Desulfurized gypsum 3D (three dimensional) printing alkali-activated cementing material and use method thereof

A technology of cementitious material and desulfurized gypsum, applied in the direction of additive processing, can solve the problems of poor structural stability of rheological properties during setting time, difficult application, etc., and achieve good application prospects, improve stability, and improve the effect of compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

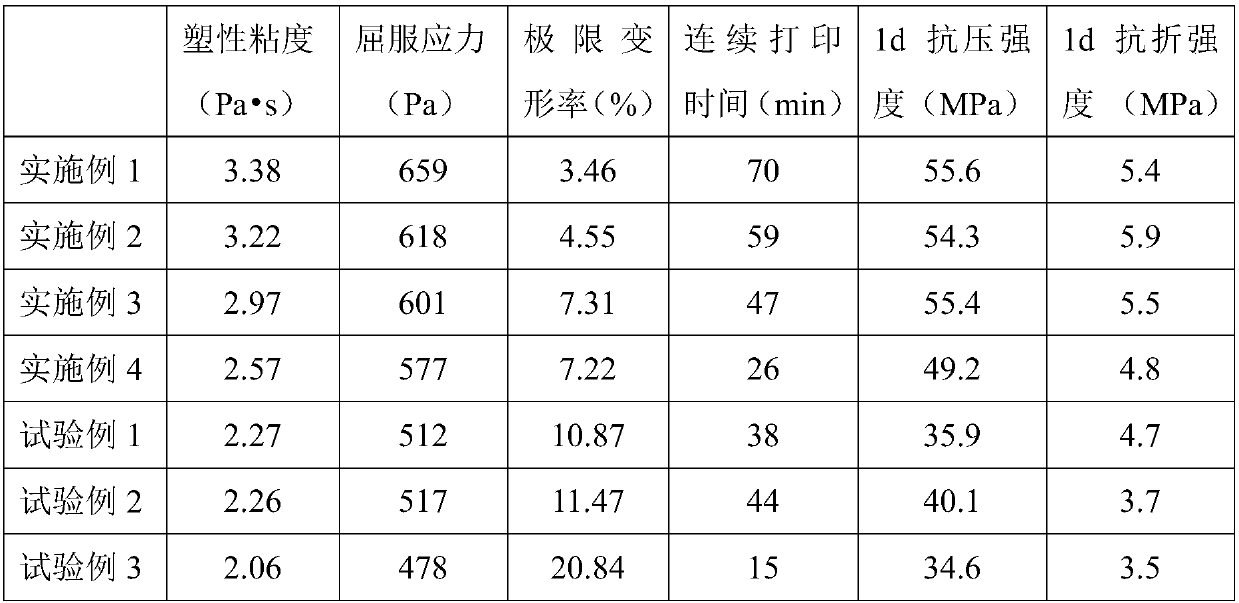

Embodiment 1

[0040] A desulfurized gypsum 3D printing alkali-activated gelling material. In parts by weight, the alkali-activated gelling material includes: 50 parts of slag, 35 parts of desulfurized gypsum, 0.02 parts of activator, 7 parts of attapulgite, and 0.5 part of thickener , 2 parts of water-absorbent resin, 25 parts of water. The alkali activator is a mixture of water glass, sodium sulfate and sodium phosphate, and the mass ratio of the three is 2:1:1 in sequence.

Embodiment 2

[0042] A desulfurized gypsum 3D printing alkali-activated gelling material. In parts by weight, the alkali-activated gelling material includes: 40 parts of slag, 22 parts of desulfurized gypsum, 0.04 parts of activator, 3 parts of attapulgite, and 0.3 parts of thickener , 5 parts of water-absorbent resin, 20 parts of water. The alkali activator is a mixture of water glass, sodium sulfate and sodium phosphate, and the mass ratio of the three is 2:1.2:1 in sequence.

Embodiment 3

[0044] A desulfurized gypsum 3D printing alkali-activated gelling material. In parts by weight, the alkali-activated gelling material includes: 40 parts of slag, 20 parts of desulfurized gypsum, 0.05 part of activator, 5 parts of attapulgite, and 0.2 part of thickener , 1 part of water-absorbent resin, 30 parts of water. The alkali activator is a mixture of water glass, sodium sulfate and sodium phosphate, and the mass ratio of the three is 2:0.8:1 in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com