Patents

Literature

37results about How to "Improve the anti-deformation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

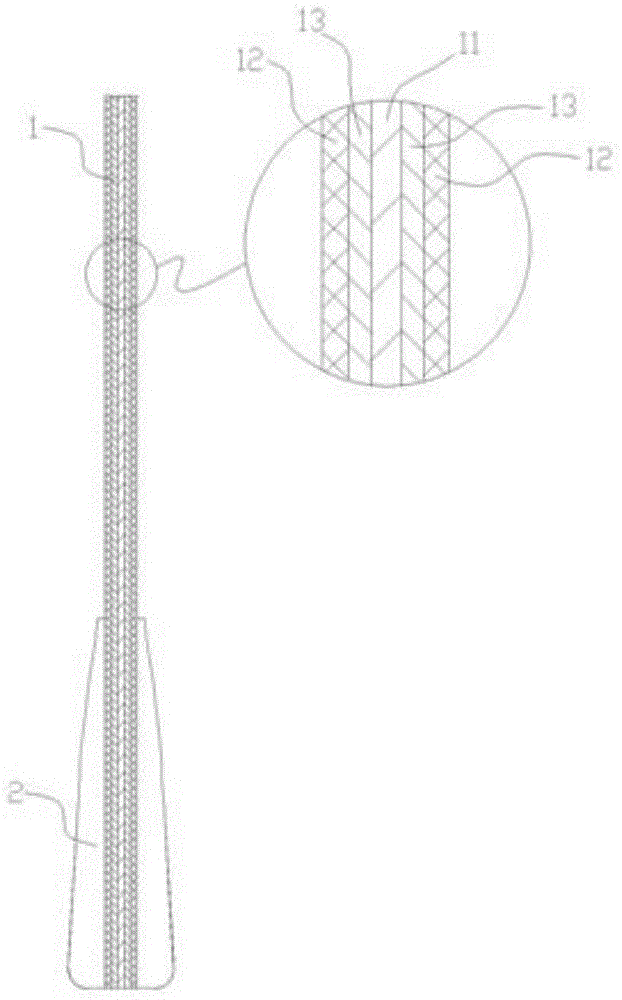

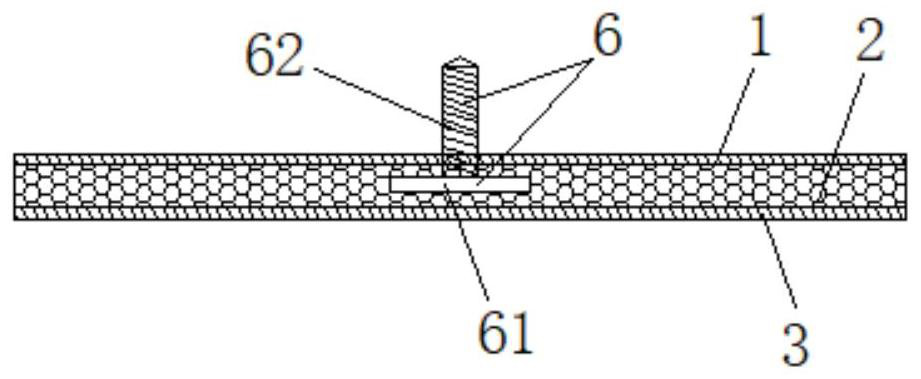

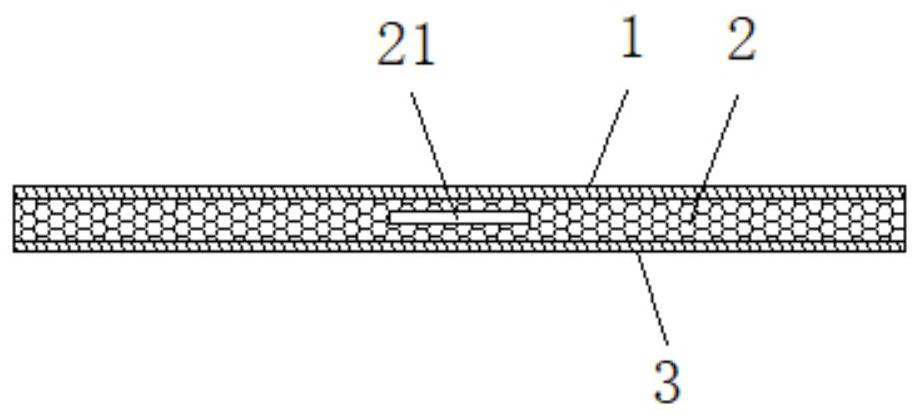

Three-layer-timber-structure solid wood floor and installment method of the same

InactiveCN103161294AImprove moisture resistanceImprove the anti-deformation effectWood layered productsFlooringSolid woodKeel

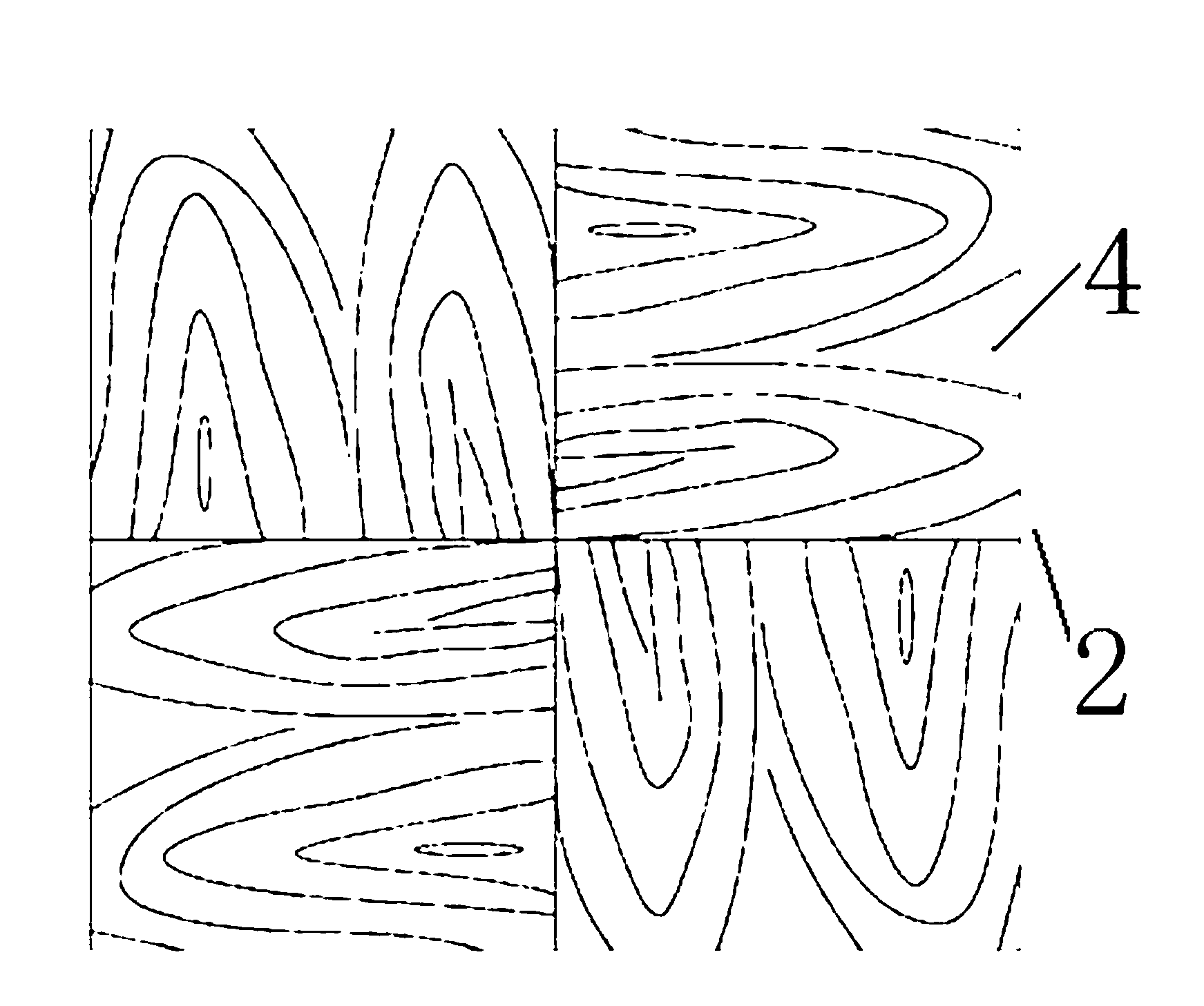

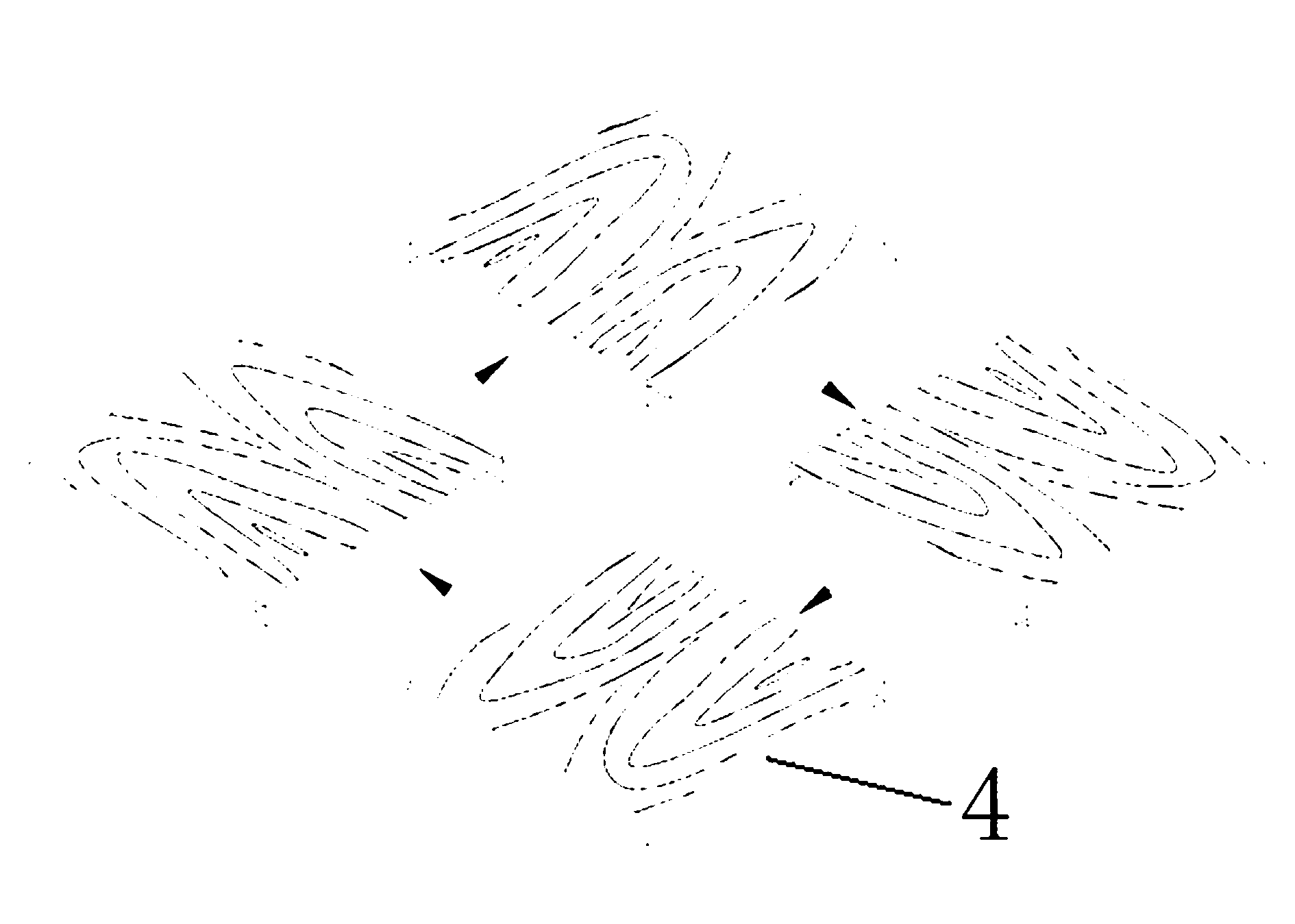

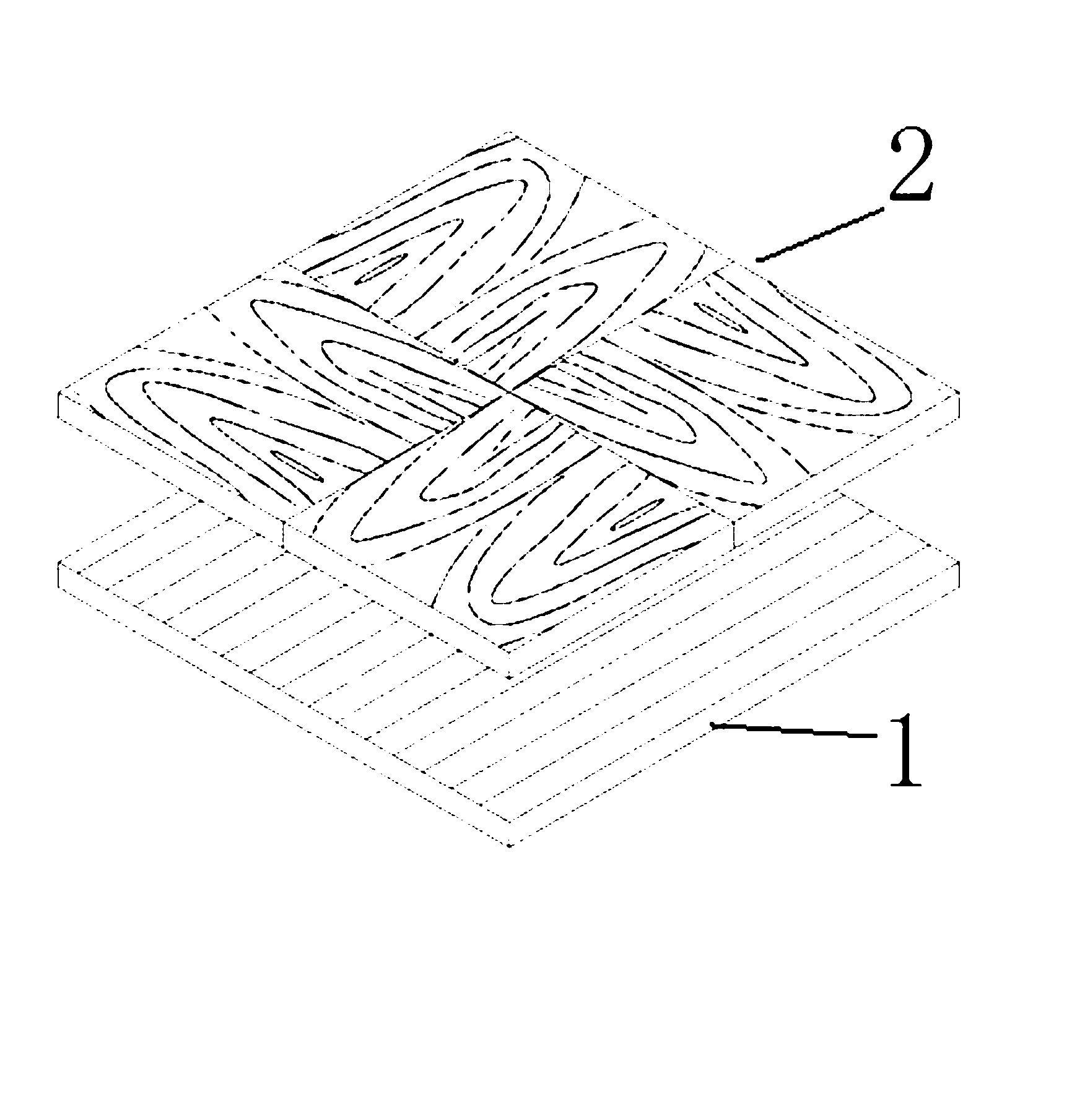

The invention relates to a three-layer-timber-structure solid wood floor. The three-layer-timber-structure solid wood floor is characterized in that a middle plate and a panel are sequentially arranged on a bottom plate, the middle plate is formed by splicing at least two floor blocks, the texture of timbers between neighboring floor blocks is criss-cross, and an included angle is arranged between the timber texture direction of the bottom plate and the timber texture direction of the floor block of the middle plate. Meanwhile, the three-layer-timber-structure solid wood floor is simple in pavement technology. Neighboring square floors are connected through U-shaped metal buckles. Keels do not need additionally arranging, and materials and manpower are saved to provide convenience for disassembling, assembling and maintenance in the future. A fixing mode is a dynamic fixing mode, and no matter a solid wood floor expands or contracts in the using process, the solid wood floor can automatically digest and absorb stress deformation of expansion and stress deformation of contraction, and accordingly the problems such as deformation and cracking can not happen in the using process of the solid wood floor.

Owner:上海筑邦木业有限公司

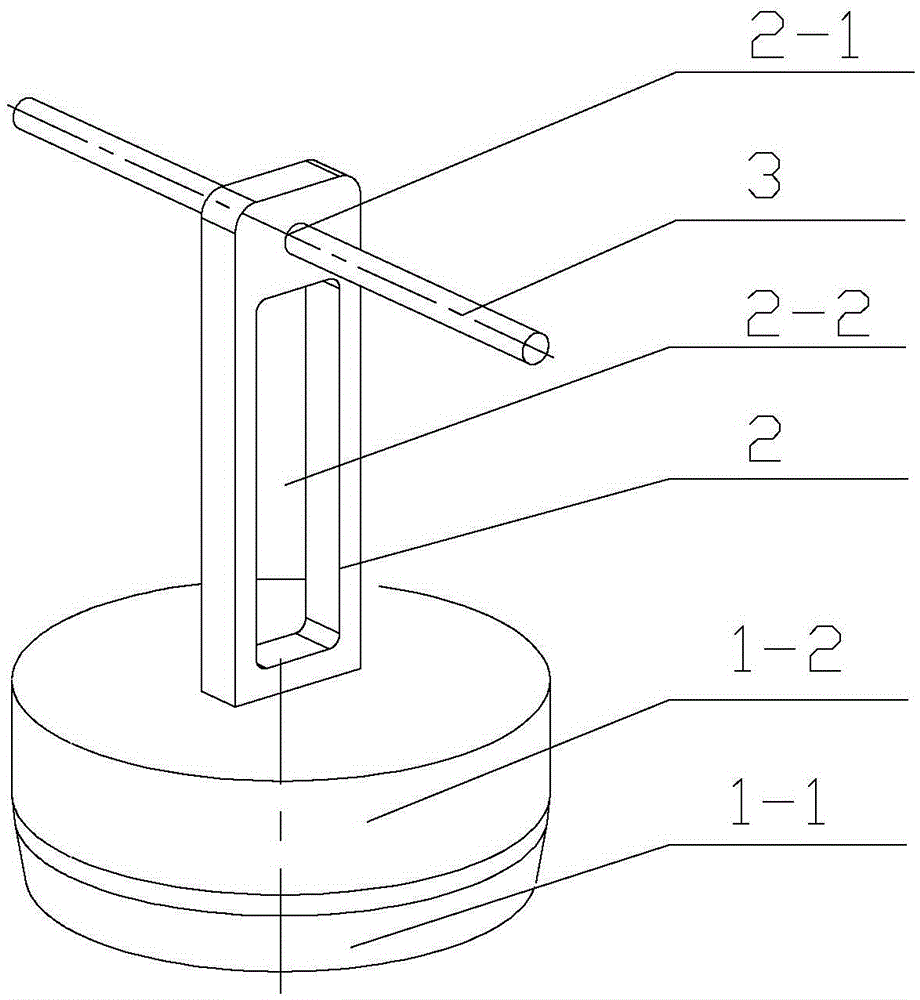

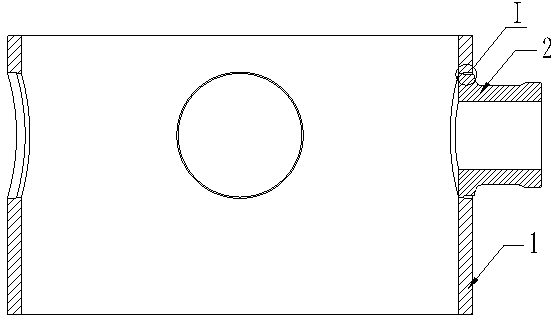

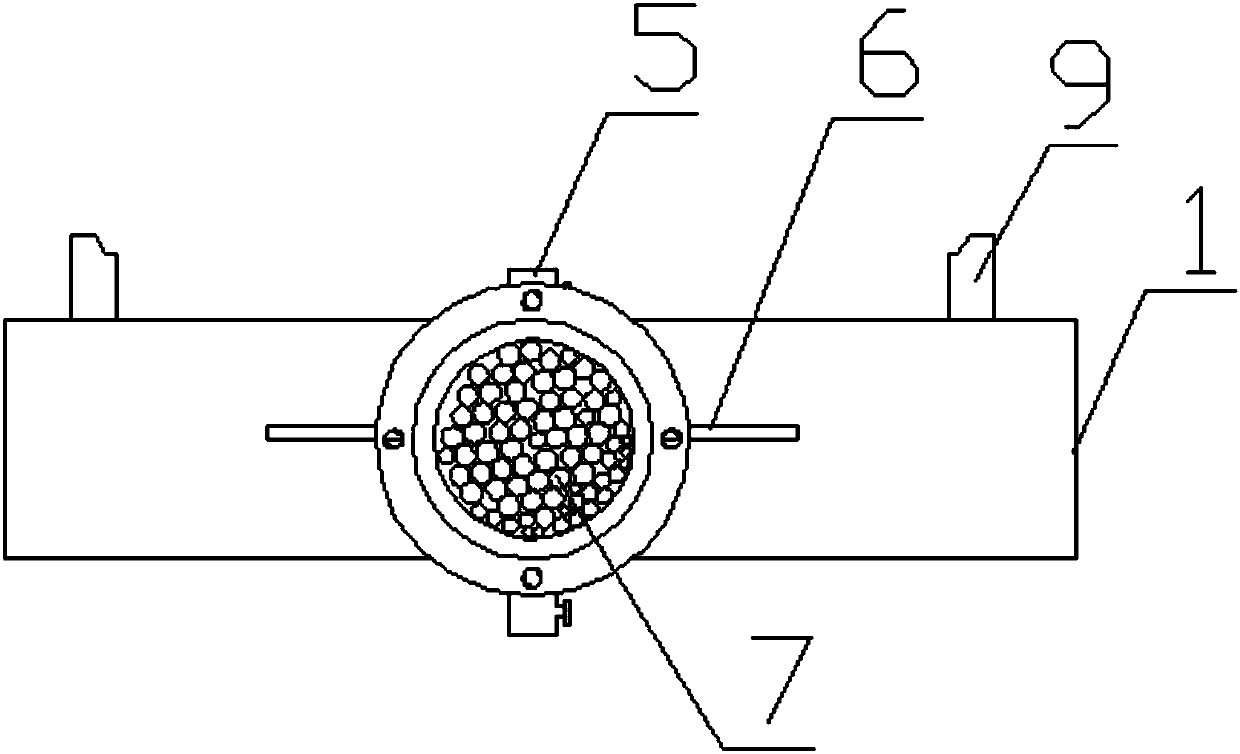

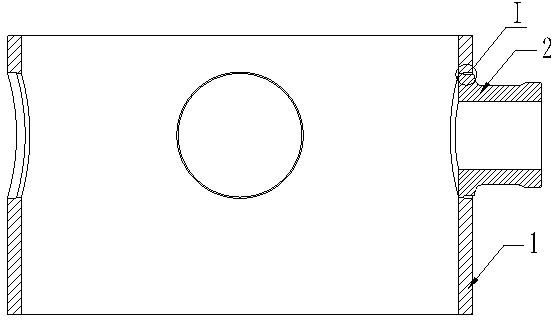

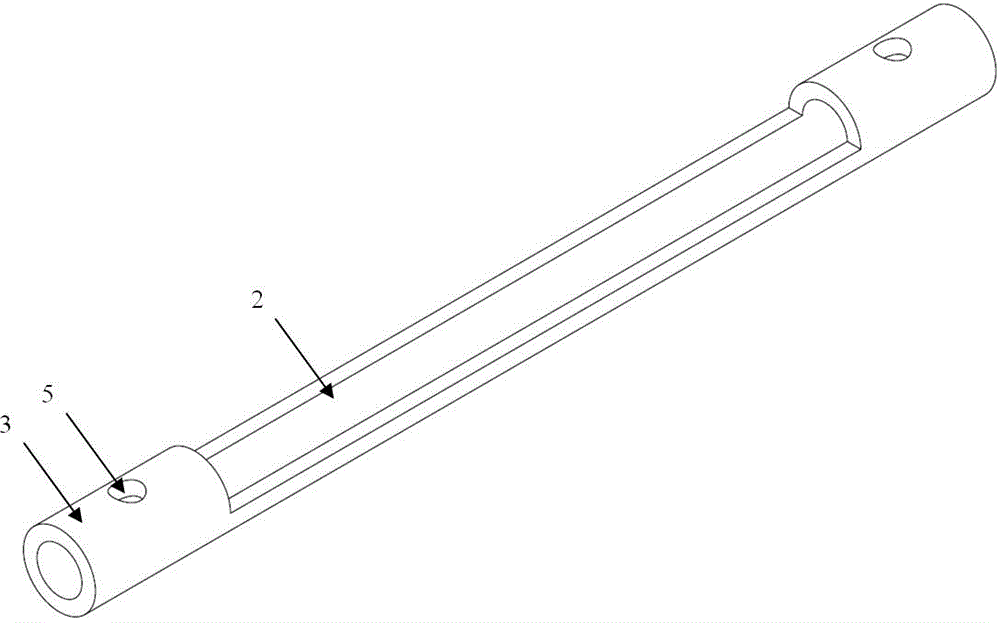

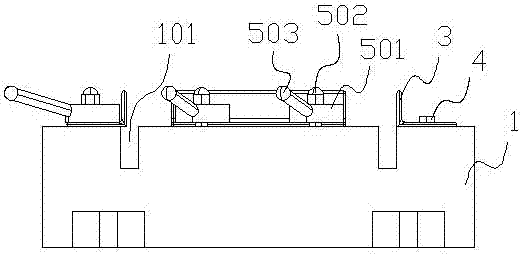

Anti-deformation supporting device for assembling and welding of thin-wall pipes

InactiveCN105522323ASimple structureImprove the anti-deformation effectWelding/cutting auxillary devicesAuxillary welding devicesButt jointIndustrial engineering

The invention discloses an anti-deformation supporting device for assembling and welding of thin-wall pipes and relates to an anti-deformation supporting device. According to the anti-deformation supporting device for assembling and welding of the thin-wall pipes, the problem that existing thin-wall pipes are prone to deformation when butting joint assembling and welding are conducted is solved. The anti-deformation supporting device for assembling and welding of the thin-wall pipes comprises a supporting piece, a lifting handle and a lifting rod. The supporting piece comprises a circular truncated cone section and a cylindrical section, and the big end of the circular truncated cone section is fixedly connected with one end of the cylindrical section. The lifting handle is a cuboid component, one end of the lifting handle is fixedly connected with the other end of the cylindrical section, and a circular through hole is machined in the other end of the lifting handle. The lifting rod is installed in the circular through hole in the lifting handle in a penetrating mode. The anti-deformation supporting device for assembling and welding of the thin-wall pipes is used for providing support during butting joint assembling and welding of the thin-wall pipes.

Owner:HARBIN TURBINE

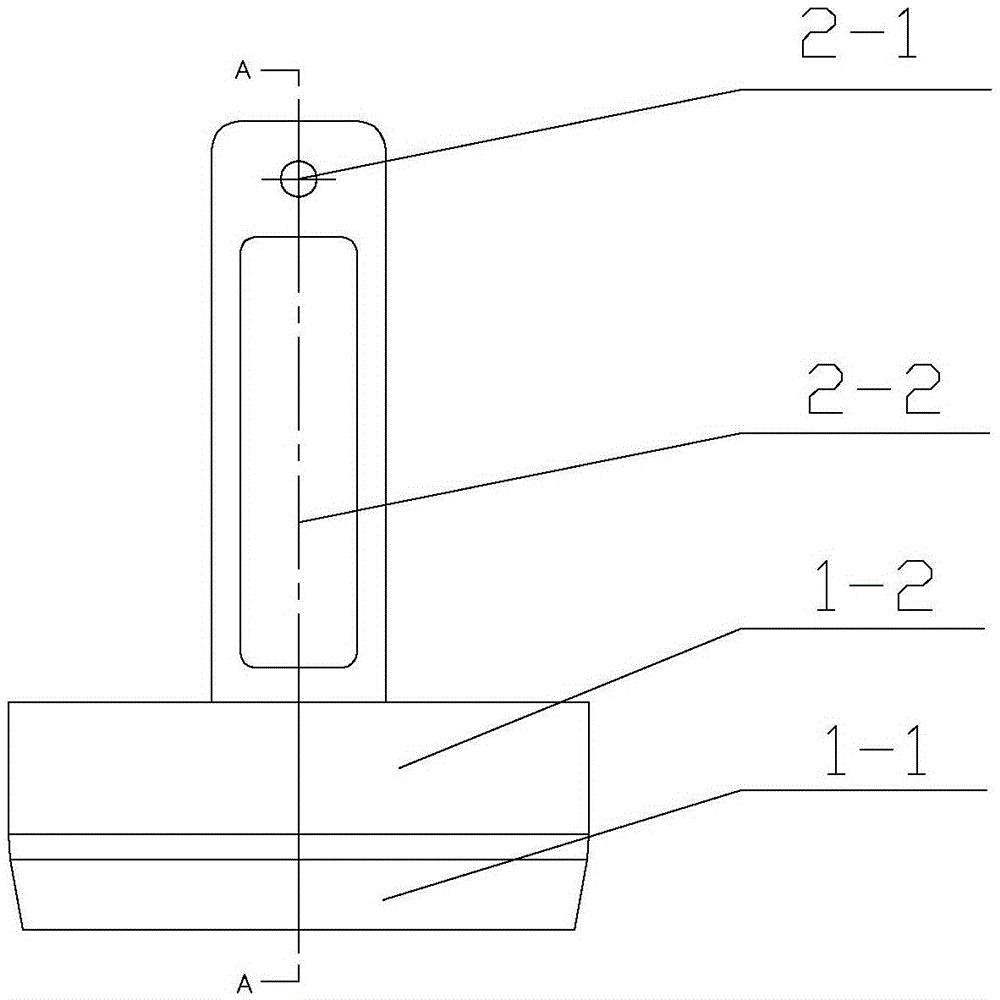

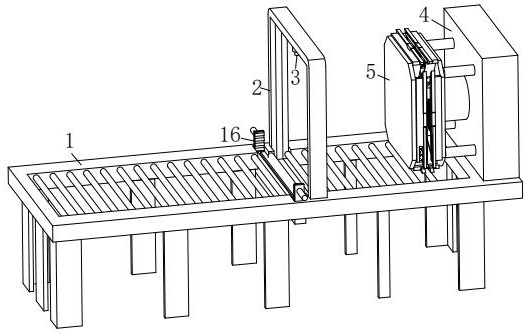

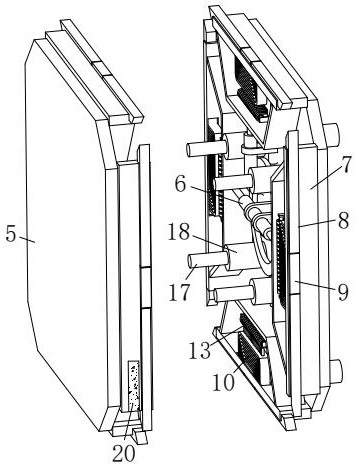

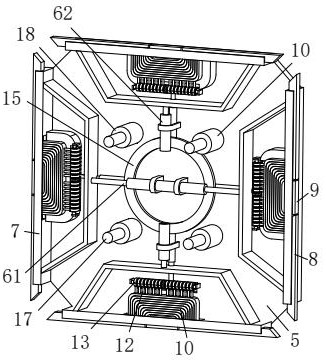

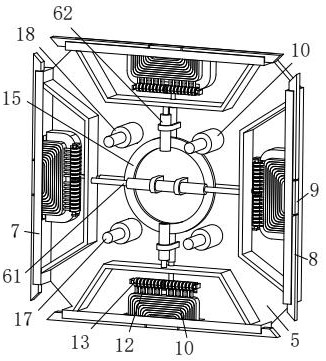

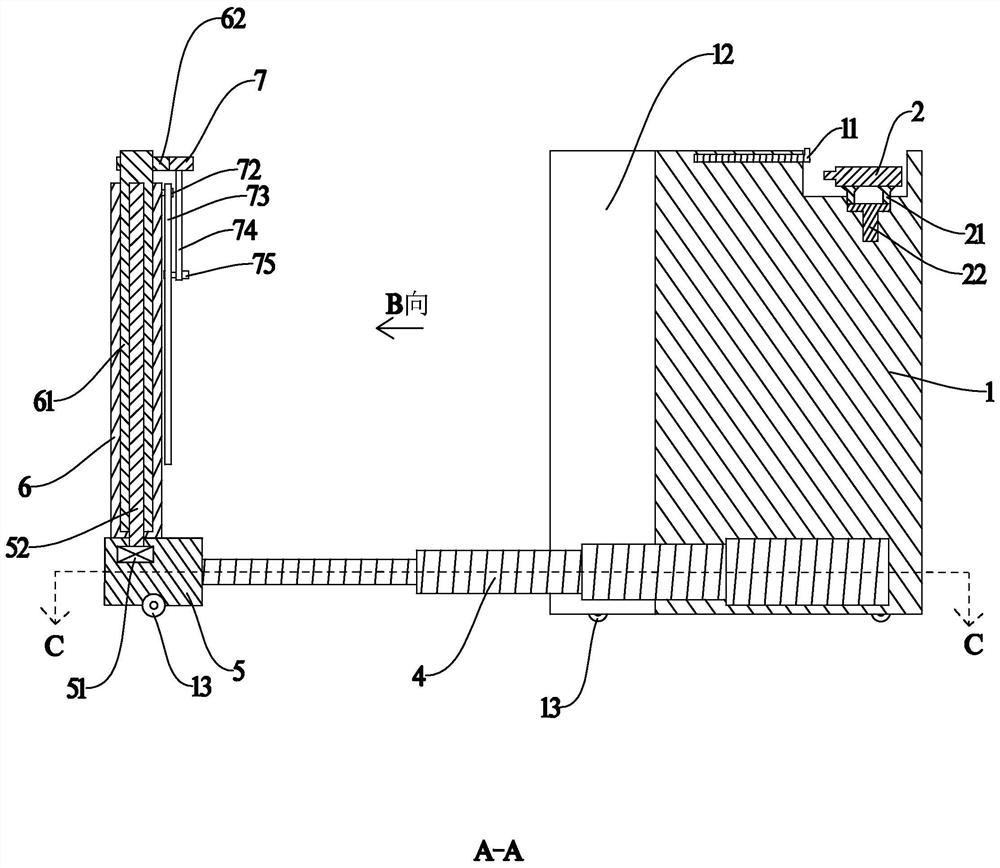

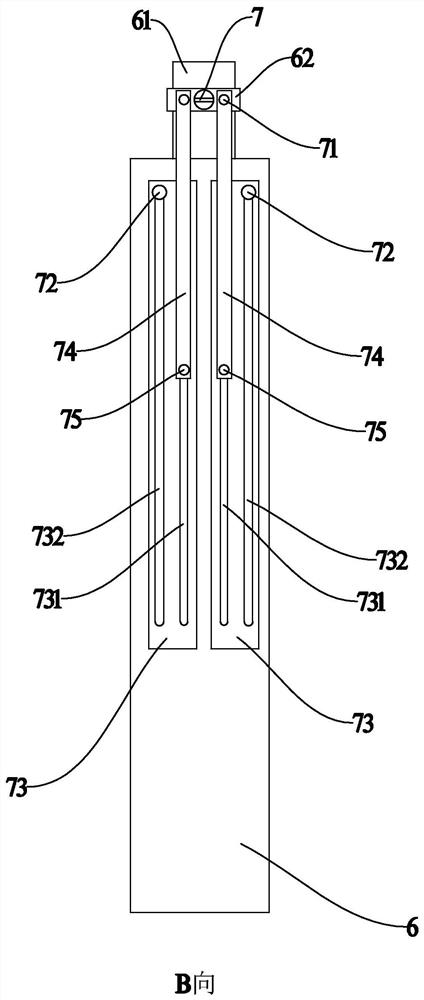

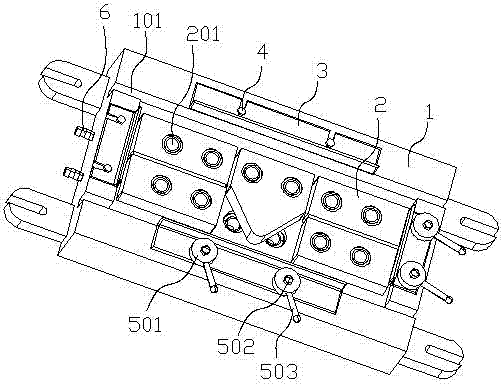

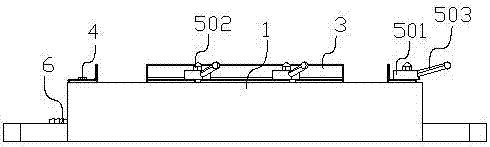

Stainless steel air pipe machining and welding equipment

ActiveCN114346585AEasy to fixImprove the anti-deformation effectWelding/cutting auxillary devicesAuxillary welding devicesMachiningOrbital welding

The invention provides stainless steel air duct machining and welding equipment, and belongs to the technical field of air duct welding, the stainless steel air duct machining and welding equipment comprises a welding machining table, a rectangular welding track is arranged on the welding machining table, a telescopic mounting seat is fixedly arranged on the welding machining table, and an inner supporting anti-deformation part is connected to the telescopic mounting seat; the telescopic mounting base is used for controlling the inner supporting anti-deformation part to do telescopic motion towards the rectangular welding track, the inner supporting anti-deformation part comprises main bearing plates which are symmetrically arranged, inner edge supporting units are symmetrically arranged on the opposite faces of the main bearing plates in a sliding mode, the number of the inner edge supporting units is four, and the inner edge supporting units are distributed on the corresponding faces in a rectangular shape. The stainless steel air duct machining and welding equipment is used for attaching, tightly supporting and fixing a stainless steel air duct from the inside, has the advantages of being good in fixing effect, high in stress uniformity, good in deformation prevention effect and high in welding efficiency, effectively improves the welding convenience and welding quality, can be suitable for stainless steel air ducts of different sizes, and is suitable for popularization and application. And the application range of the invention is correspondingly improved.

Owner:江苏美劳智能家居有限公司

Table tennis bat

The invention discloses a table tennis bat; the table tennis bat comprises a hitting plate and a handle which is used in association with the hitting plate; the hitting plate comprises a core body and panels on two sides of the core body; the panels are wood plates processed by furfuryl alcohol dipping; or, the hitting plate is an integral plate; the integral plate is a wood plate processed by furfuryl alcohol dipping; the wood processed by furfuryl alcohol dipping is applied to the hitting plate of the table tennis bat, thus the characteristics of good in stability, high in hardness, good in anti-deformation ability and good in resilience of the wood plate are well utilized, thereby effectively increasing the speed of hitting balls by the hitting plate, and giving a better user experience to the user; even if the table tennis bat is placed in environment of different room temperatures and humidity, the hardness and flatness of the hitting plate can still be ensured, thus ensuring the hitting force and hitting direction of the hitting plate, and making the table tennis bat easier to be maintained.

Owner:中山阳光体育制品有限公司

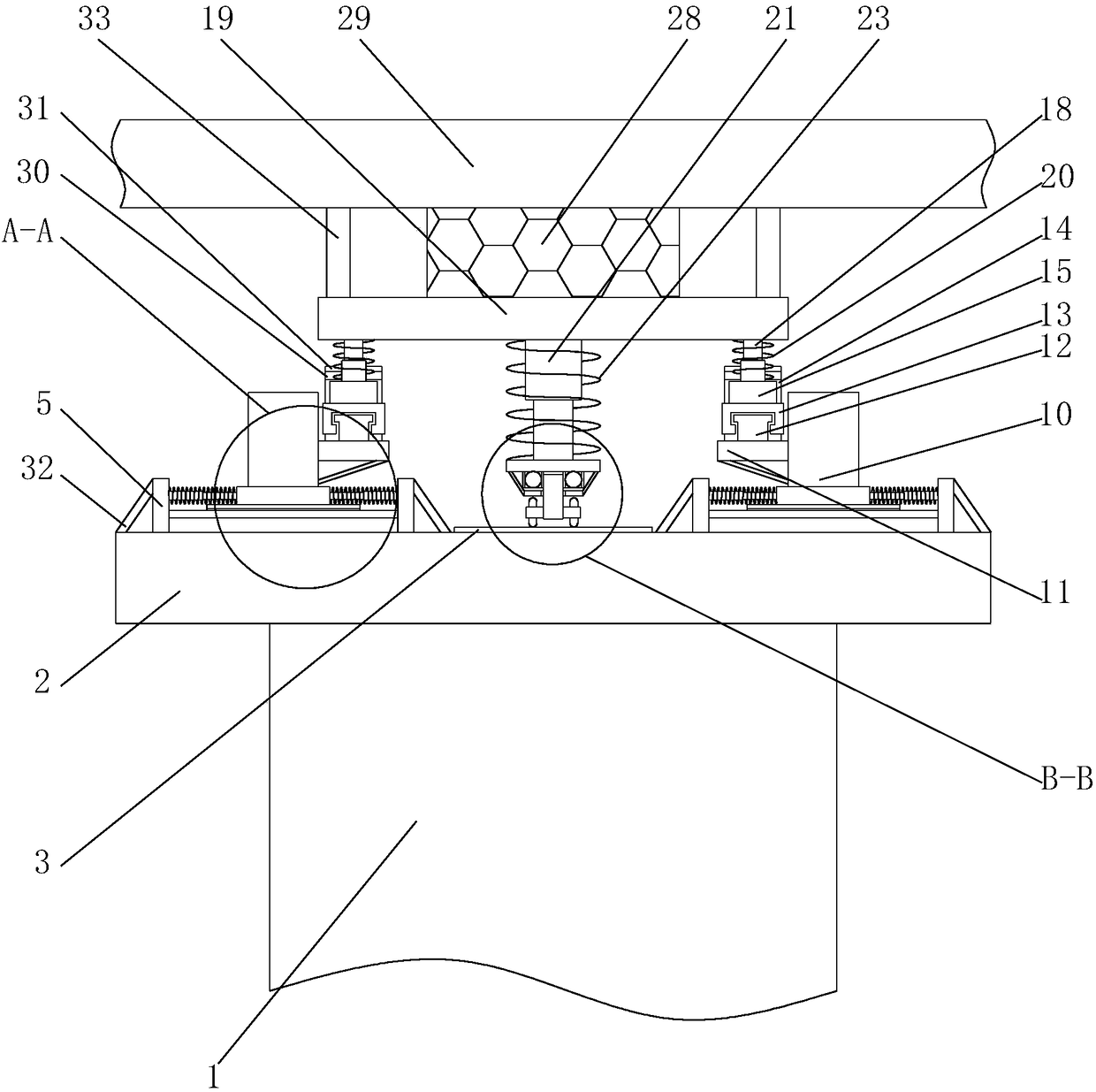

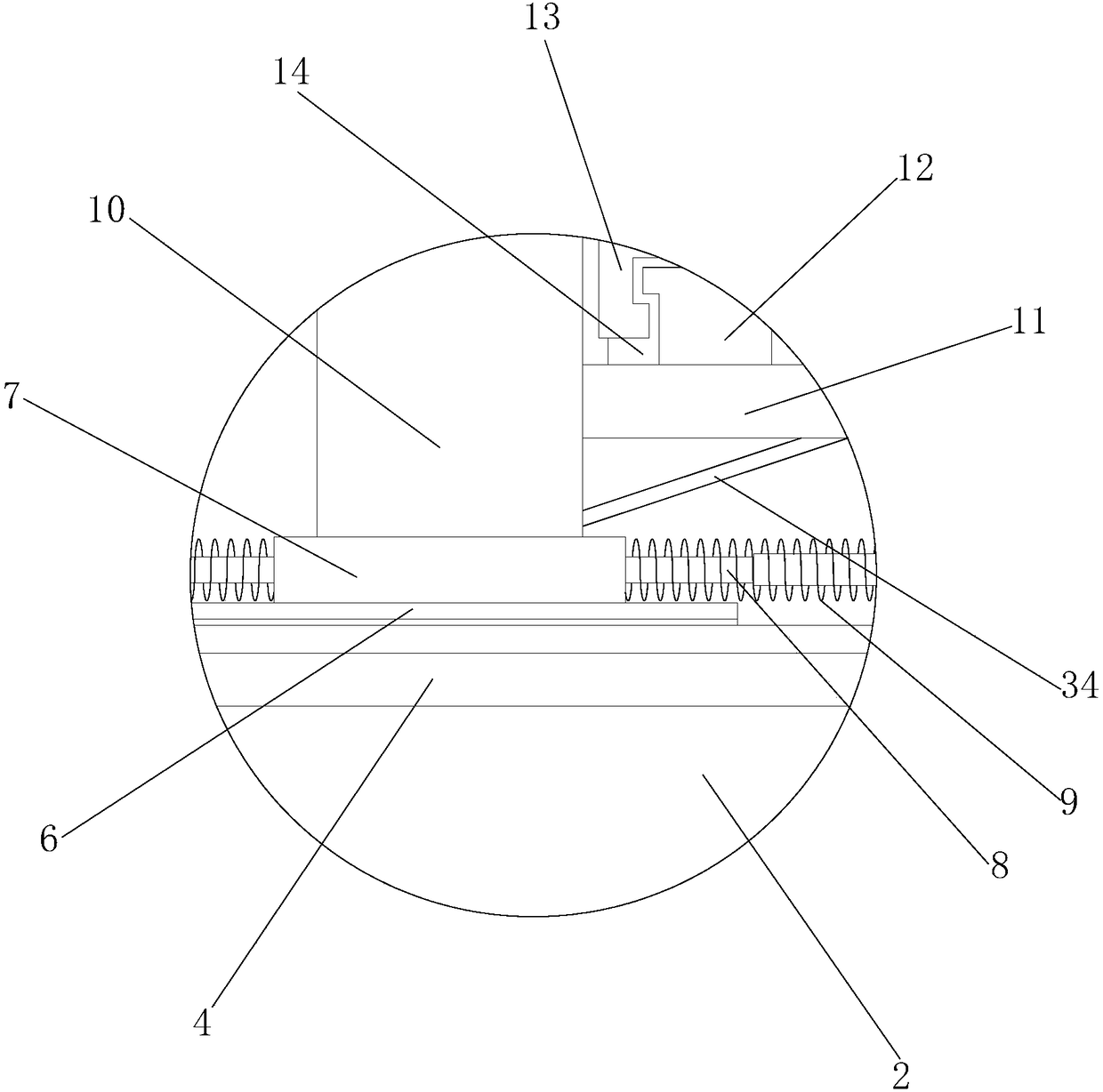

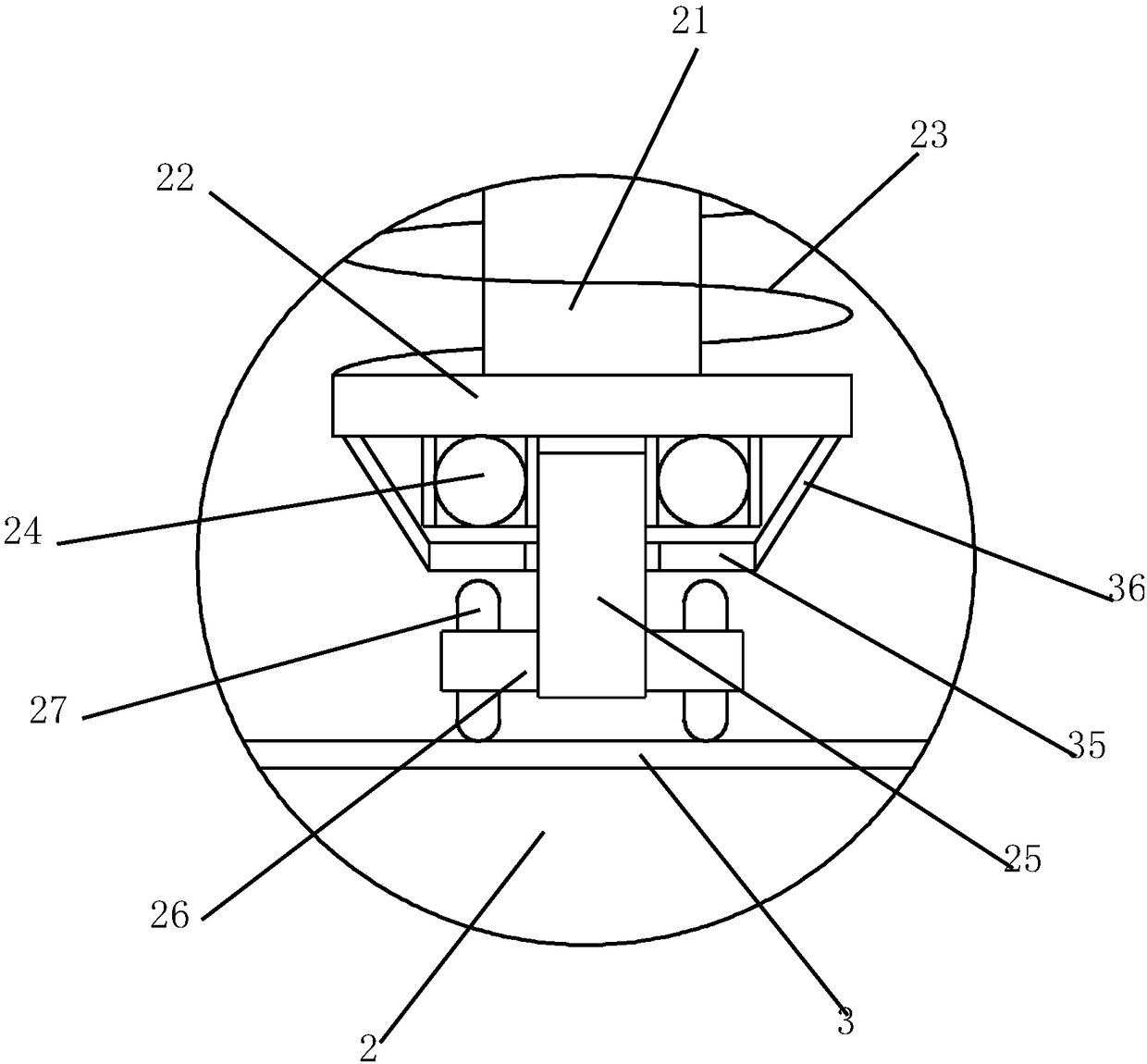

Anti-deformation device for bridge

InactiveCN108086141AGood anti-deformation effectReduce workloadBridge structural detailsDeformation effectGasket

The invention discloses an anti-deformation device for a bridge. The anti-deformation device comprises a supporting column, a fixing plate is fixedly connected to the top of the supporting column, anda smooth gasket is fixedly connected to the center point of the top of the fixing plate. First sliding rails are fixedly connected to the positions, located on the left side and the right side of thesmooth gasket, of the top of the fixing plate correspondingly. According to the anti-deformation device, by arranging the first sliding rails, first baffles, first sliding blocks, first limiting blocks, first telescopic rods, first springs, fixing strips, supporting plates, second sliding rails, second sliding blocks, second baffles, second limiting blocks, second telescopic rods, a second springs, third telescopic rods, third springs, a telescopic column, a limiting plate, a middle spring, bearings, a fixing rod, a fixed rotary shaft and rollers, the anti-deformation effect of the anti-deformation device becomes better, the work burden of workers is relieved, bridge deformation caused by external force is avoided, the service life of the bridge is prolonged, and great convenience is brought to passage of people.

Owner:成都千里之行科技有限公司

Outputting and locating mechanism for molded plastic profile

InactiveCN106829332AAvoid deformationImprove the anti-deformation effectConveyorsConveyor partsDeformation effectMolding machine

The invention provides a plastic profile molding output positioning mechanism, which includes side frames installed on both sides of the conveyor belt of the molding machine, two groups of symmetrical side guide assemblies are installed on the side frames, and a fixed plate is arranged on the top of the side frame, and the fixed plates are opposite to each other. Installed between two side frames, there is a guide post on the top of the fixed plate, and a horizontal plate is movable on the guide post, and the two ends of the horizontal plate are provided with guide post holes. After assembly, the guide post between the horizontal plate and the fixed plate The movable set has a buffer ring, and the top of the guide post is provided with a limit ring. The movable set on the guide post between the limit ring and the horizontal plate has a spring. There are two top pressure plates at the bottom of the horizontal plate, and an upper pressure plate is installed between the two top pressure plates Pressure roller. After adopting this scheme, the upper pressing roller is always in contact with the top of the profile under the action of the spring, and the profile anti-deformation effect is good.

Owner:湖州吴兴道场城乡建设发展有限公司

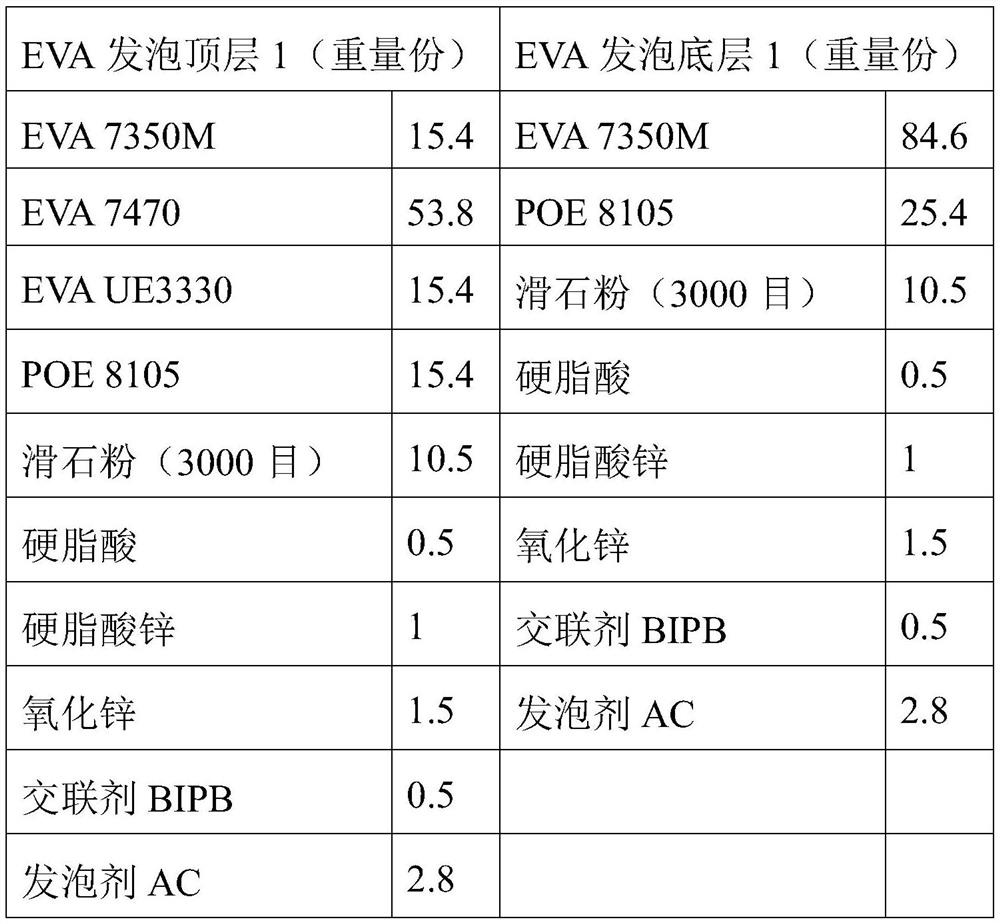

Anti-deformation EVA shoe sole and preparation method thereof, and arch-protecting anti-deformation sneaker

PendingCN112480521APrecise processingImprove processing efficiencySolesDomestic footwearPolyolefinStearic acid

The invention provides an anti-deformation EVA shoe sole and a preparation method thereof, and an arch-protecting anti-deformation sneaker. The anti-deformation EVA shoe sole comprises an EVA foamed bottom layer and an EVA foamed top layer bonded with the EVA foamed bottom layer. The EVA foamed top layer is prepared from the following raw materials in parts by weight: 82.5 to 87.5 parts of an ethylene vinyl acetate copolymer, 12.5 to 17.5 parts of polyolefin elastomer, 8 to 12 parts of talcum powder, 0.4 to 0.6 part of stearic acid, 0.8 to 1.2 parts of zinc stearate, 1 to 2 parts of zinc oxide, 0.2 to 0.8 part of a cross-linking agent and 2.5 to 3.5 parts of a foaming agent. The EVA foamed bottom layer is prepared from the following raw materials in parts by weight: 82.5 to 87.5 parts of the ethylene vinyl acetate copolymer, 22.5 to 27.5 parts of polyolefin elastomer, 8 to 12 parts of talcum powder, 0.4 to 0.6 part of stearic acid, 0.8 to 1.2 parts of zinc stearate, 1 to 2 parts of zinc oxide, 0.2 to 0.8 part of a cross-linking agent and 2.5 to 3.5 parts of a foaming agent. The anti-deformation EVA shoe sole can more effectively support the foot arch and prevent deformation damage.

Owner:莆田星昌鞋业有限公司

Water conservancy ecological protection slope drainage structure

ActiveCN114134859AImprove survival rateImprove growth qualityDamsProtective constructionWater flowEnvironmental engineering

The water conservancy ecological protection slope drainage structure comprises a slope protection frame, slope protection building blocks, a rock block base, a drainage groove, a drainage assembly, a buffer wall, a waterproof assembly, a soil fixation assembly, a concrete layer, a vegetation assembly and a protection assembly, the rock block base is arranged on the end face of the bottom of the slope protection frame, and the drainage groove is formed in the end face of one side of the rock block base; a drainage assembly is arranged in the drainage groove, and slope protection building blocks are arranged at the bottom of the inner side of the slope protection frame. The water conservancy ecological protection slope drainage structure is simple in structure, high in overall structural stability and diversified in function; during use, the protection slope has good water seepage prevention, soil fixation and ecological planting effects, and the protection slope can be well protected; meanwhile, the ecological protection slope has a good drainage function, the situation that water flows backwards can be effectively avoided, the situation that the protection slope is eroded by water bubbles is avoided, and the service life of the ecological protection slope is effectively prolonged.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

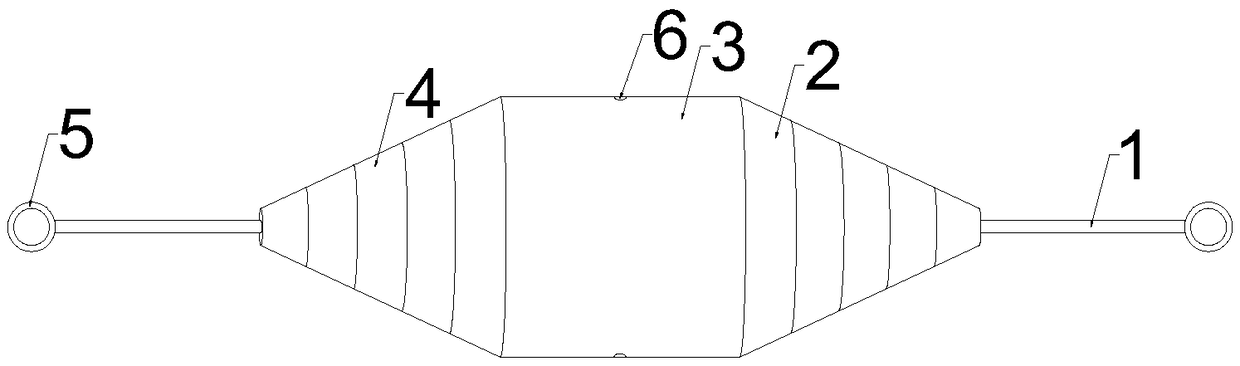

Deformation recovery device for deep underground plastic pipe, and use method thereof

The invention provides a deformation recovery device for a deep underground plastic pipe. The deformation recovery device for the deep underground plastic pipe comprises a precession cone and hangingrings, wherein the precession cone comprises a front-end precession cone, a middle-section cylinder and a rear-end precession cone; round steel is arranged at the middle part of the precession cone; and the hanging rings are arranged at the two ends of the round steel separately. According to the device and the use method thereof, the recovery device is effectively prevented from being re-deformedand blocked; the problems of deformation and blockage of a plastic pipeline are thoroughly solved; the purpose of normal water supply and drainage is achieved; the engineering quality is effectivelyimproved; the serious noise pollution of a temporary power generator in a construction field, and the adverse factors of high cost, long construction period, influence on a surrounding environment anda building, and the like in a large excavation method in a traditional process are avoided; and the device and the use method thereof have wide applicability in the field of repair for deep plastic pipes.

Owner:新疆额尔齐斯河投资开发(集团)有限公司

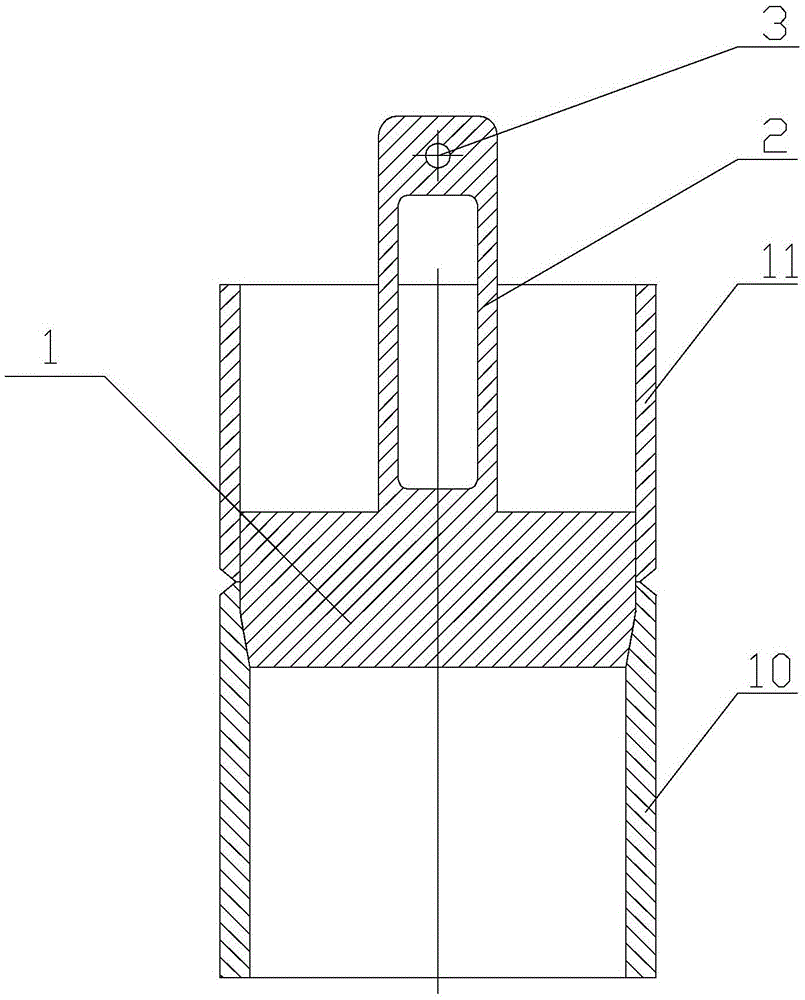

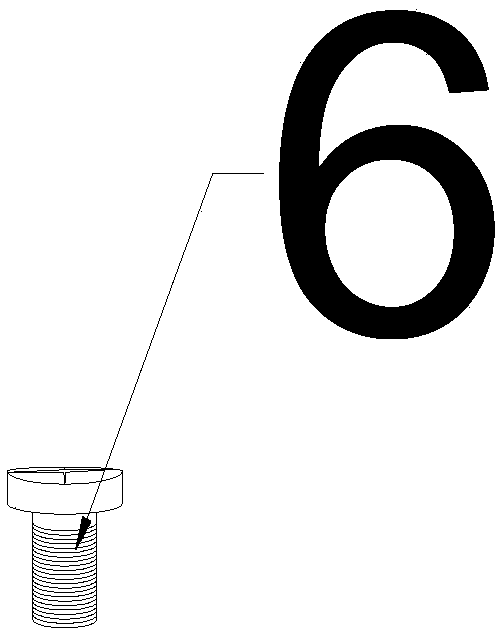

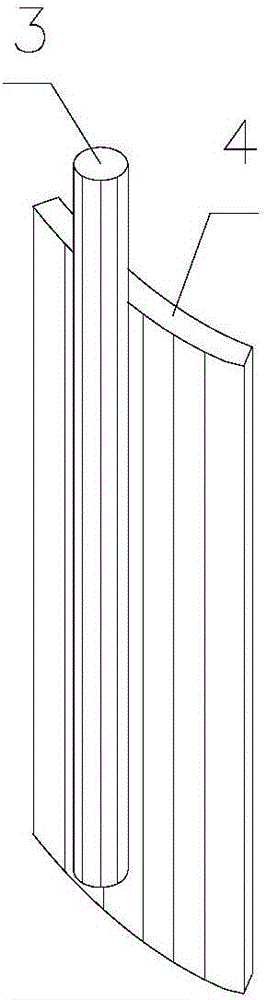

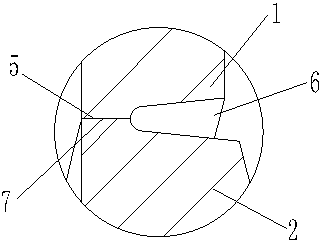

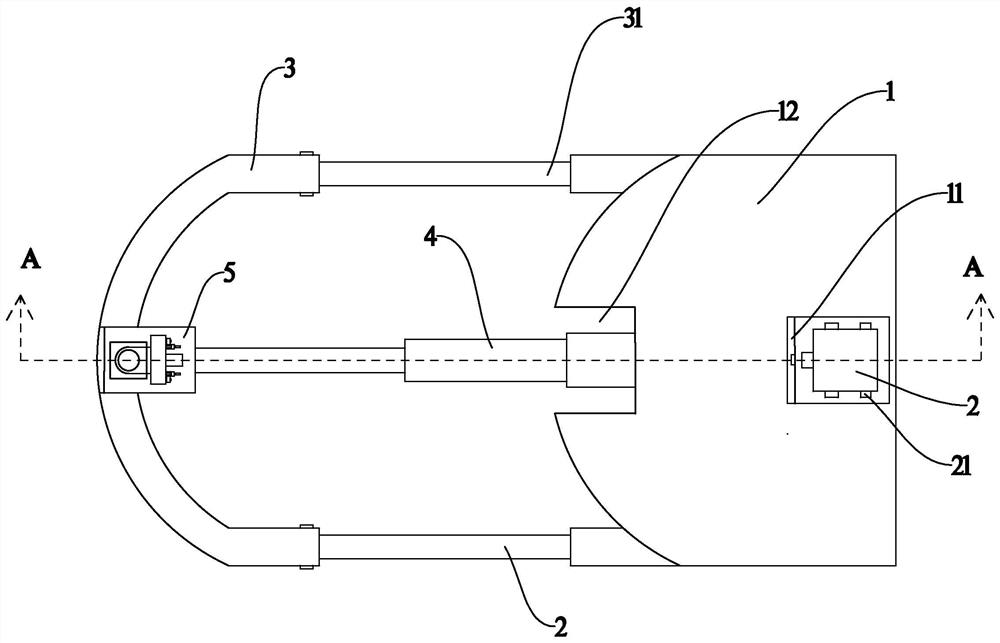

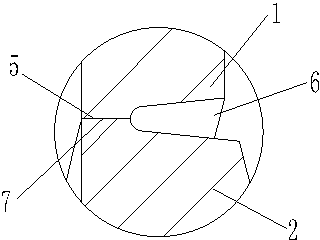

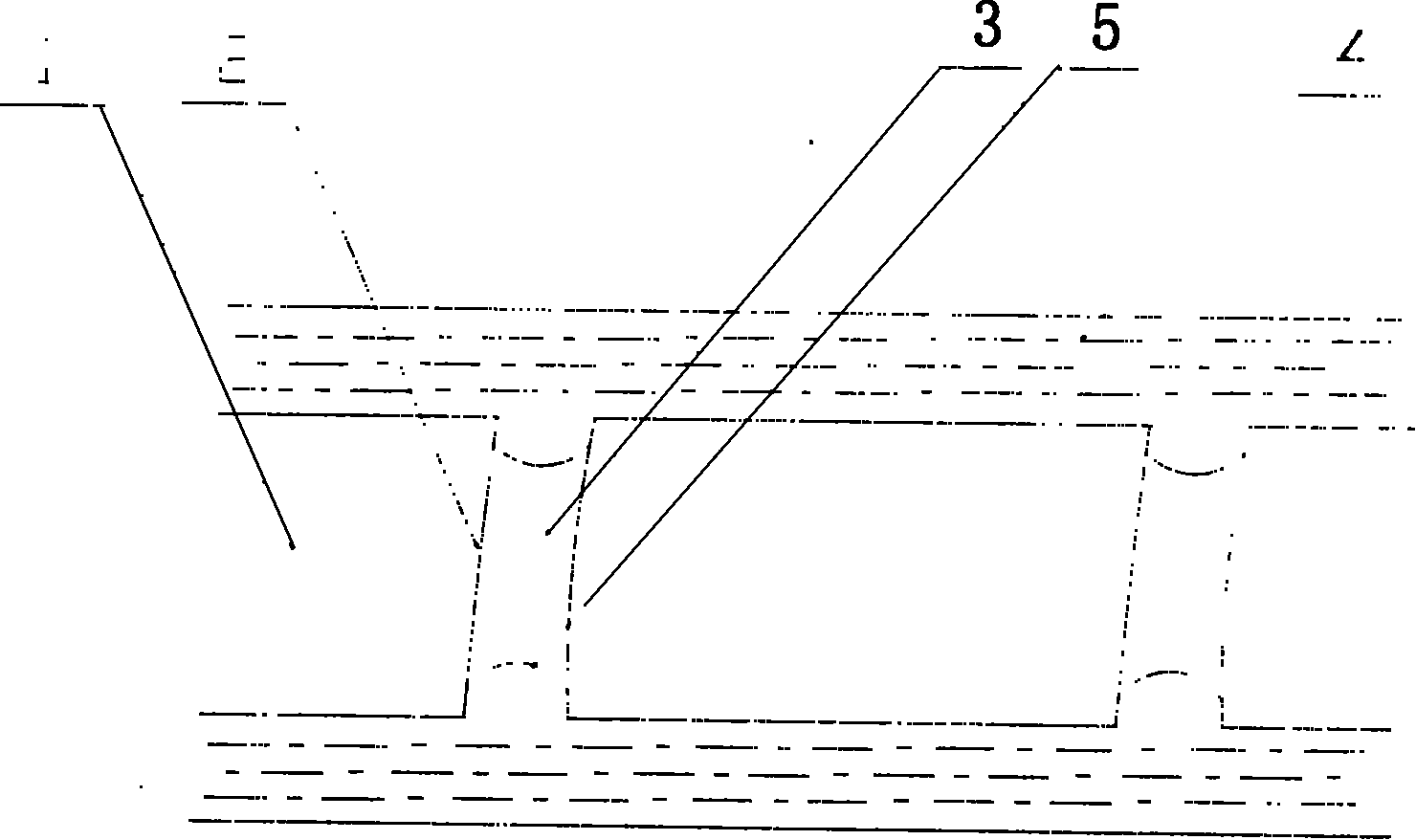

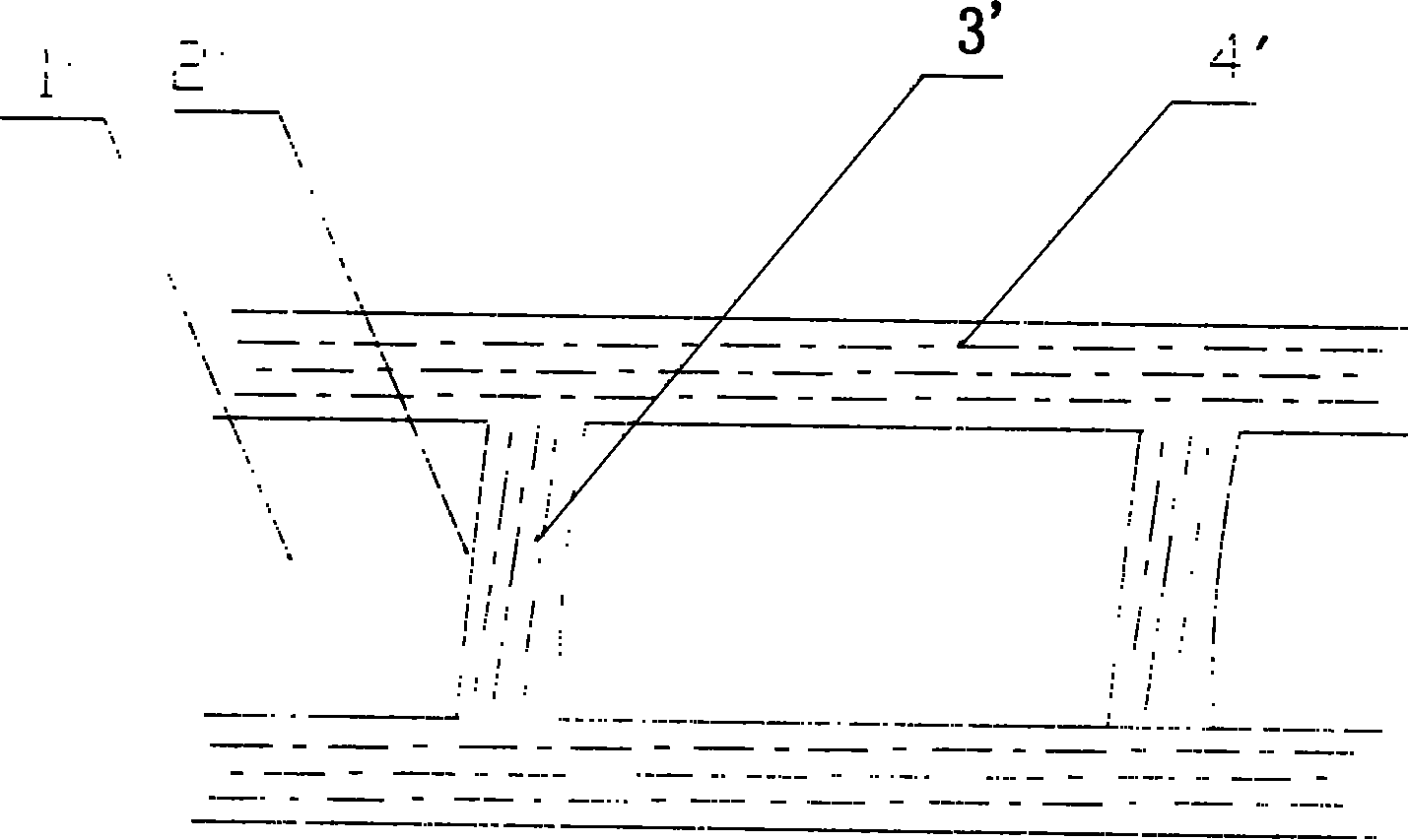

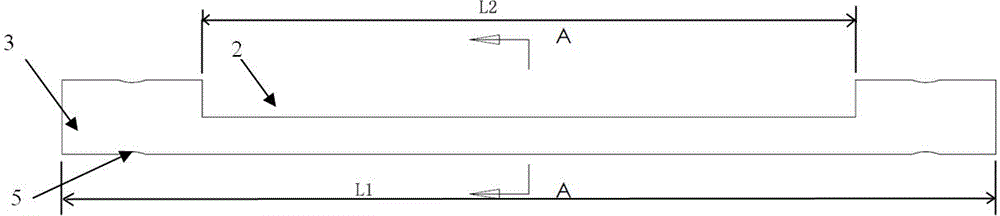

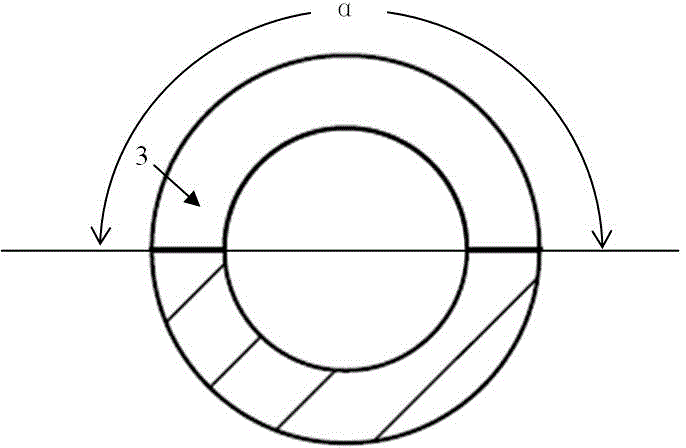

Deformation-preventing device for evanescent mode ductile iron pipe fitting bell mouth

InactiveCN106378419AImprove the anti-deformation effectAchieve fixationFoundry mouldsFoundry coresEvanescent modeStructural engineering

The invention discloses a deformation-preventing device for an evanescent mode ductile iron pipe fitting bell mouth. The evanescent mode ductile iron pipe fitting bell mouth is in a cylindrical shape. The deformation-preventing device for the evanescent mode ductile iron pipe fitting bell mouth comprises a rotating shaft rod (3), sliding blocks (4) and multiple equally-divided sand rings (1), wherein the multiple equally-divided sand rings (1) are spliced to form a sand ring cylinder. The outer surface of the sand ring cylinder is tightly attached to the inner surface of the evanescent mode ductile iron pipe fitting bell mouth (2), and every two adjacent connected equally-divided sand rings (1) are clamped to each other through the corresponding sliding block (4). Opening grooves matched with the sliding blocks (4) are formed in the two sides of the equally-divided sand rings (1). The rotating shaft rod (3) is arranged in the equally-divided rings (1) in a tapping manner. First clamping teeth are arranged on the sliding blocks (4), and second clamping teeth engaged with the first clamping teeth are arranged on the rotating shaft rod (3) so that the sliding blocks (4) can be driven to slide in the length direction of the opening grooves. According to the deformation-preventing device for the evanescent mode ductile iron pipe fitting bell mouth, the defects that in the prior art, sand rings cannot be well fixed to the end face of a bell mouth, and the size can only be fixed are overcome, and the evanescent mode ductile iron pipe fitting bell mouth can be prevented from deforming.

Owner:WUHU XINXING DUCTILE IRON PIPES

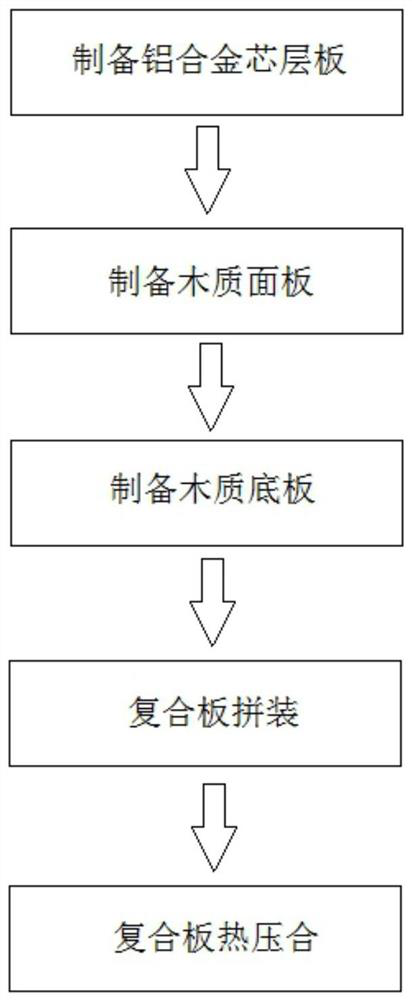

Novel aluminium alloy floor manufacturing method

ActiveCN111890481AGood thermal conductivity and deformation resistanceLow manufacturing costWood veneer joiningConstructions elementsAluminium alloyCooling speed

The invention discloses a novel aluminium alloy floor manufacturing method. An aluminium alloy floor comprises a wooden face plate, an aluminium alloy core layer plate and a wooden bottom plate; the novel aluminium alloy floor manufacturing method comprises the following steps: preparing the aluminium alloy core layer plate and the wooden face plate, carrying out grooving cutting on the compositesurface of the wooden face plate, preparing the wooden bottom plate, carrying out dampproof treatment on the bottom surface and the side surface of the wooden face plate, assembling a composite plate,enabling the aluminium alloy core layer plate to be positioned between the wooden face plate and the wooden bottom plate, carrying out thermo-compression on the composite plate, and carrying out thermal rolling and continuous pressure maintaining on the assembled composite plate. The novel aluminium alloy floor manufacturing method has the following advantages: the aluminium alloy core layer adopts the foundry technology, is high in cooling speed and dense in casting texture and has high mechanical property, compression resistance and deformation resistance; a bulge is processed on the aluminium alloy core layer plate to enable the composite plate has better heat conduction and anti-deformation capacity; and the aluminium alloy core layer plate adopts a hollow structure, can bear higher pressure while reducing the manufacturing cost and expands the application scenarios.

Owner:浙江瀚涛科技有限公司

Anti-deformation device for plastic extrudate

The invention provides an anti-deformation device for plastic extrudate. The extrudate comprises racks installed at two sides of conveying rollers of a forming machine. The top of two racks extend in opposite direction to form a base. The top of the base is provided with a top plate. The bottom of the top plate is provided with two rolling plate. The bottom between two rolling plates is provided with an upper roller. Each rack is provided with a group of side guiding assembly which comprises two side slide plates separately installed at the upper and lower portions of the rack. After the installation, a side guide roller is installed between the end portions of two side slide plates located at the side of the conveying rollers. The other end portions of the two side slide plates are provided with connecting plates. Regulating bolts penetrate through the connecting plates to be connected with the rack. The regulating bolts at two sides of the connecting plate are meshed with regulating nuts. The extrudate produced by using the technical scheme has good anti-deformation effect.

Owner:湖州市道场乡资产经营有限公司

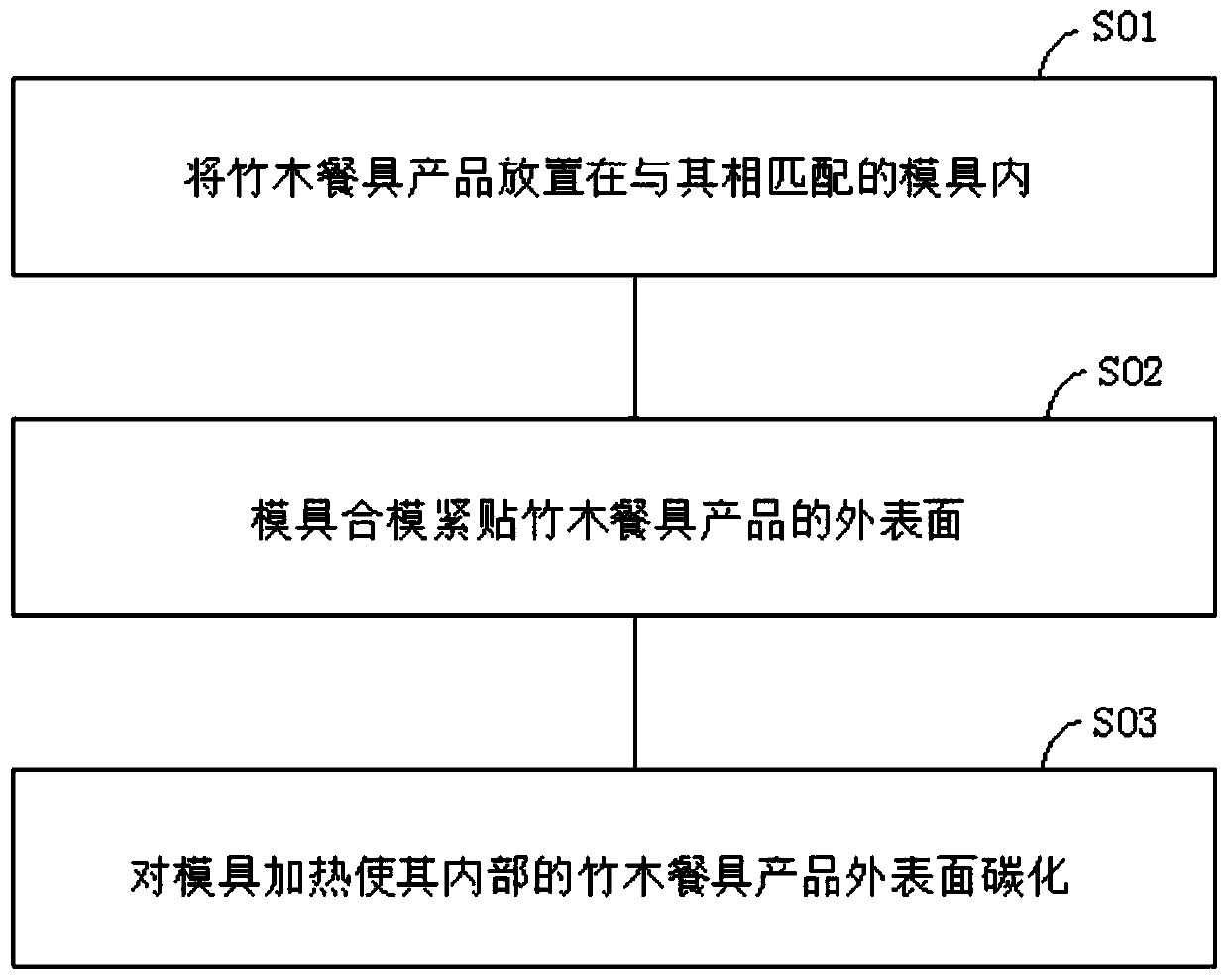

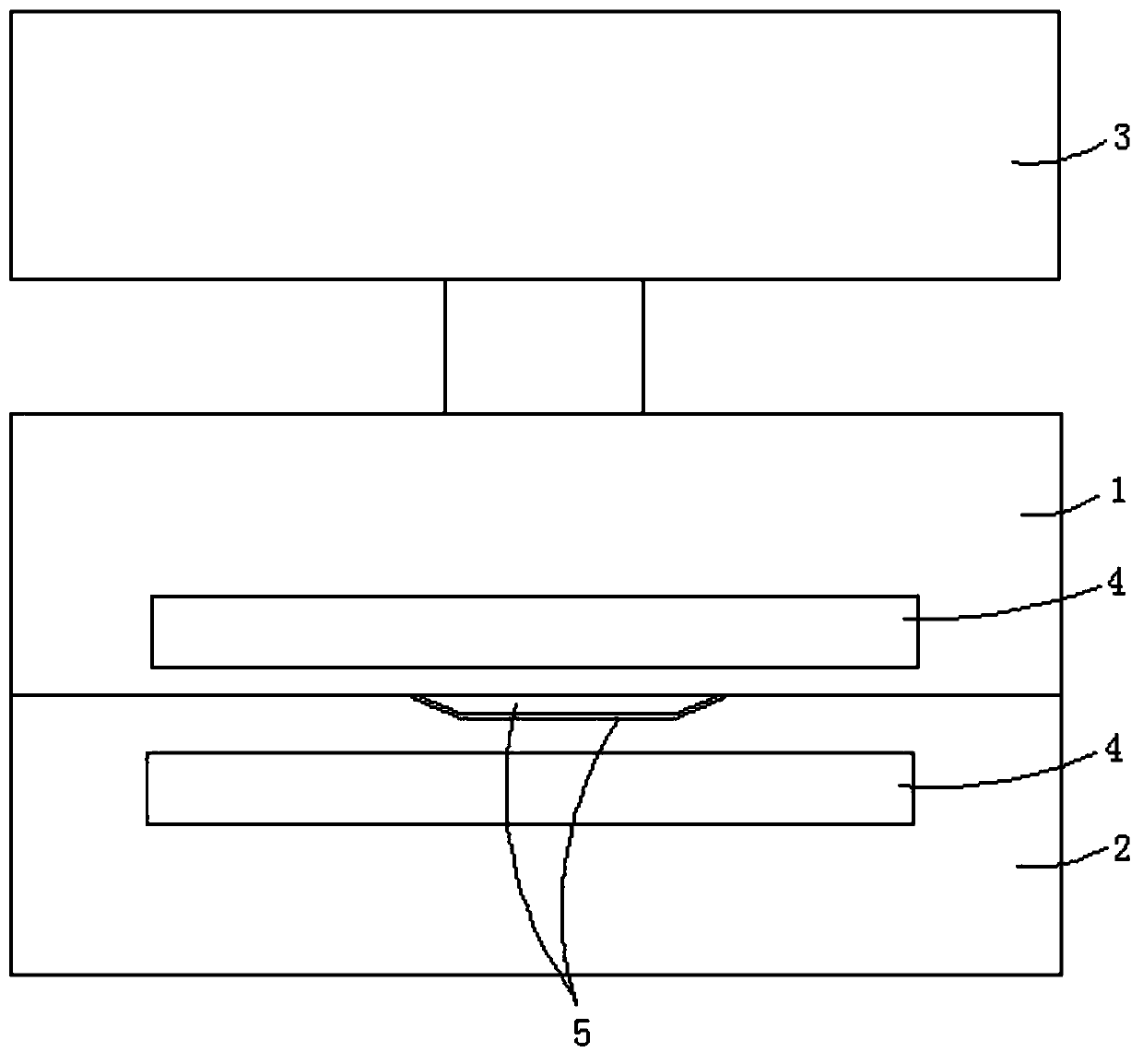

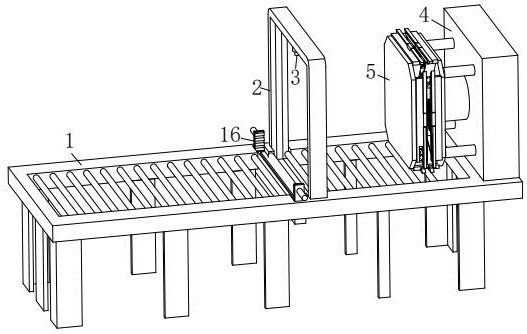

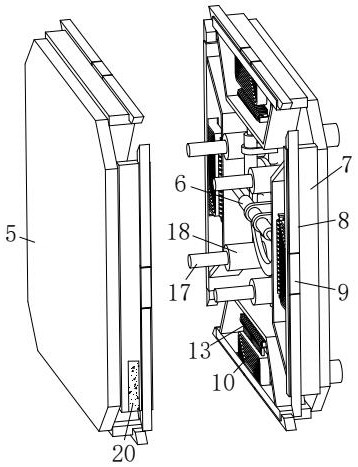

Semi-carbonization method and equipment for single-layer bamboo tableware

InactiveCN111015879ACreate pollutionDetrimental to healthWood charring/burningCarbon layerBatch manufacturing

The invention relates to a semi-carbonization method for single-layer bamboo tableware. The method comprises the following steps: putting a bamboo tableware product into a mold matched with the bambootableware product; the mold is closed and clings to the outer surface of the bamboo tableware product; heating the mold to carbonize the outer surface of the bamboo tableware product in the mold; method according to the invention, the outer surface of the bamboo tableware can be quickly and uniformly carbonized to form a compact protective carbon layer, the processing speed is high, the bamboo tableware is suitable for batch production, the mildew-proof, insect-proof and deformation-proof effects are good, additives such as chemicals and the like do not need to be additionally added, the tableware cannot pollute the environment, and the health of a user cannot be damaged.

Owner:深圳市山峰智动科技有限公司 +1

A stainless steel air duct processing and welding equipment

ActiveCN114346585BEasy to fixImprove the anti-deformation effectWelding/cutting auxillary devicesAuxillary welding devicesDeformation effectStructural engineering

The invention provides a stainless steel air duct processing and welding equipment, which belongs to the technical field of air duct welding, and comprises a welding processing table, a rectangular welding track is arranged on the welding processing table, a telescopic mounting seat is fixedly arranged on the welding processing table, and the telescopic mounting seat is connected There is an anti-deformation part of the inner support, and the telescopic mounting seat is used to control the anti-deformation part of the inner support to perform telescopic movement to the rectangular welding track. The inner edge support unit has four inner edge support units and is distributed on the corresponding surface in a rectangular shape. The stainless steel air duct processing and welding equipment fits and supports the stainless steel air duct from the inside. It has the advantages of good fixing effect, high uniformity of force, good anti-deformation effect and high welding efficiency, which effectively improves the convenience and efficiency of welding. The welding quality is high, and the present invention is applicable to stainless steel air ducts of different sizes, which correspondingly improves the scope of application of the present invention.

Owner:江苏美劳智能家居有限公司

Multi-nozzle oppositely-arranged type gasifier nozzle mounting flange installing and welding method

The invention discloses a multi-nozzle oppositely-arranged type gasifier nozzle mounting flange installing and welding method. The method includes the following steps: machining a nozzle mounting flange, selecting a gasifier assembly cylinder section where the nozzle mounting flange will be installed, installing an anti-deformation tool, machining a tube hole, where the nozzle mounting flange will be installed, in the assembly cylinder section, enabling the nozzle mounting flange to be matched with the assembly cylinder section, forming a fan-shaped groove with a big outside and a small inside between the nozzle mounting flange and the assembly cylinder section, enabling the inner bottom end of the fan-shaped groove to be in a semi-circular arc shape, enabling a location straight section to be arranged between the bottom and the inner wall of the assembly cylinder section, enabling the location straight section to have a 0.3-0.5mm fit clearance during assembling, adopting a 7-shaped connecting piece to connect and fix the nozzle mounting flange and the assembly cylinder section, detecting positional accuracy of four nozzles of the nozzle mounting flange, and welding the groove. By means of the mounting flange installing and welding method, the finally-obtained nozzle mounting flange is high in accuracy, good in quality and good in anti-deformation effect.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

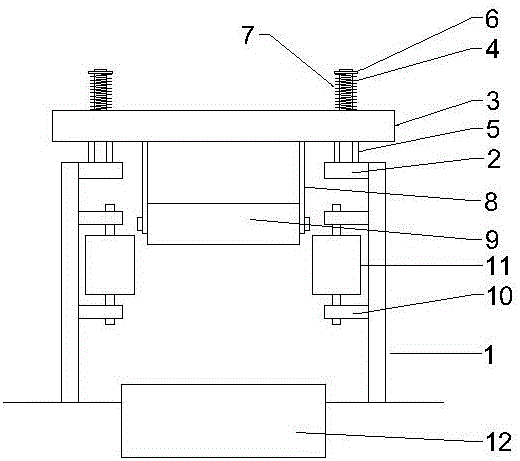

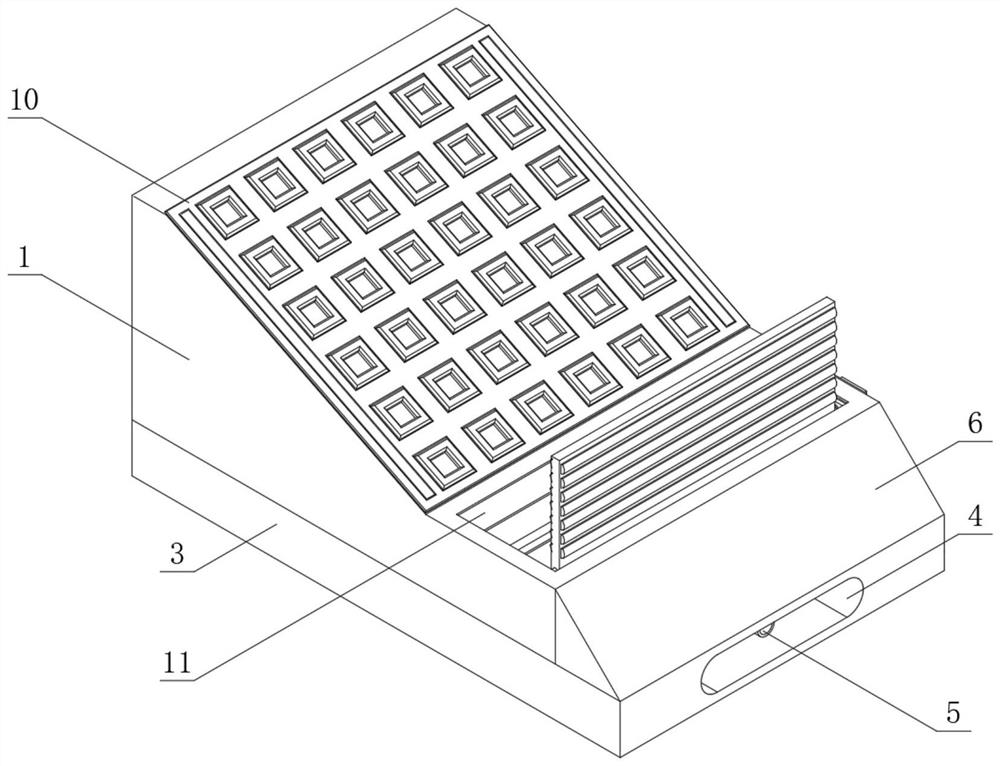

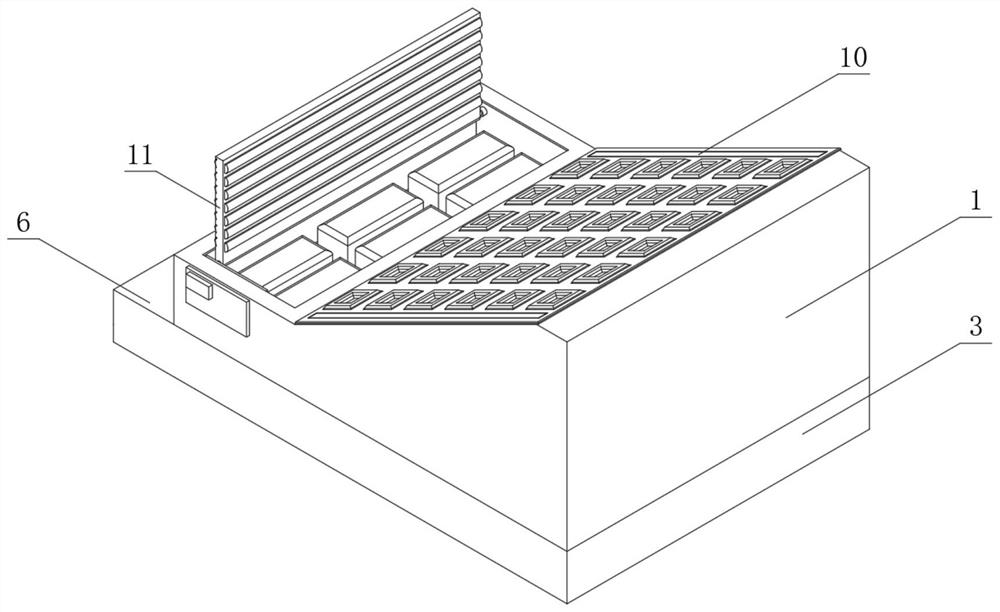

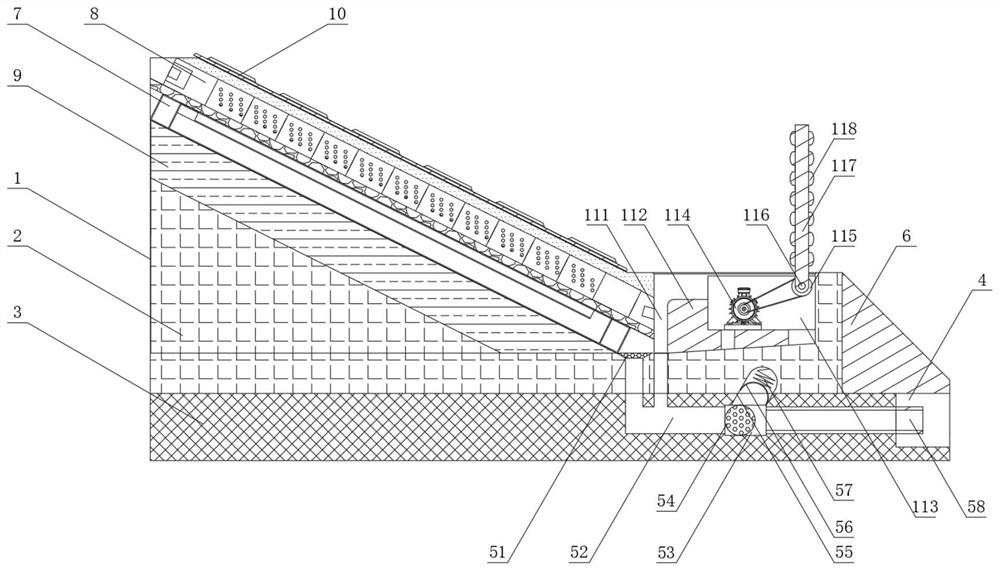

A portable projection device for marketing training and teaching

ActiveCN110880251BEasy to carryEasy to ventilate and dissipate heatProjectorsElectrical appliancesEngineeringStructural engineering

Owner:王毅 +1

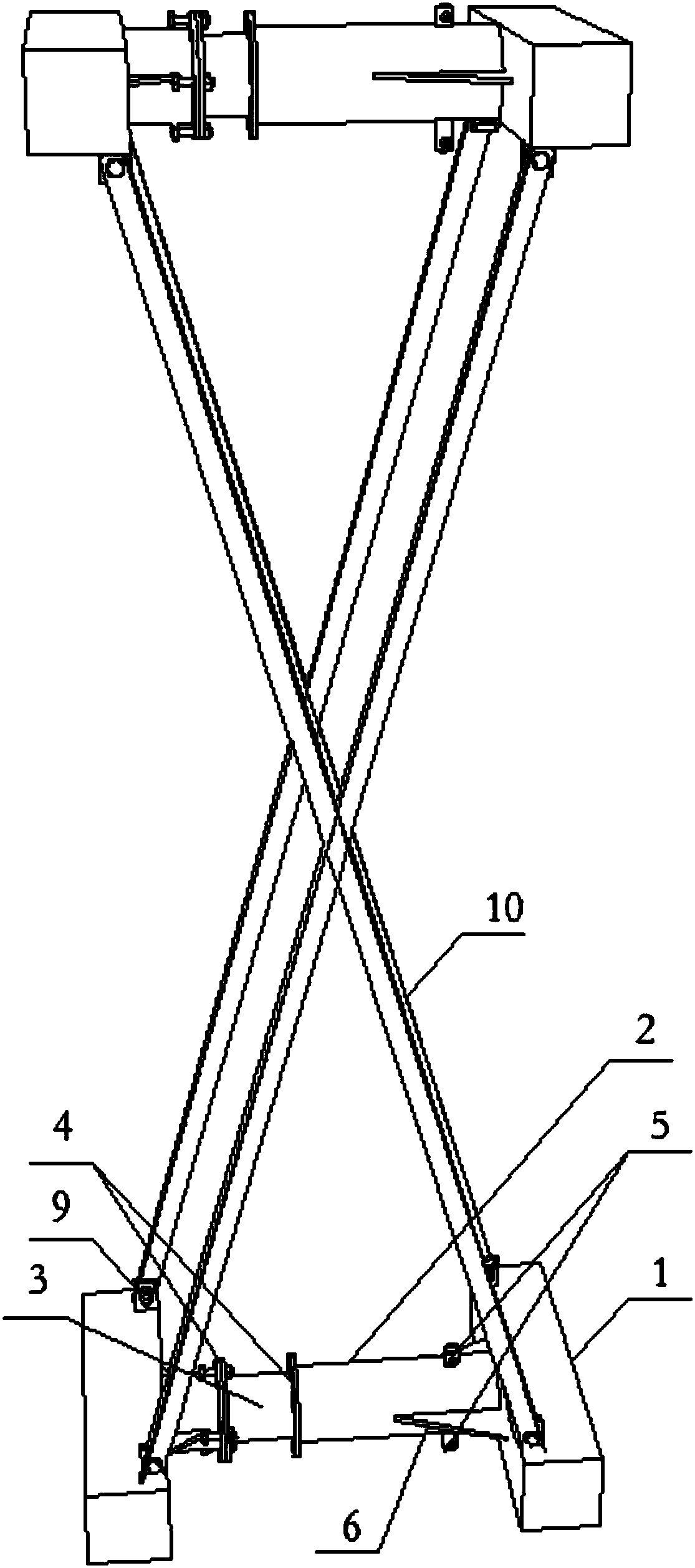

Steel arch frame closure device

PendingCN110106786ARealize automatic adjustmentReduce the difficulty of adjustmentBridge erection/assemblyArch-type bridgeReinforced concreteSteel ball

The invention provides a steel arch frame closure device. The steel arch frame closure device comprises an upper chord and a lower chord and a telescopic device, wherein the telescopic device is usedfor adjusting the length of the upper chord and / or the lower chord; the telescopic device adopts a flexible telescopic device to adjust the travel of the steel arch frame closure device, wherein the flexible telescopic device comprises a cylinder body and a telescopic rod; the telescopic rod extends into a cylinder body to form a space, for accommodating steel ball sand, together with the cylinderbody wall; and a telescopic rod moves in the axial direction of the cylinder body to extrude the steel ball sand to realize telescopic adjustment. According to the steel arch frame closure device, through coordination of the steel ball sand, the telescopic rod and the cylinder body, automatic retraction of the flexible telescopic device is realized to adjust the travel of the steel arch frame closure device so as to achieve the purpose of automatically adjusting the length of a steel arch frame arc; the steel arch frame arc length adjusting difficulty can be greatly reduced, and moreover, thesteel arch frame arc length can be automatically adjusted to guarantee that the steel arch frame arc satisfies requirements of a reinforced concrete main arch ring arc.

Owner:CHONGQING BIAOWANG MACHINERY EQUIP CO LTD

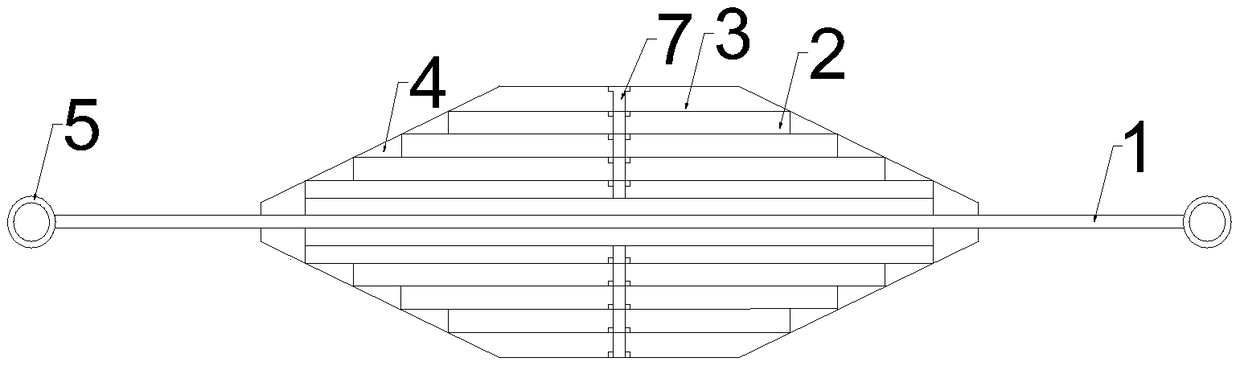

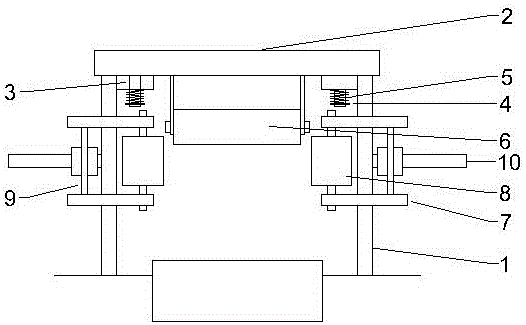

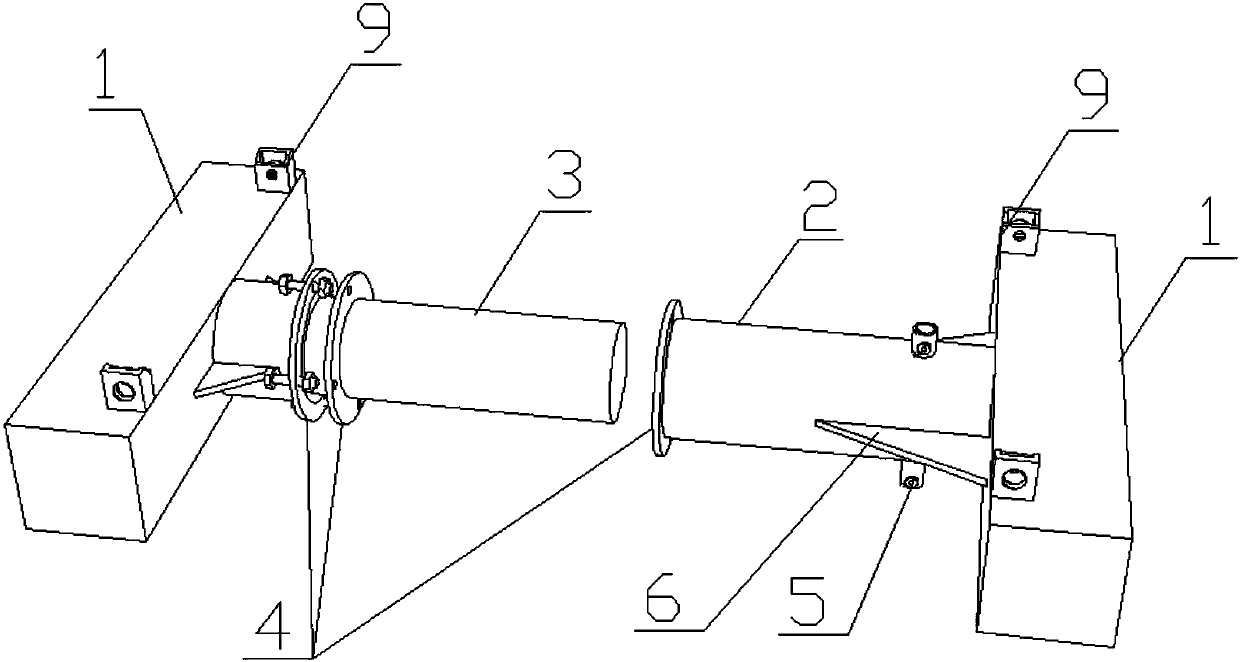

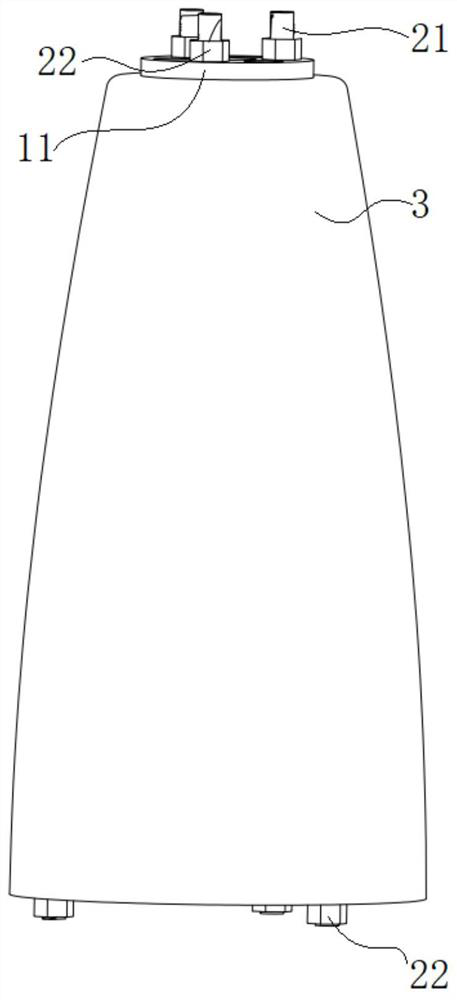

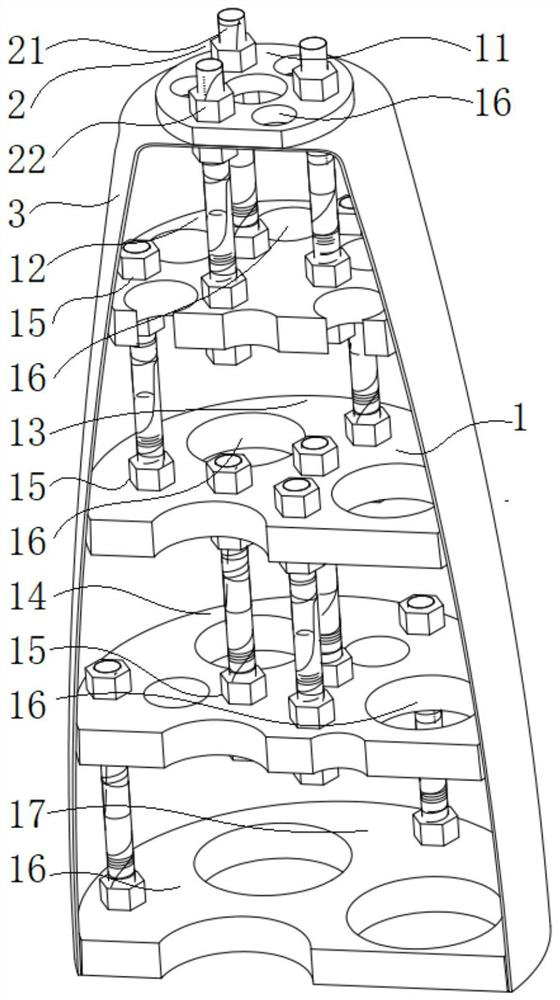

Flexible tool for solution treatment of curved generatrix thin-wall aluminum alloy structural member

PendingCN113736973AImprove the anti-deformation effectSimple structureFurnace typesHeat treatment furnacesSolution treatmentMechanical engineering

The invention discloses a flexible tool for solution treatment of curved generatrix thin-wall aluminum alloy structural member. The flexible tool comprises a supporting plate assembly and a fastening assembly, the supporting plate assembly comprises a plurality of supporting plates, the supporting plates comprise the first supporting plate, the second supporting plate, the third supporting plate, the fourth supporting plate and the fifth supporting plate, and a plurality of first through holes and second through holes are uniformly formed in each supporting plate; the fastening assembly comprises a plurality of connecting screw rods and a plurality of nuts; and the first supporting plate and the second supporting plate are connected through the plurality of connecting screw rods, one end of each connecting screw rod penetrates through the corresponding first through hole and is fixed to the first supporting plate through the corresponding nut, and the other end of each connecting screw rod penetrates through the corresponding first through hole and is fixed to the second supporting plate through the corresponding nut. The flexible tool effectively prevents deformation of parts and has a relatively strong adjusting space.

Owner:海鹰空天材料研究院(苏州)有限责任公司

Multi-nozzle oppositely-arranged type gasifier nozzle mounting flange installing and welding method

The invention discloses a multi-nozzle oppositely-arranged type gasifier nozzle mounting flange installing and welding method. The method includes the following steps: machining a nozzle mounting flange, selecting a gasifier assembly cylinder section where the nozzle mounting flange will be installed, installing an anti-deformation tool, machining a tube hole, where the nozzle mounting flange will be installed, in the assembly cylinder section, enabling the nozzle mounting flange to be matched with the assembly cylinder section, forming a fan-shaped groove with a big outside and a small inside between the nozzle mounting flange and the assembly cylinder section, enabling the inner bottom end of the fan-shaped groove to be in a semi-circular arc shape, enabling a location straight section to be arranged between the bottom and the inner wall of the assembly cylinder section, enabling the location straight section to have a 0.3-0.5mm fit clearance during assembling, adopting a 7-shaped connecting piece to connect and fix the nozzle mounting flange and the assembly cylinder section, detecting positional accuracy of four nozzles of the nozzle mounting flange, and welding the groove. By means of the mounting flange installing and welding method, the finally-obtained nozzle mounting flange is high in accuracy, good in quality and good in anti-deformation effect.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

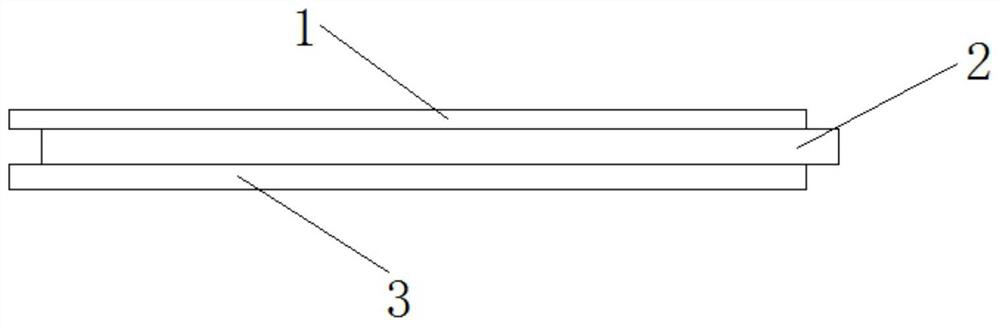

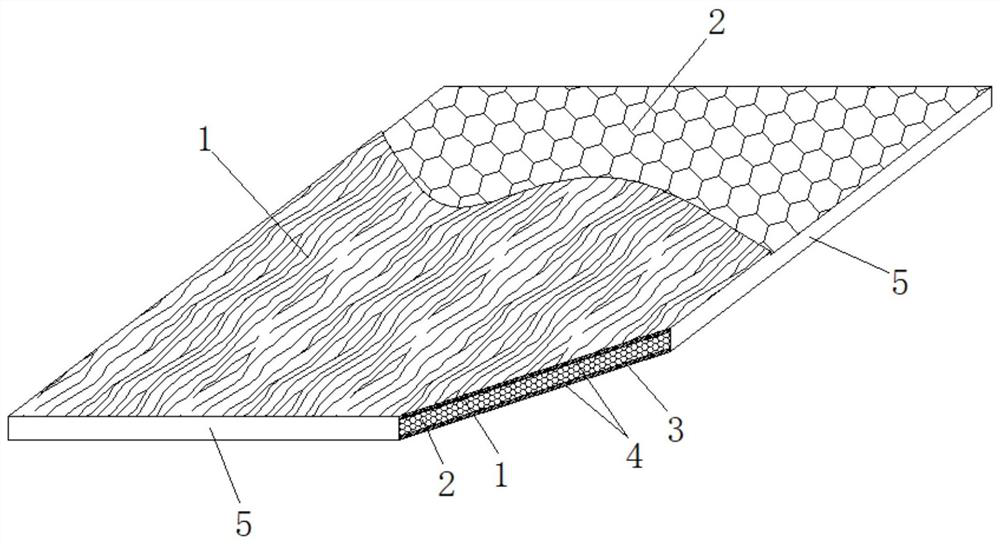

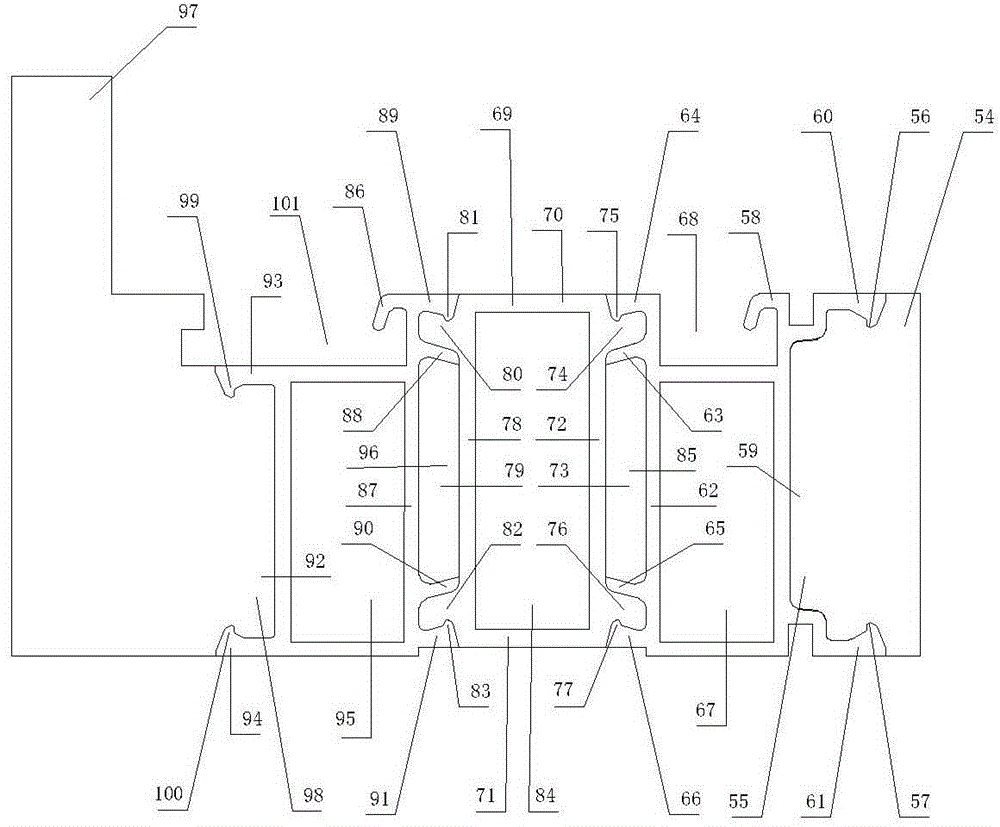

Assembly type novel composite plate

PendingCN112123894AStrong physical stabilityImprove the anti-deformation effectWood layered productsMetal layered productsAluminum honeycombComposite plate

The invention provides an assembly type novel composite plate which comprises a first raw wood plate, a second raw wood plate, a third raw wood plate and a fourth raw wood plate. The honeycomb plate is arranged on the middle layer; the second raw wood plate is arranged at the bottommost layer; the first raw wood plate and the honeycomb plate are bonded through special glue, and the honeycomb plateand the second raw wood plate are bonded through special glue; the honeycomb plate is an aluminum honeycomb plate; the first raw wood plate and the second raw wood plate are the same in thickness, and the thickness of the honeycomb plate is larger than that of the first raw wood plate and that of the second raw wood plate. The sealing edges are attached to the outer sides of the first raw wood plate, the honeycomb plate and the second raw wood plate in a sealing mode. Compared with the prior art, the invention has the advantages of favorable overall physical properties, high stability and lowtendency to deformation.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

A method for improving the corrosion resistance of willow products

ActiveCN106182248BImprove organizational structureImprove insect and mildew resistanceRadiation/waves wood treatmentWood treatment detailsHigh humidityMildew

The invention discloses a method for improving corrosion resistance of wicker products. The method comprises the following steps: (1) skin removal of wickers, (2) softening treatment, (3) wicker weaving, and (4) anti-corrosion treatment. Various steps of the method are matched scientifically and reasonably, and the manufactured wicker products are good in insect prevention, mildew prevention and corrosion resisting effects and are high in surface hardness. Compared with the prior art, the method has the characteristics that the surface hardness of the wicker products can be improved by about 25%, the wicker products are used under the condition of high acid and alkali, the anti-corrosion time of the wicker products can be 4-5 times longer than the original anti-corrosion time, the service life can be prolonged by about 30% under the conventional using conditions, and can be prolonged by 40% or above under the condition of high humidity, use stability is good, anti-deformation ability is high, corrosion resistance is good, and use value is high.

Owner:阜南县猛发工艺品有限公司

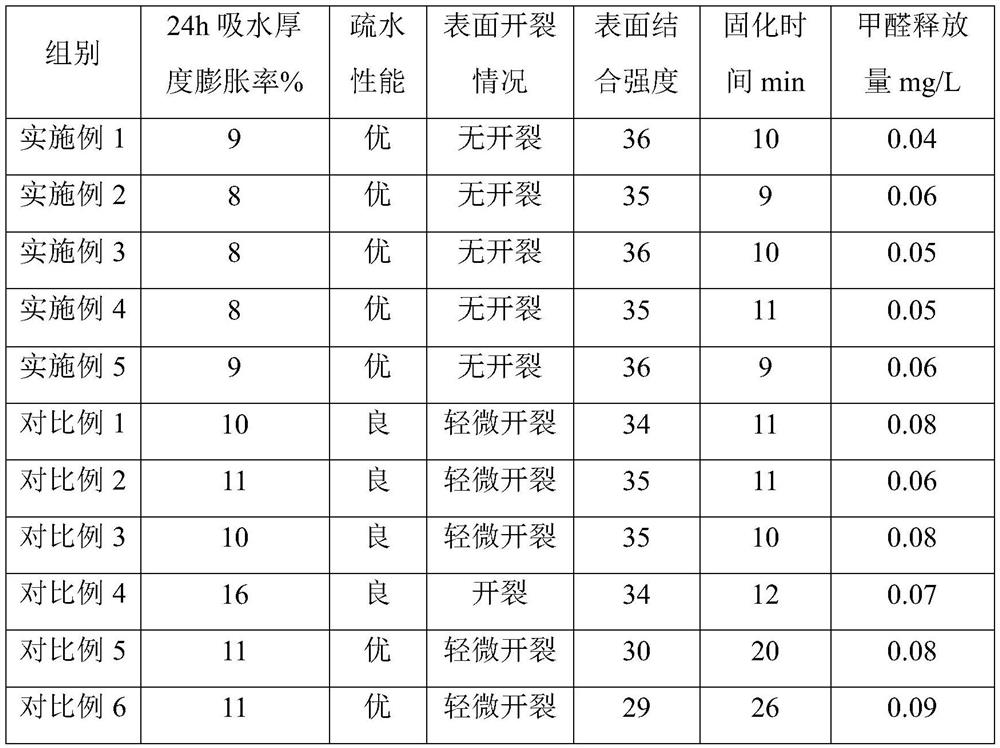

Water type multi-functional, hydrophobic, air-permeability and porous material, preparation method and application thereof

A multifunctional hydrophobic air-permeable aquatic porous material in the form of paste with high water resistance for building, furniture, etc contains water, cellulose sol, aquatic disperser, high-polymer emulsion and hydrophobic inorganic filler.

Owner:何安荣

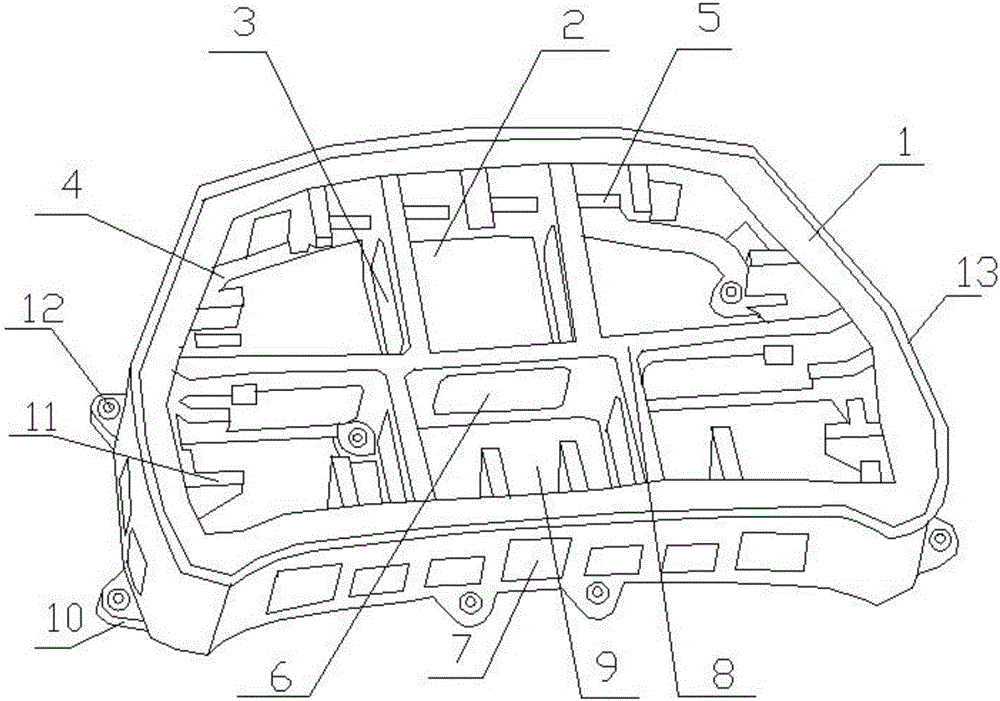

Anti-deformation machine cover edge rolling blank mold

InactiveCN106623639AImprove anti-deformation abilityImprove job stabilityShaping toolsDeformation effectEngineering

The invention discloses an anti-deformation machine cover edge rolling blank mold which comprises a body. Anti-deformation steel is arranged on the side of the body, a partition plate is arranged in the body, three front mold chambers are arranged in the upper portion inside the partition plate, a mold discharge outlet is formed in the adjacent portion of every two front mold chambers, three back mold chambers are arranged in the lower portion inside the partition plate, a mold discharge outlet is formed in the adjacent portion of every two back mold chambers, and fixing clamp strips are arranged on the two sides of each mold discharge outlet. According to the anti-deformation machine cover edge rolling blank mold, by arranging the anti-deformation steel on the exterior of a mold shell, the anti-deformation effect of the whole mold is greatly enhanced; by using anti-deformation fixing parts, a very good anti-deformation effect is achieved in the mold; by using fixing blocks, the working stability of the mold is enhanced; by applying material buffer ports, the mold effect is more steady. The anti-deformation machine cover edge rolling blank mold is simple in structure, convenient to use, economical, efficient and long in service life.

Owner:平湖市精铭模具有限公司

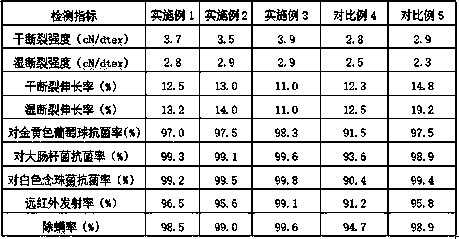

A kind of animal colloid protein compound apocynum cellulose fiber and preparation method thereof

ActiveCN107142543BHigh glossHigh fiber strengthArtificial filaments from cellulose derivativesArtifical filament manufactureBiotechnologyThiourea

The invention provides an animal colloid protein composite apocynum venetum cellulose fiber. The fiber satisfies the indicators of: dry breaking strength of greater than or equal to 3.5cN / dtex, wet breaking strength of greater than or equal to 2.8cN / dtex, an animal colloid protein content of greater than or equal to 3%, dry breaking elongation of 11-13%, and wet breaking elongation of 11-14%. The invention also provides a preparation method of the animal colloid protein composite apocynum venetum cellulose fiber. The method includes preparation of a protein dissolution solution. The preparation steps of the protein dissolution solution include: adding CHAPS, glycerin and thiourea into deionized water and performing stirring dissolving to obtain a CHAPS solution, adding animal colloid protein powder into the CHAPS solution, and conducting stirring, ultrasonic dissolution and heat preservation to obtain the protein dissolution solution. The cellulose fiber prepared by the method provided by the invention has good gloss, protein in the fiber maintains the softness of fiber and better drapability, so that the prepared cellulose fiber has high strength and low elongation, animal colloid protein in the fiber does not run off easily.

Owner:嘉禾永顺化妆品(上海)有限责任公司

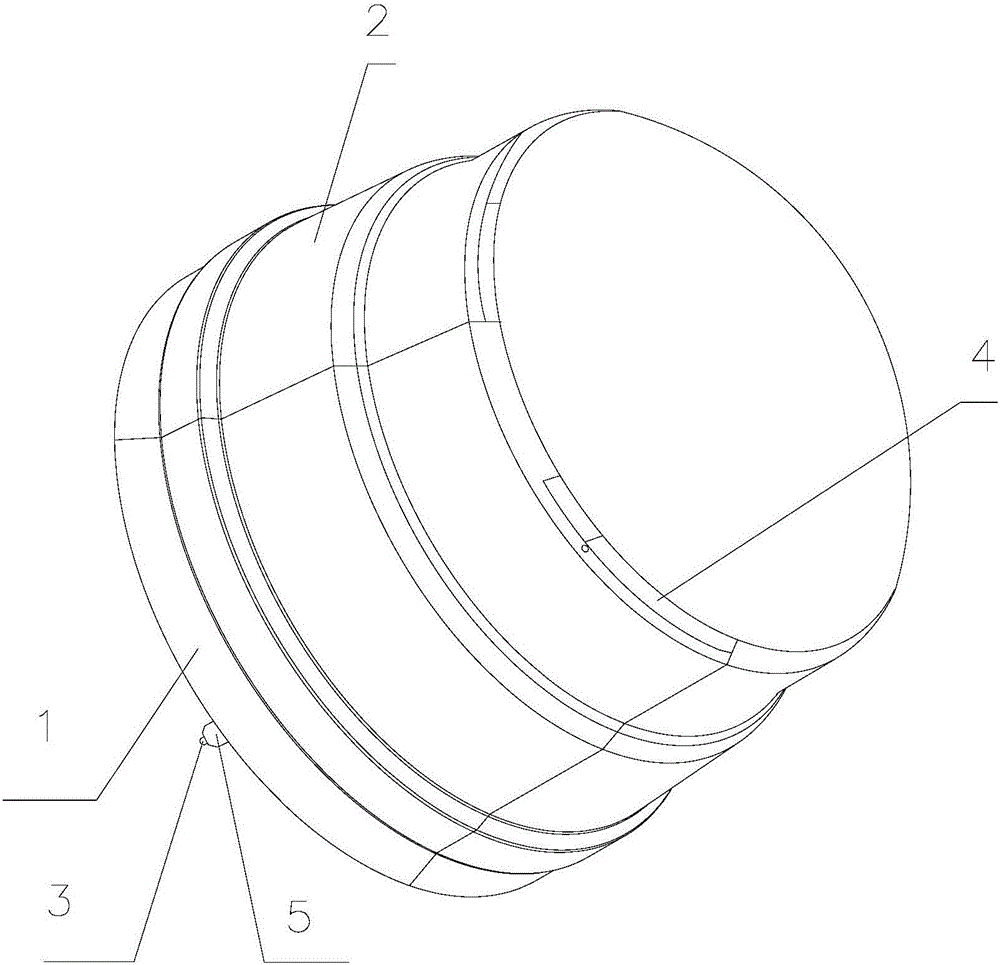

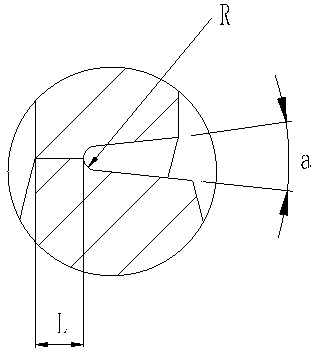

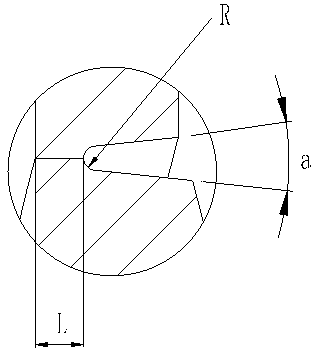

Optical coupling module

ActiveCN104914516AAdapt to temperature changesImprove coupling accuracyCoupling light guidesEngineeringOptical coupling

The invention relates to a photosensitive terminal, in particular, an optical coupling module. As for harsh use environment of TDLAS technology, a photosensitive terminal which is applicable to places such as mines and underground which require dust prevention, damp prevention and ventilation does not exist, while, the invention provides such a photosensitive terminal. The photosensitive terminal is in the shape of a cylindrical tube; a notch along the long axis of the optical coupling module is formed at the top of the optical coupling module; the length of the notch ranges from 10 to 1600mm; the included angle alpha between two long edges of the notch ranges from 160 degrees to 210 degrees; two ends of the optical coupling module are coupling fixing cylinders for fixing a collimator; and a perforating positioning hole is formed in the coupling fixing cylinders respectively. The optical coupling module of the invention has the advantages of small size, high anti-temperature deformation ability and high gas guide ability. With the optical coupling module of the invention adopted, a gas sampling end of equipment using the TDLAS technology can work under complex environments such as mines and underground.

Owner:安徽中科瀚海光电技术发展有限公司

Plywood surface glue capable of improving water resistance

InactiveCN113667411AImprove waterproof performanceImprove hydrophobicityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveMethacrylatePolymer science

The invention discloses plywood surface glue capable of improving water resistance. The plywood surface glue comprises the following raw materials of: phenol, formaldehyde, alkali, isoleucine, propyl methacrylate, sodium hexametaphosphate, polytetrafluoroethylene, a cross-linking agent and a curing agent, wherein the alkali is one or more of sodium hydroxide, ammonia water and potassium hydroxide, the cross-linking agent is a mixture of acrylic acid and divinyl benzene, and the curing agent is a mixture of imidazole and isocyanate. By using the latent curing agent, the surface glue is faster to cure, so that a surface is smoother; and the surface glue has waterproof performance and can be used in a humid environment for a long time, so that the water resistance and the service life of a plywood are improved, and the resource consumption is reduced; and the surface glue is energy-saving and environment-friendly.

Owner:广西完美木业集团有限公司

Anti-ultraviolet coffee carbon core-spun yarn knitted fabric and production method thereof

InactiveCN111101269ADimensionally stableFluffy and thick textureWeft knittingHeating/cooling textile fabricsYarnPolyester

The invention discloses an anti-ultraviolet coffee carbon core-spun yarn knitted fabric and a production method thereof, and belongs to the technical field of a textile fabric. A three-layer structureof the anti-ultraviolet coffee carbon core-spun yarn knitted fabric disclosed by the invention comprises an anti-ultraviolet layer, a loop connection intermediate layer and an antibacterial inner layer; the anti-ultraviolet layer and the antibacterial inner layer are respectively knitted and attached to both sides of the loop connection intermediate layer; the anti-ultraviolet layer is formed bycarrying out weaving processing on coffee carbon core-spun yarns and silk yarns by adopting a weft knitting two-faced machine; the loop connection intermediate layer is formed by composite filaments of cationic polyester fiber filaments and polyester fiber filaments; and the antibacterial inner layer is formed by carrying out weaving processing on cotton yarns and China hemp antibacterial yarns. The invention further discloses a production method of the anti-ultraviolet coffee carbon core-spun yarn knitted fabric. The anti-ultraviolet coffee carbon core-spun yarn knitted fabric disclosed by the invention is stable in size, fluffy and thick in texture and soft and comfortable in hand feeling, and has an excellent anti-ultraviolet function; the production method disclosed by the invention issimple, energy-saving and environmental-friendly; and industrial large-scale production and processing can be implemented.

Owner:浙江正辉针织科技股份有限公司

A fixture for milling of thin-walled frame parts

InactiveCN105397530BPrevent deformationRelieve pressurePositioning apparatusMaintainance and safety accessoriesEngineeringVacuum pump

The invention relates to the field of clamps for thin-wall-frame-class parts, in particular to a clamp used for milling thin-wall-frame-class parts. The clamp comprises a body. A groove is formed in the center of the body. Baffles are arranged on the periphery of the groove and include the two adjacent fixed baffles fixed to the body through fixing bolts and the two adjacent movable baffles installed on the body through position adjusting devices. Air holes are evenly formed in the bottom face of the groove and communicated with an air pipe formed in the body, and the air pipe is communicated with a vacuum pump connector arranged on the outer side of the body. Movable blocks are arranged in the groove and provided with matched holes communicated with the air holes. According to the clamp used for milling thin-wall-frame-class parts, an existing jaw vice working table is replaced with a sucking working table, thin-wall-frame-class parts can be evenly stressed in the clamping process, and then the problem that thin-wall-frame-class parts are deformed by a clamp during milling is solved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

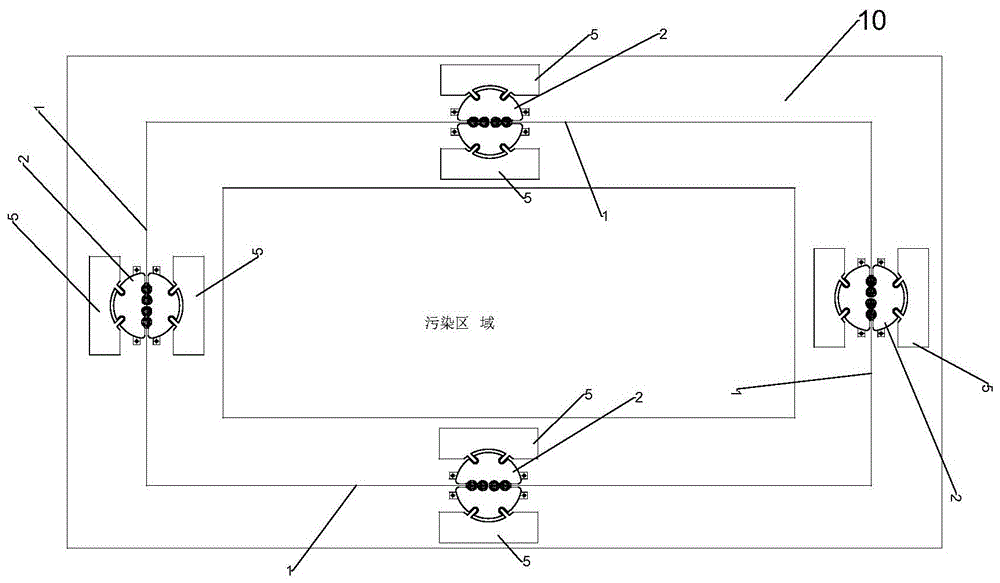

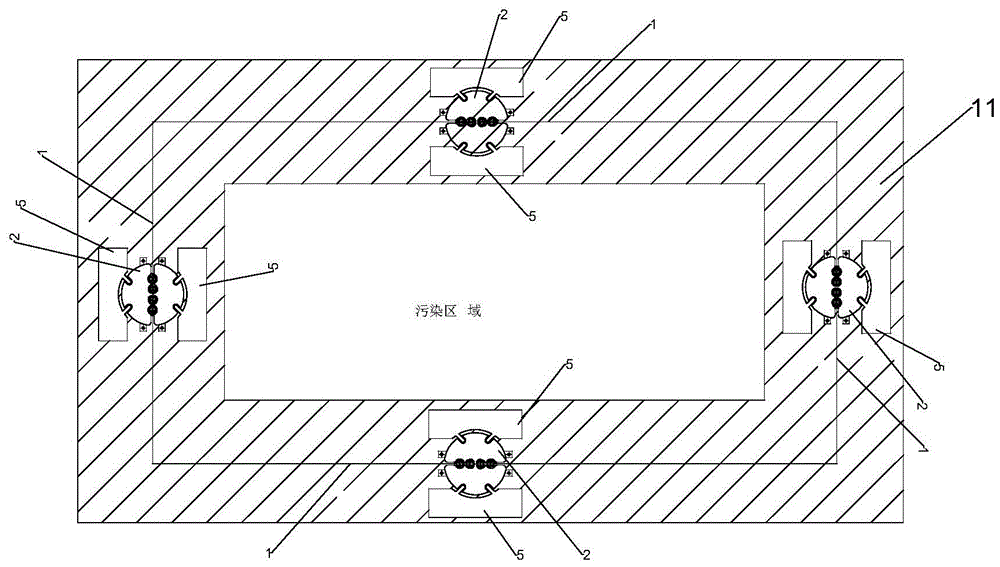

Construction method for isolating underground pollution

ActiveCN104652458BPrevent infiltrationAvoid bending deformationFoundation engineeringStructure of the EarthEngineering

Owner:SHANGHAI YUANFANG GROUNDWORK ENG

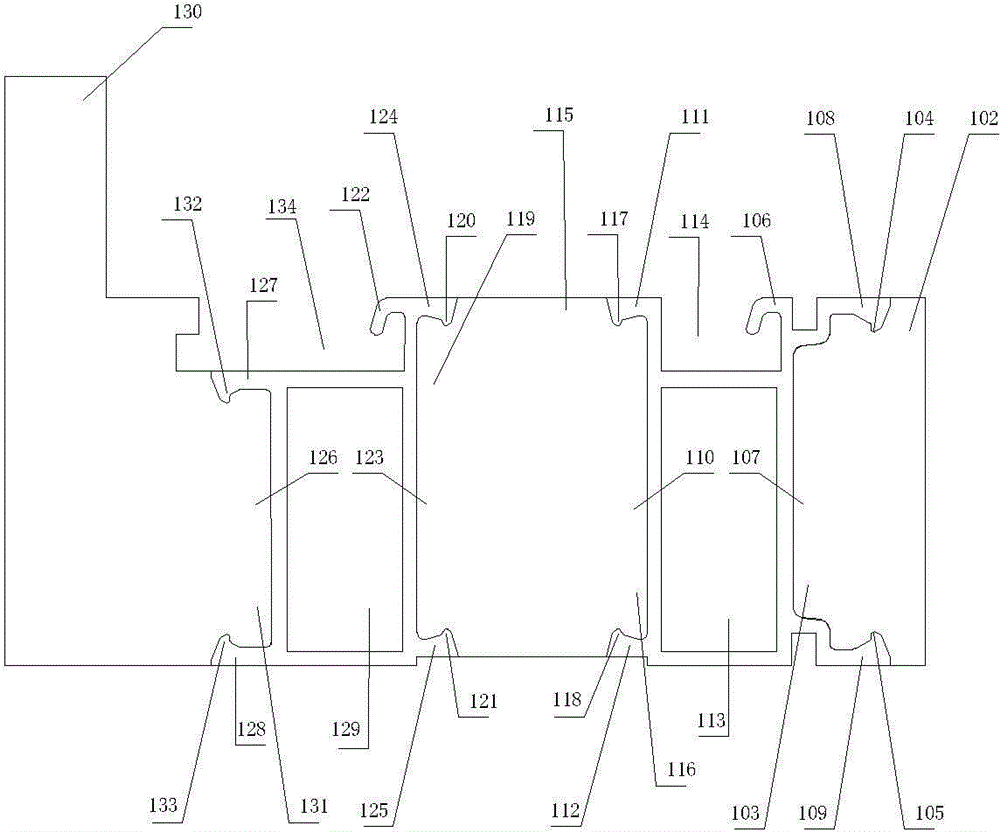

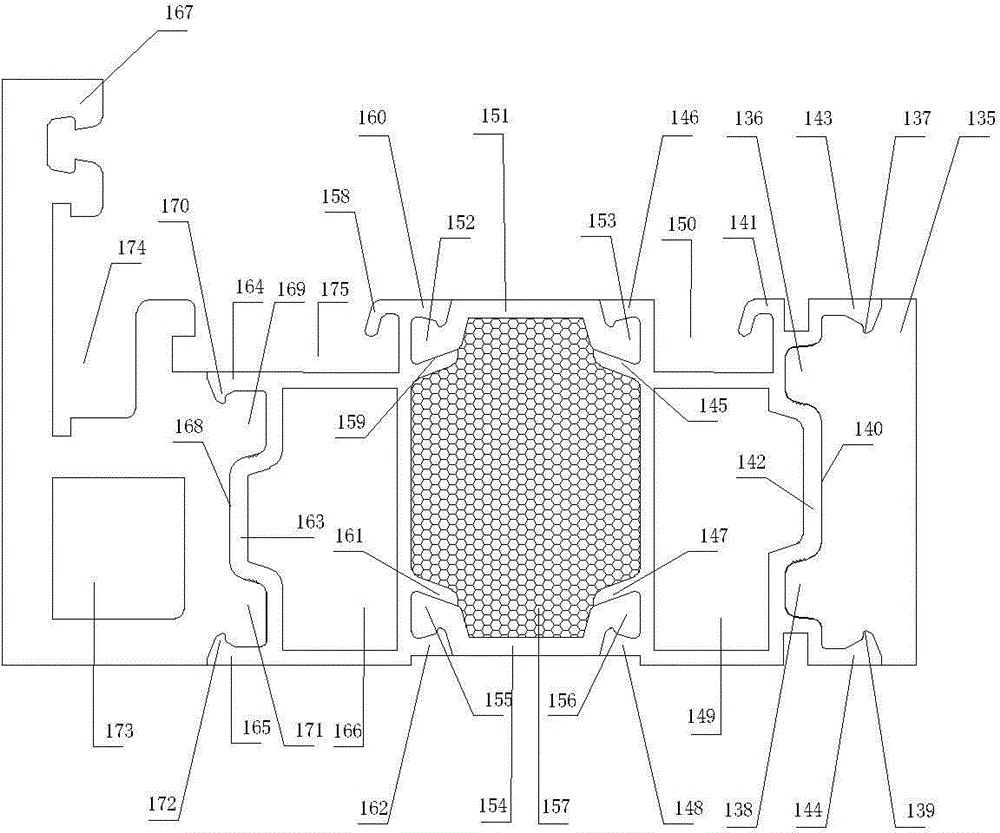

Thermal insulation profile combining inside-outside thermal insulation and middle thermal insulation

A thermal insulation profile combining inside-outside thermal insulation and middle thermal insulation is characterized in that an inner side thermal insulation profile is located on the inner side of a combined thermal insulation profile chamber; the outer side of the inner side thermal insulation profile is integrally connected with the inner side of an inner medium aluminum alloy profile provided with a corner cavity; a middle thermal insulation profile is located in the middle of the combined thermal insulation profile; the inner side of the middle thermal insulation profile is integrally connected with the outer side of the inner medium aluminum alloy profile provided with the corner cavity; the outer side of the middle thermal insulation profile is integrally connected with the inner side of an outer medium aluminum alloy profile provided with a corner cavity; an outer side thermal insulation profile is located on the outer side of the combined thermal insulation profile chamber; the outer side of the outer medium aluminum alloy profile provided with the corner cavity is integrally connected with the inner side of the outer side thermal insulation profile.

Owner:王广武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com