Patents

Literature

324 results about "Alkali activated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali activated supersulphated binder

The invention describes an activated supersulphated aluminosilicate binder containing aluminosilicates, calcium sulphate and an activator containing alkali metal salts, wherein the aluminosilicates are selected from the group consisting of blast furnace slag, clay, marl and industrial by-products such as fly ash with the proviso that the Al2O3 content is greater than 5% by weight, wherein blast furnace slag is present in an amount exceeding 35% by weight and clay, marl and / or fly ash is present in an amount exceeding 5% per weight and wherein cement kiln dust in an amount of from 3 to 10% by weight is added to the mixture as an activator and calcium sulphate is used in an amount exceeding 5% by weight.

Owner:HOLCIM

Acid and high temperature resistant cement composites

InactiveUS20140047999A1Increase resistanceReduce resistanceSolid waste managementCement productionHigh resistanceSilicon dioxide

Process for production of acid and high temperature resistant cement composites, where the matrix is alkali activated F fly ash alone, F Fly ash combined with ground slag or ground slag alone. F-fly ash produces lower quality alkali activated cement systems. On the other hand the lack of calcium oxide results in very high resistance to medium and highly concentrated inorganic or organic acids. The high strength and low permeability of pure F-fly ash cement systems is achieved by using in the composition un-densified silica fume, the amorphous silicone dioxide obtained as by products in production of ferro-silicones. Precipitated nano-particle silica made from soluble silicates and nano-particle silica fume produced by burning silicon tetra chloride in the hydrogen stream.

Owner:RAZL IVAN

Alkali-activated cementing material and preparation method thereof

InactiveCN104446045ABroaden the way of resource utilizationIncrease consumptionCement productionLiquid waterAlkali activated

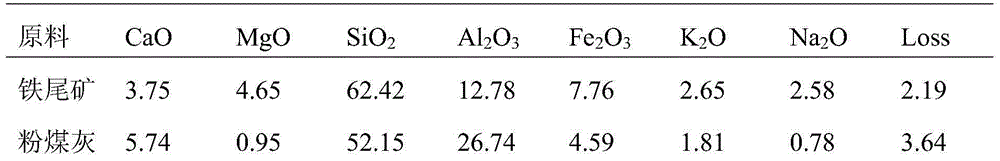

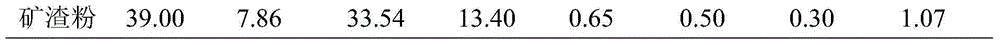

The invention relates to an alkali-activated cementing material prepared from siliceous iron tailings and a preparation method of the alkali-activated cementing material. The preparation method comprises the following steps: 1) proportionally and evenly mixing siliceous iron tailing powder, coal ash and slag powder together to obtain iron tailing powder-coal ash-slag powder compound powder; 2) mixing liquid water glass with water to obtain an alkali activating agent solution; 3) adding the alkali activating agent solution to the compound powder and stirring evenly to obtain an alkali-activated cementing material paste; 4) injecting the alkali-activated cementing material paste into a die for vibrating molding and maintaining under a normal temperature condition until knockout, thereby obtaining an alkali-activated cementing material net paste test piece; and 5) performing steam curing on the alkali-activated cementing material net paste test piece. The alkali-activated cementing material has the beneficial effects that the alkali-activated cementing material hardened paste has excellent mechanical properties, the 3d compressive strength of the optimal proportion of the hardened paste is greater than 60MPa and the 28d compressive strength of the hardened paste is greater than 80MPa.

Owner:WUHAN UNIV OF TECH

Composite pile with high permanent stability protection layer and its production and construction method

InactiveCN101343871AIncreased durabilityExtended service lifeClimate change adaptationBulkheads/pilesAlkali activatedGeopolymer

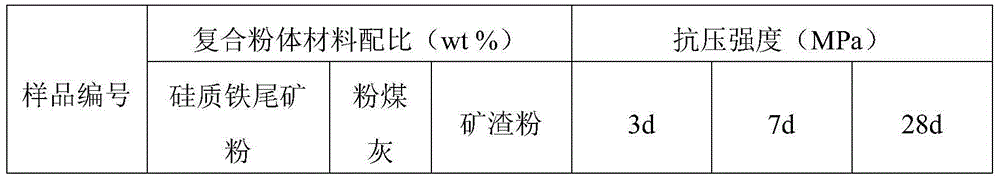

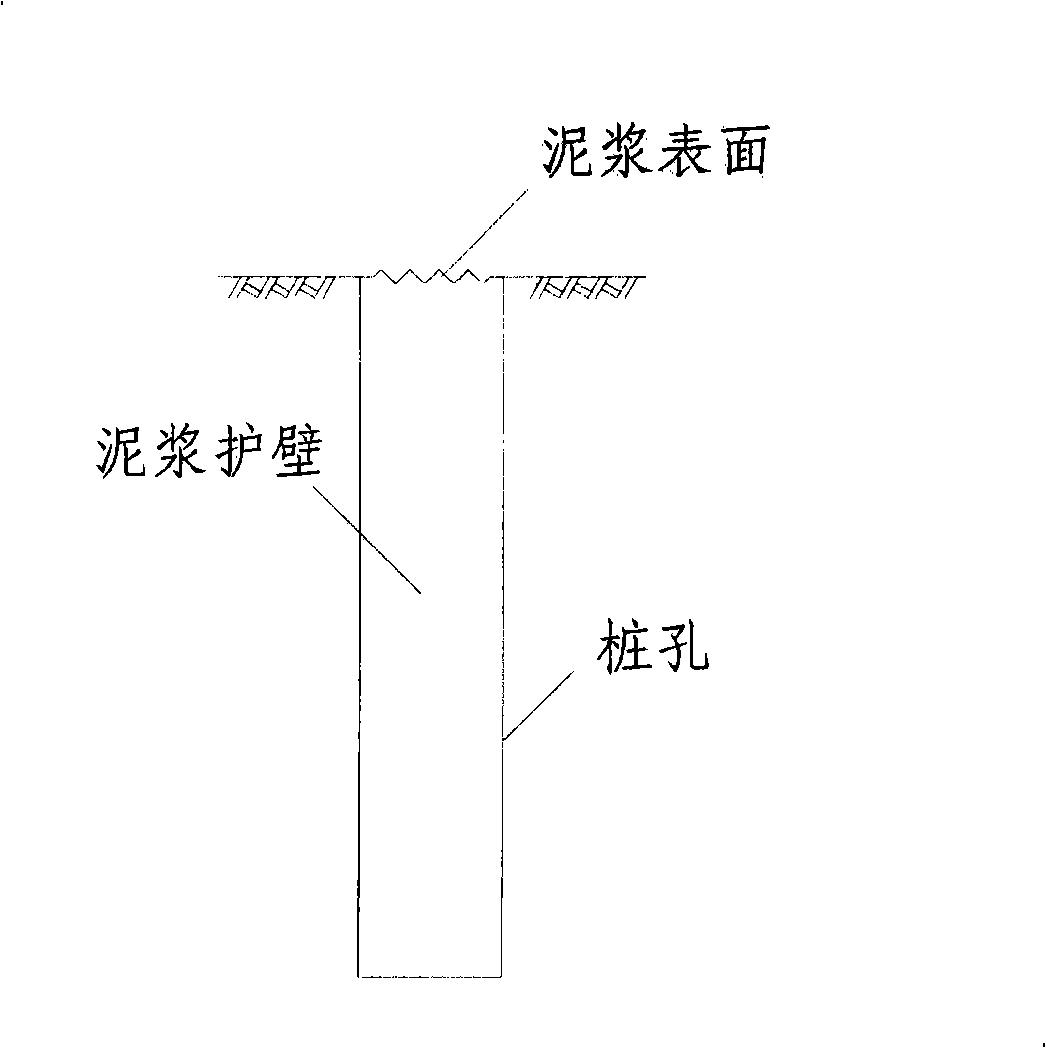

Disclosed is a high-durability protective layer compound pile. The structure of high-durability protective layer compound pile comprises: the compound pile is composed of a core bearing structure which is wrapped with a high-durability protective layer, the material of the protective layer adopts plastic or other modified products, asphalt and mortar or concrete, alkali activated material and the mortar or the concrete, geopolymer and the mortar or the concrete, reactive powder concrete, fiber reinforcement concrete base material, and resin mortar or concrete; The manufacturing and the construction can adopt six methods: firstly, site-casting can be performed to the protective layer and a core structure simultaneously; secondly, after the site-casting is performed to the protection wall of the protective layer, the site-casting is performed to the site-cast protective wall; thirdly, prefabrication is performed to the sleeve of the protective layer, and site-casting is carried out to the prefabricated sleeve of the site cast core structure of the sunk tube; fourthly, prefabrication is performed to the sleeve of the protective layer, the sleeve is taken as an outer mould plate to prefabricate the prefabricated sleeve of the core structure; fifthly, prefabrication is performed to the core structure, the core structure is taken as an inner mould plate to prefabricate the prefabricated sleeve of the core structure; and sixthly, site-casting is implemented to the protective layer and the core structure simultaneously.

Owner:BEIHANG UNIV

Flyash-based polymer concrete material and preparation method thereof

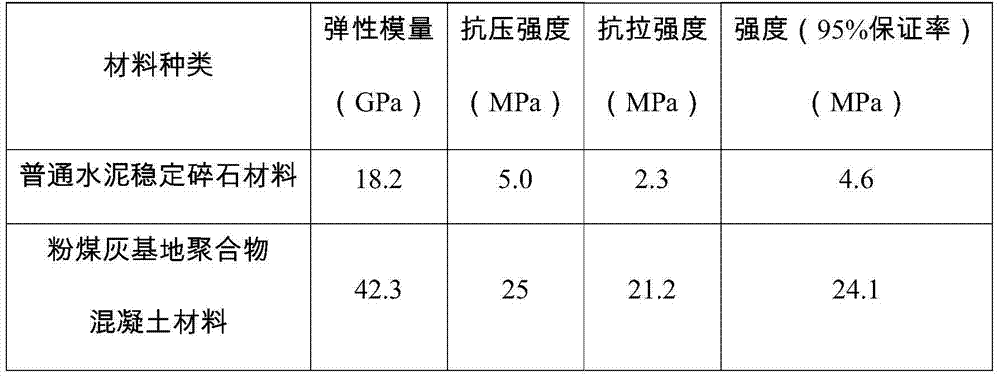

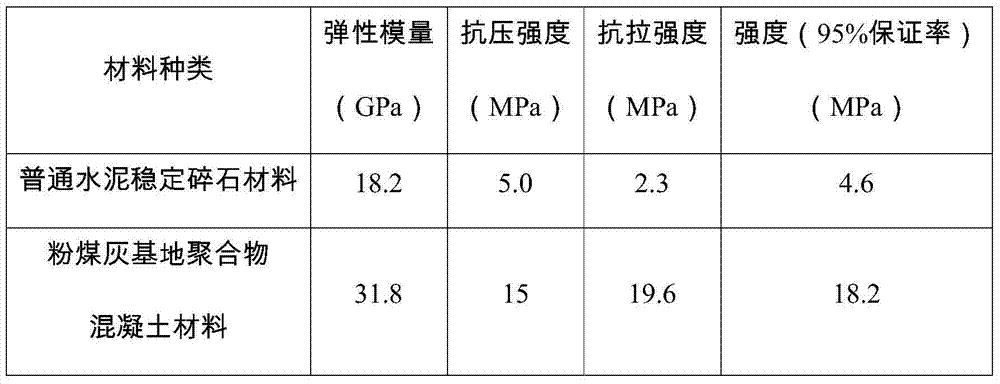

ActiveCN104496333APromote environmental protectionImprove mechanical propertiesPolymer sciencePolymer concrete

The invention discloses a flyash-based polymer concrete material and a preparation method and an application thereof. The flyash-based polymer concrete material comprises the following components in percentage by mass: 25%-45% of flyash, 0-15% of metakaolin, 10%-15% of cement, 0-5% of coal gangue and slag, 25%-35% of an alkali activator, 0.5%-1% of a retarder and 1%-5% of deionized water. An alkali-activated flyash-based polymer is adopted as a main gel material, so as to prepare an inorganic polymer concrete material; the polymer concrete material has the characteristics of high environmental protection property, good mechanical property and high early strength.

Owner:SHANGHAI PUDONG NEW AREA CONSTR GRP CO LTD

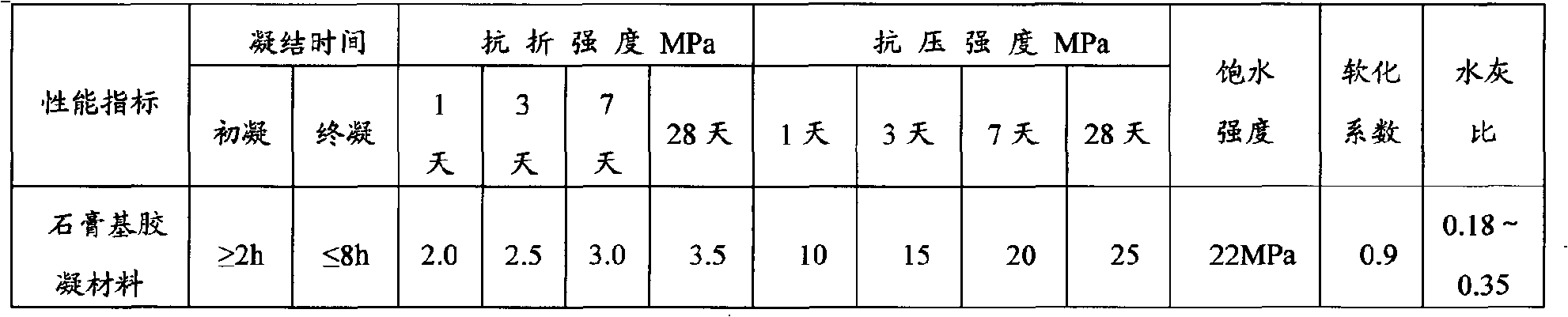

Gypsum based gel material prepared from undisturbed industry by-product gypsum and preparation thereof

InactiveCN101348340AHigh strengthImprove water resistanceSolid waste managementAlkali activatedUltimate tensile strength

The invention provides a gypsum based gelled material prepared from original state industrial by-product gypsum. The gelled material comprises the following components in mass percentage: 36 to 65 percent of original state dihydrate gypsum phase industrial by-product gypsum, 30 to 60 percent of silicon-aluminum active mineral material and 2 to 10 percent of alkali-activated material; the original state dihydrate gypsum phase industrial by-product gypsum which does not need to have impurities and adsorption water removed and be finely ground is directly mixed with the alkali-activated material and the active mineral material according a ratio, and the gypsum based gelled material with high strength, good water resistance and perfect comprehensive performance can be prepared by the extremely simple mixing-stirring step, and by taking the gypsum based gelled material as the base material, various gypsum building material products with high strength, water resistance and perfect comprehensive performance can be produced; therefore, the conventional mode of producing the gypsum building material product that the semi-hydrated building gypsum powder must be firstly prepared by calcining and dewatering, and the semi-hydrated building gypsum powder is used as the base material to produce the gypsum building material product is changed.

Owner:镇江沃地新材料投资有限公司

Pre-cured alkali-activated inorganic coating material

The invention discloses a pre-cured alkali-activated inorganic coating material, which is applied to the repair and protection of outside surfaces of underground spaces and buildings, and particularly applicable to the surface repair and protection of exterior walls, basements, water conservancy projects, tunnels, bridges, highways, docks and pools. According to the invention, through a pre-curing process, the alkali-activated coating material is more convenient to use, and pre-cured more fully; and the pre-curing process refers to a step-by-step curing process, and in the first curing, an alkali-activator is not completely put, so that the pre-curing is performed at low alkalinity, therefore, the pre-curing can be gradually performed in two steps or multiple steps.

Owner:吕孟龙

Highly dense alkali-activated coating material

The invention relates to a highly dense alkali-activated coating material which is used for repairing and protecting underground spaces and outer spaces of buildings, particularly surface repairing and protection of exterior walls, basements, water conservancy projects, tunnels, bridges, roads, yards and water pools, and belongs to the field of building materials. The highly dense alkali-activated coating material specifically comprises the following components in parts by weight: 2-80 parts of an alkali-activator, 20-120 parts of a gelatinized base material, 2-250 parts of sheet aggregates, 0-20 parts of a water repellent, 0-20 parts of a colorant, 0-80 pars of an expanding agent, 0-200 parts of filler and 0-50 parts of auxiliaries.

Owner:吕孟龙

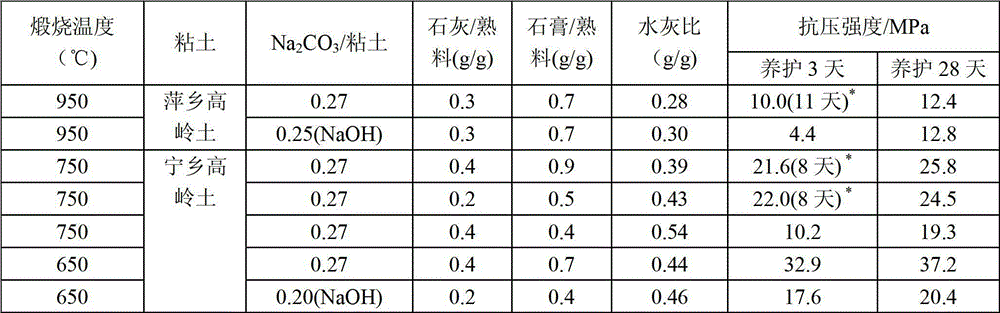

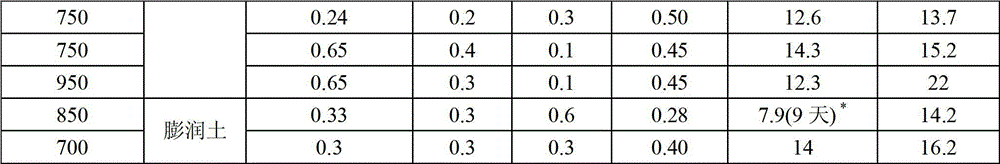

Method for preparing room-temperature curing one-component alkali-activated cement with calcination at low temperature

The invention discloses a method for preparing room-temperature curing one-component alkali-activated cement with calcination at a low temperature. The method comprises the following main steps that raw materials with silicon and aluminum oxide and an alkali activator are uniformly mixed, and then the obtained mixture is calcined for 2-3hours at the temperature of 650-950 DEG C to obtain clinkers; the obtained clinkers are uniformly mixed with lime and plaster in proportion and are ground to residues on sieve with granularity of 200 meshes, the mass ratio of the residues on sieve is at most 10 percent, and cement powder is obtained; and the powder can be hardened at the room temperature after the powder is mixed with water. Through the method, the raw materials with the silicon and aluminum oxide are alkalified, and the one-component alkali-activated cement with enough strength can be prepared at the temperature much lower than the calcination temperature (1450 DEG C) of Portland cement clinkers. The method is simple, the raw materials are easily obtained, and the early-strength performance of the cement is good. The use convenience of the alkali-activated cement is obviously increased, the performance of the cement is further optimized, the preparation cost is reduced, and the development potential is provided.

Owner:HUNAN UNIV OF SCI & TECH

Modified alkali-activated cementing material and preparation method thereof

The invention aims to provide a modified alkali-activated cementing material and its preparation method. Raw materials of the cementing material contain, by weight, 100 parts of a mixture of fly ash and slag, 25-50 parts of an alkali-activator, 0.5-2 parts of a retarder and 2-15 parts of polymer powder, wherein solid content of the alkali-activator is 30-40%. The method for modifying an alkali-activated cementing material with the polymer powder is compared with a method for modifying an alkali-activated fly ash and slag material with a polymer emulsion. The method of the invention has characteristics as follows: production technology is simple; measurement and preparation are accurate; storage and transport are safe; construction and usage are convenient; and the product has fast condensation, high bonding strength, good acid-resistance and alkali-resistance, excellent durability and the like.

Owner:SUZHOU CONCRETE CEMENT PROD RES INST +1

Fiber-reinforced alkali-activated cementing material and preparation method thereof

ActiveCN102910882AControl microcracksPrevention and inhibition of formationBreaking strengthPolyvinyl alcohol

The invention discloses a fiber-reinforced alkali-activated cementing material and a preparation method thereof. Polyvinyl alcohol fiber, water glass and water are added in slag and metakaolin; under the activation effect of the water glass, the slag and the metakaolin form the strength, and the polyvinyl alcohol fiber achieves the effect of enhancing the compressive strength and the breaking strength of the cementing material. The mass of polyvinyl alcohol is 0.08-0.25% of that of the slag and the metakaolin, and the mass of the water glass is 20-25% of that of the slag and the metakaolin. The preparation method comprises the steps as follows: dispersing the polyvinyl alcohol fiber in the slag and the metakaolin according to a formula amount, placing the mixture in a cement paste stirrer for stirring, and adding a water glass solution with adjusted modulus into the mixture to form uniformly mixed paste; and forming, and placing the product in a standard curing box for curing. The cementing material prepared according to the method has favorable long-term breaking strength and compressive strength after being cured and can reach the 28-d compressive strength of 83.7 MPa and the breaking strength of 11.7 MPa.

Owner:SHENYANG JIANZHU UNIVERSITY

Carbon/nickel-cobalt layered double hydroxide composite material and preparation method and application thereof

InactiveCN105489389AObvious cost advantageImprove stabilityHybrid capacitor electrodesHybrid/EDL manufactureActivated charcoal powderCapacitance

The invention provides a carbon / nickel-cobalt layered double hydroxide composite material which is prepared according to the following method that carbonization treatment is performed on raw material wood powder under the atmosphere of nitrogen; then the carbonized product is uniformly mixed with alkali and water, and most of the water of the mixture is heated and evaporated and then activation treatment is performed so that alkali activated charcoal powder is prepared; the alkali activated charcoal powder is added in a nitrogen doped solution, and hydrothermal reaction is performed ultrasonic uniform mixing so that nitrogen doped activated charcoal powder is prepared; the nitrogen doped activated charcoal powder is added in deionized water, and the mixed solution of nickel salt and cobalt salt is added after dispersion; an alkali solution is added after temperature rising and stirring, and heat preservation and stirring reaction is continued; and then the reaction solution is post-treated so that the finished product is obtained. Low-cost, environment-friendly, renewable and easily obtaining wood material acts as the raw material to prepare carbon material used for manufacturing of the carbon / nickel-cobalt layered double hydroxide composite material used for a supercapacitor so that the cost advantage is obvious. Besides, stability of the composite material can be enhanced by the nitrogen doped feature of the carbon material in the composite material so that capacitance output capability of the composite material can be enhanced.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for producing activated carbon for electrode of electric double-layer capacitor

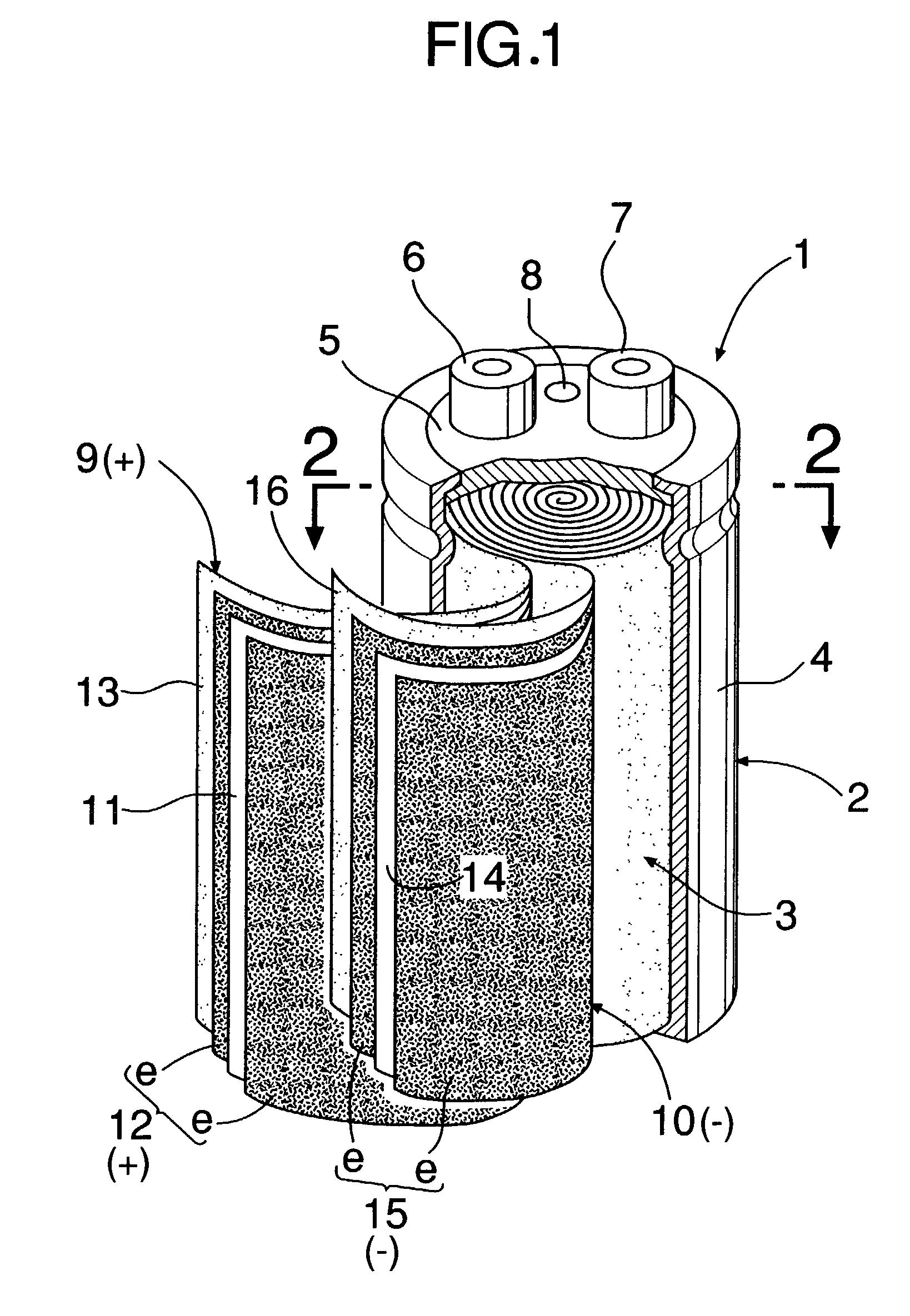

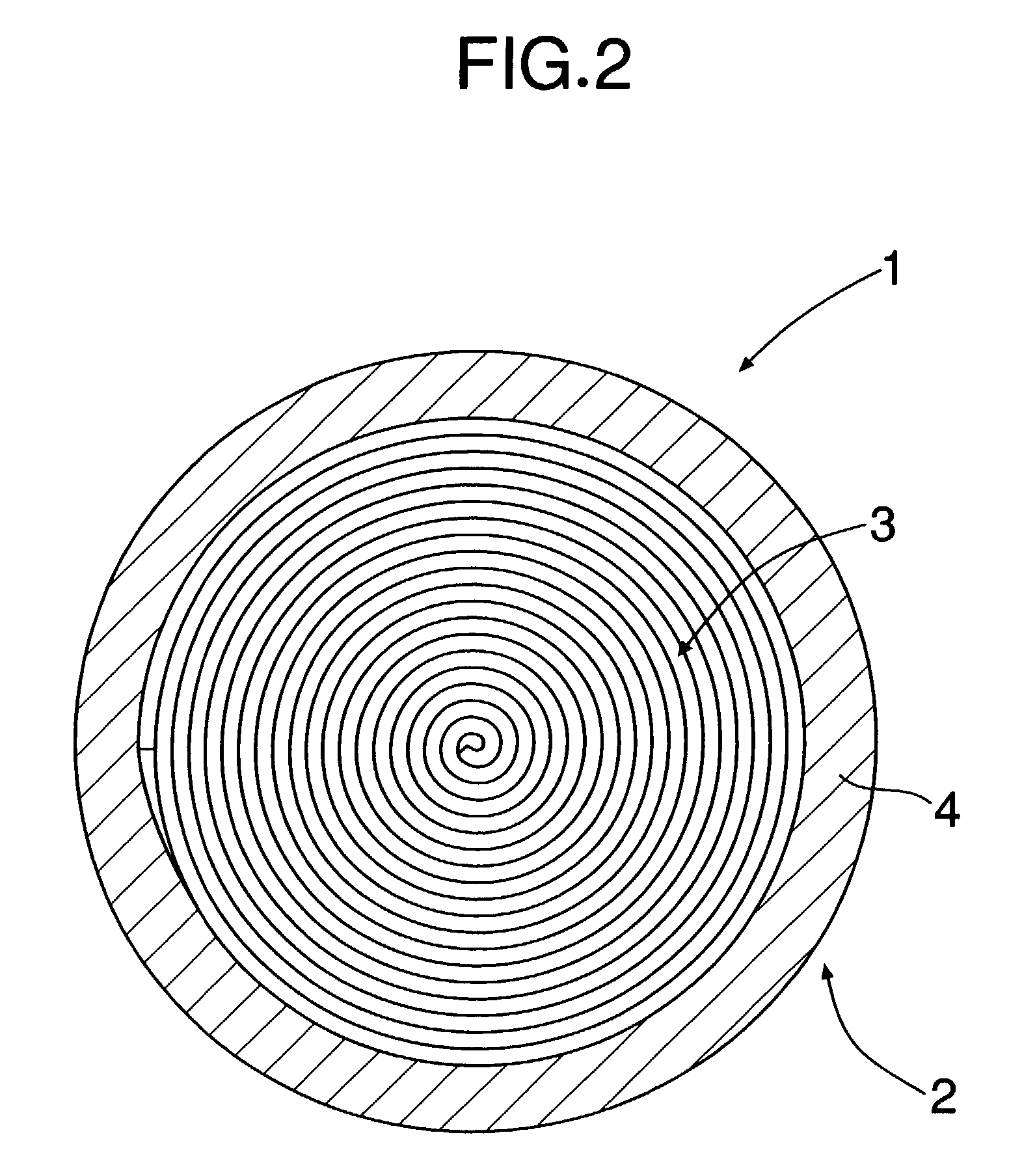

InactiveUS7214646B1Solve the small densityFacilitated DiffusionHybrid capacitor electrolytesHybrid capacitor electrodesActivated carbonAtmospheric air

To produce activated carbon for an electrode of an electric double-layer capacitor, the following steps are carried out sequentially: a step of subjecting a massive mesophase pitch to a pulverizing treatment to provide a pulverized powder; a step of subjecting the pulverized powder to an infusibilizing treatment under conditions of a temperature in a range of 300° C. (inclusive) to 450° C. (inclusive) in the atmospheric air current, a step of subjecting the pulverized powder to a carbonizing treatment under conditions of a temperature in a range of 600° C. (inclusive) to 900° C. (inclusive) in an inert gas current to provide a carbonized powder, a step of subjecting the carbonized powder to an alkali activating treatment under conditions of a temperature in a range of 500° C. (inclusive) to 1,000° C. (inclusive) in an inert gas atmosphere, followed by the post treatments, thereby producing alkali-activated carbon, and a step of subjecting the alkali-activated carbon to a pulverizing treatment. If an electrode is produced using the activated carbon, the electrode density can be increased.

Owner:HONDA MOTOR CO LTD +1

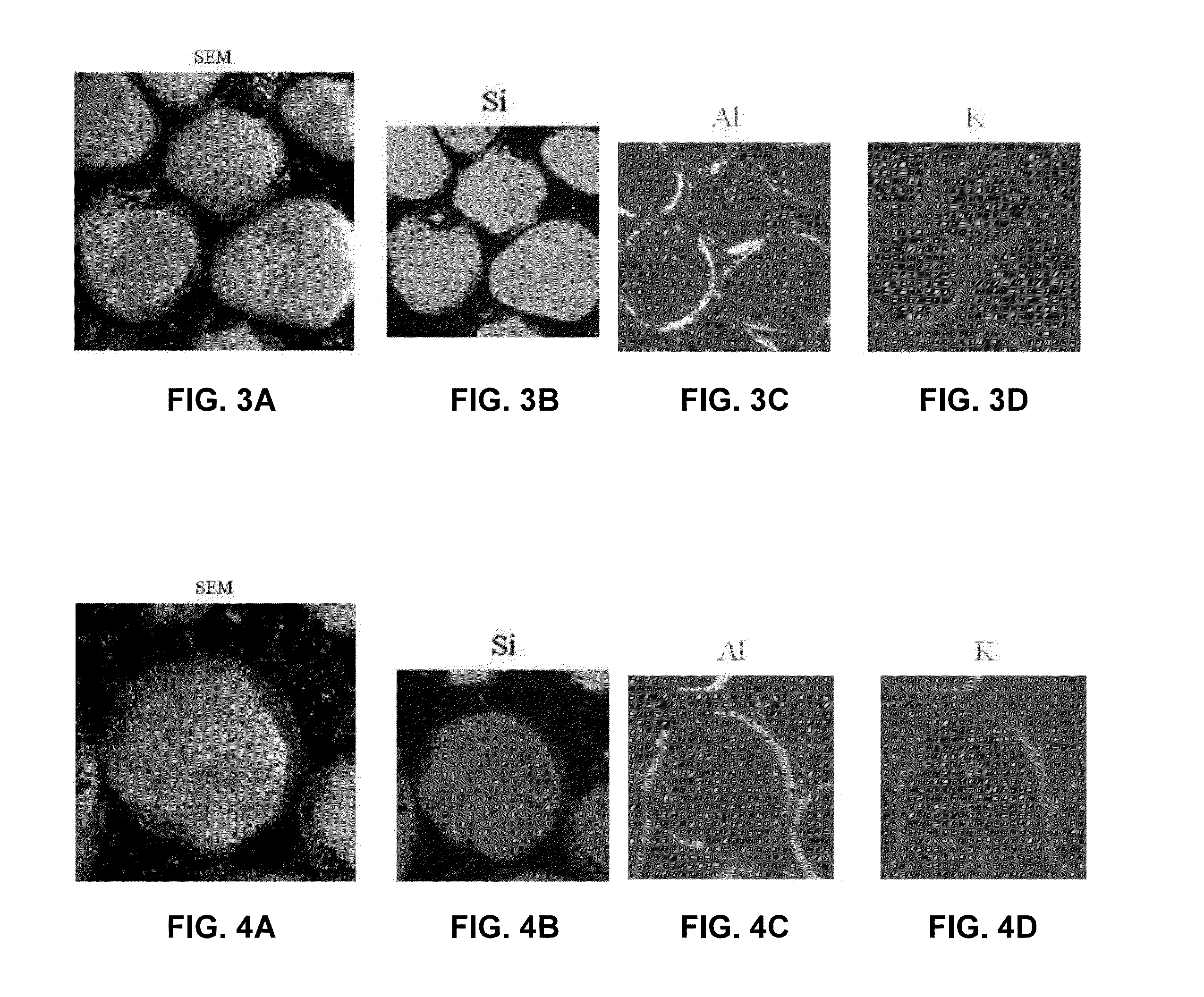

Alkali-activated coatings for proppants

InactiveUS20130274153A1Good physical propertiesHigh compressive strengthFluid removalFlushingAlkali activatedPolymer coatings

Owner:GEOPROPPANTS

Method of preparing electrode material for carbon-based supercapacitor by taking bamboo powder as raw material

ActiveCN105469999AObvious cost advantageFully removedHybrid capacitor electrodesCapacitanceHigh carbon

The invention provides a method of preparing electrode material for a carbon-based supercapacitor by taking bamboo powder as raw material. The method includes the following steps: under the protection of nitrogen, evenly mixing a carbonized product with alkali and water after bamboo powder as raw material undergoes two-stage carbonization, heating the above mixture to enable the water content of the mixture to be 10%-30% of that of the original mixture, conducting two-stage activation, cleaning and drying the mixture to obtain alkali activated bamboo powdered carbon, adding the alkali activated bamboo powdered carbon into a phosphor and nitrogen doped solution, conducting ultrasonic uniform mixing, then conducting a hydro-thermal reaction, and finally obtaining a finished product after post-treatment is conducted on a reaction solution. Cheap, environment-friendly and renewable bamboo that is easily available is taken as raw material to prepare carbon material for a supercapacitor, so the method has the noticeable cost advantage. Through two-stage carbonization and two-stage activation, impurities in bamboo material can be fully removed, and porous carbon material with high carbon content can be formed. Moreover, a phosphor, nitrogen and hetero atom codope process is introduced to enable bamboo carbon to have extra fake capacitance, so the capacitive performance of the supercapacitor can be greatly improved.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Retardation method for alkali-activated-carbonate/slag gel material

InactiveCN1699251AEasy to useThe process steps are simpleSolid waste managementBarium dichlorideBarium nitrate

The invention provides a retardation method for alkali-activated-carbonate / slag gel material which comprises, at normal temperature, calculated by mass portions, dissolving 4-10 portions of barium chloride or barium nitrate into 100 portions of water, thus obtaining retarder solution, then charging 200-300 parts of slag powder, agitating homogeneously, charging in turn 220-3100 parts of exciting agent, 200-3800 parts of marginal carbonate powdered ore, agitating homogeneously, finally obtaining the end product.

Owner:SOUTH CHINA UNIV OF TECH

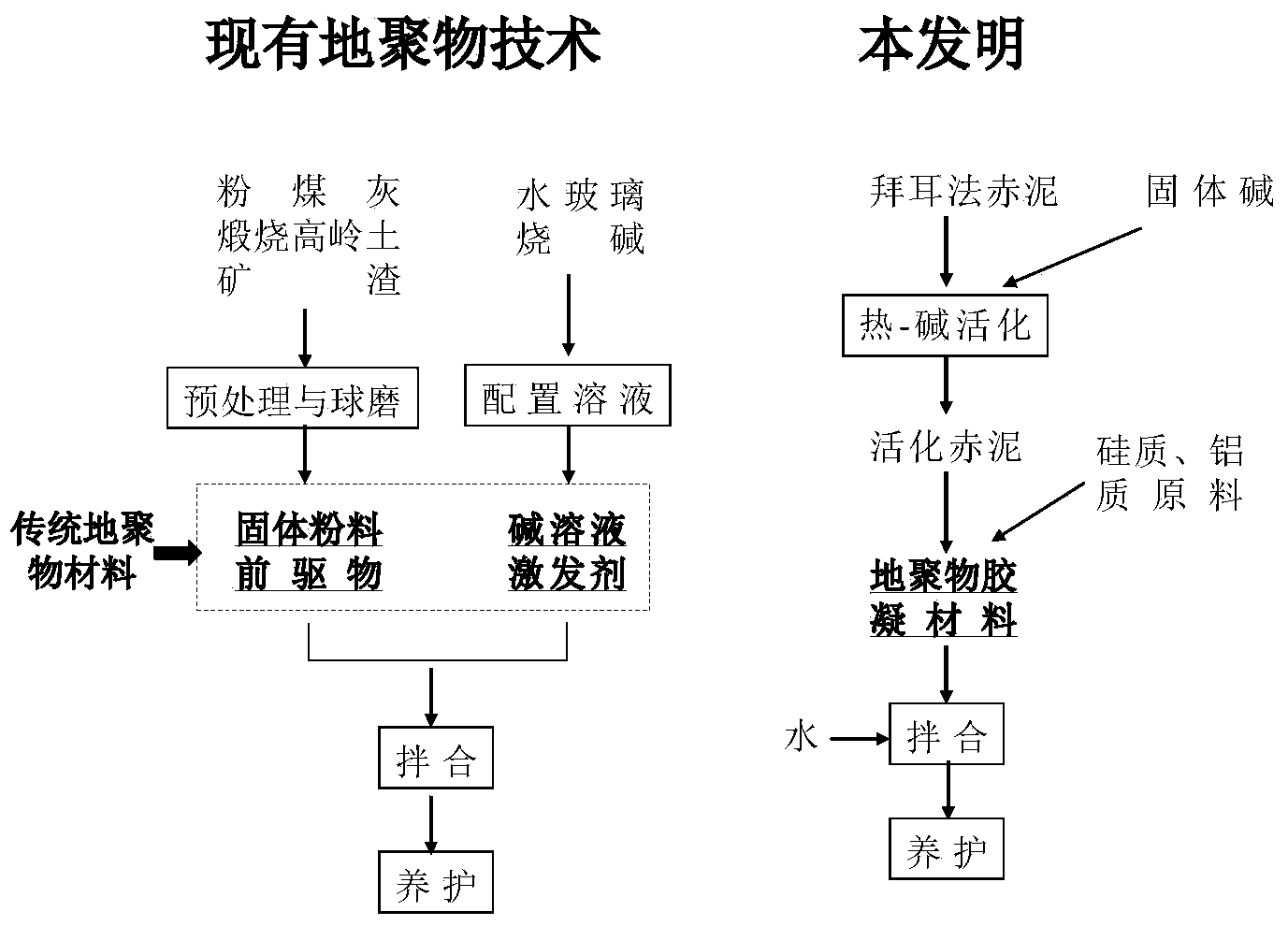

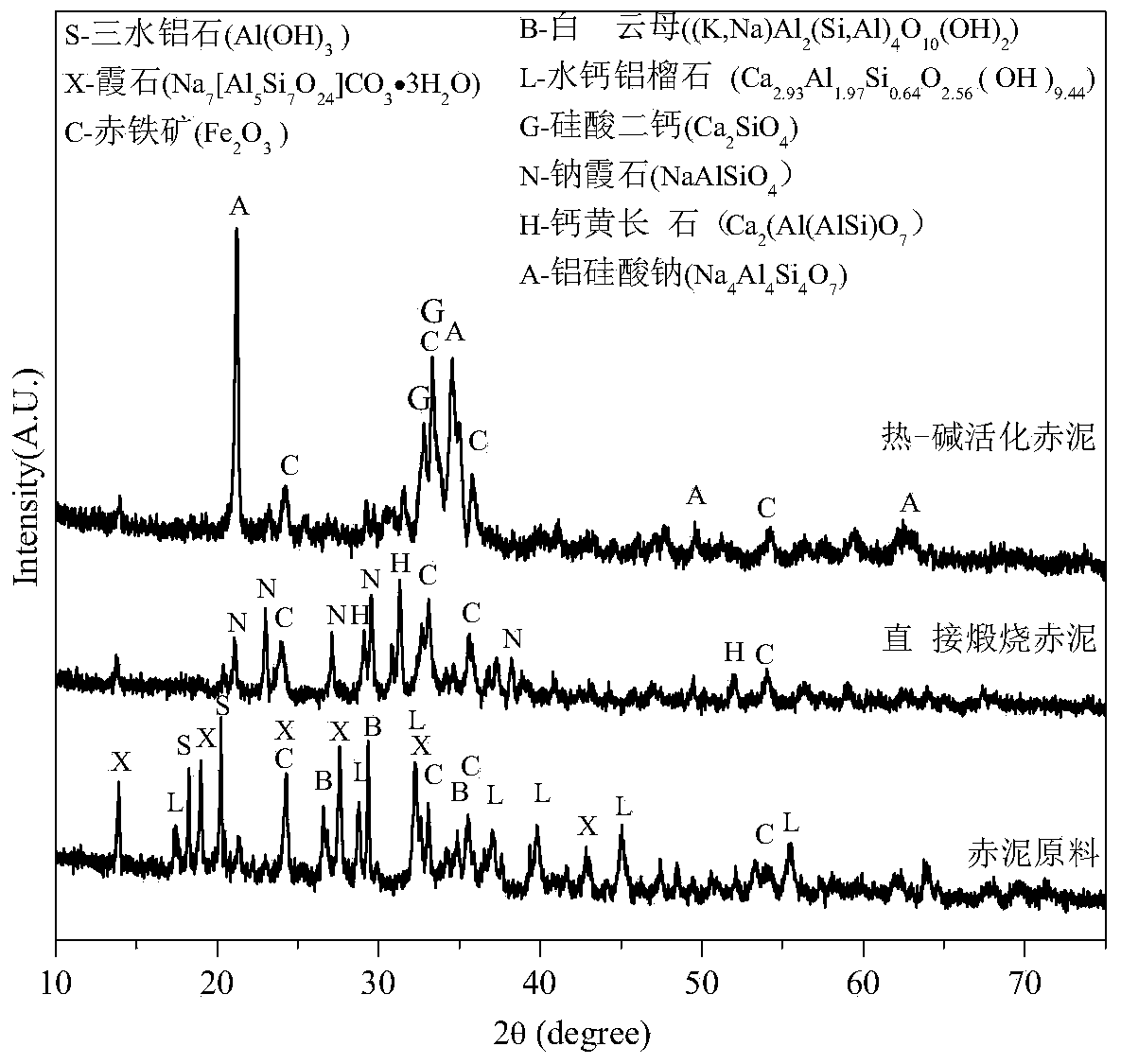

Method for producing geopolymer binding material by red mud and geopolymer binding material

The invention discloses a method for producing a geopolymer binding material by red mud and the geopolymer binding material. The method comprises the following steps: (1), the red mud is evenly mixed with hydroxide of alkali metal or carbonate, and 3 to 5 mol of alkali metal is contained in the hydroxide of alkali metal or the carbonate, which is added into the red mud per kilogram; (2), the mixture is calcined for 1 to 3 hours at the temperature of 700 DEG C to 900 DEG C, and a heat-alkali activated red mud is obtained after cooling; (3), the activated red mud is mixed with granulated blast-furnace slag powder according to the mass ratio of (1.5:1):(4:1). When being used, the geopolymer binding material produced according to the method is evenly mixed with water with the mass ratio of 60 percent to 70 percent so as to achieve maintenance formation. According to the invention, waste material red mud produced by using Bayer processes largely is environmentally friendly and low in cost. The geopolymer binding material can be directly added with water to stir during the use, alkaline boosters such as water glass and the like are not required to be added, steaming and pressing or dried formation are not required, the use is convenient, and the adaptability is good.

Owner:HUAZHONG UNIV OF SCI & TECH

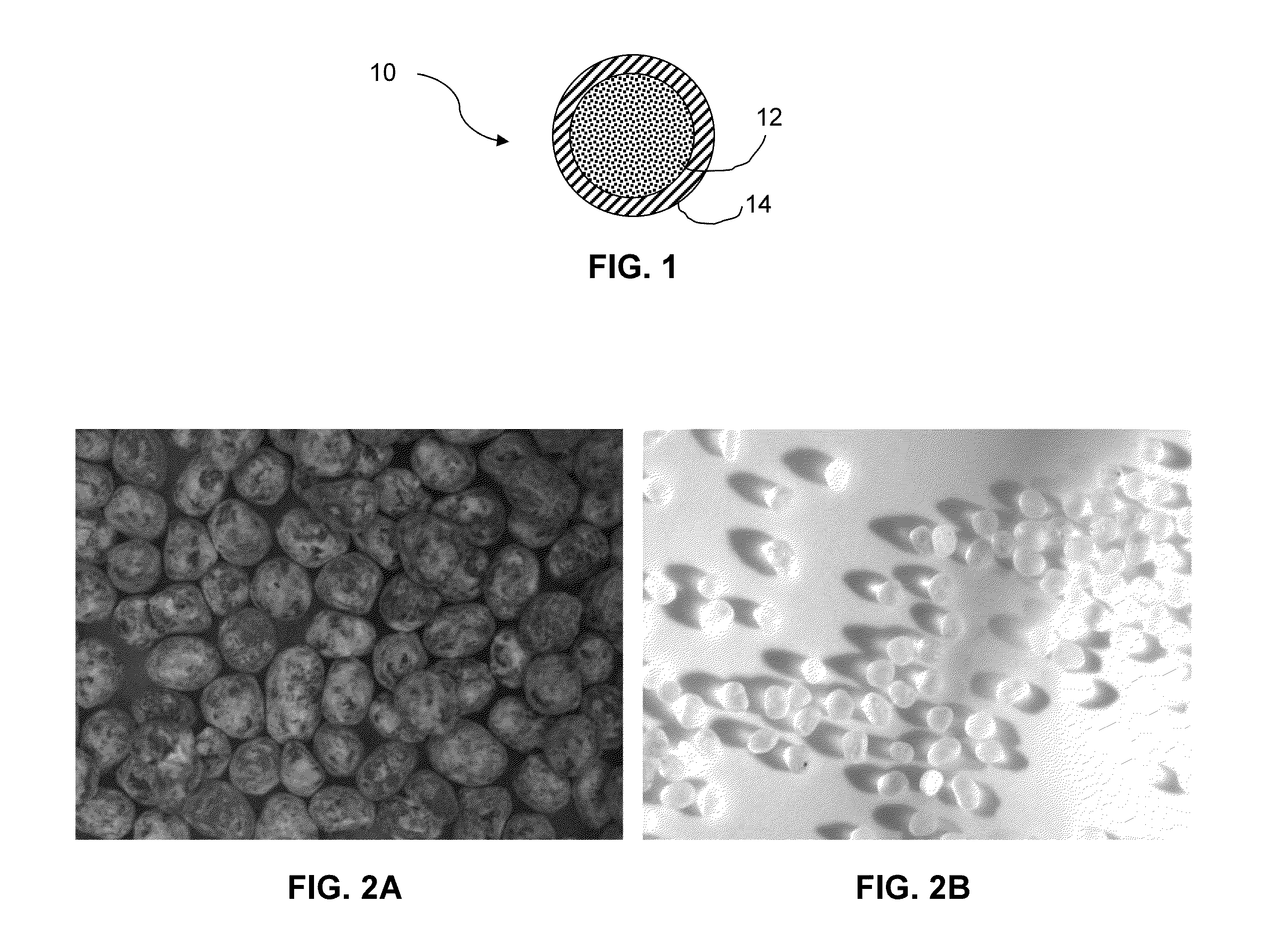

Proppants with improved strength

InactiveUS20150114640A1Liquid surface applicatorsFluid removalAlkali activatedUltimate tensile strength

Cements, such as alkali activated aluminosilicate, may be used as coatings on proppants, such as brown sand and white sand, to improve the strength thereof. The resulting coated proppants show increased strength as well as produced fines of lower than about 10 wt % at 10,000 psi closure stress.

Owner:BAKER HUGHES INC

Process for preparing super activated carbon from nut shell carbon and waste liquid activation treatment method of process

The invention discloses a process for preparing super activated carbon from nut shell carbon and a waste liquid activation treatment method of the process, belonging to the field of biochemical engineering and energy materials. The process comprises the following steps: soaking nut shell carbon which is subjected to pre-washing and thermal treatment A into an oxidization substance in a vacuum reaction kettle; performing thermal treatment B on the nut shell carbon soaked into the oxidization substance, and soaking into an alkali aquo-complex activating agent in the vacuum reaction kettle; in inert gas or reductive atmosphere, heating the nut shell carbon to perform thermal treatment C so as to obtain activated nut shell carbon; adding water to leach and separate the activated nut shell carbon so as to obtain alkali activated mother liquor A and a solid; adding water into the solid for leaching again so as to obtain carbonate mother liquor B and activated carbon slurry; performing multi-stage washing and acidization treatment on the activated carbon slurry, washing with water, and separating so as to obtain a crude activated carbon product; and performing thermal treatment D of different stages on the crude activated carbon product, thereby obtaining an activated carbon product. The super activated carbon with high yield and good properties can be prepared, and meanwhile useful byproducts such as bicarbonate and hydrated silica can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

Alkali-activated lignin-based active carbon fibers and preparation method thereof

InactiveCN106757536ALow costRealize comprehensive utilizationFilament/thread formingArtificial filament chemical after-treatmentActivated carbonCarbon fibers

The invention relates to alkali-activated lignin-based active carbon fibers and a preparation method thereof, and belongs to the field of active carbon fiber materials. The preparation method comprises the following steps of a step of preparing lignin; a step of preparing spinning solution; a step of carrying out high-voltage electrostatic spinning; a step of carrying out carbonization; and a step of carrying out alkali activation. The alkali-activated lignin-based active carbon fibers prepared by the preparation method disclosed by the invention can replace application of polyacrylonitrile-based carbon fibers and activated carbon to adsorption.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Rice hull ash and metakaolin based polymer composite fireproof paint and preparation method thereof

ActiveCN102320782ALow cost and environmental protectionImprove fire resistanceSolid waste managementCellulose fiberCarvacryl acetate

The invention discloses rice hull ash and metakaolin based polymer composite fireproof paint and a preparation method thereof. The paint mainly consists of rice hull ash and alkali-activated metakaolin based polymers. The preparation method comprises the steps that: rice hull ash is used as fillings with the mass parts being 20 to 50 mass parts; the alkali-activated metakaolin based polymers and polyvinyl acetate emulsion are compounded and prepared into adhesion agents with the mass parts being 20 to 40 mass parts; and other auxiliaries and special additives are added and mixed for preparingthe paint, wherein the auxiliaries and the special additives comprise the following ingredients in parts by mass: 0 to 10 parts of magnesium hydroxide, 4 to 8 parts of titanium pigment, 0.5 to 2 parts of sodium bentonite, 0.2 to 0.5 part of sodium lignosulphonate, 0.3 to 1 part of gamma-aminopropyl triethoxysilane and 0 to 5 parts of cellulose fibers. The paint and the preparation method have theadvantages that the raw material cost is low, in addition, the environment is protected, the preparation process is simple, and the bonding strength and the fireproof performance of products are good.

Owner:SOUTH CHINA UNIV OF TECH

Purifying process for graphene material of energy storing device

The invention discloses a purifying process for a graphene material of an energy storing device, and further relates to a purifying and washing process for a graphene material of energy storing devices such as a super capacitor, a secondary lithium ion battery and the like. The purifying process disclosed by the invention comprises the following steps of: washing graphene obtained by activating with a strong alkali with deionized water of over 30 DEG C; repeatedly purifying and cleaning with a cleaning solution of over 30 DEG C; repeatedly washing with deionized water of over 30 DEG C; and calcining the graphene at the high temperature of 500-1,200 DEG C for 0.5-10 hours to obtain high-purity graphene powder. The process flow is simple and ordered, every joint in the flow can be controlled accurately, the content of heavy metal ions can be lowered to be below 300 ppm after purification, and the content of the alkali metal ions can be lowered to be below 1,500 ppm; and the purifying process is particularly suitable for large-scale production.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Alkali-activated fly ash cementing material and preparation method thereof

InactiveCN106380167ASolving activitySolve the strength problemAlkali activatedUltimate tensile strength

The invention discloses an alkali-activated fly ash cementing material and a preparation method thereof. The cementing material comprises the following components in parts by weight: 70 to 100 parts of fly ash, 10 to 30 parts of meta-kaolin, 1 to 10 parts of cement, 1 to 10 parts of slag, and 50 to 60 parts of activator. The content of doped fly ash in the cementing material is high and can reach 70 to 80%. The problem that the activity of fly ash and the strength of the cementing material are low in the early stage is solved, and thus the cementing material can be used in novel building materials massively.

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

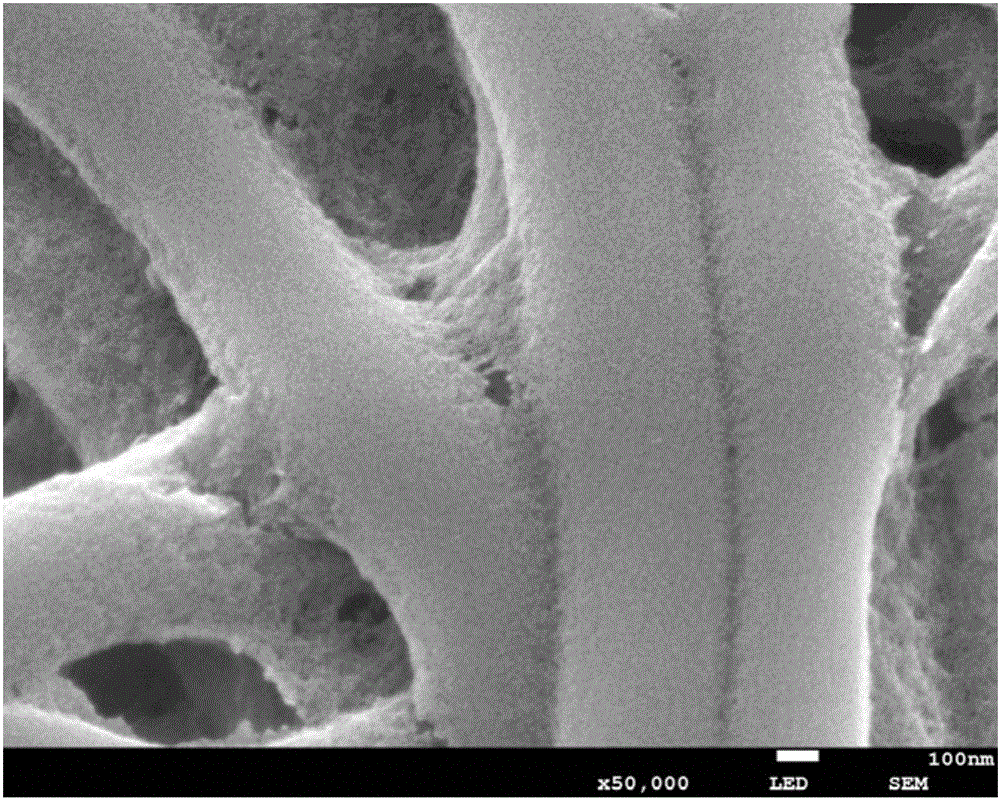

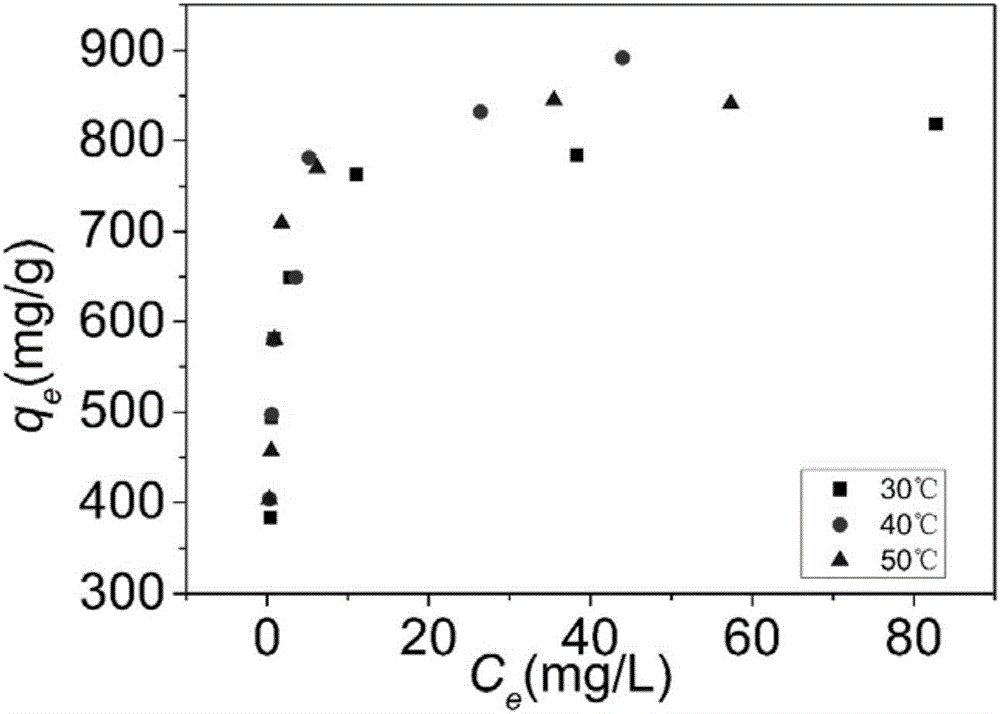

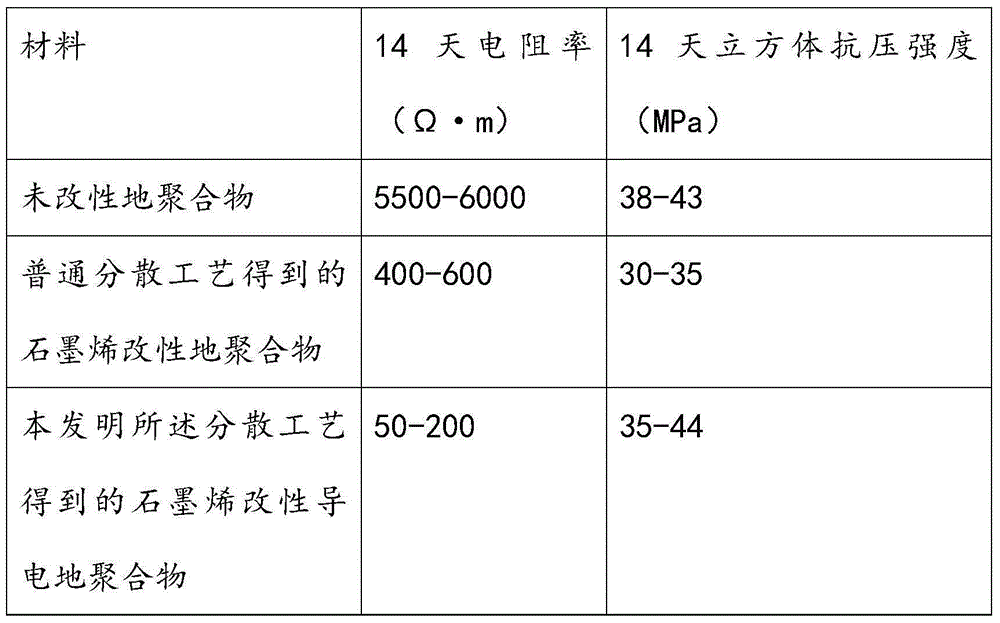

Conductive geopolymer preparation method

ActiveCN105218004AGuaranteed mechanical propertiesImprove conductivityCement productionConductive polymerAlkali activated

The present invention discloses a conductive geopolymer preparation method which comprises the following steps of: 1) mixing graphene and a dispersant A with water, and grinding and dispersing the mixture to obtain a preliminary dispersed graphene dispersion liquid; 2) mixing an alkali metal silicate solution with the graphene dispersion liquid obtained in the step 1), mixing the mixture uniformly and then adding a dispersant B, grinding and dispersing the mixture to obtain a graphene dispersed alkali-activated solution, wherein the modulus of the alkali metal silicate solution is 1-4, and the solid content is 30-60%; 3) mixing a silicon-aluminum raw material with granulated furnace slag, and grinding the mixture to obtain composite geopolymer powder; and 4) mixing the composite geopolymer powder obtained in the step 3) with the graphene dispersed alkali-activated solution obtained in the step 2), and stirring the mixture uniformly to obtain the conductive geopolymer. According to the present invention, the geopolymer has good conductivity, and meanwhile the mechanical property of the geopolymer is maintained.

Owner:ZHEJIANG UNIV

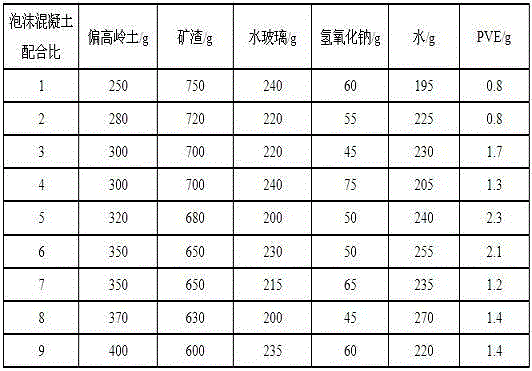

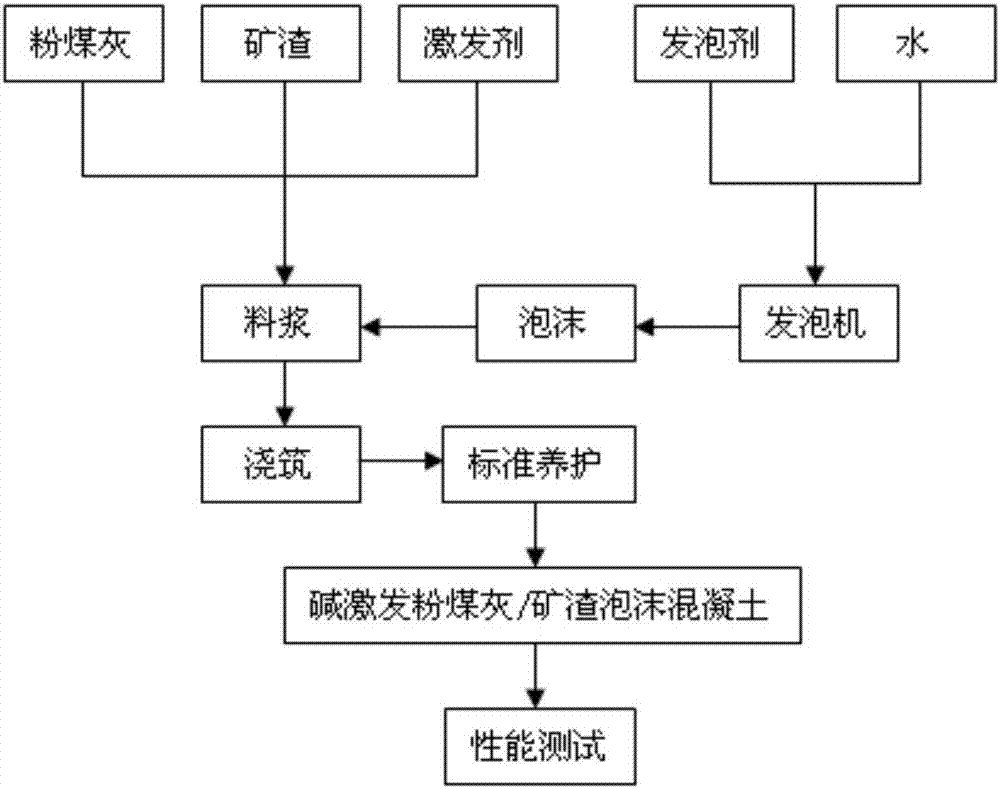

Alkali activated fly ash/slag foam concrete and preparation method thereof

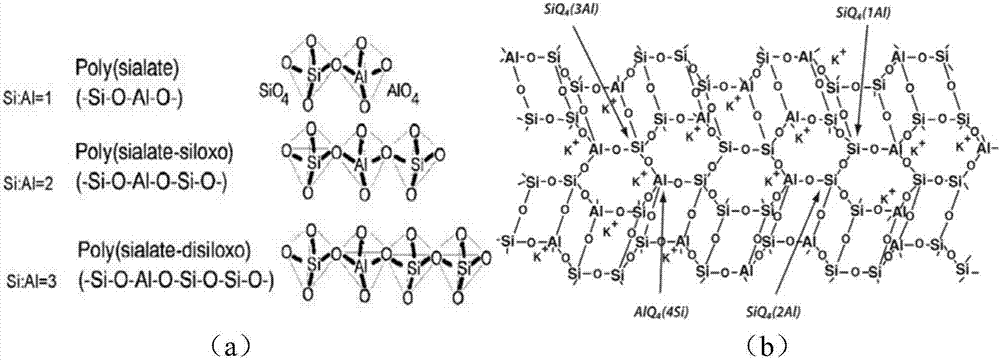

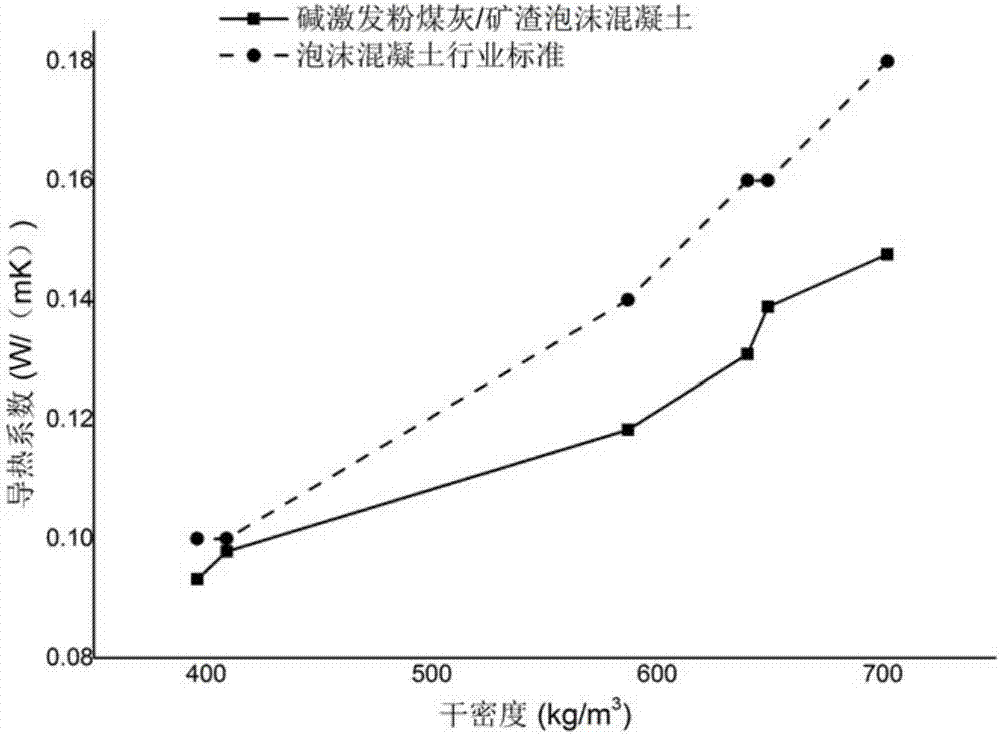

ActiveCN106946509AStable structureGood heat insulation/heat preservation performanceCeramicwareCalcium silicateFoam concrete

The invention discloses an alkali activated fly ash / slag foam concrete and a preparation method thereof. The foam concrete is composed of the following components in percentage by weight for each cubic meter: 4.6 to 10.8% of fly ash, 4.6 to 13.5% of slag, 17.4 to 20.5% of alkali activator, and 60.3 to 75.9% of foams. The foam concrete is a gel system composed of aluminosilicate polymer having a three dimensional net structure composed of AlO4 and SiO4 tetrahedral structural units and aluminum-containing hydrated calcium silicate gel. The industrial solid wastes are effectively utilized, about 80% of emission of carbon dioxide is reduced, and moreover, the foam concrete is green, environment-friendly, and light, and has a small heat conductivity coefficient. After 28d of standard maintenance of the concrete, the measured dry volume density is 300 to 700 kg / m<3>, and the heat conductivity coefficient is 0.08-0.15 W / (m.K). The foam concrete is a light and thermal insulation building material.

Owner:GUANGZHOU UNIVERSITY

Geopolymer/ waste rubber powder composite material and preparation method thereof

The invention discloses a geopolymer / waste rubber powder composite material and a preparation method thereof. The geopolymer / waste rubber powder composite material comprises the following raw material components in parts by weight: 35-70 parts of geopolymer alkali activated material and 30-65 parts of waste rubber powder / modified water glass mixed slurry; the waste rubber powder / modified water glass mixed slurry is prepared from the following components in parts by mass: 5-50 parts of waste rubber powder and 50-95 parts of modified water glass. The prepared composite material adopts cast molding; and after the composite material is cured, the compressive strength is between 15MPa and 96MPa, and the elasticity modulus is between 92MPa and 400MPa. The composite material disclosed by the invention not only solves the problem of utilization of waste rubber, but also solves the technical problems of high brittleness and insufficient toughness of geopolymer materials. The composite material can be applied in the engineering fields of buildings, traffic, military affairs and the like.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD +1

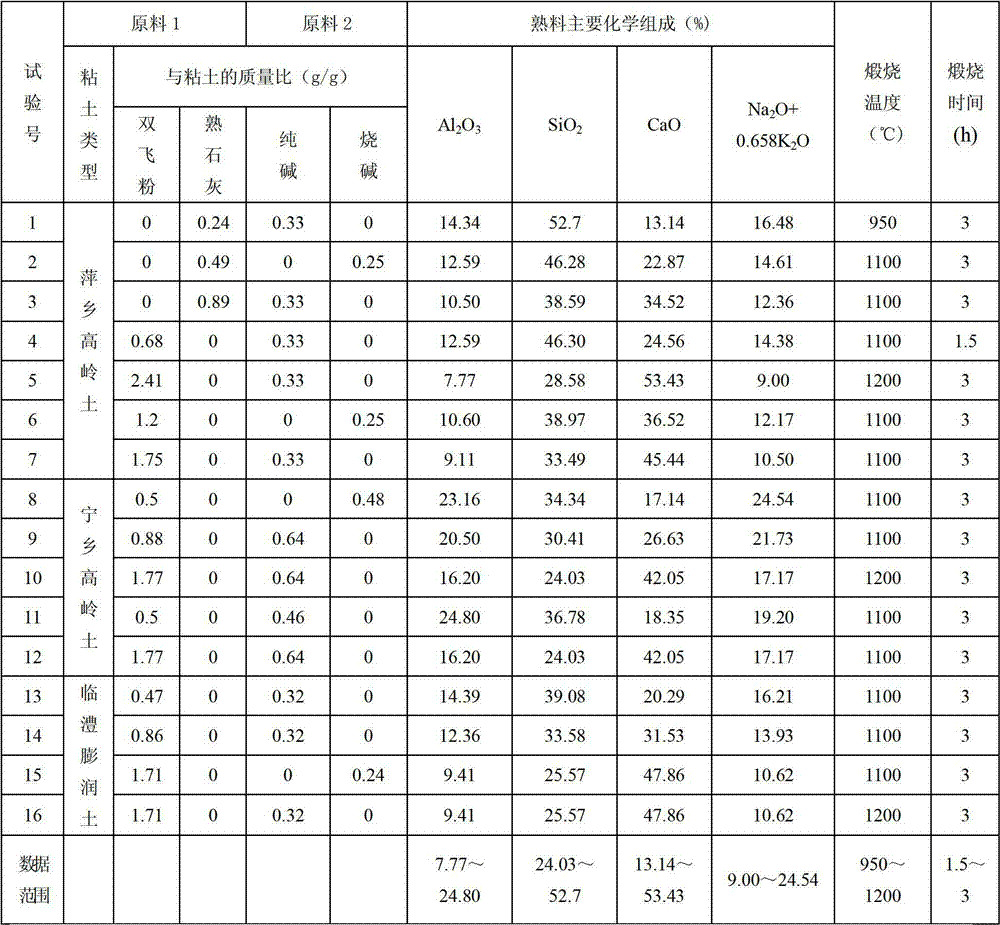

Preparation of single-component alkali-activated cement and application method thereof

ActiveCN102730996AExpand the range of raw materialsEasy to GrindClinker productionAlkali activatedMixed materials

The invention belongs to the novel cement material field and specifically relates to the preparation of a single-component alkali-activated cement and an application method thereof, wherein a raw material 1 including SiO2, Al2O3, and CaO are mixed with the raw material 2 including Na2O in a certain ratio; the ratio should be decided so that the percentage of the weight of each component of the calcined product, which is obtained by calcining the mixed materials at a temperature greater than or equal to 1100 DEG C, in the total weight is as follows: Al2O3: 8-25%; SiO2: 24-55%; CaO: 10-55%; and Na2O +0.658K2O: 6-25%; after being calcined at a temperature ranging from 950-1200 DEG C for 1.5-3 h, the mixed materials are then ground to obtain cement powder; the cement powder is mixed with water into paste; next, the paste is cured at 50-80 DEG C for 2-3 days so that neat cement paste briquettes excellent in strength can be obtained; and the strength can be continuously increased if curing is continuously performed under normal temperature. The preparation of the single-component alkali-activated cement has the following advantages that: the raw material range of the alkali-activated cement is greatly expanded; the storage, transportation and utilization of the cement are more convenient; and the improvement of the cementitious activity of the cement and the reduction of the cost are expected to be realized.

Owner:HUNAN UNIV OF SCI & TECH

Composite alkali-activating low-carbon cement and preparation method of low-carbon cement

The invention discloses composite alkali-activating low-carbon cement and a preparation method of the low-carbon cement, and belongs to the field of construction materials. According to the invention, fly ash and slag are taken as raw materials, sodium hydroxide and water glass are taken as alkali-activating agents, natural zeolite is taken as a nucleating agent and lime is taken as an adjustable solidification agent, and the low-carbon cement has good performance in a measurement system. The low-carbon cement is produced by mixing industrial solid wastes such as slag and fly ash, the alkali-activating agents, the nucleating agent and the adjustable solidification agent based on a certain proportion. The low-carbon cement and the preparation method have the advantages that the raw materials are not needed to exploit or char, the preparation process is simple, the energy consumption is low, the cost is low, the market is wide, the situations that in the production process of the traditional cement a lot of dust is generated and the carbon dioxide emission amount is large are fundamentally changed, and the industrial solid wastes can be fully used, so that the cement is a real clean and environment-friendly construction material, and a binding material with the most development potential in the twenty-first century.

Owner:CHINA RAILWAY NO 9 GRP ENG TESTING CO LTD

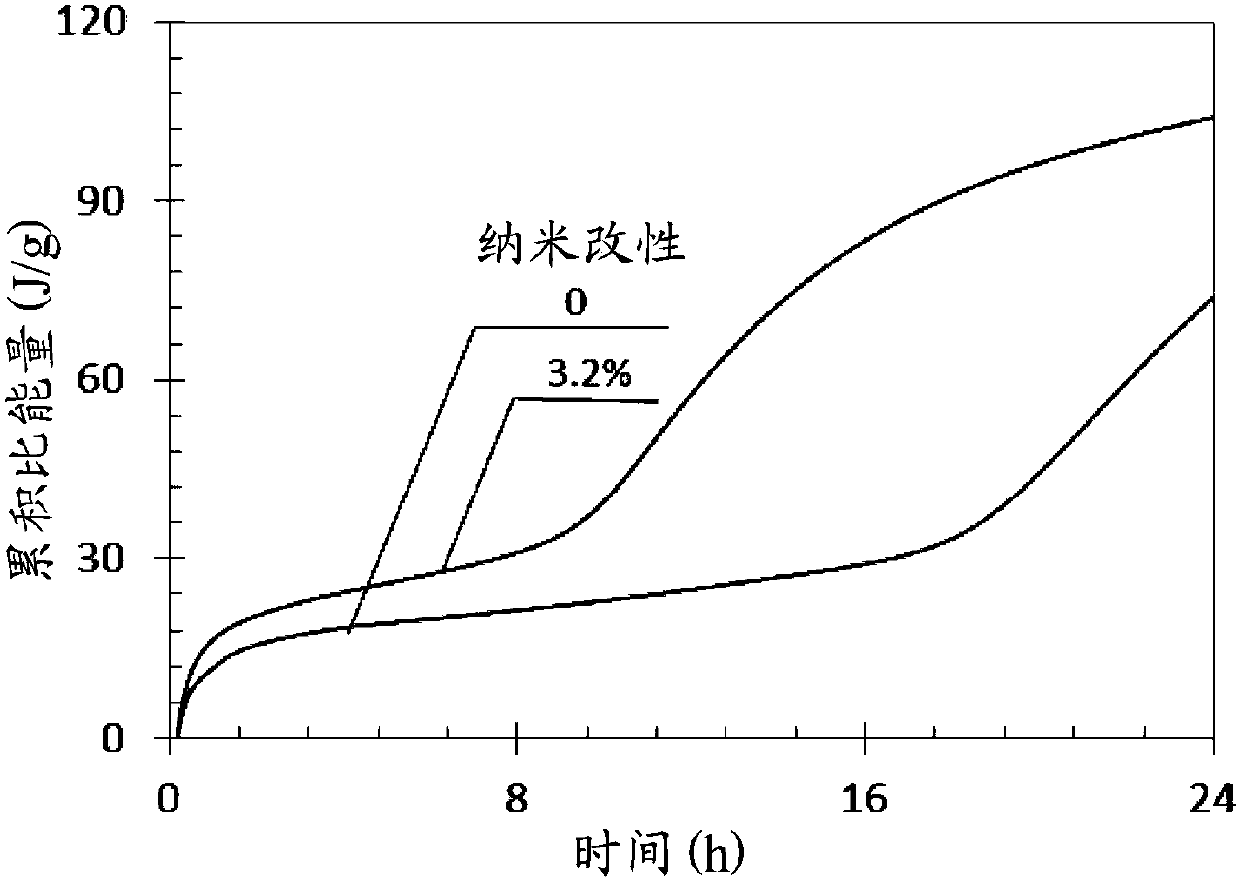

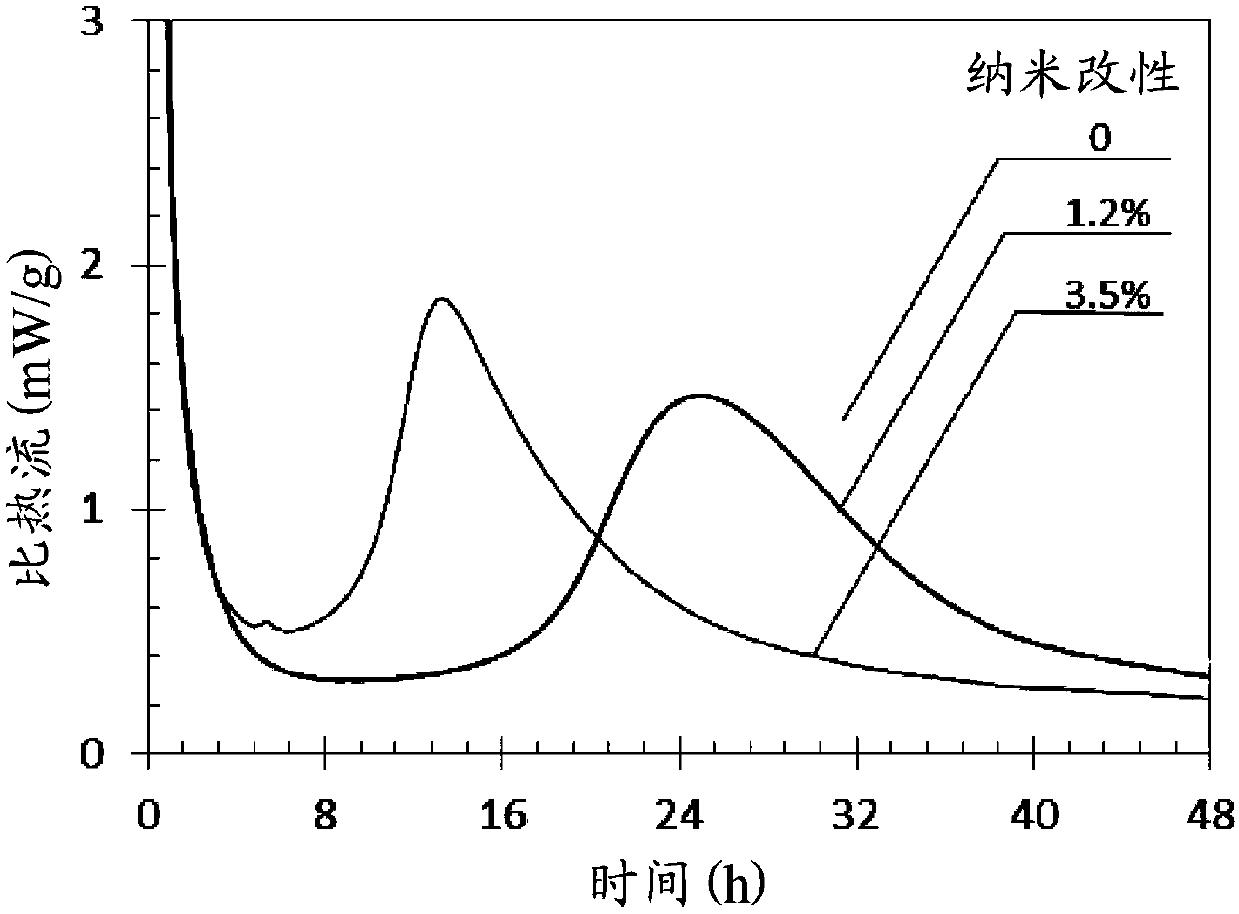

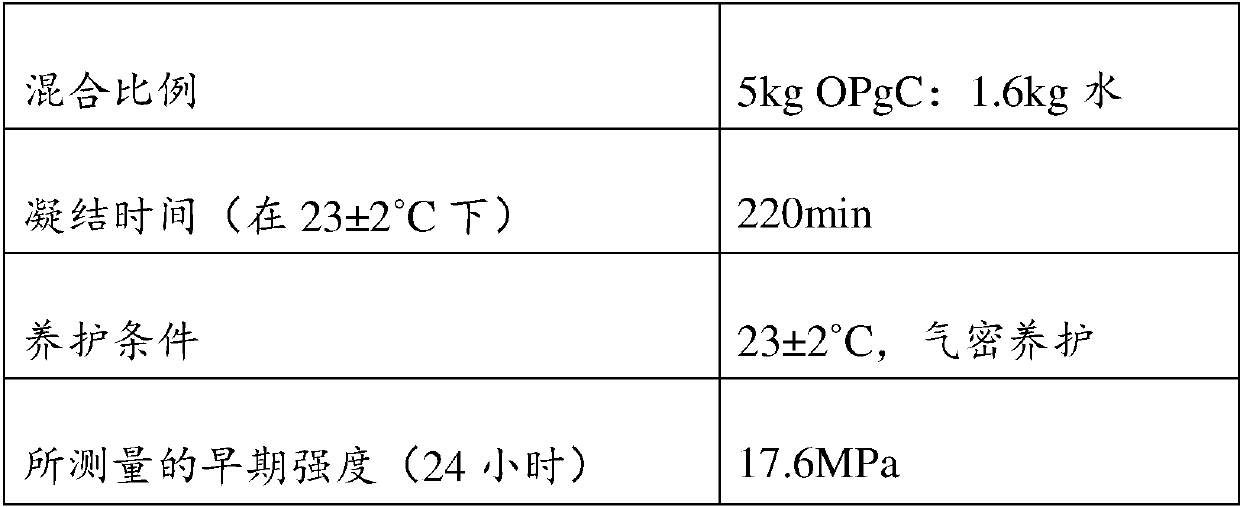

Nano-modified alkali-activated cementitious materials for rapid repair

A nano-modified dry-mixed alkali-activated cementitious, or one-part geopolymer cement (OPgC), material with high early strength is provided for rapid repair of cement-based infrastructure components.The OPgC may include an aluminosilicate rich material, an alkali material and a nano-modifier, and optionally include other functional admixtures and fibers. The OPgC can be freshly mixed with waterto obtain a repairing material. The OPgC may mix with water and fine or coarse aggregate to form mortar or concrete. The OPgC can be an alternative binding matrix for the development of an environmentally friendly and cost effective rapid repair material and can replace conventional adhesive matrix (including Portland cement, organic adhesives, etc.).

Owner:NANO & ADVANCED MATERIALS INST

Method for synthesizing pollucite by means of aluminosilicate polymer

The invention provides a method for synthesizing pollucite by means of an aluminosilicate polymer.The method comprises the steps that cesium hydroxide and sodium hydroxide are dissolved in silica sol with the mass concentration of 25%-45%, mechanical stirring is conducted, and a mixed alkali-activated solution of cesium silicate and sodium silicate is obtained; kaolin is put into an alumina crucible, the alumina crucible containing kaolin is put into a muffle furnace, the temperature is set to range from 500 DEG C to 900 DEG C, the heat preservation time ranges from 1.5 h to 2.5 h, and metakaolin powder is obtained; the mixed alkali-activated solution is put into an ice-water bath with the temperature ranging from 0 DEG C to 5 DEG C, the metakaolin powder is added, ultrasound treatment and mechanical stirring are conducted for 25 min-45 min, an aluminosilicate polymer slurry is obtained, deionized water is added to adjust the viscosity of the slurry to be 150 mPa.s-500 mPa.s when the shearing speed is 60 S<-1>-80 S<-1>, and the aluminosilicate polymer slurry is obtained; the obtained aluminosilicate polymer slurry is poured into a mold and cured for 3 h-24 h in a drying oven with the temperature ranging from 40 DEG C to 80 DEG C, and then pollucite is obtained.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com