Concrete crack-resistant grid template and production method thereof

A technology of concrete formwork and grid formwork, which is applied to the preparation of formwork/formwork components and building components on site, construction, etc., which can solve the problems of easy cracking, loss of fluidity and no strength of concrete, and achieve low construction cost , Effective micro-cracks occur, less effect of increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

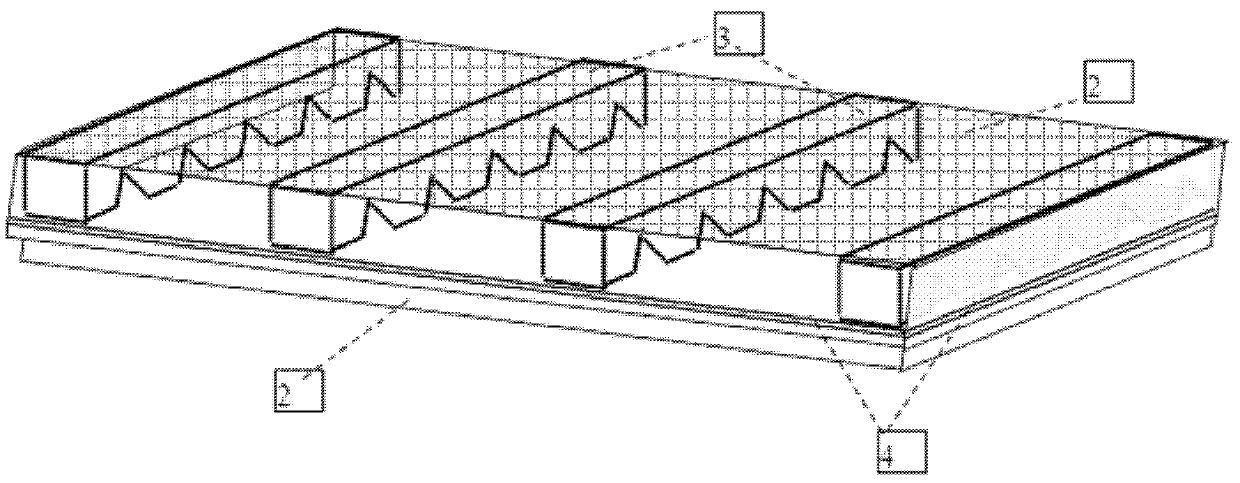

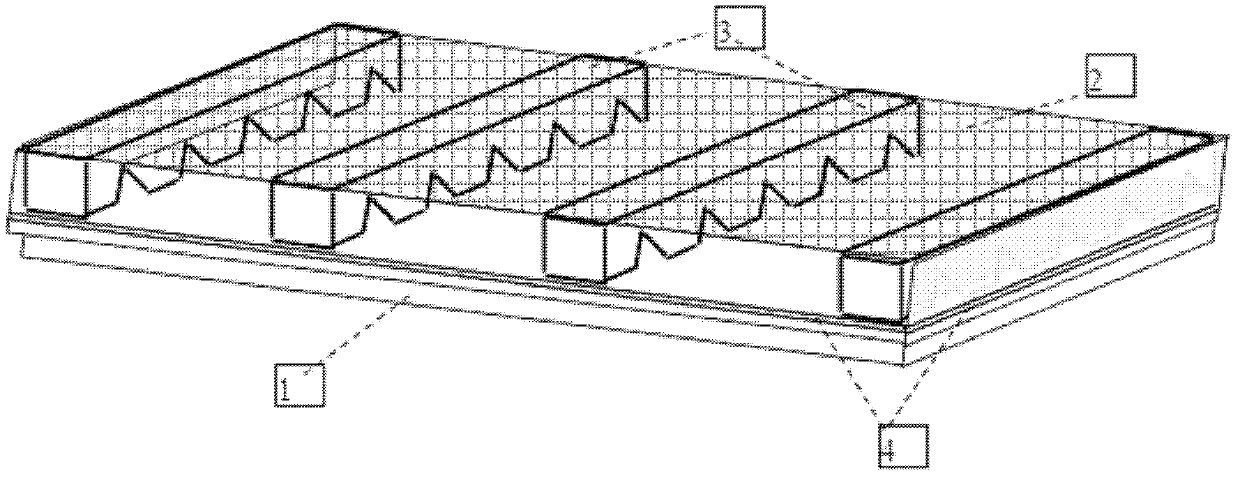

[0025] A kind of preparation method of concrete anti-crack grid formwork is: comprise the following steps:

[0026] (1) Use cement to prefabricate rebar or sawtooth-shaped support strips so that the area exposed to the concrete surface is small and consistent with the appearance of the concrete, and the thickness of the support strips is 0.5-1 cm;

[0027] (2) Use cement to fix the support strips on the ordinary concrete formwork according to a certain distance, the sawtooth tip is close to the formwork, and the distance between the support strips is generally set at 50-100 cm;

[0028] (3) Lay the mesh cloth on the concrete formwork with support strips, fix the mesh cloth on the side edges of the concrete formwork with fixed pressure strips, and tighten the mesh cloth during operation so that it is 0.5-1 away from the surface of the formwork The height in centimeters is the thickness of the support bar.

Embodiment

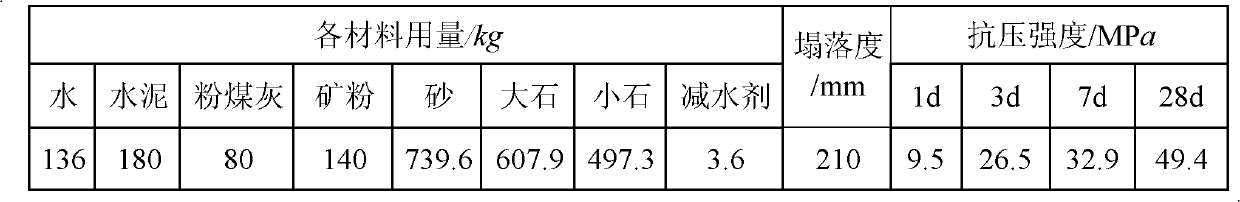

[0030] Prepare 2 identical steel concrete forming square frames with an area of 100×100 centimeters and a height of 7 centimeters, respectively use the concrete anti-cracking grid formwork of the present invention and the common concrete formwork as the bottom plate of the square frame. Table 1 shows the slump and corresponding strength results of different ages for preparing C30 pumped concrete with the concrete mix ratio in Table 2.

[0031]

[0032] Pour the concrete evenly into the two forming boxes and fully vibrate them, then turn the two groups of concrete samples together with the steel boxes so that the original bottom faces up, and follow the demoulding method described in the "Content of the Invention" The concrete crack-resistant grid formwork is removed, and the ordinary concrete formwork is also removed. The two groups of concrete were exposed to a strong dry environment with a relative humidity of about 40%, a temperature of about 42°C, and wind blowing. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com