Patents

Literature

862 results about "Alloy wheel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the automotive industry, alloy wheels are wheels that are made from an alloy of aluminium or magnesium. Alloys are mixtures of a metal and other elements. They generally provide greater strength over pure metals, which are usually much softer and more ductile. Alloys of aluminium or magnesium are typically lighter for the same strength, provide better heat conduction, and often produce improved cosmetic appearance over steel wheels. Although steel, the most common material used in wheel production, is an alloy of iron and carbon, the term "alloy wheel" is usually reserved for wheels made from nonferrous alloys.

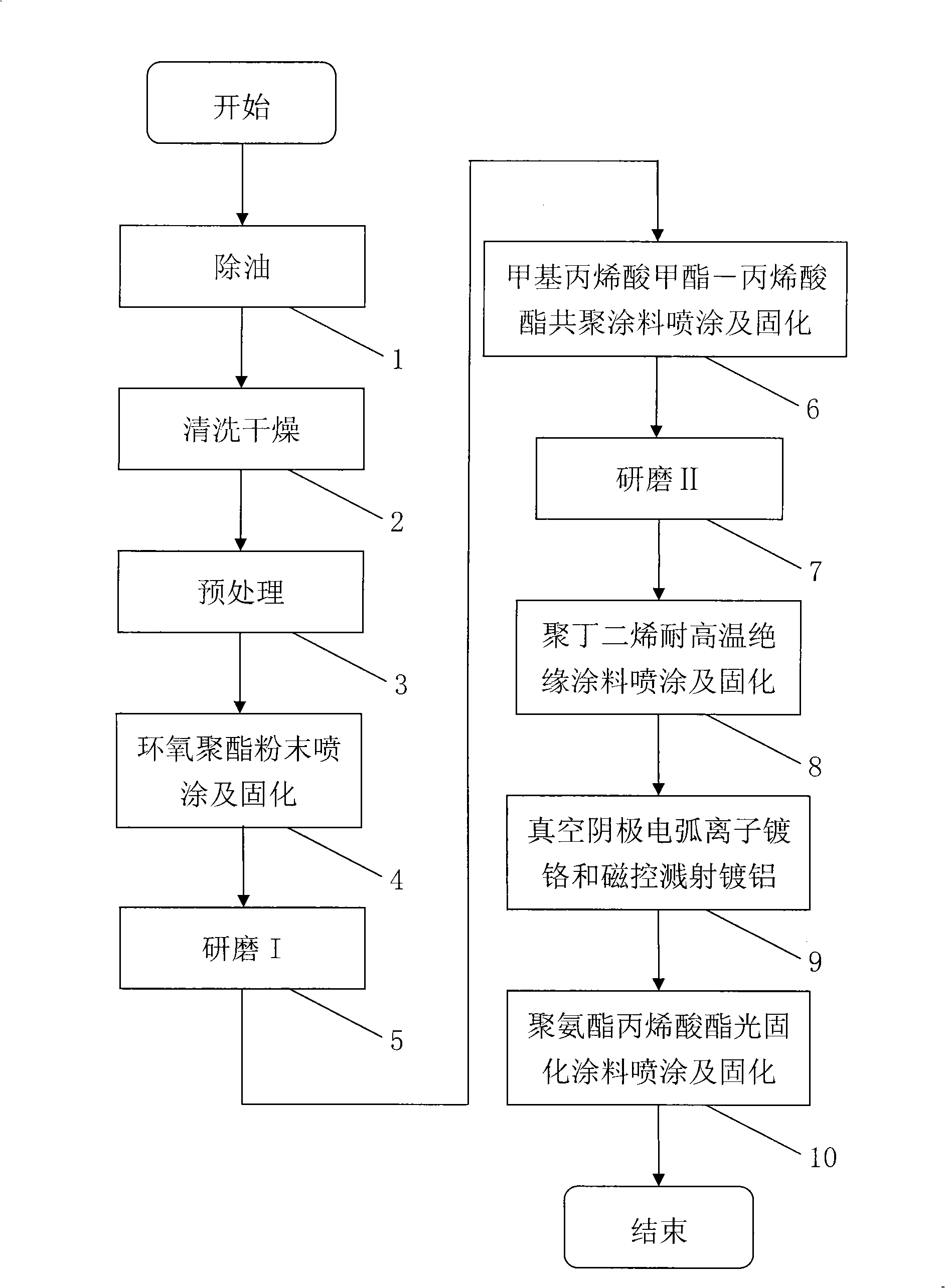

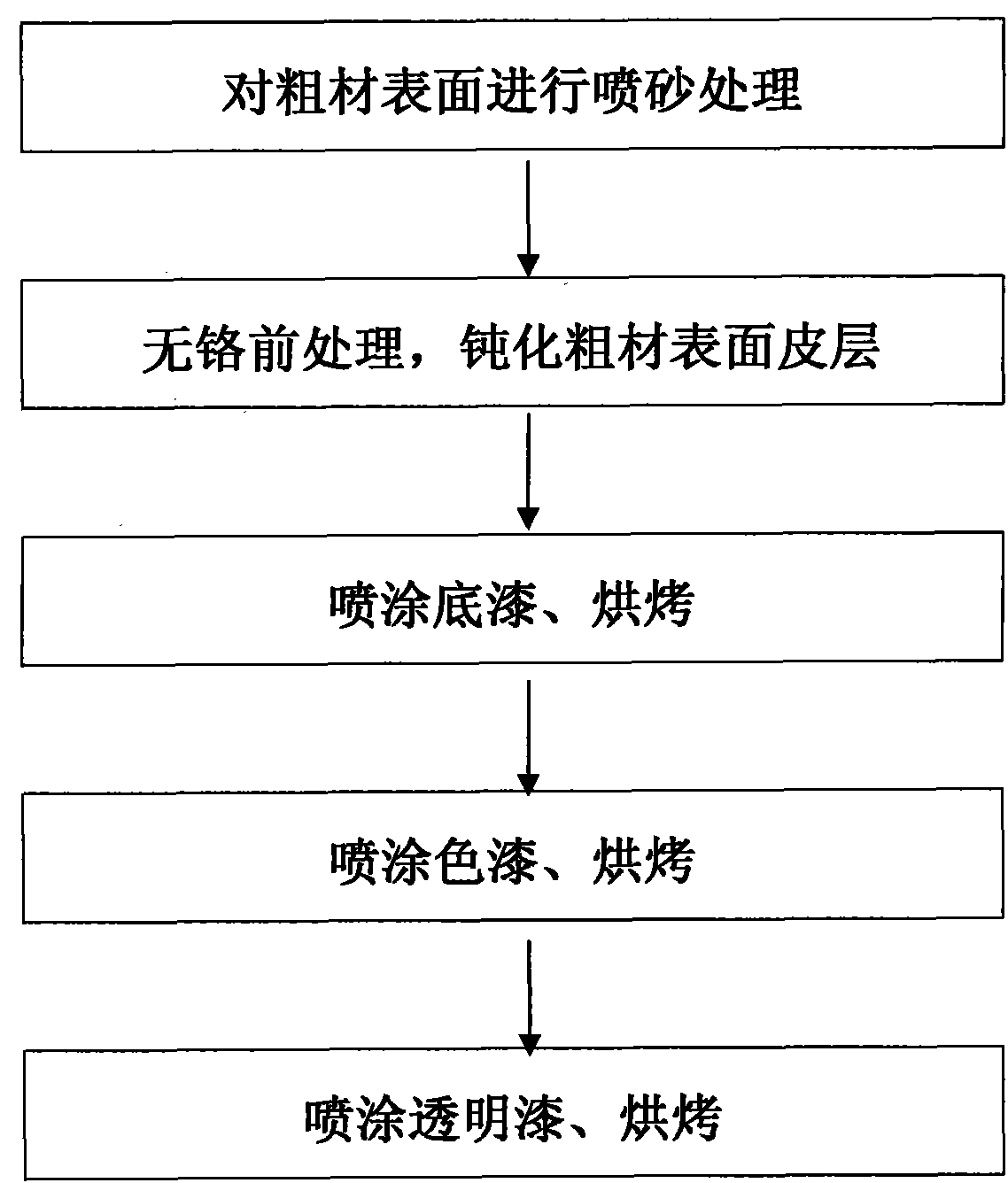

Film coating process for aluminium alloy wheel hub

InactiveCN101343740AReduce pollutionReduce energy consumptionVacuum evaporation coatingSputtering coatingPolyesterFilm coating

The invention discloses an aluminum alloy wheel hub coating technology. The aluminum alloy wheel hub coating technology comprises the procedures of oil removing, cleaning and drying, pre-treating, epoxy polyester powder spraying and solidifying, grinding I, methyl methacrylate-acrylate copolymer paint spraying and solidifying, grinding II, polybutadiene high temperature resistant insulating coating spraying and solidifying, vacuum cathode arc ion chromium plating and magnetism control sputtering aluminum plating, and polyurethane methacrylate light solidifying paint spraying and solidifying in sequence. The aluminum alloy wheel hub coating technology adopts dry electric plating to replace the traditional wet electric plating, the plating layer surface quality and the physical and chemical properties are approximately equivalent to the wet electric plated aluminum alloy wheel hub, the chromium consumption is reduced to about one fifth of the wet electric plating, the water consumption is reduced to about one seventh of the wet electric plating, precious nickel and copper are not utilized, the poisonous metal substance such as hexavalent chromium is not contained, the pollution to the environment is reduced, the energy, water and precious metal consumption is remarkably reduced, the technological flow is simplified, the production efficiency is enhanced, the heavy polishing working sequence is omitted, the working condition is remarkably improved, and the cost is reduced.

Owner:HUZHOU JINTAI PLATING IND

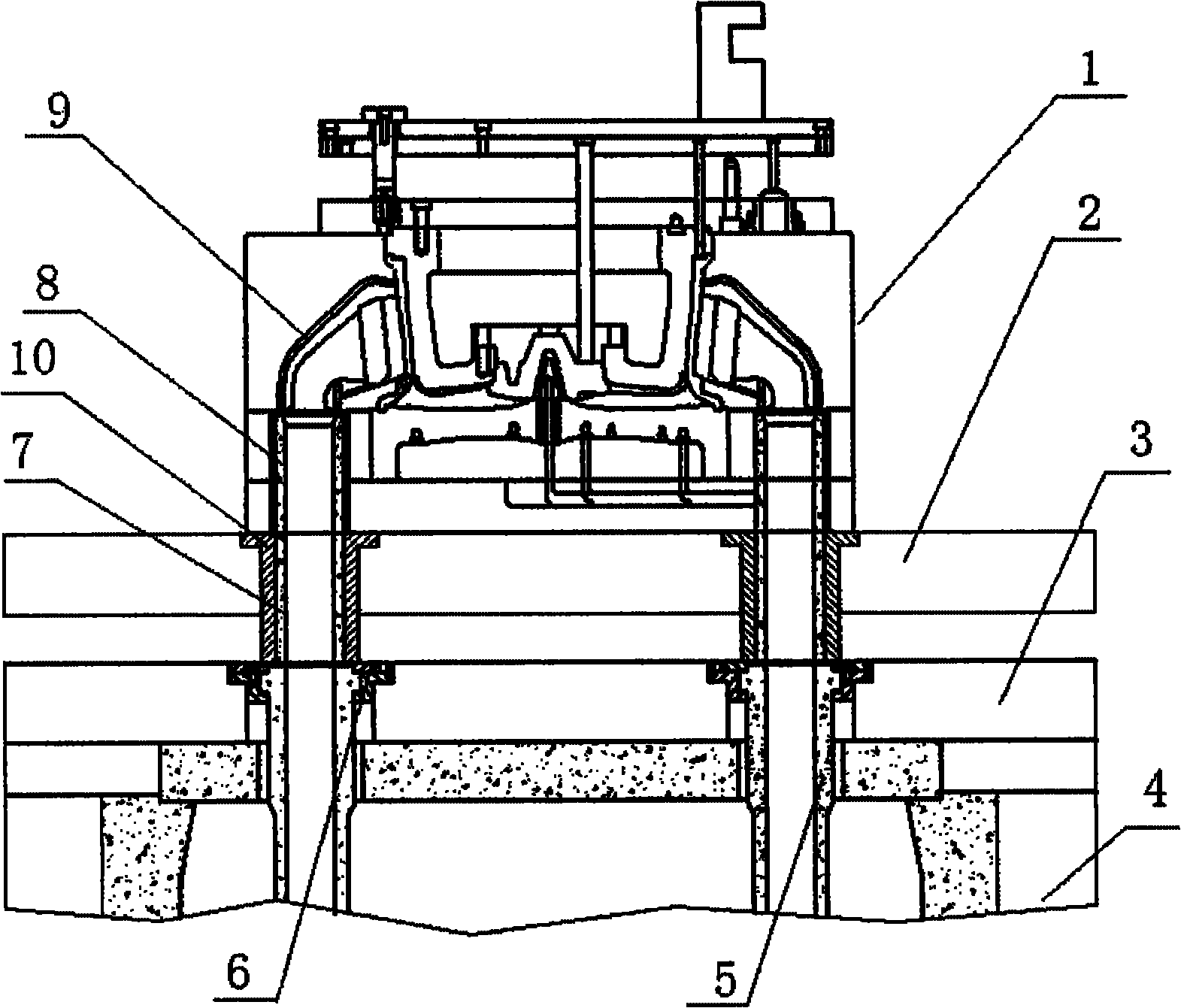

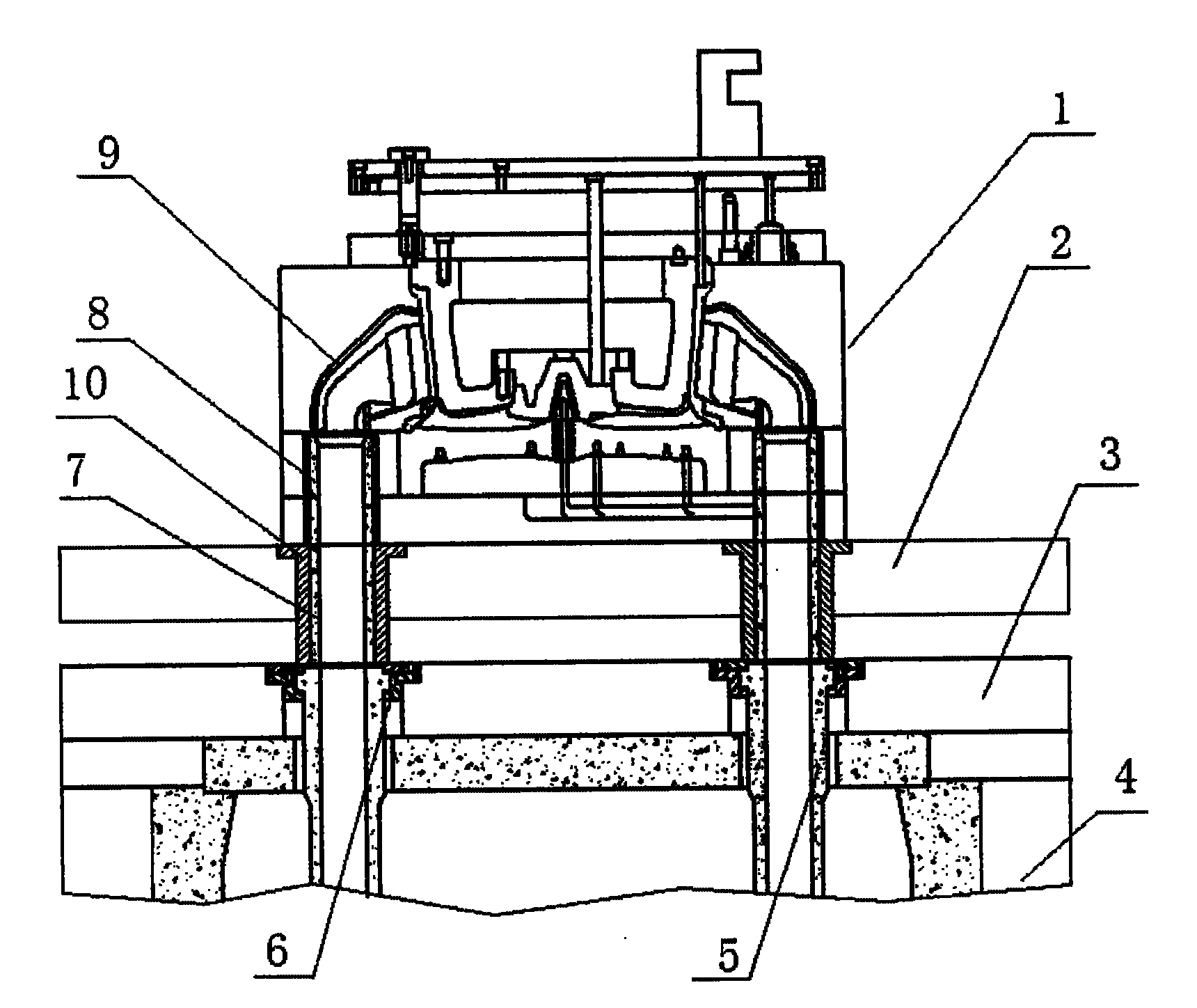

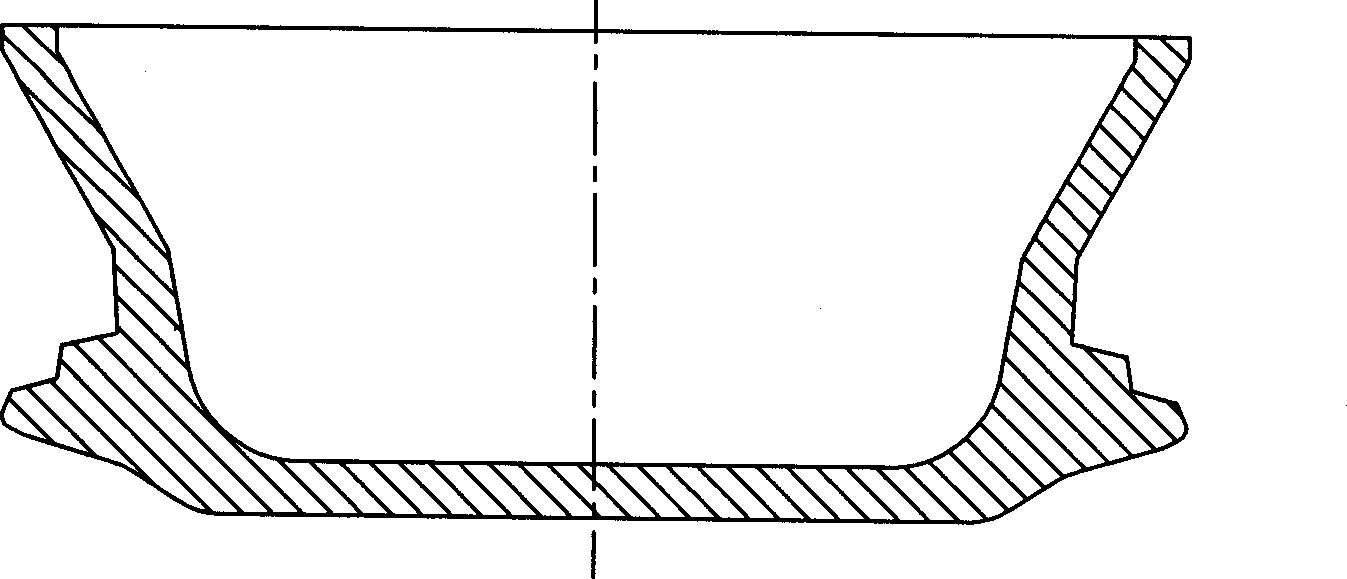

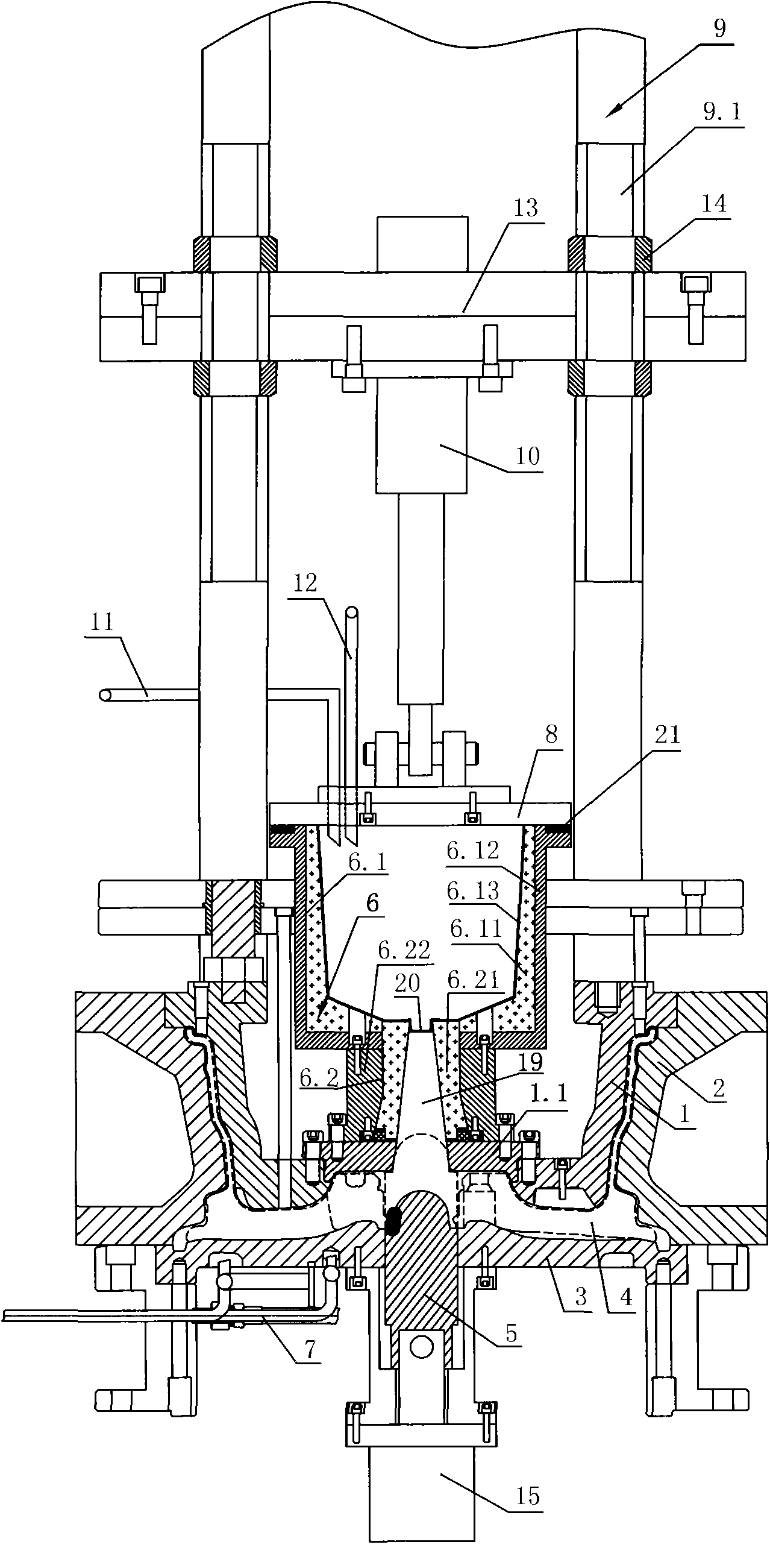

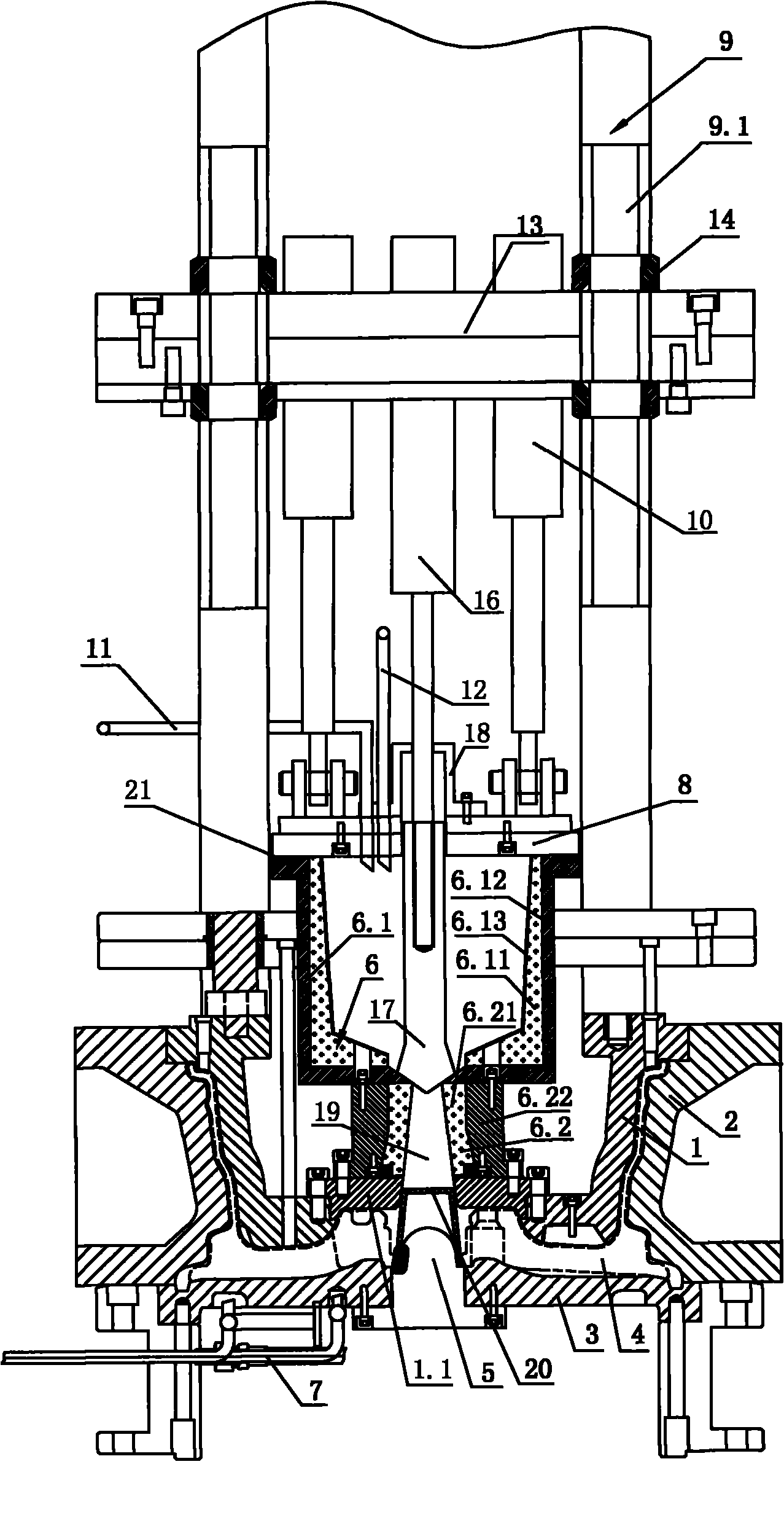

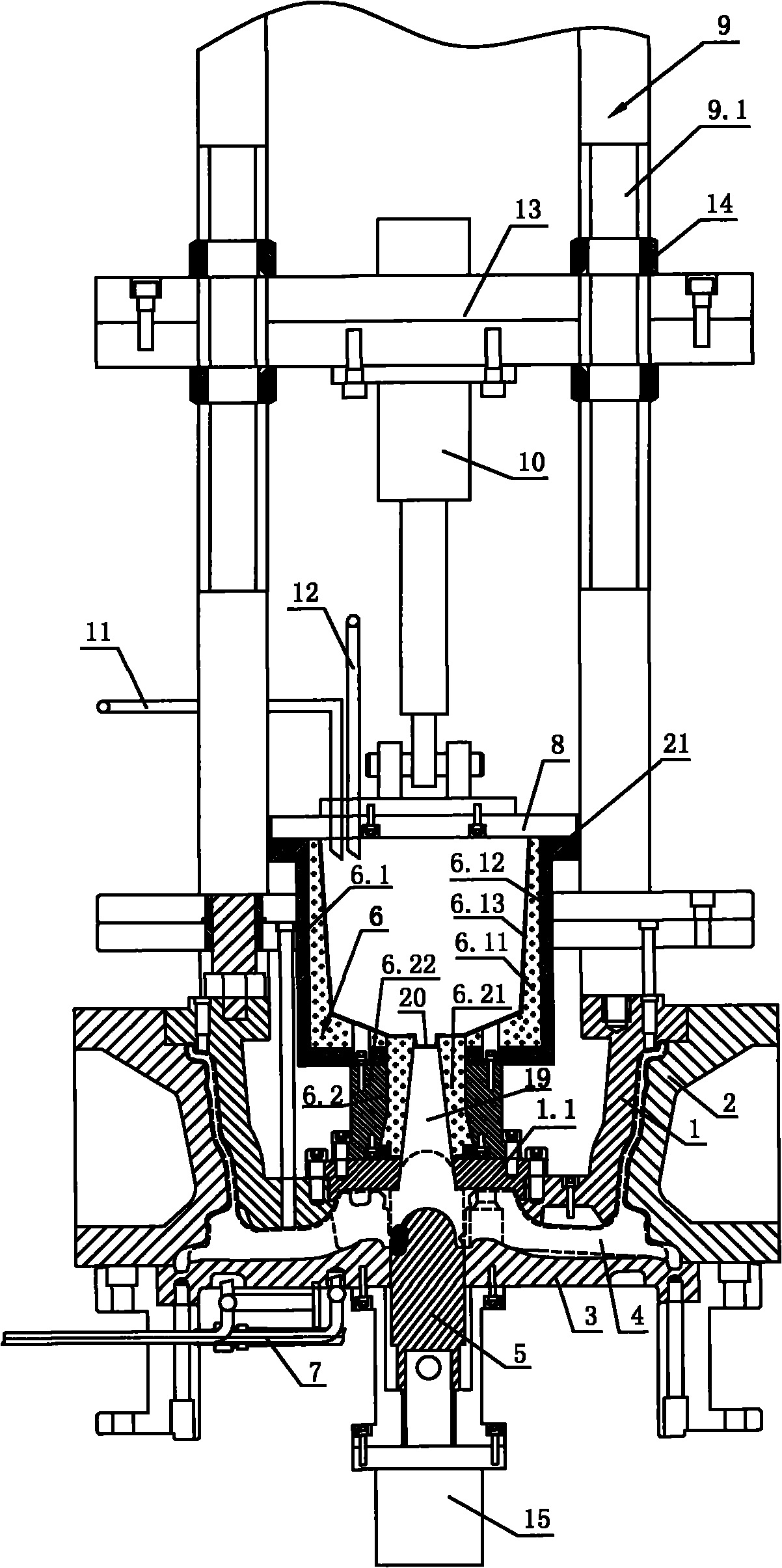

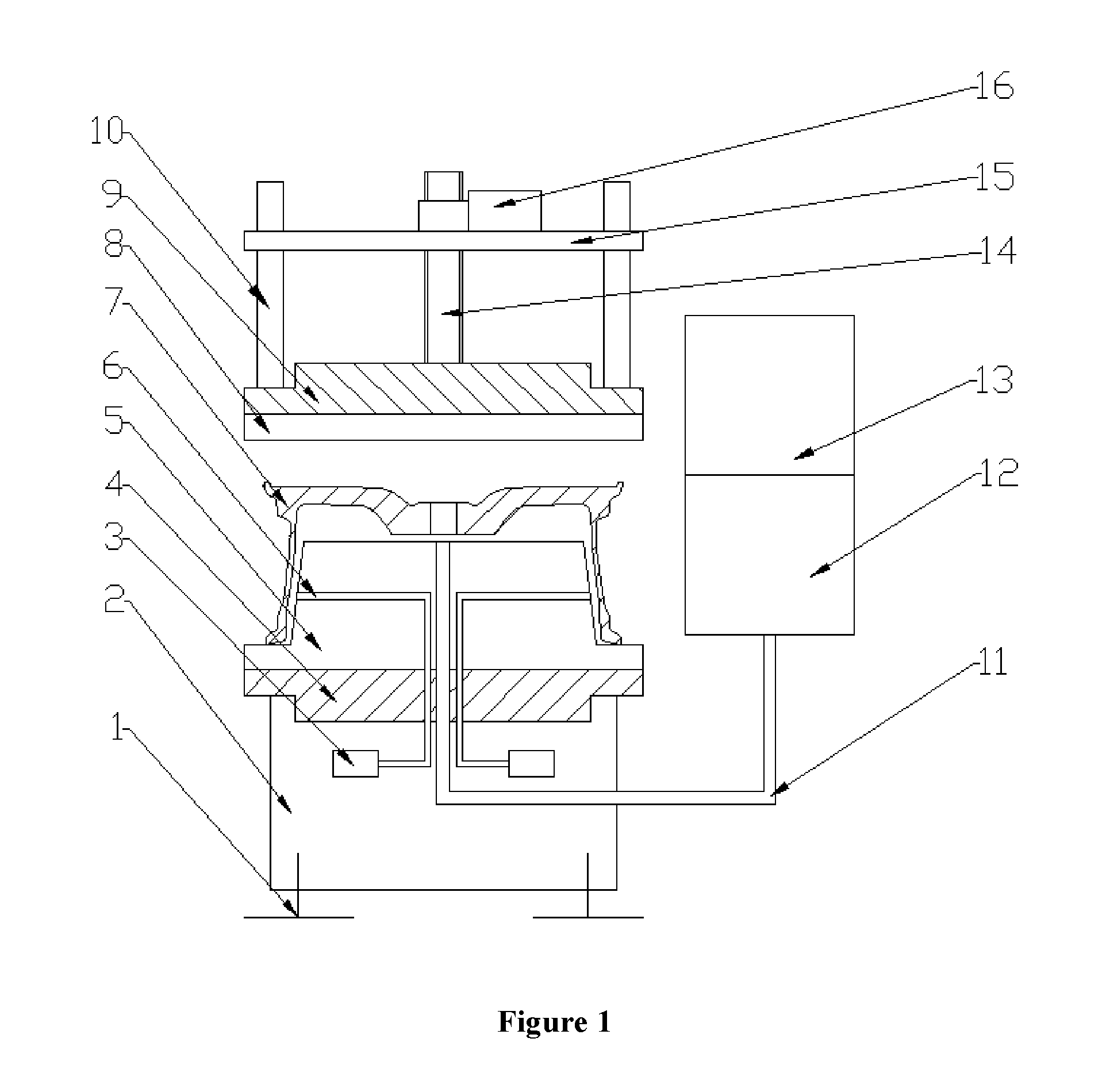

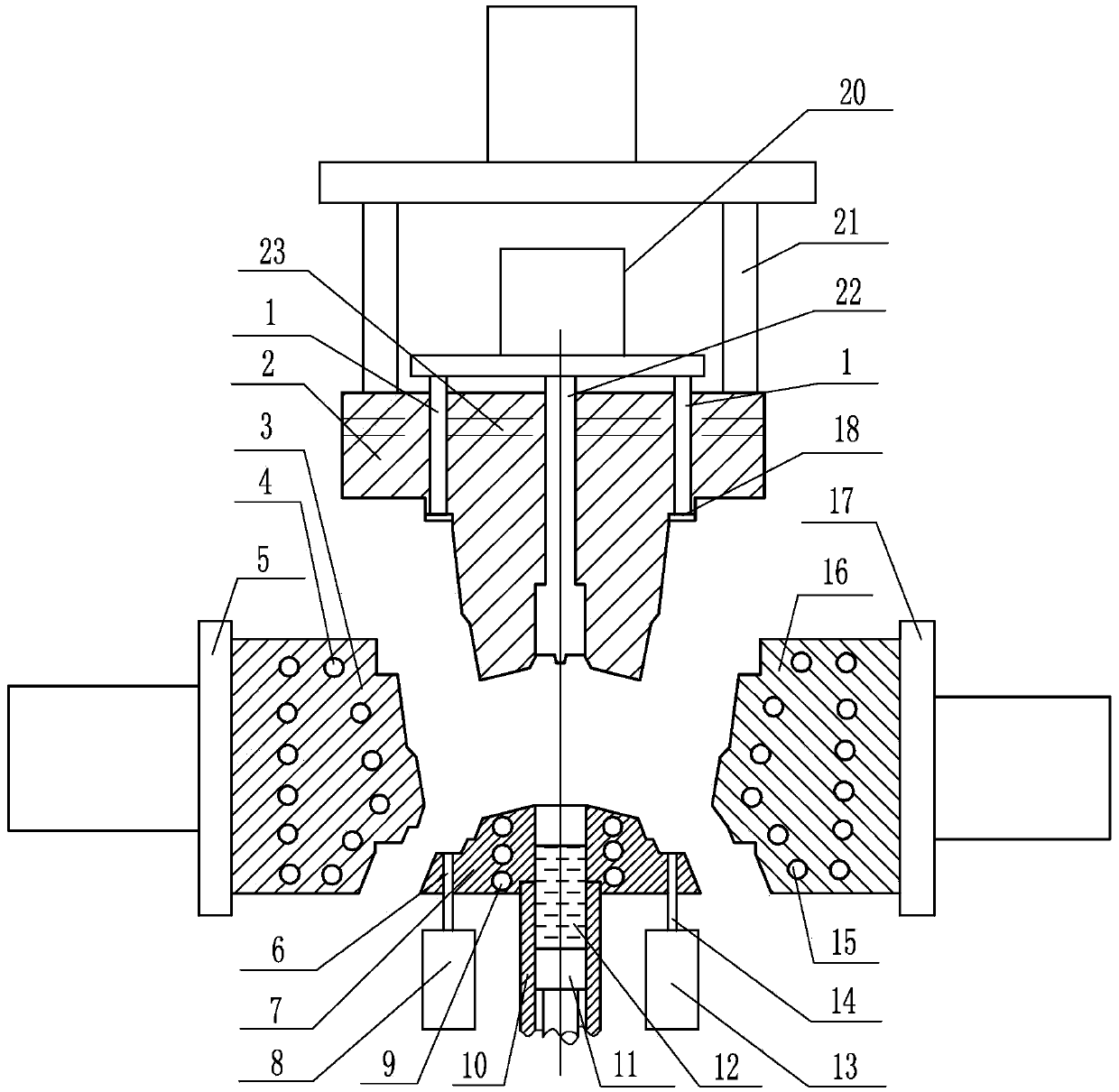

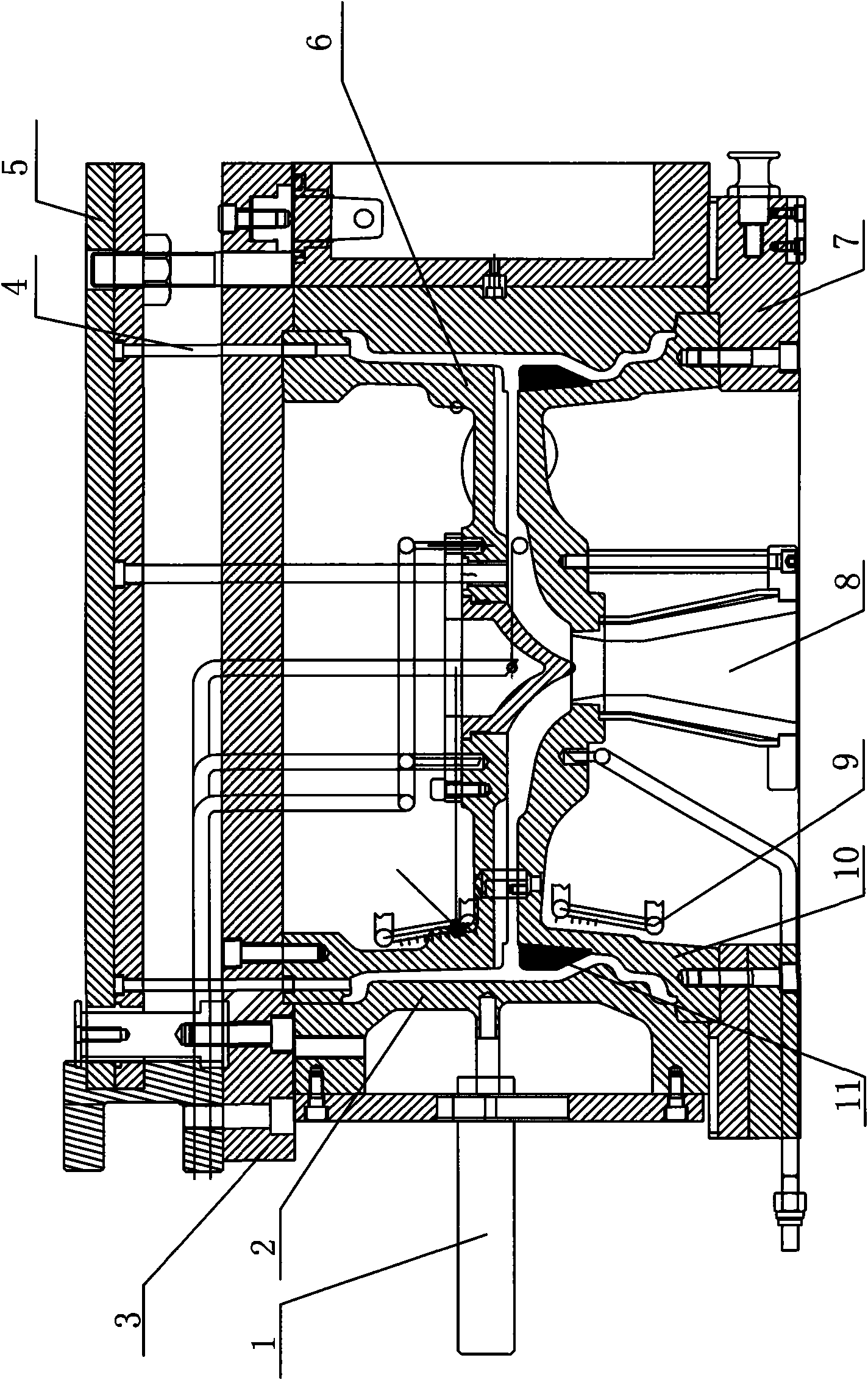

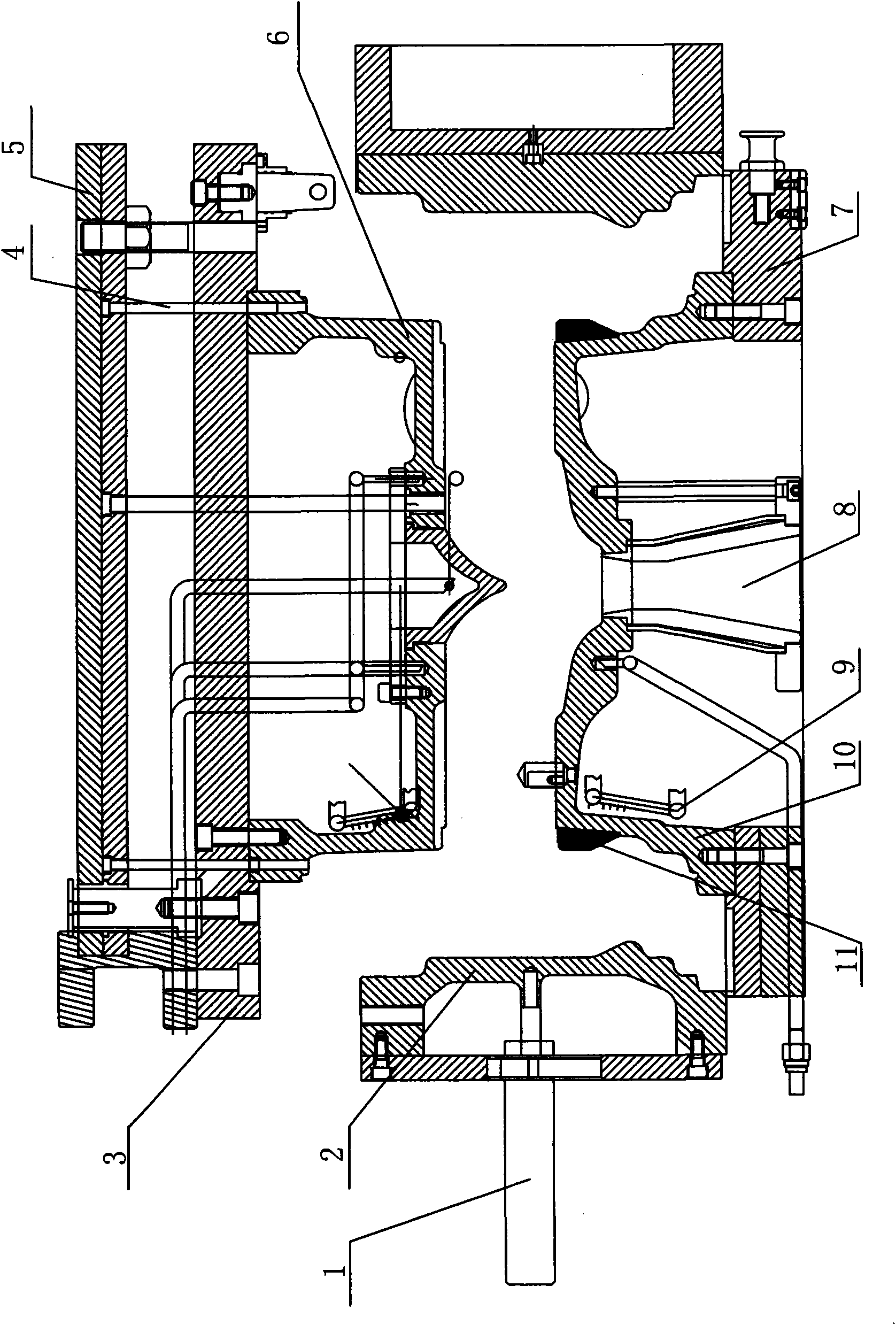

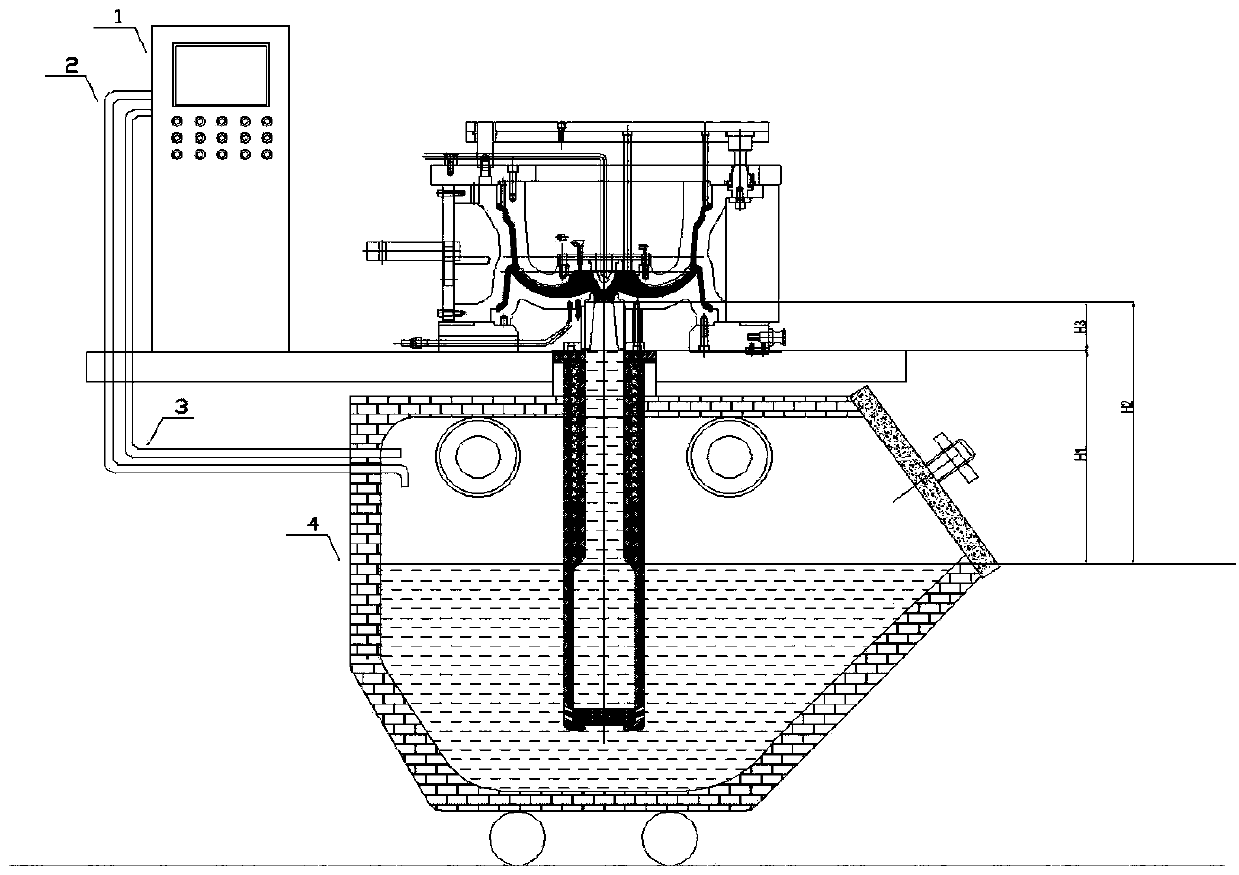

Low-pressure casting process and device for aluminum alloy wheel by bilateral pouring

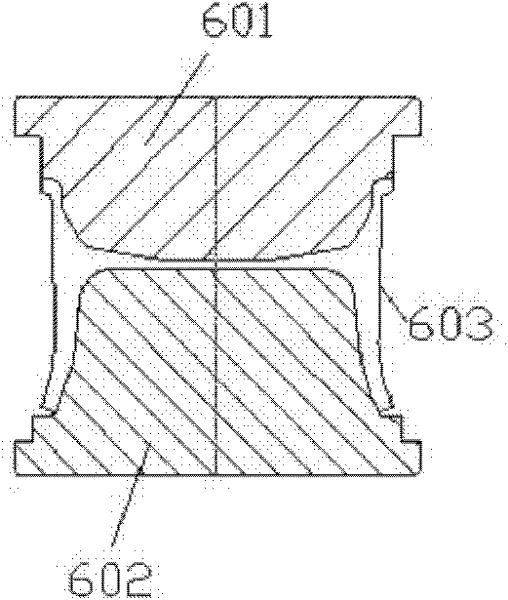

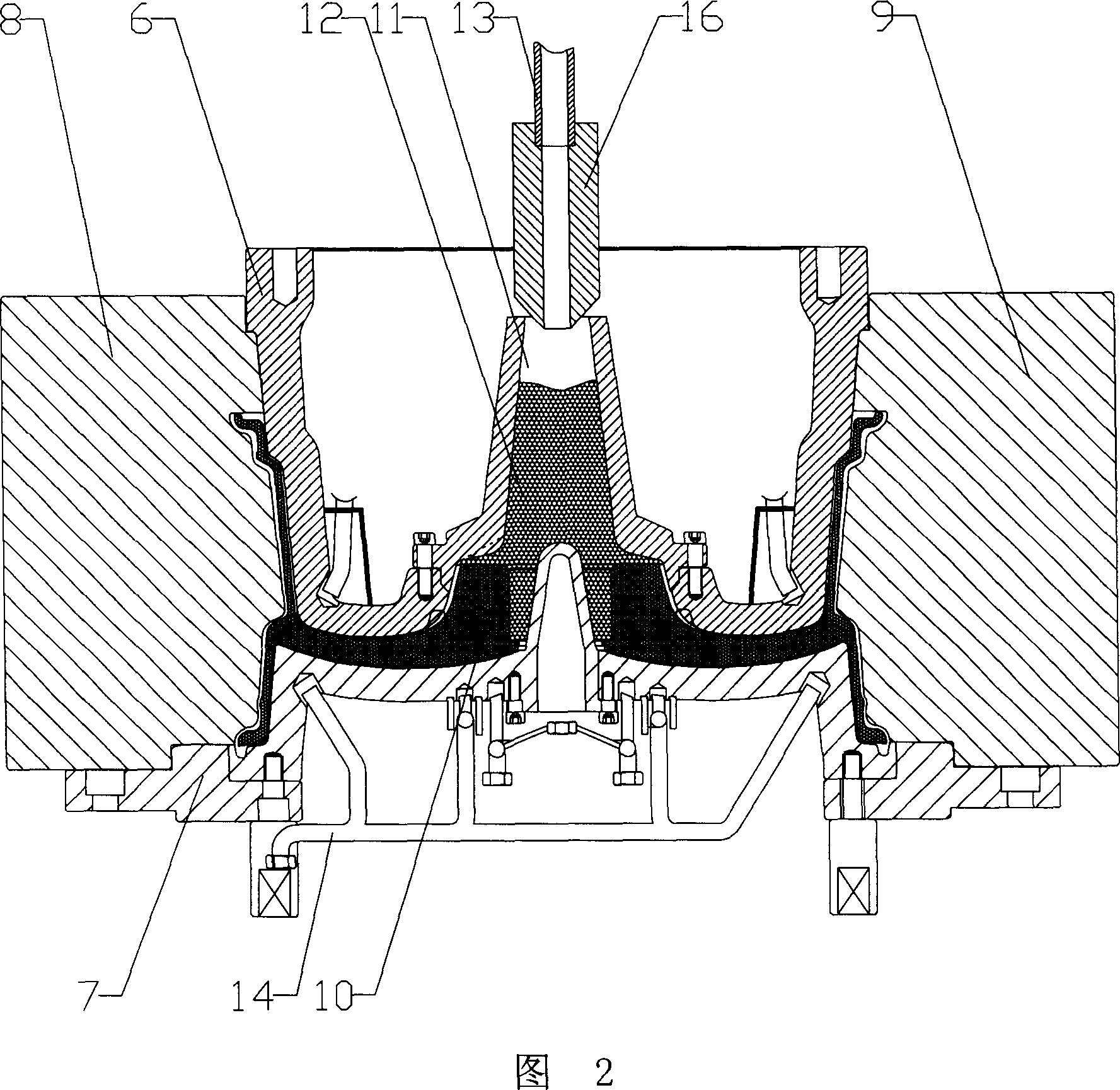

The invention discloses a low-pressure casting process for an aluminum alloy wheel and a low-pressure casting device required for realizing the process. In the casting process, a casting manner of bilateral pouring is adopted; a pouring gate is formed on two sides of the wheel to allow aluminum liquid to enter from the wheel rim; and through the control of cooling, the aluminum liquid is crystallized from the wheel core to the wheel rim at a rapidly-cooled module temperature. The low-pressure casting device comprises a bilaterally-pouring module which is arranged on a machine bed platform below which a furnace cover of a low-pressure heat preserving furnace is arranged; and the furnace cover is arranged on the heat preserving furnace body which is connected with the bilaterally-pouring module through a liquid lifting pipe. In the process, as the bilaterally-pouring process is adopted for casting and symmetrical pouring gates are formed on two sides of the wheel, the aluminum liquid symmetrically enters from the two sides of the wheel rim to ensure a high casting composition consistency and a good mechanical property; in addition, the entire casting device has the advantages of simple device, identical process with that of the general low-pressure central casting, simple entire process and easy operation.

Owner:BAODING CITY LIZHONG WHEEL MFG

Shaping device of solid hot extrusion magnesium alloy wheel hub and shaping method thereof

A solid-state hot squeezing apparatus for shaping the Mg-alloy wheel hub is composed of upper die plate, male die and its heater, heat isolating plate between said upper die plate and male die, moulding cavity heater for left and right moulding cavities, heat isolating plate between female die and its die plate, push-out rod, and temp controller. Its shaping method includes such steps as blanking, heating, holding temp, preheating die set squeezing cutting, surface treating and ageing treating.

Owner:HARBIN INST OF TECH

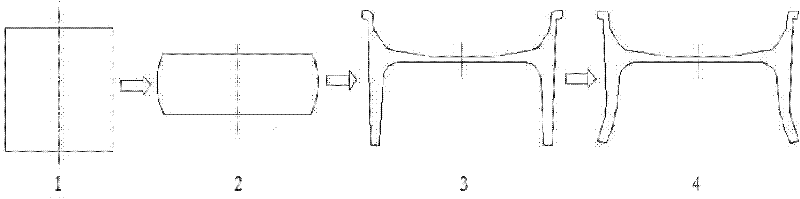

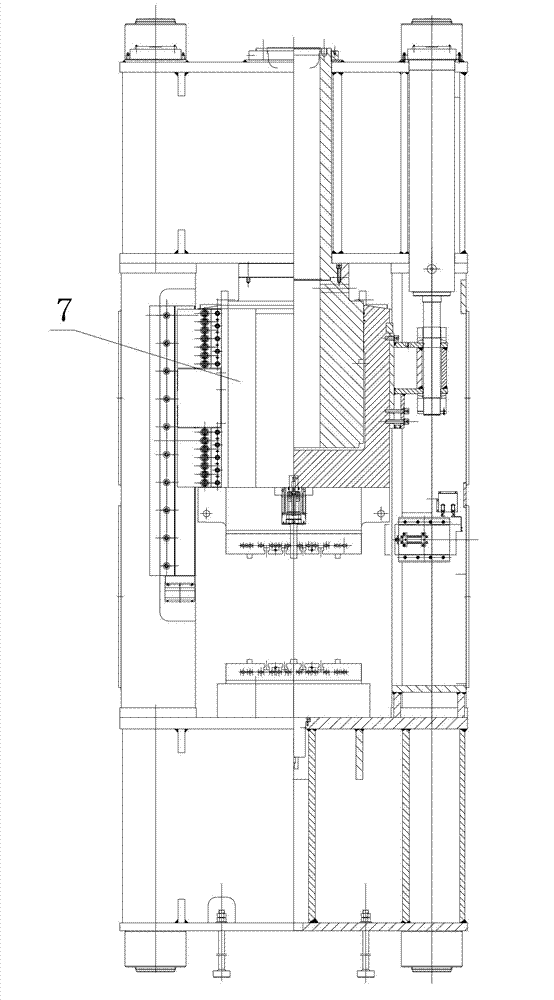

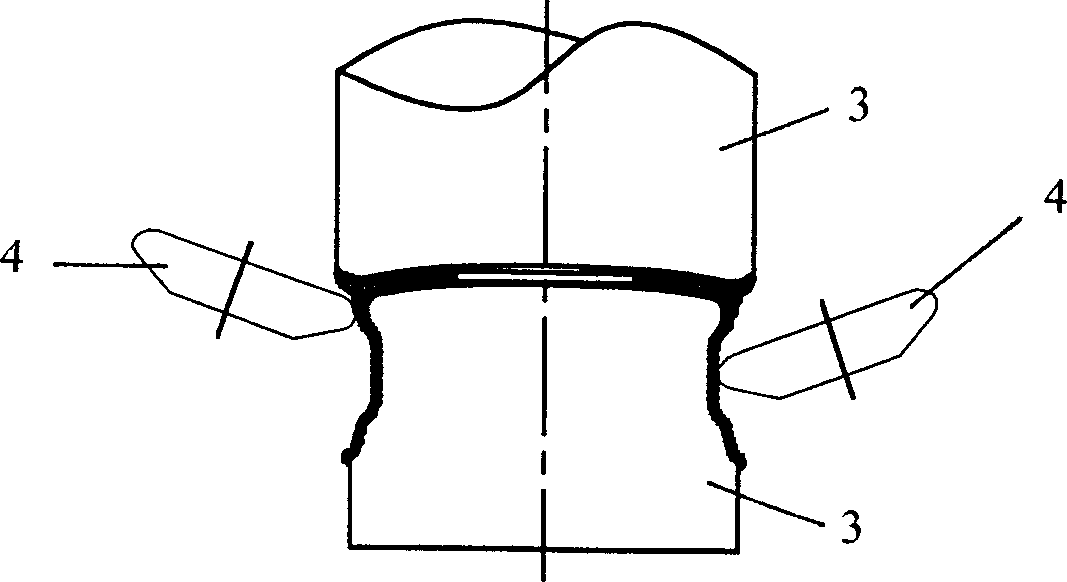

Chambering-forging forming method for aluminum alloy hub with complex structure and die thereof

InactiveCN102228951AReduce maintenance costsIncrease profitForging/hammering/pressing machinesWheelsAlloy wheelMaterials science

The invention provides a chambering -forging forming method for an aluminum alloy hub with a complex structure and a die thereof. The forming method comprises the steps of: preparing for materials; heating blanks; upsetting; mould-pressing and chambering a rim. The die for realizing the chambering-forging forming method for the aluminum alloy hub with the complex structure comprises a forging die and a rim-chambering die, wherein an upper die of the forging die consists of an upper die body and an upper die core which are sequentially nested and mounted, a lower die consists of a lower die body, a lower die core and an ejector rod which are sequentially nested and mounted; and the bottom and the side wall of the assembling part of the lower die core and the lower die body are uniformly provided with 4-8 R3 penetrating exhaust grooves, the rim-chambering die consists of an upper chambering die and a lower chambering die, and the size of a cavity of the upper chambering die is same as the size of the cavity of the upper die core of the forging die. The invention realizes once-heating forming; a non-burr forging and rim-chambering forming process is adopted, thus two trimming procedures are eliminated, material utilization rate is improved, and number of equipment is reduced; and the rim-chambering die has a simple structure and is convenient for operation.

Owner:HARBIN HAFEI IND

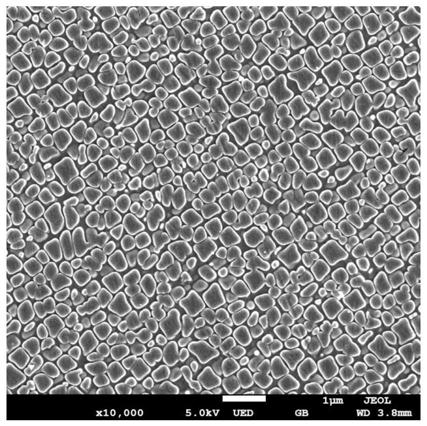

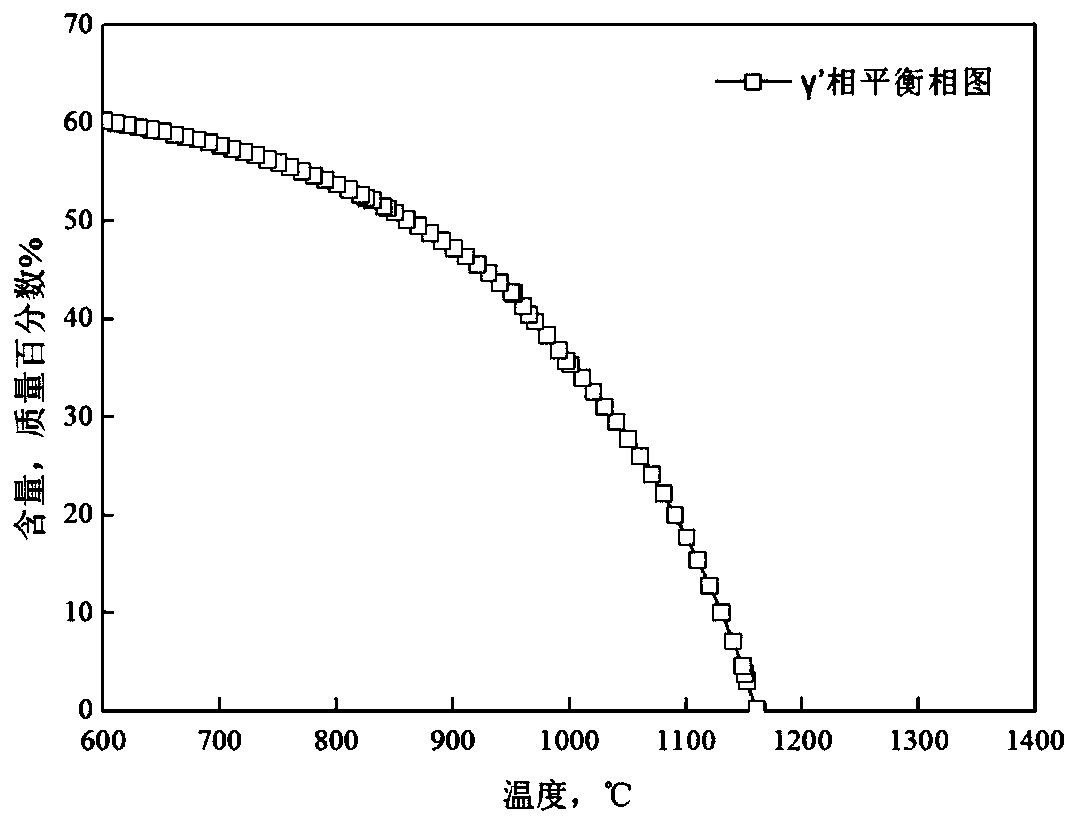

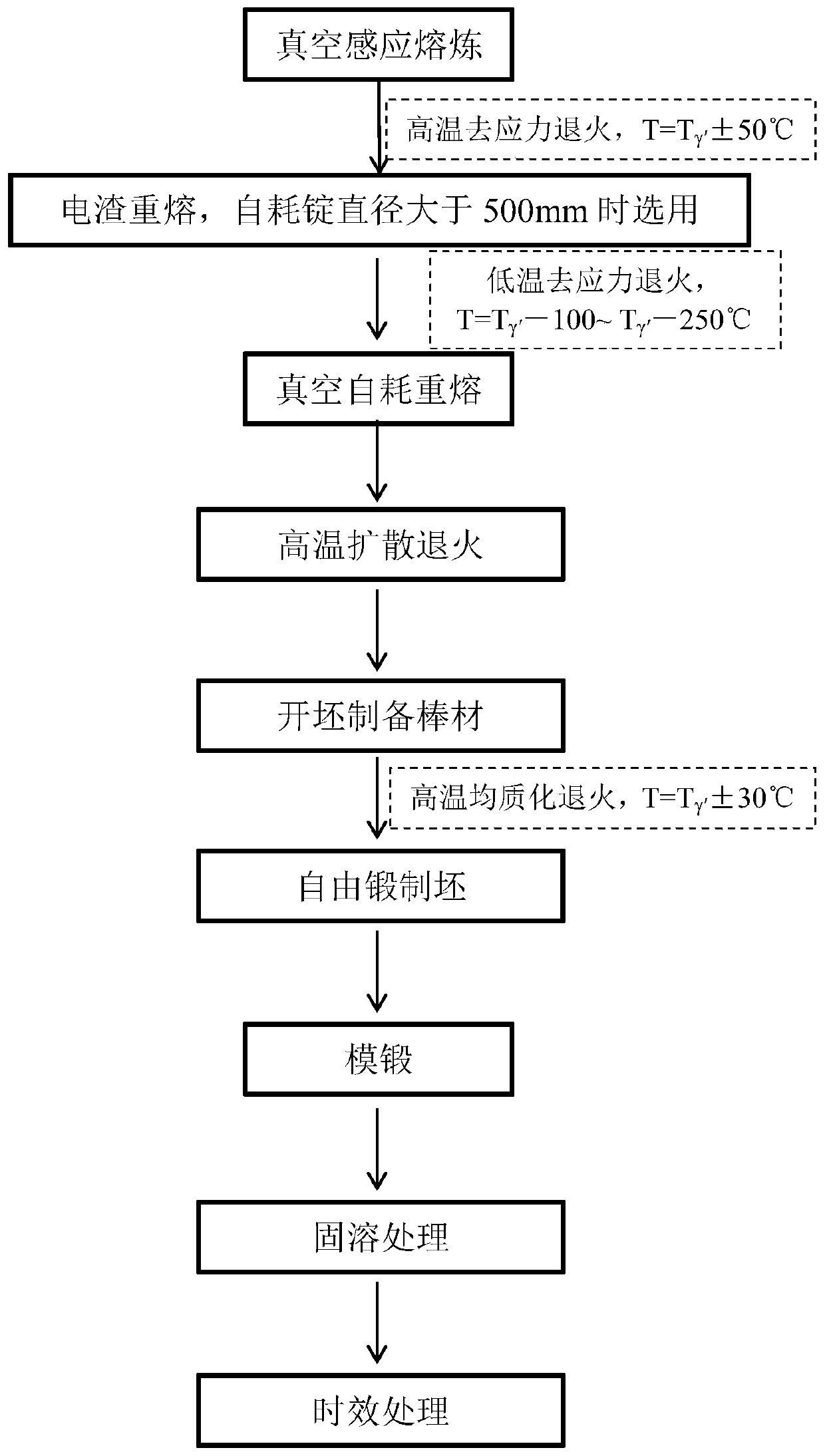

Preparation method of nickel-base deformation high-temperature alloy wheel disc forged piece used at high temperature

ActiveCN111235434AImprove mechanical propertiesSatisfied with service stabilityIncreasing energy efficiencyIngotSuperalloy

Owner:BEIJING CISRI GAONA TECH +1

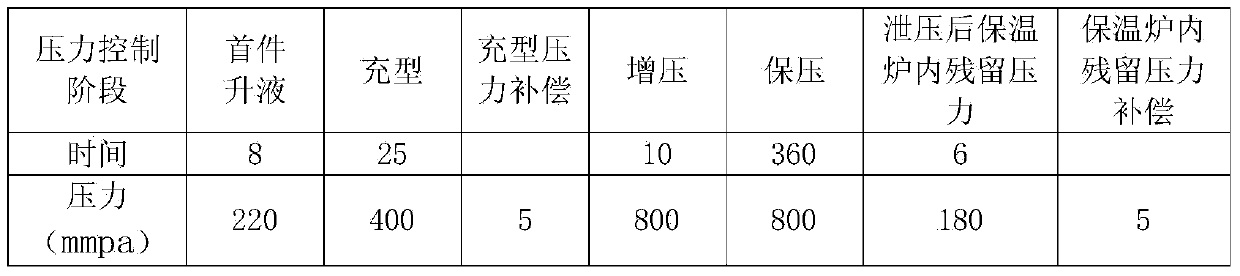

Process for smelting and lower-pressure casting of aluminum alloy wheel hub

The invention discloses a process for the smelting and low-pressure casting of an aluminum alloy wheel hub, which comprises: 1, putting an aluminum alloy smelting material into a smelting furnace for smelting, and when the temperature in the smelting furnace reaches 740 to 760 DEG C, introducing nitrogen into the smelting furnace to blow a refining agent into the body of the furnace for refining;2, transferring the molten aluminum alloy to a tundish from the liquid outlet of the smelting furnace, adding an Al-Sr intermediate alloy, mischmetal (Re) and an Al-Zr intermediate alloy into the tundish to perform modification and refinement treatment under a condition of a temperature of 710 to 730 DEG C, and blowing nitrogen to the tundish to perform secondary degassing of the molten aluminum alloy; 3, transferring the molten aluminum alloy in the tundish to a casting holding furnace, adding a slag decomposing agent into the holding furnace to remove slag and blowing nitrogen into the holding furnace to perform tertiary degassing; and 4, pressing the molten aluminum alloy into a mold by a method of prepressing, pressure stabilizing, pressurizing and pressure keeping to perform casting.The process can effectively discharge slag and degas, has excellent modification and refinement effects and contributes to improvement in product quality.

Owner:ZHEJIANG ZENT AUTO WHEEL

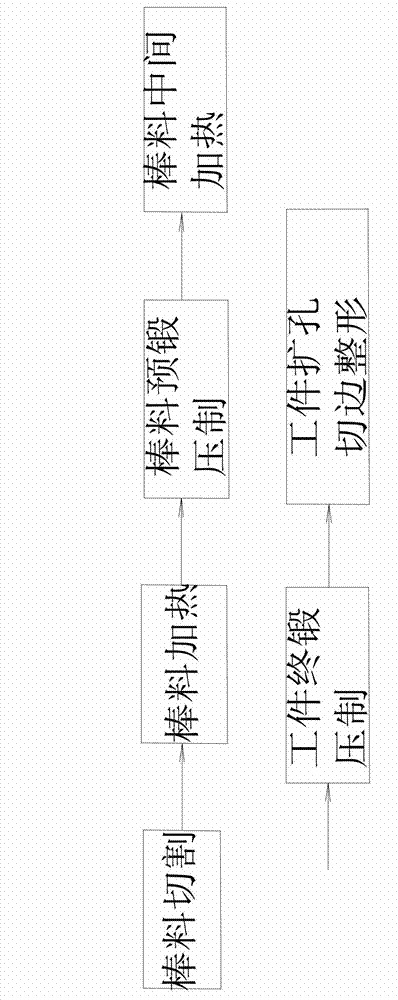

Forging process of large aluminum alloy hub

ActiveCN102873252ASimplify the pressing processWeight optimizationWheelsEjection devicesThermal insulationHeating furnace

The invention relates to a forging process of a large aluminum alloy hub. The forging process is a processing process using a production line of the large aluminum alloy hub and is characterized by including the steps of cutting an aluminum alloy bar, heating the bar, performing pre-forging and compacting to a blank by a hydraulic pre-forging machine, performing secondary heating and thermal insulation to a workpiece, performing final forging and compacting to the workpiece by a hydraulic hub final-forging machine, and performing hole expanding, edge cutting and reshaping to the workpiece. The production line comprises a bar cutting machine, a bar heating stove, workpiece clamping manipulators, the hydraulic pre-forging machine, the hydraulic hub final-forging machine, a hydraulic hub hole-expanding and edge cutting machine and a hub compacting die. The forging process for the large aluminum alloy hub has the advantages that mechanical performance, physical performance and yield of a finished hub can be increased greatly, cost, time and manpower for secondary processing and reshaping are economized greatly, and safety and operation efficiency of a device in production and manufacturing are increased. The forging process is high in automation degree, and a modern production and manufacturing process for aluminum alloy hubs can be met.

Owner:TIANJIN TIANDUAN PRESS CO LTD

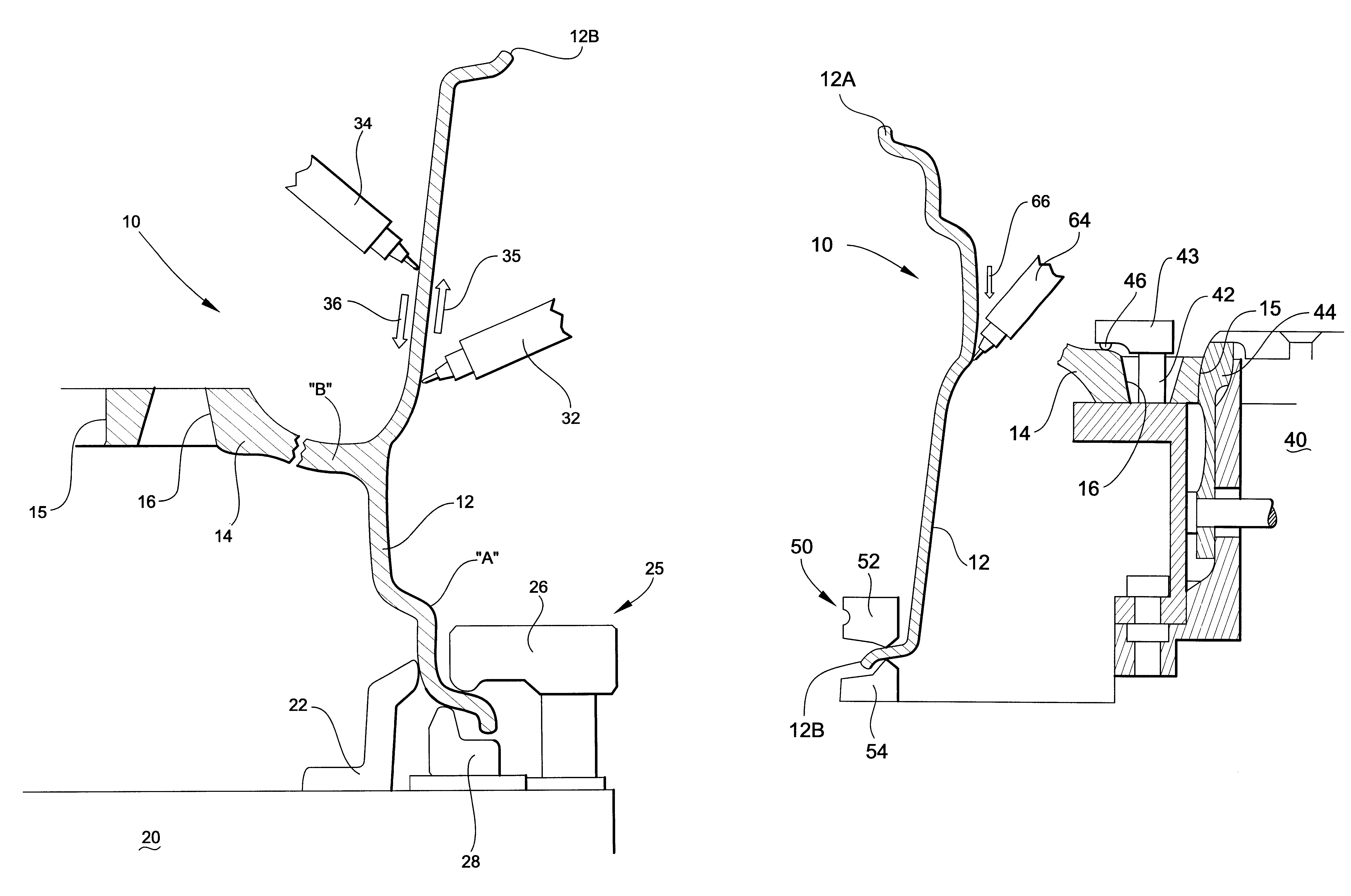

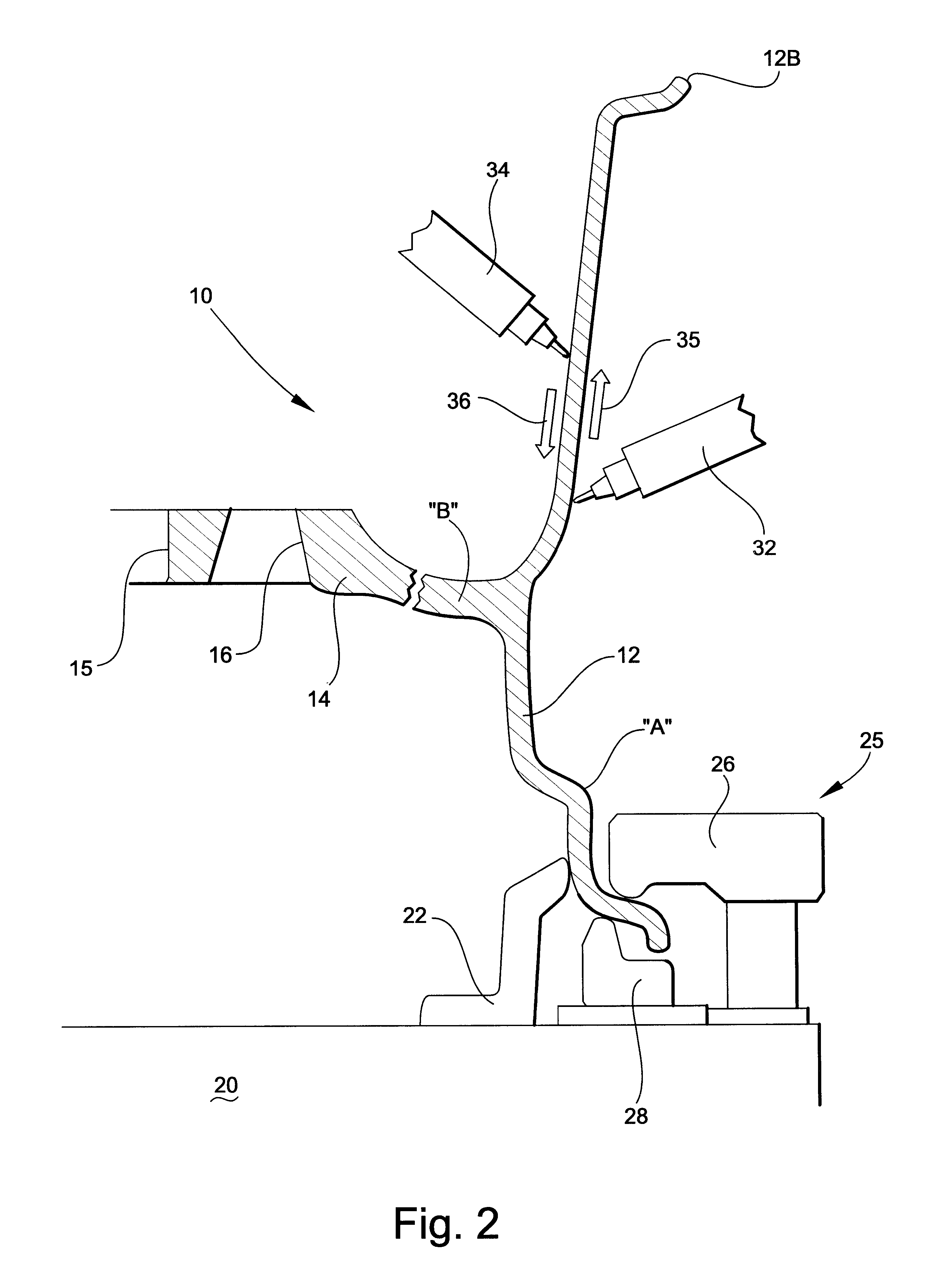

Method of manufacturing a wheel rim for a two-piece vehicle wheel assembly

InactiveUS6272748B1Fewer chatter marksFine surfaceRimsMetal rolling stand detailsMechanical engineeringAlloy wheel

A method of manufacturing a wheel rim for a two-piece vehicle wheel assembly. The method includes the step of casting a one-piece alloy wheel form. The wheel form defines an integrally-formed annular rim blank and supporting center. The rim blank includes opposing first and second annular edge portions. The first annular edge portion of the rim blank is machined, and then the second annular edge portion of the rim blank is machined. After the machining steps, the one-piece wheel form is cut to separate the machined wheel rim from the supporting center.

Owner:SMYTH LARRY C

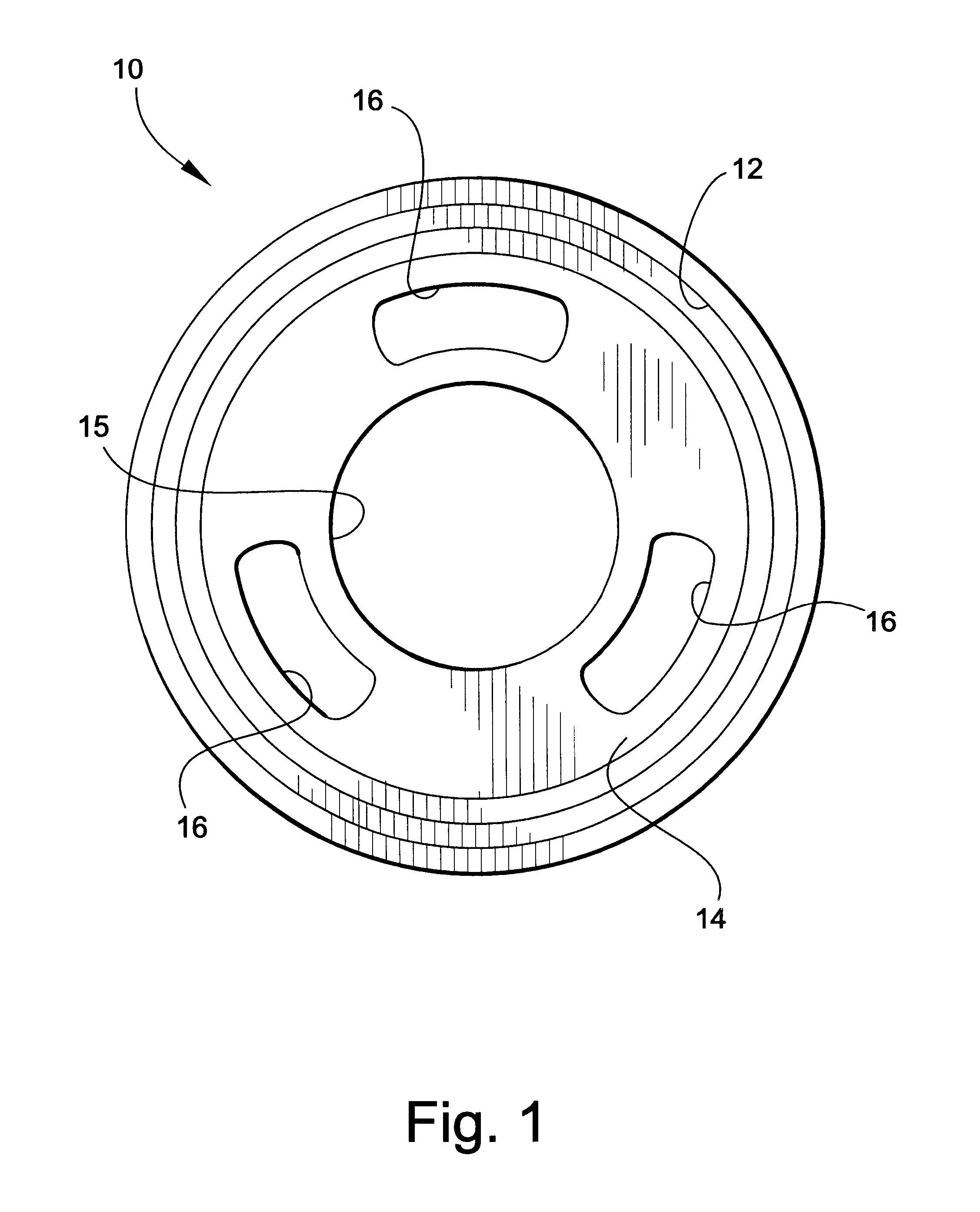

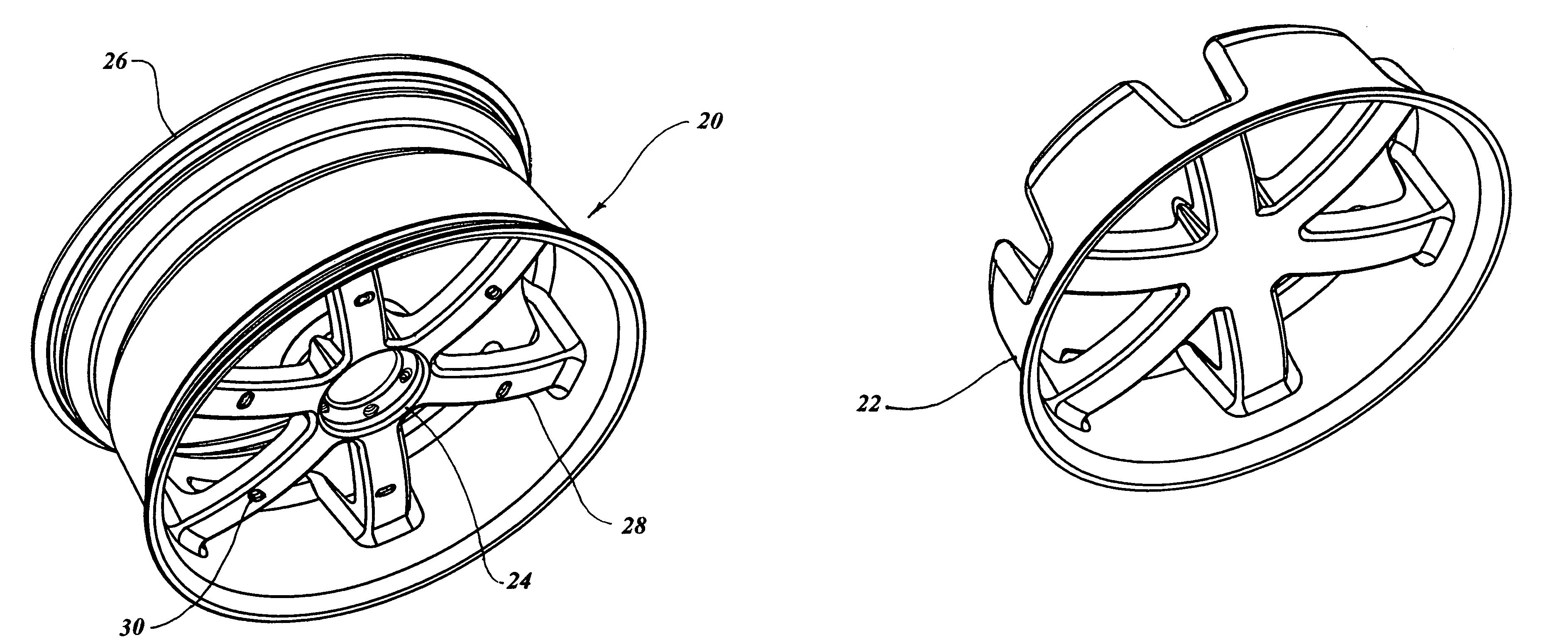

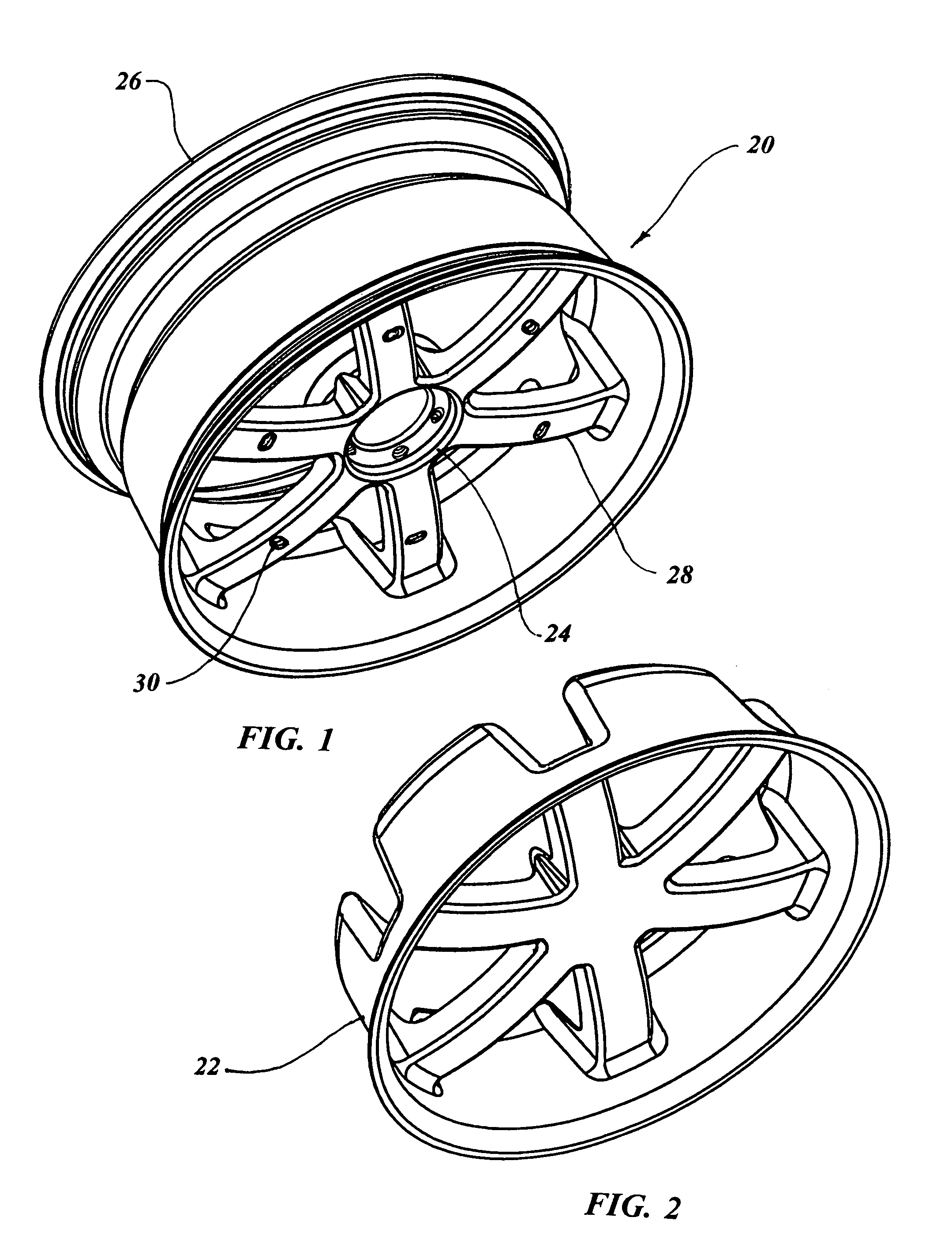

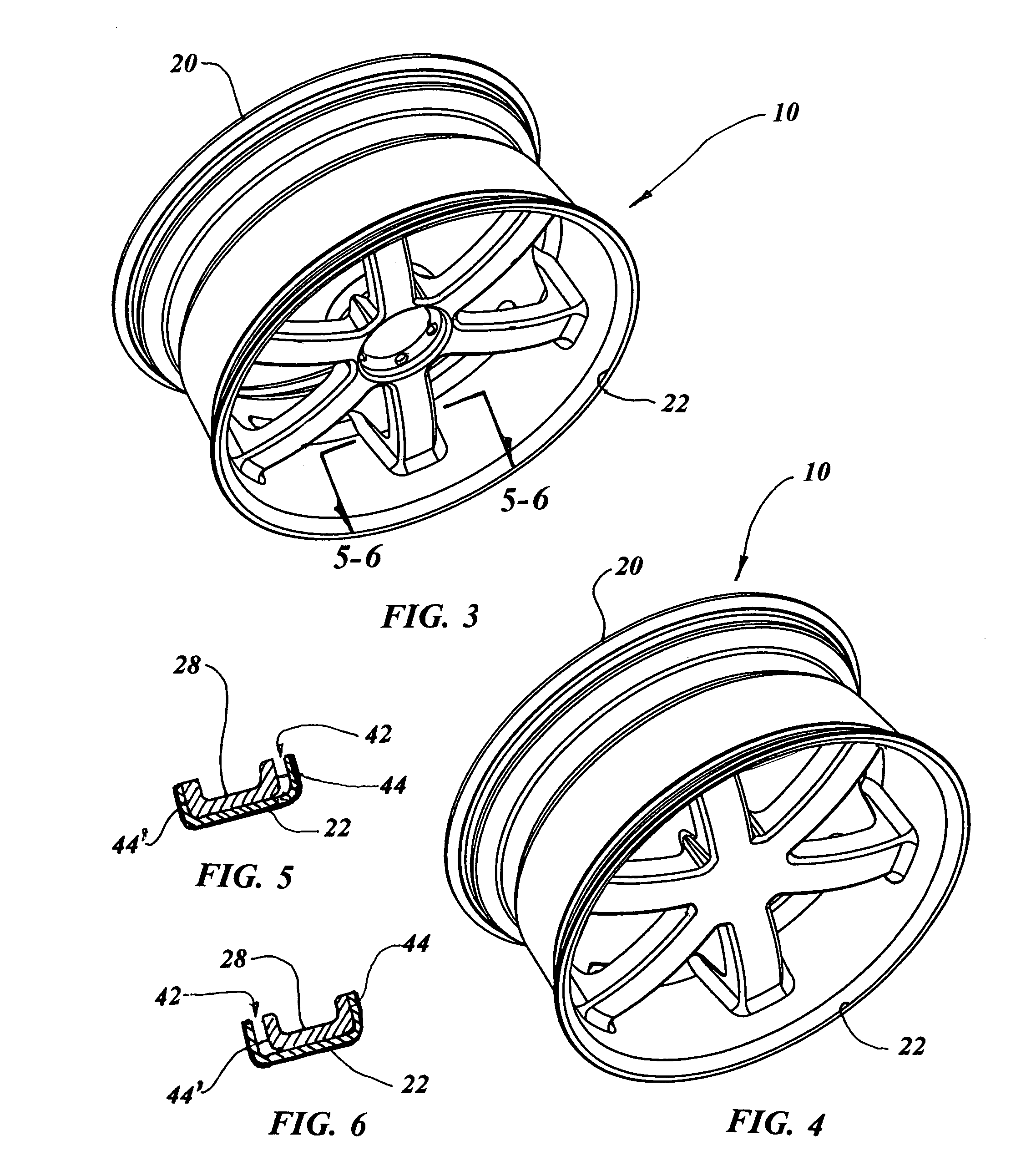

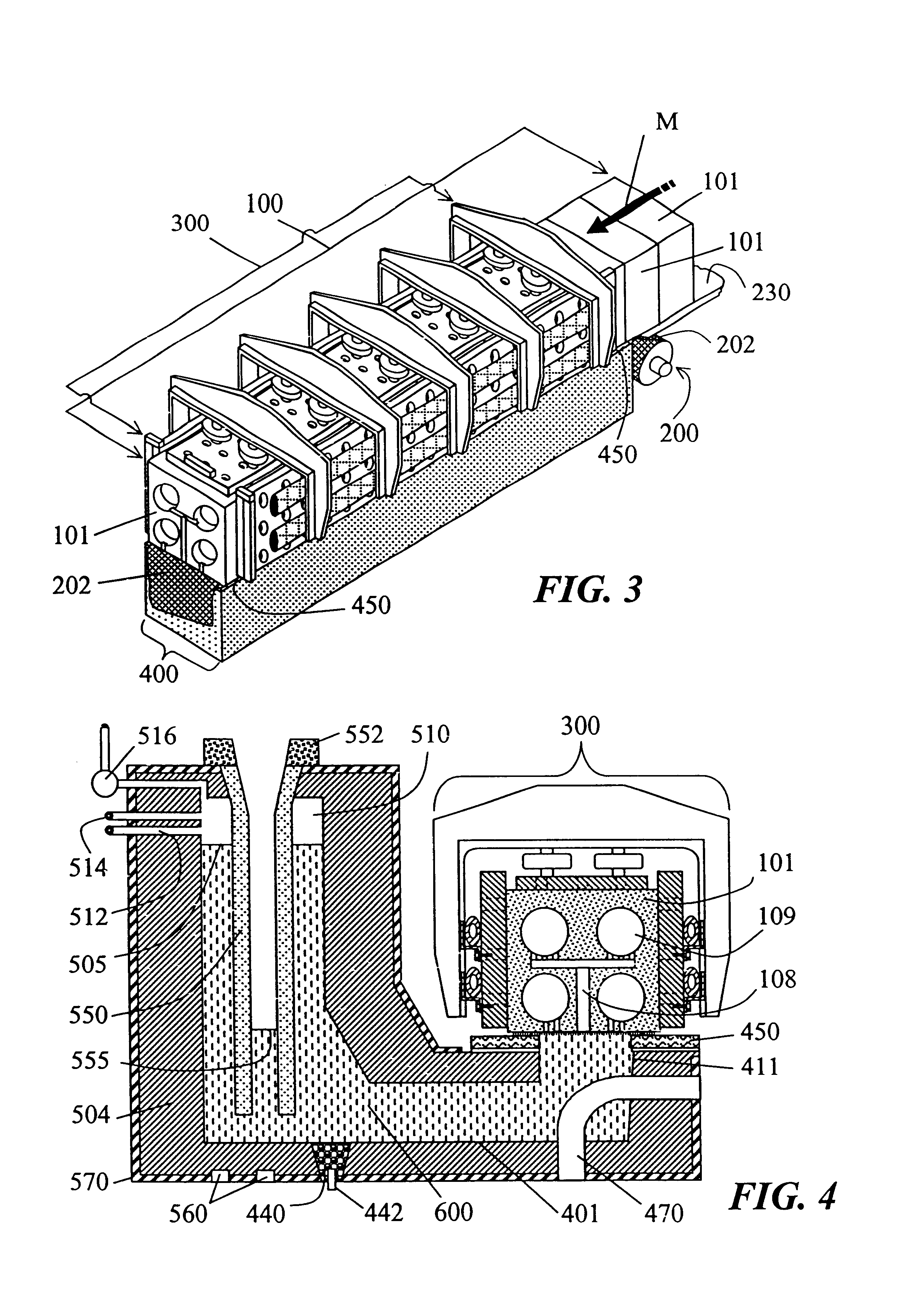

Alloy wheel with mating wheel cover

An alloy vehicle wheel (20) that includes a mating wheel cover (22), with the wheel consisting of a centrally located hub (24), a rim (26), and a number of integral spokes (28) attached to both the hub and rim. Slots (30) are incorporated into the spokes of the wheel and are configured to receive attachments. The molded wheel cover (22) is shaped to replicate the wheel and incorporates decorative design configurations (40) on its visual surfaces. Mushroom head studs (46) are integrally formed into the interior surface of the wheel cover and are positioned to penetrate the slots in the spokes as attachments for fastening the wheel cover to the alloy wheel.

Owner:WELLS FARGO BANK NAT ASSOC AS THE SUCCESSOR ADMINISTATIVE AGENT

Aluminum alloy wheel gravity casting die and casting method thereof

InactiveCN102029383ARiser lessHigh weight yieldMolten metal conveying equipmentsMetallurgyAlloy wheel

The invention discloses an aluminum alloy wheel gravity casting die and a casting method thereof. The aluminum alloy wheel gravity casting die comprises a cooling device, a top die, a side die, a bottom die and a die cavity formed by the top die, the side die and the bottom die; the bottom die is provided with a sprue spreader; the aluminum alloy wheel gravity casting die also comprises a heat insulation cup communicated with the die cavity and capable of storing molten aluminum, a pressing device capable of enabling the molten aluminum stored in the heat insulation cup to be continuously injected into the die cavity, and a plugging device capable of stopping the molten aluminum stored in the heat insulation cup from flowing into the die cavity under the action of gravity; the heat insulation cup is arranged on a rack of a gravity casting machine, and the plugging device is arranged on the bottom die or the rack of the gravity casting machine; and the casting method for the aluminum alloy wheel gravity casting die comprises molten aluminum injection, pressing, continuous casting, filling, feeding, crystallization and solidification. The cast aluminum alloy wheel has the advantages of a few dead heads, high weight and yield, and good quality stability.

Owner:何丙军 +1

Air tightness detection device for aluminum alloy wheel hub and method for detecting air tightness of wheel hub

ActiveUS20160223425A1Accurate and reliable detectionRapid and stable actionMeasurement of fluid loss/gain rateEngineeringAir tightness

The present invention provides an air tightness detection device for an aluminum alloy wheel hub, which is characterized by precision air pressure sensors, a lower clamp, a cone cylinder pressure plate, air pipes, a pressure plate, guide posts, an air inlet pipe, and a compressed gas control and detection system. A technical solution of the present invention has the following advantages that the cone cylinder pressure plate of the detection device reduces the space of an inner cavity of the wheel hub to further reduce inflating volume, thereby increasing detection efficiency; the characteristics of readily availability for preparation, no pollution and low cost are achieved by taking compressed air as a leakage indication gas.

Owner:CITIC DICASTAL

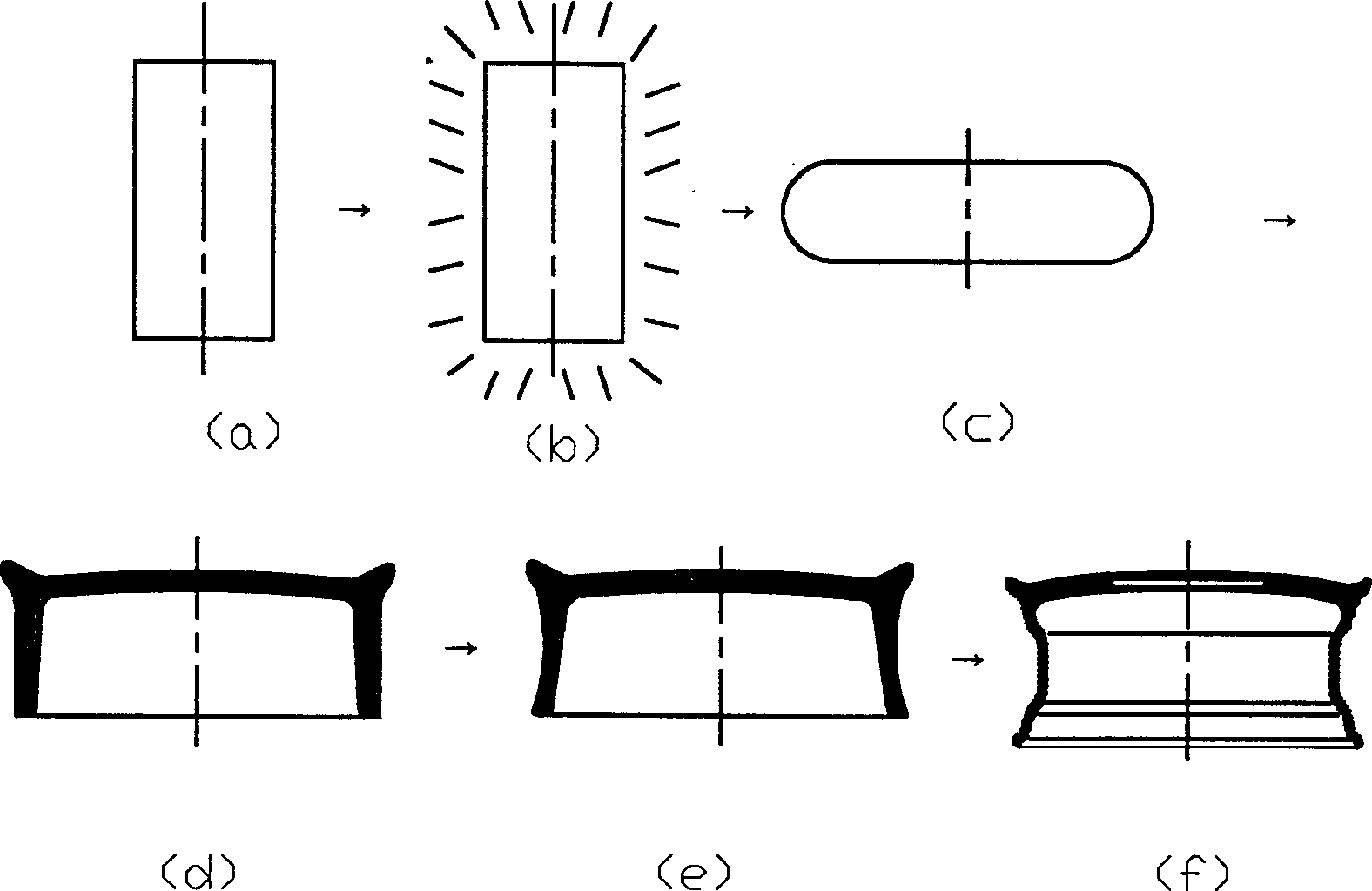

Forging and rotary extrusion forming process for aluminium alloy wheel

InactiveCN1827289AQuality improvementLight in massMetal-working apparatusMaterial consumptionRotational molding

The invention relates to a forging aluminum alloy wheel forging-rotational molding method, which combines the forging and rotational compressing techniques. In forging, molding part of spoke of wheel, and pre-molding the rim; then in rotational compressing, rotationally compressing the rim to complete the molding. Wherein, the rim is molded by forging, and the rim is mainly molded by rotational compression. The invention can combine the forging and rotational compression to express their advantages. And the inventive aluminum alloy wheel has better quality, high accuracy, less finish allowance, higher strength, and reduced material consumption.

Owner:JIAXING STONE WHEEL

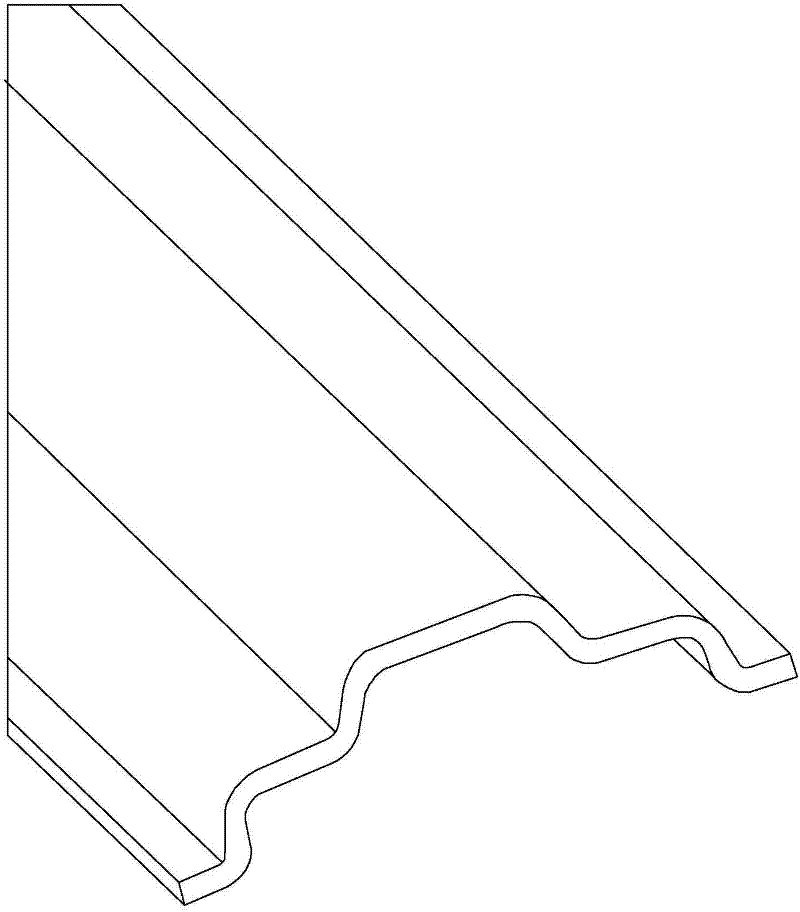

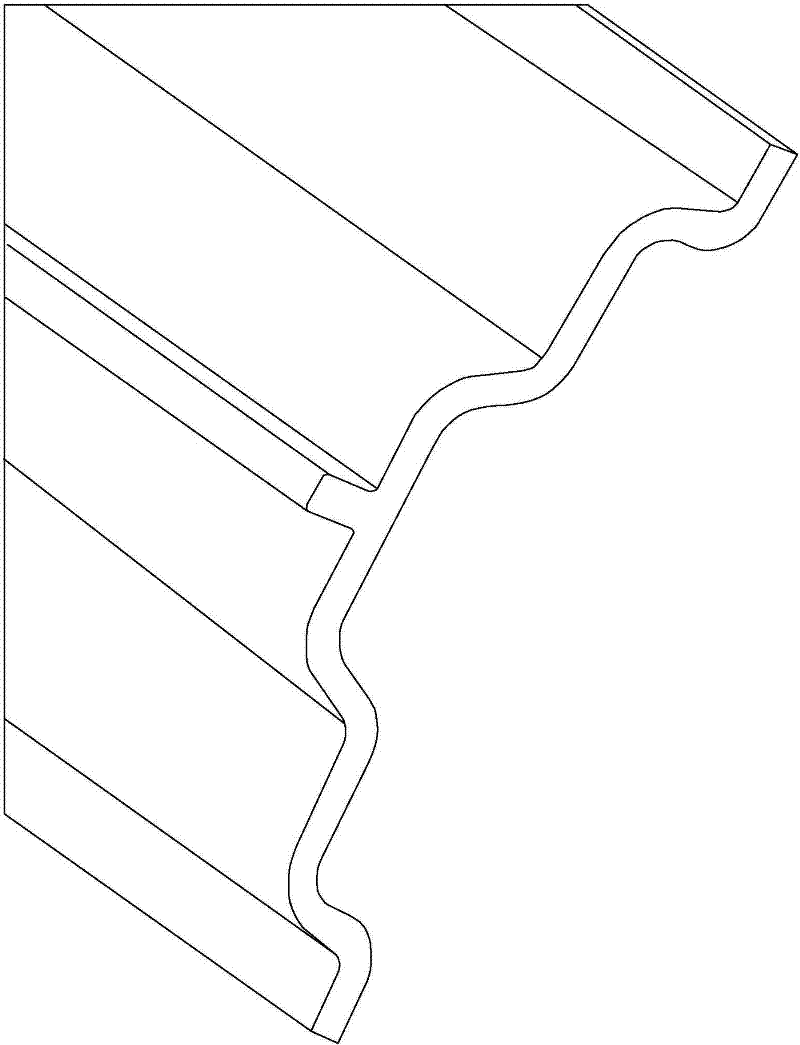

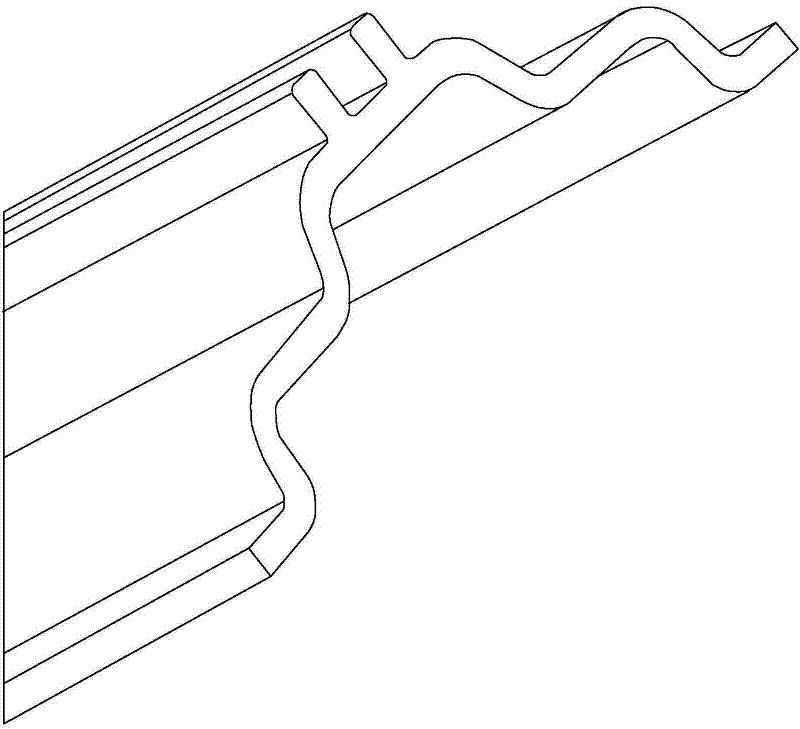

Manufacturing method of light-load automobile aluminum alloy wheel hub

The invention discloses a method for manufacturing an aluminum alloy wheel hub of a light-loaded automobile. The steps are as follows: A. Making the rim: according to requirements, select profiles of different cross-sections extruded from aluminum alloy materials, and then roll the profiles into a circle Cylinder, welding the butt joint, then rounding, and finally flanging the wheel lip; B. Spoke production: the circular aluminum plate is stretched or spun to make the aluminum plate reach the designed shape of the spoke, and then the spoke Stamping and processing various through holes; C. Manufacturing of the wheel hub: assembling the spokes in the inner circle of the rim; D. Completing the manufacturing: machining the lip parts of the wheel to complete the final manufacturing of the hub. The wheel rim in the present invention adopts the wheel rim profile that can be produced in large quantities to make the wheel rim. A large number of processing steps are reduced, manufacturing costs are saved, mass production is easier, and it can be directly entered into the ranks of low-end cars, making the promotion range of aluminum alloy wheels wider.

Owner:苏竞

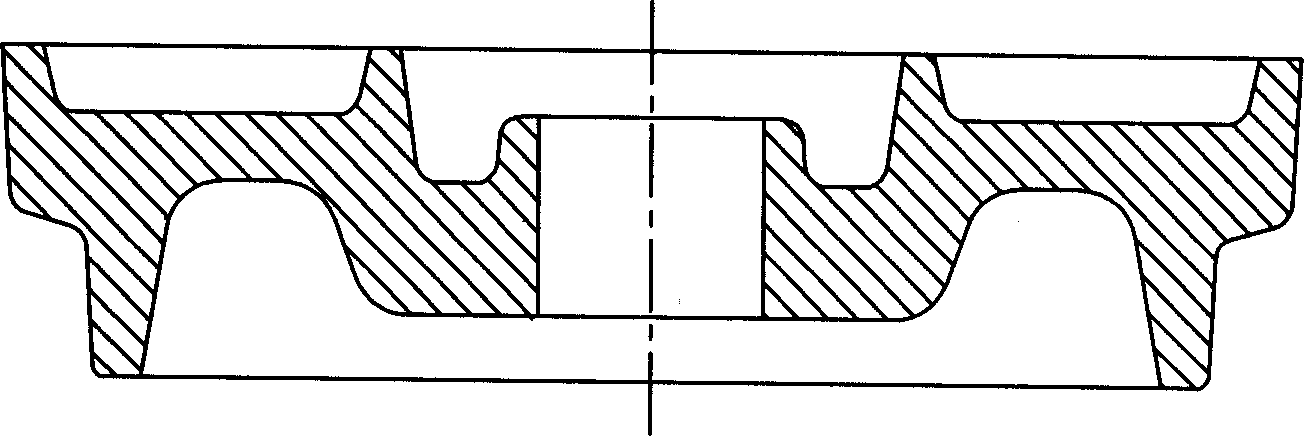

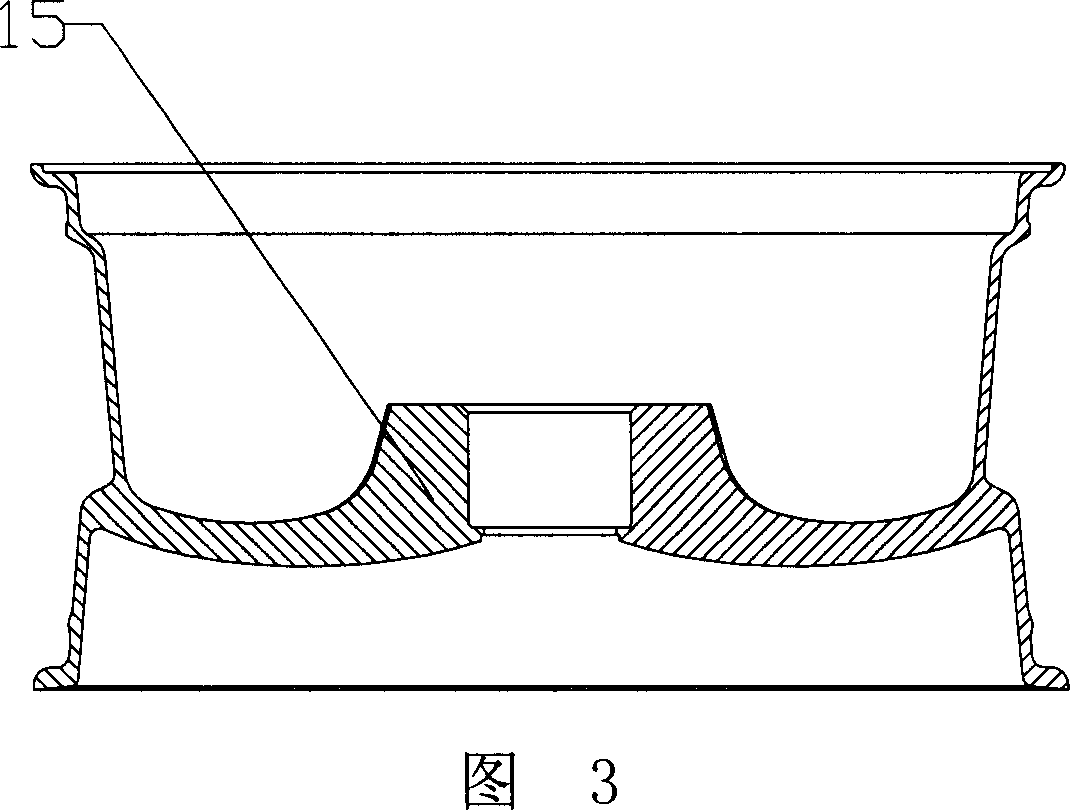

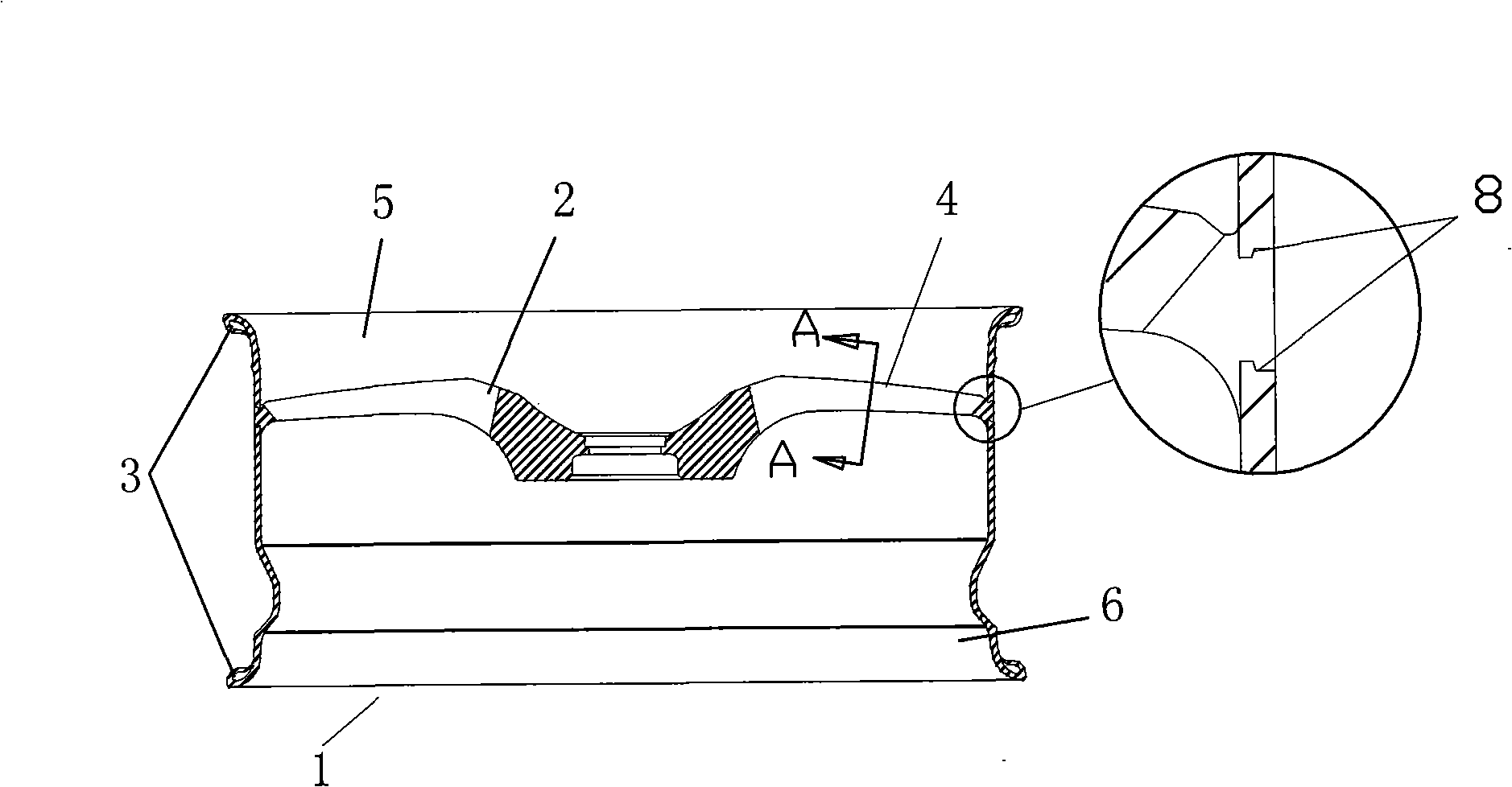

Low-pressure casting mold for aluminum alloy wheel hub and pouring method of low-pressure casting mold

The invention relates to a low-pressure casting mold for an aluminum alloy wheel hub, which comprises an upper mold, an upper mold core, a left side mold, a right side mold and a lower mold, wherein the upper mold core is arranged on the upper mold; the upper mold, the upper mold core, the left side mold, the right side mold and the lower mold are assembled to form a casting cavity for casting the wheel hub; the casting cavity comprises a rim cavity and a spoke cavity of the wheel hub; a spreader is arranged on the lower mold; a sprue is formed on each of the left side mold and the right side mold and directly communicated with the rim cavity; a sprue cup is arranged on a lower mold board; the upper end of the sprue cup is communicated with the sprues; and the lower end of the sprue cup is communicated with a riser tube inserted into a holding furnace. The invention further relates to a pouring method with the adoption of the mold. As the sprues are formed on the side molds and directly communicated with the rim cavity, when a spoke is thin, the solidification time of the spoke is shortened, a metallurgical structure becomes more dense as the solidification time of aluminum liquid is shortened, and further the mechanical property can be improved; and the mechanical property of the wheel hub is improved obviously while the wheel hub is lighter.

Owner:LIANYUNGANG QICHUANG ALUMINUM PROD MFG

Rotary swaging forming method for automobile aluminum alloy wheel hubs

The invention relates to a rotary swaging forming method for automobile aluminum alloy wheel hubs. By utilizing the capability of deformation allowance of a material under a certain temperature, and by the aid of the rotary swaging forming method, an aluminum alloy material is forced to form a shape according to a preset mould shape. The rotary swaging forming method includes: preparing a rough material, cleaning, preheating the rough material (enabling the rough material to be semi-solid), forging and pressing to form a shape, expanding an opening, and rotating and pressing to form a shape. The automobile aluminum alloy wheel hubs manufactured by the rotary swaging forming method are high in yield and stable in mechanical property, mechanical processing quantity and energy consumption for the wheel hubs are obviously lowered, raw material is saved, and production efficiency is improved.

Owner:金刚

Aluminum alloy wheel hub cutting scrap recycling and smelting process

InactiveCN102653825AEfficient removalImprove purityProcess efficiency improvementRare earthNitrogen gas

The invention discloses an aluminum alloy wheel hub cutting scrap recycling and smelting process and belongs to the technical field of new materials. The aluminum alloy wheel hub cutting scrap recycling and smelting process includes the following steps: (1) pretreatment: after impurity removal, drying, smashing and magnetic separation, adding cutting scraps produced in the machining process of aluminum alloy wheel hubs in an aluminum scrap recycling furnace for melting; (2) refinement: blowing a refining agent into a melting chamber through nitrogen for refining when the temperature in the furnace reaches 720-750 DEG C; (3) modification and double-refinement: adding aluminum-strontium bars and mixed rare earth in a tempering chamber for compound modification and double-refinement treatment of molten aluminum alloy entering the tempering chamber; (4) degassing: blowing nitrogen into the tempering chamber through a porous plug for degassing; and (5) filtering and deslagging: adding a fluxing medium in molten aluminum for fluxing, and adopting a foamed ceramic filter disc for purifying the molten aluminum alloy flowing to a using chamber and preserving heat for later use.

Owner:赵凯志

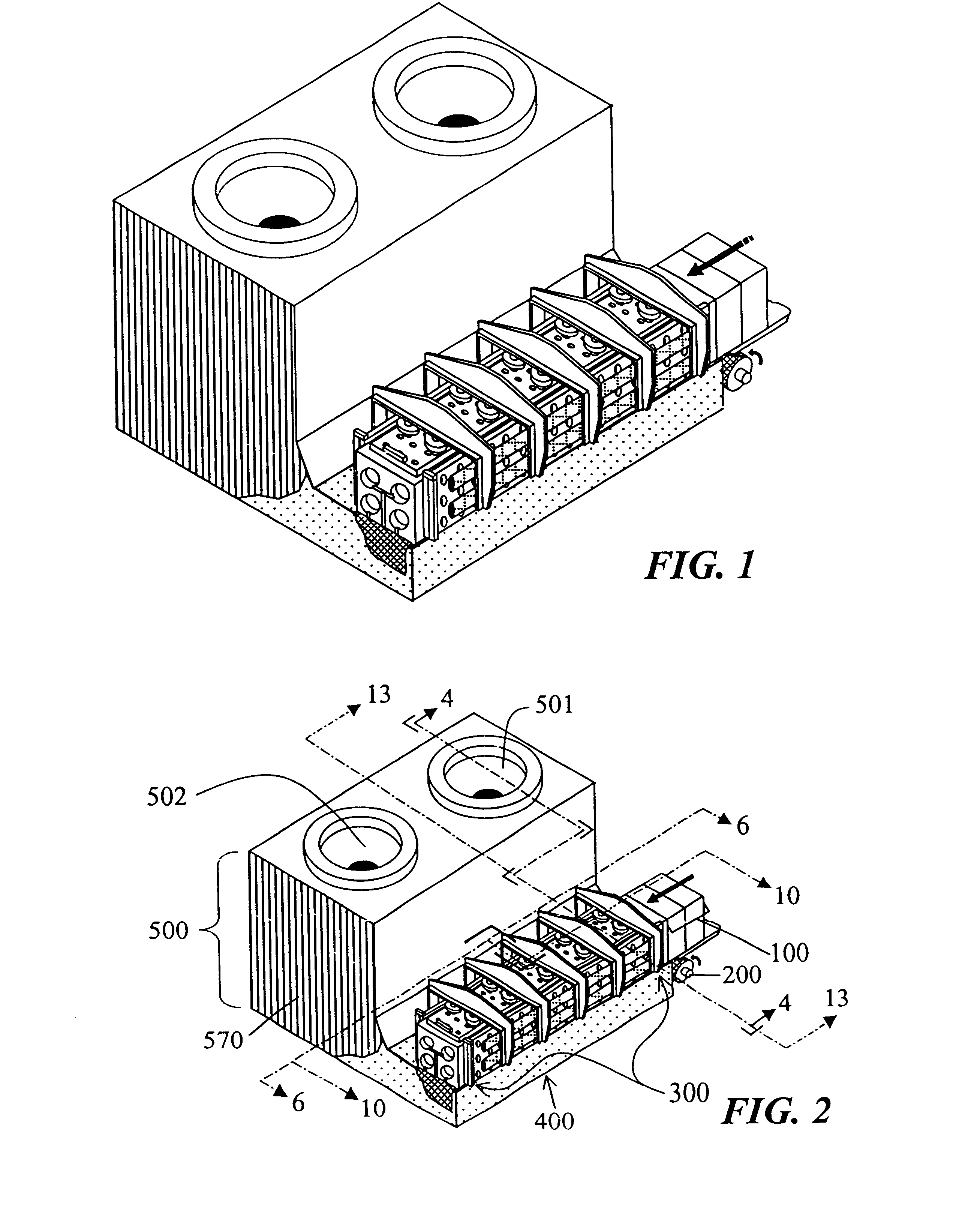

Automotive and aerospace materials in a continuous, pressurized mold filling and casting machine

Owner:HERRON DAVID J

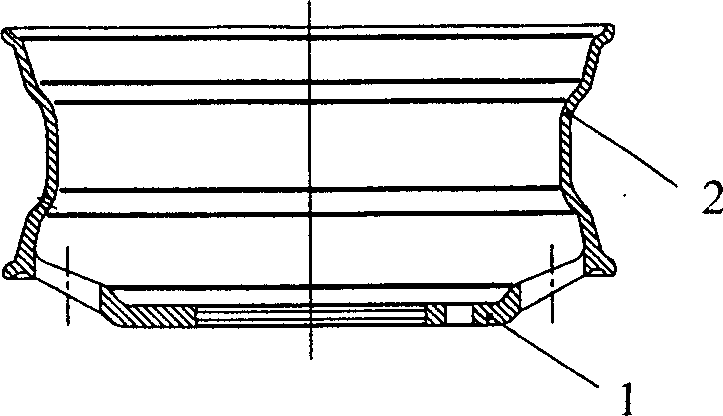

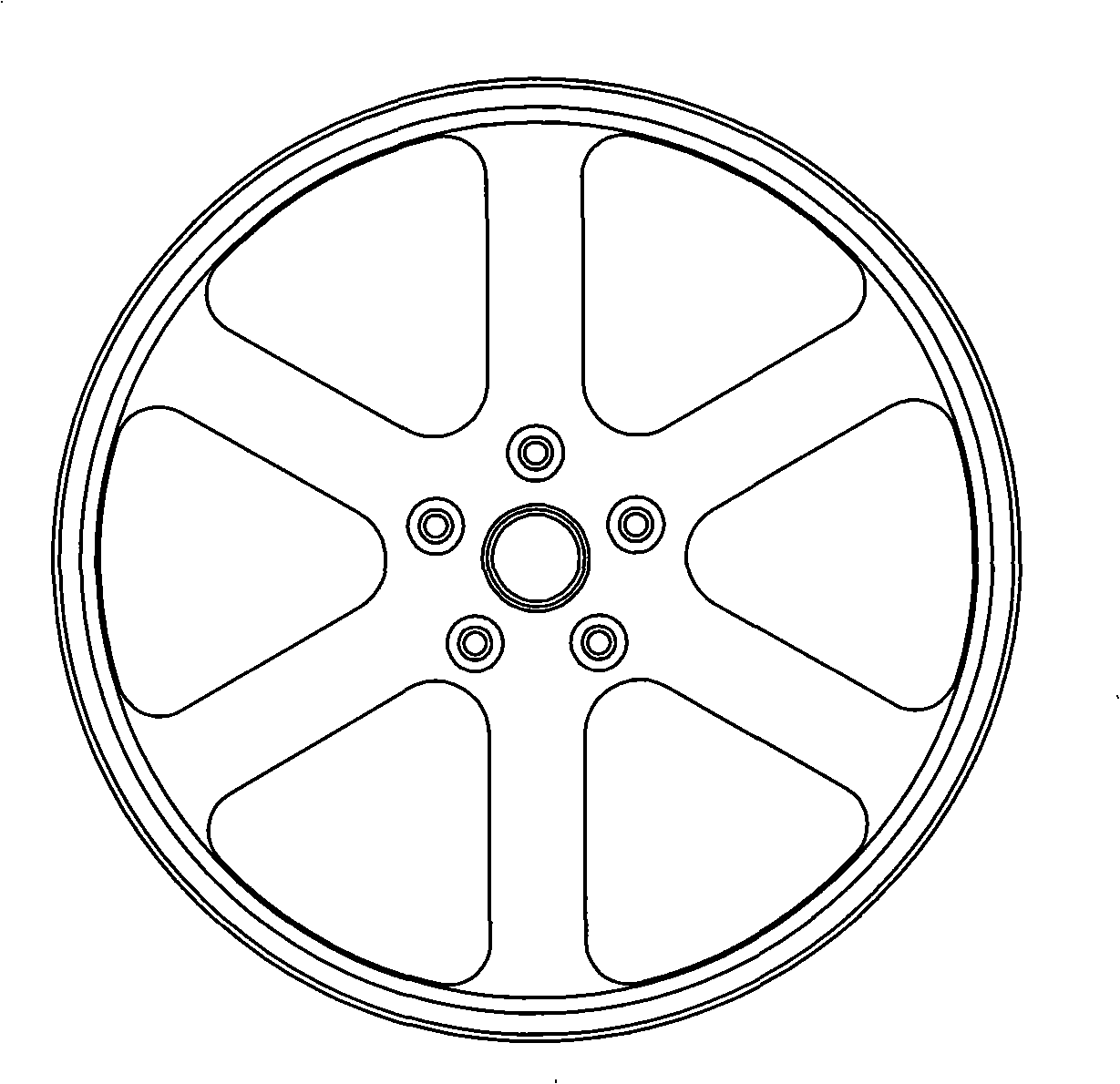

Aluminum alloy vehicle wheel and manufacturing method therefor

ActiveCN101402301AReduce weightHigh strengthRimsNon-electric welding apparatusAlloy wheelMaterials science

The invention discloses an aluminium alloy wheel, which comprises a wheel rim and a central disk arranged in the inner ring of the wheel rim. The wheel rim is an integral body consisting of an outer ring and the inner ring which are butted together axially; the wheel flange of the wheel rim is a hollow structure; the wheel spoke of the central disk is a hollow structure; and the central disk is connected with the butting part of the inner ring and the outer ring. The invention also discloses a method for producing the aluminum alloy wheel, namely adopting a spin forming method to make two sections of the wheel rim of the inner ring and the outer ring, and using a friction stir welding method to weld the wheel rim and the central disk into an integral body, wherein the position of the central disk in the wheel rim can be selected according to the requirement. Because the aluminium alloy wheel adopts the spin forming method and the 'hollow structure', half of materials can be saved, thus the wheel is light in weight, high in strength, beautiful in appearance, environment-friendly, and energy-saving. The structure and the process are suitable for mass production with high efficiency and low cost.

Owner:陈旭

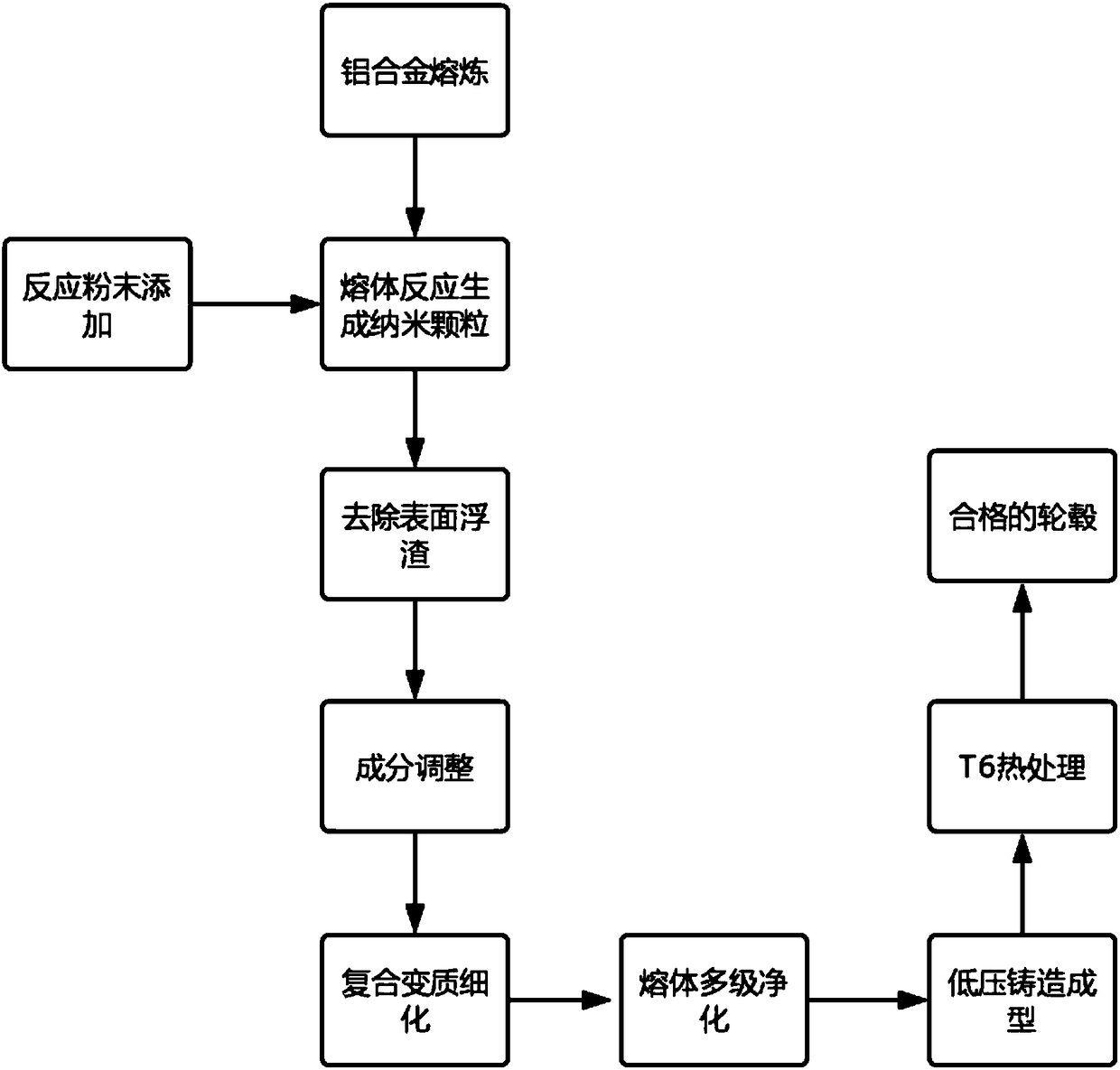

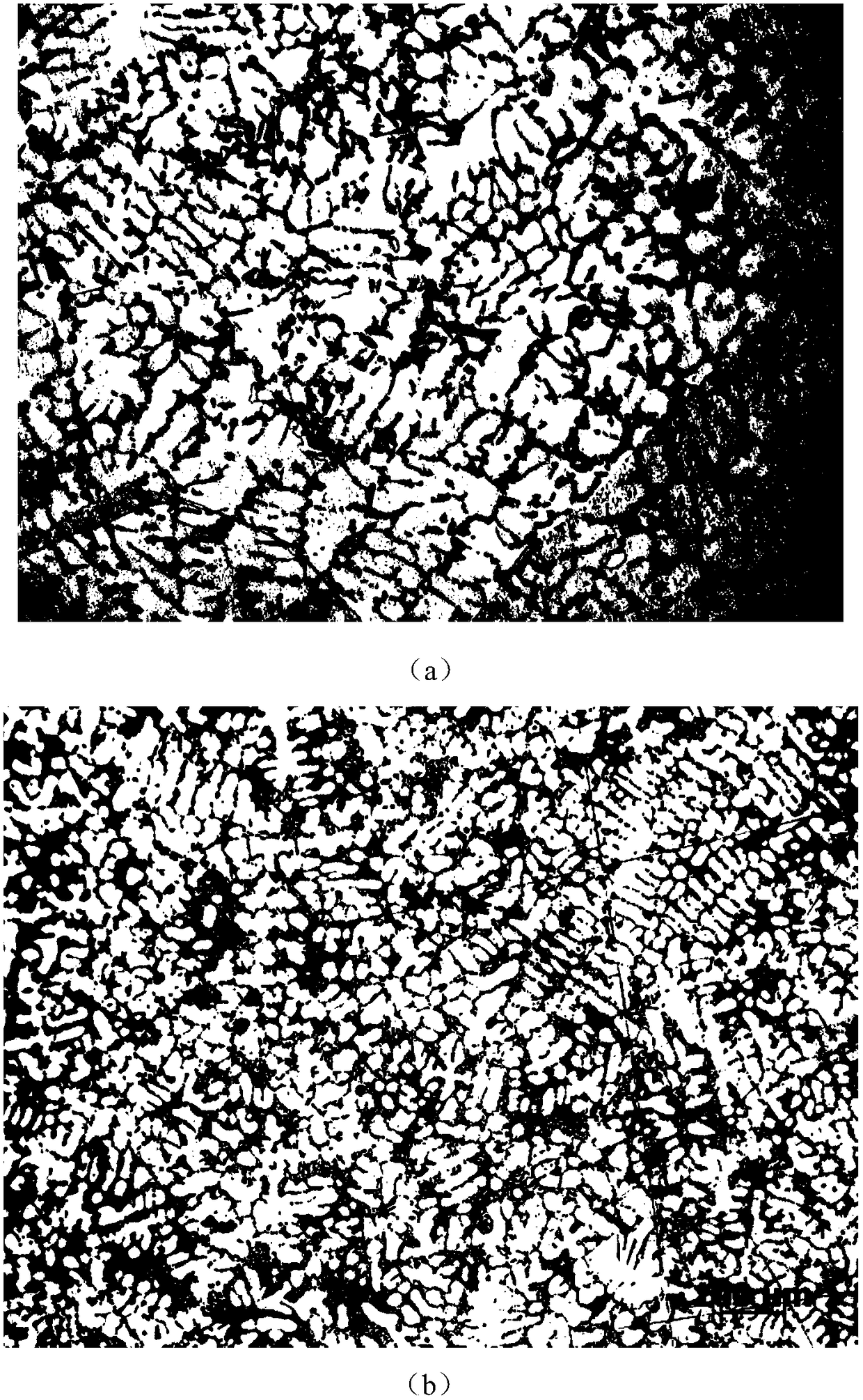

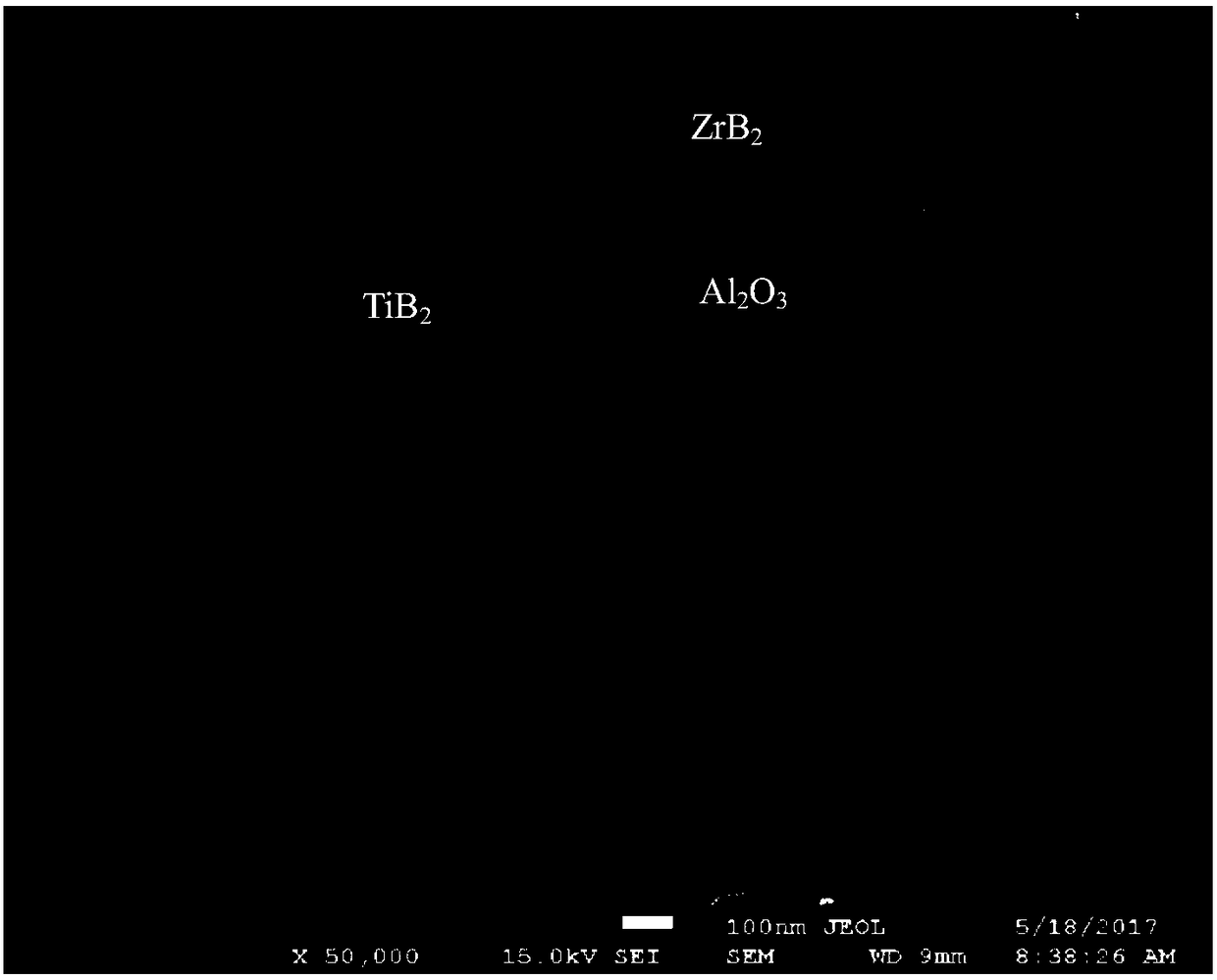

In-situ nanometer intensified aluminum alloy wheel hub for new energy automobile and manufacturing method thereof

ActiveCN108559864AReduce energy consumptionImprove battery lifeHubsWheelsChemical reactionNew energy

The invention relates to an in-situ nanometer intensified aluminum alloy wheel hub with light weight, high strength and fatigue resistance for a new energy automobile and a manufacturing method thereof. Through in-situ chemical reaction of a melted body, nanometer particle compound reinforcement is realized by Orowan reinforcement + refined crystalline reinforcement, long-term compound metamorphism and complex refinement are integrated, and the refined crystalline reinforcement is achieved. The purification technology of nitrogen and argon combined rotary air refining + aluminum-rear earth isadopted, multi-stage deep purification of aluminum melted body is realized, the characteristic that argon is greater than air in density is used for forming a protective layer on the surface of the melted body, and alloy is introduced between the aluminum-rear earth to produce intermediate compounds with the density greater than that of the particles, and therefore the deep high-efficiency purification is effectively achieved. A novel low pressure shaping technology of progressive solidification + rapid crystallization is adopted in the end, due to the fact that crystallization time is shortened, the space between secondary branch crystal arms in a casting microstructure is shortened, the structure is refined and the feeding effect is enhanced, the casting is denser in structure, and the wheel hub with high plasticity, high anti-fatigue performance and high density is obtained.

Owner:JIANGSU UNIV

High effective heat treatment method for wheel hub founded at low pressure from high performance A356 alloy

This invention relates to a method for thermal treatment of high-efficiency and high-performance low-pressure die casting A356 alloy wheel. The method comprises: performing solid solution treatment at 535-545 deg.C for 5-7 h, quenching, performing low-temperature pre-aging treatment, and then performing aging treatment at 175-185 deg.C for 3-5 h immediately. The method has such advantages as shortened solid solution treatment time, shortened aging treatment time, high strength of low-pressure die casting A356 alloy wheel, shortened thermal treatment period, increased production efficiency, and improved mechanical properties of low-pressure die casting A356 alloy wheel.

Owner:ZHENGZHOU UNIV

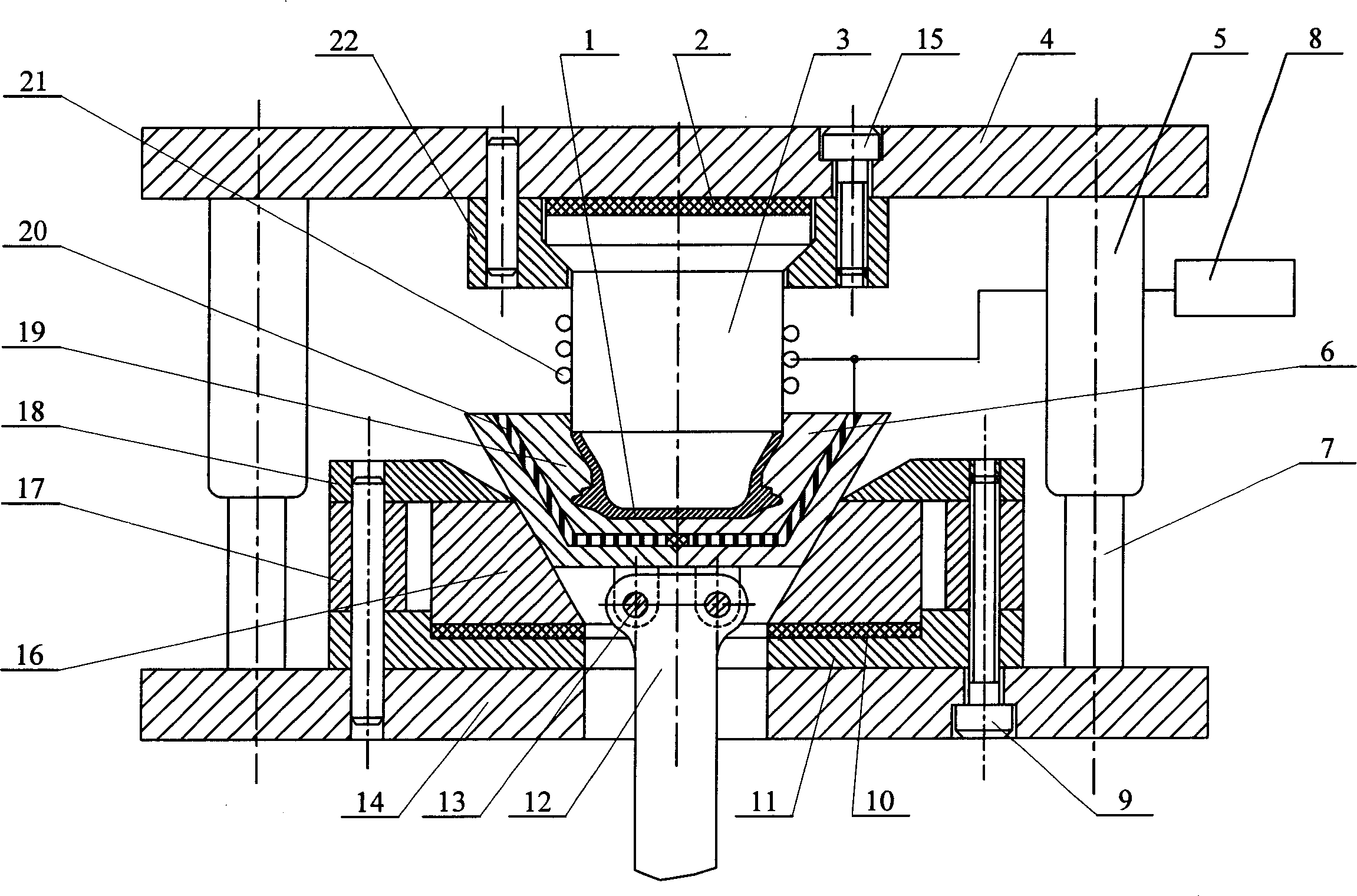

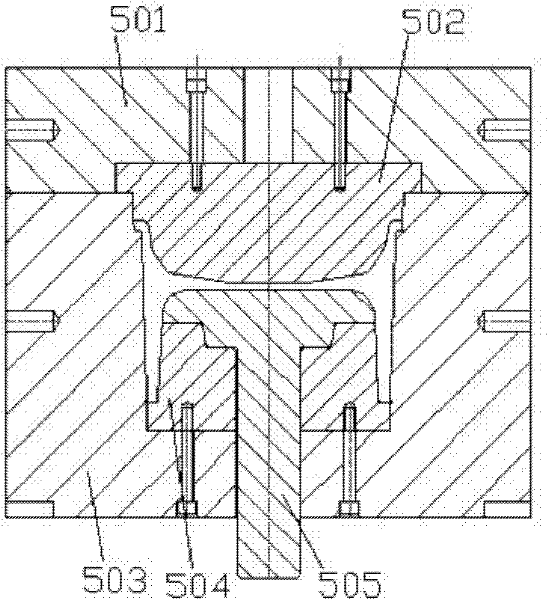

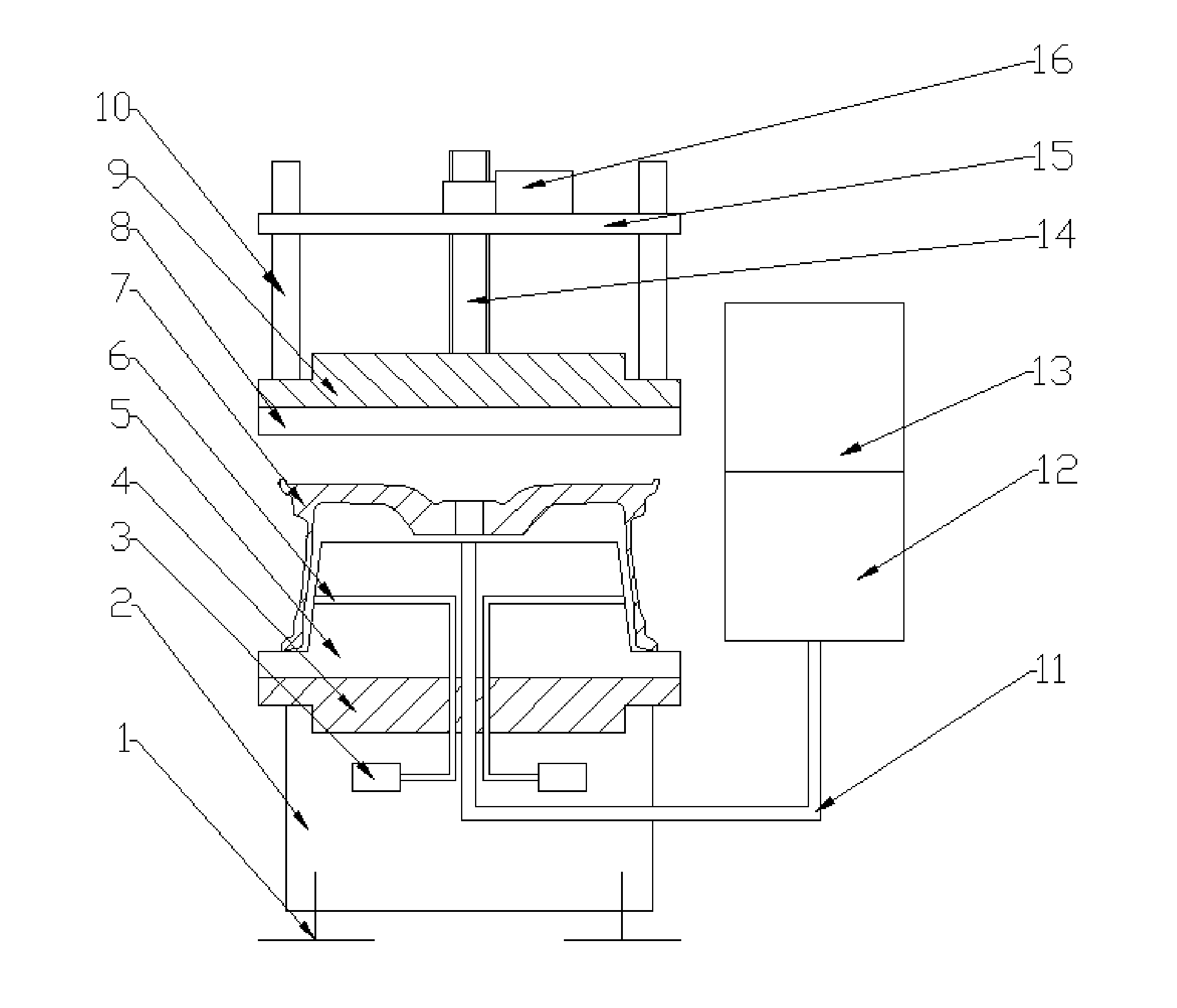

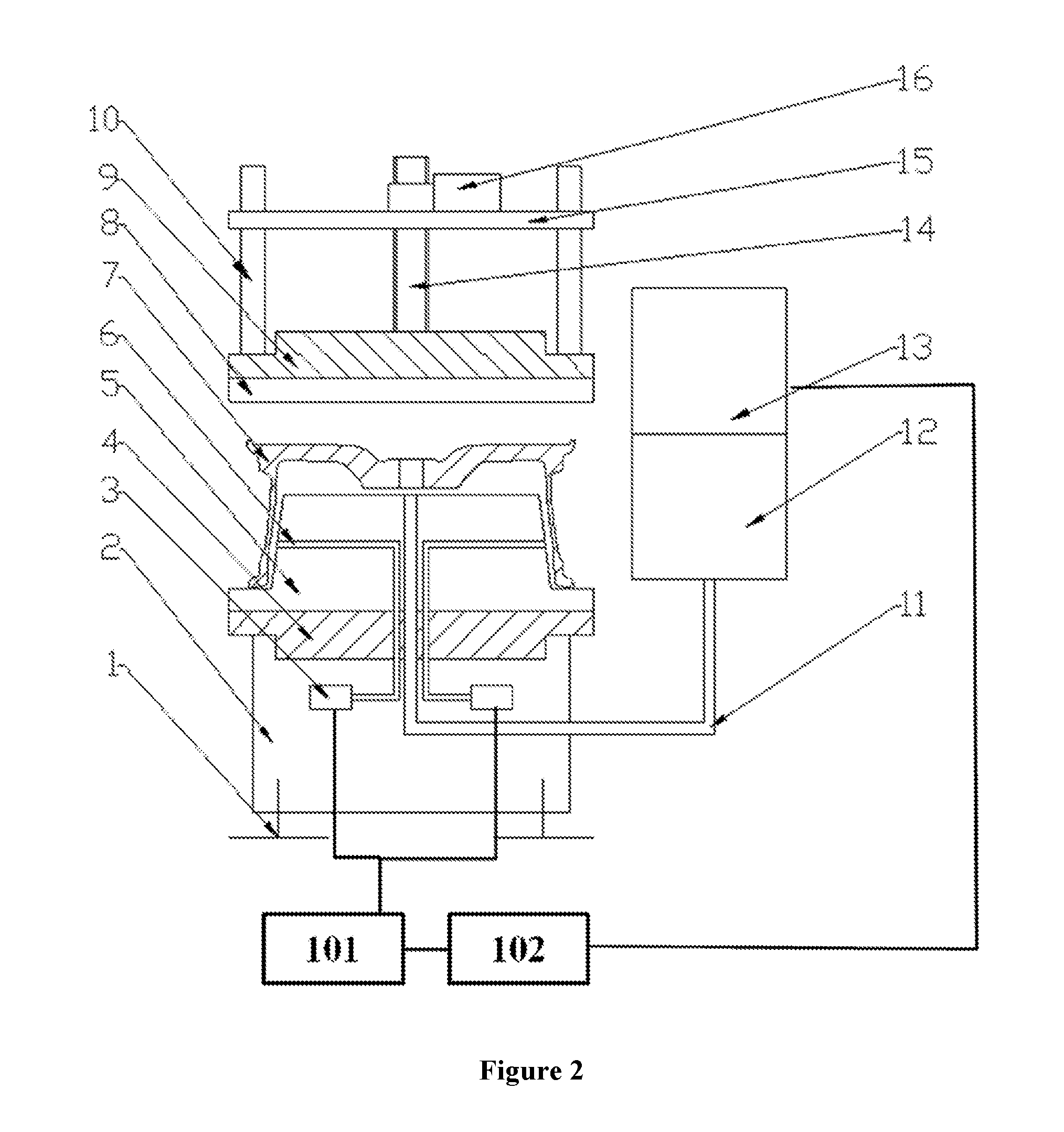

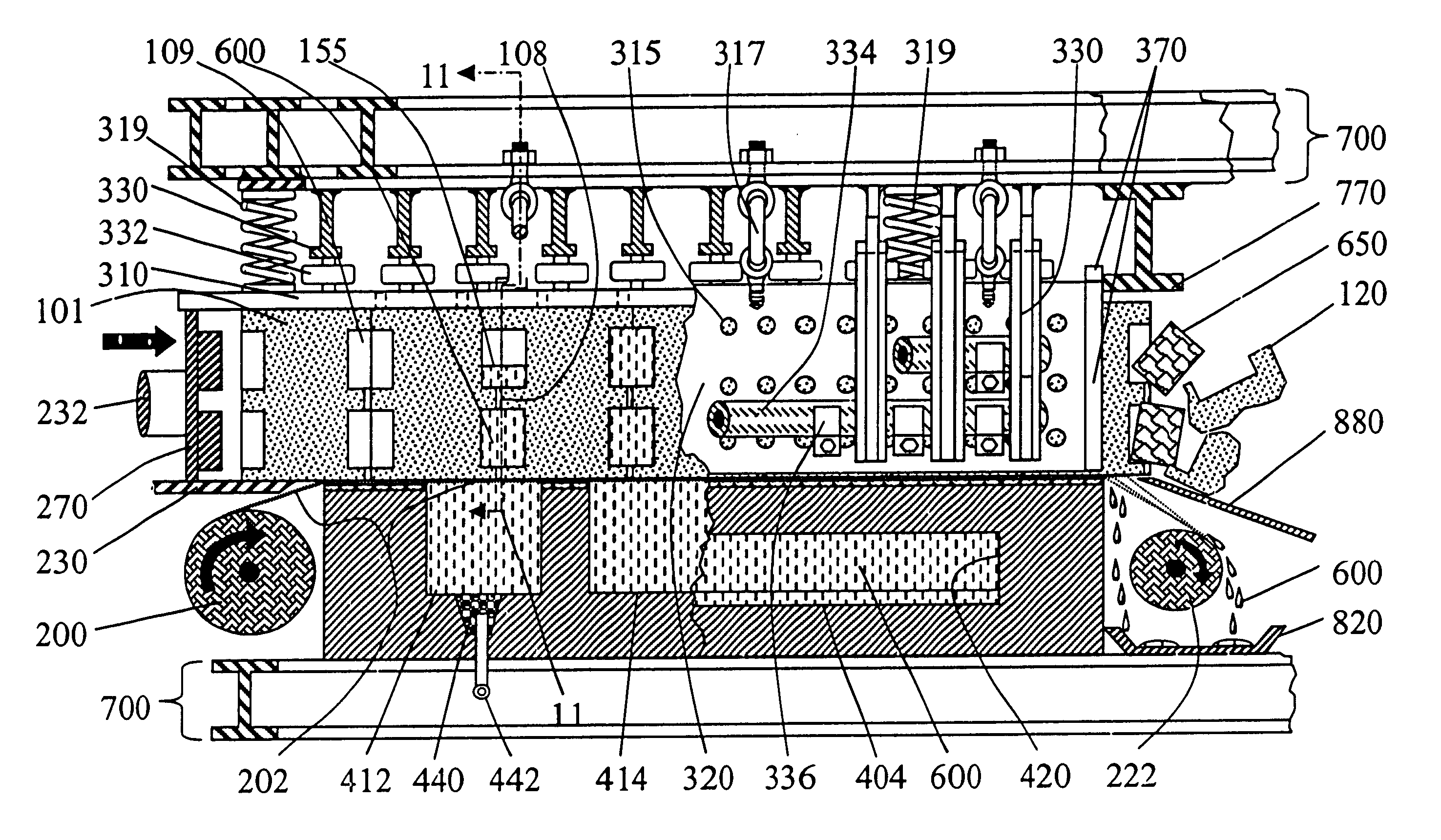

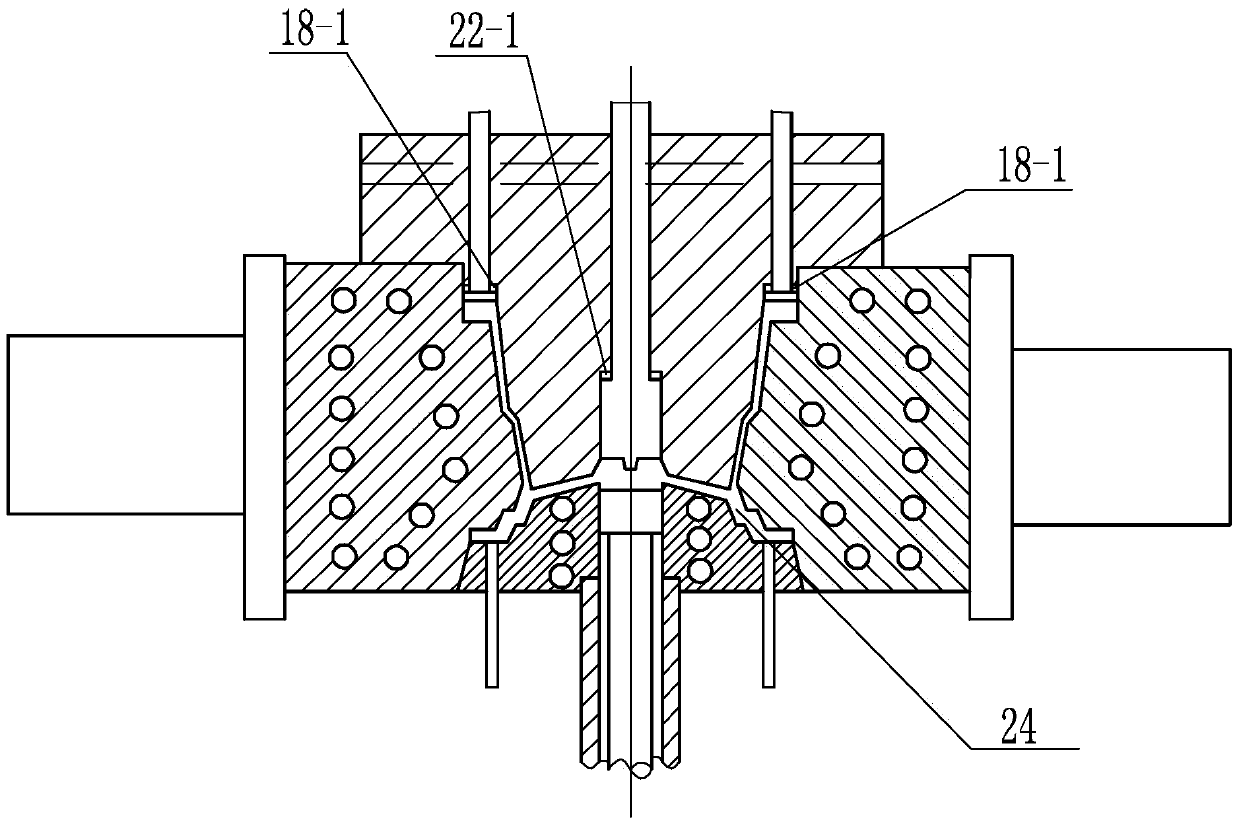

Device for manufacturing automobile aluminum alloy wheel hubs through liquid filling, local pressurizing and feeding and method thereof

InactiveCN105499513AImprove productivityImprove the level of automated productionFoundry mouldsFoundry coresEngineeringMechanical property

The invention relates to a manufacturing device for automobile wheel hubs and a method thereof, in particular to a device for manufacturing automobile aluminum alloy wheel hubs through liquid filling, local pressurizing and feeding and a method thereof. The device and the method thereof solve the problems that existing automobile wheel hub manufacturing devices and the method thereof are low in integration level and the mechanical property of wheel hub parts and the cost are mutually restricted. The upper end of a local spoke pressurizing rod and a plurality of local rim pressurizing rods are connected to a local pressurizing cylinder, the local spoke pressurizing rod is located in a center hole of an upper die, the local rim pressurizing rods are uniformly arranged in the upper die in the circumferential direction, the lower ends of the local rim pressurizing rods are fixedly connected to local rim pressurizing rings, and an injection chamber sleeve is coaxially communicated with the lower end of a central through hole of a lower die. The method comprises the steps of carrying out fusion and heat preservation; spraying release agents on the surface of a first rim splitting die, the surface of a second rim splitting die, the surface of the upper die and the surface of the lower die, closing and heating the dies and carrying out heat preservation; opening the dies and pouring molten aluminum; injecting the molten aluminum into cavities of the wheel hubs after the dies are closed; carrying out local pressurizing and retreating the dies; ejecting and forming the wheel hubs. The device and the method are used for manufacturing the automobile aluminum alloy wheel hubs.

Owner:HARBIN INST OF TECH

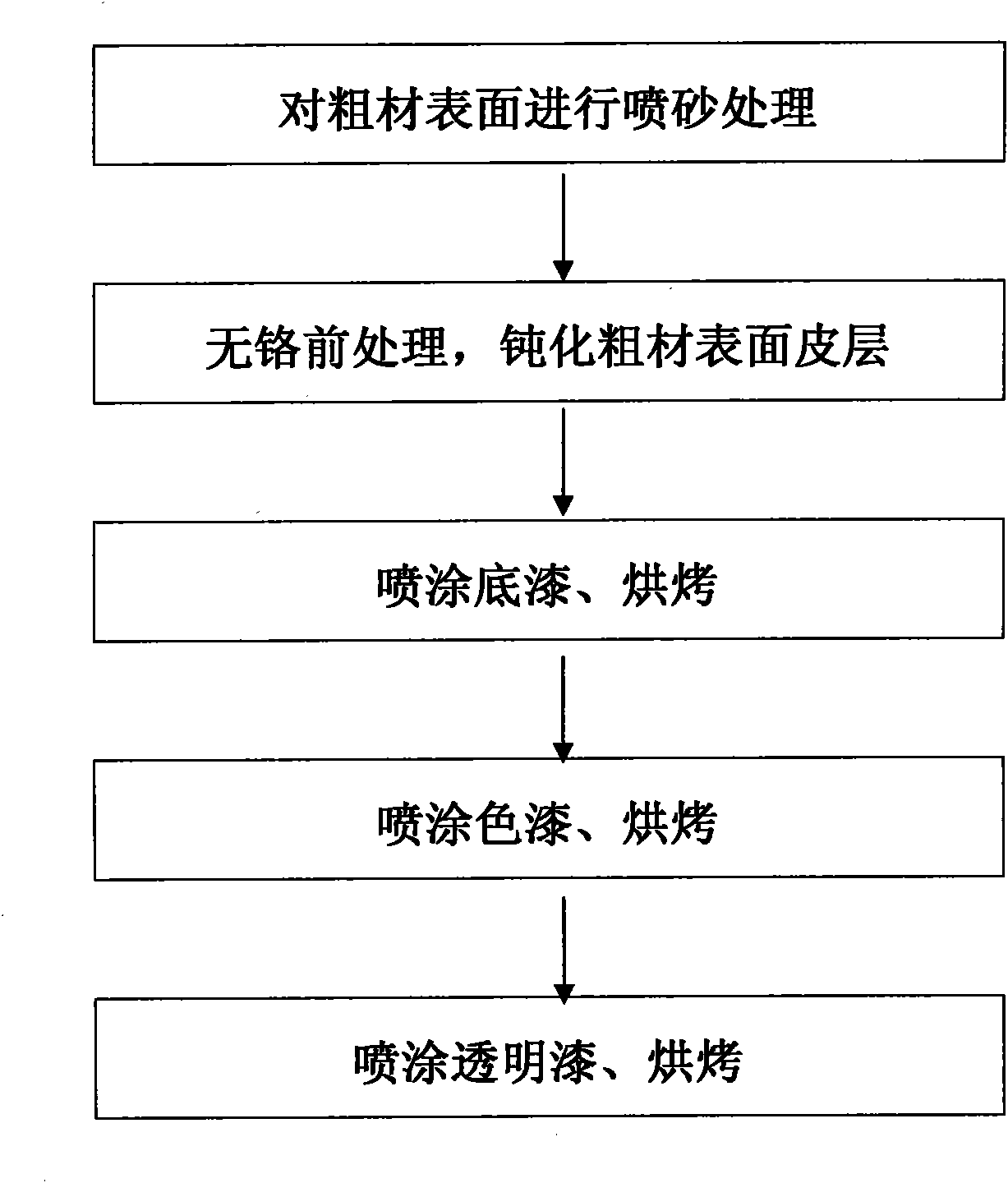

Coating method of aluminum alloy wheel rim

InactiveCN101934265AImprove adhesionSimple spraying processRimsPretreated surfacesCooking & bakingAbrasive blasting

The invention relates to a manufacturing technique of a rim in the manufacturing technical field of automobile components, in particular to a coating method of an aluminum alloy wheel rim. The coating method comprises the following steps: (1) carrying out blast sanding on the surface of raw material; carrying out non-chromium pretreatment to passivate surface layer of the raw material; (2) spraying and roasting primer via black foundation paint; (3) spraying and roasting color paint via highlighting silver paint; (4) carrying out spraying and baking of colored paint by using highlighting sliver paint; and (5) spraying and roasting transparent paint via Aksu powder transparent paint. The coating method has the advantages that the black foundation paint is primarily applied in the manufacture of the aluminum alloy rim; the adhesion force of the aluminum rim is improved by surface blast sanding and non-chromium pretreatment; the whole paint coating can be accomplished in three times of spraying and three times of roasting; the technique conditions are relaxed and the production cost is reduced; and the highlighting silver paint is successfully applied in the paint spraying of the aluminum alloy rim to ensure degree of finish and luminance of a product and be applicable to replacing plating technique in industrialized production.

Owner:六和轻合金(昆山)有限公司 +1

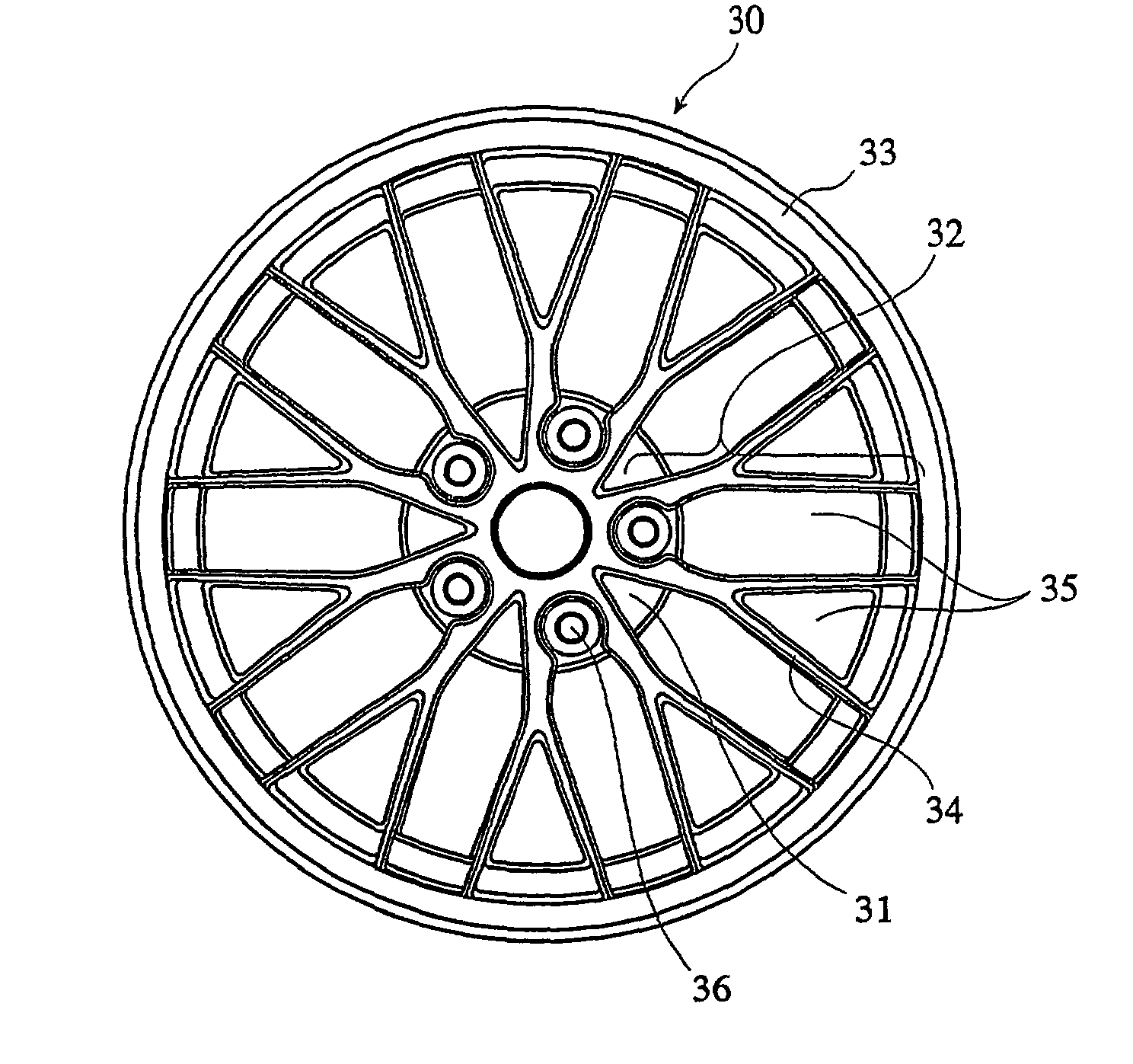

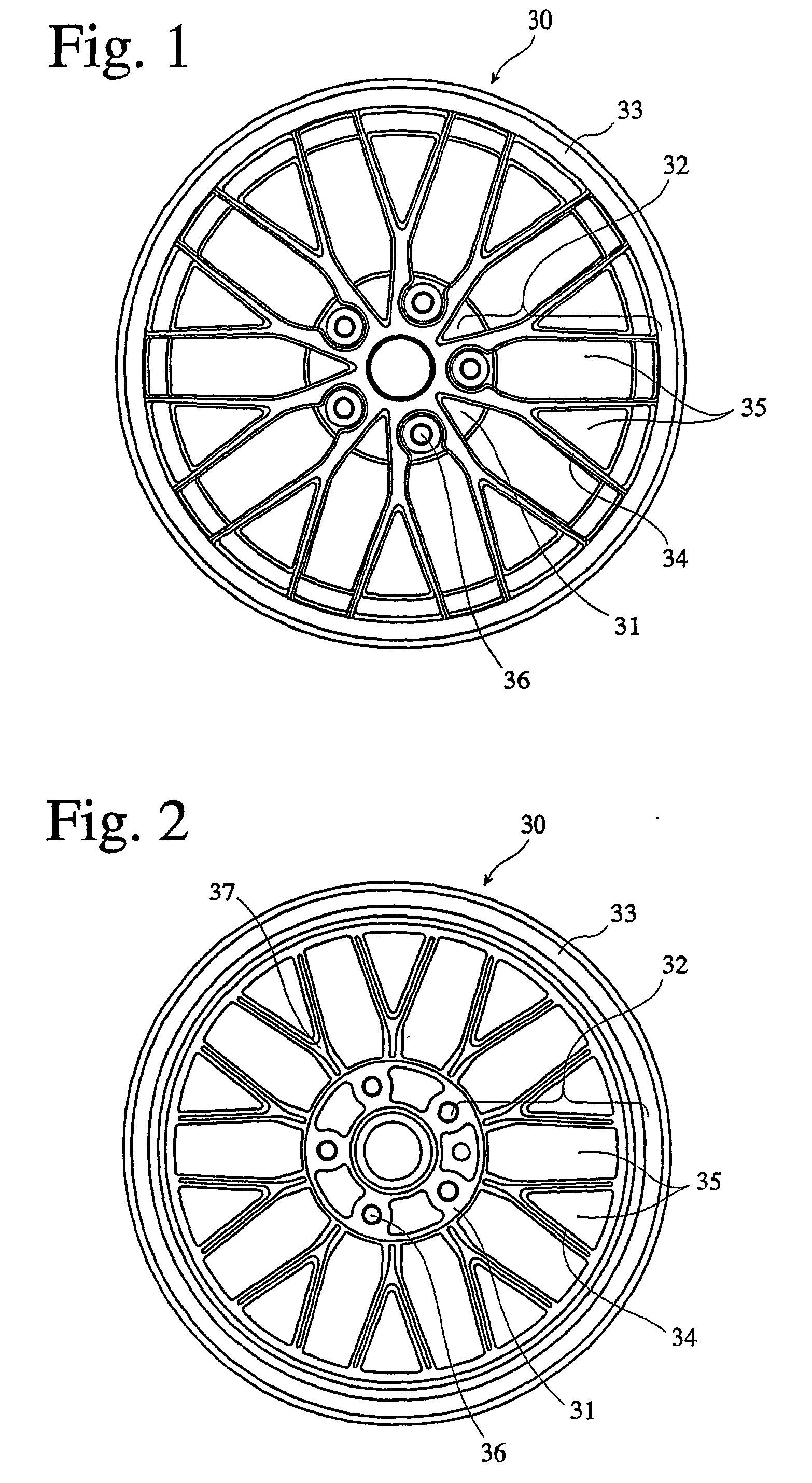

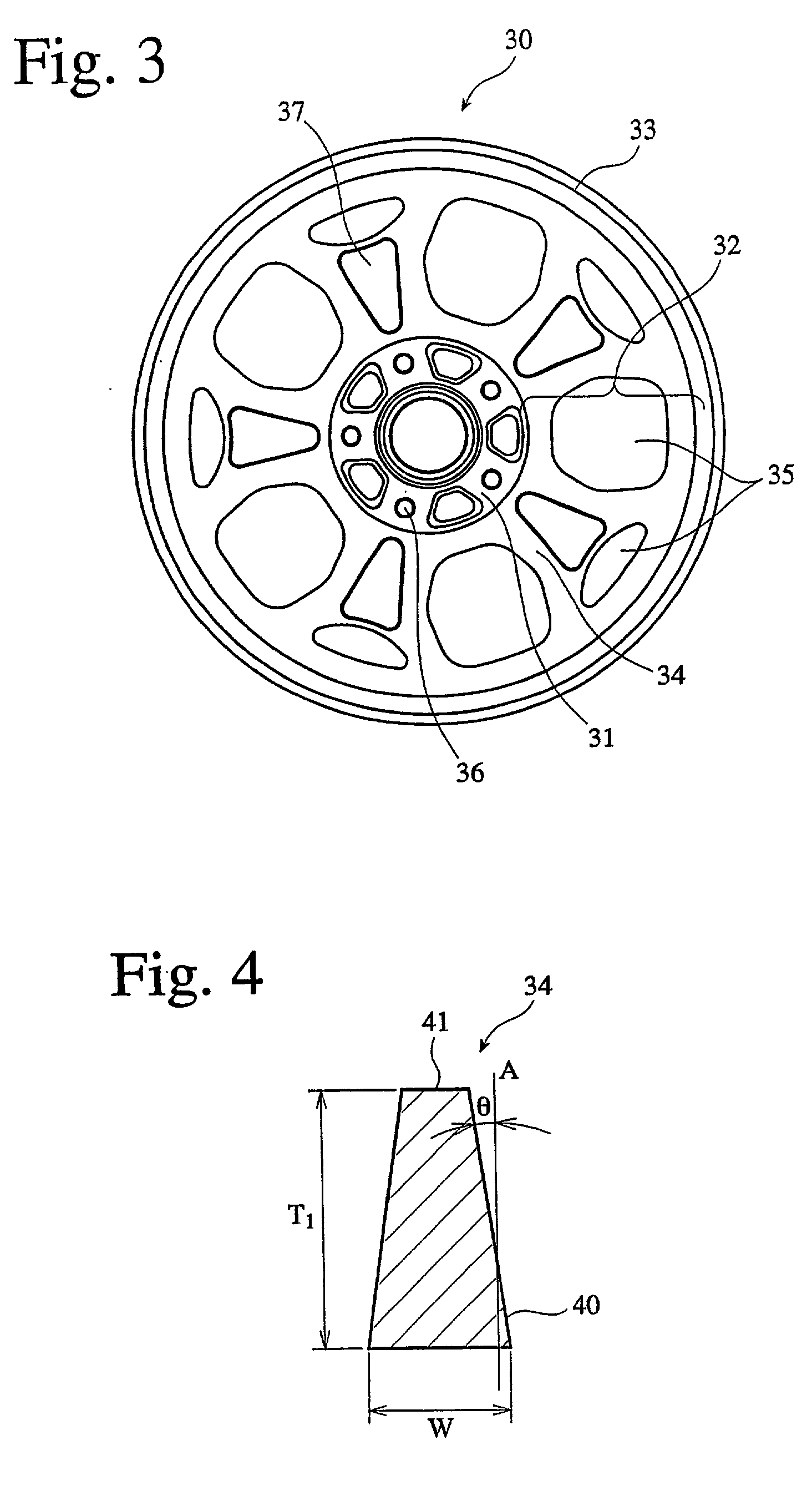

Light alloy wheel for vehicle and method and apparatus for producing same

A light alloy wheel for a vehicle comprising a disc portion comprising a hub portion and a design portion and a rim portion, the design portion having as-die-cast spoke portions having a taper angle of less than 5.0°. This wheel can be produced by using a casting apparatus comprising a die assembly comprising at least a stationary lower die and a movable upper die, a movable platen to which the upper die is fixed, a first cylinder and at least three synchronous second cylinders mounted onto a frame of the apparatus for moving the movable platen; driving the first cylinder to slowly reduce the clamping force of the lower die and the upper die; synchronously driving the second cylinders to elevate the movable platen in parallel from a position at which the lower die and the upper die are clamped to a position at which the wheel would not impinge on the lower die even if the movable platen were slanted; and then further elevating the movable platen by the first cylinder.

Owner:KOSEI ALUMINUM

Grain refiner and application of grain refiner in aluminum alloy wheel hub

The invention relates to a grain refiner and an application of the grain refiner in an aluminum alloy wheel hub. The grain refiner is characterized by being prepared through the following steps: (1) preparing powdery Al, Ti and B participating in the reaction according to mass percents of 65-75%, 15-30% and 5-10%; (2) smelting an aluminum ingot containing 6.5-7.5% of silicon and 0.3-0.45% of magnesium, adding a covering agent and a refining agent, degassing and stewing to obtain a matrix alloy fused mass; and (3) putting reaction blocks in an electromagnetic induction furnace for heating and drying, pressing the reaction blocks into the fused mass according to 5-10% by mass of the matrix melt through an immersion bell in batches, keeping the temperature for 20 min to perform thermal explosion synthetic reaction on the reaction blocks in the fused mass so as to crack and disperse the reaction blocks due to strong heat release, and mechanically stirring the fused mass to completely dilute the synthetic product and disperse the synthetic product in the aluminum fused mass. The solution and diffusion periods of the TiAl3 phase of the aluminum alloy solution prepared by the method are greatly reduced, the dispersibility of the TiB2 particles is greatly improved to facilitate the refining function, and the size of the casting crystalline grain of an intermediate alloy can be effectively controlled to be lower than 40 microns.

Owner:金刚

Casting and hot spinning process of aluminum alloy wheel

The invention discloses a casting and hot spinning process of an aluminum alloy wheel, which comprises a casting process and a spinning process. The casting and hot spinning process is characterized in that the content of Mg in aluminum liquid for casting accounts for 0.30-0.40 percent of total mass; a spinning blank is processed by adopting the casting process; a spoke is only cast by the blank; a rim is preformed and a material required for the rim is reserved by the preformed rim according to an isovolumetric deformation principle; the deformation ratio of the performing of the rim to the final forming is between 0.8 and 1; and then the performing part of the blank rim is spun and formed by adopting the spinning process. The invention uses traditional common cast equipment, so the cost of products is greatly reduced as comparison with a rotary swaging process, the rim formed by casting has strong shape change adaptability and relatively-complicated models can be finished; and meanwhile, casting defects such as the loosening and the shrinkage in the spinning and forming process disappear by spinning and the rim strength can be remarkably improved.

Owner:BAODING CITY LIZHONG WHEEL MFG

Aluminum alloy for wheel hub and preparation method thereof, and aluminum alloy wheel hub

The invention discloses an aluminum alloy for a wheel hub and a preparation method thereof, and an aluminum alloy wheel hub. The preparation method comprises the following steps: a, melting an aluminum ingot so as to prepare a primary aluminum liquid; b, mixing a slag-clearing agent with the primary aluminum liquid, and discharging molten slag so as to prepare a second-stage aluminum liquid; c, mixing a refining agent with the second-stage aluminum liquid in the presence of nitrogen and then carrying out standing and slagging so as to prepare a third-stage aluminum liquid; d, mixing a refiner and a modifier with the third-stage aluminum liquid so as to prepare a fourth-stage aluminum liquid; E, spreading the slag-clearing agent onto the surface of the fourth-stage aluminum liquid to clear slag so as to prepare a fifth-stage aluminum liquid; and f, spreading the slag-clearing agent on the surface of the fifth-stage aluminum liquid, and carrying out degassing treatment so as to prepare the aluminum alloy for the wheel hub. According to the invention, the contents of hydrogen and impurities in the aluminum alloy for the wheel hub are low, so the aluminum alloy for the wheel hub has excellent fluidity and shrinkage during solidification; therefore, the surface of the aluminum alloy wheel hub prepared from the aluminum alloy used for the wheel hub is free of pin holes and slag holes.

Owner:WUHU HUANGYAN IND

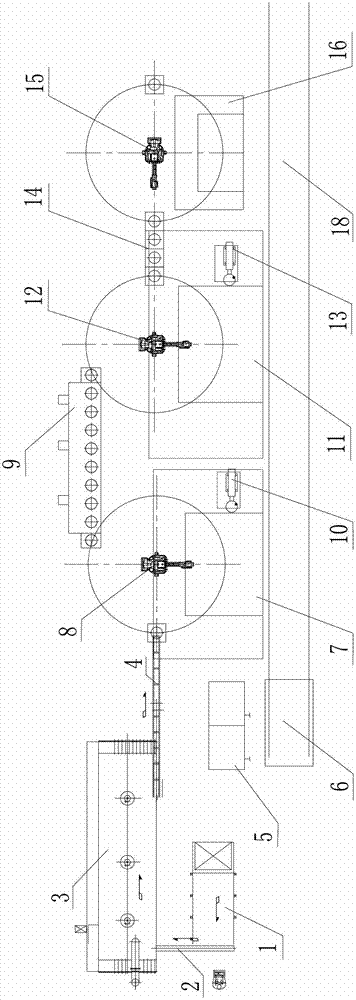

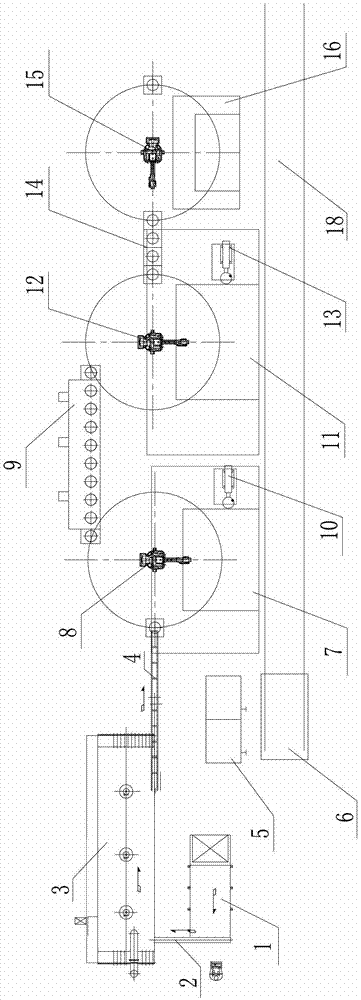

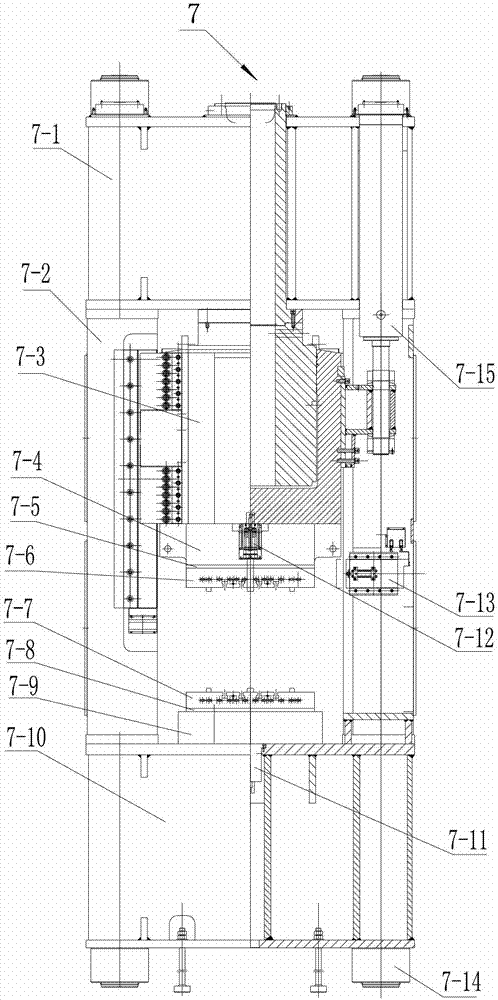

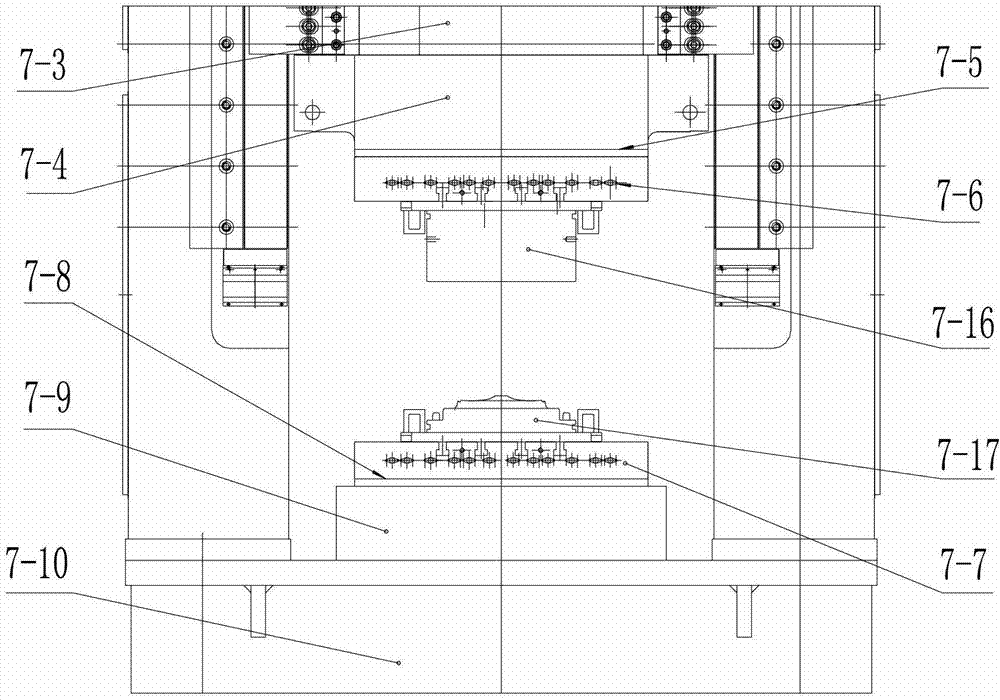

Large-scale aluminum alloy hub isothermal forging production line

ActiveCN102873253ASimplify the pressing processRealize visual operationShaping safety devicesForging/hammering/pressing machinesProduction lineHeating furnace

The invention relates to a large-scale aluminum alloy hub isothermal forging production line. The large-scale aluminum alloy hub isothermal forging production line is characterized by comprising a bar cutting machine, a bar heating furnace, a plurality of delivery manipulators, a pre-forging hydraulic press, a hub finish-forging hydraulic press, an aluminum alloy hub broaching and trimming hydraulic press and a pressing die. A cold material conveying roller table is arranged between the bar cutting machine and the bar heating furnace, a hot material conveying roller table is arranged between the other end of the bar heating furnace and the delivery manipulators, a die heating furnace, a die change trolley and a change trolley rail are arranged on one side of the pre-forging hydraulic press, a pre-forging lubrication spraying device is arranged on the other side of the pre-forging hydraulic press, a middle heating furnace or a delivery roller table is arranged between each two manipulators, and a finish-forging lubrication spraying device is arranged on one side of the hub finish-forging hydraulic press. The large-scale aluminum alloy hub isothermal forging production line has the advantages that by means of structural and technical combination of hot die forging, broaching and trimming, one-time pressing of aluminum alloy hubs can be realized, the pressing process of the aluminum alloy hubs is simplified, cost, time and labor for later-stage secondary processing and shaping can be greatly saved, and production efficiency is improved.

Owner:TIANJIN TIANDUAN PRESS CO LTD

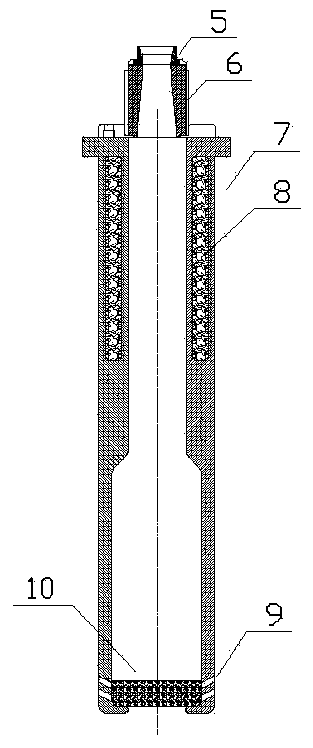

Low-pressure casting device for aluminum alloy wheels of automobile

A low-pressure casting device for aluminum alloy wheels of an automobile is composed of a low-pressure casting system control cabinet, a pressurization air inlet tube, a pressure relief air outlet tube, a molten aluminum heat preservation furnace, an iron sprue, a ceramic heat preservation cup, a molten aluminum lifting tube, a heat insulation layer, twelve to sixteen buffer holes and a ceramic filter net. The two ends of the pressurization air inlet tube and the two ends of the pressure relief air outlet tube are connected with the low-pressure casting system control cabinet and the molten aluminum heat preservation furnace. A pressure control valve is installed in the low-pressure casting system control cabinet and arranged at the end of the pressure relief air outlet tube. A pressure relief zero return button and a cumulative number zero clearing button are arranged in the low-pressure casting system control cabinet. The iron sprue is assembled at a die feed inlet, the ceramic heat preservation cup is assembled under the iron sprue, the molten aluminum lifting tube is assembled in the molten aluminum heat preservation furnace, the upper end of the molten aluminum lifting tube is provided with the heat insulation layer, the inner diameter of the part, immerged in molten aluminum, of the lower end of the molten aluminum lifting tube is greater than that of the upper end, the buffer holes with the diameter of 10-12mm are formed in the lower end of the molten aluminum lifting tube, and the included angle formed between each buffer hole and the vertical plane ranges from 15 degrees to 20 degrees. The low-pressure casting device for the aluminum alloy wheels of the automobile can remarkably reduce the burning loss, the heat loss, needle holes and slag holes.

Owner:JIANGSU KAITE AUTO PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com