Plywood surface glue capable of improving water resistance

A plywood and surface glue technology, applied in the direction of non-polymer adhesive additives, non-polymer organic compound adhesives, adhesives, etc., can solve problems such as expansion deformation, long curing time, and insufficient smooth surface, and achieve fast curing , The preparation process is simple and convenient, and the effect of high hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

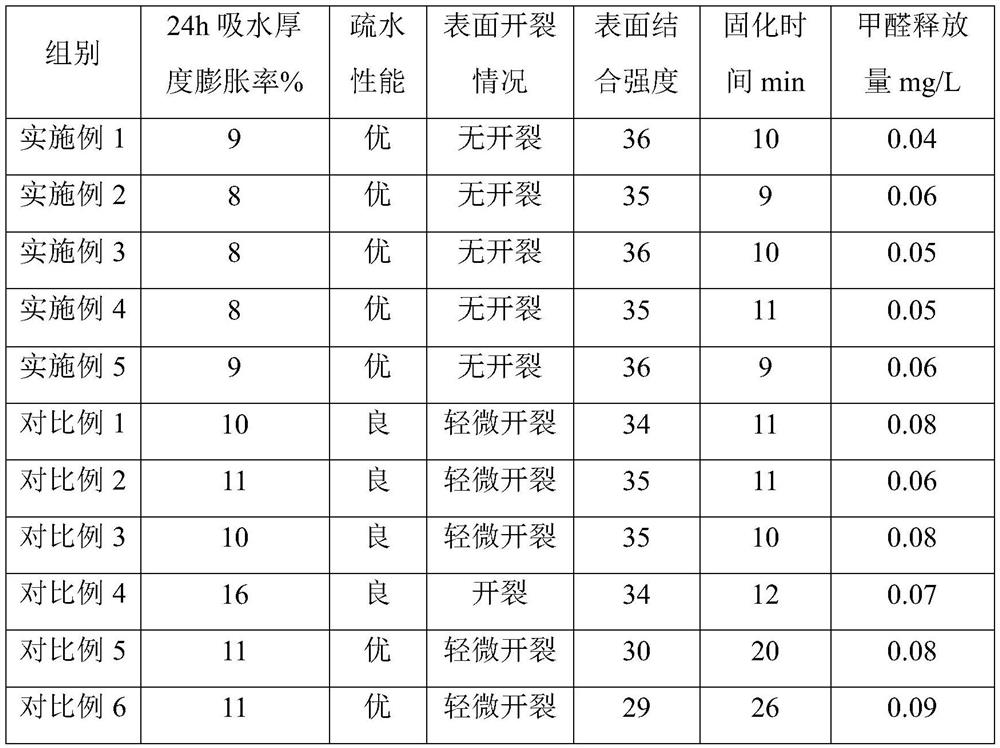

Examples

Embodiment 1

[0028] A plywood surface adhesive for improving water resistance, comprising the following raw materials in parts by weight: 800 parts of phenol, 1600 parts of formaldehyde, 50 parts of sodium hydroxide, 8 parts of isoleucine, 8 parts of propyl methacrylate, and hexametaphosphoric acid 4 parts of sodium, 40 parts of polytetrafluoroethylene, 15 parts of crosslinking agent, and 15 parts of curing agent, wherein the crosslinking agent is 5 parts of acrylic acid, 10 parts of divinylbenzene, 7 parts of curing agent is imidazole, and 8 parts of isocyanate.

[0029] The preparation method of face glue, comprises the following steps:

[0030] S1: In parts by weight, weigh 800 parts of phenol, 1600 parts of formaldehyde, and 50 parts of sodium hydroxide, first add the alkali to the reaction kettle, set the stirring speed at 120rpm, and keep stirring, and introduce high temperature into the reaction kettle Steam, control the temperature in the reactor to 40°C, add phenol into the reacto...

Embodiment 2

[0036] A plywood surface adhesive for improving water resistance, comprising the following raw materials in parts by weight: 1800 parts of phenol, 2500 parts of formaldehyde, 150 parts of ammonia water, 16 parts of isoleucine, 16 parts of propyl methacrylate, and 8 parts of sodium hexametaphosphate 30 parts, 30 parts of polytetrafluoroethylene, 25 parts of crosslinking agent, 10 parts of curing agent, wherein the crosslinking agent is 10 parts of acrylic acid, 15 parts of divinylbenzene, 5 parts of curing agent is imidazole, and 5 parts of isocyanate.

[0037] The preparation method of face glue, comprises the following steps:

[0038]S1: In parts by weight, weigh 1,800 parts of phenol, 2,500 parts of formaldehyde, and 150 parts of ammonia water, first add alkali to the reaction kettle, set the stirring speed at 150rpm, and keep stirring, and pass high-temperature steam into the reaction kettle, Control the temperature in the reactor to 55°C, add phenol into the reactor and ke...

Embodiment 3

[0044] A plywood surface adhesive for improving water resistance, comprising the following raw materials in parts by weight, 1500 parts of phenol, 2300 parts of formaldehyde, 80 parts of potassium hydroxide, 12 parts of isoleucine, 12 parts of propyl methacrylate, hexametaphosphoric acid 6 parts of sodium, 35 parts of polytetrafluoroethylene, 20 parts of cross-linking agent, 13 parts of curing agent, wherein the cross-linking agent is 7 parts of acrylic acid, 13 parts of divinylbenzene, 6 parts of curing agent is imidazole, 7 parts of isocyanate.

[0045] The preparation method of face glue, comprises the following steps:

[0046] S1: In parts by weight, weigh 1,500 parts of phenol, 2,300 parts of formaldehyde, and 80 parts of potassium hydroxide, first add alkali to the reaction kettle, set the stirring speed at 150rpm, and keep stirring, and introduce high temperature into the reaction kettle Steam, control the temperature in the reactor to 50°C, add phenol into the reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com