Chambering-forging forming method for aluminum alloy hub with complex structure and die thereof

A technology of aluminum alloy wheel hub and complex structure, applied in the field of aluminum alloy wheel hub forging, can solve the problems of high tooling investment cost, low production efficiency, low material utilization rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

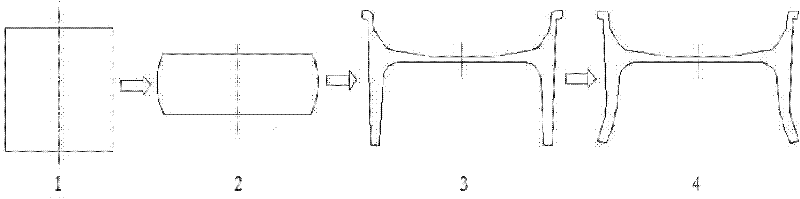

[0024] Example 1: Combining figure 2 , image 3 , taking 20×11 inches, 20×12 inches and 20×13 inches of automobile aluminum alloy forged wheels as an example, the automobile aluminum alloy wheel hub forging and expanding forming process of the present invention comprises the following steps: 1) material preparation: the 6061 aluminum alloy of φ 300 mm Alloy casting rods are cut into billets; 2) Heating billet: fixed temperature 470°C, heat preservation 450 minutes, preheating mold: constant temperature 450°C, heat preservation 6 hours; 3) Upsetting: Forge once on a 5000T press to upset the billet to φ430 mm; 4) Molding: On the 8000T press, put the blank into figure 2 In the mold, the surface of the mold cavity is evenly coated with self-made oil-based graphite lubricant, forged twice, the spokes of the hub and the rim on one side are formed, and the rim on the other side is pre-formed. The starting forging temperature is required to be 460°C, and the final forging temperatu...

Embodiment 2

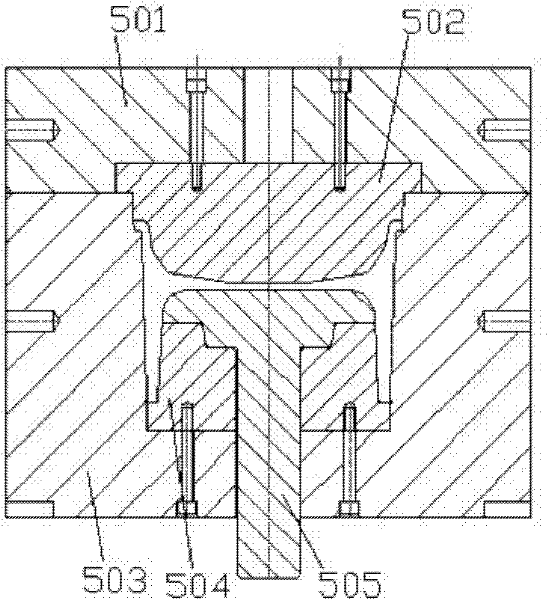

[0025] Example 2: Combining figure 2 , image 3 , taking 20×11 inches, 20×12 inches and 20×13 inches of automotive aluminum alloy forged wheel molds as examples, such as figure 2 As shown, the forging die used for the forging and expanding of automobile aluminum alloy wheels of the present invention includes an upper mold body (501), an upper mold core (502), a lower mold body (503), a lower mold core (504) and a ejector rod (505), upper mold core (502) is installed on the upper mold body (501), lower mold core (504) is installed on the lower mold body (503), and ejector rod (505) is installed on the lower mold core (504). When forging wheel hubs with different specifications of 11, 12 and 13 inches, only the corresponding upper mold core (502), lower mold core (504) and ejector rod (505) need to be replaced. The mold-guiding stop buckle adopts a round inverted wall structure. When the mold is closed, the outer wall of the upper mold core (502) stopper buckle extends into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com