Fiber-reinforced alkali-activated cementing material and preparation method thereof

A gelling material and fiber-reinforced technology, applied in the field of fiber-reinforced alkali-activated gelling material and its preparation, can solve problems such as blocking traffic, rivers, consuming manpower, financial resources, and endangering ecological balance, so as to prevent and inhibit the formation of cracks and development, good long-term flexural strength and compressive strength, and the effect of improving flexural strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

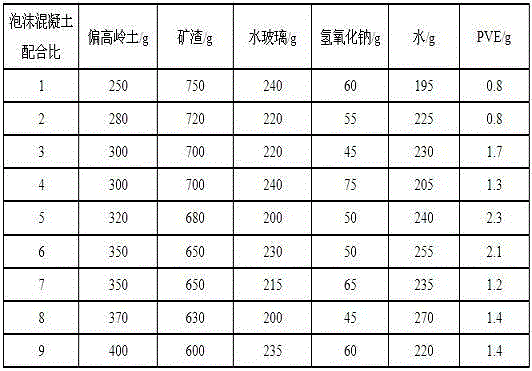

Examples

Embodiment 1

[0039] Hollow glass microsphere foam concrete, its components are:

[0040] Raw material mass g

[0041] (1) Cementitious material

[0042] Metakaolin 300

[0043] Slag 700

[0044] (2) Alkali stimulator

[0045] Water glass 220

[0047] (3) Water 230

[0048] (4) PVA 1.2

[0049]1. Accurately weigh 300g of metakaolin and 700g of slag as the basis of measurement (100%); put the weighed metakaolin and slag into the cement slurry mixer, mix evenly, then pour 12.g of PVA, start Stir evenly (low speed, make the material uniform);

[0050] 2. Weigh 220g of water glass, pour it into a container, then weigh 50g of sodium hydroxide, slowly pour it into the water glass, and stir at the same time, so that the sodium hydroxide is completely dissolved in the water glass, thereby reducing the modulus of the water glass Purpose, finally place the water glass for a period of time, so that the temperature of the water glass with adjusted modulus...

Embodiment 2

[0055] Fiber-reinforced alkali-activated gelling material, the components of which are:

[0056]

[0057] Its preparation method is identical with embodiment 1.

[0058] Experimental results show that the compressive strength of the cementitious material prepared according to the method can reach 83.7MPa, and the flexural strength can reach 11.7MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com