Patents

Literature

470 results about "Freeze thaw resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Freeze thaw resistance, or freezing and thawing resistance, is the property of solids to resist cyclic freezing and melting.

Chemical Admixtures for Hydraulic Cements

InactiveUS20130074736A1Improve propertiesImprove economySolid waste managementChemical admixtureHardness

This invention relates to a new class of chemical admixtures for hydraulic cement compositions such as pastes, mortars, grouts and concretes. The cement compositions are comprised of ordinary Portland cement, blended cements, or non-Portland cements made with Supplementary Cementitious Materials. The admixtures contain complexes of metals with derivatives of hydroxycarboxylic acids, and improve properties of cement compositions, including setting, hardness, compressive strength, shrinkage, and freeze-thaw resistance. The invention discloses a method for improving the properties of hydraulic cements by adding the disclosed chemical admixtures to cement compositions, and also discloses methods of preparing said admixtures.

Owner:GILL IQBAL

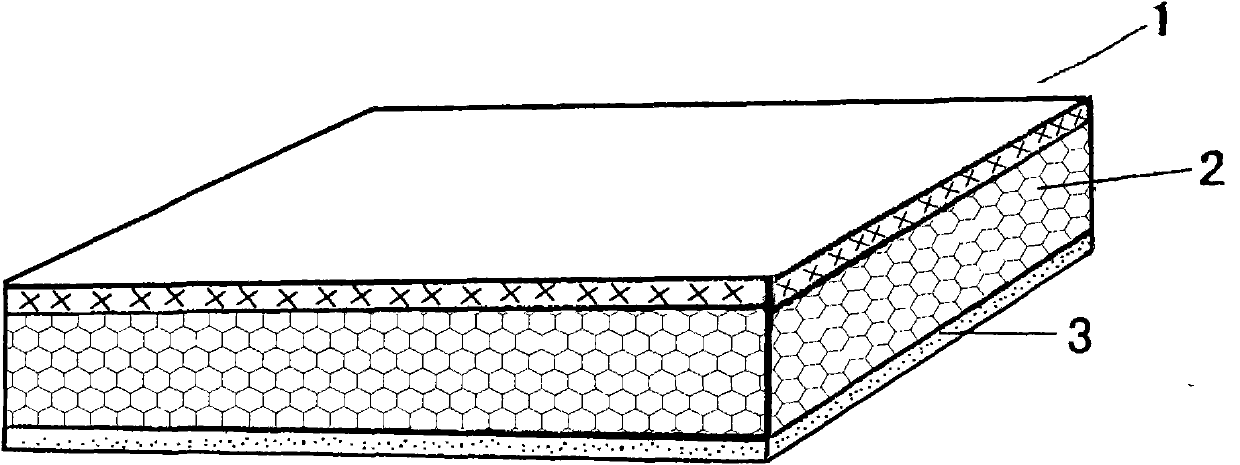

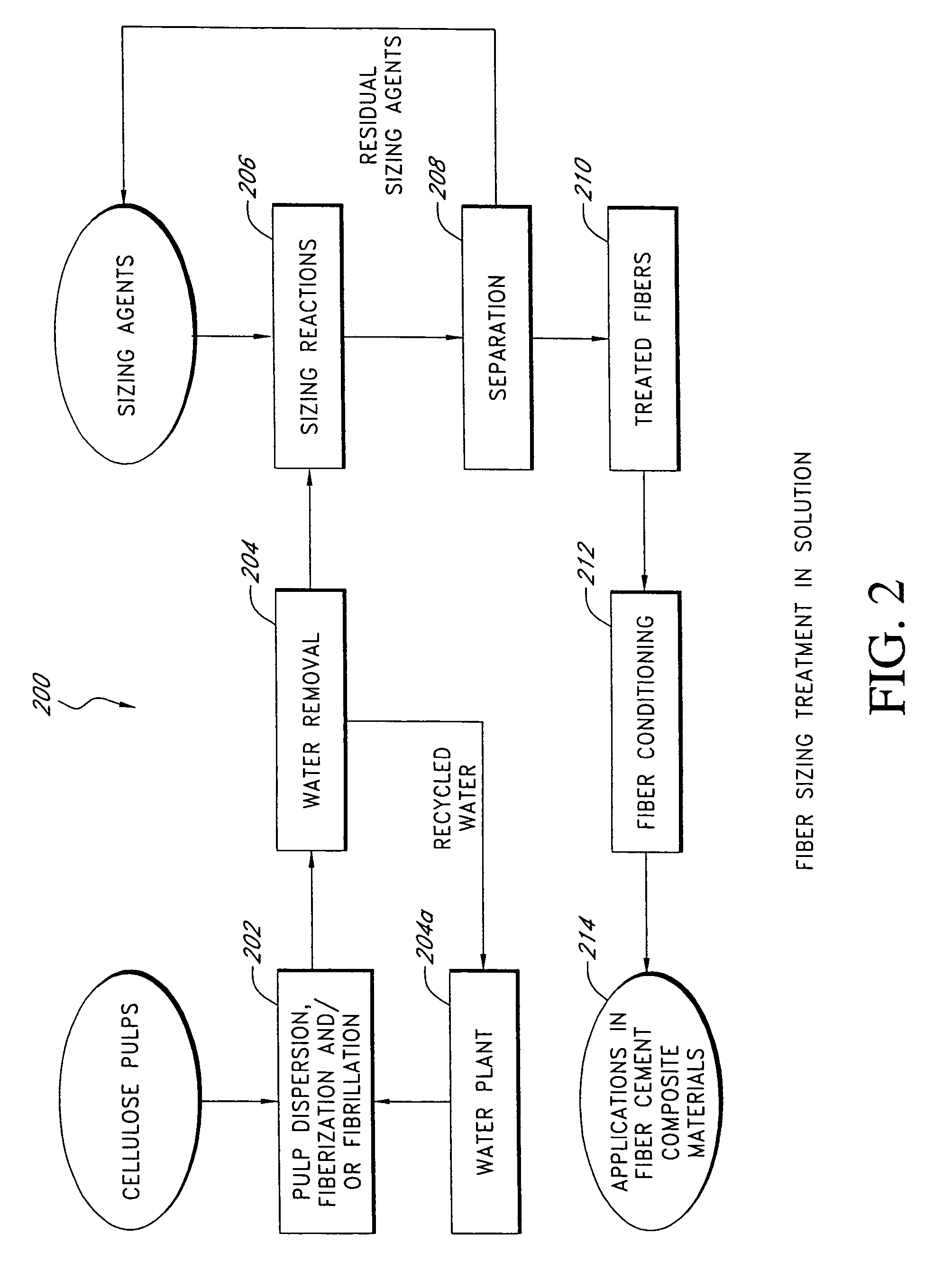

Fiber cement composite materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveUS20050235883A1Low water absorptionLow water migrationConstruction materialWater-repelling agents additionCement compositesCellulose fiber

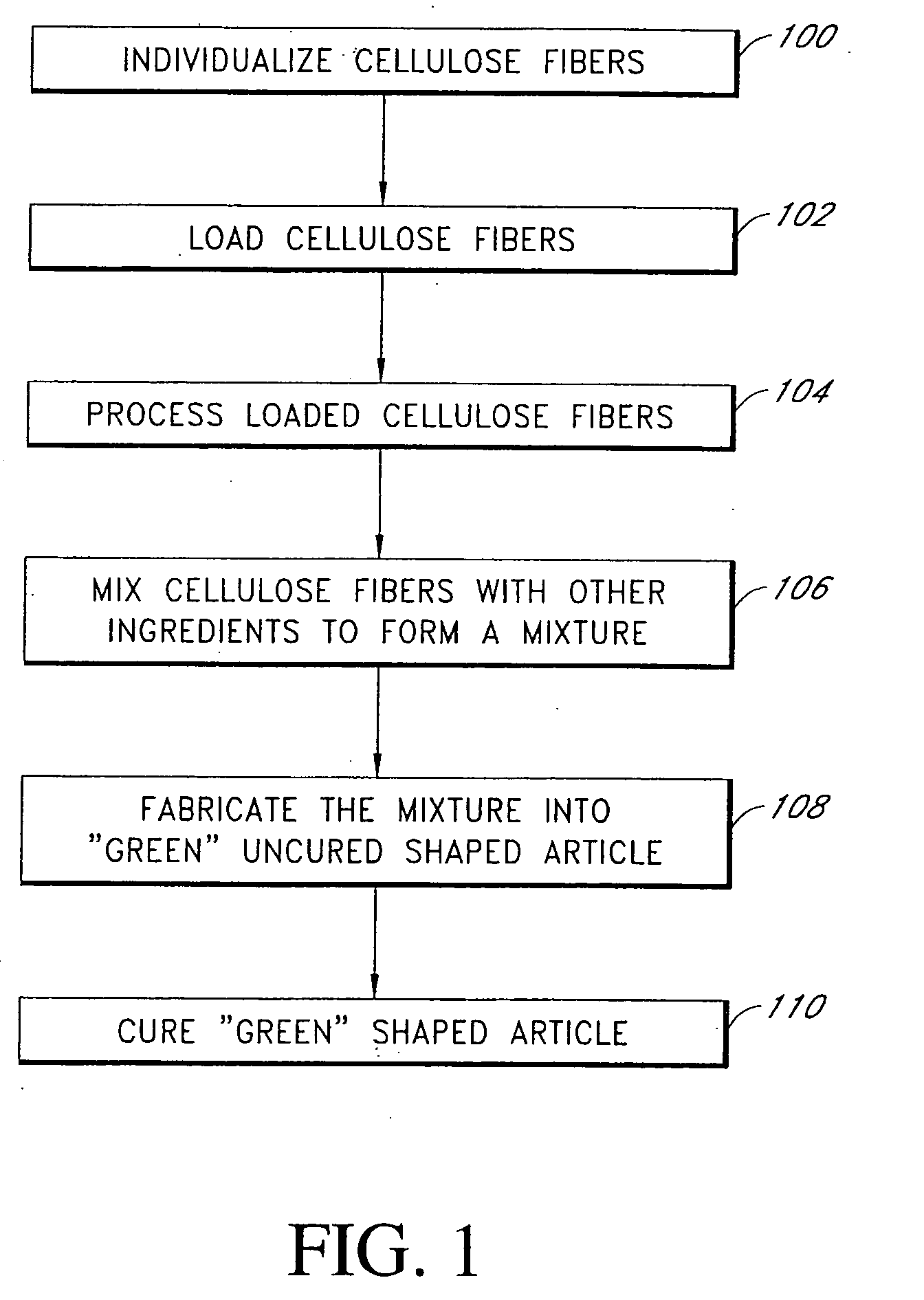

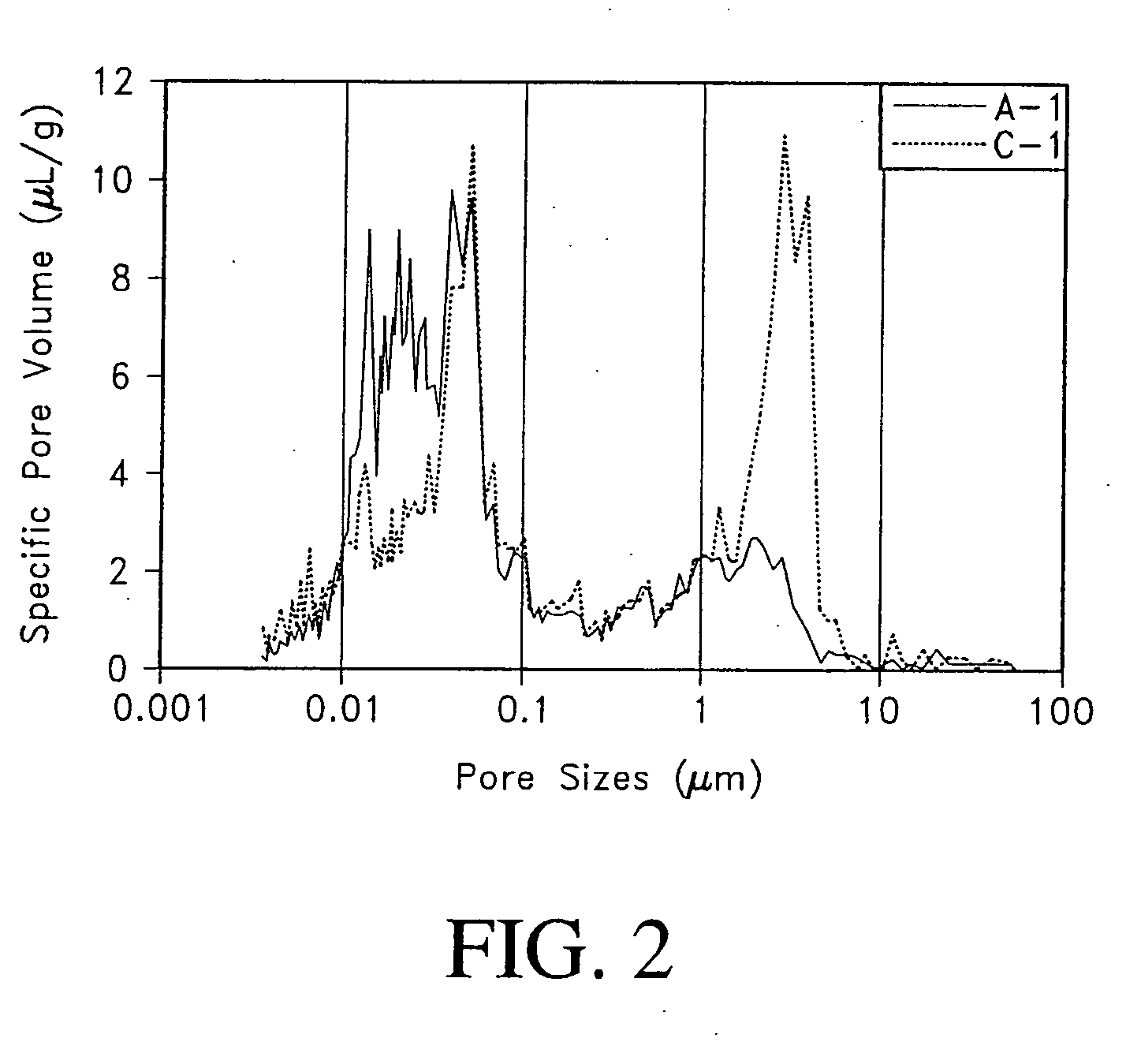

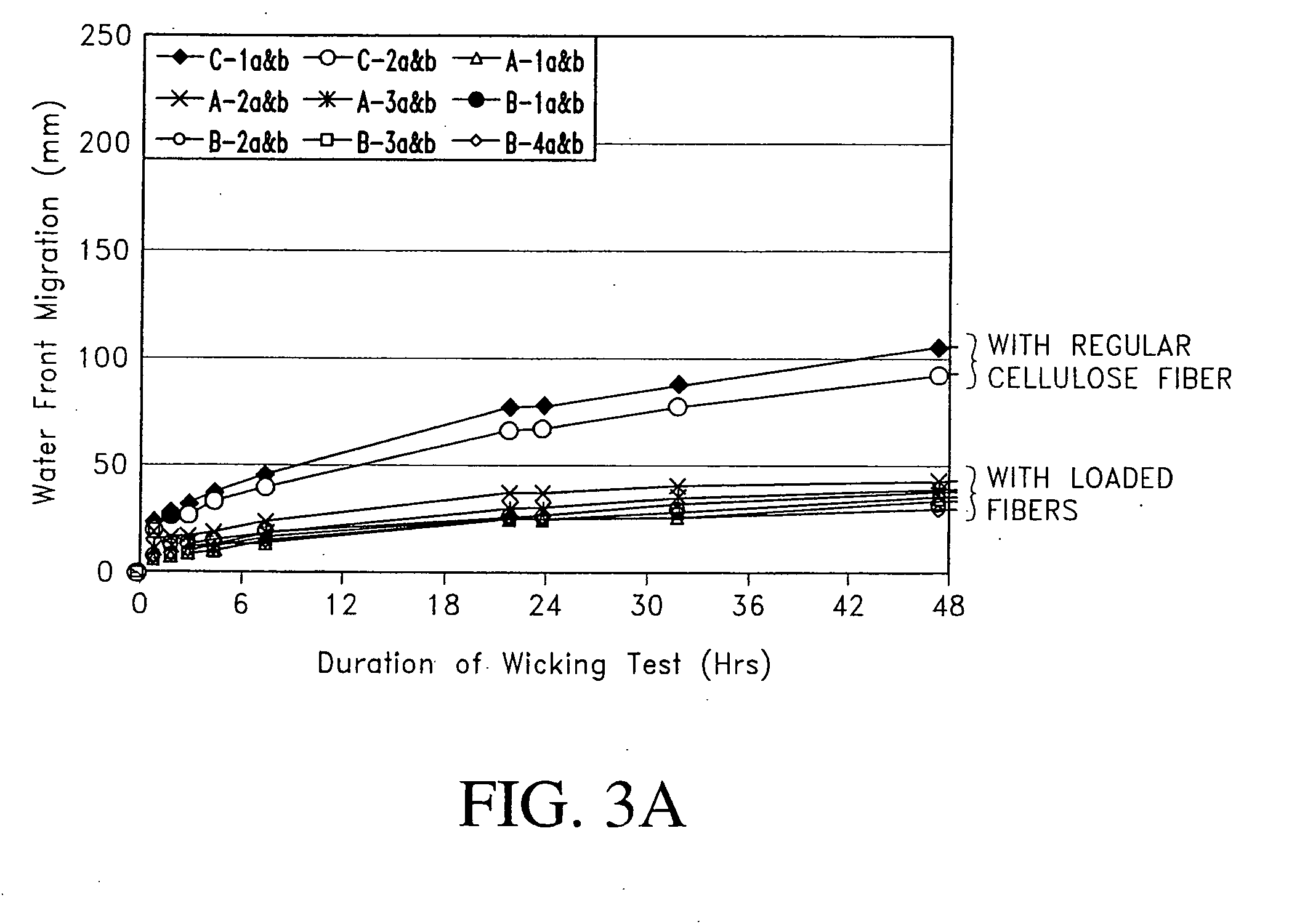

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using the loaded cellulose fibers. This invention discloses four aspects of the technology: fiber treatment, formulation, method and final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, reduced chemical dissolution and re-deposition, and improved rot and fire resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness.

Owner:MERKLEY DONALD J +1

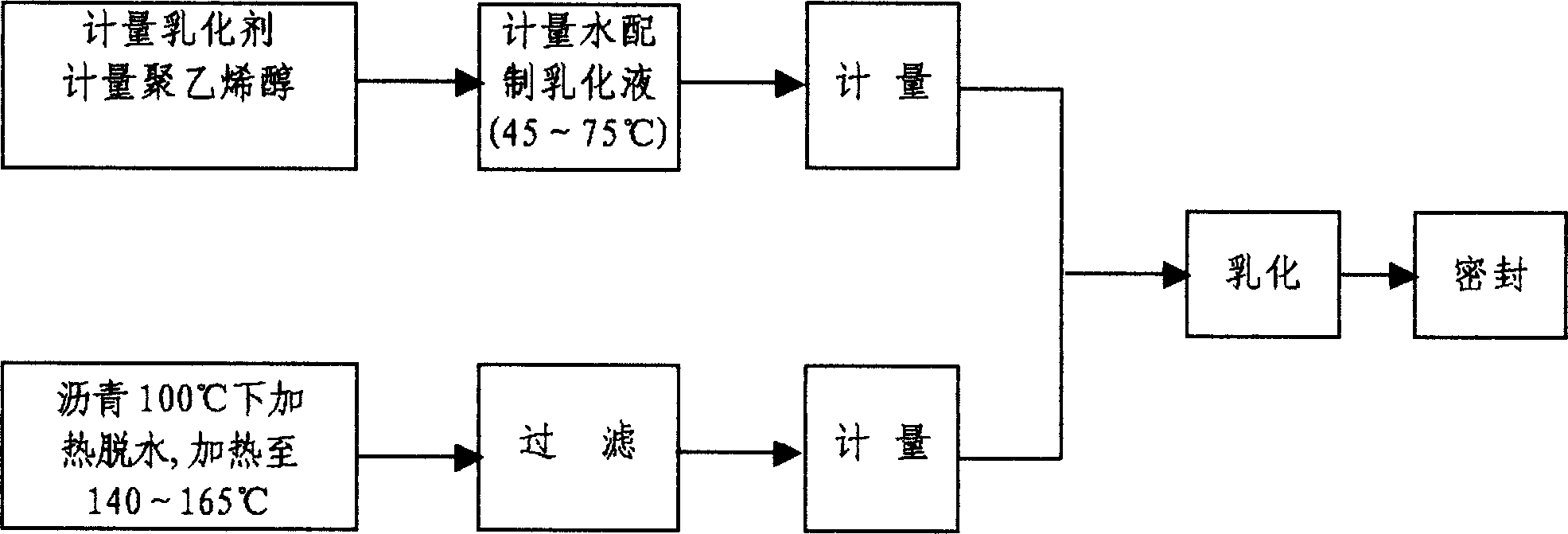

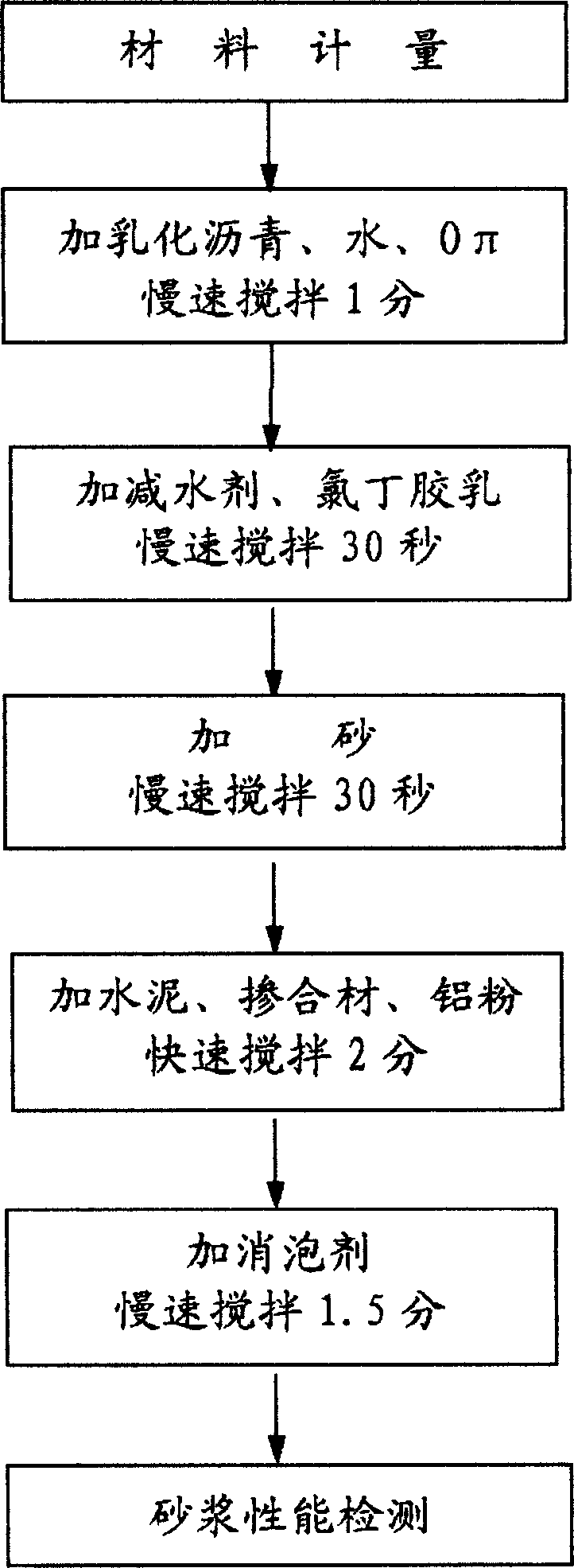

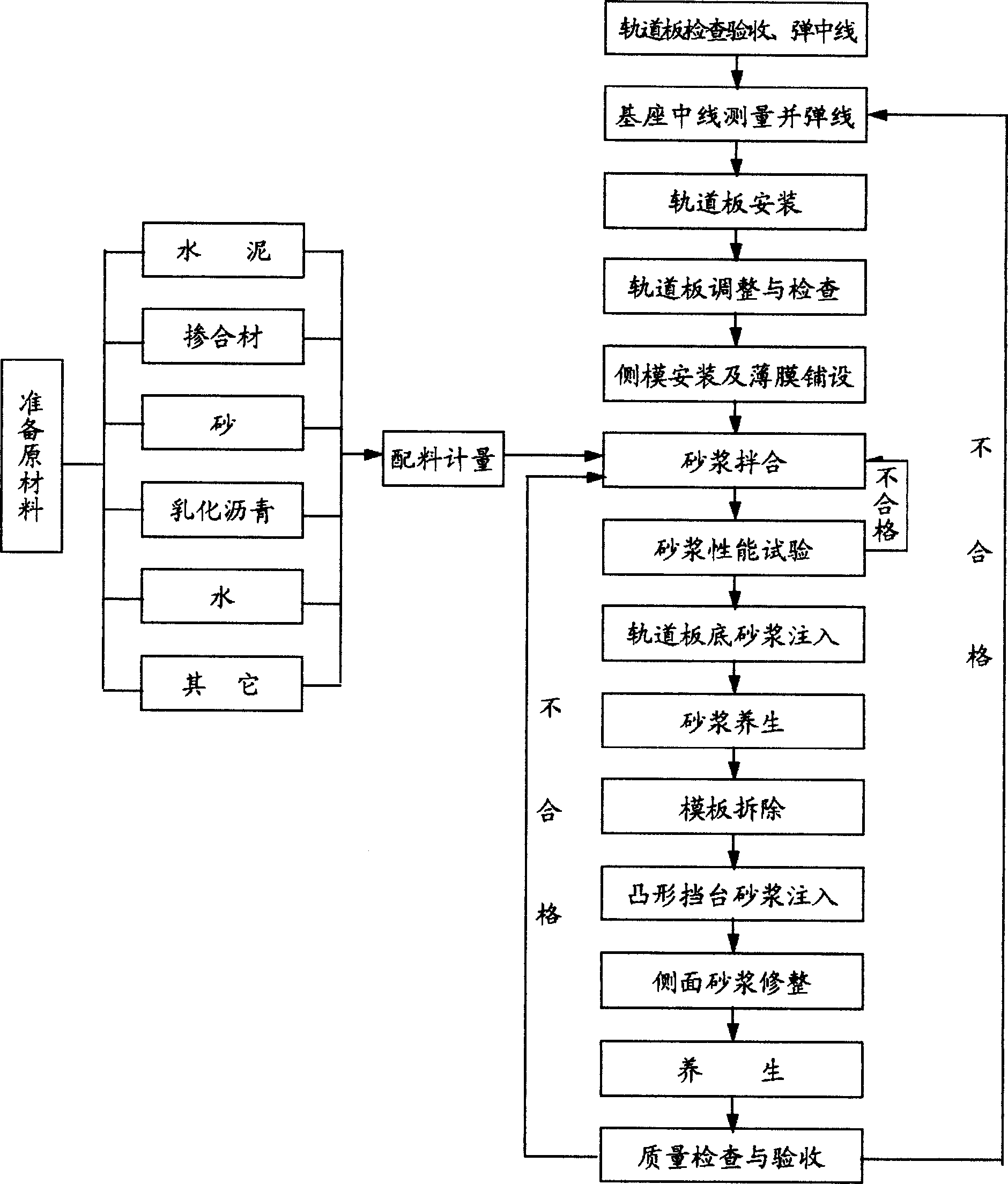

Cement emulsion asphalt mortar and its preparing method as well as application in rilroad and in ballastless track of city light rail

A cement-emulsified asphalt mortar used for railway and overhead railway in urban area contains cement and its additive, emulsified asphalt, sand, water, water-reducing agent, aluminium powder, surfactant, defoaming agent, polyacrylic fibres and chlorobutadiene latex. Its preparing process is also disclosed. Its advantages are high flowability, high strength and freeze-thawing resistance, and no environmental pollution.

Owner:CHINA RAILWAY 11TH BUREAU GRP

Method of delivery of agents providing freezing and thawing resistance to cementitious compositions

A method of delivering an admixture providing freeze-thaw resistance to a cementitious composition is provided which includes the addition of a viscosity modifying admixture containing at least one of polymeric microspheres, at least partially degradable polymeric particles, or gas generating additives to cementitious compositions. The polymeric microspheres, at least partially degradable polymeric particles, and gas generating additives provide void spaces in the material matrix, and such void spaces act to increase freeze-thaw durability of the material.

Owner:CONSTR RES & TECH GMBH

High-performance low-noise asphalt pavement conserving material and preparation method thereof

The present invention relates to a high-performance low-noise asphalt pavement maintaining material and the preparing method thereof, the maintaining material is mainly composed of conventional micro-surfacing asphalt concrete and waste rubber powder and polymer fiber, and the content of the waste rubber powder and polymer fiber respectively accounts for the gross weight of the micro-surfacing asphalt concrete 1-5% and 0.1-0.3%. The maintaining material preparing method is mixing the waste rubber power and the polymer fiber and the dry mixture of the prescribed grading aggregate to uniform, then adding filling agent, water and modified emulsified asphalt in sequence, and mixing to uniform. The material of the invention is improved with the bonding capacity to the original asphalt pavement because of the adding of the waste rubber powder and the polymer fiber, the capacity of the micro-surfacing asphalt concrete is increased, the excellent high-temperature-resisting track and low-temperature cracking capacity is facilitated to be possessed, has the advantages of excellent water-proofing and water-resisting property, excellent noise reducing, skid resistance, abrasion-proofing, impact resistance, cracking resistance and freeze-thaw resistance; and the material of the invention has the advantages of simple preparing method, low construction cost and less environmental pollution and the like.

Owner:WUHAN UNIV OF TECH

Flexible tapestry brick of external wall outer insulation system and production method thereof

The invention discloses a flexible decorated brick for exterior wall insulation system, mainly comprising main-body bricks or a composite surface coating of main-body bricks. The main-body brick formula contains major components of soil and acrylic emulsion, and further contains dispersant, softening agent, coloring agent, flame retardant, antifreeze and water according to different product performance requirements. The surface coating formula contains the main components of metal powder or a compound powder of more than two kinds of non-metallic powder or metal powder and acrylic emulsion and further contains dispersant, softening agent, coloring agent, flame retardant, antifreeze and water according to the needs of different product performances. The product of the invention is light-weighted, freeze-thaw resistance, anti-aging, high in bond strength, flexible and good in water-repellent and permeability, the pollution resistance of which is equivalent to that of polished tiles and the color of which is as rich as the paint and the appearance of which can be made into a decorative texture of metal curtain walls, stone walls, ceramic, wood, leather or cloth. Particularly, the inventive product has an excellent compatibility with the exterior insulation system, suitable for the decorated layer of the exterior insulation system. In addition, the inventive product avoids using the clay resource which is in shortage as the main production raw material and is a low-cost, environment-friendly flexible decorated material with high performance for exterior wall insulation system.

Owner:石磊

Water permeable brick with haze removal and water purification functions and making method

InactiveCN105220591AHigh strengthSatisfy normal useSingle unit pavingsCeramic shaping apparatusFiberBrick

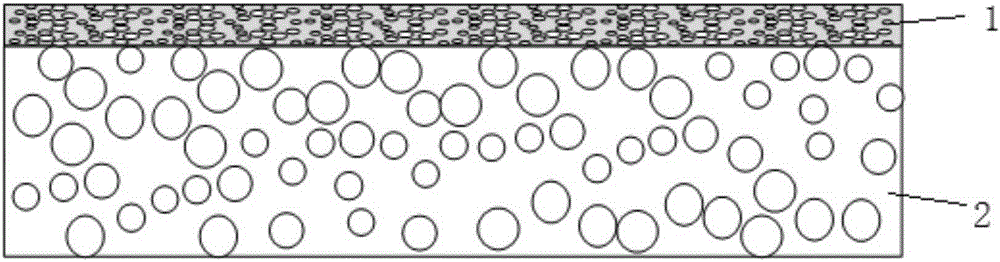

The invention relates to a water permeable brick with haze removal and water purification functions and a making method. The water permeable brick mainly comprises a surface layer with the haze removal function and a base layer with the water permeable function, and the surface layer is located on the upper portion of the base layer; the surface layer is prepared from, by weight, 80-100 parts of cement, 310-360 parts of coarse sand, 7-11 parts of silicon ash, 25-35 parts of water, 0.8-1.2 parts of water reducing agents, 3-6 parts of titanium dioxide and 1.5-4 parts of activated carbon; the base layer is prepared from, by weight, 90-110 parts of cement, 220-260 parts of stone, 70-110 parts of coarse sand, 8-12 parts of silicon ash, 8-12 parts of VAE, 0.1-0.4 part of polyethylene fibers, 25-35 parts of water and 0.8-1.2 parts of water reducing agents. According to the water permeable brick, novel substance components are designed, the good water purification and haze removal effects are achieved, and superhigh anti-freezing and thawing performance is achieved.

Owner:SHANDONG UNIV

Green environmentally-friendly broken stone active powder concrete

The invention discloses green environmentally-friendly broken stone active powder concrete. The green environmentally-friendly broken stone active powder concrete is prepared from 485 to 580 weight parts of ordinary portland cement or low-alkaline portland cement having the average grain diameter of 30 to 60 microns, 105 to 145 weight parts of silica fume having the average grain diameter of 0.18 microns and SiO2 content greater than or equal to 85%, 100 to 130 weight parts of I-grade coal ash having the average grain diameter of 10 to 20 microns, 100 to 130 weight parts of more than S95 grade of slag powder having the average grain diameter of 10 to 30 microns, 510 to 590 weight parts of quartz sand having the grain diameter of 0.16 to 1.63 millimeters, 795 to 880 weight parts of crushed stone having the grain diameter of 5 to 14 millimeters, 15 to 18 weight parts of a composite high-efficiency water reducer having a water-reducing rate more than 30%, 7 to 12 weight parts of a corrosion inhibitor, 136 to 165 weight parts of water, and 80 to 160 weight parts of copper-coated steel fibers having the diameter of 0.18 to 0.25 millimeters and the length of 10 to 15 millimeters. The green environmentally-friendly broken stone active powder concrete has a low composite cost and wide raw material sources, adopts a large amount of industrial waste materials, has good chemical corrosion resistance, good carbonization resistance, good freeze thawing resistance, high compressive strength and flexural strength, and good self-sealing performances, reduces hydration heat and workability adjustment ranges, and satisfies different process requirements.

Owner:黄贺明

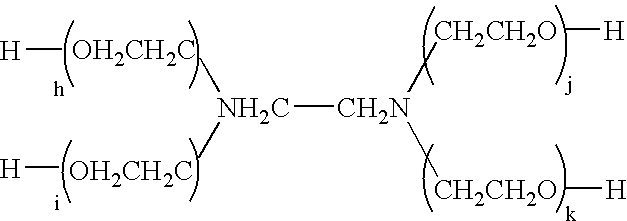

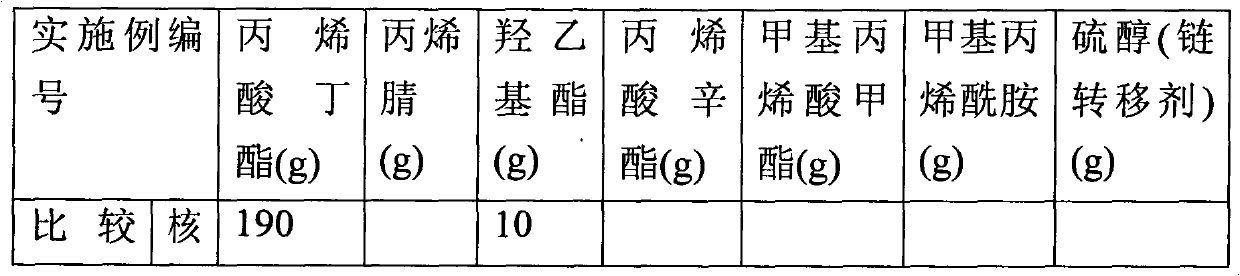

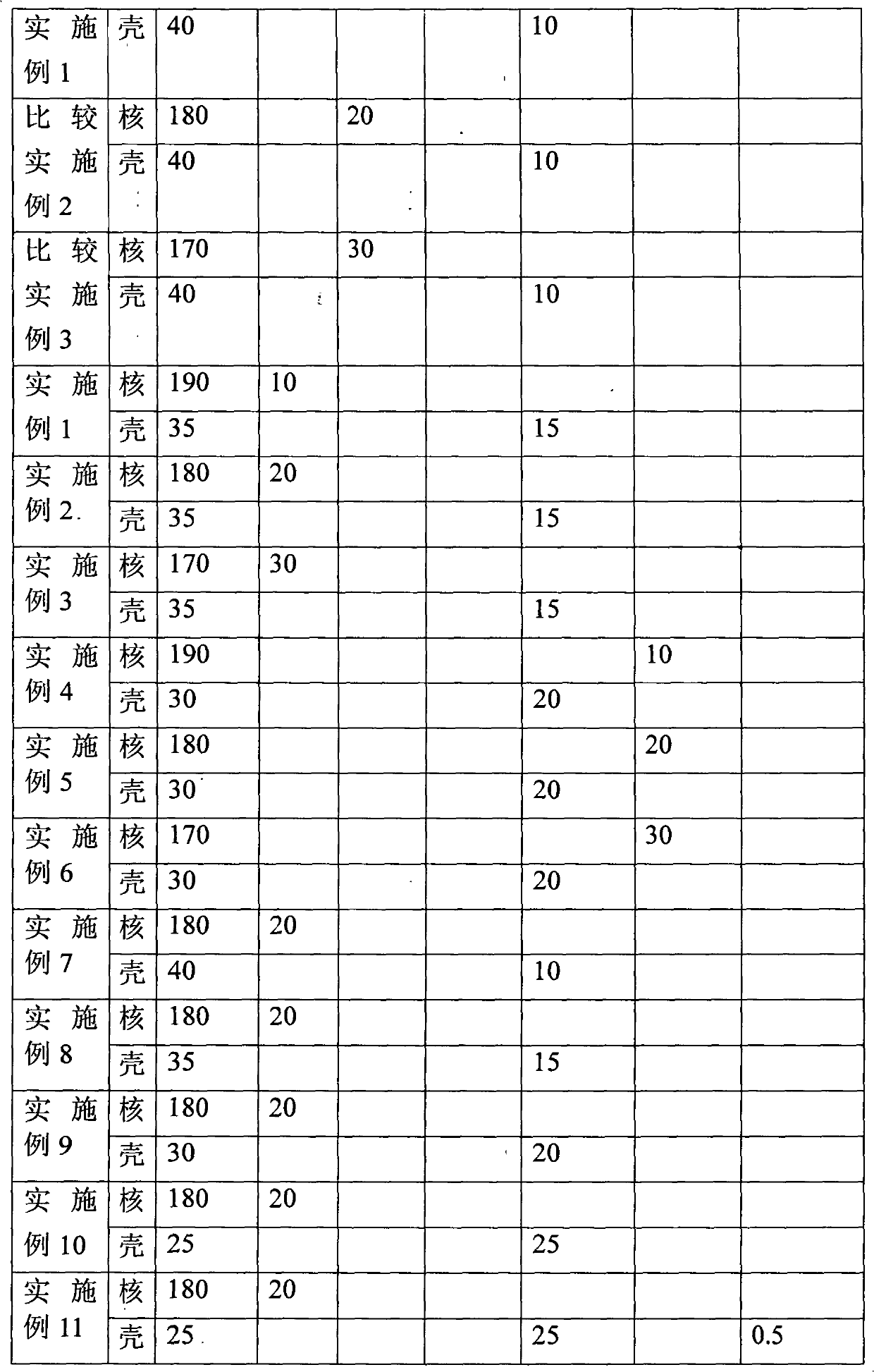

Acrylic core-shell polymer emulsion and preparation method thereof

The invention provides acrylic core-shell polymer emulsion for low temperature resisting polymer cement waterproof material. The polymer emulsion is prepared from a component (1) and a component (2) by an emulsion polymerization method, wherein the component (1) is a core layer component of the polymer emulsion and comprises at least the following two monomers in part by weight: 60 to 95 parts of butyl acrylate and 6 to 10 parts of acrylonitrile; and the component (2) is a shell layer component of the polymer emulsion and comprises at least the following two monomers in part by weight: 5 to 15 parts of butyl acrylate and 5 to 15 parts of methyl methacrylate. The invention also provides a preparation method for the acrylic core-shell polymer emulsion. The acrylic core-shell polymer emulsion has lower tg value. A polymer cement composition formed by the acrylic core-shell polymer emulsion and cement has high tensile strength and freezing and thawing resistance and high waterproofness and flexibility.

Owner:BEIJING DONGLIAN CHEM

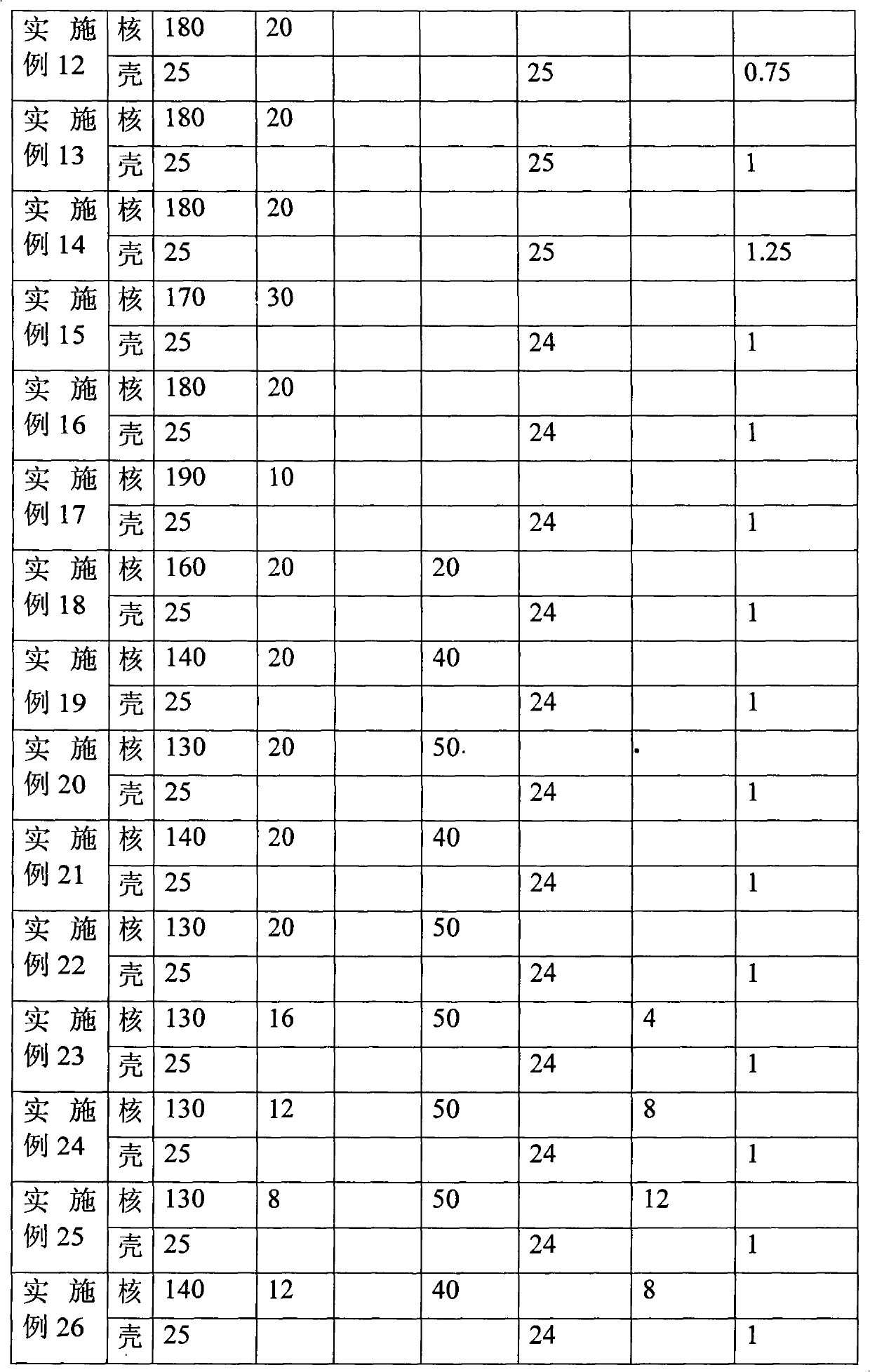

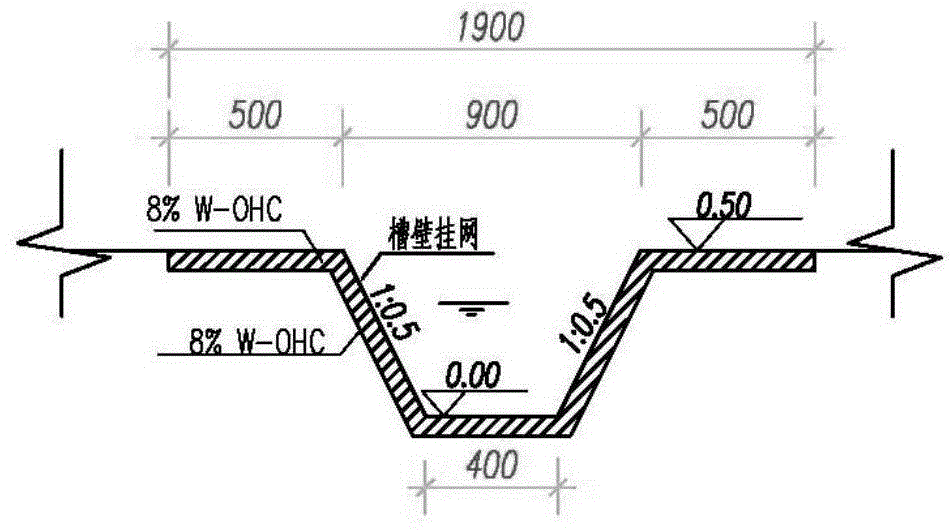

Flexible slope protection method for soft sandstone natural side slope

InactiveCN104805845AReduce penetrationImprove survival rateExcavationsHorticultureFreeze thawingVegetation

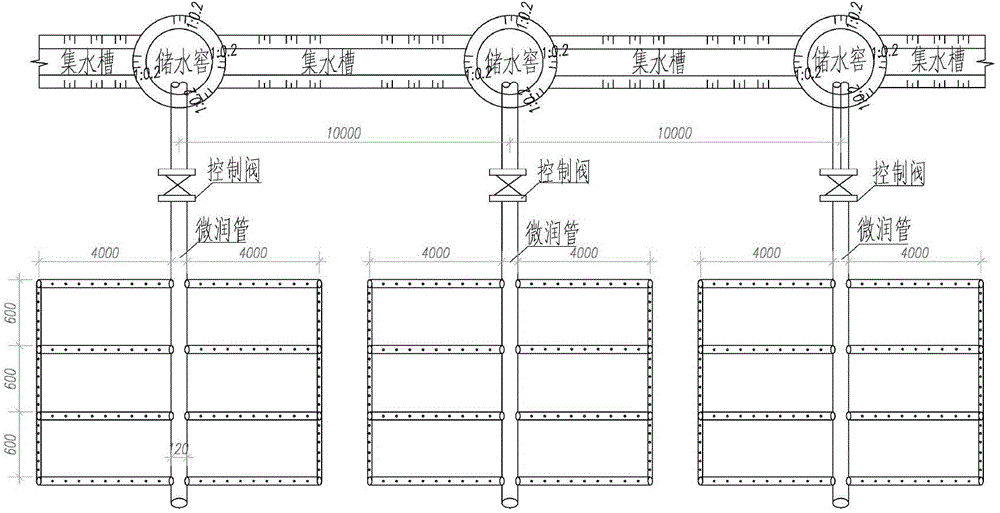

The invention provides a flexible slope protection method for a soft sandstone natural side slope. The method comprises the following steps of (1) slope surface early-stage cleaning; (2) net hanging; (3) micro lubricating system building; (4) spray coating; (5) plant planting and greening; (6) operation and maintenance. The method has the advantages that through a series of measures of the flexible slope protection method, a processed side slope surface layer soft sandstone composite body has the comprehensive performance such as excellent mechanical performance, ultraviolet degradation resistance performance, wind etching resistance performance, water etching resistance performance, gravity etching resistant performance, freeze thawing resistance, water preservation, heat insulation and fertilizer preservation, the soft sandstone can be fixed, meanwhile, the method is combined with plant-growing methods such as a seed spraying method, the vegetation recovery is promoted, and the water and soil maintaining effect is effectively improved. The flexible slope protection method is suitable for ecological control and restoration engineering of the soft sandstone natural side slope and is particularly suitable for soft sandstone regions with the serious water and soil loss.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Water wall paint for external wall

The present invention features that by selecting different sort and amount of emulsion and assistants, four kinds of wall finish paint, including styrene-acrylate wall finish paint, acrylate wall finish paint, organosilicon modified acrylate wall finish paint and high elasticicty wall finish paint, of different performance / cost ratio are proposed. They features the introduction of hydroxyethyl cellulose and non-transparent hollow polymer. Therefore, the outer wall finish paint has excellent alkali resistance, color maintaining property, antifouling property, ultraviolet ray resistance, freeze thawing resistance, waterproof property, etc.

Owner:GUANGDONG BADESE CHEM

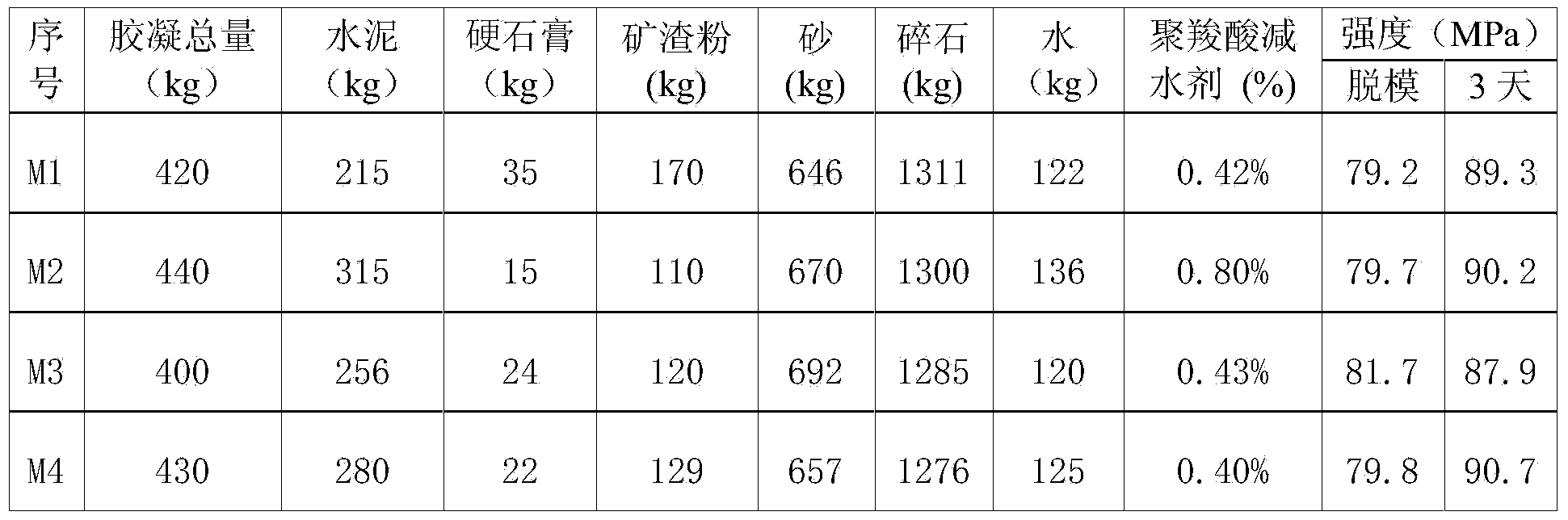

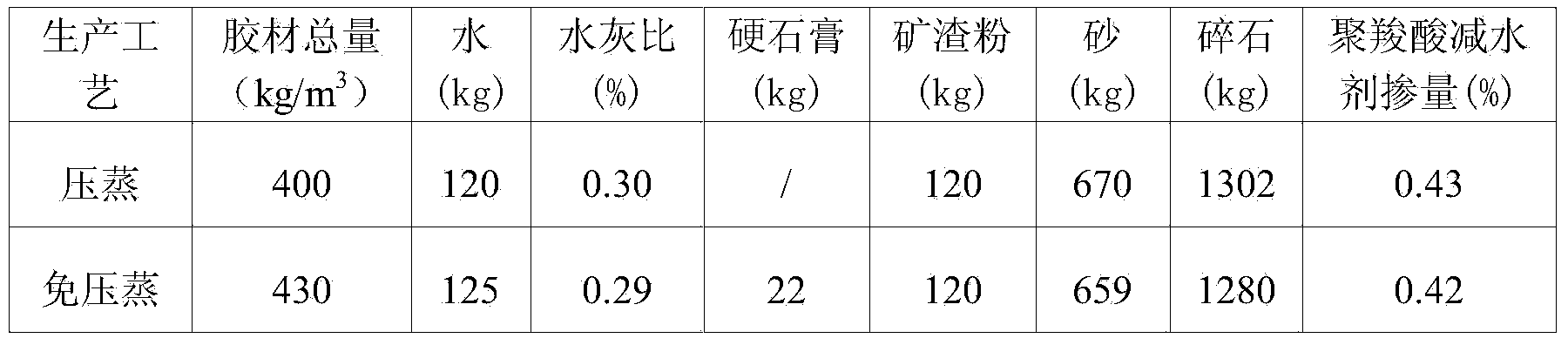

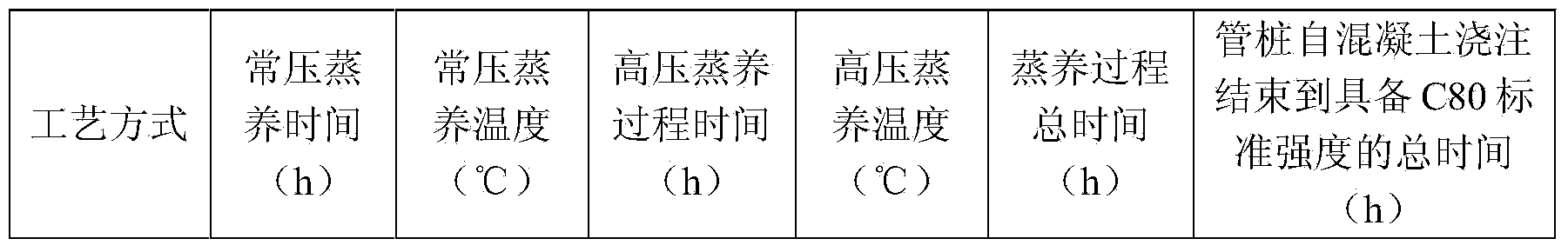

Non-autoclave primary health care (PHC) pipe pile concrete containing early strength composite mineral material and preparation method thereof

The invention relates to non-autoclave primary health care (PHC) pipe pile concrete. The concrete is characterized by being prepared from the following raw materials: a binding material, a water reducing agent, water, coarse aggregate, and fine aggregate, wherein the binding material is prepared from the following raw materials by mass ratio: 3.0-8.0% of rich calcareous material, 25-40% of rich siliceous material and the balance of cement; the water reducing agent accounts for 0.4-0.8% of weight of the binding material; the water cement ratio of the concrete is 29-31%; the sand ratio is 33-35%; the volume-weight is 2480-2500kg / m<3>. The rich calcareous material and the rich siliceous material are compounded at a ratio of 1:4 or 1:6; the cement is excited to hydrate for the second time; the early strength is improved; the C80 strength grade requirements can be met by one-time atmospheric pressure steam maintenance for 6 hours; the performances, such as the volume stability, the carbonizing resistance, corrosion of reinforcement, the chloride penetration resistance, the freeze-thaw resistance, the acid corrosion resistance, the salt corrosion resistance and the like of the PHC pipe pile concrete are improved and changed, and the late durability of the concrete is improved.

Owner:安徽省恒泰新材料有限公司

Non-sintered slag soil wall body block and preparation process thereof

The invention discloses a non-sintered slag soil wall body block and specifically relates to a non-sintered brick or building block prepared from industrial waste slag or engineering slag soil and a preparation process thereof. The non-sintered wall body block disclosed by the invention mainly comprises the following main raw materials in parts by dry weight: 55-85 parts by weight of industrial waste slag or engineering slag soil, 5-15 parts by weight of cementing material, 0-12 parts by weight of fine aggregate and 0.05-0.1 part by weight of modifying additive. The non-sintered slag soil wall body block disclosed by the invention has wide raw material sources, fully utilizes the extensive and large-quantity industrial waste slag and engineering slag soil, turns wastes into treasure, saves land resources and protects cultivated land. The produced non-sintered slag soil wall body block has the advantages of high compressive strength, good resistance to seepage, freezing and thawing, heat preservation, heat insulation and environmental friendliness. The finished product rate of a product is more than 99%, and the product is suitable for industrial batch production.

Owner:ANGU ENVIRONMENTAL SCI & TECH

Preparation method of fluorine-containing polyacrylate soap-free emulsion

InactiveCN102585086AOvercome the defect of easy migrationImprove polymerization stabilityCoatingsEnd-groupSolvent

The invention relates to a preparation method of a fluorine-containing polyacrylate soap-free emulsion. According to the invention, the fluorine-containing polyacrylate soap-free emulsion is prepared by adopting an amphiphilic segmented copolymer polyacrylic acid-b-polyhexafluorobutyl acrylate (PAA-b-PHFBA) to substitute a routine emulsifier, and carrying out soap-free emulsion copolymerization on acrylate monomers, and can be applied to the leather field, the textile field, the coating field, the papermaking field, the adhesive field and the like. The compatibility of the hydrophobic segment of the used PAA-b-PHFBA and above prepolymerization monomers is good, so a problem of bad compatibility of fluorine-containing monomers is solved, thereby the stability of the emulsion polymerization process is substantially improved. Additionally, the PAA-b-PHFBA is anchored to emulsion particles in the emulsion polymerization, and the hydrophilic segment stretches into a water phase to stabilize the emulsion particles through an electrostatic effect and a steric hindrance effect, so the storage stability and the freeze-thaw resistance stability of the emulsion are improved, disadvantages of bad adhesion, bad water resistance and bad solvent resistance of films of common emulsions are overcome, and the mechanical properties, the adhesion and the abrasive resistance of the film of the emulsion are improved.

Owner:山西佳宇丰化工科技有限公司

Basalt fiber reinforced recycled concrete

The invention discloses basalt fiber reinforced recycled concrete. The basalt fiber reinforced recycled concrete is prepared from components in parts by weight as follows: 500-800 parts of recycled coarse aggregates, 400-700 parts of river sand, 200-400 parts of ceramsite, 280-350 parts of ordinary Portland cement, 40-60 parts of fly ash, 10-15 parts of silica fume, 10-20 parts of mineral powder,3-5 parts of a water reducing agent, 8-15 parts of basalt fiber and 160-180 parts of water. Compared with common recycled concrete, the basalt fiber reinforced recycled concrete has higher compressivestrength, splitting tensile strength, breaking strength, freeze thawing resistance, impervious performance and shock resistance.

Owner:广州珠江黄埔大桥建设有限公司 +1

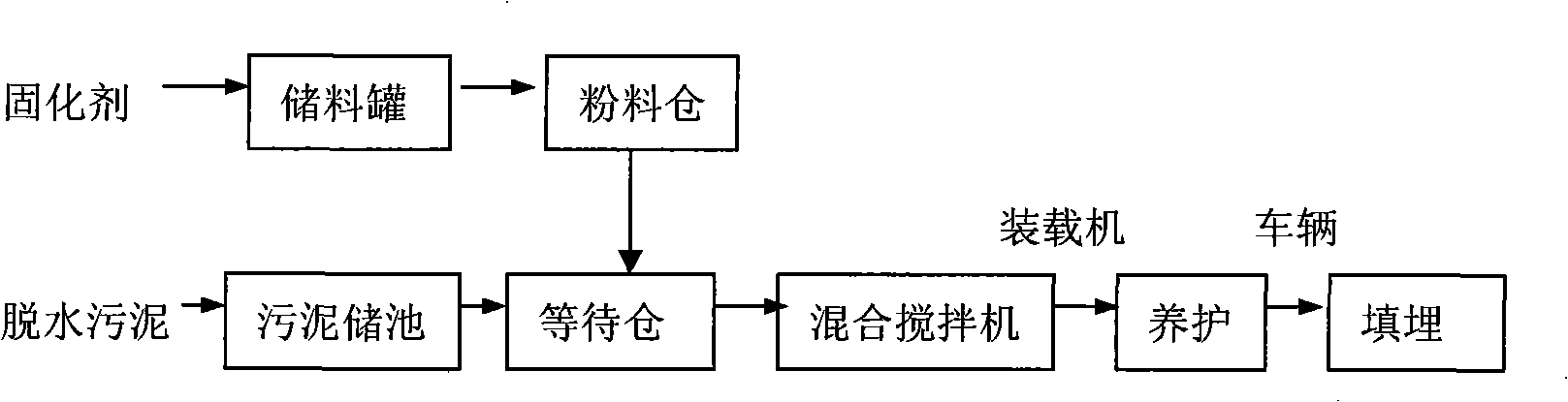

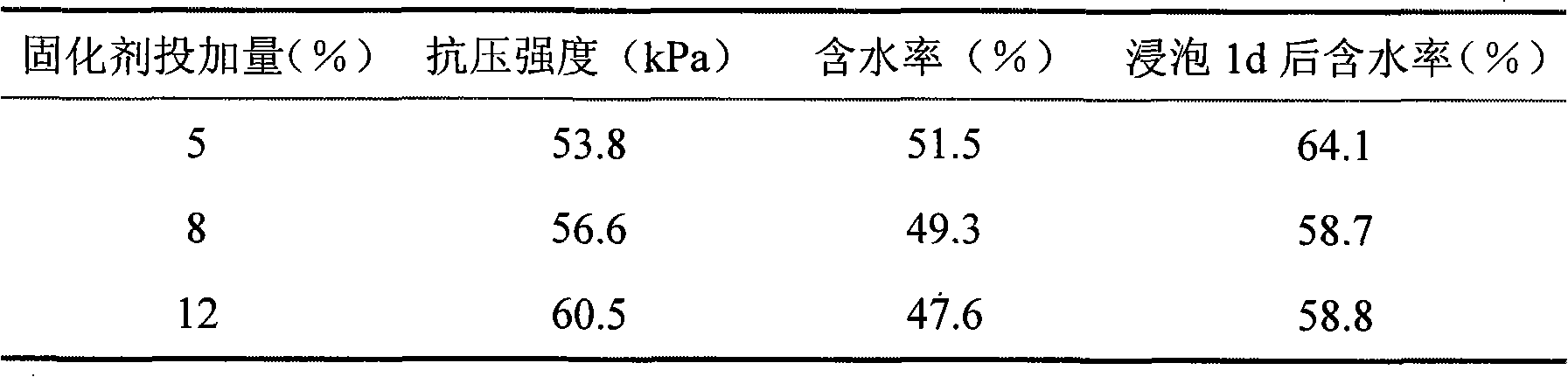

Method for treating dehydrated sludge of domestic sewage treatment plant

The invention relates to a method for treating dewatered sludge in a domestic sewage treatment plant. The water ratio of the dewatered sludge is not more than 80 percent. MgO and MgCl2 are taken as curing agents. The usage amount can be taken according to the weight percentage, namely, MgO: MgCl2=(75 per cent-85 per cent):(15 per cent- 25 per cent); then, the curing agents are added into the dewatered sludge, the adding amounts of the curing agents are taken according to the weight percentage of the dewatered sludge and the curing agent, namely, the dewatered sludge: the curing agents=(92 per cent-95 per cent):(5 per cent-8 per cent); then the dewatered sludge is evenly mixed with the curing agents and blended, and maintains for one to two days, and the solidified sludge with the water ratio lower than 60 percent is obtained and conforms to the Standard for Pollution Control on the Landfill Site of Municipal Solid Waste (GB16889-2008) of the land fill disposal; finally, the solidified sludge undergoes the land fill disposal. The invention has the advantages of simple process, convenient operation and low cost; the solidified sludge has good impermeability, leach resistance, dryness and wetness resistance, freeze-thaw resistance and sufficient mechanical strength; the invention can perform stabilization, quantity-reducing and harmlessness treatment to the dewatered sludge, and is convenient for the realization of the sludge recycling.

Owner:上海明诺环境科技有限公司

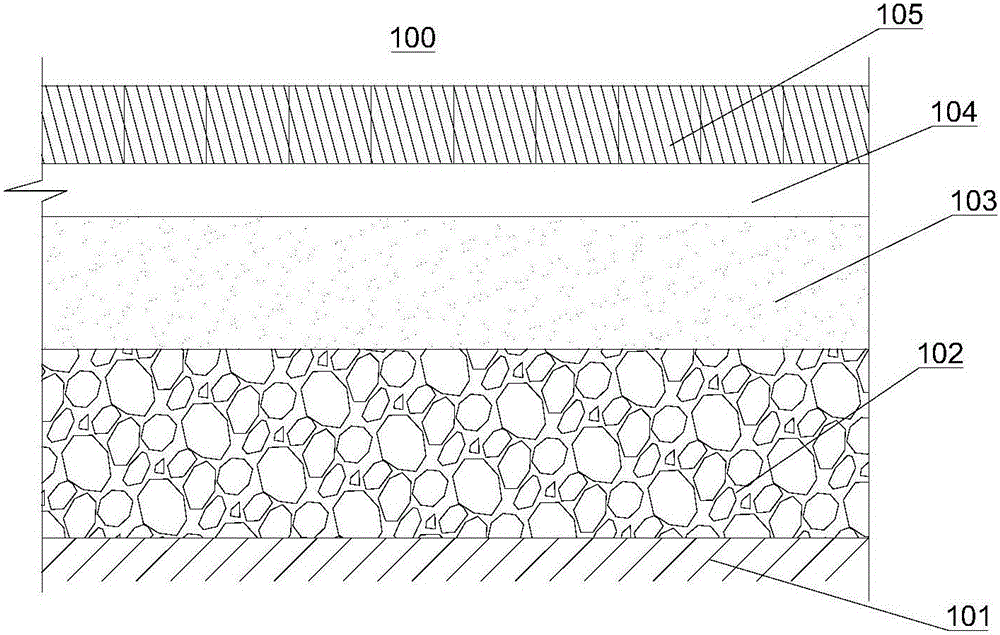

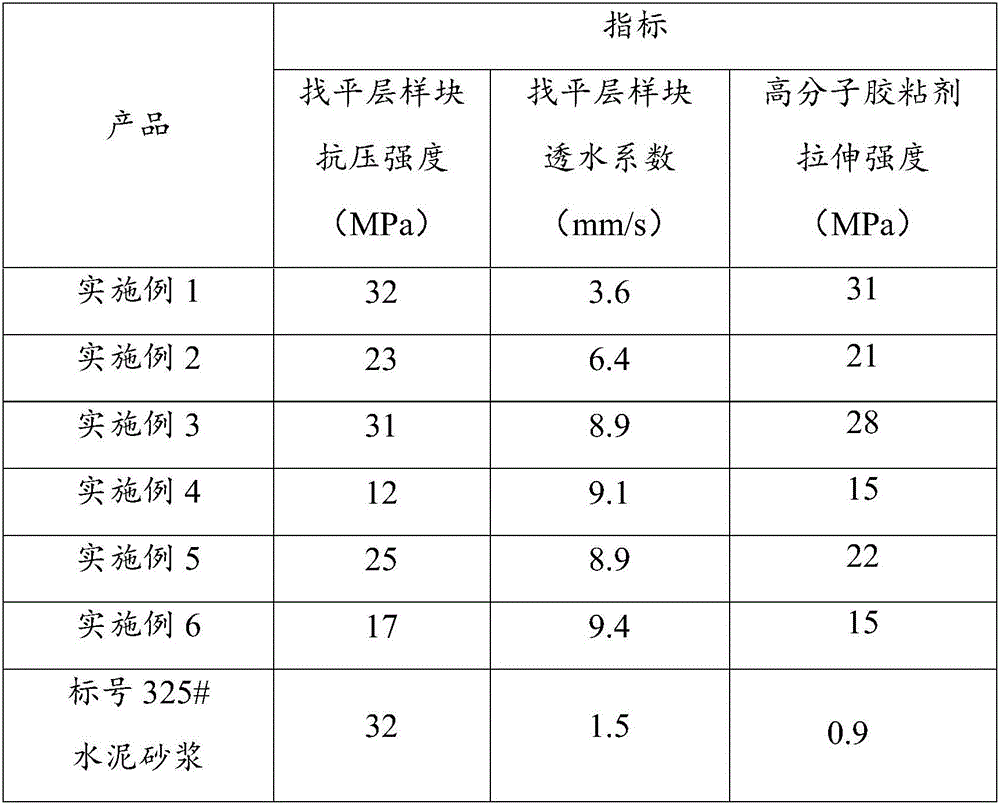

Brand new pervious pavement total-pervious leveling layer material and total-pervious pavement structure

InactiveCN106082783AHigh bonding strengthHigh compressive strengthPaving gutters/kerbsCeramicwareFreeze thaw resistanceAdhesive

The invention provides a brand new pervious pavement total-pervious leveling layer material and a total-pervious pavement structure, and belongs to the field of municipal engineering and building. The leveling layer material comprises a high-molecular adhesive and aggregate which are mutually mixed, wherein the aggregate comprises stone particles and / or grits, the stone particles and the grits are single particles or are discontinuously graded, and the stone particles have high porosity and good water permeability; and the high-molecular adhesive has better adhesion stress, extensibility and freeze thaw resistance than previous binders which are cement and lime. The leveling layer material and the pavement structure are different from pervious pavement leveling layer materials adopting cement and sands, or sands and lime sands, or pure sands, and corresponding pervious pavement structures, have the characteristics of total-pervious property of the integral pavement, high water permeability, strong adhesion stress, strong compressive strength and good freeze-thawing resistance, are helpful for realizing an integral structure between the upper layer and the lower layer of a pavement, are durable and can realize a total-pervious effect.

Owner:陈毅然

Fiber cement composition materials using cellulose fibers loaded with inorganic and/or organic substances

InactiveCN1473138AImprove mechanical propertiesEasy to useConstruction materialSolid waste managementChemical treatmentCement composites

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using cellulose fibers that are treated with inorganic and / or organic resins to make the fibers more hydrophobic, as well as other chemical treatments. This invention discloses four aspects of the technology: fiber treatment, formulations, methods and the final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, and improved rot and UV resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness. In some cases the physical and mechanical properties are improved. This invention also discloses the method of treating cellulose fibers with various chemicals to impart the fiber hydrophobicity for applications in the fiber reinforced cement composite materials.

Owner:JAMES HARDIE INT FINANCE BV

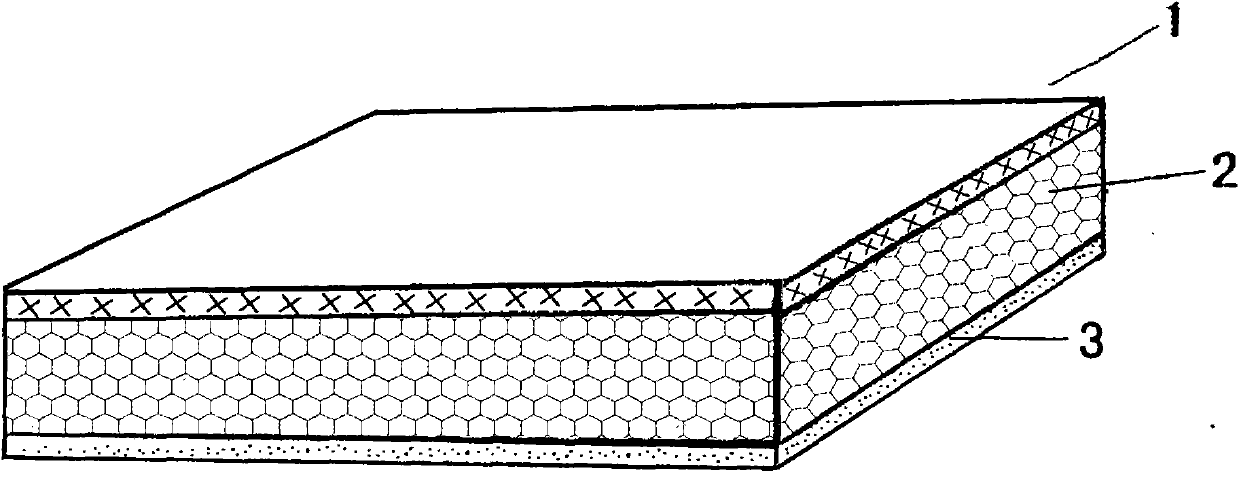

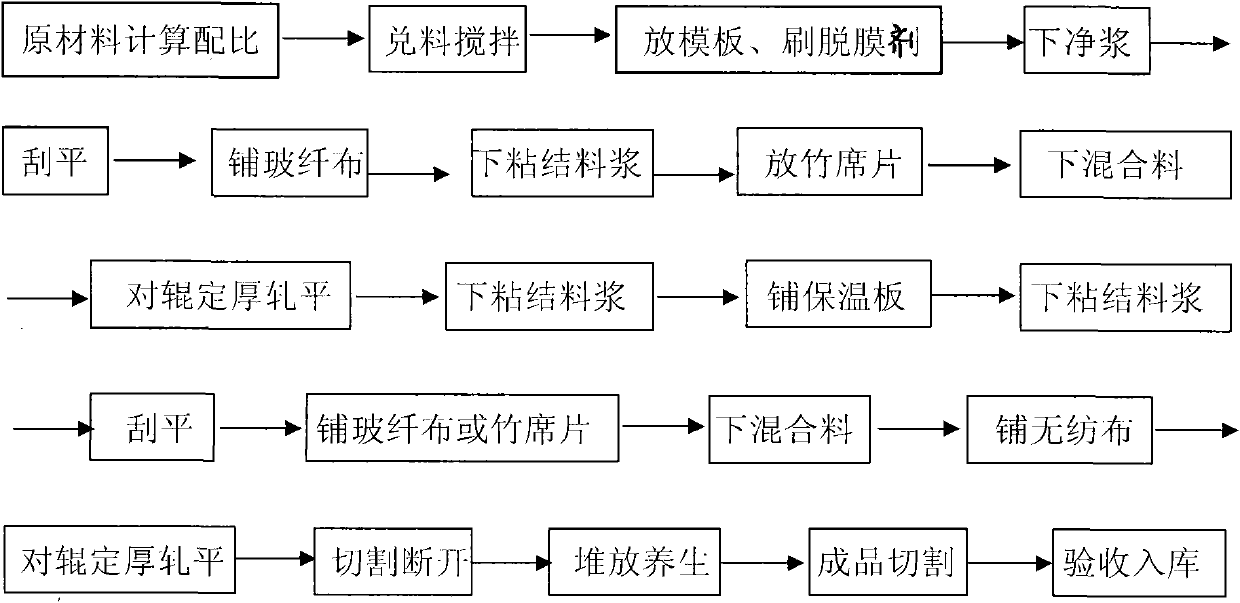

Machine-made inorganic silicon-magnesium external wall thermal insulation composite board through one-step molding and production technology thereof

ActiveCN101994348ASimple structureLow costSynthetic resin layered productsCeramic shaping apparatusFreeze thawingComposite plate

The invention relates to a machine-made inorganic silicon-magnesium external wall thermal insulation composite board through one-step molding and a production technology thereof. The composite board contains a thermal insulation composite board panel layer prepared from magnesium chloride, magnesium oxide, silicon dioxide, glass fiber cloth, mat sheets, magnesite filler and modifier, an intermediate thermal insulation layer and a thermal insulation composite board bottom board layer prepared from magnesium chloride, magnesium oxide, silicon dioxide, glass fiber cloth, magnesite filler and modifier. One-step roll forming is performed to the thermal insulation composite board panel layer, the intermediate thermal insulation layer and the thermal insulation composite board bottom board layer, thus the traditional manual field operation is changed, the mechanized factory production using inorganic silicon-magnesium cement material is realized, the labor cost and the time are reduced and the engineering quality and the operability of quality check are greatly increased; the weight of the composite board is 1 / 2 to 1 / 3 of that of the external wall thermal insulation material prepared by the traditional technology; the impact strength is more than twice of that of the common composite board; the composite board has freeze-thaw resistance and can not change after 40 times of freeze-thaws, which is better than the portland cement board; and the composite board has good toughness and high wind resistance, and is the best product of the current external wall external thermal insulation composite board.

Owner:高大礼

Conductive concrete compositions and methods of manufacturing same

InactiveUS20050194576A1Improve freeze-thaw resistanceImprove water resistanceSolid waste managementConductive materialFiberLong chain fatty acid

Modified compositions for carbonaceous concrete conductive sheathing materials for ground electrodes are described, for use in protecting installations from electrical currents. By the incorporation of discrete fibers, superior freeze-thaw resistance is imparted. The water resistance of carbonaceous concretes according to the invention is improved by the addition of a soluble soap of long chain fatty acids. A method of precasting carbonaceous cements according to the invention allows uniform and consistent development of properties for use either in shallow trench or deep well applications.

Owner:SIROLA D BRIEN +1

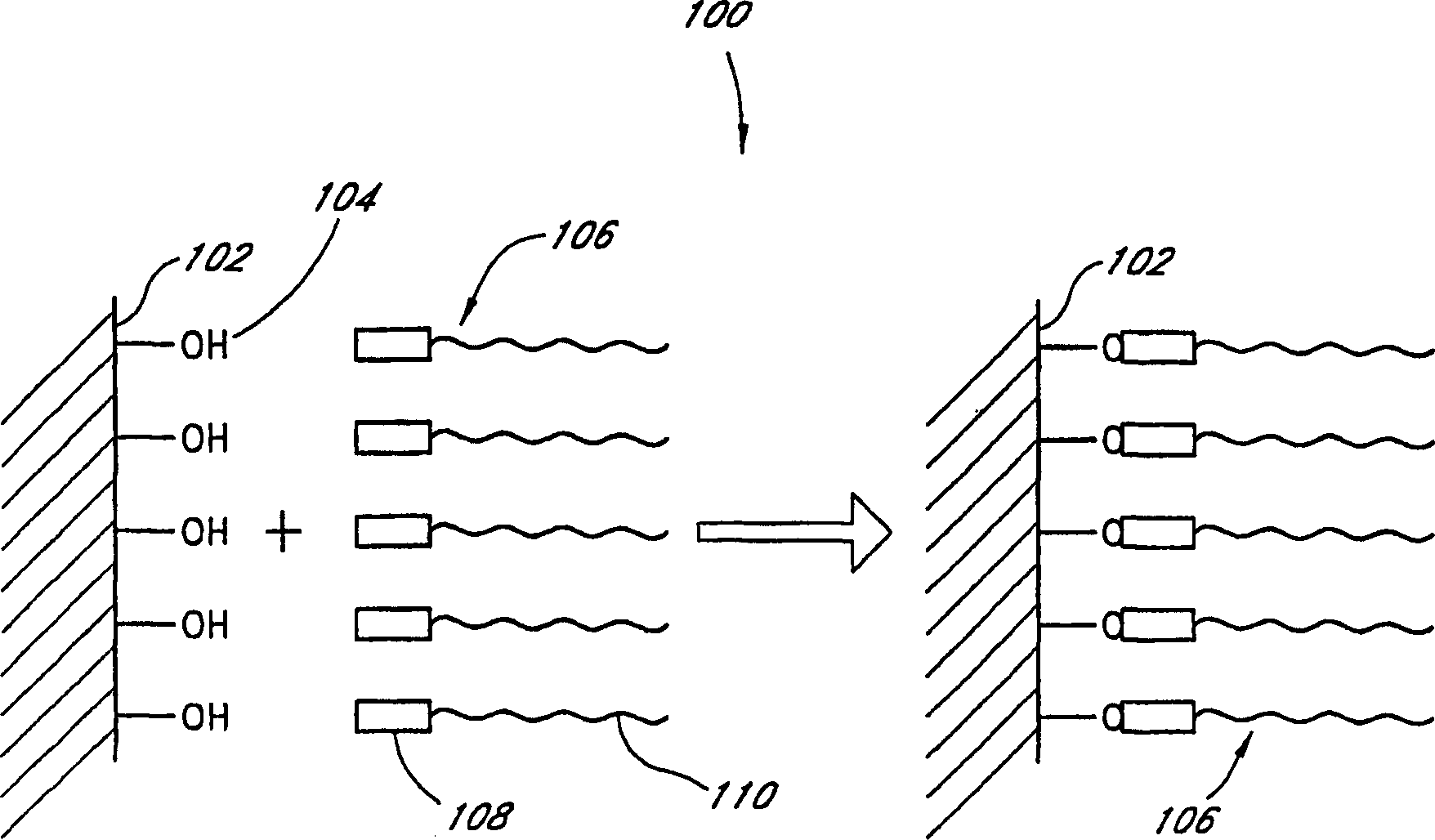

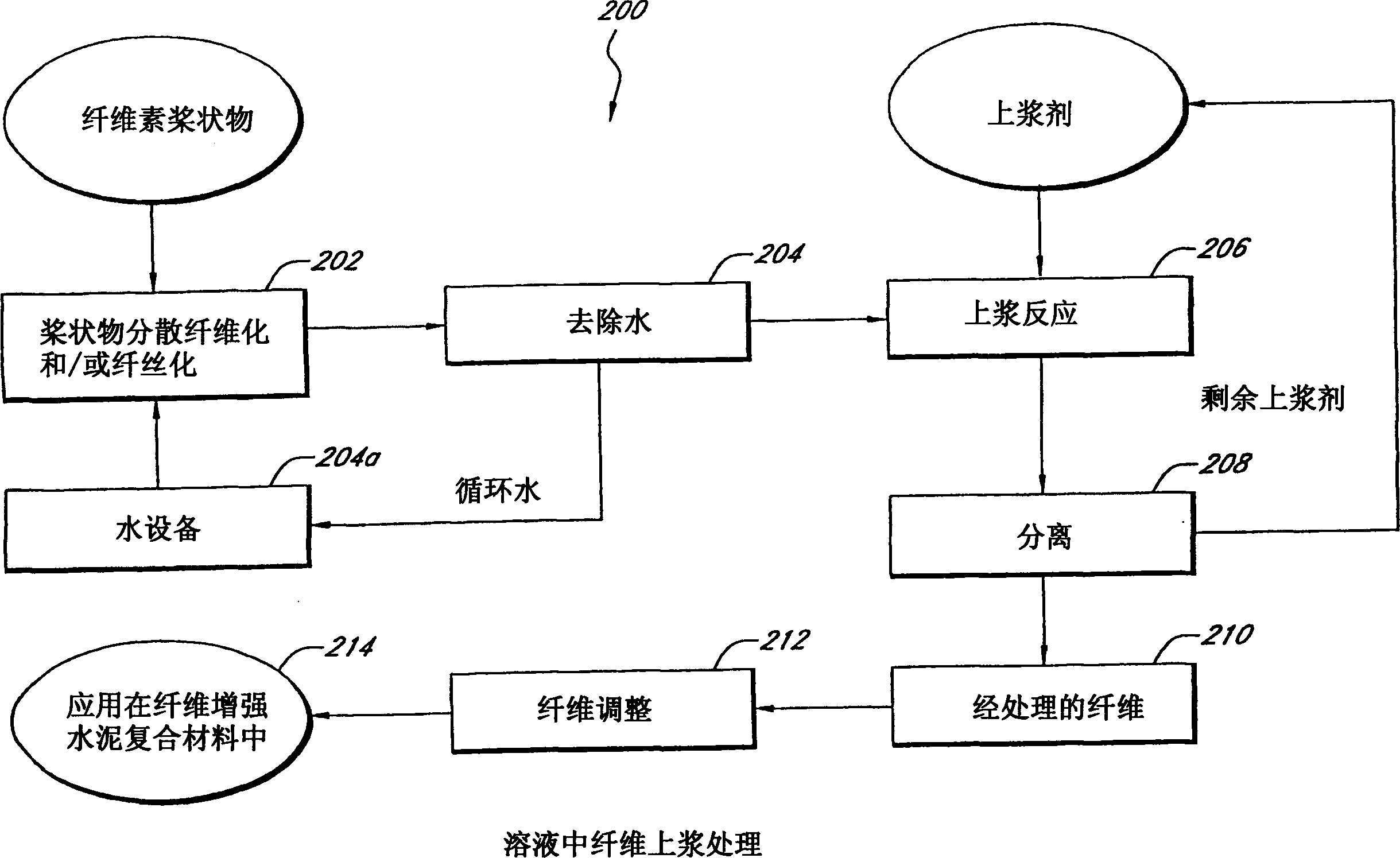

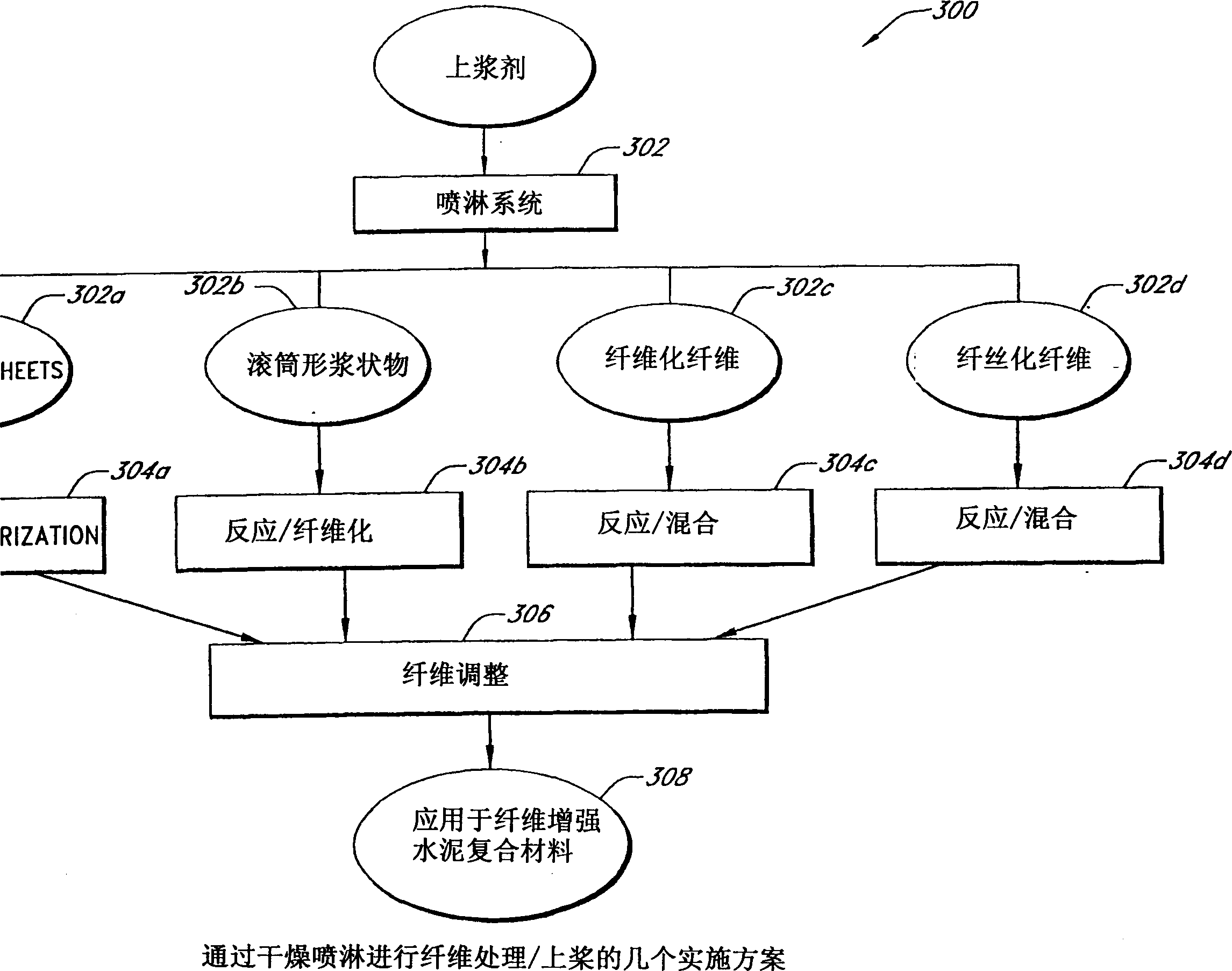

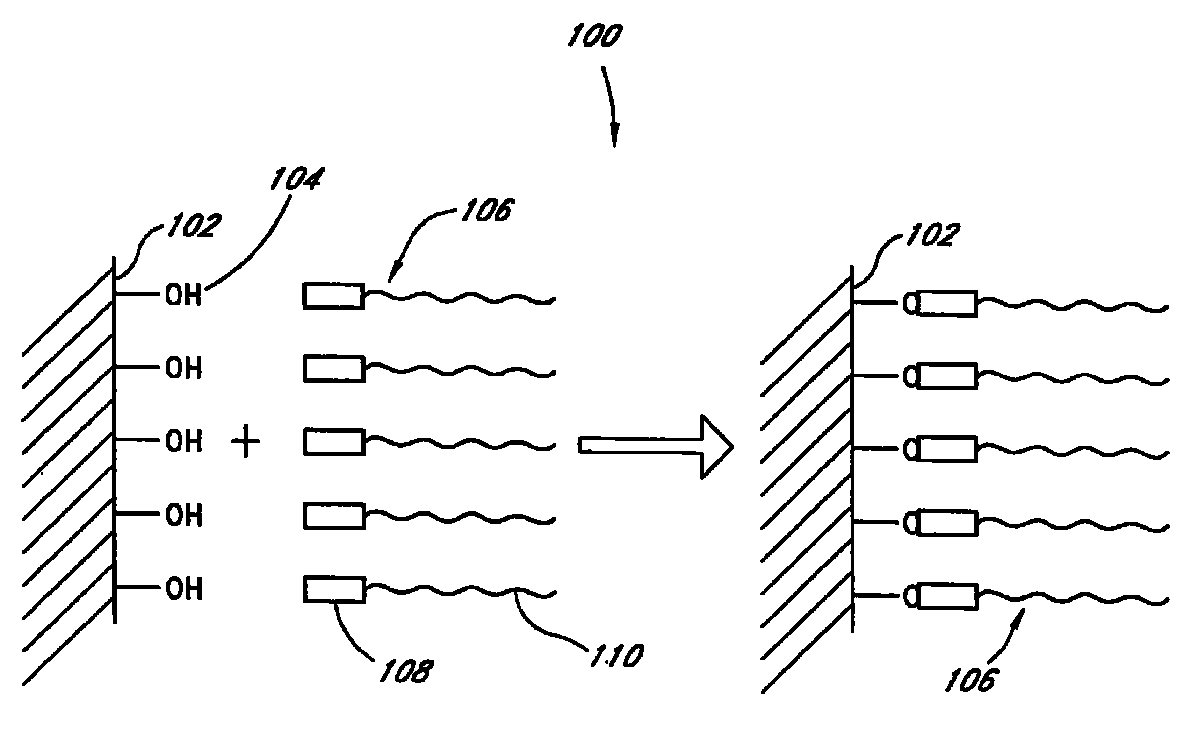

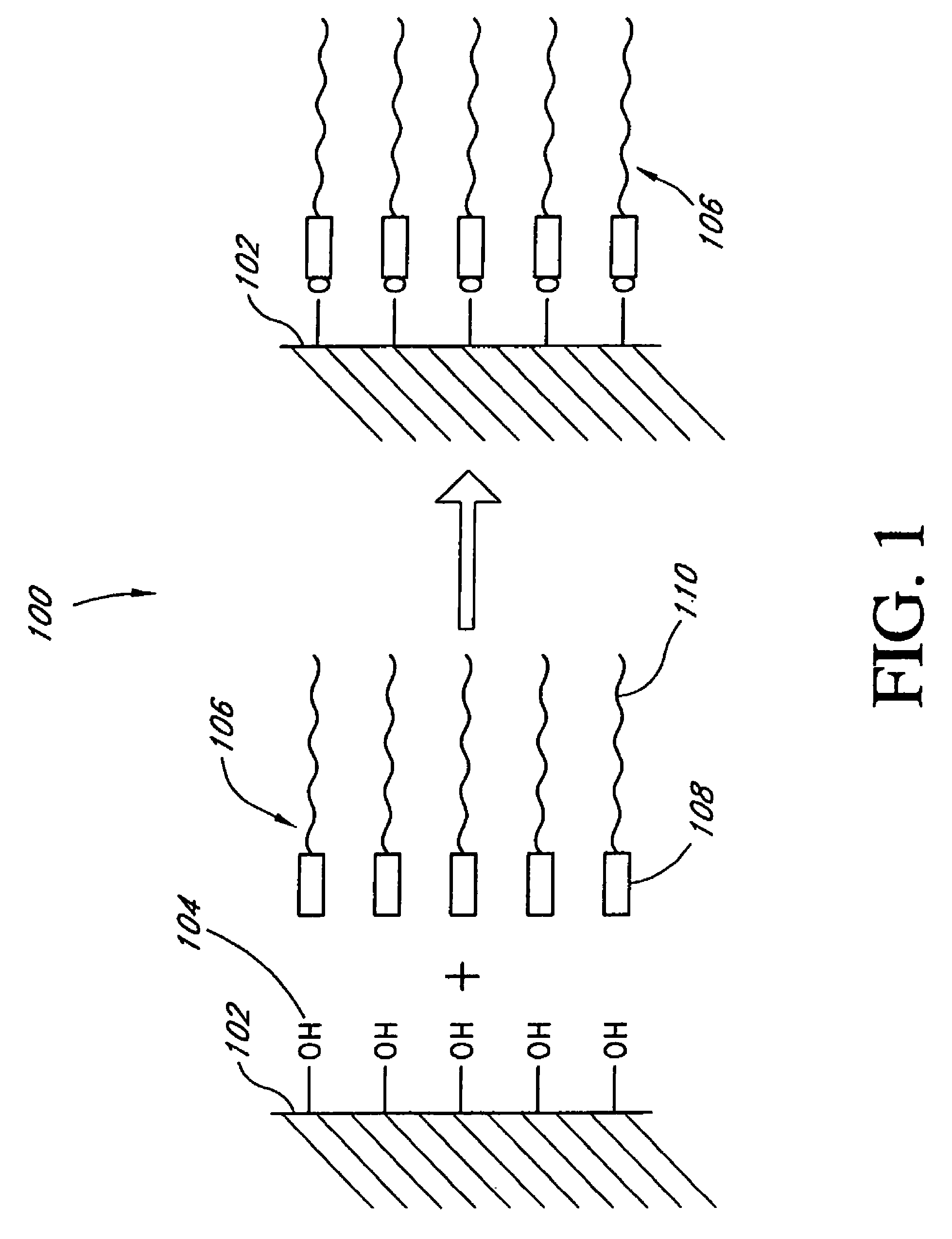

Fiber cement composite materials using sized cellulose fibers

InactiveUS7815841B2Low water absorptionImprove freeze-thaw resistanceConstruction materialWater-repelling agents additionChemical treatmentCement composites

This invention discloses a new technology related to cellulose fiber reinforced cement composite materials using cellulose fibers that are treated with inorganic and / or organic resins to make the fibers more hydrophobic, as well as other chemical treatments. This invention discloses four aspects of the technology: fiber treatment, formulations, methods and the final product. This technology advantageously provides fiber cement building materials with the desirable characteristics of reduced water absorption, reduced rate of water absorption, lower water migration, and lower water permeability. This invention also impart the final products improved freeze-thaw resistance, reduced efflorescence, and improved rot and UV resistances, compared to conventional fiber cement products. These improved attributes are gained without loss in dimensional stability, strength, strain or toughness. In some cases the physical and mechanical properties are improved. This invention also discloses the method of treating cellulose fibers with various chemicals to impart the fiber hydrophobicity for applications in the fiber reinforced cement composite materials.

Owner:JAMES HARDIE TECH LTD

High-strength permeable fiber concrete and preparation method thereof

The invention discloses a high-strength permeable fiber concrete. The high-strength permeable fiber concrete comprises cement, an additive, water, cobblestones and high-strength engineering fibers, the weight of the high-strength engineering fibers is above 3% of the weight of cement and is less than 0.8% of the total weight of the concrete. The invention also discloses a preparation method of the high-strength permeable fiber concrete. The high-strength permeable fiber concrete is obtained through organically combining common permeable concrete with permeable fiber concrete, and is a novel antifreeze permeable concrete having a high strength and a freeze-thaw resistance. The high-strength permeable fiber concrete can substantially improve the construction quality to substantially reduce the road maintenance and repairing rates in northern cold regions, so the durability and the safety of a pavement are guaranteed.

Owner:BEIJING CHUNJUEXIAO TECH

Super strengthen adhesives for adhering ceramic tile of wall and floor

The invention relates to a wall and floor tile paving ultrastrong adhesive, composed of cement, yellow sand, limestone powder, sulphoaluminate sweller, fibrin and polyvinyl acetate emulsion powder, and it can completely efficiently paving the wall surfaces and top surfaces of buildings, improving the binding strength of ceramic wall tiles and natural and man-made stone materials to the bases by a large margin, and it has high press-cut-binding strength, water resistance, high temperature resistance and good freeze-thaw resistance, and can be cold-placed and has long regulating time, and low shrinkage. It is applied to pasting the decorative materials, such as ceramic wall and floor tiles or marble, granite, man-made stone materials, etc on the surfaces of clay brick, cement mortar, cement and concrete and concrete bricks.

Owner:TONGJI UNIV

Cement stabilized base material, preparation, application and preparation method of road base

The invention discloses a cement stabilized base material, a preparation, an application and a preparation method of a road base. The cement stabilized basic material comprises the following materials: 1%-3% of basic slag and 1%-3% of cement and base materials, wherein the basic materials comprises 0.5%-8% of desulfurization gypsum and 92%-99.5% of crushed stone in mass percentage of the basic materials. The preparation method of the cement stabilized base material comprises the step of uniformly mixing the components. According to the preparation method of the road base, the road base is prepared from the cement stabilized base material with the conventional preparation process and conditions. The cement stabilized base material has the advantages as follows: the material cost is reduced, the service life of a road structure is prolonged, the economic benefit is increased, the cement setting time is delayed, the strength, the airtightness, the water retention, the water resistance, the shrinkage crack resistance, the freeze-thaw resistance, the moisture damage resistance and sulfate corrosion resistance of the material are improved, novel application of the desulfurization gypsum is exploited, and the environment is protected effectively.

Owner:SHANGHAI HIGHWAY BRIDGE (GRP) CO LTD +1

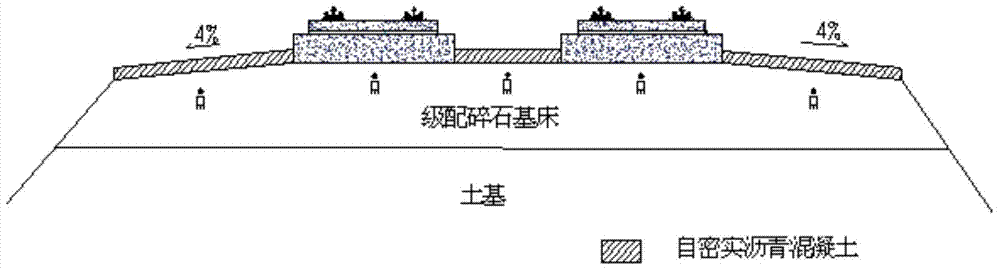

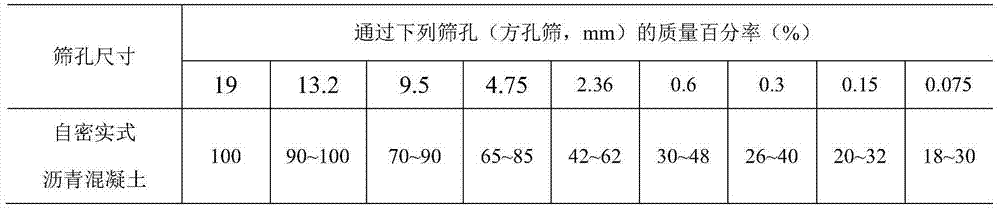

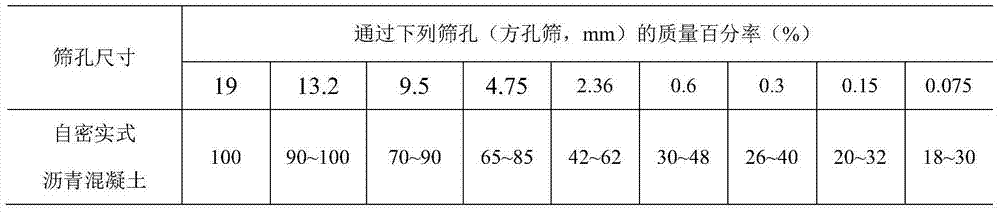

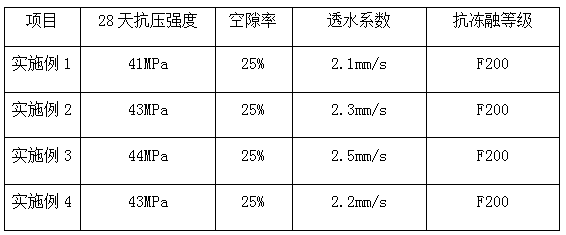

Self-compacting bituminous concrete waterproof seal and construction method thereof

ActiveCN104278598ANo crackGood deformation complianceRoadwaysRailway tracksFreeze thawingBituminous concrete

The invention relates to a self-compacting bituminous concrete waterproof seal and a construction method thereof. The self-compacting bituminous concrete waterproof seal is especially applicable to local waterproof sealing of high-speed railway or dedicated passenger line road beds in high and cold areas. Compared with the prior art, the self-compacting bituminous concrete waterproof seal and the construction method thereof have the advantages that the advantages such as good impermeability, freeze-thawing resistance, ageing resistance, deformation adaptability and high seal-healing capacity in the self-compacting bituminous concrete are given to full play, the road bed water controlling and drainage problems are solved by the use of the super-compact material structure, and water is prevented from permeating to damage the road beds; the waterproof seal is manually paved, thickness of the waterproof seal is determined through the use of wooden or steel forms, compacting by self-mobility is allowed, no compressing is required, constructing is simple and convenient, the requirement on environment is low, and the waterproof seal is suitable for structures, having small but abundant working faces, such as supports of overhead contact systems for high-speed railway road beds; the waterproof seal has ultra-long service life, less maintenance is required during using of the waterproof seal, the waterproof is easy to maintain, and a scheme about the ideal long-acting railway road bed waterproof seal is provided.

Owner:SOUTHEAST UNIV +3

Foamed coal ash geopolymer outer-wall thermal-insulation board and manufacturing process thereof

InactiveCN103214263AStrong freeze-thaw resistanceLow thermal conductivityCement productionCeramicwarePolymer scienceThermal insulation

The invention belongs to the technical field of material engineering and relates to a foamed coal ash geopolymer outer-wall thermal-insulation board and a manufacturing process thereof. The coal ash and mineral powder are foamed and maintained into a foamed coal ash geopolymer outer-wall thermal-insulation board under the excitation of alkali activator by utilizing cinerite activity of the coal ash and the mineral powder. The foamed coal ash geopolymer outer-wall thermal-insulation board comprises the following materials in percentage by weight: 60%-95% of coal ash, 4%-30% of mixed activator X, 0.01%-30% of superfine slag powder, 0.01%-30% of fine aggregate and 0.3%-10% of foam stabilizer. The fine aggregate refers to the materials including nanometer calcium carbonate, grinded kaolin, silica powder, silica fume and the like. And the mixed activator x is an alkali mixed solution containing a plurality of irons and active materials. The foamed coal ash geopolymer outer-wall thermal-insulation board has the characteristics of being strong in freeze-shaw resistance, low in heat conduction coefficient, as long as the service life of the building, and good waterproofness. Moreover, the industrial waste including waste coal ash, superfine slag powder and the like can be utilized.

Owner:德州先科地质聚合物研究所

Method for preparing green pervious concrete by using tailings

InactiveCN108409250AWide variety of sourcesQuality improvementSolid waste managementFreeze thaw resistanceDefoaming Agents

The invention relates to a method for preparing green pervious concrete by using tailings, characterized in that the green pervious concrete is prepared from the following raw materials in parts by weight: 50 to 70 parts of aggregate, 20 to 30 parts of 52.5 Portland cement, 15 to 20 parts of ceramsite, 1 to 2 parts of efficient water reducing agent, 0.1 to 0.5 part of composite early strength agent, 0.1 to 1 part of composite retarder, 0.02 to 0. 1 part of defoaming agent, and 0.02 to 0.1 part of air entraining agent; the aggregate comprises tailings and machine-made sand, the tailings have aparticle size of 5 to 10 mm, the machine-made sand has a particle size of 1 to 5 mm, and the weight ratio of the tailings to the machine-made sand is (3 to 5) to 2. According to the green pervious concrete provided by the invention, the tailings and the ceramsite are adopted as the aggregate, and the gradation of the aggregate and the composition and the quality of an admixture are adjusted, so that the strength, the durability, the water permeability and the freeze-thaw resistance of the pervious concrete are greatly improved.

Owner:GUANGXI POLYTECHNIC VOCATIONAL & TECHN COLLEGE

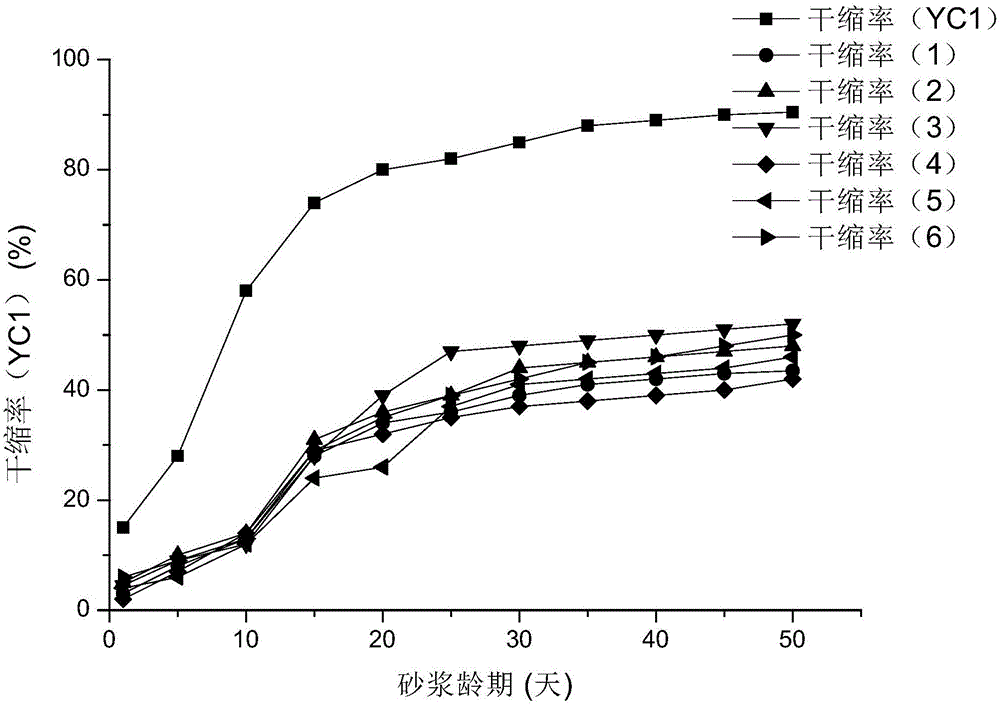

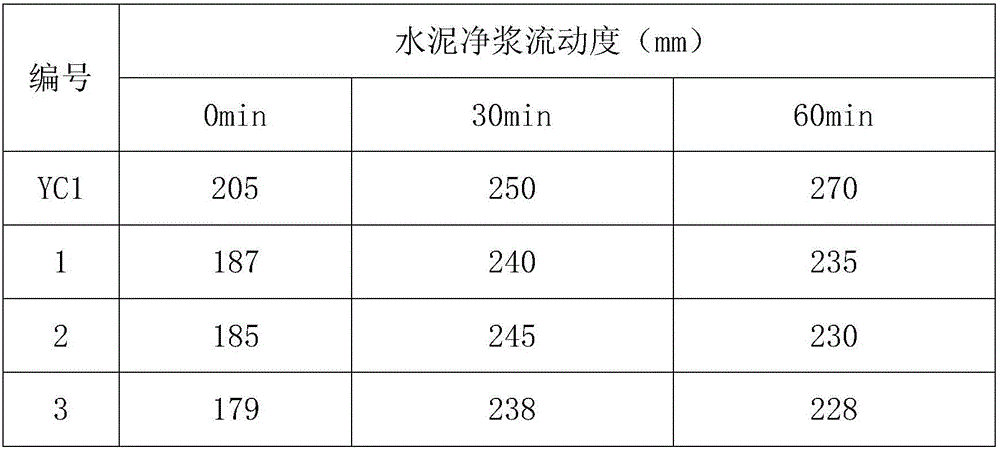

Method for preparing shrinkage reducing agent with water reducing performance

The invention discloses a method for preparing a shrinkage reducing agent with water reducing performance and particularly relates to the technical field of methods for synthesizing concrete liquid admixtures. According to the method, the method for preparing the shrinkage reducing agent with water reducing performance is achieved on the basis of systematically studying free-radical polymerization principles and optimizing matched monomers. The shrinkage reducing agent is synthesized specifically through firstly, subjecting dipropylene glycol monomethyl ether and maleic anhydride to an esterification reaction in the presence of a catalyst, and then, subjecting an esterification reaction product to copolymerization with an unsaturated double-bond polyoxyethylene ether monomer, unsaturated carboxylic acid and trifluoroethyl methacrylate in an aqueous solution in a redox system. According to the method, concrete can have excellent fluidity, good early strength, relatively low shrinkage reducing percent and good freeze-thaw resistance.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

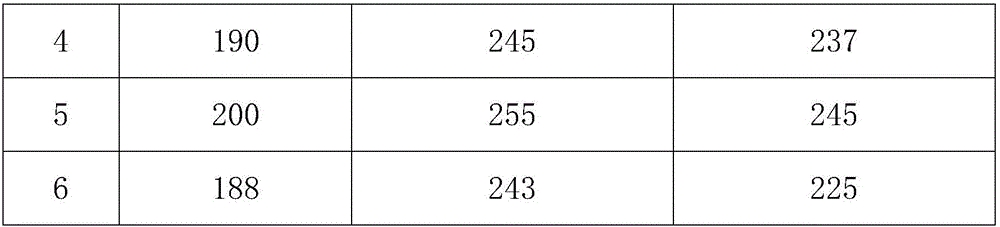

GAT (GuAnTe) Exterior formwork cast-in-place concrete composite insulation system and construction technique thereof

PendingCN109267677AReduce secondary constructionImprove insulation effectWallsHeat proofingFreeze thawingWeather resistance

The invention discloses a GAT (GuAnTe) exterior formwork cast-in-place concrete composite insulation system and a construction technique thereof. The GAT exterior formwork cast-in-place concrete composite insulation system comprises a GAT composite insulation exterior formwork that is a dismantling-free formwork; concrete is cast between the GAT composite insulation exterior formwork and an interior formwork to form a cast-in-place concrete wall; the GAT composite insulation exterior formwork and the cast-in-place concrete wall are fixedly connected via connectors. The construction technique includes layout, setting out, cutting, mounting of special connectors, tying of rebars and pads, erection of the GAT composite insulation exterior formwork, erection of the interior formwork, fitting of tie bolts, erection of formwork wooden auxiliary battens and dual-steel-tube main battens, position adjustment for formwork fixation, casting of concrete, removal of the interior formwork and the main and auxiliary battens, splicing and internal and external corner anti-cracking treatment, leveling and mortar construction, and facing layer construction. The GAT exterior formwork cast-in-place concrete composite insulation system and the construction technique thereof have the advantages that the system herein has better thermal insulation, fire resistance, weather resistance, impact resistance and freeze thawing resistance and is good in safety, well applicable, economical and reasonable, engineering quality is guaranteed at the premise of construction period shortened, energy is saved,and emission is reduced.

Owner:天津固安特节能科技有限公司

Method for producing freeze thaw resisting ground water permeable bricks from gold and antimony mine tailings

ActiveCN105967753ANo color differenceRealize high value utilizationSolid waste managementCeramic shaping apparatusFreeze thawingBrick

The invention discloses a method for producing freeze thaw resisting ground water permeable bricks from gold and antimony mine tailings. The water permeable bricks with the advantages of high strength, high water permeability, good freeze thaw resistance and beautiful color are produced by using fine gold and antimony mine tailings with high content of silicon as basic raw materials, and adding certain amounts of cement, fly ash, river sands, an air entraining agent and an inorganic pigment. The production method comprises the following steps: producing a water permeable brick base blank; producing a water permeable brick coloring layer blank; digesting the above two blanks; carrying out wheel grinding; carrying out compaction molding and autoclaved curing. The produced water permeable brick has the advantages of high compressive strength, high water permeability and good freeze thaw resistance, is especially suitable for high and cold regions in western China, accords with national relevant standards, has certain environmental protection significance, and opens up a new way for comprehensive utilization of mine tailing resources.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com