Patents

Literature

98 results about "Pressure die casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure die casting is a quick, reliable and cost-effective manufacturing process for production of high volume, metal components that are net-shaped have tight tolerances. Basically, the pressure die casting process consists of injecting under high pressure a molten metal alloy into a steel mold (or tool).

High-strength and high-corrosion-resistance cast aluminum alloy and pressure casting preparation method thereof

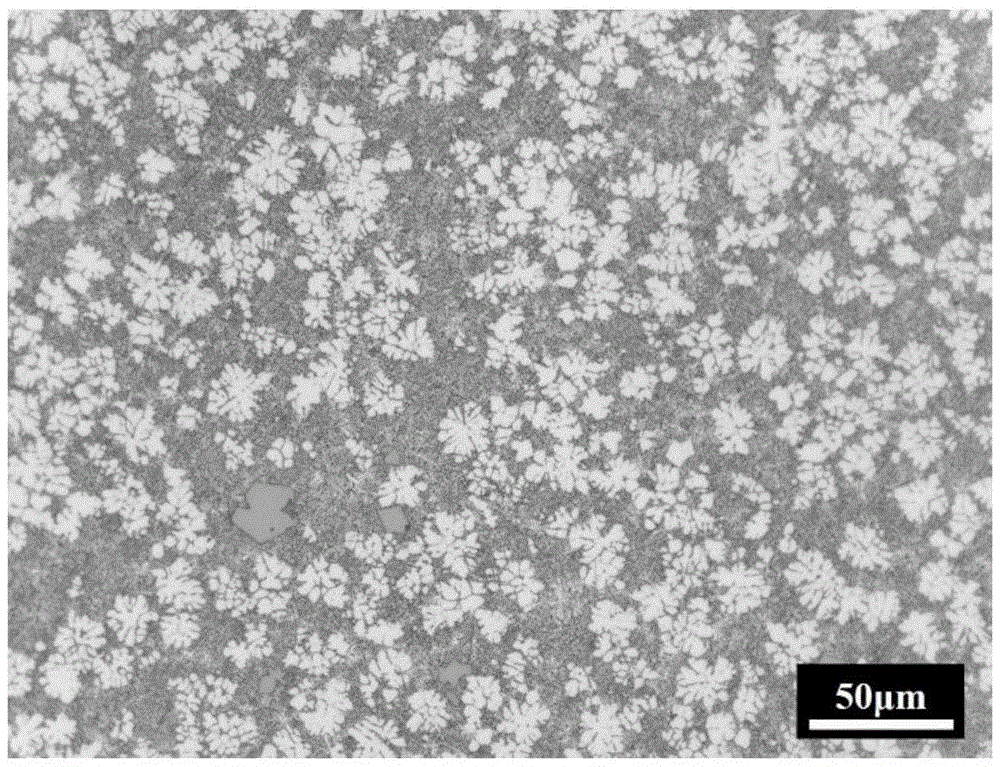

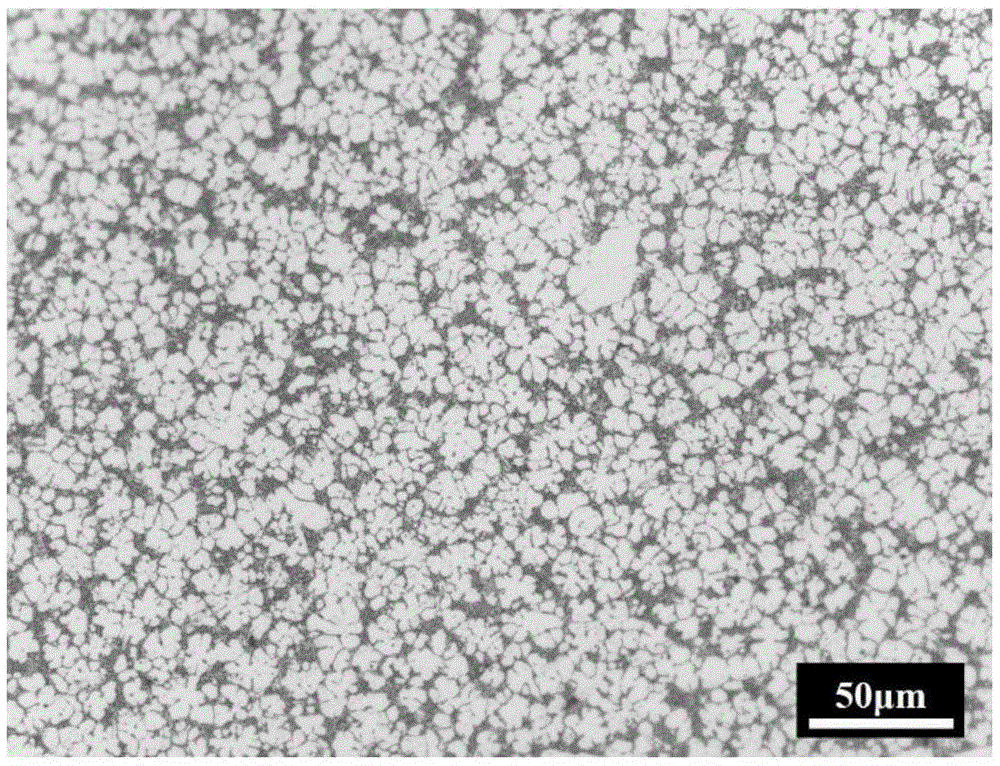

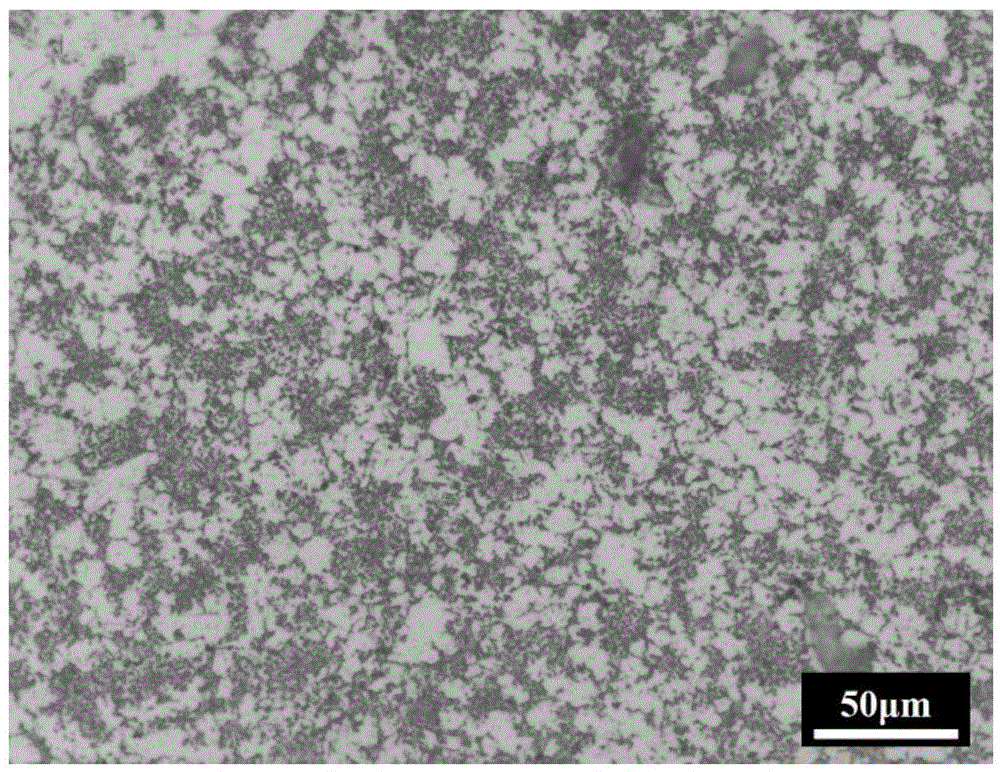

The invention provides high-strength and high-corrosion-resistance cast aluminum alloy and a pressure casting preparation method thereof. The alloy is prepared from, by a certain weight percent, Si, Mg, Fe, Mg, Zn, Sr, Cu, M and the balance Al, wherein M is at least one element of Ti, Zr and V, or the element RE is added in M. After the high-strength and high-corrosion-resistance cast aluminum alloy is subjected to pressure casting, the room temperature tensile strength sigma b of alloy not subjected to heat treatment is larger than or equal to 315 MPa, the room temperature ductility sigma of the alloy not subjected to heat treatment is larger than or equal to 3.0%, and good corrosion resistance is achieved; and the alloy can be applied to automobile parts without ageing or solid solution heat treatment, and the requirement for light automobile development is met.

Owner:SHANGHAI JIAO TONG UNIV

Insert core and method for manufacturing a cylinder for internal combustion engine by making use of the insert core

There is provided a method for manufacturing a cylinder for an internal combustion engine by making use of an insert core, which makes it possible to manufacture the cylinder by a die casting method such as a high-pressure die casting method at low cost and in high accuracy. The insert core to be employed herein includes: a cylindrical body having substantially the same outer diameter as the diameter of bore of the cylinder to be obtained; a scavenging port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of the scavenging port; a suction port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of at least the cylinder bore-side end portion of a suction port; and an exhaust port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of at least the cylinder bore-side end portion of an exhaust port.

Owner:KIORITZ

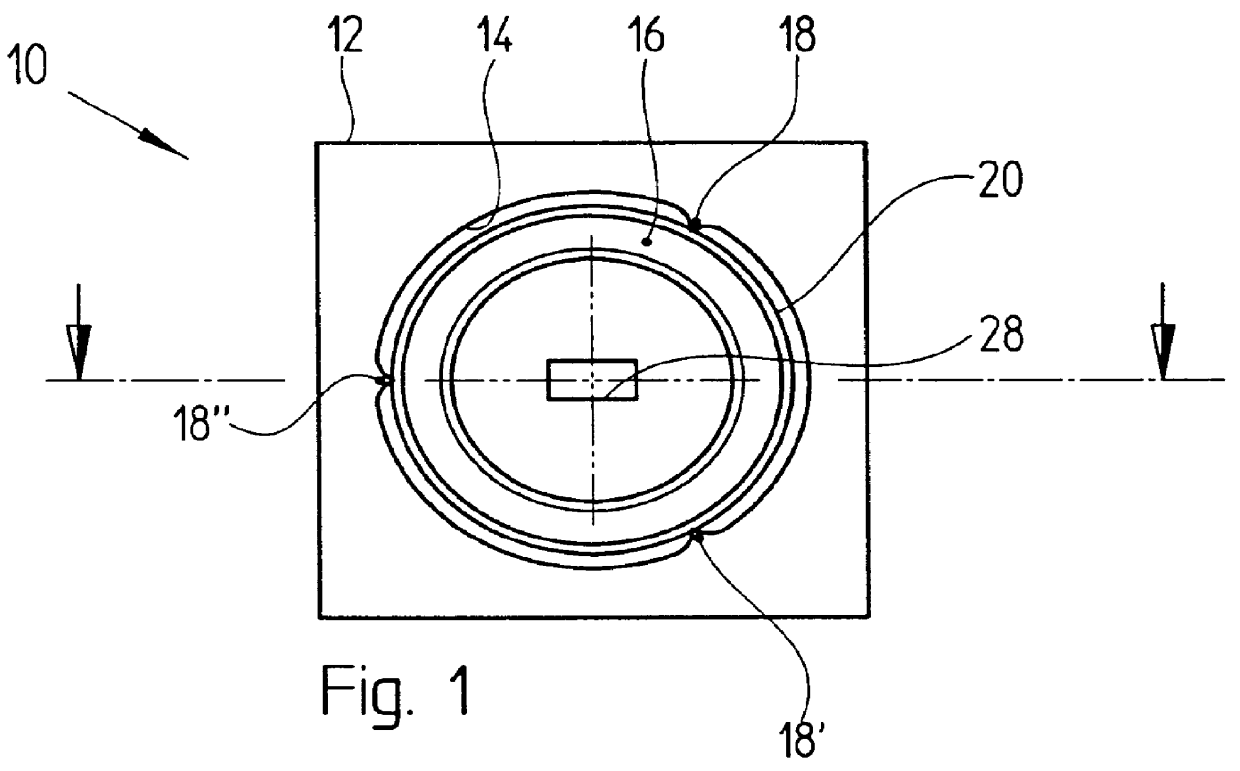

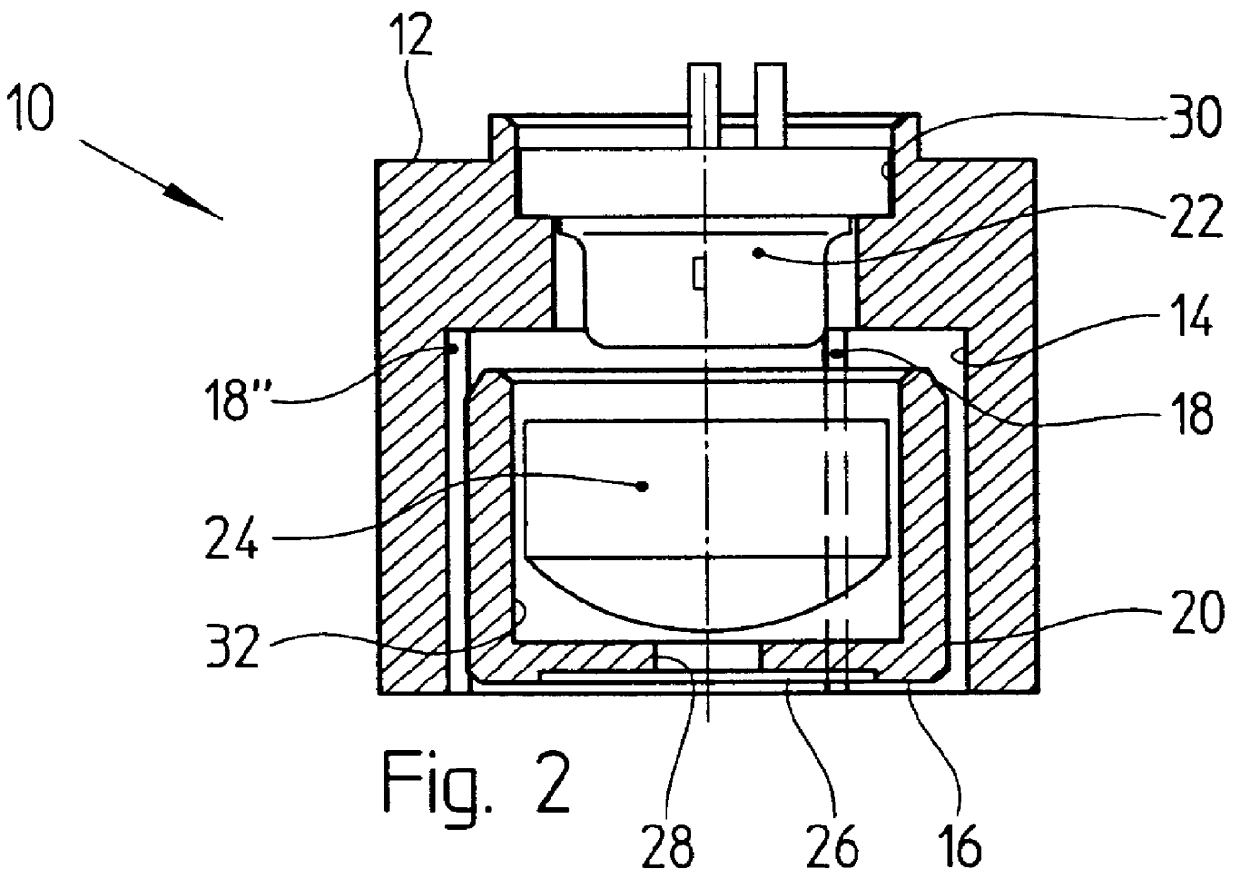

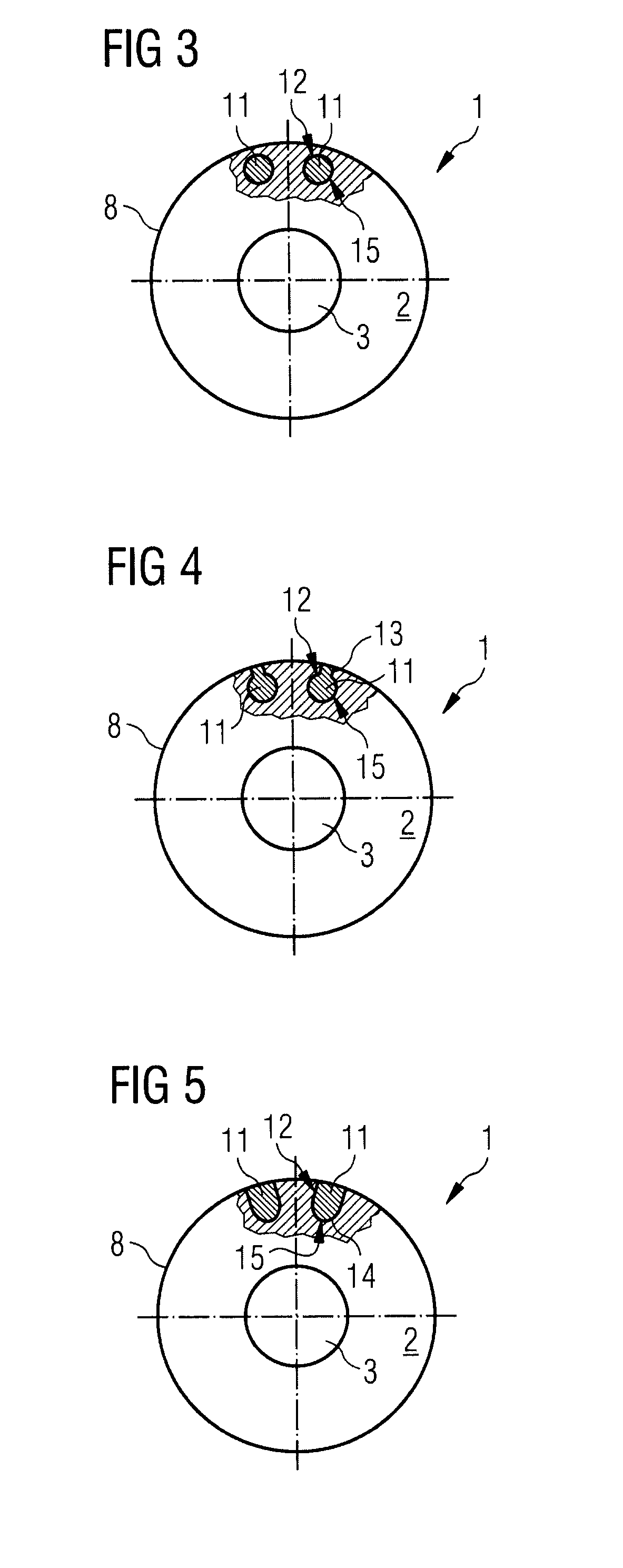

Optical apparatus comprising an adjustable holder device

InactiveUS6025963AEasy to fixImprove featuresLaser detailsCoupling light guidesComputer moduleEngineering

A laser diode module as an example has a laser diode pressed into a first housing part and a lens of an optical collimation system pressed into a cup-shaped second housing part. The second housing part is pressed into a cylindrical opening of the first housing part. In the opening there are molded three runners, which extend in the axial direction and are uniformly distributed in the peripheral direction, with the runners engaging on the jacket surface of the second housing part. The runners and the jacket surface form connection elements which are press-fitted together and which enable, apart from the connection, an adjustment of the lens relative to the laser diode. Pressure die cast zinc is in particular suitable as the material for the connection elements. An adhesive bond is not required with a holder of this kind.

Owner:SICK AG

High effective heat treatment method for wheel hub founded at low pressure from high performance A356 alloy

This invention relates to a method for thermal treatment of high-efficiency and high-performance low-pressure die casting A356 alloy wheel. The method comprises: performing solid solution treatment at 535-545 deg.C for 5-7 h, quenching, performing low-temperature pre-aging treatment, and then performing aging treatment at 175-185 deg.C for 3-5 h immediately. The method has such advantages as shortened solid solution treatment time, shortened aging treatment time, high strength of low-pressure die casting A356 alloy wheel, shortened thermal treatment period, increased production efficiency, and improved mechanical properties of low-pressure die casting A356 alloy wheel.

Owner:ZHENGZHOU UNIV

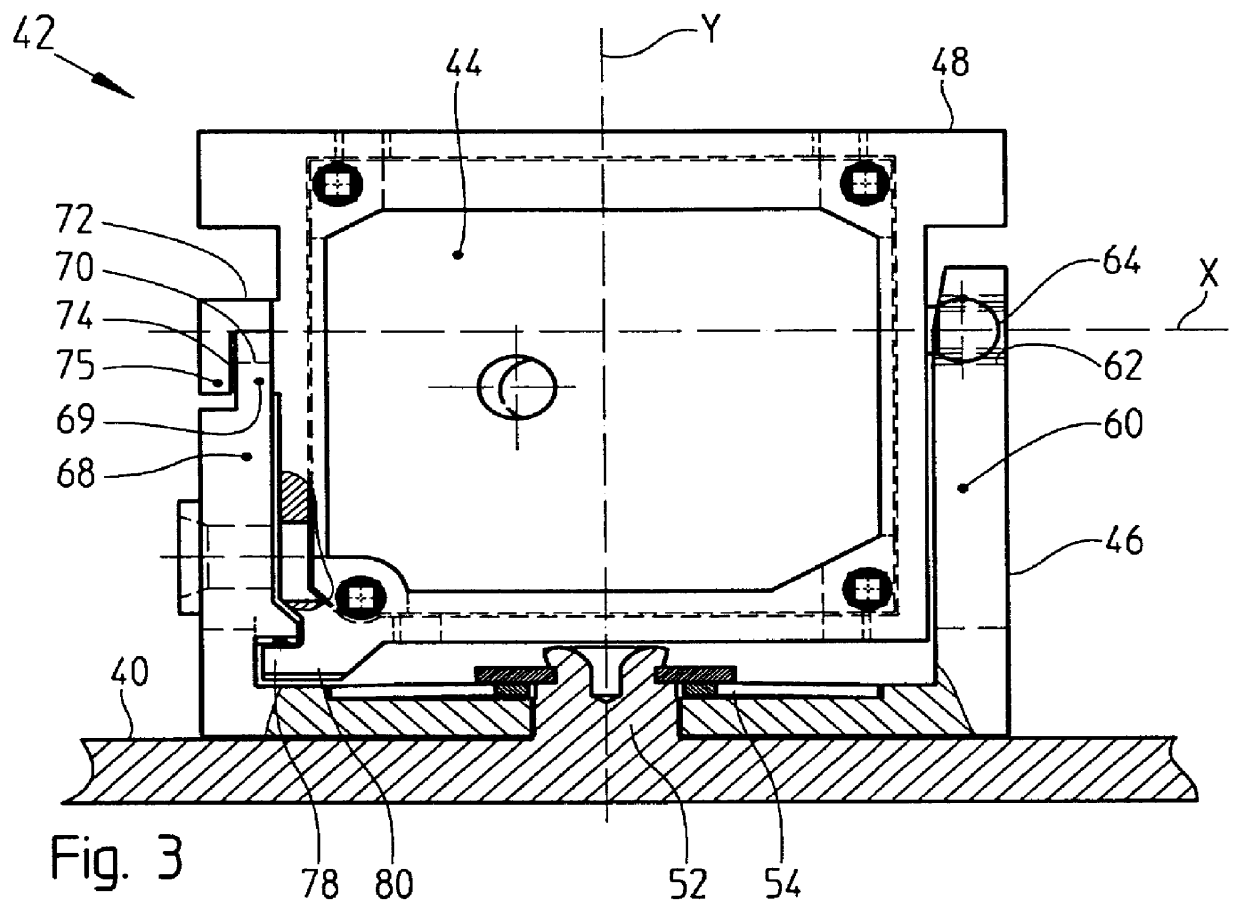

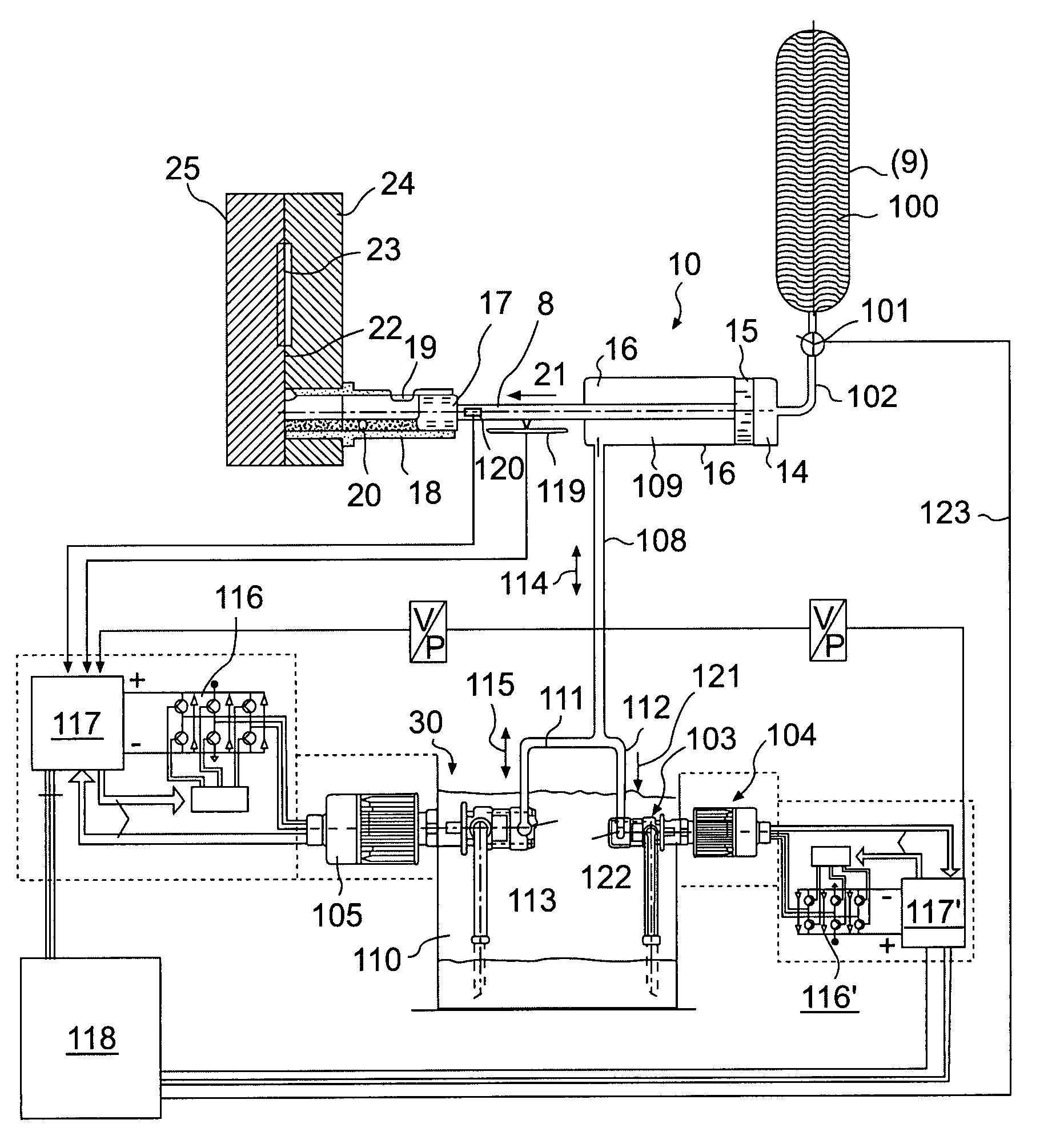

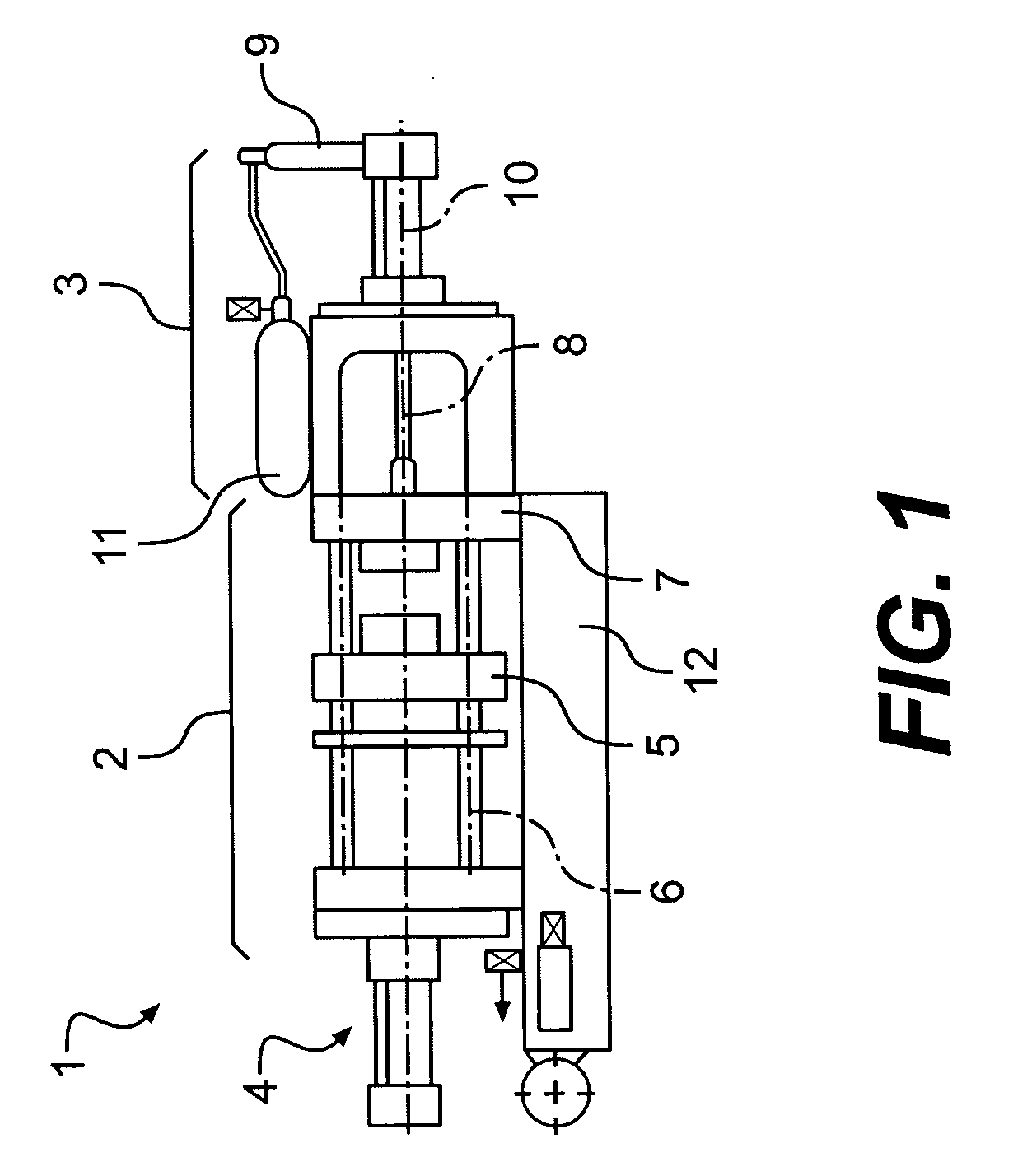

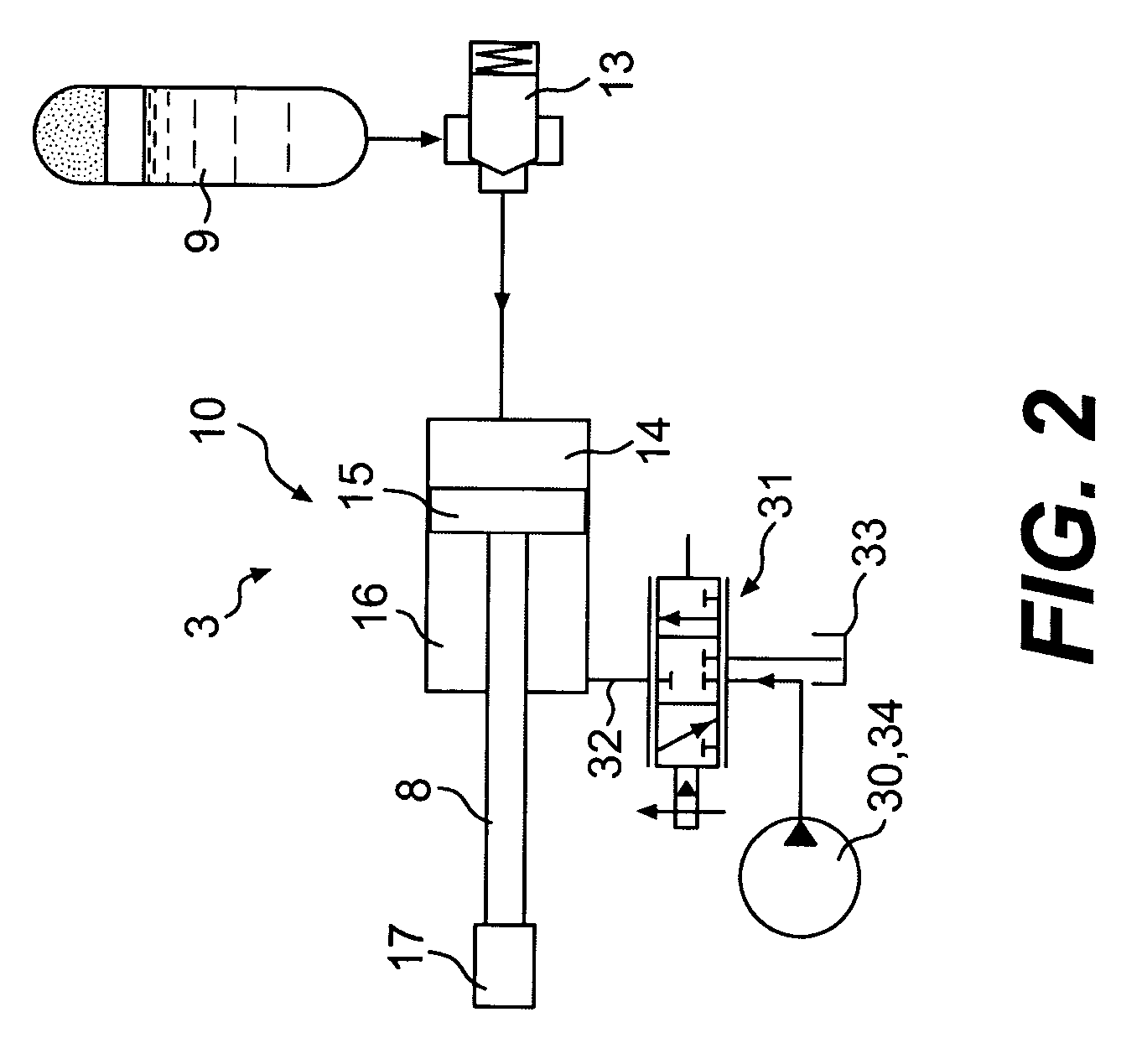

Method and drive system for the control/regulation of linear pressure/cast movement

InactiveUS20040033141A1Simple designEasy to controlServomotorsFlexible member pumpsControl mannerEngineering

The invention relates to a method for controlled driving of the cast axle (8) of pressure die casting machines, comprising a drive piston (15), wherein the forward and return motion of the piston (15) is carried out in a controlled manner. The invention is characterized in that the oil flow or oil pressure on the piston rod side is controlled / regulated by a pump (30) and additionally by a throttle valve (103) working in parallel at least during the filling phase, especially during the fast forward motion part.

Owner:PROCONTROL AG

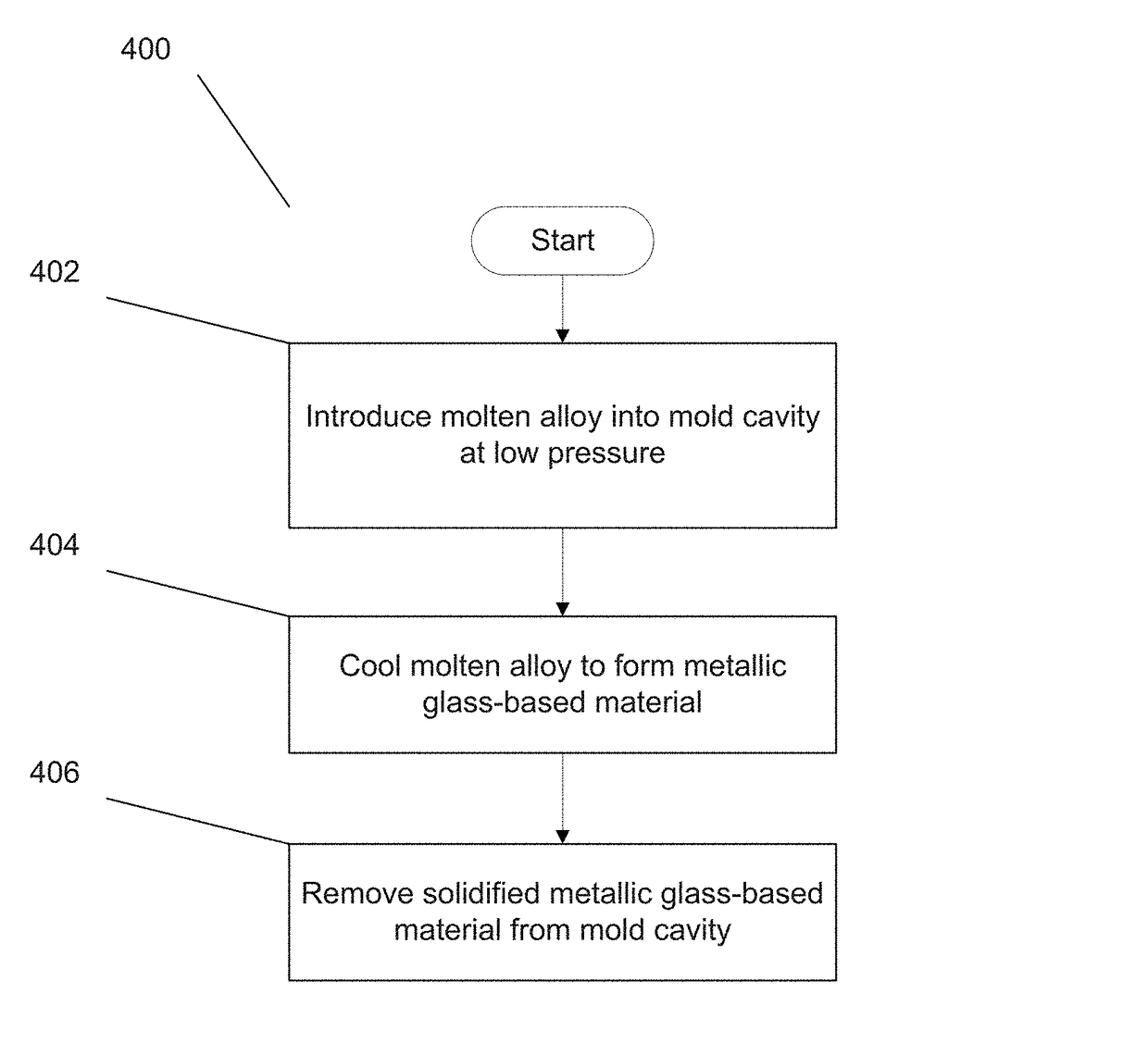

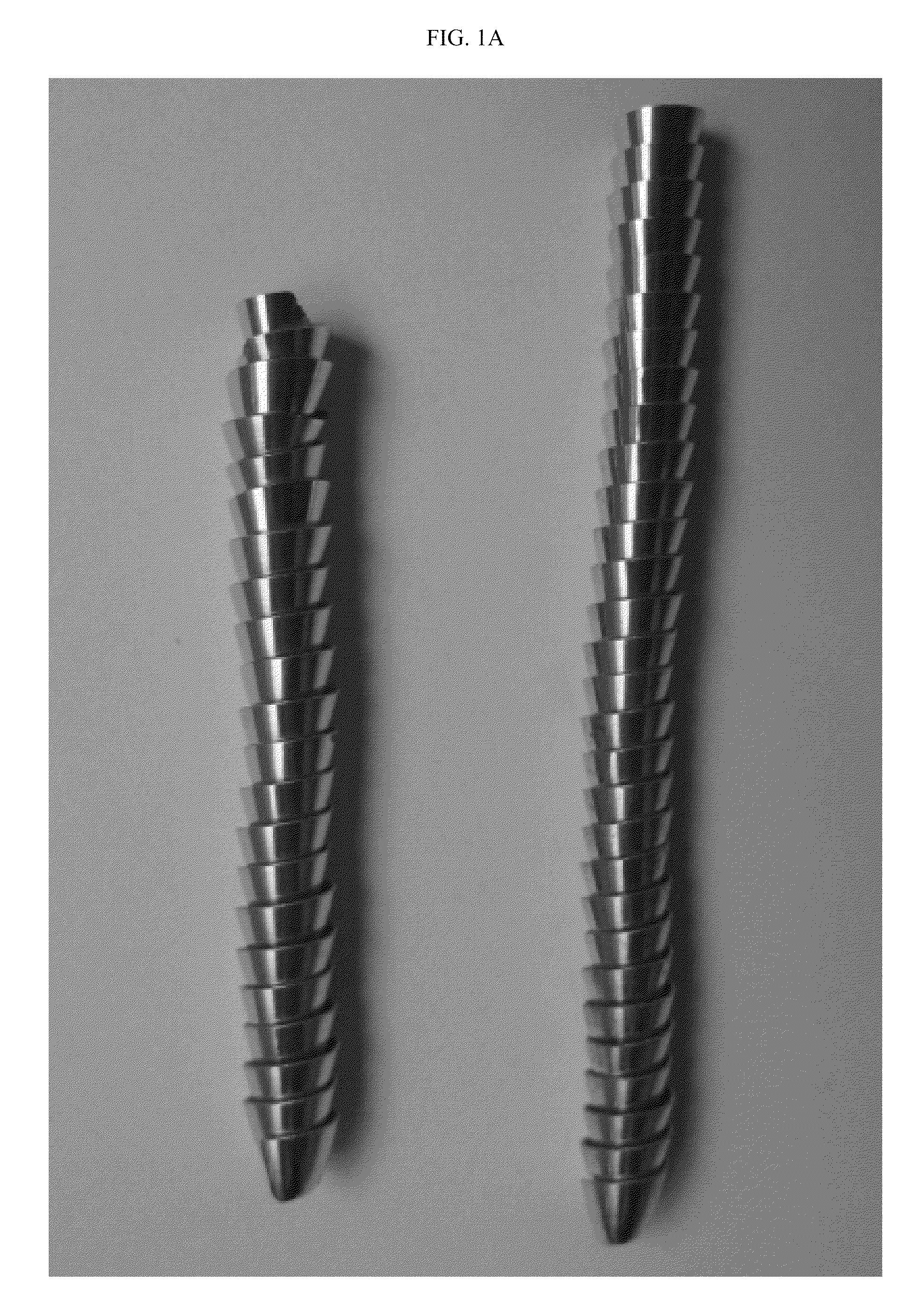

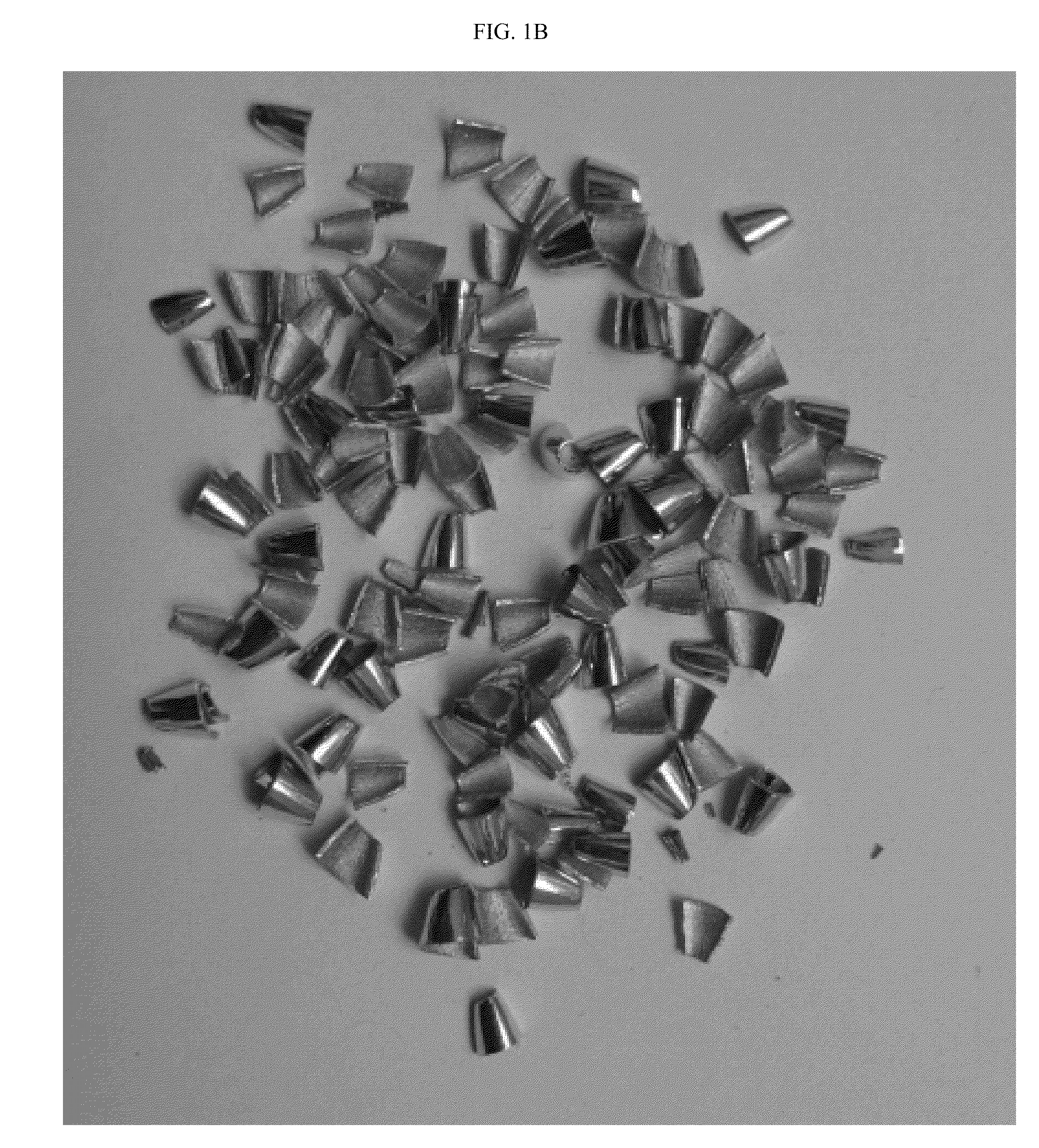

Systems and methods for fabricating structures including metallic glass-based materials using low pressure casting

Systems and methods to fabricate objects including metallic glass-based materials using low-pressure casting techniques are described. In one embodiment, a method of fabricating an object that includes a metallic glass-based material includes: introducing molten alloy into a mold cavity defined by a mold using a low enough pressure such that the molten alloy does not conform to features of the mold cavity that are smaller than 100 μm; and cooling the molten alloy such that it solidifies, the solid including a metallic glass-based material.

Owner:CALIFORNIA INST OF TECH

Heat resistant aluminium alloy

Owner:АЛЮМИНИУМ РАЙНФЕЛЬДЕН ГМБХ

High temperature aluminium alloy

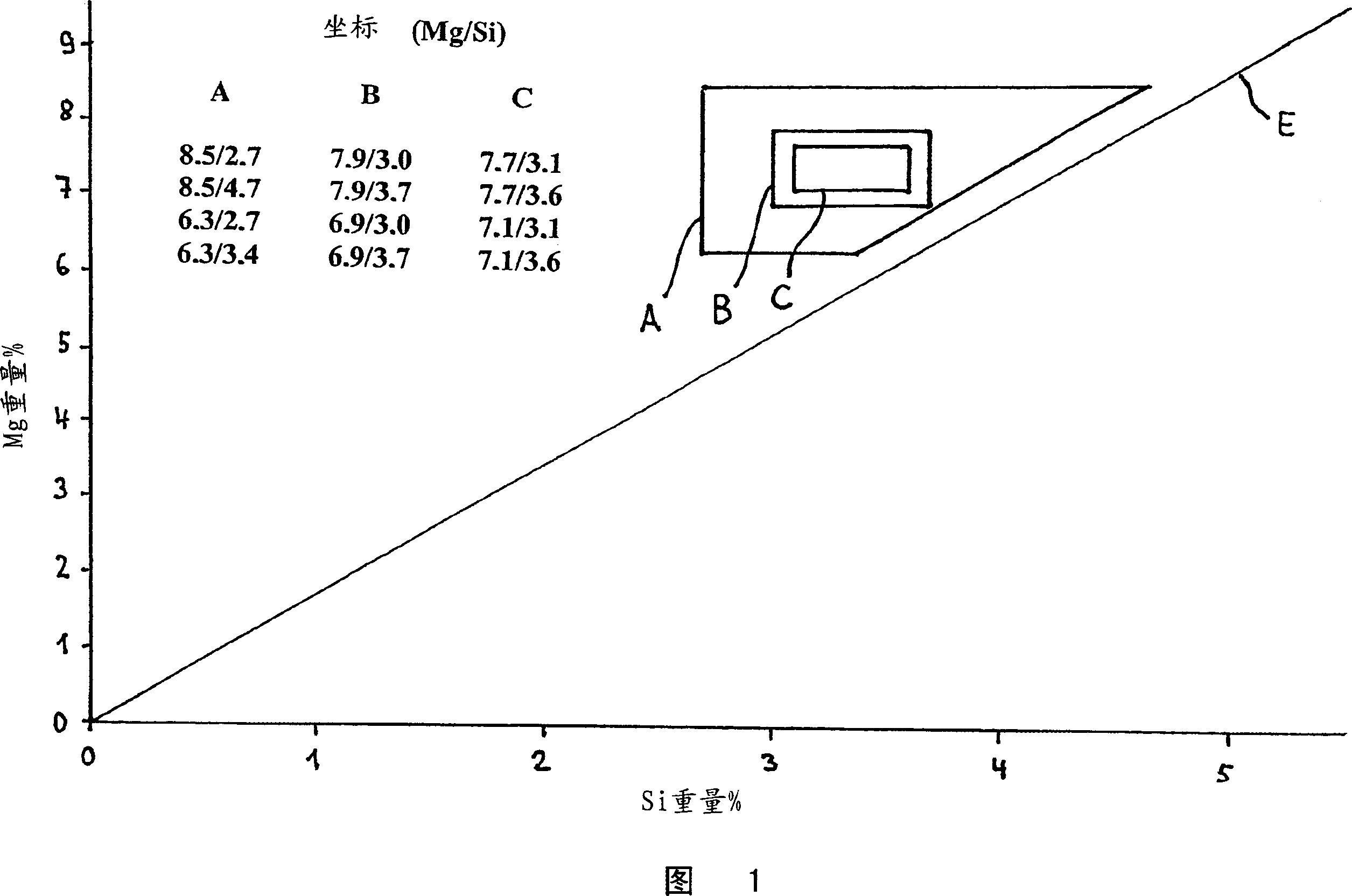

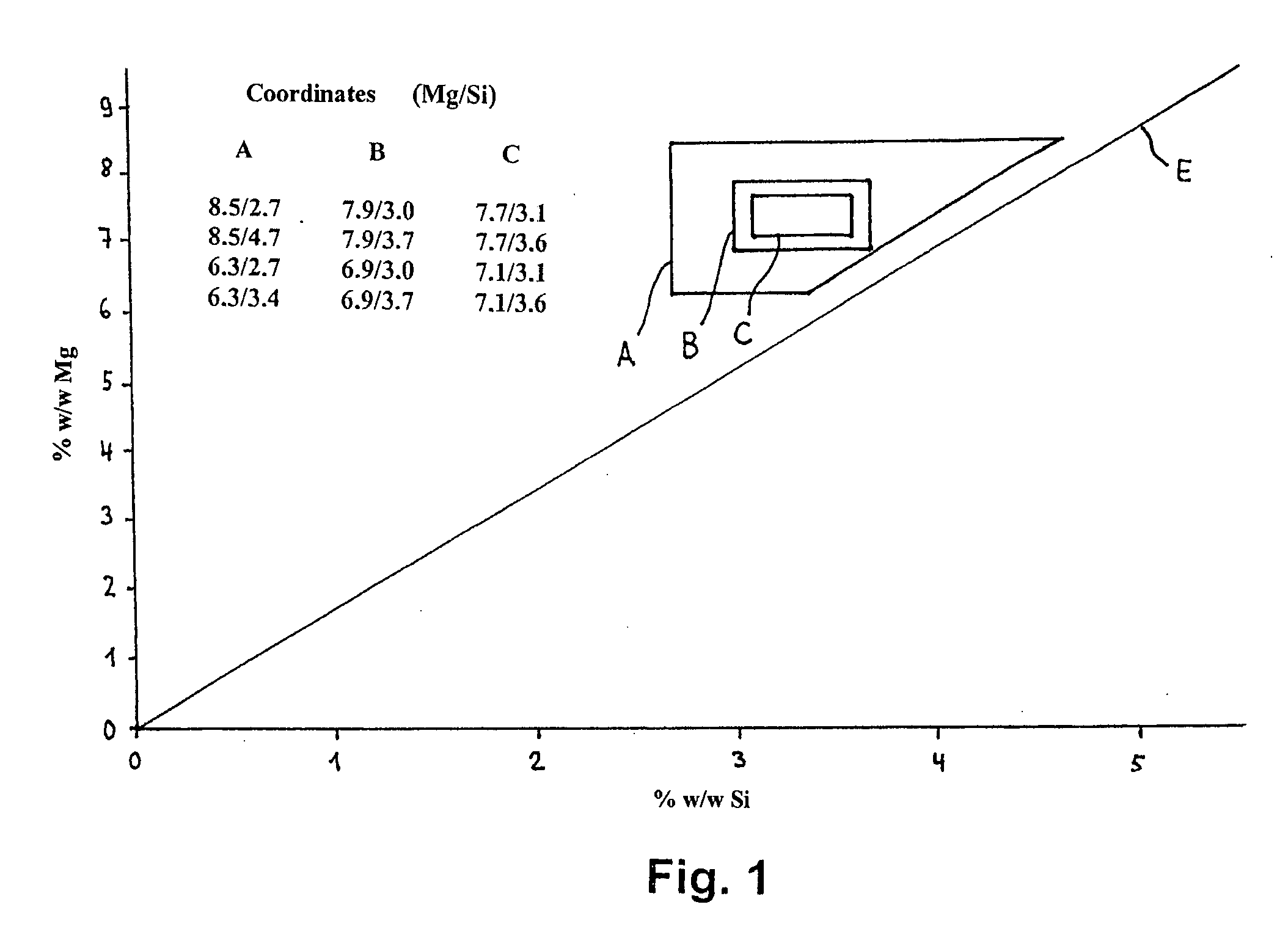

In an aluminium alloy of type AlMgSi with good creep strength at elevated temperatures for the production of castings subject to high thermal and mechanical stresses the contents of the alloying elements magnesium and silicon in % w / w in a Cartesian coordinate system are limited by a polygon A with the coordinates [Mg; Si] [8.5; 2.7] [8.5; 4.7] [6.3; 2.7] [6.3; 3.4] and that the alloy also contains0.1 to 1% w / w manganesemax. 1% w / w ironmax. 3% w / w coppermax. 2% w / w nickelmax. 0.5% w / w chromiummax. 0.6% w / w cobaltmax. 0.2% w / w zincmax. 0.2% w / w titaniummax. 0.5% w / w zirconiummax. 0.008% w / w berylliummax. 0.5% w / w vanadiumas well as aluminium remainder rest with further elements and manufacturing-related impurities of individually max. 0.05% w / w and max. 0.2% w / w in total.The alloy is suitable in particular for the production of cylinder crankcases by the pressure die casting method.

Owner:АЛЮМИНИУМ РАЙНФЕЛЬДЕН ГМБХ

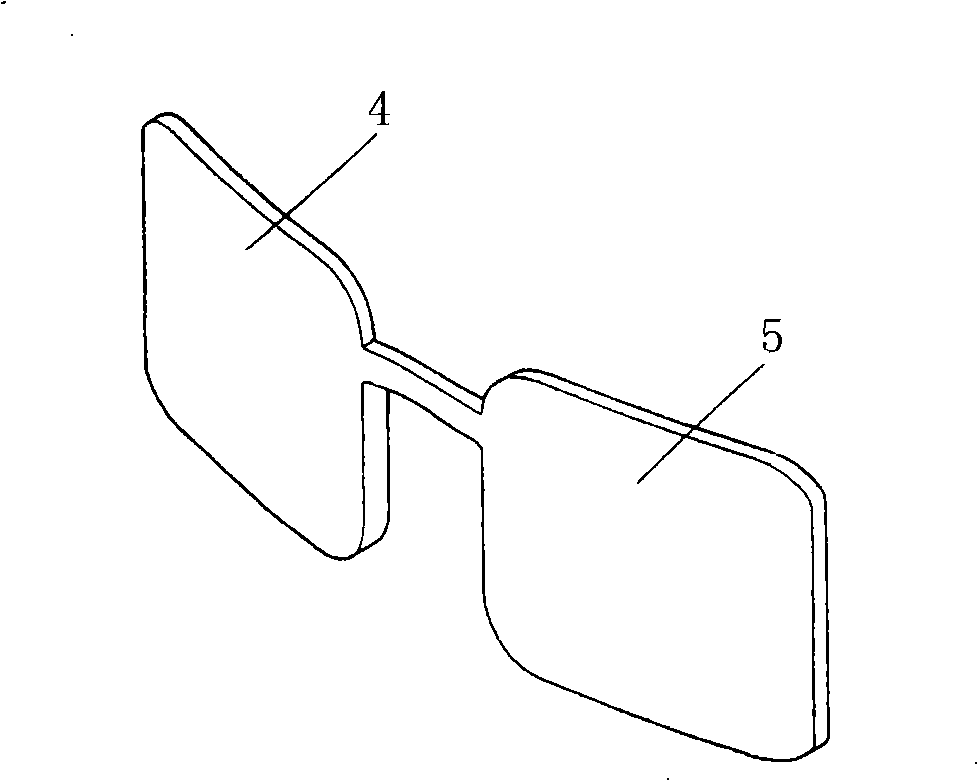

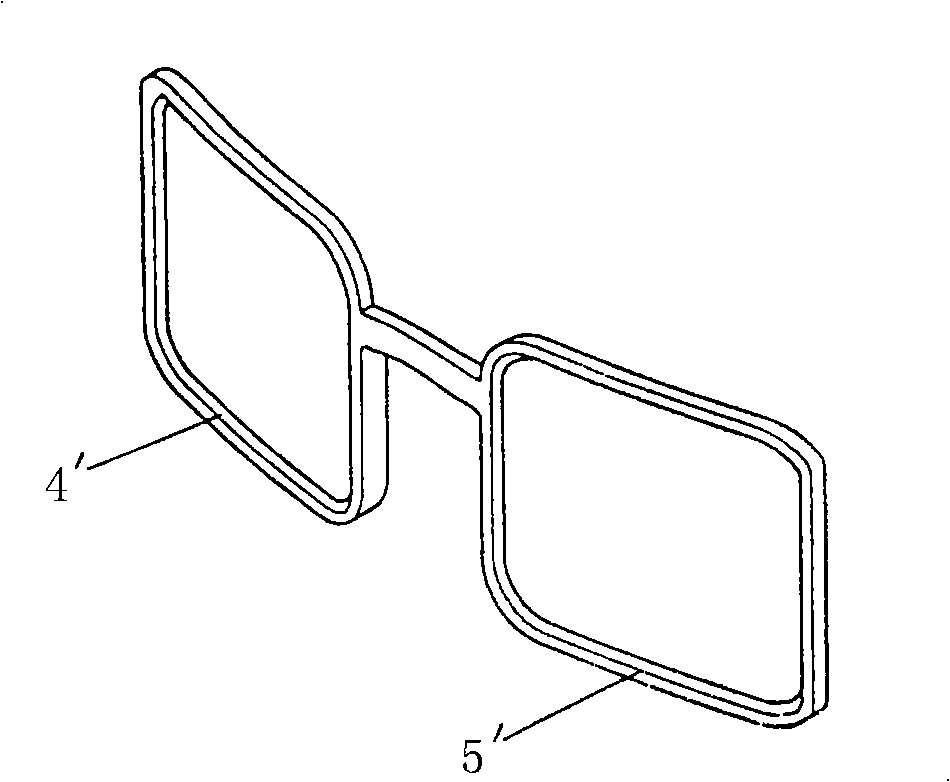

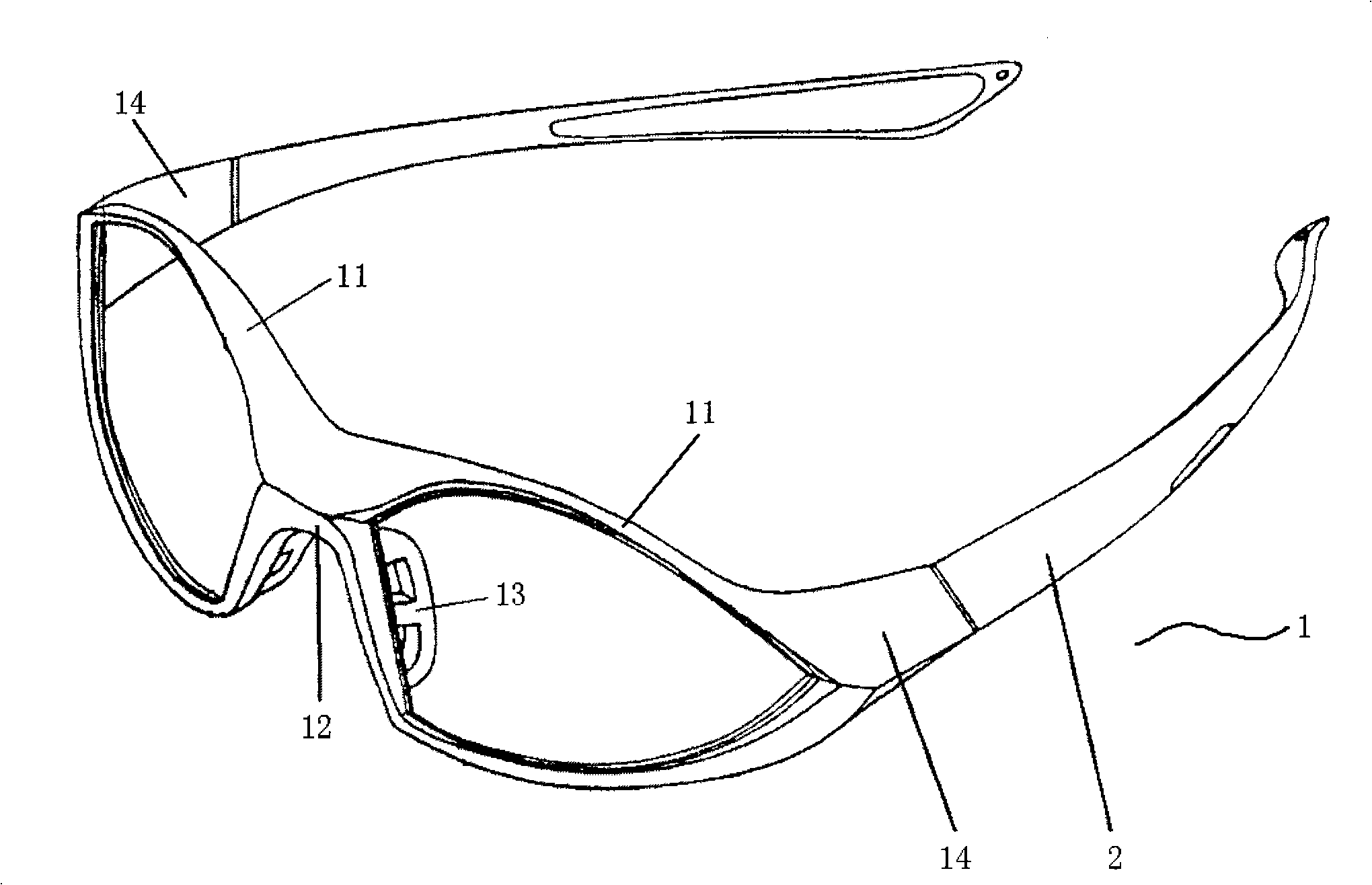

Compression-casting production method of zinc alloy spectacles frame, spectacles arm or spectacles arm head

The invention discloses a method for producing a zinc alloy spectacles frame, zinc alloy spectacles feet or zinc alloy spectacles foot heads through pressure die casting, which comprises the following steps: (1) producing corresponding casting dies according to the spectacles frame, the spectacles feet or the spectacles foot heads, which are required to be subjected to machine shaping; (2) performing hot-melting on pressure die casting zinc alloy, and injecting the molten zinc alloy into the casting dies for primary machine shaping through a pressure die casting machine; and (3) performing demoulding after cooling the molten zinc alloy, and performing machine processing, polishing and electroplating. Compared with the prior spectacles raw material, the zinc alloy has the characteristics of good casting property, capability of performing cathode treatment of electroplating, good normal-temperature mechanical property and abrasion resistance, and low melting point, so that the method is suitable for producing various spectacles; manufactured spectacles finished products have diversified colors and are more fashionable; and the method has the advantages of simple production process of pressure die casting, low cost, small labor and high grade.

Owner:杨志元

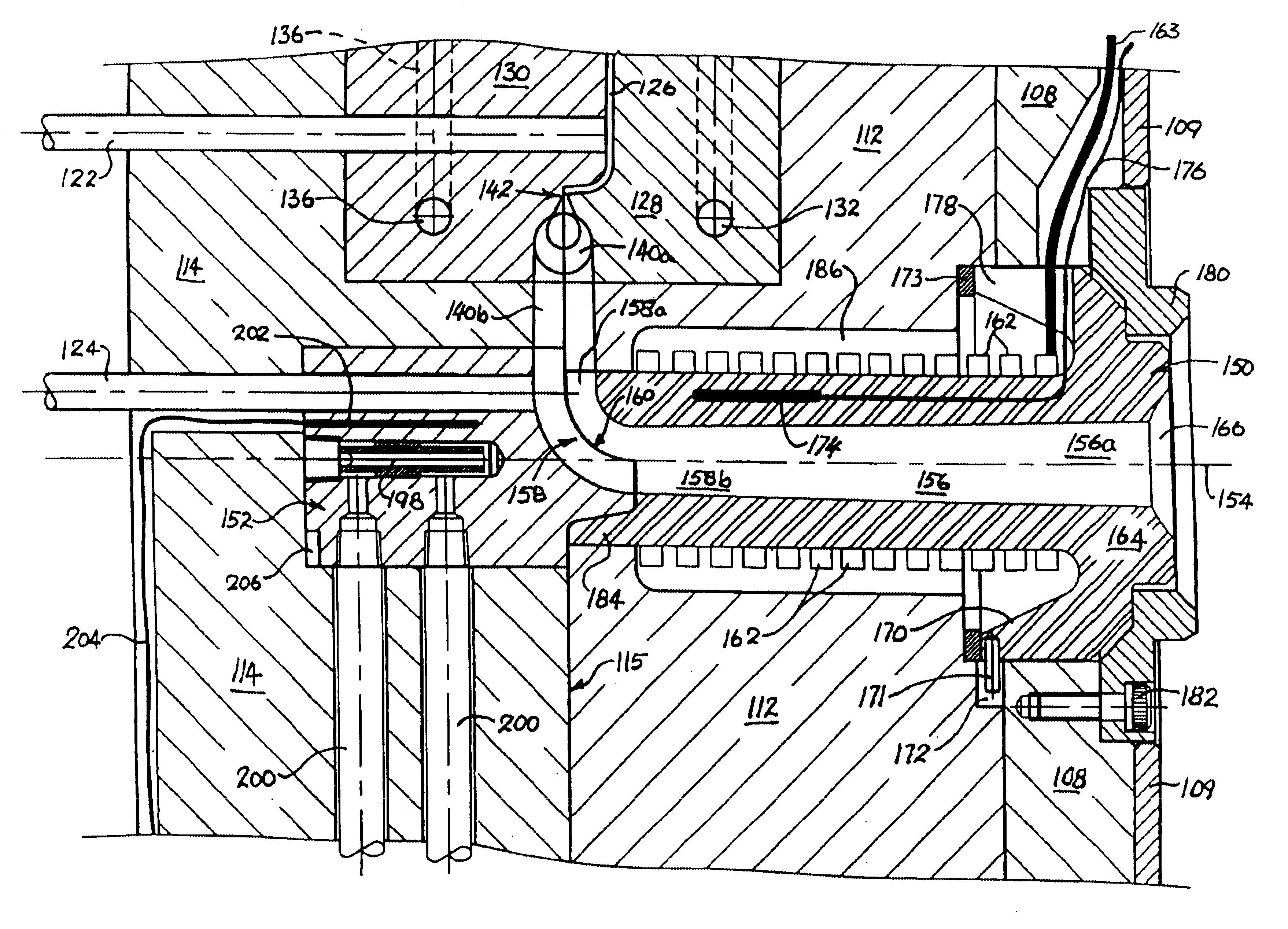

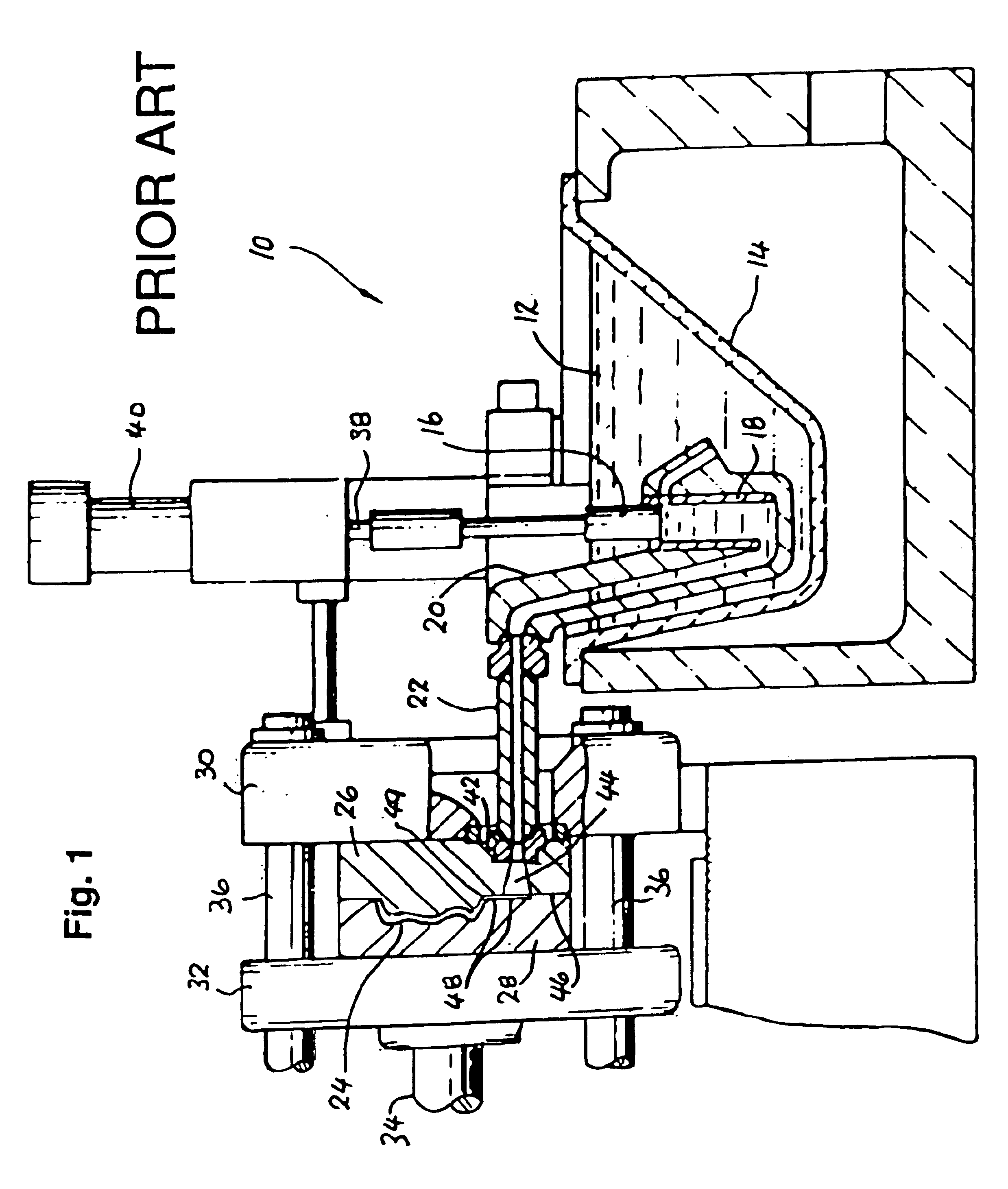

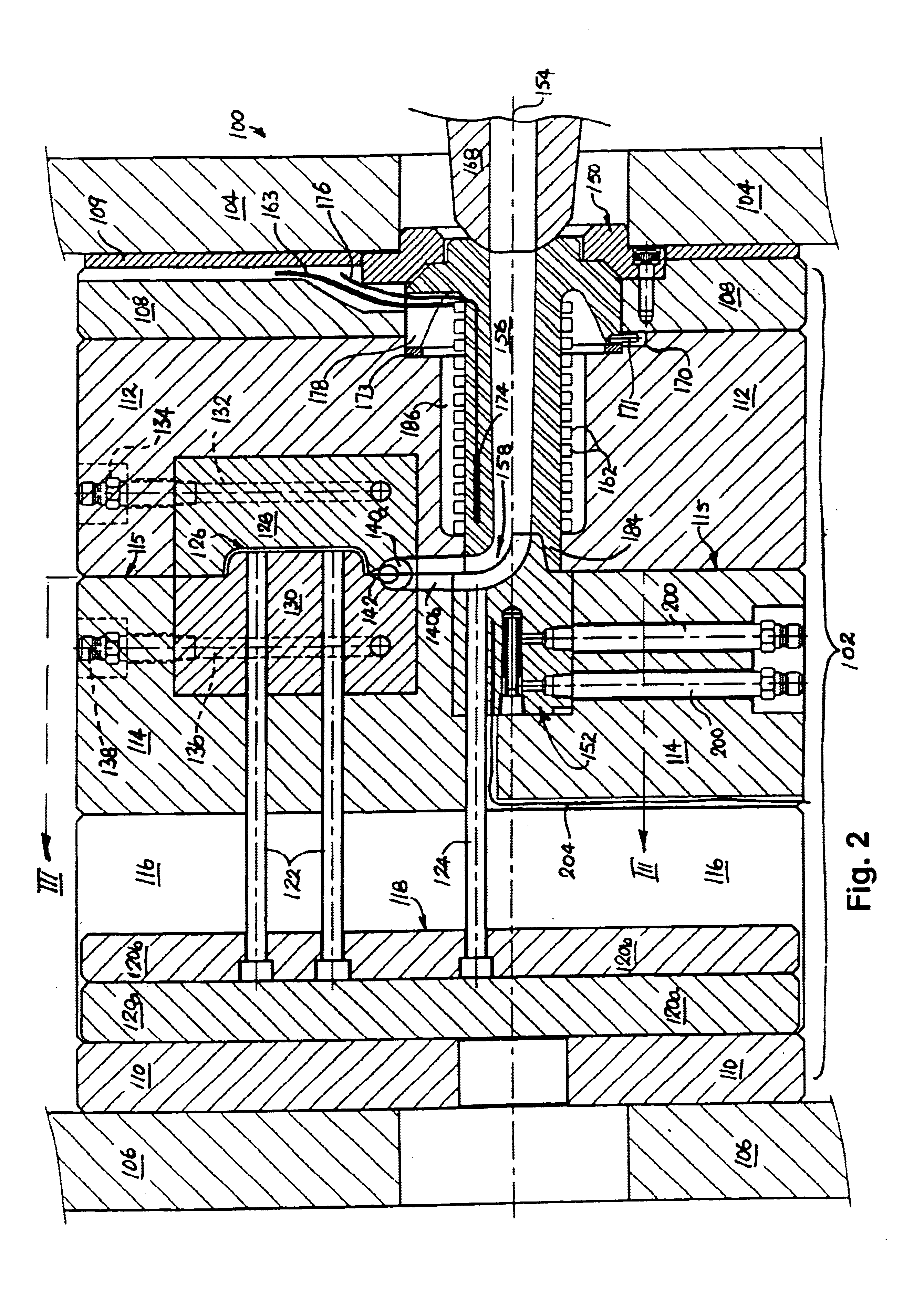

Hot sprue system for diecasting

A sprue insert-set which substantially eliminates sprue castings and improves melt-flow in high-pressure hot-chamber diecasting. The insert-set consists of (i) a heated sprue body insert for mounting in the fixed dieblock of a die set and (ii) a cooled sprue tip insert for mounting in the moving dieblock of the die set. The body and tip inserts are mounted so that their inner ends mate with one another in the region of the die parting-line to conjointly form a curved transition channel that connects the sprue channel in the body insert with a runner channel formed along the parting-line of the die set. The temperatures of the body insert and the top insert can be controlled so that the freeze-point occurs in the transition channel and the melt in the sprue channel is able to run back into the machine nozzle at the end each shot, thereby eliminating sprue castings.

Owner:HOTFLO DIECASTING

Lead-free free-cutting aluminum brass alloy and its manufacturing method

ActiveUS7776163B2Improve dezincification corrosion resistance of alloyDecrease castabilityRare-earth elementMetallic materials

Owner:XIAMEN LOTA INT CO LTD

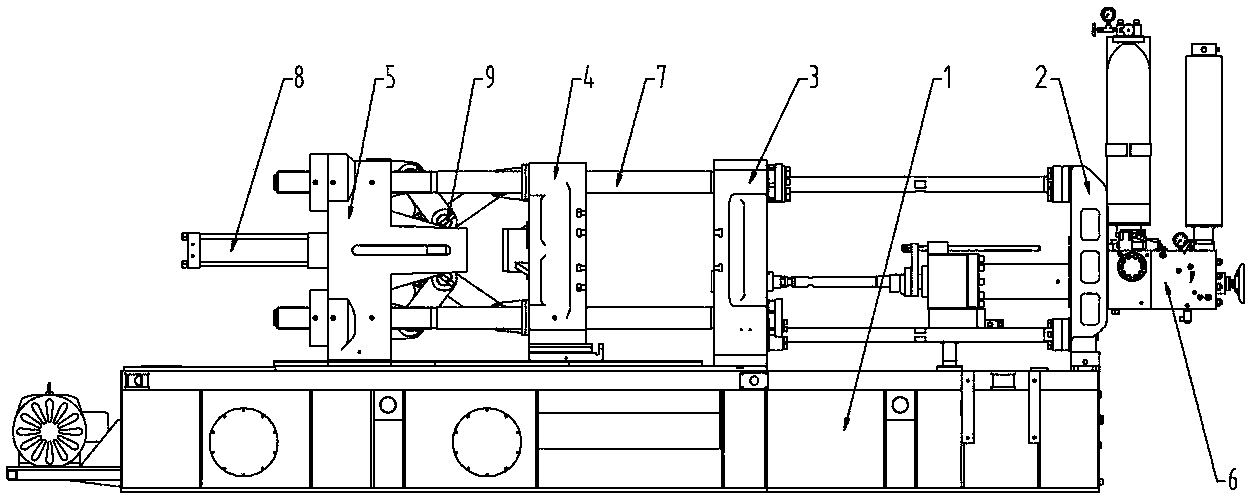

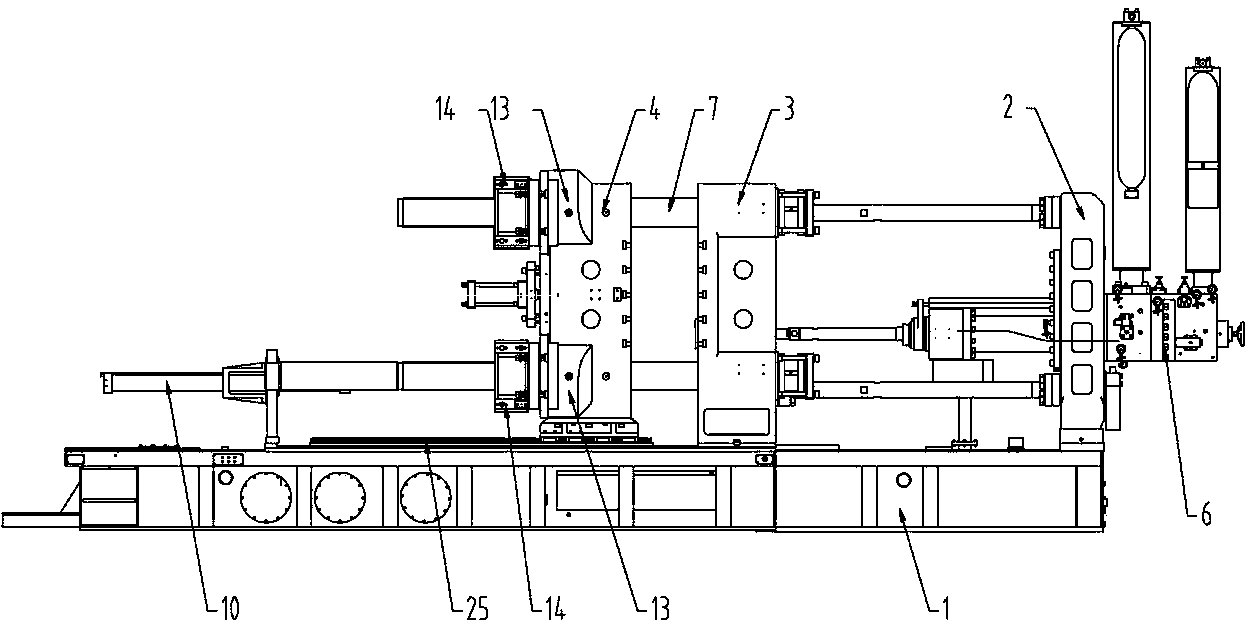

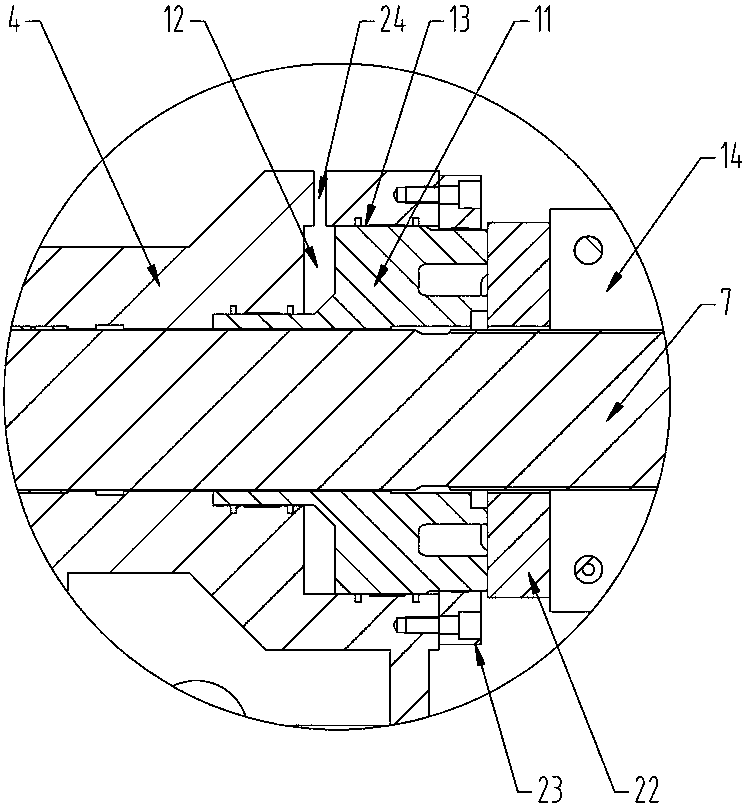

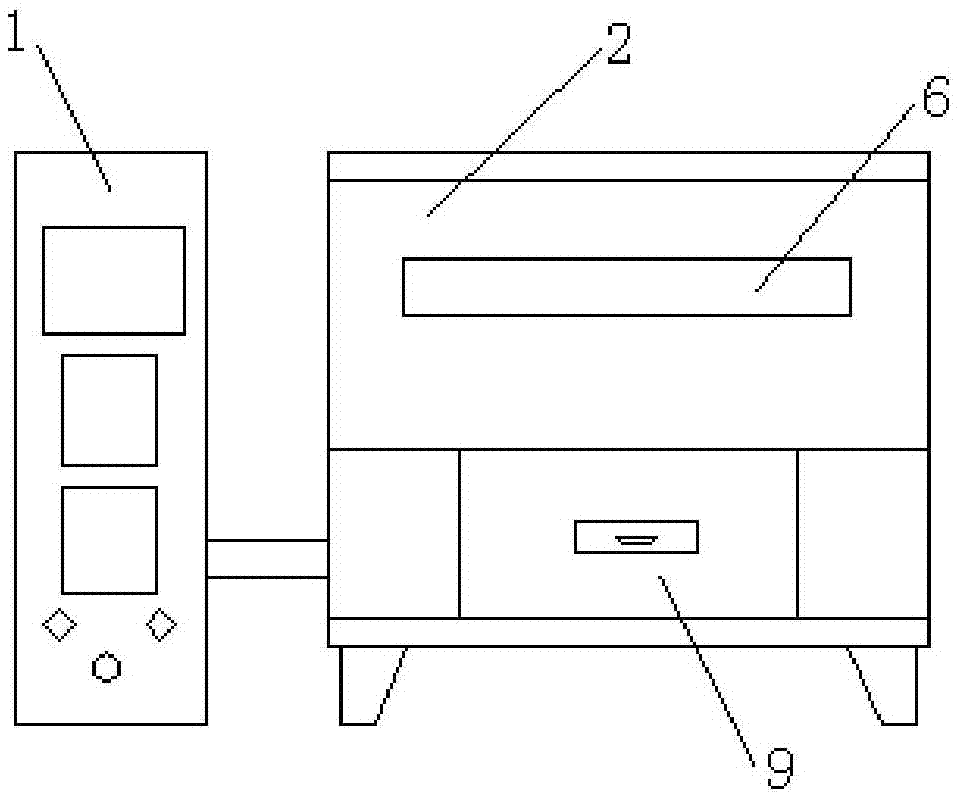

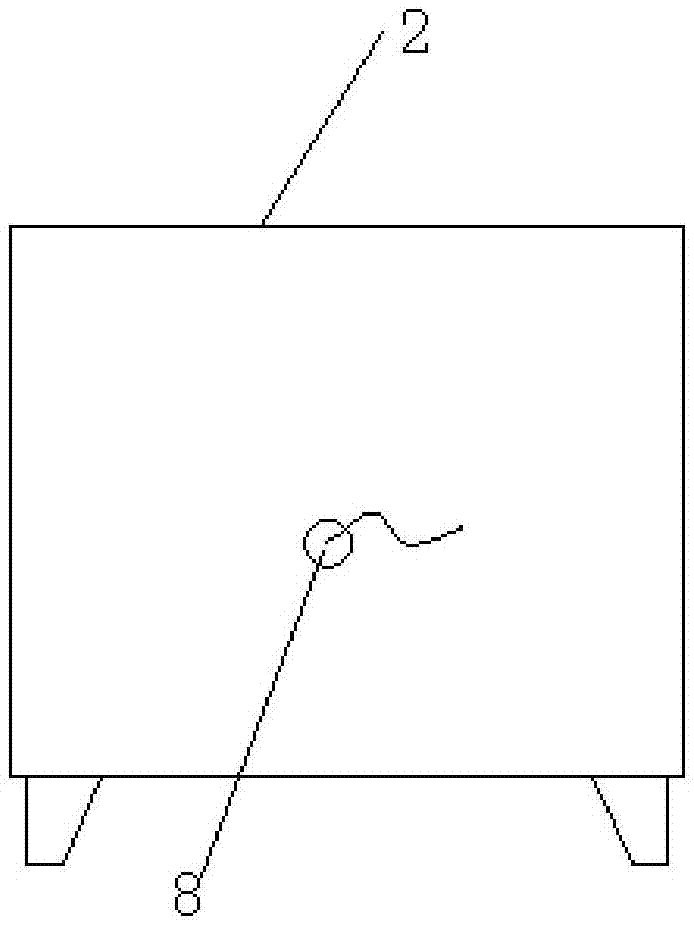

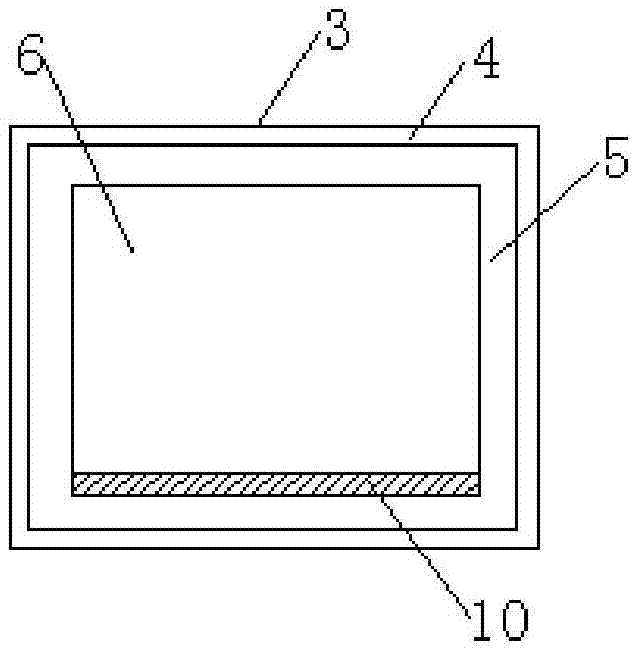

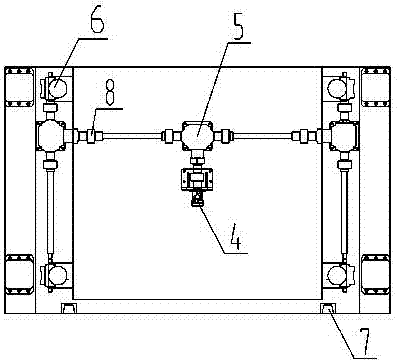

Two-plate high-speed pressure die-casting machine

The invention discloses a two-plate high-speed pressure die-casting machine, which comprises a rack (1), a fixed template (3) and a movable template (4), wherein the fixed template (3) and the movable template (4) are connected in series through four tie bars (7); a tie bar hole used for embedding a corresponding clamping piston (11) is formed at a position, at which the corresponding tie bar (7) extends, on the movable template (4); a cavity between the front side face of each clamping piston (11) and the inner cavity wall of the movable template (4) form a hydraulic cavity (12); the movable template (4), each clamping piston (11) and the corresponding hydraulic cavity (12) form a hydraulic cylinder (13) for providing a clamping force; the rack (1) is also provided with a rapid die-closing cylinder (10); a piston rod of the rapid die-closing cylinder (10) is connected with the movable template (4) so as to drive the movable template (4) to do reciprocating motion along the tie bars (7). According to the two-plate high-speed pressure die-casting machine disclosed by the invention, by adopting the drive of the rapid die-closing cylinder and the mode that the hydraulic cylinder is arranged on the movable template, the structure of the pressure die-casting machine is simplified, the die-closing efficiency is improved, and the service life of the pressure die-casting machine is prolonged.

Owner:江苏佳晨华科机械技术研究院有限公司

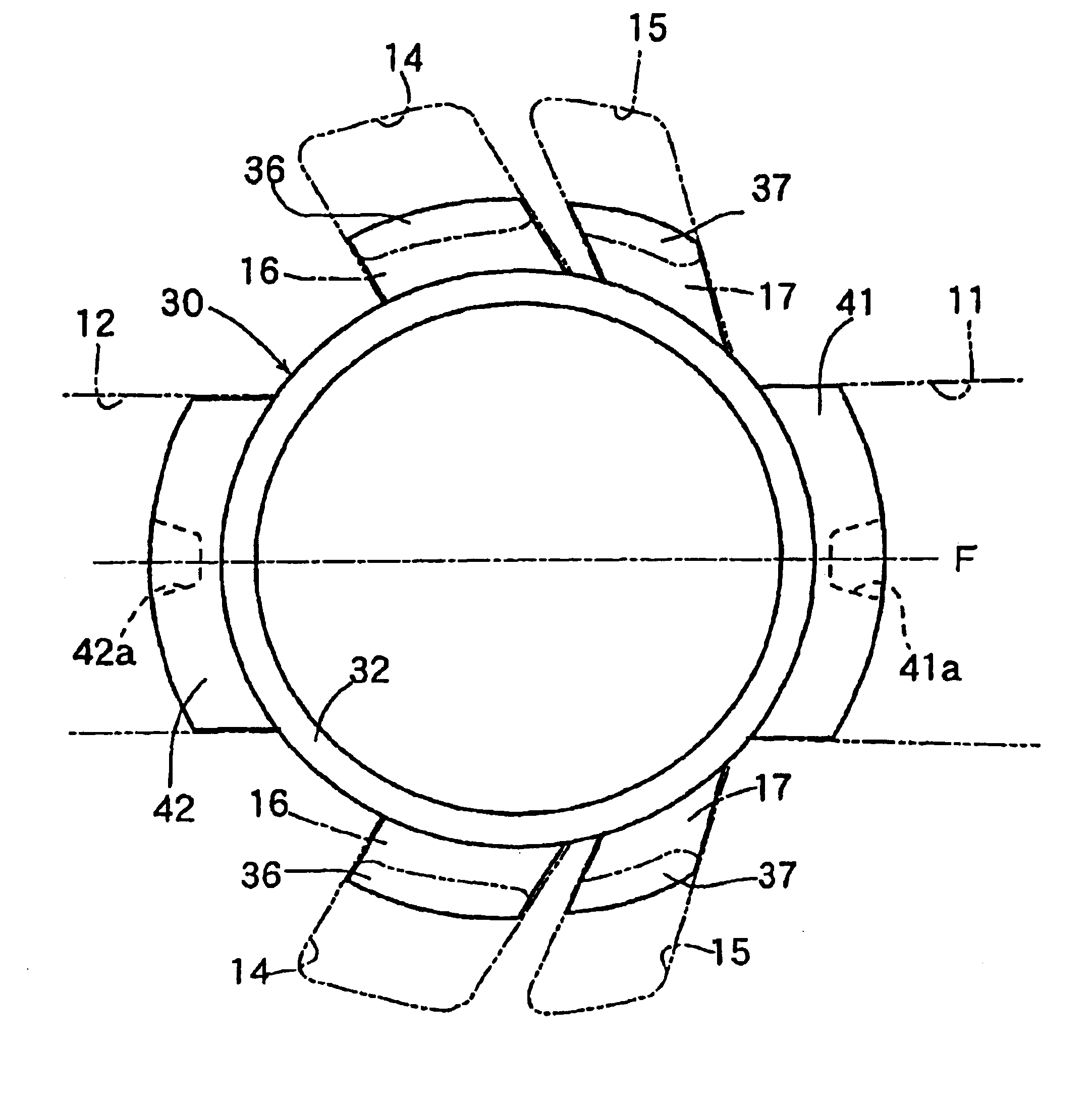

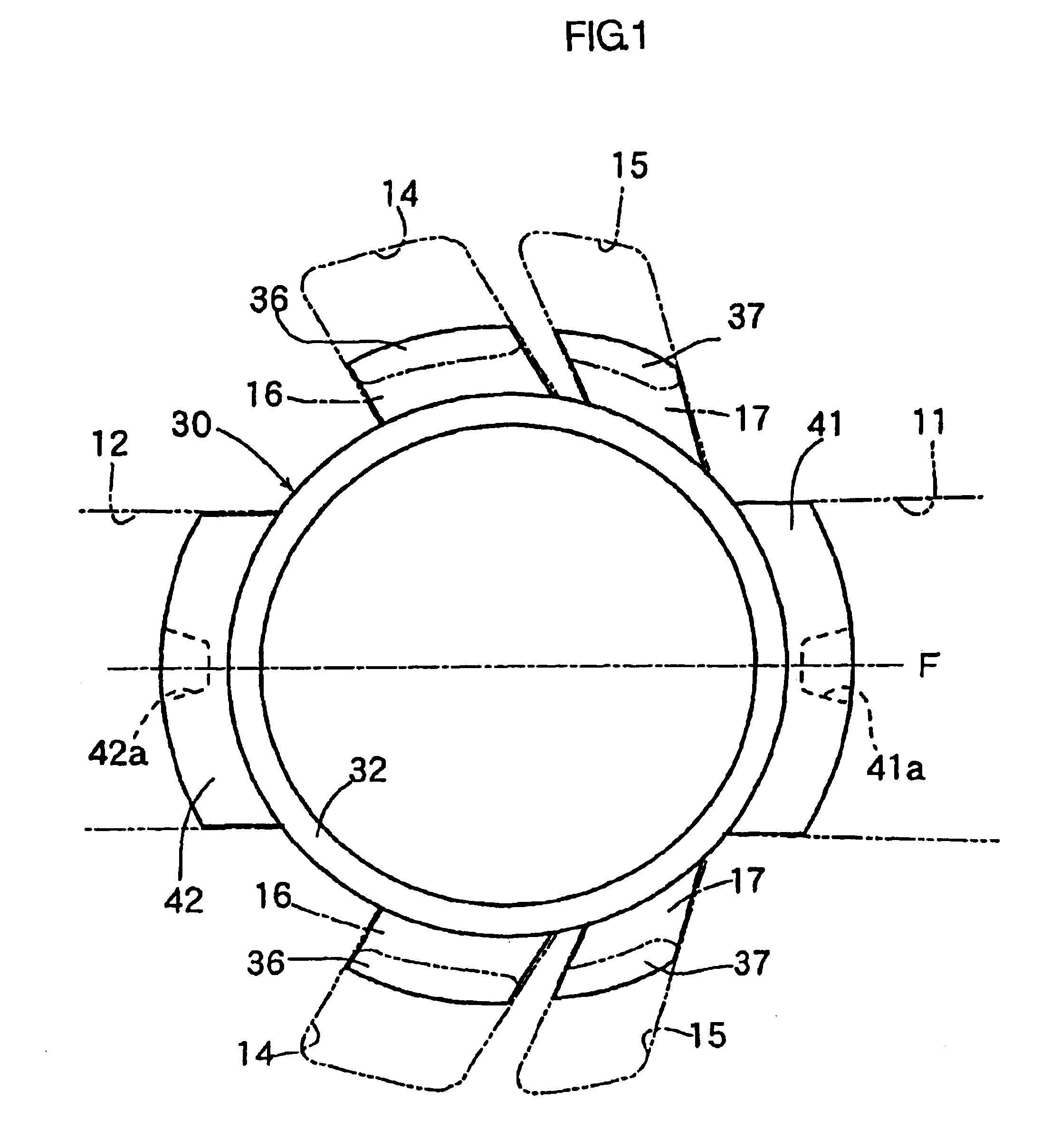

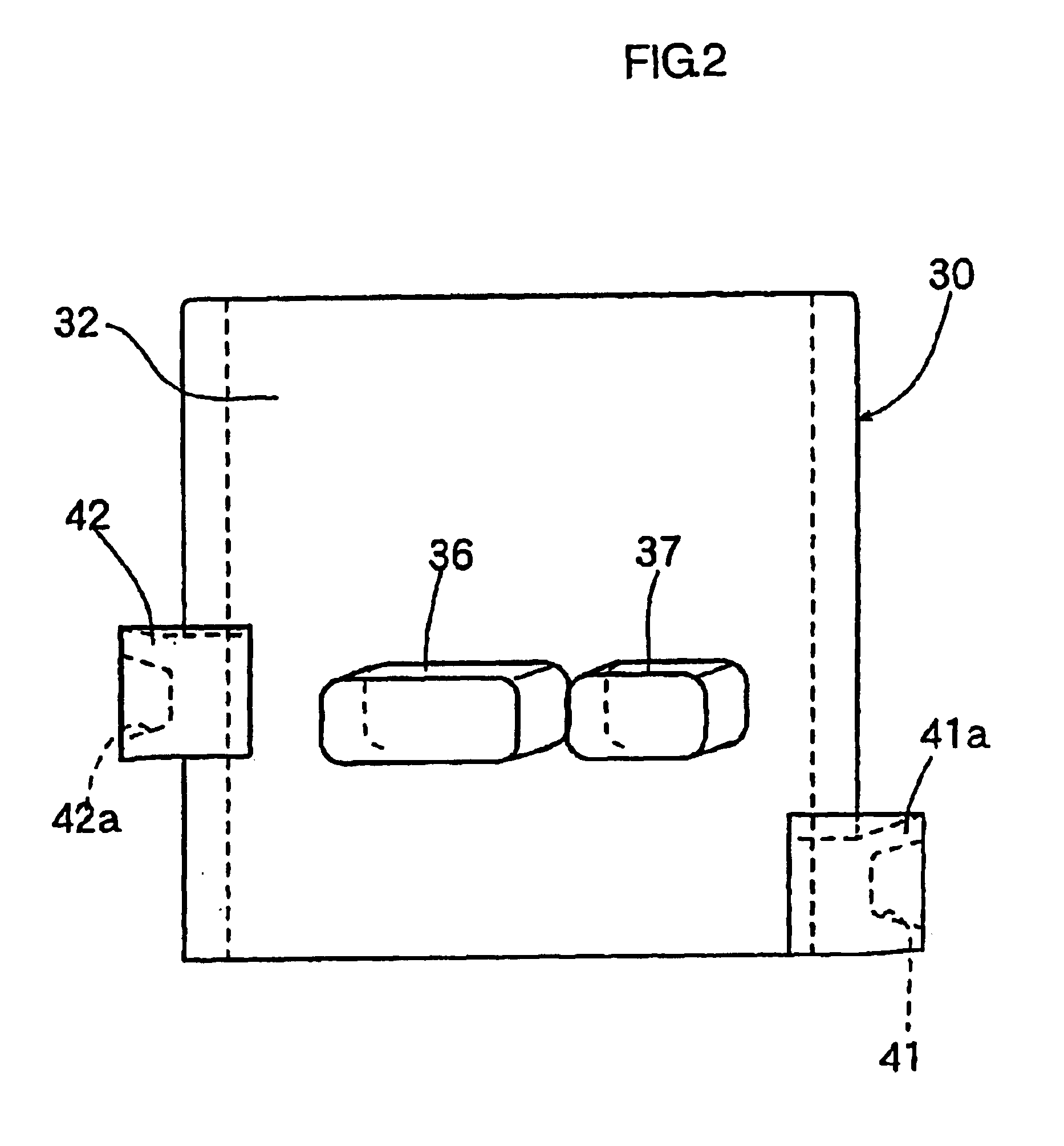

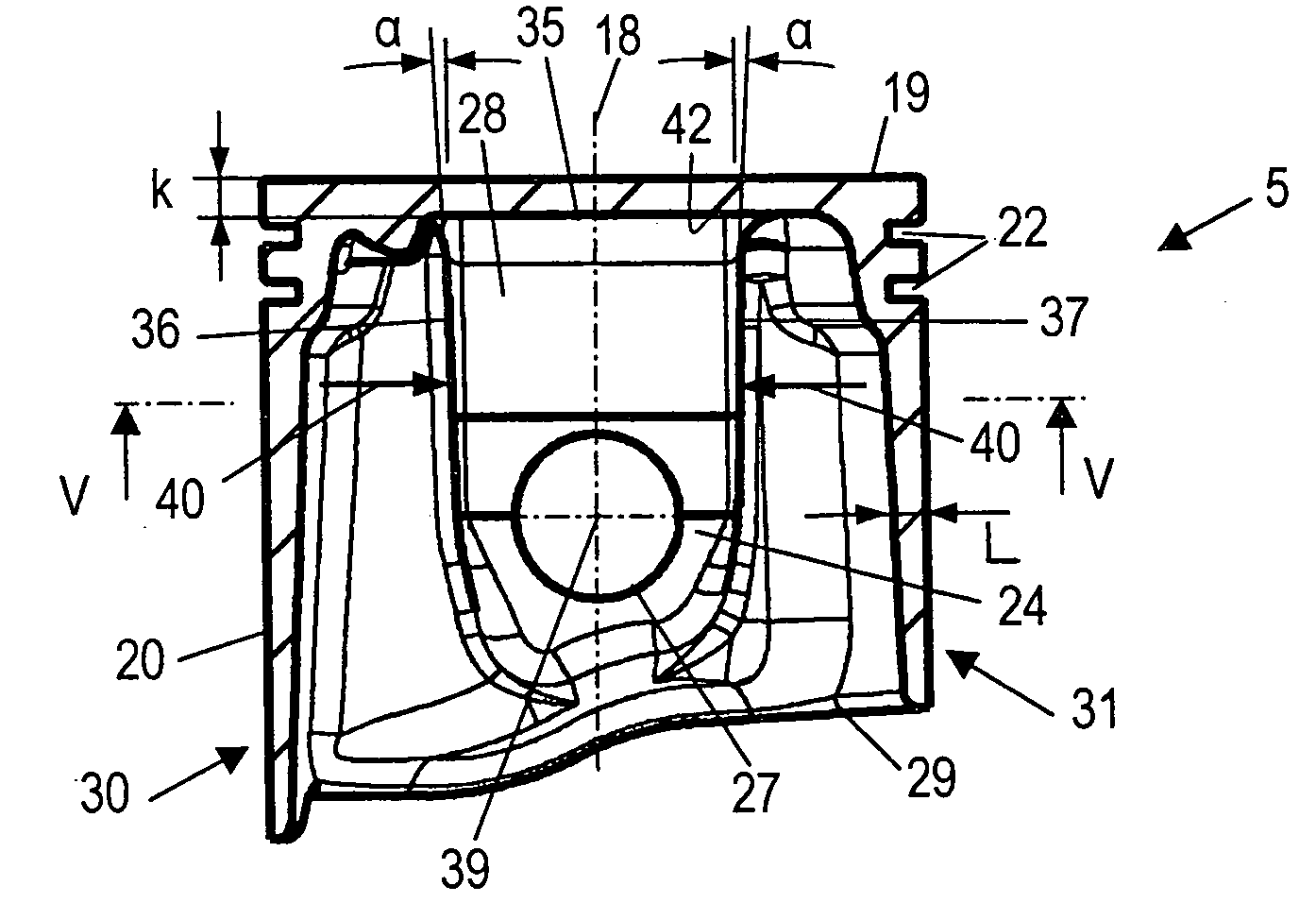

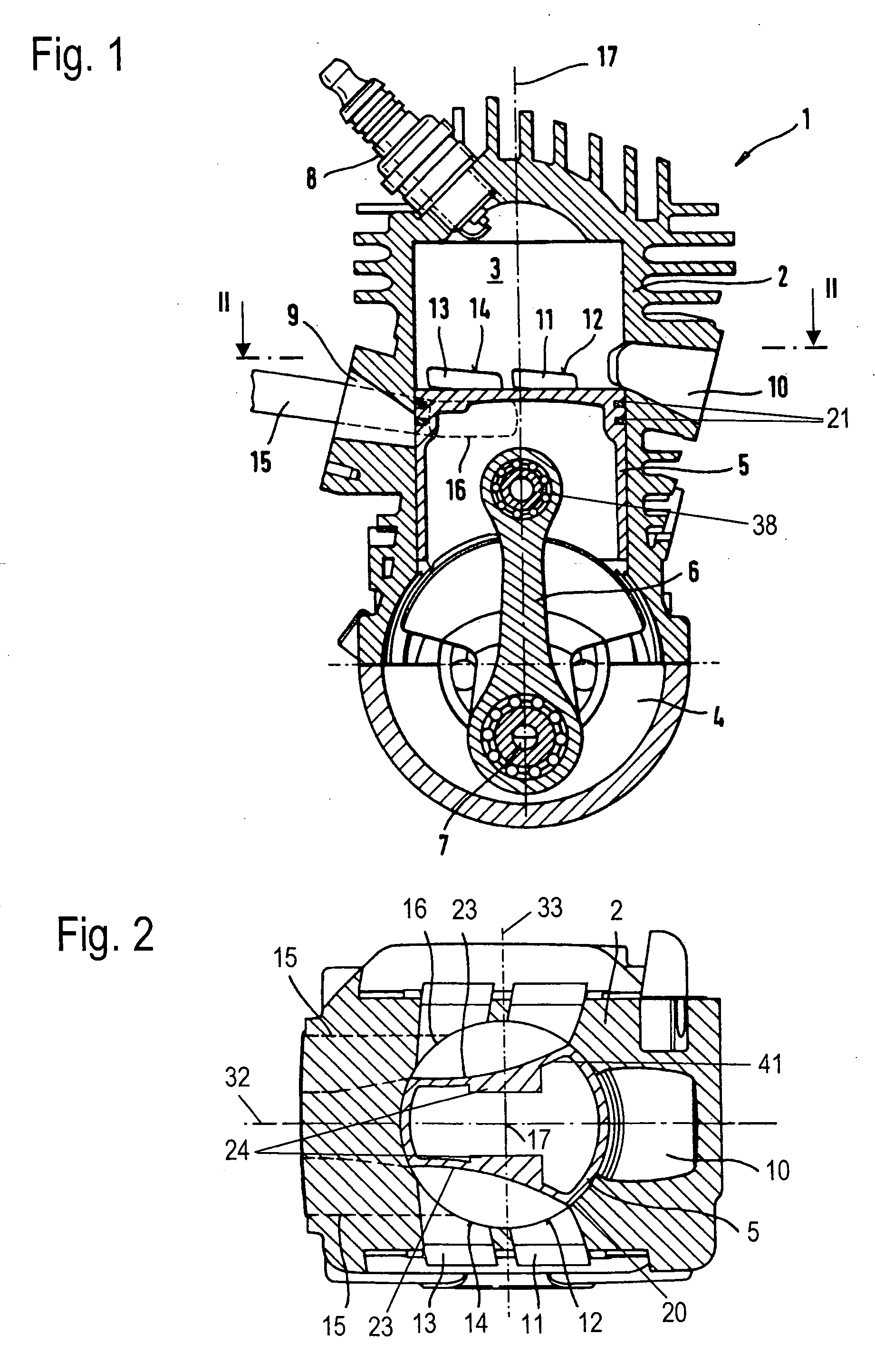

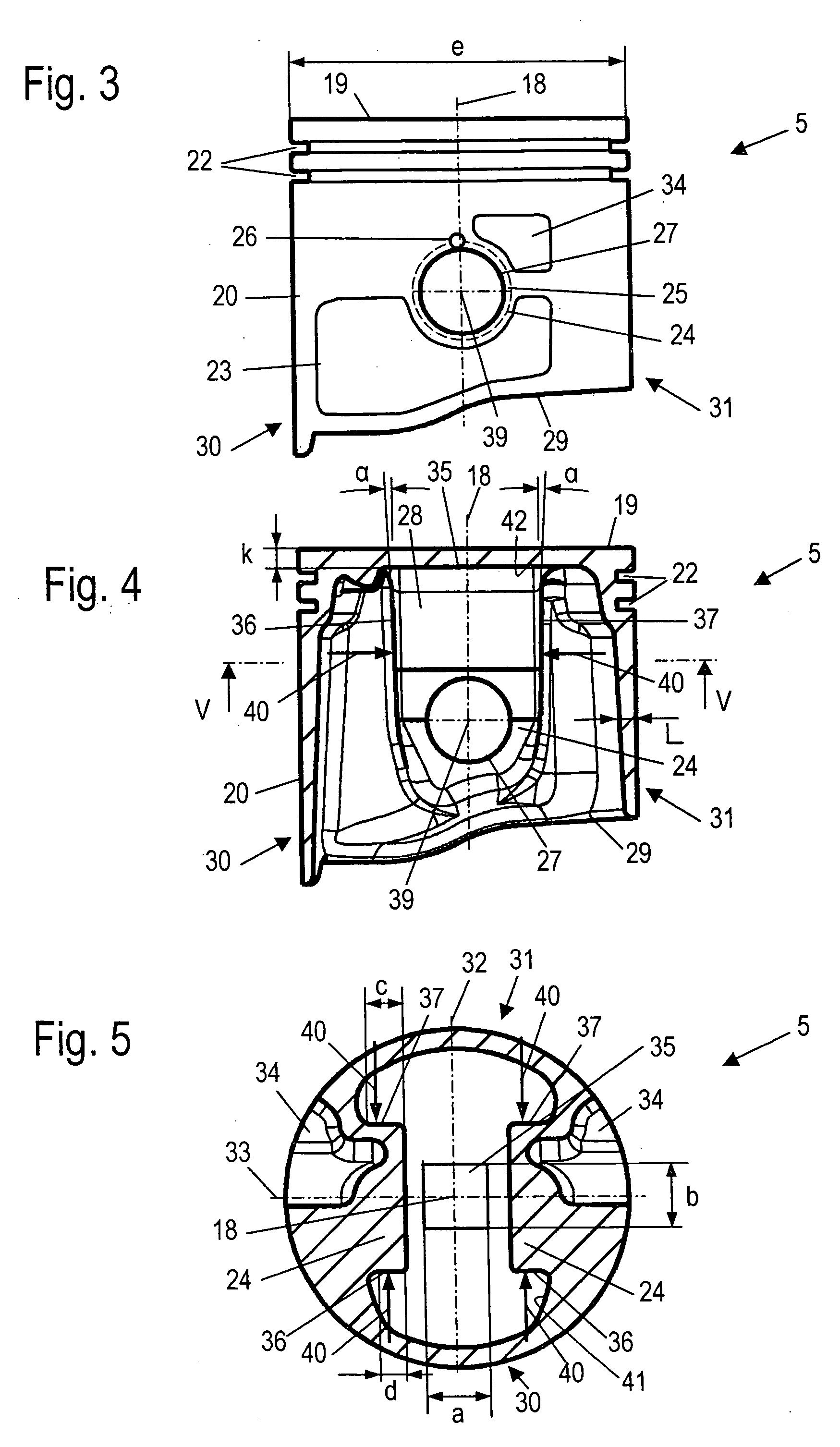

Piston for a two-stroke engine and a method of making the same

InactiveUS20070113734A1Improve accuracyHigh precision machiningInternal combustion piston enginesPlungersThermodynamicsMechanical engineering

A piston (5) for a two-stroke engine (1) has a piston base (19) and at least one piston pin boss (24). The piston pin boss (24) has a bore for accommodating a piston pin. At the piston pin boss (24), two mutually opposite-lying planar clamping surfaces (36, 37) are formed. The piston (5) is produced in a pressure die cast process and is thereafter clamped at the clamping surfaces (36, 37) and a stop surface (35). In this clamping state, all machining operations of the piston (5) can be carried out so that a high dimensional stability of the piston (5) results.

Owner:ANDREAS STIHL AG & CO KG

Copper alloy for manufacturing mould and preparation method thereof

The invention discloses copper alloy for manufacturing a mould and a preparation method thereof. The copper alloy consists of the following components in percentage by mass: 1.10 to 1.70 percent of Ni, 0.20 to 0.40 percent of Co, 0.10 to 0.40 percent of Be, 0.08 to 0.20 percent of Zr, 0.02 to 0.10 percent of Y, 0.02 to 0.05 percent of Ce, and the balance of Cu; and the copper alloy is prepared by processing steps of melting, pouring, hot forging, solid solution, cold forging and ageing. The copper alloy for manufacturing the mould has the characteristics of high strength and high thermal conductivity, and can also be used for welded joint discs and the like used on spot-welding electrodes and stainless steel besides being used for manufacturing injection moulds and nonferrous metal low-pressure die casting moulds with high thermal conductivity.

Owner:JIANGSU UNIV OF SCI & TECH

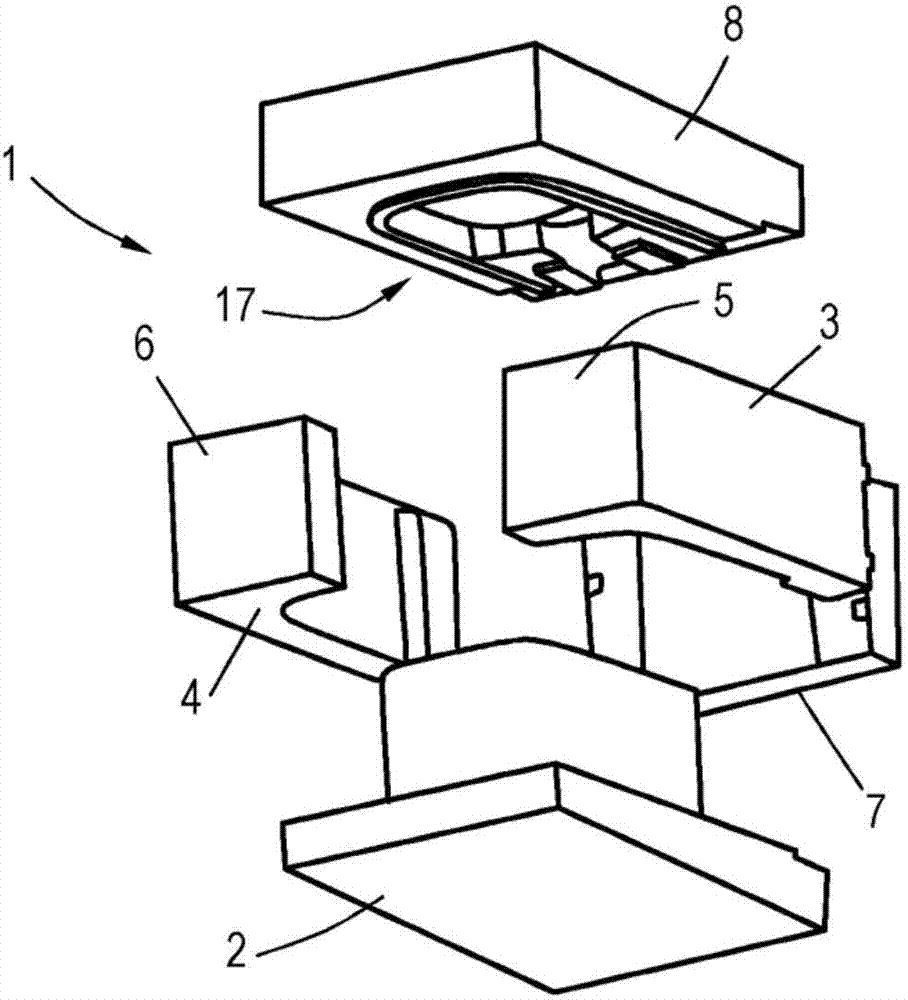

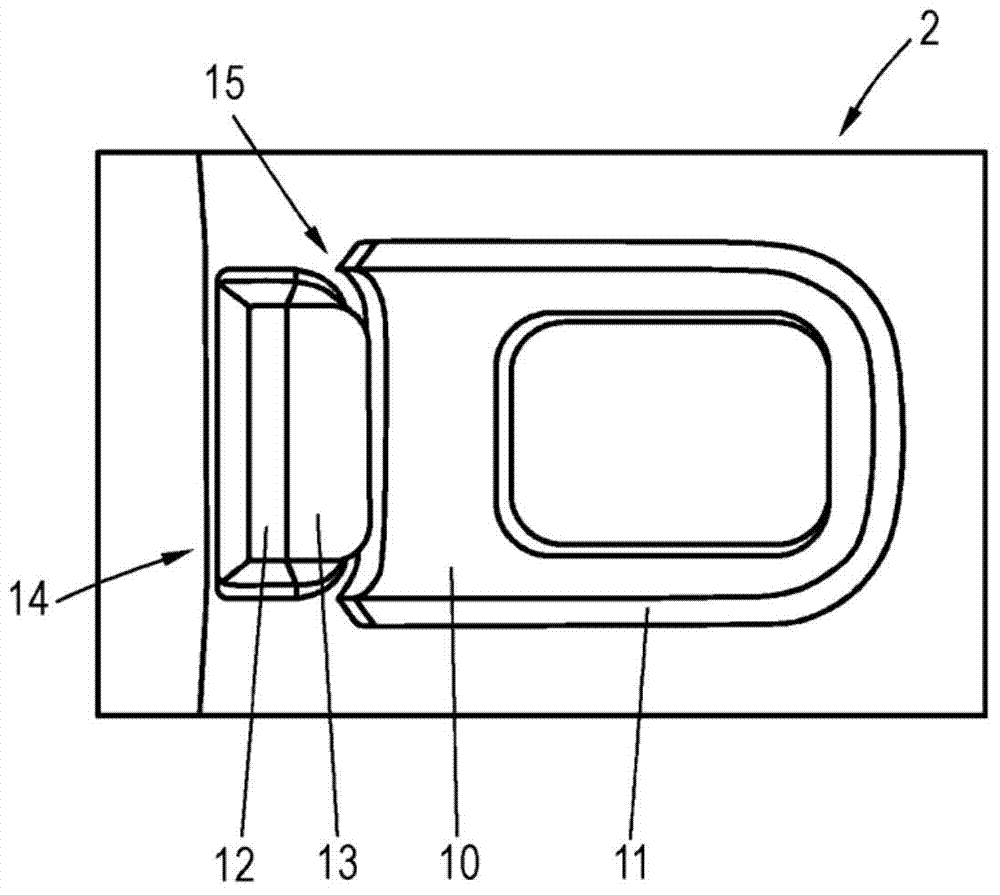

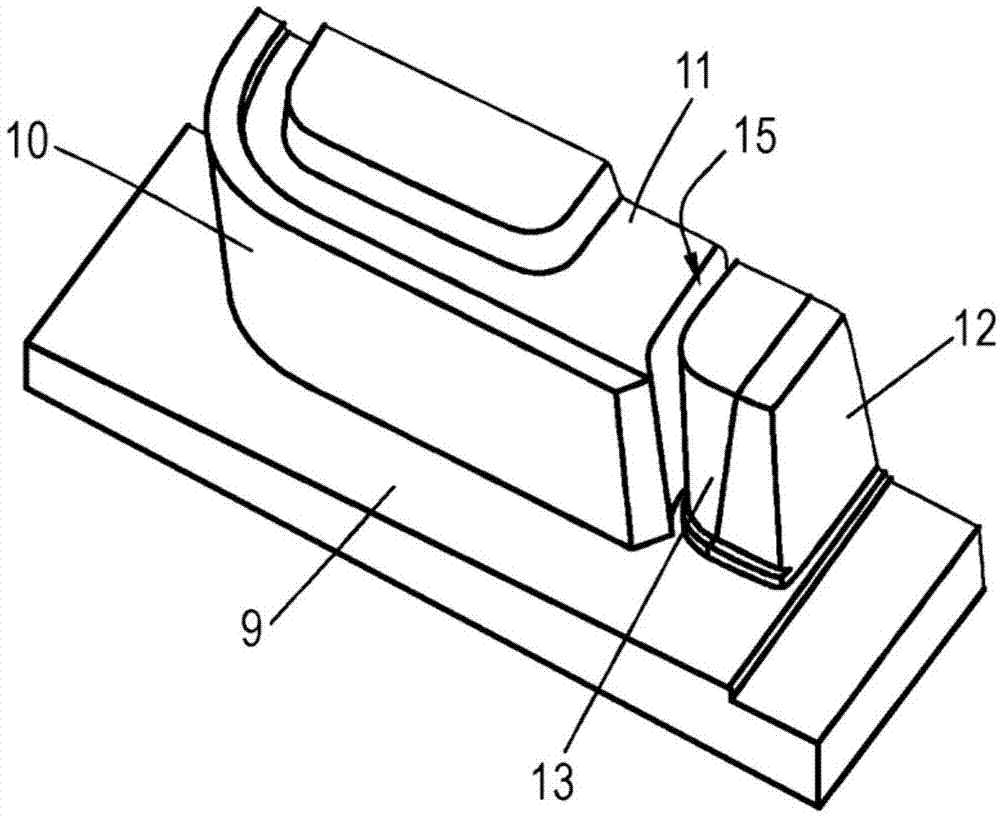

Pressure die casting mold for producing a casting

ActiveCN104742226AEasy extractionEasy to handleWater closetsMould separation apparatusEngineeringMechanical engineering

A pressure die casting mold for producing a casting which is part of an integral toilet having a body, a water ring, and a tank, wherein the casting, as an integral component, includes the water ring and the tank which is open on the upper side. The pressure die casting mold is composed of at least five molded parts which are interconnectable in a releasable manner, namely of a base part, two side parts having in each case one half of a front wall, a rear wall, and a cover part. The molded parts delimit a cavity which corresponds to the outer shape of the casting. A wedge element, which at least in portions delimits the inner shape of the water tank, is provided on the base part.

Owner:DURAVIT AG

Lead-Free, Bismuth-Free Free-Cutting Phosphorous Brass Alloy And Its Manufacturing Method

The present invention relates to a lead-free, bismuth-free free-cutting phosphorous brass alloy and its method of manufacture. The alloy comprises: Cu; Zn; 0.59 to 1.6 wt % P; and other elements in the amount of 0.005 to 0.6 wt %, which comprise at least two elements selected from the group consisting of Al, Si, Sb, Sn, Rare earth element (RE), Ti and B, and the balance being unavoidable impurities. The phosphorous brass alloy contains a combined wt % of Cu and Zn of between 97.0 wt % and 99.5 wt %, within which the content of Zn is above 40 wt %. Considering the solid solubility of P in the matrix of copper will be decreased rapidly with the temperature decrease and form the brittle intermetallic compounds Cu3P with Cu, the present invention relies upon P to ensure excellent cuttability of the invented alloy. The invented alloy is reasonably priced, and has excellent cuttability, castability, hot and cold workability, dezincification corrosion resistance, mechanical properties and weldability. The phosphorous brass alloy is a useful alloy for spare parts, forging and castings that require cutting, and particularly in forging and castings for low pressure die casting that requires cutting, grinding, welding and electroplating. The phosphorous brass alloy may also be used for faucets, valves and bushings of water supply systems, and for bar and wire materials that require high corrosion resistance and compactness.

Owner:XIAMEN LAVIDA HI TECH MATERIAL CO LTD

Lead-Free Free-Cutting Aluminum Brass Alloy And Its Manufacturing Method

The present invention provides a lead-free free-cutting aluminum brass alloy and its manufacturing method. The alloy comprises: 57.0˜63.0 wt % Cu, 0.3˜0.7 wt % Al, 0.1˜0.5 wt % Bi, 0.2˜0.4 wt % Sn, 0.1˜0.5 wt % Si, 0.01˜0.15 wt % P, at least two elements selected from the group of 0.01-0.15 wt % Mg, 0.0016-0.0020 wt % B, and 0.001-0.05 wt % rare earth elements and the balance being Zn and unavoidable impurities. The inventive alloy has excellent castability, weldability, cuttability and corrosion resistance. It is suitable for low pressure die casting, gravity casting, horizontal continuous casting, forging and extrusion. Its metal material cost is lower than bismuth brass. It is particularly applicable for components used in drinking water supply systems and other structural components. It is a new environmentally-friendly free-cutting aluminum brass alloy.

Owner:XIAMEN LOTA INT CO LTD

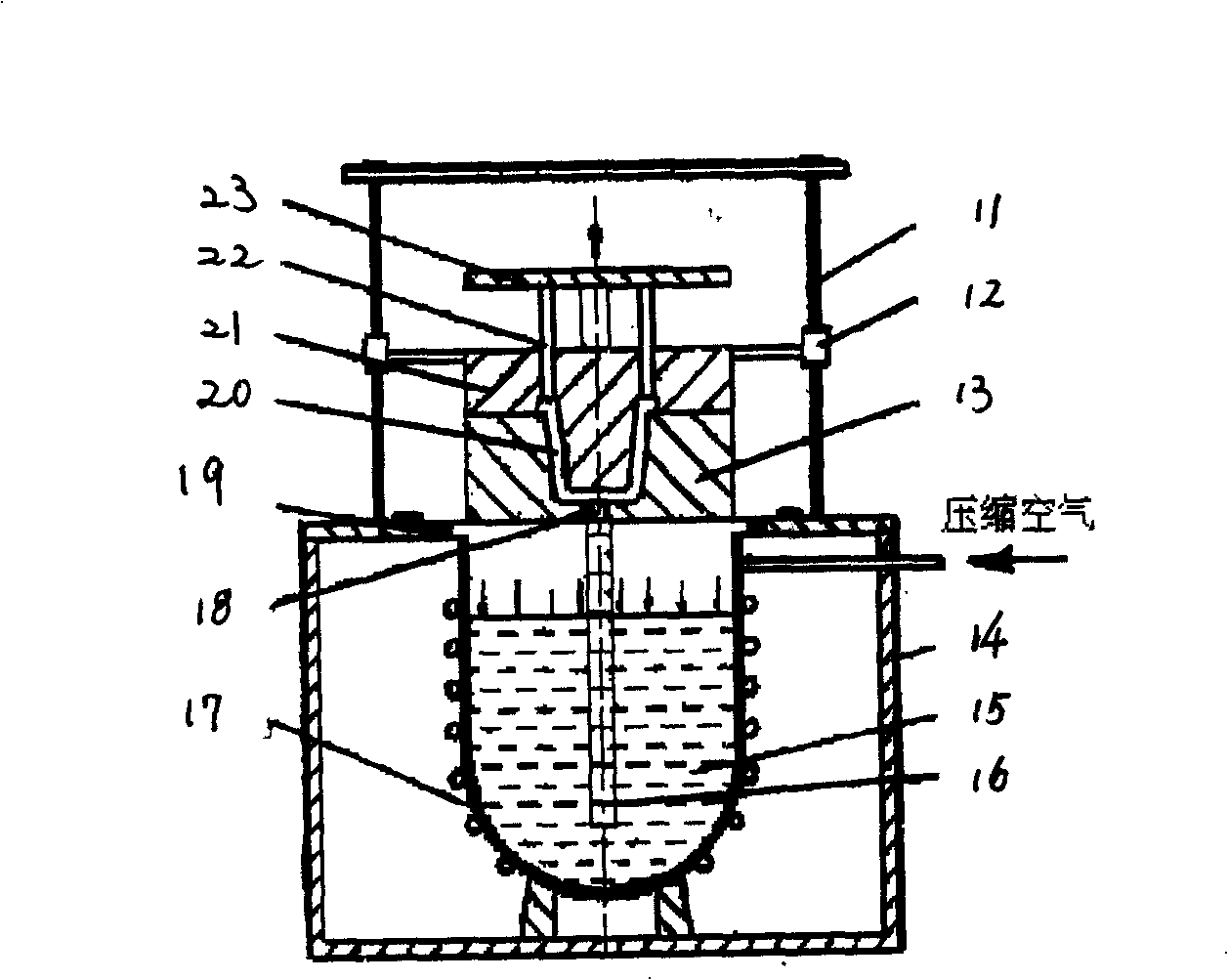

Method for supplying liquid to magnesium-alloy press caster and liquid supplier

The invention is concerned with the liquid supply method of the pressure die casting machine for magnesium alloy die-casting, it is: the magnesium alloy liquid, which the liquid surface is lower than the outputting opening of the proportioning pump in the melting furnace, passes the outputting opening to enter the pressure chamber from the bottom pressure chamber of the pressure die casting machine by the proportioning pump. The invention solves the problem of the existing method that is easy to be oxidation and mix air, provides the method that non-impact, less oxidation, non-air mix, to improve the quality of the magnesium alloy die cast, reduce the cost.

Owner:NANJING YUNHAI SPECIAL METALS CO LTD

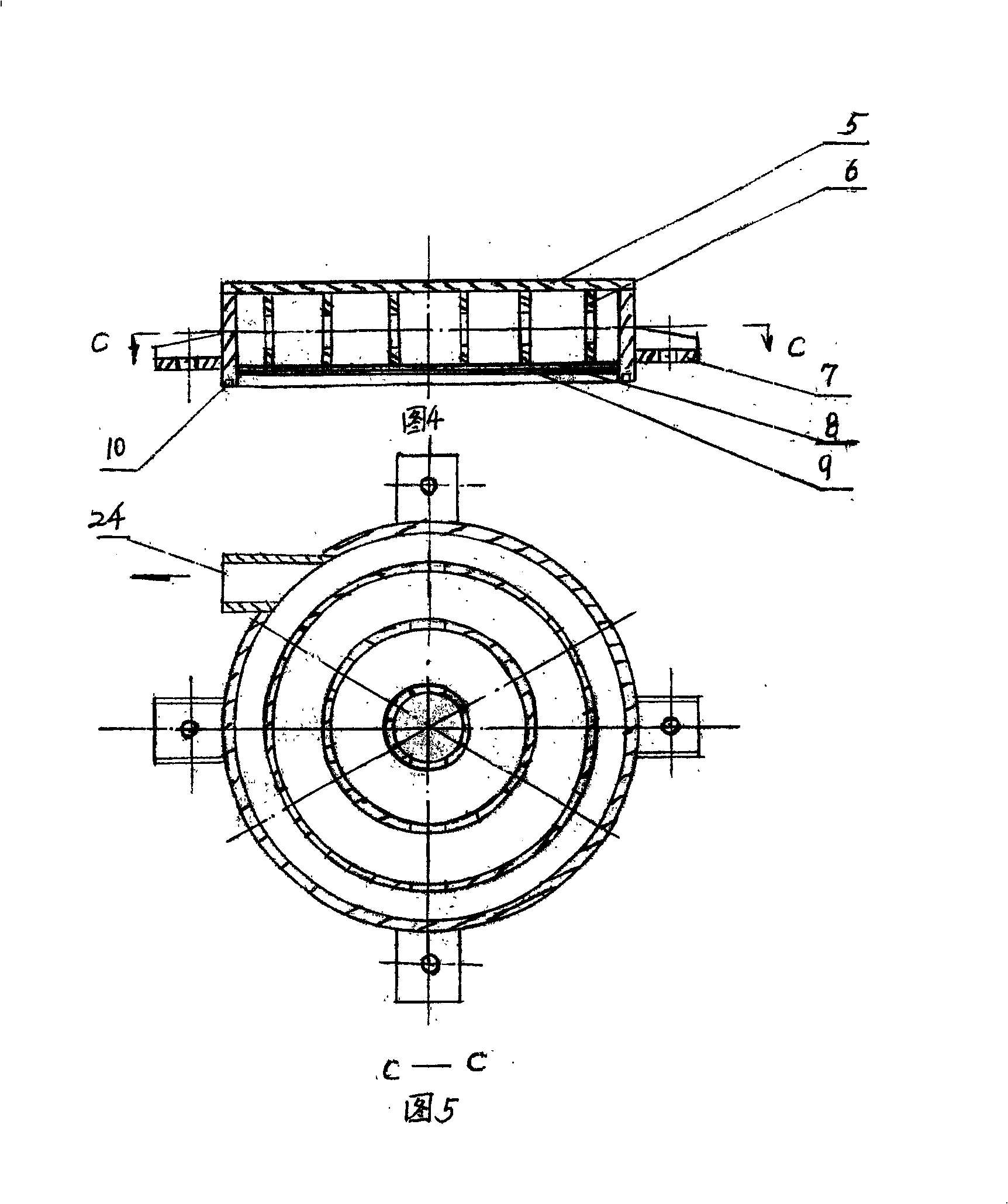

Bearing holder near net shape casting method

InactiveCN101264512AIncrease productivityReduce manufacturing costFoundry mouldsFoundry coresLiquid metalAlloy

The invention relates to a casting technology for bearing retainers, in particular to a near-net-shape casting technology for bearing retainers, which solves the problem of low using rate of metals when thick bushing roughcasts are integrally cast and is suitable for casting bearing retainers by use of ductile iron and nonferrous alloys. The casting technology comprises the following steps: (1) the foam patterns are made into dies with shape and size close to the final parts; and a back draft upper flask with integrated modeling and exhausting functions is adopted; (2) after mould closing and sealing treatment on a low-pressure die-casting machine, mold filling and casting are carried out; when casting, the vacuum evacuation valve connected with the evacuation box is opened first for vacuum pumping of the cast cavity, and then grade turbocharged process is used for filling and casting, so as to keep the castings stay at a conditions surrounded by continuous supplement of liquid metal from the pouring basin and lift tube under a high pressure until near-net-shape castings are obtained after full solidification. The casting technology has the advantages that the using rate of metal is improved to 85% to 90% from 15% to 20% and the aims for green casting, cleaner production and sustainable development in accordance with the national standards are realized.

Owner:吴成玉

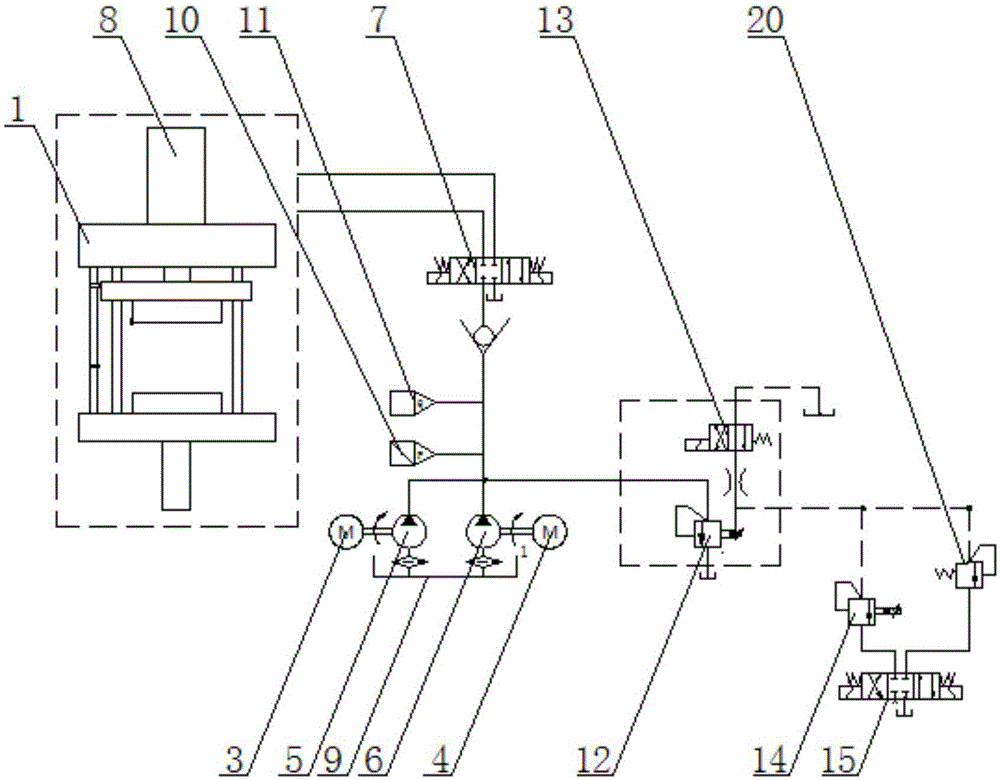

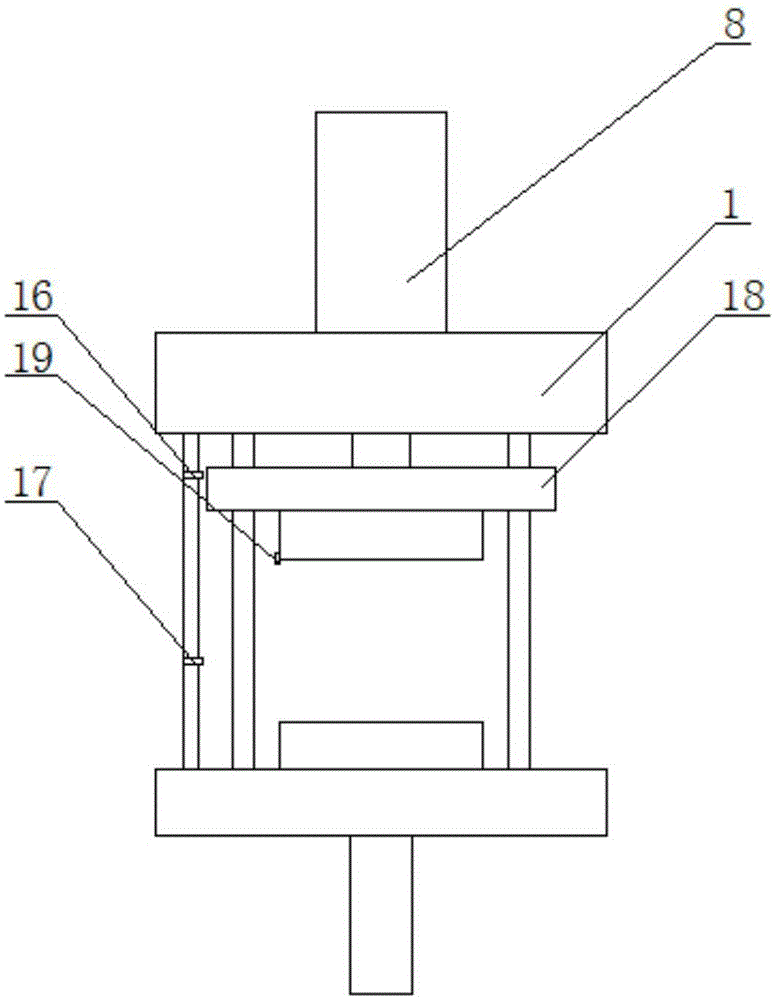

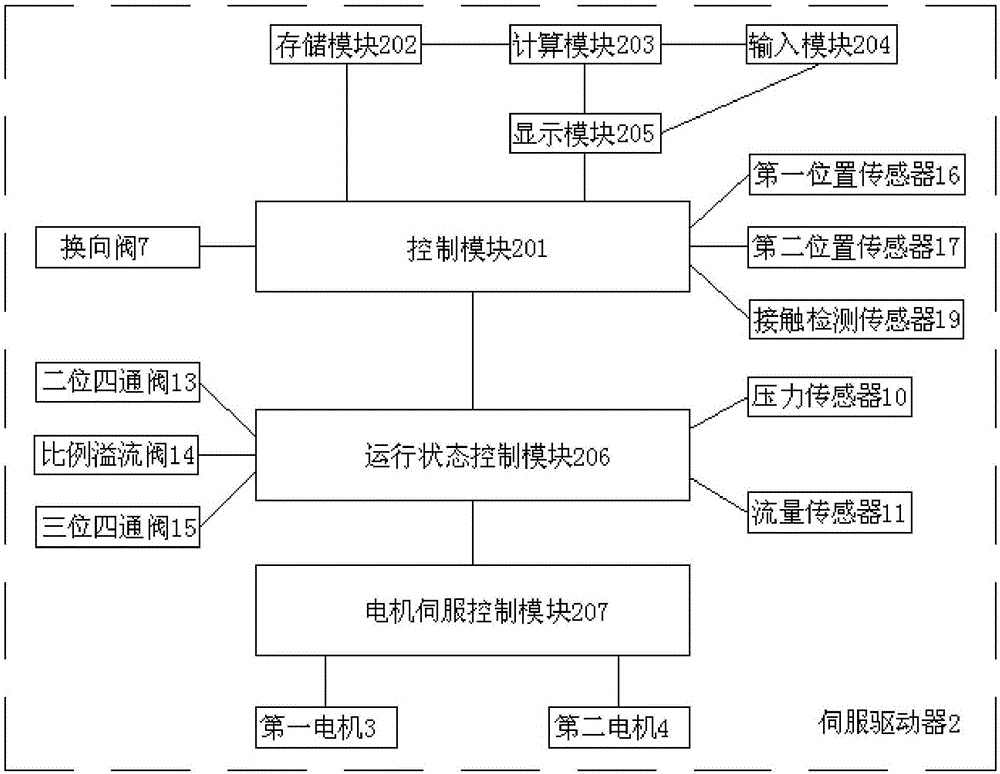

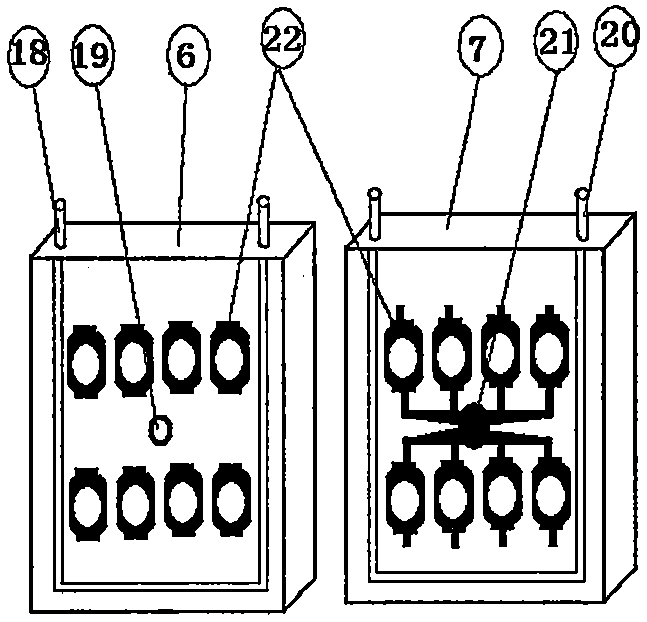

PLC control system and method of servo energy-saving control system of ceramic press

InactiveCN105041744AAvoid the phenomenon of wasting electric energySave energyServomotor componentsServomotorsAuto regulationElectricity

The invention discloses a PLC control system and method of a servo energy-saving control system of a ceramic press. A pressure \ adjusting end of a pilot overflow valve is communicated with an oil tank sequentially through a proportional overflow valve and a three-position four-way valve and is communicated with the oil tank through an overflow valve; a first position sensor and a second position sensor are arranged on a pressure die casting machine; and the first position sensor, the second position sensor, a contact detection sensor, a first motor, the proportional overflow valve, a two-position four-way valve and a three-position four-way valve are all electrically connected with a servo driver. The PLC control device enables the pressure die casing machine to achieve automatic adjusting of working pressure and flow according to the different technological stages, and aim that the amount of flow and pressure are provided according to the needed amount of flow and pressure; many resources can be saved, and the phenomenon that an original press oil pump runs at full speed all the time, and electric energy is wasted is completely avoided.

Owner:GUANGZHOU AIMODE DRIVING SYST TECH

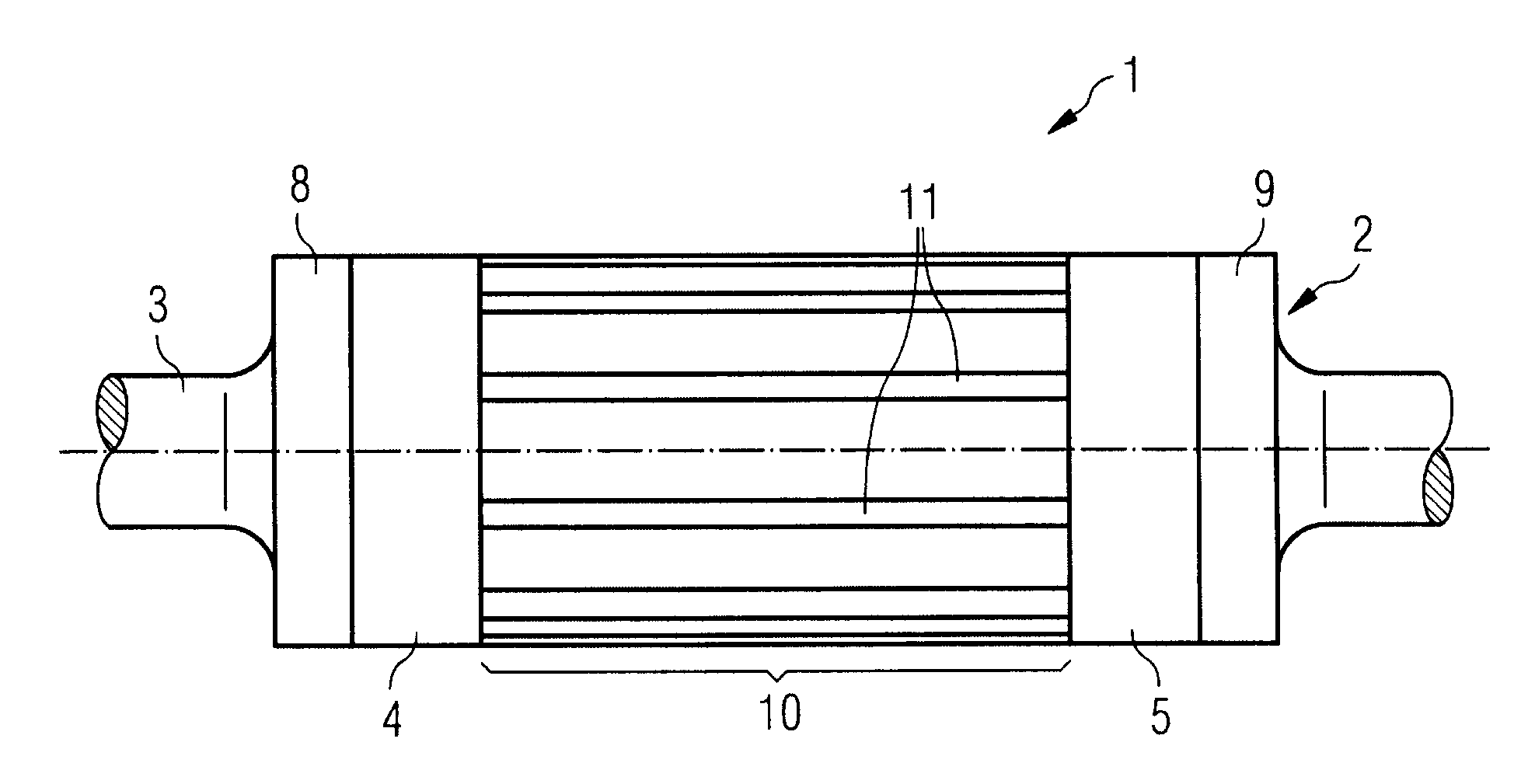

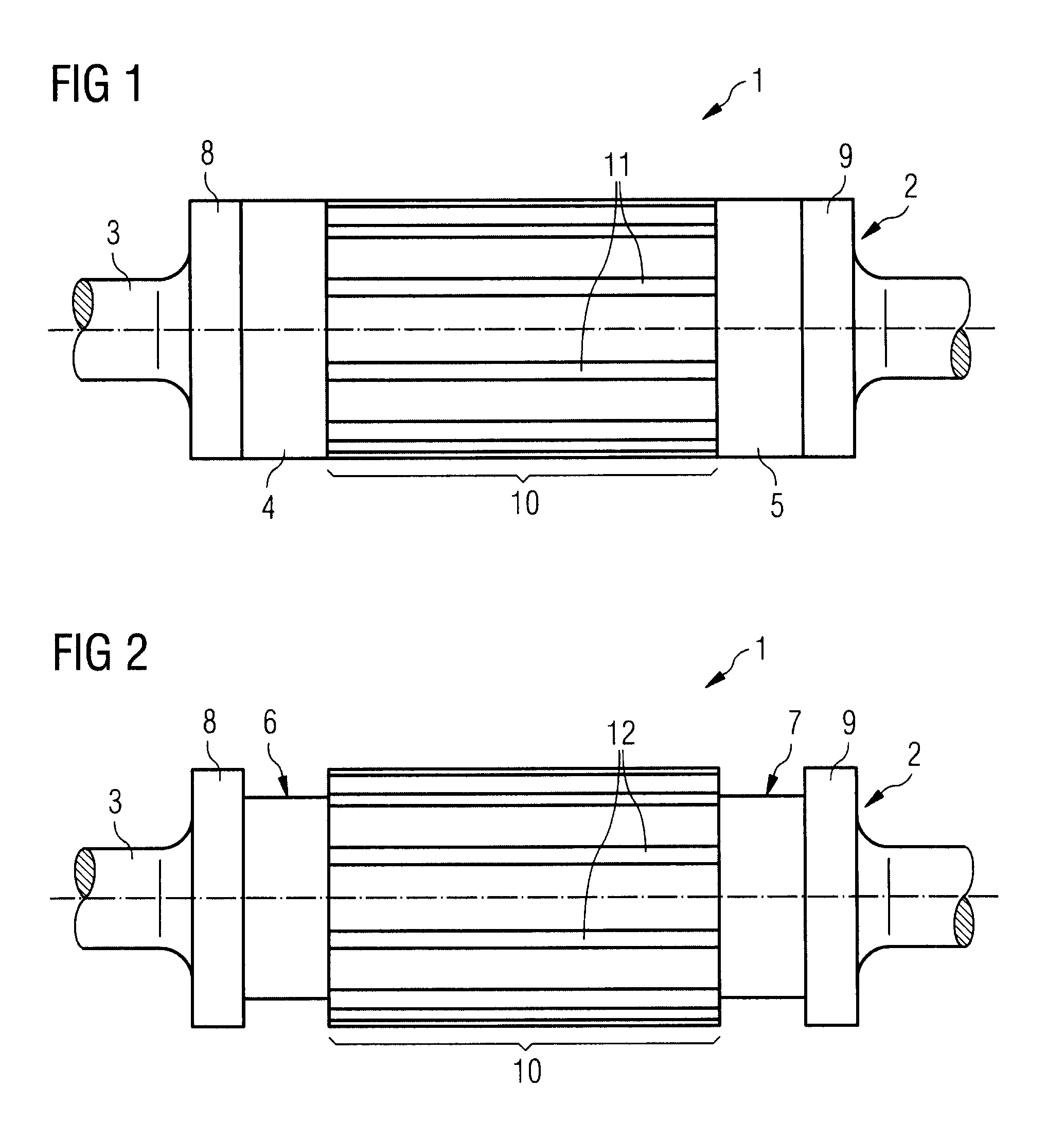

Cage rotor for an asynchronous machine and method for producing the cage rotor

ActiveUS20130062987A1Improve electrical performanceGood electromagnetic propertiesSynchronous motorsAsynchronous induction motorsElectrical conductorEngineering

A method for producing a cage rotor for an asynchronous machine is provided. The method includes providing a rotor body having a conductor bar segment in which conductor bars are provided, producing conductor bar slots in the conductor bar segment, wherein one conductor bar slot is provided for each of the conductor bars and producing short circuit ring recesses for short circuit rings, wherein the conductor bar slots each open into the short circuit ring recesses, pressure die casting cage material in the conductor bar slots, in situ, so that the conductor bars are formed of the conductor bar material in the conductor bar slots and the short circuit rings are formed in the short circuit ring recesses, and generating an area in the conductor bar material and the rotor body material including a metallurgical bond between the conductor bar material and the rotor body material at interfaces between the conductor bars and the rotor body.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

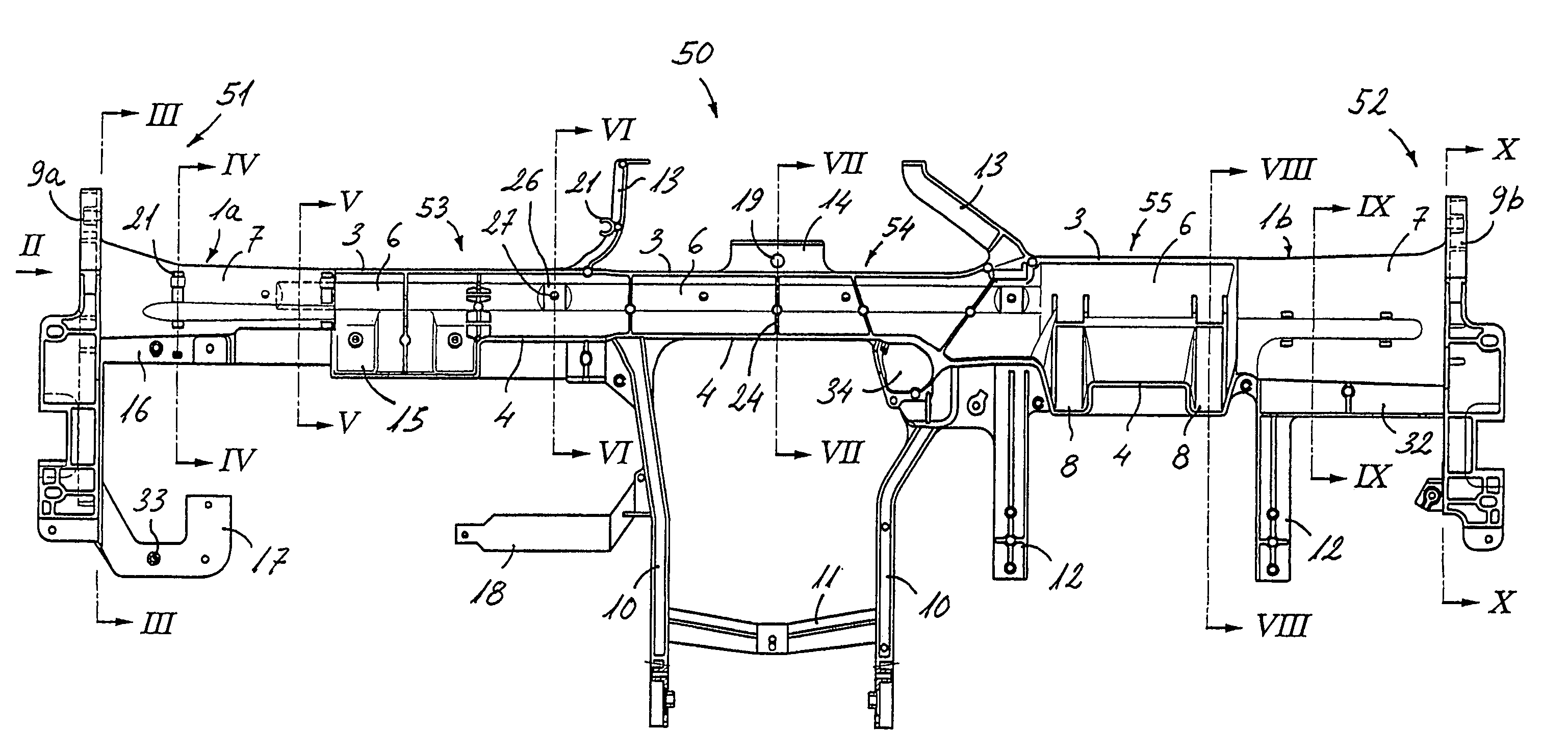

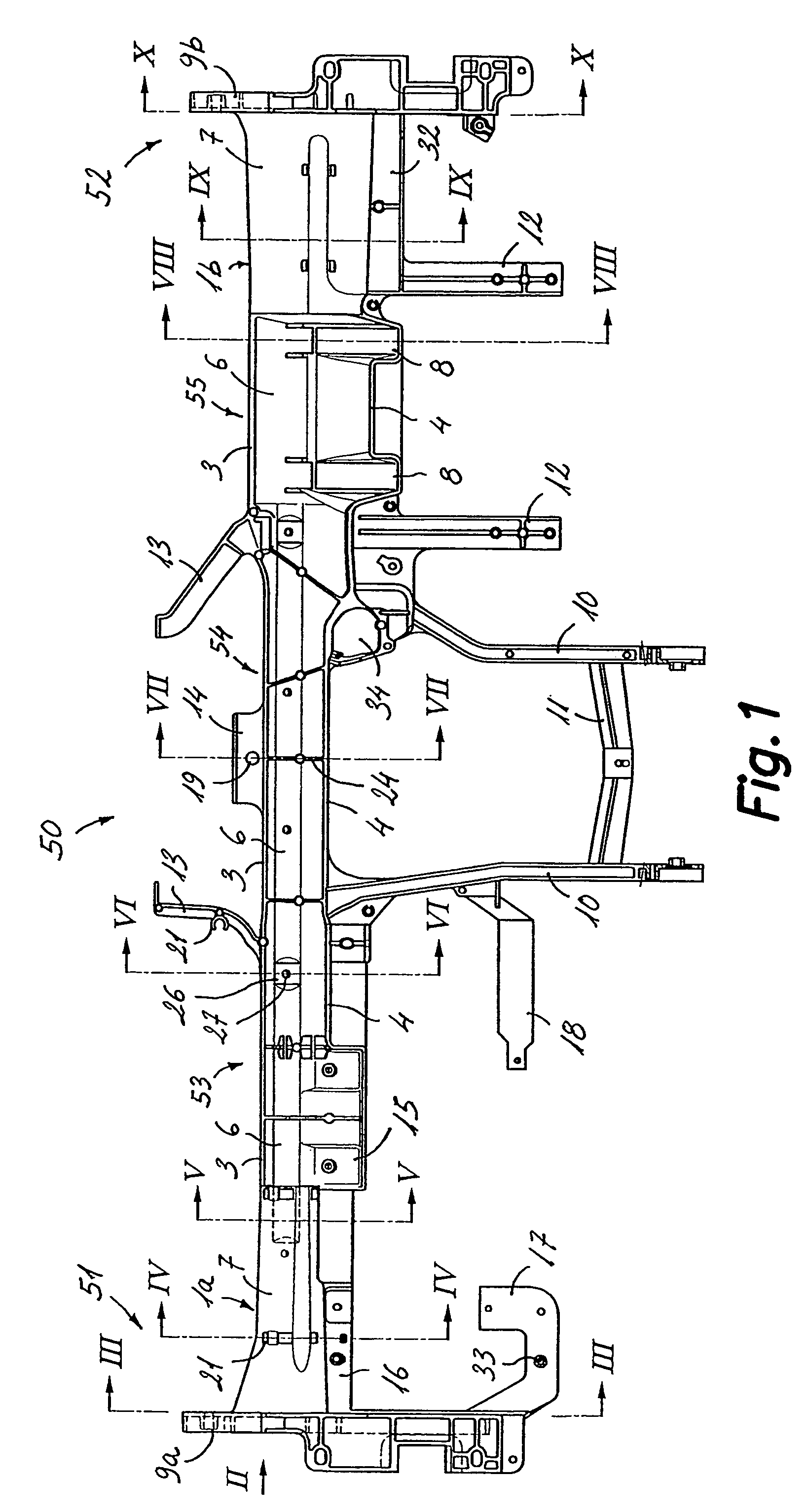

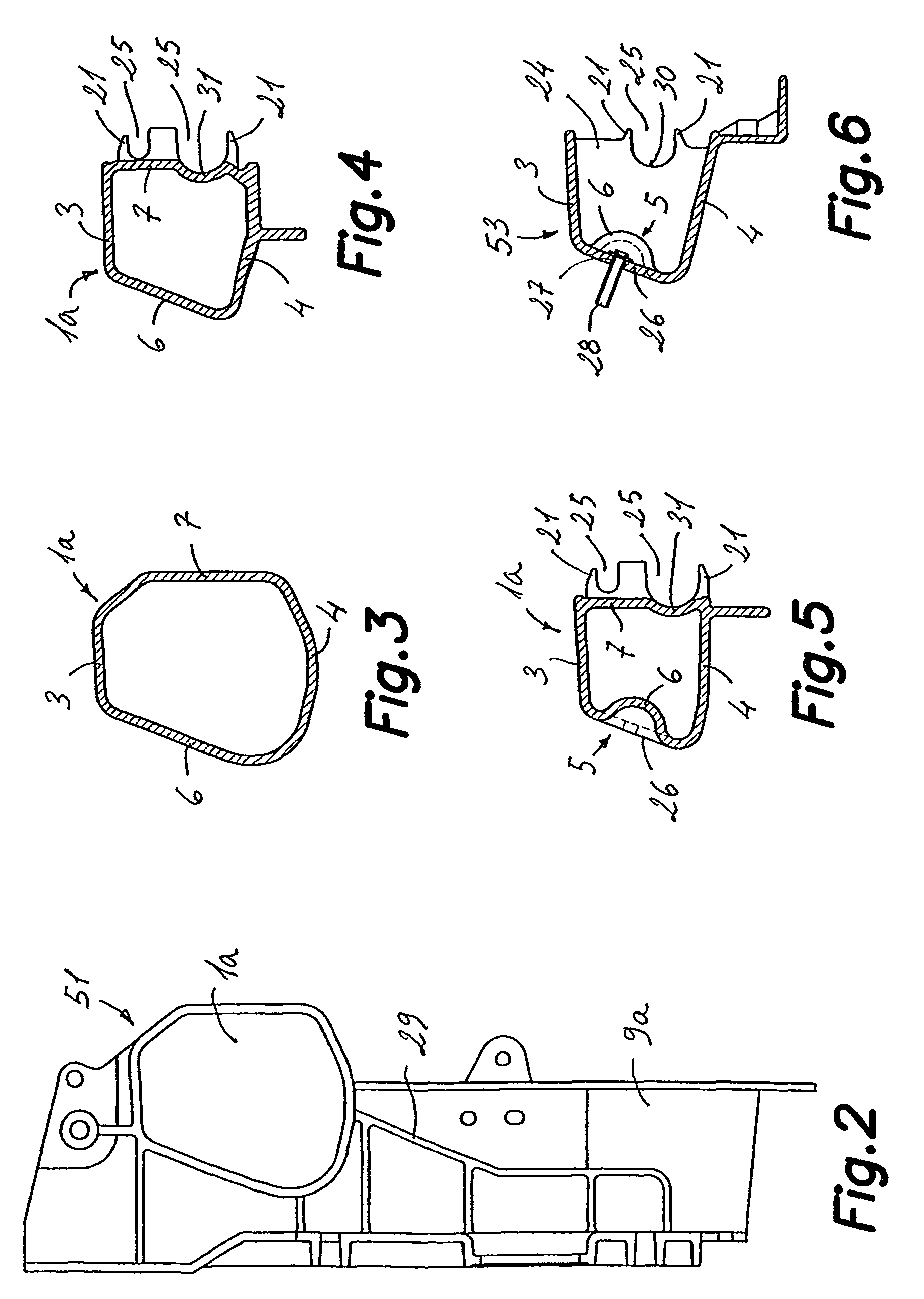

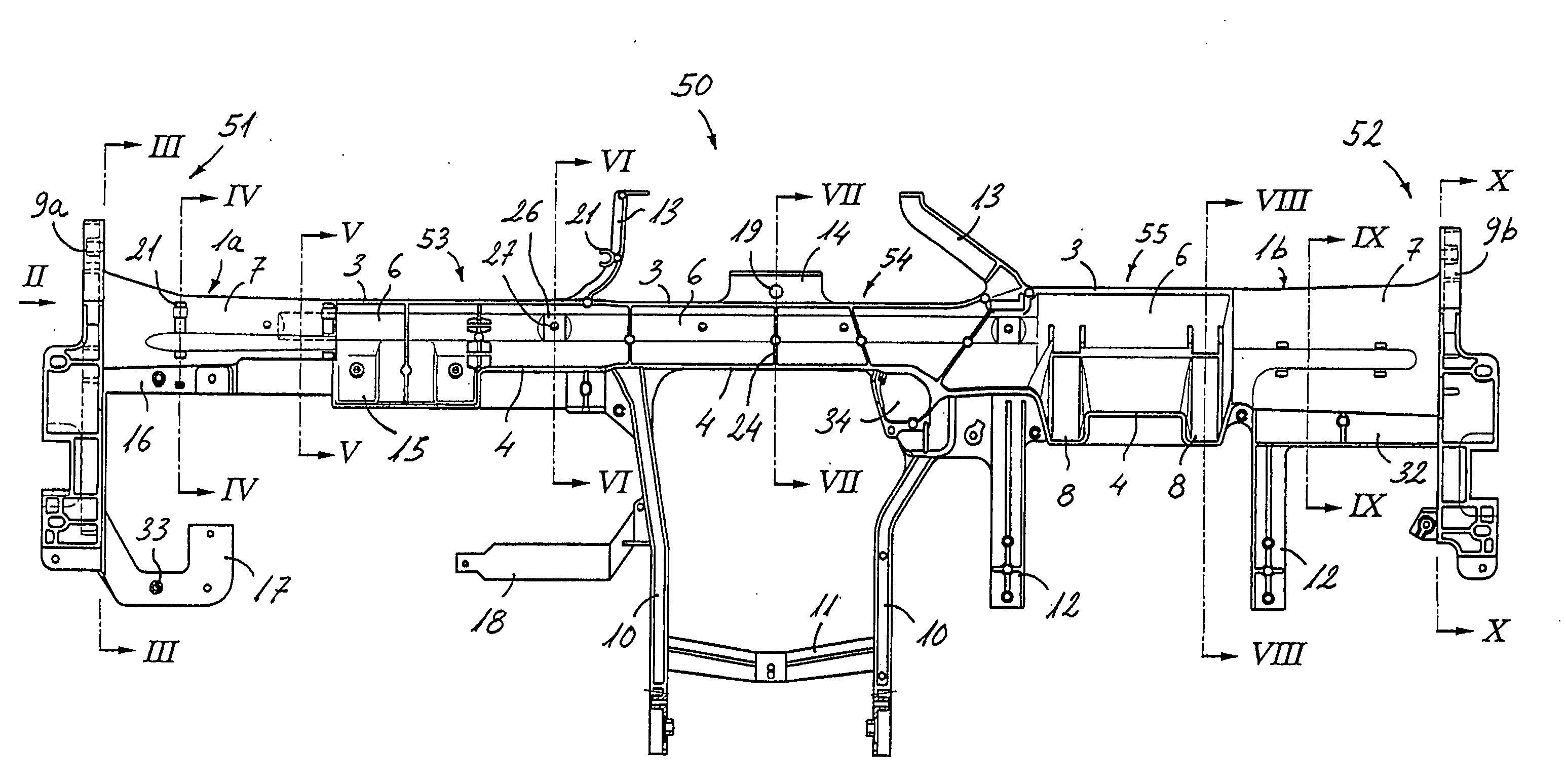

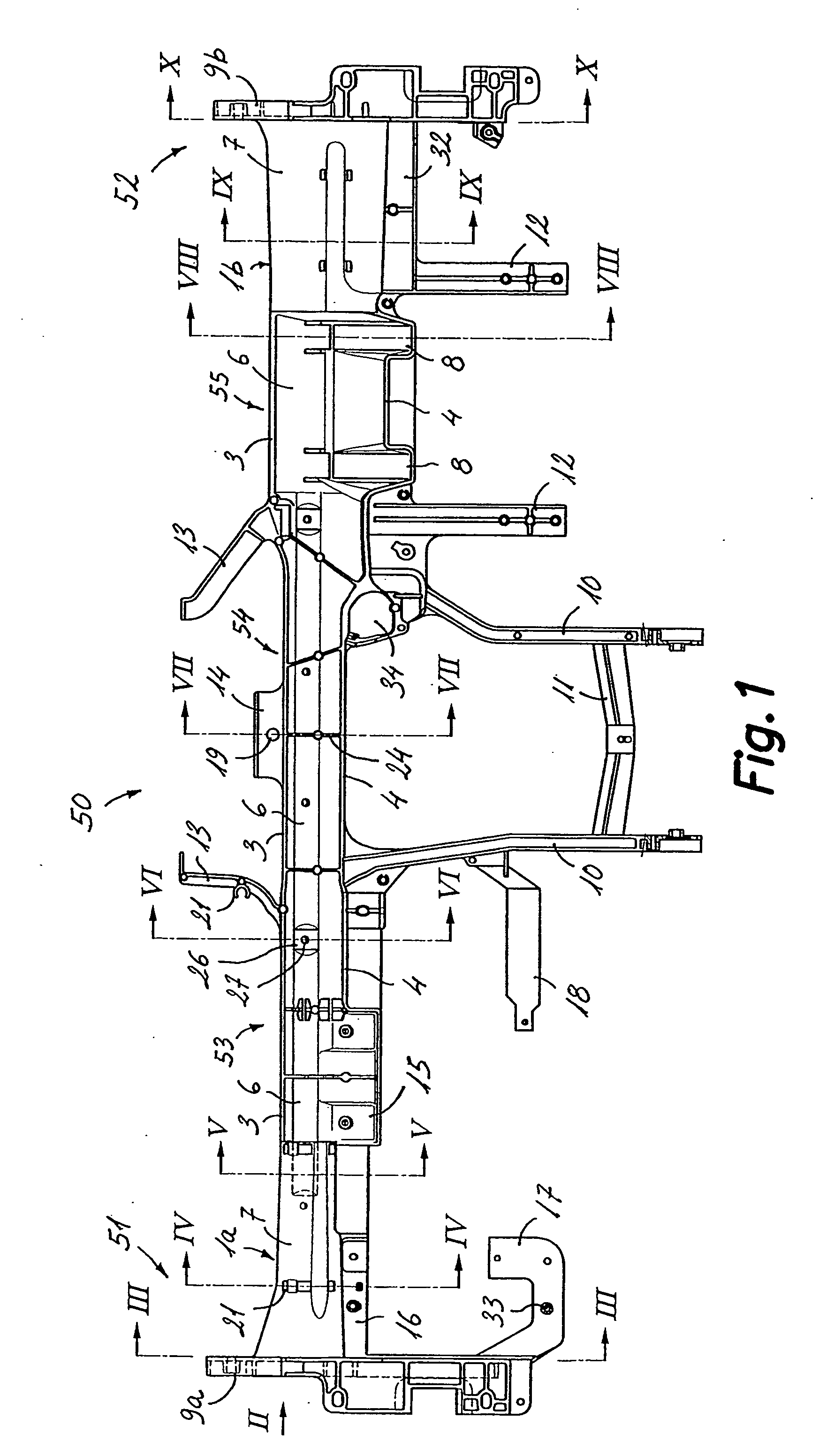

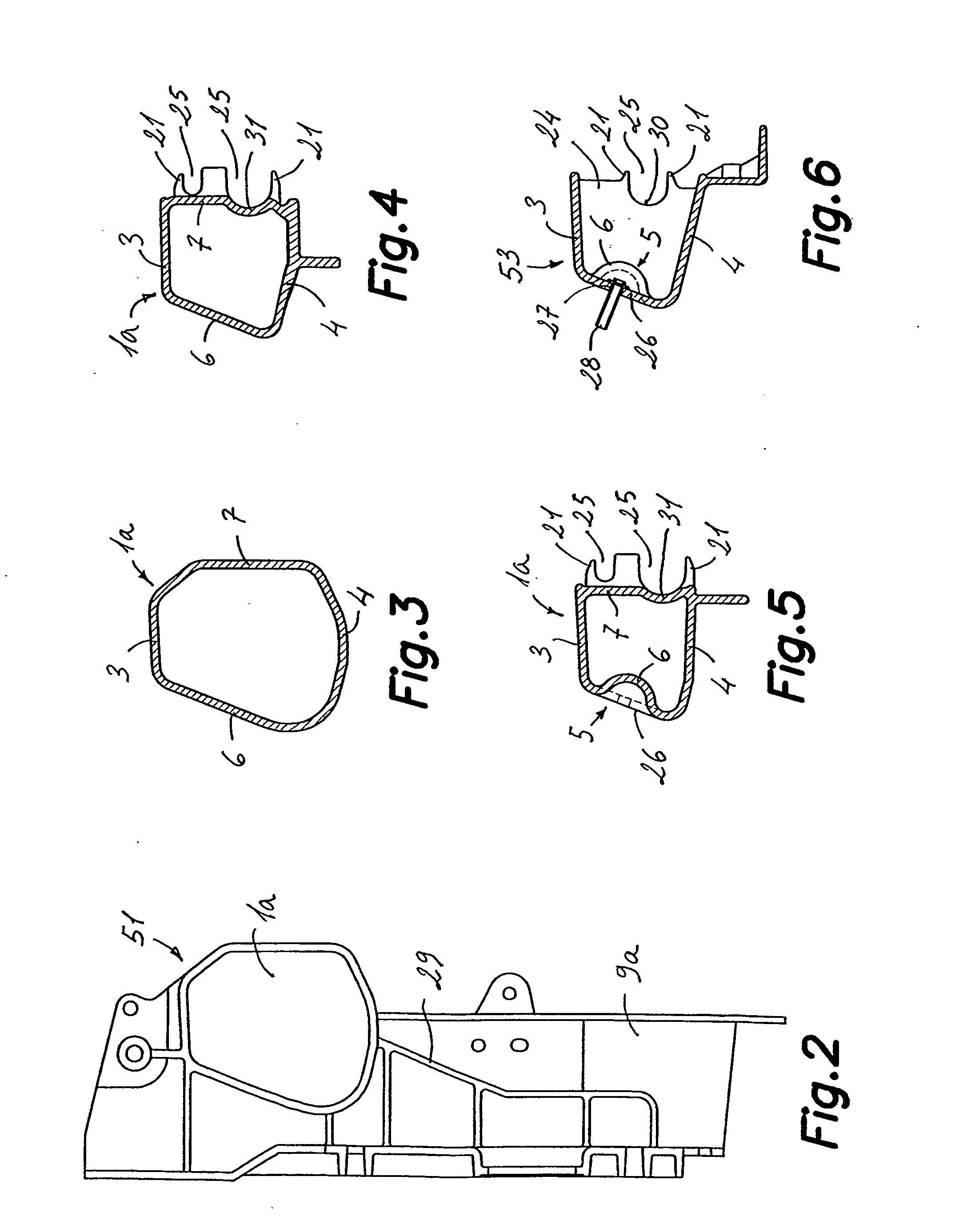

Support crossbeam for an instrument panel

ActiveUS7841648B2Improve the immunityIncrease in sizeVehicle seatsSuperstructure subunitsMobile vehicleSteering column

The invention relates to a support crossbeam for an instrument panel to be assembled between two side elements of a frame of an automotive vehicle next to a front part of an interior. The crossbeam integrates several anchoring and supporting configurations for the steering column, several airbags, fuse boxes, ventilation system elements, sound equipment, among others, and is obtained by pressure die-casting of a light metal alloy, such a magnesium alloy, in an elongated single part extending between first and second ends. This single part has an open cross-section general profile, adapted to be demolded in a transverse direction of the crossbeam, with at least one tubular portion with a cross-section closed in at least one of said first or second ends, adapted to be demolded in the longitudinal direction of the crossbeam.

Owner:AUTOTECH ENG SL

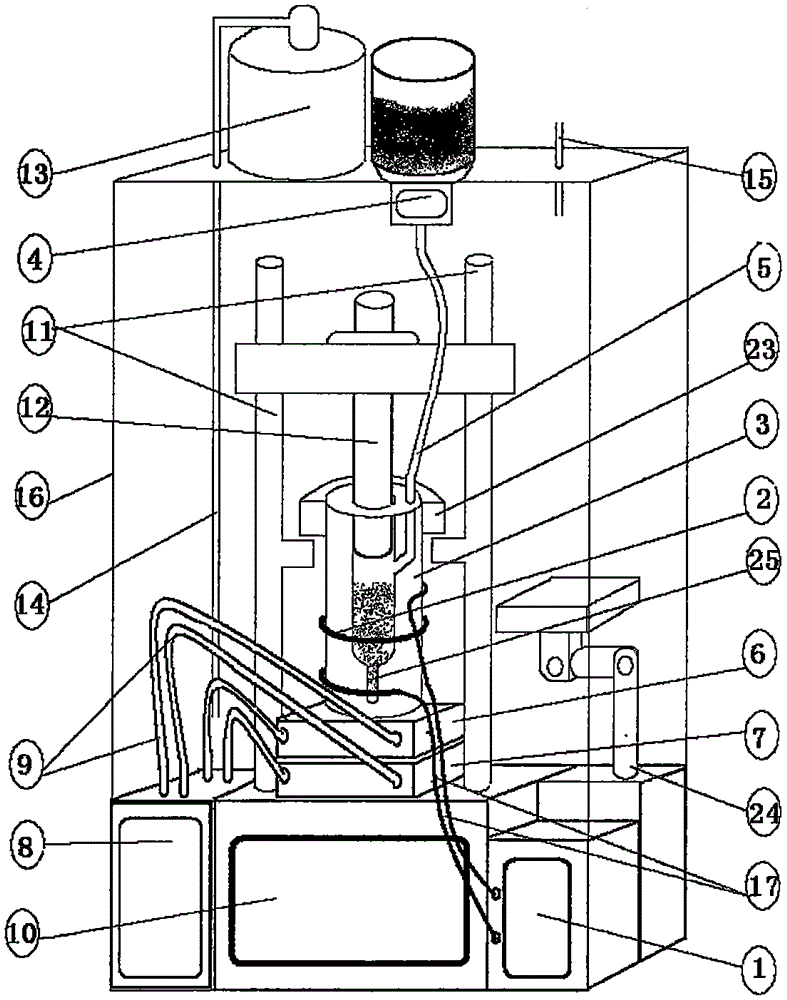

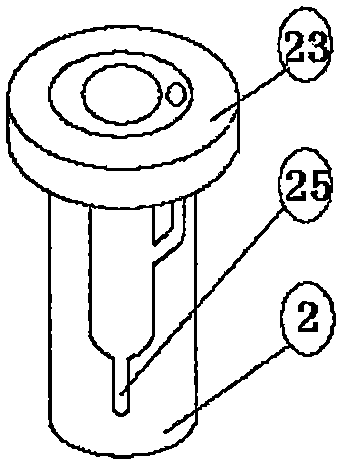

Manufacturing technology and device for shell of amorphous alloy watch

InactiveCN105344964ASolve the problem of rapid liquefactionSolve the problem of rapid solidification and one-shot moldingPressure die castingSlipcasting

The invention discloses a manufacturing technology and device for a shell of an amorphous alloy watch and belongs to the technical field of metal casting. The manufacturing device is composed of a raw material melting system, a mold system, a pressure casting system and a non-vacuum system. The non-vacuum amorphous alloy material machining device is designed through a vertical pressure casting technology. The raw material melting system is used for achieving the purpose of fast liquefying of amorphous alloy. The mold system is used for systematically achieving the purpose of fast solidification and one-time molding of the shell of the watch. The vertical pressure casting system is used for achieving the purpose that amorphous alloy liquid is rapidly and perpendicularly pressed into a mold cavity of the shell of the watch, and the problem that quality is affected due to bubbles generated in a casting is solved. The non-vacuum system is used for achieving the purpose of insulating air in the melting and pressure casting processes. The manufacturing device for the shell of the amorphous alloy watch is made of granular amorphous alloy raw materials containing zirconium, aluminum, copper, nickel and zinc, and the manufactured shell of the watch has the gloss of precious metal, namely platinum and is high in hardness and invariant in color. The device is suitable for being used as a universal device for manufacturing amorphous alloy products through one-time molding.

Owner:刘南林

Lead-free free-cutting silicon brass alloy

The present invention supplies a lead-free free-cutting silicon brass alloy with high zinc which preferably comprises 35.0 to 42.0 wt % Zn, 0.1 to 1.5 wt % Si, 0.03 to 0.3 wt % Al, 0.01 to 0.36 wt % P, 0.01 to 0.1 wt % Ti, 0.001 to 0.05 wt % rare earth metals selected from the group consisting of La and Ce, 0.05 to 0.5 wt % Sn, and / or 0.05 to 0.2 wt % Ni, and the balance being Cu and unavoidable impurities. The invented alloy is excellent in castability, weldability, cuttability, electroplating properties, corrosion resistance, mechanical properties. The alloy is especially applicable in castings which need cutting and welding under low pressure die casting, such as castings for faucet bodies in the water supply system. The alloy is also suitable for use in components which are produced from casting ingots by die forging.

Owner:XIAMEN LOTA INT CO LTD

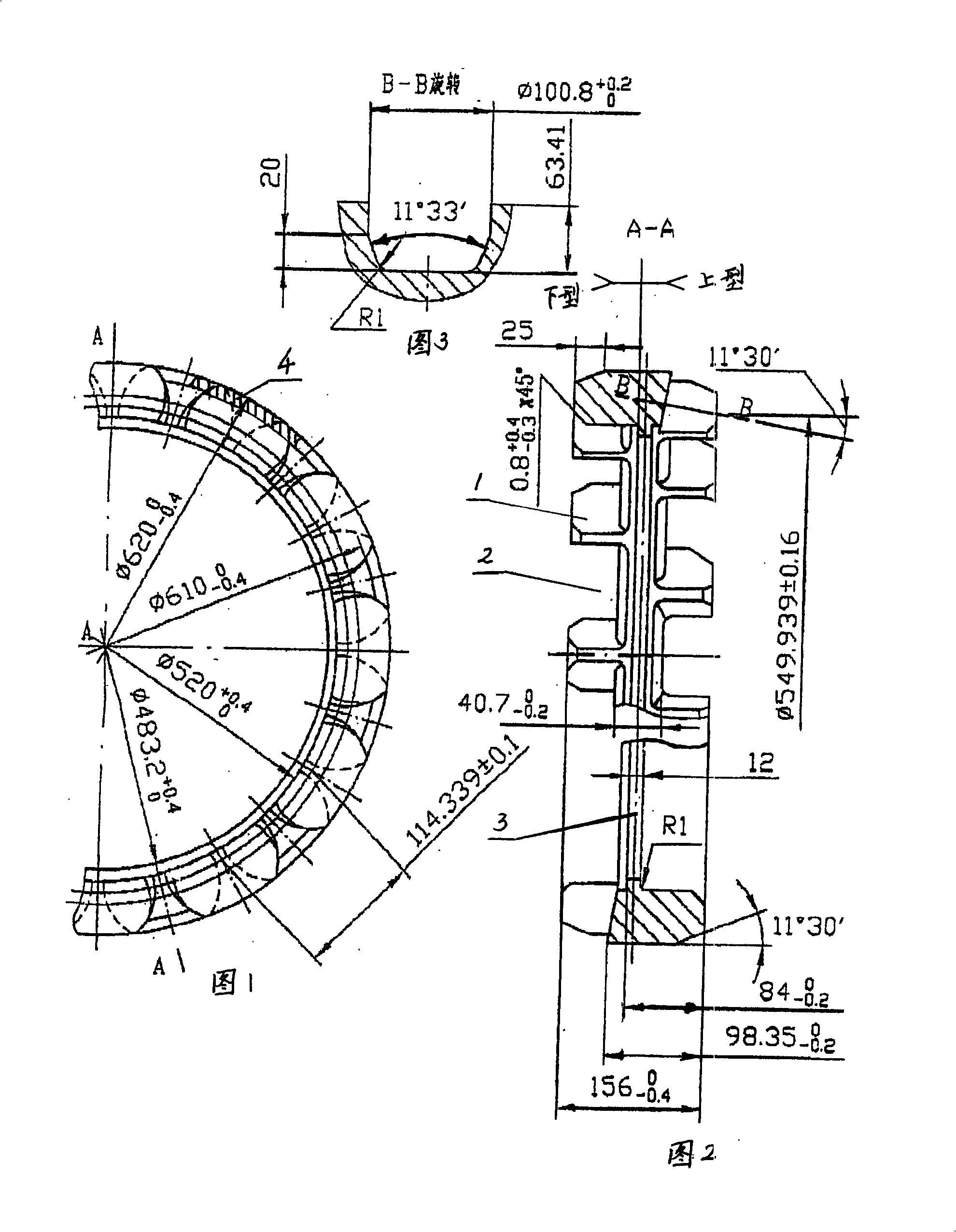

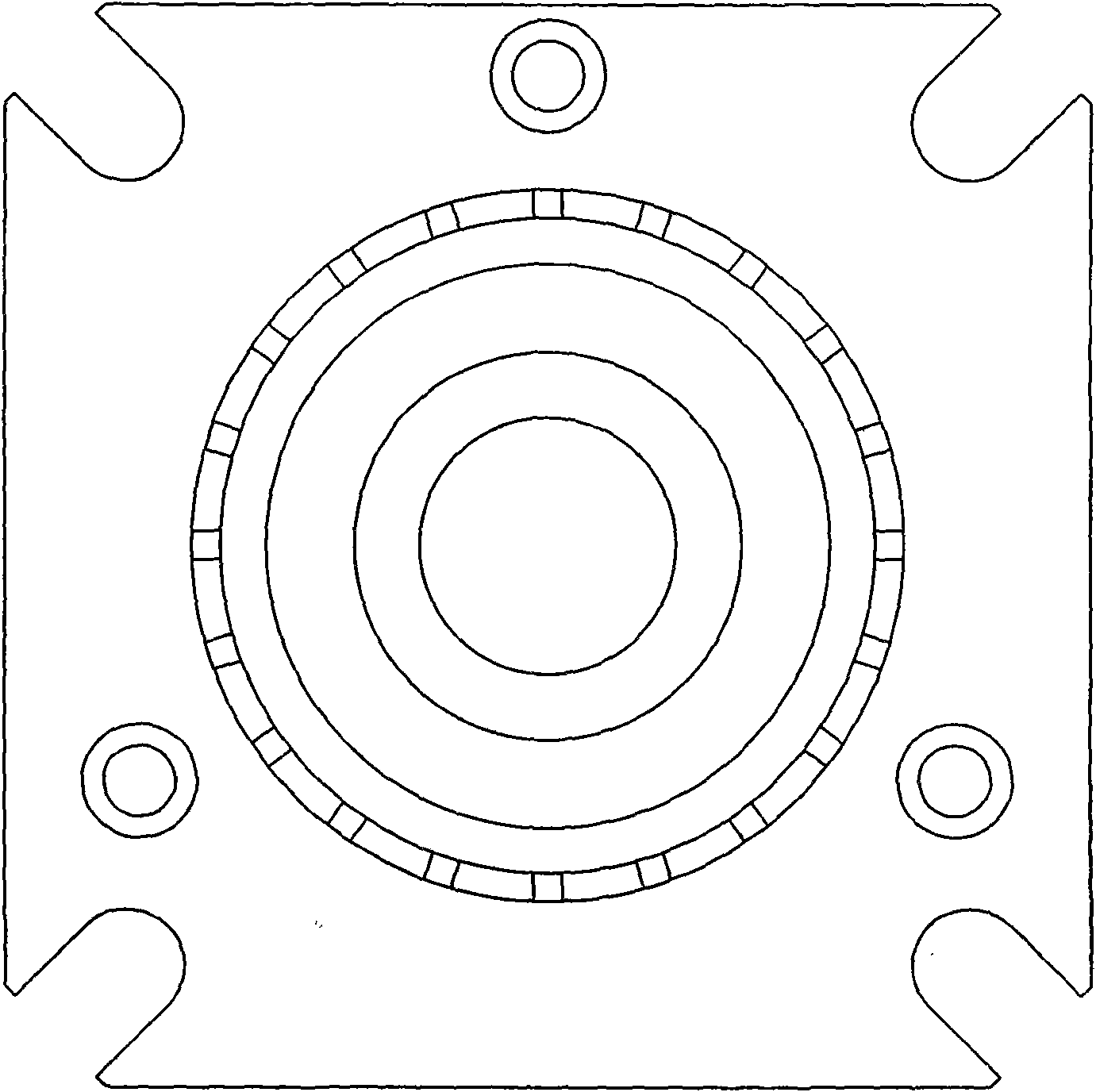

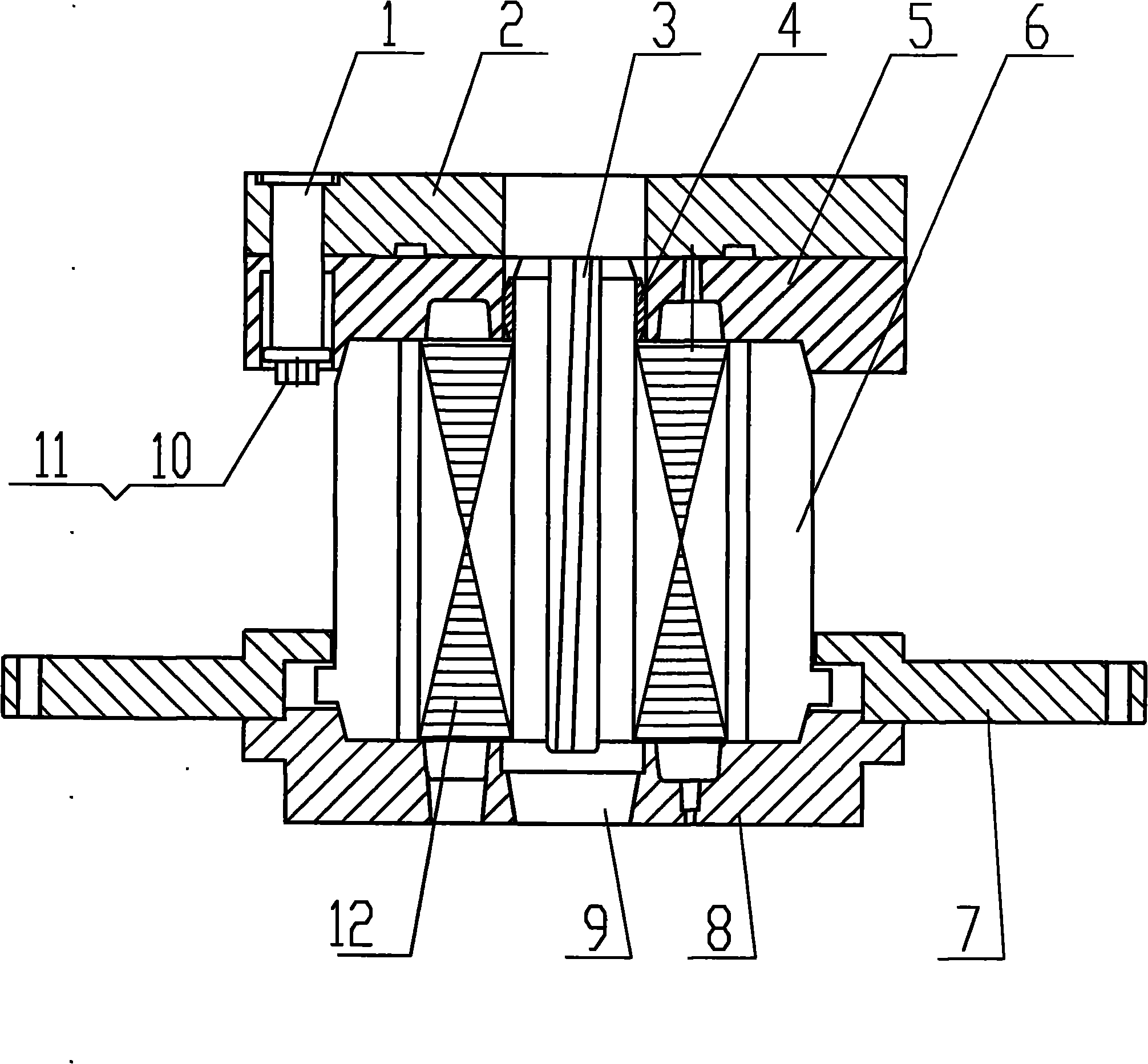

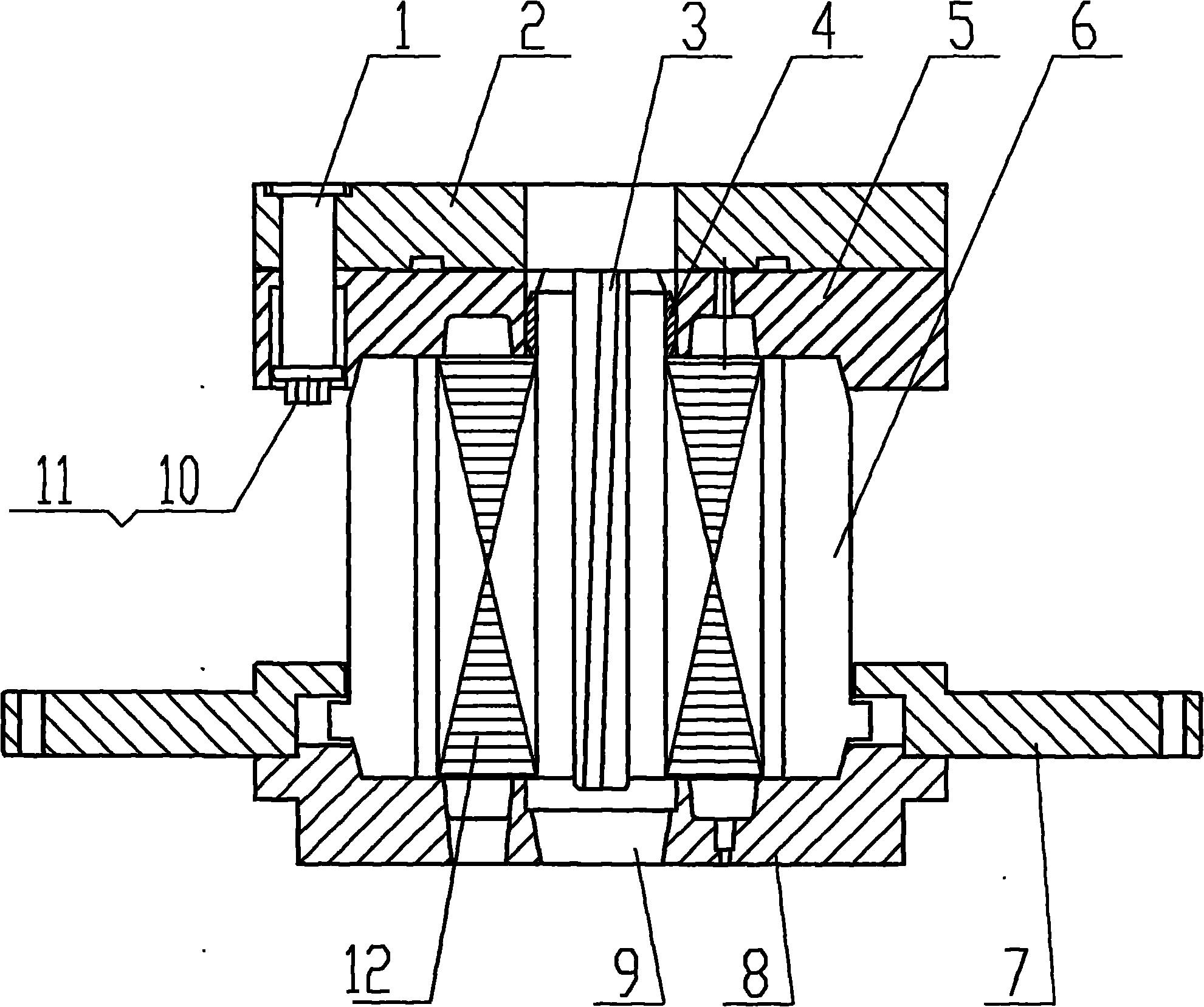

Motor rotor pressure cast aluminium die

InactiveCN101934360ASimple structureCompact structureManufacturing stator/rotor bodiesEngineeringCushion

The invention relates to a motor rotor pressure cast aluminium die comprising an upper die part, a lower die part and a rotor core part, wherein the upper die part comprises a guide post, a cushion plate, an upper die, a washer and a bolt, the upper die is connected with the cushion plate by the guide post, and one end of the guide post is fixed by the washer and the bolt; the lower die part comprises a middle die, a pressure plate and a lower die, wherein the middle die and the pressure plate are respectively arranged into an inner hole and an outer circle position of the lower die; the rotor core part comprises a tippy key, a guide sleeve, a dummy spindle and a rotor core, wherein the tippy key is inlaid into a groove of the dummy spindle, the dummy spindle is arranged into a positioning hole of the lower die, and the rotor core is sleeved into the dummy spindle when being guided by the tippy key and is sleeved into the guide sleeve after reaching technological required weight. Because exhaust grooves are reasonably arranged on the cushion plate of the motor rotor pressure cast aluminium die, air and aluminium-water residual gas are effectively discharged in the motor rotor pressure cast aluminium die in order to solve a cast aluminium roller shrinking phenomenon; and when demoulding, a cast aluminium roller is ejected by a pressure die casting machine, and the middle die automatically stays into the lower die to reduce labor intensity of workers and increase production efficiency.

Owner:WUXI ZHONGDA MOTORS

Support Crossbeam For An Instrument Panel

ActiveUS20080067835A1Improve the immunityIncrease in sizeSuperstructure subunitsVehicle cleaningMobile vehicleSteering column

The invention relates to a support crossbeam for an instrument panel to be assembled between two side elements of a frame of an automotive vehicle next to a front part of an interior. The crossbeam integrates several anchoring and supporting configurations for the steering column, several airbags, fuse boxes, ventilation system elements, sound equipment, among others, and is obtained by pressure die-casting of a light metal alloy, such a magnesium alloy, in an elongated single part extending between first and second ends. This single part has an open cross-section general profile, adapted to be demolded in a transverse direction of the crossbeam, with at least one tubular portion with a cross-section closed in at least one of said first or second ends, adapted to be demolded in the longitudinal direction of the crossbeam.

Owner:AUTOTECH ENG SL

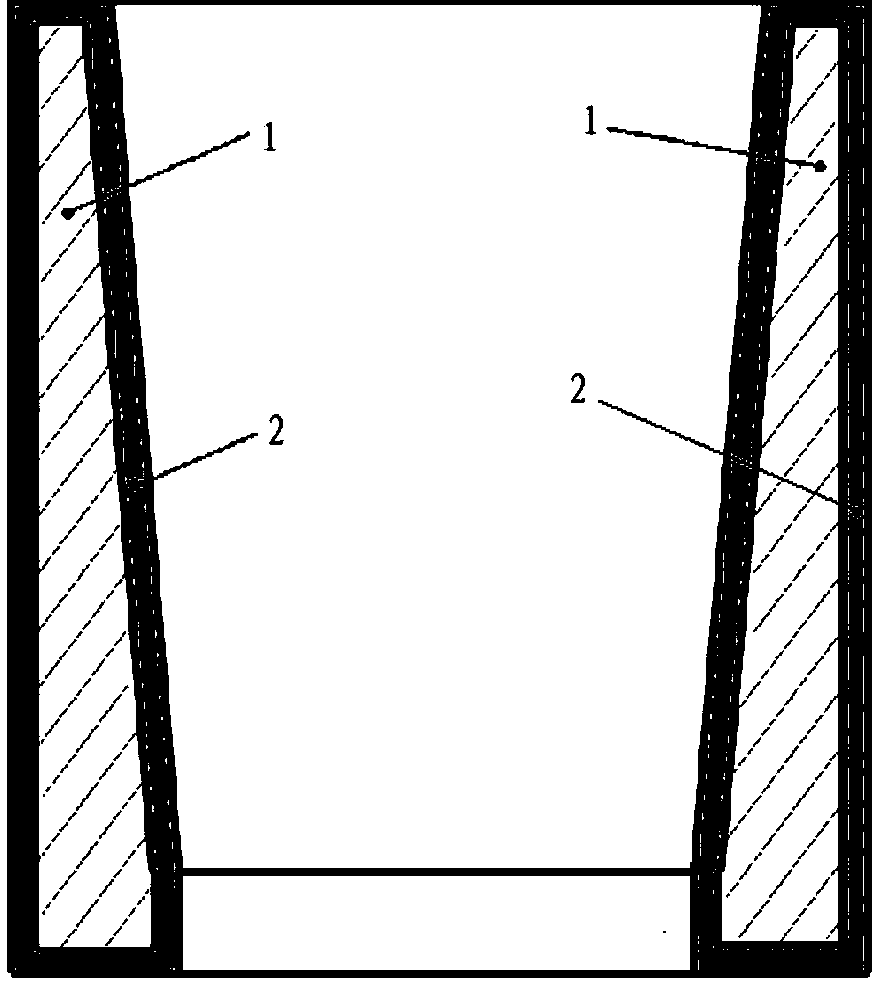

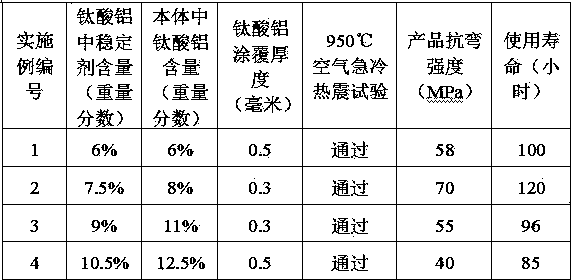

Ceramic sprue gate bushing for low pressure casting of aluminum alloy and manufacturing method thereof

ActiveCN104014764AHigh strengthSmall coefficient of thermal expansionCompression moldingCeramic coating

The invention discloses a ceramic sprue gate bushing for low pressure casting of aluminum alloy and a manufacturing method of the ceramic sprue gate bushing for low pressure casting of aluminum alloy. The bushing is tubular and comprises a bushing body and a coating layer, wherein the bushing body is made of composite ceramic materials of aluminum oxide and aluminum titanate, and the coating layer is an aluminum titanate ceramic coating layer. The manufacturing method includes the steps that first, aluminum oxide raw material powder, titanium dioxide raw material powder and stabilizing agents are fully mixed to prepare base powder; second, the base powder is roasted at the temperature ranging from 1350 DEG C to 1400 DEG C so that aluminum titanate powder can be obtained; third, the aluminum titanate powder is added into aluminum oxide raw material powder according to the weight fraction ranging from 6 percent to 13 percent to be fully mixed so that mixed powder can be obtained; fourth, after the mixed powder is palletized, compression molding is performed, and pre-sintering is performed; the aluminum titanate powder, PVA glue and water are mixed to form a sizing agent; sixth, the pre-sintered body is placed in the sizing agent, and soaked in the sizing agent and lifted out of the sizing agent several times, and then the pre-sintered body is dried; seventh, a sprue gate bushing containing the aluminum titanate coating layer is placed in a furnace and sintered at the temperature ranging from 1450 DEG C to 1650 DEG C and then the final product can be obtained.

Owner:江苏高鑫高温新材料科技有限公司

Method for preparing heating viscosity-reducing adhesive protective film

InactiveCN109294464AEasy to removeImprove bearing capacityFilm/foil adhesivesAldehyde/ketone condensation polymer adhesivesTectorial membraneFoaming agent

The invention discloses a method for preparing a heating viscosity-reducing adhesive protective film. The method for preparing the heating viscosity-reducing adhesive protective film comprises a heating viscosity-reducing adhesive, and is characterized in that the heating viscosity-reducing adhesive is foamed by mixing resin, a curing agent, a solvent, a self-expanding microsphere foaming agent, atoner and an OBSH foaming agent, The heating viscosity-reducing adhesive protective film comprises the following components in parts by mass: 25 to 60 parts of the resin, 0.5 to 10 parts of the curing agent, 30 to 60 parts of the solvent, 4 to 8 parts of the self-expanding microsphere foaming agent, 0.5 to 5 parts of the toner, and 0.5 to 2 parts of the OBSH foaming agent. The heating viscosity-reducing adhesive protective film finished product has strong bearing capacity, strong resistance to pressure die-casting, strong viscosity reduction after adhesion to FPC, and easy tearing, the protective film can be blown off the FPC by air blowing at a lower heating temperature (80 DEG C), the use effect is good, the heating temperature is higher, the tearing effect is better, and the upper limit of the use temperature can reach 250 DEG C.

Owner:东莞市工兴新材料科技有限公司

Energy-saving and environment-friendly high-temperature electric melting furnace

InactiveCN105444573AMeet the temperatureAvoid stickingControl devices for furnacesMonolithic liningsSemi openHearth

The invention discloses an energy-saving and environment-friendly high-temperature electric melting furnace. The energy-saving and environment-friendly high-temperature electric melting furnace comprises a control cabinet and a furnace body. The furnace body is composed of a hearth and a furnace lining. The hearth is composed of three insulating layers. A temperature measuring element is arranged on the back face of the furnace body. The hearth is of a semi-open type structure, and the hearth is filled with an aluminum oxide hollow ball plate. The high-frequency voltage transformation principle is adopted for saving electricity and energy, a plurality of silicon-molybdenum rods or silicon-carbide rods are used for heating, the temperature rise is fast, the effect is good, the high temperature of 1,600 DEG C can be generated, and the requirement for the temperature of pressure casting or crystal glass raw material smelting is highly met. A corundum plate, a silicon-carbide plate and a silicon oxide plate or a graphene plate are arranged in the hearth, crystal raw materials can be prevented from being attached into the hearth in the smelting process, and the cleanliness and transparency of crystal glass in the sintering process is guaranteed; meanwhile, the multiple insulating layers are arranged, dissipation of heat is effectively reduced, and resources are saved; and the external temperature of the furnace body is very low, and potential safety hazards of scalding are reduced. Noise is avoided during electric heating work, and the effects of safety, energy saving and environment friendliness are truly achieved.

Owner:聂晓彬 +1

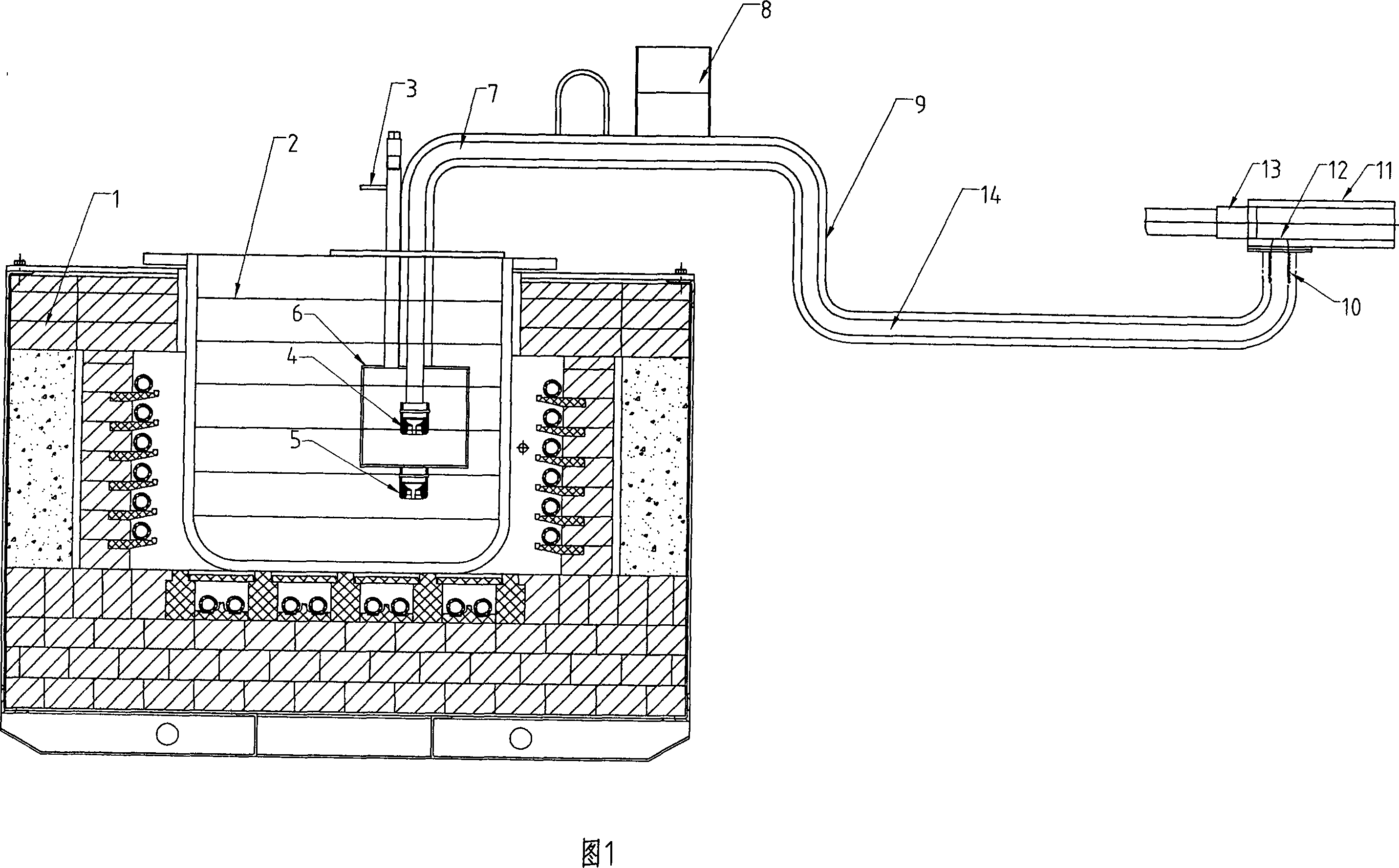

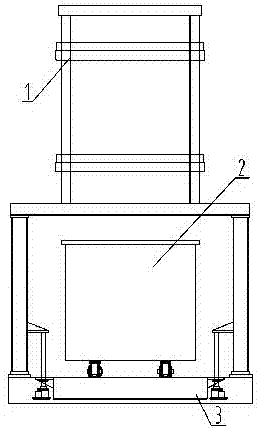

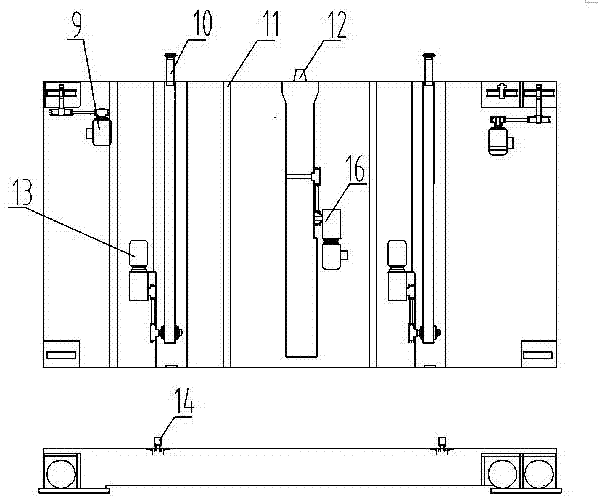

Low-pressure die casting machine with liftable and changeable heat preserving furnace

A low-pressure die casting machine with a liftable and changeable heat preserving furnace consists of a low-pressure die casting machine body (1), a transfer car and a smelting furnace (17), wherein a lifting mechanism and the heat preserving furnace (2) are arranged in the low-pressure die casting machine body (1); and the transfer car is parallel to the low-pressure die casting machine body (1) and the smelting furnace and is used for conveying an empty solid aluminum liquid heat preserving furnace from the smelting furnace to the die casting machine body. The low-pressure die casting machine is characterized in that a lifting table (3) is arranged under a table board of the low-pressure die casting machine (1); a variable-frequency reducing motor (4) and a machine table heat preserving furnace guide track (8) are arranged in the middle of the lifting table (3); and a worm gear (6) transfers a force in the height direction to push the lifting table (3) and the heat preserving furnace (2) to lift and fall together. By the low-pressure die casting machine with the liftable and changeable heat preserving furnace, automated operation is achieved in a whole process, the purity of pouring aluminum liquid in the low-pressure die casting machine is ensured, moreover, the service life of the heat preserving furnace is greatly improved, the working efficiency is greatly improved, and the labor intensity of workers is reduced.

Owner:JIANGSU TIANHONG MACHINERY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com