Lead-free free-cutting aluminum brass alloy and its manufacturing method

a free-cutting, aluminum brass alloy technology, applied in the direction of faucets and valves, etc., can solve the problems of increasing negative effects, inability to use brass alloys in drinking water supply systems such as faucets and valves, and increased susceptibility to hot and cold cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

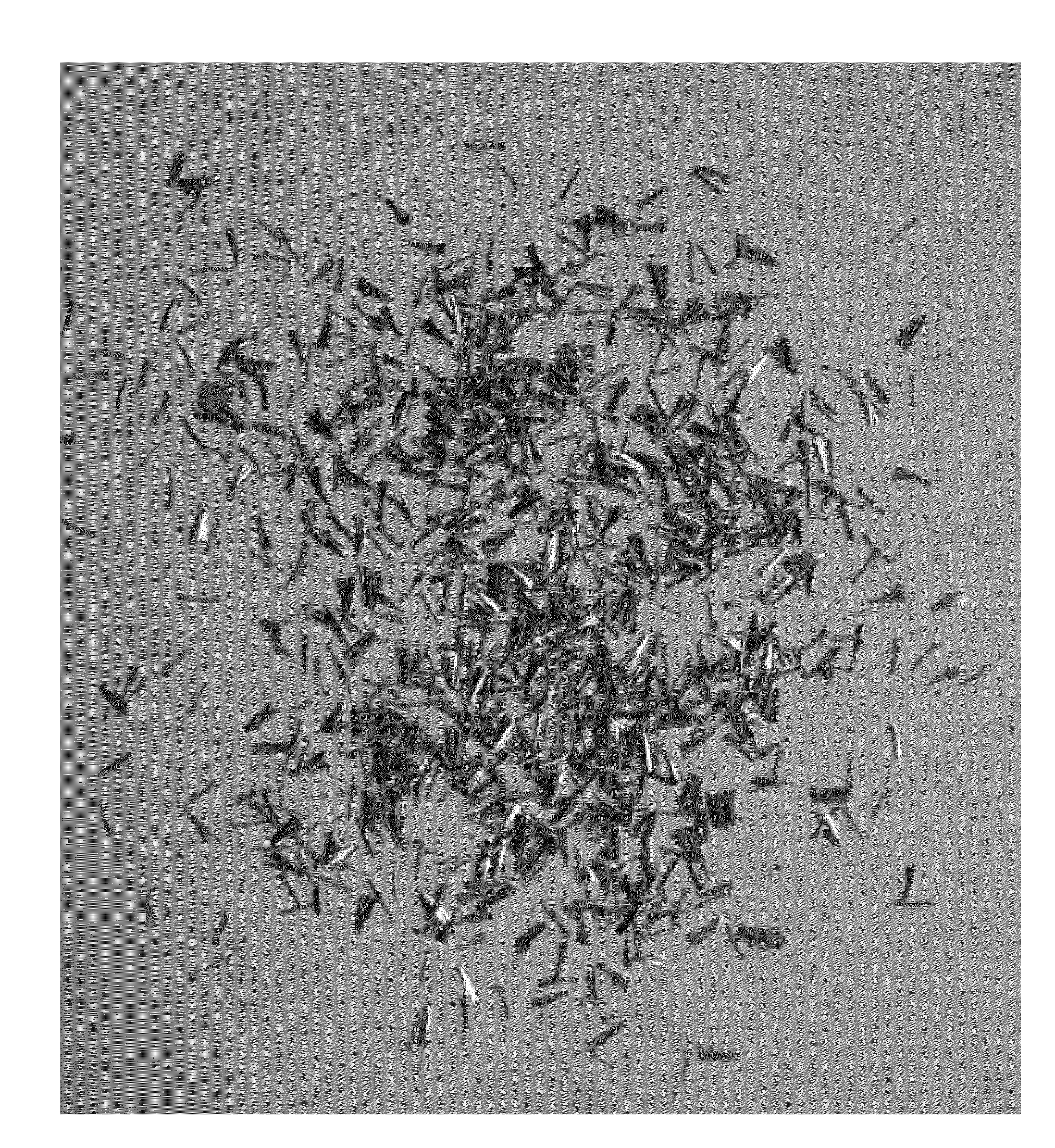

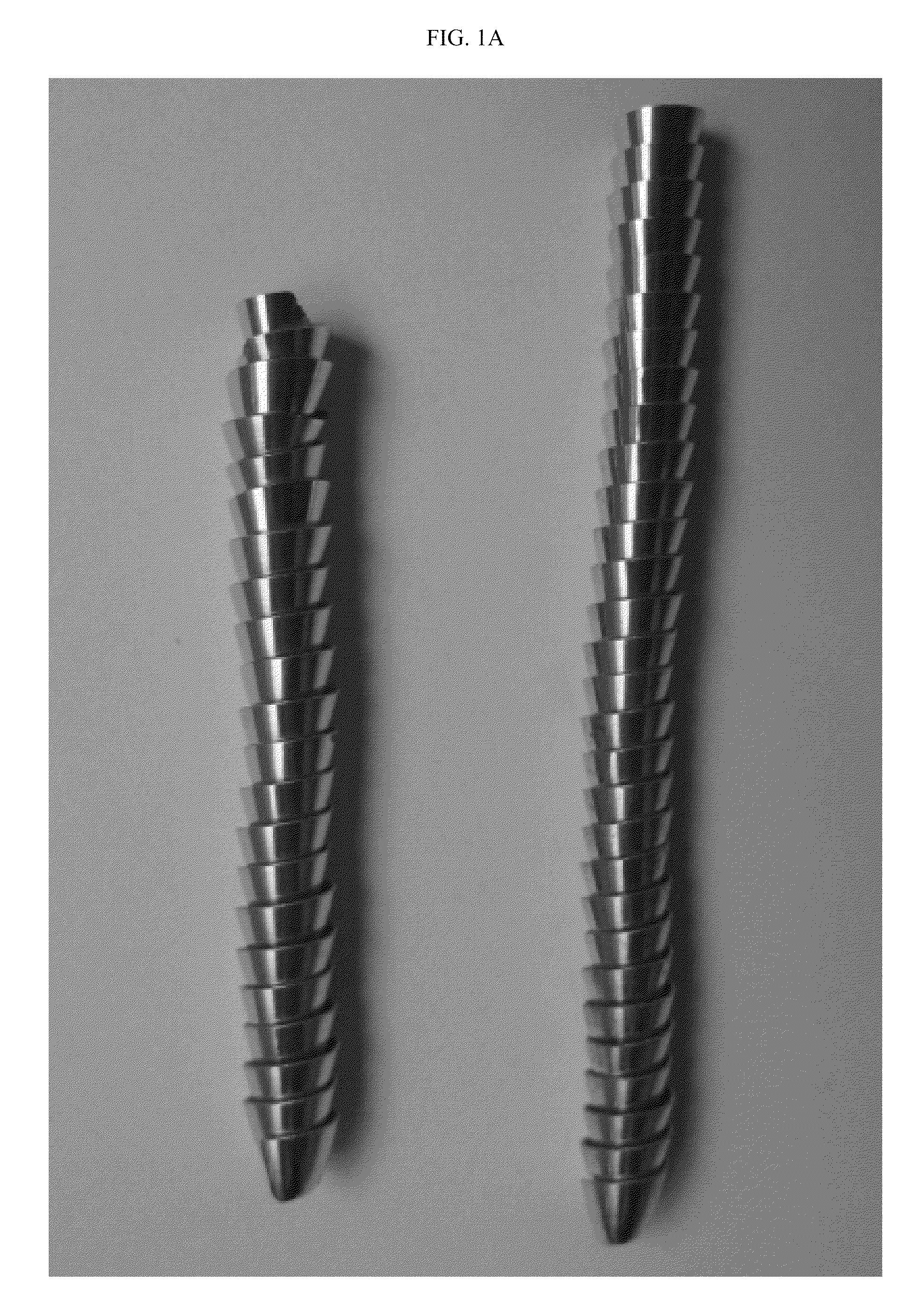

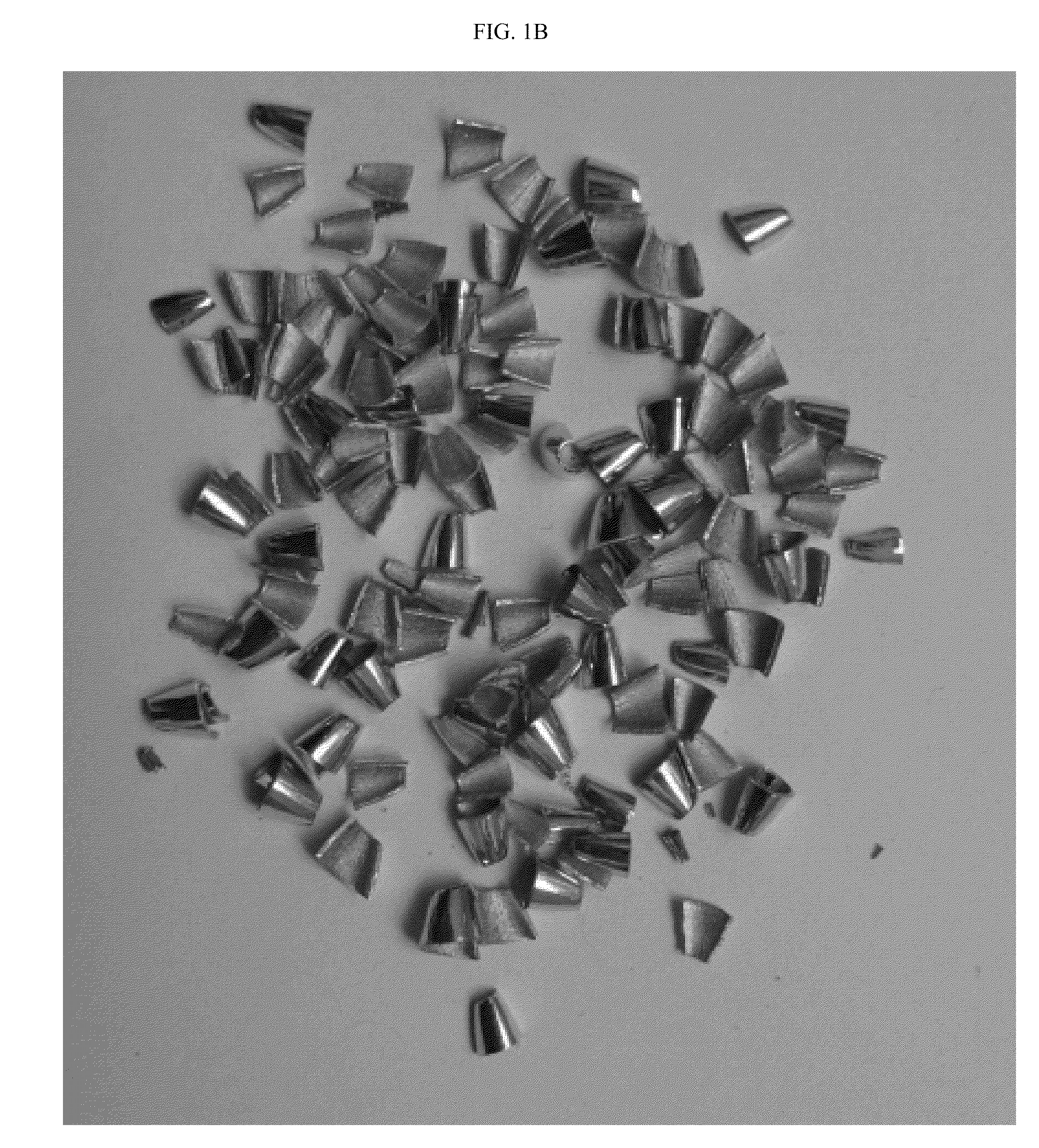

Image

Examples

examples

[0048]The alloy composition in examples is shown in Table 1.

[0049]

TABLE 1Alloy composition in examples (wt %)ExamplesCuAlBiSnSiMgBRePZn160.130.520.480.2750.12—0.0017 0.0050.0653Balance258.720.380.410.1650.230.090.0016—0.093Balance359.600.490.300.1330.1820.070.0017—0.0128Balance461.060.420.240.2420.130.105—0.010.051Balance561.270.430.290.2510.270.133—0.030.062Balance660.820.390.230.3180.240.08—0.010.075Balance760.260.420.370.3270.310.070.019 0.040.082Balance

[0050]1. Castability

[0051]Castability of the inventive alloy is measured by four kinds of common standard test samples for casting alloys.

[0052]Volume shrinkage test samples are used for measuring the shrinkage condition. If the face of the concentrating shrinkage cavity is smooth, and there is no visible shrinkage porosity in depth, it will be shown as “O.” It indicates the alloy has good fluidity, strong feeding capacity and high casting compactability. If the face of the concentrating shrinkage cavity is smooth but the height o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com