Patents

Literature

270results about "Slip casting moulds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gel casting molding method based on gelose and ceramic slurry mixed solution

ActiveCN106079032ADoes not affect compactnessWith strengthSlip casting mouldsOrganic contentGel casting

The invention discloses a gel casting molding method based on a gelose and ceramic slurry mixed solution. The method comprises the specific steps that firstly, ceramic powder and a dispersing agent are added into water for preparing ceramic slurry with the solid phase volume fraction of 53-59%; then a gelose solution with the concentration of 3-4.5 wt% is added into the ceramic slurry, so that the pH value is regulated to 8-11, and the ceramic slurry is made even by means of ball-milling; the mixed slurry is injected into an imperforate mould for to be heated sufficiently after vacuum bubble removing is conducted; and then ceramic parts are obtained after cooling, drying and sintering are conducted. Due to the fact that the gelose solution and the ceramic slurry are mixed firstly and made even by means of ball-milling, and then are subjected to vacuum bubble removing and casting molding, bubbles are not generated in the process, and ceramic blanks are free of defects. By means of the method, the mixed slurry with the high solid phase content and the low viscosity can be prepared, and the compact ceramic parts in complicated shapes and with different sizes can be obtained after the blanks are sintered. In addition, the gelose is naturally macromoledular, the organic content in the blanks is low, and debonding is not needed; and the ceramic blanks have certain strength and can be processed to a certain extent before being sintered.

Owner:湖北迪洁膜科技有限责任公司

Single-surface pressure grouting forming method of ITO rotating target blank body and mold

ActiveCN106985261AUniform structureImprove uniformitySlip casting mouldsSurface pressureForming processes

The invention discloses a single-surface pressure grouting forming method of an ITO rotating target blank body and a mold. The mold is arranged on a rotating platform, and is provided with a cylindrical molding cavity inside for accommodating pulp; micro holes are formed in the mold wall on the inner side and the outer side of the cylindrical molding cavity; the pulp is injected in the cylindrical molding cavity of the mold; and when the mold rotates to form a centrifugating effect, compressed air is fed in the cylindrical molding cavity through the micro holes in the mold wall on the inner side of the cylindrical molding cavity for single-surface pressurization to the pulp from inside to outside, so that water in the pulp is discharged by the micro holes in the mold wall on the outer side of the cylindrical molding cavity to form the ITO rotating target blank body. The centrifugal grouting formation is adopted to combine with the single-surface ventilation pressurization and single-surface drainage modes; the pulp has no need to feed in the forming process; and the formed blank body is uniform in structure, cannot generate the interlayer defect, and further improves the density. The inner side of the formed cylindrical blank body cannot be bonded with the mold, so that the demolding yield rate is higher, and the process is simpler and more convenient.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

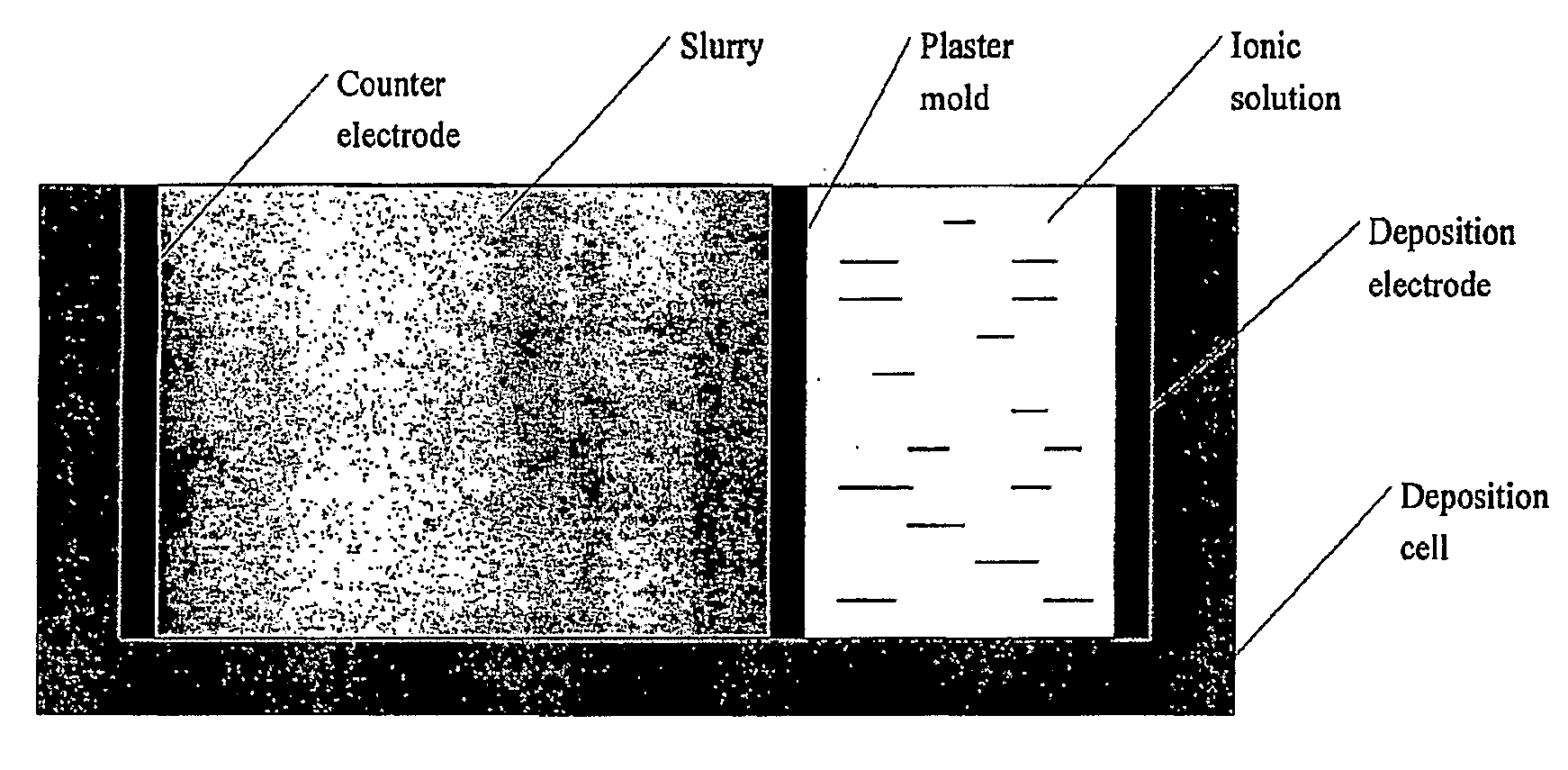

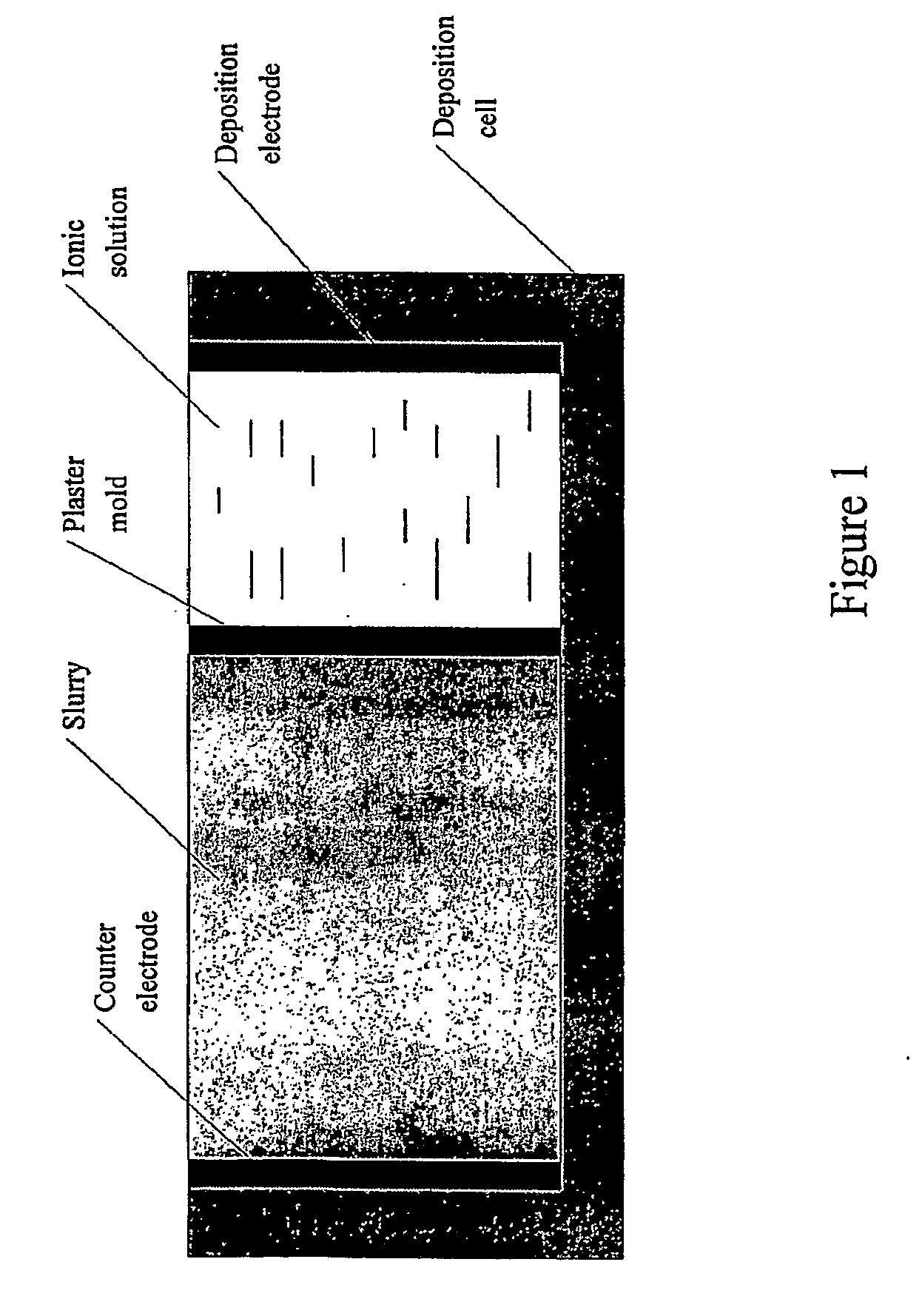

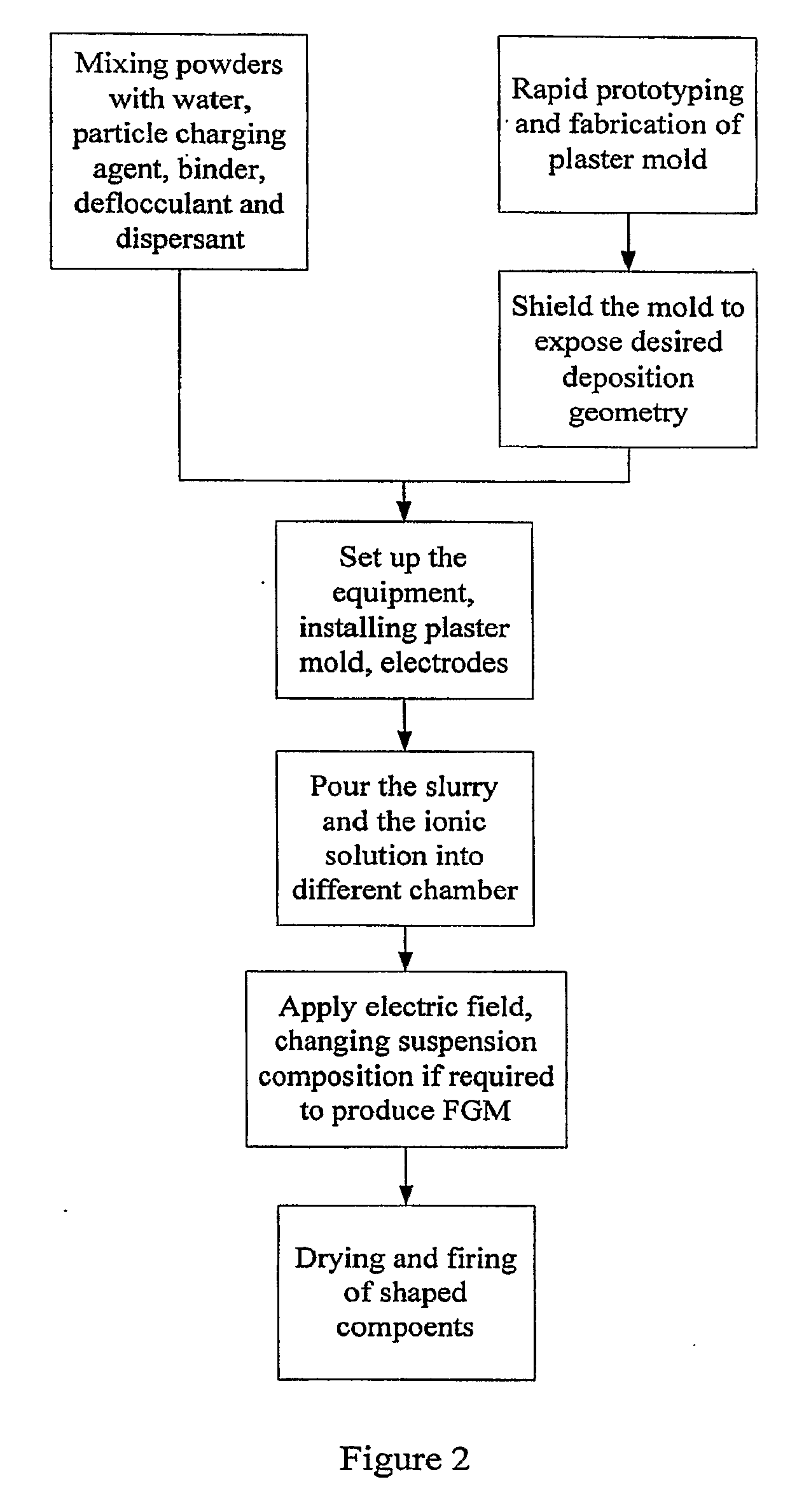

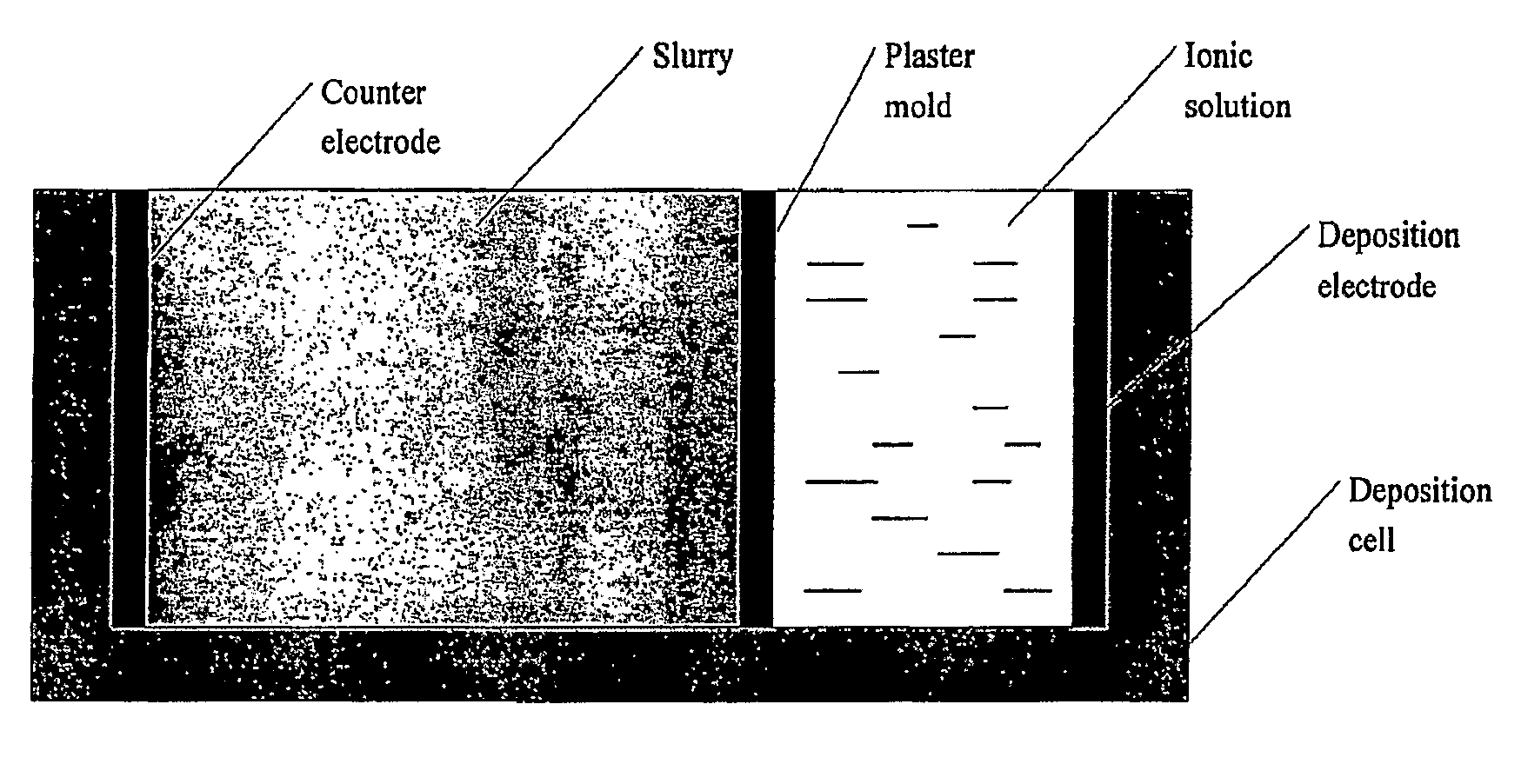

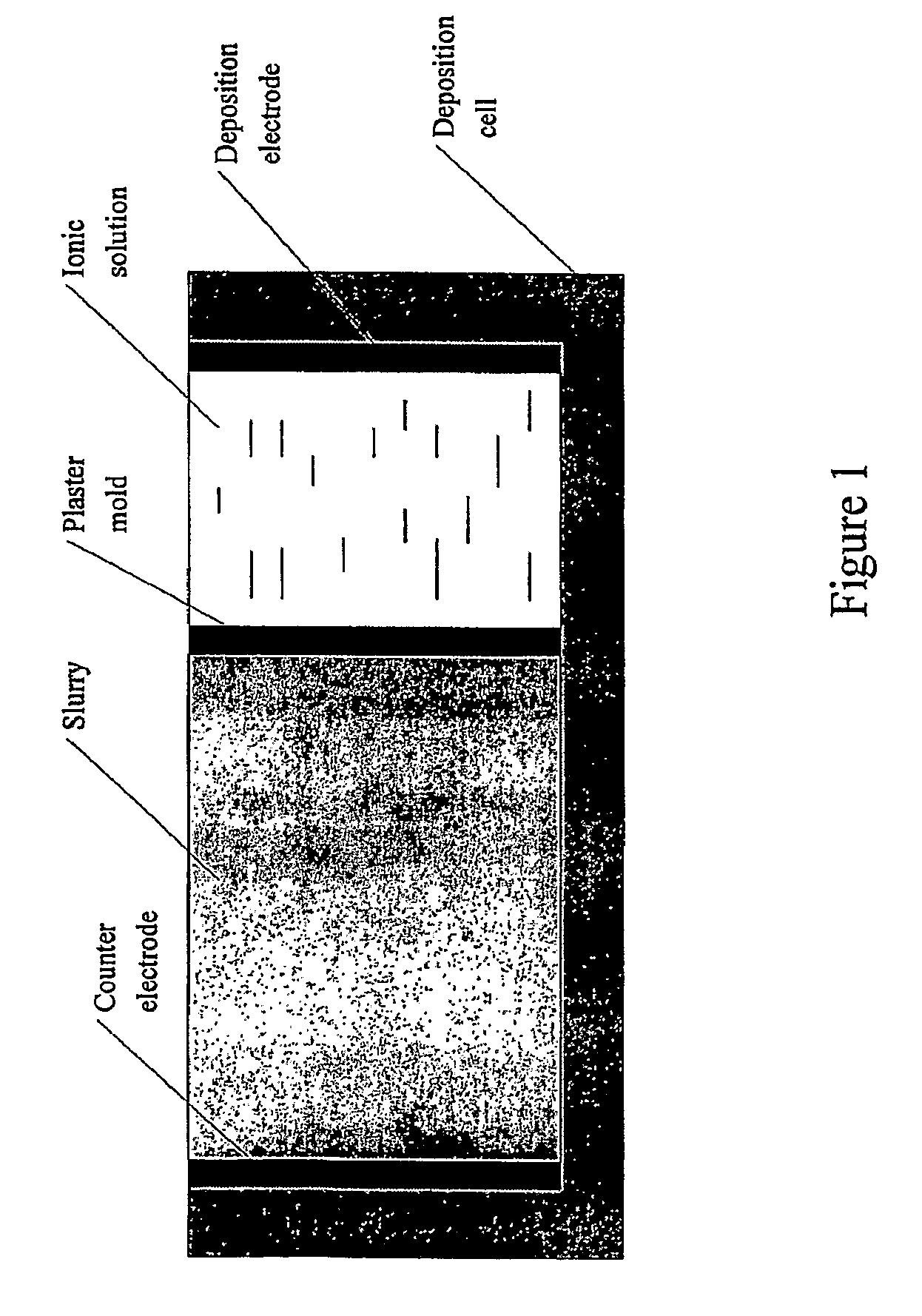

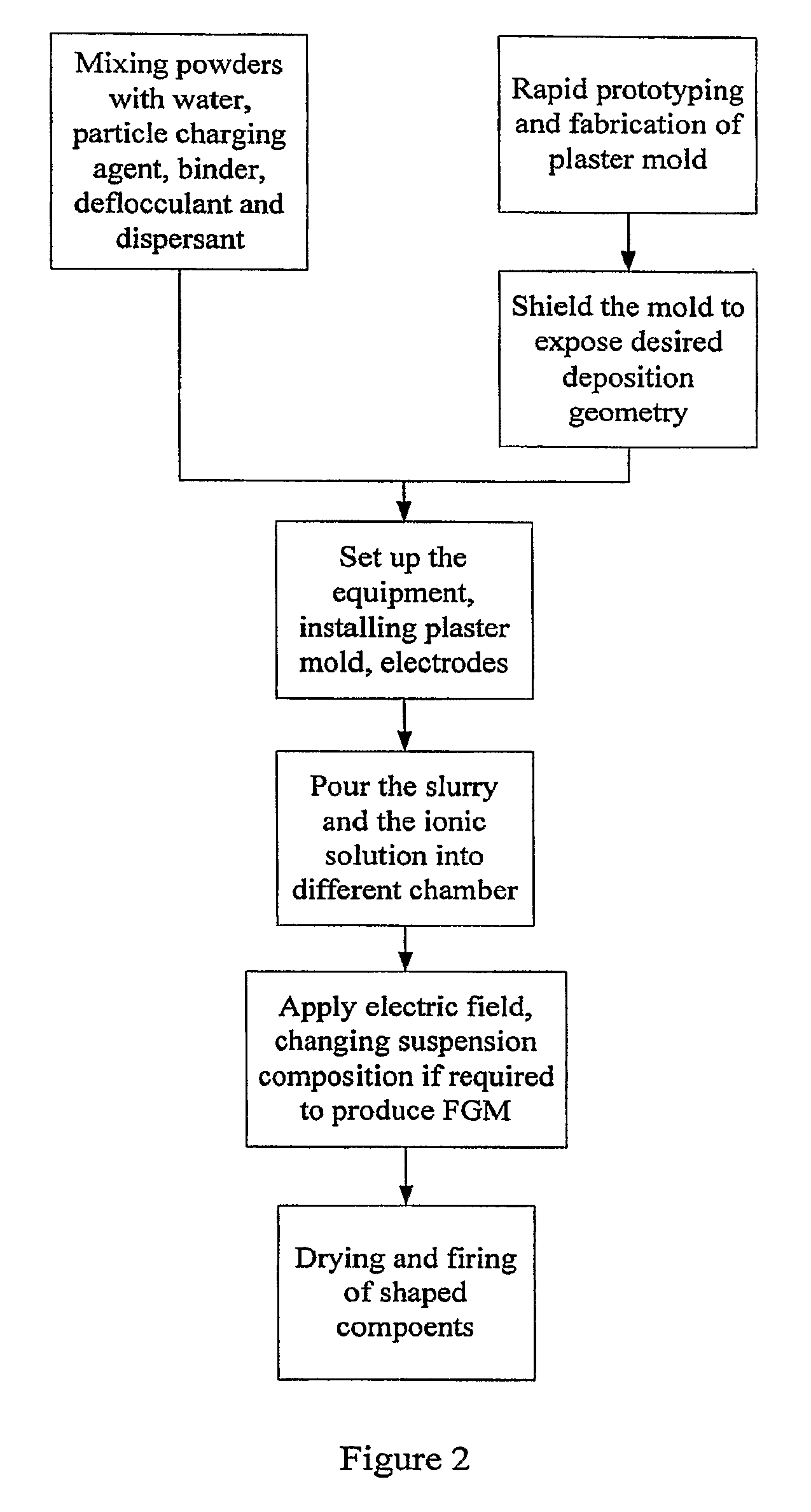

Hybrid slip casting-electrophoretic deposition (EPD) process

ActiveUS20090288952A1Well formedEliminate depositsElectrolysis componentsVolume/mass flow measurementEngineeringFunctionally graded material

The invention provides novel a hybrid slip casting-Electrophoretic Deposition (EPD) process which can be used to produce arbitrary shape geometries with controlled materials properties. The invention provides processes for the fabrication of Functionally Graded Materials (FGM) by a controlled Electrophoretic Deposition (EPD).

Owner:SAN DIEGO STATE UNIV RES FOUND

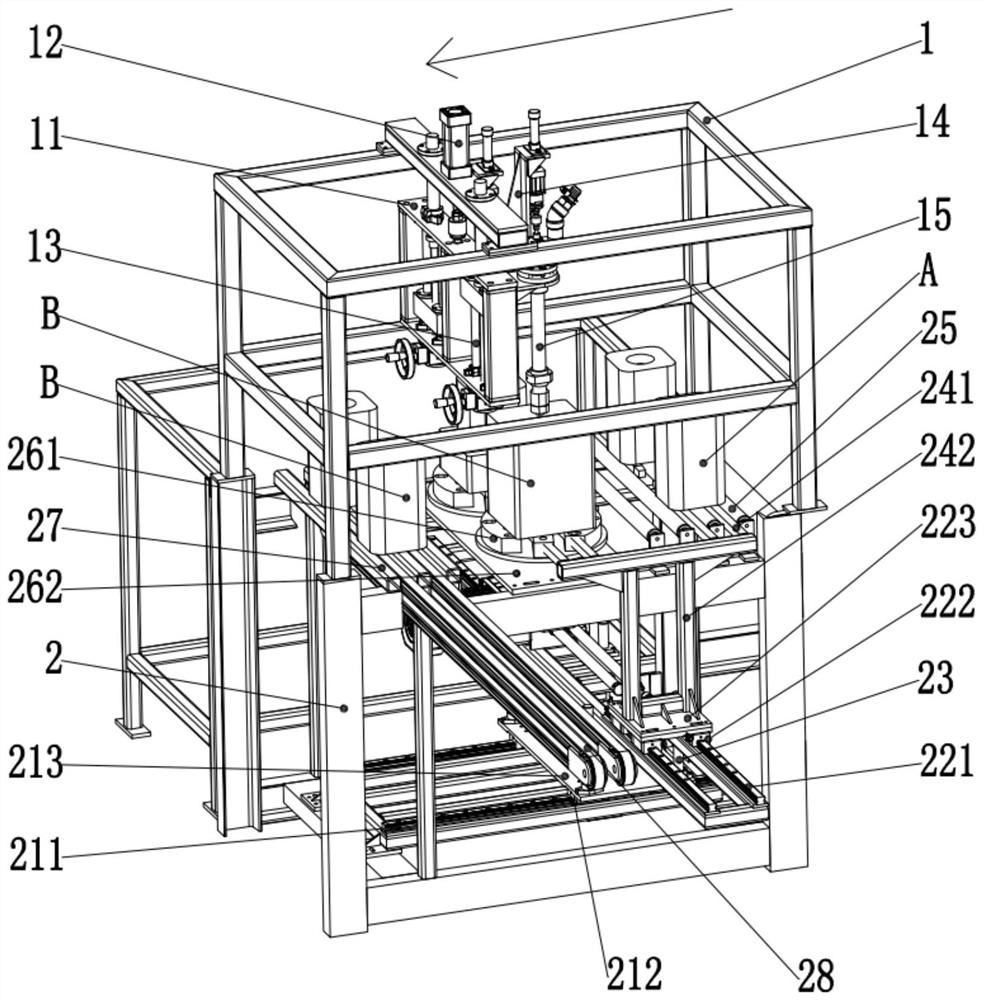

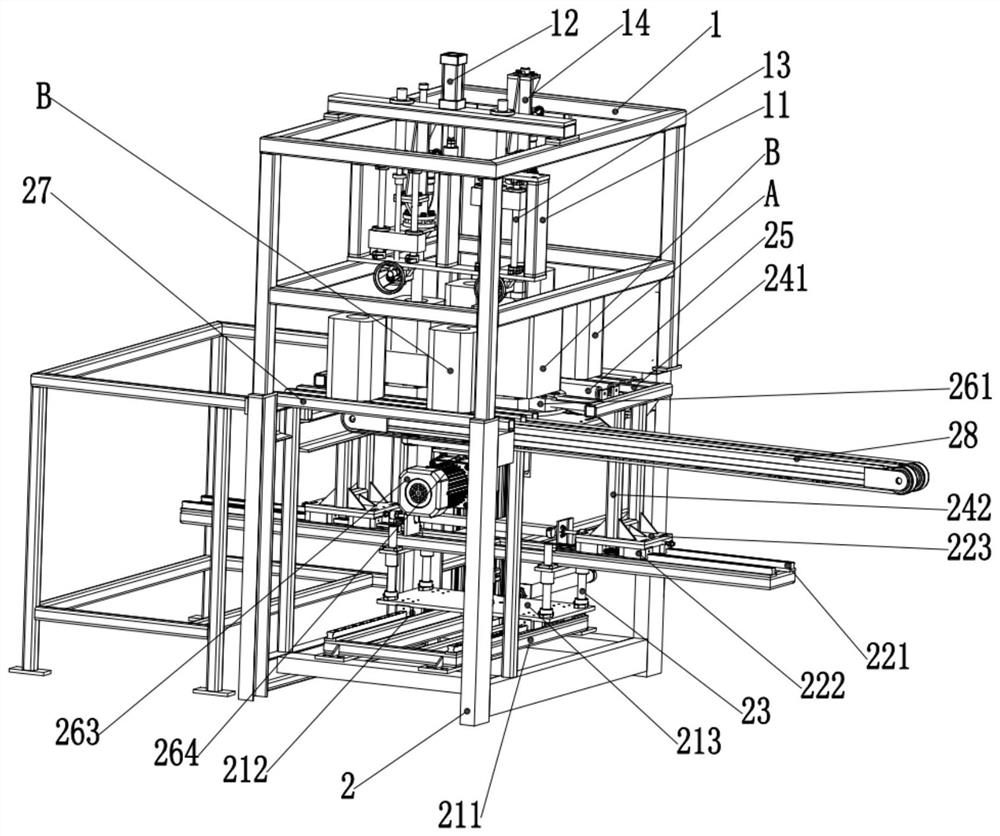

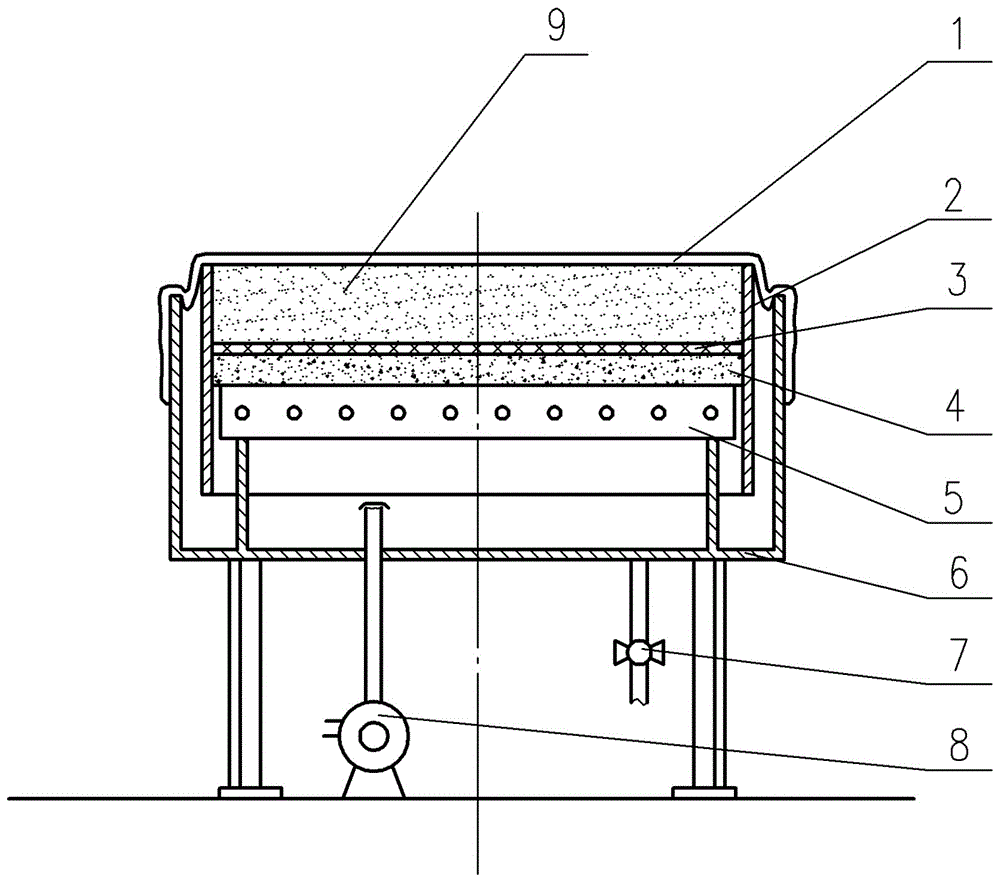

High-pressure grouting forming device for ceramic sanitary ware

PendingCN107042572AReduce labor intensityIncrease productivityMouldsFeeding arrangmentsAir pumpAtmospheric pressure

A high-pressure grouting forming device for ceramic sanitary ware comprises a rack, a grouting device, a forming mechanism and an air pressure device. The rack comprises a main frame, a bottom frame, guide rails and a pushing device. The guide rails are arranged above the bottom frame in parallel. The pushing device is arranged on one side of the main frame. The forming mechanism is arranged on the guide rails, and the forming mechanism and the pushing device are located on the same axis. The grouting device is arranged on one side of the rack. The air pressure device comprises an air pump and a strengthening air pipe. The compression air pump is connected with a pressure pulp tank and the strengthening air pipe through pipelines, and the strengthening air pipe is connected with the forming mechanism. Providing the high-pressure grouting forming device for the ceramic sanitary ware is the purpose, through operation of various procedures of die assembling, die stripping and blank stripping, the labor intensity of operators is relieved, and the production efficiency is improved; and meanwhile, in the die pressure applying forming process, residual water in pulp can be rapidly discharged through a water drainage mechanism, a die is made of porous resin, hydroscopicity is good, and the blank manufacturing efficiency is greatly improved.

Owner:佛山市鸣门卫浴家居有限公司

Ceramic slurry injection forming system

ActiveCN106313277AAvoid sizeAvoid stabilityCeramic shaping plantsAuxillary shaping apparatusSlurryVacuum pump

The invention provides a ceramic slurry injection forming system. When a slurry injection device injects slurry into a plaster mold, a movable supporting pipe rises up from the bottom of the plaster mold while being subjected to slurry injection, so that the phenomenon that air is mixed in slurry due to mutual collision of the slurry can be avoided during slurry injection; meanwhile, a rotating part drives the plaster mold to rotate to enable the slurry in the plaster mold to be uniformly distributed; a slurry supplementation device supplements the slurry to the plaster mold, so that the phenomenon of unstable size and thickness of a product due to the fact that the plaster mold is not full of the slurry because of various reasons in the slurry injection device is avoided; a drying device enables the plaster mold to absorb the slurry for forming; a main pipe in a slurry extraction part is connected with a vacuum pump, so that residual slurry in the plaster mold can be extracted; a slurry throwing part drives the plaster mold to move, so that a little of slurry extracted from the bottom of the plaster mold is thrown to the inner wall of the plaster mold so as to be absorbed by the inner wall; and therefore, the ceramic slurry injection forming system provided by the invention is high in automation degree and high in product quality, and is relatively clean in production and high in production efficiency.

Owner:QUANZHOU KUNTAI MACHINERY PRECISION MFG CO LTD

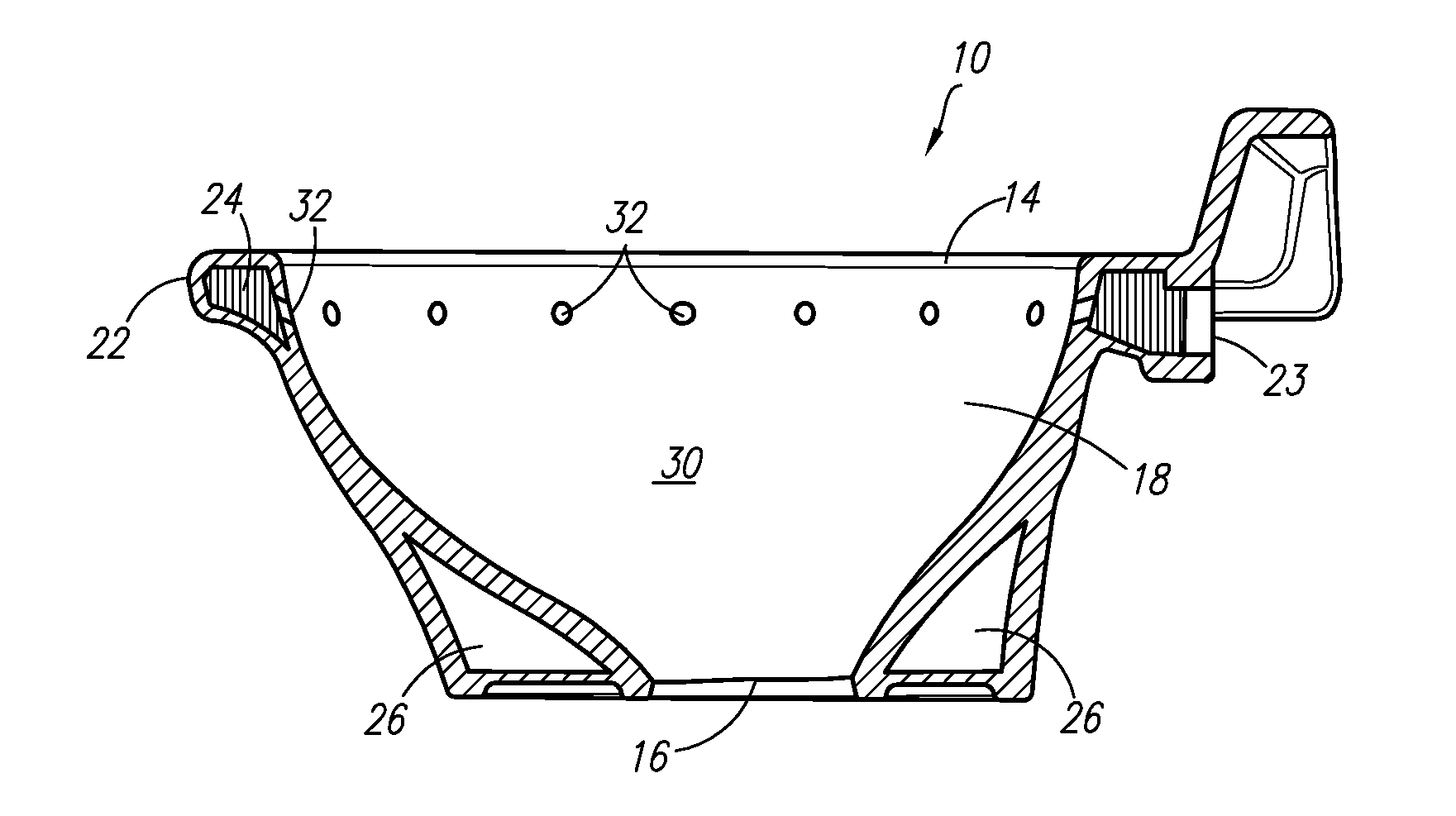

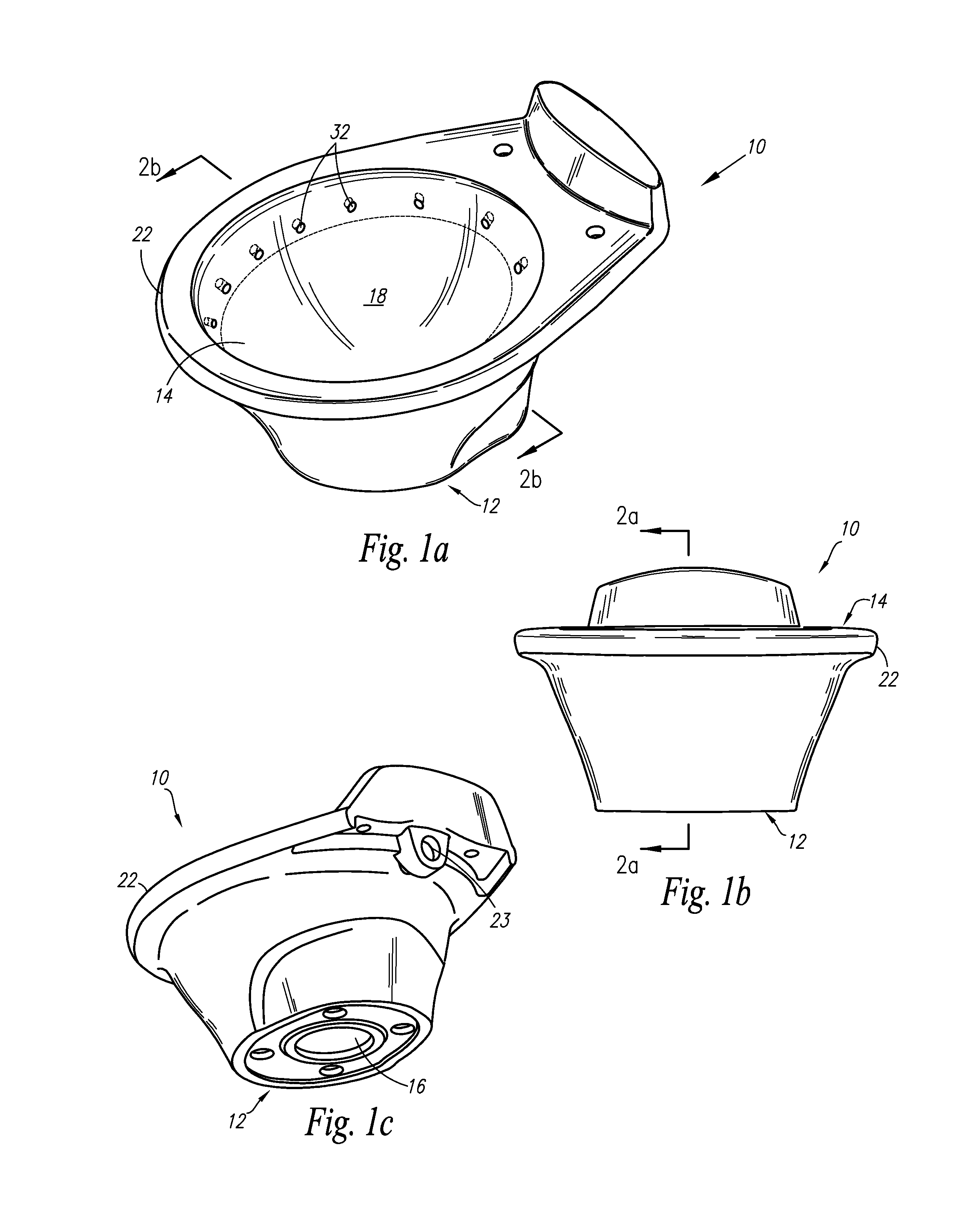

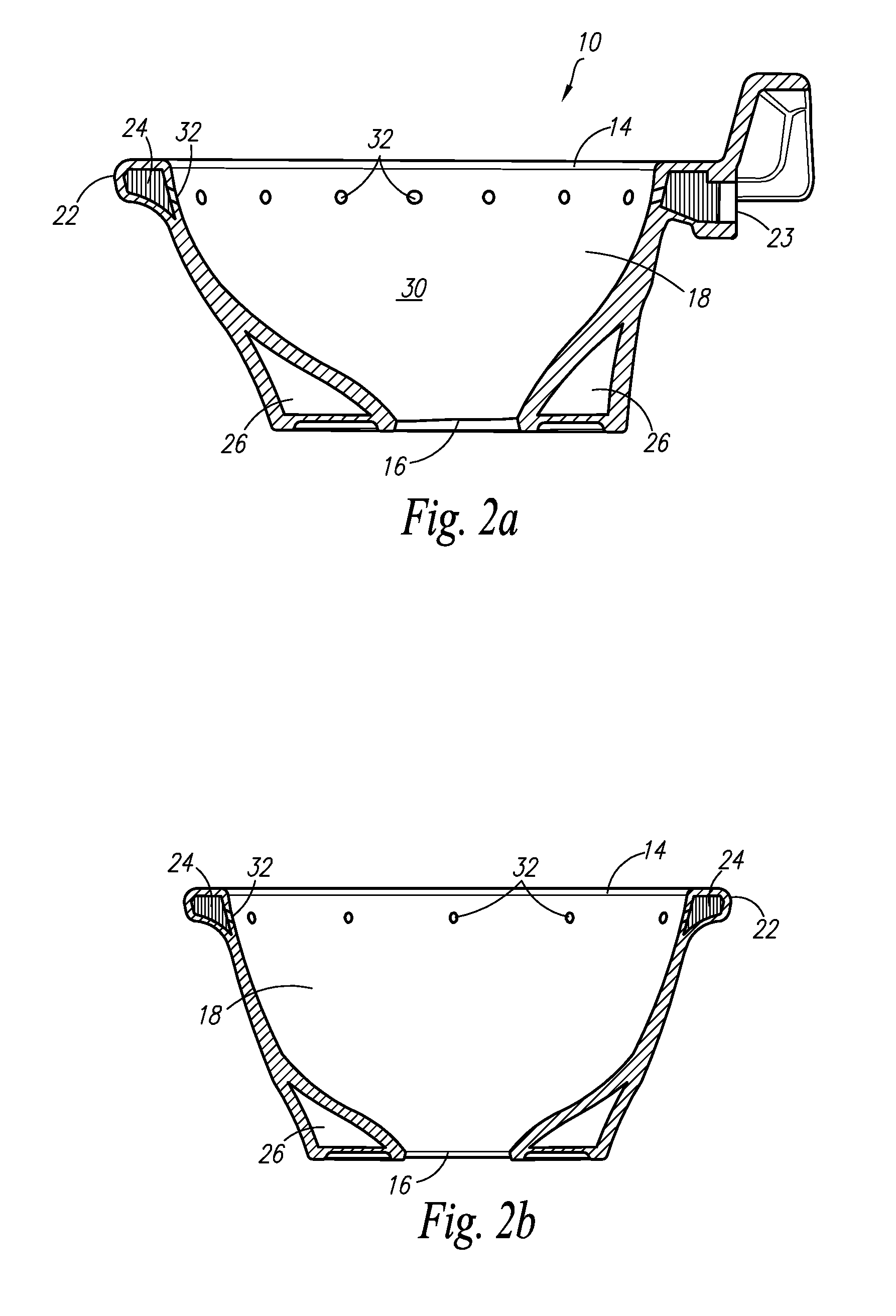

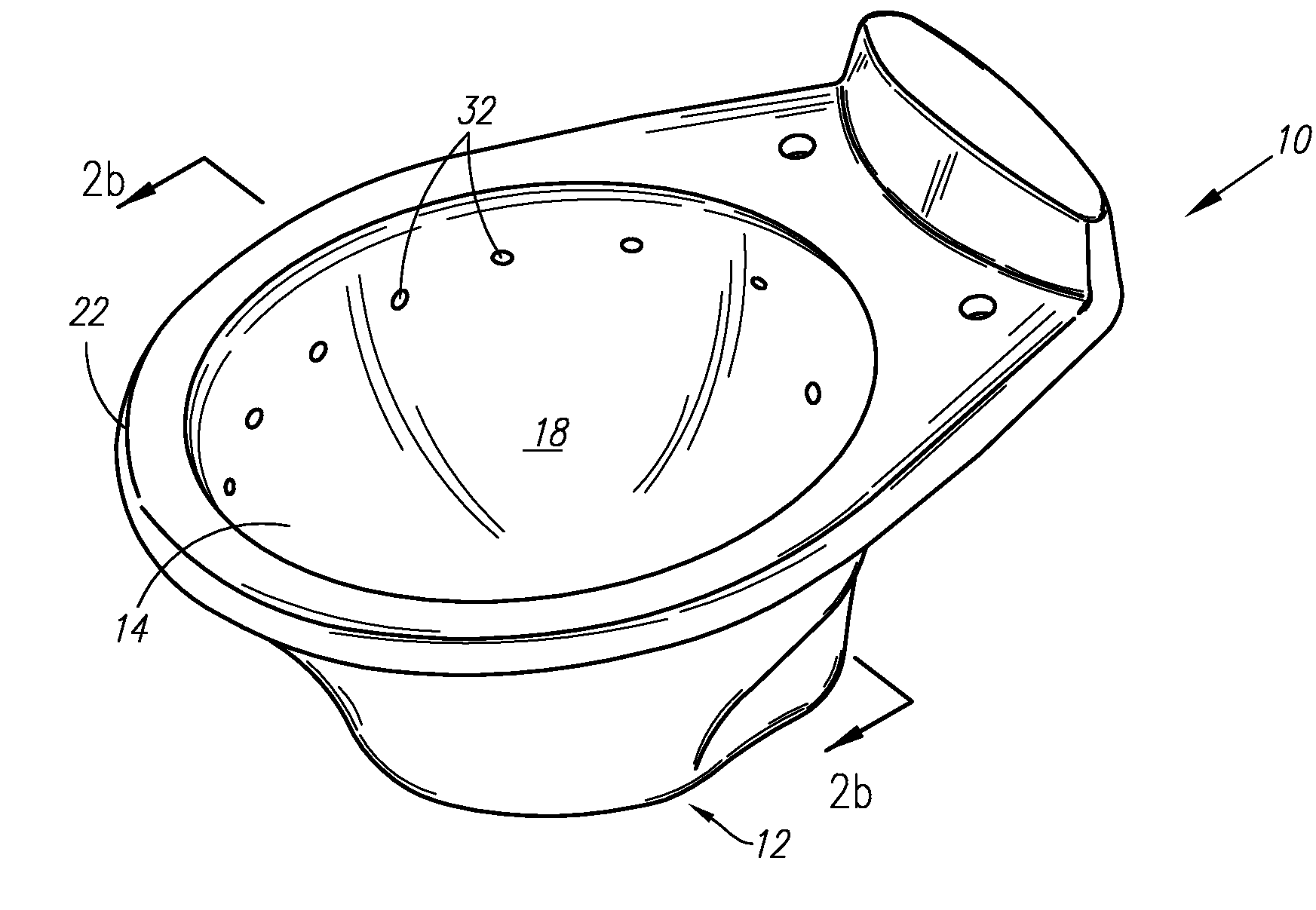

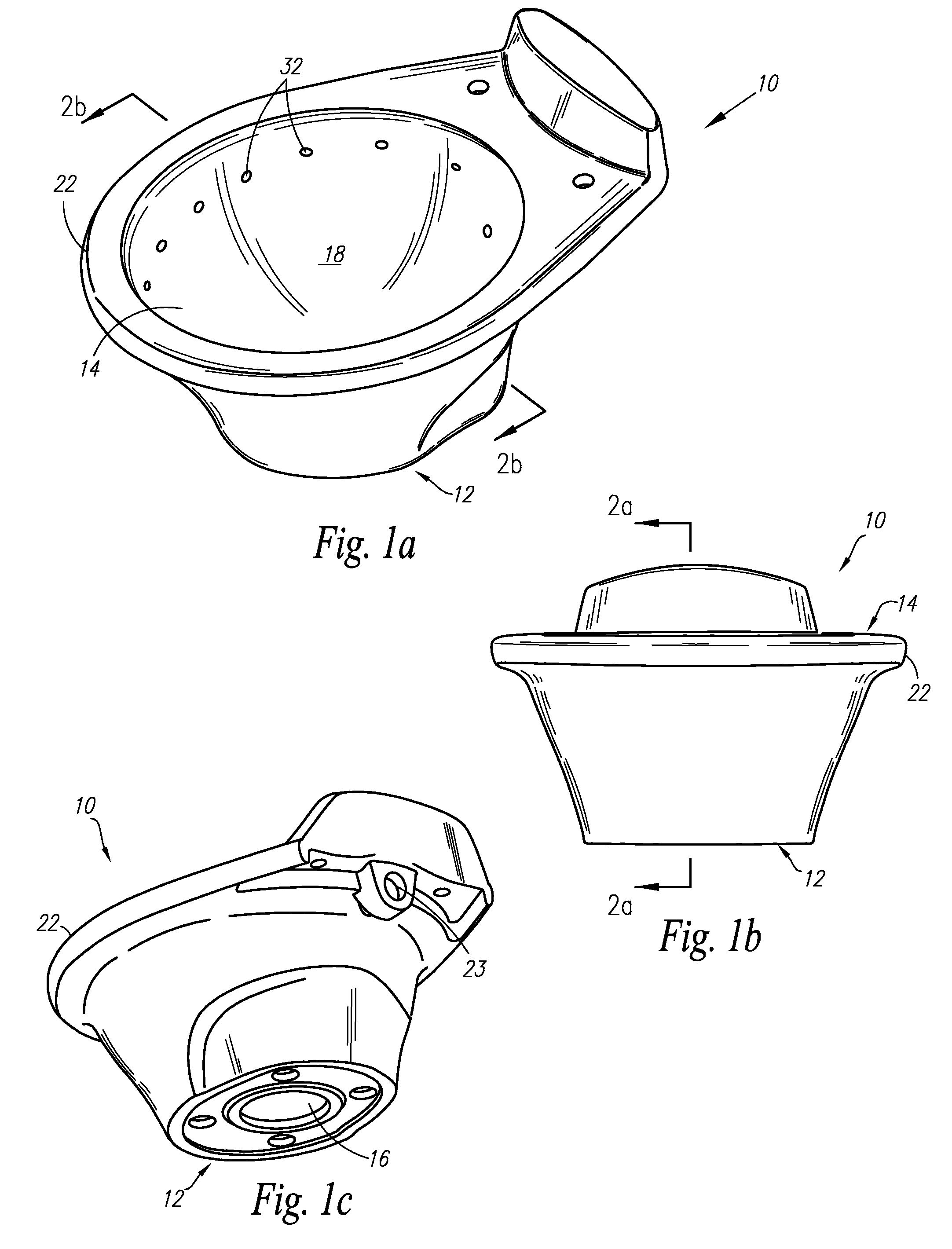

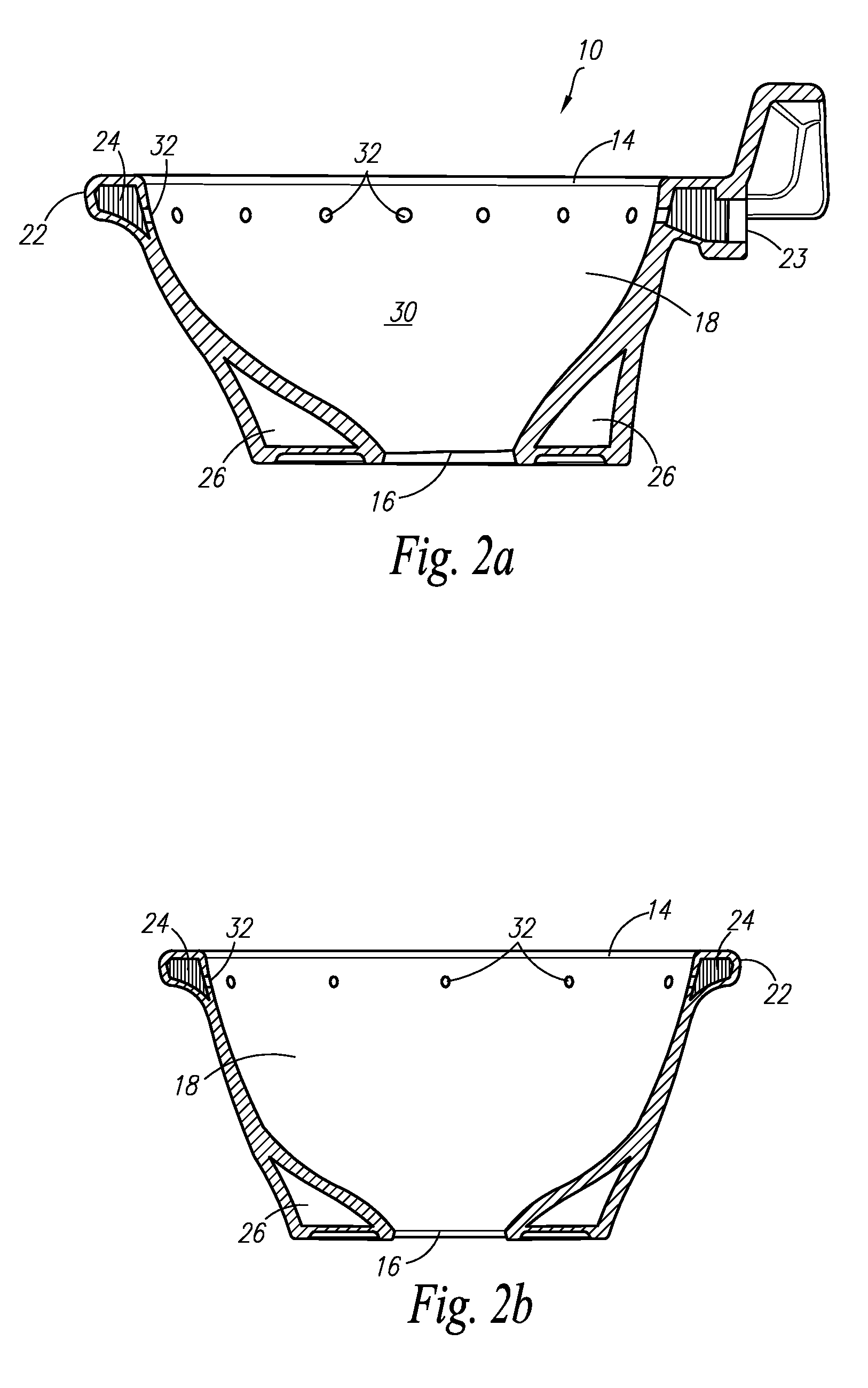

Exterior rim wash bowl

A one-piece bowl including an open top, a bottom opening, a rim portion, an interior space and a plurality of cavities is provided. The rim portion substantially surrounds the bowl near the open top, and an inner channel is formed along and within the rim portion. The interior space is substantially defined by an interior surface, the open top and the bottom opening. The plurality of cavities extends from the inner channel to the interior space. The inner channel and the cavities are configured to pass fluid from an outer fluid source to the interior space. A mold assembly and a method for forming a one-piece greenware piece for the bowl are also provided. The mold assembly includes a top mold component and a bottom mold component that are configured to mate and thereby form a reservoir substantially defining the bowl.

Owner:DOMETIC APPLIANCES

Preparation method of ITO tubular target material

ActiveCN107244911AIncrease profitMeet application requirementsDischarging arrangementVacuum evaporation coatingHigh densitySlurry

The invention discloses a preparation method of an ITO tubular target material. The preparation method comprises: using ITO nanometer powder as a raw material, dewatering and molding a prepared ITO slurry by using a rotation mold and an ultrasonic wave vibration device to obtain an ITO target material billet, carrying out degreasing treatment on the billet at a low temperature, and sintering the degreased billet under a certain sintering condition to obtain the ITO tubular target material. According to the present invention, with the preparation method, the automated production is easily performed so as to reduce the labor intensity and the labor cost; and the prepared ITO rotating target material product has characteristics of uniform and stable structure, high density and good market prospect, and can meet the application requirements of downstream enterprises.

Owner:KUNMING UNIV OF SCI & TECH

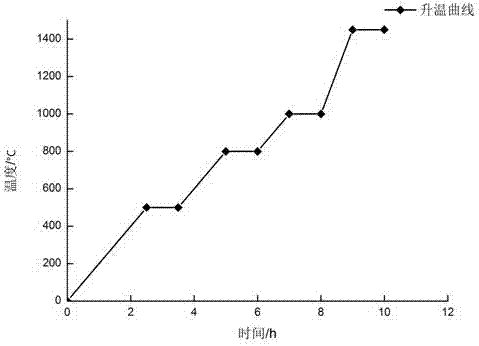

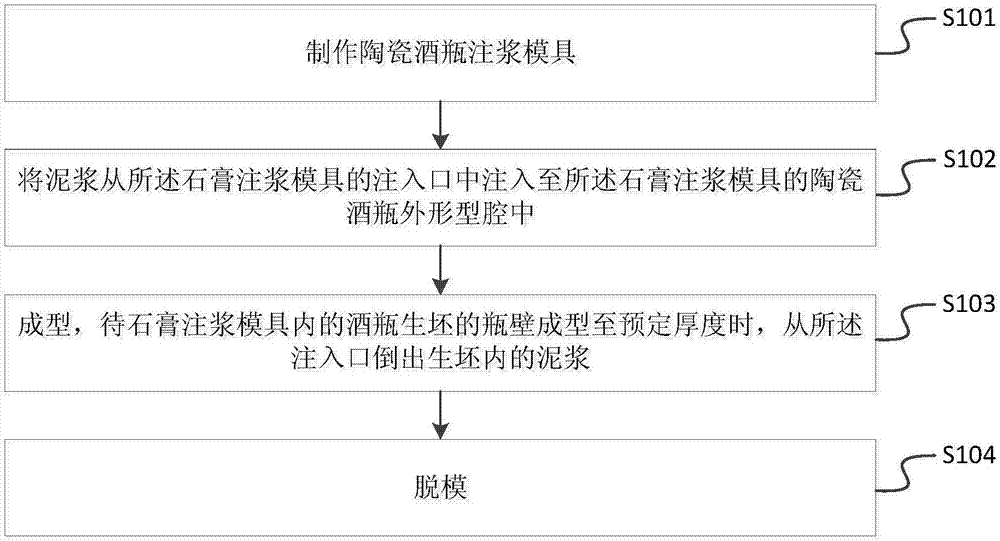

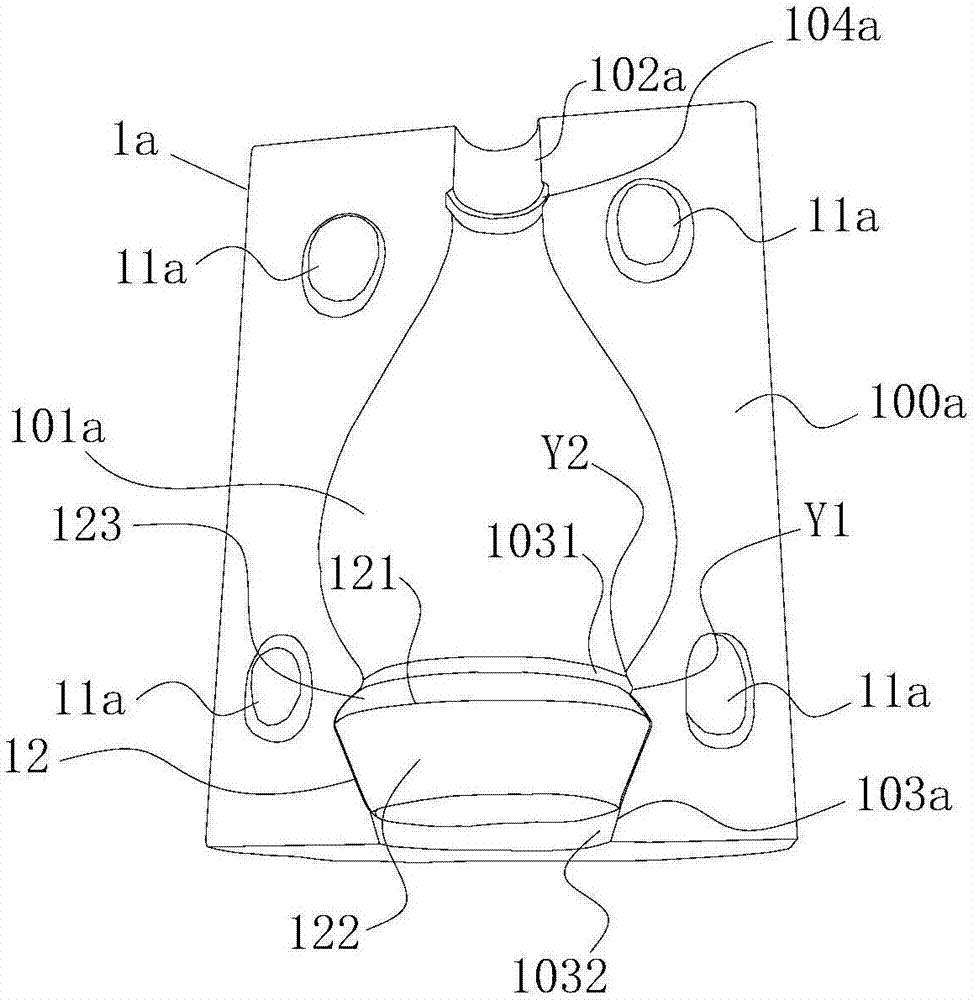

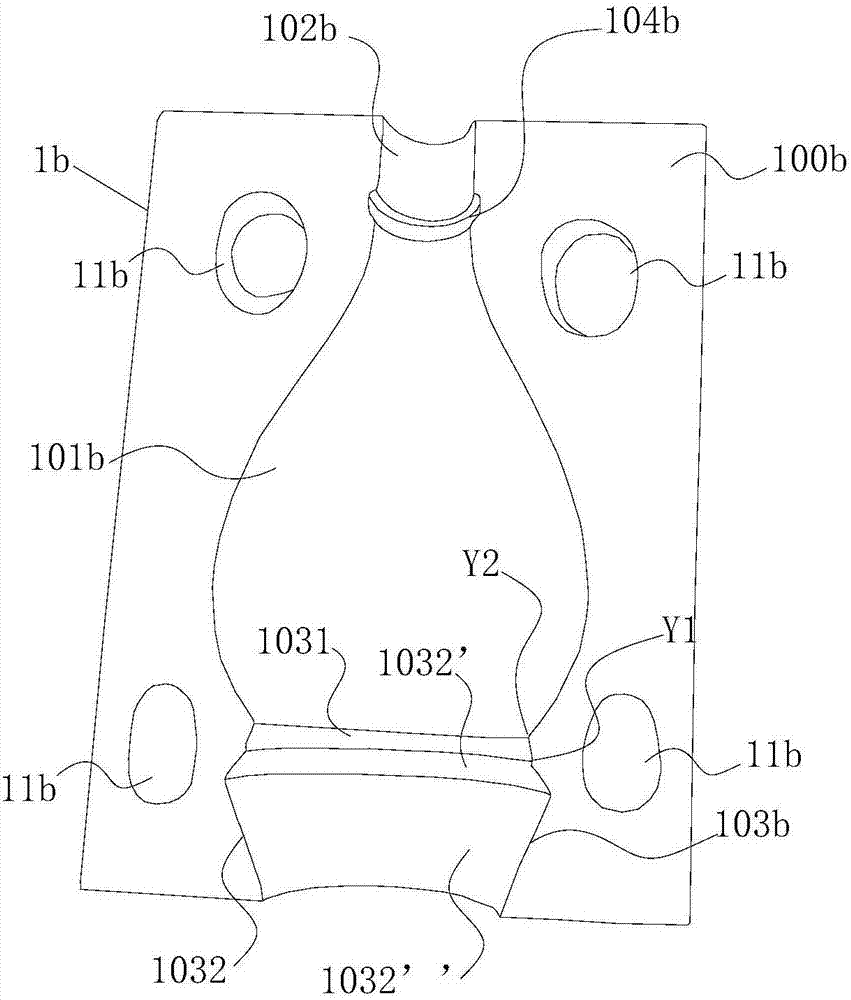

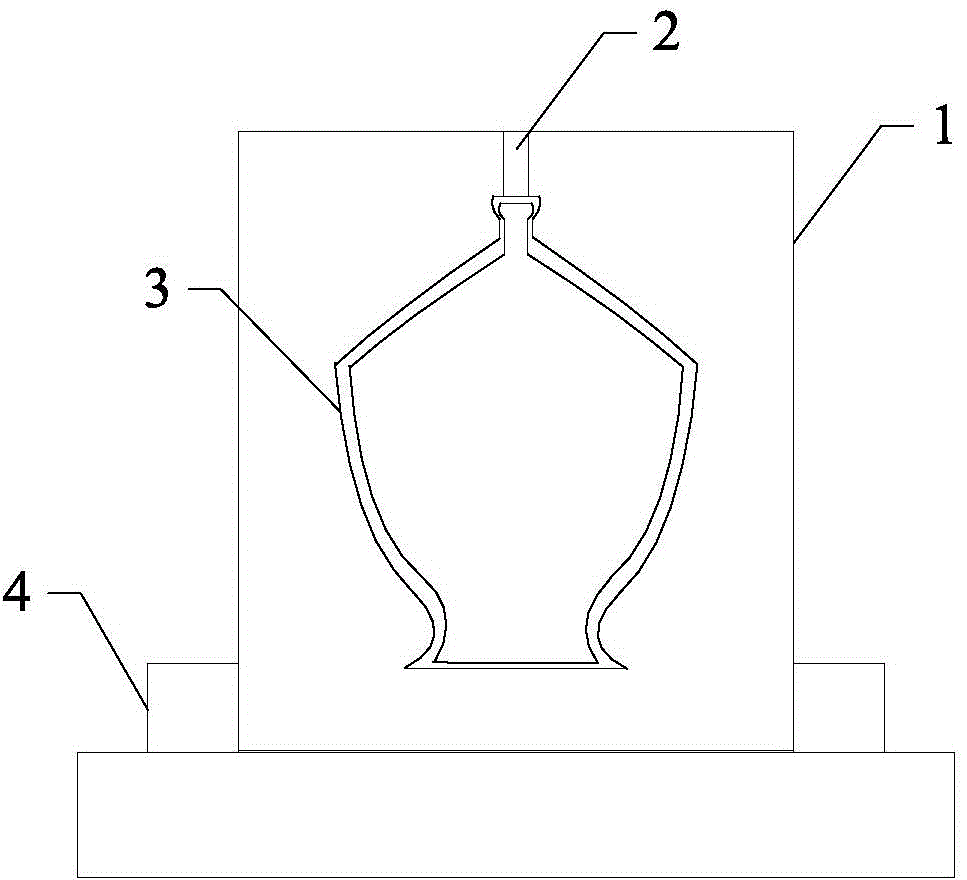

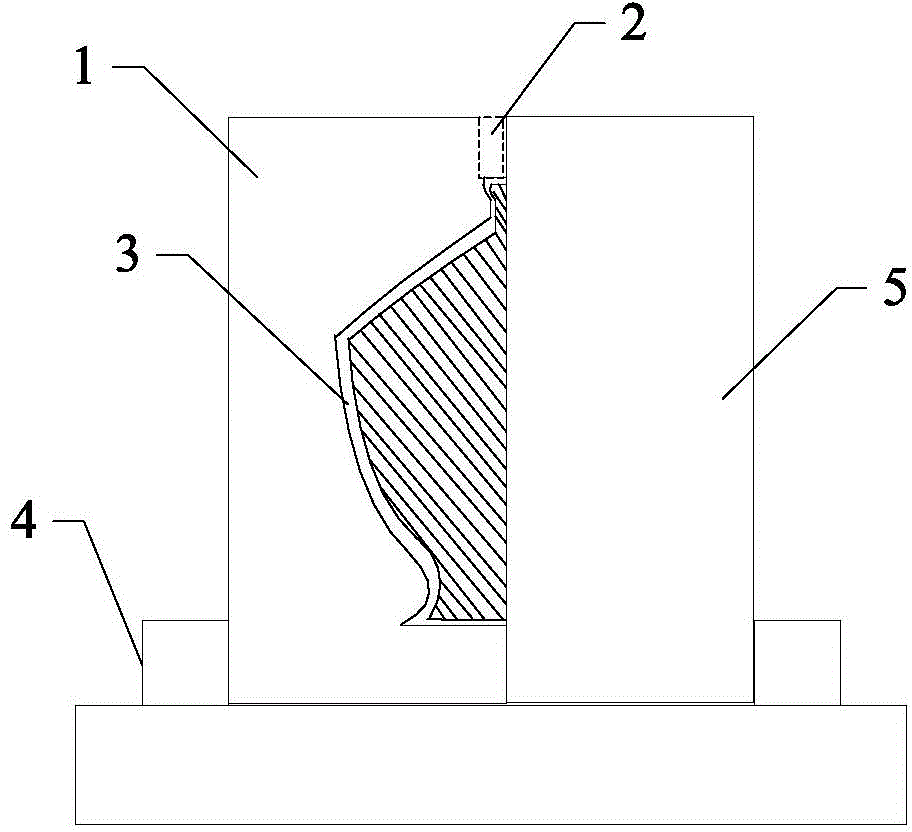

Grouting technology and manufacturing technology of ceramic wine bottle and ceramic wine bottle grouting mould

InactiveCN107322760AGuaranteed appearance integrityImprove yield rateSlip casting mouldsManufacturing technologyInjection port

The invention discloses a grouting technology and a manufacturing technology of a ceramic wine bottle and a ceramic wine bottle grouting mould. The grouting technology of the ceramic wine bottle comprises the following steps that S101, the ceramic wine bottle grouting mould is manufactured, specifically, the grouting mould is provided with a ceramic wine bottle outline mould cavity; the gypsum grouting mould comprises a first half-mould and a second half-mould; the first mould-closing surface of the first half-mould is provided with a first half-mould-cavity, and a plurality of bulges arranged on the first mould-closing surface in a bulged mode and positioned around the first half-mould-cavity; and the second mold-closing surface of the second half-mould is provided with a second half-mould-cavity, and a plurality of indentations arranged in the positions, corresponding to the multiple bulges, in the second mould-closing surface in a sunken mode and matched with the multiple bulges in a concave-convex mode; S102, slurry is injected from an injection port of the gypsum grouting mould into the ceramic wine bottle outline mould cavity of the gypsum grouting mould; S103, forming is conducted, specifically, when the bottle wall of a wine bottle blank in the gypsum grouting mould is formed to reach the predetermined thickness, the slurry in the blank is poured out from the injection port; ad S104, the mould is released.

Owner:重庆市民益陶瓷有限公司

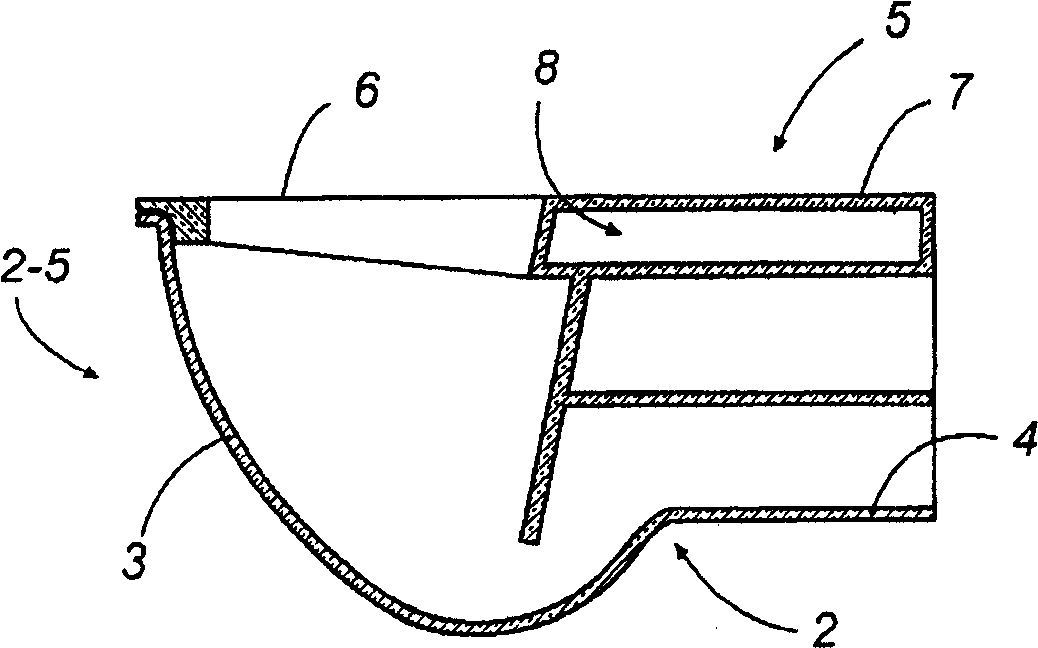

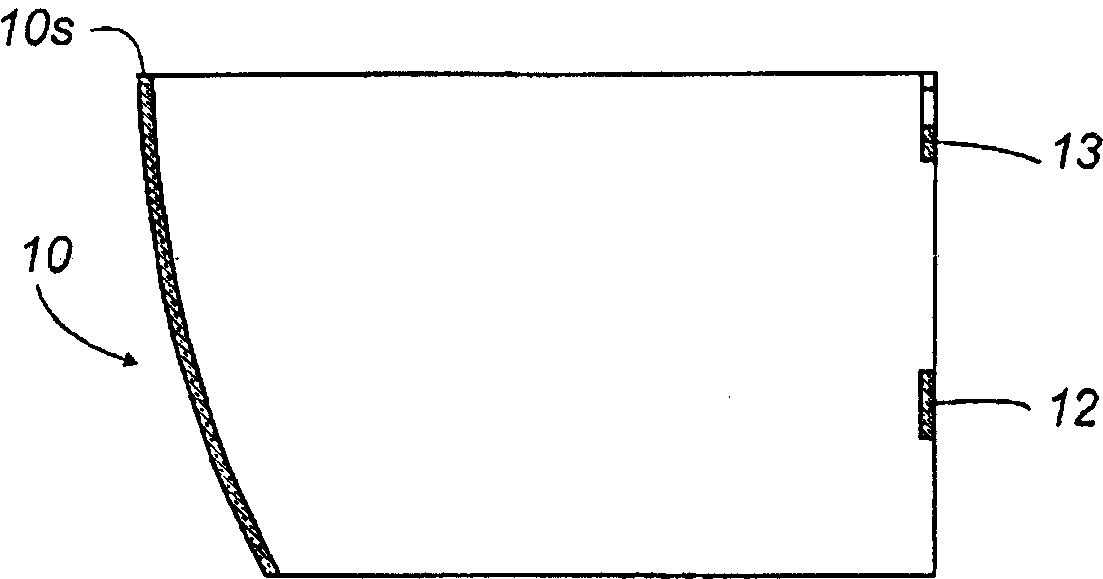

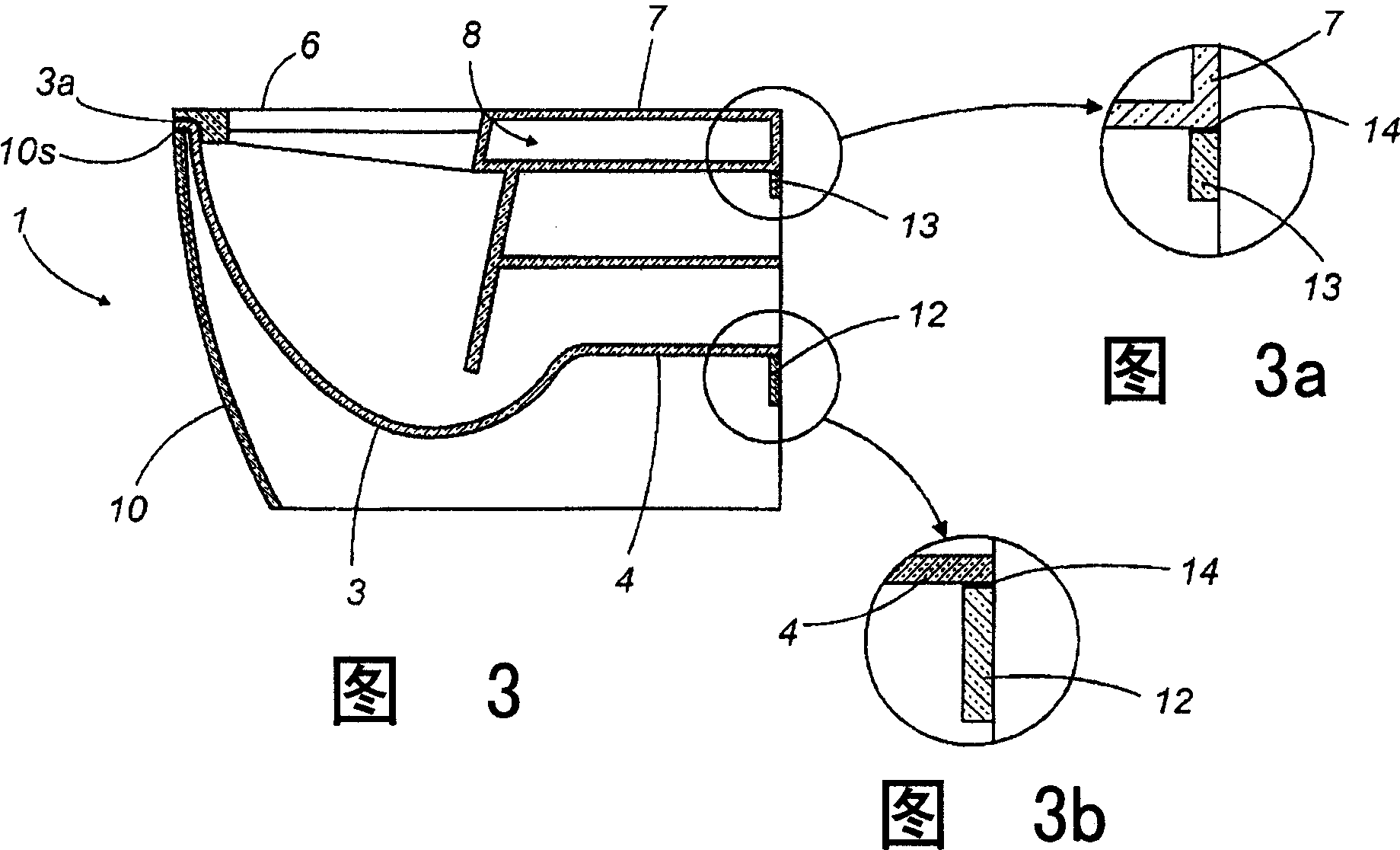

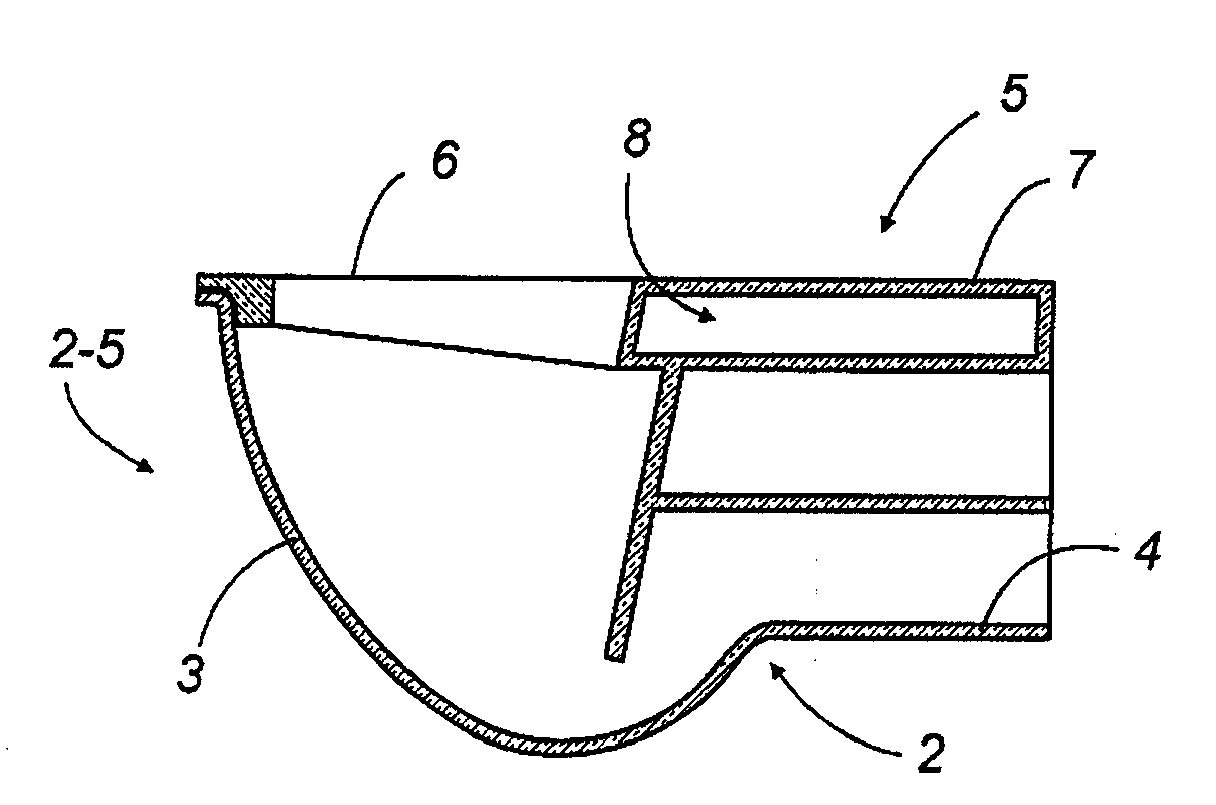

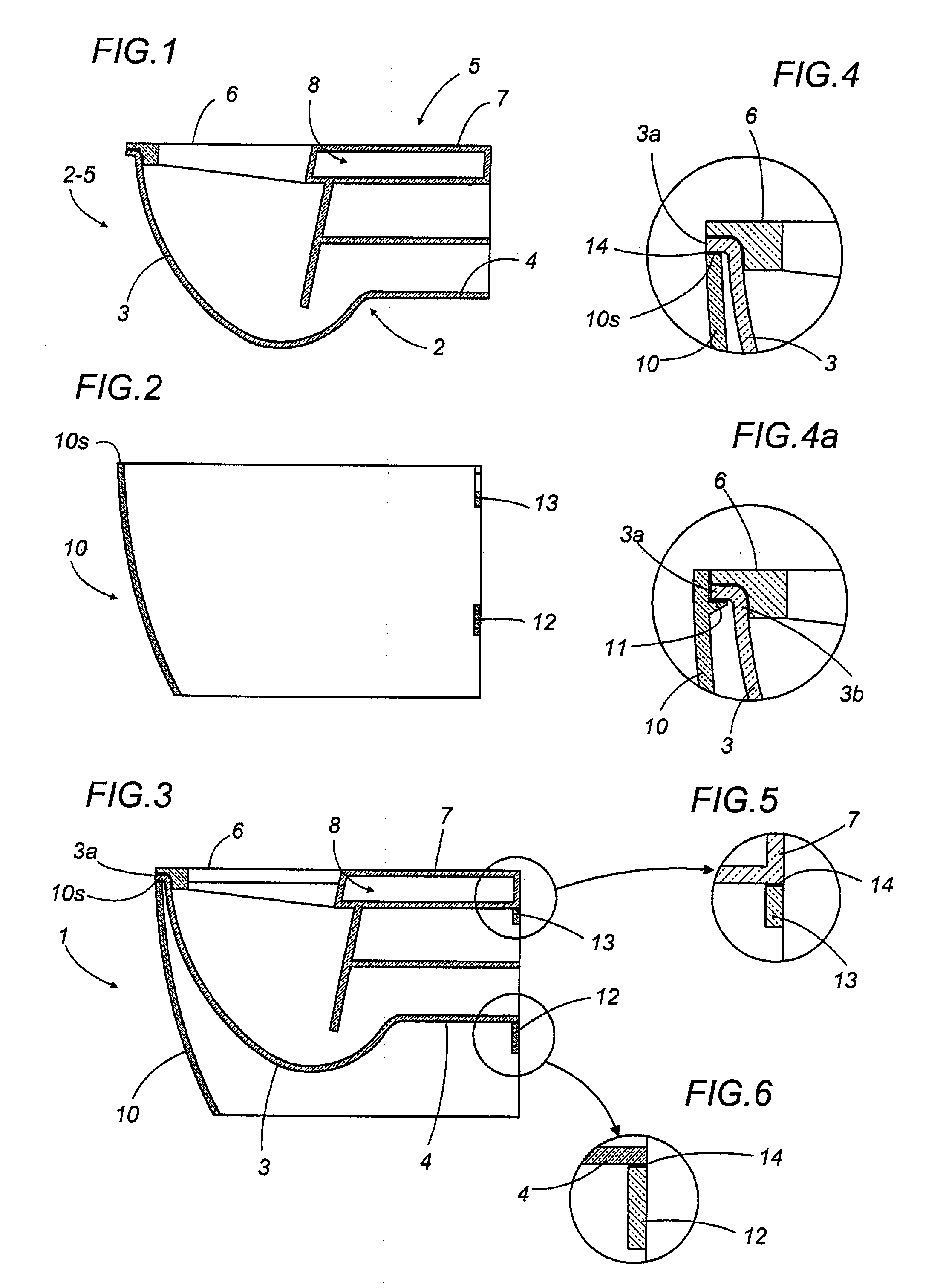

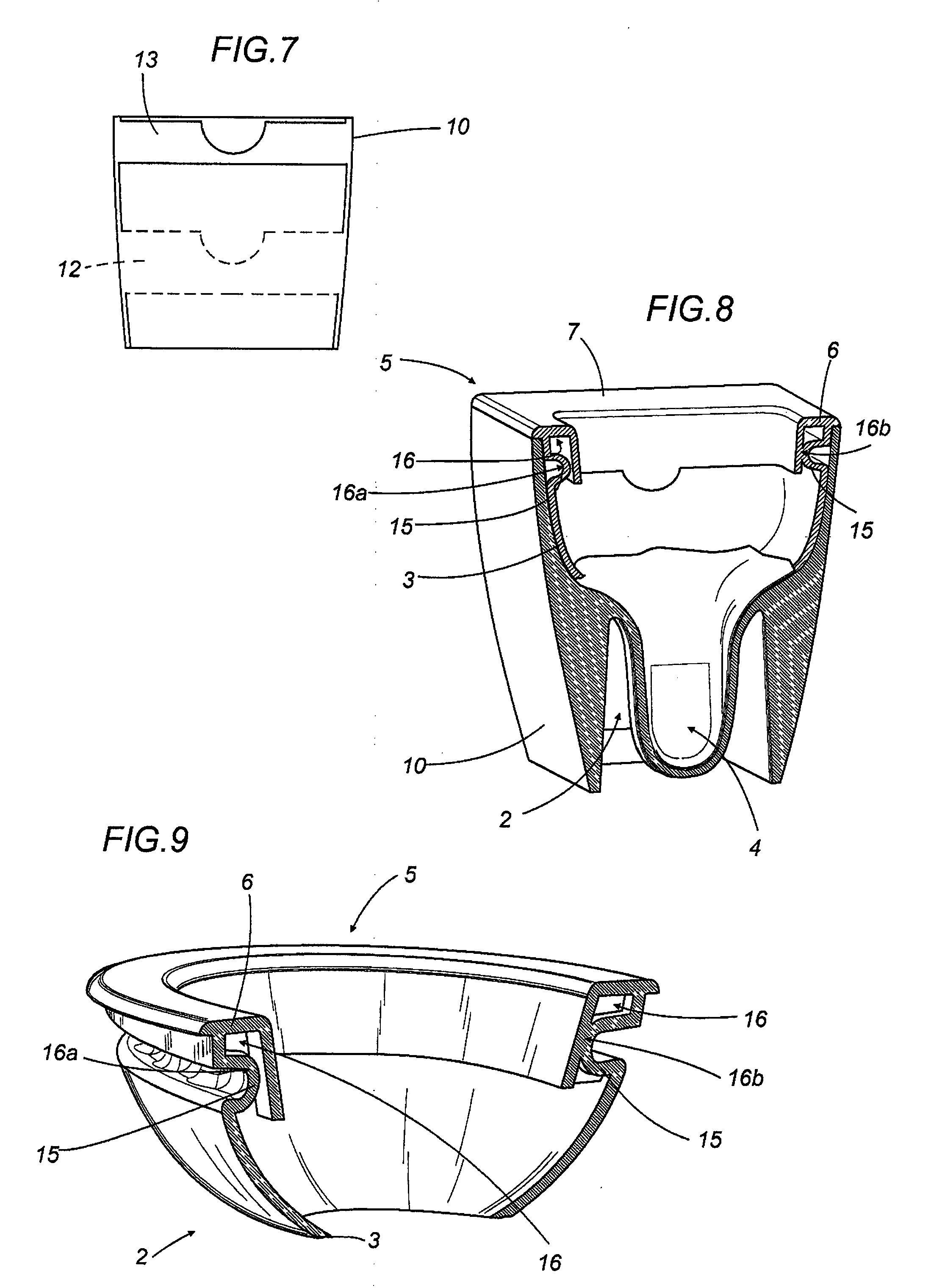

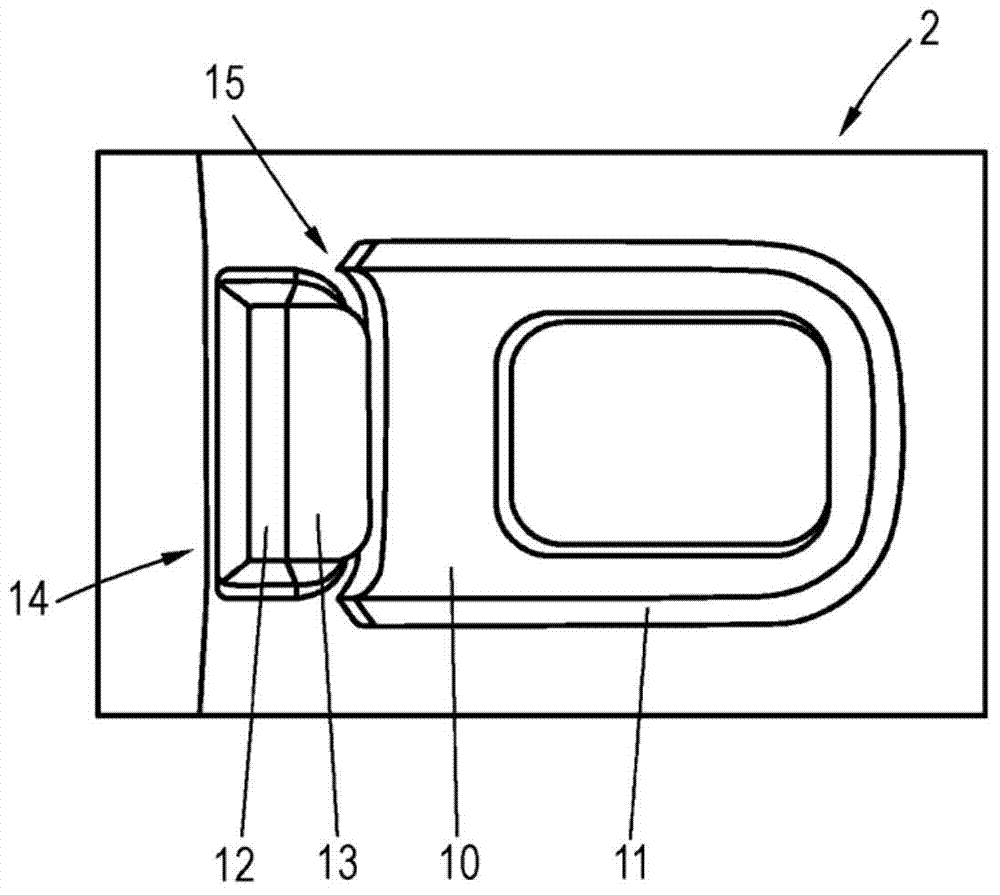

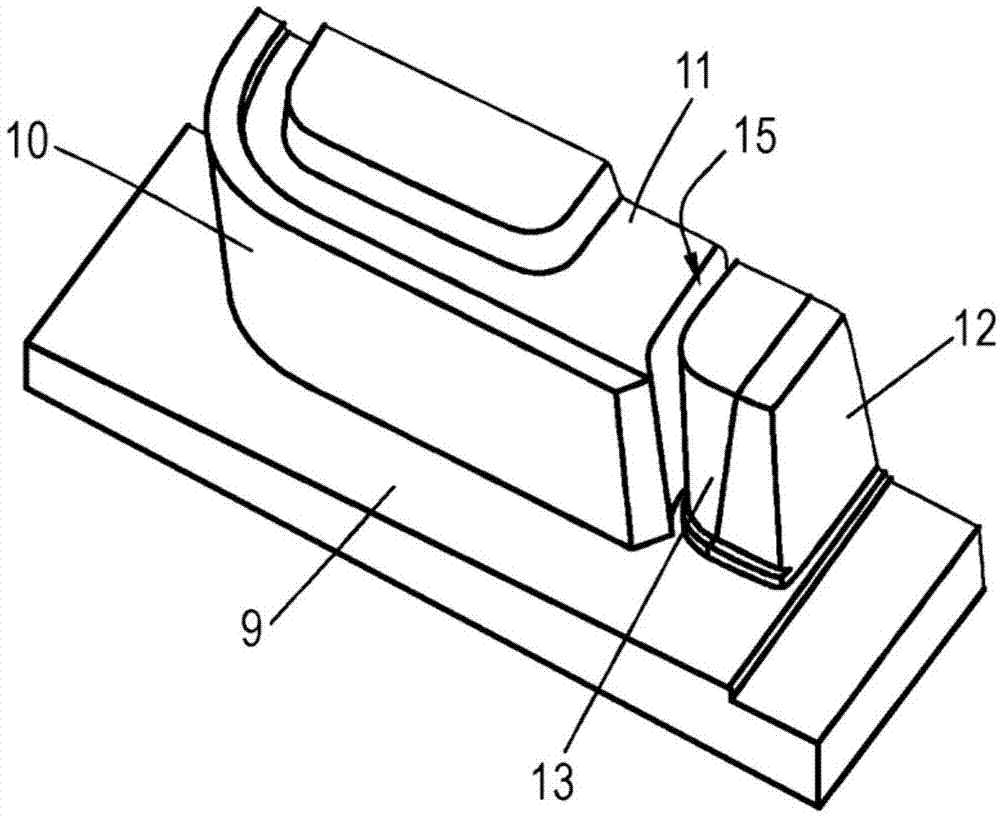

A ceramic sanitary fixture

A ceramic sanitary fixture, in particular a ceramic toilet bowl (1) made by casting in resin or porous moulds comprises: a first, bottom component (2) comprising a liquid collection pan (3) and a siphon portion (1) for draining out the liquids; a second, top component (5), or rim, composed of a front portion (6) forming the upper edge of the pan (3) and a rear extension (7) comprising a channel (8) for the passage of liquids; Lhe first component (2) and the second component (5) of the bowl (1) are made in one piece in the mould to form a single part (2-5) and there is also a third, covering component (10), or outer casing, in which the single part (2-5) can be housed, the latter being able to be associated and assembled with the casing (10) at least at its upper edges.

Owner:SACMI MASCH COOP IMOLA

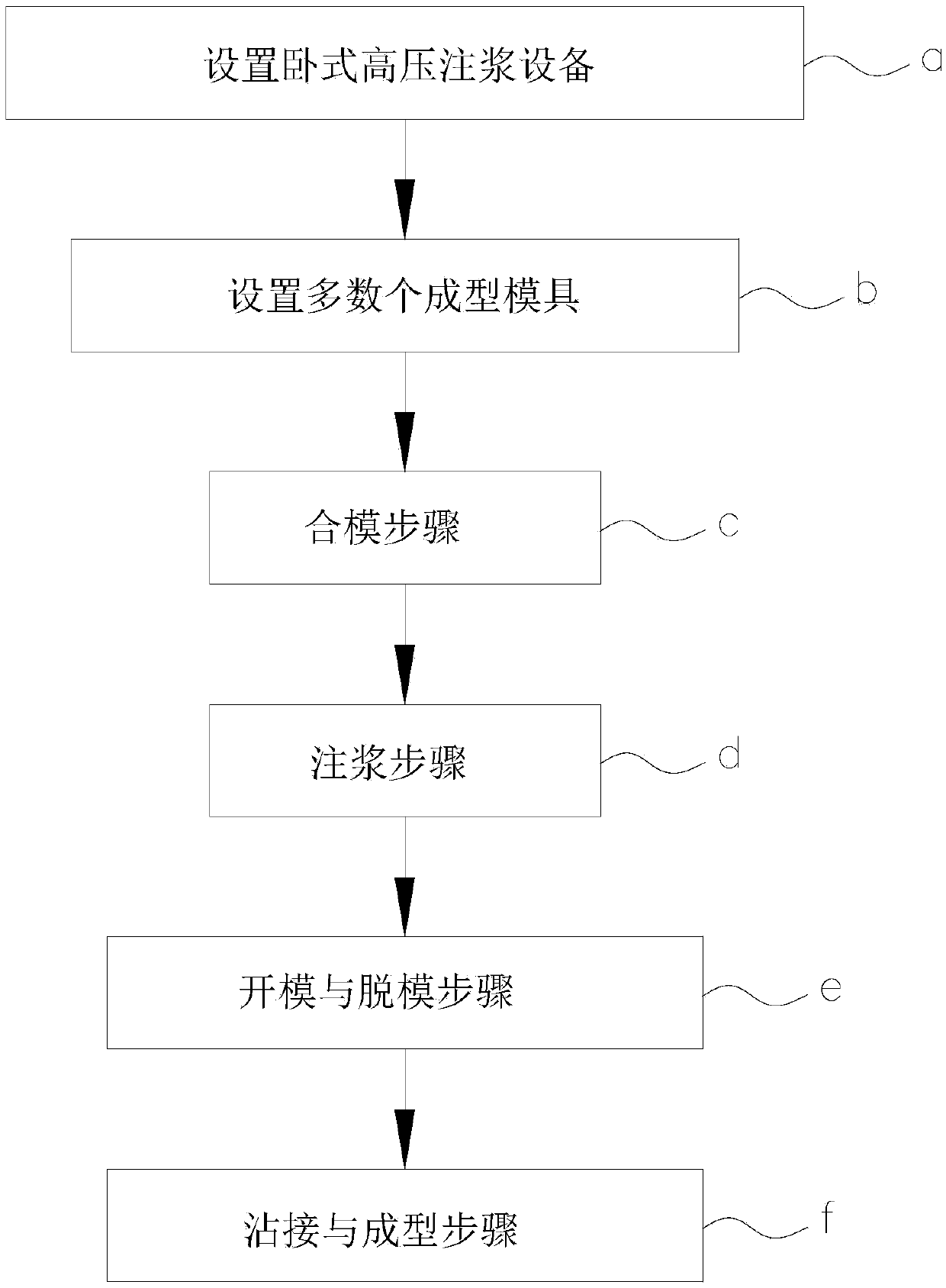

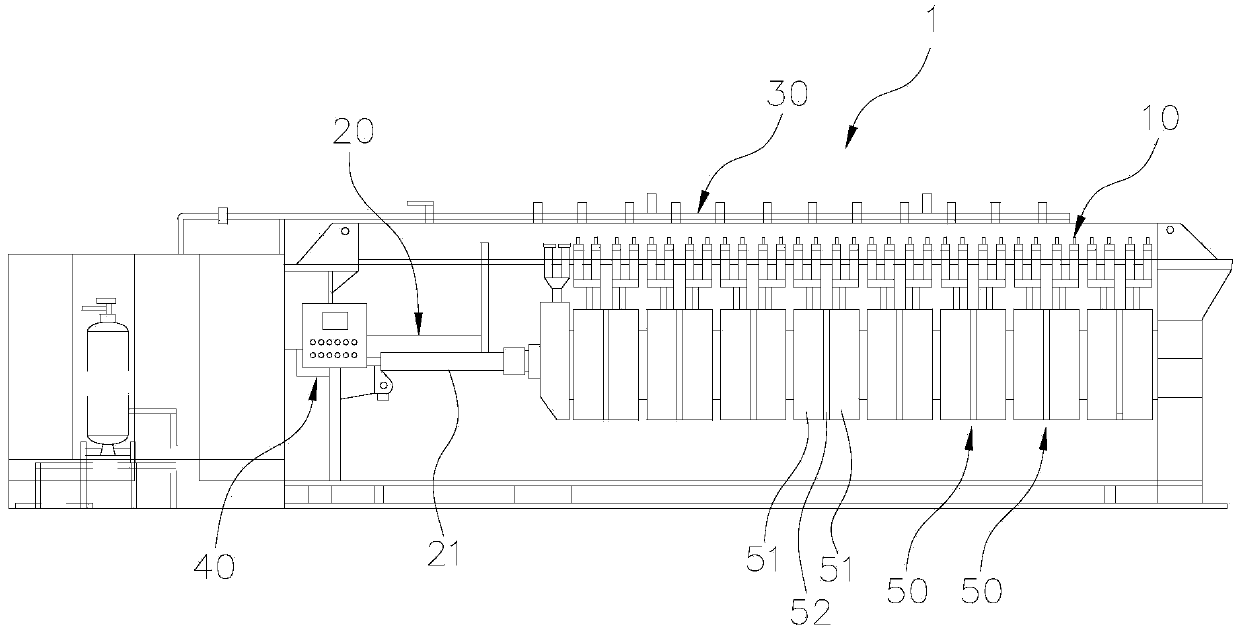

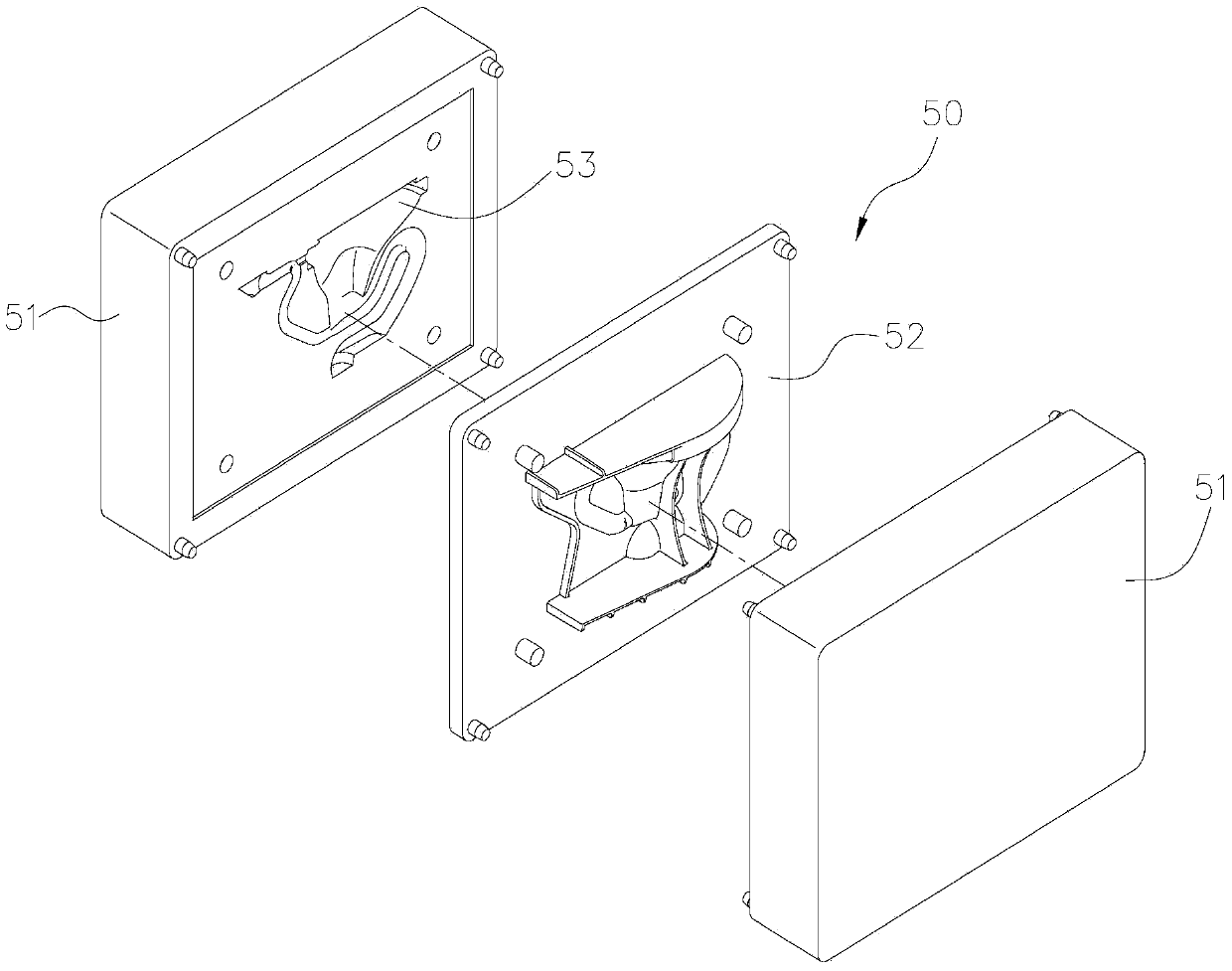

High-pressure grouting molding manufacturing process of toilet bowl, molding die of high-pressure grouting molding manufacturing process and ceramic toilet bowl

InactiveCN105365030AImprove structural strengthImprove structural qualityWater closetsAuxillary shaping apparatusHigh pressureToilet

The invention relates to the field of manufacturing processes, molding dies and finished products of sanitary ceramic products, and provides a high-pressure grouting molding manufacturing process of a toilet bowl. The high-pressure grouting molding manufacturing process comprises the steps of arranging of horizontal type high-pressure grouting equipment, arranging of a plurality of molding die bodies, die closing, grouting, die opening, die releasing and bonding and molding. Each molding die body comprises two female dies and a male die between the female dies. The molding die bodies are arranged on a bearing system of the horizontal type high-pressure grouting equipment in the horizontal direction. Two half-edge blanks are obtained every time die opening and die releasing are carried out. A complete toilet bowl blank is molded after each step of bonding and molding. Thus, according to the high-pressure grouting molding manufacturing process of the toilet bowl, the grouting molding yield and efficacy can be increased, and equipment cost is reduced; and a double-face grout eating manner can also be adopted so that the product yield and quality can be increased, the grout return manufacturing process is omitted, and the grouting molding time is greatly shortened.

Owner:GLOBE UNION INDAL

Hybrid slip casting-electrophoretic deposition (EPD) process

ActiveUS8216439B2Well formedEliminate depositsElectrolysis componentsVolume/mass flow measurementEngineeringFunctionally graded material

The invention provides novel a hybrid slip casting-Electrophoretic Deposition (EPD) process which can be used to produce arbitrary shape geometries with controlled materials properties. The invention provides processes for the fabrication of Functionally Graded Materials (FGM) by a controlled Electrophoretic Deposition (EPD).

Owner:SAN DIEGO STATE UNIV RES FOUND

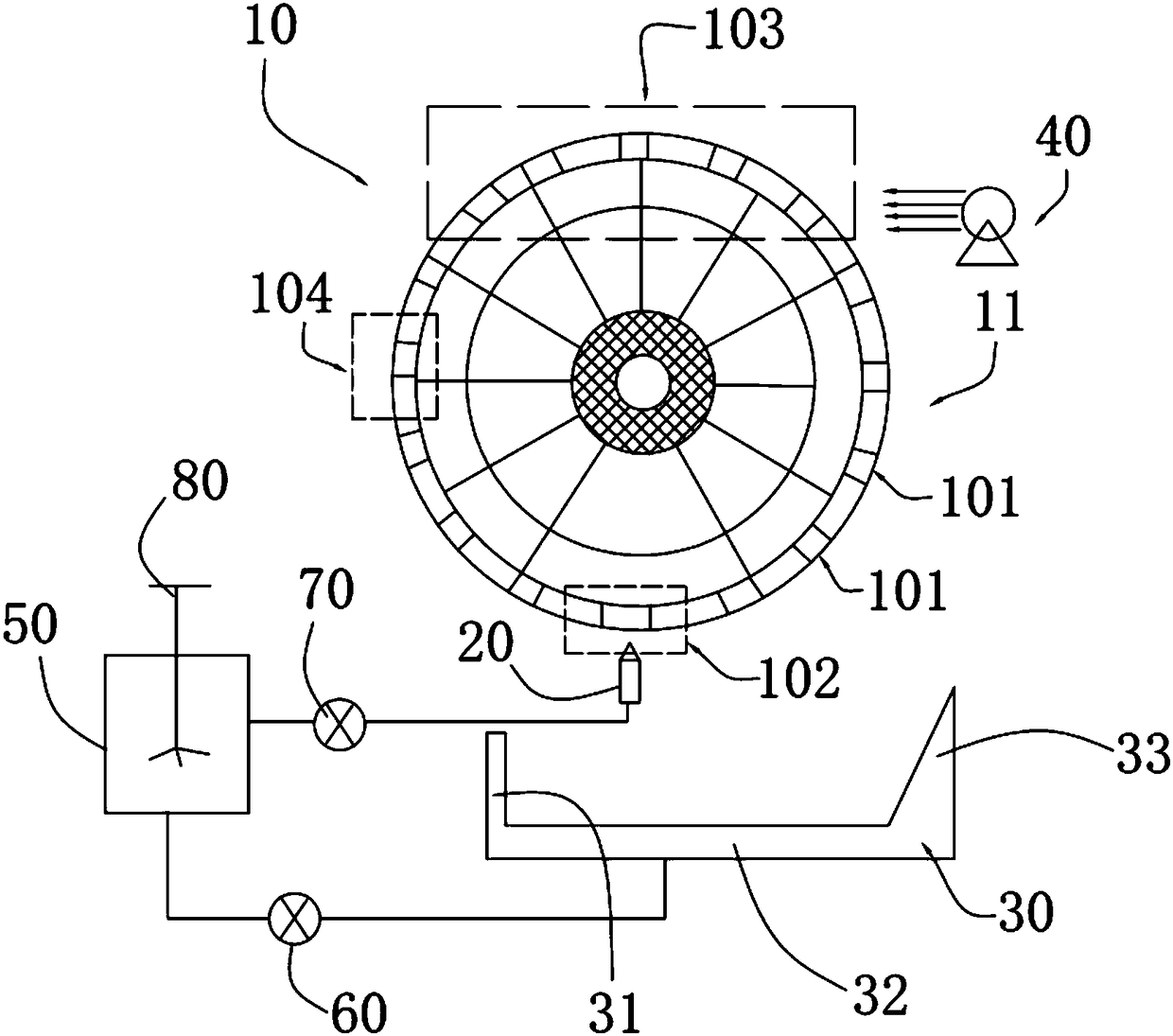

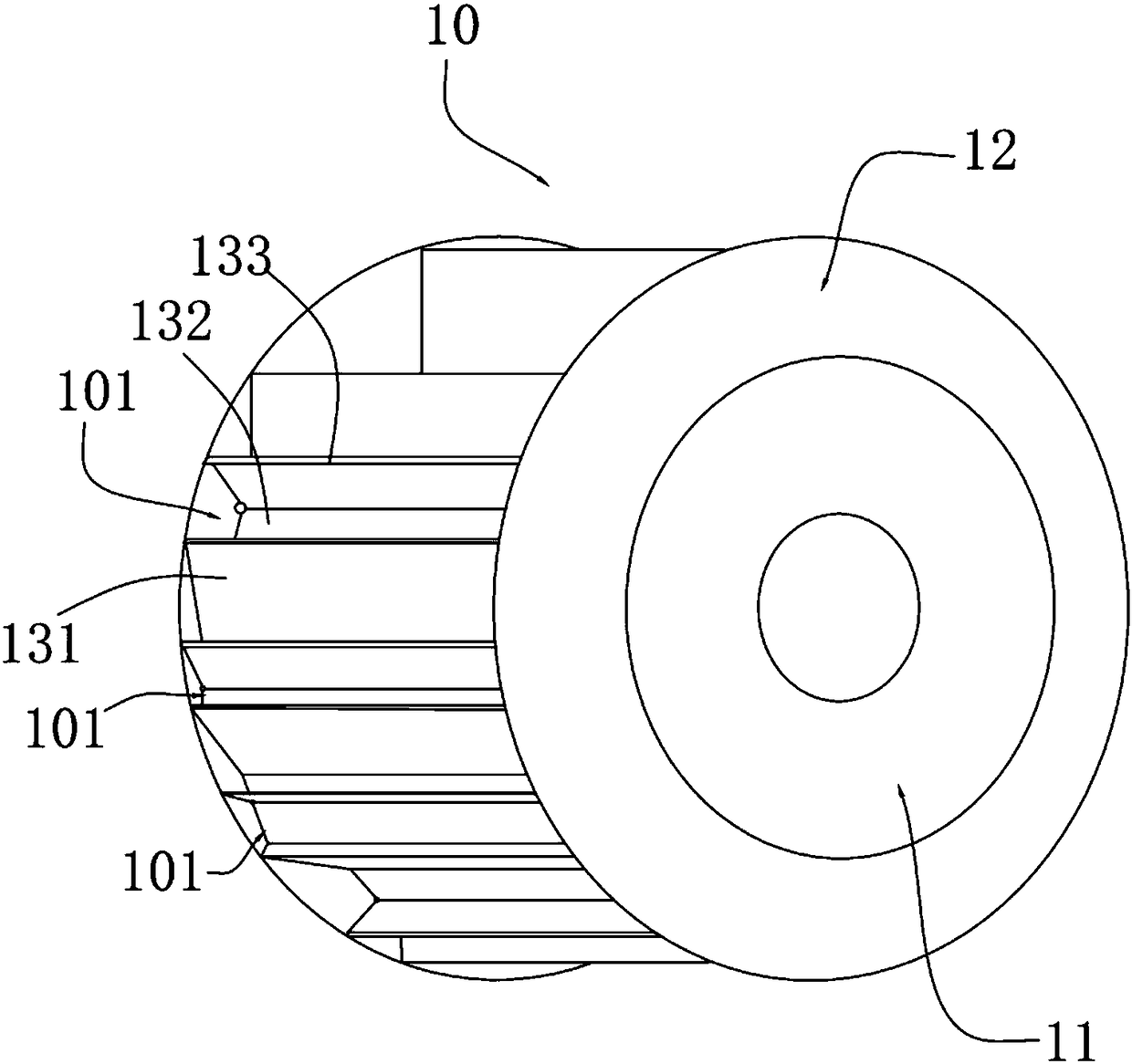

Ceramic slurry jetting forming device

InactiveCN108274584AReduce pinholesSimple structureAuxillary shaping apparatusClay mixing apparatusAutomatic controlMetallurgy

The invention provides a ceramic slurry jetting forming device. The ceramic slurry jetting forming device comprises a rotating component used for fixing multiple molds, and multiple nozzles used for slurry jetting; the multiple molds rotate along with the rotating component, and when slurry jetting openings of the molds right face the nozzles, the nozzles jet the slurry into the molds to form blank bodies. According to the ceramic slurry jetting forming device, the nozzles are used for jetting the slurry into the slurry jetting openings of the molds, the blank bodies are formed in the molds, the structure is simple, automatic control is easy, production efficiency can be improved, and manual cost is reduced.

Owner:许光权

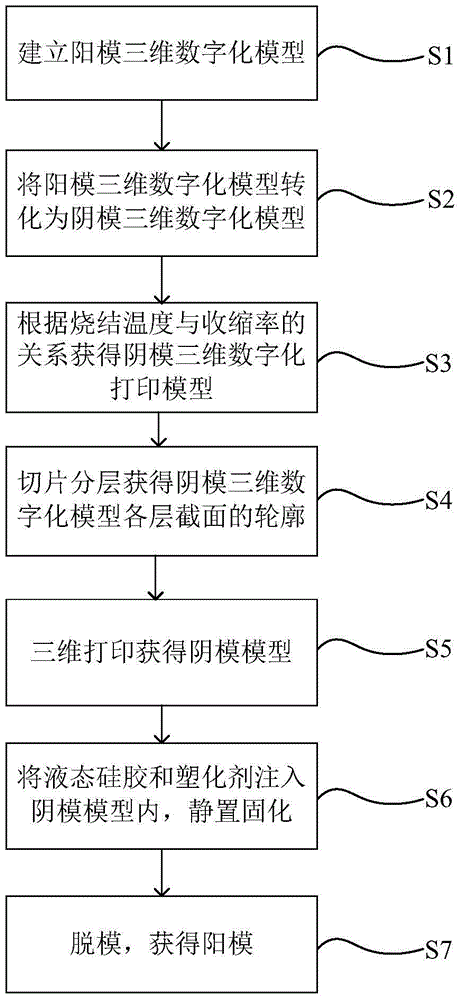

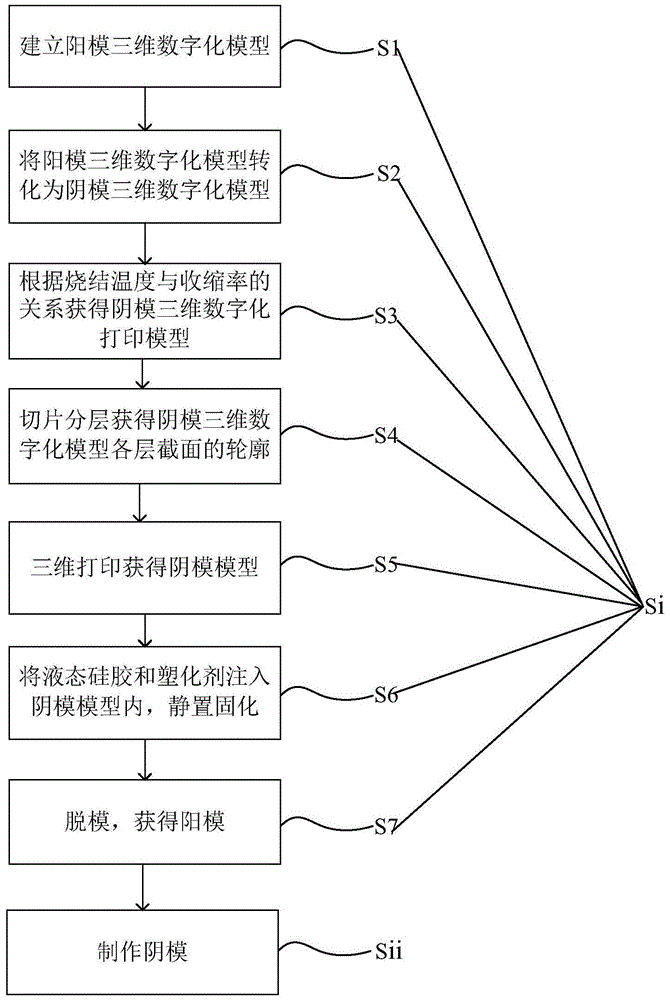

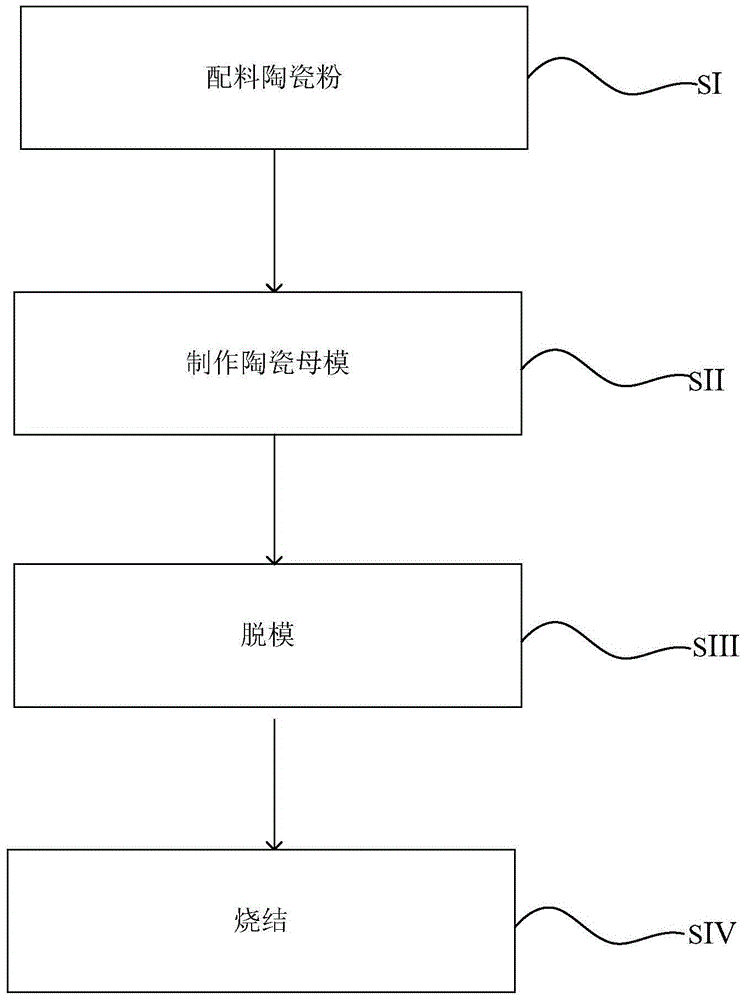

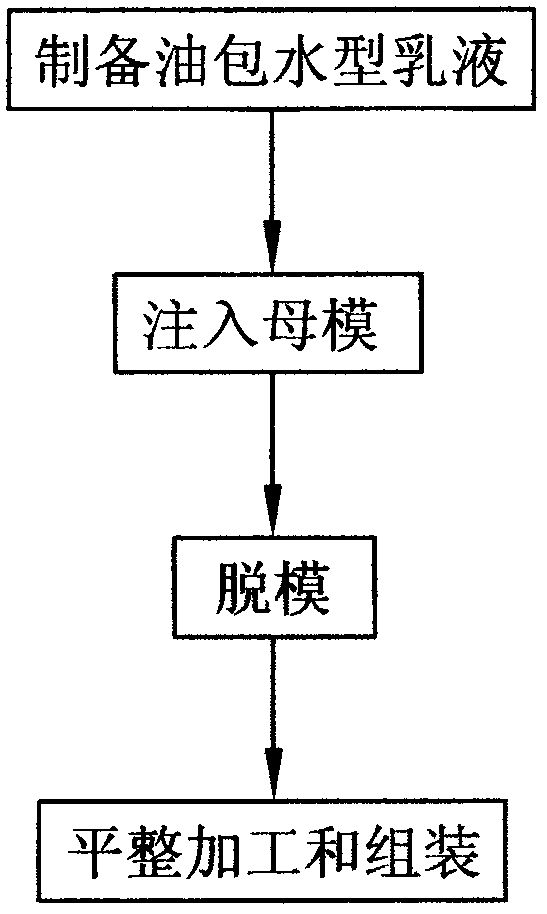

Ceramic manufacturing method, ceramic female die, a ceramic female die manufacturing method and male die manufacturing method

InactiveCN105666647AImprove processing efficiencyReduce processing timeAdditive manufacturing apparatusSlip casting mouldsEngravingPlasticizer

The invention discloses a ceramic manufacturing method, a ceramic female die, a ceramic female die manufacturing method and a male die manufacturing method. The male die manufacturing method comprises the steps of building a male die three-dimensional digitizing model, converting the male die three-dimensional digitizing model into a female die three-dimensional digitizing model, according to the shrinking percentage of ceramic in the sintering process, treating the female die three-dimensional digitizing model to obtain a female die three-dimensional digitizing printing model, performing layer-by-layer slicing treatment on the female die three-dimensional digitizing printing model, obtaining outlines of sections of all layers of the female die three-dimensional digitizing model, obtaining a female die model through printing according to a three-dimensional printing technology, injecting liquid silicone and a plasticizer into the female die model, performing standing and curing, and finally, performing demolding to obtain a male die. Compared with a manner that in the prior art, a male die is manufactured through hand engraving, the male die manufacturing method has the beneficial effects that the machining efficiency of the male die can be improved; when damaged, the male die can be directly manufactured through the female die model, the machining time of the male die is shortened, and the ceramic production efficiency is improved to a certain degree.

Owner:SHEN ZHEN QIANHAI SCICORE 3D TECH CO LTD

Ceramic sanitary fixture

InactiveUS20090019630A1Improve the level ofMaintain levelWater closetsSynthetic resin layered productsMaterials scienceToilet

A ceramic sanitary fixture, in particular a ceramic toilet bowl (1) made by casting in resin or porous moulds comprises: a first, bottom component (2) comprising a liquid collection pan (3) and a siphon portion (4) for draining out the liquids; a second, top component (5), or rim, composed of a front portion (6) forming the upper edge of the pan (3) and a rear extension (7) comprising a channel (8) for the passage of liquids; the first component (2) and the second component (5) of the bowl (1) are made in one piece in the mould to form a single part (2-5) and there is also a third, covering component (10), or outer casing, in which the single part (2-5) can be housed, the latter being able to be associated and assembled with the casing (10) at least at its upper edges.

Owner:SACMI COOP MECCANICI IMOLA S C R L

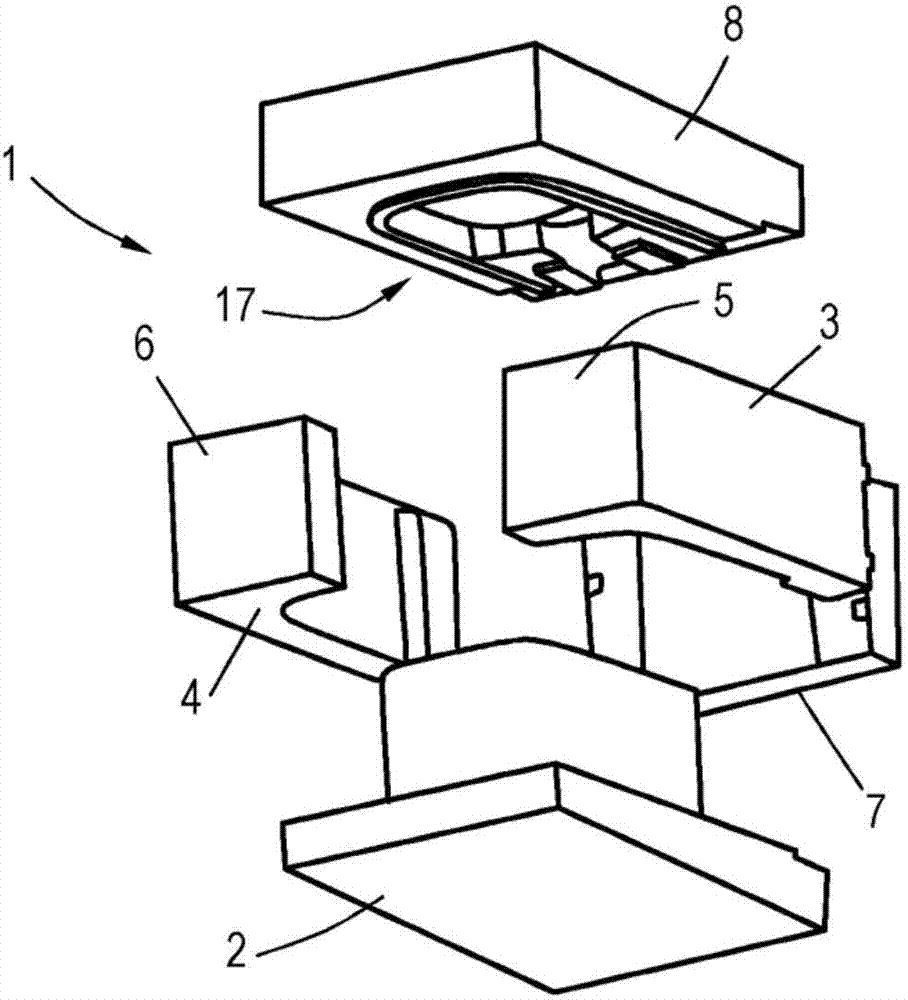

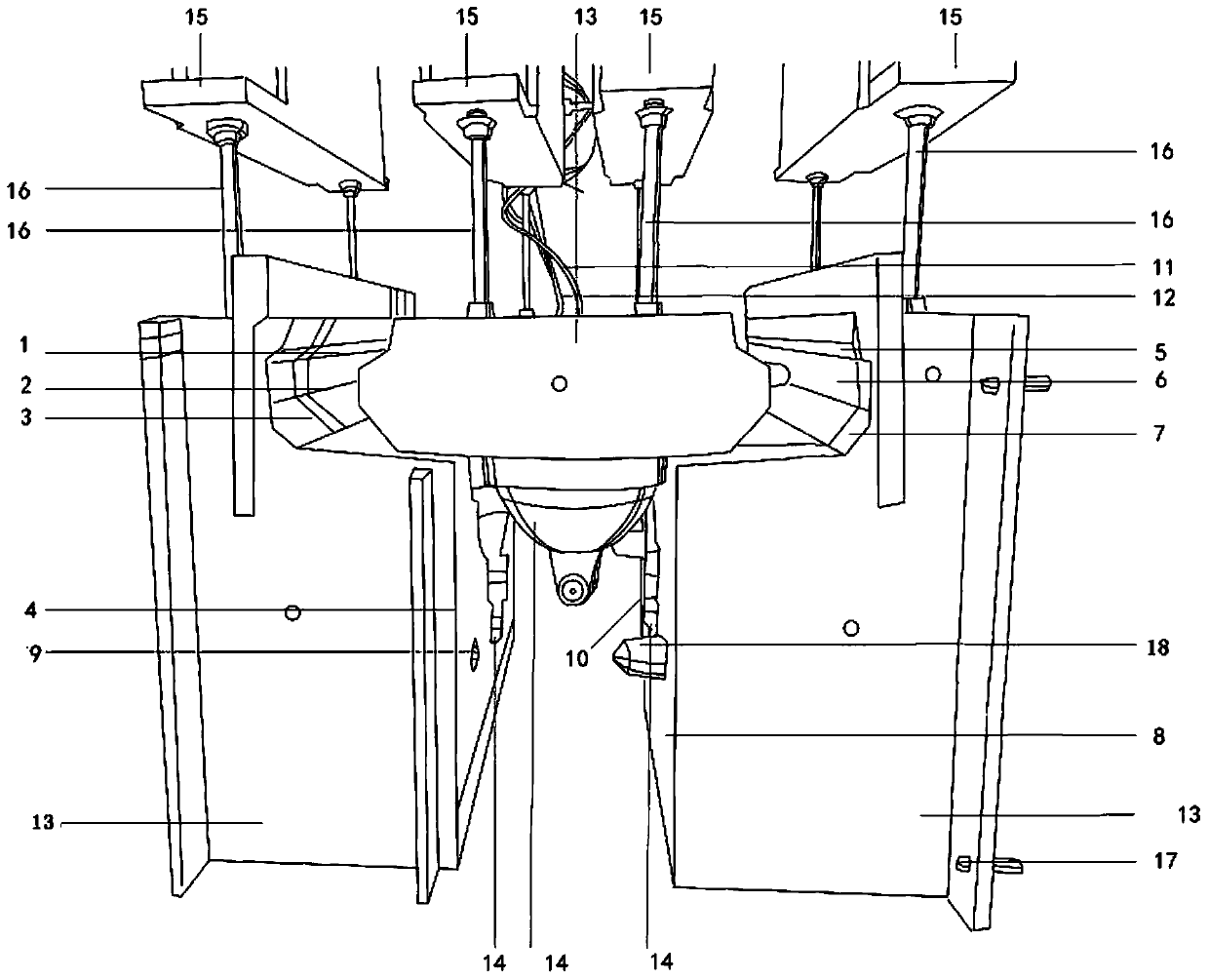

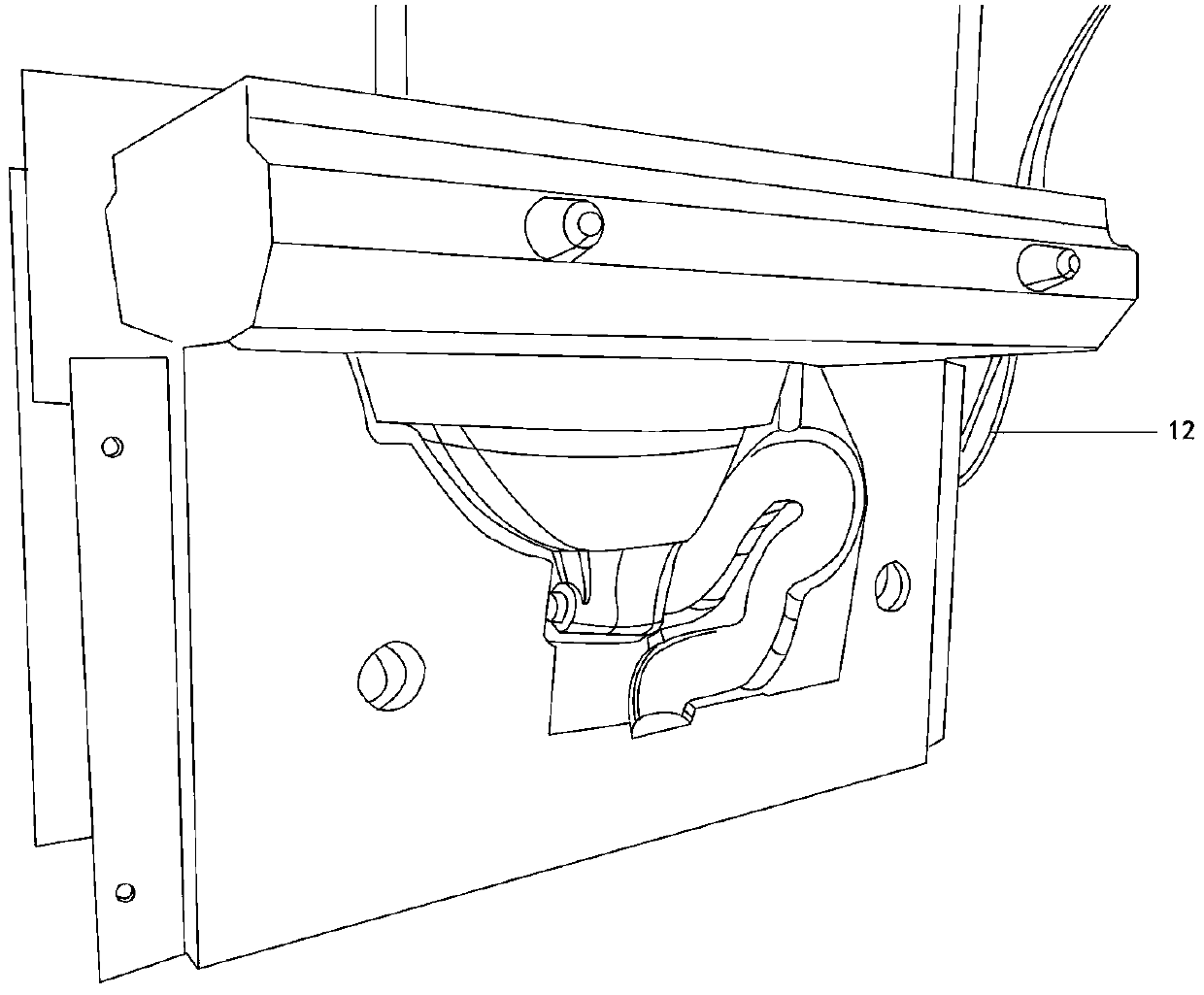

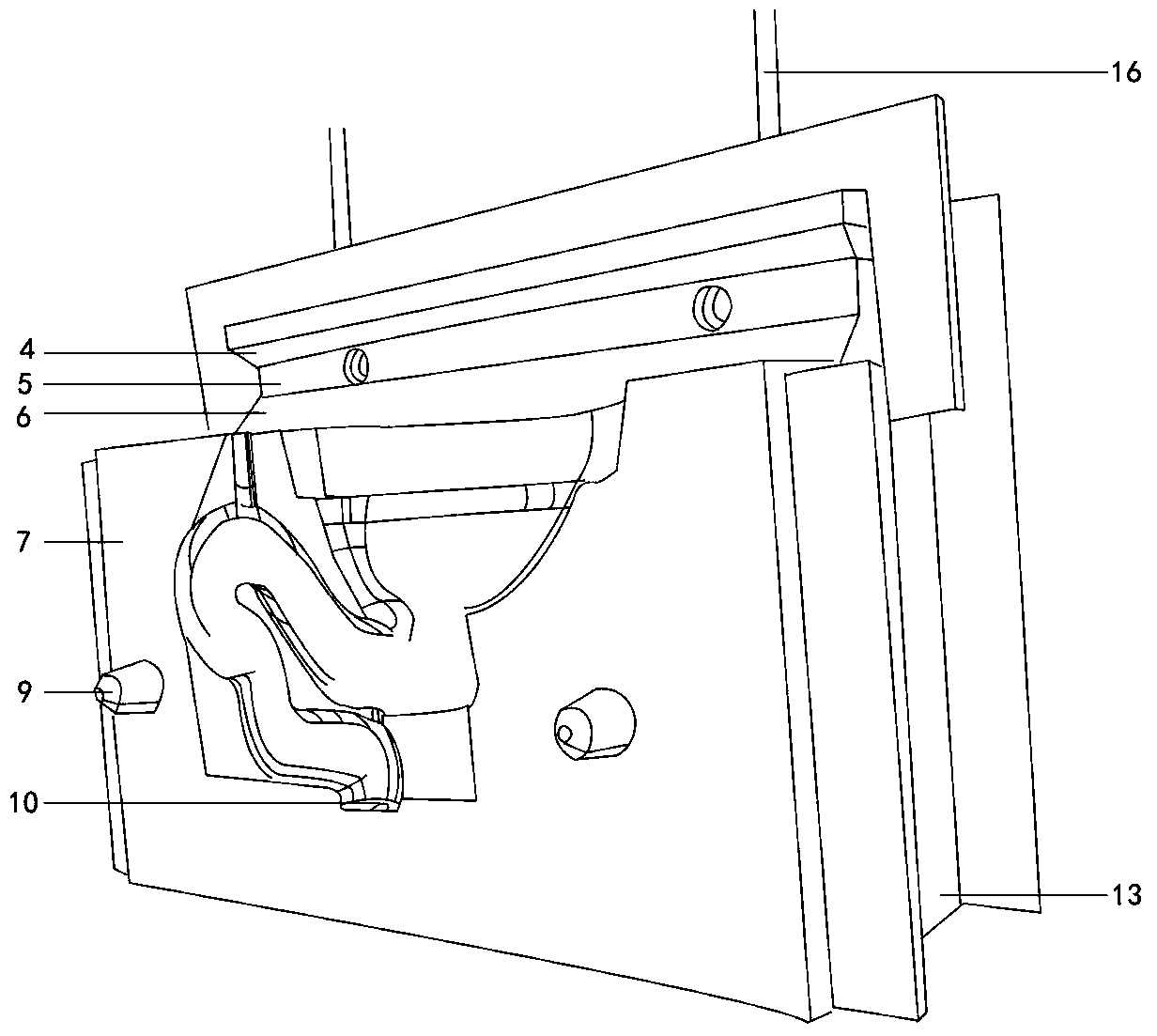

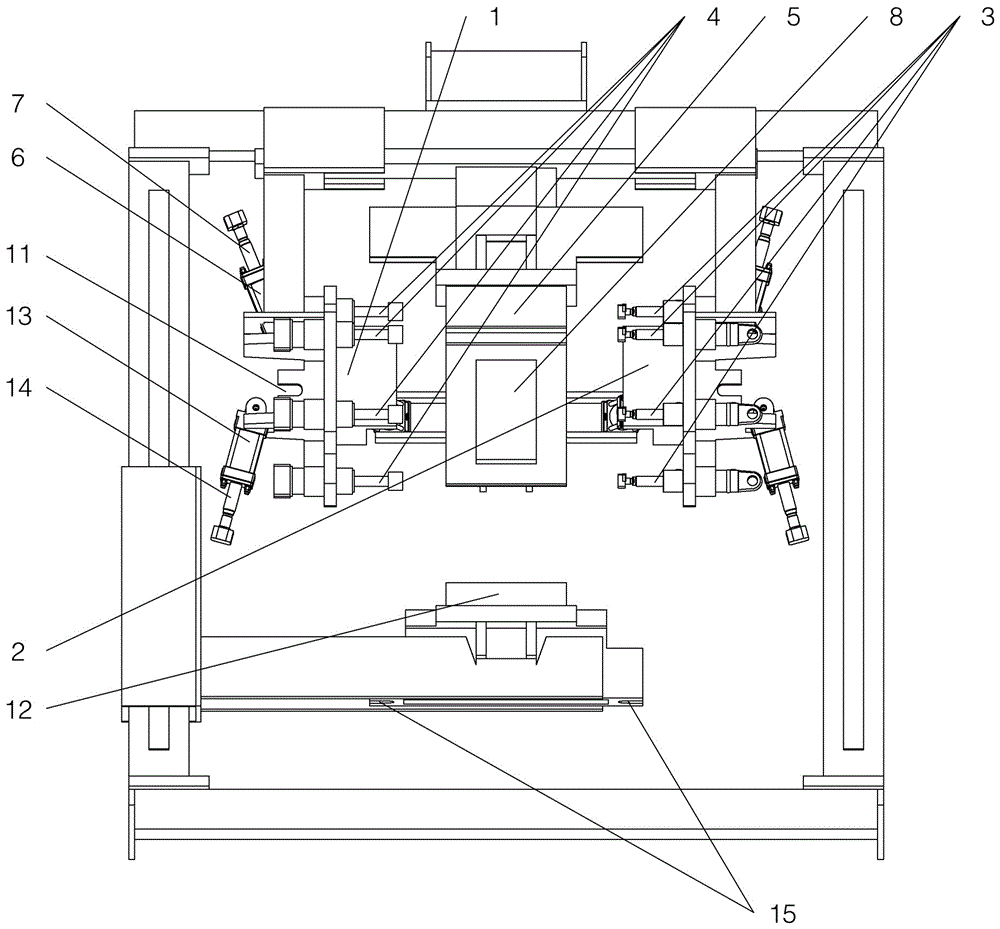

Pressure die casting mold for producing a casting

ActiveCN104742226AEasy extractionEasy to handleWater closetsMould separation apparatusEngineeringMechanical engineering

A pressure die casting mold for producing a casting which is part of an integral toilet having a body, a water ring, and a tank, wherein the casting, as an integral component, includes the water ring and the tank which is open on the upper side. The pressure die casting mold is composed of at least five molded parts which are interconnectable in a releasable manner, namely of a base part, two side parts having in each case one half of a front wall, a rear wall, and a cover part. The molded parts delimit a cavity which corresponds to the outer shape of the casting. A wedge element, which at least in portions delimits the inner shape of the water tank, is provided on the base part.

Owner:DURAVIT AG

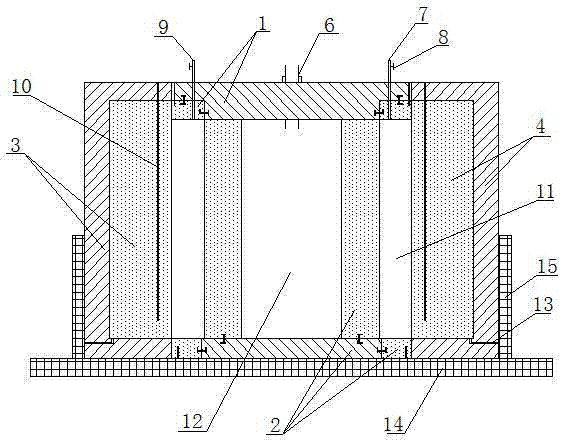

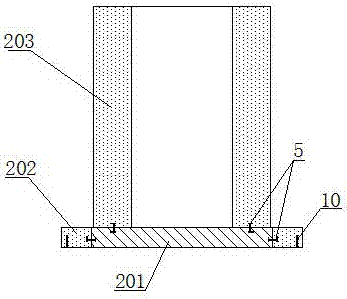

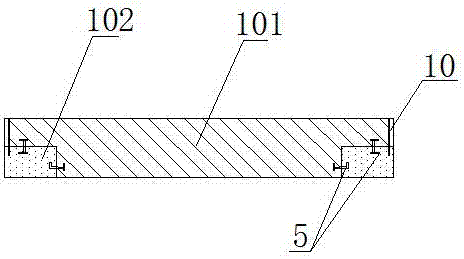

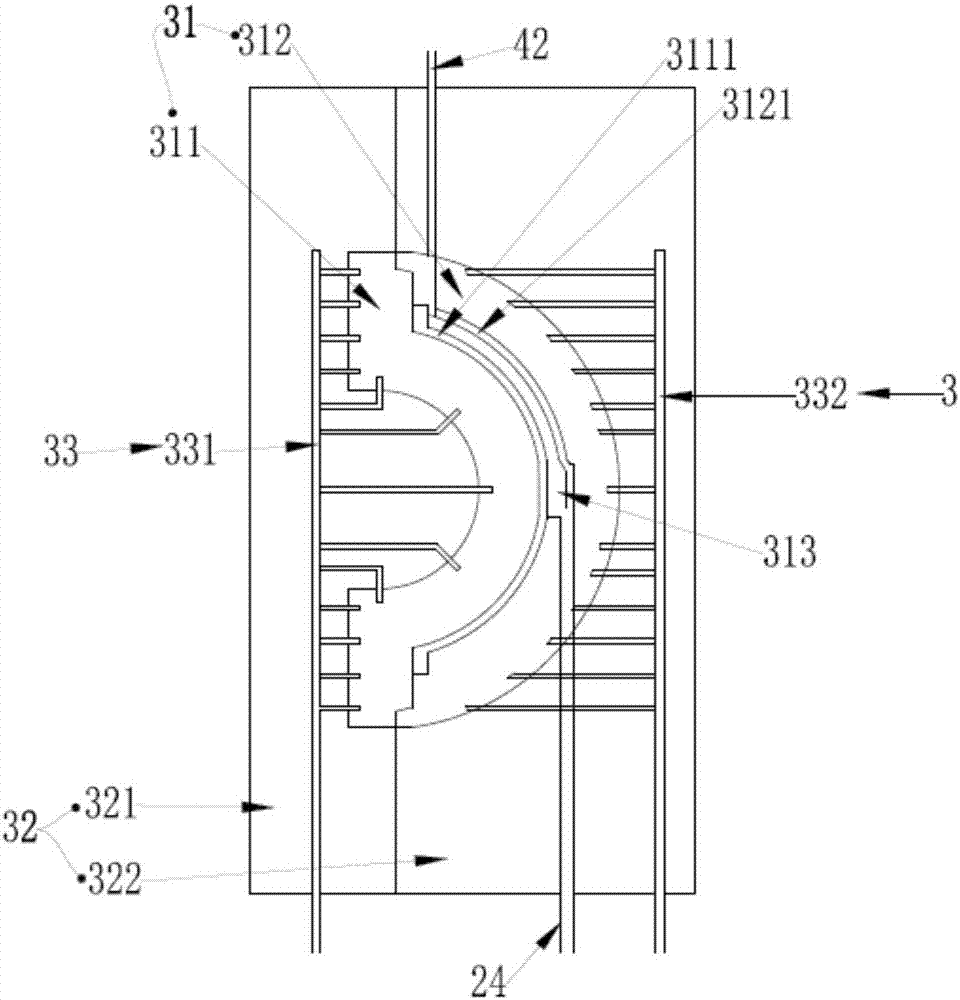

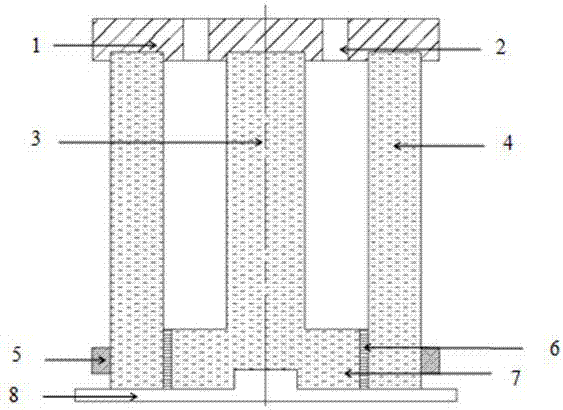

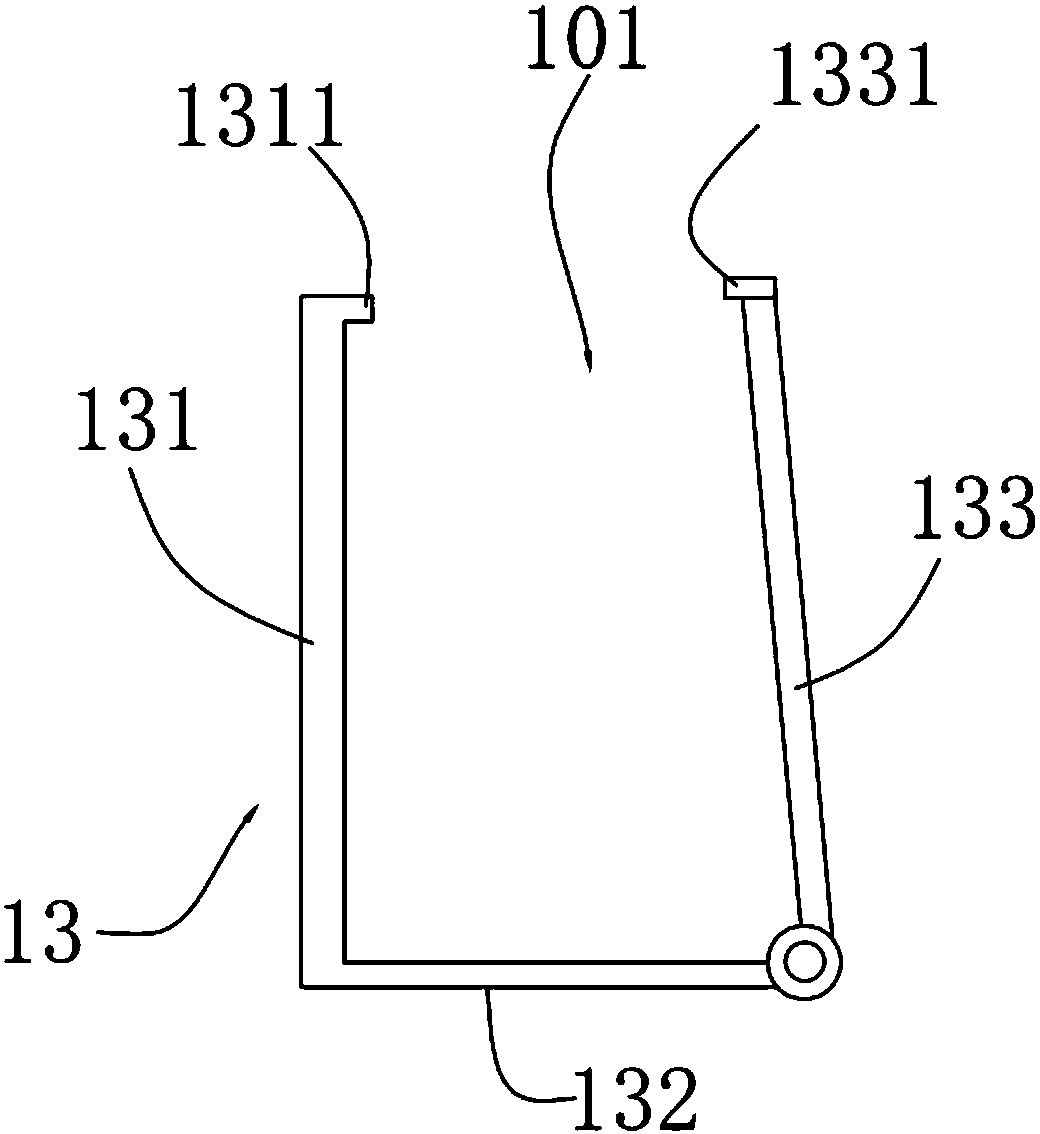

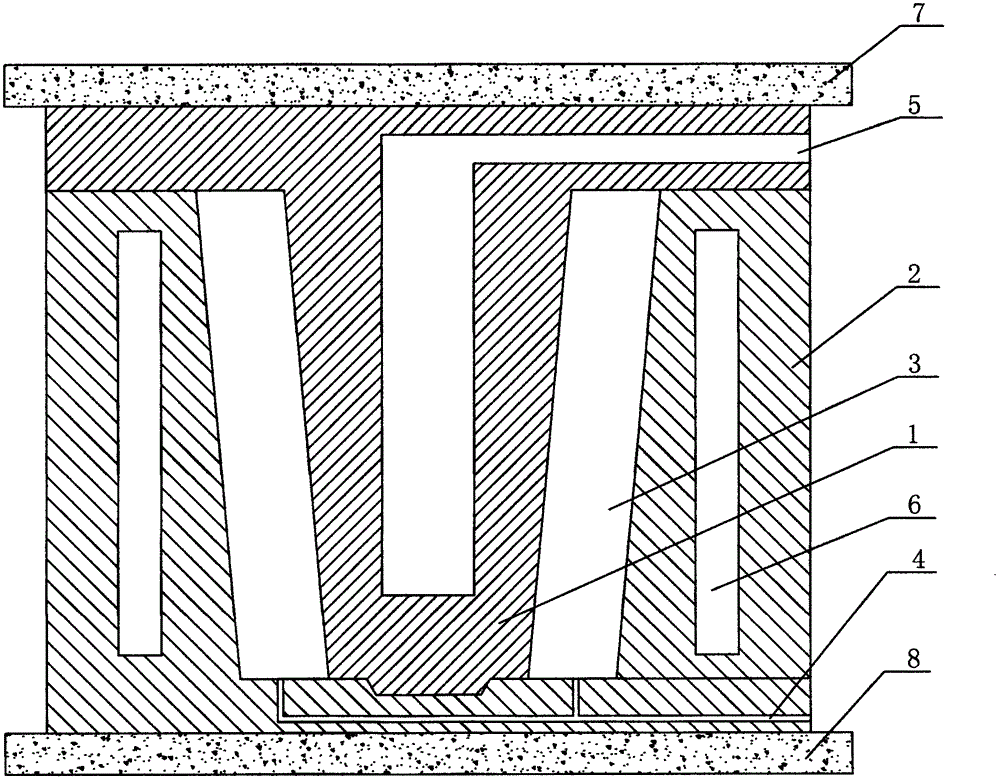

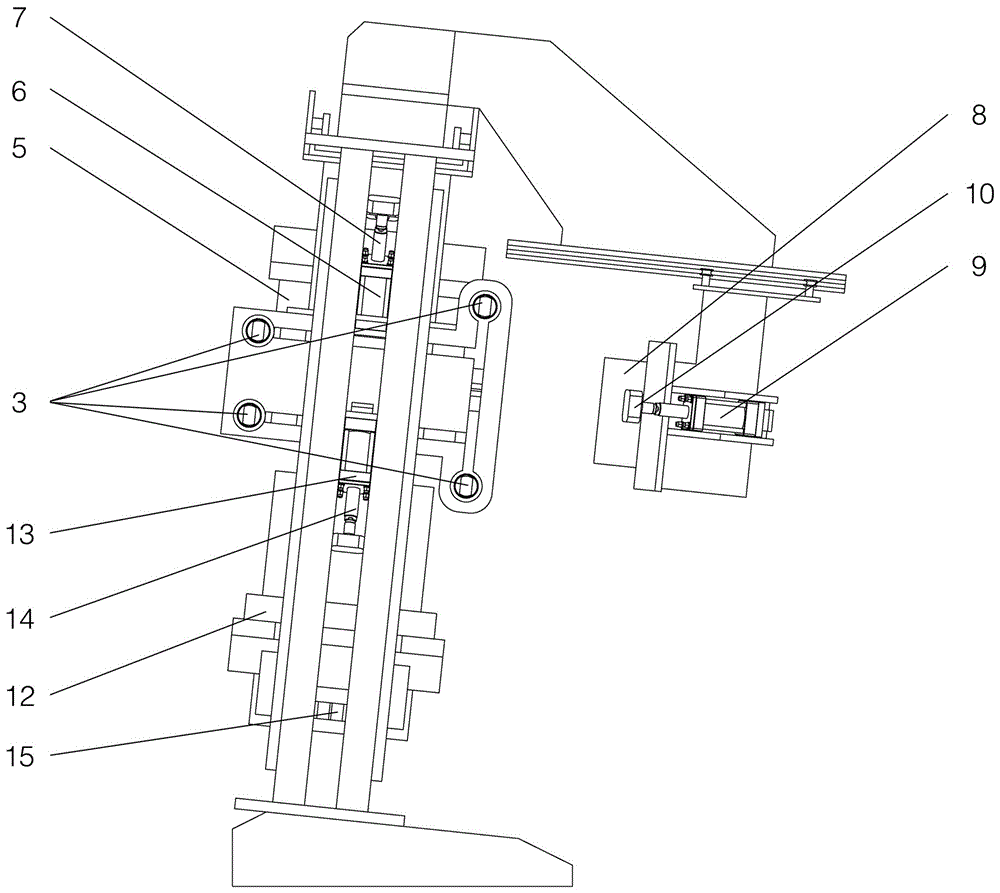

Ceramic rotary target slip casting die and manufacturing method thereof

ActiveCN104589461AIncrease green densityAvoid cloggingSlip casting mouldsSlurryVolumetric Mass Density

The invention relates to ceramic rotary target slip casting die and a manufacturing method thereof. The die is characterized by comprising an internal die (1) and an external die (2), wherein the external die (2) is hollow, and the upper part of the external die (2) is provided with an opening; the internal die (1) is T-shaped and is fixedly arranged in the hollow part of the external die (2); the upper edge of the internal die (1) is pressed on that of the external die (2); a cavity (3) is formed between the outer side wall of the internal die (1) and the inner side wall of the outer die (2); the bottom of the external die (2) is provided with a slurry inlet hole path (4) which is communicated with the cavity (3); the internal die (1) is internally provided with an air blowing hole path (5); the outer die (2) is internally provided with a drainage channel (6). The die has the effects that the die material strength is high, so that a mold made of a gypsum material can be replaced by the die, products cast by the die are high in density and uniform in density, the production period is short, and the labor intensity is low.

Owner:河北东同光电科技有限公司

Manufacturing method of three-opening mold high-pressure grouting forming toilet body

PendingCN110666928AAchieve high pressure groutingReduce labor intensityMould auxillary partsSlip casting mouldsPressure groutingWater pipe

The invention discloses a manufacturing method of a three-opening mold high-pressure grouting forming toilet body, and belongs to the field of ceramic manufacturing. The method comprises the followingsteps that S1, mold closing is carried out, specifically pressure of 195-245N is applied by a pressure cylinder through a jacking bar, and molds on a production line are jacked tightly and sealed oneby one; S2, grouting is carried out, specifically after the previous step is completed, pressure of 100-145N is applied by the pressure cylinder, slurry is pressed into a cavity in the mold through aslurry inlet pipe, the grouting is carried out for 10 minutes, and after the slurry fills the mold, the mold can absorb water in the slurry to start to form a mud blank; S3, slurry discharging is carried out, specifically after the previous step is completed, pressure of 5-8 Mpa is applied through an air pipe, and the redundant slurry in the cavity of the mold is discharged; S4, consolidation iscarried out, specifically after the previous step is completed, pressure of 1-2 Mpa is applied by a consolidating air pipe, and the mud blank is consolidated for 20 minutes; S5, mold opening and blanktaking are carried out, after the previous step is completed, depressurizing and mold opening are carried out, after the pressure of the pressure cylinder is completely drained, the mold is opened, and a blank body is taken out; and S6, mold washing and dehydration are carried out, after the previous step is completed, the mold is cleaned by water through a water pipe for 2 minutes, and pressureof 5-8 Mpa is applied through the air pipe for dehydration.

Owner:任丘市喜彪洁具有限公司

Normal-pressure solid-phase sintered silicon carbide ceramic profiled part and manufacture method thereof

InactiveCN106904974AExtended service lifeLarge particle sizeSlip casting mouldsBoron trioxideHigh pressure

The invention discloses a normal-pressure solid-phase sintered silicon carbide ceramic profiled part and a manufacture method thereof. A compact silicon carbide ceramic profiled part product is obtained by material preparation, material mixing through ball milling, high pressure grouting, drying in shade and low temperature drying and high temperature sintering. Through optimized matching of silicon carbide particles at different levels and effective design of channels of a resin die, micrometer powder is introduced to overcome obstruction of die channels, thereby obviously prolonging the service life of the die. The micrometer powder is large in size and small in specific surface area, thereby preventing loss of components, and through matching of particles with different size, sub-micrometer powder is uniformly dispersed in micrometer powder, thereby overcoming low grouting efficiency and nonuniform components. The density of a blank obtained from matching of particles with different size is obviously increased, so that the contraction is reduced and the blank is beneficial for preventing sintering deformation and cracking of a solid-phase sintered silicon carbide ceramic profiled part. Boric acid or / and diboron trioxide is adopted as a sintering aid and is dissolved in a thick liquid, so that the sintering aid is uniformly dispersed, and the density distribution of high-temperature-sintered silicon carbide ceramic profiled part is uniform.

Owner:NANTONG SANZER PRECISION CERAMICS CO LTD

Full-contact one-piece toilet bowl body mold clamping and releasing method

ActiveCN106625996AImprove bindingSimple structureDischarging arrangementAuxillary shaping apparatusHigh pressureMaterials science

The invention discloses a full-contact one-piece toilet bowl body mold clamping and releasing method. Mold clamping comprises the steps of mold clamping, mold locking and locking for a side mold, mold clamping, mold locking and locking for an upper mold, mold clamping, mold locking and locking for a front mold and mold clamping, mold locking and locking for a bottom mold. Mold releasing comprise the steps of vacuumizing for the upper mold, bottom mold opening and separation, front mold opening and separation, rough body sticking, upper mold opening and separation, side mold opening and separation and rough body transfer. By the adoption of the technical scheme, toilet bowl body mold clamping and releasing are achieved in the high-pressure grouting technology, and during multidirectional mold clamping, locking and releasing, it is ensured that a rough body is not hung to the mold and the sticking technology can be adopted in the mold releasing technology.

Owner:JOMOO KITCHEN & BATHROOM

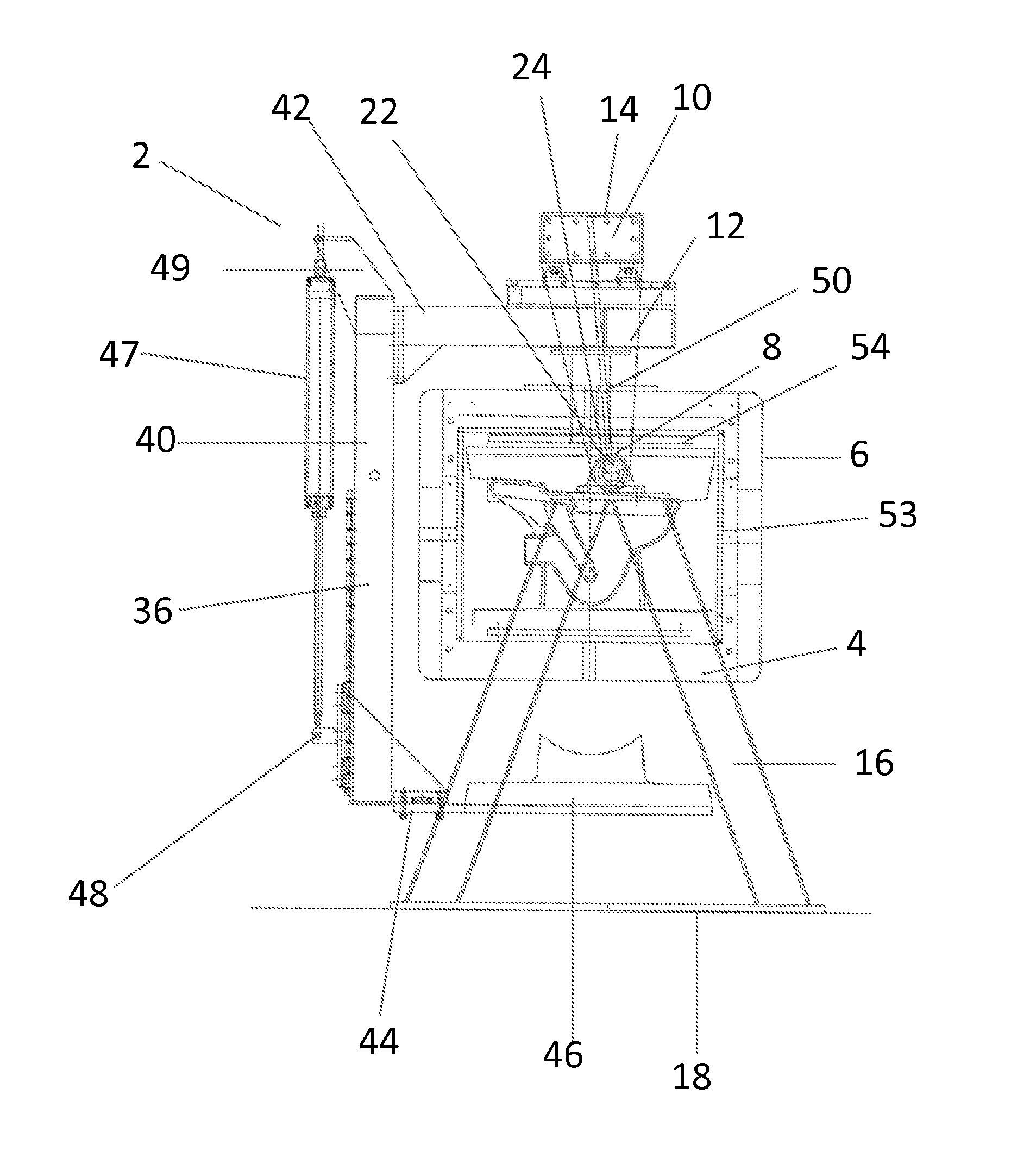

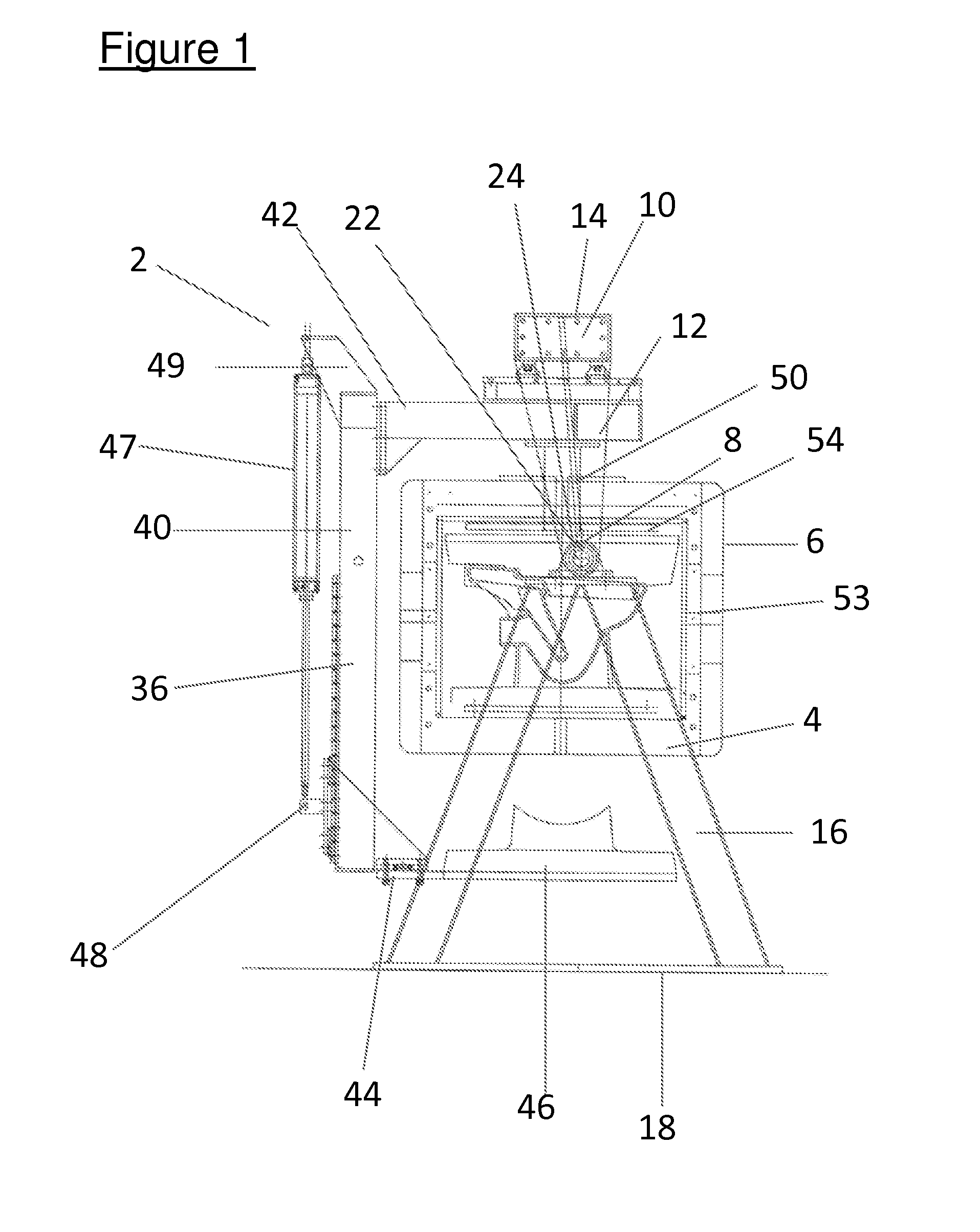

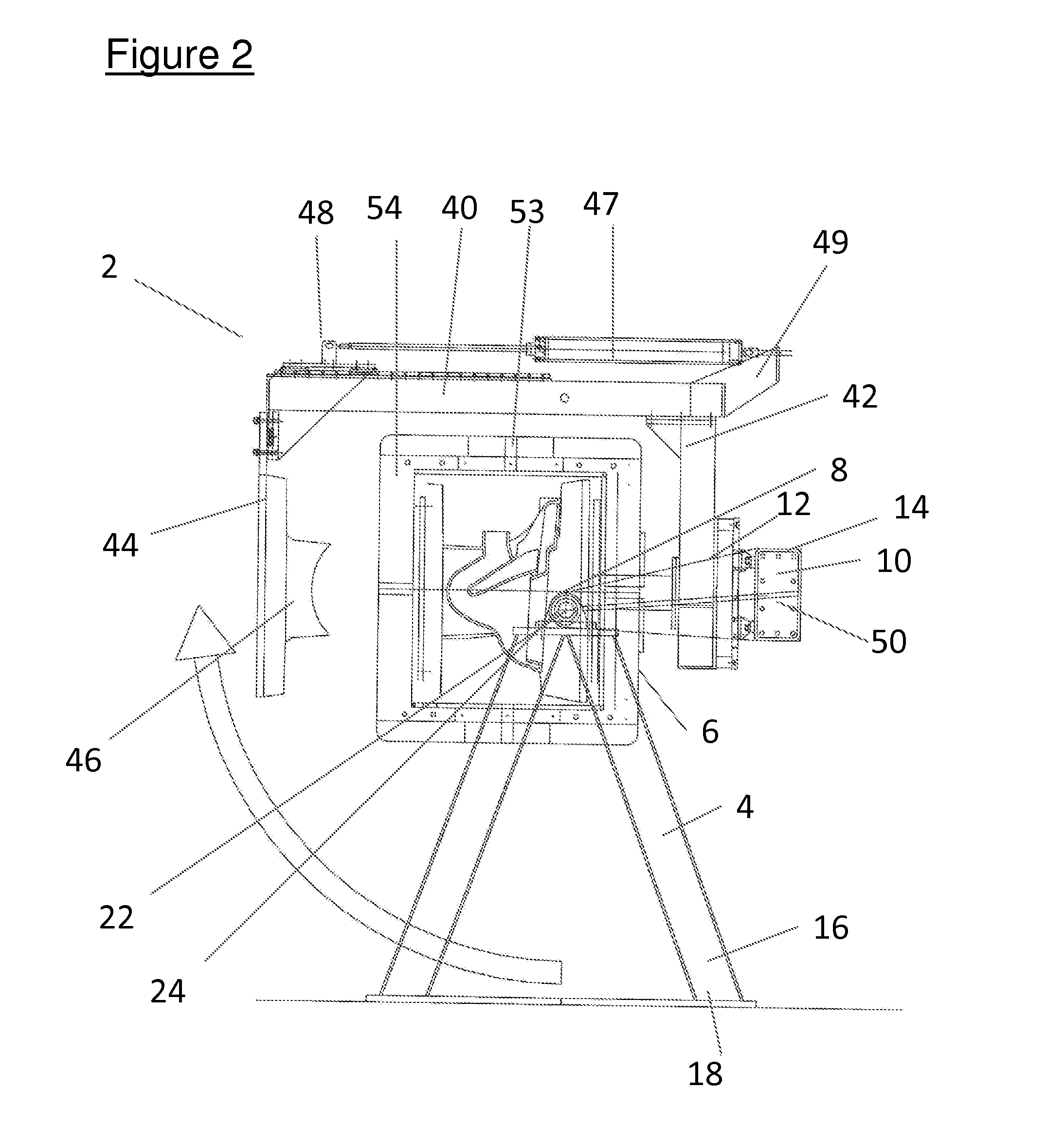

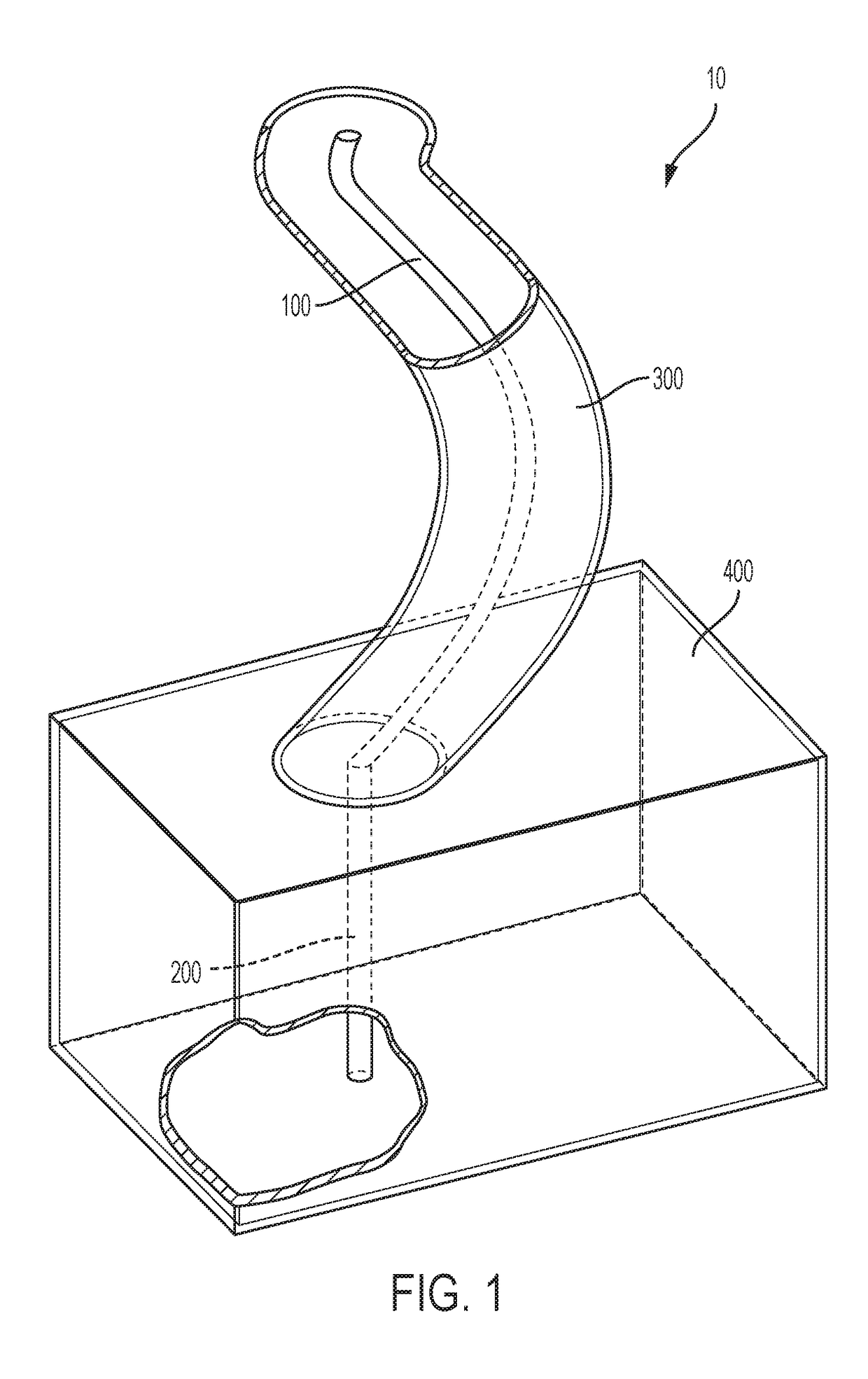

Pressure casting apparatus and method

The invention comprises a pressure casting machine comprising a support and a casting cell, wherein the casting cell is attached to the support such that the casting cell can, in use, be rotated, while at least a portion of the support remains stationary, the machine further comprising a releasable retainer to retain the casting call at a user-desired rotated position.The invention also comprises a method of pressure casting comprising the steps, in this order, of filling a mould, with slip for the purpose of producing a casting when the mould is orientated at a first angle, rotating the mould so that it is orientated at a second angle; and draining the mould.The invention is best illustrated by FIG. 1 of the diagrams.

Owner:PCL CERAMICS

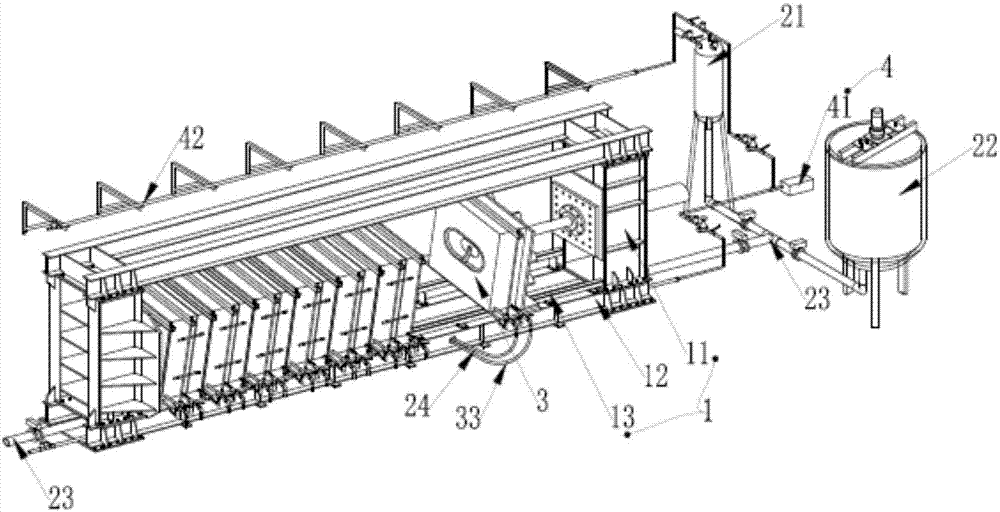

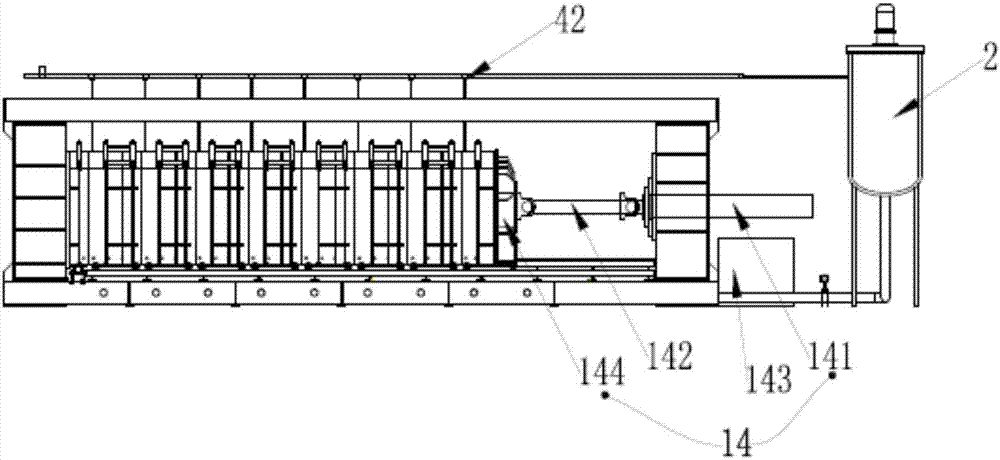

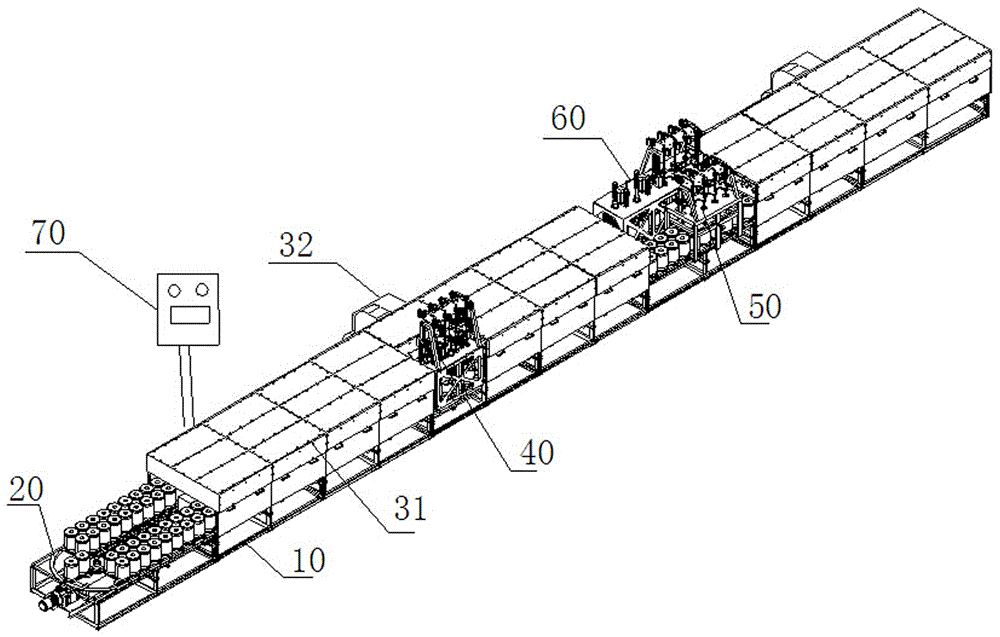

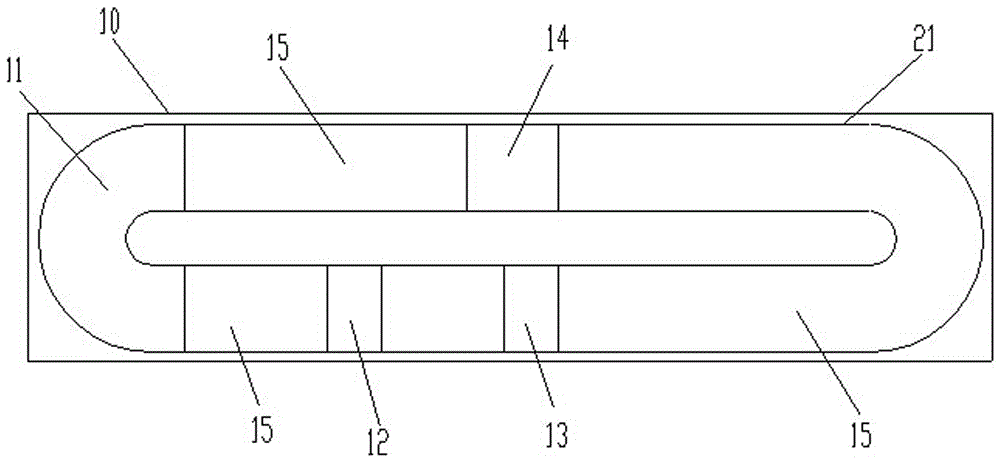

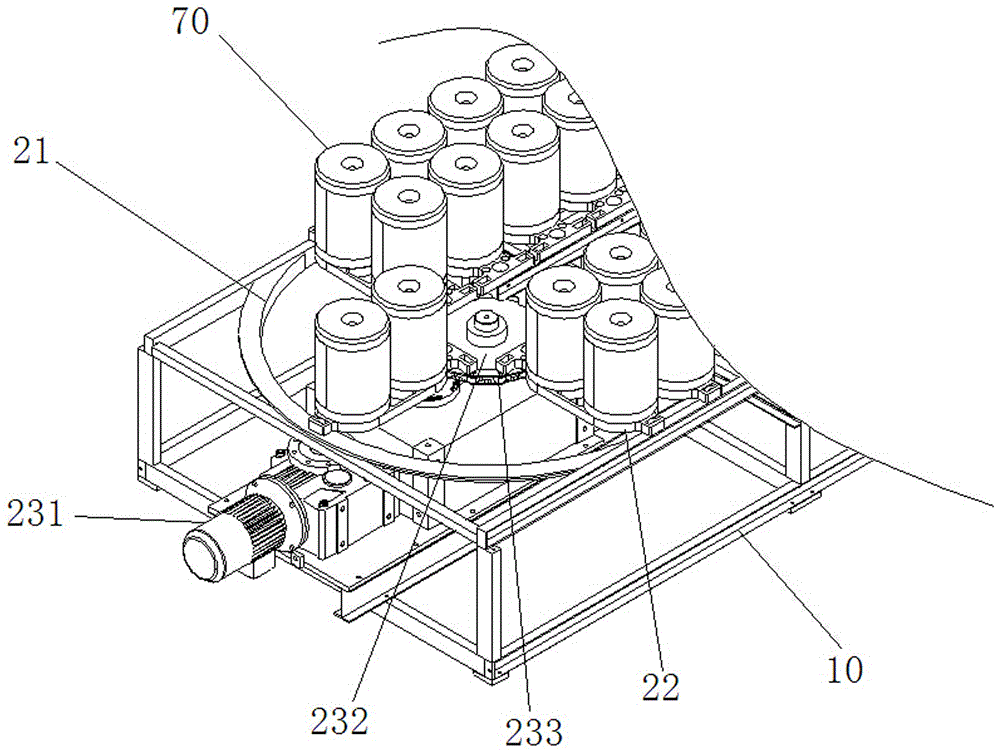

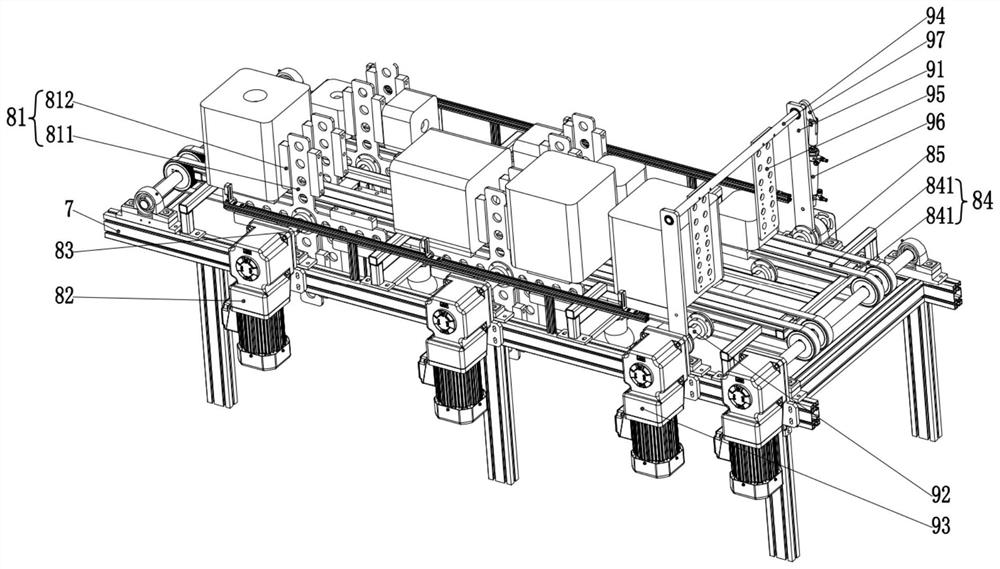

Hollow mold grouting production line

ActiveCN112077982ARealize integrationEasy to moveDrying gas arrangementsDrying chambers/containersElectric machineryEngineering

The invention discloses a hollow mold grouting production line. The hollow mold grouting production line comprises a mold moving mechanism, wherein the mold moving mechanism is provided with a conveying station, a grouting station, a forming station, a mold moving frame, a first moving component and a second moving component, and the first moving component is matched with the second moving component to drive the mold moving frame to move a plaster mold among the conveying station, the grouting station and the forming station; a slurry pouring mechanism comprises cross-shaped rotating plates and slurry pouring motors arranged on the side edge of a slurry pouring rack, wherein rotating shafts are fixed to the slurry pouring motors, each rotating shaft penetrates through the center of the corresponding cross-shaped rotating plate and stretches across the slurry pouring rack, and a filler strip is fixed to the side edge of a rotating strip of each cross-shaped rotating plate; slurry pouring conveyor belts are arranged on the slurry pouring rack, the cross-shaped rotating plates are arranged on the two sides of each slurry pouring conveyor belt, and the filler strips on the rotating strips in the transverse direction of the cross-shaped rotating plates are flush with the belt surfaces of the slurry pouring conveyor belts; and the slurry pouring motors drive the rotating shafts to rotate and drive the cross-shaped rotating plates to rotate in the advancing direction of the slurry pouring conveyor belts. According to the hollow mold grouting production line, the manual operation process in the grouting production line is replaced, and the production efficiency is improved.

Owner:ZHIXINLONG TECH (GUANGDONG) CO LTD

Method for making hybrid ceramic/metal, ceramic/ceramic body by using 3D printing process

This invention relates to a product and a method of preparing ceramic and / or ceramic hybrid materials through the construction of a printed die. The printed die being made by three dimensional printing or additive manufacturing processes possesses both an external geometry and an internal geometry.

Owner:GENERAL ELECTRIC CO

High-pressure grouting mould slurry sucking method

The invention discloses a high-pressure grouting mould slurry sucking method. The method has the main advantage that a gypsum slurry sucking block is arranged at a target position of a resin mould to suck residual slurry generated at the bottom of the mould during high-pressure grouting, so that the defect that 'slurry discharge is incomplete', 'complex products cannot be formed integrally' or the like of existing high-pressure resin mould grouting forming is made up.

Owner:JOMOO KITCHEN & BATHROOM

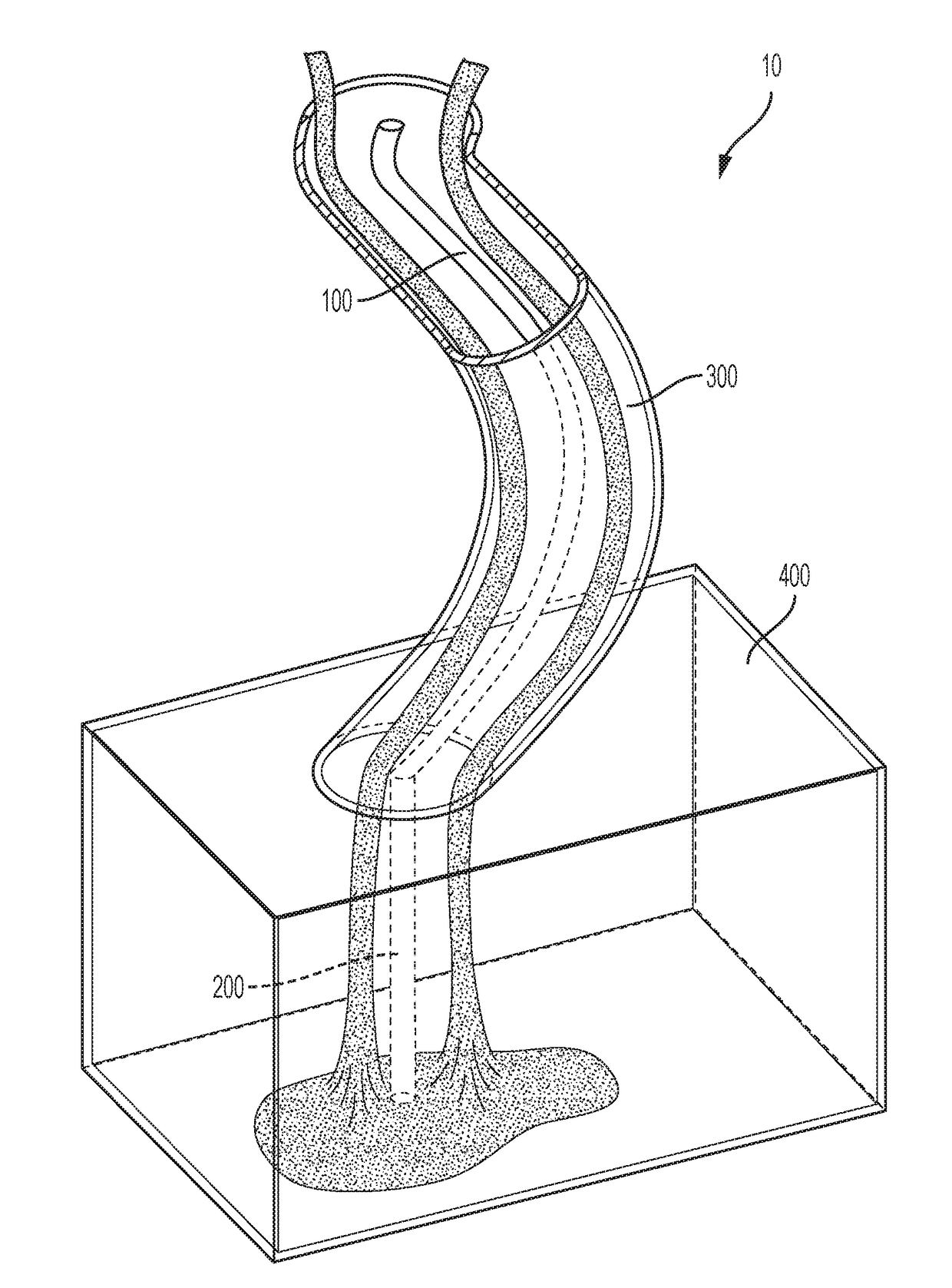

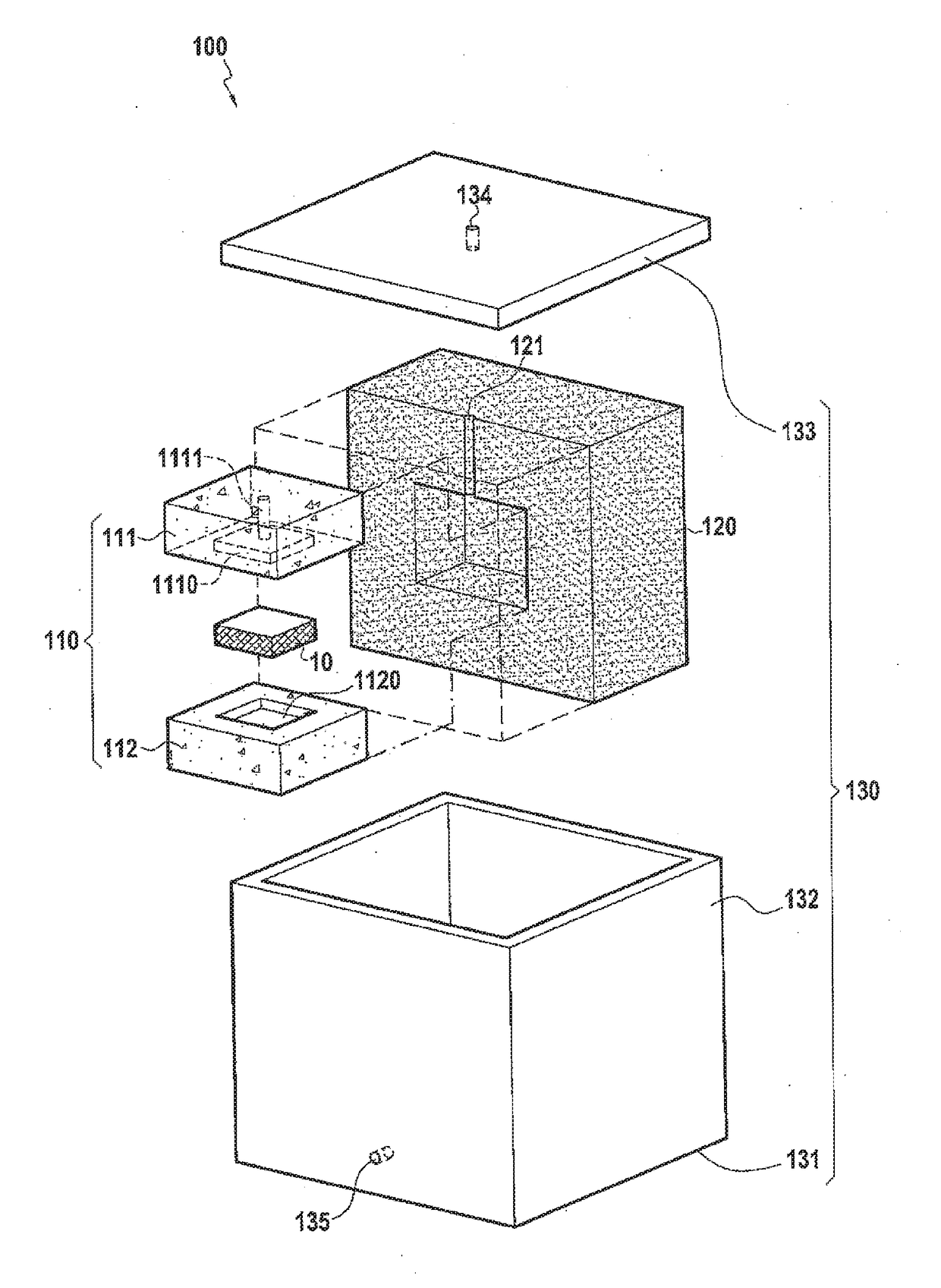

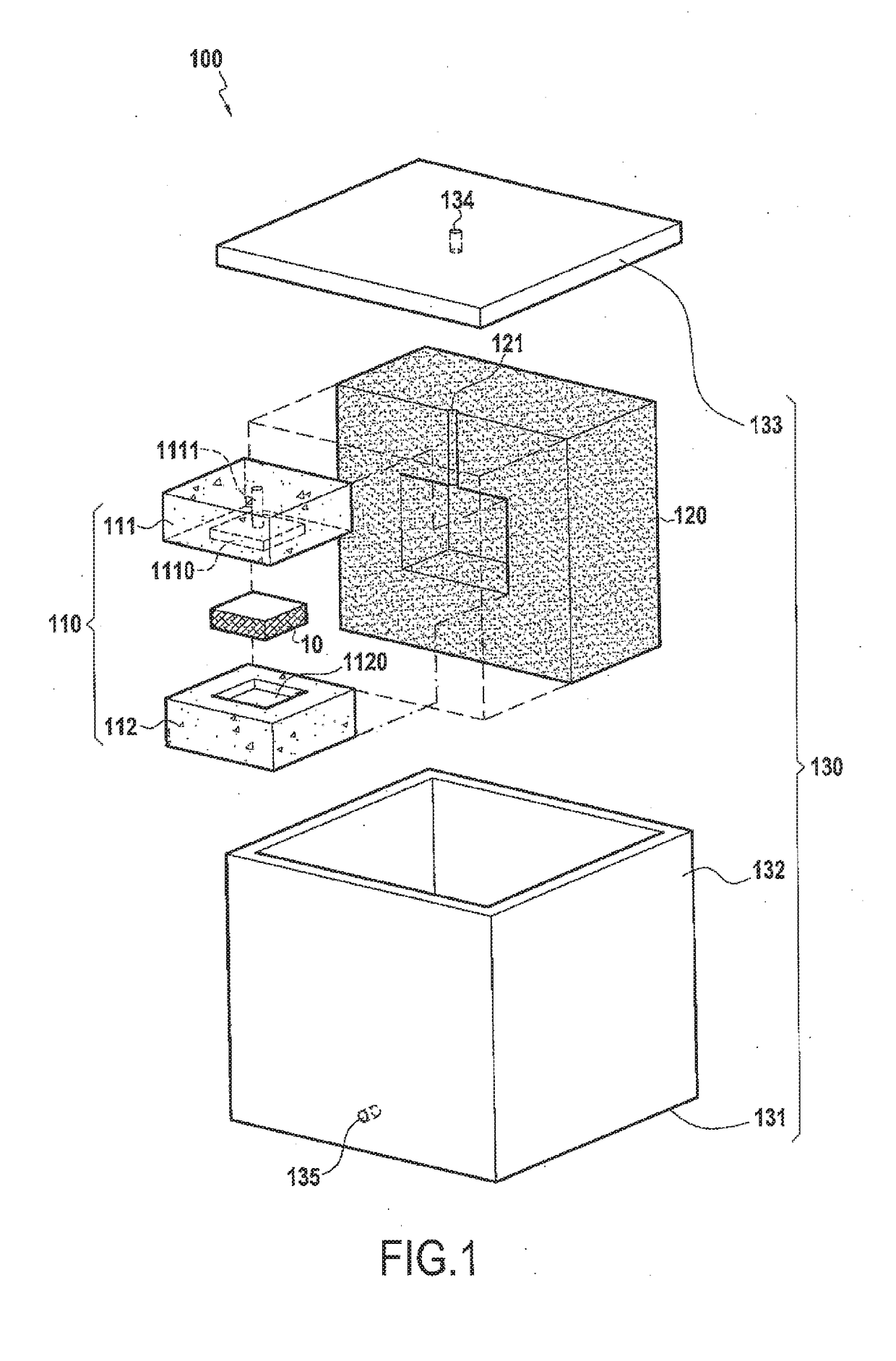

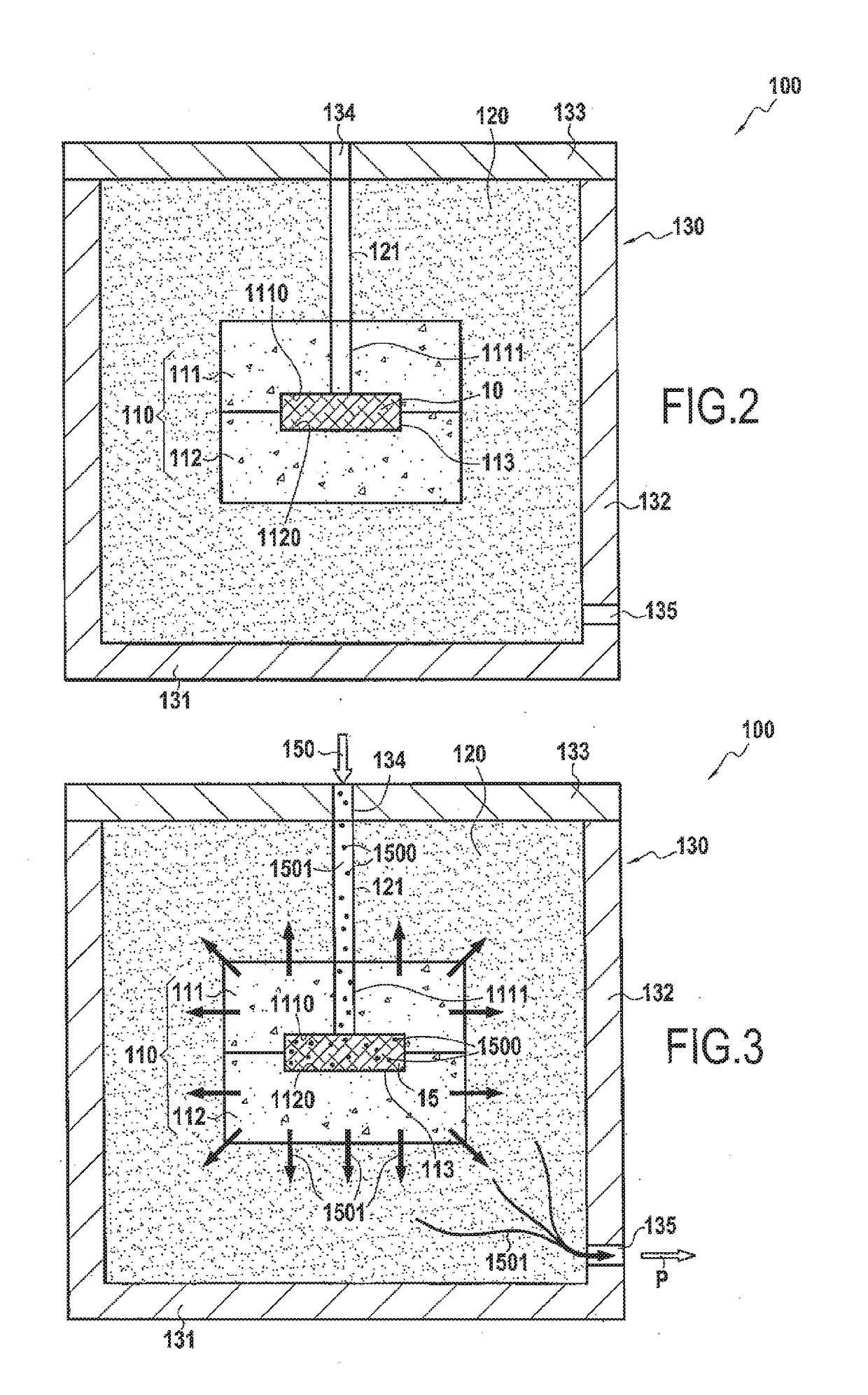

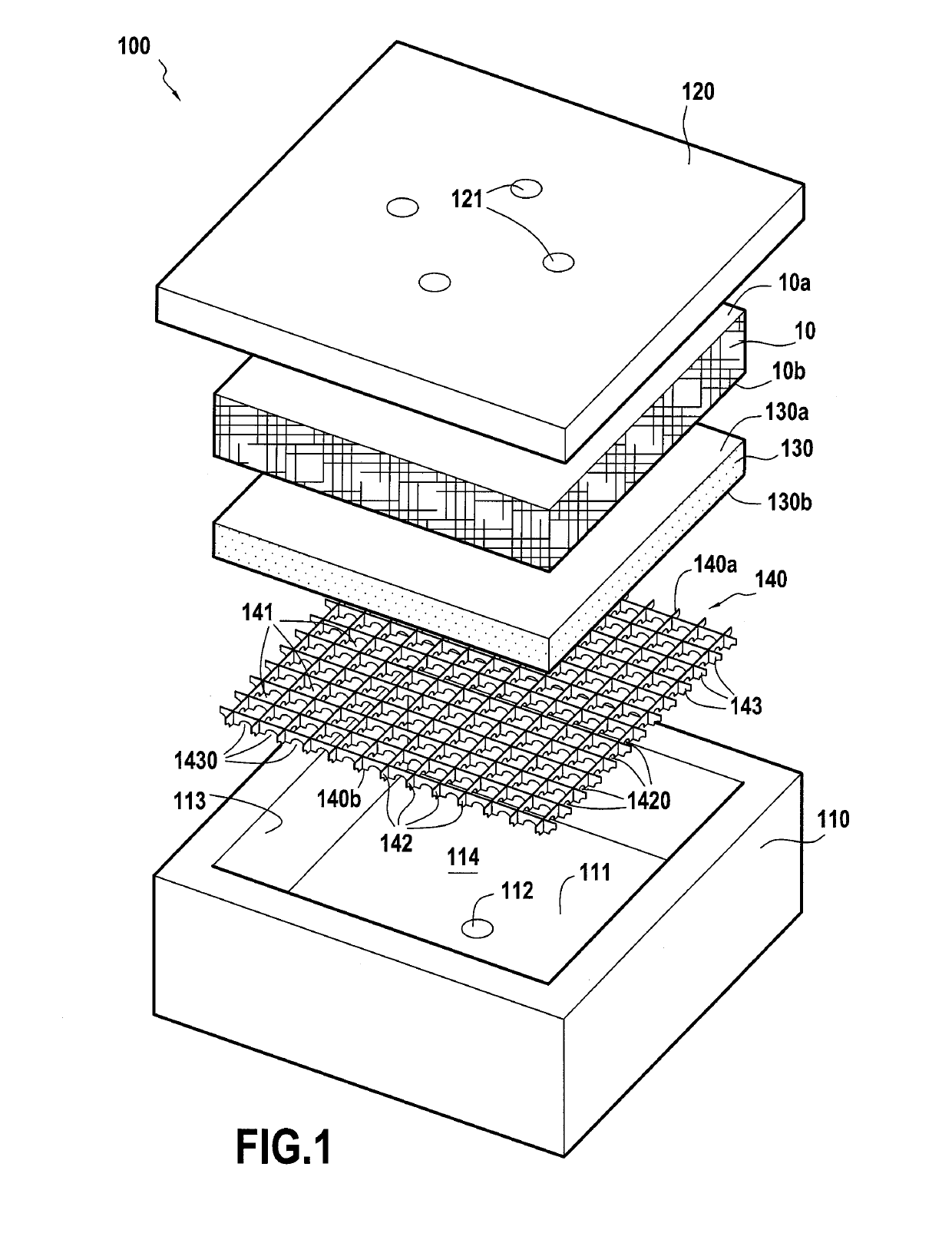

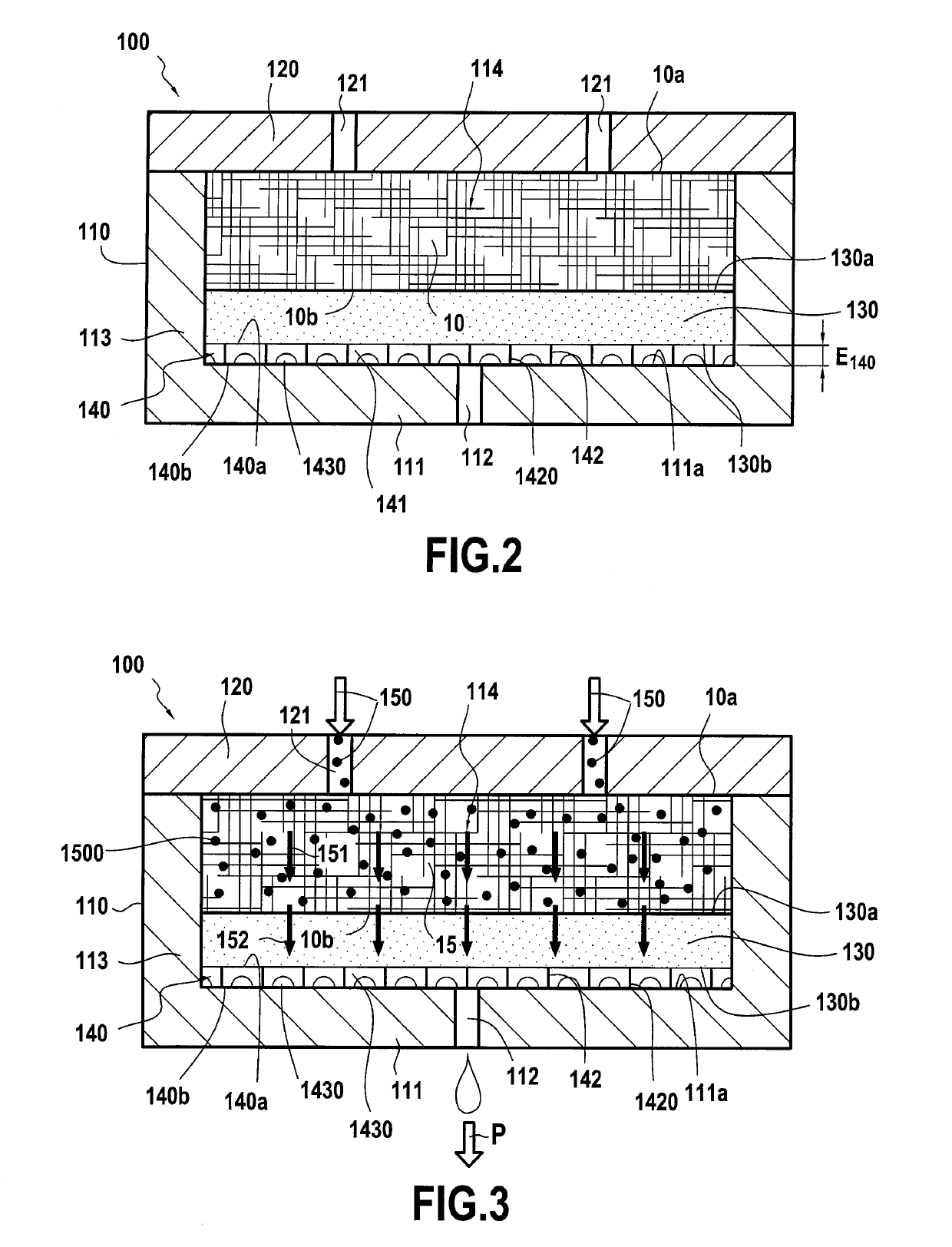

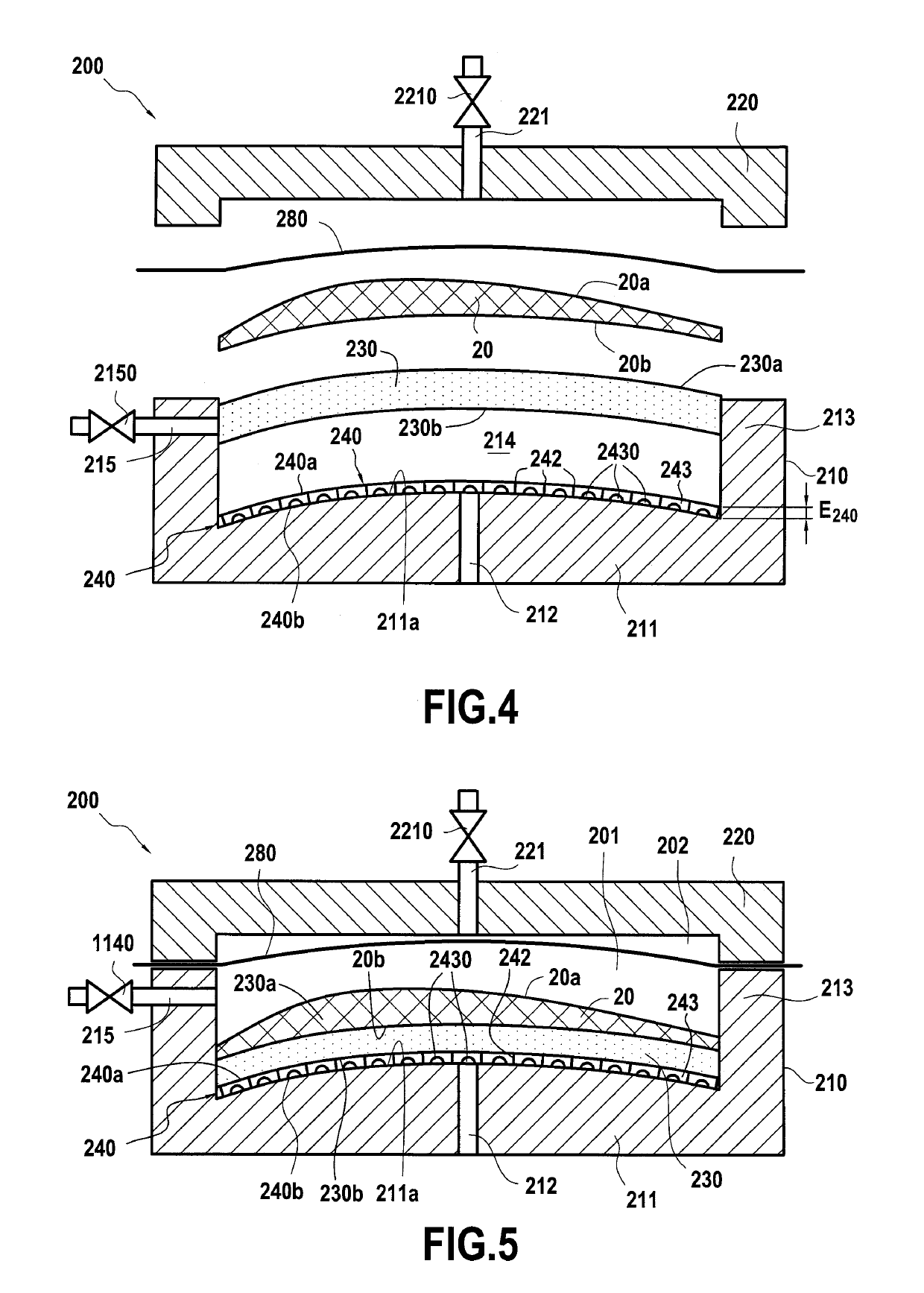

Process for manufacturing a ceramic composite material part by pressurized injection of a loaded slurry into a porous mould

ActiveUS20180297901A1Easy to controlFast and reliableBlade accessoriesMachines/enginesFiberCeramic composite

A method of fabricating a composite material part includes injecting under pressure a slurry containing a powder of refractory ceramic particles into a fiber texture; and draining the liquid of the slurry that has passed through the fiber texture, while retaining the powder of refractory ceramic particles within the texture to obtain a fiber preform filled with refractory ceramic particles. The injection tooling includes a porous material mold including an internal housing in which the fiber texture is placed, the slurry being injected into the fiber texture via an injection port in the injection tooling and leading into the internal housing of the mold. The tooling includes a rigid material enclosure in which the porous material mold is held while the slurry is injected under pressure and while the liquid of the slurry is drained, the liquid of the slurry being discharged via a vent present in the enclosure.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +1

Method using vacuum negative-pressure slip casting technology to prepare ITO target material

The invention discloses a method using the vacuum negative-pressure slip casting technology to prepare an ITO target material and relates to the field of materials. The method is characterized in that the method uses sol such as indium oxide, tin oxide, zirconium oxide, cerium oxide or bismuth oxide as the binder instead of organic binder to prepare slurry and uses vacuum negative-pressure slip casting, vacuum negative pressure is flexibly applied to the slurry to reduce the forming internal stress of a green body, and forming, drying and pre-sintering are completed in one step in an in-situ manner. The method has the advantages that the preparation time and cost of ITO can be reduced effectively, product quality can be increased, and the method is especially suitable for preparing a large-specification ITO target material; the method is suitable for the forming of the ITO target material and the forming of ceramic target materials such as AZO and IGZO.

Owner:LUOYANG RUIDE MATERIAL TECH SERVICES CO LTD

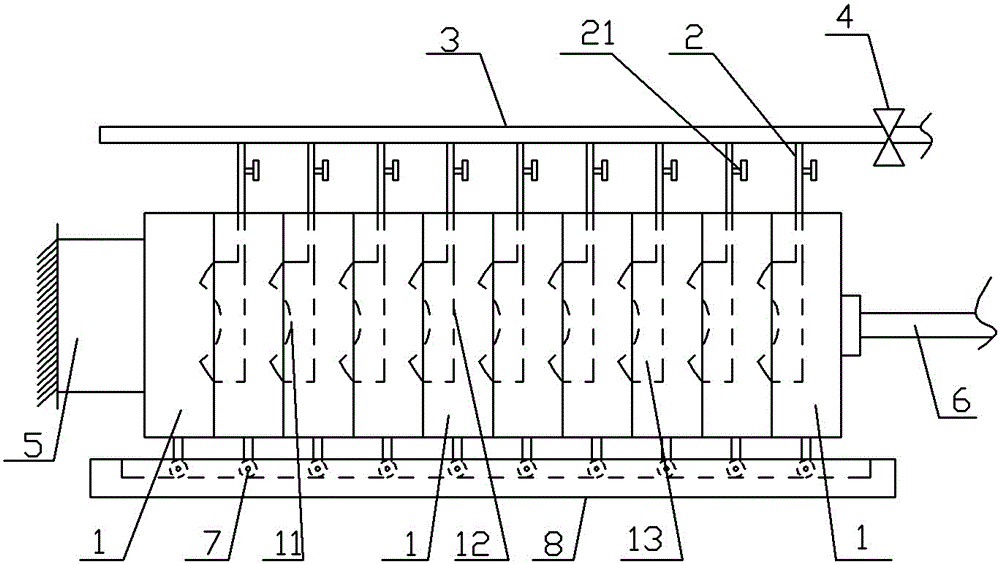

Grouting combined mould

The invention belongs to the technical field of grouting molding of ceramic products, and discloses a grouting combined mould. The grouting combined mould comprises a plurality of plaster moulds, and slurry molding cavities are formed between adjacent plaster moulds; each slurry molding cavity is connected with an independent grouting branch pipe, and the multiple grouting branch pipes are connected to slurry pipes with slurry pumps; a guide rail is arranged on the lower portions of the plaster moulds, and rollers matched with the guide rail are arranged at the bottoms of the plaster moulds; and in the multiple plaster moulds, the left side of the plaster mould located at the left end abuts against a limiting block, and the right side of the plaster mould located at the right end is fixedly connected with an air cylinder output shaft. The grouting combined mould is formed by splicing the multiple plaster moulds, the slurry molding cavities between the adjacent plaster moulds can complete grouting molding, and three plaster moulds can complete grouting molding of two ceramic products. Compared with a manner that four original plaster moulds carry out grouting to form two ceramic products at a time, the grouting combined mould is higher in efficiency, and the plaster moulds can be fully utilized.

Owner:CHONGQING XINSHENG CERAMICS

A method of fabricating a composite material part by injecting a filled slurry into a fiber texture

ActiveUS20190134848A1Good control over depositionFast and reliableBlade accessoriesMembrane filtersFiberMetallurgy

A method of fabricating a composite material part includes placing a fiber texture in a mold including in its bottom portion a porous material part on which a first face of the texture rests, injecting a liquid under pressure into the fiber texture, the liquid containing a powder of refractory ceramic particles, and draining through the porous material part the liquid that has passed through the fiber texture, while retaining the powder of refractory ceramic particles inside said texture by the porous material part. A perforated rigid element is interposed between the bottom of the mold and the porous material part.

Owner:SAFRAN

Exterior rim wash bowl

A one-piece bowl including an open top, a bottom opening, a rim portion, an interior space and a plurality of cavities is provided. The rim portion substantially surrounds the bowl near the open top, and an inner channel is formed along and within the rim portion. The interior space is substantially defined by an interior surface, the open top and the bottom opening. The plurality of cavities extends from the inner channel to the interior space. The inner channel and the cavities are configured to pass fluid from an outer fluid source to the interior space. A mold assembly and a method for forming a one-piece greenware piece for the bowl are also provided. The mold assembly includes a top mold component and a bottom mold component that are configured to mate and thereby form a reservoir substantially defining the bowl.

Owner:DOMETIC APPLIANCES

Hand-shaping blank hollow-jun-porcelain grouting manufacturing method and mold used for grouting manufacturing

InactiveCN104669405AExquisite workmanshipShorten production timeSlip casting mouldsDual functionGypsum

Owner:XUCHANG UNIV

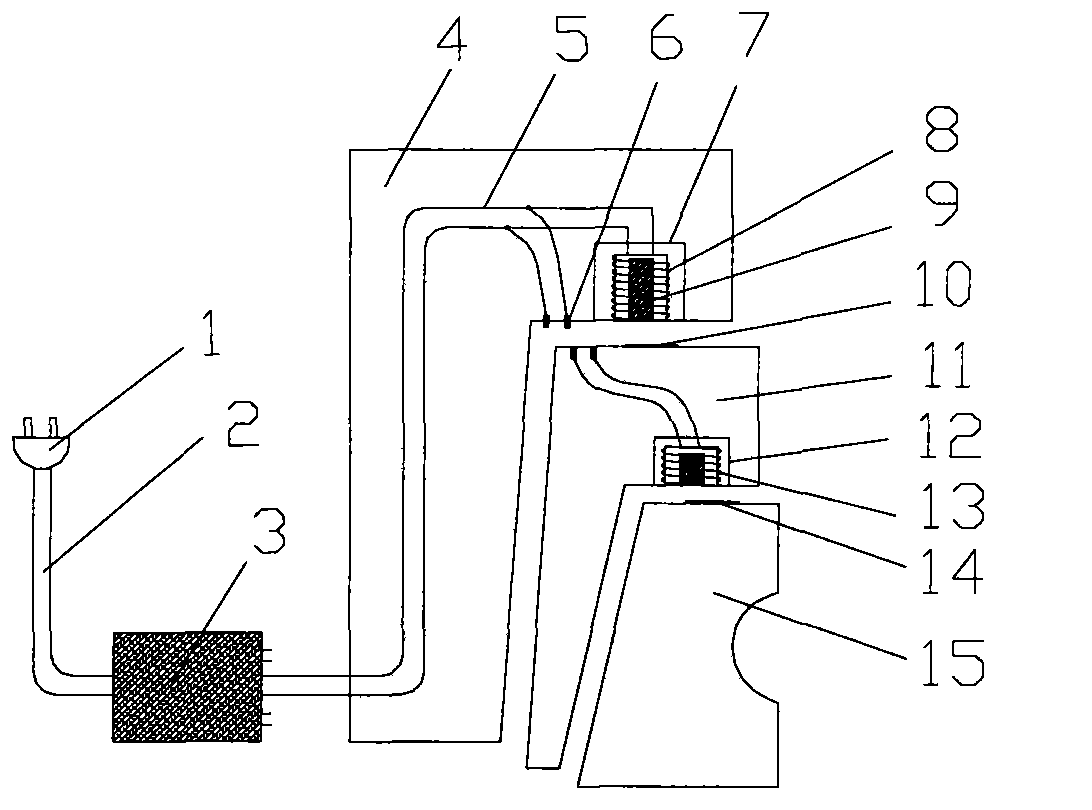

Low voltage electromagnet for ceramic die

InactiveCN103240796AEasy to operateSimple structureMould separation apparatusSlip casting mouldsLow voltageEngineering

The invention discloses a low voltage electromagnet device for a ceramic die. The low voltage electromagnet device comprises a power plug, a power line, a rectifier, an external die, a low voltage line, an elastic contact, a waterproof cover, an electromagnetic coil, an iron core, an iron sheet, a middle die, a B waterproof cover, a B electromagnetic coil, a B iron sheet and a small die. Voltage of the low voltage line passing through the rectifier is safe voltage smaller than 36 volts. Fast fixing and light and fast taking out of a master die and the small die can be achieved by aid of the principle of using a low voltage power supply to generate magnetic force between the electromagnetic coils and the iron sheets which are arranged at corresponding positions of the master die and the small die. Simultaneously, the problem that slurry leakage and gas leakage happen easily due to fixed wiring is solved.

Owner:段鳗珊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com