Composite reinforcement slurry for covering goaf of nitrate mine on railway and preparation method ofcomposite reinforcement slurry

The invention relates to a nitrate and mining technology, which is applied to the field of composite reinforcement slurry for the goaf of the overlying nitrate mine and its preparation, and can solve the problems of the overlying rock damage and slump, the influence of railway operation safety, the settlement and deformation of the railway structure, and the like. Achieve the effect of reducing settlement, inhibiting the formation and development of cracks, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

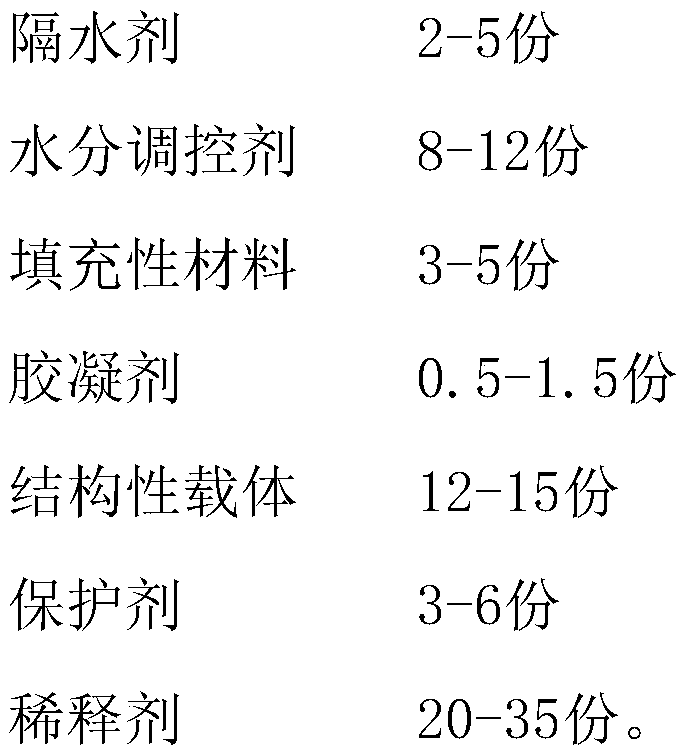

[0039] A kind of composite reinforcement slurry for the goaf of nitrate mine overlying the railway, the composite reinforcement slurry includes the following raw materials in parts by weight:

[0040]

[0041] The water-blocking agent is oil-based mud; the oil-based mud is a mixture of oil, water, organoclay and oil-soluble chemical treatment agent in parts by weight of 1:8:6:0.1; the oil is diesel oil; The oil-soluble chemical treatment agent is toluene.

[0042] The moisture regulating agent is polyacrylamide.

[0043] The filling material is salt mine waste residue, the porosity of the filling material is 10%, and the particle size is 4mm.

[0044] The gelling agent is geopolymer.

[0045] The structural carrier is construction waste, the porosity of the structural carrier is 30%, and the particle size is 2cm.

[0046] The protective agent is a fiber swelling agent; the fineness of the protective agent is 50 mesh, and the active ingredient content is 80%.

[0047] De...

Embodiment 2

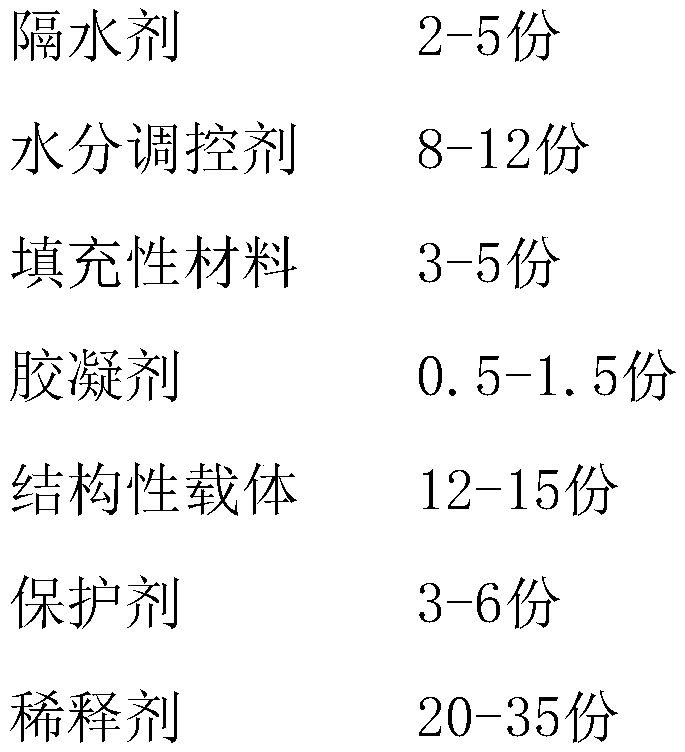

[0057] A kind of composite reinforcement slurry for the goaf of nitrate mine overlying the railway, the composite reinforcement slurry includes the following raw materials in parts by weight:

[0058]

[0059]

[0060] The water-blocking agent is oil-based mud; the oil-based mud is a mixture of oil, water, organic clay and an oil-soluble chemical treatment agent in parts by weight of 1:10:6:0.2; the oil is diesel; The oil-soluble chemical treatment agent is butanone.

[0061] The moisture regulating agent is sodium pyrosulfite.

[0062] The filling material is salt mine waste residue, the porosity of the filling material is 15%, and the particle size is 3mm.

[0063] The gelling agent is geopolymer.

[0064] The structural carrier is construction waste, the porosity of the structural carrier is 35%, and the particle size is 1 cm.

[0065] The protective agent is a fiber swelling agent; the fineness of the protective agent is 70 mesh, and the active ingredient content ...

Embodiment 3

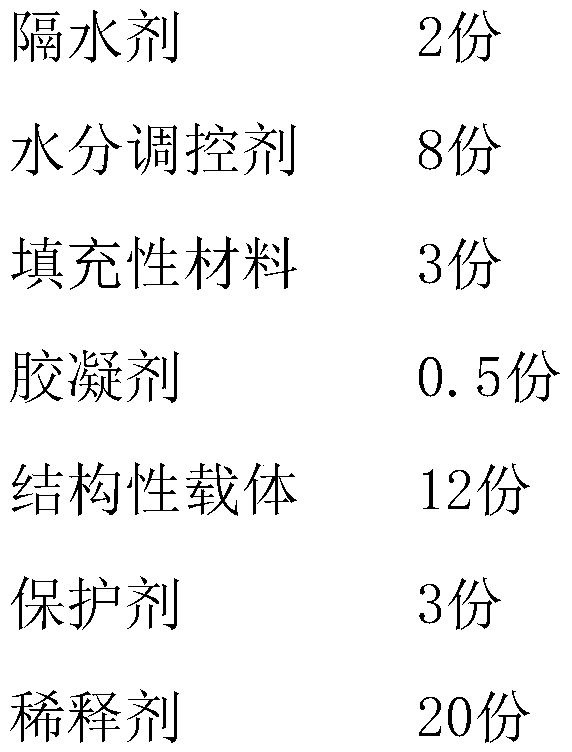

[0076] A kind of composite reinforcement slurry for the goaf of nitrate mine overlying the railway, the composite reinforcement slurry includes the following raw materials in parts by weight:

[0077]

[0078] The water-blocking agent is oil-based mud; the oil-based mud is a mixture of oil, water, organic clay and an oil-soluble chemical treatment agent in parts by weight of 1:12:6:0.3; the oil is diesel; The oil-soluble chemical treatment agent is toluene.

[0079] The moisture regulating agent is lithium bromide.

[0080] The filling material is salt mine waste residue, the porosity of the filling material is 20%, and the particle size is 2mm.

[0081] The gelling agent is geopolymer.

[0082] The structural carrier is construction waste, the porosity of the structural carrier is 40%, and the particle size is 0.5 cm.

[0083] The protective agent is a fiber swelling agent; the fineness of the protective agent is 80 mesh, and the active ingredient content is 85%.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com