Patents

Literature

155 results about "Hydraulic action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic action is the erosion that occurs when the motion of water against a rock surface produces mechanical weathering. Most generally, it is the ability of moving water (flowing or waves) to dislodge and transport rock particles. Within this rubric are a number of specific erosional processes, including abrasion, attrition, corrasion, saltation, and scouring (downcutting). Hydraulic action is distinguished from other types of water facilitated erosion, such as static erosion where water leaches salts and floats off organic material from unconsolidated sediments, and from chemical erosion more often called chemical weathering. It is a mechanical process, in which the moving water current flows against the banks and bed of a river, thereby removing rock particles.

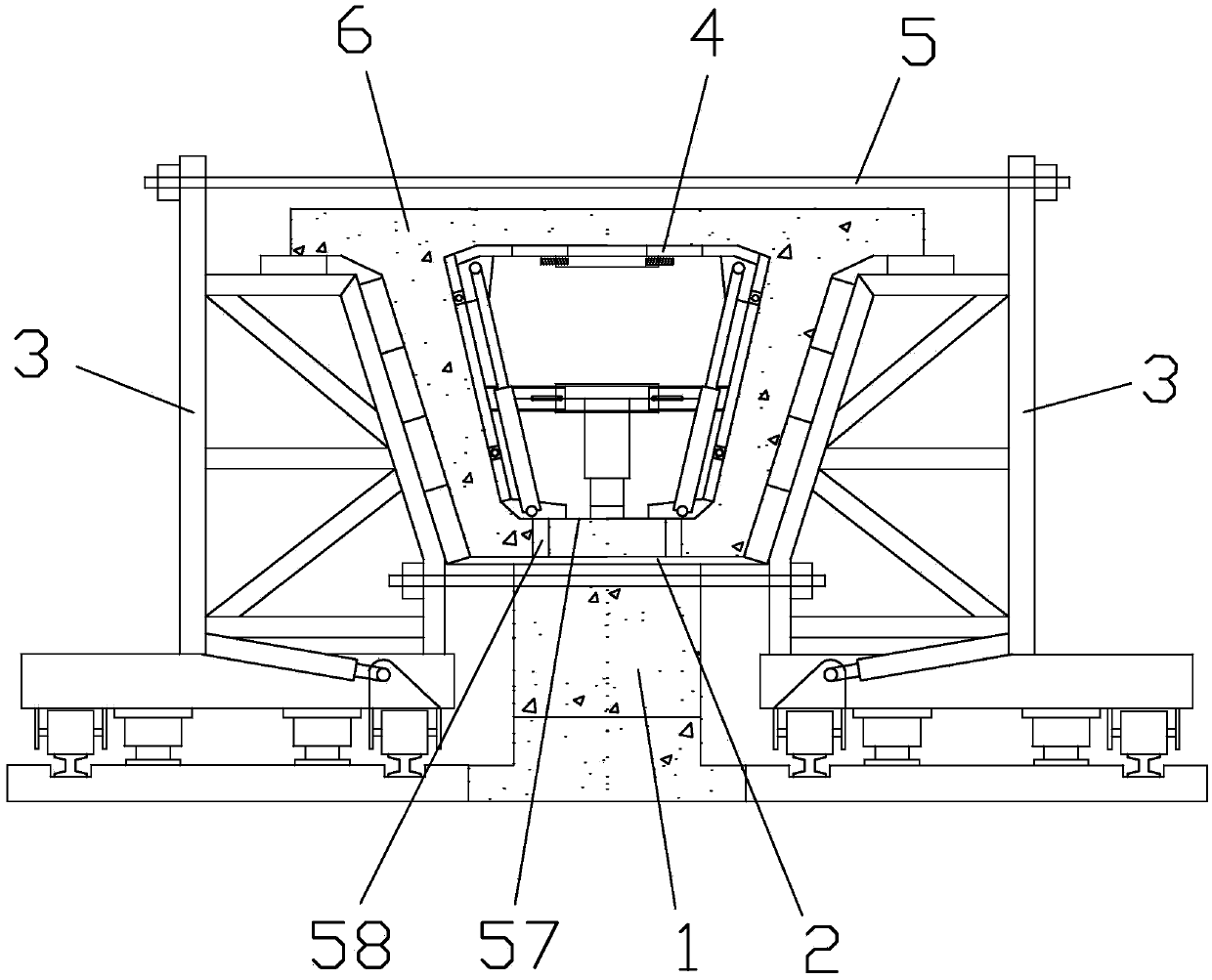

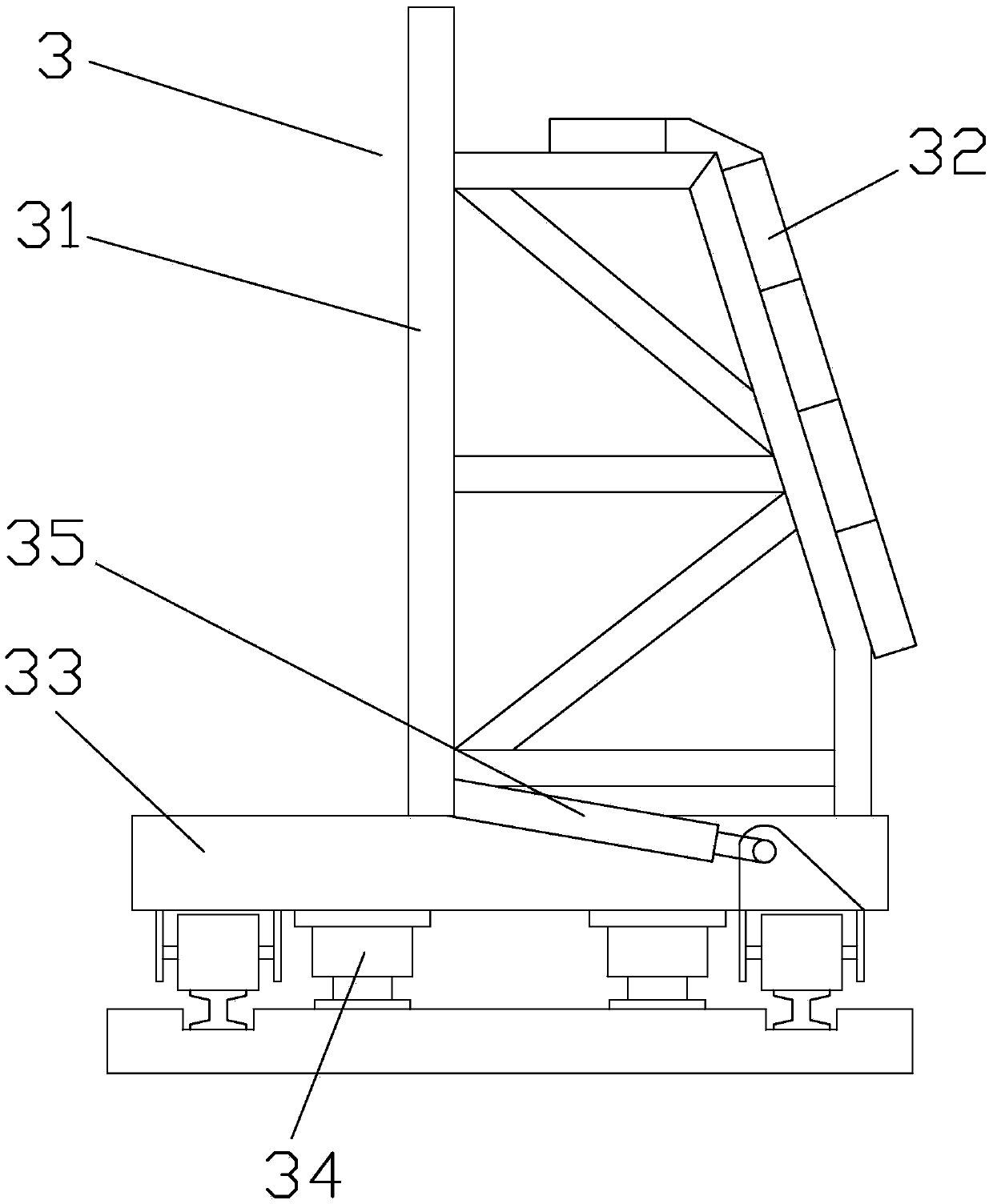

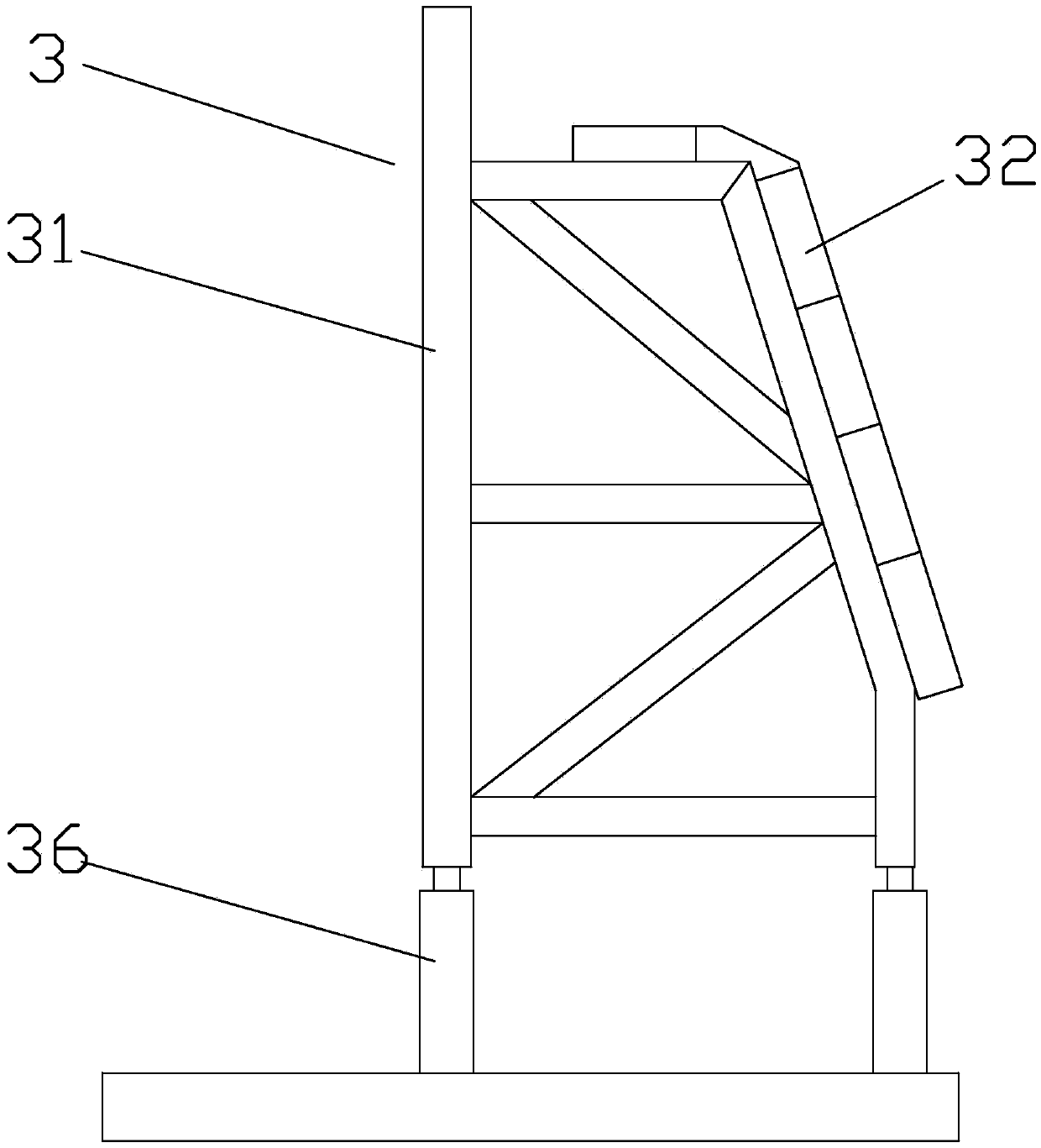

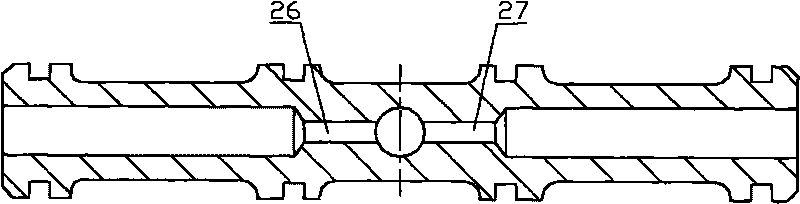

Manufacturing method of small prefabricated box girder

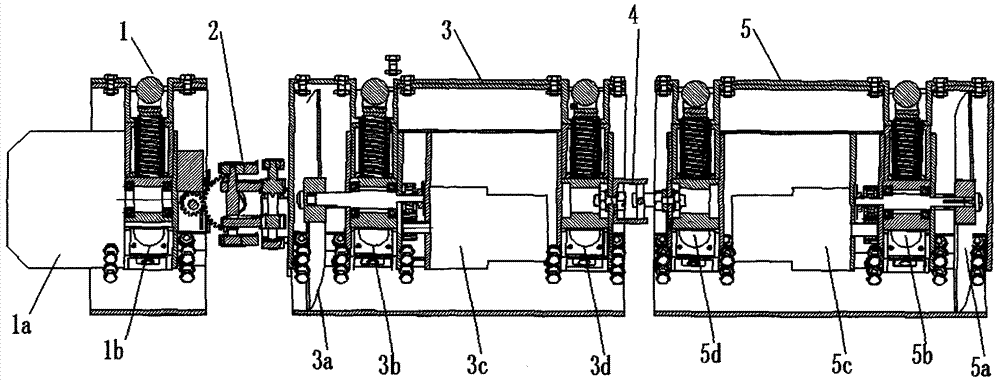

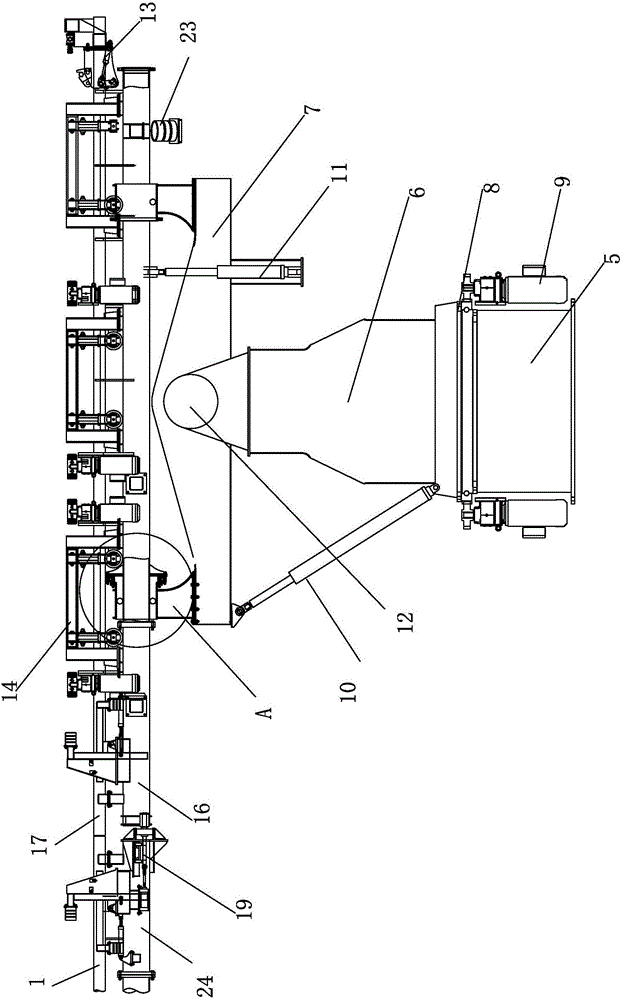

ActiveCN105365042AQuick releaseFast mold closingDischarging arrangementMouldsHydraulic actionEngineering

The invention discloses a manufacturing method of a small prefabricated box girder. The manufacturing method includes the following steps that firstly, a pedestal is prefabricated; secondly, mold plates are installed, wherein the mold plates are installed in the following sequence of bottom mold installation, side mold installation, inner mold installation, end mold installation and flange plate installation on side molds; thirdly, concrete is poured and cured; fourthly, demolding is conducted, wherein demolding includes detaching of end molds at the two ends of a girder body, inner mold demolding and side mold demolding; and fifthly, the girder body is cured. According to the manufacturing method, fully-hydraulic actions are achieved through the outer mold plates, the use effect is improved greatly, and labor intensity is lowered; and semi-automation is achieved through an inner mold, quick demolding and mold combination of the mold plates are facilitated, the operation intensity of workers in small space in the girder body is lowered, and the potential safety hazards of working under the high temperature are reduced. The mold plates are firm and general in structure, quick and convenient to use and advanced in design manufacturing and construction process idea.

Owner:FOSHAN HIGHWAY&BRIDGE CONSTR PREFAB CO LTD

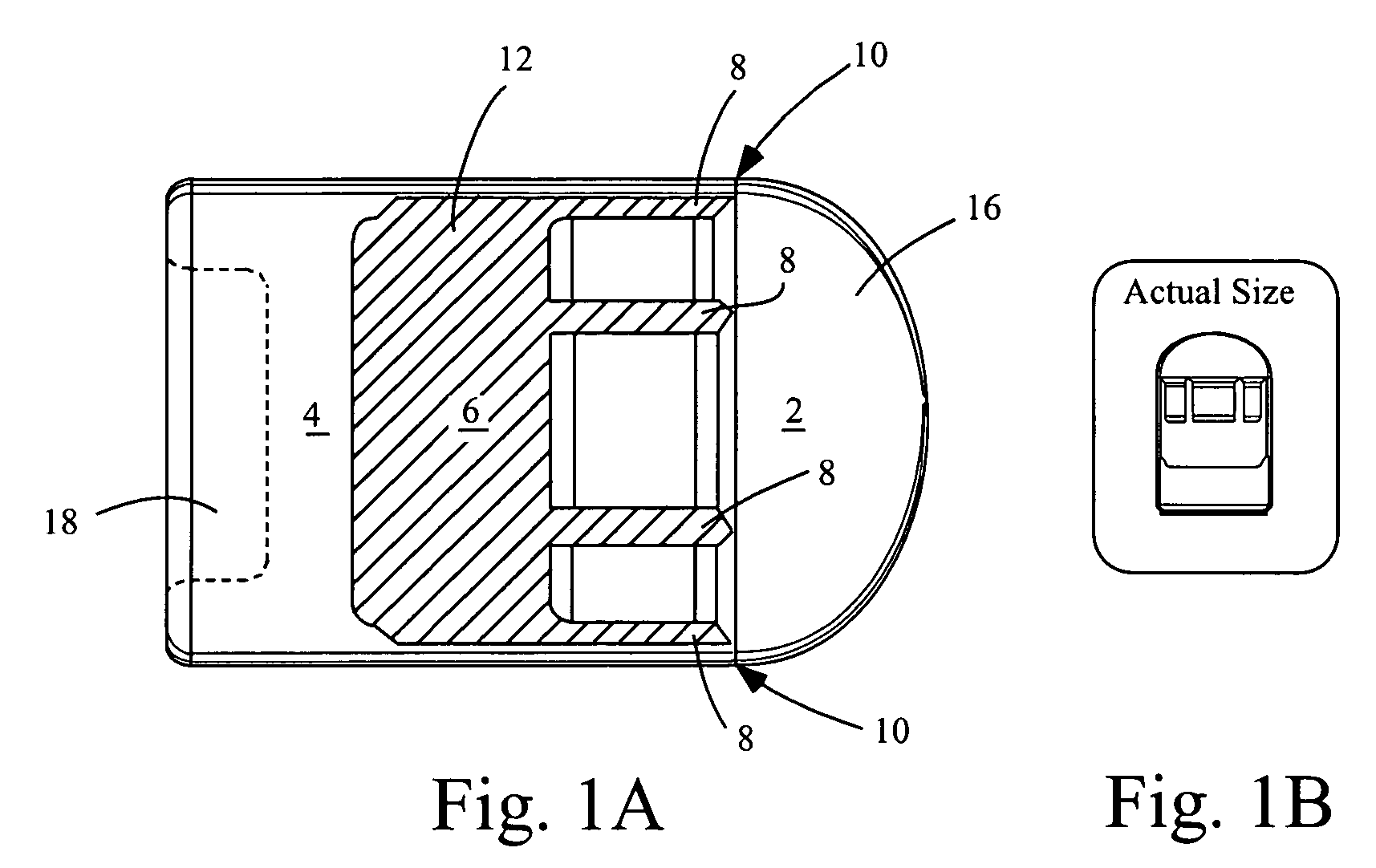

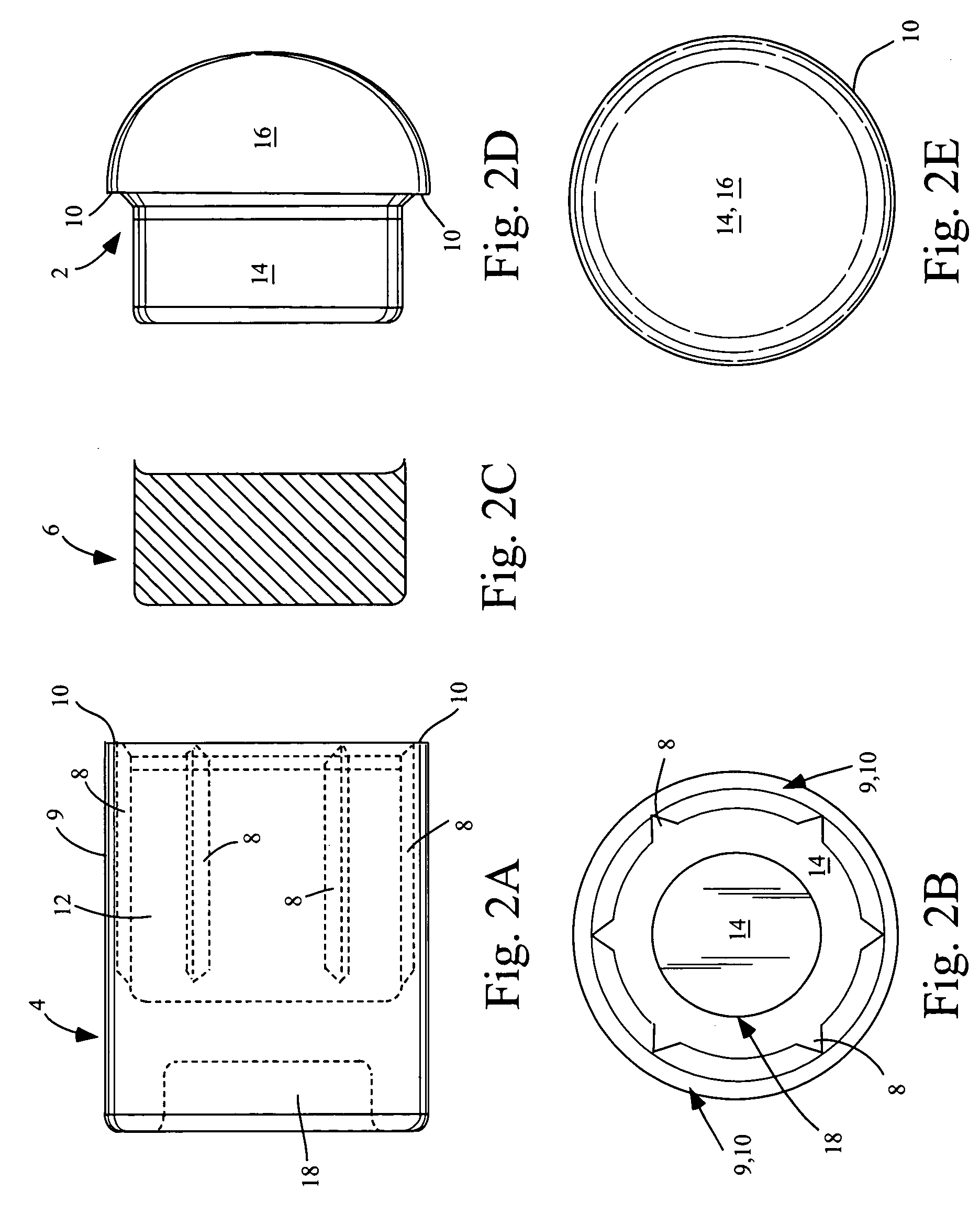

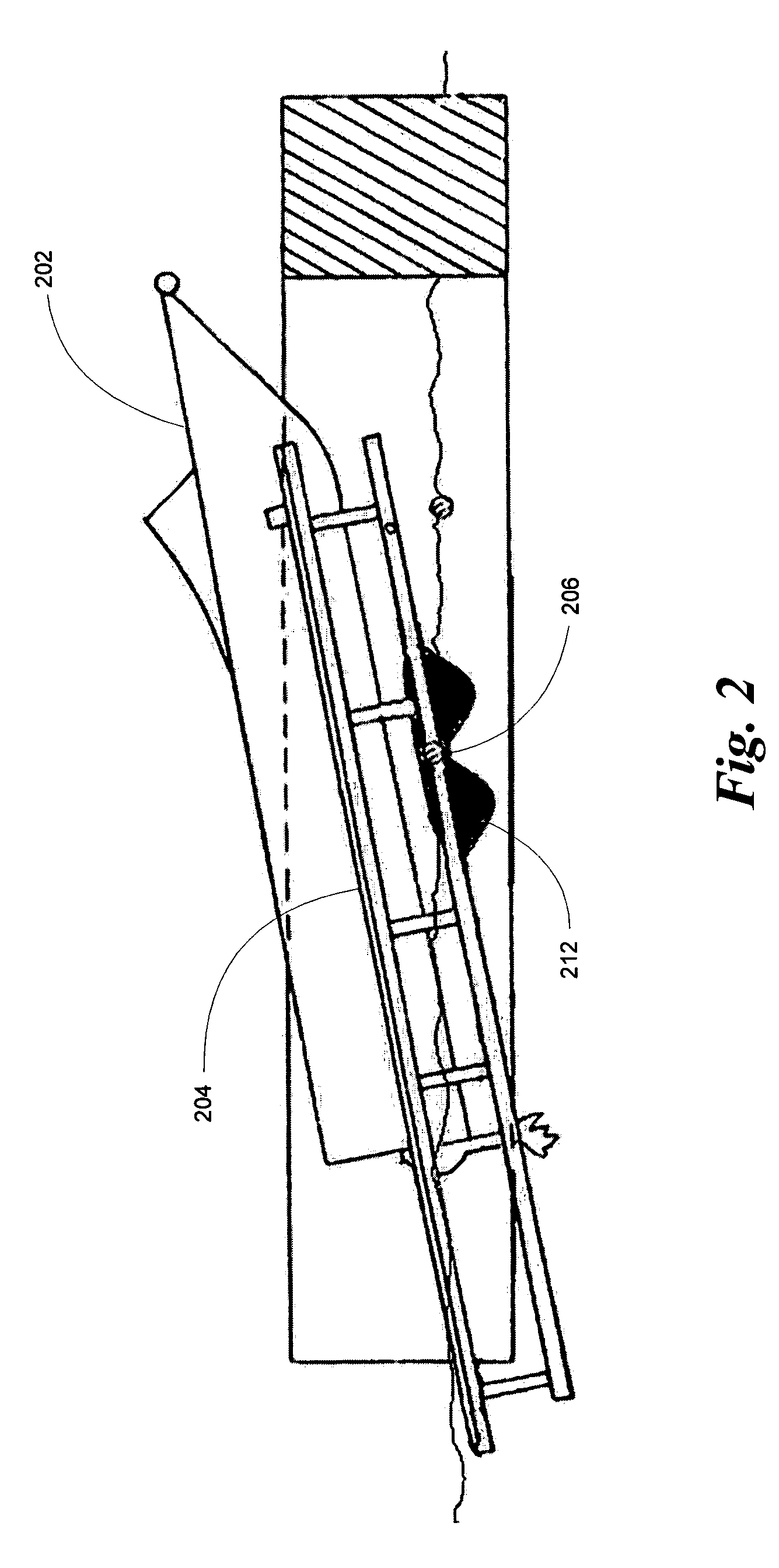

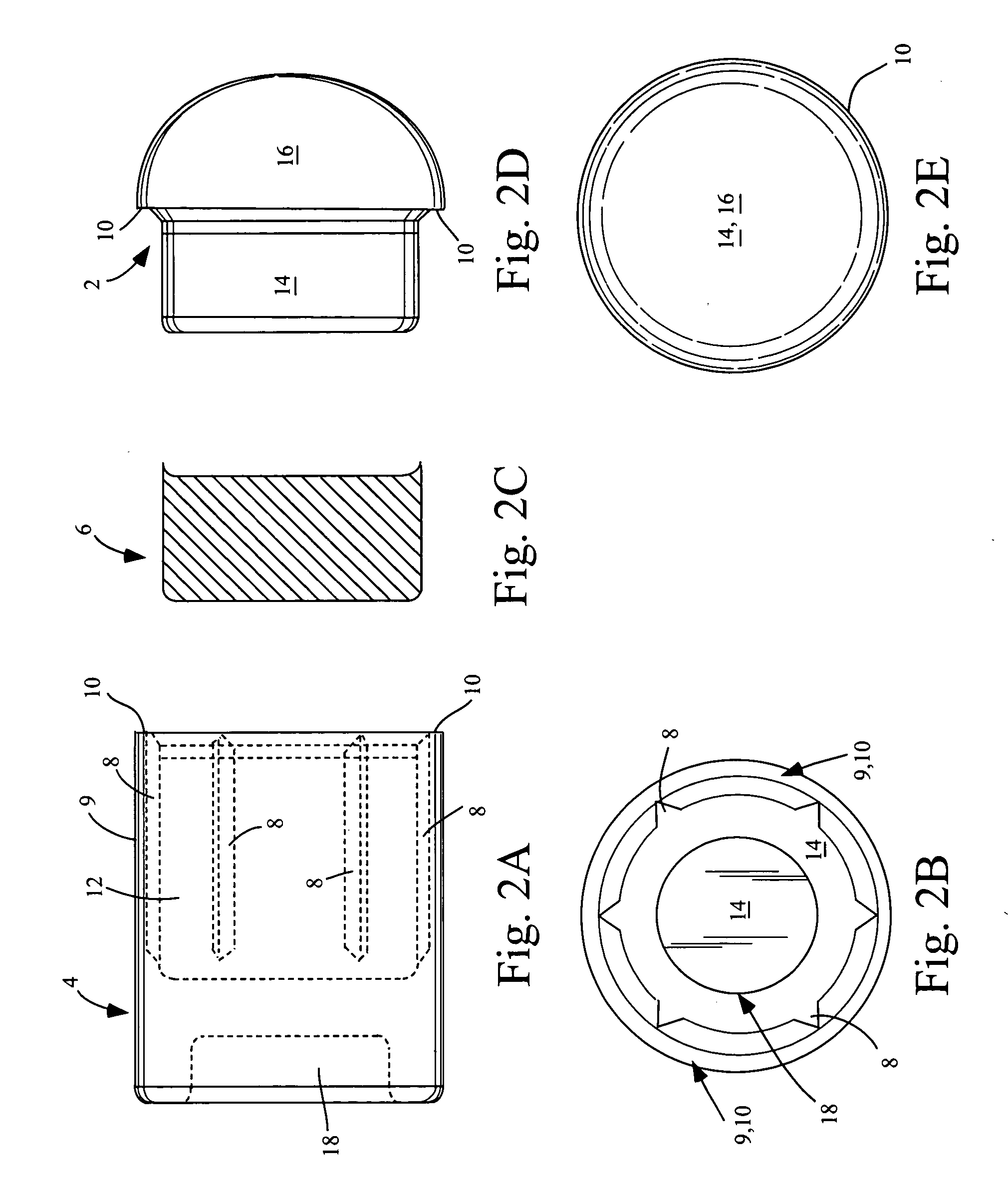

Non-lethal marking bullet for related training cartridges

Owner:GEN DYNAMICS ORDNANCE & TACTICAL SYST

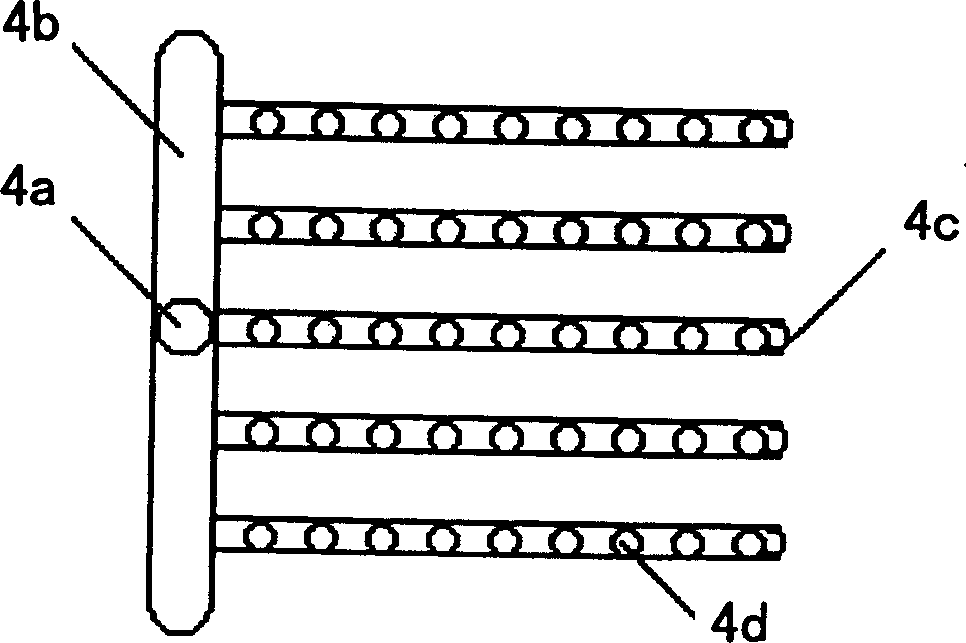

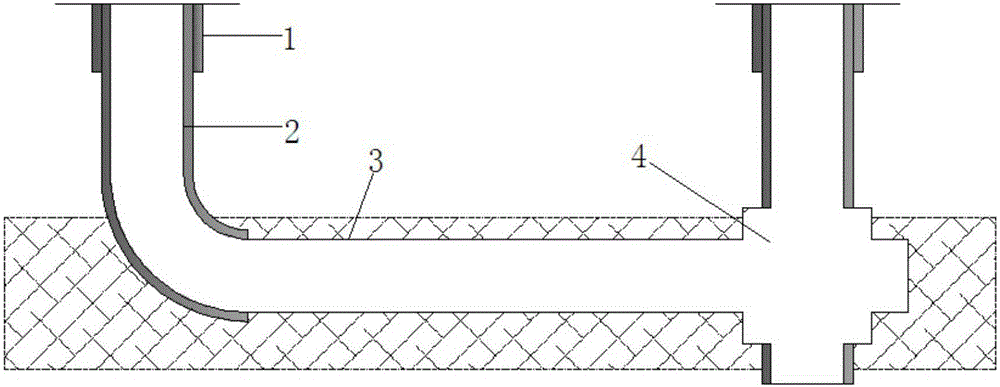

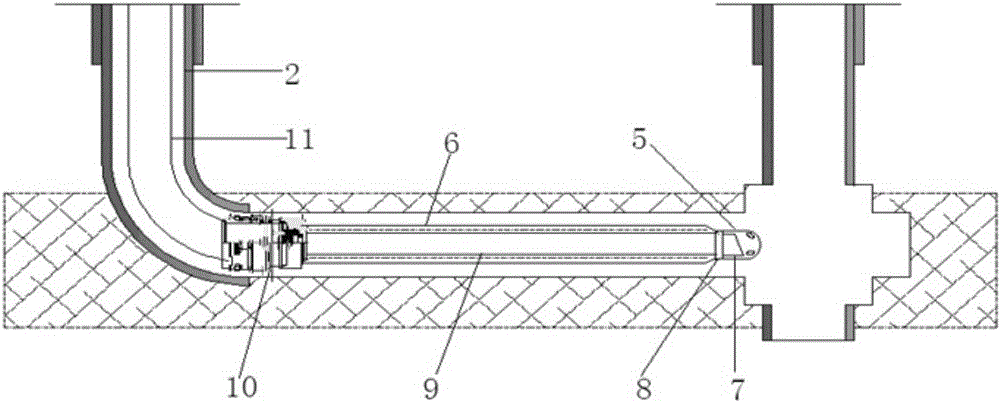

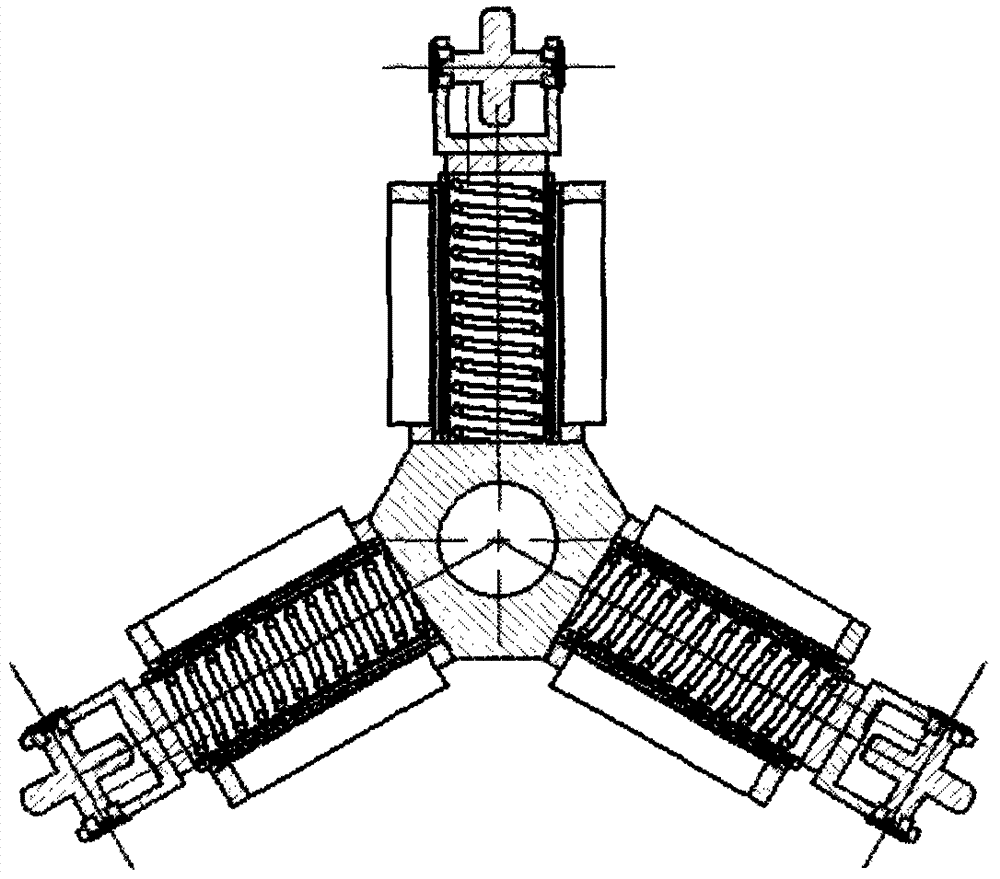

Tee joint forming die and tee joint forming method

InactiveCN102198467AImprove appearance qualityImprove consistencyBroaching machinesEngineeringHydraulic action

The invention provides a tee joint forming die. The tee joint forming die comprises an upper die and a lower die which are combined together, wherein semi-circular groove-shaped cavities for accommodating a tee joint workpiece are symmetrically arranged on the upper die and the lower die; openings of the cavity are formed on lateral sides of the upper die and the lower die; the cavity is communicated with a tee joint branch pipe cavity; a support rod capable of reciprocating displacement is arranged in the tee joint branch pipe cavity; the support rod is connected with a support cylinder and transfers pressure by the support cylinder; and a tee joint branch pipe is filled with medium in the tee joint workpiece, and is formed in the tee joint branch pipe cavity in the hydraulic action of a hydraulic cylinder. By the tee joint forming die, a tee joint finished product has higher appearance quality and excellent uniformity; the U-shaped bend of the tee joint has smooth transition, the outer diameter of each position of the tee joint can achieve the requirement of equal diameter; and the current problem that the bend is flat after lead is filled can be solved.

Owner:李镇南

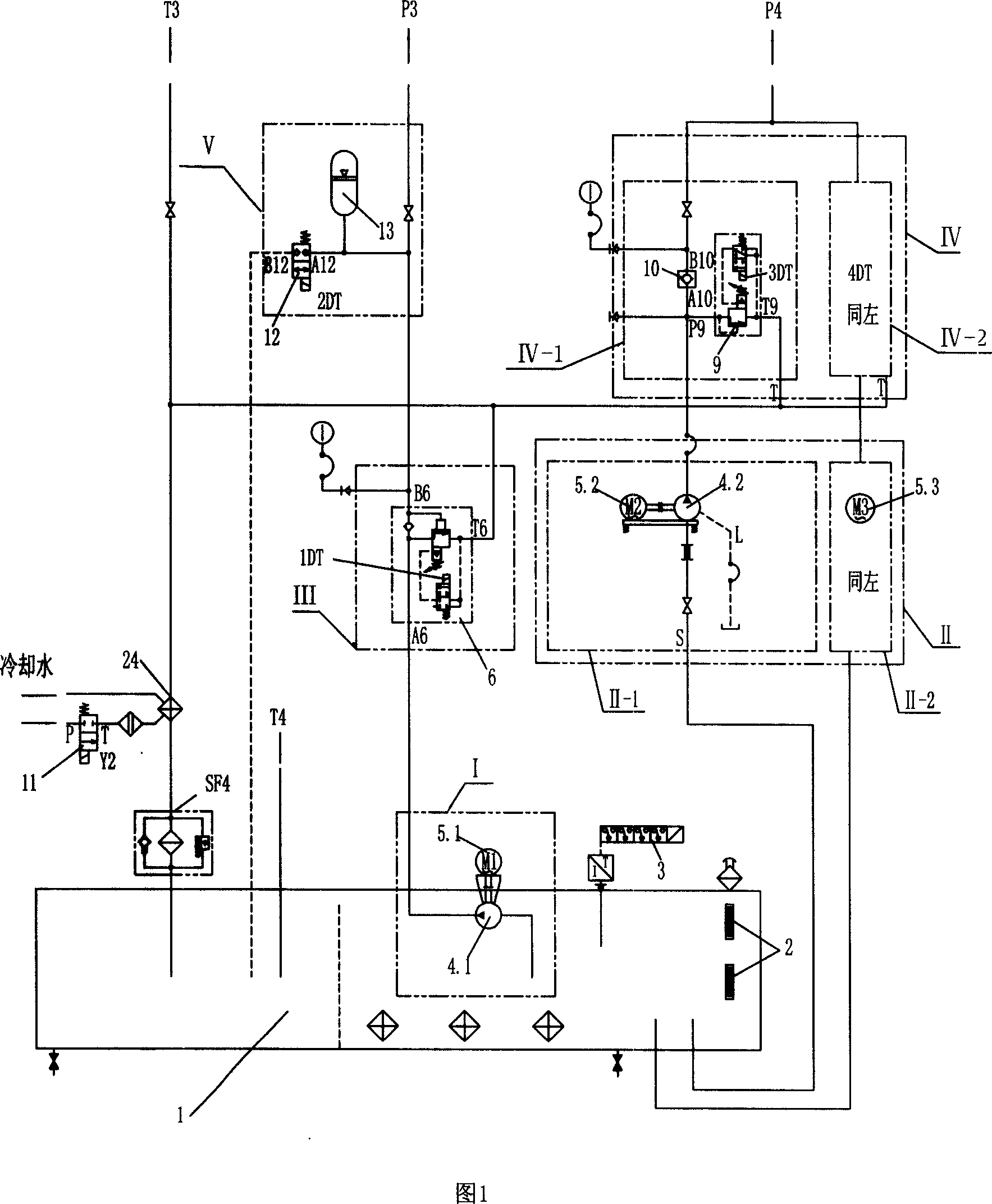

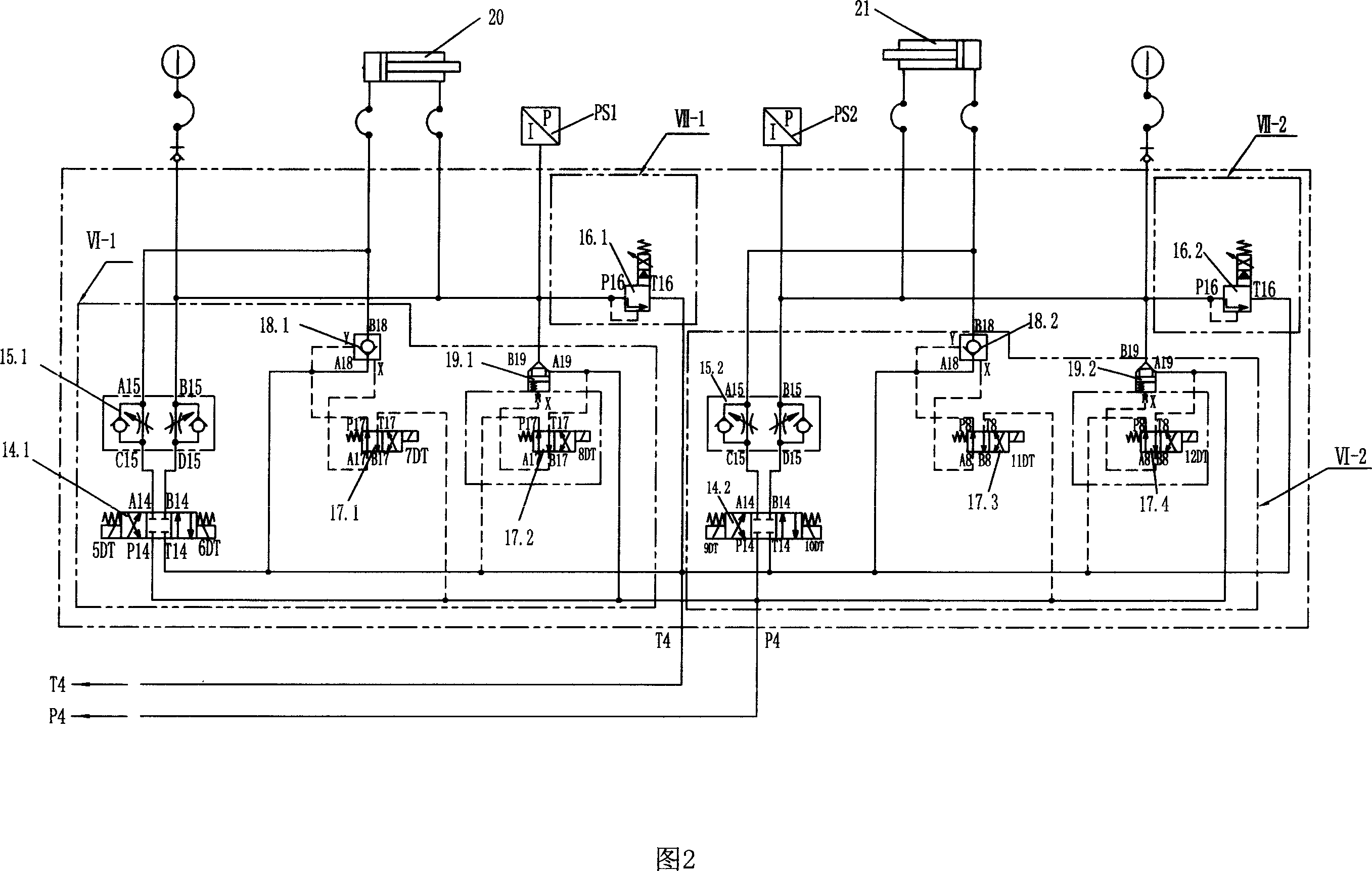

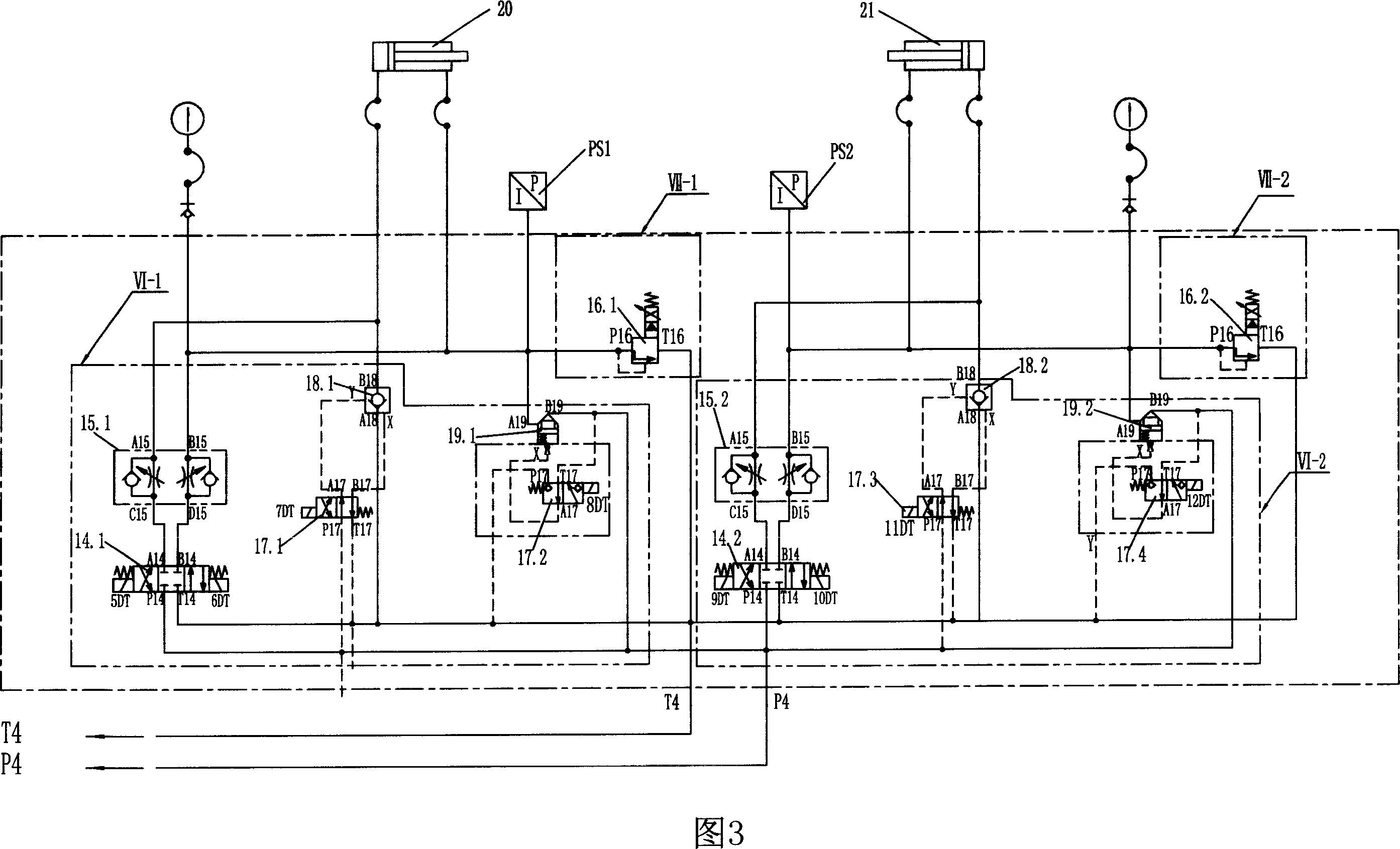

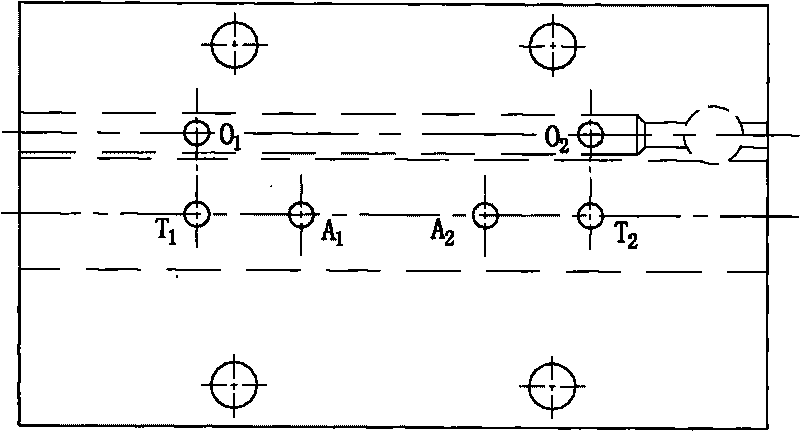

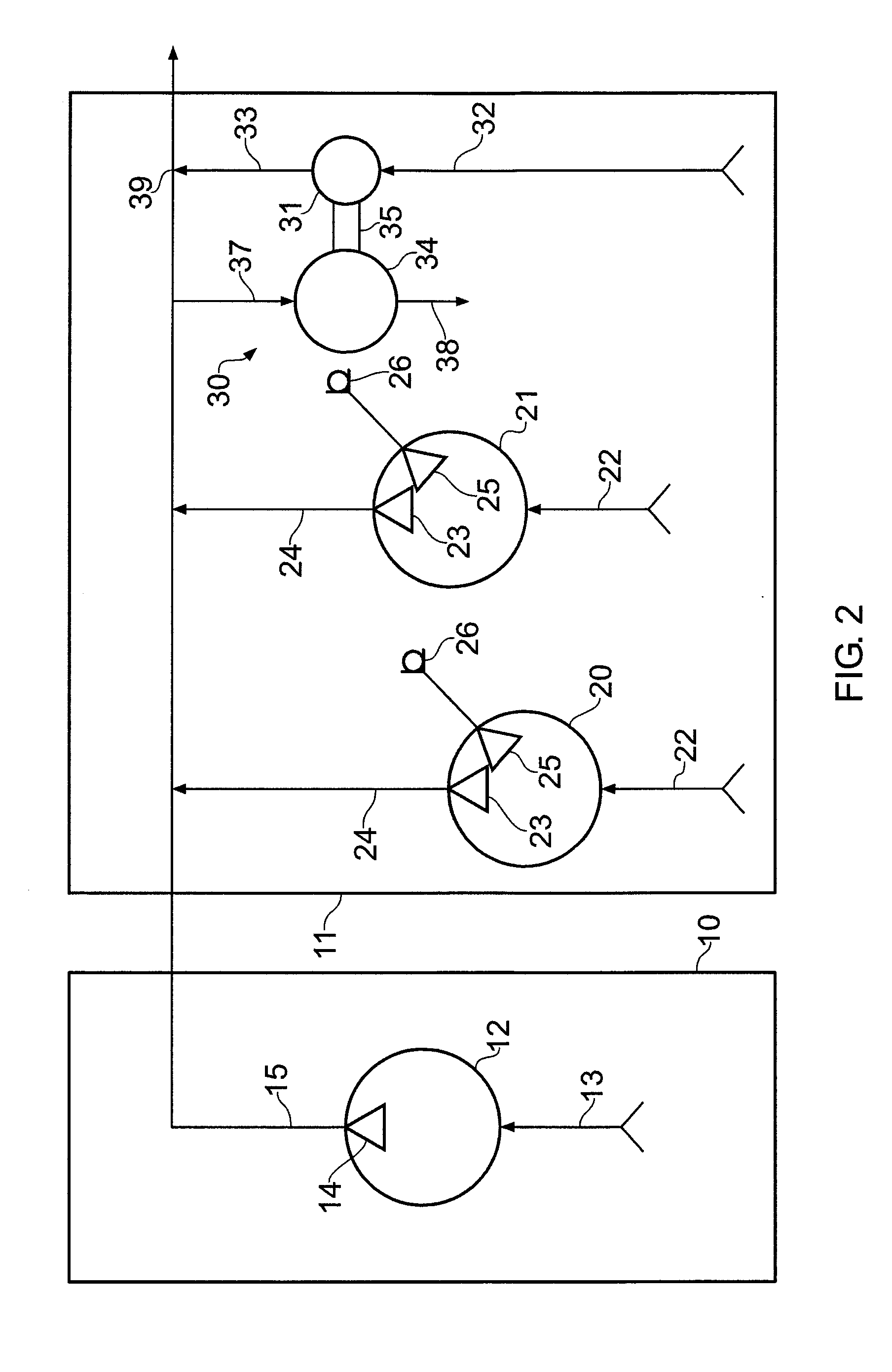

Ratio control hydraulic pressure system for implementing belt steel rolling constant-tension control

InactiveCN101011709AAchieve energy saving effectGuaranteed cleanlinessFluid-pressure actuatorsTension/compression control deviceHydraulic cylinderProportional control

The proportional control hydraulic system with steel rolling constant tension control comprises tension hydraulic cylinder, pressure sensor, tension hydraulic cylinder control, hydraulic fixture, with the tension hydraulic cylinder control composed of high pressure oil source, high pressure safety pressure control, tension hydraulic action control and proportional control, with the high pressure oil source connecting with two tension hydraulic cylinder control device and proportional control, tension hydraulic action control device, proportional control device connecting with hydraulic cylinder bar free cavity and with bar cavity, the clamping control composed of low pressure oil source, low pressure control device, energy accumulation device, clamping cylinder action control, with the low pressure oil source connecting with two clamping hydraulic cylinder through low pressure control device, energy accumulation device and clamping cylinder action control device, tension hydraulic cylinder with bar cavity connected with pressure sensor, and each oil return opening and discharge opening connecting with the oil tank.

Owner:NORTHEASTERN UNIV

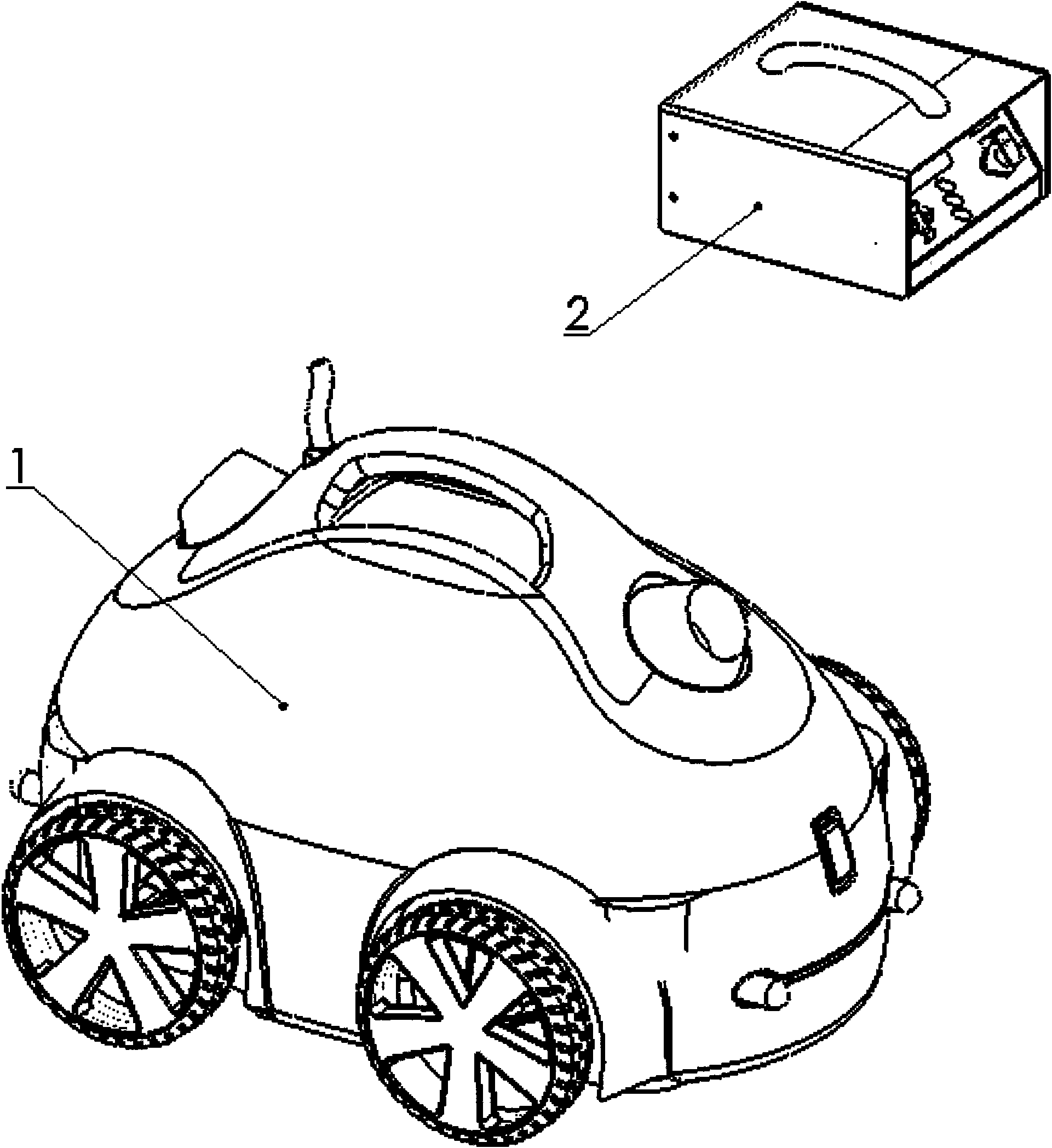

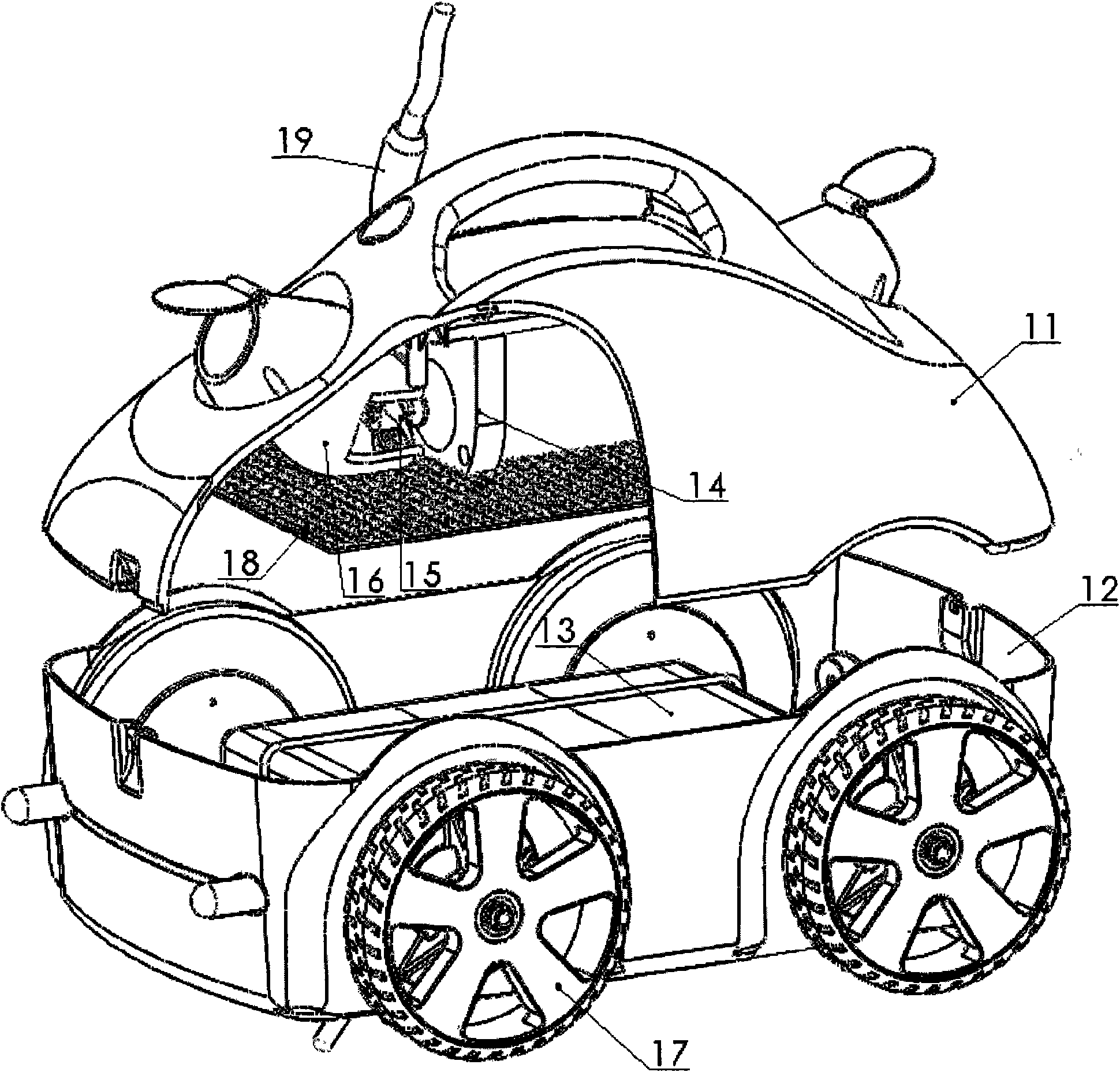

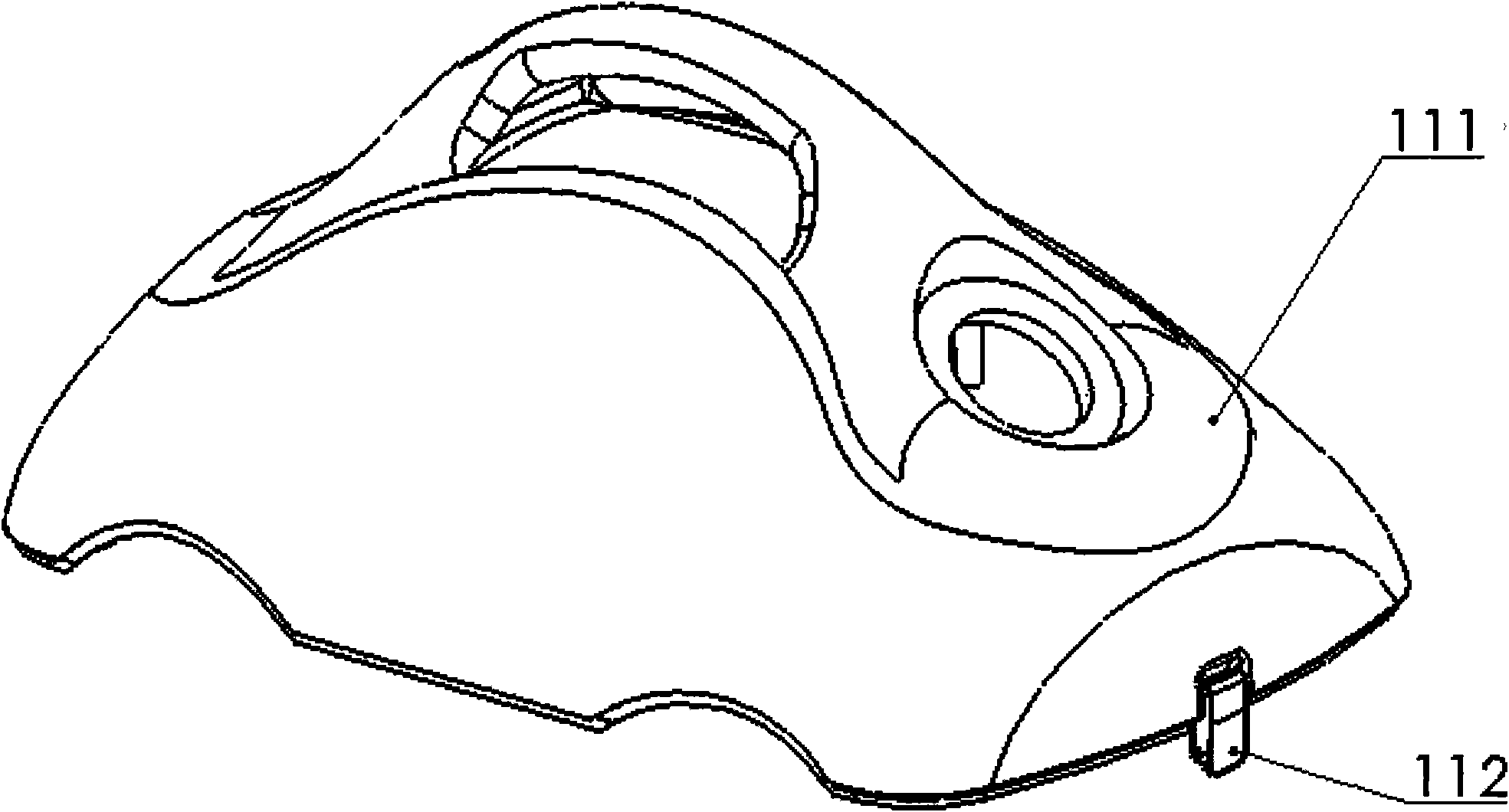

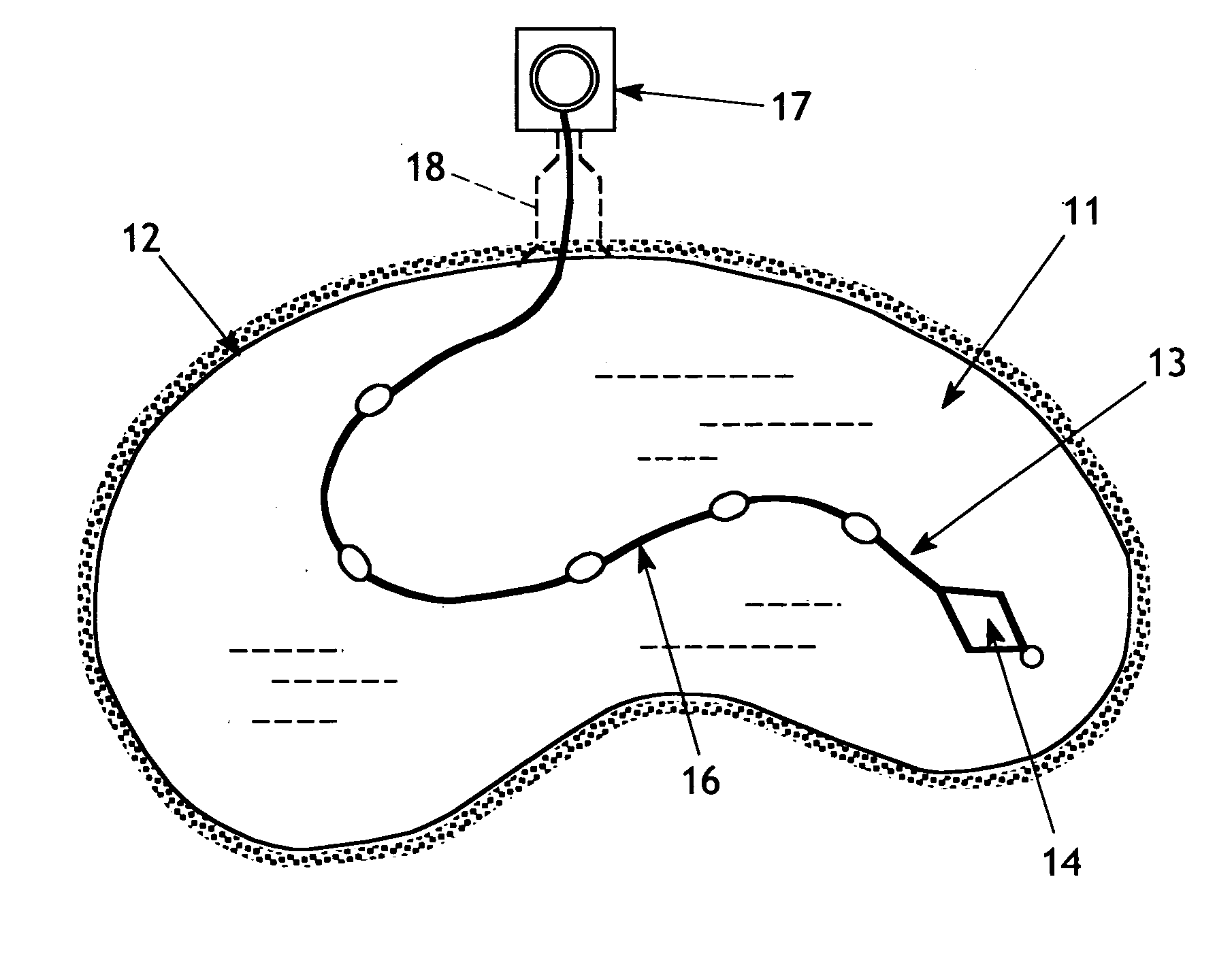

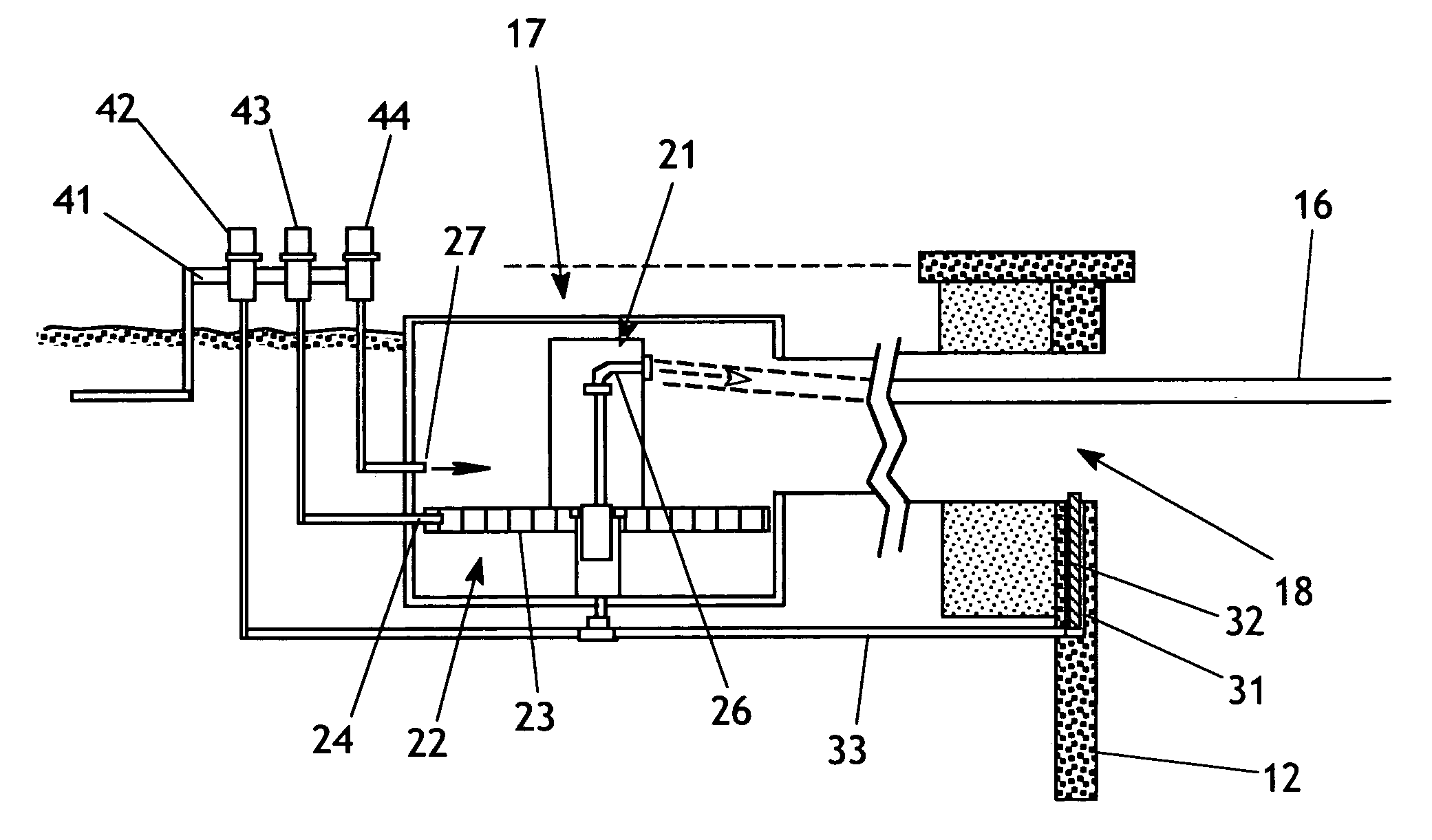

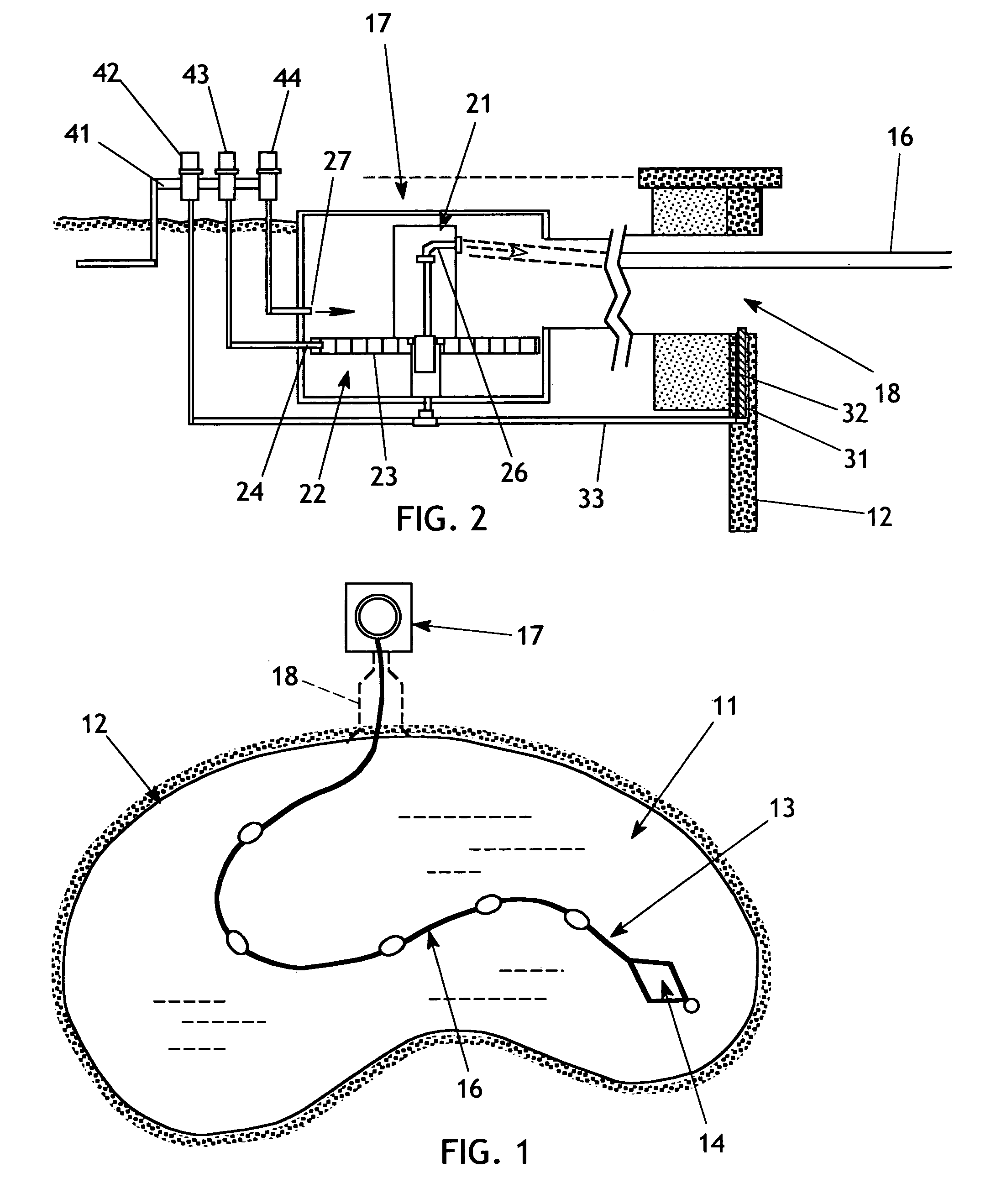

Swimming pool bottom hydro power pushed automatic cleaner

ActiveCN101666168ARealize work status changeChange water jetGymnasiumSwimming poolsAxial-flow pumpHydraulic action

The invention relates to a swimming pool bottom hydro power pushed automatic cleaner, comprising an underwater cleaner and a control power supply which are connected by a buoyancy cable; wherein the underwater cleaner comprises a shell cover part, a shell body part, a filter, a double extension motor assembly, a hydro power driven jaw clutch pulley assembly, a water flow channel, a wheel and support, an isolated hood and a cable with a buoy. Along with the rotating direction of the motor, the hydro power driven jaw clutch pulley assembly is reliably meshed or separated under the action of hydro power; the pulley changes working condition, so as to realize jet water to be flowed out and further change travel direction of the cleaner; the shell touches wall to cause the cleaner to automatically adjust direction after touching the wall, so as to change travel route after touching the wall; and an arranged suction tube and a unidirectional drainage valve avoid eddy diffusion of travel of the cleaner on sewage at the bottom and reduce the weight of the cleaner when being taken out from water. In addition, two or multiple axial-flow pumps are arranged horizontally, so that the cleaner has turning function and ordered full cover washing is realized.

Owner:TIANJIN WANGYUAN ENVIRONMENTAL PROTECTION & TECH CO LTD

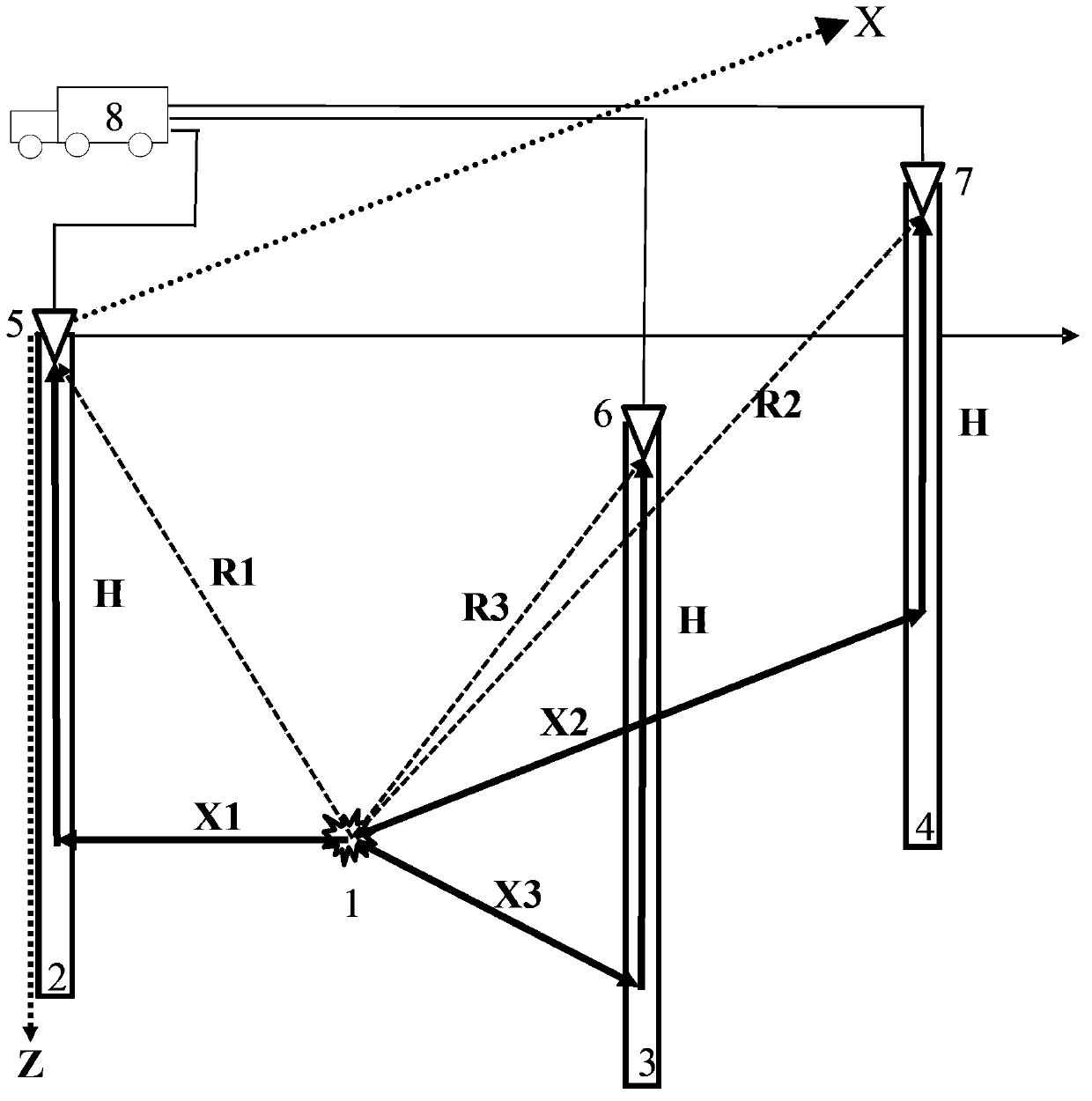

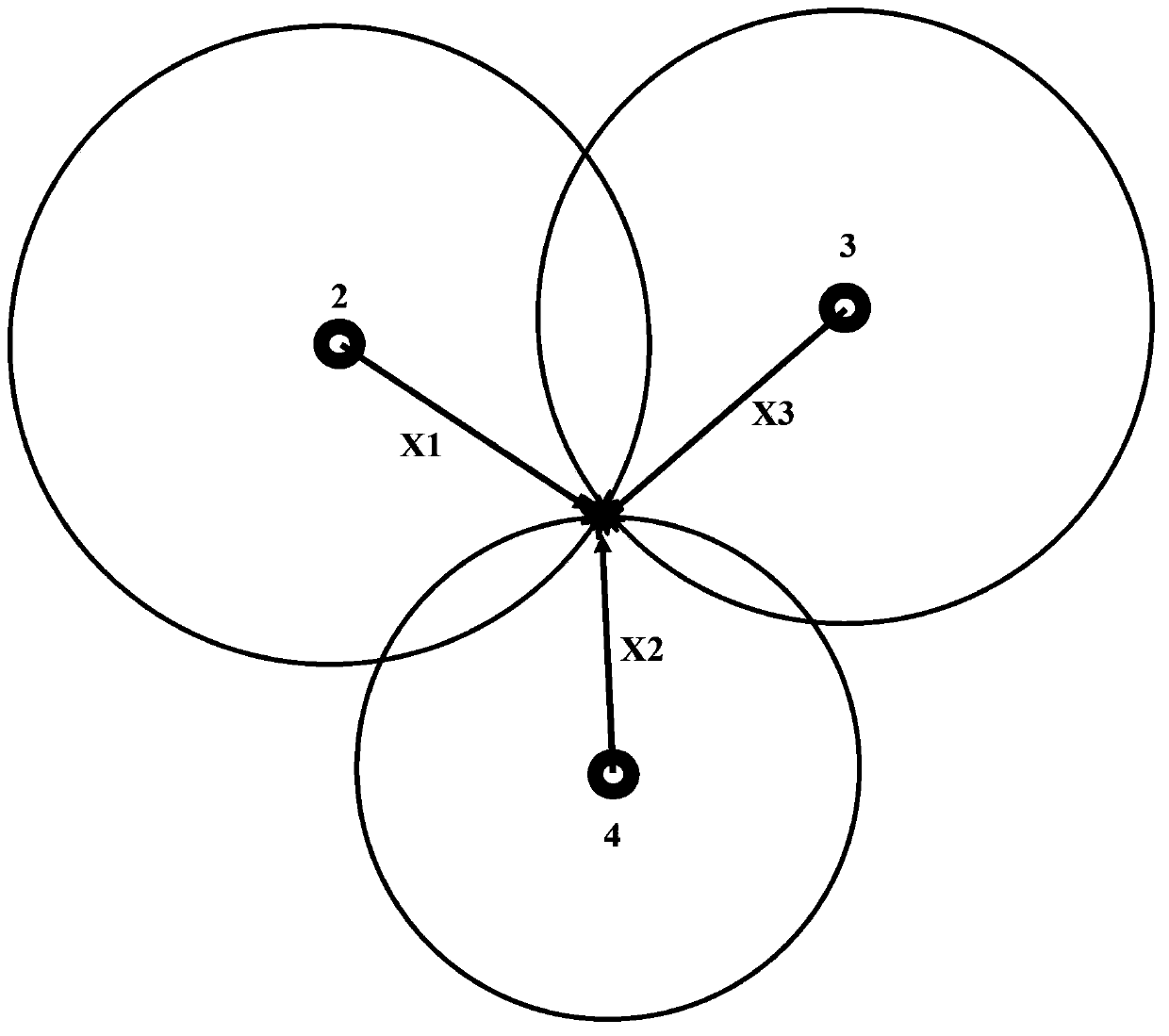

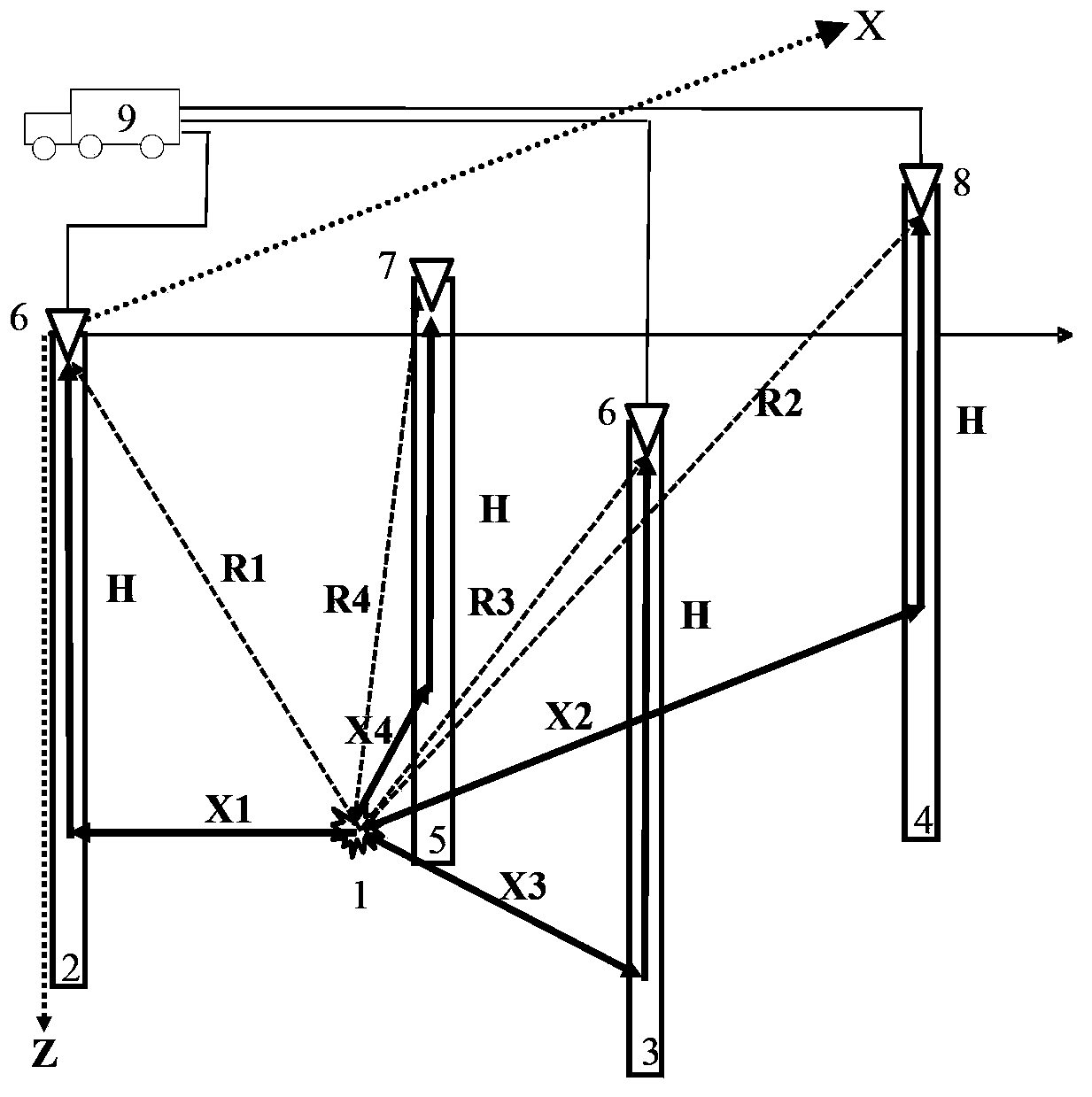

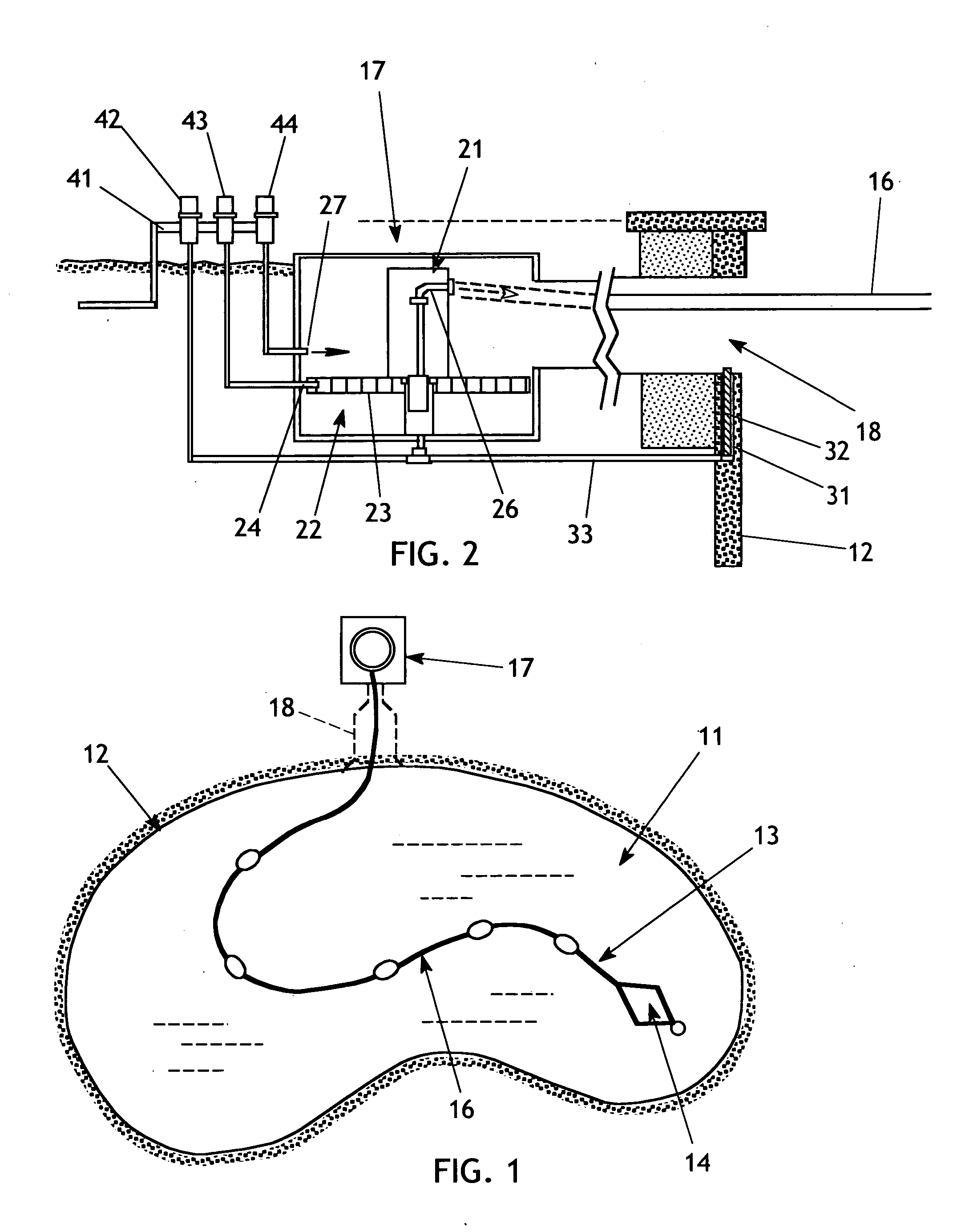

Method for performing hydraulic-fracturing microseismic monitoring by utilizing uphole geophones

ActiveCN104215934APrecise positioningEasy constructionPosition fixationSeismic signal receiversGeophoneHydraulic action

The invention relates to a method for performing hydraulic-fracturing microseismic monitoring by utilizing uphole geophones and applying geophysical prospecting. The geophones are mounted on hydraulic-fracturing uphole casings, micro-seismic signals generated by underground rock under the high-pressure hydraulic action during fracturing are recorded, and micro-seismic signal waves are transmitted to the casings along the horizontal direction to be converted into sound waves which are transmitted along the steel casings to be recorded by the uphole geophones. By the method, geometric position coordinates of underground rock failure points can be determined rapidly and accurately on a fracturing construction site, and the method and device simple in construction can be applied to dynamic imaging and rapid post-fracturing assessment of hydraulically created fractures of low permeability reservoirs and shale reservoirs of oil fields.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

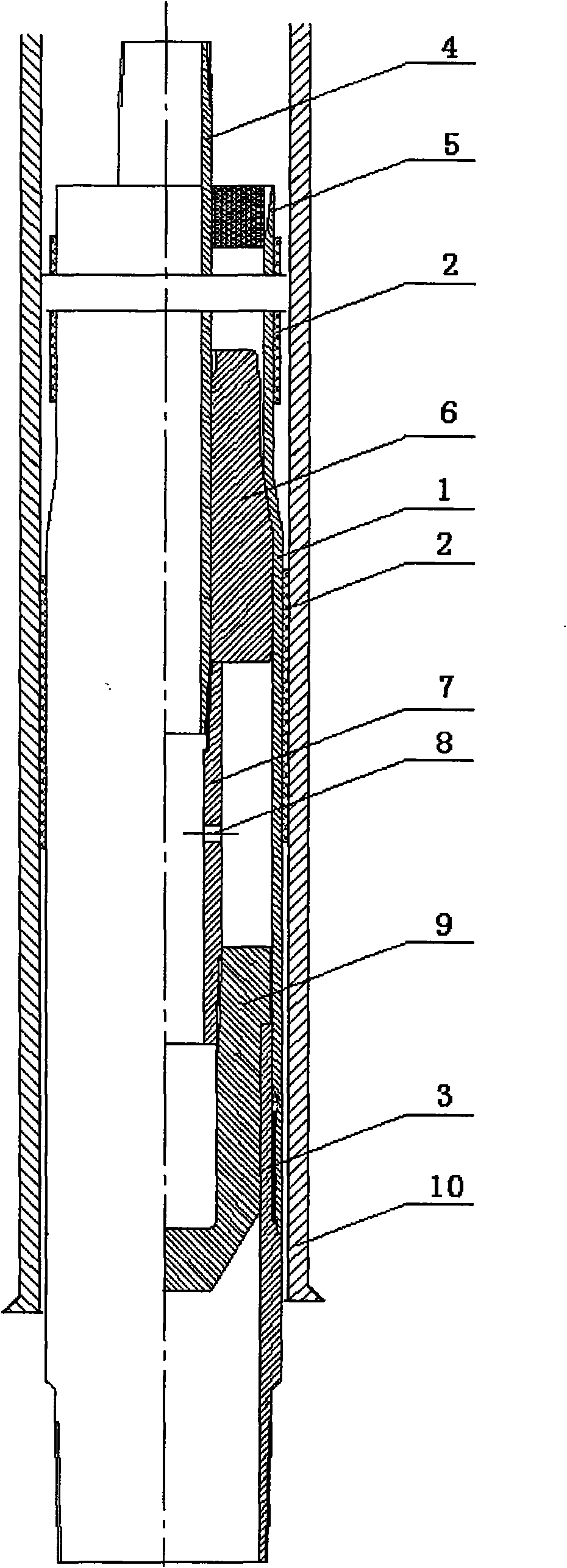

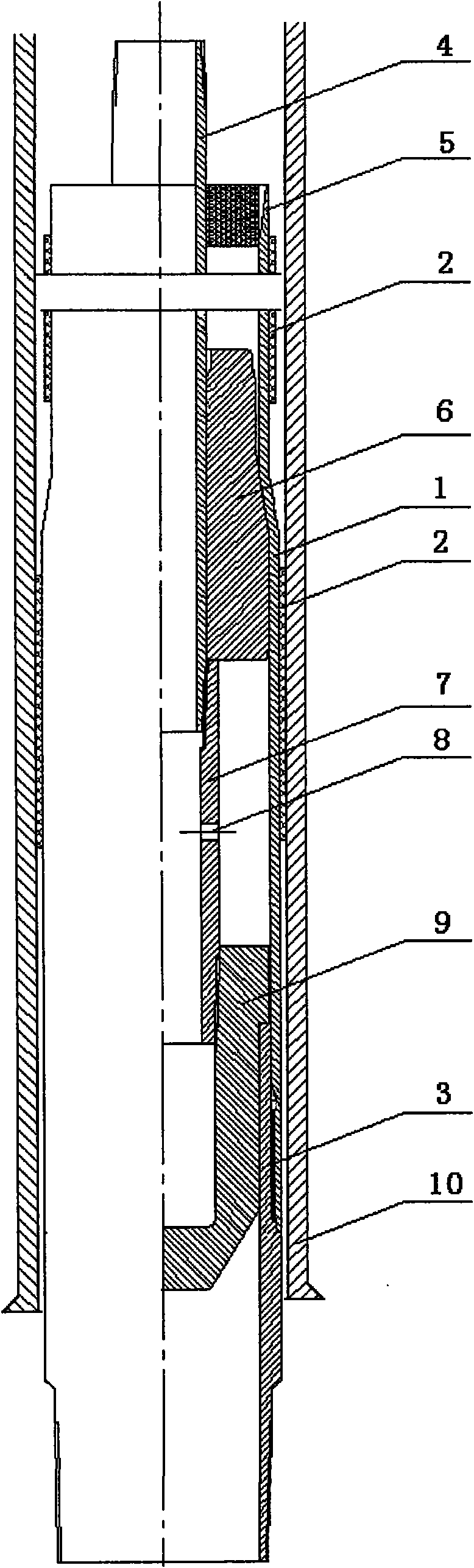

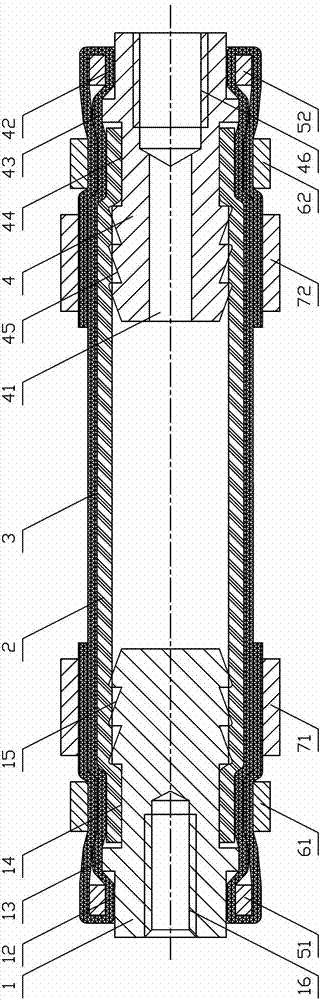

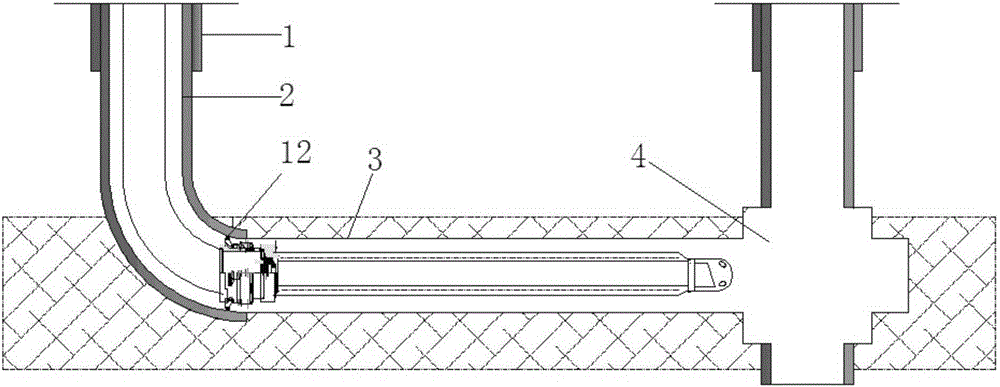

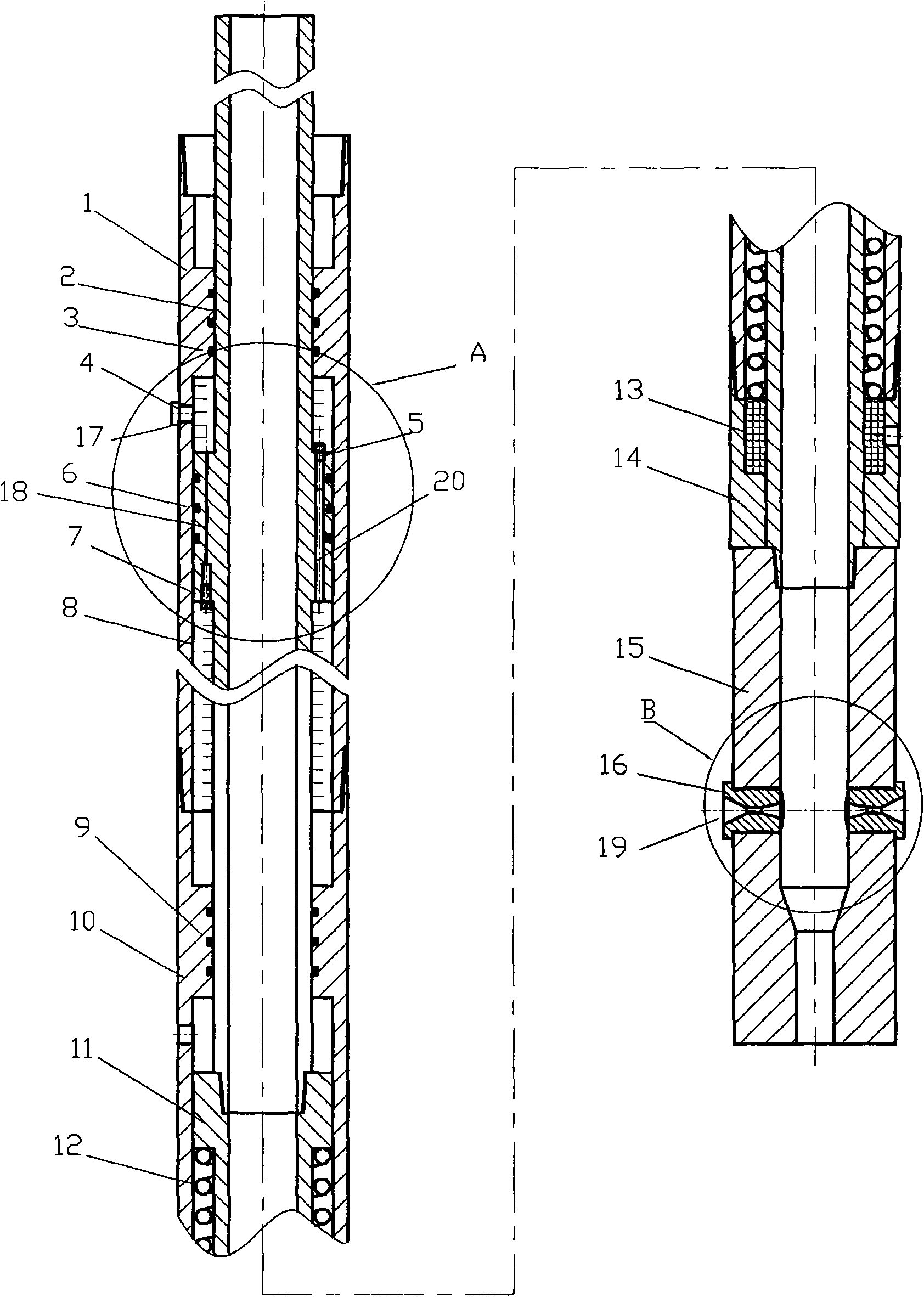

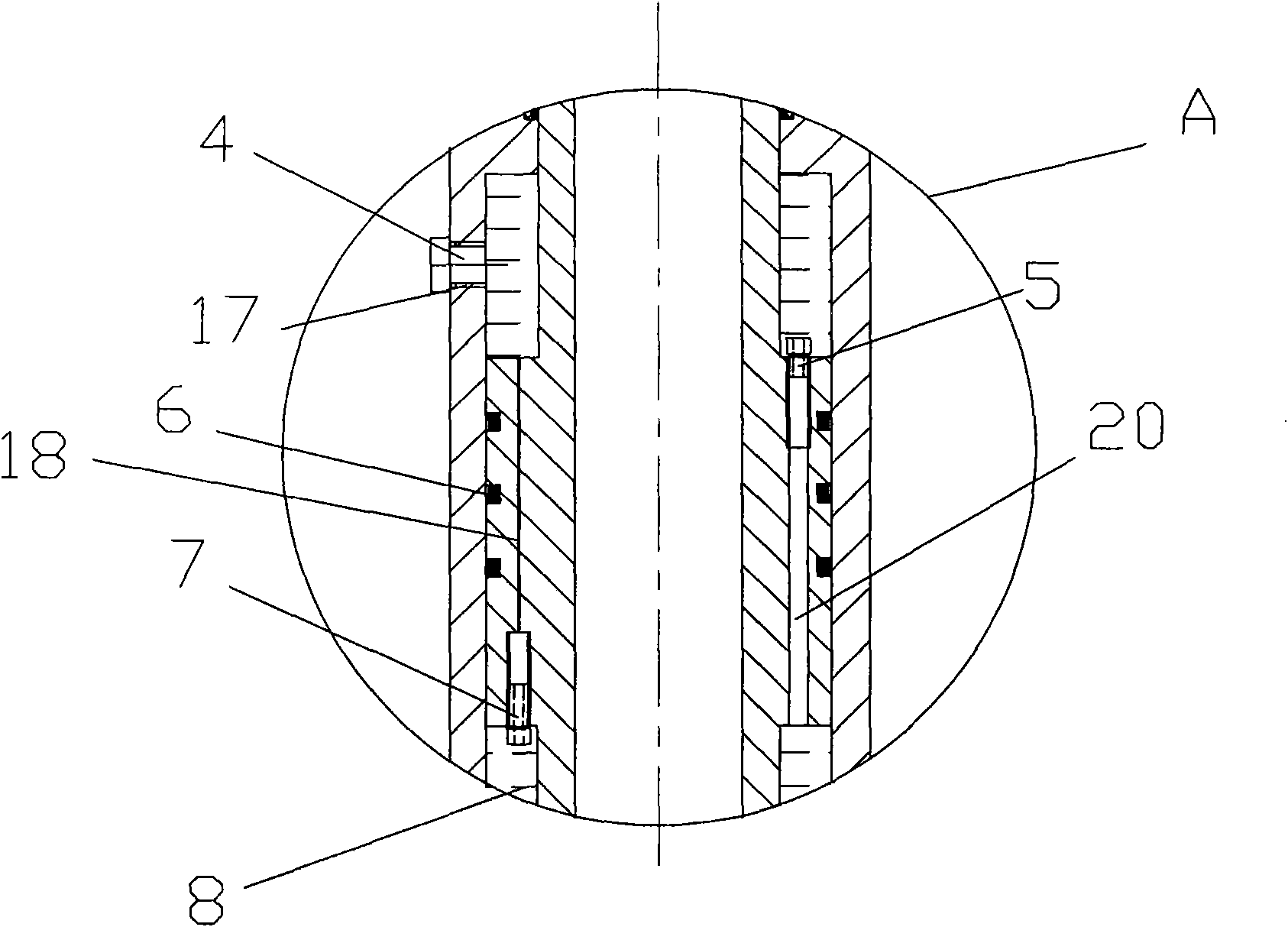

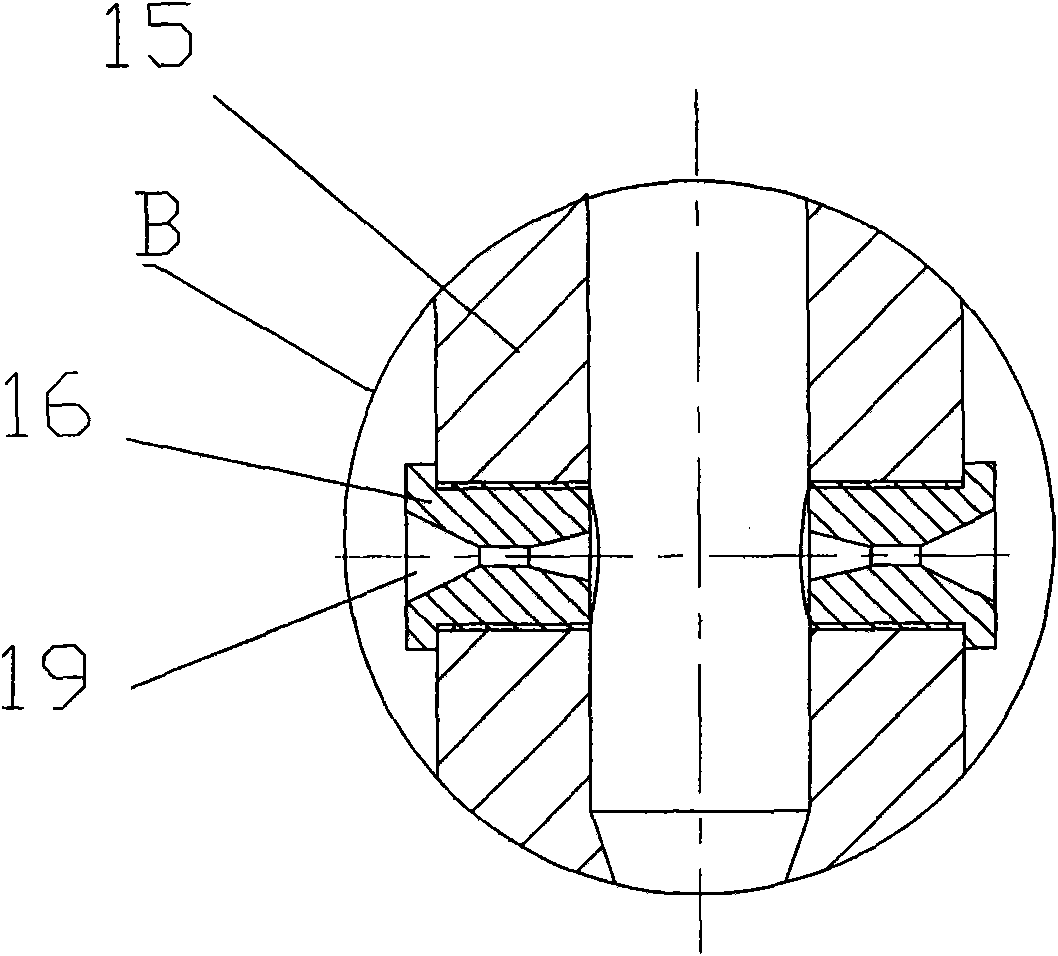

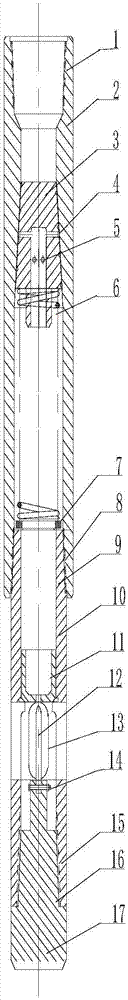

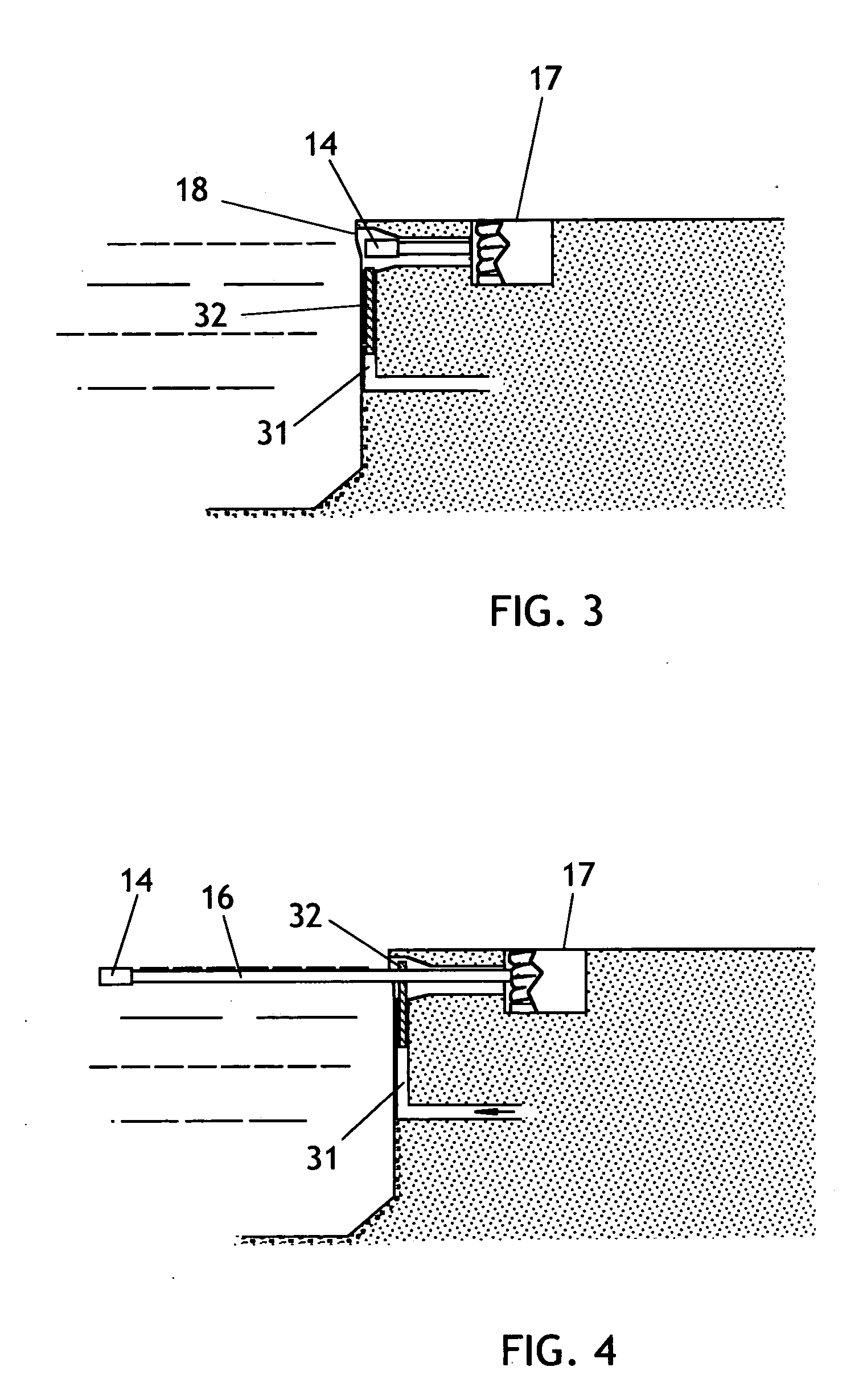

Hydraulic expansion hanger for expandable screen pipes

The invention discloses a hydraulic expansion hanger for expandable screen pipes, which consists of a hanger body, rubber, a sealing diameter-variable buckle, a central light pipe, an object-falling prevention plug, an expansion cone, a fixed pup joint, a pressure transfer hole and a sealing end cap. The hydraulic expansion hanger is characterized in that: the expansion cone axially moves from top to bottom along the central pipe under hydraulic action to radially plastically deform an expansion sleeve and compress the rubber between the outer wall of the expansion sleeve and the inner wall of an outer-layer sleeve so as to realize the function of hanging sealing. The invention has the advantages that: the hydraulic expansion hanger integrates the functions of a tail pipe hanger and a tail pipe upper packer; during expansion, the lower part of the hanger can be sealed by the movable end cap, and when released, the expandable screen pipe is directly pulled out of an inner pipe string without back-off; after the expandable screen pipe is released, plug drilling is not needed, and the drift diameter of the hanger is much greater than that of the conventional hanger, so well production and post-borehole operation are benefited; and the hanger can hang screen pipes or the expandable screen pipes, is applied to the sand control completion of the screen pipes, shortens a completion period, saves completion cost and has vast market application prospect and development potential.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

Hydraulic artificial muscle

The invention discloses hydraulic artificial muscle comprising a closed end connector, an elastic rubber tube, a high-strength fiber woven mesh, a water end connector, two end fastener rings, two middle fastener rings and two inverted-taper-tooth-surface fastener rings. When the hydraulic artificial muscle operates, the elastic rubber tube and the high-strength fiber woven mesh deform under the hydraulic action, the diameter of the hydraulic artificial muscle increases with the increased length, and a drive object connected to a threaded blond hole of the closed end connector is pulled. The elastic rubber tube closes water of certain pressure inside. The high-strength fiber woven mesh is in a tubular shape tightly woven with high-strength fibers and covers the outside of the elastic rubber tube, and accordingly the hydraulic artificial muscle can bear sufficient inner hydraulic pressure. Under the fastening action of the fastener rings and the structural action of the inverted-taper-tooth-surface and the shoulders, the hydraulic artificial muscle can bear large pull load, thus the high-strength hydraulic artificial is formed.

Owner:DALIAN MARITIME UNIVERSITY

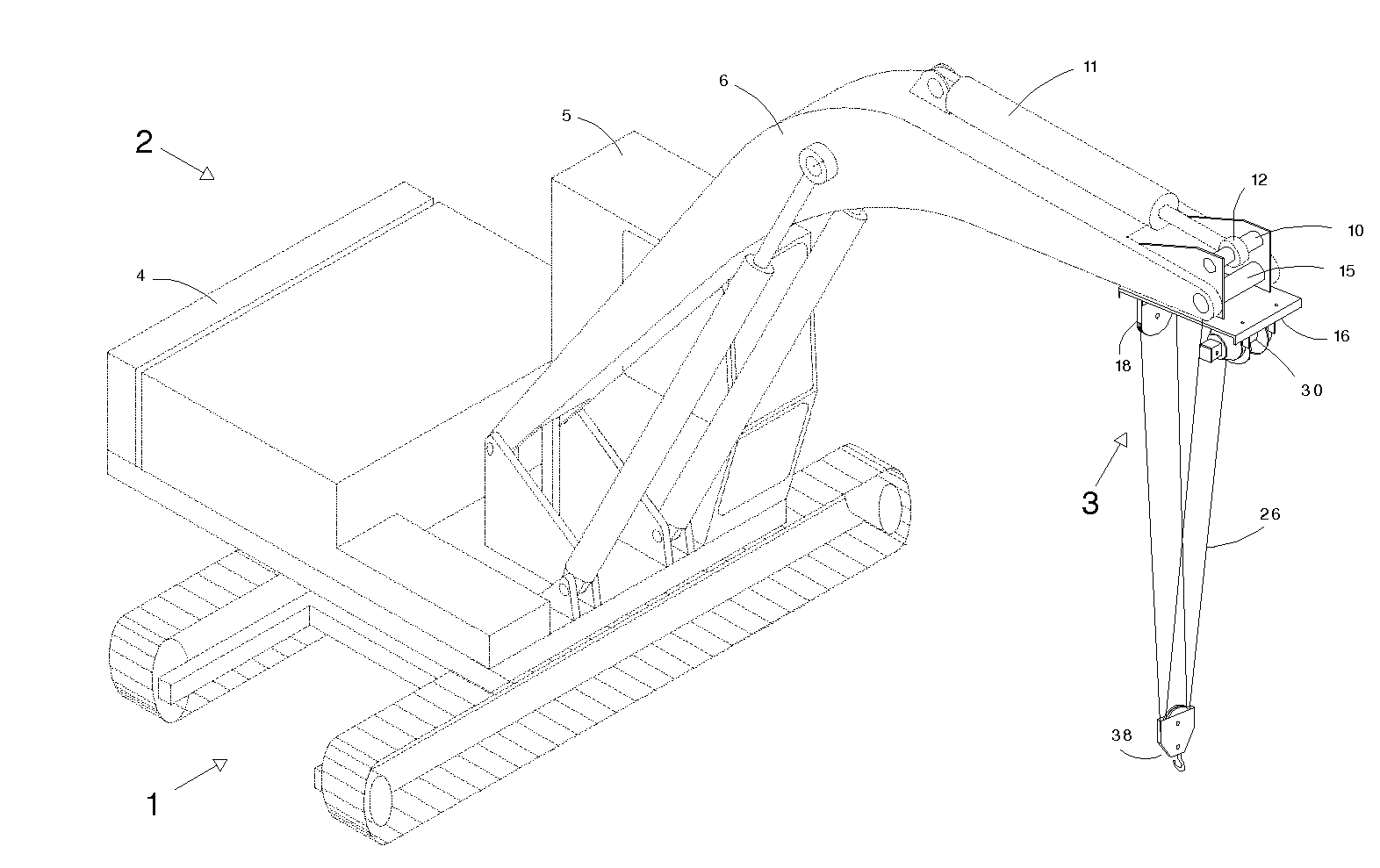

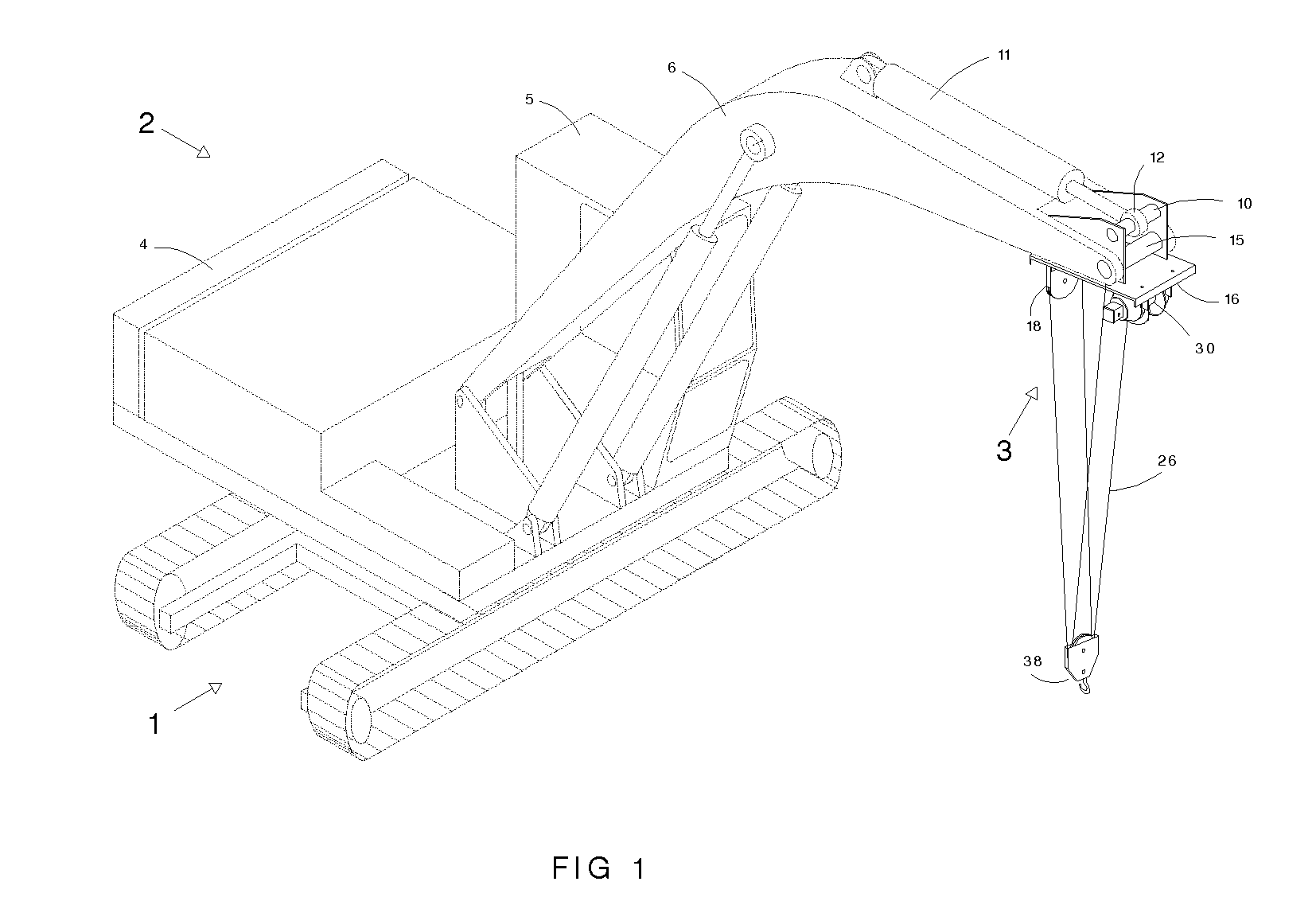

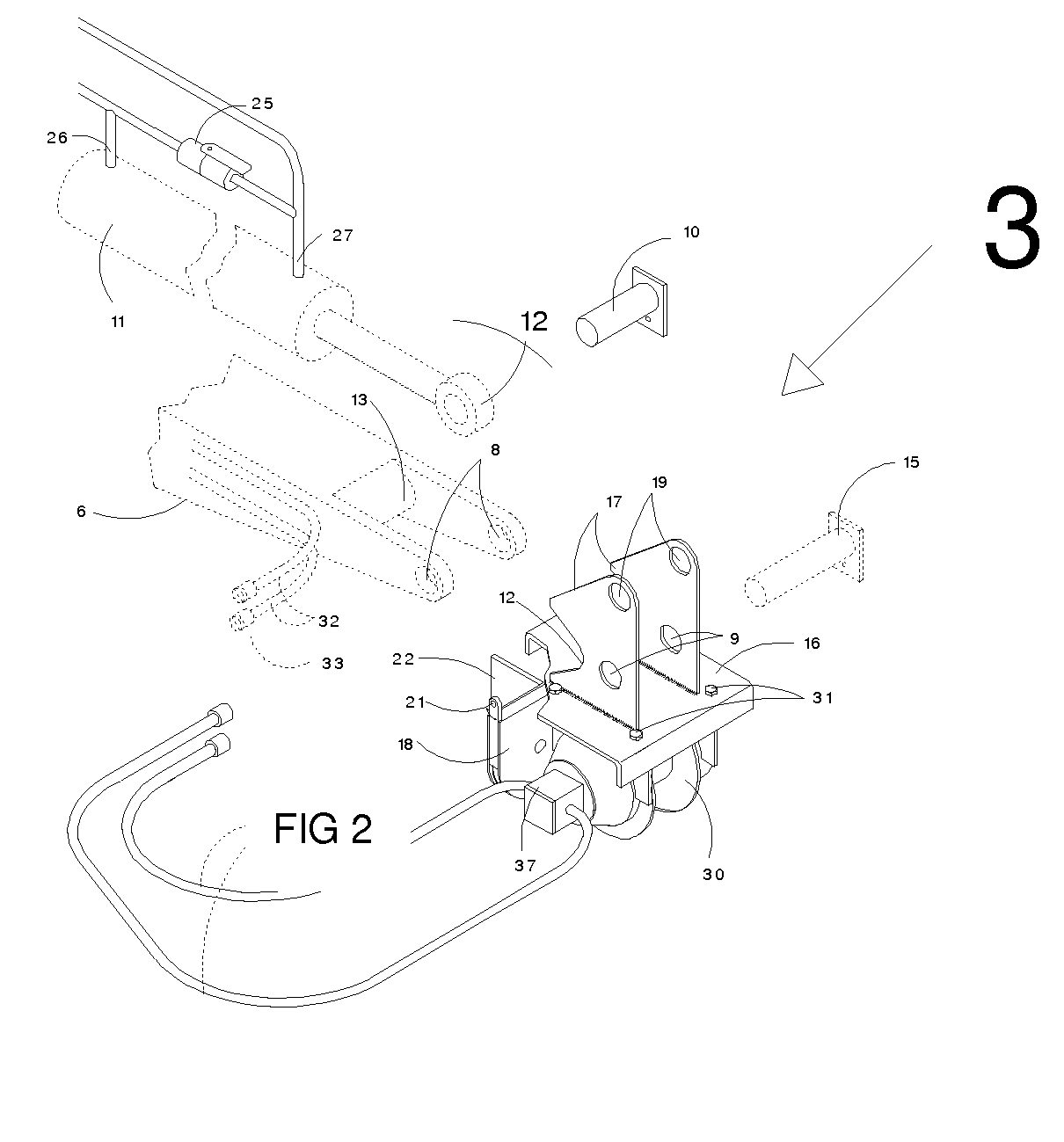

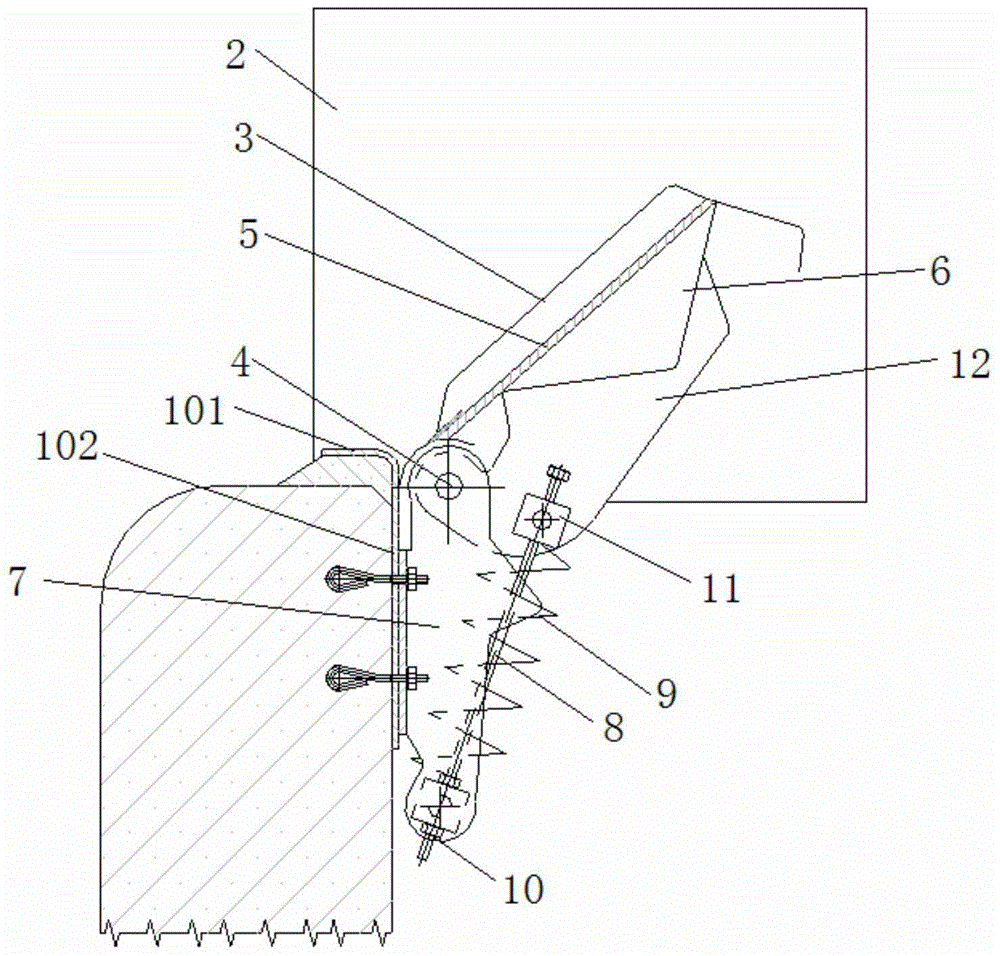

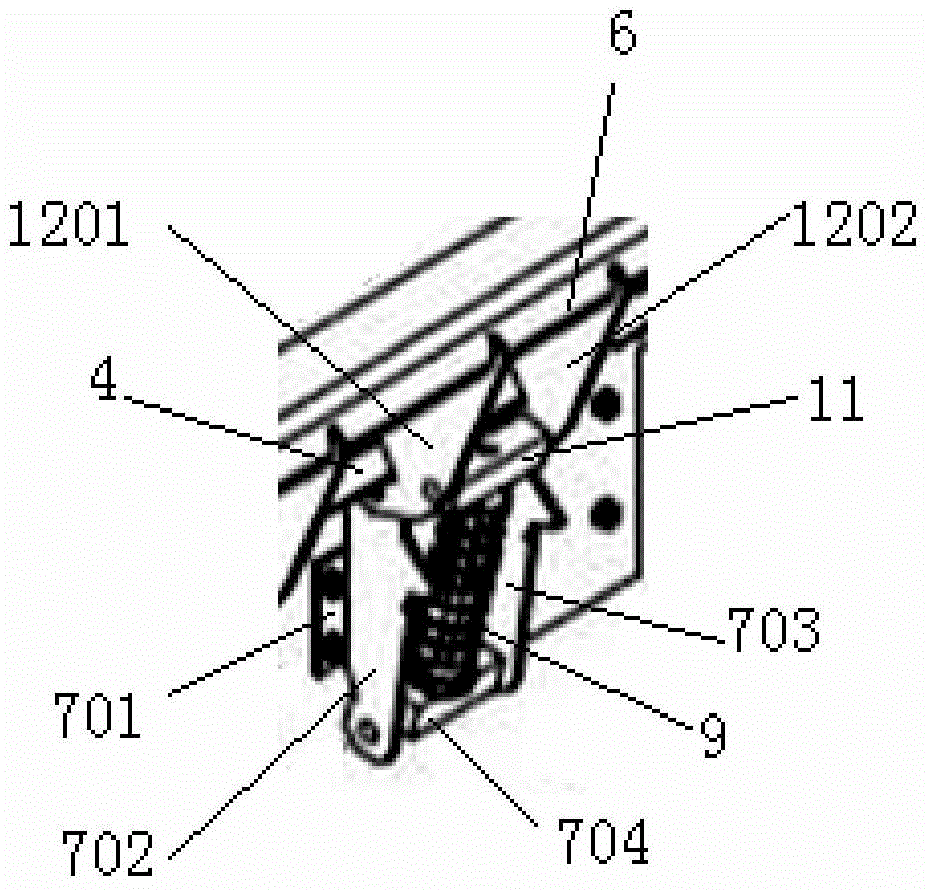

Accessory For Converting Excavators

InactiveUS20090260265A1Facilitates unloading operationLess timeMechanical machines/dredgersLifting capacityHydraulic action

Accessory for providing an excavator with a dual function in earth-moving tasks: digging and refilling trenches, and as a crane (hoisting capability), to be used with advantage in the construction of pipelines. The accessory includes a frame, sheaves and a winch with hydraulic action, installable on top of the boom of a hydraulic excavator without involving modifications to the original machine, thereby providing the excavator with hoisting capability.

Owner:AESCHBACHER HANS MANUEL +1

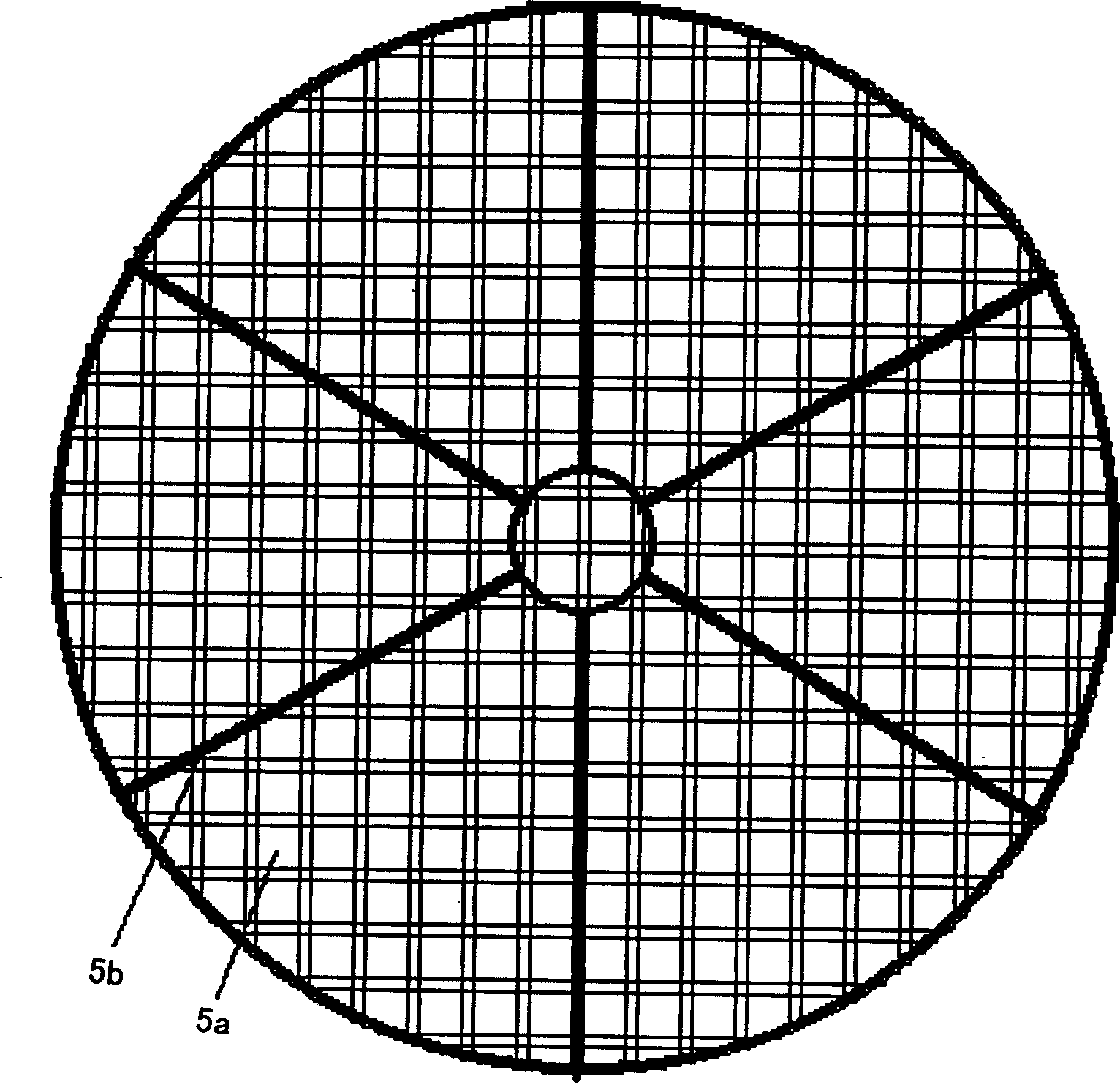

Fiber clock deep filter for reclaiming sewage

InactiveCN1557524AHigh filtration precisionTo achieve the purpose of backwashingFatty/oily/floating substances removal devicesLoose filtering material filtersFiberSingle stage

The present invention is one sewage reusing fiber fabric filter as one oil bearing sewage processing apparatus, and is developed on the basis of single stage efficient fiber fabric filter. The sewage reusing fiber fabric filter has increased upper planar sieve plate, lower planar sieve plate, side spiral propeller, lower spiral propeller, upper distributor, lower distributor and choking ring, and has no conic sieve plate, high pressure water nozzle and stirring sieve plate. The choking ring makes the side flow forming whirl flow raising filtering precision; the lower spiral propeller loosens the compressed filtering material under the hydraulic action; and the side spiral propeller rotates the loosened filtering material to reach the aim of back washing. The present invention has high filtering precision, high yield and low cost and may industrially applied.

Owner:程中和

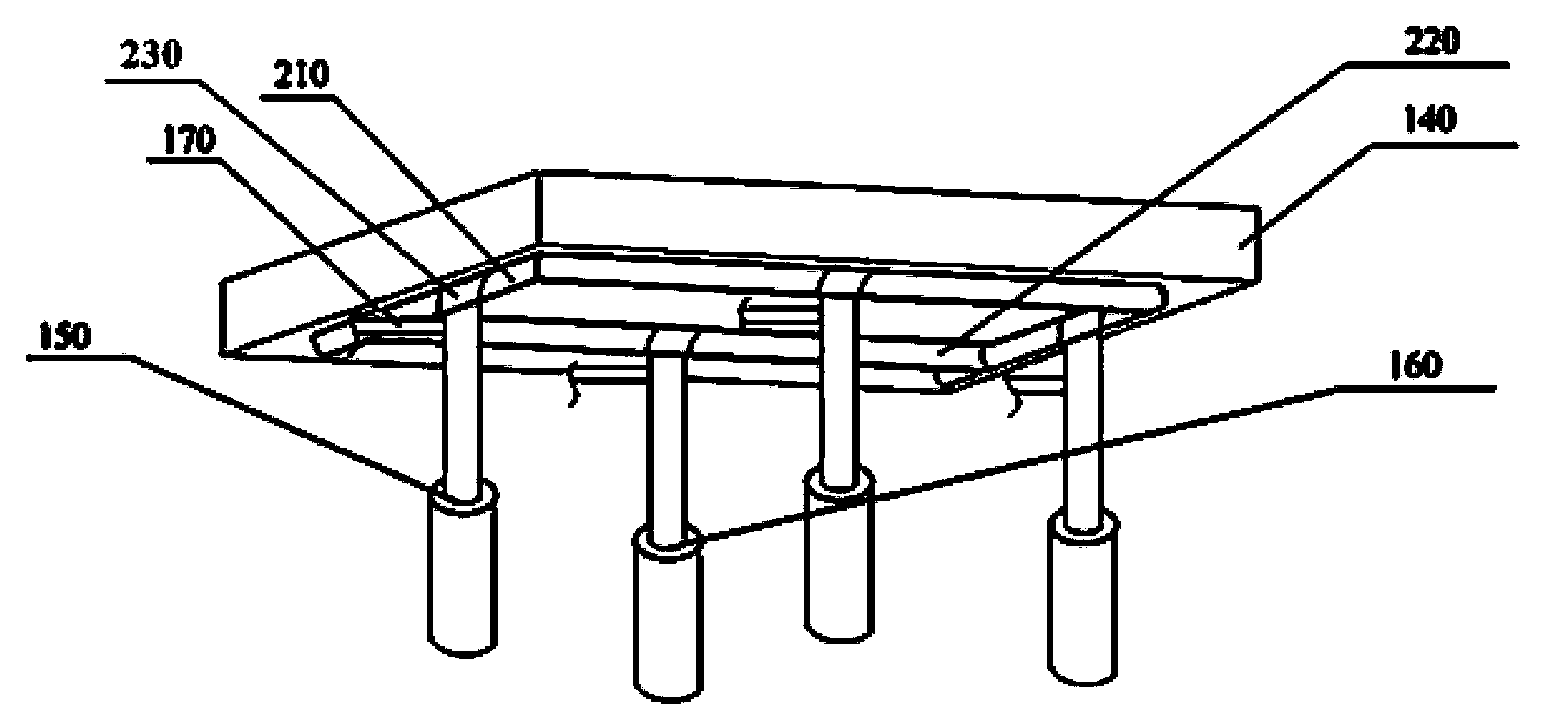

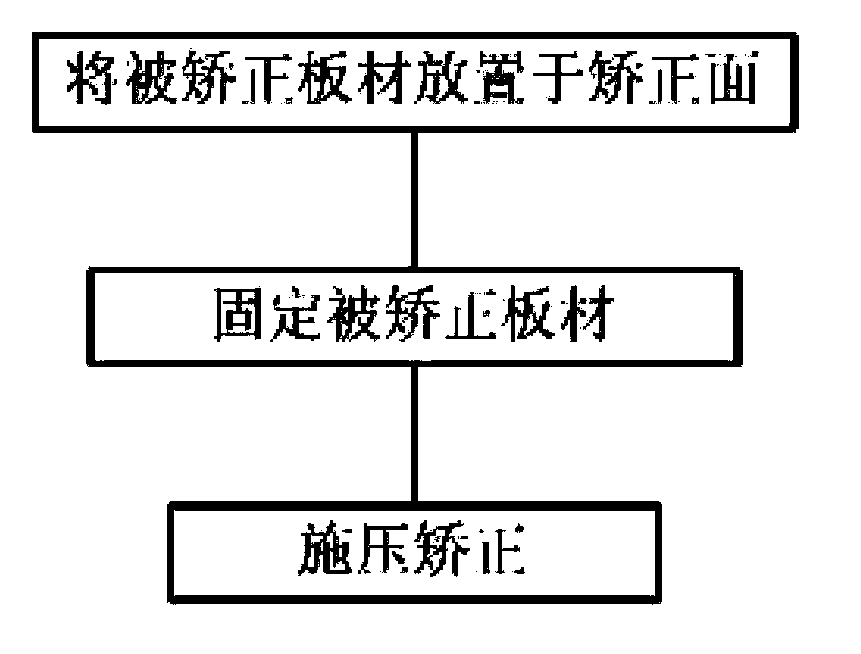

Plate flatness correction unit and operation method thereof

ActiveCN103567257APrevents excessive pressure damagePrevent the problem of uneven pressure damageHydraulic actionEngineering

The invention provides a plate flatness correction unit and an operation method thereof. The plate flatness correction unit comprises a hydraulic control system, a correction table, an upper plate, and pressure posts. The correction table comprises a correction face used for holding a plate under correction. The upper plate faces the correction table so that correction space forms between the upper plate and the correction table. The pressure posts are disposed in the correction space and include the first and second pressure posts; one end of every pressure post is mounted on the upper plate, and the other end of every pressure post can press on the correction table under the internal hydraulic action of the post. The second pressure posts can be moved to multiple positions of the plate under correction to apply pressure. The correction unit has functions of multi-point support and fixation and multi-point pressure application; the pressures of the pressure points can be adjusted at the same time and can also be adjusted independently; accordingly, the problem that the plate under correction bears excessive pressure and is damaged during the simultaneous pressing process can be prevented, and the problem that the plate under correction is damaged due to bearing uneven pressure can also be prevented.

Owner:广东江丰电子材料有限公司

Well completion method for glass fiber reinforced plastic sieve tube of coal bed gas horizontal well

ActiveCN105201458ALarge relief areaLarge pressure relief area (compared to PE screen), its high strengthFluid removalFlushingGlass fiberHydraulic action

The invention discloses a well completion method for a glass fiber reinforced plastic sieve tube of a coal bed gas horizontal well, which is characterized in that the glass fiber reinforced plastic sieve tube is adopted for carrying out well completion, a washing tube is inserted in the glass fiber reinforced plastic sieve tube, hydraulic action is applied to the stacked pulverized coal blocking a horizontal well section at the end of the glass fiber reinforced plastic sieve tube by assistance of the washing tube, and the annular space between tubular columns is separated and sealed by matching of a sealed chamber and a sealed tube so as to increase the hydraulic action effect, so that the glass fiber reinforced plastic sieve tube can be smoothly inserted, the insertion of the glass fiber reinforced plastic sieve tube in a horizontal well with a large ratio of horizontal length to vertical depth can be applicable, coal bed wall support is improved while a channel for subsequent coal bed gas reforming is provided, gel breaking and hydraulic cleaning for any well section of a coal bed can also be realized through the washing tube during well completion operation, wall cakes can be eliminated in time, the coal bed is protected, and the pollution is avoided.

Owner:CHINA NAT OFFSHORE OIL CORP +1

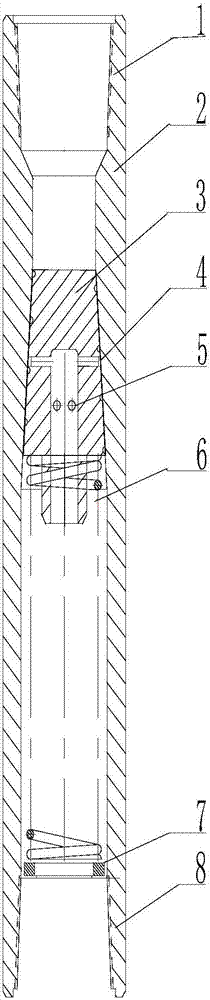

Downhole hydraulic cutting tool

The invention discloses a downhole hydraulic cutting tool and belongs to the field of the development of coal gas layers. The tool comprises a shifter, a resetting device and a spraying nozzle; the shifter is driven to downwardly move by a hydraulic drive device, the spraying nozzle is driven to downwardly move, the spraying nozzle can carry out perforation and fracture on a coal layer at a specified depth through high-pressure hydraulic action, a plurality of artificial fractures can appear in the original coal layer, coal layer gas discharge passages can be formed, the gas permeability of the coal layer is increased, and the pressure drop of a large area appears around a mine hole when gas is discharged from a mine, so that the gas desorption surface area of the coal layer is increased, and the rapid and relatively-lasting discharge of coal layer gas is guaranteed; and according to the tool, the shifter is reset through resetting springs. Thus, the downhole hydraulic cutting tool has the advantages of simple structure and convenience in operation and maintenance.

Owner:PETROCHINA CO LTD +2

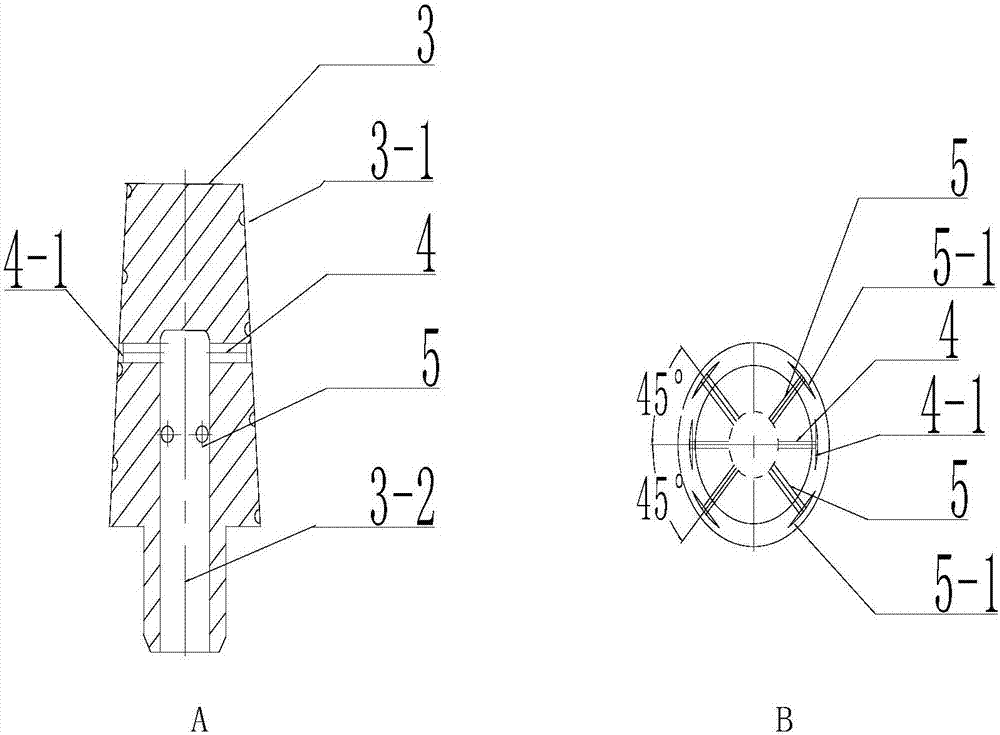

Downhole low-frequency hydraulic pulsation coupled hydraulic ultrasound generation system applied to injection augmentation of low-permeability reservoirs

ActiveCN107152265ARealize downhole low frequency pulsationOil displacement effect is goodFluid removalSweep efficiencyHydraulic action

The invention discloses a downhole low-frequency hydraulic pulsation coupled hydraulic ultrasound generation system applied to injection augmentation of low-permeability reservoirs. The system comprises a low-frequency hydraulic pulsation generation part and a hydraulic ultrasound generation part, wherein the low-frequency hydraulic pulsation generation part mainly comprises a frustum-shaped cylinder assembly, a compound frustum-shaped piston matched with the frustum-shaped cylinder assembly, a returning spring and the like; the cylinder body, the piston and the returning spring form a hydraulic reciprocating vibration system for generating low-frequency hydraulic pulsation in water injection process of a water injection well; the hydraulic ultrasound generation part comprises a flowing channel nozzle and a vibrating reed and is used for generating ultrasound under hydraulic action of the injected water flow and applying the ultrasound to the reservoirs; the hydraulic ultrasound is capable of removing blockage of reservoirs close to the well wall; the low-frequency hydraulic pulsation is capable of effectively improving permeability of the reservoirs, reducing the surrounding flow of the injected water, improving the volumetric sweep efficiency and augmenting injection and assisting for increasing recovery ratio; the system is capable of outputting low-frequency hydraulic pulsation and hydraulic ultrasound of a hydraulic driving manner based on operation displacement range of the low-permeability water injection well, integrally augmenting injection and improving the recovery ratio.

Owner:XI'AN PETROLEUM UNIVERSITY

Hydraulic auto-oscillation control system for fire water monitor

InactiveCN101721782ARealize automatic reversingSimple drive formServomotor componentsFire rescueHydraulic cylinderHydraulic action

The invention discloses a hydraulic auto-oscillation control system for a fire water monitor, which comprises a hydraulic cylinder, a watercourse base plate, a hydraulic change valve and a mechanical feedback device, wherein the hydraulic cylinder comprises a cylinder body, a piston, a piston rod, a cylinder body end cover and the like; the hydraulic change valve comprises a valve plug, a valve body, a positioning end cover, an end cover spacer and the like; and the mechanical feedback device comprises a bumping head, a bumping block, an adjusting handle, a drive bracket and the like. When the valve plug is positioned at a left position of the valve body, water enters a left cavity of the cylinder body, and the piston rod moves rightwards, when the piston rod moves to a certain position, the bumping block positioned on the left side presses the bumping head to plug a water outlet, and then the pressure of the left cavity of the cylinder body increases to push the valve plug to move rightwards; and when the valve plug moves to a right position of the valve body, water enters a right cavity of the cylinder body, and the piston rod moves leftwards. Under the action of the water power, the control system can drive the piston rod to move back and forth so as to drive a fire water monitor head to jet at a certain angle and in a certain oscillating frequency, has a wide coverage and is in particular suitable for a large space and the places where firefighters are unapproachable.

Owner:EAST CHINA JIAOTONG UNIVERSITY

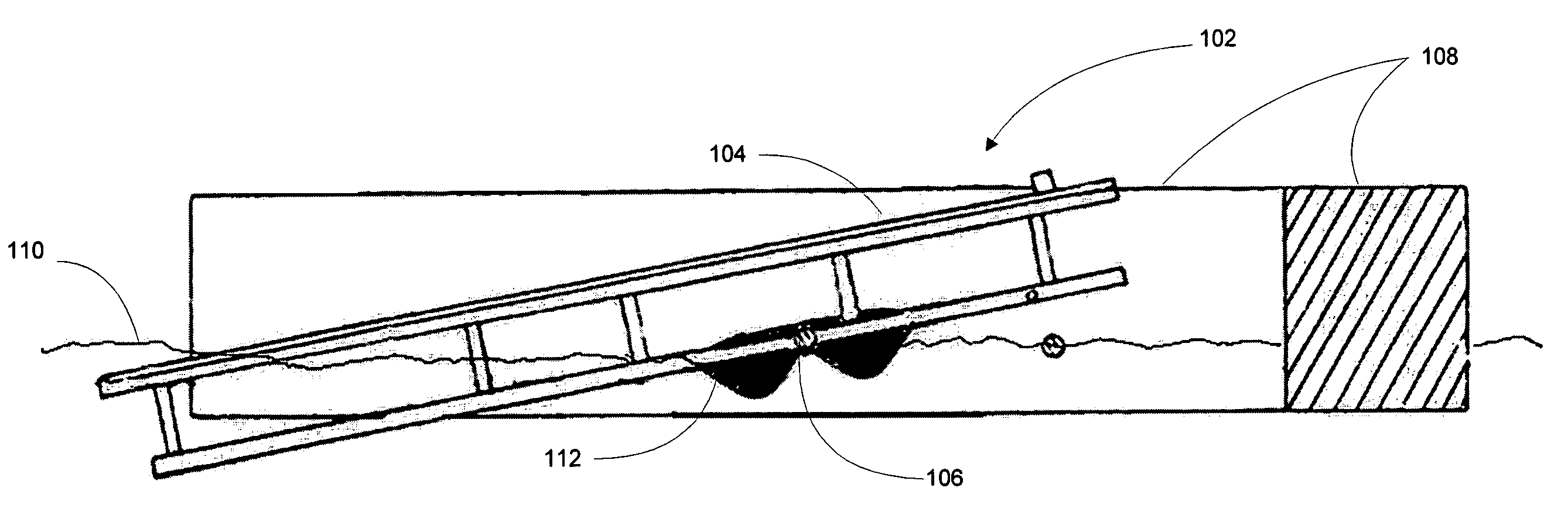

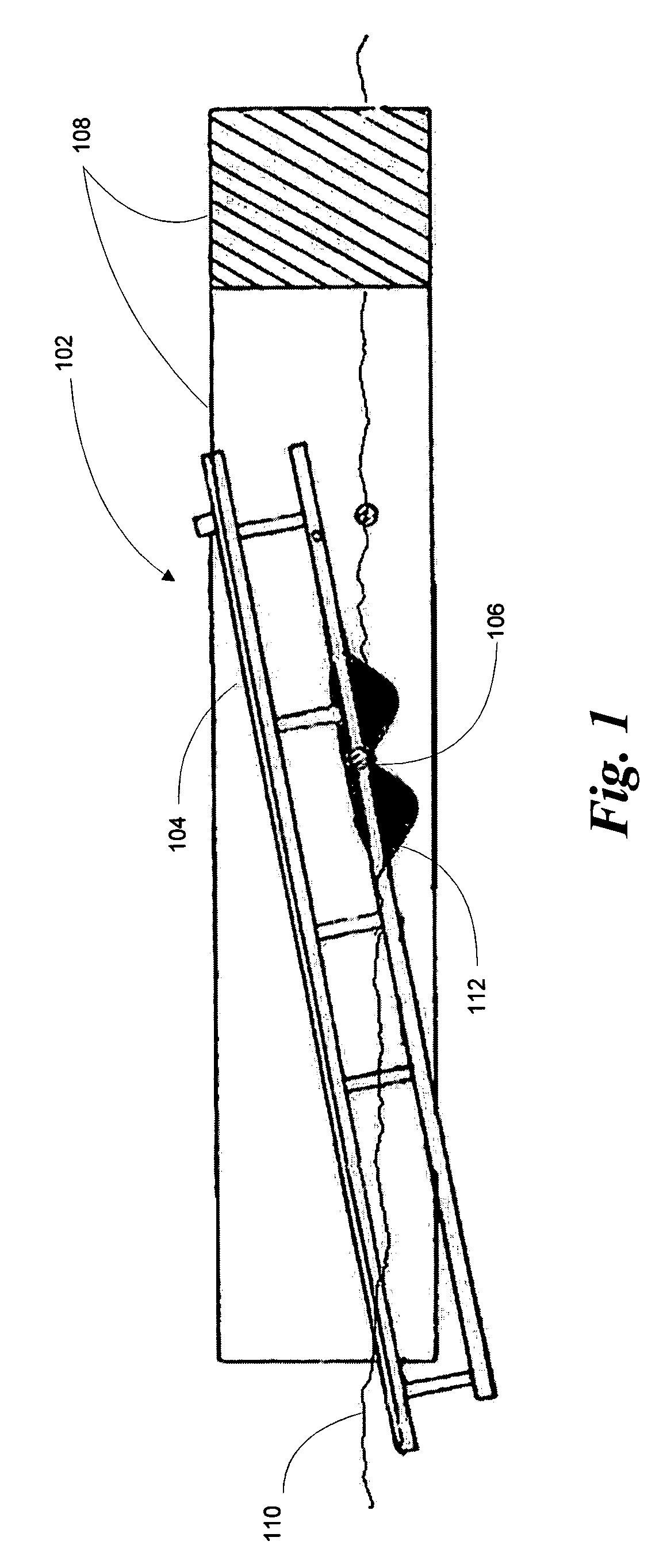

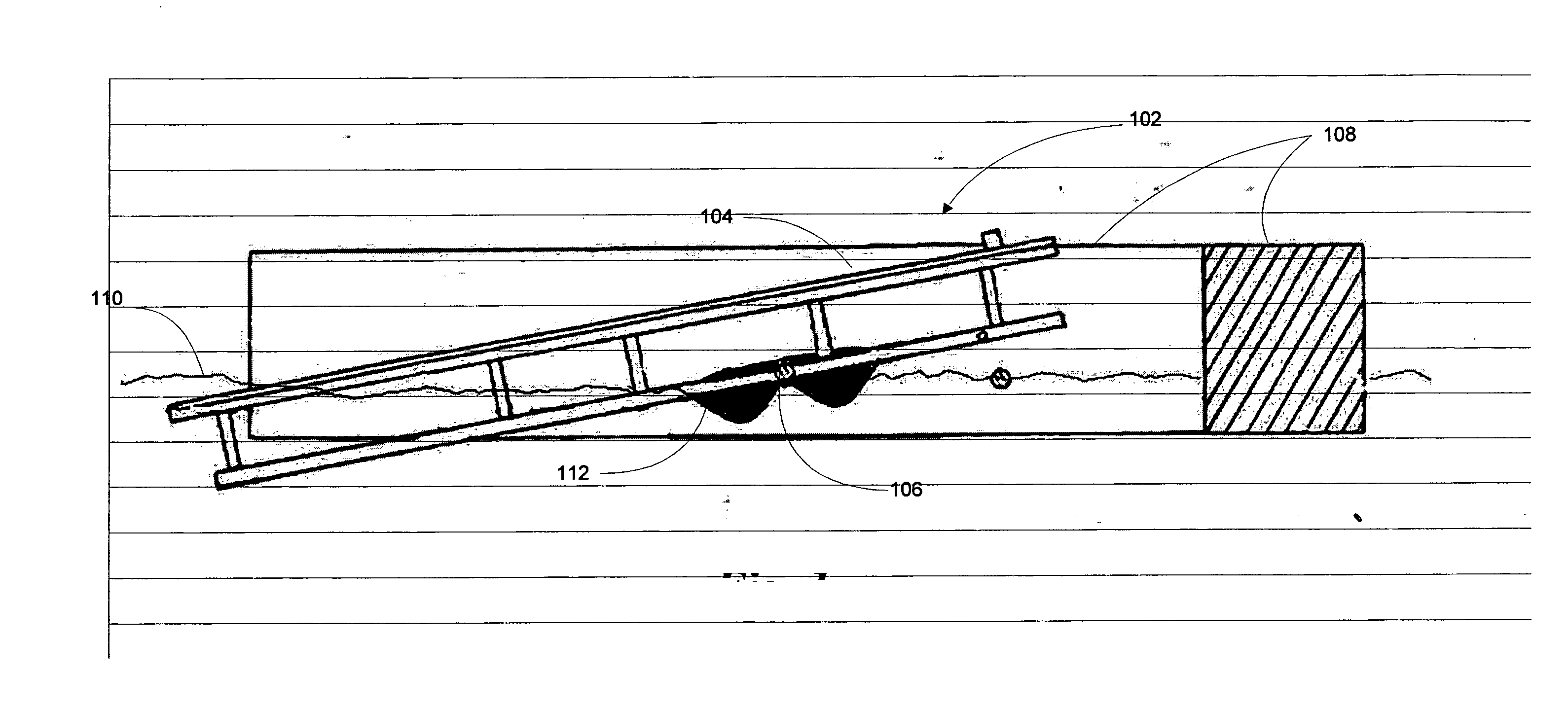

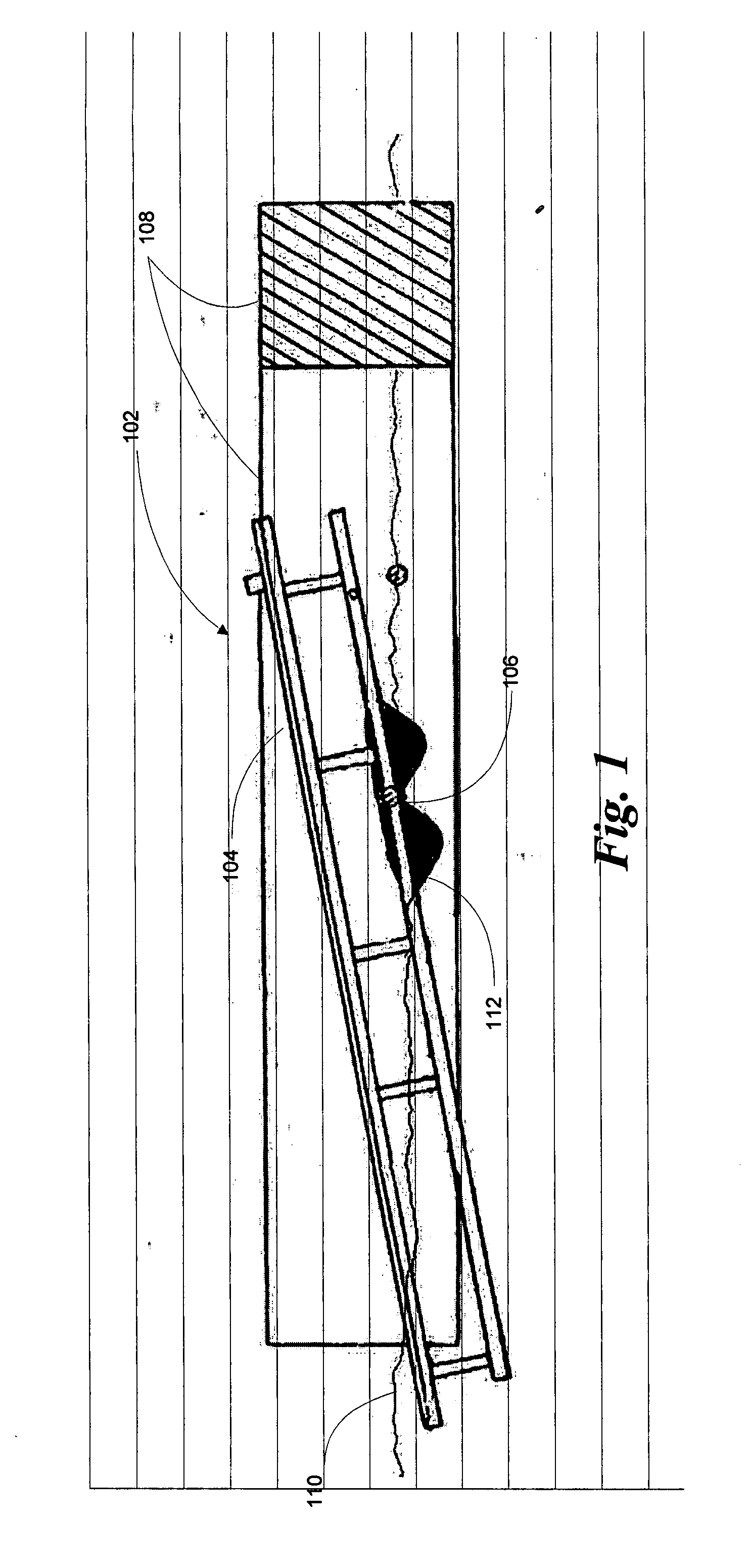

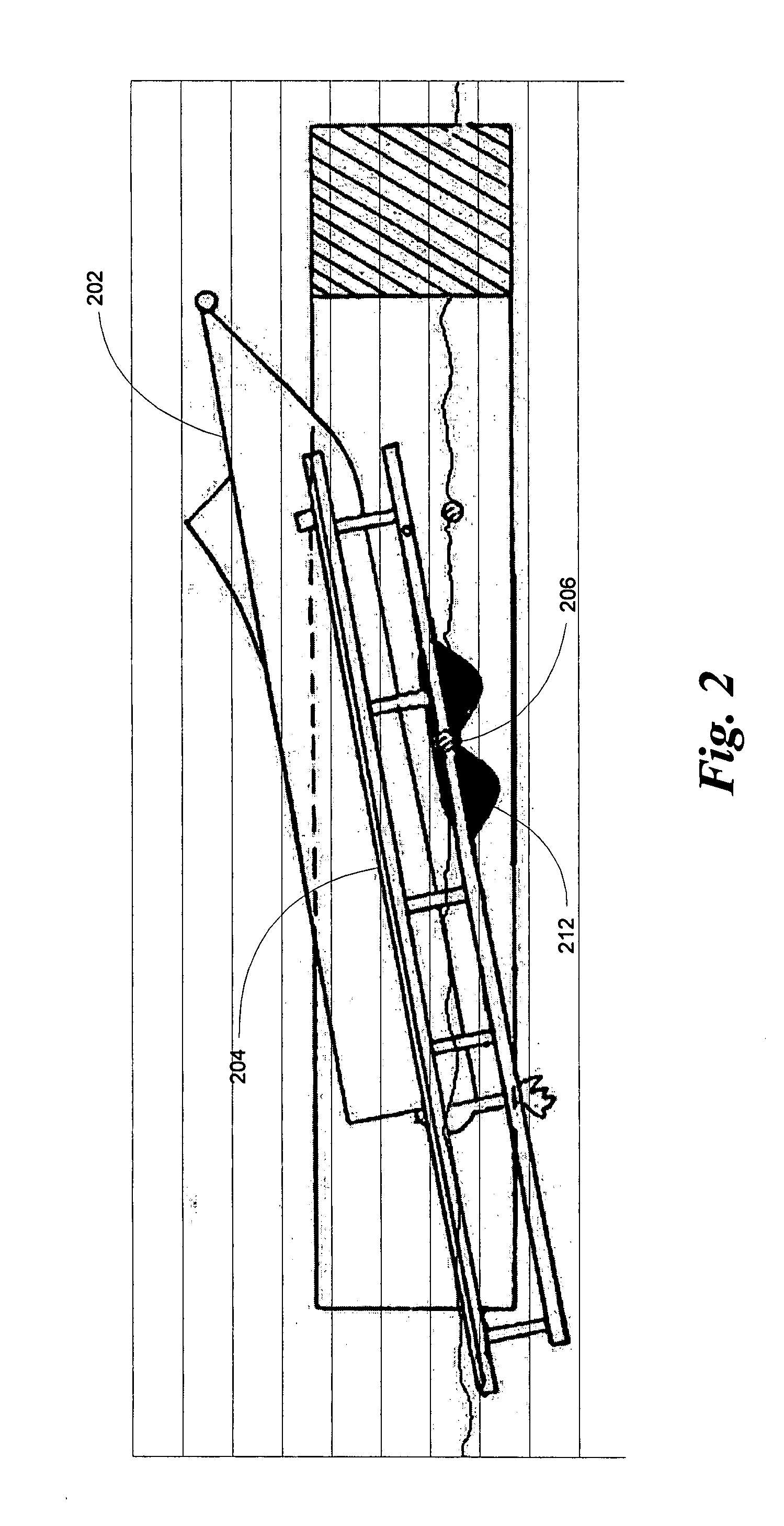

Floating drive on boat docking apparatus

ActiveUS7210420B1Dampening pivotingAdjustable buoyancySlipwaysVessel salvagingHydraulic actionMarine engineering

An improved floating boat lift incorporates a passive hydraulic pivoting lift mechanism, onto which a boat can be driven and positioned ready for storage using only the motive power of the boat itself. The passive hydraulic pivoting lift mechanism provides mechanical advantage in the pivoting action of the apparatus by way of passive hydraulic action, while at the same time dampening pivoting of the apparatus. Embodiments further provide means for adjusting the elevation of the pivot point relative to the surface of the body of water by way of adjusting the buoyancy of the pivoting lift mechanism.

Owner:BASTA IP INC

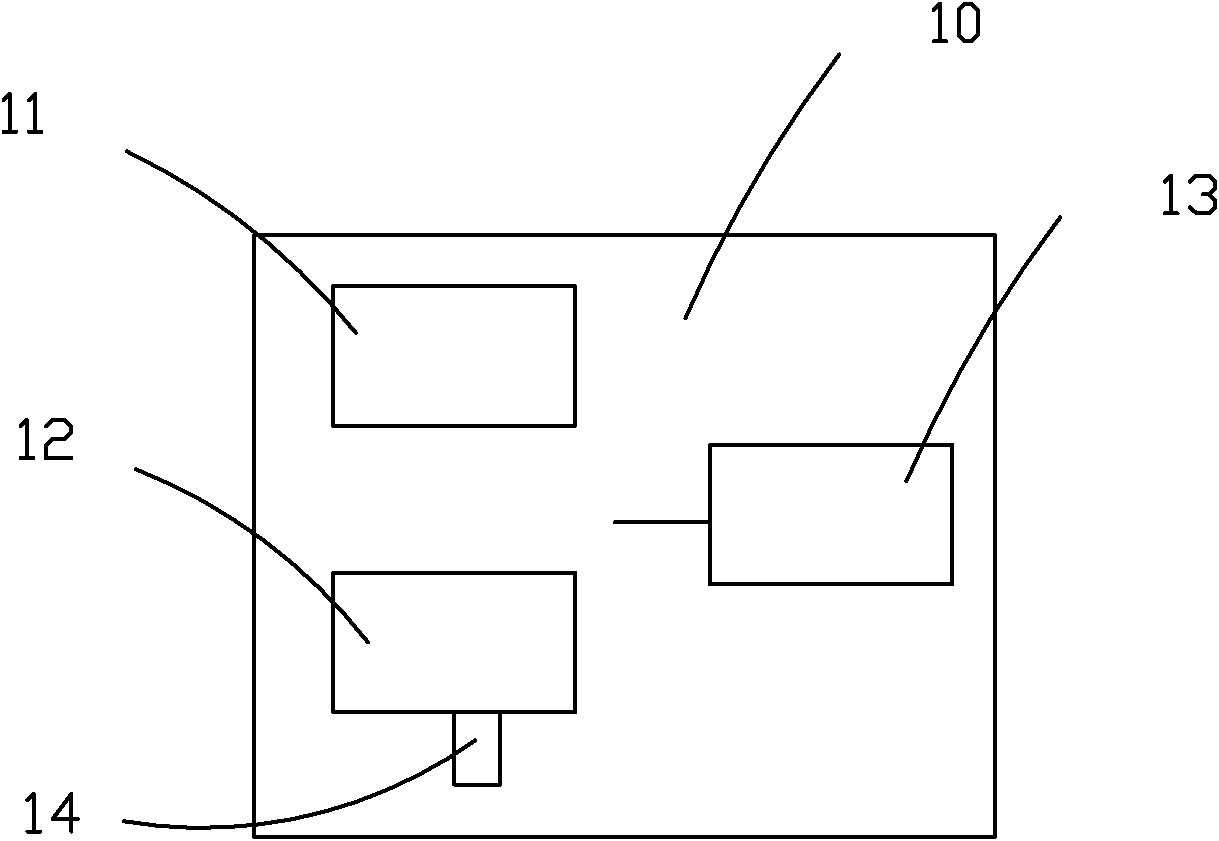

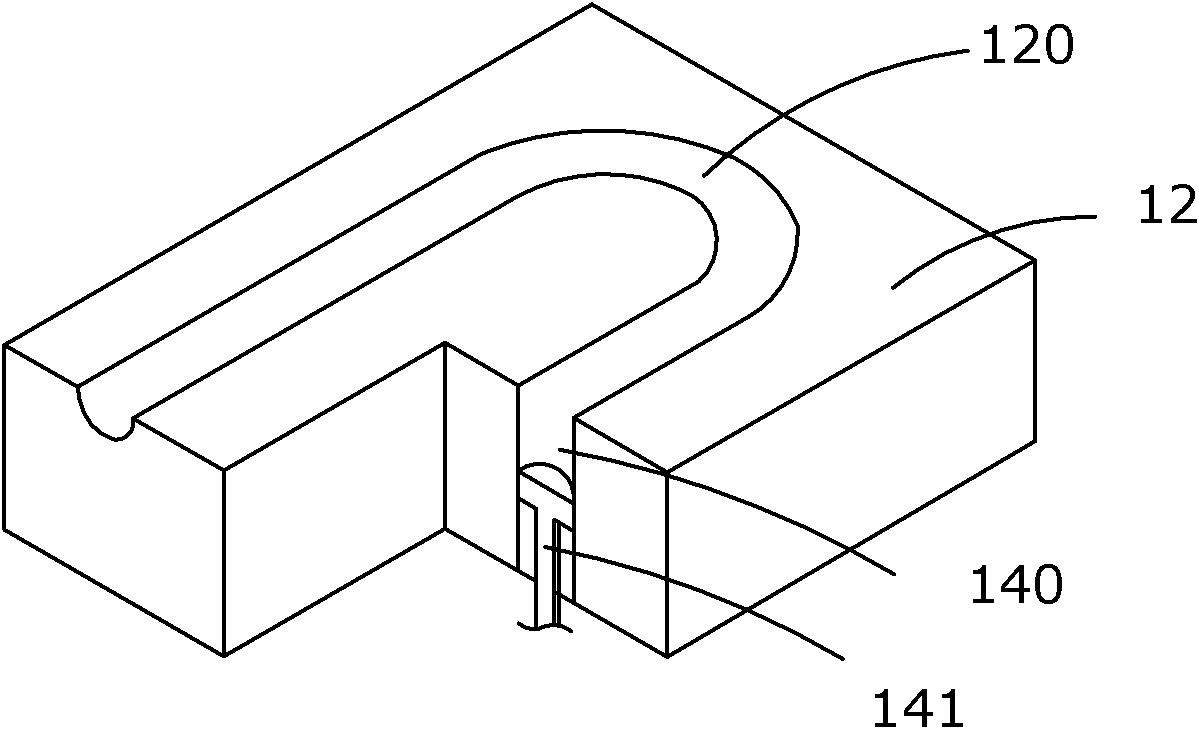

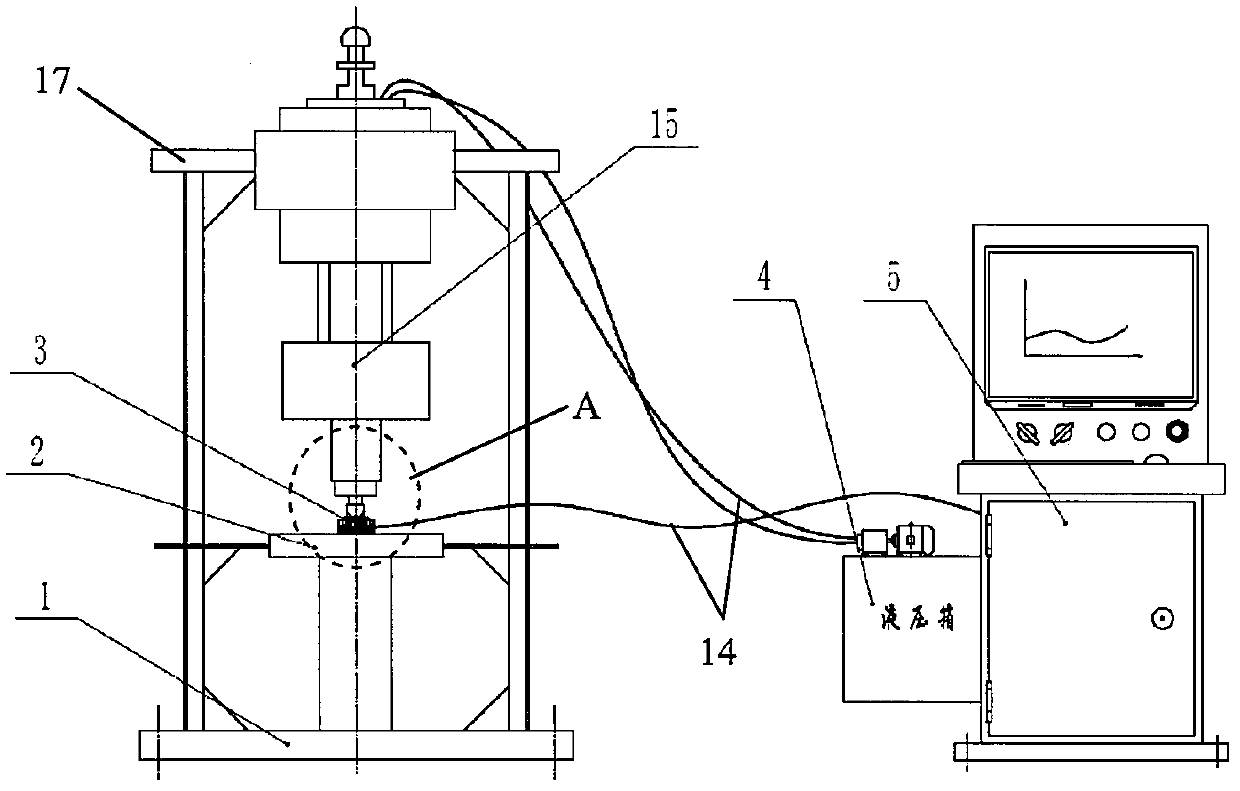

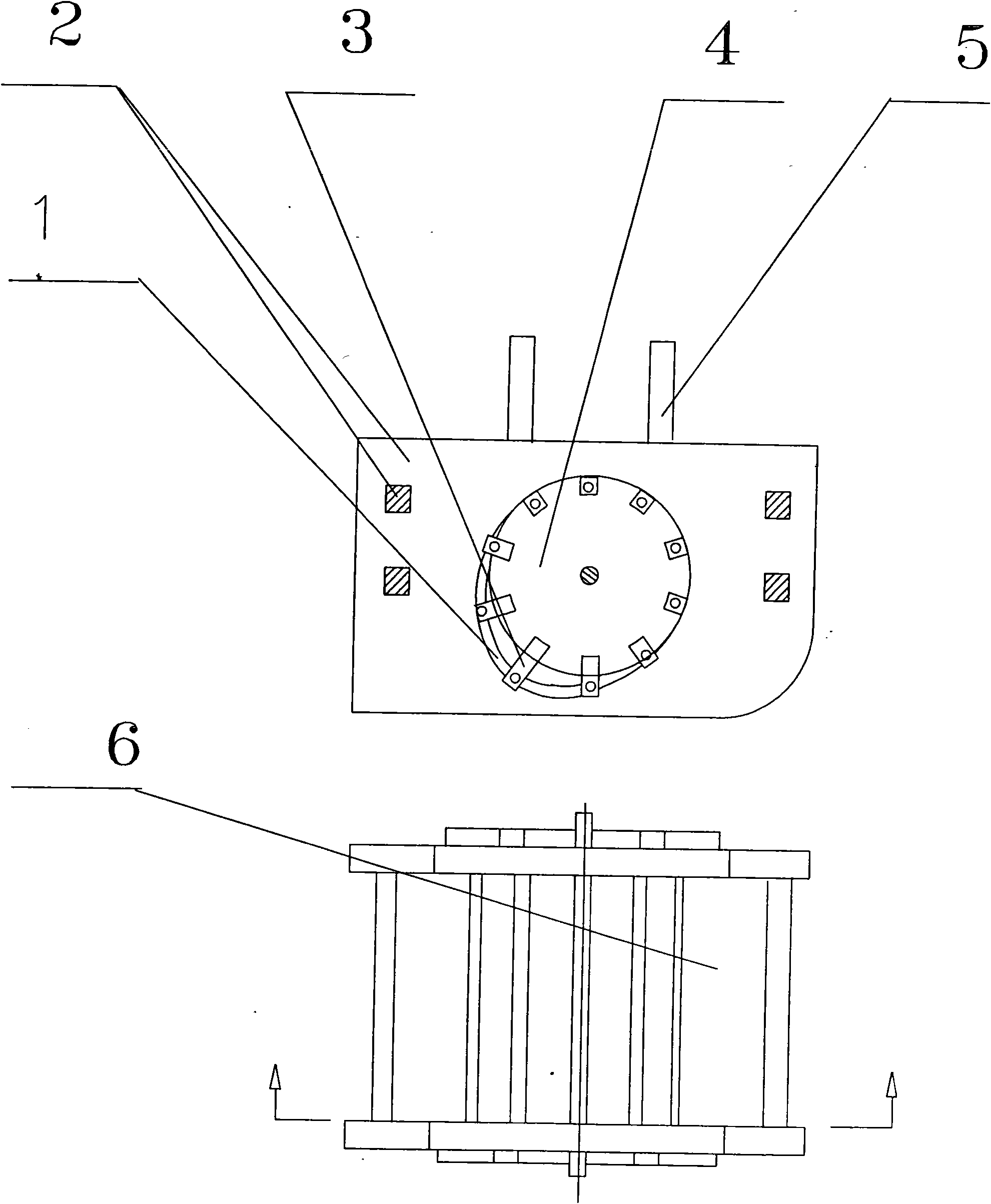

Knuckle bearing detection device

A knuckle bearing detection device comprises a detection workbench, a knuckle bearing clamping device mounted on the detection workbench, a loading system and a control system. The knuckle bearing clamping device comprises a knuckle bearing fixing seat and a knuckle bearing fixing cover which are respectively provided with a central hole. The loading system comprises a loading head, a hydraulic action system used for driving the loading head, and a pull pressure sensor arranged between the loading head and the hydraulic action system. The detection device further comprises a knuckle bearing outer ring fixing piece used for fixing the outer ring of a knuckle bearing on the loading head and a displacement sensor which is mounted on the detection workbench and is opposite to the knuckle bearing outer ring fixing piece. The control system carries out signal collecting and processing on the pull pressure sensor and the displacement sensor and controls the loading system according to collected signals. The detection device can accurately and reliably detect the fixing quality of the knuckle bearing under the action of actual loads and detect the needed axial loads for generating set displacement by the knuckle bearing.

Owner:COMAC +1

Hydraulic automatic adjustable flip weir

ActiveCN104099906AEasy to overflowAdjustable overflow levelBarrages/weirsArtificial water canalsRear quarterHydraulic action

The invention discloses a hydraulic automatic adjustable flip weir, which comprises a fixed base, wherein both ends of the fixed base are respectively provided with a side plate; a flip shaft is connected between the two side plates; the flip shaft is hinged to a weir plate; the bottom of the weir plate is in seal match with the fixed base; both ends of the weir plate are in seal match with the corresponding side plates; strengthening ribs are arranged on the back of the weir plate; a spring fixing support is connected onto the fixed base; a spring guide rod is connected onto the spring fixing support; a spring is arranged on the spring guide rod in a sleeving manner; a guide block is arranged on the top end of the spring on the spring guide rod in a sleeving manner, and is fixedly connected with a guide block fixing support; the top end of the guide block fixing support is fixedly connected with the strengthening ribs; the bottom end of the guide block fixing support is hinged to the flip shaft. The weir plate can be flipped under pure hydraulic actions, the overflow capacity is increased, the overflow water level before the weir is thus controlled, timely flood discharge is achieved, the weir plate can be reset by means of the spring force, and adjustment of the overflow water level can be adjusted by adjusting the spring force.

Owner:WUHAN SHENGYU DRAINING SYST

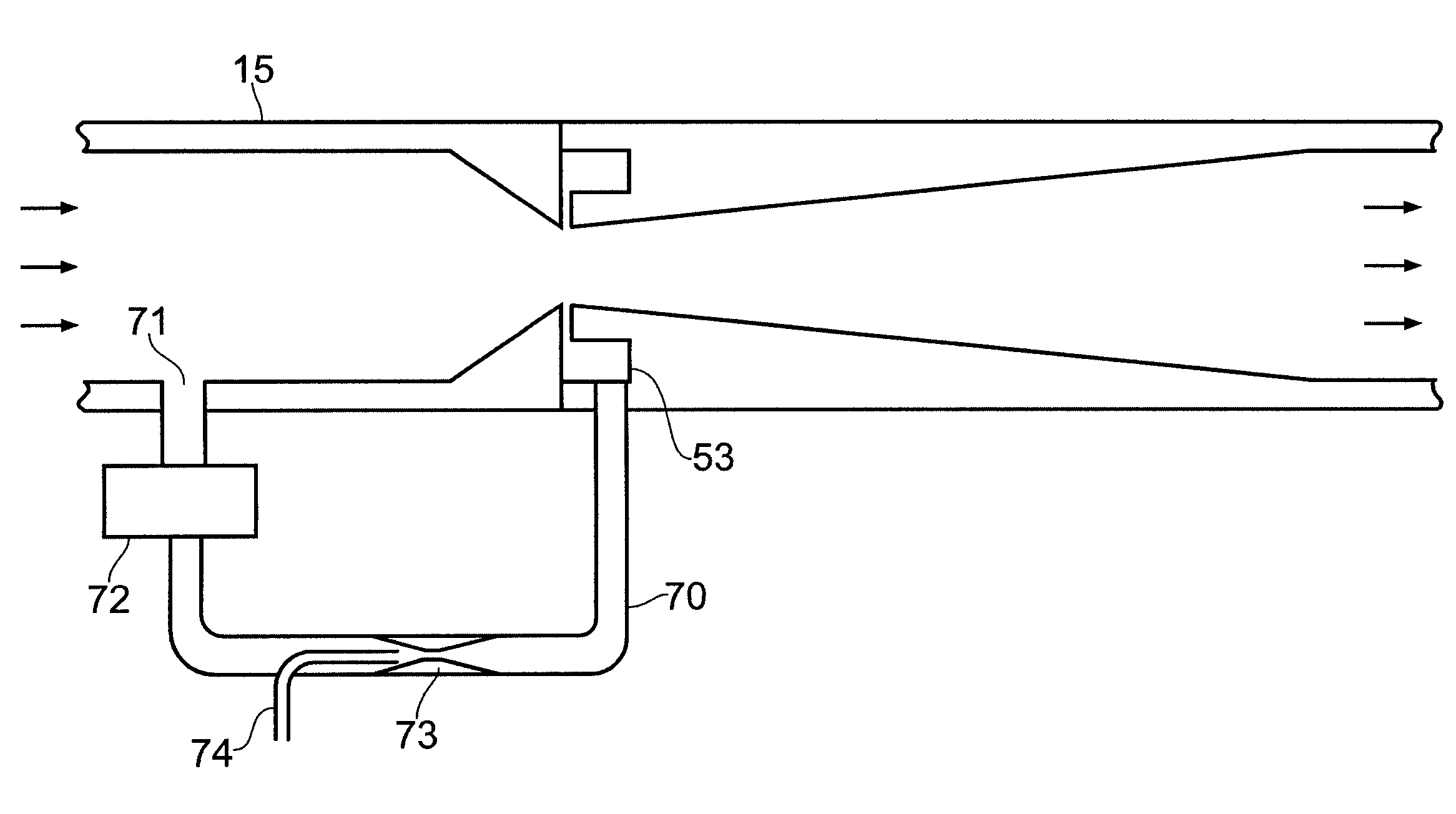

Water scavenging system

A fuel system comprising: a fuel line coupled to an engine; a fuel pump having an inlet coupled to a fuel tank and an outlet coupled to the fuel line; and a water scavenging system having an inlet for collecting water and an outlet coupled to the fuel line in parallel with the pump. The water scavenging system is powered by the hydraulic action of fuel in the fuel line using for example a venturi arrangement or a motor / pump combination.

Owner:AIRBUS OPERATIONS LTD

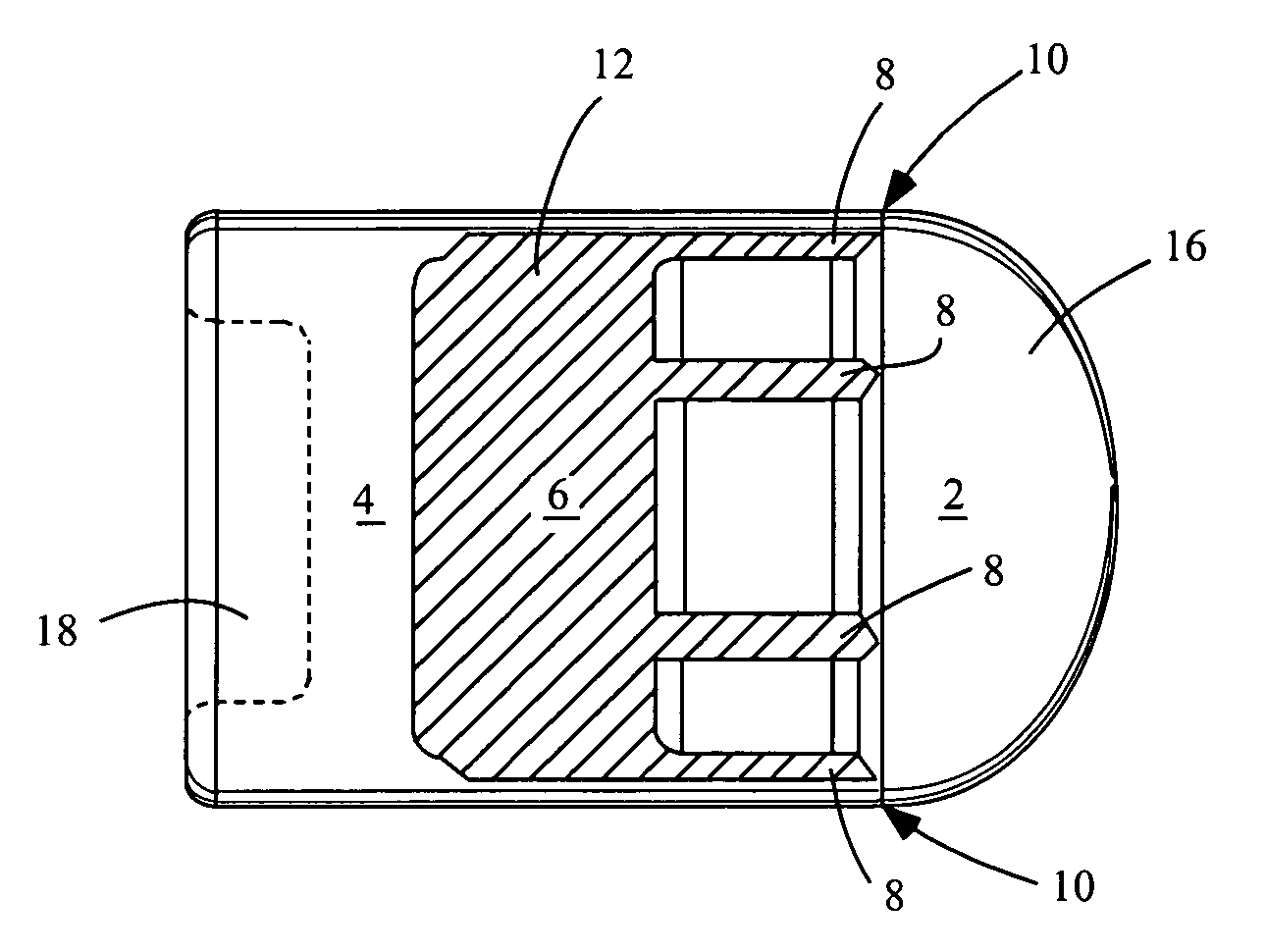

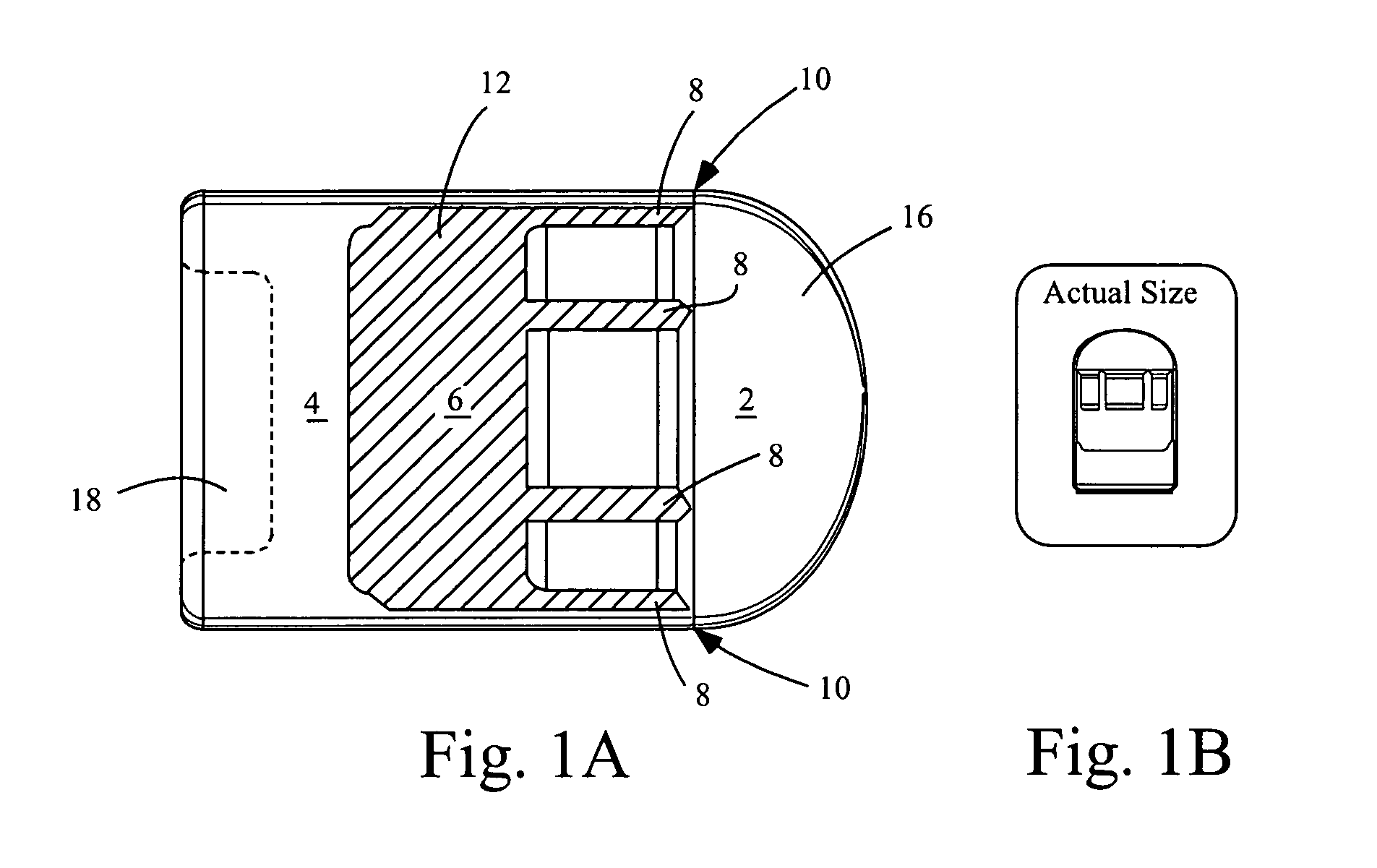

Pool cleaner storage arrangement

An improved storage receptacle for an automatic swimming pool cleaning device that incorporates a cleaning head secured to a retractable hose includes a barrier that is selectively operated to block the opening of the storage receptacle and prevent the cleaning head from entering the storage receptacle during use and becoming trapped. The barrier is a rod slidably disposed within a tube adjacent to the receptacle opening, and hydraulic action drives the rod upwardly to block the opening of the storage receptacle.

Owner:PANSINI ANDREW L

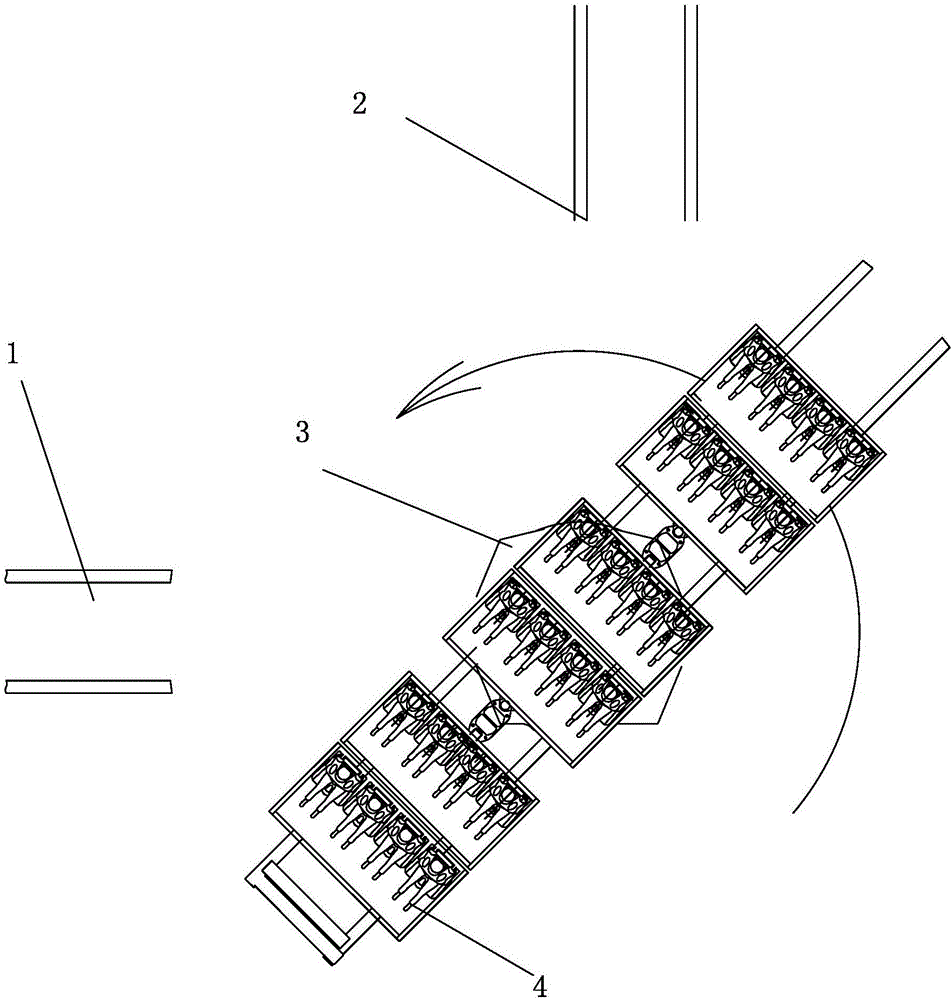

Hybrid drive pipeline robot

InactiveCN103615629AAdaptability to a wide range of tasksEfficient walkingPipe elementsHydraulic actionUniversal joint

The invention discloses a hybrid drive pipeline robot comprising a task unit, a steering unit, a front power unit, a rear power unit, and a drive control unit. The task unit is disposed at the front-most end of the robot. A function component and the drive control unit are mounted at the front-most end of the task unit. The steering unit is connected between the task unit and the front power unit. The rear power unit is mounted behind the front power unit through a universal joint. When the robot moves, turbine blades rotating in opposite directions generate pushing force pushing the robot to walk, and the robot can move forward or back by changing the rotation directions of the turbine blades. When the robot has low power, a support wheel brake block brakes a support wheel under the elastic action of springs, and the robot is held in a pipeline; liquid axially penetrates a body of the robot through the head end, and the turbine blades generate power under the hydraulic action to charge batteries. The hybrid drive pipeline robot is widely applicable to tasks, efficient walking and precise positioning are unified, power consumption is low, and online failure detection can be implemented conveniently.

Owner:ZHEJIANG FORESTRY UNIVERSITY +1

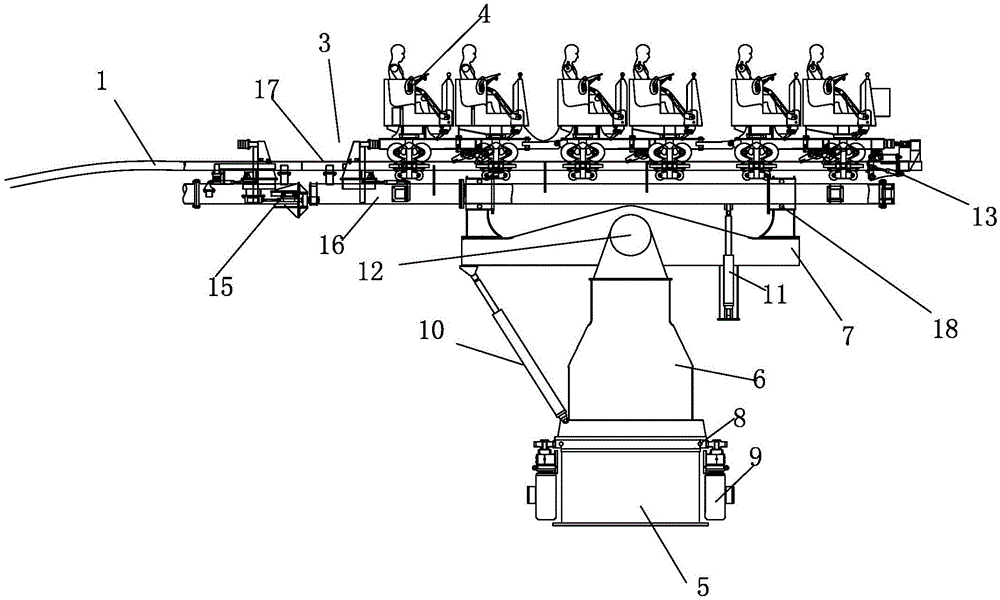

Rail changing device for roller coaster

The invention discloses a rail changing device for a roller coaster. After the roller coaster enters a rail changing zone, the roller coaster is rotated for a certain angle through the rail changing device, then can be connected to a subsequent fixed rail section and continues to move ahead. The rail changing device for the roller coaster comprises a fixed pedestal, a rotating pedestal and a swinging bracket, wherein the fixed pedestal and the rotating pedestal are connected through a rotary bearing, so that the rotating pedestal can rotate for 360 degrees around the axis of the fixed pedestal; the top of the rotating pedestal is rotationally connected with the swinging bracket through a rotary bearing; a hydraulic cylinder capable of swinging the swinging bracket with the rotary bearing as a fulcrum is arranged between the swinging bracket and the rotating pedestal; a movable rail section for the roller coaster to drive therein is mounted on the top of the swinging bracket. After passengers in the roller coaster enter the movable rail section, the movable rail section is rotated around a vertical axis to break away from the fixed rail section, the posture of a rail is adjusted through a rotating pair and a hydraulic action, and the roller coaster is rotated for a certain angle and is then connected to the subsequent fixed rail section to achieve rail change.

Owner:DALIAN WANDA GROUP CO LTD

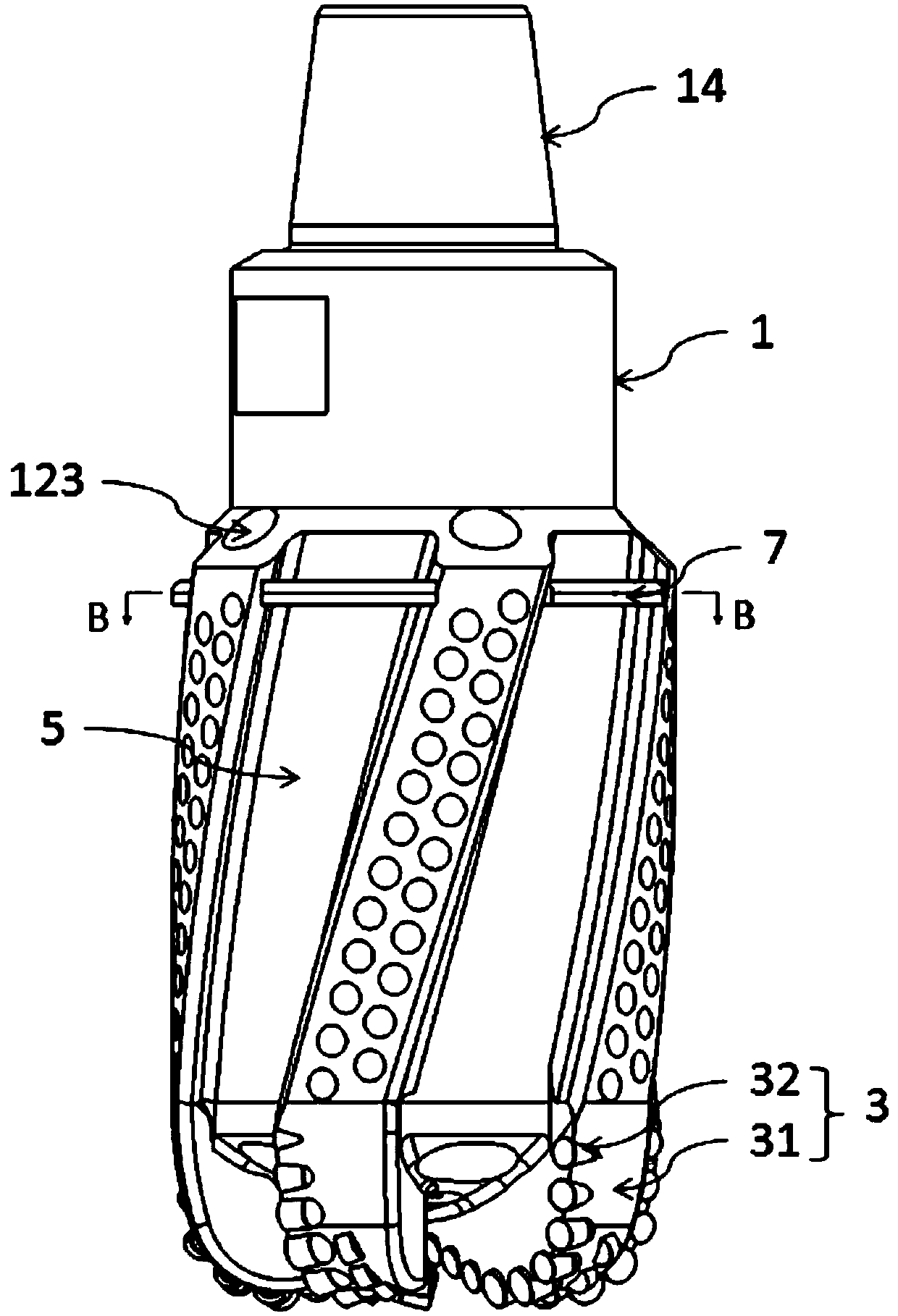

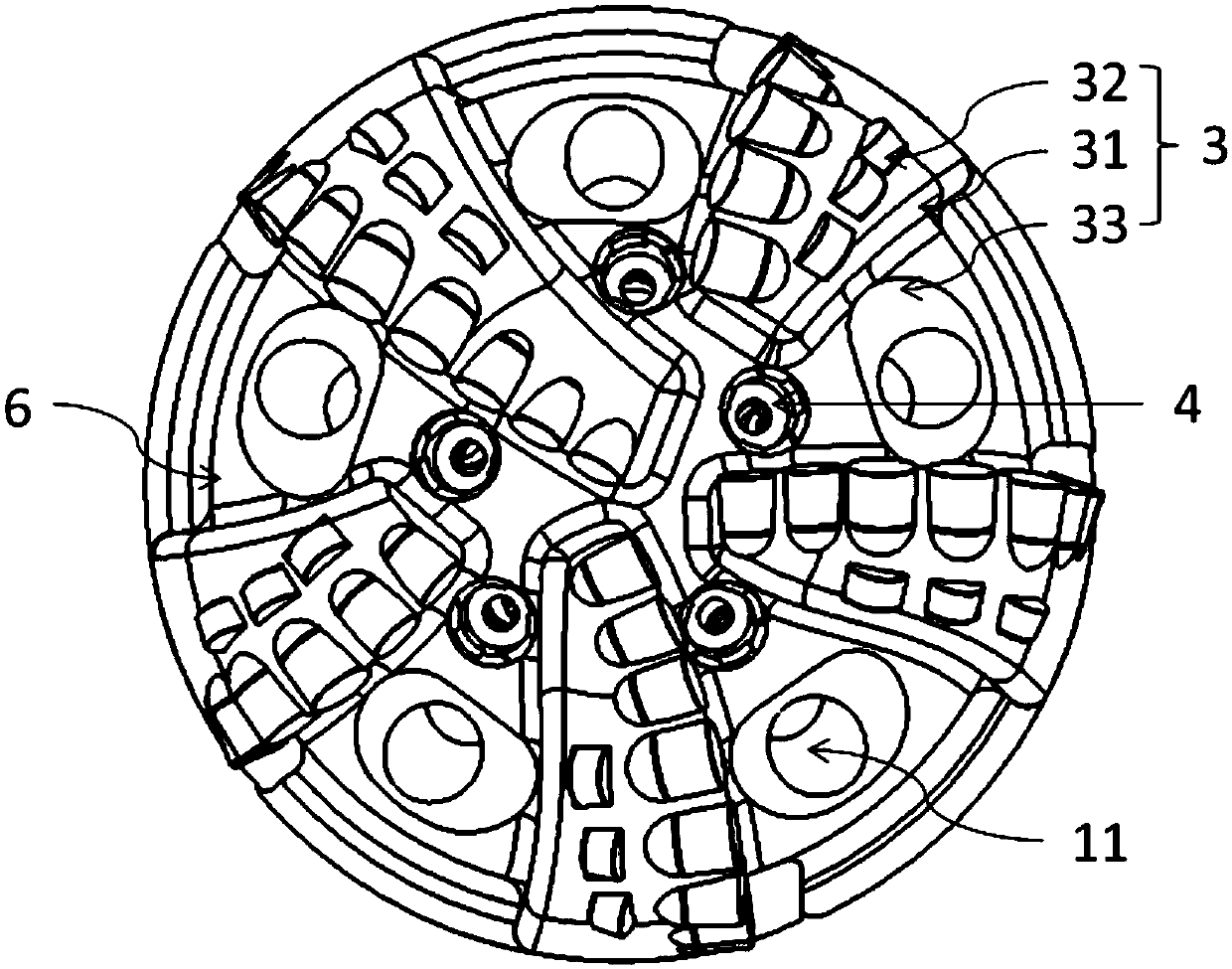

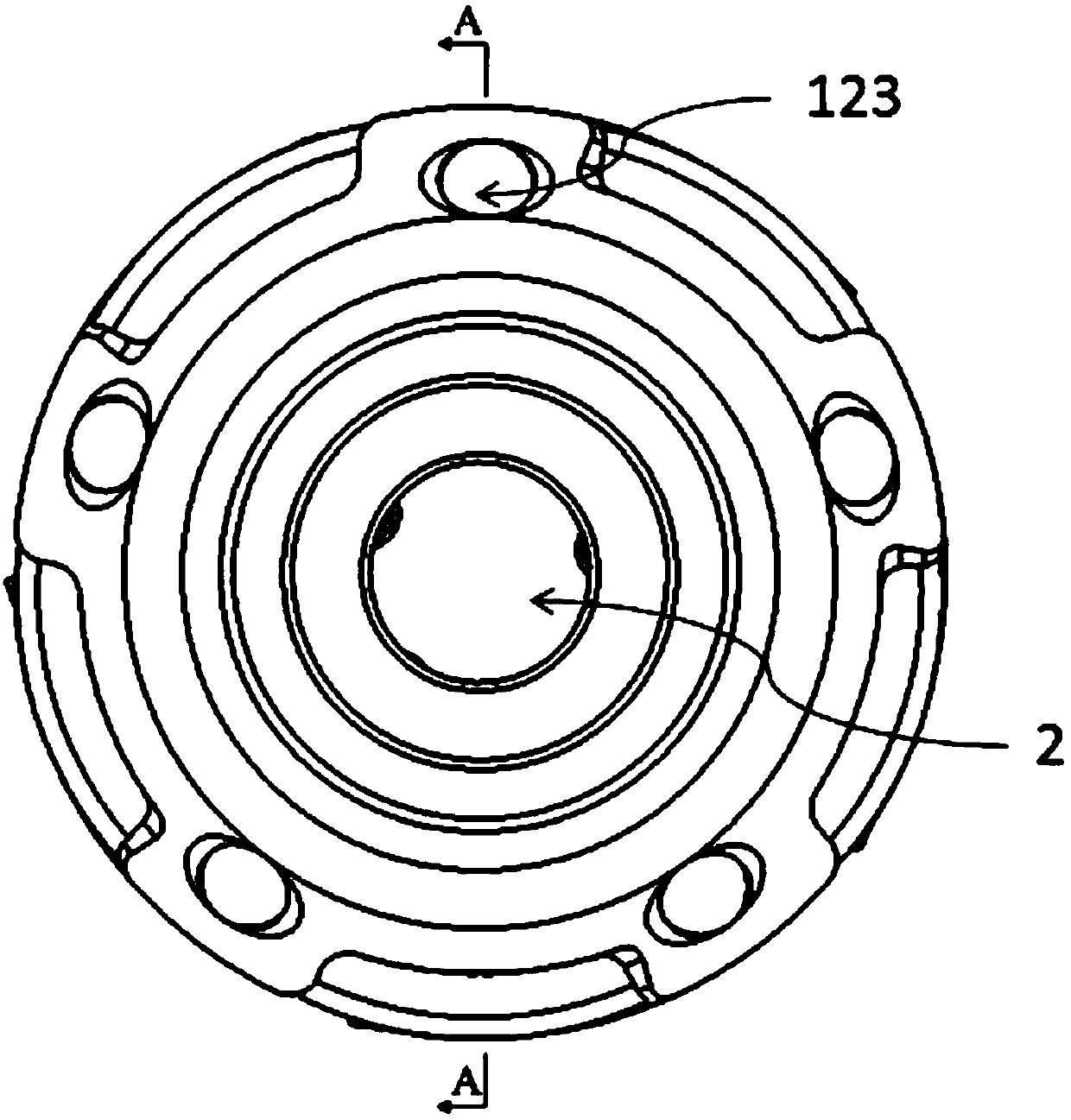

Jet flow drill bit with variable chip groove

InactiveCN109611030AAids in cutting and crushingRelieve pressureDrill bitsHydraulic actionWell drilling

The invention discloses a jet flow drill bit with a variable chip groove, and relates to the field of oil and gas well drilling. The jet flow drill bit comprises a body extending along an axis and provided with a runner; a cutting mechanism is arranged on the body and used for cutting rocks; a first jet flow nozzle communicating with the runner is arranged at the lower end of the body and used forjetting flows to the bottom of a well and flushing rock debris particles generated by the cutting mechanism; a chip groove extending in an axis direction is formed in the side wall of the body; a notch for accommodating a sealing plate is formed in the side wall of the body; a first channel communicating with the runner and the notch is formed in the body in the radial direction; a telescopic mechanism in transmission with the sealing plate is arranged in the first channel; and the telescopic mechanism can drive the sealing plate to move in the radial direction under the hydraulic action of the flow channel, so that the chip groove has a blocking state and a smooth state. The state of the chip groove can be changed according to the working state of the drill bit, so that the using effectof the jet drill bit is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

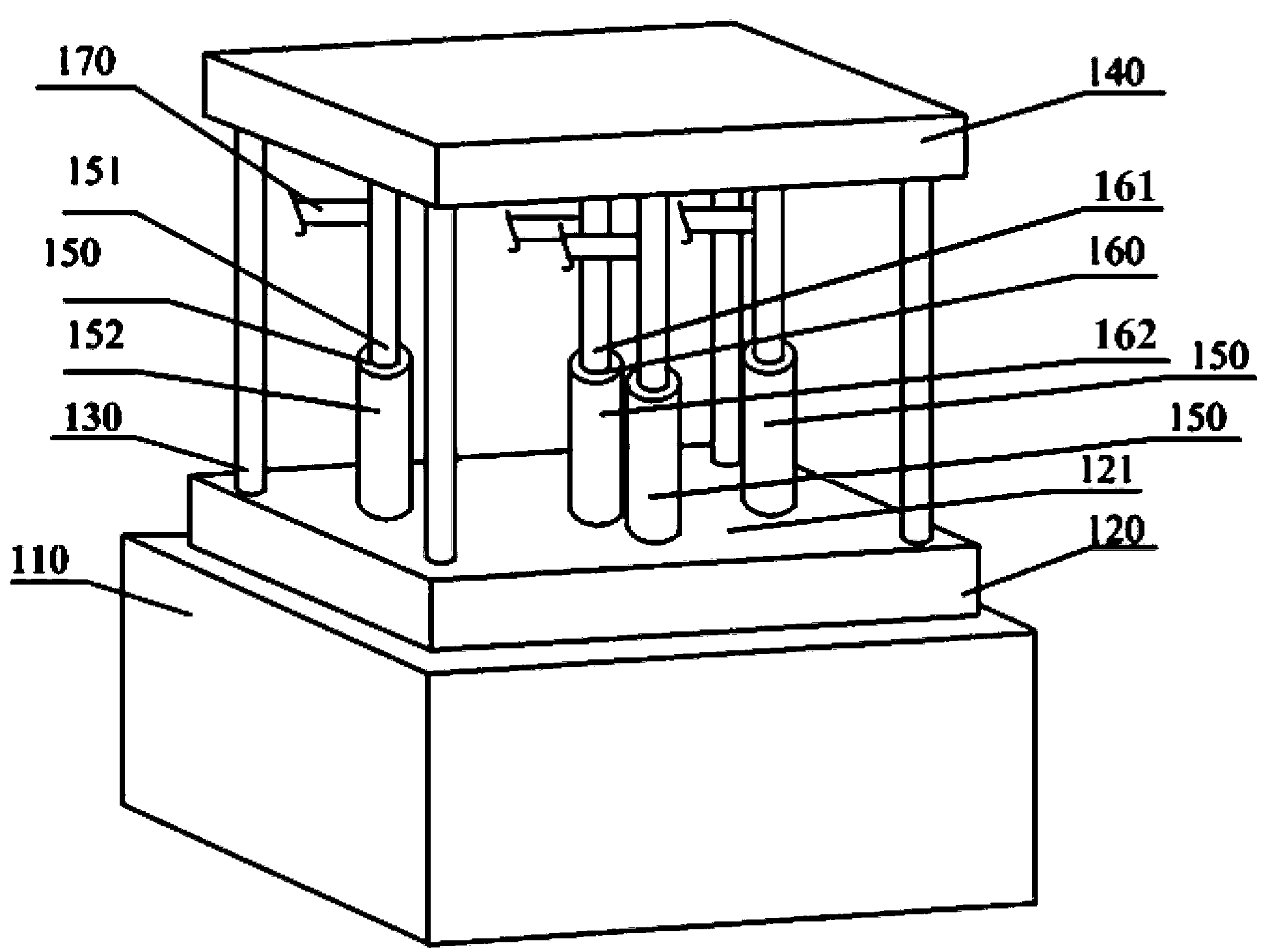

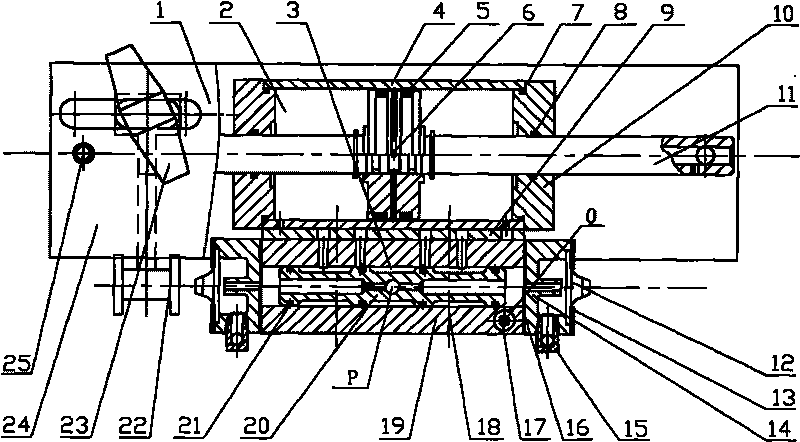

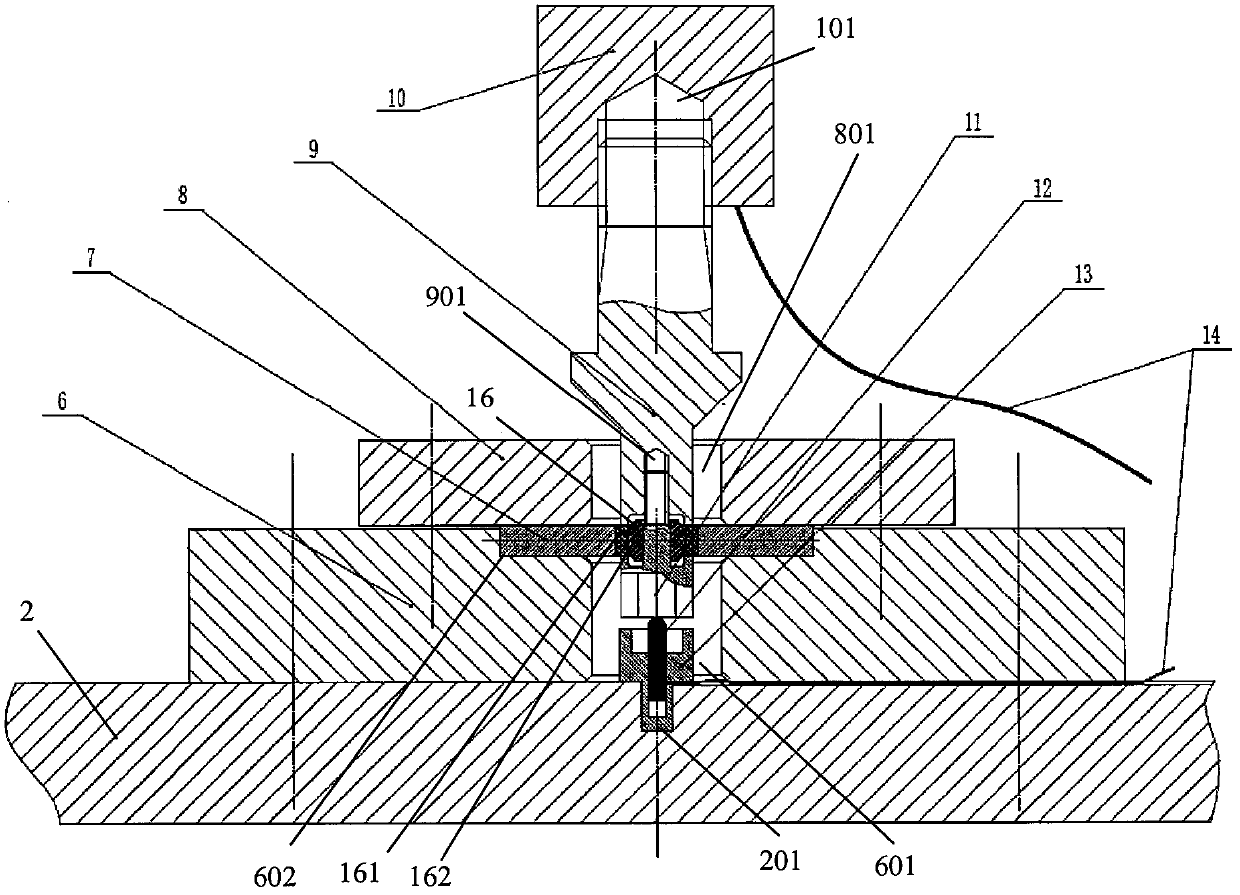

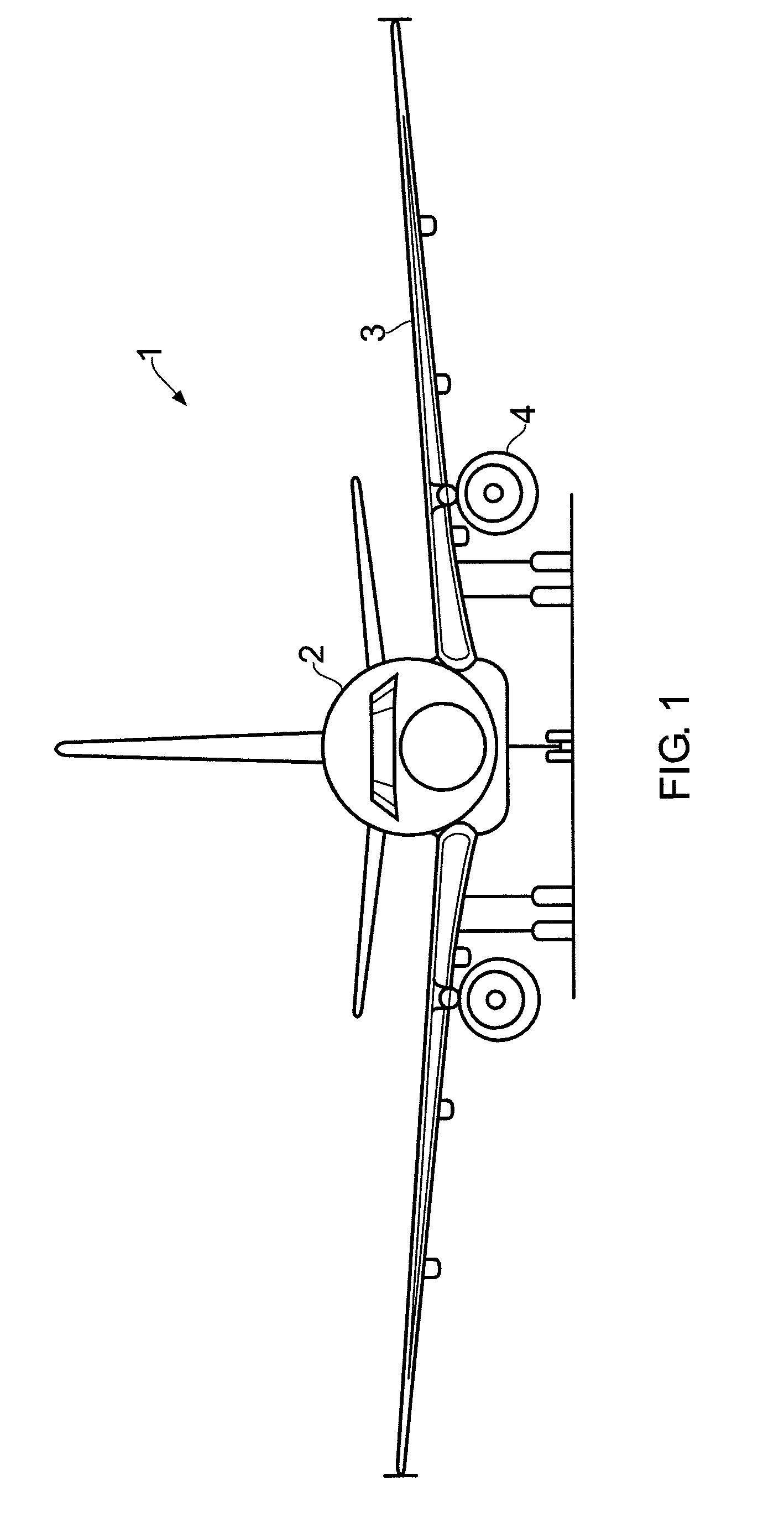

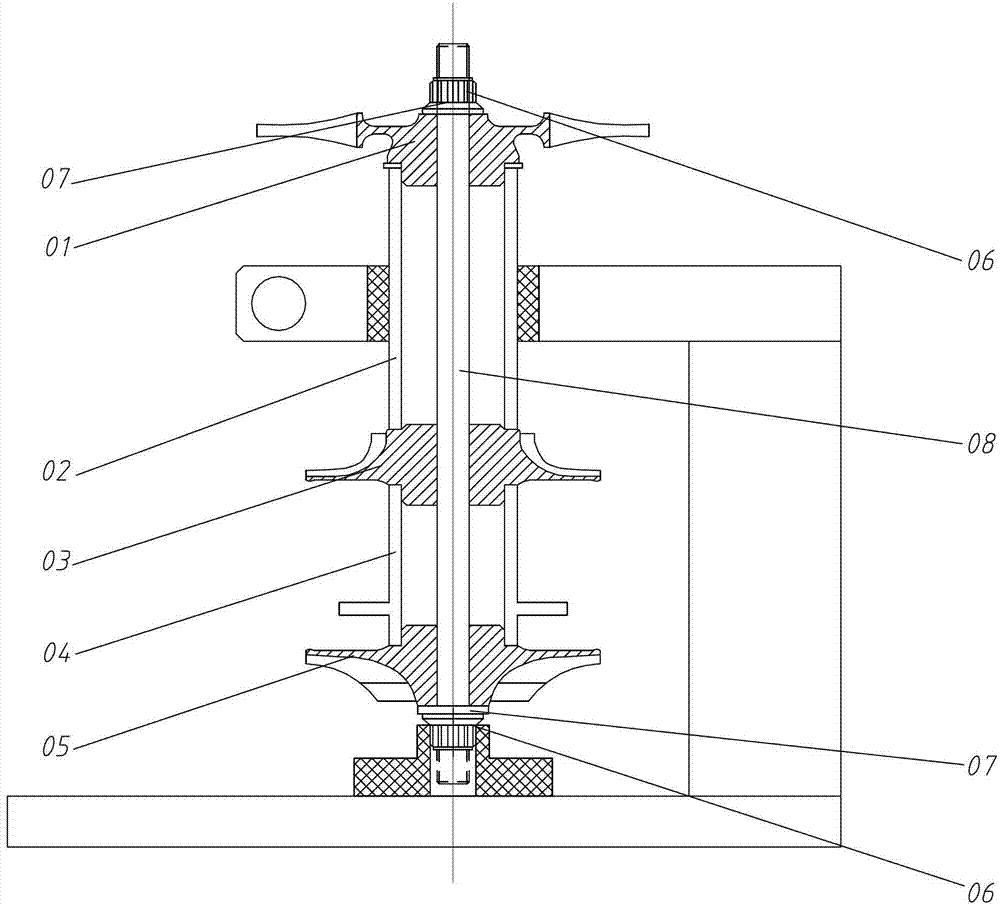

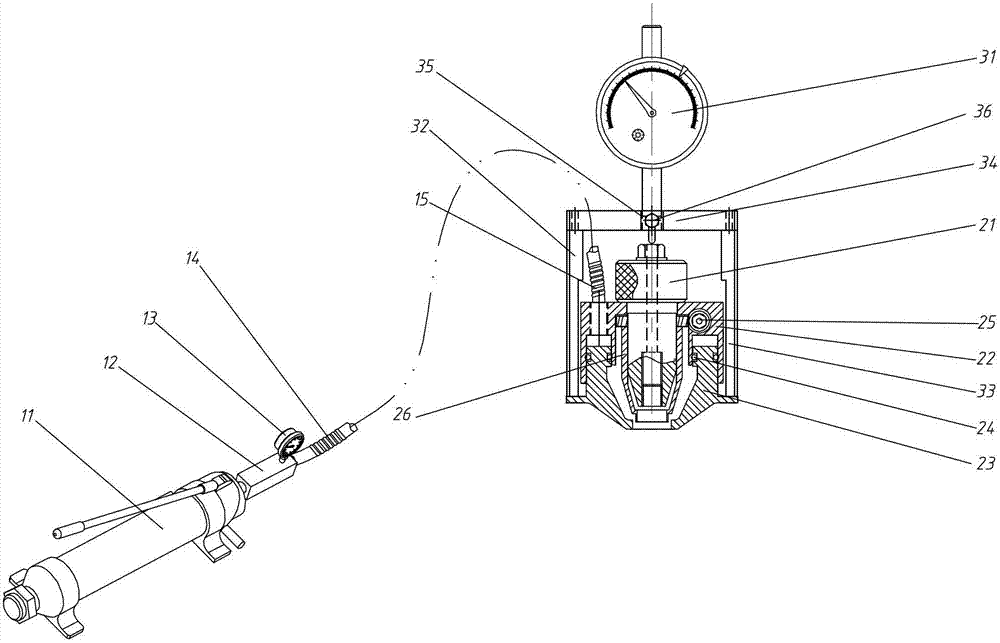

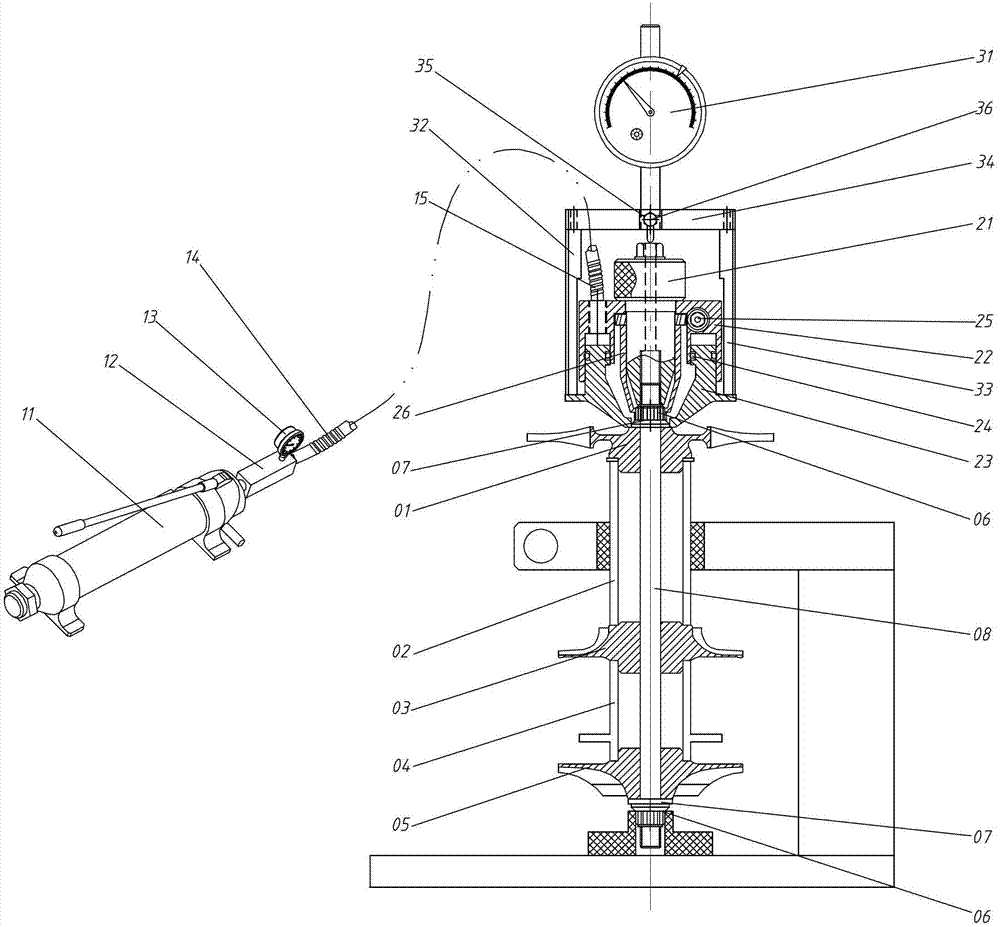

Hydraulic axial load device for airplane air circulator rotating components

ActiveCN103240588AAccurate and reliable extensionMetal working apparatusAir cycle machineHydraulic action

The invention discloses a hydraulic axial load device for airplane air circulator rotating components. The hydraulic axial load device comprises a hydraulic supply unit, an axial load action unit and a public pull-rod elongation detecting unit, wherein the axial load action unit is connected with a public pull rod of an air circulator rotating component to be detected, the hydraulic supply unit is communicated with the axial load action unit and supplies hydraulic power for the same, the axial load action unit moves to elongate the public pull rod under the hydraulic action, the public pull rod elongation detecting unit is provided with a dial indicator installed above the axial load action unit and contacts with the same, the axial load action unit pushes the dial indicator during moving, and elongation of the pull rod after elongation can be obtained by reads of the dial indicator. The hydraulic axial load device can apply axial load on the airplane circulator rotating components and can reliably acquire accurate elongation of the public pull rod.

Owner:GUANGZHOU AIRCRAFT MAINTENANCE ENG

Hydraulic action device

InactiveCN101676550AAvoid negative forcesImprove hydraulic efficiencyPropulsion power plantsHydro energy generationElectricityHydraulic action

The invention relates to a hydraulic action device for developing the waterpower resources. The device is characterized in that the device comprises a waterpower position control mechanism, a rotor and blades, wherein the waterpower position control mechanism contains a stator, the stator is provided with a water-surge port and a blade slideway; the slideway of the slideway changes the radial position of blades around the rotor, stream in relative motion acts on the blades, the acting forces of steam on different blades of the rotor are different so as to promote the rotation of the rotor andgenerate directional acting force, the kinetic energy of the rotor can be used to generate electricity, pump water or even use the energy of adverse current to promote the marine vehicle to move; furthermore, the directional acting force of the rotor can balance the other acting forces such as gravity of the marine vehicle. The invention has novel conception and great practical value.

Owner:周文珺

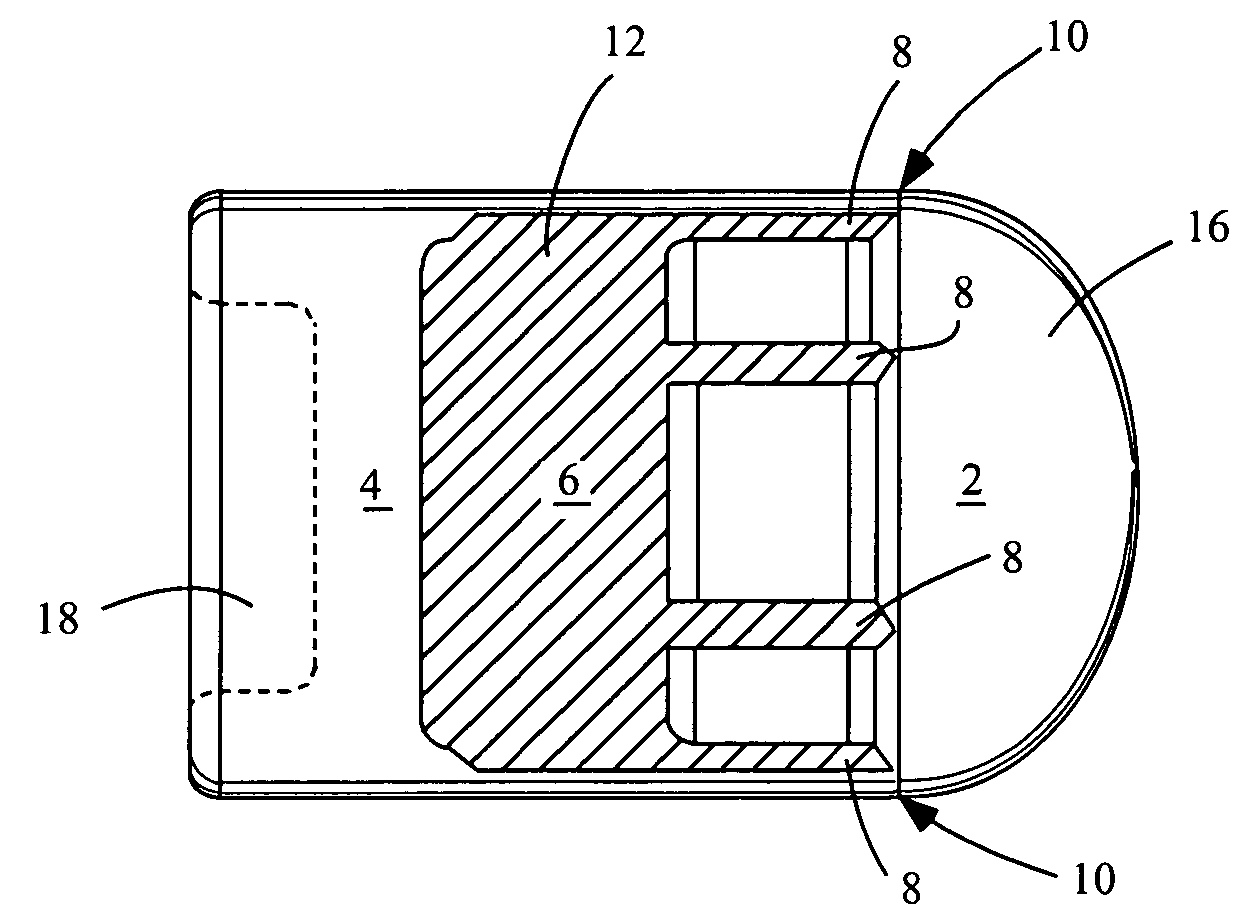

Non-lethal marking bullet for related training cartridges

A projectile of non-lethal composition includes an outer casing that is substantially sealed prior to impact with a target both when the projectile is in a static condition and when the projectile is in a dynamic condition. A marking material is encapsulated within the outer casing prior to impact. The outer casing is configured to deform and unseal upon impact such that the marking material disperses forward via hydraulic action.

Owner:GEN DYNAMICS ORDNANCE & TACTICAL SYST

Floating drive on boat docking apparatus

InactiveUS20070169675A1Dampening pivotingAdjustable buoyancyDry-dockingSlipwaysHydraulic actionMarine engineering

An improved floating boat lift incorporates a passive hydraulic pivoting lift mechanism, onto which a boat can be driven and positioned ready for storage using only the motive power of the boat itself. The passive hydraulic pivoting lift mechanism provides mechanical advantage in the pivoting action of the apparatus by way of passive hydraulic action, while at the same time dampening pivoting of the apparatus. Embodiments further provide means for adjusting the elevation of the pivot point relative to the surface of the body of water by way of adjusting the buoyancy of the pivoting lift mechanism.

Owner:BASTA IP INC

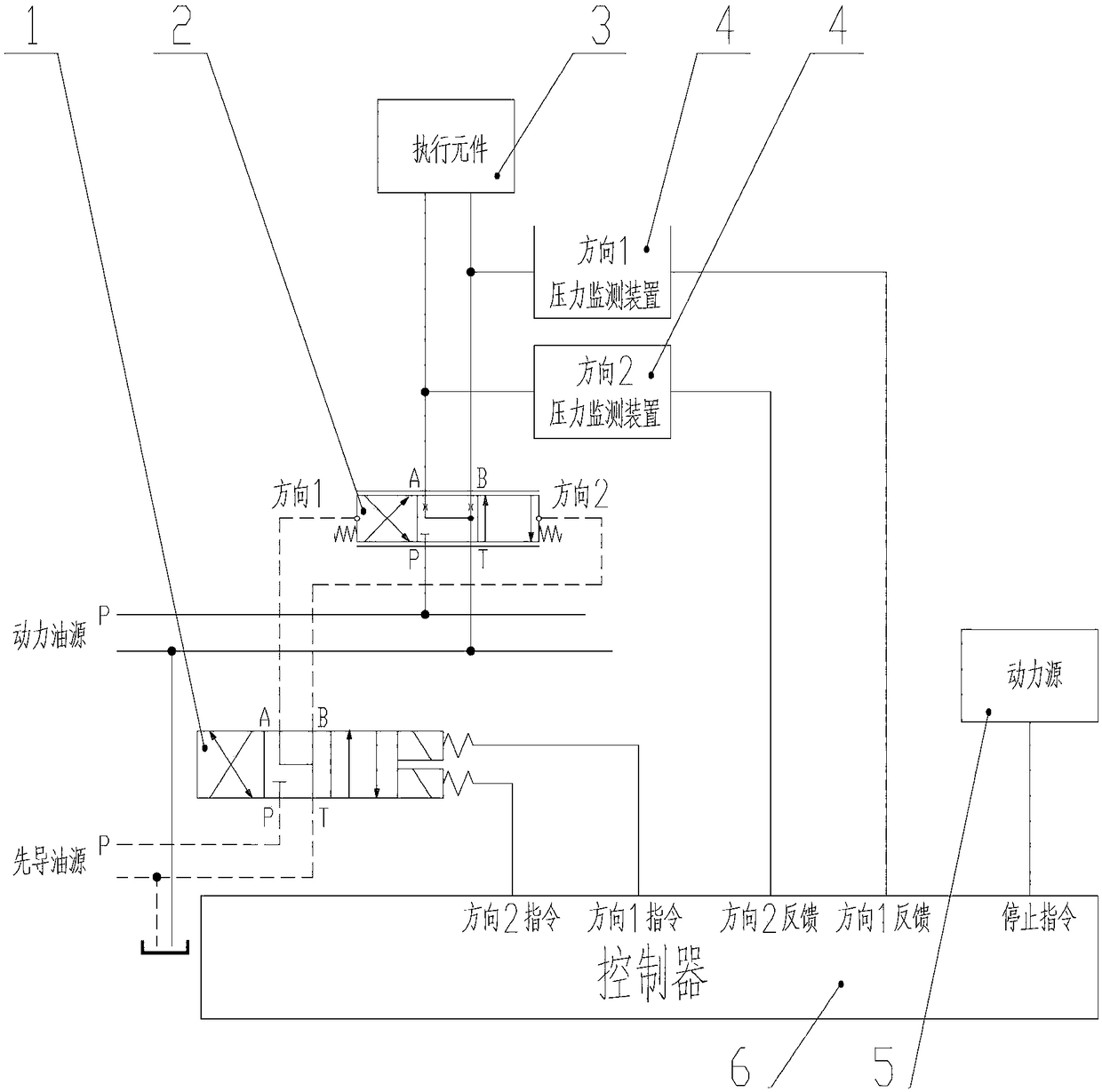

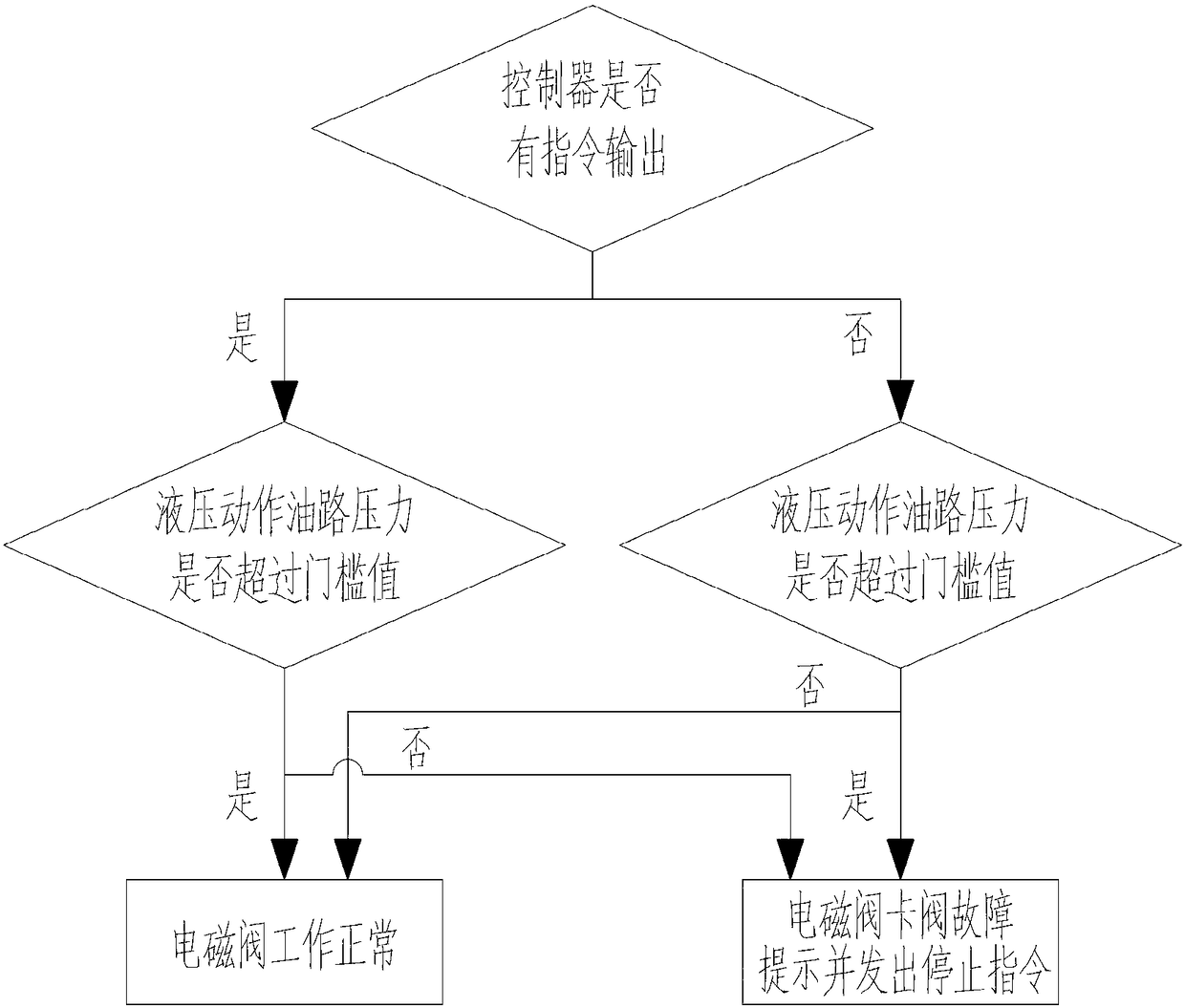

Valve jamming fault monitoring device for hydraulic solenoid valve

ActiveCN108286542AAvoid safety accidentsAvoid getting out of controlFluid-pressure actuator testingServomotor componentsHydraulic actionSolenoid valve

The invention discloses a valve jamming fault monitoring device for a hydraulic solenoid valve. The valve jamming fault monitoring device for the hydraulic solenoid valve comprises the hydraulic solenoid valve, a pressure monitoring device, a controller and a power source. The hydraulic solenoid valve is a target monitored article. The pressure monitoring device is used for monitoring the pressurestate of a hydraulic oil way in the hydraulic action circuit controlled by the hydraulic solenoid valve. The hydraulic solenoid valve, the pressure monitoring device and the power source are all connected with the controller. When the controller finds that the valve jamming fault happens through monitoring, the controller outputs the stop instruction to cut off the power source.

Owner:XUZHOU XUGONG FOUND CONSTR MACHINERY

Pool cleaner storage arrangement

An improved storage receptacle for an automatic swimming pool cleaning device that incorporates a cleaning head secured to a retractable hose includes a barrier that is selectively operated to block the opening of the storage receptacle and prevent the cleaning head from entering the storage receptacle during use and becoming trapped. The barrier is a rod slidably disposed within a tube adjacent to the receptacle opening, and hydraulic action drives the rod upwardly to block the opening of the storage receptacle.

Owner:PANSINI ANDREW L

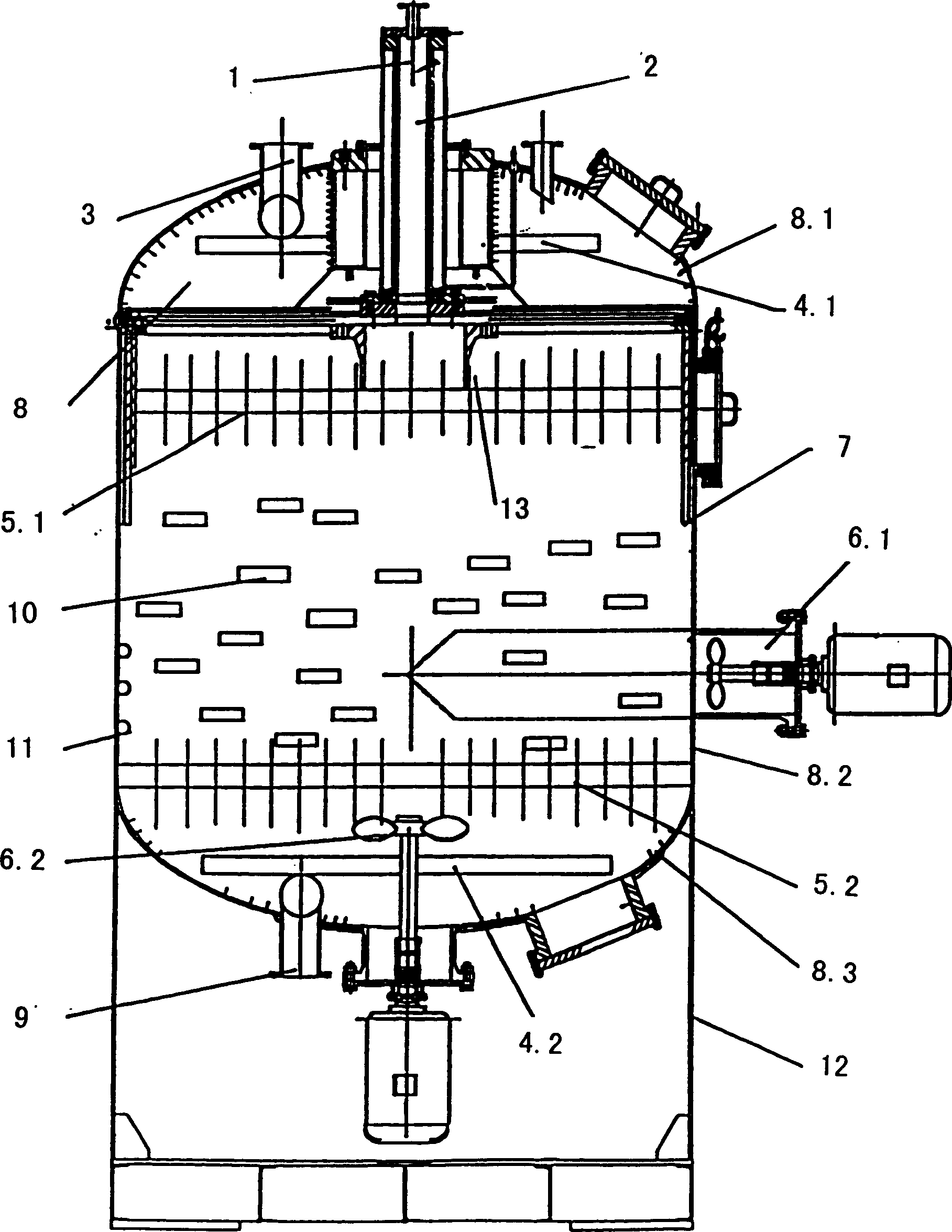

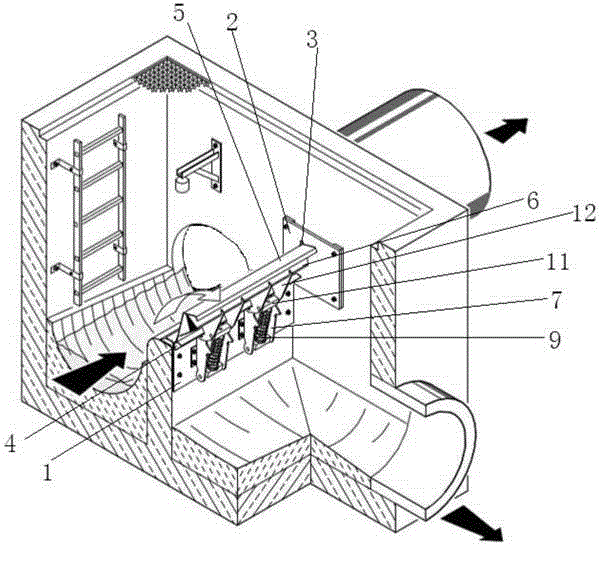

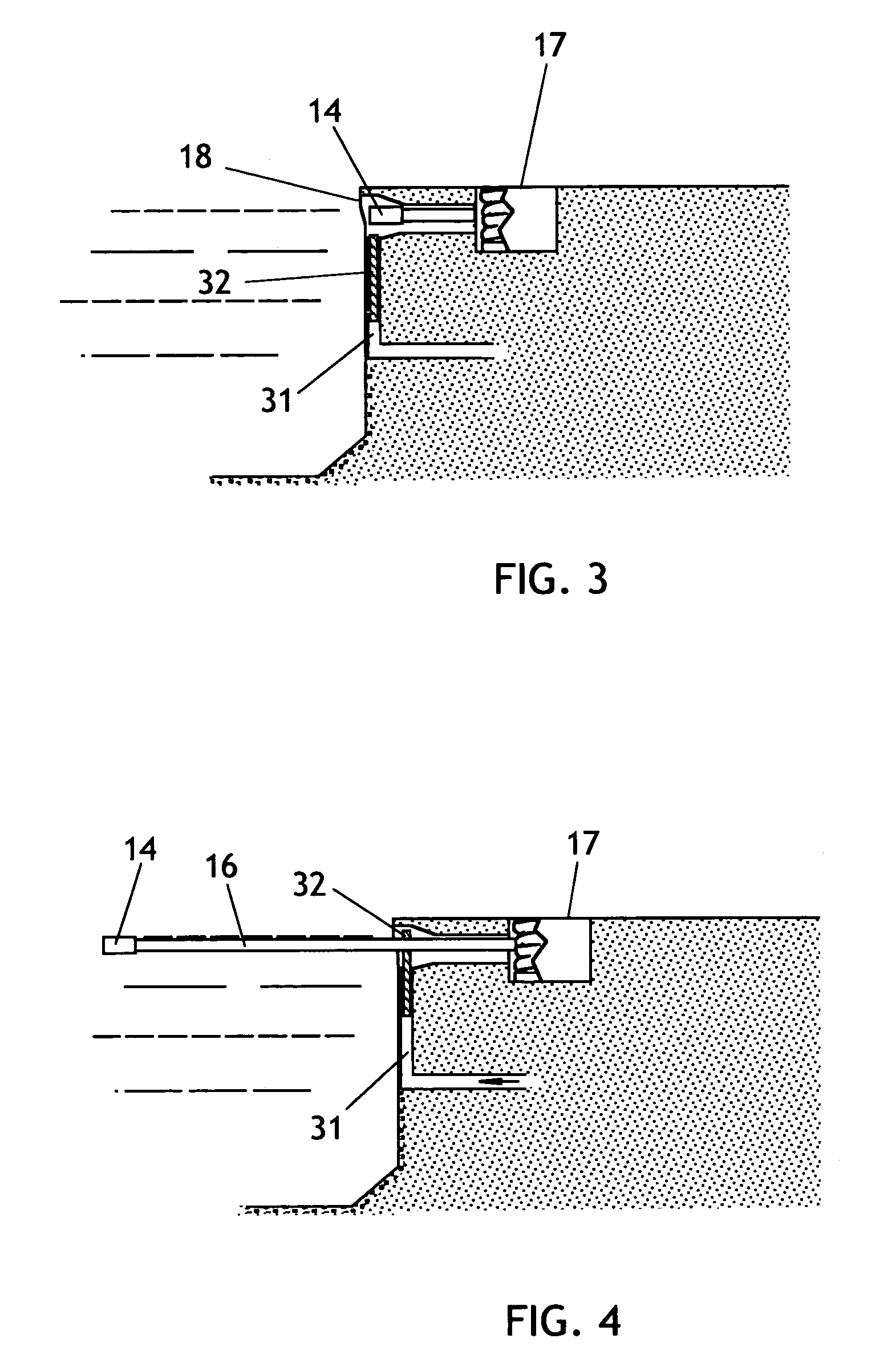

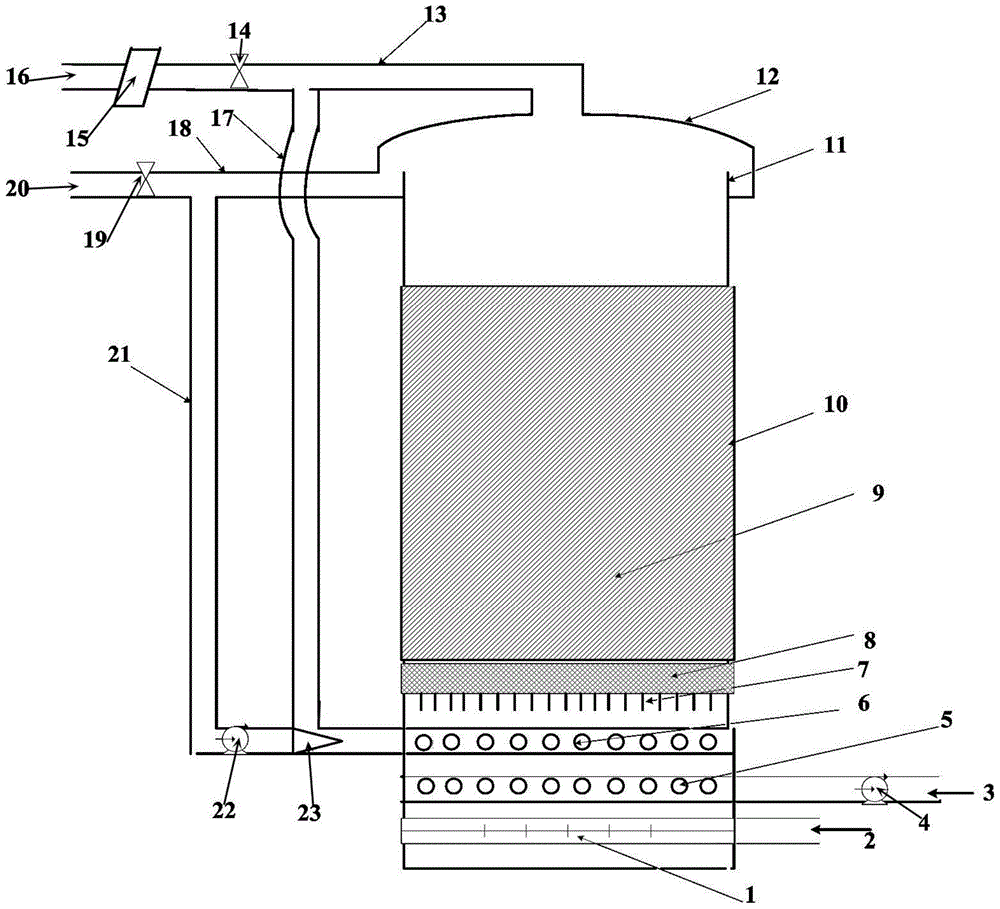

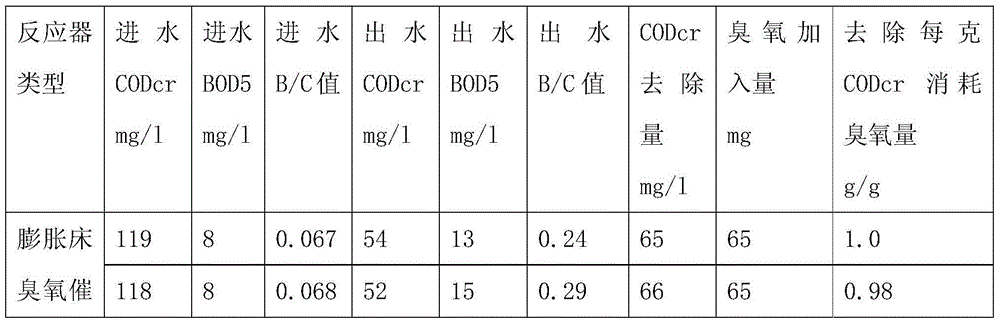

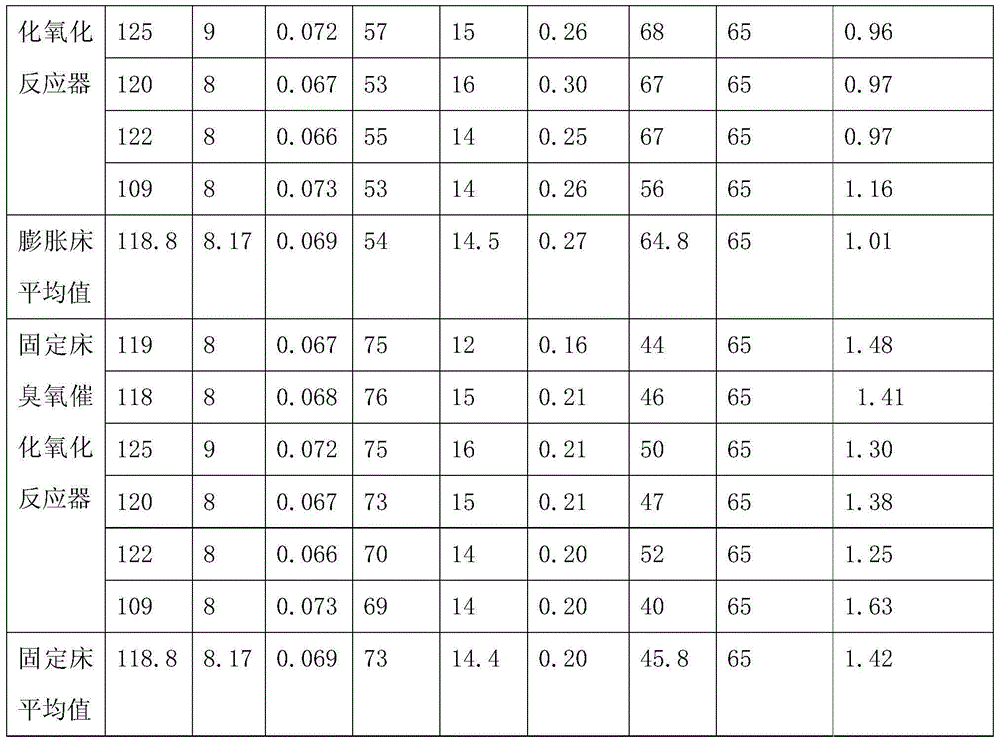

Catalytic ozonation reactor for expanded bed and sewage treatment method of catalytic ozonation reactor

ActiveCN104478065AReduce the difficulty of operationPrevent channelingWater/sewage treatment by oxidationHydraulic actionGas phase

The invention discloses a catalytic ozonation reactor for an expanded bed. An ozone distributor, a feedwater distributor and a catalyst bed are sequentially arranged inside the reactor from bottom to top, a tail gas pipe and a sewage outlet pipe are arranged at the upper part of the reactor, a tail gas return pipe is arranged at the tail gas pipe, a sewage return pipe is arranged on the sewage outlet pipe, the tail gas return pipe and the sewage return pipe are respectively communicated with a gas phase inlet and a water phase inlet of a water injector; a return water / gas distributor is arranged between the catalyst bed and the feedwater distributor, and an outlet of the water injector is communicated with the return water / gas distributor by virtue of a pipeline; in an operational process of the reactor, the catalyst bed is in an expanded state under the hydraulic action of feedwater and return sewage. The invention also discloses a sewage treatment method applying the catalytic ozonation reactor for the expanded bed. The sewage treatment method disclosed by the invention has the advantages that sewage treatment depth can be improved, ozone utilization rate can be greatly increased, and tail gas can meet discharge standard requirements, so that the sewage treatment method is environmentally friendly, and resource can be saved.

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com