Copper target material surface processing method

A processing method and technology for copper targets, which are applied to surface polishing machine tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of non-conformity with manufacturing, low yield of copper targets, and scrapped copper targets, etc. Achieve the effect of reducing repair rate and scrap rate, good surface color and roughness, and shortening cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The existing copper target mirror surface treatment method usually adopts mechanical processing method, which easily leads to the repair or scrapping of copper target material. After processing, there are also residual liquids such as oil stains and cutting fluids. The residual liquid oxidizes the copper target material seriously and is difficult to remove, and it is difficult to achieve the same surface roughness and color as the mirror surface of the copper target material made by mechanical processing. Lead to repair or scrap of copper target.

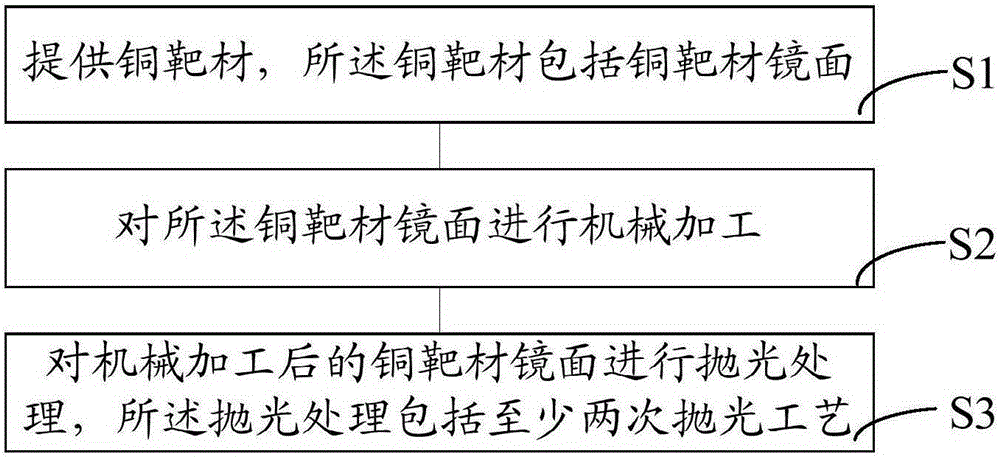

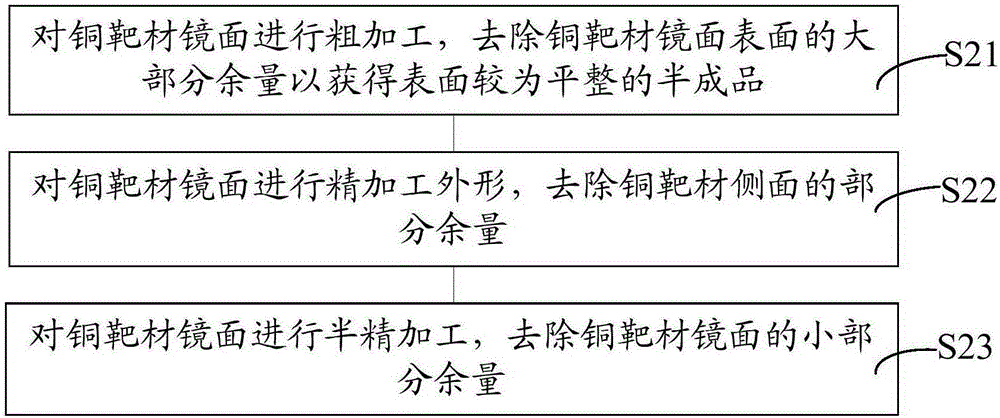

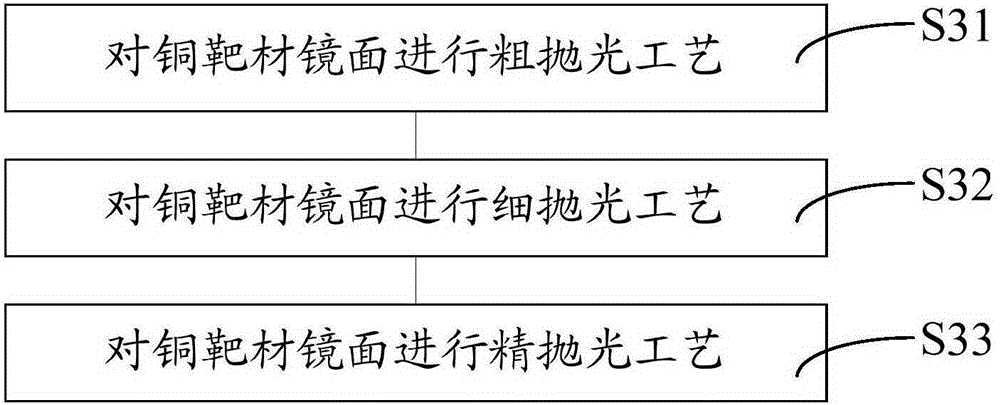

[0029] In order to solve the above problems, the present invention provides a method for treating the surface of a copper target, including: machining the mirror surface of the copper target; and then polishing the machined mirror surface of the copper target, the polishing process includes at least two secondary polishing process.

[0030] The present invention performs at least two polishing processes on the mirror surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com