Pressure die casting mold for producing a casting

A technology of die-casting molds and castings, applied in the direction of die-casting molds, manufacturing tools, molds, etc., can solve the problems of cost, manufacturing and processing troubles, and achieve the effect of simplifying processing and speeding up manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

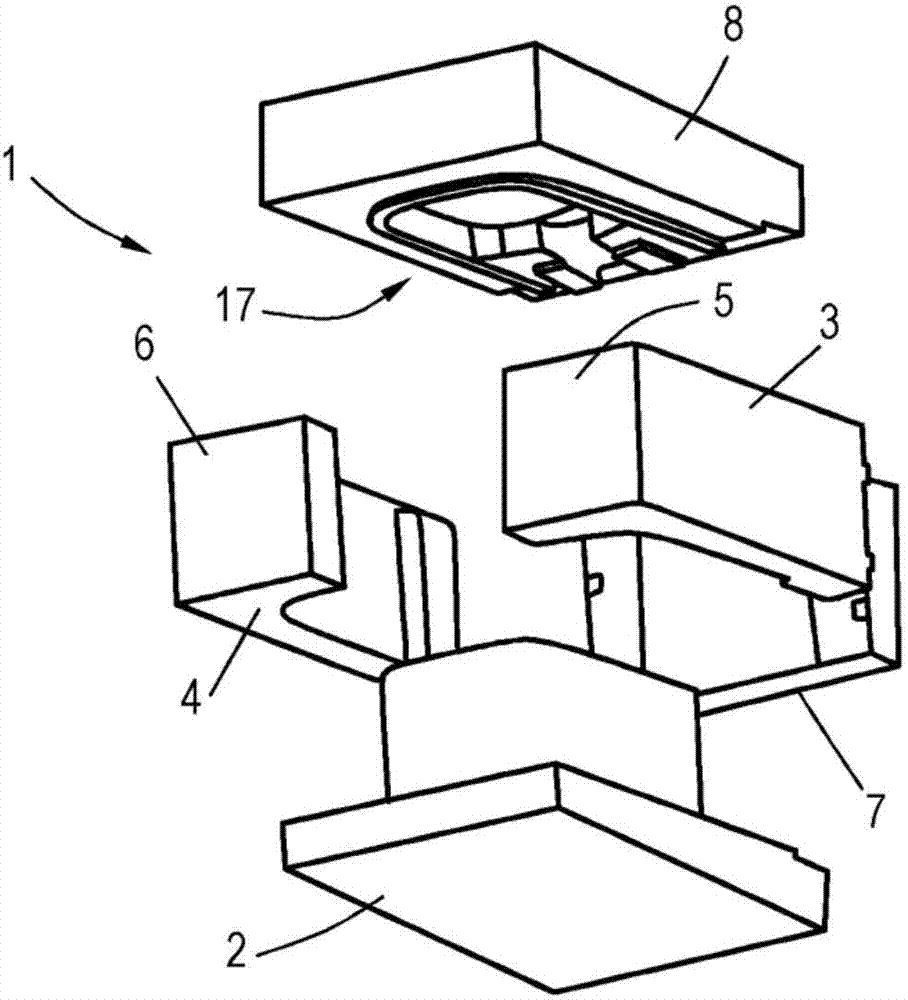

[0030] figure 1 An injection molding die 1 according to the invention is shown in an exploded view, comprising a bottom part 2, two side parts 3, 4, as well as a rear wall 7 and a cover part 8, on which the halves of the front wall are respectively arranged 5,6. In the closed state, the mold parts define a cavity in which a cast part is produced, said cast part comprising a water ring and a water reservoir, wherein the two form a one-piece cast part.

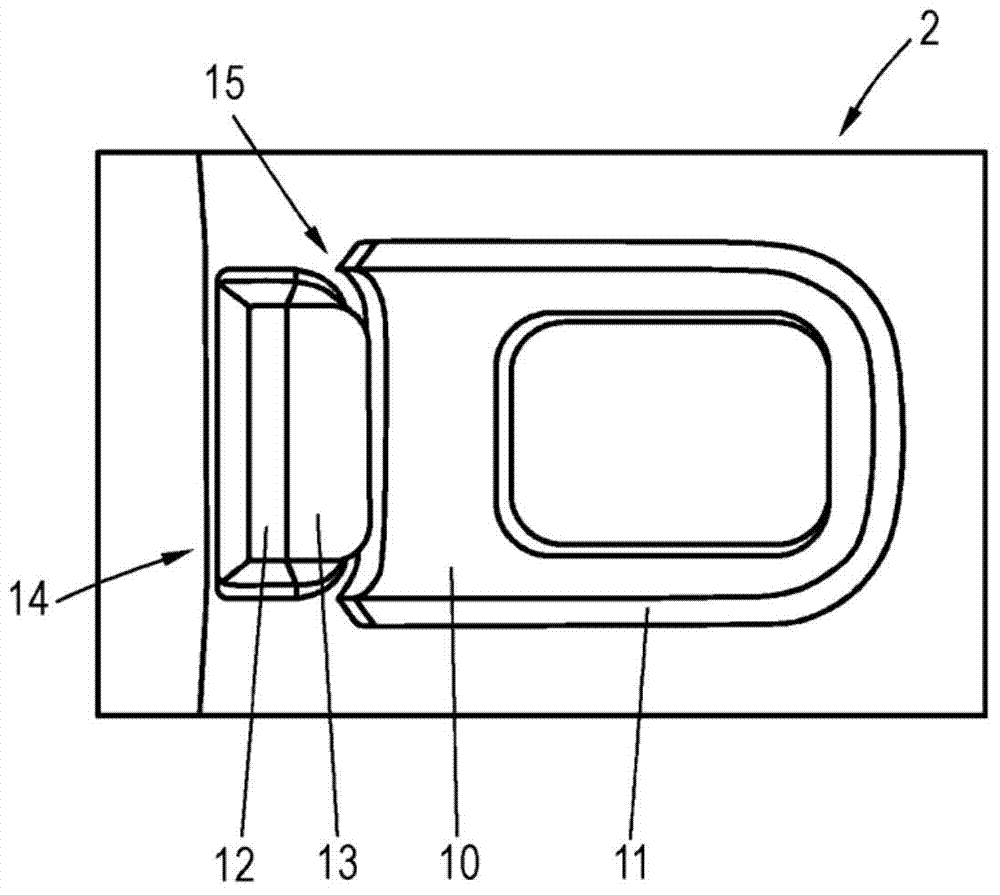

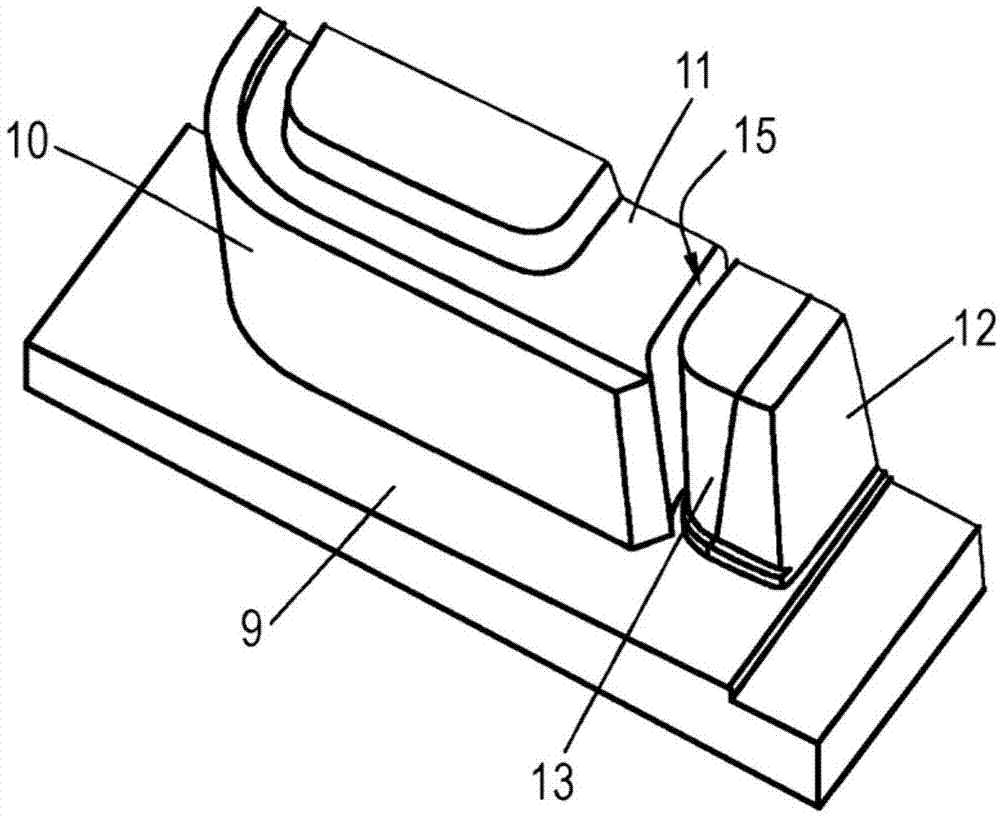

[0031] Figures 2 to 4 The bottom part 2 is shown in plan view and sectional view. The bottom part consists of a base plate 9 and a shaped body 10 protruding from the base plate, the upper side of which is designed with a shaped structure 11 for forming a water ring. Adjacent to the shaped body 10 is a first wedge-shaped element 12 protruding outwards from the base plate 9 . Adjacent to this first wedge element, a detachable, ie separate, second wedge element 13 is arranged. The wedge elements 12, 13 complementarily form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com