Ultra-fine microcrystalline cellulose and preparation thereof

A technology of microcrystalline cellulose and crystalline cellulose, which is applied in the field of ultra-fine crystalline cellulose and its preparation, and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

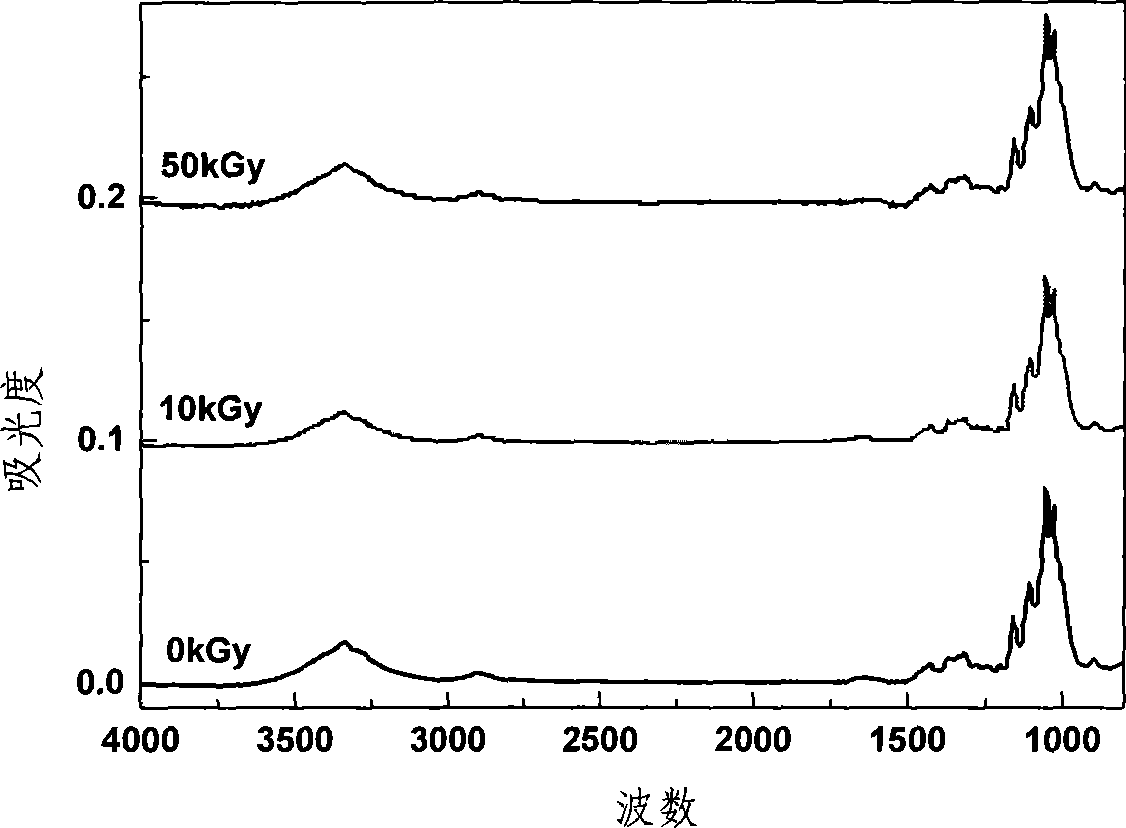

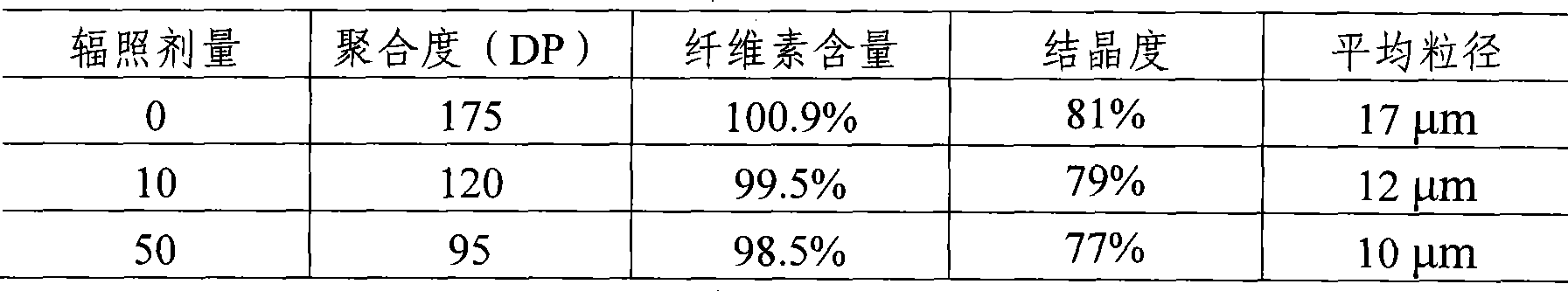

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1 ultrafine MCC

[0029] 40 kg of commercially available MCC with an average particle size of 50 μm was irradiated with Co-60 gamma rays at 50 kGy, and ultrafinely pulverized with a jet mill to obtain ultrafine MCC with an average particle size of 10 μm.

example example 2

[0030] The preparation of example example 2 ultrafine MCC

[0031] 1 kg of the ultrafine MCC with an average particle diameter of 10 μm was mixed with 5 kg of pure water, ground with a wet mill for 30 min, and then vacuum-dried to obtain an ultrafine MCC with an average particle diameter of 8 μm.

Embodiment 3

[0032] The preparation of embodiment 3 ultrafine MCC

[0033] The ultrafine MCC with an average particle diameter of 10 μm in Example 1 was mixed according to the following feed ratio: 400g MCC, 1440mL hydrochloric acid, 160mL sulfuric acid, 2400mL purified water. React at 95°C for 24h. The obtained product is neutralized and washed with sodium hydroxide, finally centrifuged and spray-dried to obtain superfine MCC with an average particle diameter of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com