Patents

Literature

573results about How to "Reduce repair rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

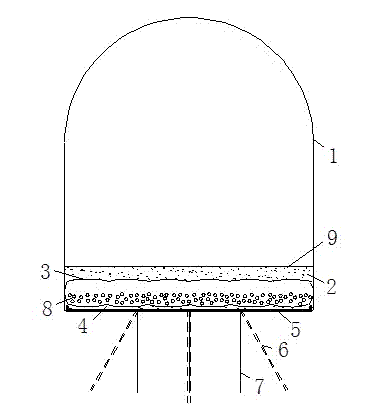

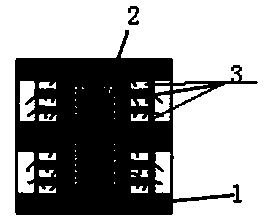

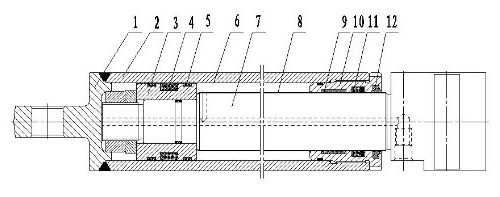

Assembly process of cylindrical lithium-ion cell

ActiveCN103779528ASave spaceReduce repair rateFinal product manufactureCell component detailsLithiumEngineering

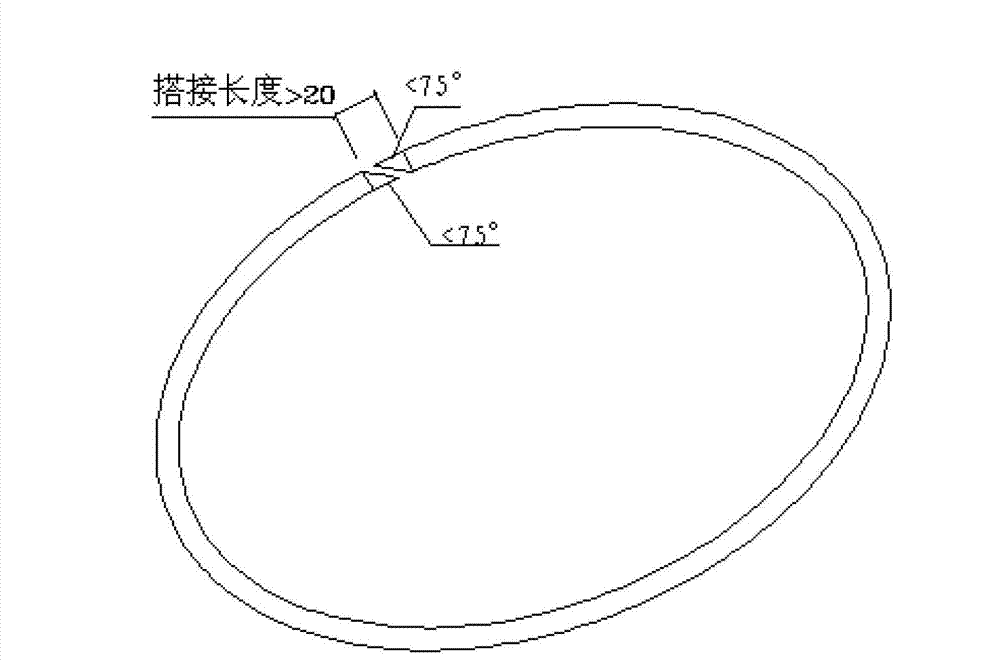

The invention discloses an assembly process of a cylindrical lithium-ion cell. The assembly process comprises the steps of (1), ultrasonically flattening two ends of a winding core; (2), wrapping two ends of the winding core with bottom adhesive tapes; (3), inserting the winding core into a shell; (4), welding a combined body of a flow collection plate and a cover plate on two ends of the winding core; (5), bending a flow collection plate lug; (6), bending the cover plate; (7), forming a lug; (8), embedding the cover plate; and (9), welding the cover to the shell through laser. The assembly process of the cylindrical lithium-ion cell is standard and normal in process; due to adoption of the combination of the flow collection plate and the cover plate, the combined cover plate is welded to the two ends of the winding core, so that the time for shaping the lug is shortened; due to the adoption of a welding manner of ultrasonically flattening and welding two ends through laser, the winding core is inserted into the shell, and then two ends of the winding core are welded, so that the bending and abrasion of the winding core plug are reduced; the yield of subsequent periphery welding is improved, thereby ensuring that the product performance is safer and more reliable.

Owner:上海电气国轩新能源科技(南通)有限公司 +1

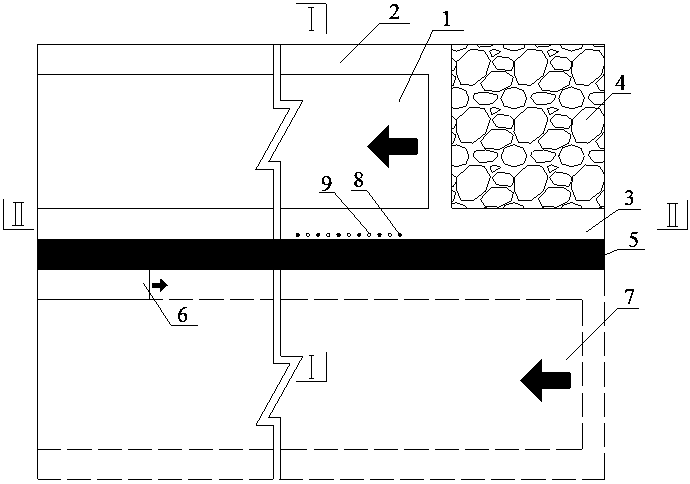

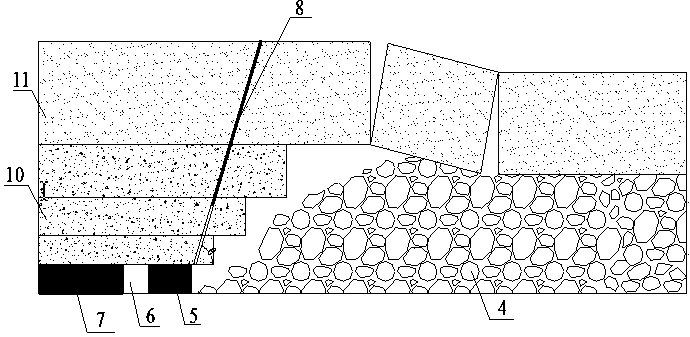

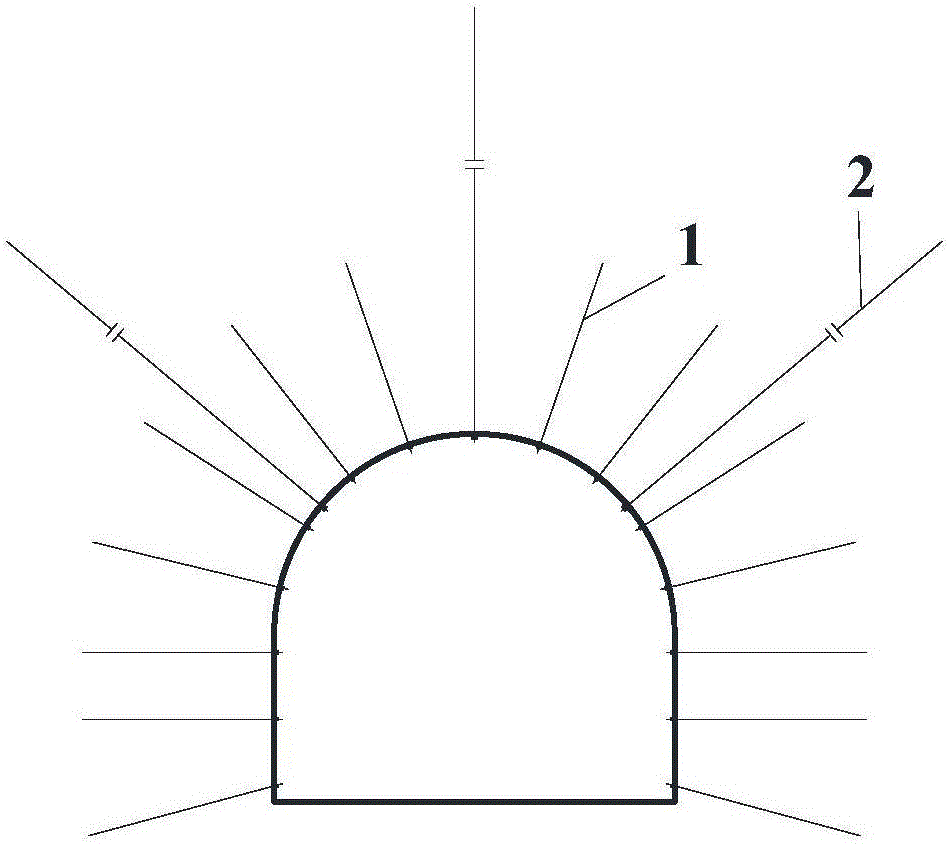

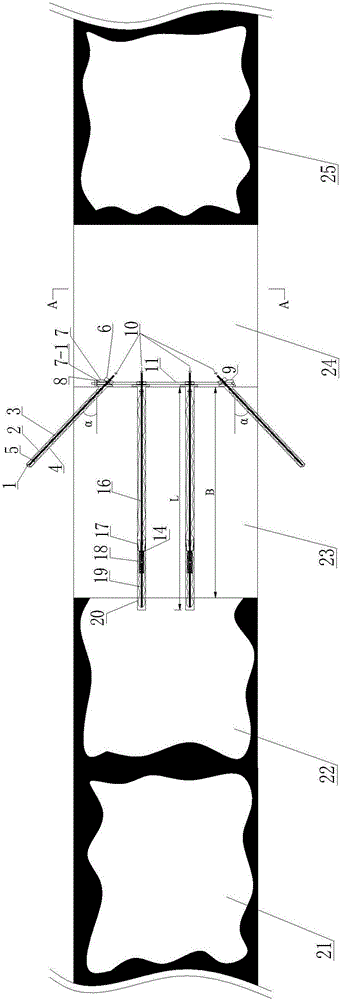

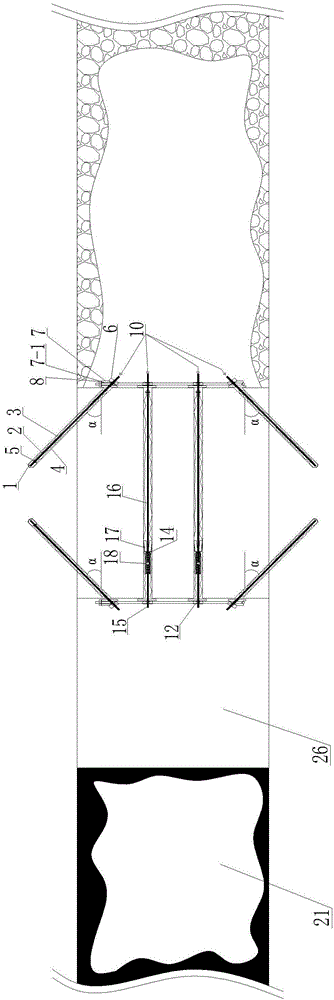

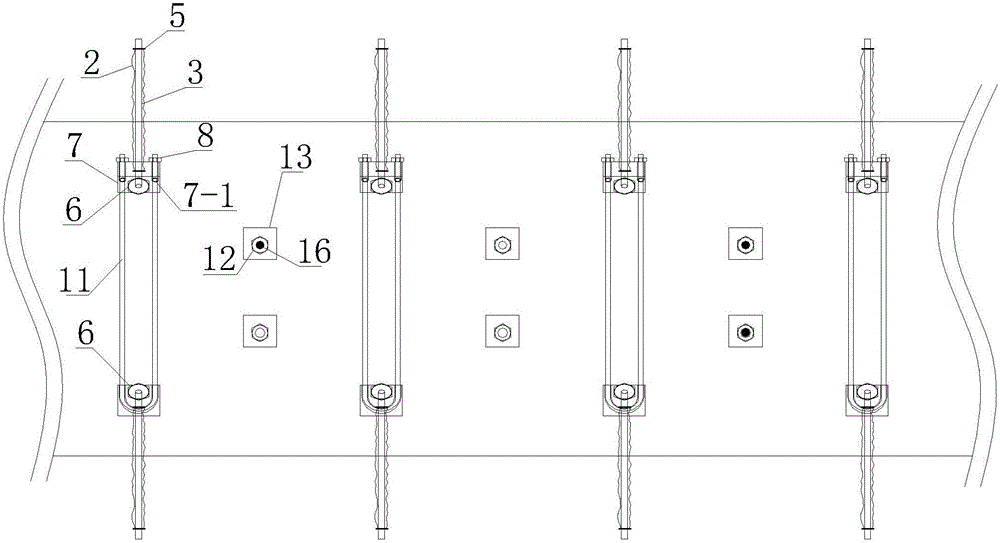

Method of roof cutting pressure relief of narrow coal pillar gob side through static bursting for gob-side entry driving

ActiveCN107701188AEliminate dynamic pressure effectsAlleviate connection tensionUnderground miningSurface miningBurstingEngineering

The invention discloses a method of roof cutting pressure relief of the narrow coal pillar gob side through static bursting for gob-side entry driving. According to the method, firstly, the drilling position and drilling relevant parameters of the separation distance, the diameter, the angle and the depth are determined; secondly, drilling construction and hole sealing operation are conducted; thirdly, slurry grouting of a static bursting agent is conducted, and roof cutting pressure relief is conducted through static bursting; and fourthly, gob-side entry driving is conducted. According to the method, recovery of an upper section working face and forward groove driving of a lower section working face are conducted simultaneously, and the problem of intense linkage of mine excavation is effectively relieved; and after entry-side roof cutting pressure relief, the stress environment of gob-side entry driving surrounding rock is greatly improved, surrounding rock deformation is greatly reduced in the entry driving process and after entry forming, the engineering quantity of entry supporting is small, and the repair rate is low.

Owner:TAIYUAN UNIV OF TECH

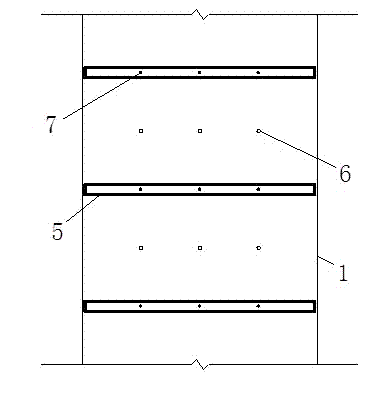

Strong resistance and strong evasion floor heave governing construction method of high-stress large-deformation soft rock drift

InactiveCN103206224AImprove stress distributionHigh pressureUnderground chambersTunnel liningReinforced concreteRebar

The invention discloses a strong resistance and strong evasion floor heave governing construction method of a high-stress large-deformation soft rock drift, belonging to the technical field of coal mine drift support. The strong resistance and strong evasion floor heave governing construction method is designed for solving the problems of large deformation and difficult support of the floor heaves of coal mine soft rock drifts. Certain depth is firstly dug downwards on a drift soleplate from a designed elevation, and then, a high strength deformed steel bar anchor rod, a grouting anchor rod, a steel beam and a concrete layer are used for supporting the drift soleplate to form a strong resistance supporting structure, a layer of aerated rubber air bags containing rubber granules is paved on the strong-resistance supporting structure, the air bags are used as strong evasion devices to release the pressure of the soleplate and buffer the deformation of the floor heave, and finally, a layer of reinforced concrete is poured on the rubber air bags to control the floor heave of the high-stress large-deformation soft rock drift. According to the invention, resistance is combined with evasion, the construction technique is simple, the construction speed is high, the repair rate low, the method is generally suitable for governing the floor heaves of various kinds of coal mine drifts and chambers, and the engineering practicability is strong.

Owner:SHANDONG UNIV OF SCI & TECH

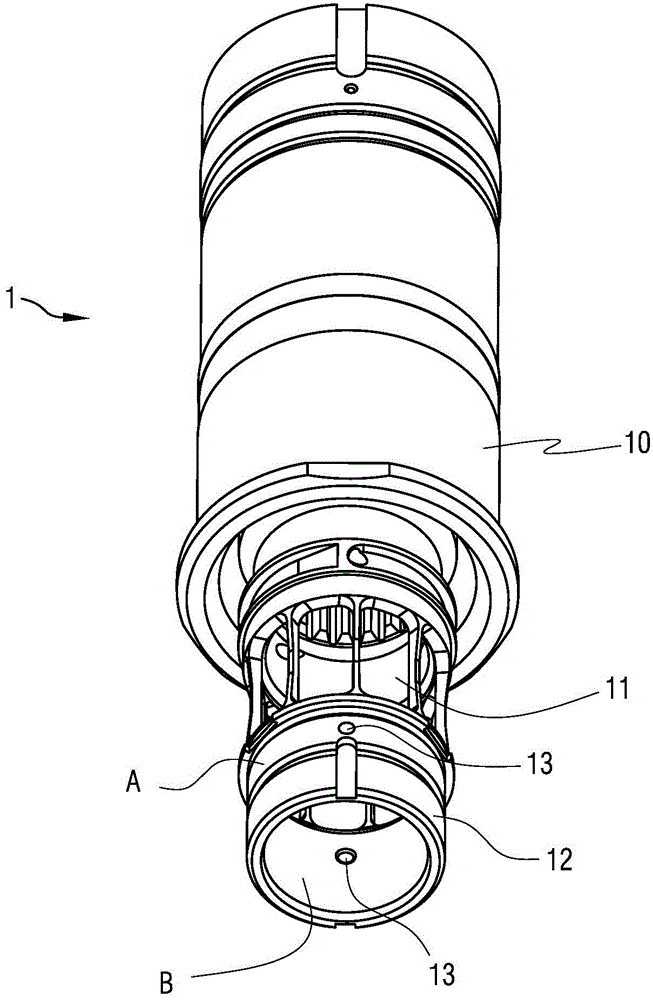

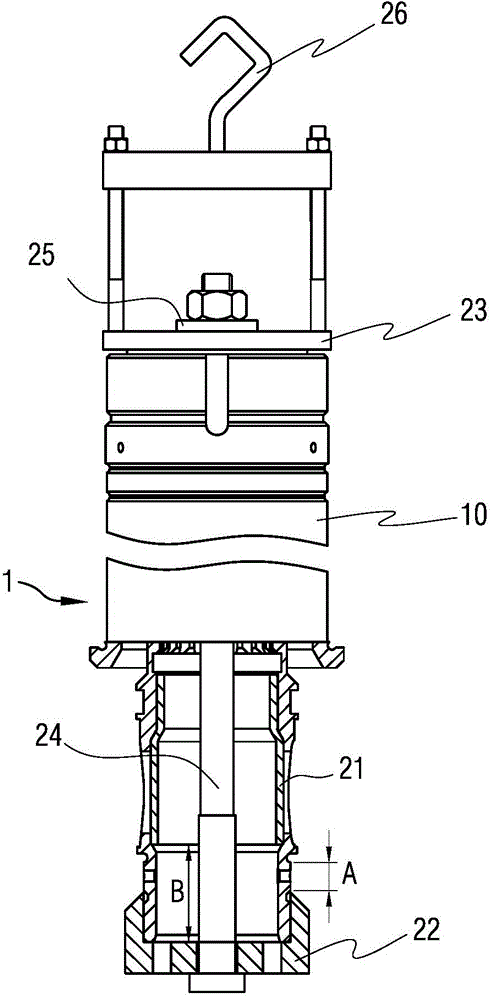

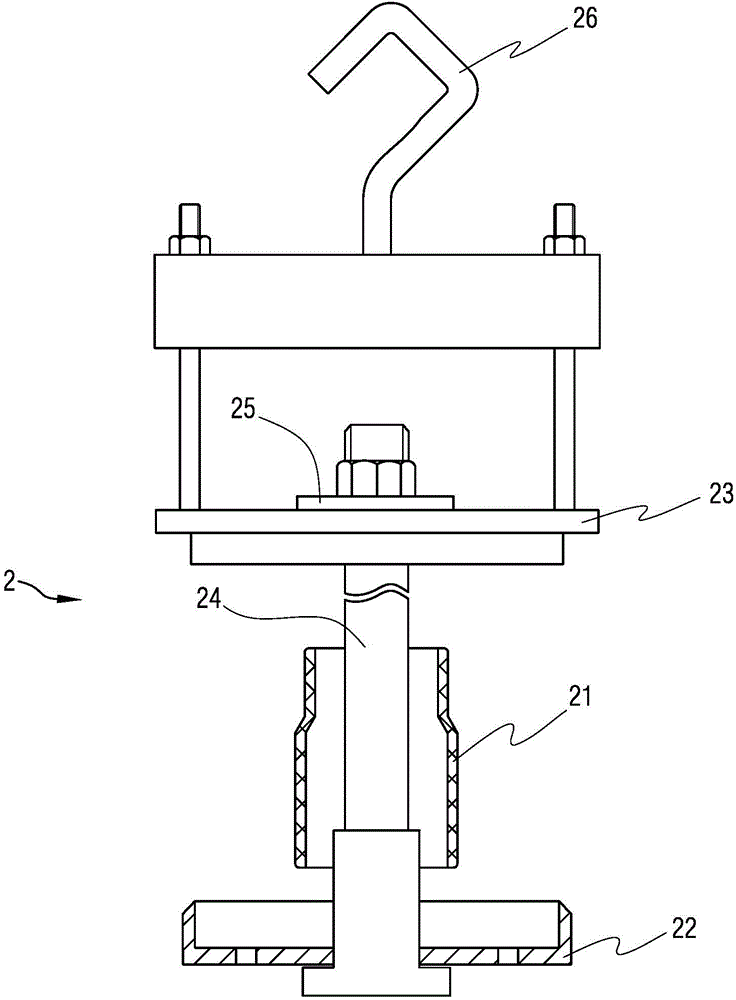

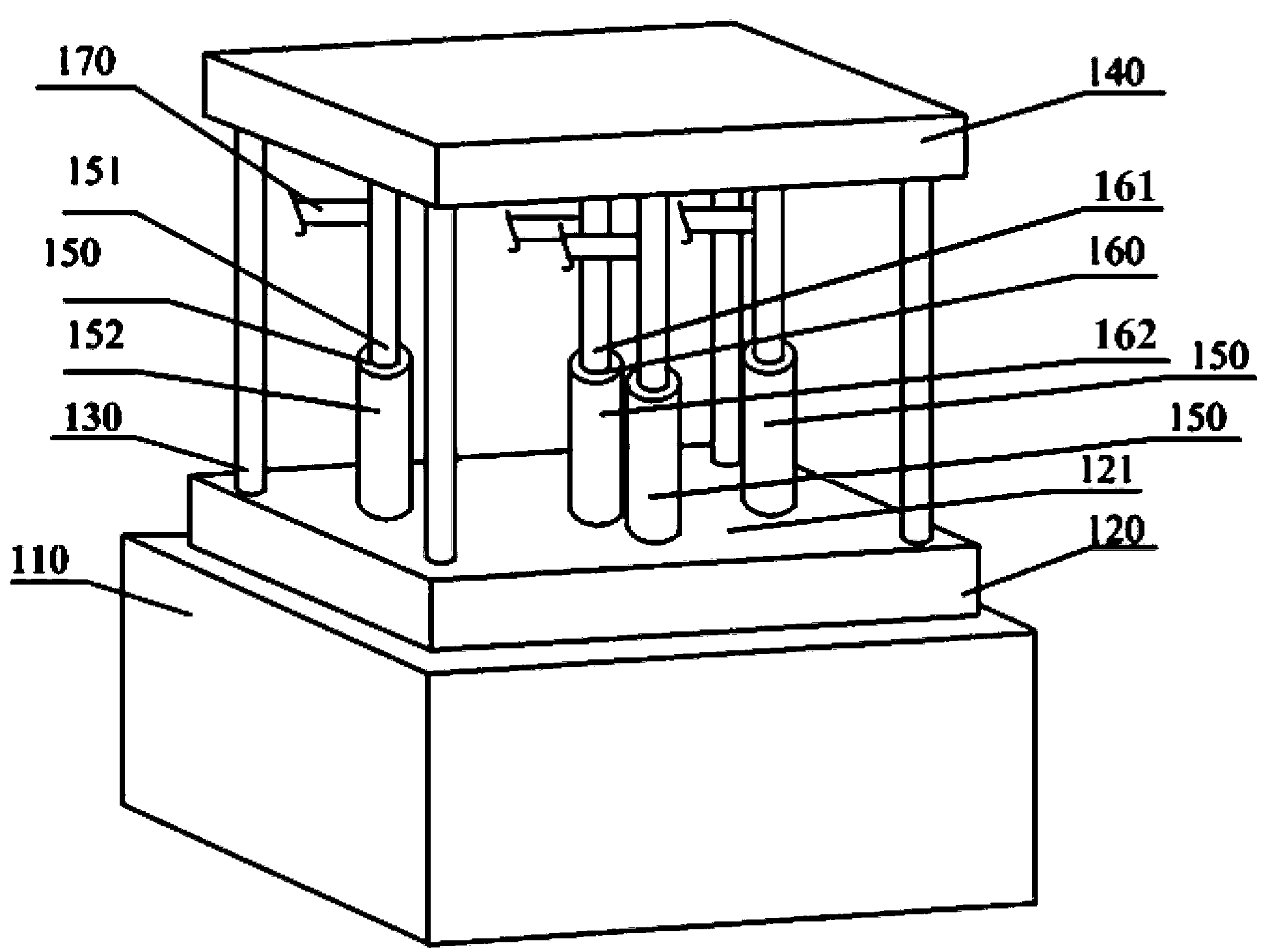

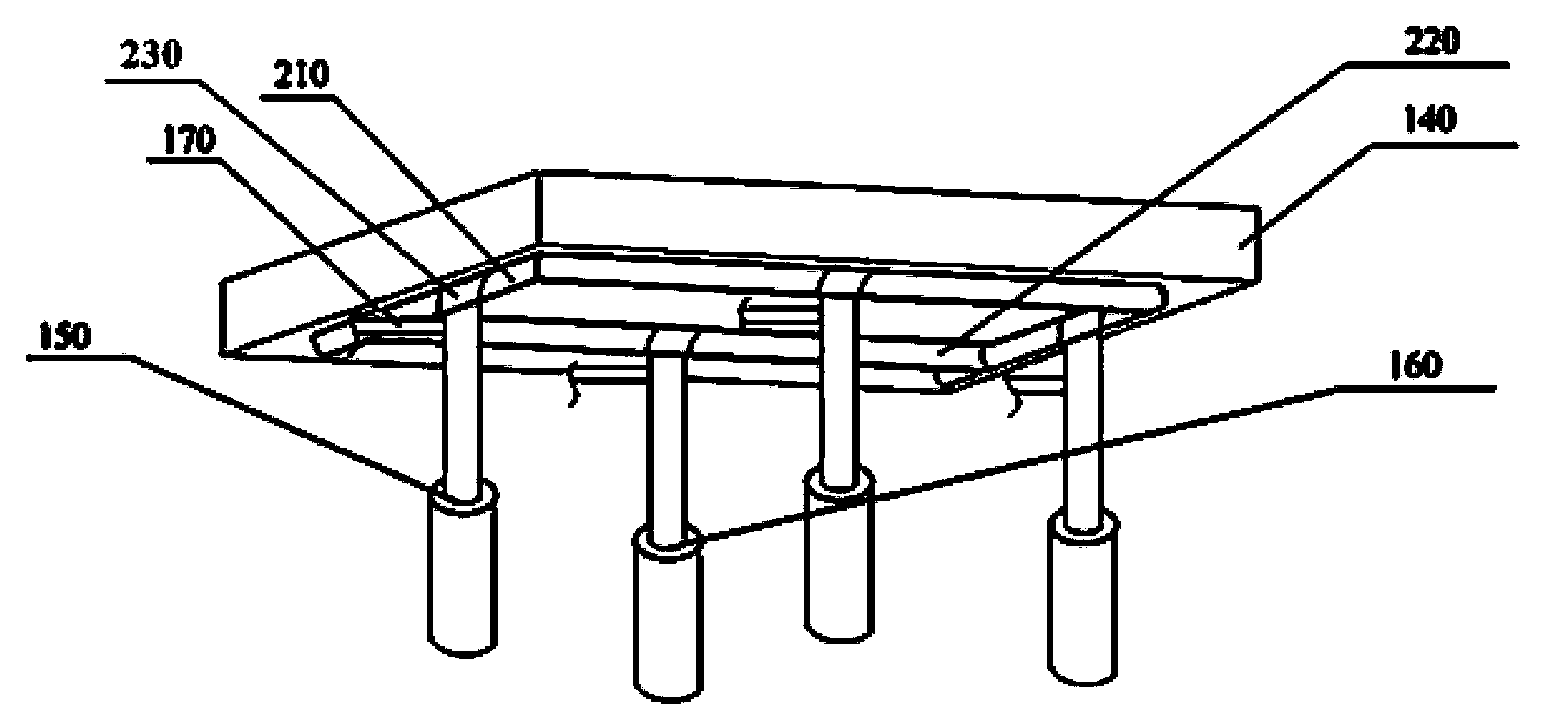

Output shaft chrome plating method and output shaft chrome plating fixture

ActiveCN104831325AShorten the processing cycleReduce repair rateElectrolysis componentsEngineeringChrome plating

The invention provides an output shaft chrome plating method and an output shaft chrome plating fixture. An output shaft comprises a cylindrical main body, and an outer circle area for chrome plating and an inner circle area for chrome plating are arranged at the first end of the main body. The fixture comprises a fluororubber sleeve, a lower cover plate, an upper cover plate and an anode center pole, the fluororubber sleeve shields an inner circle surface of a non-chrome-plating window area, and the anode center pole is connected with the upper cover plate and the lower cover plate. An insulating sleeve is arranged at the joint between the anode center pole and the upper cover plate. According to the chrome plating method, the special chrome plating fixture is provided, integral assembly and suspension are adopted, component matching tightness is achieved, anode positions for inner circle plating are fixed, the plating thickness of an inner circle is uniform, and the phenomenon that part of a chromium layer of an inner hole is too thin to grind is prevented; the method is simple and rapid to operate, the inner circle and an outer circle can be plated with chrome by the same fixture at a time, processing cycle of components is shortened greatly, repair rate of the components is reduced and production efficiency is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

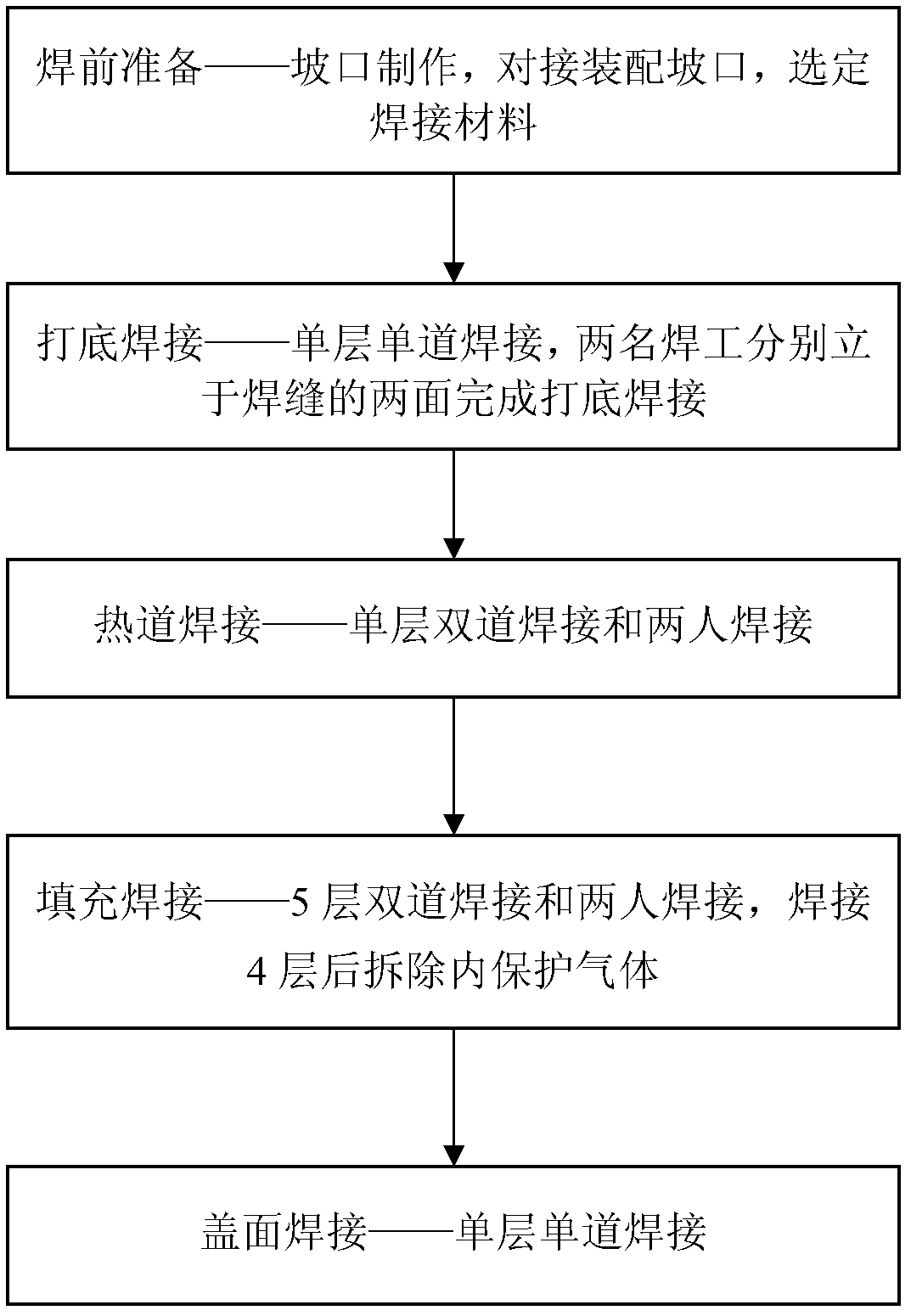

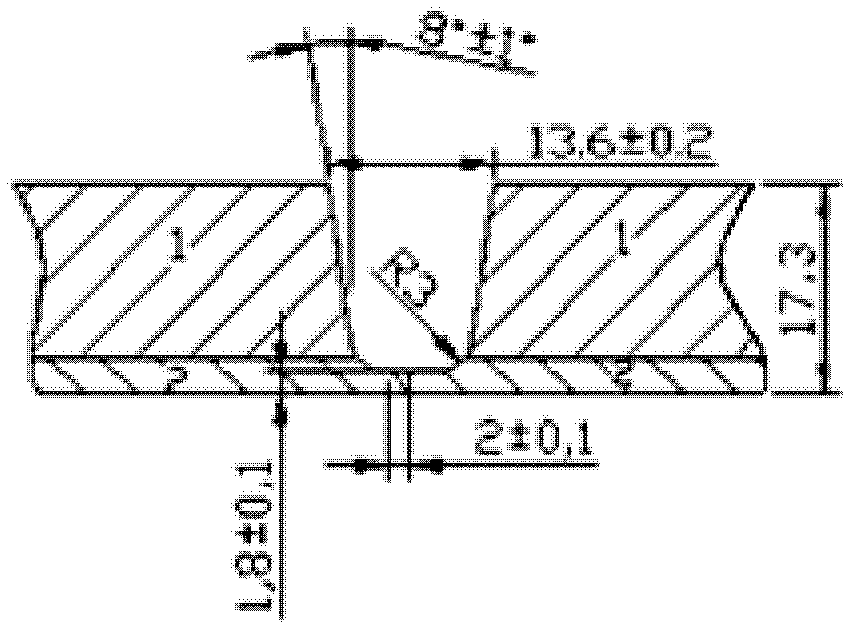

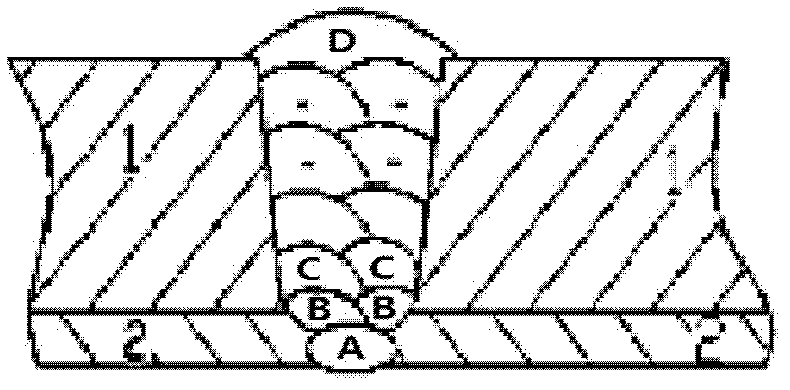

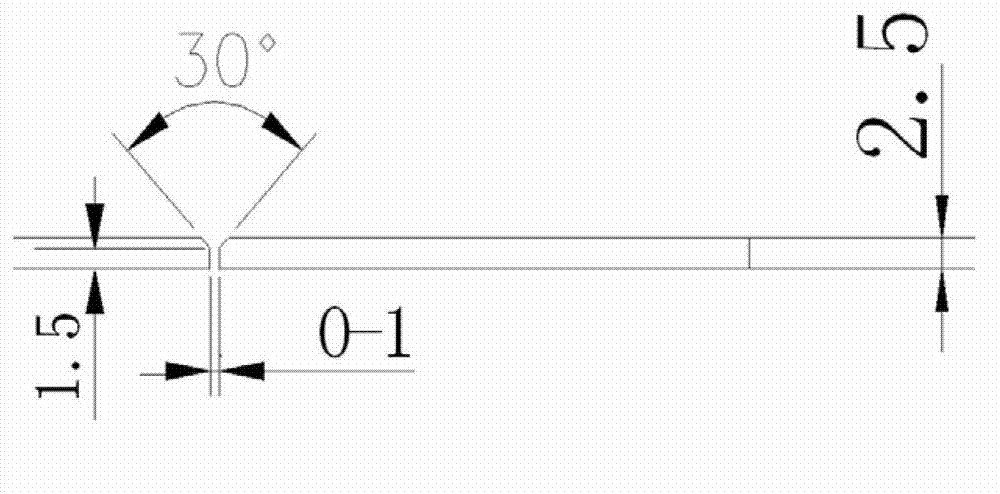

Semiautomatic argon tungsten-arc welding technological process of bimetal compounding sea pipe

The invention relates to a semiautomatic argon tungsten-arc welding technological process of a bimetal compounding sea pipe, a labour hand-held semi-automatic welding gun welding is adopted, a wire feeder continuously feeds wires, and argon gas is utilized as protective gas. The technological process comprises the following operation steps of: firstly, procedure preparation before welding: manufacturing a groove, picking up fitting the groove, and selecting a welding material; secondly, backing welding process: adopting single layer one-pass welding, wherein two welders respectively stand thetwo sides of a welding seam so as to finish the backing welding; thirdly, hot-runner welding procedure: adopting single layer two-way welding and two-person welding; fourthly, filling welding procedure: adopting five-layer two-way welding and the two-person welding, and dismantling the protective gas after welding four layers; and fifthly, a cover surface welding process: adopting the single layer one-pass welding. The technological process provided by the invention has the advantages of high welding quality, small labour intensity, low construction cost, and high production efficiency; and the technological process is suitable for a compounding submarine pipeline and welding procedure of a subsidiary vertical pipe of the compounding submarine pipeline, and is suitable for the welding of a deep water composite material pressure container and deep water pipe manifold nickel base alloy and the like.

Owner:CHINA NAT OFFSHORE OIL CORP +2

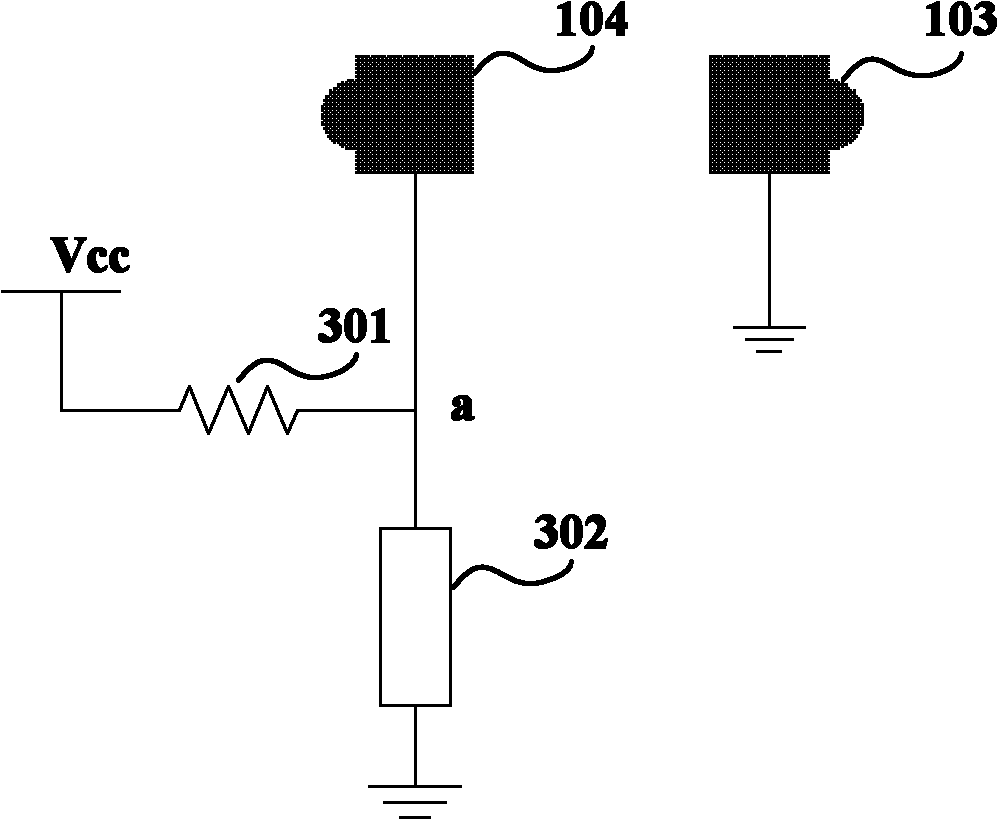

Fingerprint sensor and correction method thereof

ActiveCN104700070ACorrection coefficient automatic correctionReduce repair ratePrint image acquisitionMatching and classificationMathematical modelComputer science

The invention discloses a fingerprint sensor and a correction method thereof. The fingerprint sensor is provided with a sensing face for a finger to touch, and comprises a plurality of sensing units, a plurality of processing units and a plurality of correction units, wherein the sensing units are used to sense fingerprint signals and output first data in the beginning of correction, the processing units are used to calculate new correction coefficients of the corresponding sensing units through the first data according to a mathematic model, and the correction units are used to correct second data output by the corresponding sensing units according to the new correction coefficients. The fingerprint sensor can automatically correct the correction coefficients when self physical properties change, achieves the effects of reducing a repair probability of products and prolonging use life of the products, leaves out a correction link before the products leave a factory, and reduces production difficulty and production cost.

Owner:SHENZHEN GOODIX TECH CO LTD

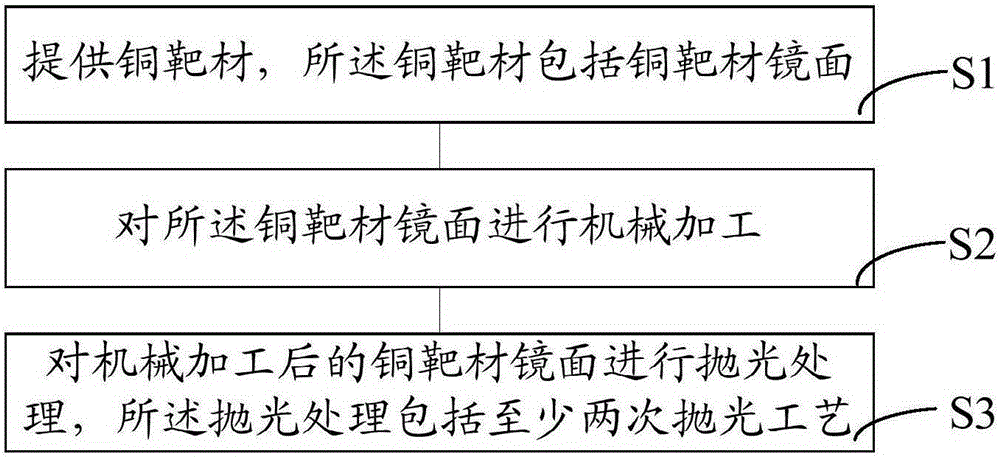

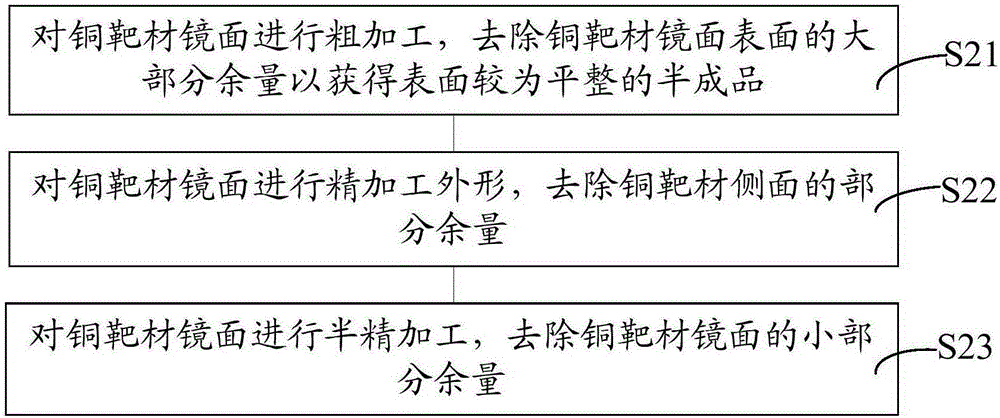

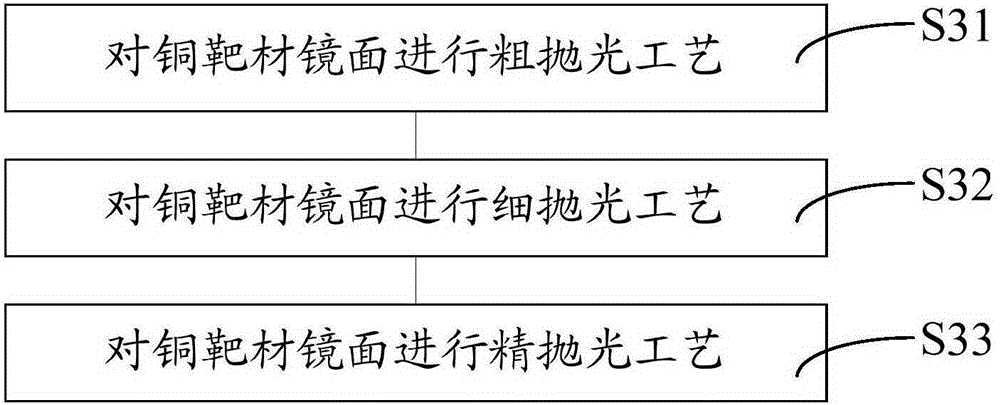

Copper target material surface processing method

The invention provides a copper target material surface processing method. The method includes the steps that a copper target material is provided and comprises a copper target material mirror surface; the copper target material mirror surface is machined; polishing processing is carried out on the machined copper target material mirror surface and includes two times of polishing processes. At least two times of polishing processes are adopted after machining, surface processing is carried out on the copper target material mirror surface, and scratches formed on the surface of the copper target material mirror surface by machining and an oxidation layer formed on the copper target material mirror surface by machining remaining liquid are removed by the polishing processes, so that surface glossiness and roughness of the copper target material mirror surface are higher, and the repair rate and rejection rate of the copper target material are reduced.

Owner:合肥江丰电子材料有限公司

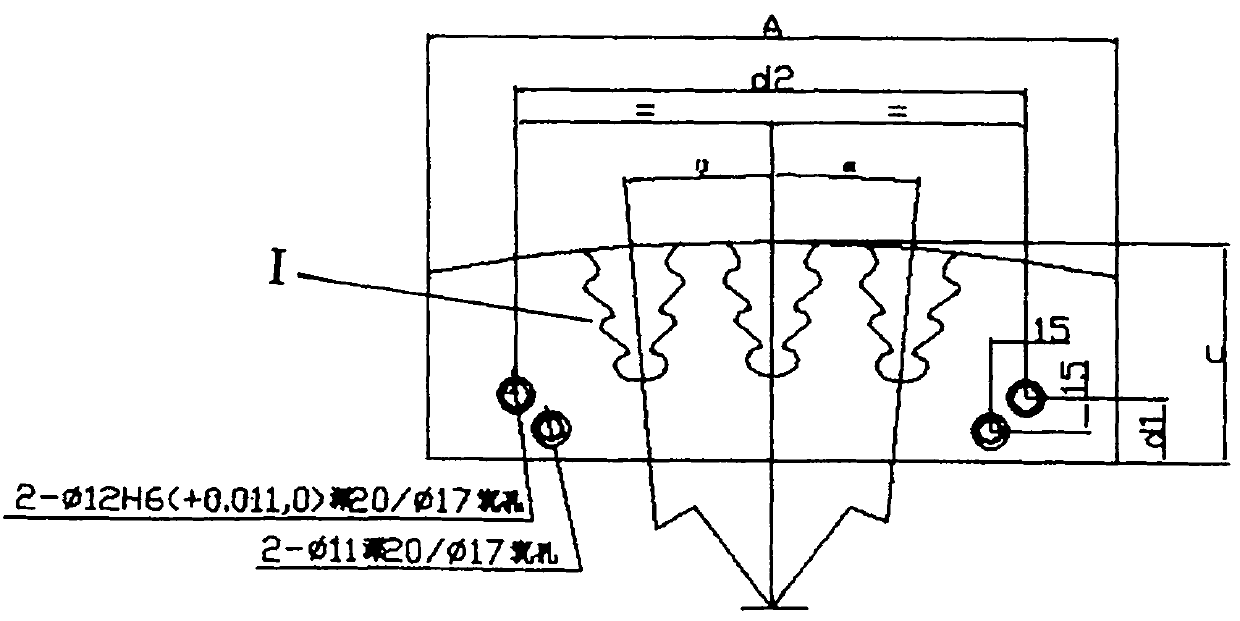

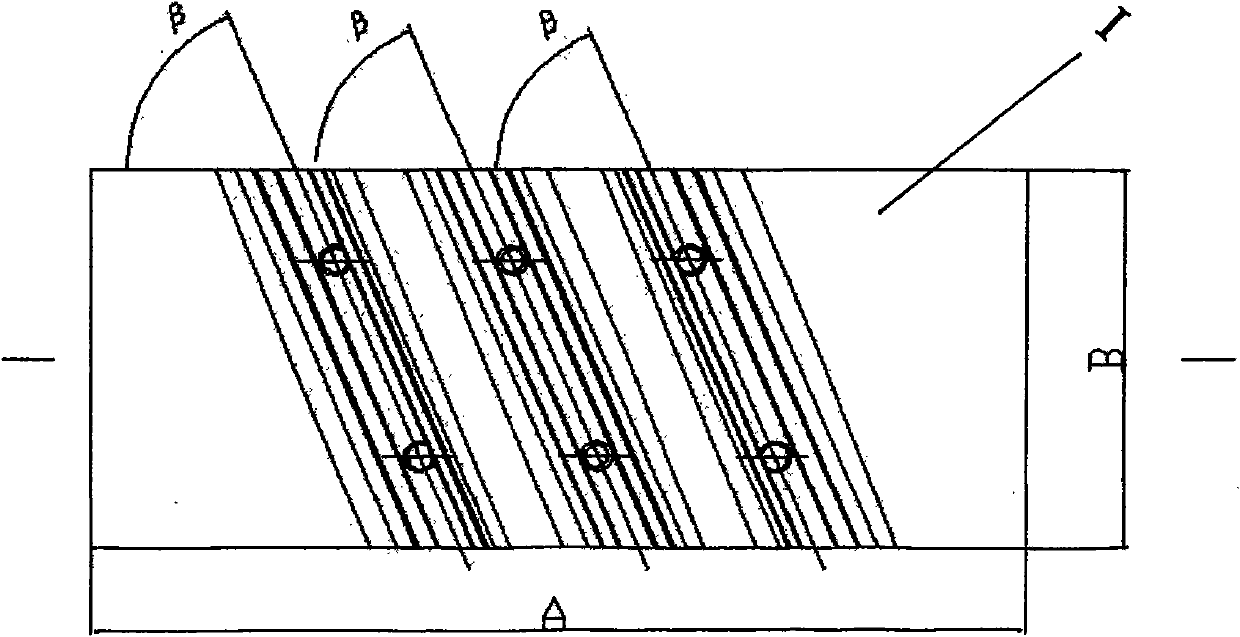

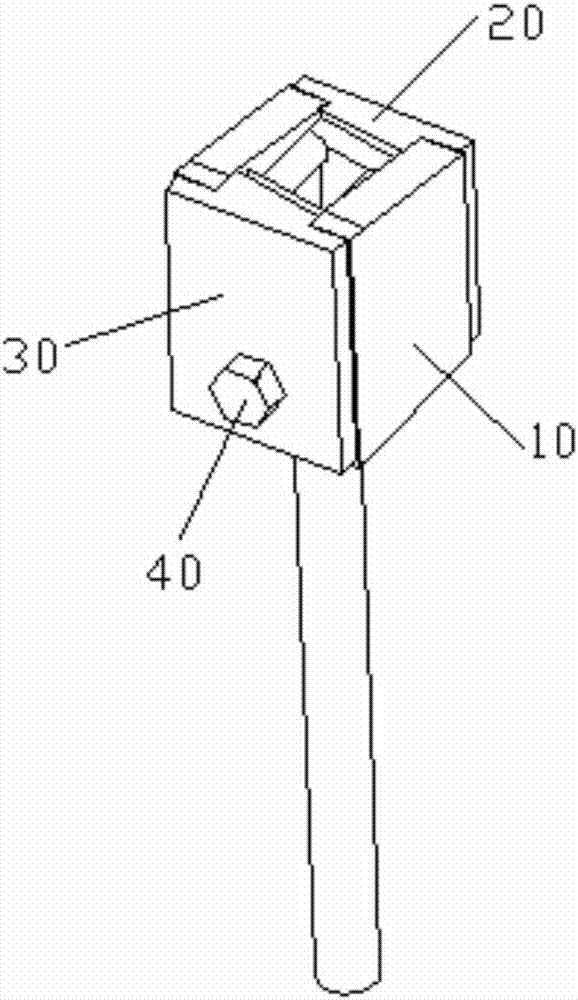

Steam turbine blade fitting measuring tool and processing technology thereof

ActiveCN101947723AAvoid Batch Quality IssuesShorten the manufacturing cycleMetal working apparatusImpellerSteam turbine blade

The invention discloses a steam turbine blade fitting measuring tool and a processing technology thereof. The fitting measuring tool is a fake impeller simulating an arc of steam turbine rotor impeller, the fake impeller is provided with a plurality of blade assembling slots distributed in a radial manner, the contour line, the radial radius and the circumferential graduation of the assembling slot are all consistent with those of the assembling slot of real impeller, and the bottom of the slot is provided with a blade locking screw hole and screws. The fitting measuring tool is used for the pre-assembly of blades, in order to inspect the quality indexes of assembly in advance, avoid the quality-related problem of blades in batch, reduce maintenance rate, enable blades to meet the assembly requirement in production workshop, enhance working efficiency, shorten assembly period of unit, and lower economic losses.

Owner:DONGFANG TURBINE CO LTD

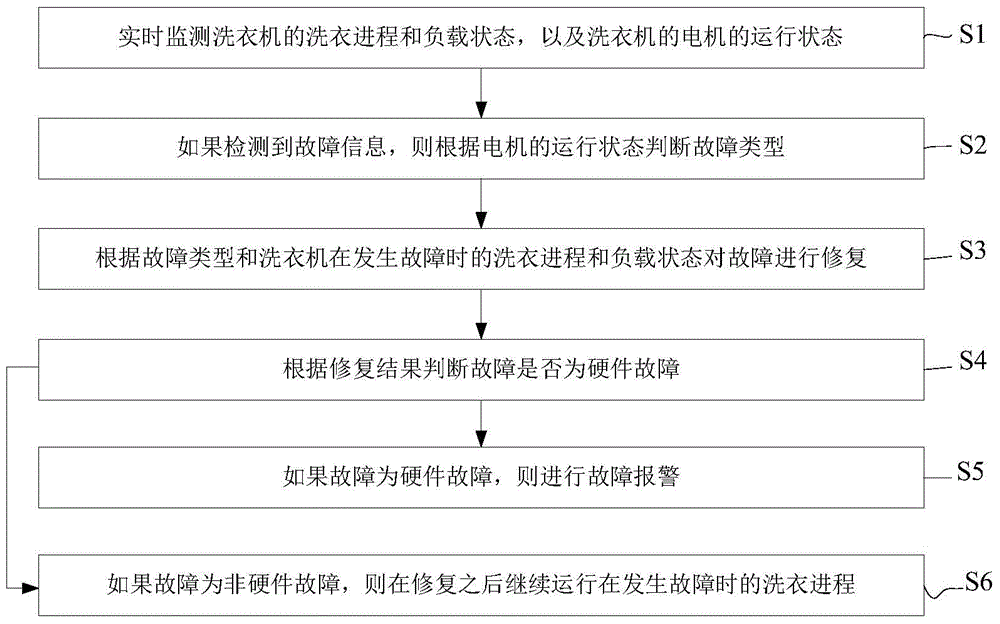

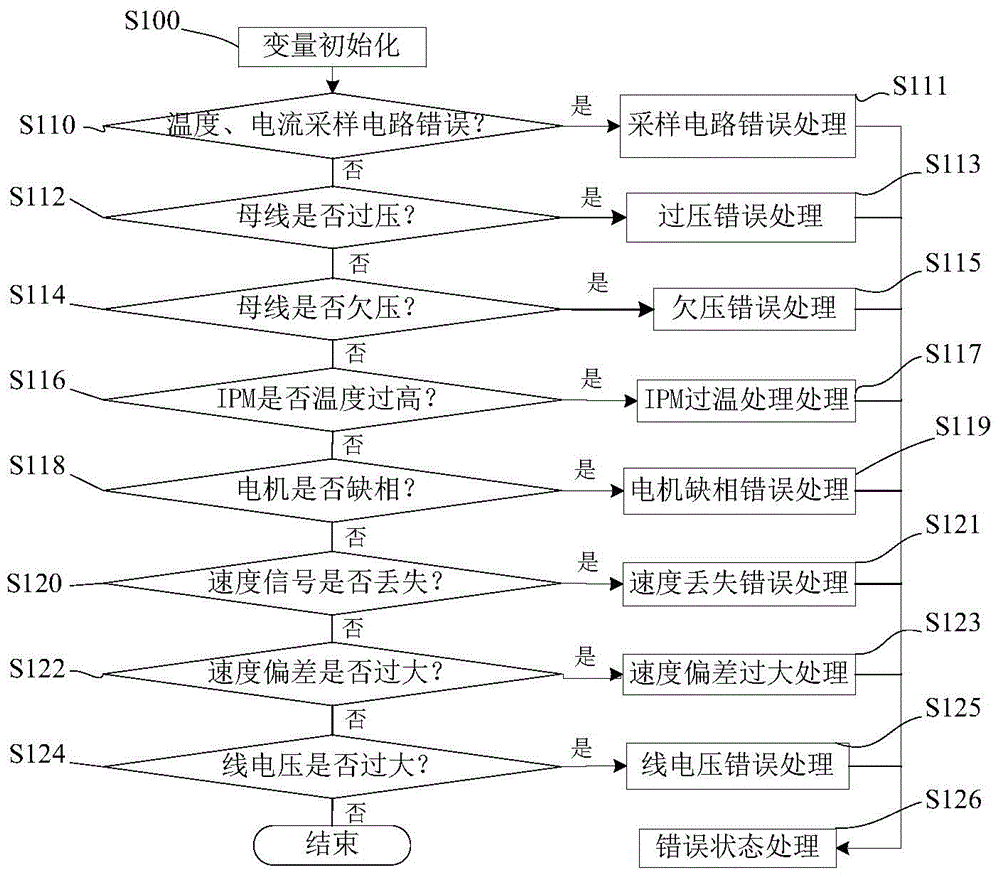

Fault diagnosing and repairing method for washing machine

ActiveCN106480641AReduce repair rateImprove qualityControl devices for washing apparatusTextiles and paperFault probabilityRepair method

The invention discloses a fault diagnosing and repairing method for a washing machine. The fault diagnosing and repairing method includes the steps of monitoring a washing progress, a loading state and a motor operation state of the washing machine in real time; if fault information is detected, judging a fault type according to the motor operation state; repairing the washing machine according to the fault type and the washing progress and the loading state of the washing machine when the washing machine breaks down; judging whether the fault is a hardware fault according to a repair result; if yes, performing fault alarming; if not, continuously operating the washing progress when the washing machine breaks down after repairing. The fault diagnosing and repairing method for the washing machine has the advantages that judgment fault probability can be lowered, and a repair rate of the washing machine can be lowered.

Owner:WUXI FILIN ELECTRONICS CO LTD

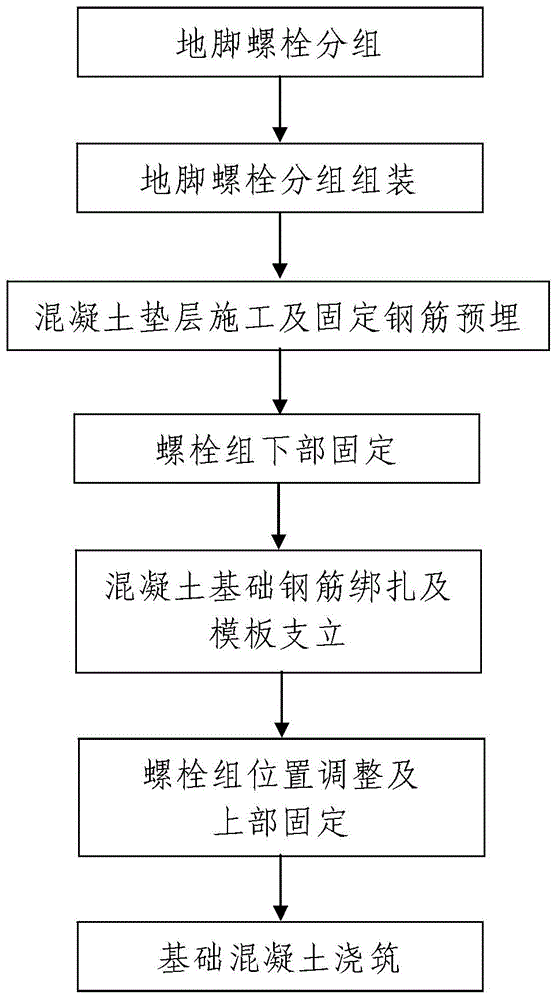

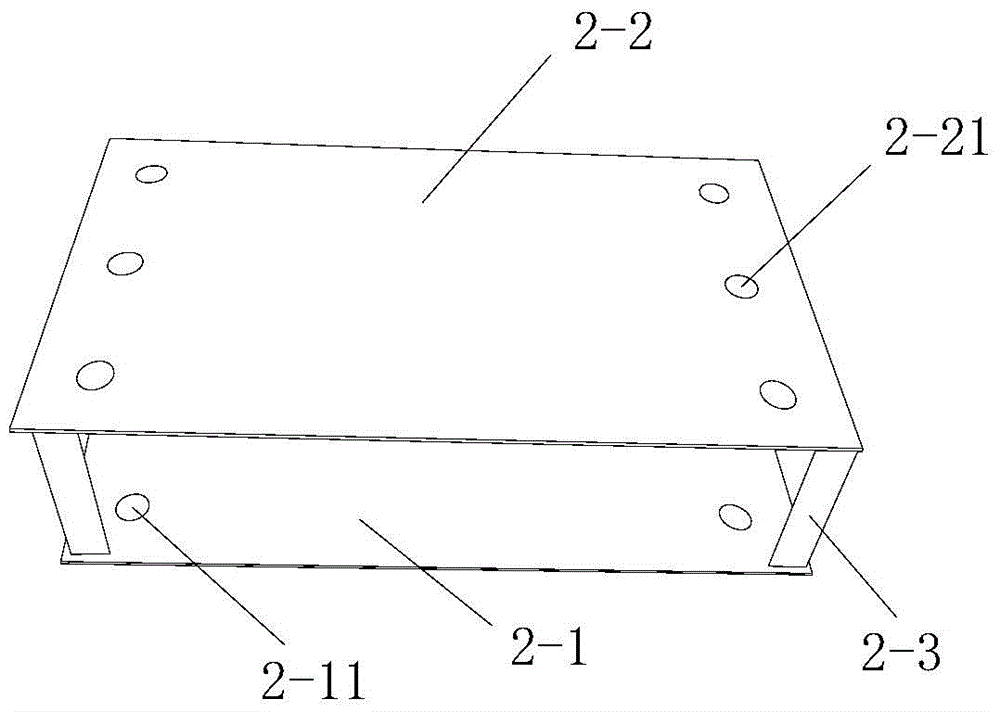

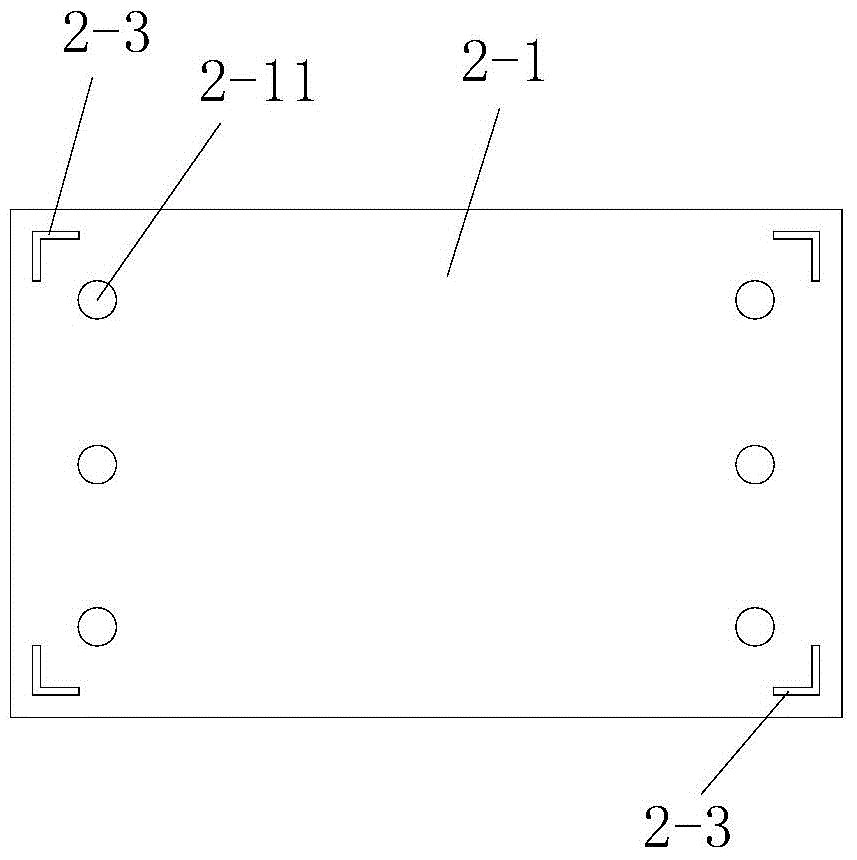

Steel structure building construction method for one-step pre-burying of foundation bolts

The invention discloses a steel structure building construction method for pre-burying of foundation bolts. The steel structure building construction method comprises the following steps: 1. grouping of the foundation bolts: all the foundation bolts to be pre-buried are divided into a plurality of groups, the groups of the foundation bolts are respectively distributed in a plurality of bolt pre-burying areas in a concrete foundation, and the foundation bolts in each group form a bolt group; 2. grouped assembly of the foundation bolts: the bolt groups are respectively assembled, and the assembly procedure comprises manufacturing of a positioning mold, inserting of the foundation bolts, fixing of the foundation bolts, and separating of the bolt groups from positioning mold; 3. concrete cushion construction and pre-burying of fixing steel bars; 4. lower part fixing of the bolt groups; 5. binding of the steel bars and support arrangement of a template erection in the concrete foundation; 6. a position adjustment and upper part fixing of the bolt groups; 7. concrete foundation pouring. The method provided by the invention is simple in procedure, reasonable in design, convenient in implementation, and good in use effects, and has the advantages that the construction process for the high-precision pre-burying of the foundation bolts in the concrete foundation can be simply, conveniently and rapidly completed with high quality.

Owner:SCEGC EQUIP INSTALLATION GRP COMPANY

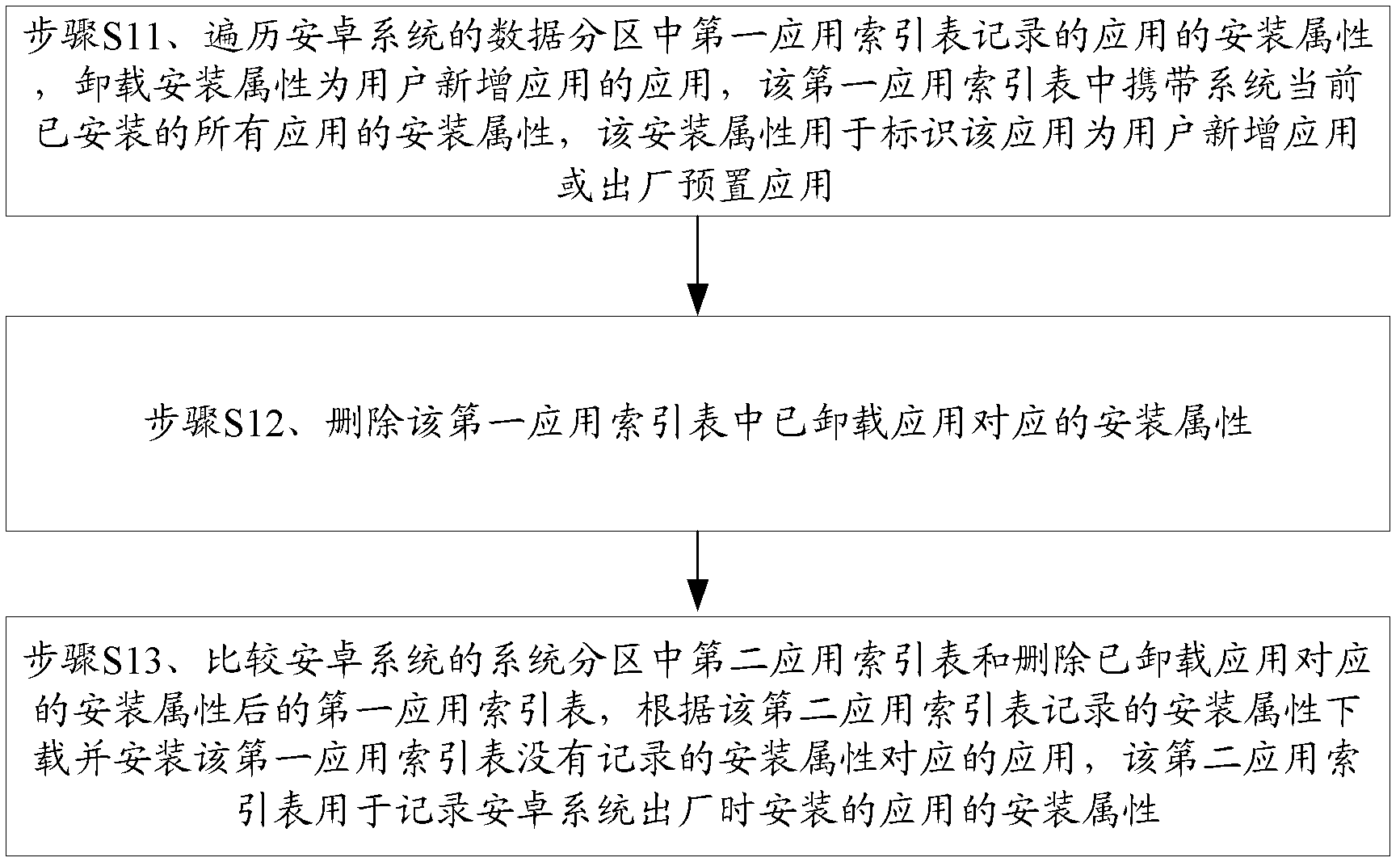

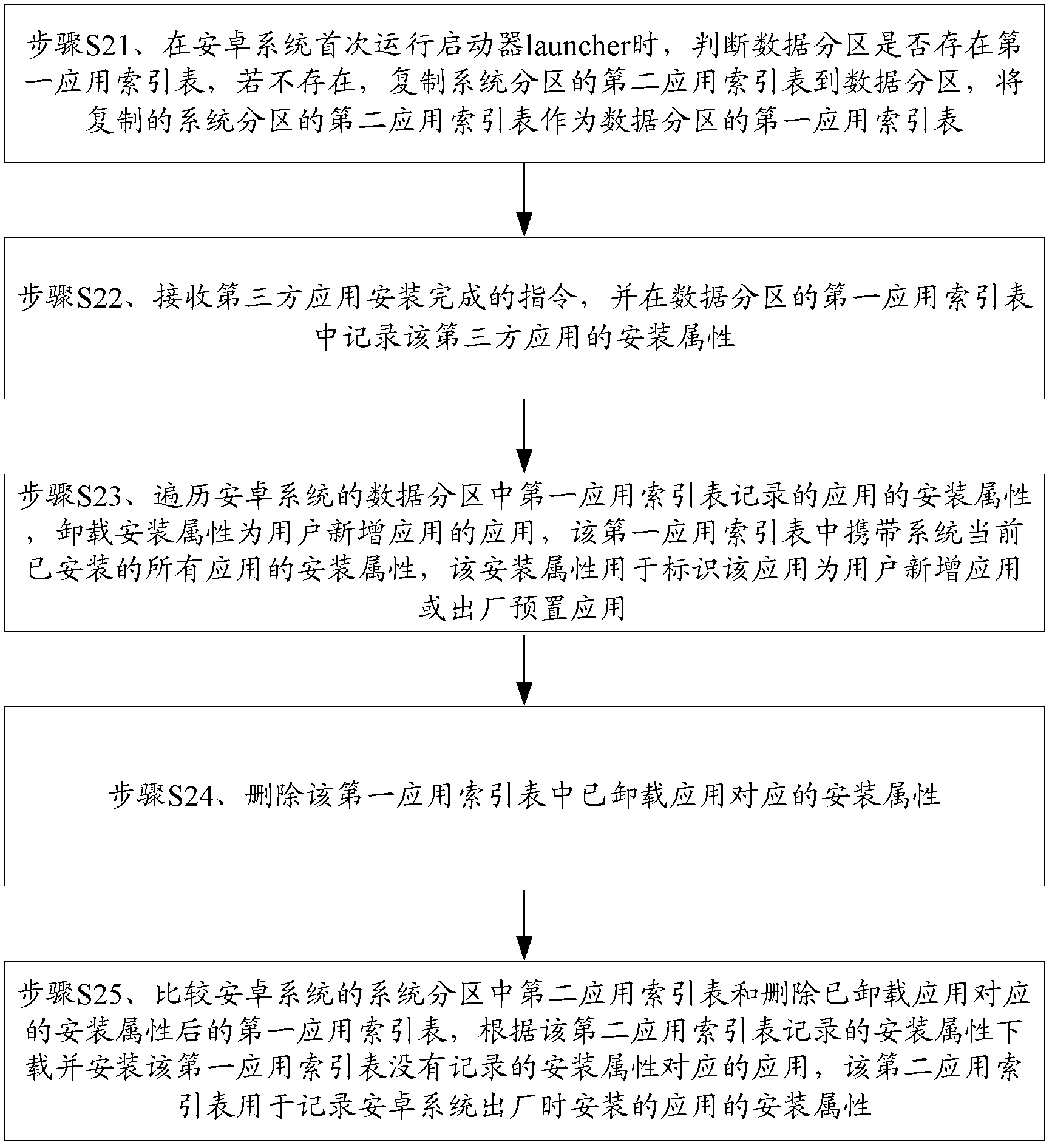

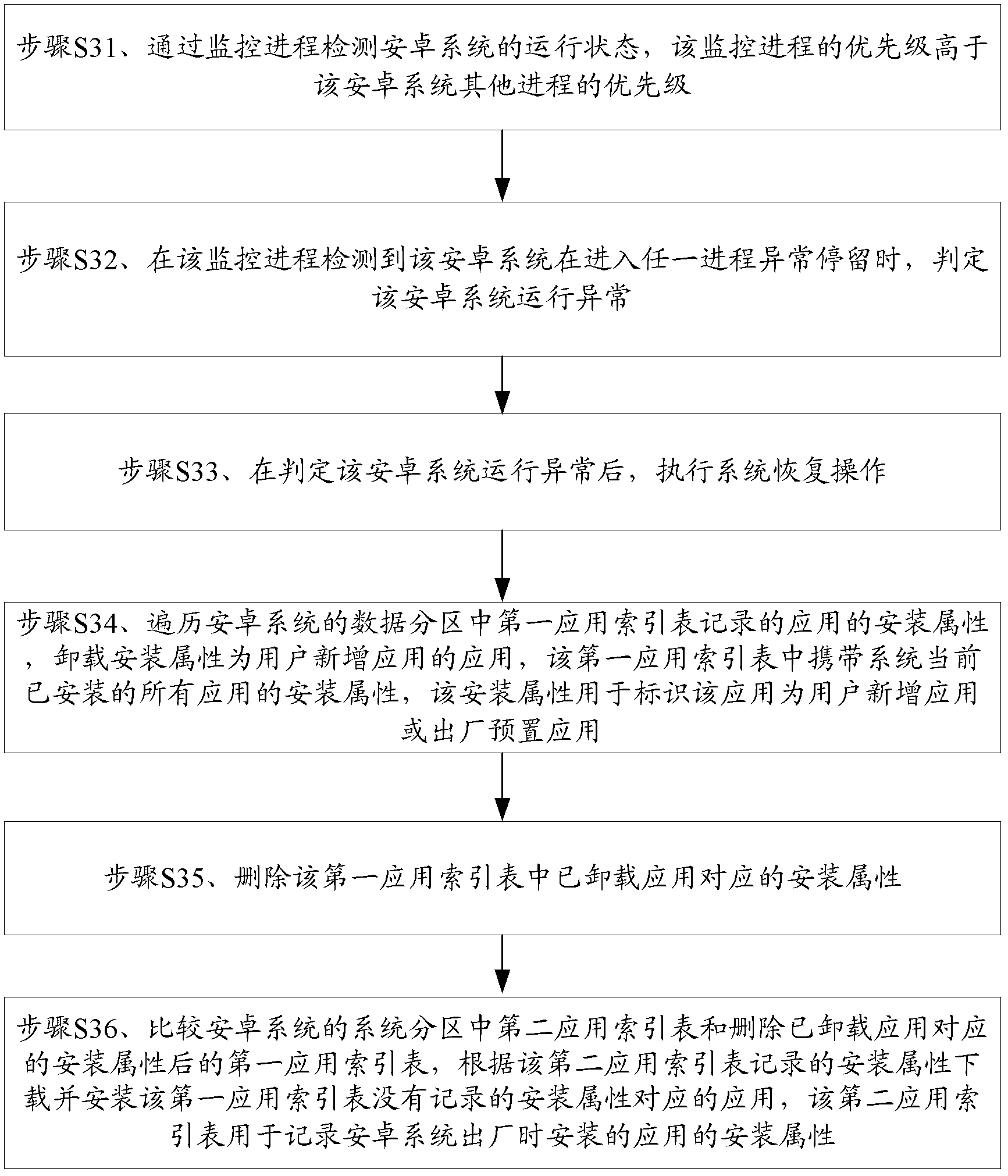

Method and device for system recovery based on android system and intelligent equipment

ActiveCN102591745AEliminate the effects ofKeep personal settingsRedundant operation error correctionSystem recoverySoftware engineering

The invention is applicable to the technical field of computers, and provides a method and a device for system recovery based on the android system and intelligent equipment. The method includes: traversing installation attributes of applications recorded in a first application index table in a data partition of the android system, and unloading the application with the attribute being a user added application; deleting corresponding installation attribute of the unloaded application in the first application index table; and comparing a second application index table in a system partition of the android system with the first application index table with the corresponding installation attribute of the unloaded application deleted, and loading and installing the applications corresponding to unrecorded installation attributes in the first application index table according to the installation attributes recorded in the second application index table. The method has the advantages of reduction of repair rate.

Owner:TCL CORPORATION

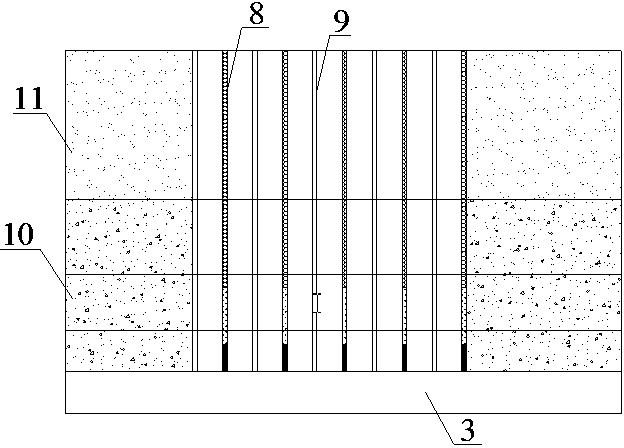

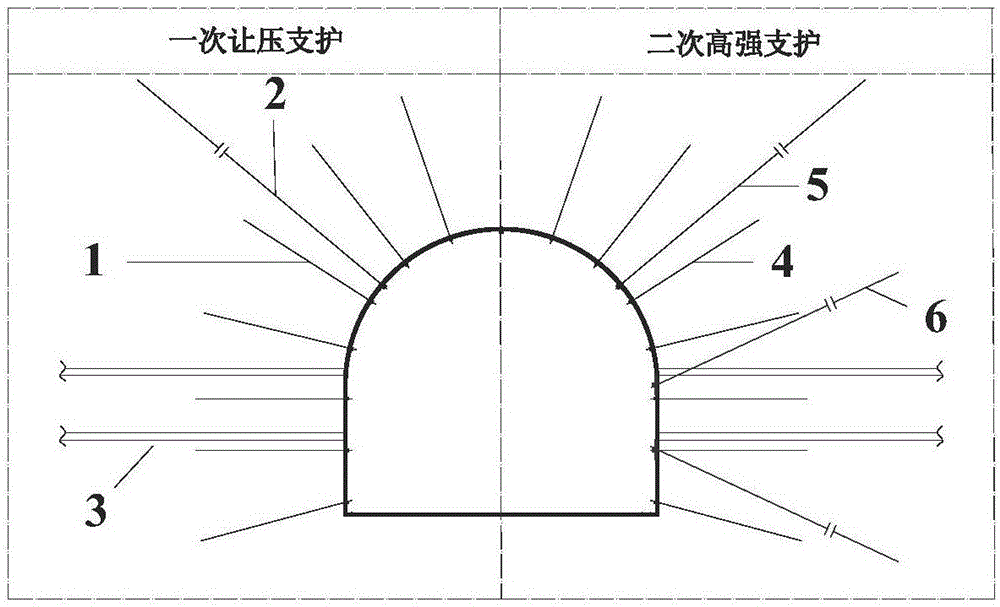

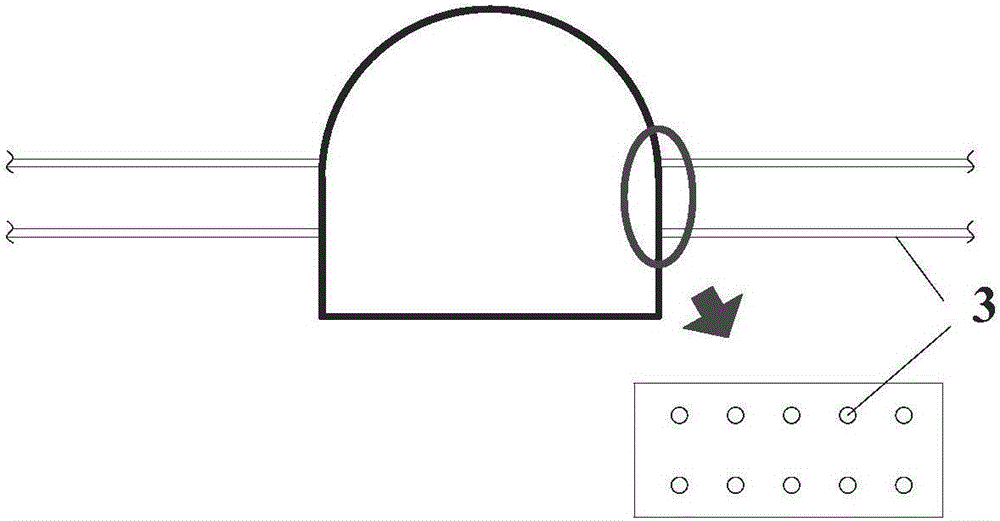

Pressure-relief support coordination control method for deep high-stress tunnel based on borehole pressure relief

ActiveCN106401645AAchieve long-term stabilityReduce repair rateMining devicesUnderground chambersLarge deformationHigh stress

The invention discloses a pressure-relief support coordination control method for a deep high-stress tunnel based on borehole pressure relief. The method comprises three steps according to a time sequence, and the three steps are respectively a primary pressure relief support step, a borehole pressure relief step and a secondary high-strength anchor grouting support step. According to the pressure-relief support coordination control method for the deep high-stress tunnel based on borehole pressure relief, surrounding rock deformation in each stage is controlled by adopting different support and reinforcement methods according to difference of surrounding rock deformation ways in different stages after the tunnel is excavated, the support performances of surrounding rocks and supporting structures are fully played, and large deformation of the surrounding rocks of a deep high-stress tunnel is reduced, so the stability of the tunnel can be maintained for a long time. Meanwhile, the method disclosed by the invention is capable of effectively reducing the repair rate of the tunnel, alleviating the labor intensity of workers and lowering the comprehensive support cost of a mine.

Owner:HENAN POLYTECHNIC UNIV

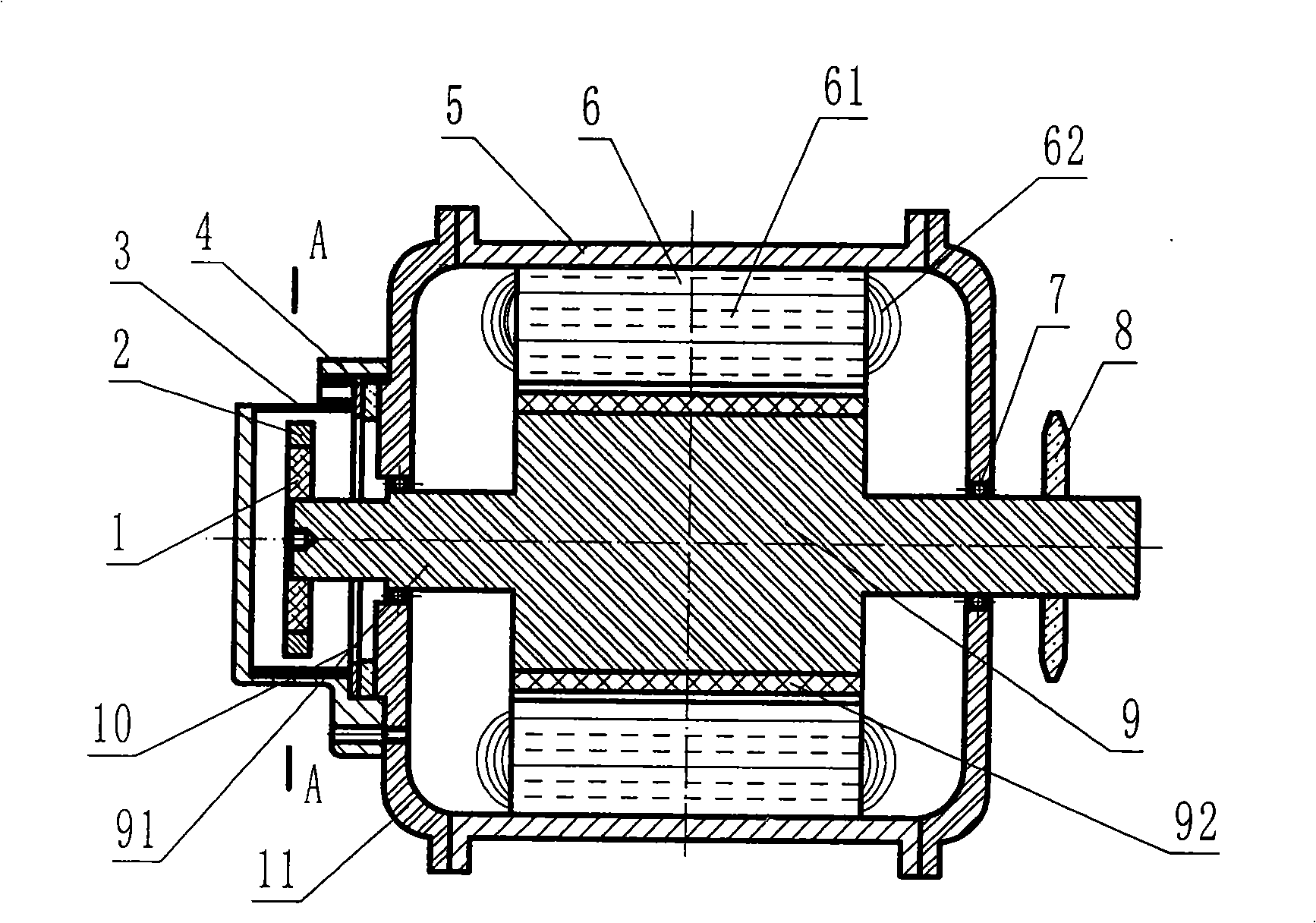

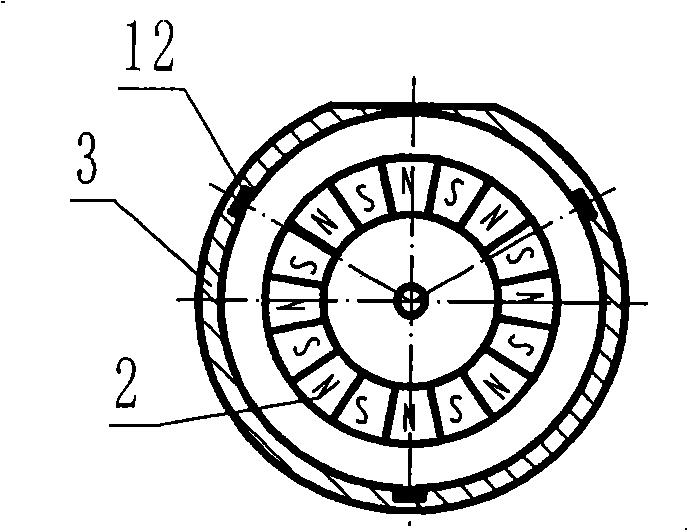

Permanent magnet brushless motor with separated Hall position transducer and motor stator

InactiveCN101295907AAvoid overheating damageReduce repair rateStructural associationPhysicsMagnetic phase

The invention provides a permanent-magnetic brushless motor, the Hall position sensor and the motor stator of which are separately positioned. The brushless motor of the invention pertains to technical filed of motors, is characterized by being provided with a phase-change sensing device of the Hall position sensor separately positioned with the motor rotor and has the structure that: a permanent-magnetic phase-change rotor and a phase-change Hall position sensor support which is matched with the rotor are arranged; the permanent-magnetic phase-change rotor and the motor permanent-magnetic rotor are connected with each other and synchronized; the Hall position sensor support and the motor stator are fixedly connected; the Hall position senor is fixedly arranged at the phase position the Hall position sensor support, which is opposite to the permanent-magnetic phase-change rotor. The invention is characterized by effectively preventing the damage to the Hall position sensor caused by overheating, thereby greatly reducing the repair rate of the brushless motor, improving working efficiency, causing the repairing to be more convenient, flexible and fast with low cost and having long service life. In addition, the brushless motor of the invention can be applied to various motors.

Owner:刘卫东

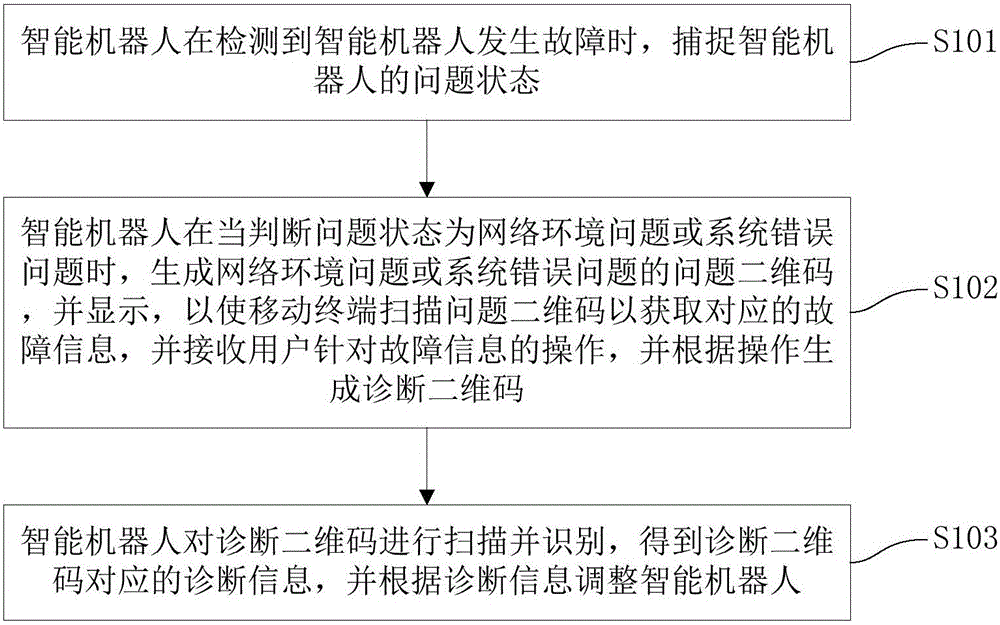

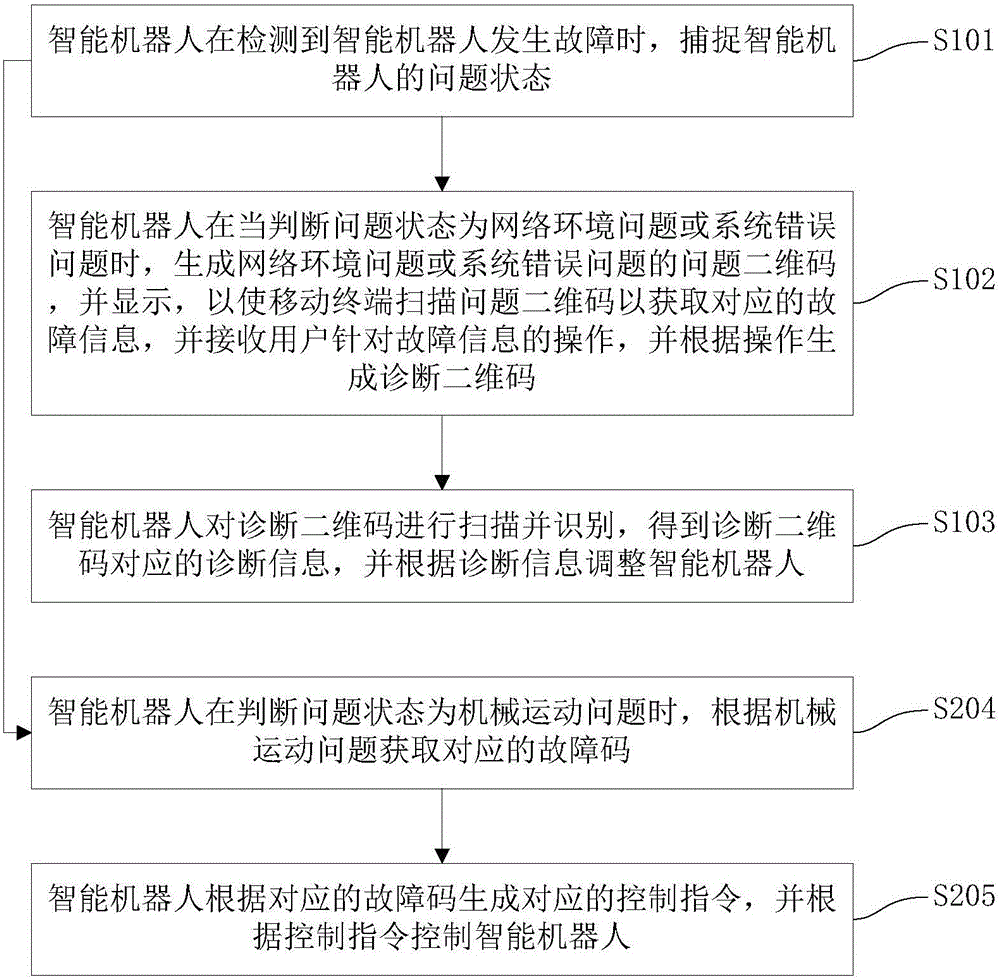

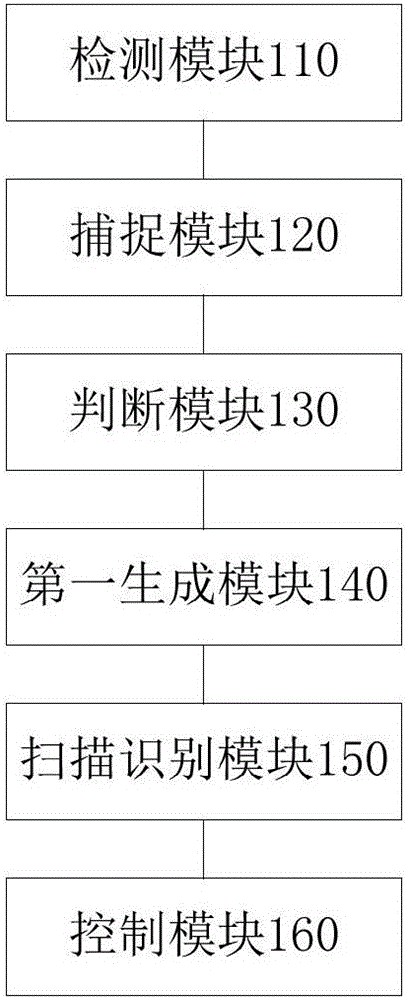

Intelligent robot fault diagnosis method based on artificial intelligence, device and system

ActiveCN105095817AEasy maintenanceReduce paralysisElectric testing/monitoringSensing by electromagnetic radiationDiagnosis methodsComputer terminal

The invention discloses an intelligent robot fault diagnosis method based on artificial intelligence, a system, an intelligent robot and a mobile terminal. The intelligent robot fault diagnosis comprises steps of capturing the problem state of the intelligent robot when the intelligent robot detects the fault produced by the intelligent robot, generating a problem two dimension code of the network environment problem or the system fault problem and displaying when the problem state is determined to be the network environment problem or the system fault problem so as to enable the mobile terminal to scan the problem two dimension code in order to obtain the corresponding fault information, receiving the user operation aiming for the fault information, generating a diagnosis two dimension code according to the operation, performing scanning and recognition on the diagnosis two dimension code to obtain the diagnosis information corresponding to the diagnosis two dimension code, and regulating the intelligent robot according to the diagnosis information. The intelligent robot fault diagnosis method enables the intelligent robot to be easy to maintain, reduces the paralysis, shut-down and repair rate of the intelligent robot, enables the user to use and maintain the intelligent robot at a pretty low learning cost, and improves the user experience.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

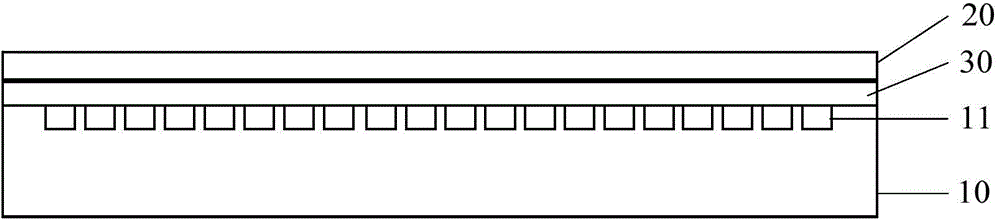

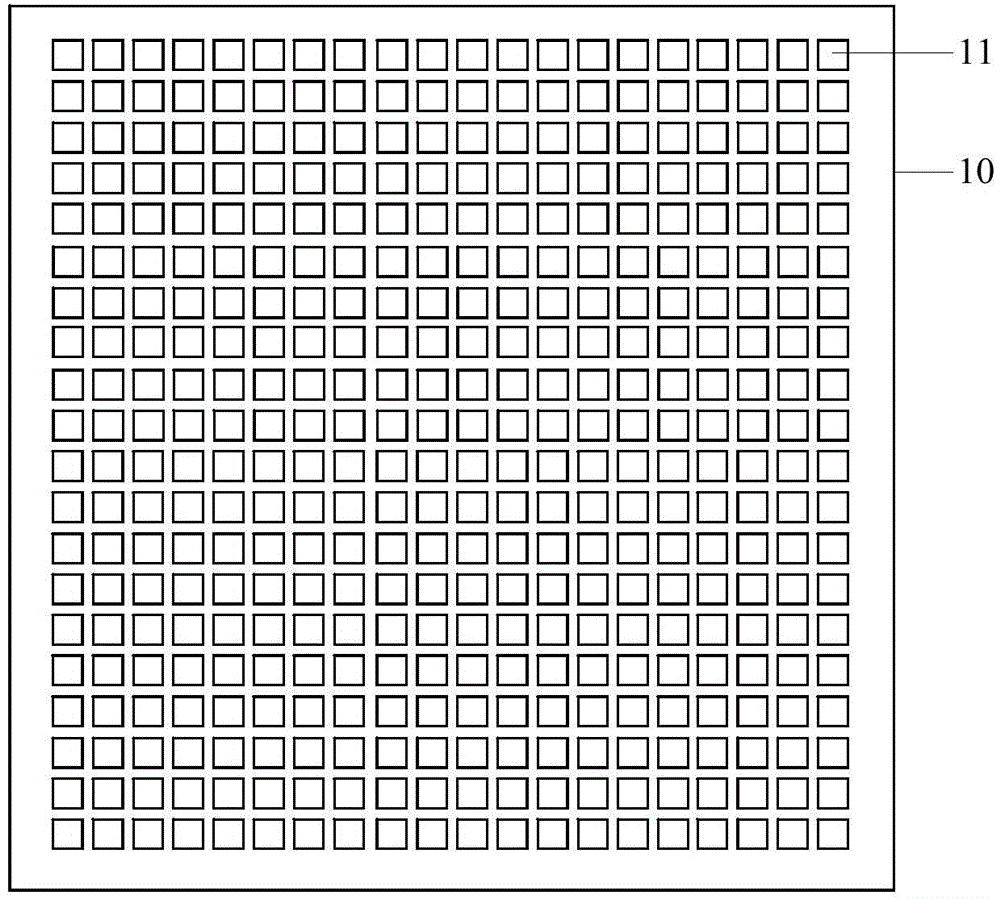

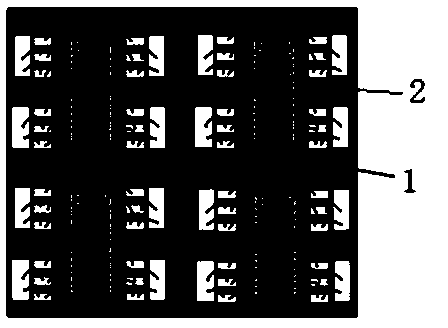

COB packaging structure of light-emitting diode

InactiveCN103594464AReduce design difficultyReduce wiring difficultySemiconductor/solid-state device detailsSolid-state devicesHigh densityChipset

The invention relates to a COB packaging structure of a light-emitting diode. The COB packaging structure comprises a substrate, n drive chips and n light-emitting diode chip sets, wherein each light-emitting diode chip set comprises N light-emitting diode chips, n and N are integers, n is larger than or equal to 1, N is larger than or equal to 1, the n drive chips and the n light-emitting diode chip sets are packaged on the front face of the substrate in a modular mode to form n sets of COB display modules, the n drive chips and the n light-emitting diode chip sets form lamp-driver co-plane devices in a one-to-one connection mode, a fixed number of bonding pads are arranged on the back face of the substrate, and all the drive chips and all the light-emitting diode chip sets are communicated with the bonding pads on the back face of the substrate in a routing and hole passing mode. The n lamp-driver co-plane devices are packaged to form a new COB device, the number of the bonding pads on the back face of the substrate is fixed and independent of the number of sets of the drive chips, and therefore a large number of pins are saved, external device cables are greatly reduced, and the higher density can be achieved compared with the density achieved through traditional packaging.

Owner:GUANGDONG VTRON TECH CO LTD

Welding method for longitudinal butt joint of thin-wall aluminum alloy non-profile long pipes

InactiveCN103111731AGuaranteed surface forming qualityGuarantee internal qualityArc welding apparatusPorosityHydrogen Nitrate

The invention discloses a welding method for longitudinal butt joint of thin-wall aluminum alloy non-profile long pipes. Firstly, grooves are formed in to-be-welded portions of parts, cleaned mechanically and then subjected to chemical cleaning through a solution of sodium hydroxide (NaOH) and a solution of hydrogen nitrate (HNO3); and then a gas metal arc welding (GMAW) process is carried out, and welding parameters include current, voltage, current polarity, protective gas, the flow rate of the protective gas, backing gas, and the flow rate of the backing gas, wherein the current is 65-95 amperes, the voltage is 18+ / -3 volts, the current polarity is alternating current, the protective gas is argon gas with purity more than or equal to 99.99%, the flow rate of the protective gas is 16+ / -3 liters per minute, the backing gas is argon gas with purity more than or equal to 99.99%, and the flow rate of the backing gas is 16+ / -3 liters per minute. Through the welding method for the longitudinal butt joint of the thin-wall aluminum alloy non-profile long pipes, the surface forming quality and the inside quality of a double-sided welded joint can be guaranteed, welding defects such as bad shape, lack of penetration, porosity, incomplete fusion, burning-through, collapse and inclusions are avoided, production efficiency is improved, the repair rate is lowered, and quality of products is guaranteed.

Owner:BEIJING CED RAILWAY ELECTRIC TECH

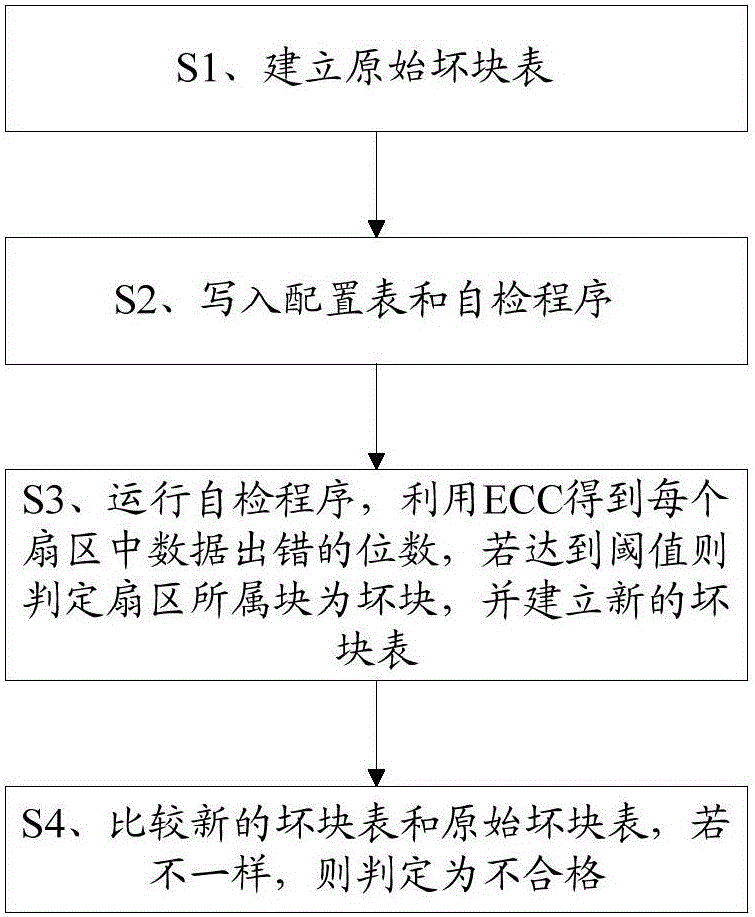

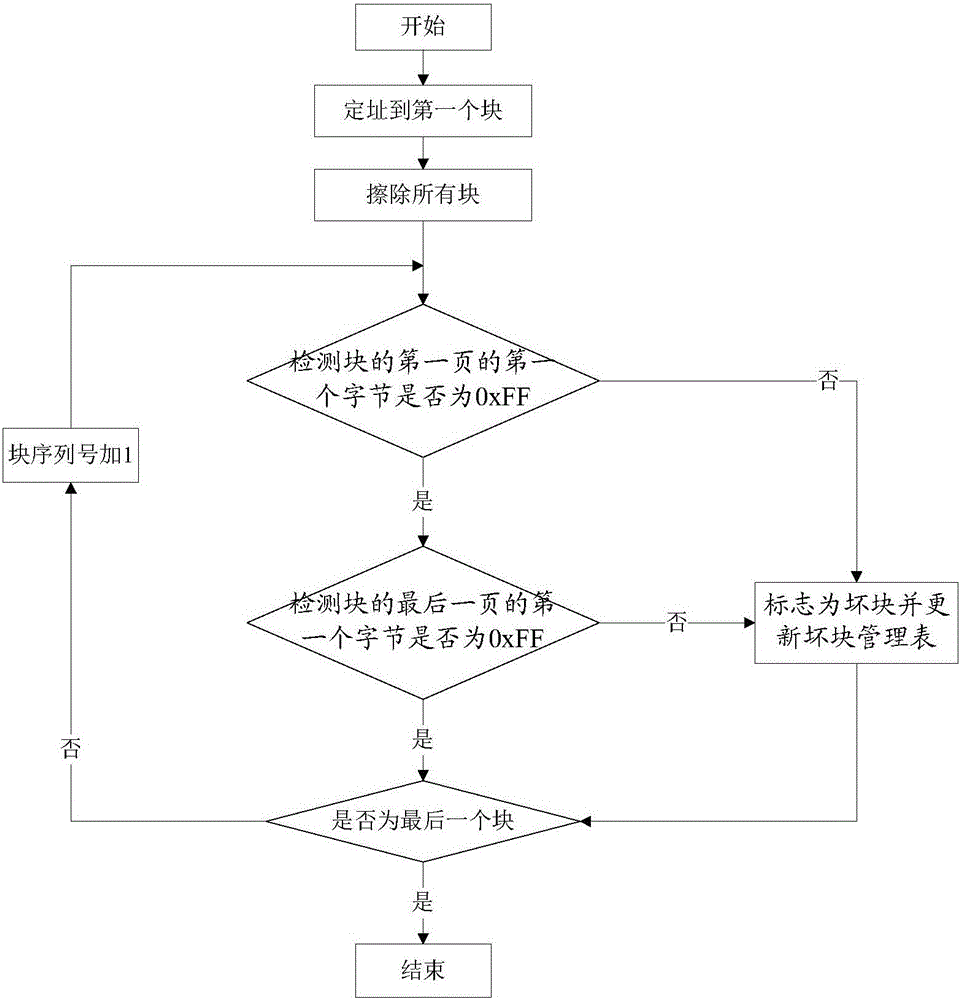

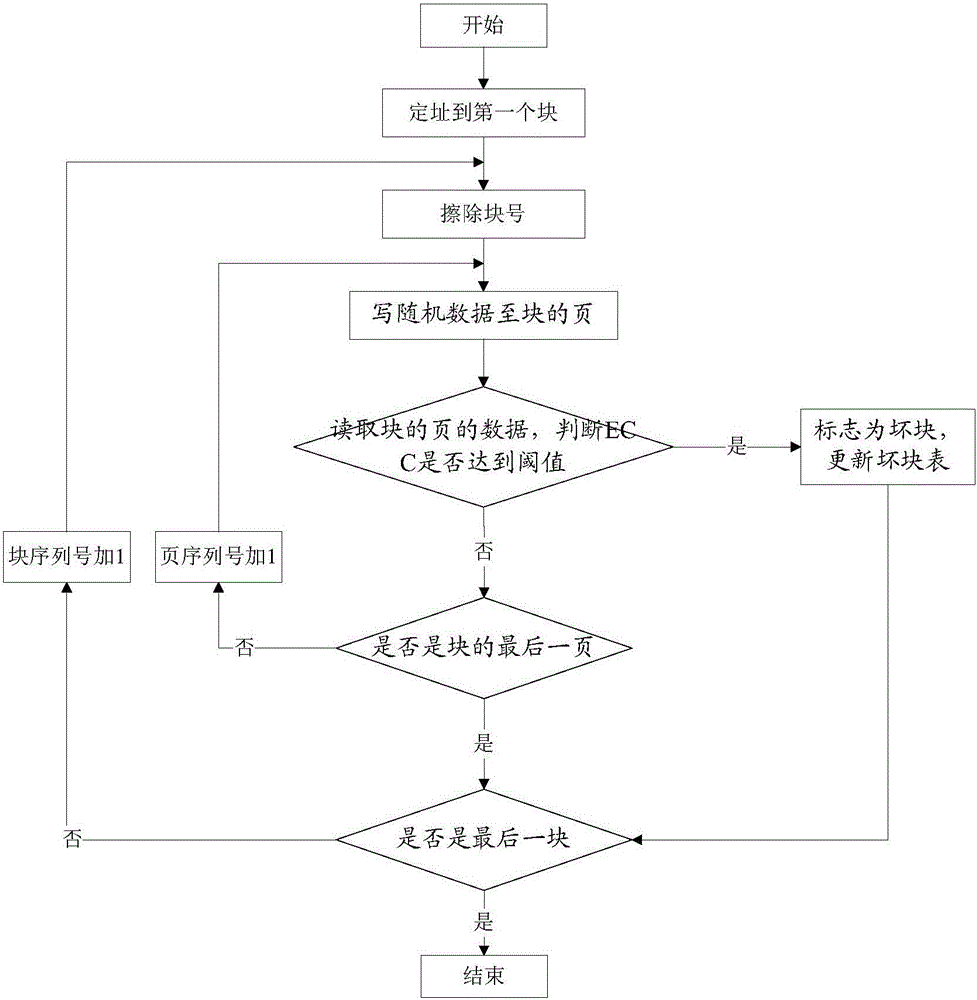

NAND FLASH testing method

Owner:BIWIN STORAGE TECH CO LTD

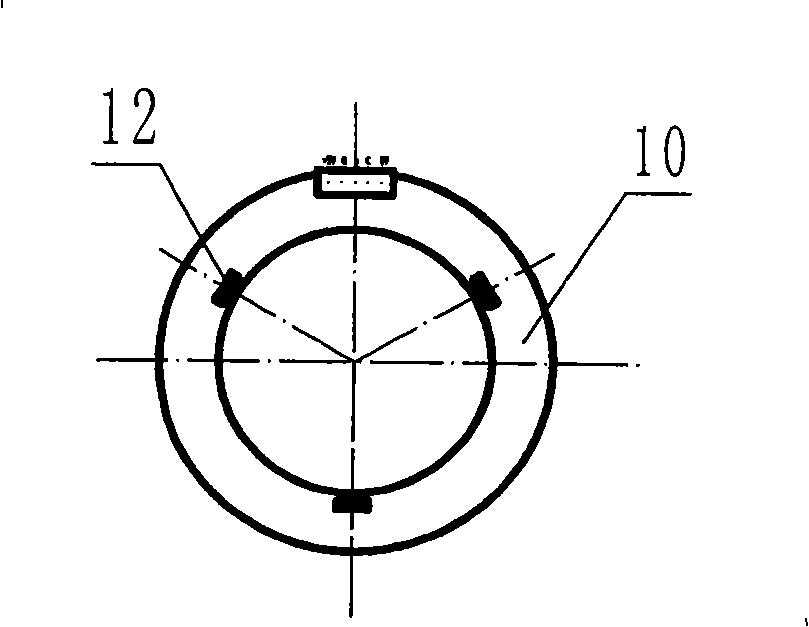

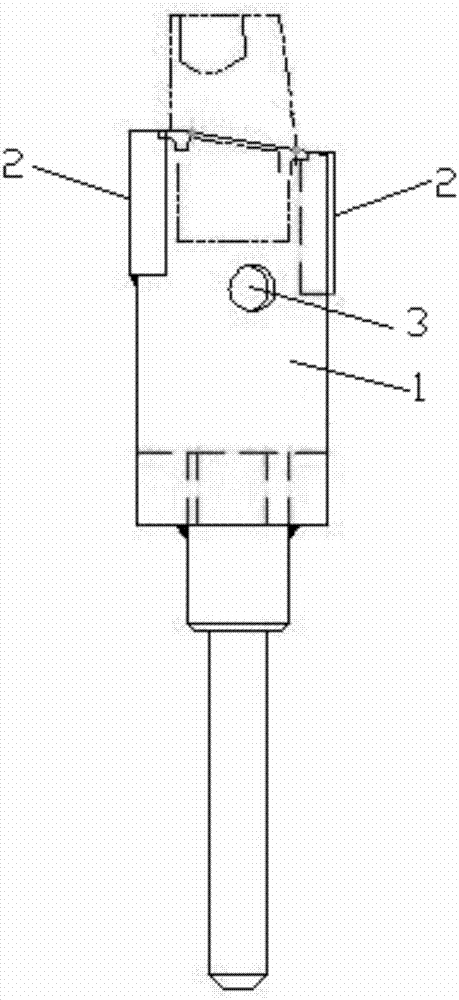

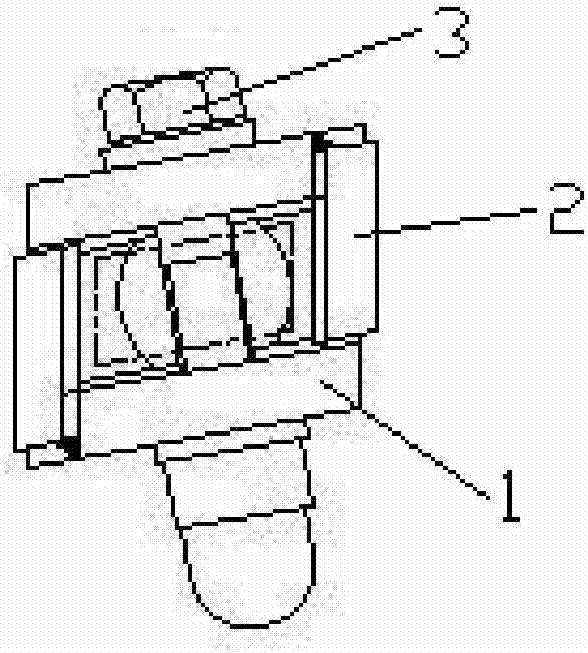

Blade spraying protective fixture

ActiveCN107138325AImprove spray uniformityNot prone to "collapse" phenomenonSpraying apparatusFlangeEngineering

Owner:CHINA HANGFA SOUTH IND CO LTD

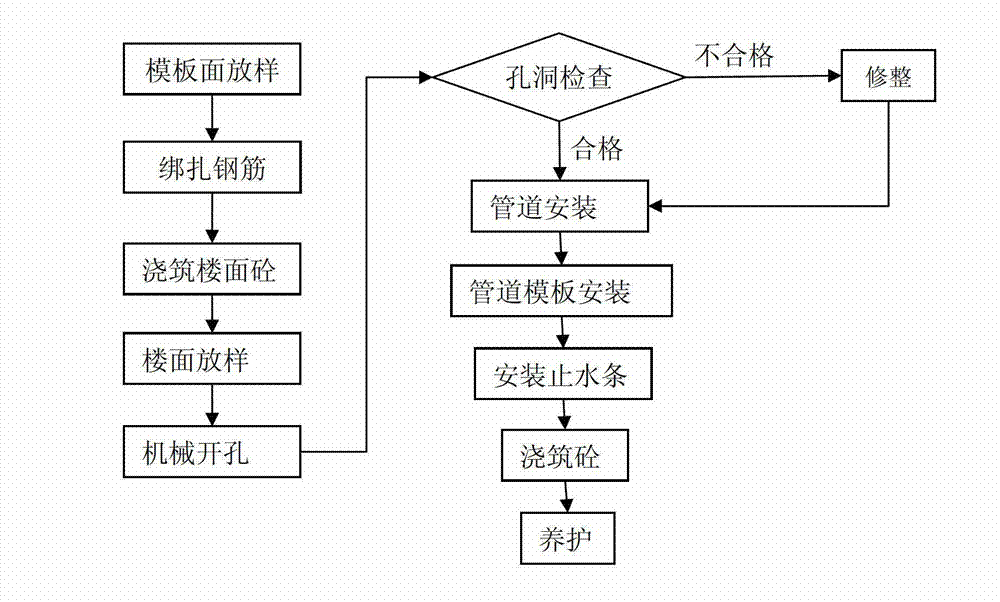

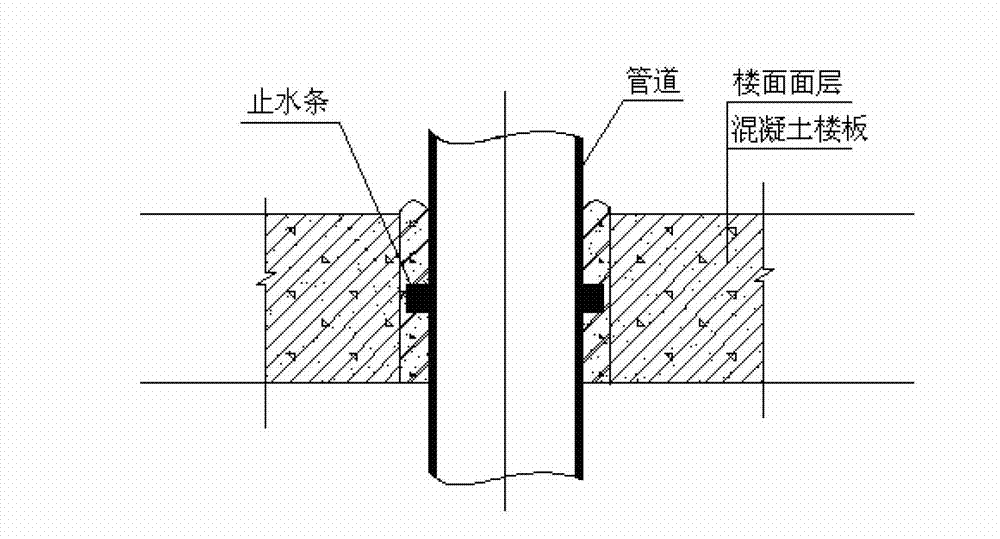

Construction method of through floor pipe

InactiveCN103089014AEasy constructionAffect the service lifeBuilding material handlingFloor slabEconomic benefits

The invention discloses a construction method of a through floor pipe. The construction method of the through floor pipe mainly includes the following steps: template face lofting, floor face steel bar binding, floor face concrete pouring, floor face lofting, mechanical pore opening, hole checking, pipe installation, pipe template installation, waterstop installation, pouring concrete in a seam between the pipe and a floor board, maintenance and the like. The construction method of the through floor pipe is simple in technology, an operation method is easy to implement, construction speed is fast, anti-leakage quality is good, repair rate is low and economic benefits are obvious. The construction method of the through floor pipe is suitable for anti-leakage construction of a rigid polyvinyl chloride (UPVC) pipe with the diameter more than 50 mm in an indoor through floor board part.

Owner:ZHEJIANG XINDONGYANG CONSTR GRP

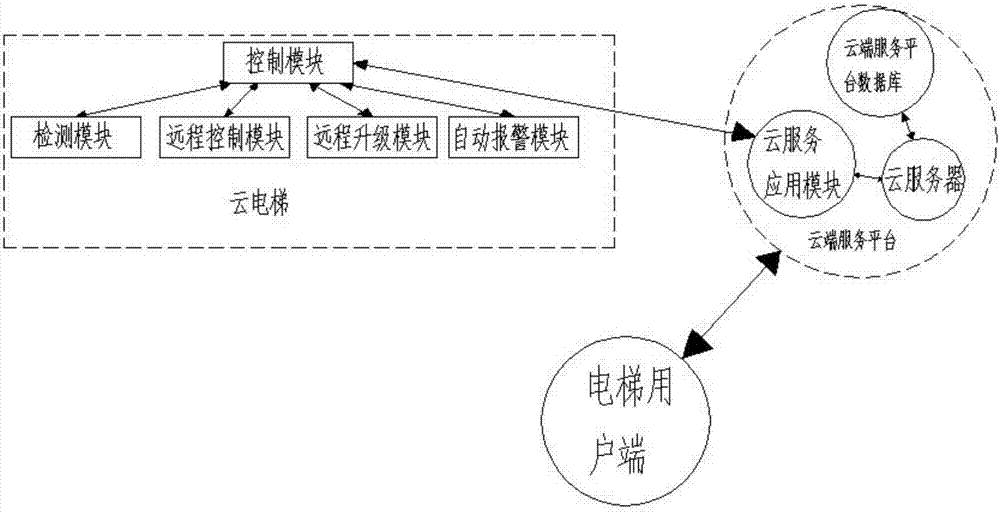

Cloud elevator system based on cloud computing

The invention discloses a cloud elevator system based on cloud computing. The cloud elevator system comprises a cloud service platform connected through a communication network, a cloud elevator and an elevator client, wherein a control module, a detection module, a remote set module, a remote upgrade module and an automatic alarm module are arranged in the cloud elevator; the control module is respectively connected with the detection module, the remote set module, the remote upgrade module and the automatic alarm module; the control module is also connected with the cloud service platform; the cloud service platform is provided with a cloud server and a cloud service platform database, and the cloud server is provided with a cloud service application module. According to the cloud elevator system, through a powerful data processing technology of the cloud service platform, the interaction among the elevator client, an elevator manufacturer and the cloud elevator can be realized, so that the elevator client and the elevator manufacturer can know an instantaneous state of cloud elevator operation at any time and carry out remote control on the cloud elevator, therefore the failure rate and the repair rate of the cloud elevator system are reduced, and the stability and the safety of the cloud elevator are improved.

Owner:芜湖中艺科技服务有限公司

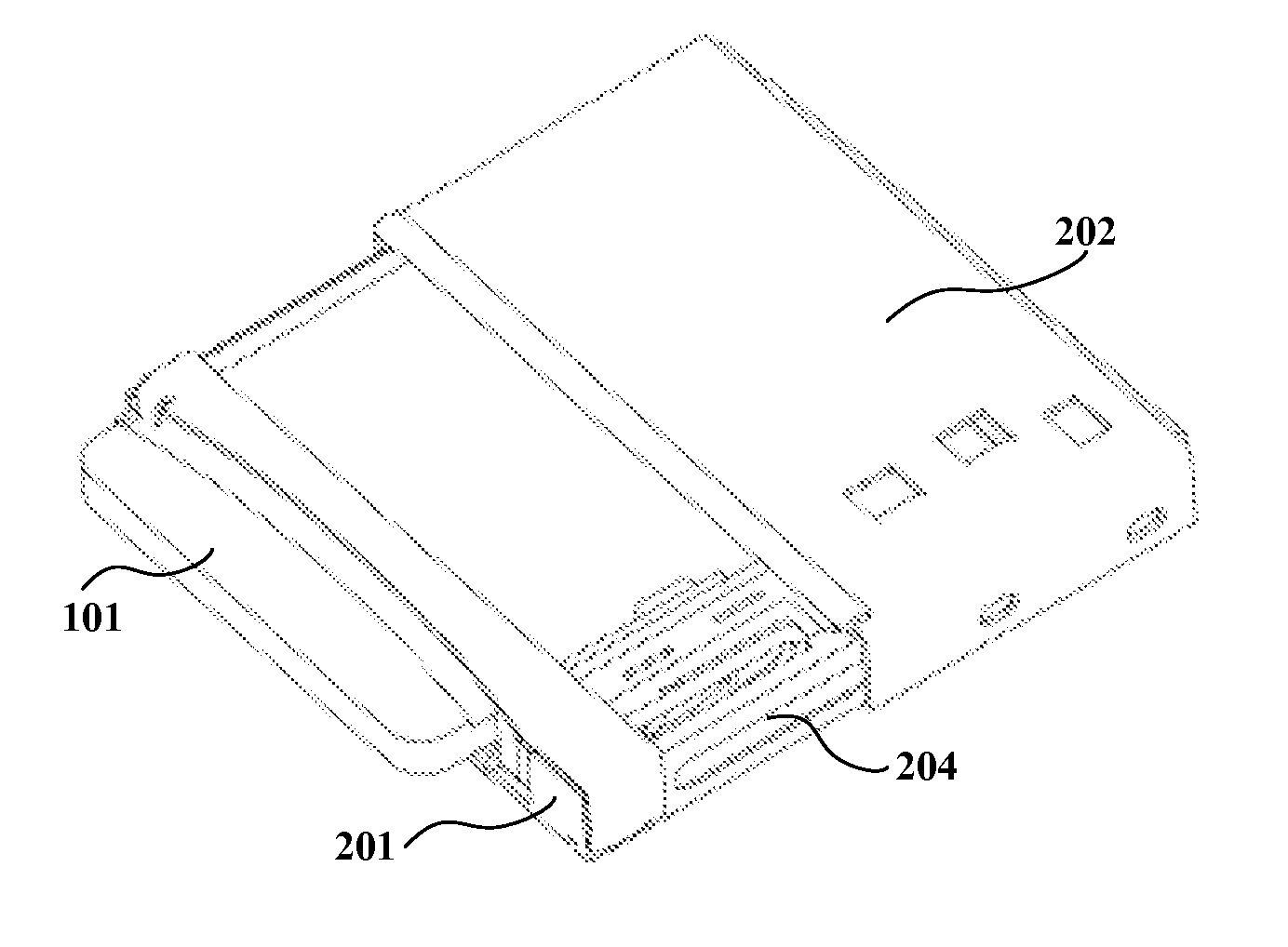

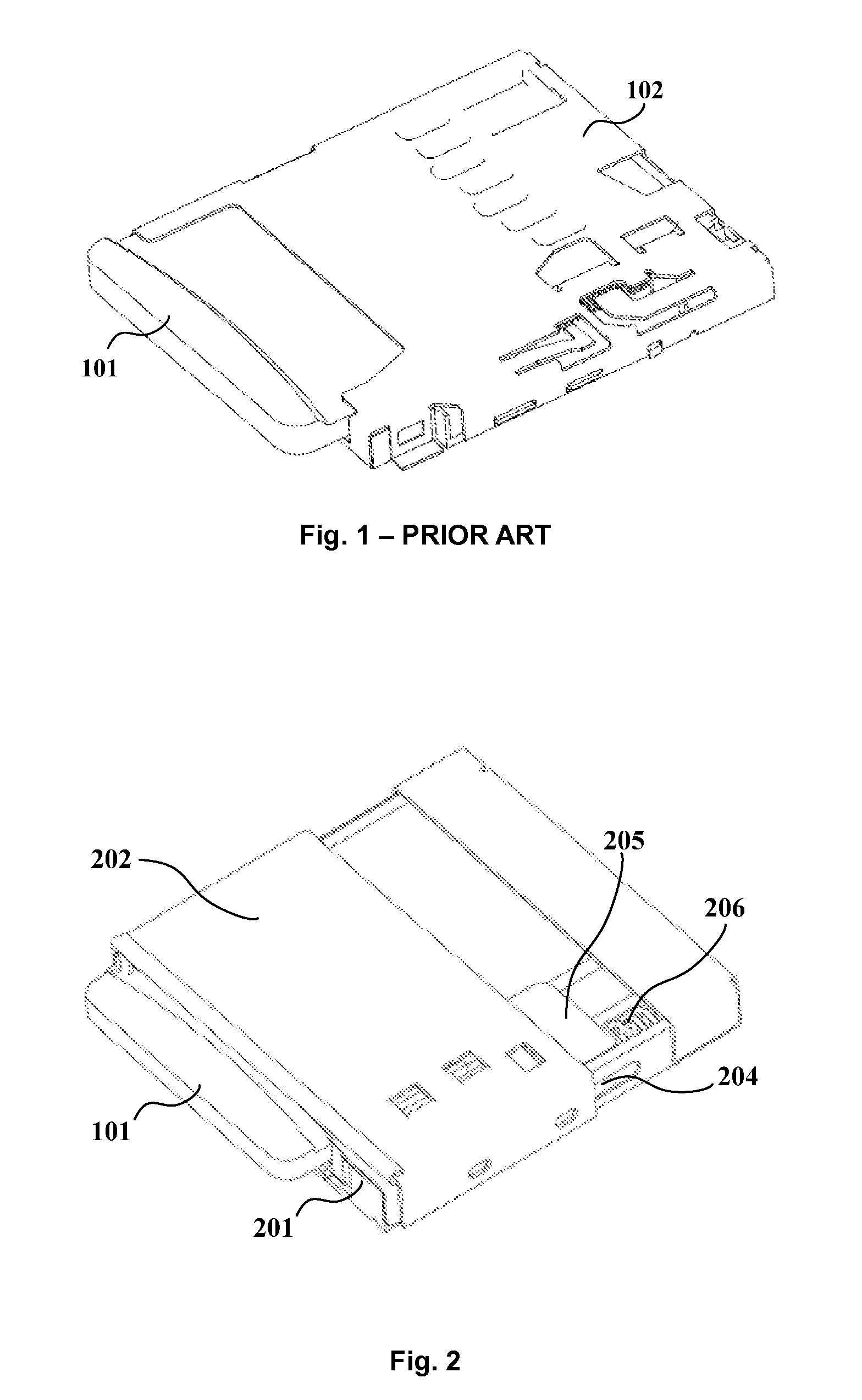

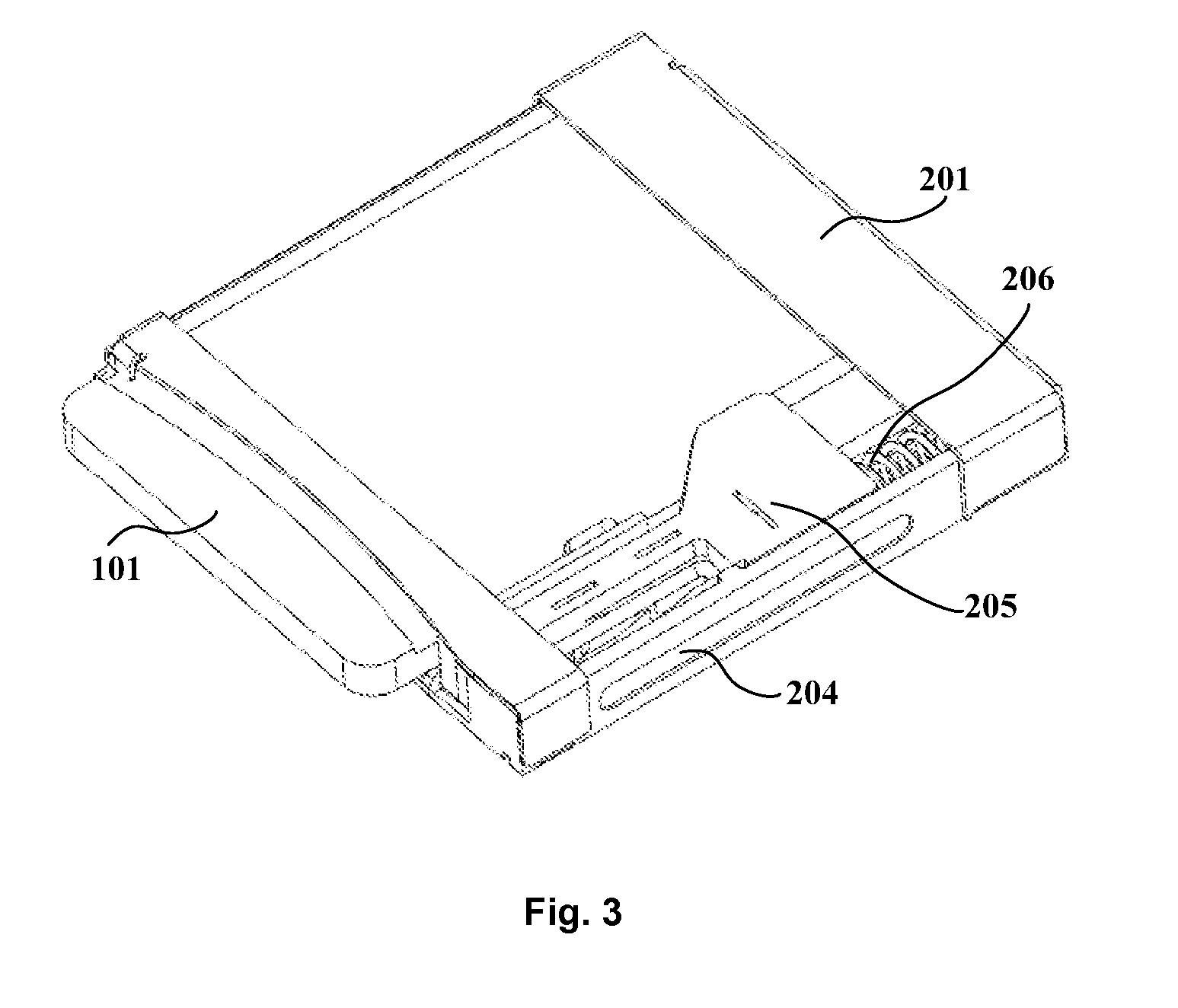

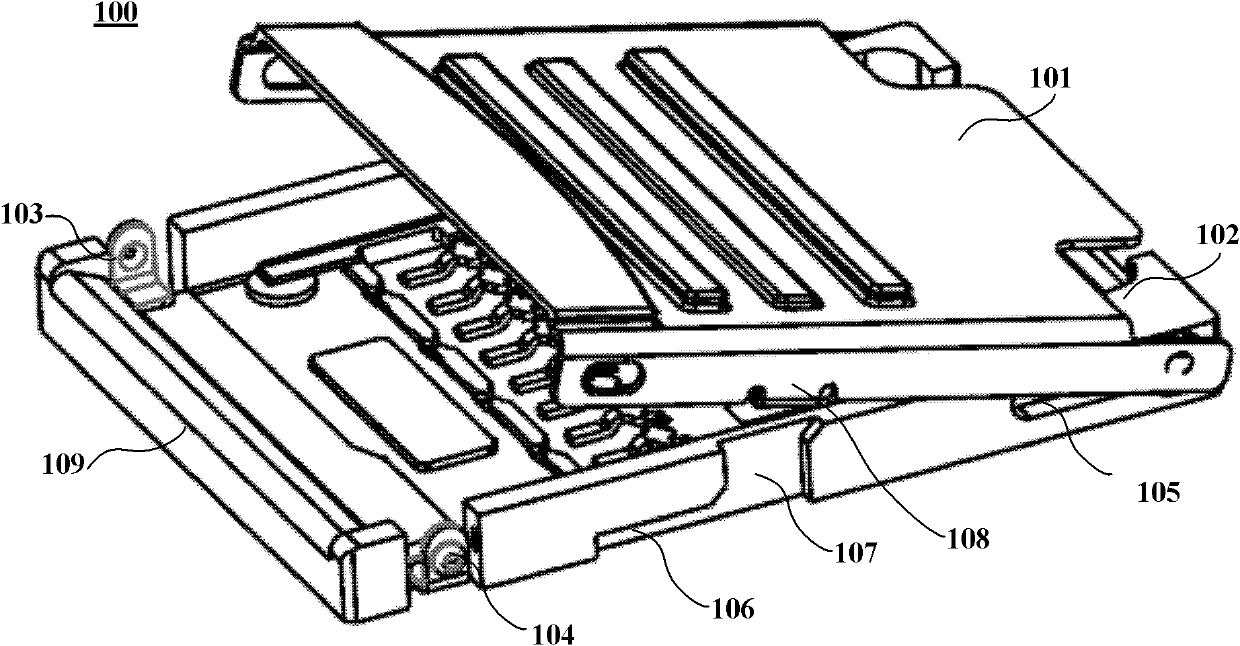

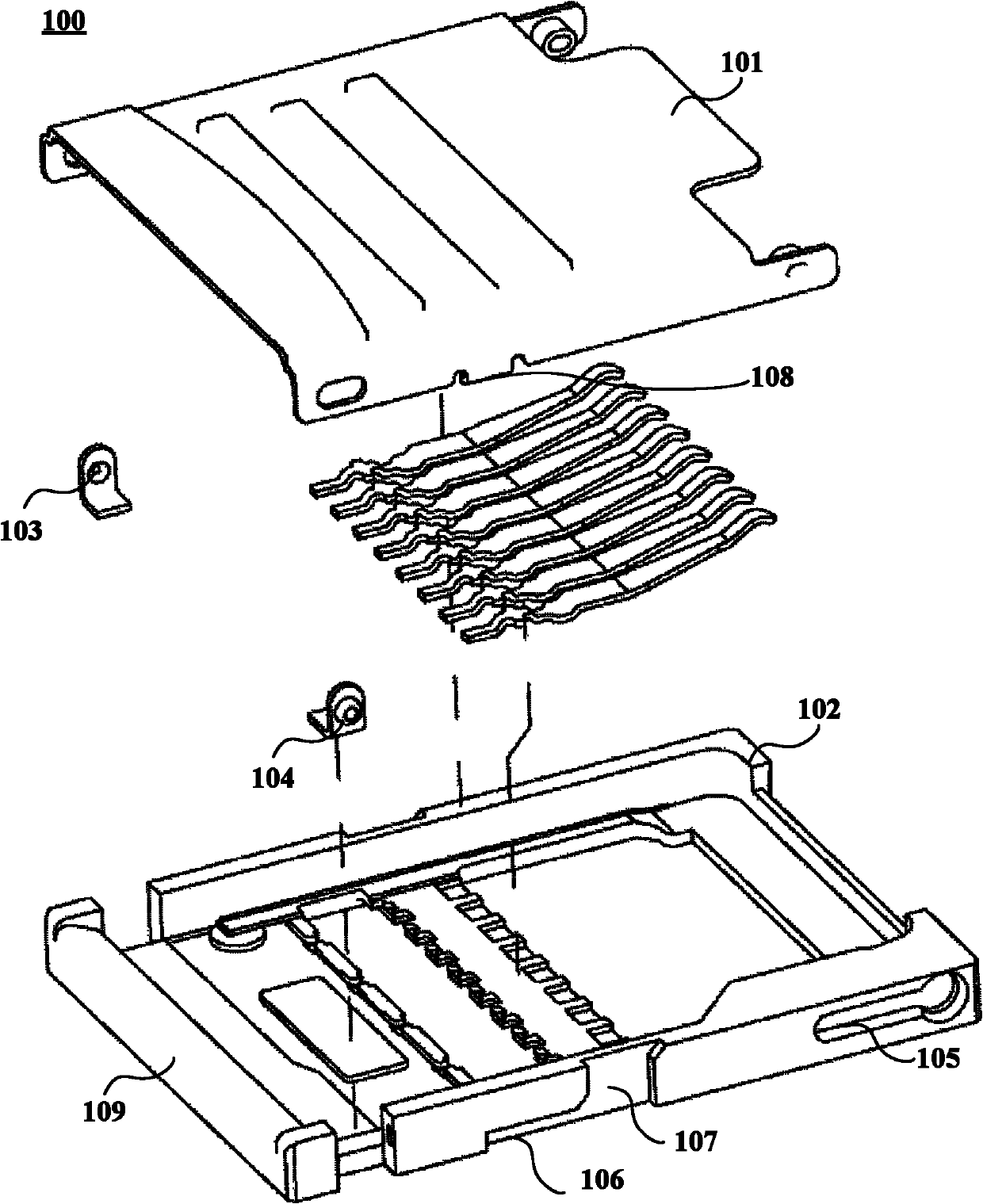

Card reader, electronic apparatus and protection method for memory card

InactiveUS20130027869A1Increasing back repair rateStop operationConveying record carriersDigital data processing detailsWrite protectionCard reader

The embodiments of the present invention provide a card reader, electronic apparatus and protection method for memory card. The card reader comprises: a card slot having an accommodation space for accommodating a memory card, with parallel guiding slots being arranged on the left side and right side walls of the card slot; and a cover arranged on the card slot and being slidable on the card slot via the guiding slots. With the embodiments of the present invention, the delay time for stopping the read-write protection may be increased, the memory card may be protected in time, and the back repair rate of the memory card may be reduce.

Owner:SONY MOBILE COMM INC +1

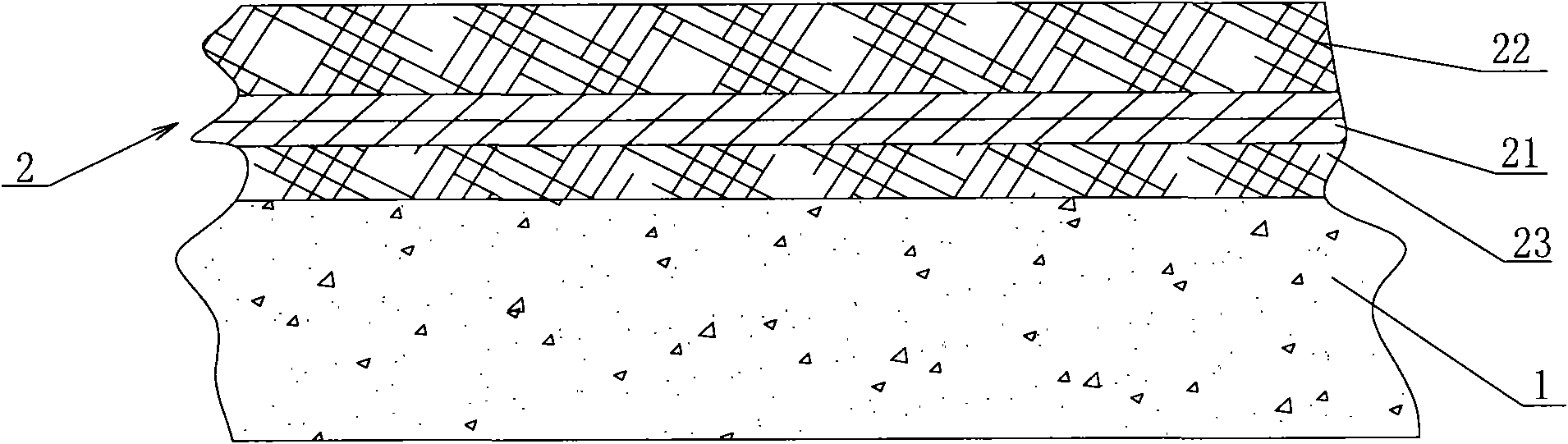

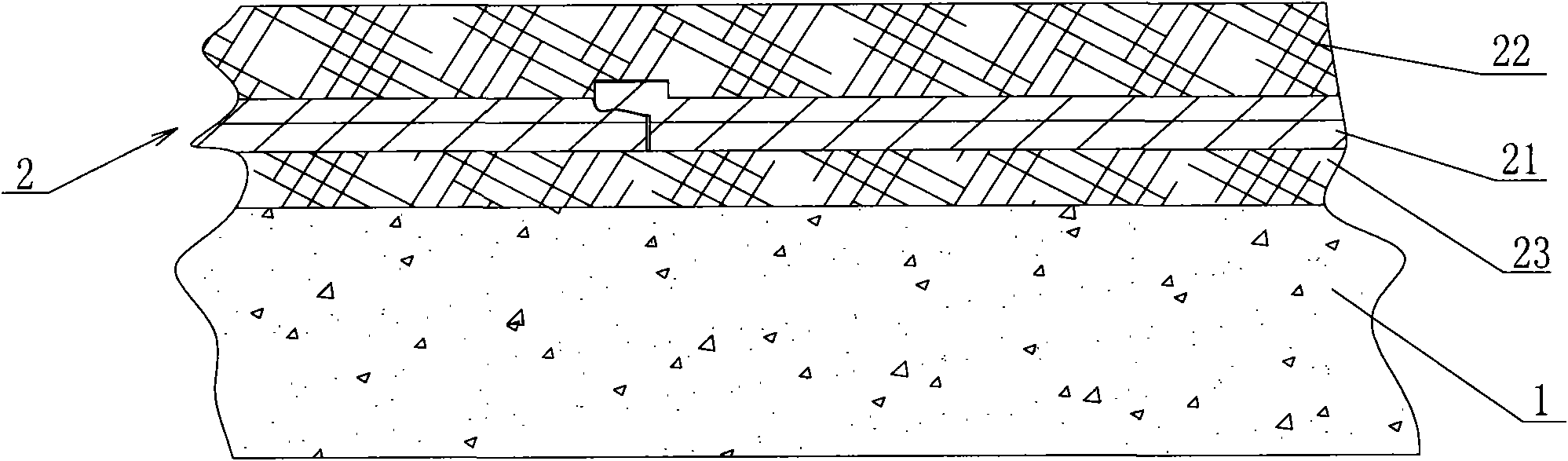

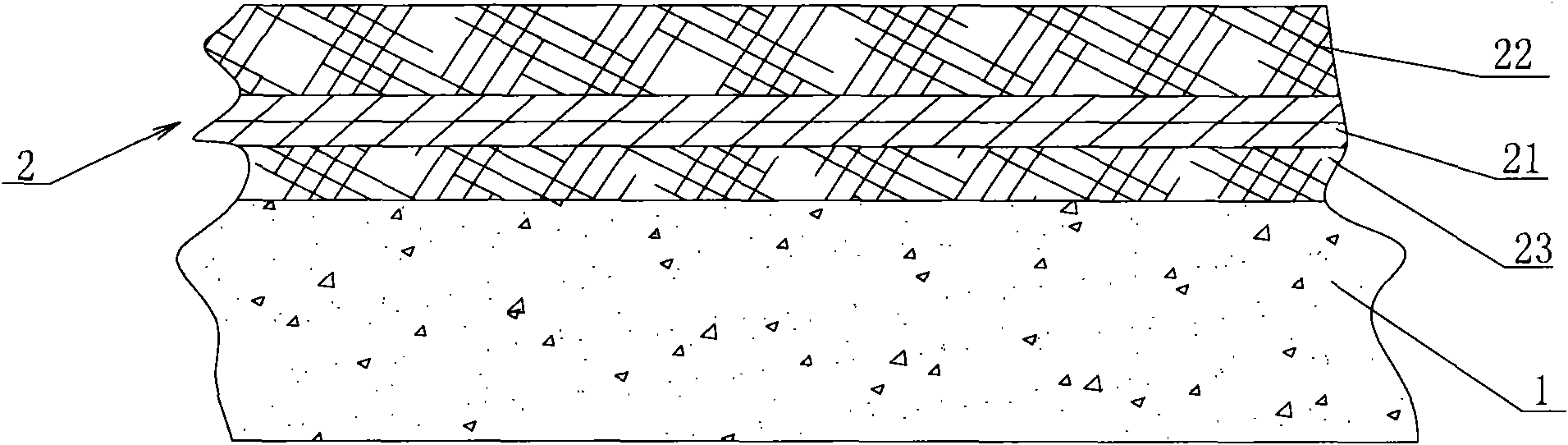

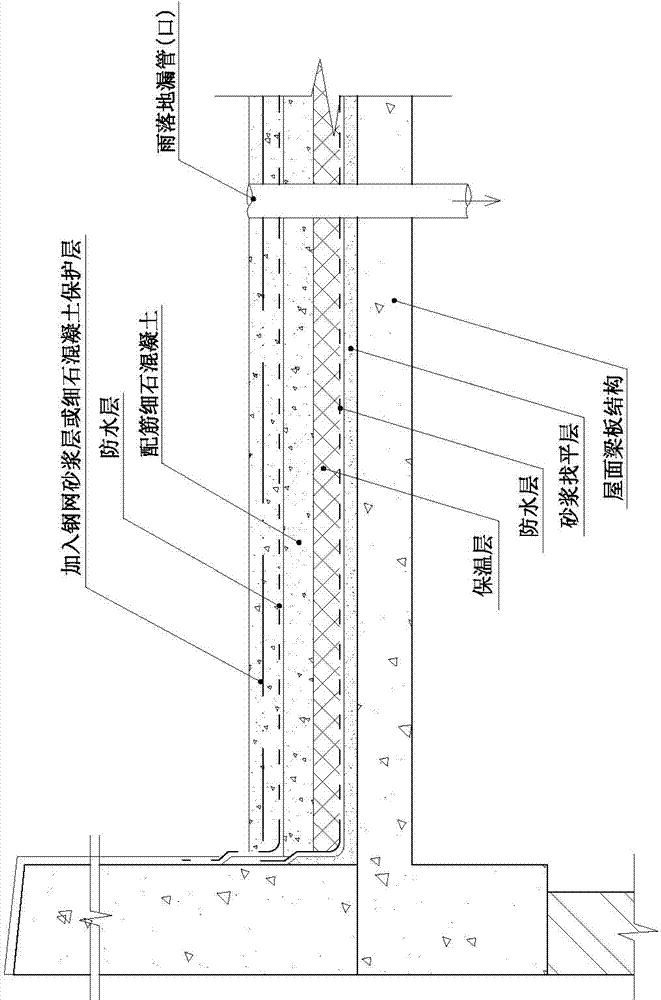

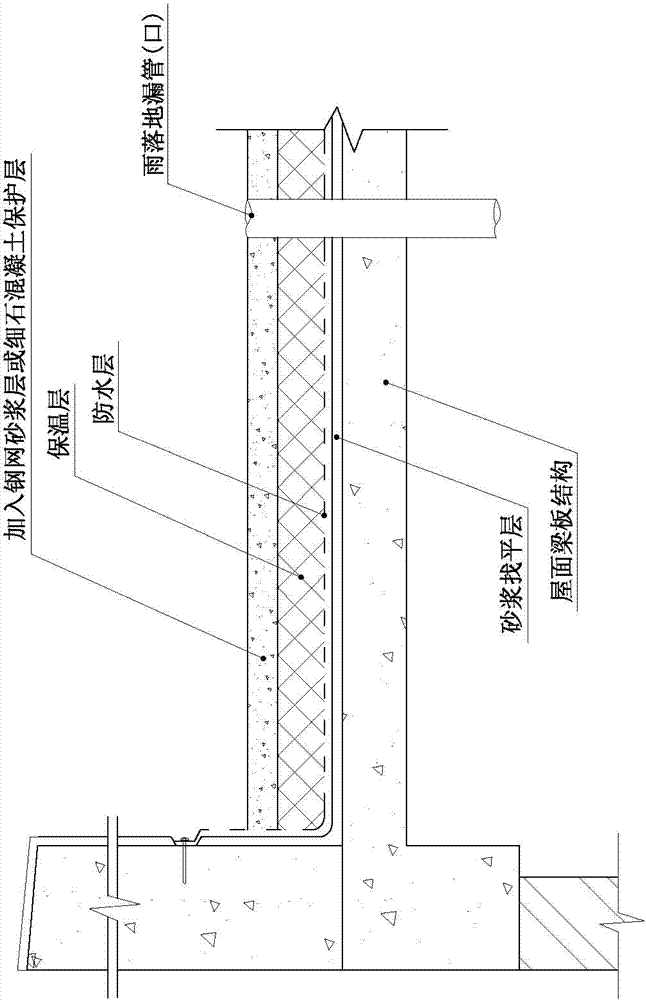

Novel waterproof structure of construction engineering and waterproof construction method

InactiveCN102021948AAchieve waterproof effectStrong adhesionUnderground chambersArtificial water canalsArchitectural engineeringAsphalt

The invention provides a novel waterproof structure of construction engineering and a waterproof construction method, which can solve the problems that the lap joint parts are difficult to be completely and closely attached and the waterproof effect is bad in the waterproof structure and waterproof construction method of coiled materials in the prior art. The novel waterproof structure of construction engineering comprises a base surface and a waterproof layer provided with no lap seam entirely and formed by a basic layer and modified asphalt layers on the upper and lower surfaces of the basic layer. The waterproof construction method comprises the steps as follows: cleaning the base surface; heating and spraying the modified asphalt; paving the base; and spraying modified asphalt to construct a waterproof layer. As the waterproof structure does not have lap seam entirely, a completely-sealed waterproof effect like skin can be achieved; and moreover, the waterproof construction method can realize construction without lap seam, has more advantages in construction of special parts and ensures reliable waterproof effect.

Owner:QINGDAO MINGHUI ARCHITECTURE DECORATE ENGCO

Storage card base, mobile terminal and method for protecting storage card

InactiveCN102738618ATimely protectionReduce repair rateLine/current collector detailsConveying record carriersElectricityWrite protection

An embodiment of the invention provides a storage card base, a mobile terminal and a method for protecting a storage card. The storage card base comprises a first contact point, a second contact point, a guide groove, and a junction embedded guide groove. The first contact point is disposed on a foundation of the storage card base. The second contact point is disposed on the foundation of the storage card base and is electrically connected with the first contact point when an upper cover of the storage card base is closed. The guide groove is disposed on the foundation of the storage card base and is located on a side of a junction which connects the foundation and the upper cover. The storage card base enables increase of delay time of stopping read-write protection. The storage card is protected timely, and repair rate of the storage card is reduced.

Owner:SONY ERICSSON MOBILE COMM AB

Detection and evaluation method for abradability of seal coating

InactiveCN108120650AMeet the needs of quality controlImprove quality controlInvestigating abrasion/wear resistanceInvestigating machinabilityThermal sprayingEngineering

The invention especially relates to a detection and evaluation method for the abradability of a seal coating, belonging to the technical field of aeroengines. The detection and evaluation method is applicable to determination of the abradability of thermally-sprayed abradable seal coatings. The method comprises the following steps: preparation of a coating; measurement and weighing; installation of blade samples; calibration of zero position; setting of test parameters; abrasion testing; and result analysis and evaluation. The detection and evaluation method provided by the invention is employed for studying the frictional wearing behaviors of three low-and-medium-temperature seal coatings, i.e., an AHB (aluminum / boron nitride) coating, a Metco601 (aluminum-silicon polybenzoate) and a Metco 307 (nickel graphite) coating, and matching pairs; and criteria are formulated for determination of the abradability of abradable seal coatings, including three qualitative criteria and four quantitative criteria, wherein the three qualitative criteria are composed of abrading force, the morphology and composition of the surfaces of abrasion scratches, and the morphology and composition of the cross sections of the abrasion scratches, and the four quantitative criteria are composed of a blade height abrasion ratio, a blade coating mass wear ratio, an abrasion scratch length ratio and an adhesion ratio.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Strengthening method for gob-side entrydriving narrow coal pillar

ActiveCN105971640AAvoid breakingEnlarged elastic nucleusUnderground chambersTunnel liningButt jointCable stayed

A strengthening method for a gob-side entrydriving narrow coal pillar comprises the steps that firstly, an ultra-long horizontal drill hole and top and bottom plate inclined drill holes are drilled in the narrow coal pillar inside an upper section mining roadway, the length of the ultra-long horizontal drill hole is larger than the width of the narrow coal pillar. A grouting off target prevention bag and horizontal and inclined grouting anchor rods are installed inside each drill hole. A unilateral cable-stayed anchoring system, a unilateral transverse side limiting strengthening device and a unilateral gob-side entrydriving opposite-pulling anchoring system are formed on one side of the mining roadway, after a lower section roadway to be dug is dug, machinable rods are cut off in the lower section gob-side dug roadway, a butt-joint short anchor rod, a cable-stayed anchoring system and a transverse side limiting reinforcing device are correspondingly installed on the other side of the narrow coal pillar, finally, grouting is performed on the grouting anchor rods, and prestressing force is applied to nuts. Safety and stability of the narrow coal pillar gob-side entrydriving are effectively ensured, roadway deformation is effectively reduced, a coal pillar plastic area is obviously reduced, and the roadway repair cost can be lowered. The structural design is reasonable and simple, construction is convenient, the strengthening effect is obvious, and the coal recovery ratio is increased.

Owner:XIAN UNIV OF SCI & TECH

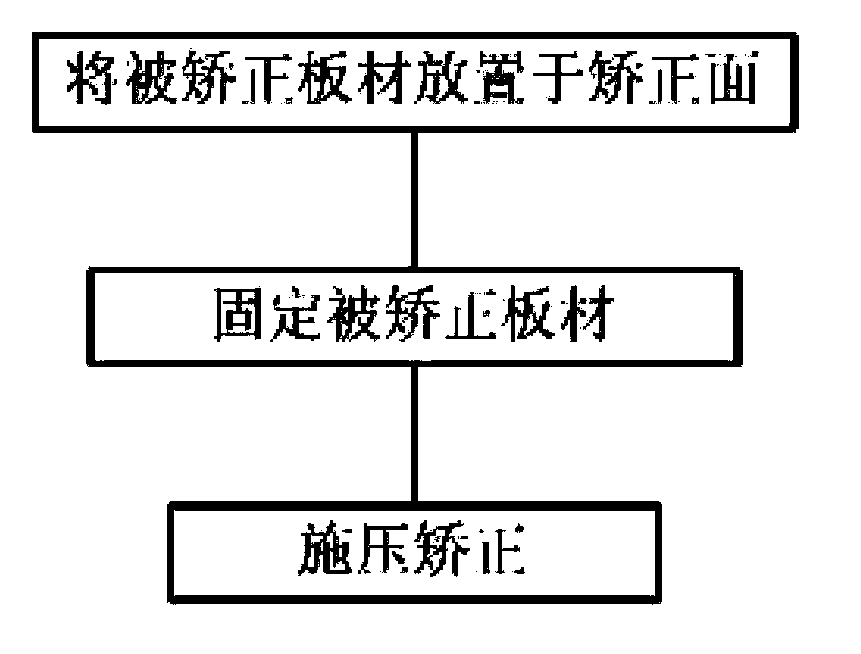

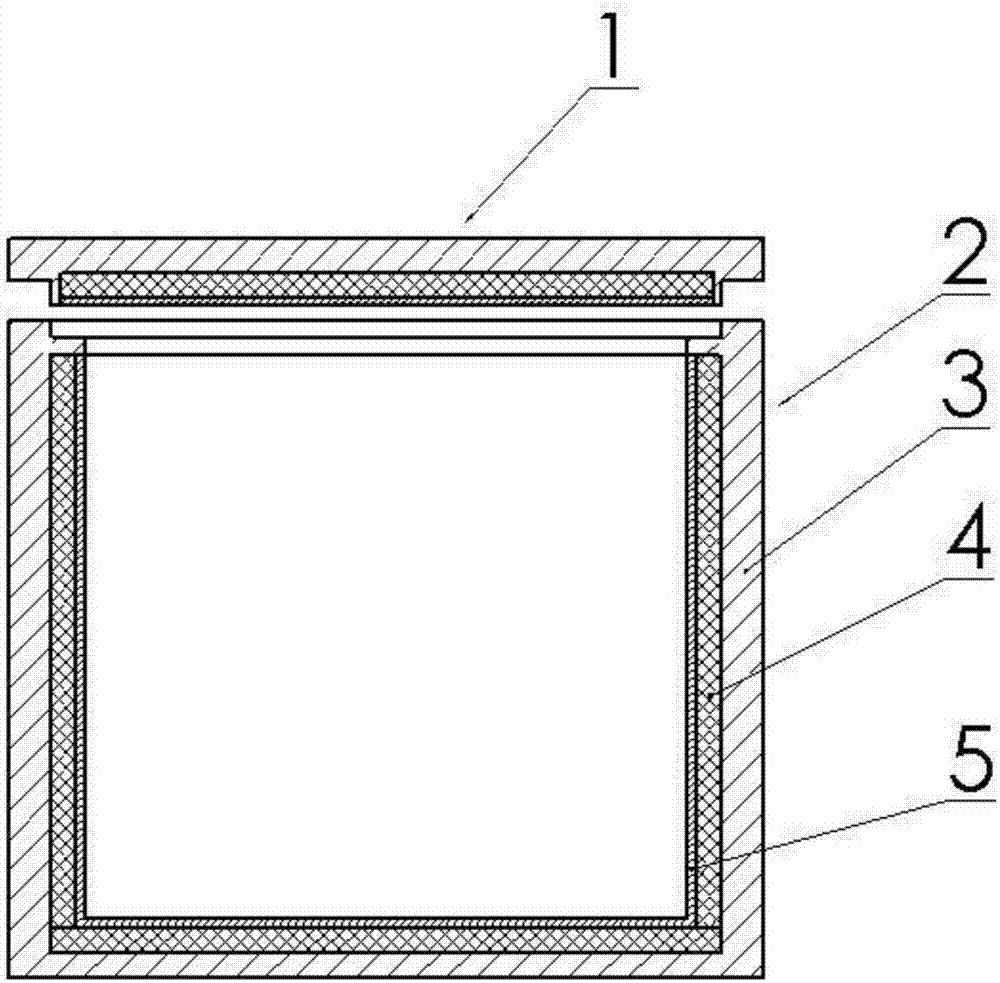

Plate flatness correction unit and operation method thereof

ActiveCN103567257APrevents excessive pressure damagePrevent the problem of uneven pressure damageHydraulic actionEngineering

The invention provides a plate flatness correction unit and an operation method thereof. The plate flatness correction unit comprises a hydraulic control system, a correction table, an upper plate, and pressure posts. The correction table comprises a correction face used for holding a plate under correction. The upper plate faces the correction table so that correction space forms between the upper plate and the correction table. The pressure posts are disposed in the correction space and include the first and second pressure posts; one end of every pressure post is mounted on the upper plate, and the other end of every pressure post can press on the correction table under the internal hydraulic action of the post. The second pressure posts can be moved to multiple positions of the plate under correction to apply pressure. The correction unit has functions of multi-point support and fixation and multi-point pressure application; the pressures of the pressure points can be adjusted at the same time and can also be adjusted independently; accordingly, the problem that the plate under correction bears excessive pressure and is damaged during the simultaneous pressing process can be prevented, and the problem that the plate under correction is damaged due to bearing uneven pressure can also be prevented.

Owner:广东江丰电子材料有限公司

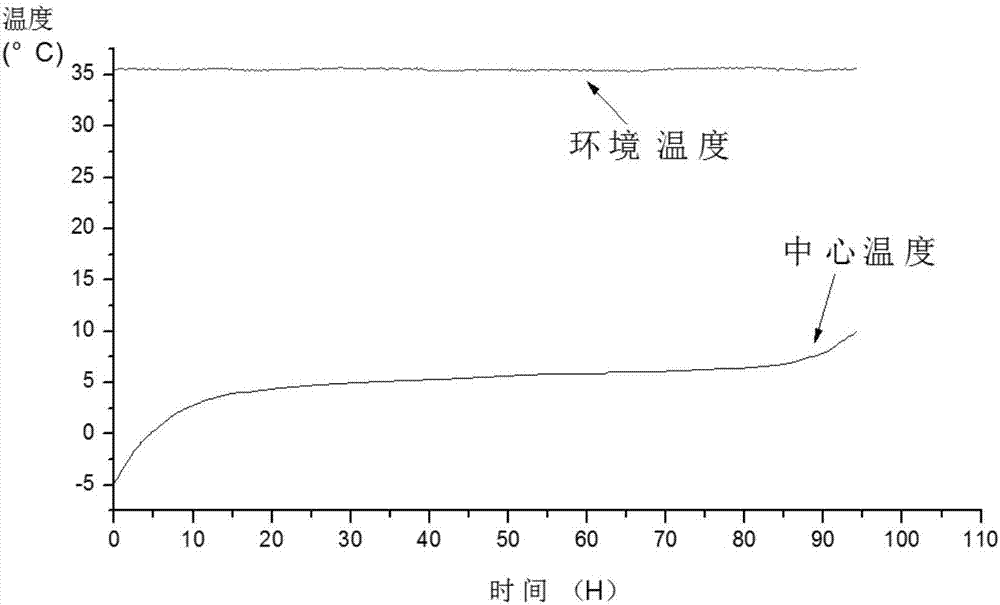

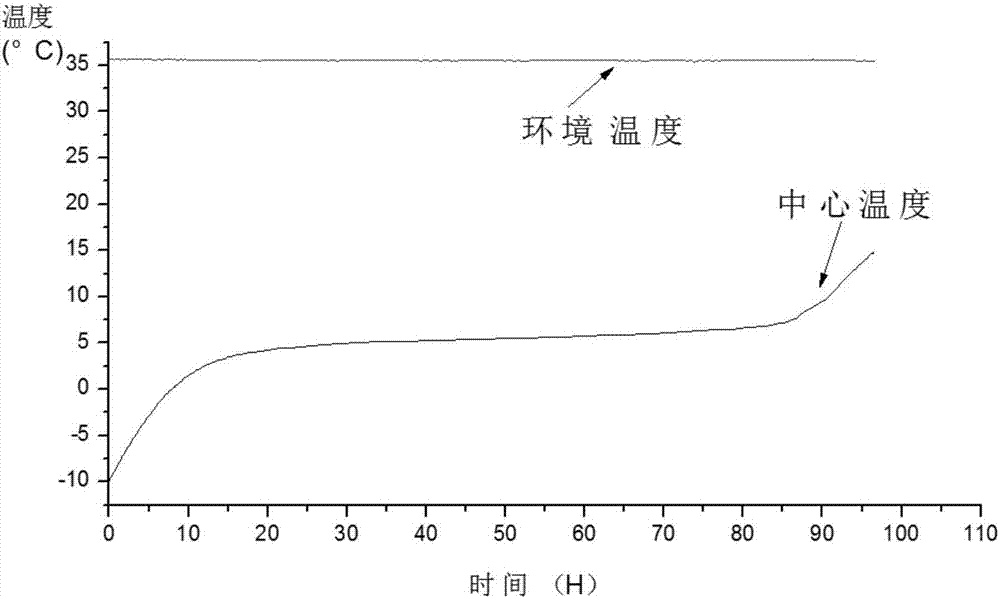

Cold chain thermal insulation box and manufacturing method thereof

PendingCN107323878ASimple processReduce processing costsDomestic cooling apparatusLighting and heating apparatusCold chainThermal insulation

The invention provides a production method for a cold chain thermal insulation box. After a VIP box of which the top end face is an open face is formed by spicing vips, a box inner mold is placed in the VIP box, and then the VIP box and the box inner mold are placed in a box outer mold; a gap space is formed between the outer wall of the VIP box and the inner wall of the box outer mold, and the box inner mold abuts against the inner wall of the VIP box; then a VIP serves as a VIP cover plate, the VIP cover plate is laid on a cover plate inner mold, and a cover plate outer mold is arranged on the VIP cover plate; a gap space is formed between the VIP cover plate and the cover plate outer mold similarly; EPP or EPS particles are injected into the gap spaces; and high-temperature high-pressure steam is led to the gap spaces, and foaming, adhering and forming of the EPP or EPS particles are completed. The production method is simple in process, the VIP box is formed integrally, machining cost is low, and the yield is high. The invention further provides the cold chain thermal insulation box small in overall weight, and protruding, adhesion failure, deformation and other problems are avoided.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

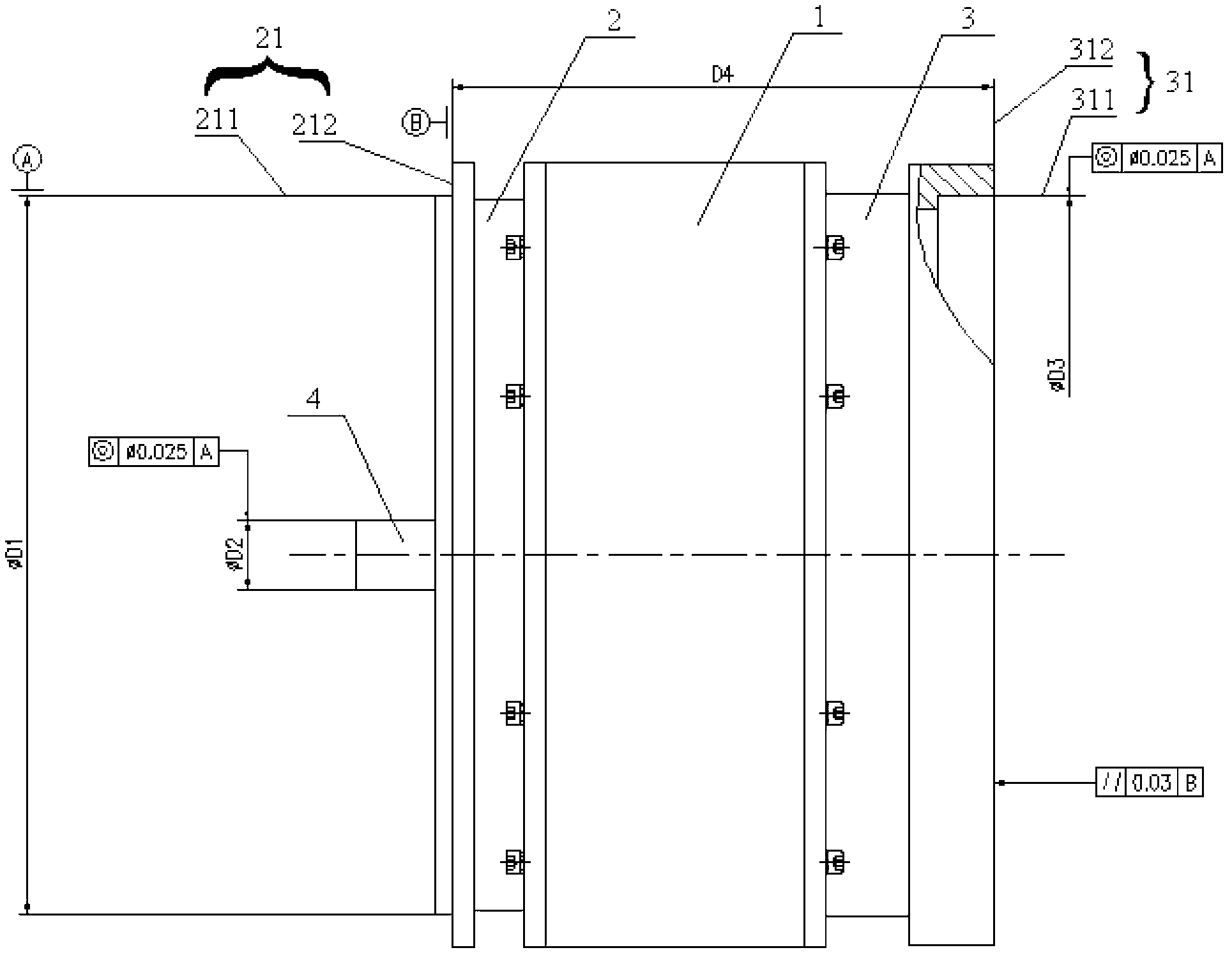

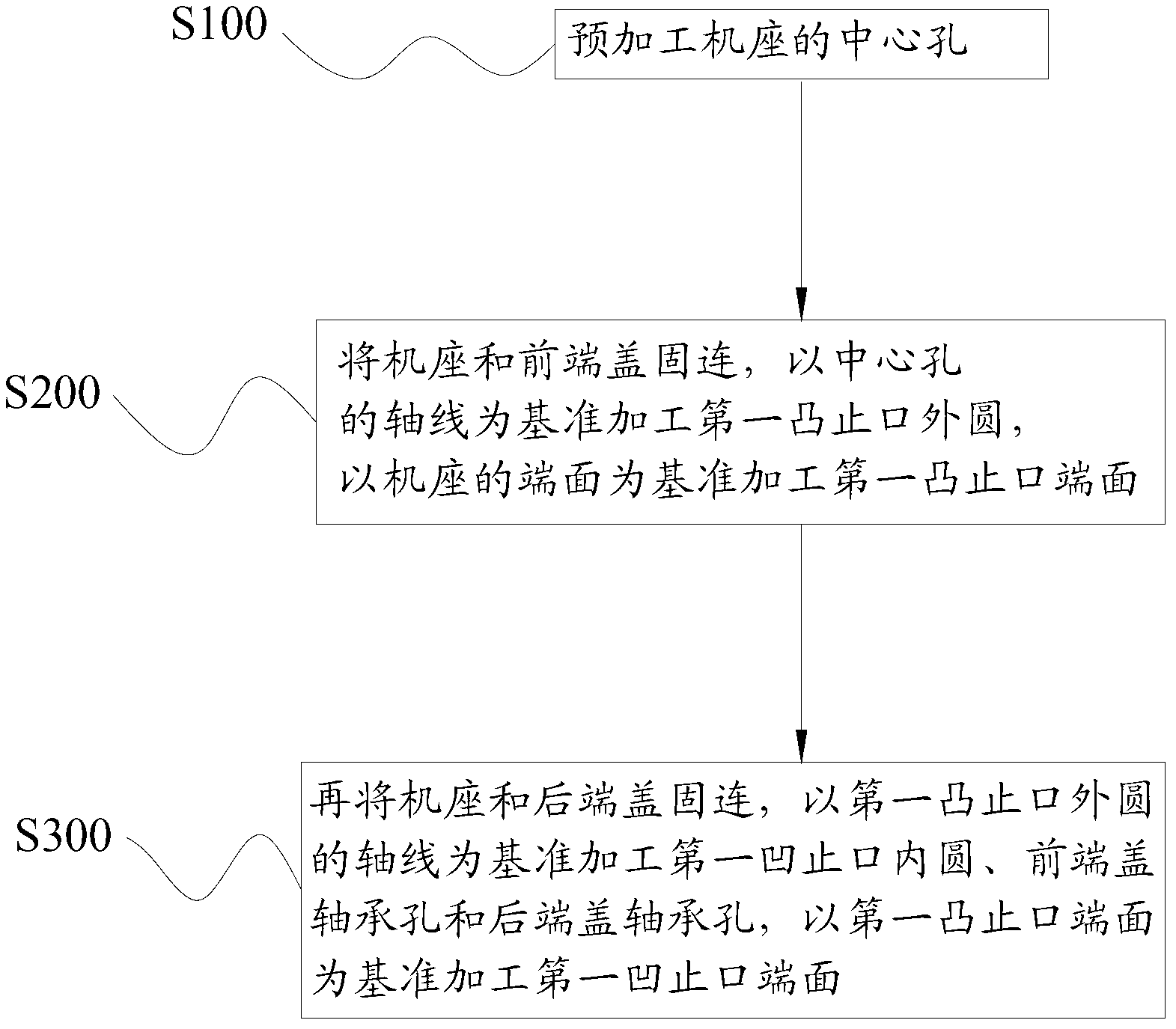

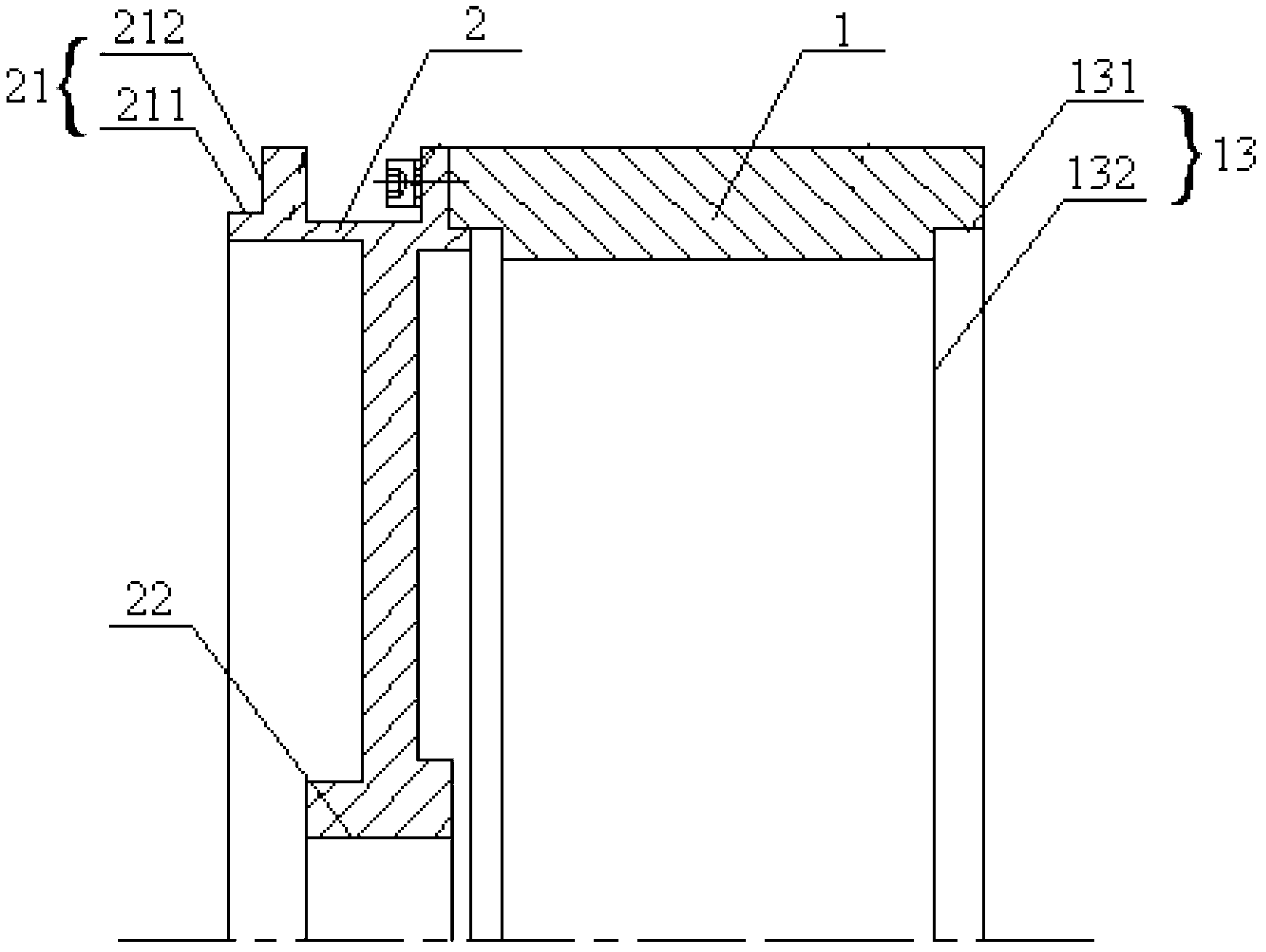

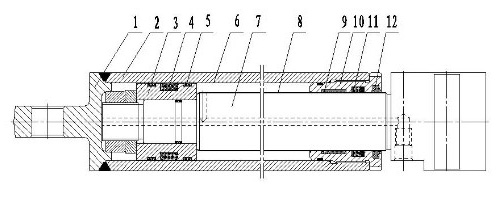

Manufacturing method for motor shell body

ActiveCN103259380AImprove coaxialityImprove flatnessManufacturing dynamo-electric machinesPosition toleranceEngineering

The invention discloses a manufacturing method for a motor shell body. The method includes the flowing steps: S100, pre-machining a central hole of a motor base; S200, fixedly connecting the motor base with either end cover, taking the axis of the central hole as a standard to machine a circle of an externally connected stopping opening of the fixedly connected end cover, and taking the end face of the motor base as a standard to machine an externally connected stopping opening end face of the externally connected stopping opening of the end cover; S300, fixedly connecting the motor base with the other end cover, taking the axis of the machined circle of the externally connected stopping opening as a standard to machine bearing installation holes of two end covers and a circle of an externally connected stopping opening of the other end cover, and taking the machined end face of the externally connected stopping opening as a standard to machine an end face of the externally connected stopping opening of the other end cover. Compared with the prior art, the manufacturing method for the motor shell body enables the motor shell body to have a high-precision form and location tolerance, an assembled motor can still meet requirements of the high-precision size and the shape position tolerance even under the condition that assembling errors exist in an accumulated assembling process, the repairing rate of the motor shell body is reduced, abrasion of a motor in the running process is reduced, and the service life of the motor is prolonged.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Integral seal jack

InactiveCN101941657AImprove securityImprove reliabilityCylindersLifting devicesPiston GuideEngineering

The invention provides an integral seal jack. The jack consists of a cylinder body, a piston rod, a piston component and a cylinder port component, wherein the cylinder body consists of a base and a cylinder tube, and the base and the cylinder tube are welded together; the piston rod is a step bar one end of which is provided with a shoulder, and is sleeved in the cylinder tube; and the piston component is sleeved on the piston rod, is positioned by the shoulder of the piston rod, and is fixed on the piston rod through a nut. The integral seal jack is characterized in that the piston component consists of a piston, two piston guide parts and a piston seal component, and is an integral piston; the two piston guide parts are positioned on the front end and the rear end of the piston respectively; the piston seal component is positioned between the two piston guide parts; the piston seal component and the two piston guide parts are integrally cast on the piston; a stainless steel sleeve is welded on the inner wall of the cylinder tube; and a laser cladding layer is arranged on the outer surface of the piston rod. The integral seal jack has the advantages of simple structure, low cost, safety, reliability, good seal performance and low repair rate, and can remarkably improve the corrosion resistance effect of the jack.

Owner:中煤邯郸煤矿机械有限责任公司

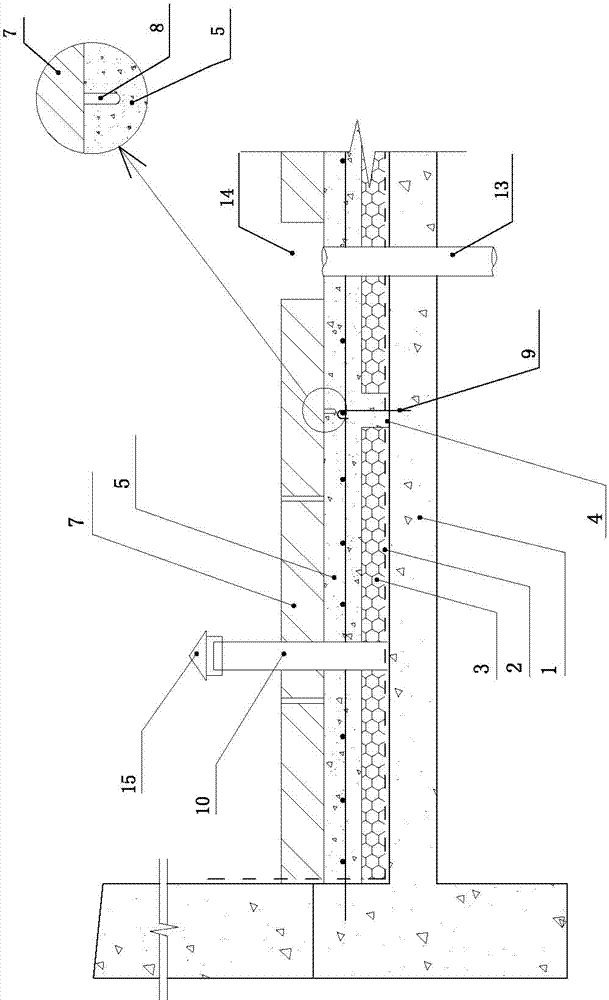

Method for building ecological roof system and ecological roof system structure

ActiveCN103774800AGuaranteed functionGuaranteed durabilityClimate change adaptationBuild-up roofsMoisture absorptionUrban area

The invention relates to the technical field of buildings, in particular to a method for building an ecological roof system and an ecological roof system structure. The method for building the ecological roof system and the ecological roof system structure are used for optimizing the structure of a roof system and the way for reasonable material selection. On the basis of the self-waterproof function of a roof structure, cracking and leakage of a roof beam and slab structure and a concrete structure cover plate on the top of a roof insulating layer are prevented, rainwater is prevented from accumulating in a roof system structure layer and is prevented from leaking, the using function of a roof and durability of the roof of a building are ensured, the construction error-tolerant rate of the roof system is increased, the repair rate of the roof is greatly reduced, repair carried out when leakage of the roof system happens is convenient, and the method for building the ecological roof system and the ecological roof system structure have the advantages that materials are saved, manpower consumption is reduced, and the time is saved. Due to the fact that a moisture absorption and release structure layer is arranged on the surface of the roof, the rainwater is used, the heat island strength of the roof in hot summer is reduced with the help of the evaporation temperature reduction natural phenomenon and the natural reconciliation principle, and cool urban area construction, cool community construction and ecological civilization construction are facilitated.

Owner:DONGGUAN CAILI BUILDING MAINTAIN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com