Thermal insulation profile combining inside-outside thermal insulation and middle thermal insulation

A technology of aluminum alloy profiles and profiles, which can be used in wing sash frames, windows/doors, building components, etc., and can solve problems such as insufficient thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

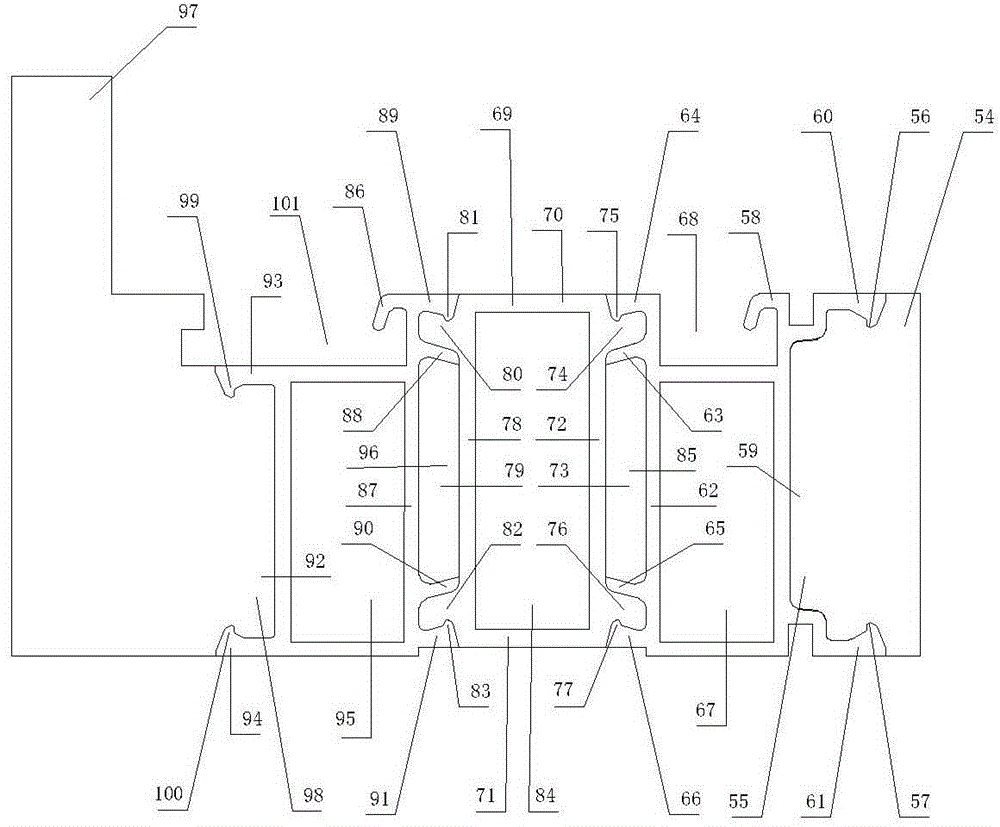

[0031] A combination of internal and external heat insulation and intermediate heat insulation combined heat insulation profile window frame end face Figure as shown 1 As shown, among them: 1 is the inner heat insulation profile, 2 is the outer and upper connection protrusion, 3 is the outer and upper pressing gap, 4 is the outer and lower connecting protrusion, 5 is the outer and lower pressing gap, 6 is the opening in the middle of the outdoor side Groove, 7 is the inner and middle aluminum alloy profile, 8 is the inner and middle convex rib, 9 is the inner and upper fixed pressure plate, 10 is the inner and lower fixed pressure plate, 11 is the outer and upper convex rib, 12 is the outer and upper fixed pressure plate, and 13 is the outer and lower convex Rib, 14 is the outer and lower fixed pressure plate, 15 is the corner cavity of the inner and middle aluminum alloy profile group, 16 is the buckle inlay groove, 17 is the middle heat insulation profile, 18 is the upper h...

Embodiment 2

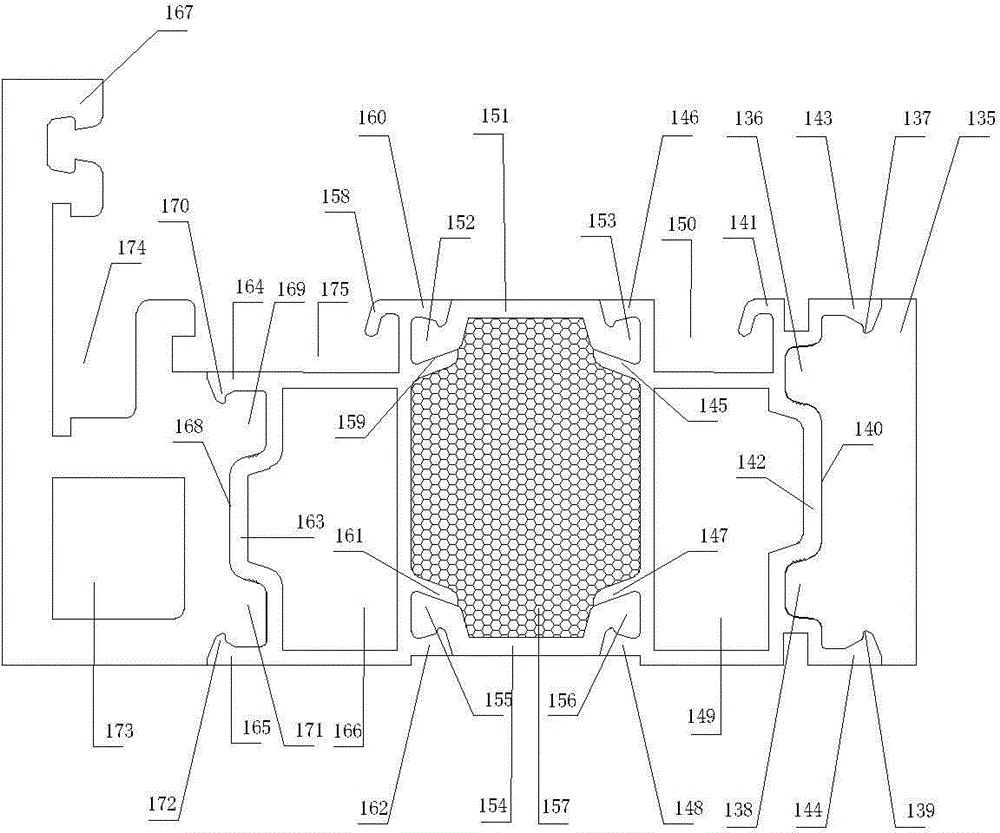

[0040] An end face of a wooden window frame with internal and external thermal insulation and intermediate thermal insulation combined thermal insulation profile Figure as shown 2 As shown, among them: 54 is the inner wood heat insulation profile, 55 is the outer and middle connecting protrusion, 56 is the outer upper pressing gap, 57 is the outer lower pressing gap, 58 is the inner and middle aluminum alloy profile, and 59 is the inner and inner inlay Groove, 60 is the inner upper fixed pressing plate, 61 is the inner lower fixed pressing plate, 62 is the outer vertical rib, 63 is the outer upper convex rib, 64 is the outer upper fixed pressing plate, 65 is the outer lower convex rib, 66 is the outer lower fixed pressing plate, 67 is the inner and middle aluminum alloy profile group corner cavity, 68 is the buckle inlay groove, 69 is the middle heat insulation profile, 70 is the upper horizontal rib, 71 is the lower horizontal rib, 72 is the inner vertical rib, 73 is the inn...

Embodiment 3

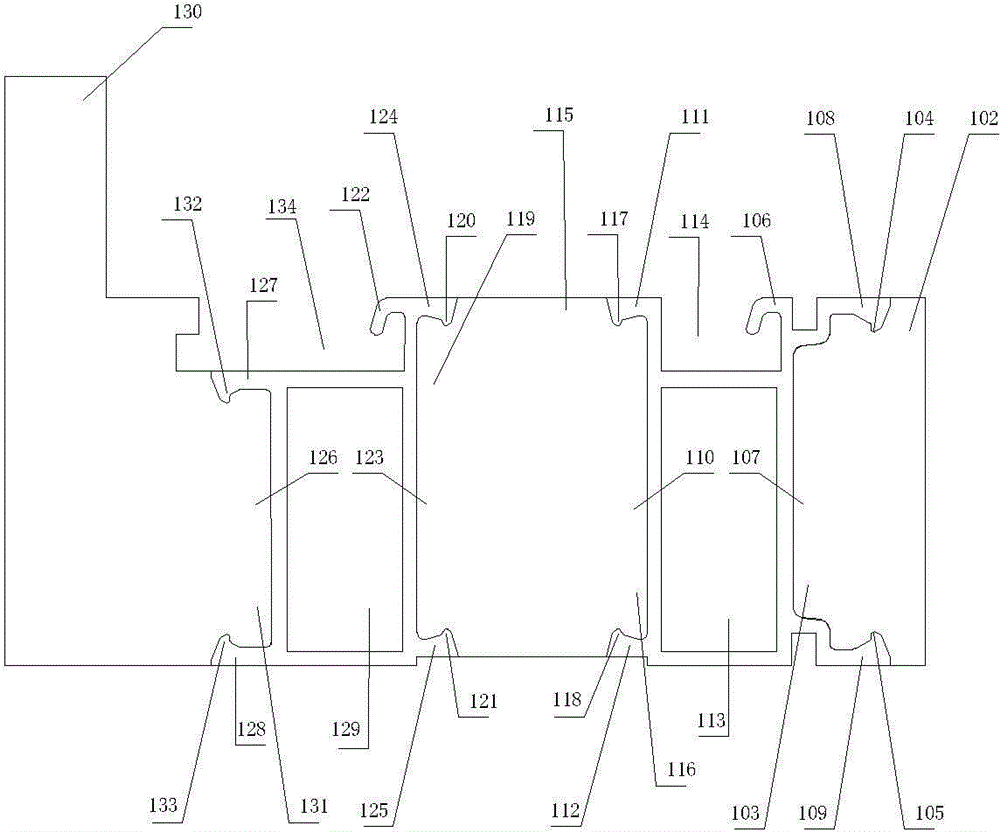

[0048] An end face of a wooden window frame with internal and external thermal insulation and intermediate thermal insulation combined thermal insulation profile Figure as shown 3 As shown, among them: 102 is the inner wood heat insulation profile, 103 is the outer and middle connecting protrusion, 104 is the outer upper pressing gap, 105 is the outer lower pressing gap, 106 is the inner and middle aluminum alloy profile, and 107 is the inner and inner inlay Groove, 108 is the inner upper fixed pressure plate, 109 is the inner lower fixed pressure plate, 110 is the outer middle inlay groove, 111 is the outer upper fixed pressure plate, 112 is the outer lower fixed pressure plate, 113 is the inner and middle aluminum alloy profile group corner cavity, 114 is Buckle mosaic groove, 115 is the middle wooden heat insulation profile, 116 is the inner protrusion, 117 is the inner upper pressing gap, 118 is the inner lower pressing gap, 119 is the outer protrusion, 120 is the outer u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com