Novel preparation technology of polyoxymethylene fiber

A polyoxymethylene fiber, a new type of technology, applied in fiber processing, filament/thread forming, textiles and papermaking, etc., can solve the problem of insufficient stability of fiber structure uniformity and performance, and can not adapt to the change of velocity gradient in the deformation area under the plate and other problems, to achieve the effect of preventing melt fracture, prolonging the time of viscous flow deformation, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

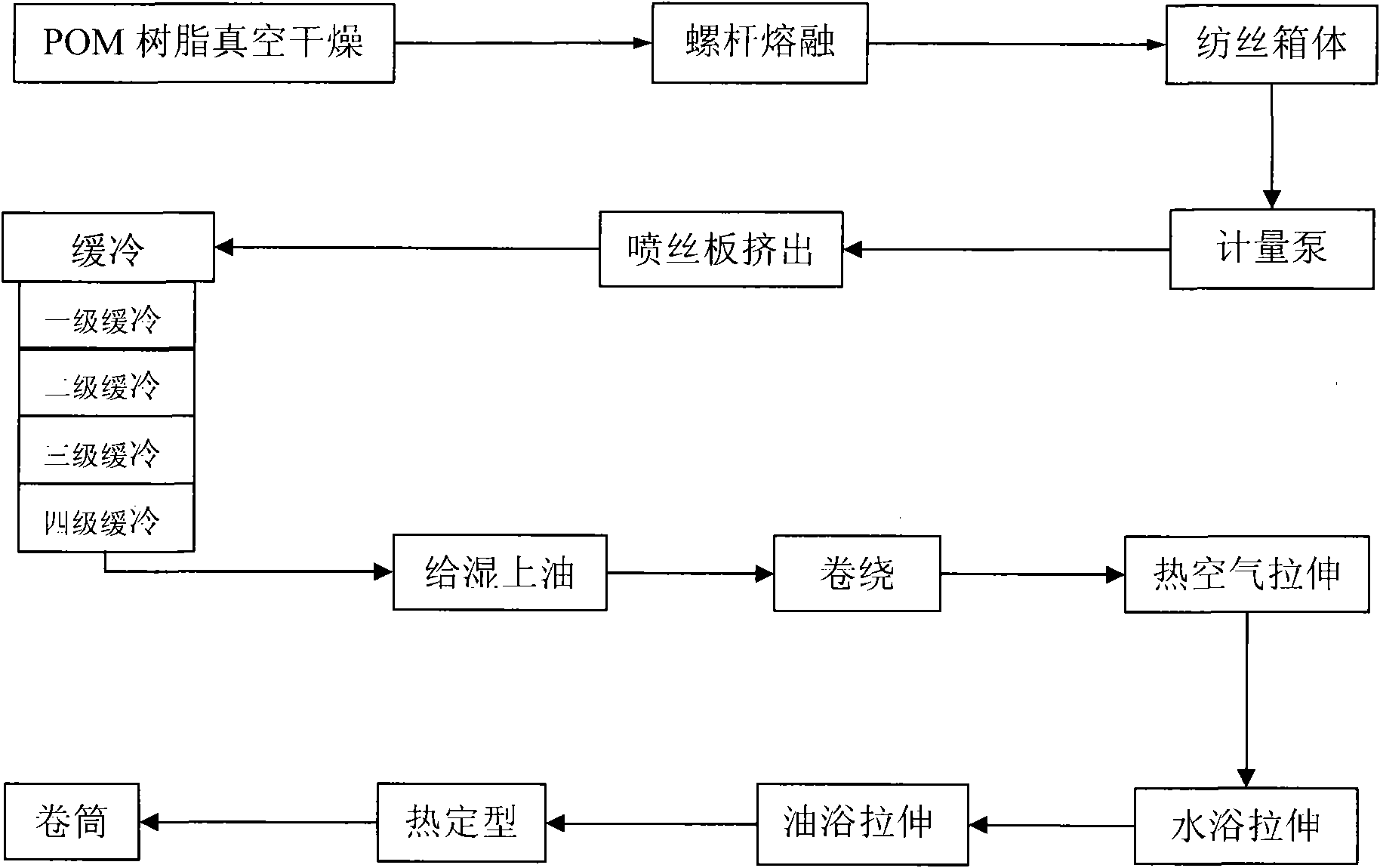

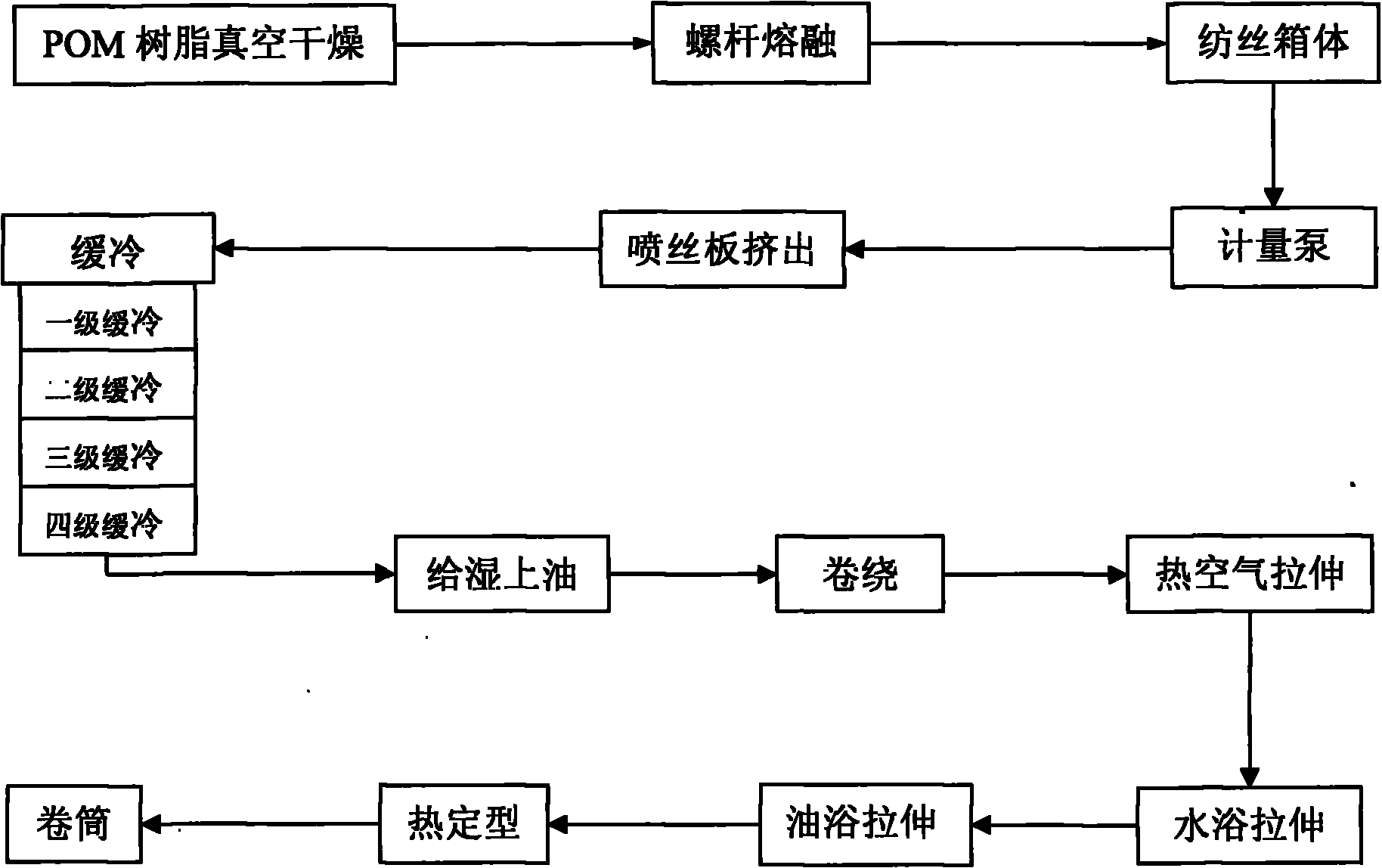

Method used

Image

Examples

Embodiment 1

[0026] POM pellets with a melt index of 1.8 g / 10 min as measured by ASTM D1238 were dried for 4.5 hours at a temperature of 115°C and a vacuum of -0.1 MPa. The pellets are heated and melted by the screw extruder, and then melted and extruded by the spinneret after being metered by the metering pump. The zone is 217°C, the metering zone is 216°C; the spin beam is 216°C. The melt flow passes through the four-stage slow cooling, and the slow cooling device: the first-stage slow cooling, the air temperature is 220°C, and the action range is 1-160mm under the spinneret plate; the second-stage slow cooling, the air temperature is 175°C, the effect The interval is 161-220mm under the spinneret plate; the third-stage slow cooling, the air temperature is 140°C, and the action range is 221-280mm under the spinneret plate; the fourth-stage slow cooling, the air temperature is 100°C, and the action interval is The distance under the spinneret plate is 281-450mm; and high-speed traction i...

Embodiment 2

[0028]Other conditions are as embodiment 1, just change the temperature of the slow cooling device: first-level slow cooling, the air temperature is 210°C; second-level slow cooling, the air temperature is 170°C; third-level slow cooling, the air temperature is 130°C; Cold, the ambient temperature is 90°C. At this time, the as-spun fiber is stretched by hot air and then stretched by two different solvents. The first stage of hot air stretching has a draw ratio of 3.4; the second stage of water bath stretching has a draw ratio of 2; the third stage of oil Bath stretching, the stretching ratio is 1.6. The resulting POM fiber has the best uniformity, high strength and modulus, and stable performance.

Embodiment 3

[0030] Other conditions are as embodiment 1, just change the temperature of the slow cooling device: first-level slow cooling, the air temperature is 190°C; second-level slow cooling, the air temperature is 150°C; third-level slow cooling, the air temperature is 100°C; Cold, the ambient temperature is 80°C. At this time, the as-spun fiber is stretched by hot air and then stretched by two different solvents. The first stage of hot air stretching has a draw ratio of 3.2; the second stage of water bath stretching has a draw ratio of 1.9; the third stage of oil Bath stretching, the stretching ratio is 1.4. The uniformity of the obtained POM fiber is average, the strength and modulus are not high, and the performance is relatively stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com