Nanometer hydroxyapatite powder preparation method

A nano-hydroxyapatite, powder technology, applied in chemical instruments and methods, phosphorus compounds, chemical/physical/physical-chemical processes of applying energy, etc. problems such as group agglomeration, to achieve the effect of reducing the preparation cost, good crystallinity, and no agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Embodiment 1: first calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 O and diammonium hydrogen phosphate (NH 4 ) 2 HPO 4 , mix according to the molar ratio of Ca:P=1.67:1, add distilled water to dissolve, and make the Ca in the solution 2+ The concentration of ions is 0.05mol / L; add urea powder in the solution according to the total mass of calcium nitrate tetrahydrate and diammonium hydrogen phosphate: urea=1:5, and stir evenly; under magnetic stirring, the multi-frequency acoustic chemical generator Put the generating head into the above solution, and carry out sonochemical synthesis for 3 hours at 80°C with an ultrasonic frequency of 35KHz; filter and wash the suspension, first wash 2 times with distilled water, then wash 3 times with absolute ethanol, and filter out The materials were put into a vacuum drying oven and dried at 80°C to obtain nano-hydroxyapatite powder.

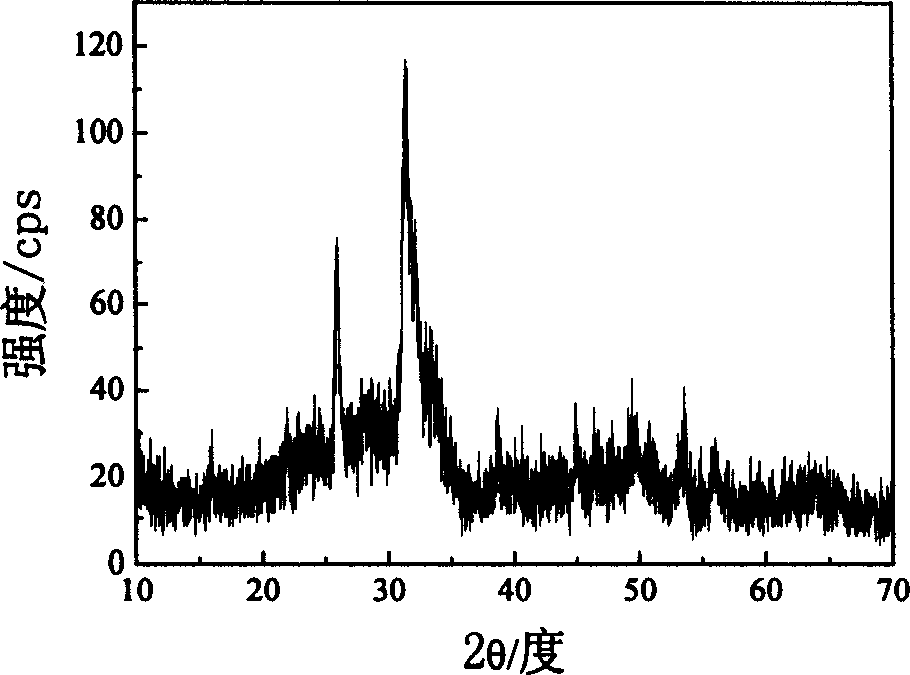

[0009] The crystal structure and particle size of the obtained powder were analyzed by the Ja...

Embodiment 2

[0010] Embodiment 2: first calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 O and diammonium hydrogen phosphate (NH 4 ) 2 HPO 4, mix according to the molar ratio of Ca:P=2:1, add distilled water to dissolve, and make the Ca in the solution 2+ The concentration of ions is 0.01mol / L; add urea powder in the solution according to the total mass of calcium nitrate tetrahydrate and diammonium hydrogen phosphate: urea=1:6, and stir evenly; under magnetic stirring, the multi-frequency acoustic chemical generator Put the generating head into the above solution, and carry out sonochemical synthesis for 3 hours at 80°C with an ultrasonic frequency of 25KHz; filter and wash the suspension, first wash 2 times with distilled water, then wash 3 times with absolute ethanol, and filter out The materials were put into a vacuum drying oven and dried at 90°C to obtain nano-hydroxyapatite powder.

[0011] The crystal structure and particle size of the obtained powder were analyzed by the Japane...

Embodiment 3

[0012] Embodiment 3: first calcium nitrate tetrahydrate Ca(NO 3 ) 2 4H 2 O and diammonium hydrogen phosphate (NH 4 ) 2 HPO 4 , mix according to the molar ratio of Ca:P=2.5:1, add distilled water to dissolve, and make the Ca in the solution 2+ The concentration of ions is 0.01mol / L; add urea powder in the solution according to the total mass of calcium nitrate tetrahydrate and diammonium hydrogen phosphate: urea=1:7, and stir evenly; under magnetic stirring, the multi-frequency acoustic chemical generator Put the generating head into the above solution, and carry out sonochemical synthesis for 3 hours at 80°C with an ultrasonic frequency of 35KHz; filter and wash the suspension, first wash 2 times with distilled water, then wash 3 times with absolute ethanol, and filter out Put the material into a vacuum drying oven and dry it at 100°C to obtain nano-hydroxyapatite powder.

[0013] The crystal structure and particle size of the obtained powder were analyzed by the Japanes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com