Method for laser pulse sputtering deposition preparation of polycrystalline silicon thin film

A technology of polysilicon thin film and sputtering deposition, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, can solve the problems of unfavorable batch production, limited application of devices, and high requirements for substrates, and achieve a good degree of crystallization , good combination and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The coating material is selected as a 99.99% silicon target, and the substrate is a 20*35*3mm copper sheet. First, the copper substrate is pre-treated: the copper substrate is mechanically polished, cleaned with deionized water, firstly ultrasonicated in acetone for 10 minutes, then cleaned with absolute ethanol for 10 minutes and then dried; then the silicon target and the copper substrate are placed Into the PLD-450 vacuum system, vacuum to 1.0×10 -4 Pa, the temperature of the copper substrate is 600°C, the distance between the copper substrate and the silicon target is 4cm, and then the TOL-25B excimer laser is used as the laser source to emit laser light at a frequency of 4HZ, sputtering for 3 hours, and finally after Annealed at 800°C to prepare a polysilicon film.

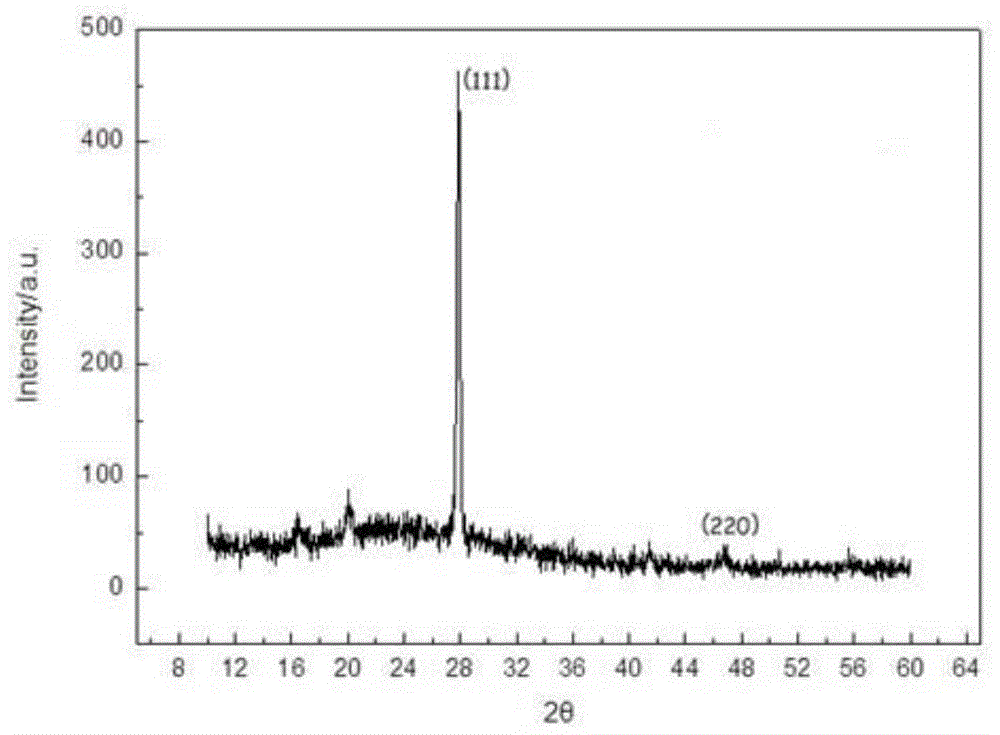

[0027] Such as figure 1 Shown is that the polysilicon thin film prepared in Example 1 carries out XRD test at room temperature, and the characteristic diffraction peak of crystalline silicon appears ...

Embodiment 2

[0031] The coating material is selected as 99.99% silicon target material, and the substrate is 30*30*3mm quartz glass. First, the quartz glass substrate is pre-treated: the quartz glass substrate is cleaned with deionized water, ultrasonicated in acetone for 10 minutes, cleaned with absolute ethanol for 10 minutes, and then dried; the silicon target material of the coating material and the quartz glass substrate are placed in a PLD-450 vacuum system, evacuate to 1.0 x 10 -4 Pa, the temperature of the quartz glass substrate is 600°C, the distance between the quartz glass substrate and the silicon target is 4cm; then the TOL-25B excimer laser is used as the laser source to emit laser light, the frequency is 4HZ, and the sputtering is 3h; finally after 800 ℃ annealing for 3h to prepare a polysilicon film.

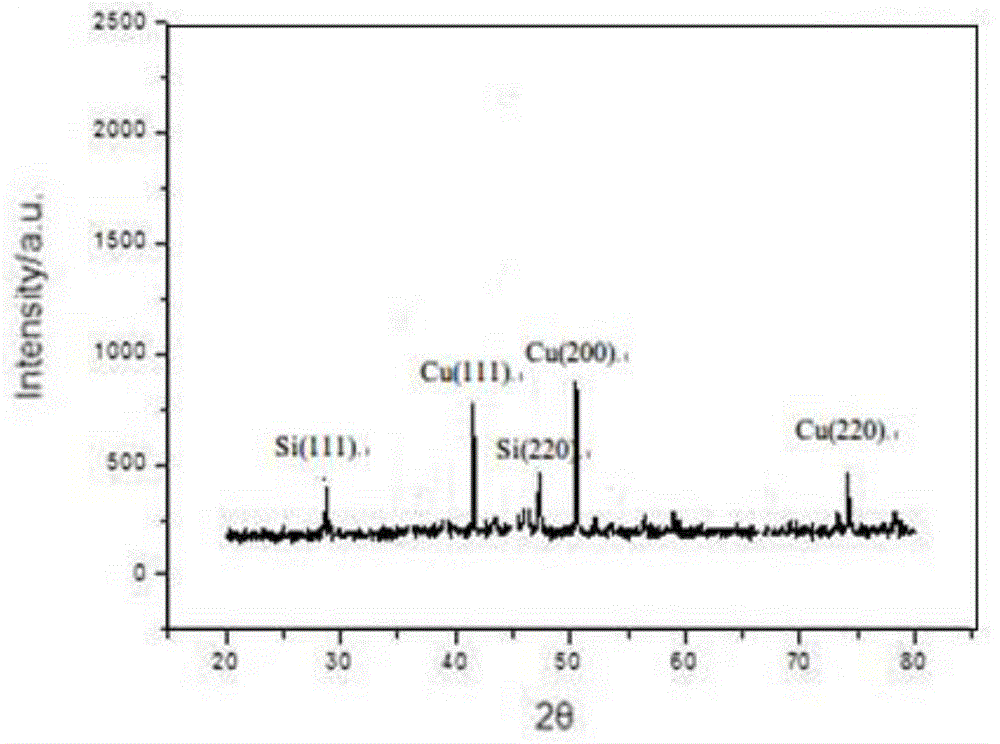

[0032] The polysilicon thin film prepared in embodiment 2 is carried out XRD test at room temperature, by figure 2 It can be seen that the characteristic diffraction peaks...

Embodiment 3

[0036] The coating material is selected as a 99.99% silicon target, and the substrate is a 20*35*3mm copper sheet. First, pre-treat the copper substrate: mechanically polish the copper substrate, wash it with deionized water, ultrasonicate it in acetone for 10 minutes, clean it with absolute ethanol for 10 minutes, and then dry it; then put the silicon target and copper substrate into the PLD-450 vacuum system, evacuate to 1.0 x 10 -4Pa, the temperature of the copper substrate is 500°C, the distance between the copper substrate and the silicon target is 3cm, and then the TOL-25B excimer laser is used as the laser source to emit laser light at a frequency of 4HZ, sputtering for 3 hours, and finally after Annealed at 600°C to prepare a polysilicon film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com