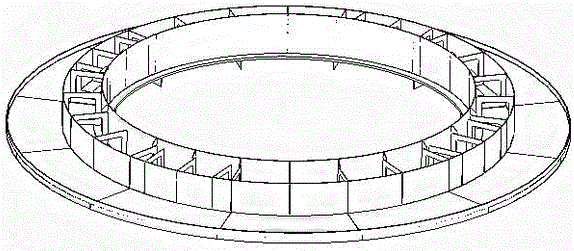

Gantry crane large pinwheel manufacturing accuracy control method

ActiveCN106475698AReasonable preparation processReduce construction difficultyWelding apparatusEngineeringGantry crane

The invention relates to a gantry crane large pinwheel manufacturing jig and accuracy control method, and belongs to the field of gantry crane structure manufacturing. Bottom plate, track plate and whole assemblage manufacturing processes are carried out on a plane jig and an assemblage jig; a bottom plate is subject to assemblage-welding on the plane jig in a marking manner, and track steel is also subject to assemblage-welding on the plane jig; the bottom plate and a track plate which are obtained after assemblage are placed on the assemblage jig, and meanwhile, a rib plate, a panel and a needle pin ring plate are subject to assemblage-welding; a reasonable assembling-welding sequence is used; and the bottom plate is subject to assembling-welding, the steel track steel is subject to assembling-welding, and the bottom plate, the track plate, a stiffening plate, the panel and a needle hole plate are subject to assembling-welding. The reasonable welding sequence is used in a matched manner, the basic principle is that a T-shaped welding opening is firstly achieved, a separating plate is welded in the vertical direction and the horizontal direction in sequence, symmetry welding is adopted in bottom plate and track welding and separating plate welding, the middle of a needle pin ring plate is welded firstly, and the two sides of the needle pin ring plate are welded secondly. According to the gantry crane large pinwheel manufacturing jig and accuracy control method, through the reasonable manufacturing process, the construction difficulty can be reduced, and the cost is reduced.

Owner:大连船舶重工集团装备制造有限公司

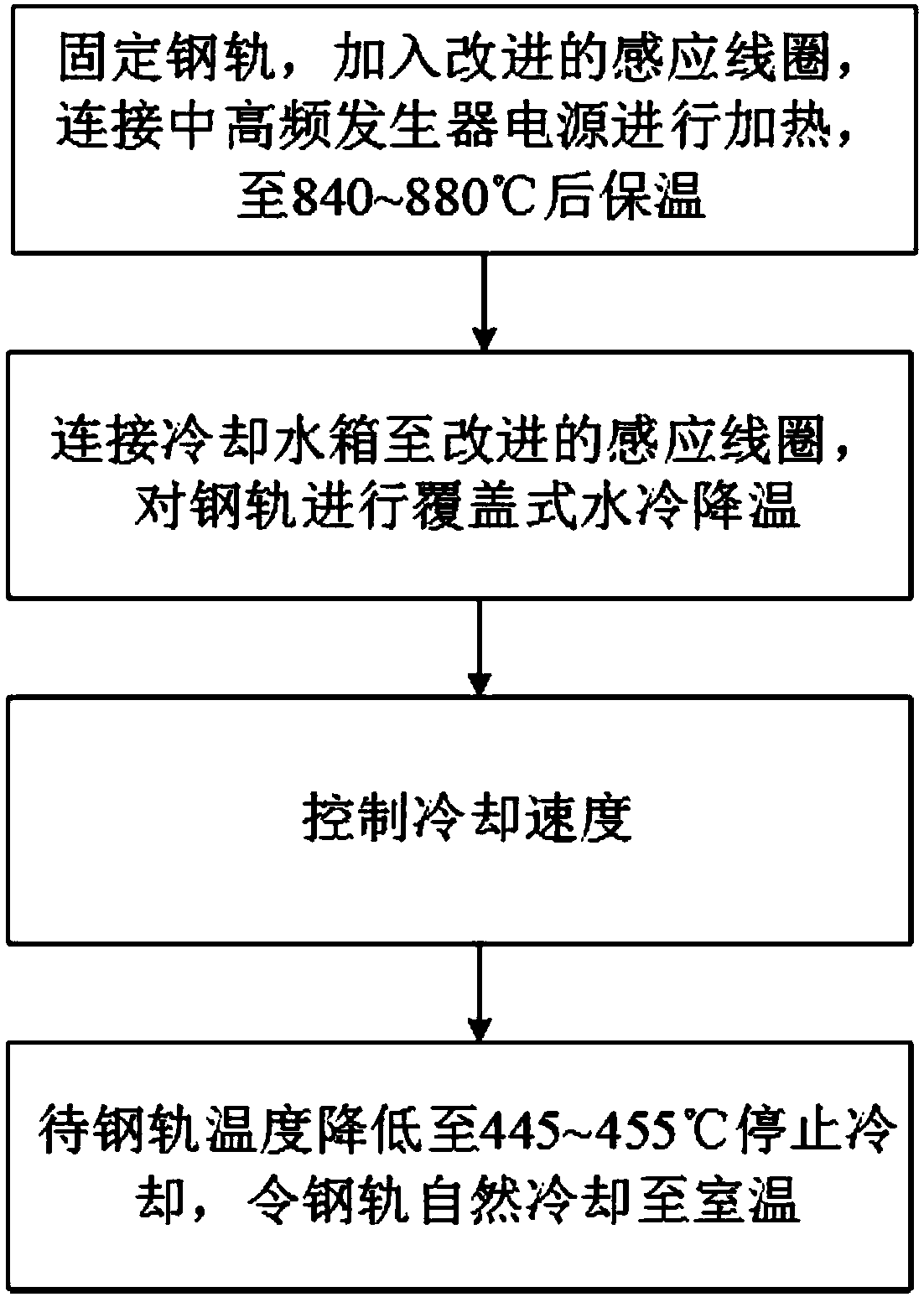

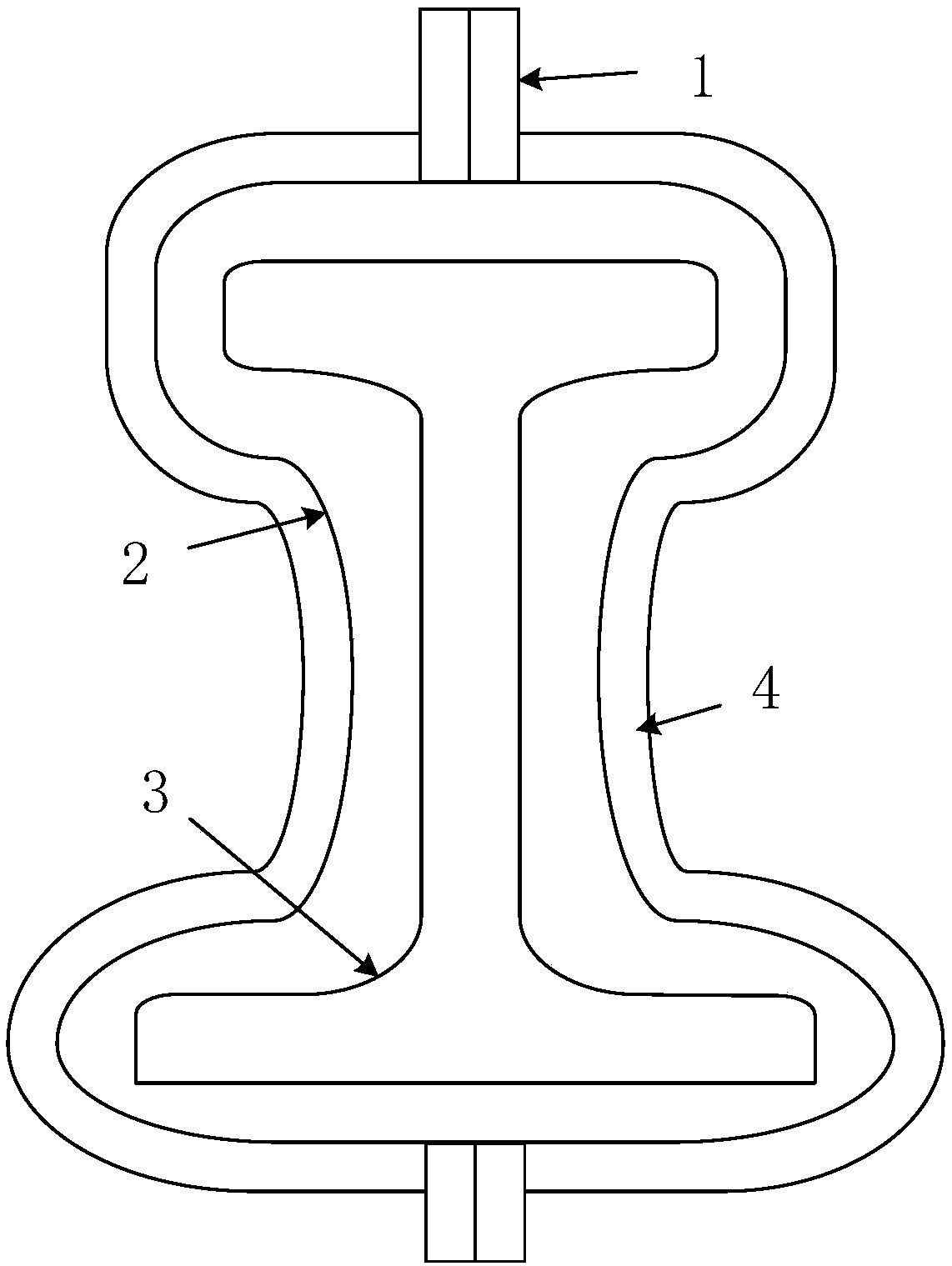

Induction normalizing method for steel rail

InactiveCN109593941AThe skin effect is obviousCool down in timeIncreasing energy efficiencyFurnace typesMedium frequencyFree cooling

Owner:SHANGHAI UNIV OF ENG SCI

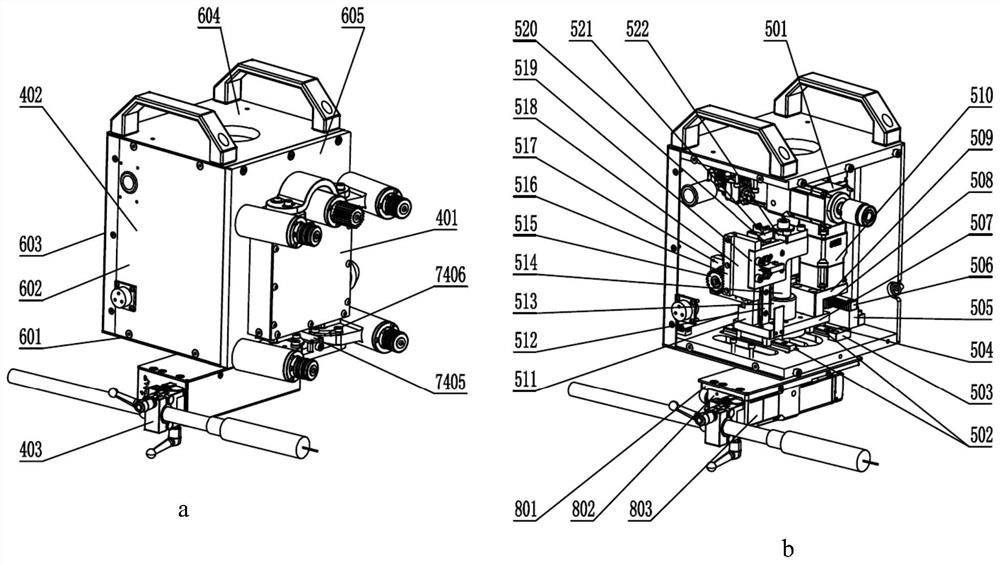

Camera and wire feed solution for orbital welder system

The technology described herein generally pertains to a system related to a camera device and wire guide system that includes a bracket for a wire guide and a camera device, wherein the bracket aligns the camera device to aim on a position of a welding zone for an orbital welding system. In particular, the bracket supports a wire guide to be positioned on a welding zone while also supporting a camera device that can be positioned on the welding zone. The bracket enables the welding zone to be captured by the camera device and is centered on the wire guide to remain positioned on the welding zone. The bracket provides placement of a camera device to provide video / camera visibility of the welding zone while allows adjustment of the camera device with wire location adjustment or independent of wire location adjustment.

Owner:LINCOLN GLOBAL INC

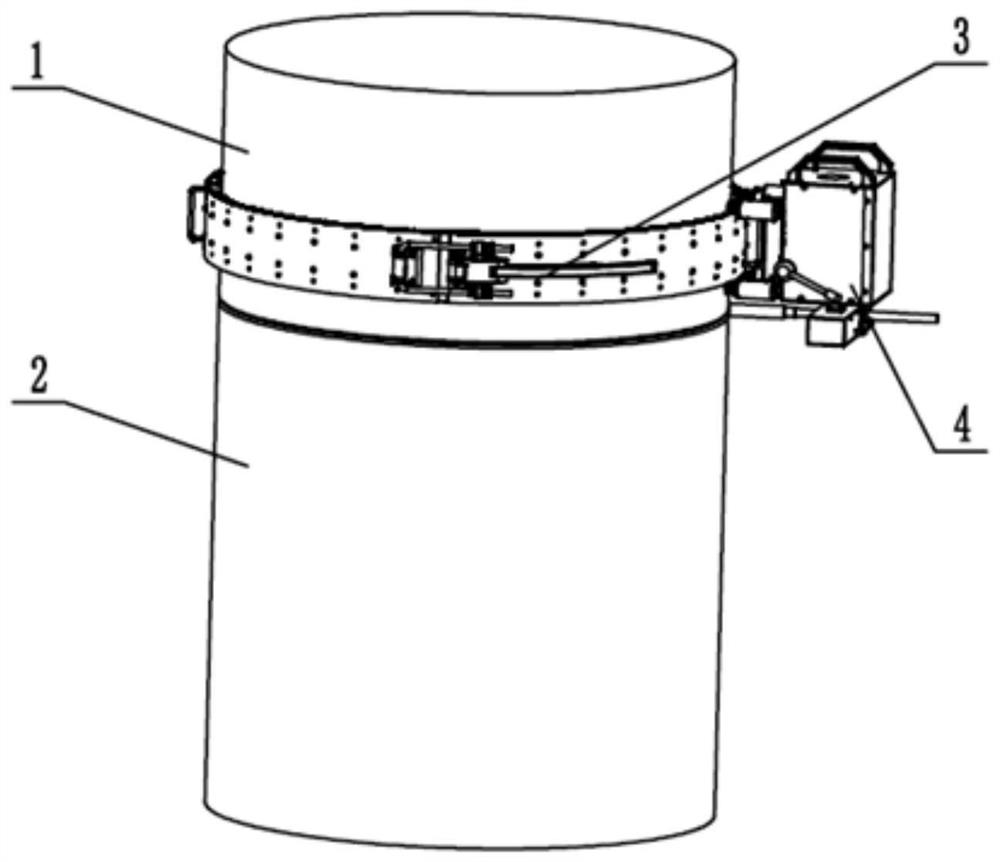

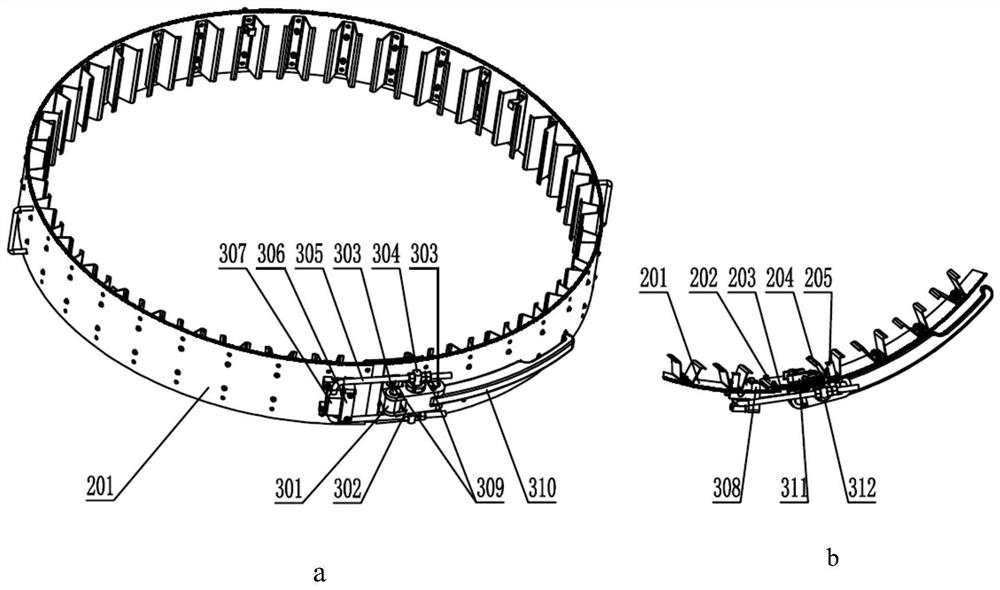

Tubular pile welding vehicle capable of being mounted and dismounted quickly and provided with locking track

ActiveCN113399901AGuaranteed stabilityGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesControl systemOrbital welding

The invention provides a tubular pile welding vehicle capable of being mounted and dismounted quickly and provided with a locking track. The tubular pile welding vehicle comprises the quick locking track, a welding trolley, a control system and an operating handle. The welding trolley comprises a clamping mechanism, and the welding trolley is clamped on the quick locking track through the clamping mechanism. The control system is installed on the welding trolley and connected with the welding trolley. The operating handle is connected with the control system and used for controlling the welding trolley by controlling the control system. According to the tubular pile welding vehicle capable of being mounted and dismounted quickly and provided with the locking track, the welding trolley is clamped on the quick locking track through the clamping mechanism, manual locking is not needed, and the stability in the welding process can be ensured.

Owner:广州市市政工程试验检测有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com