Patents

Literature

432results about How to "Reduce deformation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

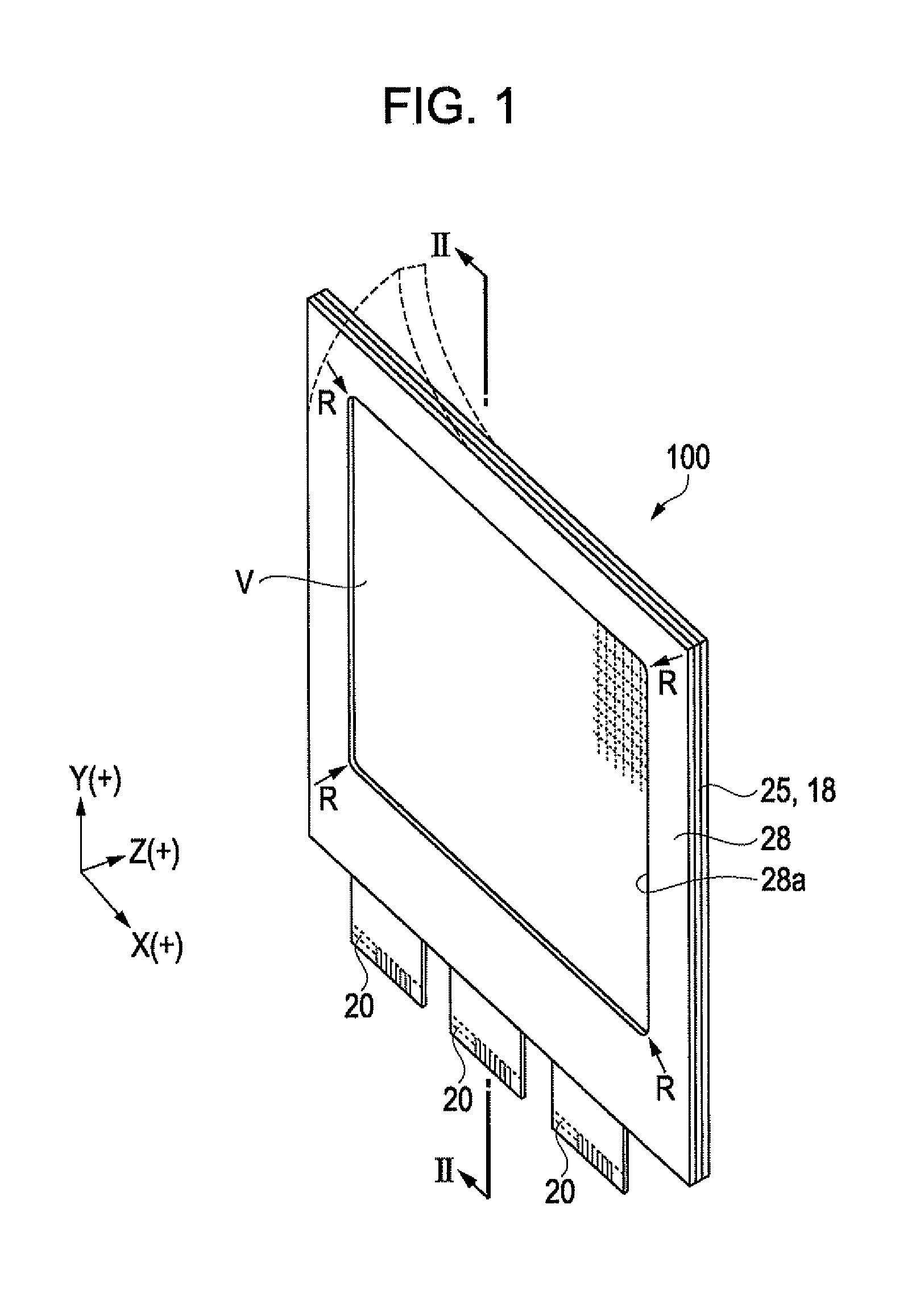

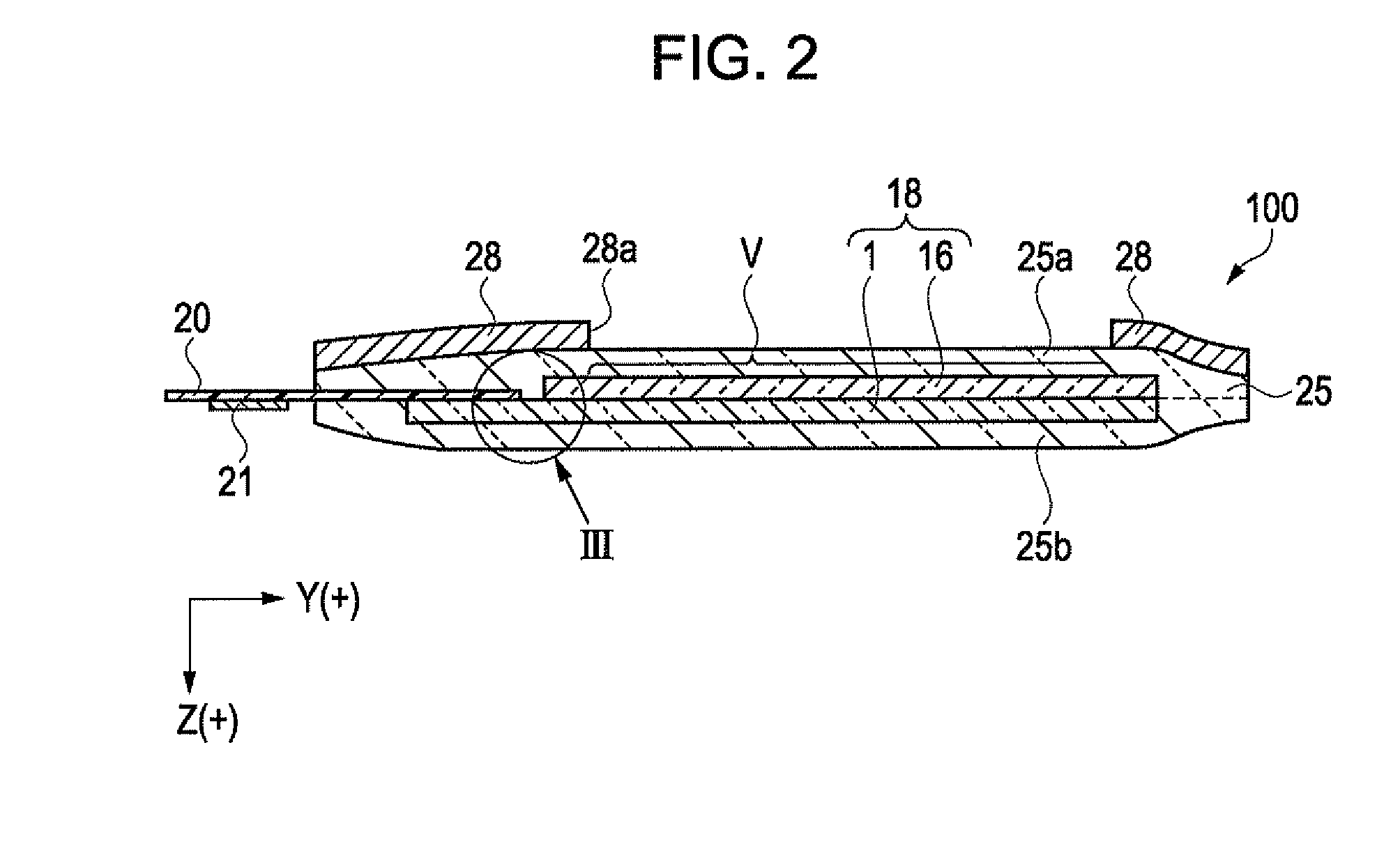

Electro-optical device, electronic device, and illumination apparatus

ActiveUS20100327737A1High tensile strengthReduce deformation rateDischarge tube luminescnet screensSpotlightingEngineeringElectron

An electro-optical device includes a display panel having an electro-optical layer, a first resin film stacked on the display panel to cover a first surface on the side of a display area of the display panel, and a second resin film stacked on the display panel to cover a second surface opposite the first surface, and at least one reinforcing member disposed on at least one of the first resin film and the second resin film.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

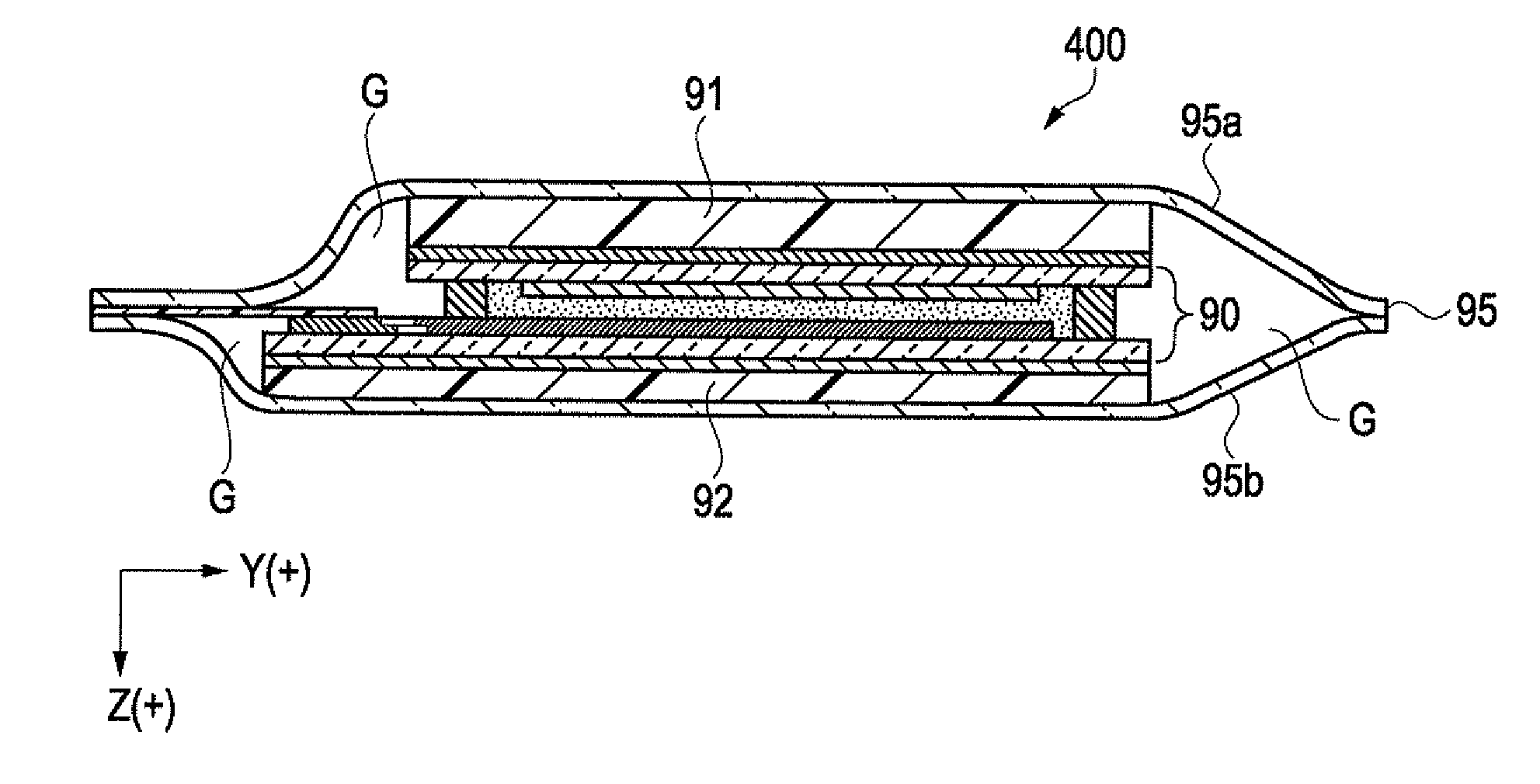

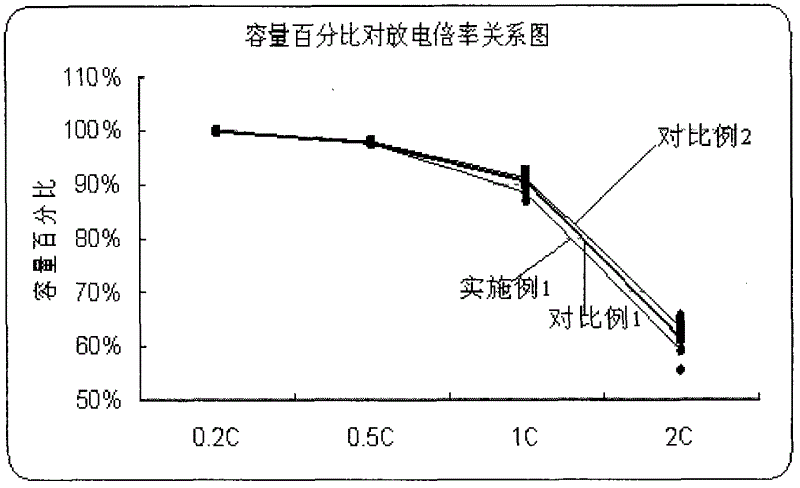

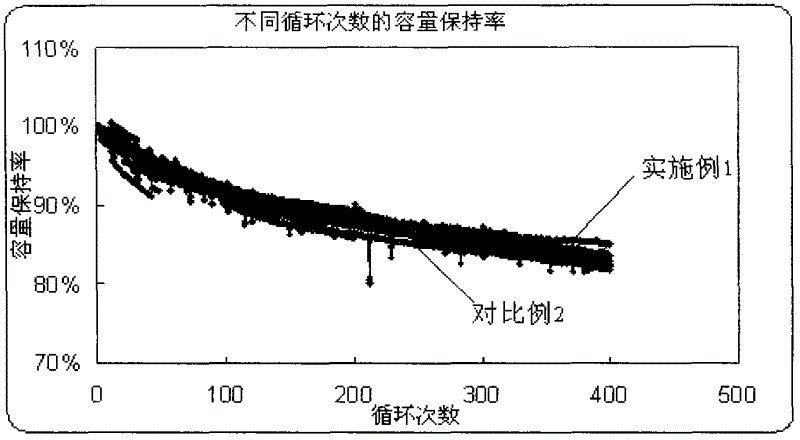

Diaphragm and preparation method thereof, and lithium ion battery

ActiveCN102623658AThe absolute value of the surface potential is largeEvenly distributedSecondary cellsCell component detailsHexafluoropropyleneLithium-ion battery

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an inorganic and organic composite multihole diaphragm. The diaphragm comprises a multihole diaphragm base material and an active coating layer attached to at least one surface of the multihole diaphragm base material, wherein the active coating layer comprises inorganic particles, vinylidene fluoride and hexafluoropropylene copolymer, cellulose based polymer with the molecular weight of 100,000 to 1,000,000 and at least one of polyacrylic acid and polyacrylate. Compared with the prior art, the diaphragm keeps relatively high air permeability and lithium ion transmission capacity; the active coating layer and the multihole diaphragm base material are well bonded; and the overheating contraction performance and the puncture strength of a diaphragm base can be improved remarkably. Furthermore, the invention also discloses a preparation method for the diaphragm and a lithium ion battery with the diaphragm.

Owner:NINGDE AMPEREX TECH +1

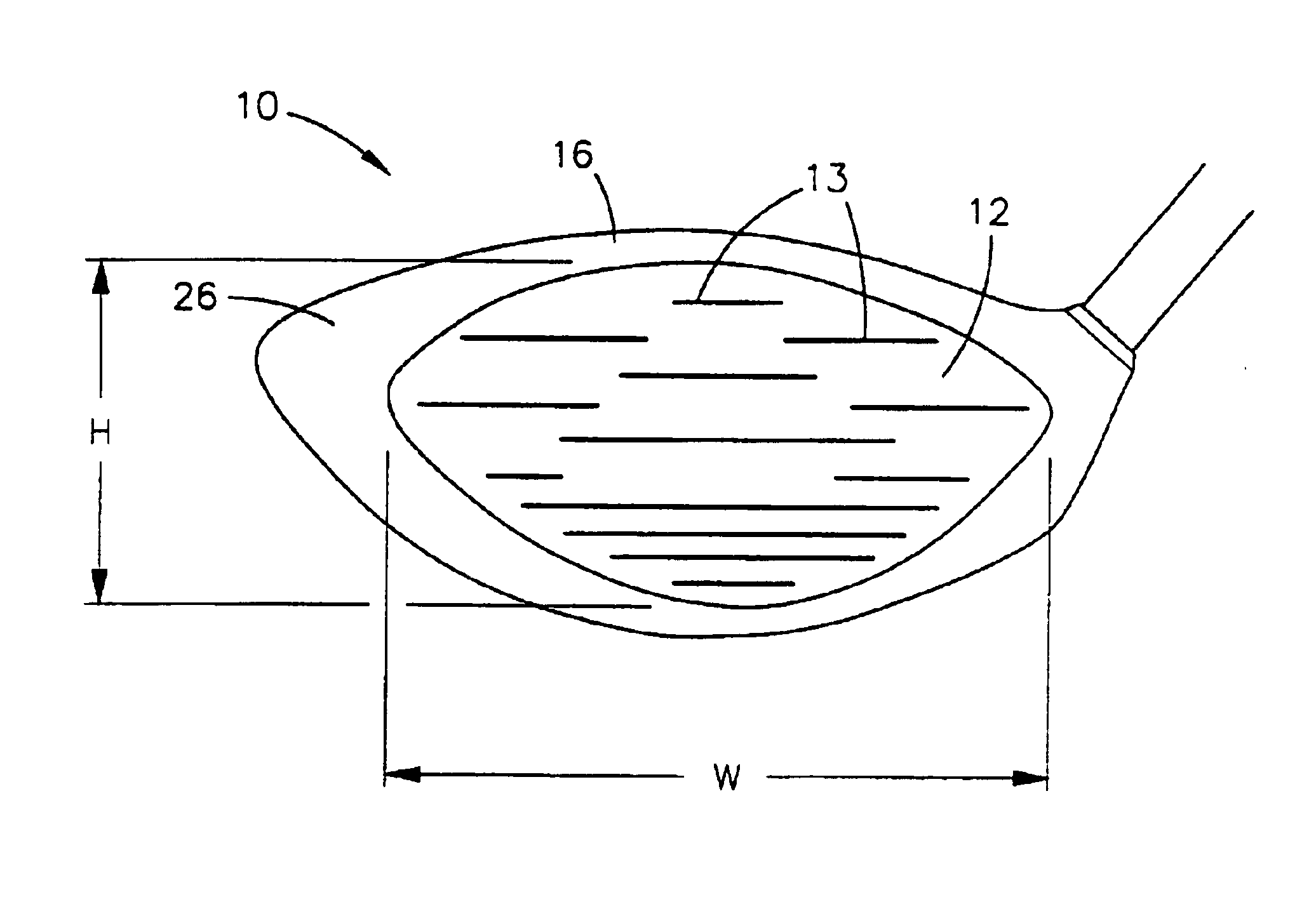

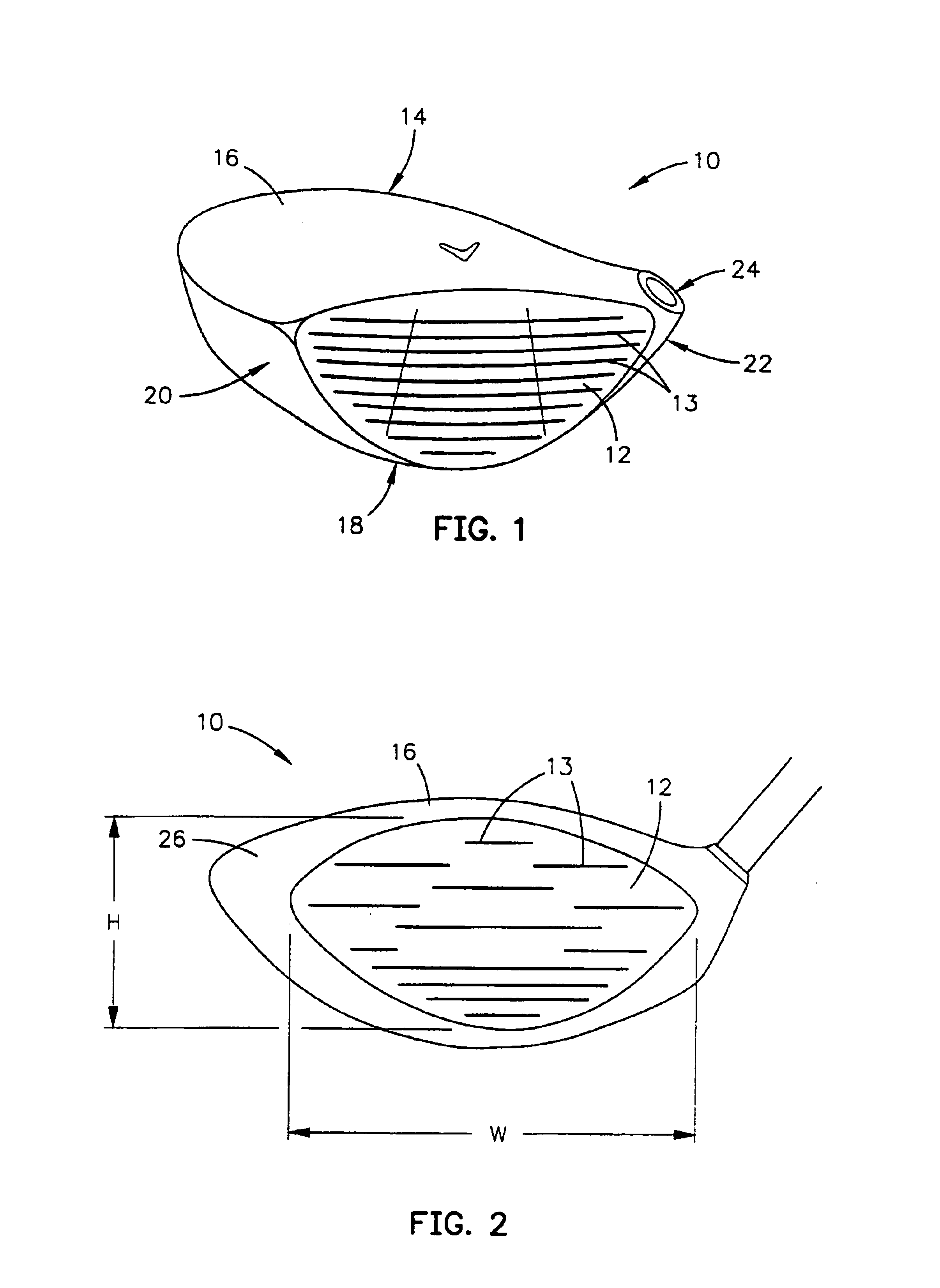

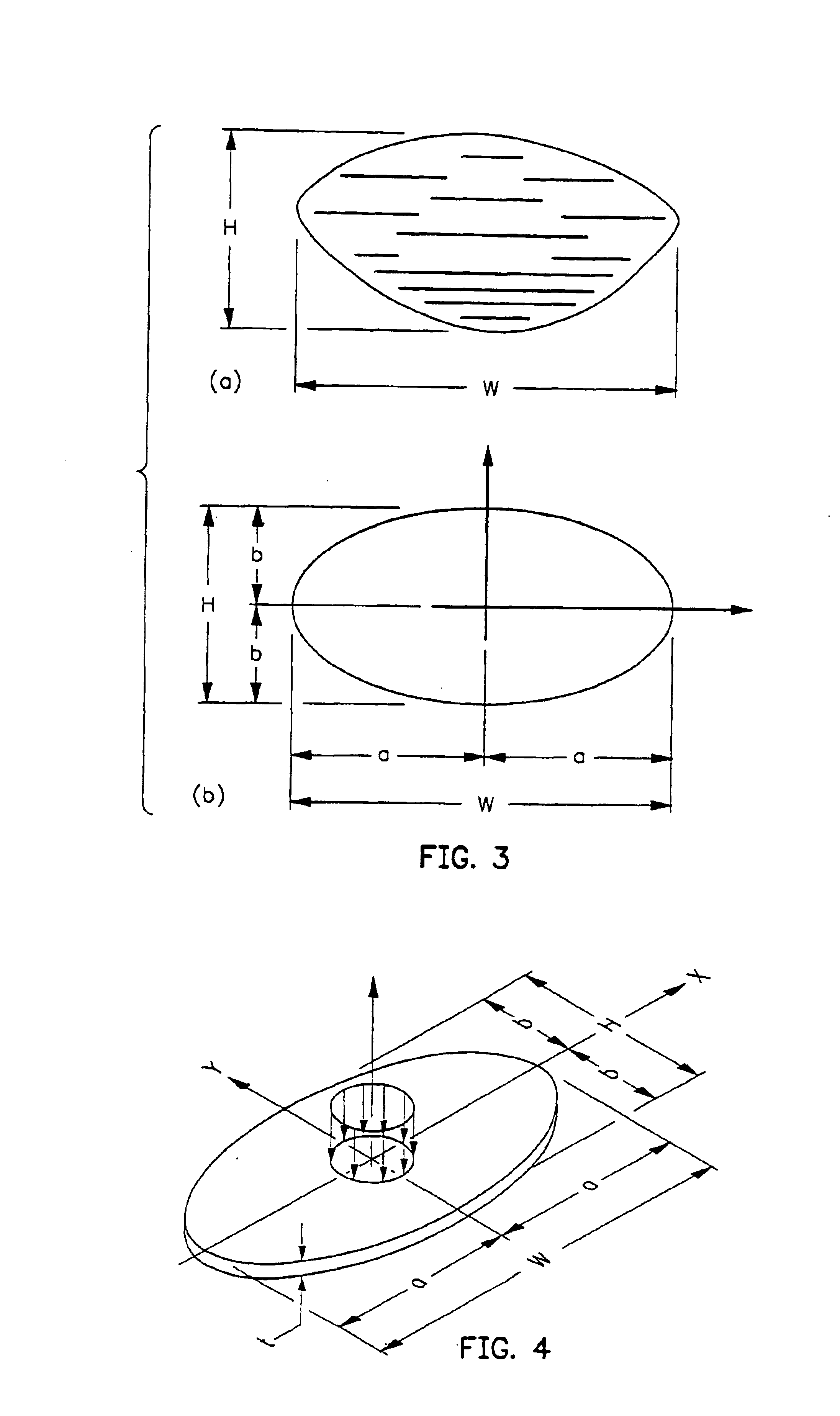

Golf club head having a striking face with improved impact efficiency

InactiveUS6949032B2Improve energy efficiencyReduced magnitudeGolf clubsRacket sportsStrain rateEnergy loss

A compliant golf club head permits a more efficient impact between a golf ball and the golf club head. Material and geometry constraints of a striking plate of the golf club head can reduce energy losses caused by large strain and strain rate values of the golf ball, these constraints on the striking plate yield a measure of the impact efficiency of the golf club head. Designating a required natural frequency range of the striking plate provides improved impact efficiency between the golf ball the golf club head.

Owner:CALLAWAY GOLF CO

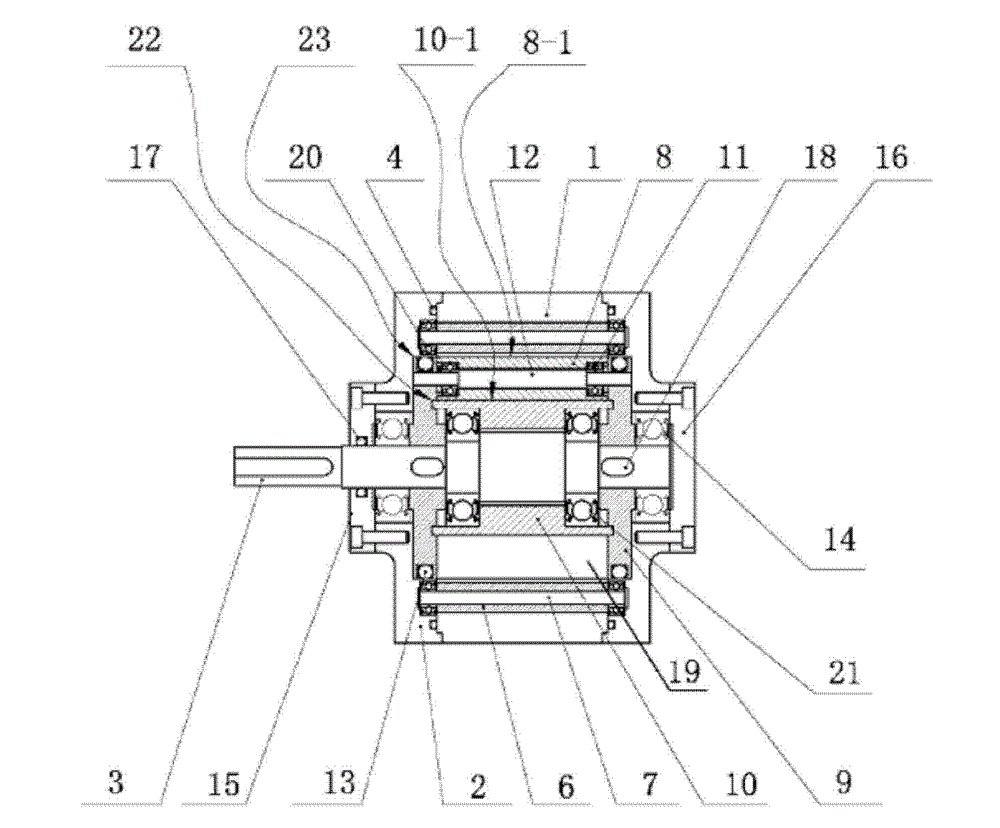

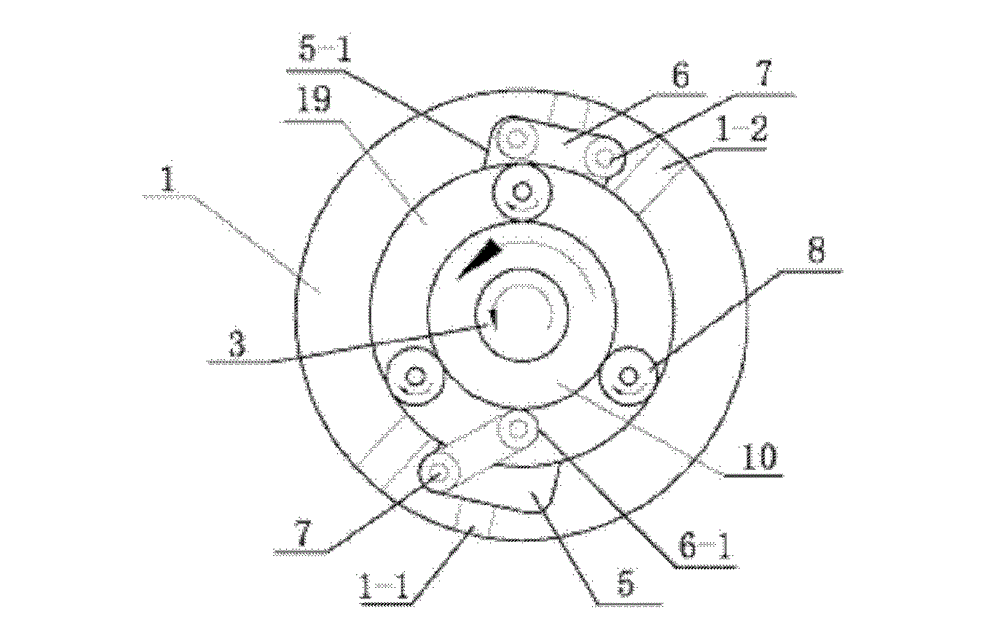

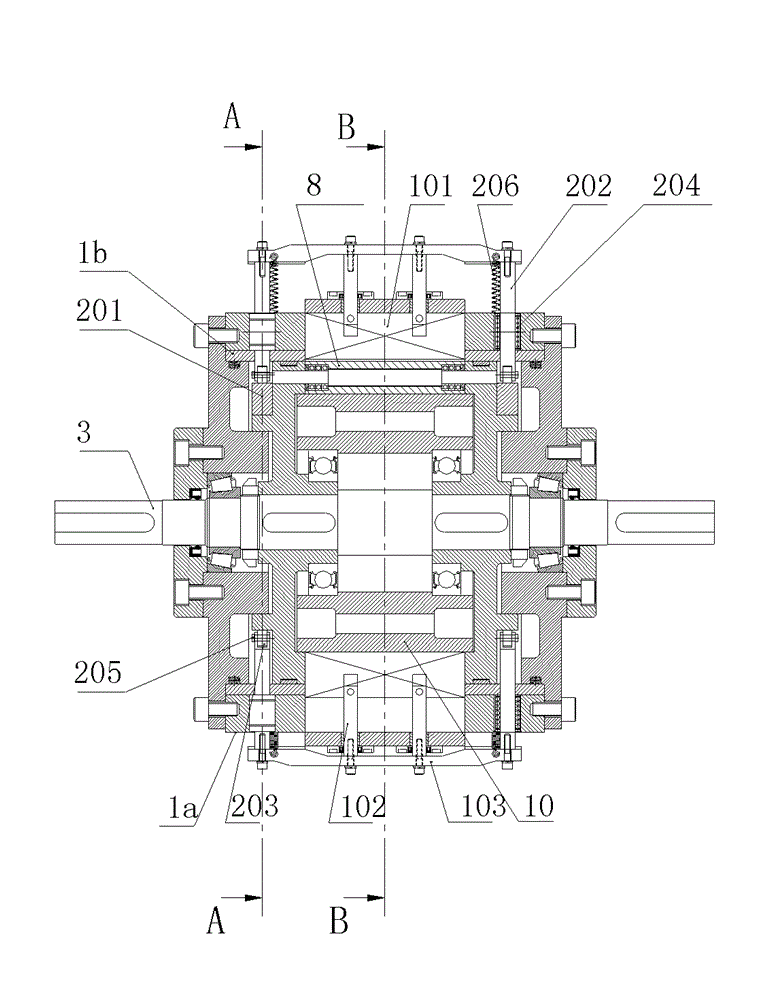

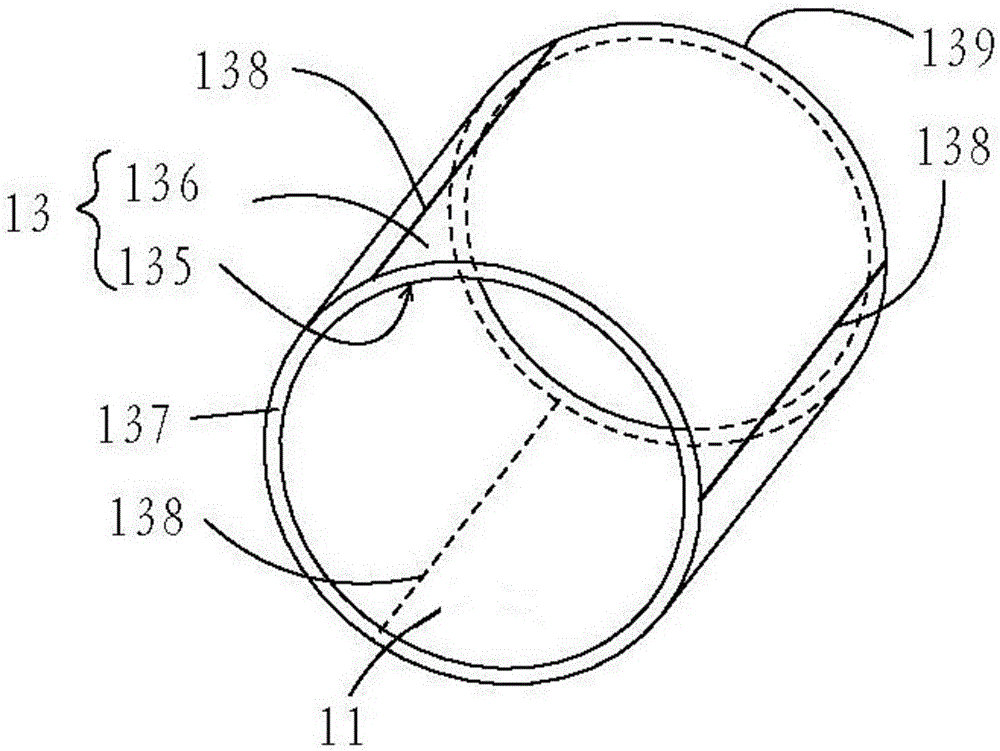

Star-rotation type rotary device adopting gate valve structure

ActiveCN103061822AReduce processing difficultyEasy to processRotary piston pumpsRotary piston liquid enginesEngineeringPiston

The invention discloses a star-rotation type rotary device adopting a gate valve structure. The star-rotation type rotary device comprises a cylinder body and a main shaft, wherein a circular-barrel-shaped cavity is formed in the cylinder body; the main shaft is supported by cylinder body sealing end covers at the two sides of the cylinder body; a centre sun gear roller is sleeved on the main shaft; a gate valve groove is formed on the cylinder body along the centre line direction of the cylinder body; a gate valve plate is arranged in the gate valve groove; the gate valve plate is switched between a withdrawing status and an extending status; an annular piston space is formed by an outer cylindrical surface of the centre sun gear roller and an inner cylindrical surface of the cylinder body; a cylindrical planetary piston wheel is arranged in the annular piston space in a rolling manner; when the gate valve plate is in the withdrawing status, the planetary piston wheel passes through the gate valve plate; and when the gate valve plate is in the extending status, the far end of the gate valve plate contacts the outer cylindrical surface of the centre sun gear roller at the inner side surface of the annular piston space. According to the star-rotation type rotary deice adopting the gate valve structure disclosed by the invention, the difficulty of machining the cylinder body can be reduced, and the integral intensity of the cylinder body is improved.

Owner:BEIJING ROSTAR TECH

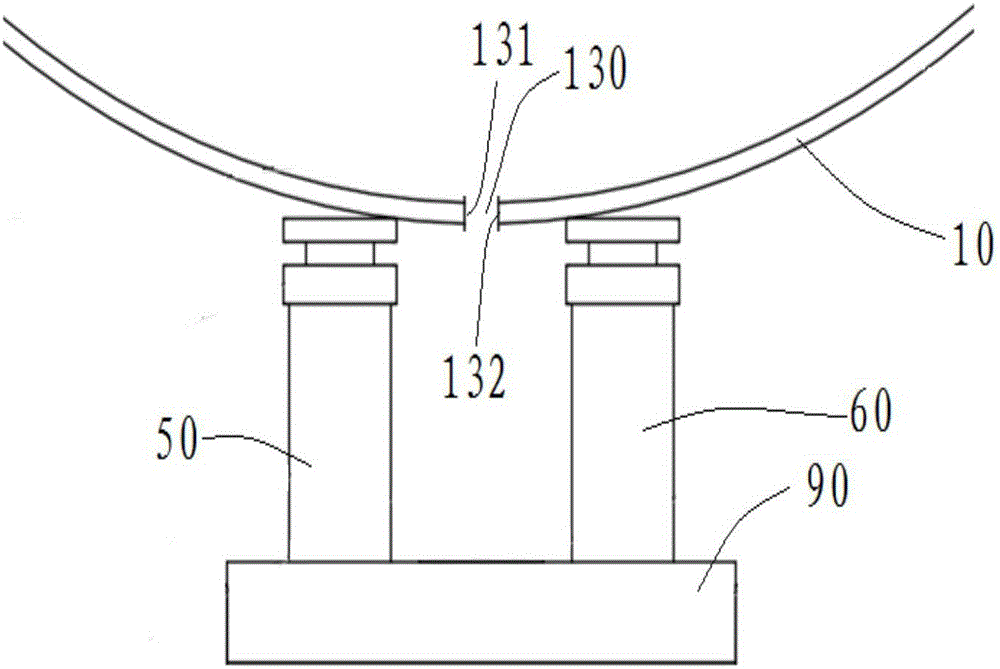

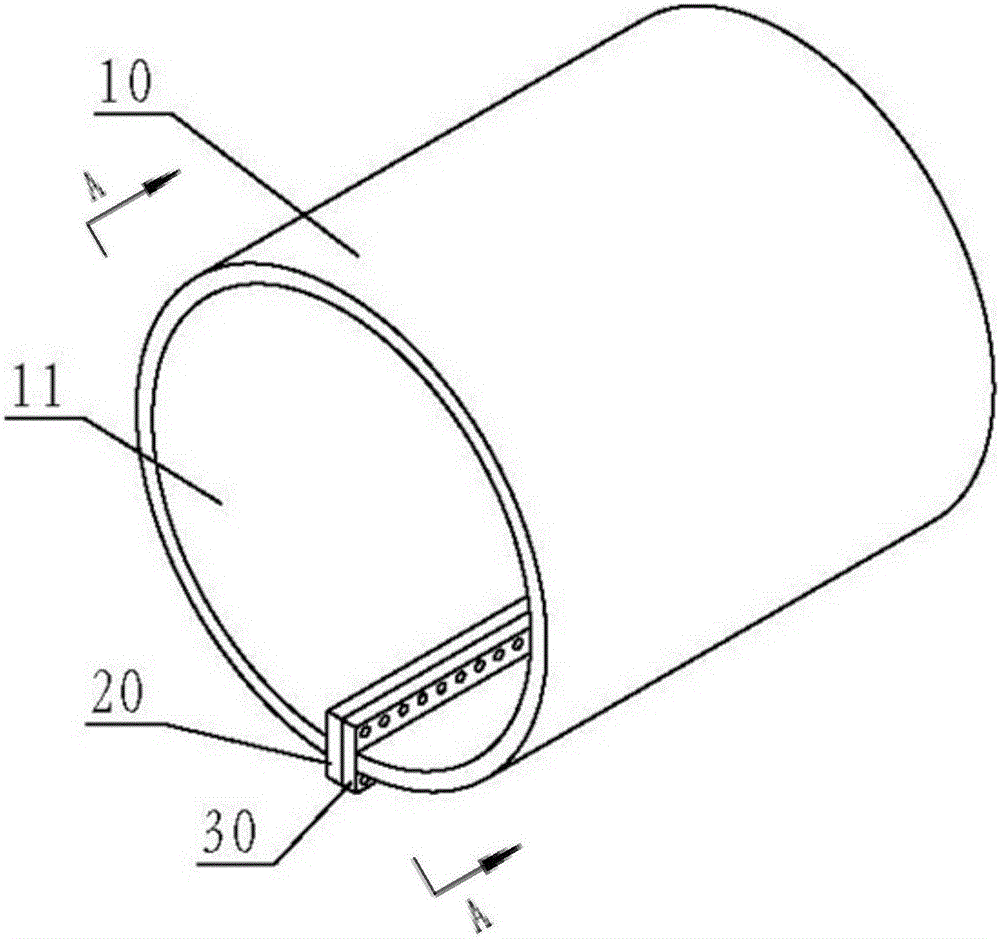

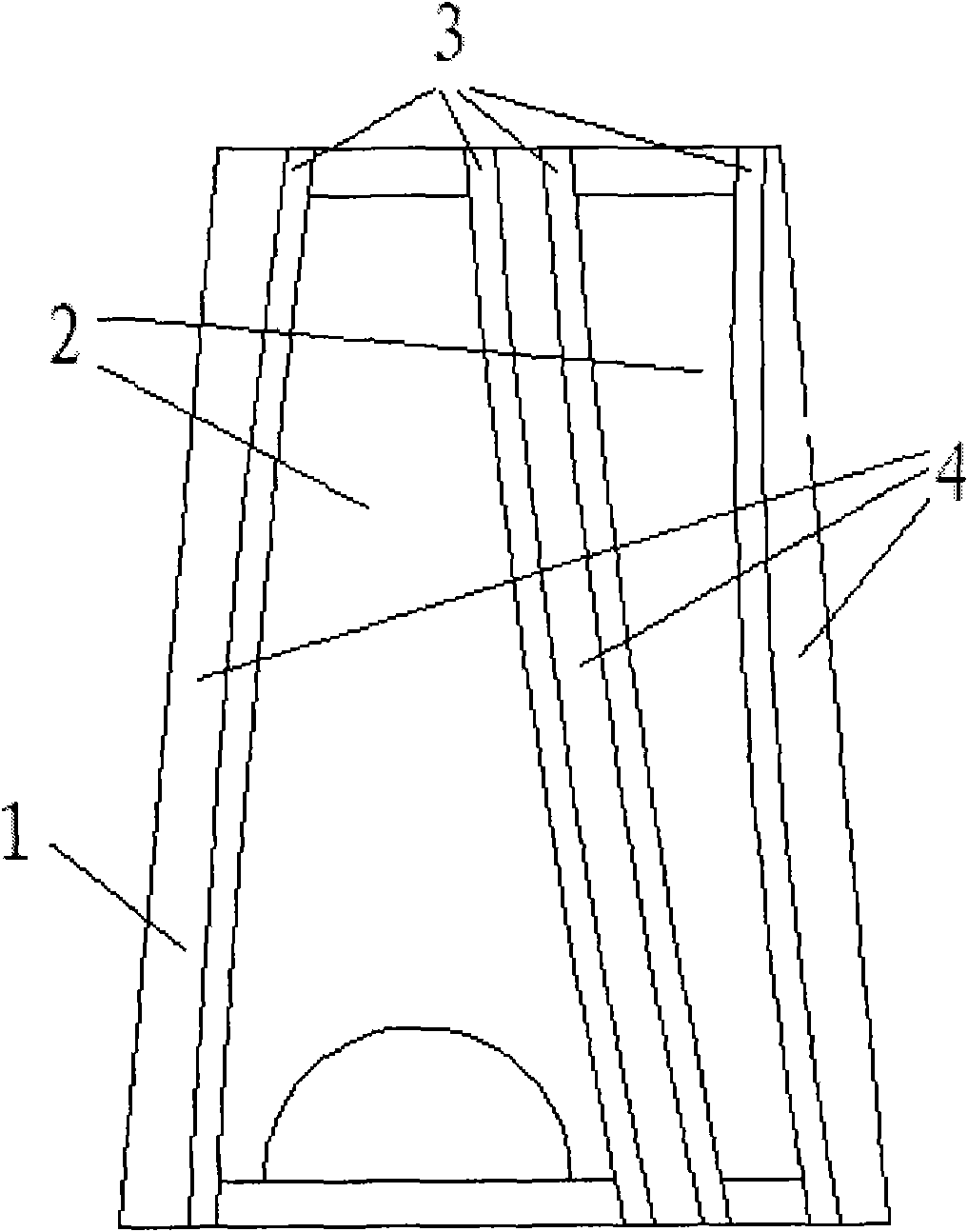

Tower piece body, tower section, tower and manufacturing method of tower piece body

ActiveCN106762444AGuaranteed roundness accuracyImprove rigidityFinal product manufactureWind motor supports/mountsPulp and paper industryTower

The invention discloses a tower piece body, a tower section, a tower and a manufacturing method of the tower piece body. The manufacturing method of the tower piece body includes the following steps that the tubular tower section is provided, and the tower section comprises a longitudinally extending through hole and a tower wall surrounding the through hole; cutting is carried out sequentially along two or more pre-cutting lines of the tower section, a seam which extends in the axial direction and penetrates through the wall thickness of the tower is formed at each cut position, and a first cutting surface and a second cutting surface are formed in the tower wall and correspond to the seams; and connecting pieces are arranged, specifically, after the seam is formed after each time of cutting, the first connecting piece and the second connecting piece are arranged on the first cutting surface and the second cutting surface correspondingly, so that the first connecting piece and the second connecting piece are made to be at least partially opposite to each other, and the opposite parts are positioned on the inner side or the outer side of the tower wall.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP

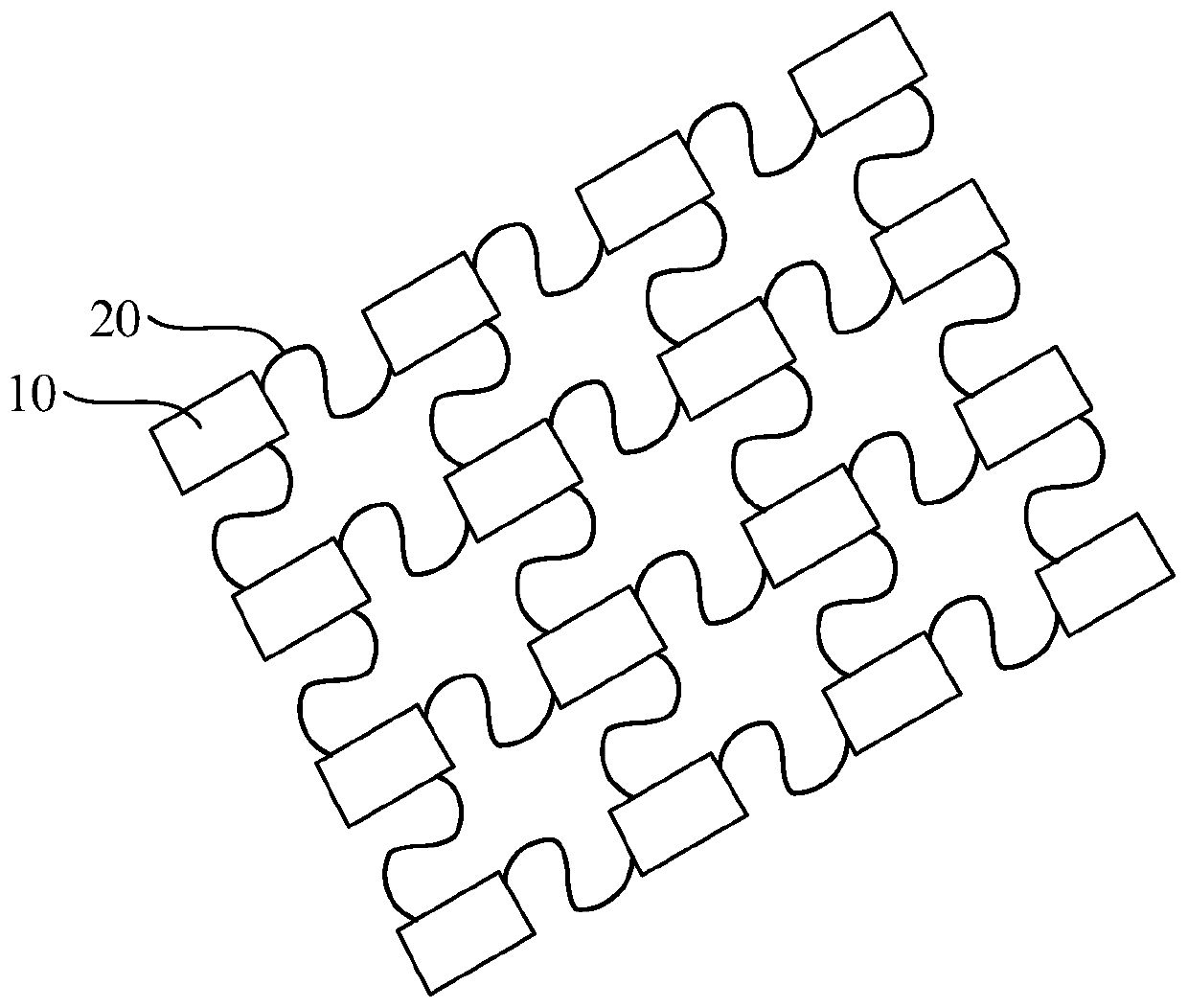

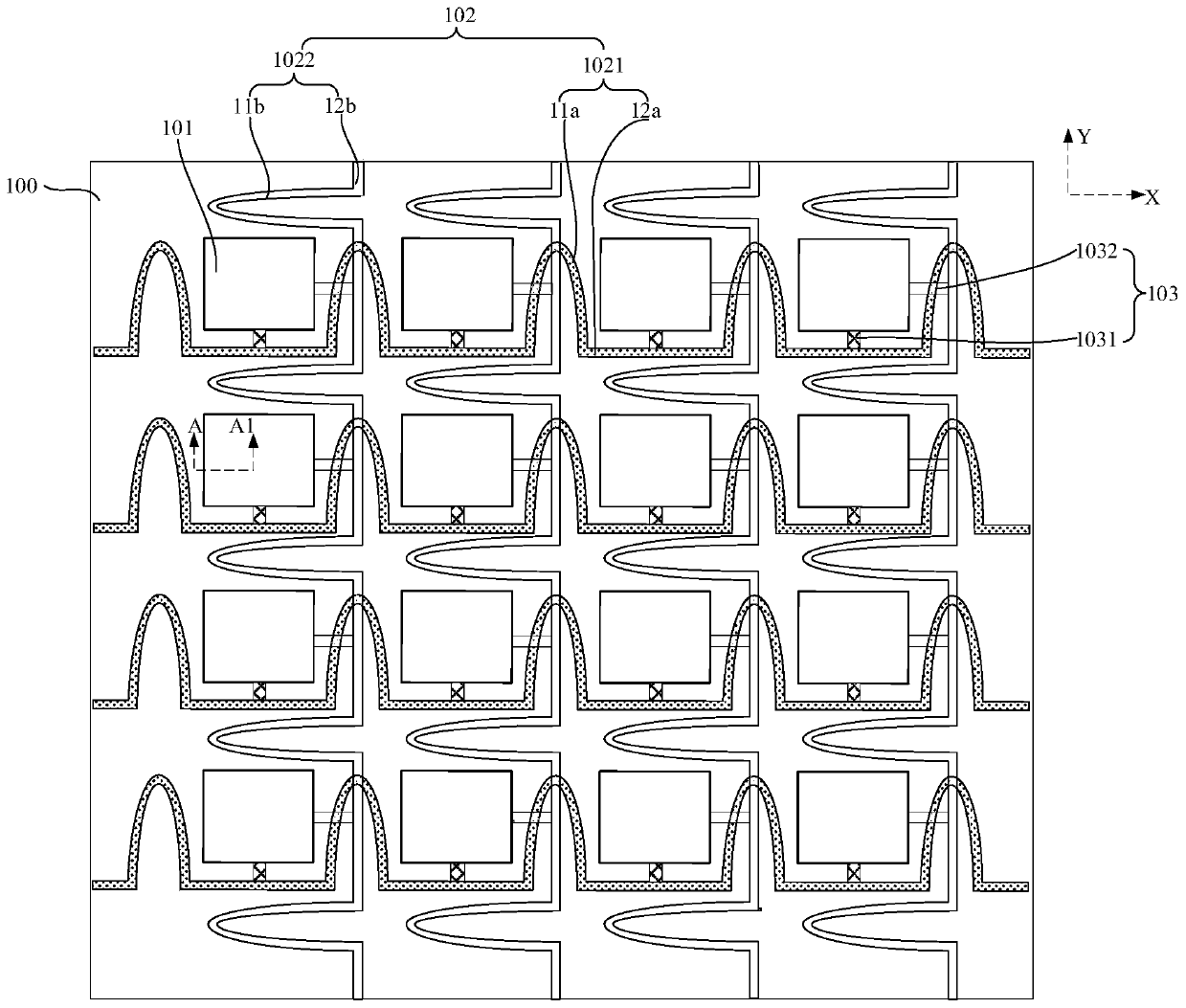

Stretchable display structure and manufacturing method, and display device

InactiveCN109830504AImprove structural performanceReduce RC delaySolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention relates to a stretchable display structure and a manufacturing method, and a display device. The stretchable display structure comprises a substrate, a plurality of pixel modules locatedon the substrate, a plurality of conductive wirings arranged at intervals on the substrate, and a plurality of electric connection wires, wherein each conductive wiring includes a plurality of bending portions and a connecting portion connecting the adjacent bending portions, and the bending portions are located between the adjacent pixel modules; and each electric connection wire is electricallyconnected to each pixel module and each conductive wiring. In the invention, the stretchable amount of the stretchable structure is increased, and simultaneously the stretchable display structure isensured to have a good display effect.

Owner:YUNGU GUAN TECH CO LTD

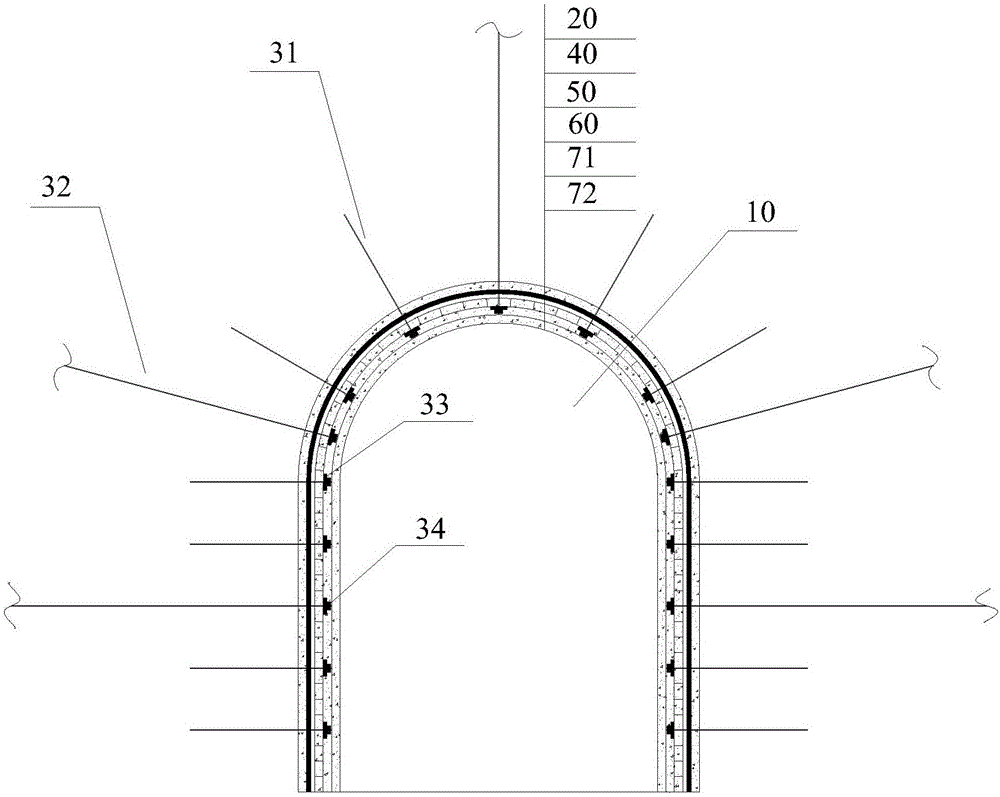

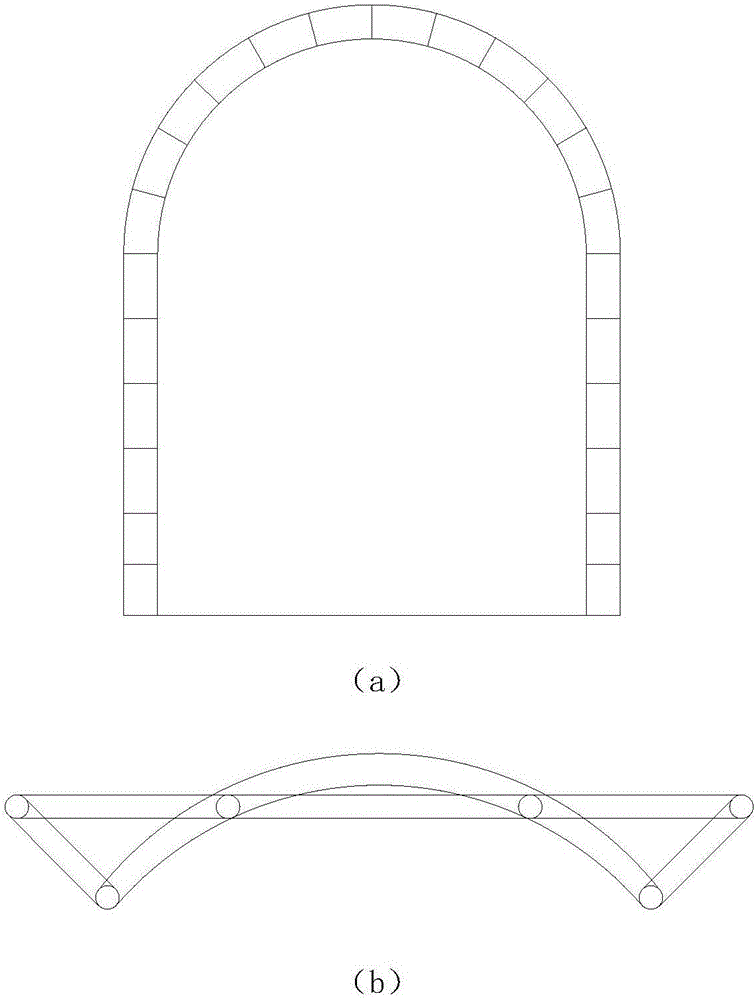

Process for excavating and constructing micro-steps of tunnels on basis of method for excavating steps

InactiveCN105257295AReduce deformation rateEnsure construction safetyTunnelsAnchoring boltsBedrockEngineering

The invention provides a process for excavating and constructing micro-steps of tunnels. The process includes steps of excavating upper steps without reserved core soil, obliquely and downwardly drilling foot lock anchor rods at arch feet and hermetically attaching the foot lock anchor rods to base rock by means of grouting or by the aid of anchor agents; controlling and keeping the lengths of the upper steps, simultaneously excavating the upper steps and intermediate steps without reserved core soil and arranging foot lock steel pipes and lock anchor rods for the intermediate steps; circularly carrying out the steps by three times; keeping synchronously excavating the upper steps and the intermediate steps, simultaneously erecting trestles, starting to excavate lower steps and close inverted arches without reserved core soil, and then closing the inverted arches; synchronously advancing excavation of the upper steps, the intermediate steps and the lower steps, and carrying out alternate circular operation for synchronously excavating each upper step, the corresponding left intermediate step and the corresponding right lower step and synchronously excavating the upper step, the corresponding right intermediate step and the corresponding left lower step until the tunnels are completely integrally excavated. The process has the advantage that effects of guaranteeing the tunnel construction safety and increasing the construction speeds can be effectively realized.

Owner:CCCC SECOND HIGHWAY ENG CO LTD +1

Fixation fluid for saving cast-off cells and manufacturing method of cell shallow layer smear

InactiveCN101182506AEasy to separateEvenly distributedImmobilised enzymesTissue cultureMethanolEthanol

The invention discloses a preservation solution for exfoliated cell and a preparation method which uses the preservation solution to process cell thin layer smear. The preservation solution for exfoliated cell comprises the components which are prepared by the volume proportion of 10 to 15 portions of methanol, 10 to 15 portions of alcohol, 1 to 2 portions of glycerin, 1 to 2 portions of glycol polyethylene, 10 to 12 portions of formaldehyde, 0.5 to 1 portions of glacial acetic acid, 10 to 20 portions of sodium chloride with 0.85 percent to 0.9 percent of mass concentration and 33 percent to 68.5 percent of phosphate buffer. The steps of the preparation method for cell thin layer smear are that: 1) the collected sample is put in the preservation solution for exfoliated cell for shaking; the sample is transferred to a centrifuge for centrifugal treatment after standing; 2) the supernatant is removed until 1ml to 2ml residue is left in the centrifuge tube; the cell suspension is obtained after uniform vibration; 3) 0.5ml to 1ml cell suspension is put into a smear preparation cup which is made into cell thin layer smear by a cell smear preparation machine.

Owner:曾思恩 +1

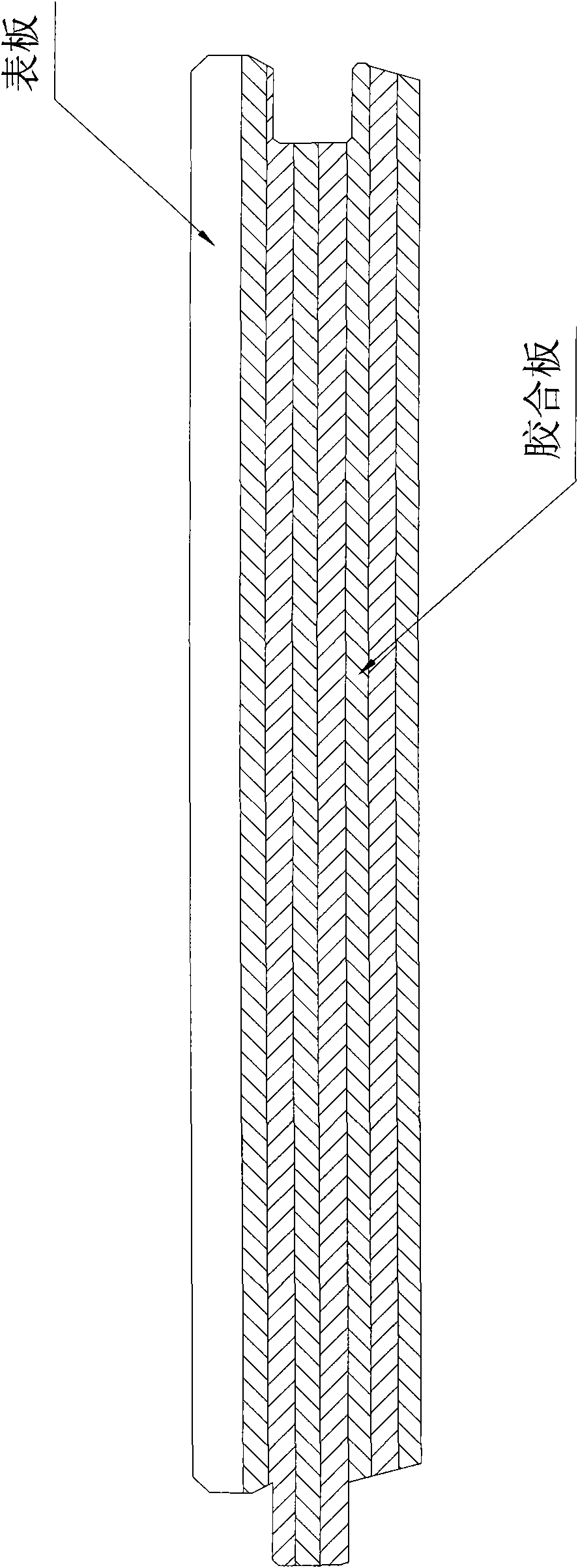

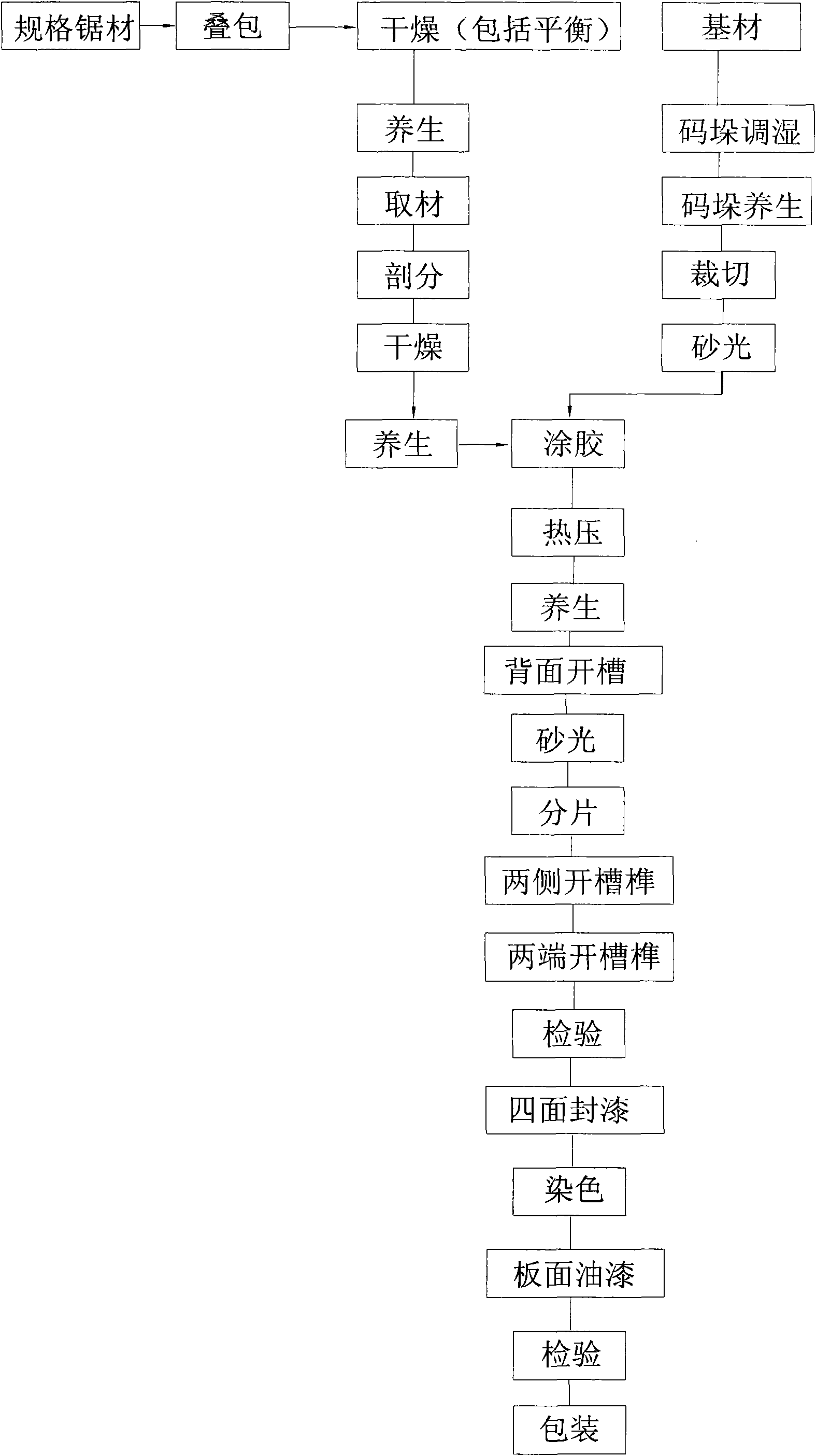

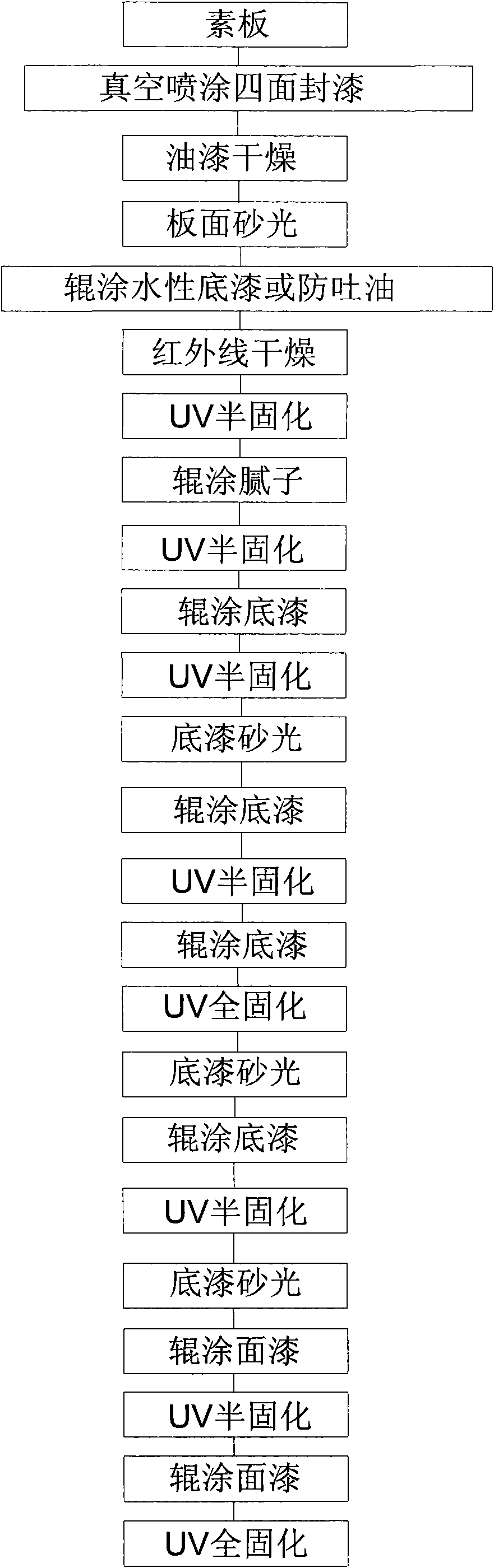

Production method of weather-proof multilayer composite wood floor

ActiveCN101628440AReduce water lossReduce stressWood veneer joiningWood dampingPulp and paper industryWater content

The invention discloses a production method of weather-proof multilayer composite wood floor, comprising the following steps: after normal procedures of drying, balancing and nourishing life, the water content of a wood panel is lowered to 12-16% from originally more than 16%; after sawn into face veneers with thickness being 1-4mm, the water content of the wood panel is lowered to 6-9% by low temperature drying, balancing and nourishing life; then the water content of plywood basal material with water content being 9-14% is lowered to 10-8% by lower temperature drying, balancing and nourishing life; then, plywood basal material which conforms to water content requirement is cut, sanded and glued to assemble with the face veneers, and hot-pressing or cold-pressing procedure is adopted to glue into a floor blank; and finally, the floor blank is nourished, processed with a mortise and decorated by painting on the surface so as to form the weather-proof multilayer composite wood floor. The multilayer composite wood floor produced with the method has small warping degree and deformation ratio when used, has small possibility of cracking, has strong weather-proof performance and can be used as heating wood floor.

Owner:SHANDONG YIHUA FURNITURE CO LTD

Potassium titanate whisker( K2O.6TiO2) preparation method

Disclosed is a process for preparing potassium hexatitanate whisker material with high factor of porosity, high bending strength, strong caustic corrosion resistance, low rate of deformation and high liquid holdup, which consists of charging mixture of other types of titanates and potassium-containing compound into potassium hexatitanate whisker, then carrying out granulating, modeling, sintering at 700-1050 deg. C, and water scrubbing.

Owner:NANJING UNIV OF TECH

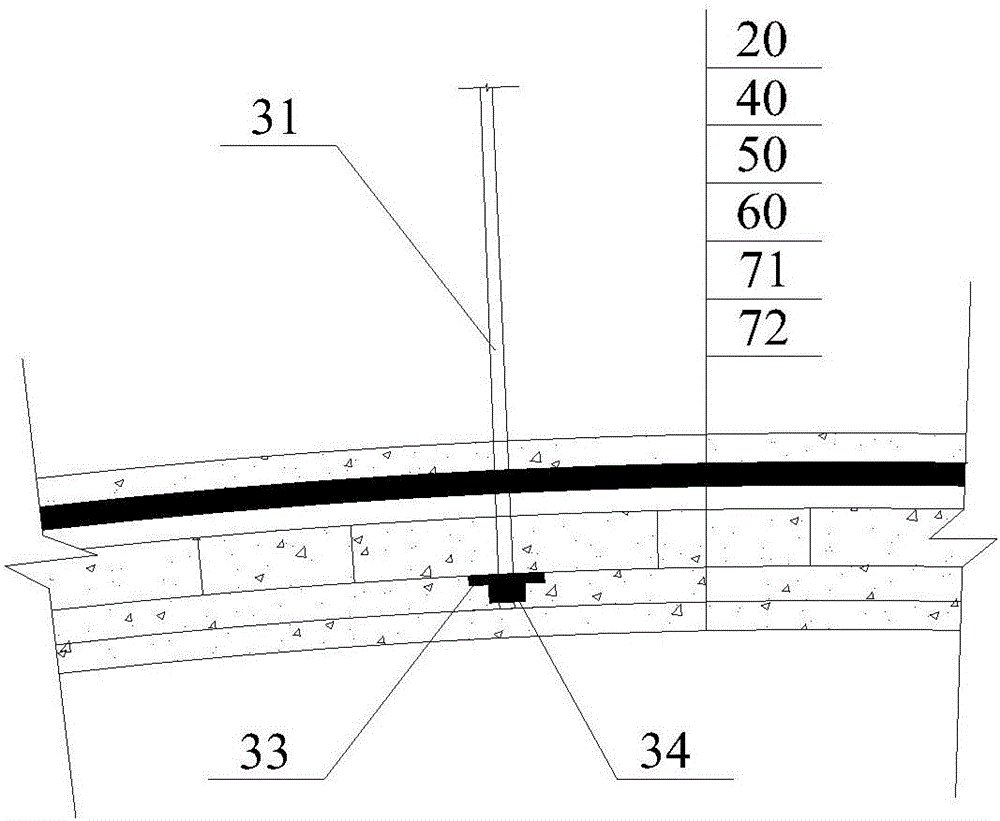

Supporting structure for composite anchor mesh steel bar support of deep well high-stress soft rock roadway and construction method thereof

InactiveCN106761811AImprove stabilityAvoid loose damageUnderground chambersTunnel liningSupporting systemShotcrete

The invention provides a supporting structure for a composite anchor mesh steel bar support of a deep well high-stress soft rock roadway and a construction method thereof. Firstly, anchor rods and anchor ropes are stroke into the interior of surrounding rock, and the set length is exposed; then, steel bar meshes and polyester fiber meshes are laid and hung through the outward-exposing portion of the anchor rods and the anchor ropes, the steel bar meshes are closely attached to the surrounding rock to be laid, and the polyester fiber meshes are closely attached to the steel bar meshes to be laid; a steel bar mesh shell support is erected; the anchor rods and the anchor ropes pass through the steel bar meshes, the polyester fiber meshes and the steel bar mesh shell support in sequence and are fixed on the steel bar mesh shell support through trays and nuts; a first concrete shotcrete layer is poured to close the whole supporting structure, and initial supporting is finished; and finally, a second concrete shotcrete layer is poured, and second supporting is finished. Through initial supporting, the whole structure and the surrounding rock deforms jointly, the yielding effect is given play, and surrounding rock pressure is released, and then second supporting is conducted. Meanwhile, the flexibility and pressure releasing effects of the polyester fiber meshes are utilized, so that the surrounding rock pressure is evenly distributed in the whole supporting system.

Owner:ANHUI UNIV OF SCI & TECH

Method for hot-rolling and preparing composite plates by means of hot spraying preset brazing filler materials

InactiveCN102581573AReduce deformation rateImprove the bonding strength of the interfaceMolten spray coatingWelding/cutting media/materialsThermal sprayingMetallic materials

The invention belongs to the field of machining of metal materials, and particularly relates to a method for manufacturing metal composite plates. The method includes cleaning and roughening to-be-compounded surfaces of two metal plates at first; then uniformly spraying a thin brazing filler material layer on the surface of a joint of a surface plate or a base plate; then overlaying the surface plate and the base plate; rolling the surface plate and the base plate within the range of 10% and 30%; and obtaining a rolled composite plate. The method aims to solve problems that deformation of composite plates required to be rolled is high, and poor combination and unstable quality are caused by oxidation of base plates and surface plates on boundaries when the composite plates are machined in an atmospheric atmosphere.

Owner:SHENYANG HANGXIN METAL COMPOSITE TECH

High-solid-content quick-drying water-based white primer and preparation method thereof

The invention relates to a high-solid-content quick-drying water-based white primer and a preparation method thereof. The high-solid-content quick-drying water-based white primer is basically prepared from 25-35% of acrylic emulsion, 15-25% of white slurry, 10-18% of calcium carbonate, 5-10% of kaolin, 5-10% of talcum powder, 2-5% of assistant, 2-6% of film-forming agent, 3-5% of thickening rheologic agent and 15-25% of water. The white primer has the characteristics of excellent sanding property, excellent filling property and high drying rate, does not adhere to abrasive paper after drying 1 hour in summer, and is economical and practical; the white primer can effectively seal the wood seams in a medium-titer plate base, and stabilize the internal structure of the base material; after construction, the deformation rate of the base is low, and the fibers do not expand basically; and thus, the white primer can be used for solid color painting of a medium-titer plate base wood door, and can also be used for painting a sealed splint base, thereby having high market application value.

Owner:UNION FOSHAN CHEM

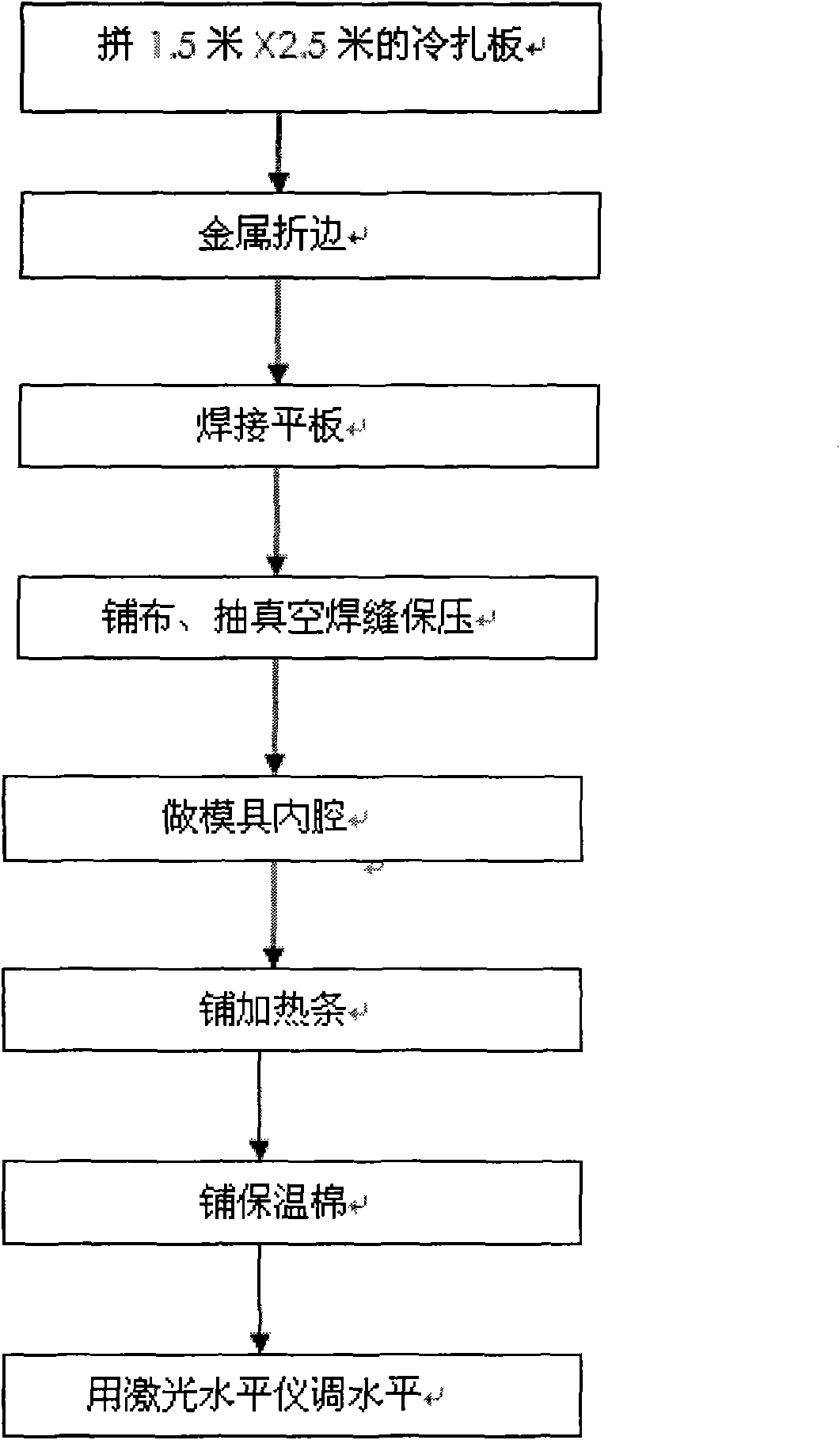

Manufacturing process of shearing rib mold

The invention discloses a manufacturing process of a shearing rib mold, which is characterized by comprising the following steps: (1) splicing plates, and lofting; (2) folding a metal edge: folding a steel plate into a right angle at the edge of the steel plate to manufacture the edge of a shearing rib, and ensuring the angle; (3) welding a flat plate; (4) maintaining pressure of welded seams; (5) manufacturing an inner cavity of the mold; (6) laying heating strips; (7) laying heat-insulating cotton; and (8) adjusting the level of the mold. In the invention, the problems that in the prior art, the shearing rib mold is manufactured by adopting glass fiber reinforced plastics, the cost is high, and the shrinkage rate and the deformation rate of the finished mold are higher are solved. The invention provides the manufacturing process for manufacturing the shearing rib mold by using the steel plate as a raw material.

Owner:昆山华风风电科技有限公司

Processing method of nutritional frozen Hibiscus esculentus slice

ActiveCN102640788AReduce lossesValid reservationFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by freezing/coolingAdditive ingredientPollution

The invention provides a processing method of nutritional frozen Hibiscus esculentus slice. The method comprises the steps of material selection, color protection, sterilizing (ozone combined with microwave), freezing (cooling, and ultrasonic-assisted freezing), thawing, preparing, screening, slicing, quick-freezing, packaging, sealing and delivering. The method provided by the invention adopts ultrasonic-assisted freezing to solve tissue structure disintegration problem in single freezing process, effectively promotes nucleation under simultaneous mass-transfer action and heat-transfer action of ultrasound, avoids damage of functional ingredients in Hibiscus esculentus, and avoids nutritional ingredients loss by adopting two-step operation of freezing and sterilizing. Under joint action of ozone and microwave in sterilization process, the method has thorough sterilization and obvious effect; in combination with sterilization with 75% ethanol, bacterial count can be controlled at 500-300 / g, sterilization time is shortened by above 30%, and the product is safe, pollution-free and residue-free.

Owner:浙江佳伊乐食品有限公司

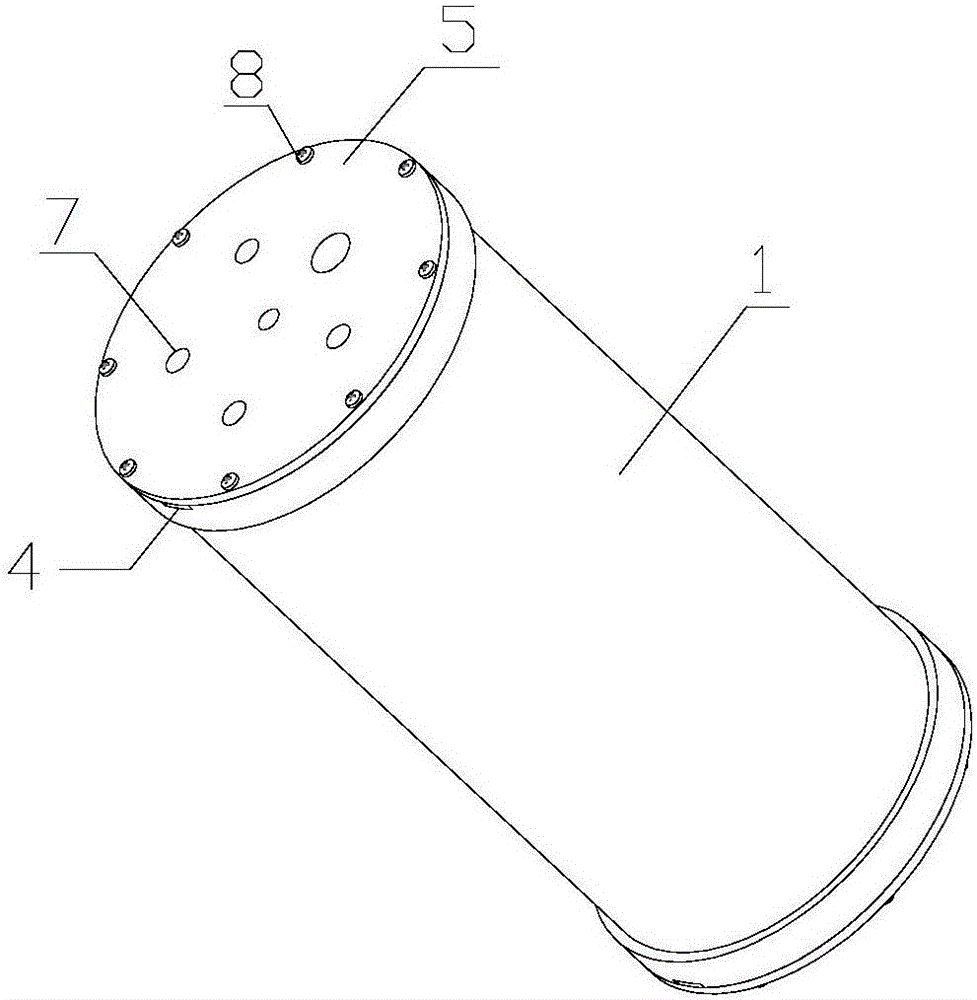

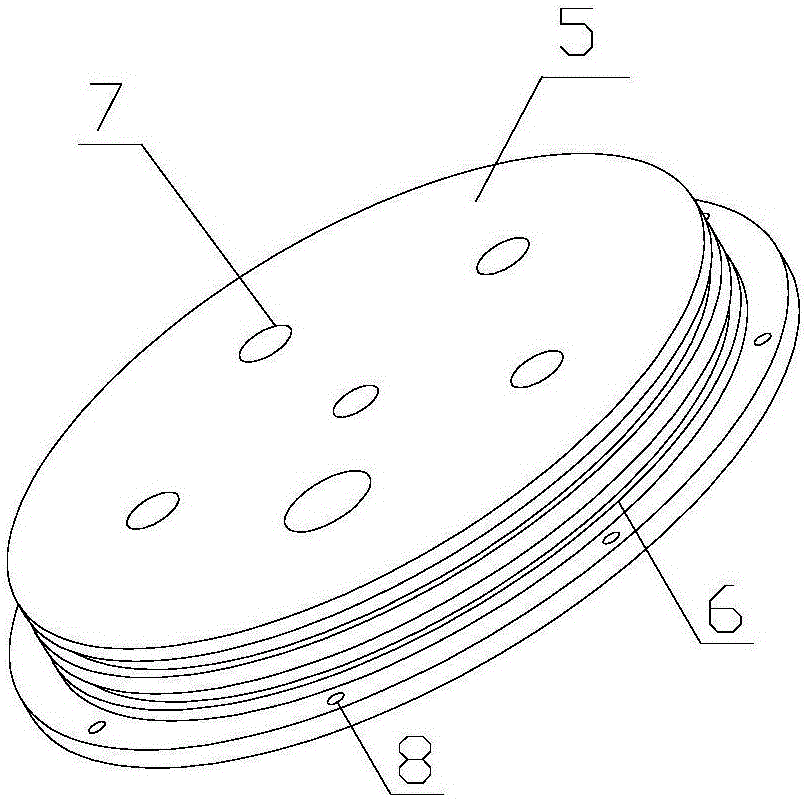

Water-cooled heat dissipation type pressure-resistant electronic cabin

ActiveCN106413351AEasy to installImprove the convenience of loading and unloading and post-maintenanceModifications by conduction heat transferUnderwater vesselsHeat sinkWhole systems

The invention discloses a water-cooled heat dissipation type pressure-resistant electronic cabin which comprises a main cabin body. A front end cover and a rear end cover are respectively arranged on both ends of the main cabin body. The main cabin body is sealed into a cavity by the front end cover and the rear end cover. A heat dissipation device is arranged in the cavity. The heat dissipation device comprises four heat sinks which are supported by cross-shaped telescopic brackets on both ends and are arranged on the inner wall of the cavity through the cross-shaped telescopic brackets. The heat sinks are arranged on electrical components. According to the water-cooled heat dissipation type pressure-resistant electronic cabin, the pressure-resistant cabin casing and the internal electrical device are respectively two separate systems, and can be completely separated; the convenience of assembling and debugging is improved; the electrical device is arranged on a separate heat dissipation bracket; the heat dissipation bracket can transfer heat of the electrical components to the wall of the pressure-resistant cabin and water outside the cabin; heat dissipation of the electrical device in the cabin body is realized; and in addition, the support effect of the heat dissipation bracket on the cabin wall enhances the pressure-resistant ability of the pressure-resistant cabin casing and improves the reliability of the whole system.

Owner:JIANGSU UNIV OF SCI & TECH

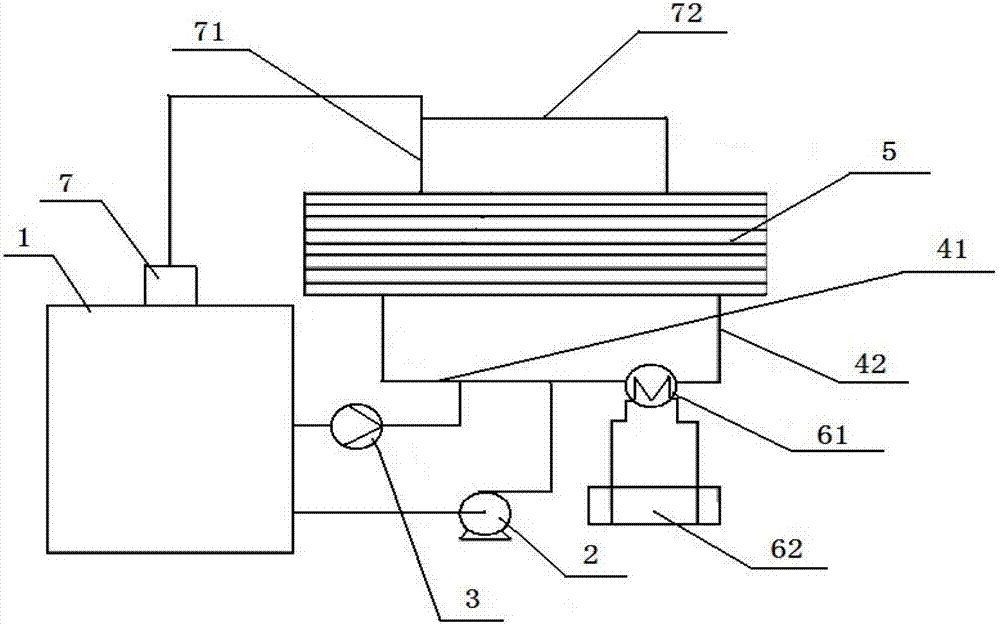

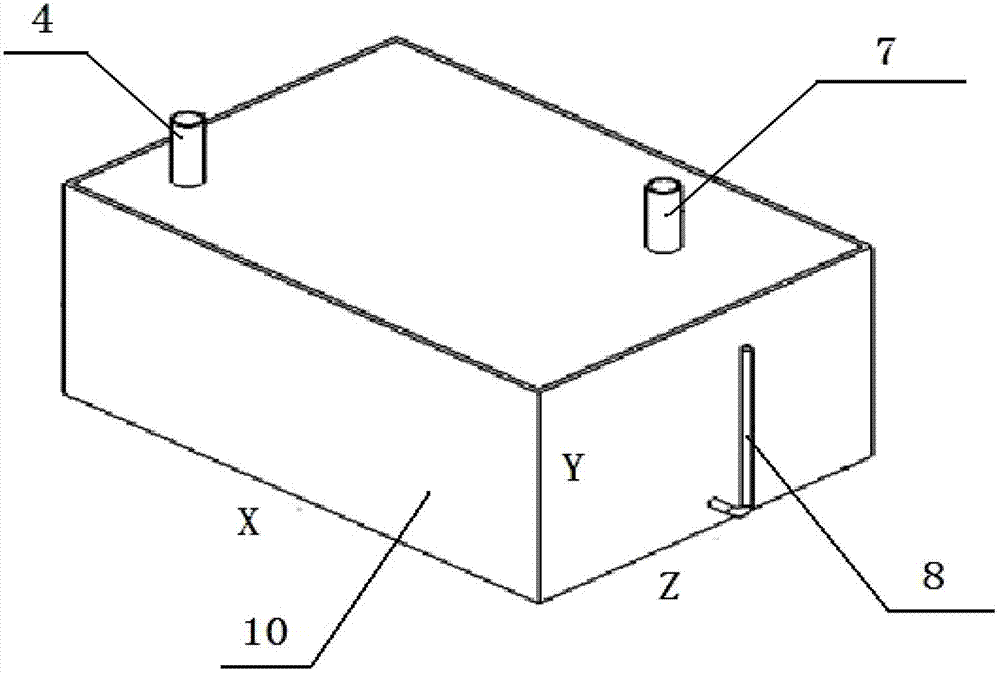

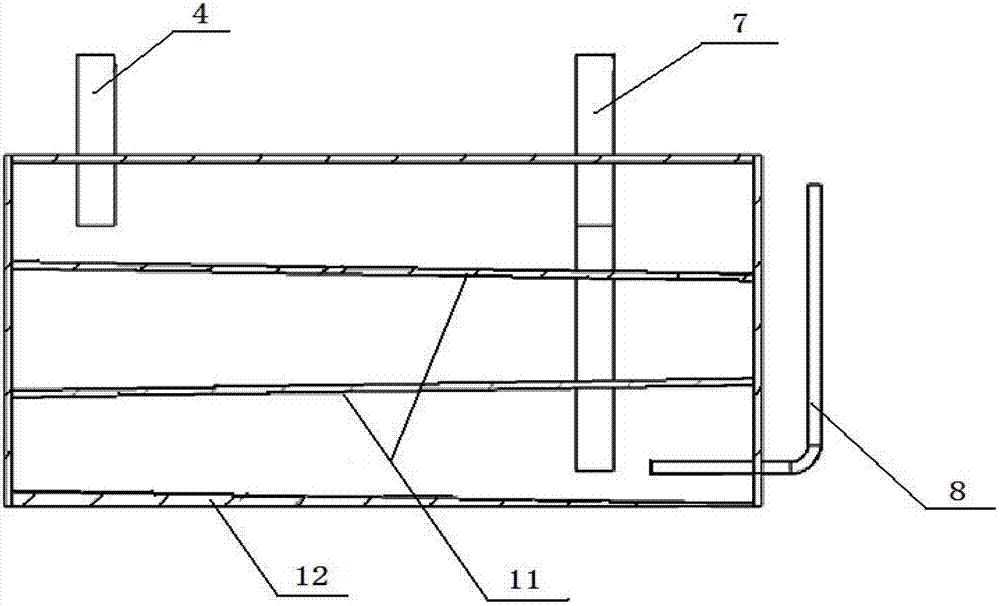

Integrated liquid storage pot and novel zinc-bromine redox flow battery

ActiveCN102780018ATroubleshoot MigrationExtended stayFuel cell auxillariesIndirect fuel cellsBromineOxidation-Reduction Agent

The invention discloses a structure and a fabrication method of an integrated liquid storage pot, and a novel zinc-bromine redox flow battery. The novel zinc-bromine redox flow battery comprises a liquid storage pot 1, a liquid supply pump A2, a liquid supply pump B3, an anode pipeline system 41, a cathode pipeline system 42, a galvanic pile 5, an anode return pipe 71 and a cathode return pipe 72; the liquid storage pot 1 is connected to the liquid supply pump A2, the liquid supply pump B3, the anode return pipe 71 and the cathode return pipe 72, respectively; the galvanic pile 5 is connected to the anode pipeline system 41, the cathode pipeline system 42, the anode return pipe 71 and the cathode return pipe 72, respectively; the liquid supply pump B3 is connected to the anode pipeline system 41; and the liquid supply pump A2 is connected to the anode pipeline system 41 and the cathode pipeline system 42. The anode and the cathode of the battery are connected back to the same liquid storage pot 1, so that the migration problem is fundamentally solved; the system is simple and the fault rate is low; and the same liquid supply pumps are adopted for supplying liquid so that the pressure on the two sides of the anode and cathode pipeline systems is balanced, and the deformation rate of the material is reduced.

Owner:江苏恒安储能科技有限公司

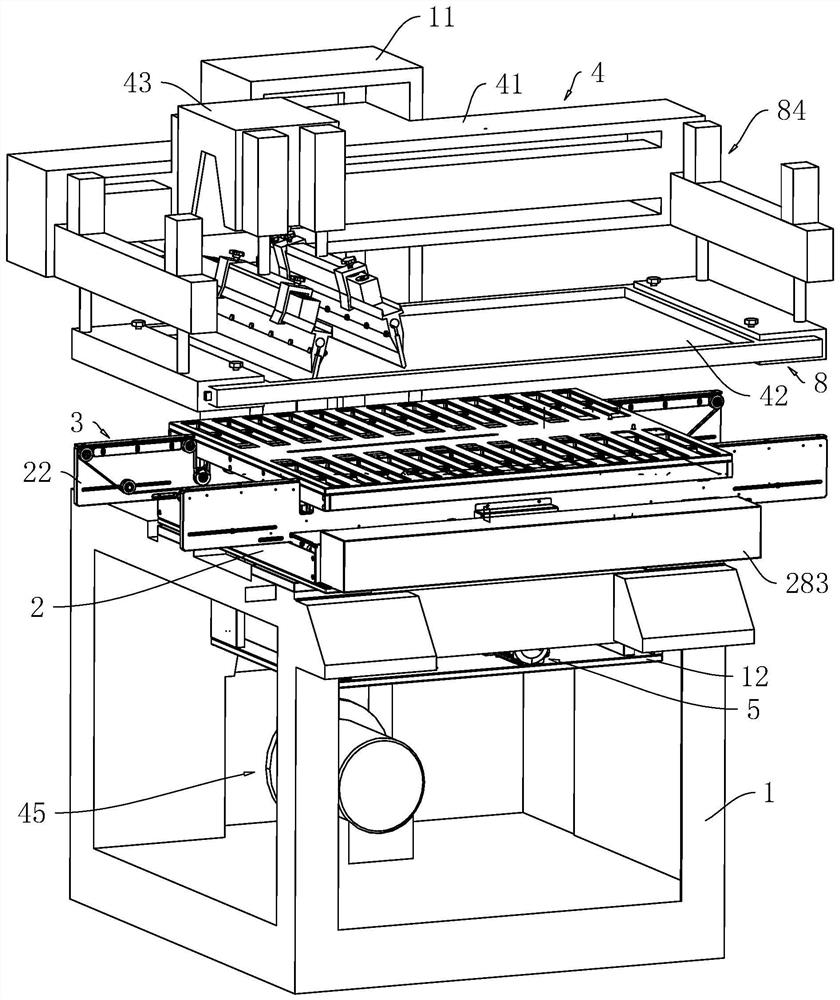

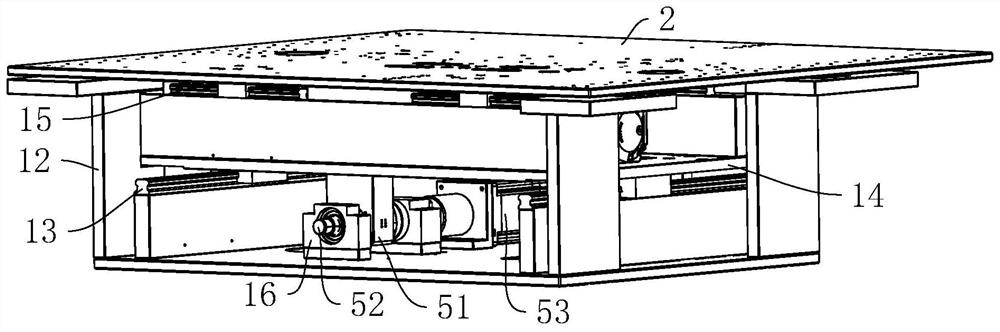

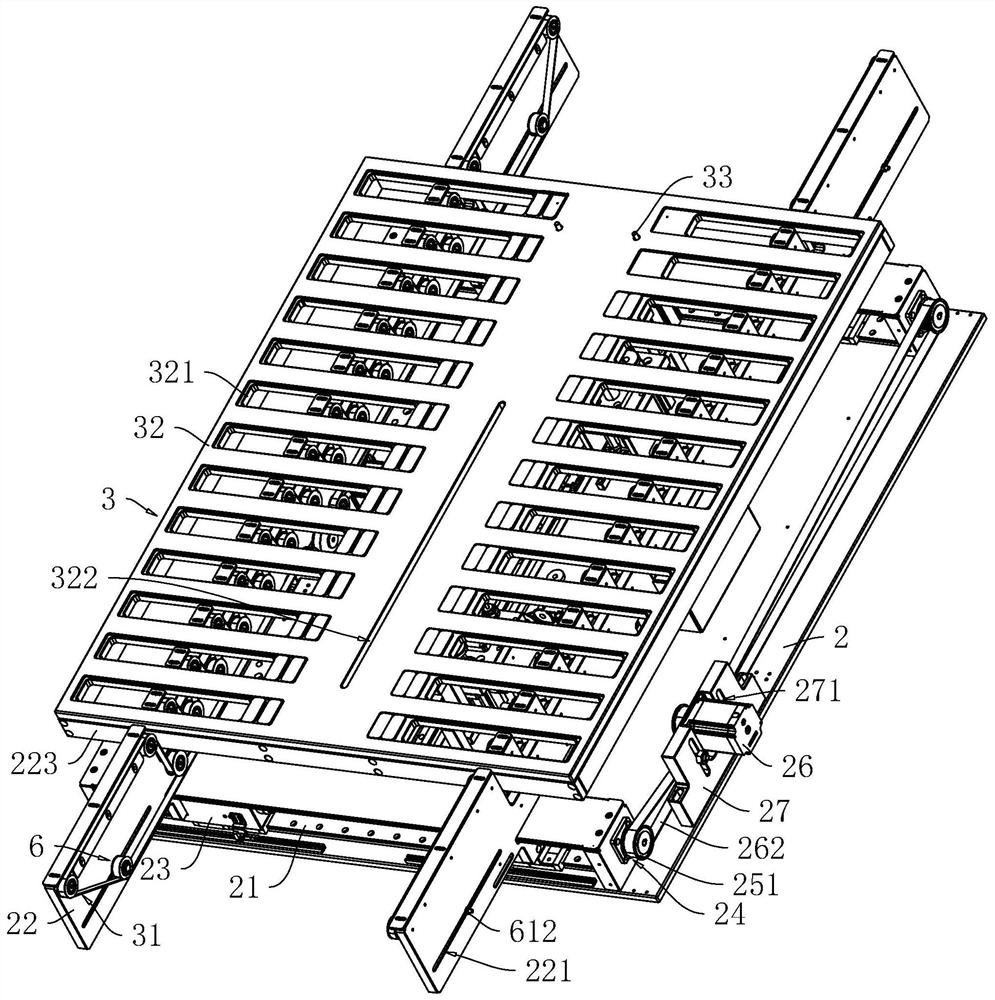

Screen printing equipment for circuit board

ActiveCN112046134AIncrease productivityShorten the timePrinted circuit assemblingScreen printersScreen printingConveyor belt

The application relates to screen printing equipment for a circuit board, and the screen printing equipment comprises a rack. A conveyor device and a screen printing mechanism are arranged on the rack; the conveyor device comprises a conveyor belt, a placing plate, a locating column and a lifting device, and the conveyor belt, the placing plate, the locating column and the lifting device are arranged on the rack; the screen printing mechanism comprises a sliding seat, a silk screen, a sliding table, an ink scraping assembly, a first driving assembly and a second driving assembly, and the sliding seat is arranged on the rack; and the silk screen and the sliding table are arranged on the sliding seat, and the ink scraping assembly is arranged on the sliding table. According to the screen printing equipment, the circuit board is driven by the conveying belt to move forwards, and the lifting device is started for driving the locating column to locate the circuit board; then, the first driving assembly is started to enable the silk screen to come into contact with the circuit board, and the second driving assembly is started to print soldering paste on the silk screen onto the circuit board; Manual work is required in the soldering paste printing process of the circuit board, and the time is saved; and the problem of lower production efficiency of a screen printing machine is solved.

Owner:SHENZHEN HAISIKE AUTOMATION TECH

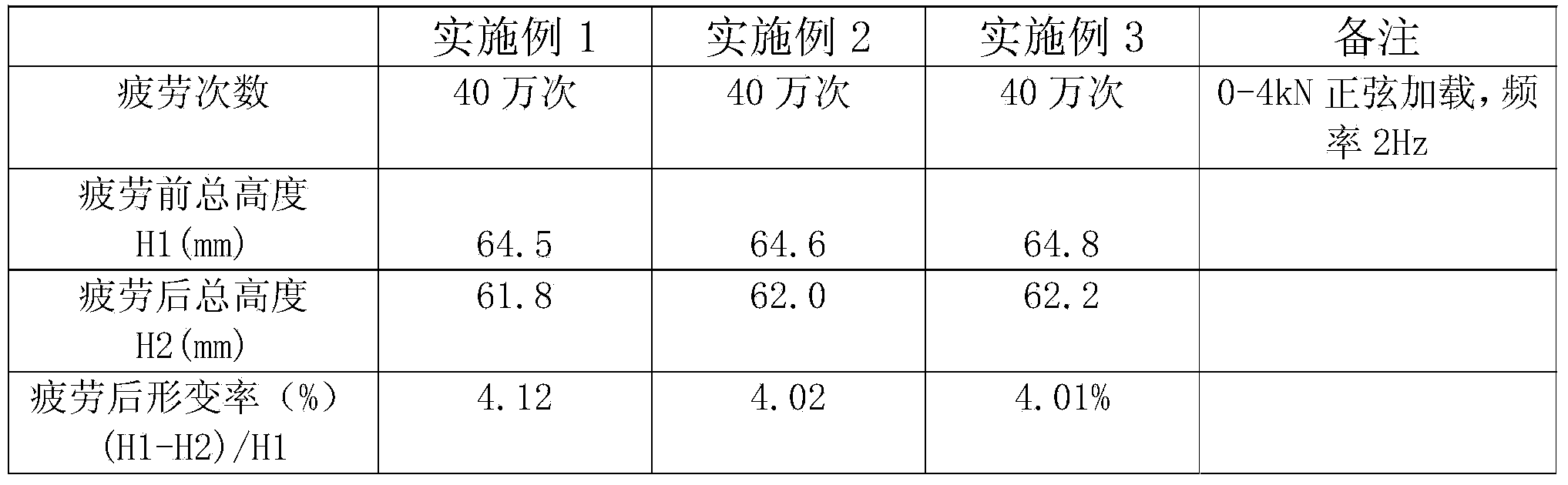

Method for preparing low-deformation polyurethane damping bumper block

ActiveCN104341579AIncreased chemical crosslinkingReduce deformation ratePrepolymerIsocyanate compound

The invention relates to a method for preparing a low-deformation polyurethane damping bumper block. The method is used for solving the technical problem in the prior art that the deformation rate is high after the polyurethane bumper block for an automobile is subjected to dynamic fatigue, and is used for improving the safety and comfort of the bumper block in a continuous working environment. The method comprises the processing steps: (1) pretreating isocyanate; (2) preparing a prepolymer; (3) preparing a chain extender; (4) blending; (5) carrying out cast molding; (6) carrying out post-vulcanization. The prepared low-deformation polyurethane damping bumper block has the advantage that the deformation rate of the fatigued bumper block is lowered on the premise that the dynamic fatigue performance and comprehensive performance of the bumper block are maintained. According to the method disclosed by the invention, modified MDI and macromolecular and polyfunctional ether polyalcohol are adopted to react, and a microporous elastomer material, of which both hard segment phase and soft segment phase contain certain chemical crosslinking, is prepared, so that the requirements of current medium- and high-end automobiles on bumper blocks which have low deformation after dynamic fatigue are met.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

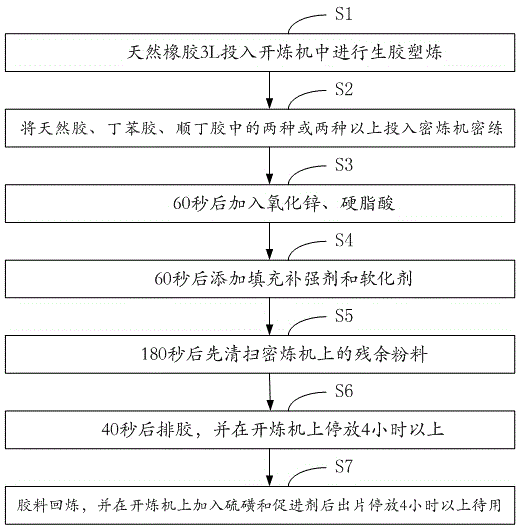

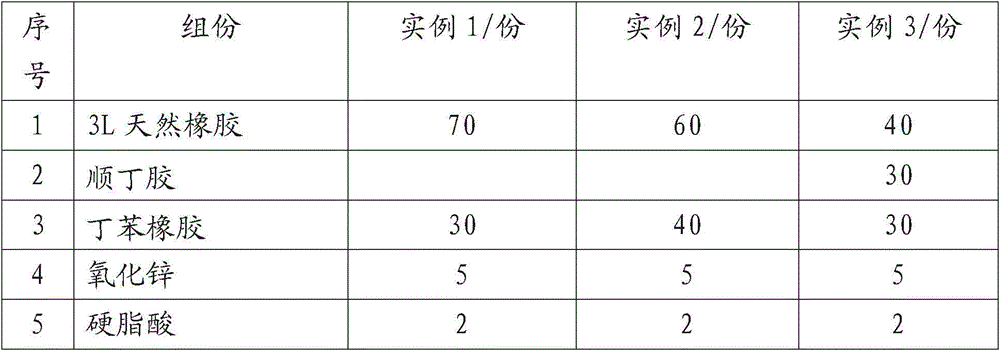

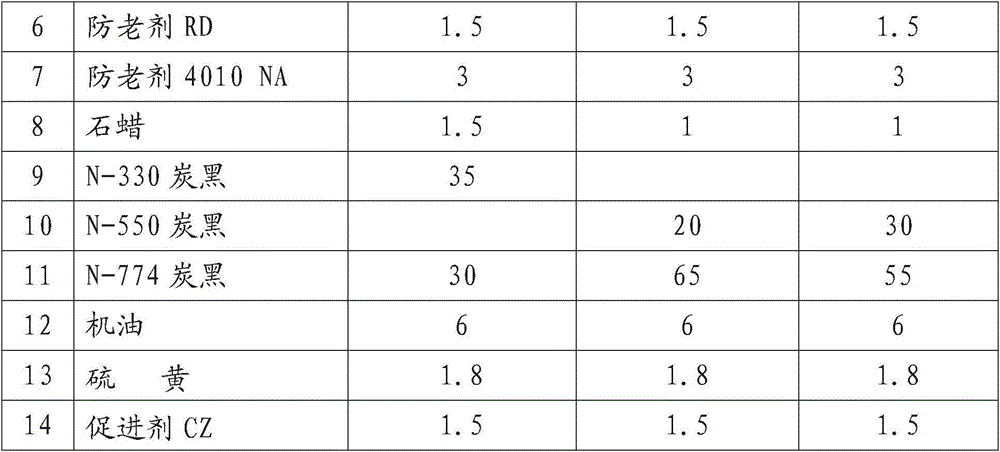

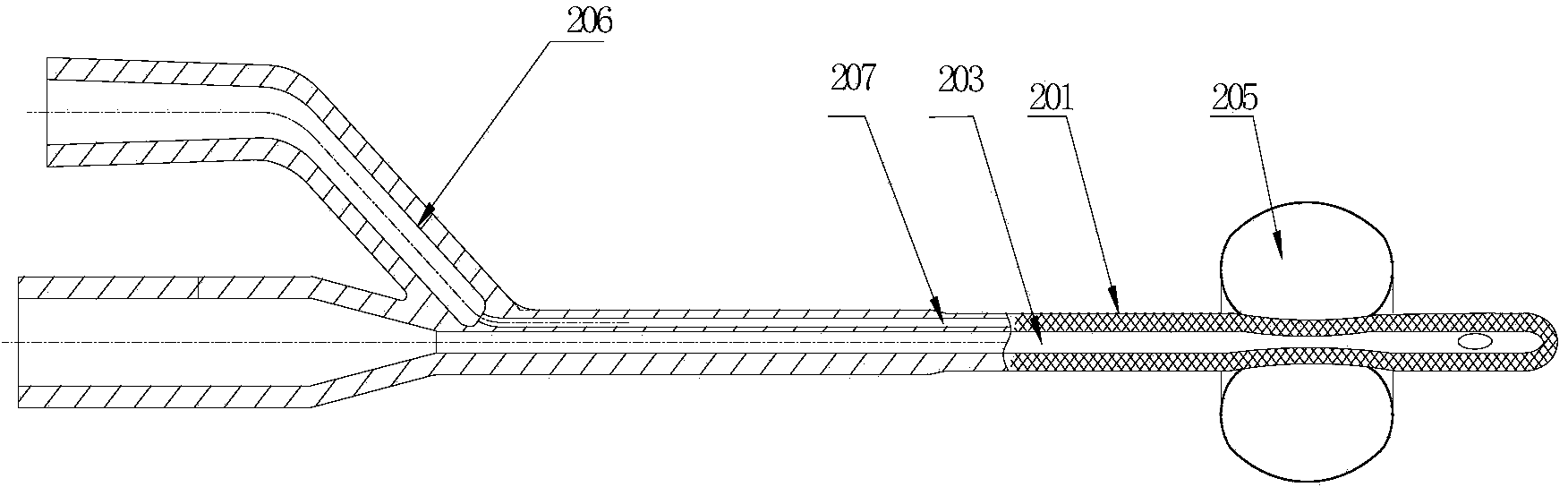

Nylon rubber for bushing and preparation method of nylon rubber

The invention is suitable for the technical field of rubber, and provides nylon rubber for a bushing. The nylon rubber comprises or contains the following components in parts by weight: 100-170 parts of rubber, 4-8 parts of an active agent, 1-3 parts of stearic acid, 2-6 parts of an anti deteriorant, 80-12 parts of a stuffing strengthening agent, 4-10 parts of a softener, 1-2.5 parts of a vulcanizing agent and 1-4 parts of an accelerant. The rubber and the nylon have favorable adhesivity; the fatigue life of products is prolonged. The nylon rubber disclosed by the invention is simple in formula, the hardness of the generated rubber is high, the weariness resistance is high, the deformation rate is reduced, and the density is high.

Owner:柳州日高汽车减振技术有限责任公司

Hardly-deformable polyethylene wood-plastic composite and preparation method

The invention provides a durable and hardly-deformable polyethylene wood-plastic composite. The hardly-deformable polyethylene wood-plastic composite comprises the following components: by weight, 100-150 parts of high density polyethylene, 30-40 parts of polyvinyl chloride, 10-20 parts of chlorinated polyethylene modified polyvinyl chloride, 10-20 parts of an epoxy resin, 5-10 parts of coumatone resin, 3-6 parts of butyl rubber, 5-10 parts of polyacrylamide, 5-10 parts of boric acid alkylolamide, 2-4 parts of dioctyl sebacate, 10-12 parts of tricresyl phosphate, 3-8 parts of polyester imides, 10-20 parts of epoxidized soybean oil, 5-10 parts of vaseline , 10-15 parts of polyvinylbutyral resin, 50-80 parts of a wood flour, 10-20 parts of zinc oxide, 10-15 parts of figuline, 5-10 parts of lithopone, 3-15 parts of calcium carbonate and 5-8 parts of a glass fiber. The hardly-deformable polyethylene wood-plastic composite has the advantages of good mechanical properties, hydroscopicity of 0.3% or less, tensile strength of 15MPa or more, and heat deformation temperature of 115DEG C or above. After destruction by high temperature and high humidity, deformation rate of the hardly-deformable polyethylene wood-plastic composite is less than that of contrast products.

Owner:SUZHOU NEW DISTRICT JIAHE PLASTIC

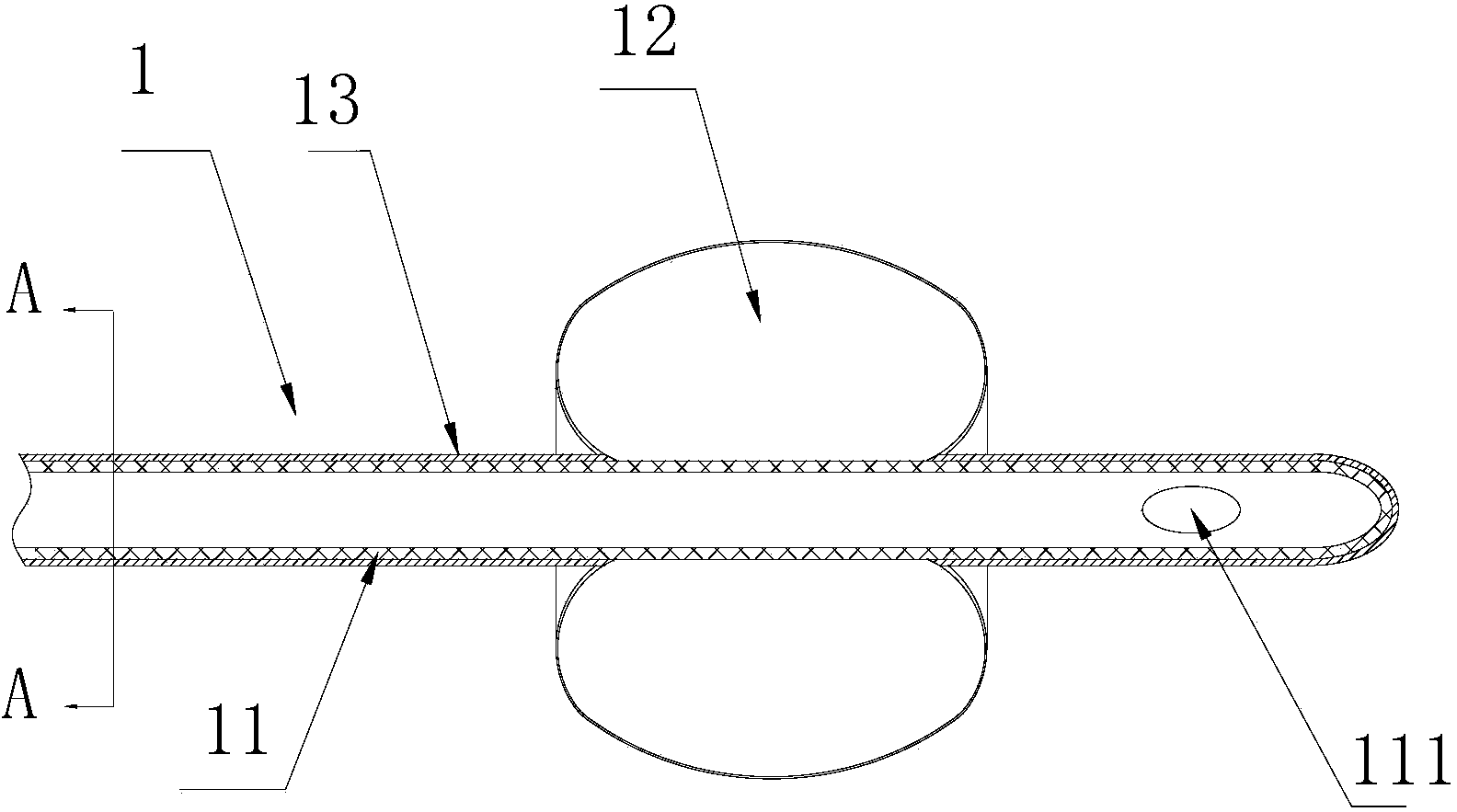

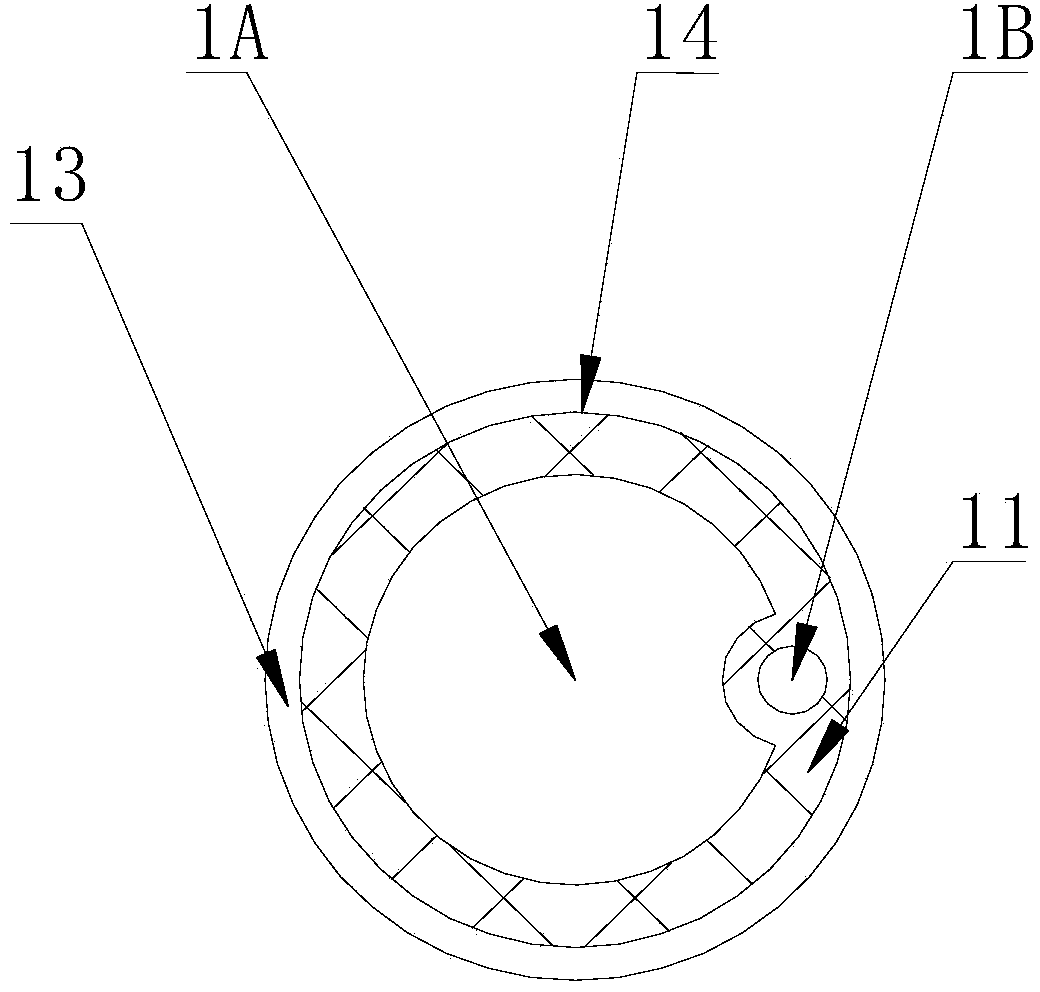

Novel balloon urethral catheter

ActiveCN104127951AHigh strengthStable supportBalloon catheterUrethral catheterizationUrethral catheter

The invention discloses a novel balloon urethral catheter which comprises a catheter body. The catheter body comprises an inner layer catheter tube and an outer layer wrapping the surface of the inner layer catheter tube, a balloon tube is arranged between the inner layer catheter tube and the outer layer, a balloon filling cavity channel communicated with the balloon tube is formed in the catheter wall of the inner layer catheter tube, the inner layer catheter tube is made of thermoplastic materials, and the outer layer is made of thermosetting materials. The novel balloon urethral catheter is capable of guaranteeing smoothness of a liquid drainage cavity channel and the balloon filling cavity channel, and lowering medical risks when products are used and machining difficulty when the products are machined.

Owner:海南维力医疗科技开发有限公司

Vacuum deshydroxy method for quartz glass cell

InactiveCN101050054AImprove thermal stabilityHigh temperature resistanceGlass shaping apparatusAfter treatmentCrack resistance

This invention discloses a method for removing hydroxyls from quartz glass tube in vacuum. The method adopts 12 steps to realize hydroxyl removal from quartz glass tube by adjusting current and voltage. The method can retain or improve the thermal stability of quartz glass tube, improve the heat resistance and crack resistance of quartz glass tube, reduce the high-temperature deformation rate of quartz glass tube, and improve the adaptability of quartz glass tube. After treatment, the hydroxyl content in quartz glass tube is reduced to below 2 ppm. The high-temperature deformation rate of quartz glass tube is low, and the high-temperature deformation rate of quartz glass tube with a diameter below 120 mm is within 3%, which can satisfy the requirement of semiconductor filed for large-diameter quartz glass tube.

Owner:徐胜利

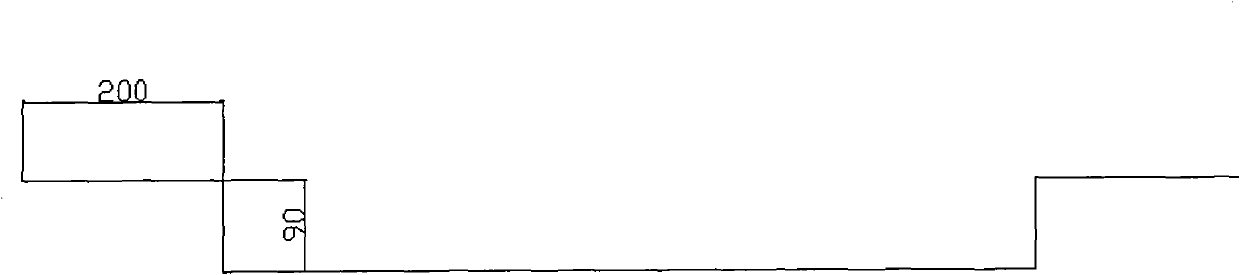

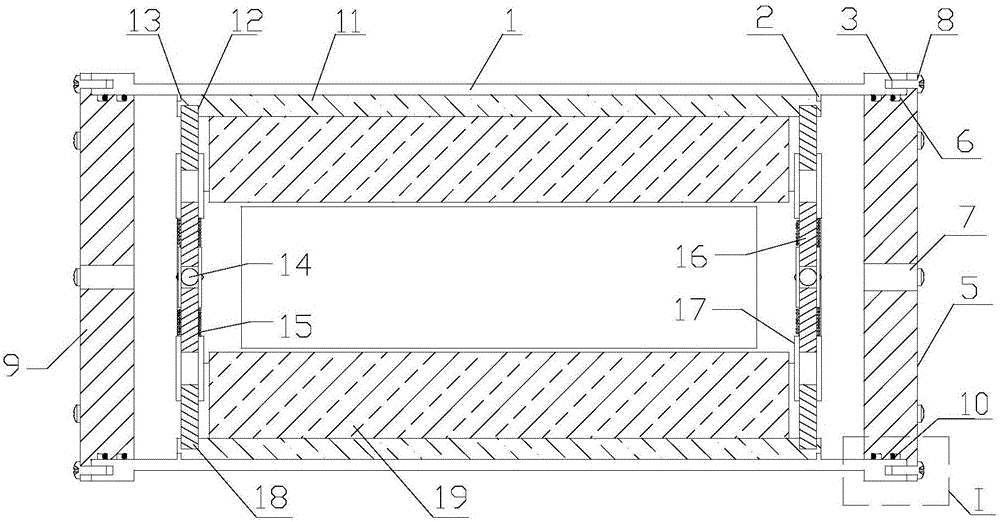

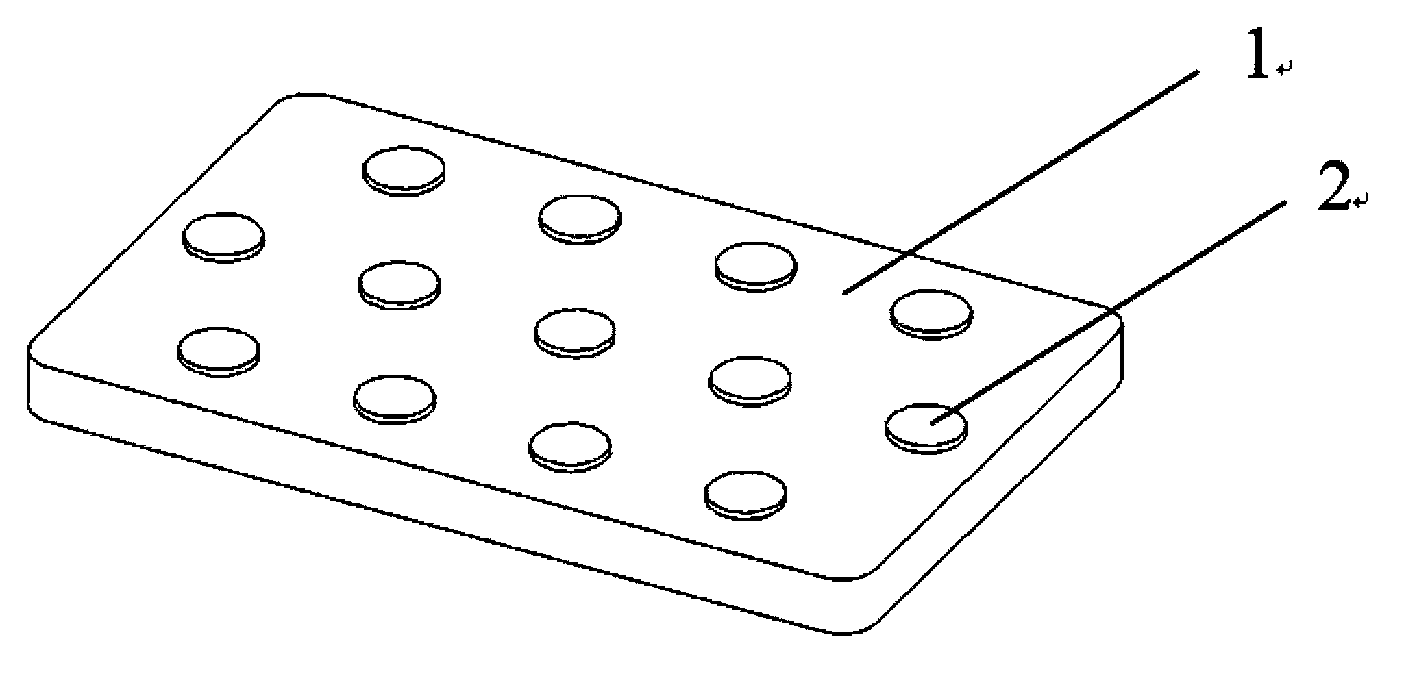

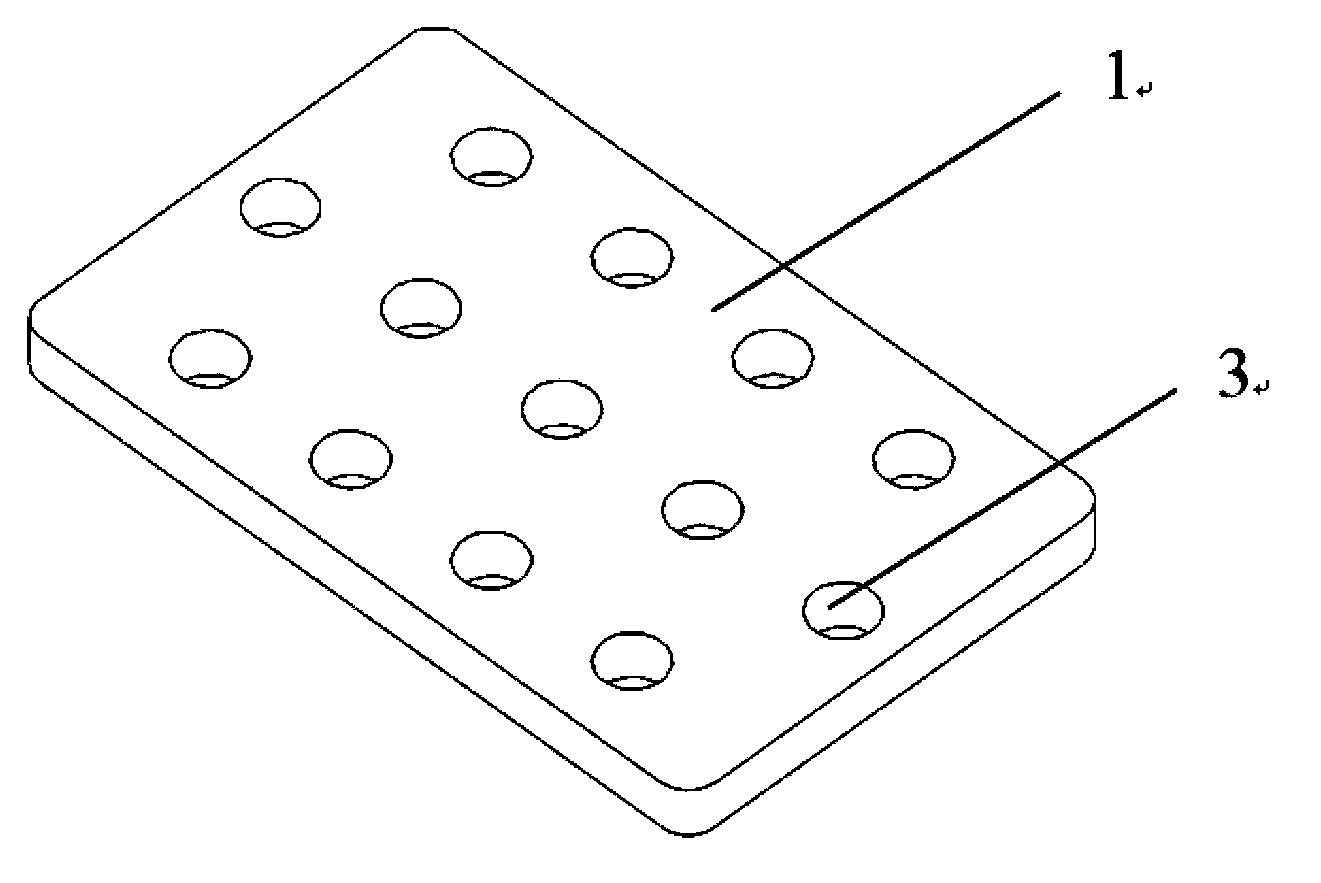

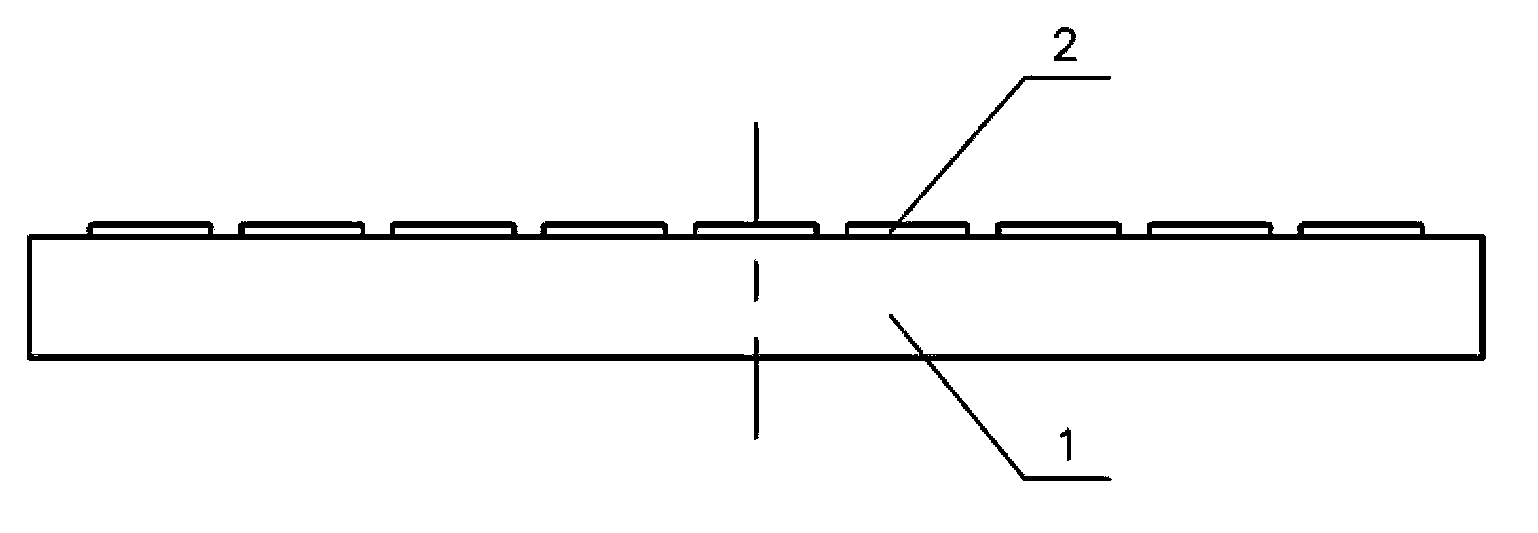

Split-type embedded and combined elastic base plate for rail transit fasteners

ActiveCN103669124AForm the effect of double stiffnessReduce deformation rateRail fastenersEngineeringNoise reduction

The invention relates to a split-type embedded and combined elastic base plate for rail transit fasteners. The elastic base plate is characterized by comprising a basic elastic base plate body (1), through holes (3) are formed in the basic elastic base plate body (1), and elastic columns (2) are arranged in the through holes (3) in a penetrating mode, wherein the thickness of the basic elastic base plate body (1) is different from the height of each elastic column (2). The elastic base plate is simple in structure and convenient to manufacture; the rigidity of the basic elastic base plate body and the rigidity of the elastic columns can be adjusted at will according to different needs, so compatibility of the elastic base plate is improved; the elastic base plate is convenient to maintain and replace, reduces maintenance cost and improves the vibration and noise reduction performance.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +3

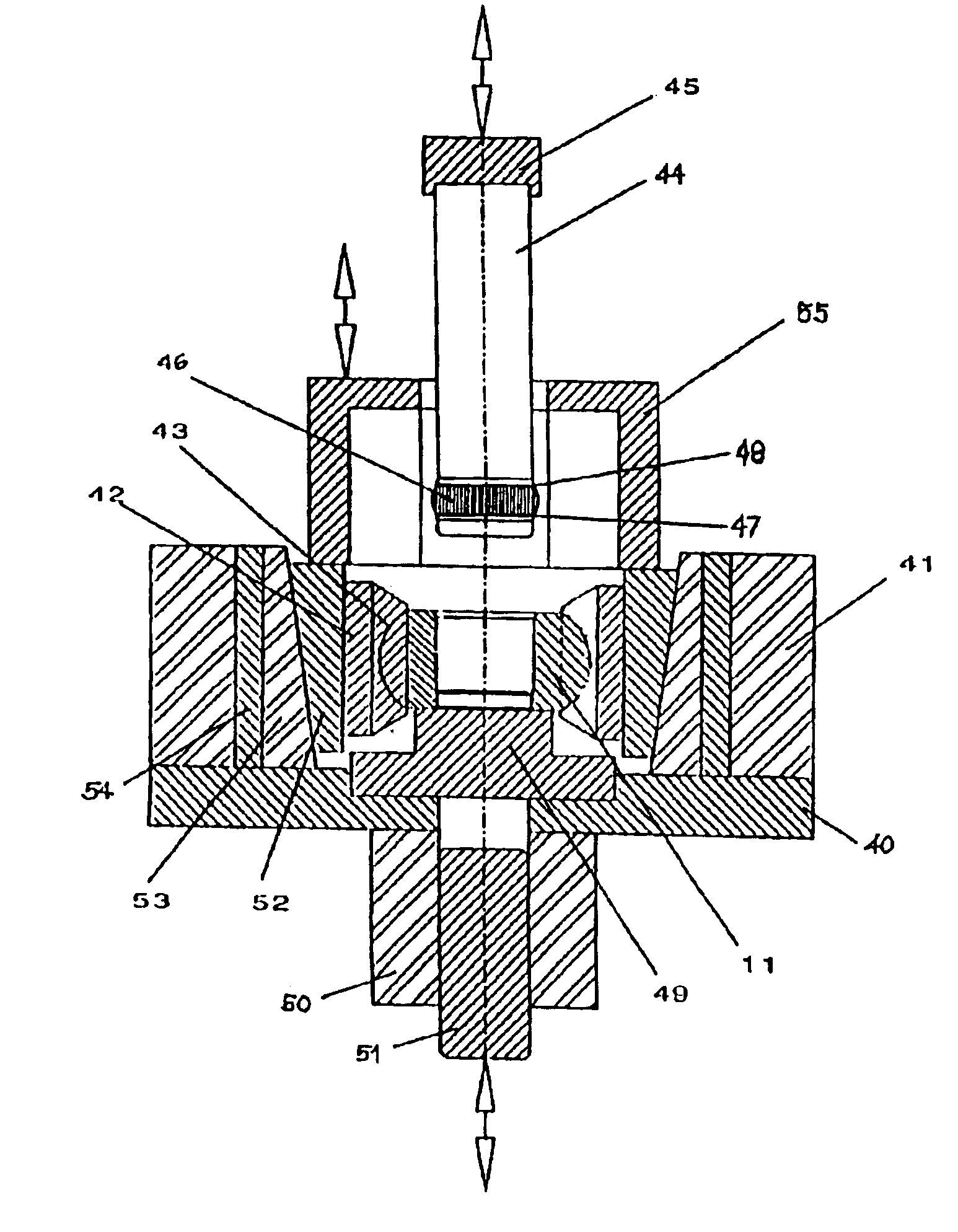

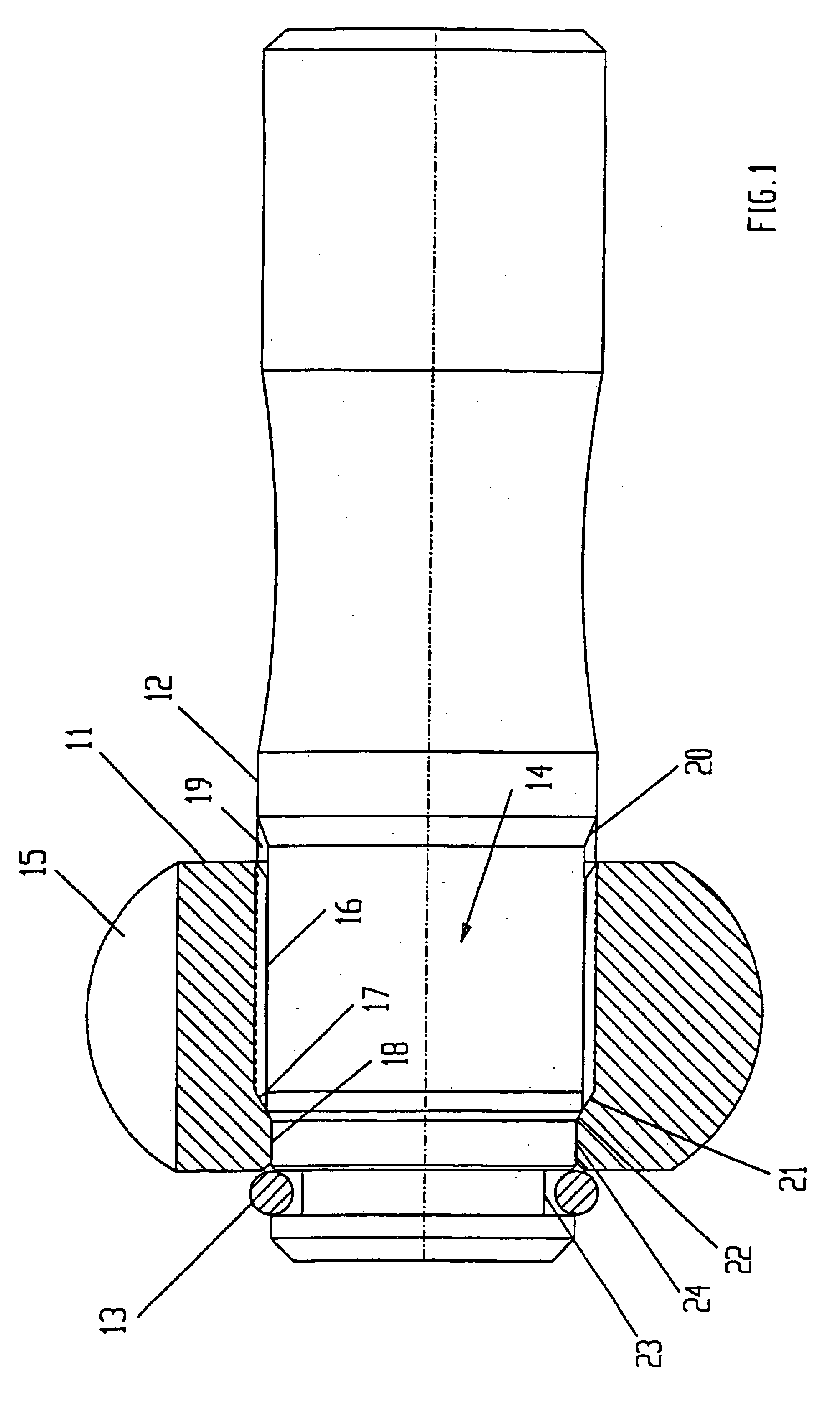

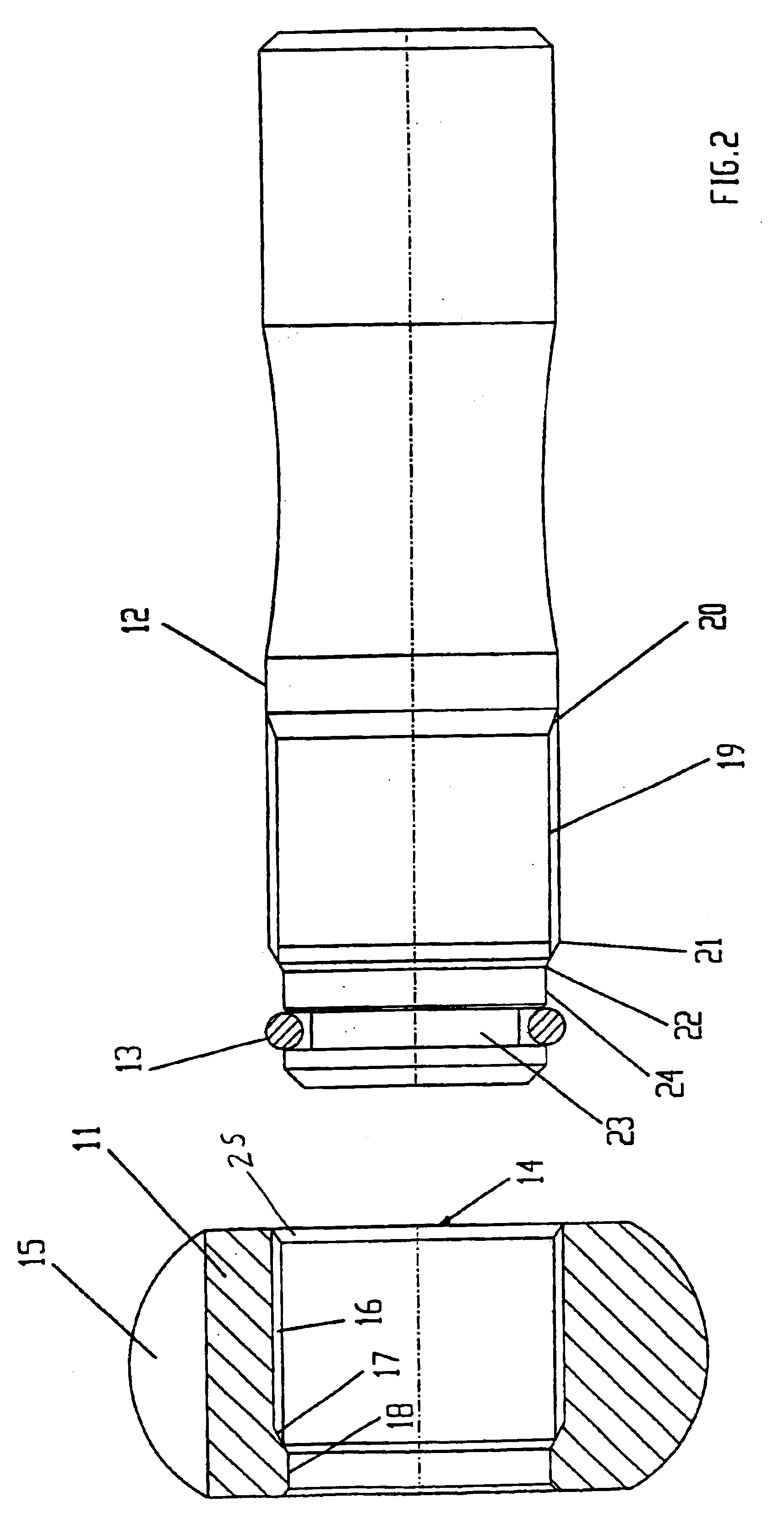

Hub member and shaft journal assembly and method

A production method involving forming an inner joint part of a constant velocity universal ball joint in the form of a hub member (11) which comprises a central through-aperture (14) with inner toothing (16) for receiving a shaft journal (12), and ball tracks (15) for receiving torque transmitting balls on the outer circumference, wherein a blank with largely finish-formed ball tracks is produced by non-chip-forming deformation; wherein, at the blank, outer surfaces and a smooth through-aperture (14) are finish-turned; and wherein, during simultaneous working stages, the ball tracks (15) are calibrated by non-chip-forming deformation and the inner toothing (16) in the through-aperture (14) is produced by pressing in a non-chip-forming way.

Owner:GKN AUTOMOTIVE GMBH

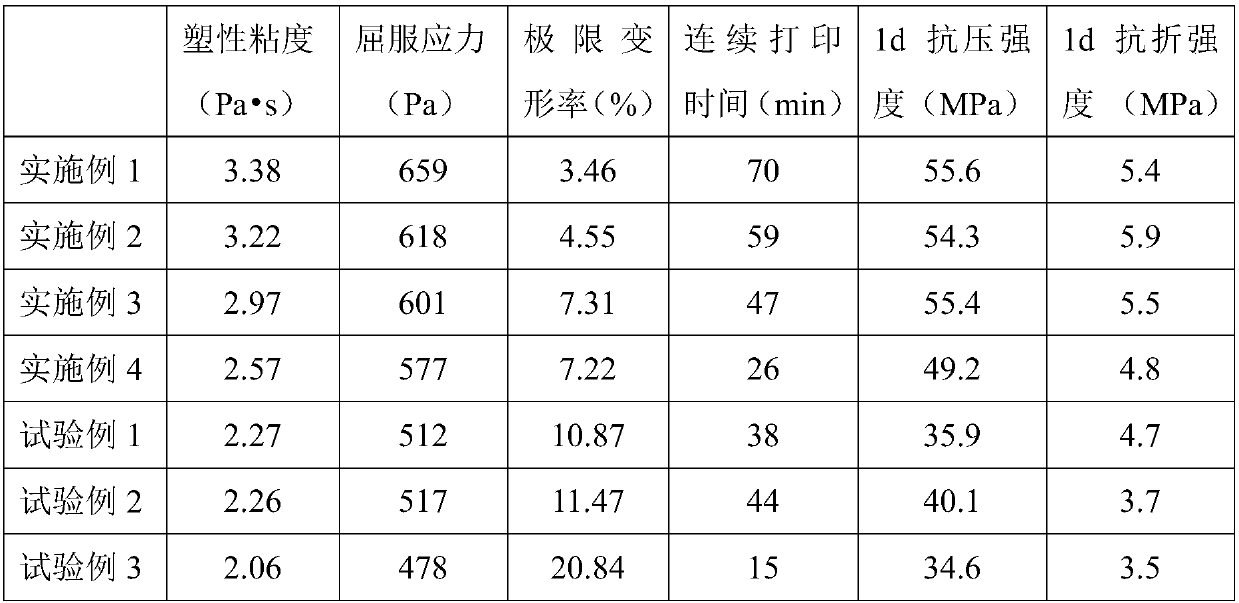

Desulfurized gypsum 3D (three dimensional) printing alkali-activated cementing material and use method thereof

ActiveCN109678445ARegulating the rate of setting and hardeningImprove mechanical propertiesAdditive manufacturing apparatusSolid componentAlkali activated

The invention belongs to the field of 3D (three dimensional) printing building materials and particularly relates to a desulfurized gypsum 3D printing alkali-activated cementing material and a use method thereof. The alkali-activated cementing material is prepared from a solid component and a liquid component which are separately stored, wherein, in parts by weight, the solid component comprises 40 to 60 parts of slag, 20 to 50 parts of desulfurized gypsum, 0.02 to 0.05 part of an activator, 3 to 10 parts of attapulgite clay, 0.1 to 0.5 part of a thickening agent and 1 to 5 parts of water absorbent resin; the liquid component comprises 20 to 40 parts of water. According to the invention, the desulfurized gypsum is taken as a main raw material; the extrusion requirements necessary for 3D printing are met by adding an admixture to synergistically regulate the setting and hardening rate and rheological property of the alkali-activated cementing material. The desulfurized gypsum can be recycled, and the use amount of the slag is reduced, so that the cost is reduced; in addition, the alkali-activated cementing material can be applied to 3D printing on a large scale to develop high-efficiency and green building materials.

Owner:UNIV OF JINAN

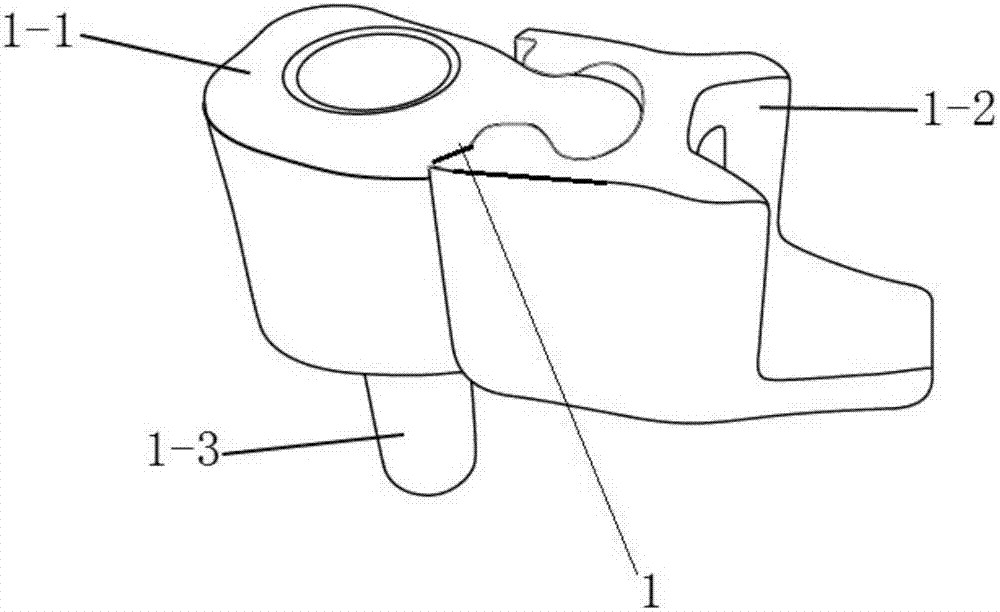

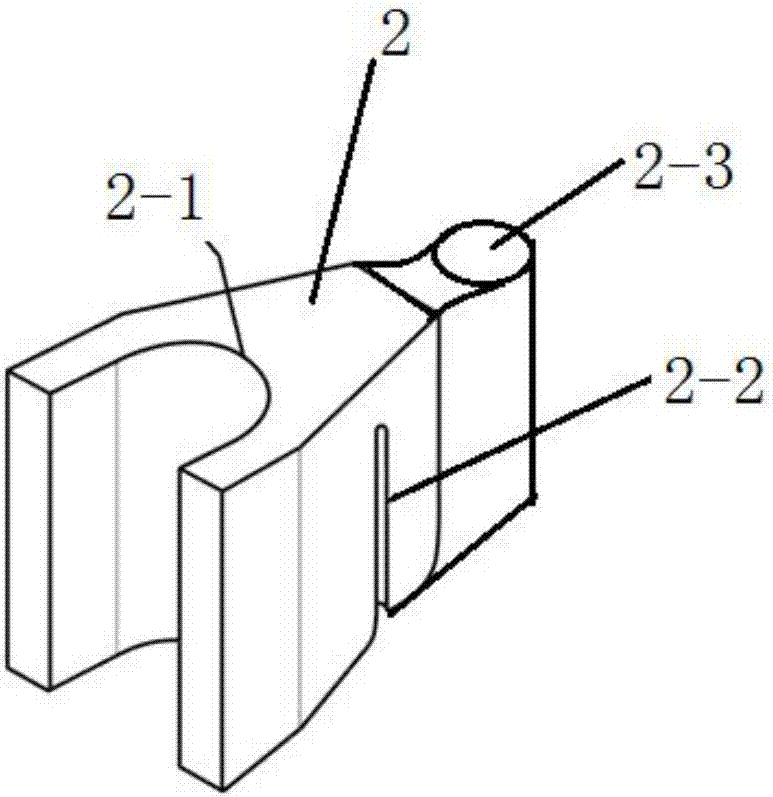

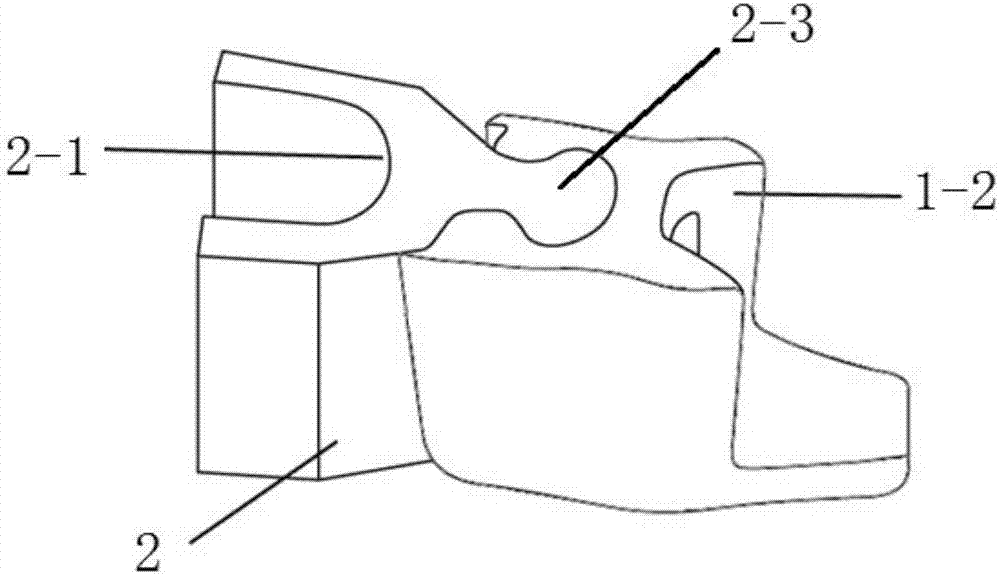

Near-chair designed dental implant guiding device capable of positioning and performing cavity preparation step by step

InactiveCN107184285AIncrease flexibilityReduce the probability of implant complicationsDental implantsBone drill guidesSEMI-CIRCLEMedical equipment

The invention belongs to the technical field of dental implant and medical equipment, and discloses a near-chair designed dental implant guiding device capable of positioning and performing cavity preparation step by step. The guiding device comprises a set of positioning devices and a set of semi-circle clasp devices. The positioning devices and the semi-circle clasp devices are connected by concave-convex fittings. The device has the advantages that a dentist can precisely implant a dental implant to a correct position near the chair only through a dental X-ray film, the complicated guiding plate manufacturing step is simplified, the work efficiency is improved; the position, depth, and direction of the dental implant can be determined, the success rate of dental implanting is increased, and the time is greatly saved for the dentist.

Owner:SICHUAN HONGZHENGBOEN DENTAL TECH CO LTD

Planographic plate for laser digital scanning and manufacture method thereof

ActiveCN101373333AHigh sensitivityHigh printing durabilityPhotosensitive materials for photomechanical apparatusLithographic artistLaser scanning

The invention relates to printing lithography, in particular to a printing lithographic plate (UV-CTP) for laser digital scanning and the preparation method thereof. The preparation method of the printing lithographic plate (UV-CTP) comprises the following steps: firstly cleaning, neutralizing, electrolyzing and oxidizing aluminum plate strip materials and hole-sealing to obtain the plate base; then, spread-coating the prepared photosensitive coating liquid on the plate base through extruding; and obtaining the UV-CTP after drying. The UV-CTP plate, following the photosensitive CTP plate and the thermosensitive CTP plate, belongs to a novel plate which can be directly imaged through computer digital laser scanning without pretreatment. Compared with the conventional PS plate and CTP plate, the UV-CTP plate has the following characteristics and advantages that the aluminum plate rolling technique with low deformation rate and low surface defect ensures that the plate base of the plate has better physical properties, particularly, the UV-CTP plate is advantageous in manufacturing cost, preservation period and universality over other CTP plates; and the UV-CTP plate has the characteristics of high dot reducibility, high photosensitive speed, great operating latitude and wide application, etc., therefore, the UV-CTP plate is applicable to printing materials, such as metal, plastic, etc., by the UV ink.

Owner:龙马铝业集团有限公司

Production technique of corrosion-resistant solid wood frame

InactiveCN105904560AHigh whitenessImprove corrosion resistanceWood treatment detailsWood impregnation detailsSolid woodVarnish

The invention provides a production technique of a corrosion-resistant solid wood frame and relates to the field of wood processing. The production technique comprises four steps including raw material treatment, cutting, assembling and paint coating. The raw material treatment step comprises four substeps including bleaching, soaking, drying and compressing. According to the production technique, frame bar wood used by the frame is subjected to corrosion resistance treatment such as soaking with a soak solution and varnish coating, so that the corrosion resistance of the frame is further optimized based on the prior art by means of the production technique, and the service life of the frame is effectively prolonged.

Owner:NINGGUO DINGXUAN CULTURAL & CREATIVE CO LTD

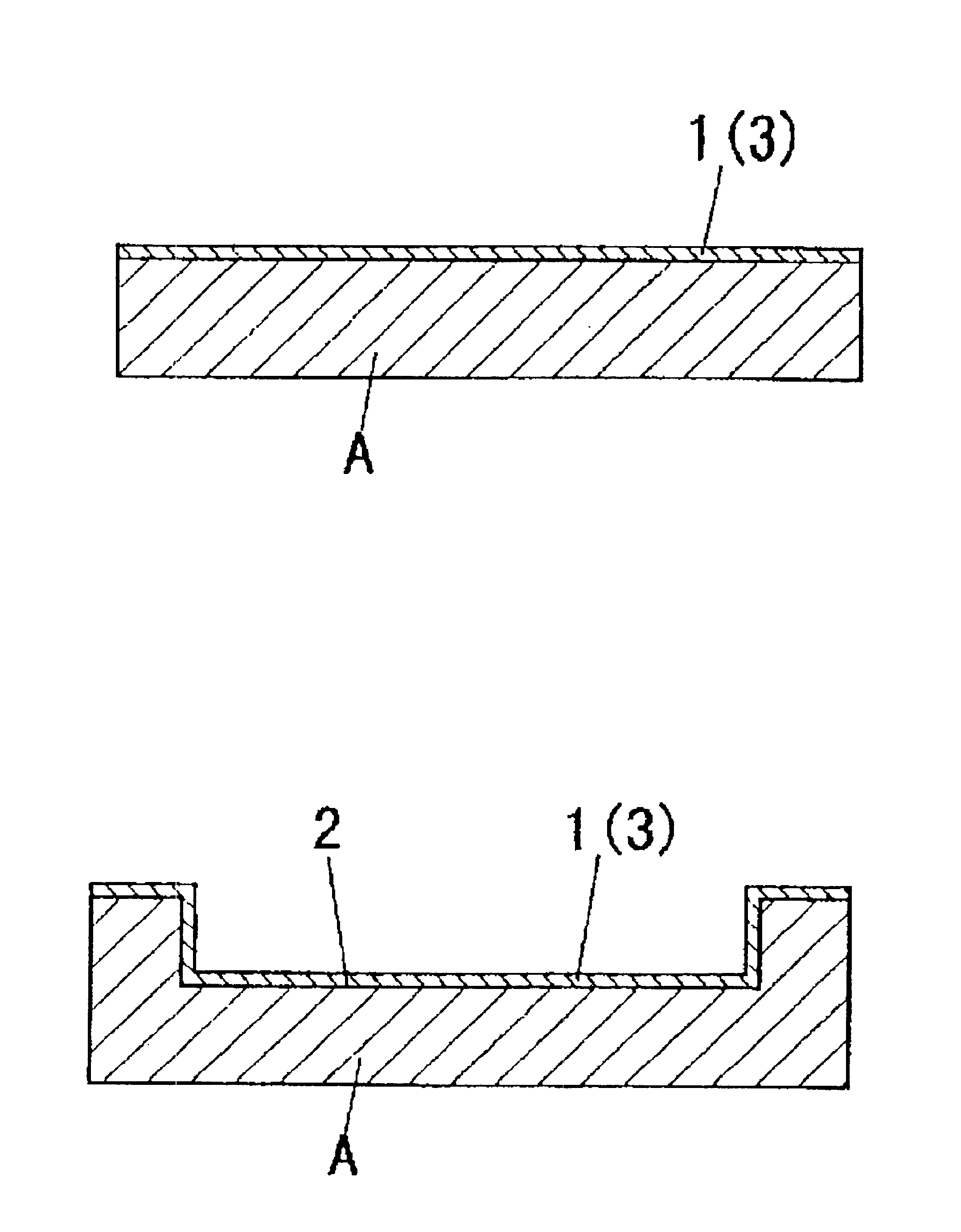

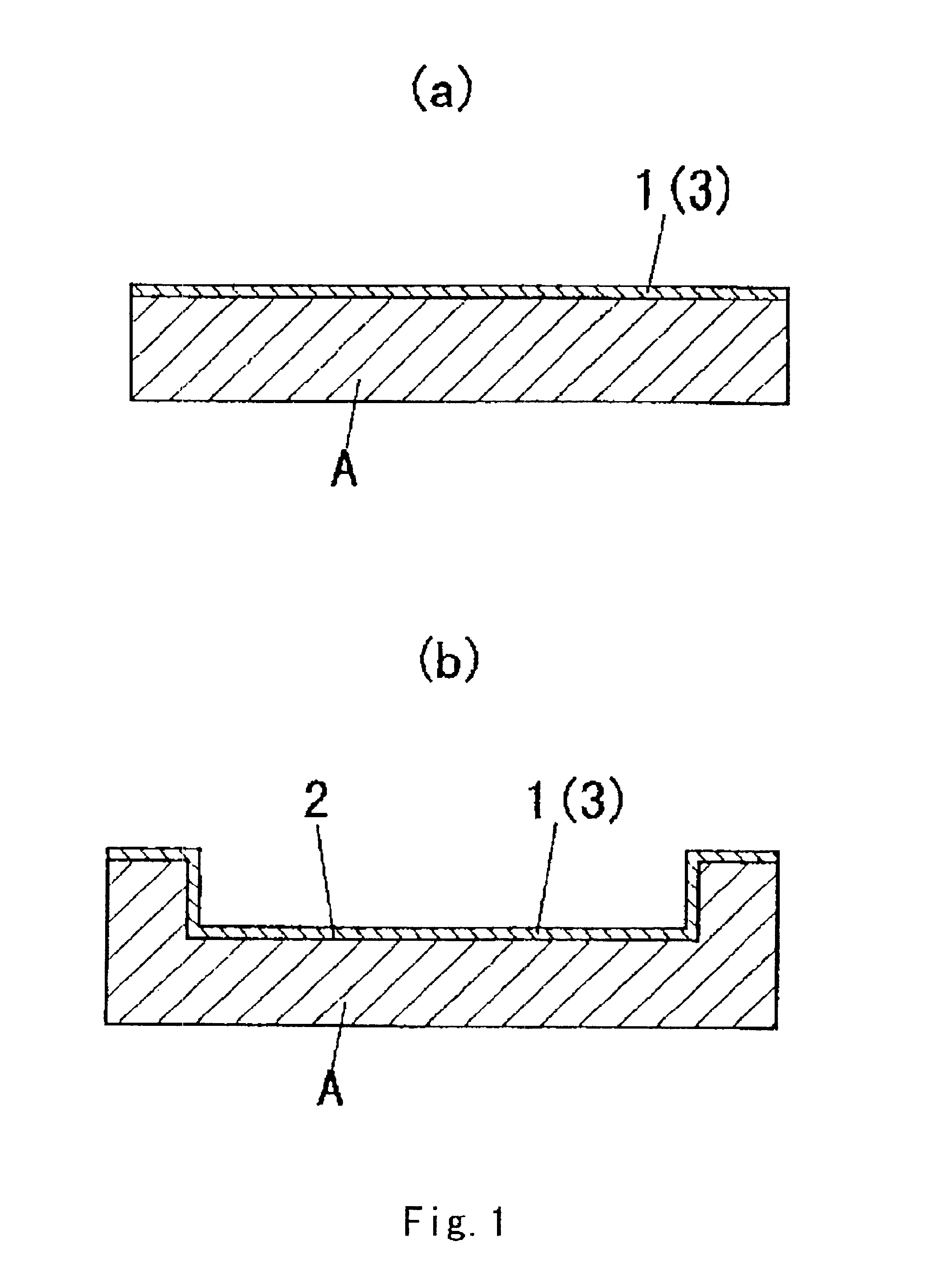

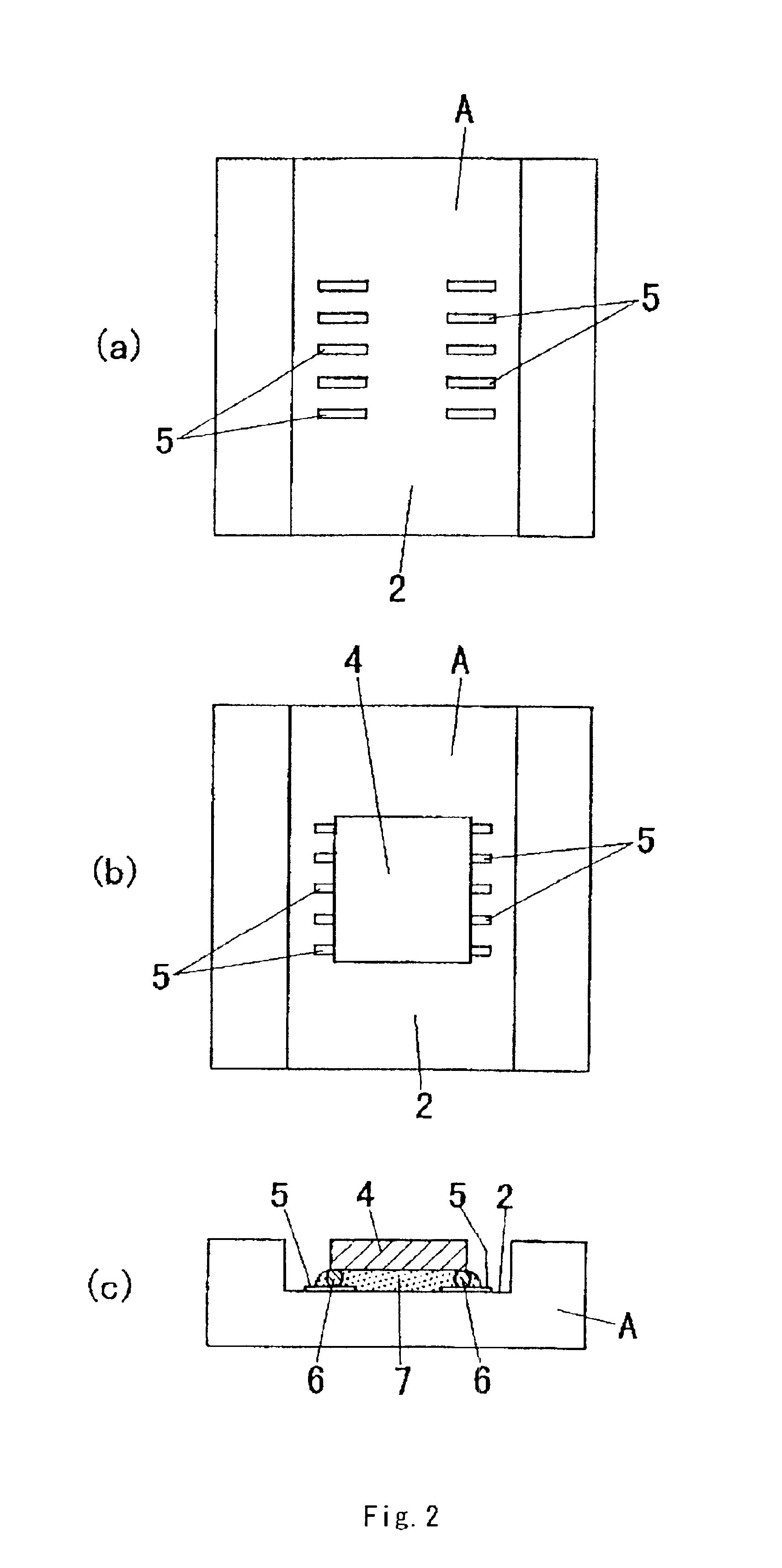

Resin moldings

InactiveUS6916527B2Improve adhesionStructuredVacuum evaporation coatingSolid-state devicesElectroplatingIon plating

A resin molded component, comprising metal coating treatment being provided on the surface by a physical deposition method chosen from among sputtering, vacuum deposition, and ion plating after the surface is activated by plasma treatment, and is produced by forming a resin composition combined a base resin comprising of a thermoplastic resin or a thermosetting resin with a rubber-like elastic material.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com