Selective catalytic reduction urea air premixing jet system

An injection system and selective technology, applied in exhaust treatment, exhaust devices, chemical instruments and methods, etc., can solve the most difficult technical and economic problems that cannot effectively solve the low temperature crystallization of urea solution, increase the burden on the urea solution delivery pump, and are difficult to achieve. Optimization and other issues to achieve the effect of reducing wet wall deposition, improving stability and accuracy, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

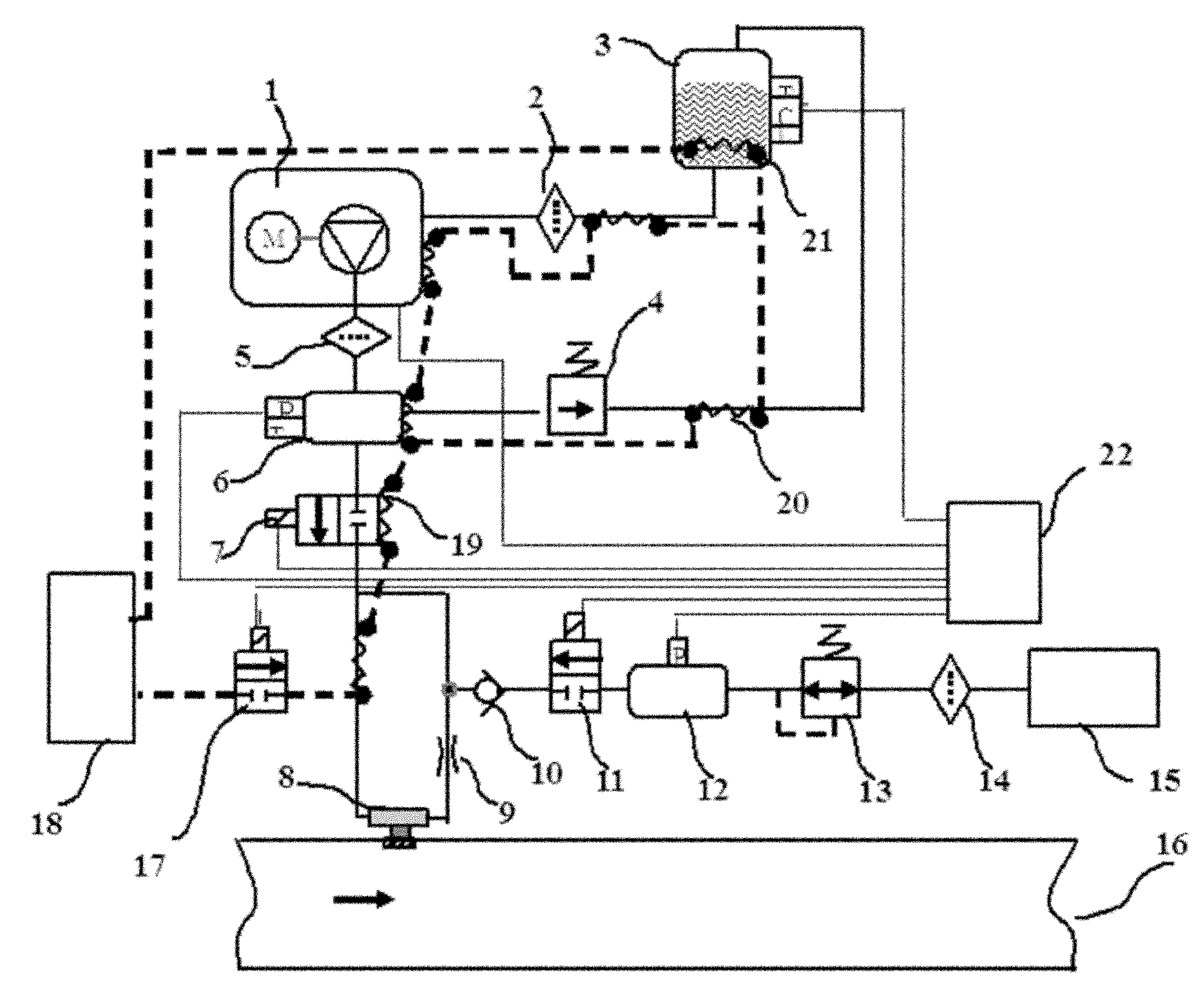

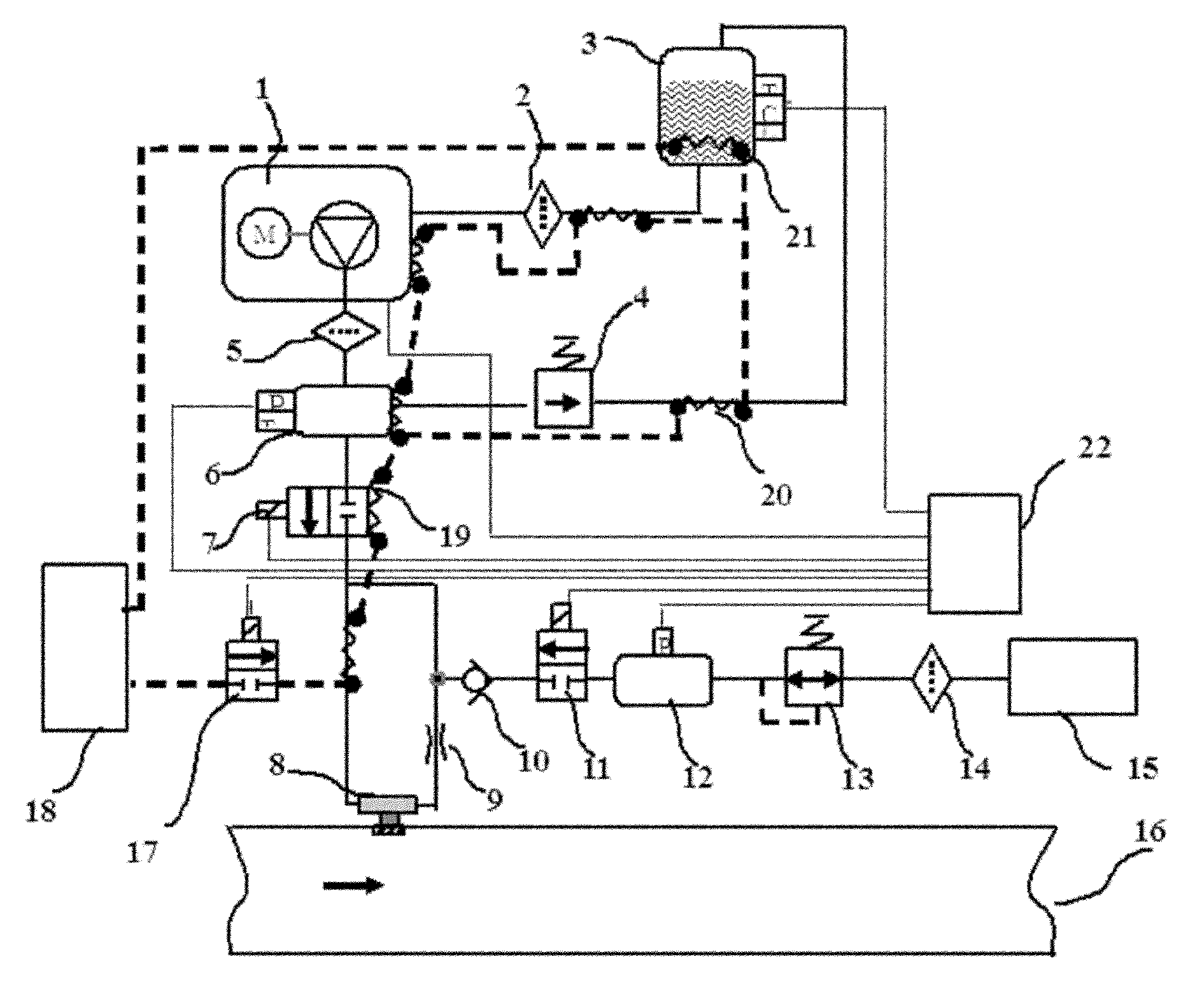

[0033] Such as figure 1 As shown, this embodiment includes: metering pump 1, first filter 2, urea solution tank 3, return valve 4, second filter 5, urea solution pressure stabilizing chamber 6, injection solenoid valve 7, air atomization Nozzle 8, air pressure adjustment hole 9, one-way valve 10, air solenoid valve 11, air pressure chamber 12, air pressure reducing valve 13, air filter 14, compressed air tank 15, coolant solenoid valve 17, integrated Heat exchange device 19, pipeline heat exchange device 20, urea solution tank heat exchange device 21, wherein: the first connection end of metering pump 1 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com