Waterproof cold resistant heatproof flame-retardant polychloroethylene insulation material

A technology of flame-retardant polyvinyl chloride and insulating materials, applied in the direction of insulated conductors, insulated cables, organic insulators, etc., which can solve the problems that do not involve waterproof performance, low temperature resistance and high temperature resistance, and cannot meet the needs of outdoor use of wires and cables and connectors and other problems, to achieve the effects of excellent low temperature embrittlement resistance, excellent physical and mechanical properties and temperature resistance, and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

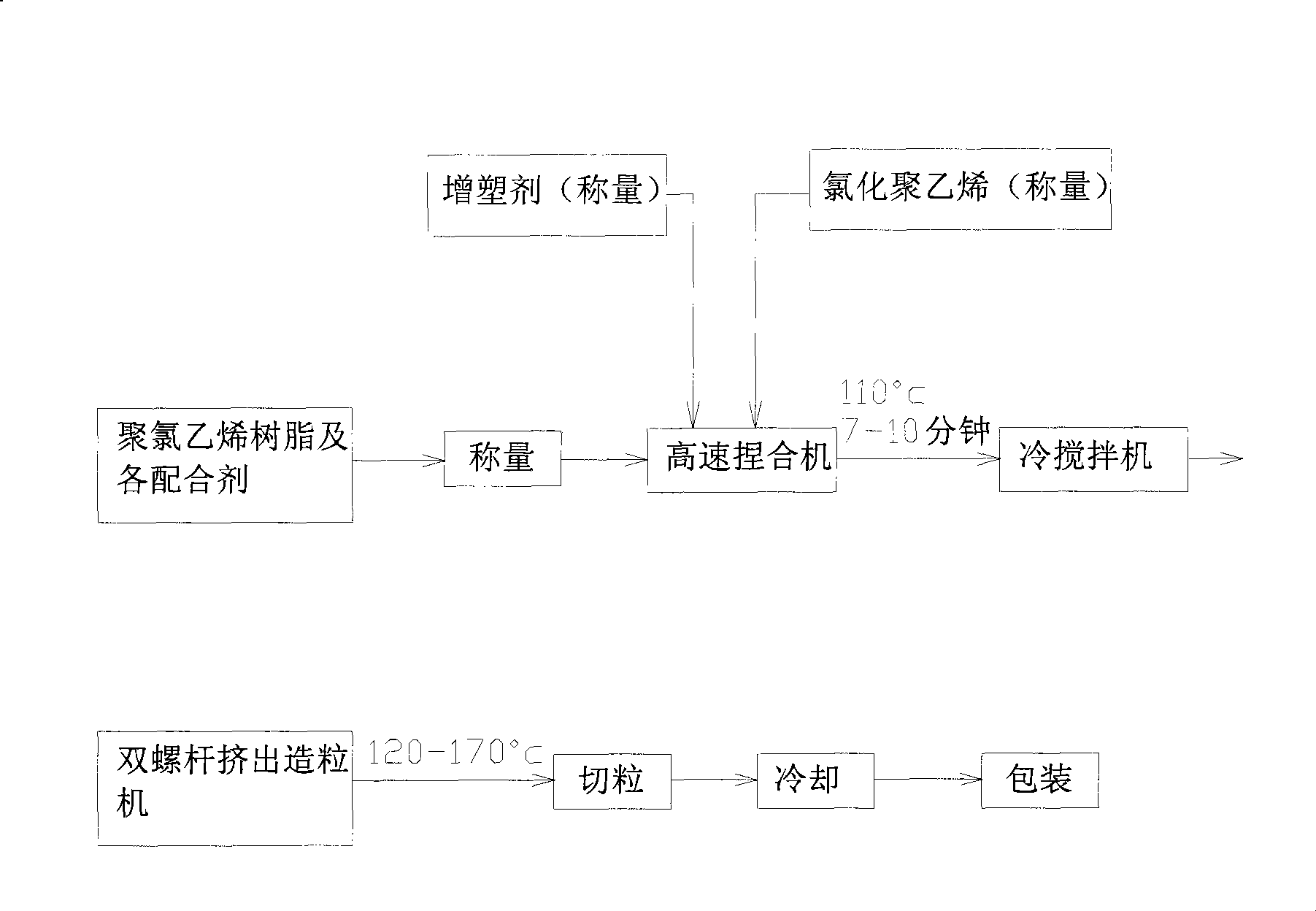

Method used

Image

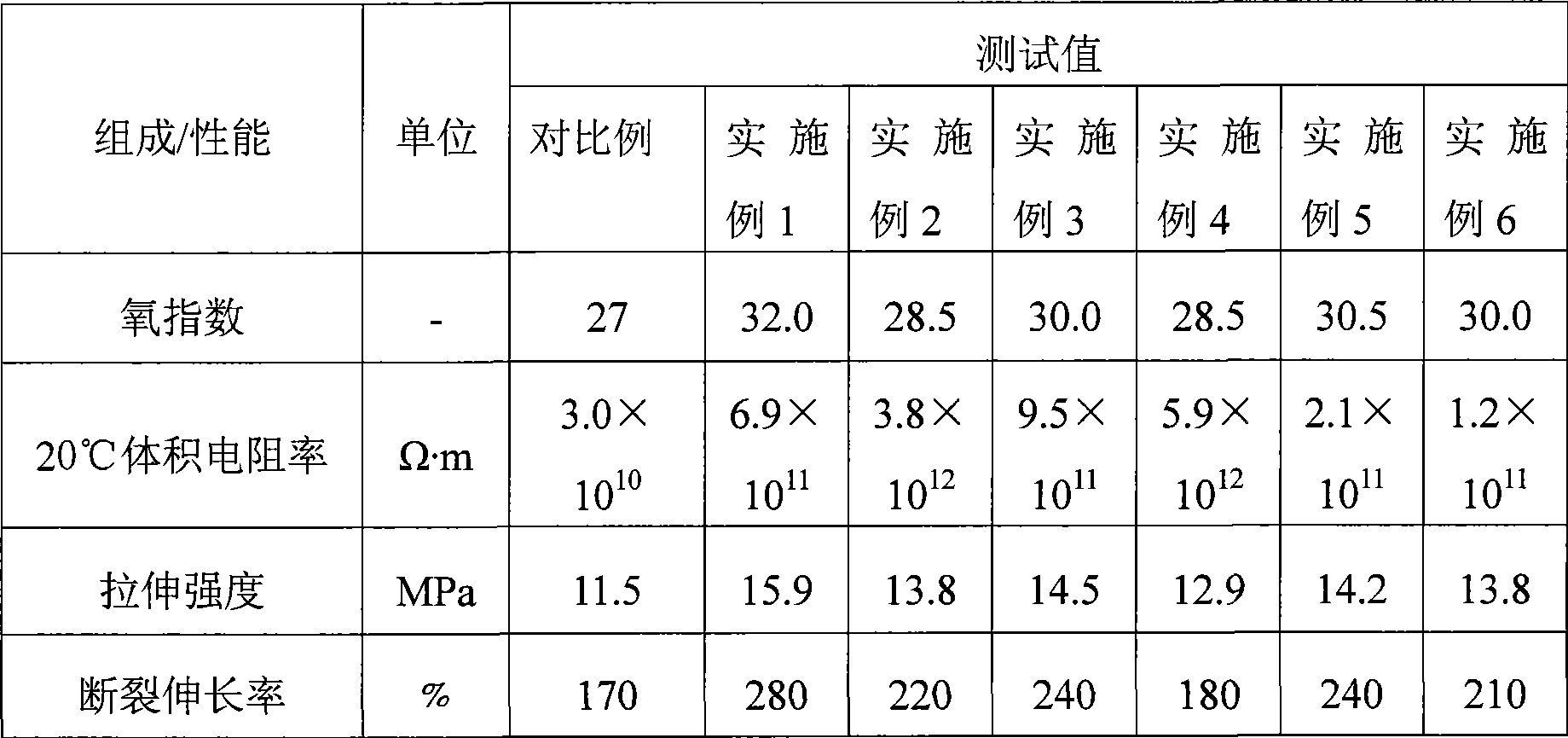

Examples

Embodiment 1

[0064] Ingredient parts by weight (quantity parts)

[0065] Polyvinyl chloride resin (SG3 type) 100;

[0066] Trioctyl trimellitate (TOTM) 50;

[0067] Bis(2-ethylhexyl) adipate (DOA) 6;

[0068] Chlorinated polyethylene (CPE135B) 15;

[0069] Calcium zinc composite stabilizer 3;

[0071] Magnesium hydroxide (5000 mesh) 7;

[0072] Ground calcium carbonate 25;

[0073] Active Nano Calcium Carbonate 10;

[0074] Calcined Kaolin 8;

[0075] Polyethylene wax (molecular weight about 2000) 0.3;

[0076] Stearic acid 0.2.

Embodiment 2

[0078] Ingredient parts by weight (quantity parts)

[0079] Polyvinyl chloride resin (SG5 type) 100;

[0080] Trioctyl trimellitate (TOTM) 70;

[0081] Bis(2-ethylhexyl) adipate (DOA) 6;

[0082] Chlorinated polyethylene (CPE 135B) 10;

[0083] Calcium zinc composite stabilizer 9;

[0085] Magnesium hydroxide (5000 mesh) 7;

[0086] Ground calcium carbonate 35;

[0087] Calcined kaolin 35;

[0088] Polyethylene wax (molecular weight about 2000) 2;

[0089] Stearic acid 1.5.

Embodiment 3

[0091] Ingredient parts by weight (quantity parts)

[0092] Polyvinyl chloride resin (1300 degree of polymerization) 100;

[0093] Trioctyl trimellitate (TOTM) 40;

[0094] Bis(2-ethylhexyl) adipate (DOA) 7;

[0095] Chlorinated polyethylene (CPE135B) 10;

[0096] Calcium zinc composite stabilizer 6;

[0098] Magnesium hydroxide (5000 mesh) 6;

[0099] Ground calcium carbonate 15;

[0100] Active Nano Calcium Carbonate 20;

[0101] Calcined Kaolin 10;

[0102] Polyethylene wax (molecular weight about 2000) 0.8;

[0103] Calcium stearate 0.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com