Surface mortar for heat insulation system of foam glass building

A technology of building thermal insulation and foam glass, which is applied in the field of plastering mortar, can solve the problems of low bonding strength between plastering mortar and foam glass, cracking of foam glass, weak interface penetration, etc., achieve dimensional stability and thermal stability, and improve the surface The effect of accelerated strength and anti-slip performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

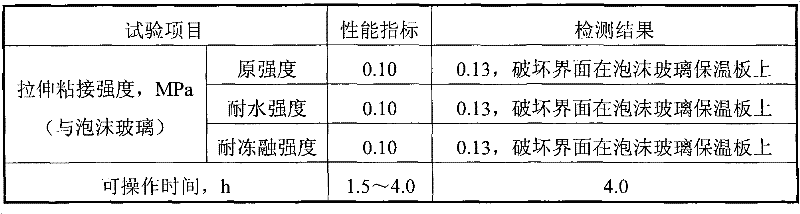

Image

Examples

Embodiment 1

[0024] Example 1 ① Raw material: cement is selected from Yongdeng Qilianshan Cement Co., Ltd. 42.5 grade ordinary portland cement, and its performance index conforms to the provisions of GB175-1999 "Portland cement, ordinary portland cement"; the fly ash is selected from Lanzhou The performance index of the first-grade fly ash produced by the Second Thermal Power Company complies with the provisions of GB / T1596-2005 "Used for Fly Ash in Cement and Concrete"; the fine sand is 40-80 mesh fine sand produced by Lanzhou Yellow River Sandstone Factory. Sand, its performance indicators are in line with the provisions of G / T14684-2001 "Sand for Construction"; the dispersible rubber powder and hydroxypropyl cellulose ether are products from Wacker Chemical Co., Ltd.; the lignocellulose ether and crack-resistant fiber filaments are from Changzhou The polypropylene fiber and amide produced by Zhuwei Building Materials Co., Ltd. are selected from Beijing Anshunda Decoration Materials Co., ...

Embodiment 2

[0028] Example 2 ① The cement is 32.5-grade ordinary Portland cement produced by Yongdeng Qilianshan Cement Co., Ltd., and its performance index meets the requirements of GB175-1999 "Portland Cement, Ordinary Portland Cement"; The polyacrylonitrile fiber produced by Wei Building Materials Co., Ltd.; other raw materials and 3. preparation, 4. test basis are the same as embodiment 1.

[0029] ②To prepare a total of 1000kg of foam glass building insulation system plastering mortar, 250kg of cement, 150kg of fly ash, 600kg of fine sand, 3.5kg of dispersible rubber powder, 0.4kg of hydroxypropyl cellulose, and 0.2kg of lignocellulose, Amide is 0.8kg, anti-crack fiber is 1.0kg.

Embodiment 3

[0030] Embodiment 3 1. raw material, 3. preparation, 4. test basis are the same as embodiment 1.

[0031] ②To prepare a total of 1000kg of foam glass building insulation system plastering mortar, 220kg of cement, 200kg of fly ash, 580kg of fine sand, 3.2kg of dispersible rubber powder, 0.5kg of hydroxypropyl cellulose, and 0.3kg of lignocellulose, The amide is 0.9kg and the anti-crack fiber is 1.1kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com