Ratio control hydraulic pressure system for implementing belt steel rolling constant-tension control

A proportional control, hydraulic system technology, applied in tension/pressure control, fluid pressure actuating devices, etc., can solve the problems of high cost of coiling machinery and equipment, inability to meet short rolling pieces, complex control models, etc., to meet the requirements of a simple control system , Improve the availability and ensure the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: as shown in Figure 5, a single-stand four-high rolling mill is adopted, and a tension hydraulic cylinder 20 and 21 are respectively arranged before and after the rolling mill 26, and the rolled piece 27 is placed between the two work rolls 28 of the rolling mill 26, and on both sides of the rolled piece 27 One clamp hydraulic cylinder 7 and 8 are set respectively; diameter of backup roll 29: φ550 / φ500×450mm, diameter of work roll 28: φ150 / φ140×470mm; maximum rolling force: 2500kN, equipped with hydraulic AGC system; rolling speed: 0 ~0.1~0.24m / s; rolling tension range: 5~100kN; maximum stroke of hydraulic tension cylinder: 1500mm; minimum initial length of rolled piece: Lmin=500mm.

[0030] The basic configuration of the proportional control hydraulic system used to realize the constant tension control of strip rolling is as follows:

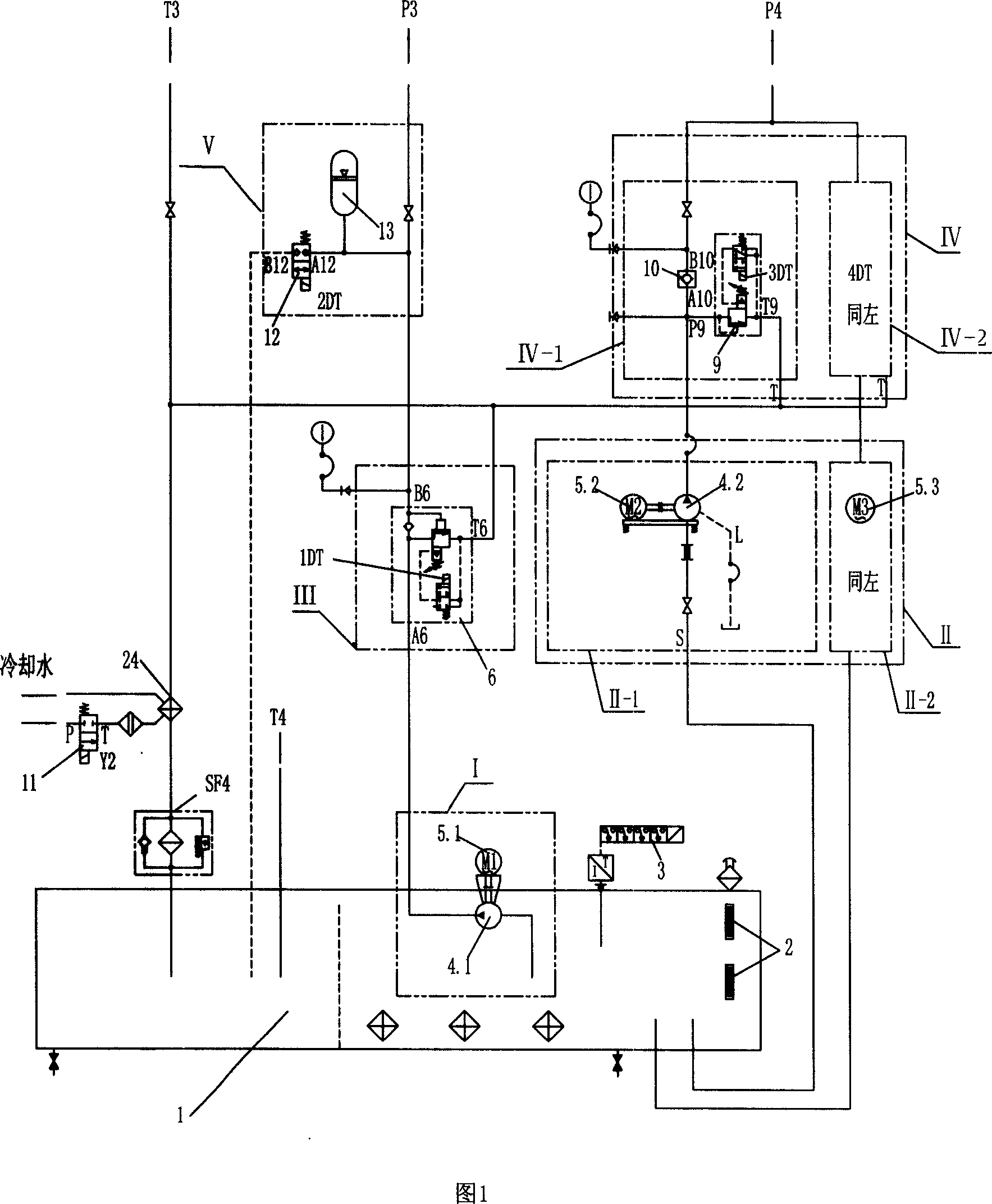

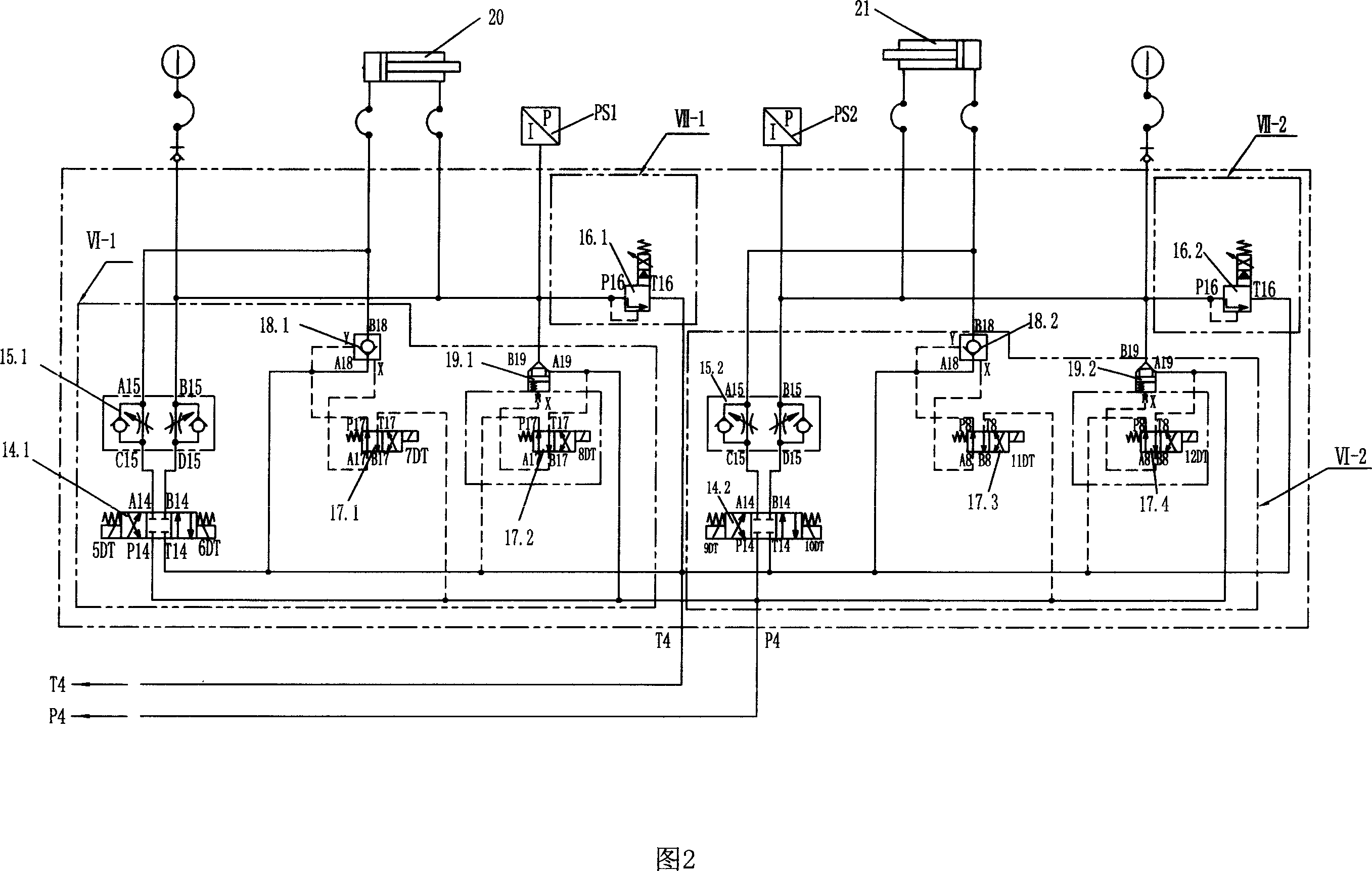

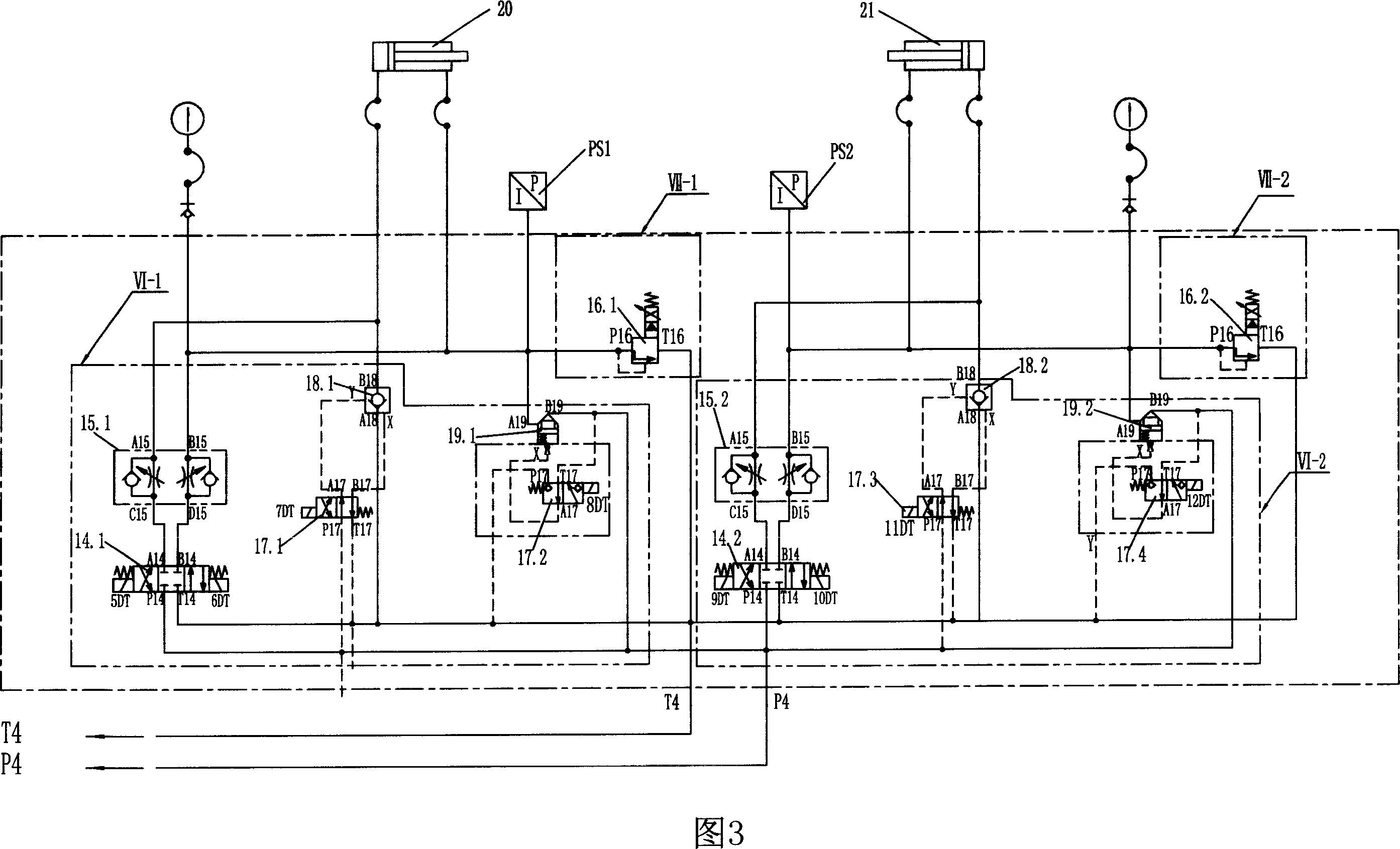

[0031] Hydraulic schematic diagrams are shown in Figure 1, Figure 2, and Figure 4: Low-pressure oil source: low-pressure p...

Embodiment 2

[0035] Embodiment 2: As shown in Figure 1, a single-stand four-high rolling mill is adopted, and a tension hydraulic cylinder 20 and 21 are respectively arranged before and after the rolling mill 26, and the rolled piece 27 is placed between the two work rolls 28 of the rolling mill 26, and on both sides of the rolled piece 27 One clamp hydraulic cylinder 7 and 8 are set respectively; diameter of backup roll 29: φ550 / φ500×450mm, diameter of work roll 28: φ150 / φ140×470mm; maximum rolling force: 2500kN, equipped with hydraulic AGC system; rolling speed: 0 ~0.1~0.24m / s; rolling tension range: 5~100kN; maximum stroke of hydraulic tension cylinder: 1500mm; minimum initial length of rolled piece: Lmin=500mm. The specifications of each valve, pressure sensor, and tension hydraulic cylinders 20, 21 are the same as those of Embodiment 1.

[0036] The high-pressure oil source, high-pressure safety pressure control device, proportional control device, and low-pressure oil source in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com