Manufacturing method for motor shell body

A processing method and motor housing technology, applied in the field of mechanical processing, can solve problems such as unsatisfactory motors, motor wear, affecting motor quality and life, and achieve the effects of reducing wear, prolonging service life, and reducing repair rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

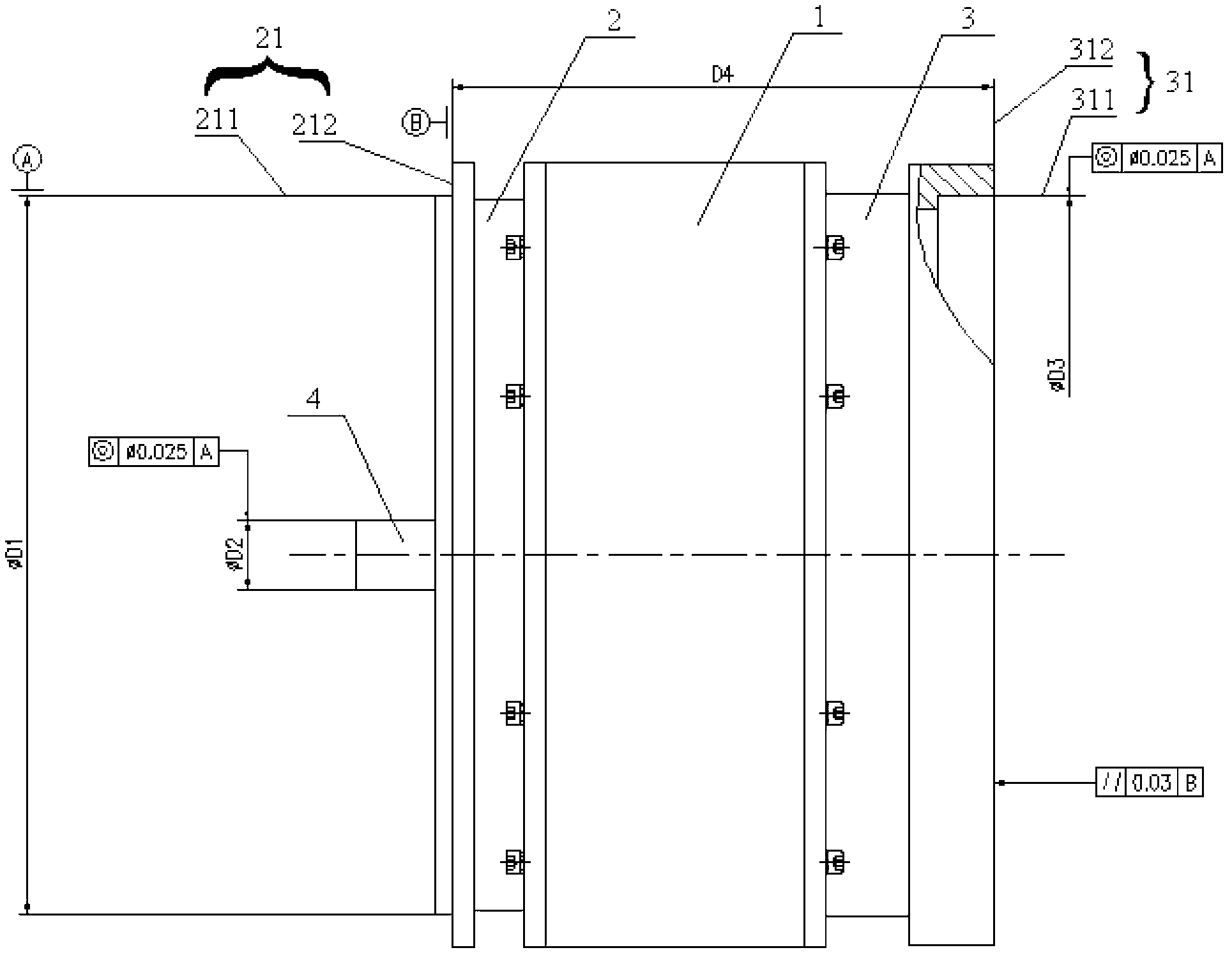

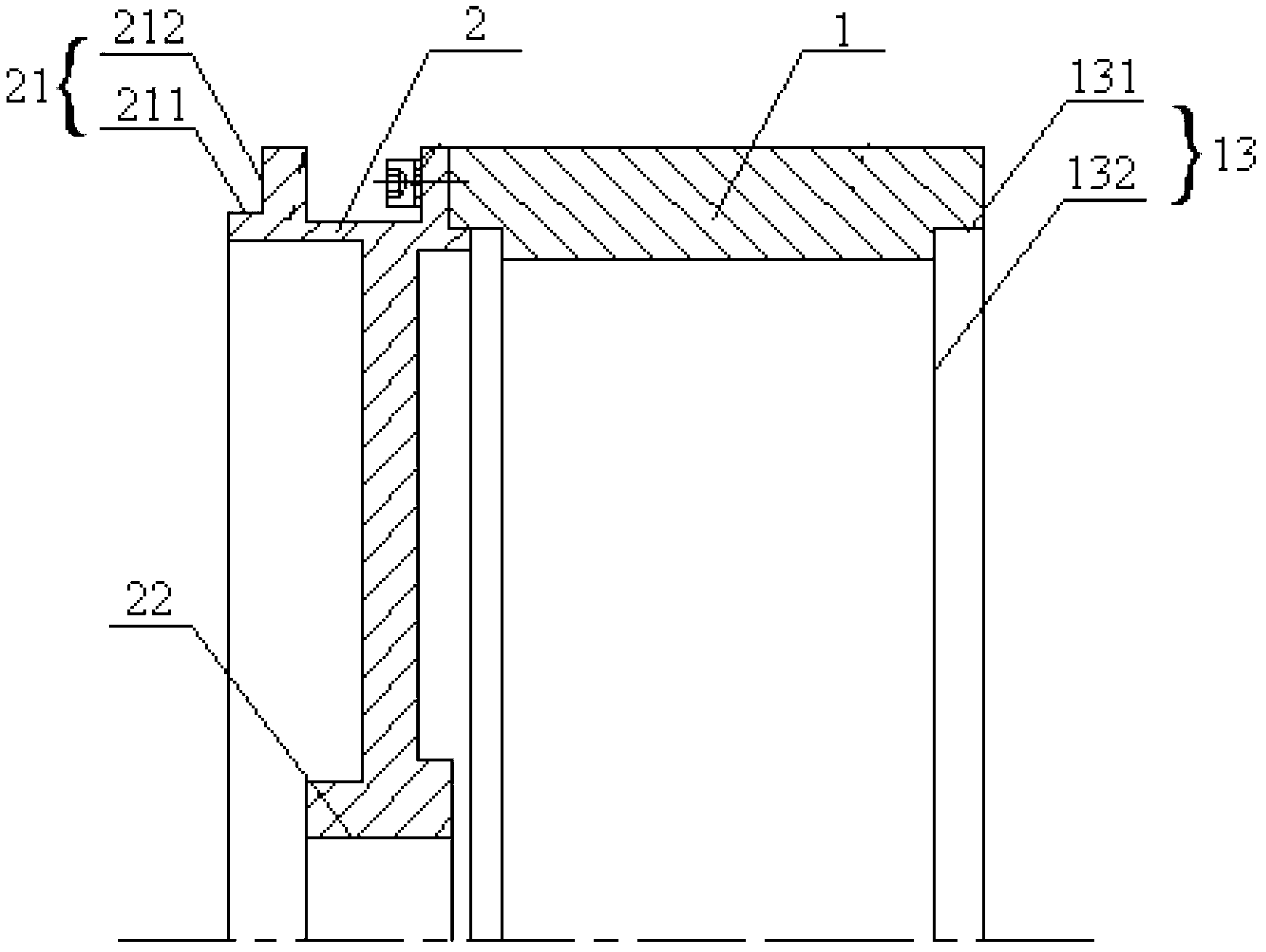

Method used

Image

Examples

no. 2 Embodiment approach

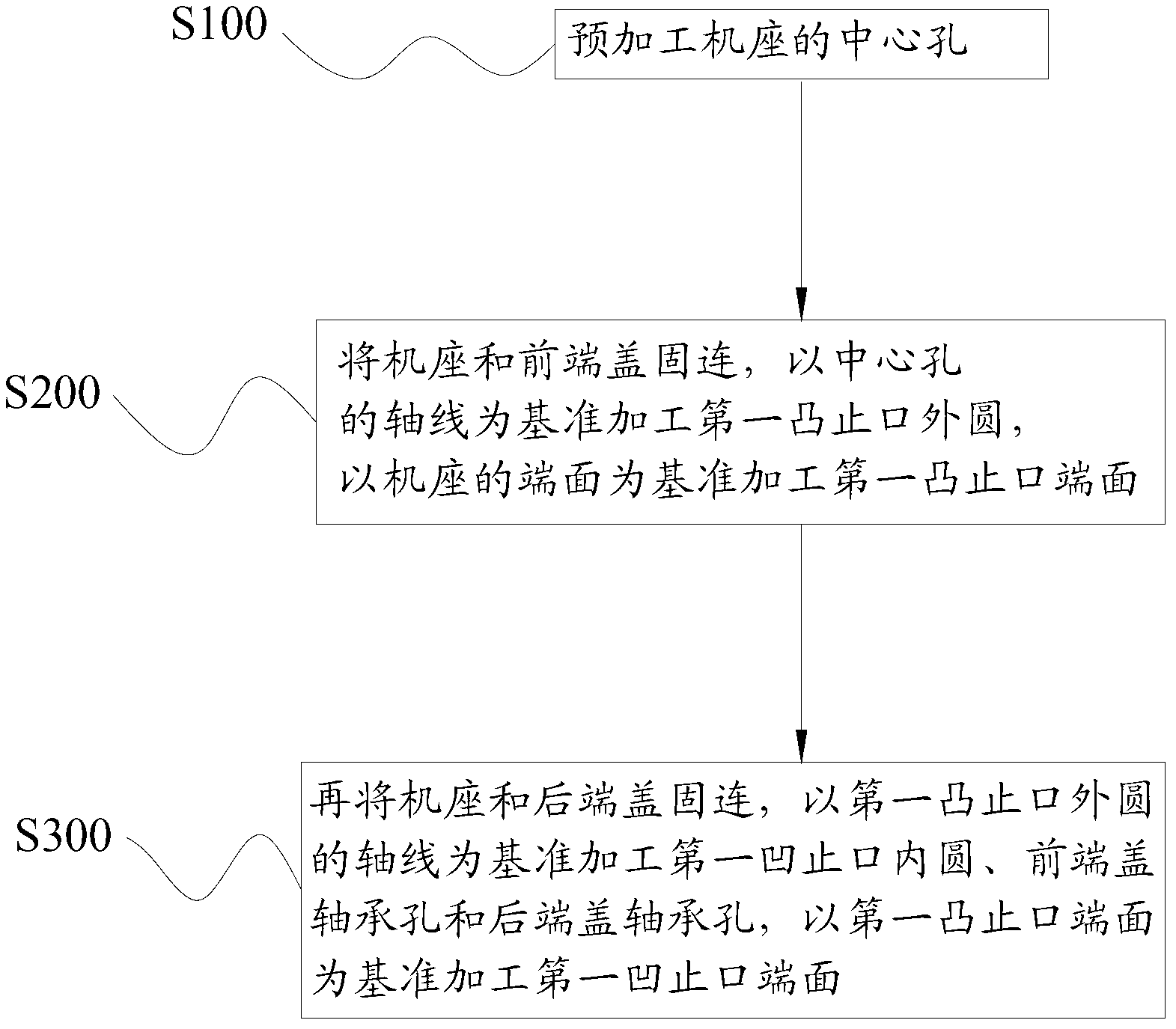

[0039] It should be noted that the processing method provided by the present invention can also be completed through the second specific embodiment, and its beneficial effect is the same as that of the first specific embodiment, so it will not be repeated here. The second embodiment includes the following steps:

[0040] S100′) Preprocessing the center hole 11 of the machine base 1;

[0041] S200') Fix the base 1 and the rear end cover 3, process the inner circle 311 of the first notch with the axis of the central hole 11 as the reference, and process the end face 312 of the first notch with the end face of the support 1 as the reference;

[0042] S300') then connect the base 1 and the front end cover 2, and process the outer circle 211 of the first convex stop, the bearing installation hole 22 of the front end cover and the bearing installation hole 32 of the rear end cover with the axis of the inner circle 311 of the first concave stop as the reference. , process the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com