Single-surface pressure grouting forming method of ITO rotating target blank body and mold

A technology of grouting molding and rotating targets, which is applied in die-casting molds, ceramic molding machines, manufacturing tools, etc., which can solve the problems of easy interlayers and other problems, and achieve the effects of reducing raw material costs, increasing density, and small body processing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

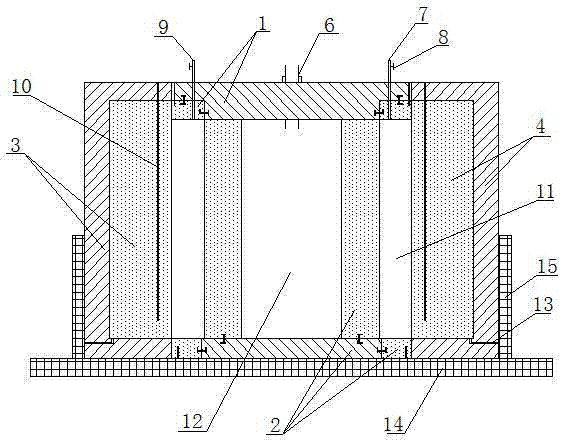

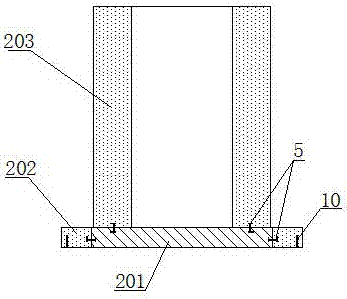

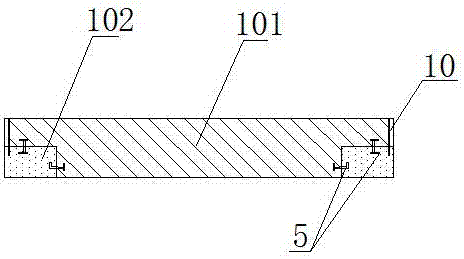

[0034] Embodiment: After the top mold 1, the bottom mold 2, the left half mold 3, and the right half mold 4 are closed, pressurize and seal them with a jack or other fixtures and fix them on the cylindrical fixed table 15 of the rotary platform 14 . Take the prepared ITO slurry with a solid phase content of 85%, a viscosity lower than 600mPa·s, and add a small amount of defoamer, and use an air pump to pump the slurry into the cylindrical cavity 11 from the grouting pipe 7 until the slurry The material slightly exposes the outlet of the transparent exhaust pipe 9, indicating that the cavity 11 has been filled. Then close the valves of the grouting pipe 7 and the exhaust pipe 9, and the compressed air with an initial pressure of 0.3 MPa is introduced from the pressurizing pipe 6, and the gas passes through the micropores of the cylindrical plaster mold 203 to the ITO slurry in the cavity 11. Pressurize the material evenly, start the rotating platform 14 after starting to press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com